Patents

Literature

36results about How to "Hit full" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

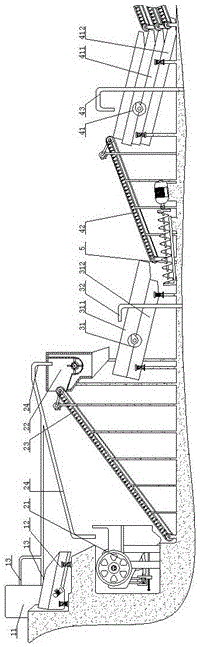

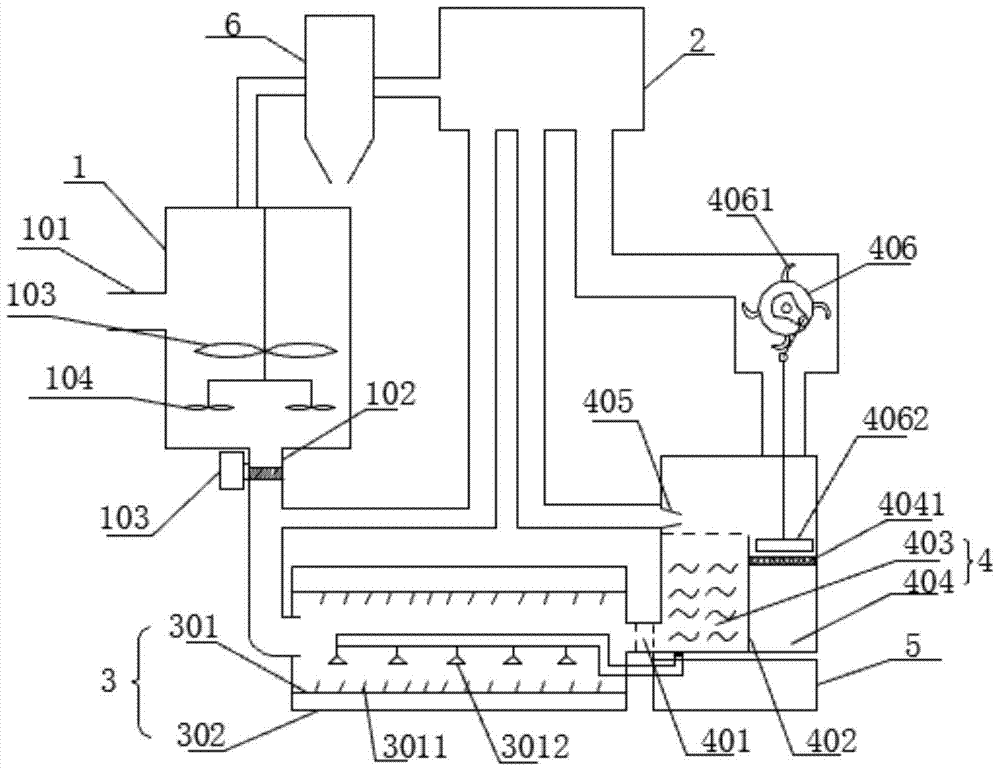

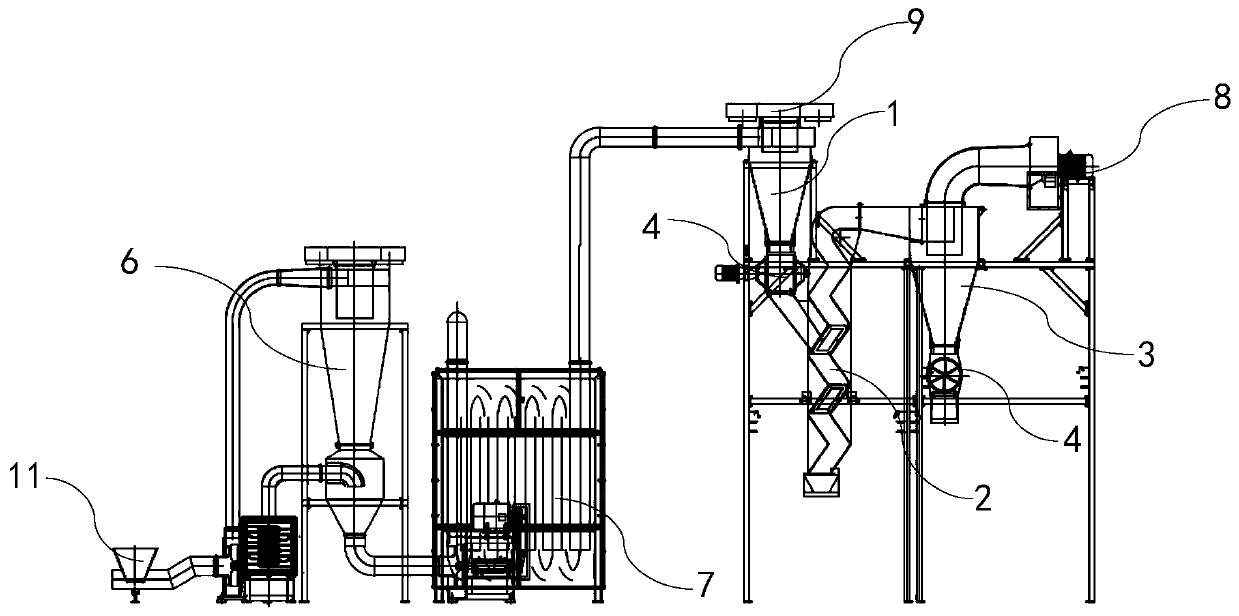

Mudstone environmental protection regeneration system

The invention discloses a mudstone environmental protection regeneration system. The mudstone environmental protection regeneration system comprises a feeding mechanism; the feeding mechanism comprises a stock bin, a vibrating feeding machine, a crushing mechanism which comprises a jaw type rough crushing machine and a hammer type fine crushing machine, a sand and gravel separating mechanism, a gravel fine separating mechanism and a mud and sand water passing mechanism; the sand and gravel separating mechanism comprises a rough separating vibrating screen; the rough separating vibrating screen comprises a gravel layer and a mud and sand layer; the gravel fine separating mechanism comprises a fine separating vibrating screen; the fine separating vibrating screen comprises a multi-layer finished product layer and a fine sand layer; the mud and sand water passing mechanism comprises a spiral conveyer; other devices except the spiral conveyer is provided with a spraying water pipe respectively. The mudstone environmental protection regeneration system can crush and clean gravel residues containing soil to enable the gravel residues to be recycled and has huge economic benefits and a remarkable environmental friendly effect.

Owner:魏根友

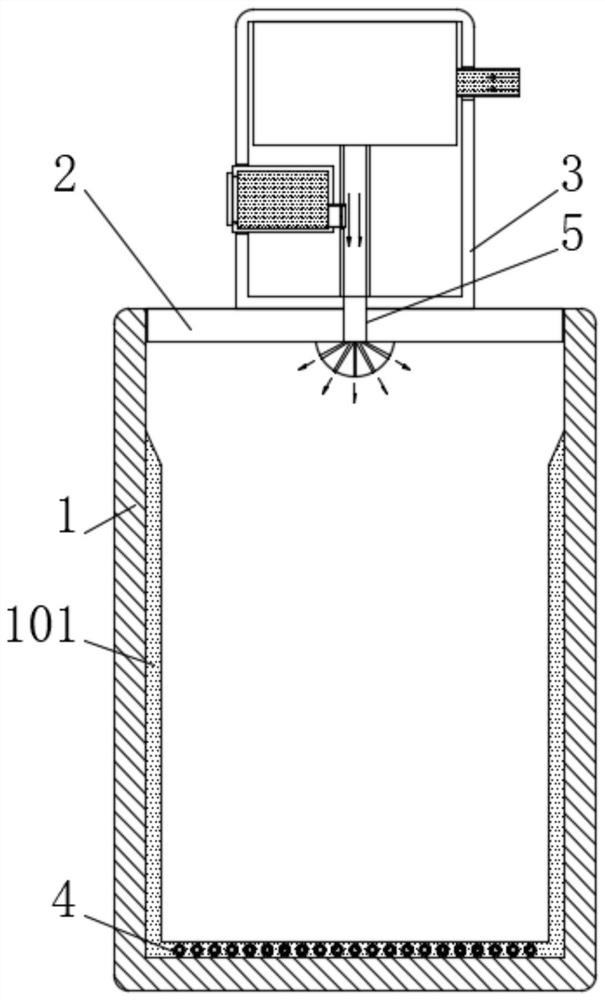

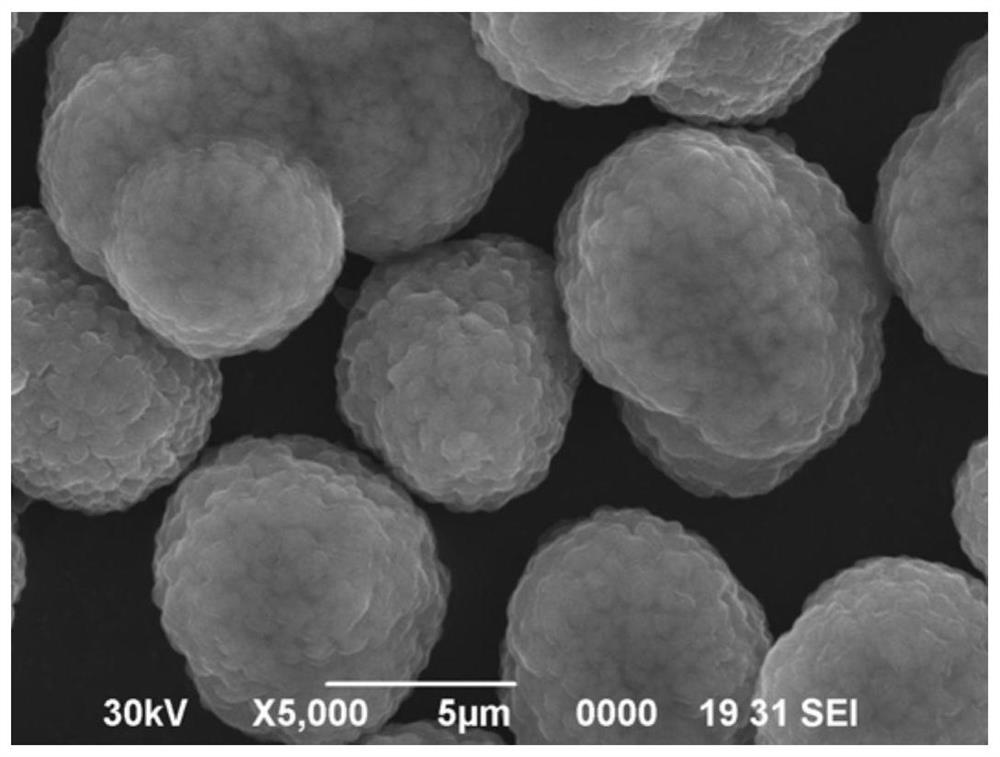

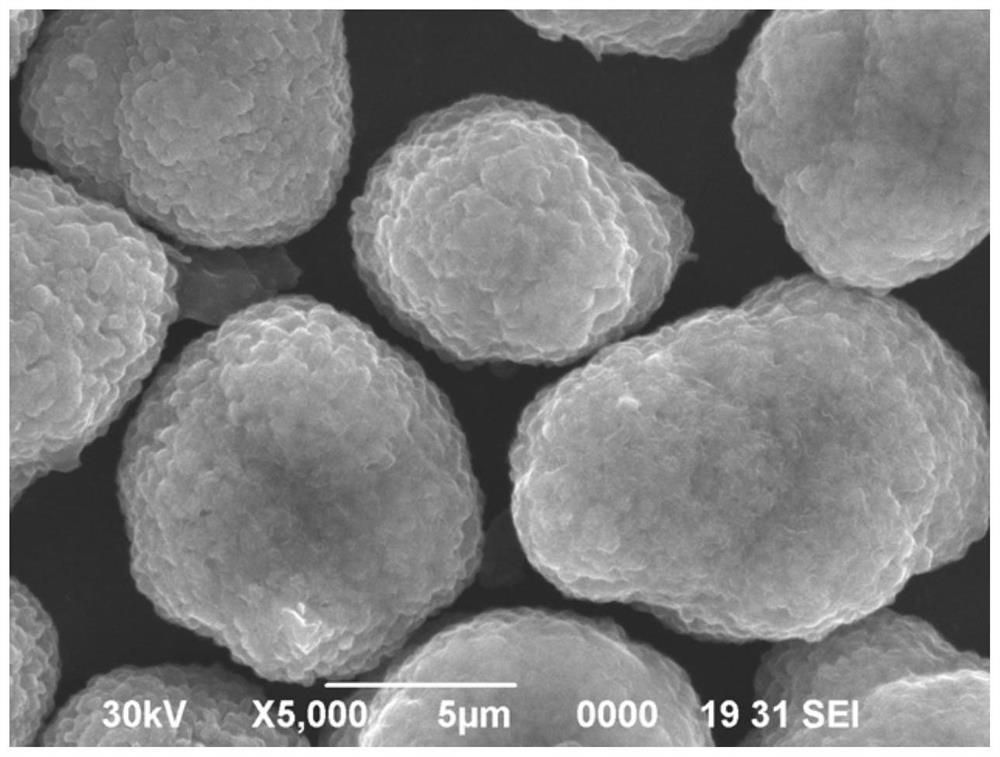

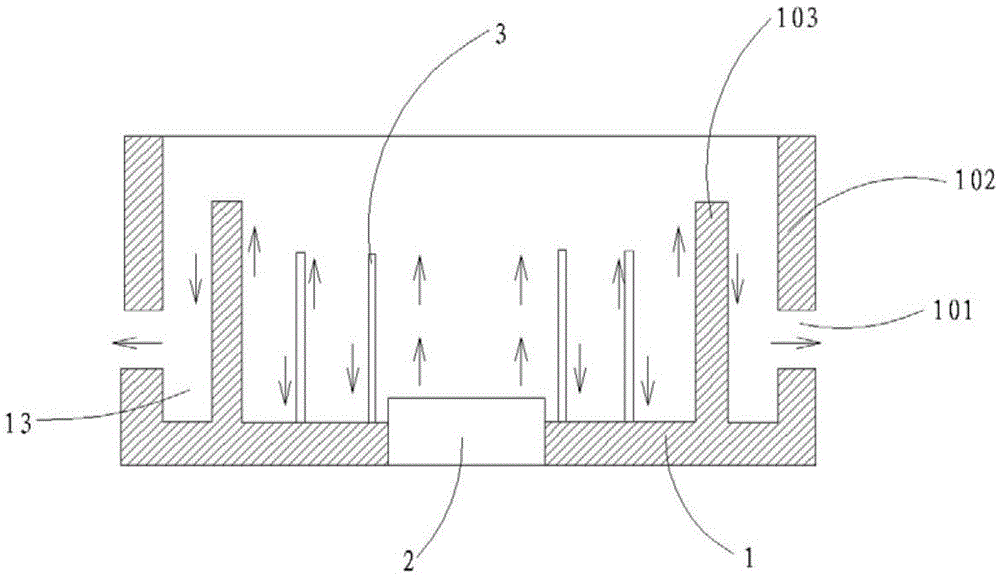

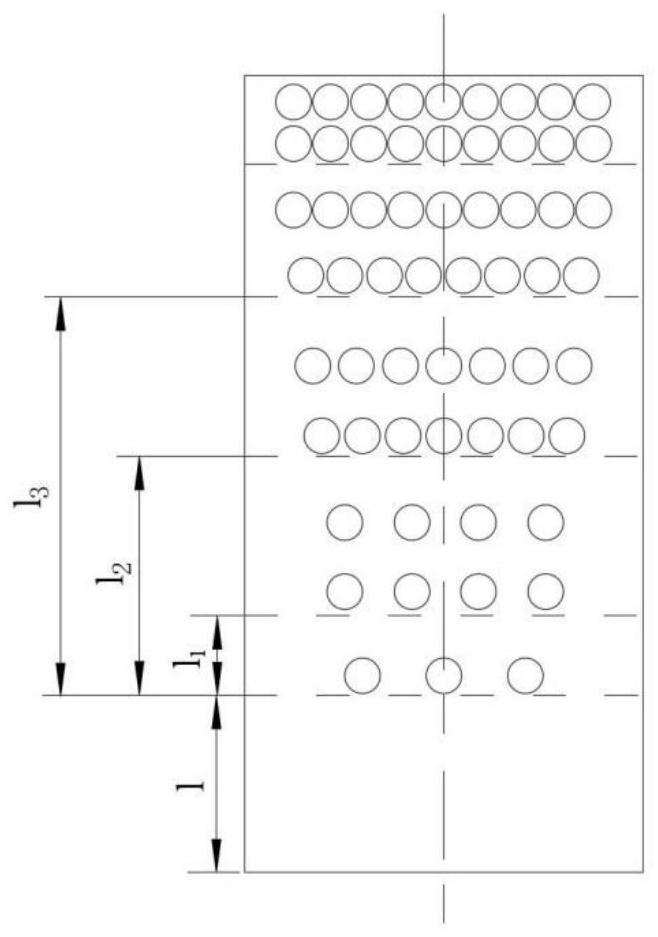

Modified positive electrode material precursor, preparation method thereof, modified positive electrode material and lithium battery

ActiveCN109921013AImprove coating efficiencyUniform sizeCell electrodesSecondary cellsMaterials scienceMetal salts

The invention provides a modified positive electrode material precursor, which comprises an positive electrode material precursor and metal salt coated on the positive electrode material precursor. The safety performance and the cycle performance of the battery obtained by the modified positive electrode material precursor are significantly improved.

Owner:微宏先进材料公司

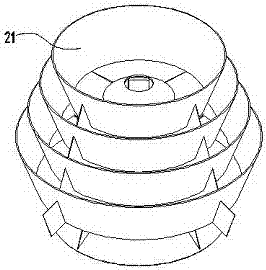

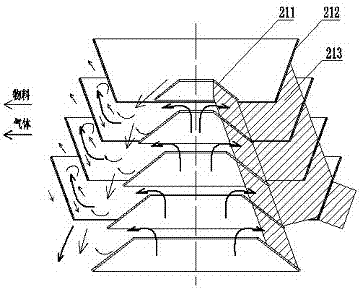

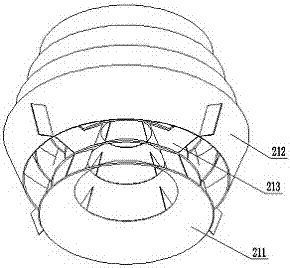

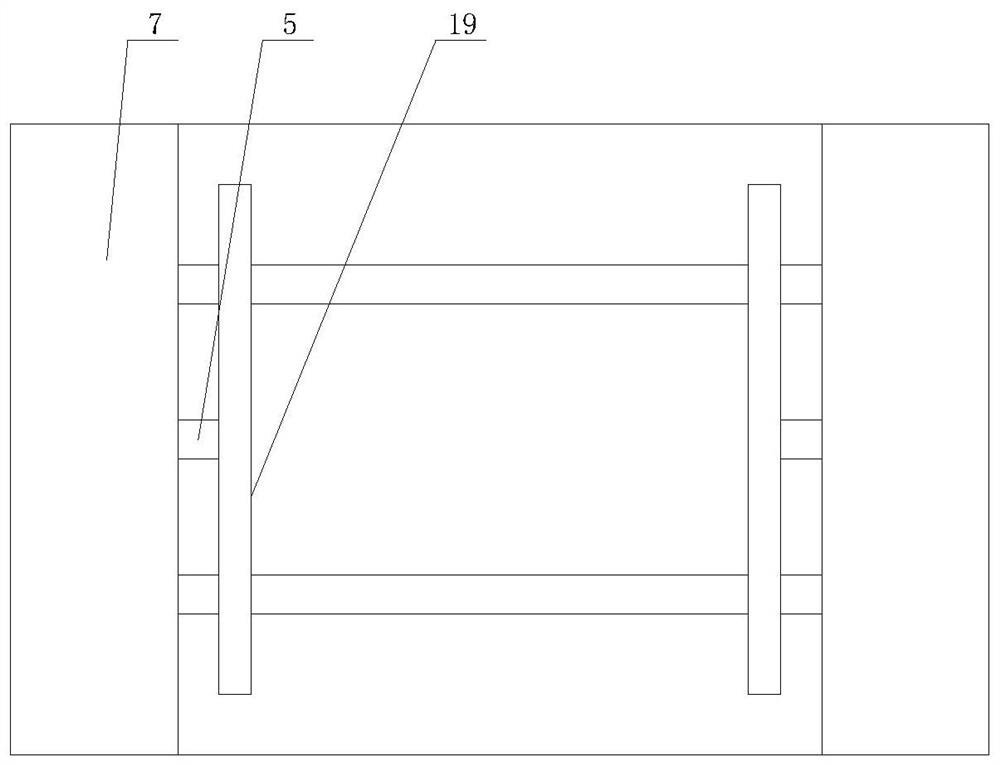

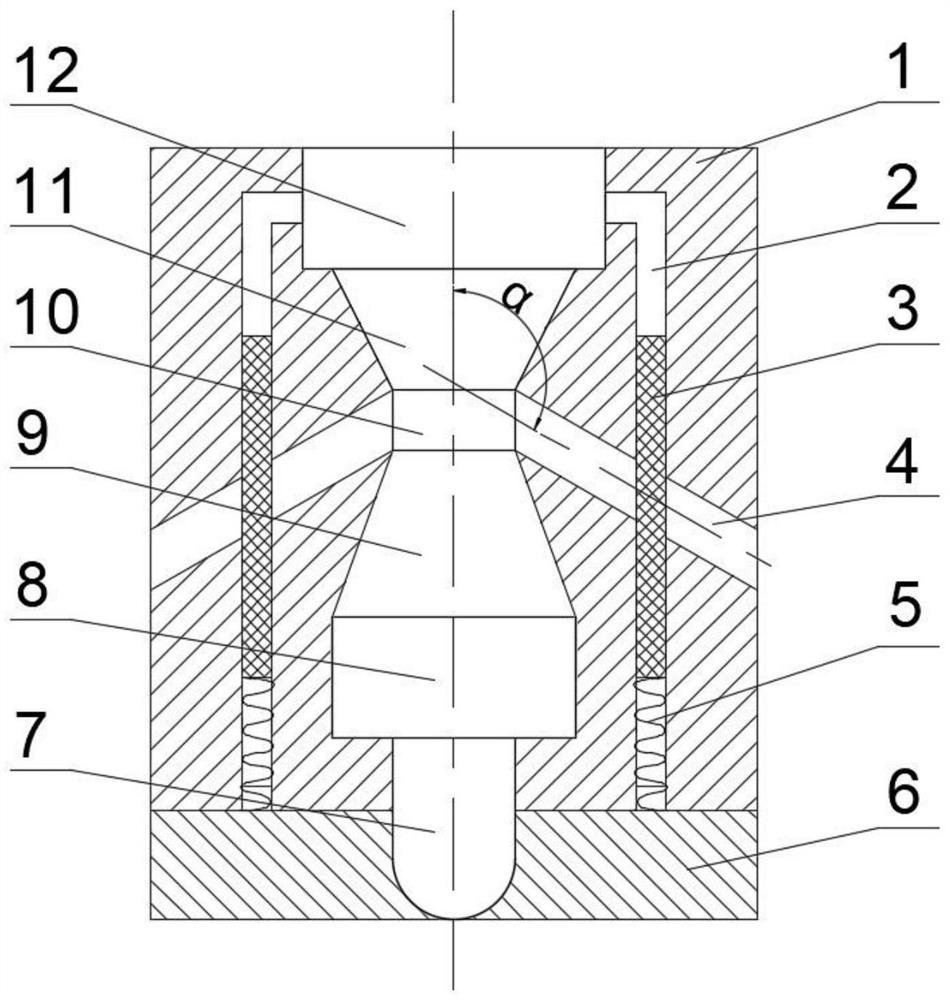

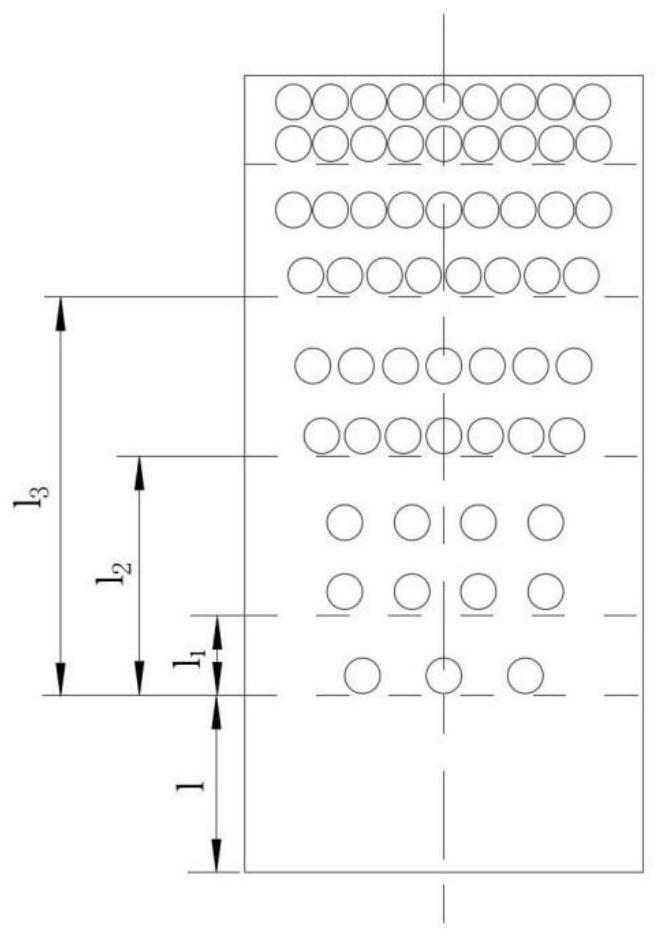

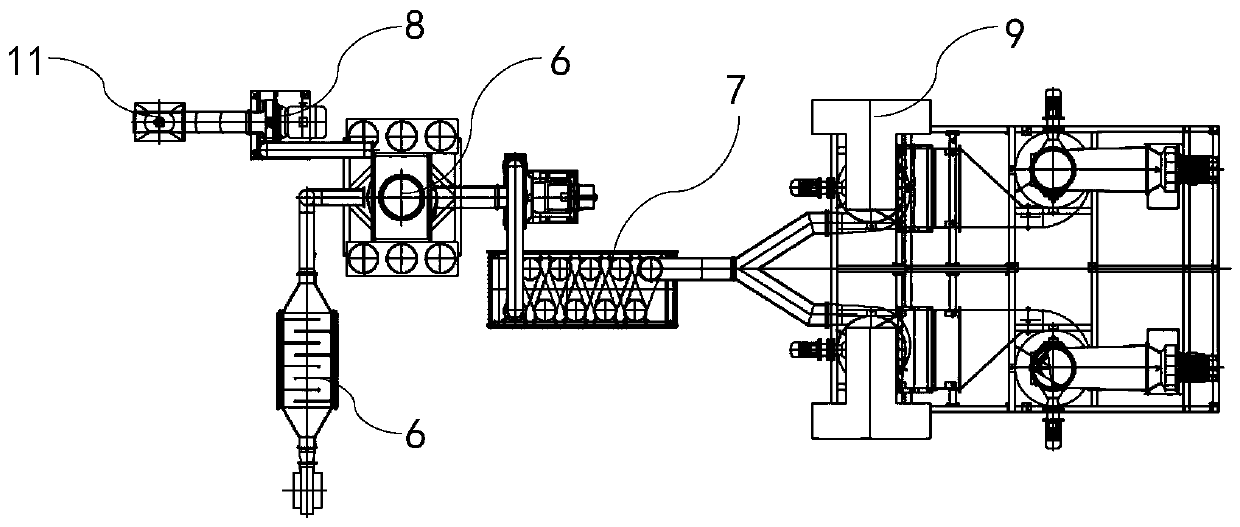

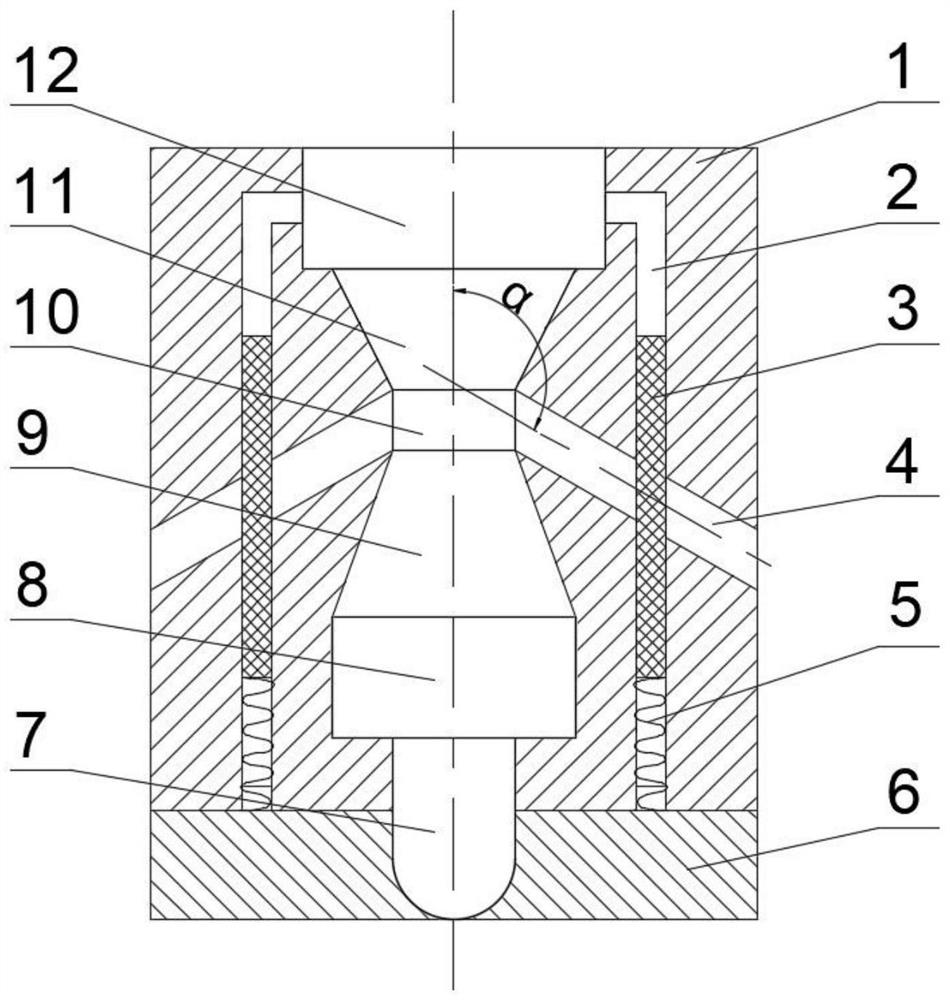

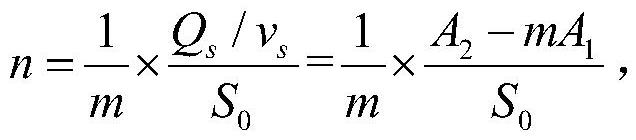

Sorting grid and powder selecting machine for sorting by sorting grid

PendingCN106975609ACompact structureIngenious designGas current separationEngineeringMechanical engineering

The invention discloses a sorting grid. The sorting grid comprises multiple inverted frustum type outer grid plates, multiple forward frustum type inner grid plates, and a sorting grid consisting of multiple grid plates; the outer grid plates and the inner grid plates are coaxially sleeved along the center axis of the sorting grid; and multiple outer and inner grid plates inserted one by one are connected as a whole from top to bottom through the grid plates arranged in the radial direction to form wind ways for enabling wind to pass through and scattering and sorting channels for enabling materials to fall step by step. The invention further discloses a powder selecting machine for sorting by the sorting grid; and the powder selecting machine includes a shell provided with a material sorting cavity inside, a sorting grid mounted in the material sorting cavity, a feed mechanism and a discharge mechanism. The sorting grid is used for enabling the materials to collide by multiple times for full scattering in the natural falling process under the effect of self weight in limited space; and a sorting machine once sorts the materials in the gradual scattering process to effectively improve the sorting efficiency and the sorting rate.

Owner:MIANYANG LANAO HEAVY MACHINERY MFG

Sludge dewatering process combining physical and chemical methods

ActiveCN102126823AEven mixing effectImprove efficiencySludge treatment by de-watering/drying/thickeningSludge cakeProcess engineering

The invention relates to a sludge dewatering process combining physical and chemical methods, in particular to a sludge treatment process which combines physical and chemical methods to achieve a higher dewatering rate. The process comprises the following steps: 1) delivering primary sludge into a sludge modifying machine; 2) adding a dewatering assistant into the sludge modifying machine, and stirring for 5-10 minutes; 3) adding a second dewatering assistant into the sludge modifying machine, and continuing to stir for 5-10 minutes; 4) discharging the sludge from the sludge modifying machine to obtain modified sludge; and 5) mechanically dewatering the modified sludge to obtain sludge cakes of which the water content is not higher than 40%. When being used for treating sludge, the invention has the advantages of high efficiency, low investment and low operating cost.

Owner:浙江旺能生态科技有限公司

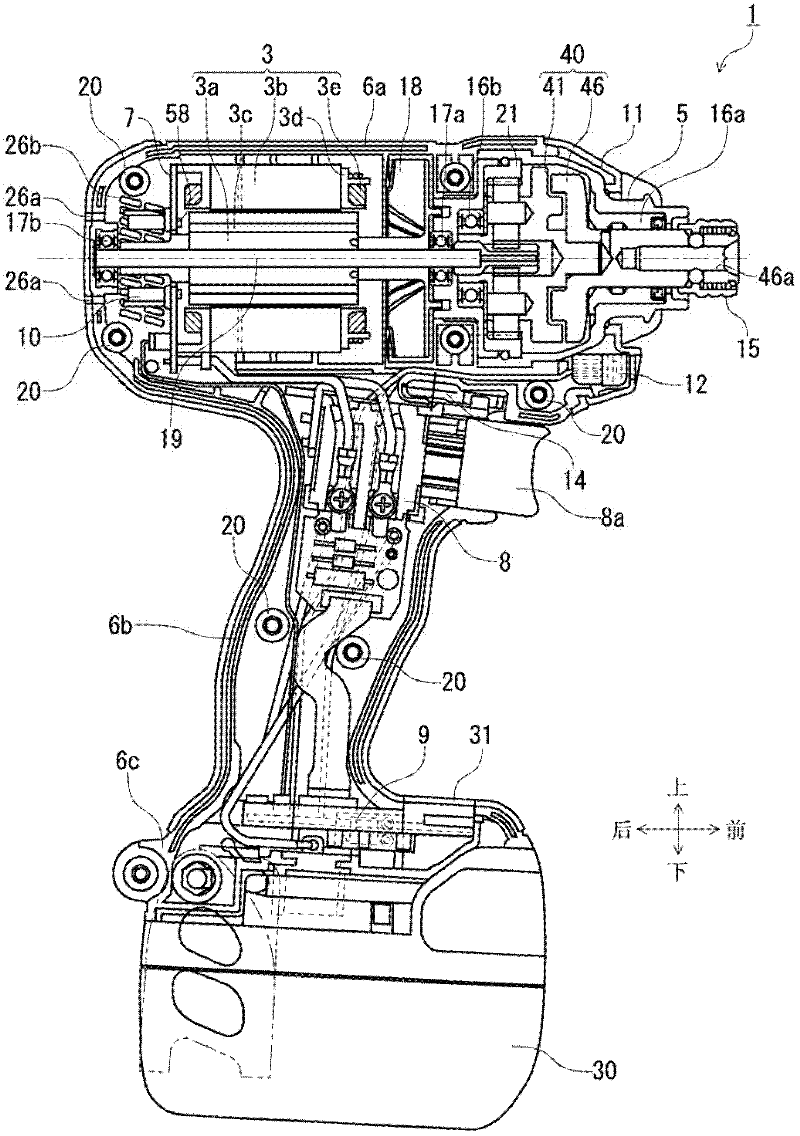

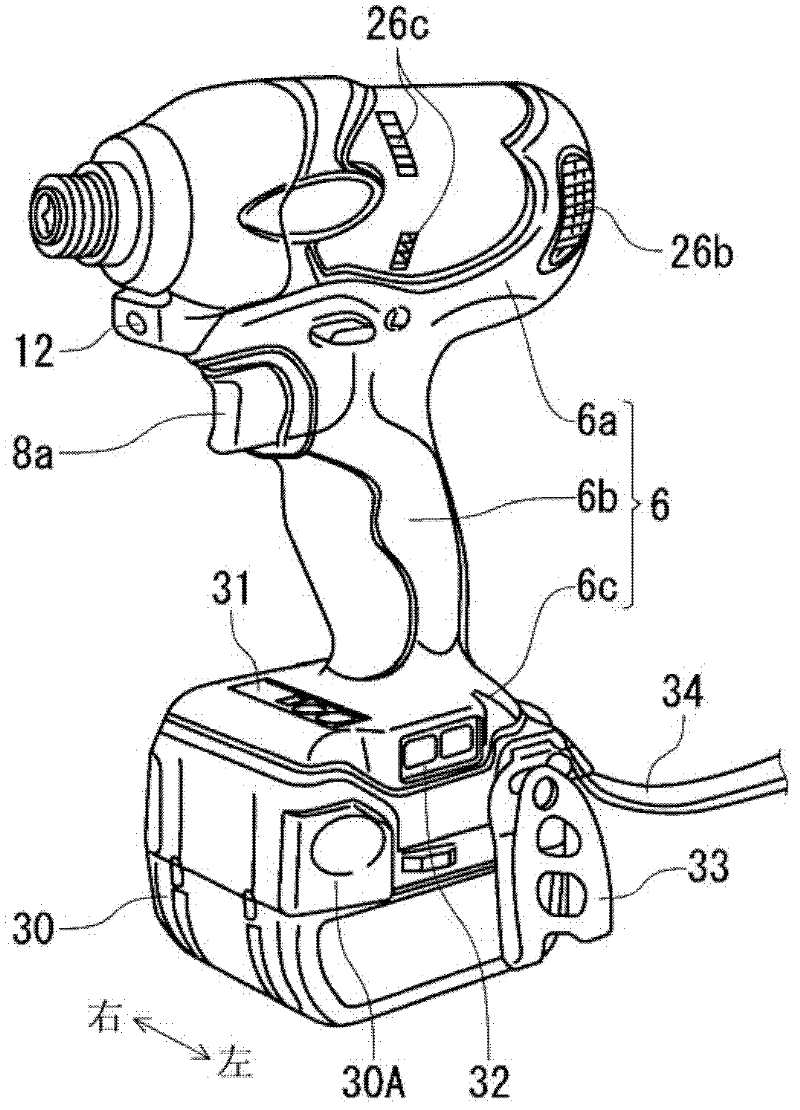

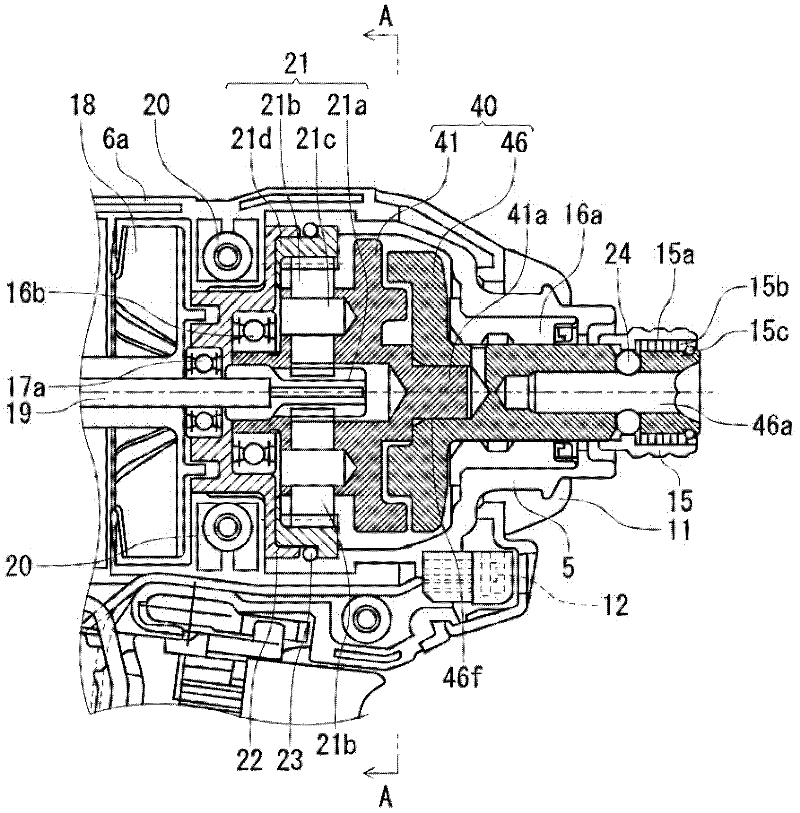

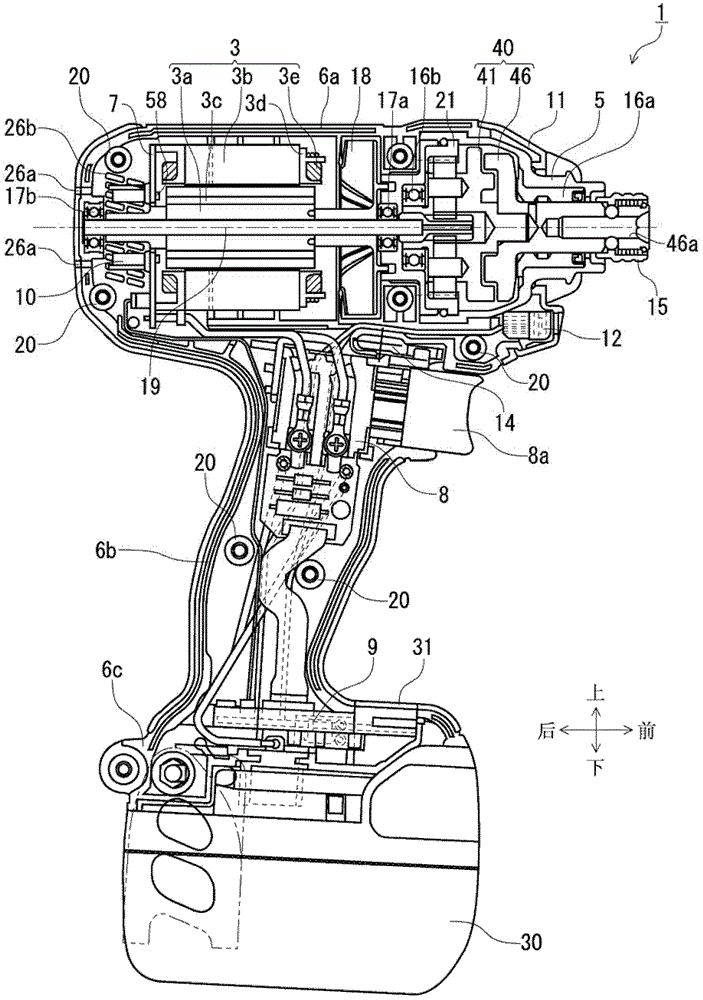

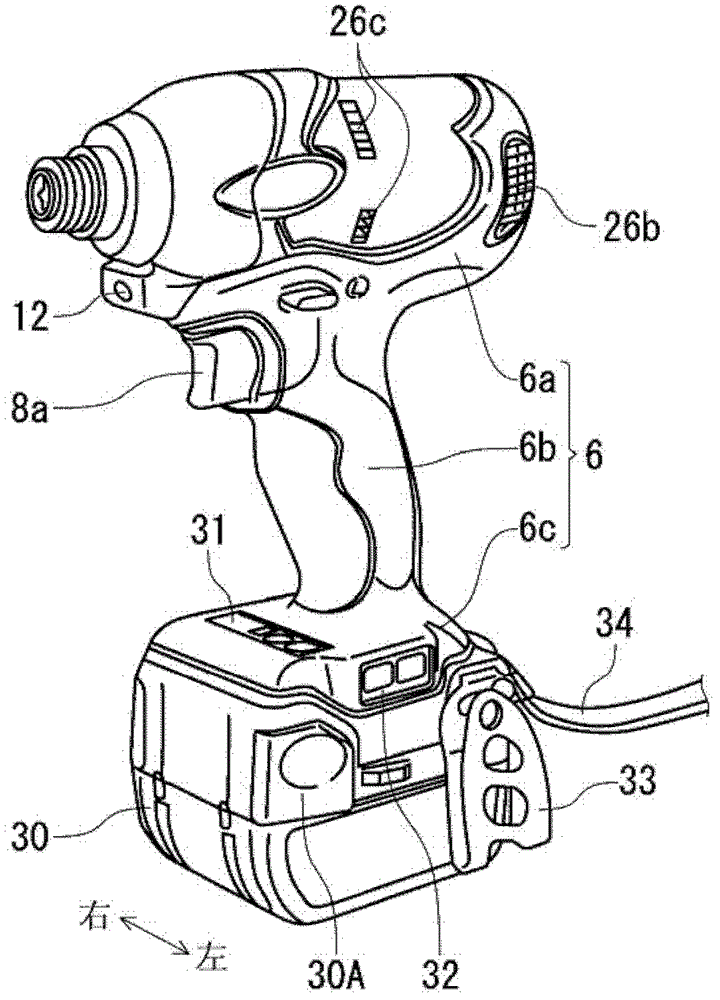

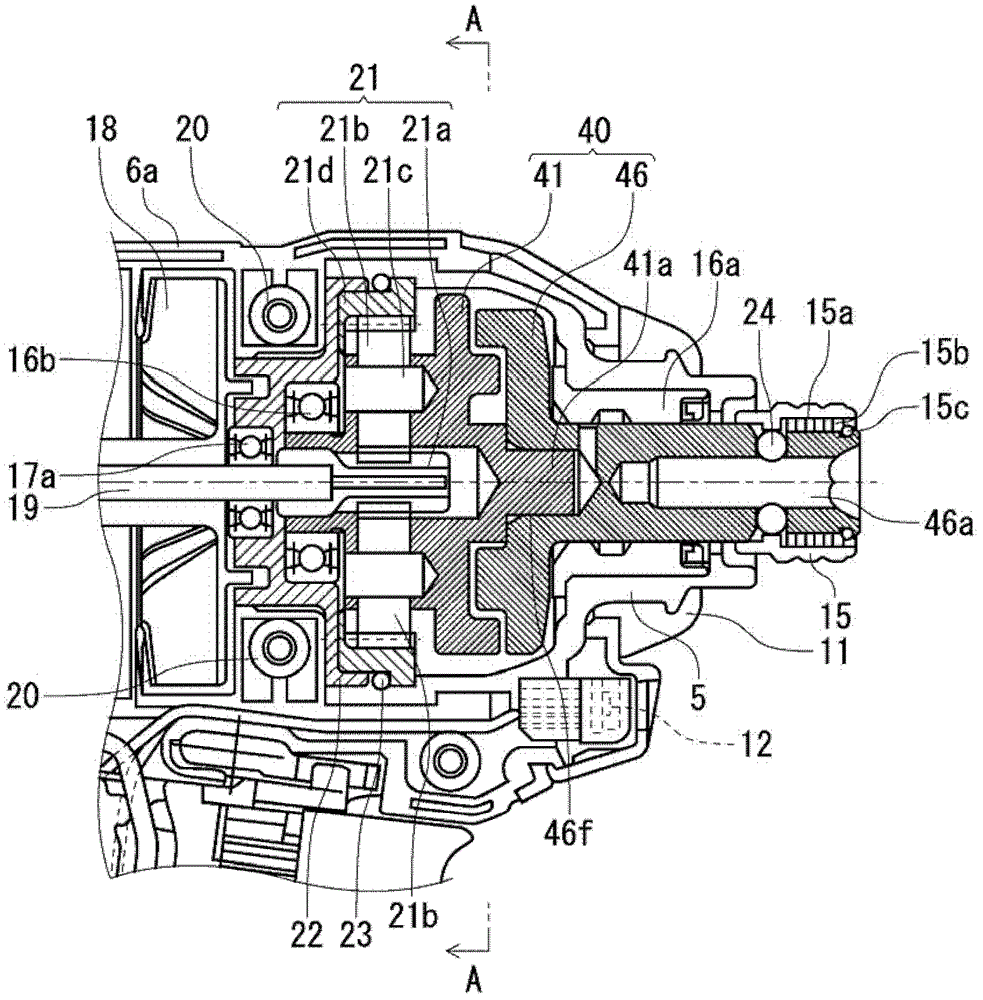

Impact tool

InactiveCN102470518AAxial front-to-back length shortSimple structureSpannersWrenchesEngineeringControl theory

According to one embodiment, an impact tool includes: a motor (3); and a hammer (11) that is connected to the motor and that has a striking-side surface; and an anvil (16) that is journalled to be rotatable with respect to the hammer (11), that has a struck-side surface and that provides a striking power to a tip tool, wherein the motor (3) is drivable in: a first driving mode in which the motor (3) is continuously driven in a normal rotation; a second driving mode in which the motor (3) is intermittently driven only in the normal rotation; and a third driving mode in which the motor (3) is intermittently driven in the normal rotation and in a reverse rotation.

Owner:KOKI HLDG CO LTD

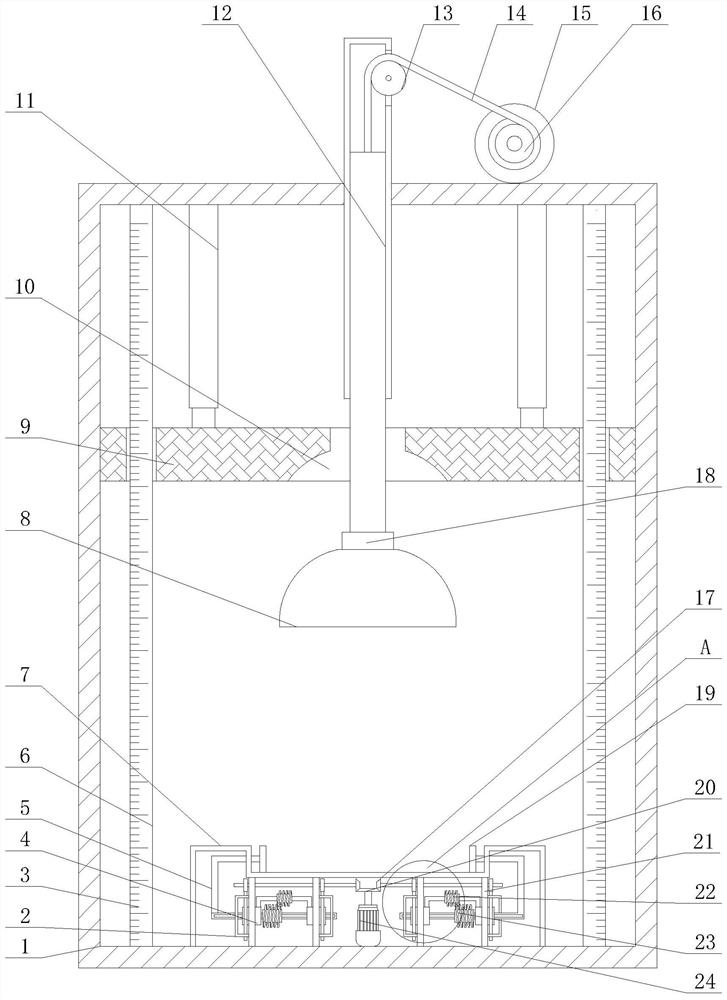

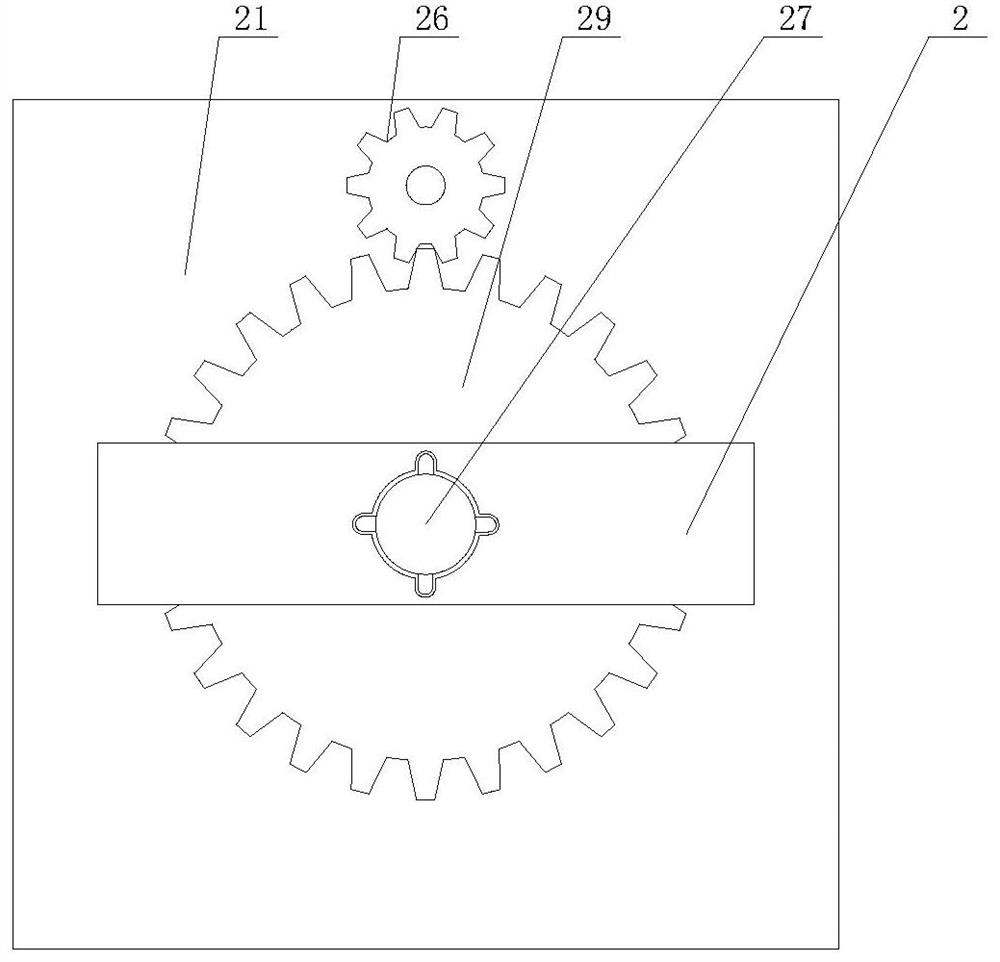

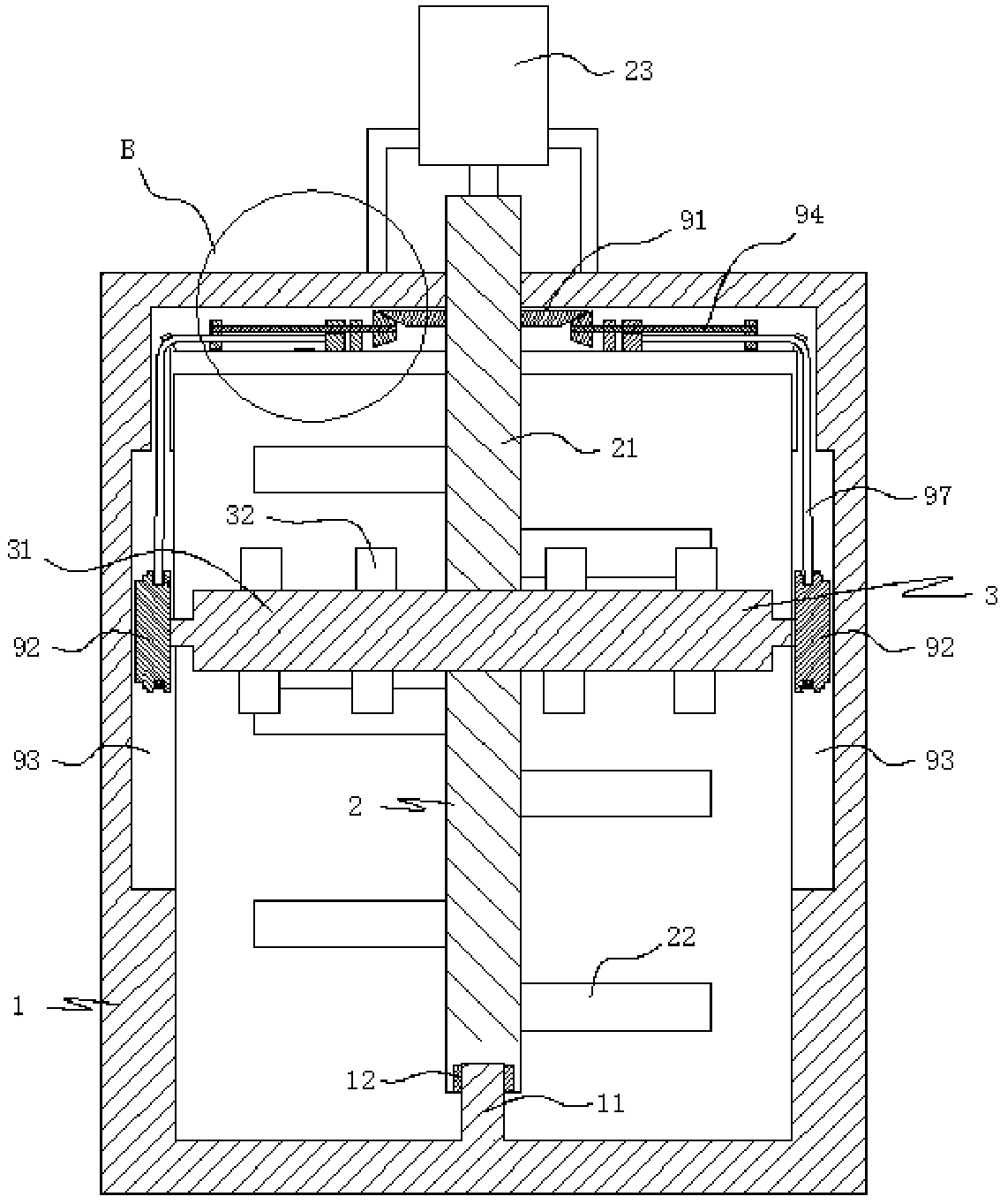

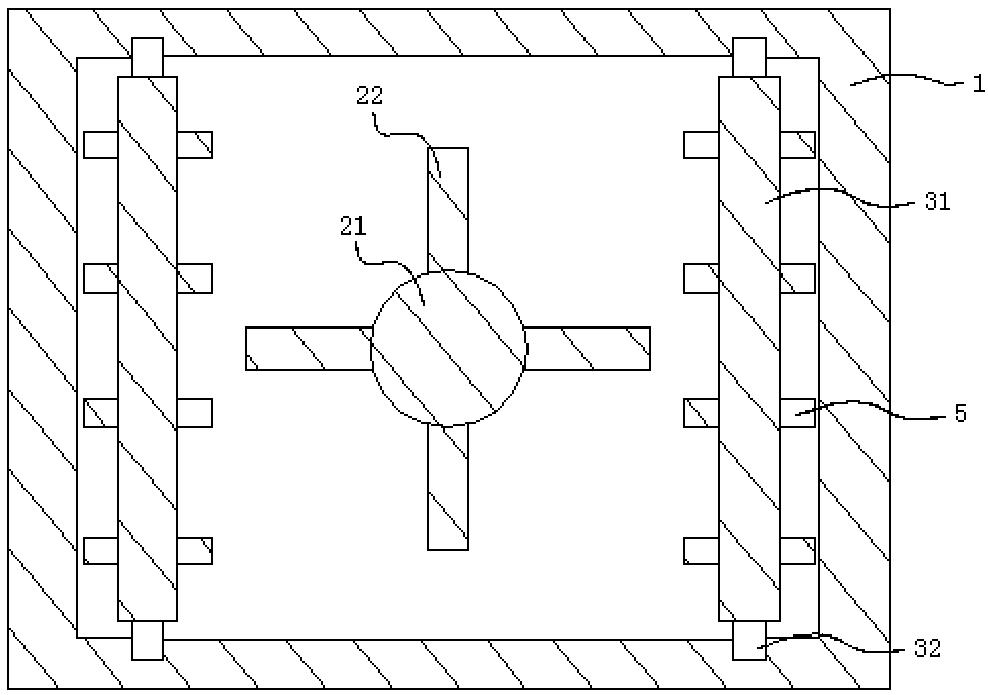

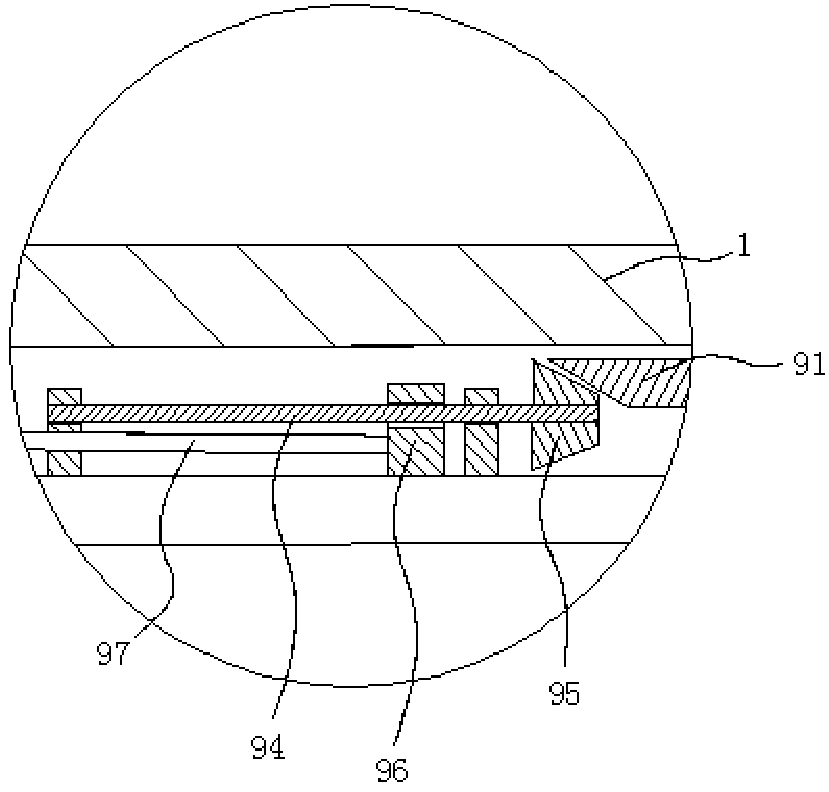

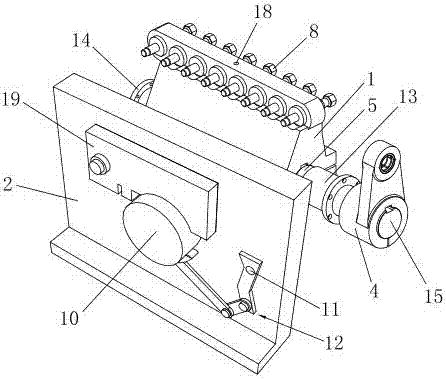

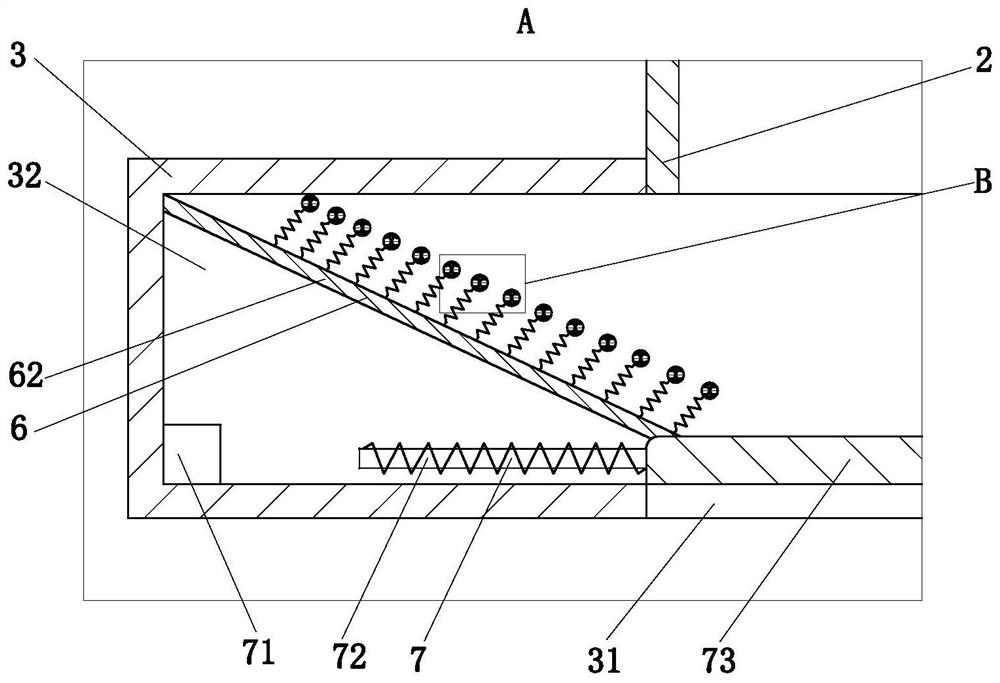

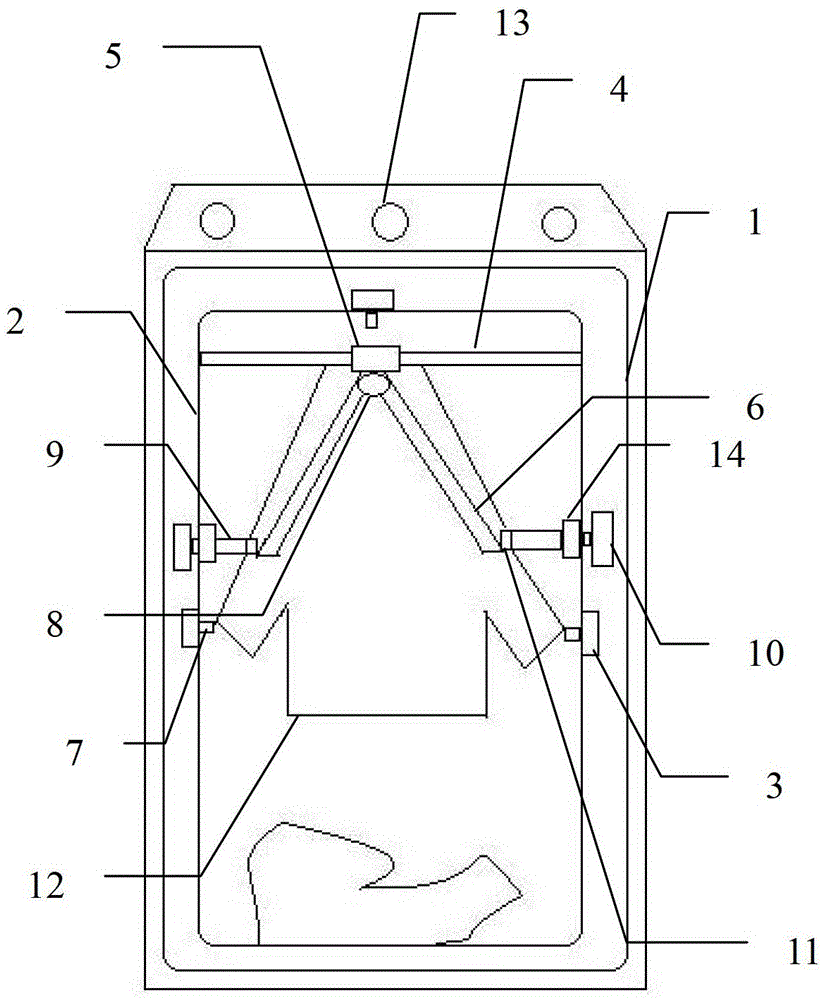

Compression resistance detection device for automobile part production and processing

InactiveCN112014246AEasy clampingHit fullMachine part testingMaterial strength using tensile/compressive forcesElectric machineGear wheel

The invention discloses a compression resistance detection device for automobile part production and processing. The device comprises a mounting rack, u-shaped plates, metering lines, rotary drums, L-shaped guide rods, guide columns, placement seats, striking hammers, adjusting plates, limiting grooves, electric push rods, telescopic columns, fixed pulleys, pull ropes, first stepping motors, winding wheels, driven bevel gears, electromagnets, clamping plates, driving bevel gears, mounting frames, small worms, large worms, second stepping motors, shaft rods, driving gears, sliding rods, U-shaped guide rods and driven gears. According to the device, spare and accessory parts can be better clamped; the position deviation of spare and accessory parts during impact is avoided; the striking hammers can strike the spare and accessory parts more sufficiently, the striking efficiency is greatly improved, different striking forces are better applied to the spare and accessory parts for strikingdetection, the detection efficiency is greatly improved, the detection result is also greatly improved, and meanwhile, the practicability is also enhanced.

Owner:芜湖肯昌机电有限公司

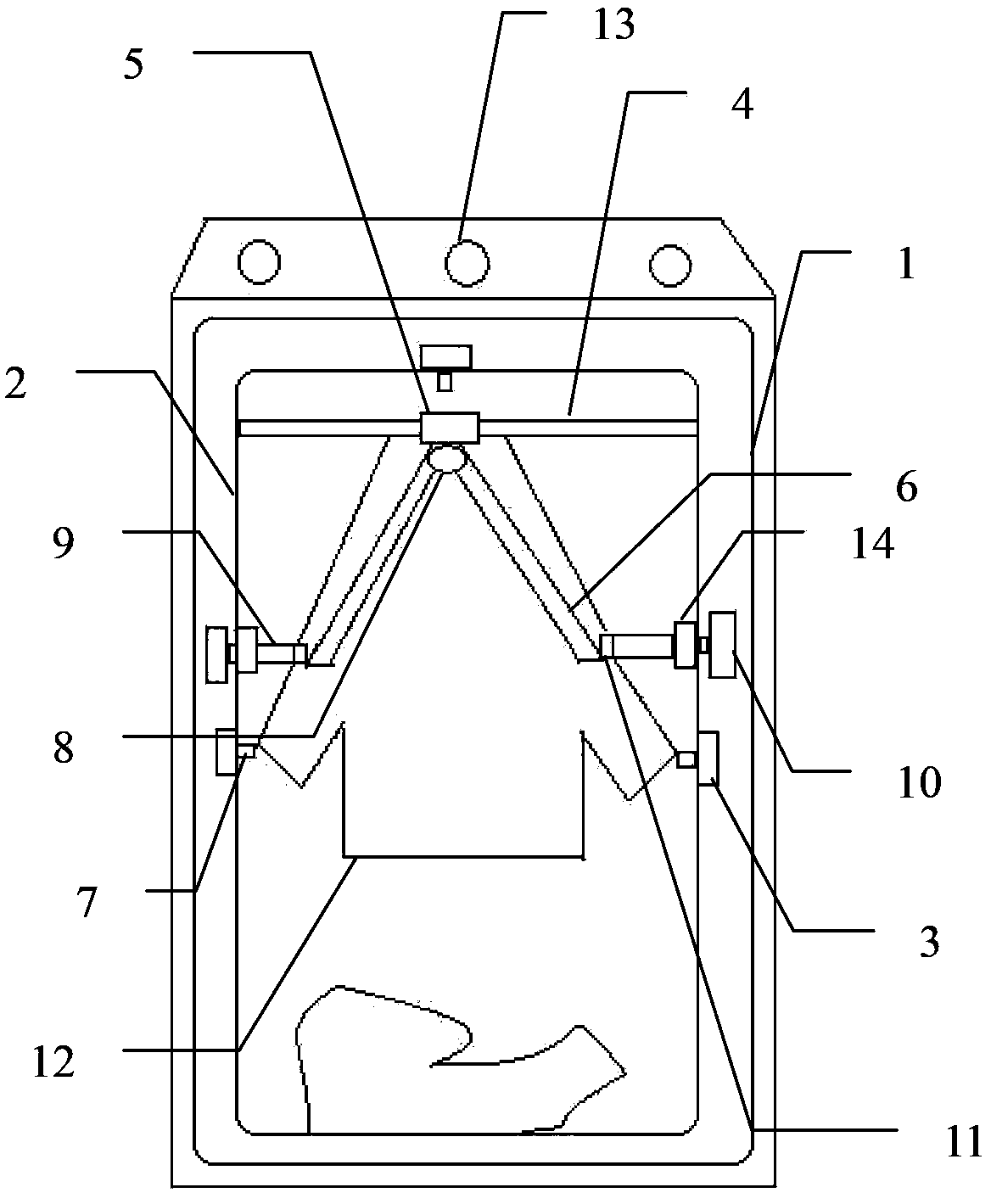

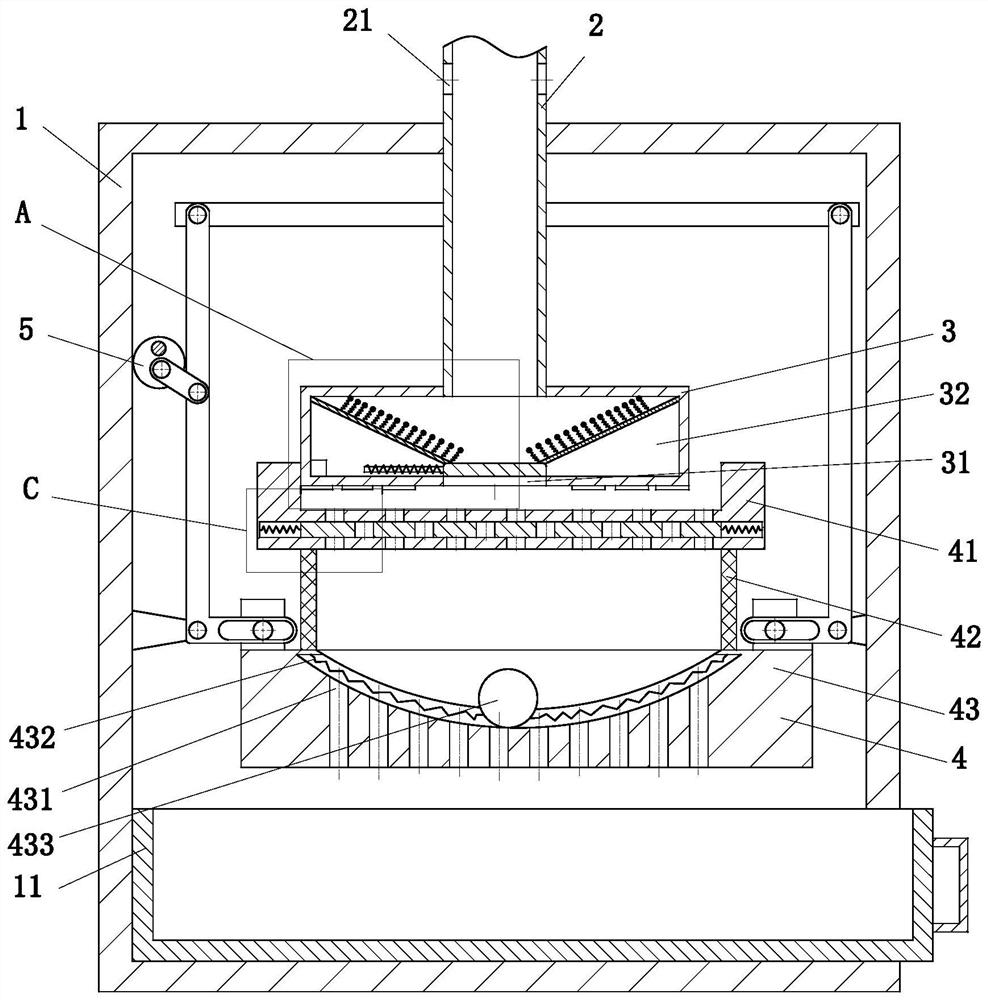

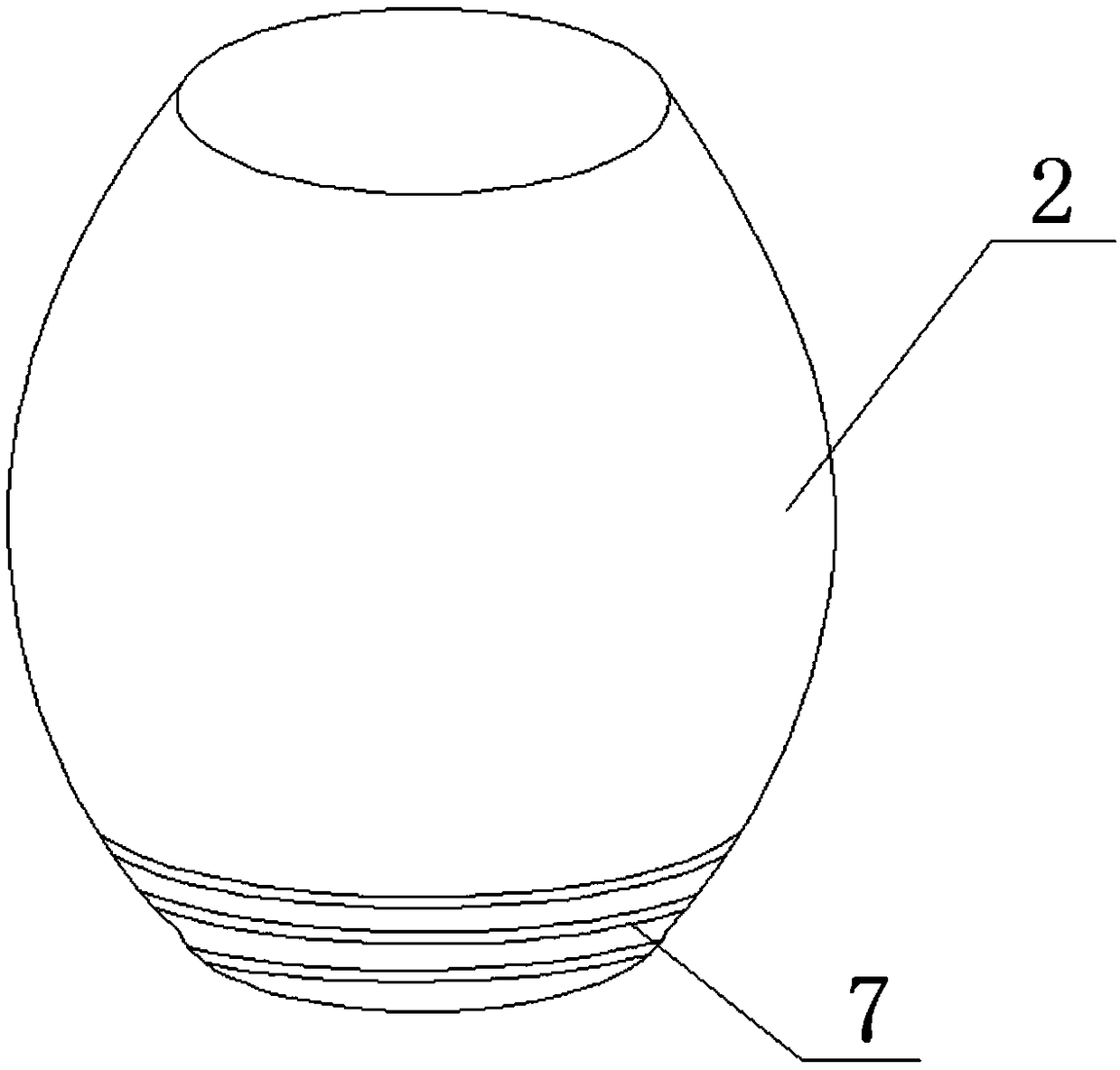

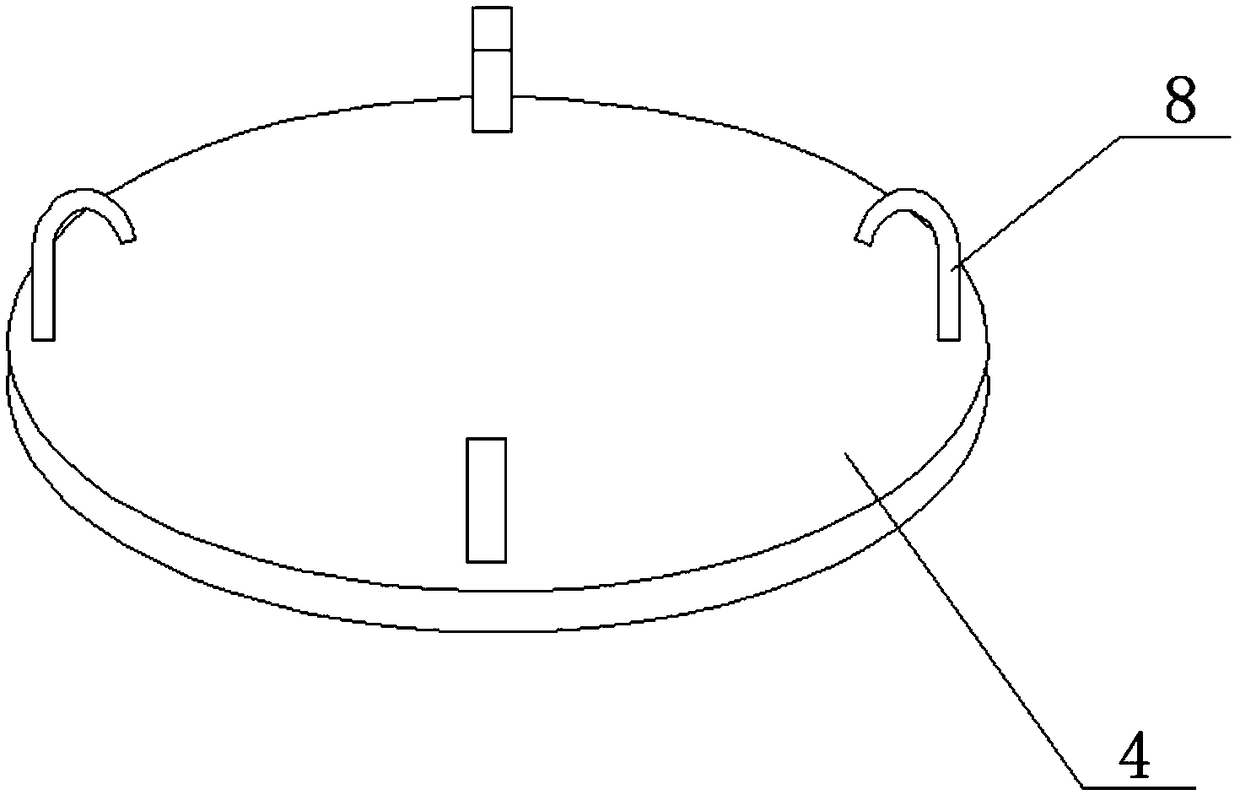

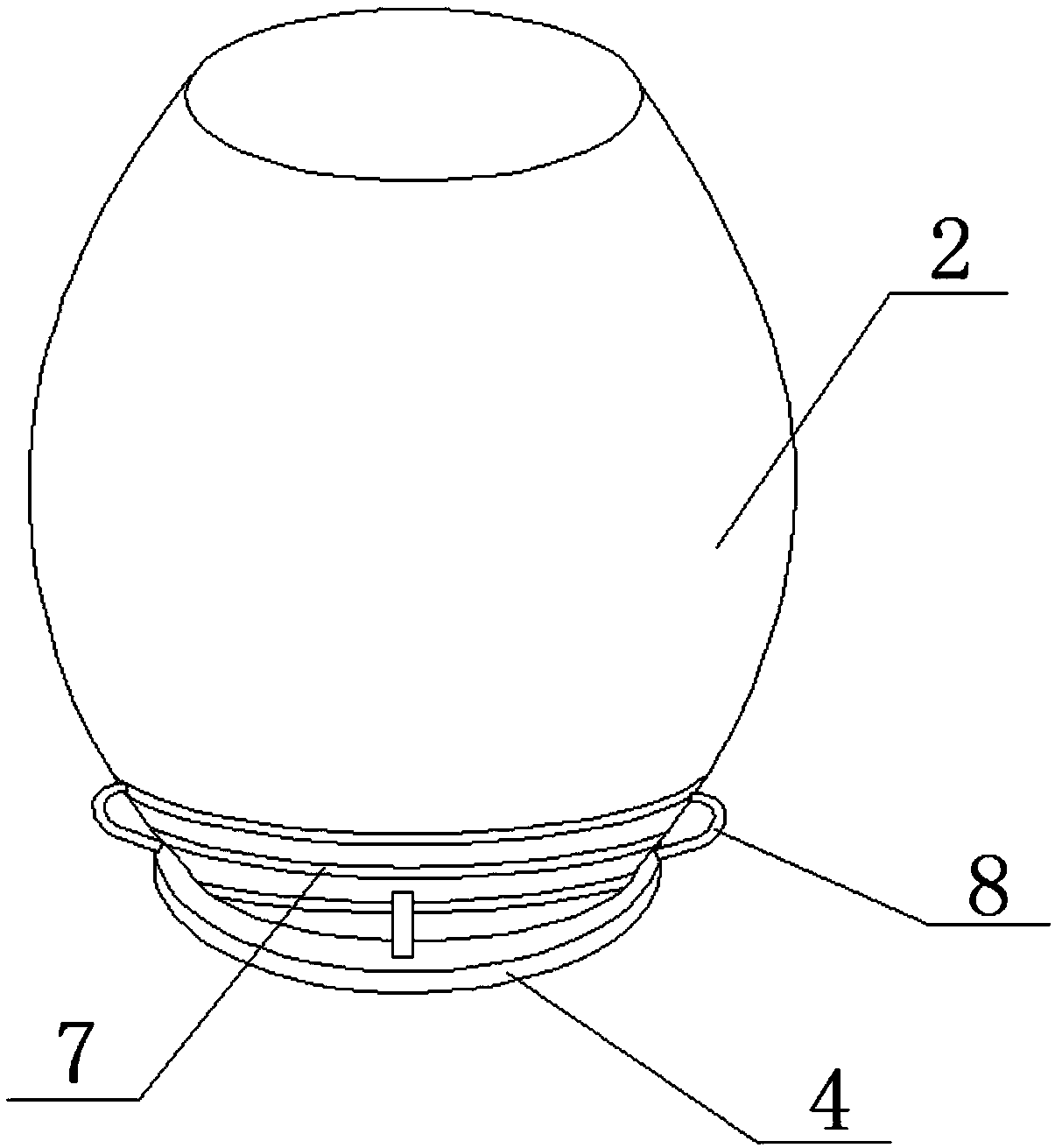

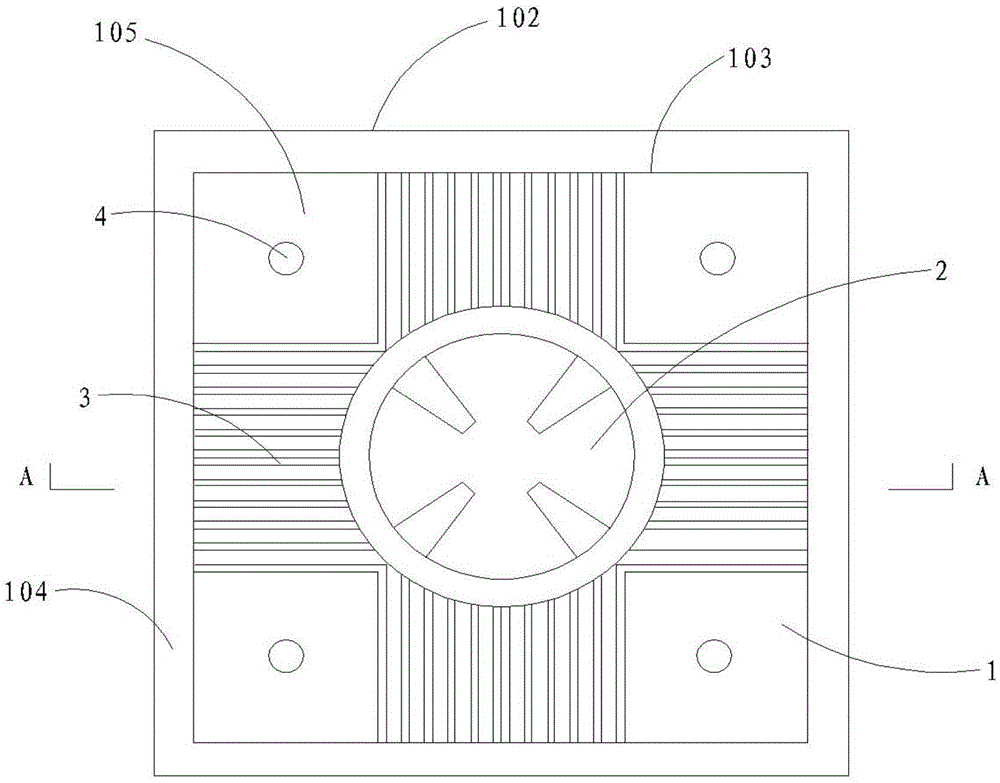

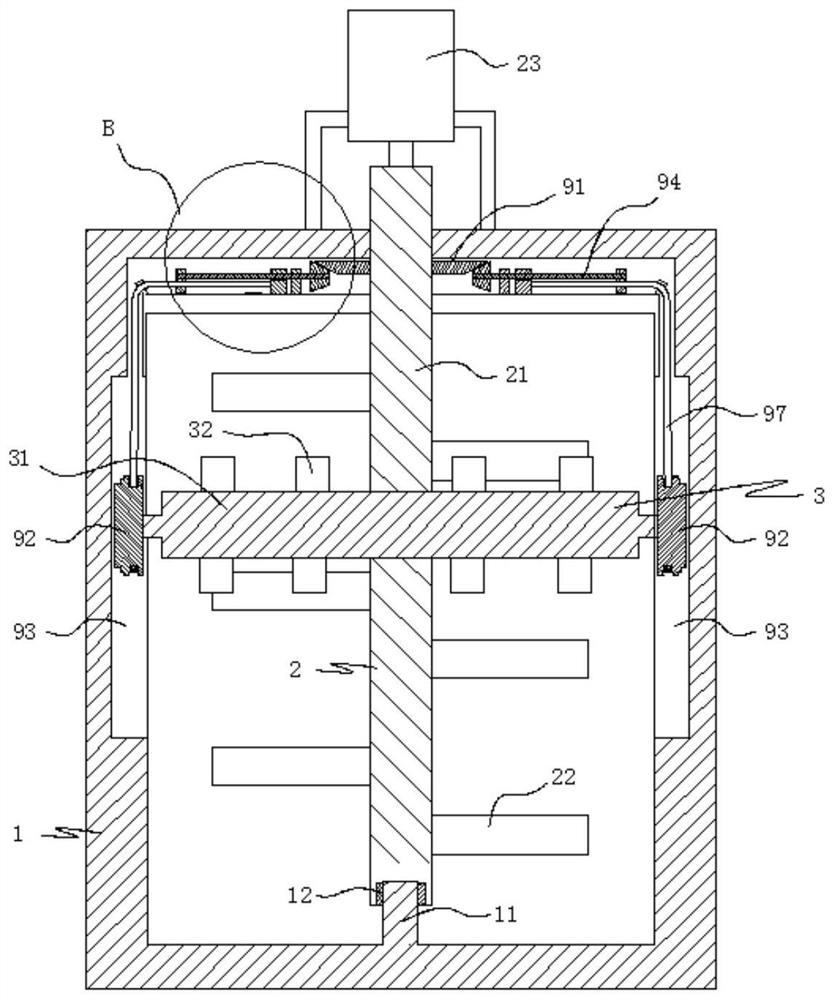

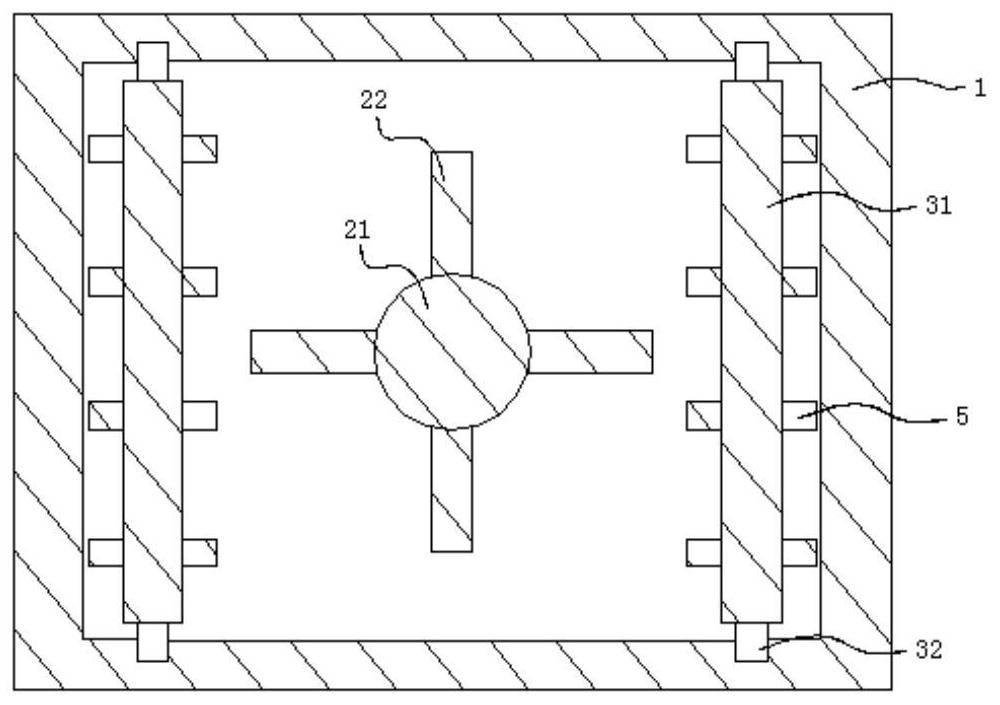

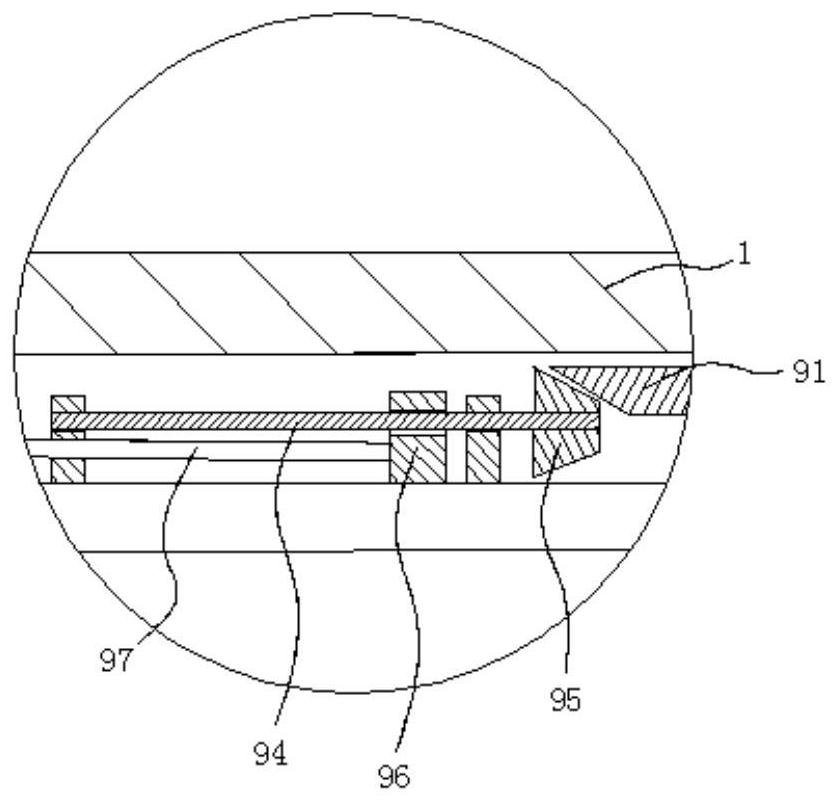

Clothing vertical-hanging type plasma washing machine

ActiveCN103422321AHit fullEfficient removalOther washing machinesTextiles and paperPlasma generatorAerospace engineering

The invention relates to the field of washing machines, in particular to a clothing vertical-hanging type plasma washing machine. The clothing vertical-hanging type plasma washing machine is characterized by comprising an outer washing barrel, an inner washing barrel and a plurality of plasma generators, and the inner washing barrel is sleeved in the outer washing barrel rotationally; the upper end of the inner washing barrel is a plasma clothing washing part, and the lower end of the inner washing barrel is a washing part; a horizontal rod is arranged at the clothing inlet at the upper end of the inner washing barrel, and a rotating device is fixed at the center of the horizontal rod, a vertical-hanging type hanger is mounted on the rotating device which is used for unfolding the clothing to be washed and which is capable of rotating in the range of 360 degrees under the action of the rotating device; the plasma generators are arranged on the outer wall of the inner washing barrel corresponding to the rotating device and in the middle of the side wall of the inner washing barrel respectively; the plasma generators input plasma to the inner washing barrel through gas input pipes. The clothing vertical-hanging type plasma washing machine can perform plasma wash on special parts of the clothing particularly, and decontaminating effect and washing efficiency are improved.

Owner:哈威光电科技(苏州)有限公司

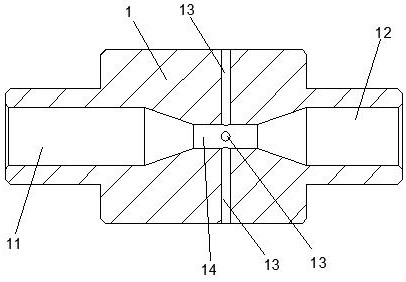

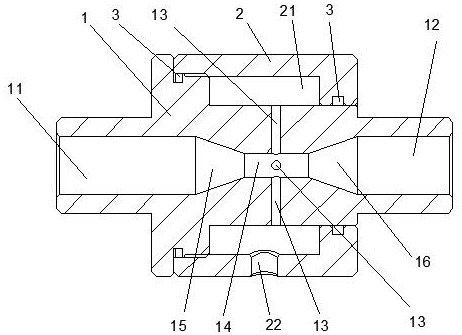

Fan-shaped air suction nozzle capable of automatically adjusting air suction speed

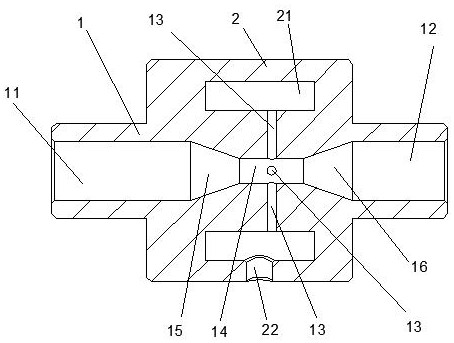

The invention provides a fan-shaped air suction nozzle capable of automatically adjusting the air suction speed. The fan-shaped air suction nozzle capable of automatically adjusting the air suction speed comprises a nozzle body, a liquid channel, a pressure tank and an air inlet channel, wherein the liquid channel communicated with a spray hole is arranged in the nozzle body; the inlet section of the liquid channel is communicated with the pressure tank; the air inlet channel penetrates through the pressure tank and then is communicated with the liquid channel; an air inlet hole plate is installed in the pressure tank through an elastic damping device; the air inlet hole plate is made to move at the intersection of the pressure tank and the air inlet channel through changes of the inlet pressure of the liquid channel; a plurality of through holes with the same size or different sizes are formed in the air inlet hole plate; and the air inlet hole plate moves in the pressure tank to change the air inflow in the liquid channel. According to the fan-shaped air suction nozzle capable of automatically adjusting the air suction speed provided by the invention, the air inlet speed can be automatically adjusted according to the pressure change of liquid flowing into the nozzle, so that sucked air more sufficiently collides with the liquid in a straight column section at the air inlet part of the liquid channel, and air and pressure liquid are better mixed.

Owner:JIANGSU UNIV

Energy-saving and environment-friendly mixing stirrer for building material coating production

ActiveCN111701521AFull of irregular movementIncrease buoyancyRotary stirring mixersTransportation and packagingArchitectural engineeringMechanical engineering

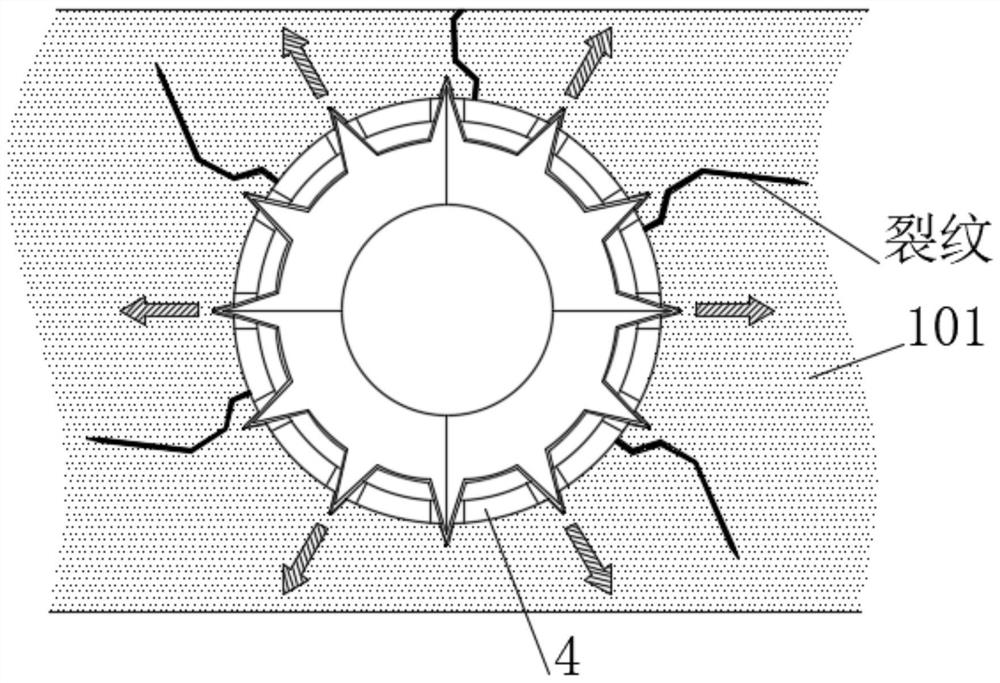

The invention discloses an energy-saving and environment-friendly mixing stirrer for building material coating production. The invention belongs to the technical field of coating production, accordingto the scheme, the air pump is started to continuously blow high-speed airflow into the stirring box; the pressure difference generated when the airflow flows is used; magnetic powder and sand are sprayed out in a radial shape; meanwhile, the mixed coating stirring box is heated, and then the built-in expansion ball is heated and expanded in the paint coating; therefore, cracks are generated in the paint coating; along with the continuous expansion of the built-in expansion ball, the coating at the bottom end in the mixed paint stirring box is broken; and by means of the adsorption effect ofthe magnet ball, the magnetic powder is tightly adsorbed on the surface of the built-in expansion ball; therefore, the built-in expansion ball is simulated into an abrasive paper bottom piece, the magnetic powder is simulated into gravel, the built-in expansion ball automatically moves along with the change of the size of input airflow, and the built-in expansion ball is matched with sand to fullyimpact the inner wall and the inner bottom end of the mixed coating stirring box, so that coating layers on the inner wall and the inner bottom end of the mixed coating stirring box are removed.

Owner:SHANDONG CUIBAO NEW MATERIAL TECH CO LTD

impact tool

InactiveCN102470518BAxial front-to-back length shortSimple structureSpannersWrenchesEngineeringDriving mode

According to one embodiment, an impact tool includes: a motor; and a hammer that is connected to the motor and that has a striking-side surface; and an anvil that is journalled to be rotatable with respect to the hammer, that has a struck-side surface and that provides a striking power to a tip tool, wherein the motor is drivable in: a first driving mode in which the motor is continuously driven in a normal rotation; a second driving mode in which the motor is intermittently driven only in the normal rotation; and a third driving mode in which the motor is intermittently driven in the normal rotation and in a reverse rotation.

Owner:KOKI HLDG CO LTD

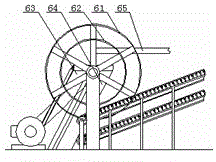

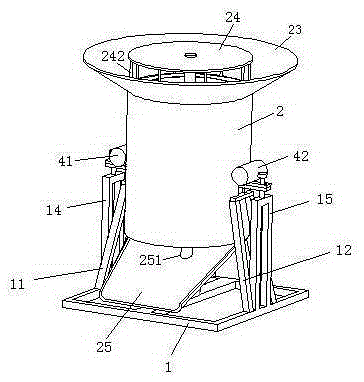

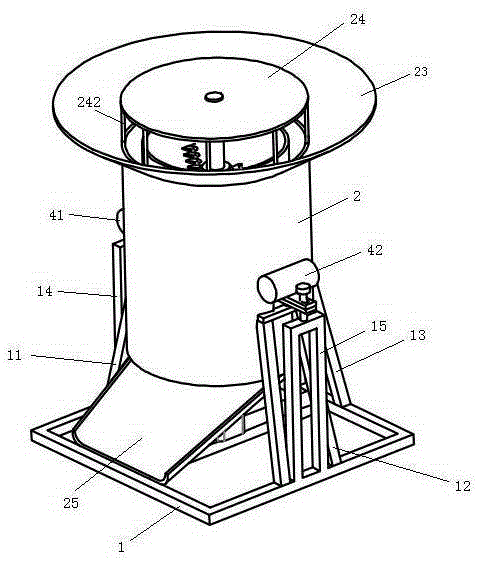

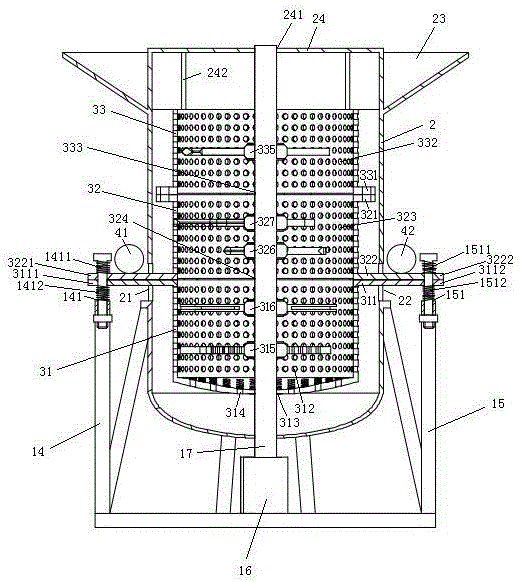

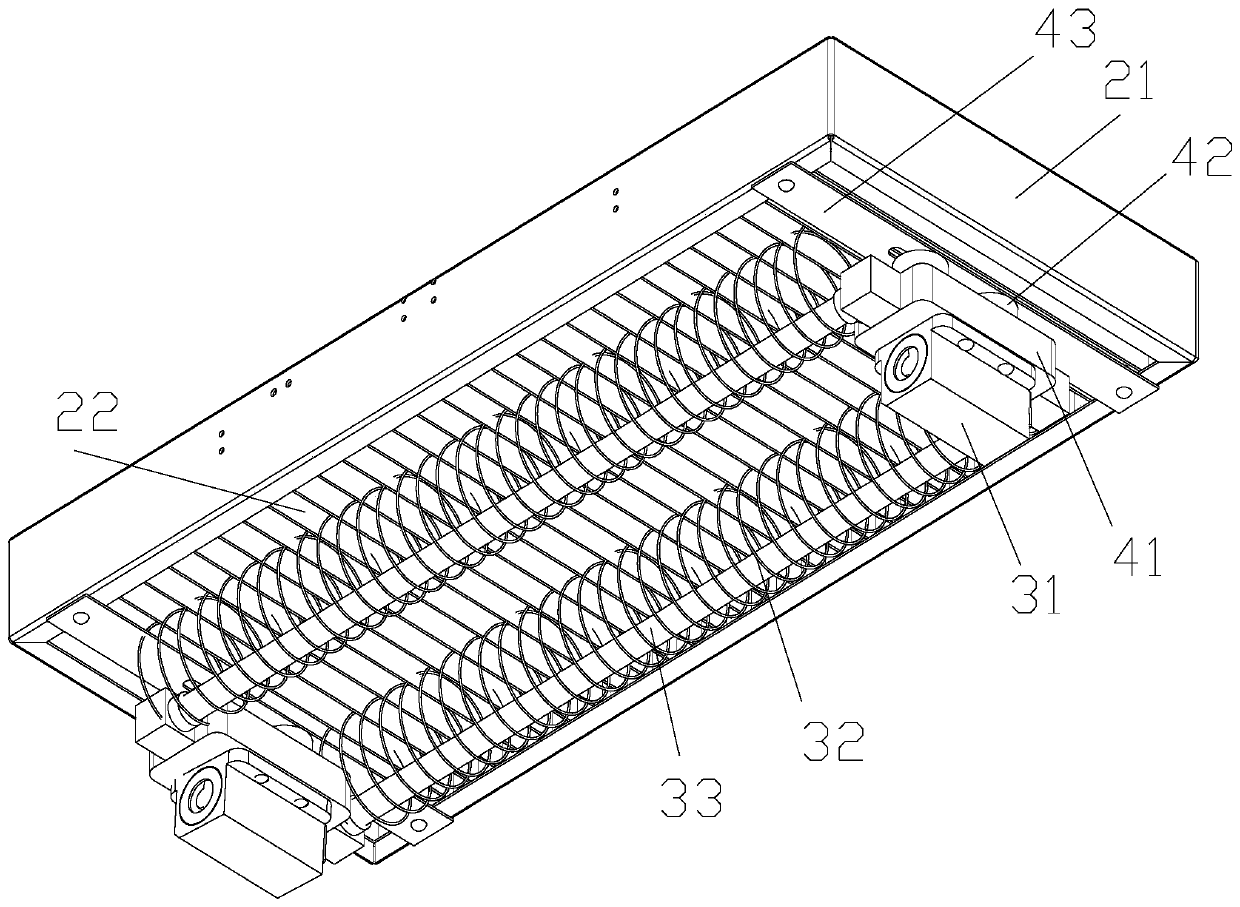

Vertical multi-stage straw grinder

A vertical type multistage straw pulverizer comprises a machine base and is characterized in that an inner screen drum formed by a bottom-layer drum body, a middle-layer drum body and an upper-layer drum body, a square-tooth hammer pulverizing cutter, a groove hammer pulverizing cutter, a small curve blade pulverizing cutter, a large curve edge pulverizing cutter and a roughing cutter are arranged in an outer machine shell, with a top cover, on a machine base; the square-tooth hammer pulverizing cutter and the groove hammer pulverizing cutter are arranged in the bottom-layer drum body, the small curve blade pulverizing cutter and the large curve edge pulverizing cutter are arranged in the middle-layer drum body, the roughing cutter is arranged in the upper-layer cylinder body, and the square-tooth hammer pulverizing cutter, the groove hammer pulverizing cutter, the small curve blade pulverizing cutter, the large curve edge pulverizing cutter and the roughing cutter are arranged on a transmission shaft of a driving motor one by one in a series mode; screen holes are evenly distributed in the peripheral wall and the inner bottom face of the bottom-layer drum body, the peripheral wall and the inner bottom face of the middle-layer drum body and the peripheral wall and the inner bottom face of the upper-layer drum body; the bottom-layer drum body, the middle-layer drum body and the upper-layer drum body are fixedly connected through flange bases; an upper left spring and a lower left spring are arranged on the overlapped upper end face and the lower end face of a left lower middle layer vibration arm and a right lower middle layer vibration arm of the middle-layer drum body, and an upper right spring and a lower right spring are arranged on the overlapped lower end face and the upper end face of a left bottom layer vibration arm and a right bottom layer vibration arm of the bottom-layer drum body; the upper left spring, the lower left spring, the upper right spring and the lower right spring are connected to a left vibration arm base and a right vibration arm base respectively through bolts and adjusting nuts; a left vibration motor and a right vibration motor are arranged on the left vibration arm base and the right vibration arm base respectively. The vertical type multistage straw pulverizer is used for straw pulverizing.

Owner:SHANGHAI OCEAN UNIV

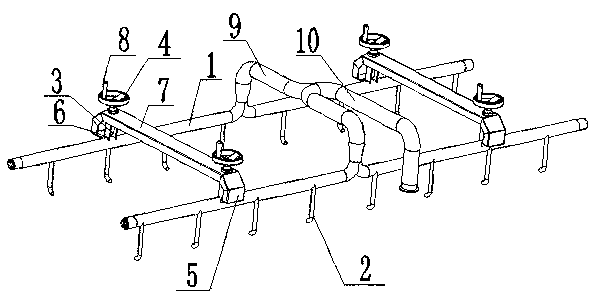

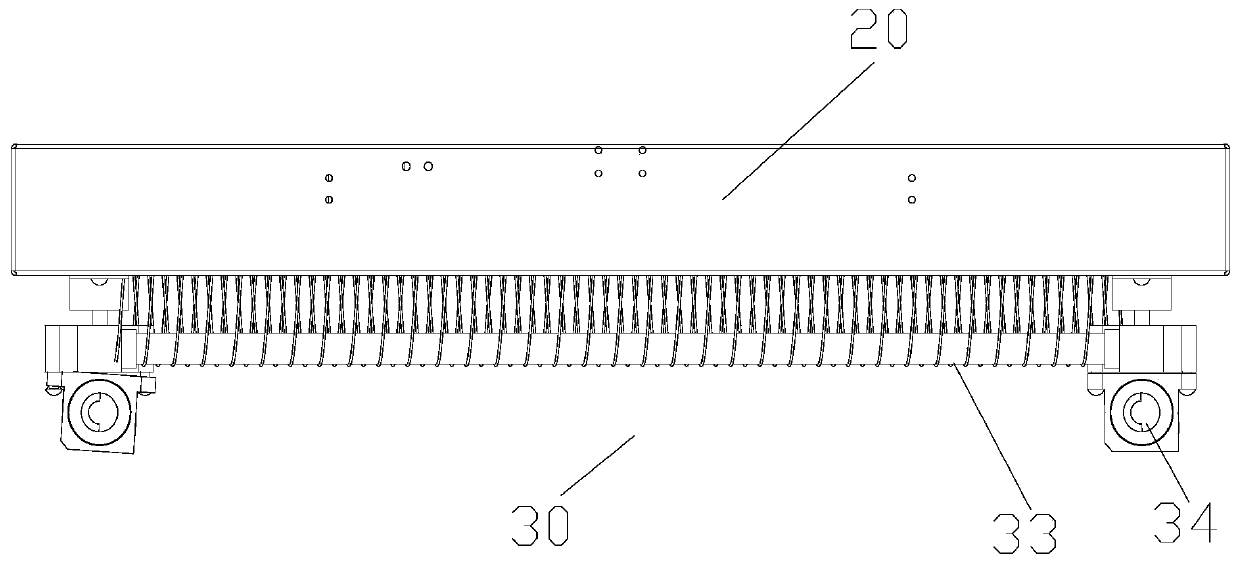

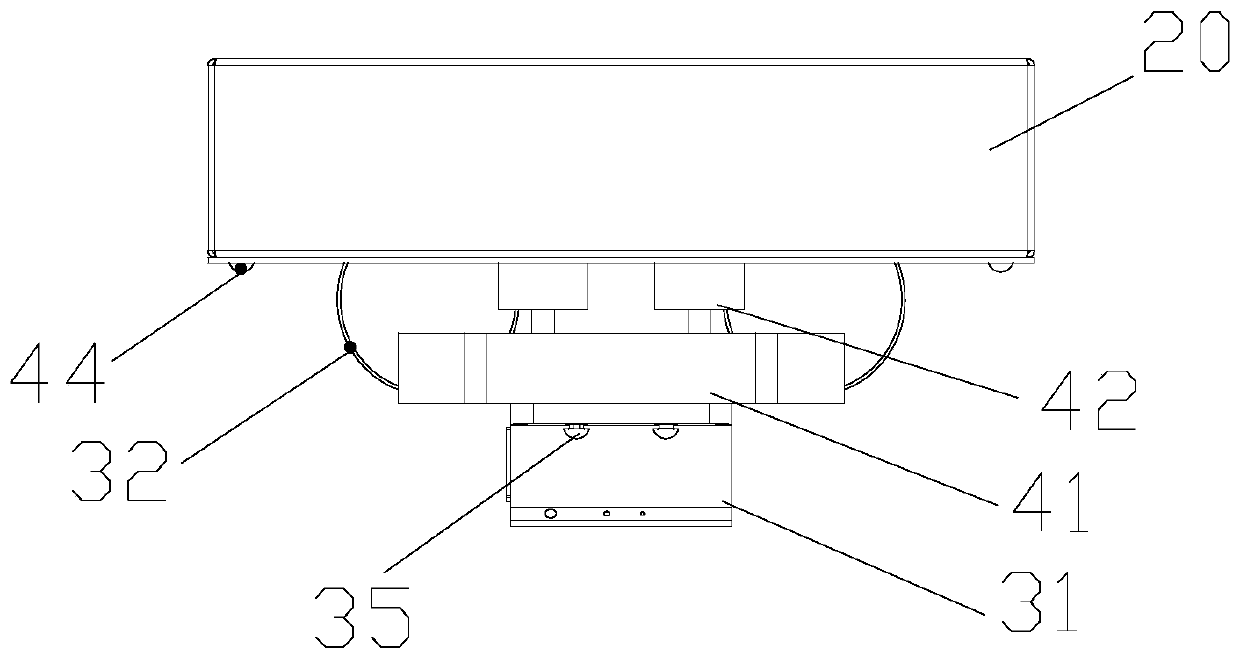

Cross-flow cleaning spray device

Owner:山东瑞帆果蔬机械科技有限公司

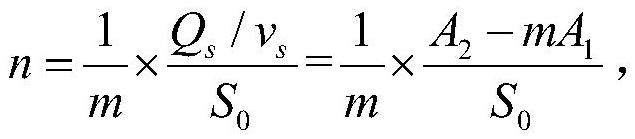

Stirring apparatus used for producing polyvinyl chloride

InactiveCN108201839AHit fullWell mixedShaking/oscillating/vibrating mixersTransportation and packagingPolyvinyl chlorideEngineering

The invention discloses stirring apparatus used for producing polyvinyl chloride. The apparatus comprises a stirring chamber and a stirring device arranged in the stirring chamber, the stirring devicecomprises a stirring shaft, stirring paddles arranged on the stirring shaft and a driving member used for driving the stirring shaft to rotate; and each stirring paddle is provided with turbulent passages for guiding a fluid to flow in the rotation process of the stirring paddles to generate turbulence in the stirring chamber. According to the apparatus provided by the invention, the turbulent passages are arranged, so that when the stirring apparatus works, the stirring chamber can be in a turbulent state, materials are fully impacted, the materials are uniformly mixed, and the stirring effect is good; and the performance of the prepared polyvinyl chloride is effectively improved, and the impact resistance and bending resistance of the polyvinyl chloride are improved.

Owner:李国俊

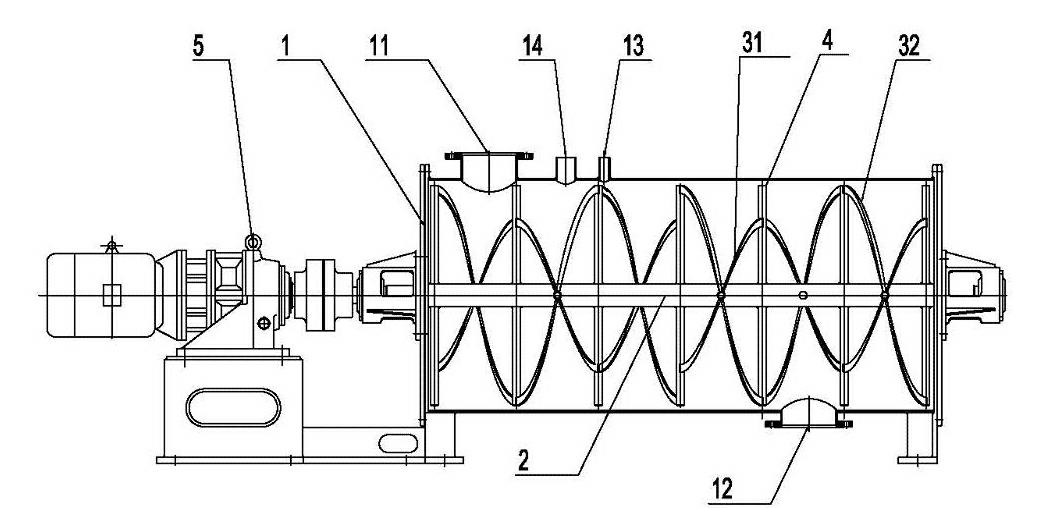

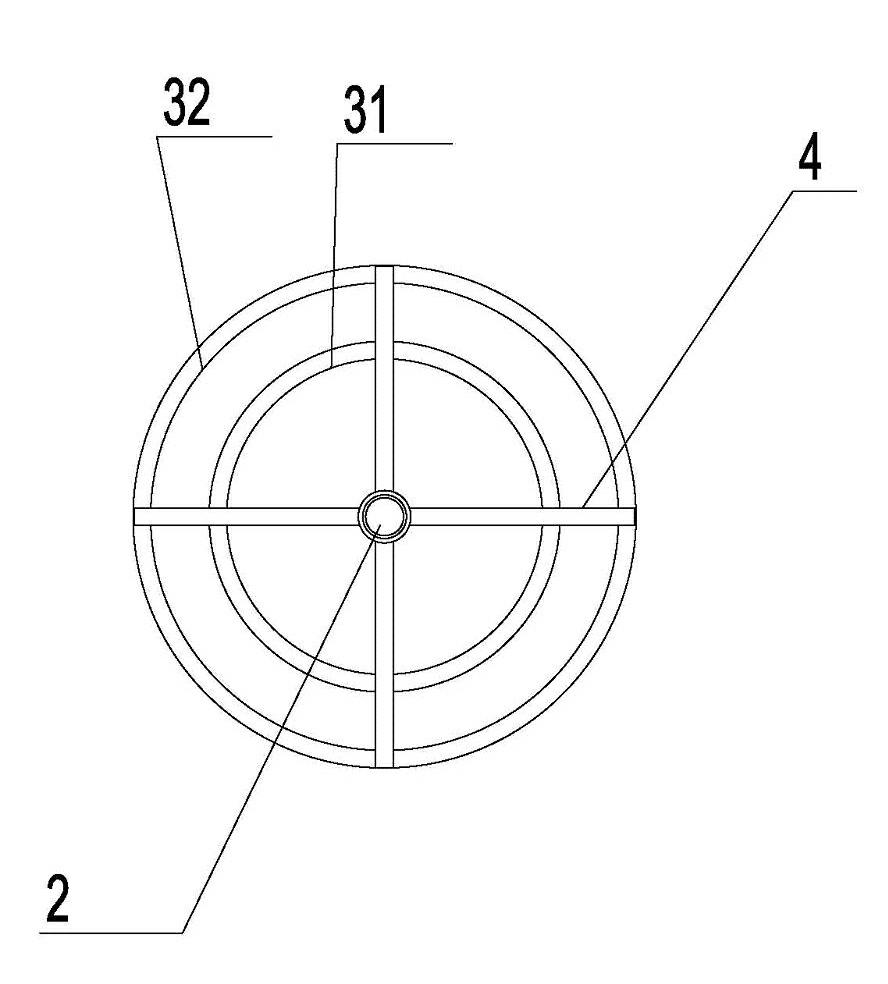

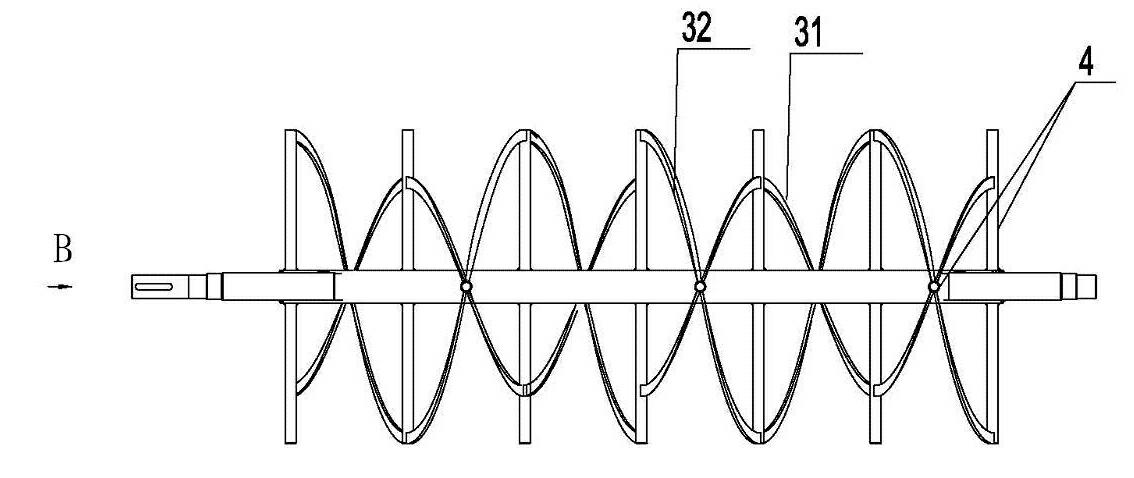

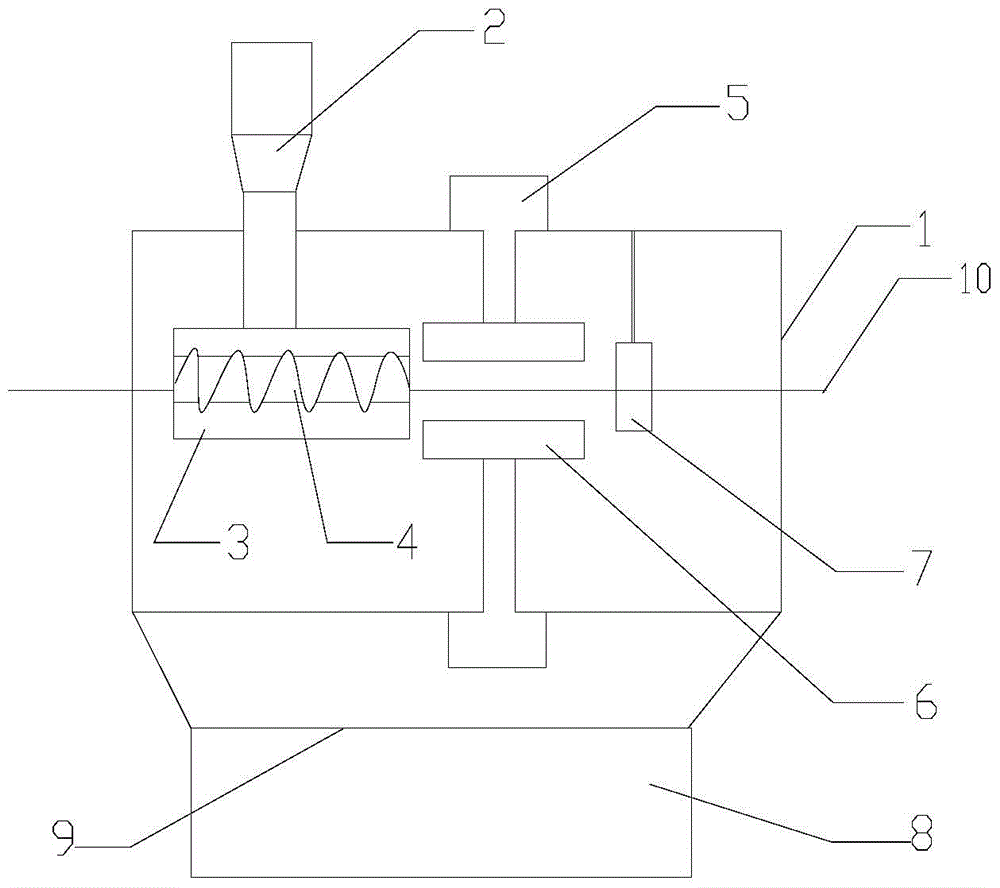

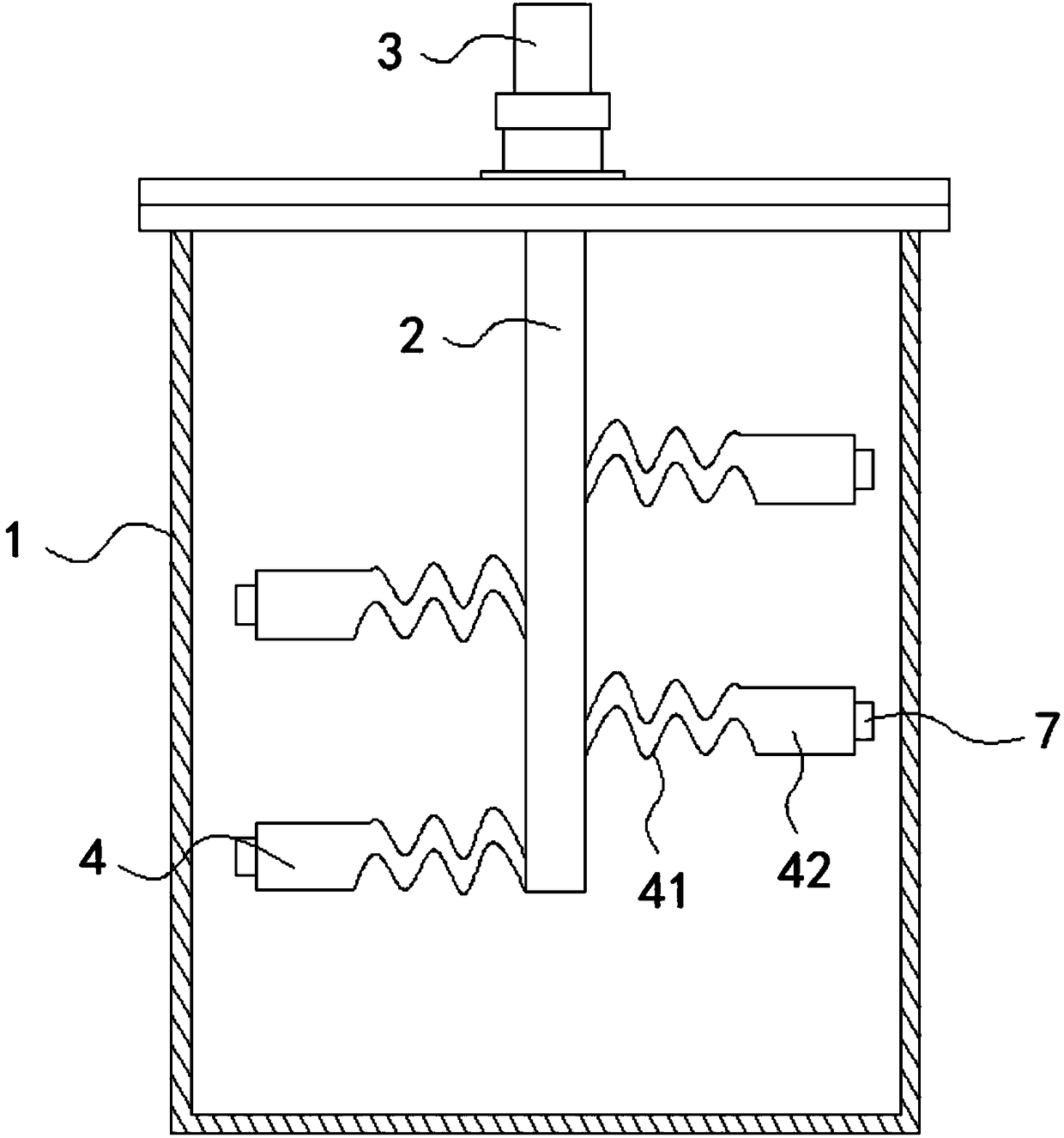

Cable surface oil stain removing device

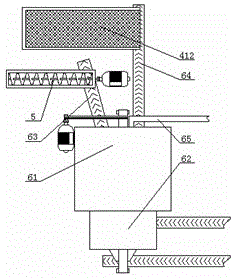

InactiveCN105666898AIncrease temperatureImprove cleaning efficiencyCleansing AgentsPetroleum engineering

The invention discloses a cable surface oil stain removing device. The device comprises a shell (1) with an inner cavity; a storage box (2) is arranged at the top of the shell (1); a cleaning box (3) is arranged in the inner cavity; the storage box (2) communicates with the cleaning box (3) to supply a cleaning agent into the cleaning box (3); a spiral rotating shaft (4) is arranged in the cleaning box (3) for winding a cable (10) and driving the cable (10) to spirally rotate; and a drying block (7) is additionally arranged in the inner cavity, wherein the cable (10) can penetrate through the drying block (7) after passing through the cleaning box (3). The cable surface oil stain removing device can perform efficient oil stain removing treatment for the cable.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

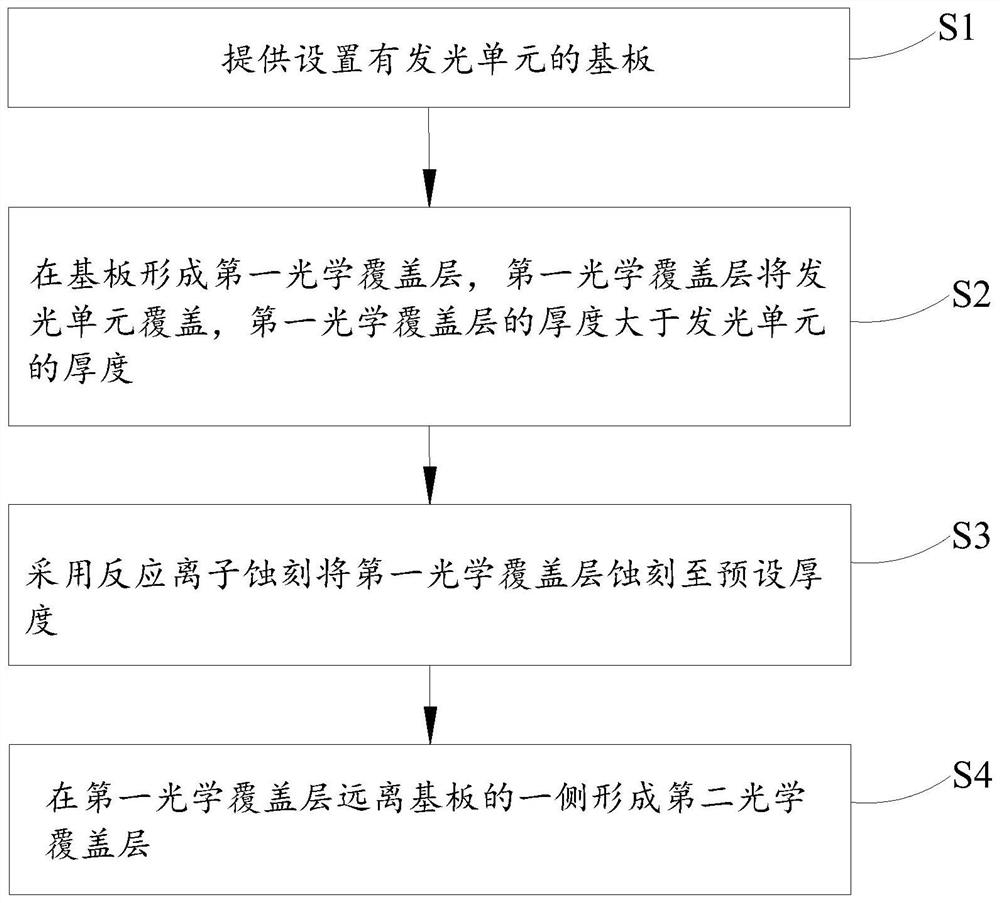

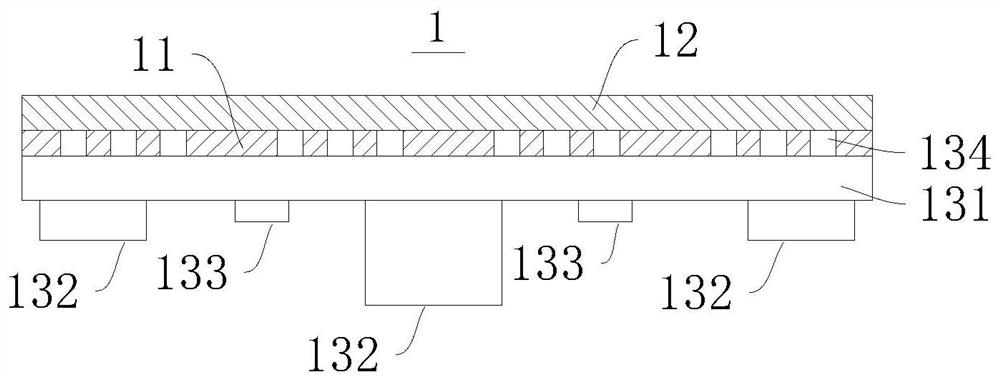

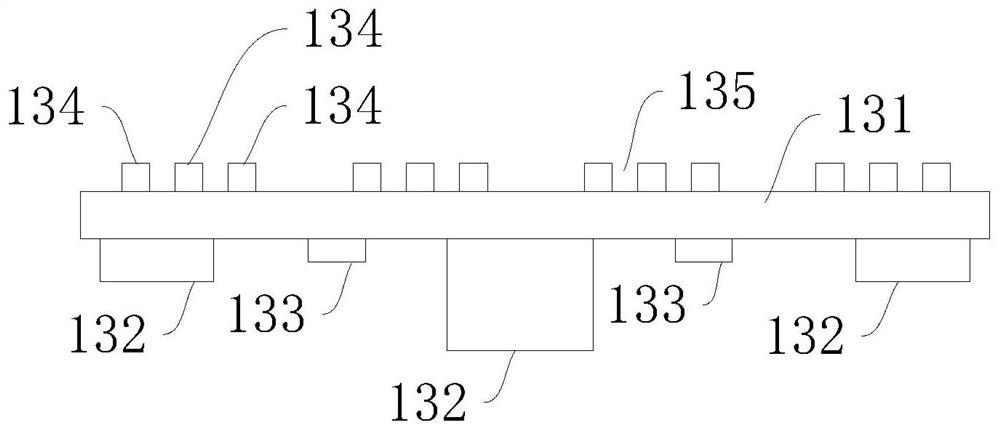

Preparation method of display module and display module

ActiveCN113130462AGuaranteed flatnessGuaranteed uniformitySolid-state devicesIdentification meansEngineeringReactive-ion etching

The invention belongs to the field of display components and relates to a preparation method of a display module and a display module.The preparation method comprises the steps that: a substrate provided with a light-emitting unit is provided; a first optical covering layer is formed on the substrate, the first optical covering layer covers the light-emitting unit, and the thickness of the first optical covering layer is larger than that of the light-emitting unit; the first optical covering layer is etched to a preset thickness by adopting reactive ion etching; and a second optical covering layer is formed on one side, far away from the substrate, of the first optical covering layer. The flatness and uniformity of an etched surface can be guaranteed, and the product quality and the light emitting effect are improved. The display module is prepared through the preparation method, and the light emitting effect of the display module is good.

Owner:广州市鸿利显示电子有限公司

Stirring equipment

InactiveCN108404732AHigh strengthHigh temperature resistantShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringSlurry

The invention discloses stirring equipment comprising a shell and a stirring device arranged in the shell; the stirring device comprises a stirring shaft, stirring paddles arranged on the stirring shaft and a driving element for driving the stirring shaft to rotate; the stirring paddles are provided with vibration devices; each vibration device comprises a vibration element capable of telescopically acting and a vibration driving element matched with the vibration element; a sealing element is arranged between the vibration element and each stirring part, and a first connecting structure is arranged between each sealing element and each stirring paddle; and each stirring paddle comprises a turbulent part arranged in a wavy structure and a stirring part arranged in a strip-shaped structure.The vibration devices are arranged on the stirring shaft, so that the vibration elements can vibrate in a rotation process of the stirring shaft to effectively discharge air bubbles existing in slurry, and the prepared green body is more compact and stable in structure and higher in strength.

Owner:陈城

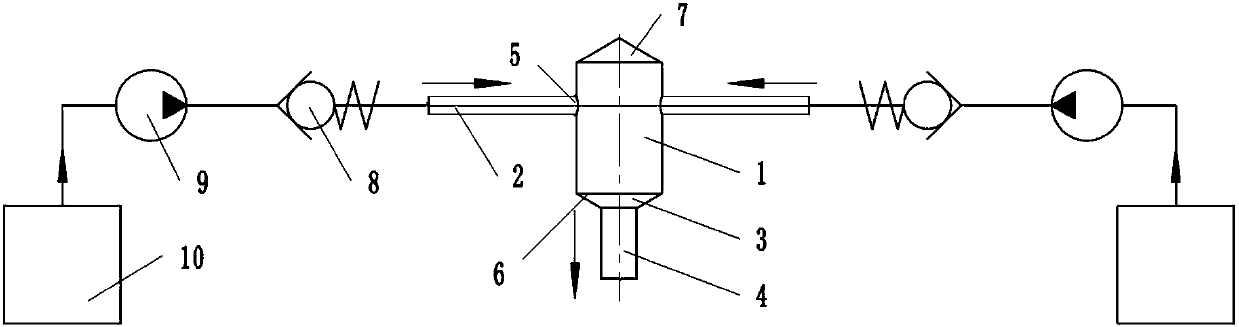

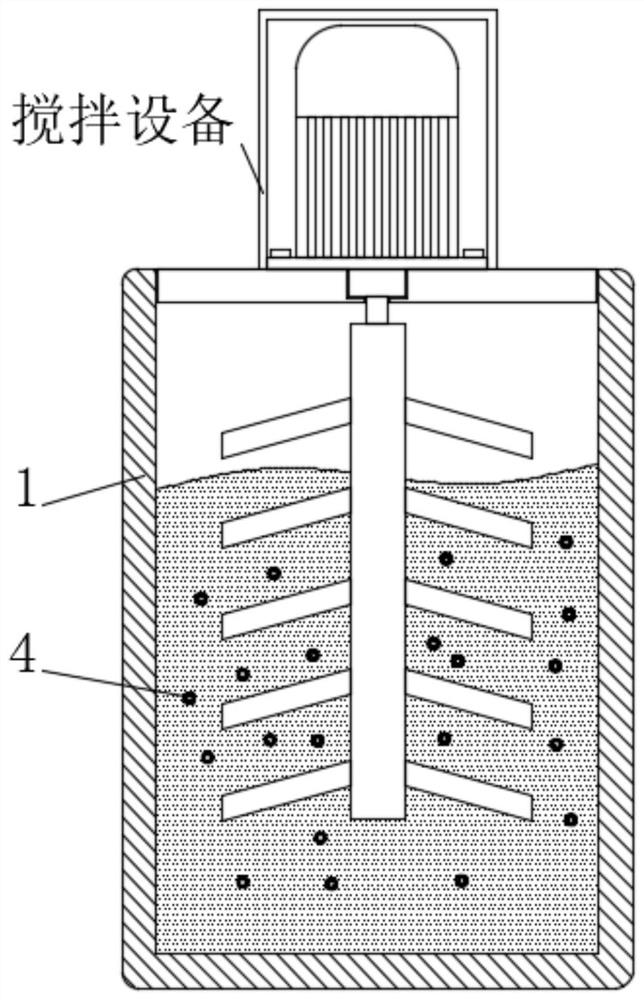

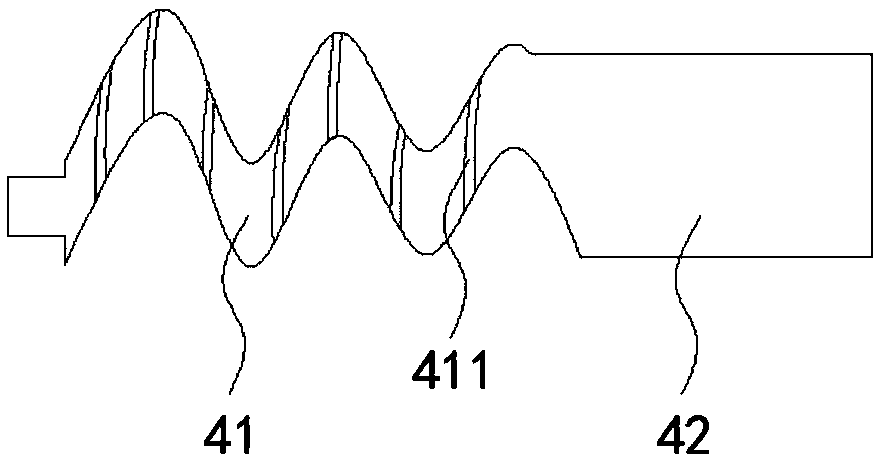

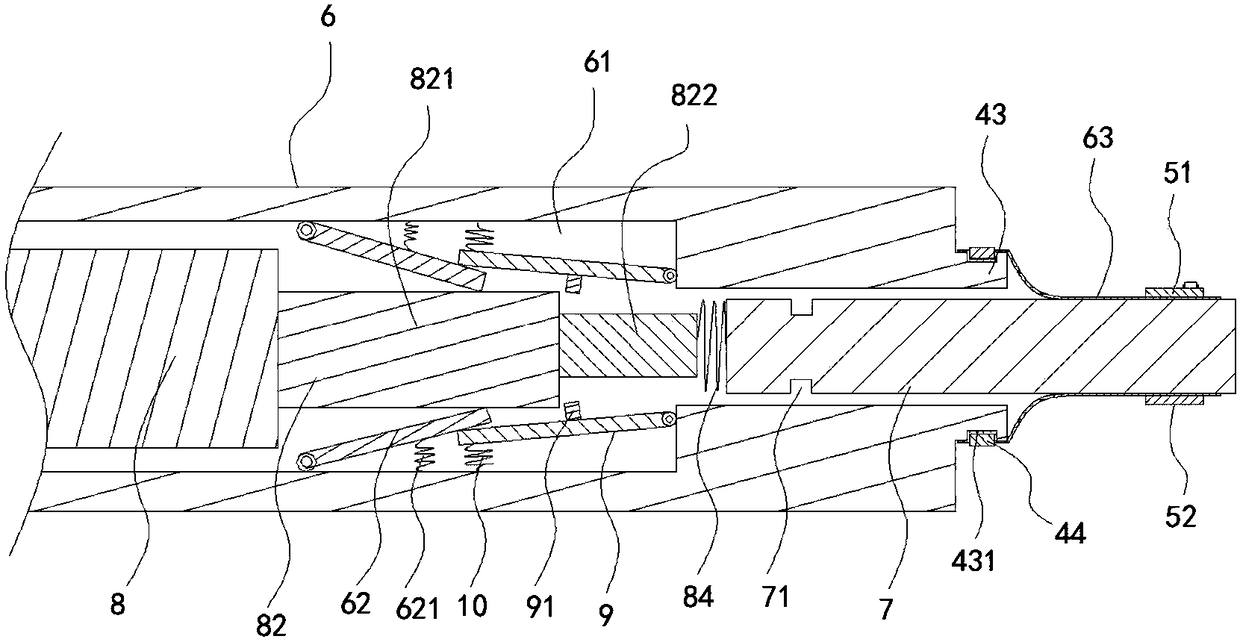

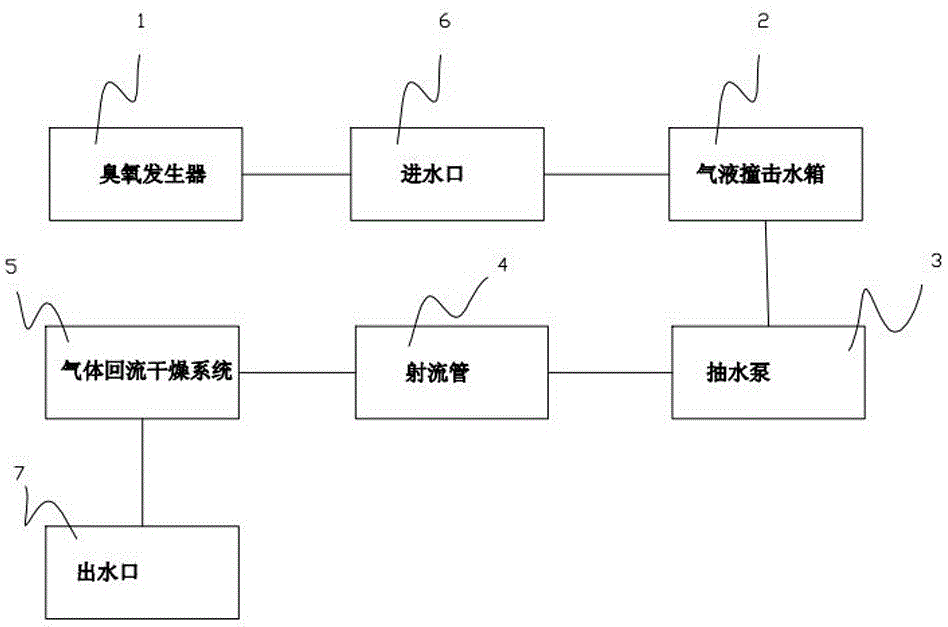

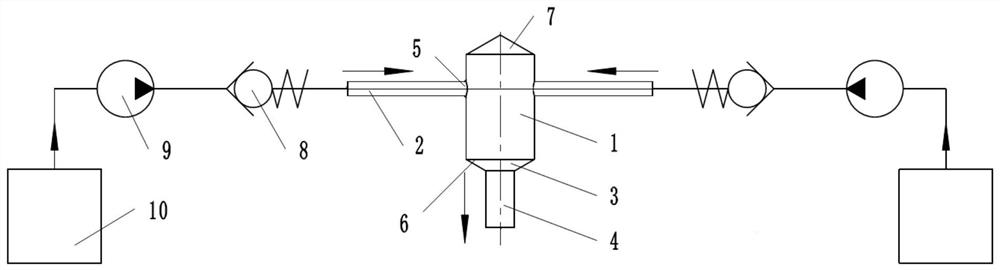

Ozone gas-liquid impact mixer

InactiveCN106110920AHit fullImpact mixing wellFlow mixersTransportation and packagingOzone generatorWater flow

The invention discloses an ozone gas-liquid impact mixer which comprises an zone generator, a gas-liquid impact water tank, a water suction pump, a jet pipe, a gas reflux drying system, a water inlet and a water outlet. The ozone generator, the gas-liquid impact water tank, the water suction pump, the jet pipe, the gas reflux drying system, the water inlet and the water outlet are sequentially connected. By the aid of the principle that a large amount of gas can be brought in when a water column flows into static water, the gas can automatically float upwards in the water, ozone gas and water flow are repeatedly impacted within a certain volume space, so that the ozone gas and the water are sufficiently mixed while the ozone gas cannot diffuse towards an external space after floating upwards, and leakage of the ozone gas is avoided.

Owner:李锦明

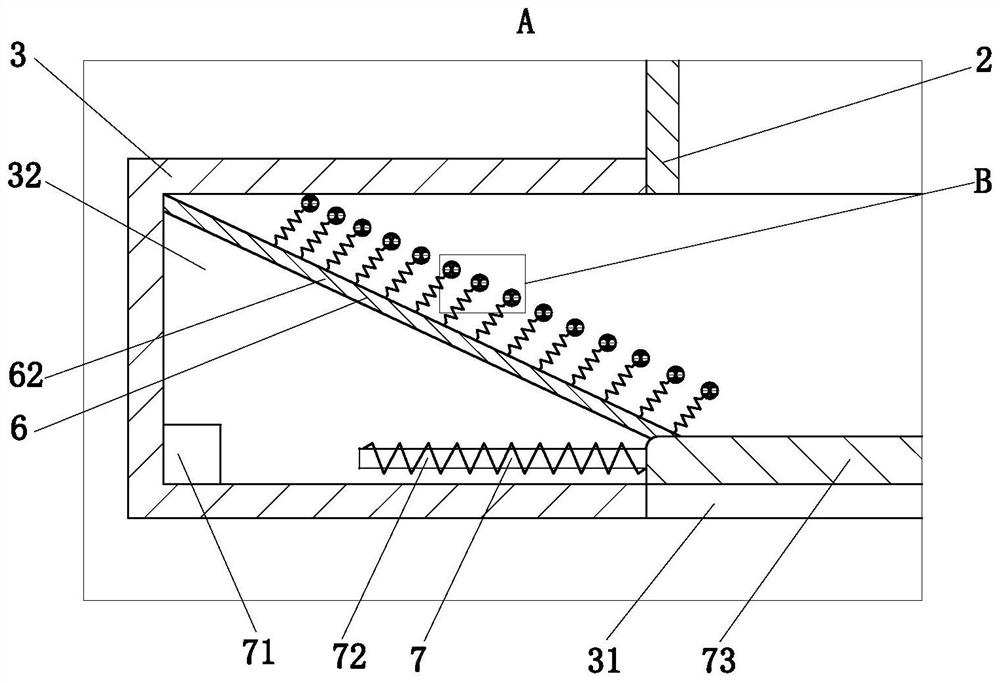

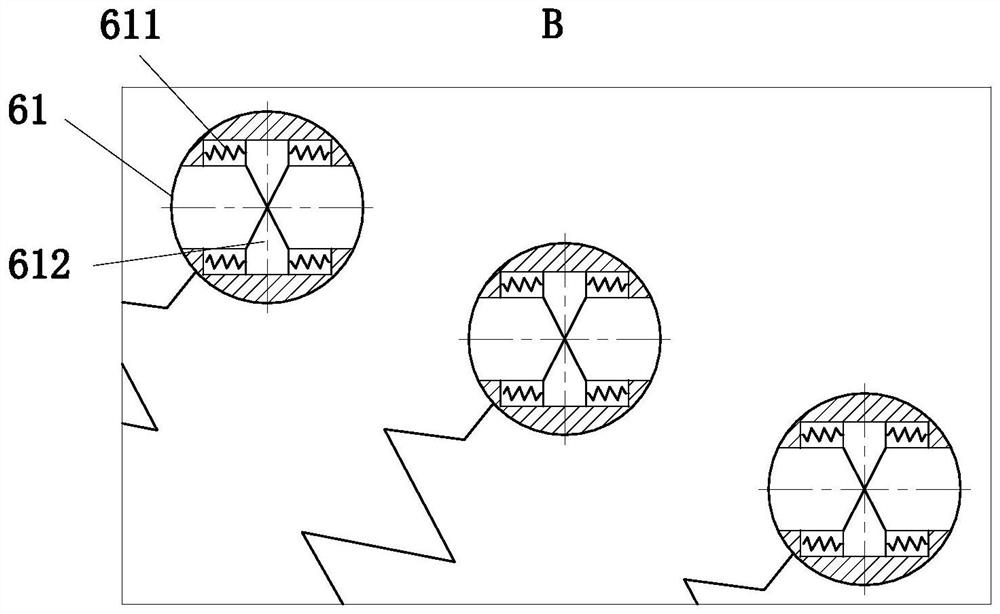

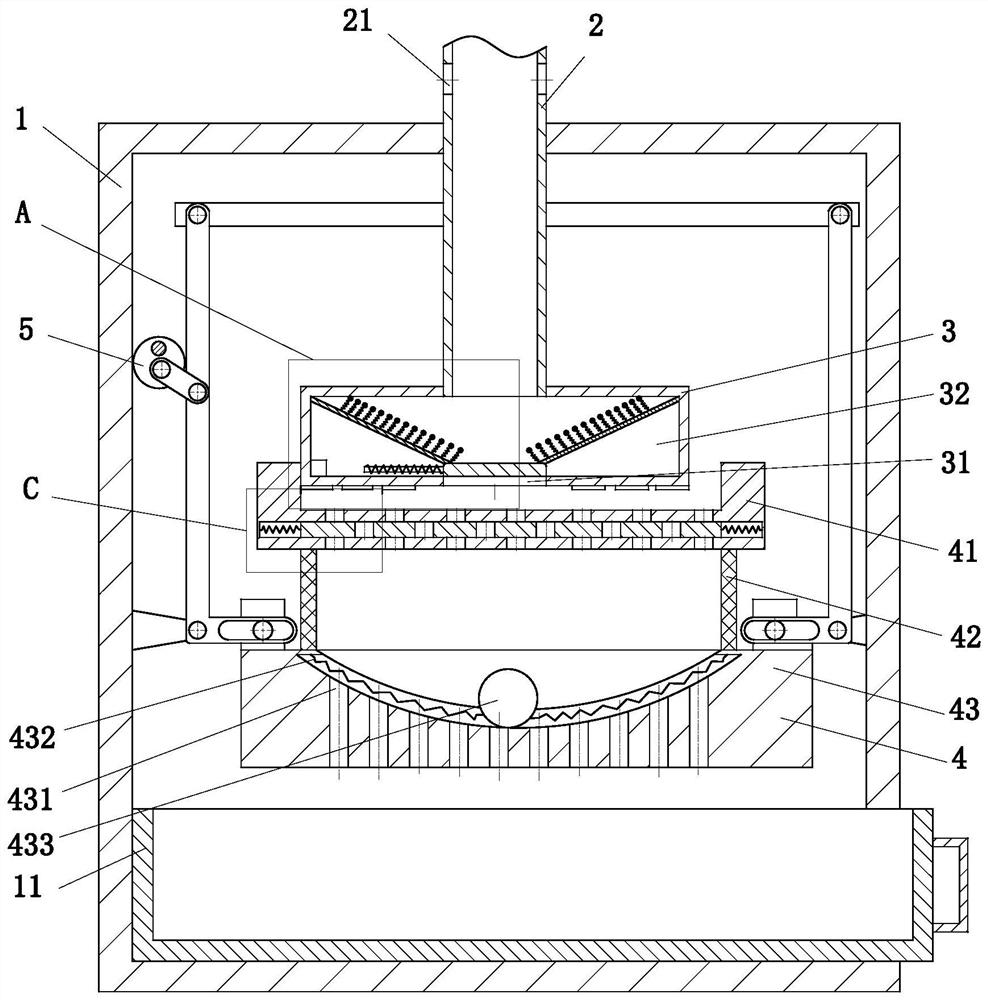

A water-based paint grinding device

ActiveCN109013008BImprove grinding efficiencyIncrease contact areaGrain treatmentsEngineeringMaterials science

The invention belongs to the technical field of grinding equipment, and particularly relates to a water-based paint grinding device. The water-based paint grinding device comprises a cylinder body, ahollow shaft, an upper grinding disc, a lower grinding disc, a collecting box and a driving unit. The cylinder body is internally provided with the upper grinding disc and the lower grinding disc. Theupper grinding disc is located above the lower grinding disc. The lower grinding disc is connected with the driving unit. The driving unit is used for driving the lower grinding disc to match with the upper grinding disc for grinding. Primary water-based paint breaking is conducted by a grinding ball. Then the driving unit drives the lower grinding disc to move vertically and horizontally. The upper grinding disc and the lower grinding disc match with each other to fully grind water-based paint, and therefore grinding efficiency of the water-based paint is improved. The water-based paint is cleared from a first grinding disc to prevent influence on sequential water-based paint grinding, and therefore the water-based paint grinding effect is improved.

Owner:杭州迪升涂料有限公司

A modified positive electrode material precursor, its preparation method, modified positive electrode material and lithium battery

ActiveCN109921013BHit fullImpingement flow response is adequateCell electrodesSecondary cellsElectrical batteryPhysical chemistry

The invention provides a modified cathode material precursor, including the cathode material precursor and a metal salt coated on the cathode material precursor. Both the safety performance and cycle performance of the battery obtained by the modified positive electrode material precursor are significantly improved.

Owner:微宏先进材料公司

Pneumatic conveying peanut device

The invention discloses a device for pneumatically conveying peanuts, which comprises: a collection chamber, which is provided with a feed inlet and a discharge outlet, the discharge outlet is arranged at the bottom of the collection chamber, and the top of the collection chamber It communicates with the inlet of the exhaust fan through a pipeline; the impurity removal bin communicates with the collection chamber, and the impurity removal bin includes: a drum, one end of which is connected to the discharge port through a material transfer pipe, and the exhaust fan The outlet of the outlet is connected to the material transfer pipe through the first pipeline, and the wall of the drum is provided with a lifter that moves the peanuts to the other end of the drum, and a water mist nozzle is provided in the drum, and the The cylinder wall of the drum is evenly covered with through holes; and the outer cylinder has an inner space for accommodating the drum, and the outer cylinder is provided with a sewage hole; wherein, the space in the collection chamber is lower than the feeding port There are several rotors inside. The invention has the advantages of simple structure, rich functions, resource saving and the like.

Owner:海宁经开产业园区开发建设有限公司

A gas-liquid mixing device

The invention relates to the technical field of fire fighting equipment, in particular to a gas-liquid mixing device, comprising a mixing main body, the mixing main body comprises a foam liquid inlet and a foam liquid outlet communicating with the foam liquid inlet, and the foam liquid inlet and the foam liquid outlet are between the foam liquid inlet and the foam liquid outlet. There is a foam-liquid mixing chamber, and the foam-liquid mixing chamber is provided with a plurality of air inlets for introducing compressed air, and the air inlets are communicated with the foam liquid inlet. Contacting and mixing with the mixed foam liquid, the diameter of the formed foam is more uniform and the stability is better, and the problem that the compressed air is mixed and foamed with the mixed foam liquid from one direction in the prior art is solved, and the gas-liquid mixing device has a simple structure. , By fully contacting and impacting the compressed air and the mixed foam liquid, the mixed foam liquid is fully foamed, the foaming ratio is high, and the foaming effect is better.

Owner:成都启特安全技术有限责任公司

Intelligent lottery drawing robot and control method

InactiveCN109448214AThe steps are simple and clearImprove credibilityLottery apparatusElectric machineryEngineering

The invention discloses an intelligent lottery drawing robot and a control method. The intelligent lottery drawing robot comprises a mechanical arm, a clamping structure and a dice cup, the clamping structure comprises a clamping claw and a motor, one end of the clamping claw is fixed on an output shaft of the motor while the other end of the same is fixedly connected with the dice cup, the motoris fixed at the free end of the mechanical arm, and a detachable base is arranged at the lower end of the dice cup. The intelligent lottery drawing robot can realize sufficient and violent shaking ofthe dice cup to enable dices inside to rotate and collide randomly to finally generate a random result, and the whole process is transparent, visible, clear and simple in step and high in credibility.

Owner:杨阳

High Efficiency Indoor Air Purifier

ActiveCN104107634BGuaranteed stayFully catalyzed degradationDispersed particle separationRadiationRoom air cleanersLiving room

The invention discloses a high-efficiency indoor air purifier, which comprises a shell. Double-layer side walls are arranged around the inner cavity of the shell. The height of the inner wall is lower than that of the outer wall; the lower end of the outer wall is provided with an air outlet. ; The center of the bottom of the shell cavity is provided with an exhaust fan, and a number of upright photocatalyst quartz glass sheets are evenly arranged around the bottom of the shell cavity around the exhaust fan; LED lamps that can emit ultraviolet light are fixedly installed around the bottom of the shell cavity; The invention is simple in structure and reasonable in design. Based on the principle of photocatalyst and the encapsulation technology of ultraviolet LED, it is designed and manufactured to save power and make no noise. The ultraviolet light does not leak out and harm the human body. It has several times the removal efficiency of harmful gases such as formaldehyde and benzene. Portable air purifier; can be used in living room, bedroom, bathroom, office, car, and can also be widely used in food display cabinets, hospitals, schools, shops, shopping malls and other public places, effectively inhibiting bacteria, viruses and mold.

Owner:泉州市宜百佳展示用品有限公司

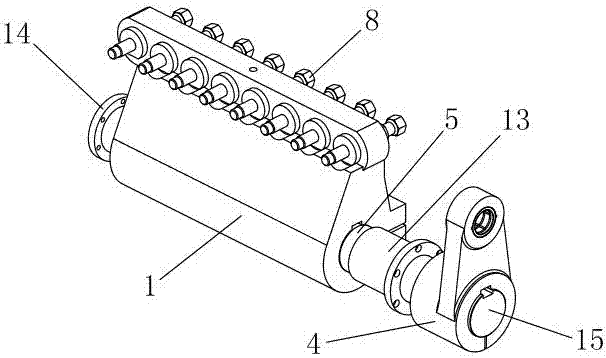

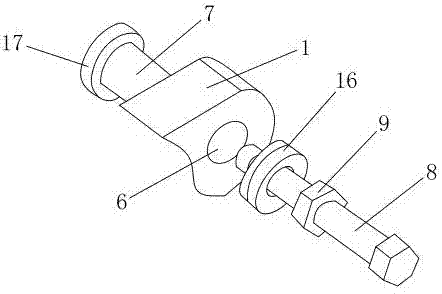

Industrial ejection device

InactiveCN106914579AReduce frictionEasy and quick passForging/hammering/pressing machinesPunchingEngineering

The invention discloses an industrial ejection device, comprising a rear punching striking base and an adjusting base. The adjusting base is provided with a supporting platform. The rear punching striking base is movably connected with the supporting platform. One side of the rear punching striking base is provided with a single-arm rocking bar. The single-arm rocking bar is connected with a rear beating shaft. The rear beating shaft is arranged in the rear punching striking base. The rear punching striking base is provided with a mounting hole. The mounting hole is internally provided with a bolt sleeve. The rear punching striking base is internally provided with a striking base bolt. The striking base bolt is provided with a striking base nut. The striking base nut fixedly connects the striking base bolt in the rear punching striking base. The striking base bolt is arranged in the bolt sleeve. The adjusting base is provided with a central column. The central column is fixedly connected with the supporting platform. The adjusting base is provided with a rotating shaft. The rotating shaft is provided with a driving mechanism. The driving mechanism is connected with the central column in a driving manner. The device adjusts ejection positions according to workpiece positions, and improves efficiency of workpiece ejection, and according to damaged degree of the striking base bolt, the bolt is changed, so as to improve security of workpiece ejection.

Owner:全南县智护力工业产品设计有限公司

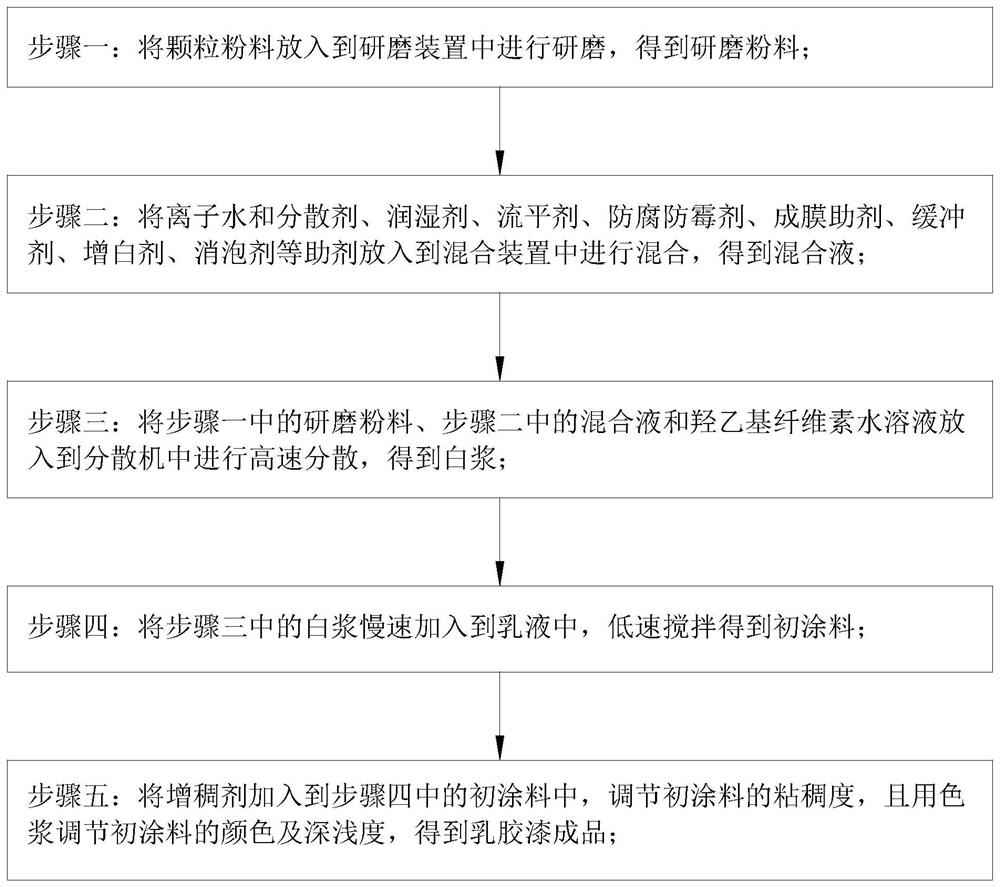

A kind of production method of latex paint

ActiveCN109201268BImprove grinding efficiencyGrind fullyCocoaPowdery paintsMaterials scienceMilk paint

Owner:浙江绿城筑乐美城市发展有限公司

A kind of equipment for preparing polyvinyl chloride

ActiveCN108159970BHit fullWell mixedShaking/oscillating/vibrating mixersRotary stirring mixersPolymer sciencePolyvinyl chloride

The invention discloses an equipment for preparing polyvinyl chloride, which comprises a stirring chamber and a stirring device arranged in the stirring chamber, the stirring device includes a stirring shaft, a stirring paddle arranged on the stirring shaft and a stirring paddle for driving the stirring A driving member for rotating the shaft; the stirring paddle is provided with a turbulent channel for guiding the fluid to flow during the rotation of the stirring paddle to generate turbulent flow in the stirring chamber. In the present invention, through the setting of the turbulent channel, the stirring device can be in a state of turbulent flow in the stirring chamber when the stirring device is working, so that the materials are fully impacted, the materials are mixed evenly, and the stirring effect is good; the prepared product can be effectively improved. Improve the performance of polyvinyl chloride, improve the impact resistance and bending resistance of polyvinyl chloride.

Owner:NANJING HONGRUI PLASTIC PROD

Vertical hanging plasma washing machine for clothes

ActiveCN103422321BHit fullEfficient removalOther washing machinesTextiles and paperPlasma generatorAerospace engineering

The invention relates to the field of washing machines, in particular to a clothing vertical-hanging type plasma washing machine. The clothing vertical-hanging type plasma washing machine is characterized by comprising an outer washing barrel, an inner washing barrel and a plurality of plasma generators, and the inner washing barrel is sleeved in the outer washing barrel rotationally; the upper end of the inner washing barrel is a plasma clothing washing part, and the lower end of the inner washing barrel is a washing part; a horizontal rod is arranged at the clothing inlet at the upper end of the inner washing barrel, and a rotating device is fixed at the center of the horizontal rod, a vertical-hanging type hanger is mounted on the rotating device which is used for unfolding the clothing to be washed and which is capable of rotating in the range of 360 degrees under the action of the rotating device; the plasma generators are arranged on the outer wall of the inner washing barrel corresponding to the rotating device and in the middle of the side wall of the inner washing barrel respectively; the plasma generators input plasma to the inner washing barrel through gas input pipes. The clothing vertical-hanging type plasma washing machine can perform plasma wash on special parts of the clothing particularly, and decontaminating effect and washing efficiency are improved.

Owner:哈威光电科技(苏州)有限公司

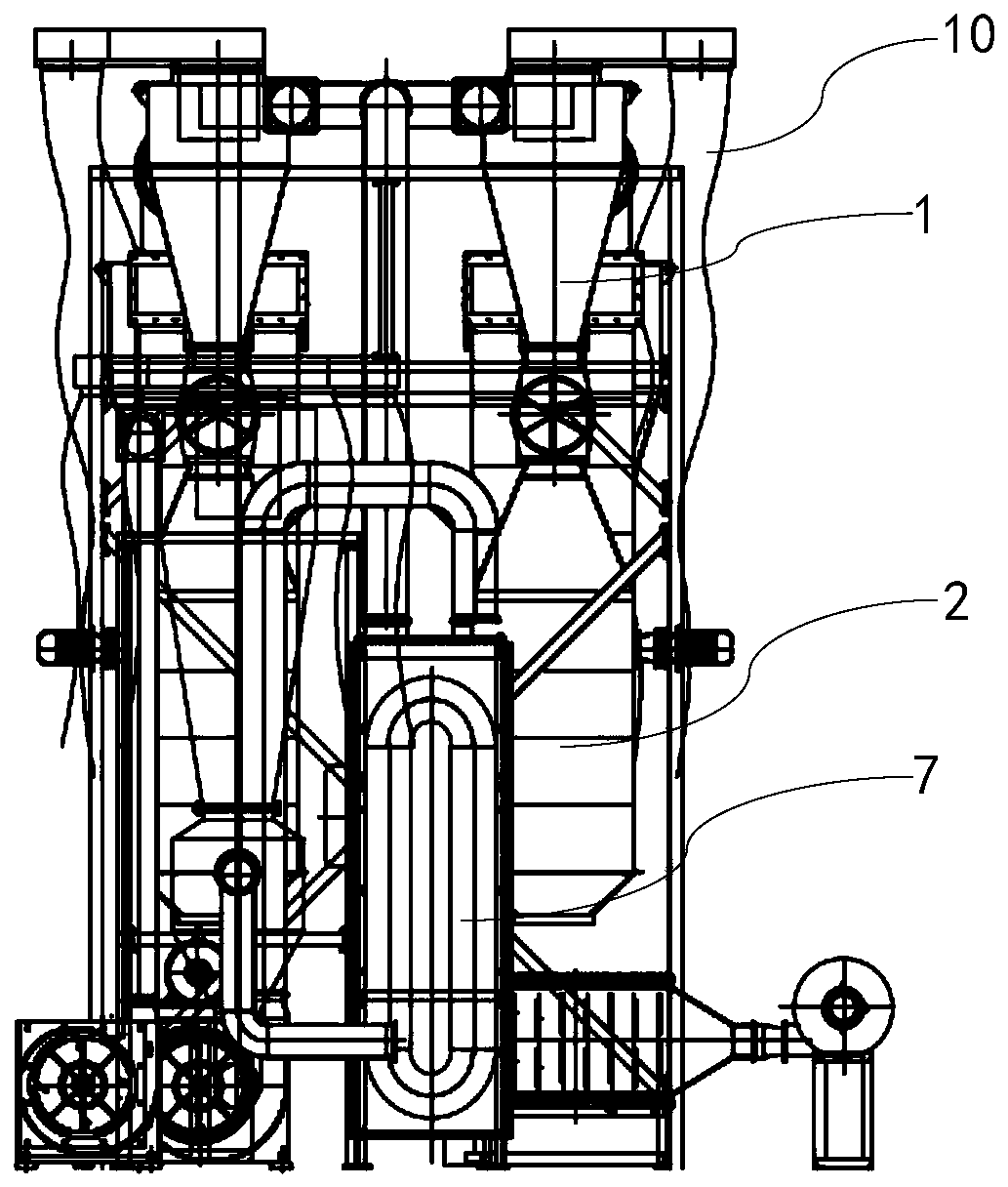

Sorter collecting system

The invention discloses a sorter collecting system. The sorter collecting system comprises a feeding area, a heating area and a sorting area sequentially arranged in the conveying direction, wherein the sorting area sequentially comprises a first hopper, a separator and a second hopper which are sequentially connected through a pipeline; the separator is provided with a feeding port, a dischargingport and a pipeline connector; a discharging port of the first hopper is connected with the feeding port of the separator; a feeding port of the second hopper is connected with the pipeline connectorof the separator; the separator is a cavity shaped like Z, the discharging port of the separator is arranged at the lower end of the cavity, the feeding port of the separator is arranged in the middle of the cavity, and the pipeline connector of the separator is arranged at the top end of the cavity; and the first hopper and the second hopper are each provided with a lock valve. According to thesorter collecting system, the sorting and collecting efficiency of crushed materials are improved.

Owner:GUANGZHOU 3E MACHINERY

A fan-shaped air suction nozzle with automatic adjustment of suction speed

The invention provides a fan-shaped air-suction nozzle that automatically adjusts the suction speed, including a nozzle body and a liquid channel. The nozzle body is provided with a liquid channel communicated with the nozzle hole, and also includes a pressure groove and an air intake channel; the liquid channel inlet The section communicates with the pressure tank, and the air inlet channel passes through the pressure tank and communicates with the liquid channel; the air inlet orifice plate is installed in the pressure tank through an elastic damping device, and the inlet orifice plate is placed in the pressure tank by the change of the inlet pressure of the liquid channel. Move at the intersection with the air intake channel; the air intake orifice plate is provided with a number of through holes of the same or different sizes, through which the air intake orifice plate moves in the pressure groove to change the air intake in the liquid channel. The invention can automatically adjust the air intake speed according to the pressure change of the liquid flowing into the nozzle, so that the inhaled gas can more fully collide with the liquid in the straight column section at the air intake of the liquid channel, so that the air and the pressure liquid can be better mixed .

Owner:JIANGSU UNIV

Dustbin for sweeper truck

PendingCN111252417AAvoid various problems caused by manual dust removalRealize automatic cleaningDispersed particle filtrationTransportation and packagingTruckElectric machinery

The invention discloses a dustbin for a sweeper truck. The dustbin comprises a bin body, a dust removal device and an automatic cleaning device, wherein the bin body is provided with a garbage suctioninlet and an exhaust port, the dust removal device is arranged at the exhaust port, the dust removal device comprises a frame body and filter cloth, the automatic cleaning device comprises vibrationmotors arranged at the two ends of the frame body oppositely, the vibration motors are respectively fixed to a base, and the base is connected with the two ends of the frame body through connecting pieces respectively. A plurality of lead screws are arranged below the filter cloth at intervals, two ends of each lead screw are fixedly connected with the connecting pieces on the two sides respectively, springs are arranged on the lead screws in a sleeving manner, the springs are fixed to the lead screws, and the springs abut against the filter cloth. According to the dustbin, the technical problems that in the prior art, filter cloth in a dustbin of the sweeper truck needs to be cleaned manually due to blockage, accordingly secondary pollution is easily caused, and time and labor are wastedare solved.

Owner:杭州众维自动化技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com