Patents

Literature

815results about How to "Grind fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

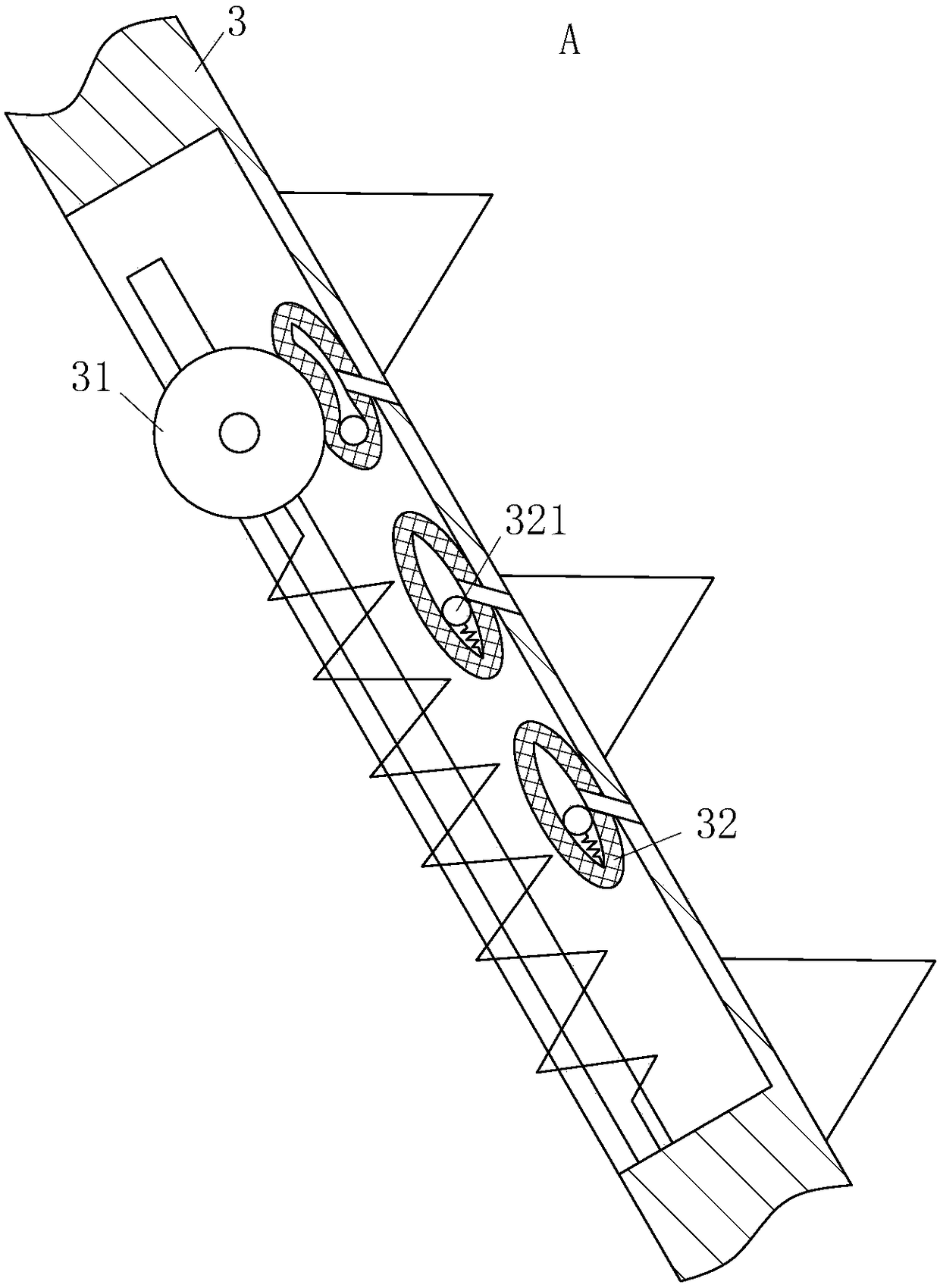

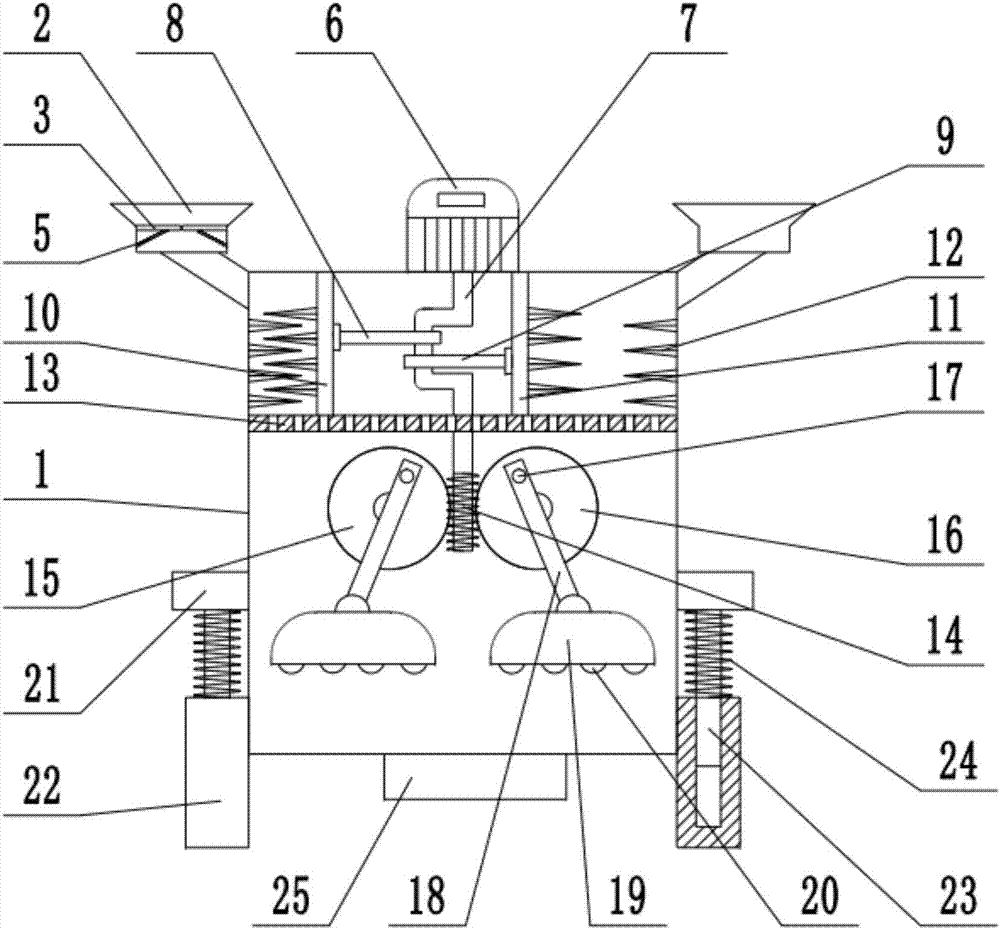

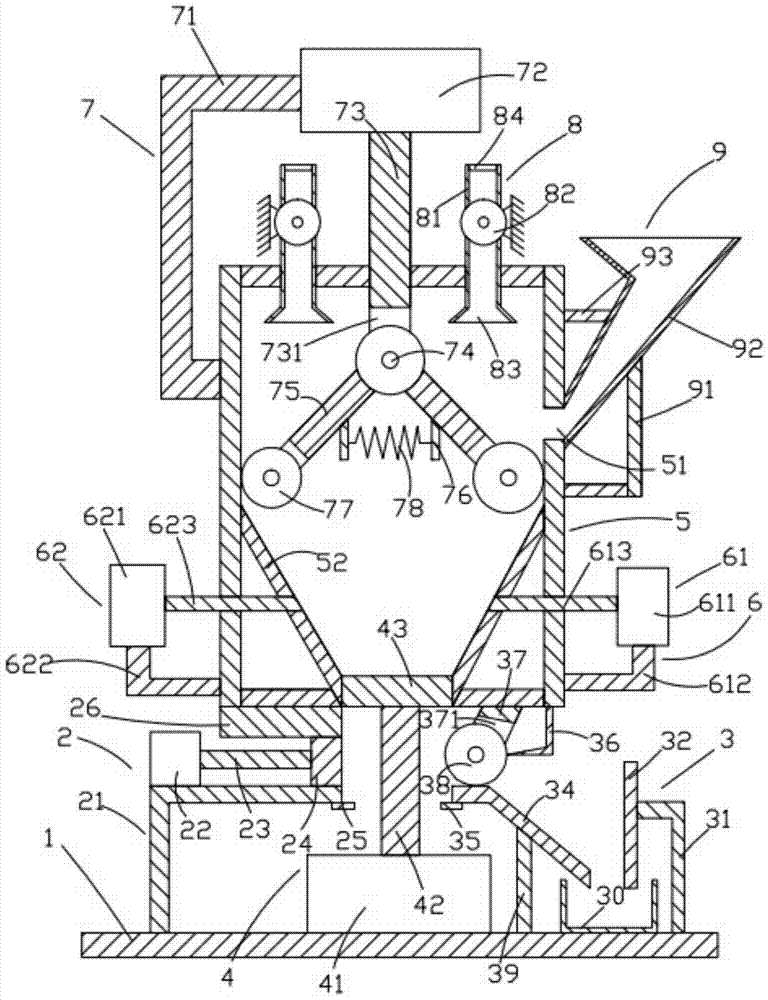

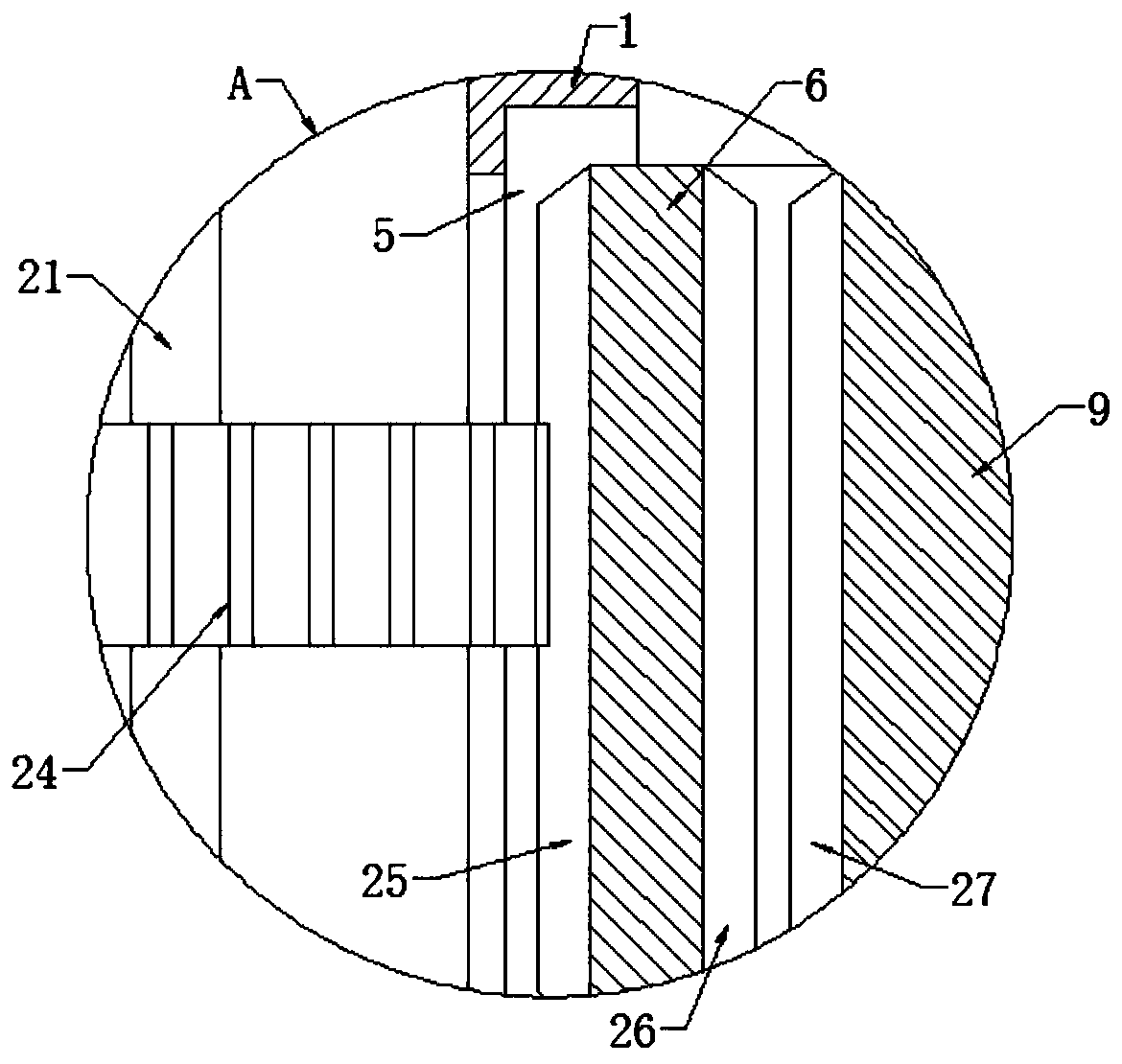

Spiral pipeline inner wall grinding and polishing robot suitable for different pipe diameters

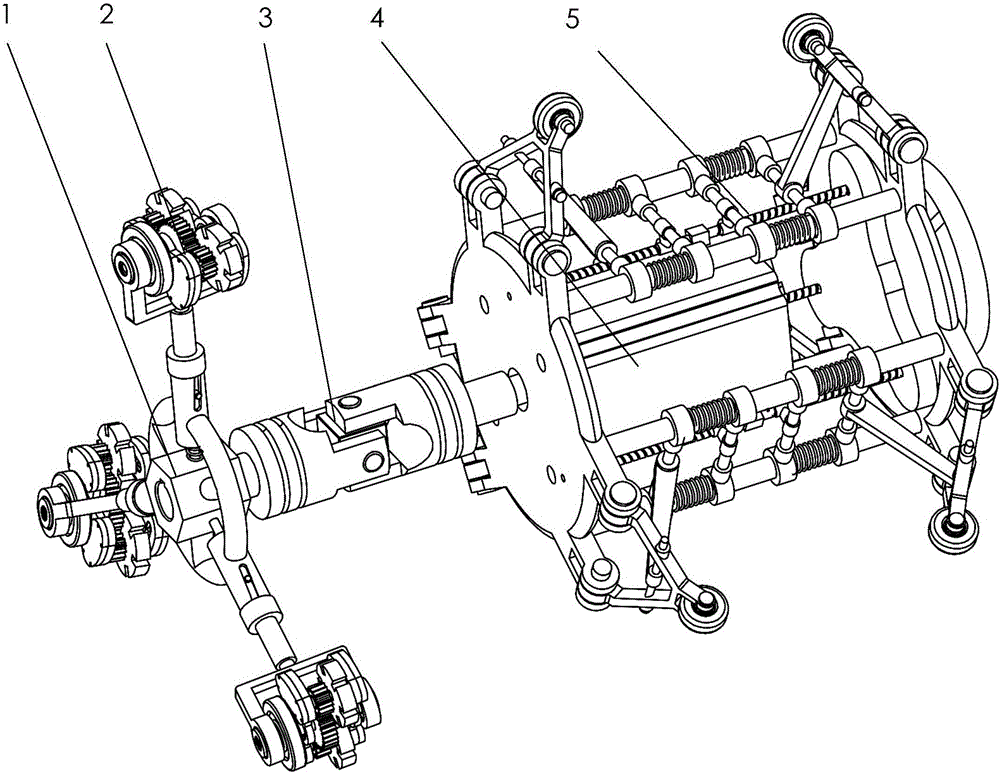

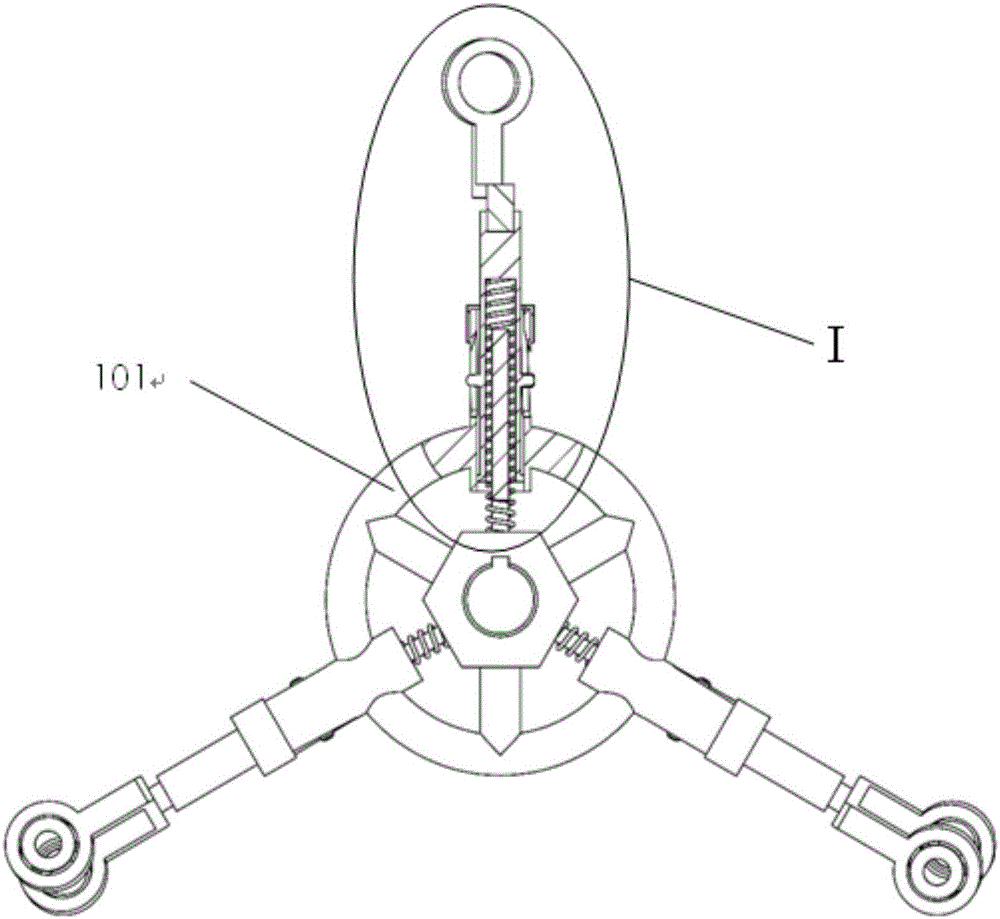

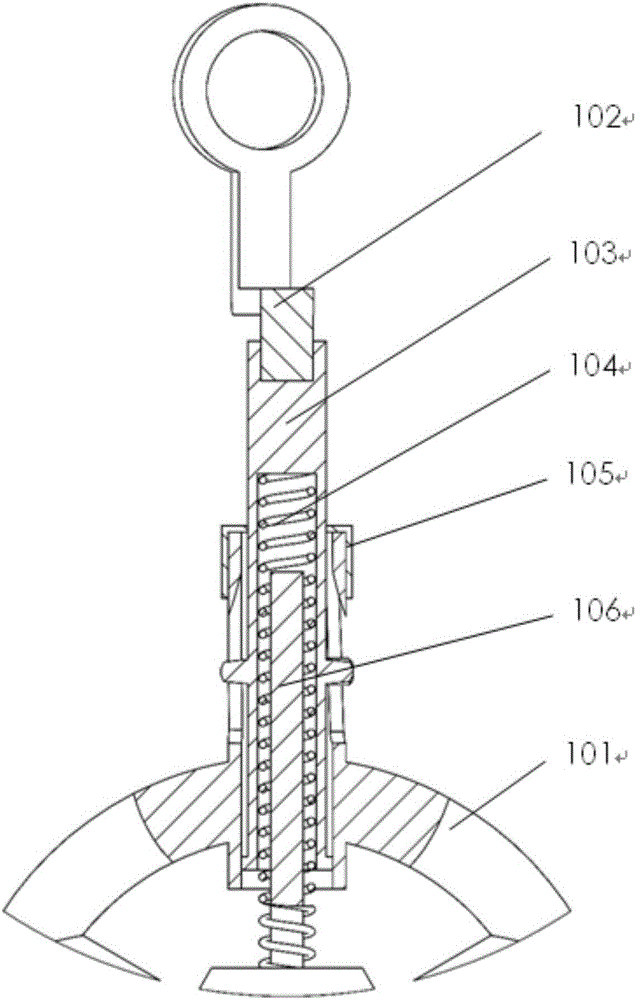

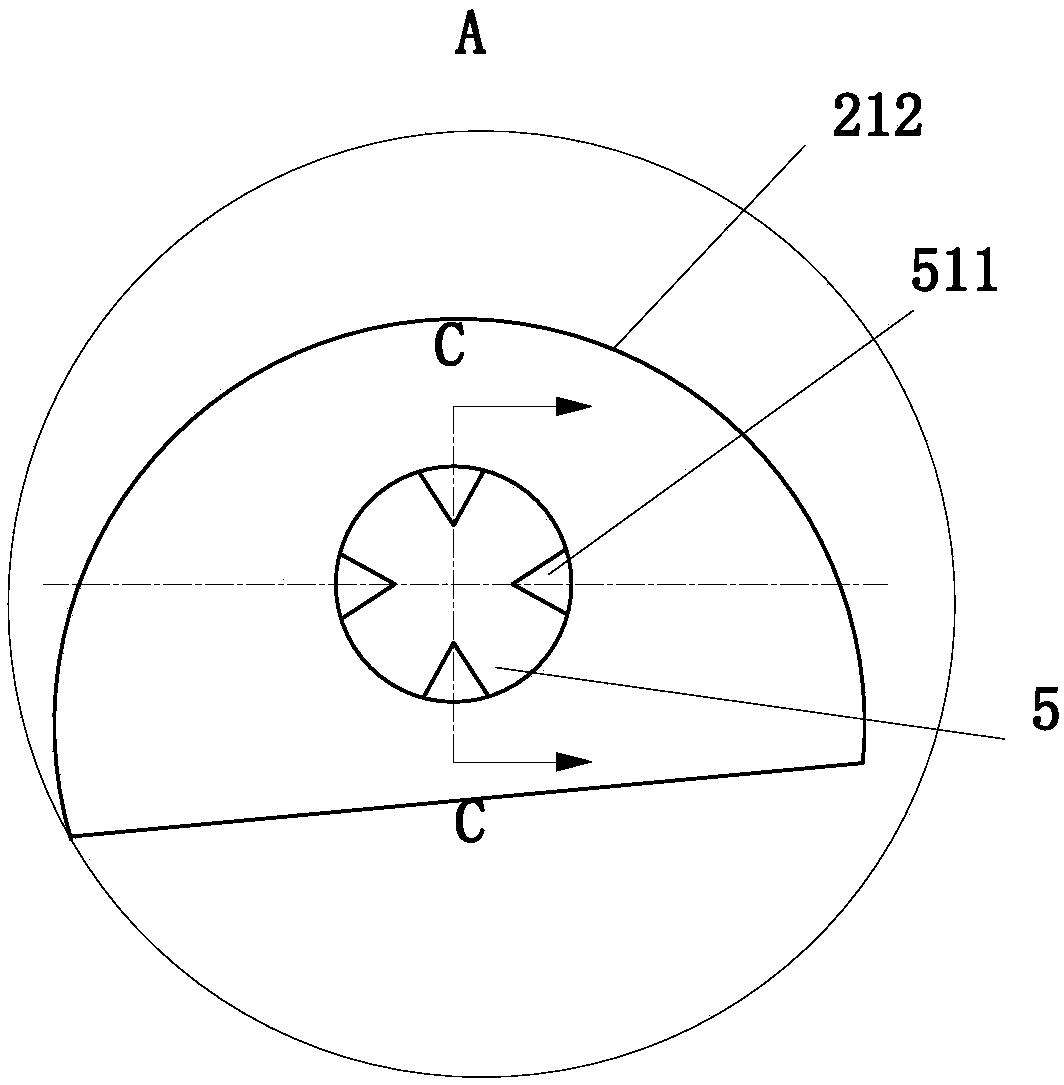

ActiveCN106239284AGrinding muchLow costGrinding carriagesRevolution surface grinding machinesDrive wheelPipe fitting

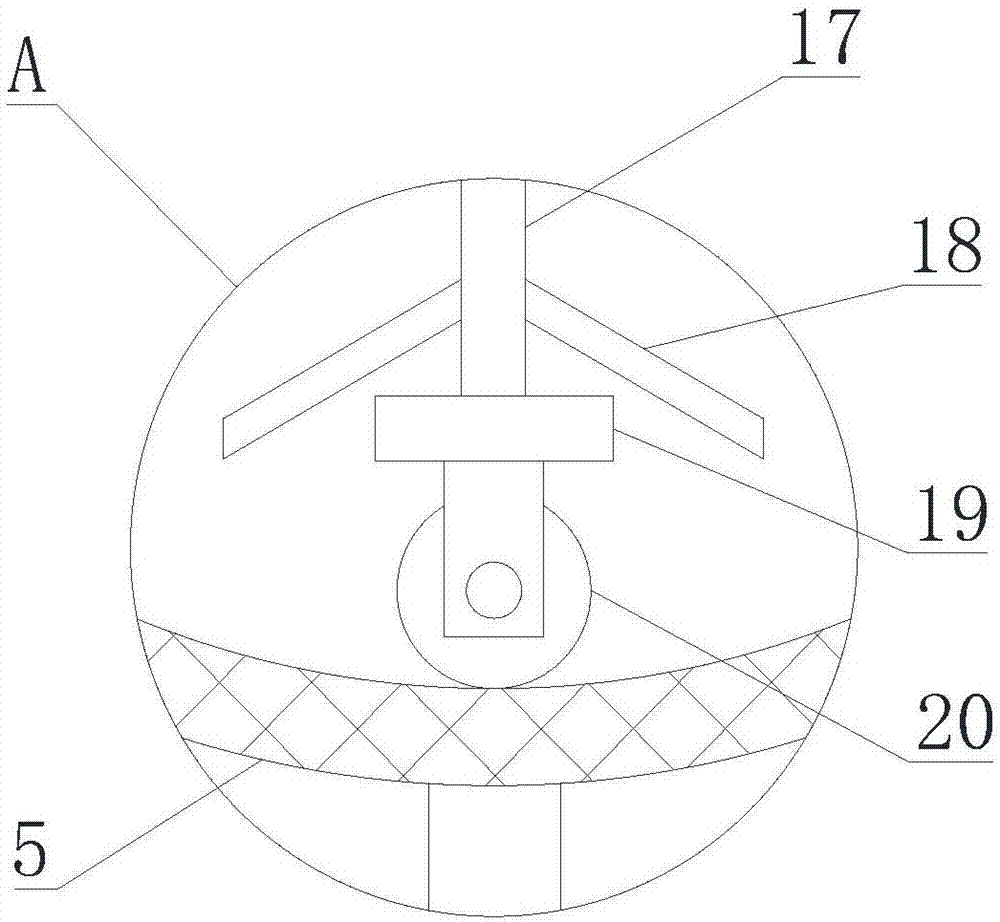

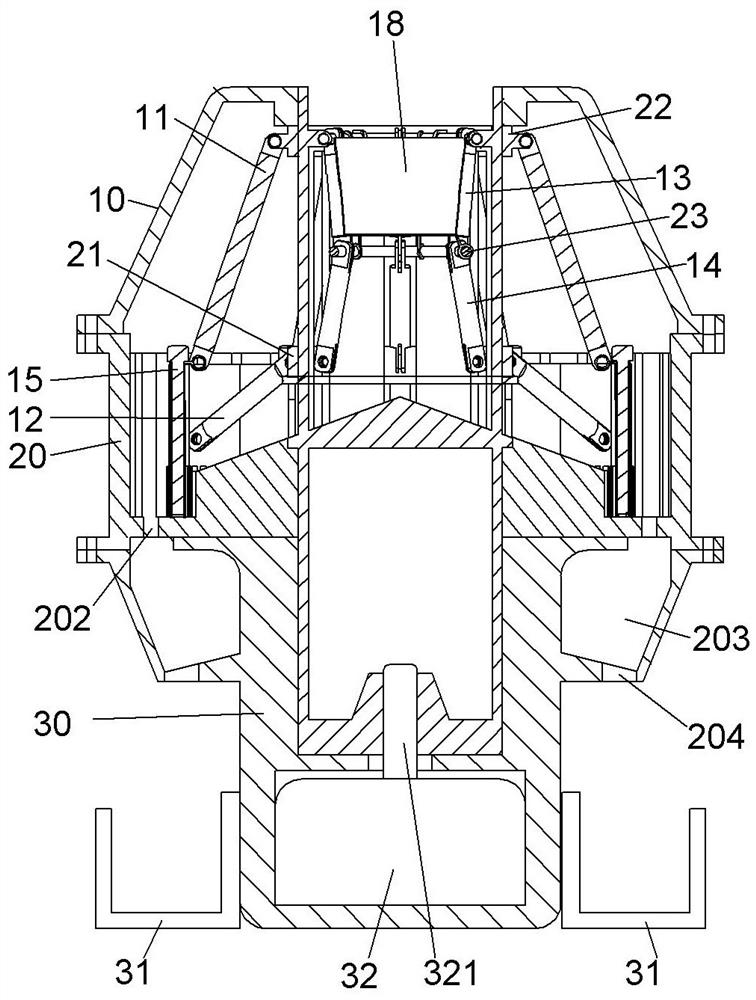

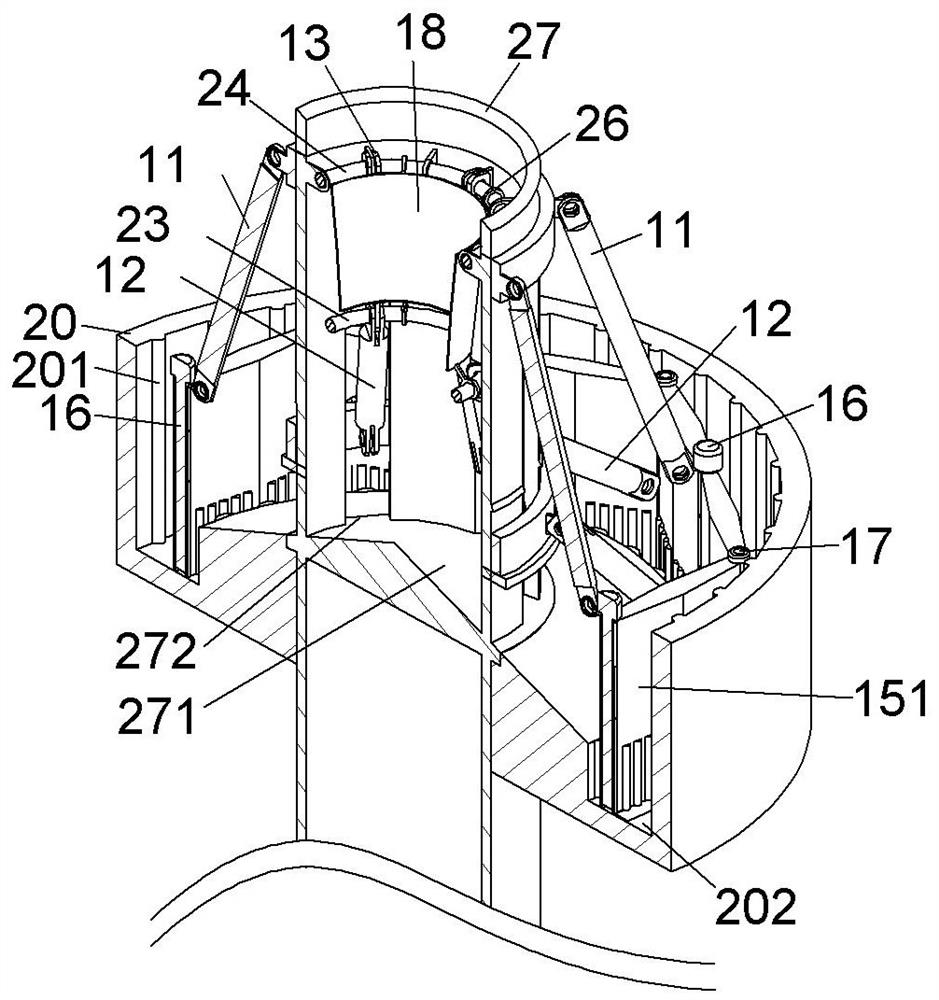

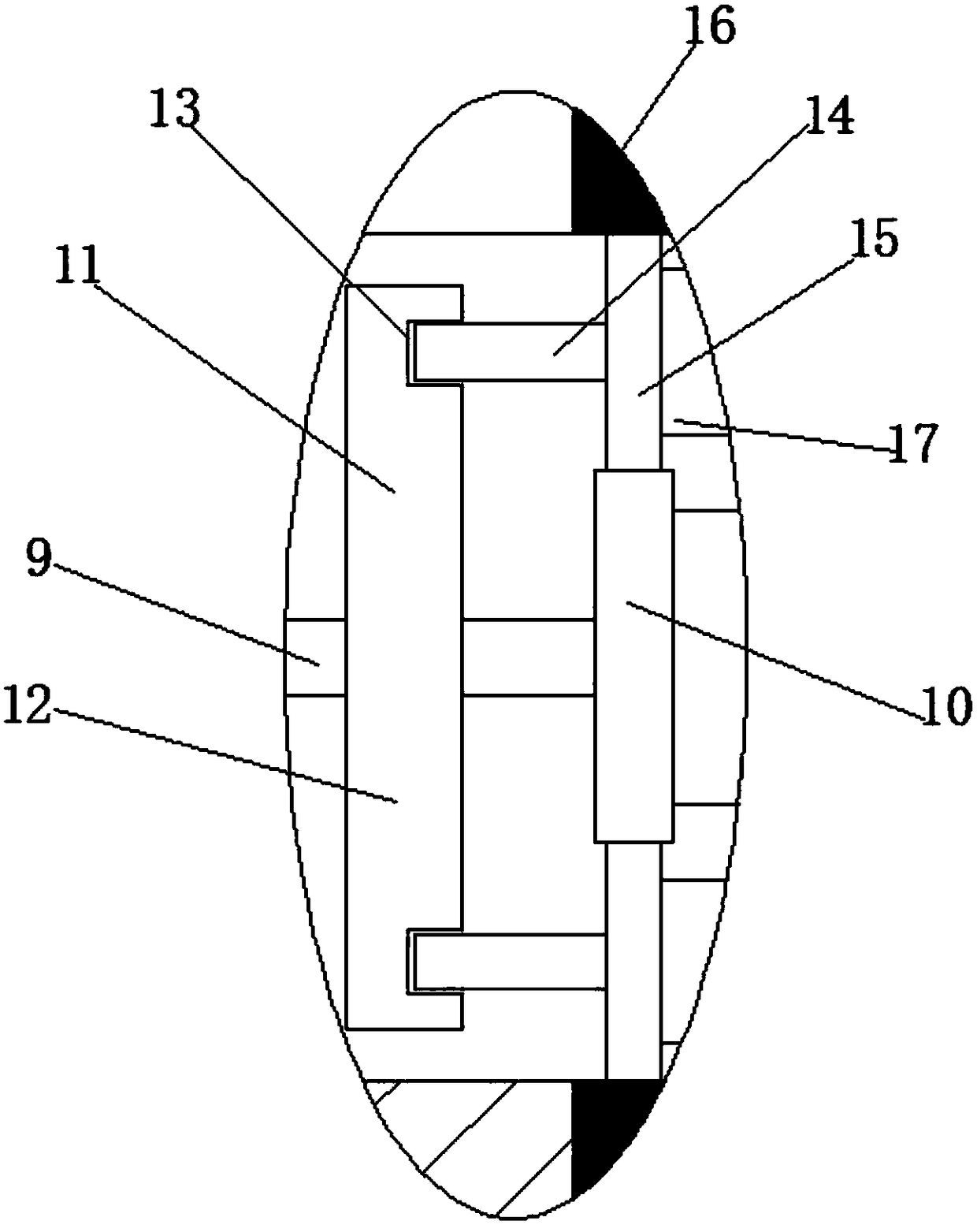

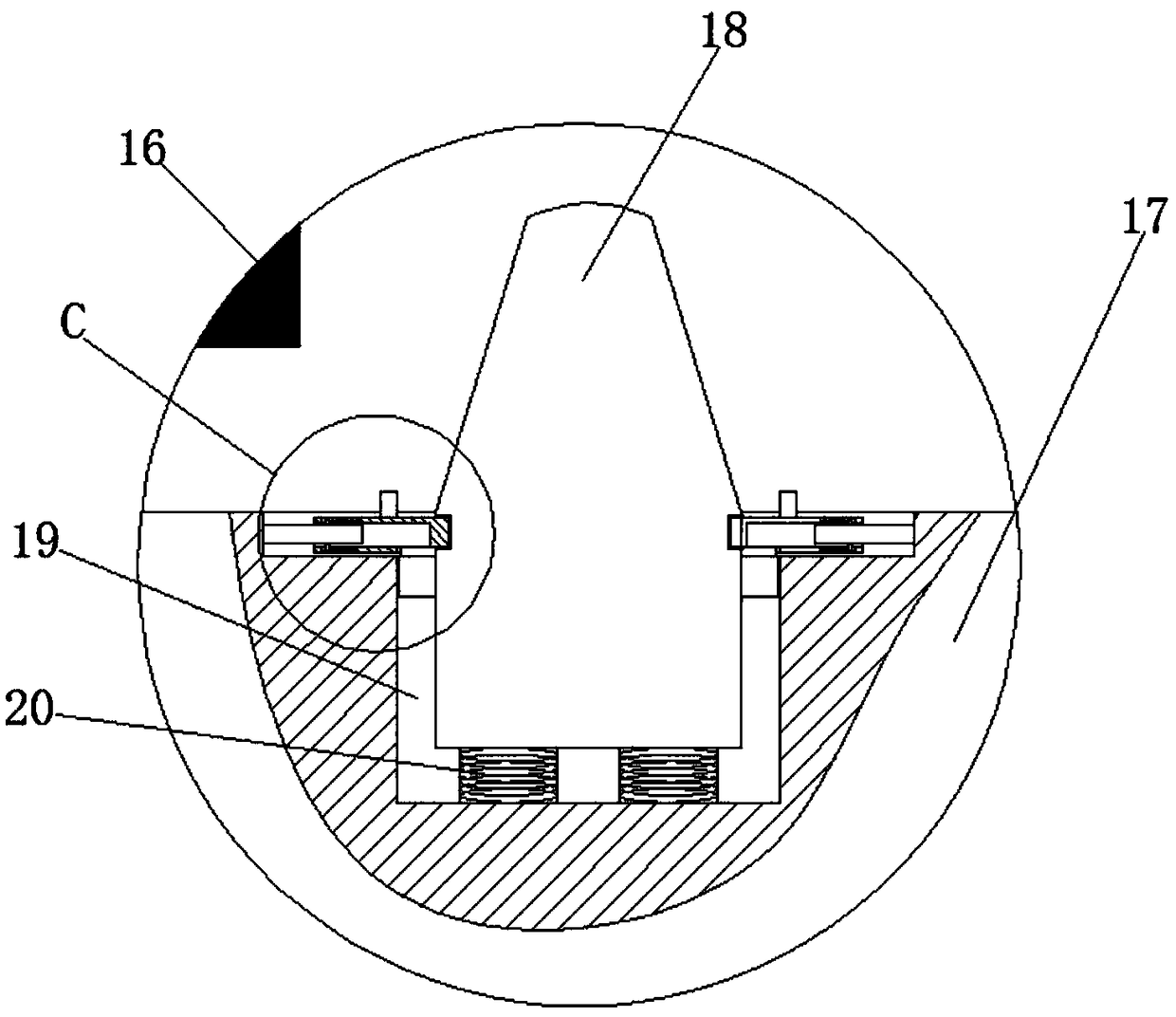

The invention relates to a spiral pipeline inner wall grinding and polishing robot suitable for different pipe diameters, and belongs to the field of pipeline robots. A hub assembly and a cross-axis universal joint are mounted in a spline fit manner, three driving wheel grinding assemblies are arranged, two ends of drive shafts of the assemblies and a drive shaft support in the hub assembly are mounted in a matched manner through bearings, a motor and control and power assembly is mounted on a direction keeping mechanism, and a motor shaft of the assembly and the cross-axis universal joint are mounted in a spline fit manner. The spiral angles of the grinding assemblies relative to the cross section of a pipe fitting are adjusted in a self-adaptation manner, and therefore the aim that the position with the small pipe diameter and many impurities is ground much, and the position with the large pipe diameter and few impurities is ground little is achieved, the robot can be matched with multiple different-size grinding assemblies for use, the aim that one robot has multiple purposes is achieved, and the cost can be saved to a certain degree.

Owner:JILIN UNIV

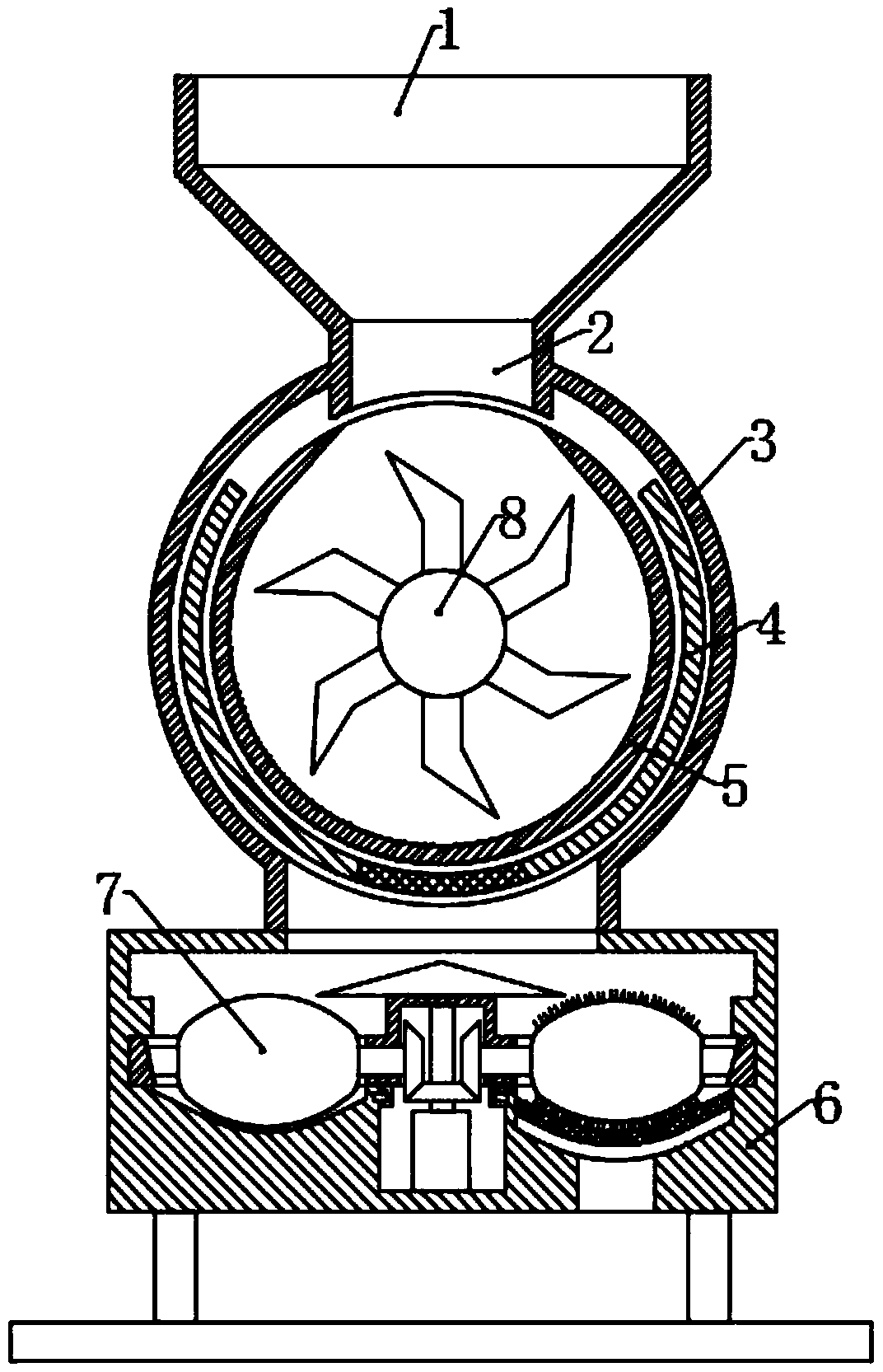

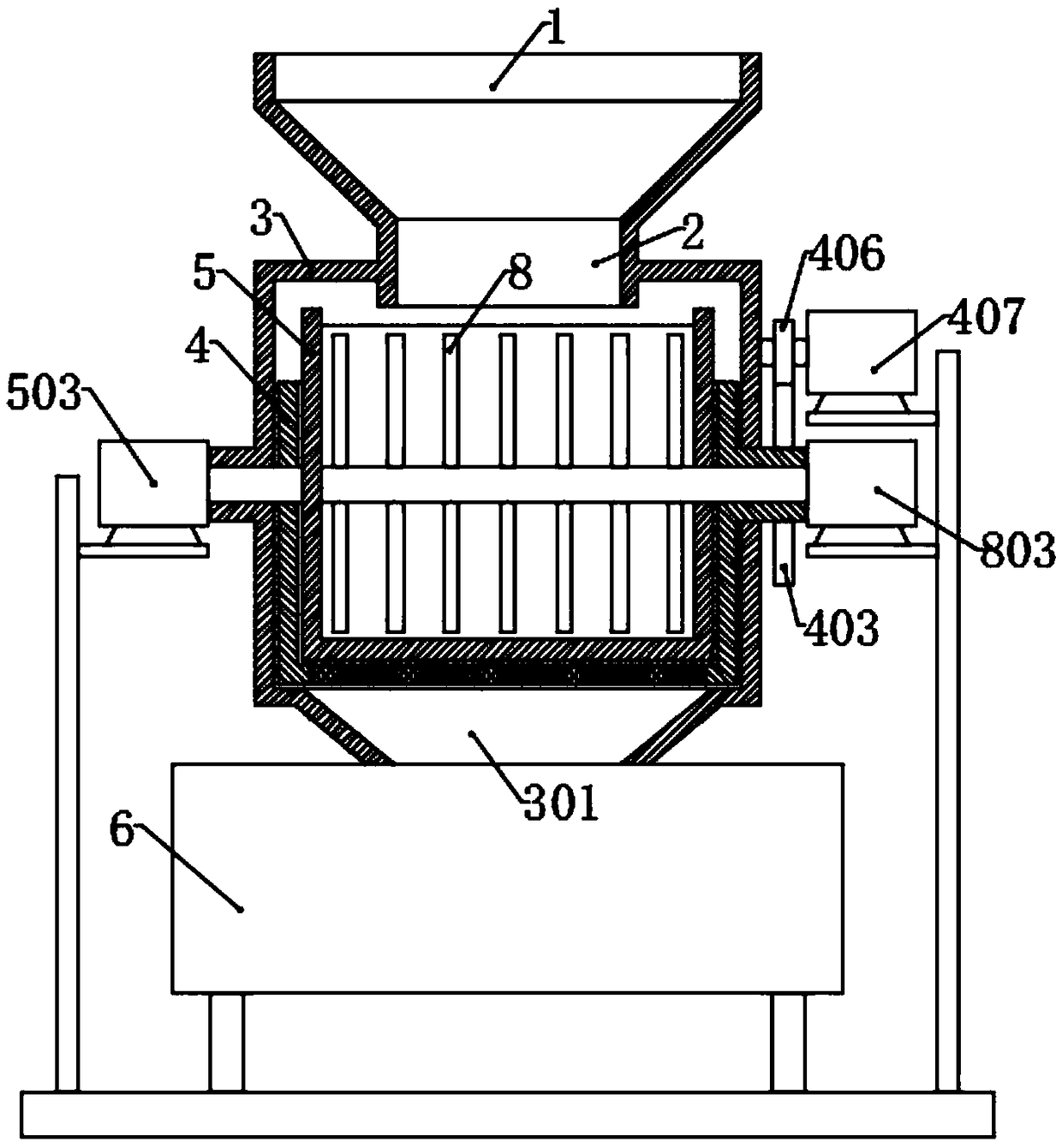

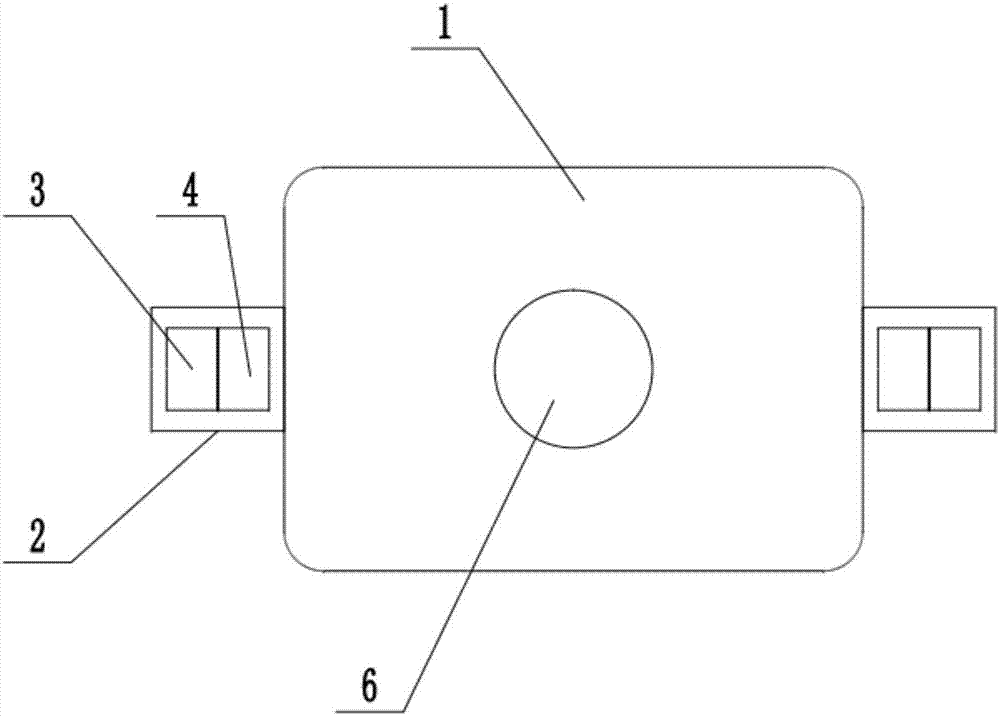

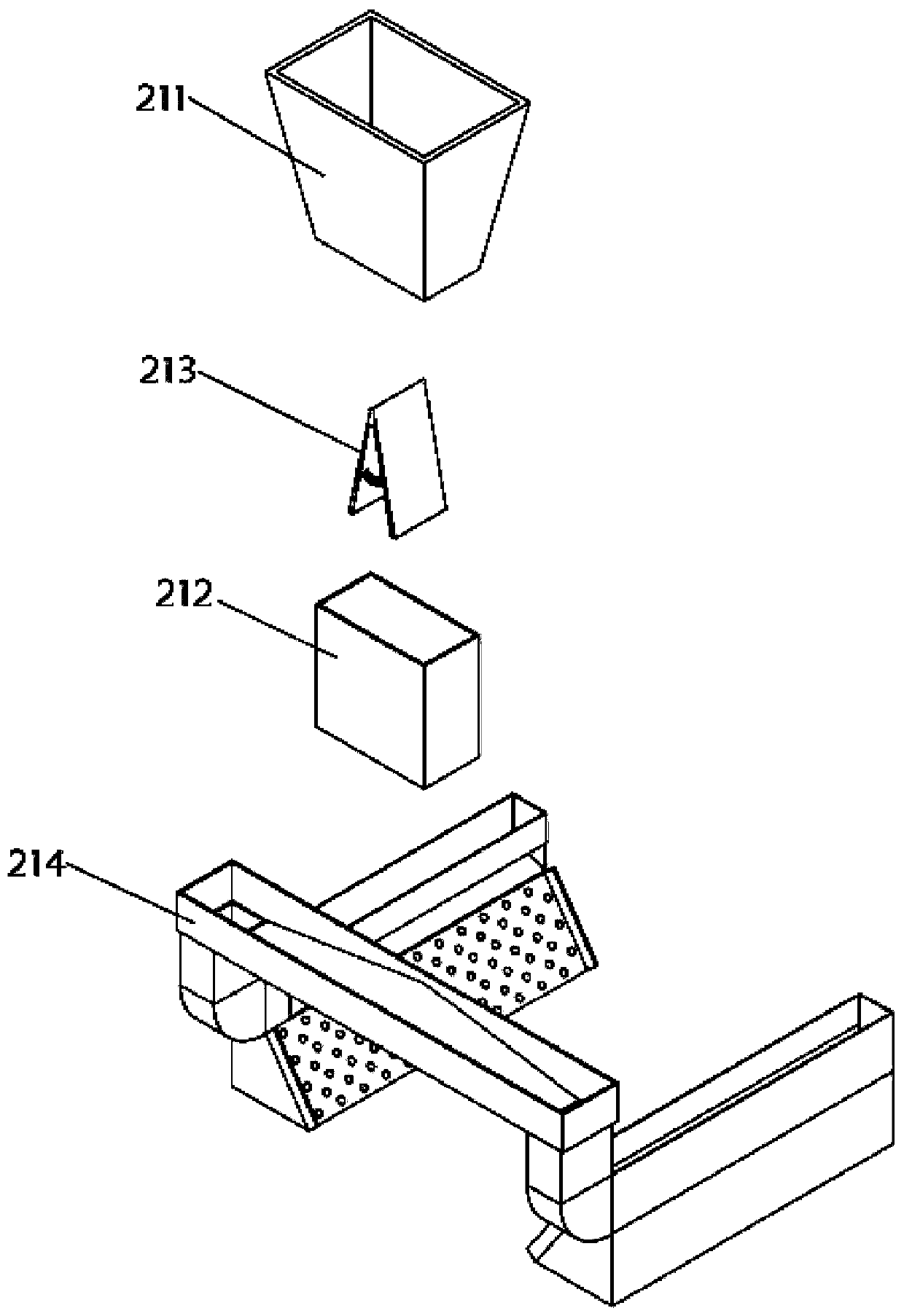

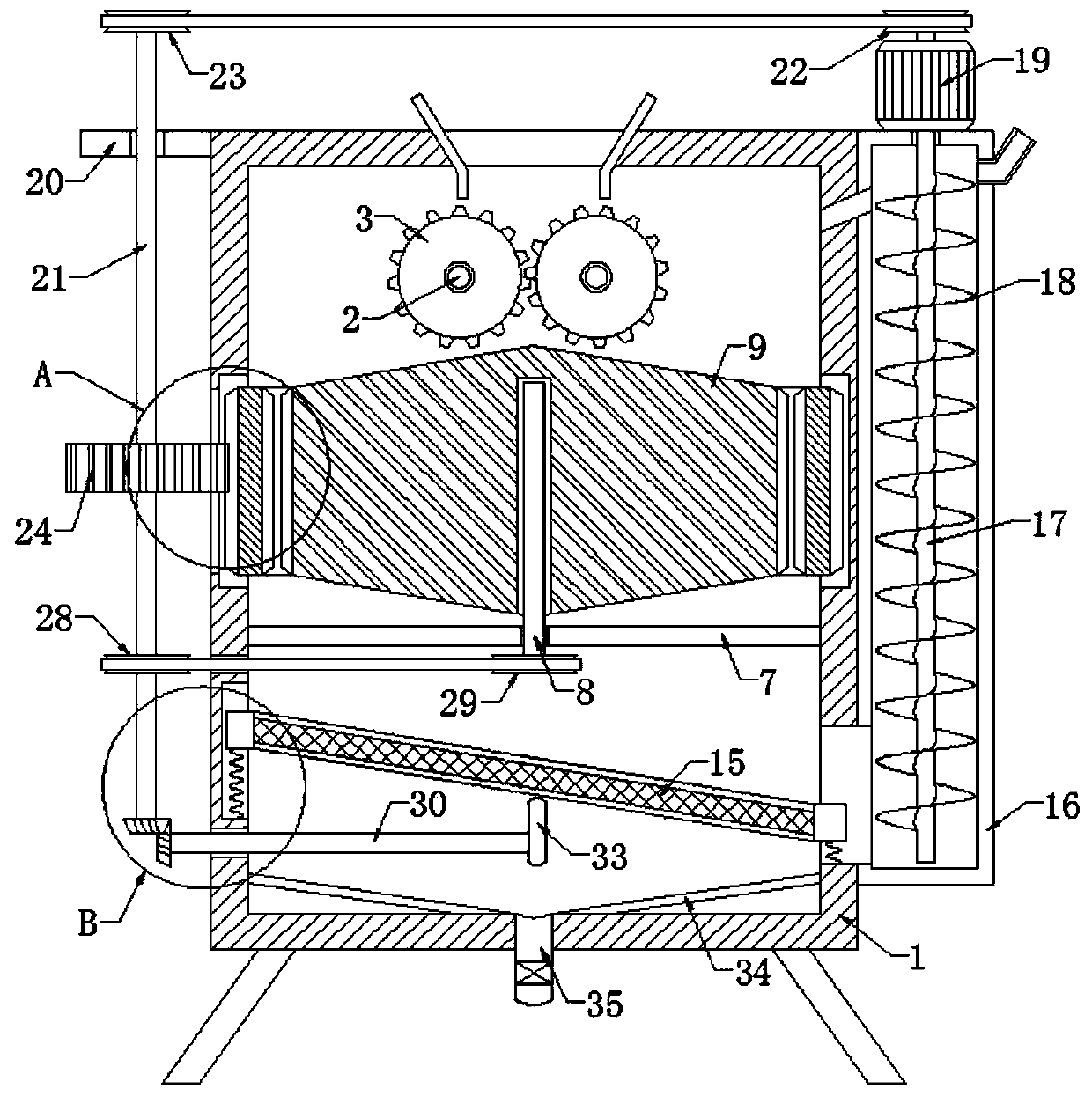

Crushing and grinding device for production and processing of traditional Chinese medicinal materials

InactiveCN108940503AAvoid enteringImprove subsequent grinding efficiencyGrain treatmentsEngineeringMaterials processing

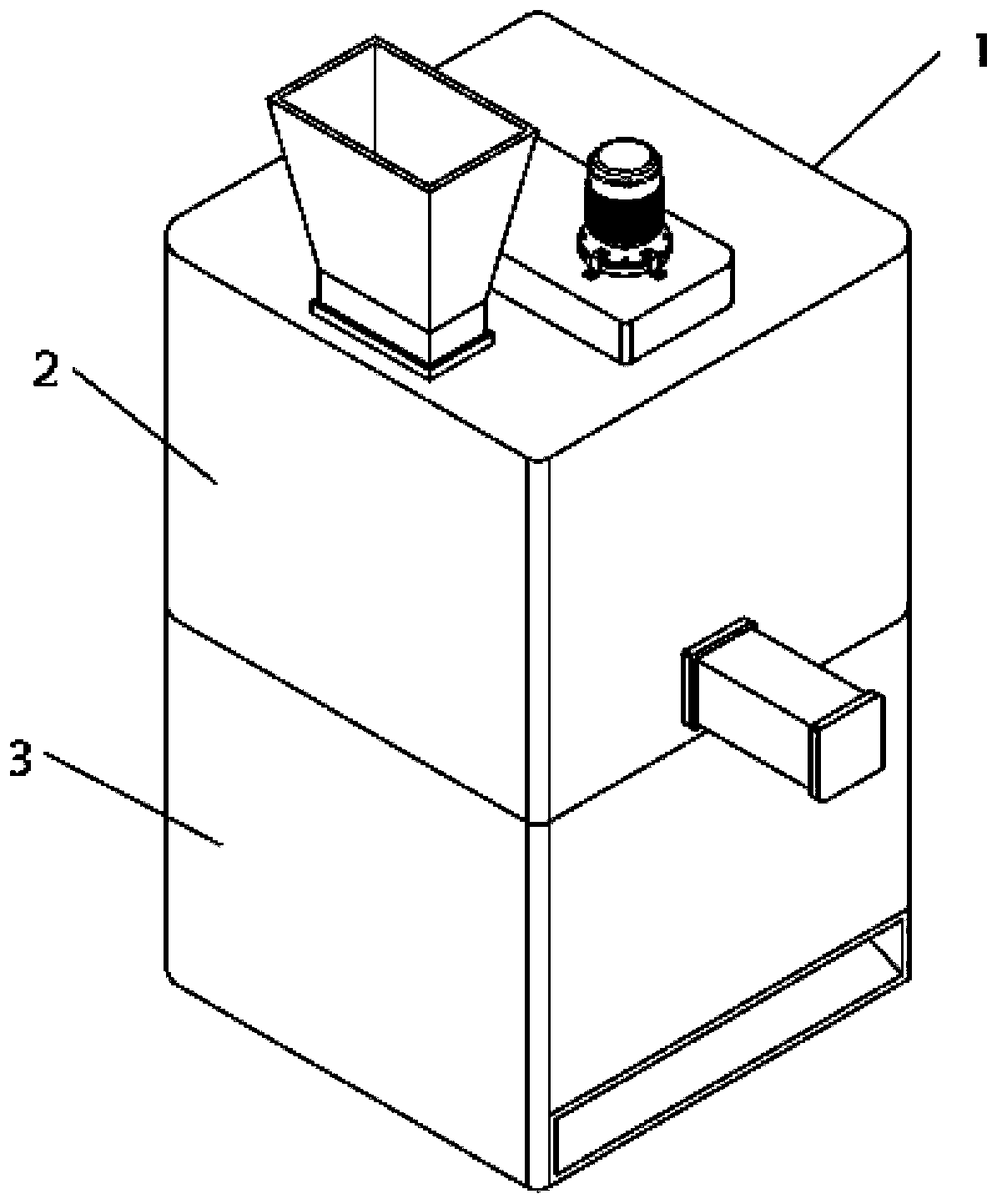

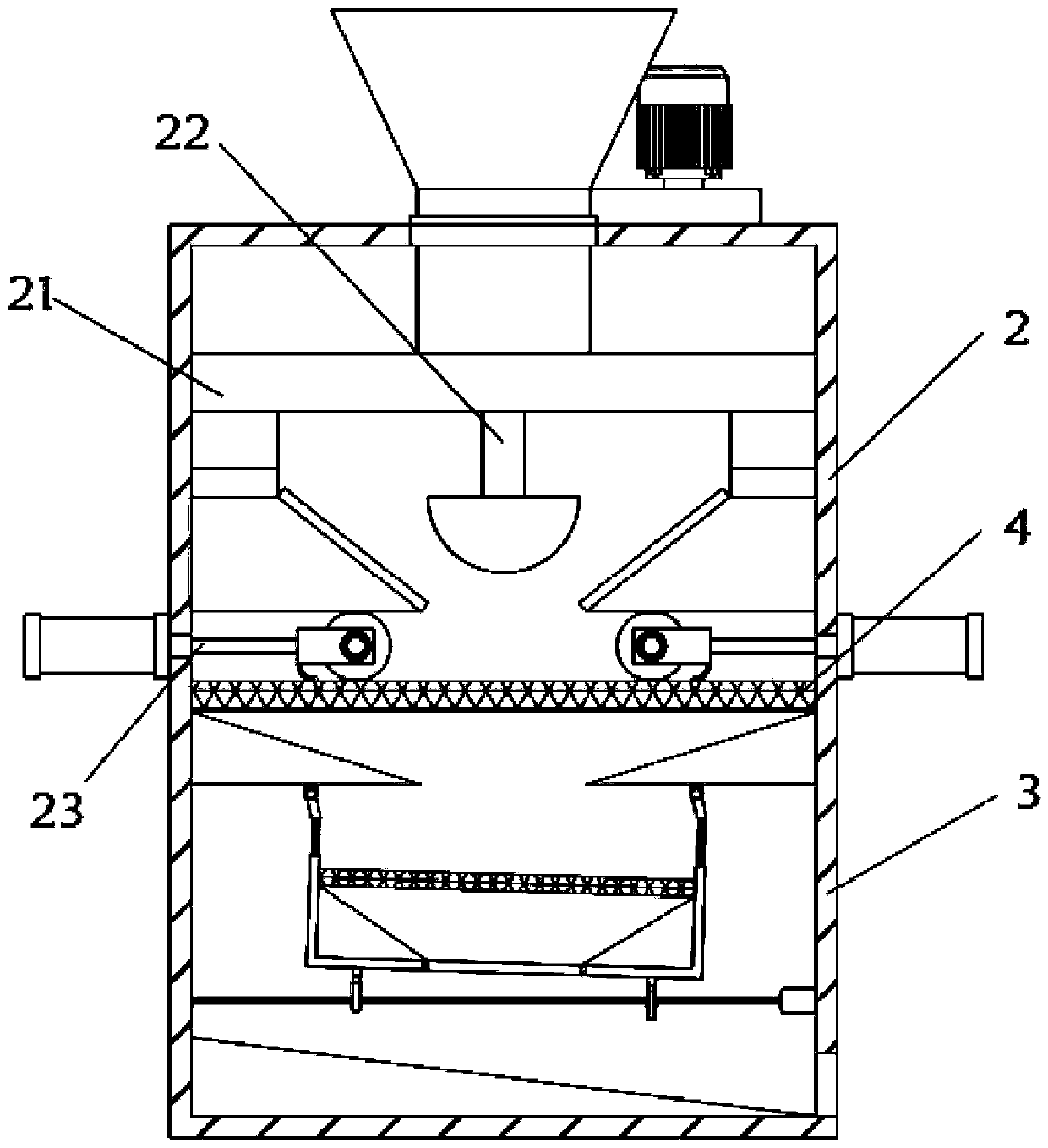

The invention discloses a crushing and grinding device for production and processing of traditional Chinese medicinal materials in the technical field of traditional Chinese medicinal material processing. The crushing and grinding device comprises a feeding hopper, a feeding pipe, a fixing case, a screening case, a crushing case and a grinding case. According to the crushing and grinding device, the traditional Chinese medicinal materials are put into the feeding hopper and then enter the crushing case along the feeding pipe, a crushing mechanism is used for crushing the traditional Chinese medicinal materials, and a feeding inlet of the crushing case conducting crushing rotates to face downwards; the traditional Chinese medicinal materials are screened through the screening case, and thenthe feeding inlet of the crushing case is rotated to face upwards; the traditional Chinese medicinal materials which do not penetrate through a first screening mesh return to the crushing case through the shovel face at the feeding inlet and are subjected to secondary crushing along with next batch of to-be-crushed medicinal materials, and the traditional Chinese medicinal materials enter the grinding case and are ground through a grinding mechanism; and meanwhile, completely ground medicine powder is fed into a powder outlet through a rotating brush, so that the situation that powder particles are too fine due to the fact that ground medicine powder is left in a grinding groove and ground repeatedly is avoided, and the grinding effect is good.

Owner:周意

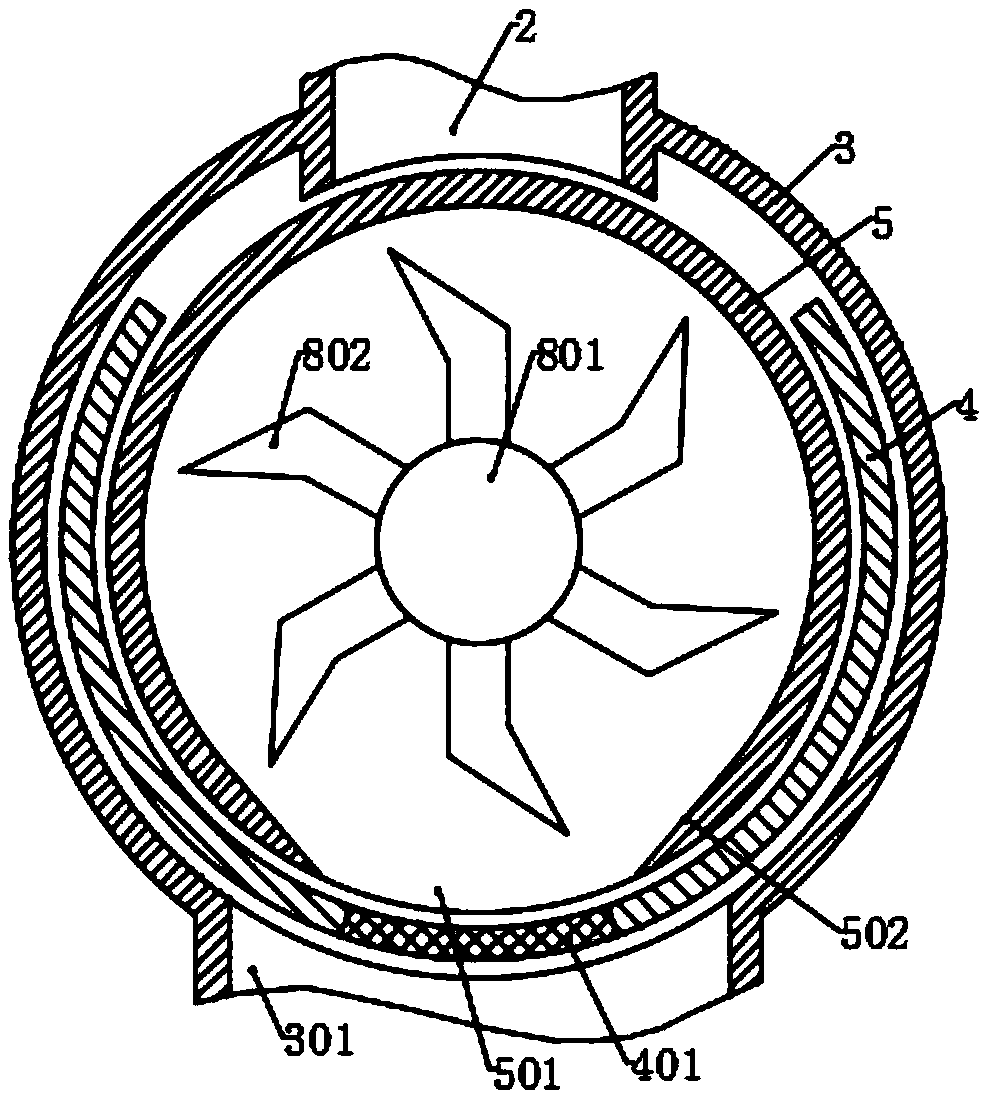

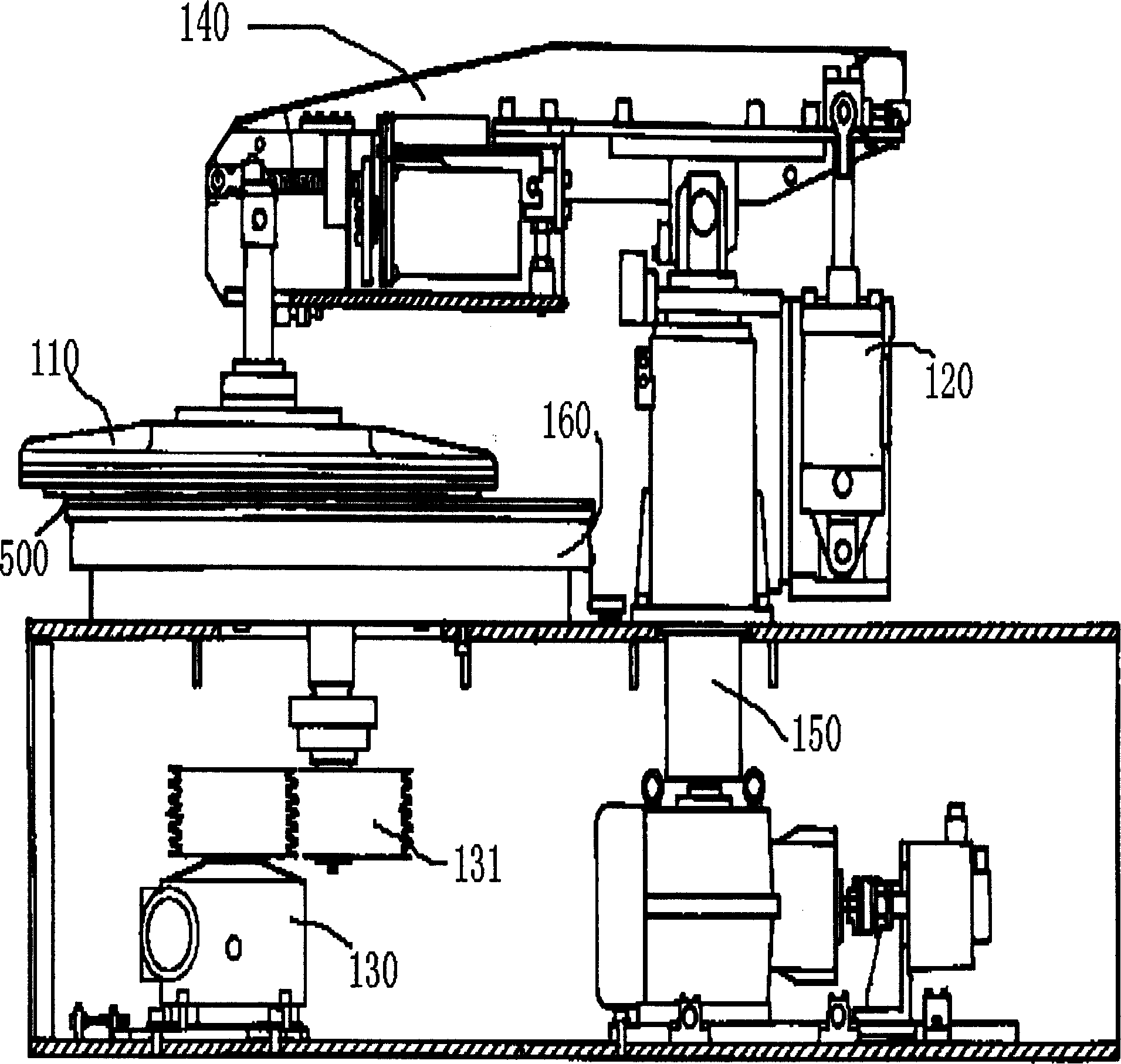

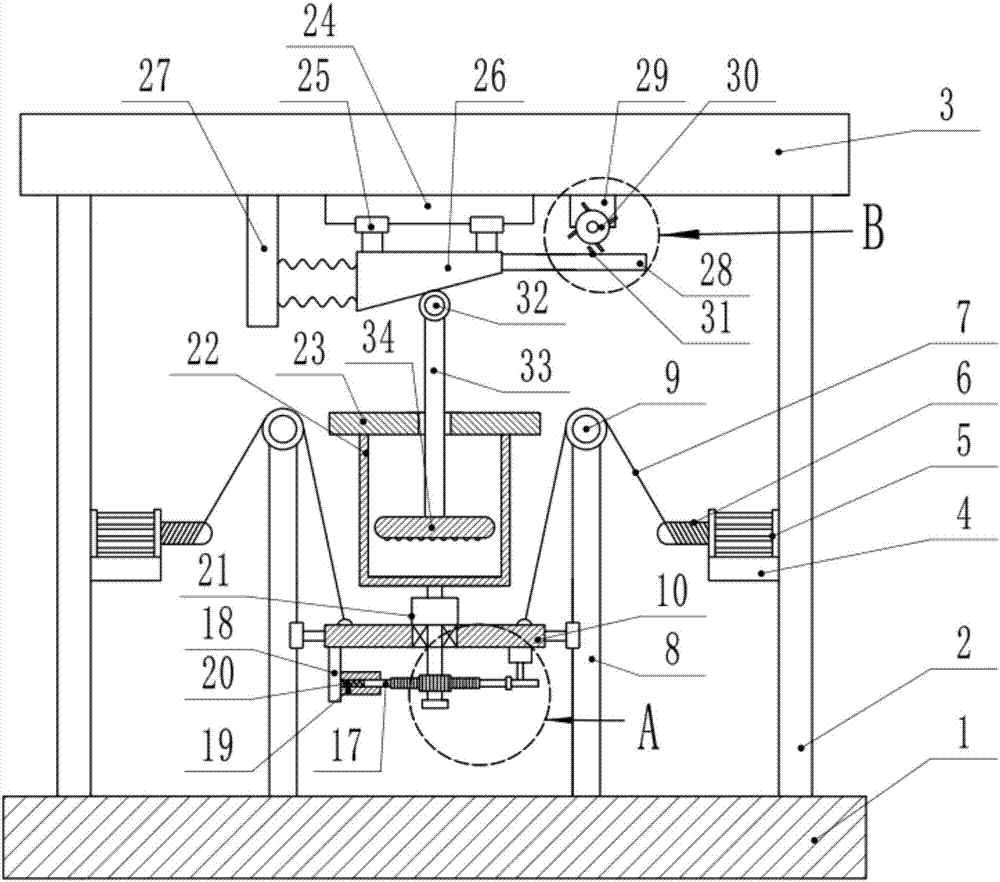

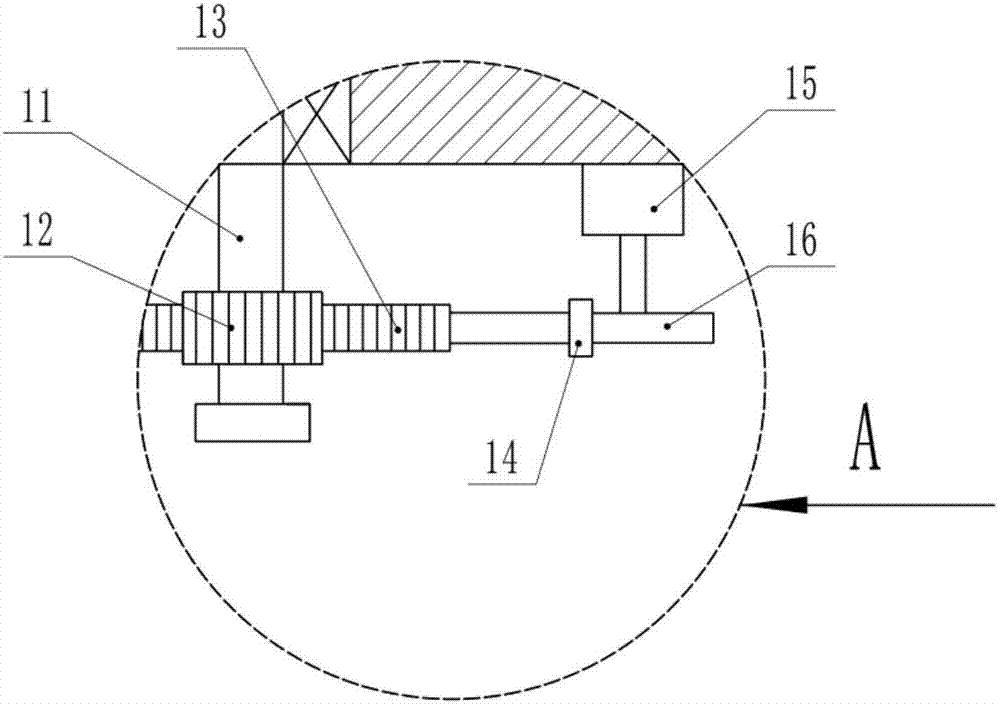

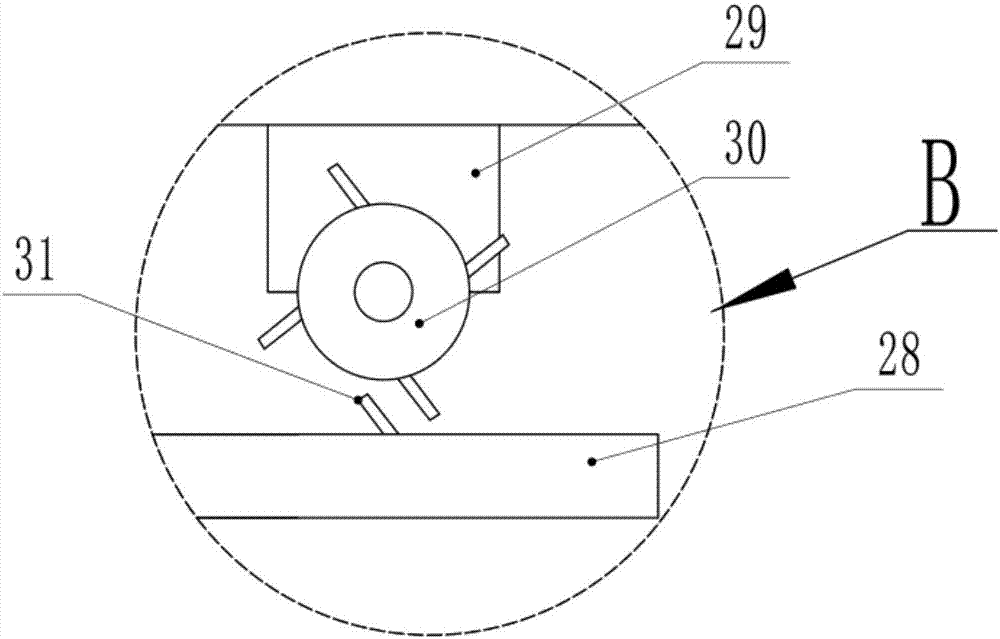

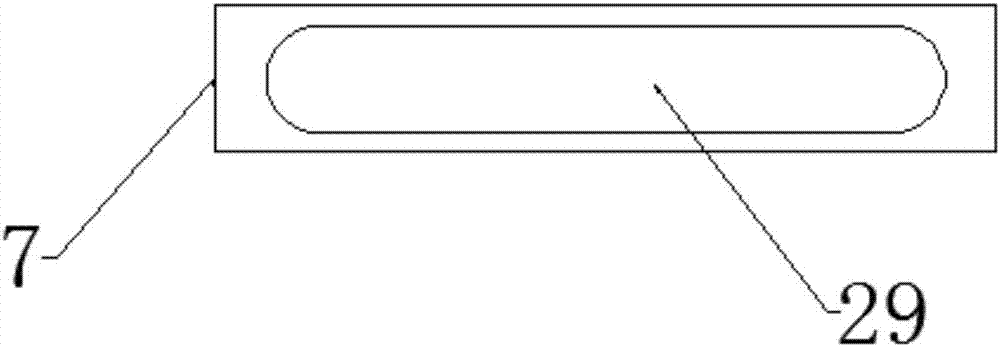

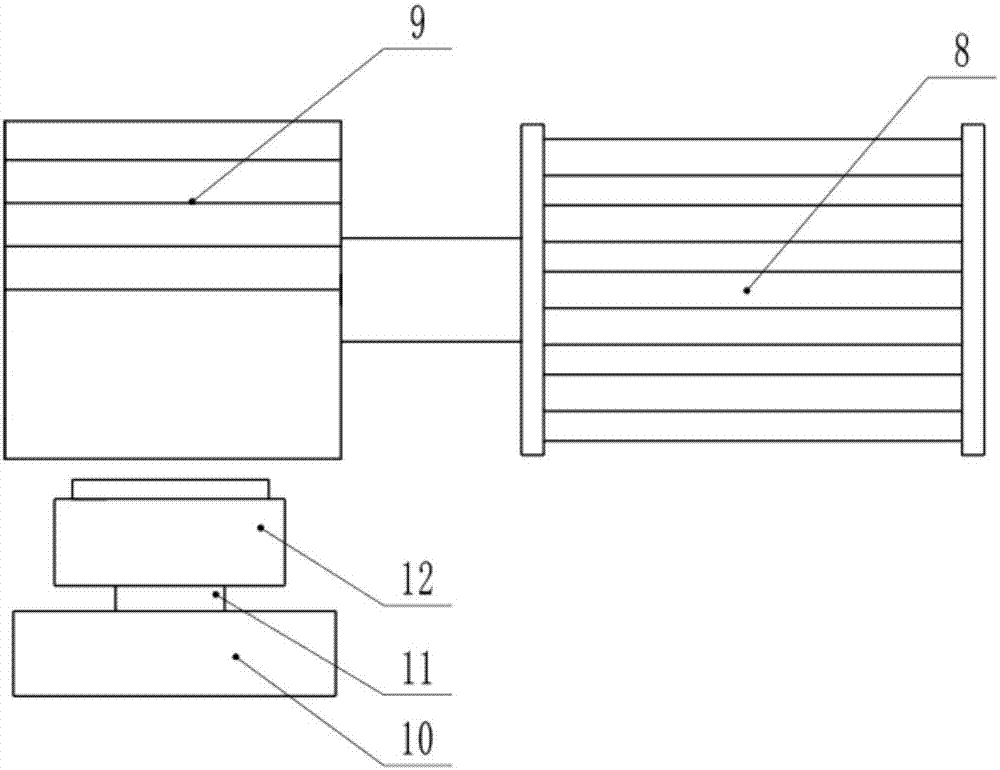

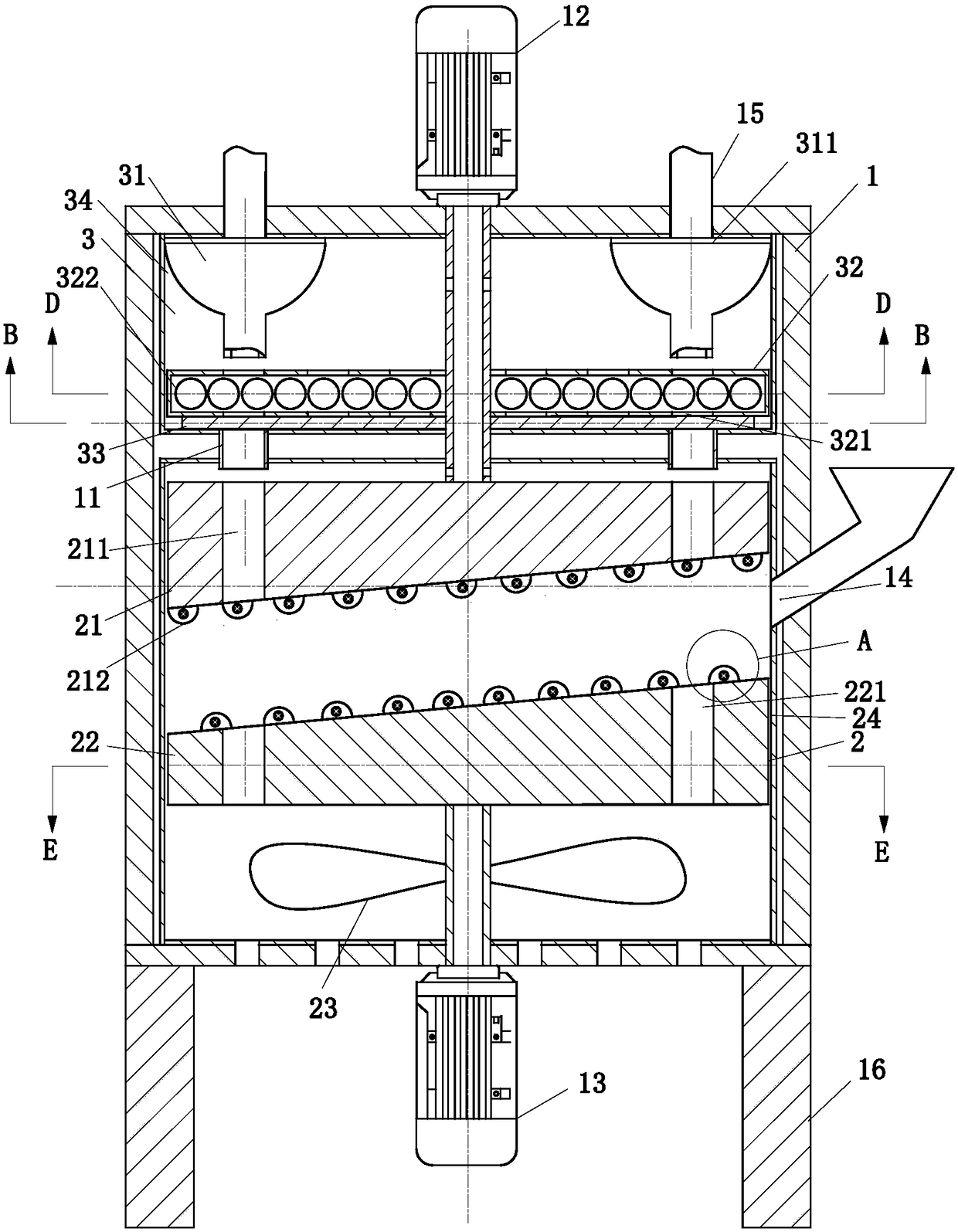

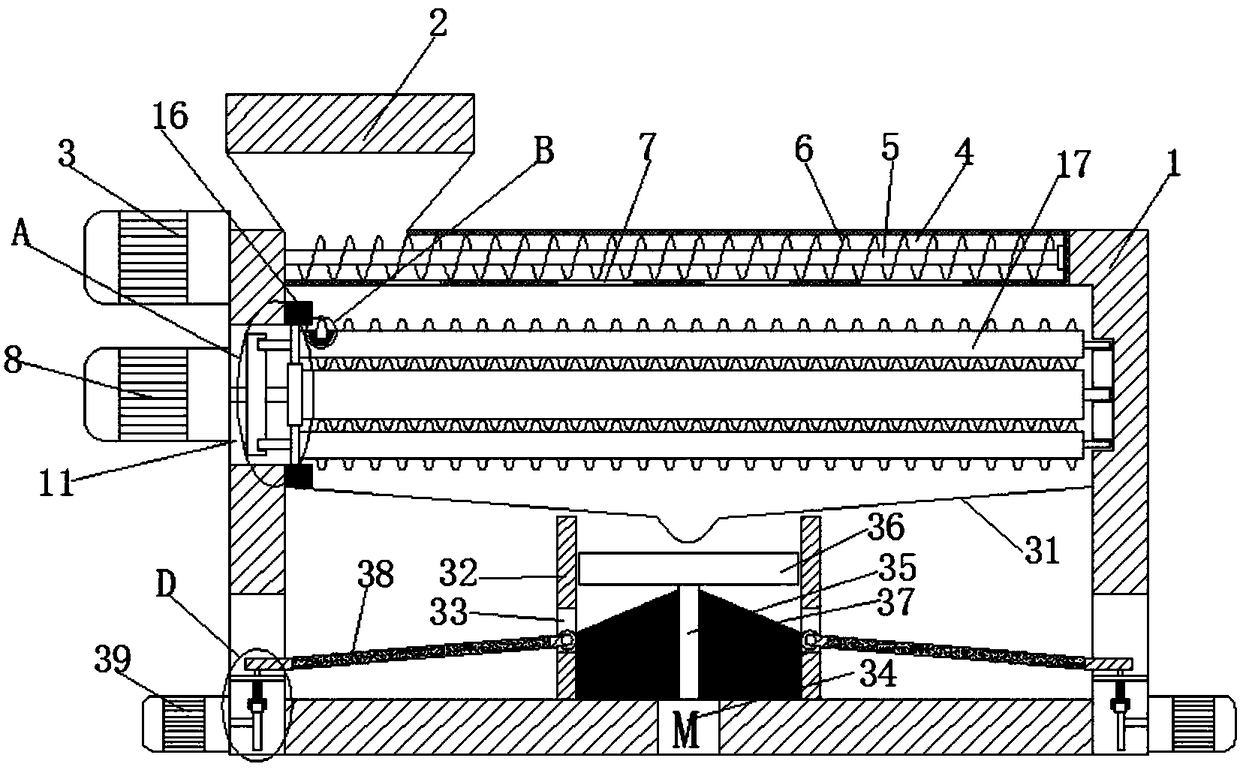

Grinding equipment of plate material and grinding method

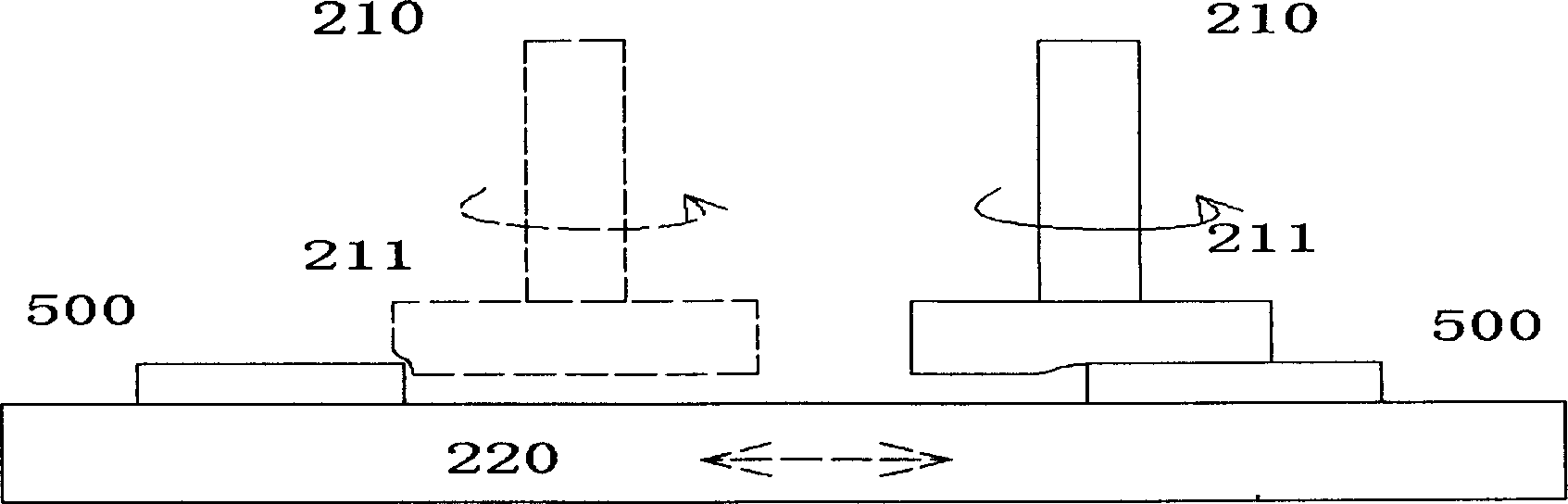

InactiveCN1830621ARealize longitudinal reciprocating motionAchieve fixationGrinding feed controlPlane surface grinding machinesReciprocating motionEngineering

A method for grinding on the plate object, especially the FPD glass substrate, features that the moving trace on the surface to be ground is programmed, and a novel loading-unloading technology for the plate object is used. Its grinder features that is grinding pressure and rotation speed is adjustable and its grinding mechanism can move longitudinally and transversely.

Owner:HENAN ANCAI HI-TECH

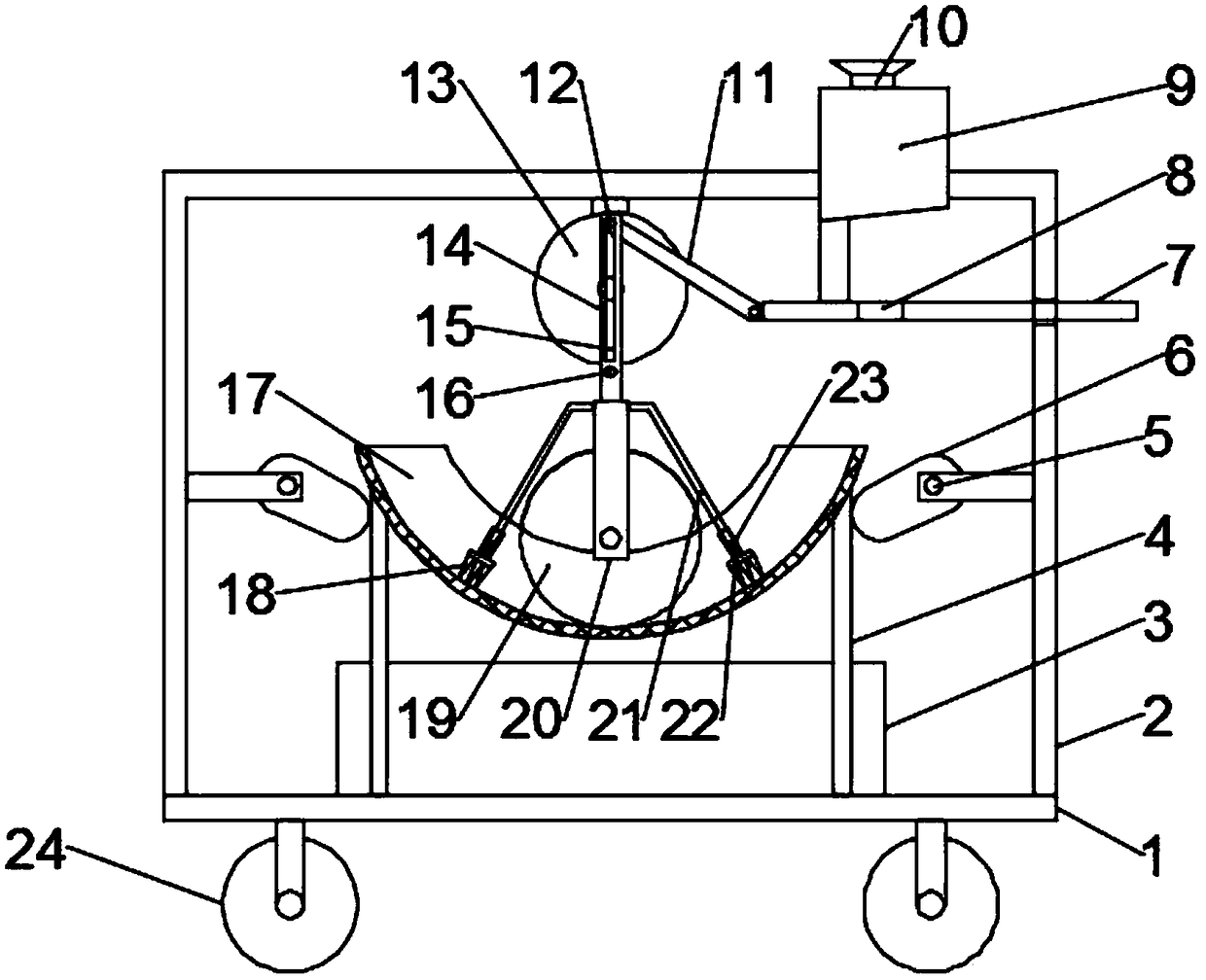

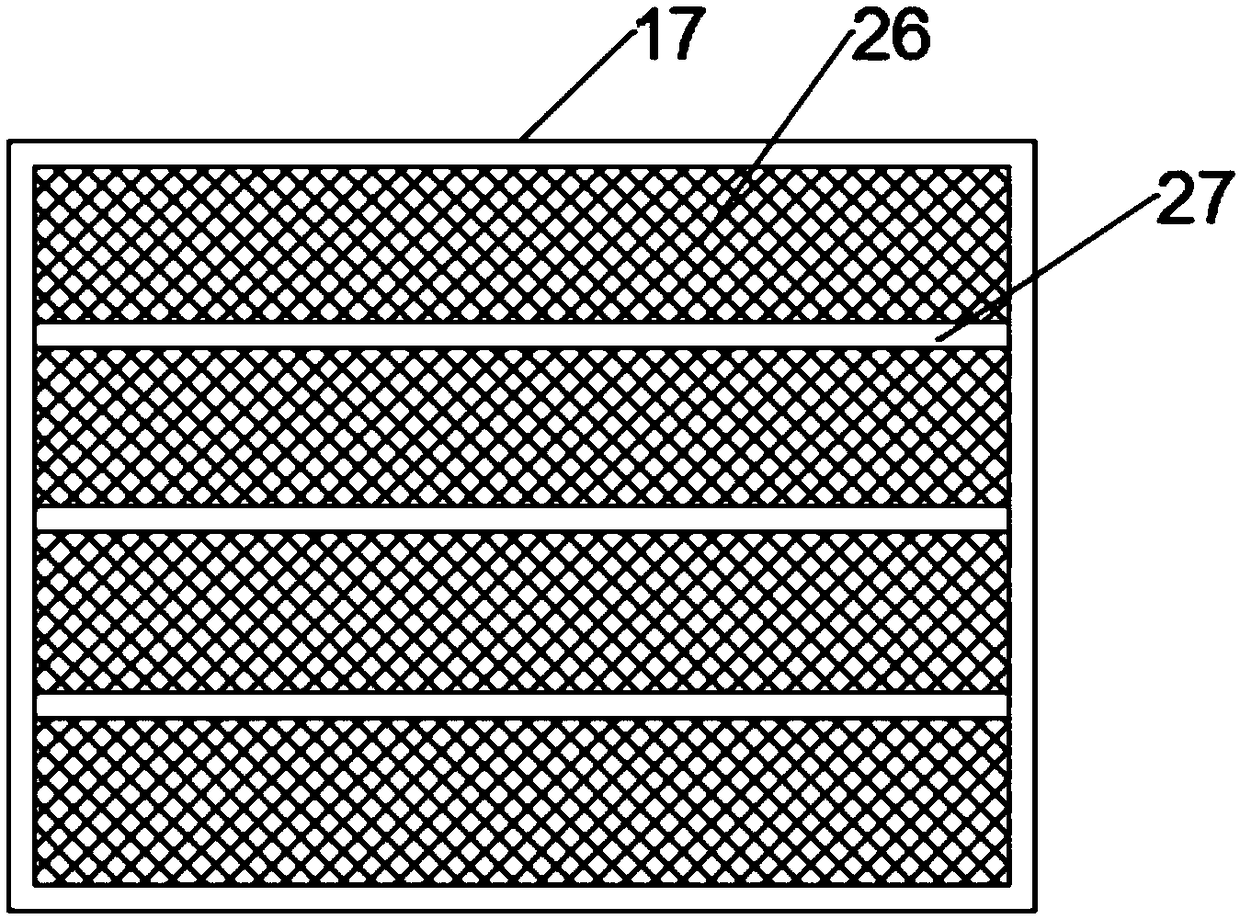

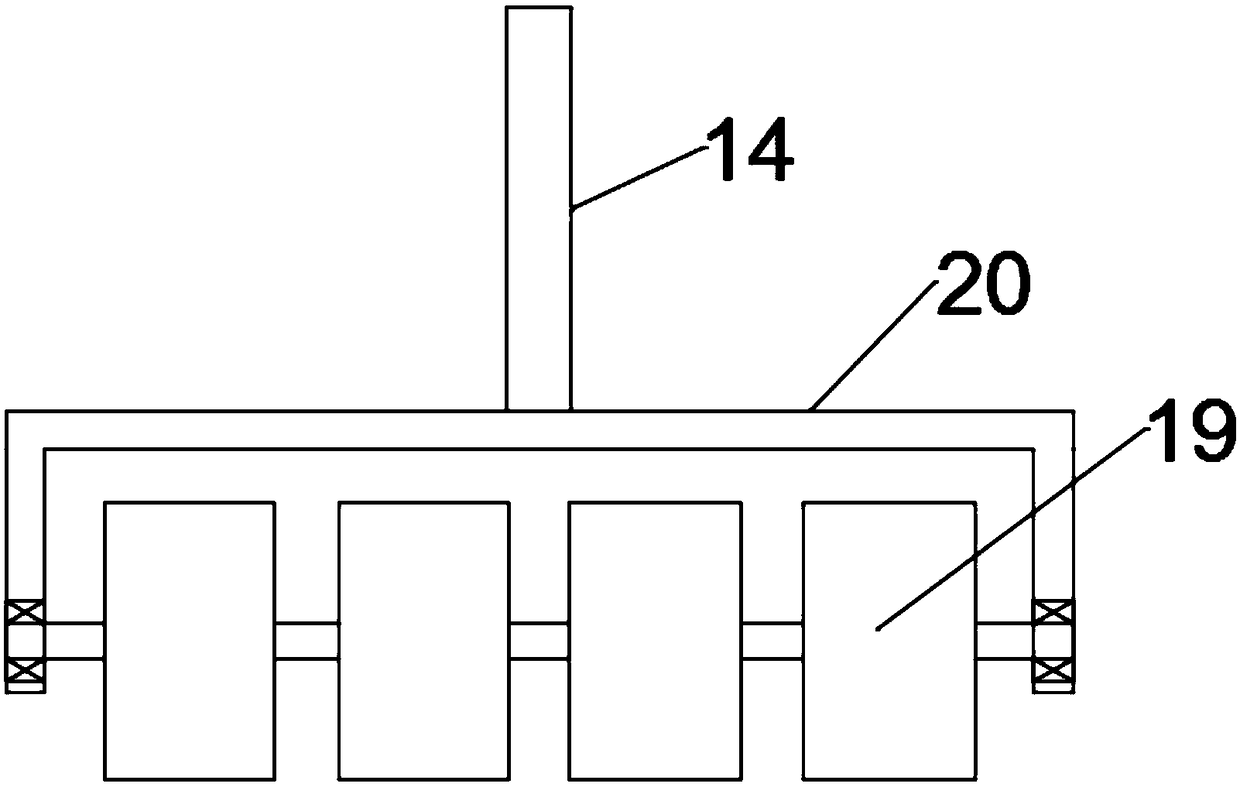

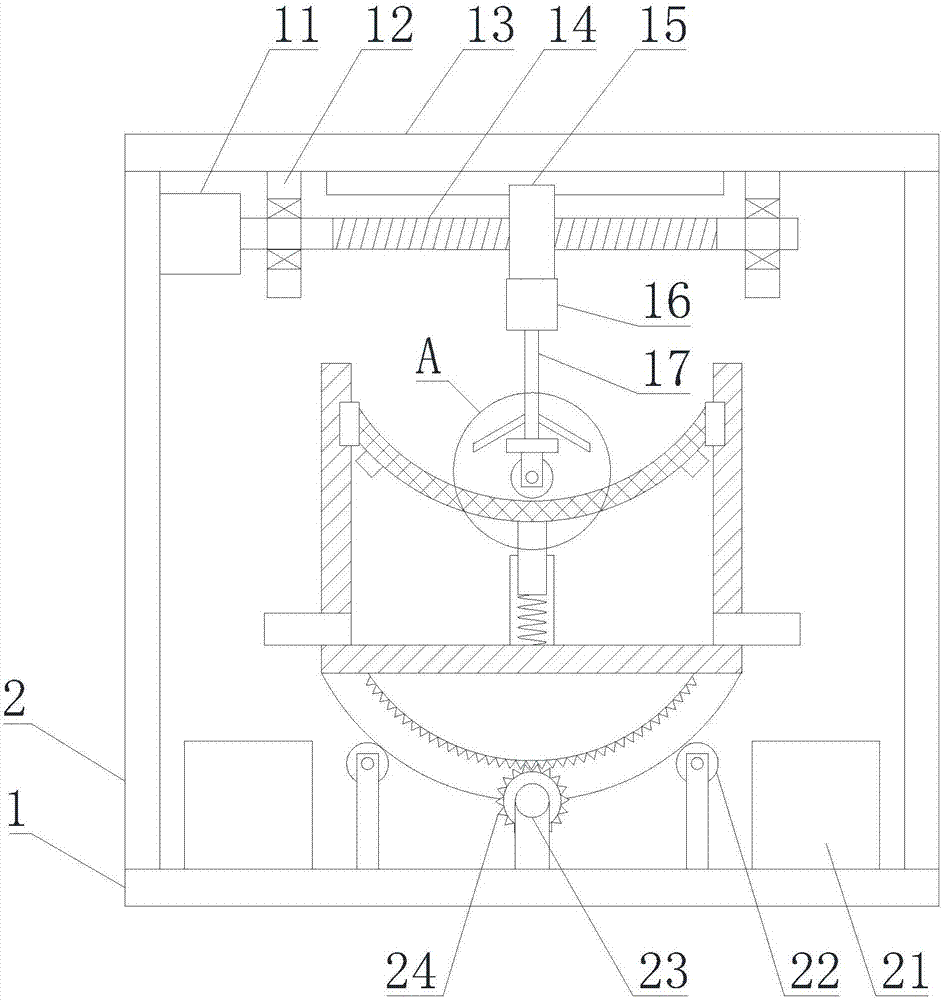

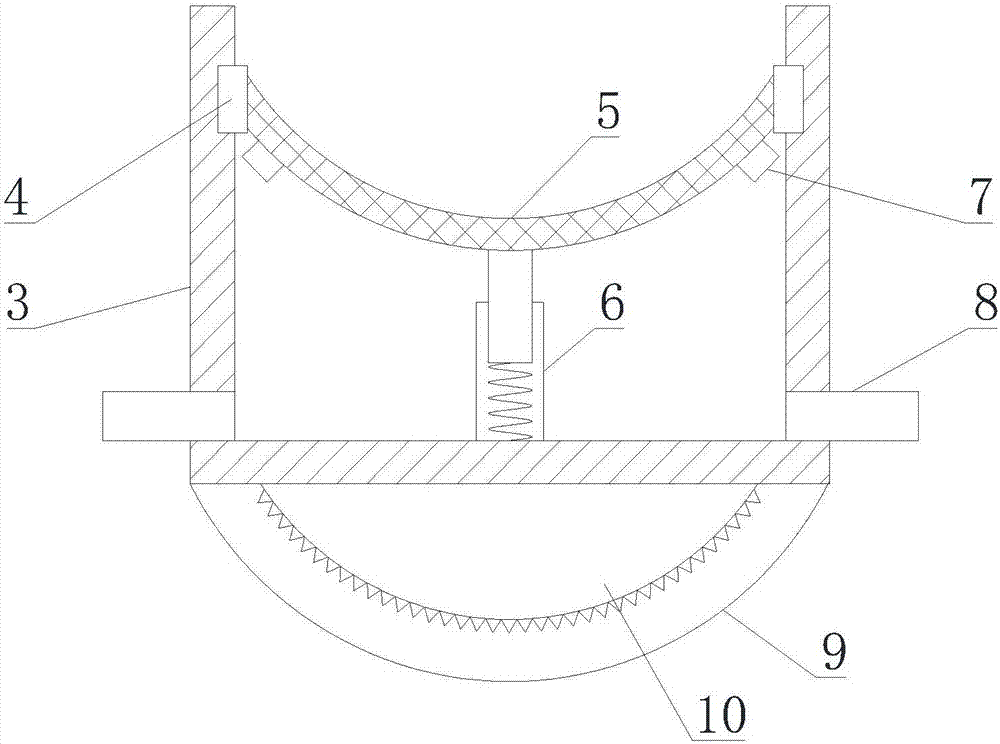

Chinese herbal medicine cutting-up and grinding integrated device

The invention discloses a Chinese herbal medicine cutting-up and grinding integrated device. The Chinese herbal medicine cutting-up and grinding integrated device comprises a base, supporting legs, a supporting column, a cutting-up plate, a left fixing board, a right fixing board, a top board, a grinding hammer and a grinding tank, wherein the supporting column is hinged to the upper surface of the base; a first motor is fixedly connected to the top of the supporting column; a second motor is fixedly connected to the outer wall of the left side of the left fixing board; a double-way screw rod is fixedly connected to the shaft extension end of the second motor; the left end and the right end of the double-way screw rod are sleeved with a left sliding block and a right sliding block correspondingly; a crank shaft is fixedly connected to the right end of the double-way screw rod; the grinding hammer is rotationally connected to a journal of the crank shaft; and the grinding tank is disposed on the upper surface of the base. Chinese herbal medicines in the cutting-up plate are cut up through blades, the cutting-up plate continuously rotates in the cutting-up process of the Chinese herbal medicines, then the Chinese herbal medicines are more uniformly cut up, and the cutting-up efficiency is improved; and after cutting-up of the Chinese herbal medicines is finished, the cut-up Chinese herbal medicines in the cutting-up plate are put in the grinding tank, and the grinding tank swings back and forth in the grinding process, so that grinding is complete, the grinding efficiency is improved, and the manpower is saved.

Owner:WUHAN MATENG TECH DEV

High-heat-conductivity electric-insulation heat-conducting silica gel gasket and preparation method thereof

ActiveCN103436019AImprove thermal conductivityRealize a reasonable distributionHeat-exchange elementsHydrogenHeat conducting

The invention discloses a high-heat-conductivity electric-insulation heat-conducting silica gel gasket and a preparation method thereof. The preparation method comprises the following steps: taking the following raw materials in parts by weight: 600-1000 parts of spherical aluminum oxide, 5-15 parts of methylvinylsiloxane rubber, 30-70 parts of dimethyl silicon oil, 2-15 parts of hydrogen-containing silicon oil and 0.5-1.5 parts of catalyst; and screening the aluminum oxide particles, sintering, grinding the methylvinylsiloxane rubber and dimethyl silicon oil, stirring, vacuumizing, vulcanizing to form, and the like. The spherical aluminum oxide particles are screened and sintered to implement reasonable distribution of the aluminum oxide particles in the silica gel base and enhancement of the heat conductivity coefficient of the aluminum oxide particles; and the base material is sufficiently ground to implement sufficient fusion of the silica gel base and the aluminum oxide heat-conducting particles, thereby enhancing the heat-conducting property of the silica gel gasket. The silica gel gasket has favorable electric insulativity, and the heat conductivity coefficient is enhanced to 5.0W above.

Owner:SHENZHEN HFC SHIELDING PRODS CO LTD

Traditional Chinese medicinal material fine grinding device for pharmacy

The invention discloses a fine grinding device for Chinese medicinal materials used in a pharmacy, which comprises a base, a lifting motor, a rope winding shaft, a lifting slide plate, a first driving motor, a cam, a grinding bucket, a wedge block and a second driving motor. The lifting motor outputs A rope winding shaft is fixedly connected to the shaft, and a rotating shaft is installed in the center of the lifting slide, and a grinding bucket is connected to the upper end of the rotating shaft; several groups of sliders are slidably installed on the slide rail, and a The wedge-shaped block, the output shaft of the second driving motor is forward and is fixedly connected with a toggle wheel block to cooperate with the toggle wheel. Adjust the distance between the grinding head and the bottom of the grinding bucket through the lifting motor to adjust the size of the extrusion force, so as to obtain Chinese herbal medicine powder with different grinding degrees; through the cooperation between the wedge block and the roller, the grinding rod drives the grinding head down intermittently Movement, so as to increase the extrusion force between the grinding head and the Chinese herbal medicine, so as to make the grinding more fully and improve the grinding effect.

Owner:袁润栋

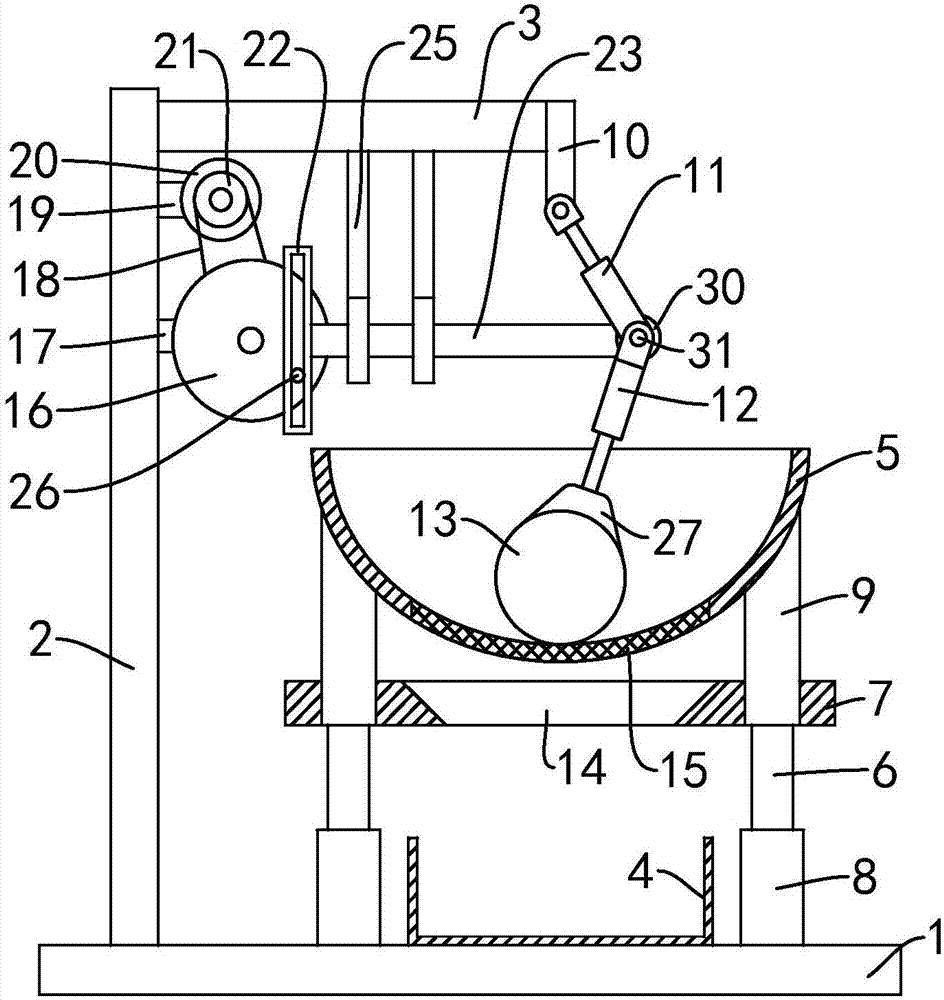

Refined grinding device for Chinese medicinal herbs

InactiveCN107282250AImprove grinding effectRealize the grinding operationGrain treatmentsCircular discMedicinal herbs

The invention discloses a refined grinding device for Chinese medicinal herbs. The refined grinding device comprises a base, a collecting box, a grinding groove, a support platform, a first telescopic sleeve rod, a second telescopic sleeve rod, grinding balls, a rotating disk, a movable sleeve plate and a push-pull rod. The bottom end of a coupling sleeve on the first telescopic sleeve rod is rotatably hinged with the top of the coupling sleeve on a second telescopic sleeve through an articulated shaft, and the end of the articulated shaft is fixedly provided with a connecting block; the upper part of the grinding balls is fixedly provided with a connecting plate, and the bottom end of a connection sliding rod on the second telescopic sleeve rod is connected to the connecting plate; the outer ring surface of the grinding balls is fixedly provided with a guide pillar, and the movable sleeve plate is sheathed on the guide pillar; and the movable sleeve plate is fixedly installed on one end of the push-pull rod of which the other end is fixedly connected to the connecting plate. The refined grinding device disclosed by the invention has the advantages of simple structure, easy operation, smart design, full and uniform grinding, and time and labor saving in the grinding process, and is suitable for popularization and application.

Owner:侯添有

Flour processing technology

InactiveCN104646087AIncrease powder yieldImprove completenessGrain treatmentsMaterials preparationWheat Brans

The invention relates to the field of food, in particular to a flour processing technology. The flour processing technology comprises the following steps of (1) material preparation; (2) clean wheat proportion; (3) wheat wetting; (4) grinding; (5) powder purification; (6) flour blending. According to the flour processing technology, the problem that some smaller particles in materials, which are processed by 9 reduction roller mills, 6 shelling mills and a purifier, are difficultly grinded sufficiently in a tail mill in the grinding process is solved. The flour processing technology has the advantages that the smaller particles are grinded more sufficiently by utilization of impact mills, so that the flour yield is improved, the integrity rate of wheat bran is improved at the same time, and the quality of flour and by-products are guaranteed.

Owner:山东津宜润德面业有限公司

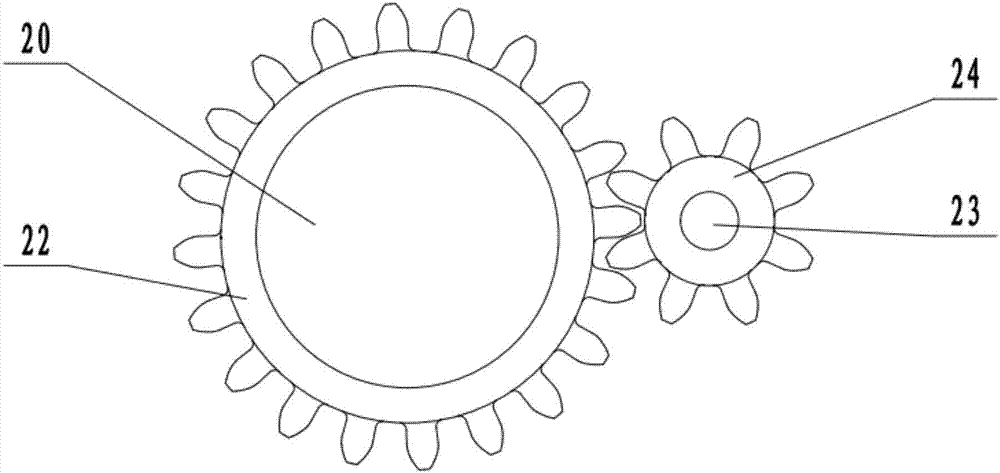

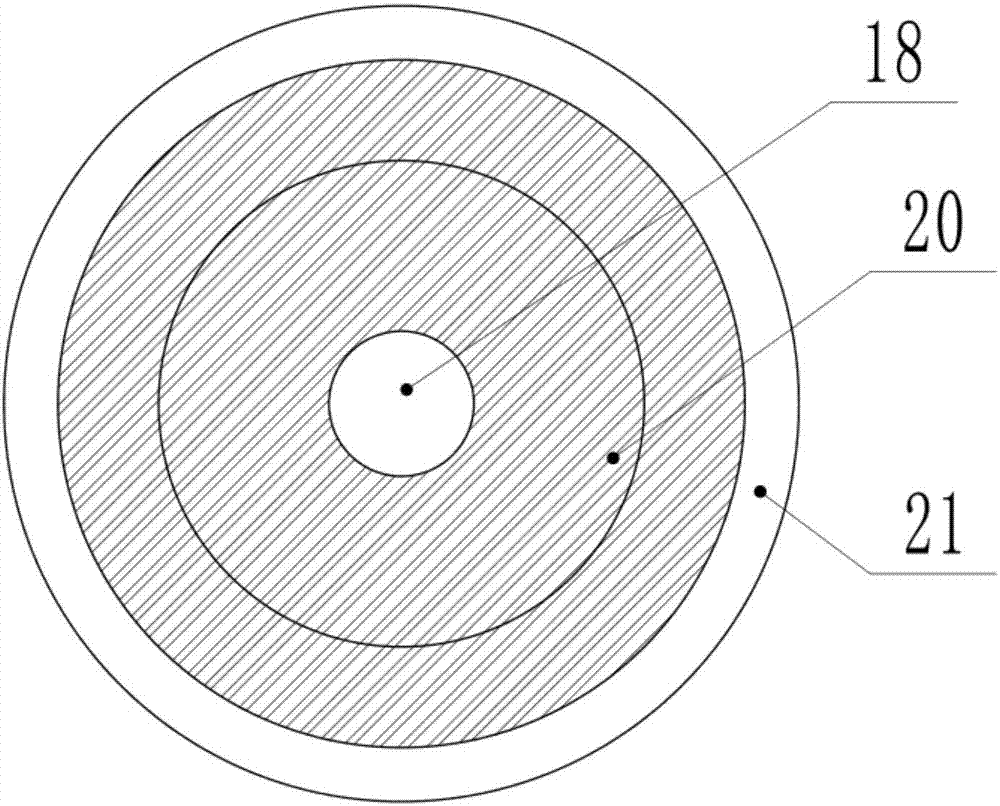

Efficient crushing and grinding equipment for traditional Chinese medicine

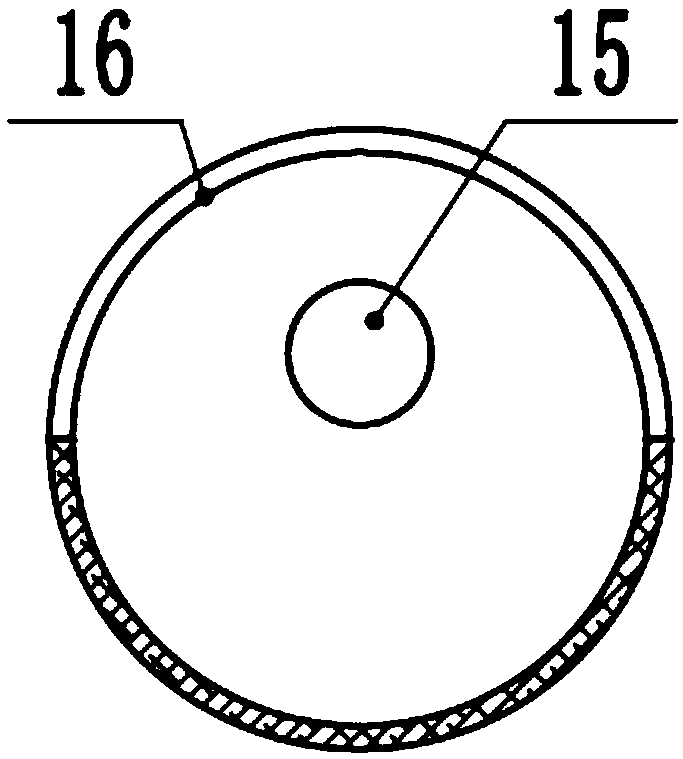

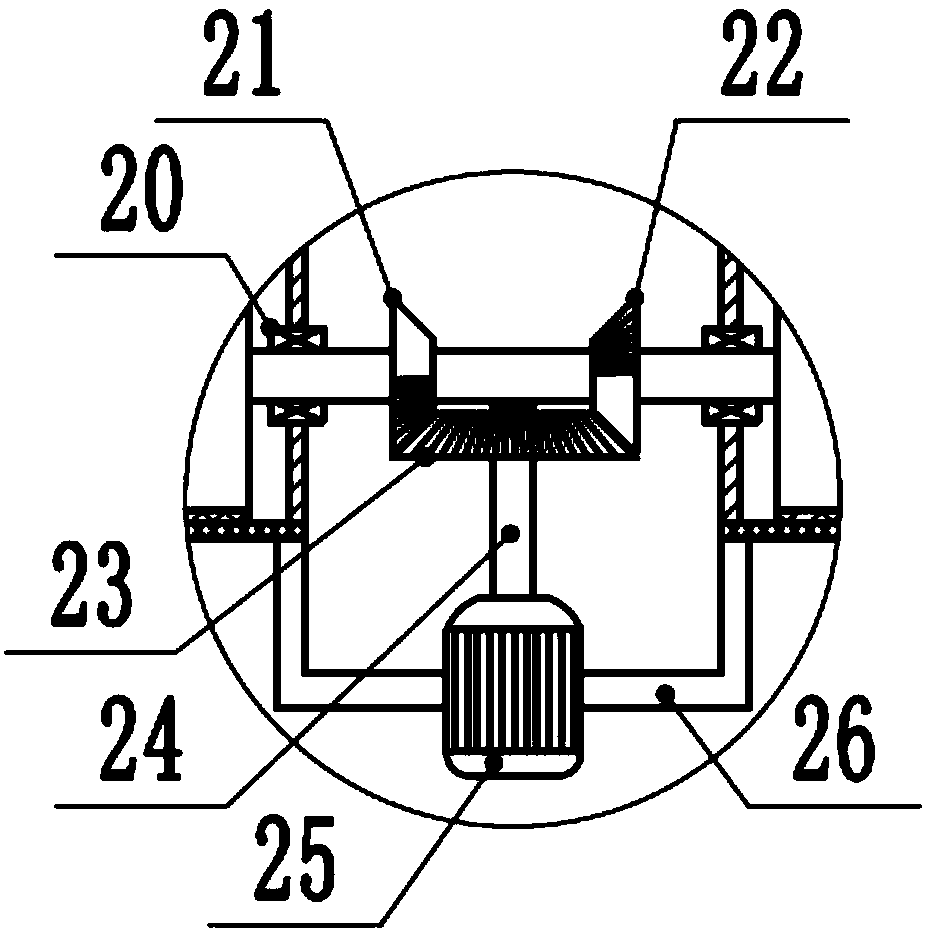

PendingCN107486321AAvoid cloggingAvoid insufficient crushingSievingScreeningGear wheelElectric machinery

The invention discloses efficient crushing and grinding equipment for traditional Chinese medicine. The efficient crushing and grinding equipment for traditional Chinese medicine comprises a grinding barrel, a crushing barrel, a first screen mesh, an round feed inlet, a first motor, a rotary shaft, an annular baffle plate, a first crushing blade, a second crushing blade, a brush, a second motor, a first installing shaft, a first grinding roller, a second installing shaft, a second grinding roller, an active gear, a driven gear, an inner gear ring and a second screen mesh. The efficient crushing and grinding equipment for traditional Chinese medicine is provided with the first motor, the rotary shaft, the round feed inlet and the annular baffle plate, and through cooperation of the first motor, the rotary shaft, the round feed inlet and the annular baffle plate, intermittent feeding is achieved, insufficient crushing caused by excessive feeding at one time is avoided and the crushing efficiency is improved; the first crushing blade and the second crushing blade are further provided and set dislocated, so that the crushing speed is high and the crushing efficiency is high; and the second motor, the active gear, the driven gear, the inner gear ring, the first grinding roller and the second grinding roller are further provided, and through cooperation, continuous grinding of traditional Chinese medicine is conducted, the grinding is sufficient and fast, and the grinding efficiency is improved.

Owner:ZHENGZHOU UNIV

Swing grinding device for traditional Chinese medicines

The invention discloses a swing grinding device for traditional Chinese medicines. The device comprises a base plate, an arc grinding frame, a grinding wheel, a mounting frame, a collecting frame, a separation plate, a first motor, a disc, a connecting rod, a baffle plate, traditional Chinese medicine hoppers, medicine outlet holes, a dowel pin, a swing rod, a rotating shaft, an inverted U-shapedplate, a poking rod and vibration devices; the vibration devices comprise second motors, second rotating shafts and cams; different traditional Chinese medicines are added in different traditional Chinese medicine hoppers for synchronously grinding different types of traditional Chinese medicines to improve the working efficiency; meanwhile, the traditional Chinese medicines in the traditional Chinese medicine hoppers intermittently fall down from the medicine outlet holes to prevent insufficient grinding caused by excessive continuous medicine discharging; the grinding wheel repeatedly grindsthe traditional Chinese medicines in the arc grinding frame, and meanwhile, the poking rod can overturn the traditional Chinese medicines, so that the traditional Chinese medicines are grinded more fully and uniformly; and the vibration devices are arranged on the two sides of the arc grinding frame for continuously beating a screen at the bottom of the arc grinding frame to prevent blockage of the screen at the bottom of the arc grinding frame and to improve the screening and grinding efficiency.

Owner:安徽汉盛药业有限公司

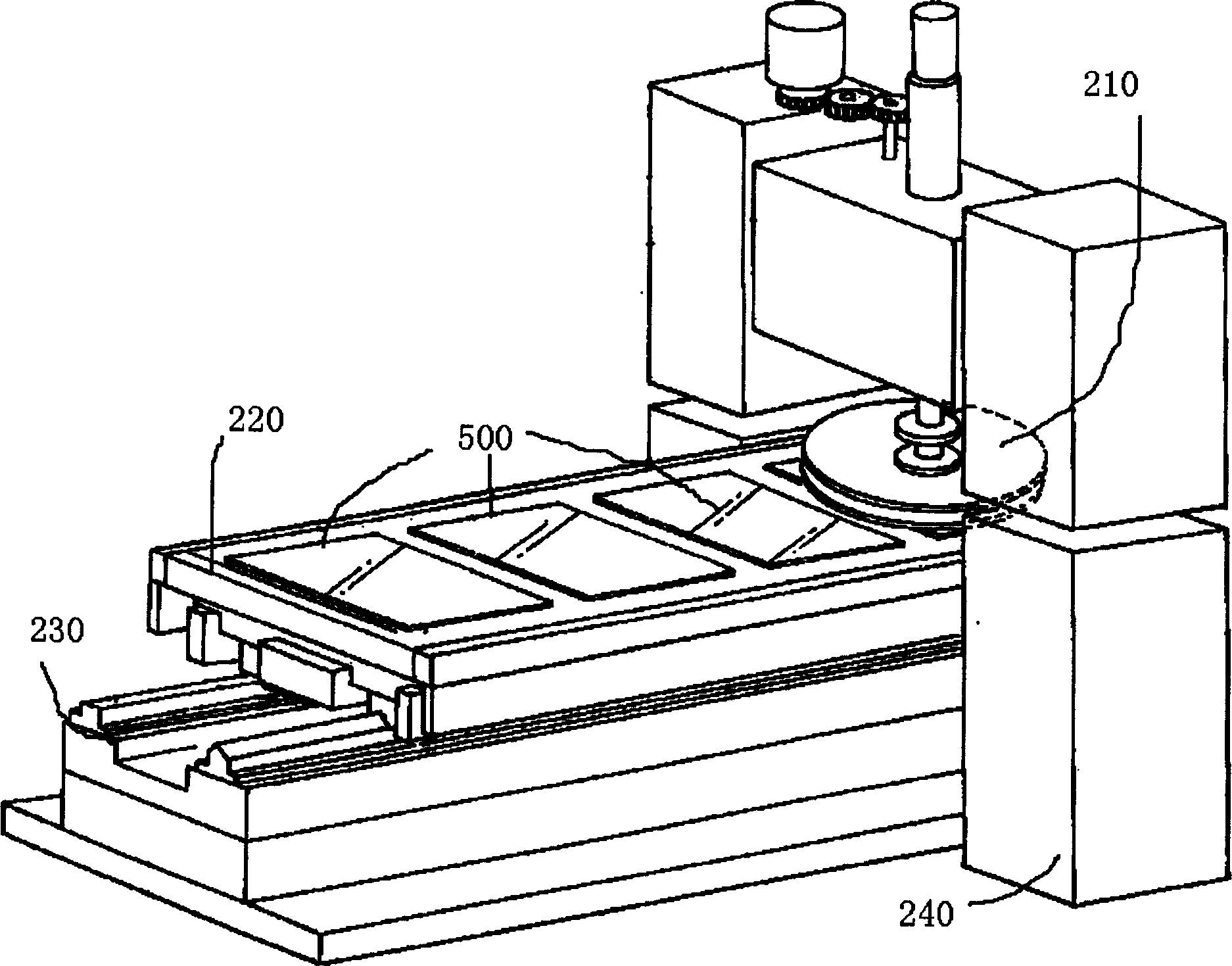

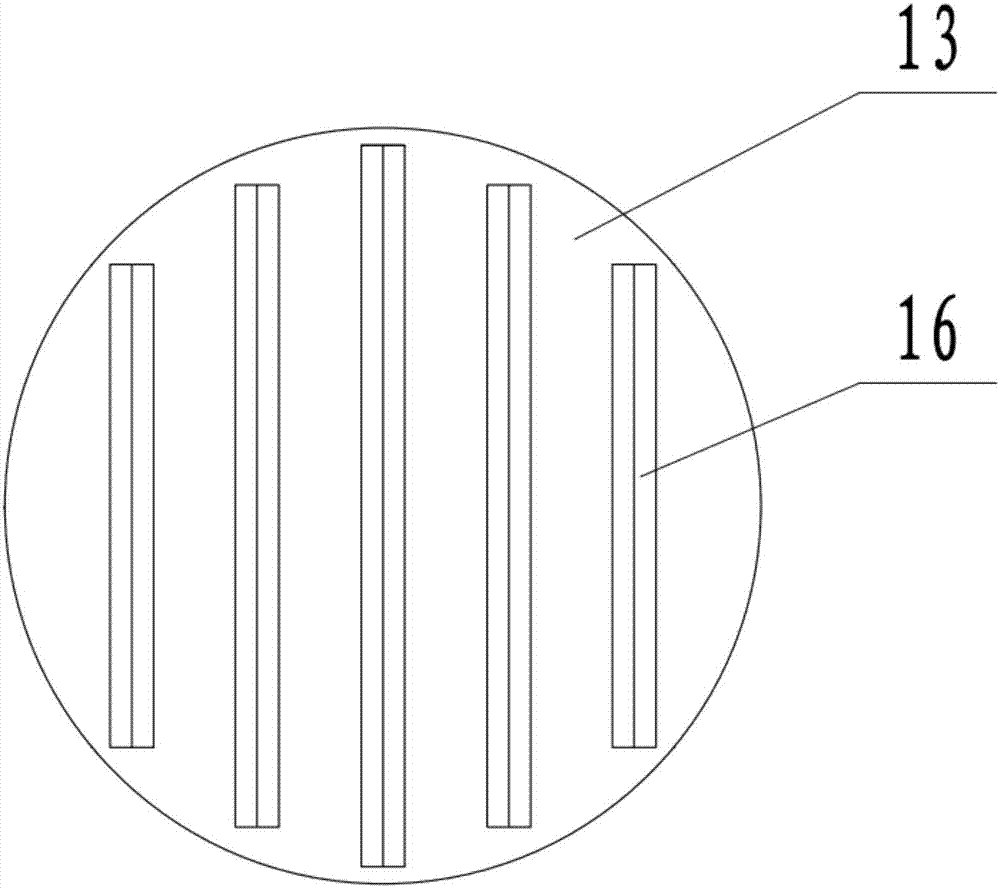

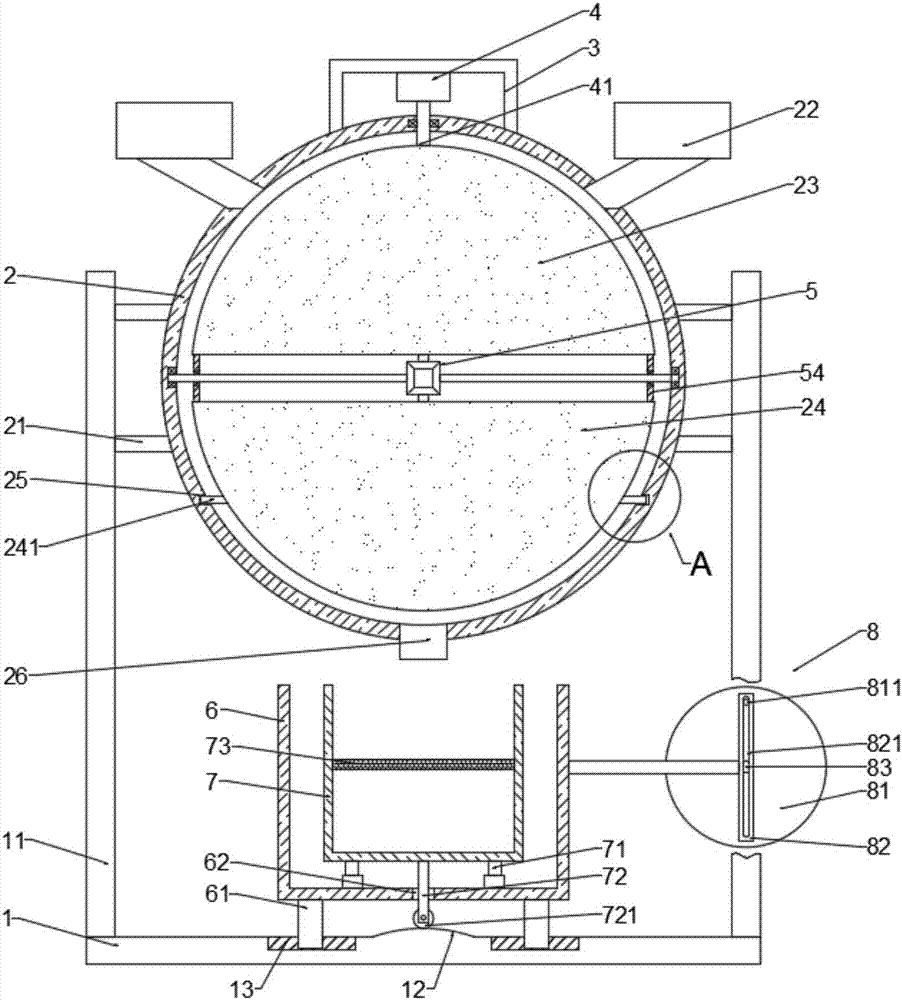

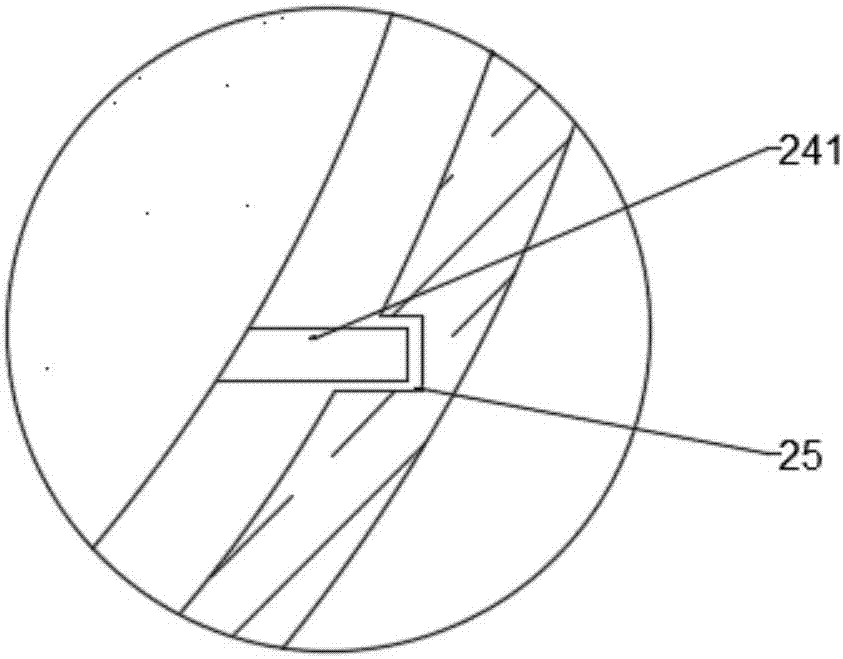

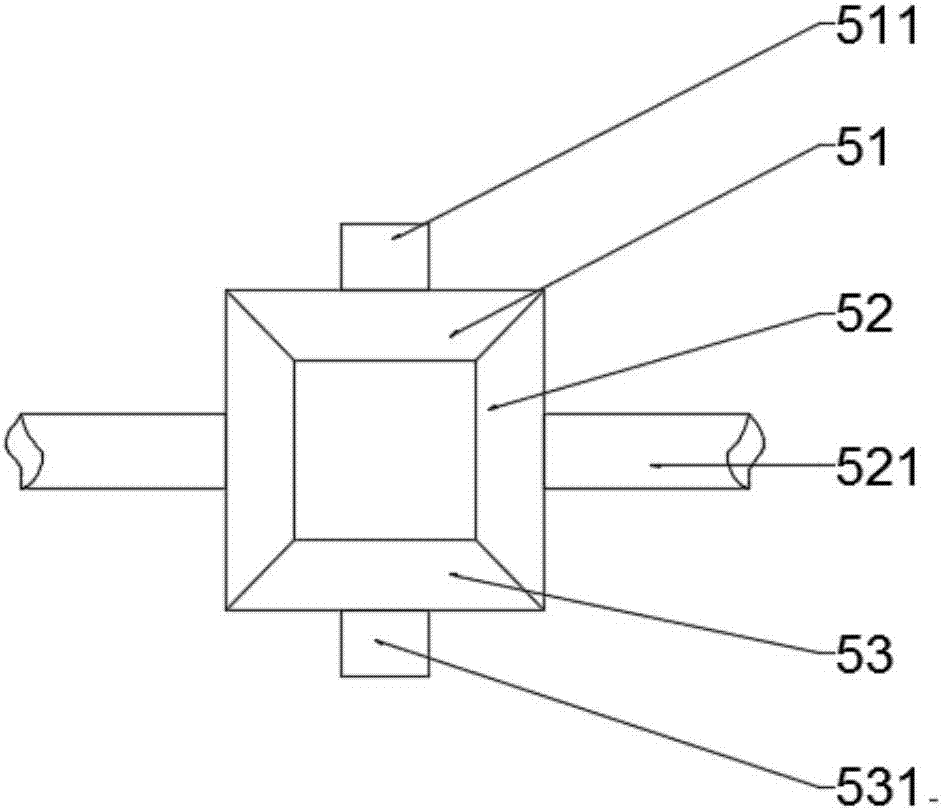

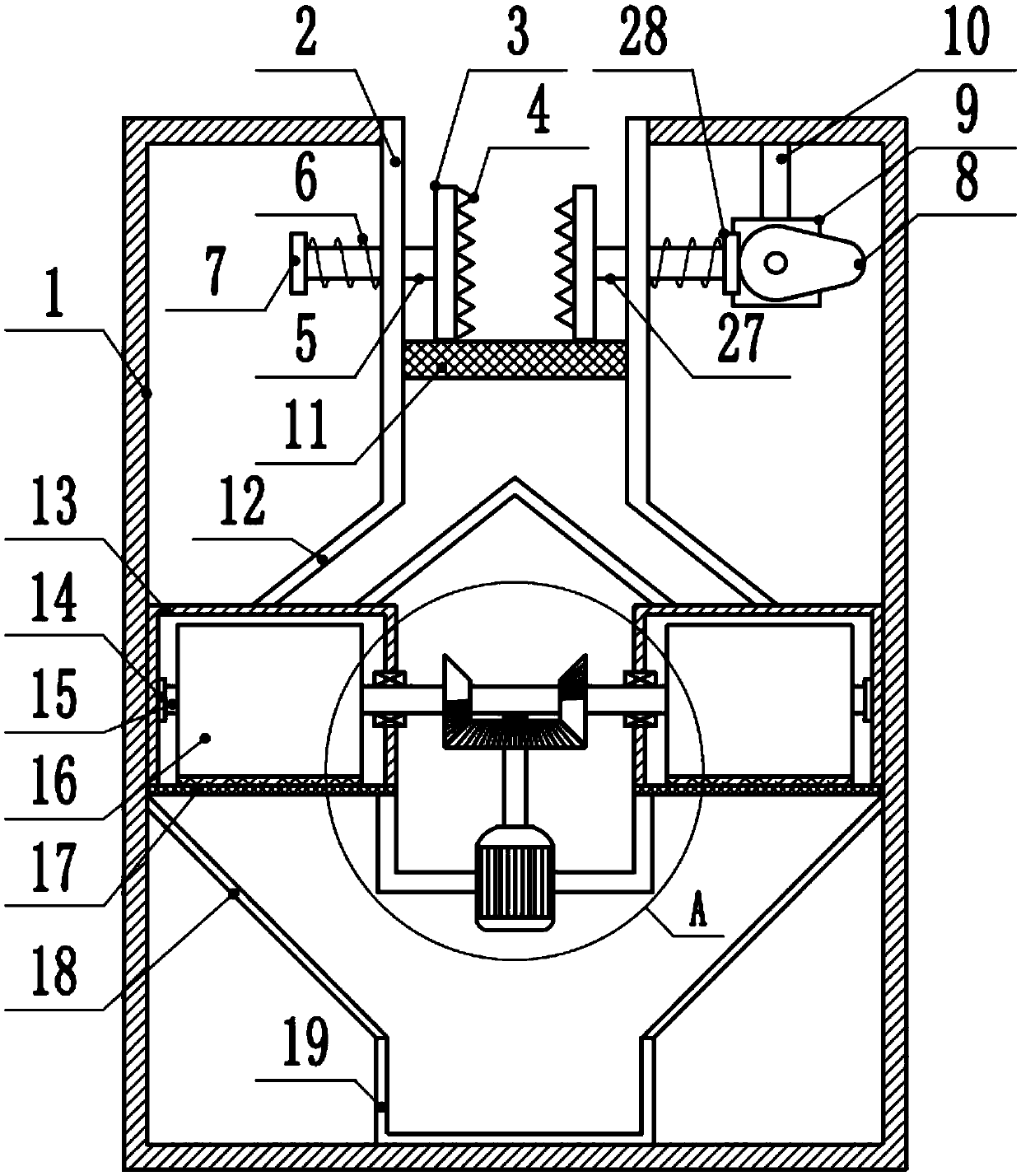

Efficient Chinese medicinal material grinding and screening integrated machine

InactiveCN107486315AAvoid affecting screening efficiencyGrind fullySievingScreeningBevel gearScreening effect

The invention discloses an efficient all-in-one machine for grinding and screening traditional Chinese medicinal materials, which comprises a base, a spherical shell, an outer frame and an inner frame. In the present invention, the reverse rotation of the upper grinding block and the lower grinding block is realized through the bevel gear set, so that the Chinese herbal medicines are successively ground in two directions during the falling process, so that the grinding is more sufficient and the grinding effect is guaranteed; The driving mechanism drives the outer frame to move left and right, so that the medicinal materials falling from the feeding pipe evenly fall onto the sieve plate, so as to avoid the accumulation of medicinal materials on the sieve plate, which will affect the screening efficiency. At the same time, the inner frame follows the outer frame to reciprocate left and right The movement makes the pulley move left and right on the raised surface, thereby driving the connecting frame to move up and down, and then making the inner frame drive the sieve plate to vibrate up and down, resulting in a vibrating sieve effect and improving the screening efficiency.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

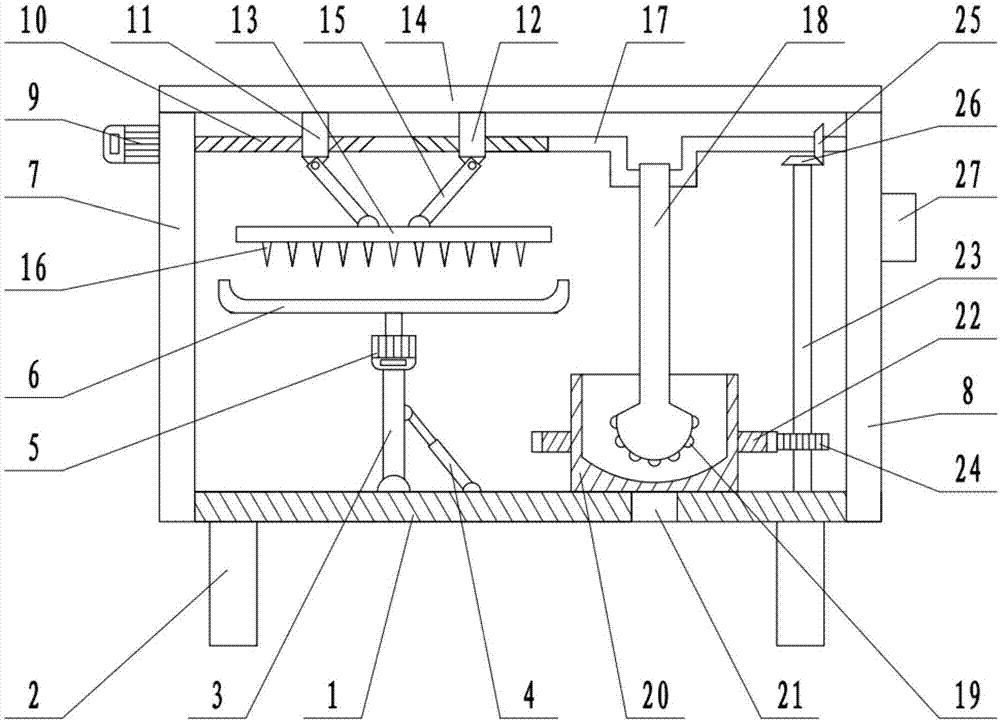

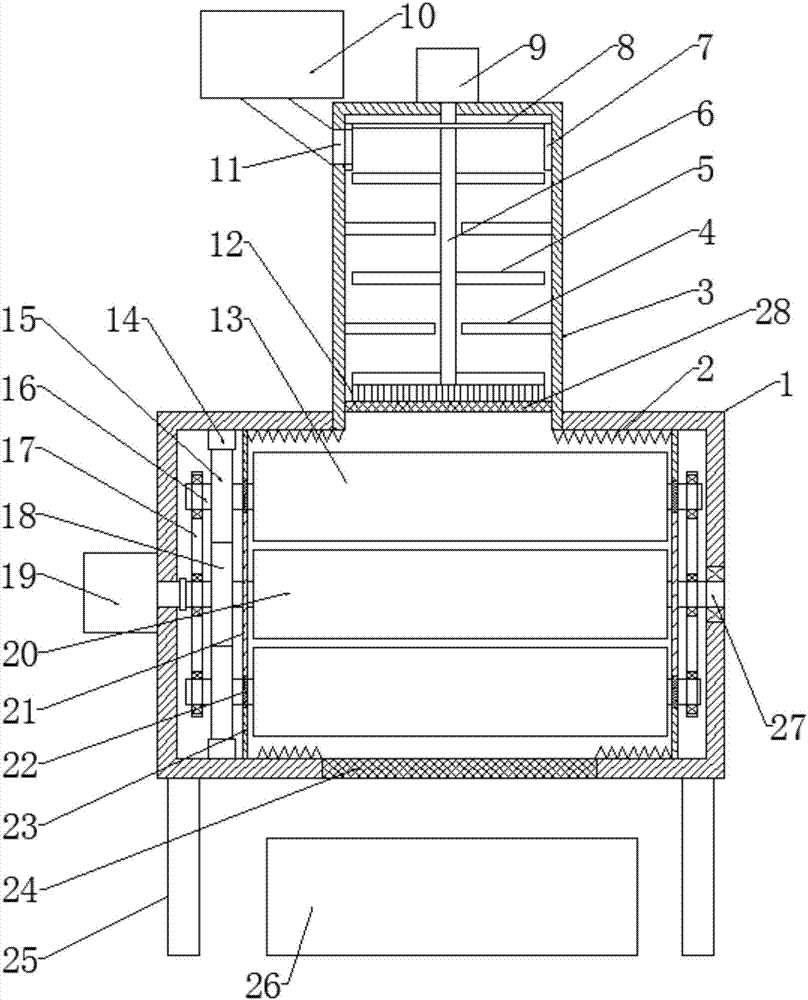

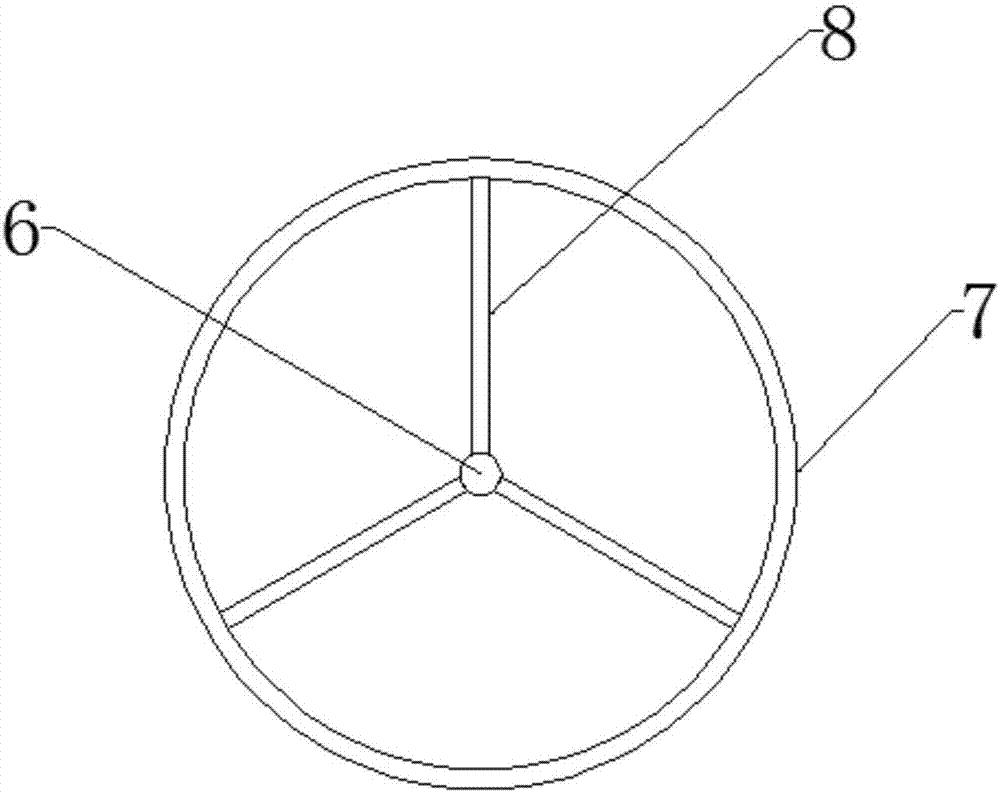

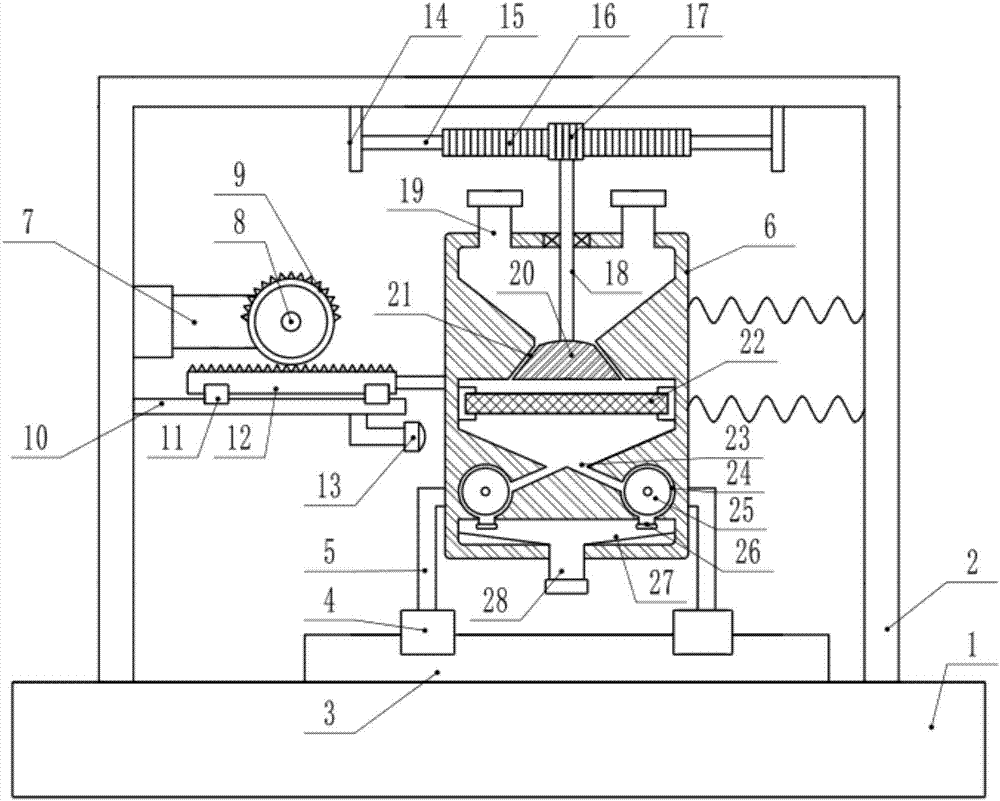

Automatic grinding device used for coating

The invention discloses an automatic grinding device used for coating. The automatic grinding device used for coating comprises a base and a machining box; rollers facilitating device carrying are symmetrically arranged on the left side and the right side of the base, the machining box is arranged on the base, supporting legs are symmetrically arranged on the two sides of the lower end of the machining box, the lower ends of the supporting legs and the upper end face of the base are fixedly connected, a gap is formed in the upper end face of the machining box, a motor frame is arranged on thegap, a grinding motor is arranged on the motor frame, the output end of the grinding motor is provided with a rotating shaft, the lower end of the rotating shaft is connected with a movable grinding block, the movable grinding block is a conical table with the large lower and the small upper, and a fixed grinding block matched with the movable grinding block is arranged on the inner wall of the machining box. The device is simple and reasonable in structure, carrying is convenient, materials can be circularly pulverized, it is ensured that all materials are sufficiently ground, material wasteis avoided, adjustment of grinding precision is achieved, and practicability is high.

Owner:邝芳

Medicine powder grinding device for capsule tablet preparation

The invention discloses a medicine powder grinding device for capsule tablet preparation. The medicine powder grinding device comprises a base, a rack, a grinding box, a driving motor, a semi-gear, a collision head, a grinding head, a preliminary grinding cavity and exquisite grinding cavities; the other end of a fixed support is fixedly provided with the driving motor, an output shaft of the driving motor is forward, the semi-gear is installed on the output shaft of the driving motor in an interference fit manner, a grinding shaft is installed at a gear core in an interference fit manner and extends into the preliminary grinding cavity, the grinding head is installed in the preliminary grinding cavity, a screen net is connected to the interior of the grinding box through a neck, and the two exquisite grinding cavities are further arranged inside the grinding box. According to the grinding device, the collision head is arranged, and therefore medicine powder can be effectively prevented from adhering to the inner wall of the grinding box; through left-right movement of the grinding box, the medicine powder screening speed is increased; and meanwhile, through the arrangement of the preliminary grinding cavity and the exquisite grinding cavities, medicine powder grinding is more sufficient, and the human body absorbing speed after a tablet is taken by a patient is increased.

Owner:ZHENGZHOU UNIV

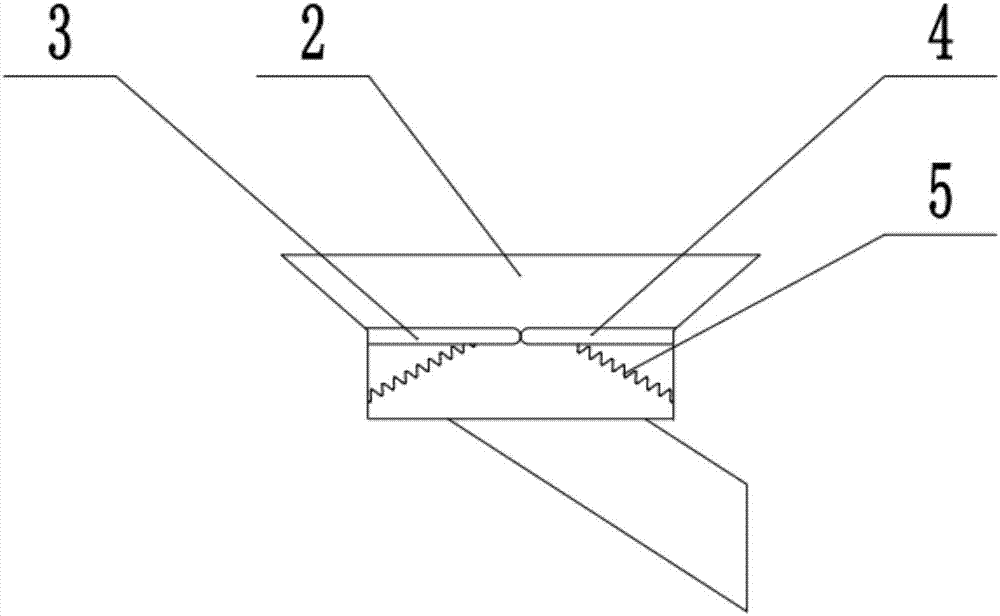

Fine grinding device for producing and processing powder cosmetics

The invention discloses a fine grinding device for producing and processing powder cosmetics and relates to the field of cosmetics. The fine grinding device comprises a device box, wherein a crushingcylinder is fixedly connected with the interior of a middle part of an upper box body of the device box; a first pushing rod and a second pushing rod are in contact connection with the interiors of box bodies on the left side and the right side of the crushing cylinder; the right end of the first pushing rod and the left end of the second pushing rod are respectively fixedly connected with extrusion plates; crushing teeth are respectively fixedly mounted on the surfaces of the extrusion plates; the crushing teeth are in engaged connection with each other; the right end of the second pushing rod is fixedly connected with a second stop block; the outer surface of the right end of the second pushing rod is in contact connection with a spring; the other end of the spring is fixedly connected with the surface of the second stop block; the surface of the right side of the second stop block is in contact connection with a cam; the right rear part of the center of the cam is connected with a first motor. According to the fine grinding device, eccentric grinding rollers are capable of alternately and repeatedly rotating clockwise and counterclockwise so as to grind, so that the raw materials of the cosmetics can be more fully and completely ground; the fine grinding device has better grinding effect and high practicability.

Owner:张玉娥

Efficient grinder

InactiveCN106694184AGrind fullyImprove grinding effectHollow article cleaningGrain treatmentsReducerEngineering

The invention creatively provides an efficient grinder. The efficient grinder comprises a case, a support, a ceramic mortar, an upper rotary rack, a lower rotary rack, a support frame, a rotating shaft, a turntable, a reducer, a motor, a ceramic pestle, a connecting piece, a grinding cylinder and a controller, wherein the support is fixed on the case; the grinding cylinder is fixed on the support; the bottom end of the grinding cylinder is connected with the connecting piece; the connecting piece penetrates the support to be connected with the ceramic pestle; the lower rotary rack is positioned on the case; and the ceramic mortar is fixed on the lower rotary rack. The efficient grinder is provided with a scraper plate, the scraper plate is positioned on the inner side of the ceramic mortar and can strike off raw materials in the grinding process to prevent wall sticking, grinding dead angles are reduced, the the grinding efficiency is improved.

Owner:天津雪赢世纪专利技术有限公司

Silicone rubber production equipment

The invention belongs to the technical field of rubber production, and particularly relates to silicone rubber production equipment. The silicone rubber production equipment comprises a shell, drivingdevices, crushing plates, an opening adjusting device and a grinding device. The driving devices are used for supplying power to the crushing plate. The driving devices are matched with the crushingplates to crush talc. The opening adjusting device adjusts an opening below the crushing plates. The grinding device comprises a mounting seat, an air cylinder, a swinging plate, a grinding disc, a third motor, a corrugated pipe and an elastic funnel. The end portion of a cylinder rod of the air cylinder is rotatably mounted at one end of the swinging plate. A long rotating support on the mountingseat is rotatably connected with the other end of the swinging plate. The grinding disc is fixedly connected with the shaft end portion of the third motor. The grinding disc is used for grinding thegranular talc. The silicone rubber production equipment is mainly used for grinding the talc added in the rubber production process, and crushing, grinding and partial position cleaning of the talc are realized.

Owner:温州合丰胶业股份有限公司

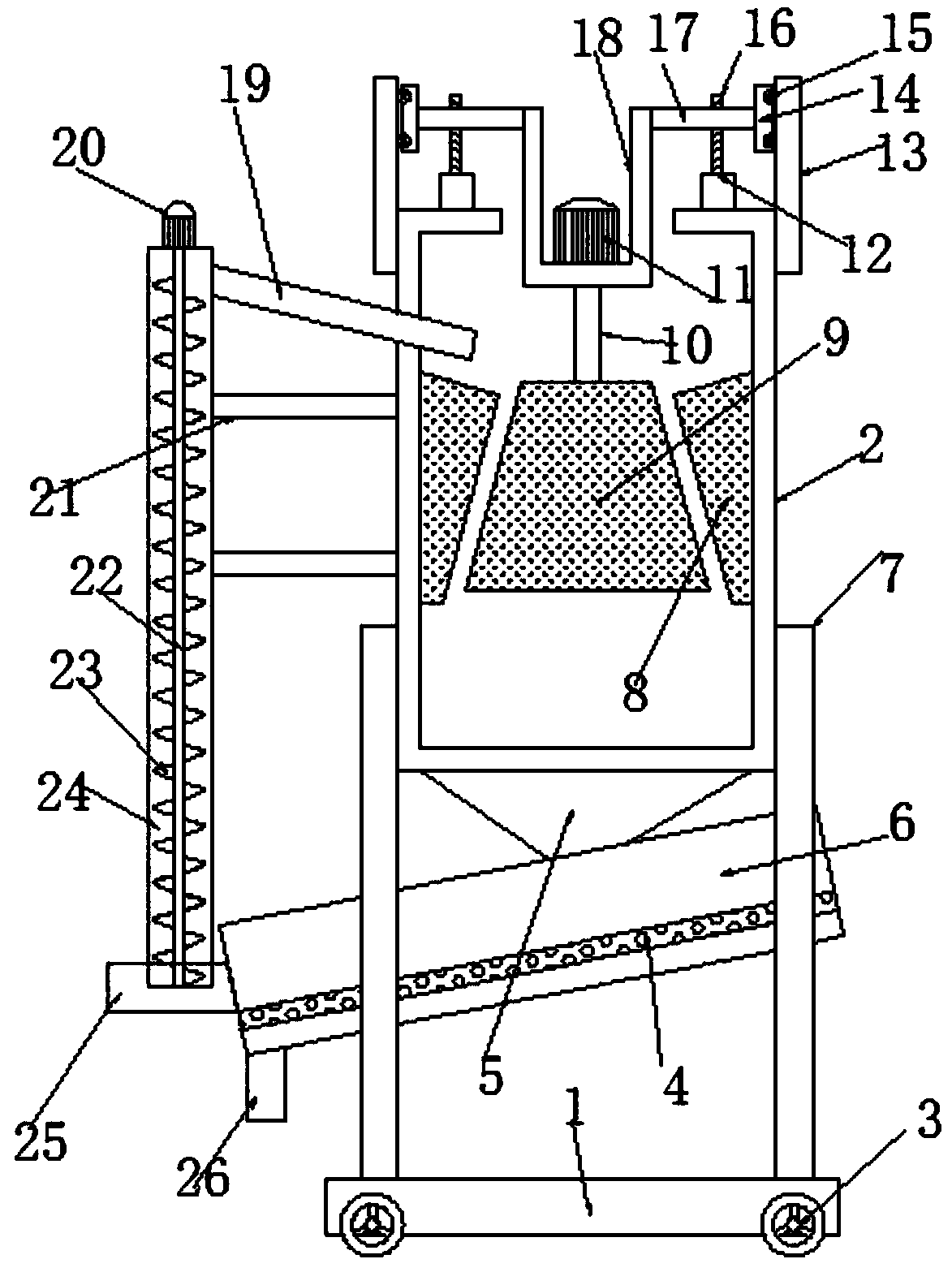

Efficient Chinese medicinal material smashing and grinding device convenient for discharging

InactiveCN107008552AImprove grinding effectImprove processing efficiencyGrain treatmentsMotor shaftEngineering

The invention discloses a high-efficiency crushing and grinding device for Chinese herbal medicines which is convenient for unloading. Supporting wheels are connected through the bracket, and the supporting wheels support the fan-shaped shaking plate; the base is fixedly connected with the top plate through the support plate, the first reduction motor is arranged on the left support plate, and the motor shaft at the right end of the first reduction motor is connected with a screw. The upper part is connected with a slider, and the joint between the slider and the screw is provided with an internal thread matched with the screw; the bottom of the slider is fixedly connected with a motor, the motor is connected with a rotating shaft, the rotating shaft is provided with crushing blades, and the bottom of the rotating shaft is connected with a second bearing with seat , the bottom of the second belt seat bearing is connected with a grinding roller. In the present invention, when the crushing blades rotate to crush the Chinese medicinal materials, the grinding roller moves left and right to grind the Chinese medicinal materials, and the crushing and grinding work together to improve the processing efficiency.

Owner:长沙鼎成新材料科技有限公司

Production technology of high stability asphalt by modification of waste tyre rubber powder

InactiveCN101381519AHomogeneous combined stateGuaranteed stabilityPlastic recyclingBuilding insulationsPolymer scienceAsphalt

The invention relates to a process for producing waste-tire rubber powder modified asphalt, in particular to a process for producing high-stability waste-tire rubber powder modified asphalt. The process is characterized in that the surface of waste-tire rubber powder is first activated; then the activated waste-tire rubber powder is added to hot asphalt, fully stirred, swollen, sheared, ground and then injected into a development tank for inoculation reaction, so as to obtain stable waste-tire rubber powder modified asphalt; the production course of the process belongs to chemical-physical action; the activated waste-tire rubber powder and the asphalt are subjected to crosslinking reaction and form a stably linked molecular structure; and the modified asphalt is stable in performance and capable of long-term storage. The high-stability waste-tire rubber powder modified asphalt has the characteristic of good stability.

Owner:ANHUI ZHONGYI NEW MATERIAL TECH CO LTD

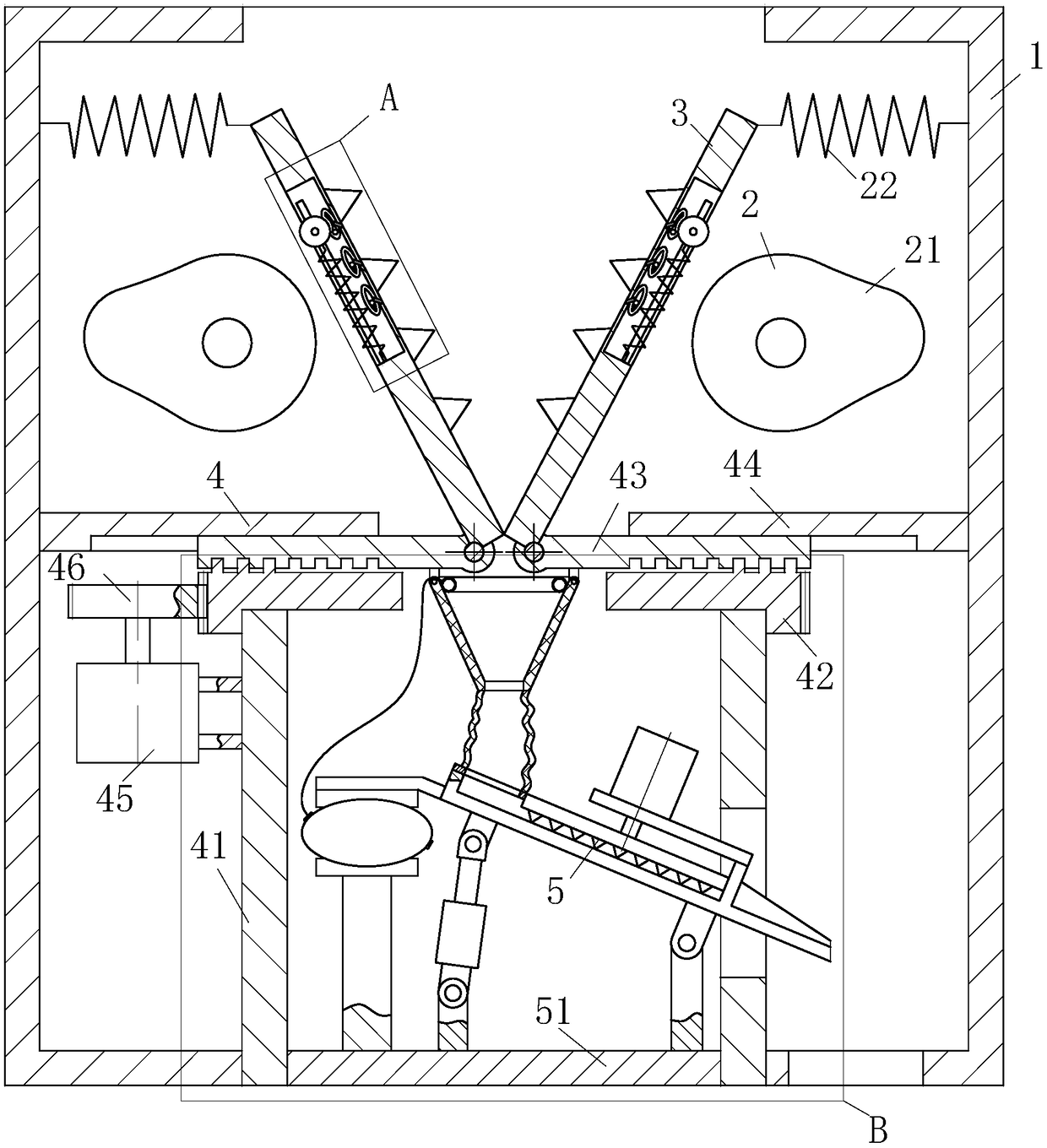

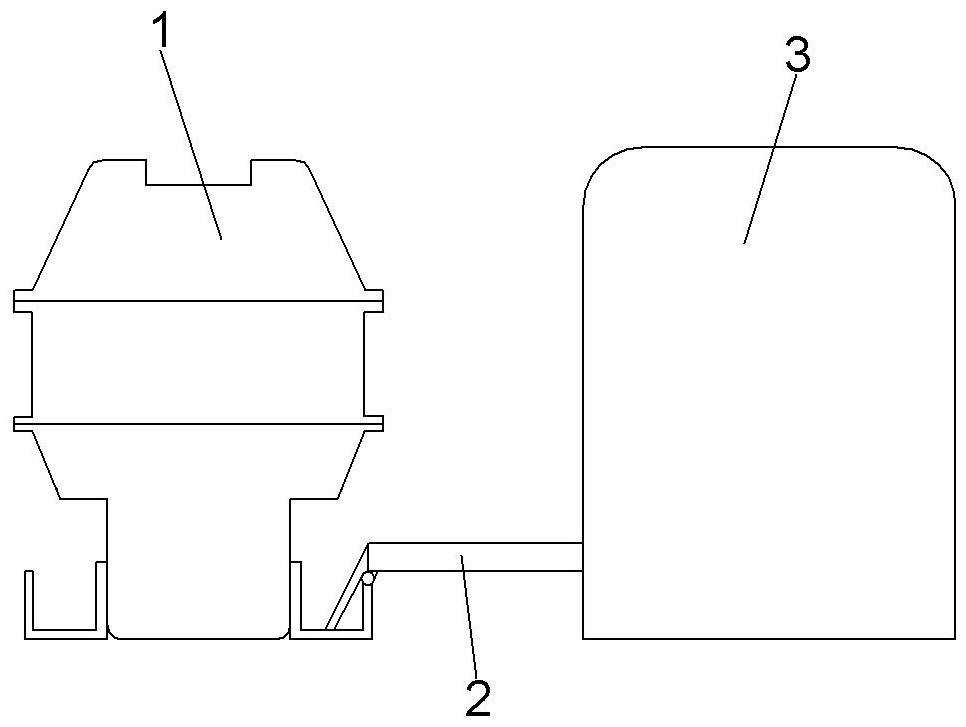

Crushing-grinding all-in-one machine for traditional Chinese medicines

The invention discloses a traditional Chinese medicine crushing and grinding machine, which comprises a machine case, a feeding port, a motor, a crankshaft, a crushing blade, a sieve plate and a grinding hammer; The journal of the crankshaft is provided with a left connecting rod and a right connecting rod. The left end of the left connecting rod is hinged with a left movable plate, the right end of the right connecting rod is hinged with a right movable plate, and the lower end of the crankshaft is fixedly connected with a worm. The left and right worm gears are respectively arranged on the left and right sides, and the surfaces of the left and right worm gears are fixedly connected with fixed rods close to the edge, and a movable rod is set on the fixed rod, and a grinding hammer is hinged at the lower end of the movable rod, and the left cover plate and the right cover The plate is closed, which can prevent the Chinese medicine in the case from splashing out from the feeding port; the left movable plate and the right movable plate move left and right, and the Chinese medicine is crushed by the crushing blade, and the crushed Chinese medicine falls into the bottom of the case through the sieve plate; the vibration motor runs Drive the chassis to vibrate at the same time, improve the grinding efficiency.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

Glass fiber reinforced plastic decomposition and recovery equipment and recovery method

The invention relates to the technical field of glass fiber reinforced plastic recovery, in particular to glass fiber reinforced plastic decomposition and recovery equipment and a recovery method. The glass fiber reinforced plastic decomposition and recovery equipment comprises a grinding device, a high-temperature heat treatment device, a cooling device, a dust removal device and a catalysis device. The grinding device comprises a base, a rotating cylinder, a grinding ring groove body, a feeding hopper, a grinding cylinder and an adjusting device. An annular grinding cavity with an upward opening is defined in the grinding ring groove body, and a discharging opening is formed in the bottom of the grinding ring groove body. The grinding cylinder is arranged in the grinding cavity and comprises a plurality of grinding plates, a plurality of first hinge shafts and a plurality of second hinge shafts. The adjusting device comprises a sliding ring, an elastic rope, a plurality of first connecting rods, a plurality of second connecting rods and a plurality of third connecting rods. During normal work, the lower end of the feeding hopper is opened, the lower end of the feeding hopper is closed when the feeding hopper is clamped, the grinding cylinder is in a dynamic change process in the grinding process and cannot be clamped till glass fiber reinforced plastic waste is ground to the preset size, manual unclamping is not needed, and the grinding efficiency is further improved.

Owner:江苏华纳环保科技有限公司

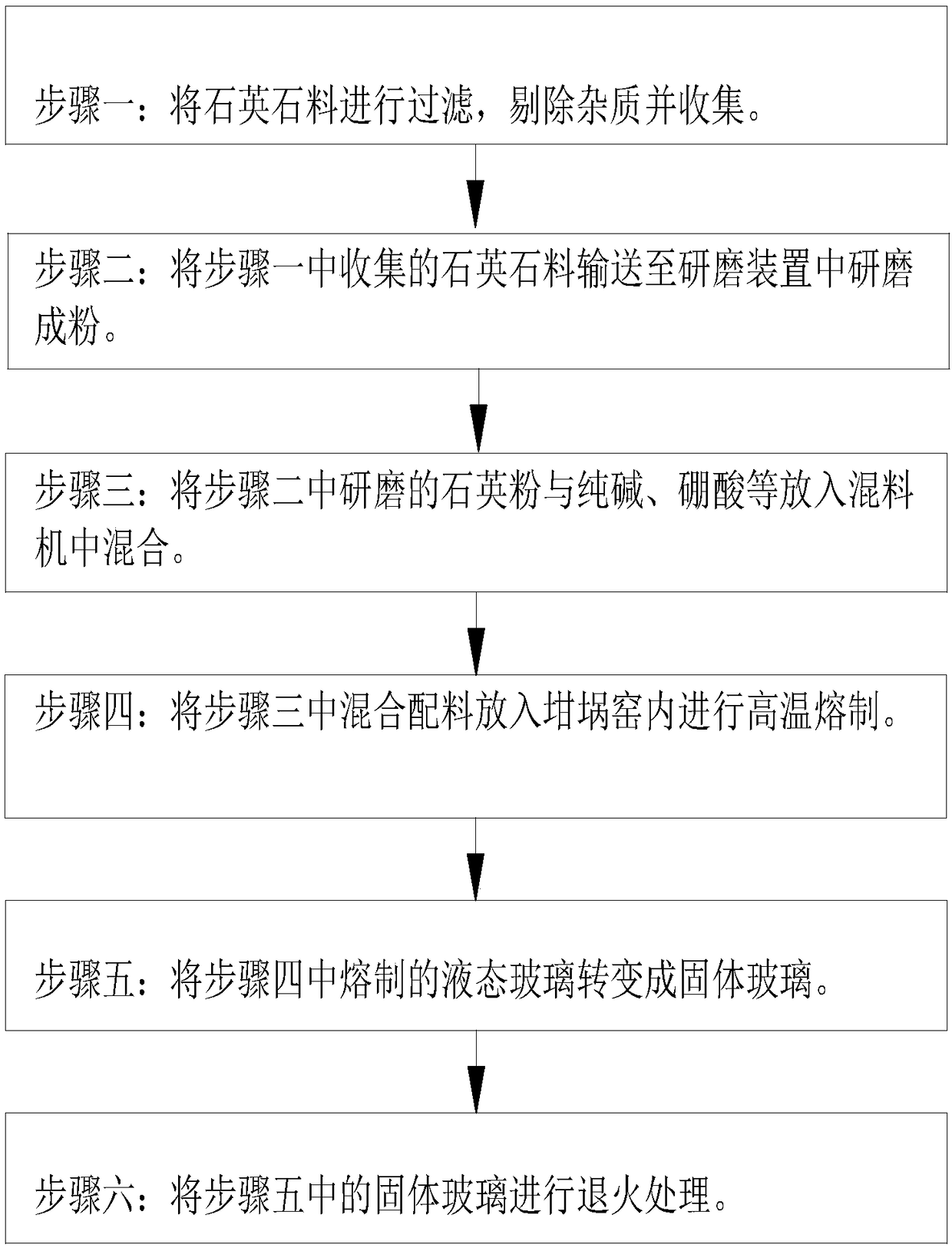

Glass production method

ActiveCN108328907APromote fragmentationImprove grinding efficiencyCocoaGrain treatmentsEngineeringFan blade

The invention belongs to the technical field of glass, and particularly relates to a glass production method. The method comprises the step 1 to the step 6, wherein in the step 2, a used grinding device comprises a tube body, a grinding module and a filtering module; the grinding module is arranged at the bottom of the tube body; the filtering module is arranged on the top of the tube body; the grinding module comprises a No.1 grinding post, a No.2 grinding post, a fan blade and a No.2 installing cabin; semicircular grinding blocks are respectively arranged on the surfaces of the No.1 grindingpost and the No.2 grinding post; a cutting unit arranged in the semicircular grinding block is used for cutting quartz raw materials; the grinding efficiency is improved; the filtering module comprises a funnel, a ball milling disc, a cleaning unit and a No.1 installing cabin; the funnel and the ball milling disc are mutually matched; the ground quartz is selected; the quartz quality is improved.The used device mainly performs collision and cutting grinding on the quartz raw materials; the mixing time of the quartz with sodium carbonate, boracic acid and the like is shortened, so that the glass production efficiency is improved.

Owner:信和光能(安徽)有限公司

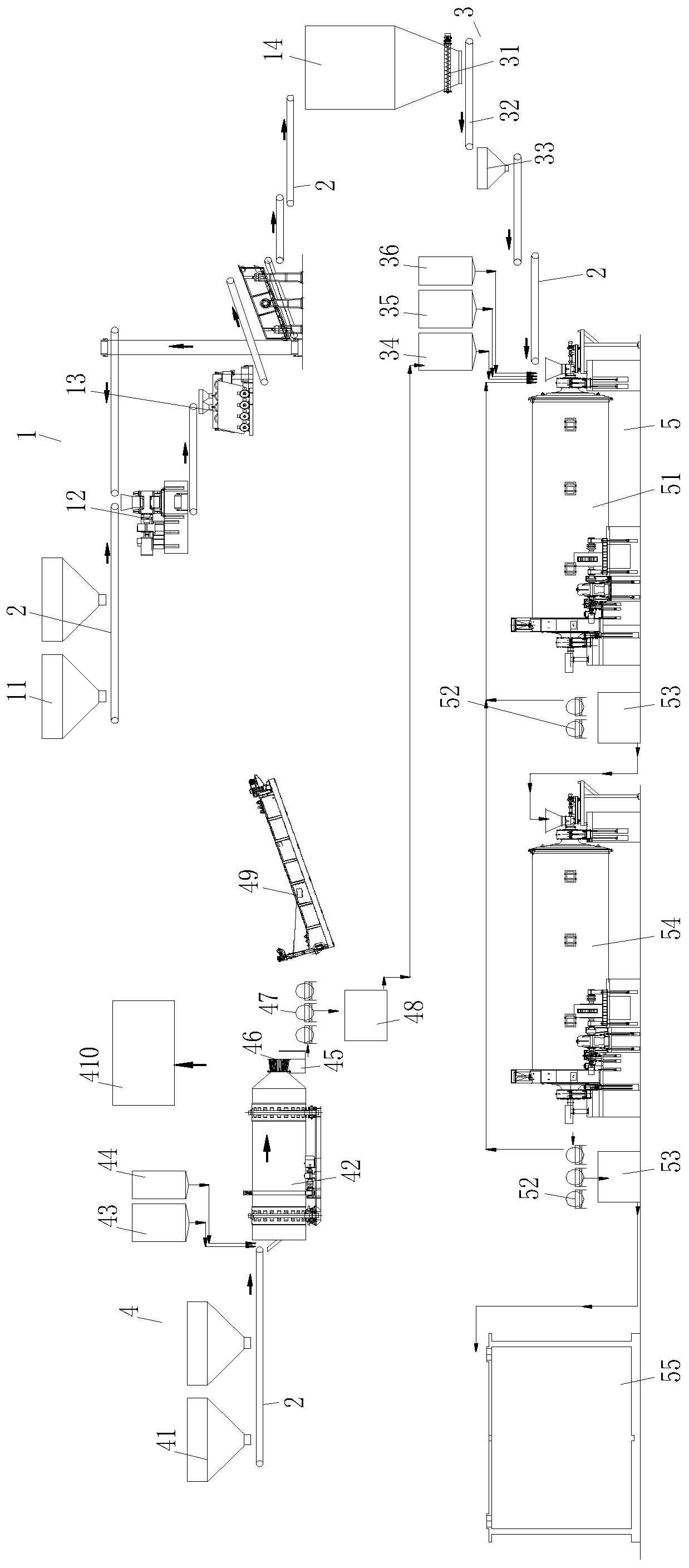

Intelligent wet powdering production technology for ceramic raw materials

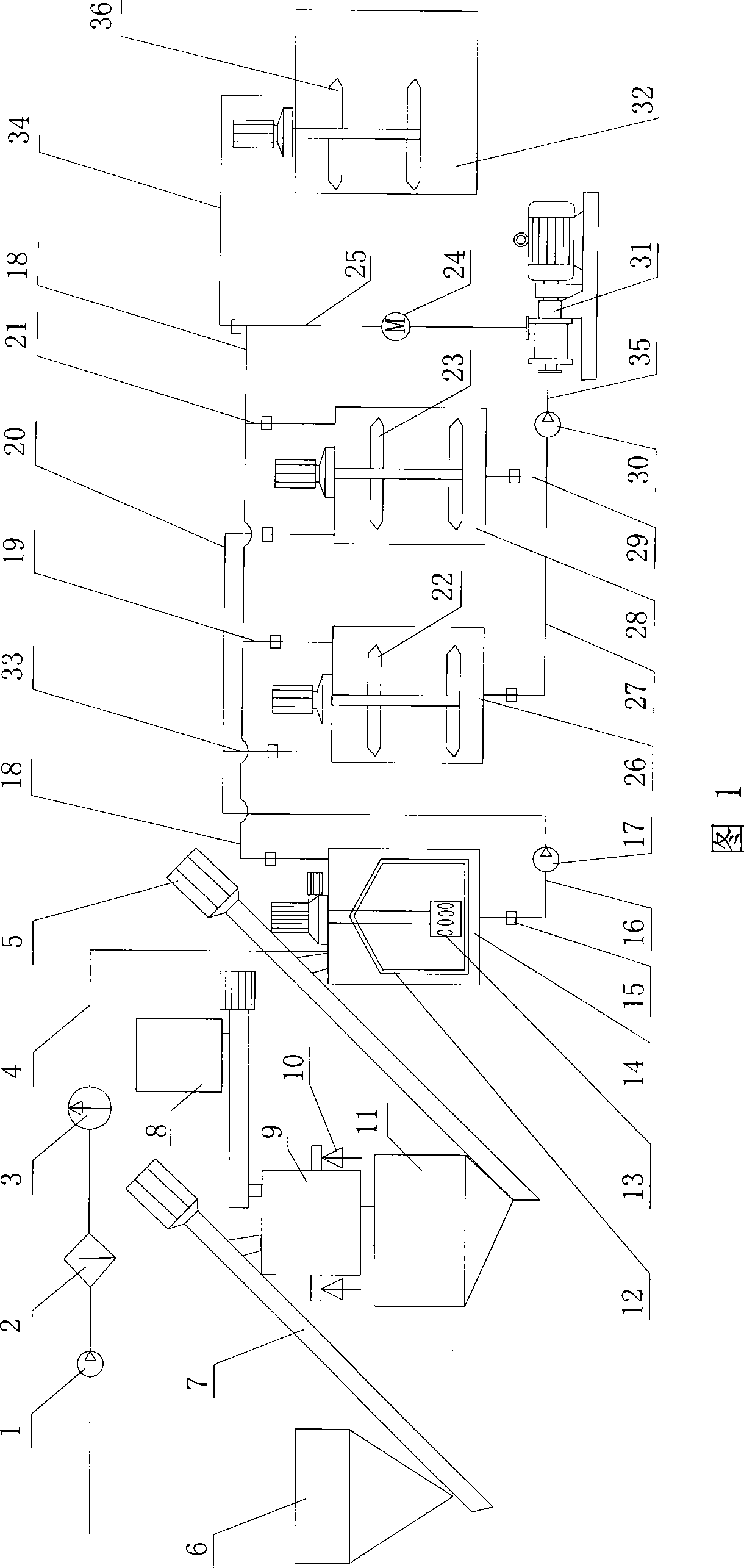

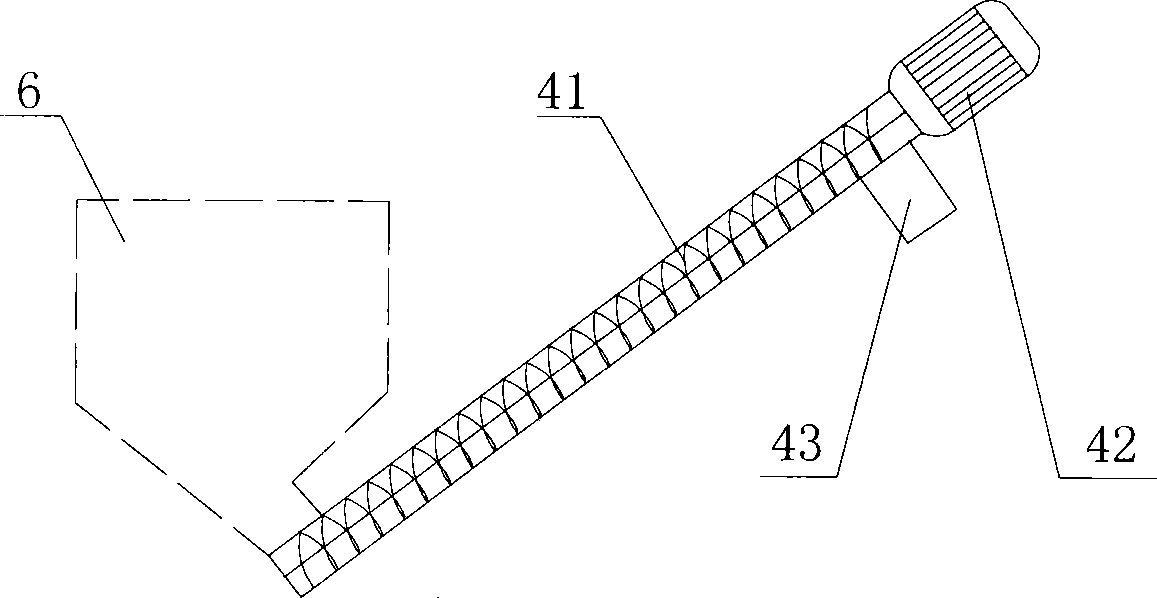

InactiveCN110404657ARealize full automationIncrease production capacityGrain treatmentsNumerical controlProduction line

The invention relates to the technical field of ceramic raw material powdering and particularly relates to an intelligent wet powdering production line for ceramic raw materials. The intelligent wet powdering production line for ceramic raw materials comprises a raw material pre-crushing system, a belt conveying line, an automatic metering and batching system, a pug slurrying system and a continuous ball miller system. Transferring and conveying at the discharge end of the raw material pre-crushing system are carried out through a belt conveying line, the automatic metering and batching systemis located on the raw material pre-crushing system, the discharge end of the automatic metering and batching system is communicated with the feeding end of the pug slurrying system, and the other discharging end of the automatic metering and batching system is communicated with the continuous ball miller system. By means of the intelligent wet powdering production line for ceramic raw materials,the purposes of whole process automation, numerical control production and intelligent manufacturing of ceramic wet powdering technology are achieved, and thus the superior product rate and the production efficiency of ceramic products are improved; and besides, good mobility can be still ensured under the condition that the water content of slurry is low, and product defects are reduced.

Owner:广东鼎汇能科技股份有限公司

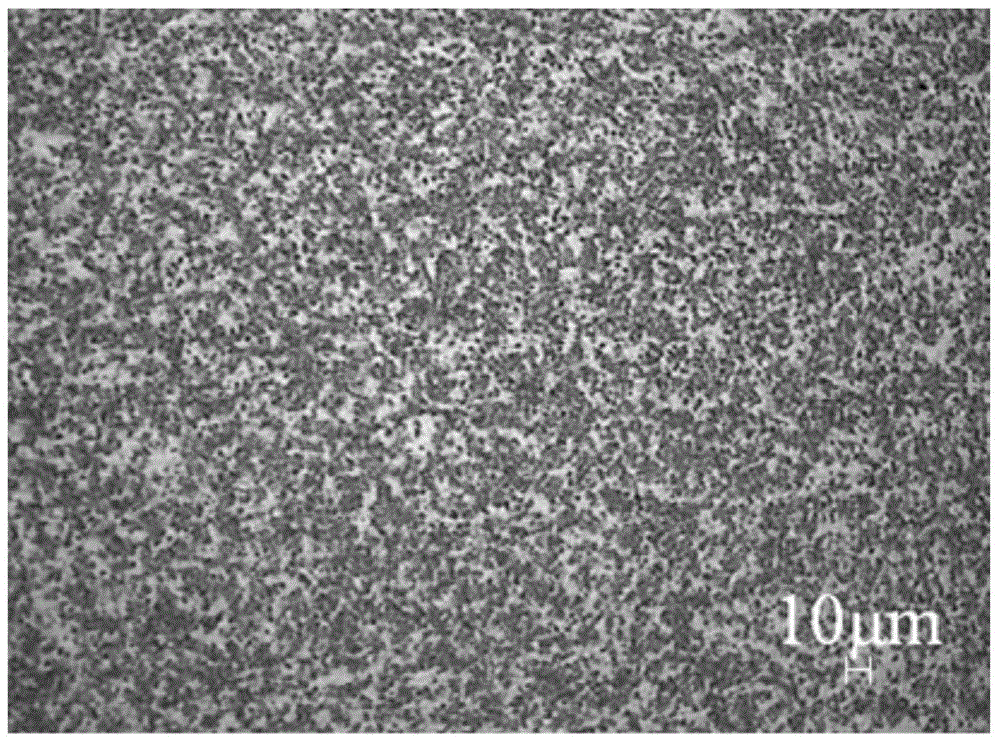

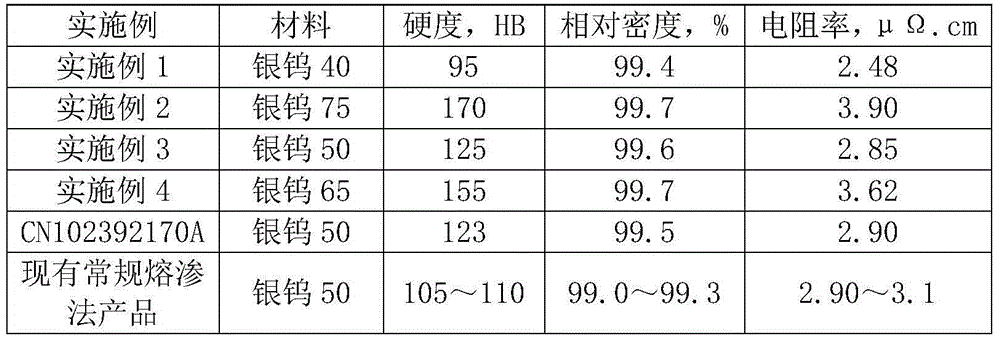

Preparation method of silver tungsten contact material

The invention discloses a preparation method of a silver tungsten contact material. The method comprises the following steps: mixing silver powder and tungsten powder, carrying out ball milling on the silver-tungsten mixed powder, high-purity nickel balls and water in a ball mill, and carrying out drying, annealing, molding and infiltration treatment on the silver-tungsten mixed powder subjected to ball milling, wherein the weight ratio of the high-purity nickel balls to the silver-tungsten mixed powder is (4-10):1, 120-200ml of water is added to every 1kg of silver-tungsten mixed powder, and the ball milling time is 12-50 hours. The silver-tungsten mixed powder, high-purity nickel balls and water are subjected to ball milling in the ball mill for special time in a specific proportion, so that the silver powder and tungsten powder are mixed more uniformly, the ball milling and additive nickel addition can be implemented at the same time, and the nickel lost on the high-purity nickel balls due to ball milling can be uniformly coated to the tungsten granule surface, thereby achieving the goal of effectively improving the wettability of the tungsten. The obtained material has the advantages of uniform structure, high density and low resistivity.

Owner:桂林金格电工电子材料科技有限公司

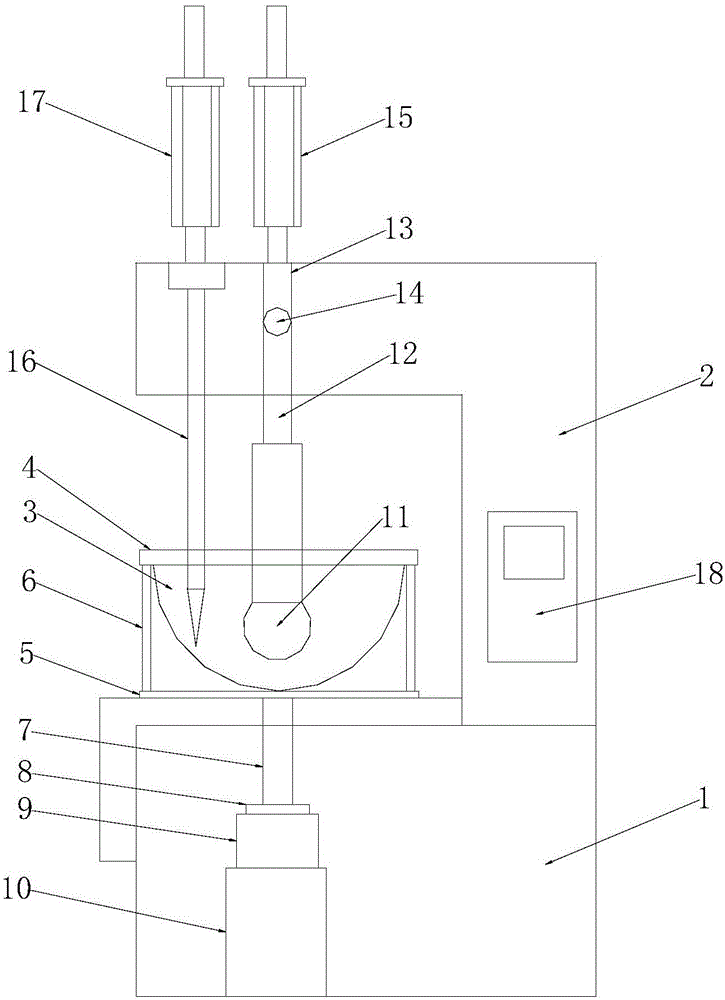

Plant liquid grinding and extracting equipment for medical cosmetology

InactiveCN107583307AGrinding speed is fastImprove grinding effectSolid solvent extractionGrain treatmentsEngineeringMedical treatment

The invention relates to plant liquid grinding and extracting equipment, in particular to plant liquid grinding and extracting equipment for medical cosmetology, which aims at solving the technical problem and providing the plant liquid grinding and extracting equipment for the medical cosmetology with the beneficial effects of high extracting efficiency, better grinding effect and simple operation. To solve the technical problem, the plant liquid grinding and extracting equipment for the medical cosmetology comprises a bottom plate, an n-shaped frame, a collecting box, a fixed plate, a driving mechanism, a grinding mechanism and the like, wherein the n-shaped frame is fixedly arranged at the top part of the bottom plate; the collecting box is arranged in the middle part of the top part ofthe bottom plate; the fixed plate is arranged at the top part of the interior of the n-shaped frame; the driving mechanism is arranged at the lower part of the front side of the fixed plate; a movement mechanism is arranged at the upper part of the front side of the fixed plate; a vertical rod is arranged at the bottom part of the driving mechanism. The plant liquid grinding and extracting equipment has the beneficial effects that the extracting efficiency is high, the grinding effect is better, and the operation is simple; by mutually matching the driving mechanism and the grinding mechanism, the plant liquid is ground, and the grinding speed is high.

Owner:钟光文

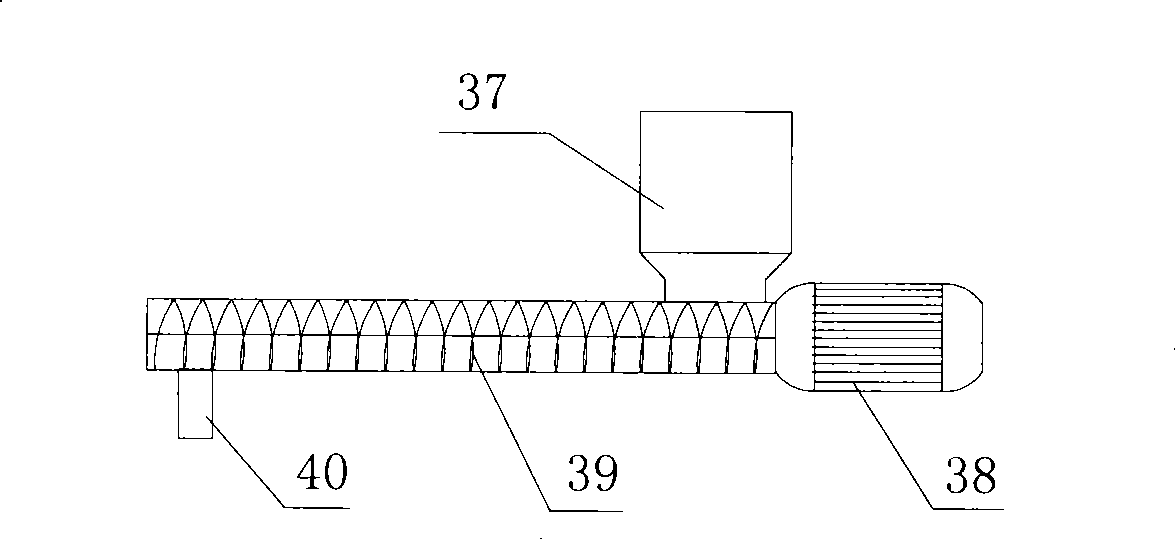

Flour-milling machine for grain processing

The invention discloses a flour-milling machine for grain processing. The flour-milling machine comprises a casing, wherein the casing is of a hollow structure; in addition, a feeding opening is formed in the side wall of the upper side of the casing; a conveying pipe in transverse arrangement is arranged in the casing; the conveying pipe is arranged in a way of communicating with the feeding opening; a first driving motor is arranged on the side wall of one side of the casing; an output shaft of the first driving motor penetrates through the side wall of the casing and is connected with a first rotating shaft in transverse arrangement; the first rotating shaft is positioned in the conveying pipe; a spiral fan blade is arranged on the side wall of the outer side of the first rotating shaft; a plurality of material discharging openings are formed in the side wall of the lower side of the conveying pipe; the sizes of the openings of the plurality of material discharging openings are sequentially increased from the left side to the right side; a cavity is formed in the side wall of one side of the casing; a second driving motor is arranged on the side wall of one side of the casing. The flour-milling machine for grain processing has the advantages that the grinding on the grain is sufficient; the grinding effect is good; in addition, abraded crushing teeth can be dismounted; in addition, the dismounting operation is convenient and fast.

Owner:武汉市麦浪面业有限公司

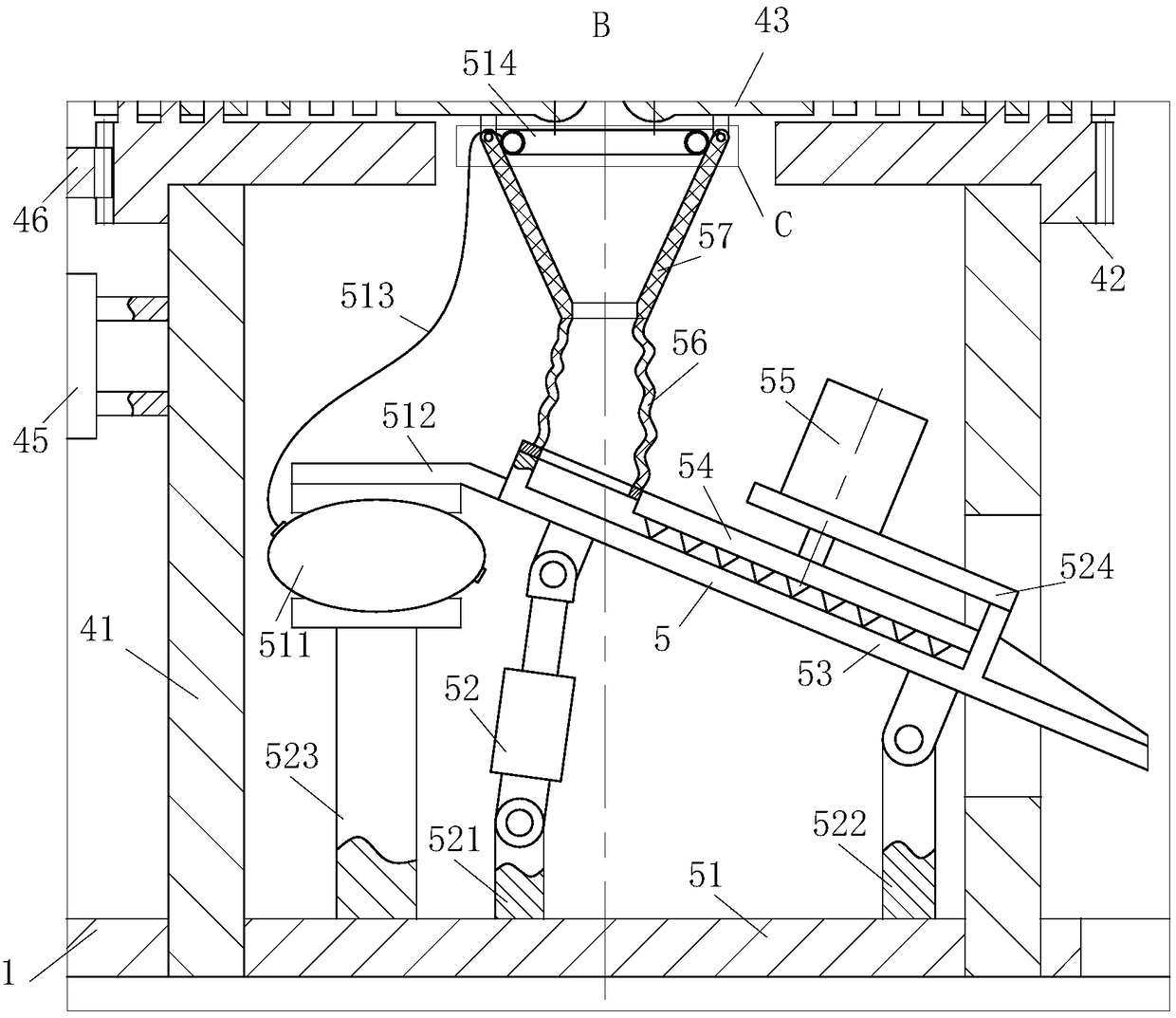

Grinding and screening integrated traditional Chinese medicine processing device

ActiveCN110935543ASimplify the process stepsImprove work efficiencySievingScreeningReciprocating motionElectric machinery

The invention relates to the technical field of traditional Chinese medicine processing, and particularly relates to a grinding and screening integrated traditional Chinese medicine processing device.The grinding and screening integrated traditional Chinese medicine processing device comprises a processing box body, wherein the processing box body comprises a grinding box body and a screening boxbody, a filter screen is mounted between the grinding box body and the screening box body, and a material distributing device, a grinding device and a rolling device are arranged in the grinding boxbody. According to the grinding and screening integrated traditional Chinese medicine processing device, the filter screen is arranged in the processing box body, the processing box body is divided into the grinding box body and the screening box body, so that grinding and screening are carried out in the same process, the process steps are simplified, and the working efficiency is improved; an electric push rod pushes a grinding block to do up-down reciprocating motion, meanwhile, a connecting shaft drives the electric push rod to rotate, so that the mechanical grinding work of traditional Chinese medicines is realized; and a working motor drives a rotating shaft to rotate, so that two elliptical teeth rotate synchronously, the two elliptical teeth are attached to a fixed pulley to slide,and the two elliptical teeth are different in height, so that a screening box can shake up and down, and the mechanical screening work is completed.

Owner:安徽豪门国药股份有限公司

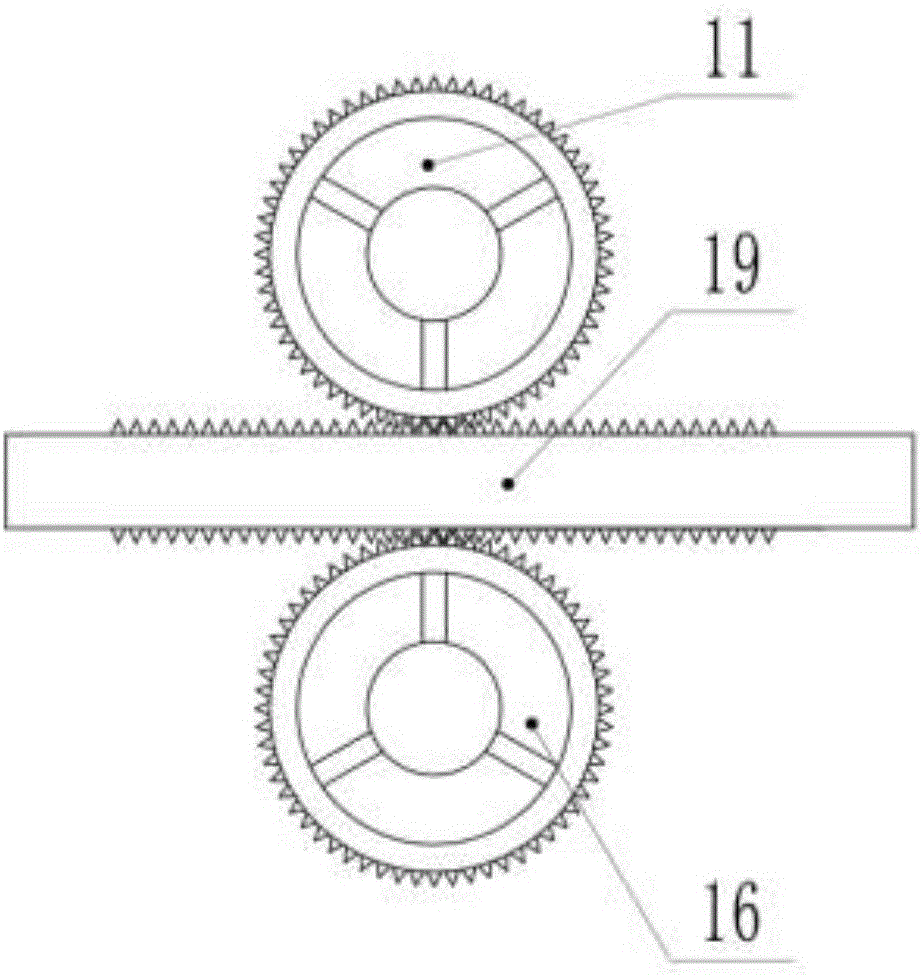

Manual feed grinding device for household livestock breeding

The invention discloses a manual feed grinding device for raising domestic livestock, which includes a base, a main support, a screw rod, a lifting block, a gear A, a grinding head, a gear B, a grinding box and a double-sided rack. The bearing is rotatably installed with a screw rod, and a lifting block is threaded on the screw rod, and a fixed shaft is fixedly welded on the lower side of the lifting block, and a grinding head is fixedly mounted on the lower end of the fixed shaft, and a gear B is fixedly mounted on the rotating shaft. A grinding box is fixedly installed on the fixed seat; the lifting block in this device moves downward to drive the grinding head down to cooperate with the rotating grinding box to grind the feed, which is more time-saving and labor-saving than manual grinding, and the grinding is more complete; by adjusting the handle The pulling distance can adjust the descending height of the lifting block and the downward pressure of the grinding head, so as to adjust the size of the feed particles after grinding, so as to meet the needs of livestock of different ages for feeding.

Owner:ZHENGZHOU BINGTONG LIZHI ELECTRONICS TECH CO LTD

Flotation separation method for refractory sulfide ore and high-sulfur copper-zinc ore

The invention discloses a flotation separation method for refractory sulfide ore and high-sulfur copper-zinc ore. The method comprises the following steps: performing first-stage ore grinding on a raw ore and then performing first-stage flotation on the raw ore, wherein the raw ore after being subjected to the first-stage ore grinding meets the demand that more than 90% of ore fineness is less than 200 meshes; adopting the processes of once rough flotation, once fine flotation and once scavenging; performing second-stage ore grinding on the ore after being subjected to the first-stage flotation, wherein tailings of the first-stage flotation are sulfur concentrates; performing second-stage flotation on the ore which is subject to the second-stage ore grinding and meets the demand that more than 90% of ore fineness is less than 400 meshes; performing copper-zinc separation flotation; adopting the processes of once rough flotation, triple fine flotation and once scavenging; adding C6MT sodium phosphate as a modifier and separating copper concentrates from the tailings; performing third-stage flotation on the tailings; and adopting the processes of once rough flotation, triple fine flotation and twice scavenging, thereby separating zinc concentrates from the sulfur concentrates. The method provided by the invention has the advantages of reasonable process, saved investment and low cost. By using the method, the flotation precision of copper-zinc ore is increased, the recovery rate of copper and zinc concentrates is increased, the national mine resource is furthest recovered, utilized and protected, and the national technical level of separating copper-zinc ore is promoted.

Owner:TURPAN XUEYIN METAL MINING

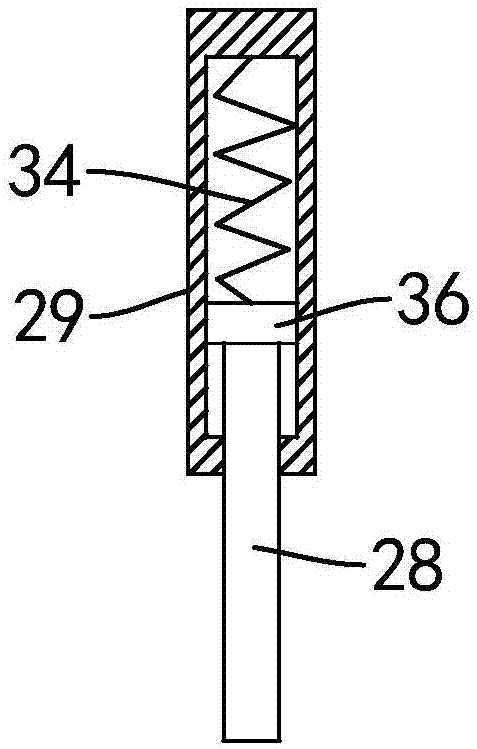

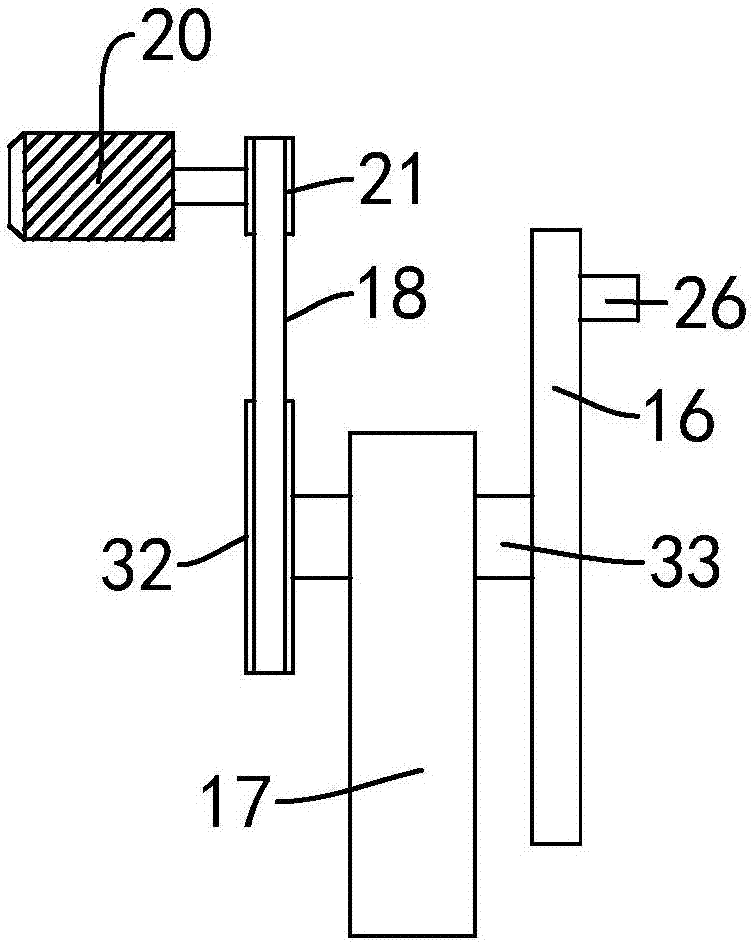

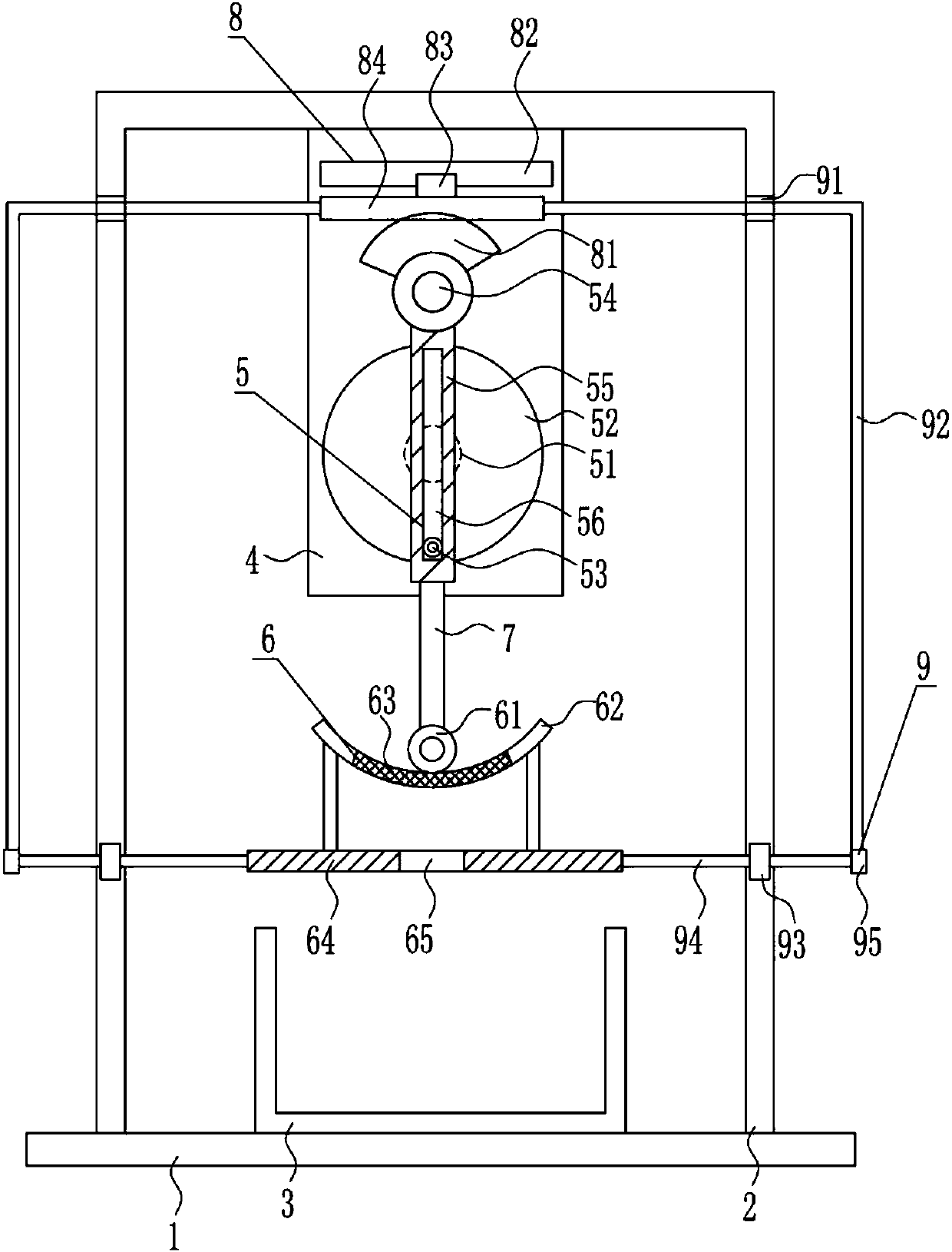

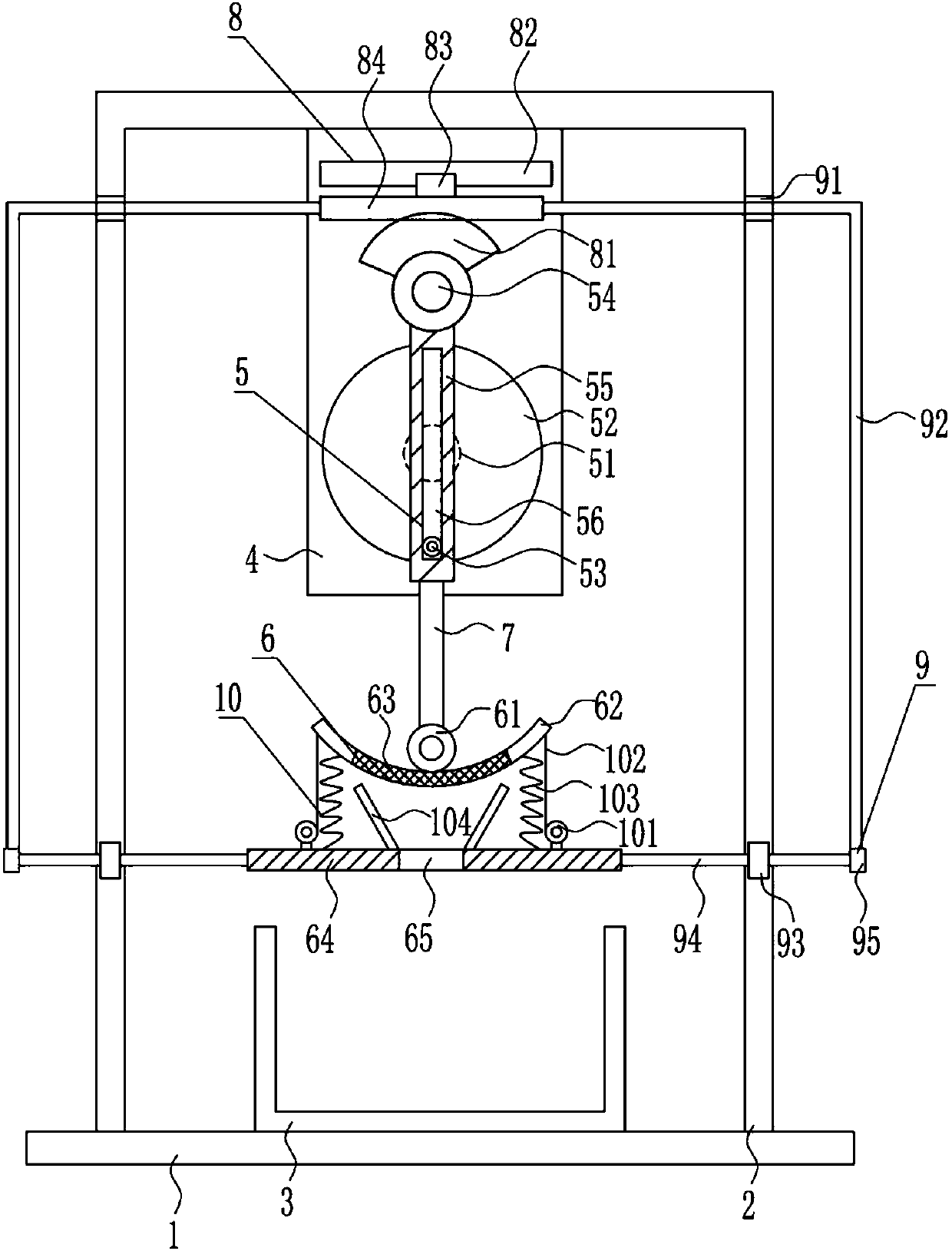

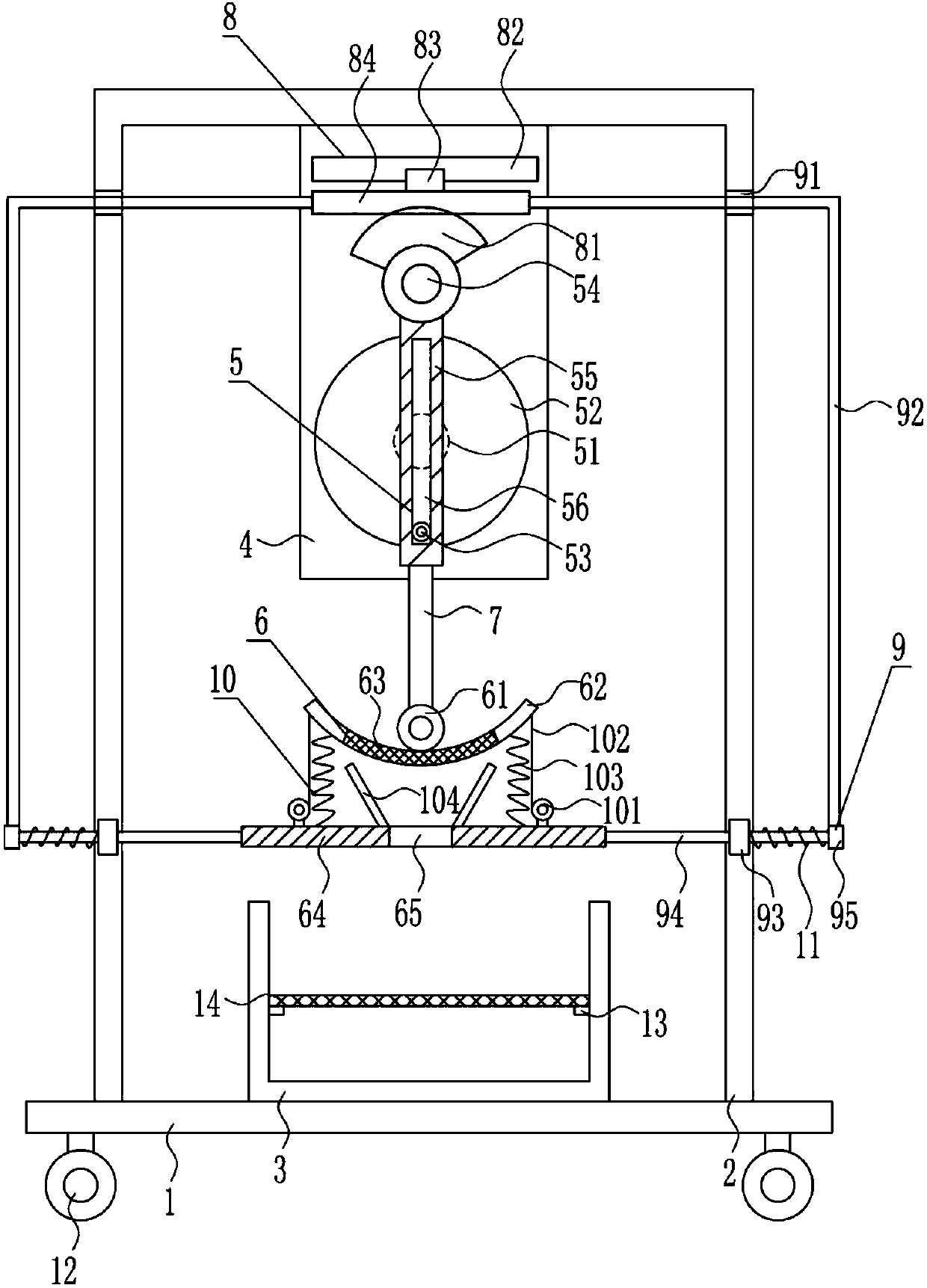

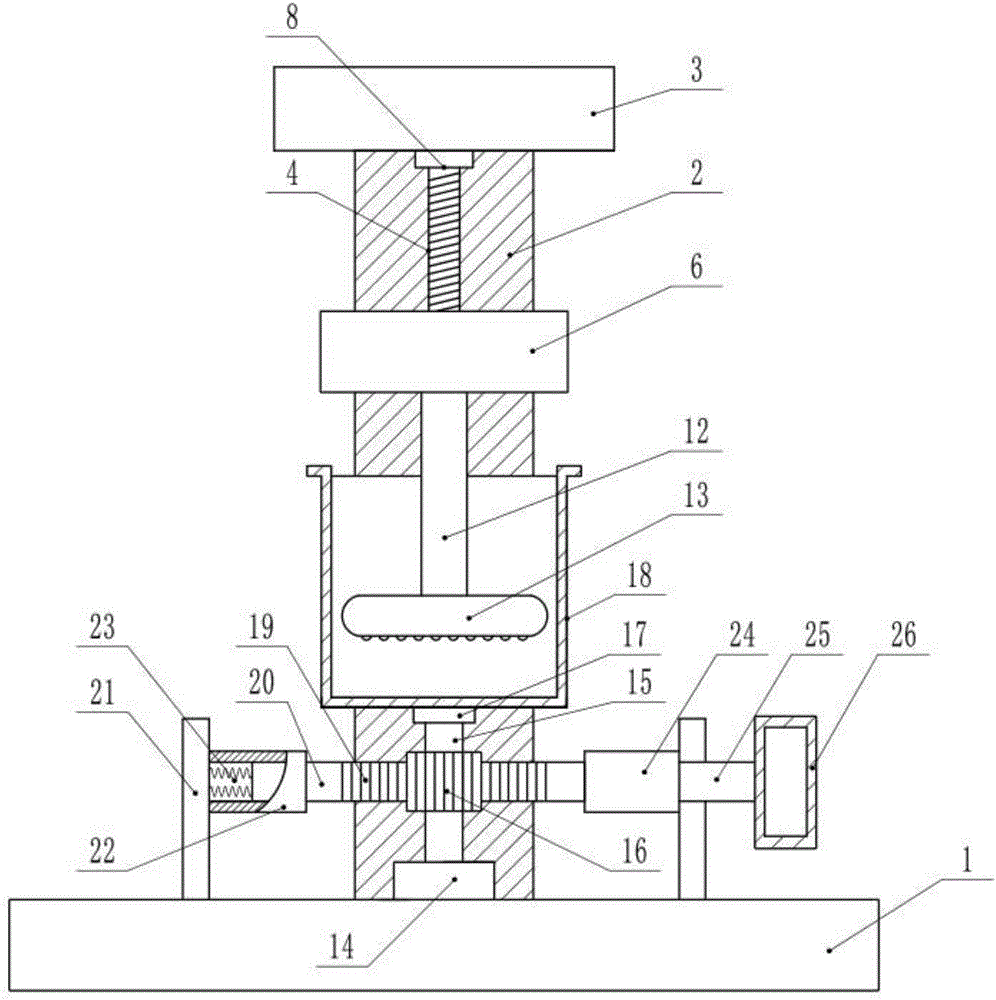

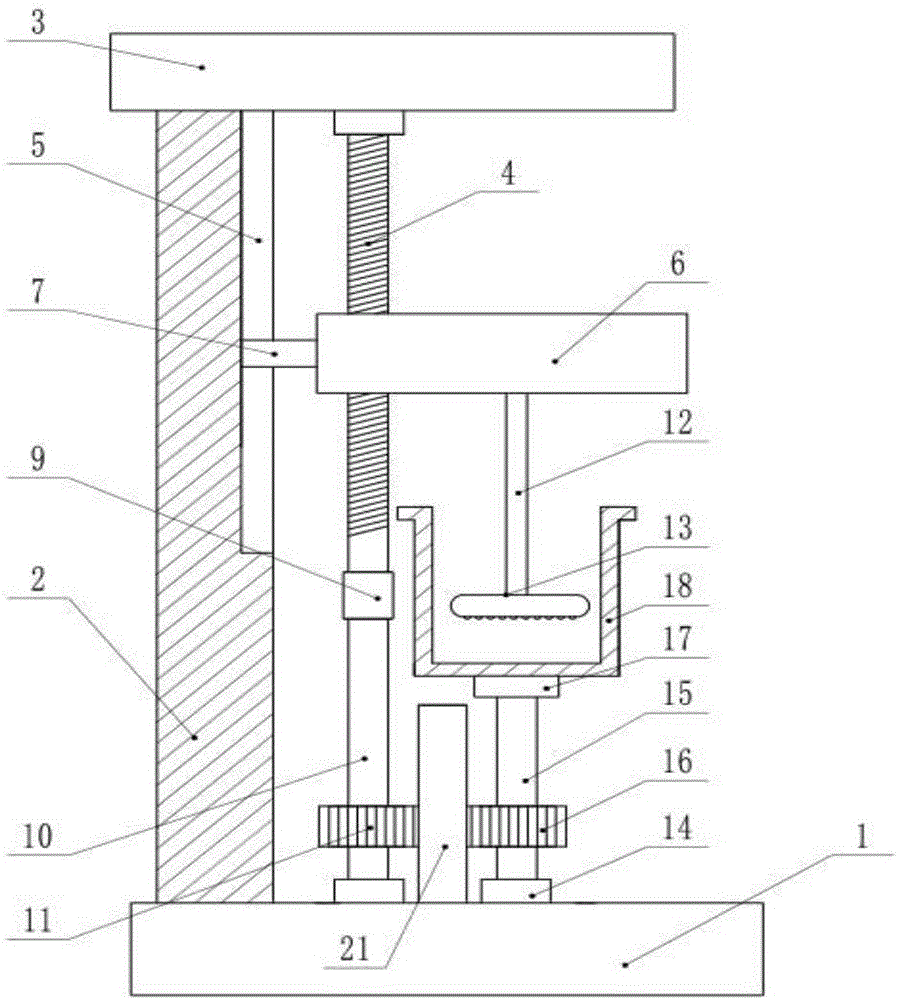

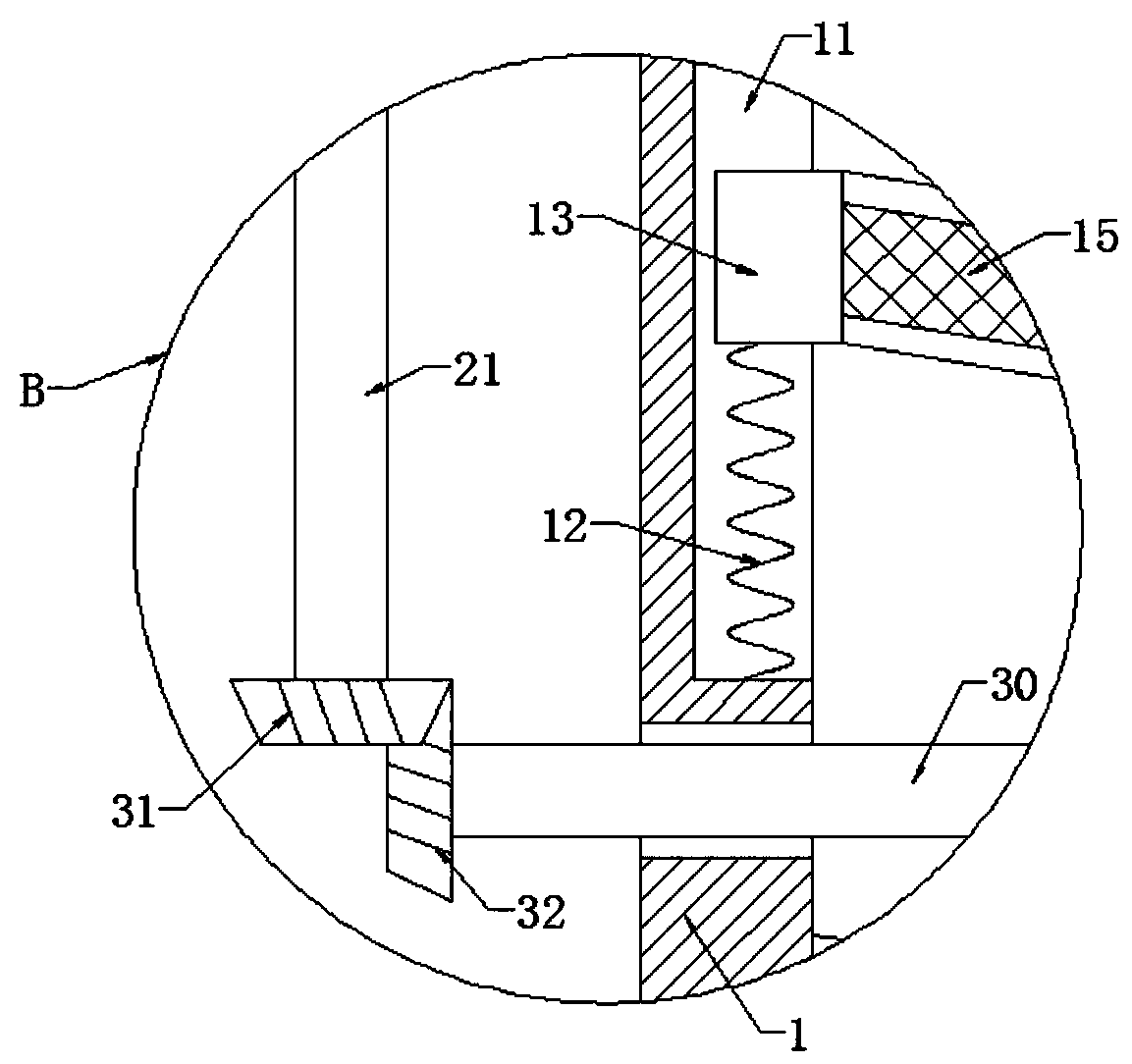

Drug grinding device

The invention discloses a drug grinding device. The drug grinding device comprises a base (1), a material pushing device (2), a recovery device (3), an air cylinder device (4), a frame body (5), a pushing device (6), a grinding device (7), an air blowing device (8) and a feeding device (9), wherein the material pushing device (2) comprises a first support (21), a first air cylinder (22), a material pushing rod (23), a material pushing block (24), a first check block (25) and a locating plate (26); the recovery device (3) comprises a second support (31), a right wall (32), a left wall (34), a second check block (35), a scraper blade (36), an inclined rod (36), a first roller (38), a first supporting rod (39) and a material collecting frame (30); the air cylinder device comprises a second air cylinder, a first pushing-against rod and a pushing-against plate; and the frame body comprises a first through hole and an inclined plate. The drug grinding device can be used for fully grinding drugs or chemical raw materials and has high grinding efficiency.

Owner:梁洁

Ball-milling mixer for producing drilling-milling-integration hard alloy

The invention discloses a ball-milling mixer for producing a drilling-milling-integration hard alloy. The ball-milling mixer comprises a barrel, wherein two grinding rollers are rotationally connectedto the upper portion of the inner wall of the barrel through two rotating shafts correspondingly, a first annular groove is formed in the inner wall of the barrel, a first circular ring is slidably connected to the inner wall of the first annular groove, a transverse plate is fixedly connected to the inner wall of the barrel, the upper end of the transverse plate is rotationally connected with acylinder through a connecting rod, and the upper end and the lower end of the cylinder are conical. According to the mixer, by arranging the grinding rollers, first grinding teeth and second grindingteeth, materials can be fully and finely ground, a cam collides with a transverse rod in a clearance mode through rotation of a transverse column, the materials ground again can be filtered, large particles in the ground materials are removed, through rotation of a spiral blade of an auger, the large particles filtered by a filter screen can be conveyed, manual conveying of the large particles isnot needed, and the working intensity is reduced.

Owner:北京享云智汇科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com