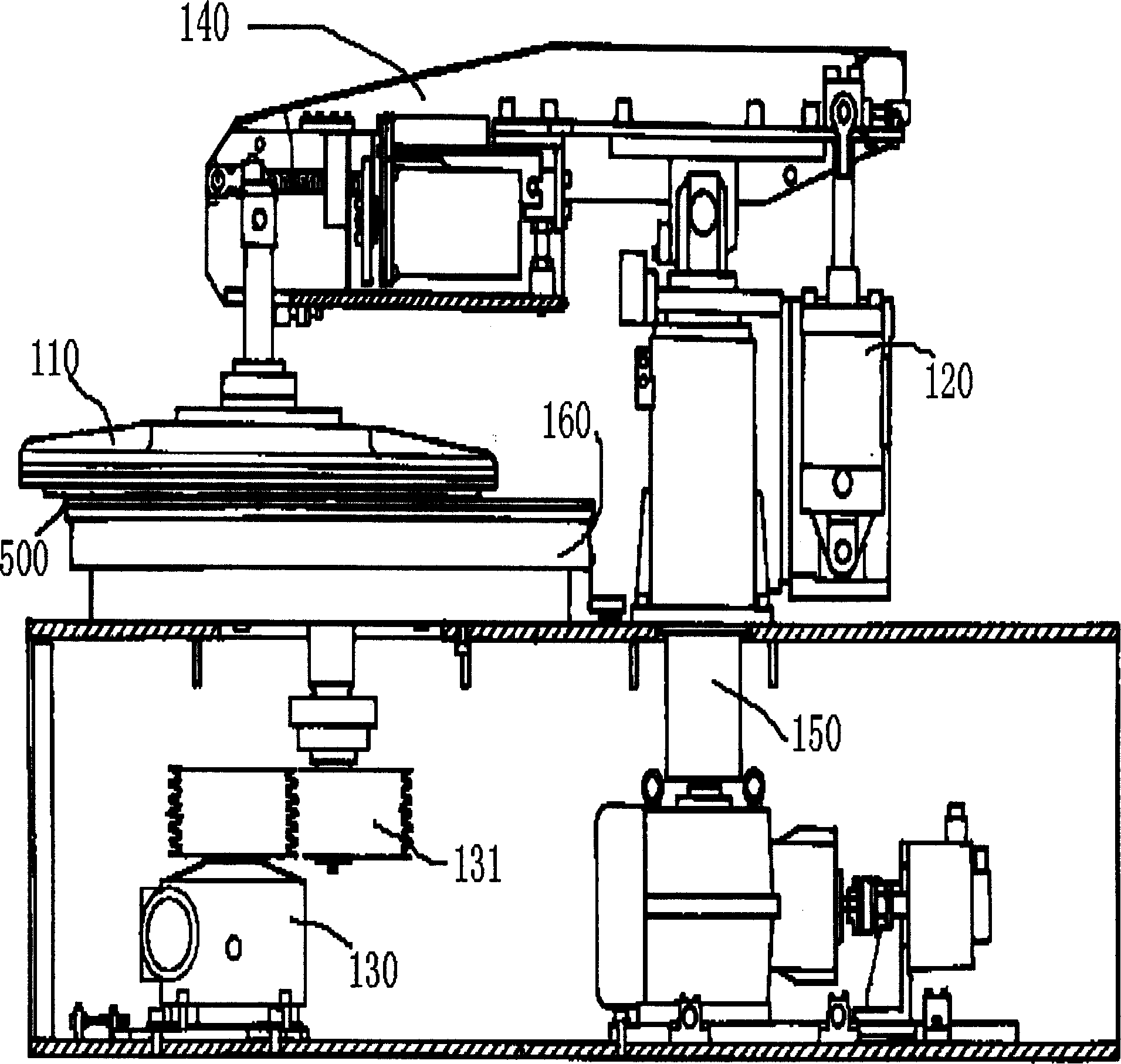

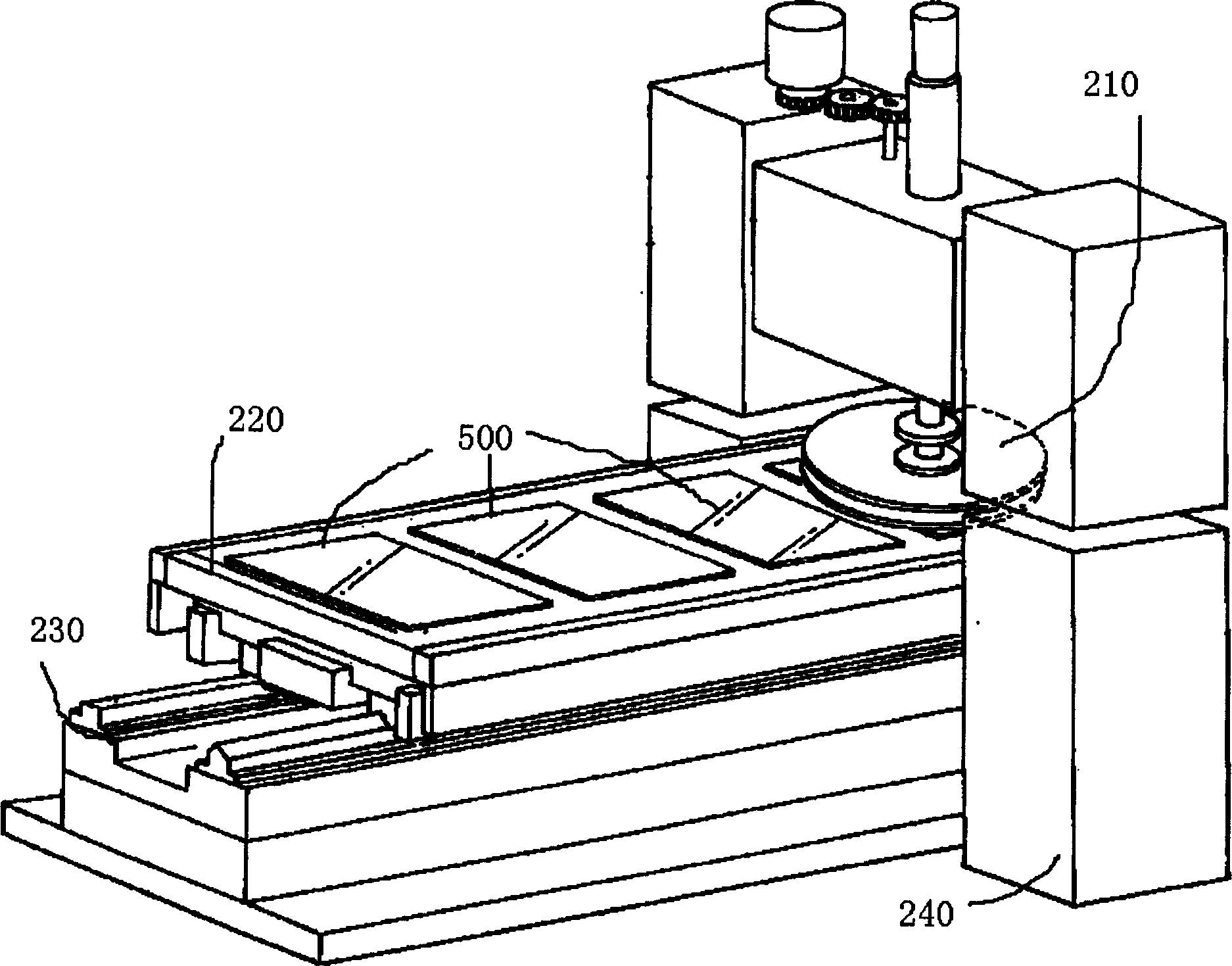

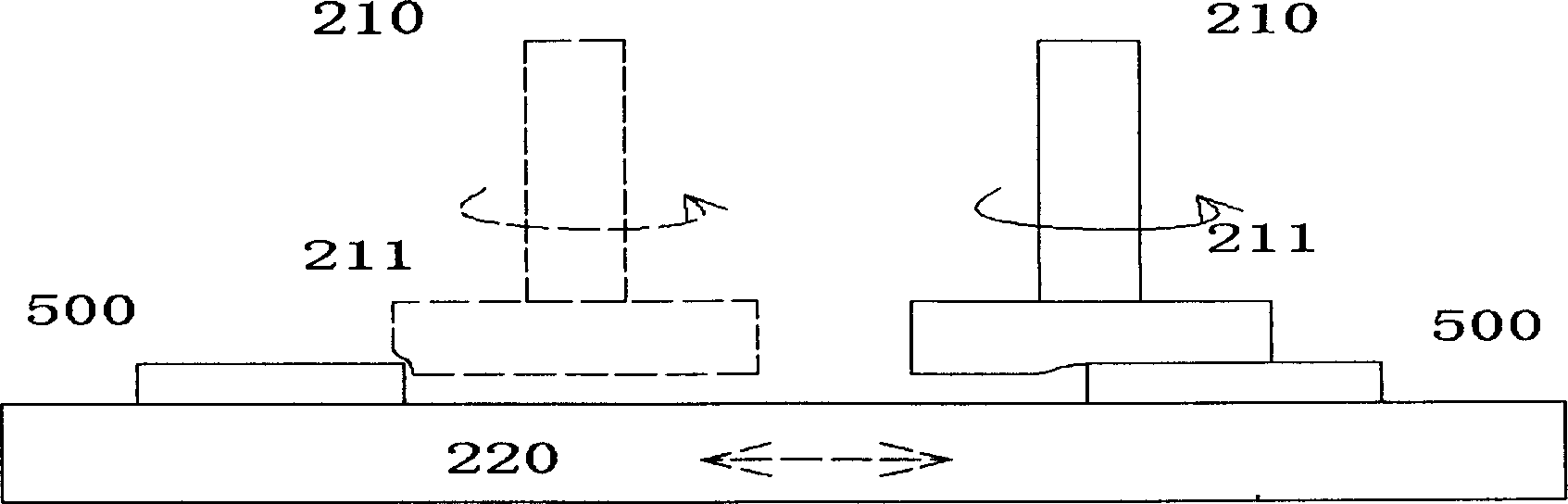

Grinding equipment of plate material and grinding method

A grinding method and technology for plate-like objects, which are used in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve problems such as low efficiency, inability to adapt to production efficiency, and difficulty in peeling off glass substrates 500

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The glass substrate fixture structure involved in the present invention is: the glass substrate of the present invention has been applied for independently. Figure 5 It is a typical schematic diagram of a glass substrate fixture. The upper surface of the fixture is designed with a special elastic material 410. The glass substrate 500 and the fixture 400 are firmly adsorbed together by the principle of vacuum through rolling and other methods. The lower edge of the fixture is designed with The boss 430 corresponding to the groove of the workbench can be positioned relatively accurately with the groove of the workbench through the boss 430 on the fixture. When grinding, the glass substrate 500 is adsorbed on the glass substrate holder 400, and the glass substrate holder 400 is fixed on the grinder workbench 350 by vacuum through the air holes on the workbench; Vacuum, if it is inconvenient to load and unload, you can also use the air holes of the workbench to blow air, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com