Patents

Literature

502 results about "Loading unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Unloading - the labor of taking a load of something off of or out of a vehicle or ship or container etc. handling - manual (or mechanical) carrying or moving or delivering or working with something. loading - the labor of putting a load of something on or in a vehicle or ship or container etc.; "the loading took 2 hours".

Preparation method for sodium alginate-acrylamide-based hydrogel

InactiveCN103396562AOvercome the shortcomings of generating air bubbles and forming uneven hydrogelsEasy to operateCross-linkPolyacrylamide Hydrogel

The invention discloses a preparation method for sodium alginate-acrylamide-based hydrogel. The preparation method comprises the following steps of: dissolving sodium alginate powder in deionized water; then sequentially adding an acrylamide monomer, a methylene diacrylamide cross-linking agent, ammonium persulfate and an N,N,N',N'-tetramethylethylenediamine catalyst; uniformly stirring the materials, pouring the mixture into a glass die, and heating the mixture to obtain a hydrogel; completely soaking the hydrogel in a 0.01-1 mol / L non-monovalent cation aqueous solution for 1-10 hours, wherein cations diffuse and enter in a hydrogel network structure, and induce sodium alginate to cross-link, so as to generate the high-strength and high-toughness sodium alginate-acrylamide-based hydrogel during the process. The hydrogel disclosed by the invention has the following performances: the highest tensile strength can achieve 1 MPa, and the highest tensile elasticity modulus can achieve 250 KPa; a loading-unloading test is performed on the hydrogel, and when the great tensile multiple before unloading is 8, the highest dissipated energy can achieve 2180 KJ / m<3>.

Owner:XI AN JIAOTONG UNIV

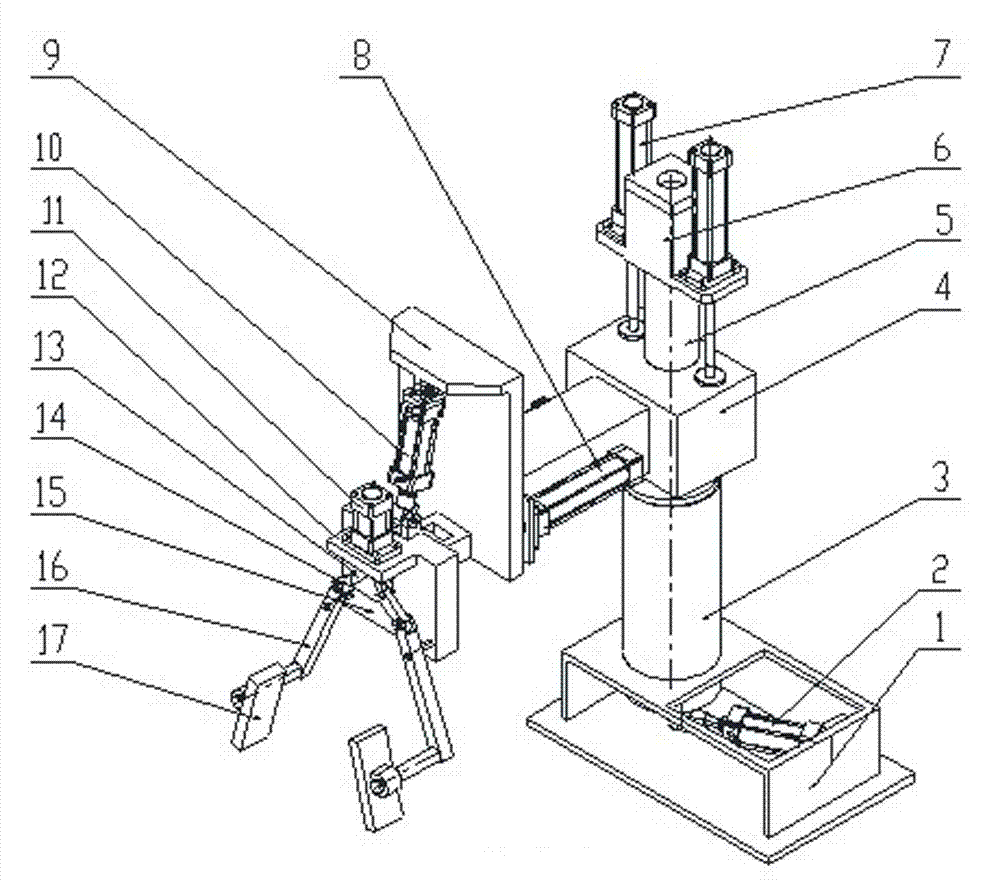

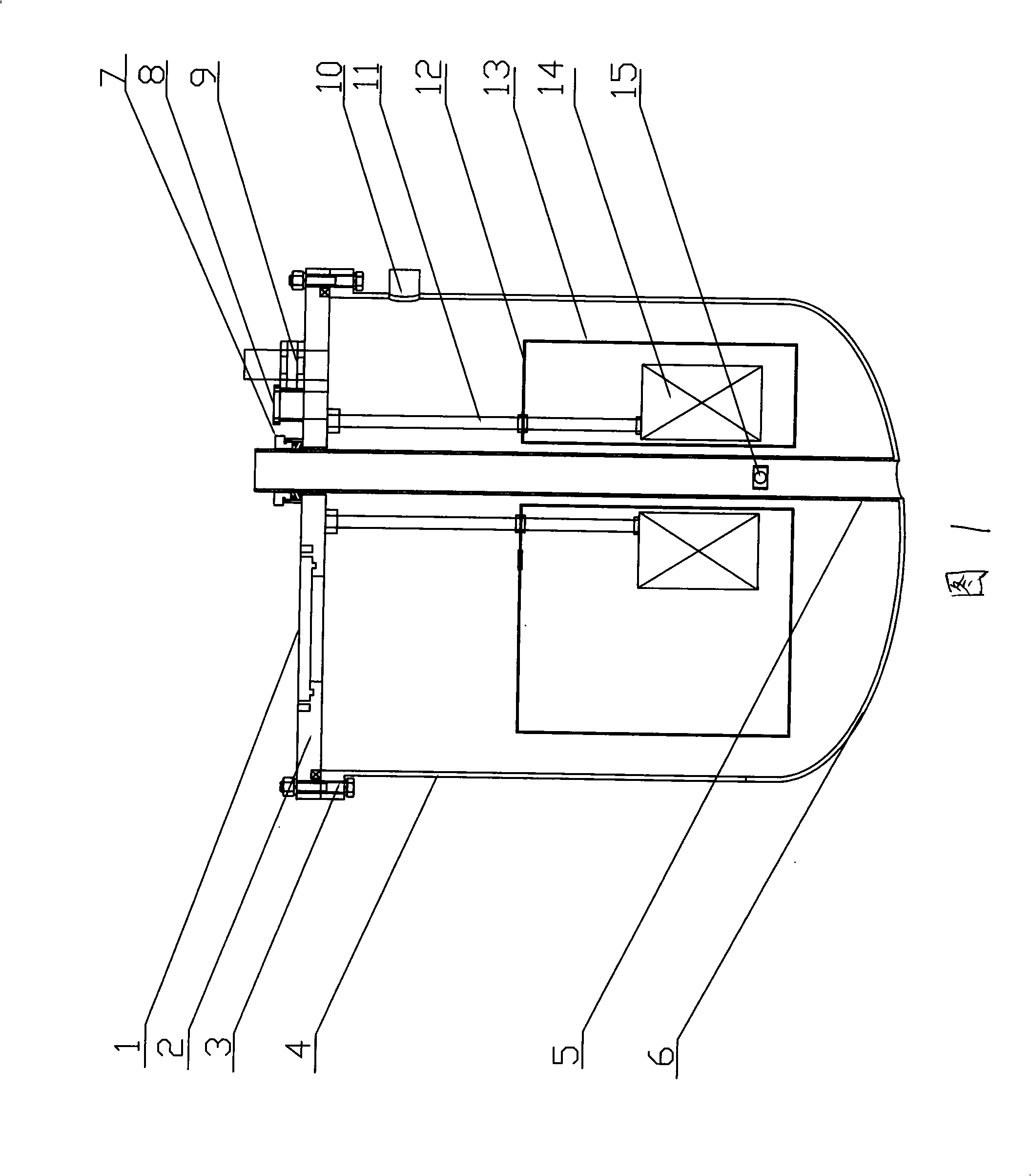

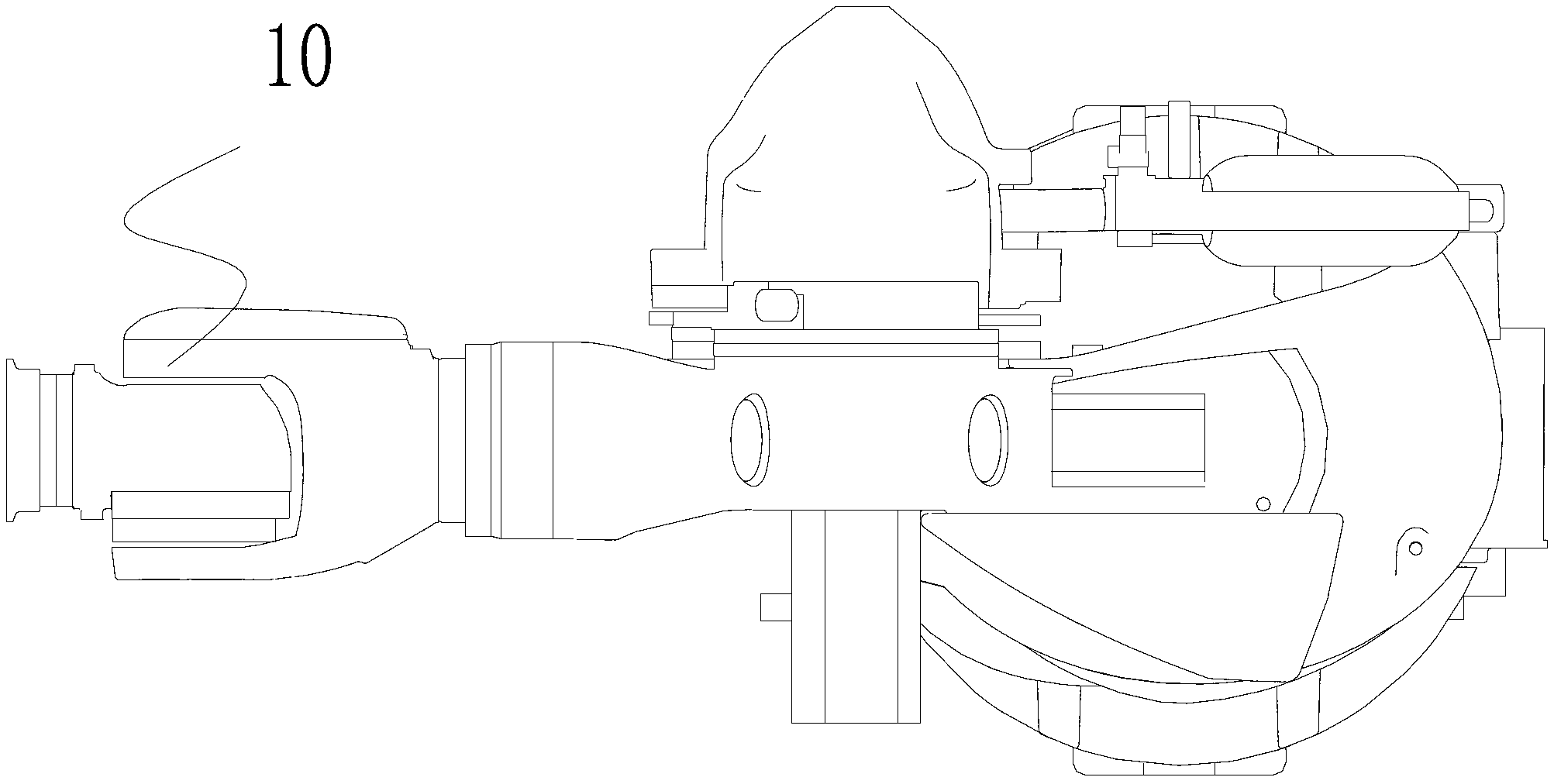

Automatic work piece loading-unloading robot

InactiveCN102825496AHigh positioning accuracyImprove efficiencyProgramme-controlled manipulatorMetal working apparatusRotational axisEngineering

The invention discloses an automatic work piece loading-unloading robot which comprises a machine seat, a rotating shaft, a lifting frame, a telescopic frame, a turnover bracket and a manipulator, wherein the rotating shaft is arranged on the machine seat rotationally; the rotating shaft is connected with a driving device I which is used for driving the rotating shaft to rotate; the lifting frame is arranged on the rotating shaft in a vertical sliding manner; the lifting frame is connected a driving device II which is used for driving the lifting frame to slide up and down; the telescopic frame is arranged on the lifting frame in a horizontal sliding manner; the telescopic frame is connected a driving device III which is used for driving the telescopic frame to slide left and right; the turnover bracket is arranged on the telescopic frame in a vertical turnover manner; the turnover bracket is connected with a driving device IV which is used for driving the turnover bracket to turn; the manipulator is arranged on the turnover bracket; and the manipulator is connected with a driving device V for driving the catching and releasing actions of the manipulator. The automatic work piece loading-unloading robot can be used for conveying the work piece to the preset position accurately and has the high positioning accuracy on the work piece; and the machine is used for replacing the manual labor, so the loading-unloading speed is fast.

Owner:SHANDONG FIN CNC MACHINE

Laser marker for fully automatic IC material bar

InactiveCN101127301AReduce labor intensityPrecise and rational marking processSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingLocation detectionEngineering

The utility model relates to a full automatic IC strip laser marking machine, comprising a body; wherein, a PC device and an electric control system are arranged in the body; a loading-unloading outlet device, a strip conveying device, a laser marking device, a detection system and a removing device which are controlled by the PC device are arranged on the body; the loading outlet device and the unloading outlet device are arranged on both sides of the body, and the strip conveying device is arranged between the two devices. Besides, a direction detection device, a batch number detection device, a pre-marking removing device, a laser marking device, a post-marking quality detection device and a post-marking removing device are arranged on two conveying lines of the both sides of the strip conveying device in sequence, and a marking position detection device is arranged under the laser marking device. Because the loading, conveying, detecting, removing and marking devices which are controlled by the PC device are arranged on the marking machine, the whole marking process is accurate and reasonable; meanwhile, the labor intensity can be reduced.

Owner:GRAND TECH SHENZHEN

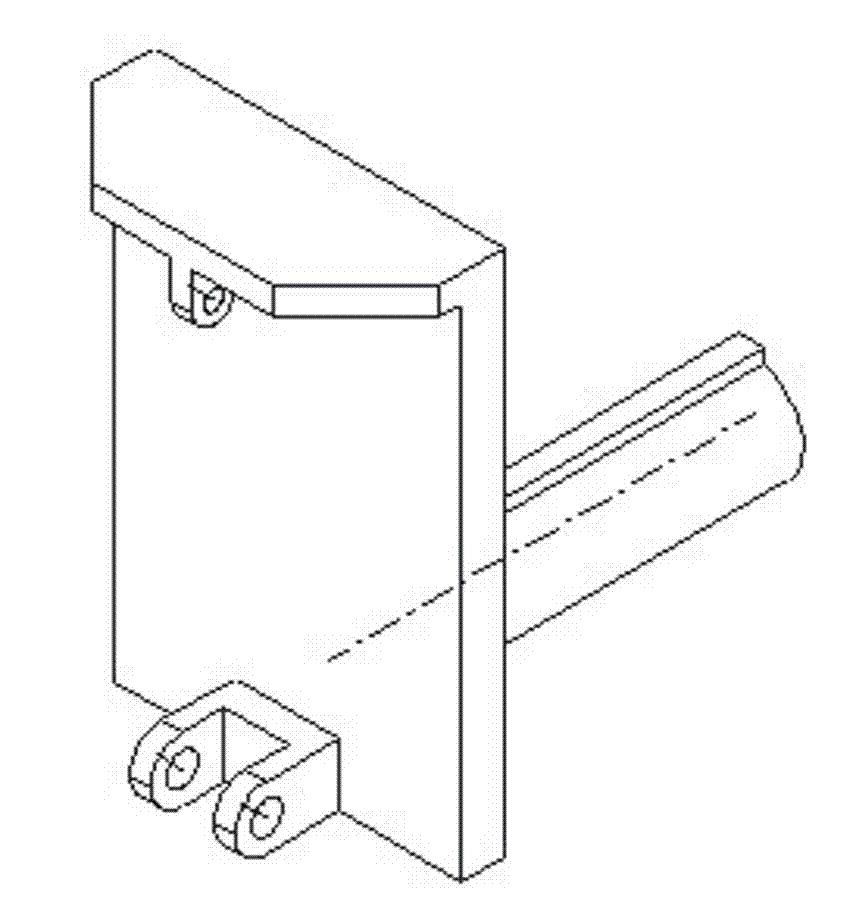

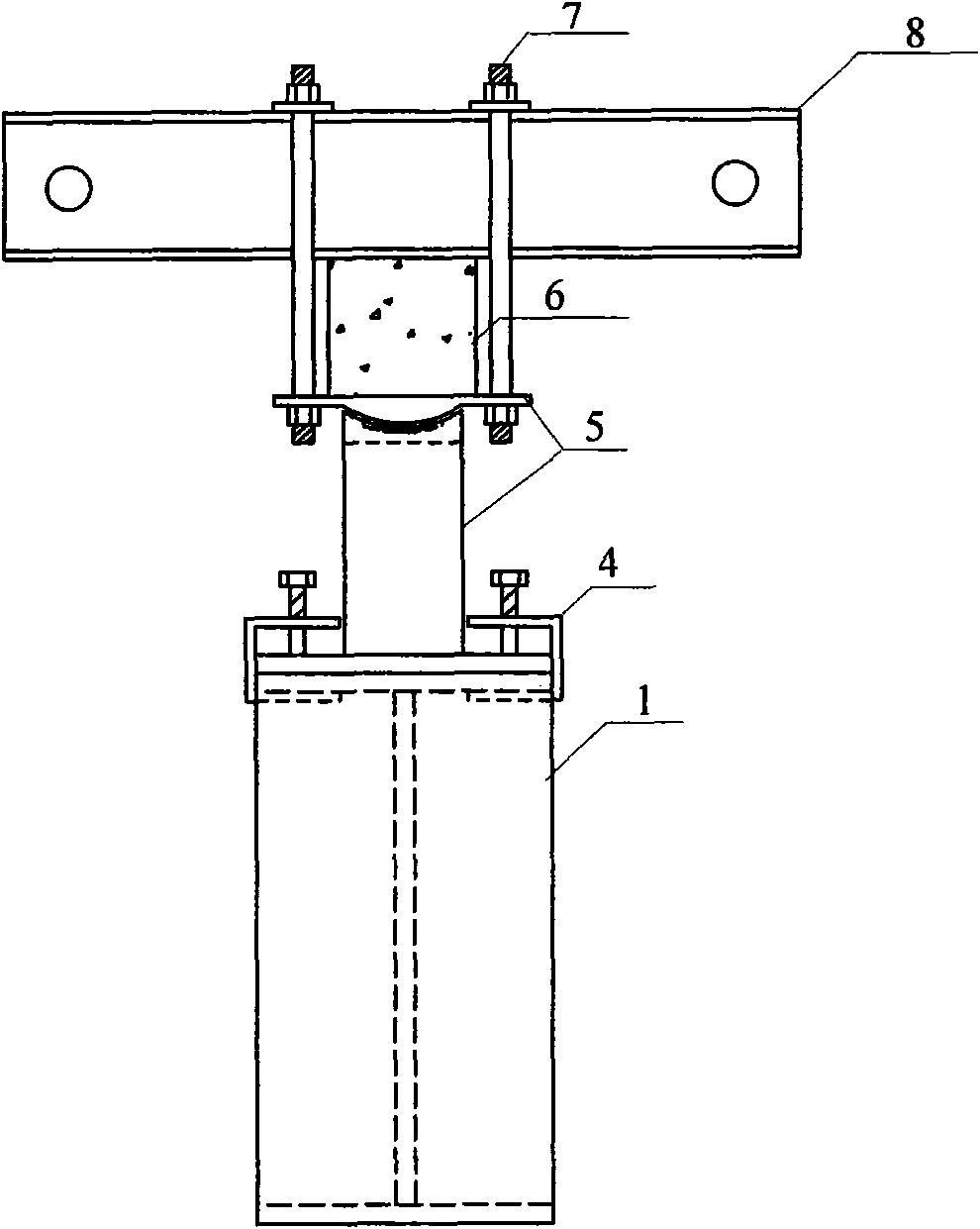

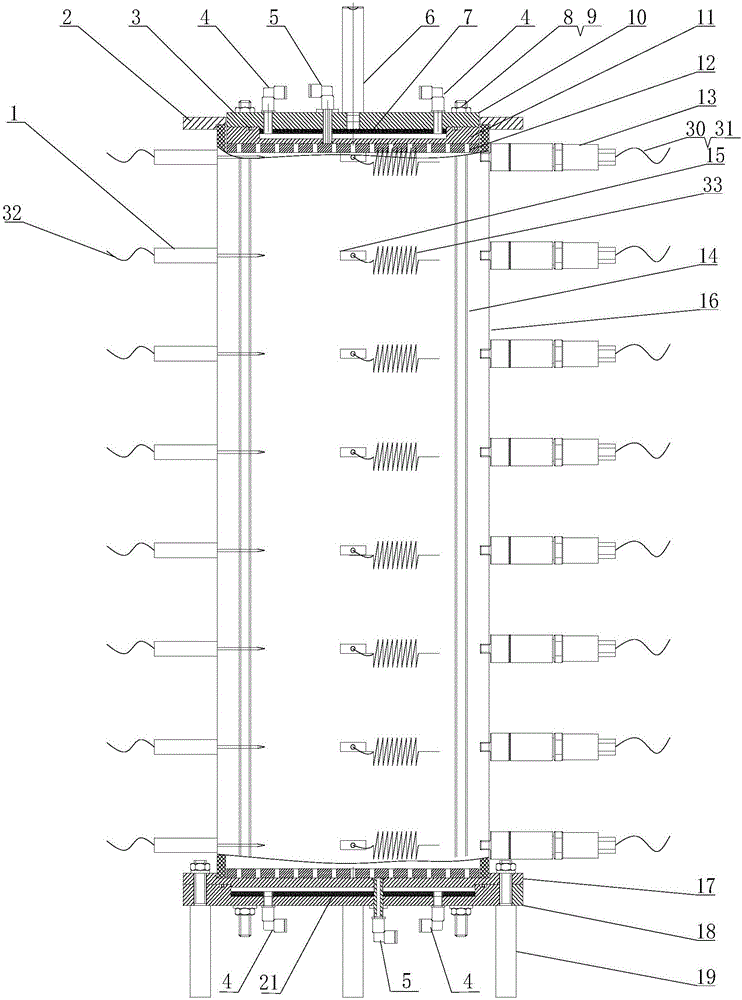

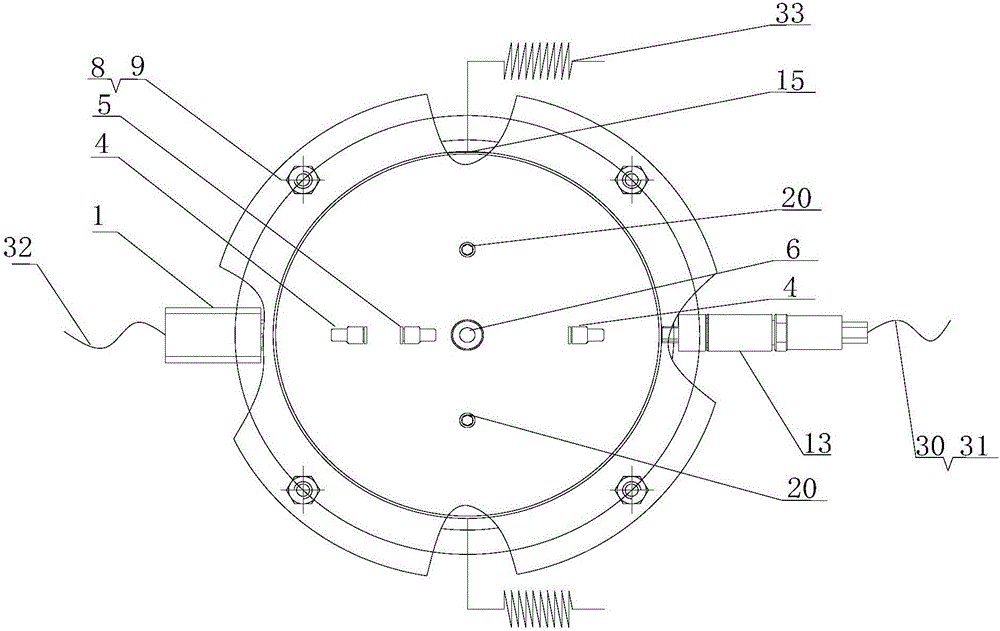

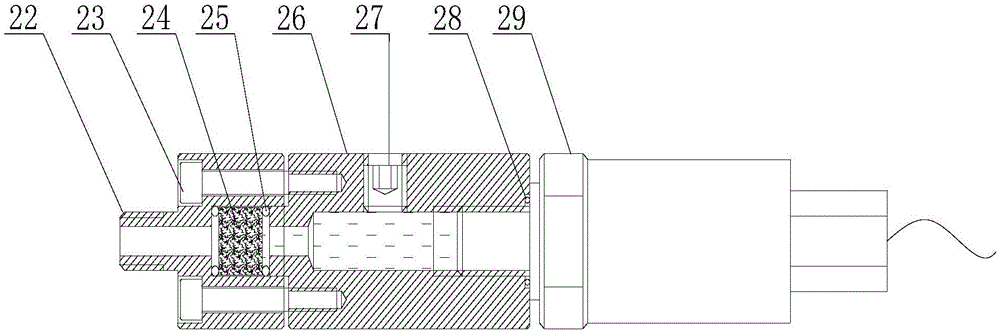

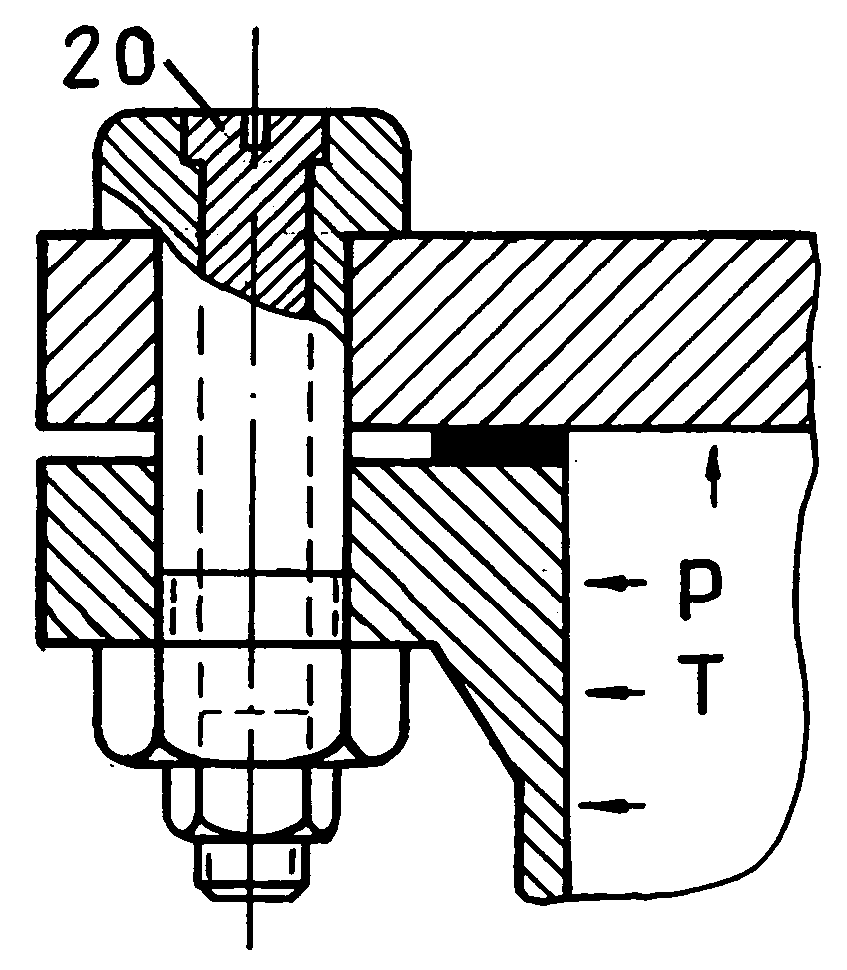

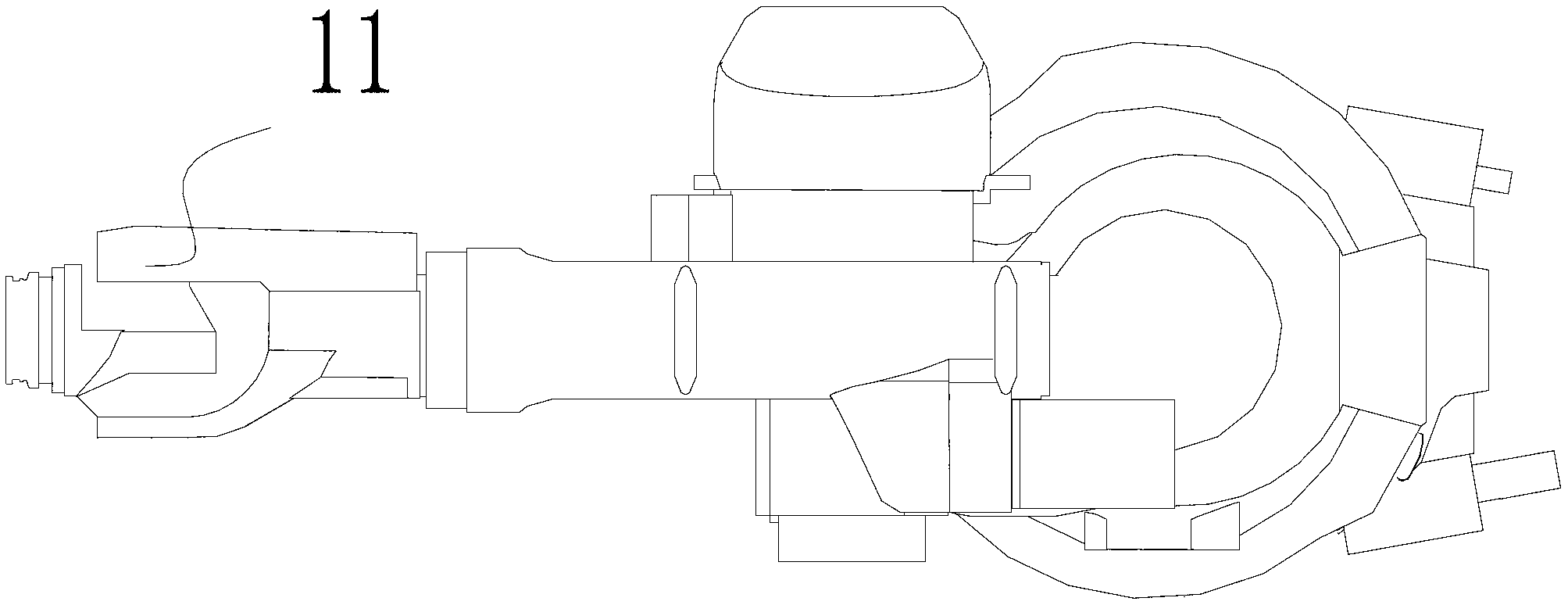

Conduction cooling superconducting magnet dewar convenient for loading and unloading

The invention relates to a conduction-cooled superconducting magnet Dewar with easy loading-unloading, comprising a Dewar cylinder. The conduction-cooled superconducting magnet Dewar is characterized in that the Dewar cylinder is a hollow annular cylinder, the middle of the annular cylinder is provided with a room temperature hole, an annular copper cold shield is arranged in the Dewar cylinder, a refrigerator and a superconducting magnet are arranged in the copper cold shield, a vacuum pumping port is arranged on the Dewar cylinder, a measuring device is arranged on an upper cover of the Dewar cylinder and the Dewar cylinder is in a vacuum state. Compared with the prior Dewar container, the conduction-cooled superconducting magnet Dewar is simpler, has small conduction heat leakage, and has the advantages of easy installation and disassembly; the refrigerator is used for conducting and cooling without a low temperature liquid (such as liquid helium and so on) cooling system; because of simple and safe system, a first-level cold junction of the refrigerator is operated under a temperature of 77K, thereby realizing heat sink of the copper cold shield, an electric lead and a support device; the first-level cold junction of the refrigerator adopts soft connection, thereby reducing temperature increment of the magnet due to vibration of the refrigerator; and the conduction-cooled superconducting magnet Dewar has the advantages of easy operation of manufacture, processing and installation, and is applicable to scale production.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

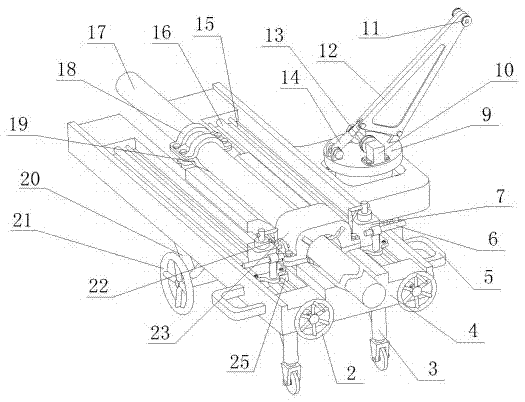

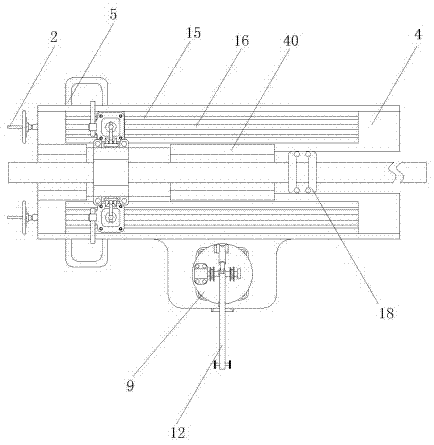

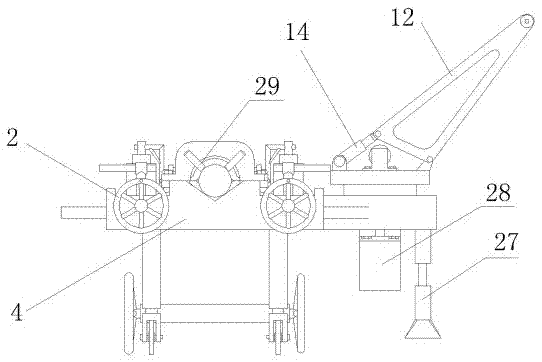

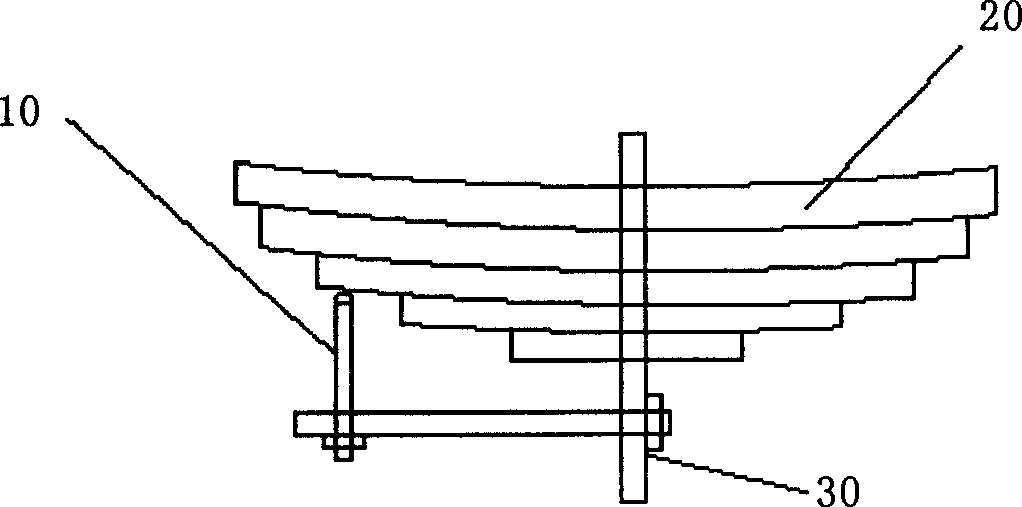

Power-grid telegraph-pole erecting self-loading-unloading device and construction method thereof

The invention discloses a power-grid telegraph-pole erecting self-loading-unloading device. The power-grid telegraph-pole erecting self-loading-unloading device comprises a vehicle frame. A support is installed below the vehicle frame. Wheels are installed on the support, and universal wheels are installed at the front end of the vehicle frame. The power-grid telegraph-pole erecting self-loading-unloading device is characterized in that lead screws are installed on the two sides of the vehicle frame, and sliding blocks controlled through lead screw hand wheels to slide on the lead screws back and forth are installed on the lead screws; a first clamping sleeve formed by assembling a fixing-fastening-frame upper cover and a fixing-fastening-frame lower cover is installed at one end of the middle of the vehicle frame, and rotating shafts are arranged on the two sides of the first clamping sleeve and inserted into the vehicle frame. The power-grid telegraph-pole erecting self-loading-unloading device and a construction method of the power-grid telegraph-pole erecting self-loading-unloading device have the advantages that when a telegraph pole is erected, use is convenient, labor is saved, walking is stable, the construction speed is high, and meanwhile the power-grid telegraph-pole erecting self-loading-unloading device and the construction method are suitable for a flat-road region with sufficient power in a construction region and a remote mountain road rough region, high in practicability and suitable for use and popularization.

Owner:江苏东方宏达电力发展有限公司

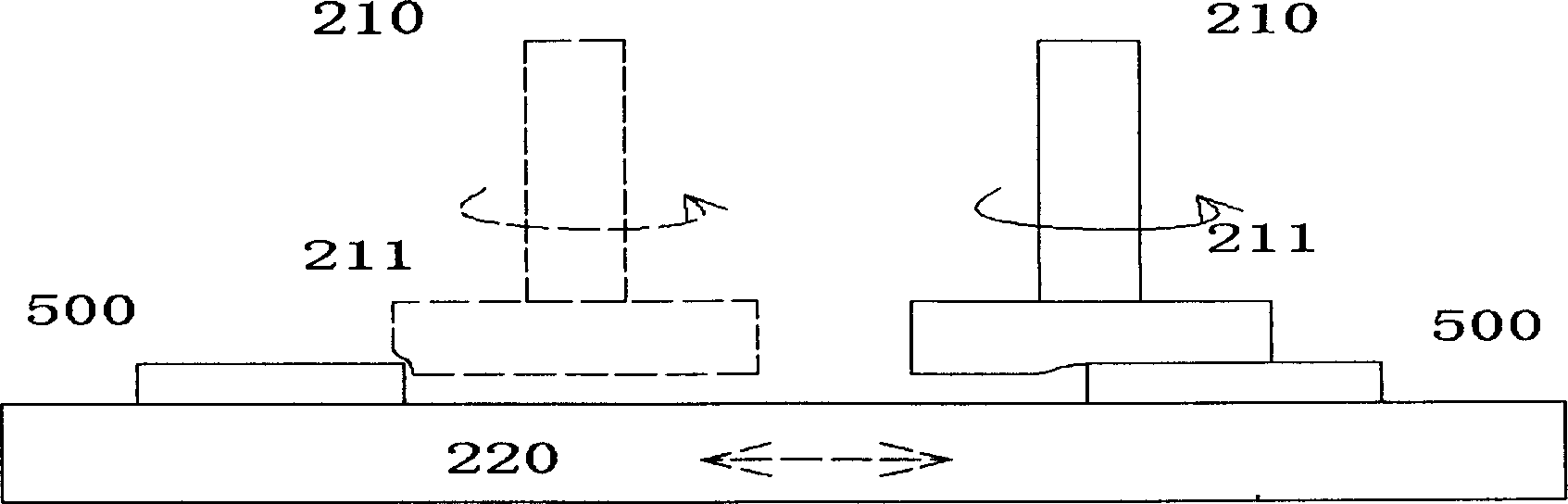

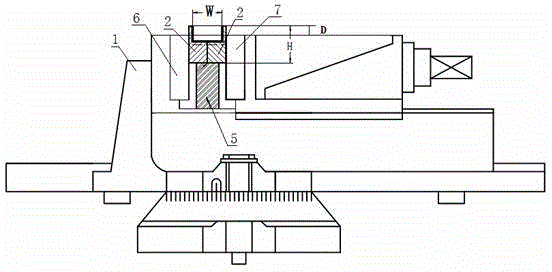

Grinding equipment of plate material and grinding method

InactiveCN1830621ARealize longitudinal reciprocating motionAchieve fixationGrinding feed controlPlane surface grinding machinesReciprocating motionEngineering

A method for grinding on the plate object, especially the FPD glass substrate, features that the moving trace on the surface to be ground is programmed, and a novel loading-unloading technology for the plate object is used. Its grinder features that is grinding pressure and rotation speed is adjustable and its grinding mechanism can move longitudinally and transversely.

Owner:HENAN ANCAI HI-TECH

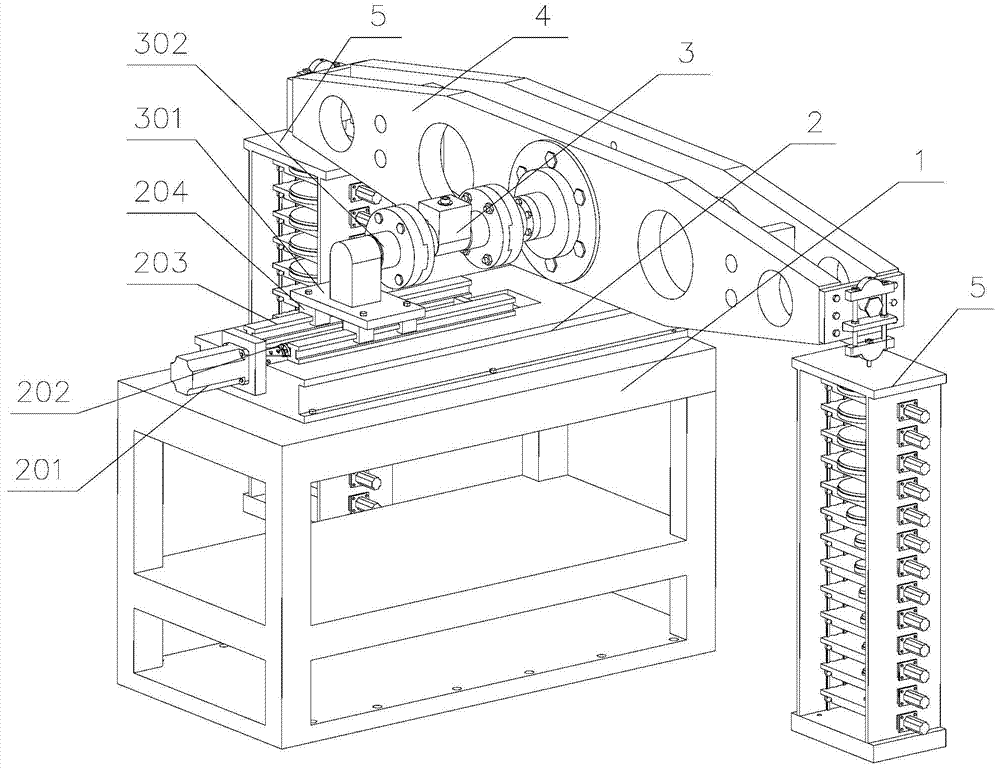

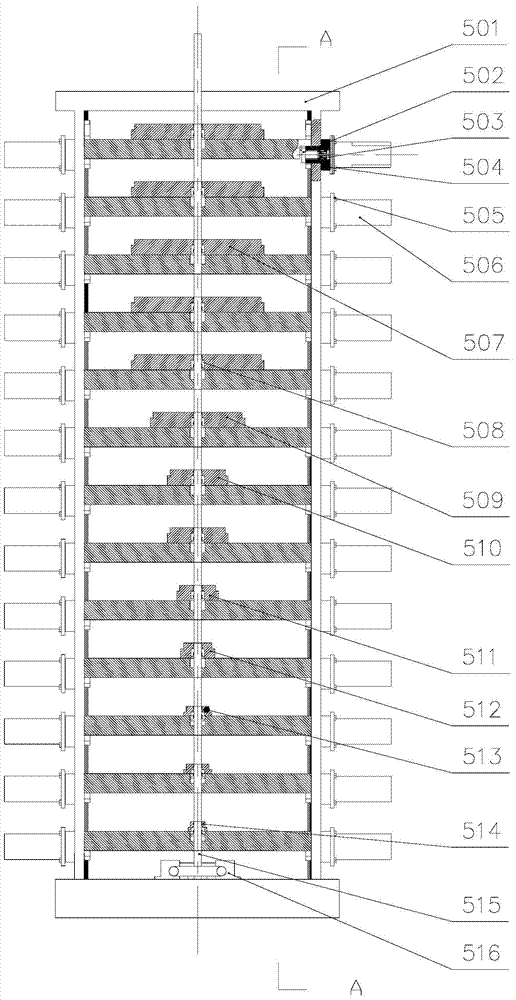

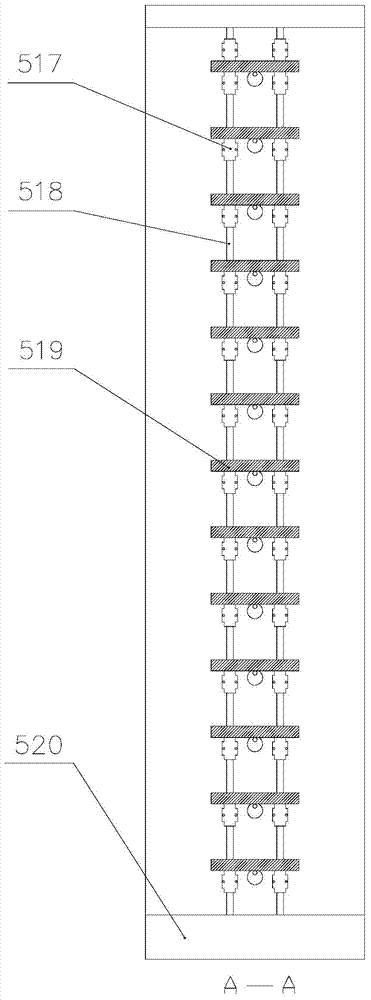

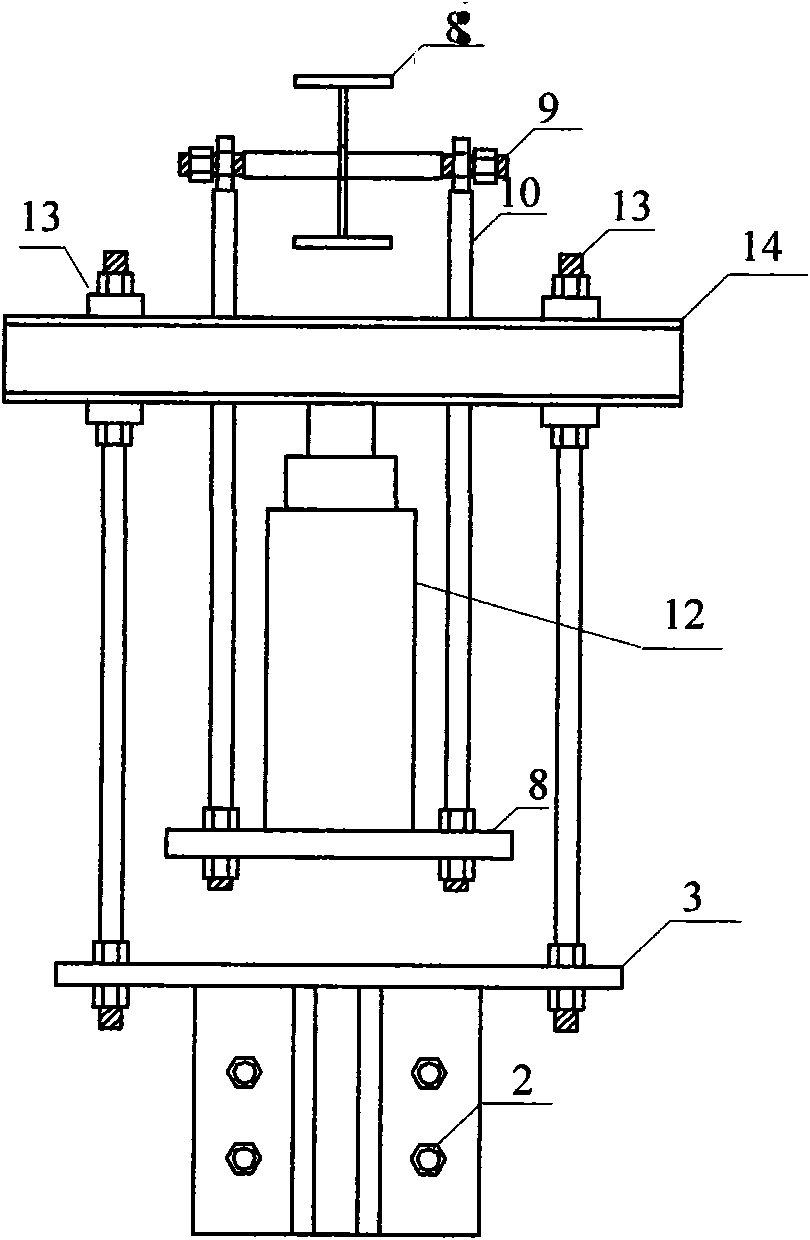

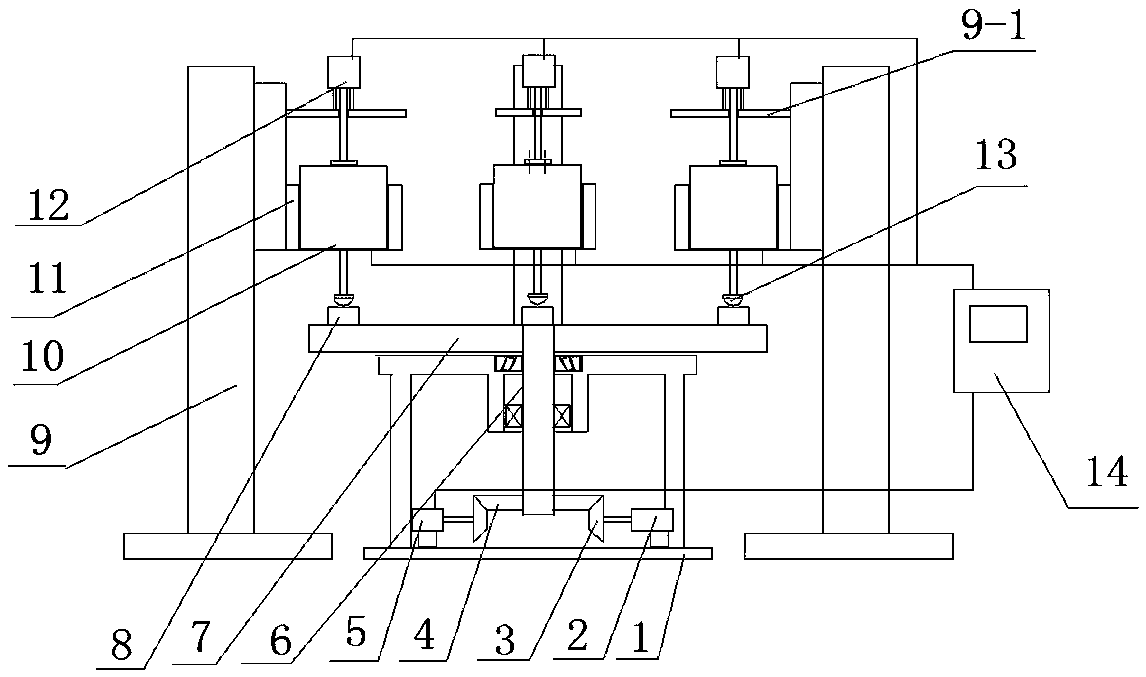

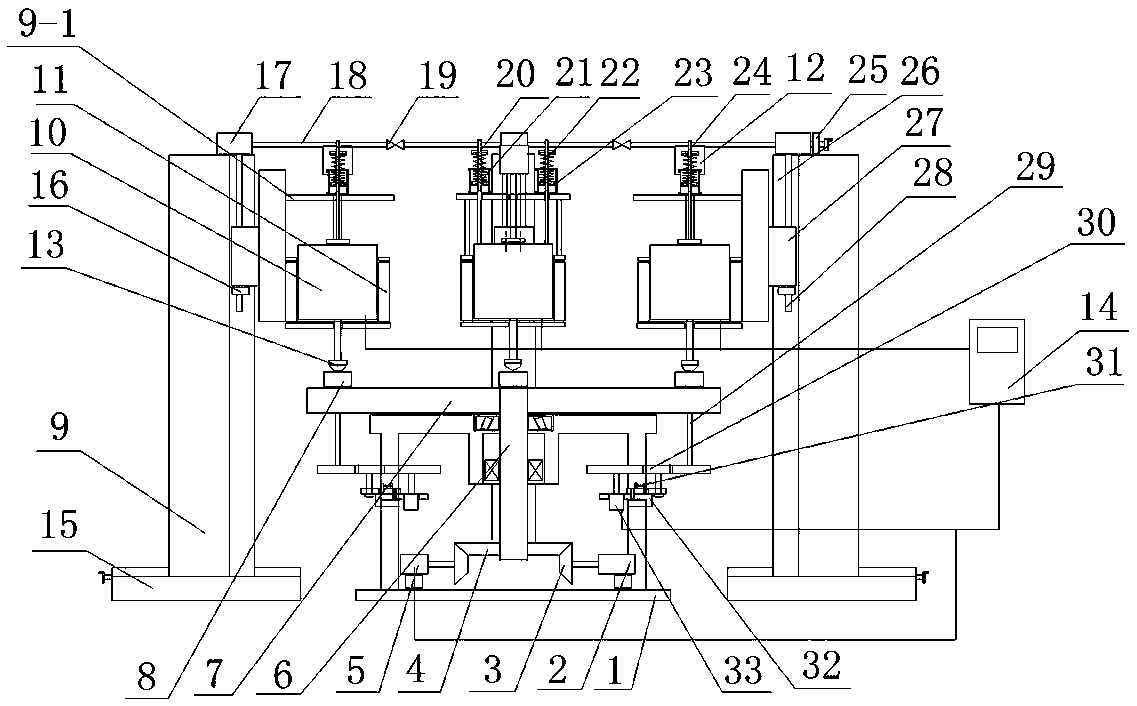

Independent weight loading-unloading dead-load type torque measurement device

InactiveCN103575463AImprove rigidityImprove stabilityForce/torque/work measurement apparatus calibration/testingMeasurement deviceMotor drive

The invention discloses an independent weight loading-unloading dead-load type torque measurement device, and belongs to the technical field of measuring testing. The independent weight loading-unloading dead-load type torque measurement device aims at solving the problems that in the prior art, the loading speed is low, a control device is complex, operation is difficult to achieve, and automation is difficult to achieve. The independent weight loading-unloading dead-load type torque measurement device comprises a supporting device, a loading device, a torque installation part, a leveling device and automatic loading devices, wherein the loading device is fixed on the upper surface of the supporting device, the torque installation part is connected with a guide rail sliding block and a nut supporting base of the loading device, the leveling device is connected with the other end of a long shaft of the torque installation part, and the automatic loading devices are fixed at the two ends of the leveling device. The automatic loading devices are characterized in that eccentric wheels are driven by stepping motors B to perform rotational motion, trays are driven by the eccentric wheels to perform linear lifting, and therefore automatic loading and automatic unloading of weights are achieved. According to the independent weight loading-unloading dead-load type torque measurement device, the eccentric wheels are driven by the stepping motors B to perform the rotational motion to achieve the automatic loading and the automatic unloading of the weights with any number, measurement on different torque values is accordingly achieved, and the motor driving structure is simple.

Owner:JILIN UNIV

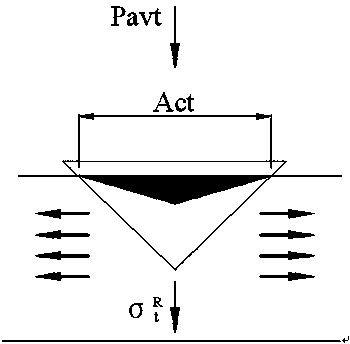

Method for extracting fracture toughness of materials

InactiveCN101566542AThe testing process is simpleReliable resultsMaterial strength using tensile/compressive forcesUsing optical meansLoading unloadingTest material

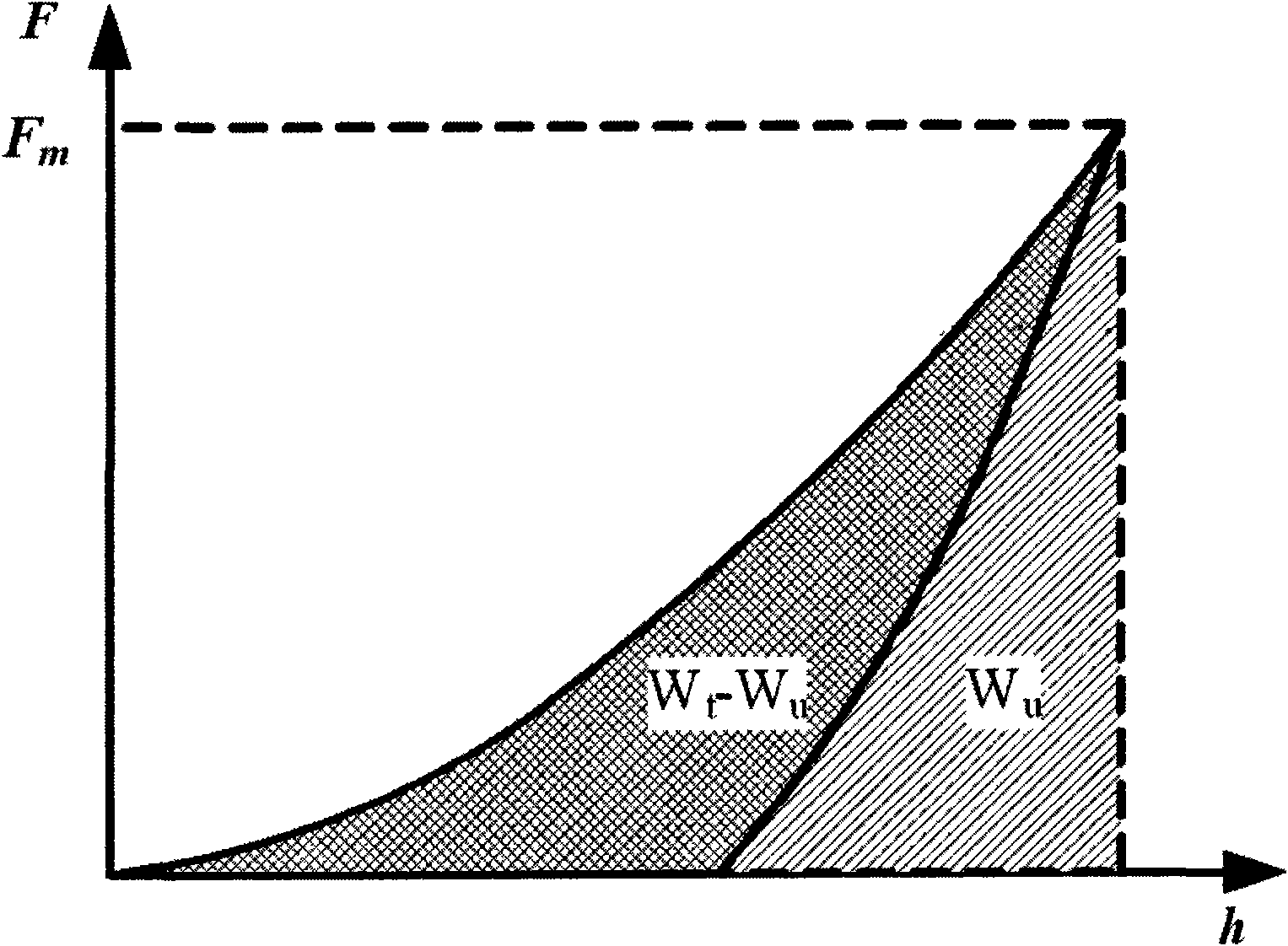

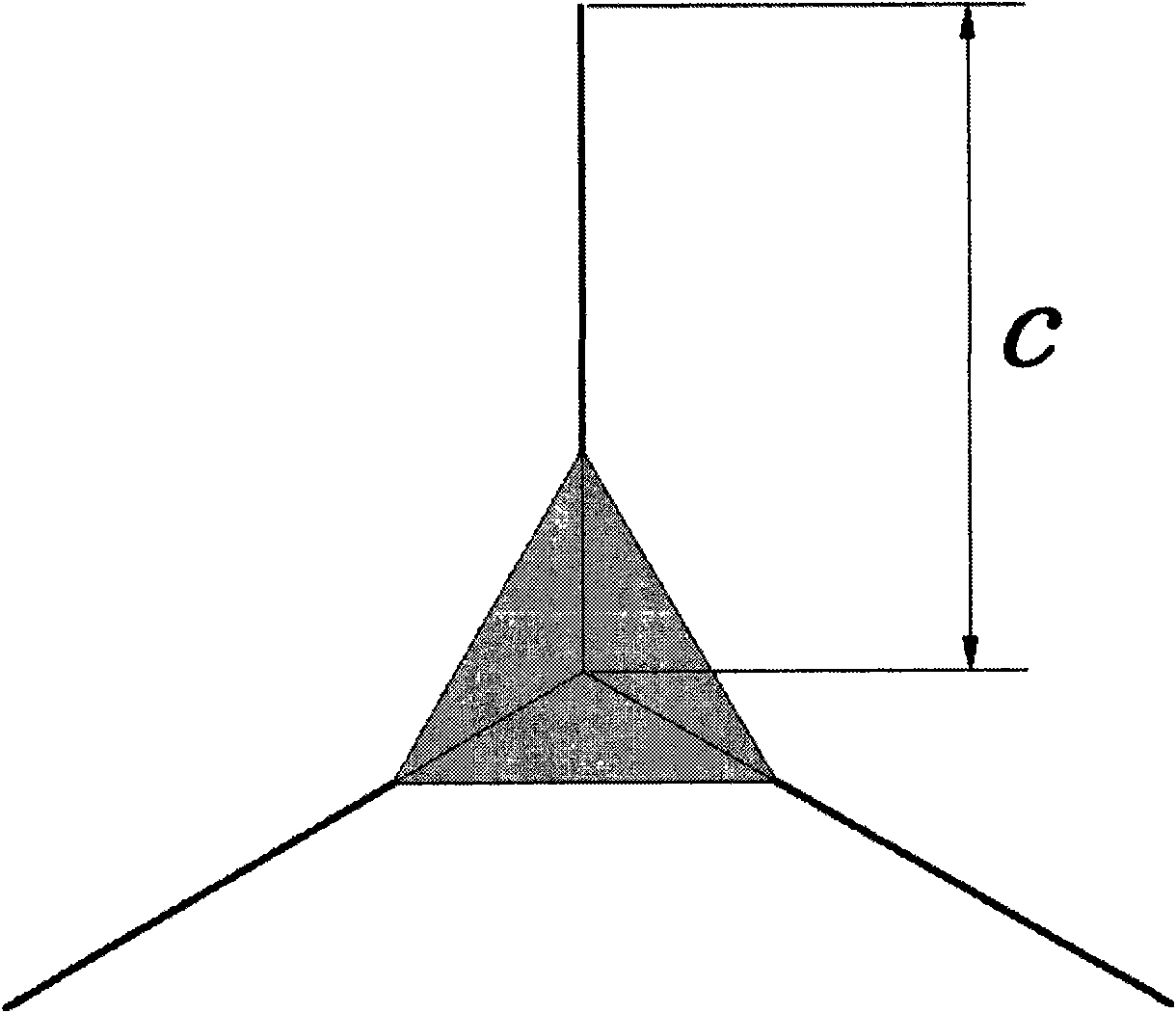

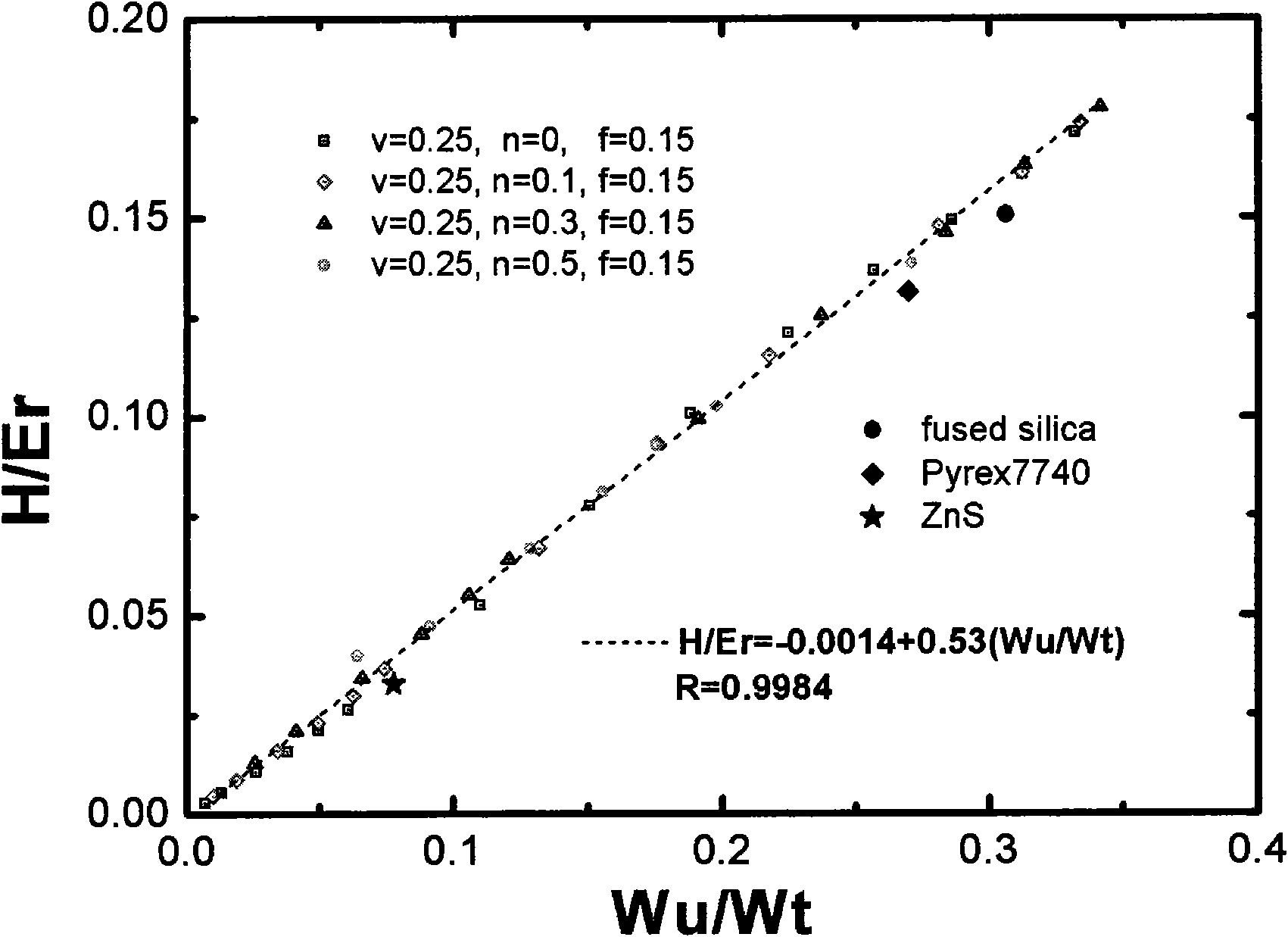

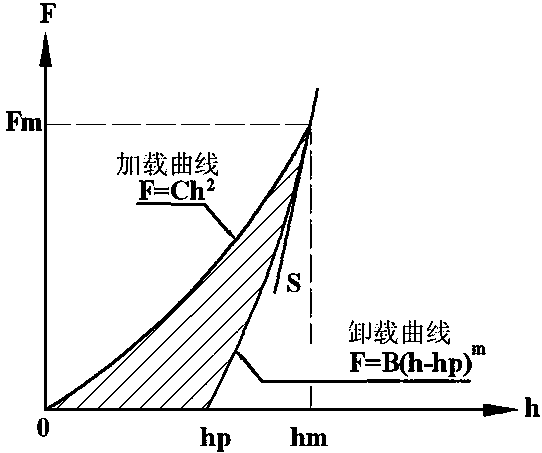

The invention provides a method for extracting the fracture toughness of materials, which comprises the following steps of: 1) adopting cube-corner indenter to conduct indentation test on the materials; 2) obtaining unloading power, loading power and the maximal indenter load from a loading-unloading curve (F-h curve); 3) using microscopy observation technology for obtaining the size of radial crack on the surface of an unloaded sample; 4) testing the test result; and 5) bringing the parameters which simultaneously satisfy the testing result in step 4), namely the unloading power Wu, the loading power Wt, the maximal indenter load Fm and the radial crack length c into the formula: KIC=0.018(Wu / Wt)(Fm / c) and obtaining the fracture toughness KIC of the tested materials through calculation.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

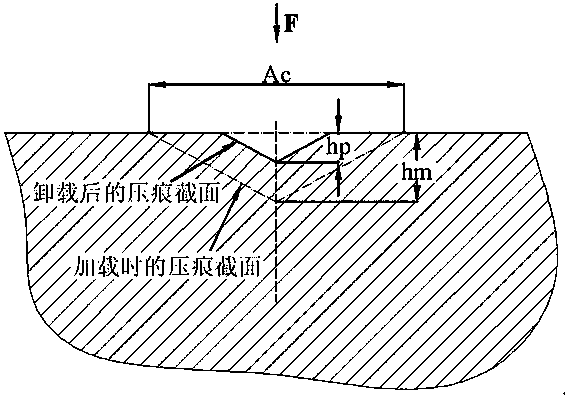

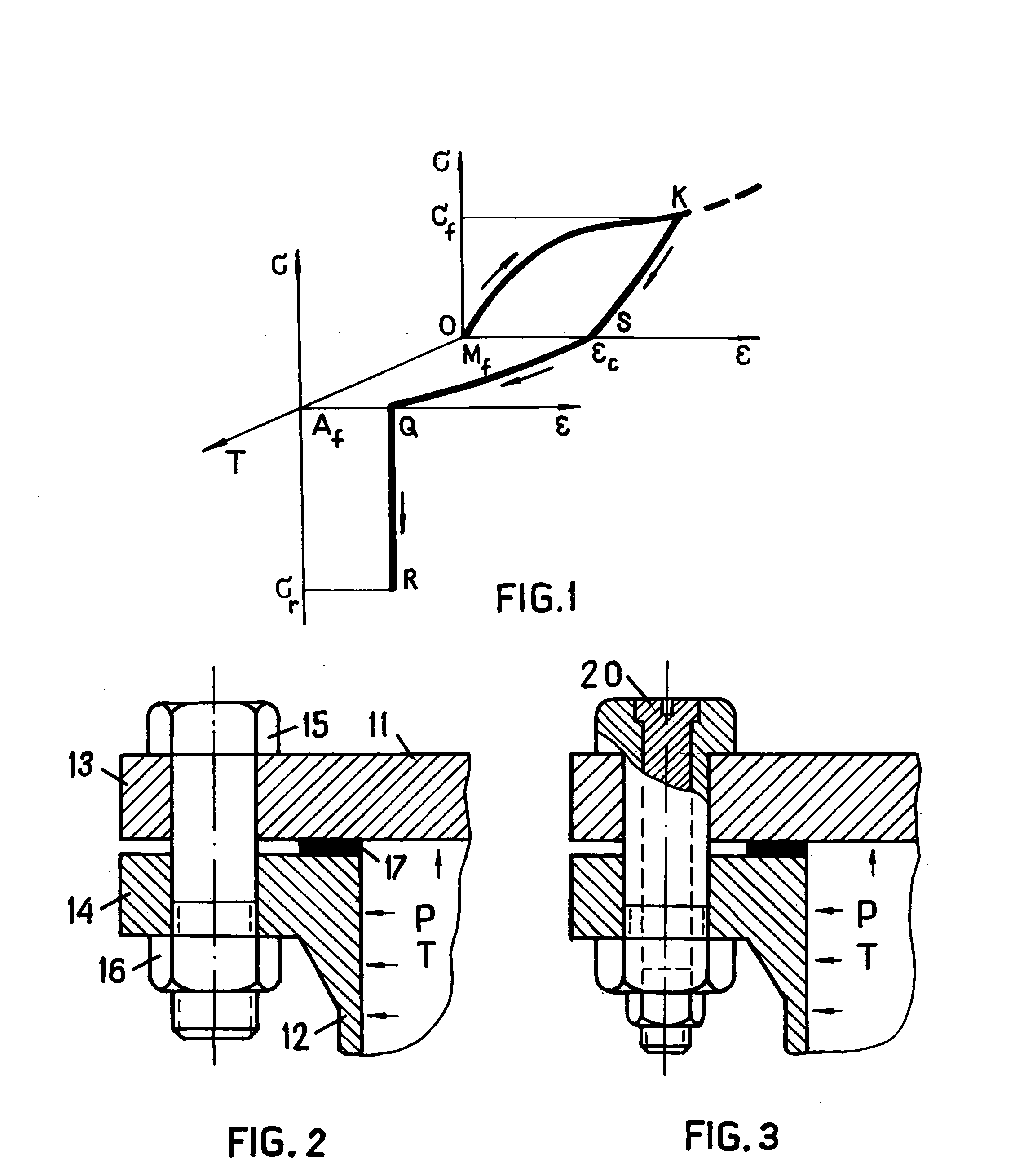

Micro-indentation-based method for testing residual stress of tiny area of tough block material

InactiveCN103439206AEnables residual stress testingForce measurementInvestigating material hardnessContact pressureTest sample

The invention discloses a micro-indentation-based method for testing residual stress of a tiny area of a tough block material and belongs to the technical field of nondestructively testing the residual stress of the tiny area. The method comprises the following steps: performing micro-indentation experiment on a test sample block and a standard sample block to obtain a loading-unloading curve; according to the loading-unloading curve, obtaining parameters for calculating the residual stress under the combination of a dimensionless function; and analyzing the types of the residual stress according to the loading-unloading curve and calculating the residual stress by virtue of average contact pressure and a residual stress expression. The method is used for testing the residual stress of a tiny area of a tough block material.

Owner:XUZHOU UNIV OF TECH

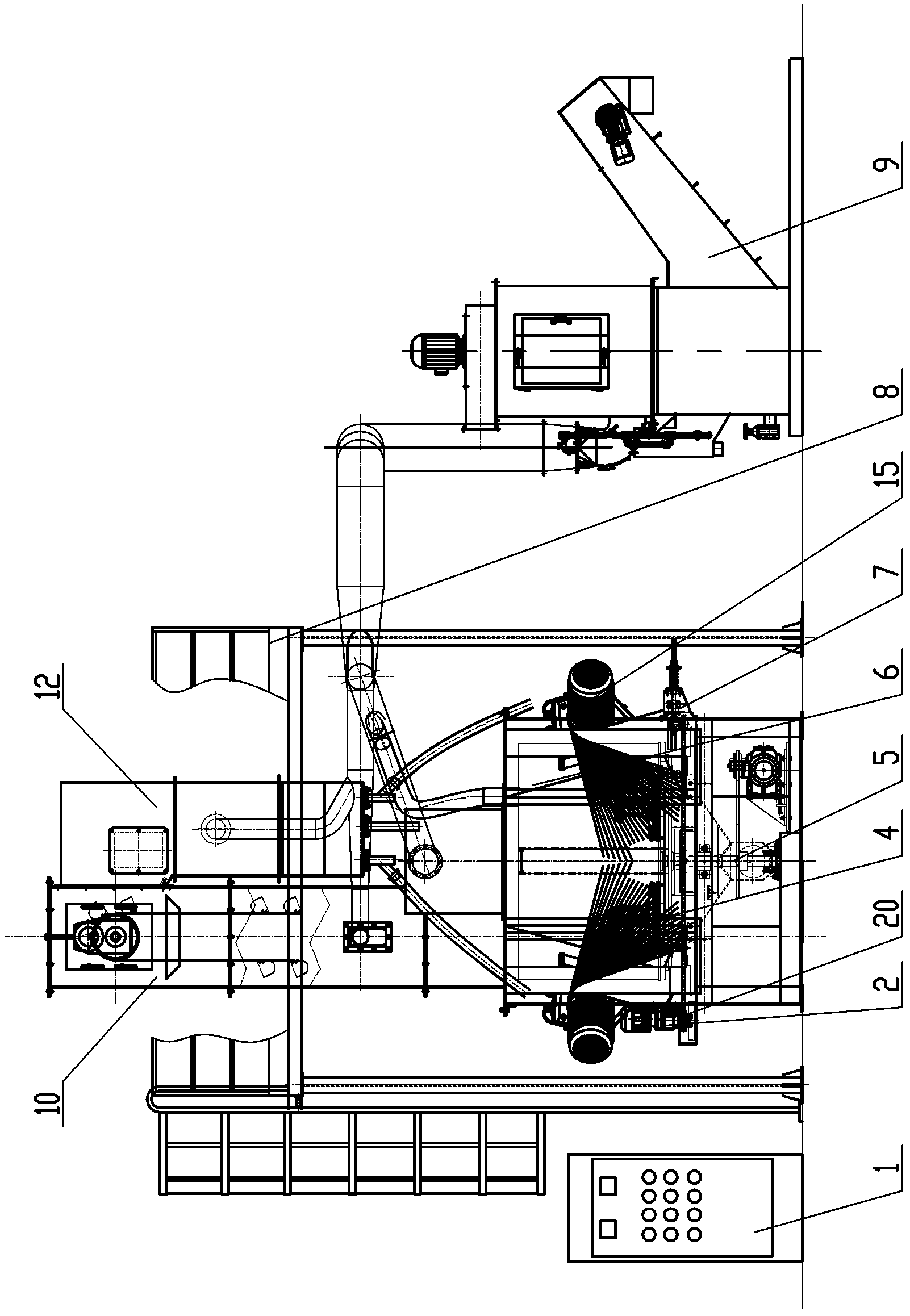

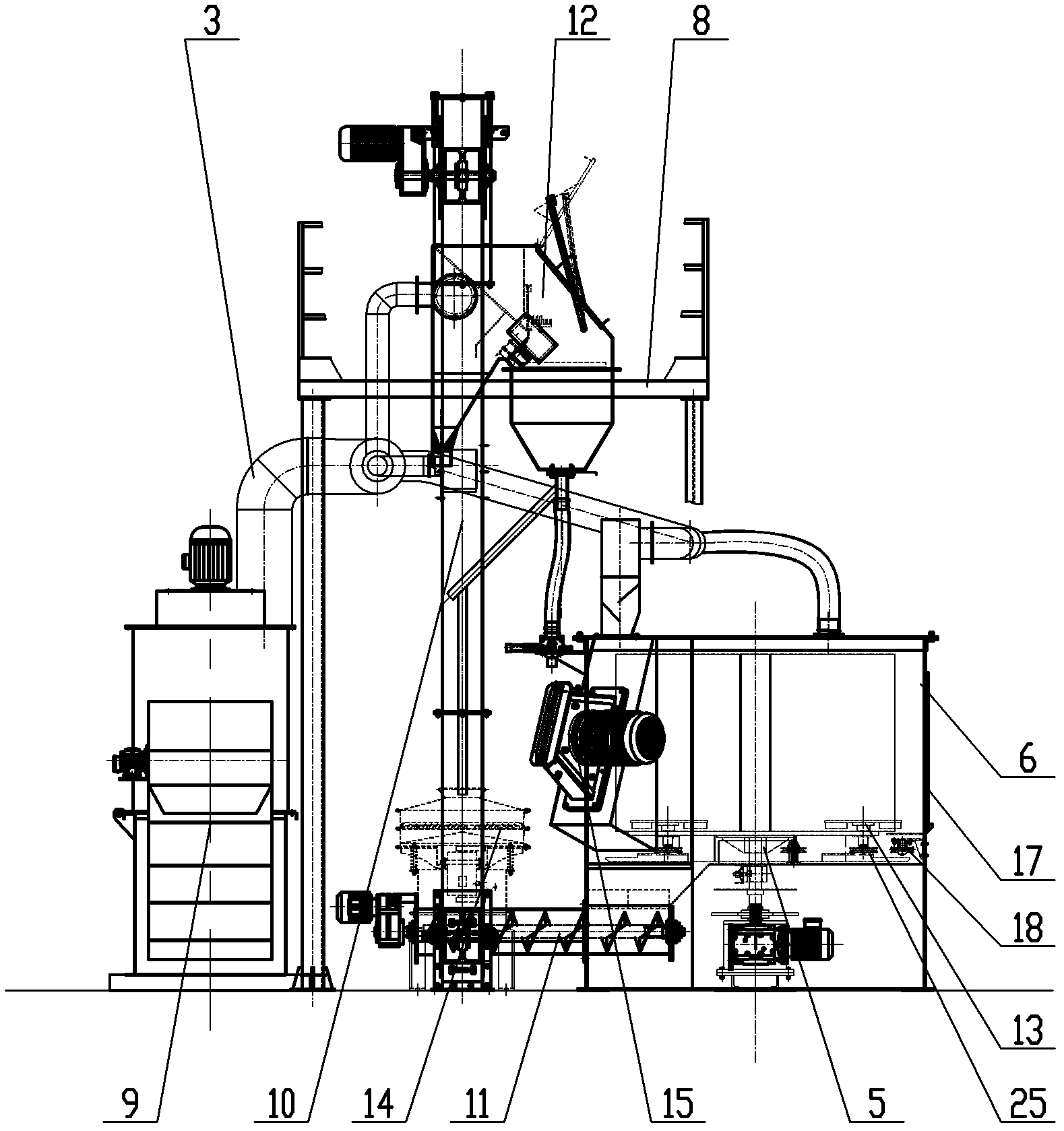

Reinforced shot blast machine for multi-position turntable

InactiveCN102248493APrevent flying outPrevent splashAbrasive blasting machinesEngineeringLoading unloading

The invention relates to a reinforced shot blast machine for a multi-position turntable. A main rotary worktable is mounted in a shot blast cleaning room, a shot blast machine is arranged out of the shot blast cleaning room, a steel shot selector is fixed above the shot blast cleaning room, a helical conveying device is fixed below the shot blast cleaning room, a hopper-type lifter is arranged behind the shot blast cleaning room, a feeding port and a discharging port of the hopper-type lifter are respectively connected with the helical conveying device and the steel shot selector, a discharging port of a steel shot separator is connected with the shot blast machine; the main rotary worktable is fixed with a partition wall assembly for partitioning the table-board of the main rotary worktable into five stations which are respectively two shot blast stations, two isolation stations and a loading-unloading station, and each station is rotatably equipped with a planetary worktable. The main rotary worktable is partitioned into the shot blast stations, the isolation stations and the loading-unloading station, the isolation stations are arranged between the loading-unloading station andthe shot blast stations with the effect of sealing; therefore, the shot can be prevented from flying out from the shot blast station, and the security is good.

Owner:无锡国达机械设备有限公司

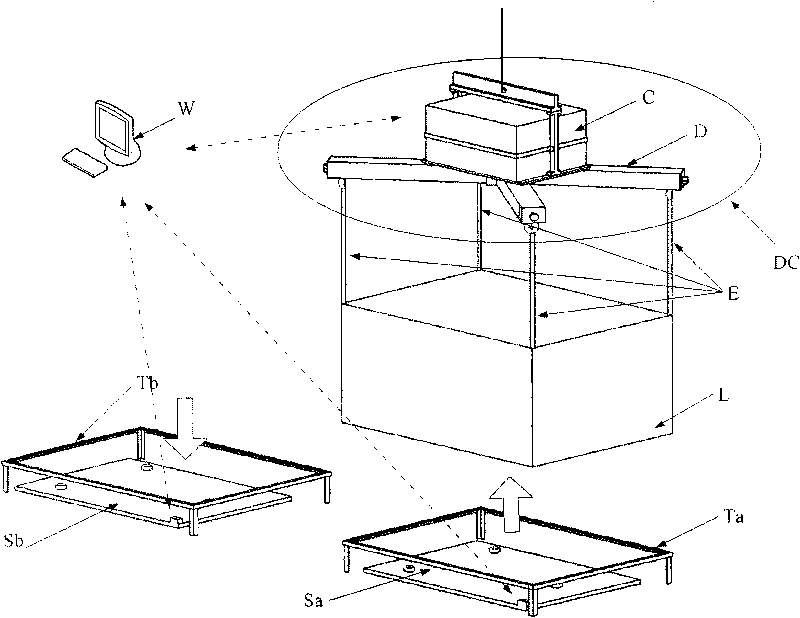

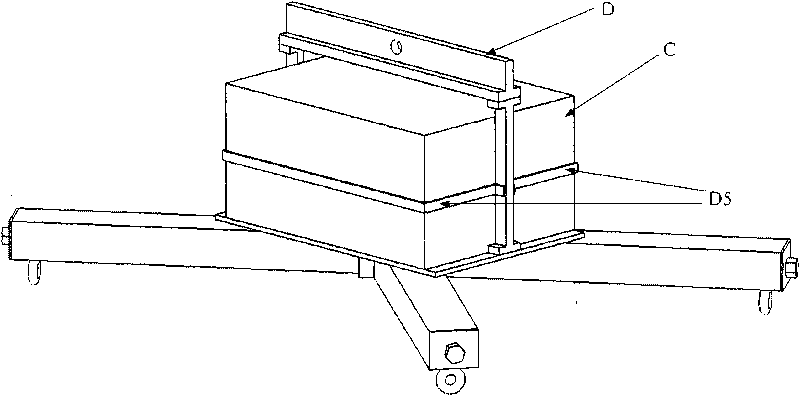

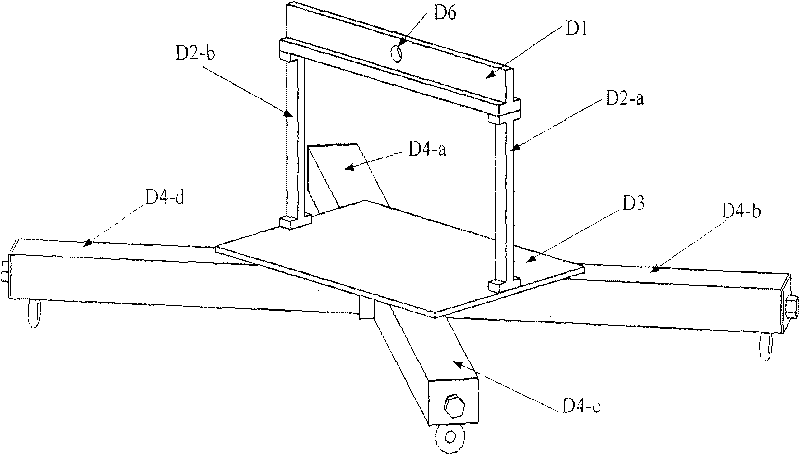

Single counterweight type automatic levelling spreader and using method thereof

InactiveCN101759092AEasy to adjust the position of the hanging pointEasy to adjustTravelling cranesLoad-engaging elementsButt jointControl signal

The invention relates to a single counterweight type automatic levelling spreader and a using method thereof, belonging to the technique of loading-unloading winching device. The single counterweight type automatic levelling spreader comprises a bearing spreader, an automatic levelling device, an initial bottom surface distance measurer, a target bottom surface distance measurer and a computer, wherein the automatic levelling device is mounted on the bearing spreader and is provided with counterweight blocks; the initial bottom surface distance measurer and the target bottom surface distance measurer are respectively located below an initial bearing bracket and a target bearing bracket; the computer communicates with both the bottom distance measurers, calculates the leveling inclination angle of the loading butt joint surface according to information measured by the initial bottom surface distance measurer and the target bottom surface distance measurer and based on the input structural size of the loading butt joint surface, calculates control signals, transmits the control signals to the automatic levelling device, controls the position of the counterweight block in the automatic levelling device and keeps the initial bearing bracket and horizontal target bearing bracket of the loading butt joint in the horizontal state so as to realize precise and easily damaged hoisting. The invention has the advantages of high precision, fast speed, safety and reliability.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

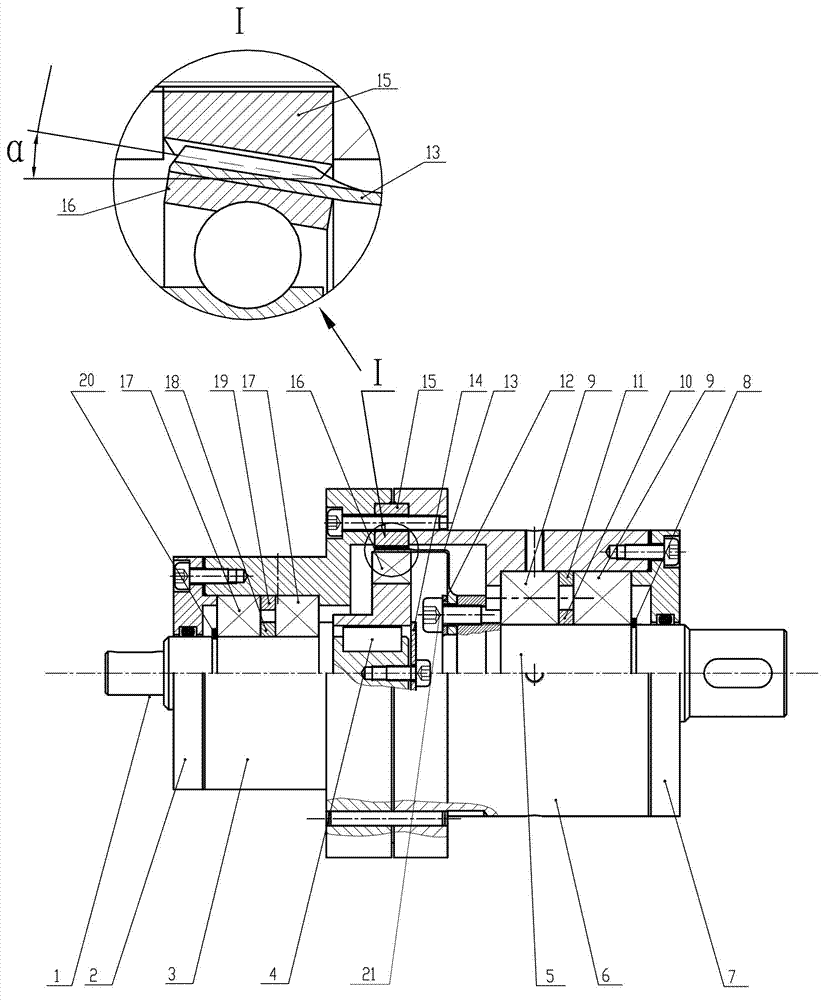

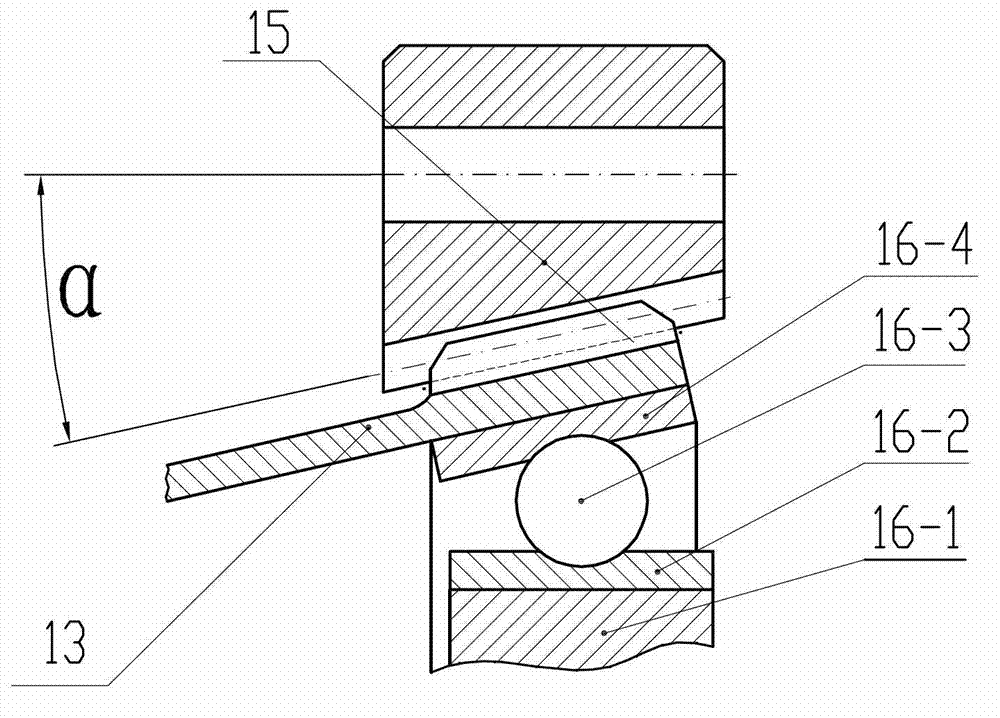

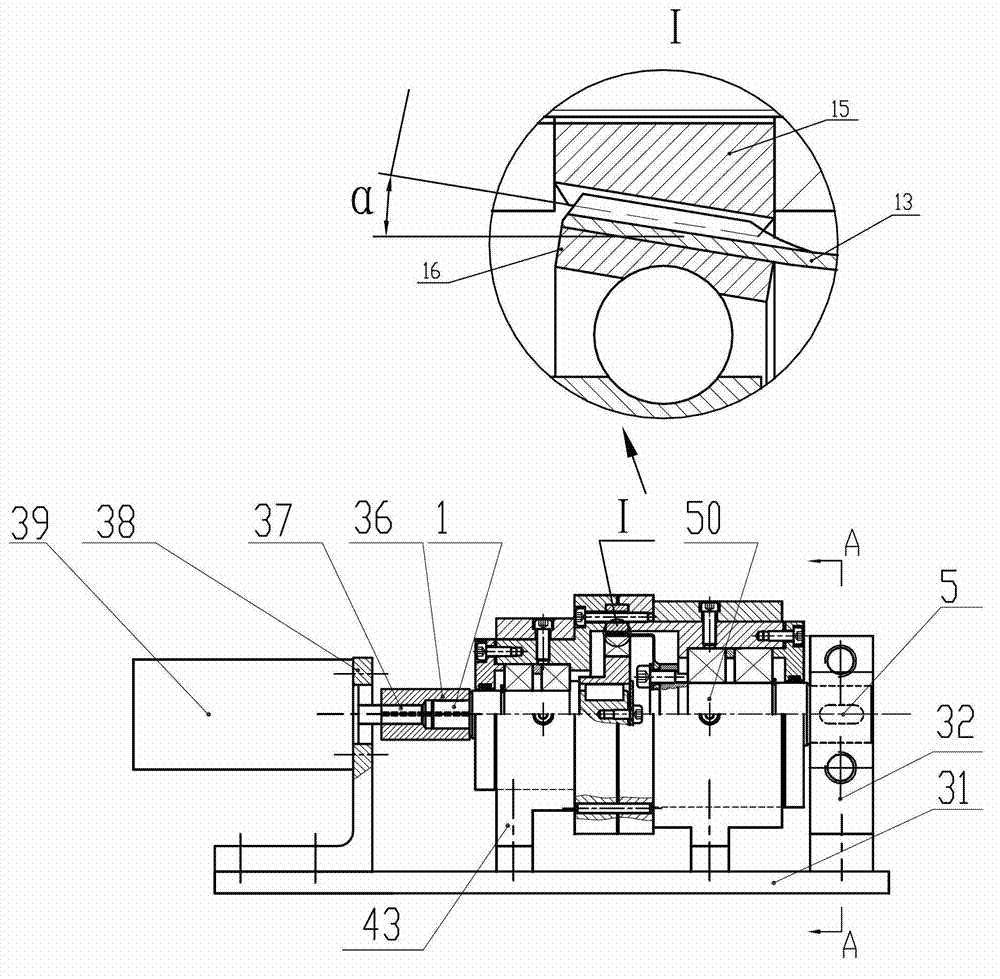

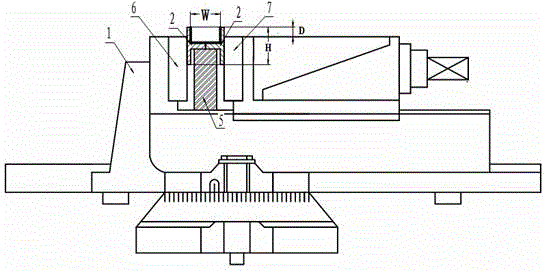

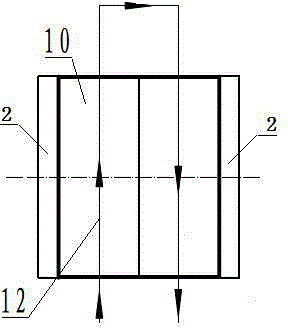

Short tube flexible gear harmonic reducer of rigid wheel tooth dip angle and transmission rigidity testing device thereof

ActiveCN102777546AEasy meshImprove transmission stiffnessMachine gearing/transmission testingToothed gearingsDiameter ratioEngineering

The invention discloses a short tube flexible gear harmonic reducer of a rigid wheel tooth dip angle and a transmission rigidity testing device thereof, and relates to the technical field of harmonic reducers. According to the invention, the deflection of the flexible wheel gear teeth is caused by the reduction of the axial size of the short tube flexible gear harmonic reducer, so as to realize the reduction of the surface area between the rigid wheel gear teeth and the flexible wheel gear teeth, and to realize the lowering of the transmission rigidity; the problem of complicated operating process of the existing harmonic drive rigidity experiment testing device is solved; and the length diameter ratio of a soft wheel is 1 / 4 to 3 / 5 of a short tube wheel, the inner wheel of the rigid wheel with a dip angle is the wheel teeth with the dip angle alpha along the rigid wheel axial direction, and the deflection direction and the field angle direction of the soft wheel on a long shaft are coincident. The transmission rigidity testing device of the short tube flexible gear harmonic reducer implements current control namely torque control through a computer and a servo driver, and the harmonic drive output end realizes continuous loading unloading; and the harmonic drive rigidity of the short tube soft wheel is obtained, and the transmission rigidity is serially, rapidly accurately obtained.

Owner:DONGGUAN RICHTEK ELECTRONICS CO LTD

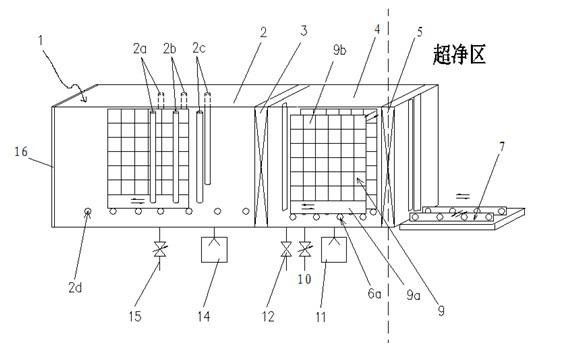

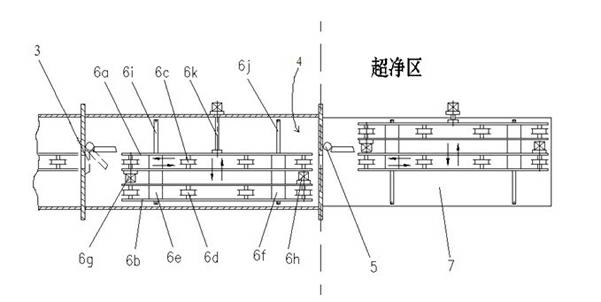

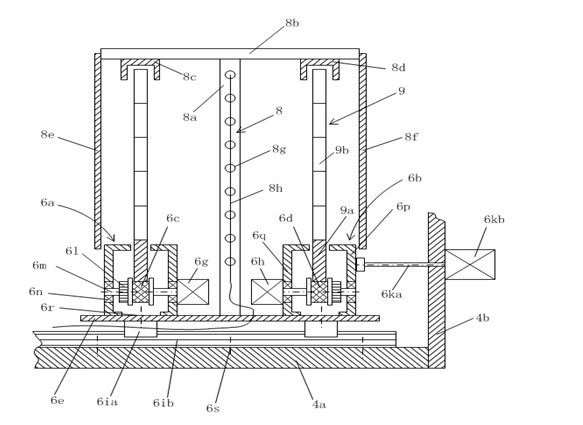

Same end entrance-exit type continuous sputtering film plating device

ActiveCN102181839AReduce throughputSmall footprintVacuum evaporation coatingSputtering coatingSputteringIsolation valve

The invention relates to a same end entrance-exit type continuous sputtering film plating device, which comprises a vacuum cavity and a vacuum gas suction device, wherein the vacuum gas suction device is communicated with the vacuum cavity. The same end entrance-exit type continuous sputtering film plating device is characterized in that: the vacuum cavity consists of two vacuum chambers including a pre-suction chamber and a sputtering chamber which are adjacent to and communicated with each other; an isolating valve is arranged between the two vacuum chambers; the tail end and the front end of the cavity are provided with a blind flange and a vacuum lock valve respectively; the outer side of the vacuum lock valve is provided with a loading-unloading film board; a workpiece rest conveyor is arranged in the sputtering chamber; a composite conveyor is arranged in the pre-suction chamber; at least three pairs of relatively-arranged magnetron sputtering targets are arranged in the sputtering chamber; and the workpiece rest conveyor can be matched with a workpiece rest. The same end entrance-exit type continuous sputtering film plating device has the advantages of compact structure, small floor area, less required ultra-clean area, high throughput, low energy consumption, good film layer quality and the like.

Owner:杭州比凡科电子科技有限公司

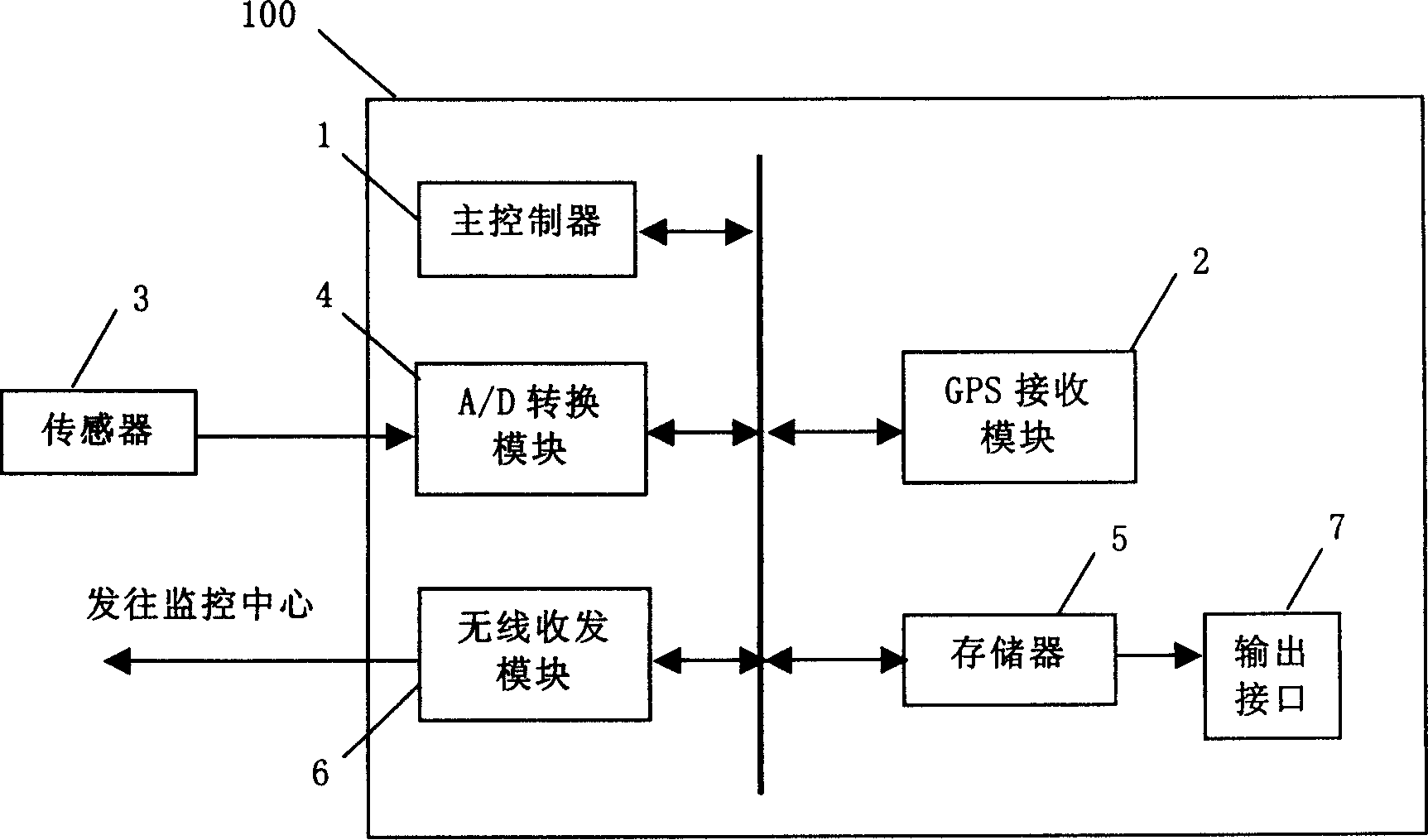

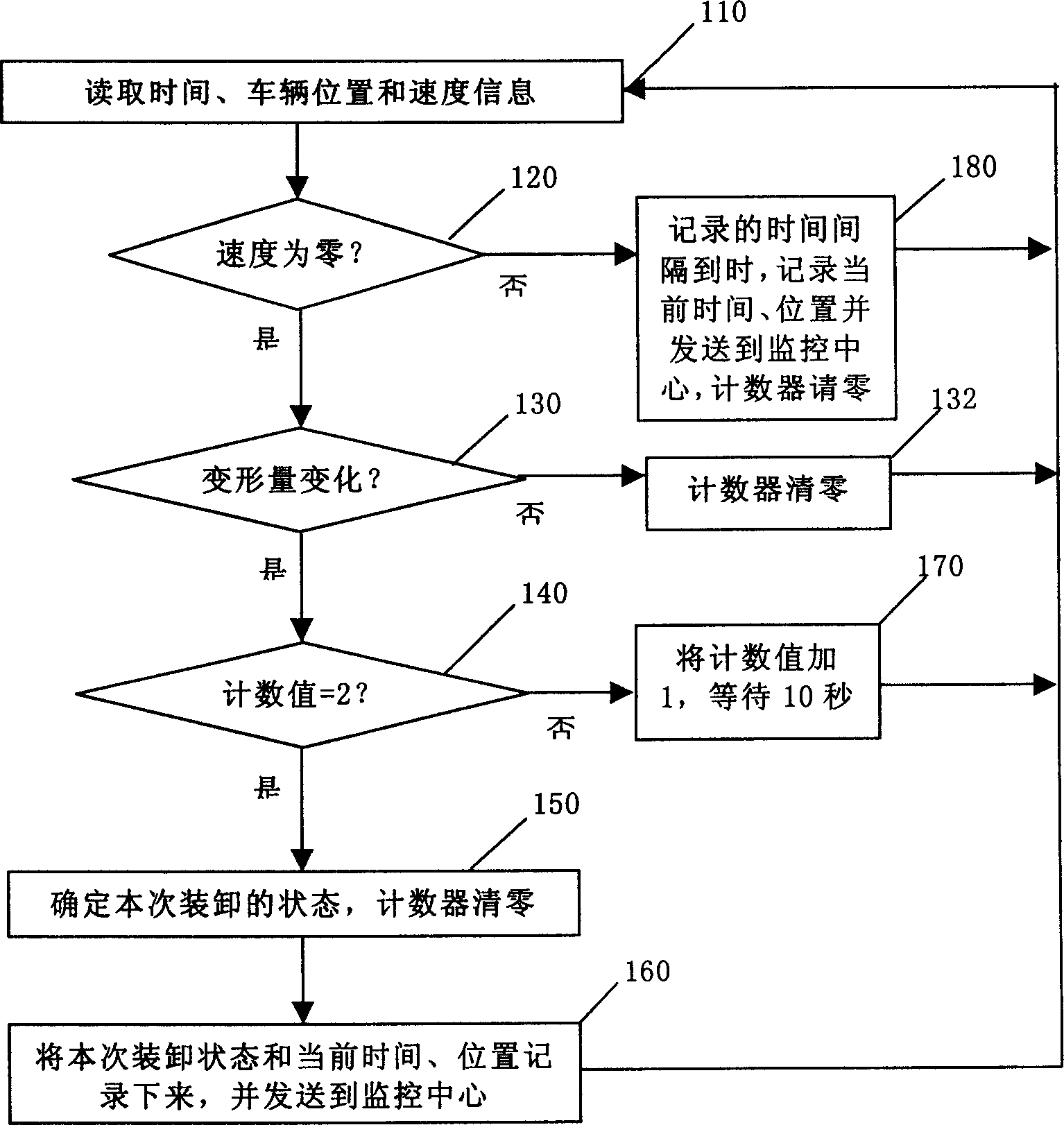

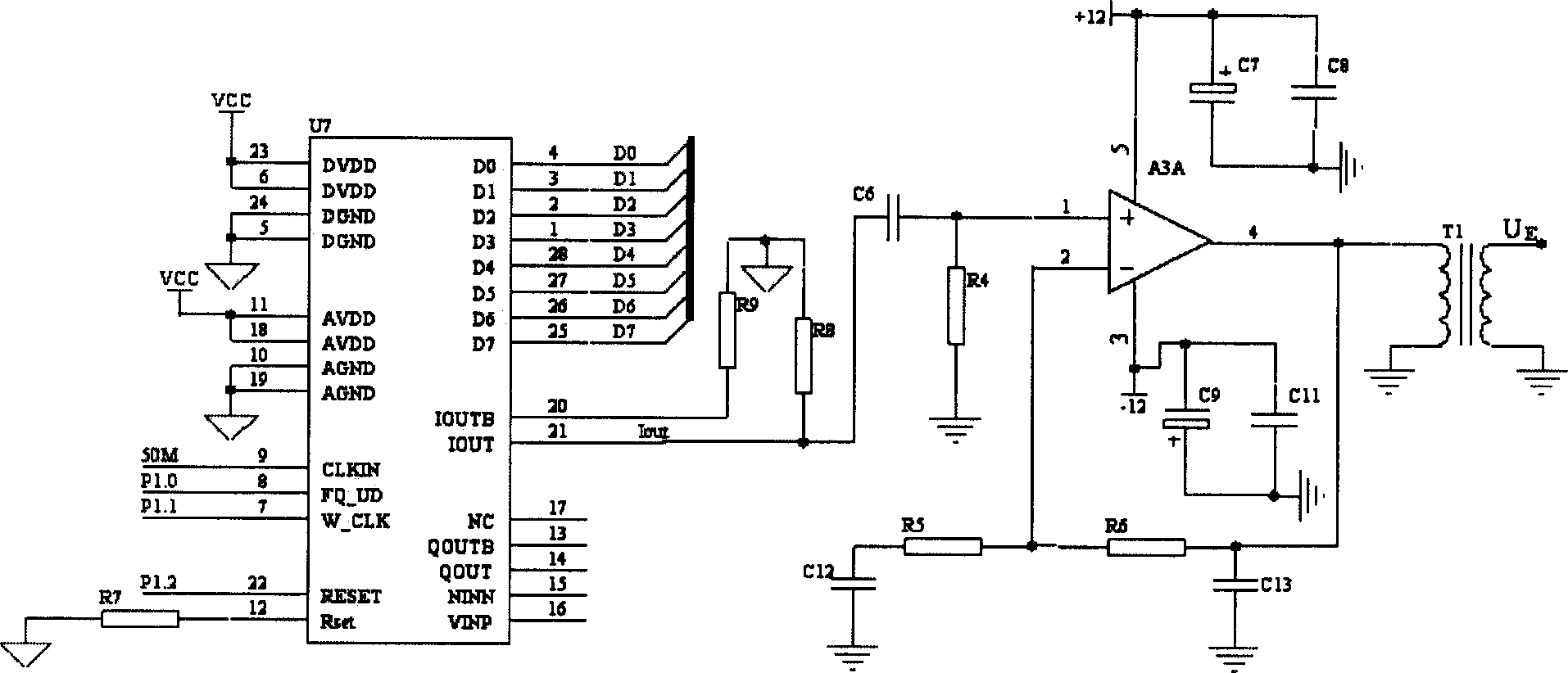

Recording method and device for vehicle transport loading unloading condition

InactiveCN1560757ARealize the monitoring functionAvoid polluting the environmentMeasurement devicesElectric/fluid circuitComputer moduleEngineering

The invention discloses a recording method and device for vehicle traffic load / unload state, it calculates current time, position of vehicle and speed through GPS receiving model, detects the deformation quantity of the vehicle spring steel board through sensor, when several judgment results are zero, and the deformation quantity is changed, determines the state of this time of load / unload, at the same time, records current time, position and state, and transmits the data of load / unload state to the supervising centre through wireless receiving and transmitting model, otherwise records and transmits the data of traveling path. The method and device of the invention uses integral design, the character that the GPS can localize accurately, combines with the vehicle load, realizes the supervising function to material flow which can be realized in current technology, it also can record the traveling path at the same time.

Owner:北京创亿新世纪科技发展有限公司

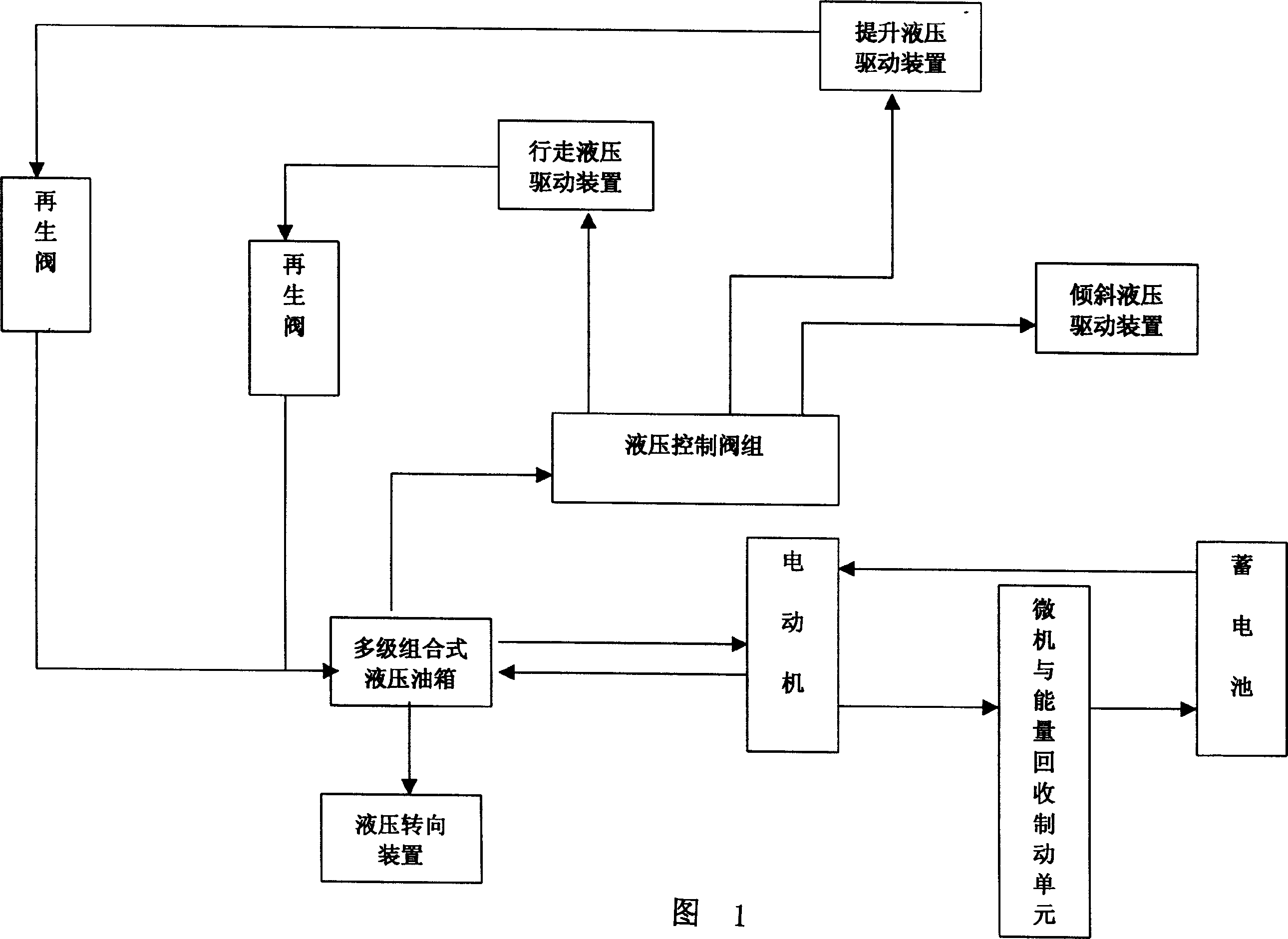

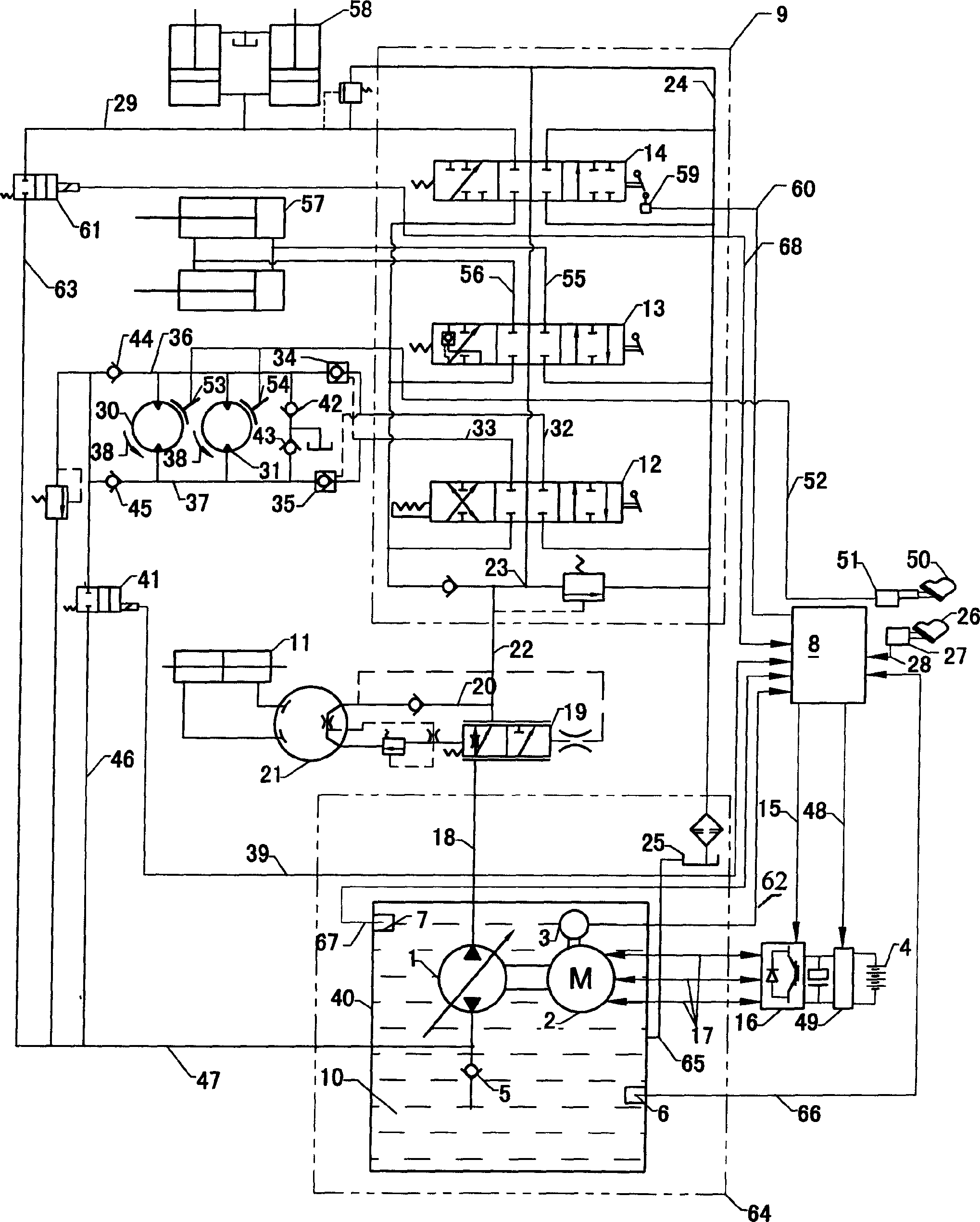

Energy-saving electrocar for loading unloading and transporting

An energy-saving electric vehicle for loading, unloading and transporting goods is composed of electric accumulator as power source, hydraulic drive systemwith microprocessor control unit for controlling the electric vehicle and hydraulic pump set, the potential energy and kinetic energy recovering unit, the speed regulating unit consisting of motor and variable pump, and the multiple stages combined hydraulic oil tank.

Owner:上海市闸北区物流工程技术研究所

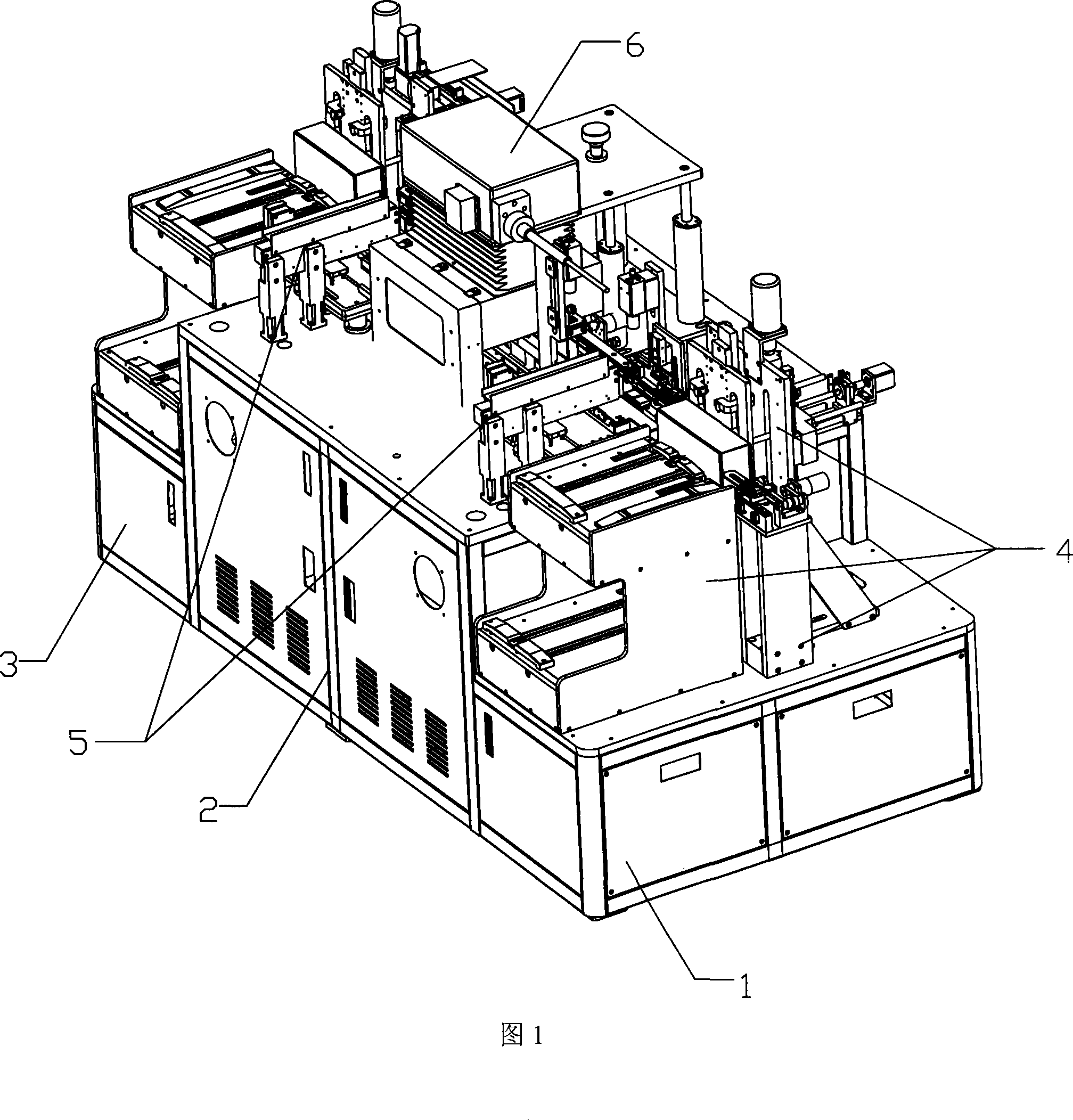

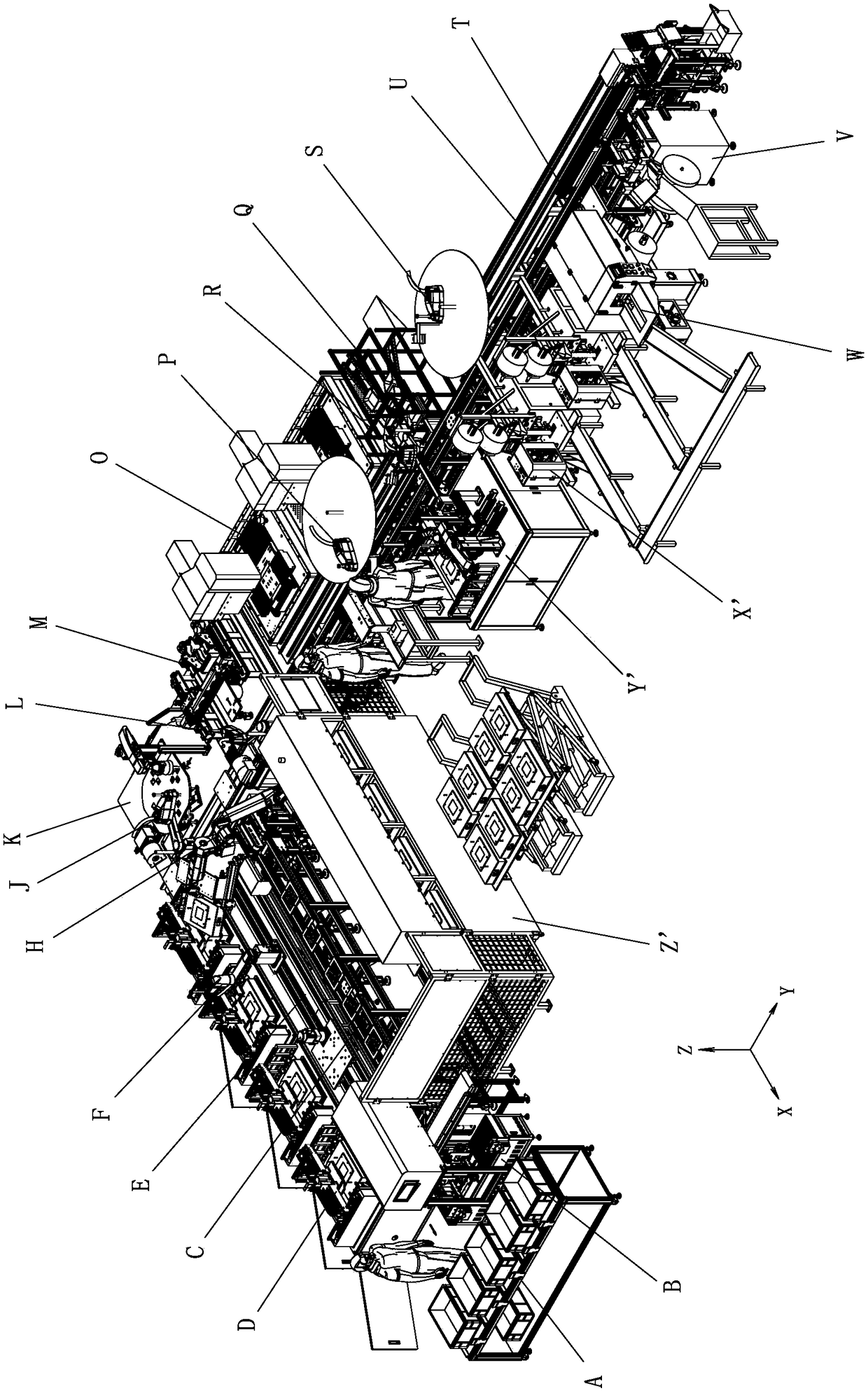

Automatic PCB production line

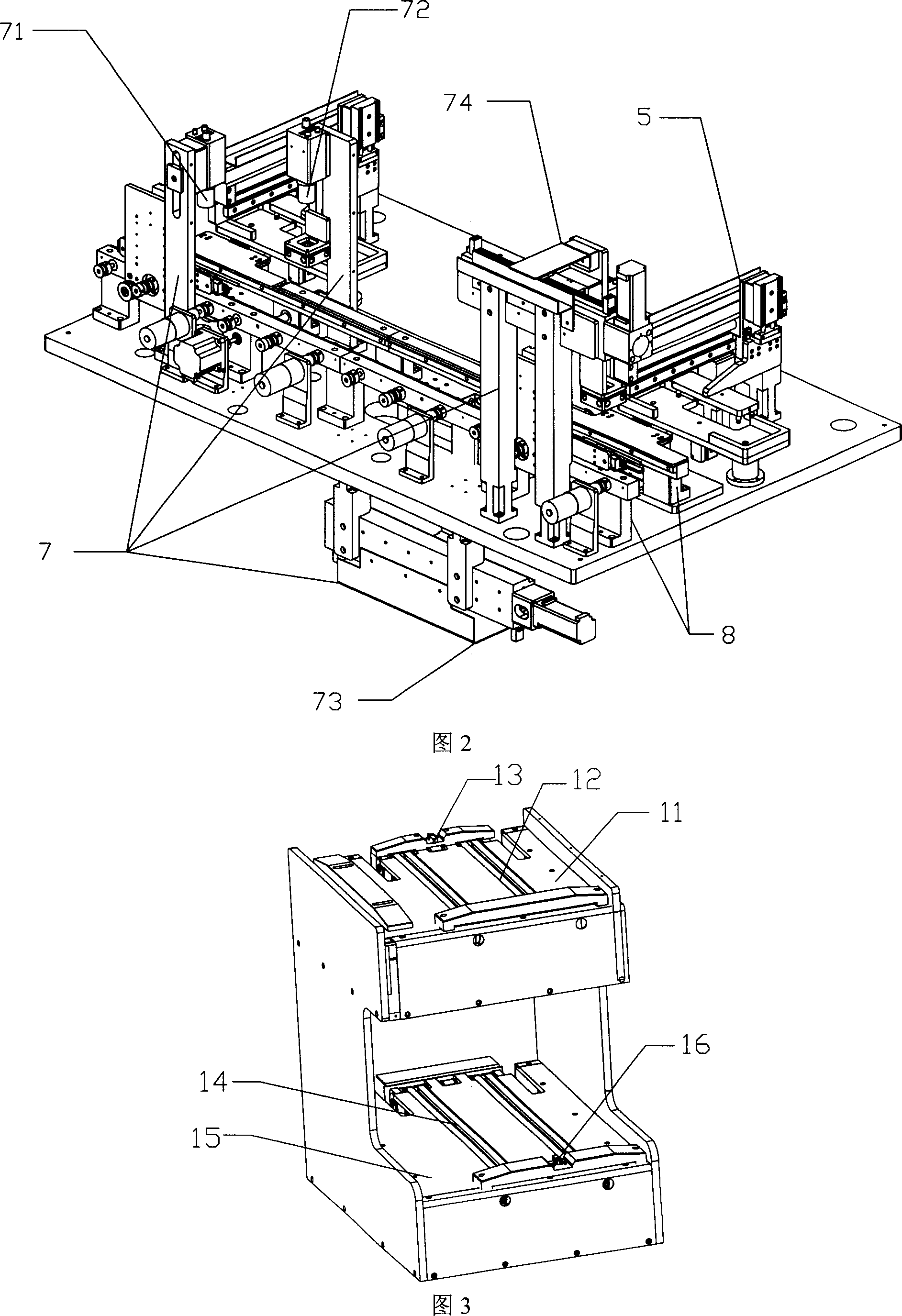

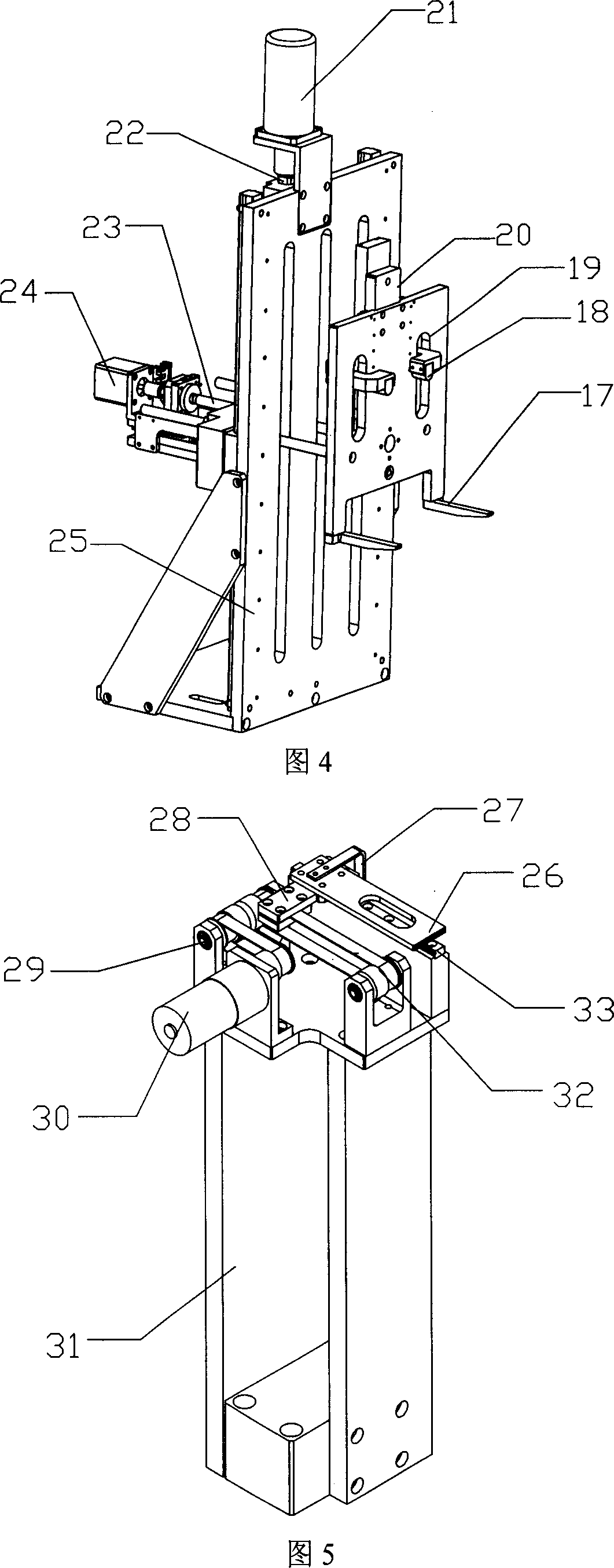

PendingCN108282991AReduce in quantityReduce labor intensityCircuit board tools positioningElectrical componentsProduction lineLoading unloading

The invention relates to an automatic PCB production line. The automatic PCB production line comprises a production transmission line, multi-station loading equipment, PCB burning equipment, PCB coding equipment, PCB labeling equipment, PCB separation equipment and a PCB package system, wherein the production transmission line is used for driving a PCB to move along the production line, the multi-station loading equipment is used for loading the PCB onto a loading transmission line, the PCB burning equipment is used for burning the PCB, the PCB coding equipment is used for coding the PCB, thePCB labeling equipment is used for labeling the PCB, the PCB separation equipment is used for separating the PCB, and the PCB package system is used for packaging the PCB. The processes of automatic burning, coding, labeling, separation and package are achieved by matching of an industrial robot, automatic induction position and automatic loading unloading operation are achieved, and the purpose of high-efficiency and safe production is achieved; and moreover, different PCBs can be produced and worked, the automatic PCB production line is wide in application range and high in universality andpracticability, the arrangement number of the equipment can be greatly reduced, and the manual cost and the investment cost are reduced.

Owner:广东埃华路机器人工程有限公司

Fully-automatic laser cutting production workstation

ActiveCN105689899AReduce labor costsIncrease productivityLaser beam welding apparatusLaser cuttingEngineering

The invention relates to the technical field of laser cutting equipment, and particularly relates to a fully-automatic laser cutting production workstation. The fully-automatic laser cutting production workstation comprises a fully-automatic scribing machine and an automatic blanking-sorting machine which are mutually connected, wherein the fully-automatic scribing machine comprises a scribing rack; a slide table of the rack is provided with a scribing fixed-distance compression jig; the scribing rack is provided with a fixed slide rail; a double-end laser system is arranged above the scribing fixed-distance compression jig; the fixed slide rail is slidably connected with an automatic loading-unloading device; the scribing rack is provided with a scribing loading pre-location device; the automatic blanking-sorting machine is provided with a four-station index plate; a cleaning mechanism and a waste recovery mechanism are arranged at the sides of the four-station index plate respectively; a taking manipulator is arranged between each of the cleaning mechanism and the waste recovery mechanism, and the corresponding station; a high-speed sorting parallel robot is arranged above the four-station index plate; and a blanking-sorting rack is provided with a CCD visual scanning mechanism. According to the fully-automatic laser cutting production workstation disclosed by the invention, production efficiency is improved, and the human cost of enterprises is greatly reduced.

Owner:东莞市盛雄激光先进装备股份有限公司

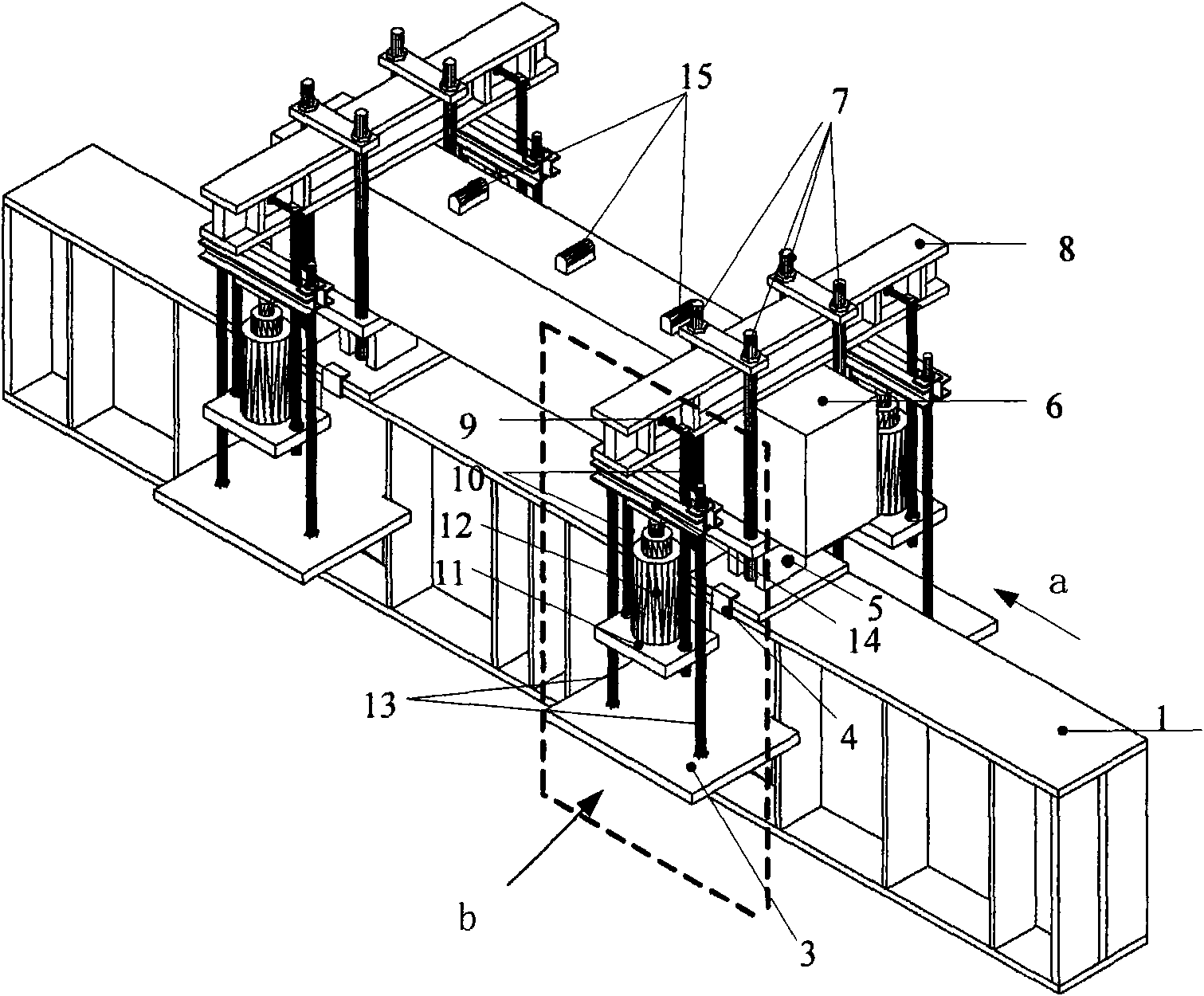

Test-piece torsion test system

InactiveCN101603902AEasy to implement composite force testAvoid difficultiesMaterial strength using steady torsional forcesEducational modelsEngineeringLoading unloading

A test-piece torsion test system comprises a test loading system and a data acquiring and processing system; wherein the test loading system comprises a supporting device and a loading device. A test piece is supported above the supporting device, and the loading device is arranged at the two ends of the test piece to carry out pressor test on the test piece. The supporting device comprises a pedestal and a curved support; wherein the curved support is fixed on the pedestal to support a test piece and comprises two fit parts of an upper part and a lower part, corresponding position of the upper part and the lower part is opened with a shallow slot to place balls, so as to realize zero friction free rotation of the test piece support. The loading device is arranged at the two ends of the test piece, and the two sides of the loading device are respectively provided with a jack and a jack crest beam used as a reaction force end. Diagonal loading of the jacks at the two ends of the test piece of the invention can realize monotonic torsion. If the four jacks are combined, two diagonal jacks are in a group, the two groups complete loading-unloading-loading alternately, and the process is repeated, so that reverse torsion can be realized and defect that a fixed end node is firstly destroyed as the fixed end is provided is avoided.

Owner:TONGJI UNIV

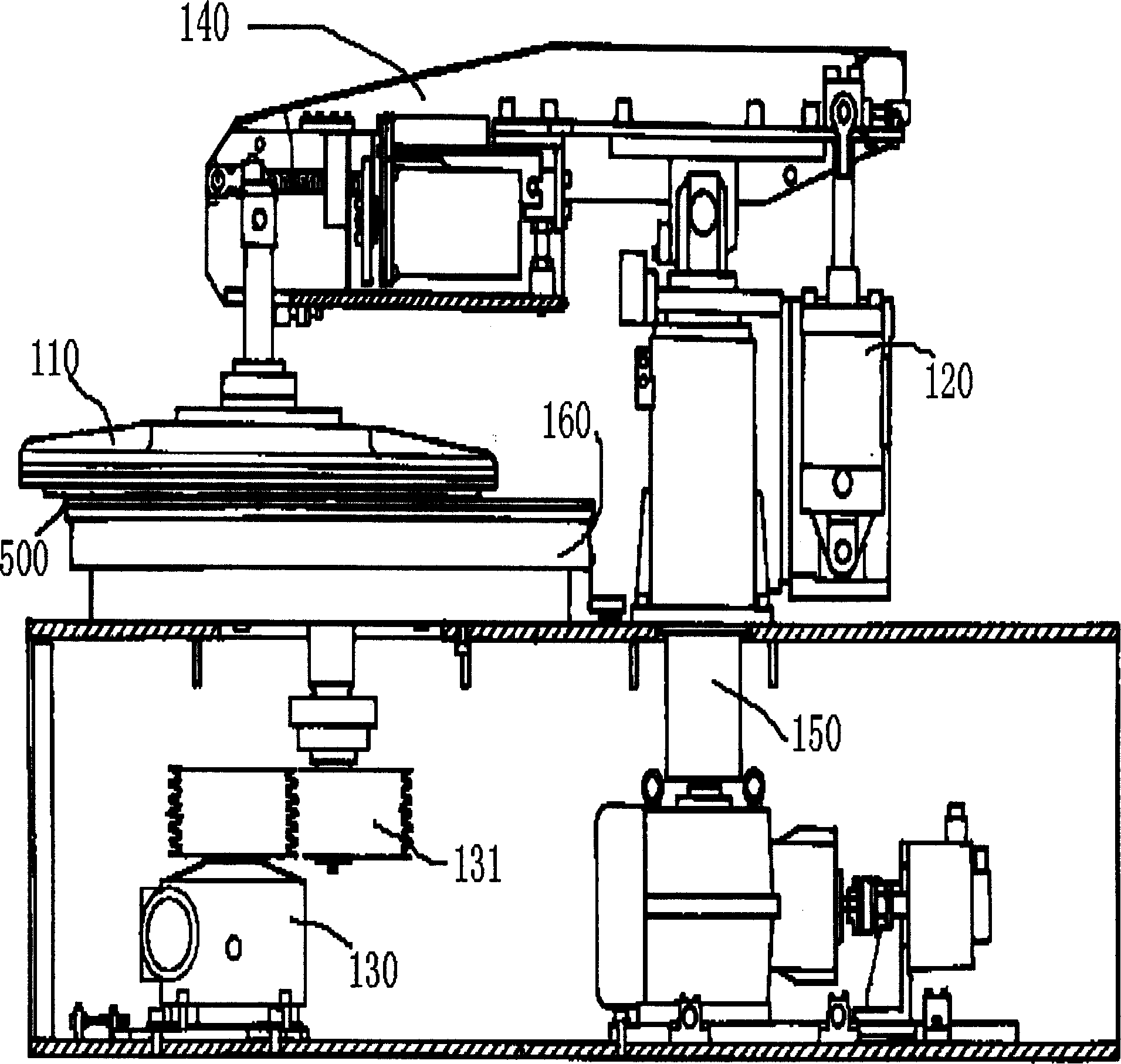

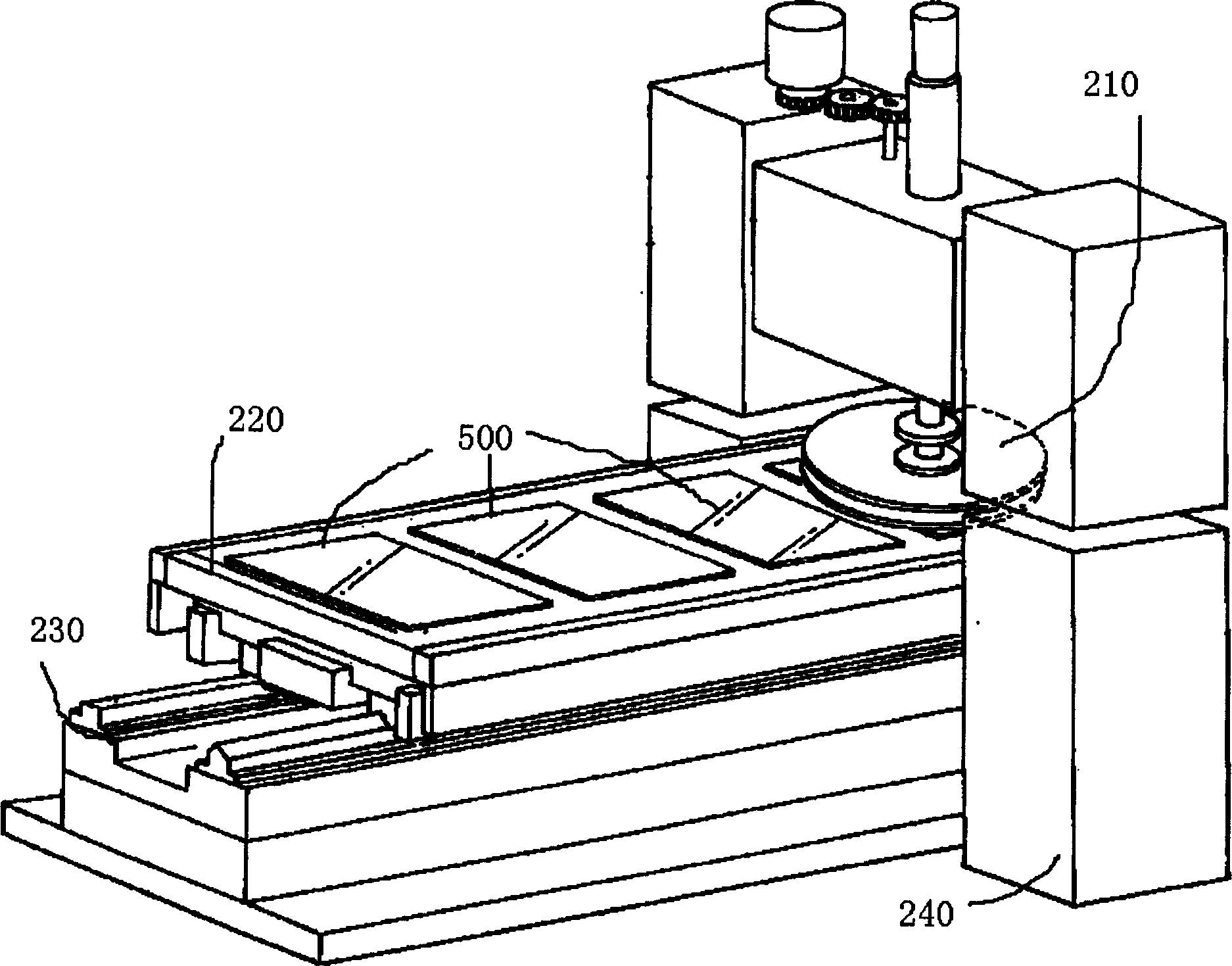

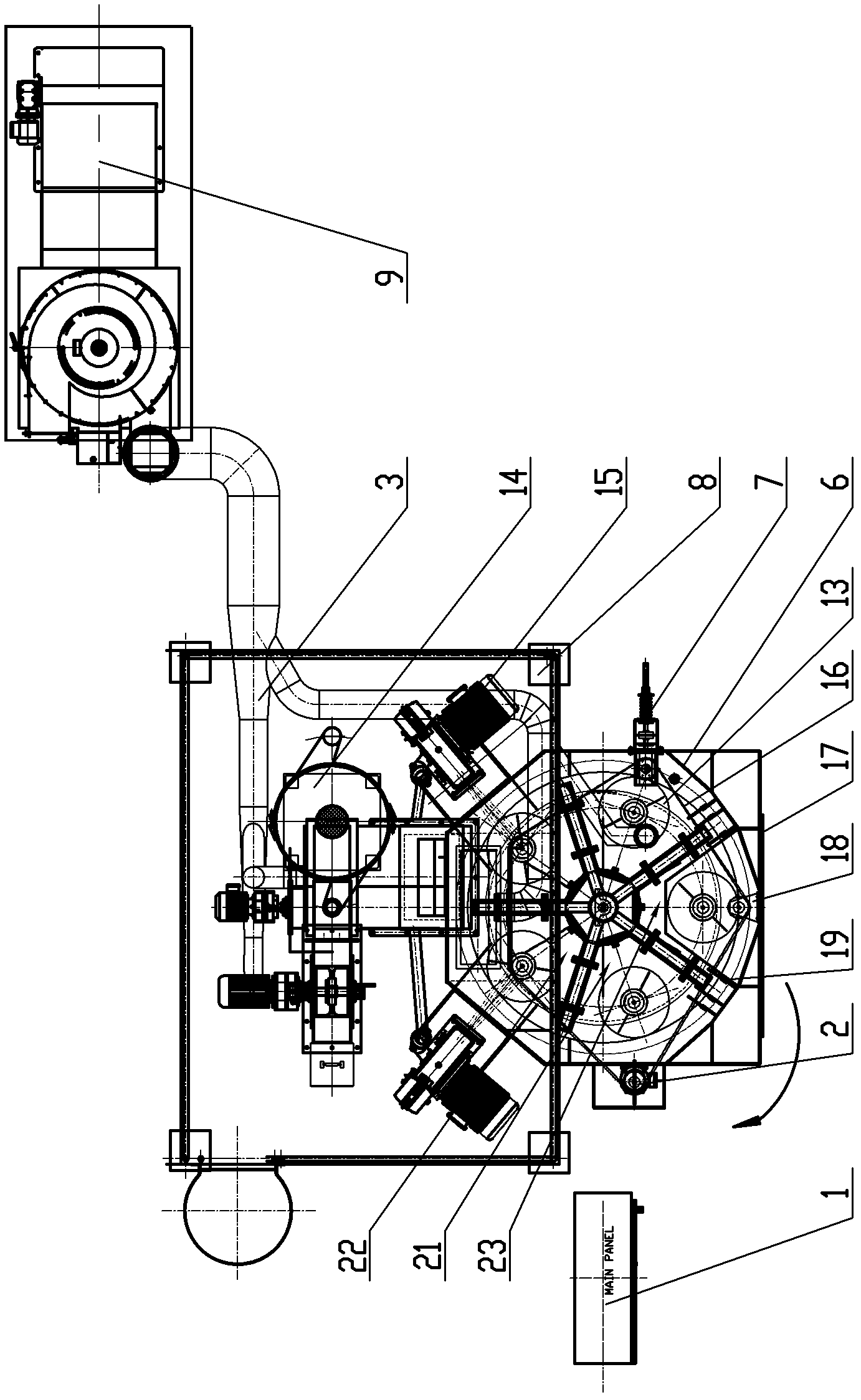

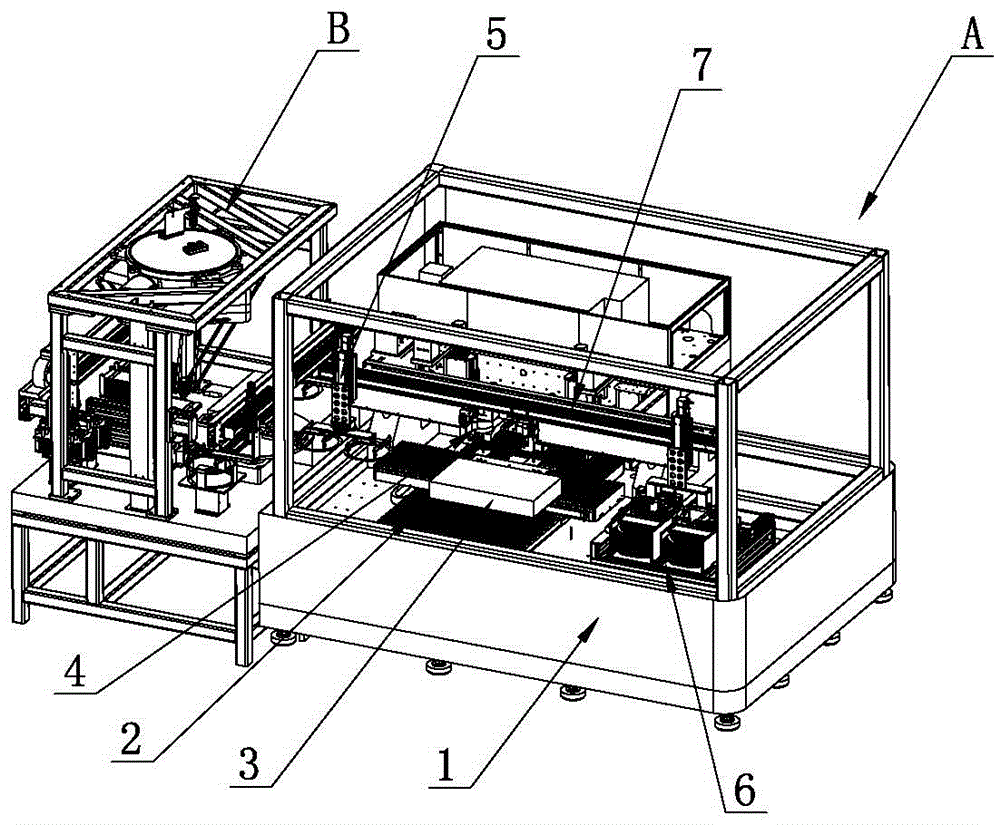

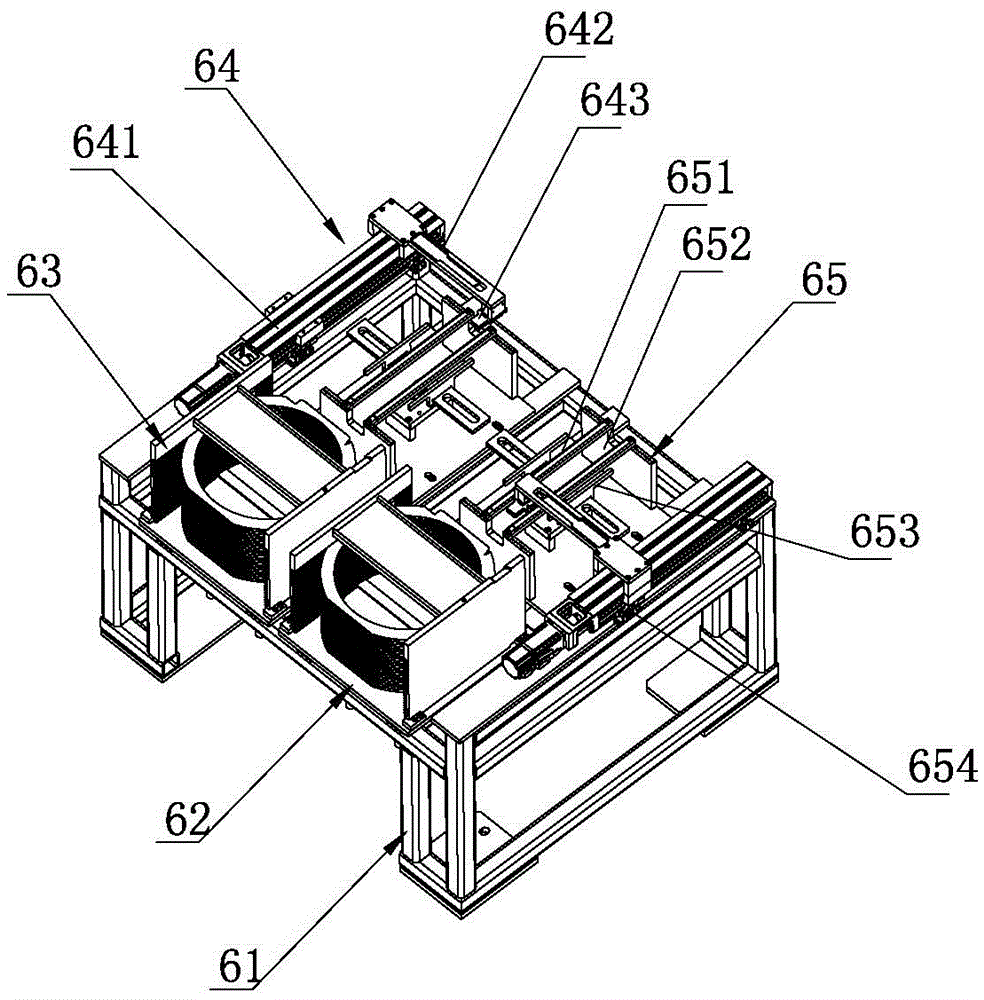

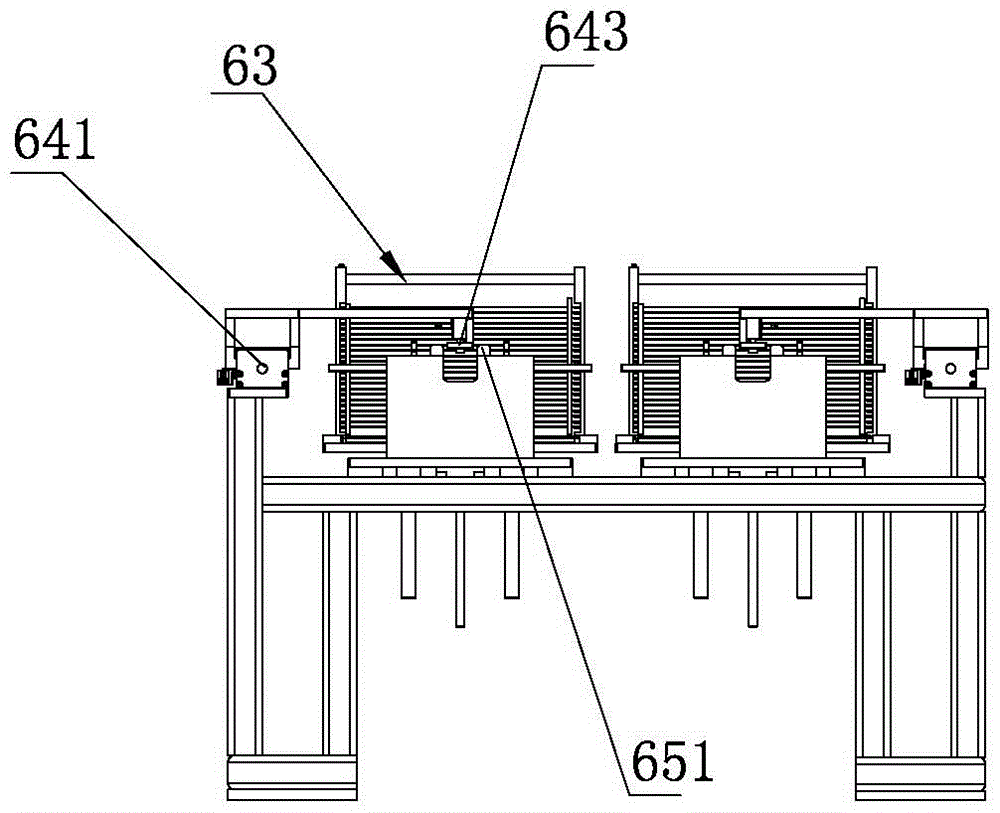

Multi-station grinding device for optical lenses

InactiveCN105500146ASimple structureLow costOptical surface grinding machinesGrinding drivesEngineeringLoading unloading

The invention discloses a multi-station grinding device for optical lenses. The multi-station grinding device comprises a machine seat, a rotating disc, at least two stations and lens fixtures, wherein the lens fixtures are arranged on the stations; a rotating positioning mechanism is arranged at the bottom of the rotating disc through a central shaft; the stations include a grinding station and a workpiece loading-unloading station which are located at the side part of the outer periphery of the rotating disc and are distributed in an even central angle relative to the rotating disc; at least one grinding mechanism is arranged on the periphery close to the rotating disc; the rotating positioning mechanism is a multi-station-switched precise positioning device. Compared with existing multi-station grinding equipment, the multi-station grinding device has the advantages that the structure is simple, the cost is low, and the occupied mounting space is small; the multi-station grinding device is particularly applicable to general large, medium, small-sized optical lens production enterprises; furthermore, the operation is simple and convenient, and requirements on the technological level of operators are low.

Owner:韩金桥

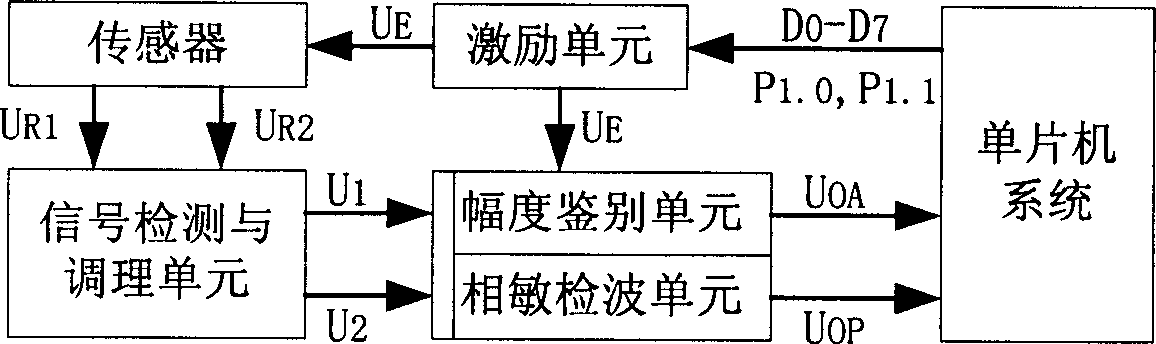

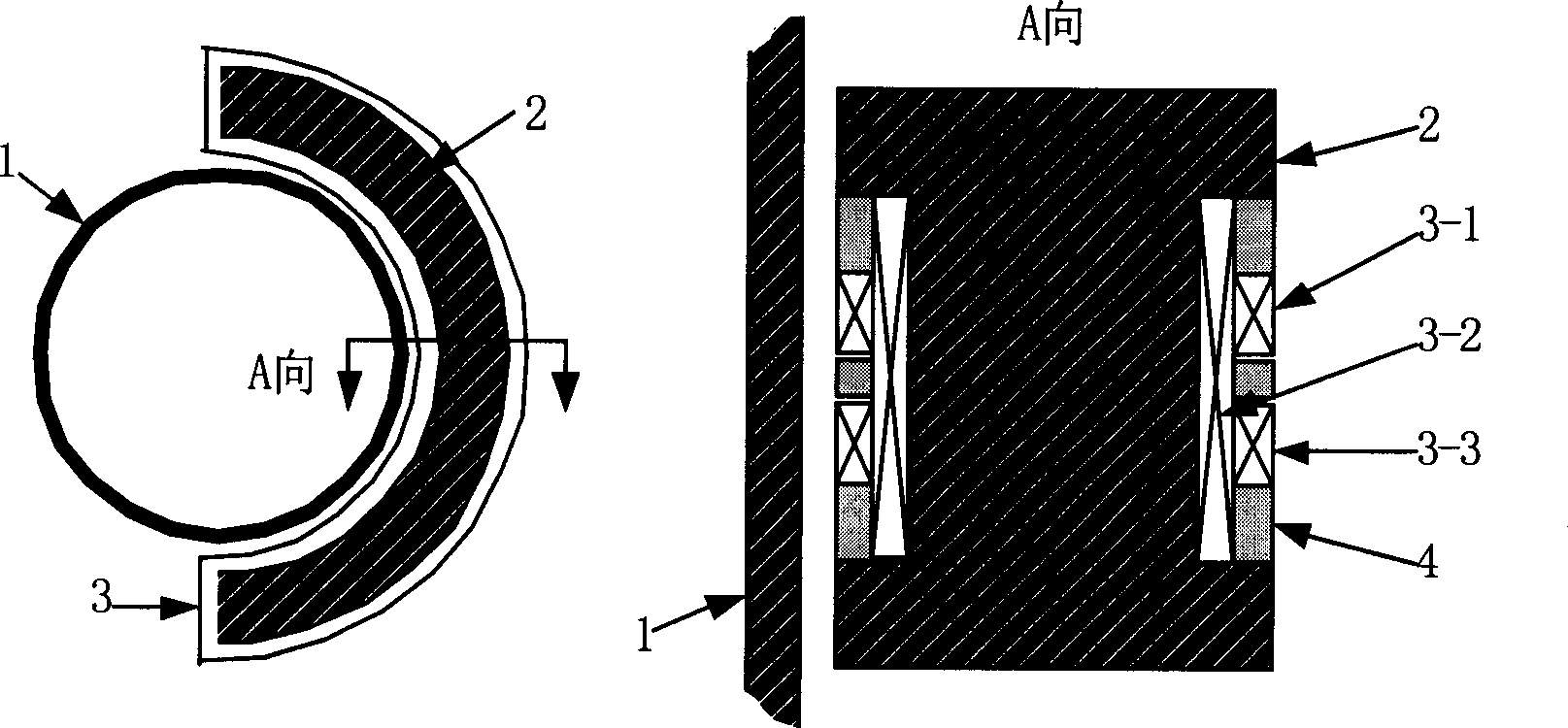

Overball inspection and external inspecting system for loading-unloading system of ball-bed piled fuel component

ActiveCN1819065AEasy to installSimple structureNuclear energy generationNuclear monitoringHigh pressureSensor materials

The ball bed piles the fuel element loading and unloading systematic ball examination method and outside installs the type examination system to belong to the ball bed type reactor fuel part examination area of technology. Is by installs has installed the type examination system outside ball pipeline outside, examines two examination coils using the distant field turbulent flow principle the voltage, and carries on the demodulation keleck and phase demodulation processing separately to this two examination coil voltage, obtains contains has had ball information demodulation keleck output voltage UOA and phase demodulation output voltage UOP, then carries on to this voltage UOA and UOP further analyzes and processing, thus judges in the ball pipeline whether has the ball process. This invention also proposed outside installs the type examination system. Uses this invention, the installment and the service does not need to destroy the ball pipeline, guaranteed installs the ex-denning pipeline the integrity and high-pressured gas tightness, reduces the radiation pollution; The sensor coil, the skeleton and other appendices with the radioactive fuel ball contact, are directly low to the entire examination sensor material radioresistance request, are advantageous in enhance the sensor the service life.

Owner:TSINGHUA UNIV

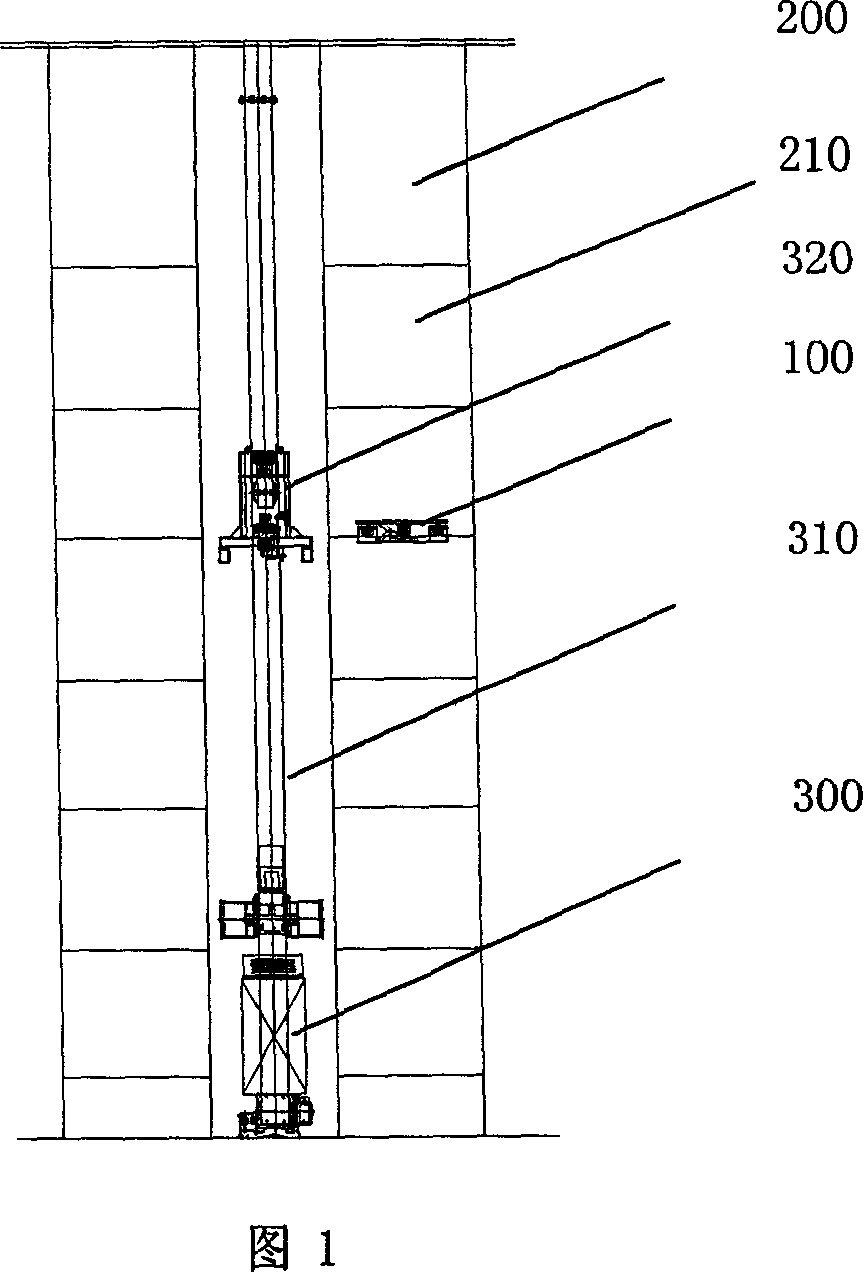

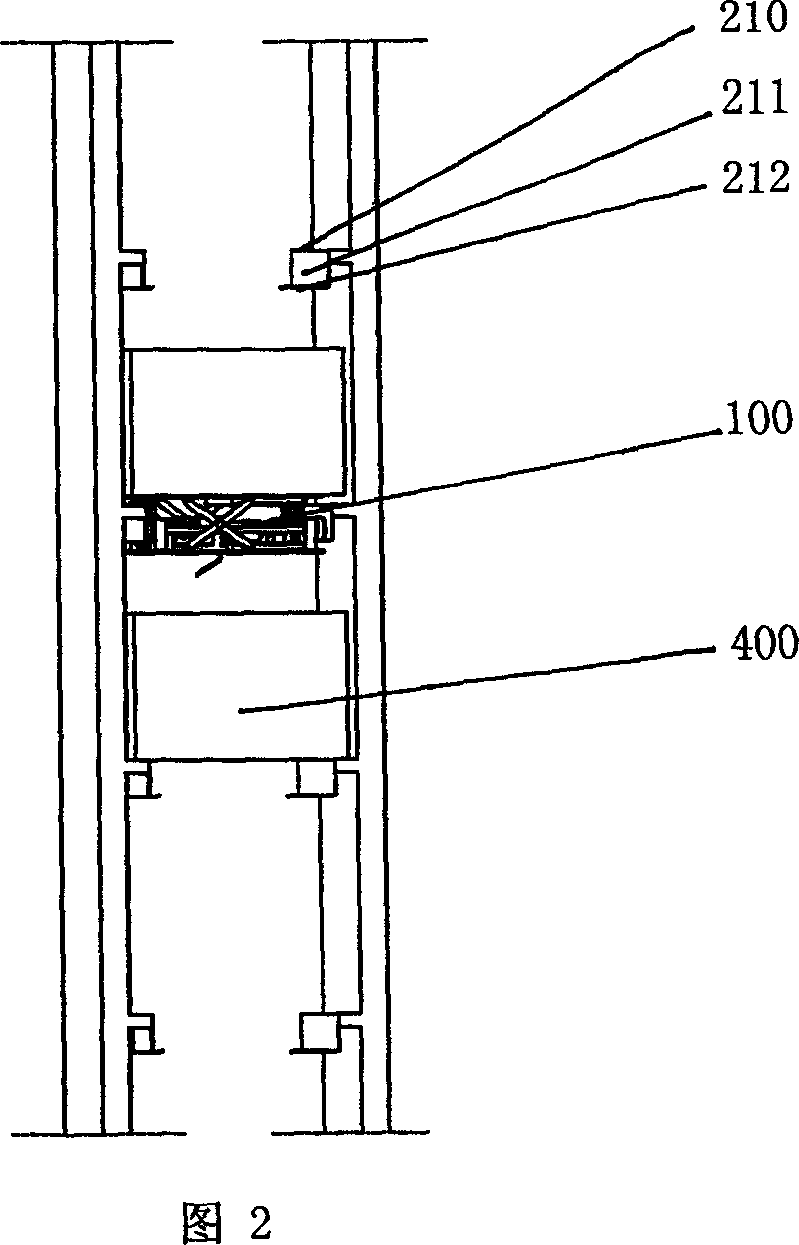

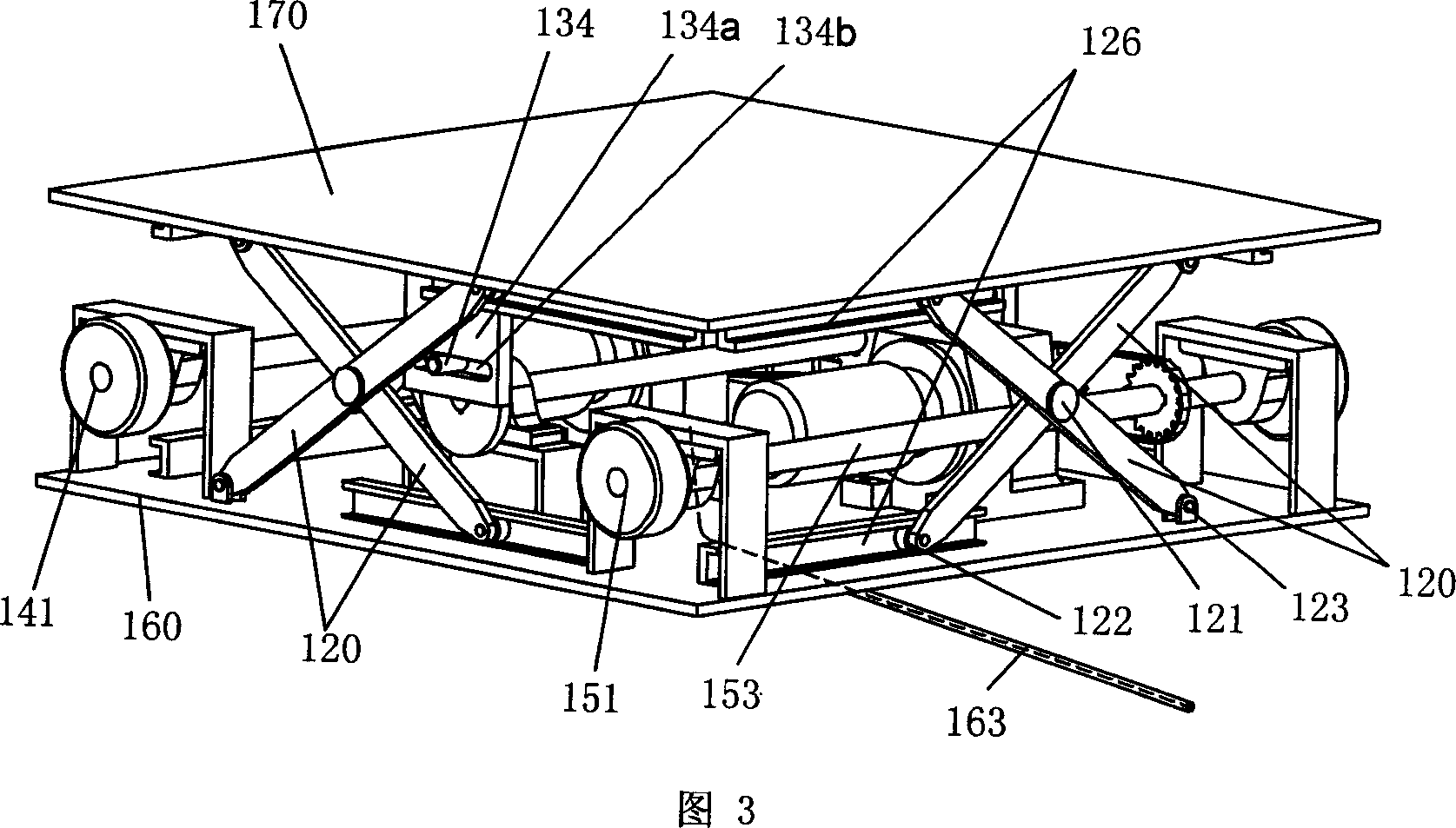

Stacking machine and stereo storage rack

ActiveCN1958409AIncrease widthImprove loading efficiencyStacking articlesStorage devicesStack machineLoading unloading

A stacking machine is composed of a lifter, a lifting system, a lifting platform, the tracks on said lifting platform, and a loading-unloading carriage running on said tracks and consisting of base frame, goods carrying unit, running unit, driver unit, lifting unit and auxiliary supporter. A high 3D goods shelf is composed of a high 3D frame and multiple goods storage positions on said frame and consisting of two goods shelves and the tracks under said goods shelves and fixed to them.

Owner:深圳中集天达物流系统工程有限公司 +1

Device for testing electric conductivity and soil-water characteristics of loess

PendingCN106324045ASimple structureEasy to operateEarth material testingApparatus for force/torque/work measurementSuction stressData acquisition

The invention discloses a device for testing electric conductivity and soil-water characteristics of loess. The device comprises a base, wherein a sleeve is arranged on the base; a pull rod is arranged in the sleeve; the sleeve is divided into a plurality of layers from top to bottom; each layer of the sleeve is connected with a resistivity measuring system, a suction measuring system and a moisture measuring system; a porous plate is arranged at each of two ends of the sleeve; an upper cover plate is arranged on the porous plate at one end of the sleeve; and a pressure rod is arranged on the upper cover plate. The device for testing electric conductivity and soil-water characteristics of loess realizes the purpose of simultaneously obtaining the resistivity and soil-water characteristic curve of the loess on the same equipment, realizes automatic measurement, enables data acquisition to be convenient and reliable, records the resistivity, moisture volume percentage and suction evolution condition of the loess at any time, can reflect the microscopic evolution rule of moisture migration in the loess, and can realize loading-unloading and simulation of long-term deformation characteristics of remolded loess and the moisture migration and pore state evolution rule in the loess.

Owner:XIAN UNIV OF TECH

Preparation method for sodium alginate-acrylamide-based hydrogel

The invention discloses a preparation method for sodium alginate-acrylamide-based hydrogel. The preparation method comprises the following steps of: dissolving sodium alginate powder in deionized water; then sequentially adding an acrylamide monomer, a methylene diacrylamide cross-linking agent, ammonium persulfate and an N,N,N',N'-tetramethylethylenediamine catalyst; uniformly stirring the materials, pouring the mixture into a glass die, and heating the mixture to obtain a hydrogel; completely soaking the hydrogel in a 0.01-1 mol / L non-monovalent cation aqueous solution for 1-10 hours, wherein cations diffuse and enter in a hydrogel network structure, and induce sodium alginate to cross-link, so as to generate the high-strength and high-toughness sodium alginate-acrylamide-based hydrogel during the process. The hydrogel disclosed by the invention has the following performances: the highest tensile strength can achieve 1 MPa, and the highest tensile elasticity modulus can achieve 250 KPa; a loading-unloading test is performed on the hydrogel, and when the great tensile multiple before unloading is 8, the highest dissipated energy can achieve 2180 KJ / m<3>.

Owner:XI AN JIAOTONG UNIV

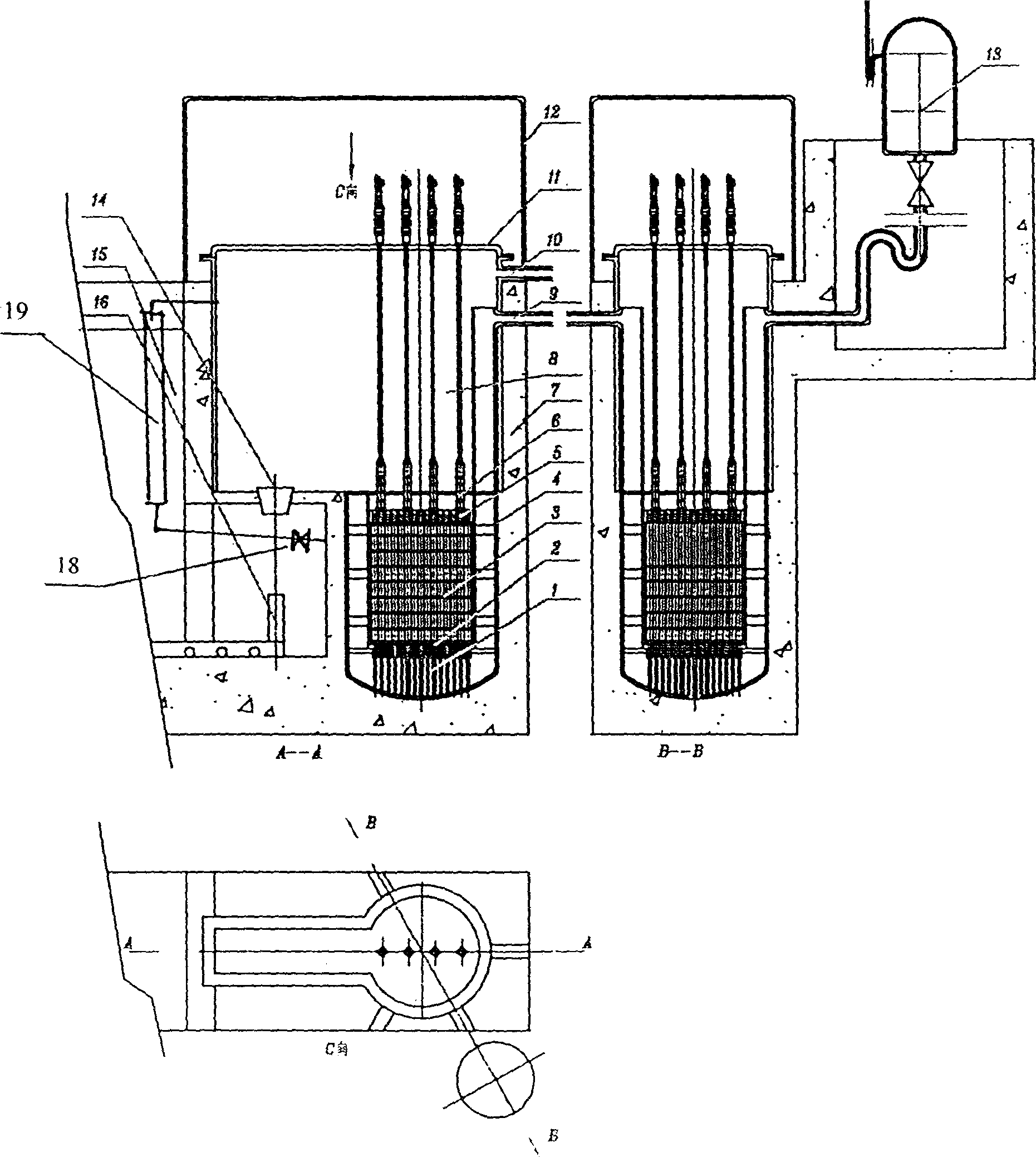

Method and devices to limit a creep of mechanical fasteners

InactiveUS20050244245A1Improve sealingExtended service lifeFlanged jointsWashersMartensite transformationShape-memory alloy

A method and devices to limit or to exclude operating creep of mechanical fasteners is disclosed. The method consists in use of mechanical fasteners such as bolts, gaskets, screws, washers and other power elements manufactured from shape memory alloys having temperature interval of martensitic phase transformations corresponding to the operating temperature of industrial equipment. The power elements are previously shape-memorized either to tension or to compression, flexion, torsion, or to their combinations under temperature of martensite state with suitable quantity of conserved residual shape-memorized deformation obtained during loading-unloading of the power elements. Further constrained recovery of shape-memorized deformation under operating temperature generates reactive shape-recovering forces having direction inverse to the direction of operating creep. The process of creep limitation is called “Method of “negative creep”.

Owner:EFREMOV ANATOLY

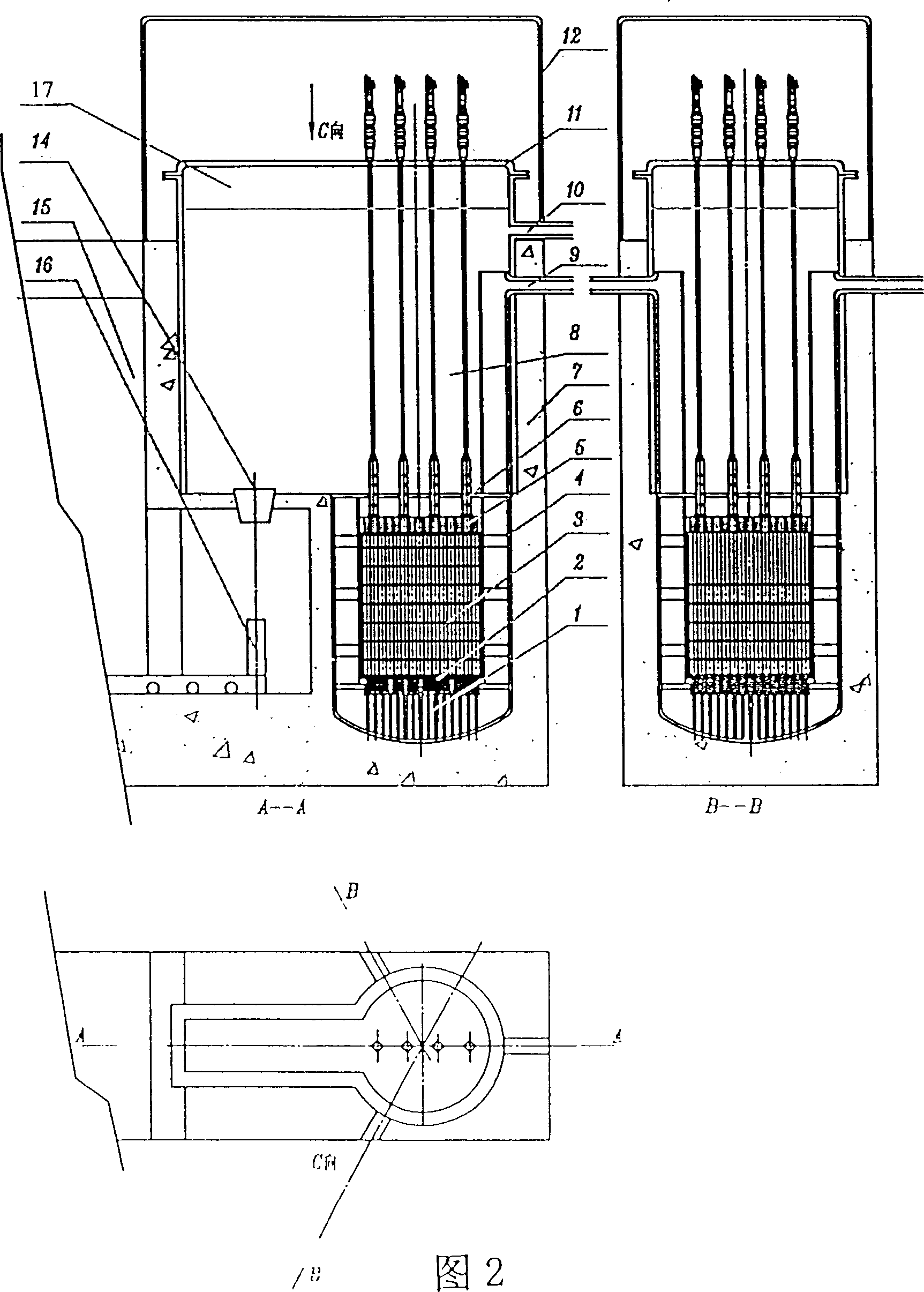

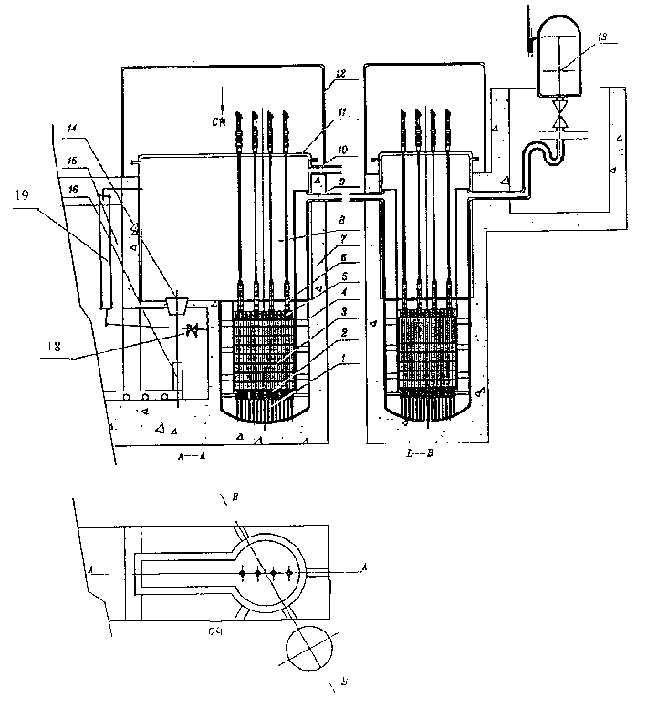

Low-temp nuclear reactor with hypofuel for nuclear power station

InactiveCN1396603AImprove use valueSave fuelNuclear energy generationNuclear engineering problemsRadioactive gasNuclear reactor

A low-temp. nuclear reactor using the deleted fuel of nuclear power station has a reactor core in its water pool with a sealing cover. The gas with a certain pressure is aerated in the water pool via the sealing cover. At the side of the water pool, there is a fuel loading-unloading channel communicated with the water pool where the deleted fuel is stored. Its advantages are low cost, high utilization rate of U-resource, and no radioactivity pollution.

Owner:李玉仑 +2

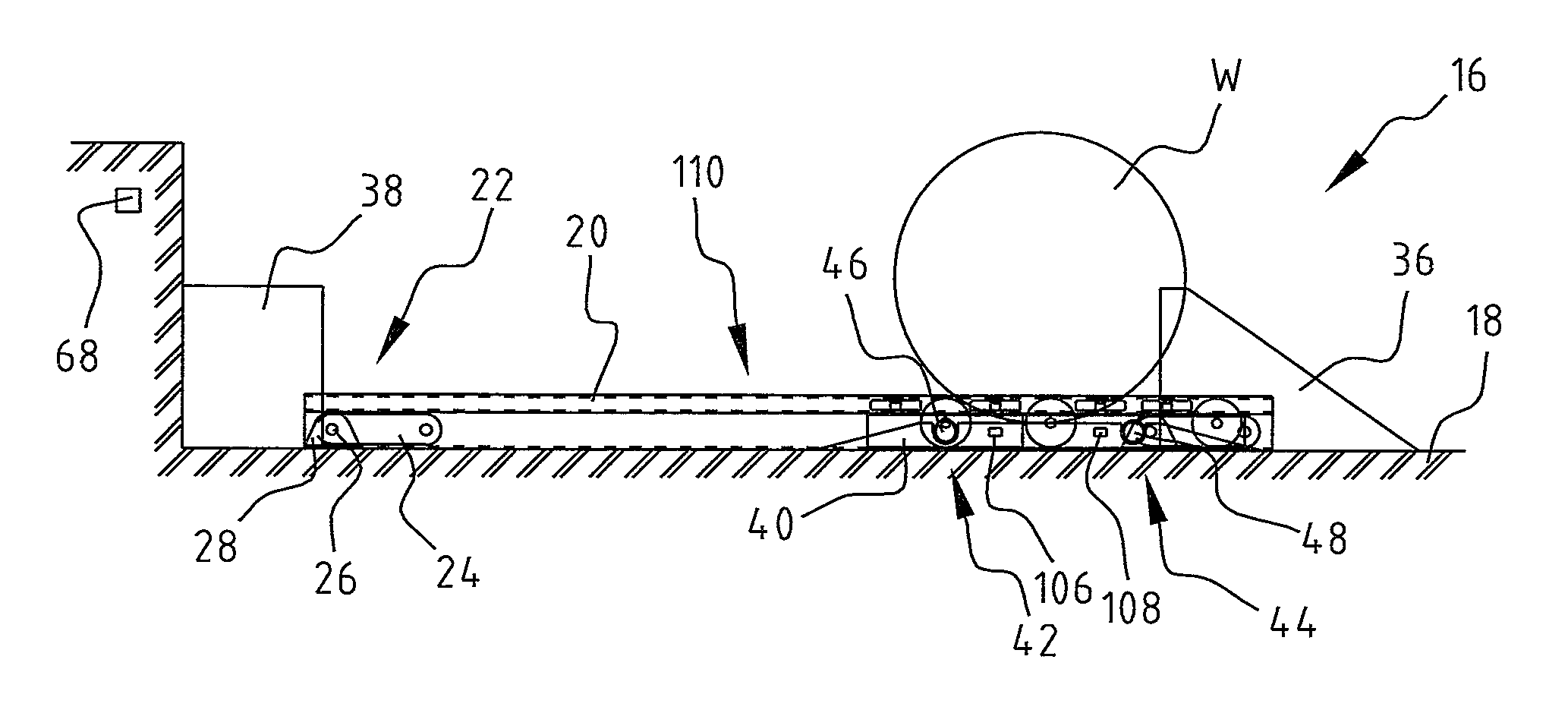

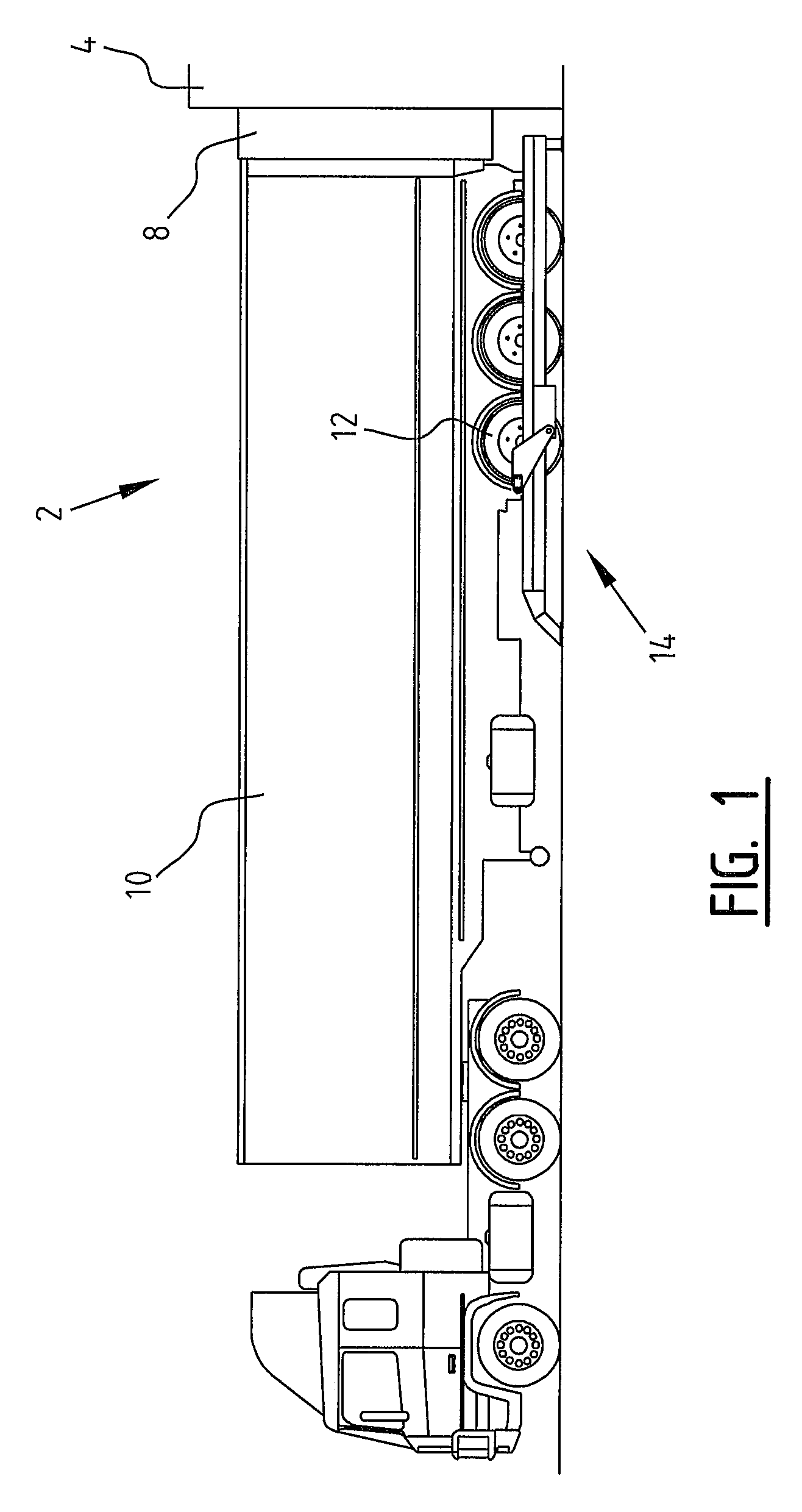

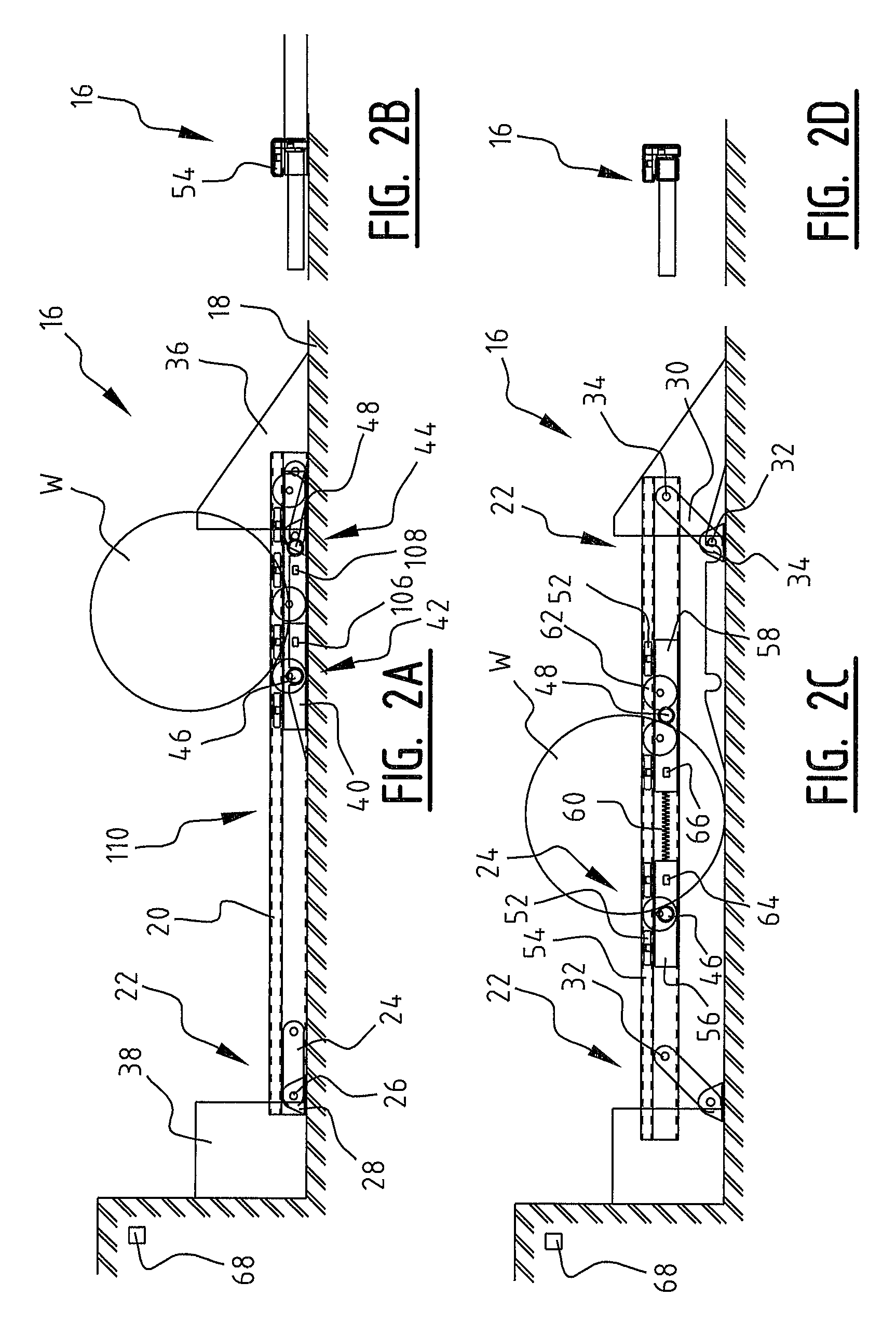

Device for blocking a vehicle, method therefor and loading-unloading station provided therewith

ActiveUS9162831B2Enhances applicability and possible usHigh engaging heightPortable braking systemItem transportation vehiclesEngineeringLoading unloading

Disclosed is a device for blocking a vehicle, a method making use of such a device and a loading-unloading station provided therewith. The device includes a guide track disposed along a driveway, a blocking component for blocking a wheel of the vehicle, and height-adjusting component for height adjustment of the guide track and / or the blocking component during use. The device preferably includes an anti-roll mode, wherein the blocking component engages at a first height, and a locking mode, wherein the blocking component engages at a second, greater height.

Owner:STERTIL

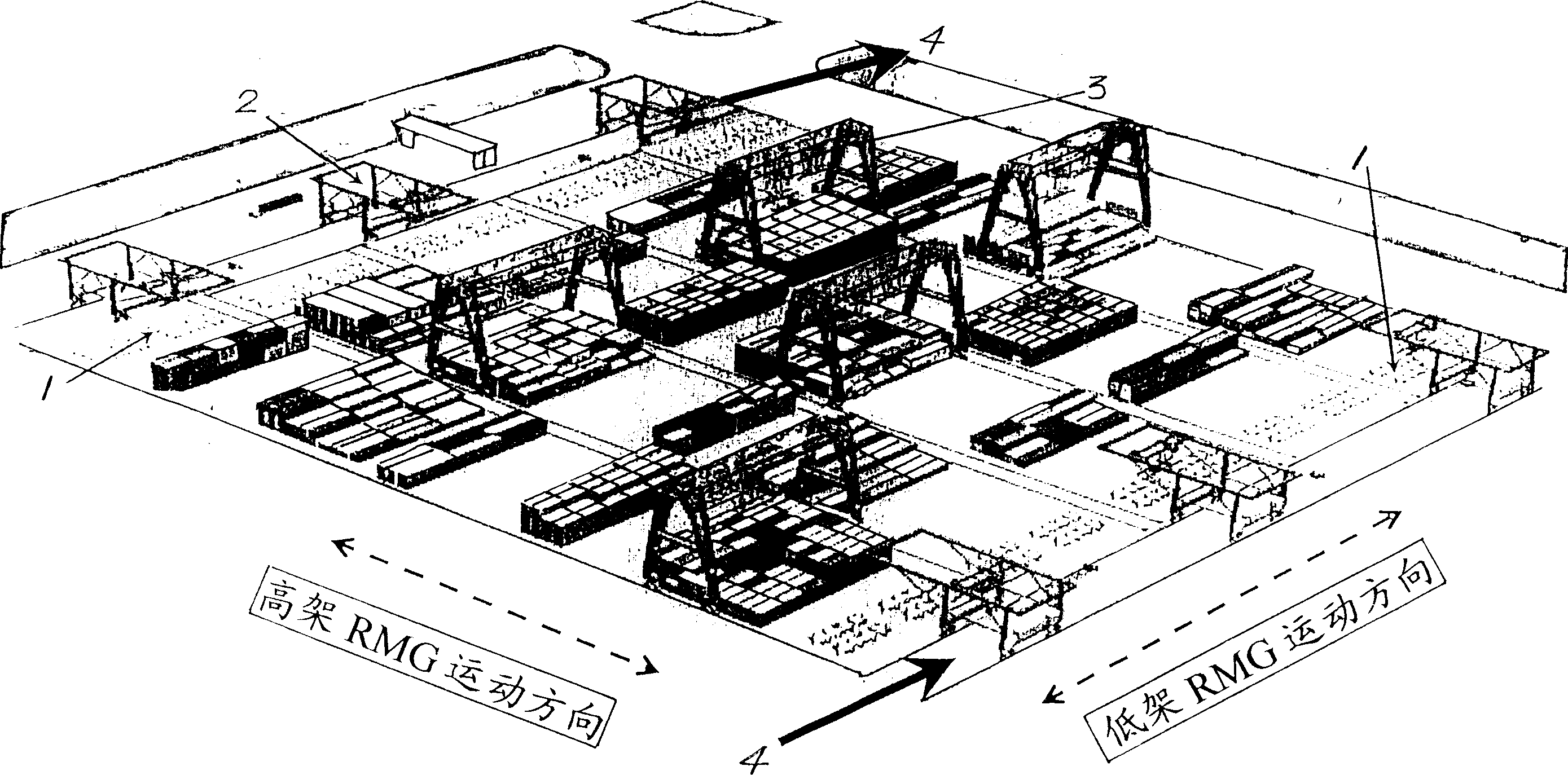

Automatization piling yard of containers and piling yard loading unloading process

InactiveCN1903684AIncrease productivity in yard operationsImprove loading and unloading speedStorage devicesLoading/unloadingYardLoading unloading

The present invention discloses a container automatic yard and yard loading and unloading process. It is characterized by that two ends of yard are respectively equipped with low-height container rail-mounted gantry crane, said low-height container rail-mounted gantry crane is positioned in the loading and unloading zone of yard end portion and is operated; on every stacking line of yard container zone a high-height container rail-mounted gantry crane is set. Said low-height rail-mounted gantry crane and high-height rail-mounted gantry crane are respectively connected with automatic yard management system. Said invention can greatly raise loading and unloading speed and raise production efficiency of yard work.

Owner:包起帆 +1

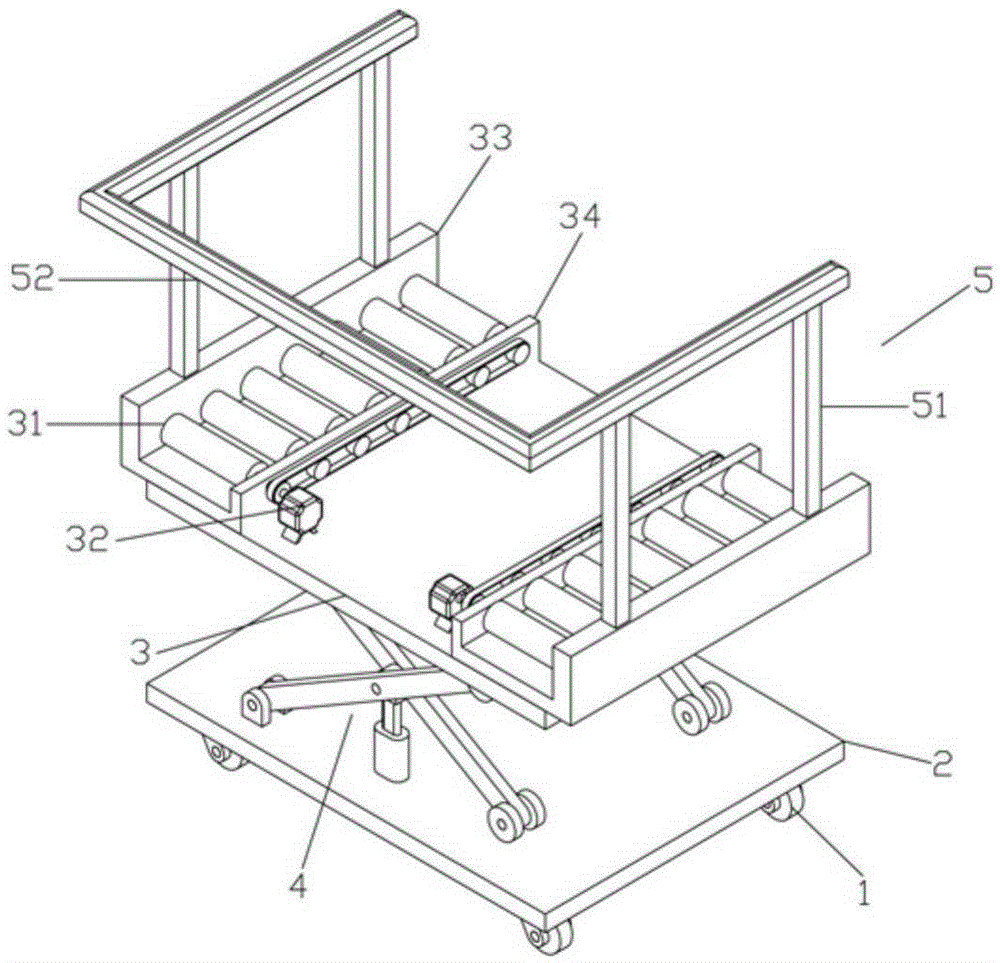

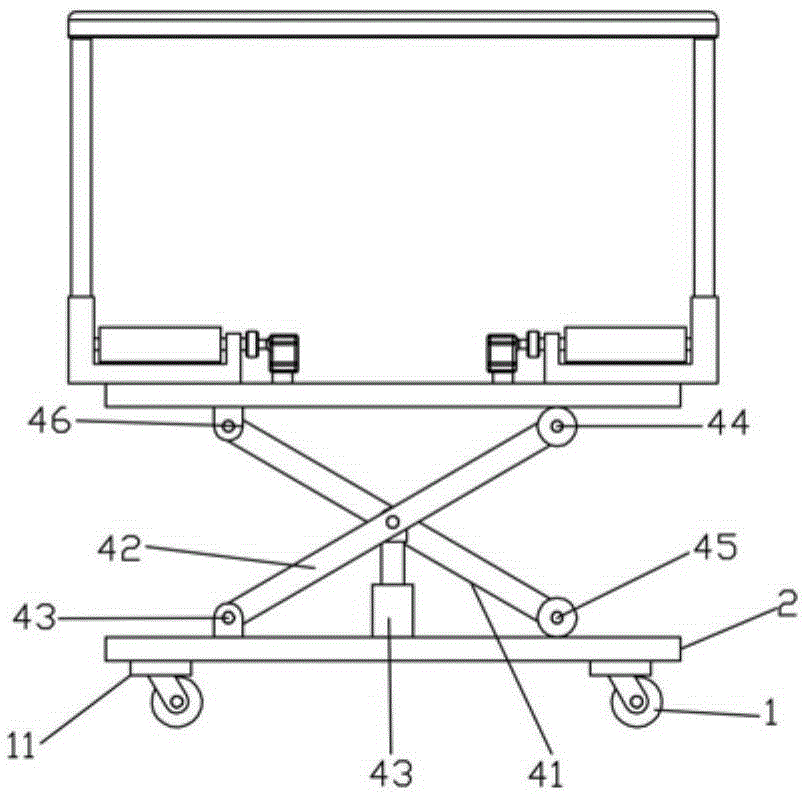

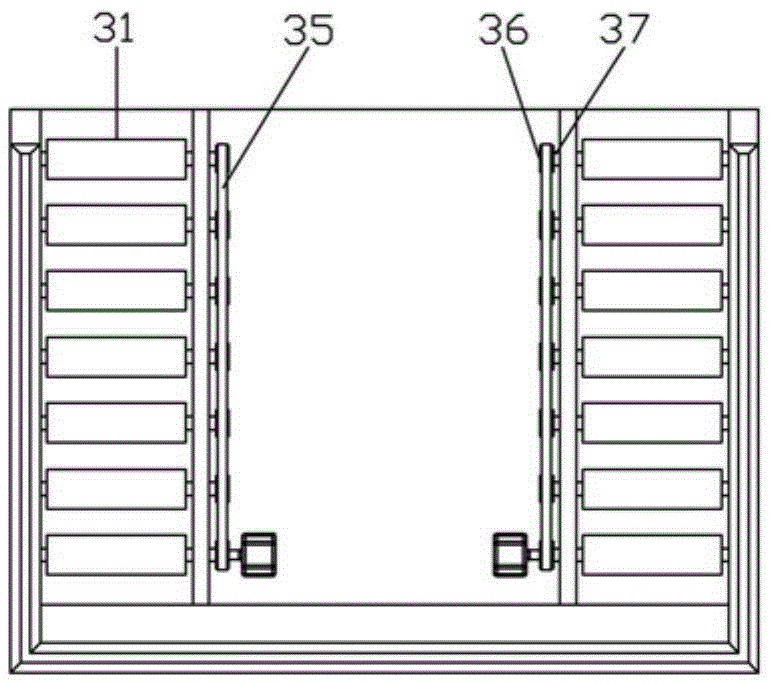

Automatic loading-unloading and conveying device for tray

InactiveCN105384122AImprove loading efficiencyImprove unloading efficiencyLifting framesPackagingEngineeringLoading unloading

The invention discloses an automatic loading-unloading and conveying device for a tray. The automatic loading-unloading and conveying device comprises a frame, castors, a lifting device, a roller loading-unloading unit and a handle unit, wherein the castors are located on the lower part of the frame, and are fixed on the lower part of the frame through castor frames, the lifting device is located between the frame and the roller loading-unloading unit, and the handle unit is fixedly connected to the roller loading-unloading unit; and the roller loading-unloading unit drives rollers to rotate under the driving of motors, thus inward loading and outward unloading for the tray are realized. The automatic loading-unloading and conveying device effectively increases the loading and unloading efficiency for the tray, and can reduce labour investment and save human resources.

Owner:SUZHOU PINFA ELECTROMECHANICAL TECH CO LTD

Processing method for T-shaped thin-walled parts

ActiveCN104526030AGood symmetryImprove quality and efficiencyMilling equipment detailsPositioning apparatusEngineeringLoading unloading

The invention relates to a processing method for T-shaped thin-walled parts. The main point lies in that: a low feed layer-by-layer processing method adopting cushion block supporting and vice paired clamping, and combining rough machining and finish machining is employed to process the T-shaped thin-walled parts. The processing method is convenient to load and unload parts, simplifies loading-unloading and processing procedure, and reduces the labor intensity of part loading and unloading, the processing process is simple, and parts are difficult to deform during loading-unloading processing. The method employs a low feed layered milling and rigid clamping mode, and rough machining and finish machining combined stepwise layer-by-layer processing, reduces the vibration of cutting tools and parts, improves the processing efficiency of T-shaped thin-walled parts, has stable processing quality stable and good reliability, lowers the loss and processing cost of cutting tools, and is suitable for large-scale production and processing.

Owner:中国航发湖南南方宇航工业有限公司

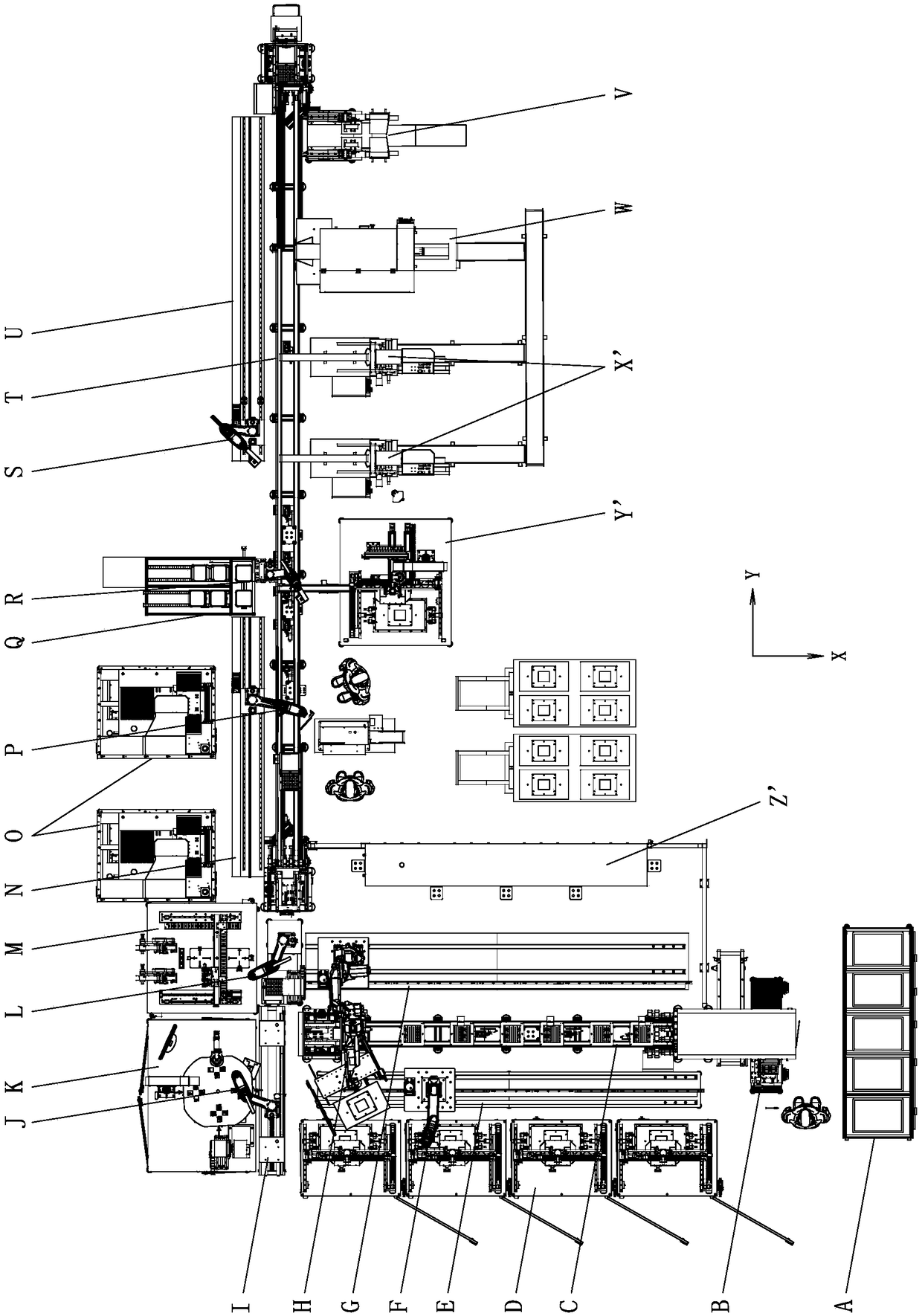

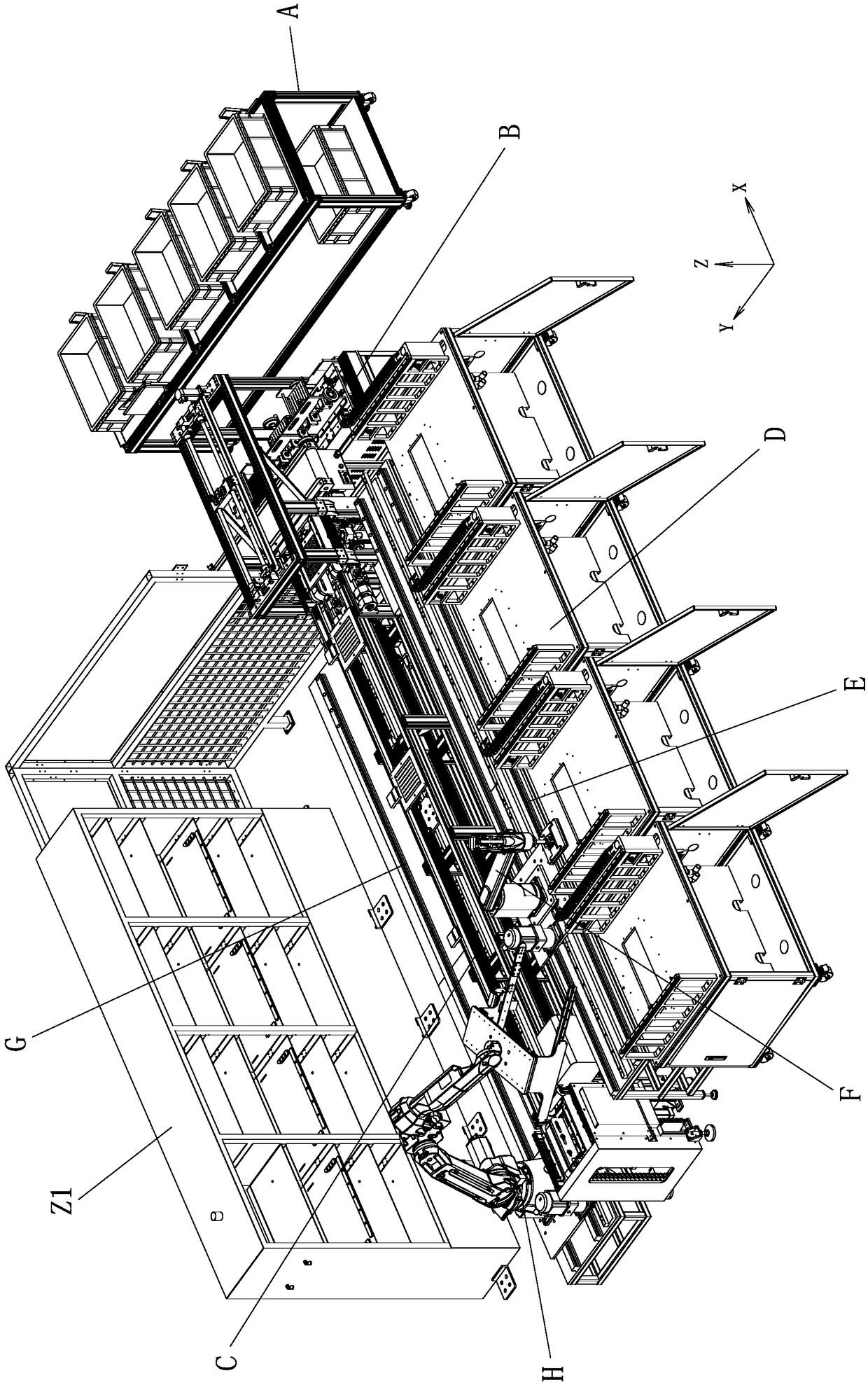

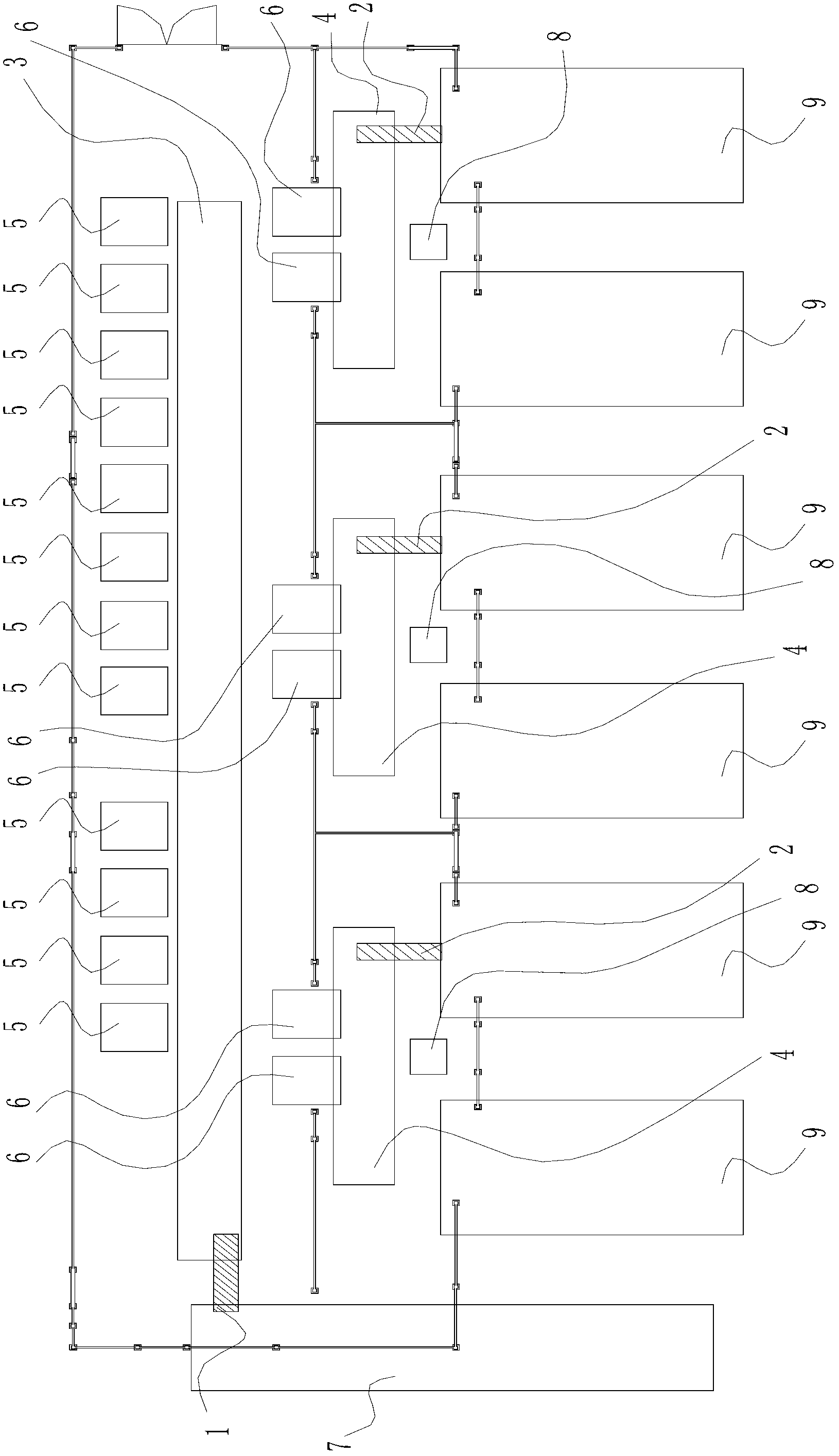

Automatic loading-unloading line for workpiece machine tool machining

ActiveCN103192288AReduce manpower requirementsReduced man-hour requirementsMetal working apparatusHuman–machine interfaceProgrammable logic controller

The invention discloses an automatic loading-unloading line for workpiece machine tool machining. The automatic loading-unloading line comprises a first robot, a second robot, a first transferring mechanism, a second transferring mechanism, a material flow caching area, a robot loading-unloading area, a manual loading-unloading area, a chamfering device, a machine tool and an electric control system. Both the first robot and the second robot are provided with grippers. The manual loading-unloading area is provided with a conveying device. The electric control system comprises a PLC (programmable logic controller) safety module and a touch screen HMI (human machine interface). Compared with manual loading-unloading, the automatic loading-unloading line has the advantages that operators only need to check operation of equipment in real time, labor for the line is reduced, robot loading-unloading is utilized, robots cab repeat actions with consistency without being interfered by the outside and can work continuously for 24 hours, working hours are reduced, daily output of products is increased greatly, and production cost is saved.

Owner:WECAN M&E SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com