Stacking machine and stereo storage rack

A technology of stacker and base frame, which is applied in the field of three-dimensional warehouse and its operating equipment, can solve the problems of high manufacturing cost, complex structure of friction stacker, and limitation of three-dimensional shelf width, so as to reduce shelf cost and improve loading Efficiency, the effect of simplifying the shelf structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

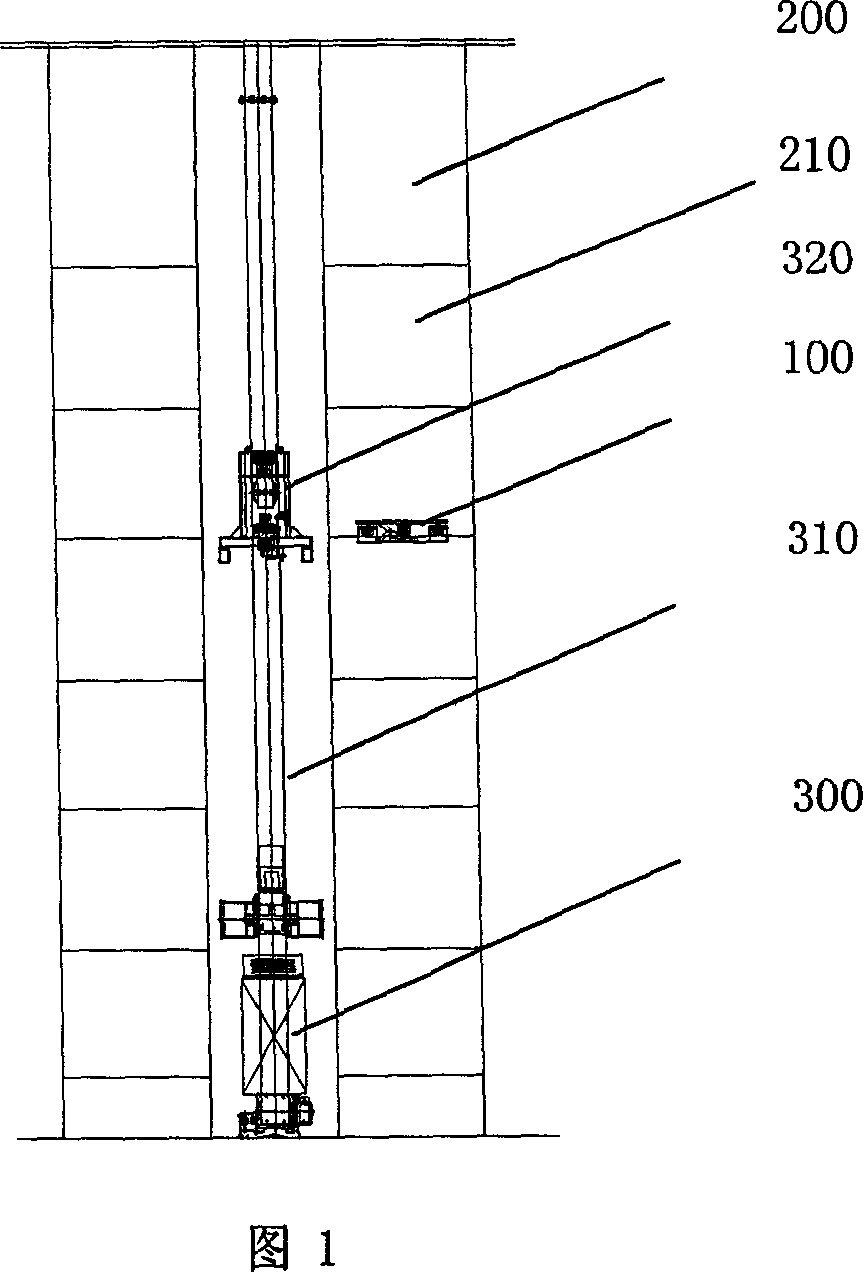

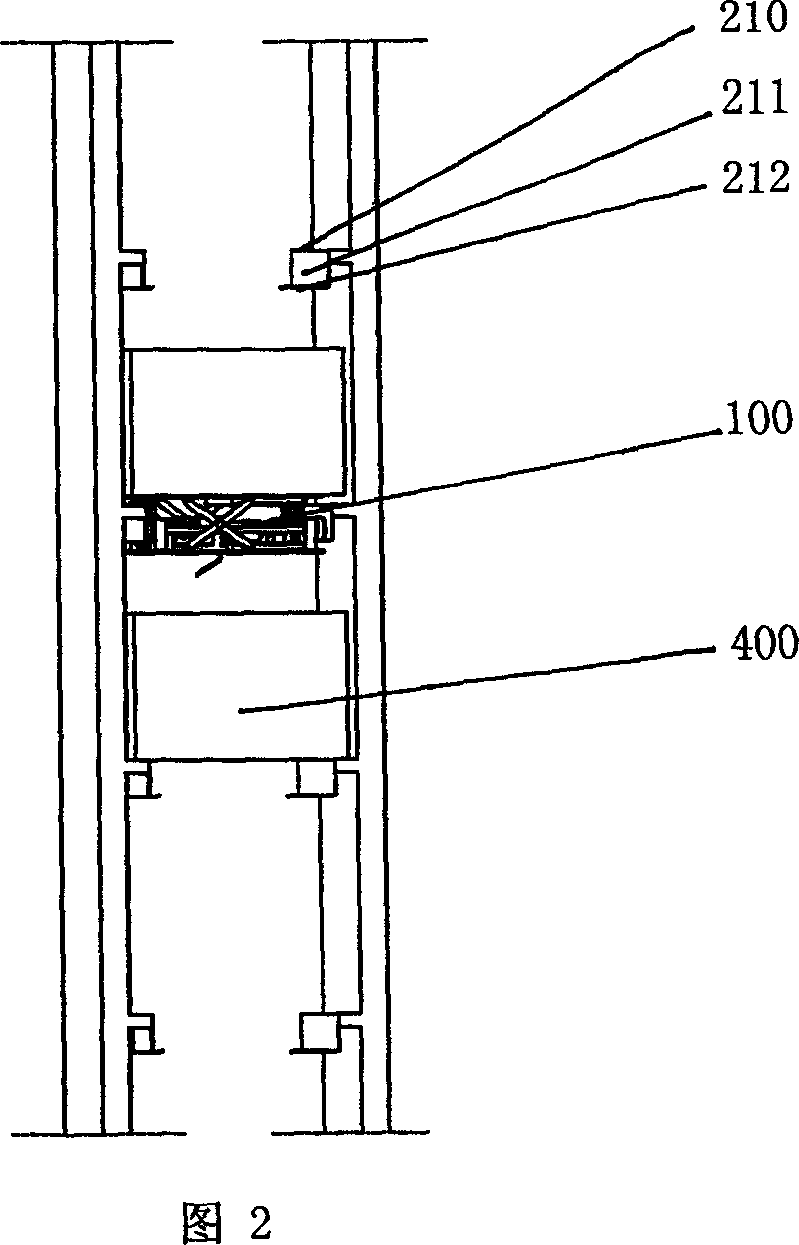

[0028] As shown in FIG. 1 and FIG. 2 , a stacker 300 of the present invention includes an elevator 310 moving along the ground, a lifting device 320 moving up and down along the elevator, and a cargo trolley 100 . The three-dimensional shelf 200 includes a plurality of storage positions 210 arranged according to the required width, height and transverse length. Each storage position 210 includes a storage rack 211 and a storage position track 212. The three-dimensional shelves 200 are arranged vertically to form a roadway with each other. 300 moves in the aisle of the three-dimensional shelf 200.

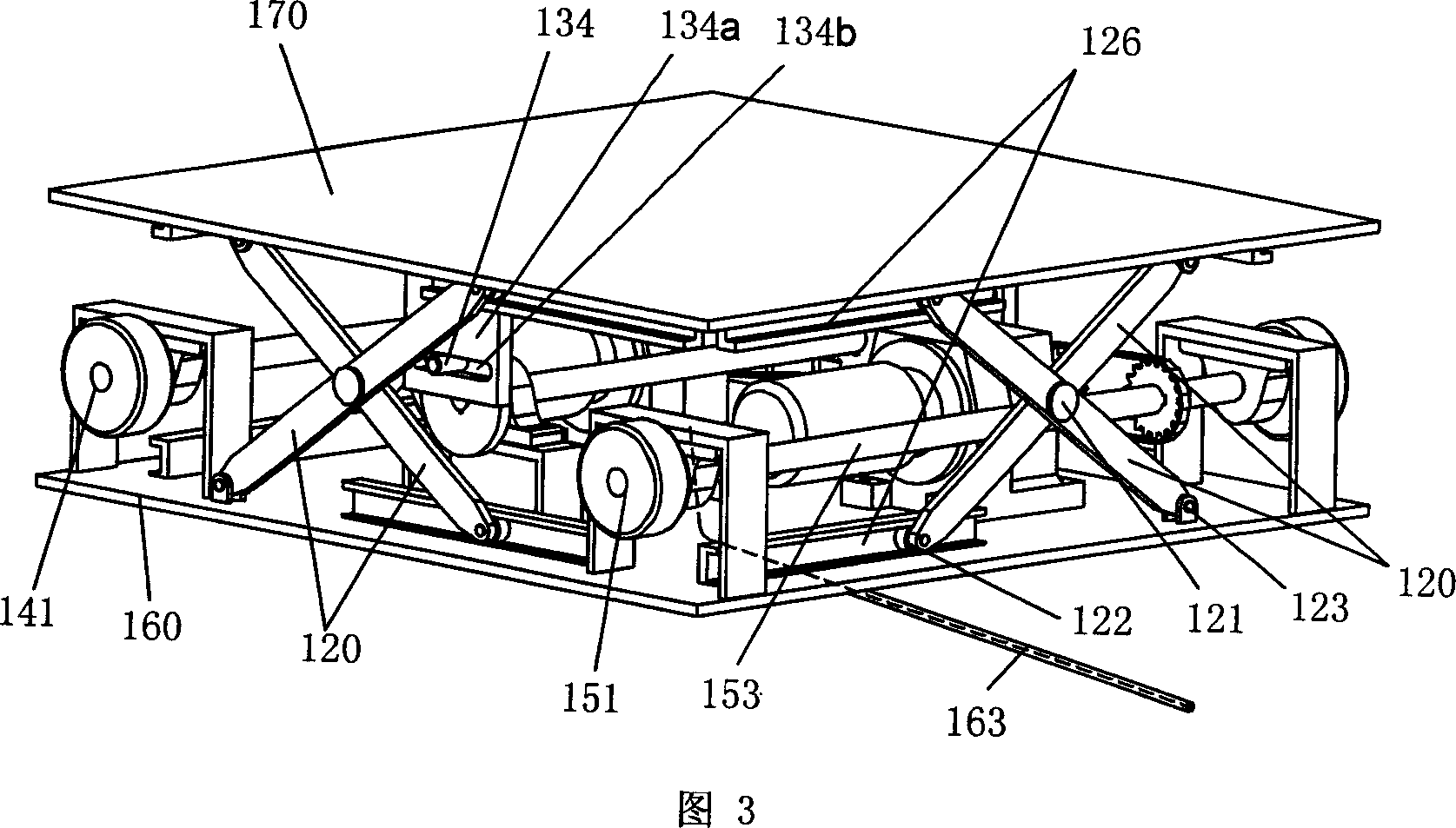

[0029] The lifting device 320 includes a lifting platform, and also includes a platform track arranged on the lifting platform. The direction of the platform track meets the direction parallel to the storage position track 212 when the stacker 300 loads and unloads goods. The platform track can adopt two cross-sections L One side of the L-shaped monorail is horizontal and the L-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com