Patents

Literature

508results about How to "Avoid polluting the environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Test element for analyzing body fluids

ActiveUS20080060424A1Avoid polluting the environmentEasy to wetPreparing sample for investigationPretreated surfacesAnalyteMedicine

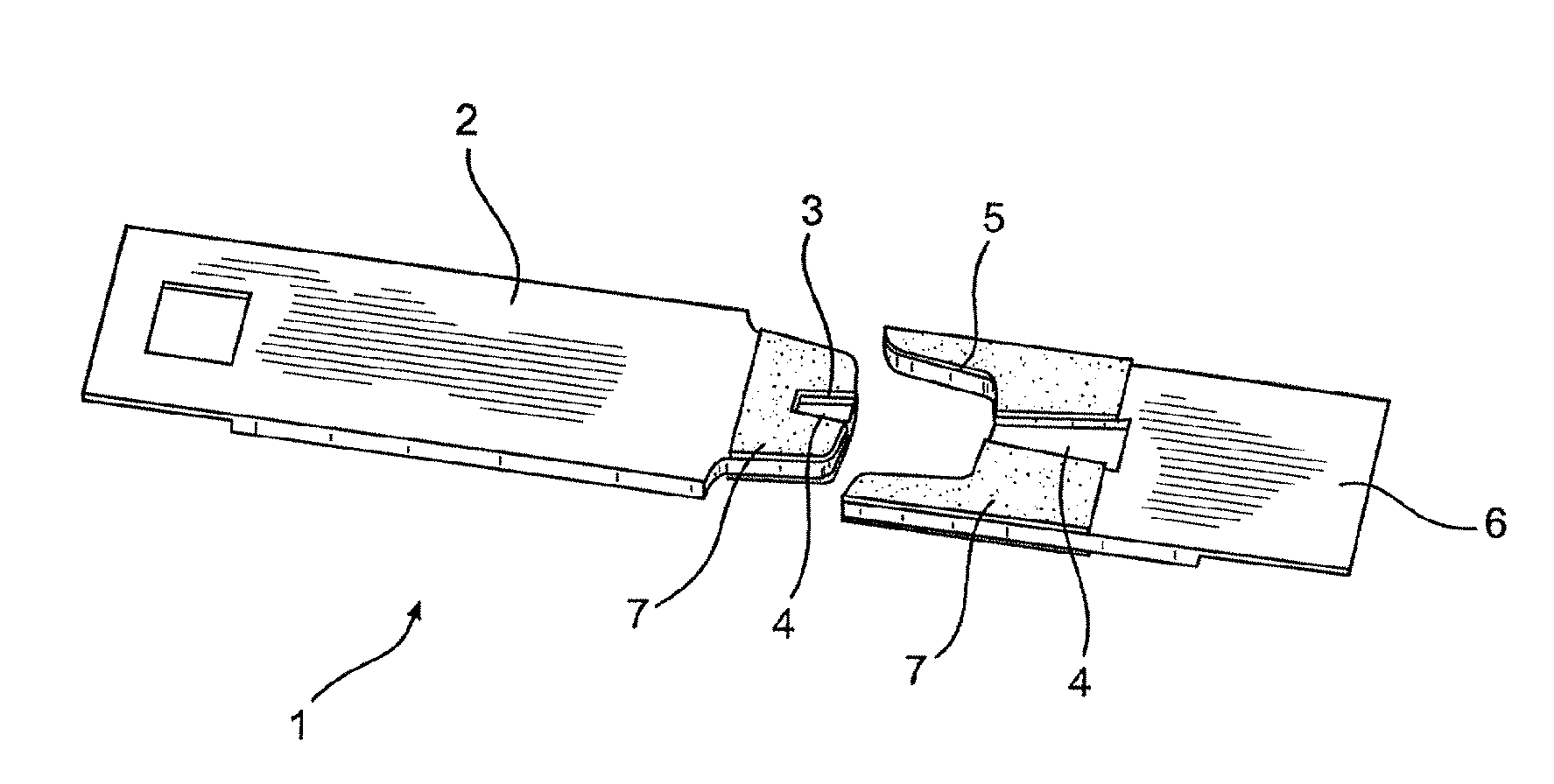

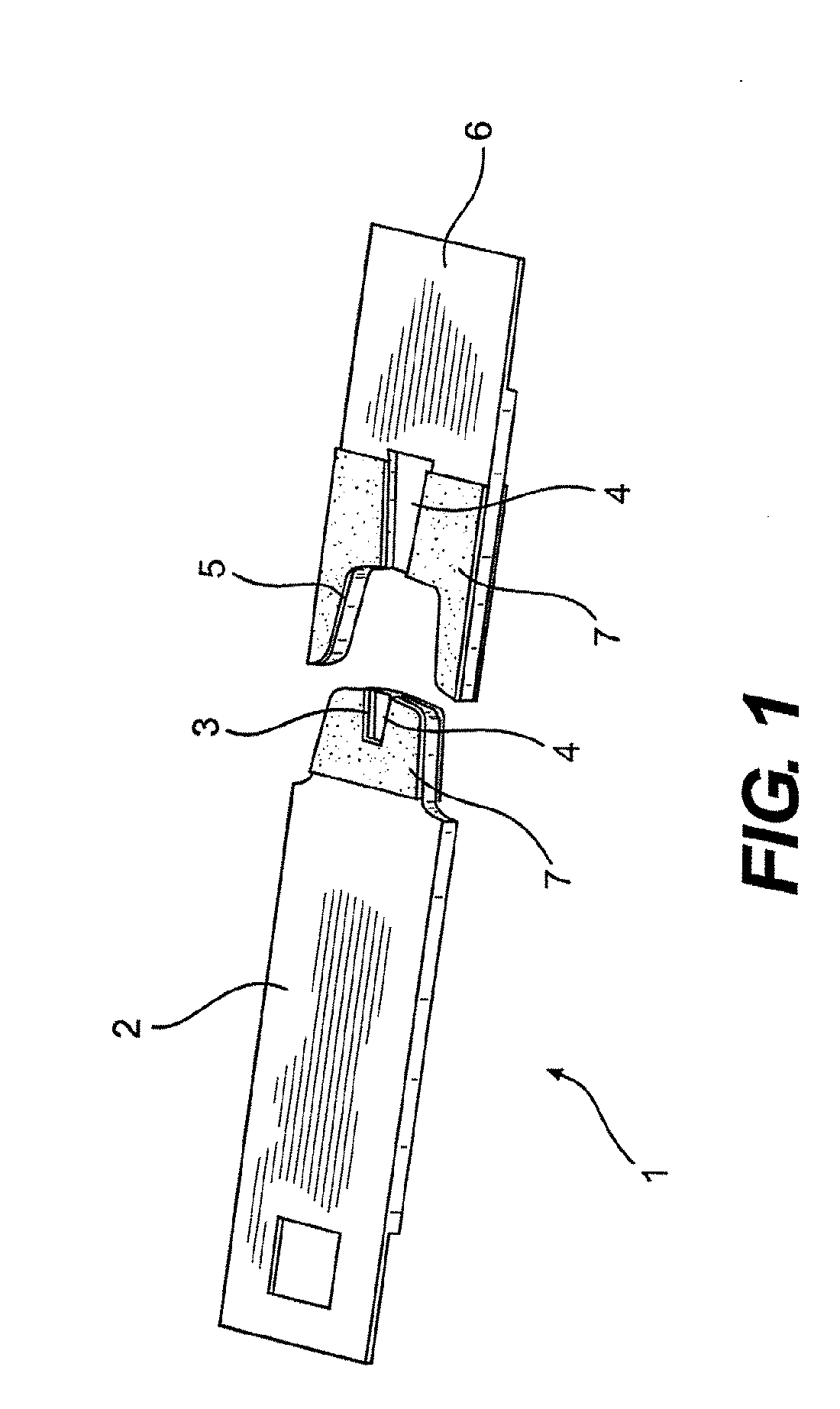

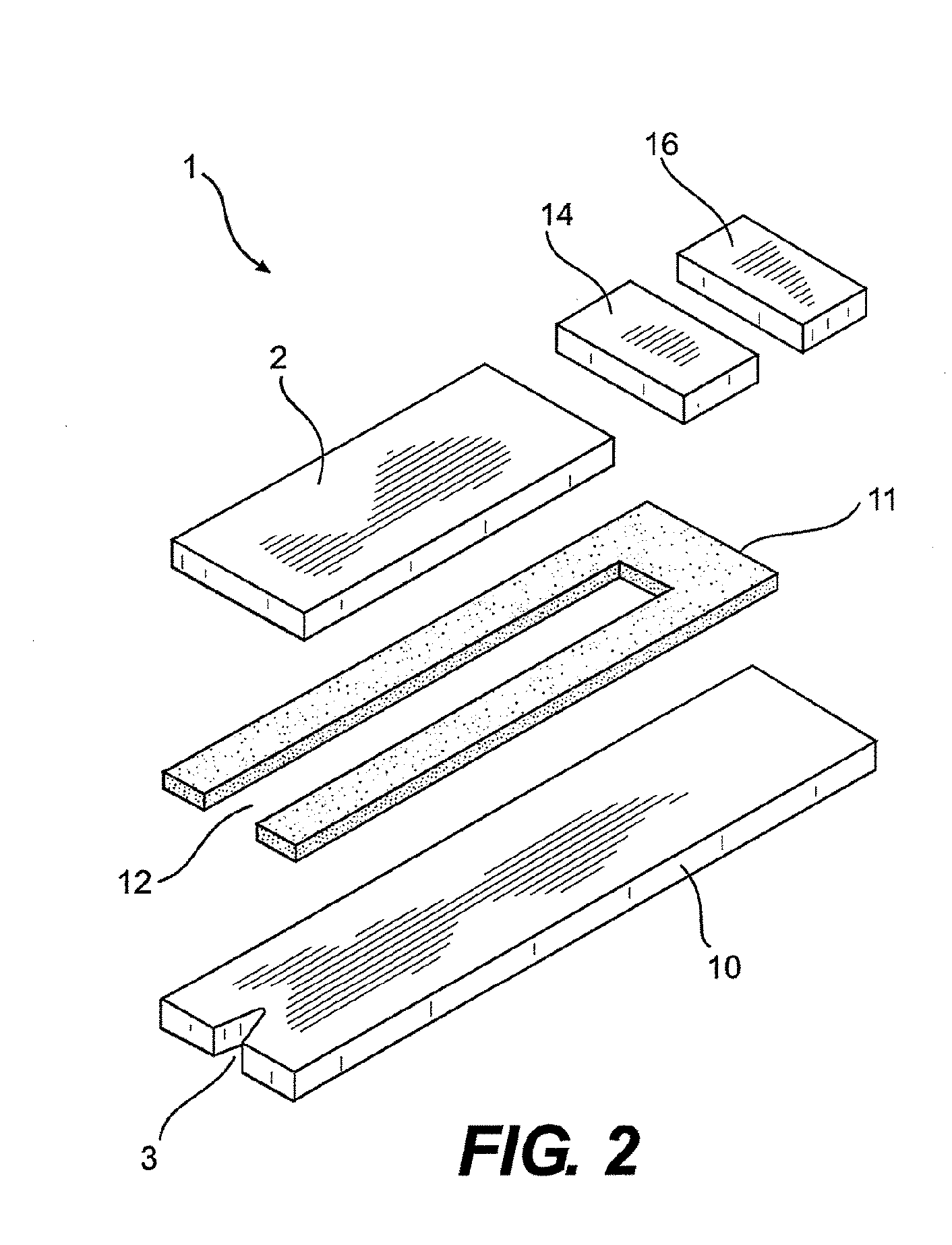

An analytical test element for determining an analyte in a body fluid comprises a detection area in which the analyte is detected and an application site at which the body fluid can be applied to the test element. The application site is spaced apart from the detection area, wherein at least some of the body fluid applied to the application site moves from the application site to the detection area. The test element also comprises a contamination area which at least partially adjoins the application site, wherein an adhesive substance is applied to at least part of the contamination area of the test element. The adhesive substance adheres to the contamination area of the test element and is able to interact with an excess amount of applied body fluid such that at least some of the body fluid adheres to the test element and thereby an excess amount of body fluid remains in the contamination area. An additional embodiment provides for test elements which, after use, can be stored in a storage container. Another embodiment provides for the production of the test elements.

Owner:ROCHE DIABETES CARE INC

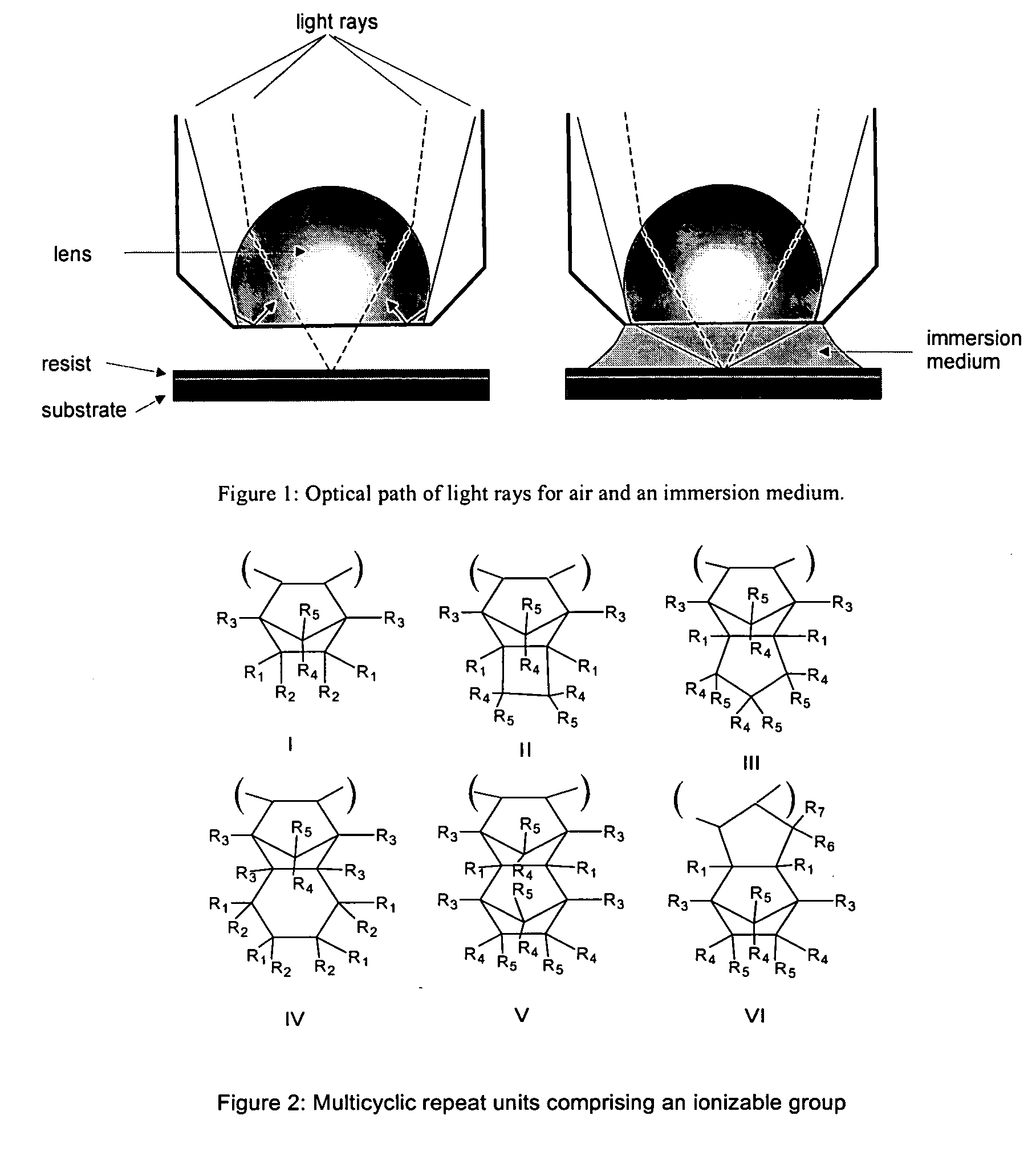

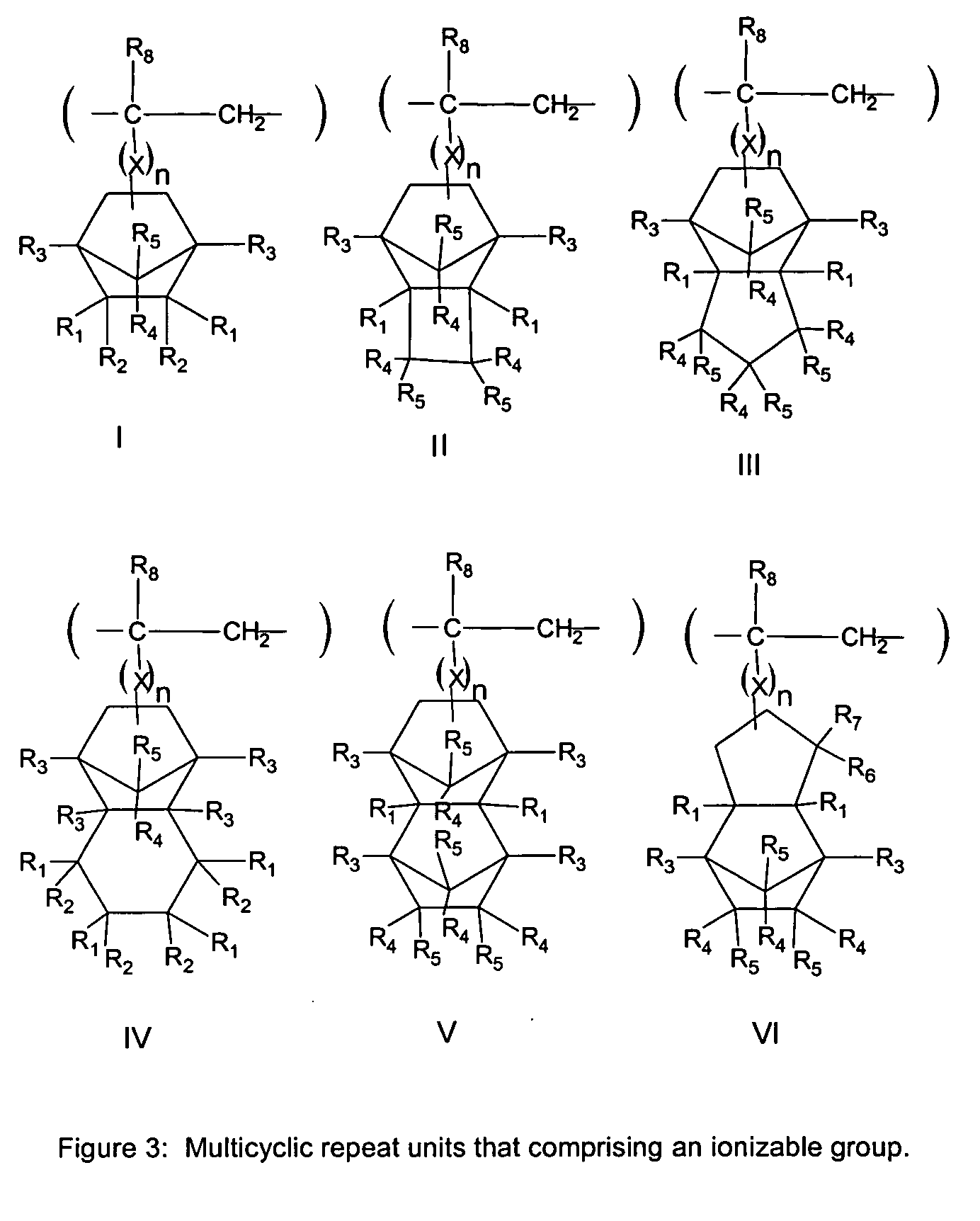

Process of imaging a deep ultraviolet photoresist with a top coating and materials thereof

InactiveUS20050202347A1Avoid polluting the environmentSemiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersUltravioletPhotoresist

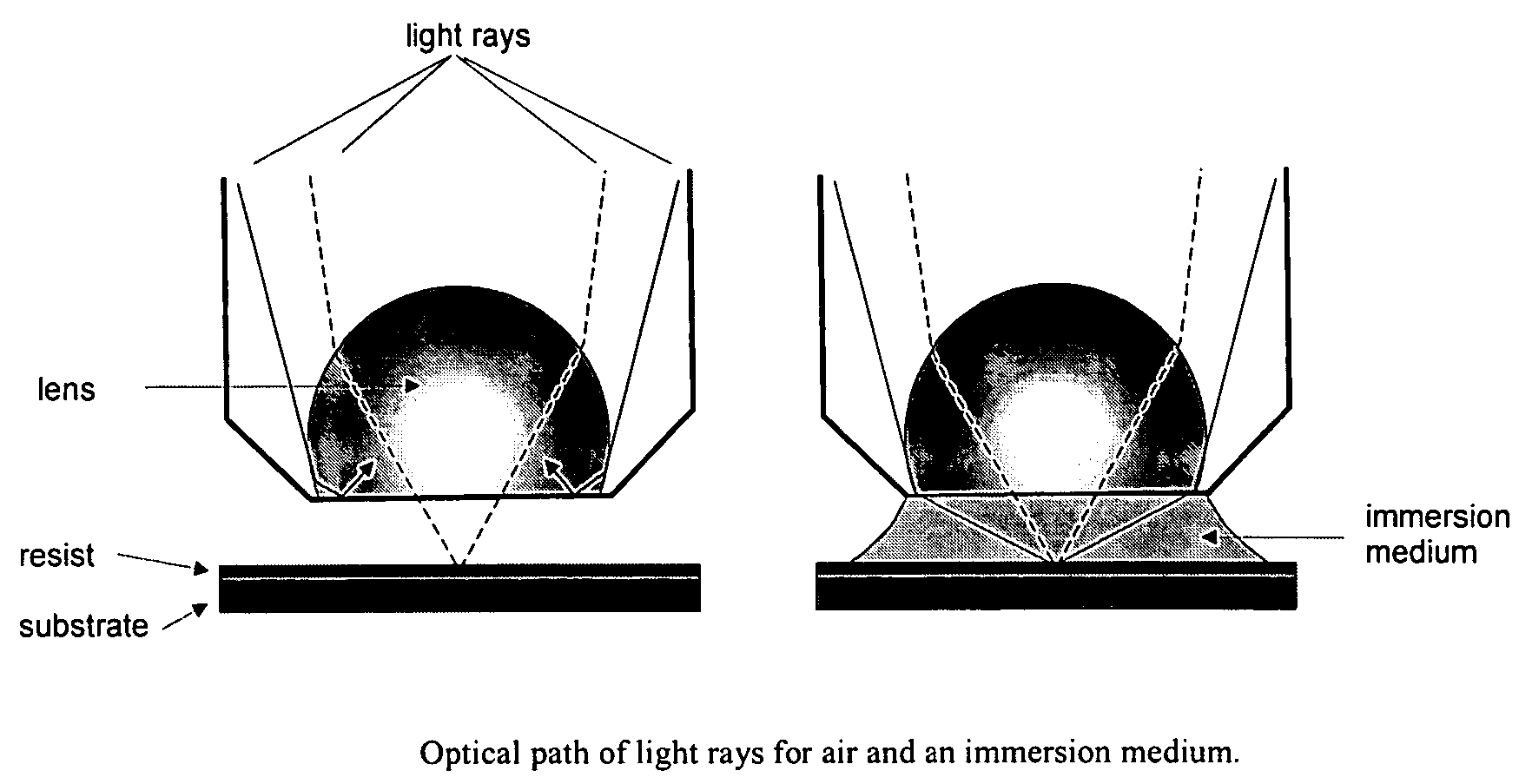

The present invention relates to a process for imaging deep ultraviolet (uv) photoresists with a topcoat using deep uv immersion lithography. The invention further relates to a topcoat composition comprising a polymer with at least one ionizable group having a pKa ranging from about −9 to about 11. The invention also relates to a process for imaging a photoresist with a top barrier coat to prevent contamination of the photoresist from environmental contaminants.

Owner:AZ ELECTRONICS MATERIALS USA CORP

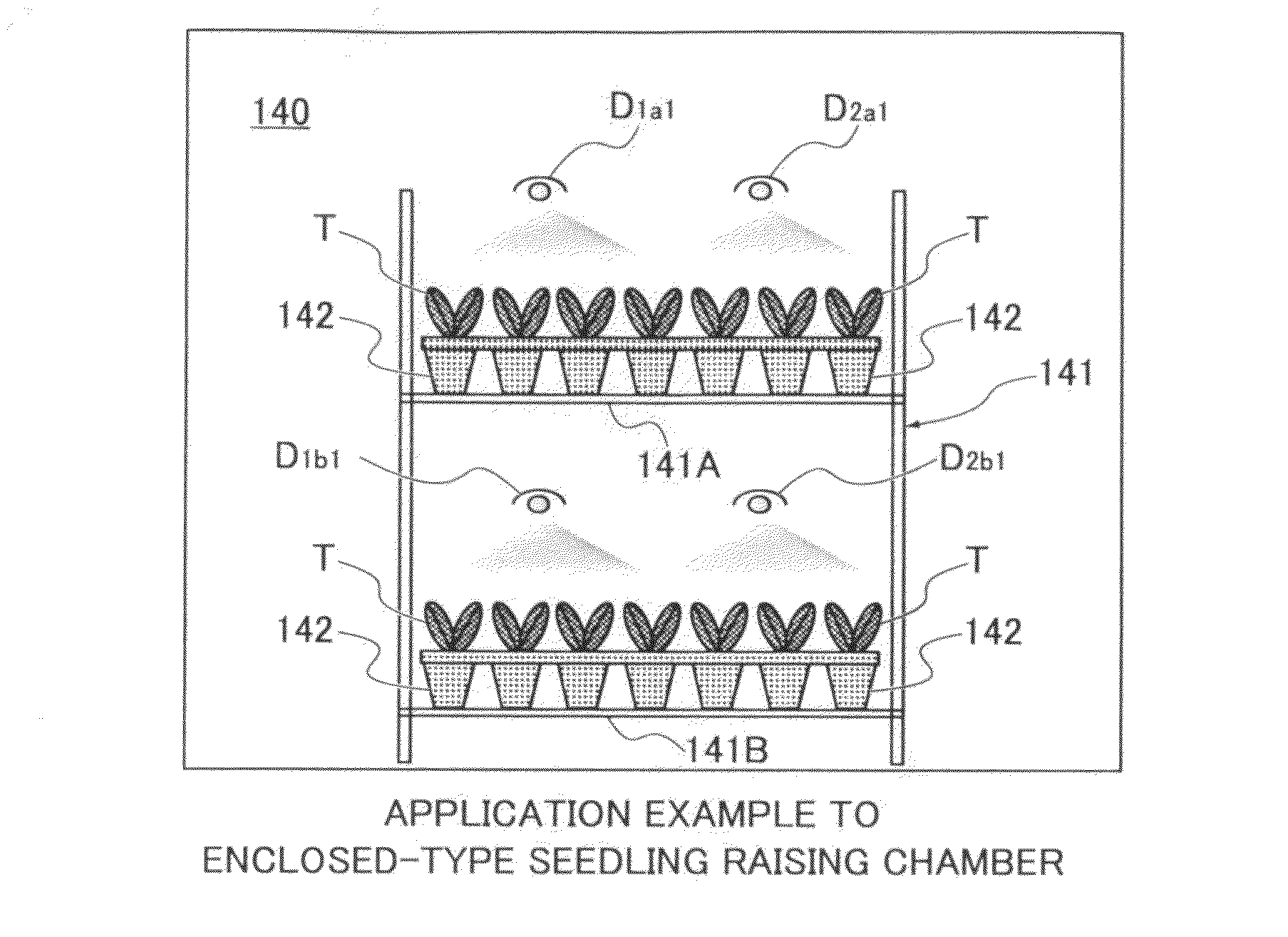

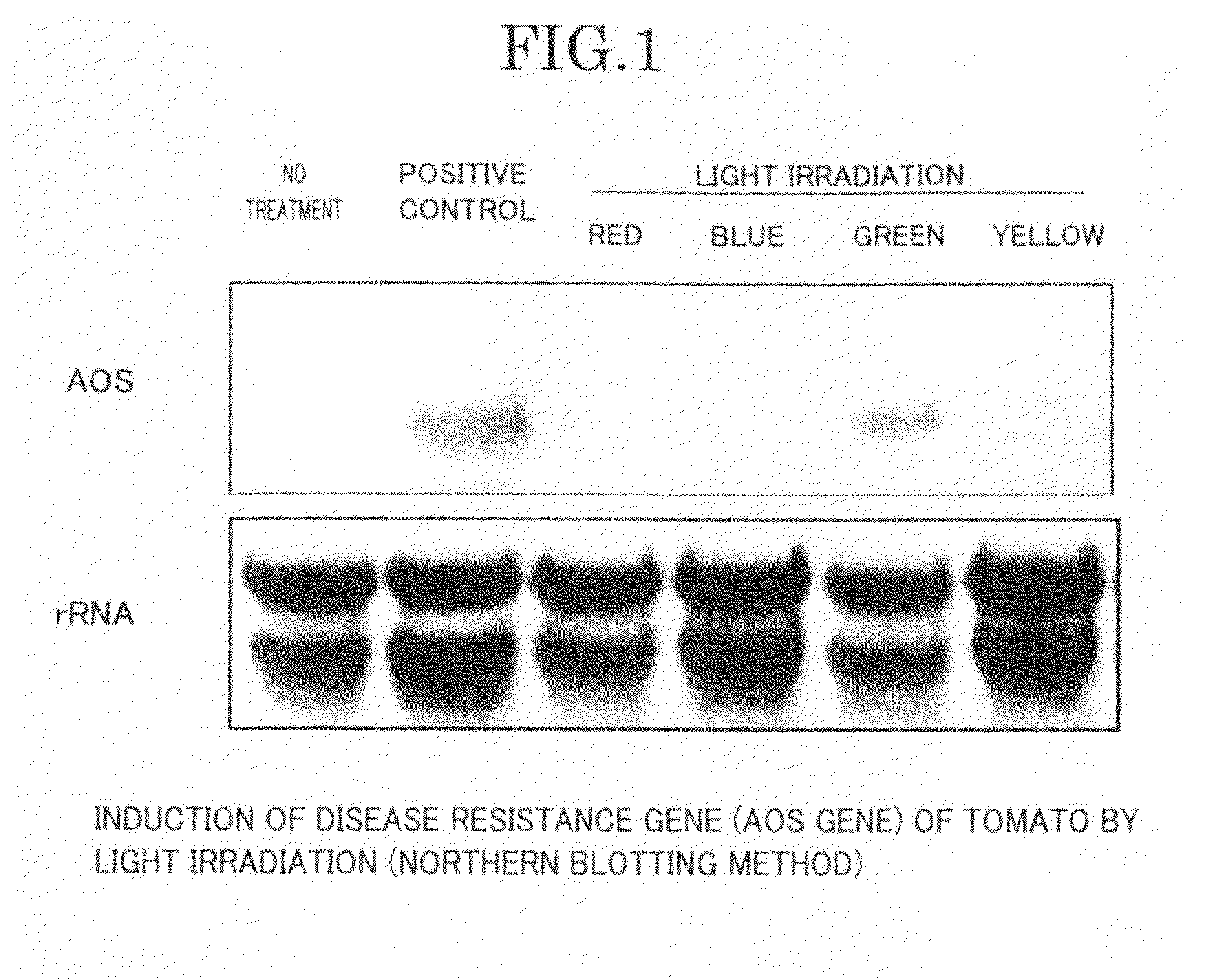

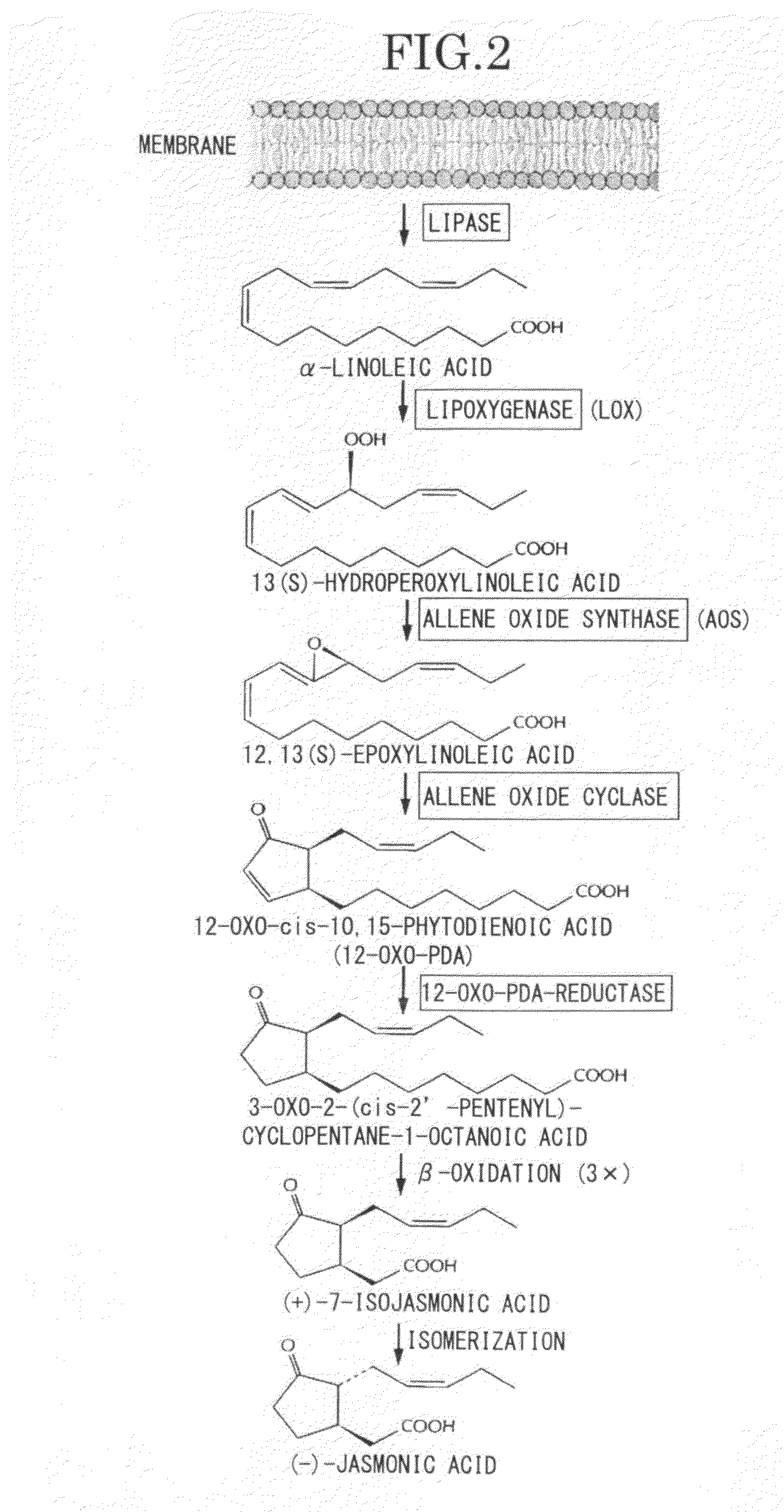

Disease Control Method and Disease Control Device

InactiveUS20100281771A1Improve plant resistanceReduce the amount requiredRoot feedersSaving energy measuresGreen-lightIrradiation

A disease control device has light emitting diodes (D1 to Dn) emitting green light and a controller (2) controlling a drive circuit (1) for turning on the light emitting diodes (D1 to Dn). The drive circuit (1) is controlled by the controller (2) to cause the light emitting diodes (D1 to Dn) to emit green light to irradiate plants with the light. The irradiation with the green light enhances resistance of the plants against diseases.

Owner:SHIKOKU RES INST +1

Biaxial drawing polylactic acid compound film with barrier property and preparation method thereof

ActiveCN102501529AAvoid white pollutionAvoid polluting the environmentSynthetic resin layered productsThin membraneAnoxomer

The invention discloses a biaxial drawing polylactic acid compound film with a barrier property and a preparation method thereof. The compound film comprises two polylactic acid layers and a barrier layer arranged between the two polylactic acid layers, wherein each polylactic acid layer comprises the following components in weight percentage: 75-100 percent of crystalline polylactic acid, 0-5 percent of melt reinforcing agent, 0-5 percent of toughening agent, 0-5 percent of antistatic agent, 0-5 percent of antioxygen, 0-5 percent of slipping agent and 0-5 percent of antiblocking agent, and the barrier layer is fully biodegradable and is provided with a carbon dioxide copolymer with the gas barrier property. According to the preparation method, a multilayer co-extrusion gradual or synchronous biaxial drawing process is adopted. The compound film can be fully biodegradable, has very good oxygen, carbon dioxide and moisture barrier property, higher tensile strength, high puncture resistance and high deflection, and can be used for packages of foods, cosmetics, electronic products, chemicals and the like.

Owner:FSPG HI TECH

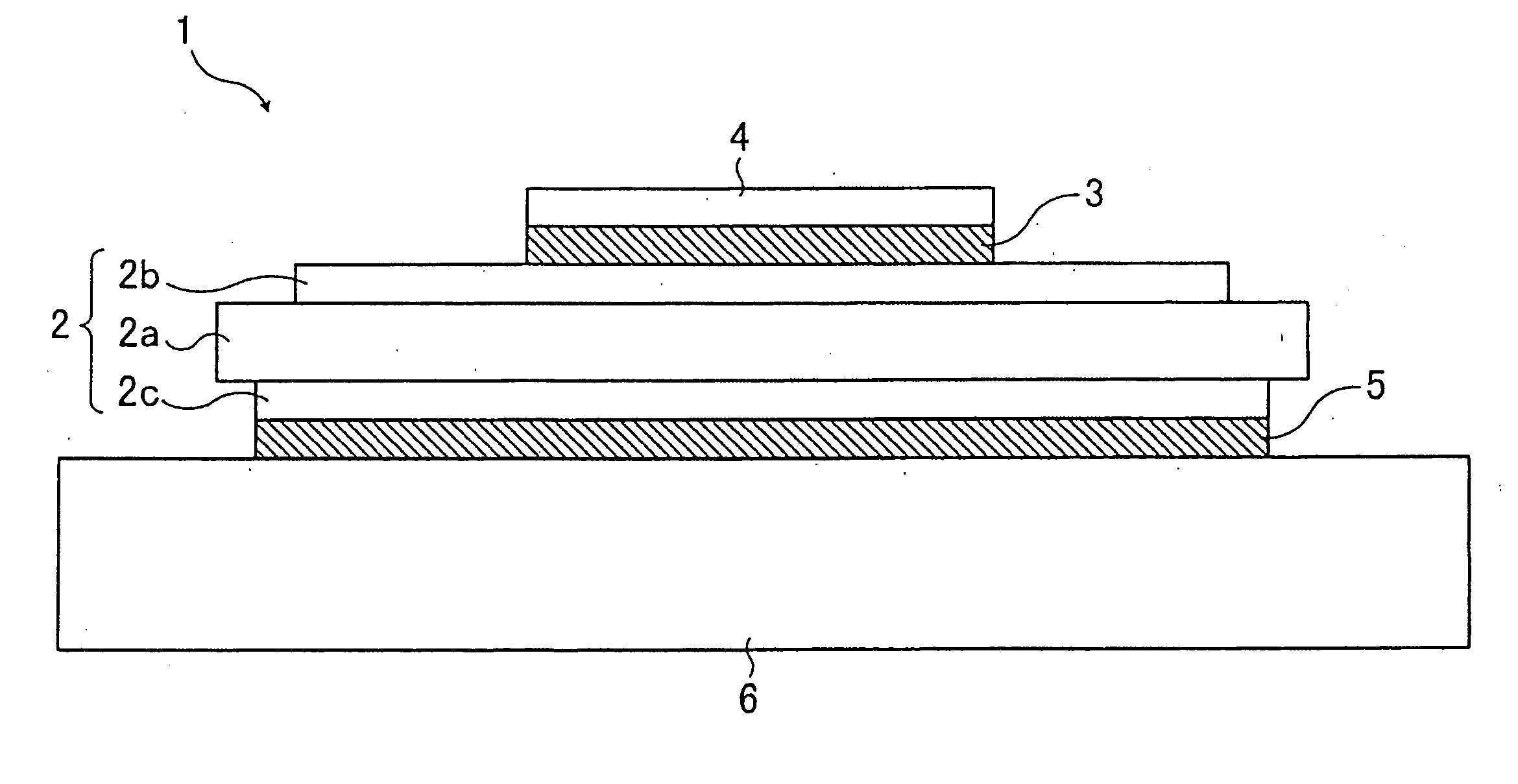

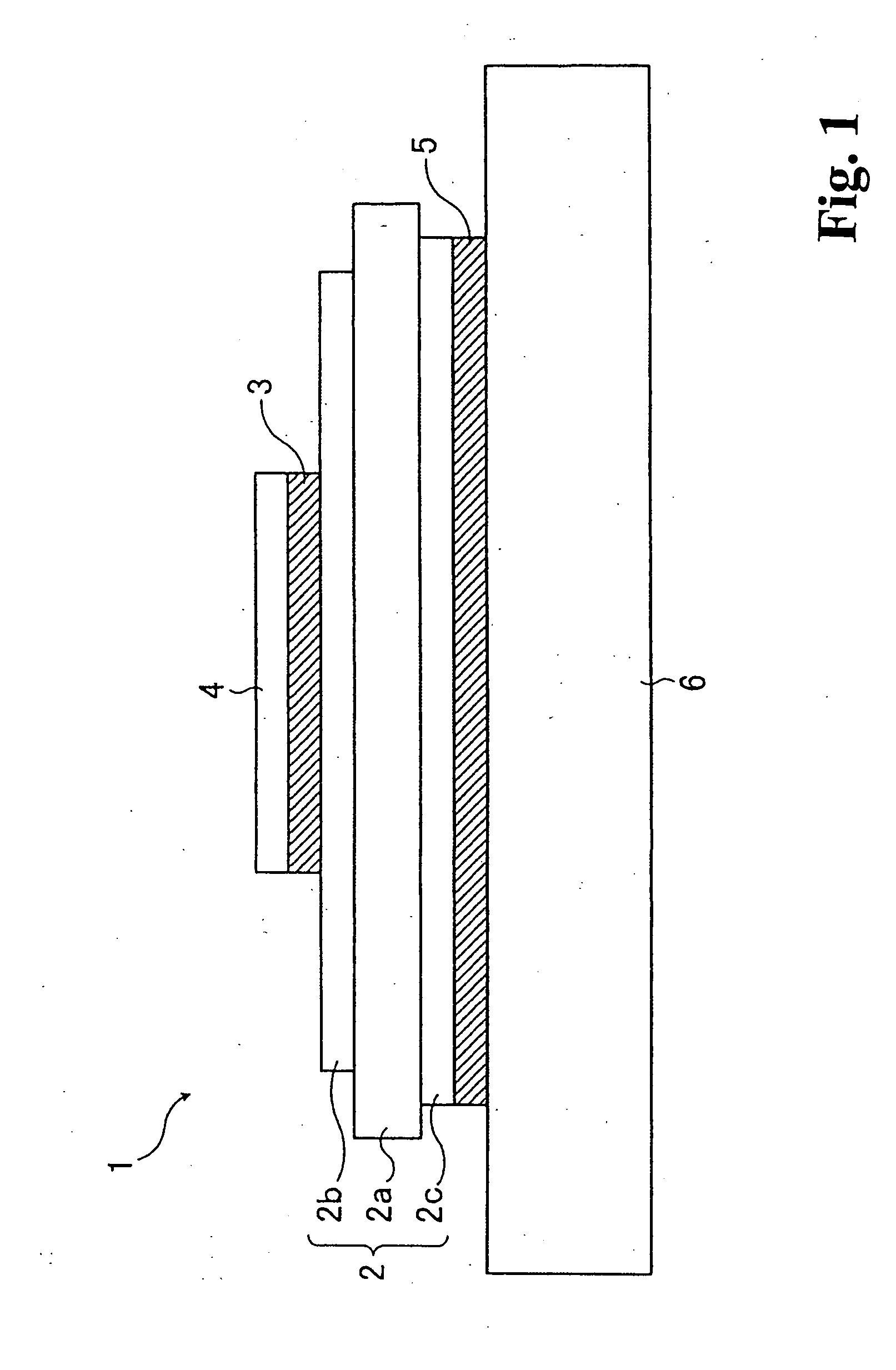

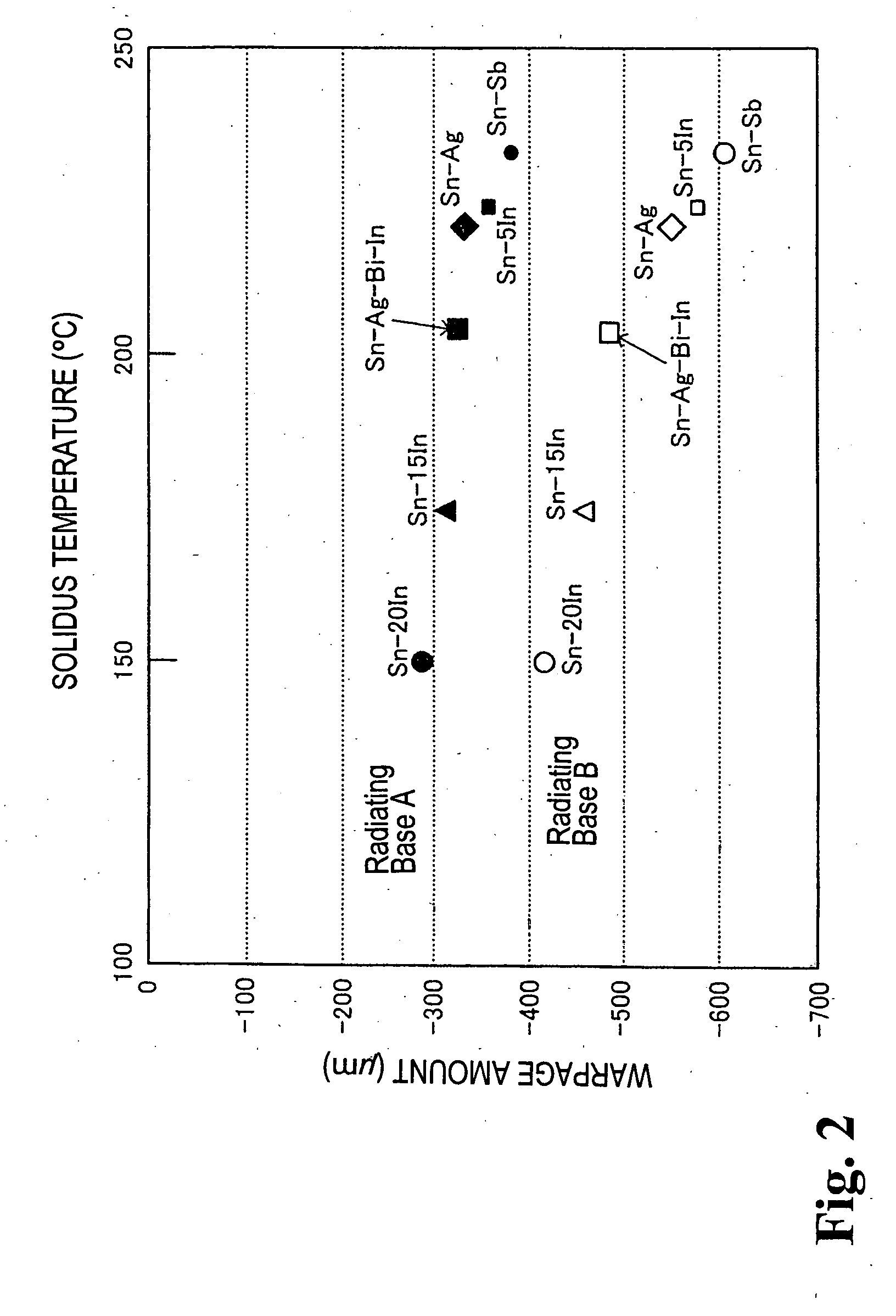

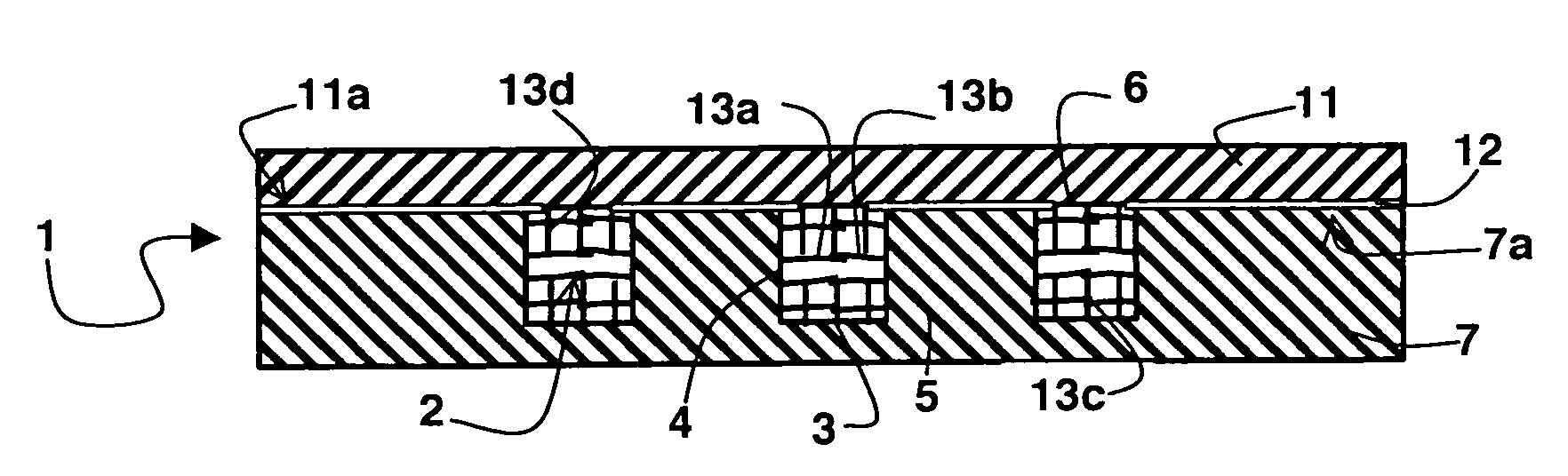

Semiconductor device and method for producing the same

InactiveUS20060157862A1Deterioration of the ceramic board can be preventedInhibit deteriorationGarment special featuresSemiconductor/solid-state device detailsPower semiconductor deviceElectrical conductor

A high-reliability power semiconductor device uses a lead-free solder layer to connect a semiconductor chip such as an IGBT to an insulating substrate having a ceramic board and conductor layers, and a lead-free solder layer to connect the insulating substrate to a radiating base. Before the insulating substrate and the radiating base are solder-connected, the radiating base is warped such that the surface of the radiating base on the side opposite to the insulating substrate is convex. The insulating substrate is solder-connected onto the warped radiating base with the lead-free solder so as to provide a substantially flat solder-connected radiating base. When the radiating base is attached to a cooling fin, the thermal resistances are lower, and heat from the semiconductor chip is effectively dissipated so as to prevent abnormal temperature rise.

Owner:FUJI ELECTRIC CO LTD

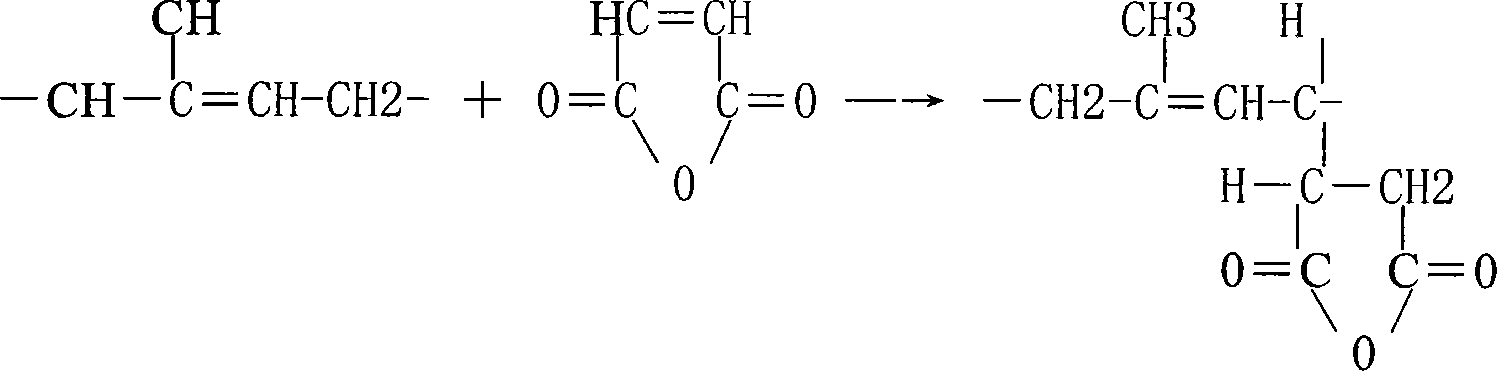

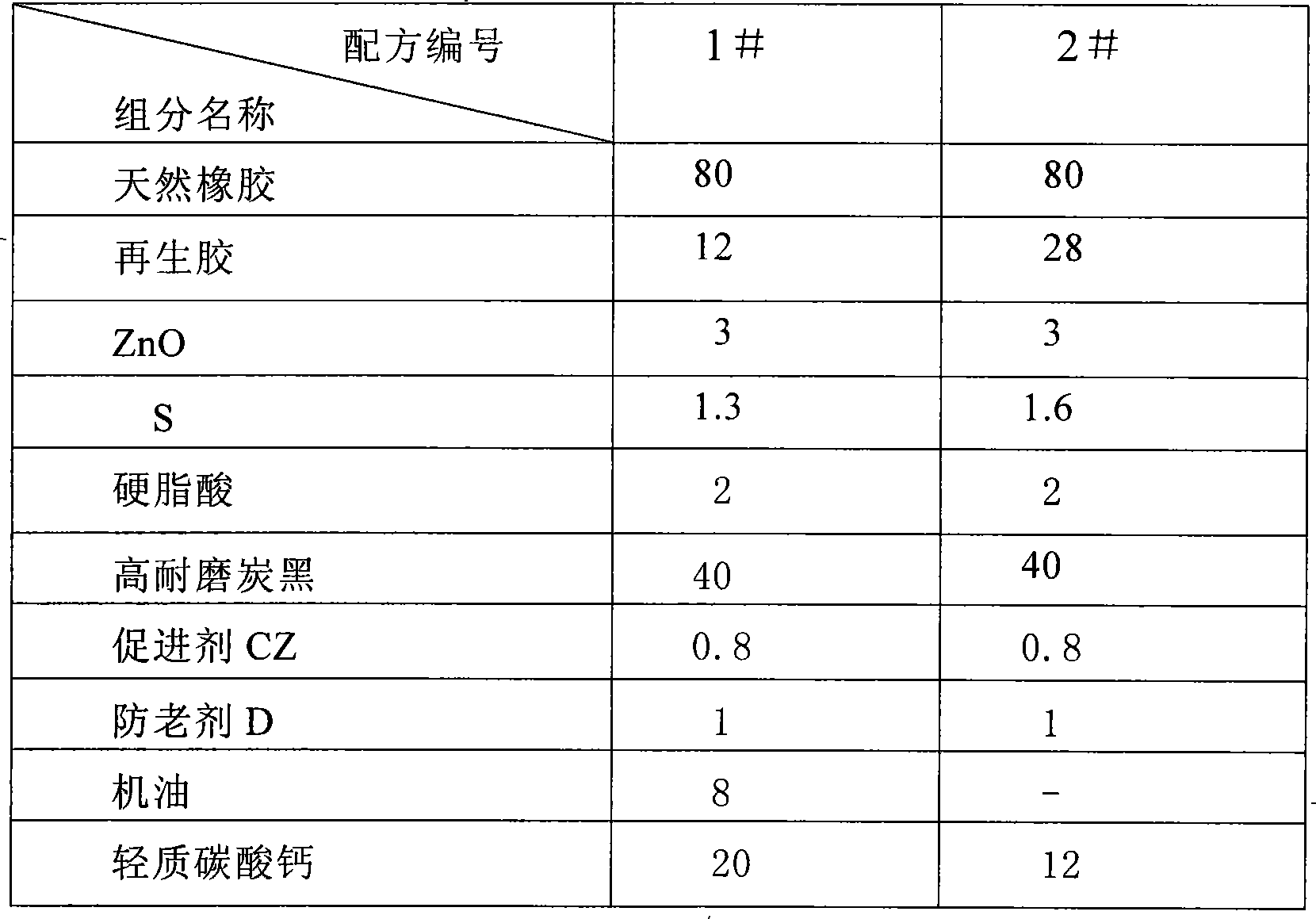

Plaster-shape regenerated rubber and preparation method thereof

InactiveCN101100534ASimple processNo need to consume electricityPlastic recyclingFiberPolymer science

A creamed reclaimed rubber and its production are disclosed. It consists of 20-50 mesh vulcanized rubber powder 100 proportion, paraffin oil as solvent 70-90 proportion, solid coumarone 10-30 proportion as solvent, catalyst and catalyst accessory phthalic acid anhydride 2-5 proportion, methyl aldehyde aqueous solution 4-6 proportion, 1,3-benzenediol 0.2-0.5 proportion. The process is carried out by adding vulcanized rubber powder into vertical de-polymerizer, adding into solvent, catalyst and catalyst accessory successively, closing feeding open, agitating, raising temperature to 160-180 deg. C, controlling pressure to 0.5-0.7 MPa, reacting for 2-2.5 hrs, lowering temperature, releasing gas, discharging and filtering to obtain final product. It's simple, has stable quality, waterproof and antiseptic performances and no environmental pollution. It can be used to synthesize rubber with petrochemical asphalt and to paving road.

Owner:TIANJIN YATENGDA RUBBER & PLASTIC PRODS DEV

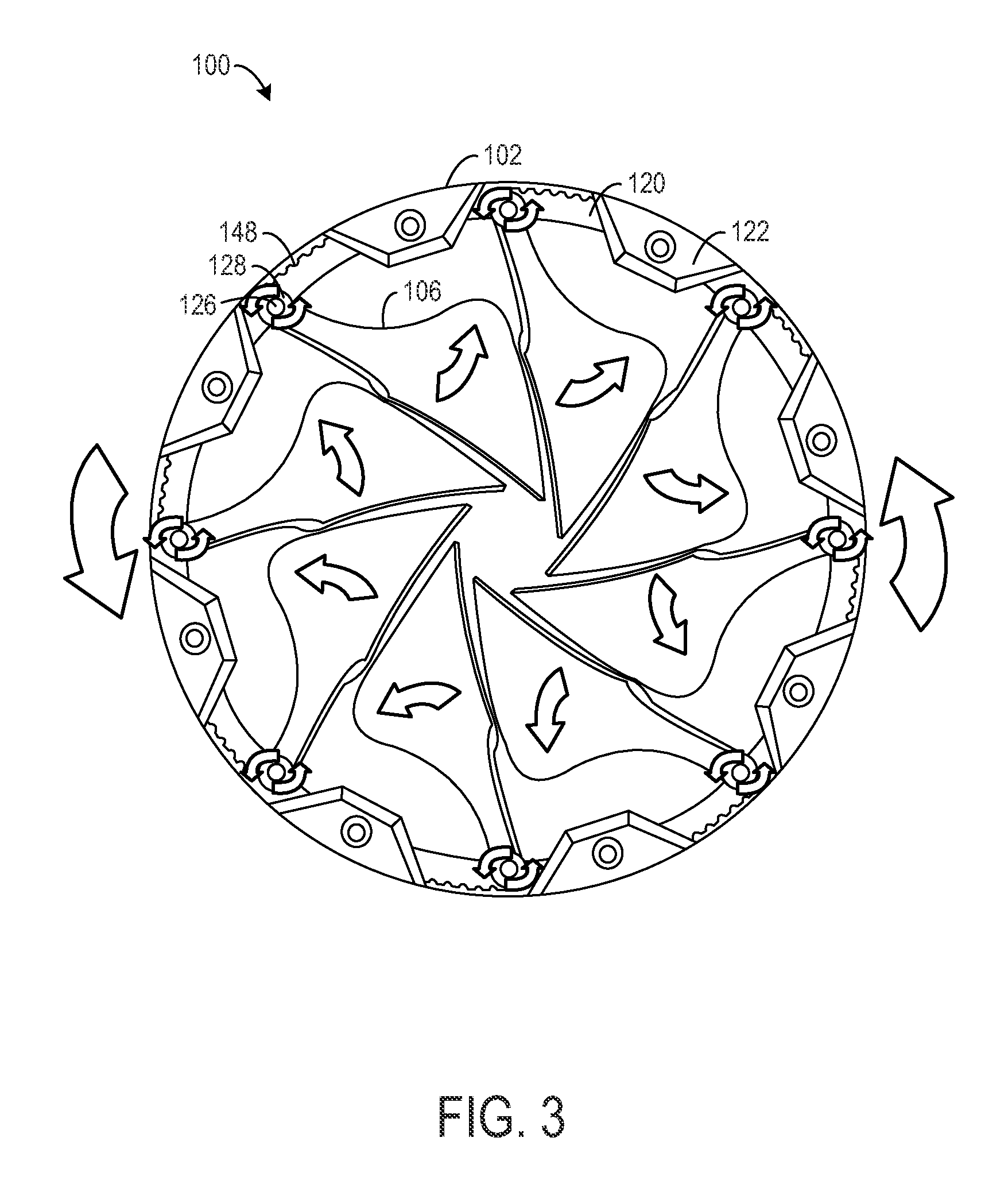

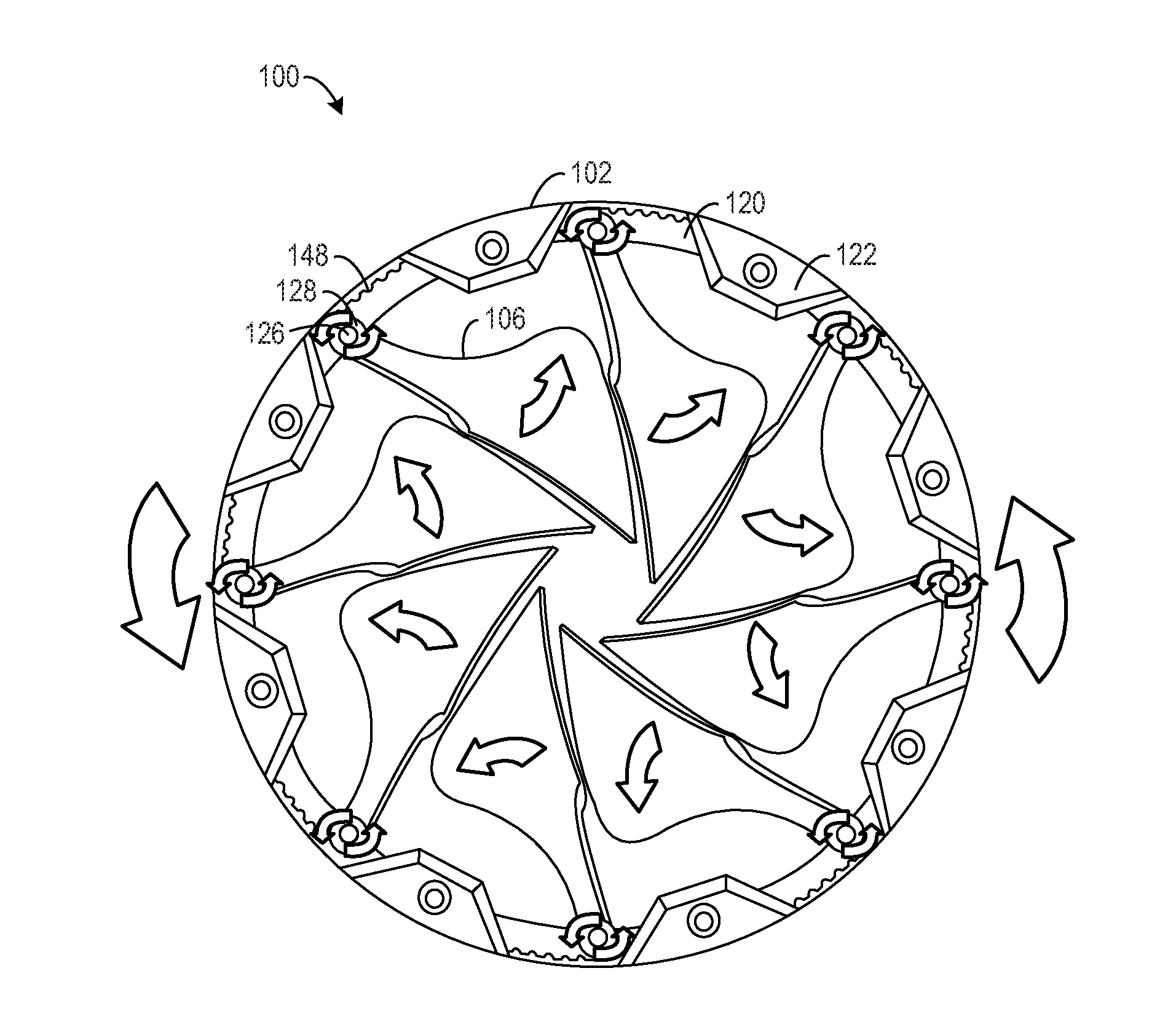

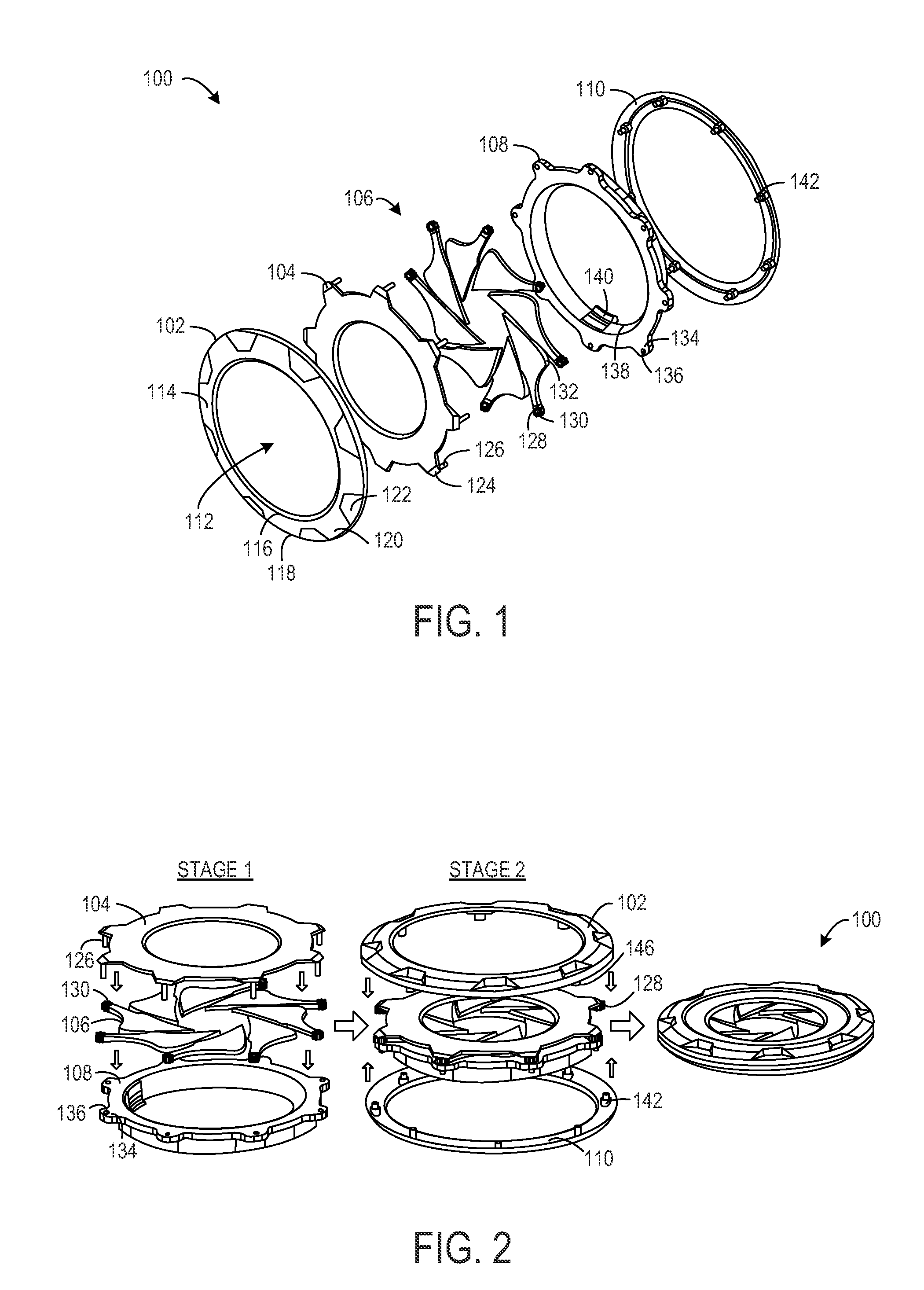

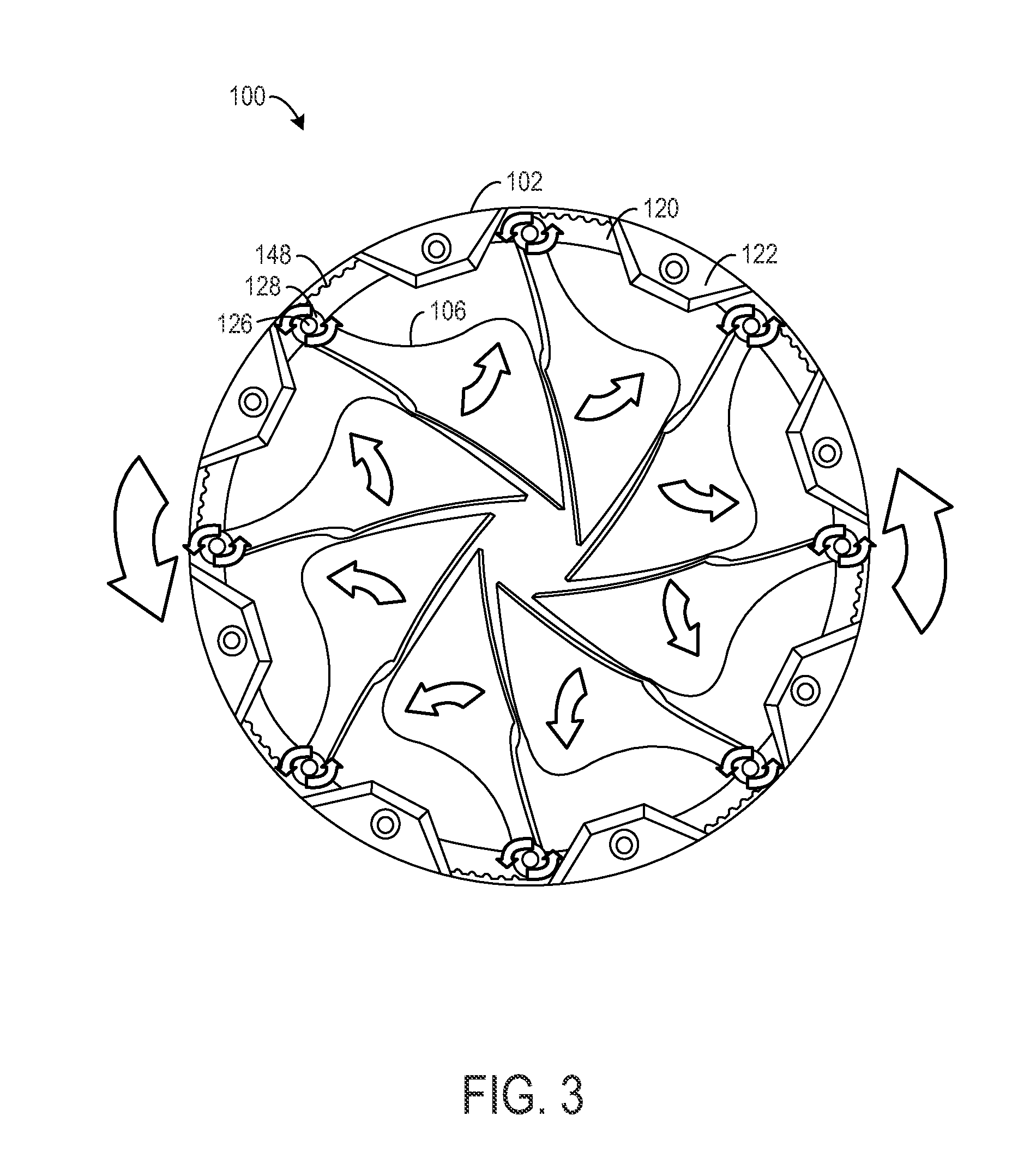

Capless fuel-filling closure assembly

InactiveUS8430140B2Simplifies refuelingSimple processSuperstructure subunitsSolid materialEngineeringMechanical engineering

Owner:FORD GLOBAL TECH LLC

Capless fuel-filling closure assembly

InactiveUS20110132905A1Simplify refueling processSimplifies refuelSuperstructure subunitsSolid materialMechanical engineering

Owner:FORD GLOBAL TECH LLC

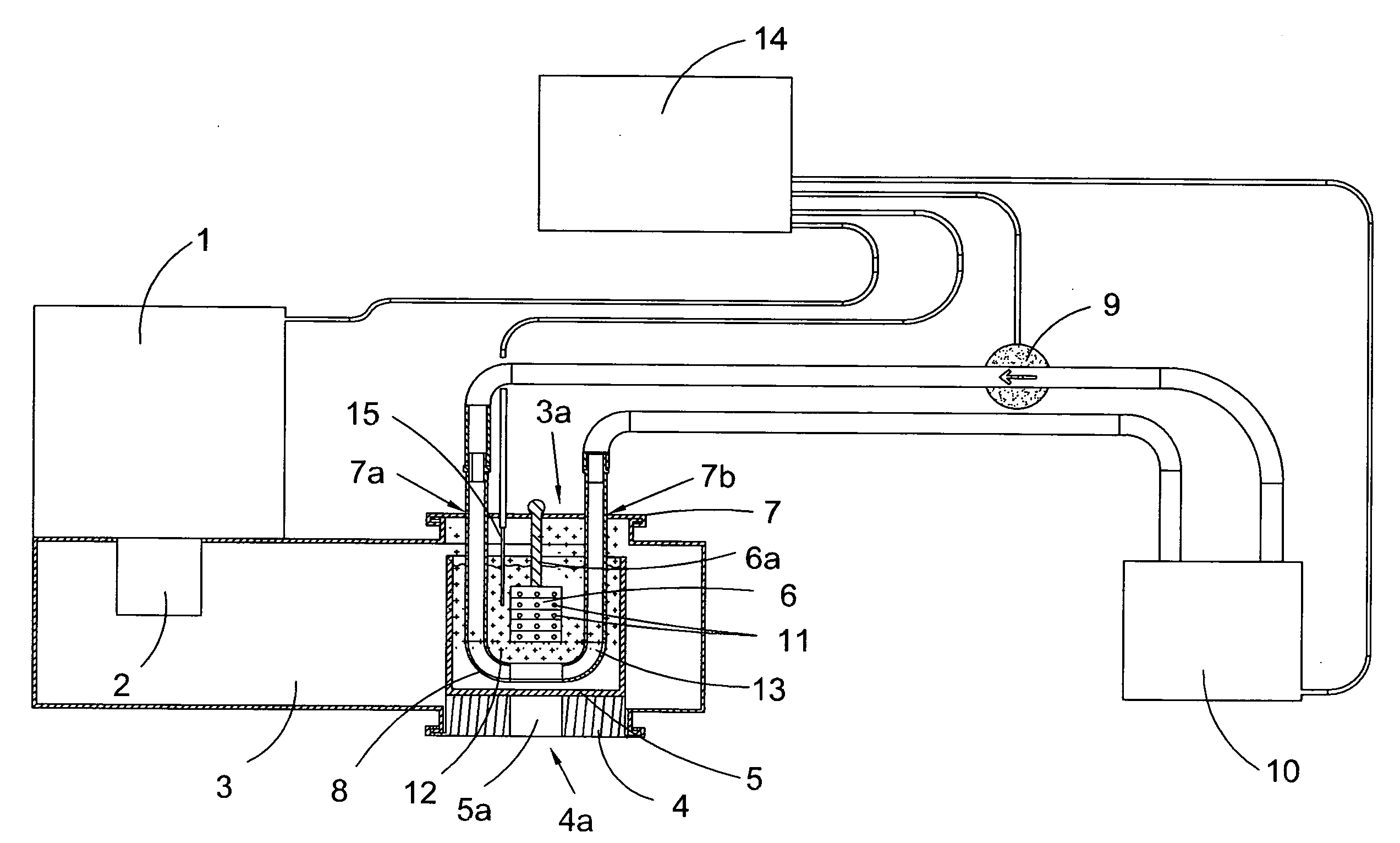

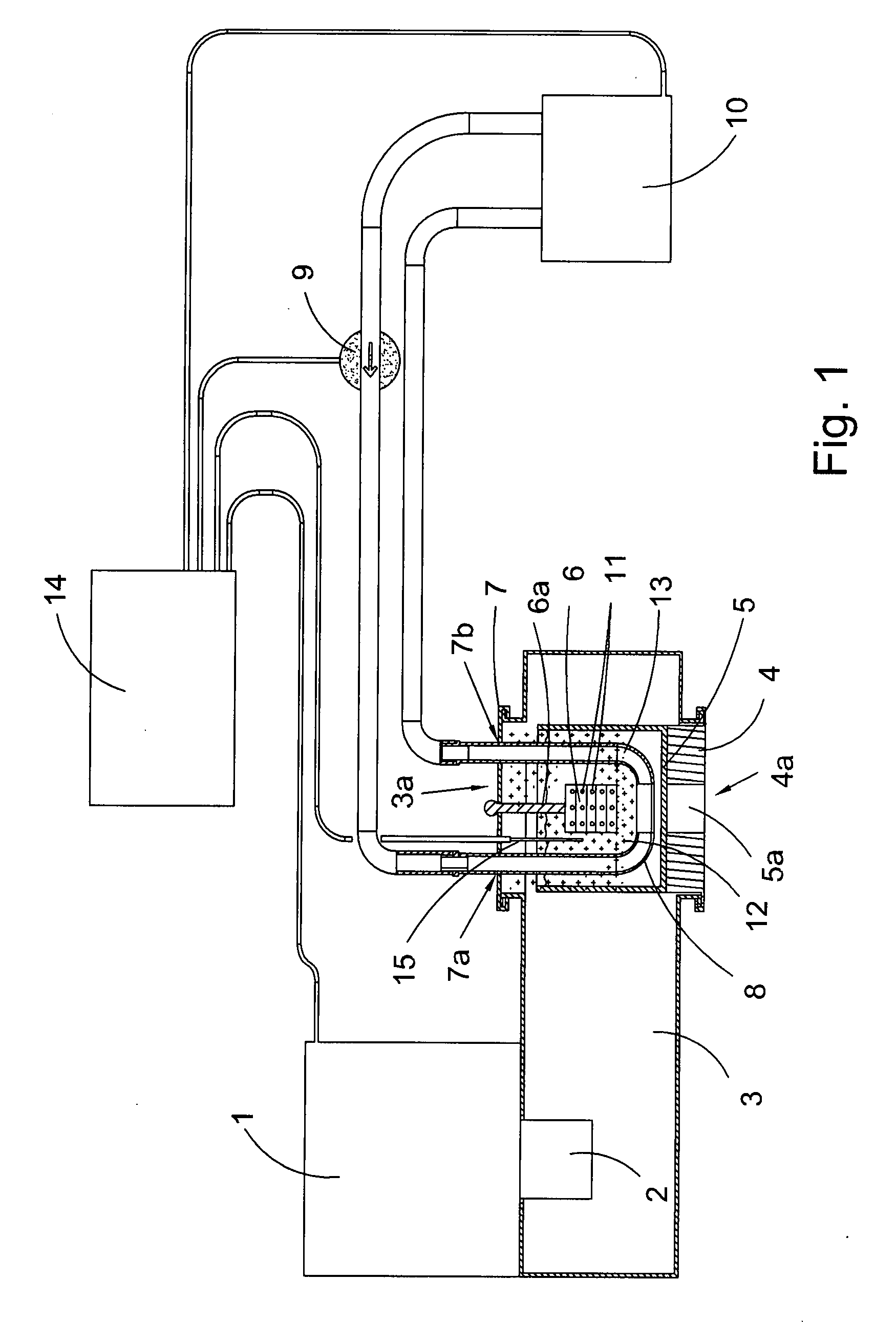

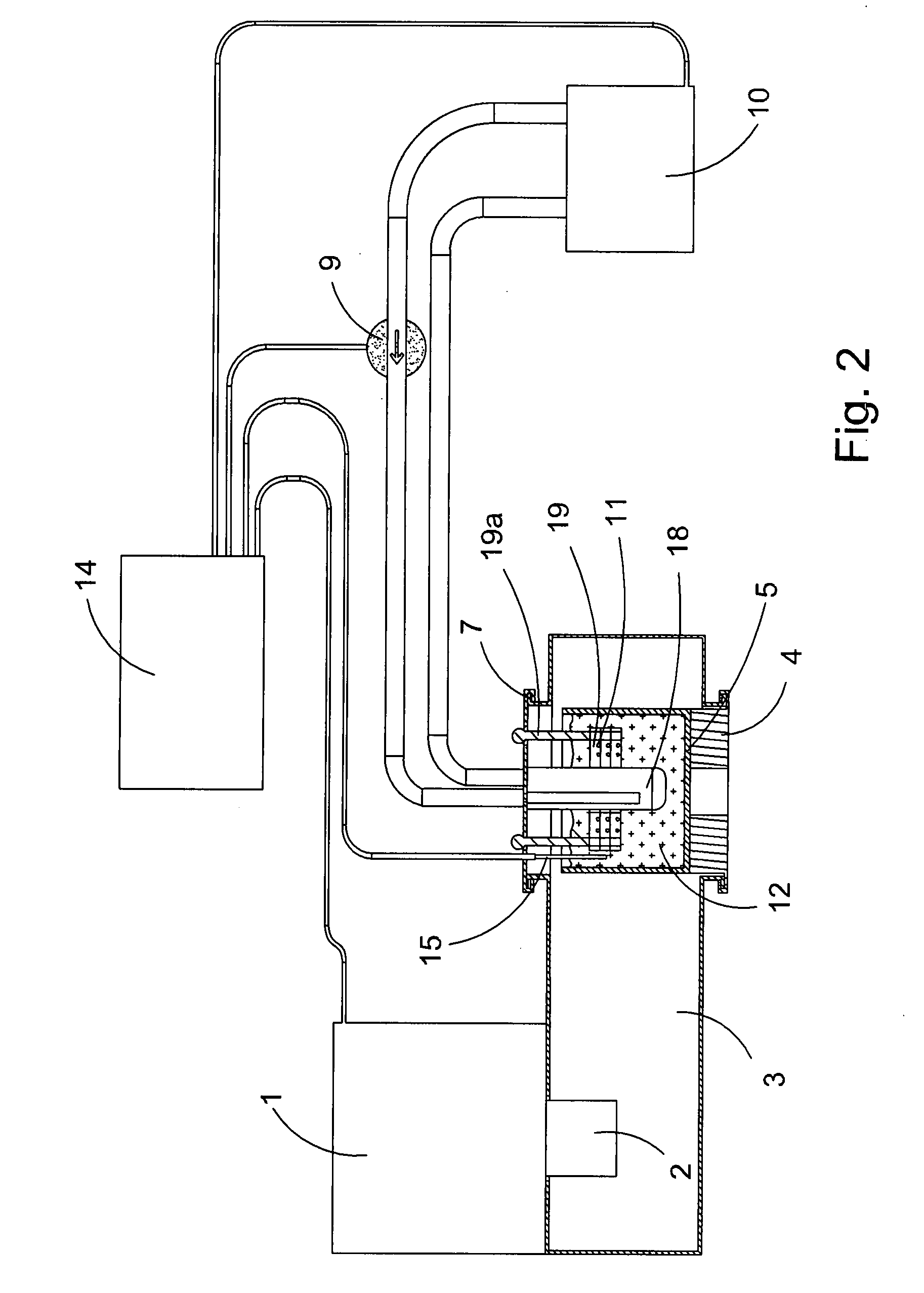

Apparatus for microwave-assisted specimen preparation

InactiveUS20070235448A1Easy to monitorHighly homogeneousPreparing sample for investigationMicrowave heatingSpecimen preparationWaveguide

In an apparatus for microwave-assisted preparation of specimens, the microwave chamber for reception of specimens to be processed is embodied as a waveguide (3), in particular as a monomode waveguide, and is equipped with at least one opening (3a) for introduction of the at least one specimen (11) into the waveguide. A cooling circuit comprises a cooling means (8) adapted to cool the fluid (12), which fluid surrounds the at least one specimen and is separated from the cooling liquid of the cooling circuit, in the region of the at least one specimen (11) inside the waveguide. The opening (3a) can be sealed in microwave-tight fashion, by means of a closure means (7), during operation of the apparatus.

Owner:LEICA MICROSYSTEMS GMBH

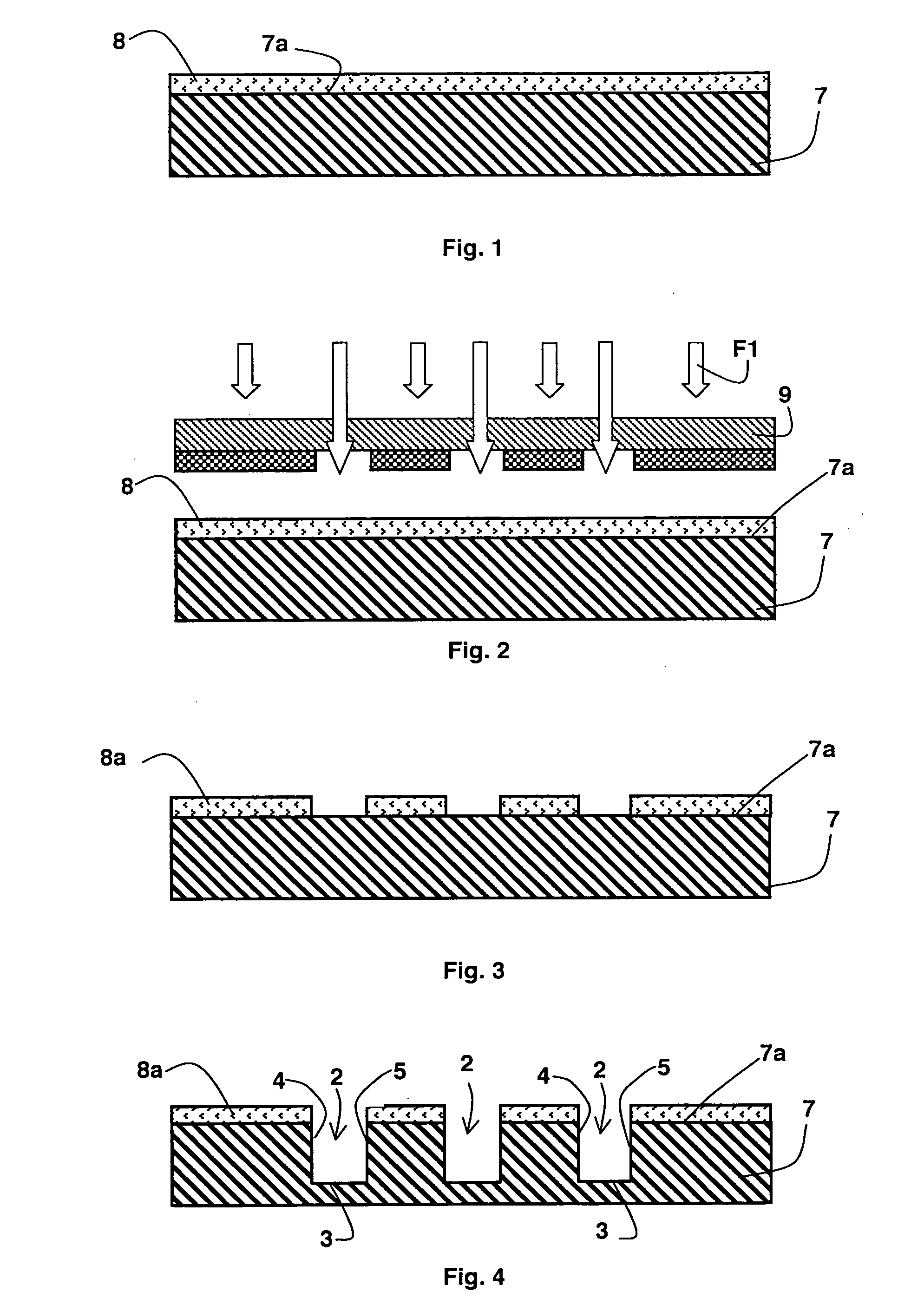

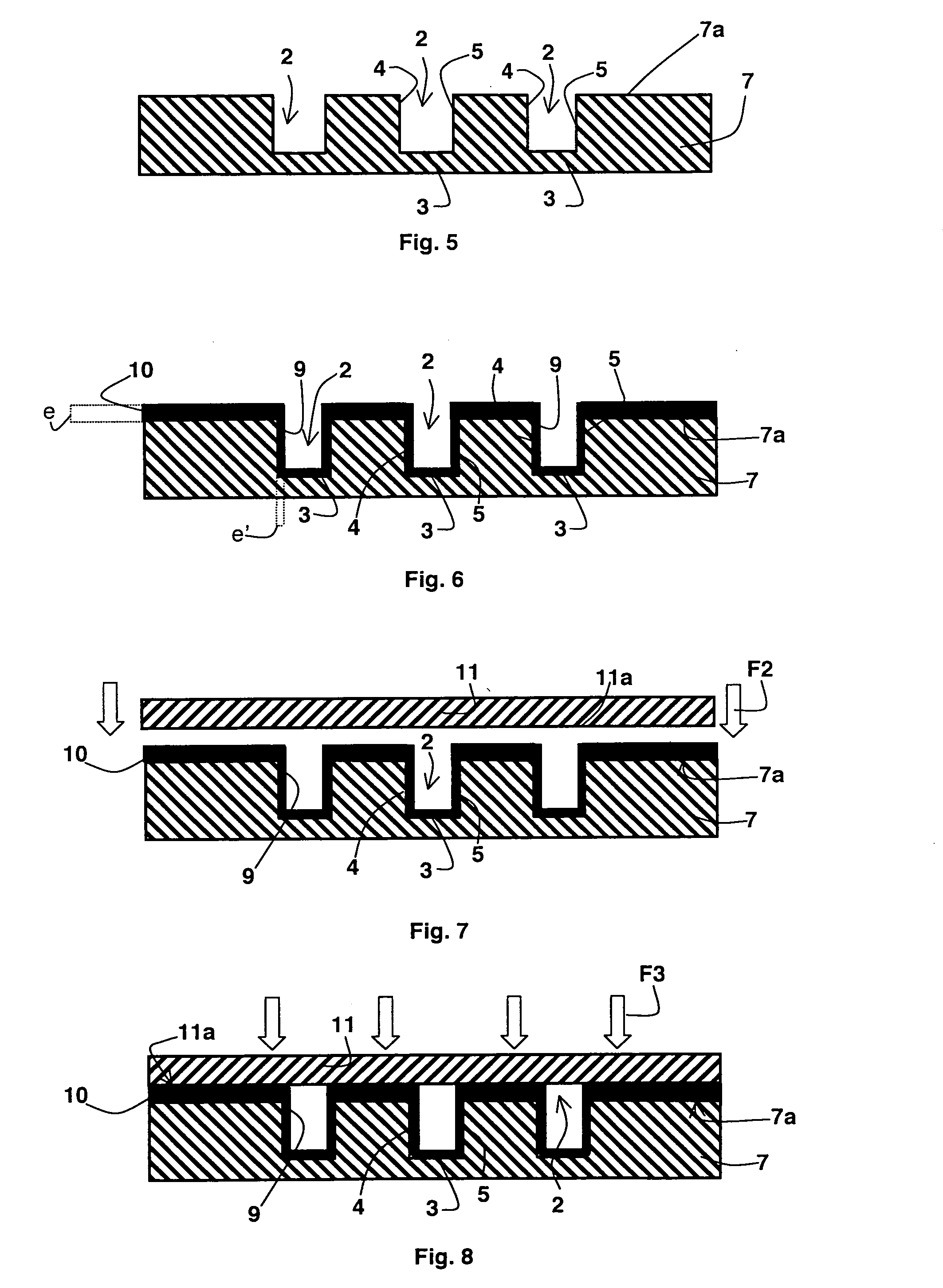

Method for fabricating a microfluidic component comprising at least one microchannel filled with nanostructures

InactiveUS20090084496A1Avoid polluting the environmentEasy and inexpensiveLamination ancillary operationsChemical/physical/physico-chemical microreactorsEngineeringNanostructure

A microfluidic component comprises at least one closed microchannel filled with nanostructures. The microchannel is produced by previously forming an opening delineating a bottom wall and two opposite side walls of the microchannel in a surface of a substrate. The nanostructures filling said microchannel are formed by in situ growth to constitute a layer of metallic catalyst deposited on said side walls and on said wall bottom. The microchannel is closed, before the nanostructures are formed, by sealing a protective cover onto said surface of the substrate. Sealing is obtained by formation of an eutectic compound between a material of the cover and the metal of the catalyst used for in situ growth of the nanostructures and deposited on the surface of the substrate designed to come into contact with the cover.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Polyvinyl butyral foamed material

The invention discloses a polyvinyl butyral foamed material, which belongs to the field of high molecular materials. Recycled waste and used polyvinyl butyral is taken as a main raw material; rubber or an elastomer is taken as a main auxiliary material; a foaming agent, a foaming auxiliary agent, a plasticizing agent, a foamed hole nucleating agent, a foamed hole regulating agent, a crosslinking agent, a filler and the like are taken as the auxiliary materials; all the materials are mixed in a high-speed mixing machine at high speed, melted and blended in an extruding machine or an enclosed mixing machine, and formed through compression molding foaming in a flat-plate vulcanizing machine to obtain a polymer foamed material. The foamed material has excellent performance of an elastomer foamed material, has excellent cohesive property, is easy to process, and can be changed from wastes to valuables.

Owner:LUOHE IRON HORSE RUBBER PROD CO LTD

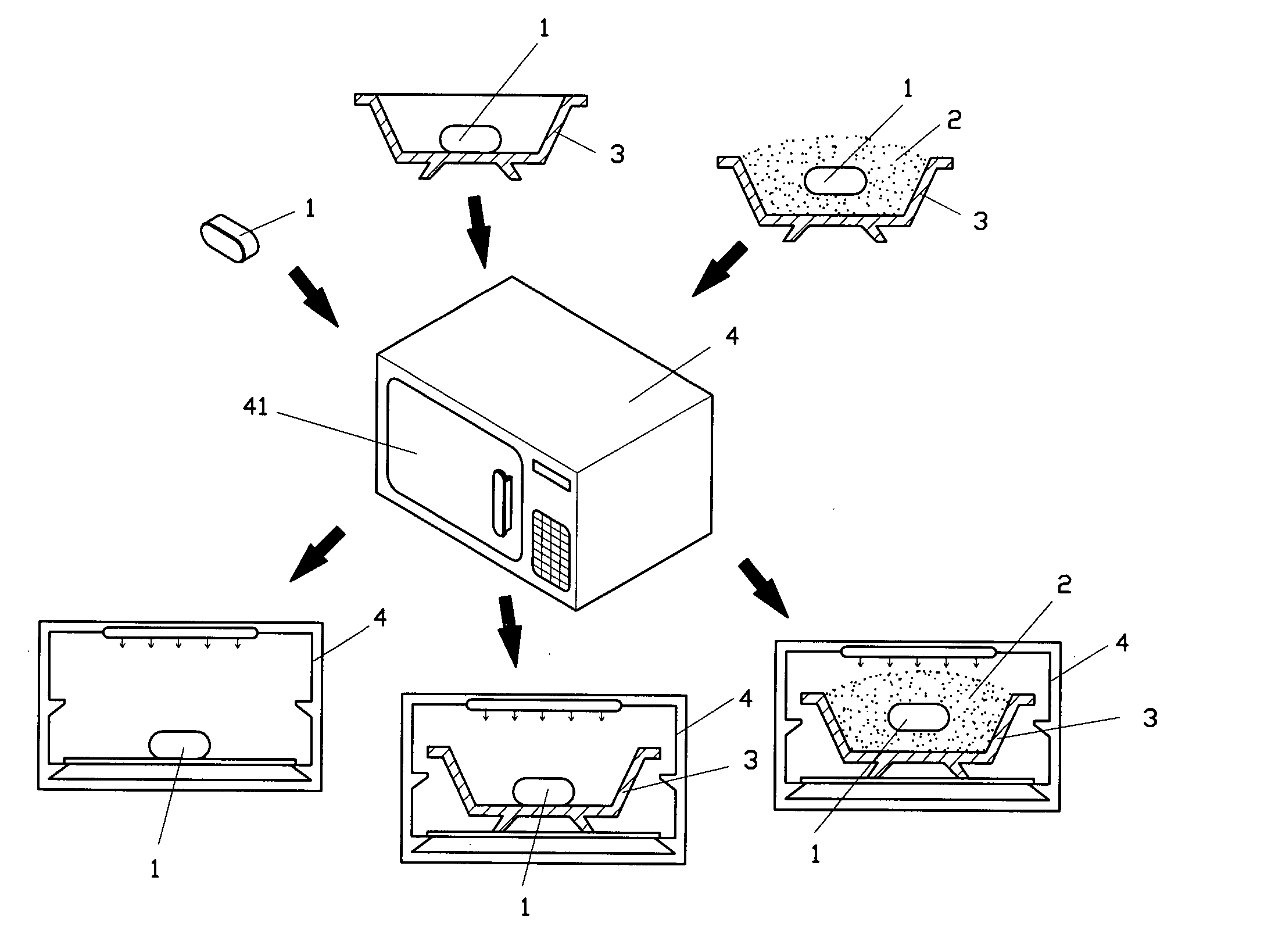

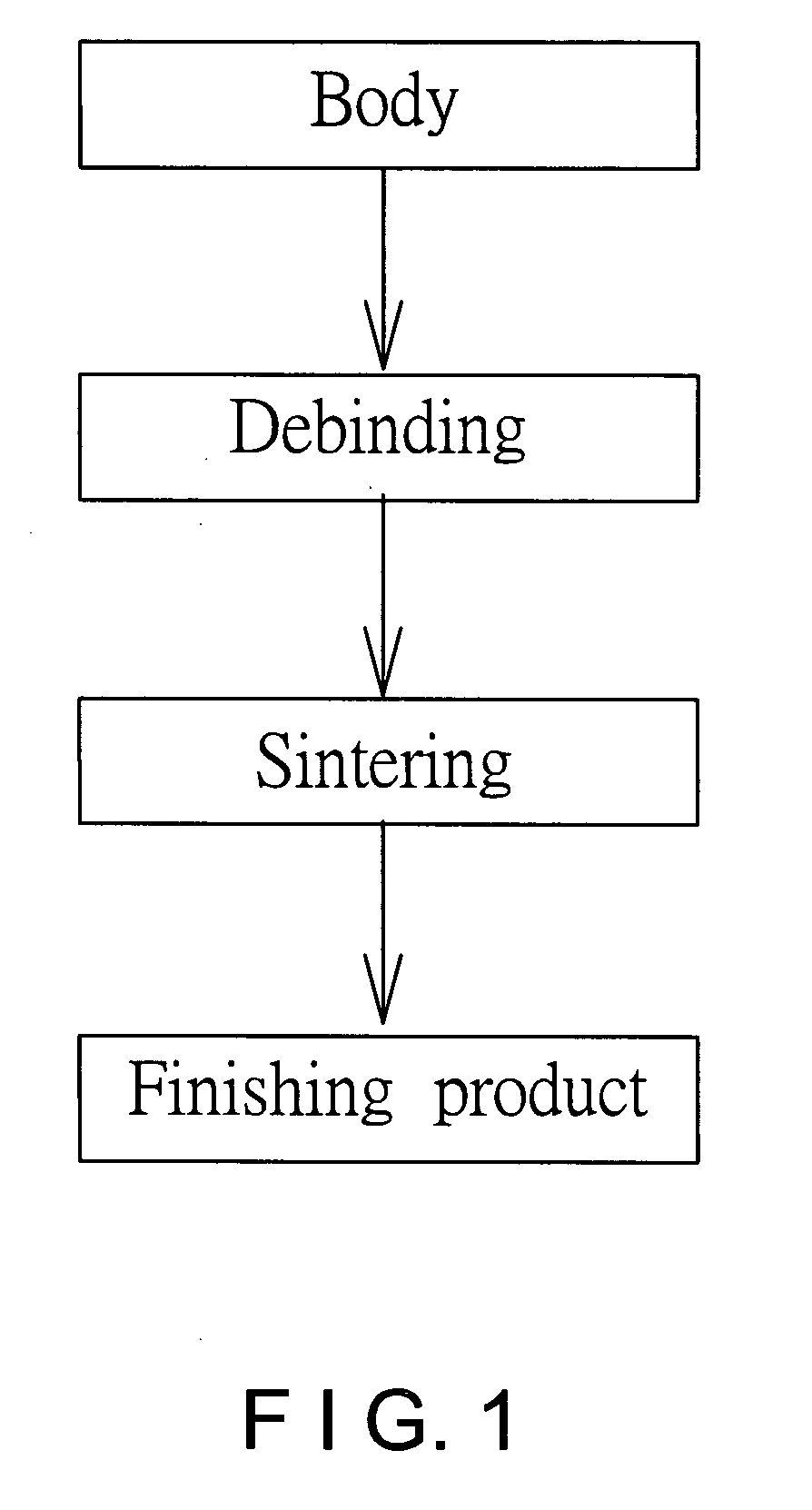

Manufacturing process using microwave for thermal debinding

A manufacturing process using microwave for thermal debinding according to the invention is mainly applied in manufacturing process of powder metallurgy. Wherein, metal powder is mixed polymer materials such as adhesives, fillings or lubricants, and a body is formed by means of molding, forging, extrusion, injection or scraping. The body to be debinded is placed in a microwave environment in an exposed manner or covered with powder, and power and work time of microwave are set for rapidly heating and debinding the body. The manufacturing process according to the invention is capable of accelerating manufacturing procedure, economizing production cost, reducing defects, quickly drying and rapidly removing polymer materials.

Owner:FAR EAST COLLEGE

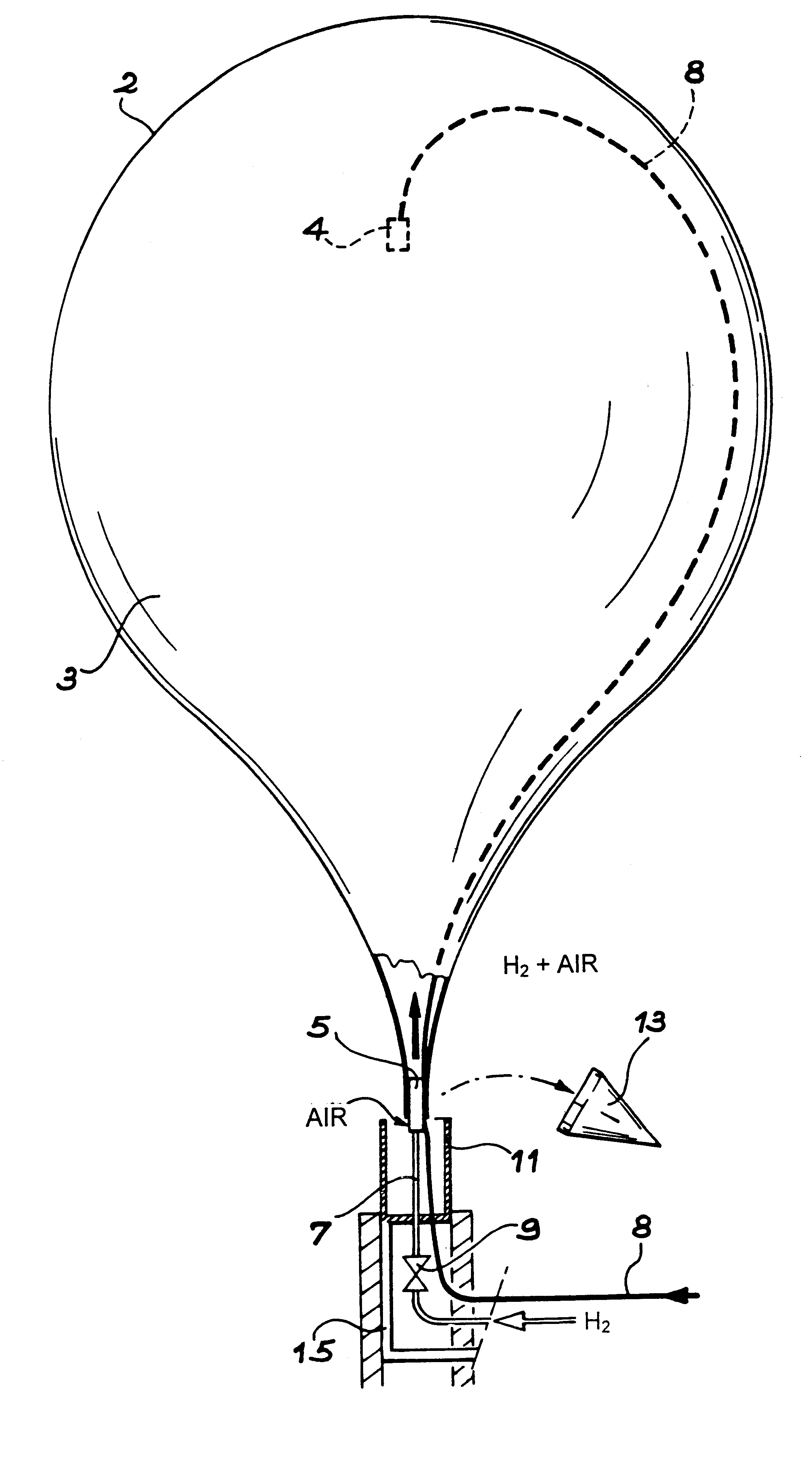

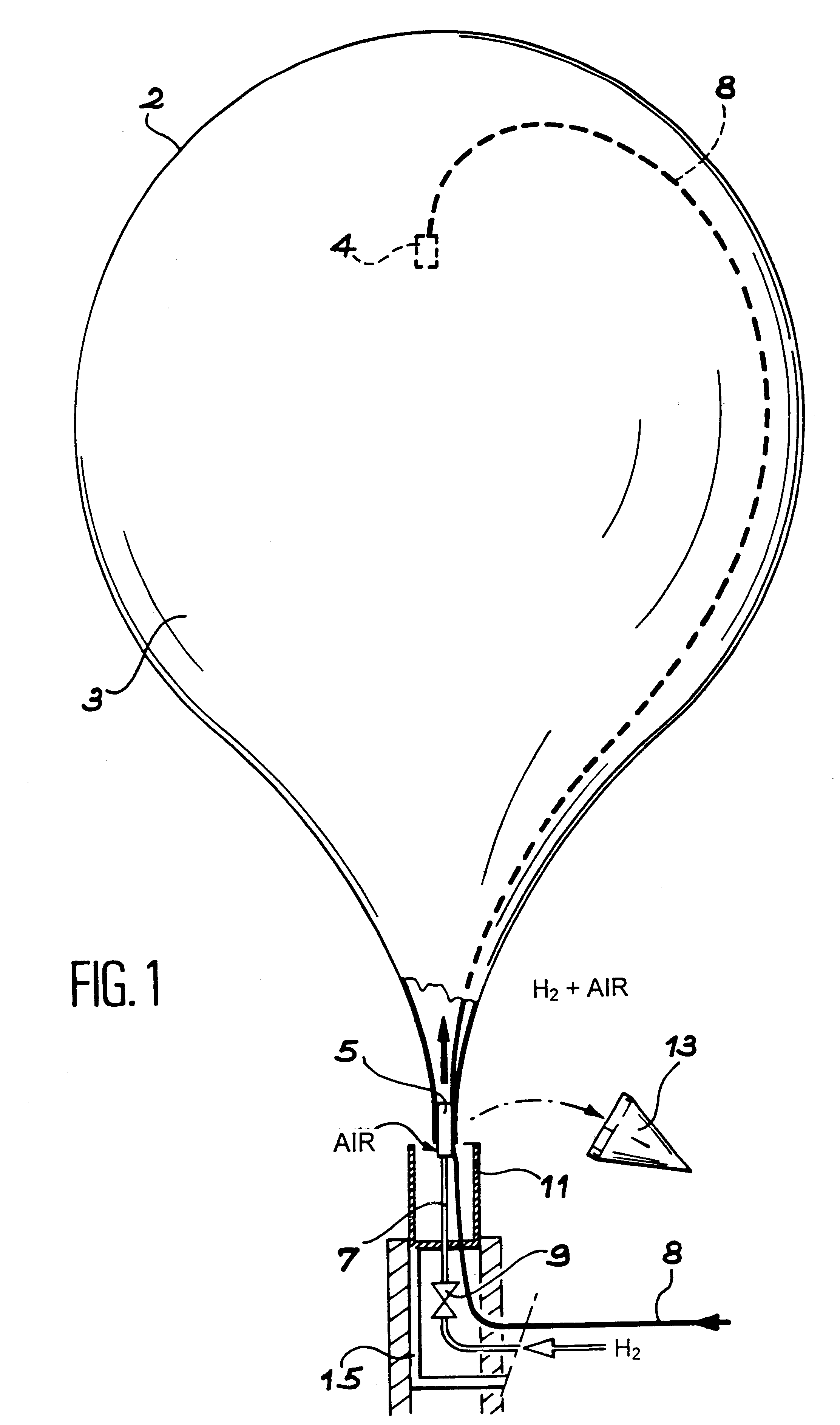

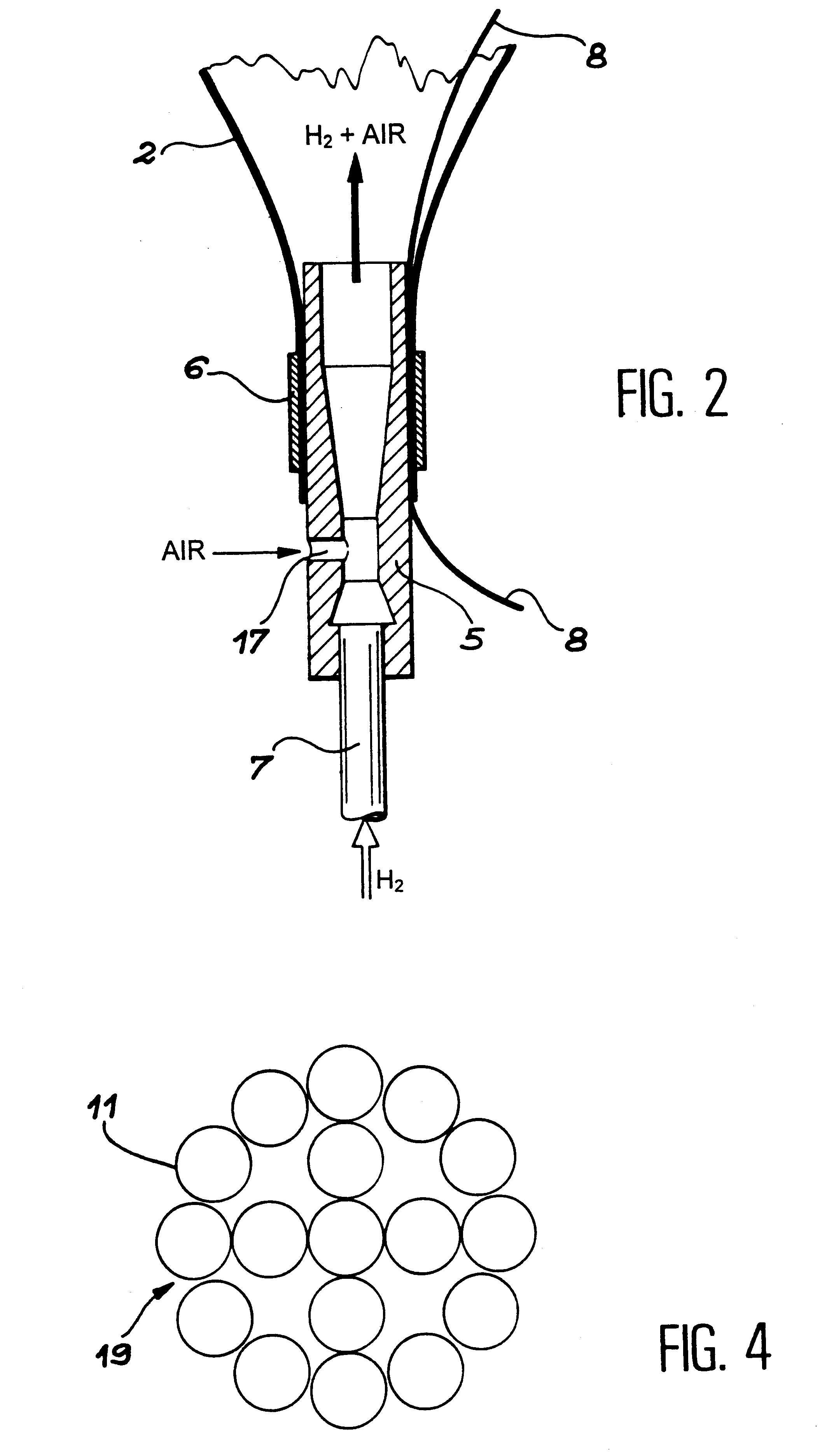

Process for artificially triggering an avalanche and device for applying this process

InactiveUS6324982B1Avoid pollutionAvoid polluting the environmentAmmunition projectilesTraining ammunitionEngineeringBlanket

The invention involves a process for artificially triggering an avalanche. The invention process includes a first step of filling at least one flexible envelope with an explosive fluid and a second step of triggering an explosion of the aforesaid fluid within each envelope, each envelope being destroyed by the explosion of the fluid. The destruction of the envelope allows for propagation of an aerial spherical overpressure wave which will affect an optimal area of the blanket of snow to be removed and will shake the aforesaid area and trigger an avalanche. The invention also involves a device for applying this process, the aforesaid device including at least one envelope to contain the explosive fluid, and means to trigger the explosion of this fluid within each envelope.

Owner:TECH ALPINE DE SECURITE

Graphene heat-conducting anticorrosive water-based paint, and preparation and application methods thereof

ActiveCN106366710AAvoid polluting the environmentImproves corrosion protection performanceAnti-corrosive paintsCvd graphenePre treatment

The invention belongs to a surface treatment technique, and relates to a graphene heat-conducting anticorrosive water-based paint, and preparation and application methods thereof. The invention is characterized in that the graphene heat-conducting anticorrosive water-based paint is formed by mixing a component I and a component II in a weight ratio of 100:(58-65). The preparation method comprises the following steps: preparing the component I; and mixing the component I and component II. The application method comprises the following steps: substrate pretreatment; coating; and curing. The graphene heat-conducting anticorrosive water-based paint avoids environment pollution, and has the advantages of higher anticorrosive property and wider application range.

Owner:北京石墨烯技术研究院有限公司

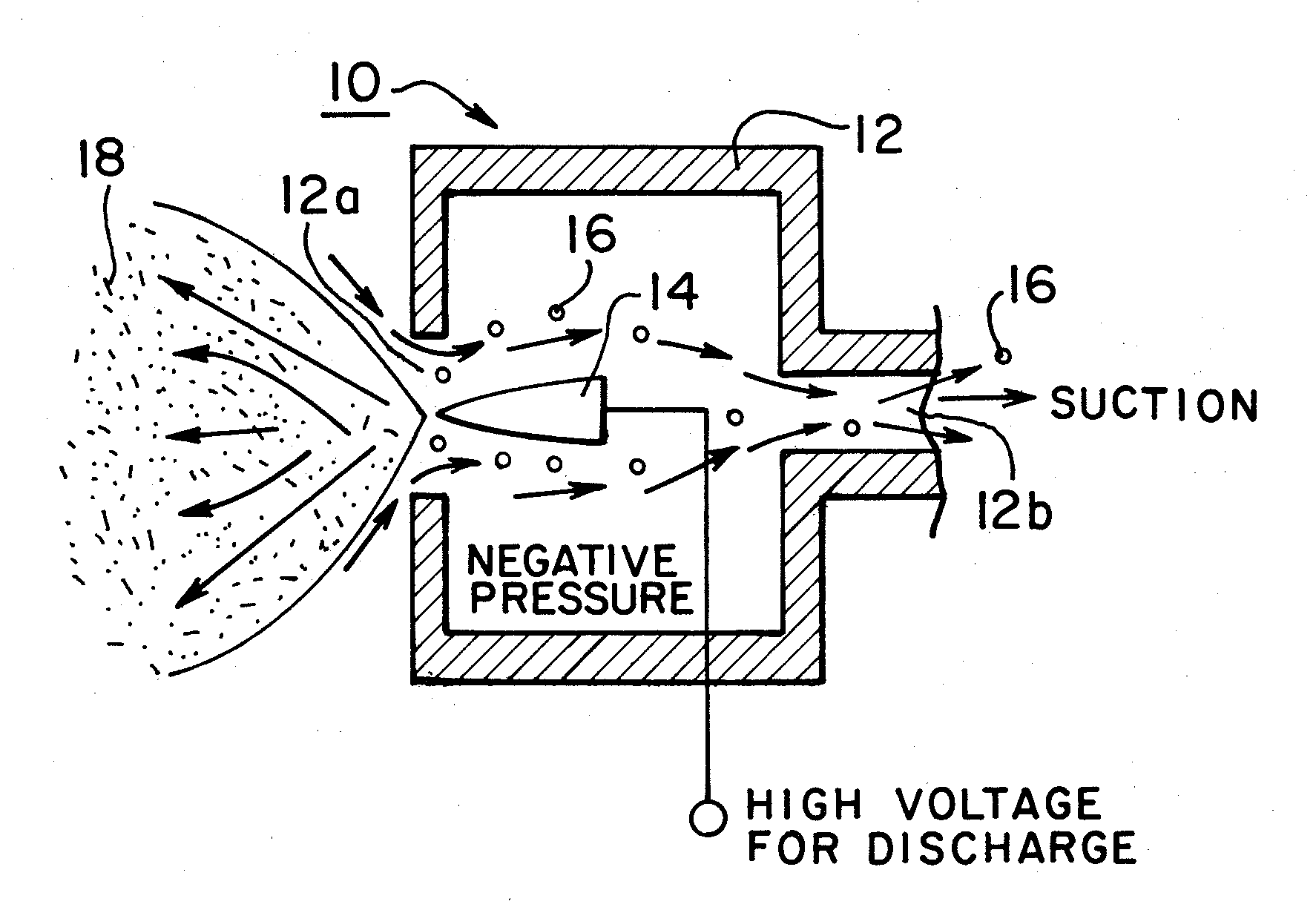

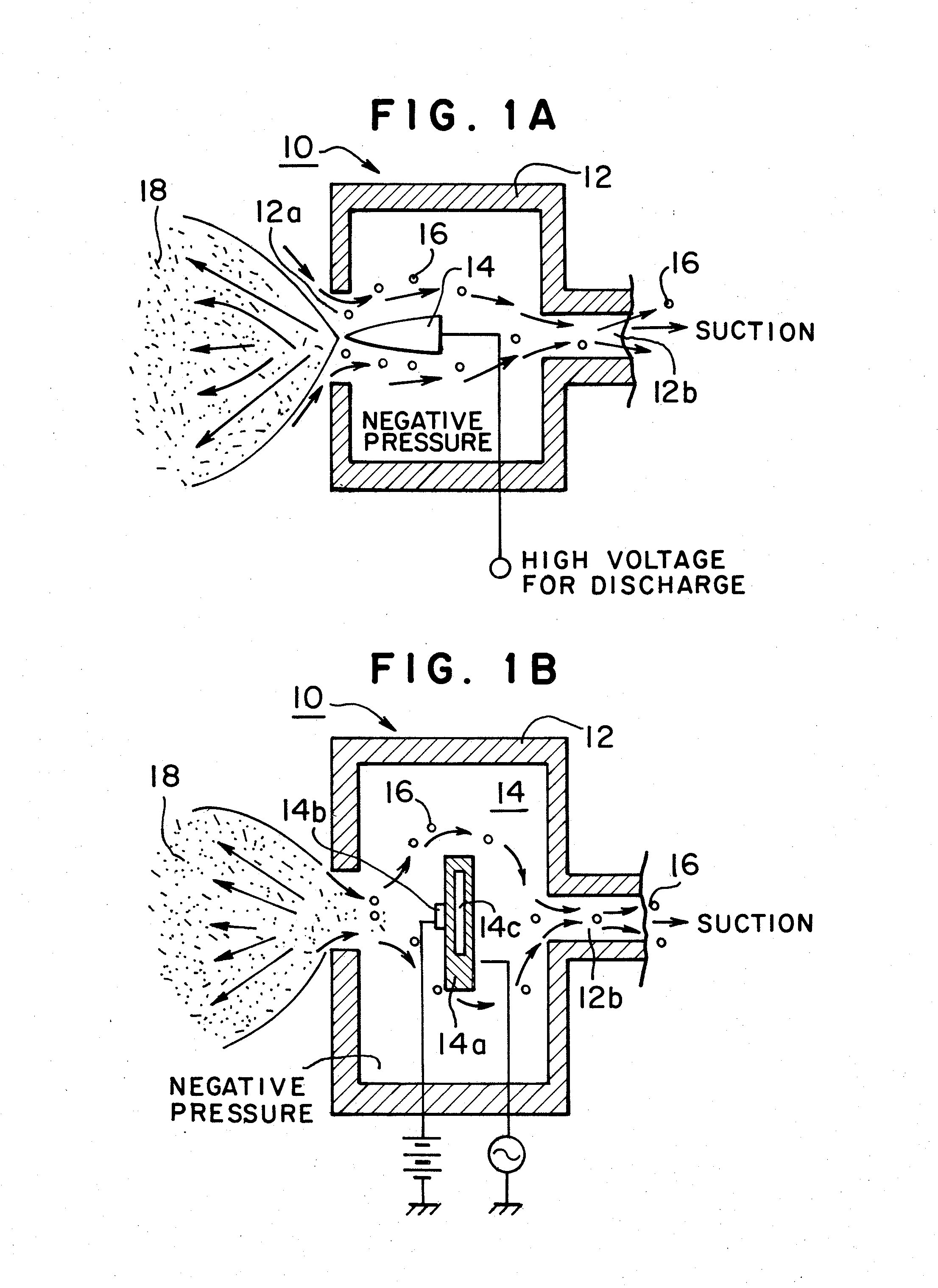

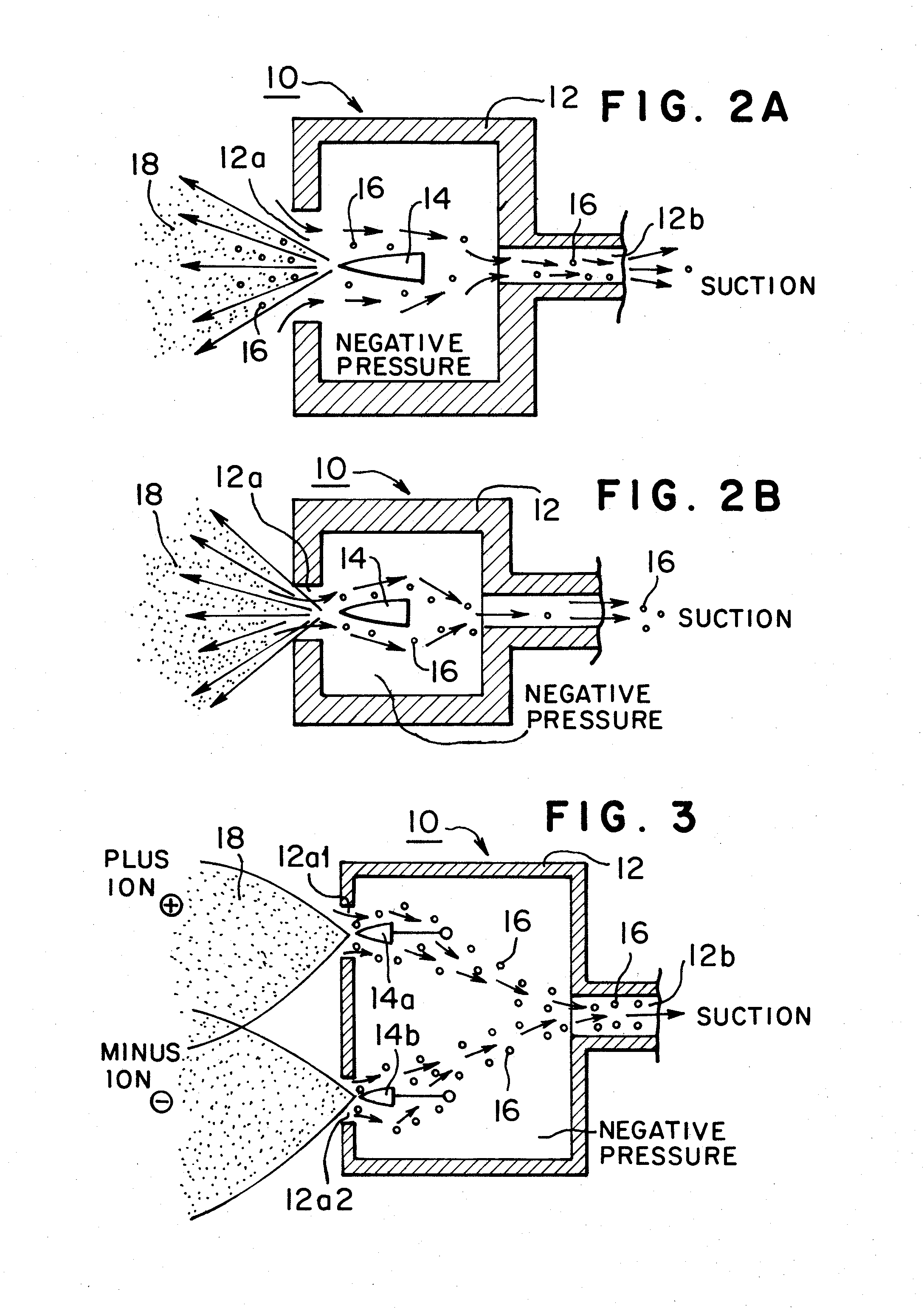

Ozone-less static eliminator

InactiveUS20100128408A1Avoid polluting the environmentElectrographic process apparatusCorona dischargeElectric dischargeOptoelectronics

A static eliminator comprises an electric discharge portion, and a case in which the discharge portion for emitting ions in front thereof is disposed. The case includes an ion emitting opening and an ozone, etc suction opening. The ozone, etc generated in the discharge portion is sucked through the ozone, etc suction opening resulting in sucking air from the ion emitting opening in a direction opposite to that of ion emission through the ion emitting opening.

Owner:TRINC

Method and apparatus for manufacturing laminate for flexible printed circuit board having metal plated layer using vacuum deposition

InactiveUS20060024428A1Avoid polluting the environmentImprove reliabilityVacuum evaporation coatingSputtering coatingEngineeringCopper

Disclosed herein is a method of manufacturing a laminate for a flexible printed circuit board, including surface treating a base film, forming a tie layer on the base film, forming a metal conductive layer on the tie layer, and depositing a metal on the metal conductive layer by radiating electronic beams to form a metal plated layer thereon, all of which are conducted in a vacuum chamber. In addition, an apparatus for manufacturing a laminate for a flexible printed circuit board is provided, including an unwinding roller for unwinding a base film therefrom, film guide rollers for guiding and transferring the base film, a surface treating part for surface treating the transferred base film, tie layer and copper conductive layer forming parts for sequentially forming a tie layer and a metal conductive layer on the surface treated base film, a vacuum depositing part for depositing a metal on the metal conductive layer by radiating electronic beams to form a metal plated layer thereon, and a winding roller for winding the base film having the metal plated layer formed thereon, all of which are provided in a vacuum chamber. The vacuum depositing part includes a metal boat, an electron gun for radiating electronic beams onto the metal boat, and a main depositing drum for depositing a metal on the metal conductive layer by radiating electronic beams to form the metal plated layer thereon when the base film is in contact with the depositing drum.

Owner:TORAY SAEHAN

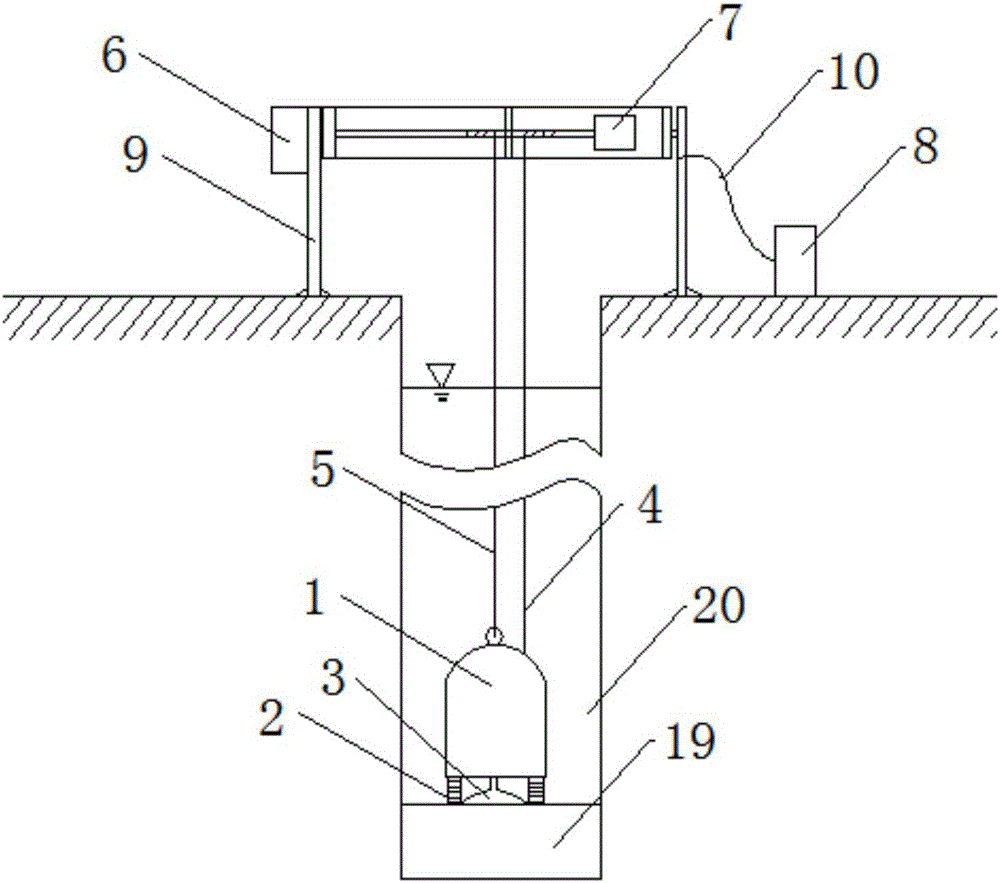

Sediment removal machine for removing sediment at bottom of pile and working method thereof

ActiveCN105821881AThorough slag removalAvoid the risk of hole collapseBulkheads/pilesSediment FilterDischarge return

The invention discloses a sediment removal machine for removing sediment at the bottom of a pile and a working method thereof. The sediment removal machine comprises a sediment removal device and a main controller for controlling work of the sediment removal device. The sediment removal device comprises an outer cover, a sediment suction tube for sucking the sediment is arranged in the outer cover, and the bottom end of the sediment suction tube extends out of the outer cover so that the sediment at the bottom of the pile can be sucked into the outer cover. At least one layer of sediment filter screen is arranged between the outer cover and the sediment suction tube. The positions where the sediment filter screens are located are lower than an outlet of the sediment suction tube. A water outlet is formed in the bottom surface of the outer cover so as to discharge return mud flowing down the sediment filter screens. A sediment amount sensor is arranged on the upper portion of the inner side face of the outer cover and connected with the main controller. Mud displacement does not exist, mud pouring is not needed, the automation degree is high, operability is high, the sediment removal efficiency and effect are improved, the hole collapse risk caused by mud displacement is avoided, and the problem that the environment is polluted because a large amount of mud is used is solved.

Owner:SHANDONG UNIV

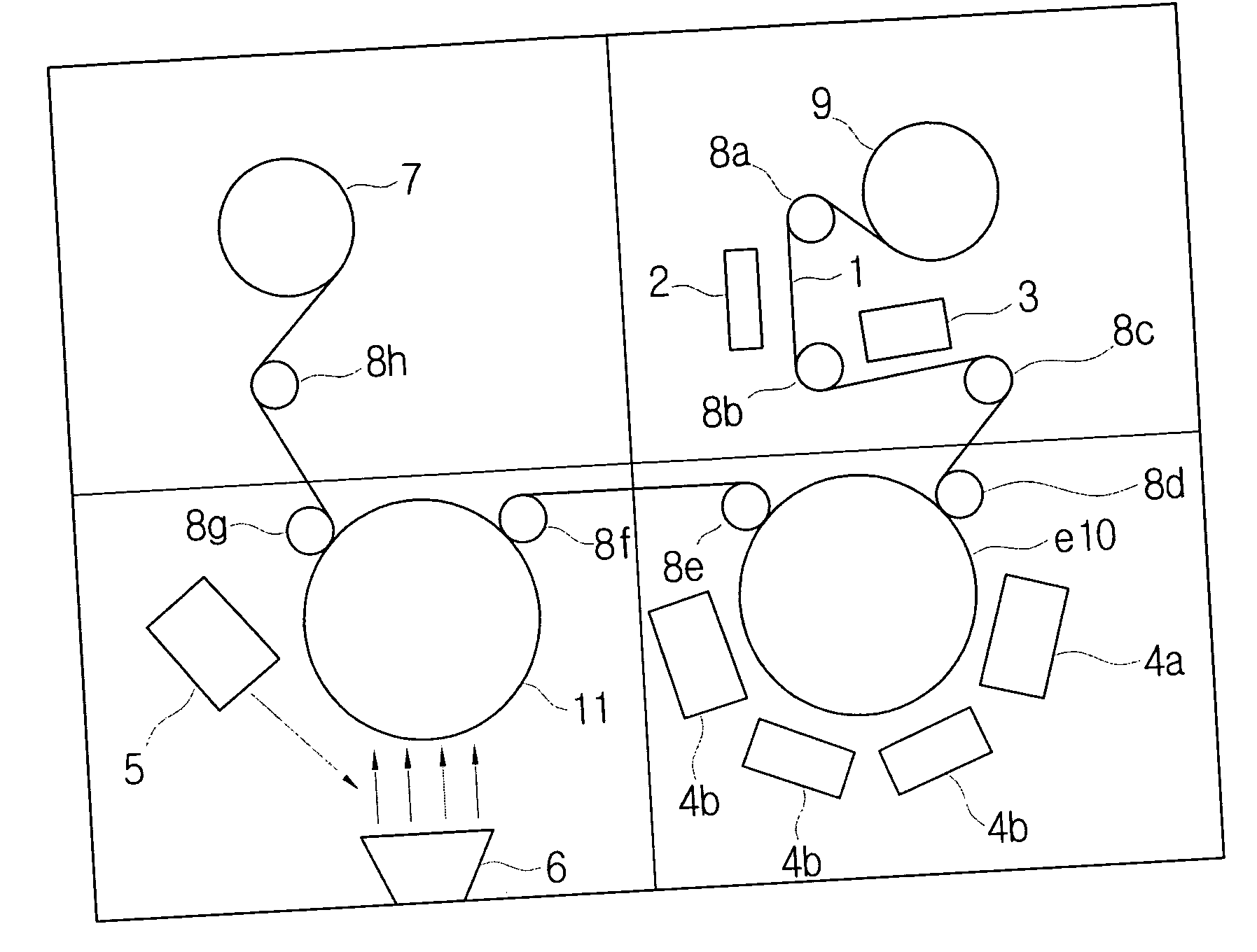

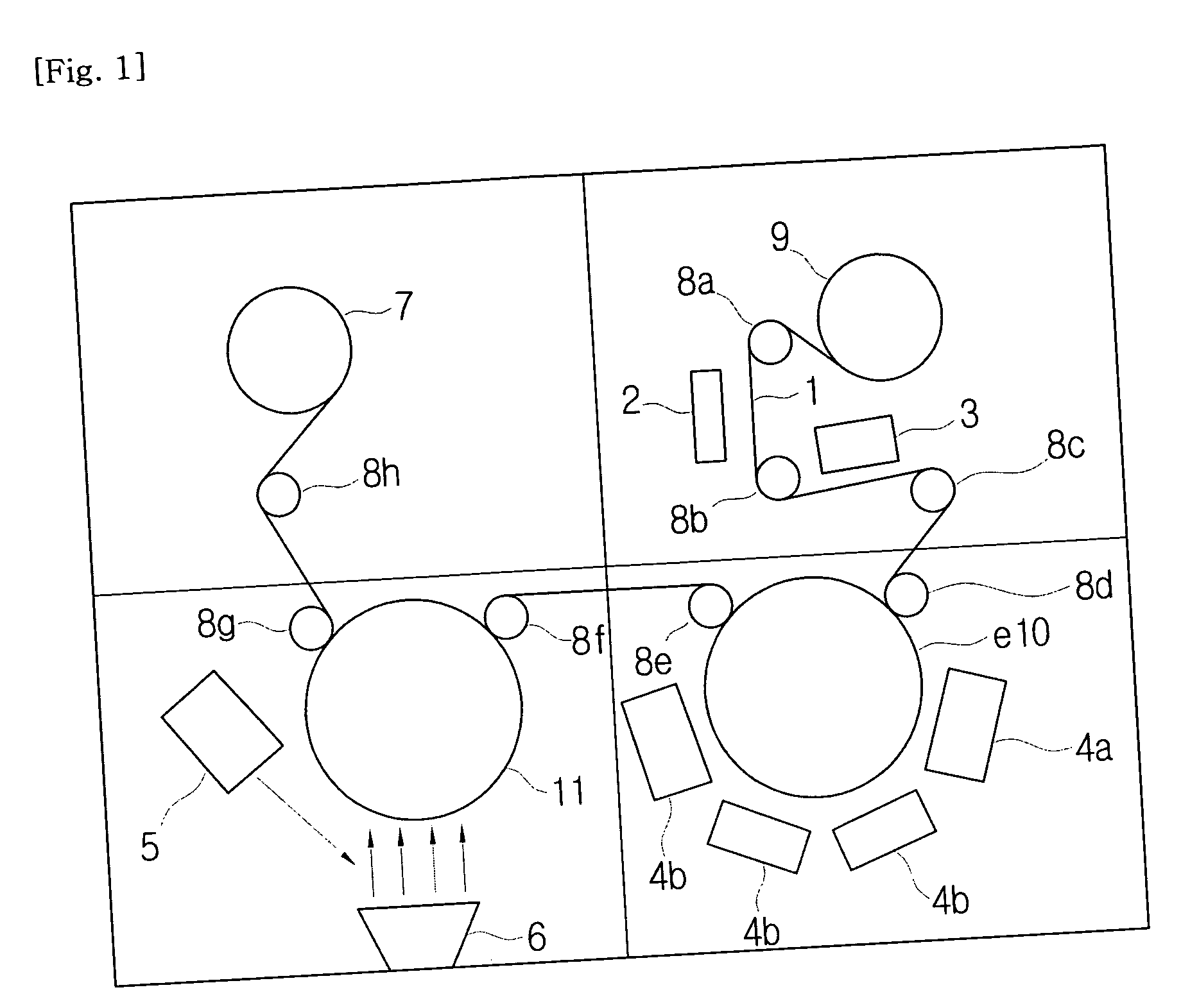

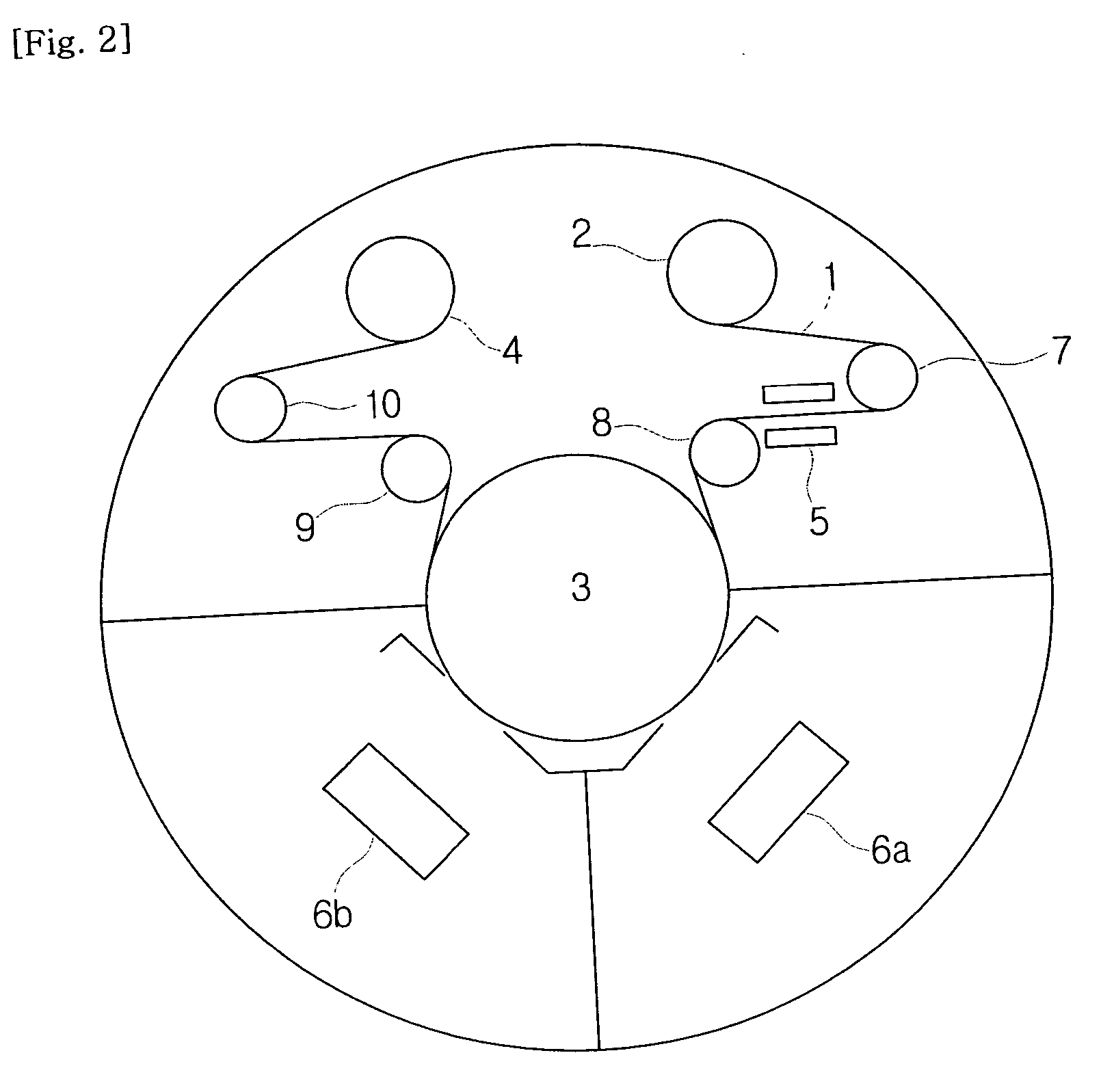

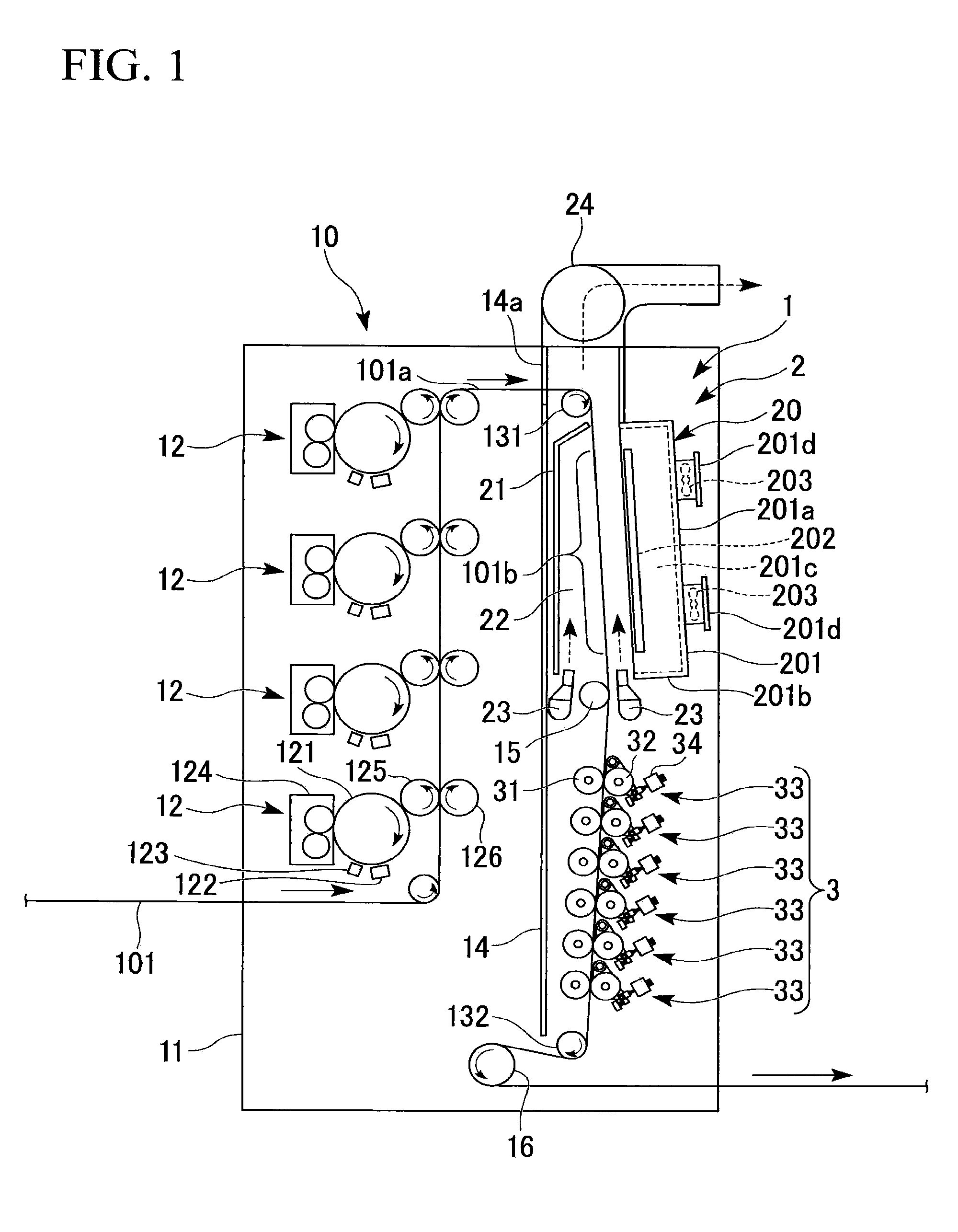

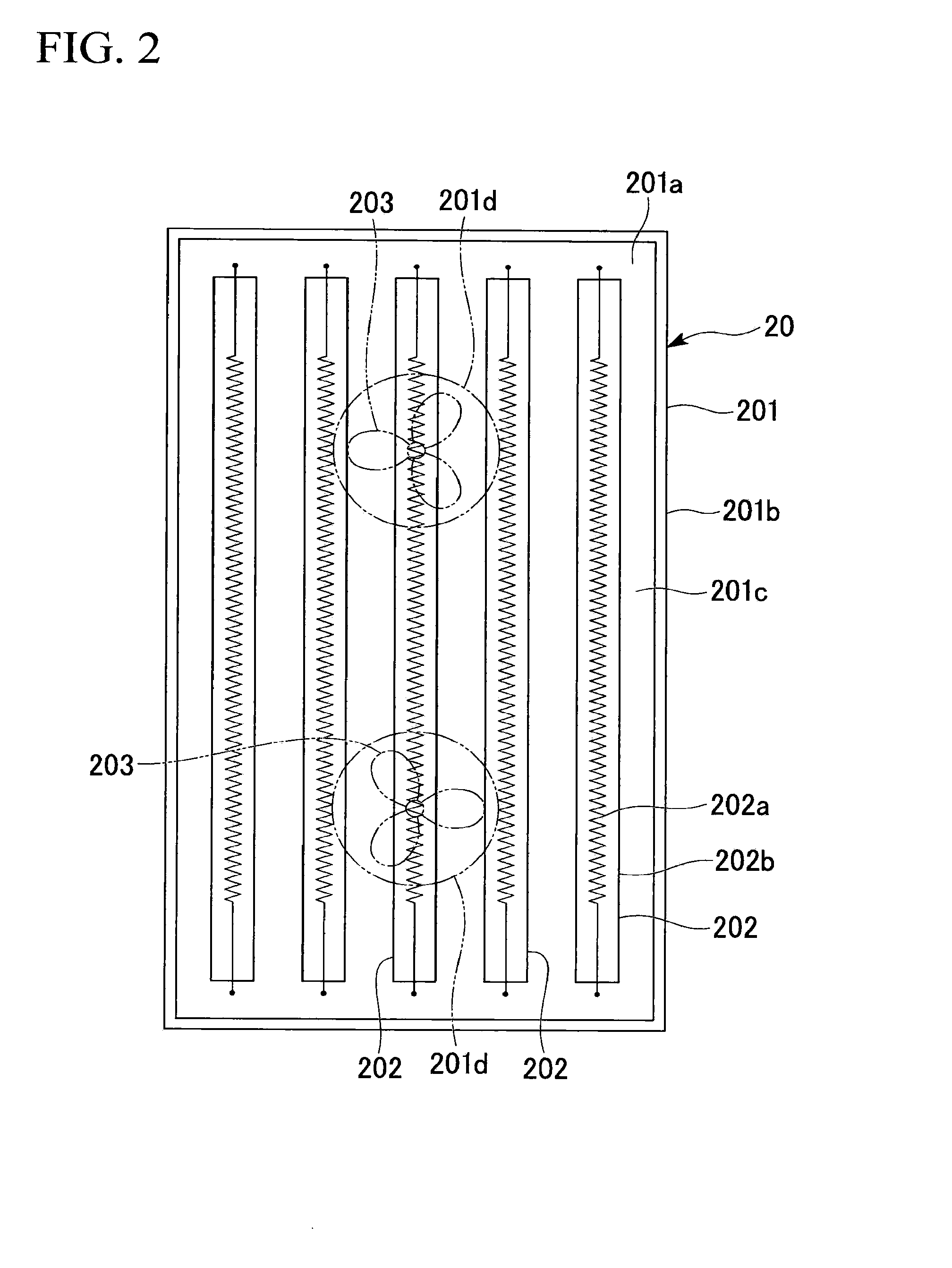

Toner, method of manufacturing the toner, developing device, and image forming apparatus

ActiveUS20090011355A1Avoid polluting the environmentIncreased durabilityDevelopersEngineeringContamination

There are provided a toner that allows prevention of environmental contamination and is nevertheless free from toner durability degradation, wherein a sufficiently wide color reproduction range can be secured even when it is applied to color toner, and variation in characteristics among toner particles can be suppressed, as well as a method of manufacturing a toner, a developing device, and an image forming apparatus. In the toner particle is formed the biomass resin-containing domain.

Owner:SHARP KK

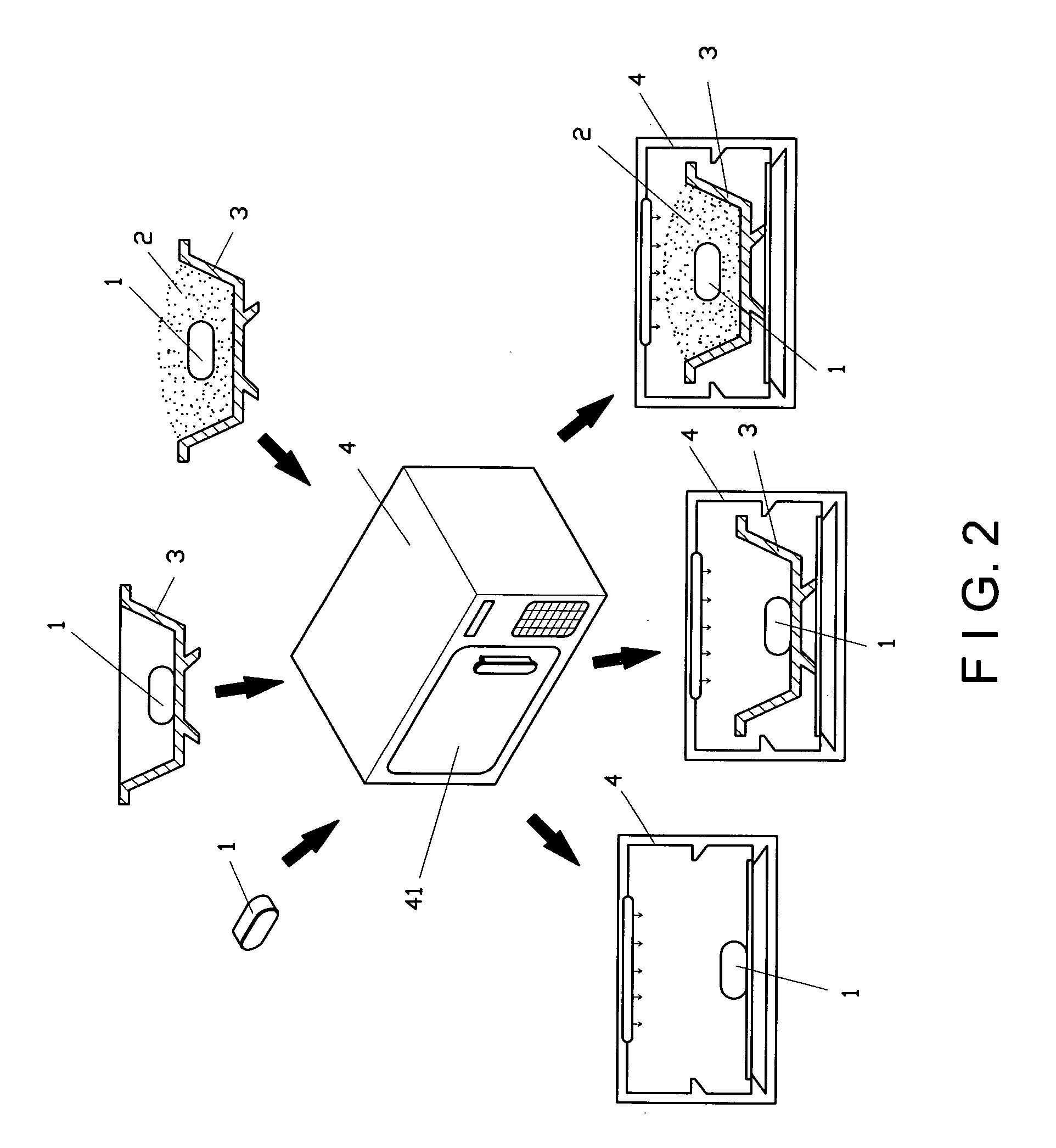

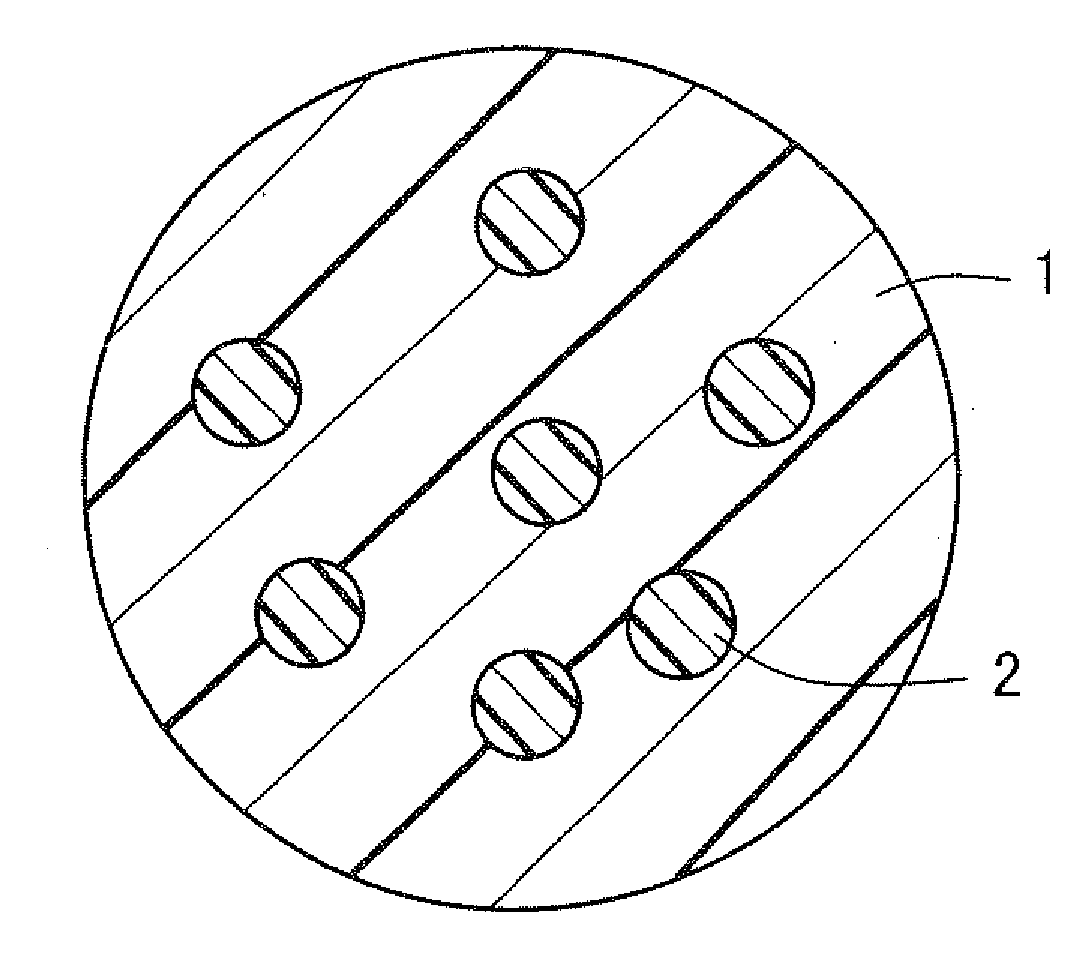

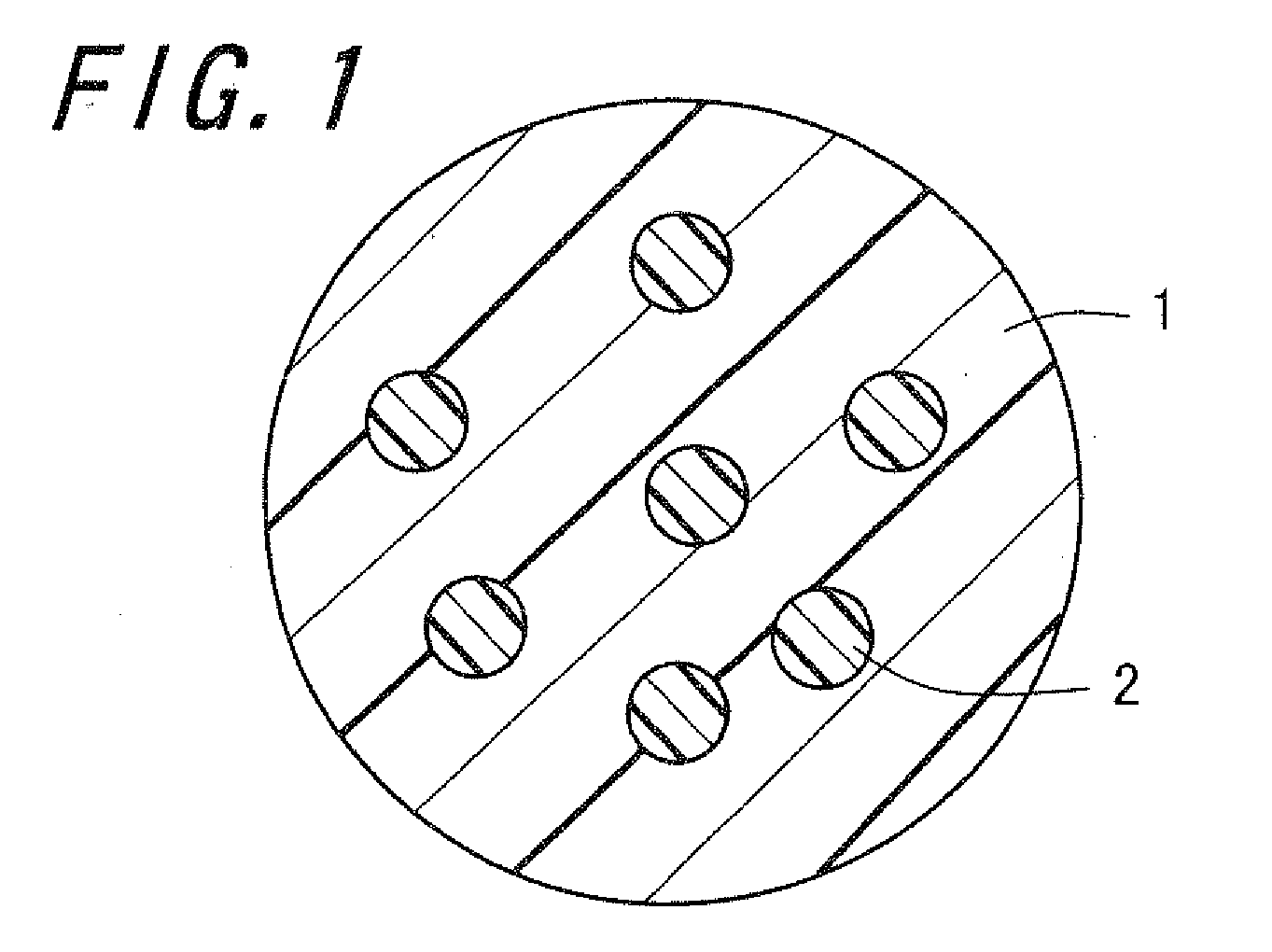

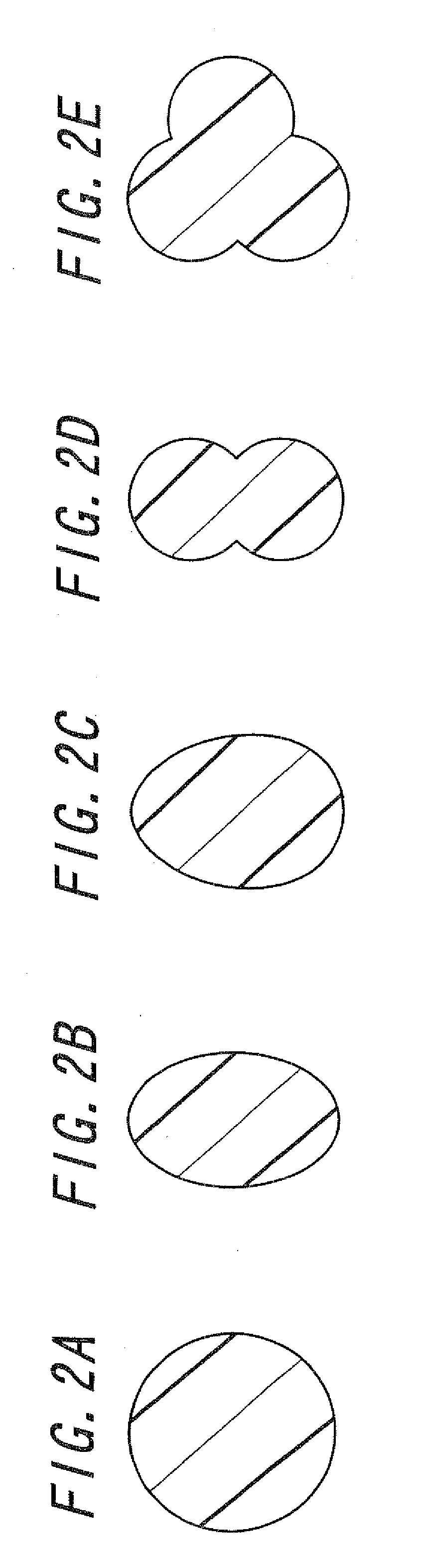

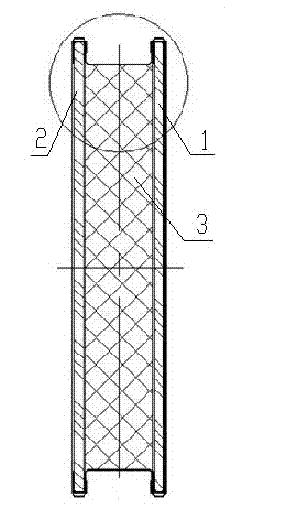

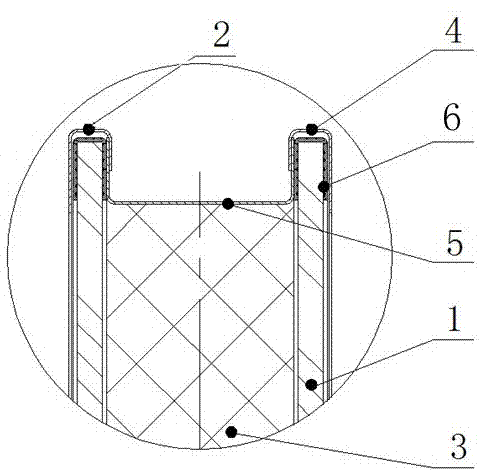

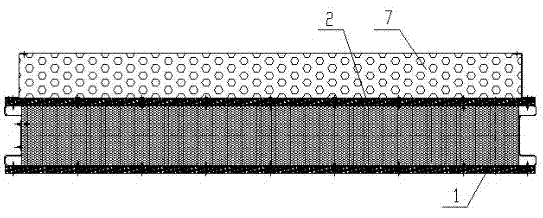

Sound insulation module and sound absorption and insulation composite structure of embedded truss structure with sound insulation module

ActiveCN102828564AEliminate gapsPrevent structural sound leakageWallsSound proofingEngineeringSound Absorber

The invention discloses a sound insulation module which comprises a first sound insulation board (1), a second sound insulation board (2) and sound absorbers (3) arranged between the two sound insulation boards or attached and connected to the surface of the first sound insulation board (1) or second sound insulation board (2). The invention also discloses a sound absorption and insulation composite structure of an embedded truss structure with the sound insulation module. The sound absorption and insulation composite structure comprises truss uprights (9) being embedded in uprights (8) of a plant and being capable of being fixed to the ground, embedded bottom cross beams between bottoms of the truss uprights (9), and a #-shaped truss structure formed by transverse support trusses (11) fixedly connected with the truss uprights (9), and grooves of the sound insulation module are embedded and sleeved on the truss uprights (9) and positioned between the embedded bottom cross beams and the transverse support trusses (11). The insulation composite structure eliminates a gap of a wall body to realize the cutting-off an acoustic bridge, and is good in wall body rigidity and simple in installation procedure.

Owner:ZISEN ENVIRONMENTAL TECHNOLOGY CO LTD

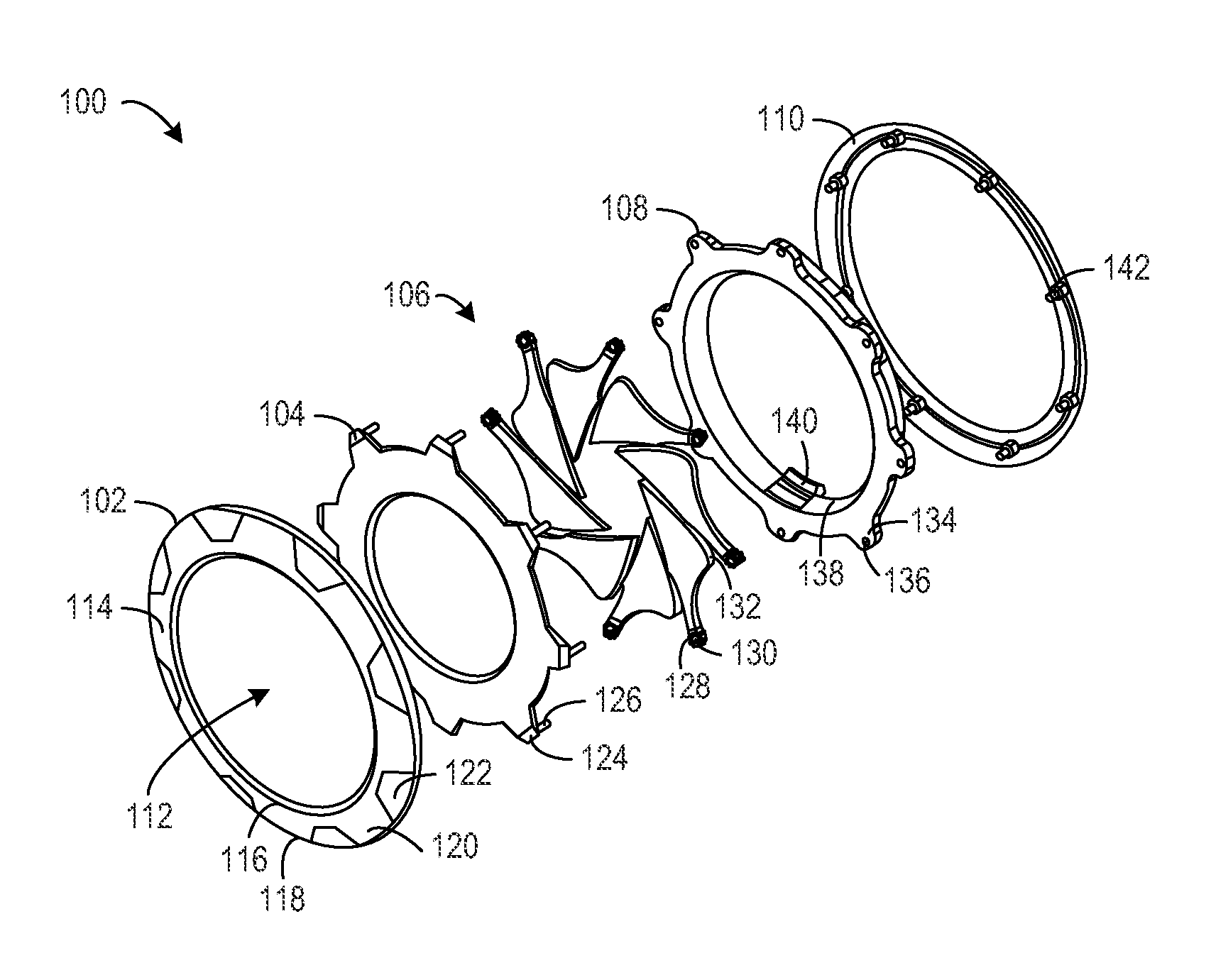

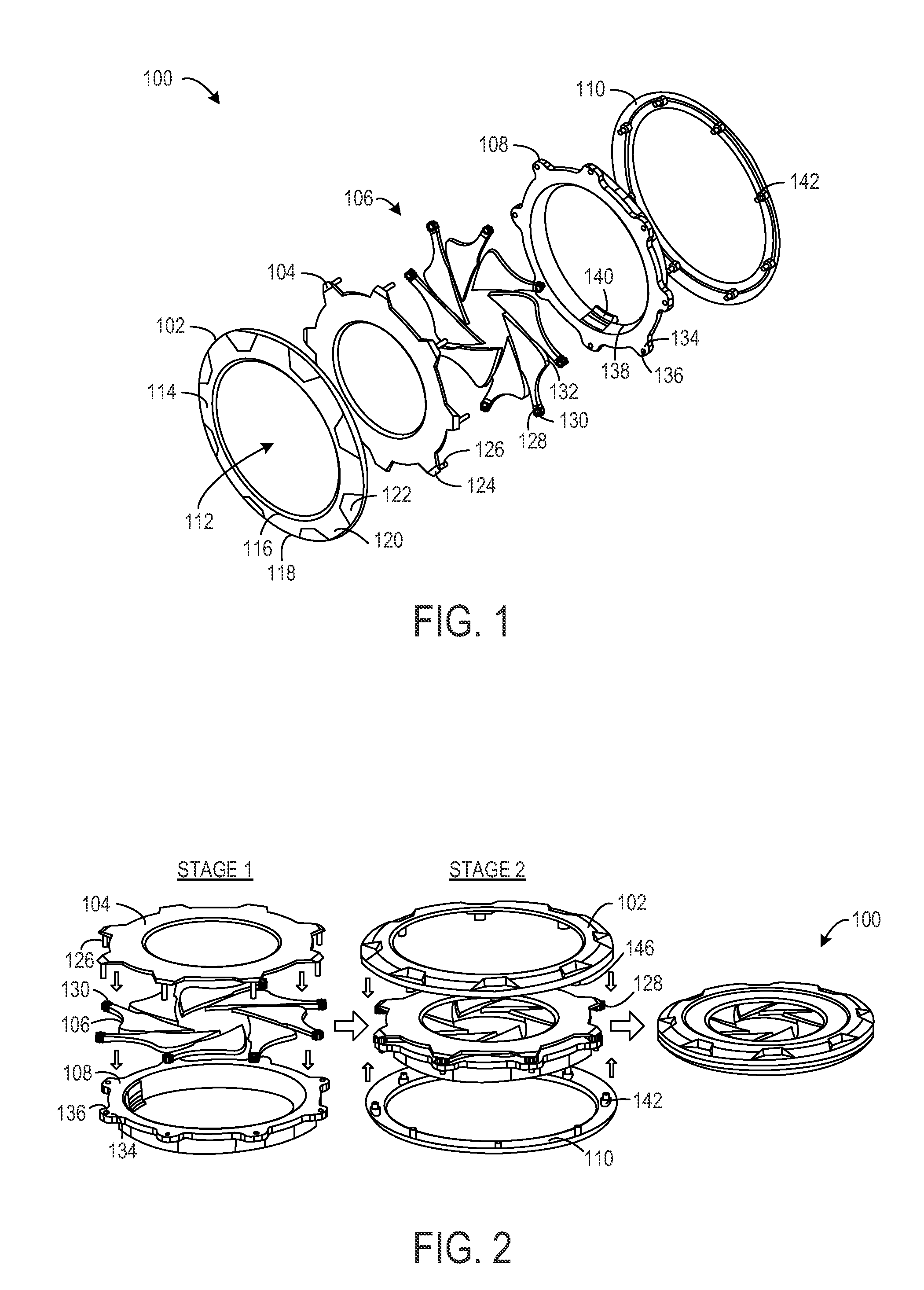

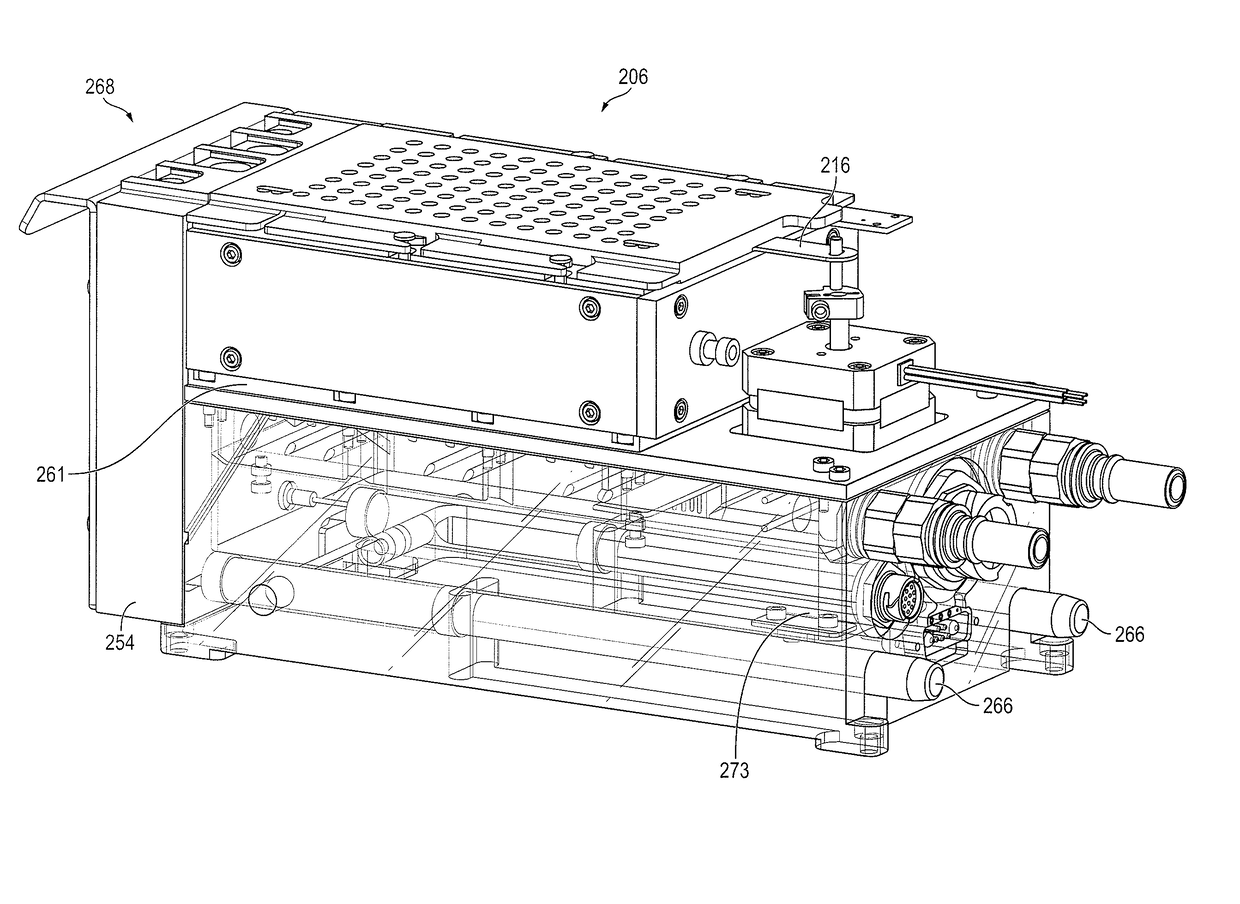

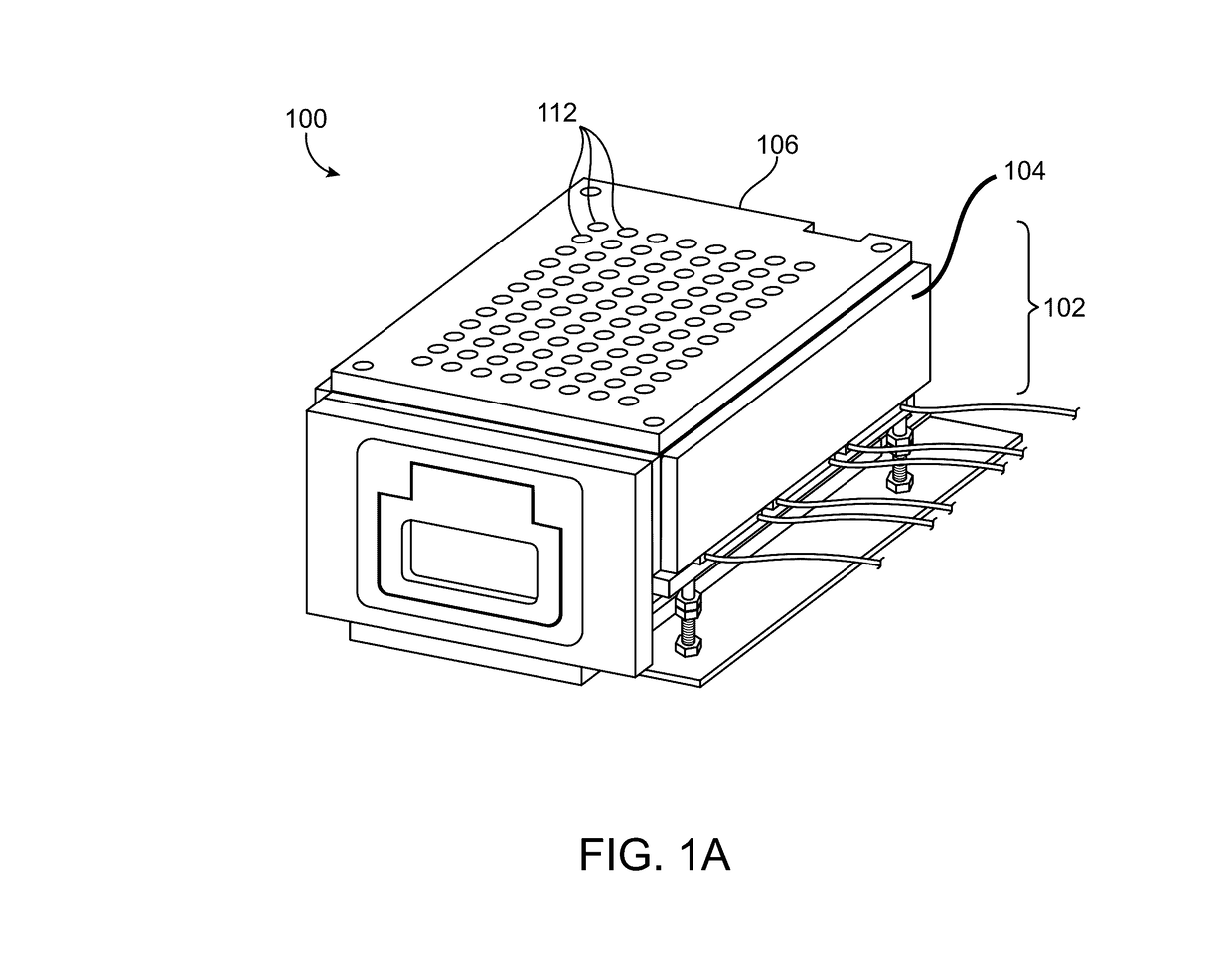

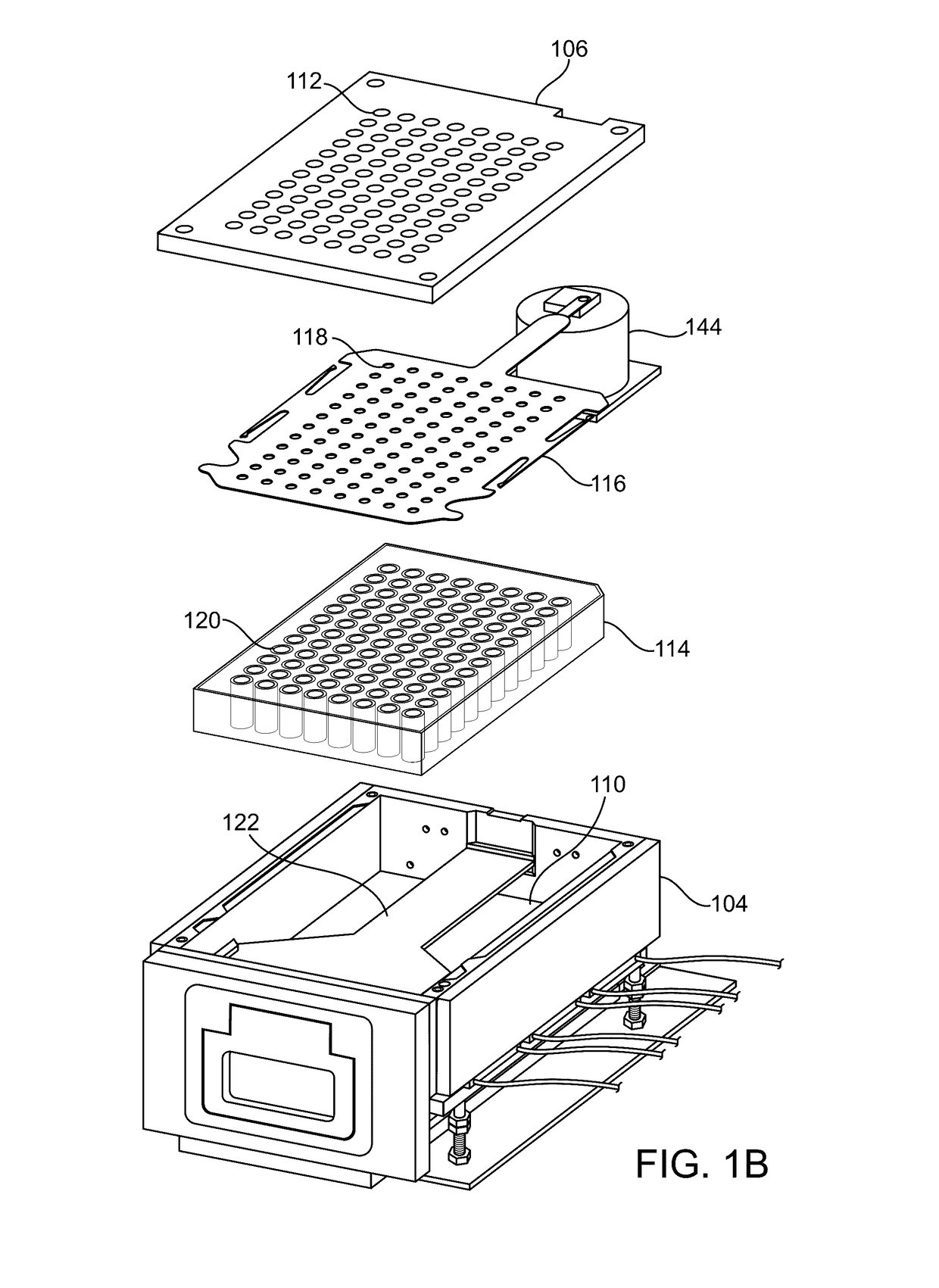

Well plate incubator

ActiveUS20170114316A1Improved accessPrevent contamination of environmentBioreactor/fermenter combinationsBiological substance pretreatmentsCell cultureEngineering

Incubators including an enclosure with an internal chamber configured to support a cell culture plate comprising a plurality of wells are disclosed. The enclosure includes a plurality of openings configured to allow access to the wells. The incubators include a sealing element configured to seal the plurality of openings in the enclosure. The sealing element comprises a plurality of openings corresponding to at least a subset of the plurality of openings in the enclosure. Access to the internal chamber can be provided by aligning the plurality of openings in the sealing element with the plurality of openings in the enclosure. Methods for using the incubators are also provided.

Owner:BERKELEY LIGHTS

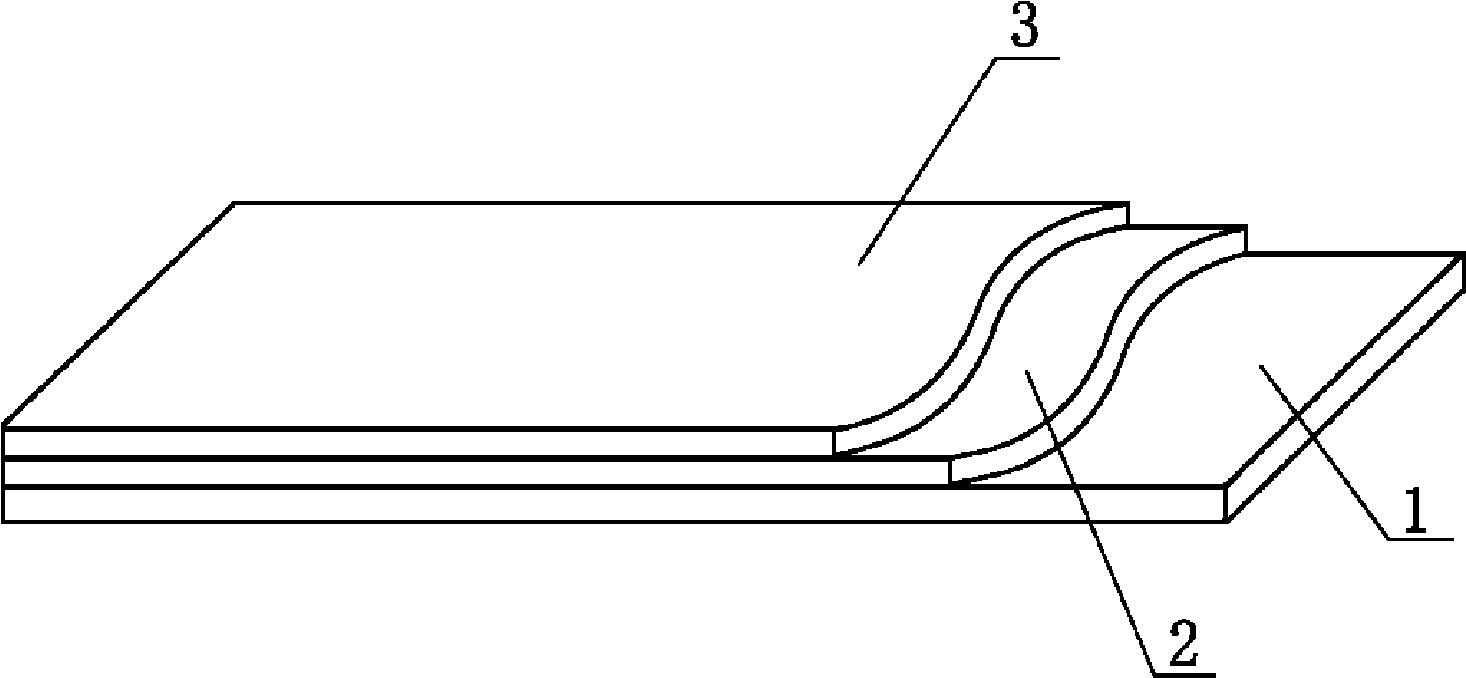

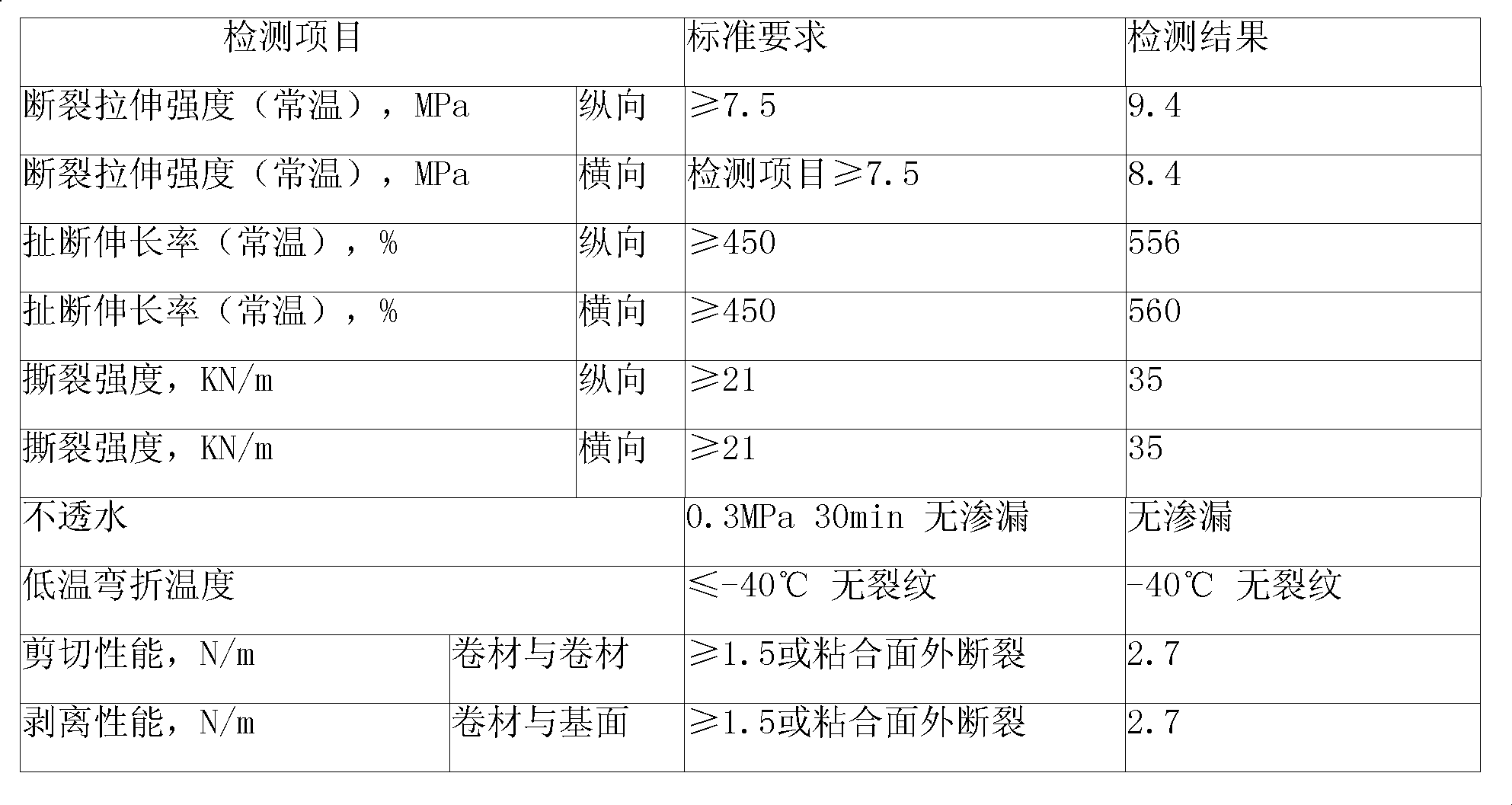

Self-adhering rubber water-proof coiled material and method for preparing same

InactiveCN101545285AUnique "self-locking water" functionSolve the problem of water leakageProtective foundationMarine site engineeringGlass fiberEngineering

A self-adhering rubber water-proof coiled material and a method for preparing the same composed of a rubber water-proof coiled material basal layer, a glue spreading reinforcement layer and a self-adhering rubber waterproof layer on the glue spreading reinforcement layer. The glue spreading reinforcement layer is glue spreaded nonwoven cloth or glue spreaded glass-fiber cloth. The self-adhering rubber waterproof layer is produced by mixing the following materials in proportion by weight: 60-70 portions of ethylene propylene terpolymer (PET); 10-26 portions of butyl rubber; 4-25 portions of chloroprene rubber; 50-70 portions of black carbon; 50-70 portions of fine particle calcium carbonate; 2-7 portions of coumarone; 10-20 portions of naphthenic oil; 5-10 portions of zinc oxide and 0.7-1.2 portions of stearic acid. The construction art is simple and fast. Because the self-adhering base material contains hydrophilic material, the basal layer can be in wet lay up if the basal layer has no water. The method has no glue brushing and glue shining process so as to save time limit for a project and the cost, effectively avoid hollow casing and burst phenomenon and form a whole a complete waterproof sealing system.

Owner:北京立高科技股份有限公司

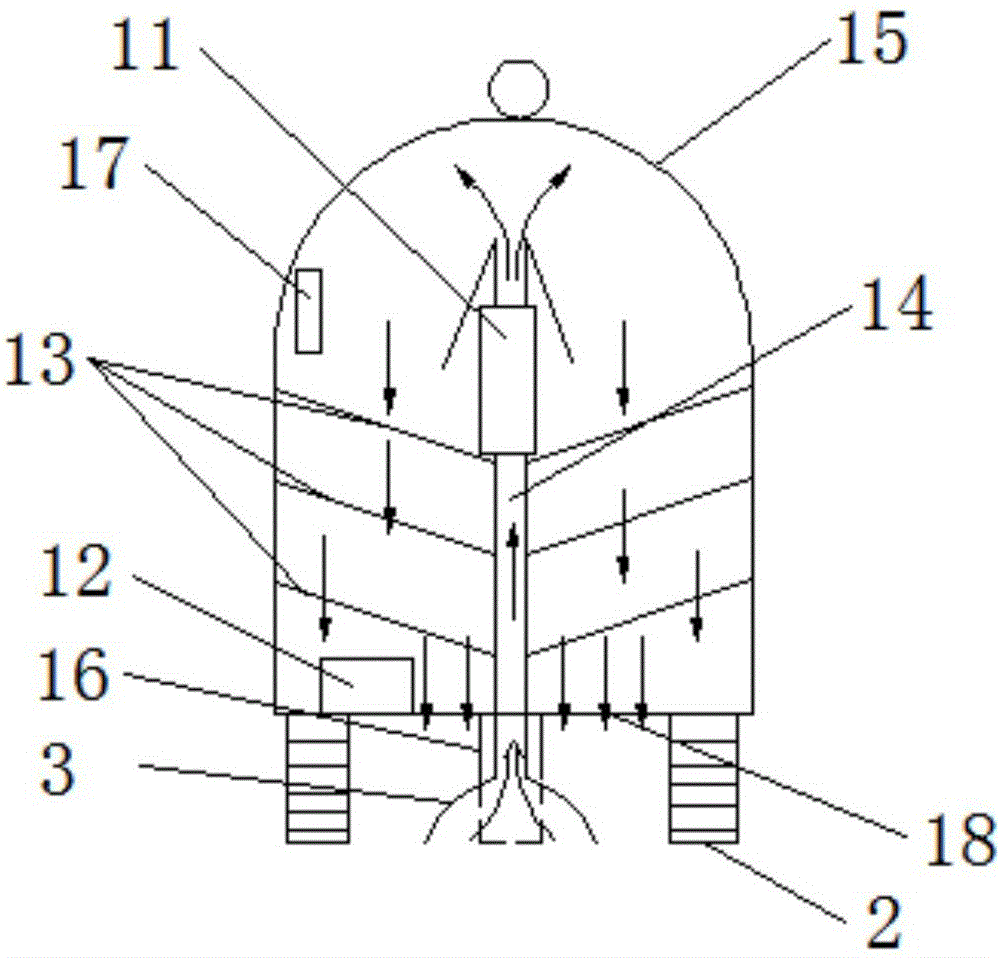

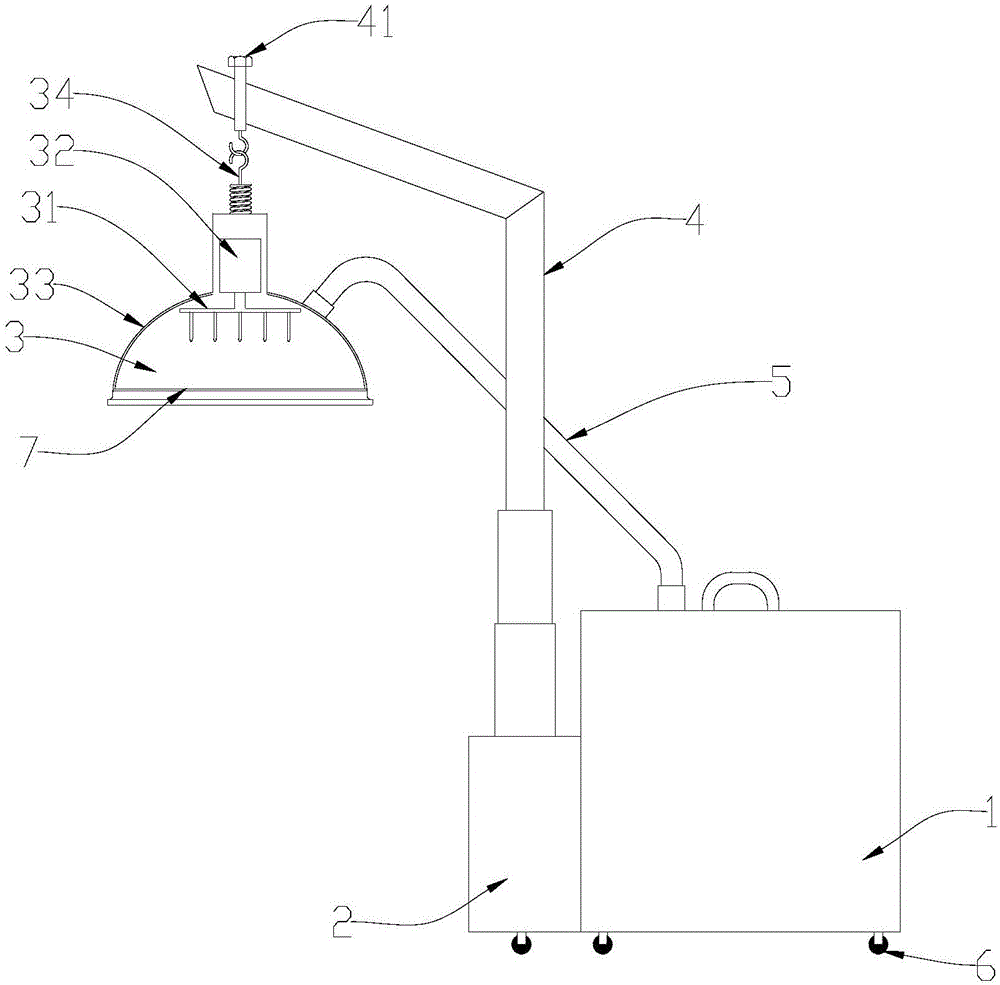

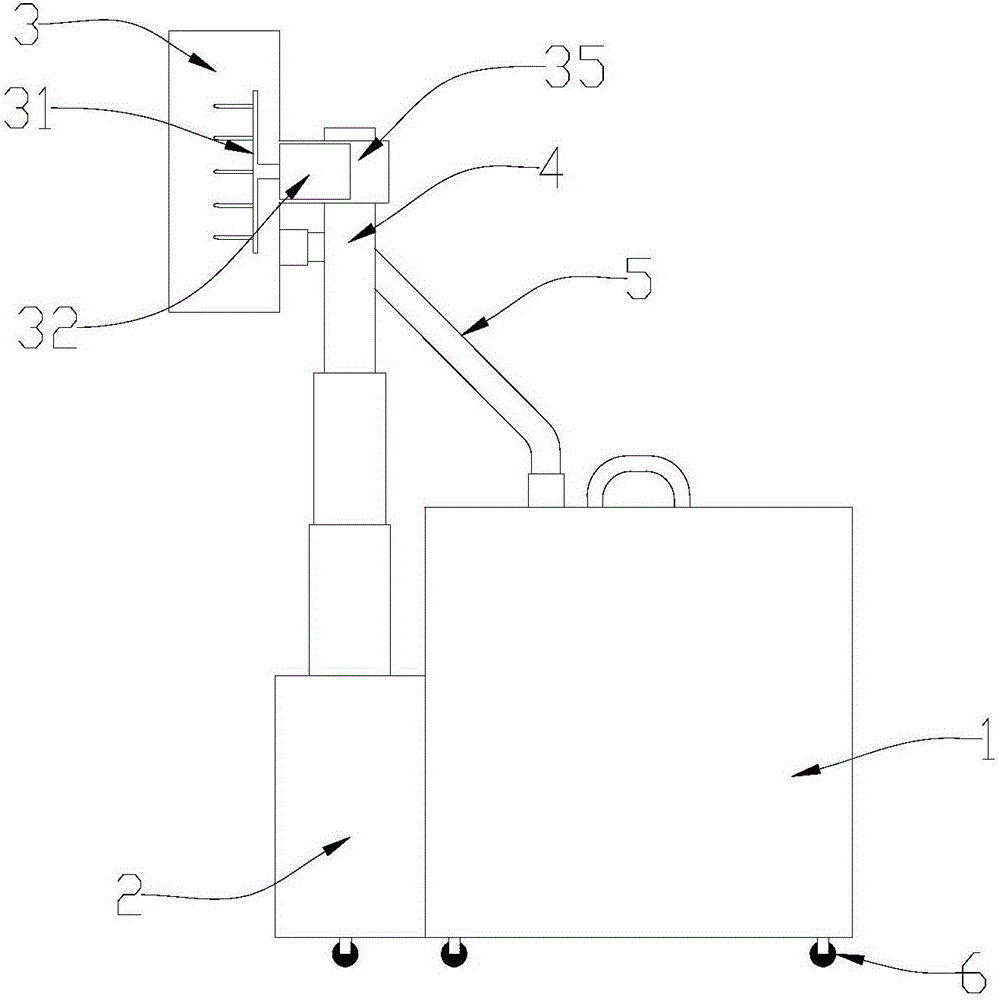

Moxibustion device capable of stereoscopically positioning moxa stick and purifying moxa smoke

InactiveCN106214473AAvoid polluting the environmentWon't spreadDevices for heating/cooling reflex pointsCombination devicesEngineeringCombustion

The invention discloses a moxibustion device capable of stereoscopically positioning a moxa stick and purifying moxa smoke. The moxibustion device comprises a lifting device, a control panel, a supporting frame, a smoke head, a smoke pipe and a smoke purifying system, wherein the smoke head is arranged on the supporting frame, the moxa stick is fixed into the smoke head, the lifting device drives the supporting frame so that the smoke head vertically moves under control of the supporting frame, the smoke pipe is connected with the smoke head, and the smoke purifying system is used for purifying the moxa smoke of the smoke head. A rotating mechanism for driving the moxa stick to rotate is arranged in the smoke head and comprises a smoke cover, a moxa stick fixing plate and a rotating motor, the moxa stick fixing plate and the rotating motor are arranged in the smoke cover, and the rotating motor is connected with the moxa stick fixing plate and drives the moxa stick fixing plate to rotatably move. The moxa stick can be all-dimensionally positioned, the technique of a doctor can be simulated to perform moxibustion, and the moxa smoke generated by combustion of the moxa stick can be automatically cleaned and filtered.

Owner:包德华

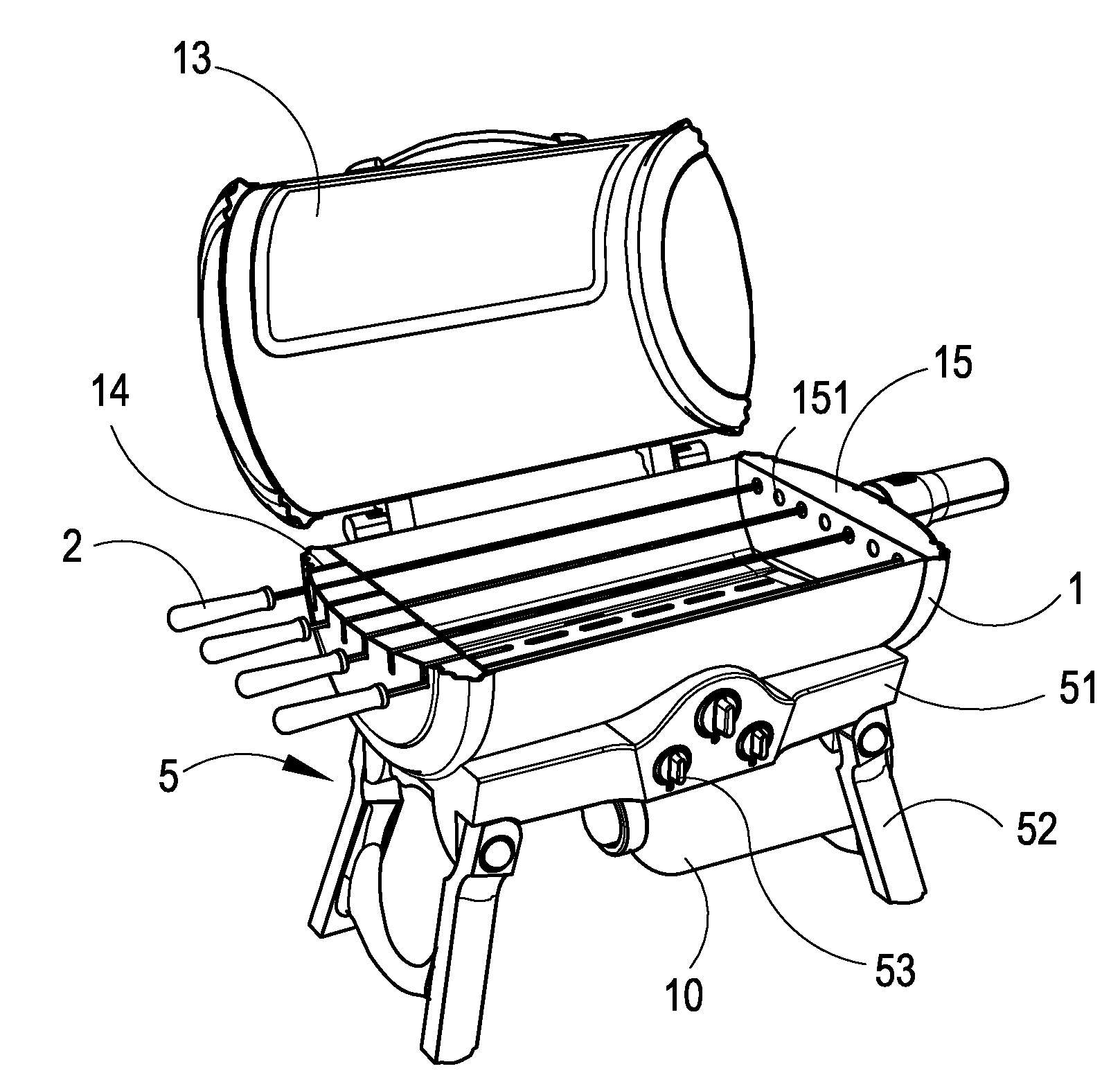

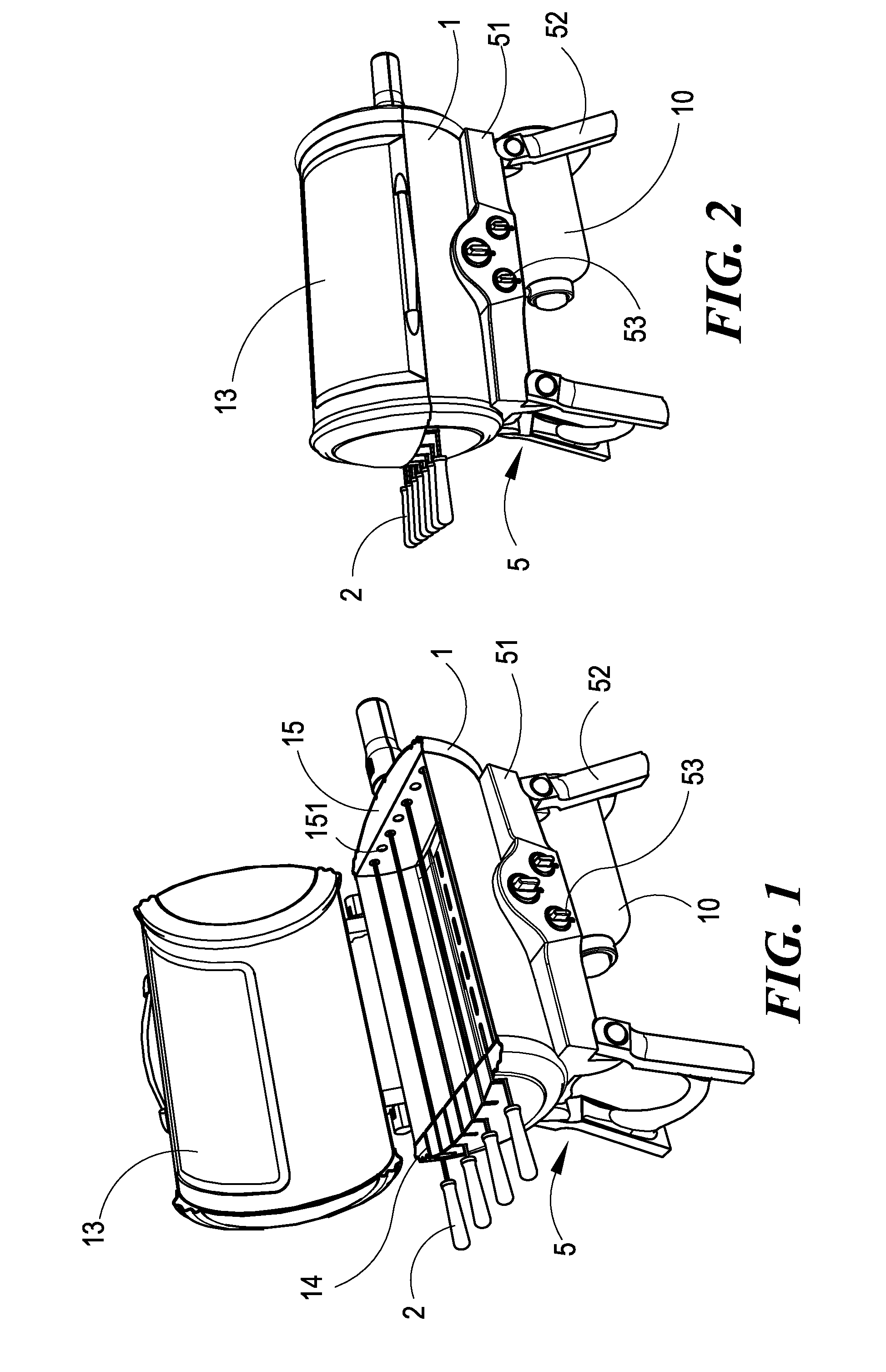

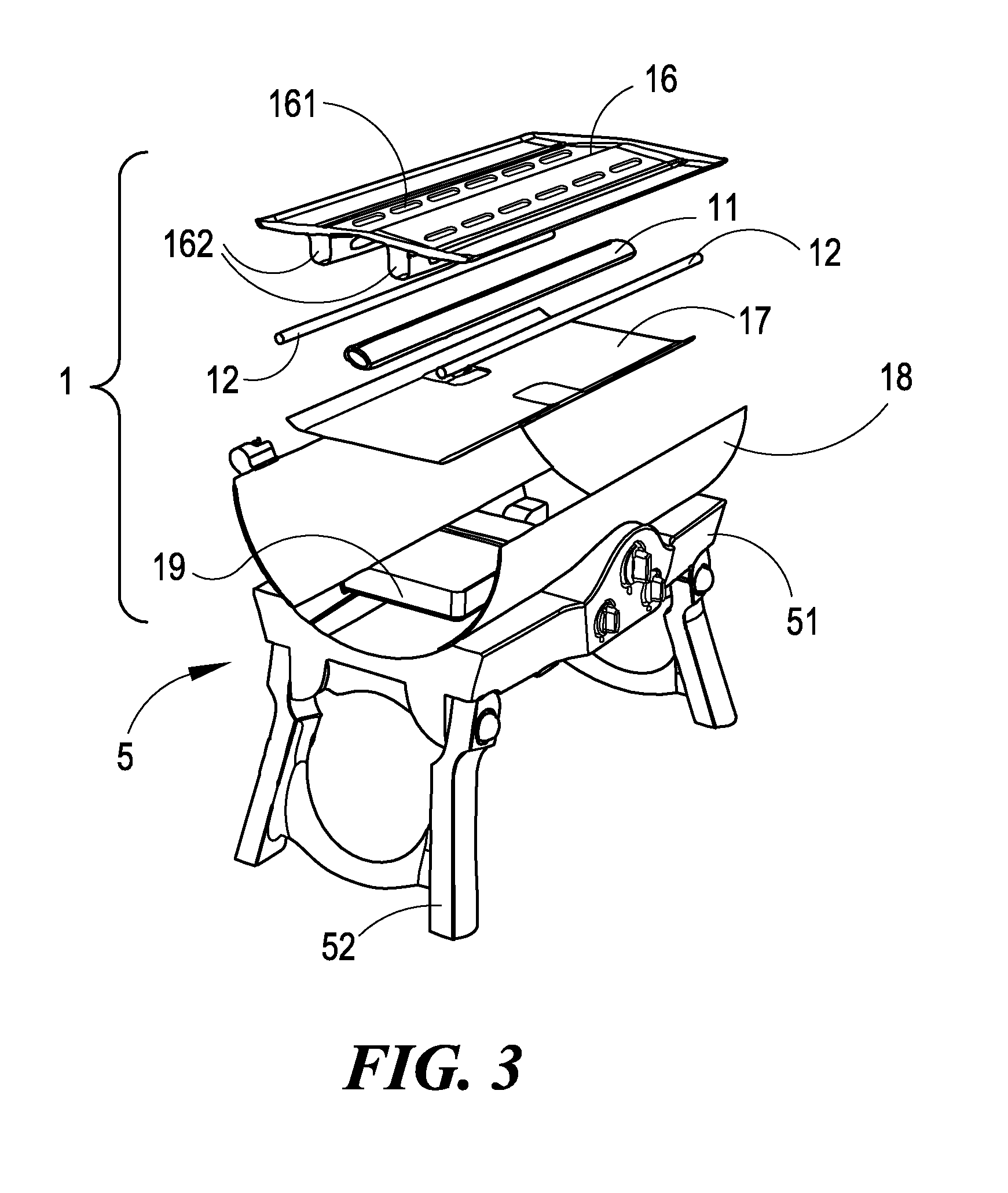

Portable Folding Roaster

InactiveUS20080163865A1Lower the volumeEasy to operateDomestic stoves or rangesLighting and heating apparatusFood materialEngineering

A portable folding roaster comprises: a heating box, having a baffle disposed therein and a partition disposed at the bottom thereof, a heat source being disposed between the baffle and the partition, and the baffle having small apertures arranged on the surface thereof for facilitating heat dissipation; a folding leg stand, having a base there over for fixing the heating box, the base having a plurality of supporting legs pivoted there below such that the supporting legs may be opened or closed with respect to the base; and a roasting tool, disposed on the heating box, and being used for holding food materials.

Owner:HO WEI TEH

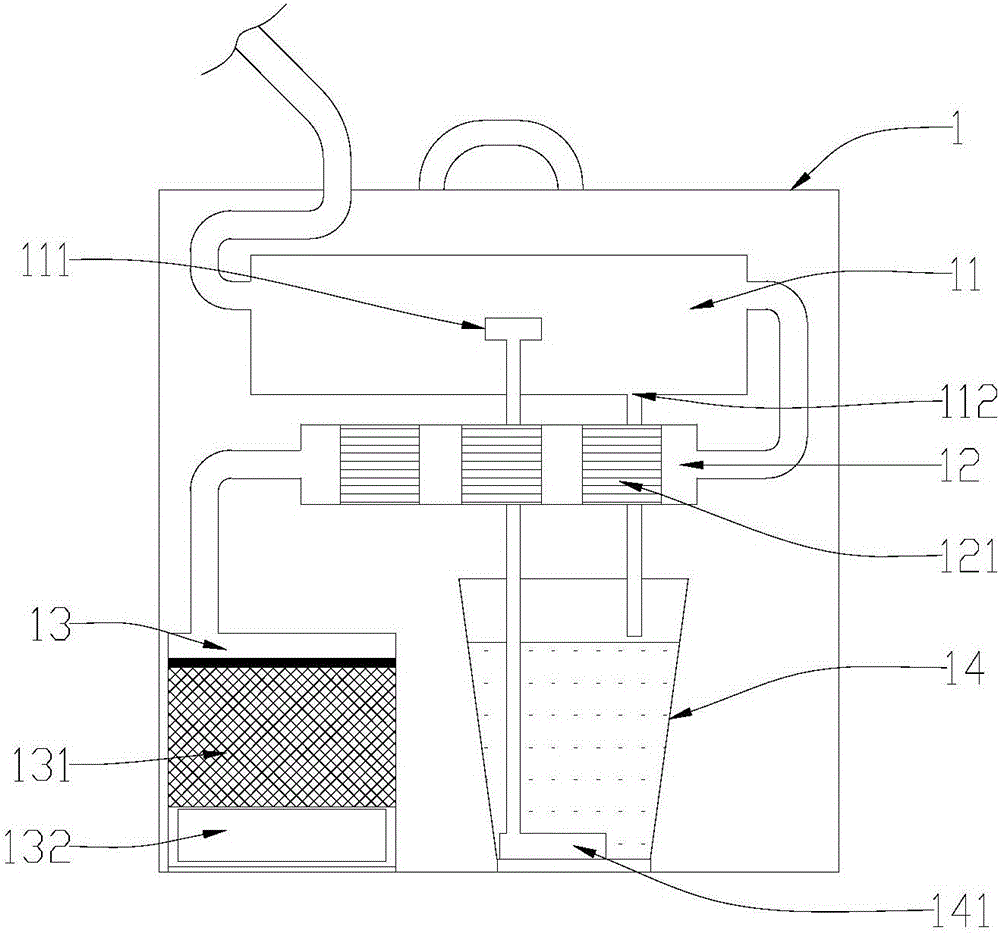

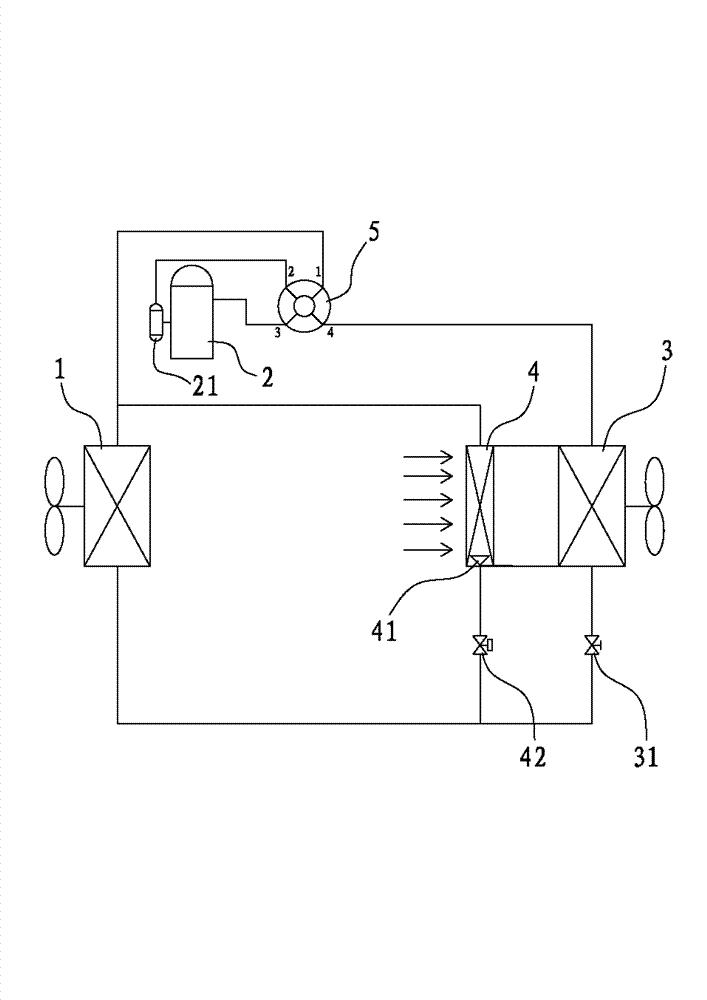

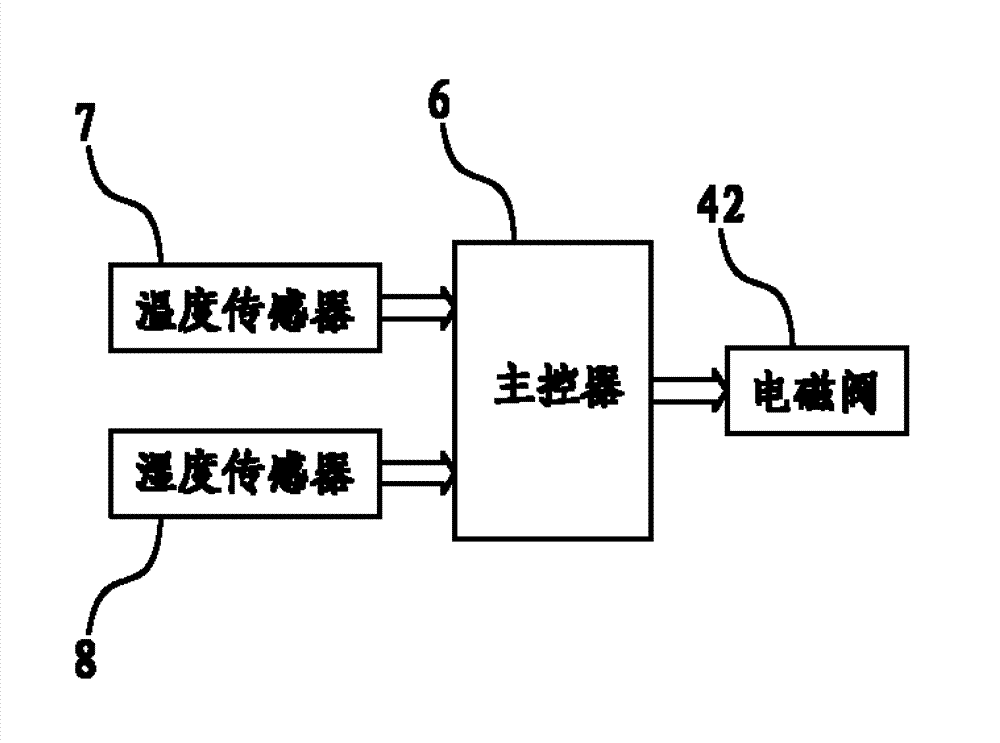

Internal recycle moist-air latent heat recovering type heat pump drying device

ActiveCN102954672AImprove work efficiencyAvoid polluting the environmentHeat pumpsFluid circulation arrangementCondensed waterEvaporator

The invention relates to heat pump drying device technology, in particular to an internal recycle moist-air latent heat recovering type heat pump drying device. The heat pump drying device comprises an air source evaporator, a compressor, a drying condenser positioned in a drying chamber and a dehumidifying evaporator. An input end of the dehumidifying evaporator is connected with an output end of the drying condenser, an output end of the dehumidifying evaporator is connected with the output end of the air source evaporator, and the dehumidifying evaporator is provided with a water collection channel used for discharging condensed water. Heat of air in an outdoor environment can be absorbed through the air source evaporator, latent heat of moist-air in the drying chamber can be absorbed through the dehumidifying evaporator, and accordingly dehumidifying effect is achieved, and the latent heat of the moist-air in the drying chamber is fully utilized. Besides, the condensed water can be discharged out of the drying chamber by the water collection channel, namely, the heat is not discharged to the outside, and accordingly environment pollution is avoided.

Owner:DONGGUAN LANGUAN ENVIRONMENTAL PROTECTION ENERGY SYST

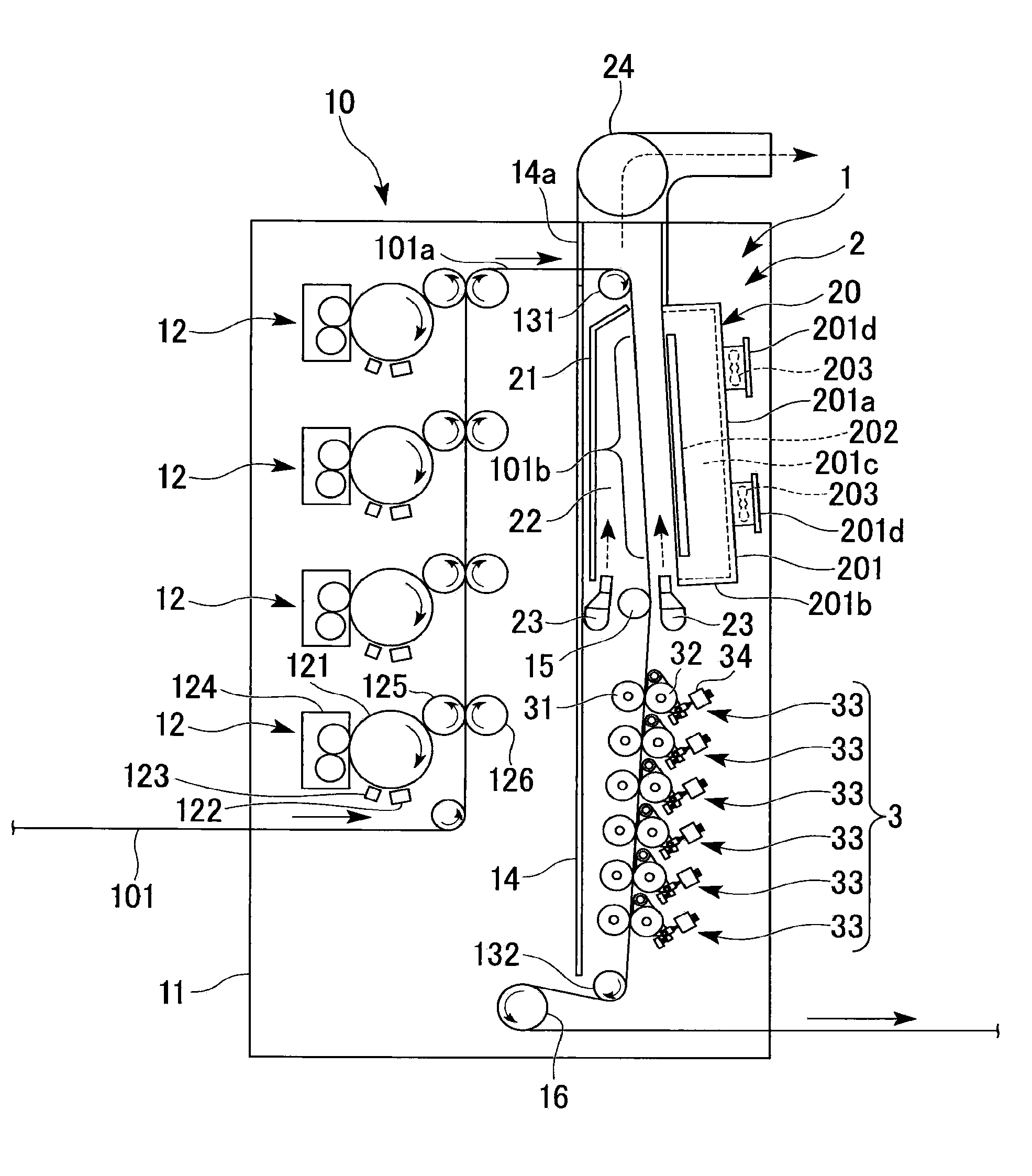

Toner fixing apparatus and electrophotographic printing device

InactiveUS20100086336A1Keep dryEasy to useElectrographic process apparatusElectrographic processes using charge patternImage formationEngineering

A toner fixing apparatus characterized by provision of a provisional fixing portion provided with a provisional fixing component having an infrared heater irradiating infrared radiation onto a printed surface of the web and a main fixing portion provided downstream in the web flow in the provisional fixing portion and nipping the web with heat rollers performing a main fixing operation or having a plurality of main fixing units. According to this invention, a toner fixing apparatus and an electrophotographic printing device including the toner fixing apparatus are provided which display excellent fixing properties during multicolor image formation, excellent heating efficiency and excellent economy with respect to installation space.

Owner:MIYAKOSHI PRINTING MACHINERY

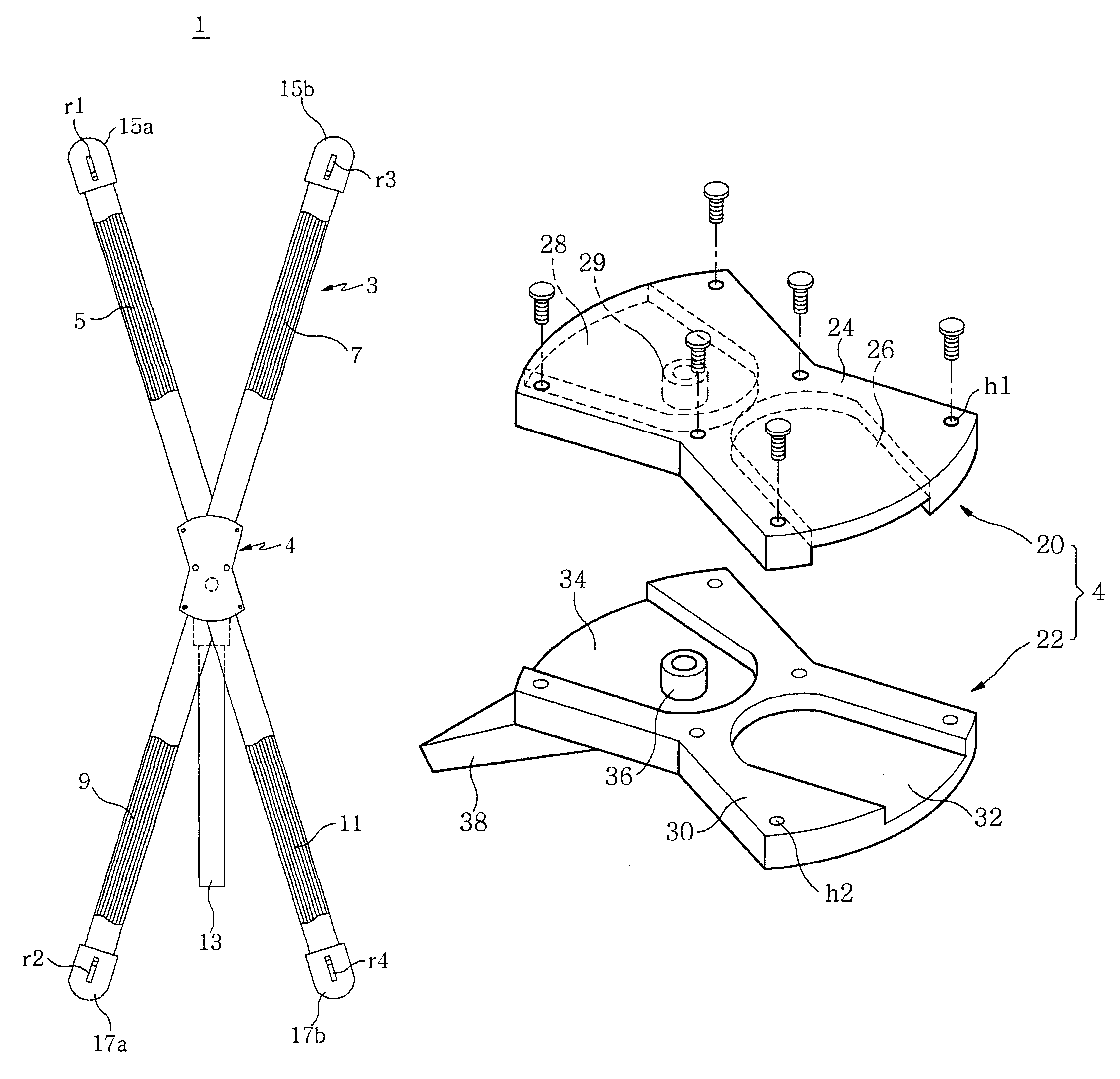

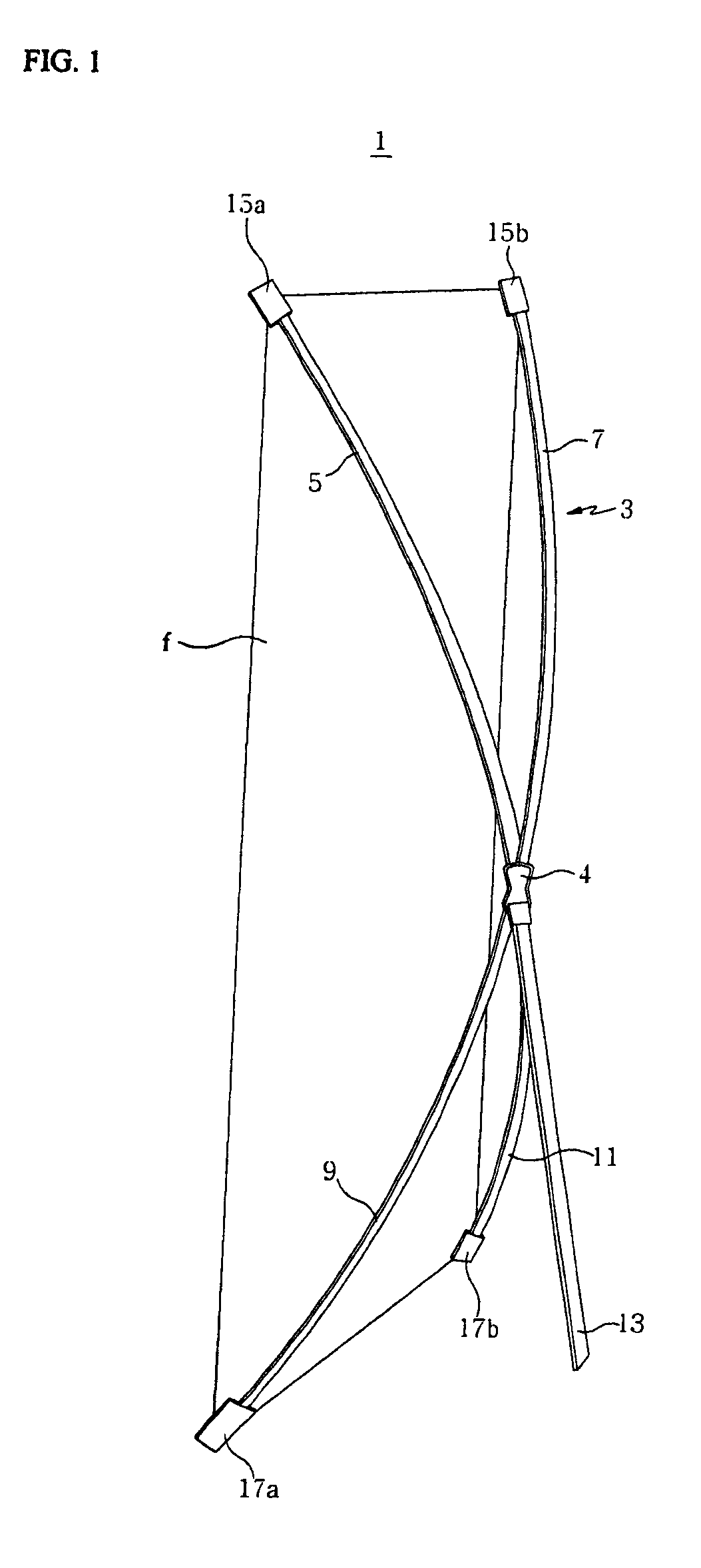

Apparatus for supporting banner

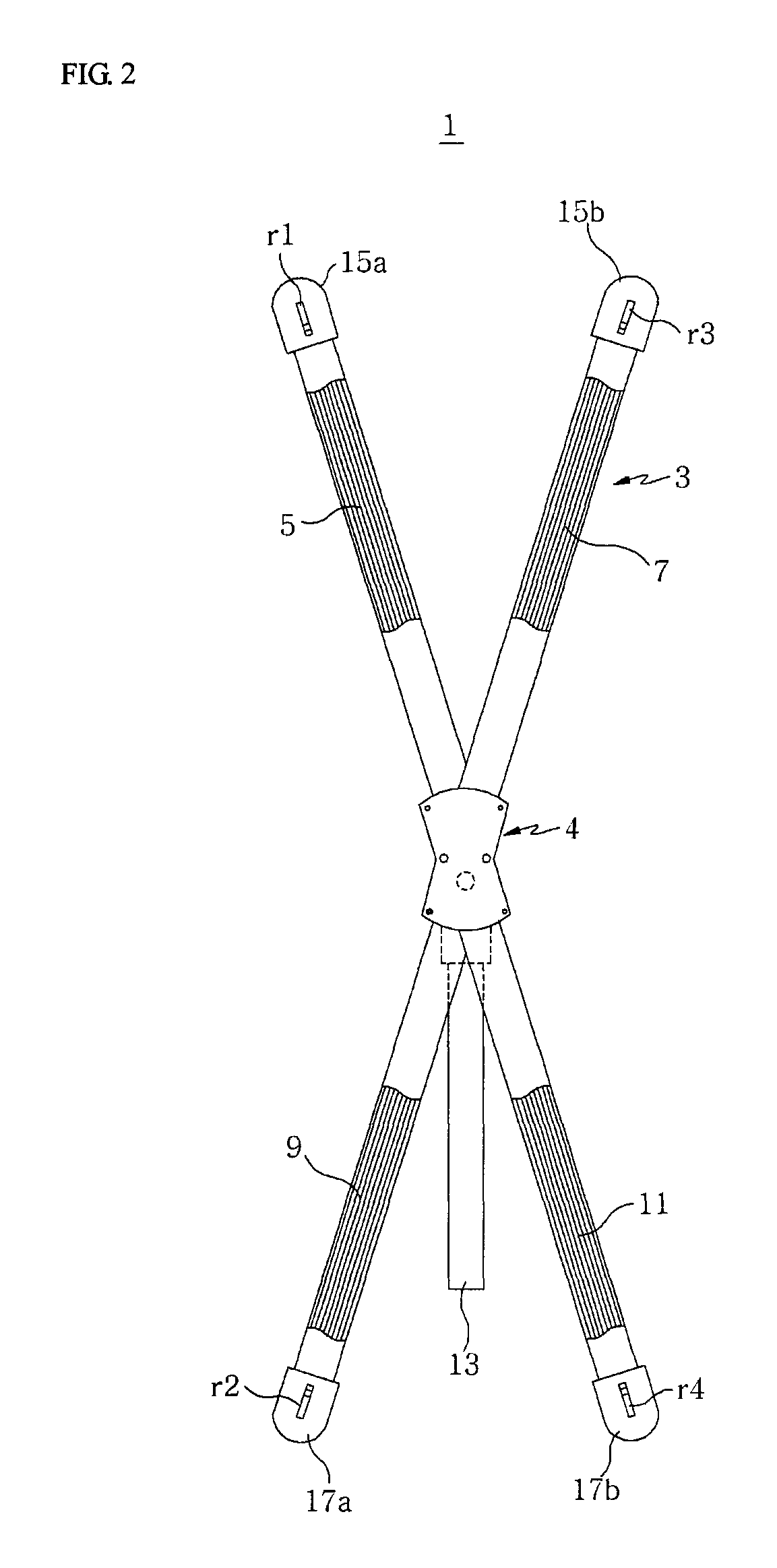

InactiveUS7966757B2Avoid polluting the environmentEasy to foldDoor/window protective devicesStands/trestlesMechanical engineeringEngineering

Disclosed is an apparatus for supporting a banner. The apparatus includes a plurality of frames, each being formed by stacking a plurality of plates, a connection unit having an interior cover and an exterior cover connected to each other by inserting the plurality of frames into the interior and exterior covers, respectively, a supporter provided to each end of the plurality of frames to support the banner, and a support frame connected to one side of the connection unit to support the plurality of frames. In the apparatus, the plurality of environmentally friendly bamboo plates are adhered to each other and integrated into a single body, thereby obtaining both elasticity and rigidity of bamboo.

Owner:HYUNG CHUL CHO

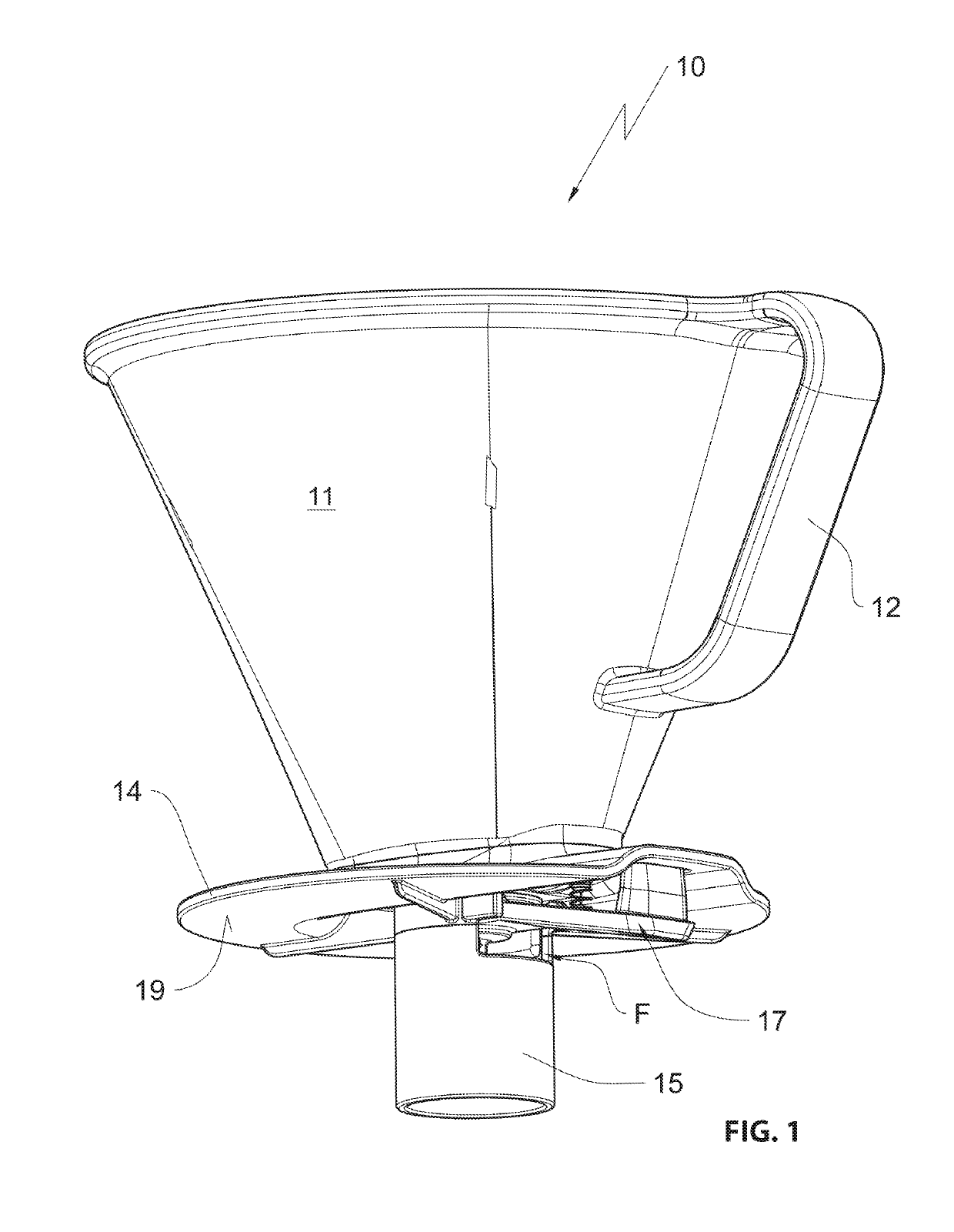

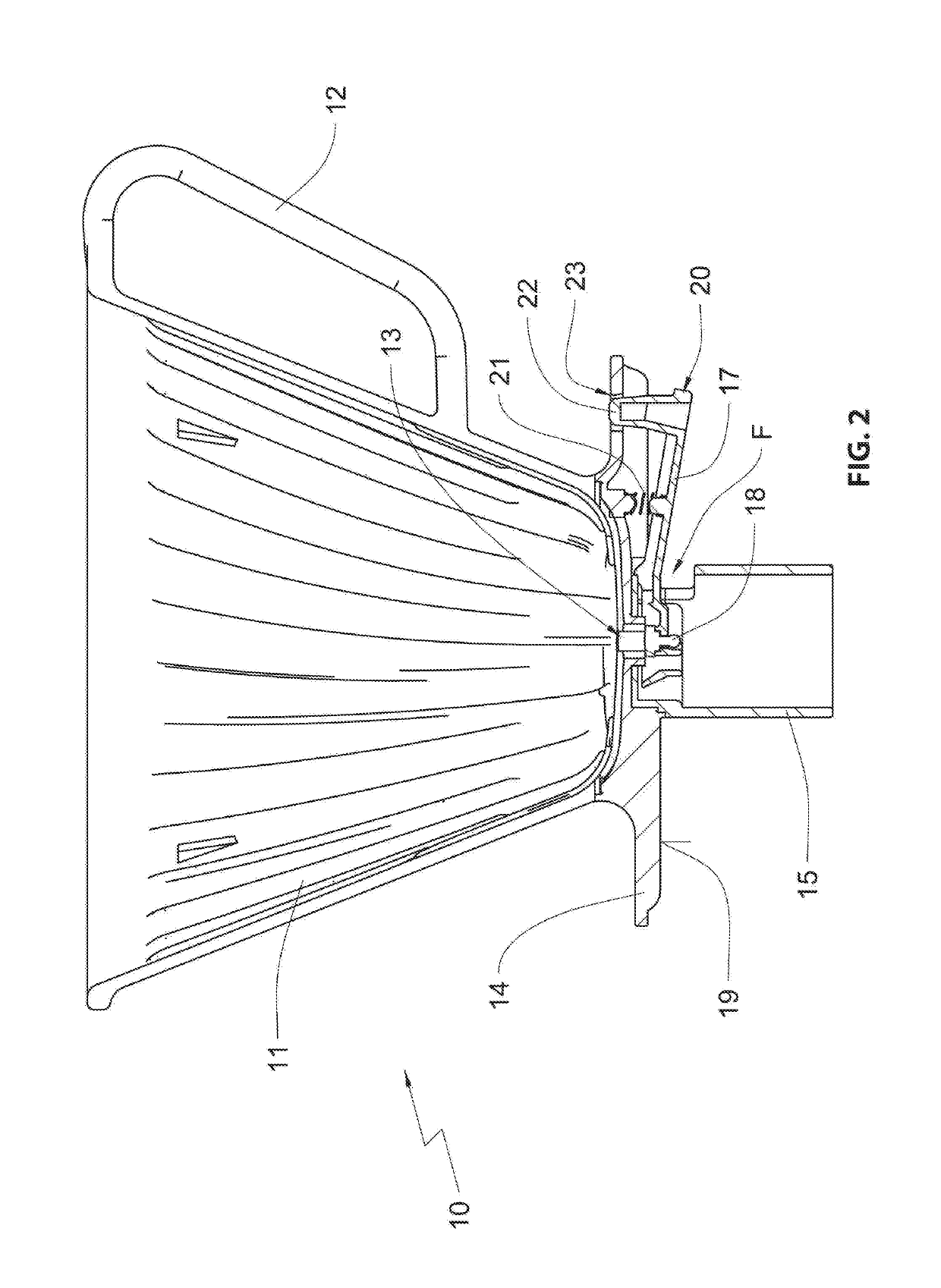

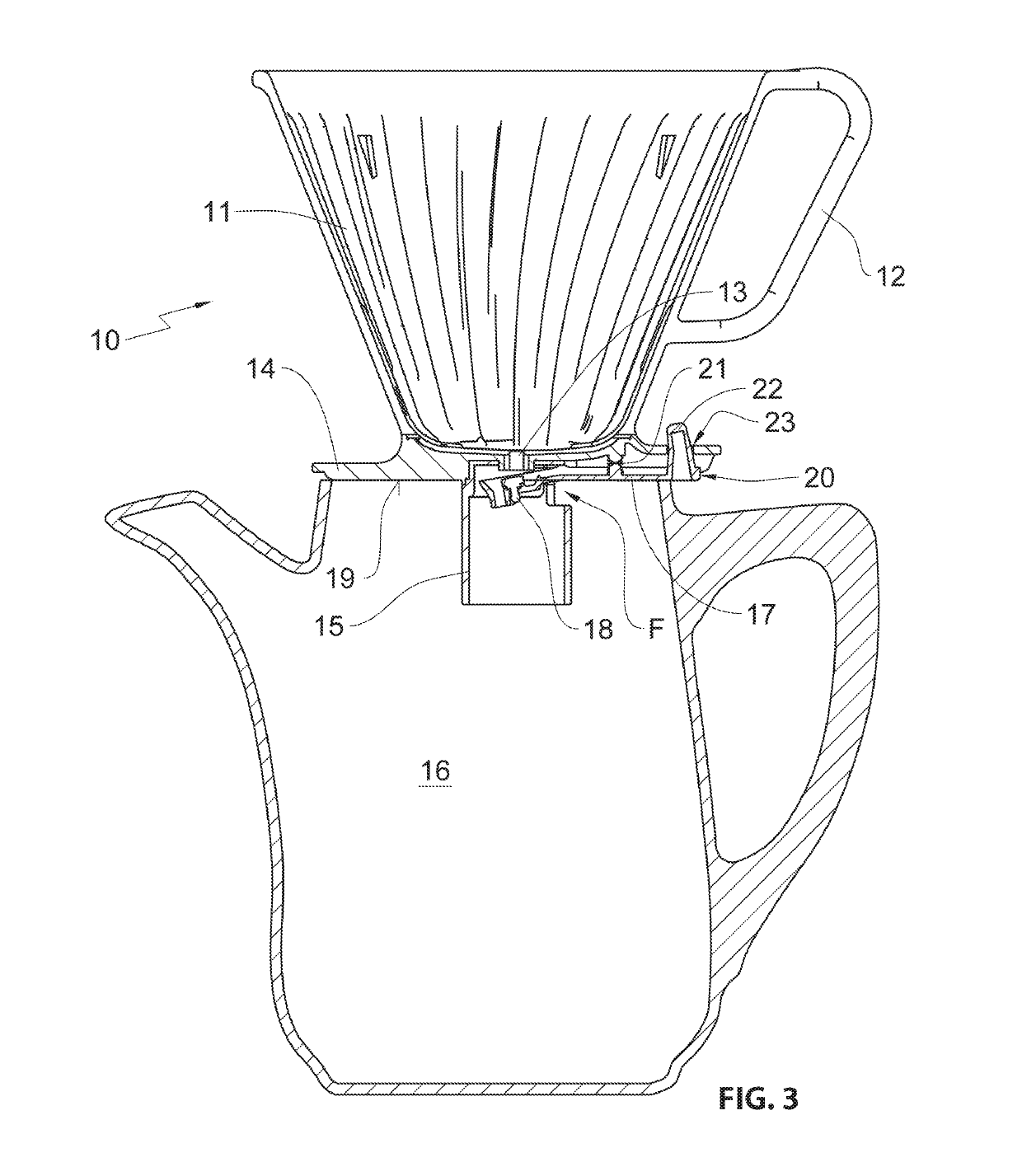

Coffee filter holder

InactiveUS20190191914A1Prevent contamination of environmentAvoid polluting the environmentBeverage vesselsFilter holderWaste management

A coffee filter holder configured to be placed on a coffee pot and to receive a filtering arrangement that is at least partially filled with coffee powder, the coffee filter holder including a conical receiver for the filtering arrangement, the conical receiver including a base side pass through opening and a base plate configured to support the coffee filter holder on the coffee pot; and a valve arrangement that is arranged below the base plate wherein the valve arrangement is actuated by a weight of the coffee filter holder when the coffee filter holder is placed on the coffee pot.

Owner:SCHILLHEIM RUDOLF

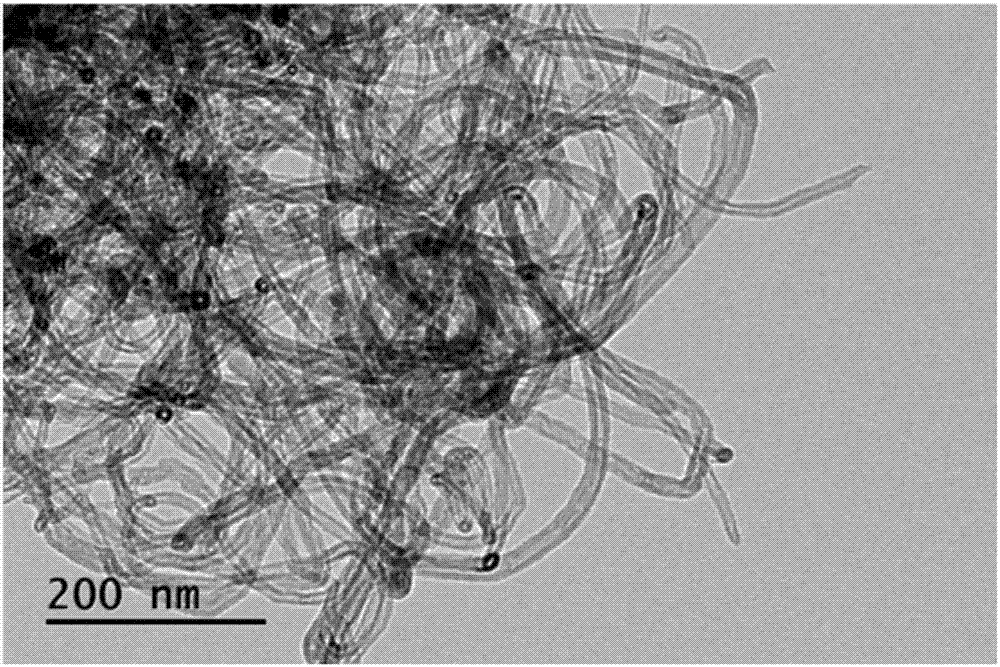

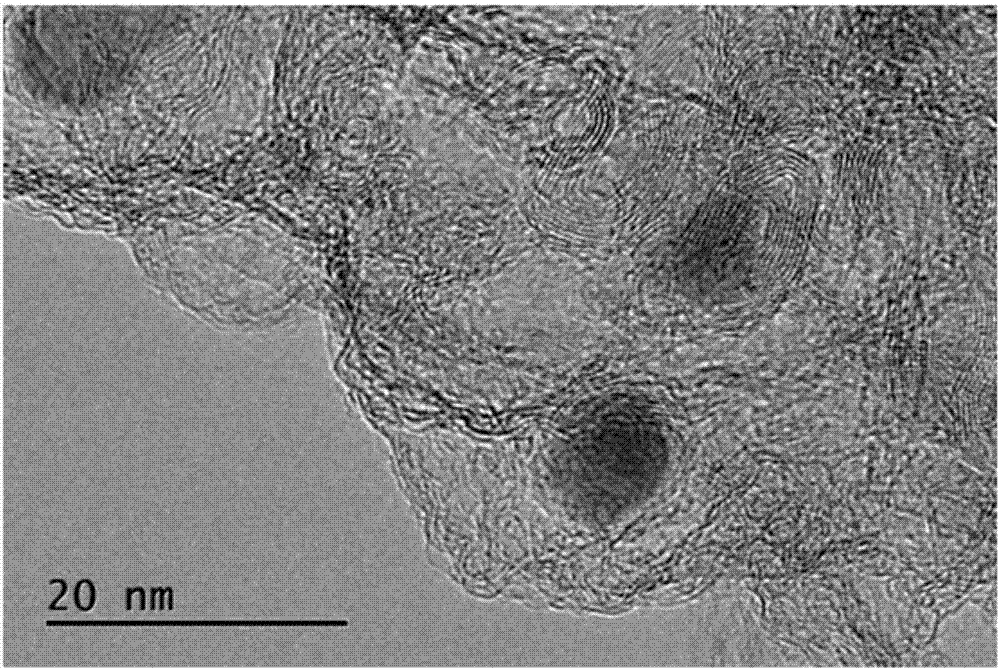

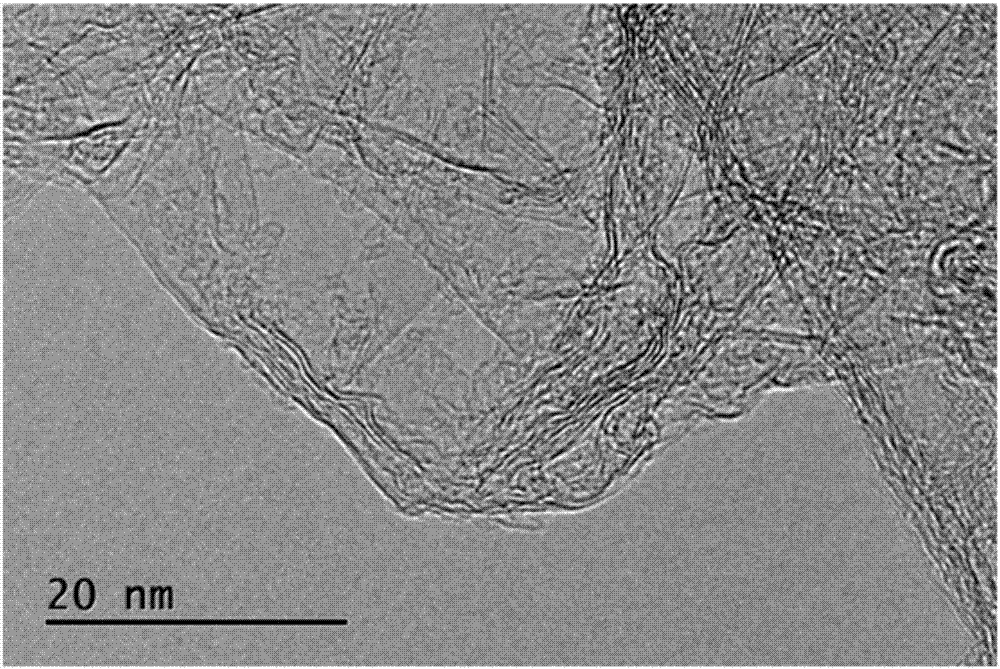

Preparation method for carbide catalyst for organic carbon vapor phase growth and application thereof

InactiveCN107252682AReduce manufacturing costShape controllableHeterogenous catalyst chemical elementsGrapheneRare-earth elementSolvent

The invention discloses a preparation method for a carbide catalyst for organic carbon vapor phase growth and an application thereof. The method comprises the following steps: adding a precipitator or a complexing agent or a dispersing agent, or a precipitator and a dispersing agent, or a complexing agent and a dispersing agent into a compound or complex containing a catalytic element, wherein the compound or complex containing the catalytic element is the compound containing one or more of rare earth elements, iron, cobalt, nickel, molybdenum, zirconium, copper, zinc, magnesium, aluminium and silicon or the complex thereof; through one or more of a precipitation method, a complexing method, a hydrothermal method, a high-pressure hydrothermal method and a sol-gel method, synthesizing to prepare mixed solution containing the catalytic elements, spray-drying the mixed solution by a spray drying machine, rapidly removing a solvent to form a catalyst precursor with catalytic element nano-state distribution, and calcinating the catalyst precursor in the high temperature, to obtain the carbide catalyst for the organic carbon vapor phase growth.

Owner:陈永

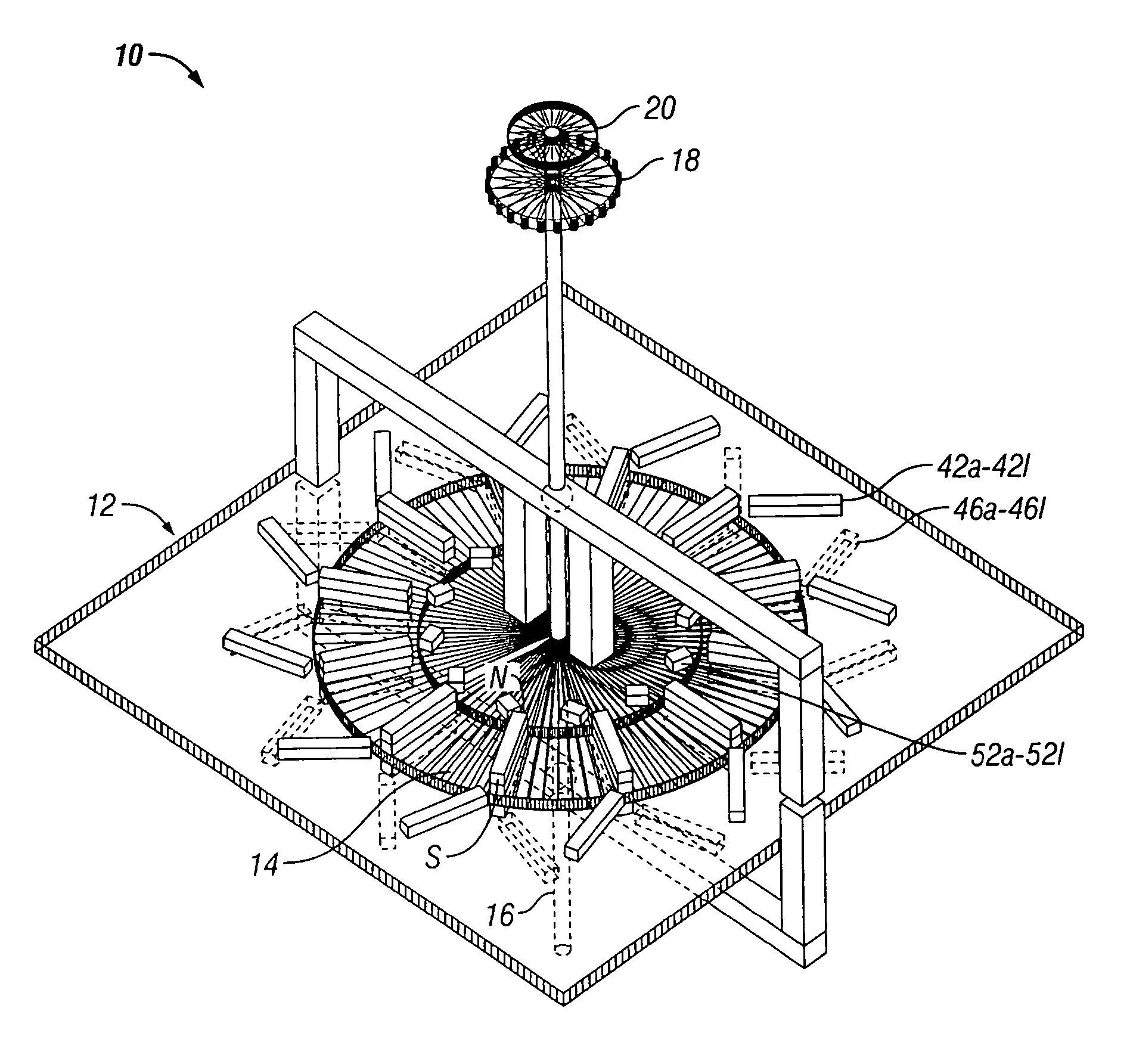

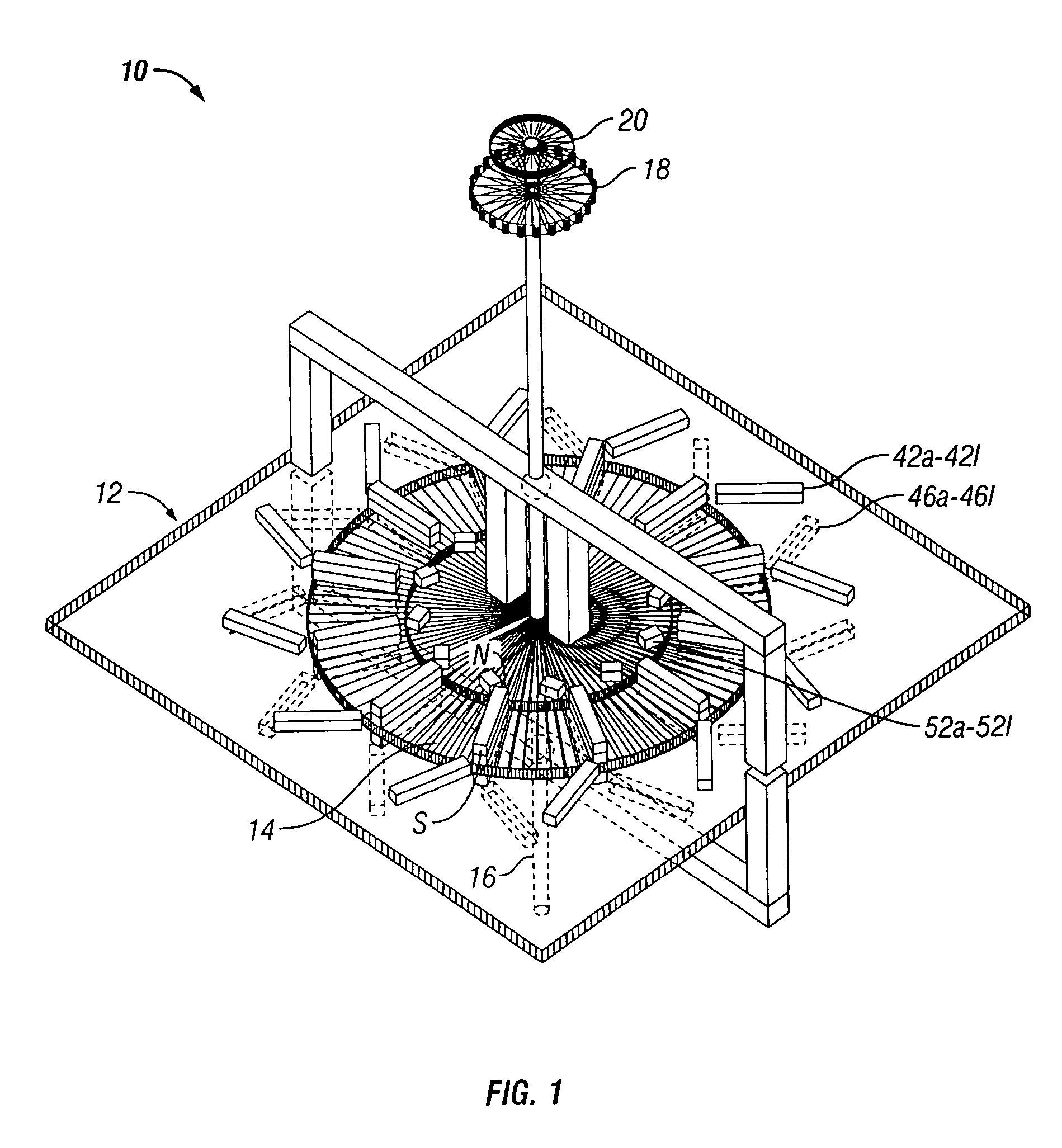

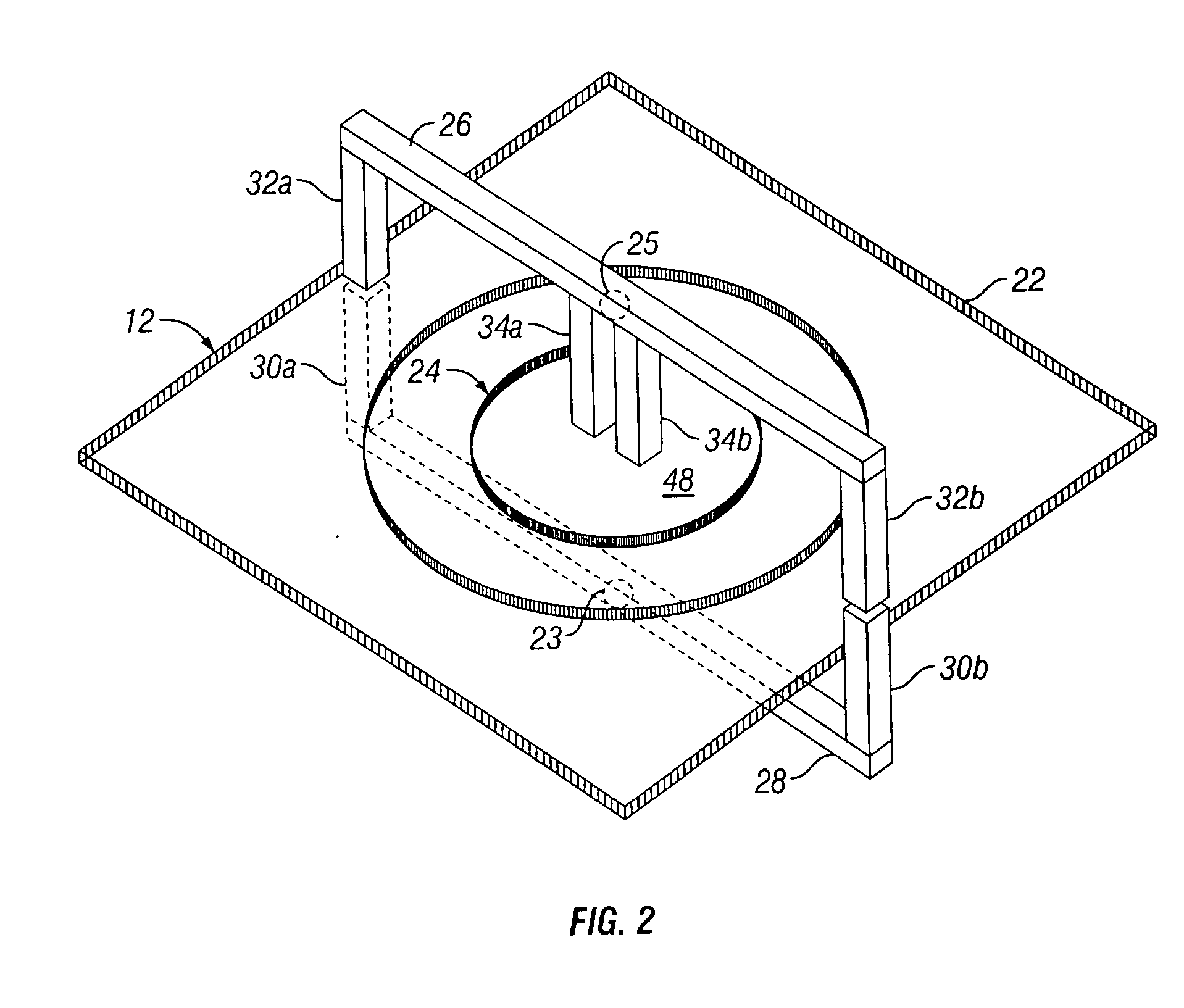

High efficiency magnet motor

InactiveUS20070222309A1Simple and inexpensive in designSimple and inexpensive in and constructionDynamo-electric brakes/clutchesSynchronous machinesRotor magnetsEngineering

A high efficiency non-electrically induced magnet motor includes a stator assembly and a rotor assembly having a rotor shaft extending therethrough at its center and disposed operatively for relative rotation respect to the stator assembly about the rotor shaft between a counter-clockwise direction and a clockwise direction. First and second groups of magnets are affixed to respective top and lower surfaces of an outer field magnet holder plate of the stator assembly. A third group of magnets is affixed to a top surface of an inner core magnet holder plate of the stator assembly. Fourth and fifth groups of magnets are affixed to respective top and lower surfaces of a rotor plate of the rotor assembly. First and second flux gate window control devices are provided for selectively allowing repulsive flux from the first through third groups of stator magnets to be coupled to the fourth and fifth groups of rotor magnets for causing rotation of rotor assembly between the counter-clockwise and clockwise directions.

Owner:MINKER GARY A

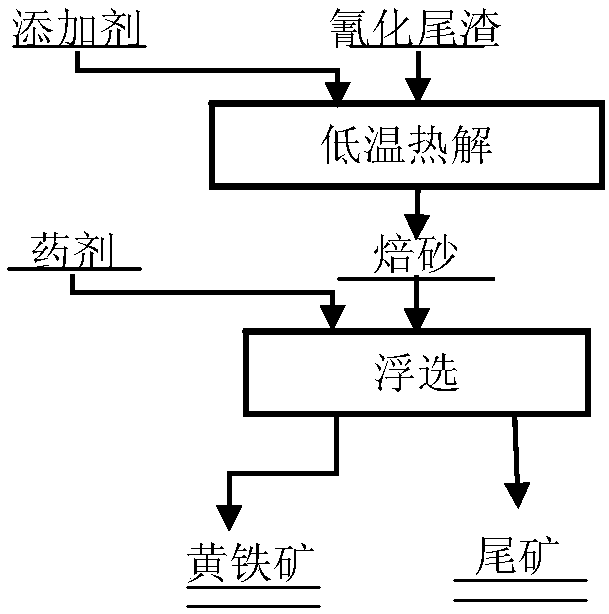

Harmless disposal method of cyanidation tailings

ActiveCN108515073AGood cyanide removal effectAvoid polluting the environmentSolid waste disposalTransportation and packagingThermal insulationCyanogen

A harmless disposal method of cyanidation tailings comprises the following steps: (1) using cyanidation tailings as a raw material, or adding an additive CaO into cyanidation tailings as mixed raw materials; (2) heating the raw material or the mixed raw materials to 250-450 DEG C for pyrolysis and carrying out thermal insulation for less than or equal to 90 min so as to obtain calcine; and (3) directly using calcine as backfill treatment, or extracting pyrite through flotation. The method of the invention has a good cyanogens removal effect, and the cyanidation tailings which have undergone low-temperature pyrolysis meets requirements of common solid wastes.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com