Harmless disposal method of cyanidation tailings

A technology of harmless treatment and cyanidation of tailings, which is applied in the direction of chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of high anti-corrosion ability, pollution, long time, etc., and achieve cyanide removal Good effect, avoid the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

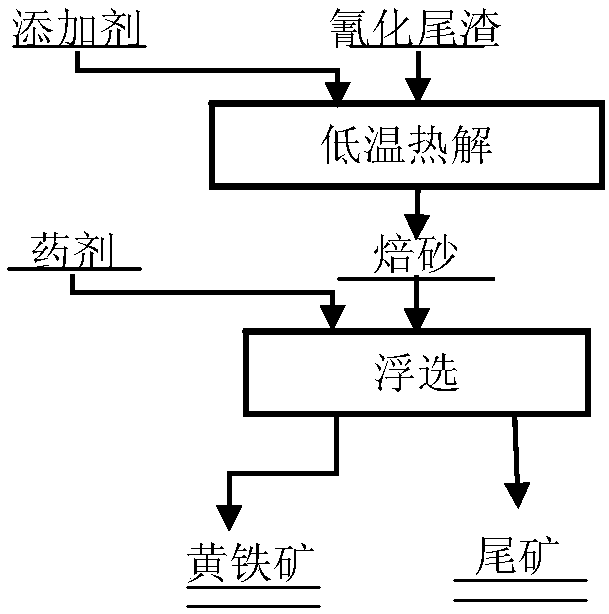

Method used

Image

Examples

Embodiment 1

[0027] The cyanide tailings are cyanide tailings produced by a company in Shandong, the mass percentage of water is 12.4%, and the solid content contains Fe 41.41%, S 48.40%, SiO 2 5.72%, Al 2 o 3 1.48%, CaO 0.47%, CN — Content 340mg / kg;

[0028] Prepare cyanide tailings as raw material;

[0029] Heat the raw material to 250°C for pyrolysis, and heat it for 90 minutes after reaching 250°C to complete the pyrolysis to remove cyanide and obtain calcined sand;

[0030] Use calcined sand directly for backfill treatment;

[0031] After testing, it was found that the total cyanide in the cyanide tailings (in CN — Count) gradually decreases, and at the end of pyrolysis, the pyrolysis material basically does not contain cyanide, CN — It is almost 0, and the cyanide removal rate reaches more than 99%.

Embodiment 2

[0033] Method is with embodiment 1, and difference is:

[0034] (1) The mass percentage of water in the cyanidation tailings is 16.9%, and the solid content contains Fe 29.92%, S 33.30%, SiO by mass percentage 2 24.95%, Al 2 o 3 5.25%, CaO 1.15%, CN — Content 500mg / kg;

[0035] (2) Heat the raw material to 350°C for pyrolysis, and heat it for 15 minutes after reaching 350°C to complete the pyrolysis;

[0036] (3) Add water to the calcined sand to make a pulp with a mass concentration of 35%; add flotation agent xanthate, foaming agent and inhibitor to the pulp, and then carry out flotation; wherein the amount of xanthate added is based on the amount of xanthate in the pulp The concentration is 0.5×10 -5 mol / L, the addition of foaming agent is 100mg / L by the concentration of foaming agent in the ore pulp, and the addition of suppressor is 100g / t calcine; Described foaming agent is 2# oil, and described The inhibitor is water glass; the flotation temperature is 15° C. an...

Embodiment 3

[0038] Method is with embodiment 1, and difference is:

[0039] (1) The mass percentage of water in the cyanidation tailings is 23.7%, and the solid content contains Fe 29.92%, S 33.30%, SiO by mass percentage 2 24.95%, Al 2 o 3 5.25%, CaO 1.15%, CN — Content 1160mg / kg;

[0040] (2) Heat the raw material to 450°C for pyrolysis, and complete the pyrolysis after reaching 450°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com