A method for preparing sulphoaluminate cement by using cyanide tailings

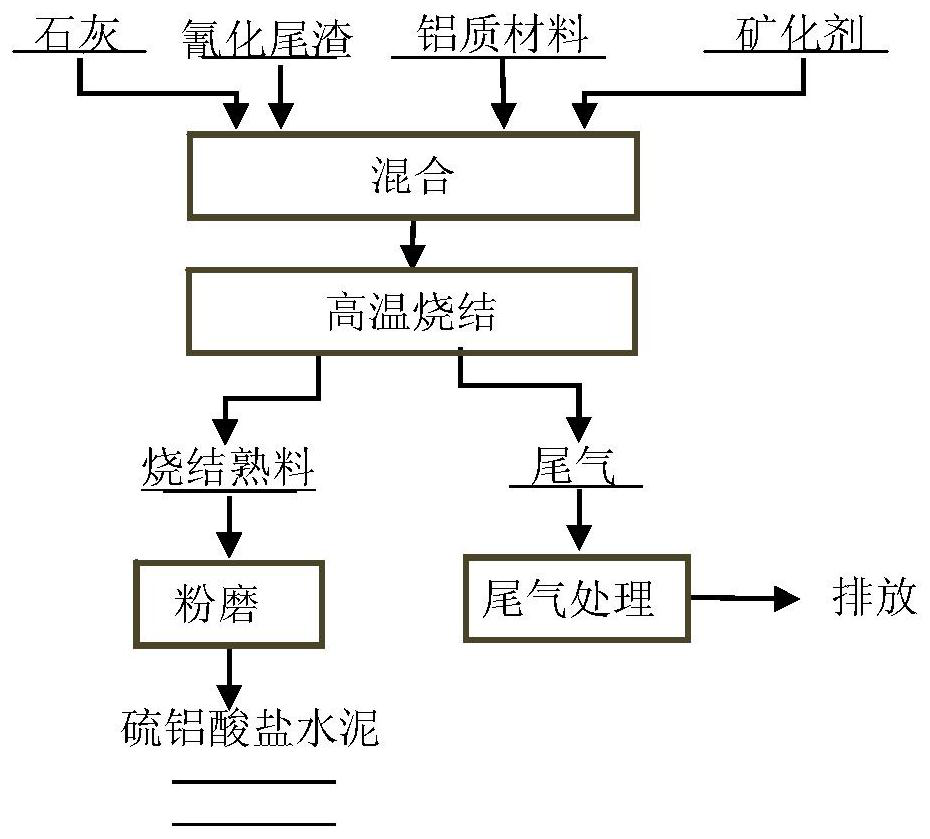

A technology of sulphoaluminate cement and cyanide tailings, which is applied in cement production, etc., can solve problems such as high roasting temperature, pollution, and hidden safety hazards in the surrounding environment, so as to improve the easy-to-burn performance, avoid environmental pollution, and remove cyanide. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The cyanide tailings are cyanide tailings produced by a company in Shandong. After drying, they contain Fe 41.41%, S48.40%, SiO 2 5.72%, Al 2 o 3 1.48%, CaO 0.47%, CN — The content is 340mg / kg;

[0029] Cyanide tailings, lime and aluminum materials are respectively crushed to a particle size of 2-5 mm, and then ground to a particle size of -0.074 mm, accounting for more than 85% of the total weight;

[0030] Prepare cyanidation tailings, lime and aluminum materials as raw materials, and mix all the raw materials evenly; in all raw materials, there are 4 parts by mass of cyanide tailings, 18 parts of lime, and 20 parts of aluminum materials; the aluminum The material is bauxite;

[0031] The mixed material is sintered at high temperature in a high-temperature kiln. The high-temperature kiln is a rotary kiln, the sintering temperature is 1300°C, and the time is 60 minutes to obtain sintered clinker; the atmosphere is air during high-temperature sintering;

[0032] ...

Embodiment 2

[0035] Method is with embodiment 1, and difference is:

[0036] (1) After drying, the cyanide tailings contain Fe 29.92%, S 33.30%, SiO by mass percentage 2 24.95%, Al 2 o 3 5.25%, CaO 1.15%, CN — The content is 500mg / kg;

[0037] (2) In all raw materials, by mass parts, 5 parts of cyanidation tailings, 17 parts of lime, 30 parts of aluminum material; Described aluminum material is fly ash;

[0038] (3) The high-temperature furnace is a shaft kiln, the sintering temperature is 1300°C, and the time is 60 minutes; the average cooling rate is controlled at 20°C / min.

Embodiment 3

[0040] Method is with embodiment 1, and difference is:

[0041] (1) The cyanide tailings contain 16.37% Fe, 16.50% S, SiO by mass percentage after drying 2 41.96%, Al 2 o 3 9.71%, CaO 2.10%, CN — The content is 1200mg / kg;

[0042] (2) In all raw materials, there are 5 parts by mass of cyanidation tailings, 11 parts of lime, and 8 parts of aluminum materials;

[0043] (3) The sintering temperature is 1300°C, and the time is 60 minutes; the average cooling rate is controlled to be 25°C / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com