Doped monocrystal multi-component material for lithium ion batteries and preparation method of such doped monocrystal multi-component material

A lithium-ion battery and single-crystal-like technology, which is applied in the field of single-crystal-like multi-element cathode materials and their preparation, can solve the problems of low specific capacity of lithium-ion batteries, prone to lithium precipitation, and low first discharge efficiency of cathode materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

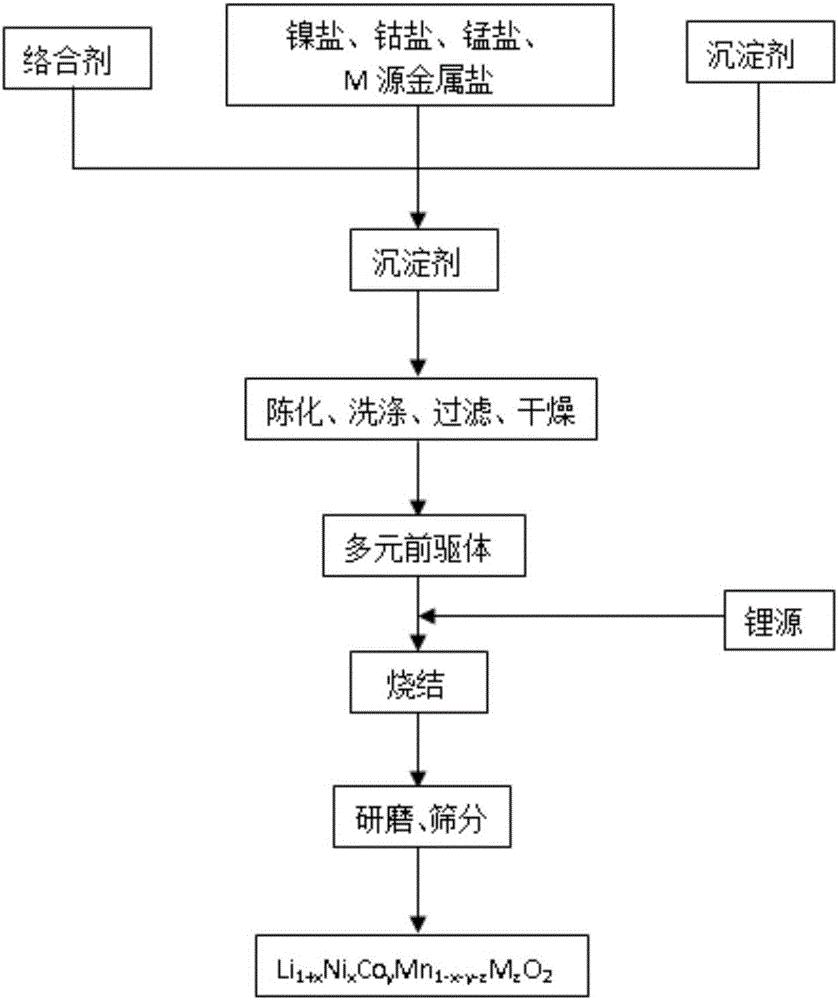

[0061] A method for preparing a doped lithium-ion battery-like single-crystal multi-element positive electrode material of the present invention comprises the following steps;

[0062] S1: Preparation of Ni by co-precipitation method x co y mn 1-x-y-z m z (OH) 2 Multicomponent composite material precursor

[0063] Mix nickel salt, cobalt salt, manganese salt, and M source salt according to the metal molar ratio of x:y:1-x-y-z:z to obtain mixed solution A. The concentration of solution A is 0.5-2.5mol / L. The solution A and the precipitating agent are added together into the reactor containing the complexing agent for reaction, the stirring speed is controlled at 500-800r / min, the pH is controlled at 10.5-14, the reaction time is 15-36 hours, and the reaction temperature is controlled at 40 -80°C, get precipitate B after reaction, age the precipitate B, the aging time is 10-30h, wash, wash with deionized water, the number of washes is 4-6 times, filter, wash again, the numb...

Embodiment 1

[0099] (1) Nickel salt, cobalt salt, manganese salt, and titanium salt are mixed according to the metal molar ratio of 0.75:0.1:0.1:0.05, and dissolved in deionized water to make a mixed salt solution with a concentration of 1mol / L. The mixed salt solution, 2mol / L precipitant NaOH solution and complexing agent NH 3 ·H 2 O solution three co-flow, join in the reactor that fills the NaOH solution that pH is 11.25 and be bottom liquid, control pH to keep 11.25 ± 0.05 all the time, stir and react at 50 ℃ for 24 hours (nitrogen is used as protective gas in the reaction process), The product slurry is obtained by overflowing, the product slurry is aged for 20h, and filtered to obtain the multi-component precursor intermediate product;

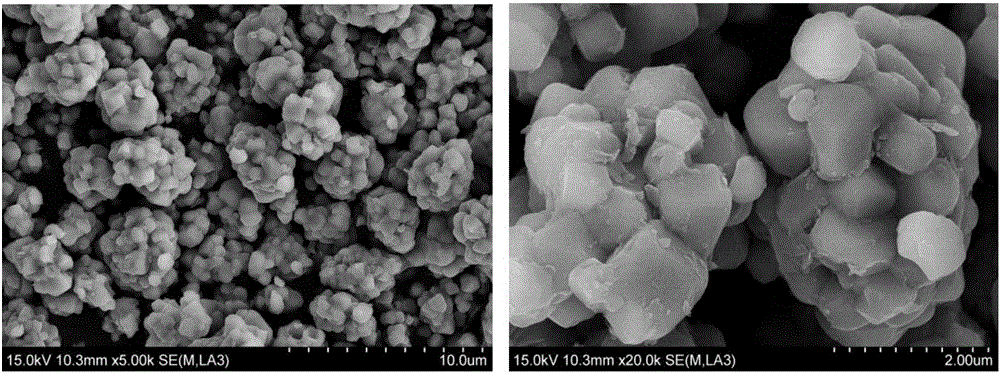

[0100] (2) Wash the above-mentioned intermediate product with 80°C deionized water 6 times to remove excess impurity ions, filter and dry at 80°C for 24 hours to obtain Ni 0.75 co 0.1 mn 0.1 Ti 0.05 (OH) 2 Multi-component precursors, the particl...

Embodiment 2

[0109] (1) Nickel salt, cobalt salt, manganese salt, zirconium salt and lithium source are carried out ball milling, and the rotating speed is 400r / min, and the time is 55min;

[0110] (2) Nickel salt, cobalt salt, manganese salt, and zirconium salt are mixed according to the ratio of metal molar ratio of 0.7:0.15:0.12:0.03, mixed with a vertical drum mixer, dissolved in deionized water to make a concentration of 2mol / L mixed salt solution. The mixed salt solution, 4mol / L precipitant NaOH solution and complexing agent NH 3 ·H 2 O solution three co-currents, join in the reactor that fills the NaOH solution that pH is 11.55 and be the bottom liquid, control pH to keep 11.55 ± 0.05 all the time, stir and react at 60 ℃ for 30 hours (nitrogen is used as protective gas in the reaction process), The product slurry is obtained by overflowing, the product slurry is aged for 28h, and filtered to obtain the multi-component precursor intermediate product;

[0111] (3) Wash the above-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com