Patents

Literature

423 results about "Lithium manganese oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Lithium ion manganese oxide battery is a lithium ion cell that uses manganese dioxide, MnO. 2, as the primary cathode material. They function through the same intercalation/de-intercalation mechanism as other commercialized secondary battery technologies, such as LiCoO.

Asymmetric electrochemical supercapacitor and method of manufacture thereof

InactiveUS20080158778A1Increase energy densityImprove power densityHybrid capacitor electrodesLiquid electrolytic capacitorsAqueous electrolyteLithium manganese oxide

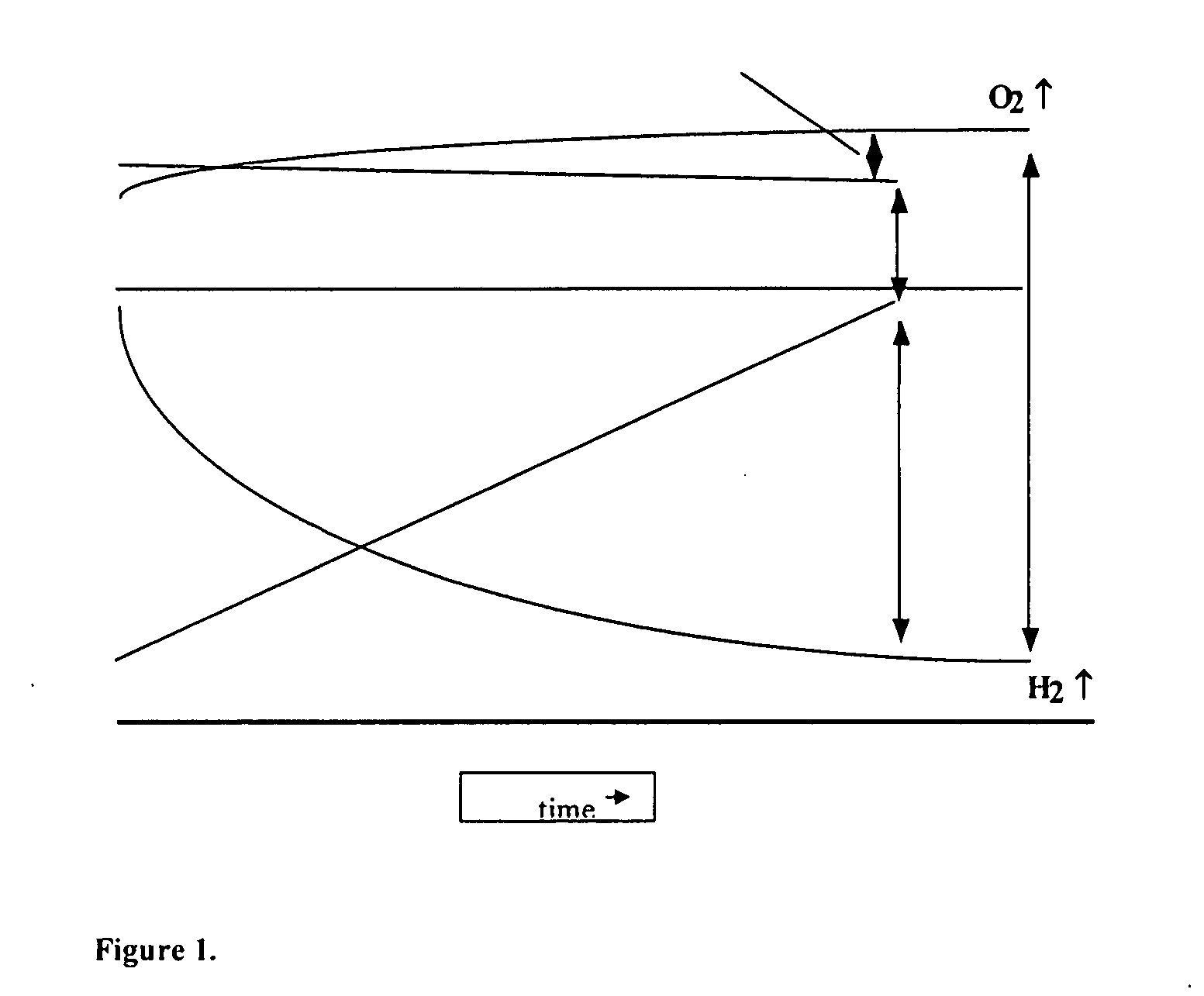

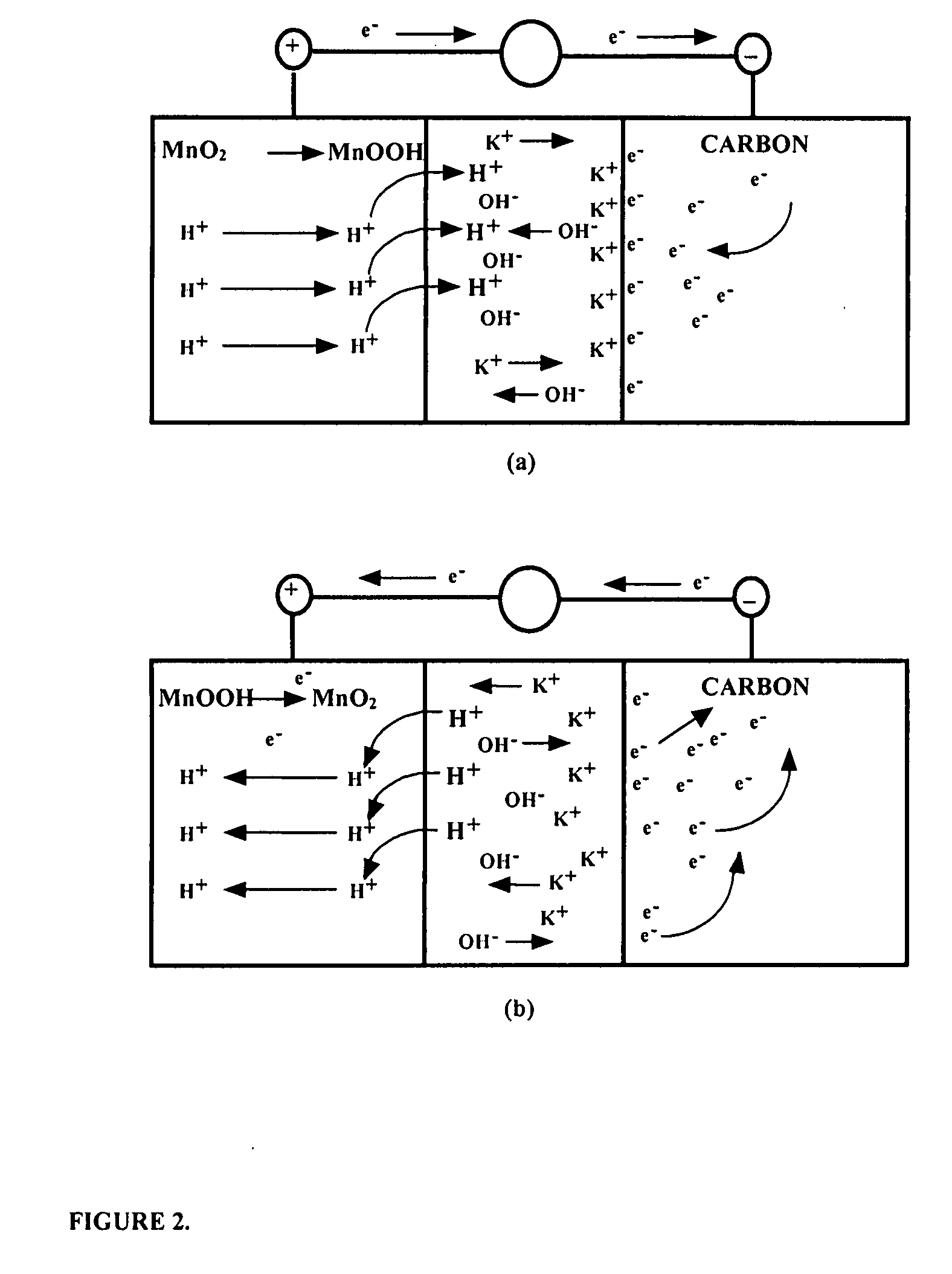

Asymmetric supercapacitors comprise: a positive electrode comprising a current collector and a first active material selected from the group consisting of manganese dioxide, silver oxide, iron sulfide, lithium manganese oxide, lithium cobalt oxide, lithium nickel oxide, lithium iron phosphate, and a combination comprising at least one of the foregoing active materials; a negative electrode comprising a carbonaceous active material; an aqueous electrolyte solution selected from the group consisting of aqueous solutions of hydroxides of alkali metals, aqueous solutions of carbonates of alkali metals, aqueous solutions of chlorides of alkali metals, aqueous solutions of sulfates of alkali metals, aqueous solutions of nitrates of alkali metals, and a combination comprising at least one of the foregoing aqueous solutions; and a separator plate. Alternatively, the electrolyte can be a non-aqueous ionic conducting electrolyte or a solid electrolyte.

Owner:U S NANOCORP

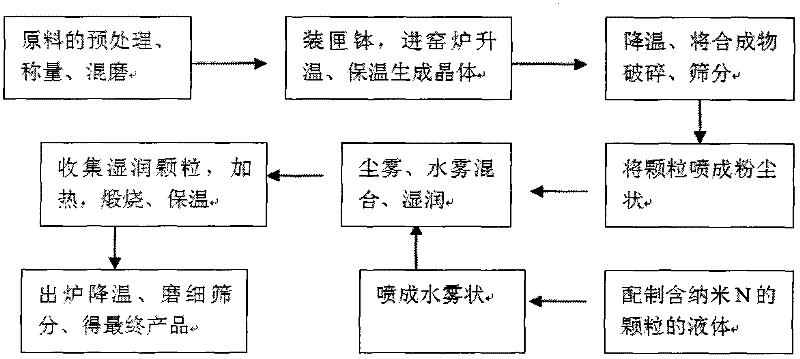

Lithium manganese oxide material and preparation method thereof

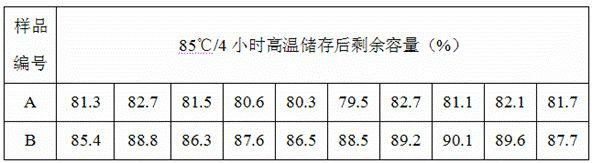

InactiveCN102054985AEasy to prepareNormal temperature is goodCell electrodesHigh temperature storagePhysical chemistry

The invention discloses a lithium manganese oxide material and a preparation method thereof, in particular to a high-crystallinity lithium manganese oxide material and a preparation method thereof, wherein the high-crystallinity lithium manganese oxide material is used for coating a lithium ion battery. The lithium manganese oxide material is obtained by being coated on a lithium manganese oxide precursor with the one-time crystal particle of 0.01-20mum and has the general formula of LiaMn2-b-cMbGcO4-d-eXdZe, wherein M and X are doped elements, G and Z are coating elements of which the concentration is distributed in a decreasing gradient from outside to inside, a is not less than 0.9 and is not more than 1.2, b is not less than 0 and is not more than 0.2, c is more than 0 and is not more than 0.2, d is not less than 0 and is not more than 0.2, and e is not less than 0 and is not more than 0.2. The material serves as the positive pole material of the lithium ion battery, has better normal-temperature and high-temperature cycle performance and excellent high-temperature storage performance, is simple in preparation and easy to operate, control and carry out industrial production.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

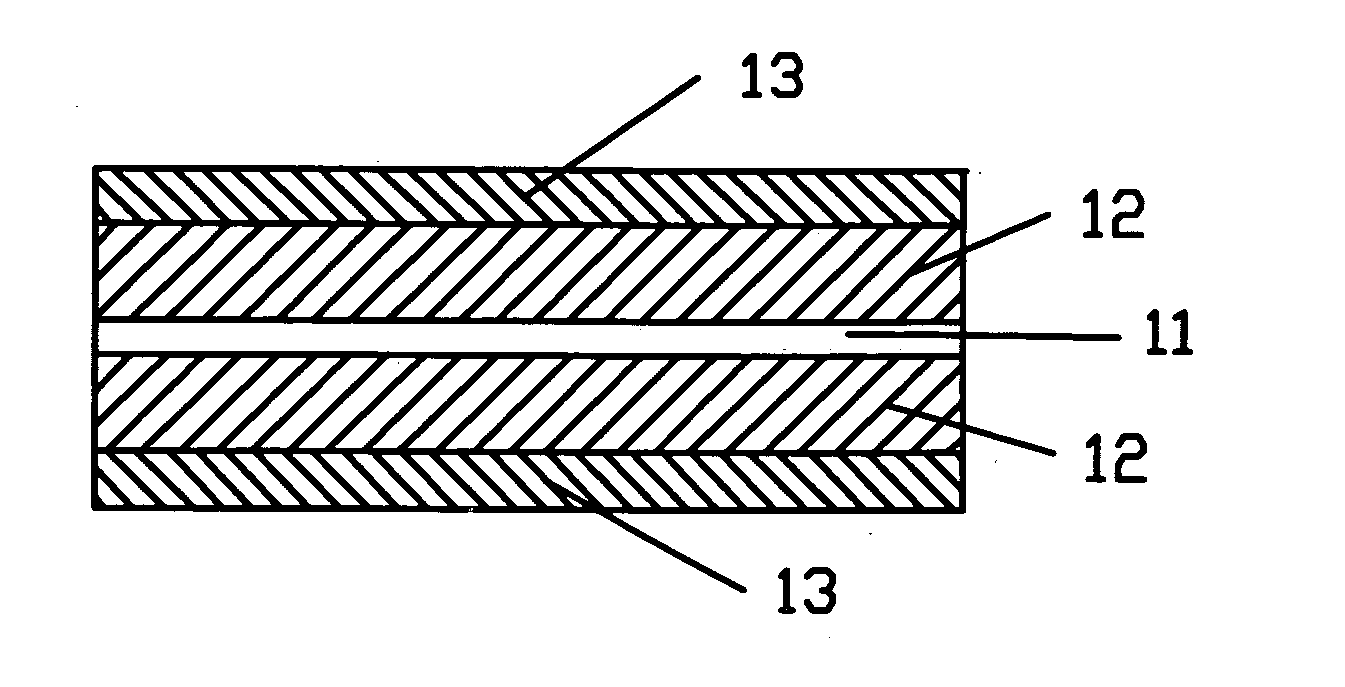

Positive electrodes for lithium batteries and their methods of fabrication

InactiveUS20050186474A1Low costImprove cycle performanceSecondary cellsPositive electrodesSpinelLithium manganese oxide

The present invention discloses positive electrodes and their methods of fabrication. These electrodes are low in cost. Lithium rechargeable batteries that use these positive electrodes have excellent cycling properties at high temperature. The positive electrode of the embodiments of this invention comprises of a current collector coated by two layers of active materials for positive electrodes. The active material for the first layer of coating is one or more active materials selected from the following: spinel lithium manganese oxide, and spinel lithium manganese oxide derivatives. The active material for the second layer of coating is one or more active material selected from the following: lithium cobalt oxide, lithium cobalt oxide derivatives, lithium nickel oxide, and lithium nickel oxide derivatives. To fabricate these positive electrodes, a first layer of coating comprising of the active materials stated above is applied onto a current collector and then dried before a second layer of coating is applied onto the surface of the first layer of coating. The positive electrode is obtained after the current collector with the two layers of coating is dried a second time and then pressed to form a slice.

Owner:BYD AMERICA CORP

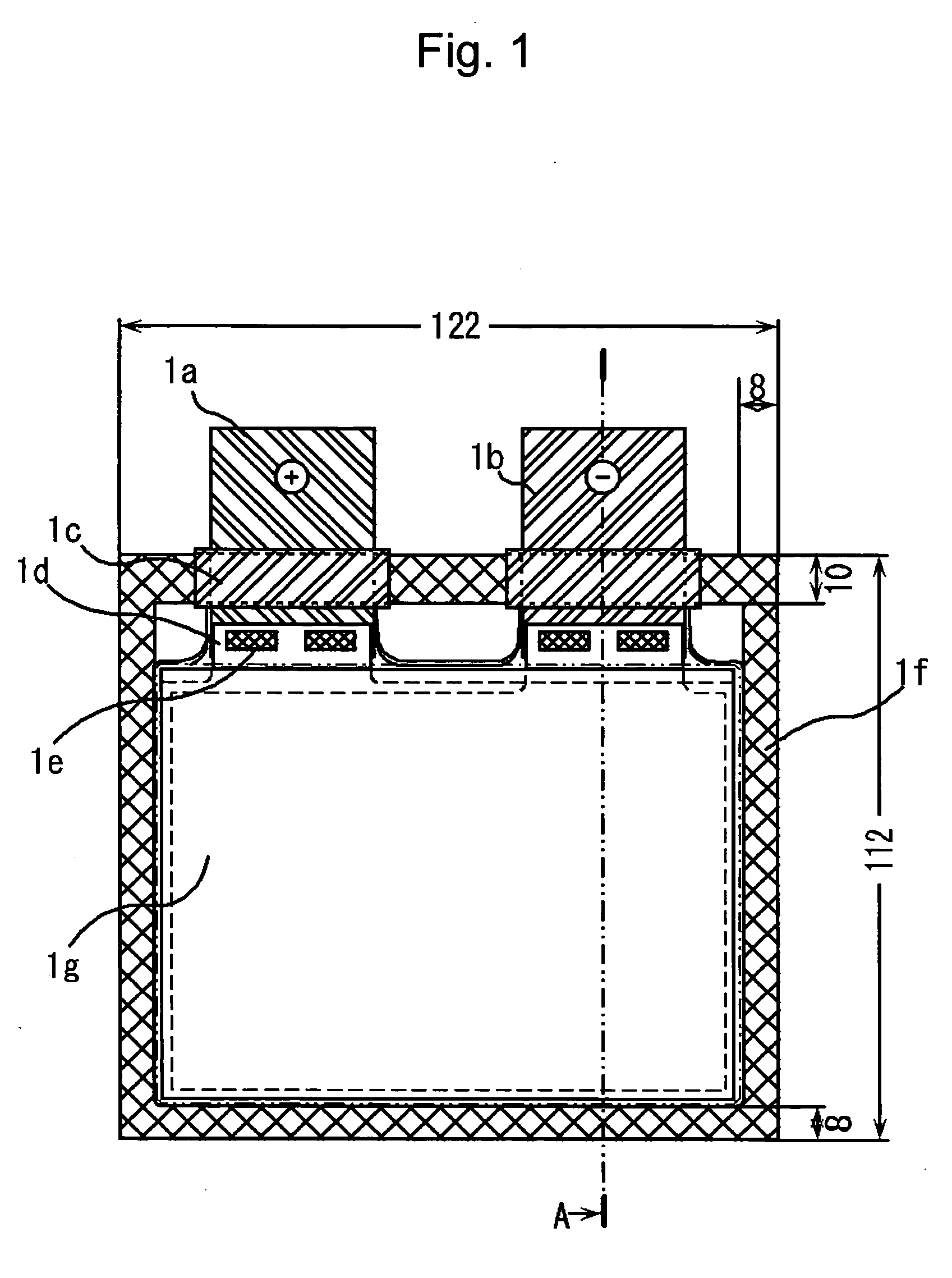

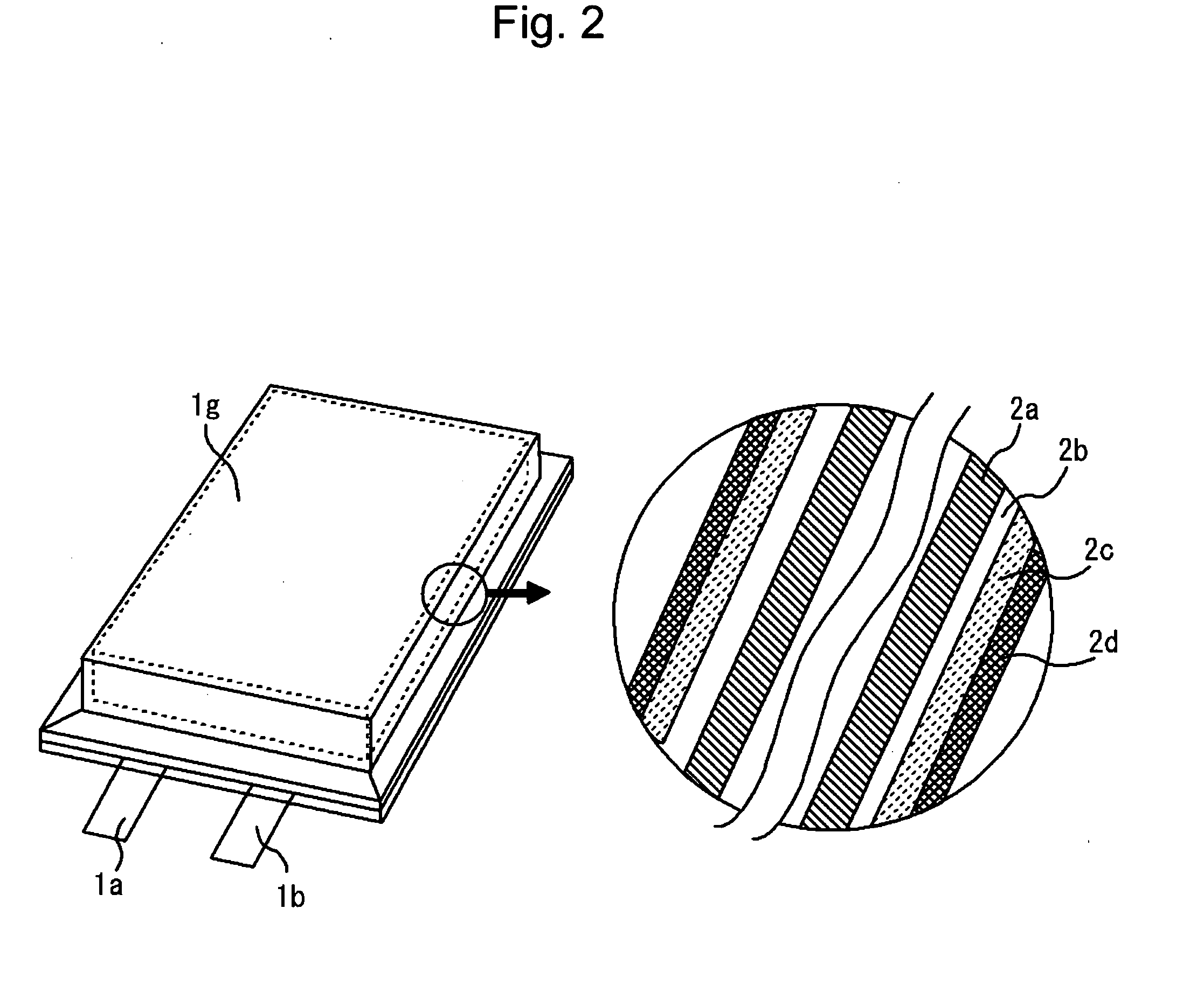

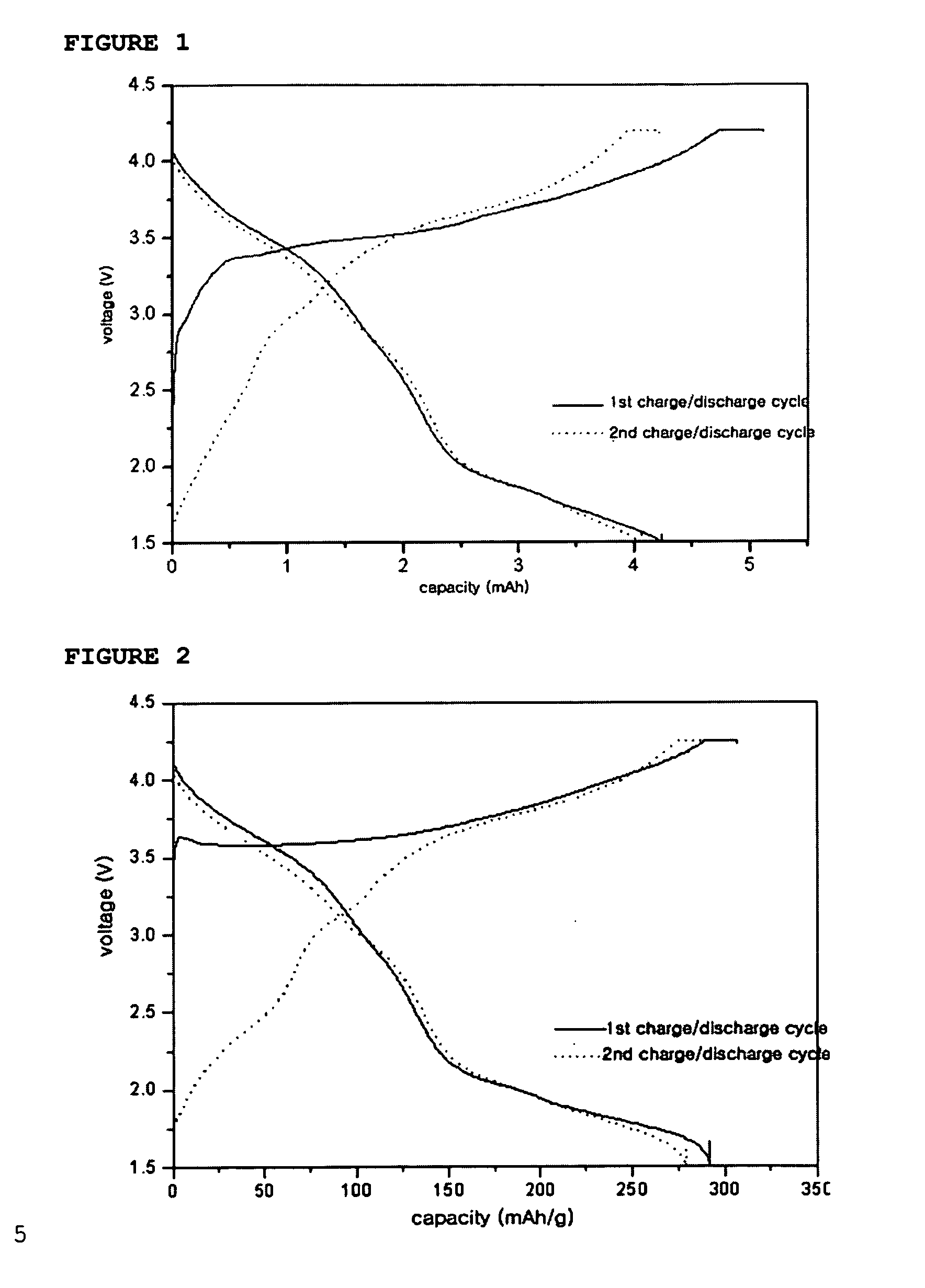

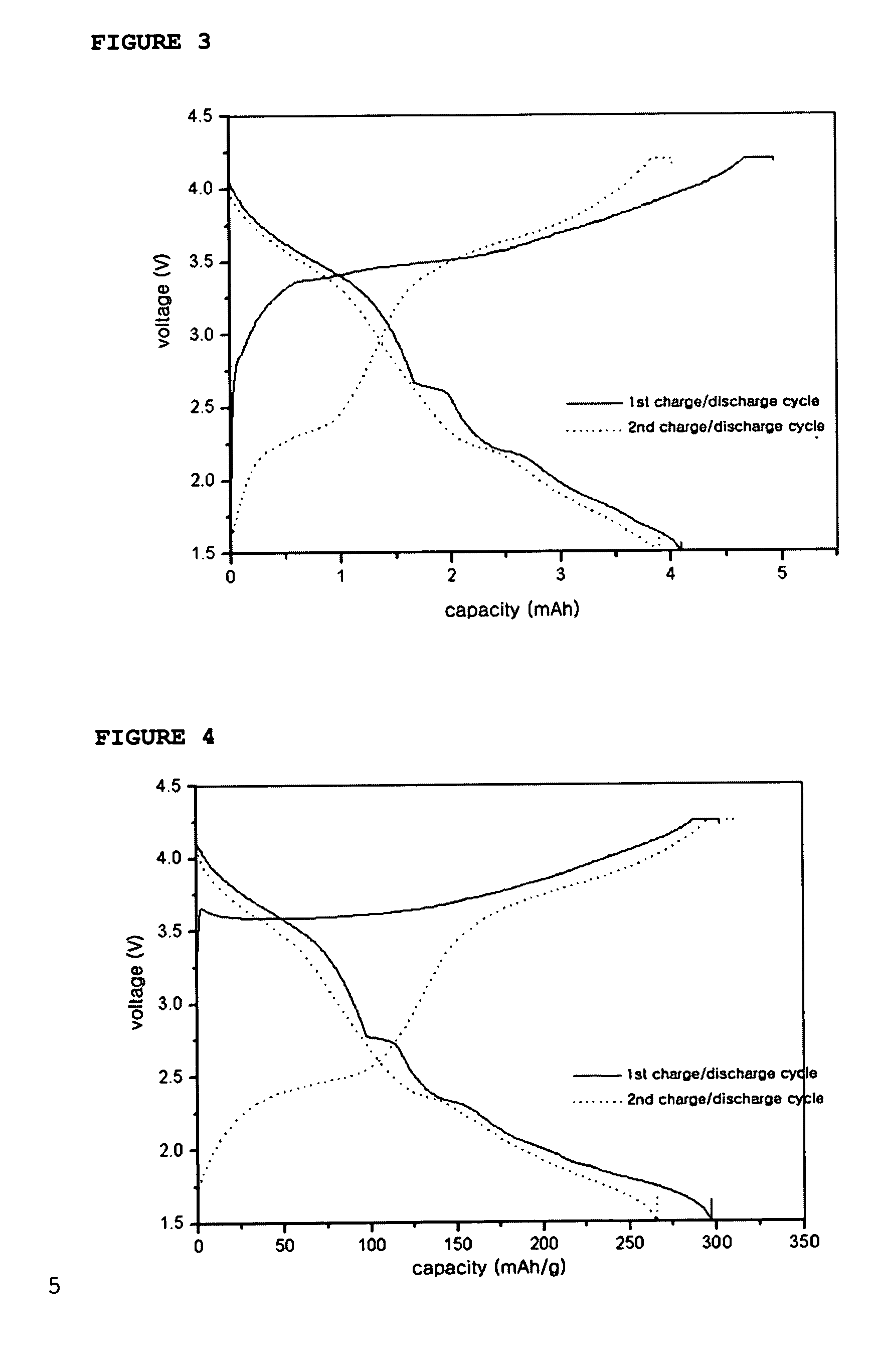

Nonaqueous secondary cell

InactiveUS20070134558A1Inhibit deteriorationImprove cycle performanceNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsSpinelManganese oxide

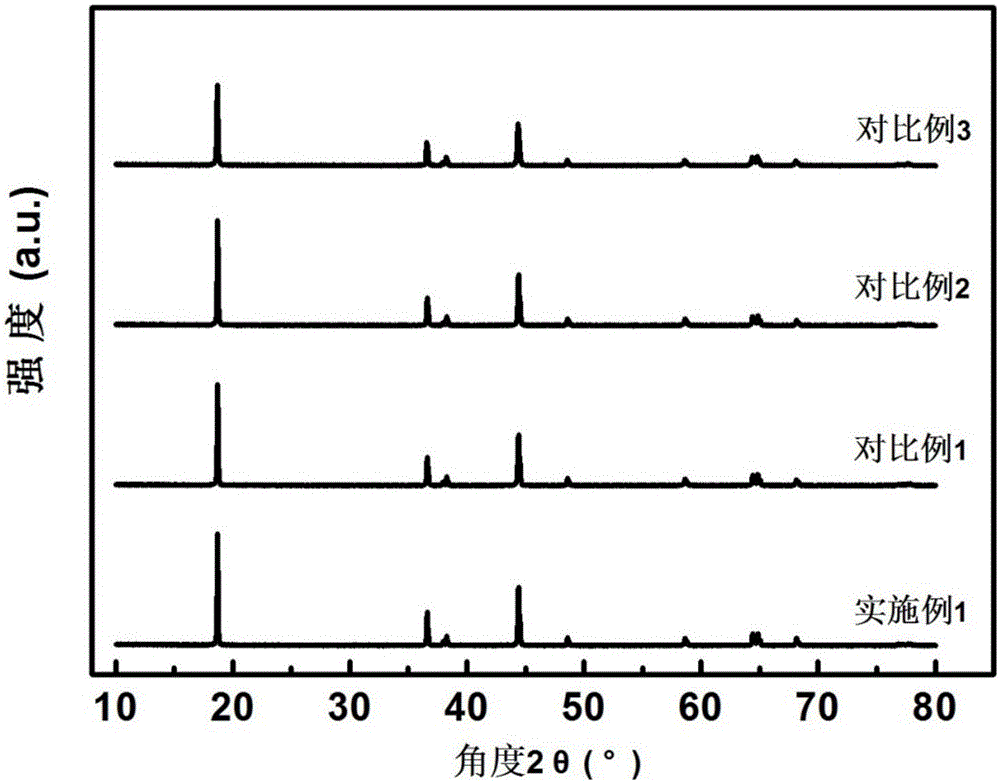

Using a positive electrode active material including spinel type manganese oxide as the main constituent, a novel low cost and high output power flat type nonaqueous secondary cell for HEVs that has increased safety at overcharge, and superior storage properties and cycle life is provided. A flat type nonaqueous secondary cell that has increased safety and is superior in storage and cycle properties even though the cell is a laminate type cell which does not have a blocking mechanism can be obtained by blending the spinel type lithium manganese oxide of the positive electrode and 5 wt % to 40 wt % of layered type lithium manganese oxide, to suppress storage deterioration at a high temperature and to simultaneously achieve safety when overcharged, and further, by adding a Li compound having a structure as shown in Formula (1) structure, to suppress deterioration of a mixed positive electrode active material during a high temperature cycle.

Owner:HITACHI LTD +1

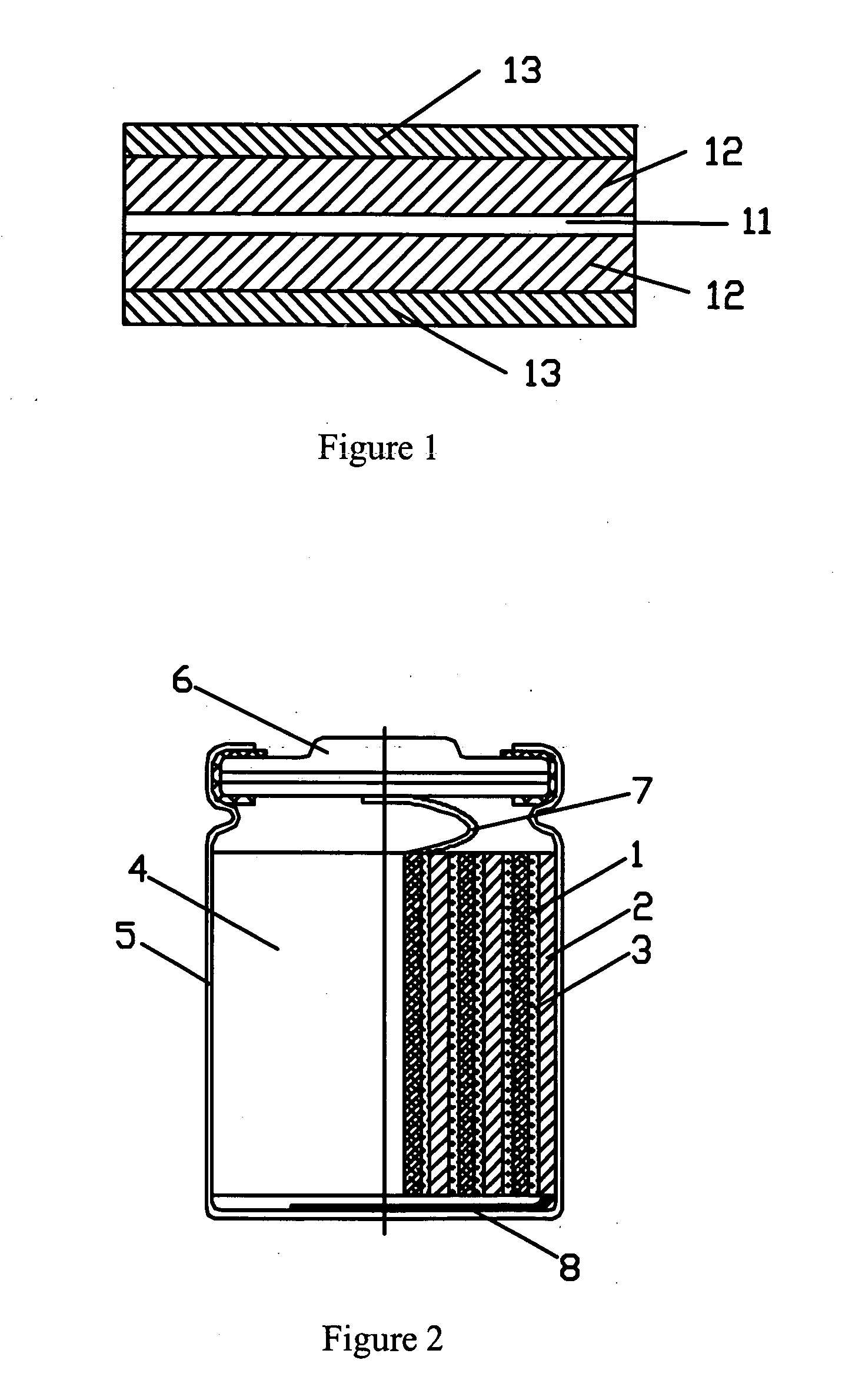

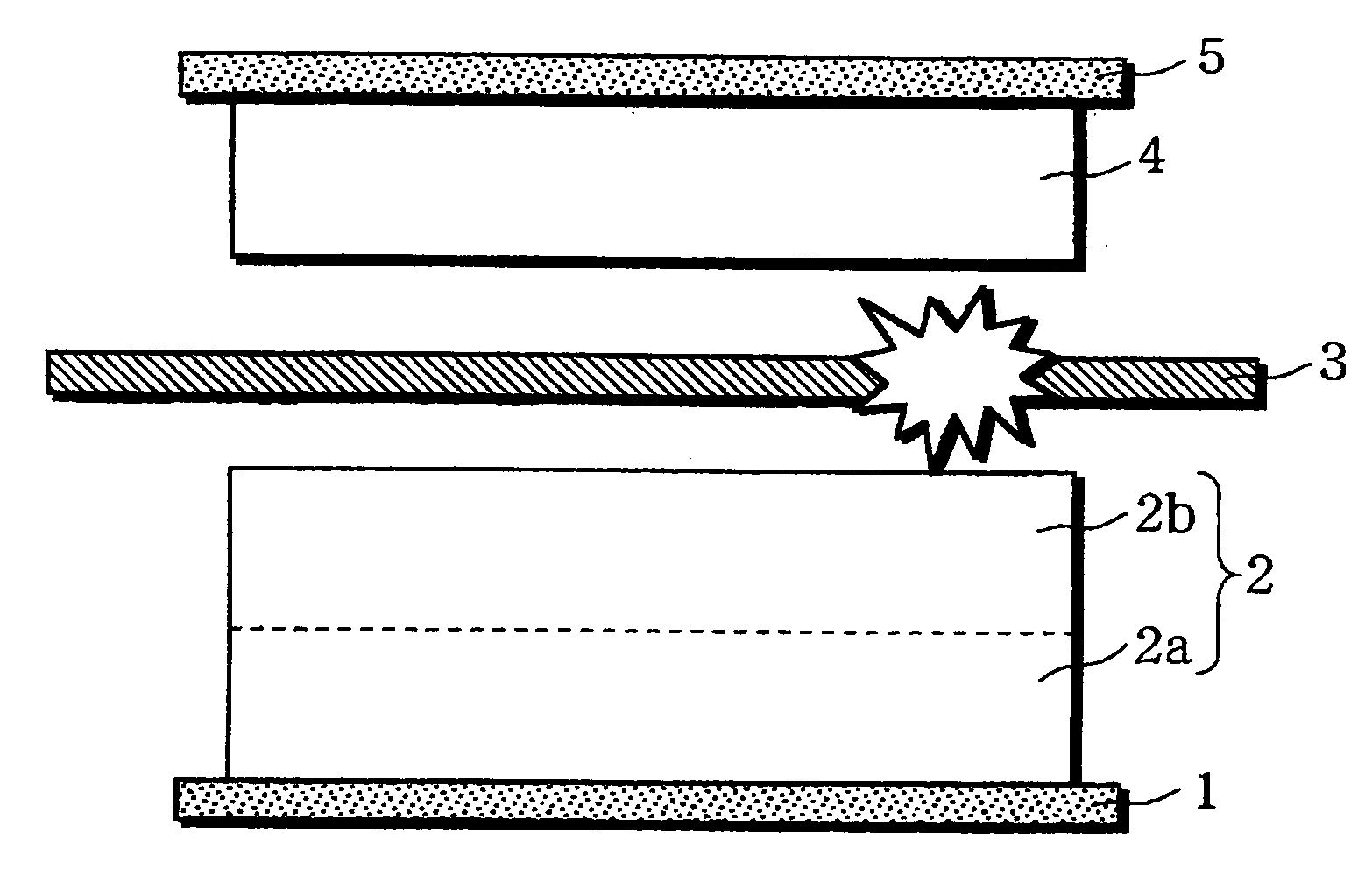

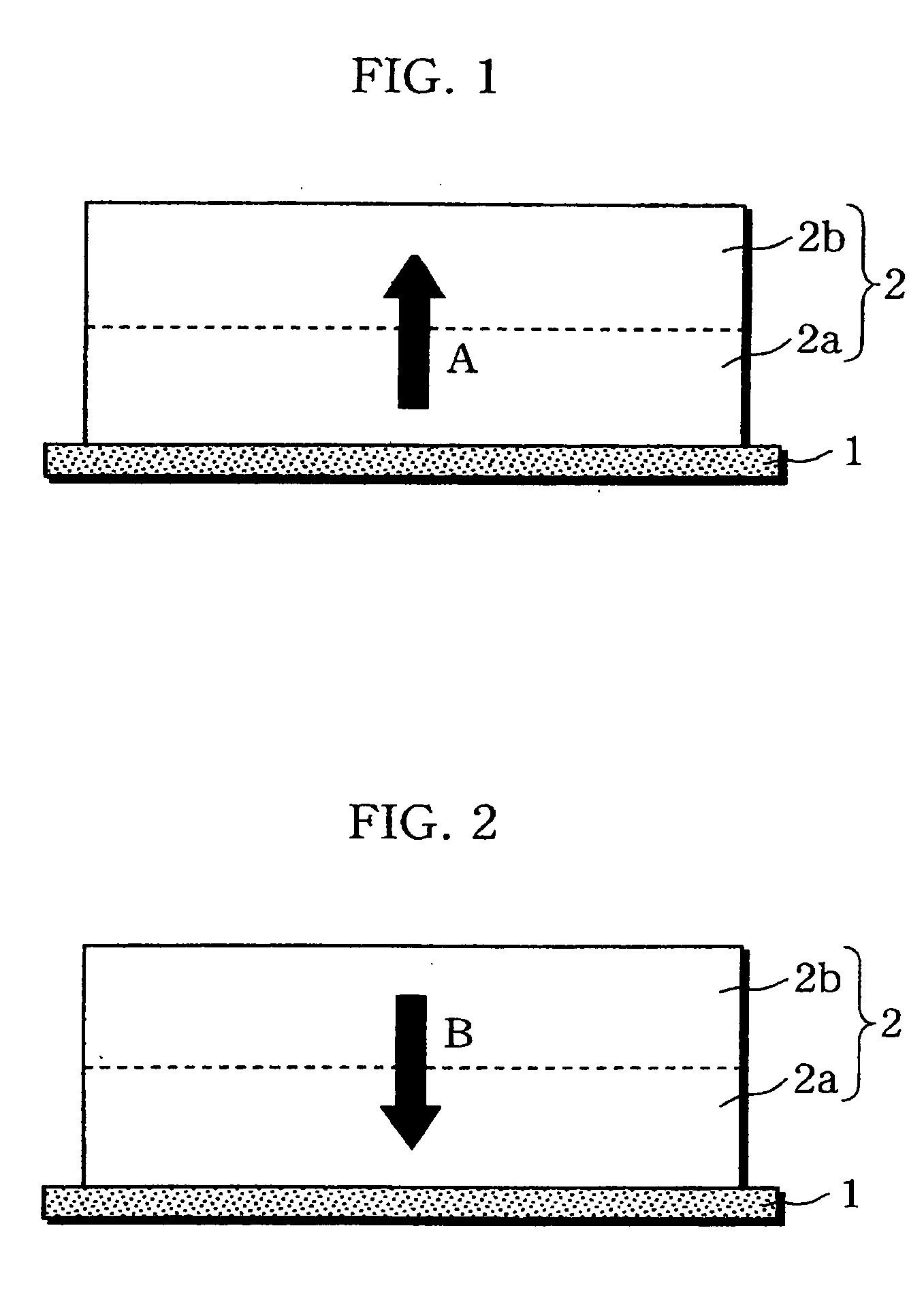

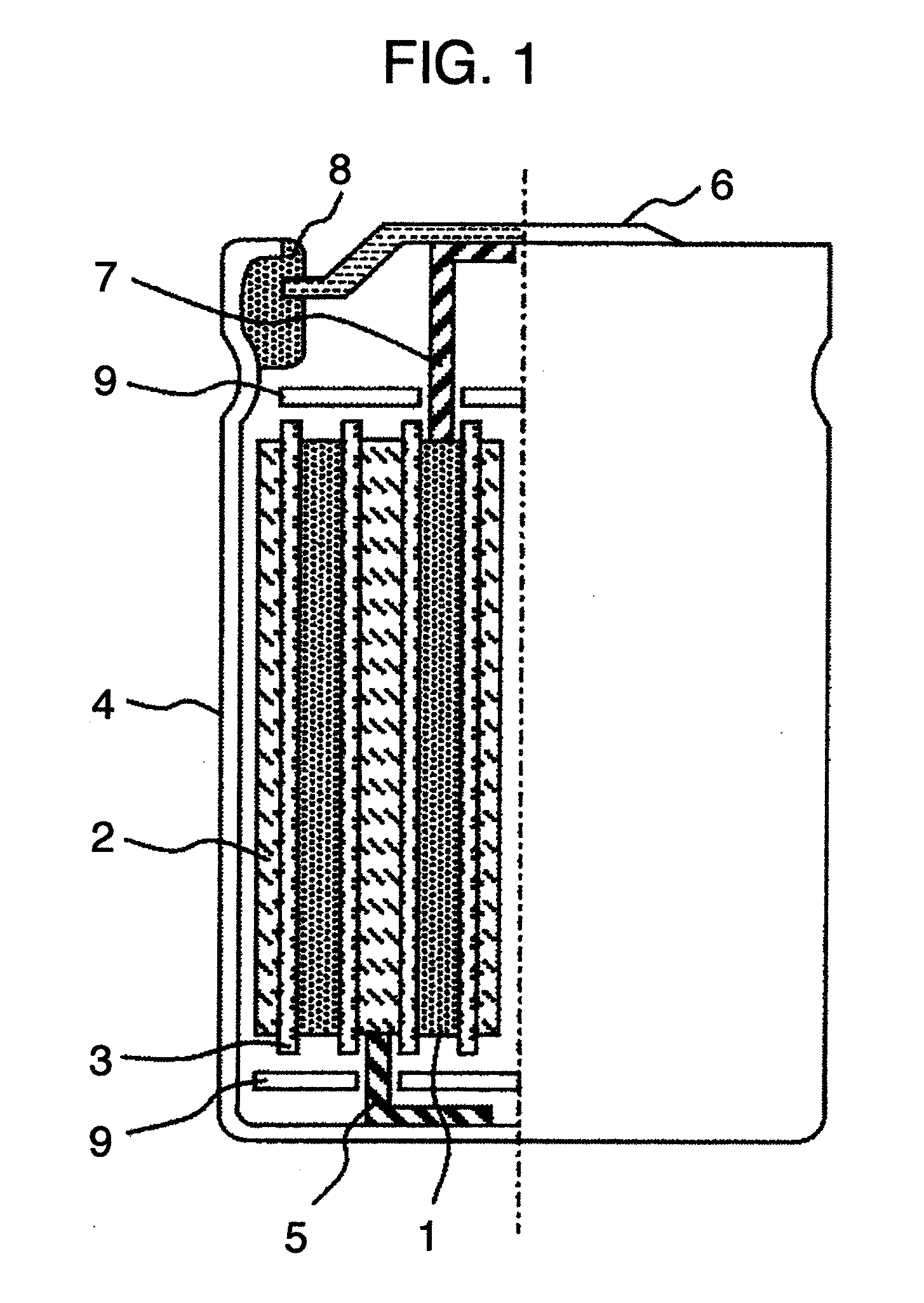

Non-aqueous electrolyte battery

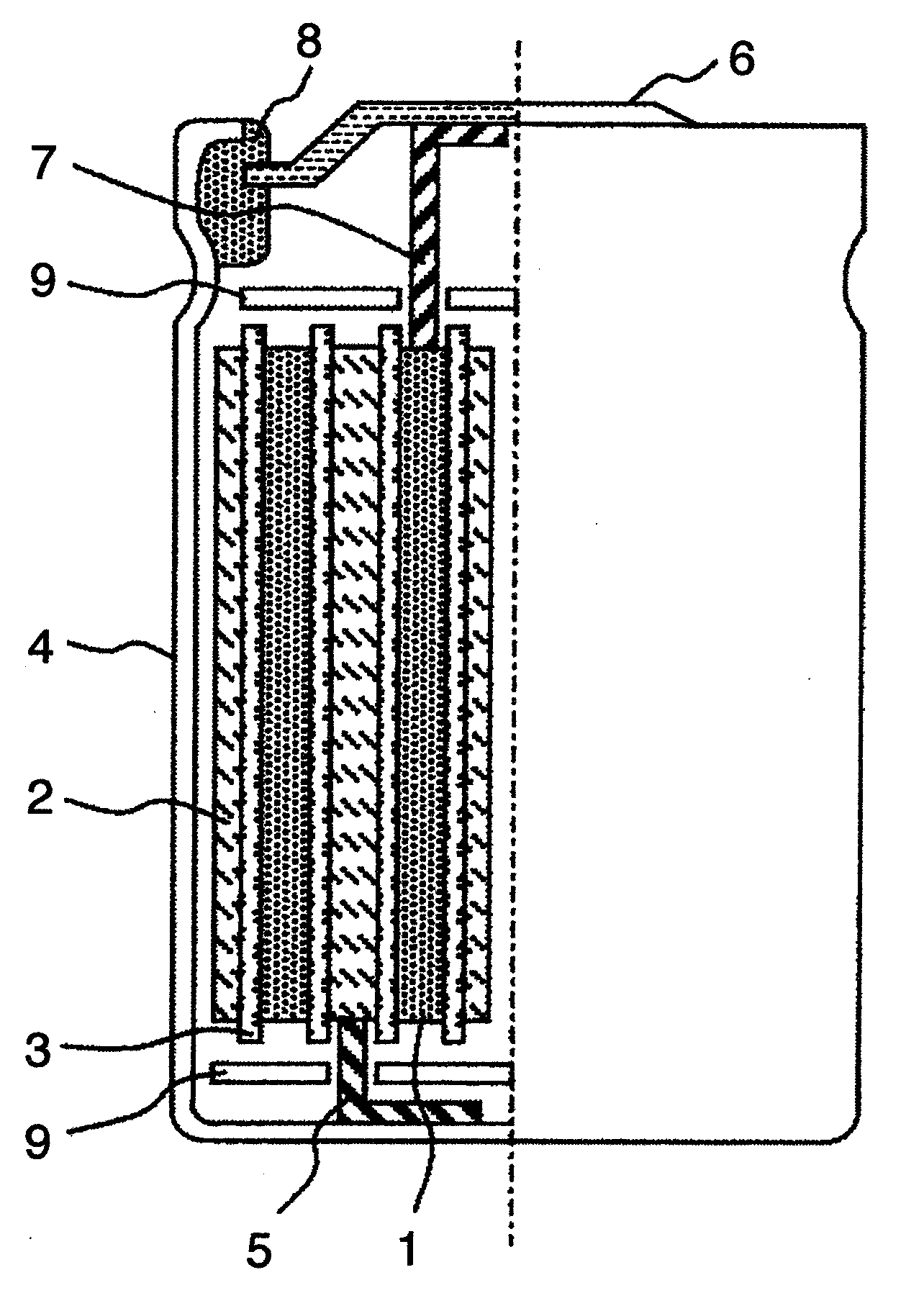

InactiveUS20060019151A1Avoid depositionIncrease probabilityFinal product manufactureCell temperature controlSpinelEngineering

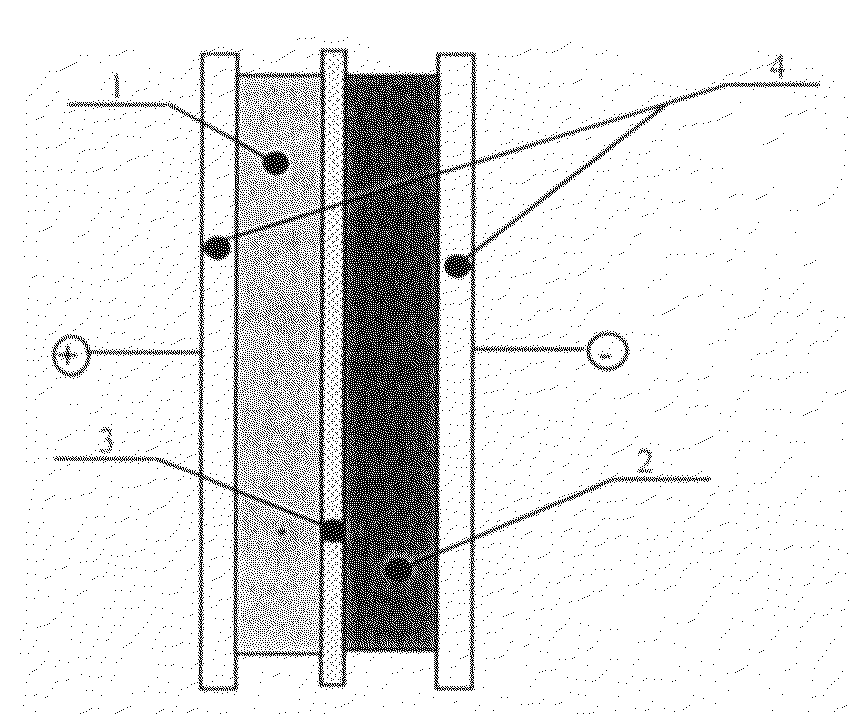

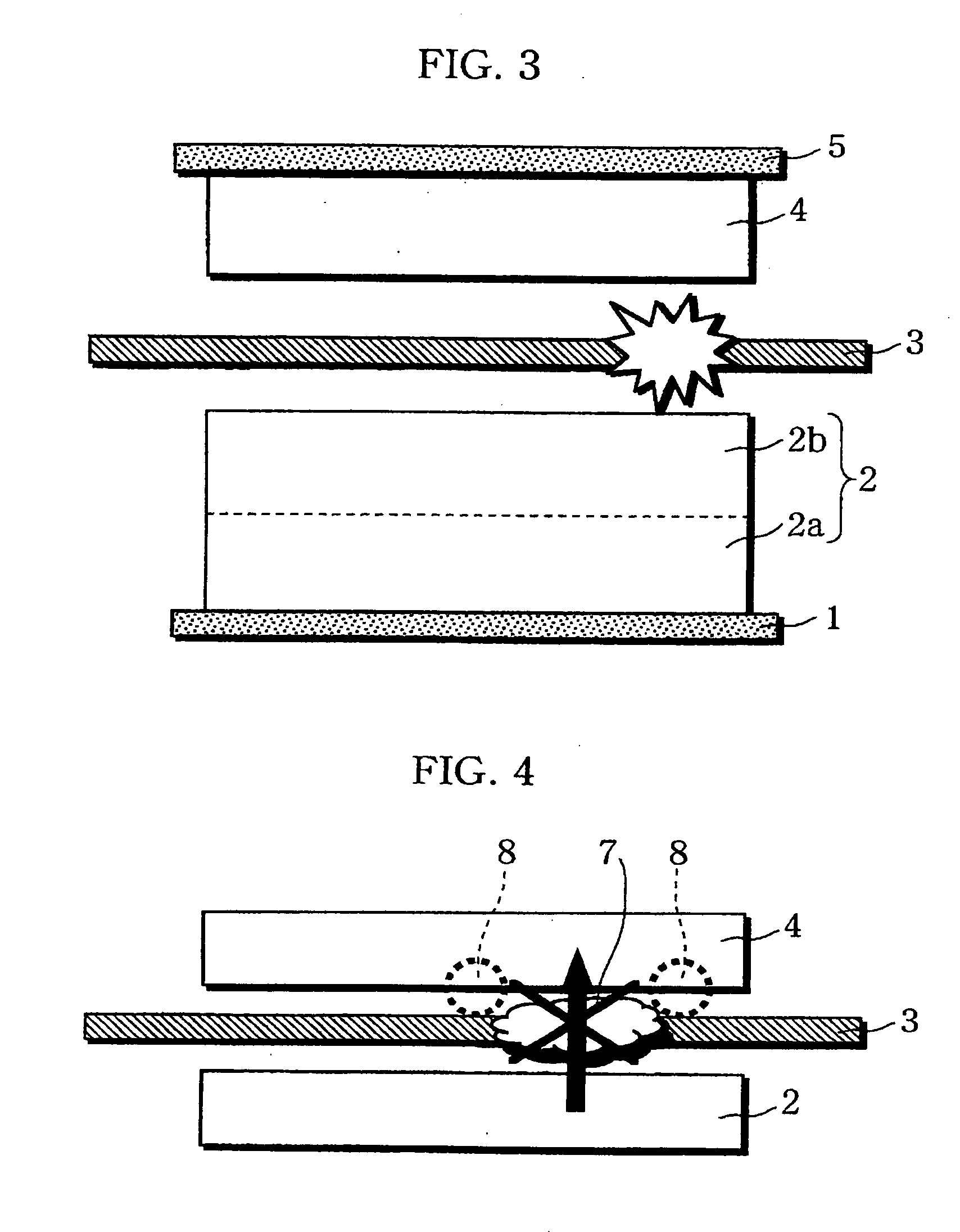

A non-aqueous electrolyte battery is provided that is capable of improving safety, particularly the tolerance of the battery to overcharging, without compromising conventional battery constructions considerably. A non-aqueous electrolyte battery is furnished with a positive electrode including a positive electrode active material-layer (2) containing a plurality of positive electrode active materials and being formed on a surface of a positive electrode current collector (1), a negative electrode including a negative electrode active material layer (4), and a separator (3) interposed between the electrodes. The positive electrode active material-layer (2) is composed of two layers (2a) and (2b) having different positive electrode active materials, and of the two layers (2a) and (2b), the layer (2b) that is nearer the positive electrode current collector contains, as its main active material, a spinel-type lithium manganese oxide or an olivine-type lithium phosphate compound.

Owner:SANYO ELECTRIC CO LTD

Novel electrolyte for power battery

InactiveCN102064344AGood high temperature cycle performanceAvoid adsorptionSecondary cellsElectrolytic agentElectrical battery

The invention relates to the technical field of battery electrolytes, and in particular discloses a novel electrolyte for a power battery, which comprises the following raw materials in percent by weight: 8-15 percent of conductive lithium salt as a component A, 73-90 percent of organic solvent as a component B and 1-10 percent of additive as a component C. A sulphonate organic compound as the additive is added in the electrolyte of the common lithium ion battery, the addition of the sulphonate organic compound accounts for 1-10 percent of the weight of the electrolyte of the lithium ion power battery and is chemically compounded with 8-15 percent of conductive lithium and 75-90 percent of organic solvent to prepare the novel electrolyte for the power battery, which has better high-temperature circulating performance and is suitable for the power battery. A power battery especially using lithium manganese oxide as a cathode material can prevent Mn smelted at high temperature from being attracted on the surface of the cathode, thereby inhibiting the impedance rise, effectively improving the circulating periodicity and greatly prolonging the circulating service life.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

Polycrystal high-nickel positive electrode material used for lithium ion battery and preparation method for polycrystal high-nickel positive electrode material

InactiveCN105958062AExtended storage timeReduce lithiumCell electrodesSecondary cellsSodium-ion batteryLithium-ion battery

Disclosed is a polycrystal high-nickel positive electrode material used for a lithium ion battery. The polycrystal high-nickel positive electrode material comprises a base material with a layered structure and a coating layer which is arranged outside the base material and has a spinel structure; the general formula of the base material is LiNi<1-x-y>Co<x>M<y>O<2>, wherein M is at least one kind of Mn and Al; the coating layer is lithium manganese oxide; the mass percentage of the total impurity lithium on the surface of the base material is less than 0.085% based on the total mass percentage of the base material; the preparation method for the positive electrode material comprises the following steps of weighing Ni<1-x-y>Co<x>M<y>(OH)<2>, and mixing with a lithium source, then carrying out thermal treatment, cooling, crushing and sieving to obtain the base material; measuring the content of the residual impurity Li<2>CO<3> and LiOH on the surface of the base material, adding into the metal Mn compound according to the measurement result, and carrying out low-temperature thermal treatment in an oxygen atmosphere to obtain the polycrystal high-nickel positive electrode material used for the lithium ion battery. The polycrystal high-nickel positive electrode material provided by the invention has the advantages of low material alkalinity, low inflatable degree, excellent processing property and cycling performance, and the like.

Owner:HUNAN SHANSHAN NEW ENERGY CO LTD

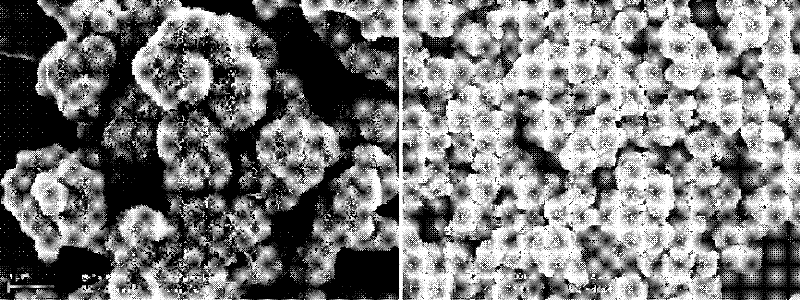

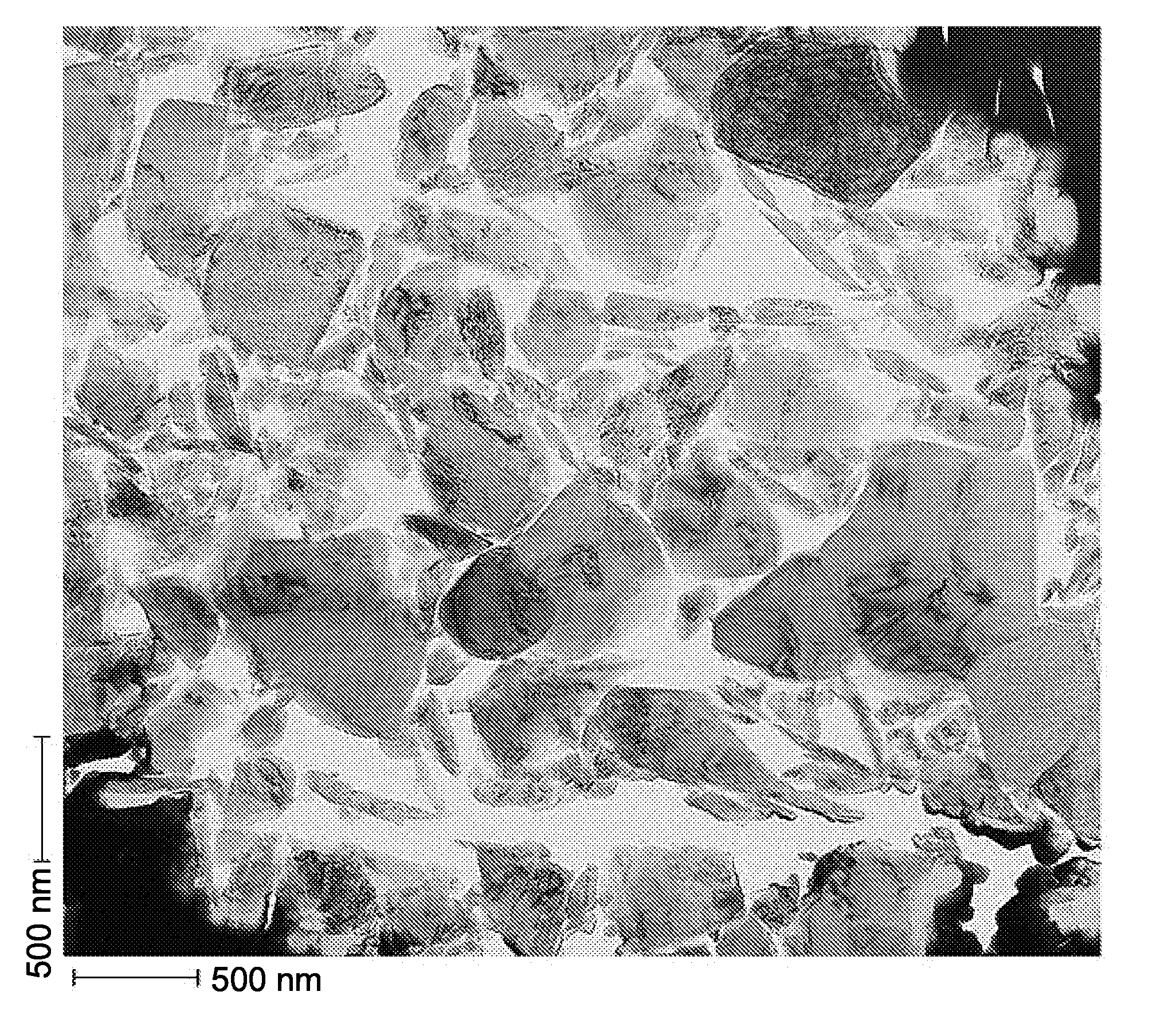

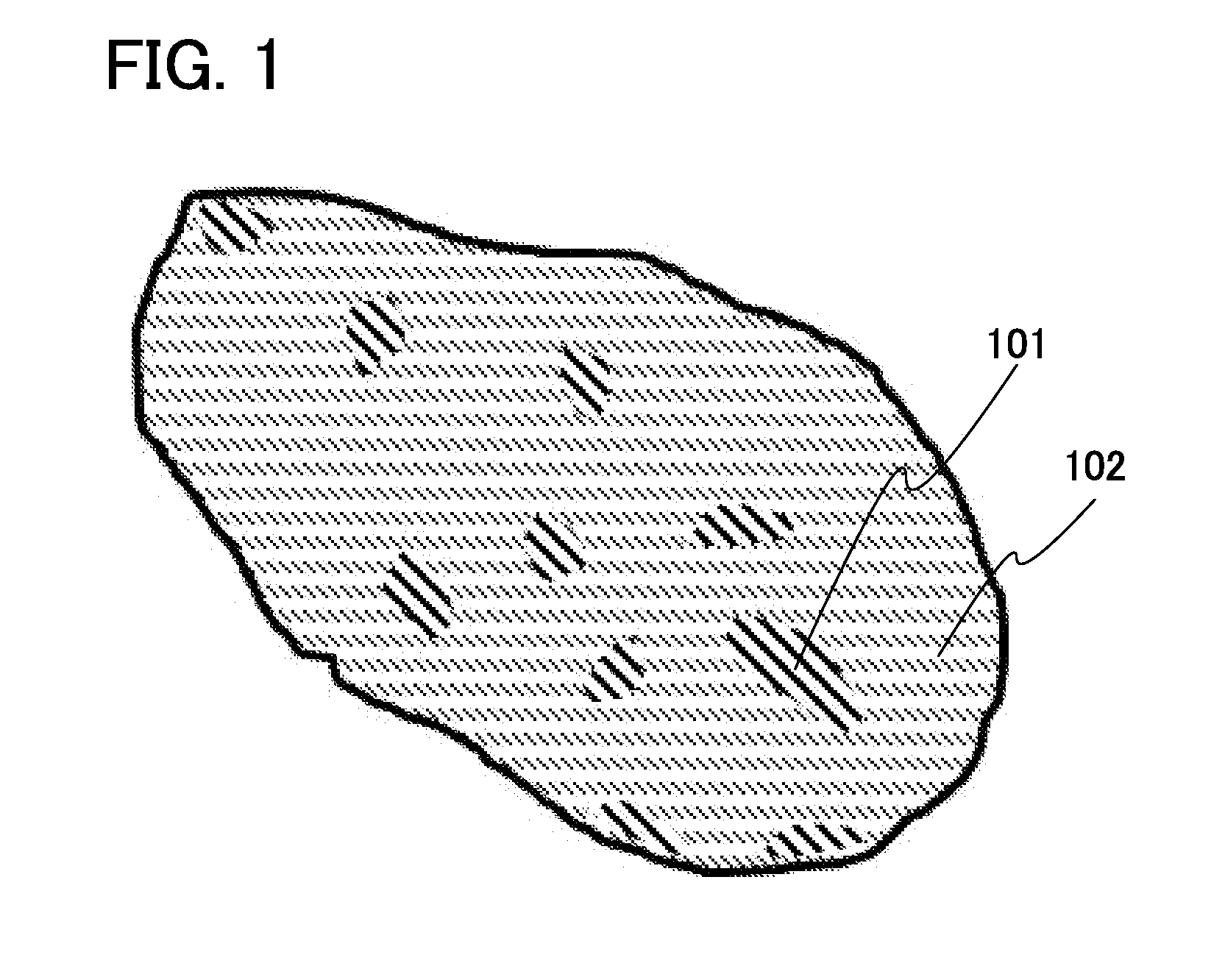

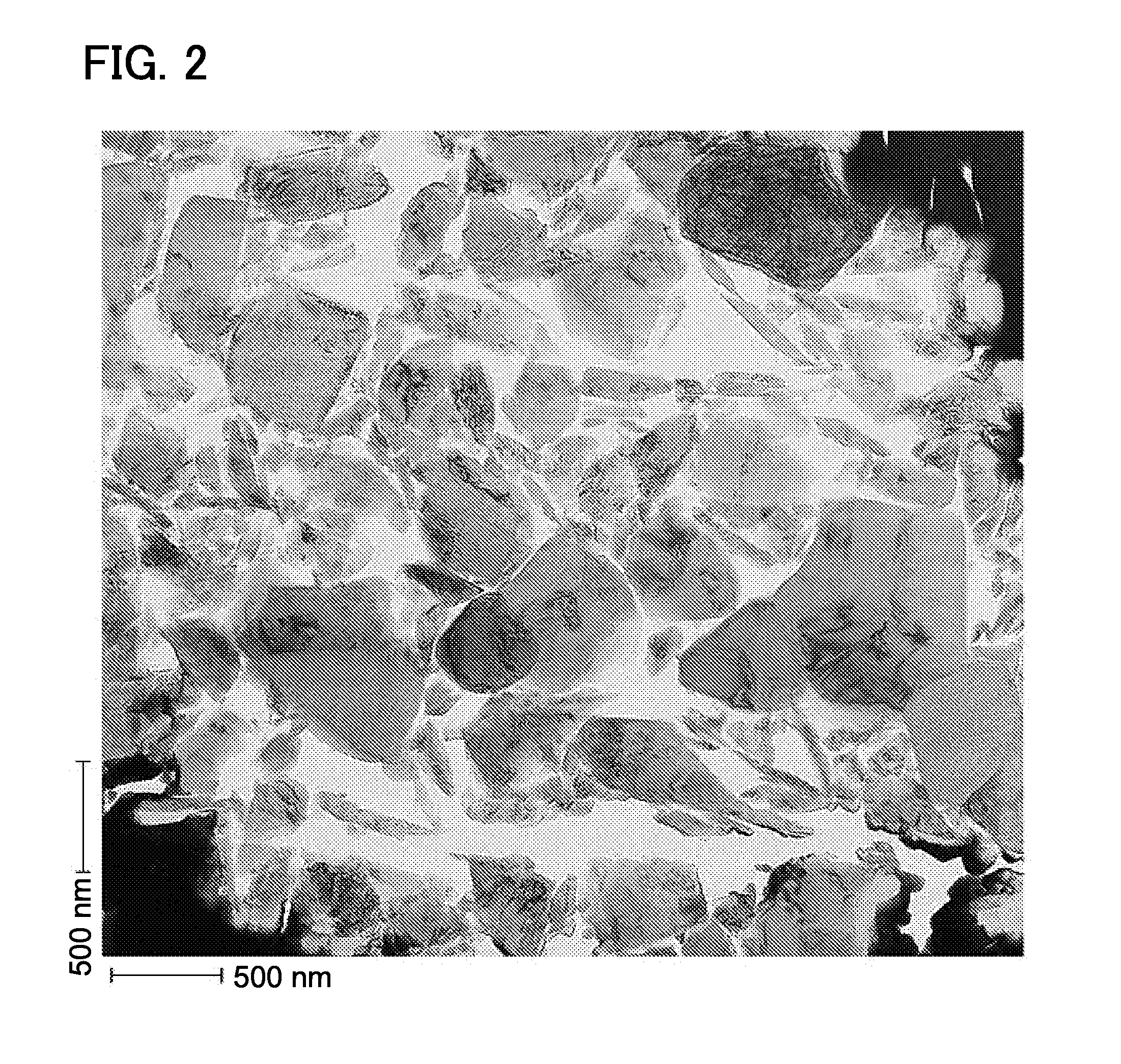

Nanostructured and layered lithium manganese oxide and method of manufacturing the same

Nanostructured and layered lithium manganese oxide powders and methods of producing same. The powders are represented by the chemical formula, LixMn1-yMyO2, where 0.5<x<1.33, 0≦y≦0.5 and have an average primary particle diameter from 5 nm to 300 nm, preferably between 5 and 100 nm, and M is at least one cation dopant. The powders can be formed into active cathode materials in Li-ion and Li rechargeable batteries.

Owner:NANOPOWDER ENTERPRISES

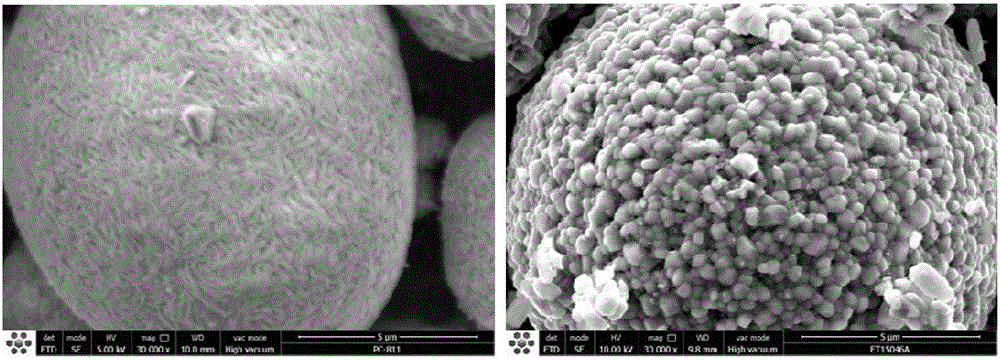

Preparation method of spinel type lithium manganese oxide for spherical high-voltage anode material

The invention discloses a preparation method of spinel type lithium manganese oxide for a spherical high-voltage anode material. The preparation method comprises the following steps of: preparing the spinel type lithium manganese oxide for the spherical high-voltage anode material by utilizing a hydrothermal-solid-phase two-step method; uniformly mixing a nickel source, a manganese source and a doped element chemical solution with a sodium / ammonium carbonate solution; adding surfactant into the mixed solution and preparing under a hydrothermal condition to prepare a spherical lithium manganese carbonate sediment; washing and drying, and then sintering to obtain a spherical lithium manganese oxide; mixing the oxide with a lithium source by liquid-phase ball milling, and drying; and finally, sintering to obtain an anode active material. According to the preparation method disclosed by the invention, the synthesis method is simple, the process is easy to control and the doped elements are introduced; physical and chemical properties of the material are optimized and the grain size of the material is uniform; and the discharge capacity is high and the multiplying power performance is good.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

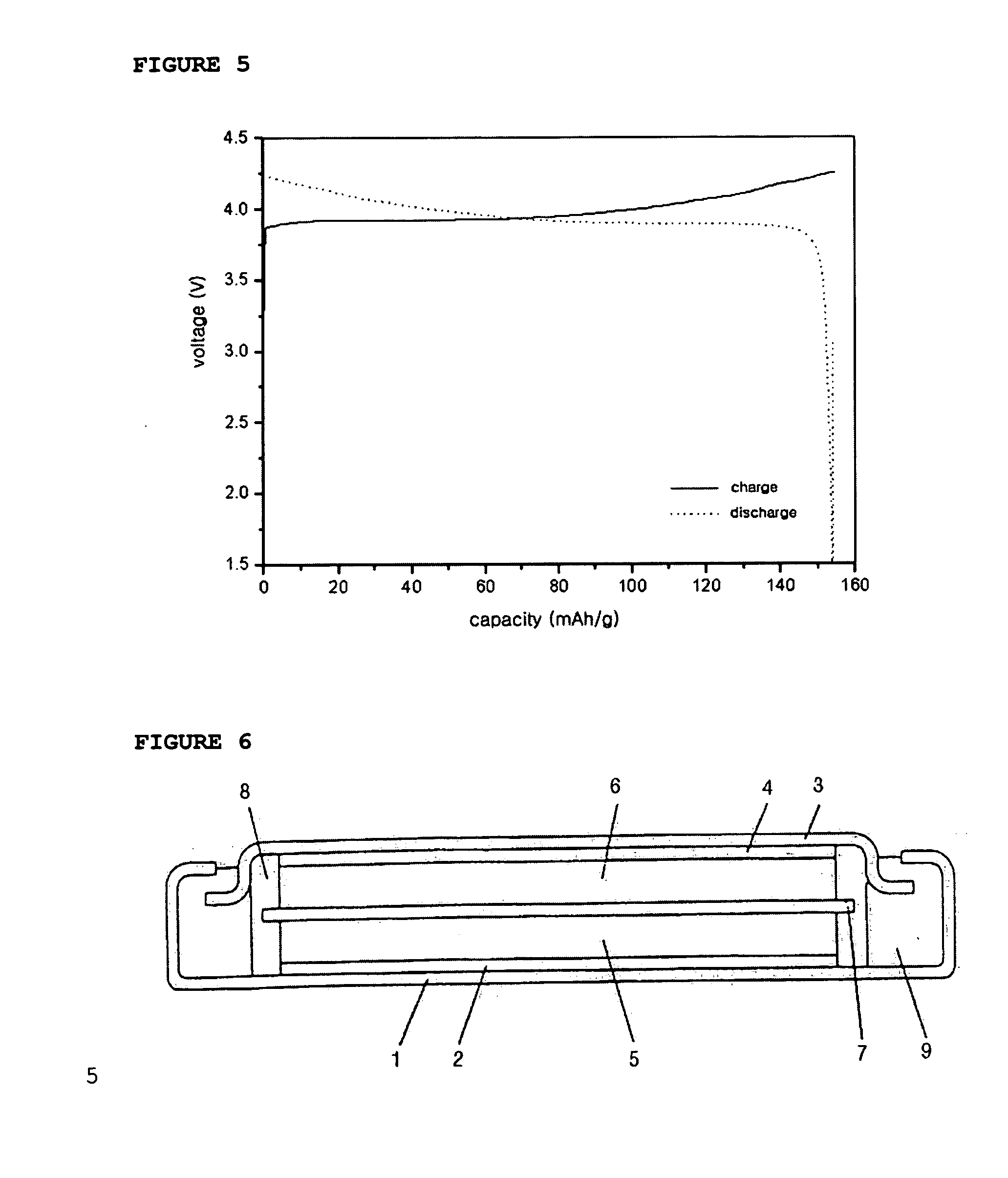

Positive electrode active material with high capacity and lithium secondary battery including the same

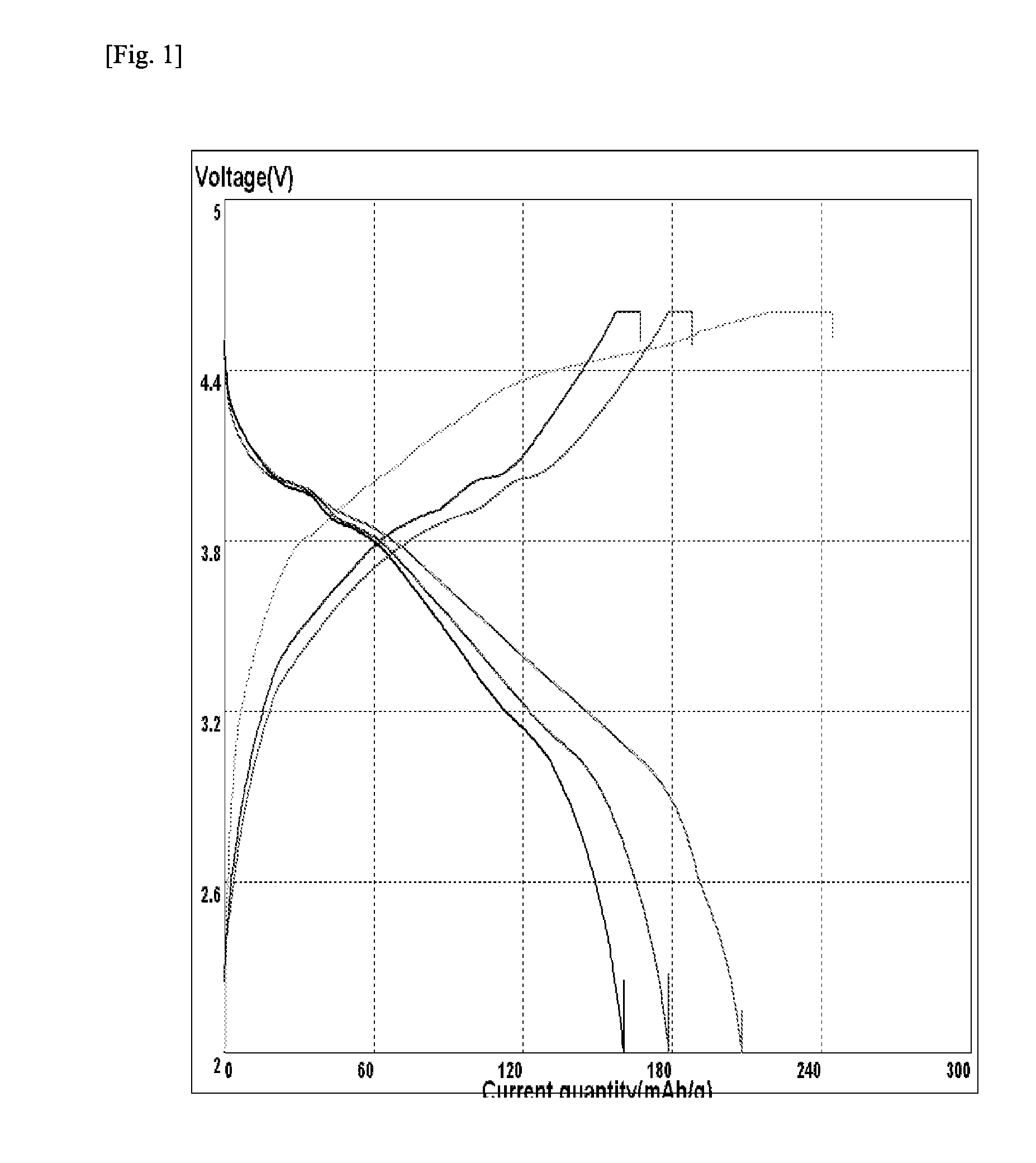

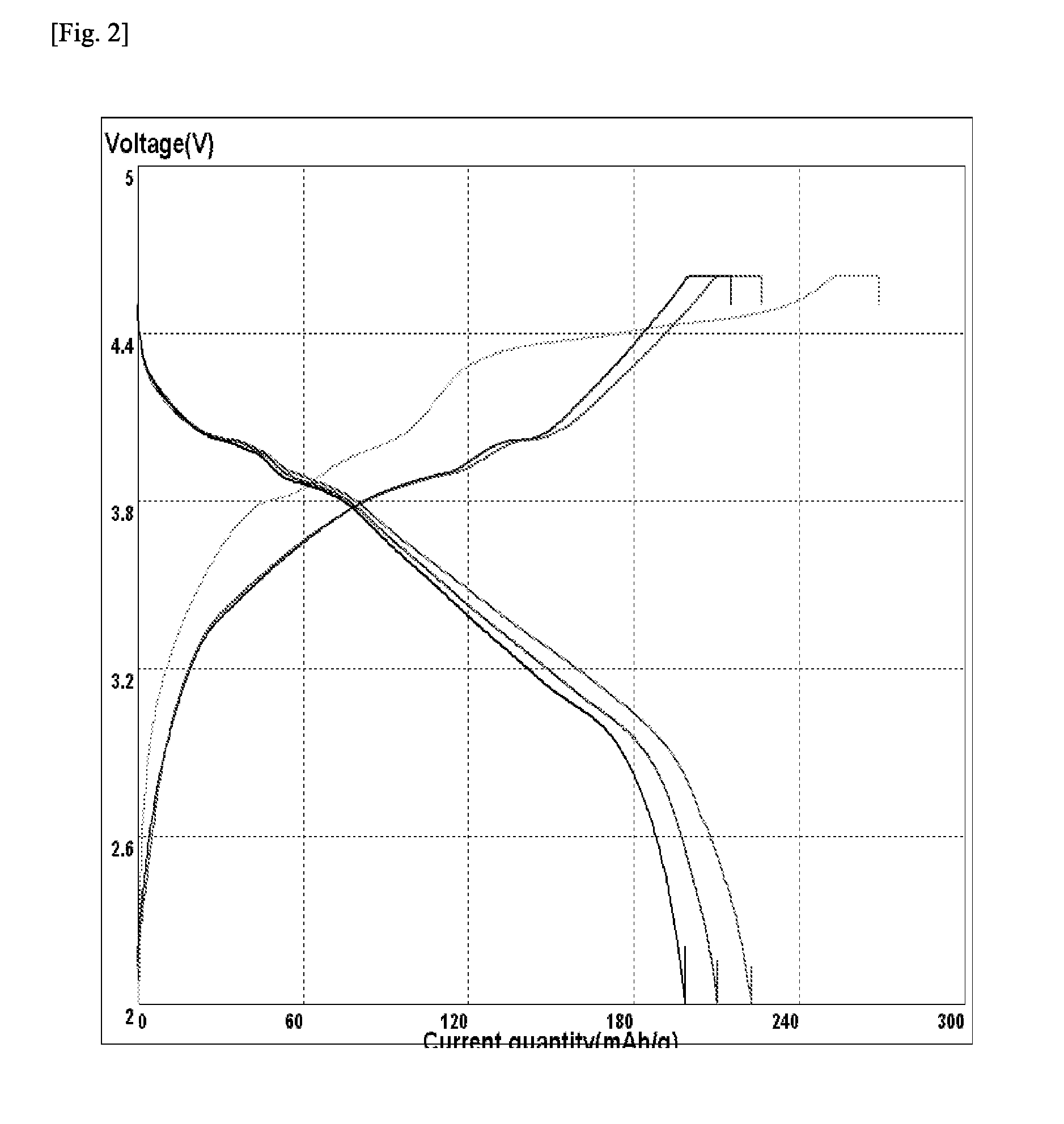

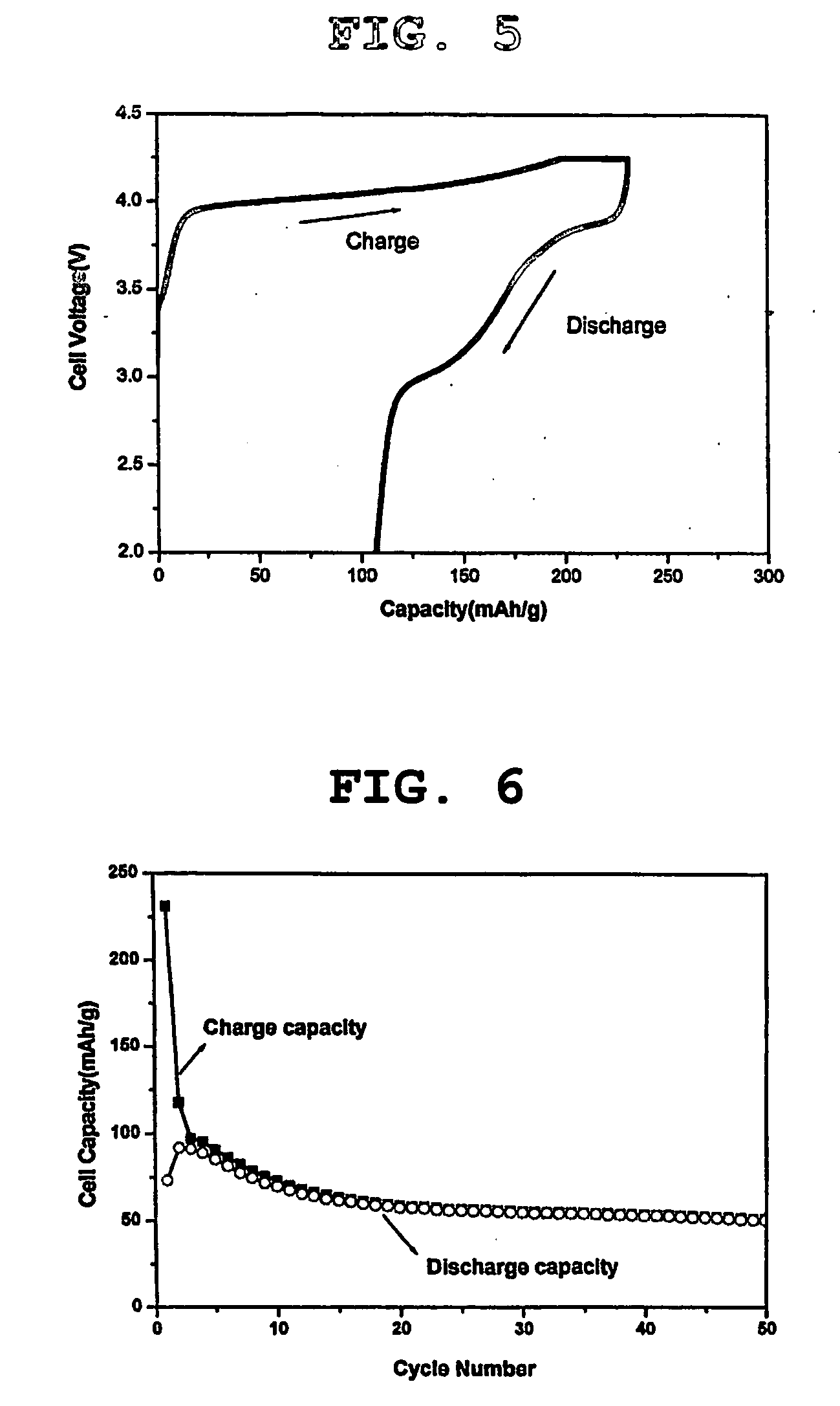

ActiveUS20110311869A1Improve charge and discharge performanceImprove thermal stabilityMaterial nanotechnologyElectrode manufacturing processesElectrode potentialVoltage drop

A high capacity lithium secondary battery includes a lithium manganese oxide having a layered structure exhibiting a great irreversible capacity in the event of overcharging at a high voltage and a spinel-based lithium manganese oxide. Because it is activated at a high voltage of 4.45 V or higher based on a positive electrode potential, additional lithium for utilizing a 3V range of the spinel-based lithium manganese oxide can be provided and an even profile in the entire SOC area can be obtained. Because the lithium secondary battery includes the mixed positive electrode active material including the spinel-based lithium manganese oxide and the lithium manganese oxide having a layered structure, and is charged at a high voltage, its stability can be improved. Also, the high capacity battery having a large available SOC area and improved stability without causing an output shortage due to a rapid voltage drop in the SOC area can be implemented.

Owner:LG ENERGY SOLUTION LTD

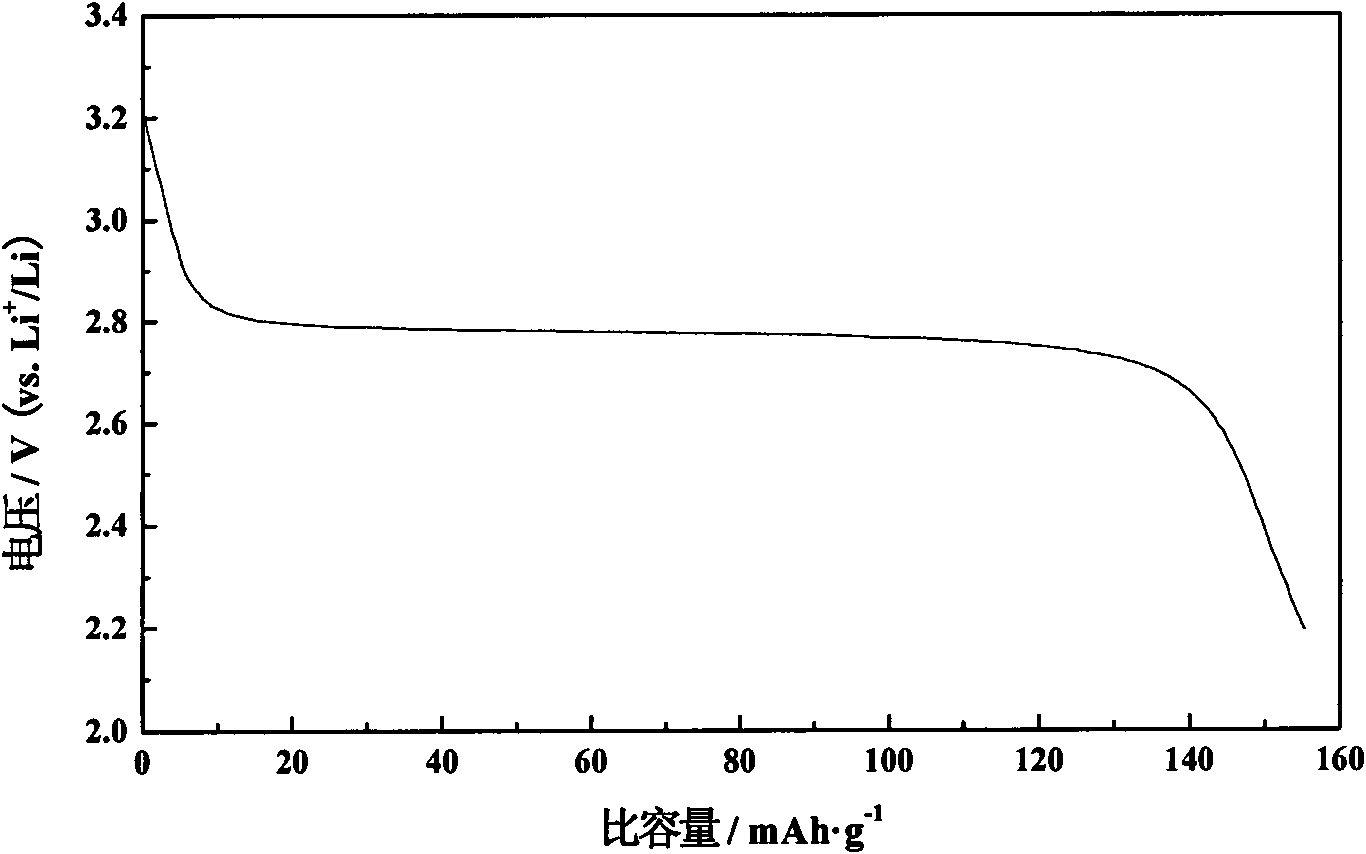

Method for preparing lithium-enriched lithium manganese oxide solid solution cathode material

ActiveCN102544475AFlexible adjustment ratioHomogeneous coprecipitationCell electrodesOXALIC ACID DIHYDRATENickel salt

The invention relates to a method for preparing a lithium-enriched lithium manganese oxide solid solution cathode material. The method comprises the following steps of: adding a mixed aqueous solution of nickel salt, cobalt salt and manganese salt into an oxalic acid or oxalate aqueous solution by an oxalate coprecipitation high-temperature solid state method, and stirring and reacting to generate nickel, cobalt and manganese oxalate coprecipitation; performing solid and liquid separation, washing and drying to obtain a nickel, cobalt and manganese oxalate precursor; and mixing and grinding the precursor and lithium salt, drying, baking at high temperature in an air atmosphere, and thus obtaining the lithium-enriched lithium manganese oxide solid solution cathode material. During preparation of the precursor, the proportion of the nickel salt, the cobalt salt and the manganese salt is adjusted, so that the constituents of the lithium-enriched lithium manganese oxide solid solution cathode material can be adjusted flexibly. The preparation method is suitable for large-scale, economic, stable and reliable production of the lithium-enriched lithium manganese oxide solid solution cathode material, has obvious advantages, and is high in practical value.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

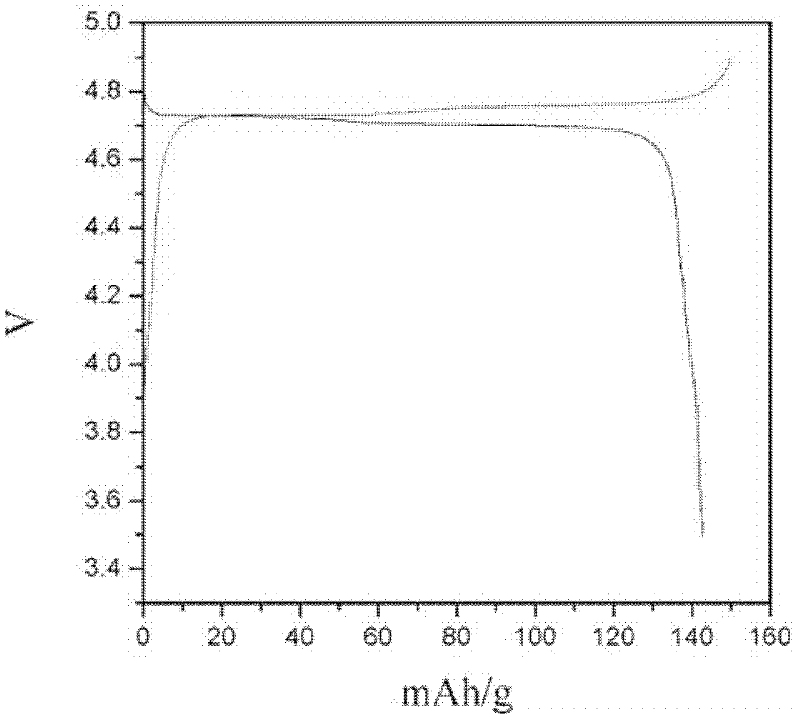

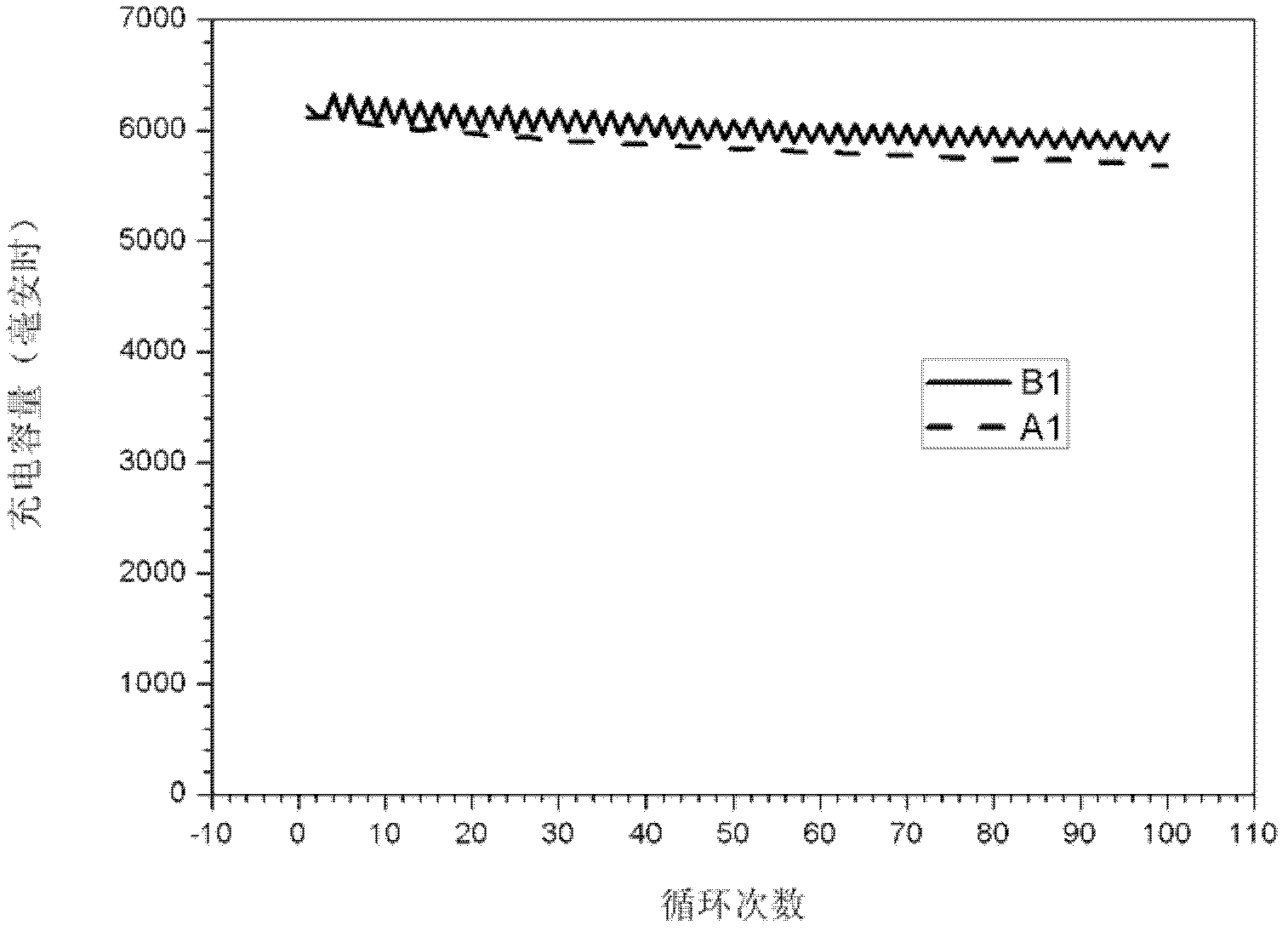

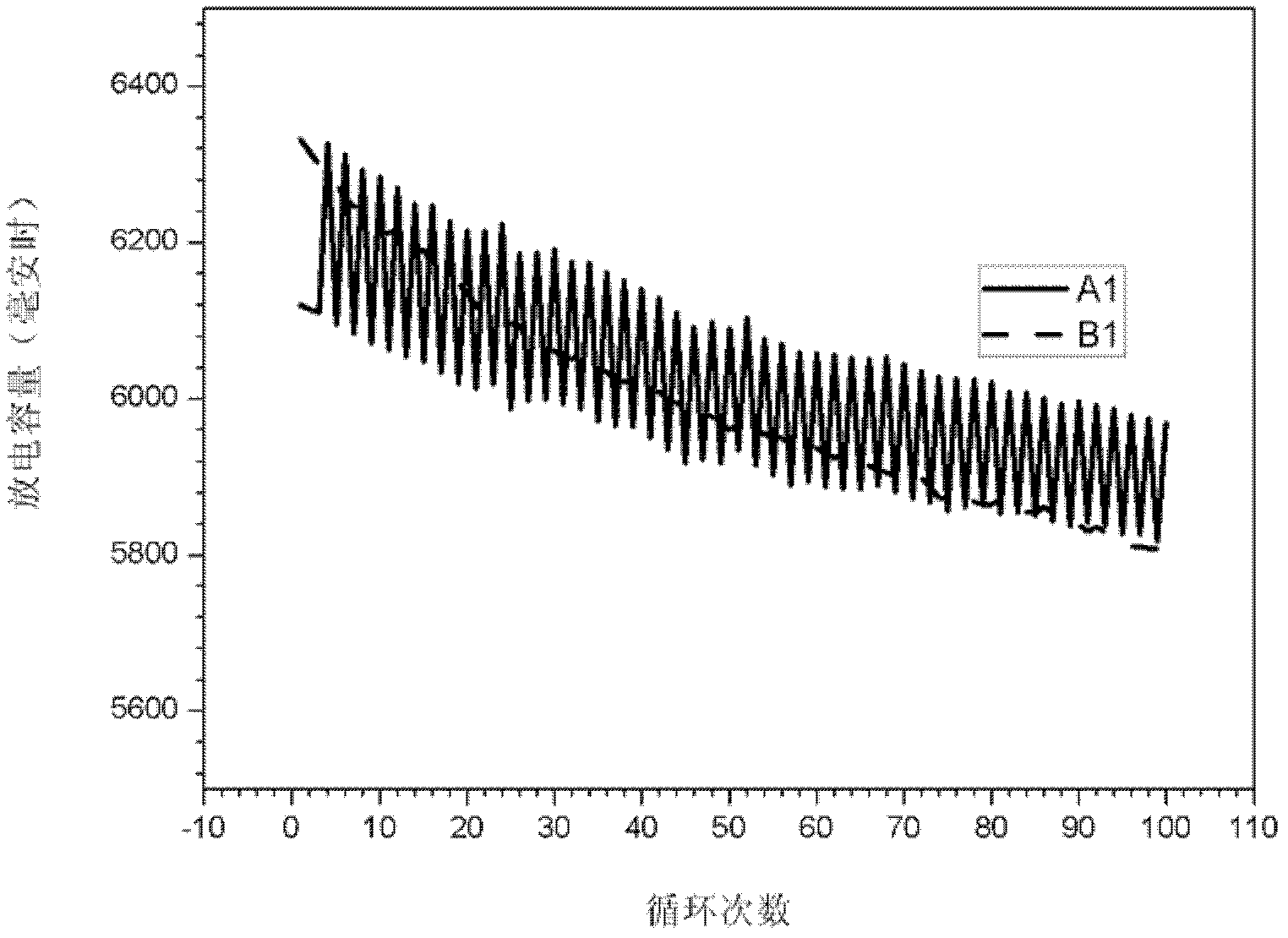

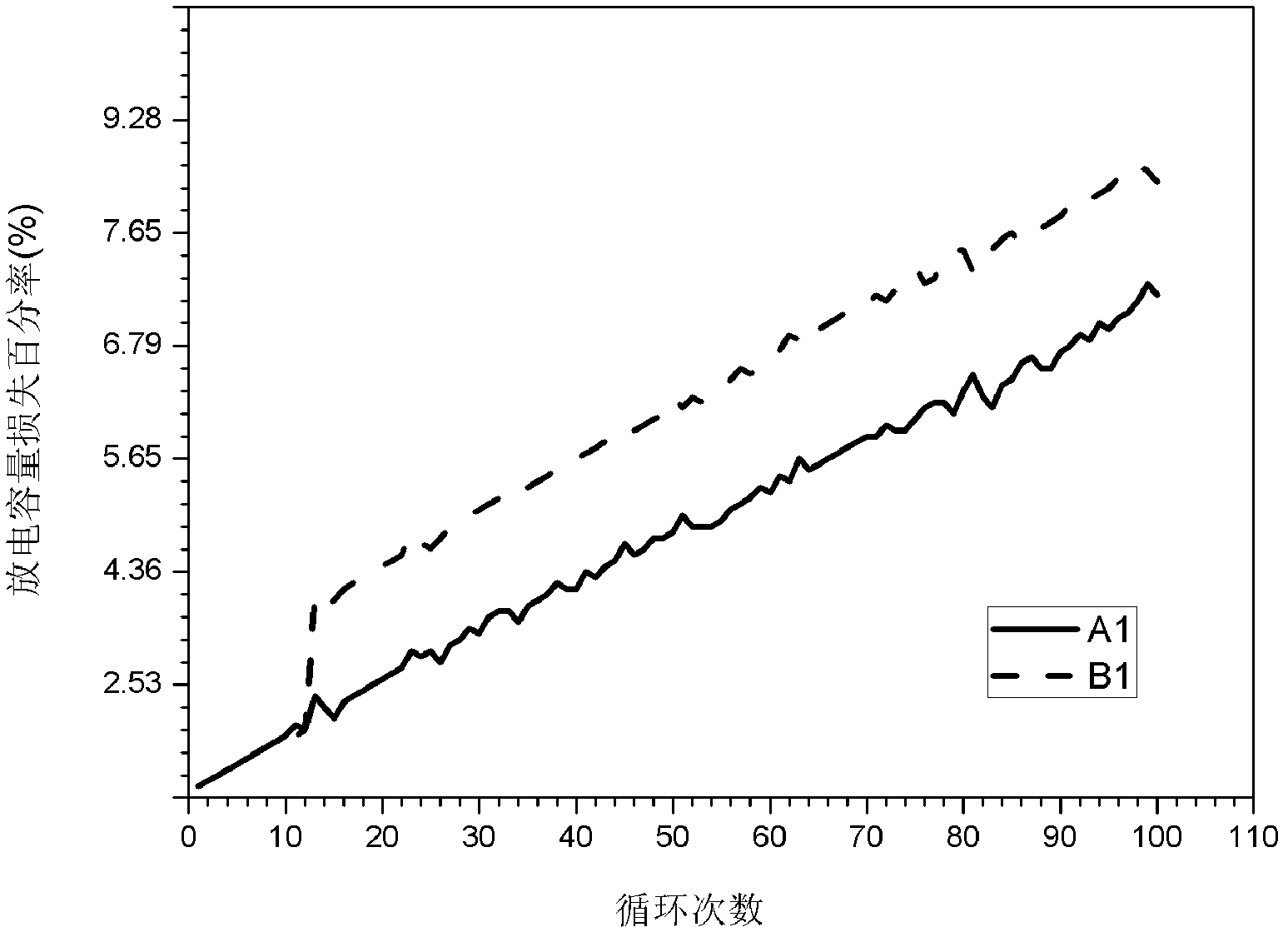

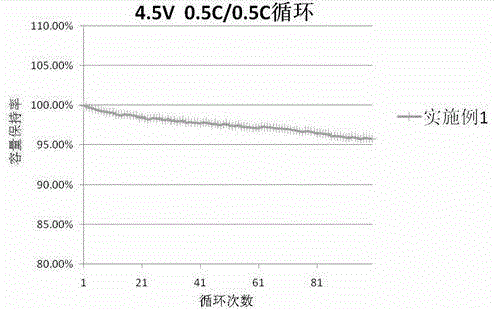

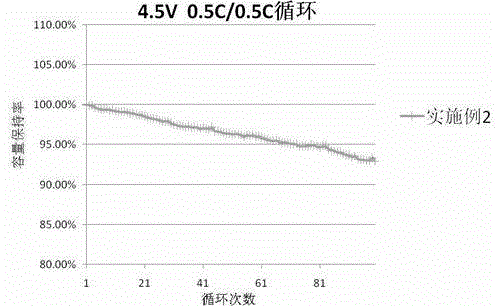

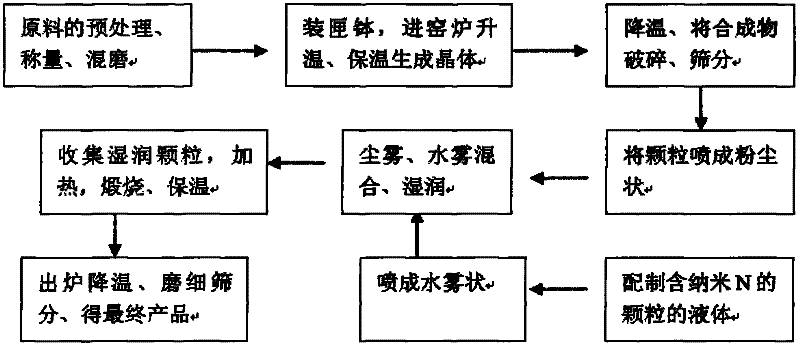

Power spinel lithium manganese oxide anode material and preparation method thereof

The invention discloses a power spinel lithium manganese oxide anode material and a preparation method thereof. The power spinel lithium manganese oxide anode material consists of power spinel lithium manganese oxide LiaMn2-x-zNbxAlyMzO4 and a coating layer on the surface thereof. The preparation method comprises the following steps: ball-milling and mixing the treated a lithium source, a manganese source, a niobium source, an aluminum source and a doped element M, and calcining at the temperature of 550-900 DEG C; and crushing and classifying the calcined preliminary products followed by adding coating materials for secondary calcination at 750-950 DEG C, and crushing and classifying to obtain the power spinel lithium manganese oxide anode material. The invention has the advantages that the spinel lithium manganese oxide material provided by the invention has high compacted density and specific capacity, has good recycle property in normal temperature and high temperature environments, stable property and good consistency and industrialized prospect. The preparation method of the material is simple, the preparation process is easy to control and operate, and the production cost is low.

Owner:QUFU ENERGY

Preparation of spinel type Li-Mn-oxide lithium ion screening materials by hydrothermal method

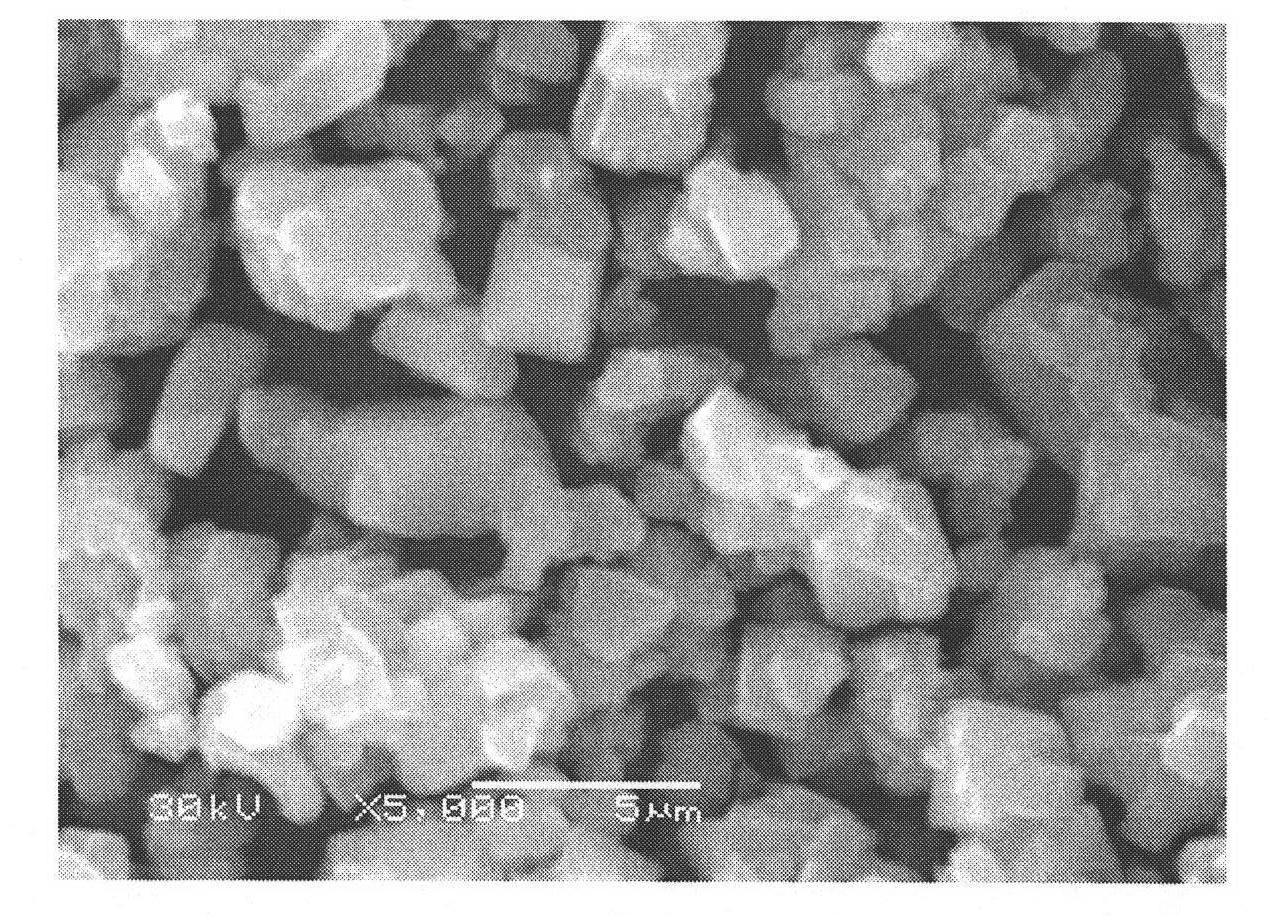

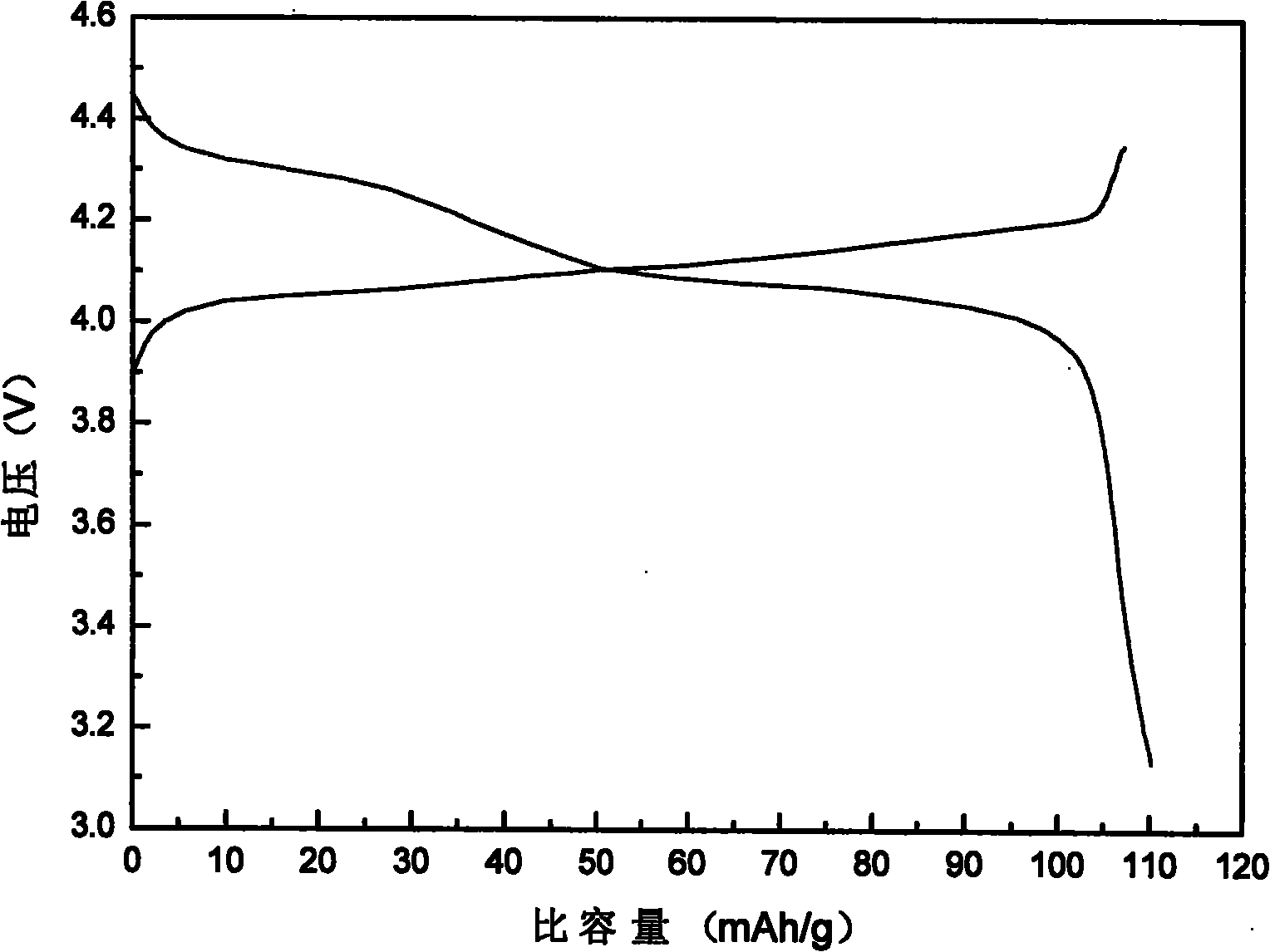

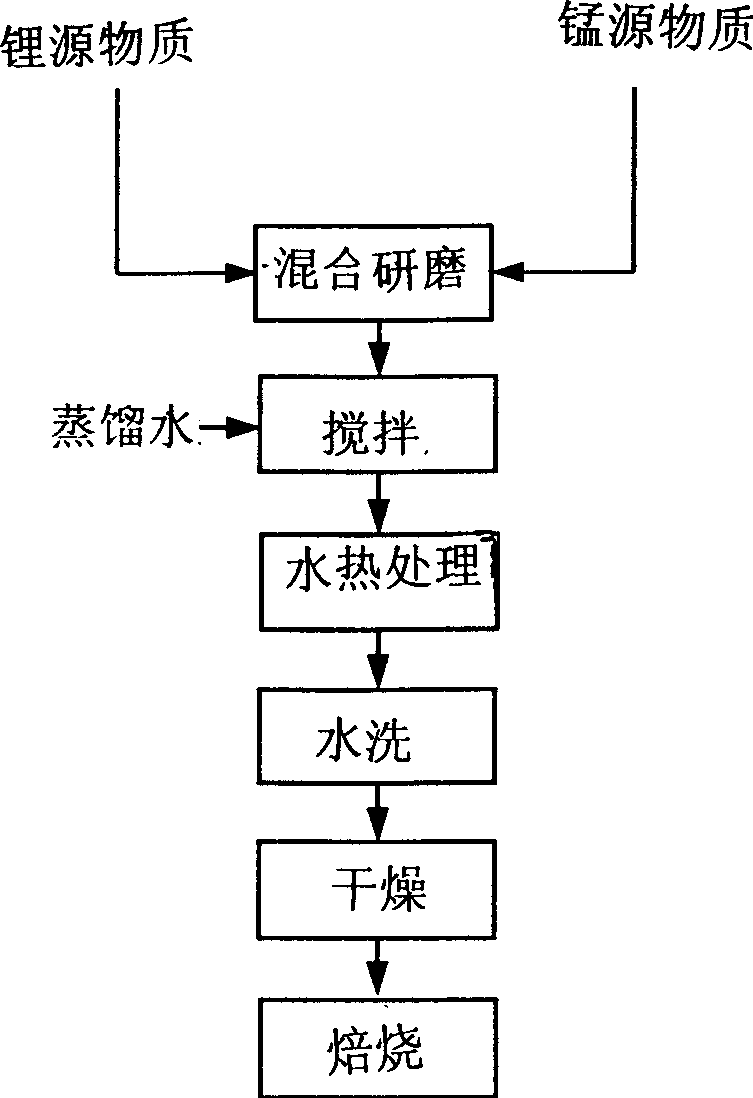

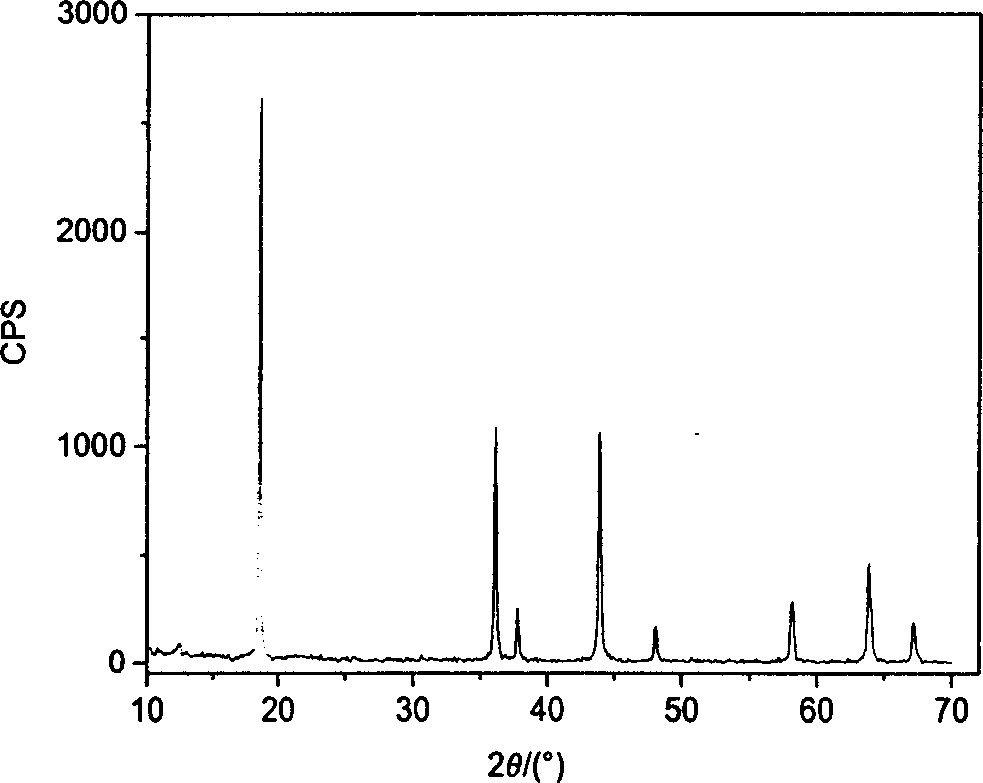

InactiveCN1702043AUniform compositionUniform particle size distributionManganese compoundsAir atmosphereGranularity

The invention relates to a hydrothermal production method of lithium ion bolting material of lithium-manganese oxide compound, which comprises the following steps: batching lithium oxidate and manganese oxidate with mole ratio of 0.5-3.0:1; delivering it to high-pressure hydrothermal autoclave after adequate mixing and grinding; adding distilled water to the mixture and processing it under 100-24 0 DEG C with 4-96h after full mixing; after filtering and rinshing to get colature of pH=7 to 8; drying it under 40-120 DEG C and processing preparatory roasting under 300 DEG C for 2h; roasting it under 300-800 DEG C in air atmosphere for 1-24h. The invention can get spinel structure lithium-manganese oxide of good crystal perfection, stable structure, and equal component. Said lithium-manganese oxide compound ionic screened material has the advantages of high selectivity and adsorption capacity when it is used to extract lithium resource from seawater and Salt Lake. The invention has the advantages of simple manufacturing process, mild conditioned response, cheap and available material and low cost of manufacture. Said lithium-manganese oxide compound can be used as electrode material of lithium ion secondary battery.

Owner:WUHAN UNIV OF TECH

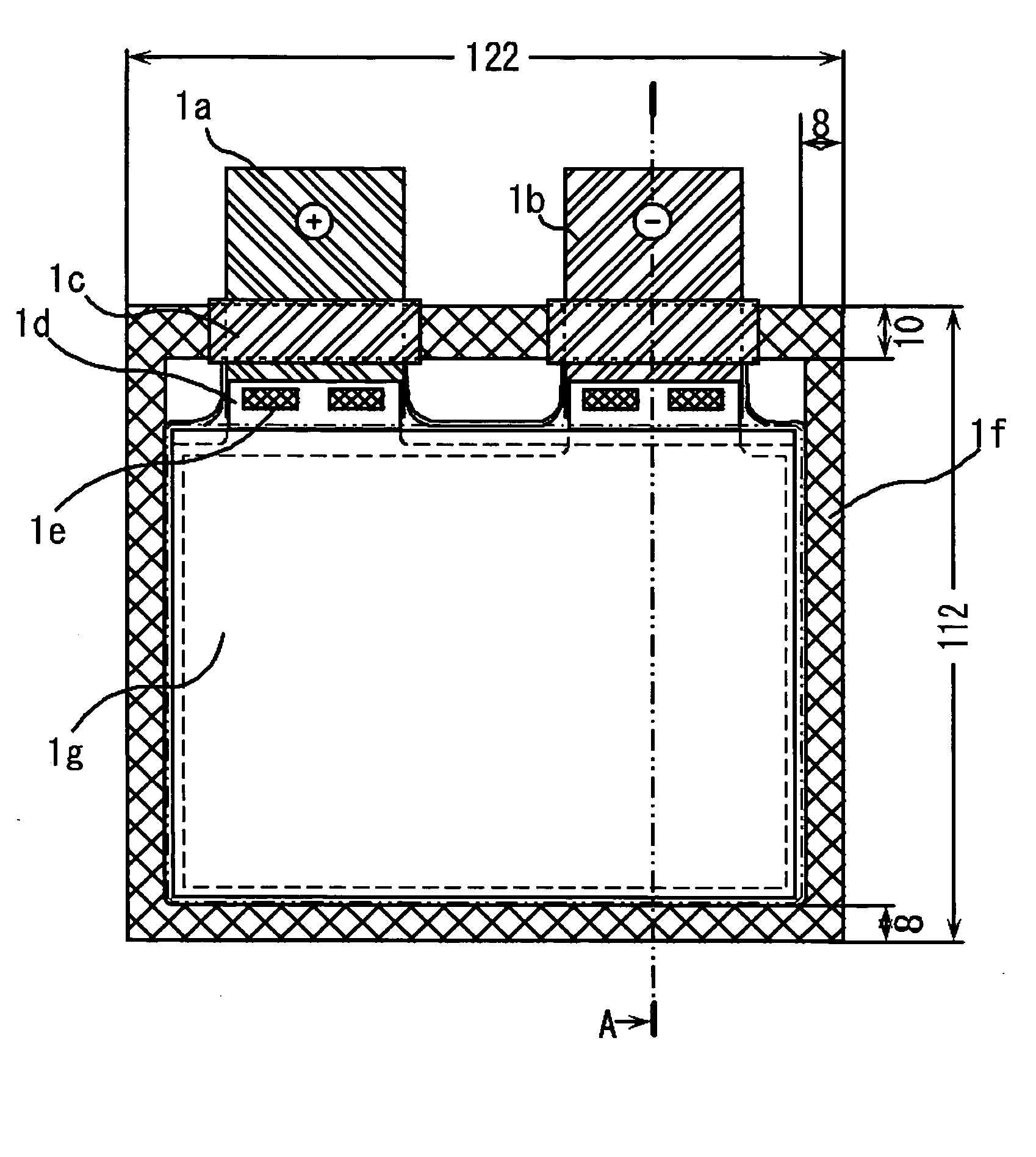

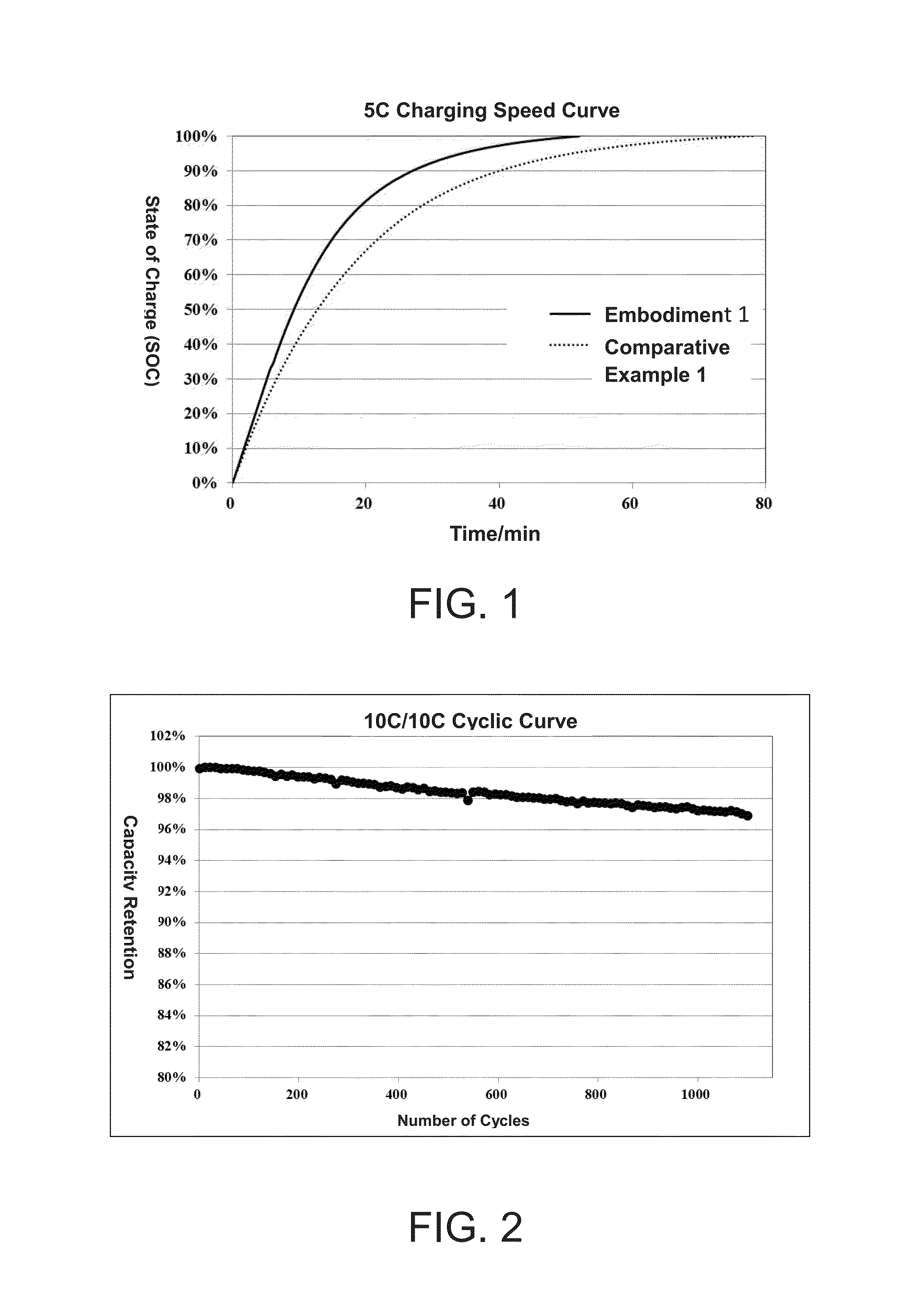

Rapid charge lithium-ion battery

InactiveUS20160104880A1Firmly connectedReduce contentSecondary cellsNegative electrodesAdhesiveElectrical battery

A rapid charge lithium-ion battery comprises a positive plate, a negative plate, a separator disposed at intervals between the positive plate and the negative plate, and an electrolyte. The positive plate includes a positive current collector and a positive active material layer disposed on a surface of the positive current collector; the positive active material layer includes a positive active material, a positive conductive agent and a positive adhesive; the positive active material includes a component A and a component B; the component A is selected from at least one of lithium nickel cobalt aluminum oxide (NCA), lithium nickel cobalt manganese oxide (NCM), lithium manganese oxide (LMO) and lithium cobalt oxide (LiCoO2); the component B is selected from at least one of lithium iron phosphate (LFP) and lithium titanium oxide (LTO); and the component B accounts for 5 to 90 percent by mass of the positive active material.

Owner:DONGGUAN AMPEREX TECH

Cathode active material comprising additive for improving overdischarge-performance and lithium secondary battery using the same

InactiveUS20070015055A1Increase cell capacityAvoid dischargeElectrode manufacturing processesOrganic electrolyte cellsCapacity lossManganese

Disclosed is a cathode active material providing a cell performance that is not adversely affected by overdischarge, and a lithium secondary cell using the same. More particularly, the cathode active material for a lithium secondary cell comprises a lithium-transition metal oxide capable of lithium ion intercalation / deintercalation, wherein the cathode active material further comprises a lithium manganese oxide having a layered structure represented by the following formula 1 as an additive:[formula 1] LiMxMn1-x02 wherein, x is a number satisfying 0.05 x<0.5, and M is at least one metal selected from the group consisting of Cr, Al, Ni, Mn and Co. The lithium manganese oxide of formula 1 used as an additive for a cathode active material of a lithium secondary cell provides lithium ions in such an amount as to compensate for an irreversible lithium ion-consuming reaction at an anode, or more, thereby providing a lithium secondary cell which is low in capacity loss by over-discharge.

Owner:LG CHEM LTD

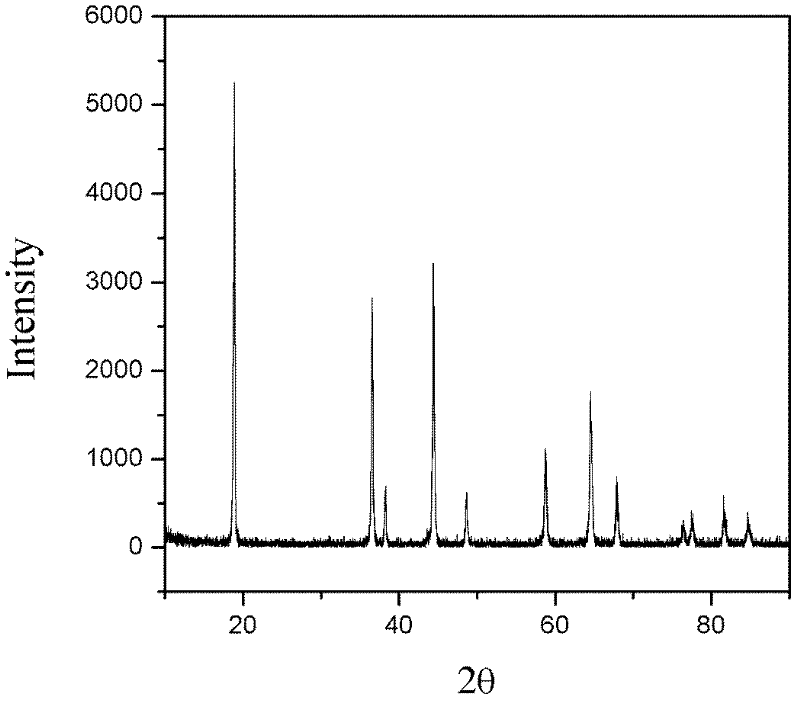

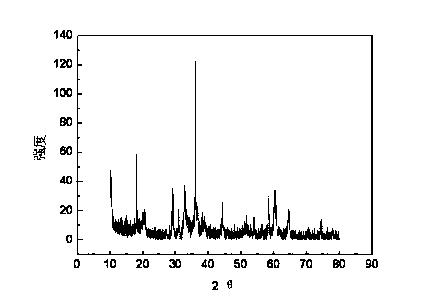

Lithium manganese oxide spinel of anode materials of lithium ion batteries and method for manufacturing lithium manganese oxide spinel

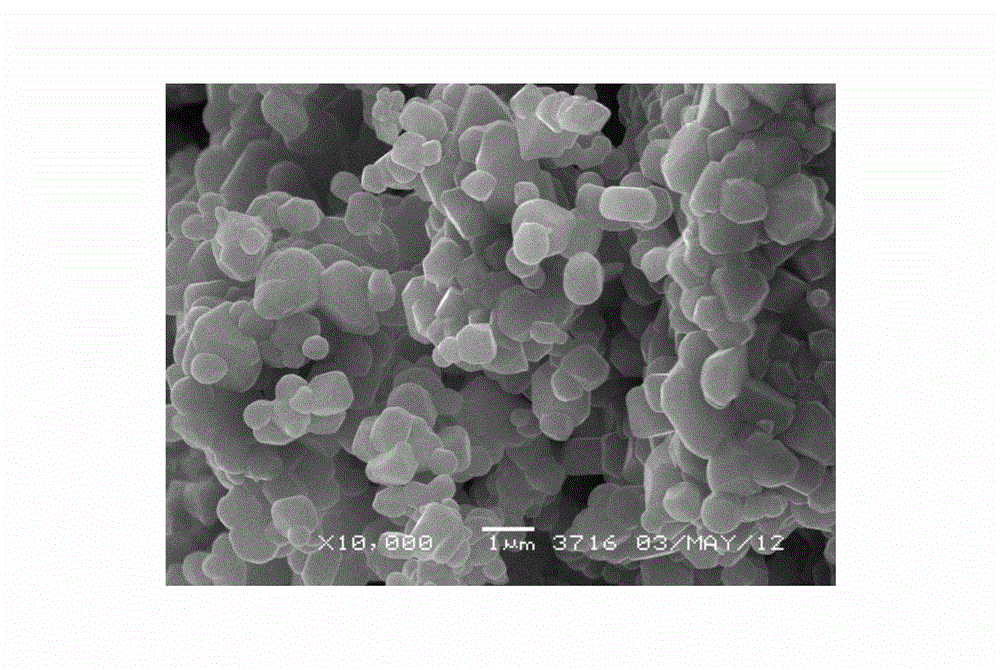

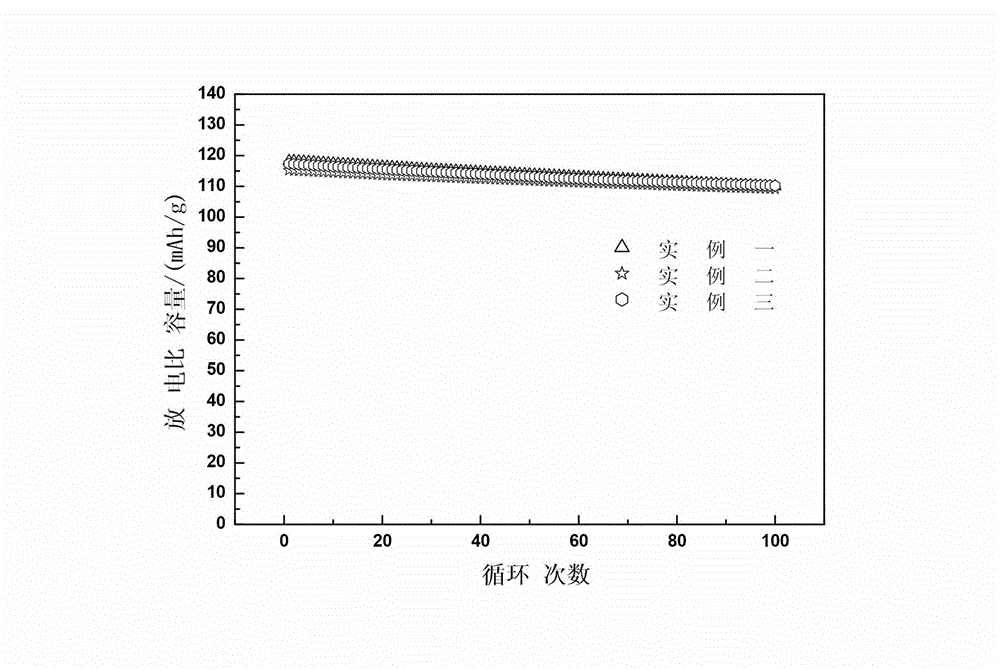

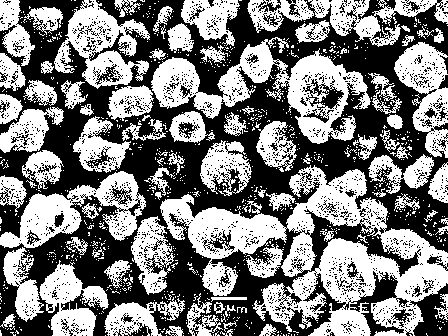

InactiveCN102916175ARegular particle shapeLow impurity contentCell electrodesManganates/permanganatesElectrical batteryPhysical chemistry

The invention discloses lithium manganese oxide spinel of anode materials of lithium ion batteries. The specific surface area of the lithium manganese oxide spinel ranges from 0.2m<2> / g to 0.6m<2> / g, the content of K ions in the lithium manganese oxide spinel is lower than 800ppm, the content of other impurities in the lithium manganese oxide spinel is lower than 200ppm, the compaction density of the lithium manganese oxide spinel is higher than 3.35g / cm<3>, the initial discharge capacity of a 0.1C button battery is higher than 115mAh / g, and the 100-cycle capacity fading is lower than 8%. The method includes proportioning a lithium source, a manganese source and doping metal additives, and presintering the manganese source at the temperature ranging from 500 DEG C to 1000 DEG C; mixing the presintered manganese source, the lithium source and the doping metal additives to obtain a mixed raw material; performing multi-section sintering for the mixed raw material to obtain a sintered sample, washing the sintered sample by water, and centrifugally spinning and drying the sintered sample; and screening and grading to obtain a lithium manganese oxide product. The lithium manganese oxide product is regular in granule morphology, high in compaction density, low in impurity content and good in both processability and electric performance.

Owner:HUNAN CHANGYUAN LICO CO LTD

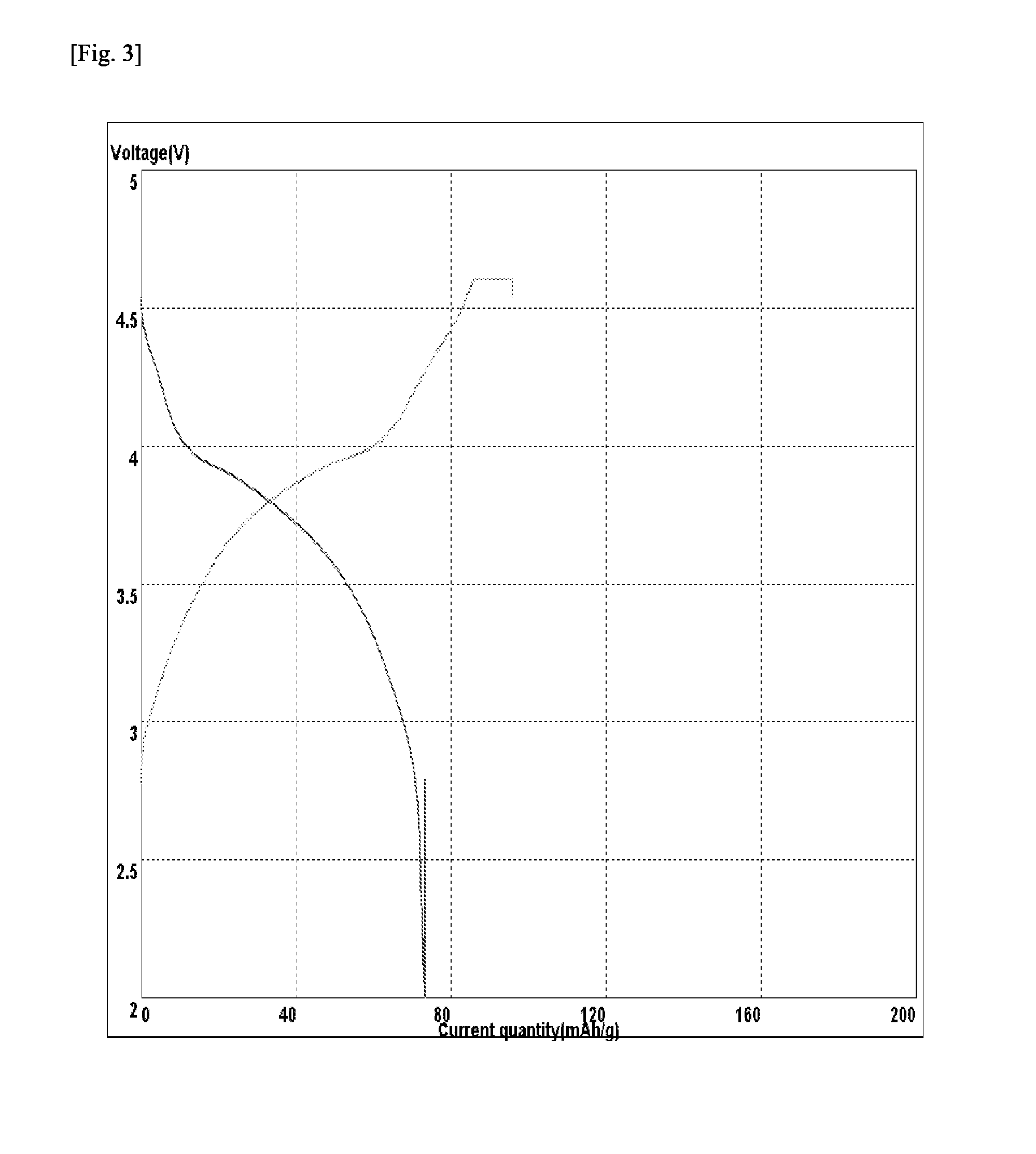

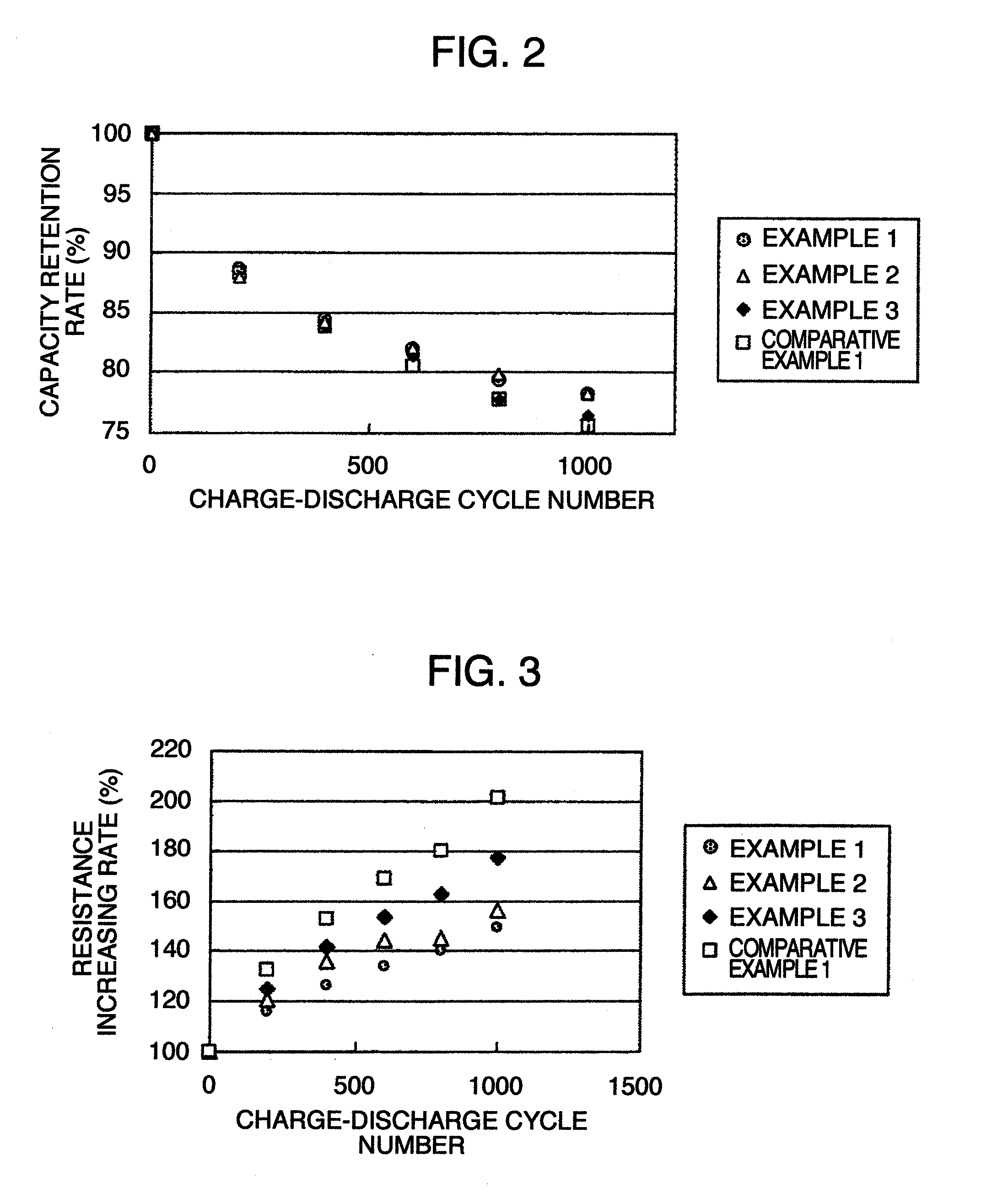

Lithium ion secondary battery

InactiveUS20110059351A1Suppressing resistance increaseSolution to short lifeCell electrodesSecondary cellsManganeseSpinel

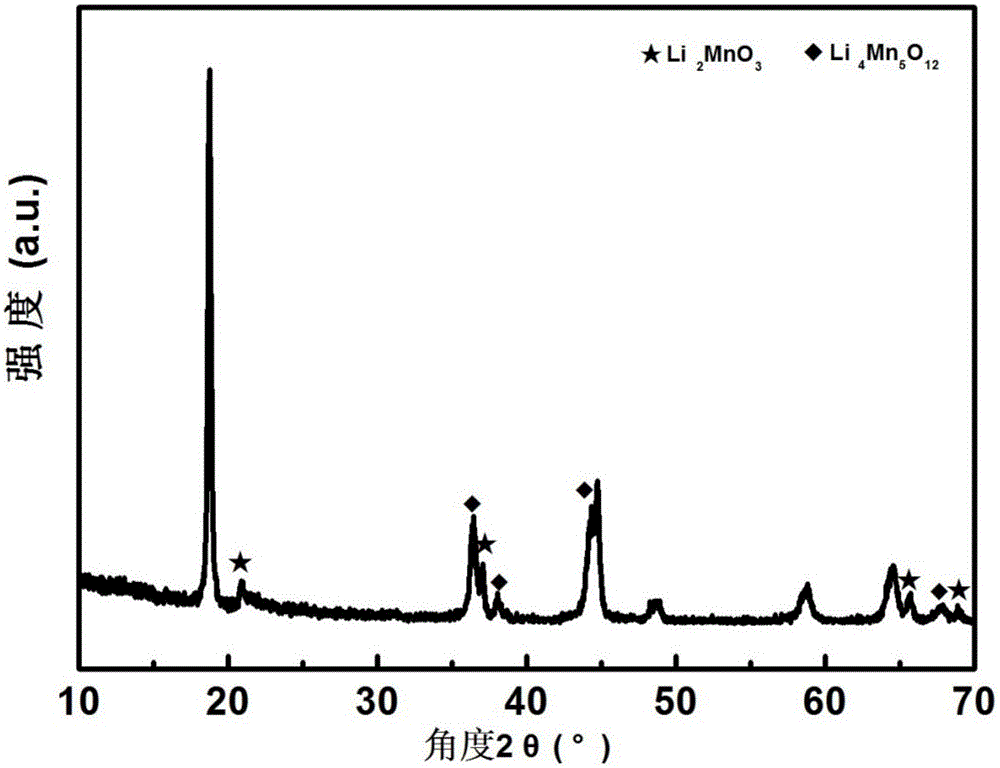

A lithium ion secondary battery comprising a positive electrode plate containing a positive electrode active material, a negative electrode plate containing a negative electrode active material, a separator, an electrolyte, and a battery can for enclosing these, wherein the positive electrode active material comprises manganese spinel and a layer-type lithium manganese oxide, and the electrolyte comprises vinylene carbonate and unsaturated sultone.

Owner:HITACHI LTD

Modified lithium manganese oxide electrode material for lithium ion secondary battery and synthesizing method thereof

InactiveCN102208640AImprove featuresImprove crystallization propertiesCell electrodesAluminium-ion batterySodium-ion battery

The invention provides a modified lithium manganese oxide electrode material for a lithium ion secondary battery, which is characterized in that the general formula is Li(4-x)A(x+y)Mn(5-y)O12.epsilonBOz. The synthesizing method comprises the following steps: weighing and mixing raw materials evenly in accordance with the stoichiometric ratio in the general formula and then adding the mixture of the raw materials to a container; adding an oxidizing solution, evening mixing and reacting for over 10 minutes, and then taking the materials out, washing and drying; and then carrying out high-temperature calcination and reaction for 1-30 hours at a temperature of 400-1200 DEG C under an oxygen-contained atmosphere, and cooling to obtain the modified lithium manganese oxide electrode material. Compared with an existing electrode material and a synthesizing technology, the modified lithium manganese oxide electrode material produced in the production process can improve the crystalline characteristic and the purity of products as well as the specific capacity, the initial coulomb efficiency, the cyclical stability and other characteristics in electrochemical property; and the modified lithium manganese oxide electrode material improves performances of the lithium ion battery, promotes the wider applications of the lithium ion battery and has significant economic meanings and practical value.

Owner:王明月

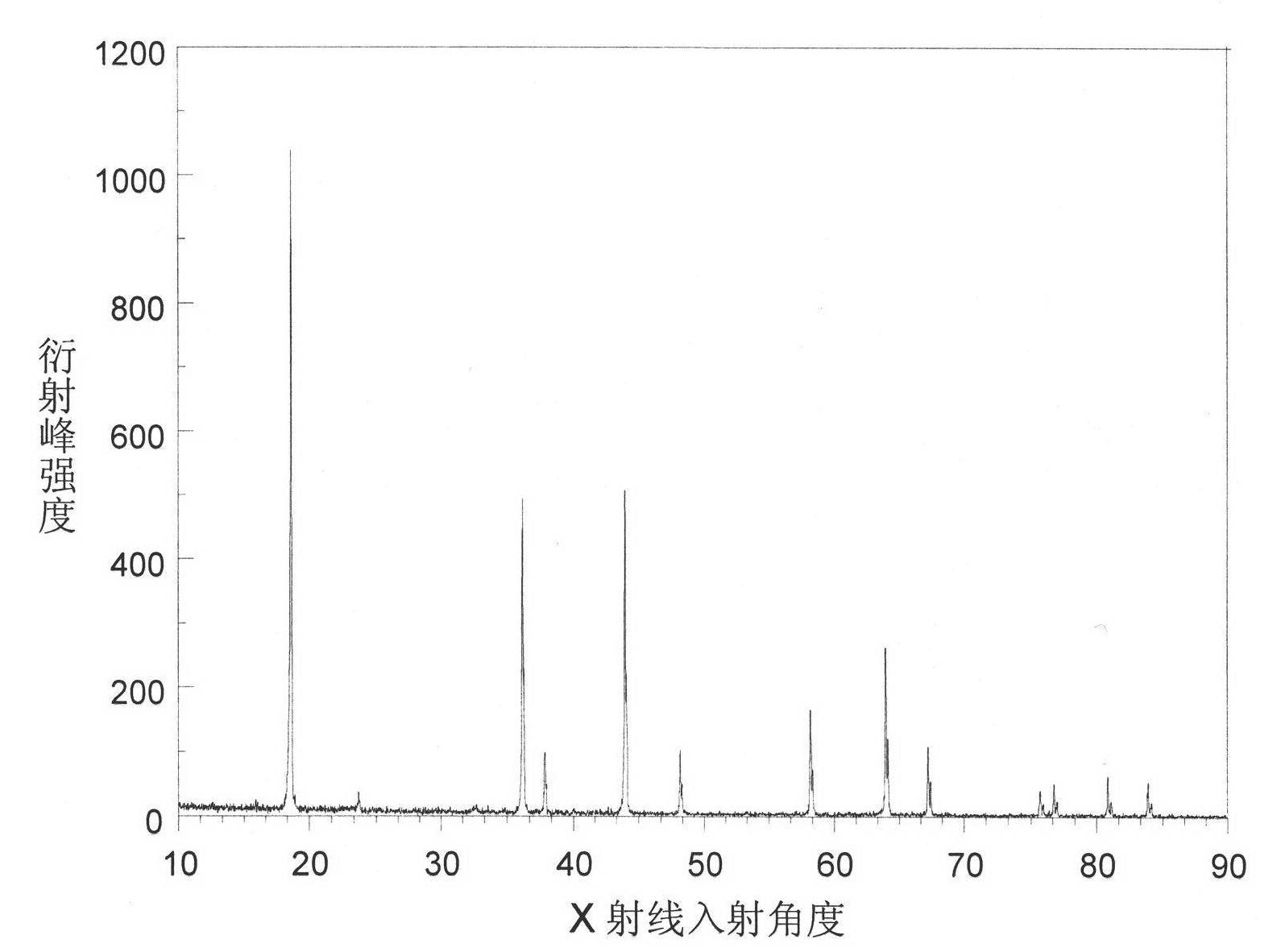

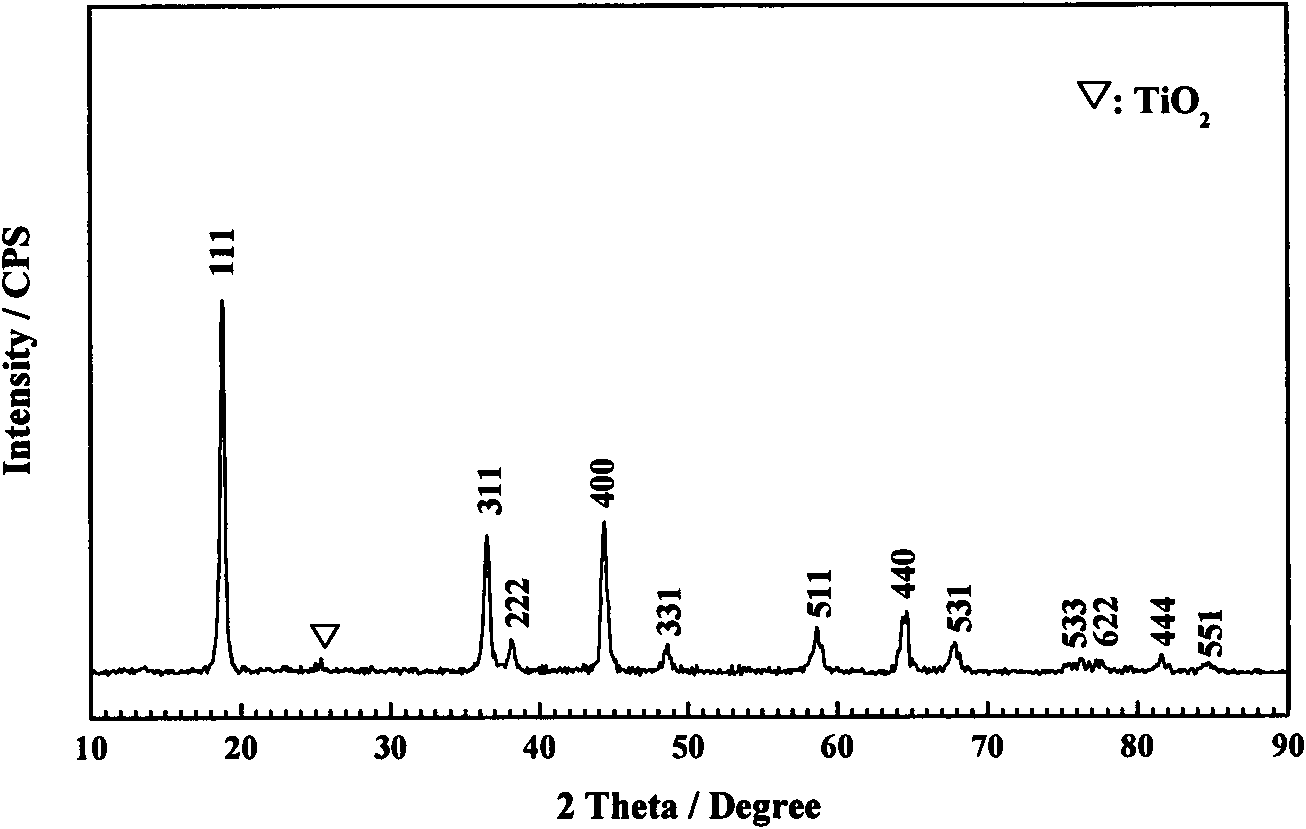

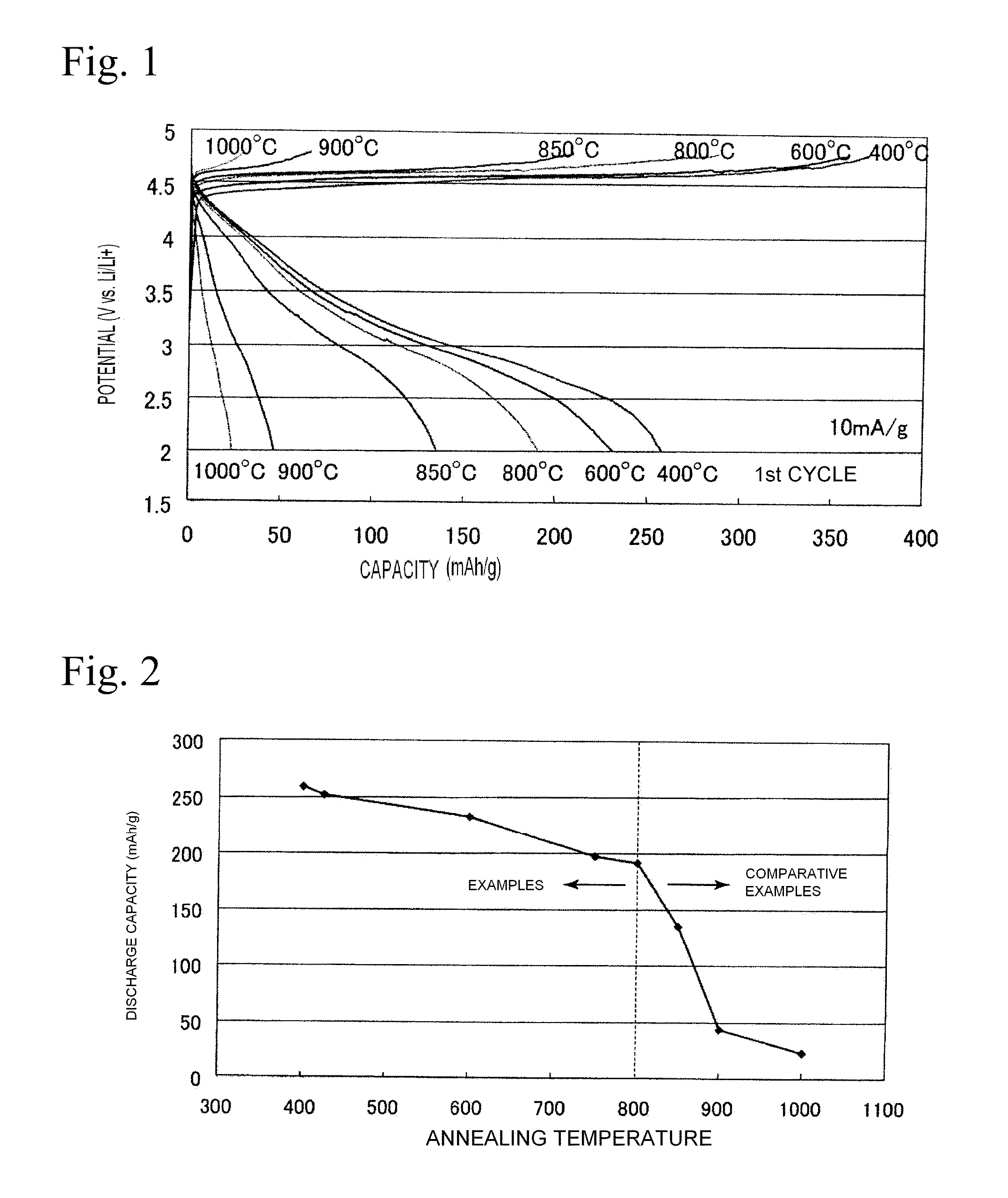

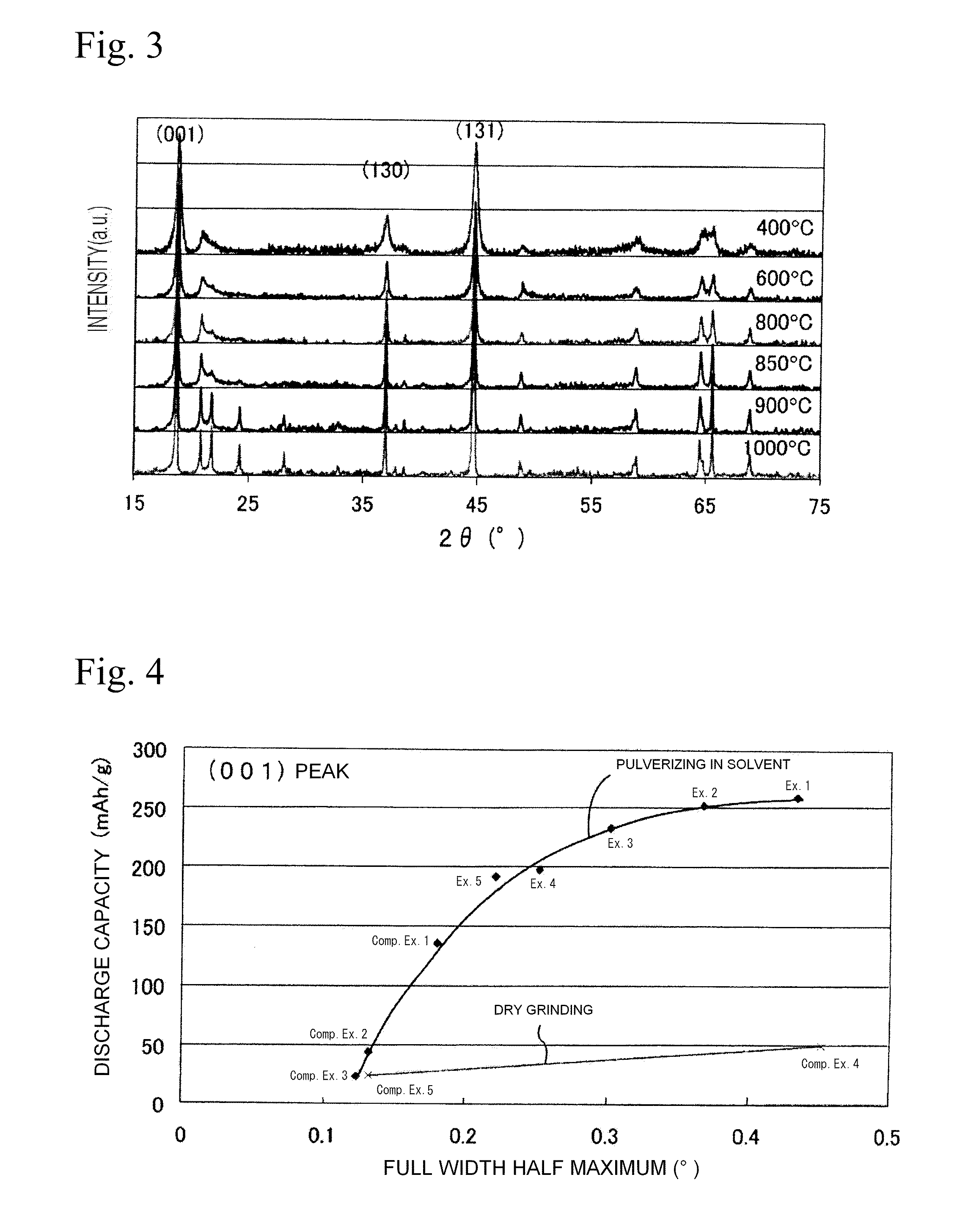

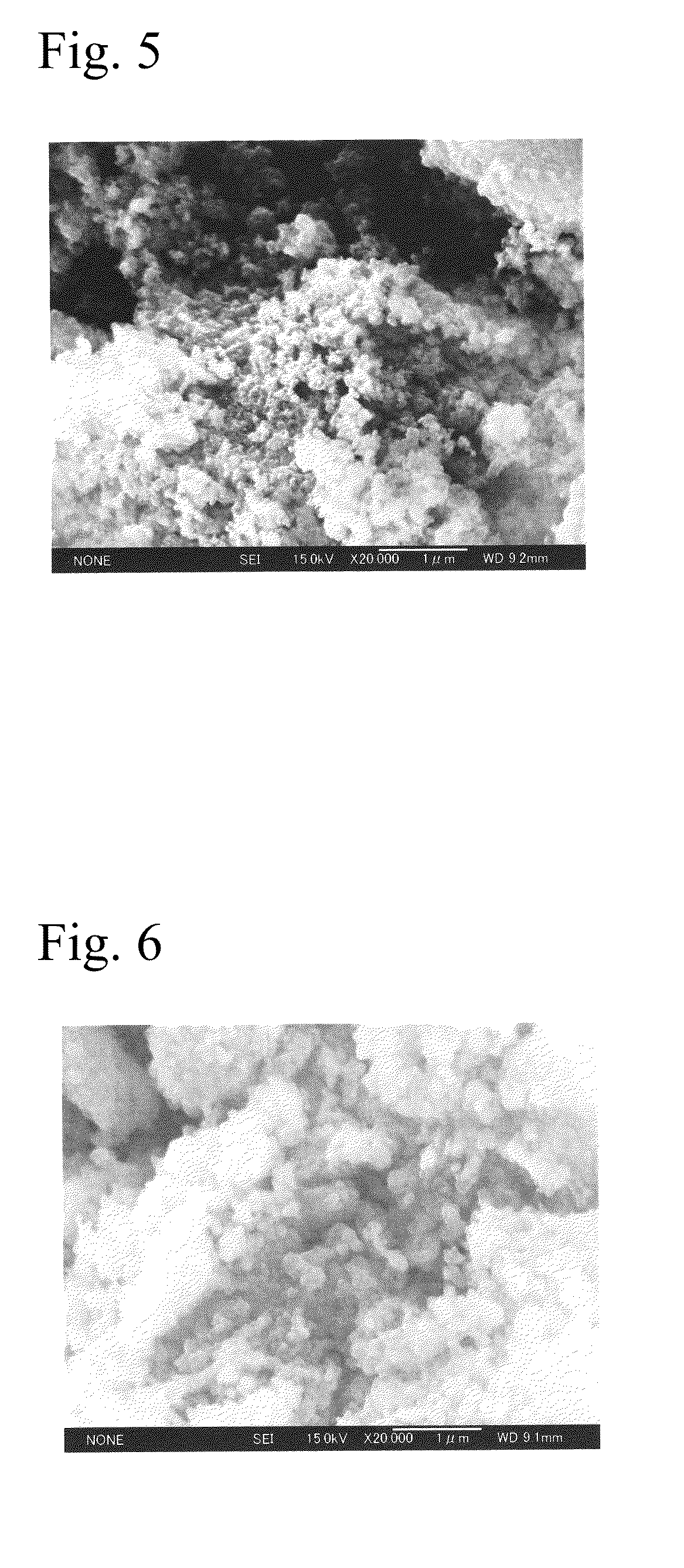

Positive electrode active material for lithium secondary battery and method of manufacturing the same

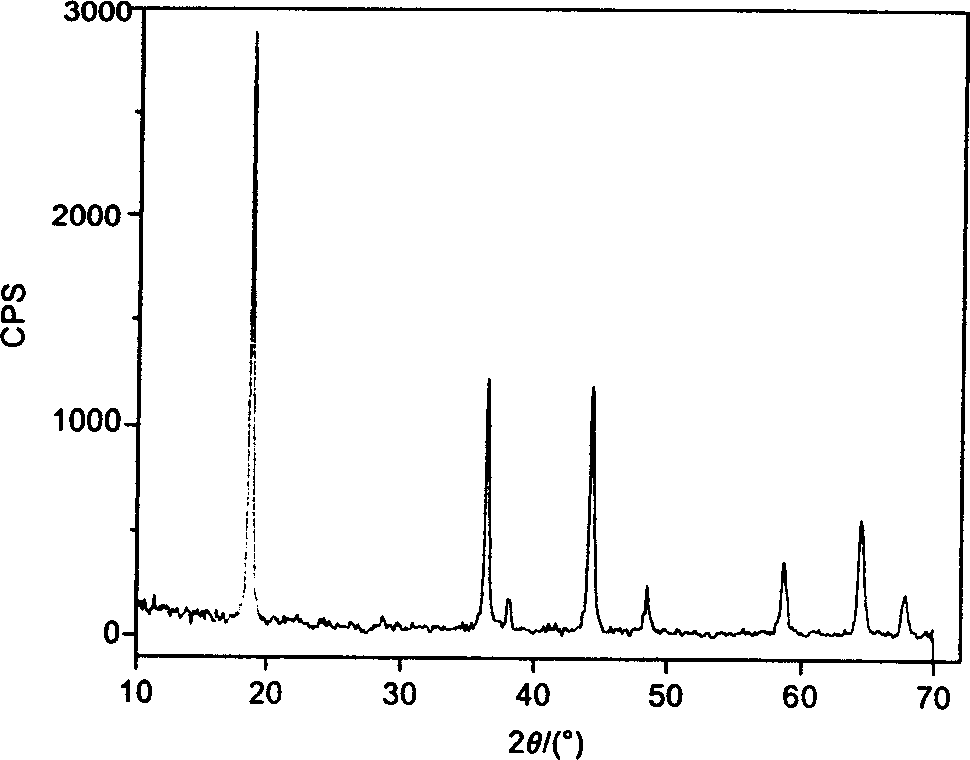

InactiveUS20100112448A1Improve discharge capacityEasy and efficient to manufactureSecondary cellsNon-aqueous electrolyte accumulator electrodesX-rayCrystal plane

A positive electrode active material includes a layered lithium-manganese oxide represented by the general formula Li2-xMn1-yO3-p, where 0≦x≦2 / 3, 0≦y≦1 / 3, and 0≦p≦1, the lithium-manganese oxide having a full width half maximum of a peak of the (001) crystal plane, as determined by an X-ray diffraction analysis, of 0.22° or greater, and an average particle size of 130 nm or less.

Owner:SANYO ELECTRIC CO LTD

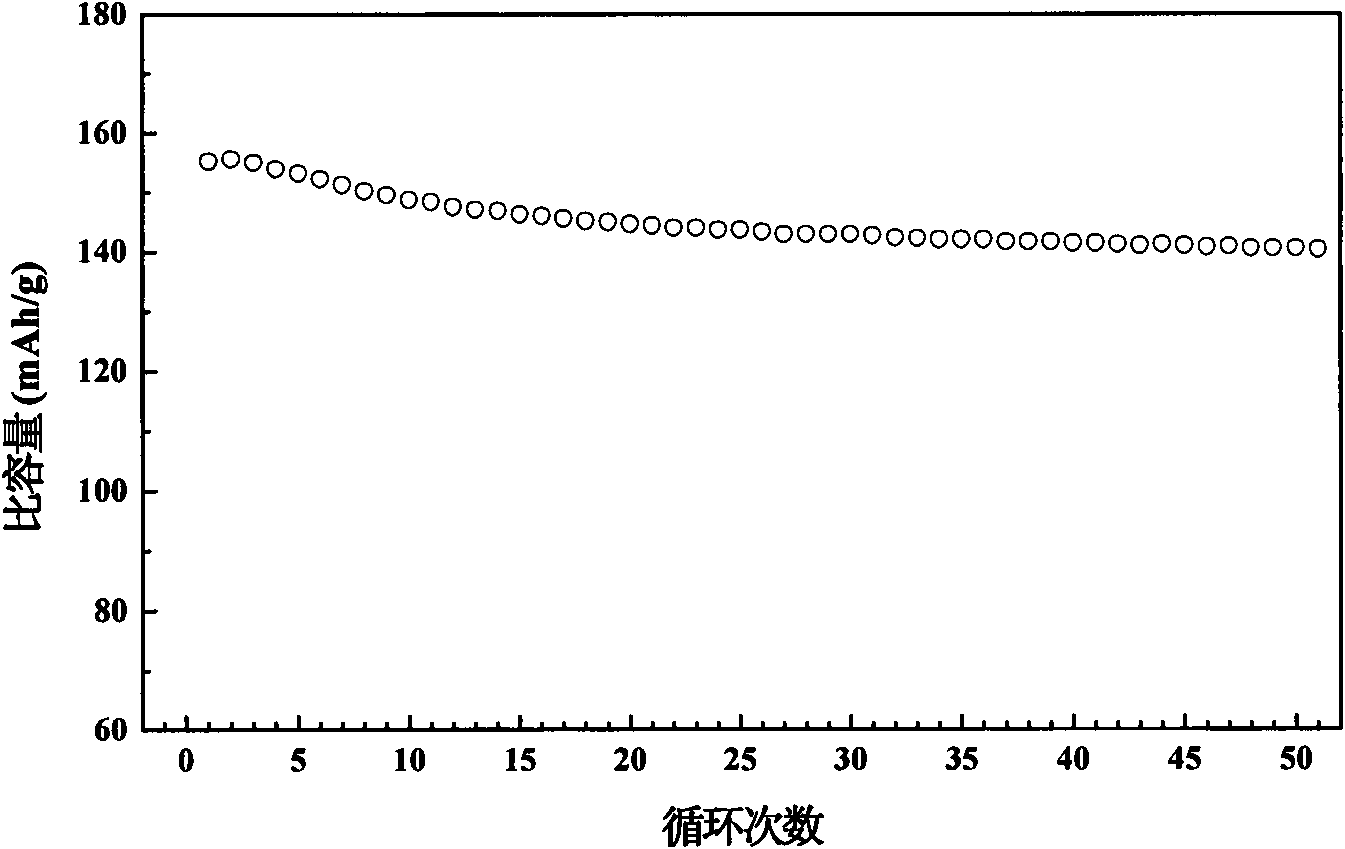

Lithium secondary battery and preparation method thereof

ActiveCN102983353AEasy to storeEasy to useFinal product manufactureElectrolyte accumulators manufactureOrganic solventLithium manganese oxide

The invention provides a lithium secondary battery. The lithium secondary battery comprises an anode, a cathode, a nonaqueous electrolytic solution and a diaphragm between the anode and the cathode. The anode comprises at least one anode active material which can realize reversible intercalation / deintercalation of lithium ions. The cathode comprises at least one cathode active material which can realize reversible intercalation / deintercalation of lithium ions. The nonaqueous electrolytic solution comprises a lithium salt and an organic solvent. The lithium secondary battery is characterized in that the at least one anode active material is at least one of a lithium manganese oxide, a doped lithium manganese oxide and a surface-modified lithium manganese oxide; and the lithium salt is an asymmetric lithium fluorosulfimide. The invention also provides a preparation method of the lithium secondary battery.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

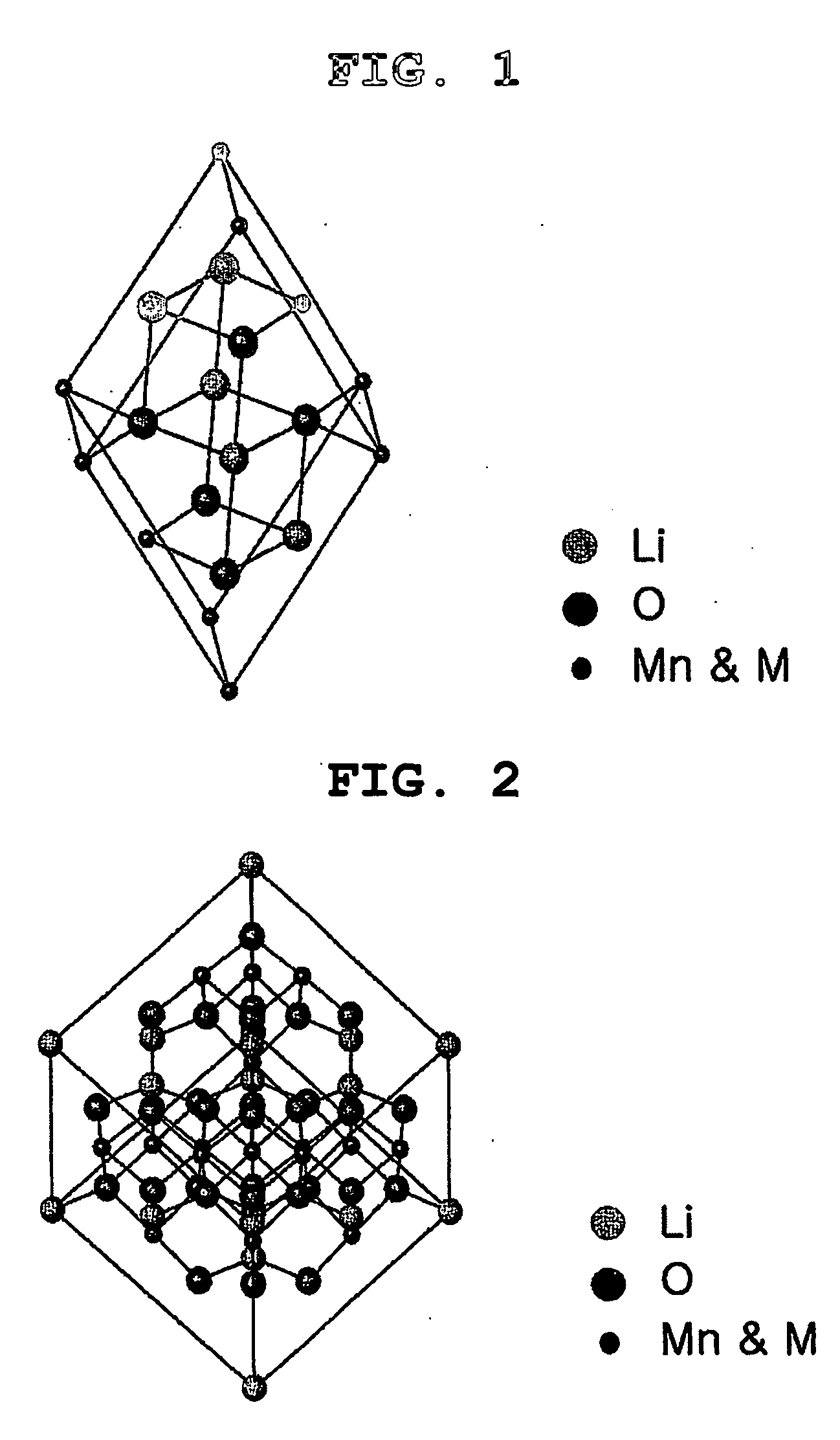

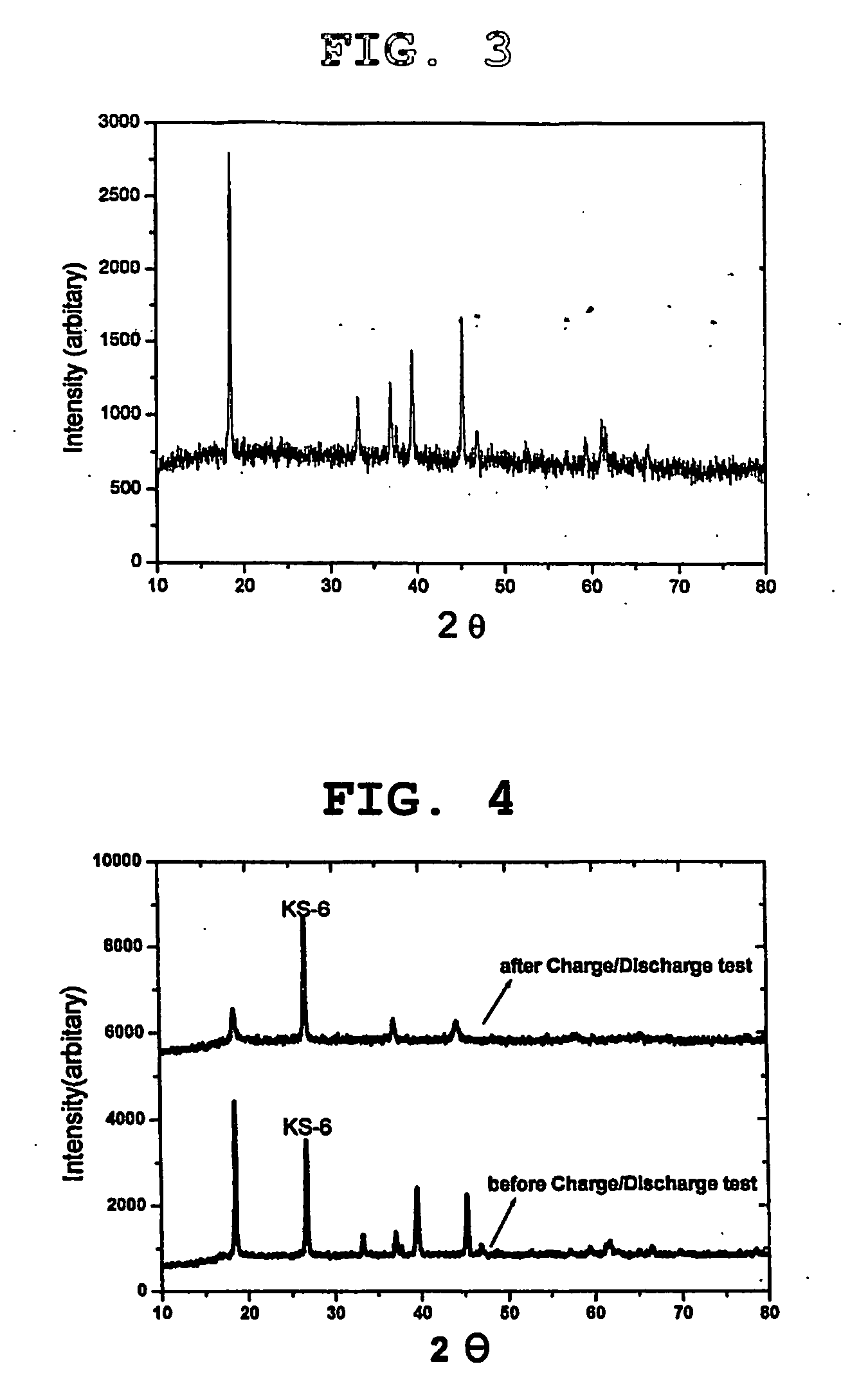

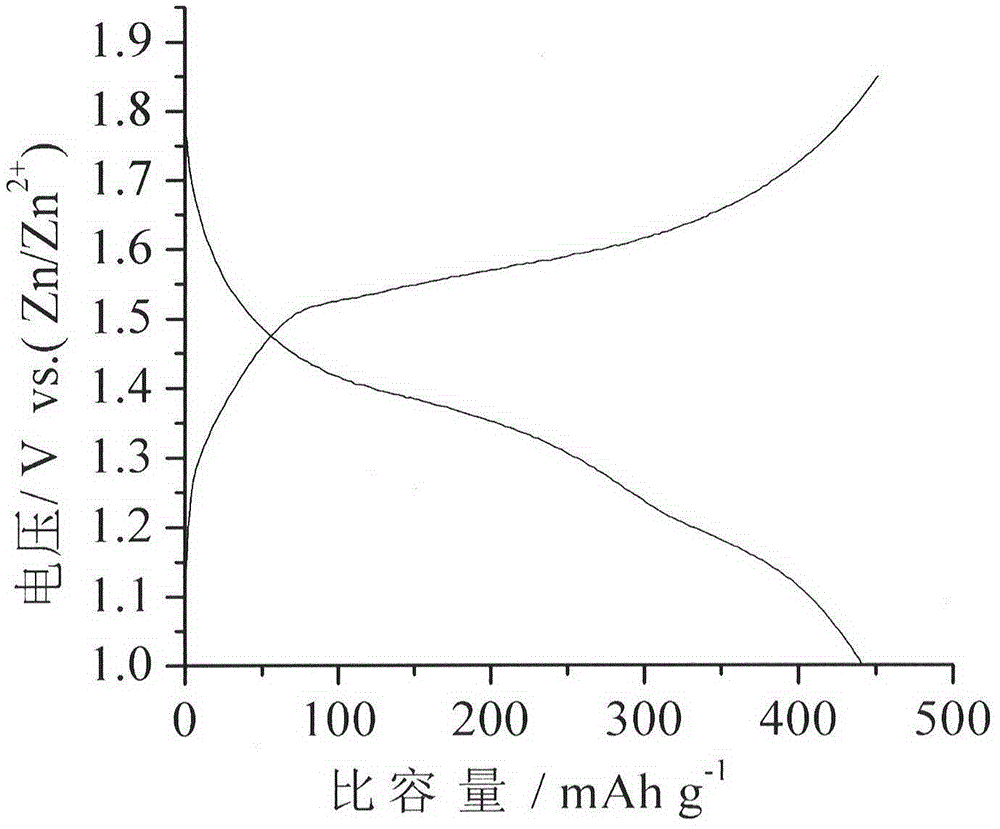

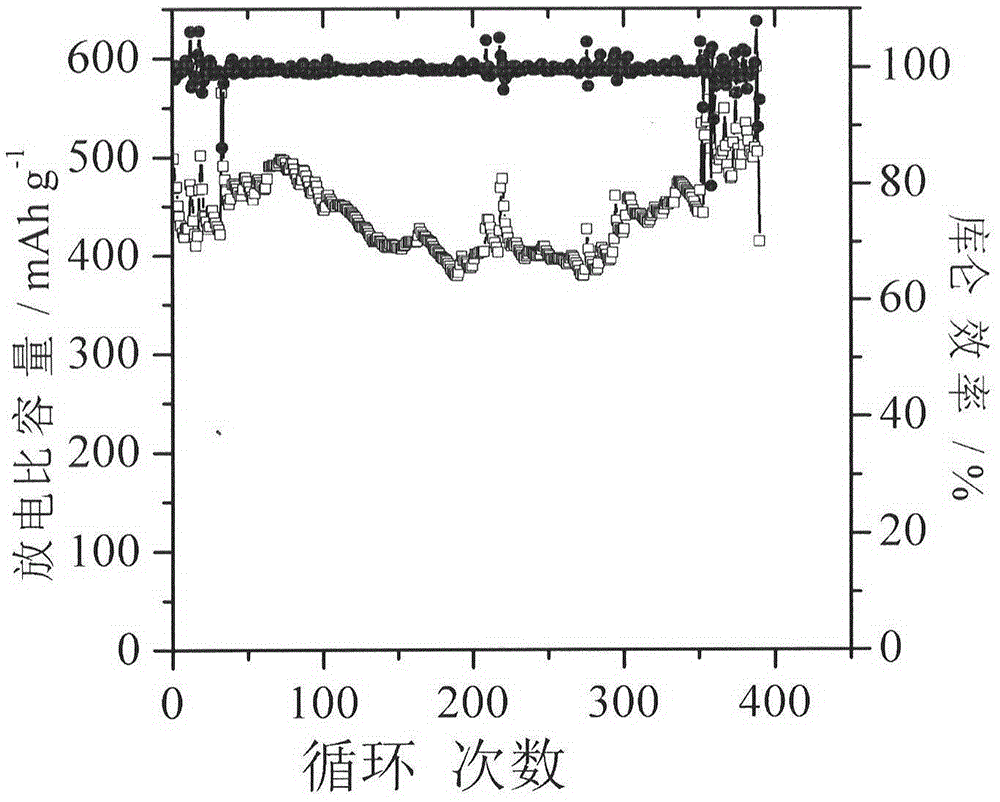

Lithium manganese oxide composite, secondary battery, and manufacturing method thereof

ActiveUS20140332715A1Improve structural stabilityLow costFinal product manufactureCell electrodesHigh energyCrystal structure

To increase the amount of lithium ions that can be received and released in and from a positive electrode active material to achieve high capacity and high energy density of a secondary battery. A composite material of crystallites of LiMn2O4 (crystallites with a spinel crystal structure) and crystallites of Li2MnO3 (crystallites with a layered rock-salt crystal structure) is used as a positive electrode active material. The lithium manganese oxide composite has high structural stability and high capacity.

Owner:SEMICON ENERGY LAB CO LTD

Preparation method of lithium ion battery electrolyte solution

InactiveCN104934639AImprove performanceImprove overcharge resistanceFinal product manufactureElectrolytesOrganic solventInternal resistance

The invention discloses a lithium ion battery electrolyte solution and a preparation method thereof. The solvent of the lithium ion battery electrolyte can be water or an organic solvent, and contains lithium salt and an additive; the content of the additive accounts for 0.01% to 20% of the total weight of the electrolyte lithium salt; and the lithium ion battery electrolyte is particularly suitable for a water system or organic system lithium ion battery using a lithium manganese oxide or lithium-rich manganese based material as a cathode. The special electrolyte salt additive is introduced, so that comprehensive performance of the electrolyte is improved, the specific discharge capacity of the lithium ion battery using the lithium manganese oxide or lithium-rich manganese based material as the cathode is obviously increased, high coulombic efficiency and long cycle stability are maintained, and the internal resistance of the battery is reduced to a certain extent. Moreover, the lithium ion battery electrolyte can enable the lithium ion battery using the lithium manganese oxide or lithium-rich manganese based material as the cathode to be of good overcharging performance.

Owner:ZHANGJIAGANG SMARTGRID FANGHUA ELECTRICAL ENERGY STORAGE RES INST +1

Anode active material, positive plate of lithium ion battery and lithium ion battery

InactiveCN101369658AImprove performanceGood value for moneySecondary cellsActive material electrodesMass ratioManganese

The invention provides a anode active material, especially a mixture of LiaNixCoyM1-x-yO2 and LiCoO2, the mixed mass ratio between the LiaNixCoyM1-x-yO2 and the LiCoO2 is 9 : 1-1 :1; in the LiaNixCoyM1-x-yO2, 0.97<=a<=1.07, 0.3<=x<=0.95, 0<=y<=0.5, M is one or more of manganese, aluminum, magnesium, titanium and vanadium. By combining the LiaNixCoyM1-x-yO2 and the LiCoO2, the anode active material according to the invention can improved synthesis performance of the anode active material, with high cost performance higher than lithium manganese oxide, lithium cobalt oxide with single component, or nickel radical material / unit triplet material of nickel, cobalt, manganese. The anode material according to the invention has simple manufacture method, being convenient for industrial manufacture and control.

Owner:SHENZHEN BAK BATTERY CO LTD

System of lithium ion battery containing material with high irreversible capacity

ActiveUS20060257737A1Improve securityImprove security levelCell seperators/membranes/diaphragms/spacersSecondary cellsLithium metalLithium.free

Disclosed is a cathode active material comprising a lithium-free metal oxide and a material with high irreversible capacity. A novel lithium ion battery system using the cathode active material is also disclosed. The battery, comprising a cathode using a mixture of a Li-free metal oxide and a material with high irreversible capacity, and an anode comprising carbon instead of Li metal, shows excellent safety compared to a conventional battery using lithium metal as an anode. Additionally, the novel battery system has a higher charge / discharge capacity compared to a battery using a conventional cathode active material such as lithium cobalt oxide, lithium nickel oxide or lithium manganese oxide.

Owner:LG ENERGY SOLUTION LTD

Cathode material for boracic lithium ion battery and preparation method thereof

InactiveCN105244492AGood electrochemical performance of the batteryGood capacity retentionCell electrodesComposite cathodeLithium iron phosphate

The invention discloses a cathode material for a boracic lithium ion battery and a preparation method thereof. The cathode material for the lithium ion battery disclosed by the invention comprises two parts including a composite oxide core and a coating layer. The core is single or is doped with ternary materials such as modified lithium cobalt oxide, nickel cobalt manganese or nickel cobalt aluminum, lithium manganese oxide, lithium iron phosphate, lithium-rich manganese and the like, and the coating layer is a high-molecular polymer containing boron-oxygen bonds. The preparation method of the composite cathode material for the lithium ion battery disclosed by the invention is simple in technology, easy in process control and convenient for industrial production.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

A method to manufacture precursor of nickel-cobalt-lithium-manganese-oxide of lithium ion cell anode material

ActiveCN1964103ASolve particle sizeResolution granularityElectrode manufacturing processesLithium compoundsLithium hydroxideManganese

The related preparation method for Li1.05NixCoyMn(1-x-y)O2 precursor for Li-ion cell anode material comprises: a. preparing the first mixed solution with nitrates of Ni, Co and Mn, and some NH4NO3; b. adding proper NH3H2O into the cooled NaOH solution to form the second mixed solution, and adding NH3H2O into the a little pure water in reactor as base solution; c. adding continually mixed solution into the base solution for stirring; d. cleaning the hydroxide deposition by LiOH, NaOH or KOH, while controlling pH value in 10-10.5; e. drying deposition in oven. This invention is convenient to control and prepare fit to industrial production.

Owner:BYD CO LTD

Anode material of lithium ion battery and preparation method thereof

The invention discloses an anode material of a lithium ion battery and a preparation method thereof. The anode material which is granular comprises: an internal nucleus which is a substance having a molecular formula of LixMn2-yMyNzO4; and an external surface crystal shell which is nitrogen-containing nanometer oxide particles. According to the anode material of the lithium ion batter disclosed in the invention, M is doped to replace partial Mn, and the crystal lattice volume is reduced because the bond energy of M-O is greater than the bond energy of Mn-O, so the spinel structure of lithium manganate is stabilized, the manganese solution in the cycle process is reduced, and the product cycle performance is improved. The preparation method of the anode material of the lithium ion battery disclosed in the invention, which allows the lithium manganese oxide to be doped and coated through a two-step reaction, has the advantages of simple production technology, no pollution, no waste discharge, simple equipment, low cost of raw materials and the production cost, and the like.

Owner:QINGDAO HUAGUAN HENGYUAN LI TECH

Gradient doped type lithium-ion cathode material and method for preparing same

The invention discloses a gradient doped type lithium-ion cathode material and a method for preparing the same, and is used for solving the problem of quick high-temperature circulation attenuation of conventional lithium manganese oxide. The molecular formula of the lithium manganese oxide is LiMn2(3-x) / 3M2x / 3O4, wherein 0<x<=0.5, and M is a doping metal ion and is selected from one or a plurality of magnesium, nickel, iron, titanium, zinc, cobalt, aluminium, niobium and vanadium. The gradient doped type lithium-ion cathode material is a material with the manganese content which is gradually reduced and M content is gradually increased along the radius from the inside to the outside. The method for preparing has short technological process, is easy to control and is easily industrialized. The obtained gradient doped lithium manganese oxide has the characteristics of high specific capacity, good circulation performance, excellent rate capability and the like, and is suitable for the power battery application field.

Owner:HUNAN JOYFLY TECH DEV

Lithium secondary battery

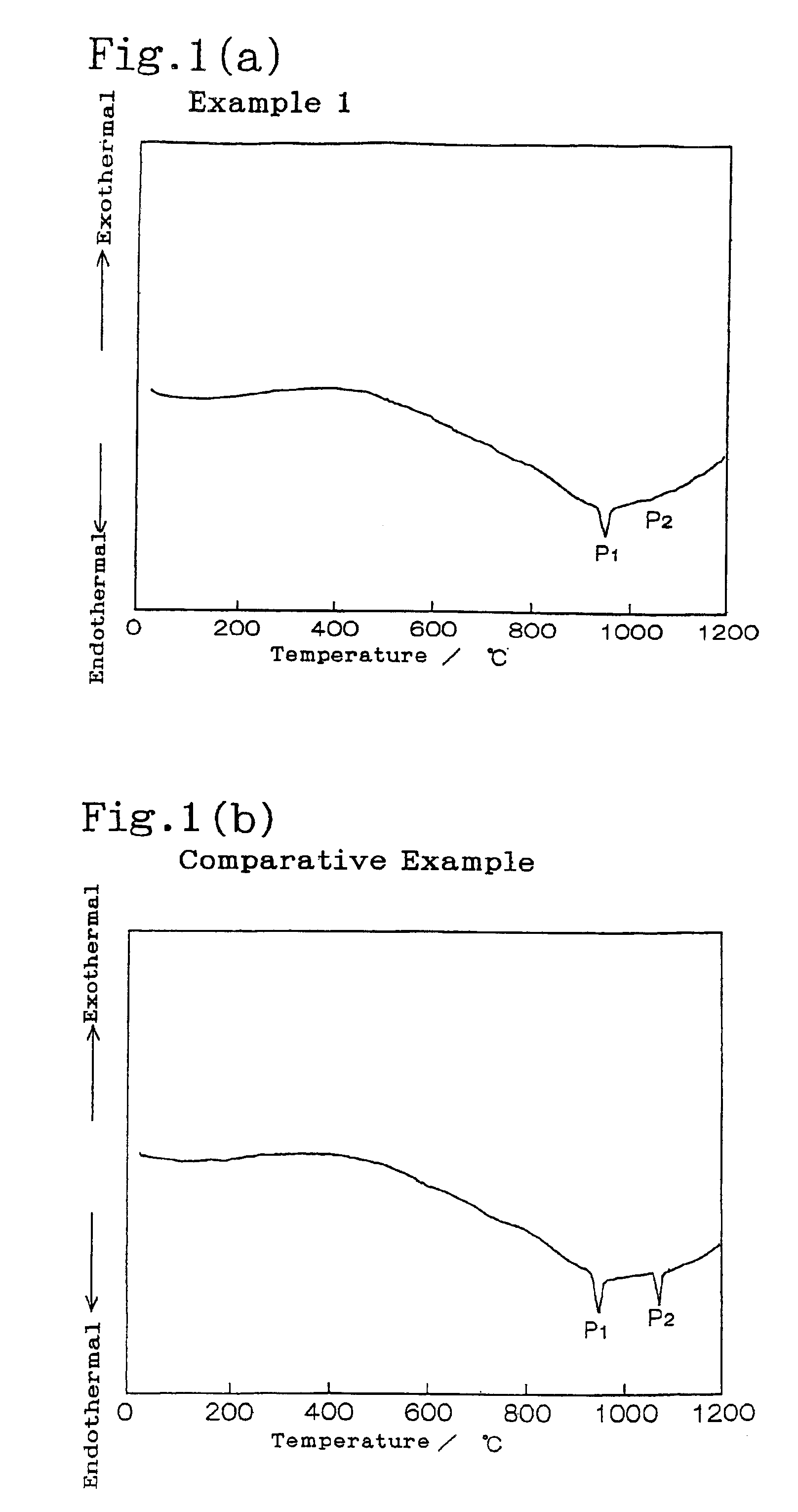

InactiveUS6964830B2Stable crystal structureImprove cycle performanceActive material electrodesNon-aqueous electrolyte accumulator electrodesSpinelLithium-ion battery

A lithium secondary battery using lithium manganese oxide as a positive active material and having excellent charge and discharge cycle properties.As a positive active material of a lithium secondary battery, lithium manganese oxide having a cubic spinel structure, in which the strength ratio (P2 / P1 strength ratio) of the primary endothermal peak (P1) appearing around 950° C. and the secondary endothermal peak (P2) appearing around 1100°0 C. in differential thermal analysis is under 1, is used.

Owner:NGK INSULATORS LTD

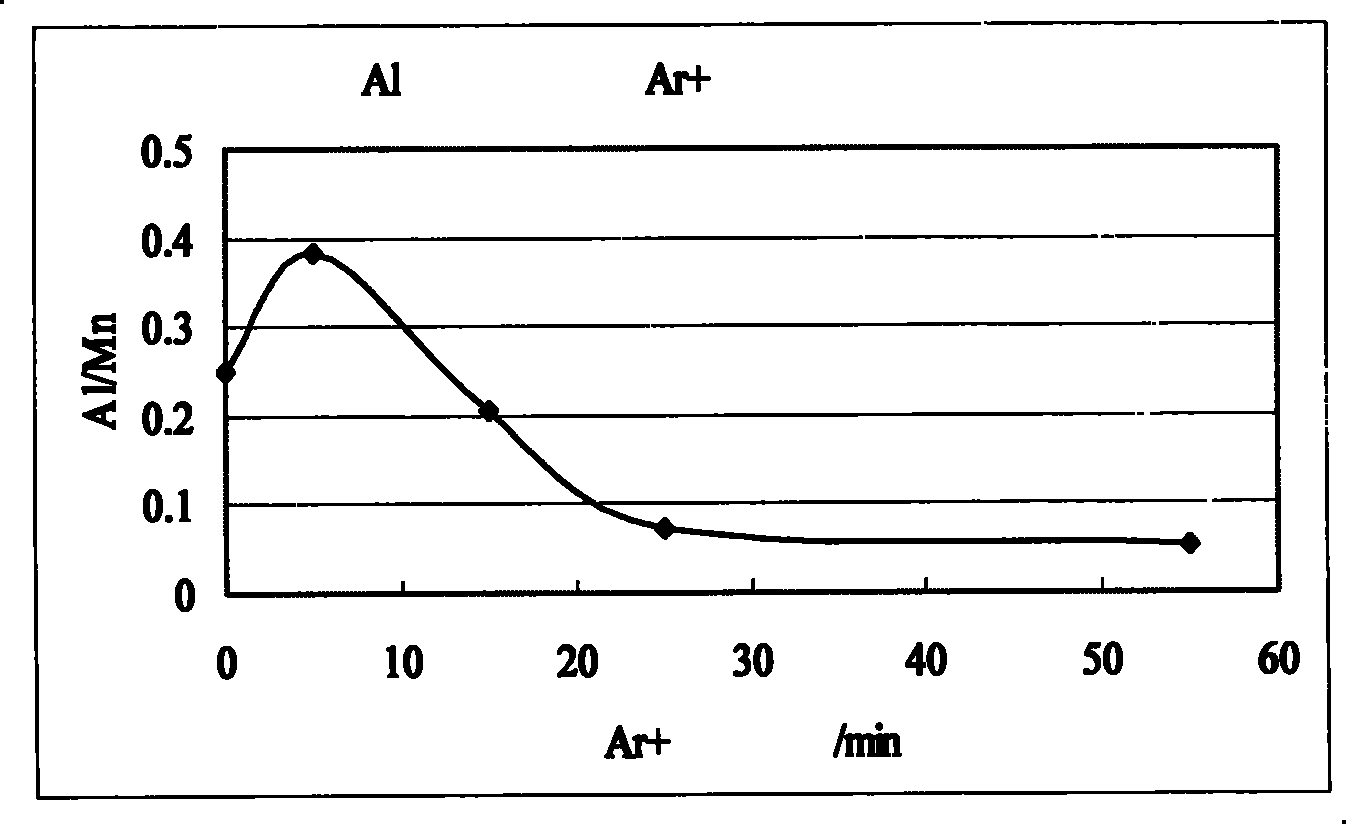

Oxide sintering body, its manufacturing method, transparent conductive film, and solar energy cell obtained by using the same

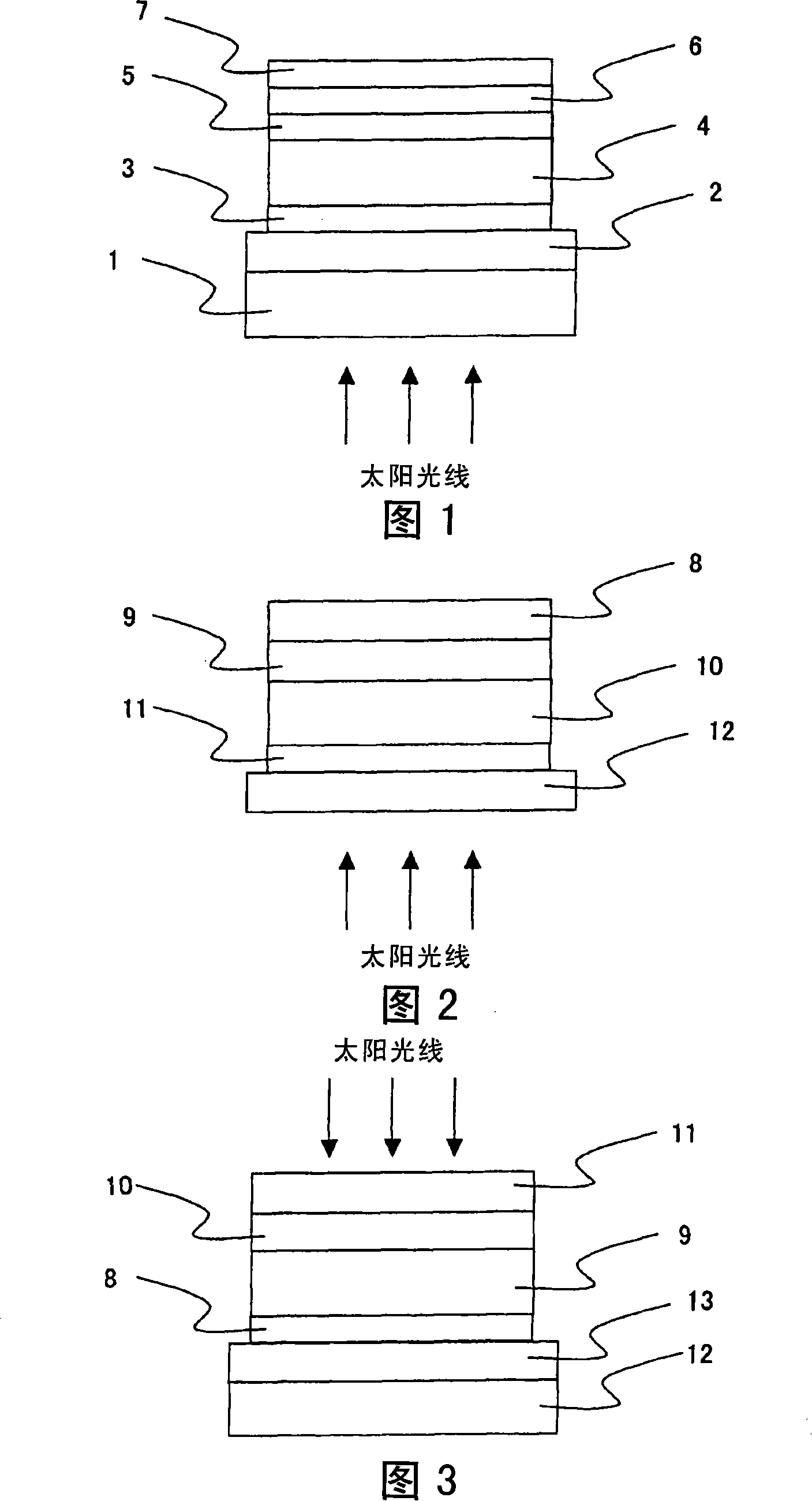

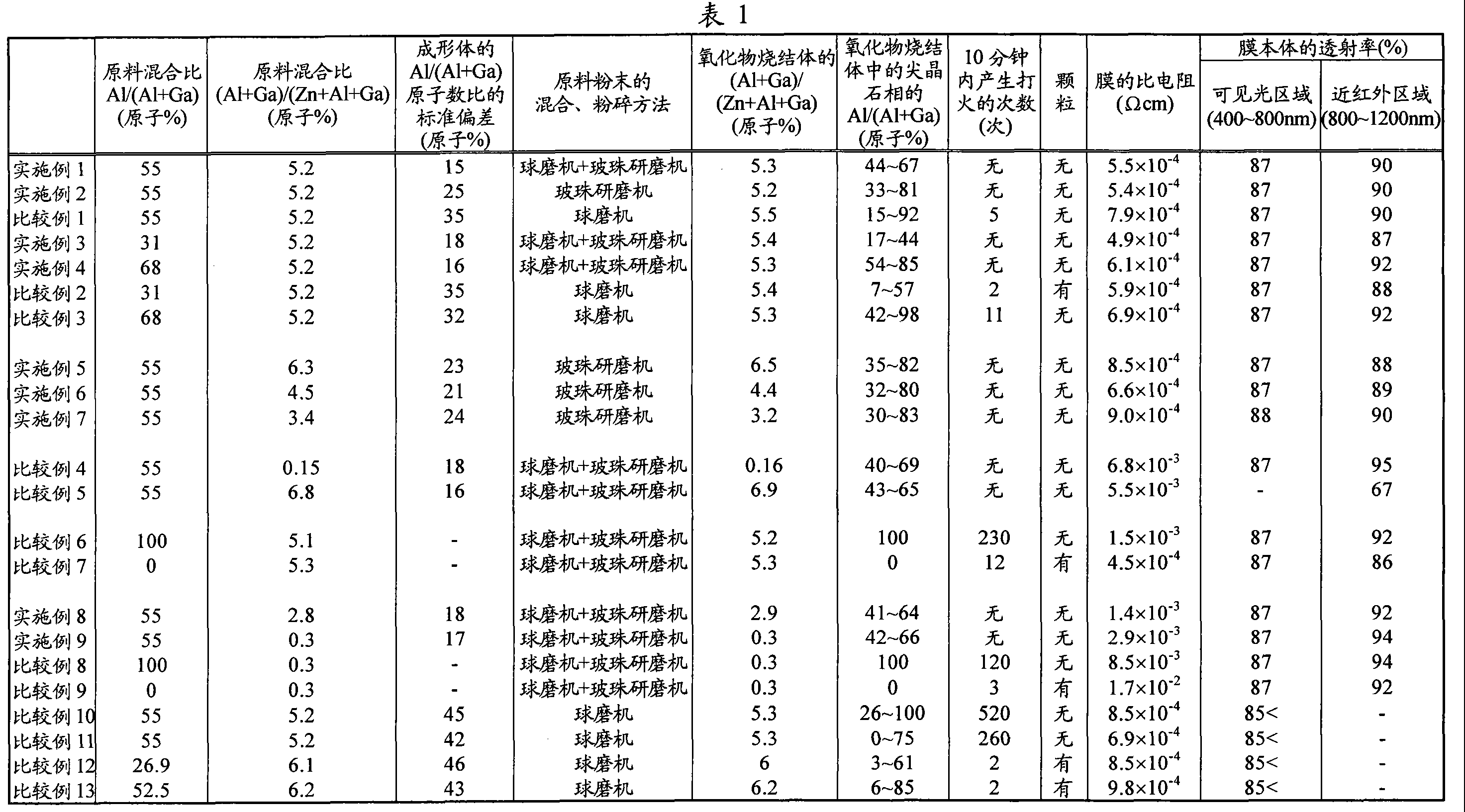

ActiveCN101164966AIncrease productivityIncrease production capacityConductive layers on insulating-supportsVacuum evaporation coatingAbnormal dischargeSolar battery

The invention provides an oxide sintered body which takes the zinc oxide as main components and further includes aluminum and gallium, as well as a production method thereof. The invention comprises targets which can produce no abnormal discharge and can form membranes continuously and long-time with spurting method, transparent electric membranes with the advantages of low resistance, high transmission performance and high quality; and solar batteries with a high conversion rate. The oxide sintered body includes zinc, aluminum and gallium, actually consisting of crystal phases of wurtzite zinc oxide phase and spinel lithium manganese oxide phase. The invention is characterized in that (1) the aluminum and the gallium contents (Al+Ga) / (Zn+Al+Ga) of the oxide sintered body are 0.3 to 6.5 atom percentages by atom quantity, and the aluminum and the gallium contents (Al+Ga) / (Zn+Al+Ga) of the oxide sintered body are 30 to 70 atom percentages by atom quantity; (2) the aluminum contents of the spinel lithium manganese oxide phase are 10 to 90 atom percentages by atom quantity.

Owner:SUMITOMO METAL MINING CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com