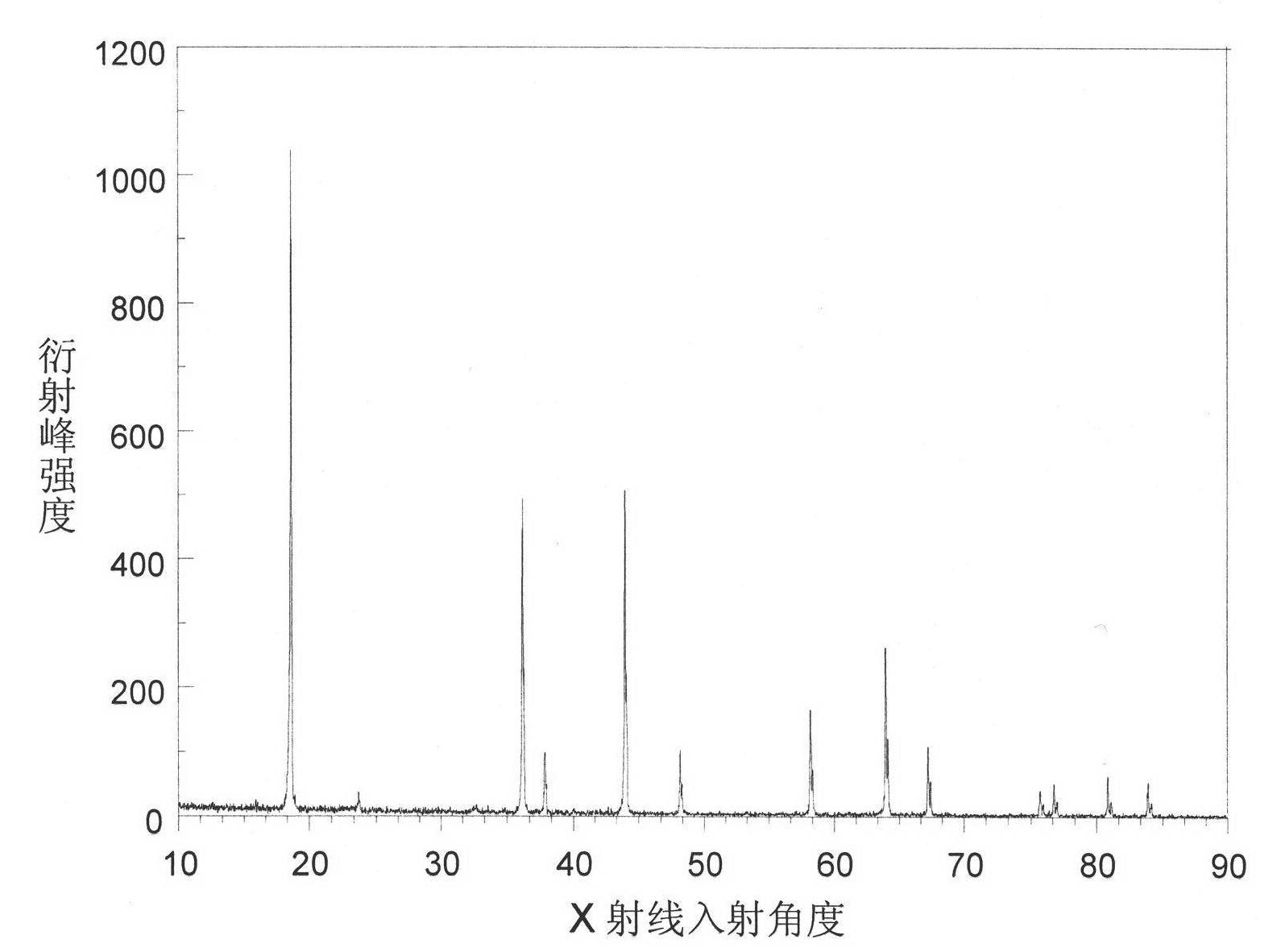

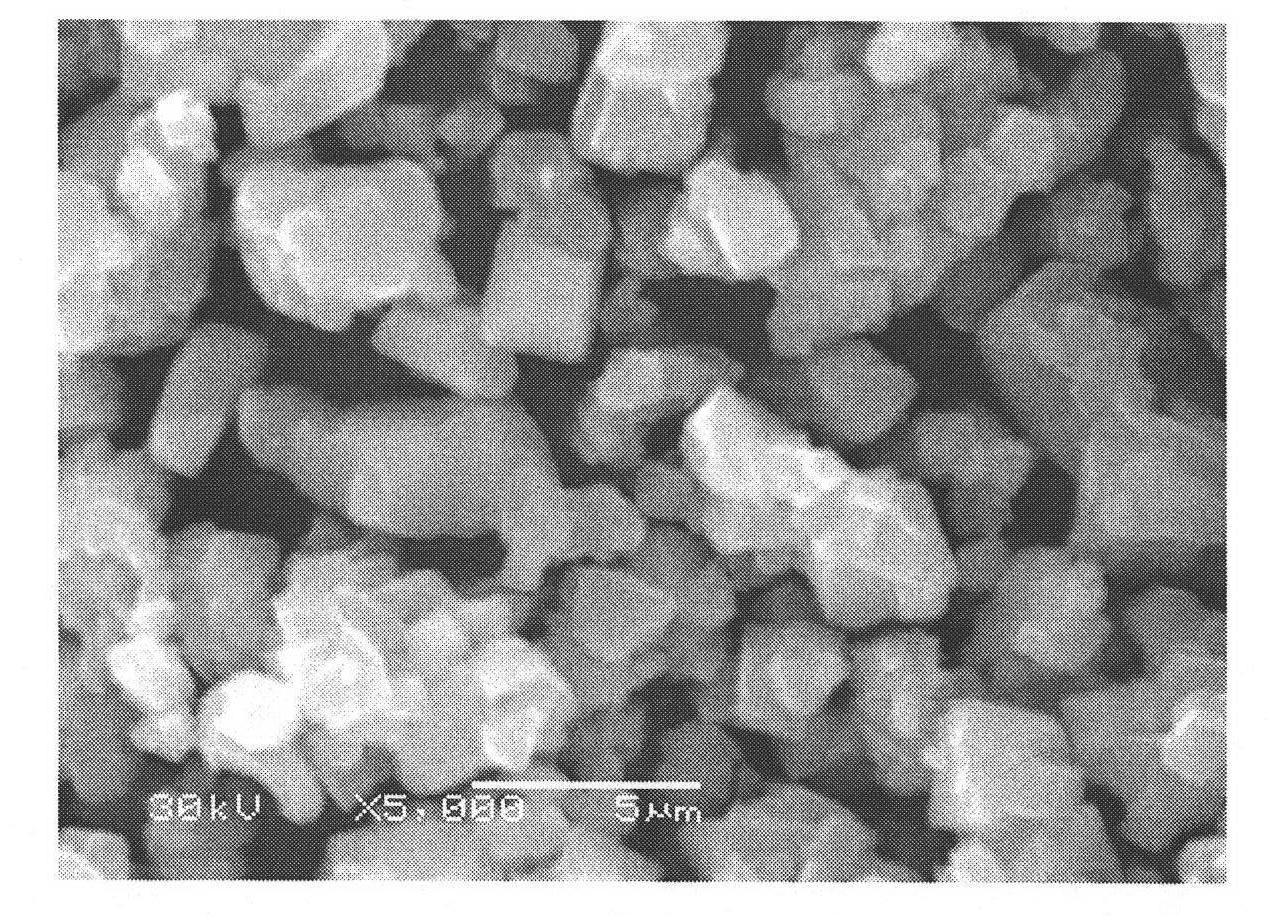

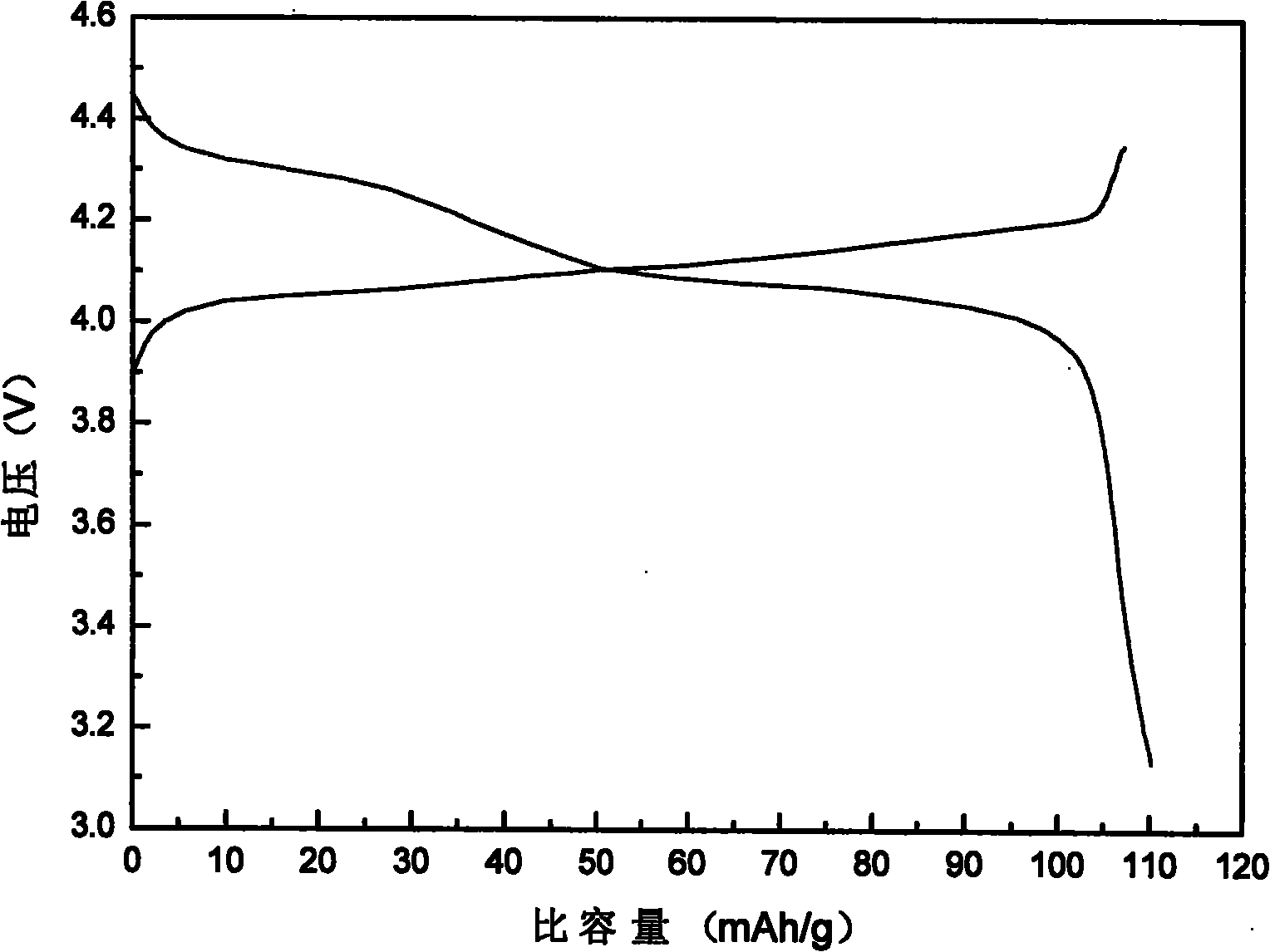

Power spinel lithium manganese oxide anode material and preparation method thereof

A technology of spinel lithium manganese oxide and positive electrode materials, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of poor cycle performance, low volume specific capacity, fast cycle decay at high temperature, etc., and achieve stable performance, high ratio The effect of low capacity and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 100Kg of lithium hydroxide, and take polyurethane balls according to the mass ratio of 1:1 (material weight / ball weight) and add them to the inclined mixer for ball milling for 3 hours for later use; weigh 400Kg of electrolytic manganese dioxide (EMD), and use a cyclone Jet mill pulverized for later use; LiOH H 2 O (ball-milled), electrolytic manganese dioxide (crushed), niobium pentoxide, nano-aluminum oxide and nano-titanium dioxide are put into an inclined mixer, and polyurethane ball milling of 1 times the weight is added to mix; The raw materials are calcined at 550°C for 6 hours in a pusher plate resistance furnace, according to 1~6m 3 The flow rate of / h is fed into air or oxygen during calcination; after natural cooling to room temperature, it is taken out and ground, sieved (250 mesh) to obtain the preliminary product Li 1.12 mn 1.99 Nb 0.004 Al 0.004 Ti 0.002 o 4 . Take by weighing the preliminary product 500Kg, by molar ratio of tricobalt tetroxi...

Embodiment 2

[0036] Weigh lithium carbonate 100Kg, and take polyurethane balls according to the mass ratio of 1:1 (material weight / ball weight) and add them to the inclined mixer for ball milling for 3 hours for later use; weigh 400Kg of chemical manganese dioxide, and use a cyclone jet mill to pulverize Standby; according to the elemental molar ratio Li:Mn:Nb:Al:Ce:Zr=1.10:1.954:0.02:0.02:0.001:0.005 respectively weigh Li 2 CO 3 (calculated according to Li content / ball milled), chemical manganese dioxide (crushed), niobium oxide, aluminum hydroxide, cerium oxide and zirconia are put into the inclined mixer, and polyurethane ball milling of 1 times the weight is added to mix; Calcinate the mixed raw materials at 600°C for 8 hours in a pusher-type resistance furnace, according to 1-6m 3 The flow rate of / h is fed into air or oxygen during calcination; after natural cooling to room temperature, it is taken out and ground, sieved (250 mesh) to obtain the preliminary product Li 1.10 mn 1.95...

Embodiment 3

[0040] Weigh 100Kg of lithium carbonate, and take zirconia balls according to the mass ratio of 1:1 (material weight / ball weight) and add them to an inclined mixer for ball milling for 3 hours for later use; weigh 400Kg of manganese carbonate, and use an airflow mill to pulverize it for later use ; According to the elemental molar ratio Li: Mn: Nb: Al: Cu=1.00: 1.957: 0.02: 0.02: 0.003 respectively weigh Li 2 CO 3 (calculated according to the Li content / ball milled), manganese oxalate (crushed), niobium pentoxide, aluminum hydroxide and copper oxide are put into the oblique mixer, and 1 times the weight of zirconia balls are added and mixed by ball milling; the mixed The raw materials are calcined at 650°C for 8 hours in a tunnel-type resistance furnace, according to 1-6m 3 The flow rate of / h is fed into air or oxygen during calcination; after natural cooling to room temperature, it is taken out and ground, sieved (250 mesh) to obtain the preliminary product Li 1.00 mn 1.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com