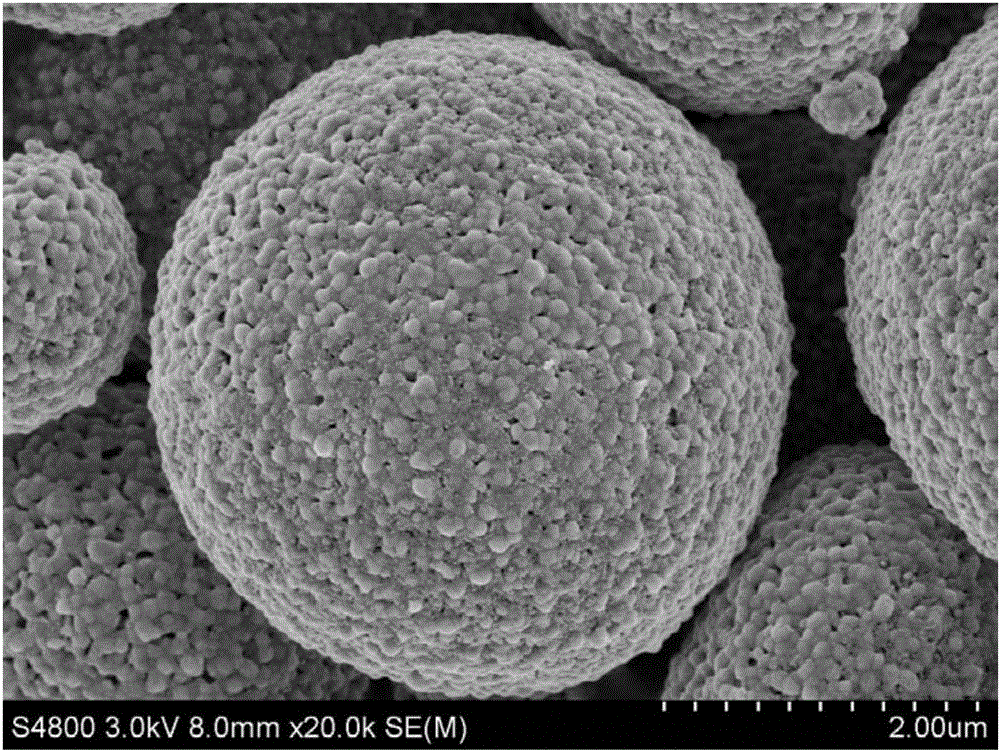

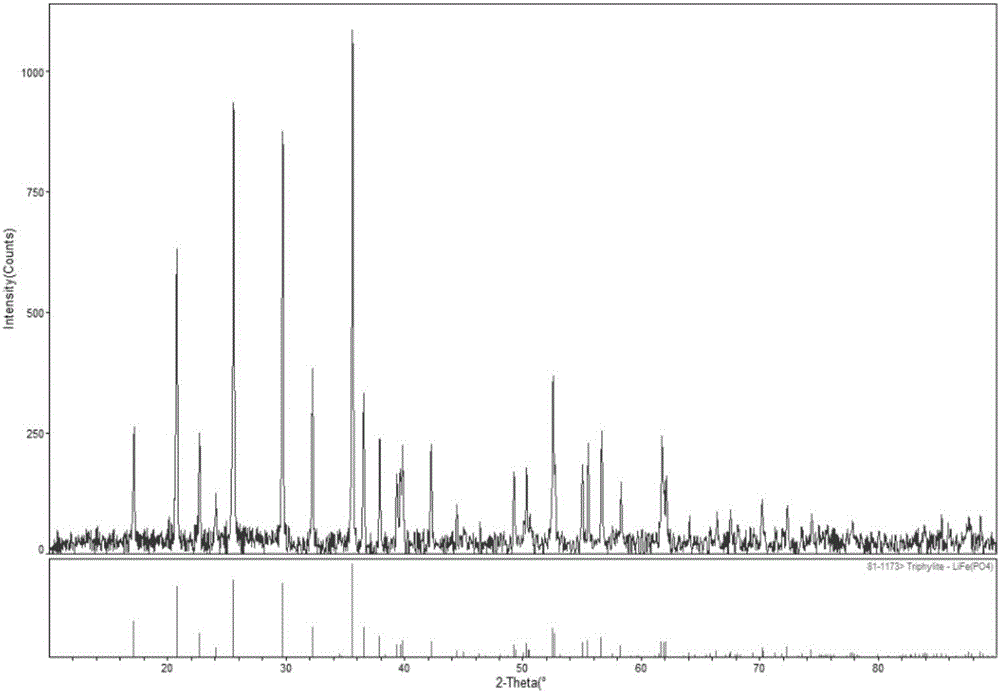

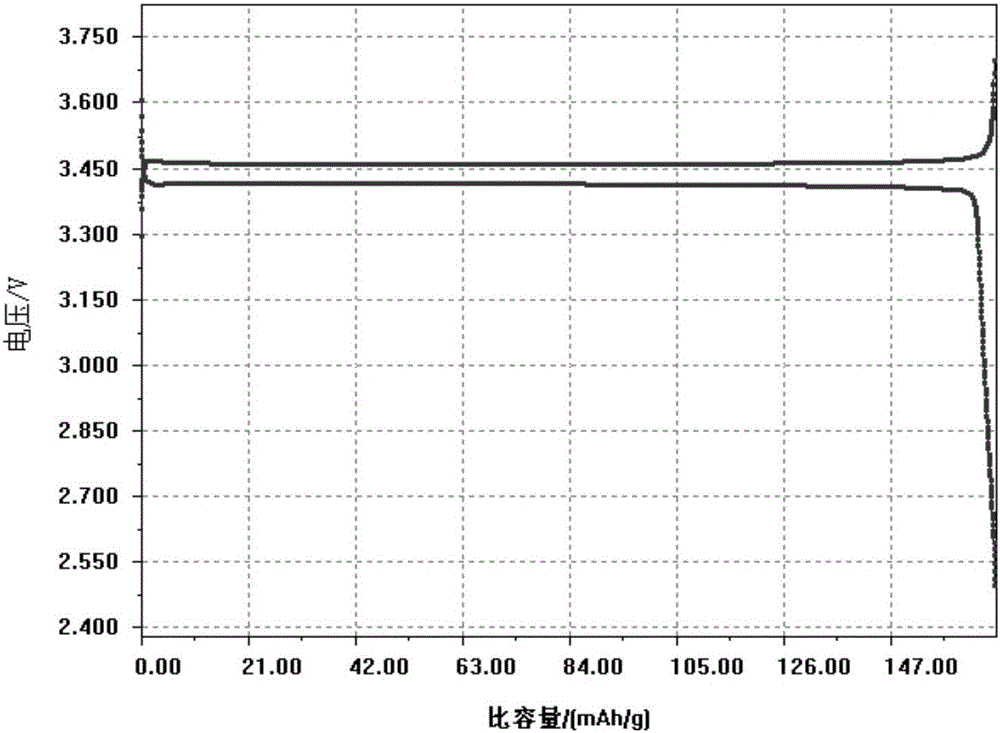

High density spherical nano lithium iron phosphate material, a preparation method thereof, and lithium ion battery containing same

A lithium iron phosphate, high-density technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of material capacity, low temperature, rate performance and processing, cycle performance can not be well balanced, etc., to achieve compaction density High, good slurry fluidity, taking into account the effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Lithium hydroxide monohydrate, ferric orthophosphate, magnesium oxide and sucrose, with a molar ratio of Li:Fe:P:M=1.02:1:1.02:0.02, and a carbon content of 1%, are added to the three-dimensional mixer , mixed for 6h;

[0057] (2) Put the mixed material in N 2 Pre-burn at 450°C for 10 hours in a protected box-type furnace;

[0058] (3) The calcined material is mixed with polyethylene glycol and deionized water, and ultrafinely ground for 6 hours to obtain a slurry with a suitable particle size, wherein the quality of polyethylene glycol is 0.2% of the calcined material, and 0.2% of the deionized water The quality is 4 times that of pre-fired material;

[0059] (4) The obtained slurry is subjected to two-fluid spray drying, the inlet temperature of the spray dryer is 260° C., and the outlet temperature is 80° C. to obtain a spherical nano-lithium iron phosphate precursor with a secondary particle size of 4 μm;

[0060] (5) Place the above-mentioned spherical nano-...

Embodiment 2

[0064] (1) Add lithium carbonate, ferric orthophosphate, manganese oxide and glucose, with a molar ratio of Li:Fe:P:M=1.05:1:1.02:0.005, and a carbon content of 1.5%, into a VC mixer and mix for 10 hours ;

[0065] (2) Put the mixed material in N 2 Pre-fired at 550°C for 4 hours in a protected roller kiln;

[0066] (3) Mix the calcined material with glucose and deionized water, and ultrafinely grind it for 10 hours to obtain a slurry with a suitable particle size, wherein the quality of glucose is 0.2% of the calcined material, and the quality of the deionized water is 0.2% of the calcined material. 4 times;

[0067] (4) The obtained slurry is subjected to four-fluid spray drying, the inlet temperature of the spray dryer is 200° C., and the outlet temperature is 60° C. to obtain a spherical nano-lithium iron phosphate precursor with a secondary particle size of 8 μm;

[0068] (5) Place the above-mentioned spherical nano-lithium iron phosphate precursor in a rotary furnace, ...

Embodiment 3

[0071] (1) Lithium hydroxide monohydrate, ferric phosphate dihydrate, niobium oxalate and citric acid are added to the dry method with a molar ratio of Li:Fe:P:M=1:1:1.05:0.02 and a carbon content of 0.5%. In a ball mill, mix for 6 hours;

[0072] (2) Put the mixed material in N 2 Pre-fired at 350°C for 8 hours in a protected roller kiln;

[0073] (3) Mix the calcined material with sucrose and deionized water, and ultrafinely grind it for 2 hours to obtain a slurry with a suitable particle size, wherein the quality of glucose is 2% of the calcined material, and the quality of deionized water is 2% of the calcined material. 1 times;

[0074] (4) The obtained slurry is subjected to four-fluid spray drying, the inlet temperature of the spray dryer is 350° C., and the outlet temperature is 120° C. to obtain a spherical nano-lithium iron phosphate precursor with a secondary particle size of 10 μm;

[0075] (5) Place the above-mentioned spherical nano-lithium iron phosphate precu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com