Positive pole material of lithium ion battery and preparation method of positive pole material

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of lithium-ion battery positive electrode materials and its preparation, and can solve the problems of not being able to well suppress the pulverization of secondary particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

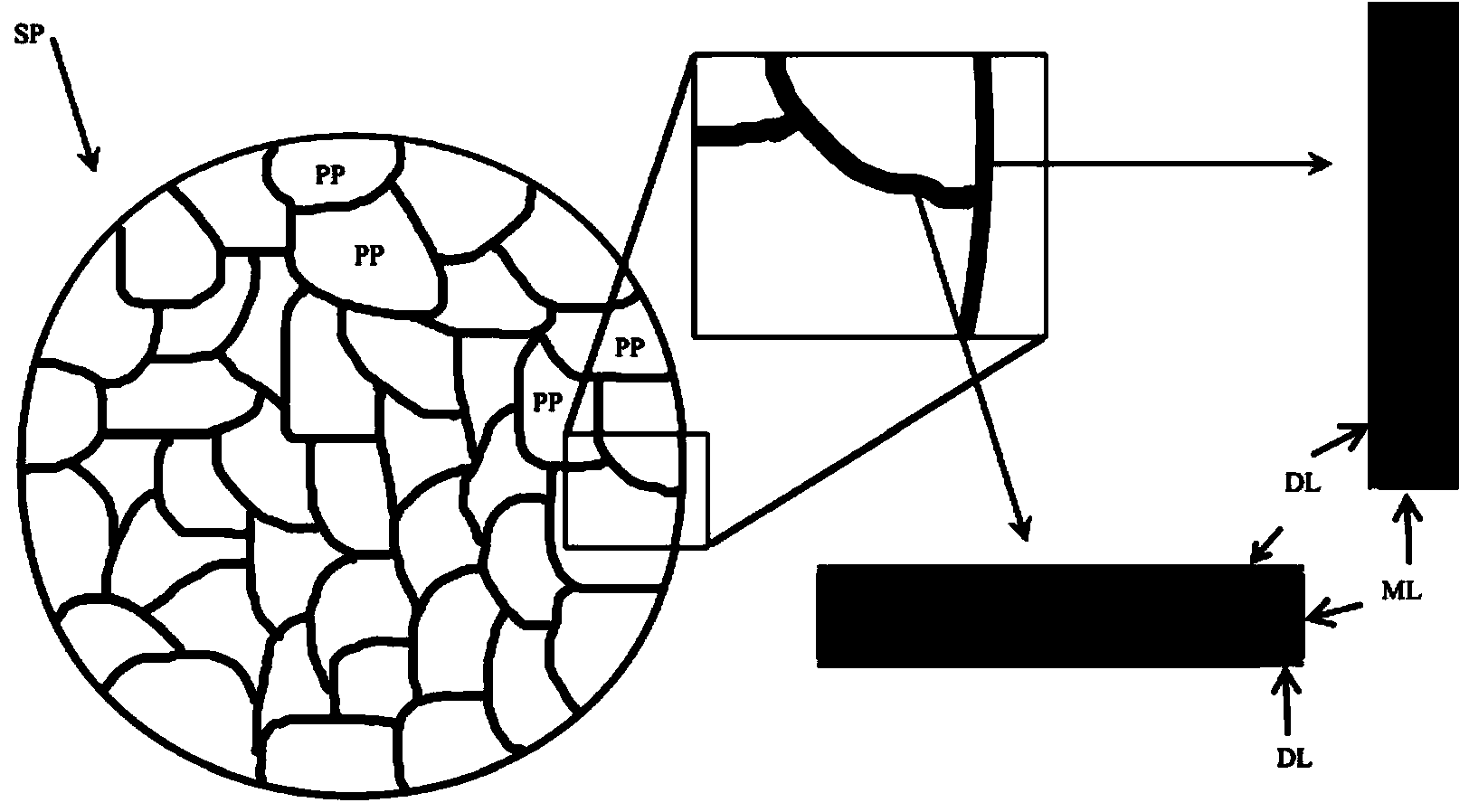

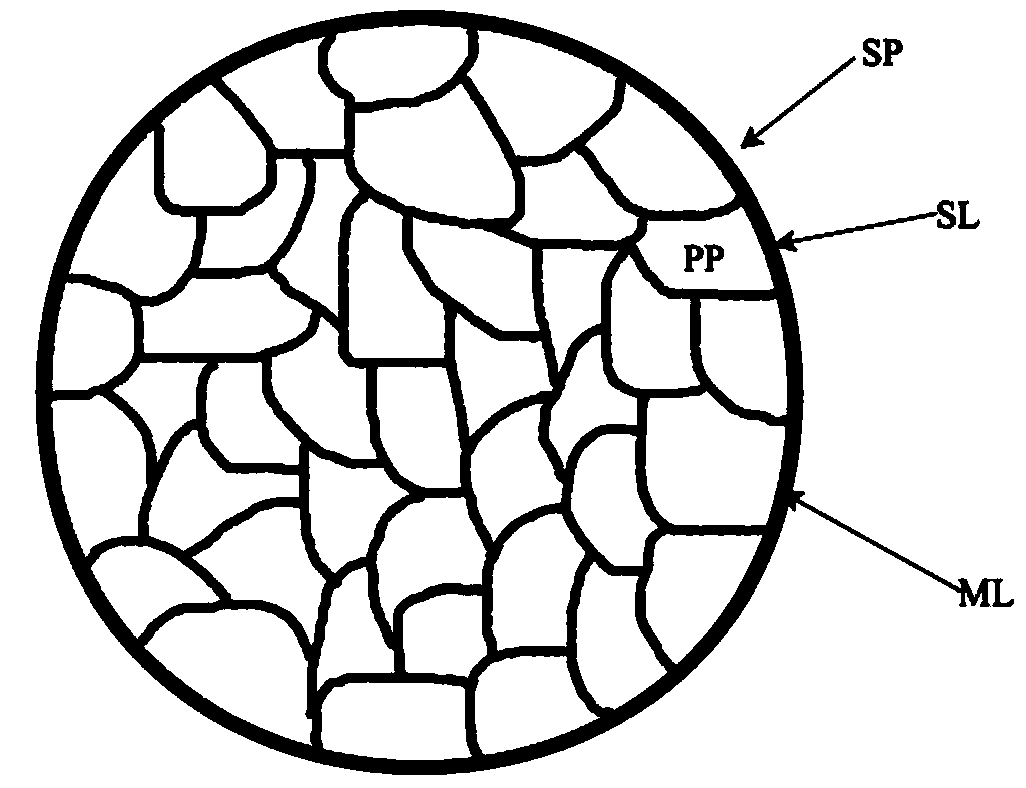

[0043] refer to figure 1 , in the first mode, the preparation method of the positive electrode material of lithium ion battery according to the second aspect of the present invention is used to prepare the positive electrode material of lithium ion battery according to the first aspect of the present invention, which includes the steps of: providing lithium-containing multiple transition Group metal oxide primary particle PP; the primary particle PP is dispersed in the dispersion liquid, and then the second phase material or the precursor of the second phase material is added in the dispersion liquid, so that the second phase material or the second The phase substance precursor is distributed on the surface of the primary particle PP, and then the precursor of the secondary particle is synthesized by granulation; the precursor of the secondary particle is sintered, and the secondary particle SP of the positive electrode material of the lithium ion battery is obtained after sint...

Embodiment 1

[0058] Example 1 The prepared lithium-containing multi-element transition metal oxide is Li 0.98 Ni 1 / 3 co 1 / 3 mn 1 / 3 o 2 , the second phase substance is TiO 2 .

[0059] Step a: first synthesize Li by gel-sol method 0.98 Ni 1 / 3 co 1 / 3 mn 1 / 3 o 2 Primary particles: Lithium acetate, nickel acetate, cobalt acetate, and manganese acetate are dissolved in deionized water according to the atomic ratio Li:Ni:Co:Mn=1.03:0.33:0.33:0.33, and the total concentration is 1mol / L. solution, then add citric acid, the concentration of citric acid in the mixed solution is 1mol / L, put the above solution in a water bath at 85°C, evaporate the water, and form a gel-like substance, and then transfer it to an oven at 160°C for 5 Hours, a brownish-black substance is formed, ground into powder, and sintered at 650°C for 2 hours in an air atmosphere to form particles with an average particle size of 300nm.

[0060] Step b: Disperse the primary particles obtained after the above-mentioned si...

Embodiment 2

[0063] Example 2 The prepared lithium-containing multi-element transition metal oxide is Li 0.98 Ni 1 / 3 co 1 / 3 mn 1 / 3 o 2 , the second phase material is MgO.

[0064] Step a: first synthesize evacuated secondary particles by co-precipitation method: NiSO 4 、CoSO 4 , MnSO 4 Dissolve in deionized water according to the atomic ratio Ni:Co:Mn=0.33:0.33:0.33, configure a mixed solution with a total concentration of 1mol / L, and then add the prepared 1mol / L NaOH solution to the above solution, While adding and stirring, the temperature is controlled at 75°C. After sufficient reaction, disperse secondary particles with a dispersive structure are formed, that is, the disperse secondary particles are composed of Li particles with an average particle size of 600nm. 0.98 Ni 1 / 3 co 1 / 3 mn 1 / 3 o 2 The formation of irregular primary particle aggregation of hydroxide precursors, Li 0.98 Ni 1 / 3 co 1 / 3 mn 1 / 3 o 2 There are large gaps between the primary particles of the hydroxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com