Patents

Literature

130results about How to "Diffusion distance is short" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

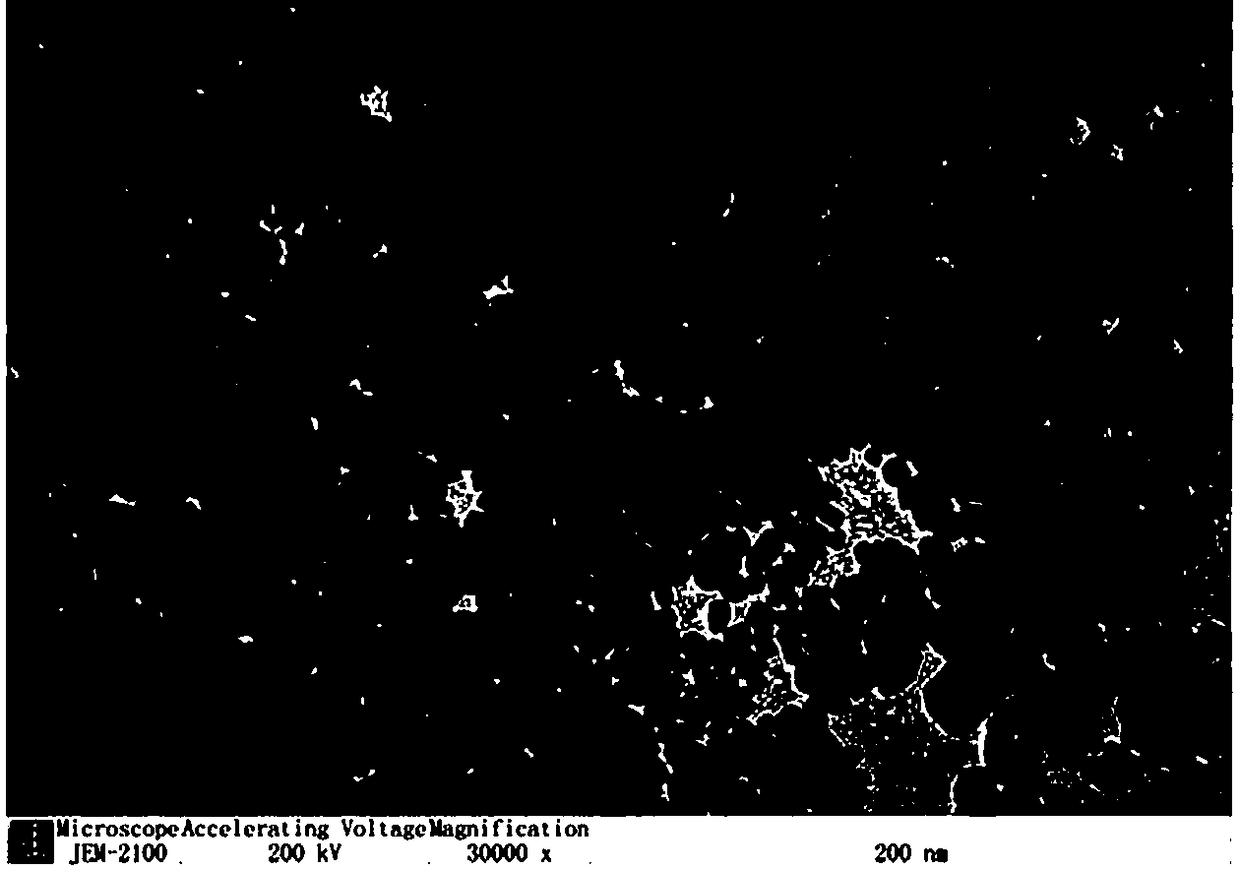

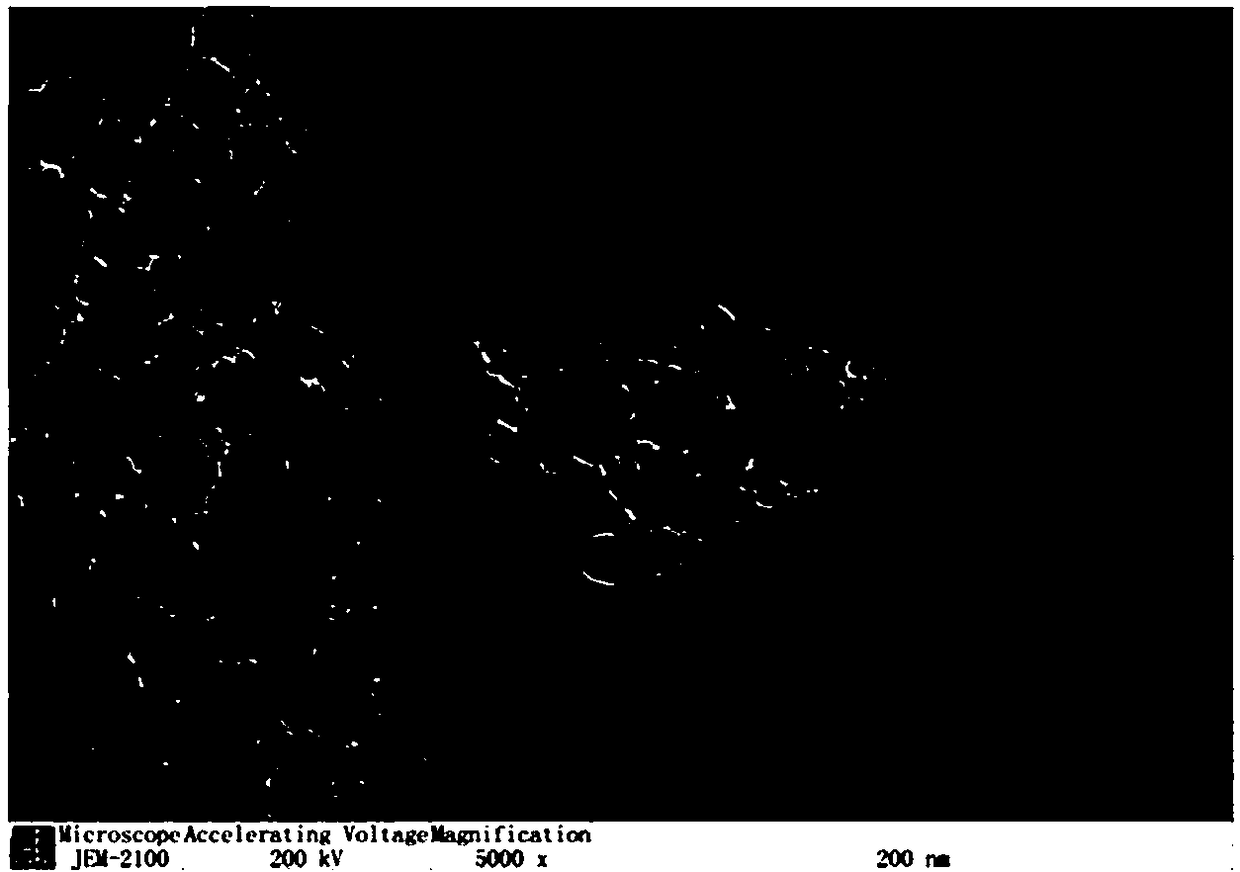

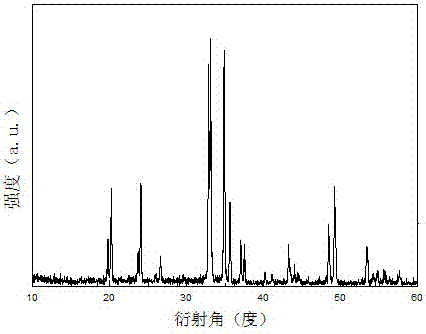

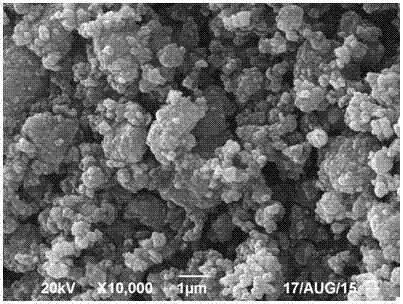

Preparation method of carbon coated vanadium sodium phosphate positive electrode material

InactiveCN105336924AEasy diffusion distanceImprove electrochemical performanceNon-aqueous electrolyte accumulatorsCell electrodesSodium phosphatesElectrical battery

A preparation method of a carbon coated vanadium sodium phosphate positive electrode material comprises the steps: with glucose as a reducing agent and a carbon source and water as a dispersant, carrying out ball milling of NH4VO3, NaH2PO4.2H2O and glucose in water, carrying out spray drying, calcining, and thus obtaining the carbon coated vanadium sodium phosphate positive electrode material. The method has the advantages of low synthesis temperature, simple steps, easily obtained raw materials, and advantageous industrialization; the obtained carbon coated vanadium sodium phosphate positive electrode material has a structure with uniform primary particles, has the particle size of 100-200 nm, and has the characteristics of short sodium ion diffusion distance, fast transmission speed, high specific surface area, high electrical conductivity and fast ion transmission and the like. The obtained carbon coated vanadium sodium phosphate positive electrode material is assembled into a battery; in a voltage scope of 2.0-3.75 V and under 1 C multiplying power, the highest first charge and discharge capacity per gram can reach 93.5 mAh*g<-1>, the capacity retention rate can be up to 97.7% after cycling for 50 circles with the 1C multiplying power, and excellent electrochemical performance is showed.

Owner:CENT SOUTH UNIV

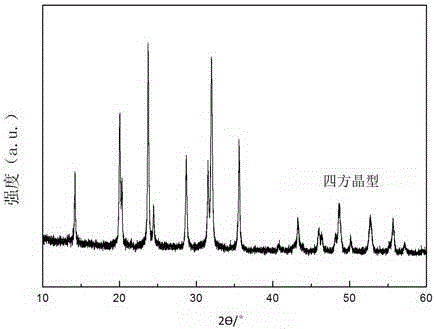

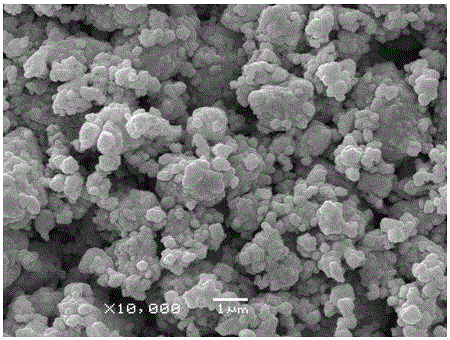

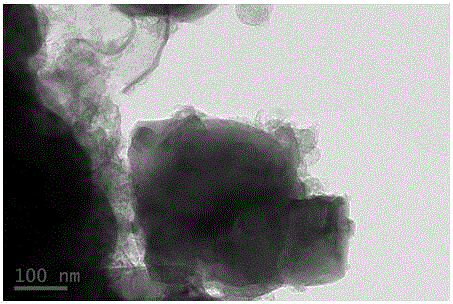

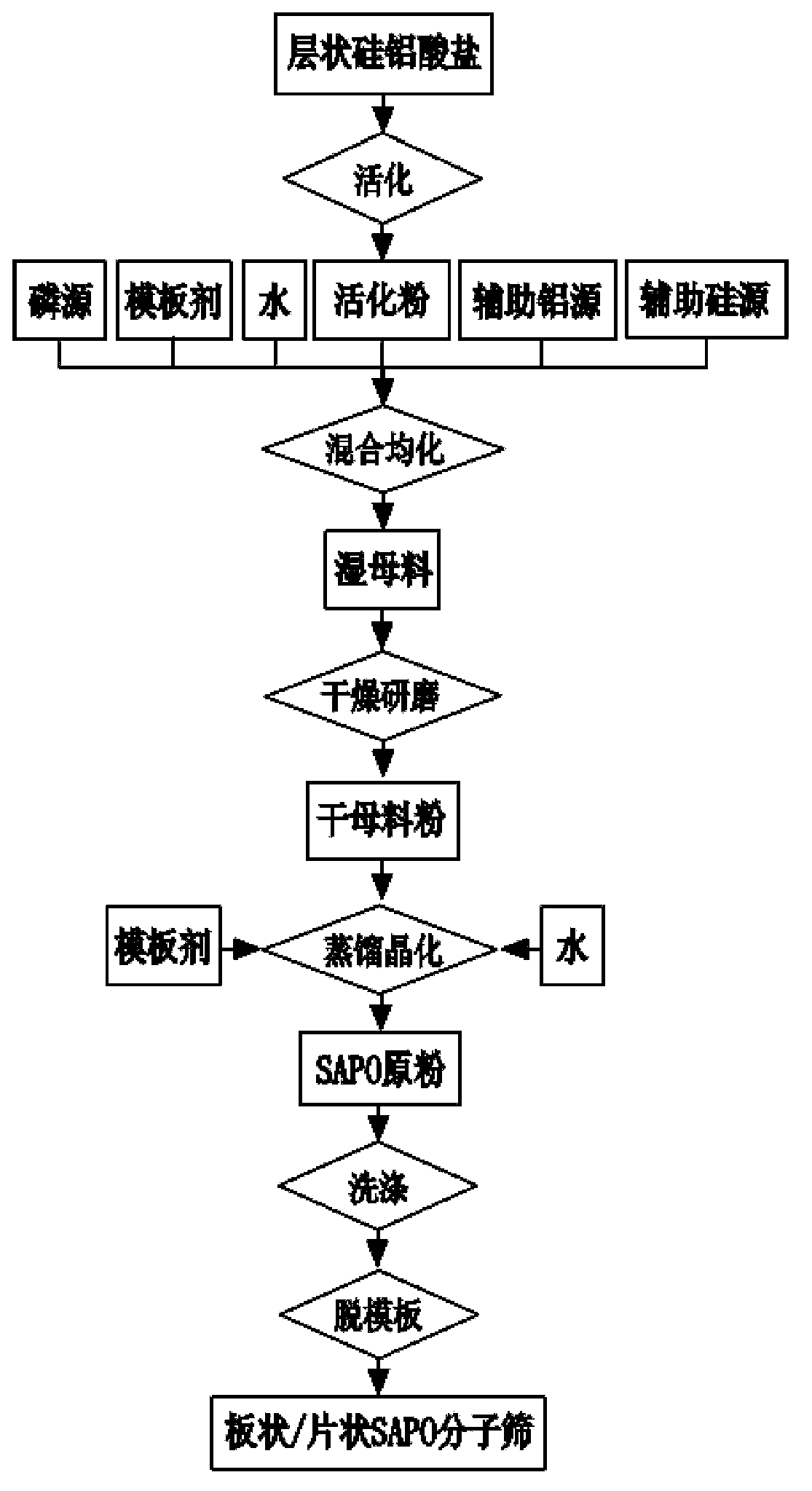

SAPO molecular sieve, and preparation method and purpose thereof

ActiveCN103964457AShorten the diffusion distanceImprove diffusion efficiencyMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMolecular sieveChemistry

The invention discloses an SAPO molecular sieve, which has single crystals in sheet structure. The SAPO molecular sieve has moderate pore size, and can be used as a catalyst with long service life for olefin preparation from methanol. The invention also discloses a preparation method of the SAPO molecular sieve. The method us as below: activating a raw material of layered aluminosilicate, mixing the raw material with an phosphorus source and water, and homogenizing to obtain a wet masterbatch; drying and grinding the wet masterbatch to obtain a dry powder; and finally distilling the dry powder for crystallization, so as to obtain a raw powder for sheet SAPO molecular sieve. The method requires addition of a template agent, realizes low cost synthesis of SAPO molecular sieve and high additional value utilization of natural layered aluminosilicate, accelerates the rate of diffusion of various substances in the channels of the molecular sieve, increases the diffusion efficiency, and the advanategs of low equipment investment, simple operation and environment-friendliness.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

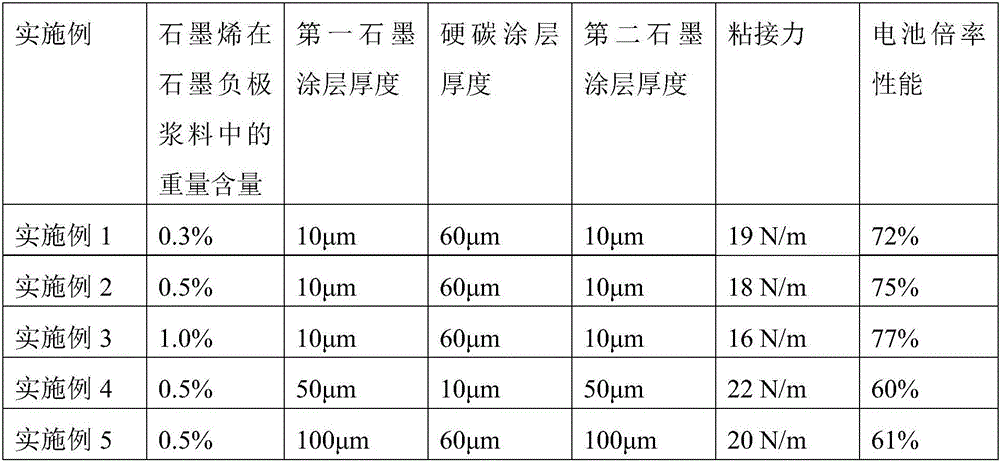

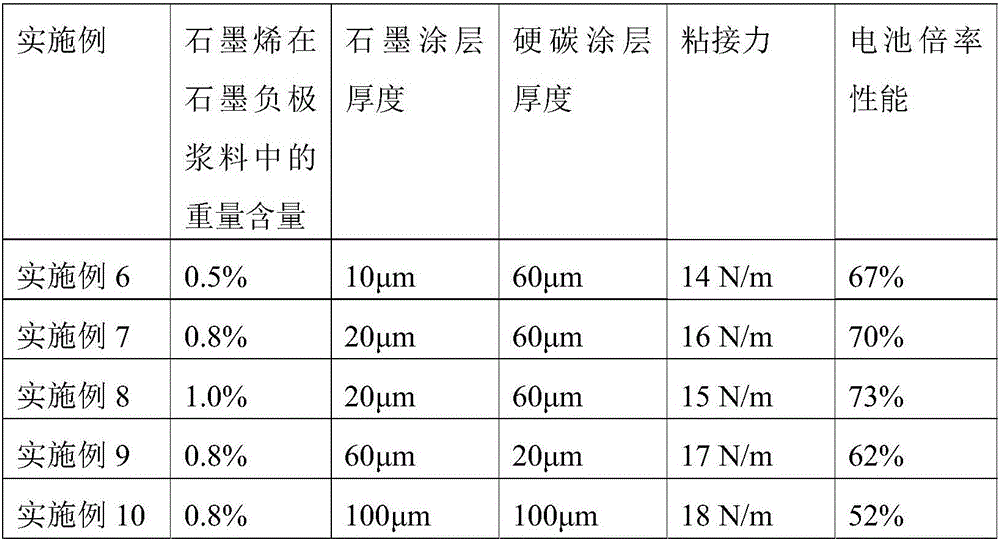

Pole piece of negative electrode and preparation method of pole piece as well as lithium-ion battery using negative electrode

InactiveCN106058154AIncrease compaction densityImprove dynamic performanceCell electrodesSecondary cellsCarbon coatingPole piece

The invention relates to the field of lithium-ion battery materials and in particular relates to a pole piece of a negative electrode and a lithium-ion battery using the negative electrode. The pole piece of the negative electrode, provided by the invention, comprises a negative electrode current collector, a graphite coating and a hard carbon coating; graphene is used as a conductive agent and is added into the graphite coating, so that on one hand, dynamics properties of the graphite coating can be improved; on the other hand, the lubrication effect of the graphene conductive agent is utilized, so that damage to materials by residual stress caused by cold pressing can be reduced, and the compaction density of the negative electrode is improved. A corresponding negative electrode preparation method is simple and feasible, and the materials do not need to be modified, so that the manufacturing cost of battery cells is reduced.

Owner:DONGGUAN AMPEREX TECH

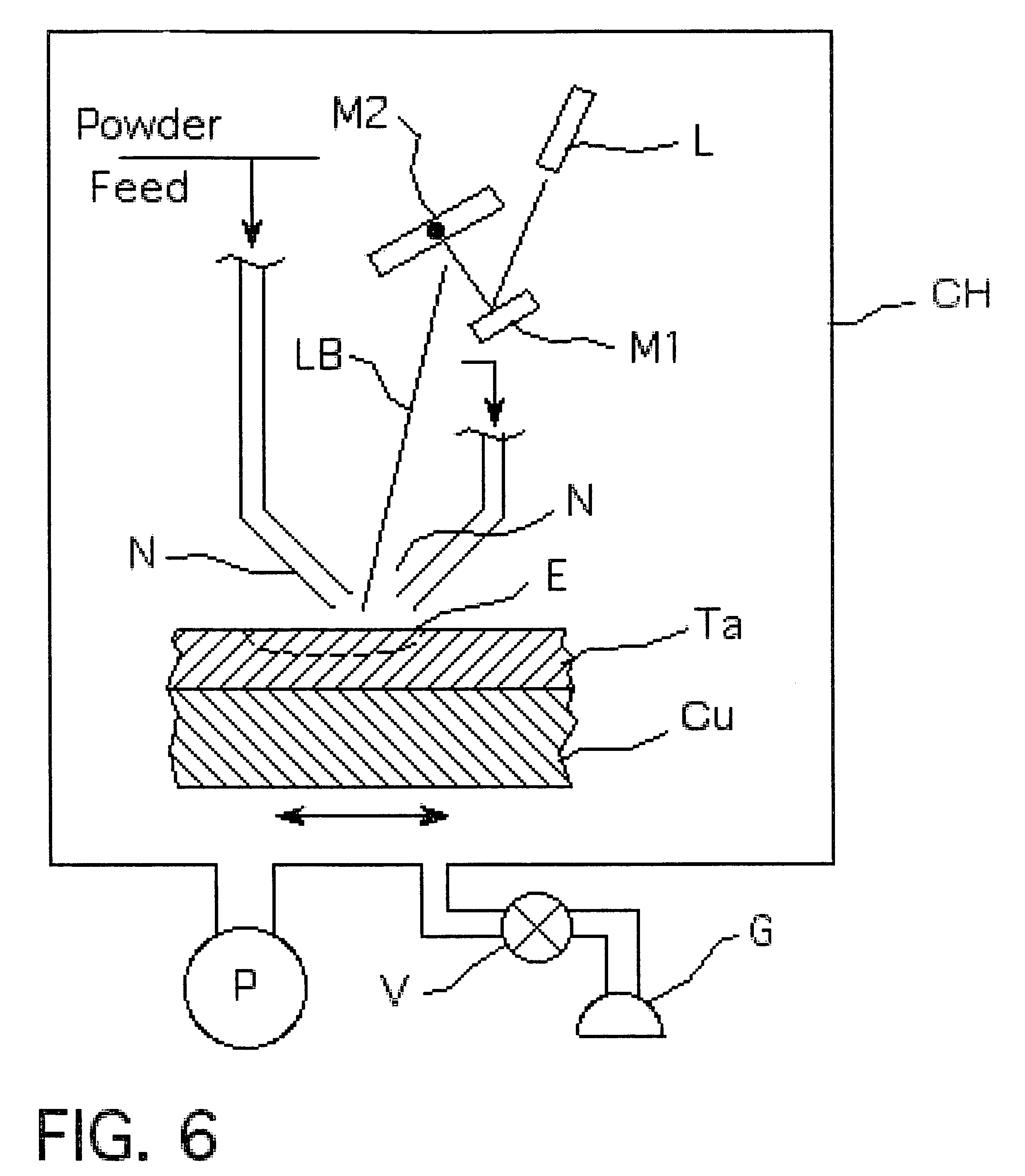

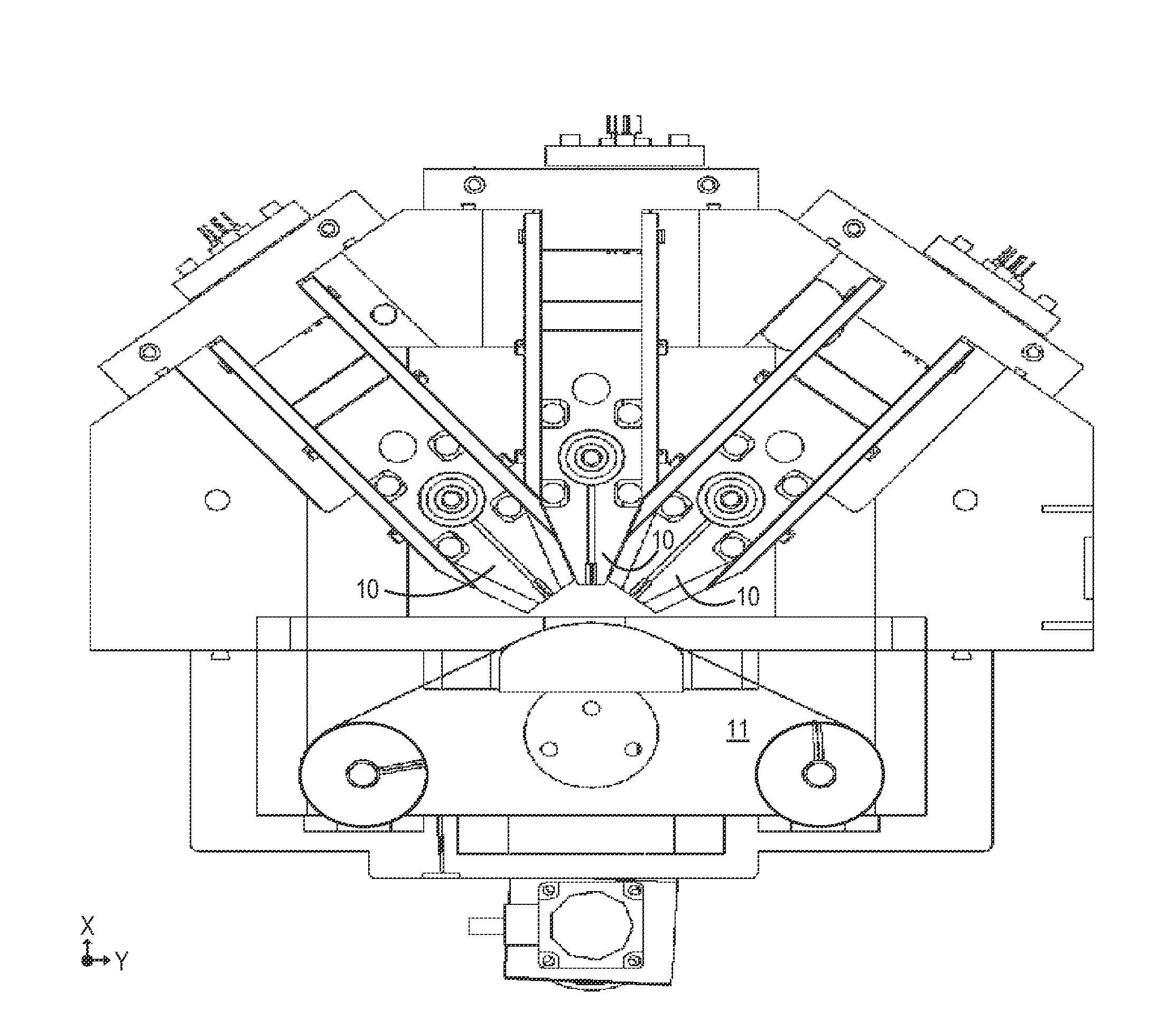

Refractory metal and alloy refining by laser forming and melting

ActiveUS7651658B2Improve throughputMore consistencyRadiation applicationsVacuum evaporation coatingNiobiumNear net shape

A process to chemically refine and consolidate tantalum, niobium and their alloys to a fabricated product of net shape or near-net shape with higher throughput, more consistency, and lower manufacturing costs compared to prior art routes or rejuvenate damaged and deteriorated refractory metal parts. Powder metal is loaded into hoppers to be fed into laser forming / melting equipment. A suitable substrate is loaded into a laser forming / melting chamber onto which the powder will be deposited and consolidated in a point-scan process. As the powder is fed onto successive points of the surface of the substrate in linear traces, the laser is used to heat and partially melt the substrate and completely melt the powder. A combined deposition and melt beam traces the substrate surface repeatedly over a selected area to build up a dense coating of controlled microstructure in multiple layers. A fully dense deposit is built up that becomes the desired shape.

Owner:MATERION NEWTON INC

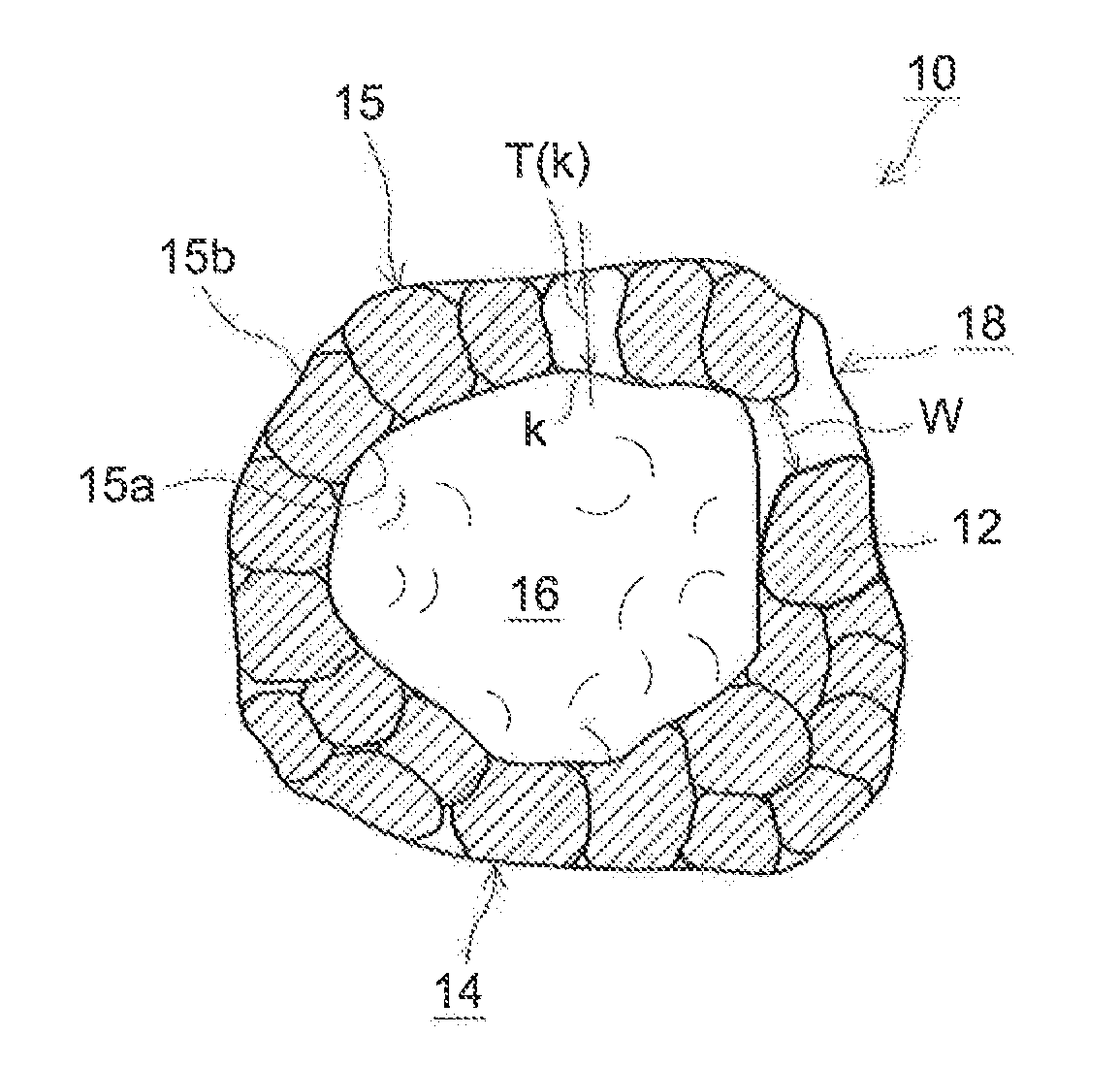

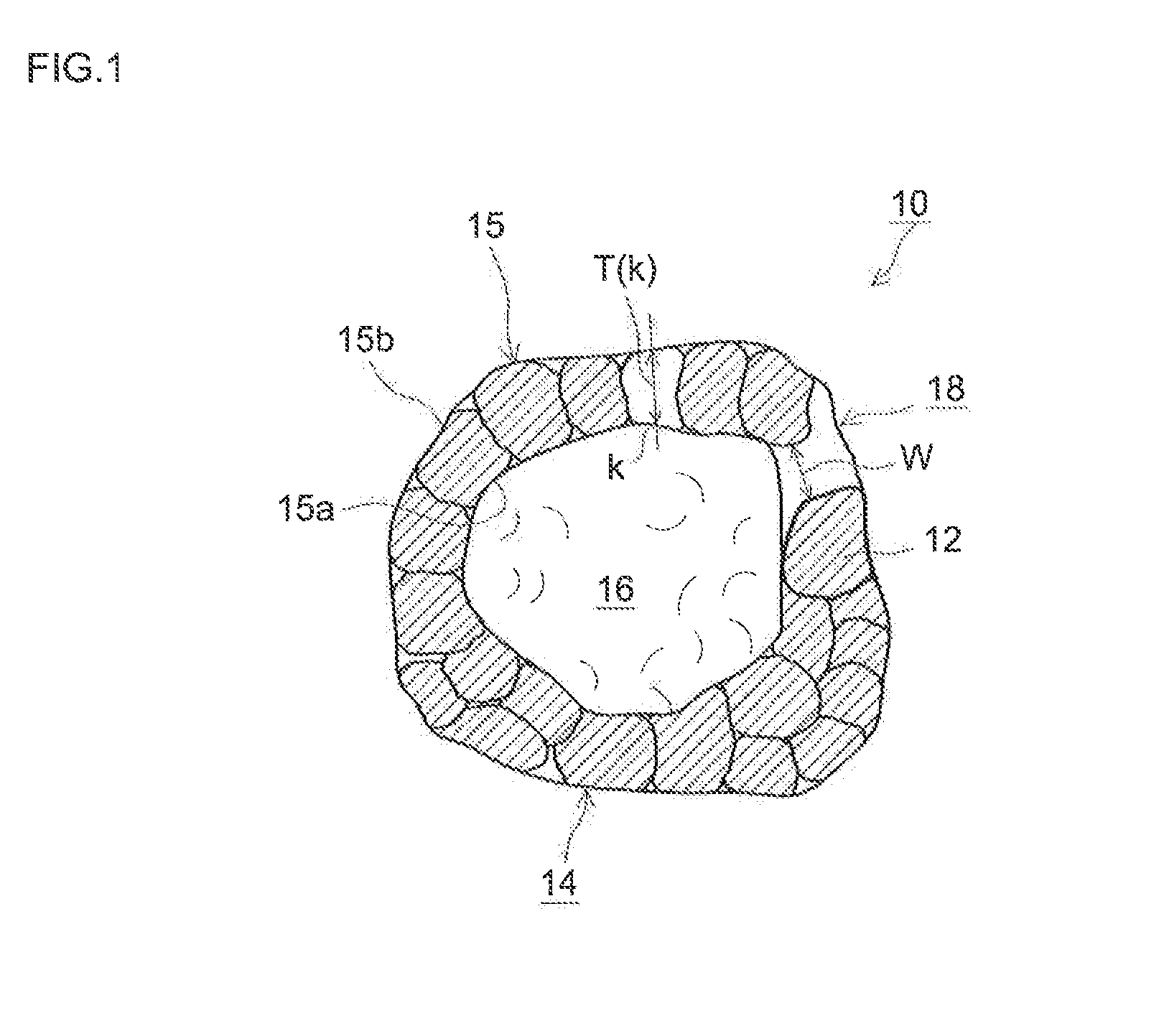

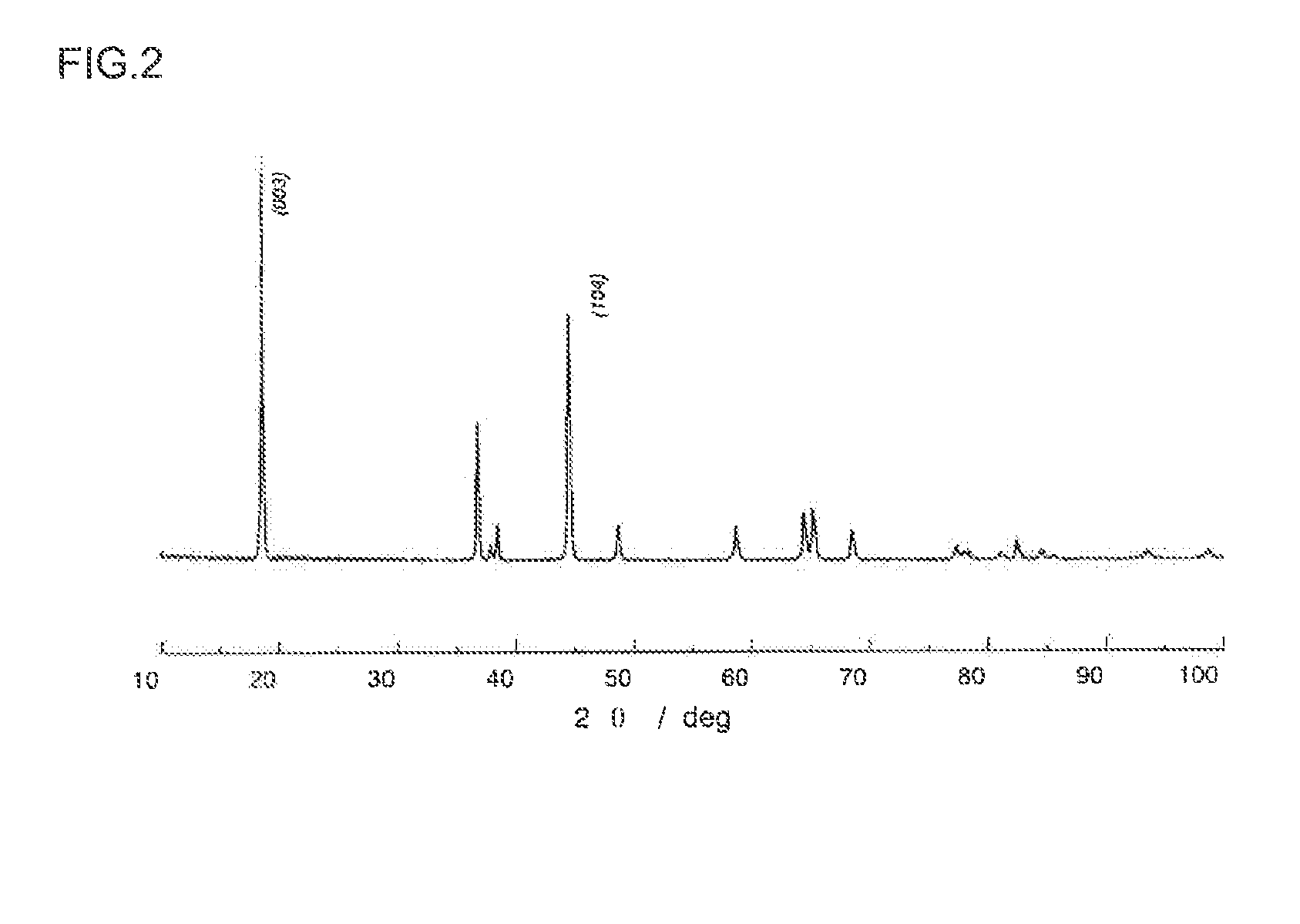

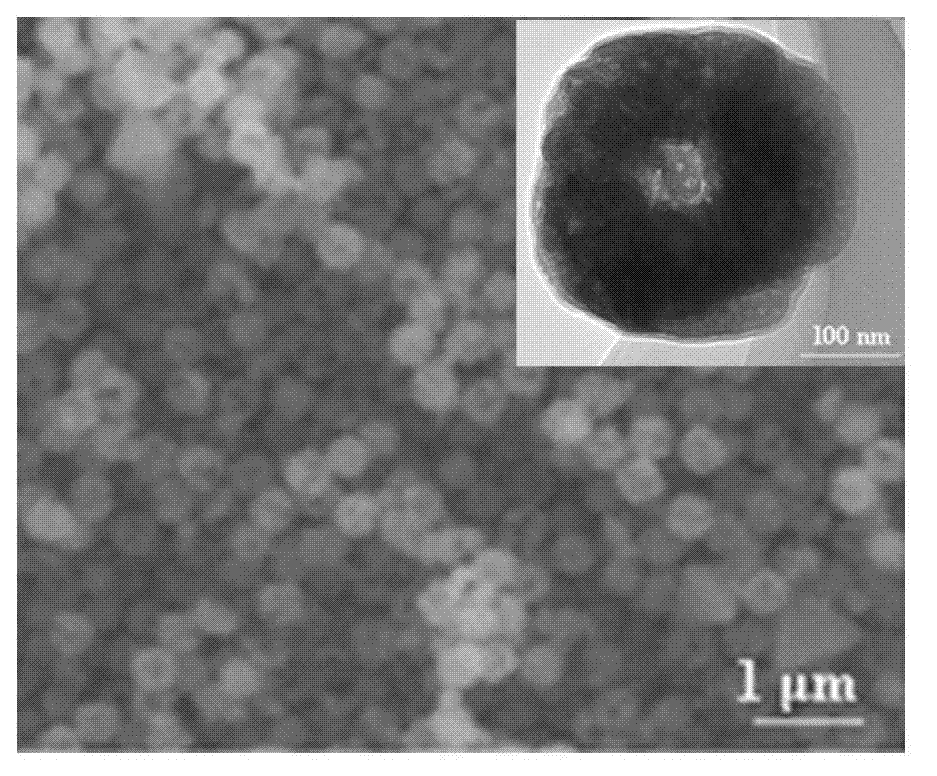

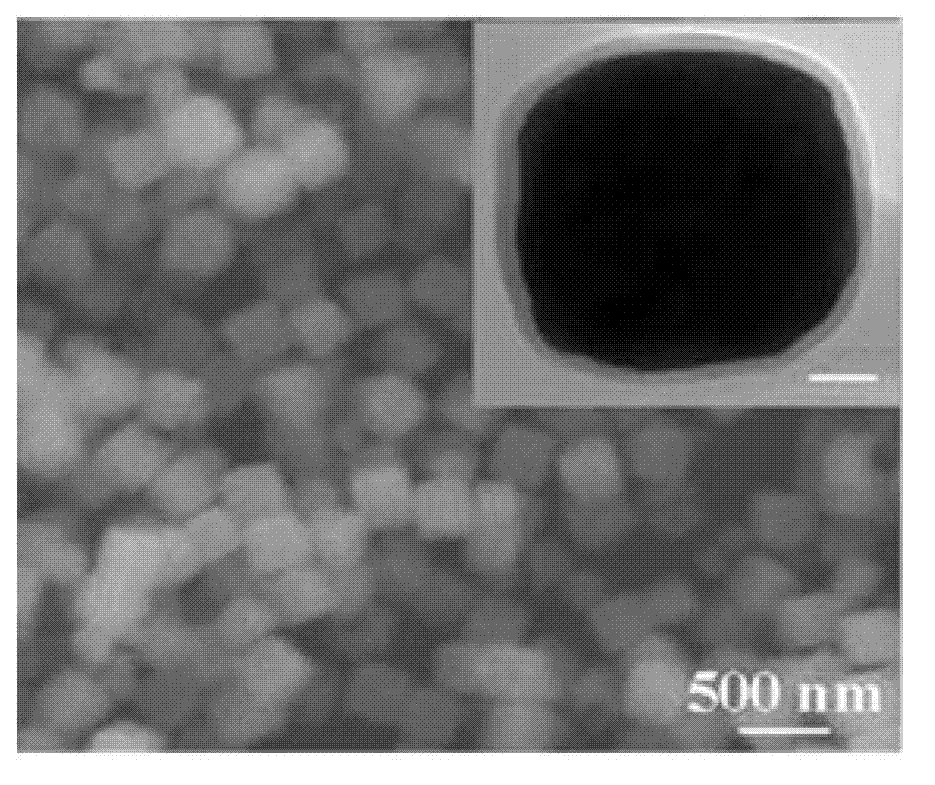

Lithium rechargeable battery

ActiveUS20140205901A1Guaranteed uptimeOperation can be performedFinal product manufactureActive material electrodesLithiumX-ray

Owner:TOYOTA JIDOSHA KK

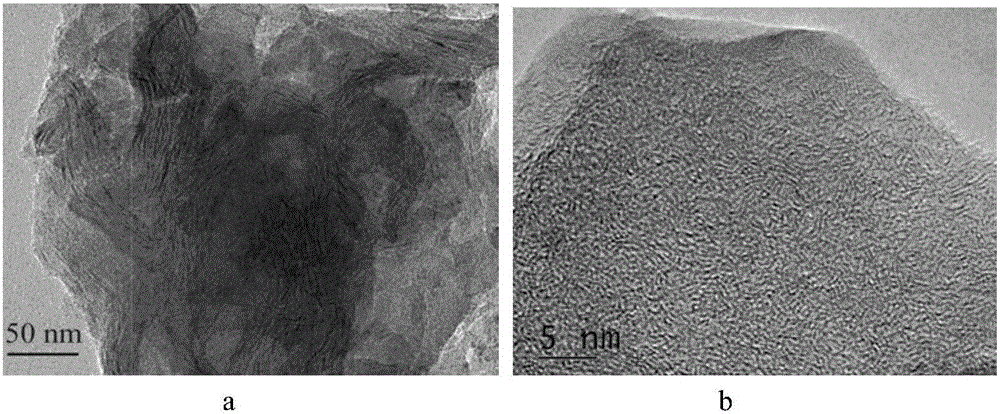

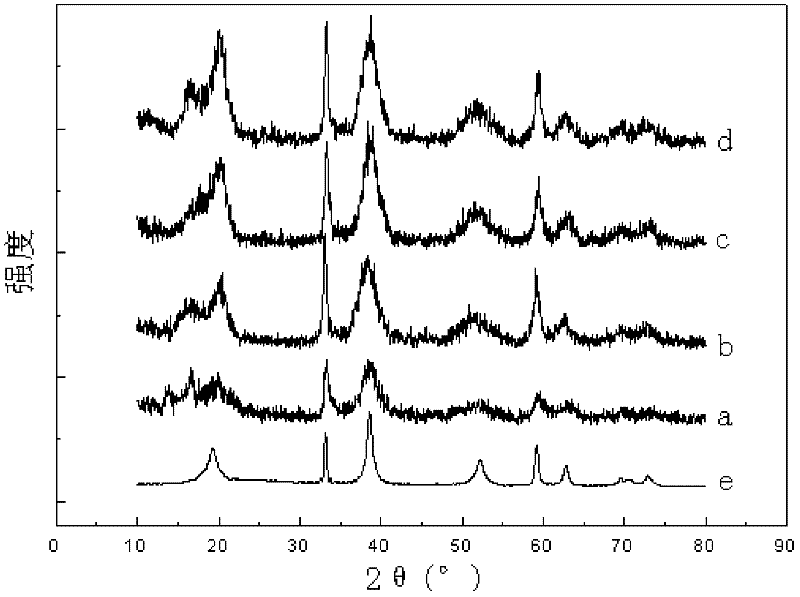

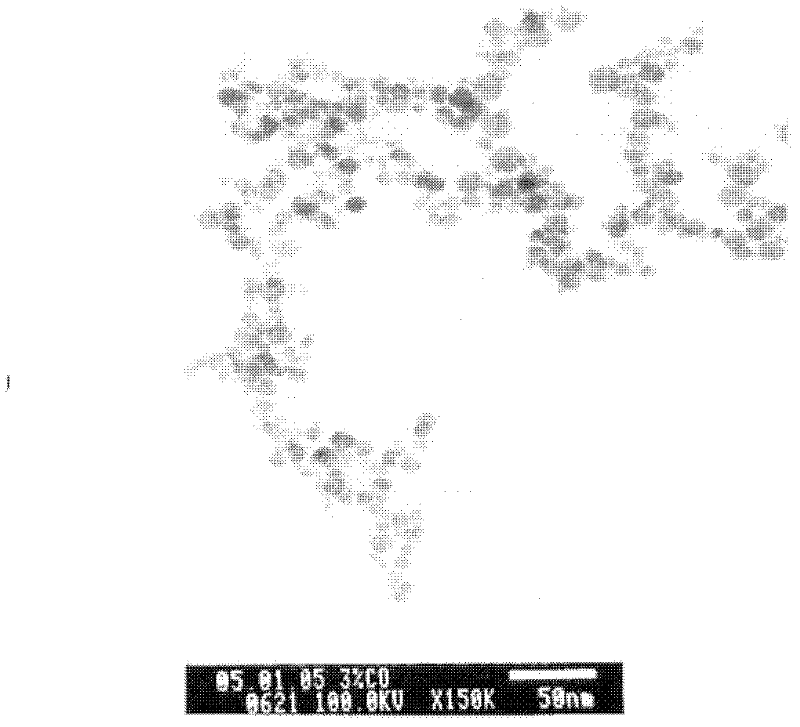

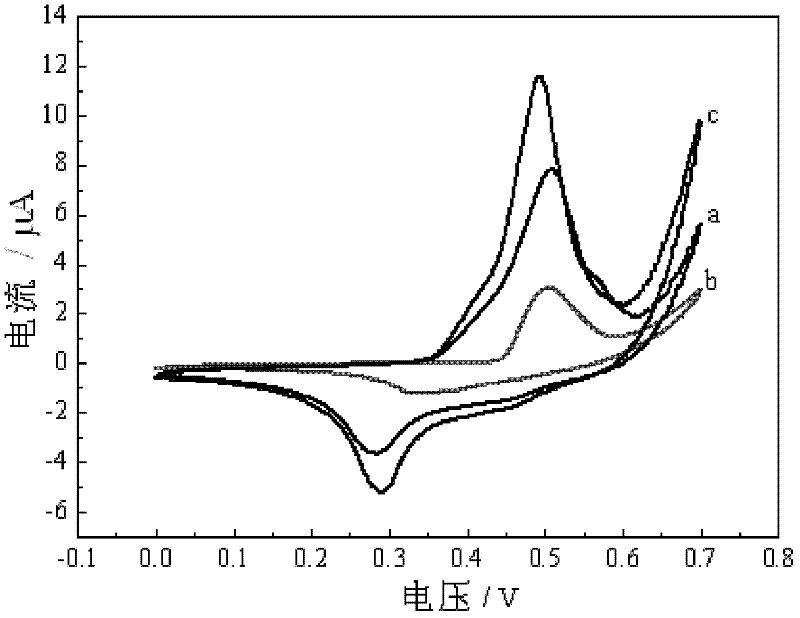

Co3O4/C lithium ion battery cathode material and preparation method thereof

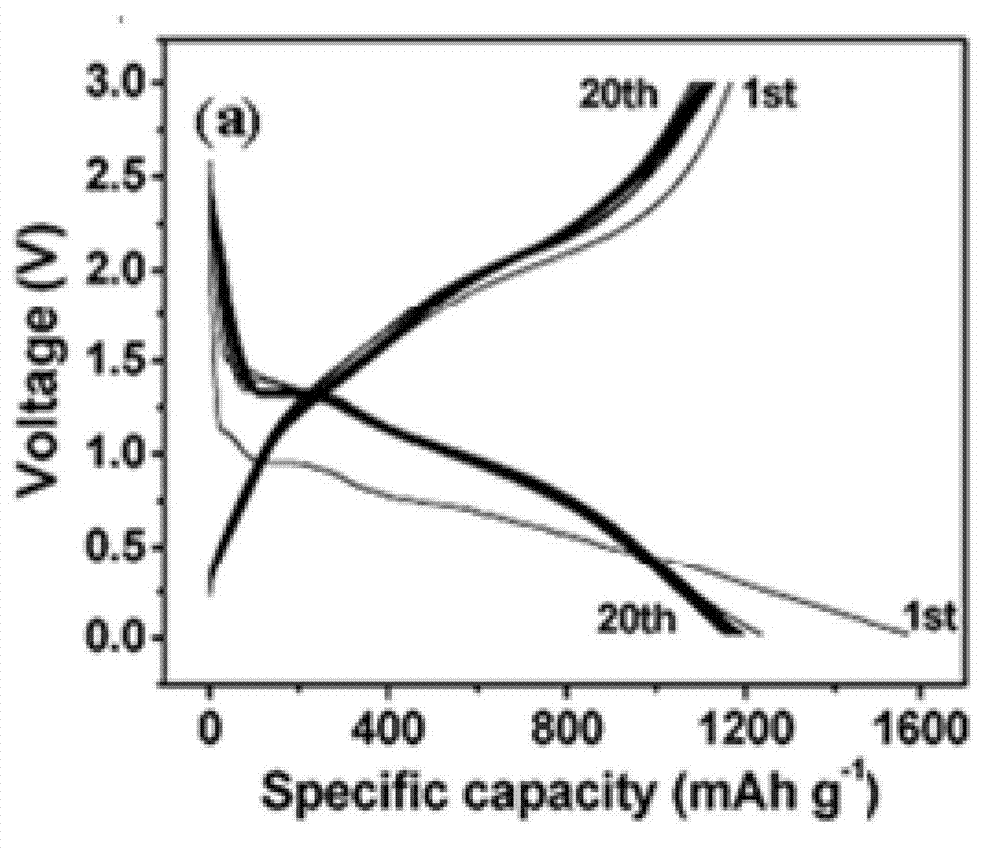

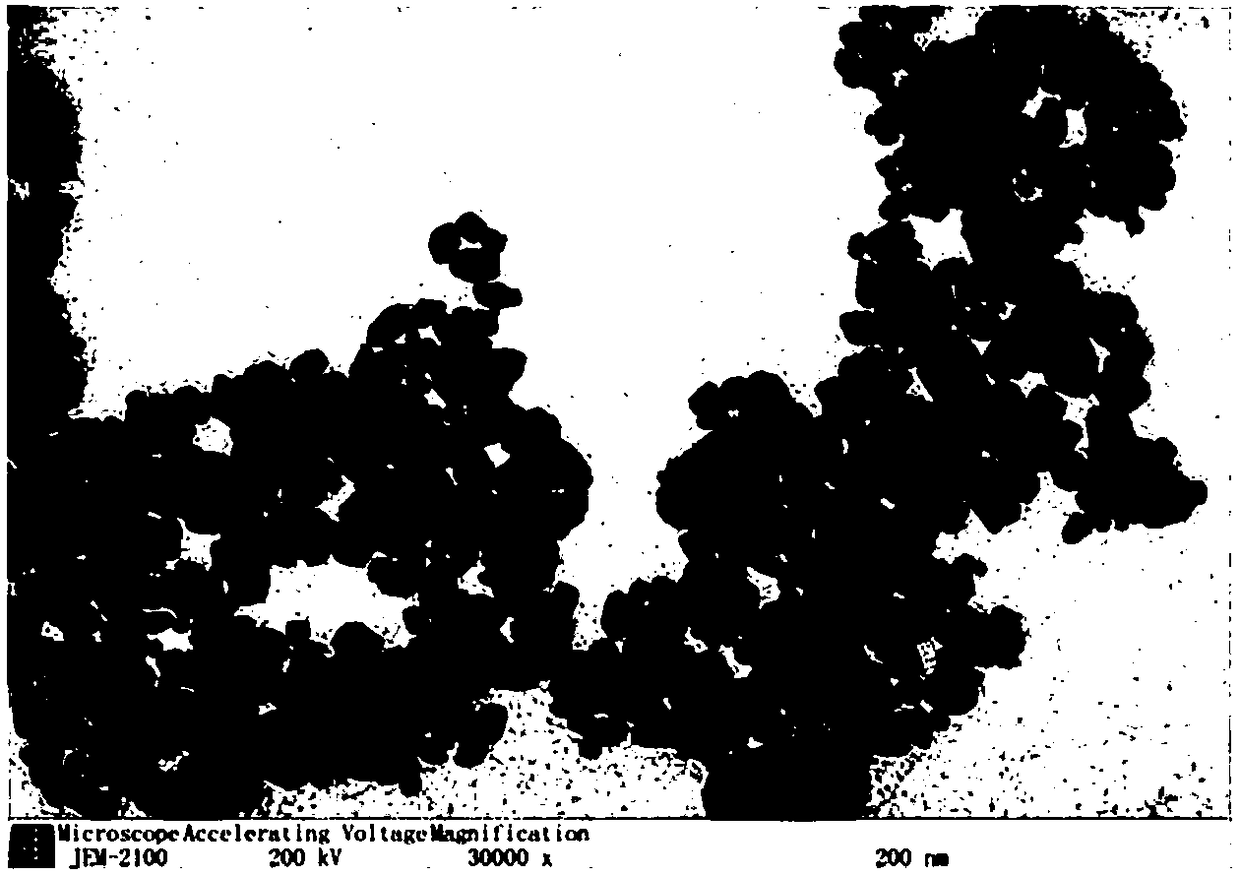

InactiveCN103094559ADiffusion distance is shortImprove cycle lifeCell electrodesCharge and dischargeLithium electrode

The invention discloses a Co3O4 / C lithium ion battery cathode material and a preparation method thereof. The cathode material is prepared by coating a thin carbon layer on the surface of a porous nano ball consisting of Co3O4, and distributing nano holes in the surface of the thin carbon layer. The preparation method comprises the following steps: dissolving cobalt nitrate and glucose in a mixture of ethanol and distilled water, uniformly stirring, adding a dispersing agent, and transferring the mixture into a sealed reaction kettle for reacting; cooling after the reaction is finished, performing centrifugal treatment on the reaction solution, washing the obtained precipitate, drying, annealing the precipitate under protection of inert atmosphere, and cooling the precipitate to obtain the cathode material. The Co3O4 / C lithium ion battery cathode material is high in reversible capacity, stable in cycle performance, excellent in charging and discharging rate performance and has good application prospects; and moreover, according to the method, the cost is low, the preparation process is simple and continuous and large-scale production is easy.

Owner:XIANGTAN UNIV

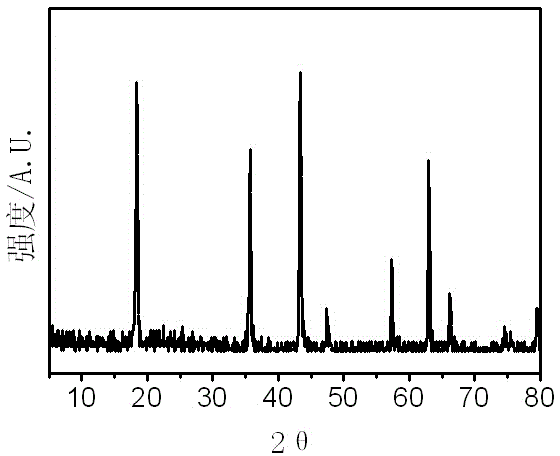

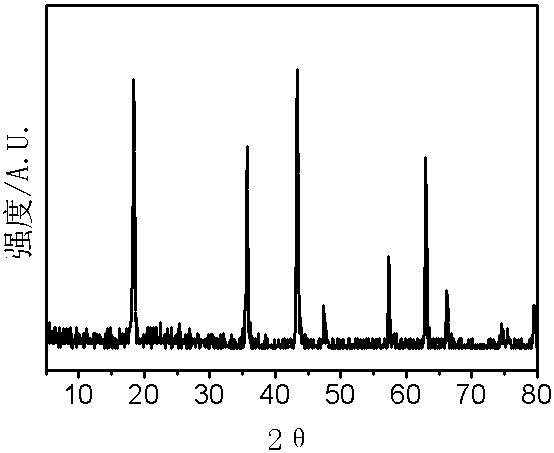

Carbon-coated nano lithium titanate composite material as well as preparation method and application thereof

ActiveCN104681804AImprove high rate charge and discharge performanceAvoid reunionMaterial nanotechnologyHybrid capacitor electrodesCarbon coatingElectrical battery

The invention discloses a carbon-coated nano lithium titanate composite material and a preparation method thereof. The preparation method comprises the following steps: 1, preparing nano lithium titanate, namely, respectively preparing micro emulsions of a lithium source and a titanium source, mixing the two types of micro emulsion, standing, centrifuging, alternatively washing with an organic solvent and water, drying, and performing high-temperature calcinations; 2, performing carbon coating on nano lithium titanate, namely, preparing a solution from an organic carbon source, adding lithium titanate granules prepared in the step 1 into the solution, performing ultrasonic dispersion, performing hydrothermal reaction, cooling after the reaction, alternatively washing with the organic solvent and water, filtering, and drying, thereby obtaining the carbon-coated nano lithium titanate composite material. Refining of lithium titanate can be achieved through a micro emulsion method, the solution can be prepared from the carbon source, and carbon coating of the nano lithium titanate can be achieved through hydrothermal reaction, so that a conductive carbon network which is uniform and dense in combination can be formed on the surface of lithium titanate, the conductivity and the large-power charge / discharge property of an electrode material are remarkably improved, and the carbon-coated nano lithium titanate composite material can be used for preparing lithium ion electric containers and lithium ion batteries.

Owner:SOUTH CHINA NORMAL UNIVERSITY

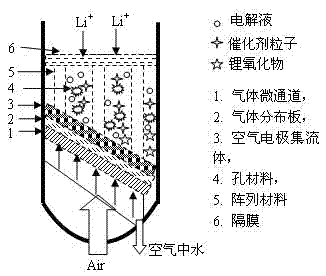

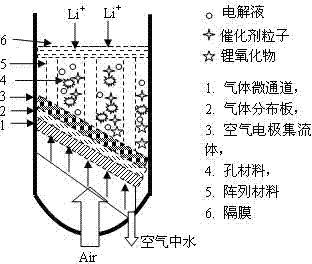

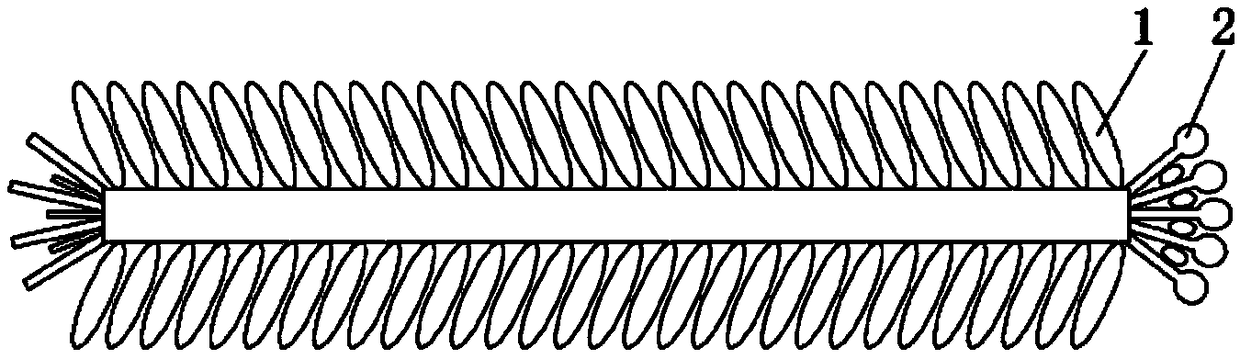

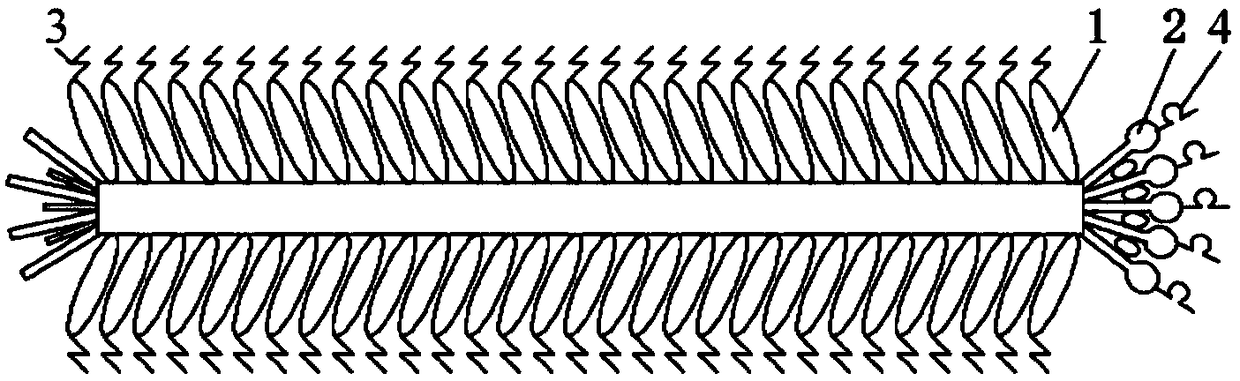

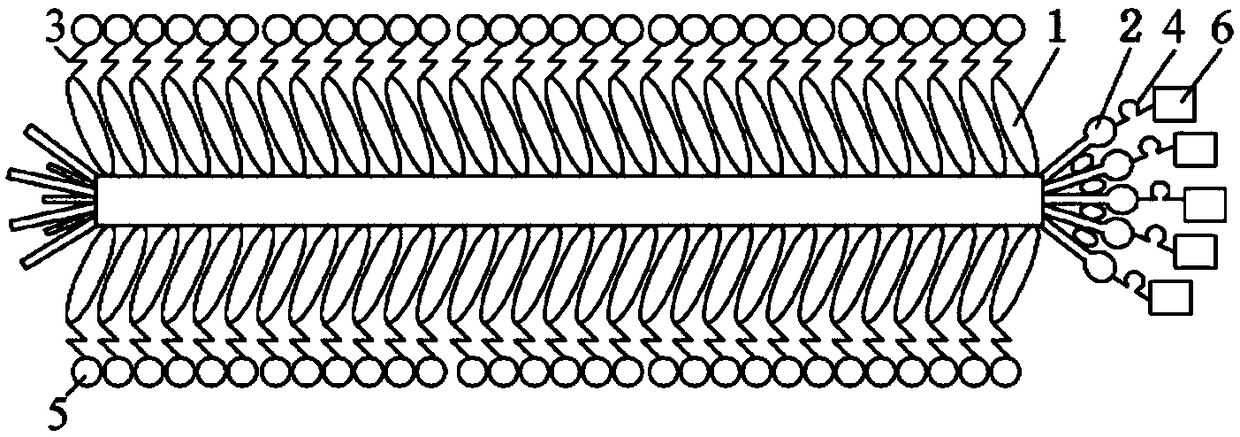

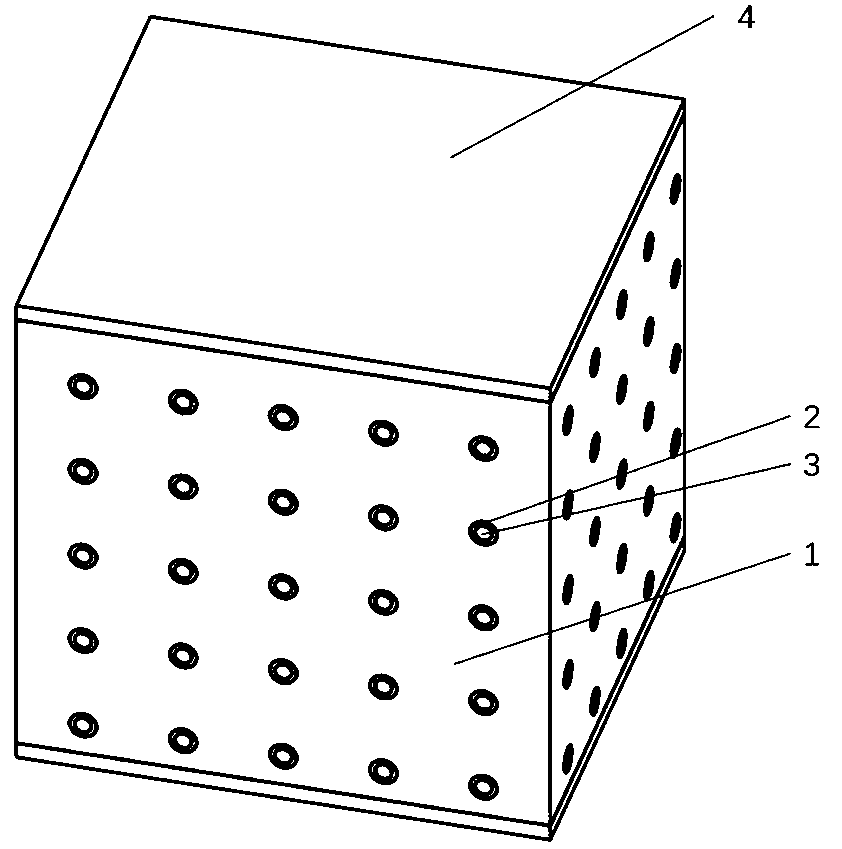

Novel sufficient metal air battery oxygen electrode and preparation method thereof

InactiveCN102509806AReduced risk of cloggingGood diffusion distanceCell electrodesCollectors/separatorsChemical physicsElectrical battery

The invention relates to a novel sufficient metal air battery oxygen electrode and a preparation method thereof, belongs to a high performance chemical electric power source and the relative field. The oxygen electrode and the preparation method can be used for solving technical problems of eliminating the phenomenon that a reaction is stopped caused by an oxidative product deposits on a gas path when metal is discharged, the reaction efficiency and loop stability of the oxygen electrode of a chargeable metal air battery are effectively improved, a three-phase reaction interface is reduced, and poison of moisture in the air to an electrode reaction and corrosion to an electrode are reduced. In the technical scheme provided by the invention, a gas micro channel is adopted to reduce moisture in the air, a gas distribution plate is used for improving airflow direction and a gas distribution state, a hole carbon material and an array materials combine to form a high efficiency three dimensional electrode, and a cathode reaction chamber is separated from a metal anode through a diaphragm. The oxygen electrode provided by the invention has the advantages of high catalytic reaction efficiency, good loop stability, short diffusion distance of gas and metallic ions, full air liquid solid three-phase contact; and unblocked gas path, reasonable gas distribution, strong metal oxide deposition resistance, good mass transferring and diffusion process effect, strong operability, and is suitable for a high energy density power supply occasions in a long term repeatedly.

Owner:SICHUAN UNIV

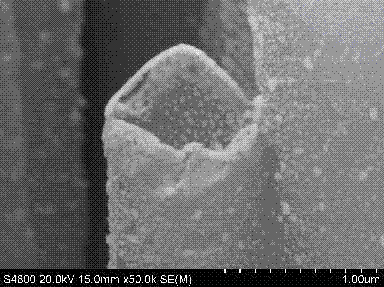

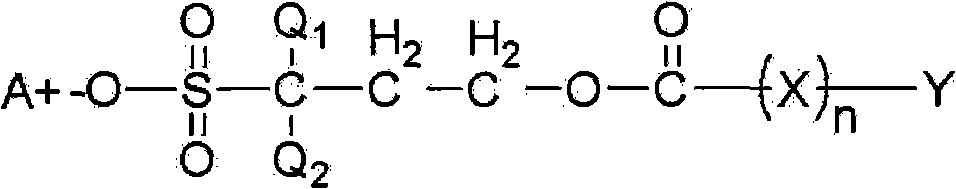

Photoacid generator, its preparation method and resist composition containing the photoacid generator

ActiveCN102289149AReduced diffusion rateDiffusion distance is shortSulfonic acids salts preparationPhotosensitive materials for photomechanical apparatusAlkaneResist

There are provided a photoacid generator, a method for manufacturing the same, and a resist composition comprising the same. The photoacid generator is a compound represented by the following formula 1, wherein Y represents any one selected from the group consisting of analkyl group substituted with an aryl group, and an aromatic hydrocarbon group; Q1 and Q2 each independently represent a halogenatom; X represents any one selected from the group consisting of an alkanediyl, an alkenediyl, NR', S, O, CO and combinations thereof; R' represents any one selected from the group consisting of a hydrogen atom and an alkylgroup; n represents an integer from 0 to 5; and A+ represents an organic counterion. The photoacid generator can produce, at the time of exposure, an acid which has a low diffusion rate, has a short diffusion distance, and exhibits an appropriate of degree of acidity so that the line width roughness (LWR) characteristics can be improved, and elution of which in a solvent such as pure water that is used in the process can be controlled.

Owner:SK MATERIALS PERFORMANCE CO LTD

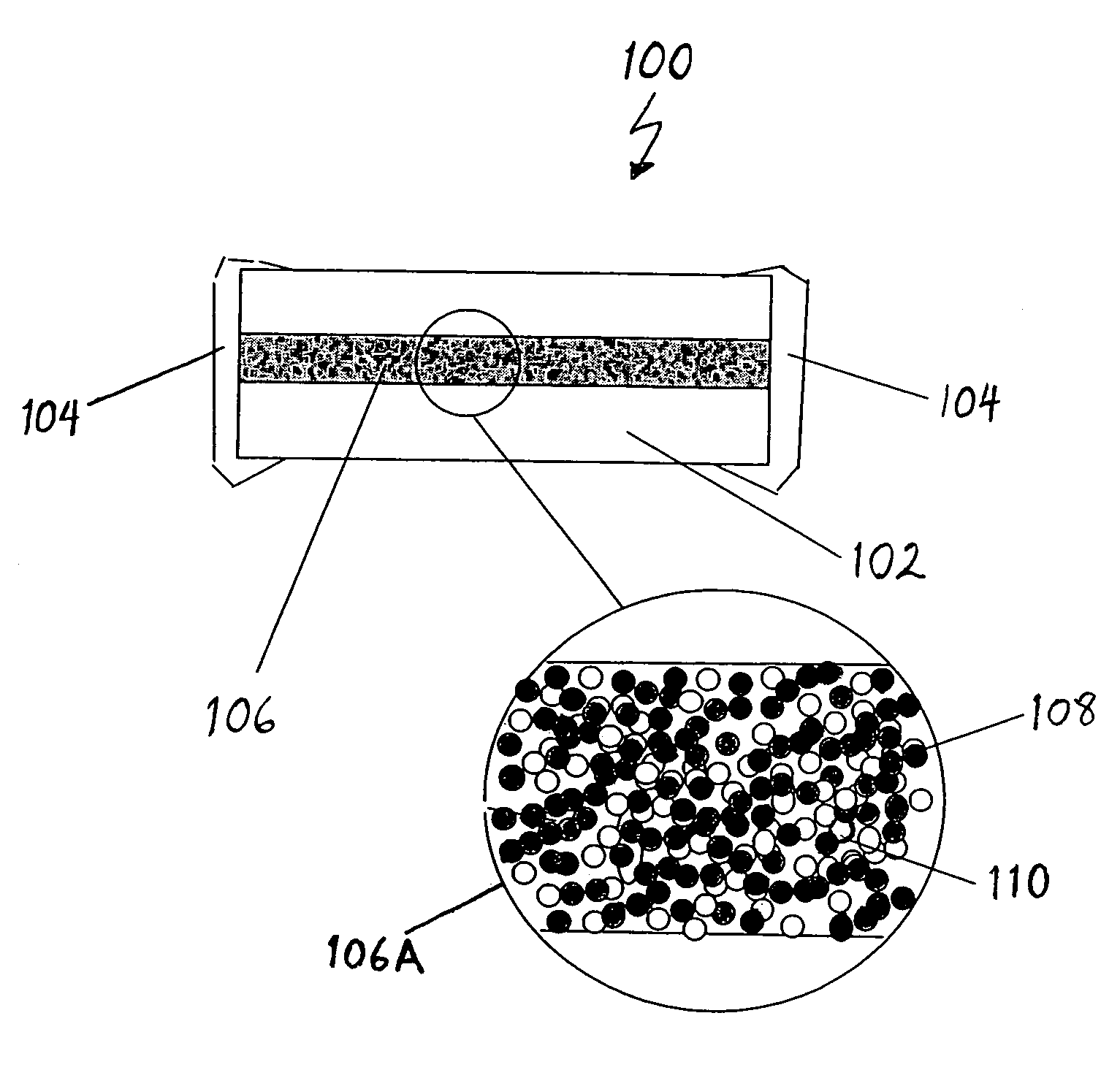

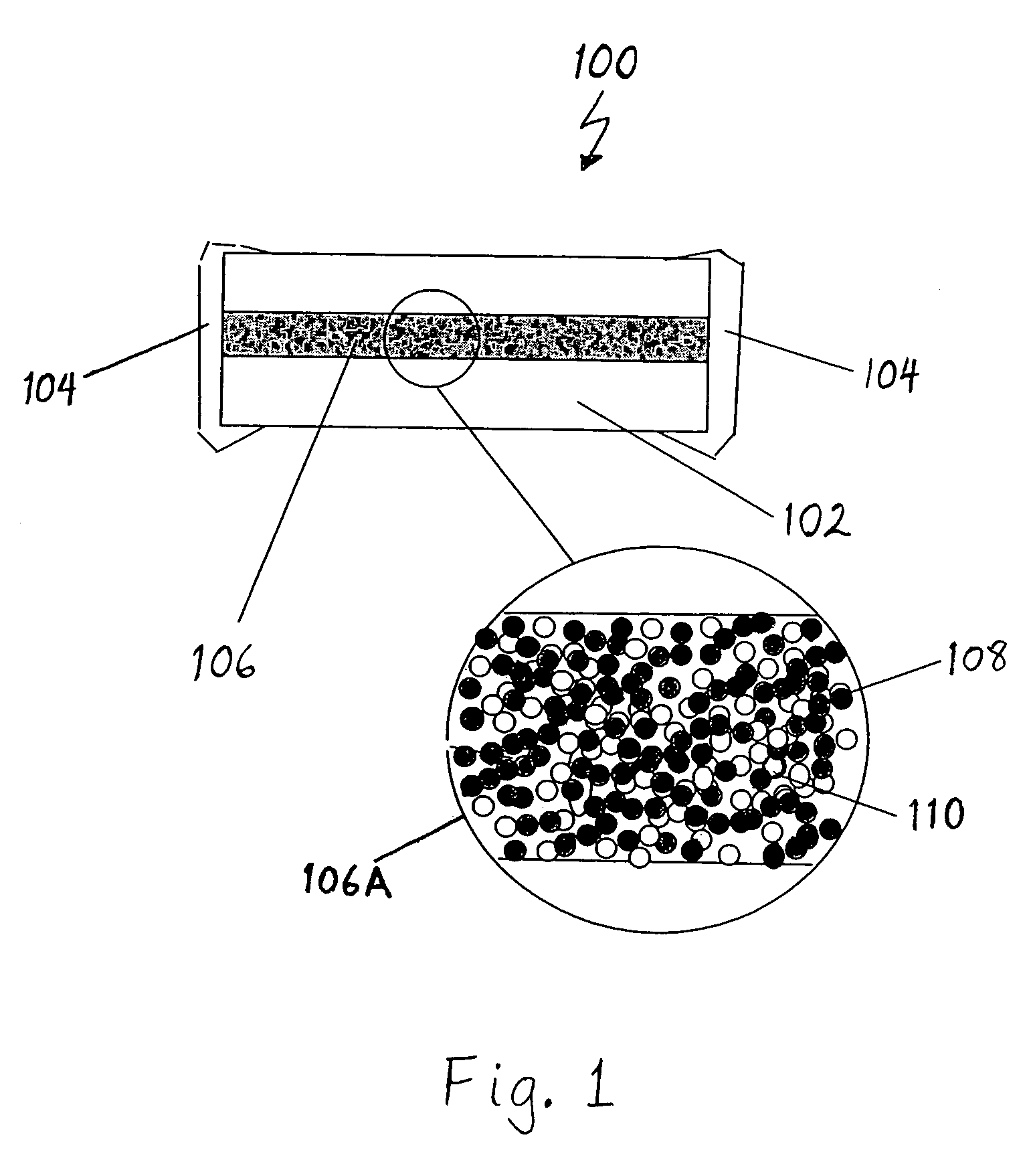

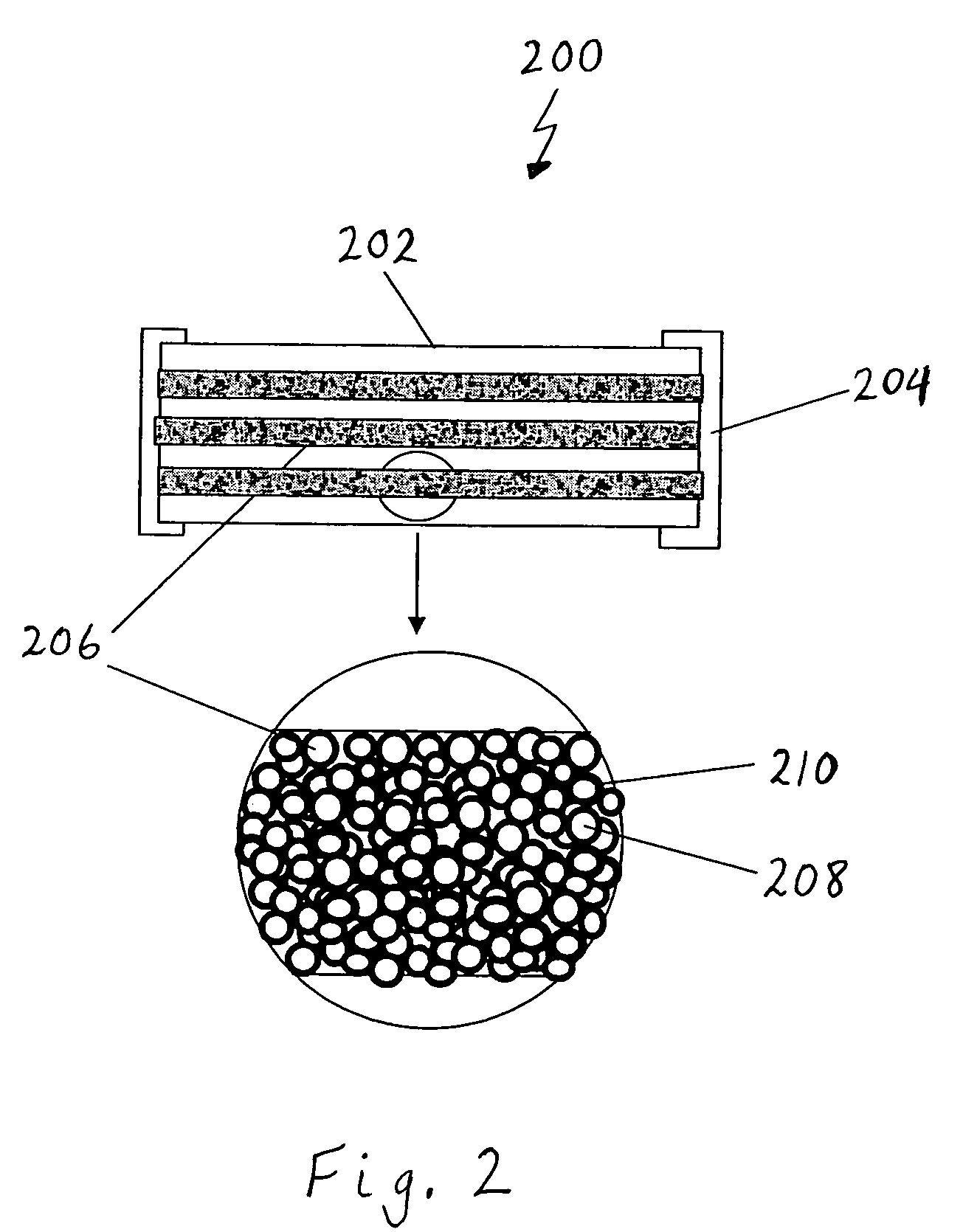

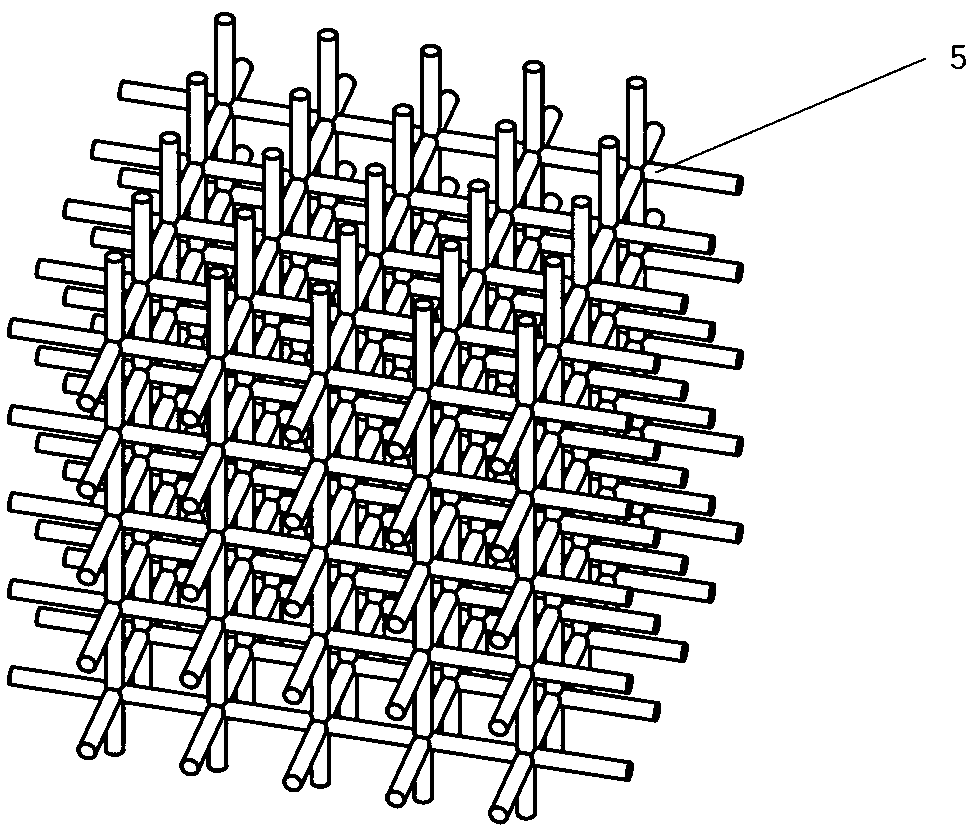

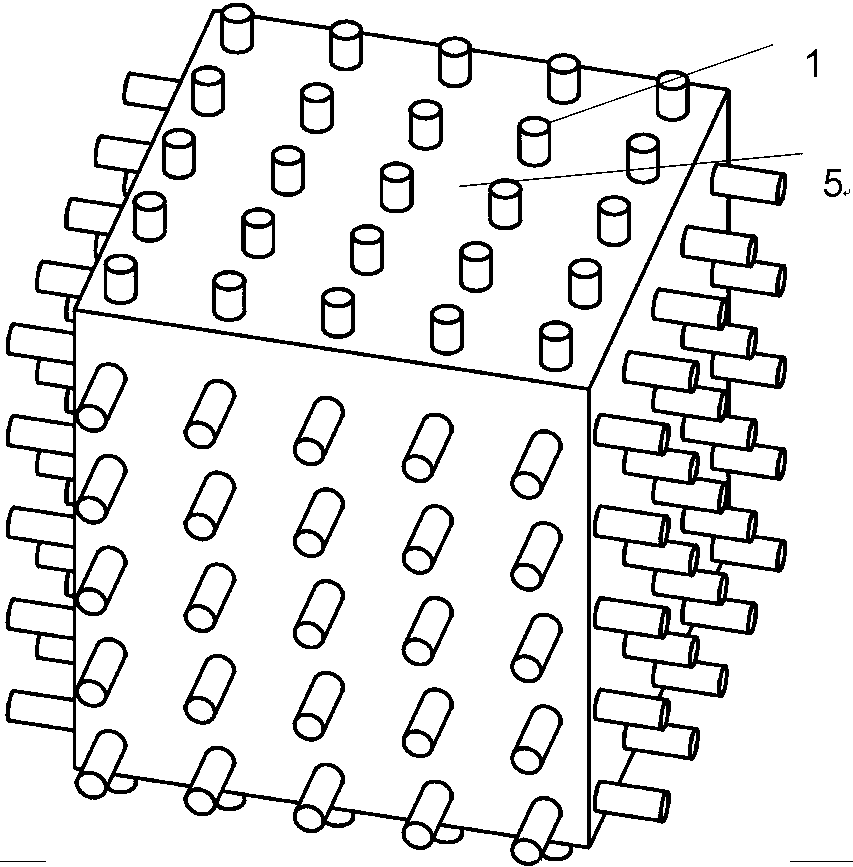

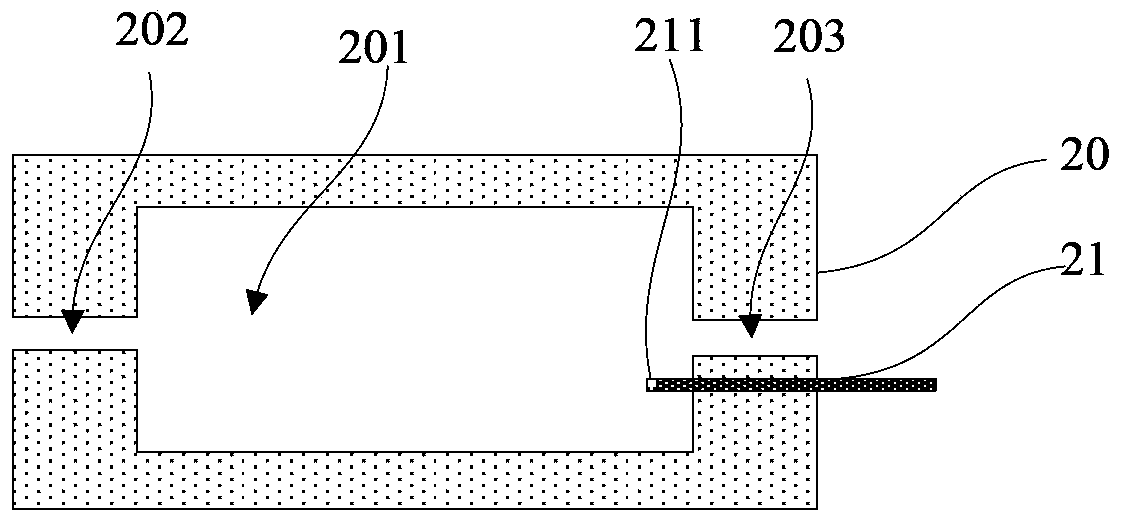

Composite fuse element and methods of making same

ActiveUS7268661B2Increased and faster arc quenching capabilityShort timeEmergency protective devicesConductive materialsOptoelectronics

A composite fuse element includes a network or matrix of conductive material that is in contact and interspersed with arc suppressing materials at a particle level. In such a matrix, the conductive (e.g., metal) network and the arc suppressing material particles provides a large contact surface area between these materials. When the conductive network melts or vaporizes, the resulting conductive vapors are adsorbed into the arc suppressing particles in a short time due to the large contact area between conductive and arc suppressing materials and the short diffusion distance that the conductive vapors are required to travel before they are absorbed by the arc suppressing material.

Owner:AEM COMPONENTS (SUZHOU) CO LTD

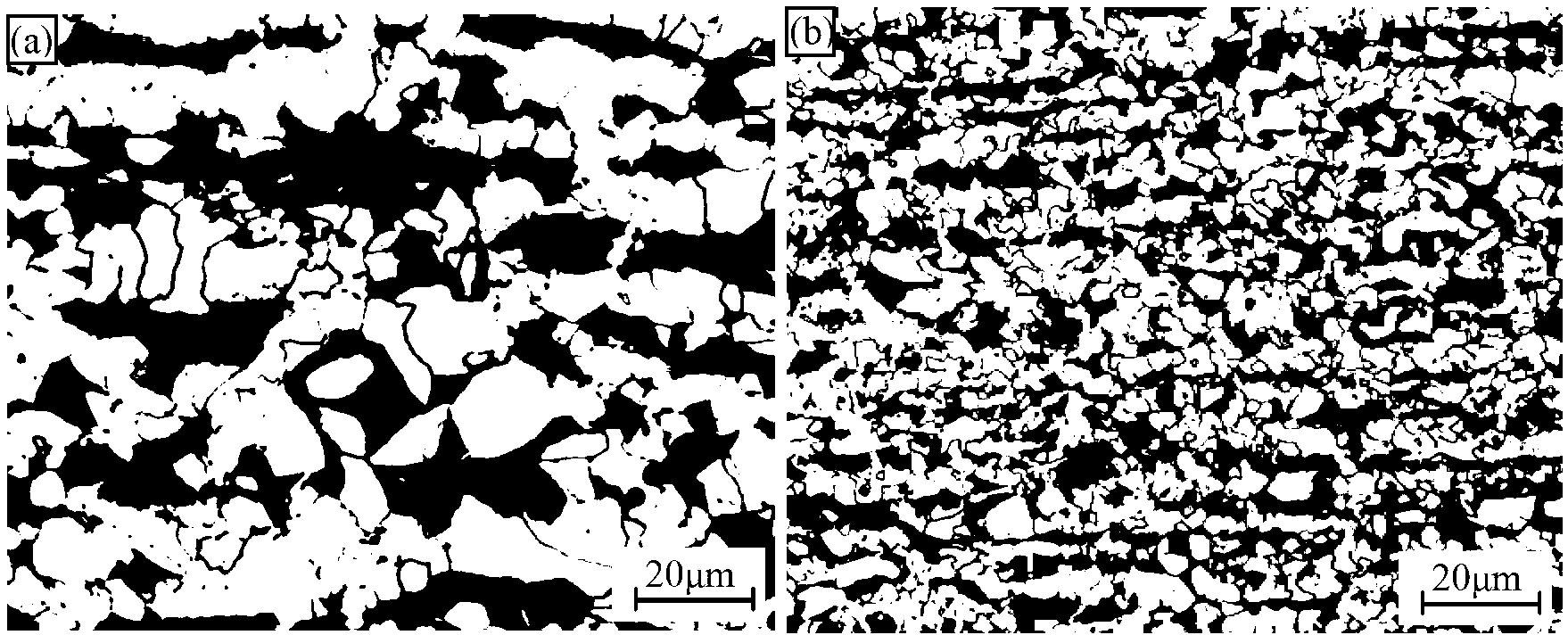

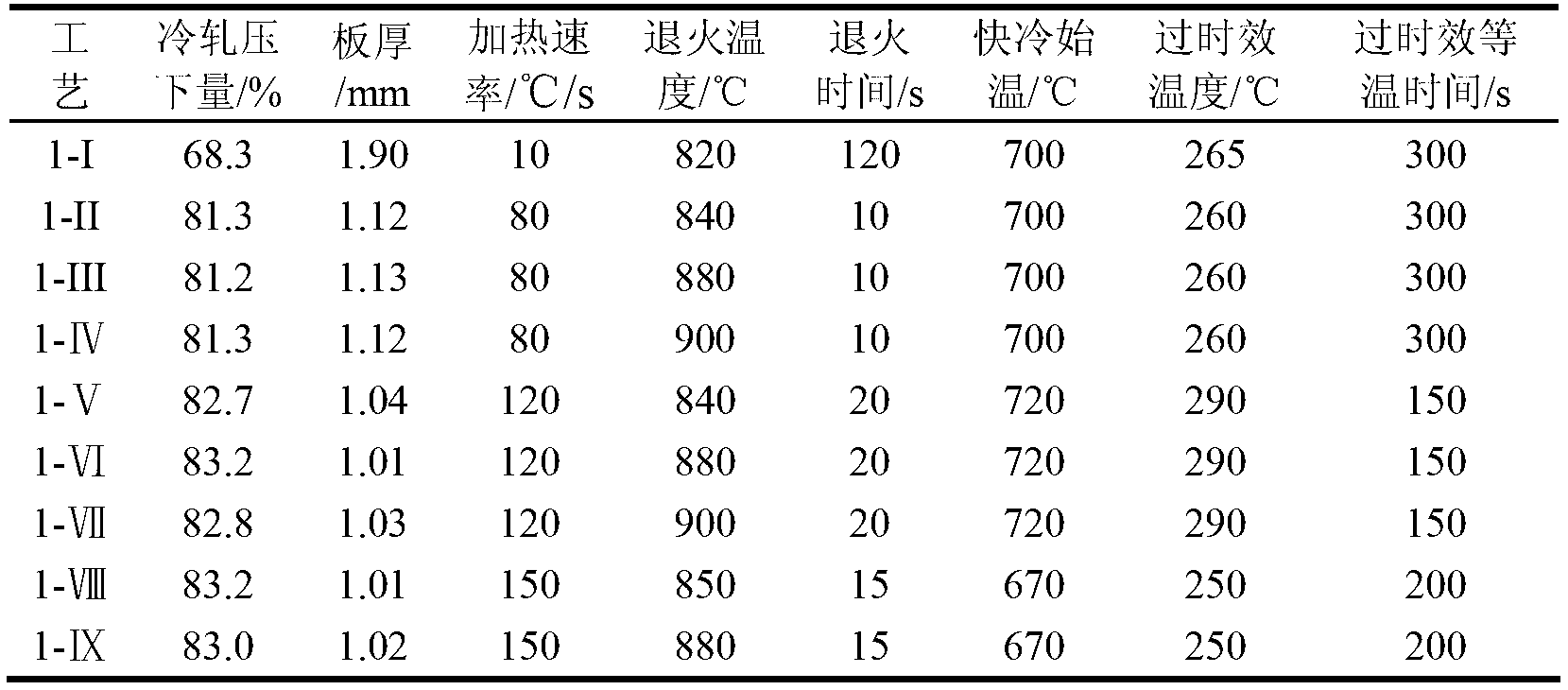

Method for improving mechanical property of low-carbon silicomanganese series cold rolling dual-phase steel

The invention belongs to the technical field of roll steel and relates to a method for improving the mechanical property of low-carbon silicomanganese series cold rolling dual-phase steel. The method comprises the following steps of: smelting and forging the low-carbon silicomanganese series cold rolling dual-phase steel to manufacture a plate blank, heating to 1100-1250 DEG C, carrying out heat preservation, carrying out rough rolling and finish rolling at 820-1100 DEG C, wherein the hot rolling and finish rolling temperature is (Ar3+30) DEG C-(Ar3+100) DEG C, then carrying out laminar cooling to (Ar3-50) DEG C-(Ar3-100) DEG C at cooling rate of 20 DEG C, and carrying out air cooling to room temperature; pickling, heating to (Ac3-50 DEG C)-(Ac3+100 DEG C) after cold rolling by adopting higher than or equal to 80% of rolling reduction, carrying out annealing treatment for 10-20s, carrying out slow cooling to 600-720 DEG C at rate of 5-8 DEG C / s, cooling to 250-300 DEG C at rate of higher than or equal to 30 DEG C / s for isothermal treatment, and carrying out air cooling and water-cooling or naturally cooling to room temperature. A cold rolling dual-phase steel plate with excellent mechanical property can be obtained by adopting the preparation method; the strength, the total percentage elongation after fracture and the work-hardening index of the cold rolling dual-phase steel plate are improved; and the strength of the cold rolling dual-phase steel plate is obviously improved.

Owner:LAIWU IRON & STEEL GRP

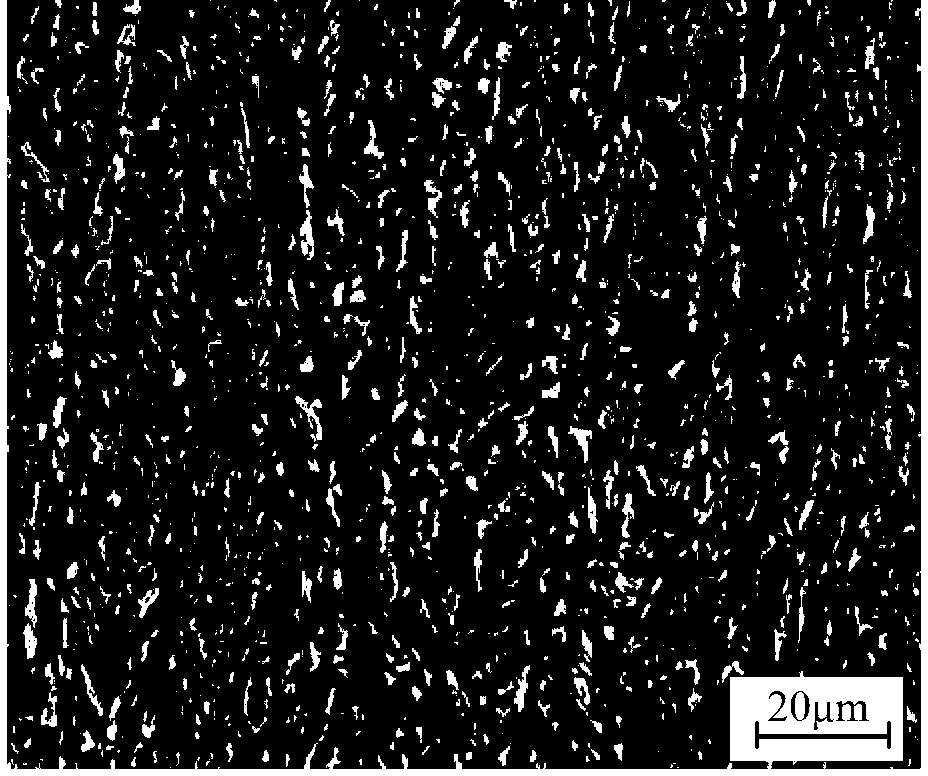

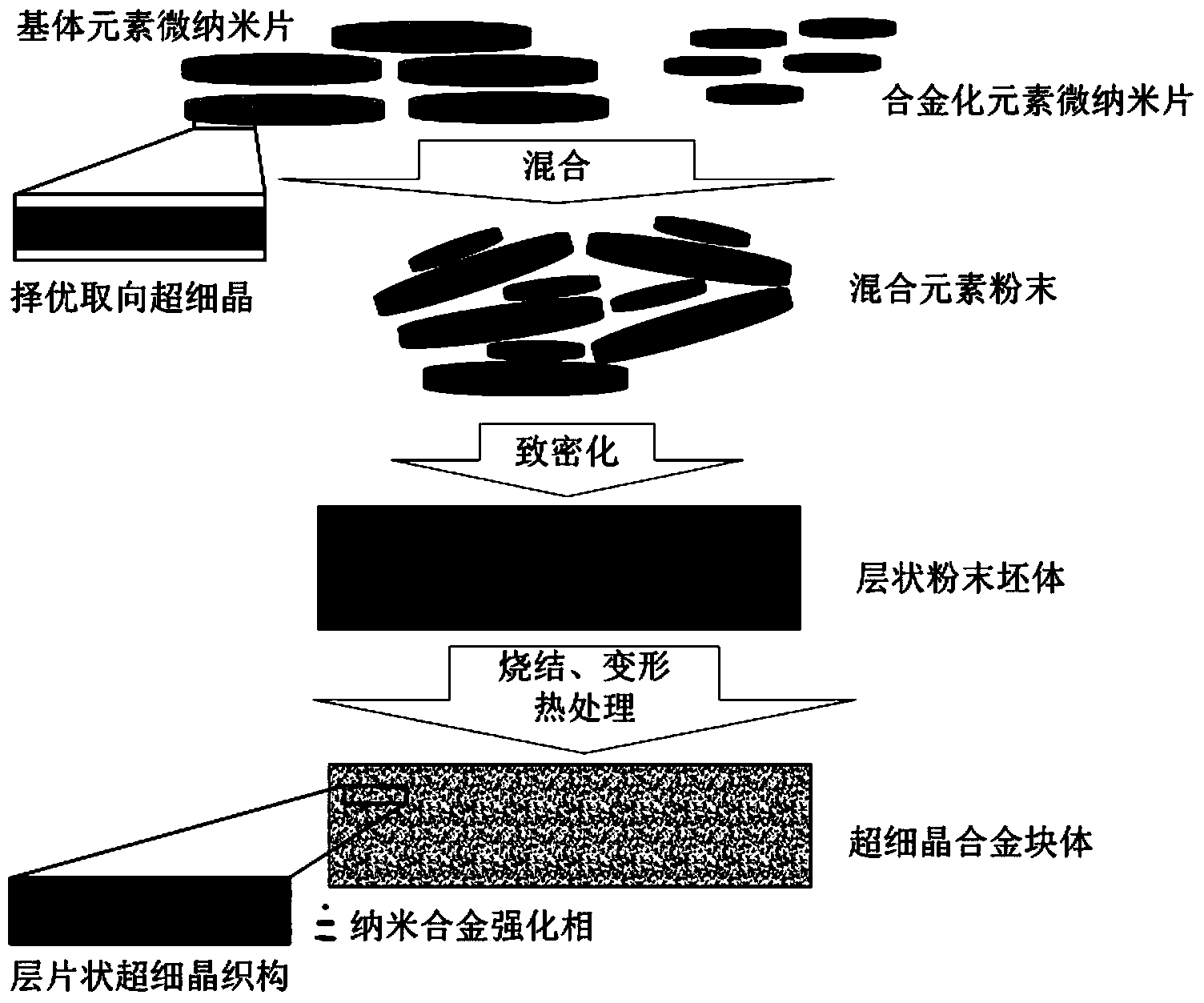

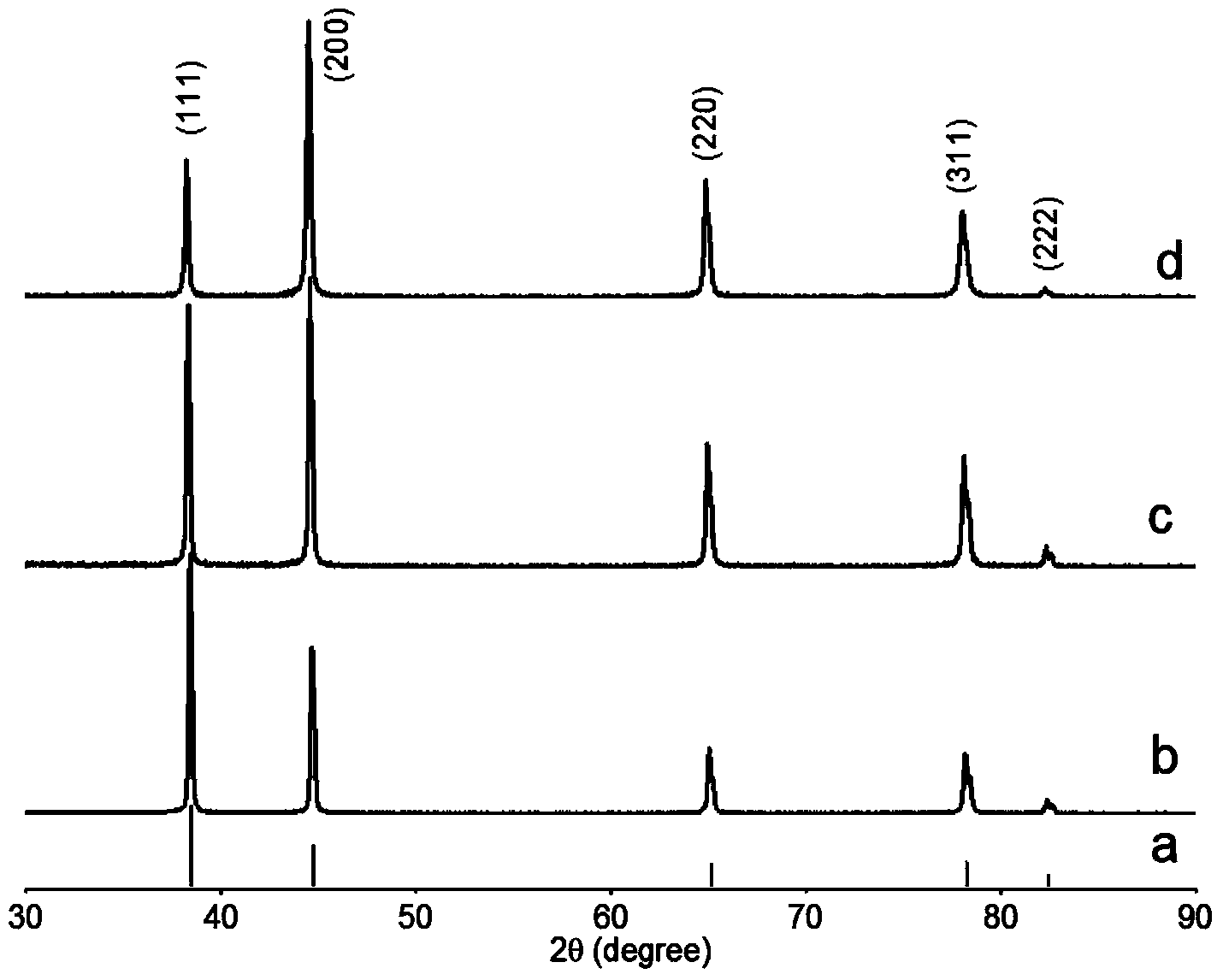

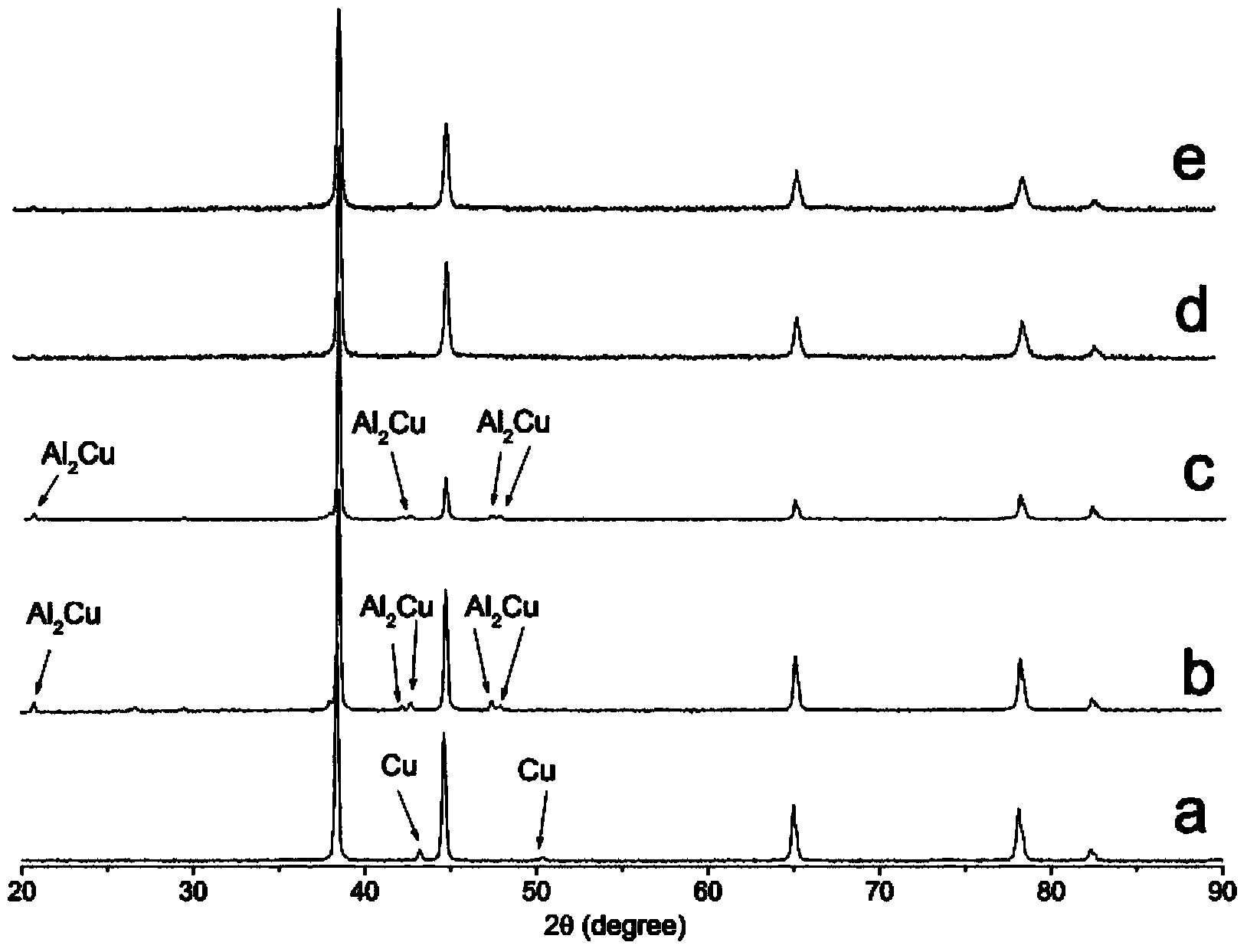

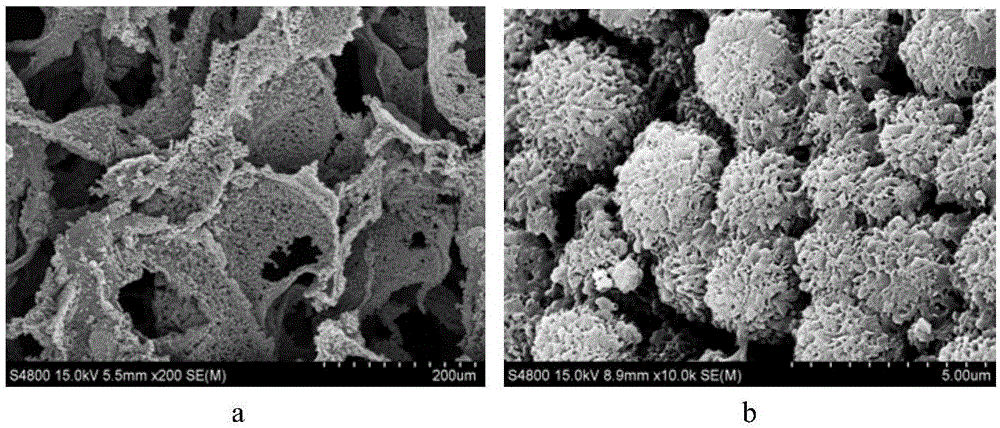

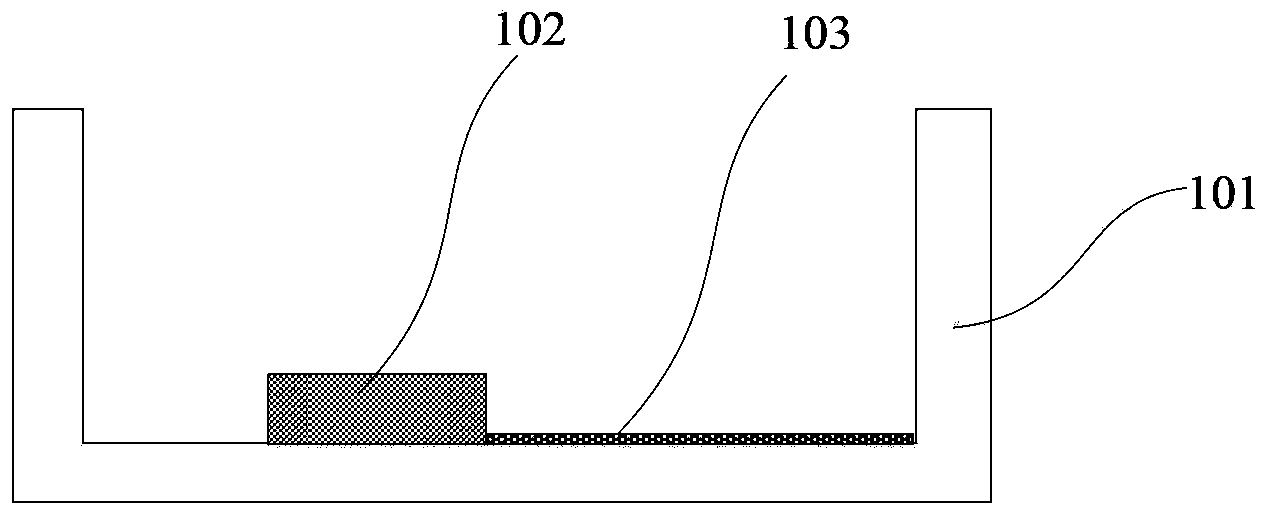

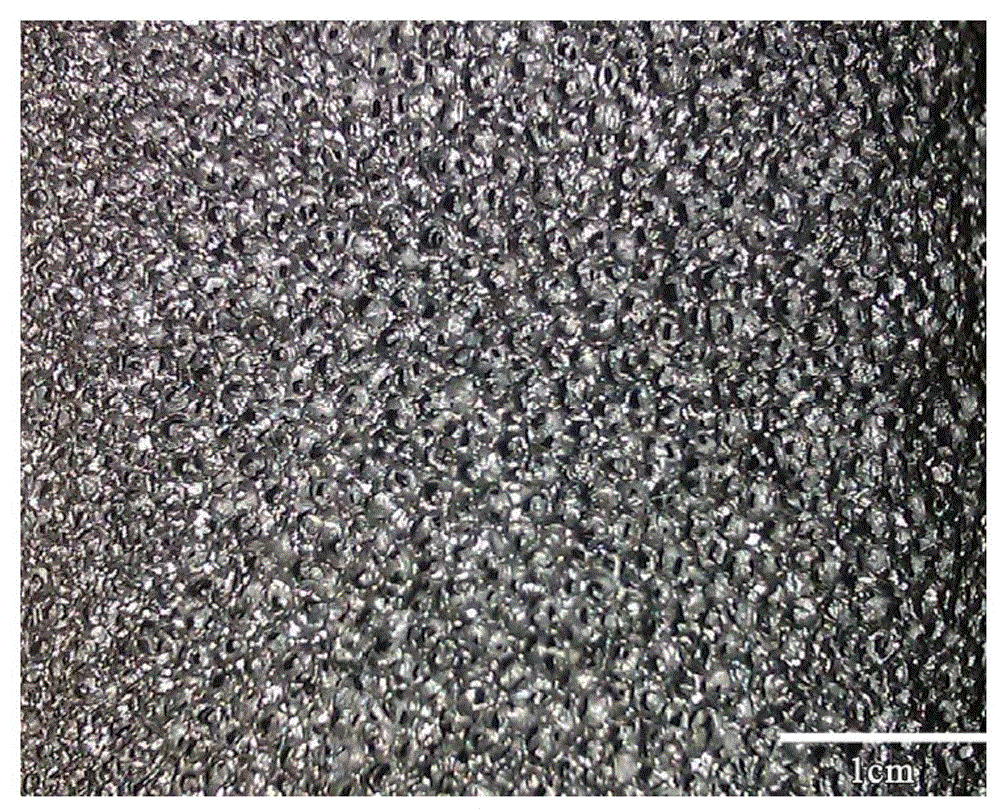

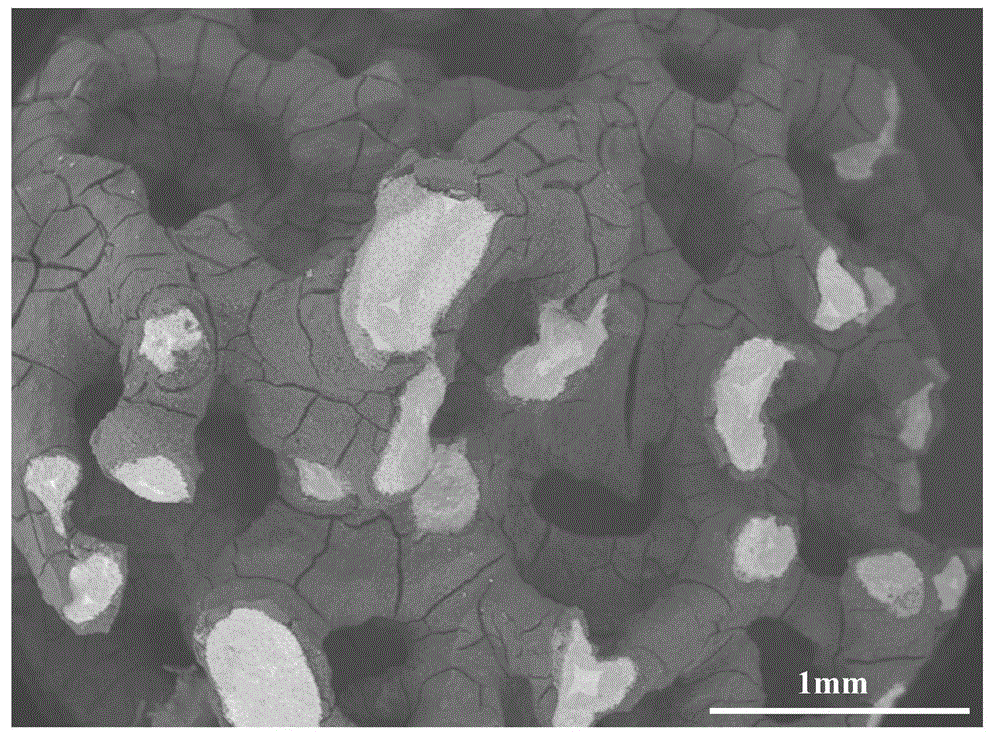

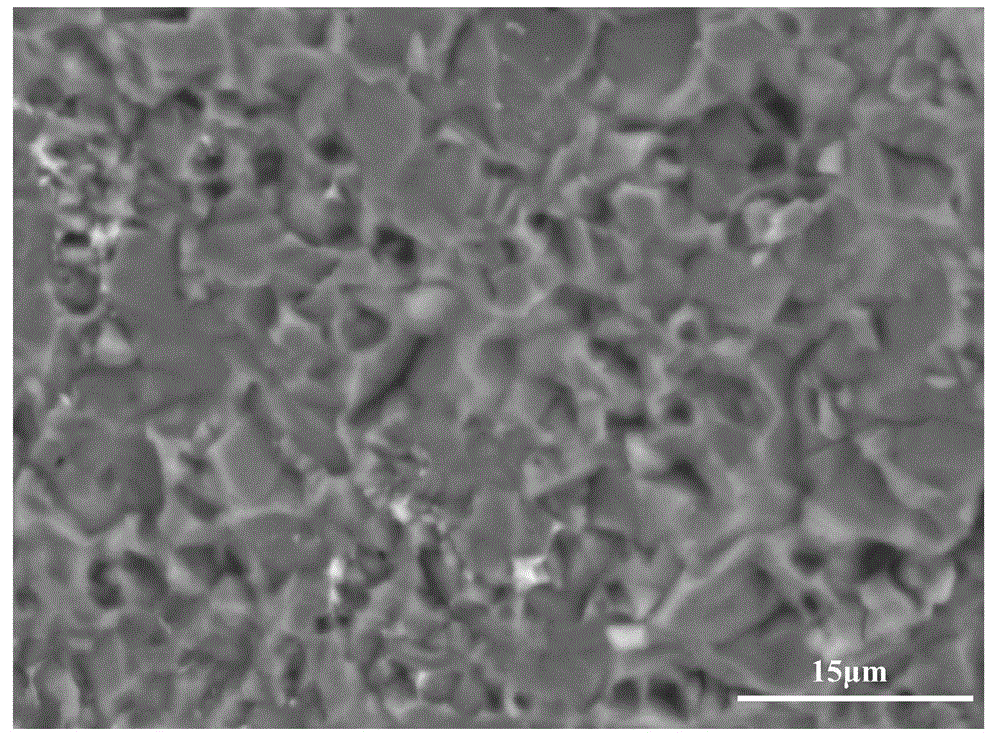

Powder metallurgy method for preparing superfine crystalline alloy by use of micro-nano laminated sheet

The invention provides a powder metallurgy method for preparing superfine crystalline alloy by use of a micro-nano laminated sheet. The method comprises the steps of pre-preparing a micro-nano laminated matrix with preferred orientation and alloying element powder, mixing, and carrying out densification and sintering to form an ingot blank with a laminated structure, wherein the thickness of the alloying element powder is hundreds of nanometers, interlaminated interdiffusion is facilitated, alloying uniformity is realized, a texture formed by laminated superfine crystalline grains is obtained through further deformation processing, dislocation movement inside the crystalline grains is facilitated, and good plasticity is kept under a condition that the superfine crystalline strengthening and alloying strengthening mechanisms are brought into full play. The method saves time and energy, has low cost and wide application range, can be used for preparing bulked alloy material and has large-scale application potential, and the performances of the prepared alloy material are remarkably improved compared with the alloy material prepared by the conventional mechanical alloying method.

Owner:SHANGHAI JIAO TONG UNIV

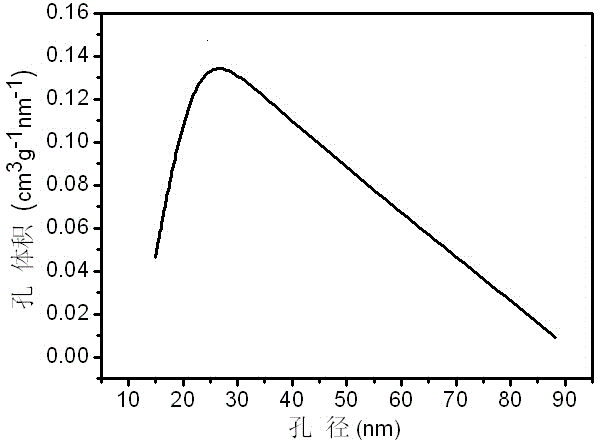

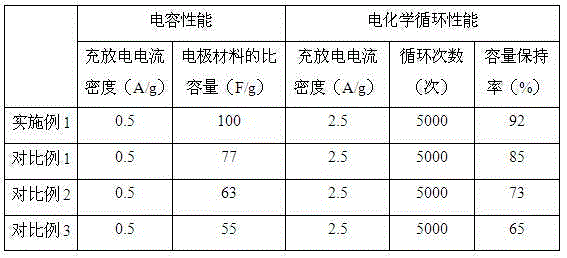

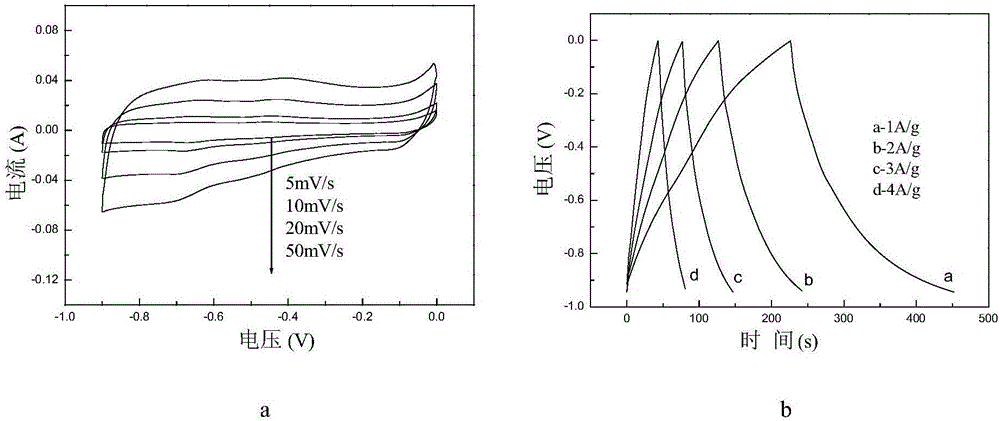

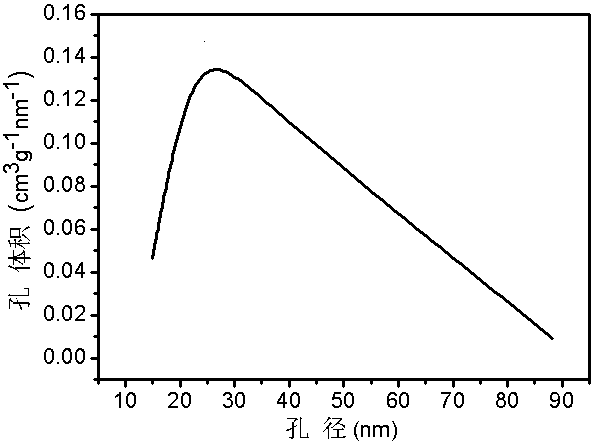

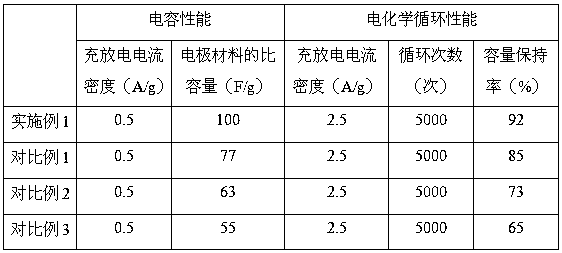

Method for preparing hierarchical pore carbonic oxide microsphere material

InactiveCN106449130AChange structureChange natureHybrid capacitor electrodesHybrid/EDL manufactureFlower likeMicrosphere

The invention discloses a method for preparing a hierarchical pore carbonic oxide microsphere material. The method comprises the following steps: A, impregnating PU foam with a PAA solution, and drying for 6-20 hours at 50-90 DEG C in vacuum; B, heating the PU foam after impregnating and drying in an inert gas atmosphere, namely heating for 0.5-3 hours at 80-120 DEG C, increasing the temperature to 170-230 DEG C and heating for 0.5-3 hours, and increasing the temperature to 270-330 DEG C and heating for 0.5-3 hours; and C, roasting for 1-6 hours at 500-800 DEG C in the inert gas atmosphere after the heating treatment in the step B is completed, and cooling to room temperature. The method is simple, has low cost and short reaction time, and is suitable for industrial production; and the prepared carbonic oxide microsphere material has an ideal flower-like spherical shape, a micropore-mesopore-macropore hierarchical porous structure, a large specific surface area, high nitrogen content and excellent electrochemical performance, and has huge application prospects in the field of super-capacitors.

Owner:CHONGQING UNIV OF ARTS & SCI

Graphene coated inorganic filler composite resin adhesive material

InactiveCN106010403AHigh reactivityImprove adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesChemical industryConducting pathway

The invention relates to a graphene coated inorganic filler composite resin adhesive material. The material is prepared from, by weight, 20-35 parts of resin matrix, 40-60 parts of graphene coated inorganic filler and 20-30 parts of curing agent. According to the composite resin adhesive, the composite resin matrix, the composite inorganic filler and the composite curing agent are adopted, and a heat-conducting pathway and a conductive network can be effectively formed; the product has an extremely high heat-conducting property and a certain flame-retardant property, and the heat-conducting coefficient of the finally prepared composite resin adhesive is larger than 9.0 W / mK, and the electric conductivity is larger than 37 S / m; the heat-resistant property is good, and a certain anti-corrosion capability is achieved; the graphene coated inorganic filler composite resin adhesive material can be widely applied to the fields of heat-sink devices, electronic packages, electronic equipment, chemical industry energy, automobile industry, aerospace and the like.

Owner:SICHUAN WUXIN ENERGY TECH

Method for preparing single crystal blades based on double-induction directional recrystallization of ultrafine nickel powder area

ActiveCN107159896ALower crystallization temperatureGrain refinementTurbinesZone meltingSingle crystal

The invention relates to a method for preparing single crystal blades based on double-induction directional recrystallization of an ultrafine nickel powder area. Ultrafine single crystal nickel powder serves as a main raw material; other ultrafine metal powder is added according to the high-temperature alloy material prescription requirement; and the nickel-based high-temperature alloy single crystal turbine blades of an airplane engine are prepared through the method of smelting, directional solidification and recrystallization of the double-constraint induction area of an electromagnetic field after forming. Compared with the prior art, the method for preparing the single crystal blades based on double-induction directional recrystallization of the ultrafine nickel powder area has the advantages that alloying and recrystallization are completed at a time, the recrystallization process is easy to control, the single crystal finished product rate is high, mechanical performance of products is high, the production cost is high, a mould shell and a mold core are not needed, and waste is not generated in crystal guiding and selecting sections.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method for composite photocatalytic material based on microbial template

ActiveCN108906128AReduce photosensitive areaDiffusion distance is shortOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationMicroorganismSpecific adsorption

The invention discloses a preparation method for a composite photocatalytic material based on a microbial template, and belongs to the field of photocatalysis. The method comprises the following steps: firstly screening polypeptide with specific adsorption and nucleation ability by utilizing a phage display technology, expressing the polypeptide on a capsid protein of a specific microorganism through a genetic modification technology, finally putting the modified microorganism into a sol of a photocatalytic material by using the modified microorganism as a template, and putting the obtained microorganism into a sol of a co-catalysis supported material by using the obtained microorganism as a template to prepare the composite photocatalytic material. The preparation method for the compositephotocatalytic material based on the microbial template disclosed by the invention can realize preparation of mass nano composite photocatalytic materials, the preparation process is nano-scale controllable, and the photocatalytic efficiency can be effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing Nb3Sn superconducting wire by winding process

ActiveCN110444337AShorten the diffusion pathFine grainSuperconductors/hyperconductorsSuperconductor devicesAlloyConductor Coil

The invention belongs to the technical field of superconducting material processing, and relates to a method for preparing an Nb3Sn superconducting wire by a winding process. The preparation method comprises the following steps: preparing a wound combination formed by an Sn alloy foil, a Cu foil, an Nb foil and a copper rod; putting the wound combination in a first oxygen-free copper tube, and sealing the two ends of the first oxygen-free copper tube to obtain a CuNbSn composite rod; performing hydrostatic extrusion on the CuNbSn composite rod to obtain a blank, drawing the blank, and sizing and cutting the blank to obtain hexagonal CuNbSn sub-components; putting the hexagonal CuNbSn sub-components into a second oxygen-free copper tube, and assembling the hexagonal CuNbSn sub-components according to a close-packed hexagonal form to obtain a final Nb3Sn blank; drawing the final Nb3Sn blank to prepare a finished Nb3Sn precursor wire; and carrying out heat treatment on the finished Nb3Snprecursor wire to prepare the finished Nb3Sn superconducting wire. According to the method, the manufacturing process of the Nb3Sn superconducting wire is simplified, and the Nb / Sn diffusion reactionkinetics conditions are reduced.

Owner:西部超导材料科技股份有限公司

Preparation method of doped spherical nanoscale Ni(OH)2

InactiveCN102509787AEvenly distributedDiffusion distance is shortAlkaline accumulator electrodesNanotechnologyAlkaneSpherical shaped

The invention relates to a preparation method of doped spherical nanoscale Ni(OH)2, which solves the problem that the existing doped spherical nanoscale Ni(OH)2 has irregular shape. The preparation method comprises the following steps: adding alkane or cycloalkane in the mixed solution of n-hexanol and surfactant; stirring uniformly; adding a solution doped with metal ions and Ni<2+>, and stirring uniformly; adding an alkaline solution dropwise to adjust pH value to 8 to 11; separating precipitate; washing; calcining; and milling to obtain the final product. The nanoscale Ni(OH)2 prepared by the method has a spherical or nearly spherical shape, and a beta-type crystal form. The maximum 1C discharge specific capacity of a Cd-Ni (cadmium-nickel) battery prepared from Co-doped spherical nanoscale Ni(OH)2 reaches 245 mAh / g, which is improved by 16% in comparison with that of Cd-Ni battery prepared from doped nonspherical nanoscale Ni(OH)2, and the cycle specific capacity is also improved remarkably. The discharge specific capacities of Zn-doped spherical nanoscale Ni(OH)2 and Al-doped spherical nanoscale Ni(OH)2 are also improved.

Owner:HARBIN INST OF TECH

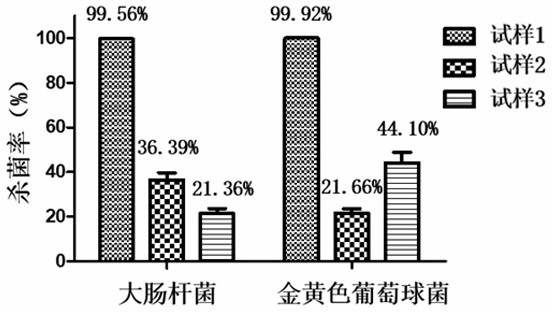

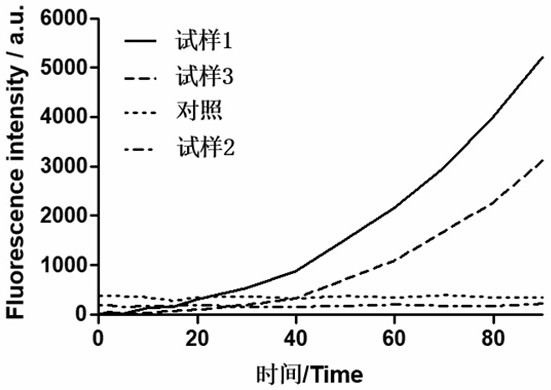

Preparation method of photosensitive antibacterial material

InactiveCN112021333AHas dual antibacterial propertiesBroad spectrum antibacterialBiocideDisinfectantsPhotosensLight irradiation

The invention discloses a preparation method of a photosensitive antibacterial material, and the photosensitive antibacterial material is prepared by enriching a photosensitizer with carboxyl on the surfaces of zinc oxide nanoparticles through a strong adsorption effect by adopting a precipitation method. The photosensitive antibacterial material can generate a large amount of active oxygen through light irradiation, so that the photosensitive antibacterial material has very strong antibacterial performance, is simple in preparation process, relatively mild in reaction condition and suitable for industrial production, and can be used for preparing medical antibacterial materials or building coating materials.

Owner:FUZHOU UNIV

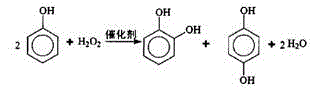

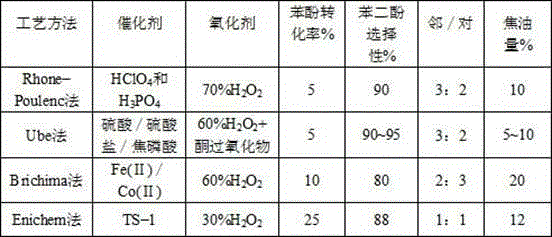

Phenol and hydrogen peroxide hydroxylation microchannel reaction method

InactiveCN105566072ADiffusion distance is shortLarge specific surface areaOrganic chemistryOrganic compound preparationPtru catalystOrganic synthesis

The invention belongs to the technical field of organic synthesis, and particularly relates to a phenol and hydrogen peroxide hydroxylation microchannel reaction method. The method comprises the steps of mixing the raw materials phenol, water, hydrogen peroxide and a water-soluble catalyst according to certain proportions to prepare a raw material solution, adding the raw material solution into a mixing tank, setting the reaction temperature of a microchannel reactor to be 30-150 DEG C, and inputting the raw material solution into the microchannel reactor at the flow rate of 5-150 mL / min through continuous charging and discharging for hydroxylation reaction, so that catechol and hydroquinone are obtained. The method is simple, operation is convenient, the conversion rate is high, selectivity is high, efficiency is high, and the content of tar in reaction liquid is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

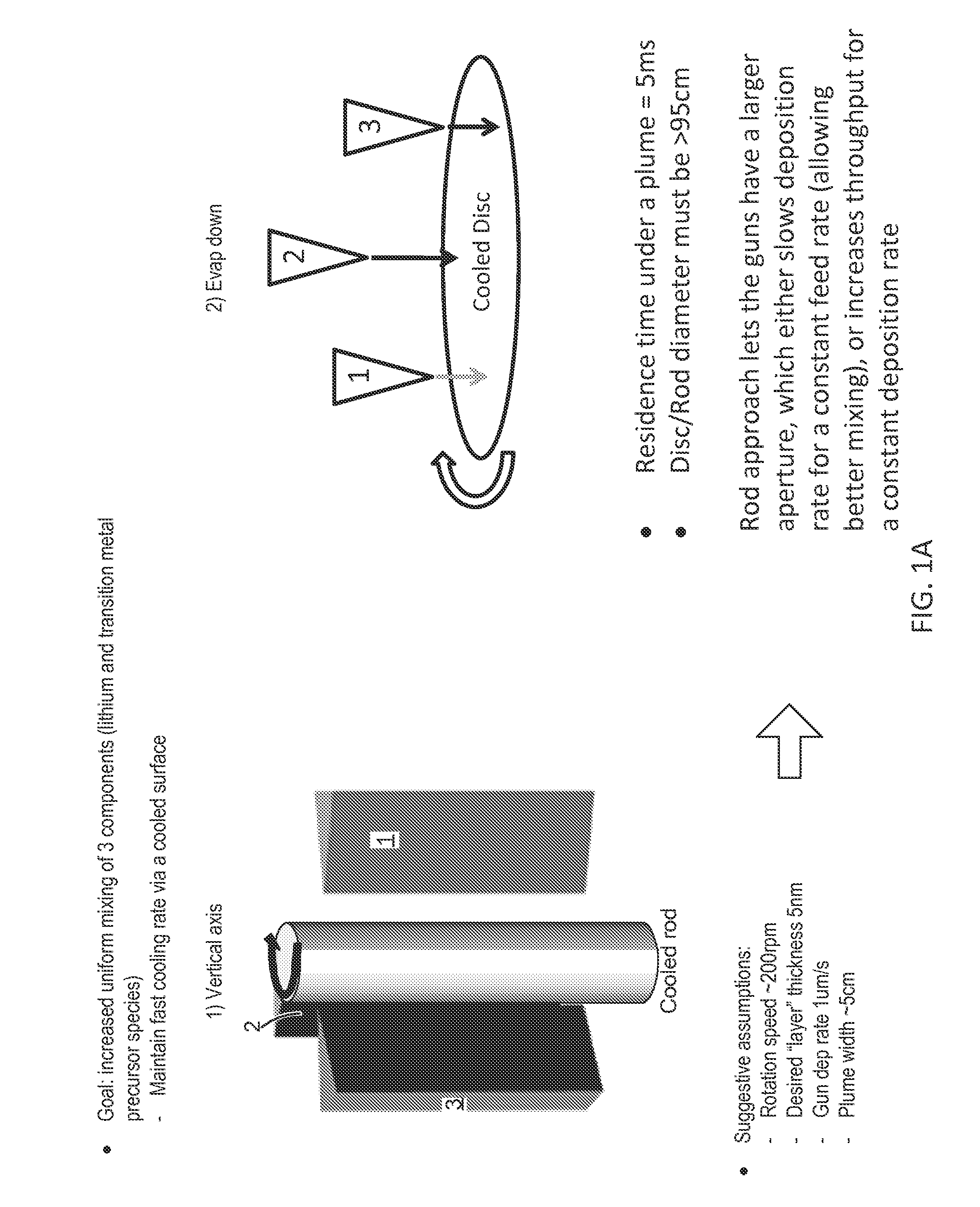

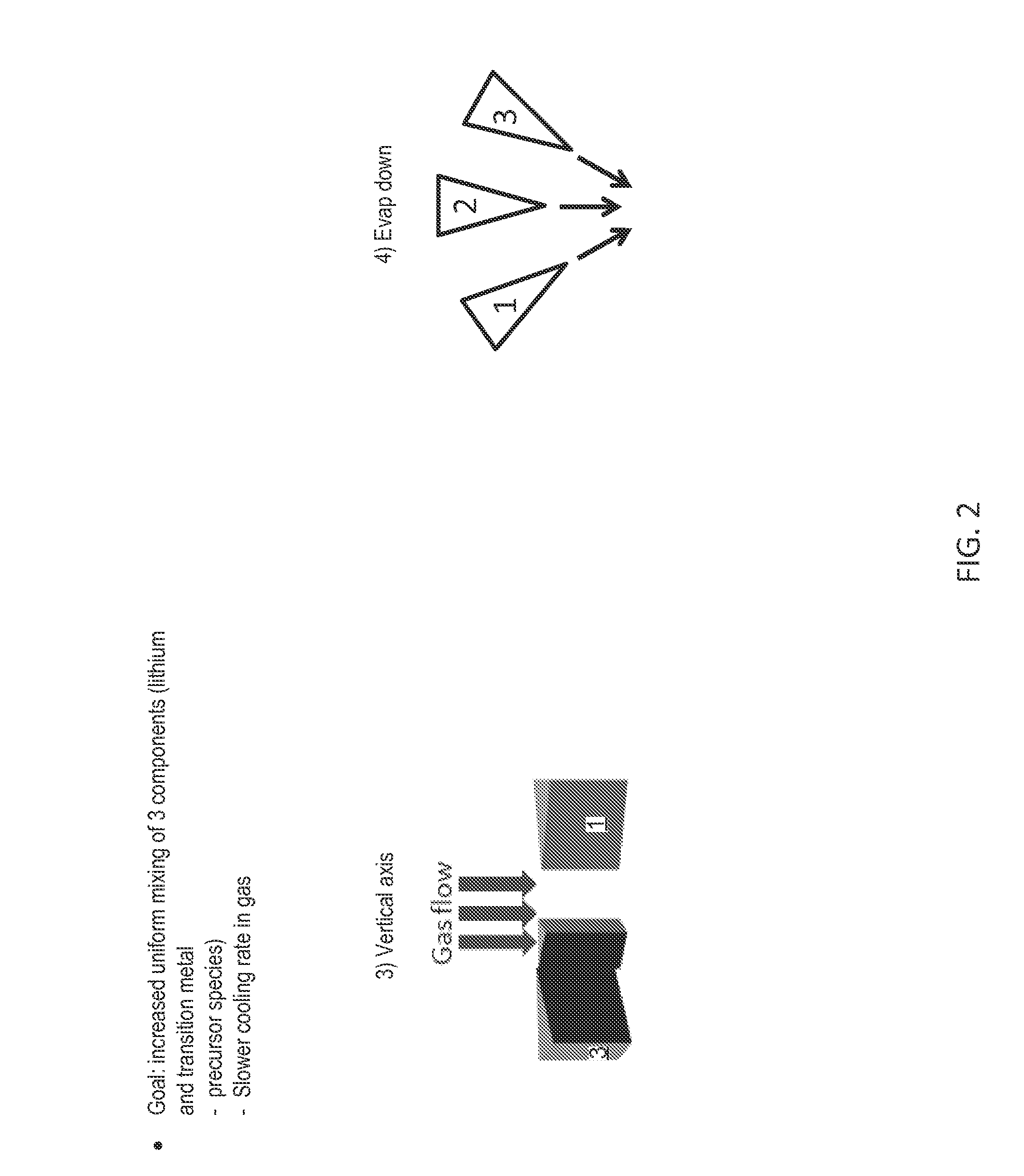

Flash evaporation of solid state battery component

ActiveUS20160093874A1Improve rate performanceShort diffusion pathTransportation and packagingMetal-working apparatusEngineeringSolid-state battery

In an example, the present invention provides a method for forming a film of material for a solid state battery or other energy storage device. The method includes providing a first precursor species, and providing a second precursor species. The method also includes transferring the first precursor species through a first nozzle and outputting the first precursor species in a first molecular form and transferring the second precursor species through a second nozzle and outputting the second precursor species in a second molecular form. The method includes causing formation of first plurality of particles, ranging from about first diameter to about a second diameter, by intermixing the first precursor species with the second precursor species. The method also includes cooling the first plurality of particles at a rate of greater than 100° C. / s to a specified temperature.

Owner:QUANTUMSCAPE BATTERY INC

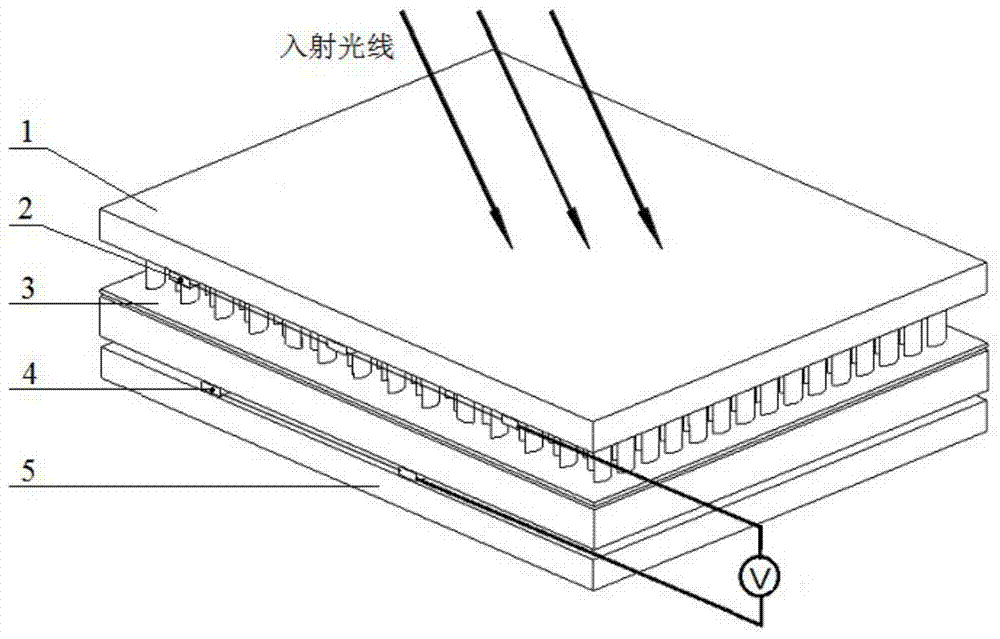

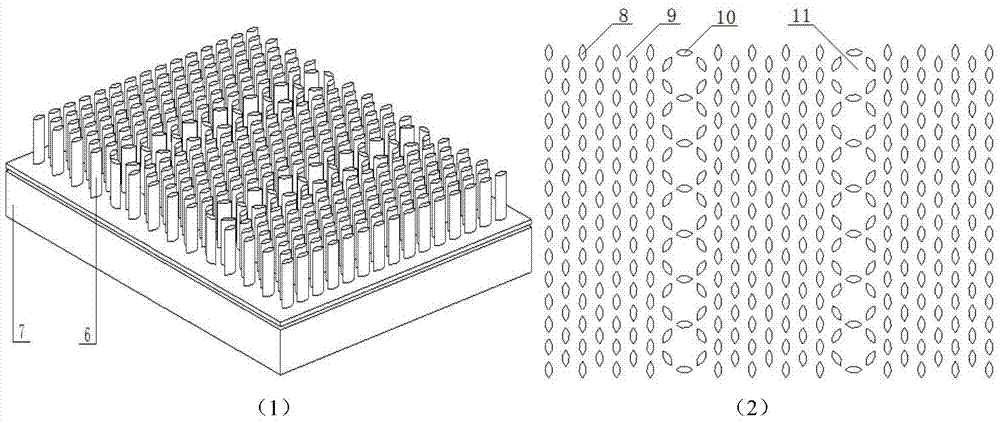

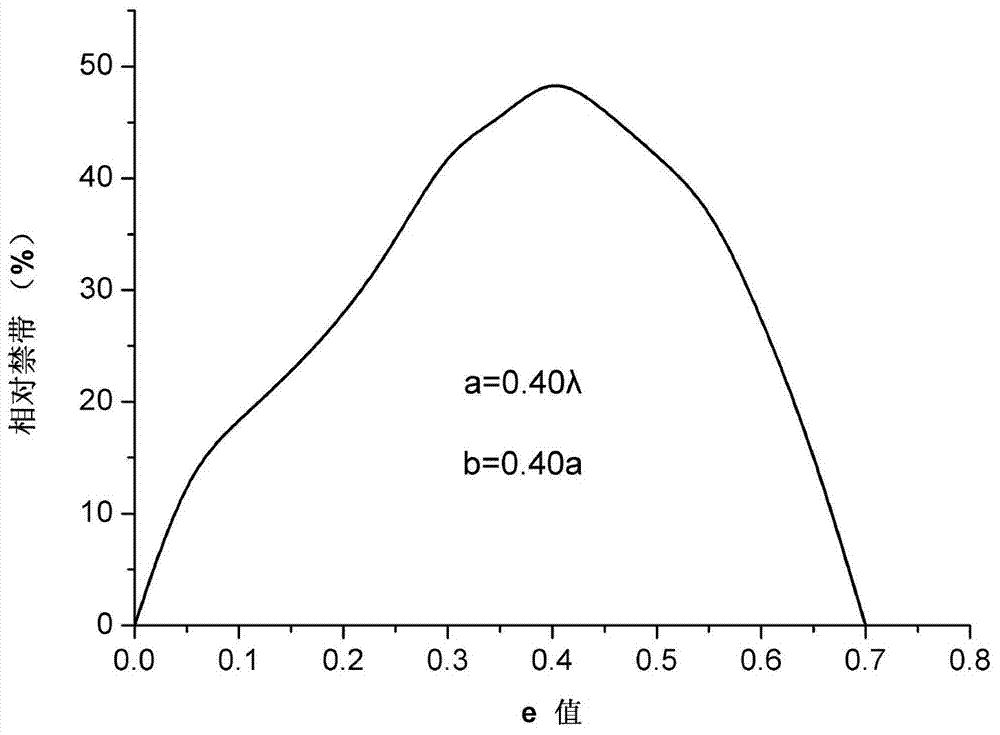

Two-dimensional silicon-based micro-nano photonic crystal solar cell

InactiveCN104241428AIncrease collection rateImprove photoelectric conversion efficiencyPhotovoltaic energy generationSemiconductor devicesMicro nanoContact layer

The invention belongs to the technical field of solar cells, and relates to a two-dimensional silicon-based micro-nano photonic crystal solar cell. The two-dimensional silicon-based micro-nano photonic crystal solar cell is characterized in that front electrodes which are periodically arrayed are arranged on the lower side surface of a front contact layer; a two-dimensional silicon-based micro-nano photonic crystal solar cell structure is arranged between the front electrodes and back electrodes, upper layers of the two-dimensional silicon-based micro-nano photonic crystal solar cell structure are type-n silicon semiconductor layers, a lower layer of the two-dimensional silicon-based micro-nano photonic crystal solar cell structure is a type-p silicon semiconductor layer, and PN junctions are formed by the type-n silicon semiconductor layers and the type-p silicon semiconductor layer; a back contact layer is arranged at the bottoms of the back electrodes, and the back contact layer and the front contact layer are made of identical materials; the back electrodes which are of aluminum thin layer structures are arranged in slow-light regions or band-gap regions of the type-p silicon semiconductor layer. The two-dimensional silicon-based micro-nano photonic crystal solar cell has the advantages that the two-dimensional silicon-based micro-nano photonic crystal solar cell is simple in structure, small in size, low in threshold, short in carrier diffusion distance and high in stability, light coupling efficiency and light transmission efficiency, is far thinner than the traditional silicon solar cell and becomes a new-generation low-cost and efficient solar cell device with the maximum potential, and mature processing and composite technologies are implemented.

Owner:QINGDAO UNIV

Method for efficiently preparing nano barium sulfate with uniform particles

InactiveCN108726554ASmall particle sizeNarrow particle size distributionMaterial nanotechnologyCalcium/strontium/barium sulfatesDispersityAfter treatment

The invention discloses a method for efficiently preparing nano barium sulfate with uniform particles. Soluble BaS raw ore is used as a raw material to prepare the nano barium sulfate by virtue of pretreatment, main reaction and after-treatment. The method specifically comprises the following steps: adding the raw material soluble BaS raw ore into deionized water, dissolving to obtain a 0.1 to 5 mol / L BaS solution, wherein the BaS solution is used as a reaction solution a for standby use; preparing a sulfuric acid solution with the same concentration as the reaction solution a, wherein the sulfuric acid solution is a reaction solution b which is used for the standby use; pumping the reaction solution a and the reaction solution b into a micro reactor to react at a speed of 50 to 150 ml / min, standing for 0.1 to 20 s in the micro reactor, collecting a product c at an outlet of the micro reactor, and recovering H2S gas generated in the main reaction; and centrifuging, washing and drying the product c to obtain a target object nano barium sulfate with uniform particles. The nano barium sulfate product prepared by the method has the characteristics of uniformity in size distribution, good dispersity, narrow distribution of particle size and the like, and the particle size of the product is in a range of 30 to 50 nm.

Owner:KUNMING UNIV OF SCI & TECH

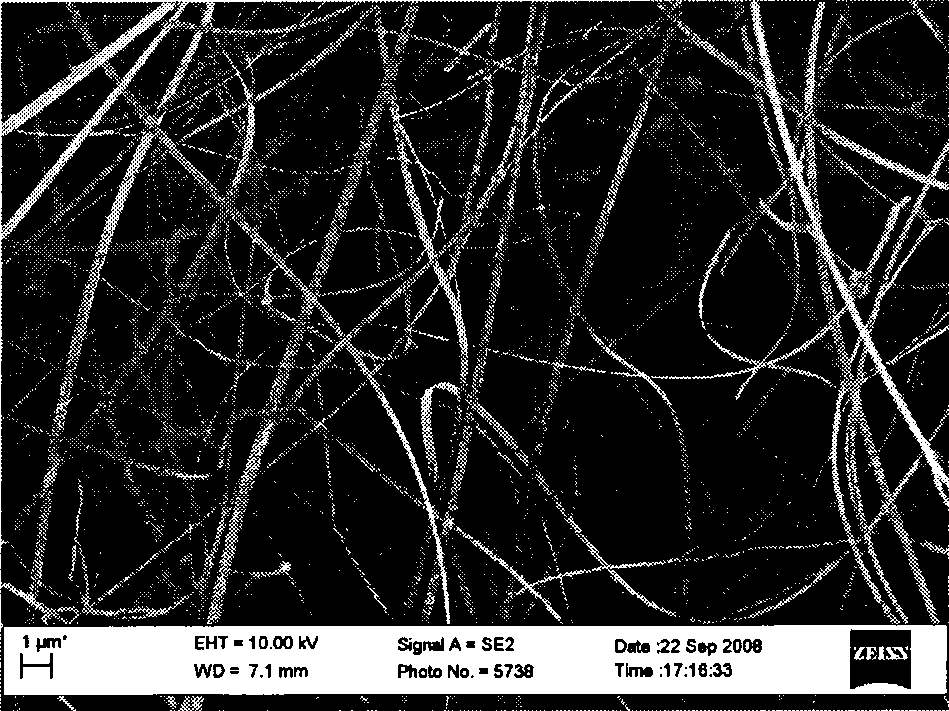

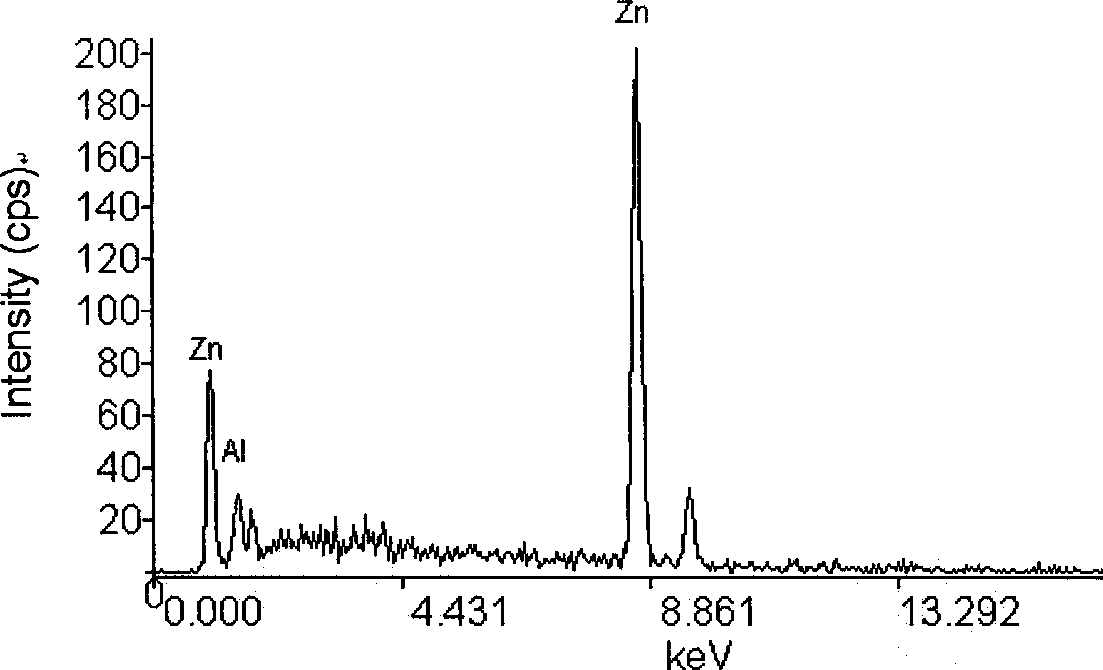

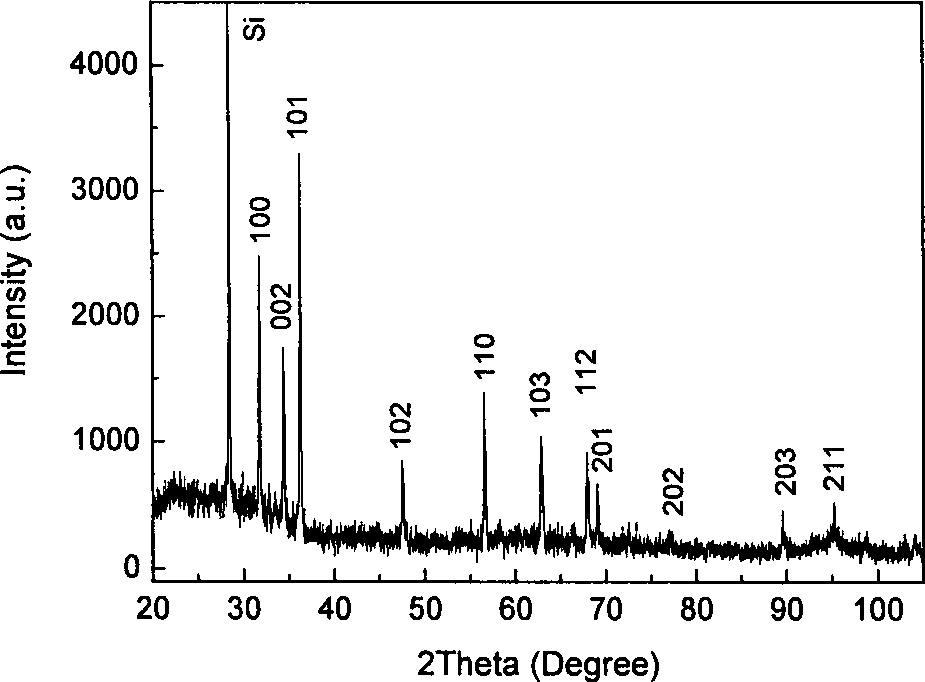

Preparation of aluminum doped zinc oxide nano-wire

InactiveCN101372356ASuitable for industrial productionReproducibleZinc oxides/hydroxidesAluminum doped zinc oxideRoom temperature

A method for preparing an aluminum-doped zinc oxide nanowire belongs to the field of photoelectric information functional materials. In the method, zinc powder and aluminum powder are taken as an evaporator source, and adjacently put in an aluminum oxide boat; the washed silicon wafer is put at a position 1-2mm vertical distance from and over the evaporator source, and then the boat is put in a horizontal tubular furnace which is heated to 800-850 DEG C and heat is preserved for 45-60min; in the whole growth process, argon is consecutively introduced into the furnace chamber at the flow rate of 40-50ml / min, when the growth is completed, the tubular furnace naturally cools to room temperature, and then the silicon wafer is taken out with the surface sedimented with the aluminum-doped zinc oxide nanowire. The method can synthesize the aluminum-doped zinc oxide nano-wire with the diameter of 40-370nm and the length of 30-150mum under the normal pressure without any vacuum equipment; in addition, the synthesis temperature is low, which greatly lowers the production cost.

Owner:UNIV OF SCI & TECH BEIJING

A carbon-coated nano-lithium titanate composite material and its preparation method and application

ActiveCN104681804BLarge specific surface areaImprove high rate charge and discharge performanceMaterial nanotechnologyHybrid capacitor electrodesUltrasonic dispersionCarbon coated

Owner:SOUTH CHINA NORMAL UNIVERSITY

Foam type tritium breeder and a preparation method thereof

InactiveCN109859858ADiffusion distance is shortFacilitated releaseNuclear energy generationThermonuclear fusion reactorGas phaseContact force

The invention discloses a foam type tritium breeder and a preparation method thereof. The main body of the foam type tritium breeder is an open cell foam made of the breeder material, which is beneficial to the tritium release and heat transfer of the material. A layer of skeleton structure can be formed on that inner surface of the breeder foam as needed to reduce steam transport of the breeder at high temperatures and in a hydrogen environment, and a layer of low density foam can be deposited on the outer layer of the whole foam to relieve contact force. The foam type tritium breeder is madeby using reticulated glassy carbon foam as template and melt solidification method to ensure that the final foam has a connected gas phase, while the skeleton and buffer foam can be produced by chemical vapor injection method and chemical vapor deposition method respectively. The foam type tritium breeder of the present invention can improve the loading density and thermal conductivity of lithiumatoms, improve the structural stability of the breeder, and improve the tritium proliferating performance and thermal safety of the cladding layer. The preparation method of the foam type tritium breeder of the present invention is simple and easy to produce on a large scale.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Integrated structure of optical fiber provided with label-free optical sensing element on one end face and microfluid

ActiveCN104165841AReduce usageDiffusion distance is shortMaterial analysis by optical meansEngineeringOptical sensing

The invention provides an integrated structure of an optical fiber provided with a label-free optical sensing element on one end face and a microfluid. The structure at least comprises a microfluid structure and at least an optical fiber which is provided with a label-free optical sensing element arranged on one end of the optical fiber. The end, which is provided with the label-free optical sensing element, is inserted into the frame of the microfluid. The structure integrates an optical fiber provided with a label-free optical sensing element and a microfluid, thus has the advantages of simple structure, agility, convenience, good stability, little using amount of biological sample of microfluid chip, short diffusion distance of biomolecule, multichannel parallel detection, and integrated microfluid functions, and is suitable for industrial production.

Owner:SHANGHAI JIAO TONG UNIV

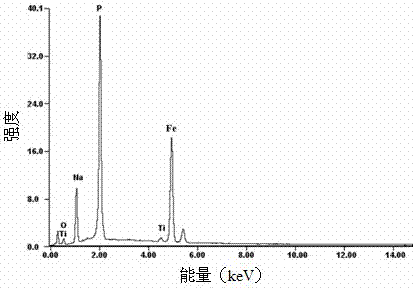

Method for preparing maleic anhydride through n-butane

InactiveCN104557817AShort diffusion timeDiffusion distance is shortPhysical/chemical process catalystsOrganic chemistryChemical reactionActive component

The invention relates to a method for preparing maleic anhydride through n-butane. The method comprises the following steps: contacting and chemically reacting n-butane and air which serve as the raw materials and a vanadium phosphorus oxide / foamed SiC structural catalyst which is used as an active component through a reactor to obtain a maleic anhydride product, wherein the vanadium phosphorus oxide / foamed SiC structural catalyst is a structural catalyst prepared by loading a vanadium phosphorus oxide coating and / or a vanadium phosphorus oxide crystal on a SiC carrier; the chemical reaction is performed at the temperature of 350 to 550 DEG C, and the temperature is preferably 400 to 500 DEG C; the reaction pressure is 0 to 3.0MPa and preferably 0 to 1.0MPa; the foamed SiC is high in heat transfer capacity, and therefore, the phenomena of sudden inactivation and temperature runaway of the catalyst due to local overheat of the catalyst can be effectively avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

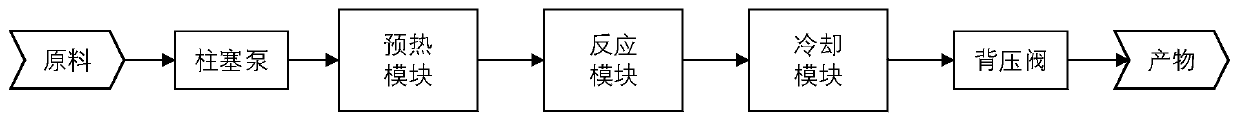

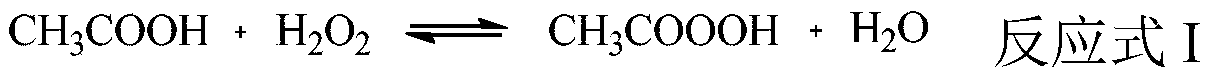

Method for quickly preparing peracetic acid through continuous flow

PendingCN111333559ASmall sizeSmall liquid holding capacityOrganic compound preparationChemical/physical/physico-chemical microreactorsProcess engineeringManufacturing engineering

The invention provides a method for quickly preparing peracetic acid by continuous flow, which utilizes a continuous flow micro-channel reactor for reaction, and comprises the following steps: 1) mixing acetic acid, a hydrogen peroxide solution, a catalyst and a stabilizer, and introducing the mixture into a micro-channel reaction preheating module; (2) enabling the mixture preheated in the step (1) to continuously enter a micro-channel reaction module, wherein the reaction temperature range is 80-150 DEG C, the pressure is maintained at 0.5-2.0 MPa, and the retention time is 10-200 seconds; and 3) enabling a product obtained at the outlet of the micro-channel reaction module in the step 2) to enter a cooling module. By utilizing the characteristics of the micro-channel reactor, the peroxyacetic acid can be quickly prepared by continuous flow, and compared with the traditional process, the method has the advantages that the reaction time is greatly shortened, the production efficiencyis improved, the safety risk is effectively reduced, and industrial amplification and production are easy to perform.

Owner:CHINA TIANCHEN ENG

A kind of titanium-doped carbon-coated sodium iron phosphate material and preparation method thereof

ActiveCN105140489BImprove conductivityImprove electrochemical performanceSecondary cellsPositive electrodesPhosphateSodium-ion battery

The invention relates to a titanium-doped carbon-coated sodium ferric phosphate material and a preparation method thereof. The titanium-doped carbon-coated sodium ferric phosphate material is prepared by virtue of the following method: taking cane sugar as a carbon source, taking ethanol as a dispersing agent, ball milling FeC2O4, NaH2PO4.2H2O, cane sugar and TiO2 in the ethanol, drying, re-milling, and calcining, to obtain the titanium-doped carbon-coated sodium ferric phosphate material. The particle size of primary particles of the titanium-doped carbon-coated sodium ferric phosphate material is 100nm to 300nm, the titanium-doped carbon-coated sodium ferric phosphate material has characteristics of short sodium ion dispersion distance, high transmission rate, high specific surface area, high conductivity, high ion transmission speed and the like, and is excellent in electrochemical performance, capable of being used as a positive material of a secondary sodium-ion battery, high in safety, cheap in price, wide in application range and applicable to an energy storage device, a backup power supply, a reserved power supply and the like. The preparation method is low in synthetic temperature, simple in procedures, easy for obtaining raw materials and convenient in industrialization.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com