SAPO molecular sieve, and preparation method and purpose thereof

A molecular sieve, sheet-like structure technology, applied in molecular sieve and alkali-exchanged phosphate, molecular sieve catalyst, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of complex maintenance and operation, large investment, difficult to achieve, etc., to increase utilization efficiency , low energy consumption and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

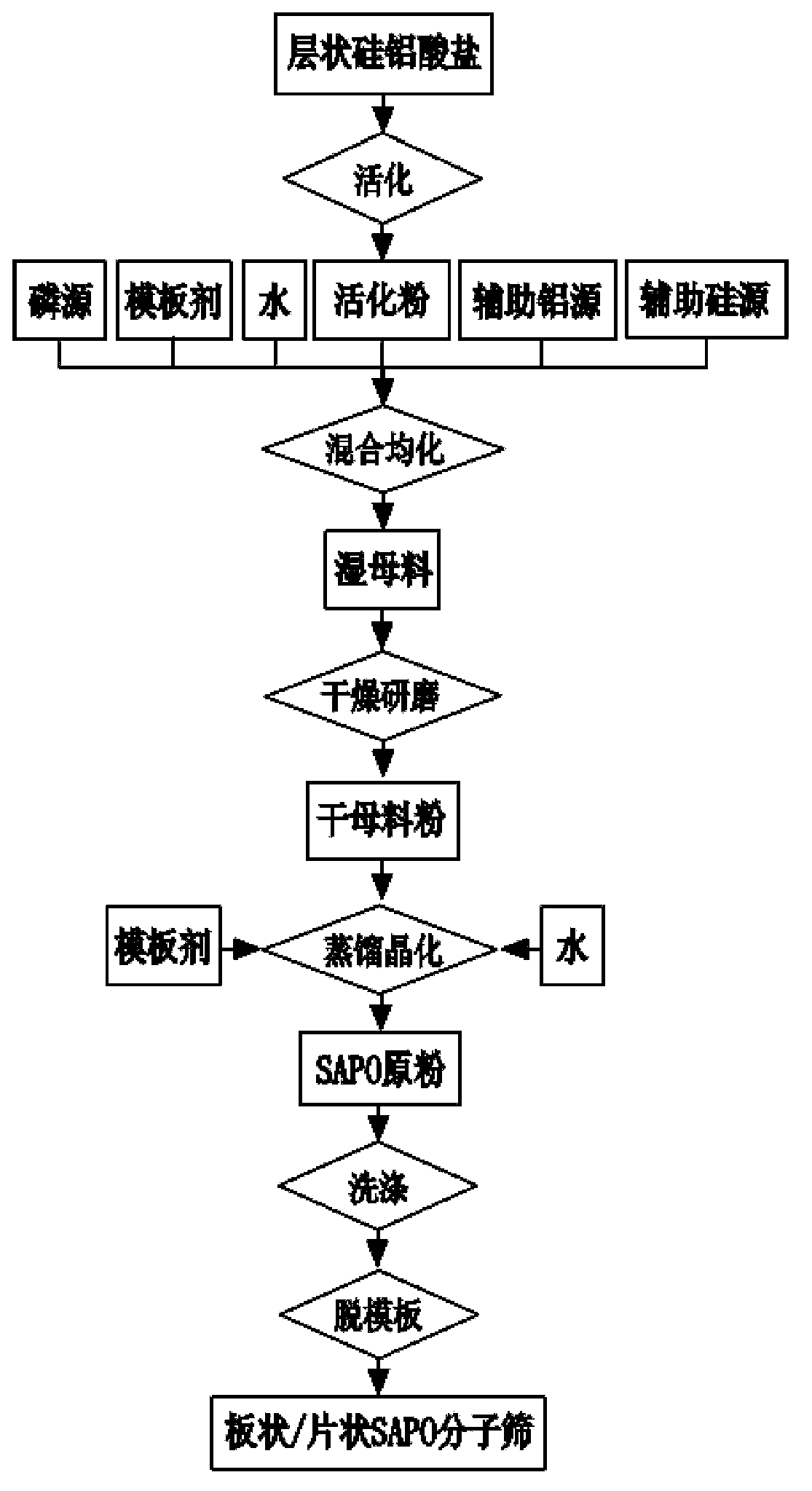

[0101] As an embodiment of the present invention, the preparation method of sheet SAPO molecular sieve of the present invention comprises the following steps:

[0102] (1) Activated layered aluminosilicate;

[0103] (2) Mix and homogenize the activated layered aluminosilicate, phosphorus source, auxiliary aluminum source, auxiliary silicon source and water to prepare a wet masterbatch; wherein, SiO in the wet masterbatch 2 、Al 2 o 3 ,P 2 o 5 、H 2 The molar ratio of O and template is (0.01-2):(0.1-1.5):(0.1-1.5):(1-500):(0-10);

[0104] (3) Dry and grind the wet masterbatch to obtain dry masterbatch powder;

[0105] (4) Place the dry masterbatch powder above the templating agent aqueous solution with a concentration of 0-90w%, raise the temperature to 160-370°C, and carry out distillation and crystallization by relying on the steam of the templating agent aqueous solution; distill and crystallize the dry masterbatch powder Obtain SAPO molecular sieve raw powder;

[0106...

Embodiment 1

[0114] A kind of preparation method of flaky SAPO molecular sieve comprises the steps:

[0115] (1) Grinding Suzhou kaolin (90.5% kaolinite content) to an average particle size of less than 0.3 μm to obtain a grinding activated powder;

[0116] (2) Take 30.0g of grinding activation powder and add it to 200.0g of deionized water, then add 52.0g of 85.0% concentrated phosphoric acid, 16.4g of pseudo-boehmite (78.2% alumina content), 20.0g of morpholine, Stir vigorously to obtain a wet masterbatch; in the wet masterbatch, SiO 2 、Al 2 o 3 ,P 2 o 5 、H 2 The mol ratio of O and templating agent is 0.244:0.248:0.226:11.54:0.230;

[0117] (3) Evaporate the above wet masterbatch to dryness in an oven at 120°C, and grind it until the average particle size is less than 50 μm to obtain dry masterbatch powder;

[0118] (4) Place 10.0 g of the above-mentioned dry masterbatch powder above 50 mL of 40.0% morpholine aqueous solution, distill and crystallize at 200 ° C for 120 h, and cool...

Embodiment 2

[0123] A method for preparing sheet-like SAPO molecular sieves, using Example 1 to prepare the solution of distillation and crystallization after rhombohedral sheet-like SAPO-34 molecular sieves, and continue to place 10.0 g of dry masterbatch powder (the same proportion as in Example 1) In the upper part of the still, keep the morpholine solution in the lower part of the still from being taken away, distill and crystallize at 200 ° C for 120 hours, cool, and the solid is rhombohedral or flaky SAPO-34 molecular sieve raw powder.

[0124] Put the raw molecular sieve powder in a muffle furnace, raise the temperature to 550°C at 2°C / min in flowing air, keep it warm for 4 hours, perform template removal treatment, and cool naturally to room temperature to obtain rhombohedral flaky SAPO-34 molecular sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com