Patents

Literature

337results about How to "Improve diffusion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

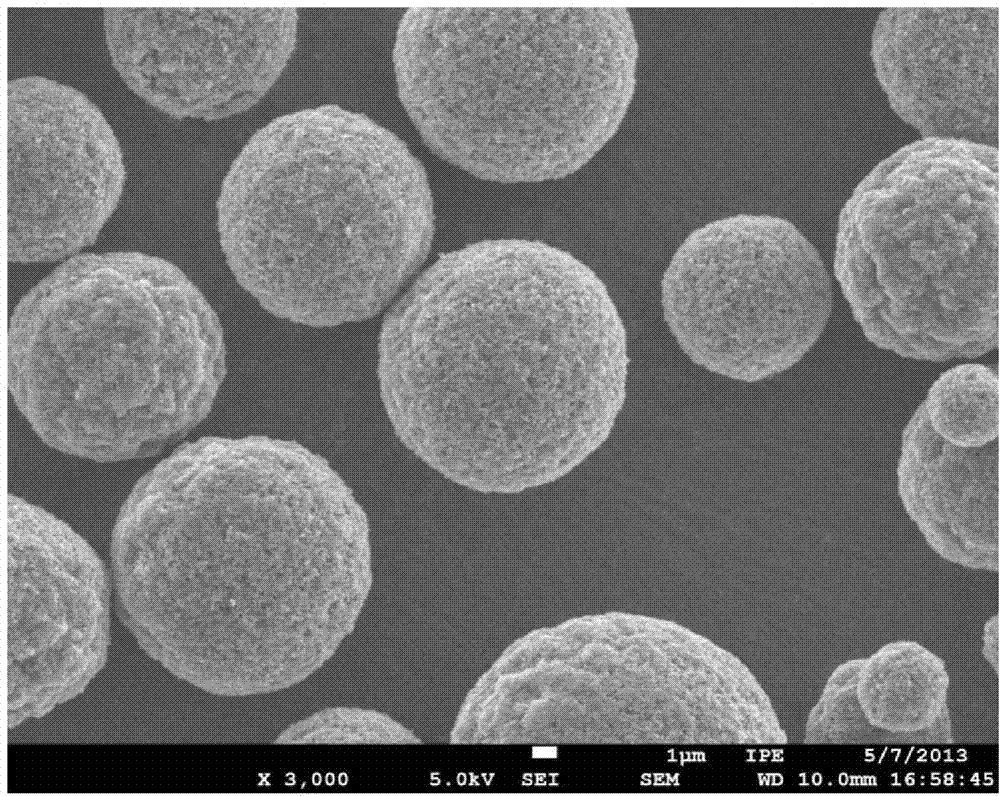

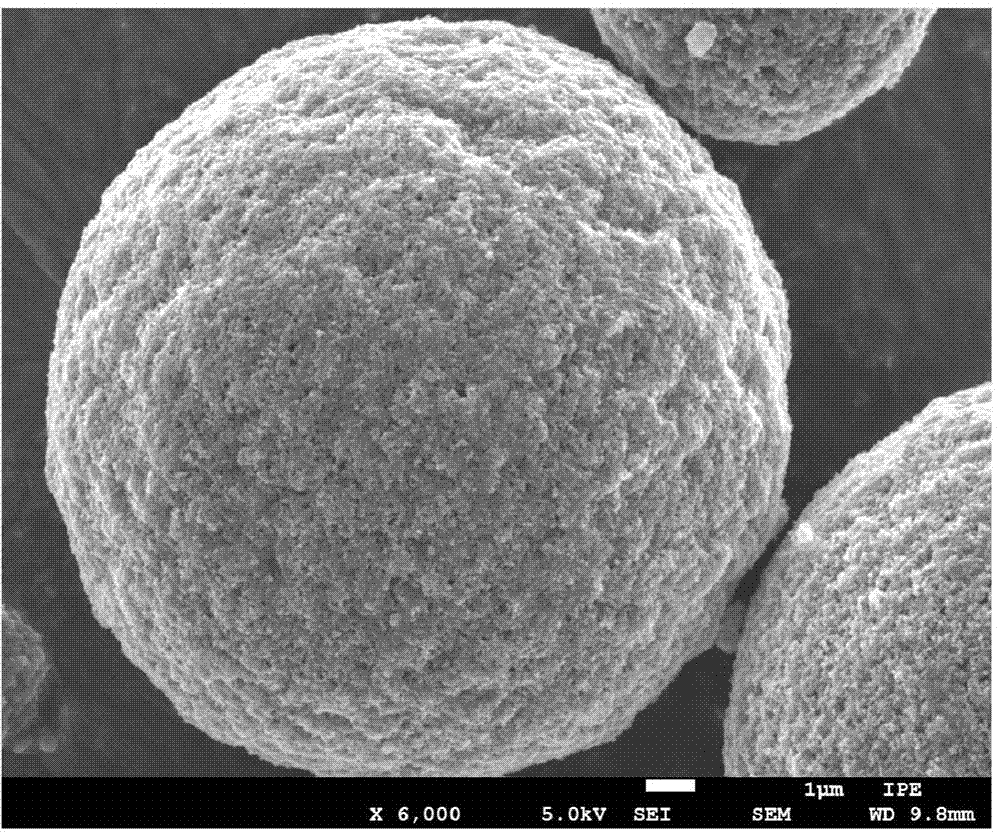

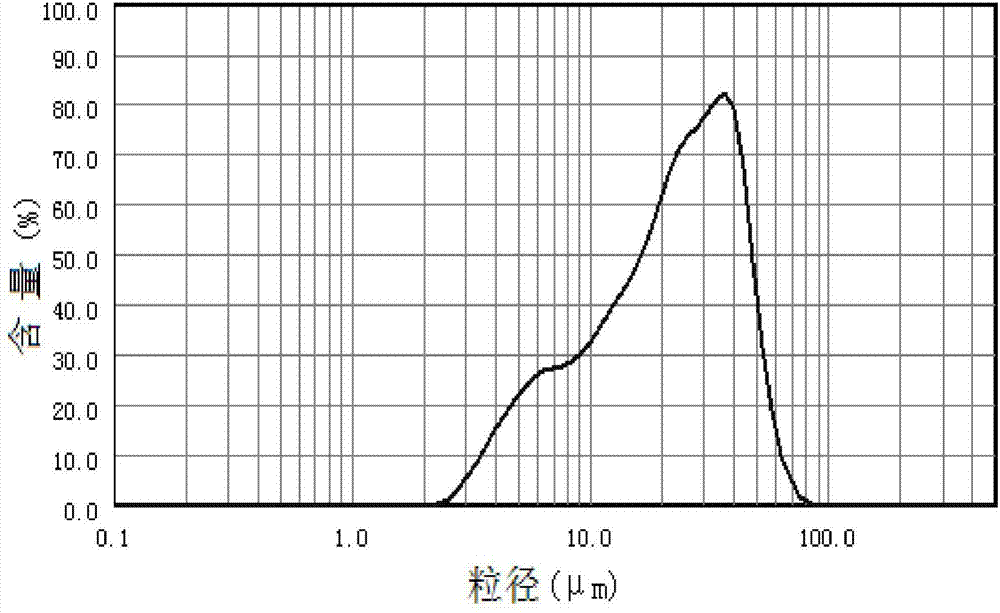

Carbon microspheres with high specific surface area and preparation method for carbon microspheres with high specific surface area

The invention relates to a preparation method for carbon microspheres with high specific surface area. The preparation method includes the following steps: a carbon material, an alkaline activator, a binder and a solvent are mixed and stirred to obtain slurry, or the alkaline activator, the binder and the solvent are mixed and stirred to obtain slurry; all the materials are granulated to obtain primary carbon microspheres; the primary carbon microspheres go through activation, pickling, washing and drying to obtain the carbon microspheres with the high specific surface area. The preparation method provided by the invention adopts low-value carbonaceous waste materials or amorphous carbonaceous raw powders to prepare the microsphere carbon material with the high specific surface area, so as to meet the use requirements of multiple fields; the preparation technique is simple, the operation is convenient, and large-scale production is facilitated; the prepared carbon microspheres with the high specific surface area have an excellent spherical structure, a high degree of sphericity and a controllable particle size, and barely contain metal impurities.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

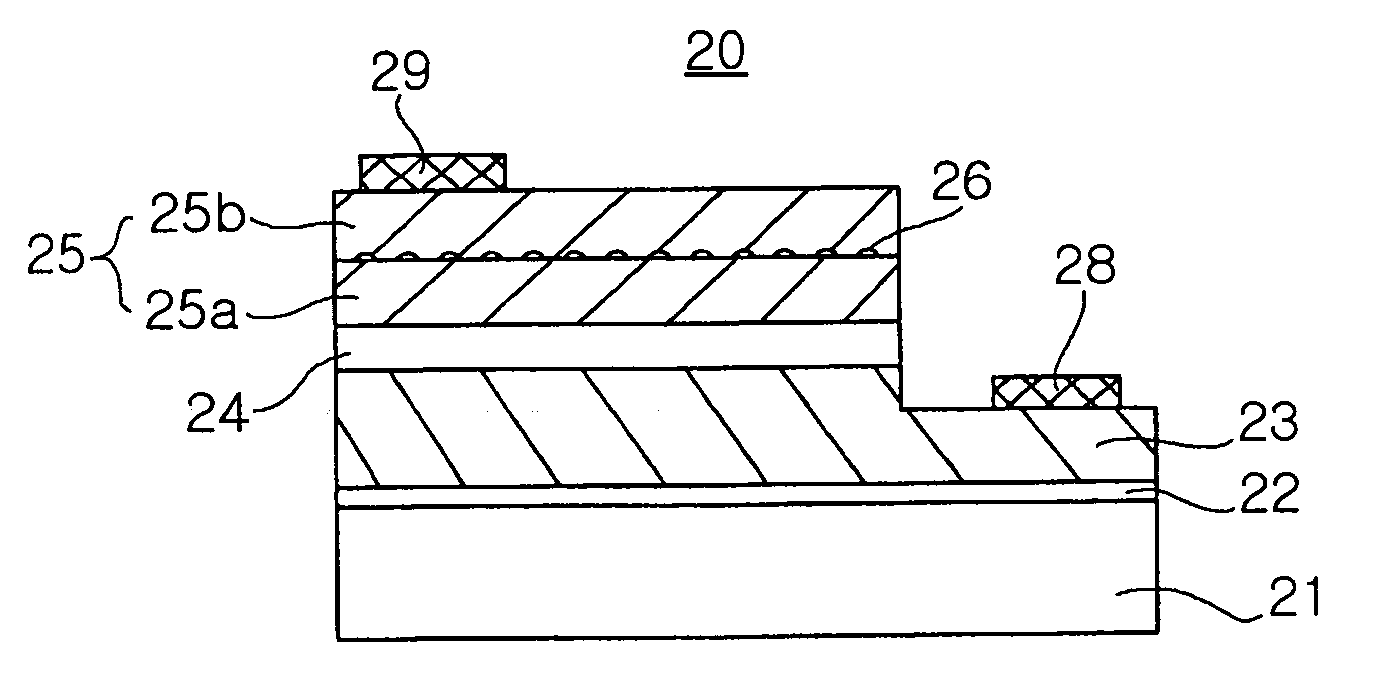

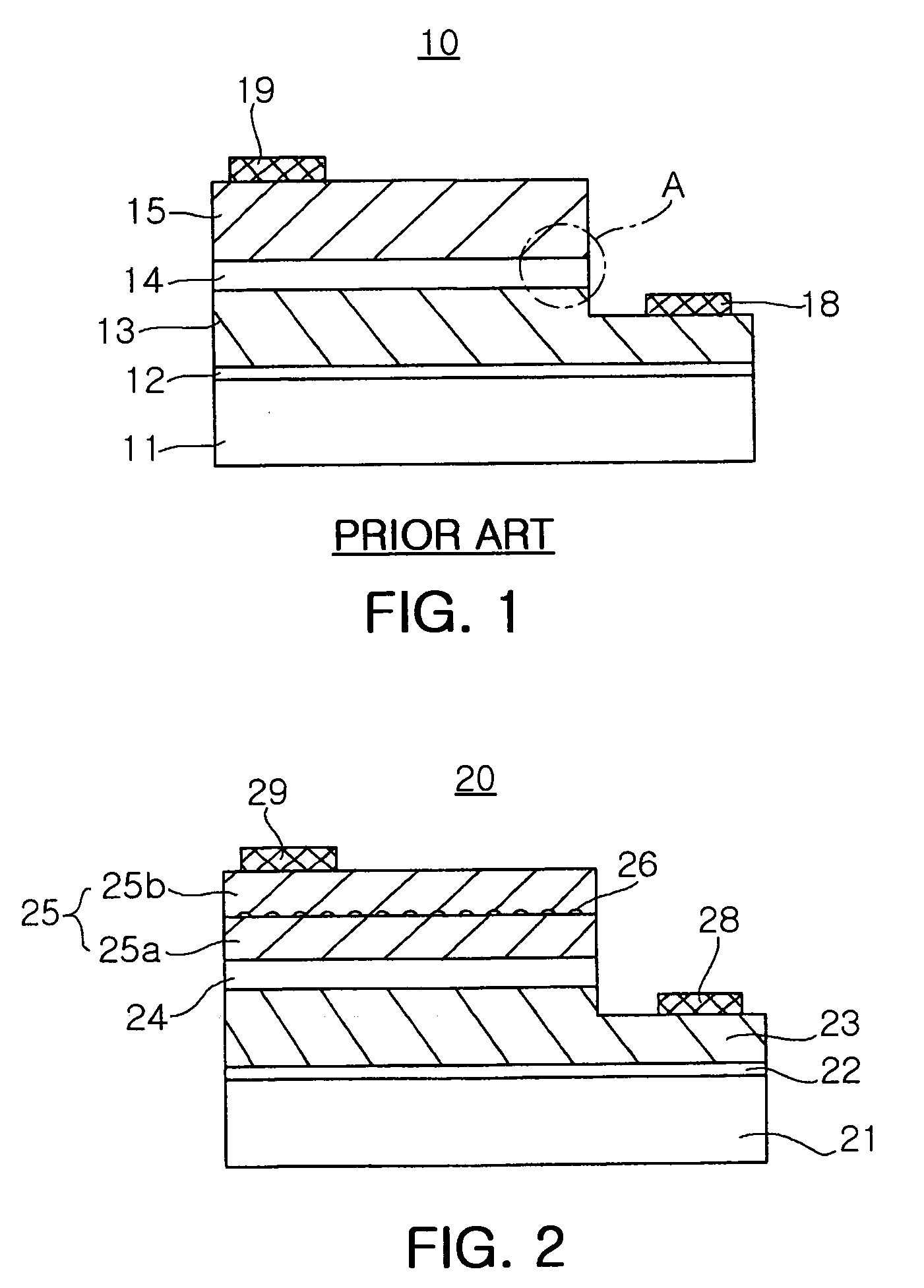

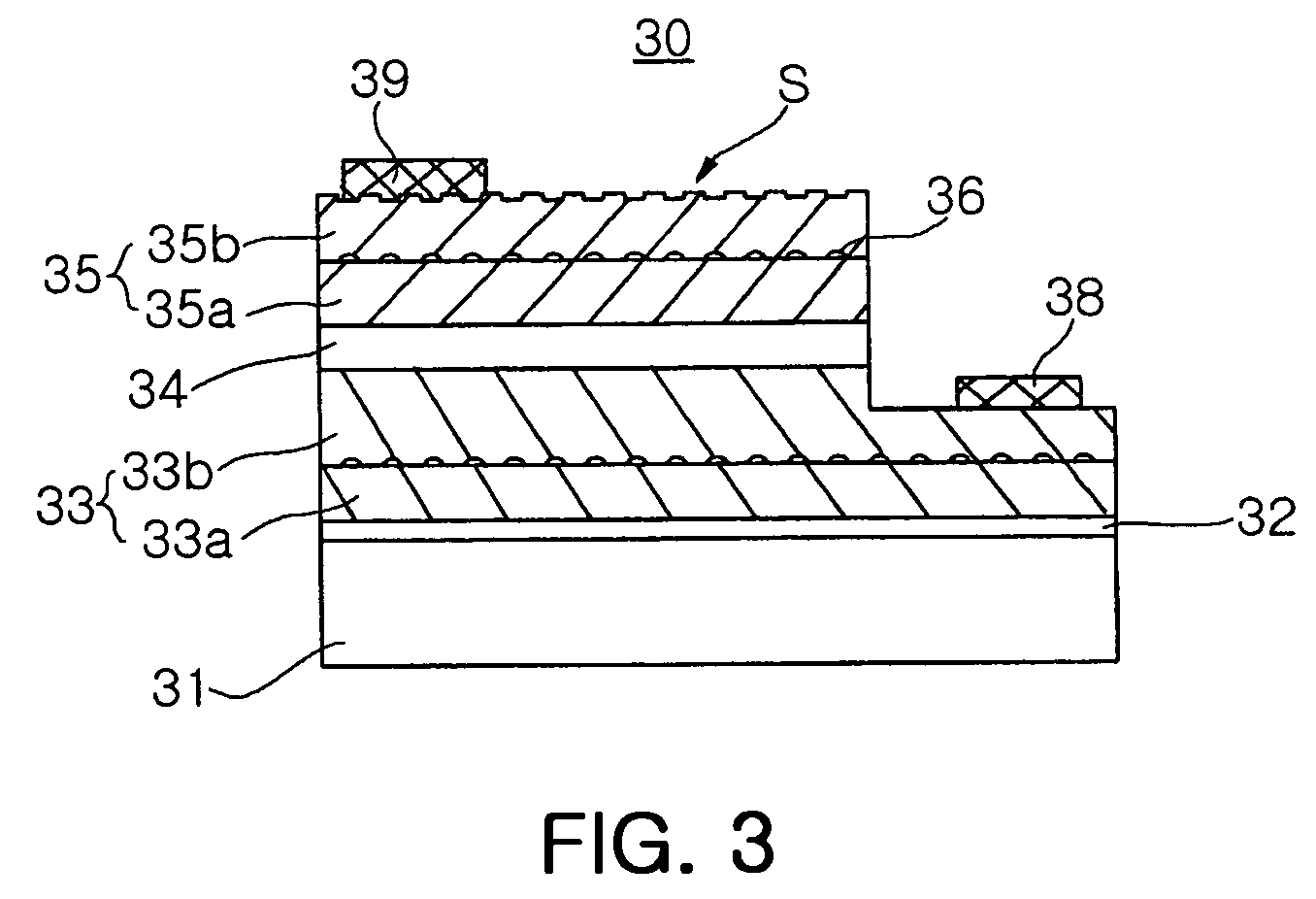

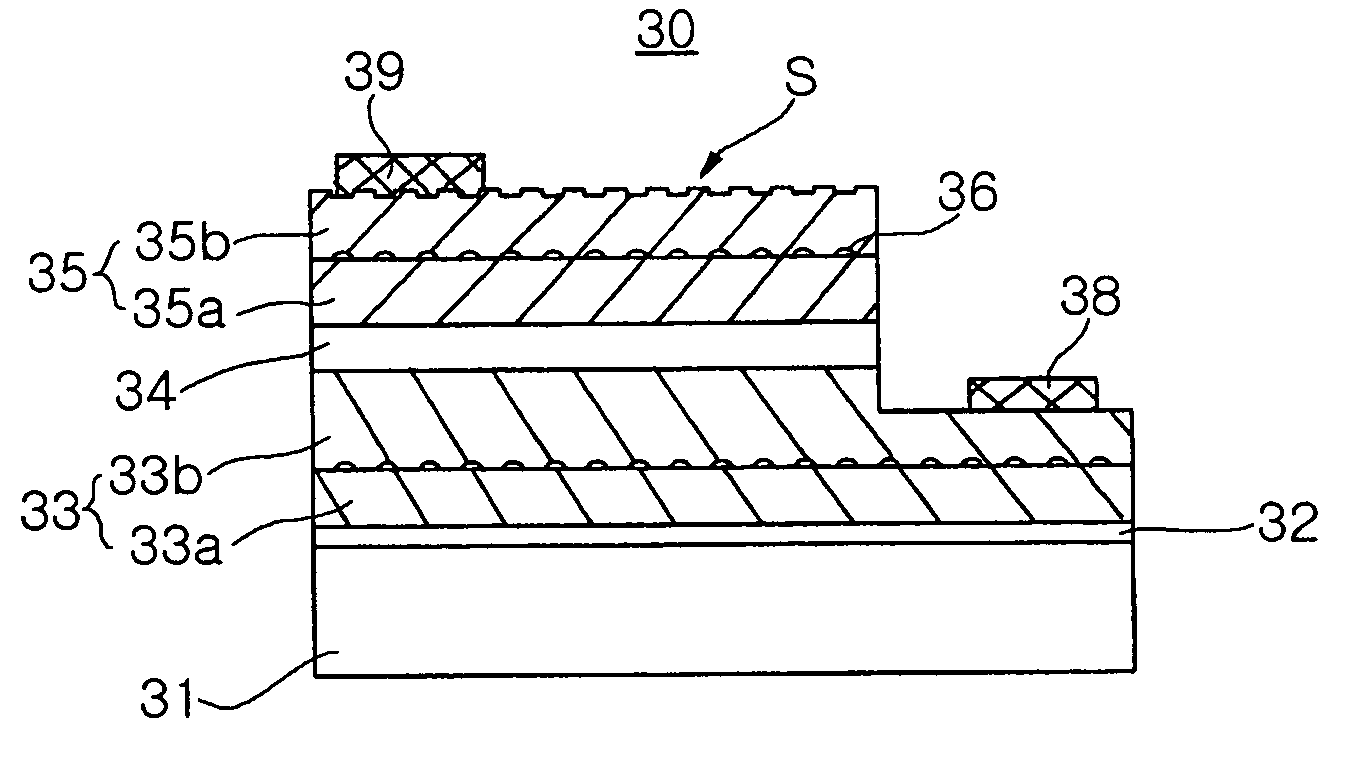

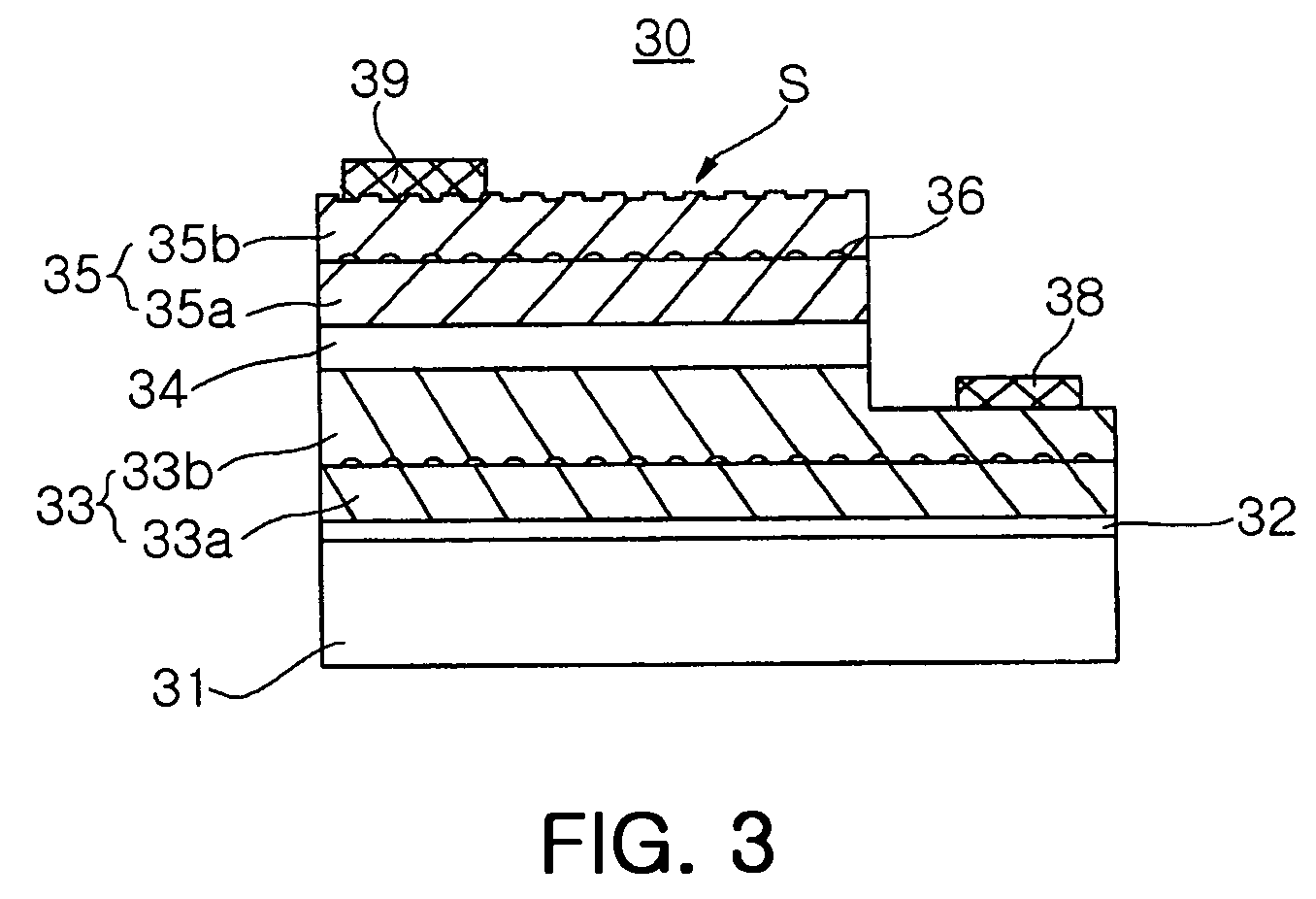

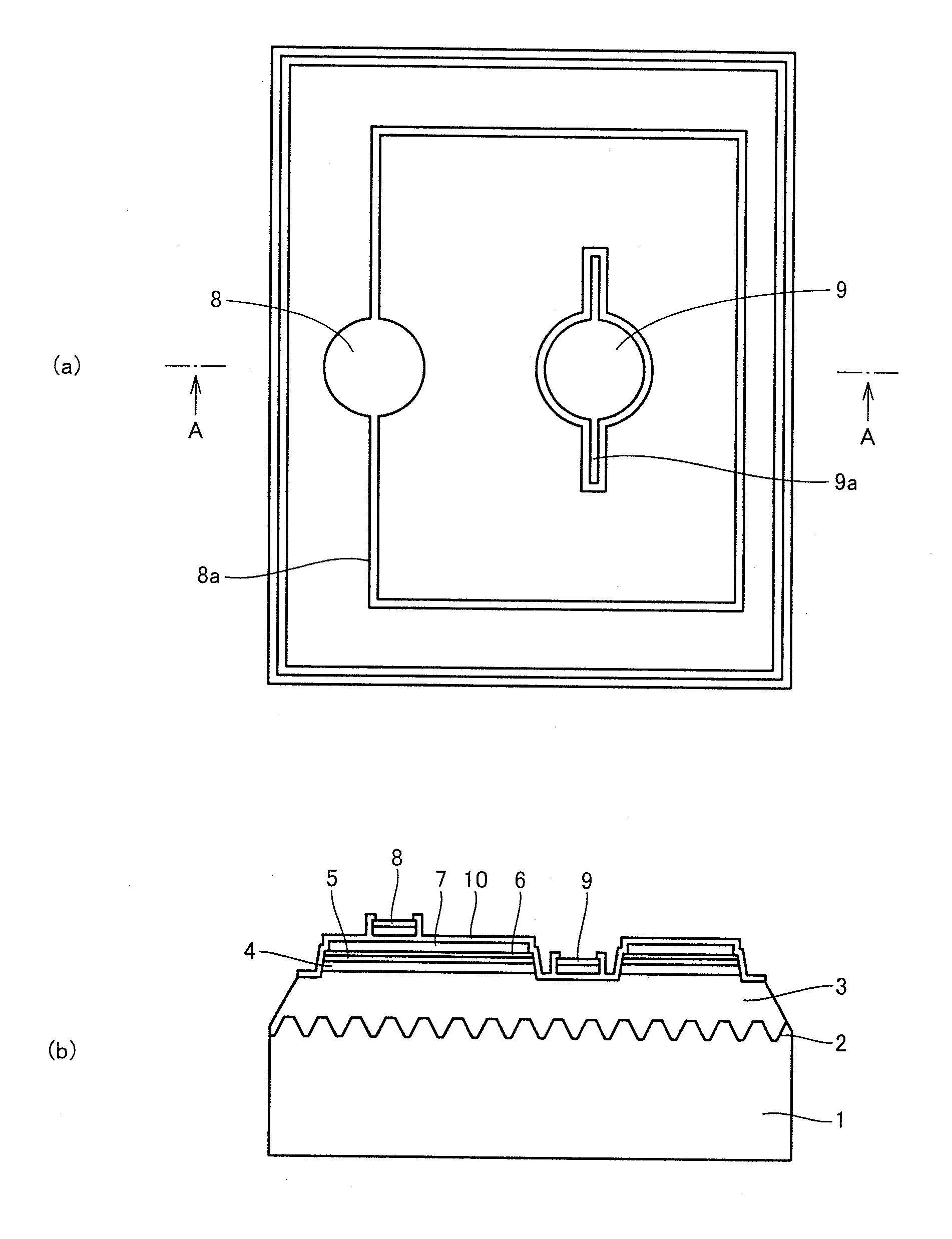

Nitride semiconductor device and method of manufacturing the same

InactiveUS20060006407A1Improve diffusion efficiencyImprove surface roughnessSolid-state devicesSemiconductor/solid-state device manufacturingActive layerCrystal growth

The present invention provides a nitride semiconductor device. The nitride semiconductor device comprises an n-type nitride semiconductor layer formed on a nitride crystal growth substrate. An active layer is formed on the n-type nitride semiconductor layer. A first p-type nitride semiconductor layer is formed on the active layer. A micro-structured current diffusion pattern is formed on the first p-type nitride semiconductor layer. The current diffusion pattern is made of an insulation material. A second p-type nitride semiconductor layer is formed on the first p-type nitride semiconductor layer having the current diffusion pattern formed thereon.

Owner:SAMSUNG ELECTRONICS CO LTD

Nitride semiconductor device and method of manufacturing the same

InactiveUS7187007B2Improve diffusion efficiencyImprove surface roughnessSolid-state devicesSemiconductor devicesActive layerCrystal growth

The present invention provides a nitride semiconductor device. The nitride semiconductor device comprises an n-type nitride semiconductor layer formed on a nitride crystal growth substrate. An active layer is formed on the n-type nitride semiconductor layer. A first p-type nitride semiconductor layer is formed on the active layer. A micro-structured current diffusion pattern is formed on the first p-type nitride semiconductor layer. The current diffusion pattern is made of an insulation material. A second p-type nitride semiconductor layer is formed on the first p-type nitride semiconductor layer having the current diffusion pattern formed thereon.

Owner:SAMSUNG ELECTRONICS CO LTD

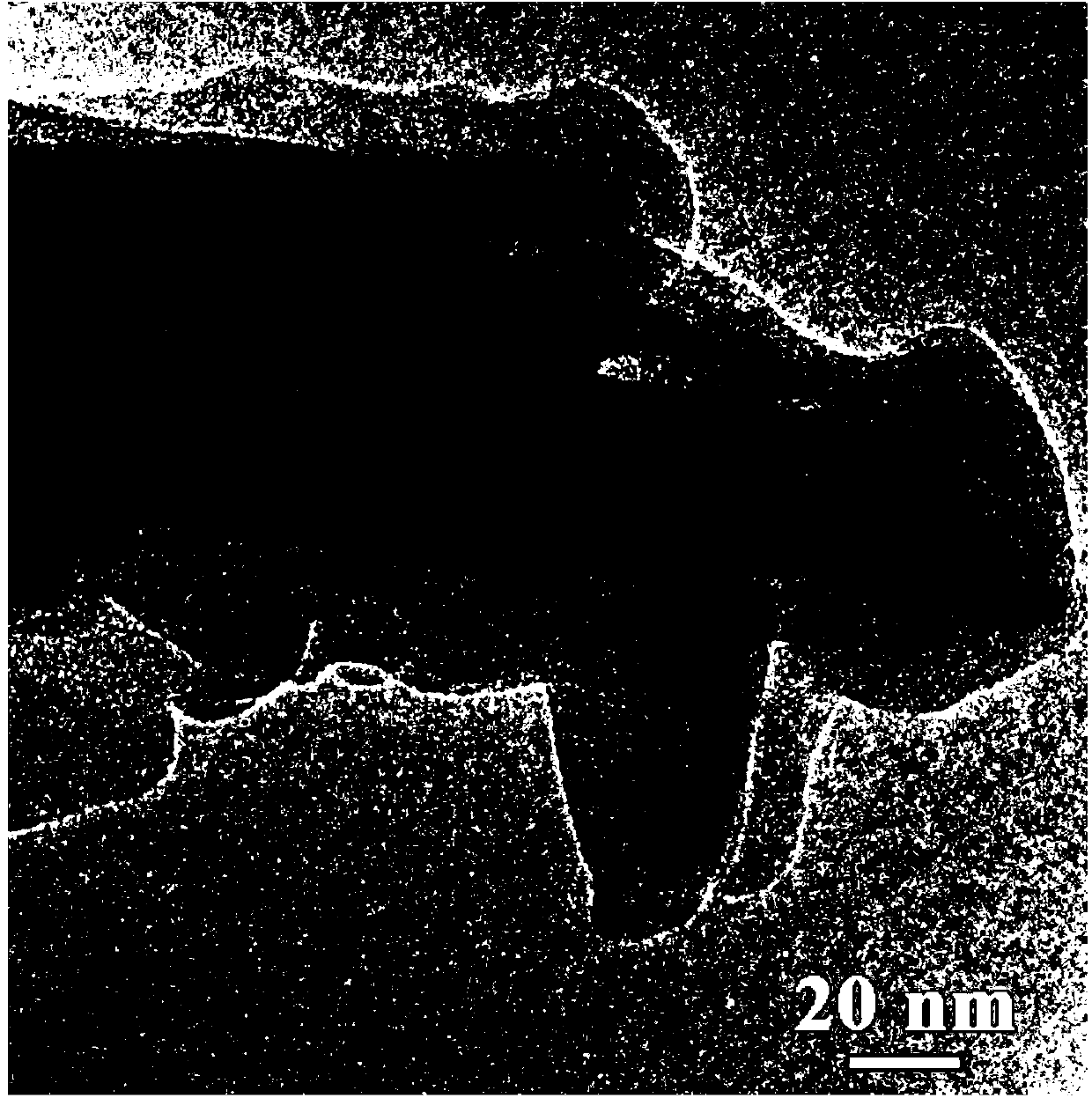

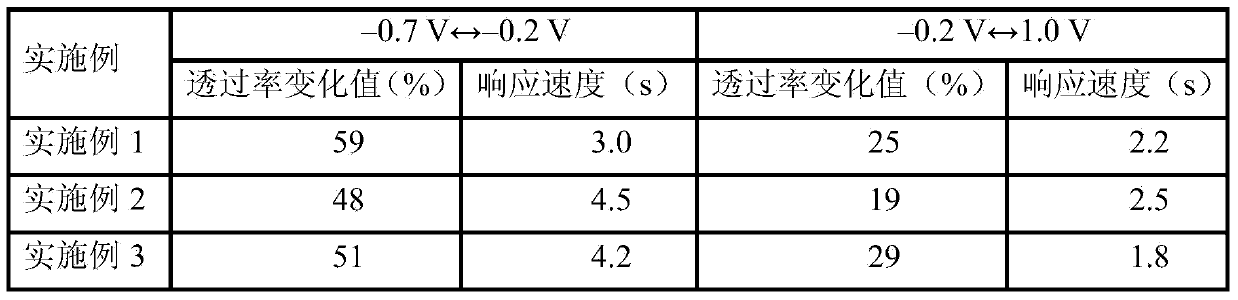

Tungsten trioxide/polyaniline core-shell nanowire array radiochromic film and preparation method thereof

ActiveCN103469272AGood electrical conductivityLarge spectrum adjustment rangeMaterial nanotechnologyNanoopticsChemistryHydrogen peroxide

The invention provides a tungsten trioxide / polyaniline core-shell nanowire array radiochromic film and a preparation method thereof. The preparation method comprises the following steps: dissolving white tungstic acid in aqueous hydrogen peroxide liquor to prepare peroxide tungstate liquor; coating the peroxide tungstate liquor on an electric conductive face of a clean electric conductive substrate; dissolving tungstate in alcohol to form precursor liquor, fixing the electric conductive substrate in a reaction kettle, adding the precursor liquor into the reaction kettle, carrying out a reaction at 150-250 DEG C for 8-16 hours, and taking out and carrying out thermal treatment at 300-450 DEG C for 1-3 hours to obtain a tungsten trioxide nanowire array; and mixing aniline and dilute sulphuric acid to form electrolyte for preparing polyaniline and carrying out electro-polymerization on polyaniline to obtain the tungsten trioxide / polyaniline core-shell nanowire array radiochromic film. The preparation process is convenient to control, lower in preparation cost and easy to realize industrialization. The film has the advantages of large spectrum adjustment range, abundant radiochromic types, high coloring efficiency, fast response speed, long cycle life and the like.

Owner:ZHEJIANG UNIV

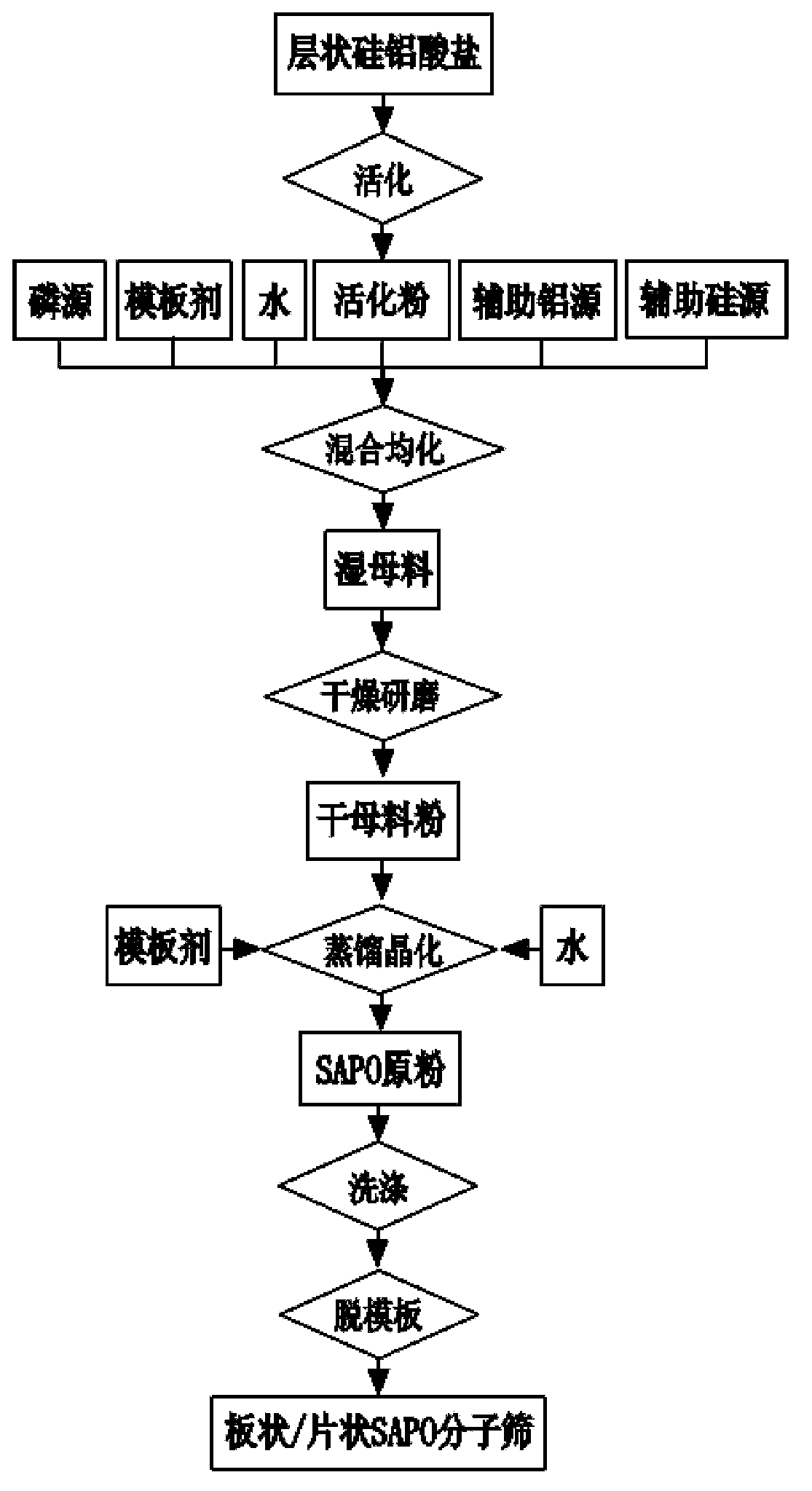

SAPO molecular sieve, and preparation method and purpose thereof

ActiveCN103964457AShorten the diffusion distanceImprove diffusion efficiencyMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMolecular sieveChemistry

The invention discloses an SAPO molecular sieve, which has single crystals in sheet structure. The SAPO molecular sieve has moderate pore size, and can be used as a catalyst with long service life for olefin preparation from methanol. The invention also discloses a preparation method of the SAPO molecular sieve. The method us as below: activating a raw material of layered aluminosilicate, mixing the raw material with an phosphorus source and water, and homogenizing to obtain a wet masterbatch; drying and grinding the wet masterbatch to obtain a dry powder; and finally distilling the dry powder for crystallization, so as to obtain a raw powder for sheet SAPO molecular sieve. The method requires addition of a template agent, realizes low cost synthesis of SAPO molecular sieve and high additional value utilization of natural layered aluminosilicate, accelerates the rate of diffusion of various substances in the channels of the molecular sieve, increases the diffusion efficiency, and the advanategs of low equipment investment, simple operation and environment-friendliness.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

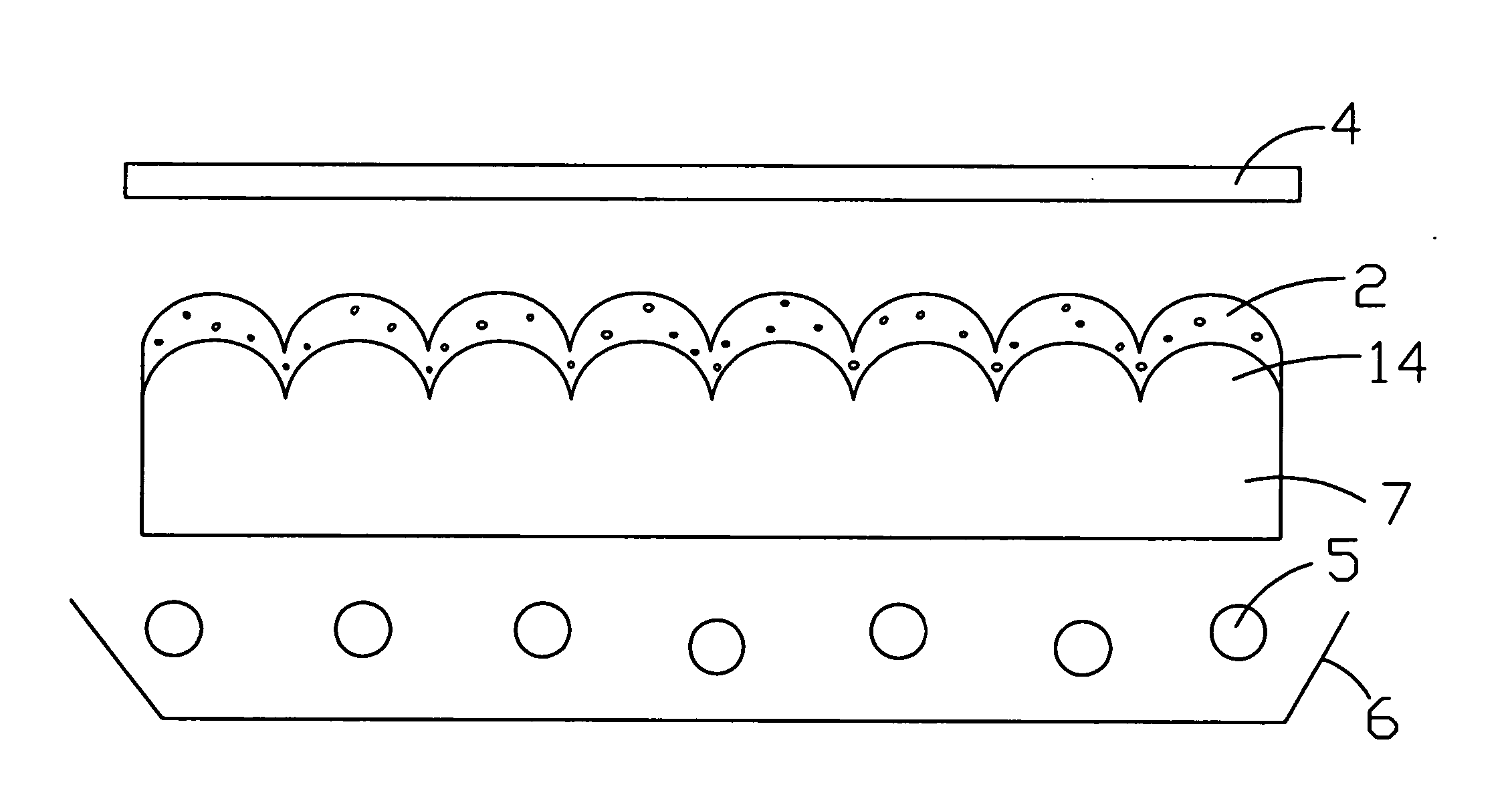

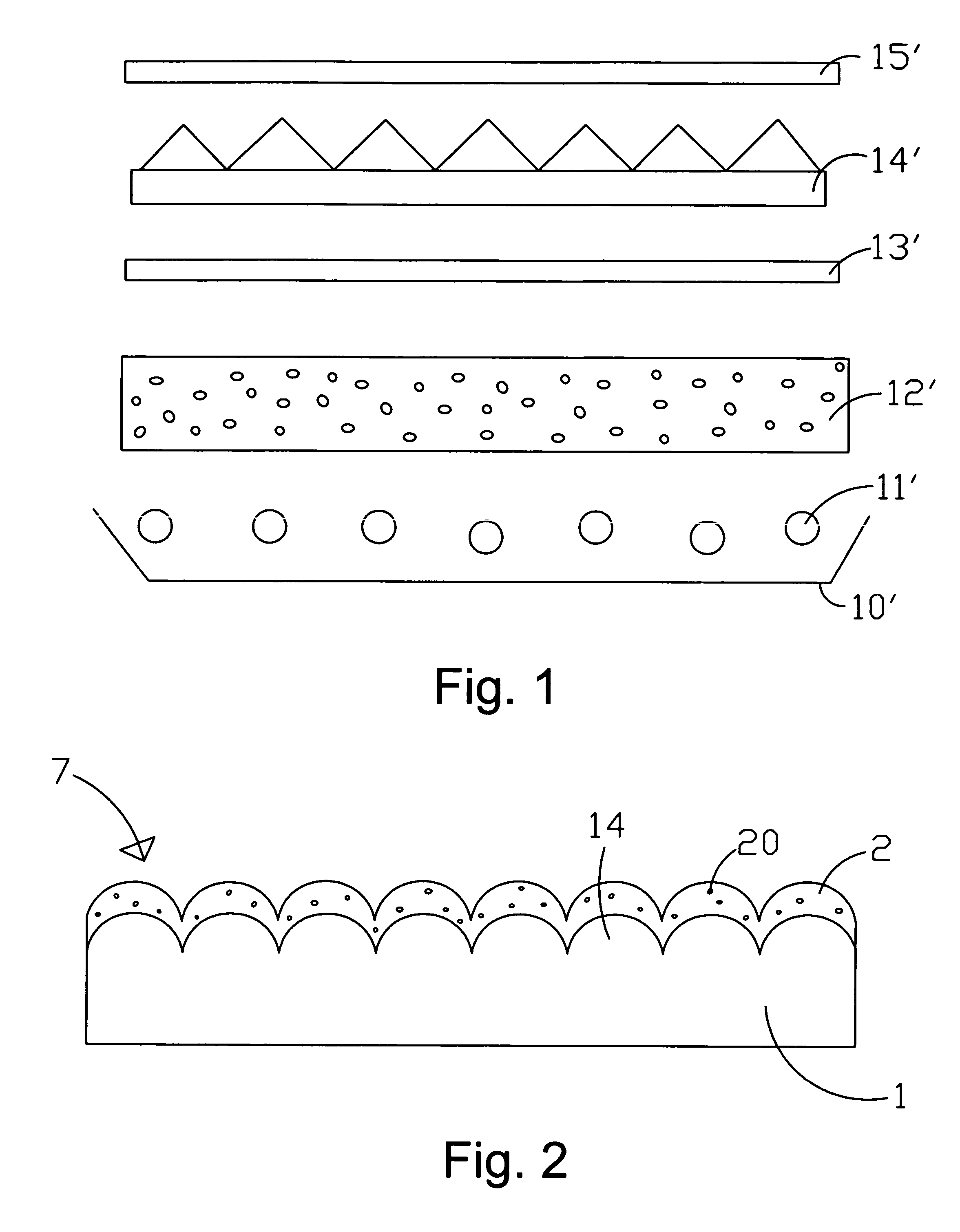

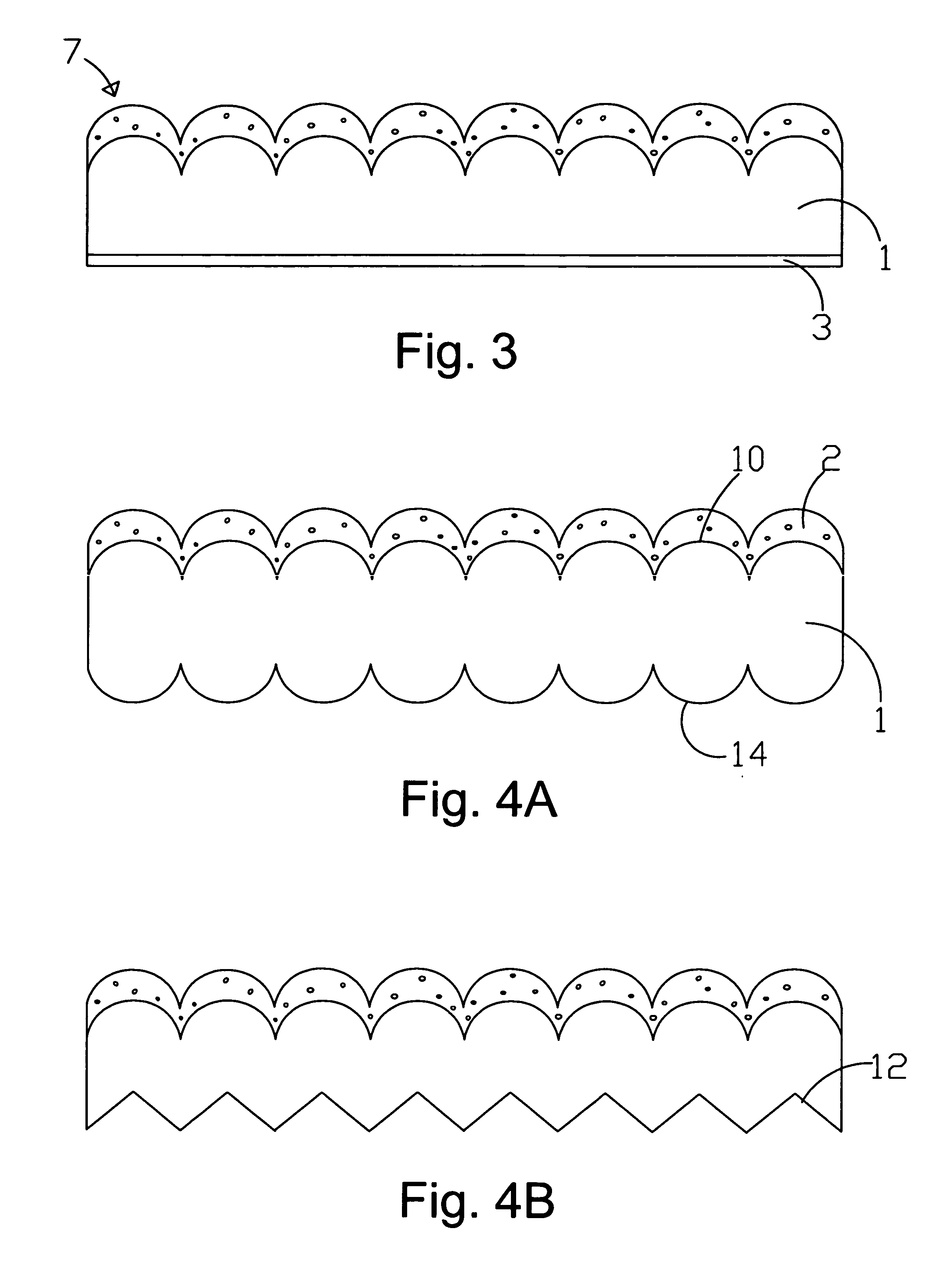

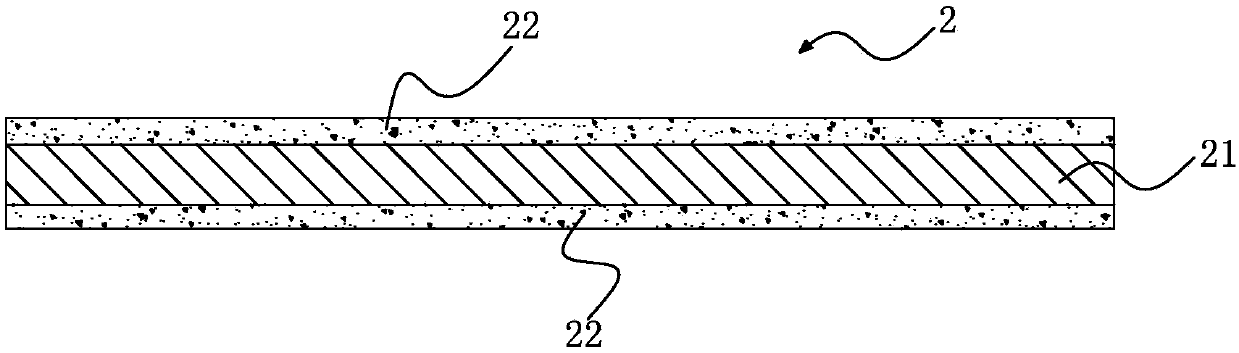

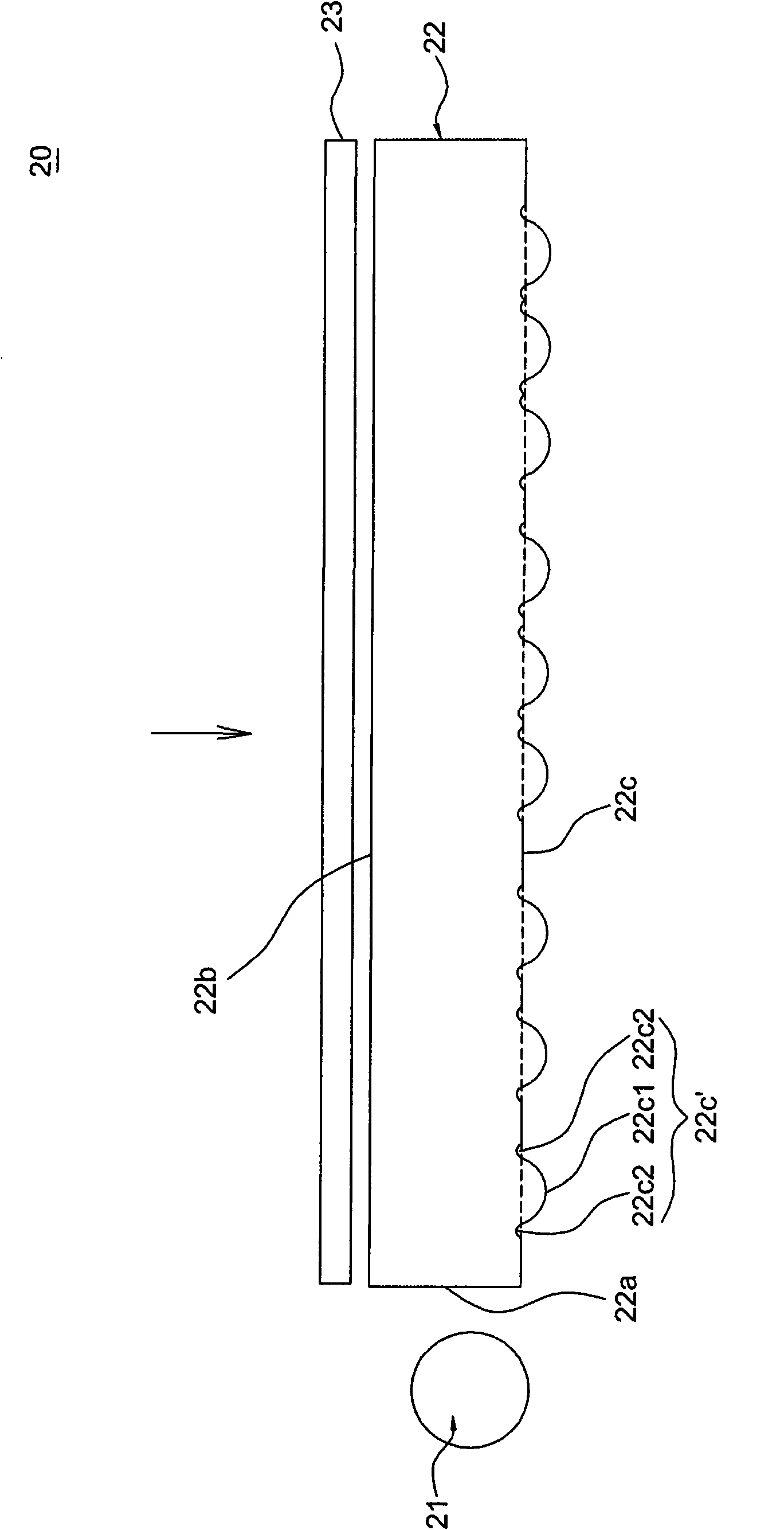

Diffuser plate with higher light diffusion efficiency and brightness

ActiveUS20070159699A1Improve diffusion efficiencyIncrease brightnessPrismsDiffusing elementsDiffusionLenticular lens

A diffuser plate with higher light diffusion efficiency and brightness applied to backlight module of Liquid Crystal Display TV (LCD TV) for providing uniform light is disclosed. An optical lens with a diffusion layer is disposed on one side of the substrate. The diffusion layer is arranged above the optical lens for enhancing diffusion effect. The other side of the diffuser plate can be a plane or having a lens structure. By Lenticular lens, the homogeneity of emitted light is improved so as to reduce the amount of diffusion particles being added into the diffusion plate Therefore, the light transmission is increased and the brightness is enhanced. Meanwhile, ability of shielding lamps is considered and Moiré effect is eliminated. Moreover, the diffusion layer is co-extruded on surface of the Lenticular lens together with the substrate so that the device is easy to be produced.

Owner:ENTIRE TECH CO LTD

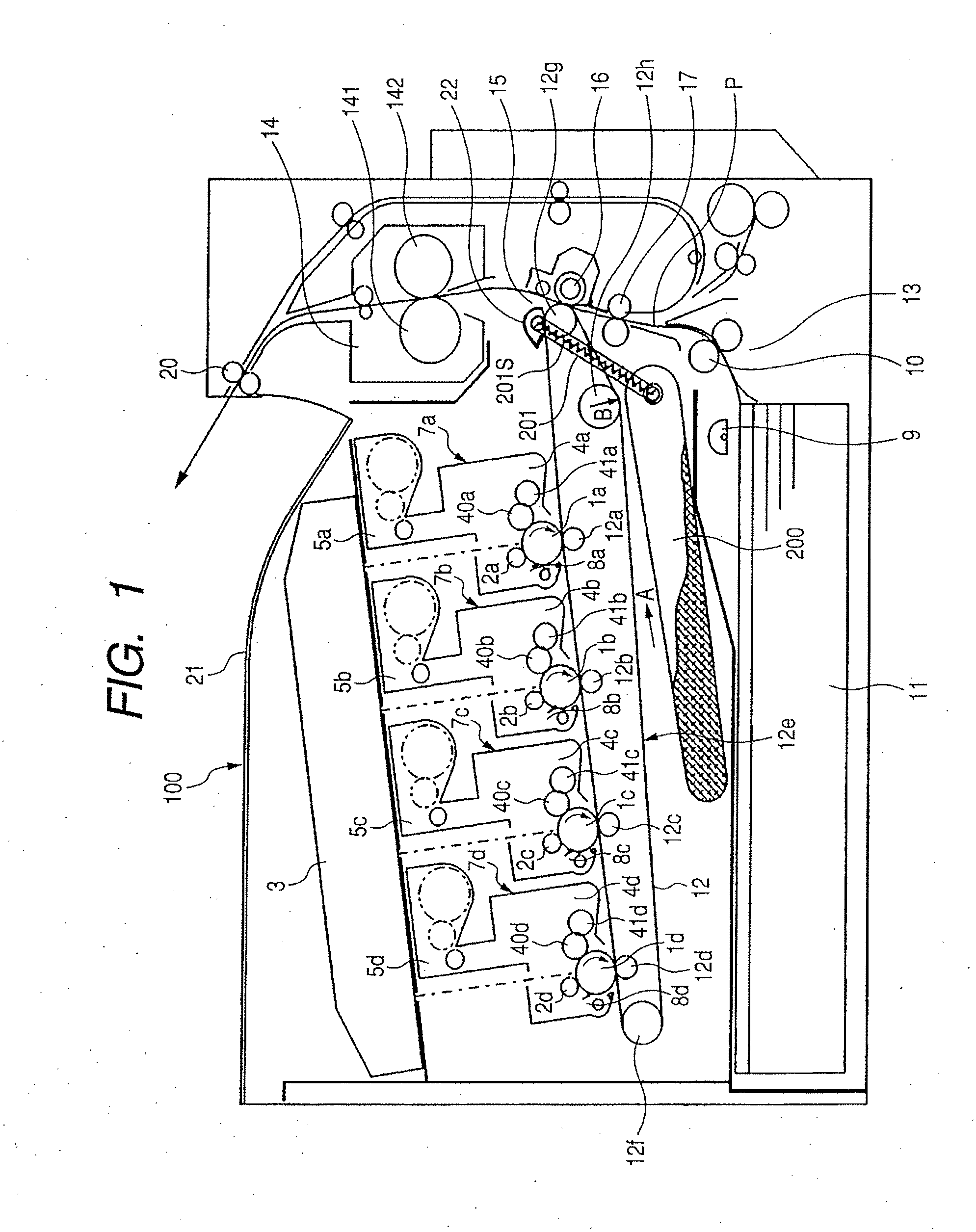

Toner container having screw for conveying toner and image forming apparatus having toner container

InactiveUS20070242993A1Improve diffusion efficiencyImprove abilitiesElectrographic process apparatusEngineeringImaging equipment

Owner:CANON KK

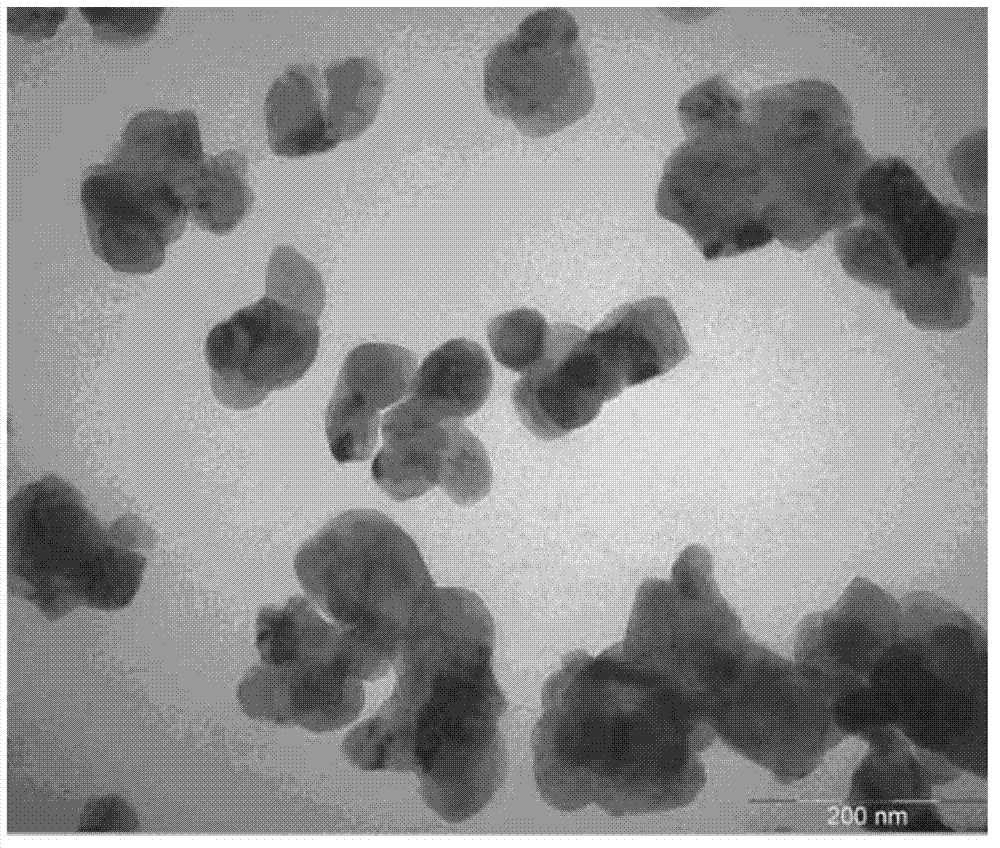

Method for preparing nano sillicalite-1 type total-silicalite molecular sieve

InactiveCN102774851ASuitable for industrial applicationsShorten the diffusion pathMaterial nanotechnologyCrystalline aluminosilicate zeolitesMolecular sieveMuffle furnace

The invention relates to a method for preparing a nano sillicalite-1 type total-silicalite molecular sieve, belonging to the method for preparing the molecular sieve, and aiming to solve the technical problem that the nano-silicalite-1 type total-silicalite molecular sieve prepared by adopting the existing method has low yield. The method comprises the following steps: preparing the mixed solution of a templating agent and an alkali source, adding a silicon source into the mixed solution, stirring in a sealing form to obtain a mixture gel system, crystallizing the mixture gel system, washing the production of crystallization, centrifuging, drying, putting in a muffle furnace, and calcinating to obtain the nano sillicalite-1 type total-silicalite molecular sieve. The nano sillicalite-1 type total-silicalite molecular sieve prepared by adopting the method has the grain size of less than 20nm and the yield of 42-50%, can be used as the inert carrier of the shape selectivity catalyst and the gas separation membrane material and can be also in the field of gas separation and purification.

Owner:HEILONGJIANG HEIKE TECH CO LTD

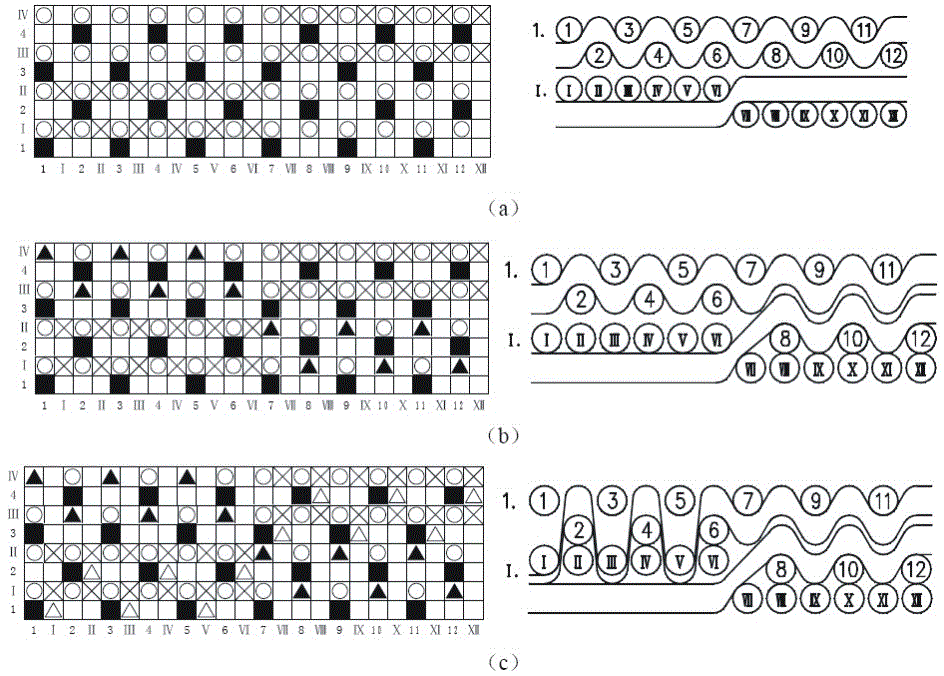

Wet-conduction quick-drying fabric

InactiveCN103147203AImprove water absorptionMany and small poresMulti-ply fabricsYarnCapillary Tubing

The invention relates to wet-conduction quick-drying fabric, which belongs to the technical field of textile. The fabric is a two-layer structure, a surface layer of the fabric is a plain structure, and an inner layer is a floating loosening structure. According to the two-layer fabric produced on the basis of plant moisture conduction effect, the floating loosening structure on the inner layer adopts a floating wire cluster structure, multiple yarns are concentrated together, interlacing points are few, the floating length is long, and pores are large; and the surface layer adopts the plain structure, interlacing is frequent, and the pores are small. A pore gradient structure which likes a trunk-stem structure of a plant is formed on the surface layer and the inner layer of the fabric, pressure difference is formed by utilizing different sizes of the pores when the water is conducted to produce a differential effect, the wet conduction capacity of a capillary pipe is obviously enhanced along with the variation of the size of capillary hoes of the fabric from the inner layer to the surface layer, and the wet conduction capacity can be realized. The surface layer is connected with the inner layer, so that better communication performance of the pores on the surface layer and the inner layer can be realized.

Owner:HENAN INST OF ENG

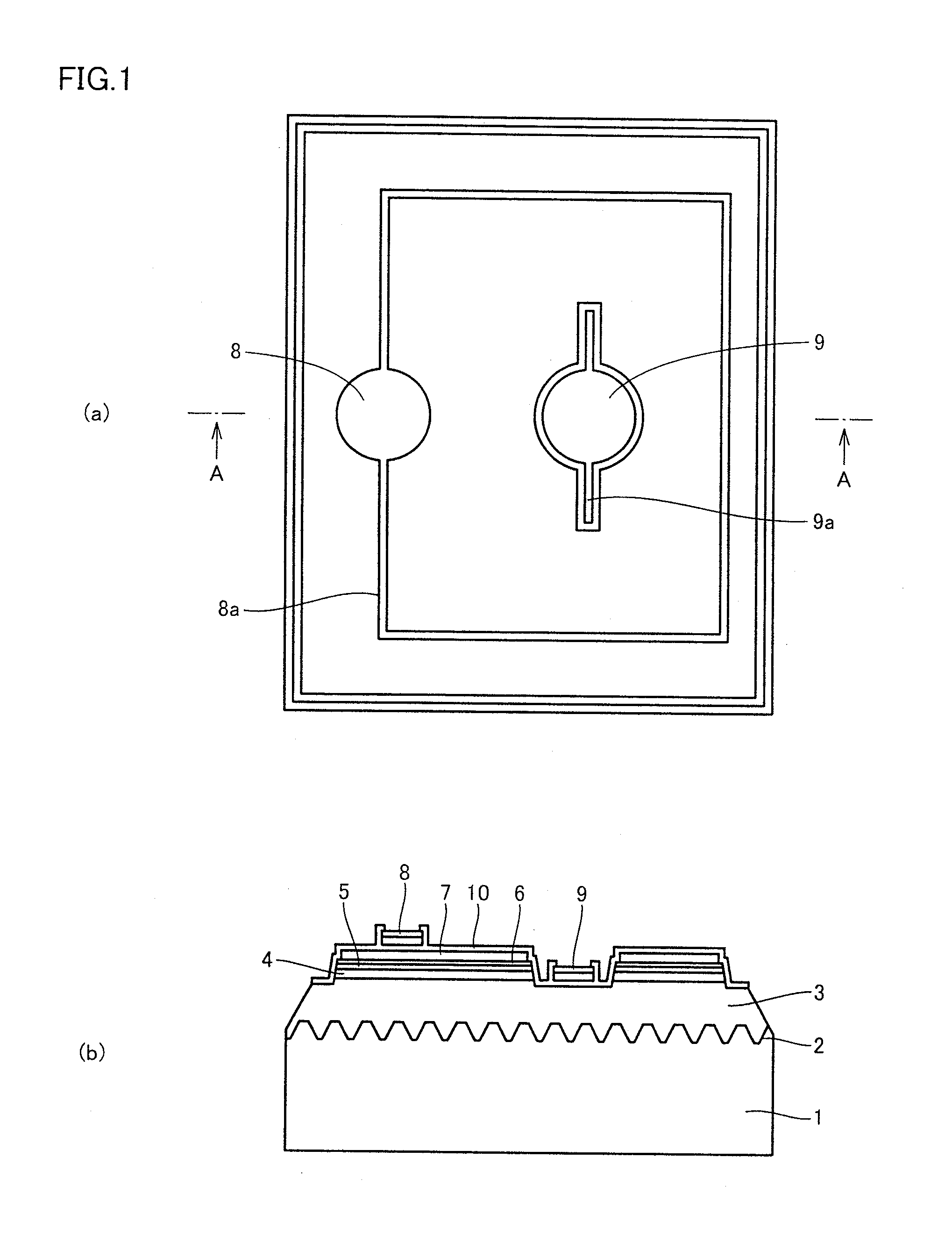

Nitride semiconductor light-emitting device and production method thereof

ActiveUS20120248490A1Improve current spreading efficiencyLow working voltageSemiconductor/solid-state device manufacturingSemiconductor devicesIn planeCurrent distribution

In a nitride semiconductor light-emitting device having an n-side and a p-side electrode pad formed on the same side of a substrate wherein current distribution in the light-emitting device is improved by forming branch electrodes extended from the p-side electrode pad (and the n-side electrode pad), when sheet resistance values of n-side and p-side layers in the device are low enough, contact resistance between a p-type nitride semiconductor layer and a current diffusion layer of a transparent conductive film formed thereon is reduced and in-plane distribution of the sheet resistance is made uniform whereby improving the optical output, by increasing in a prescribed condition the sheet resistance value of the current diffusion layer.

Owner:SHARP KK

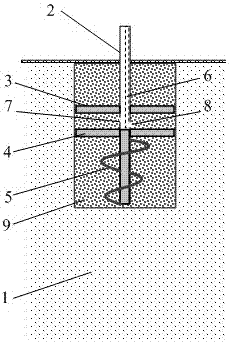

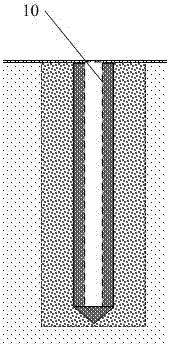

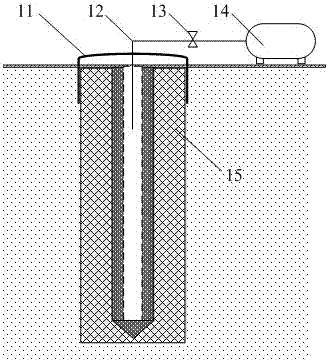

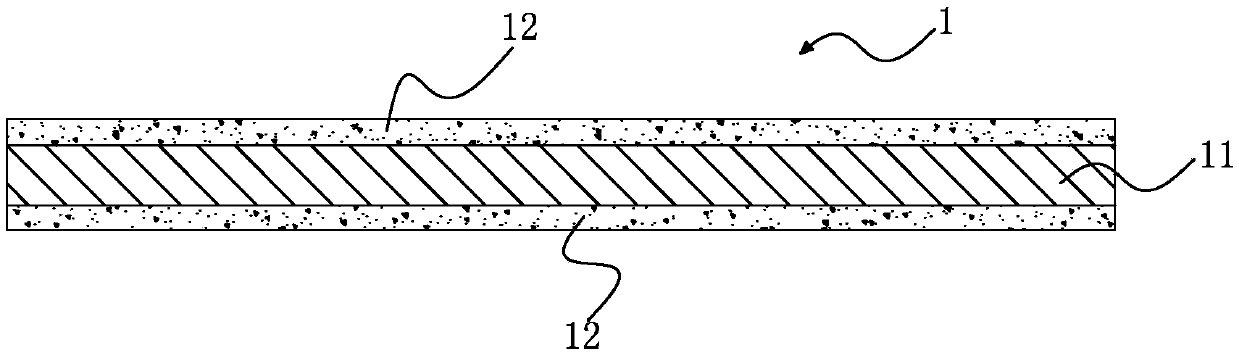

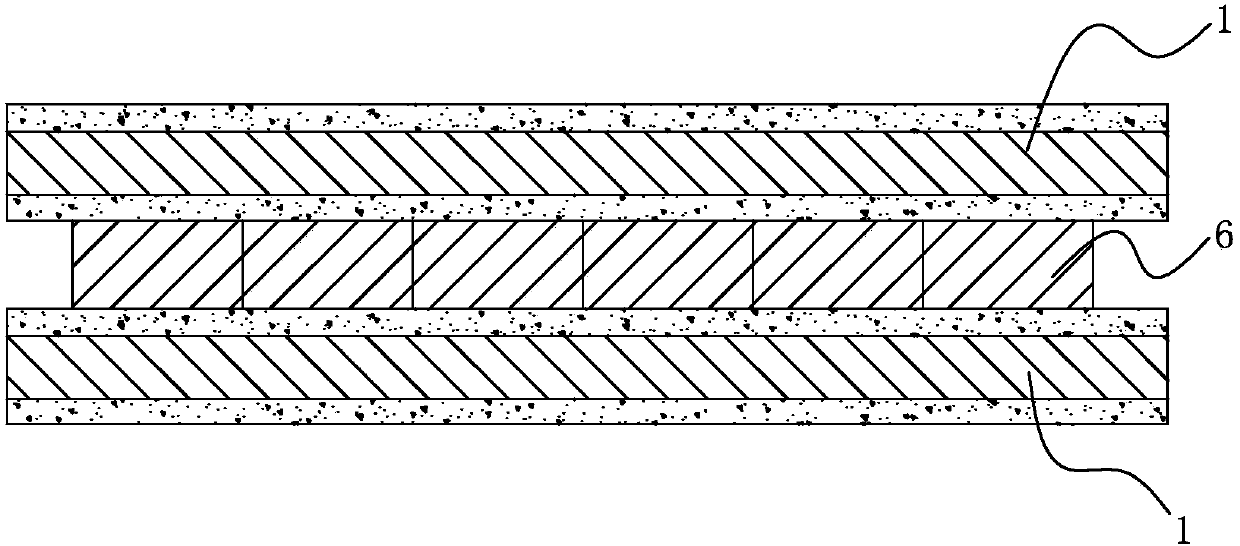

Carbonization mixing pile-ventilating pipe pile composite foundation and construction method thereof

ActiveCN106869120AImprove bearing capacityImprove construction efficiencyBulkheads/pilesResource utilizationSoil mixing

The invention relates to a carbonization mixing pile-ventilating pipe pile composite foundation and a construction method thereof, belongs to the technical field of foundation treatment for civil construction engineering, and provides the carbonization mixing pile (CMP)-ventilating pipe pile composite foundation which is high in bearing capacity, high in construction efficiency, reliable in quality, low-carbon and environmentally-friendly and the construction method of the composite foundation so as to overcome and solve the defects and the problems in existing reinforcement technologies and magnesium oxide carbonization reinforcement methods for thick and soft foundation composite piles. The carbonization mixing pile-ventilating pipe pile composite foundation comprises a carbonization magnesium oxide cement soil mixing pile and a ventilating pipe pile; and the ventilating pipe pile is composited inside the carbonization magnesium oxide cement soil mixing pile. The requirements for reinforcement of the soft foundation and carbon dioxide resource utilization are realized.

Owner:SOUTHEAST UNIV

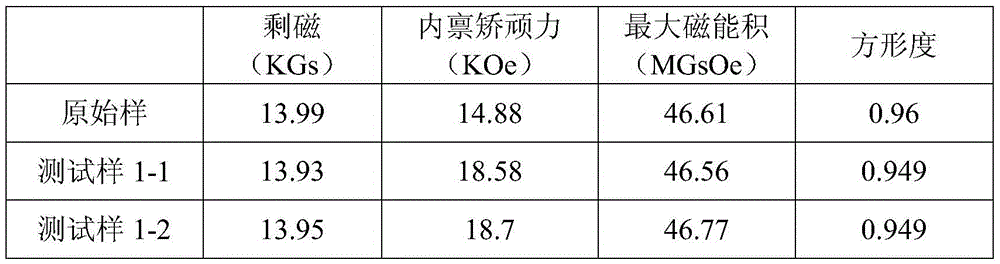

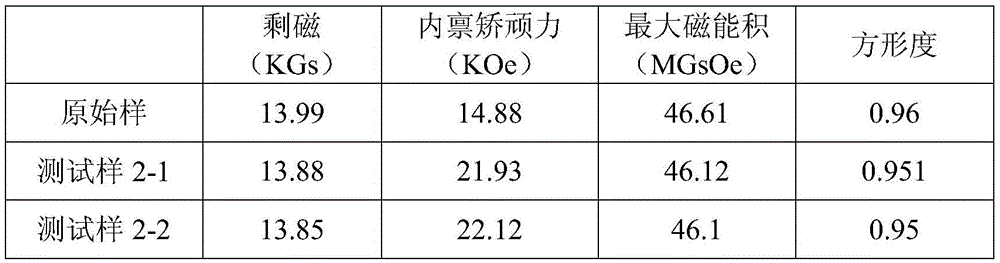

Grain boundary diffusion method of R-Fe-B rare-earth sintered magnet, HRE diffusion source and fabrication method thereof

InactiveCN107871602ASmall surface areaAdjustment methodInductances/transformers/magnets manufactureMagnetic materialsDiffusion methodsRare-earth element

The invention discloses a grain boundary diffusion method of an R-Fe-B rare-earth sintered magnet, an HRE diffusion source and a fabrication method thereof. The grain boundary diffusion method comprises the following steps of forming film engineering A on a high-temperature resistant carrier, wherein HRE compound powder is attached onto the film, and the HRE is selected from at least one of Dy, Tb, Gd and Ho; and placing the R-Fe-B rare-earth sintered magnet and the high-temperature resistant carrier processed by the engineering A in a processing room, performing thermal treatment on the R-Fe-B rare-earth sintered magnet and the high-temperature resistant carrier in vacuum or inert atmosphere, and supplying HRE engineering B to a surface of the R-Fe-B rare-earth sintered magnet from the high-temperature resistant carrier. By the method, consumption of a heavy rare-earth element can be reduced, and the loss of residual magnetism Br of the magnet is controlled as well as the coercivity is improved.

Owner:XIAMEN TUNGSTEN

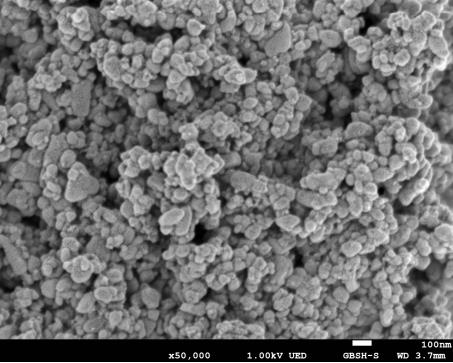

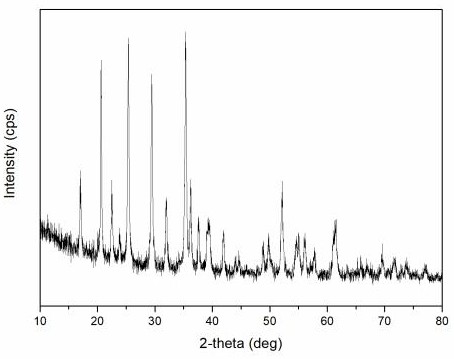

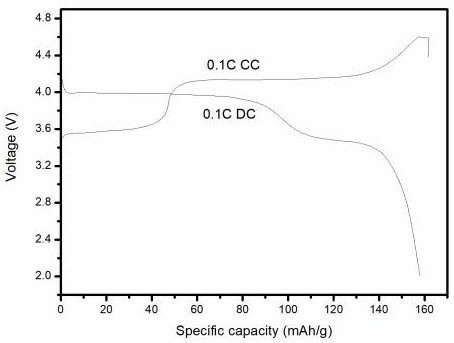

Preparation method of lithium manganese iron phosphate positive electrode material

PendingCN113929073ARealize NanoizationAchieve primary particle sizeSecondary cellsPositive electrodesLithium iron phosphatePhysical chemistry

The invention discloses a method for preparing lithium manganese iron phosphate by a solid phase method. The preparation method comprises the following steps: weighing a certain amount of a manganese source and an iron source according to a molar ratio of 7:3, weighing a lithium source, a phosphorus source, a carbon source and a dopant according to a certain stoichiometric ratio, adding pure water, carrying out ball milling and sanding, controlling the sanding particle size D50 to be less than or equal to 300 nm, and carrying out spray drying to obtain brown precursor powder; and sintering the precursor under the protection of a nitrogen atmosphere, controlling the sintering temperature to be 600-700 DEG C, then performing crushing and screening, and removing iron to obtain the lithium manganese iron phosphate positive electrode material. The lithium manganese iron phosphate prepared by the method is simple in process and easy to control in process, compared with existing lithium iron phosphate and ternary materials, the lithium manganese iron phosphate is lower in cost and higher in voltage platform, and meanwhile, the obtained lithium manganese iron phosphate has good electrical performance and cycle performance.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

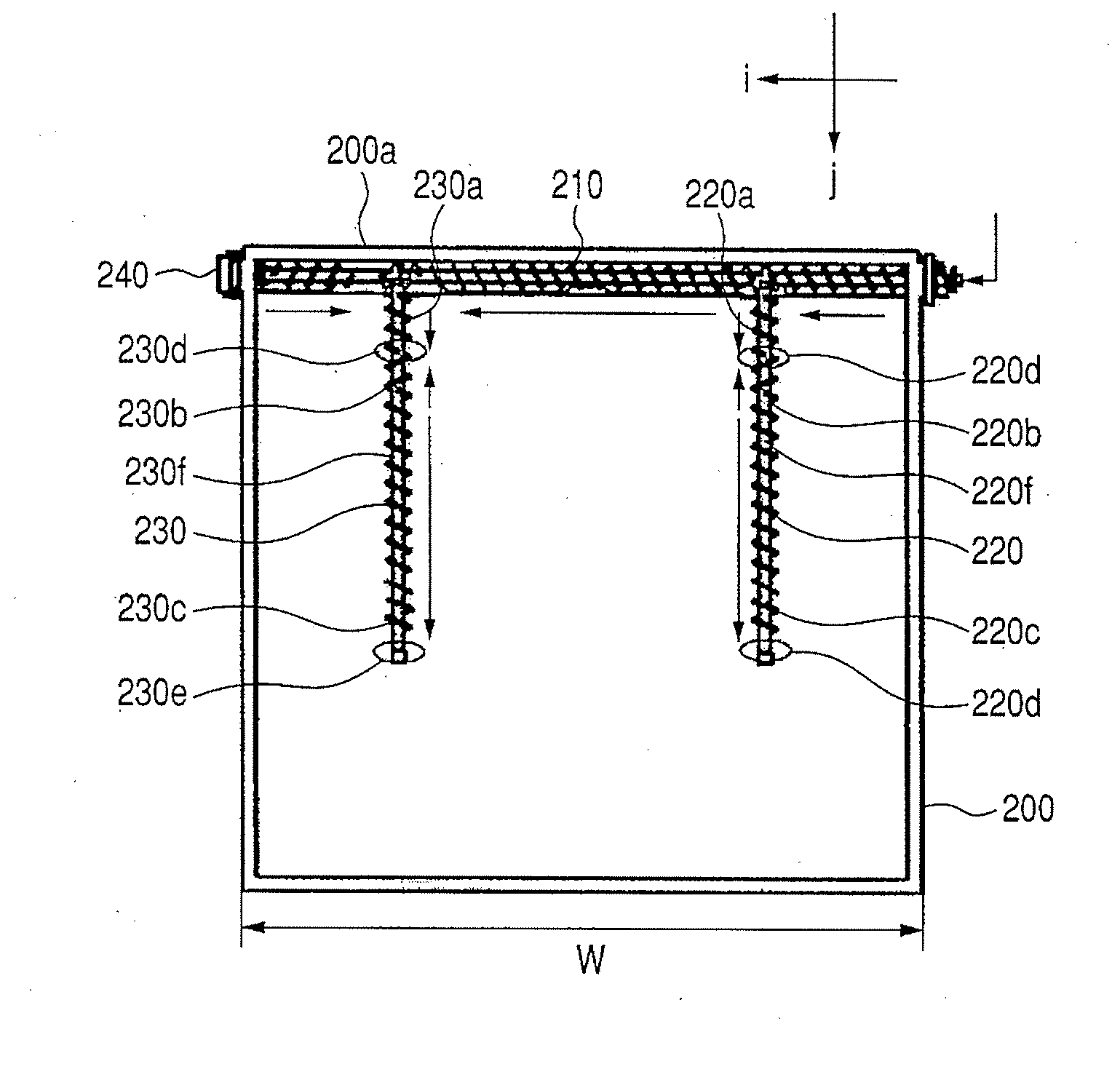

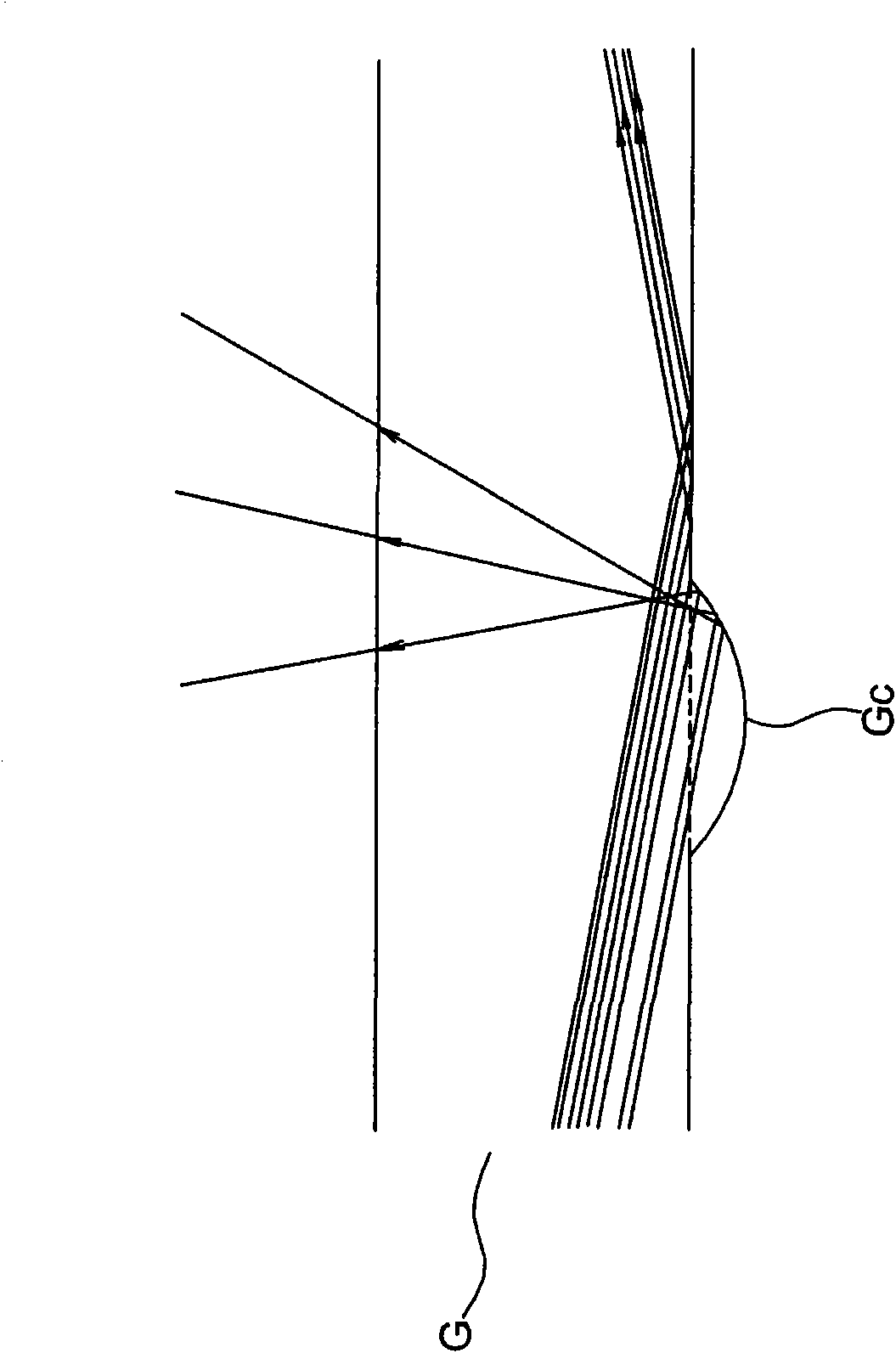

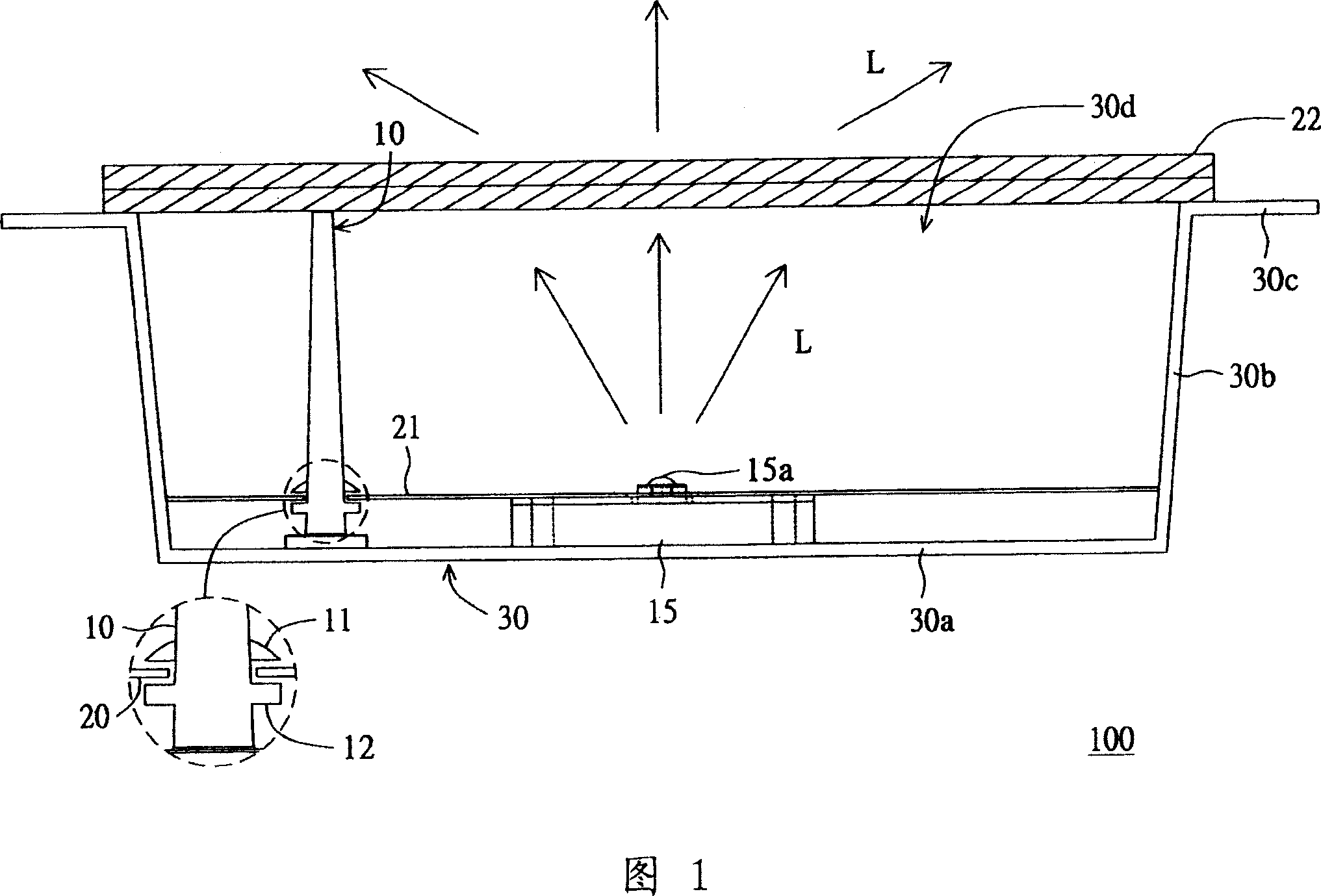

Backlight module and light guide plate

InactiveCN101614839AImprove diffusion efficiencyIncrease roughnessMechanical apparatusLight guides for lighting systemsLight guideOptoelectronics

The invention relates to a backlight module and a light guide plate. The light guide plate comprises a light inlet surface, a light outlet surface and a light reflecting surface. The light inlet surface receivers light rays emitted by at least one light source, and the light rays are educed by the light outlet surface. The light reflecting surface is arranged opposite to the light outlet surface and used for reflecting the light rays entering the light guide plate from the light inlet surface to the light outlet surface, wherein the light outlet surface and / or the light reflecting surface comprises at least one composite structure comprising a main structure and an auxiliary structure, and the auxiliary structure is arranged on the side edge of the main structure. The backlight module and the light guide plate increase the integral roughness of the light outlet surface and / or the light inlet surface by utilizing the combination of a convex curve surface and a concave curve surface of the composite structure so as to solve the problem of heterogeneous diffusion which probably occurs when the light rays enter the light guide plate, thereby achieving the effect of improving the light diffusion efficiency.

Owner:WINTEK CORP

Method for improving magnetic properties of sintered neodymium-iron-boron thin-sheet magnet

ActiveCN105632748AImprove diffusion efficiencyIncreased Diffusion DepthInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementHigh volume manufacturing

The invention discloses a method for improving magnetic properties of a sintered neodymium-iron-boron thin-sheet magnet. According to the method, the surface of the sintered neodymium-iron-boron thin-sheet magnet is coated with powder containing rare earth elements to form a surface coating layer, and diffusion treatment and aging treatment are carried out to allow the rare earth elements in the coating layer to enter the interior of the sintered neodymium-iron-boron thin-sheet magnet, wherein the powder containing the rare earth elements is a mixture of powder of rare earth oxide and powder of hydrogen storage alloy hydride. The method has the advantages that oxidation-reduction reaction is carried out between the rare earth elements and the hydrogen storage alloy hydride, the rare earth elements are reduced, hydrogen is released from the hydrogen storage alloy hydride during diffusion treatment, thus, the diffusion efficiency of the rare earth elements is remarkably reduced, the diffusion depth of the rare earth elements is increased, the content difference of the rare earth elements at different positions in the sintered neodymium-iron-boron thin-sheet magnet is reduced, the coercive force is obviously increased, and residual magnetism reduction is ensured not to be obvious; and moreover, mass production can be achieved, and the final squareness of the sintered neodymium-iron-boron thin-sheet magnet cannot be affected.

Owner:NINGBO YUNSHENG +1

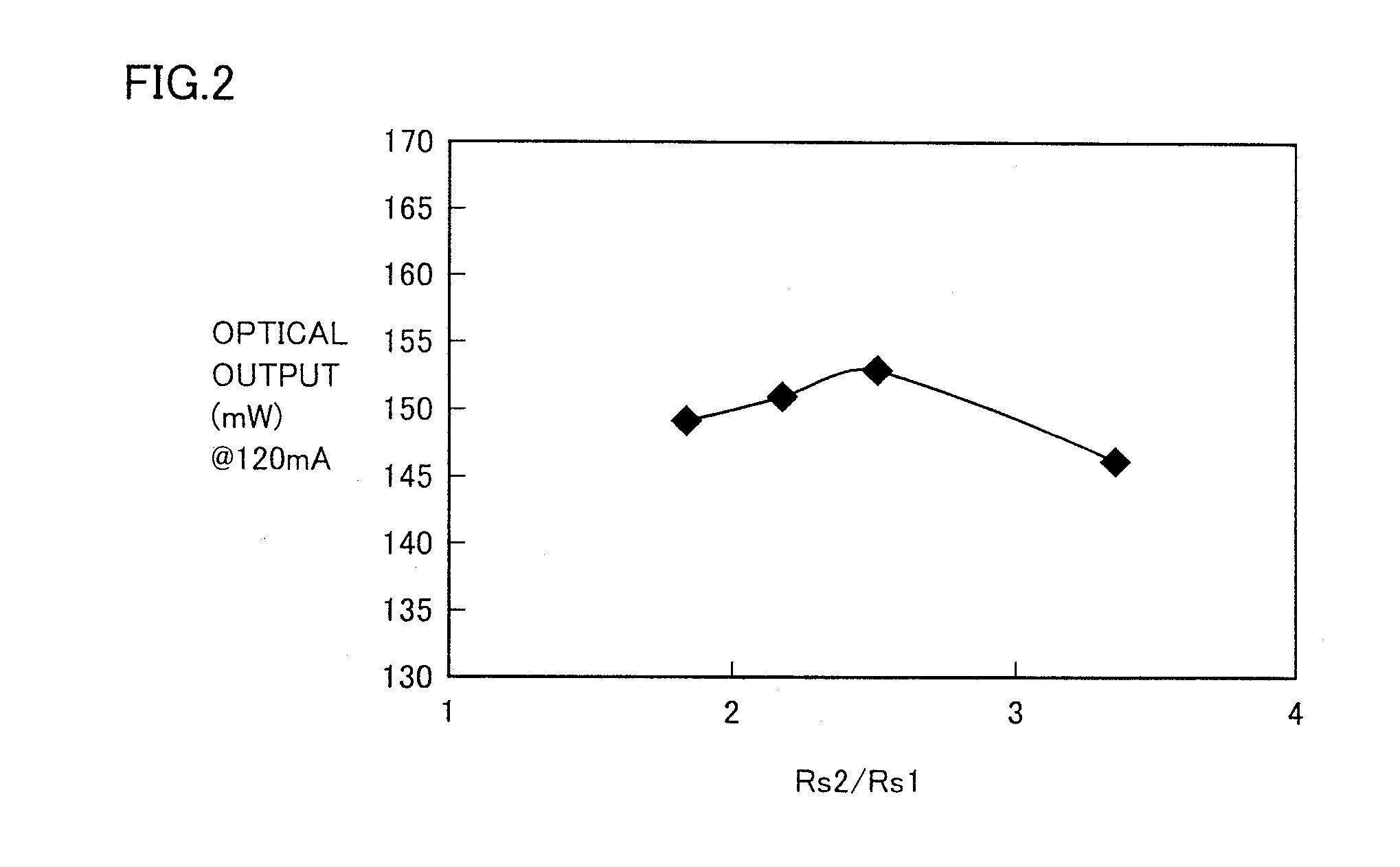

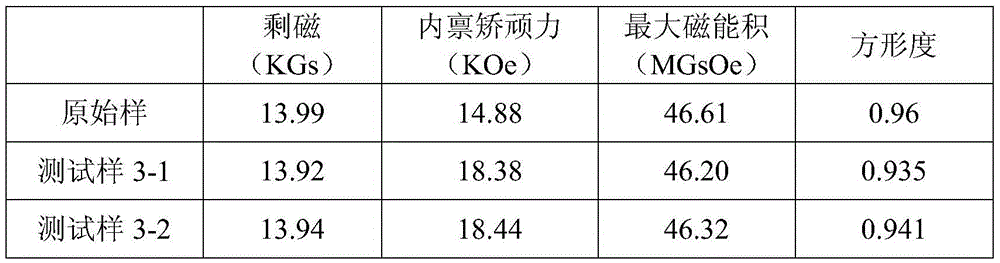

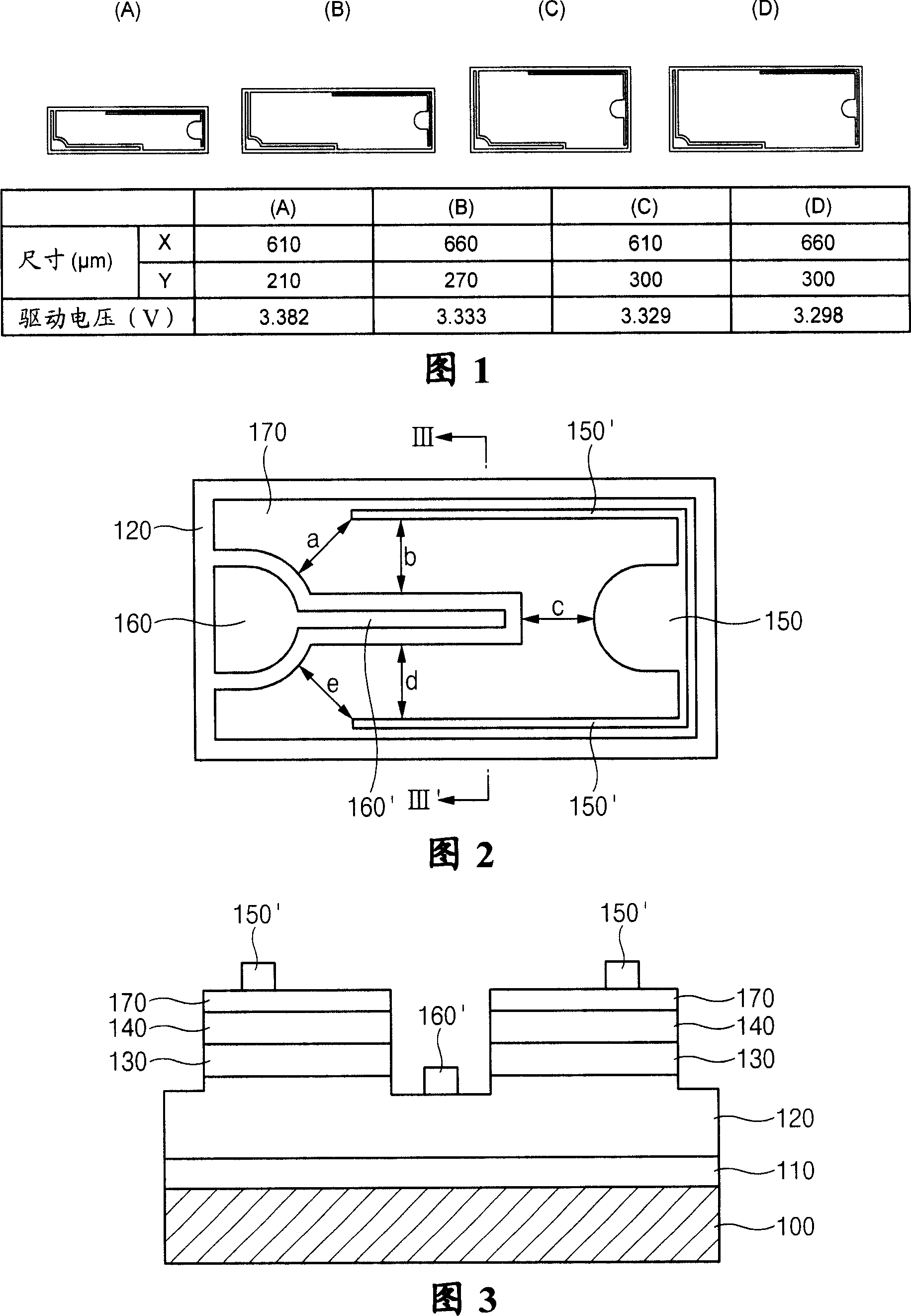

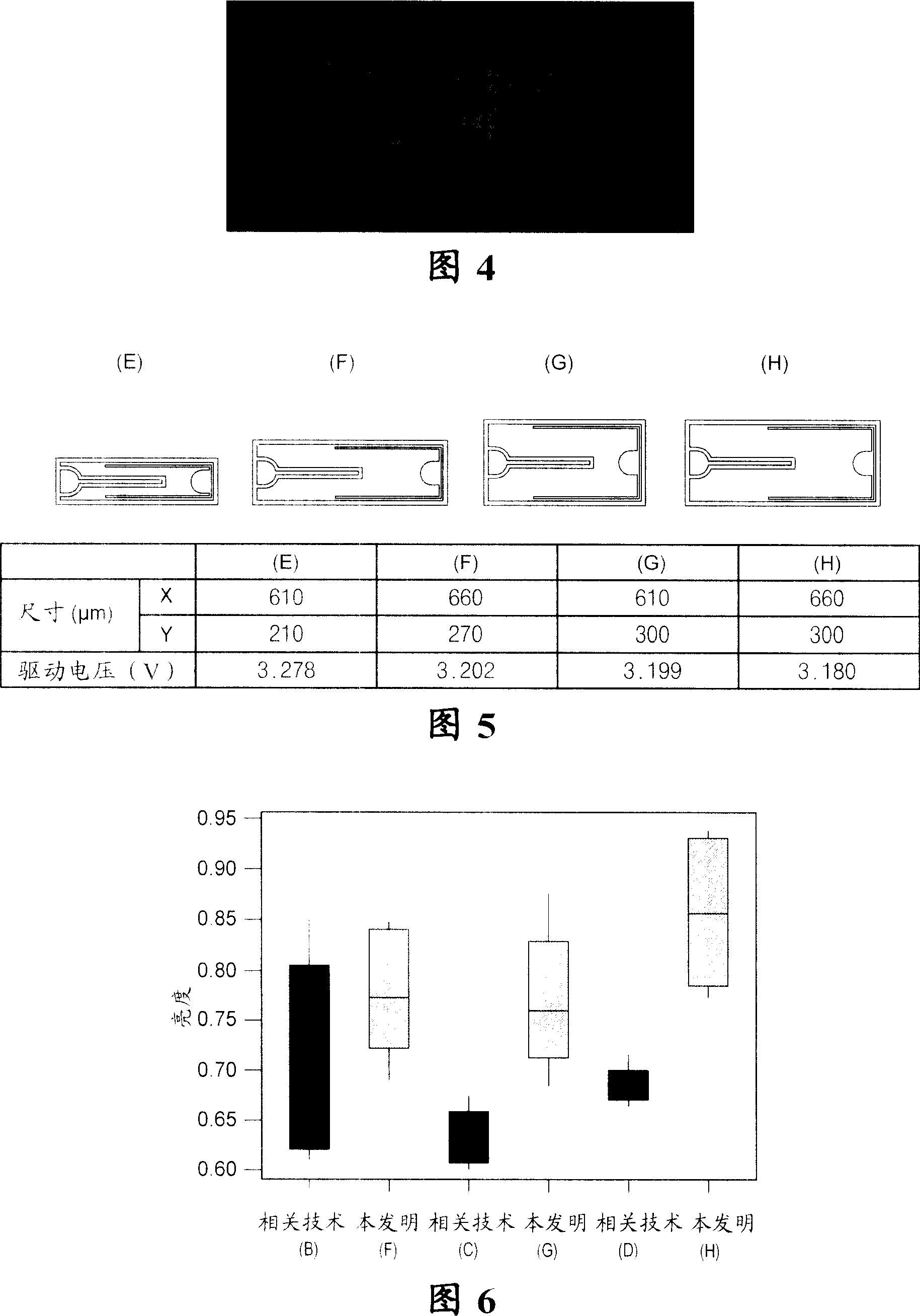

Nitride semiconductor light-emitting diode

InactiveCN1953225AImprove diffusion efficiencyReduce the driving voltageSemiconductor devicesActive layerLight-emitting diode

A nitride-based semiconductor LED comprises a substrate; an n-type nitride semiconductor layer formed on the substrate; an active layer formed on a predetermined region of the n-type nitride semiconductor layer; a p-type nitride semiconductor layer formed on the active layer; a current spreading layer formed on the p-type nitride semiconductor layer; a p-electrode formed on the current spreading layer, the p-electrode having two p-type branch electrodes; and an n-electrode formed on the n-type nitride semiconductor layer on which the active layer is not formed, the n-electrode having one n-type branch electrode. The n-type branch electrode is formed so as to be inserted between two of the p-type branch electrodes, and a distance from the outermost side of a transparent electrode adjacent to the n-electrode to the p-electrode is identical at any position.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

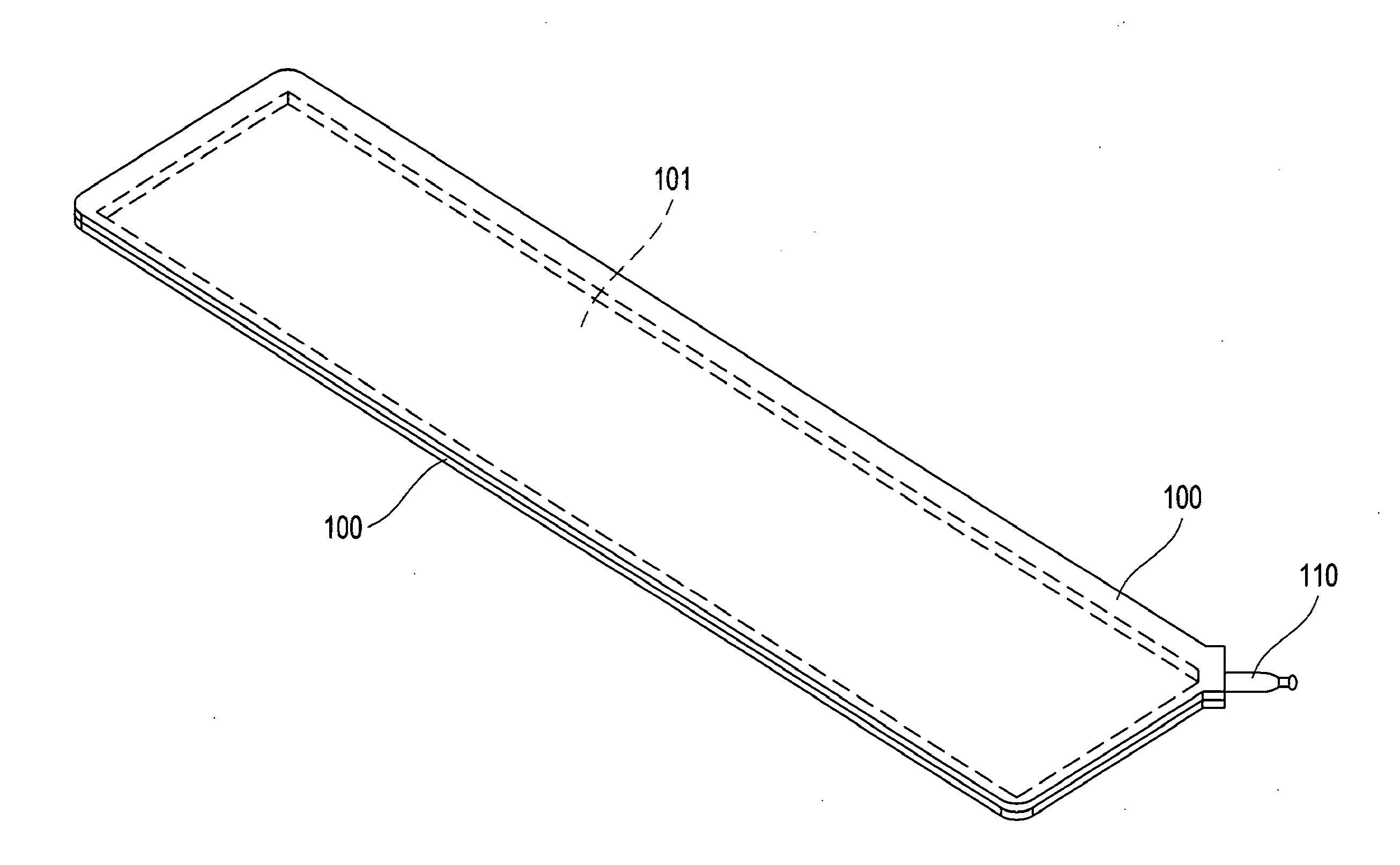

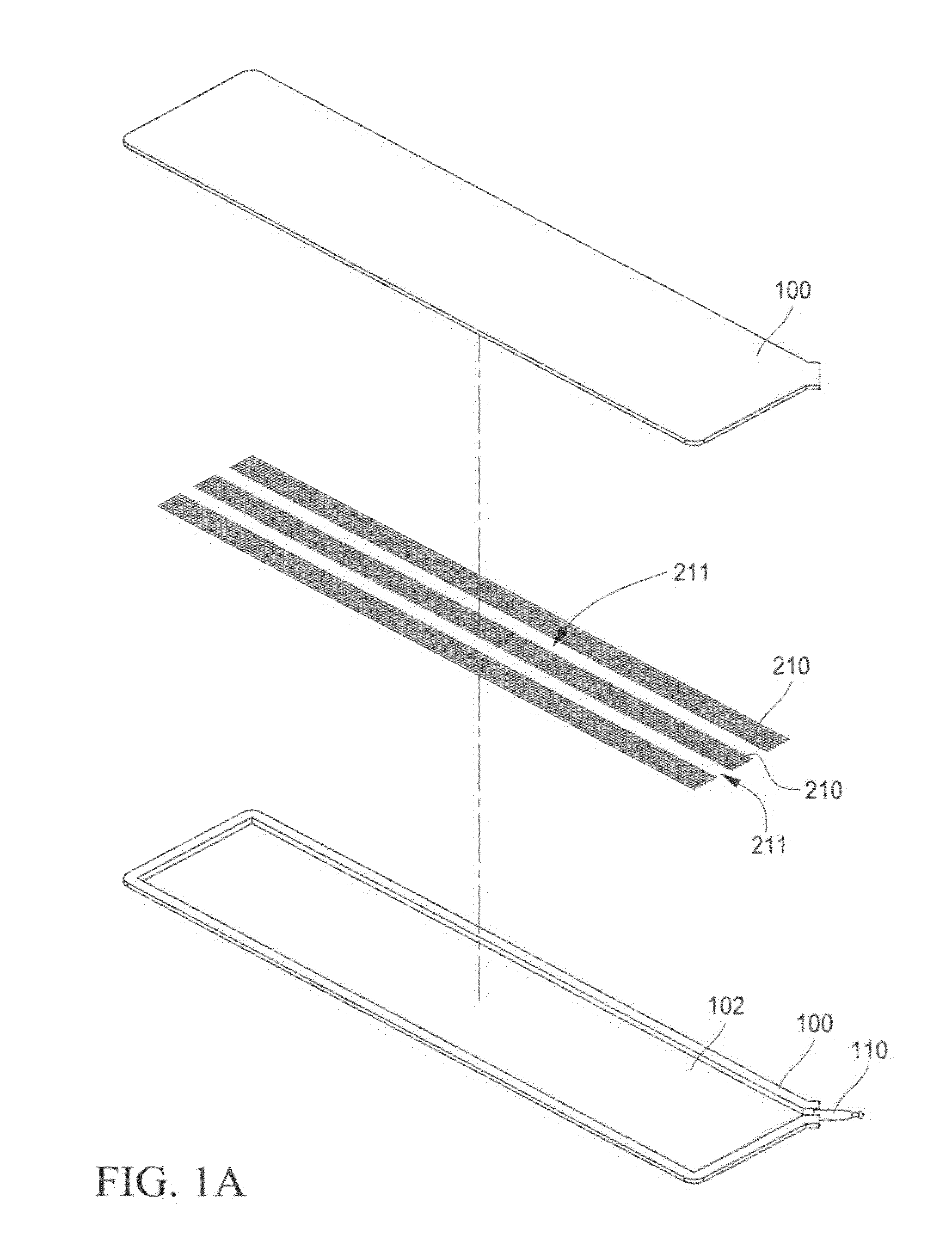

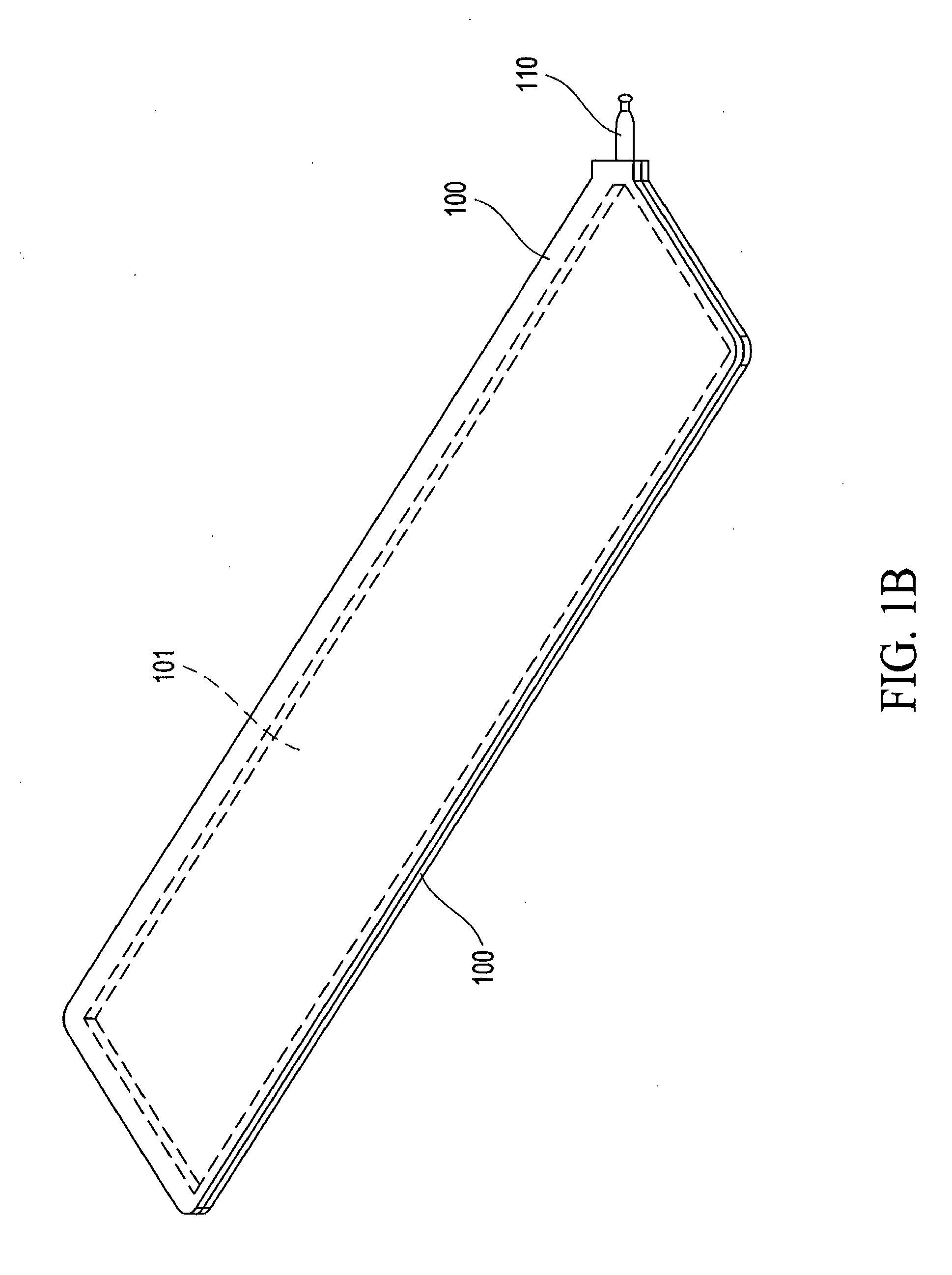

Structure of heat plate

InactiveUS20120031588A1Improve cooling efficiencyImprove diffusion efficiencyIndirect heat exchangersWorking fluidEngineering

A structure of heat plate includes two boards, which mate and are coupled to each other to define therebetween an accommodation chamber and a plurality of capillary layers arranged in the accommodation chamber in such a way that the capillary layers are set on a common horizontal plane and the capillary layers form therebetween a plurality of passages. As such, the efficiency of diffusion of vapor of a working fluid is increased and the uniformity of distribution of the working fluid is improved, so that the efficiency of temperature reduction is improved.

Owner:KUNSHAN JUZHONG ELECTRONICS

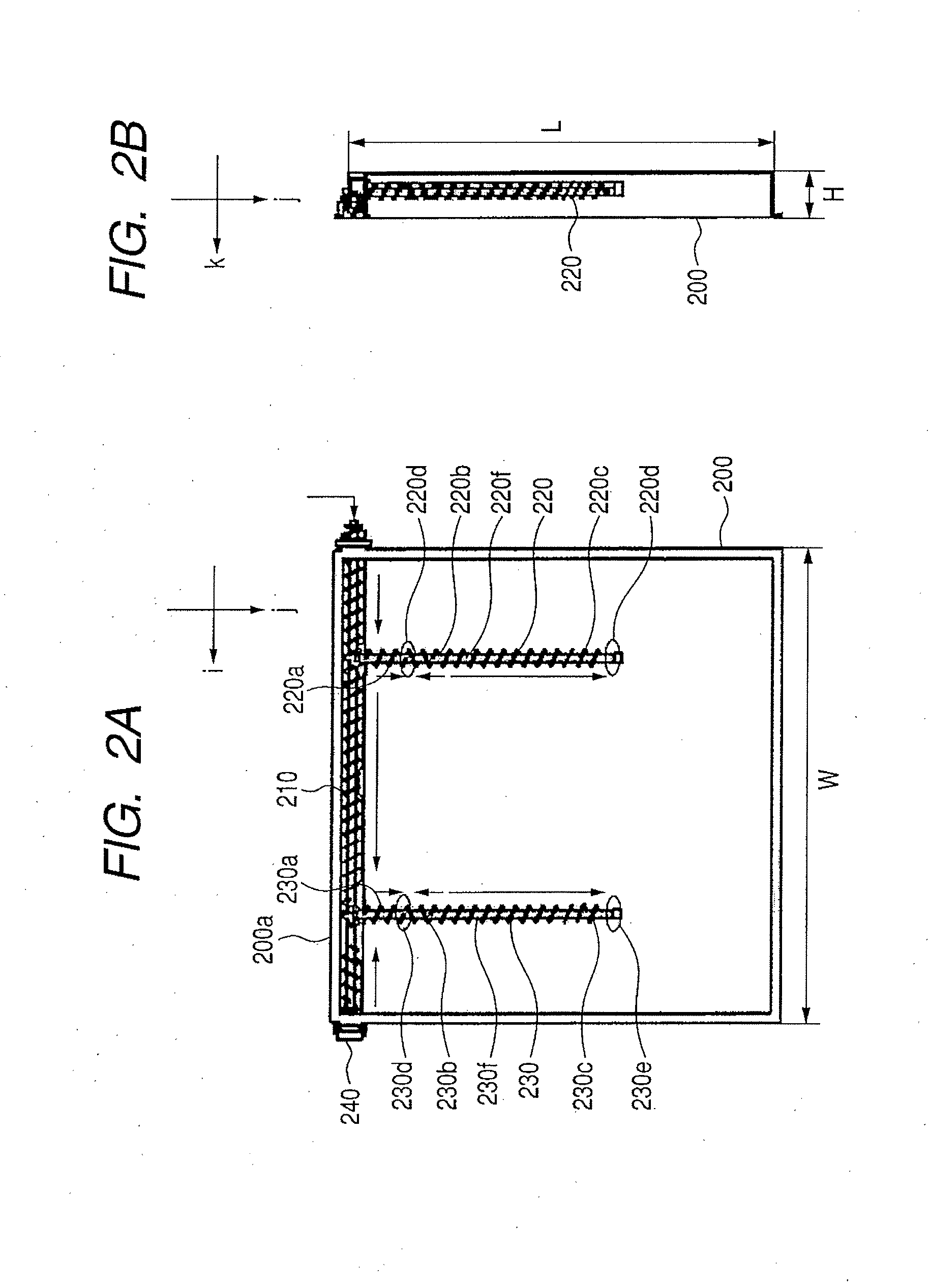

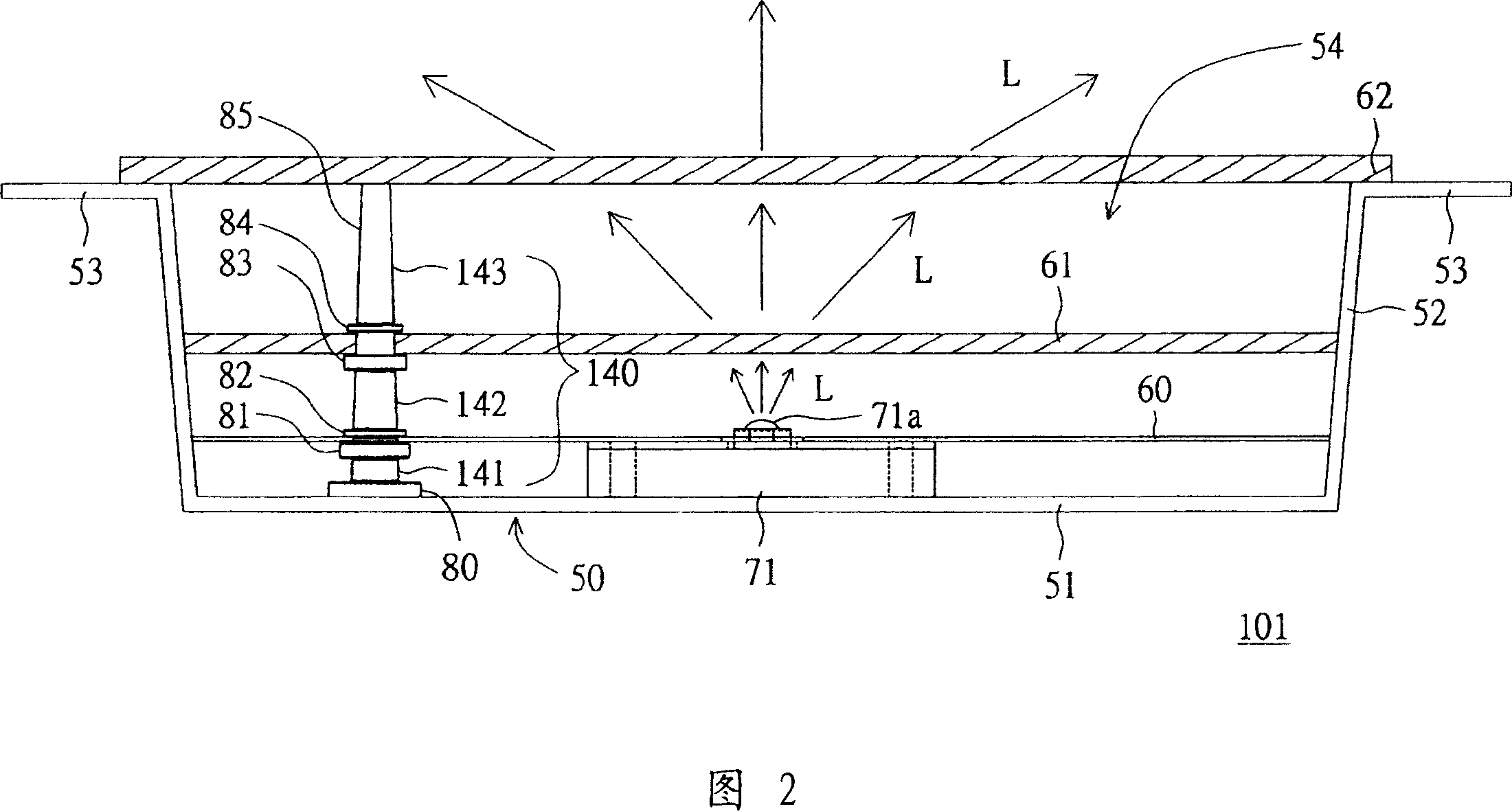

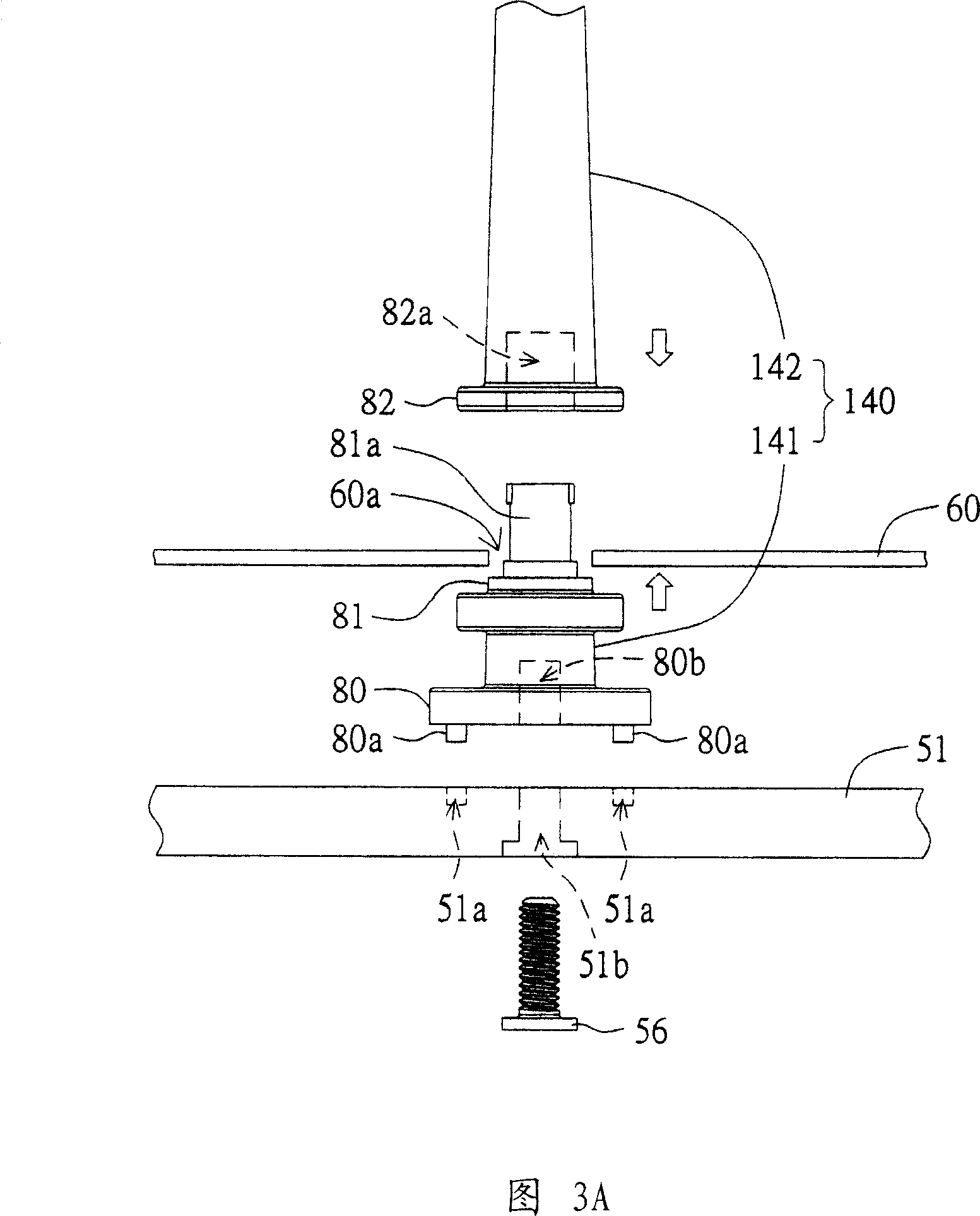

Backlight module and liquid crystal display device using same

InactiveCN101105601AReduce thicknessImprove diffusion efficiencyNon-linear opticsDiffusionLiquid-crystal display

The invention discloses a backlight module and the liquid crystal display device thereof; the backlight module comprises a light source, a frame, a first diffusion sheet material and a second diffusion sheet material; the light source emits light; the frame has a base plate and a lateral plate; the lateral plate and the base plate are limited in a containing space; the light source is equipped in the containing space; the first diffusion sheet material is equipped in the containing space and is positioned above the light source; the second diffusion sheet material is equipped on the side where the first diffusion sheet material stays far away from the base board; the first diffusion sheet material is virtually separated away from the second diffusion sheet material. After passing through the first diffusion sheet material and the second diffusion sheet material, the light radiates out of the backlight module.

Owner:INNOLUX CORP

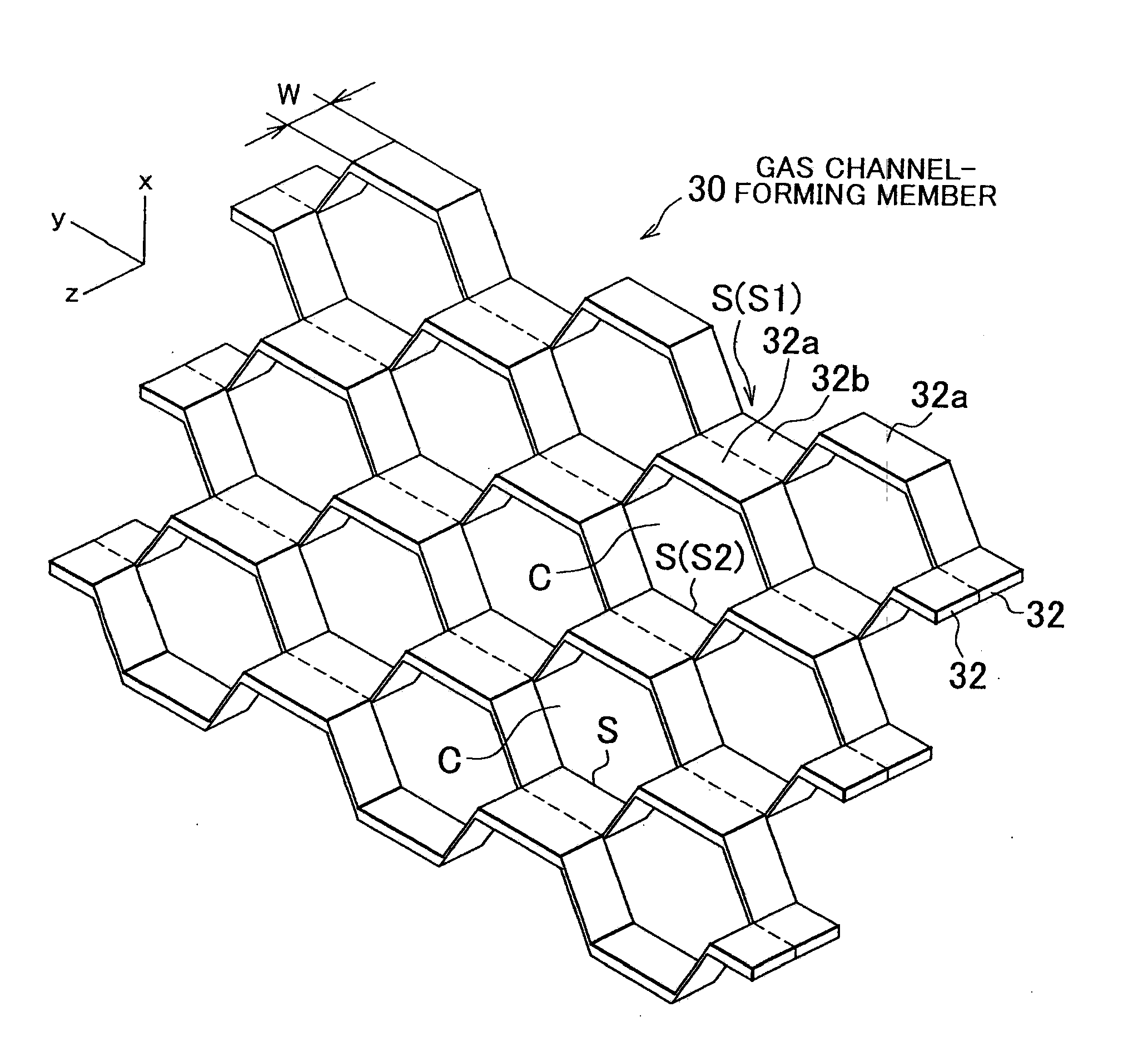

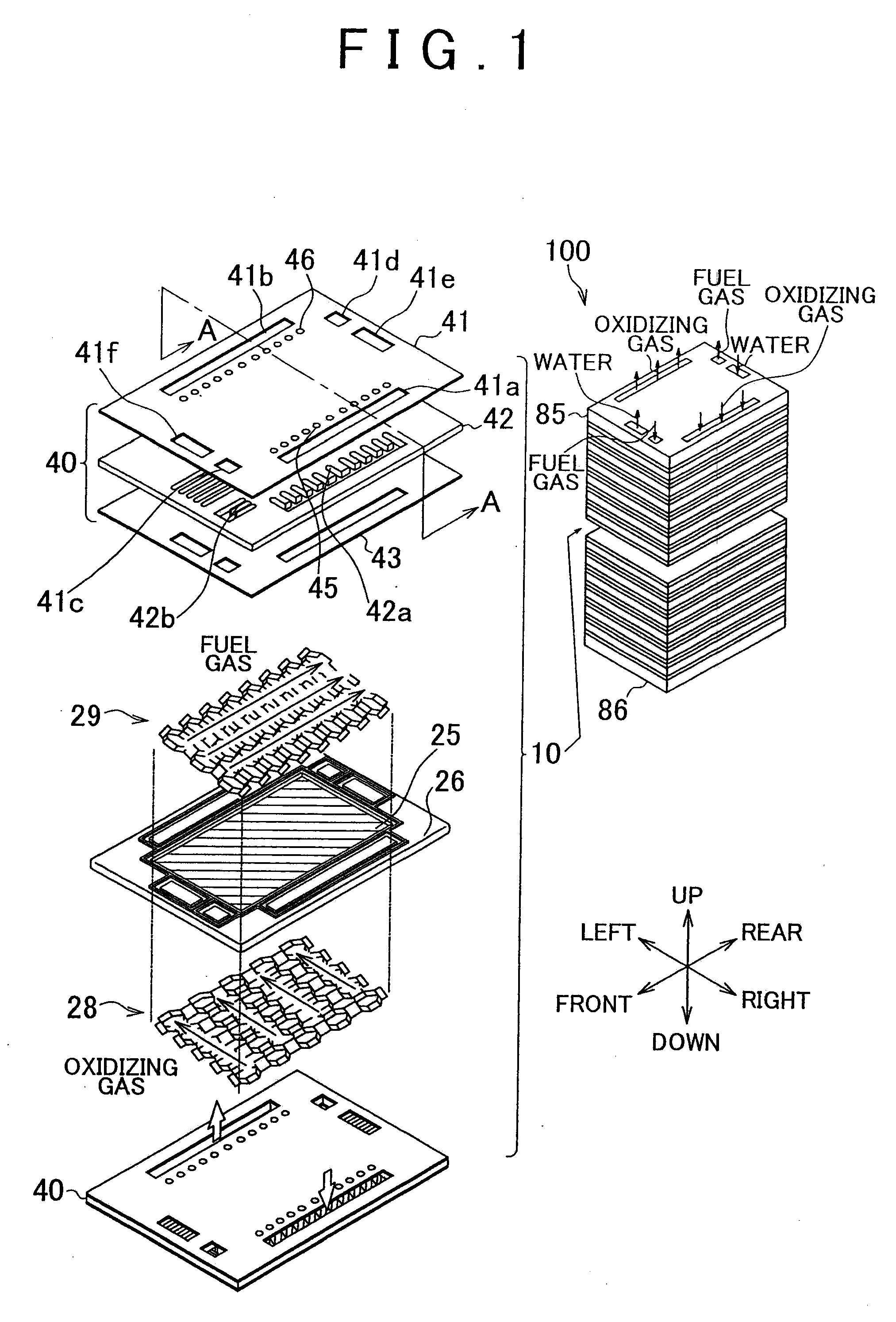

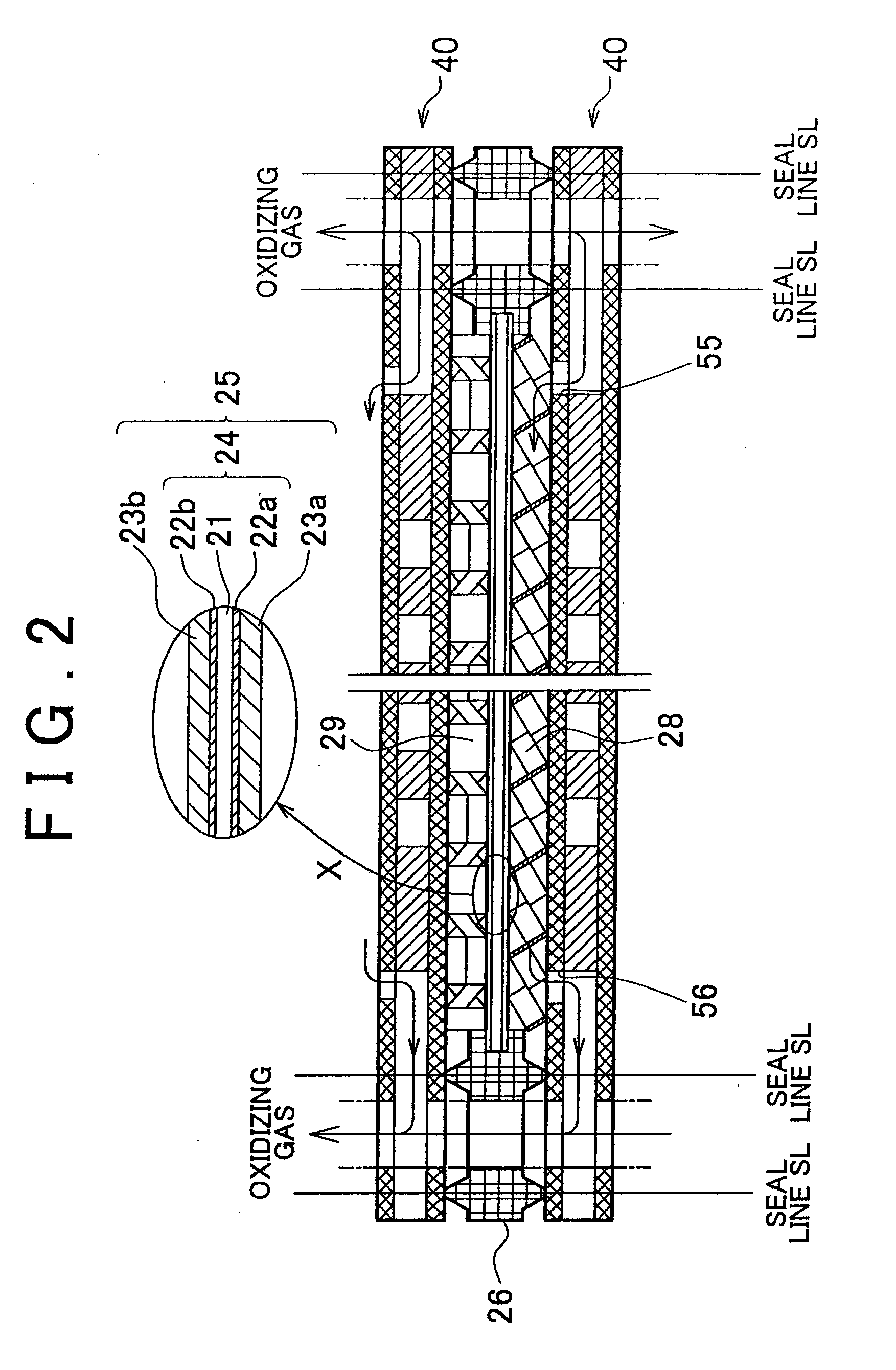

Gas diffusion layer in a fuel cell

ActiveUS20090239120A1Improve diffusion efficiencyFinal product manufactureSolid electrolyte fuel cellsFuel cellsEngineering

A fuel cell includes a gas channel-forming member that forms a channel for supplying a reactant gas to a plane of an electrode. A basic structure of the gas channel-forming member is a corrugated plate portion in which ridge portions and trough portions continuously alternate with each other. In the gas channel-forming member, a plurality of corrugated plate portions are interconnected. Specifically, two adjacent corrugated plate portions are interconnected so that the trough portions of one of the two connect to the ridge portions of the other corrugated plate portion. The gas channel-forming member is disposed so that the direction of alignment of the connection planes S formed by the interconnection between the trough portions and the ridge portions is parallel to the plane of the electrode. This structure improves the diffusion efficiency of the reactant gas in the gas channel.

Owner:TOYOTA JIDOSHA KK +1

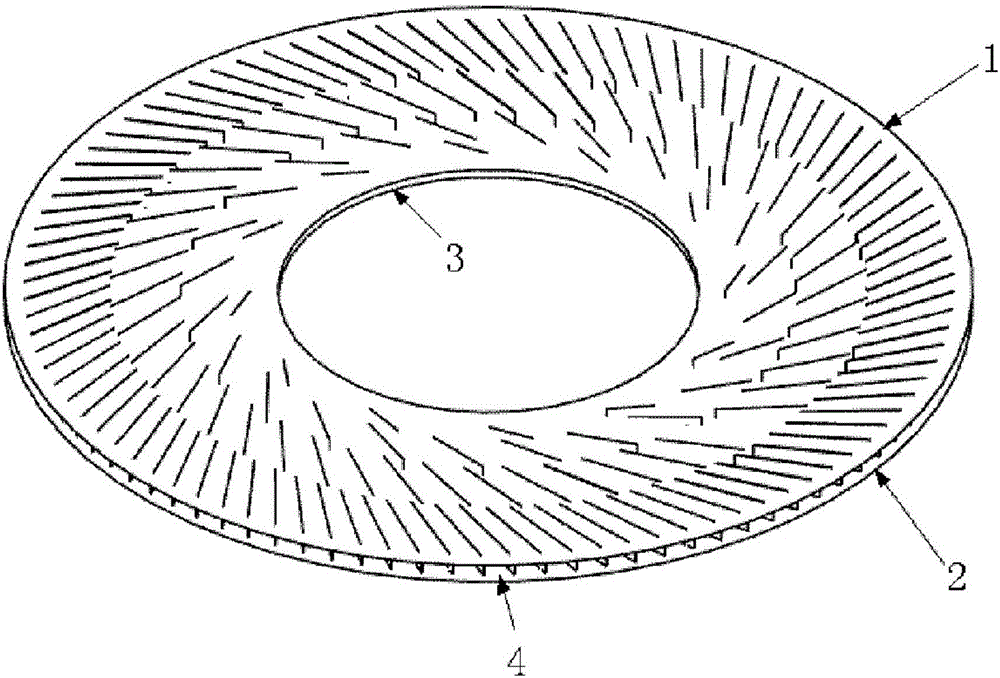

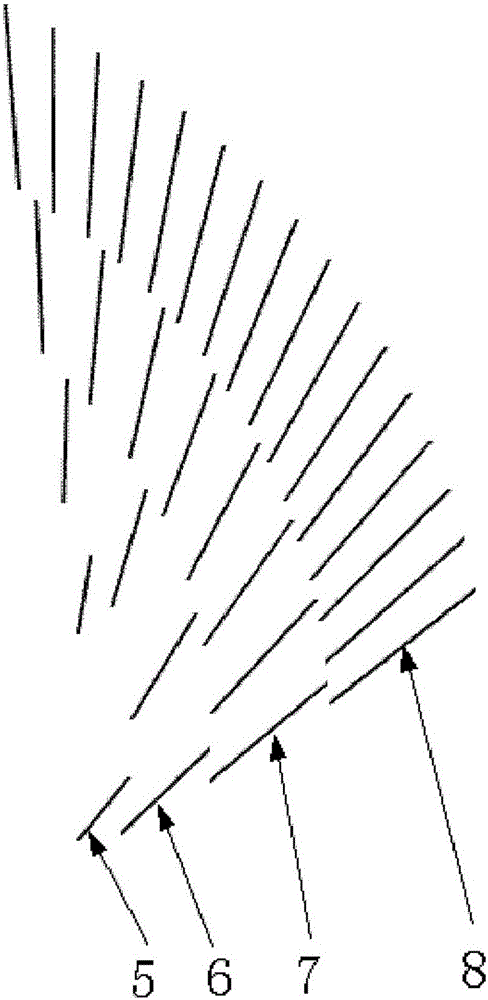

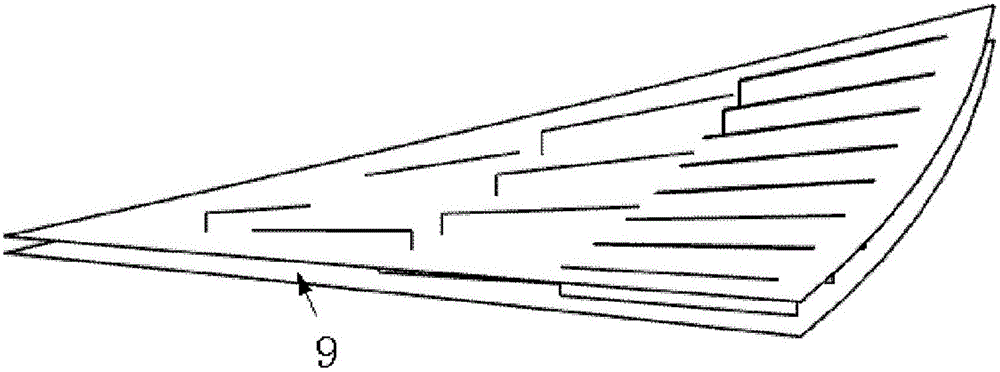

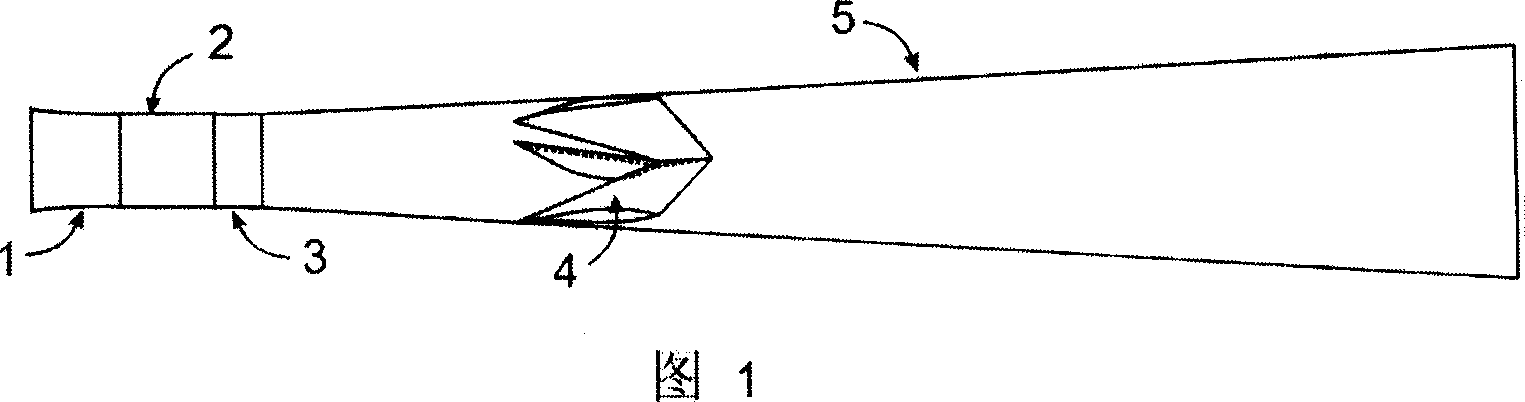

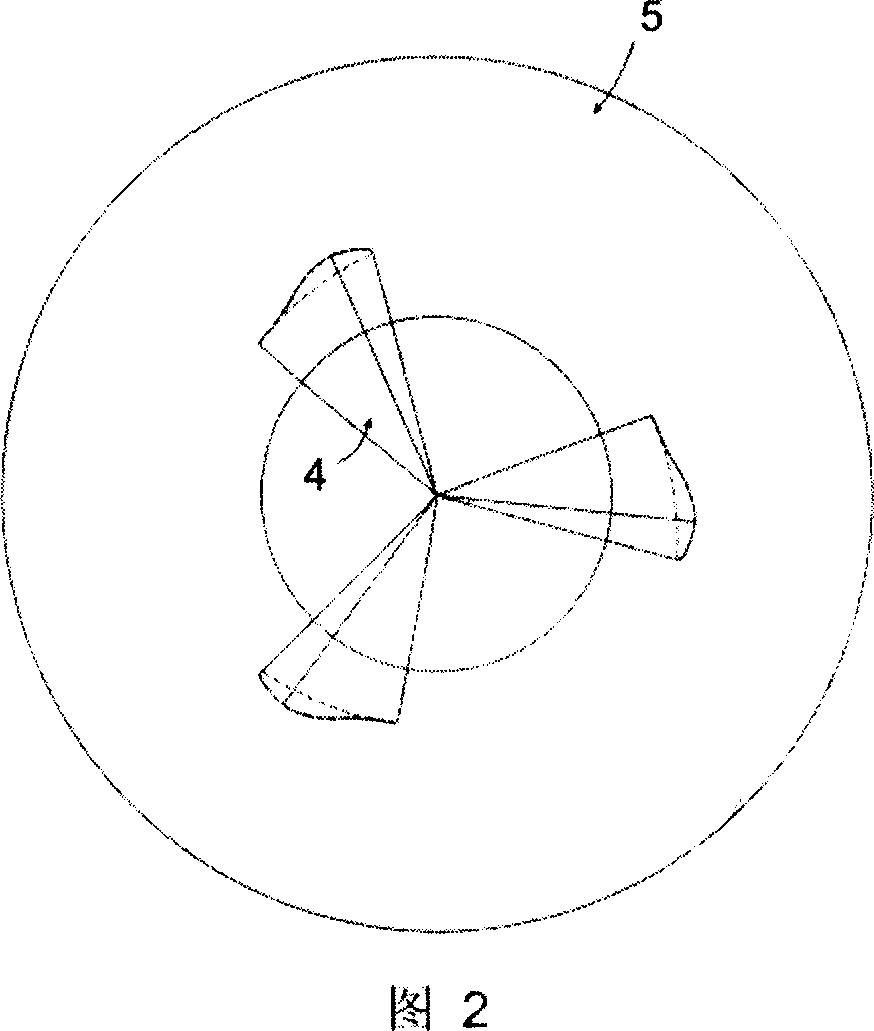

Pressure expander based on fractal blades

InactiveCN106089807AImprove the diffusion capacityImprove efficiencyPump componentsPumpsEngineeringCentrifugal compressor

The invention provides a pressure expander based on fractal blades. The pressure expander comprises an upper cover plate, a lower cover plate and a fractal blade group, wherein the fractal blade group is arranged between the upper cover plate and the lower cover plate in a clamping manner; a gas flow channel is formed among the upper cover plate, the lower cover plate and the fractal blade group; and after passing through the gas flow channel, the pressure of a gas flow is enlarged. The multi-stage fractal blades of the pressure expander disclosed by the invention can restrain flow separation, reduce flow blockage and flow loss, and improve the pressure expanding capacity and the pressure expanding efficiency of the pressure expander are improved, so that improvement of the efficiency of the whole machine, the reduction of the size of the whole machine and increase of the thrust-weight ratio / power-weight ratio are facilitated, the pressure expander disclosed by the invention is convenient to process and low in manufacturing cost, and can be directly mounted on a pressure expanding section of a centrifugal compressor, and the modifying and the upgrading of the compressor are facilitated.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

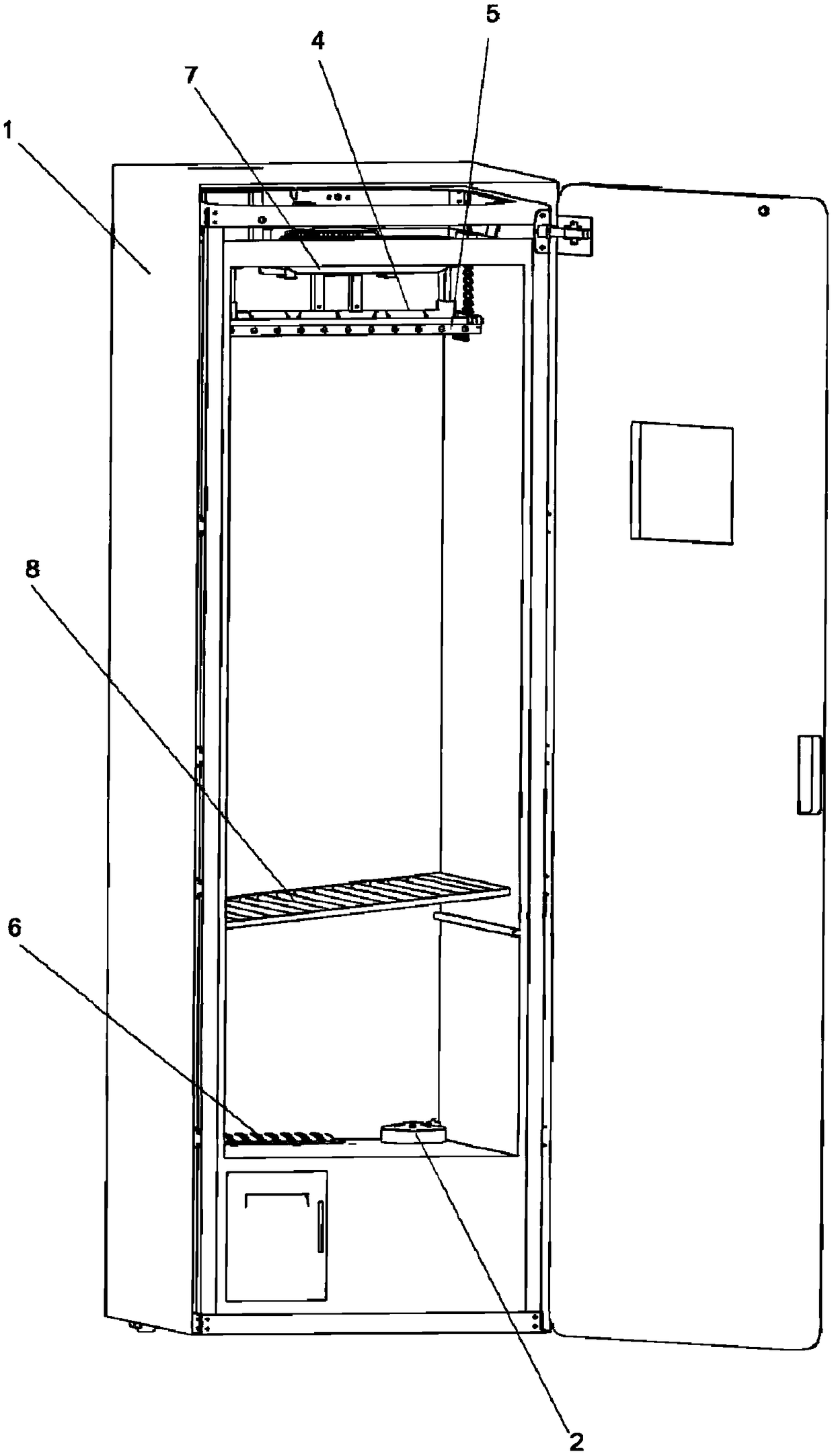

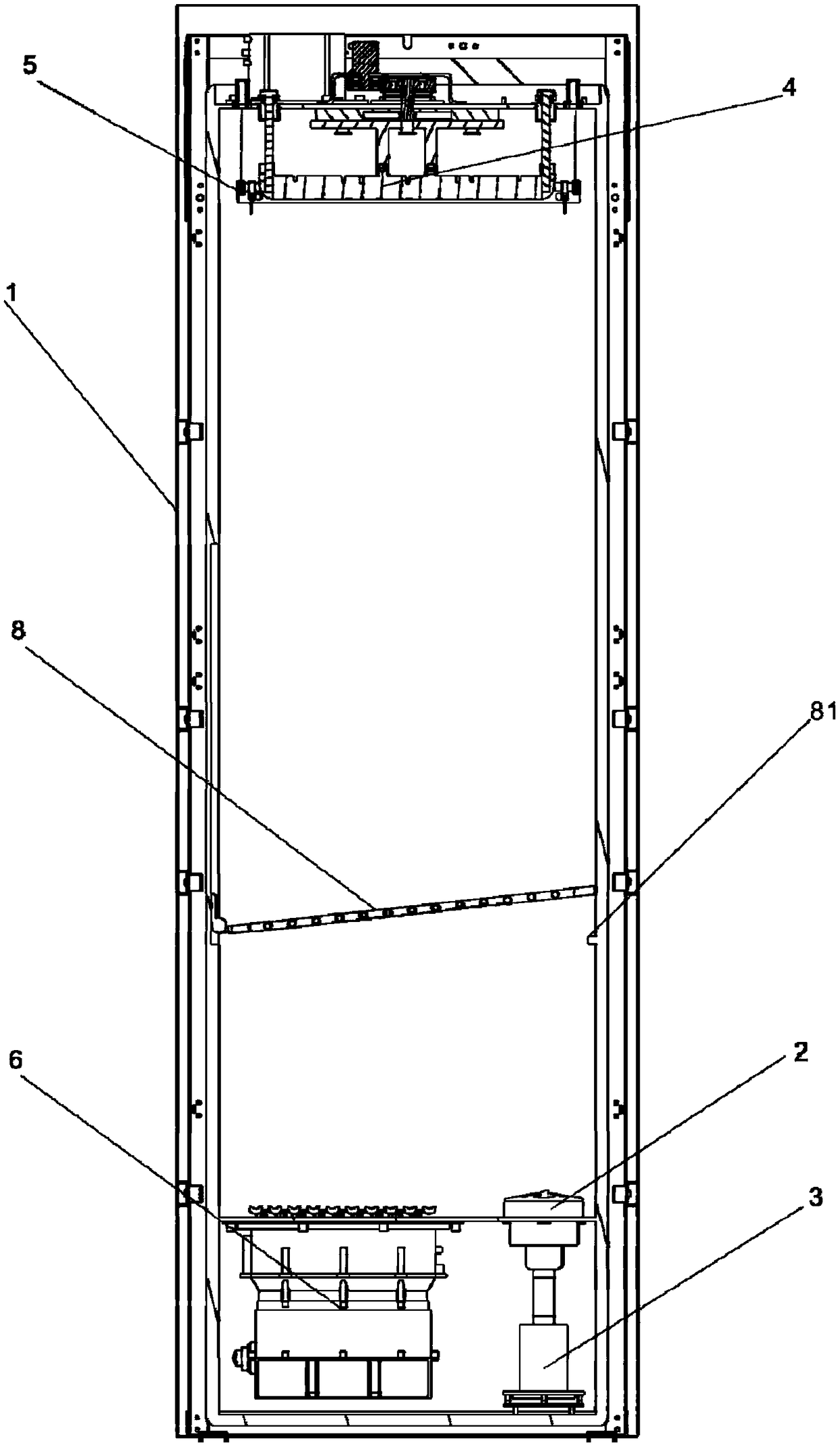

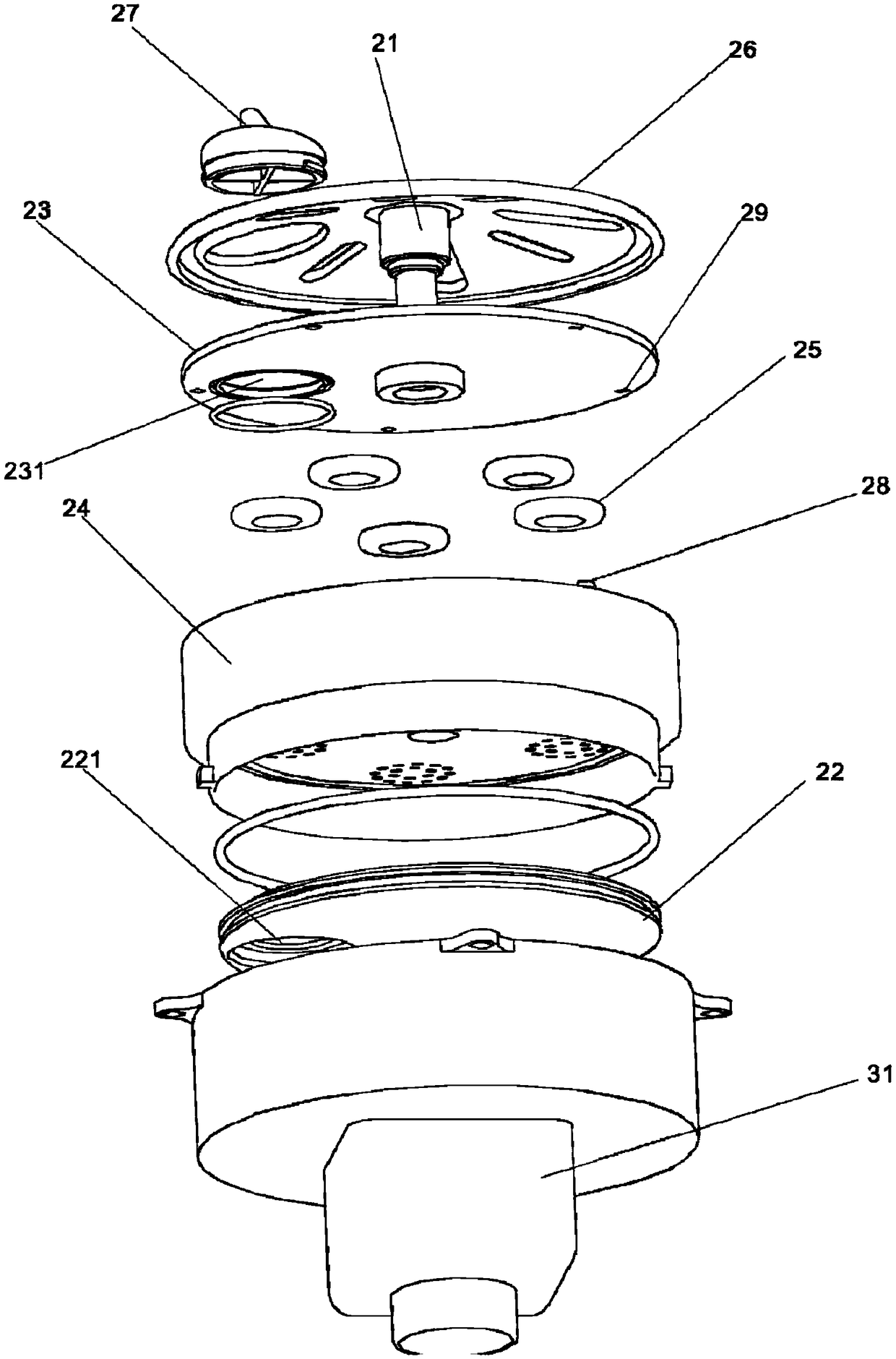

Clothing care machine

ActiveCN109082867AIncrease exerciseImprove diffusion efficiencyLiquid/gas/vapor article treatmentIroning apparatusAromatherapyEngineering

The invention discloses a clothing care machine. The machine includes a cabinet, a steam generator and an aromatherapy device, wherein the steam generator and the aromatherapy device are fixedly connected with the inside of the cabinet. The cabinet has a space for accommodating clothing, the aromatherapy device is communicated with the output end of the steam generator, and steam output by the steam generator is diffused in the space, used for accommodating the clothing, in the cabinet through the aromatherapy device. By the clothing care machine with the above structure, high-temperature steam can accelerate the movement of aromatherapy molecules in the aromatherapy device when passing through the aromatherapy device, the aroma diffusion efficiency of the aromatherapy device is improved,and thus steam ironing and deodorizing aromatherapy of the clothing can be completed in a relatively short time.

Owner:JOMOO KITCHEN & BATHROOM

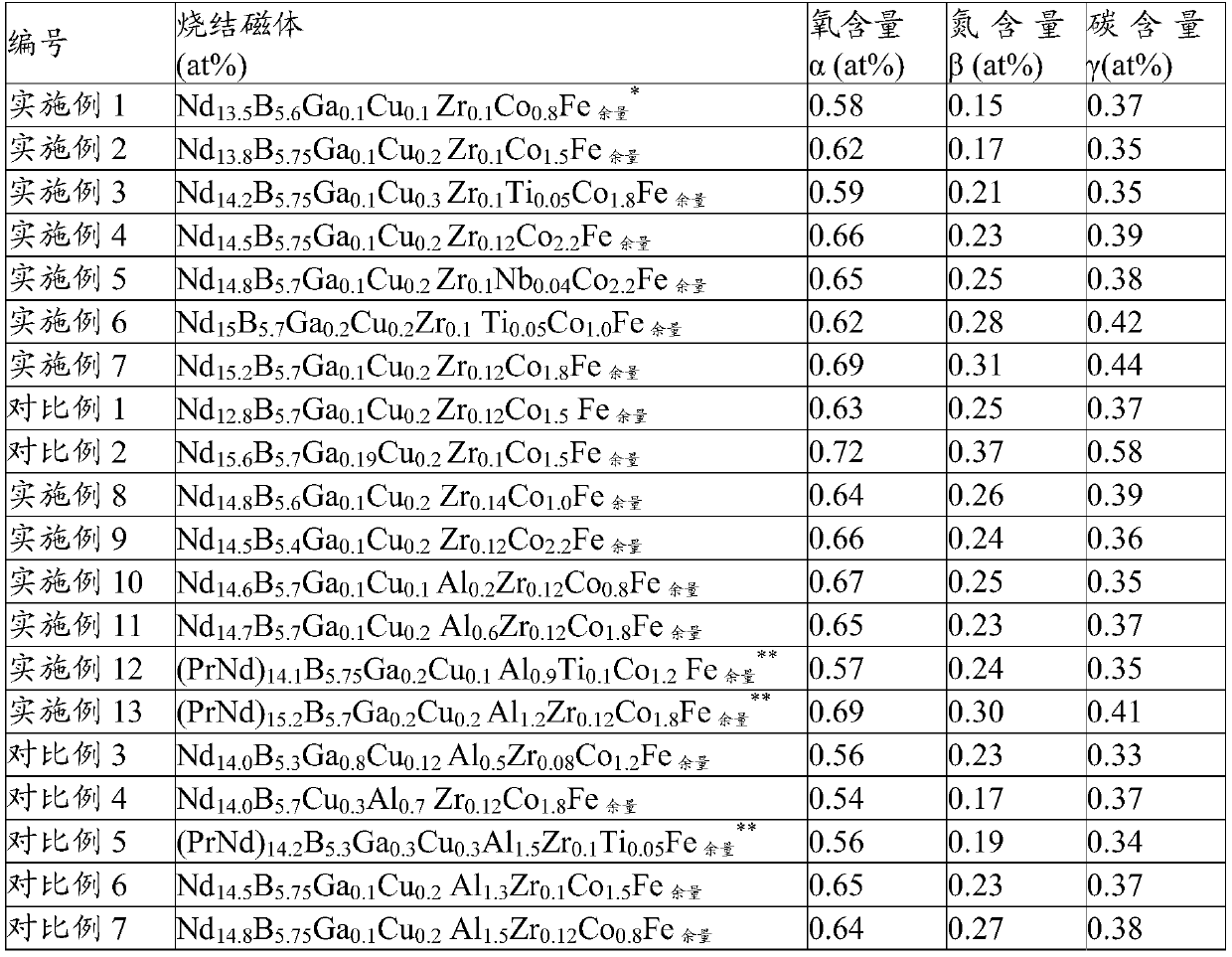

Sintered body, sintered permanent magnet and preparation method thereof

ActiveCN110444386AImprove diffusion efficiencyDiffusion fitInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementGrain boundary

The invention discloses a sintered body, a sintered permanent magnet and a preparation method thereof. The sintered body of the present invention comprises a main phase of a Nd2Fe14B crystal phase anda grain boundary phase of a rare earth-rich phase, and comprises components Ra, Bb, Gac, Cud, Ale, Mf, Cog, with the balance of Fe, wherein R is selected from at least one rare earth element and mustcontain Nd; M is selected from at least one of Zr, Ti and Nb; a is 13 to 15.3%; b is 5.4 to 5.8%; c is 0.05 to 0.25%; d is 0.08 to 0.3%; e is 0 to 1.2%; f is 0.08 to 0.2%; g is 0.8 to 2.5%; the average grain size of Nd2Fe14B crystal phase is L from 4 to 8 [mu]m, the average thickness of the grain boundary phase is t with a unit of [mu]m; t and L satisfy the following relationship: [sigma]=t / L; and sigma is 0.009-0.012. The sintered body improves the diffusion efficiency of the heavy rare earth element RH.

Owner:BAOTOU TIANHE MAGNETICS TECH CO LTD

Low-cost diffusion source alloy, grain boundary diffusion magnet and preparation method thereof

InactiveCN108417380ALow costCost-effectiveInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementCerium

The invention relates to low-cost diffusion source alloy for magnet grain boundary diffusion, a grain boundary diffusion magnet and a preparation method thereof. Chemical components of the diffusion source alloy comprise an element Ce, a light rare earth element LRE, a heavy rare earth element HRE and a metal element M, and are shown as Cex(LREaHRE1-a)yM100-x-y according to atomic percentage, wherein 0< x< / = 20, 15< / = y< / = 99.9 and 15<x+ y< / = 99.9, 0< / = a< / = 1.0; LRE is one or more of La, Pr, Nd and Y; HRE is one or more of Tb, Dy and Ho; and M is one or more of Al, Cu, Zn, Ga, Ag, Pb, Bi andSn. The light rare earth element, particularly cerium, is used for partially replacing a heavy rare earth element, raw material costs of the diffusion source alloy is reduced, the melting point of thediffusion source alloy is adjusted, by improvement of the diffusion efficiency of the heavy rare earth element, the coercivity temperature coefficient of the grain boundary diffusion magnet is increased, and the high-temperature stability of the grain boundary diffusion magnet is improved.

Owner:CENT IRON & STEEL RES INST

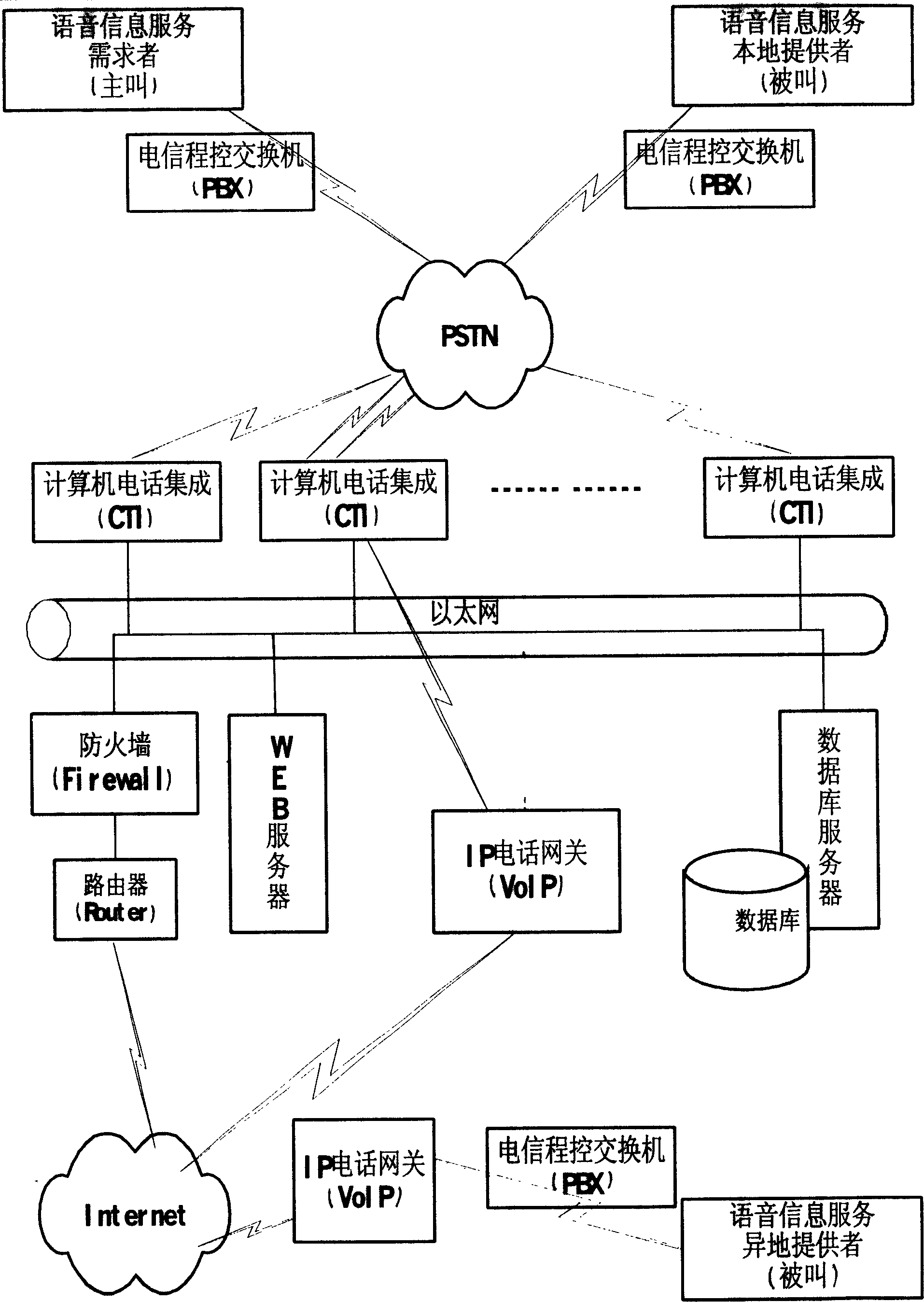

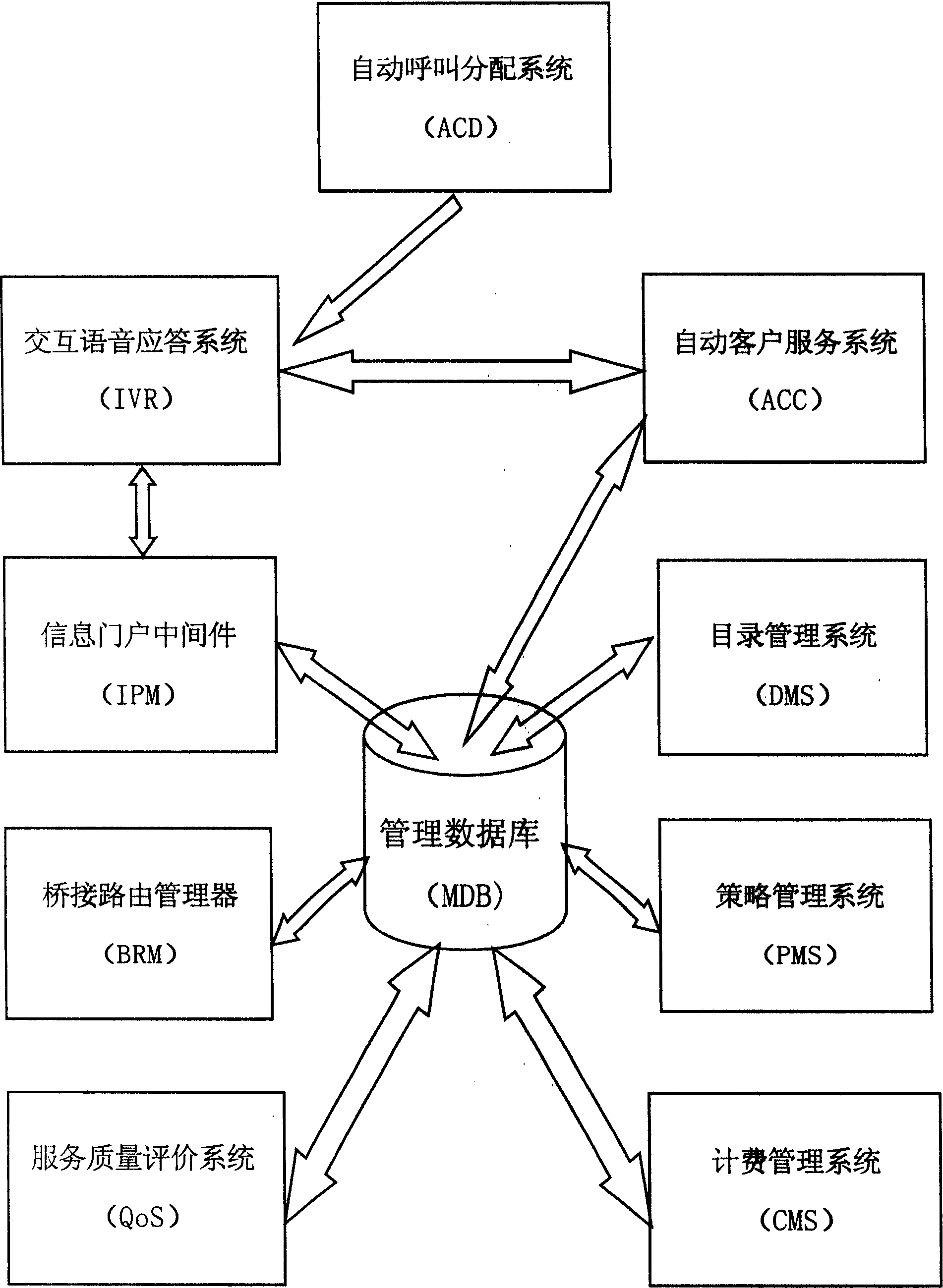

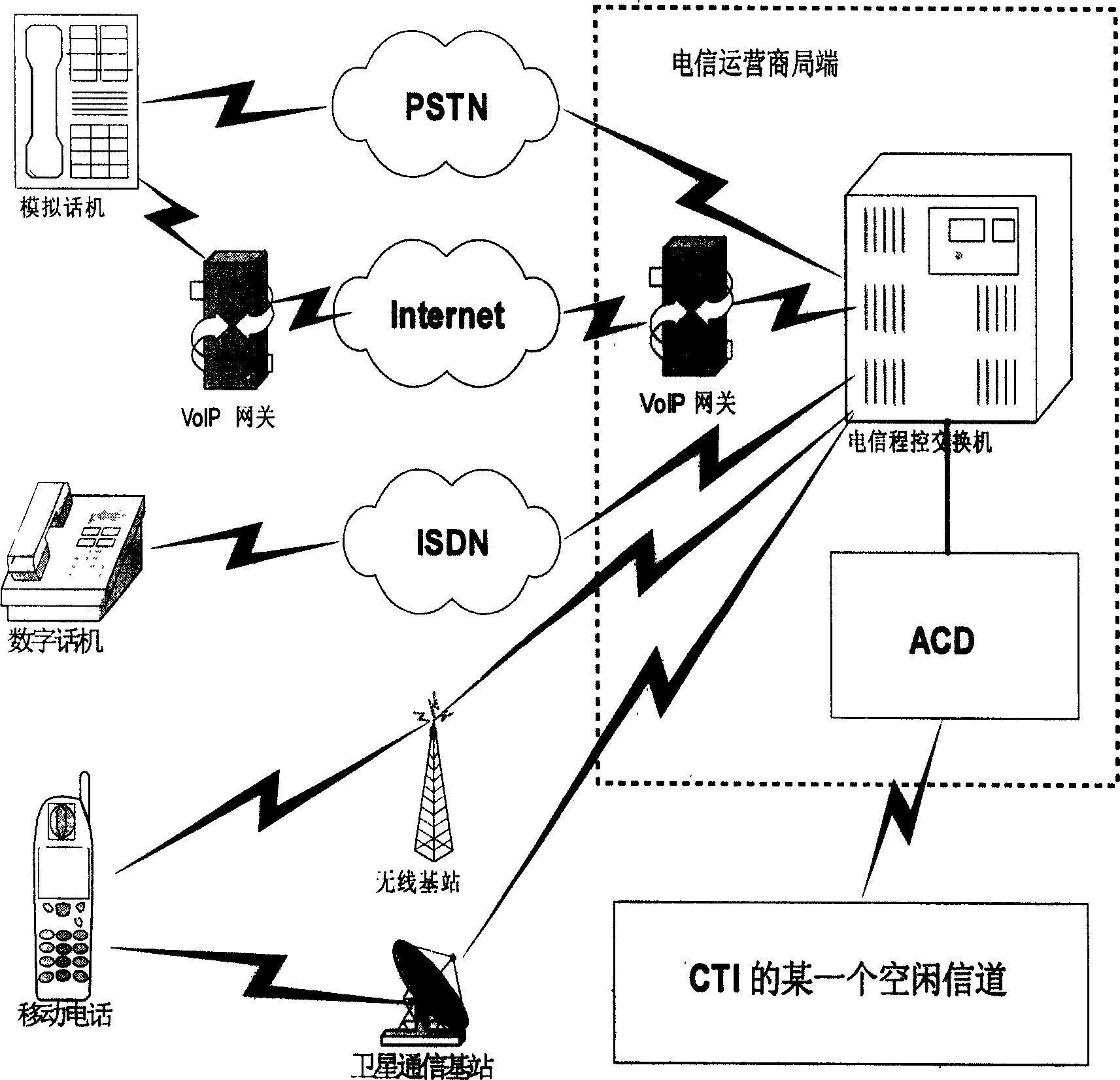

Setting method and device for intelligent voice information bridge

InactiveCN1607495AAdaptive adjustmentFacilitate communicationSound input/outputSpecial data processing applicationsPersonalizationTeleconference

A designing method for intelligent phonetic information bridge designs a program taking the telephone phones as the media and using keys of DTMF identified caller of a phone for operating the IVR system on a platform of CTI system, ACD system, IVR, MDB and an aCC systems controlled by computer and connected by PSTN to determine the calling one identity by verification and presents corresponding phone hint by finding designed situation of said calling one personality in MDB to let the calling one select concrete information service items by phone dual voice multi-frequency key to find out the information provider providing related information service and waiting for access to select one bit or multiple bits( telephone conference) according to the route strategy and connect bridges of call in-and-out to exchange information.

Owner:孙智峰

Continuous production process of polymethyl methacrylate

The invention relates to a polymer preparation method, particularly relates to a continuous production process of polymethyl methacrylate and belongs to the technical field of preparation of a polymer. According to the invention, polymethyl methacrylate is continuously produced through prepolymerization, secondary polymerization and tertiary polymerization sequentially. The continuous production method of polymethyl methacrylate is based on continuous mass polymerization, combines the advantages of mass polymerization and solution polymerization, effectively controls reaction heat, increases monomer conversion rate and enhances polymer purification efficiency.

Owner:SUZHOU DOUBLE ELEPHANT OPTICAL MATERIALS CO LTD

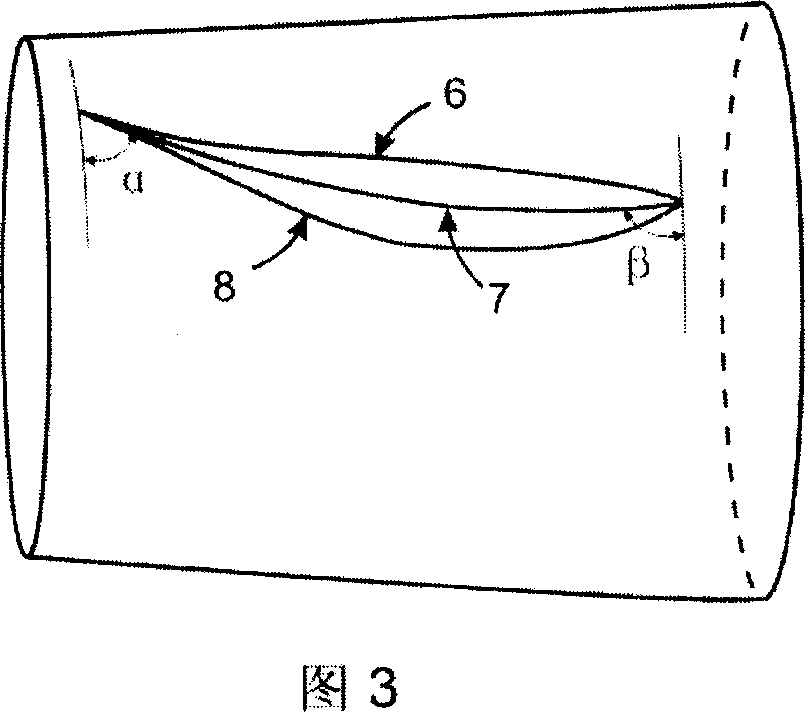

Super-sonic diffuser for super-sonic vortex flow natural gas separator

InactiveCN101053857AImprove diffusion efficiencyReduce lossesReversed direction vortexAirflowEngineering

The invention provides a supersonic velocity diffuser for a supersonic velocity rotational flow natural gas separator as an important component of the separator, wherein the diffuser is comprised of four parts of a contraction pipe part, a straight pipe part, an expansion pipe part and a diversion fin, wherein profile curve of the contraction pipe part is high order polynomial, profile curve of the expansion pipe part adopts circular arc adding straight line, while the parts are smoothly connected with each other to reduce disturbance of air current. Bottom surface of the diversion fin as a truncated cone surface corresponds with an inner wall of a panel pipe and is fixed on the inner wall. On the bottom surface, arc line is a high order polynomial curve, and the bottom surface profile thickness varies according to the high order polynomial law. Diversion fin top contraction becomes bout, parallel in axial straight line. Set up 2 -6 slices diversion fin in this supersonic velocity diffuser, may rotational flow natural gas circulation melts for axial flow, have higher expand to press efficiency, have the compression resistant force fluctuation than winner to disturb ability, can raise the step up ratio of supersonic velocity rotational flow natural gas separator, strengthen the applicability of supersonic velocity rotational flow natural gas separator. Top part of the diversion fin is contracted into a straight line parallel to an axial. 2-6 pieces of diversion fins are provided within the supersonic velocity diffuser for converting the rotational flow natural gas flow into an axial flow, which has higher efficiency of pressure expanding, stronger compression resistant force fluctuation capacity, can raise the step up ratio and applicability of the supersonic velocity rotational flow natural gas separator.

Owner:曹学文

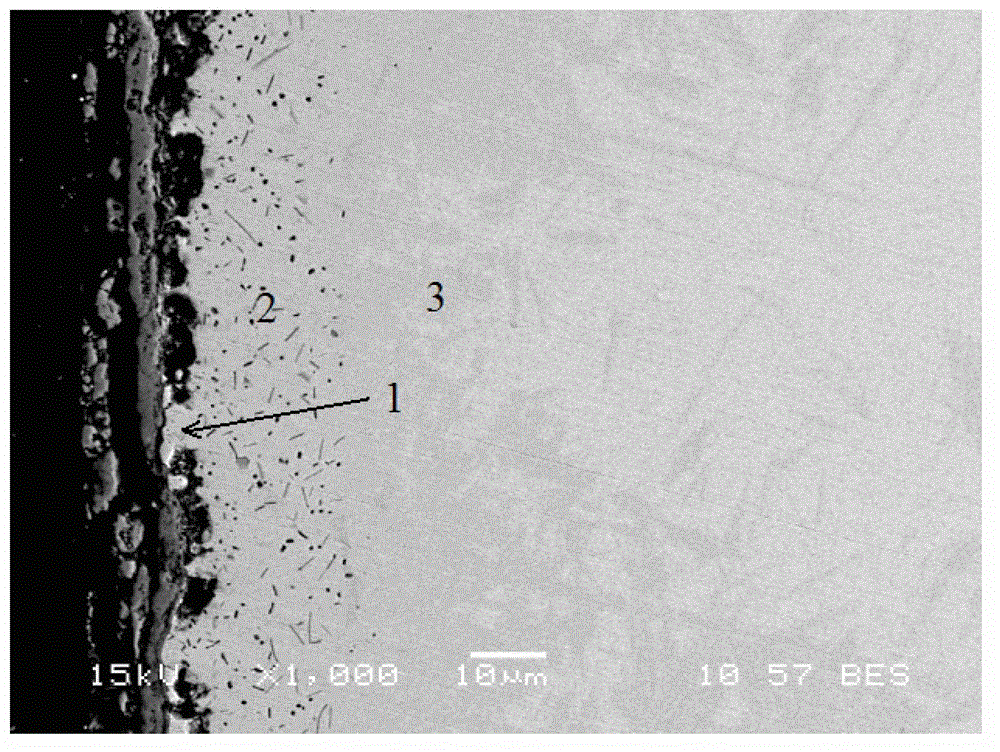

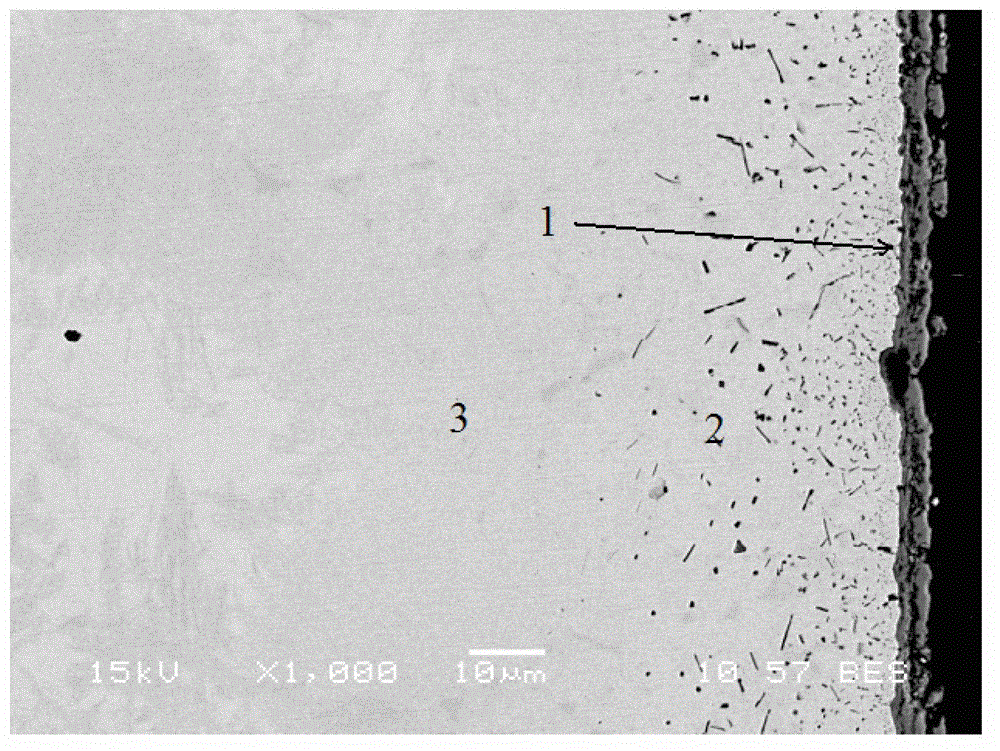

Method for carrying out anatonosis by adopting laser plasma impact wave in chemical heat treatment process

InactiveCN102978628AReduced activation energy for diffusionImprove diffusion efficiencyCorrosion resistantMaterials science

The invention relates to a method for carrying out anatonosis by adopting laser plasma impact waves in a chemical heat treatment process. According to the method, induction to generate plasma impact waves are generated by induction with high-power short-pulse laser, act on materials and are combined with chemical heat treatment, thereby improving the surface property of metal materials and members and enhancing the oxidation resistance, abrasion resistance and corrosion resistance of the metal material and the members, wherein the chemical heat treatment can be alumetizing, carburization, nitridation, aluminum-chromium penetration and the like. The method disclosed by the invention has the beneficial effects that the temperature of the chemical heat treatment in order to obtain identical penetration layer depth, the temperature of the chemical heat treatment can be obviously reduced, and the treatment time is shortened, thereby reducing the deformation of workpieces.

Owner:AIR FORCE UNIV PLA

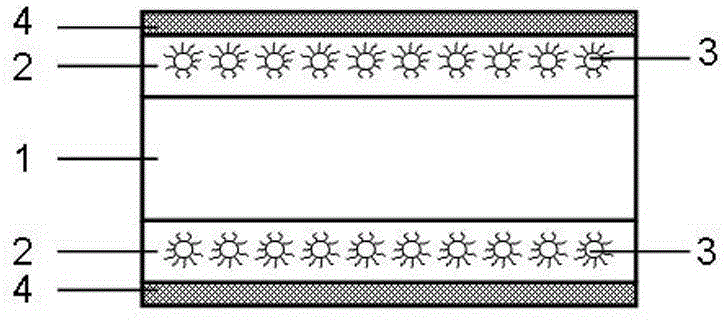

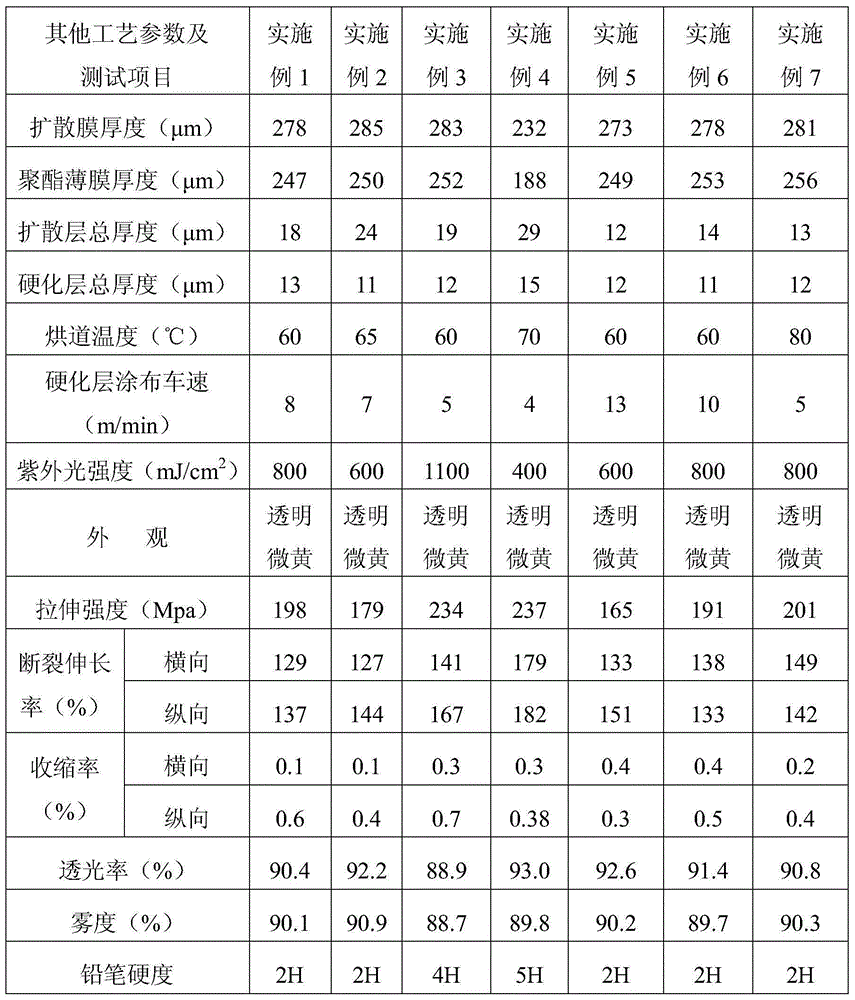

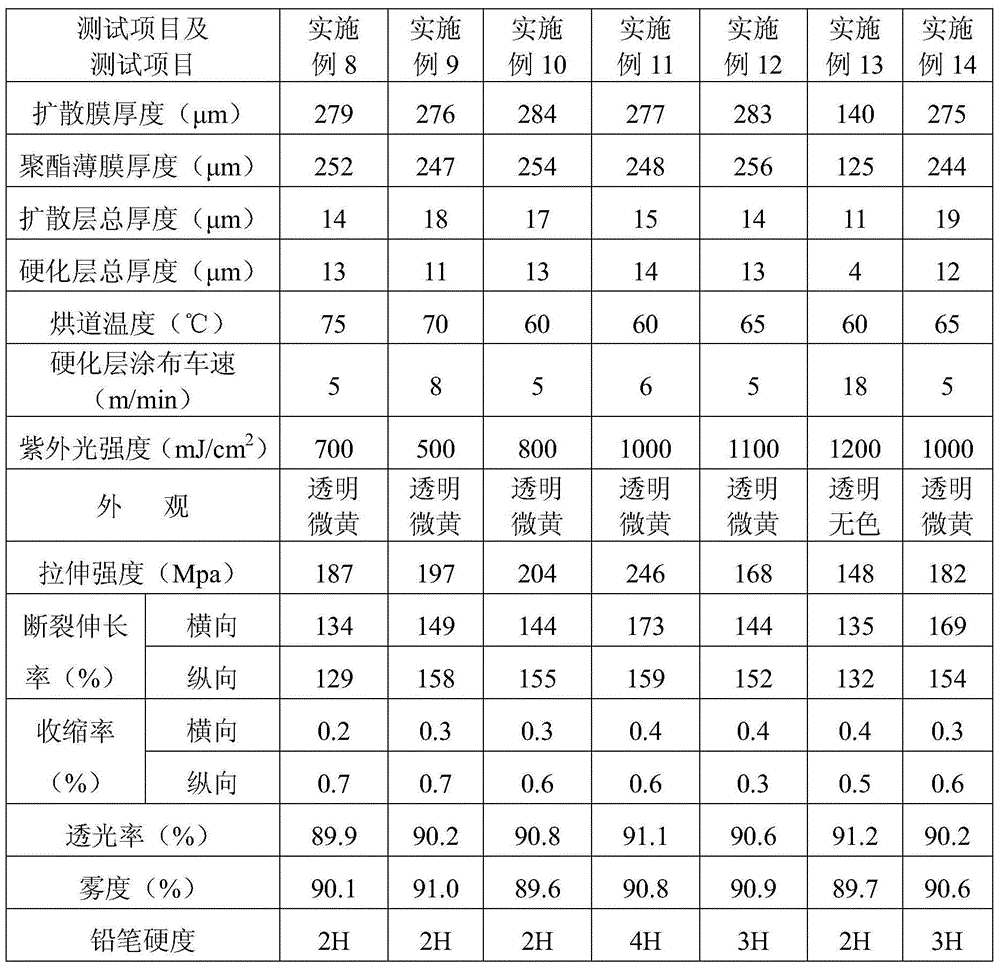

Optical diffusion film and preparation method thereof

ActiveCN104459844AWill not gather with each otherTo achieve the purpose of surface modificationDiffusing elementsPolyesterAcrylic resin

The invention discloses an optical diffusion film. The optical diffusion film is characterized by being composed of a polyester film layer, diffusion layers and hardened layers, wherein the polyester film layer is located in the middle, the two sides of the polyester film layer are coated with the diffusion layers, and the diffusion layers on the two sides of the polyester film layer are coated with the hardened layers; the thickness of the optical diffusion film ranges from 63 microns to 345 microns; each diffusion layer is a coating formed in the mode that a diffusion layer coating composition composed of a silicon source, a silane coupling agent, A-101 thermoplastic acrylic resin, ethanol, water and diluted hydrochloric acid is dried and cured at the temperature of 60-80 DEG C; each hardened layer is a coating formed in the mode that a hardened layer coating composition composed of ultraviolet cured resin, reactive diluent, photoinitiator and a leveling agent is cured under ultraviolet irradiation. The optical diffusion film has balanced light transmittance, haze and light diffusion performance, maintains high rigidity and dimensional stability and can be widely applied to manufacturing of liquid crystal display devices, advertising lamp boxes, illumination lamps and other devices requiring light sources.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

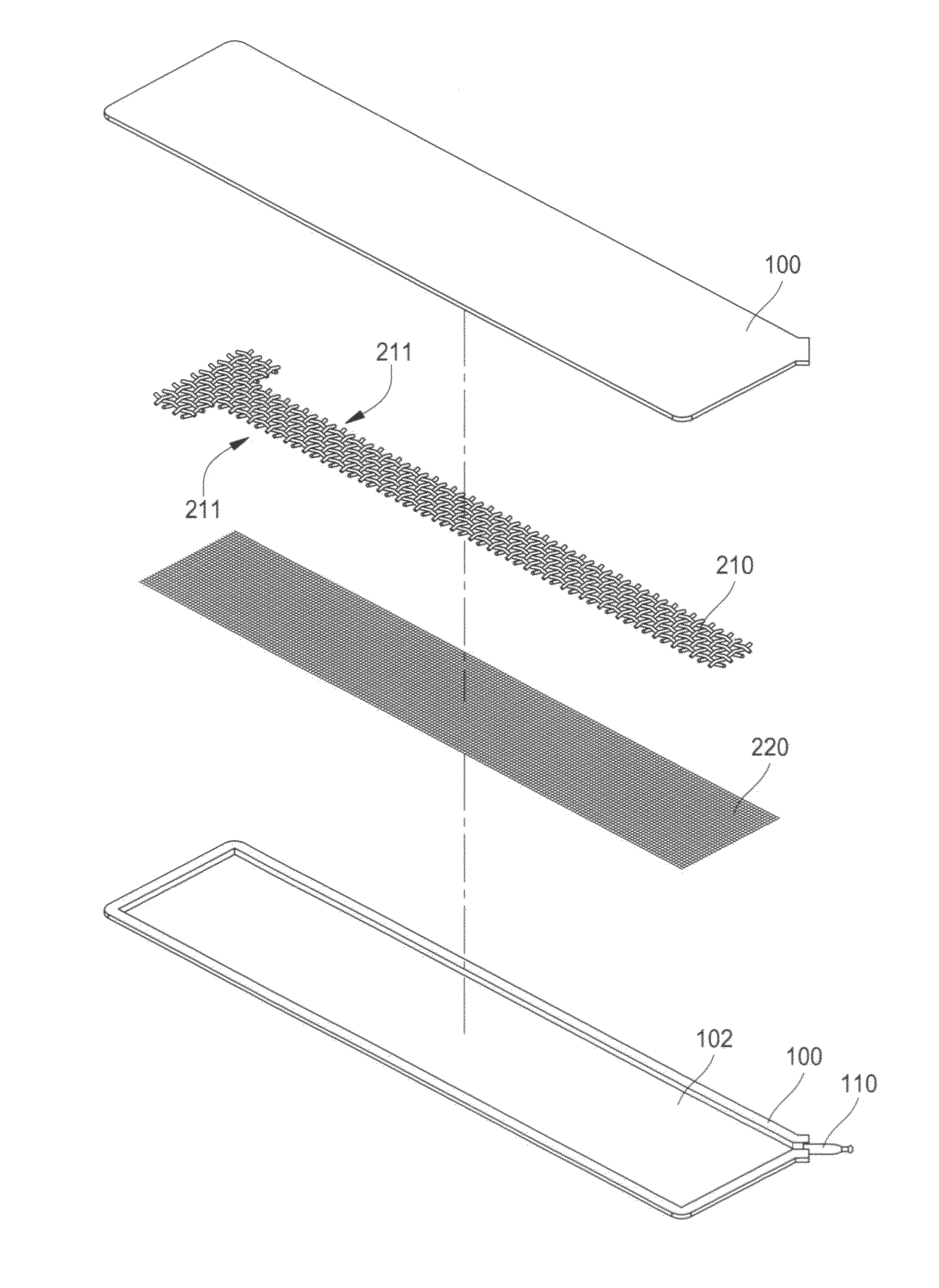

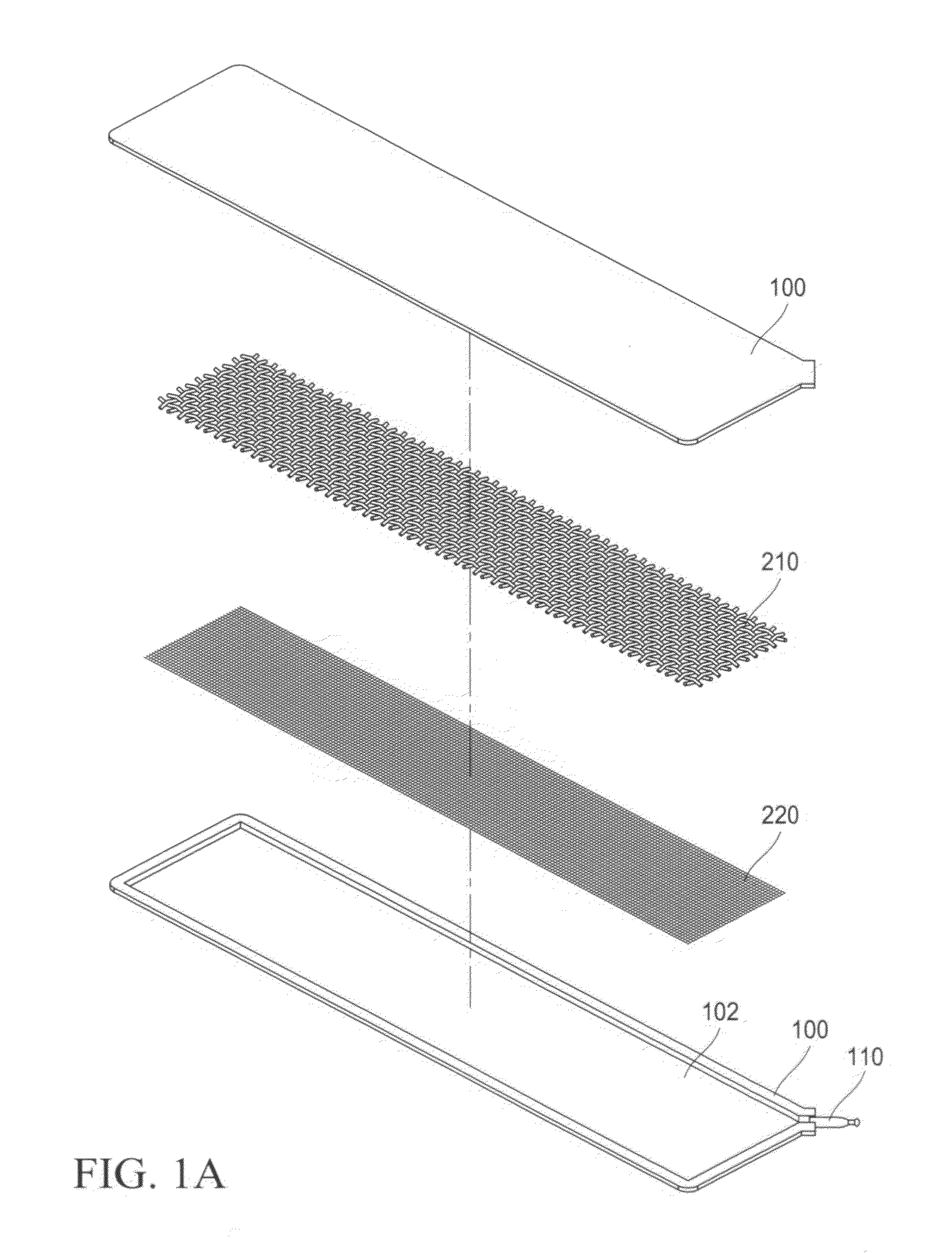

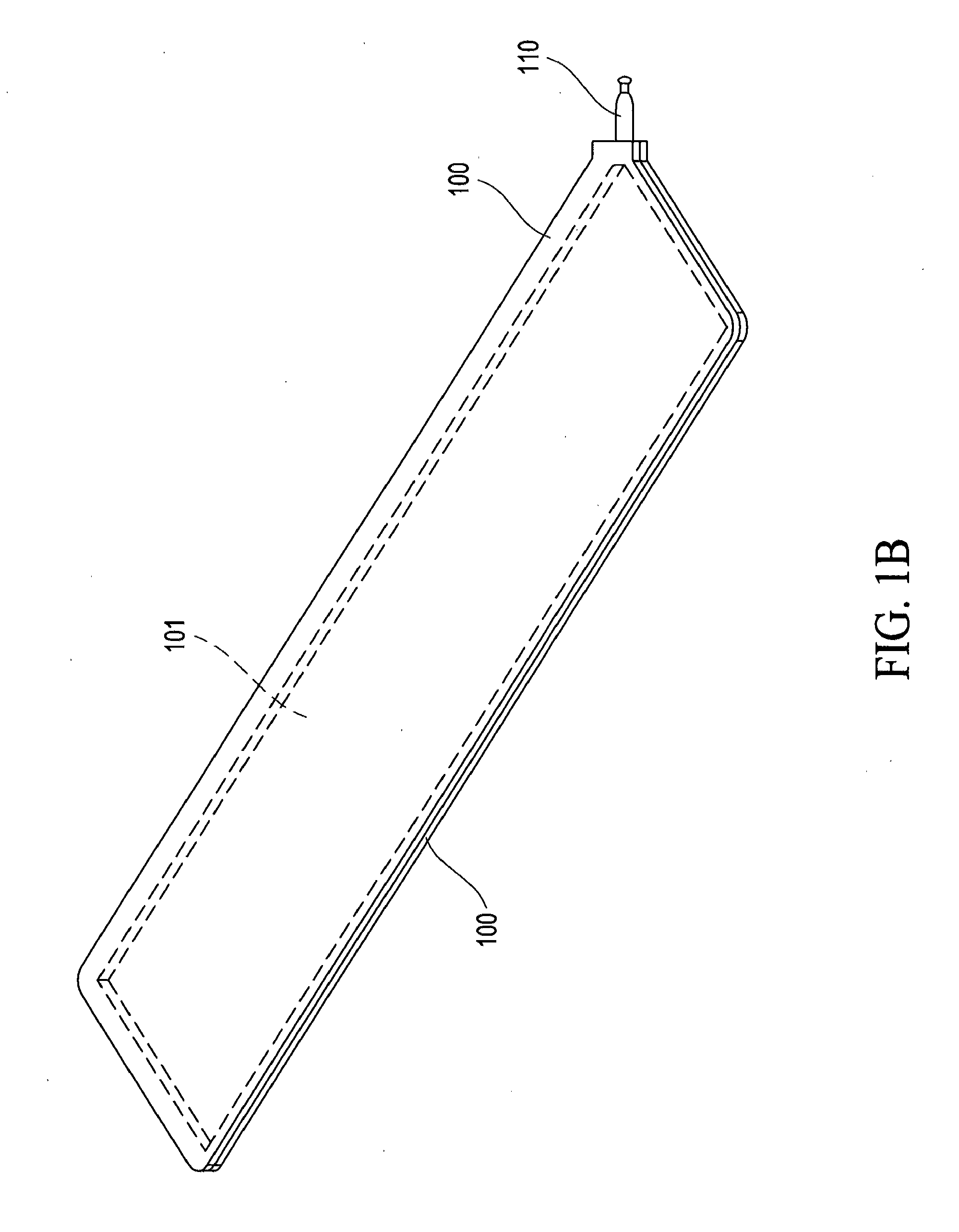

Capillary structure of heat plate

InactiveUS20120031587A1Improve cooling efficiencyImprove diffusion efficiencyIndirect heat exchangersWorking fluidEngineering

A heat plate includes two boards, which mate and are coupled to each other to define therebetween an accommodation chamber and a capillary structure of at least one first capillary layer and at least one second capillary layer arranged in the accommodation chamber in such a way that the first and second capillary layers are stacked over each other. With the arrangement of the first and second capillary layers, the efficiency of diffusion of vapor of a working fluid is increased and the uniformity of distribution of the working fluid is enhanced, so that the efficiency of temperature reduction is improved.

Owner:KUNSHAN JUZHONG ELECTRONICS

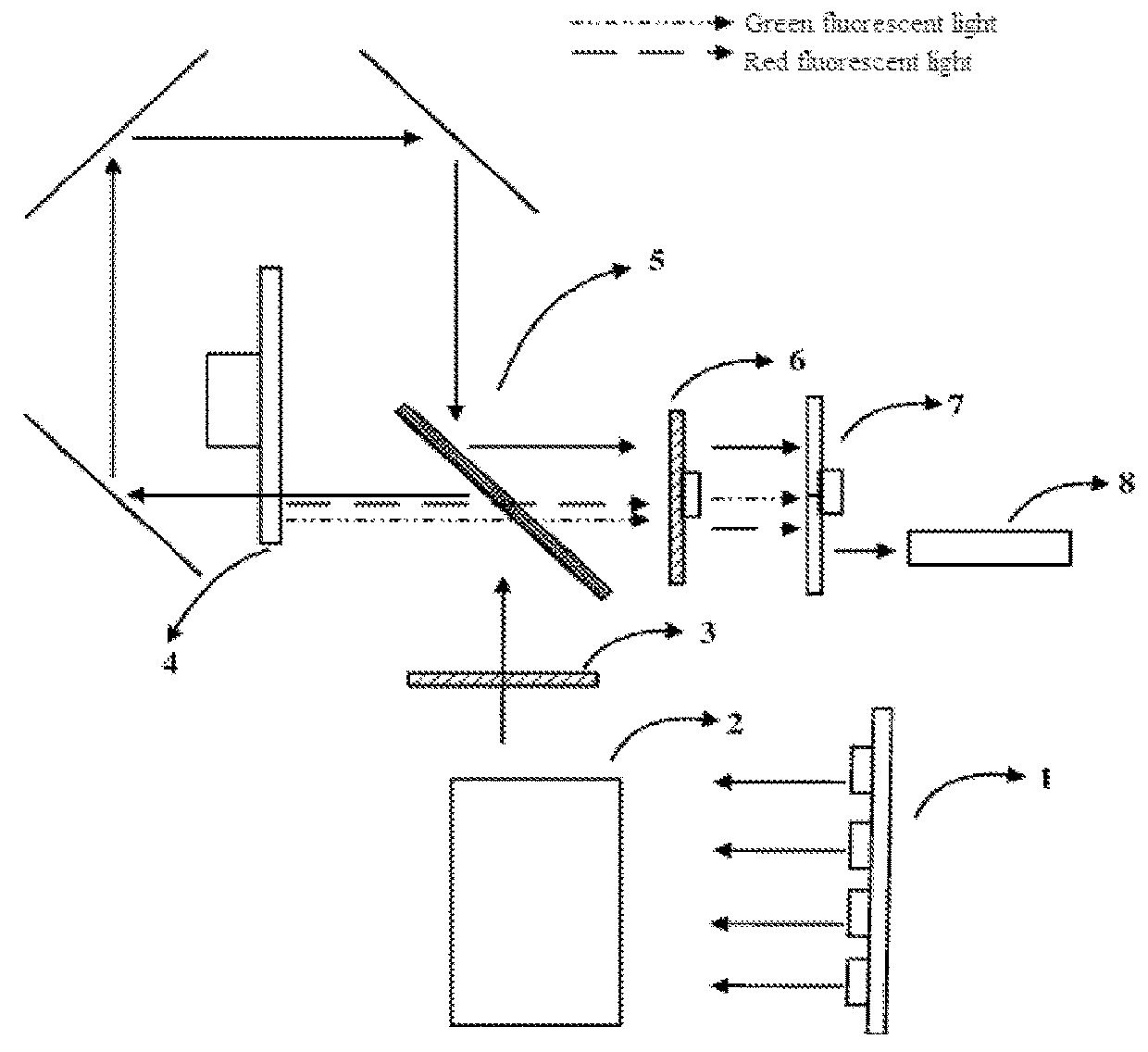

Laser light source and projection display device

ActiveUS20180164669A1Small sizeHigh light transmittanceProjectorsColor photographyFluorescenceLaser light

Owner:HISENSE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com