Carbonization mixing pile-ventilating pipe pile composite foundation and construction method thereof

A composite foundation and construction method technology, applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problem of difficulty in meeting the reinforcement needs of deep and weak foundation soil, increasing the amount of foundation treatment and construction costs, and difficulty in meeting the needs of engineering bearing capacity and other problems, to achieve the effect of high construction efficiency, lower soil strength requirements, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

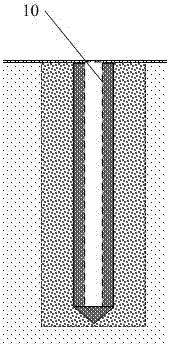

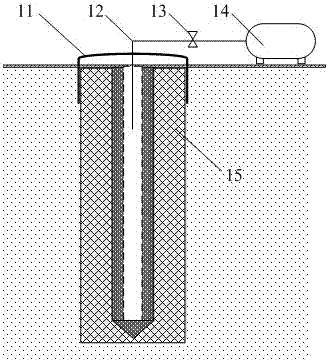

[0035] like image 3 As shown, the carbonized stirring pile-ventilating pipe pile composite foundation, the carbonized stirring pile-ventilating pipe pile composite foundation is composed of carbonized magnesia cement soil mixing pile 15 and ventilating pipe pile 10, and the ventilating pipe pile 10 is composited on carbonized magnesia cement Soil mixing pile 15 inside. The magnesia cement in the magnesia carbide cement-soil mixing pile 15 is activated magnesia, a mixture of activated magnesia and quicklime, a mixture of activated magnesia and cement, or a mixture of activated magnesia, quicklime and cement. The ventilation pipe pile 10 is a reinforced concrete prefabricated pile.

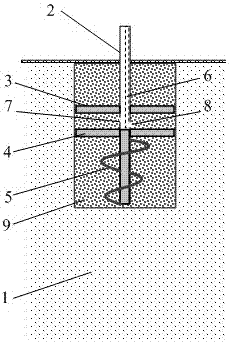

[0036] combine figure 1 , figure 2 and image 3 As shown, the construction method of carbonized stirring pile-ventilating pipe pile composite foundation includes the following steps:

[0037] a. The site is leveled, the pile driver is in place, and the drill pipe 2 and the auger bit 5 of the ...

Embodiment 2

[0051] If the natural foundation 1 is sandy soil, within 5m from the surface, the moisture content of the natural foundation is less than 10%; within 5-10m from the surface, the moisture content of the natural foundation is 10%-20%; m, the moisture content of the natural foundation is greater than 20%. The powder content of magnesia cement is selected as 10%, active magnesia is selected as the curing agent, and the magnesia cement slurry is prepared according to the water / dry powder mass ratio of 0.8. According to the design requirements, the diameter of the mixing pile is set at 1200 mm, the mixing depth is set at 10 m, the outer diameter of the ventilation pipe pile 10 is 400 mm, and the length of a single ventilation pipe pile 10 is 10 m.

[0052] The specific steps of construction are:

[0053] a. Align the pile driver drill pipe 2 and the auger bit 5 vertically to the set pile position of the natural foundation 1;

[0054] b. Start the stirring pile driver to the penetr...

Embodiment 3

[0061] If the natural foundation 1 is silt, within 3m from the surface, the moisture content of the natural foundation is less than 10%; within 3-8m from the surface, the moisture content of the natural foundation is 10%-20%; m, the moisture content of the natural foundation is greater than 20%. The powder content of magnesia cement is selected as 10%, the mixture of activated magnesia and lime is selected, the mixing ratio is 1:1, and the magnesia cement slurry is prepared according to the water / dry powder mass ratio of 0.8. According to the design requirements, the diameter of the mixing pile is set at 1400 mm, the mixing depth is set at 20 m, the outer diameter of the ventilation pipe pile 10 is 600 mm, and the length of a single ventilation pipe pile 10 is 10 m.

[0062] The specific steps of construction are:

[0063] a. Align the pile driver drill pipe 2 and the auger bit 5 vertically to the set pile position of the natural foundation 1;

[0064] b. Start the stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com