Patents

Literature

511 results about "Dynamic compaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

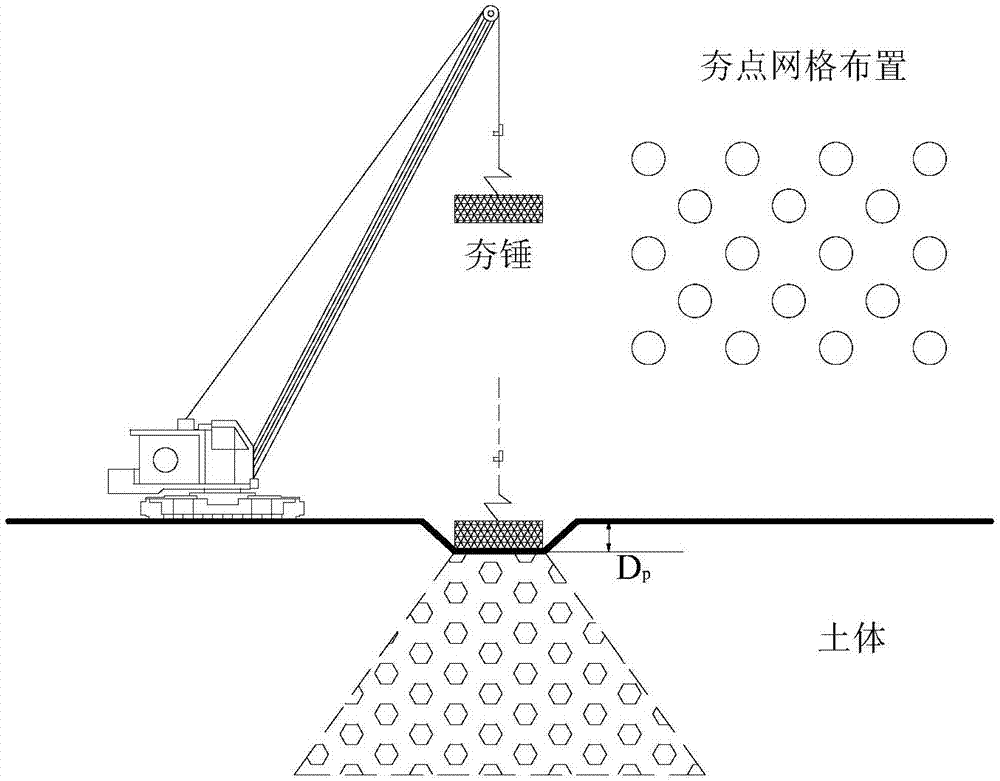

Dynamic compaction is a method that is used to increase the density of the soil when certain subsurface constraints make other methods inappropriate. It is a method that is used to increase the density of soil deposits. The process involves dropping a heavy weight repeatedly on the ground at regularly spaced intervals. The weight and the height determine the amount of compaction that would occur. The weight that is used, depends on the degree of compaction desired and is between 8 tonne to 36 tonne. The height varies from 1m to 30m.

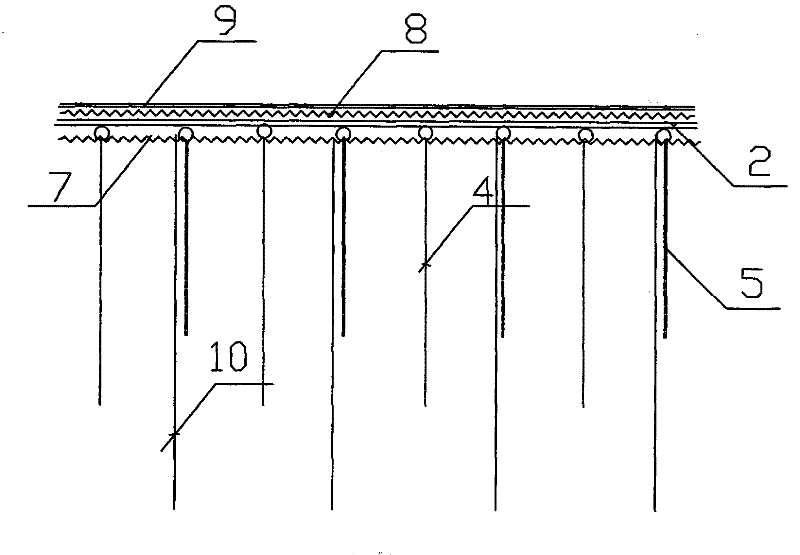

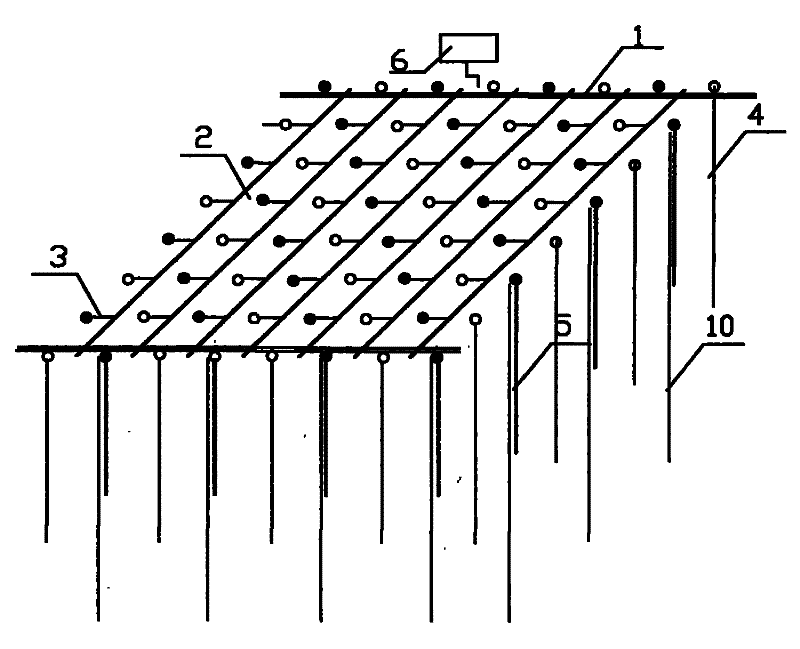

Reinforcing method for demixing sole weight, prepressing water discharge concretion combination dynamic consolidation soft ground base

InactiveCN101270571ALess investmentReduce post-construction settlementClimate change adaptationLand reclamationWater dischargeDynamic compaction

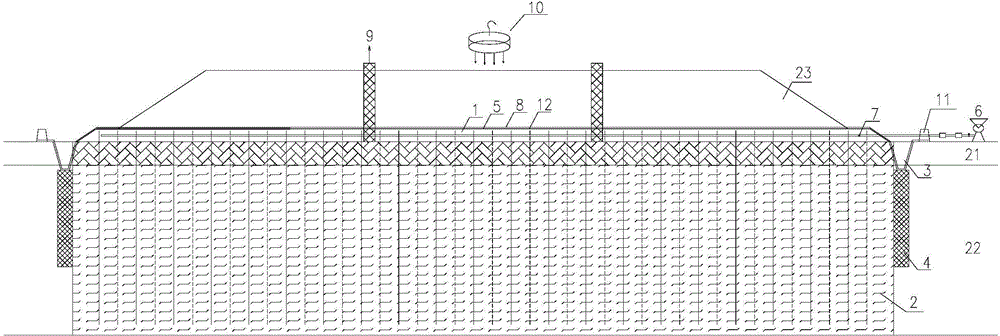

A dynamic compaction soft foundation reinforcing method by combing layered dead weight and pre-pressing drain concretion includes: filling a water-isolation cofferdam; a water collecting well is arranged in the middle of the cofferdam; a sand layer of 0.5m to 0.8m is filled by hydraulically filled or manually filled on the original water-drained ground; a horizontal drain pipe is embedded in the sand layer to carry out first earth hydraulic filling; a drain pump is arranged in the water collecting well to continuously drain water; when the thickness of hydraulic filling reaches the designed elevation of the first layer, the hydraulic filling is stopped; when the surface of the hydraulic filling earth forms a hard shell layer with a thickness of 30m to 40m under the actions of vaporizing and dead weight drain, the hydraulic filling to a second layer and a third layer are carried out according to the steps; even a required hydraulic filling height is designed; finally hill-skill soil or mixed backfill soil and sandy soil are back filled on the layers; dynamic compaction is carried out after leveling. The invention has the technical economic indexes of fast speed, saving investment, small settlement after construction and high surface layer bearing capacity, etc., and has remarkable technical advantages on lower ground elevation and the projects of polder reclamation by hydraulically fill the soft soil like silt.

Owner:张伯谦

Dynamic compaction ground stabilization reinforcement processing system and processing method

ActiveCN103088807ARealize the reinforcement effect evaluation modelReliable dataSoil preservationDynamic compactionEngineering

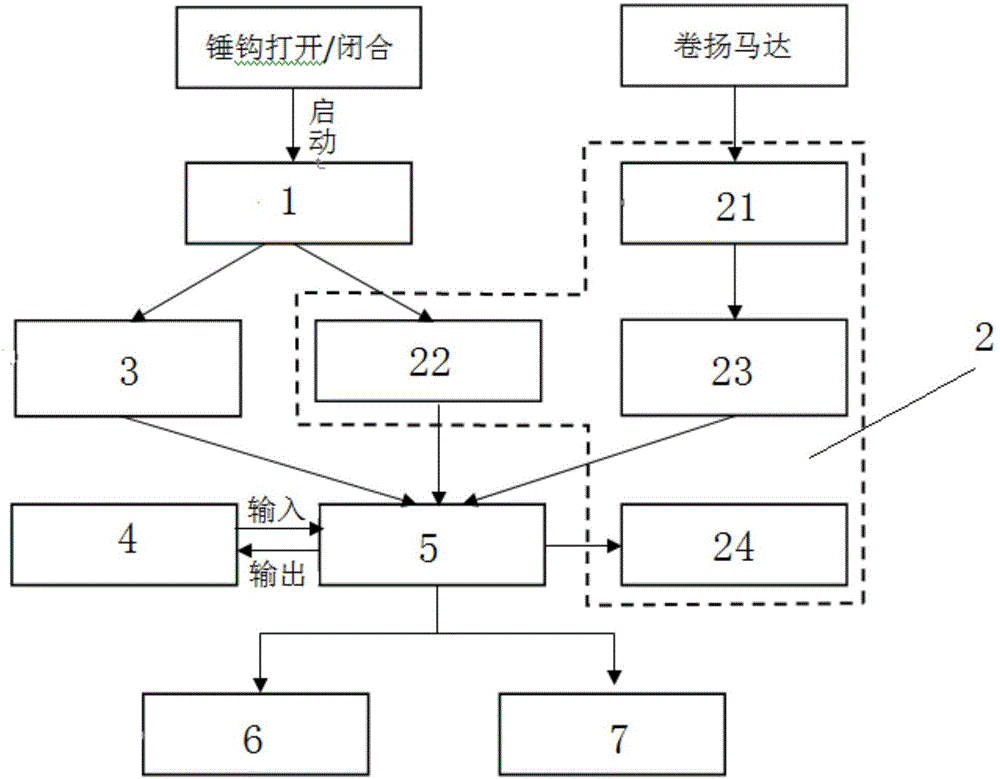

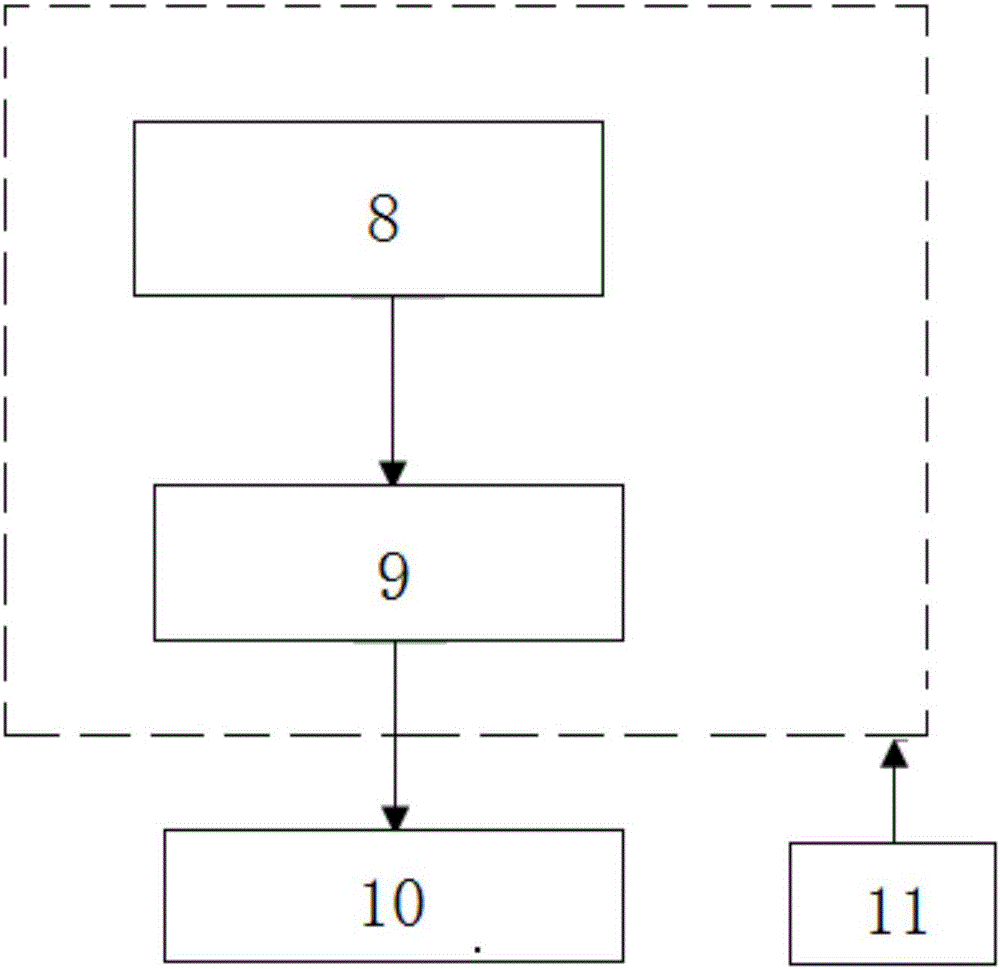

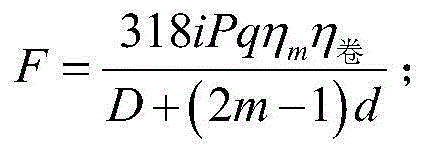

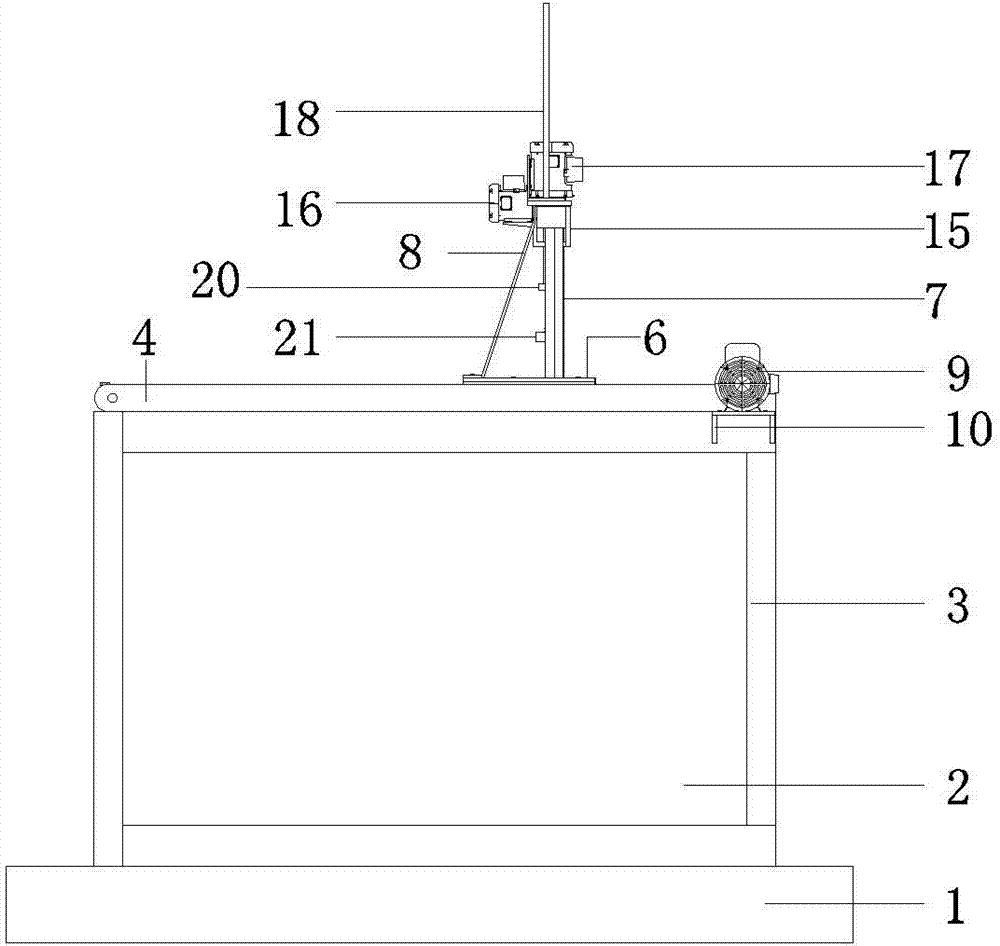

The invention discloses a dynamic compaction ground stabilization reinforcement processing system. The dynamic compaction ground stabilization reinforcement processing system comprises a dynamic compactor and a winding engine. The dynamic compactor comprises a rammer tripping gear, a rammer hook and a rammer. The winding engine comprises an arm head pulley, a rammer raising steel wire rope which is connected with the winding engine, a pulley, a dynamic compactor mast, a rammer raising steel wire rope which is connected with the hook and a fixed nut. The dynamic compaction ground stabilization reinforcement processing system further comprises a dynamic compaction real-time diagnosis device. The dynamic compactor further comprises a contact stress sensor. The winding engine further comprises a rammer subsidence quantity sensor. The pulley used for the winding engine is a sensor pulley. The dynamic compaction ground stabilization reinforcement processing system can record dynamic compaction working data in real time in the whole process, timely process the data, work out diagnosis along with rammer, and evaluate reinforcement effect. Used as a black box in the process of construction, the dynamic compaction ground stabilization reinforcement processing system can achieve seamless supervise, reduce construction cost, shorten construction period and guarantee 24-hour barrier-free construction.

Owner:QINGDAO INST OF SURVEYING & MAPPING SURVEY

Treatment method for large-thickness collapsible loess

ActiveCN105970911ASmall sinking resistanceAvoid cloggingSoil preservationDynamic compactionSoil horizon

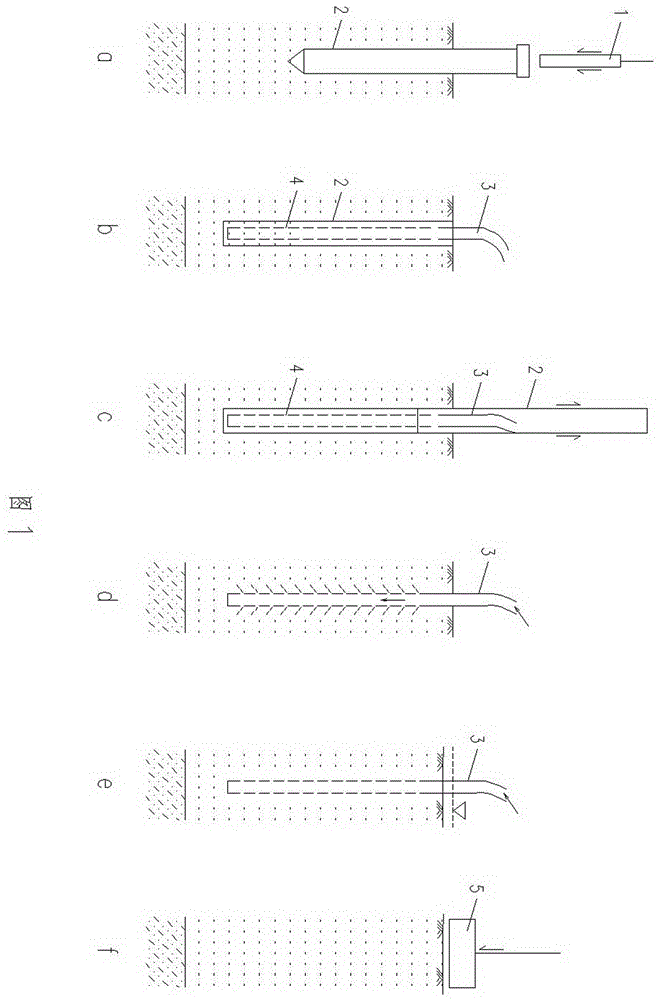

The invention provides a treatment method for large-thickness collapsible loess. The treatment method comprises the following steps: 1) sinking small-diameter steel casing into soil to form pile holes each having a depth equal to or smaller than the thickness of the collapsible loess stratum; 2) inserting (1) 1-6 drain boards or (2) hollow water pipes with a plurality of drain holes or (3) hollow steel pipes with a plurality of nozzles into the pile holes to bottom ends thereof; 3) repeating the steps 1) and 2) until the pile holes with the water injection fittings are formed everywhere in the field; 4) injecting water or injecting water under pressure into the water injection fittings in the pile holes to cause self-weight collapsible settlement of the collapsible loess after immersion; 5) observing and recoding the collapsible settlement amount of the soil mass in a foundation until the collapsible deformation of the soil mass in the foundation is stable; and 6) reinforcing the top-layer soil mass of the foundation by use of a filling compaction method or a dynamic compaction method. The treatment method has the characteristics and advantages of high construction speed, remarkable effect of eliminating loess collapse, dry operation, high bearing capacity, and the like.

Owner:王继忠

Deep soft foundation reinforcement treatment method

InactiveCN105220674AImprove reinforcementLow costSoil preservationDynamic compactionPositive pressure

Owner:CCCC FOURTH HARBOR ENG INST +4

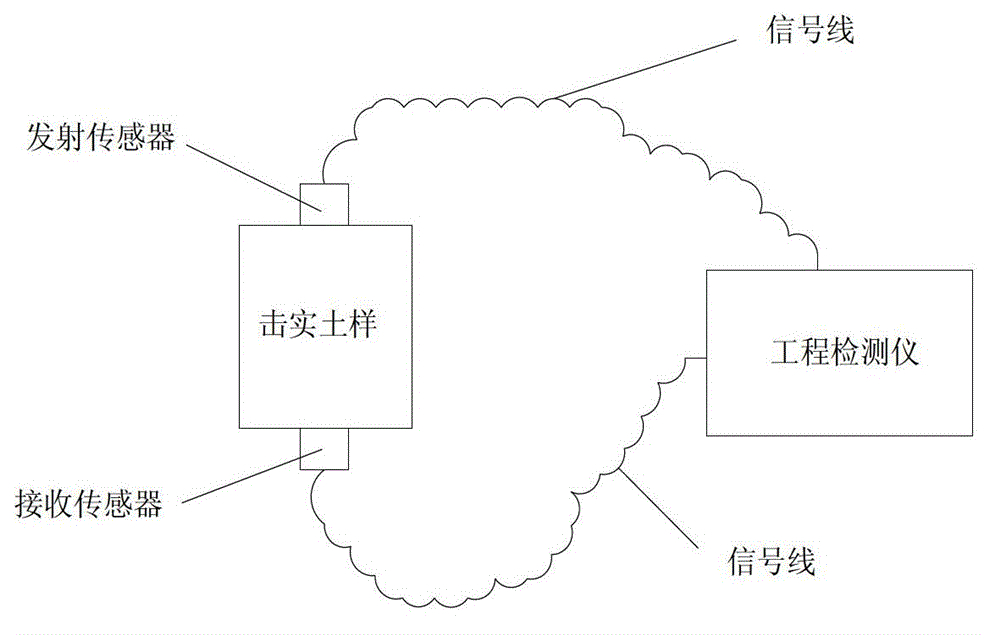

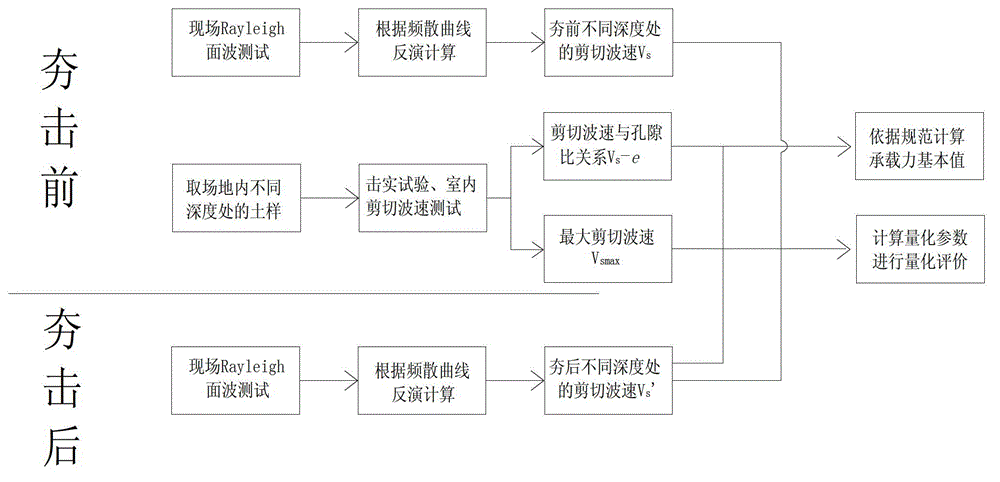

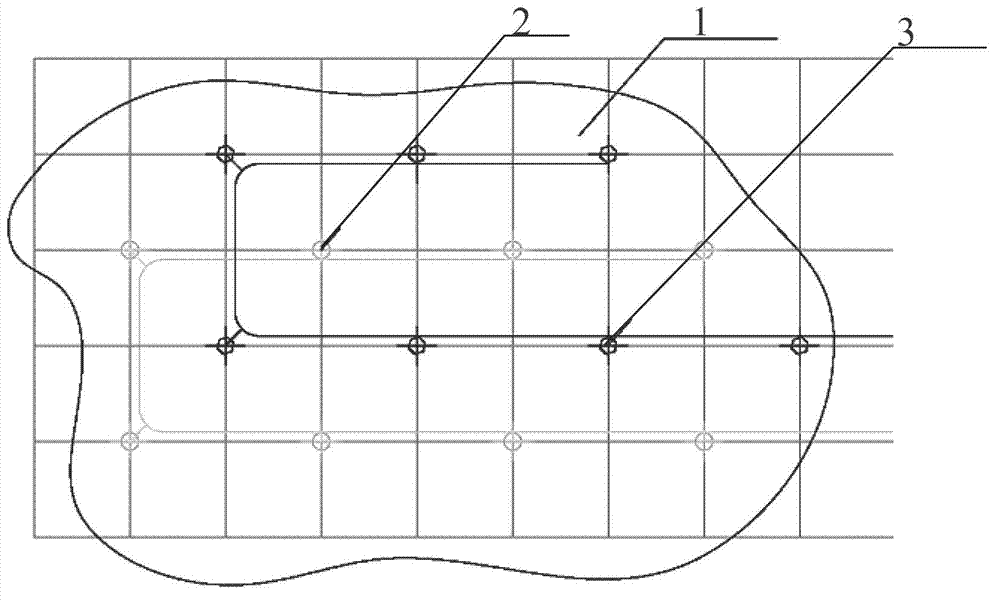

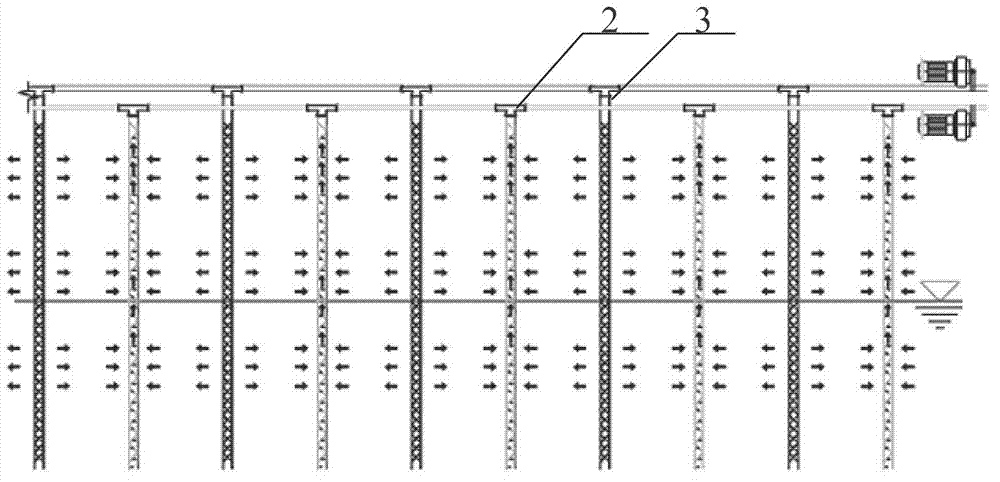

Quantitative analysis method for evaluating dynamic compaction reinforcement effect of foundation by utilizing Rayleigh surface waves

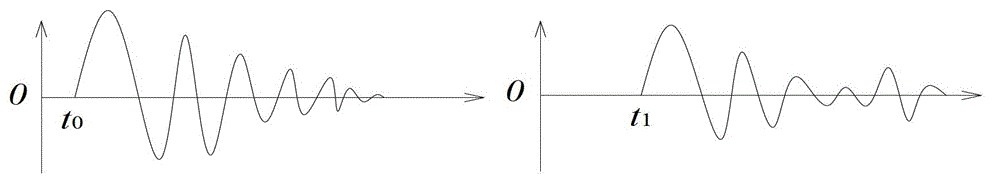

ActiveCN102943461AThe results of the effect analysis are specificThe effect analysis results are accurateIn situ soil foundationDynamic compactionVoid ratio

The invention discloses a quantitative analysis method for evaluating a dynamic compaction reinforcement effect of foundation by utilizing Rayleigh surface waves. The method comprises compacting pretreatment and compacting post-treatment, namely before compacting, performing field Rayleigh surface wave test according to frequency dispersion curve back calculation, so as to obtain a shear wave velocity Vs at different depths before compacting, performing a compacting test on a soil sample at different depths in the field, and finishing an indoor shear wave velocity test, wherein the testing result comprises a relationship Vs-e between the shear wave velocity and a void ratio, and the maximum shear wave velocity Vsmax; and after compacting, performing field Rayleigh surface wave test according to frequency dispersion curve back calculation, so as to obtain a shear wave velocity Vs' at different depths after compacting, and finally, calculating the compaction degree delta according to the parameters, and realizing evaluation on the dynamic compaction reinforcement effect according to the compaction degree delta. Compared with the prior art, the method has the advantages that the quantization parameter, namely the compaction degree delta, of the dynamic compaction reinforcement effect of the foundation is evaluated due to introduction of quantitative analysis, an evaluation effect of the dynamic compaction reinforcement effect can be quantitatively analyzed, and the method is specific and accurate.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

Soft soil foundation treatment method

InactiveCN102953369AFlow fastDischarge as soon as possibleSoil preservationDynamic compactionAfter treatment

The invention provides a soft soil foundation treatment method. The soft soil foundation treatment method comprises the following steps of: leveling the ground; arranging a vacuum pipe and a ram pipe according to the designed interval and the designed pipe insertion depth after hole formation by a high-pressure water jetting method, and filling sand for preventing clogging while inserting the vacuum pipe; connecting and sealing the vacuum pipe and the ram pipe with a horizontal pipe of a vacuumizing system horizontally laid and a horizontal pipe of a pressurization system respectively; hermetically connecting the horizontal pipe of each system with a vacuum pipe and a booster pump respectively; starting the vacuum pump and the booster pump to start vacuuming and pressurization, thereby performing forced drainage on the soft soil foundation; in 3-5 days after drainage, removing all materials used by the vacuumizing system and the pressurization system, and performing dynamic compaction on the ground according to the requirements of the designed scheme. According to the method, the construction cost is low, the construction period is short, and the bearing capability is high after treatment.

Owner:谷孝建

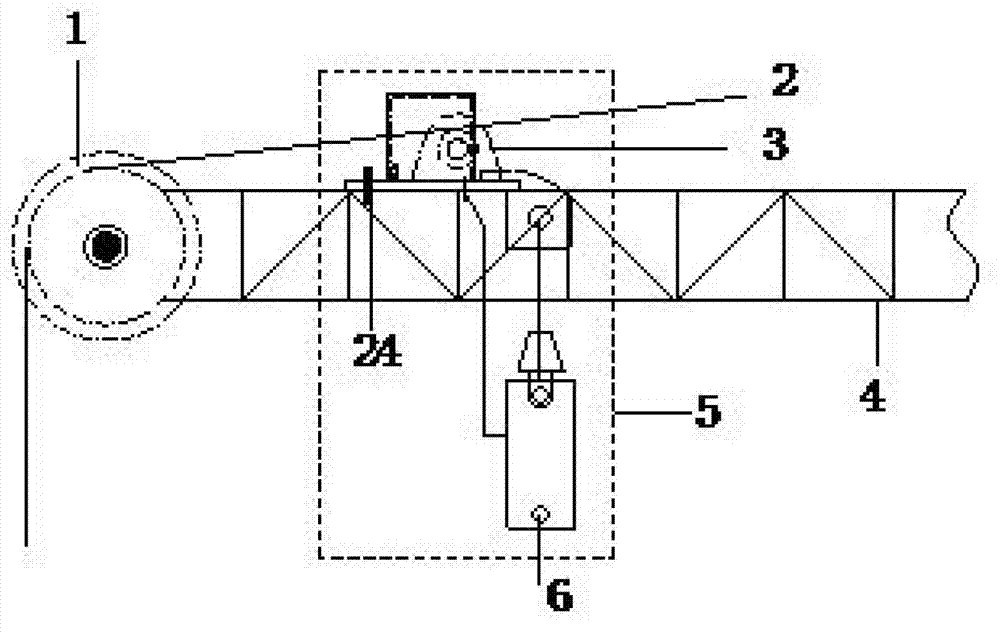

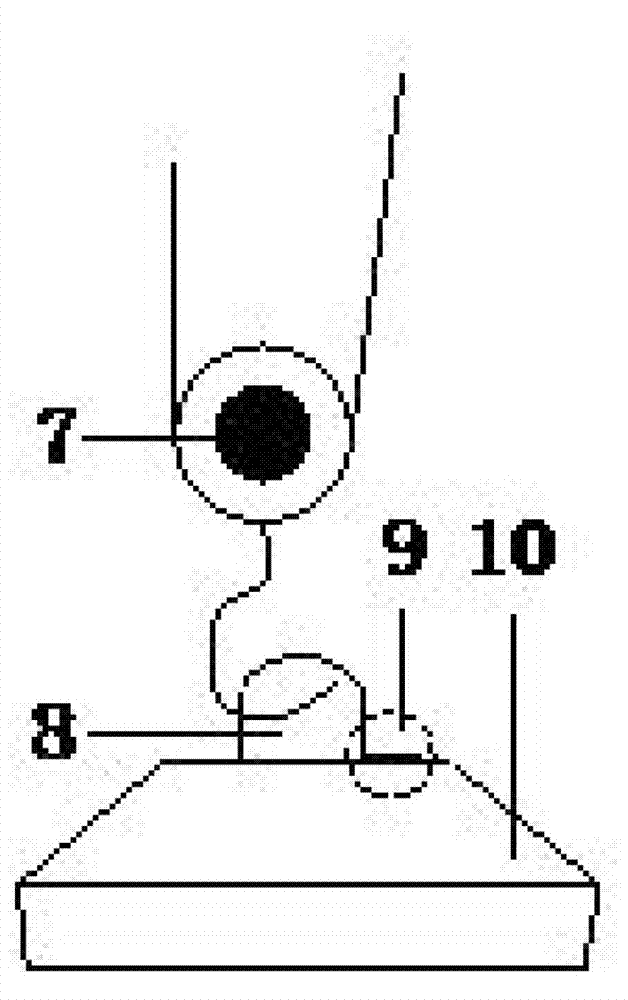

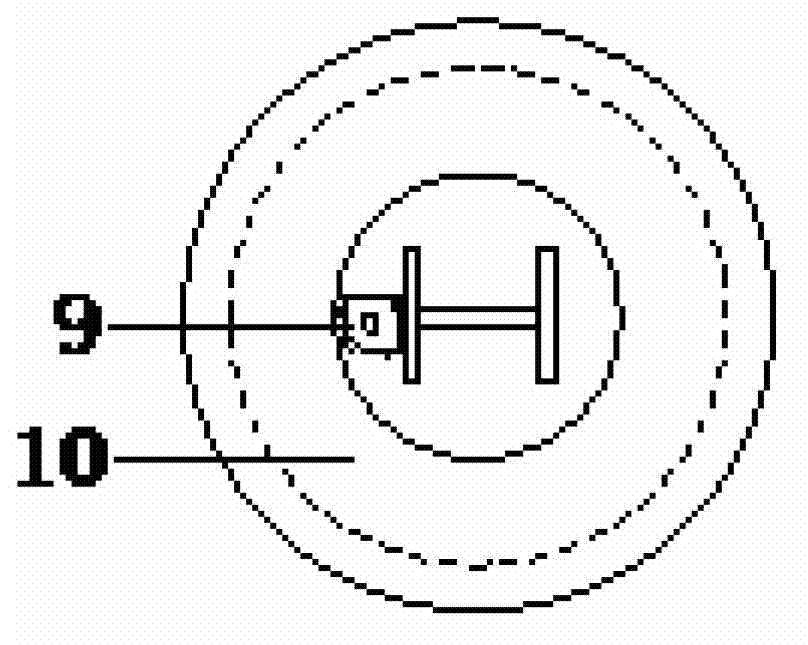

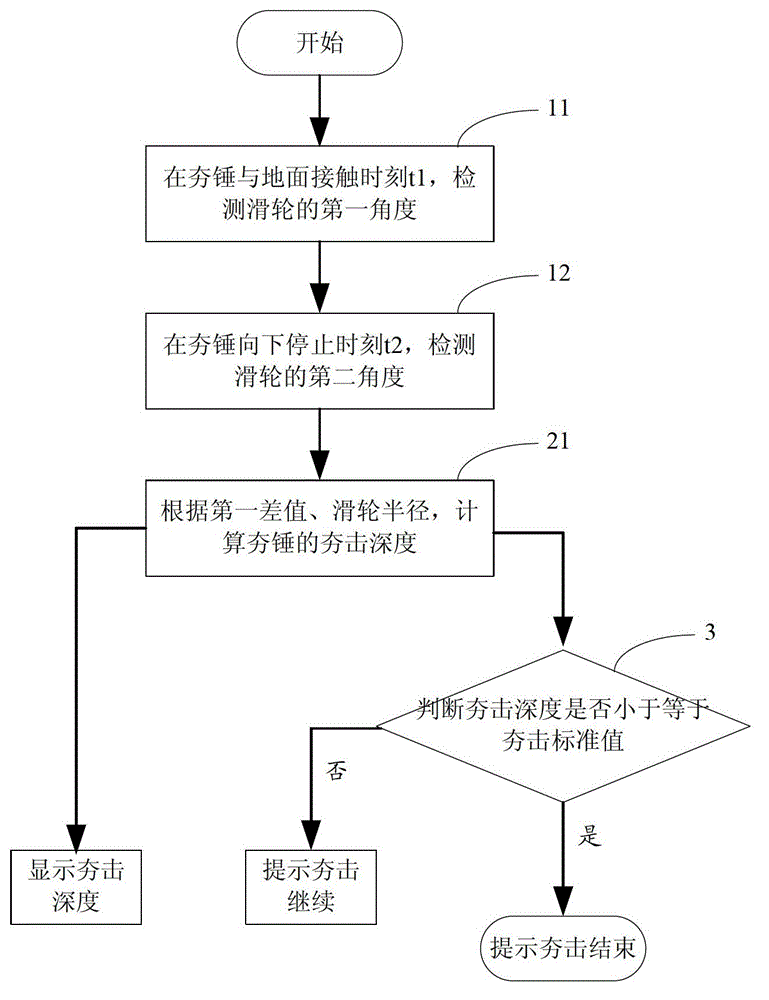

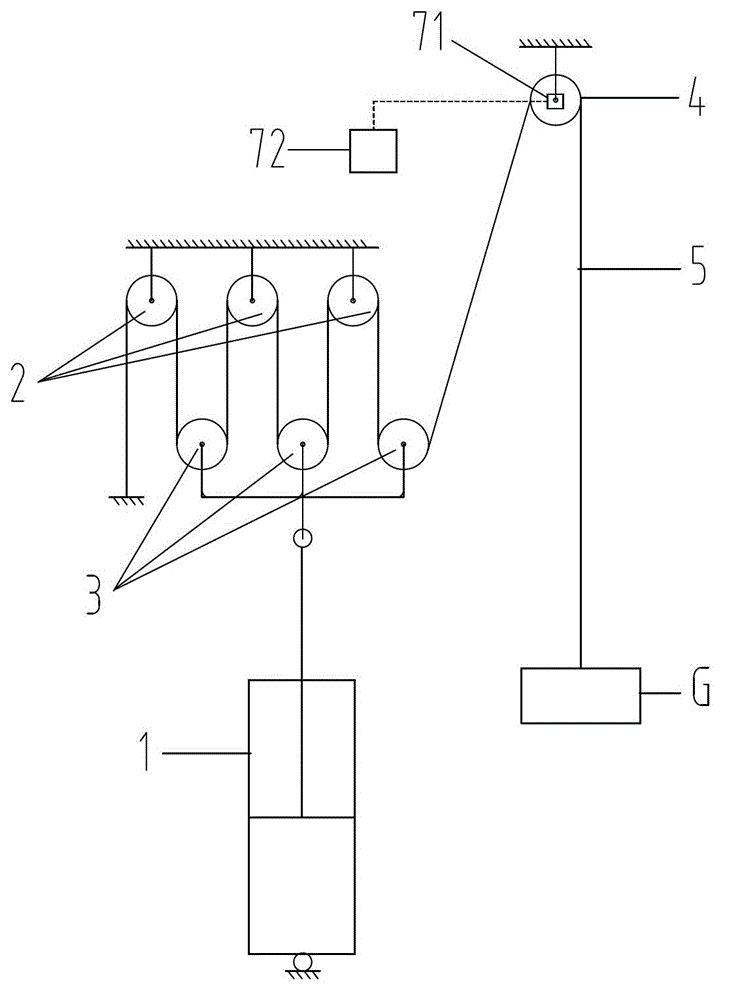

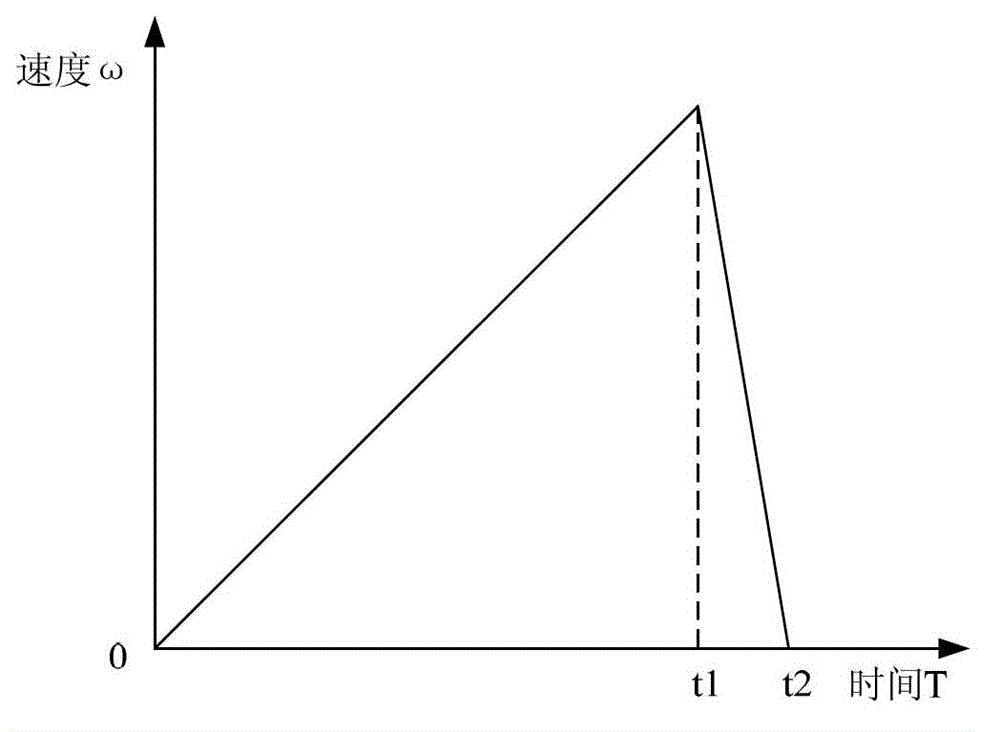

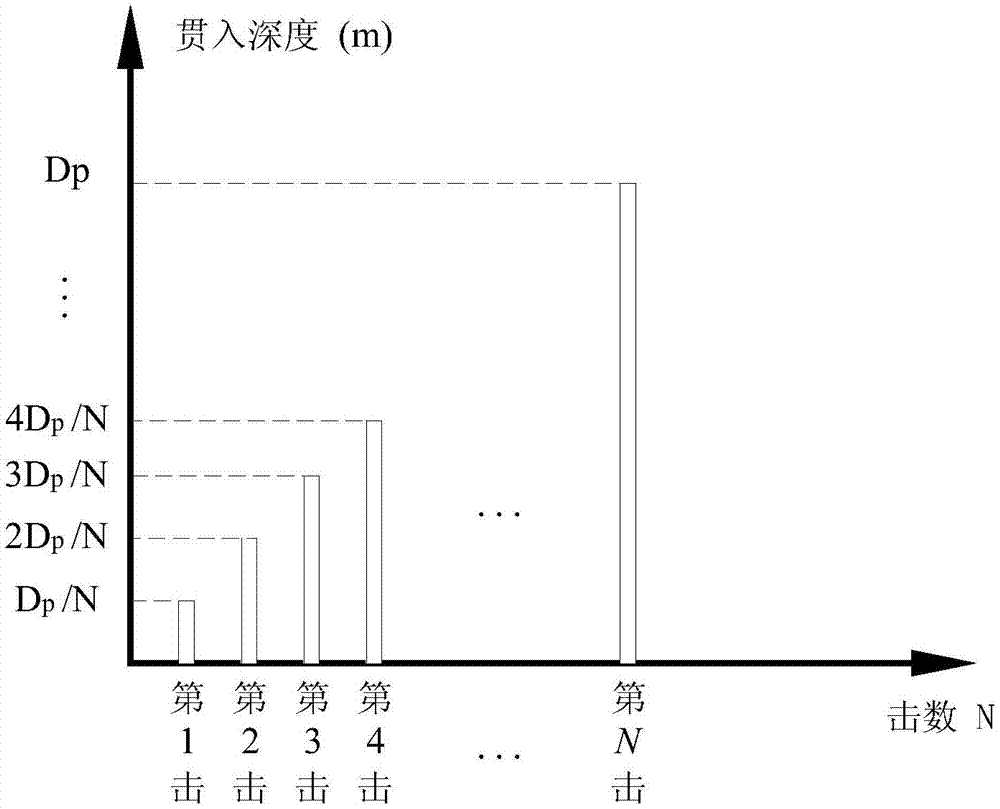

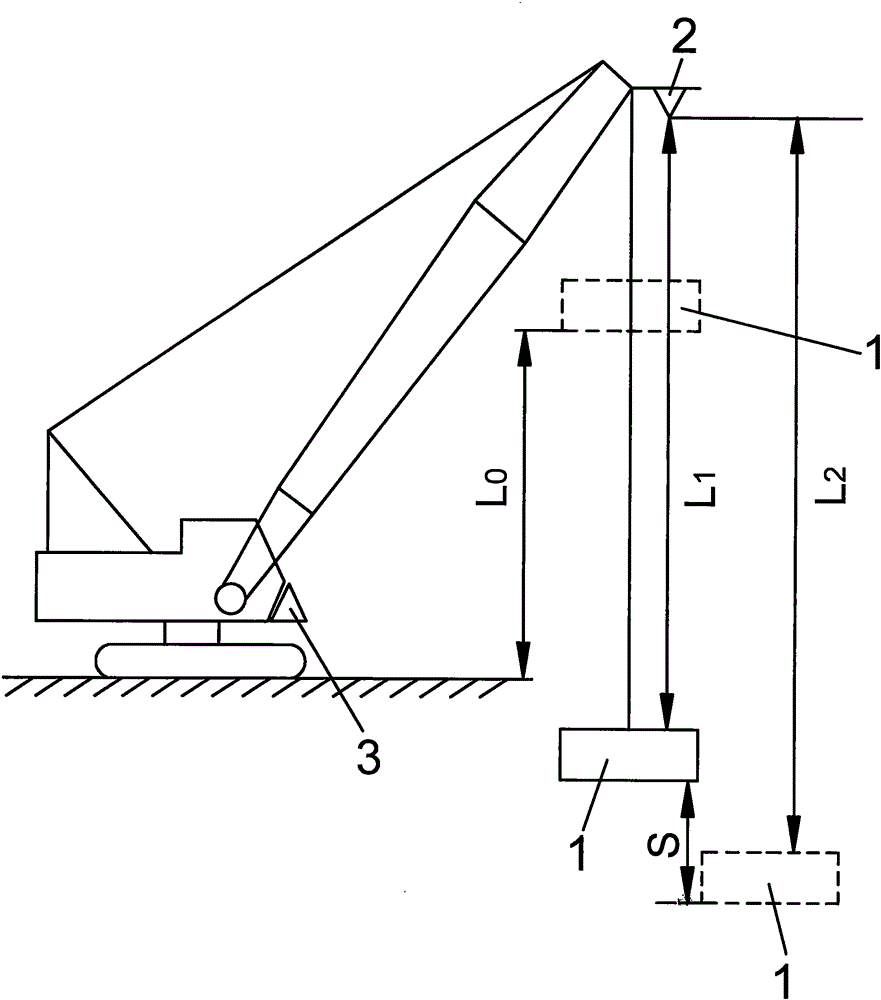

Dynamic compaction machine, ramming depth measuring method and device of dynamic compaction machine

ActiveCN102980548ARealize automatic measurementRecord automaticallyMeasurement devicesSoil preservationMeasurement deviceDynamic compaction

The invention provides a dynamic compaction machine, a ramming depth measuring method and a device of the dynamic compaction machine. The ramming depth measuring device of the dynamic compaction machine is used in a non-unhooked type dynamic compaction machine and comprises an angular displacement detecting device and a processor, the angular displacement detecting device is used for detecting rotation angular displacement of a pulley, and the processor is connected with the angular displacement detecting device and calculates ramming depth of a rammer according to the angular displacement of the pulley and a radius of the pulley. The ramming depth measuring device of the dynamic compaction machine can further comprise a display device and / or an alarming device. By means of the dynamic compaction machine, the ramming depth measuring method and the device of the dynamic compaction machine, automatic measuring of ramming depth can be achieved, the measuring is accurate, the error is small, the reliability is high, the using is convenient, automatic supervising can be achieved, construction of the dynamic compaction machine is optimized, and optimum ramming times can be guaranteed.

Owner:SANY HEAVY IND CO LTD (CN)

Soft soil foundation consolidation method

InactiveCN101225658AHigh consolidation indexGood value for moneySoil preservationSoil scienceDynamic compaction

The invention discloses a strengthening method for soft soil foundation, comprising that: a. the soft soil in the site is strengthened for the first time by low position vacuum self-weight combined preloading; b. the soft soil in the site is strengthened for the second time by the vacuum preloading electroosmosis method; c. the scove layer is strengthened by vacuum electroosmosis dewatering; and d. vibration rolling, leveling the site. The strengthening method for soft soil foundation is suitable for the strengthening engineering of the flowing mud, which mainly contains ultrafine particles and the consolidation coefficient is minimal, silt and mucky soil foundation, and particularly suitable for the site which needs high requirements of the strength and deformation, but highly susceptible and saturated soft clay, and super-soft foundation, which is not suitable to be strengthened by dynamic compaction, the strengthening method for soft soil foundation has the advantage of providing a high performance-price ratio processing method for the rapid, efficient, high-quality strengthening of the soft soil foundation.

Owner:张志铁

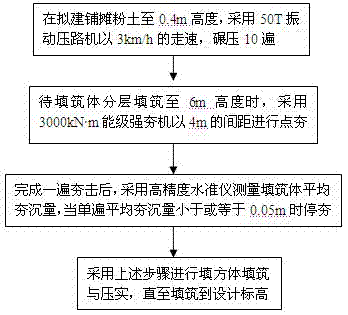

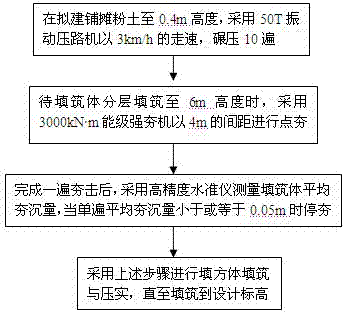

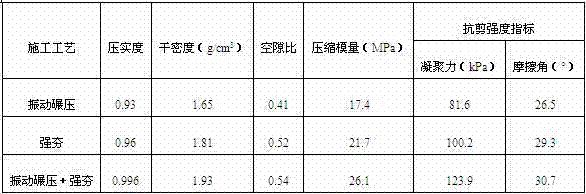

Construction method for compacting high loess-filled embankment by combining vibration roller compaction with dynamic compaction

InactiveCN102251512AGuaranteed compaction effectEliminate collapsibilitySoil preservationDynamic compactionWater level

The invention discloses a construction method for compacting a high loess-filled embankment by combining vibration roller compaction with dynamic compaction, and the specific construction method comprises the following steps: spreading out silt till the height of 0.4m and adopting a 50T vibratory roller to roll 10 times at the traveling speed of 3km / h; adopting a 3000kN.m-energy level dynamic compactor to perform point compaction at intervals of 4m when a body to be filled and built is filled and built in layers to the height of 6m; using a high-precision water level gauge to measure the average settlement of the filled and built body after completing one-time ramming and stopping ramming when the single-time average settlement is less than or equal to 0.05m; and continuously repeating the operation till the body is filled and built to the design scale height. By adopting the construction method, the problem that impact reinforcement can not be performed on the basis of the vibration roller compaction due to the limited space is solved, the loess collapsibility can be eliminated, the cost is simultaneously saved, the construction period is shorted, the degree of compaction of the filled and built body can be improved to 0.996 to the maximum extent, the dry density can be improved to 1.93g / cm<3> to the maximum extent, the characteristic value of bearing capacity of a foundation can achieve 350kPa and the post-construction differential settlement of the high embankment can be better controlled.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

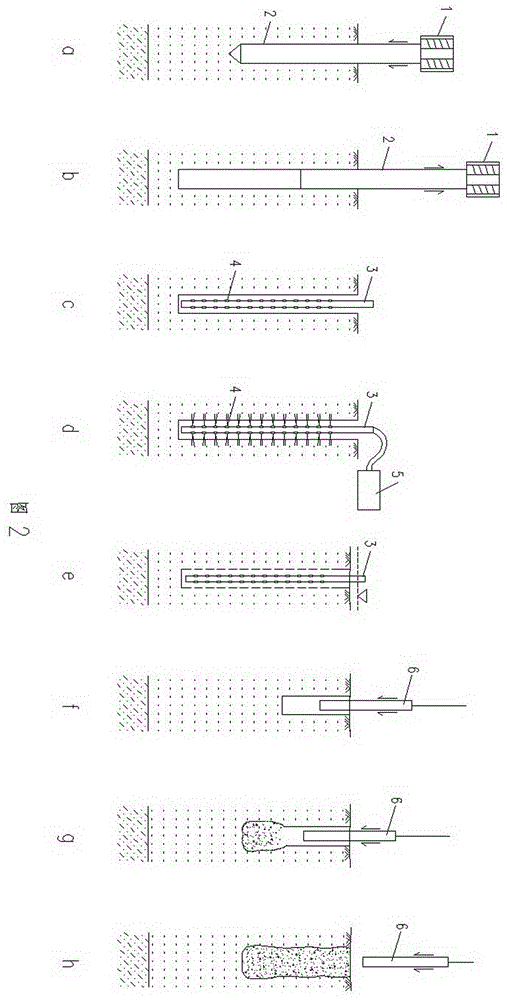

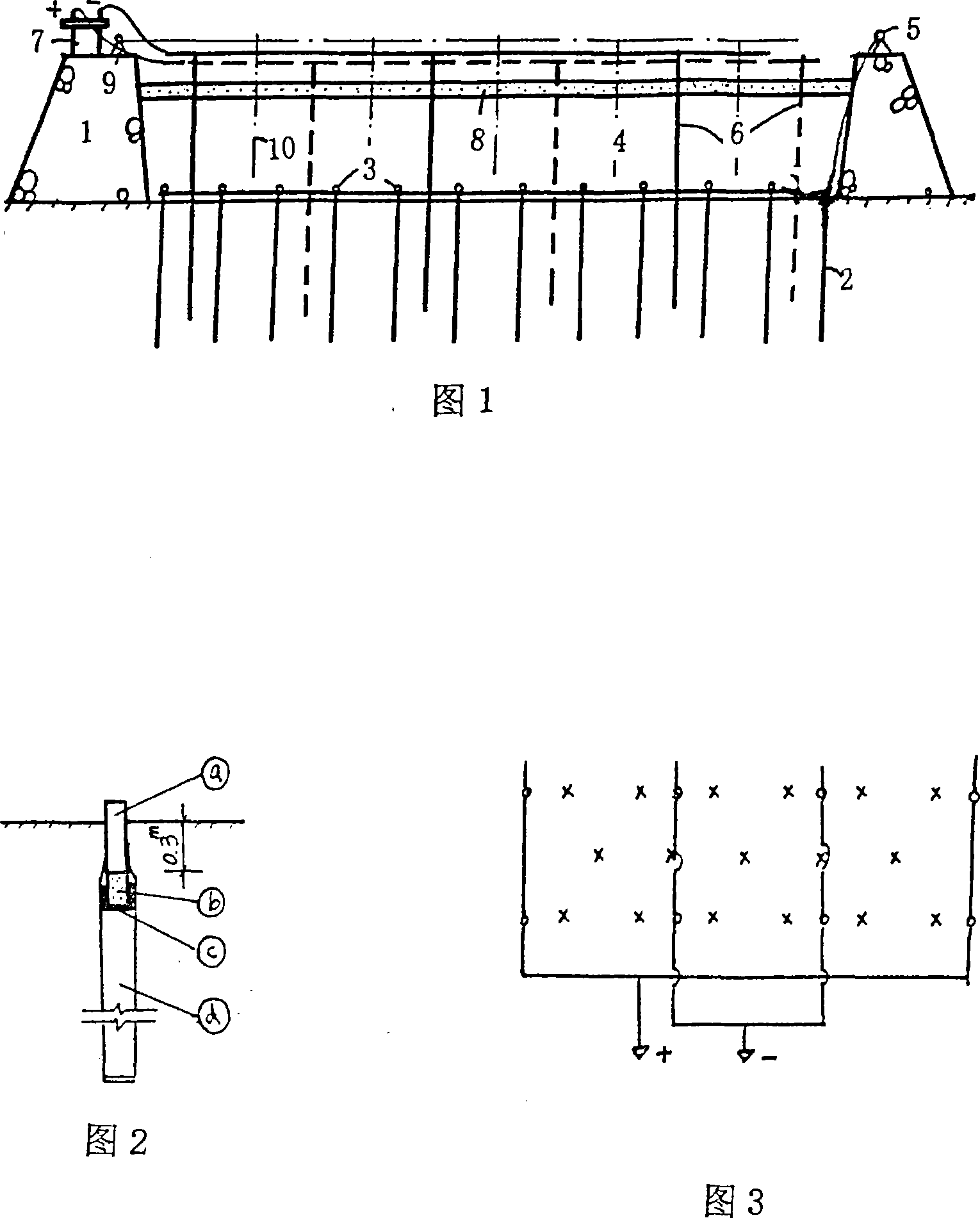

Large-area soft soil foundation duplex negative pressure consolidation processing method

InactiveCN101748721AEnhanced transfer processAccelerated dissipationSoil preservationDynamic compactionProcess region

The invention relates to a large-area soft soil foundation duplex negative consolidation processing method, comprising the following processes of: step 1, negative pressure consolidation: (a) paving plastic woven cloths in an area to be processed, driving a vertical plastic drainage board and a vertical plastic soak-away trench; (b) paving a main pipe and a branch pipe, wherein the vertical plastic drainage board and a transverse plastic drainage board are connected with the branch pipe; (c) paving a geo-membrane, and paving two to three sealing membranes on the geo-membrane; (d) excavating a side ditch pressing membrane; (e) installing a vacuum pump to vacuumize for negative pressure precipitation, wherein the main pipe is connected with the vacuum pump; step 2, well point dynamic arrangement: (a) inserting a well point pipe in a hole inserted by a vertical plastic soak-away trench or nearby the hole; (b) paving the branch pipe, the main pipe and the vacuum pump, carrying out the well point dynamic arrangement; and step 3, dynamic consolidation: a) precipitating and dynamically compacting in the first and second times, carrying out precipitation and dynamic compaction processes on the area to be processed for several times, carrying out multiple rounds of point compactions and finally carrying out a full compaction. According to the large-area soft soil foundation duplex negative consolidation processing method, the bearing capacity of the processed field is higher, the hard crust is thicker and the post-construction settlement is less.

Owner:曾国海 +3

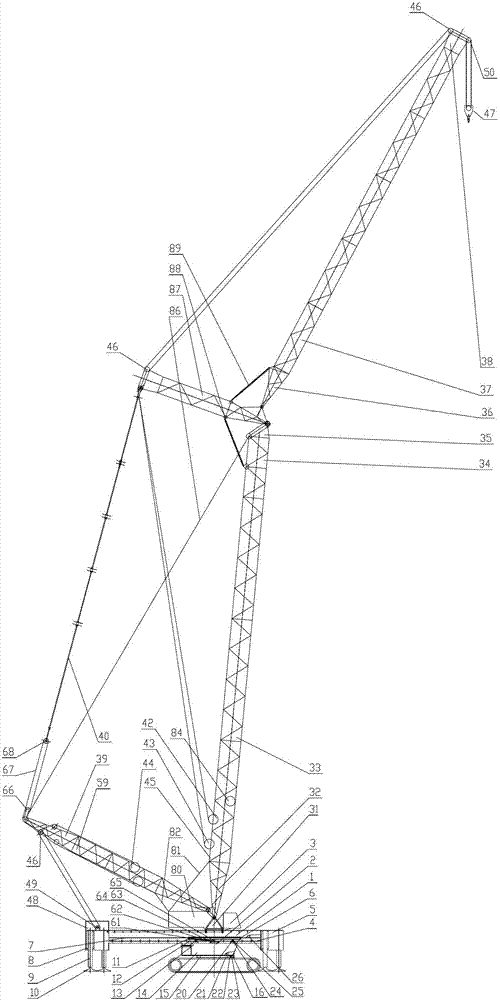

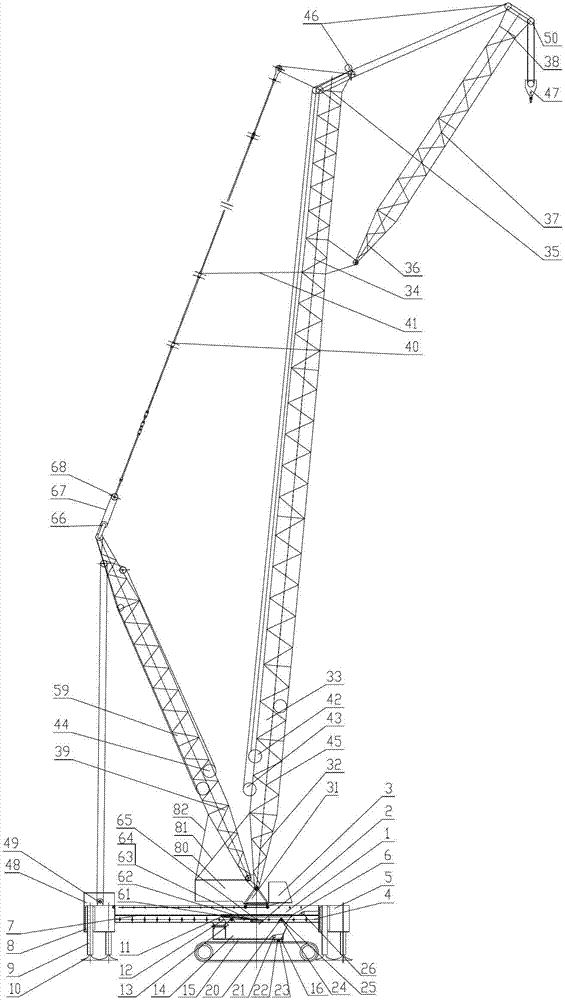

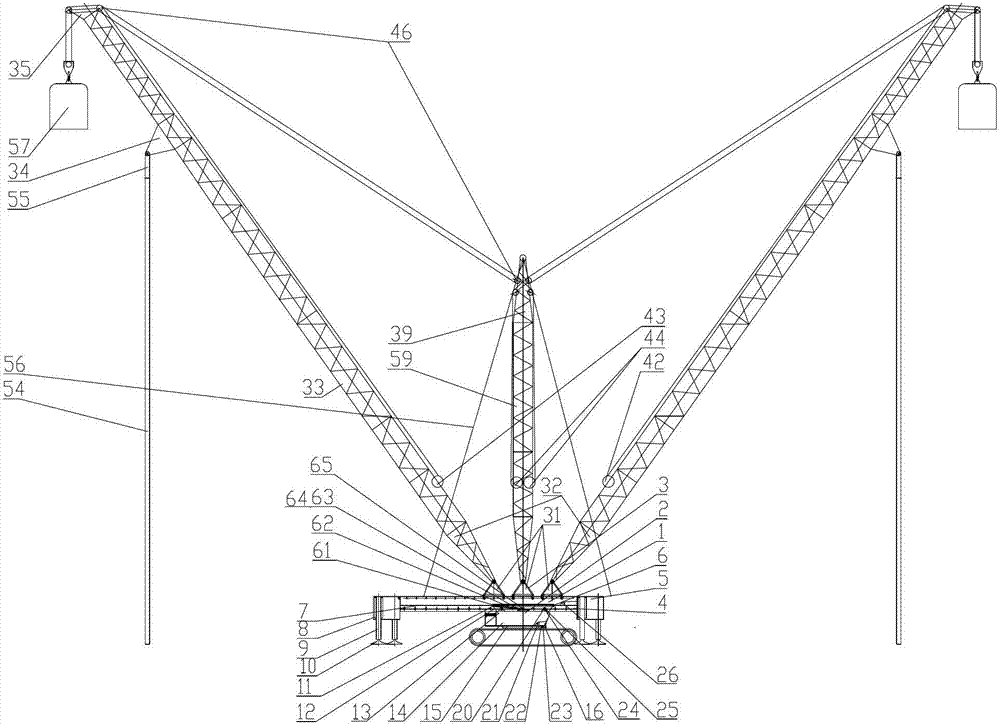

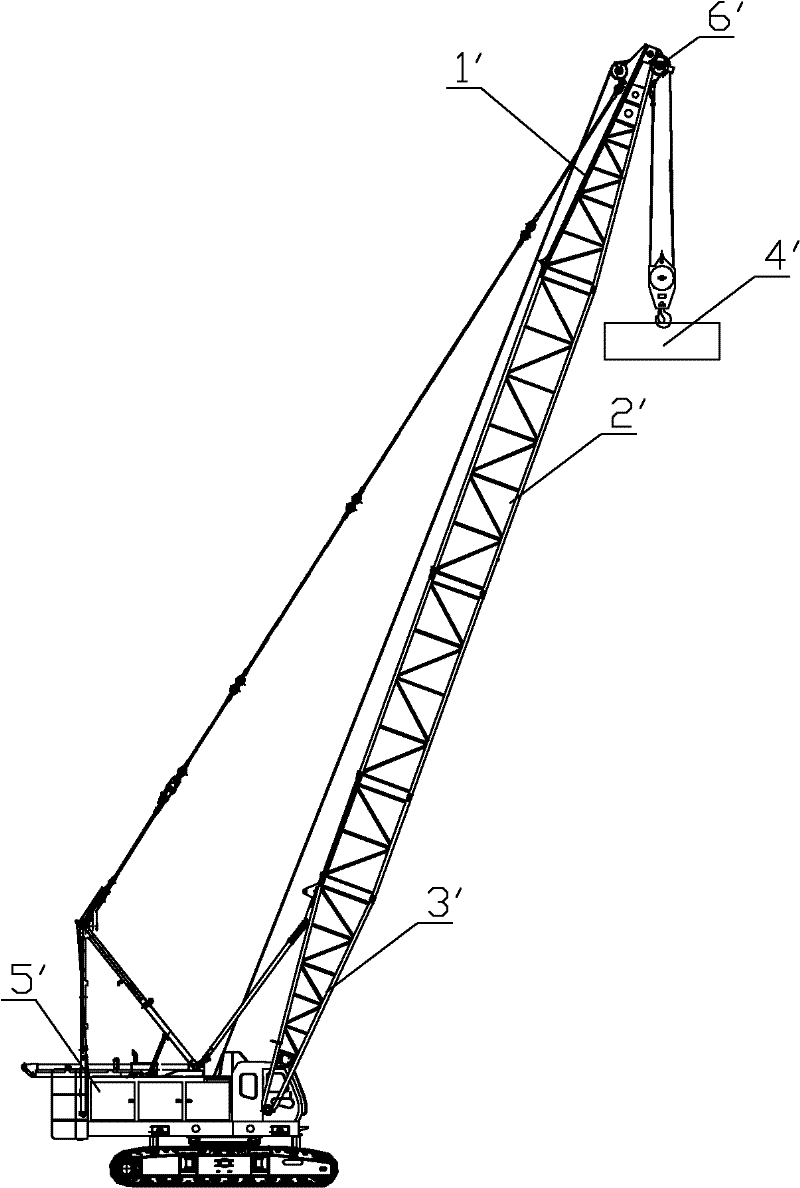

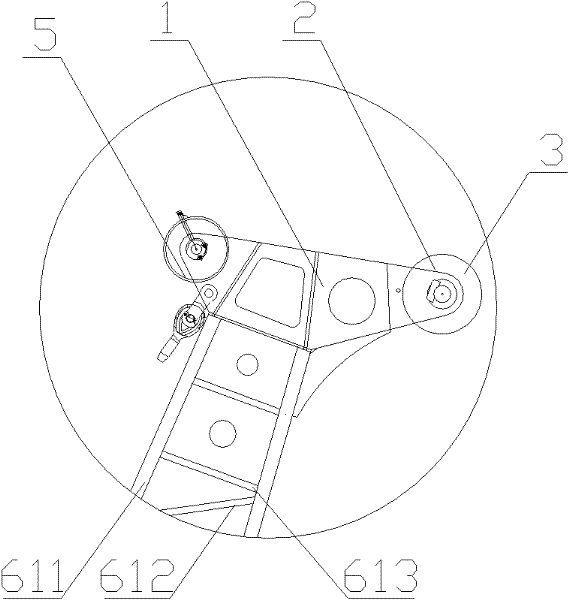

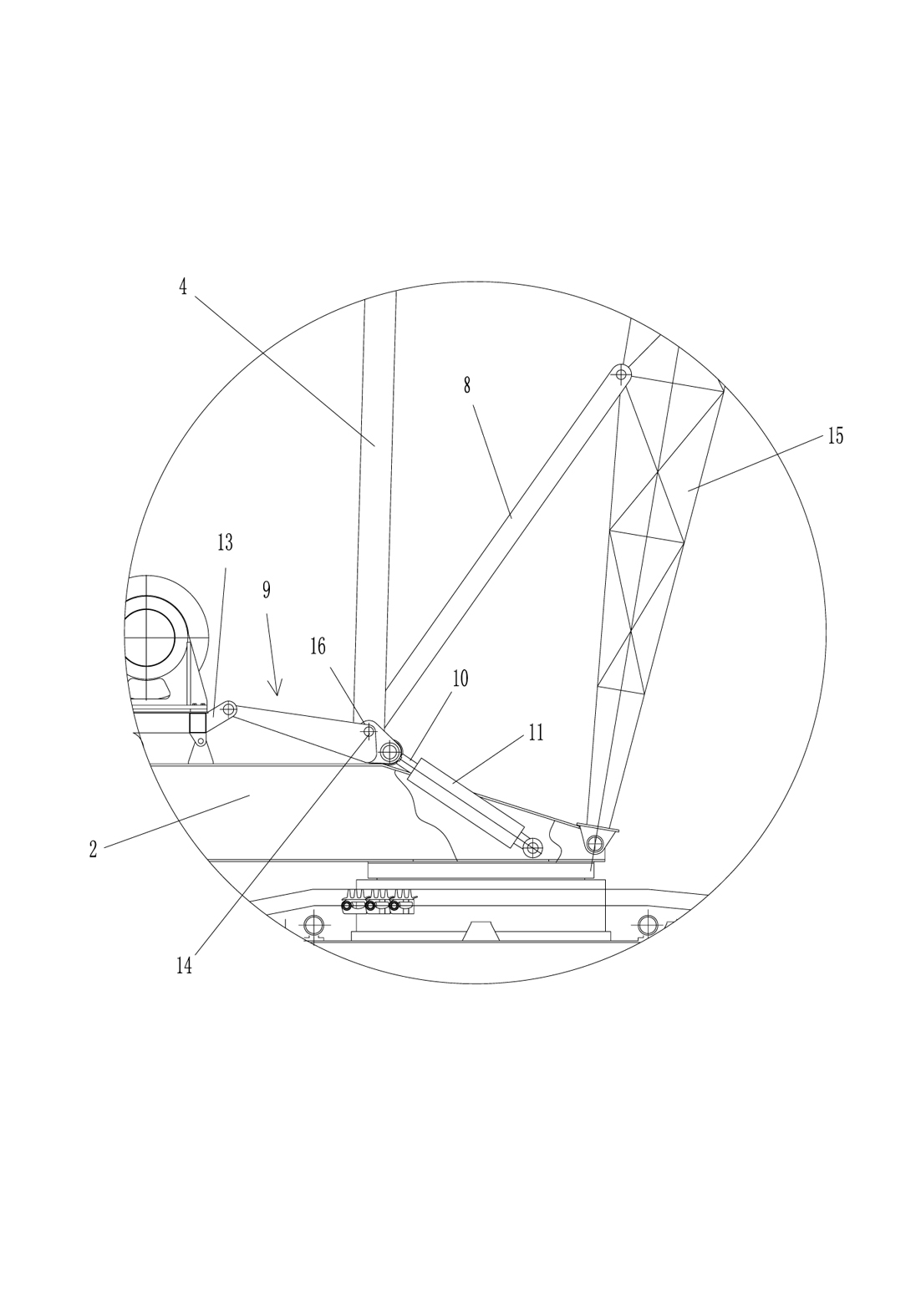

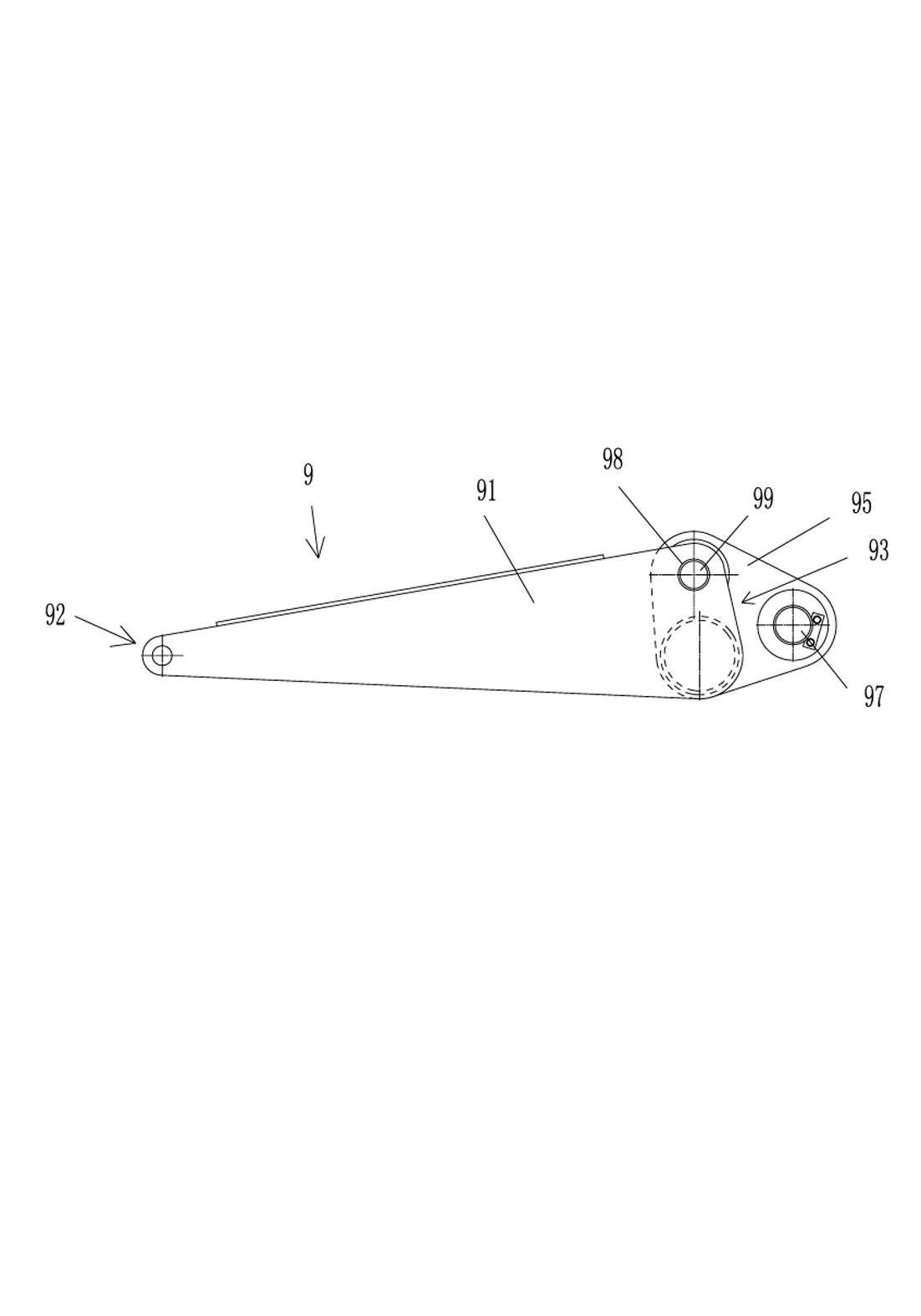

Hinge points-variable combined type multi-functional crawler crane

InactiveCN103030074ACargo handling apparatusPassenger handling apparatusLifting capacityDynamic compaction

The invention discloses a hinge points-variable combined type multi-functional crawler crane, belonging to the field of engineering machinery. The crawler crane comprises a multi-hinge point connecting unit 1, a walking rotation unit 2 and a work unit 3. The work unit 3 is connected with the multi-hinge point connecting unit 1 by one hinge pin, and the hinging relative position is confirmed when a working condition is selected, so that the multifunction of the crawler crane can be realized; and the walking rotation unit 2 is connected with the multi-hinge point connecting unit 1 by another hinge pin, and the hinging relative position is switched according to actual requirements in the process of working, so that the work capability of the crawler crane can be improved. The hinge points-variable combined type multi-functional crawler crane has an assistant crane function, so that the problem that a machine body, a ground surface under a crawler plate or a support box are seriously worn when the crawler crane rotates in situ can be perfectly solved, and the hoisting work on a slope or the climbing by means of suspended load can be realized. Compared with the work condition of a tower arm in the current market machine, the work condition of a reverse V-shaped overlapped tower is higher in hoisting capacity; and compared with the work efficiency of the work condition of the current market machine, the work efficiency of the double-hammer dynamic compaction work condition can be doubled.

Owner:易肃

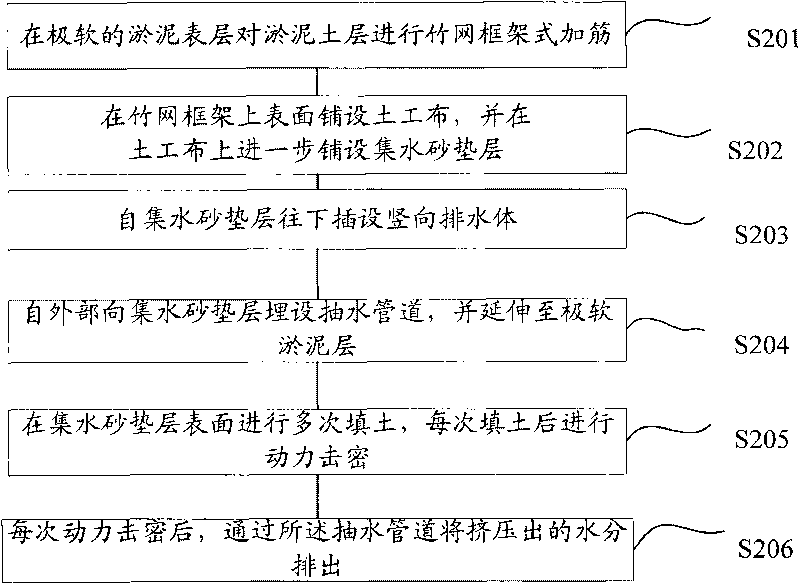

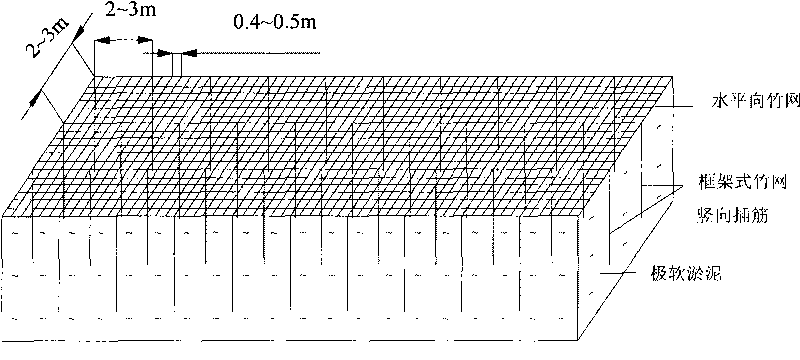

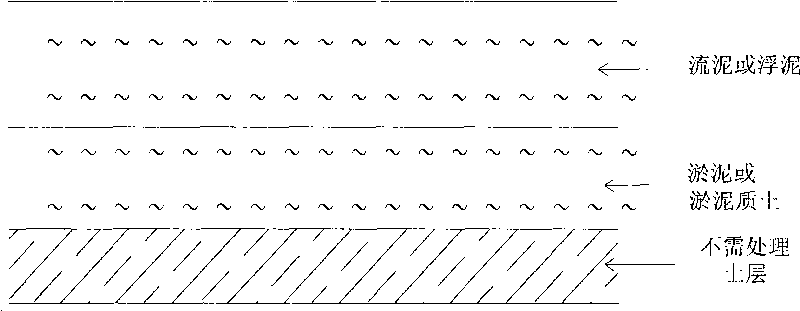

Quick strengthening method of extremely soft sludge

InactiveCN101736734AEasy to hitShorten the reinforcement periodSoil preservationSurface layerDynamic compaction

The invention discloses a quick strengthening method of extremely soft sludge. The method lays out an area of a to-be-constructed site firstly according to a project plan and comprises the following steps: (1), carrying out bamboo web frame-type reinforcement on a sludge soil layer on an extremely soft sludge surface layer; (2), laying geotextile on the upper surface of a bamboo web frame and further laying a water-collecting sand bed on the geotextile; (3), inserting a vertical water drain body downwards from the water-collecting sand bed; (4), burying a water-pumping pipeline from the outside to the water-collecting sand bed and extending the pipeline to an extremely soft sludge layer; (5), filling soil on the surface of the water-collecting sand bed time after time and carrying out dynamic compaction after filling soil every time; and (6), discharging extruded water through the water-pumping pipeline after finishing dynamic compaction every time, and quickly dissipating excess pore pressure of sludge soil caused by soil filling load and dynamic compaction load. Compared with the conventional methods, the quick strengthening method can greatly shorten a construction period and also reduce construction cost.

Owner:郭艳景 +1

Dynamic compaction quality remote monitoring system and working method

ActiveCN105043445AAccurate measurementAccurate and real-timeTransmission systemsStrength propertiesDynamic compactionCollection system

The invention discloses a dynamic compaction quality remote monitoring system and a working method. An input end of a wireless signal emitter is connected with a dynamic compaction machine integrated operation parameter collection system. The output end of the wireless signal emitter is in wireless connection with a mobile receiving end. In the dynamic compaction machine integrated operation parameter collection system, an input end of a trigger is connected with a hammer hook, the output end of the trigger is connected with a GPS position information collection module and the dynamic compaction machine operation parameter collection module, the GPS position information collection module and the output end of the dynamic compaction machine operation parameter collection module are connected with a controller, and the controller is connected with a display, a memory and a timer. The beneficial effects are that precise measurement and real-time collection of compaction point position information, compaction frequency, compaction energy (rammer weight and rammer drop distance), compaction subsidence, accumulative compaction subsidence, compaction times and intermittent time between two times of compaction are achieved, labor and material resources are saved greatly, and the cost is lowered.

Owner:SHANDONG UNIV

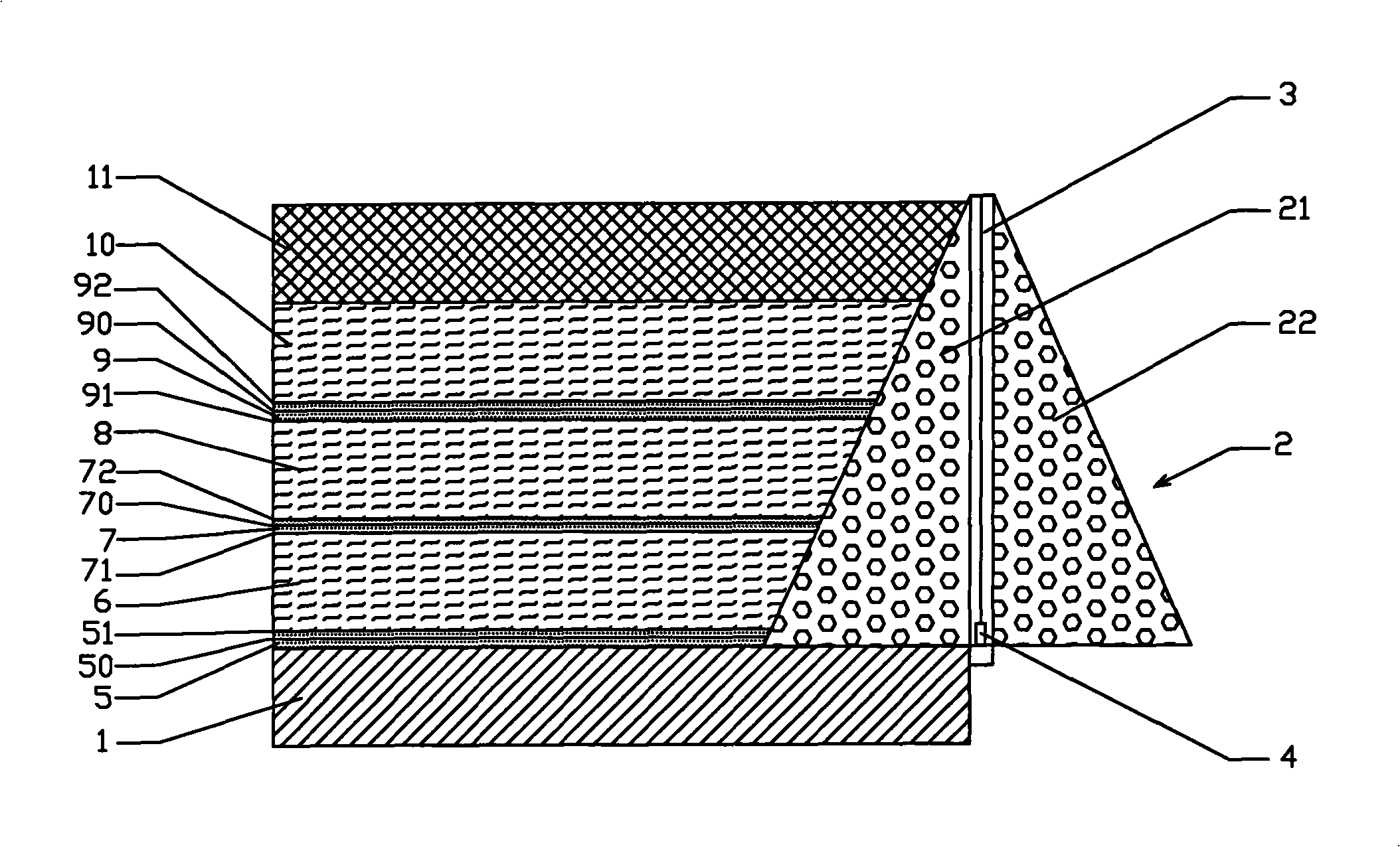

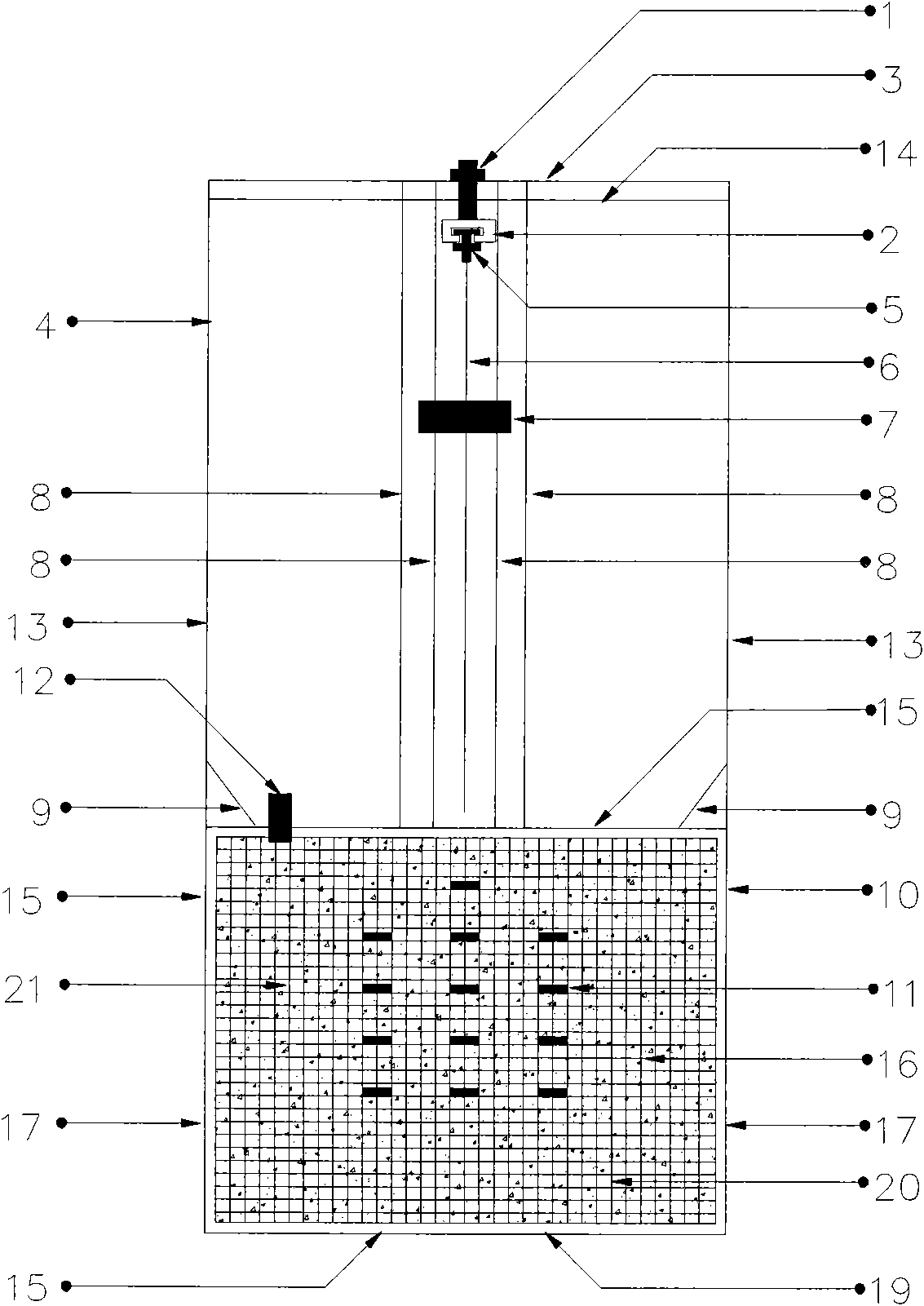

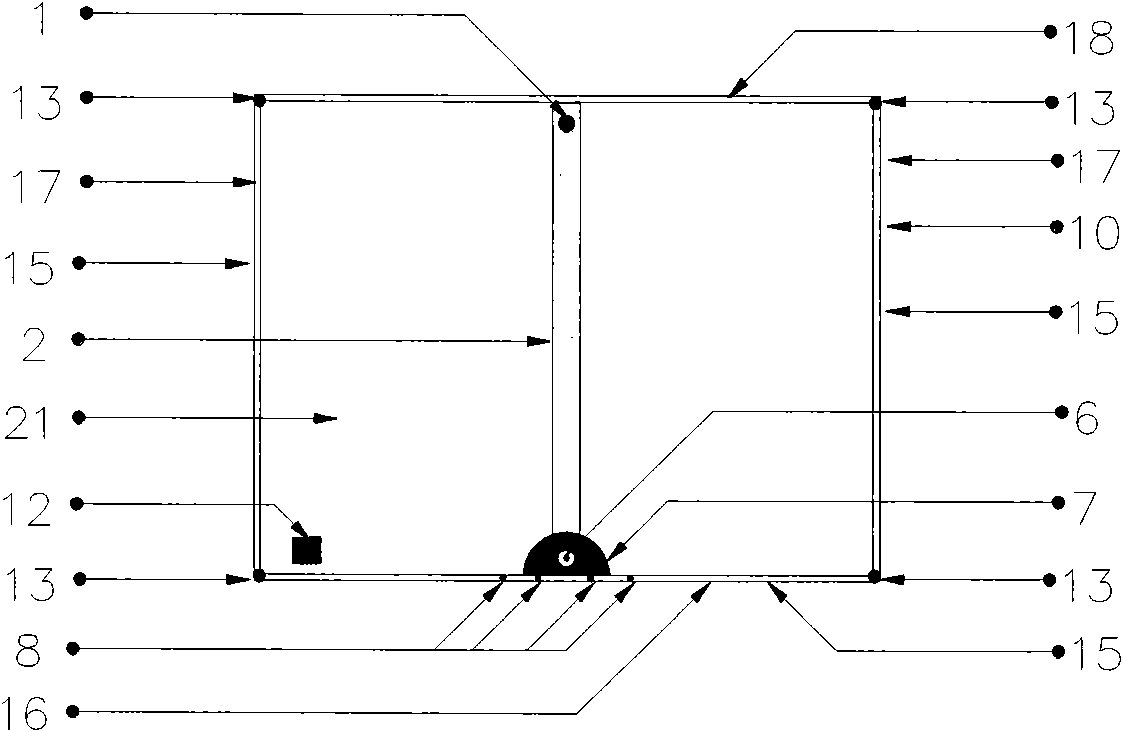

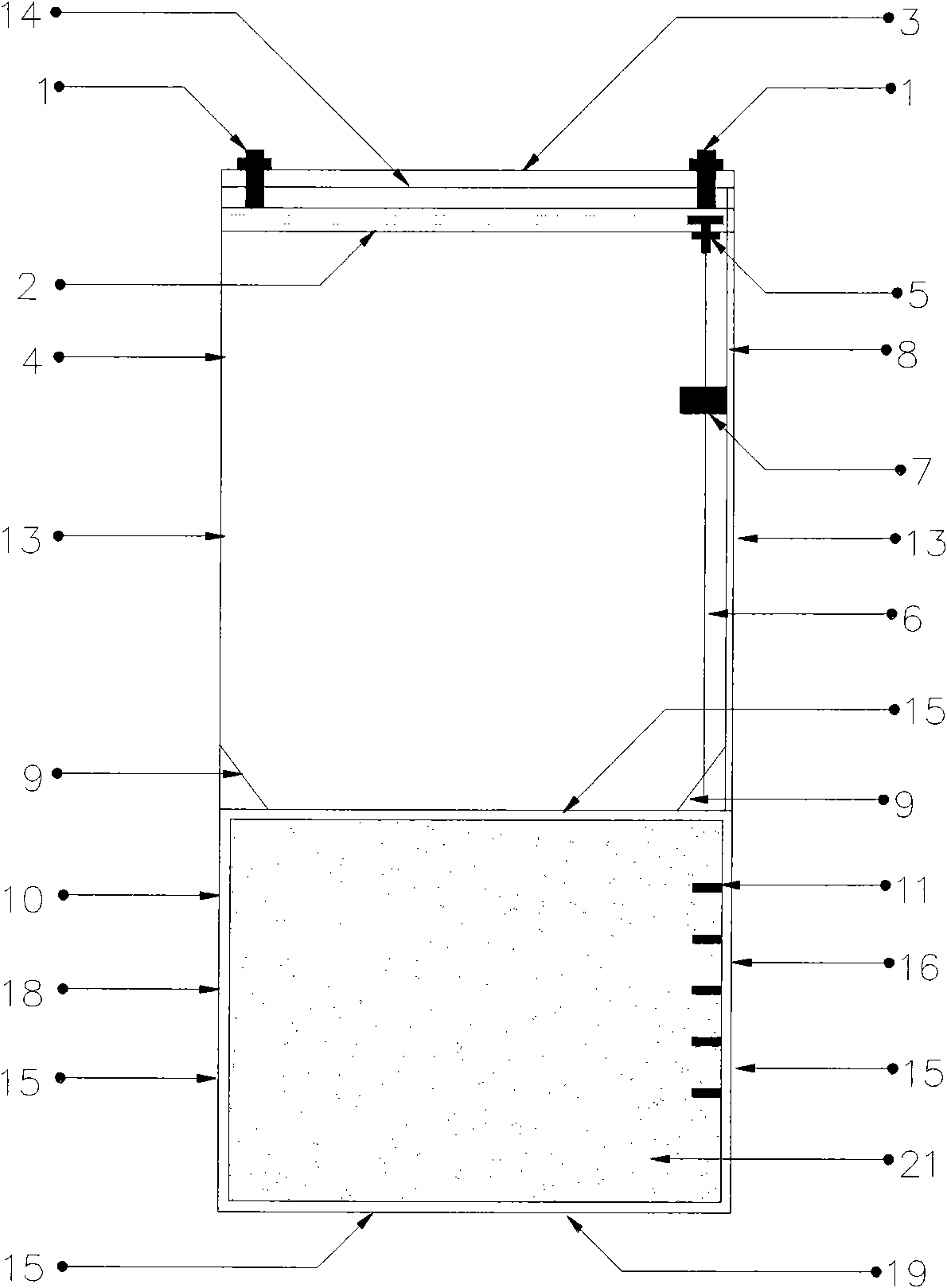

Semi-module test box for dynamic compaction reinforced foundation model test

InactiveCN101832993AEasy to observeSolve the many deficiencies that existFoundation testingForce measurementDynamic compactionEngineering

The invention belongs to the technical field of rock-soil engineering, and in particular relates to a semi-module test box for dynamic compaction reinforced foundation model test. The semi-module test box consists of a chute, a fixed cross beam, a bracket, a guide rod, a semicircular model hammer, a limit rod, a fixed corner bracket, a model box, a soil pressure box and an acceleration sensor. The fixed cross beam is welded with a cross rod; and a vertical rod in the bracket is connected with an angle steel above the model box. The chute is fixed on the cross beam; a sliding bolt is embedded into the chute, the upper end of the guide rod is connected with the sliding bolt, and the lower end of the guide rod is suspended; and the guide rod passes through a central hole of the semicircular model hammer, the limit rod is positioned above the model box, the upper end of the limit rod is welded with the cross rod in the bracket, and the lower end of the limit rod is welded with the angle steel on the model box. The model box consists of the angle steel, an organic glass board, side panels, a back board and a bottom board; the soil pressure box is embedded in a soil sample; and the acceleration sensor is placed on the top of the soil sample. The semi-module test box ensures that the internal deformation of the soil under the action of dynamic compaction can be directly and conveniently observed, and can measure related data of dynamic stress and the like.

Owner:TONGJI UNIV

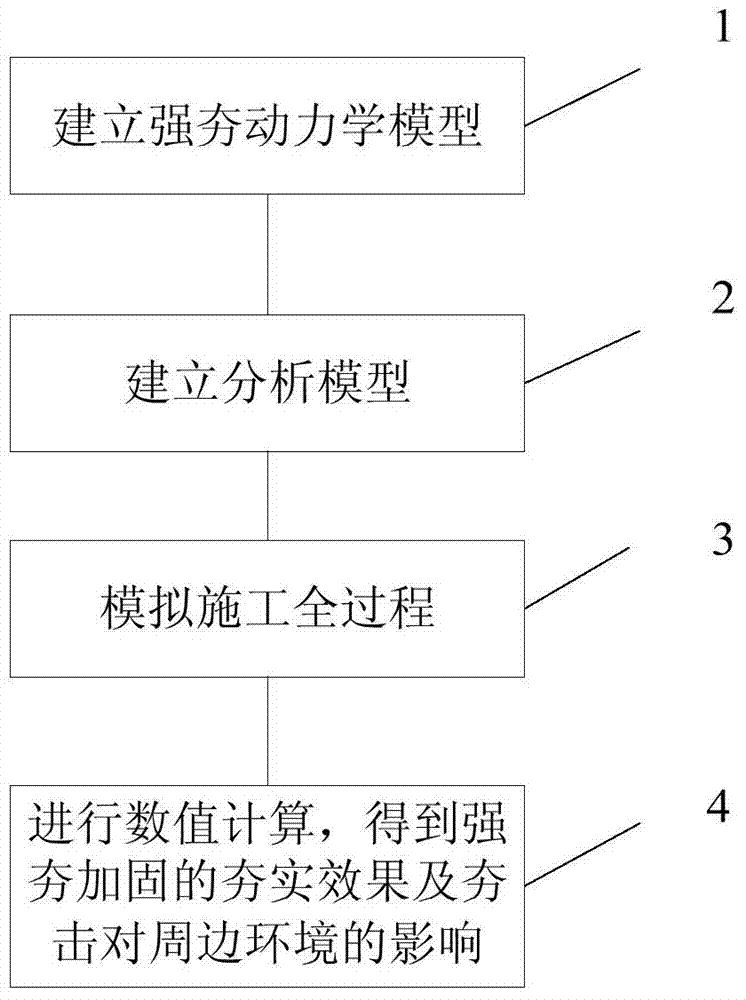

Method for predicting influence of dynamic compaction on soil body and surrounding environment

InactiveCN104328776ANo need to consider energy lossAvoid breaking non-convergent casesIn situ soil foundationProcess dynamicsEnvironmental effect

The invention relates to a method for predicting the influence of dynamic compaction on a soil body and the surrounding environment. The method is based on a construction full-process dynamic model considering the displacement history of a pounder in the dynamic compaction process, a non-linear value simulation technology is adopted for predicting the influence of the dynamic compaction construction on the soil body and the surrounding environment, and the method concretely comprises the following steps that (1) a dynamic compaction dynamic model is built; (2) an analysis model is built; (3) a construction full process is simulated; (4) the value calculation is carried out, and the dynamic compaction reinforcing compaction effect and the influence of the dynamic compaction on the surrounding environment are obtained. Compared with the prior art, the method has the advantages that the calculation is simple, the prediction is accurate, and the like.

Owner:TONGJI UNIV

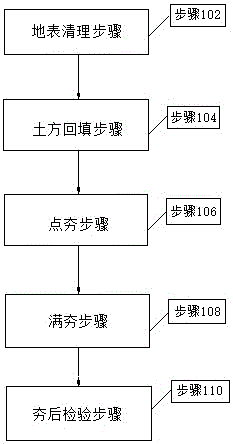

Foundation dynamic compaction construction method

InactiveCN106049407AShorten the construction periodImprove construction qualitySoil preservationDynamic compactionMonsoon

The invention belongs to the technical field of constructional engineering and particularly relates to a foundation dynamic compaction construction method. The foundation dynamic compaction construction method includes the steps that firstly, the ground surface is cleaned; secondly, earthwork backfilling is conducted; thirdly, local compaction is conducted; fourthly, full compaction is conducted; and fifth, checking is conducted after compaction, wherein various test data and test records in the trial compaction process are checked, when the test data and the test records do not meet design requirements, supplementary compaction should be conducted or other effective measures should be taken, the quality of the foundation can be checked only after a certain time interval after trial compaction construction is over, earthwork tests and dynamic penetration tests are conducted in time after trial compaction is completed, and test parameters are collected in time. By means of the foundation dynamic compaction construction method, the compaction frequency is accurately regulated, a sensor is introduced for analyzing construction data in real time, the foundation dynamic compaction construction method is very suitable for being used and popularized in subtropics monsoon climate zones, the construction period can be effectively shortened, and the construction quality is improved.

Owner:SINOHYDRO ENG BUREAU 4

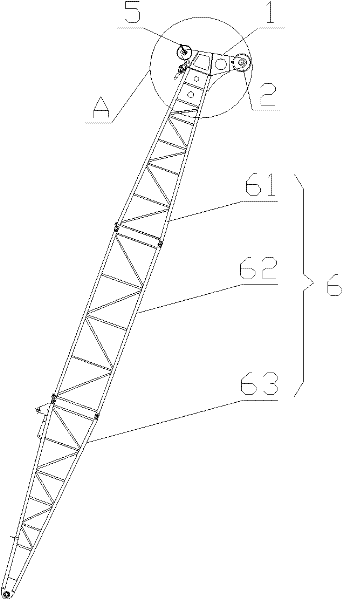

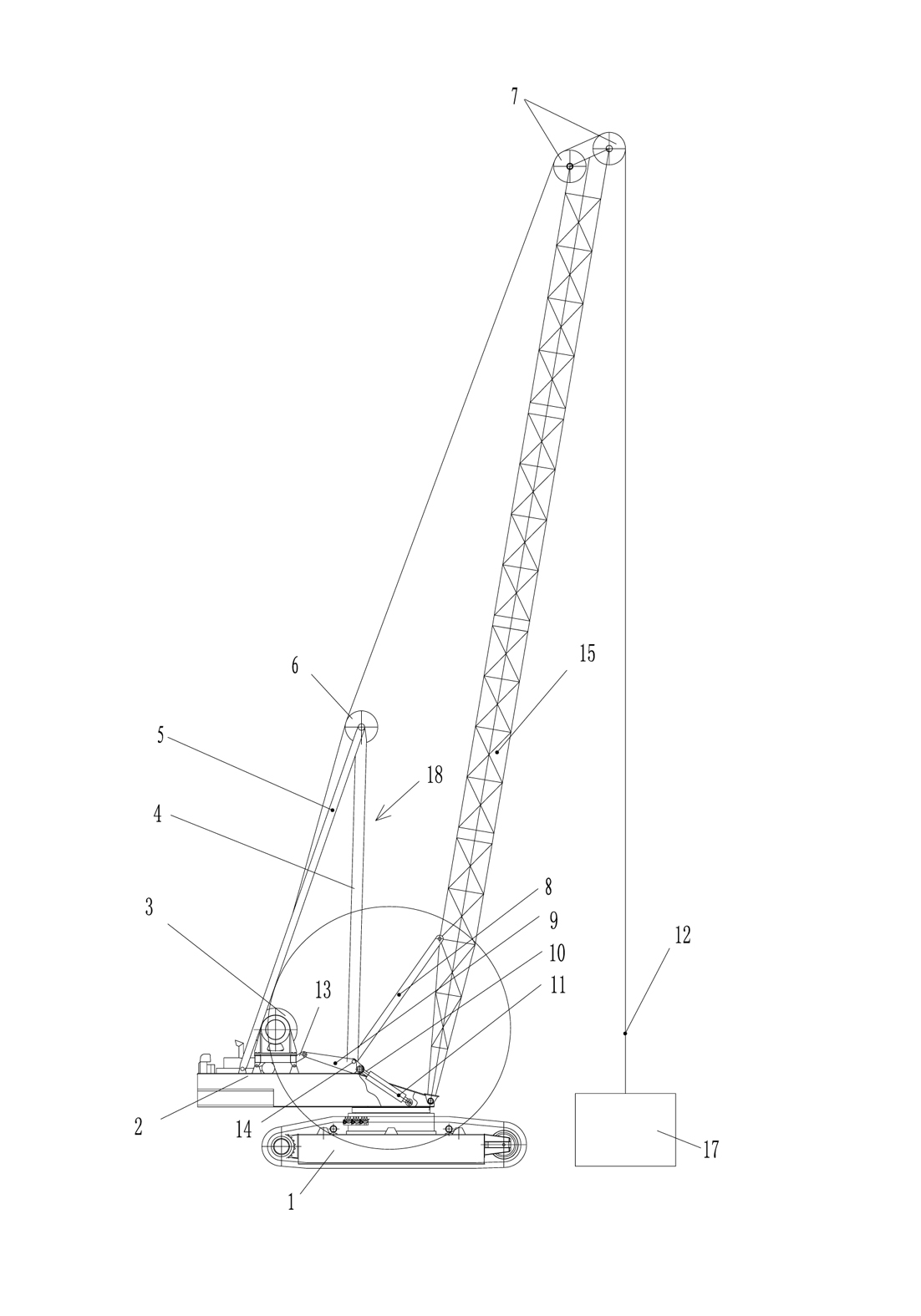

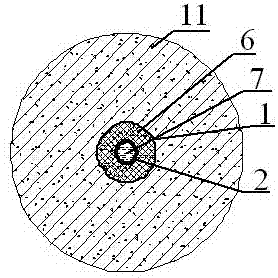

Dynamic compaction machine and arm rack device thereof

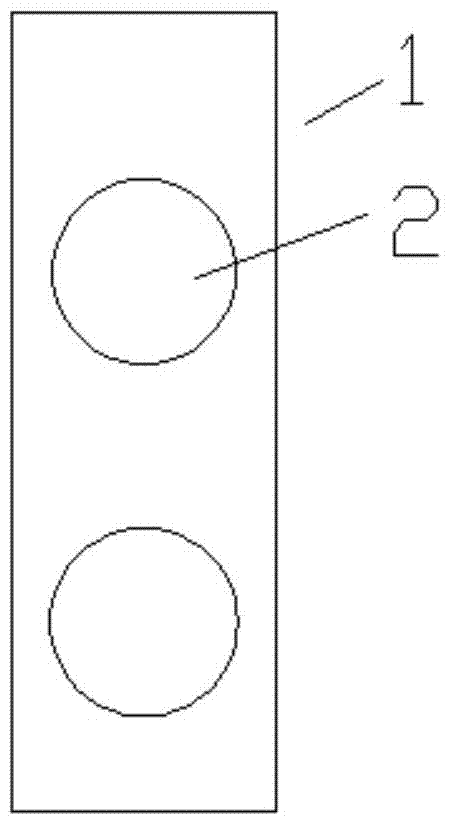

InactiveCN102251511ALarge working spaceAvoid motion interferenceSoil preservationDynamic compactionEngineering

The invention discloses an arm rack device of a dynamic compaction machine. The arm rack device comprises a supporting arm rack (6), the bottom of which is connected with the body of the dynamic compaction machine; the arm rack device also comprises a front stretching arm head device (1) arranged at the top of the supporting arm rack (6), and a fixed pulley (2) for lifting a rammer (7) of the dynamic compaction machine is arranged at the front end of the front stretching arm head device (1); the rammer (7) is relatively far from the supporting arm rack (6), so the operating space of the rammer (7) in the horizontal direction is enlarged, movement interference between the rammer (7) and the supporting arm rack (6) is avoided, and the operating safety is increased; and the rammer (7) of the same diameter can be lifted to a greater height, so that the operating performance of the dynamic compaction machine is fully exerted, and the work efficiency of the dynamic compaction machine is improved. Moreover, the invention also provides the dynamic compaction machine comprising the arm rack device.

Owner:BEIJING CSR TIMES LOCOMOTIVE & ROLLING STOCK MECHANICS

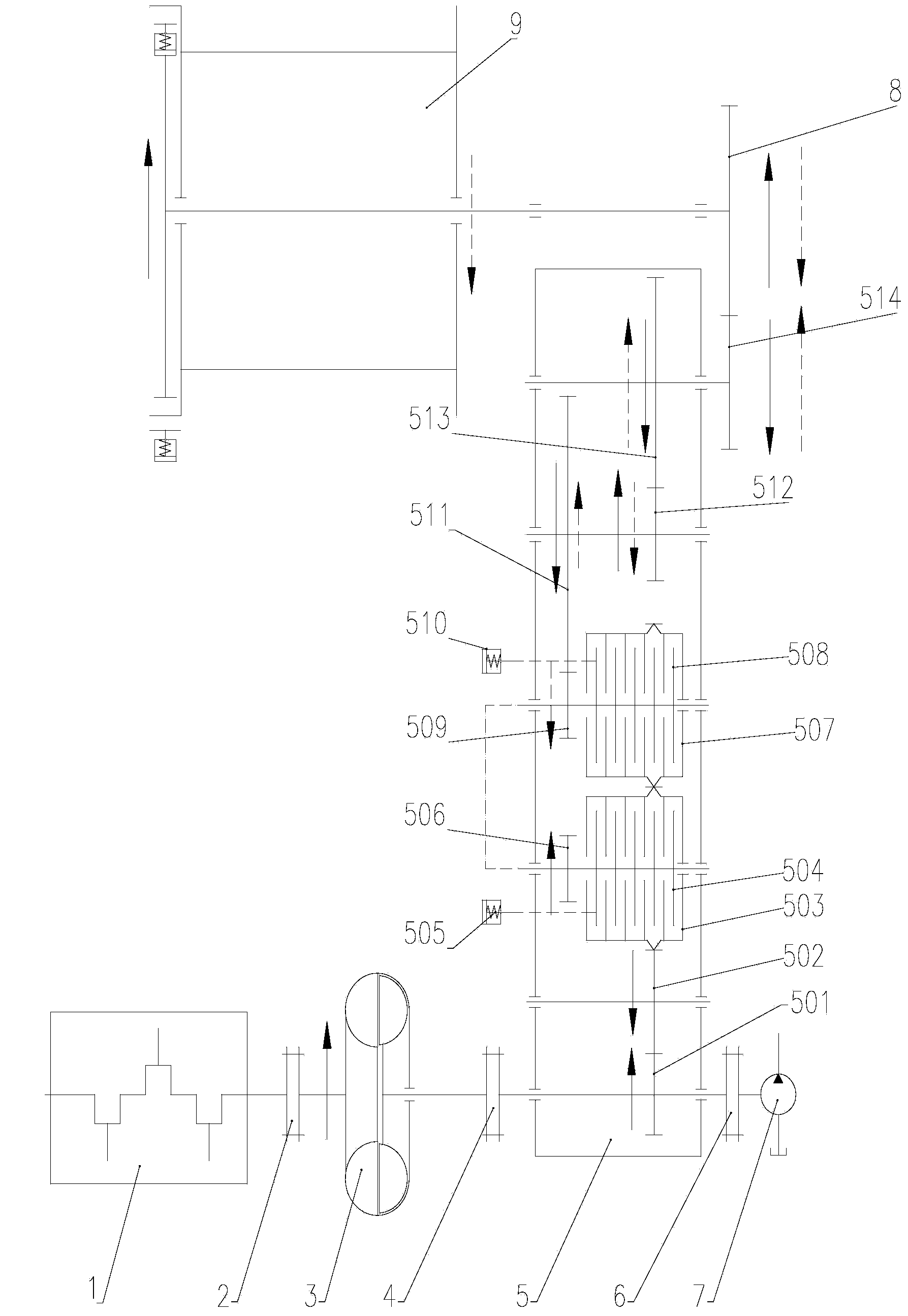

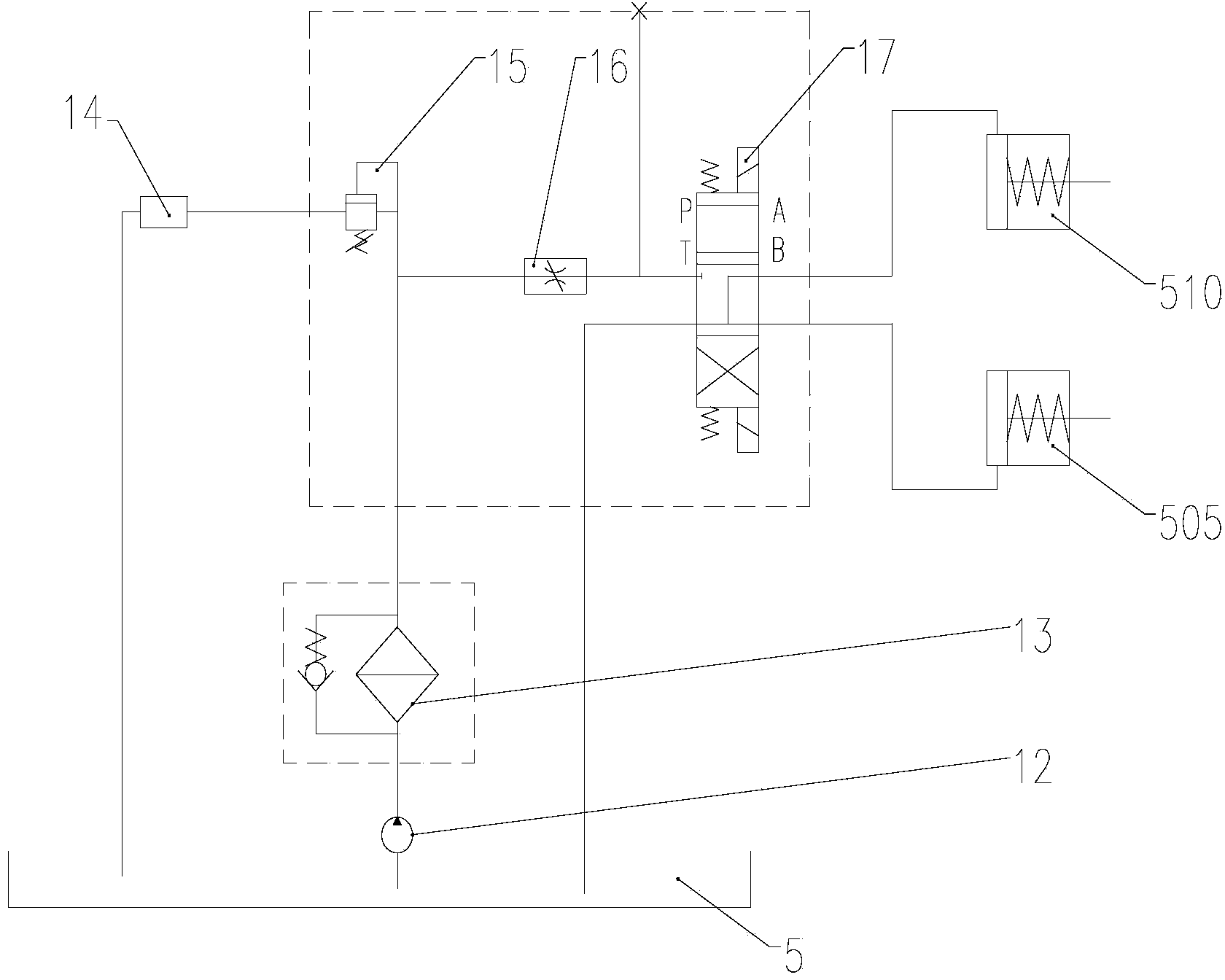

Mechanical and hydraulic integrated dynamic compaction machine

ActiveCN103924573AAvoid accidentsGood lowering stabilityFluid gearingsSoil preservationTransfer caseDynamic compaction

The invention discloses a mechanical and hydraulic integrated dynamic compaction machine. The mechanical and hydraulic integrated dynamic compaction machine comprises an engine, a main winch, a walking system, a hydraulic system driving the walking system to act, and a transmission system, wherein the transmission system comprises a transfer case which is connected with an output shaft of the engine, power of the engine is transmitted to the main winch and the hydraulic system of the dynamic compaction machine through the transfer case, a first speed reducing assembly is arranged in the transfer case, and the engine is connected with the main winch through the first speed reducing assembly so that the main winch can be driven to rotate in the positive direction; a second speed reducing assembly is further arranged in the transfer case, and the engine is connected with the main winch through the second speed reducing assembly so that the main winch can be driven to rotate in the reverse direction. According to the mechanical and hydraulic integrated dynamic compaction machine, the engine can drive the main winch to rotate in the reverse direction, then a tamper or a weight is driven to be placed downwards, and the tamper can be placed downwards quite stably due to the fact that the engine drives the winch to rotate continuously; in addition, the application flexibility of the machine is further improved due to the fact that a heavy load can be placed down by the dynamic compaction machine, and cost of devices used on a construction site can be reduced to a certain degree.

Owner:BEIJING CSR TIMES LOCOMOTIVE & ROLLING STOCK MECHANICS

Dynamic compactor capable of realizing amplitude-variable followup of A-bracket with arm support

ActiveCN102002936AReasonable forceAchieve balanceSoil preservationForce equilibriumDynamic compaction

The invention relates to a dynamic compactor capable of realizing the amplitude-variable followup of an A-bracket with an arm support, which is characterized in that a followup A-bracket is mounted on a dynamic compactor rotating platform, an amplitude-variable draw rod is arranged between an inner diagonal rod and an arm support, a swing arm mechanism is arranged at the lower parts of the amplitude-variable draw rod and the inner diagonal rod, the swing arm mechanism is composed of a swing arm rack and a telescopic oil cylinder, and the followup A-bracket forms linkage with the amplitude-variable draw rod by the swing arm mechanism. Wire ropes of a hoisting mechanism are connected with a dynamic compactor weight through a pulley at the top end of the followup A-bracket and a pulley at the top end of the arm support, so that the quantity of front wire ropes at the top end of the arm support is the same with that of back wire ropes at the top end of the arm support. When the amplitude-variable draw rod drives the arm support to realize an amplitude-variable process, the swing arm mechanism connected with the followup A-bracket synchronously drives the followup A-bracket to swing. The amplitude-variable followup of the followup A-bracket with the arm support is realized, so that the stress on the arm support of the dynamic compactor is more reasonable, the stress balancing of the arm support can be realized to the greatest extent, the structural stress of the arm support can be improved, the self-weight of the arm support can be reduced, and the dynamic compaction operating performance of the arm support and the complete machine can be improved.

Owner:CHINA ZHONGHUA GEOTECHN ENG

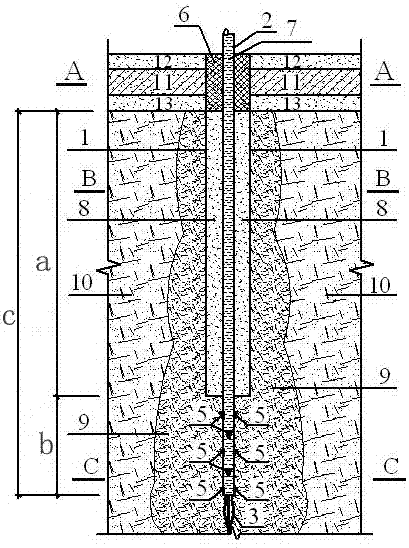

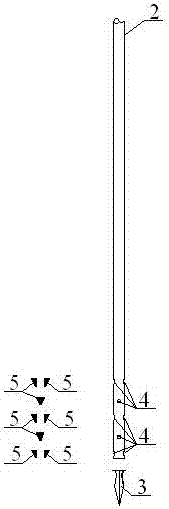

Expansive-type high-polymer cement paste, grouting reinforcement device and grouting reinforcement method

ActiveCN107417182AImprove mechanical propertiesImprove bearing capacityDrilling compositionSoil preservationDynamic compactionWhole body

The invention provides expansive-type high-polymer cement paste, a grouting reinforcement device and a grouting reinforcement method, aiming to solve the technical problems that dynamic compaction is not uniform, partial compactness does not meet requirements and differential settlement of buildings occur when a dynamic compaction substitution method is used for miscellaneous fill foundation treatment. The expansive-type high-polymer cement paste comprises, by weight, 91-95 parts of Portland cement, 2-4 parts of soundless cracking agents and 3-5 parts of polypropylene fibers. The expansive-type high-polymer cement paste is injected into stratum evenly through a steel grouting pipe, original cracks are filled with grout in the mode of filling, permeating, swelling and compacting, originally-loose soil particles are rapidly solidified into a whole body, and a mini pile is formed in a drill hole, so that mechanical property of foundation soil is improved, and the effects of improving bearing capacity of the foundation soil and consolidating the foundation are achieved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Intelligent dynamic compaction construction monitoring method and system

PendingCN105178281AIncrease credibilityEasy to detectElectromagnetic wave reradiationIncline measurementDynamic compactionMonitoring system

The invention provides an intelligent dynamic compaction construction monitoring method. The method comprises an automatic compaction degree monitoring process. The automatic compaction degree monitoring process comprises the specific steps that micro waves are sent to compacted soil with a certain sampling frequency; a micro wave echo data sequence of the compacted soil is collected; and the data sequence is processed, and the compaction degree is recognized and monitored. An intelligent dynamic compaction construction monitoring system comprises a micro wave instrument and a data processing device connected with the micro wave instrument. The intelligent dynamic compaction construction monitoring method and system have the beneficial effects that the method and system are simple, practical and high in reliability; the dynamic compaction construction process can be automatically detected and monitored, and the hammer lifting height, the effective tamping frequency, the tamper drop distance, the compaction degree and the tamping levelness are automatically detected and monitored; and complete engineering construction data can be provided for large dynamic compaction construction, and data guarantees are provided for improving engineering quality.

Owner:北京中企卓创科技发展有限公司

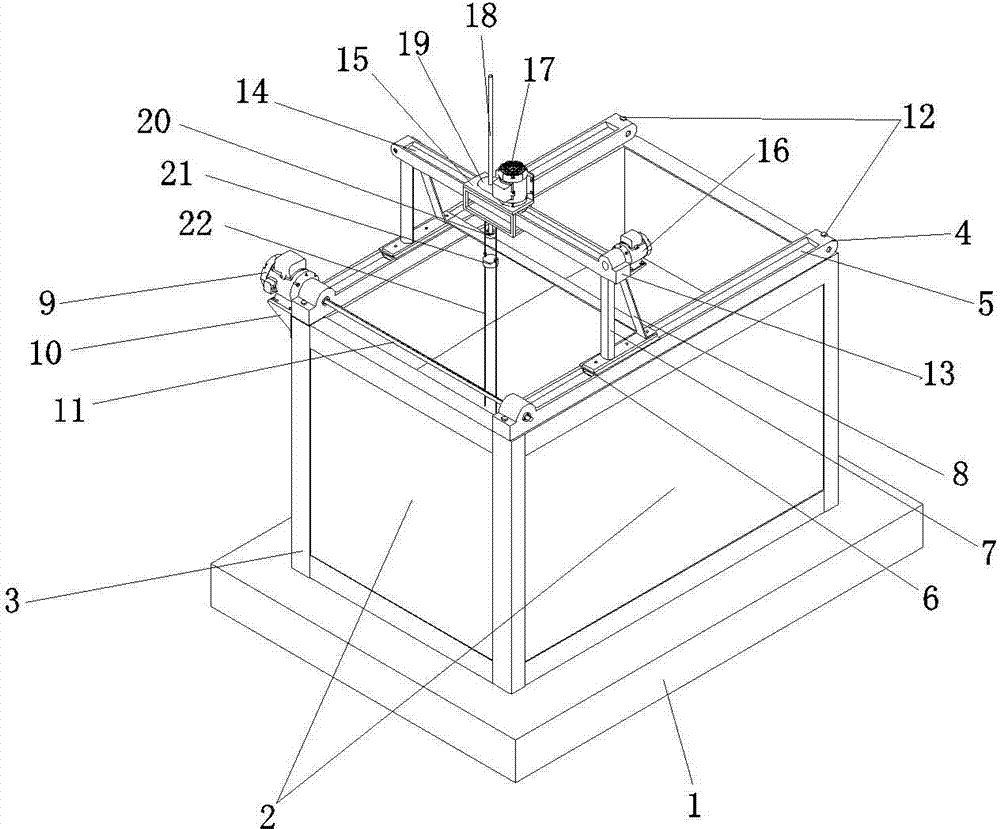

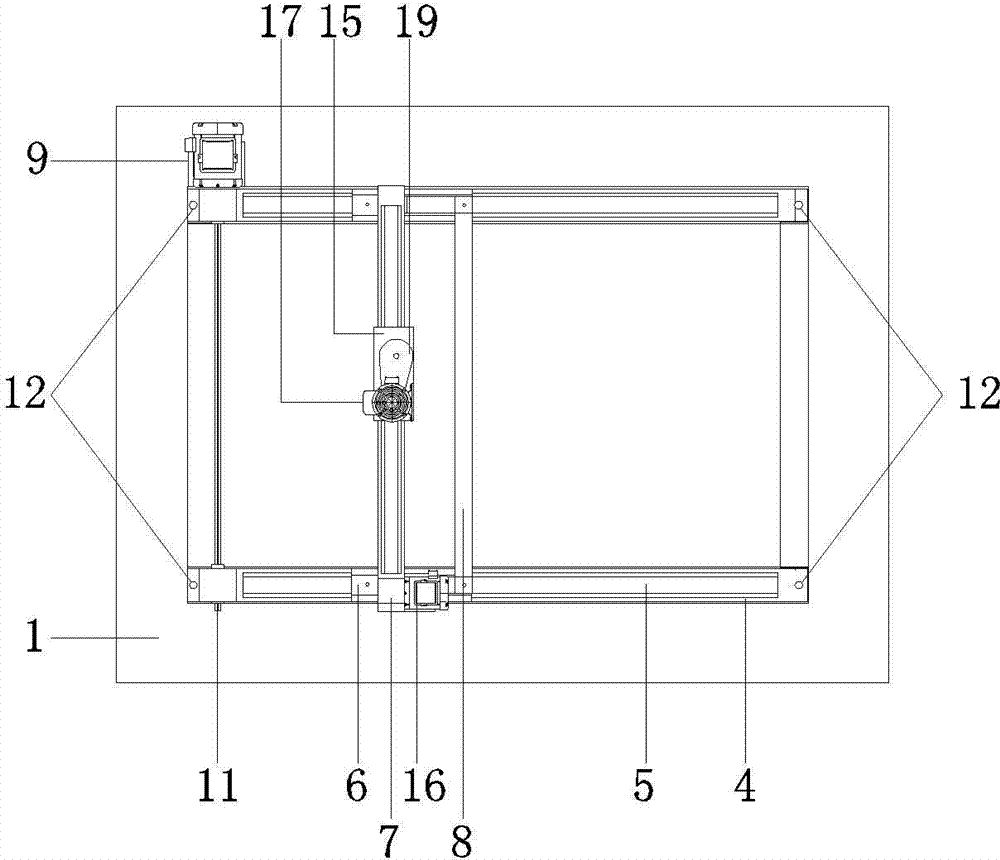

Three-dimensional controllable dynamic compaction simulated centrifuge testing mechanical arm device

The invention belongs to the technical field of geotechnical centrifuges and in particular relates to a three-dimensional controllable dynamic compaction simulated centrifuge testing mechanical arm device. The three-dimensional controllable dynamic compaction simulated centrifuge testing mechanical arm device is composed of a base, a model box, a three-dimensional displacement system and an automatic hammer dropping system, wherein a dynamic compaction mechanical arm can realize manual controllable three-freedom-degree movement in horizontal-longitudinal, horizontal-transverse and vertical directions, and can realize simulation actions such as free falling of a miniature rammer, hoisting ramming repeatedly and ramming at different points and the like based on a three-directional movement module and an electromagnetic relay system; by combining a centrifuge device, an imaging system and a sensor system, provided by a centrifugation laboratory room, the three-dimensional controllable dynamic compaction simulated centrifuge testing mechanical arm device can be used for simulating the dynamic compaction construction method, disclosing the mechanism of the dynamic compaction method and optimizing the construction scheme.

Owner:TONGJI UNIV

System and method for detecting tamping pit number of dynamic compactor and dynamic compactor

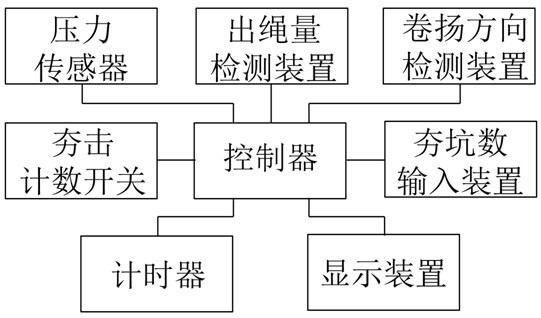

ActiveCN102693449AImprove accuracyImprove work efficiencyCounting mechanisms/objectsSoil preservationDynamic compactionHydraulic circuit

The invention discloses a system and a method for detecting the tamping pit number of a dynamic compactor and a dynamic compactor. The system relates to the operation data acquisition of the dynamic compactor, and comprises a rope-outlet quantity detection device, a pressure sensor, a hoisting direction detection device, a tamping counting switch, a controller, a tamping pit number input device and a timer, wherein the rope-outlet quantity detection device is connected with a steel wire rope of the dynamic compactor; the pressure sensor is connected with a hydraulic circuit of a hoisting motor of the dynamic compactor; the hoisting direction detection device is connected with a hoisting system of the dynamic compactor; the tamping counting switch is connected and linked with a tamping control mechanism of the dynamic compactor; the controller is respectively connected with the rope-outlet quantity detection device, the pressure sensor, the hoisting direction detection device and the tamping counting switch; the tamping pit number input device is connected with the controller; and the timer is connected with the controller. The system and method and dynamic compactor disclosed by the invention have the advantages that misoperations can be prevented, the accuracy of tamping pit counting can be improved, and then the operating efficiency of dynamic compaction operations can be improved; the manpower cost is saved; the detection accuracy is high, the error is small, the reliability is high, and the price is cheap; and the complete set of system is convenient install and simple in debug, and can be applied to various dynamic compaction devices.

Owner:ZHEJIANG SANY EQUIP

Vibration isolation plate device in soil matrix treatment engineering and construction technology thereof

ActiveCN103938657APrevent collapseGuaranteed vibration isolation performanceProtective foundationDynamic compactionFilling materials

The invention discloses a vibration isolation plate device in soil matrix treatment engineering. The device comprises a vibration isolation array composed of multiple parallel vibration isolation units, wherein the front end of the first vibration isolation unit located at one end of the vibration isolation array is closed to prevent soil from falling, the connection parts of every two adjacent vibration isolation units overlap to block soil, each vibration isolation unit comprises two vibration isolation veneers arranged in parallel in the vertical direction, and vibration isolation modules are arranged between every two vibration isolation veneers at intervals. The invention further discloses a construction technology using the device. Due to the arrangement of the vibration isolation veneers in an open trench, collapse of a trench wall during dynamic compaction caused by vibration can be avoided, and the vibration isolation effect of the vibration isolation trench can be guaranteed to the maximum degree. Due to the fact that the vibration isolation modules are arranged between the vibration isolation veneers, the vibration isolation veneers can be supported, wave energy can be absorbed, and the influence of vibration on nearby buildings can be reduced. According to the device, the vibration isolation effect of the vibration isolation trench is improved greatly, and the usage of filling materials is reduced.

Owner:SHANDONG UNIV

Railway frame bridge construction method

ActiveCN108166397AMeet the stiffness requirementsFast constructionBridge erection/assemblyExcavationsDynamic compactionCrushed stone

The invention relates to a railway frame bridge construction method which mainly aims at solving the problems that an existing construction method can hardly meet the construction quality requirementand a construction period is long. In a foundation treatment construction method, construction schemes such as a broken-stone-sandwiched sand cushion layer, CFG piles, heavy grinding and dynamic compaction are adopted; in foundation construction, the axis and the side boundaries of a frame bridge are defined through a total station, the elevation is measured through a water level, and an excavation line and the excavation depth are determined; and in bridge body construction, supports and an inner mold are installed, reinforcing steel bars are manufactured and tied, an integrally-combined formwork is adopted as a bridge body outer mold, side wall and top board concrete is poured, edge wall and top board concrete is cured, the formwork is detached, and finally retaining wall construction and settlement joint and waterproof layer construction are conducted. The method has the beneficial effects that the construction speed is high, the quality is good, and a construction period is short.

Owner:中铁十九局集团华东工程有限公司 +1

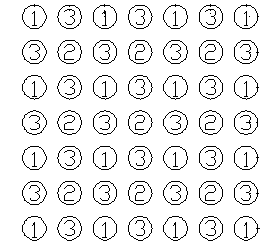

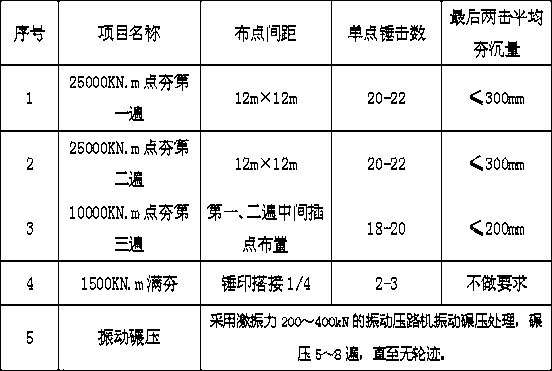

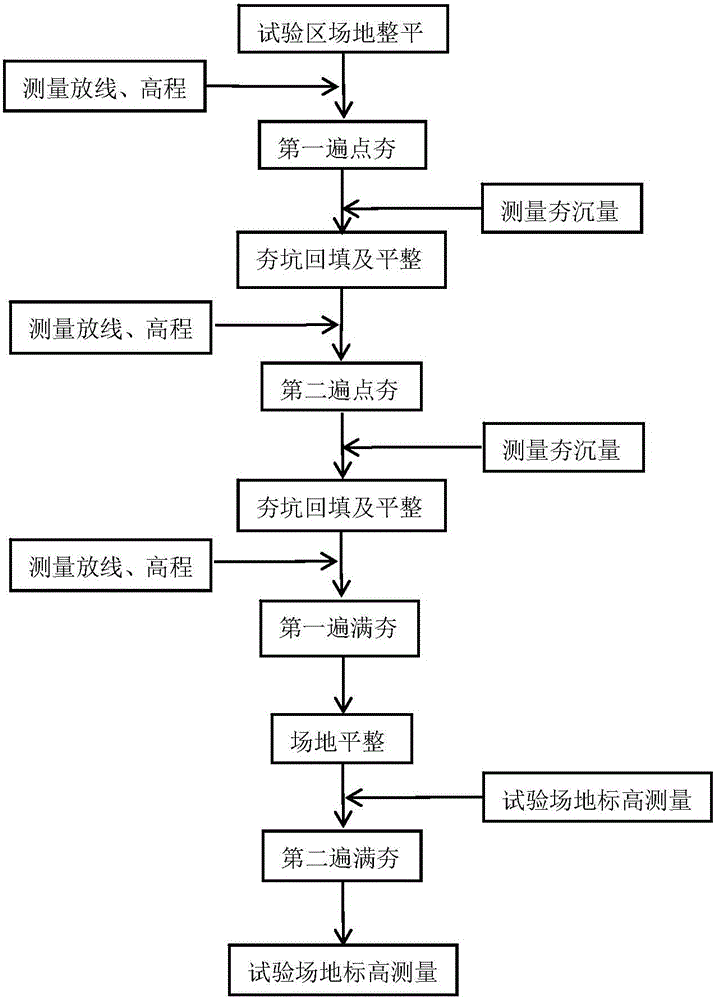

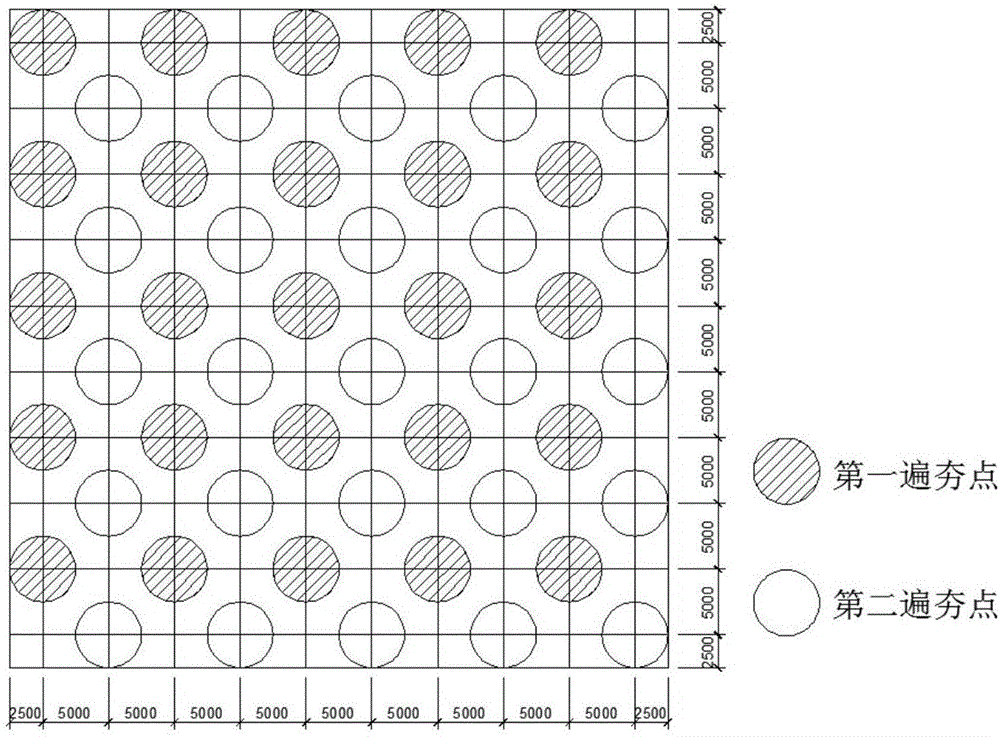

Construction method for treating costal backfill ultrathick gravel soil foundation by 25000 KN.m dynamic compaction

The invention belongs to the technical field of dynamic compaction foundation treatment in construction engineering, in particular to a construction method for treating a costal backfill ultrathick gravel soil foundation by 25000 KN.m dynamic compaction. The construction method comprises the steps of: (101) construction preparation: determination of construction of a dynamic compaction surface andleveling of a place to reach the elevation of the dynamic compaction surface, (102) primary main compaction energy level construction, (103) secondary main compaction energy level construction, (104)ternary secondary compaction energy level construction, (105) full compaction construction and (106) surface layer grinding. The construction method treats the foundation by 25000 KN.m ultrahigh energy level dynamic compaction, can once treat a gravel soil backfill foundation with a thickness of 17-20 m, meets treatment of a deep soft foundation within an influence range, and has the advantages of obvious treatment effect, simple process, lower cost, short construction period, environmental protection and the like.

Owner:山西机械化建设集团有限公司

Wet and soft soil foundation treatment method

ActiveCN104088208AAccelerated drainage consolidationAccelerated consolidationRoadwaysSoil preservationSoil scienceDynamic compaction

The invention discloses a wet and soft soil foundation treatment method which comprises the steps of 1, backfilling completely within the roadbed width range; 2, before roadbed construction, firstly, removing surface water, and then removing the surface layer salinized soil and surface organic matter of a construction region; 3, backfilling gravel soil within the treatment range, and carrying out primary rolling; after rolling is finished, leveling to form a cross slope; 4, excavating two trapezoid drainage ditches respectively at the two sides of a roadbed; 5, laying a plastic drainage plate; 6, dynamic compaction, compacting by points for twice and fully compacting for once; 7, after dynamic compaction treatment, rearranging the roadbed, and cleaning the overground part of the top of the drainage plate; laying a middle coarse sand cushion layer as a drainage channel, wherein the gradient of the middle coarse sand cushion layer is equal to that of the roadbed; placing a bending part of the plastic drainage plate in the center of the sand cushion layer to enable the bending part to be communicated with the sand cushion layer; 8, backfilling gravel soil onto the middle coarse sand cushion layer; 9, after the roadbed is finished, laying gravel on the surface layer, rolling and compacting.

Owner:JINAN MUNICIPAL ENG DESIGN & RES INSITITUTE GRP

Foundation treatment method

InactiveCN103711114ATechnical solutionEasy constructionSoil preservationDynamic compactionReplacement method

The invention relates to a foundation treatment method of loose ground soil or large-area backfill ground soil and mainly solves the problems of hole collapse, rammer losing and rammer absorbing in existing dynamic compaction technology construction. The method includes that a dynamic compaction half-replacement method is adopted to perform foundation treatment on a backfill loose ground, a flexible replacement ramming pier is formed by adopting a dynamic compaction construction process and fine-particle filled soil for filling and squeezing-in, and the flexible replacement ramming pier and an original loose soil body form compact uniformly-squeezed replacement bodies radially and vertically; the flexible ramming pier directly depends on continuous point ramming to reinforce the soil body under the pier, and a hard pier bottom bottoming layer is formed. By the technical scheme, the problems are solved well, and the foundation treatment method can be used in construction production needing foundation treatment.

Owner:CHINA PETROCHEMICAL CORP +1

Dynamic compaction reinforcing method for improving stability of cast-in-place pile collapse hole

ActiveCN106326552AFix stability issuesGuarantee the construction qualityGeometric CADDesign optimisation/simulationDynamic compactionEngineering

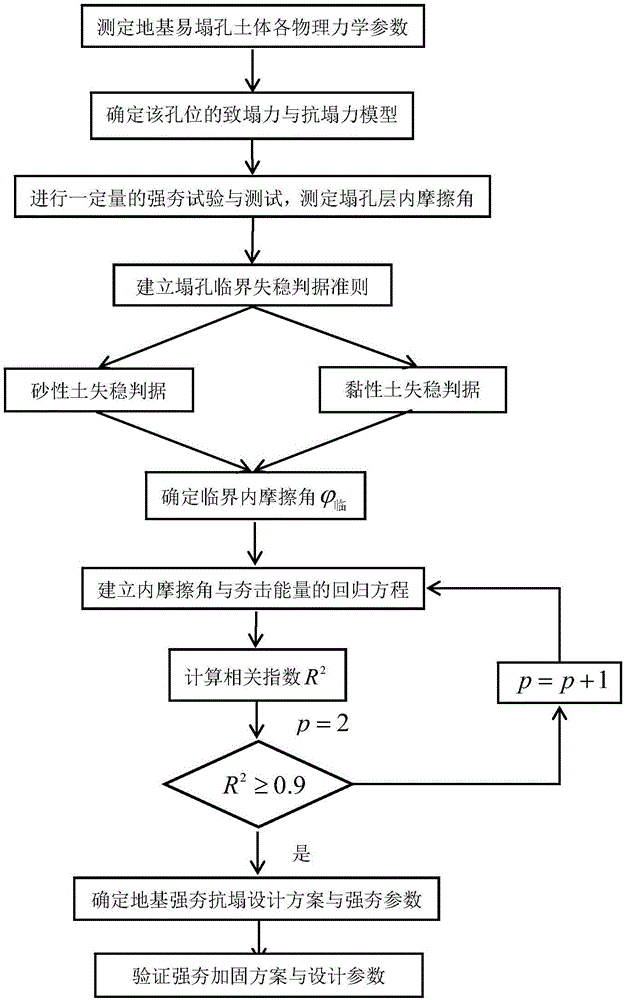

The invention relates to a dynamic compaction reinforcing method for improving the stability of a cast-in-place pile collapse hole. The method is characterized by comprising the following steps of 1, measuring relevant parameters and the layer position depth and thickness of a foundation easy collapse hole soil layer; 2, determining the collapse-induced force and the collapse-resistant force of the drilling cast-in-place pile collapse hole layer position; 3, measuring the cohesion force c' and the inner frictional angle phi' between the dynamic compaction reinforcing test experiment and a collapse hole layer; 4, determining the sandy soil layer collapse critical inner frictional angle phi<critical> of a sandy soil layer and the collapse hole instablilty criterion rule; 5, determining the quantitative relationship of the inner frictional angle phi' and the cohesion force c' of a cohesive soil layer, and performing relevant reliability inspection; 6, determining the quantitative relationship of the dynamic compaction parameter and the inner frictional angle phi' of the corresponding collapse hole layer, and performing relevant reliability inspection; 7, determining foundation dynamic compaction collapse-resistant stability reinforcing method and parameters. The method has the advantages that the problem of hole wall stability is effectively solved; in addition, the construction quality of the large-scale drilling cast-in-place pile is ensured; the requirement of the construction period is met; the construction cost is reduced.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

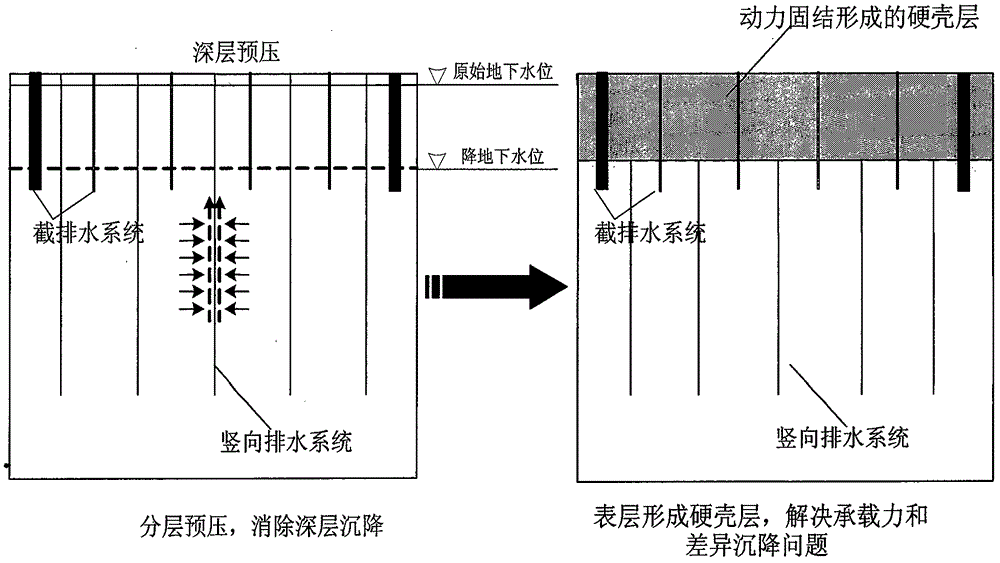

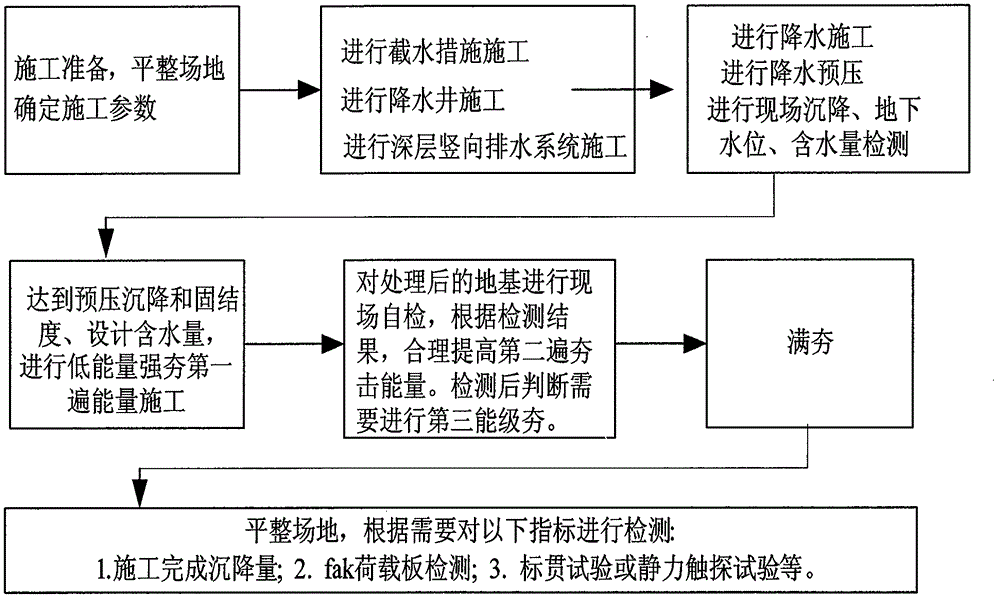

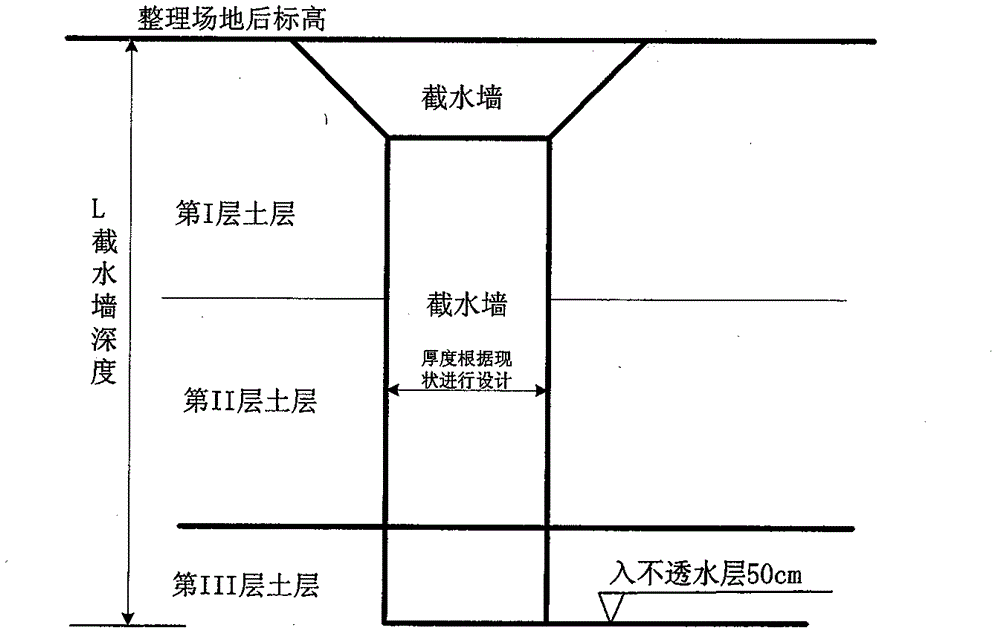

Soft foundation treatment method employing 'cutting drainage deep-layer preloading and dynamic consolidating'

InactiveCN102720180ACost advantageAdvantages of construction periodSoil preservationDynamic compactionMechanical index

The invention relates to a soft foundation treatment method employing 'cutting drainage deep preloading and dynamic consolidating'. Water sealing, strong drainage, deep-layer vertical discharge system, vibrating compacting or dynamic compaction are organically combined to reduce an additional load formed by the ground water level of a deposal field, so as to carry out deep preloading on a soft substratum, finish consolidation of a soft soil layer and remove sedimentation of a soft substratum; compactness and physical and mechanical indexes of a shallow sediment are improved by organic combination of dynamic consolidation and cutting drainage, and the capacity requirements on the field are met. The method comprises the following construction implementation processes of: 1) punching a waterstop curtain and a strong drainage system, reducing the ground water level and the moisture content of a soil body; 2) punching a vertical drainage channel penetrating a silt seam, carrying out the deep-layer preloading and removing the sedimentation; 3) carrying out the dynamic consolidating, so that the compactness and the physical and mechanical indexes of the shallow sediment are improved, and the capacity requirements on the field are met. According to the method, the problems and the defects in the prior art are overcome, and the soft foundation treatment method has the characteristics that the schedule is short, the construction cost is low, the process is simple, the quality is controllable and the difficulty of deep-layer silt engineering can be solved.

Owner:汪文彬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com