Construction method for compacting high loess-filled embankment by combining vibration roller compaction with dynamic compaction

A technology of loess high filling body and construction method, which is applied in the fields of soil protection, infrastructure engineering, construction, etc., can solve the problems of inability to impact reinforcement, etc., and achieve the effects of eliminating collapsibility, saving costs, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the drawings and embodiments of the specification.

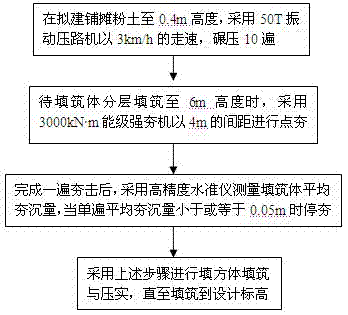

[0015] Such as figure 1 As shown, the specific steps of combined vibratory rolling and dynamic compaction in the construction area are as follows:

[0016] Evenly spread the loose powdery loess to a height of 0.4m, and roll it 10 times with a 50T vibratory roller at a speed of 3km / h; after the first rolling, spread the second layer of loose powdery loess evenly, and then crushed in the same way,

[0017] When the filling body is filled in layers to a height of 6m, a 3000kN·m energy-level dynamic compaction machine is used to carry out spot tamping at a distance of 4m, and then every 6m.

[0018] After one round of tamping is completed, use a high-precision level to measure the average ramming settlement of the filling body, and stop tamping when the average ramming settlement of the filling body meets the standard for stopping tamping;

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com