Patents

Literature

80results about How to "Eliminate collapsibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

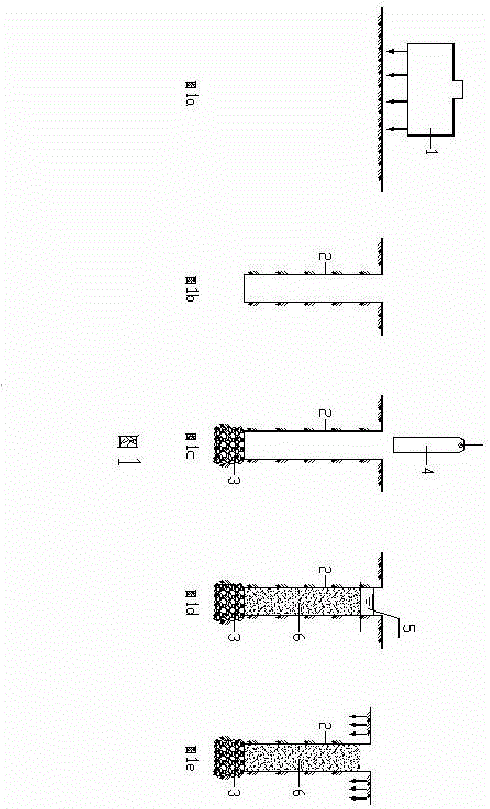

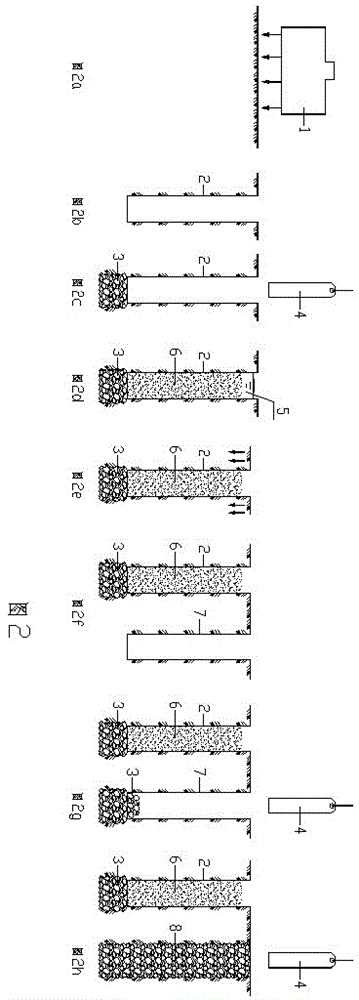

Collapsible loess foundation treatment method

ActiveCN104131546AEliminate collapsibilityImprove bearing capacitySoil preservationEngineeringSurface layer

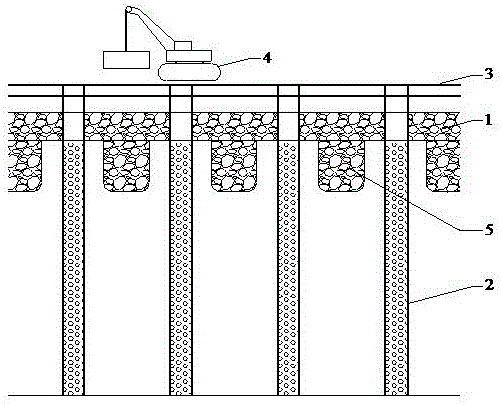

The invention aims to provide a collapsible loess foundation treatment method. A shallow-layer soil body and a deep-layer soil body of the foundation are reinforced, collapsing is eliminated, and then collapsing of the soil bodies is eliminated by adopting a water soaking method. The collapsible loess foundation treatment method includes the steps: 1), using a dynamic compaction method to ram a surface-layer soil body of the foundation; 2), uniformly forming pouring holes; 3), filling a bottom-end soil body for ramming; 4), pouring water and filling aggregate; 5), observing settlement until collapsing deformation is stable. In addition to the above objects, in order to further improve load-bearing capacity of a foundation soil body. The invention further provides another collapsible loess foundation treatment method. The treatment method includes the steps: 1), using a dynamic compaction method to ram a surface-layer soil body of the foundation; 2), uniformly forming pouring holes; 3), filling a bottom-end soil body for ramming; 4), pouring water and filling aggregate; 5), observing settlement until collapsing deformation is stable; 6), rearranging pile position points, and vibrating or hammering to form holes at certain depth; 7), filling fillers and ramming; 8), repeating filling and ramming operation until compaction pile bodies are formed.

Owner:北京波森特岩土工程有限公司

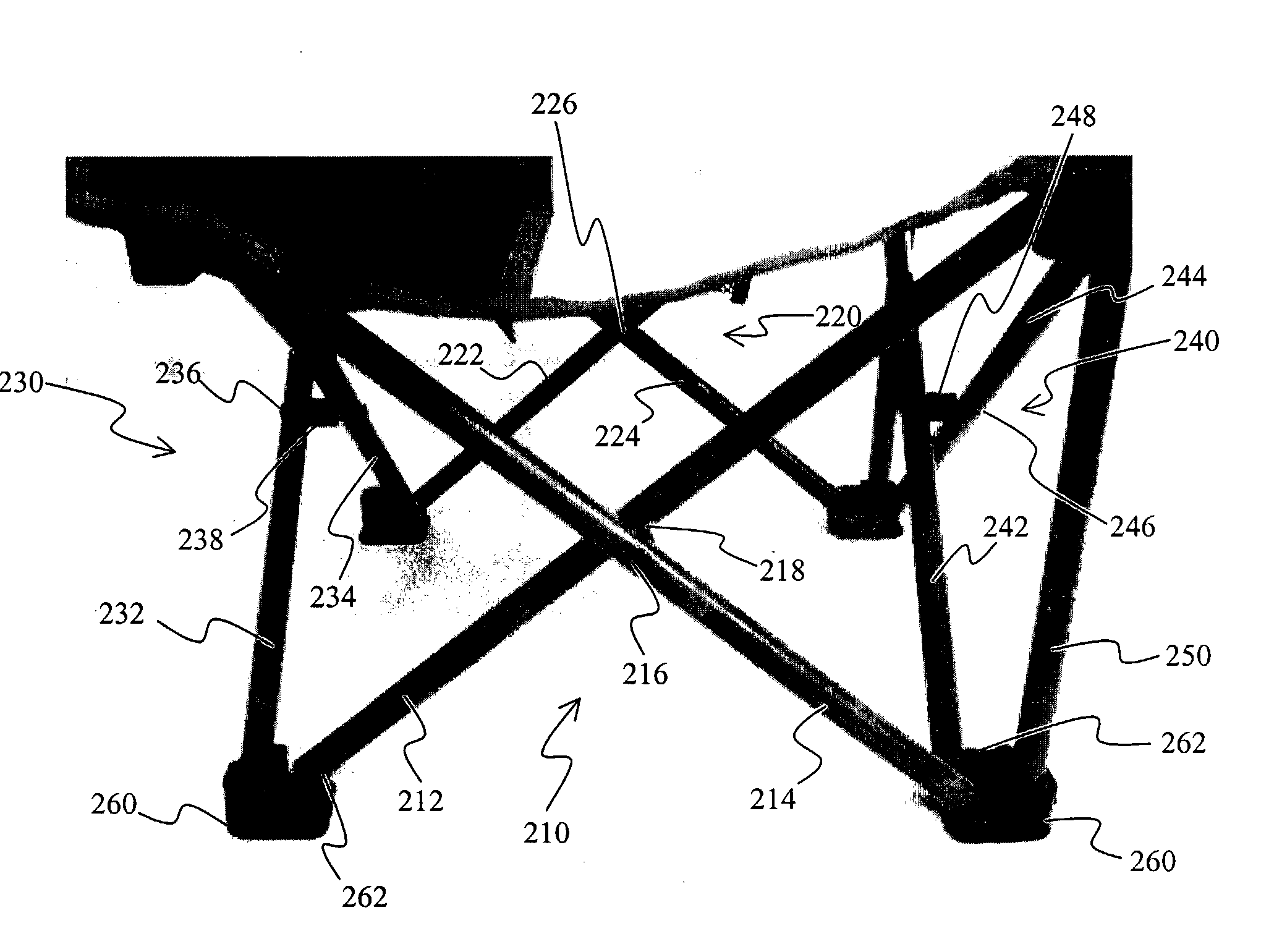

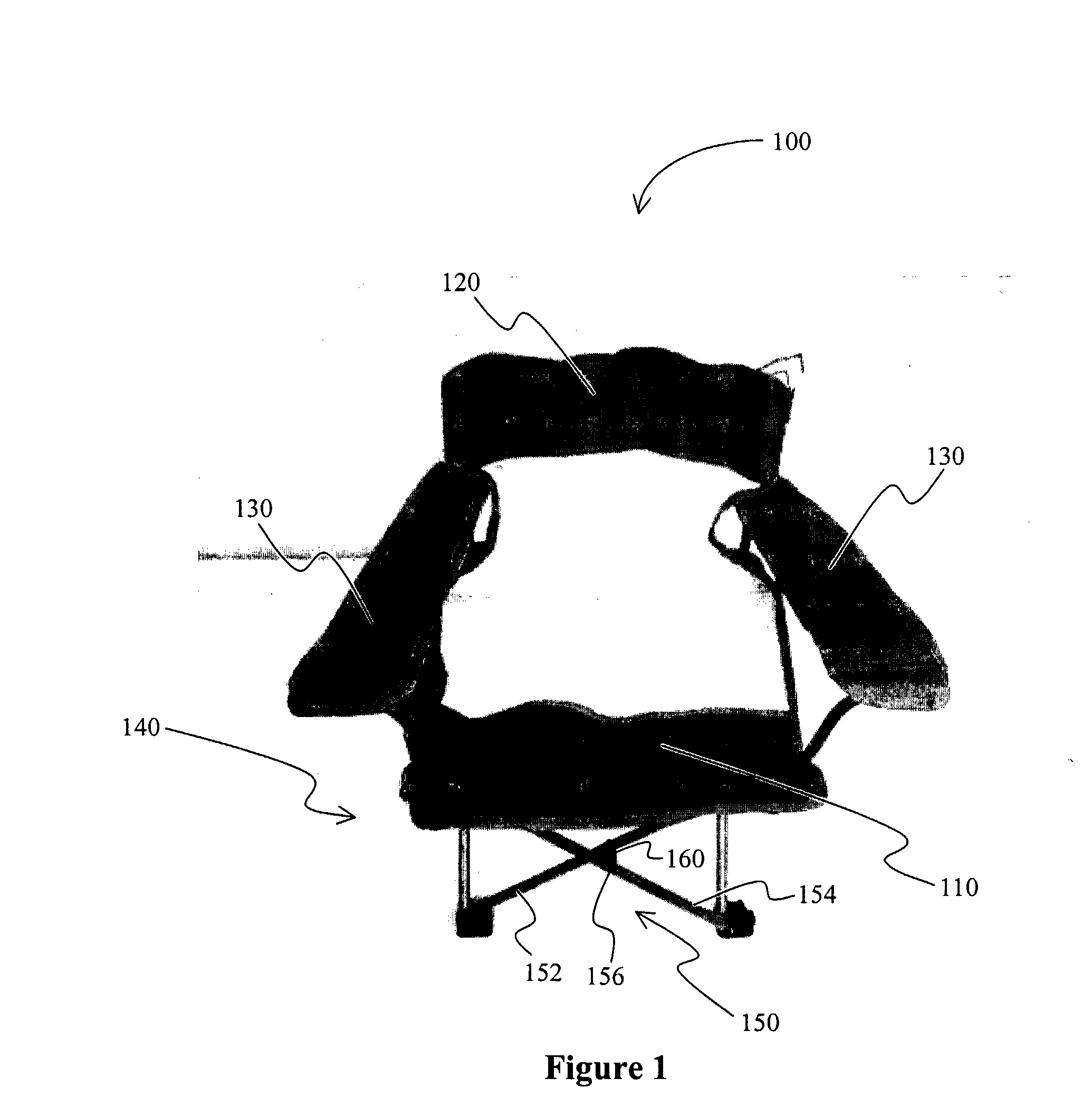

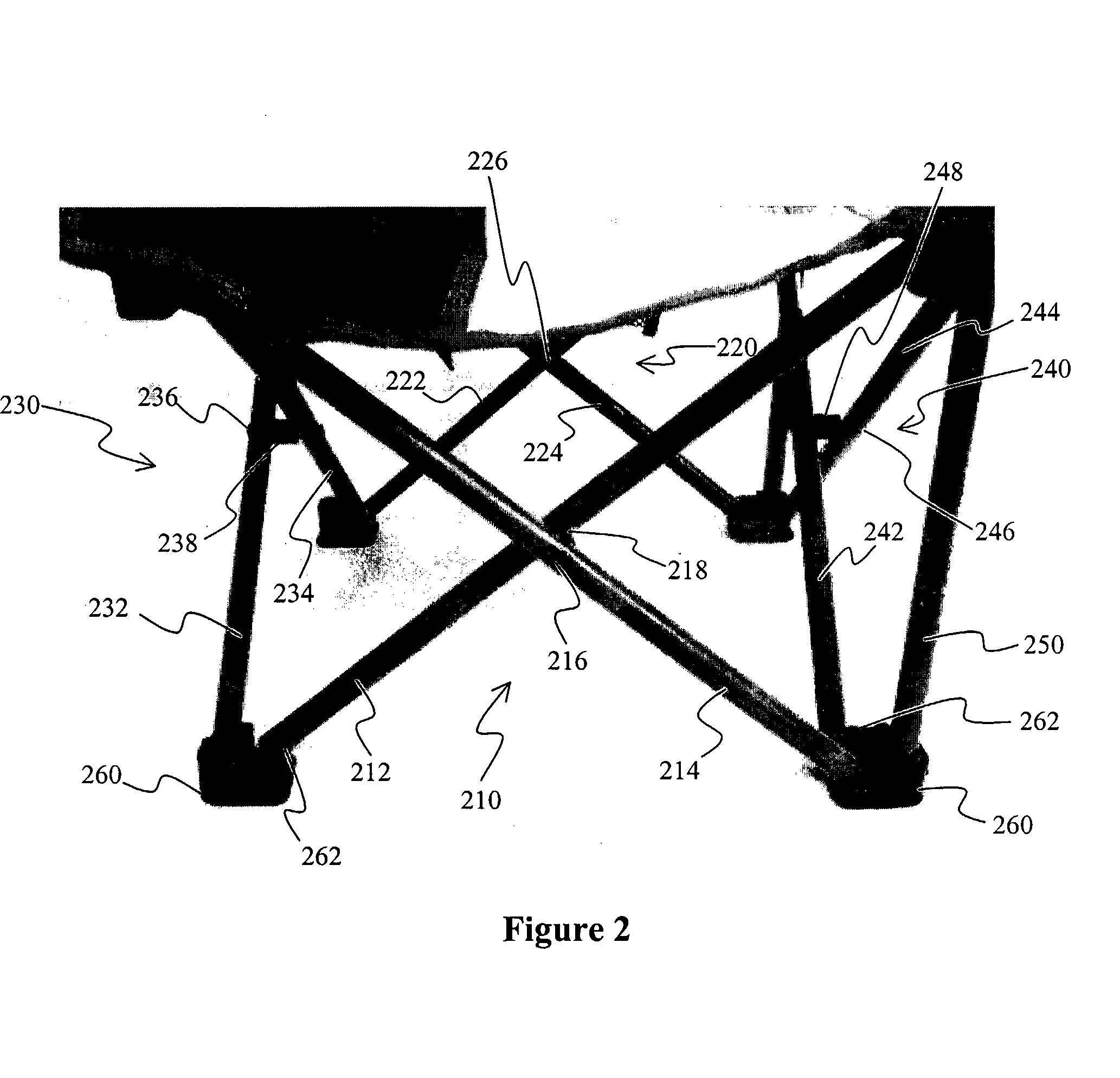

Quad Chair With Safety Spacer

InactiveUS20080231088A1Reduce prevent injuryIncrease distanceElectrical apparatusFoldable chairMostly TrueEngineering

Owner:ZHENG EDWARD

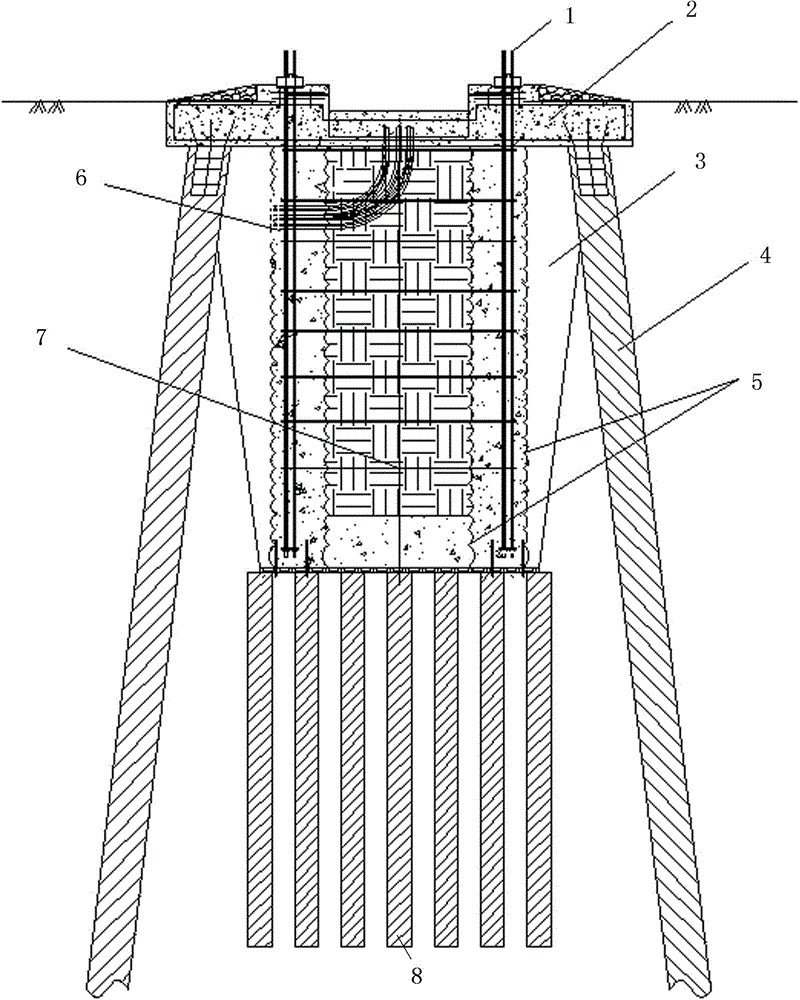

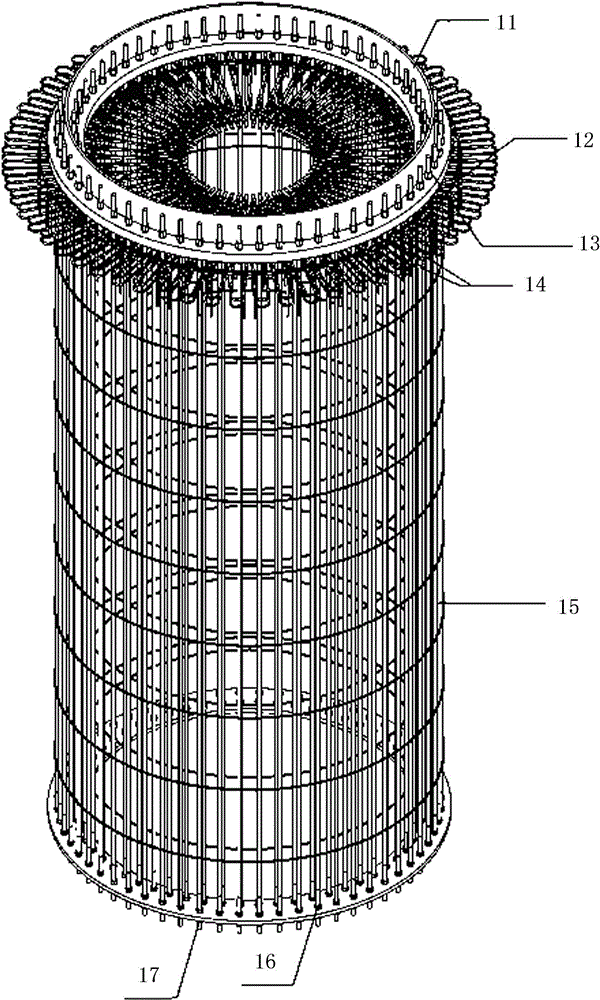

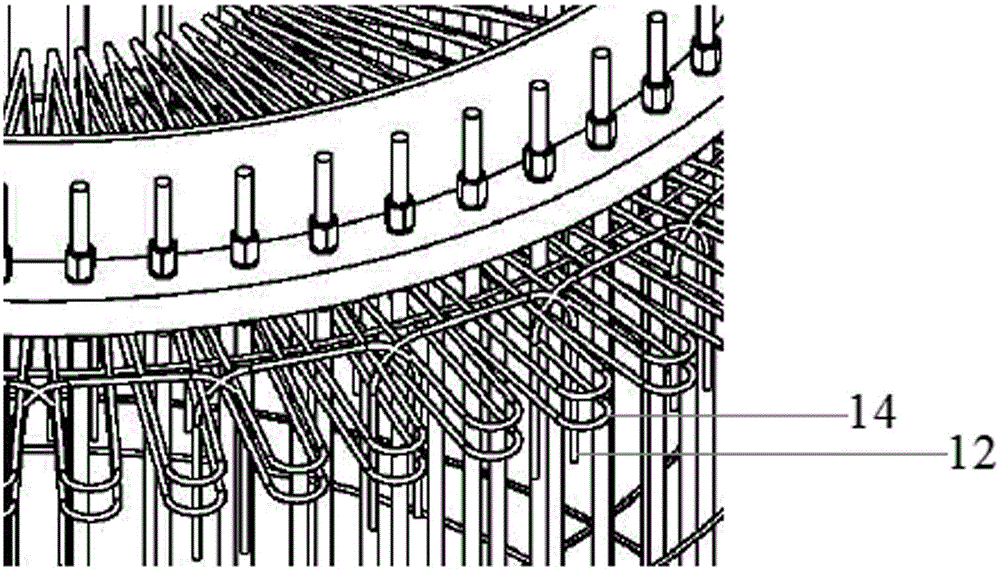

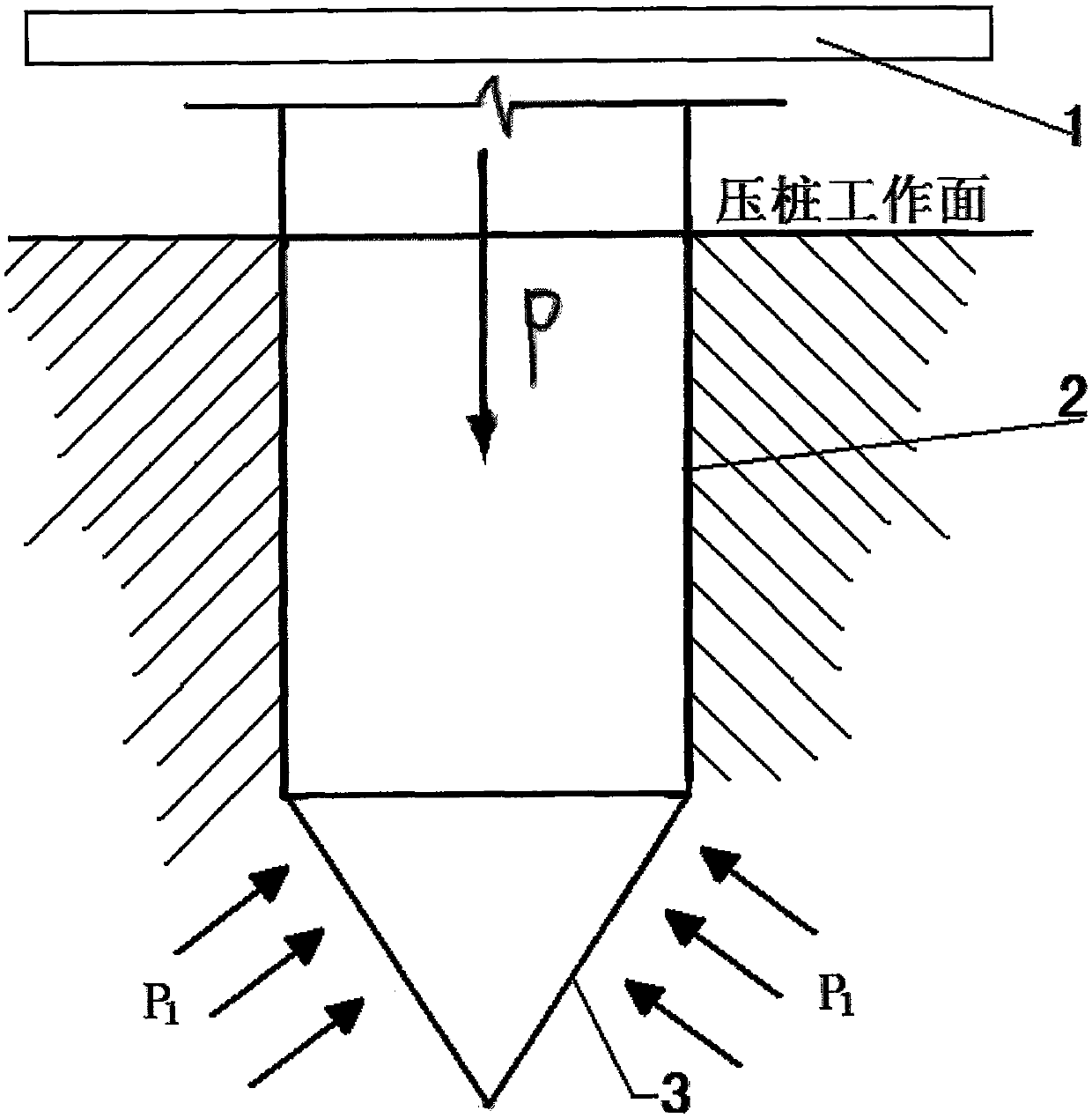

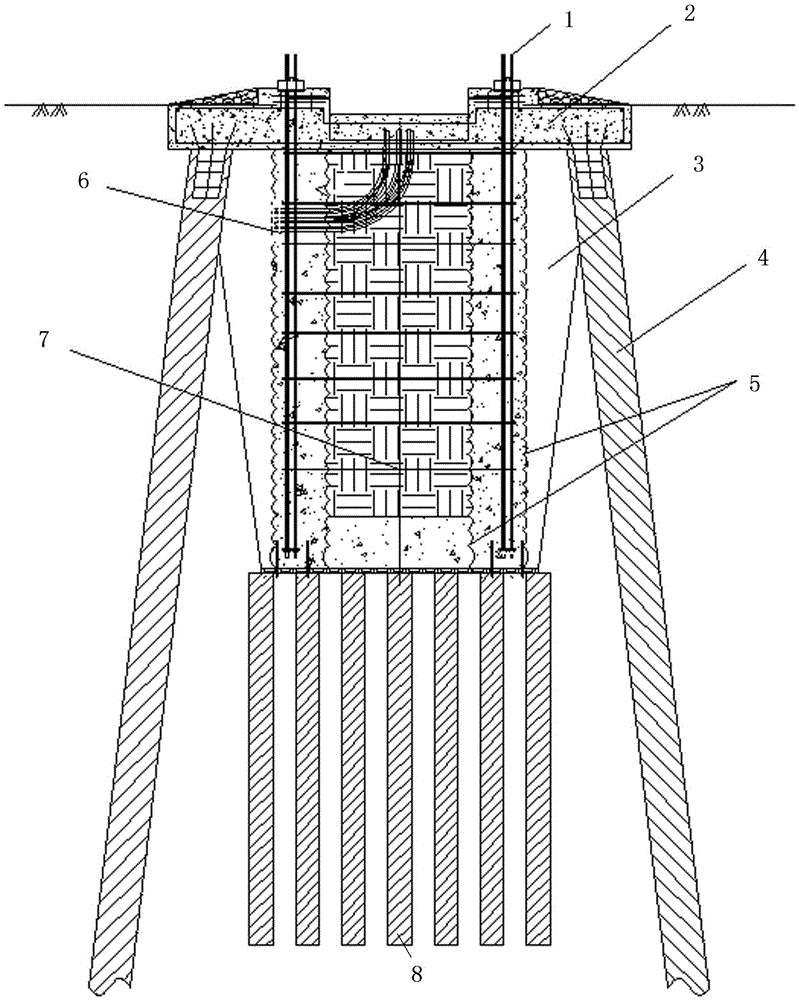

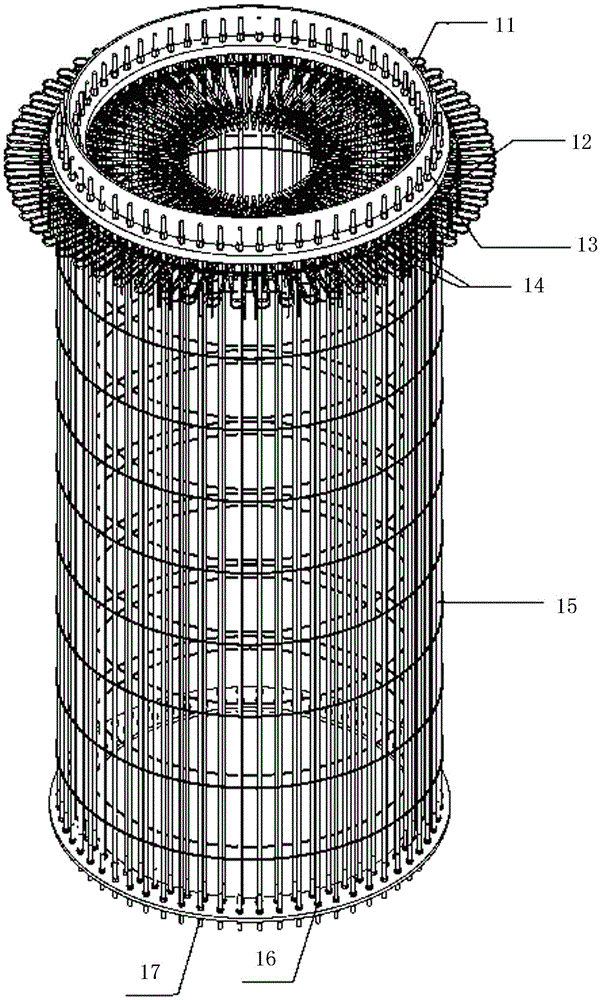

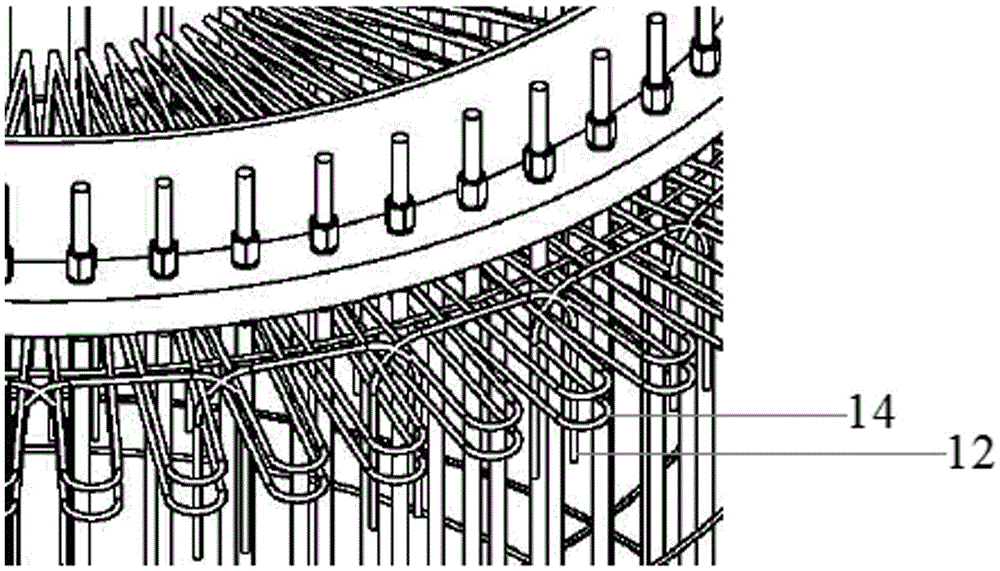

Fan pile pier foundation and construction method thereof

The invention relates to a fan pile pier foundation and a construction method thereof, and discloses a fan pile pier foundation, which comprises a center pier foundation. The fan pile pier foundation is characterized in that an anchor rod pile is arranged at the bottom part of the center pier foundation, 8-12 inclined piles are arranged around the center pier foundation, a concrete pile cap is arranged at the top part of the center pier foundation, a reinforced bar at the top part of each inclined pile is connected with a reinforced bar of the concrete pile cap, the concrete pile cap is cast together with the inclined piles, and a prestressed anchor rod is arranged in the center pier foundation. The fan pile pier foundation has the advantages that the problems of insufficient bearing capacity and loess collapsibility of soft soil are solved; at the premise of meeting the domestic standard requirements, the material is saved, the construction period is shortened, the whole safety, stability and settling control property are sufficiently guaranteed, and the higher practicality is realized for the ground foundation reinforcing and foundation design of wind power generators in eastern coastal areas and northwestern collapsibility loess areas of China.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

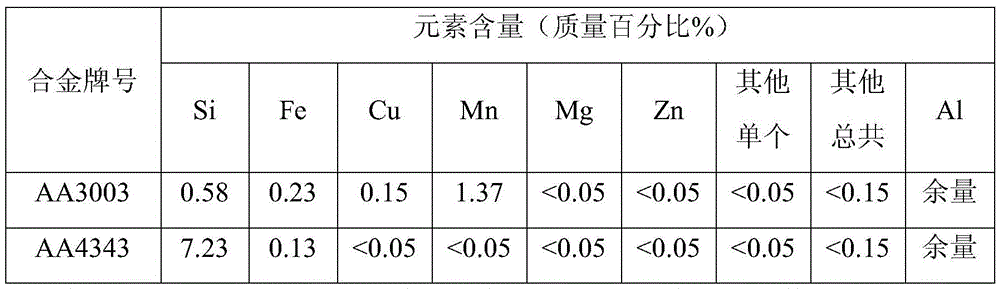

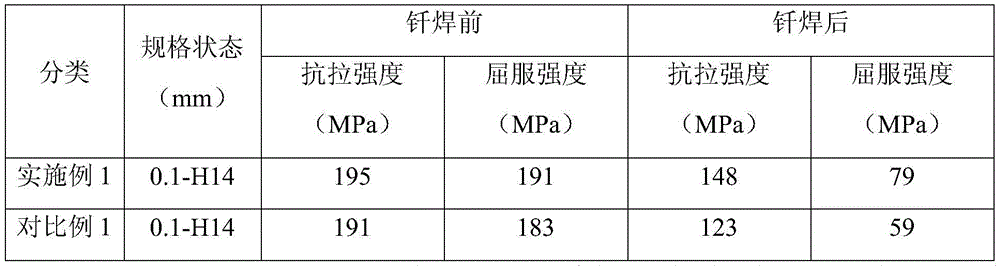

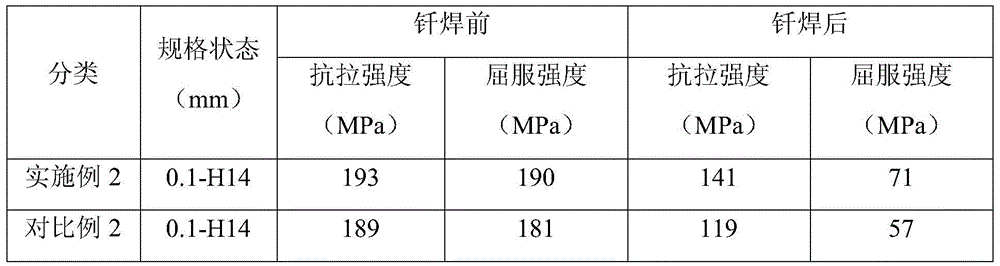

Preparation method of aluminum alloy brazing composite foil for automotive condenser fin

ActiveCN105666052ALow heating temperatureHigh strengthVehicle componentsGrain structureHeating temperature

The invention discloses a preparation method of aluminum alloy brazing composite foil for an automotive condenser fin and belongs to the technical field of aluminum alloy calendaring. The preparation method specifically comprises the steps of preparation of Al-Mn alloy of a core layer, preparation of Al-Si alloy of a brazing cladding layer, and composite rolling according to the Al-Si / Al-Mn / Al-Si combination. According to the preparation method, the low-temperature hot rolling technique is adopted, and no grain refiner is added, so that original grains of the core Al-Mn alloy of the composite foil are made large, and a large long-strip-shaped grain structure can be formed after rolling deformation; a high-angle grain boundary exists so that the number of medium channels through which main elements of the alloy of the brazing cladding layer diffuse and penetrate towards the core alloy after welding can be reduced, and accordingly mutual diffusion of alloy elements is reduced, the strength of the composite foil after brazing is improved, and the probability of collapse of materials is lowered. Meanwhile, the heating temperature of a cast ingot is low, the heating time is short, energy consumption is reduced, and good economic benefits and social benefits are achieved.

Owner:长沙众兴新材料科技有限公司

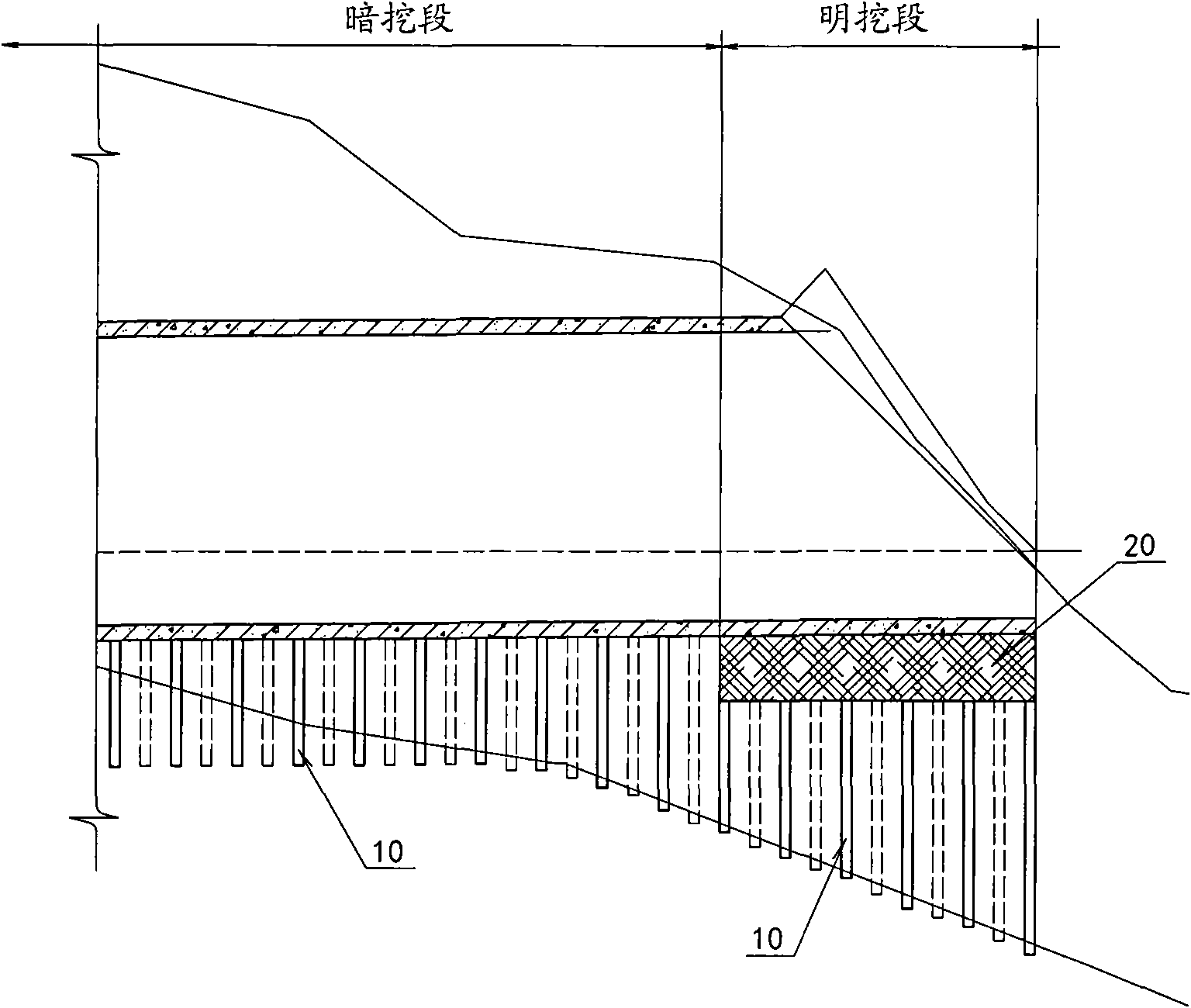

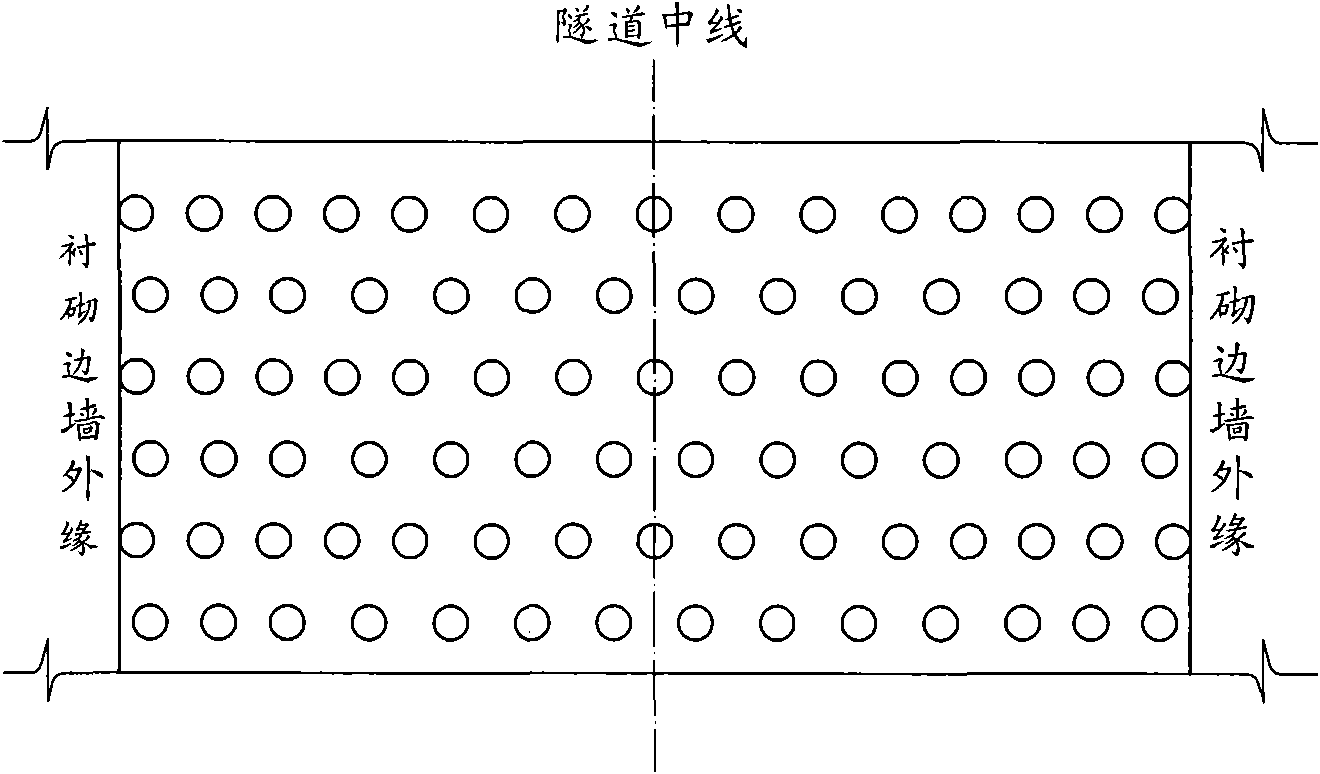

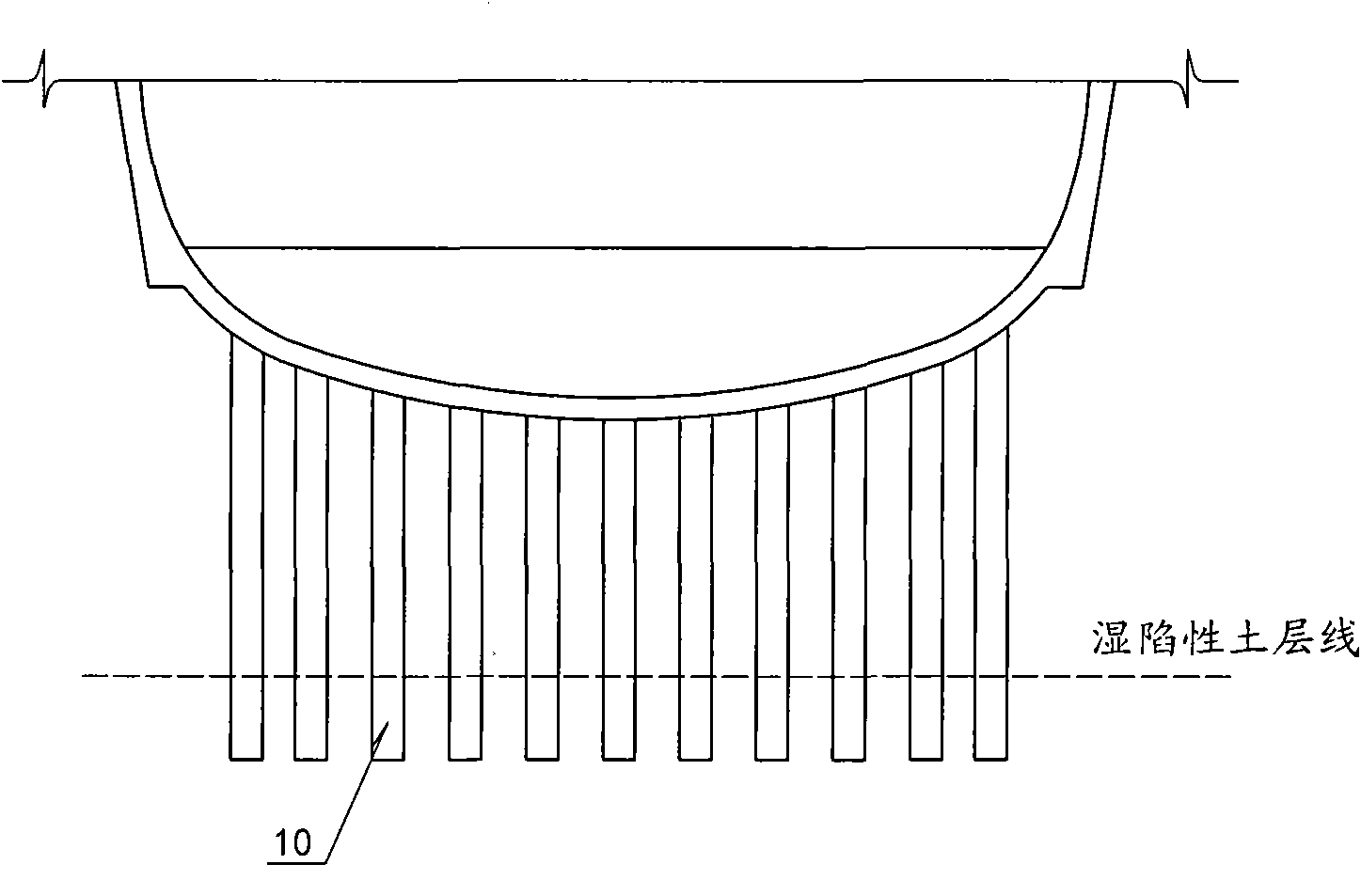

High speed railway collapsible loess tunnel foundation base configuration

InactiveCN101603282AEliminate collapsibilityMeet the requirements of high smoothnessRailway tracksBuilding constructionsSupport surfaceClerestory

The invention discloses a high-speed railway collapsible loess tunnel foundation reinforcement structure, aiming to effectively remove foundation loess collapsibility and meet the requirements on the smoothness of line height by a high-speed railway. The reinforcement structures comprise an open cut section foundation base enforcement structure and a sub-surface excavation section foundation base enforcement structure, which both comprise cement-soil compaction piles (10) arranged in rows along the longitudinal and lateral directions of the foundation in a separating way, wherein, the lower ends of the cement-soil compaction piles (10) pass through the collapsible loess line and enter the old loess stratum. The invention has the beneficial effects of effectively removing foundation loess collapsibility, meeting the requirement on the smoothness of line height by the high-speed railway, and the tunnel initial-stage supporting structure of reinforcement process is safe, which has small influence on stability, tunnel initial-stage supporting surface has no obvious crack, arch crown sinking can be controlled within 1-2mm, level convergence can be controlled within 2-3mm.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Construction method for performing humidification and ultra-high energy level treatment on collapsible loess foundation with height of 25m or more

The invention belongs to the technical field of foundation treatment of civil engineering and particularly relates to a construction method for performing humidification and ultra-high energy level treatment on a collapsible loess foundation with thickness of 25m or more. The construction method comprises the following steps: 101, determining the collapse elimination depth and a remnant collapse control value of the foundation; 102, performing reverse upward calculation from the bottom of a collapse soil layer on a treatment area according to the remnant collapse control value so as to performcollapse accumulation calculation, wherein when calculated collapse is less than or equal to the control value, depth at the moment is needed treatment depth, namely the collapse elimination depth; 103, determining water injection humidification depth; 104, determining the depth of a water injection hole; 105, determining dynamic compaction construction parameters; 106, designing a water injection system pipeline network and designing a water injection process; and 107, performing water injection humidification and ultra-high energy level dynamic compaction test construction, adjusting and optimizing the water injection and dynamic compaction construction parameters again according to a test result, and then, performing large-area application and construction. The construction method provided by the invention exceeds the limit depth of the maximum treatment depth of non-humidification ultra-high energy level dynamic compaction.

Owner:山西机械化建设集团有限公司

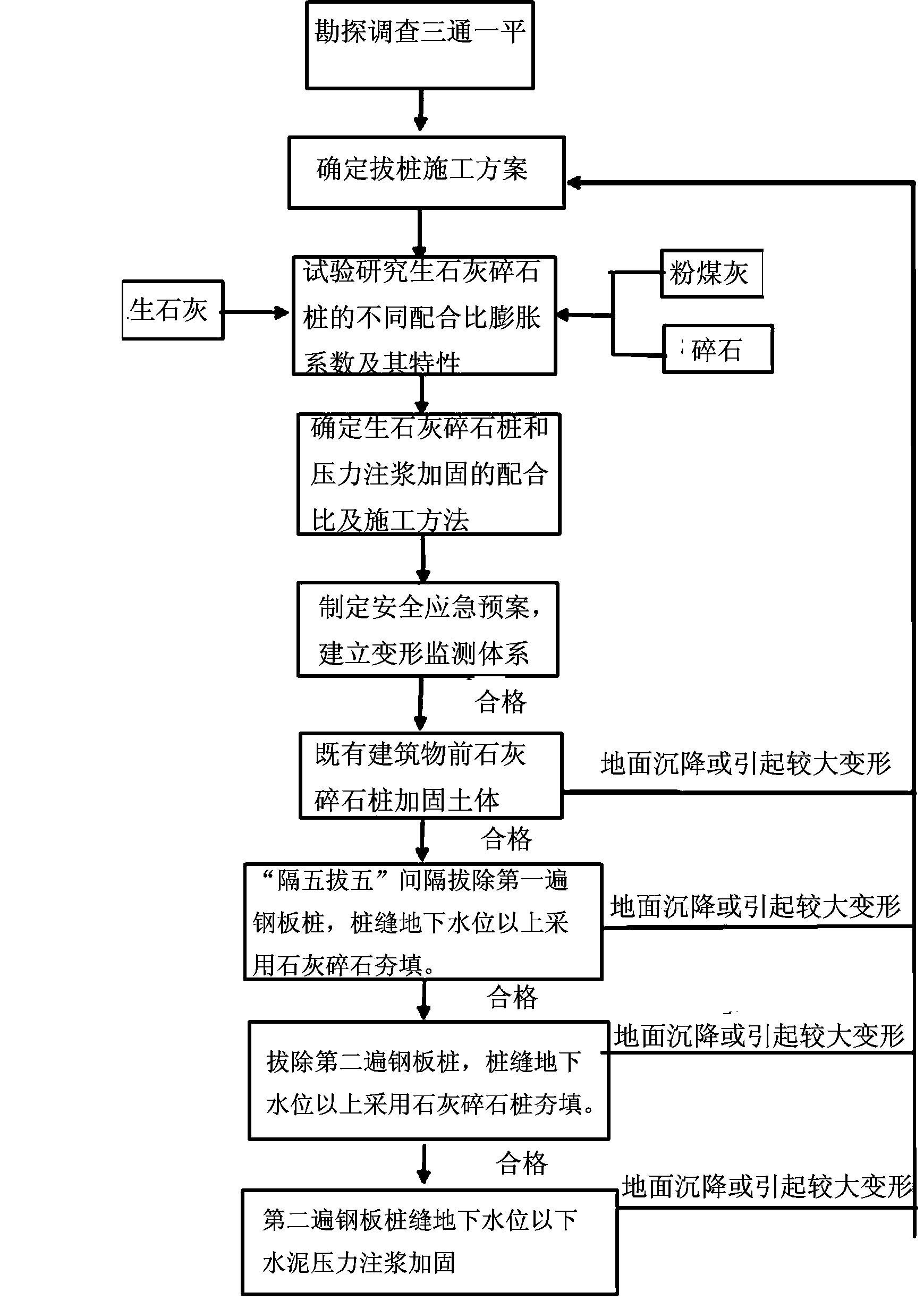

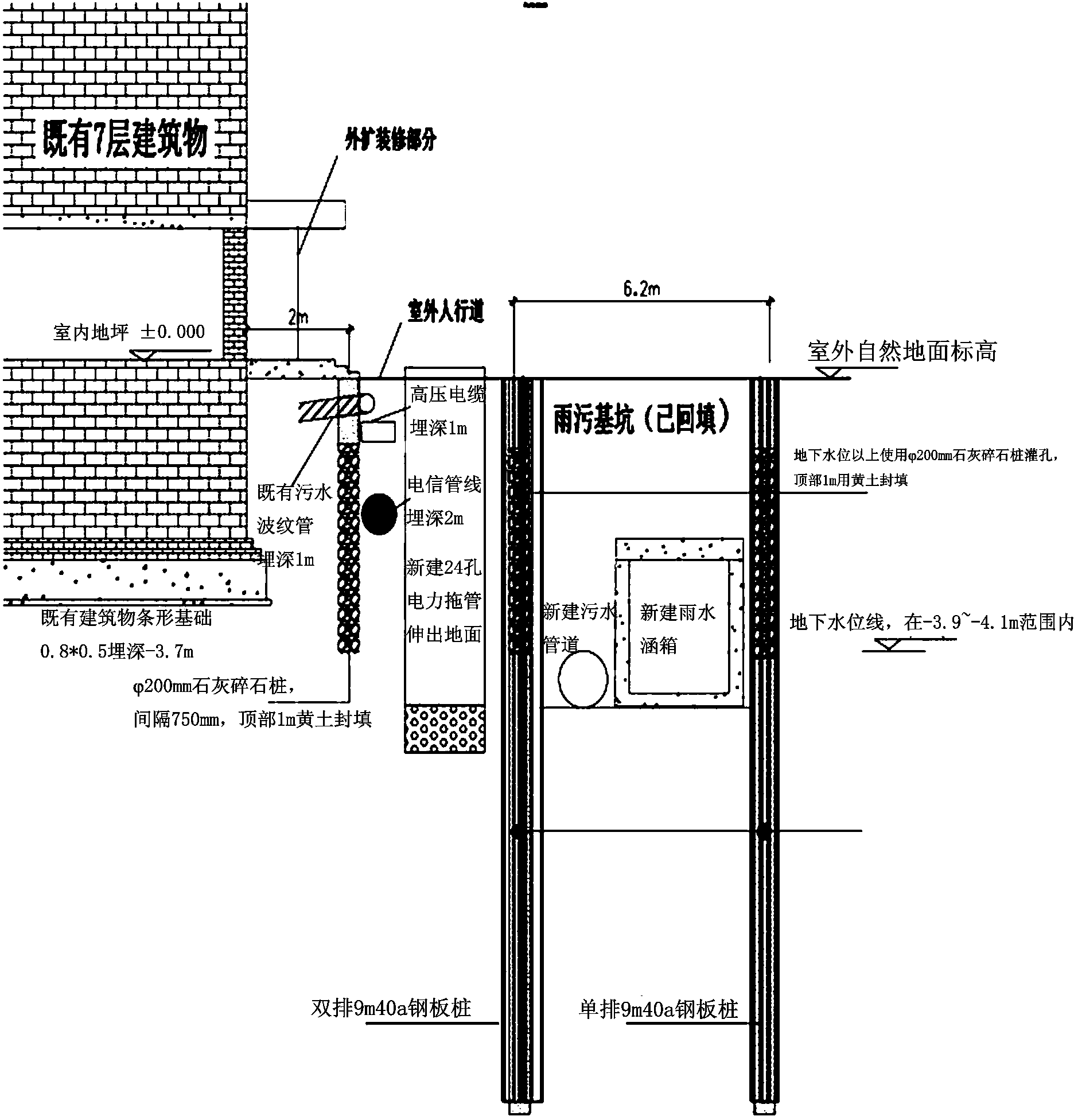

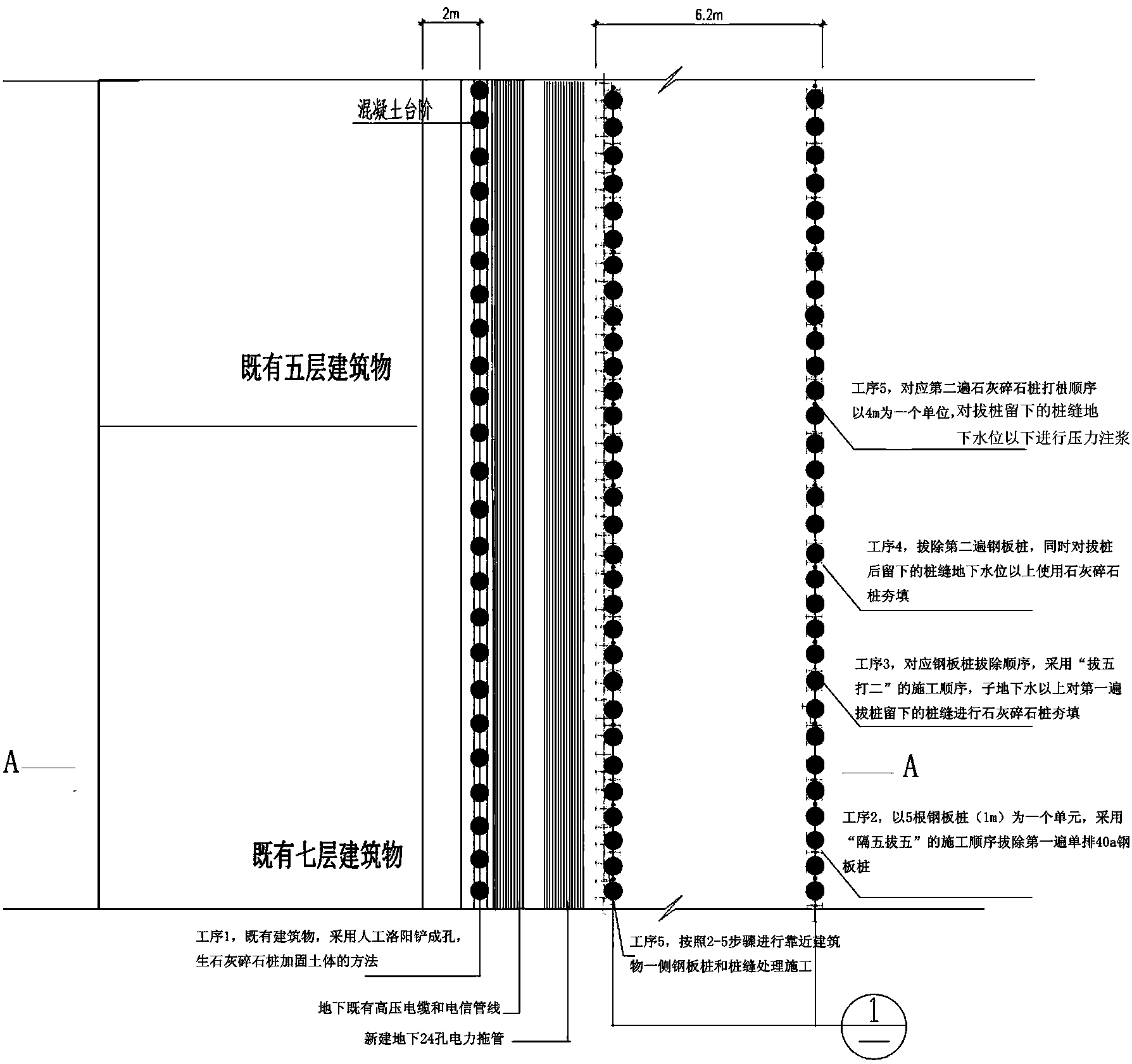

Construction method for pulling out steel sheet piles close to existing buildings

The invention relates to steel sheet pile pulling out technique, in particular to a construction method for pulling out steel sheet piles close to existing buildings, and solves the technical problem that at present, foundations of the existing buildings are prone to influences so as to influence safety of buildings when the steel sheet piles are pulled out in construction of road pipe networks close to the buildings. The construction method for pulling out the steel sheet piles close to the existing buildings is characterized by including the steps: (1) taking five steel sheet piles as a unit to pull out the steel sheet piles; (2) using a 'pulling out five and piling two' construction method, namely piling two lime gravel piles when every five steel sheet piles are pulled out, for punning and filling pile seams, above underground water level, left after first-time pulling out; (3) pulling out remnant steel sheet piles for the second time, and using the 'pulling out five and piling two' construction method for treatment of the pile seams left after second-time pulling out of the steel sheet piles. The method is safe, reliable, simple in construction operation, quick in construction, effective in reinforcement, low in manufacturing cost, low in environmental constraint and low in influences on the existing buildings and pipelines.

Owner:CHINA RAILWAY SIXTH GROUP +1

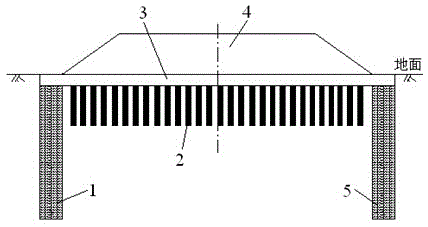

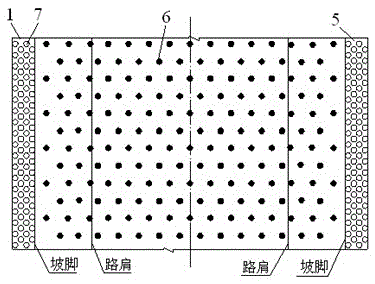

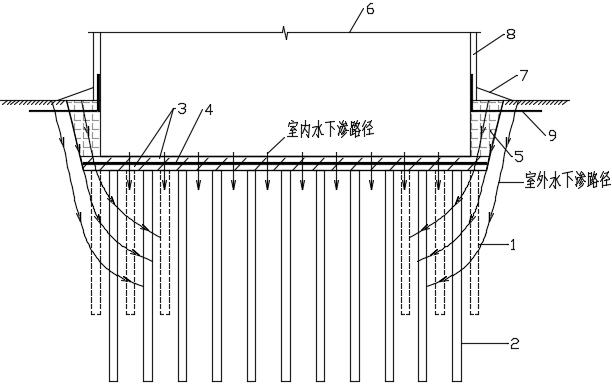

Novel long and short pile foundation treatment structure of collapsible loess area and construction method

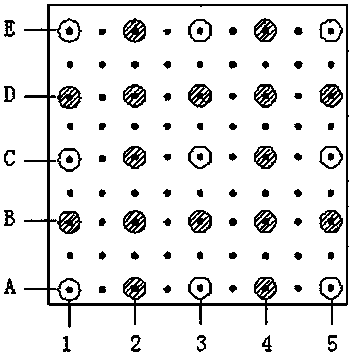

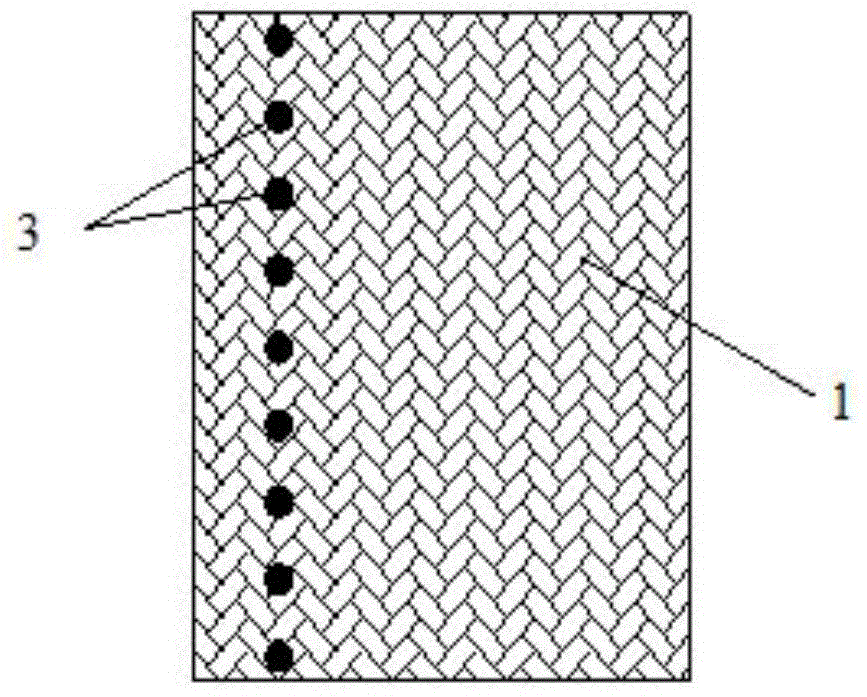

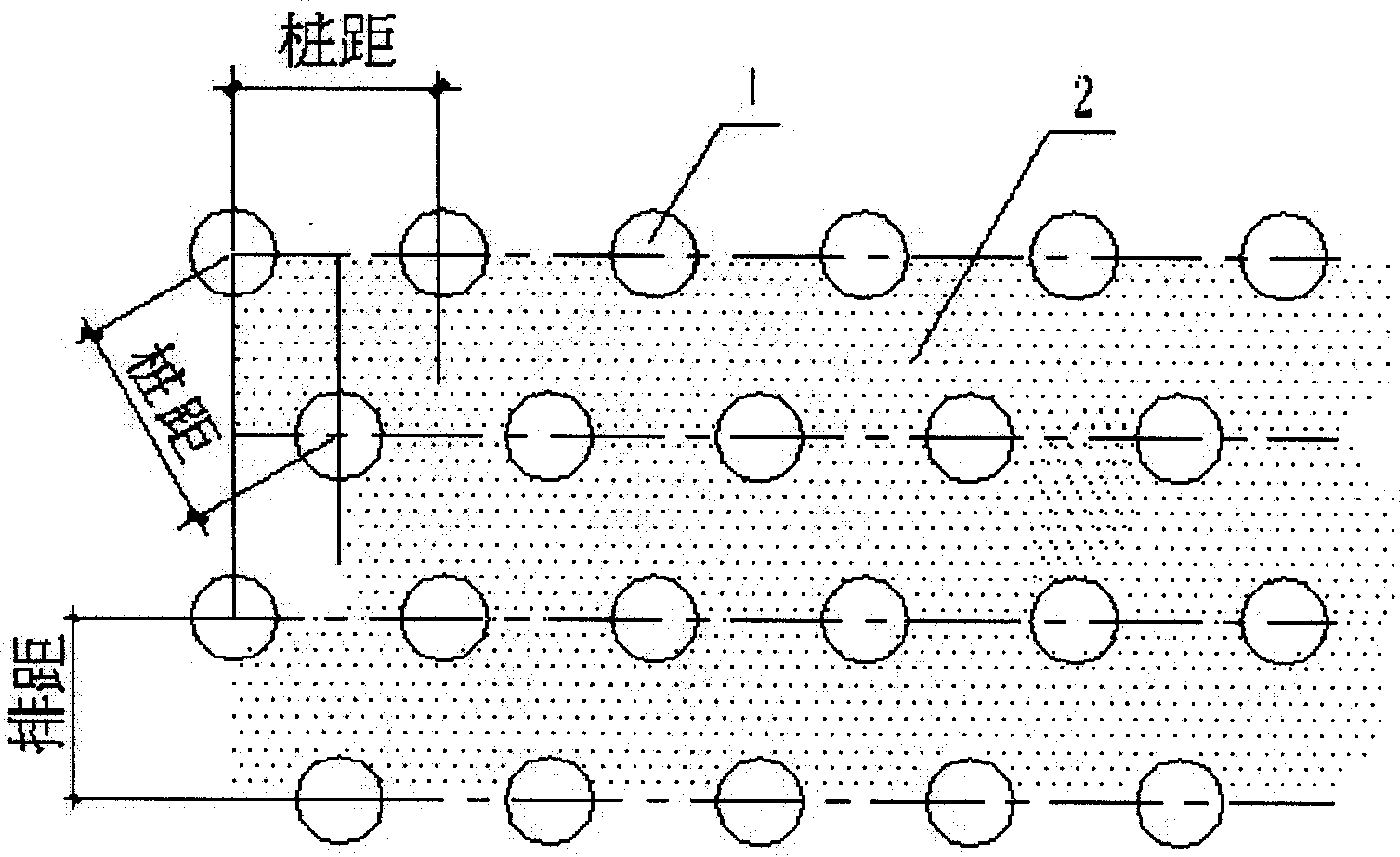

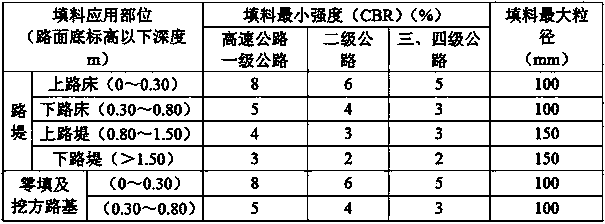

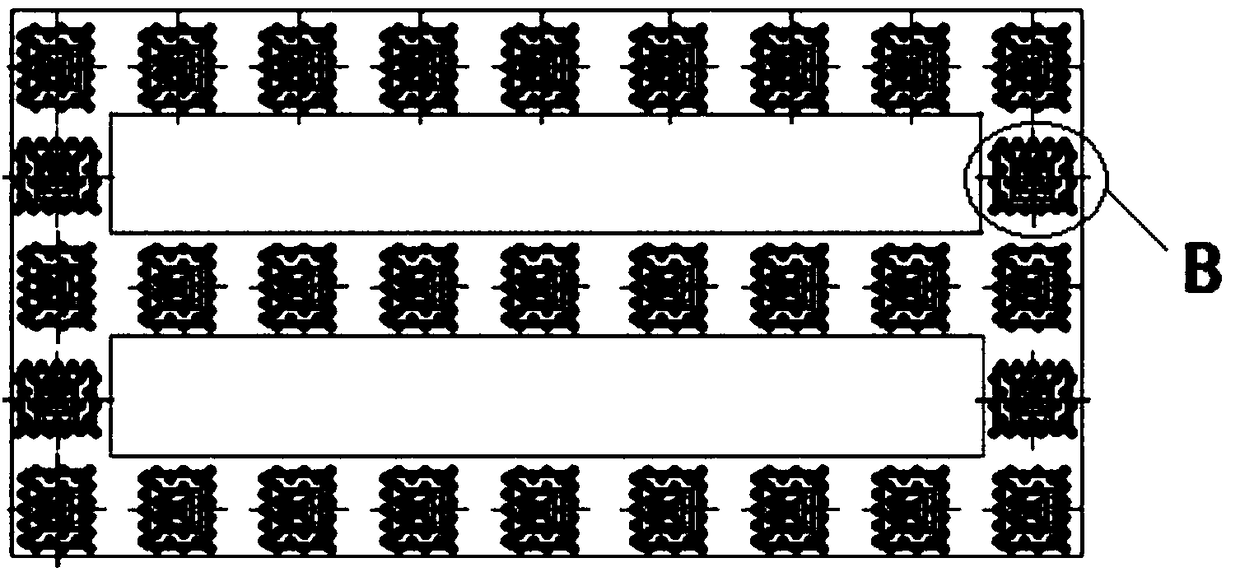

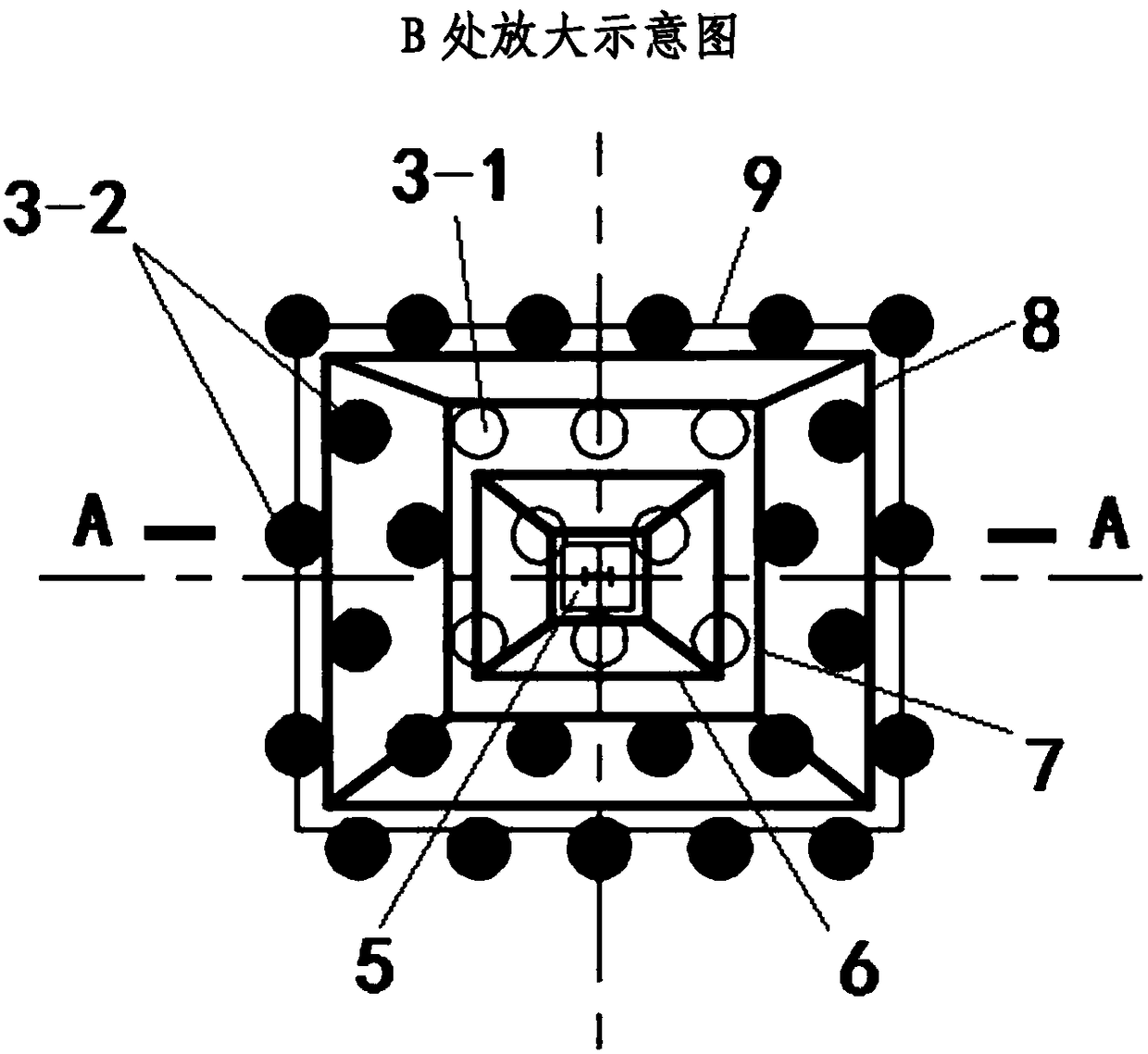

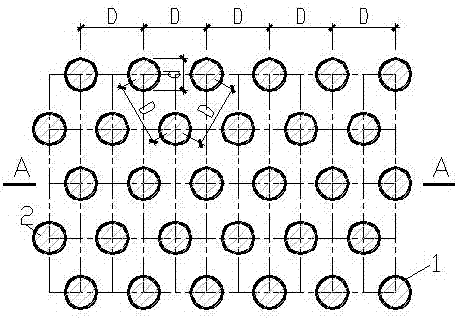

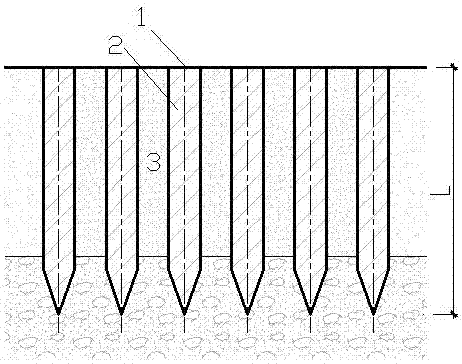

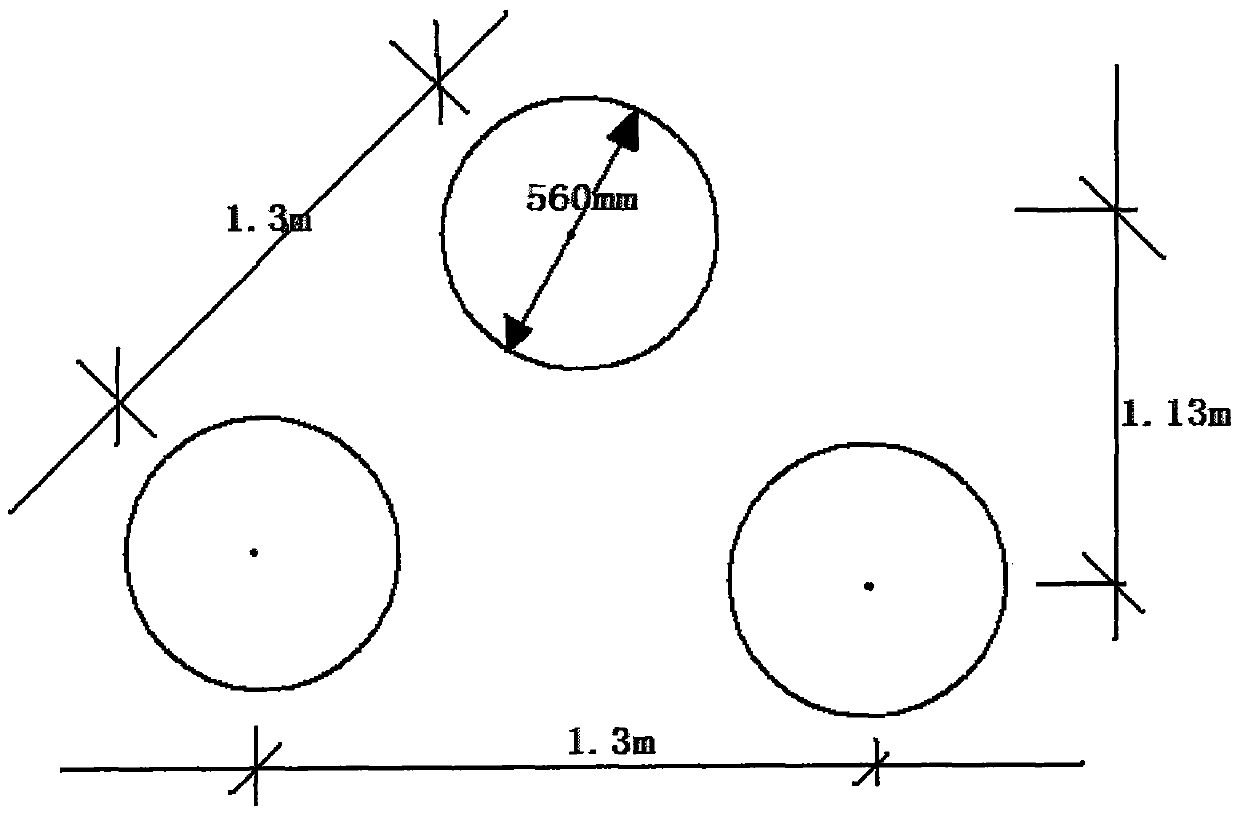

ActiveCN105464068AEliminate collapsibilityImprove the bearing capacity of the foundationSoil preservationQuincunxSubgrade

The invention relates to a novel long and short pile foundation treatment structure of a collapsible loess area and a construction method. The structure comprises two rows of waterproof curtains and a plurality of rows of reinforcing row piles between the waterproof curtains. The interior of each of the two rows of waterproof curtains and one slope toe of a roadbed are located in the same vertical plane. Each waterproof curtain is composed of four rows of compact long piles, wherein every three adjacent compact long piles are located at the three vertexes of an equilateral triangle respectively. The reinforcing row piles are composed of a plurality of compact short piles, and the compact short piles are arranged in a quincunx shape. The waterproof curtains and the reinforcing row piles are covered with a waterproof cushion layer. A soil sample is subjected to indoor soil testing, and the height of the roadbed is determined; leveling, surveying and setting out are carried out; and the waterproof curtains and the reinforcing row piles are built on the outer sides of the slope toes of the roadbed according to the existing construction technology, the waterproof cushion layer is built on the waterproof curtains and the reinforcing row piles, and construction of the foundation treatment structure is completed. The foundation treatment structure is used in highway and railway projects of the collapsible loess area, the requirements of the projects of the roadbed for the bearing capacity and deformation of the foundation are met, the construction period is shortened, the project cost is reduced, and line operation safety is guaranteed.

Owner:NORTHWEST RES INST CO LTD OF C R E C

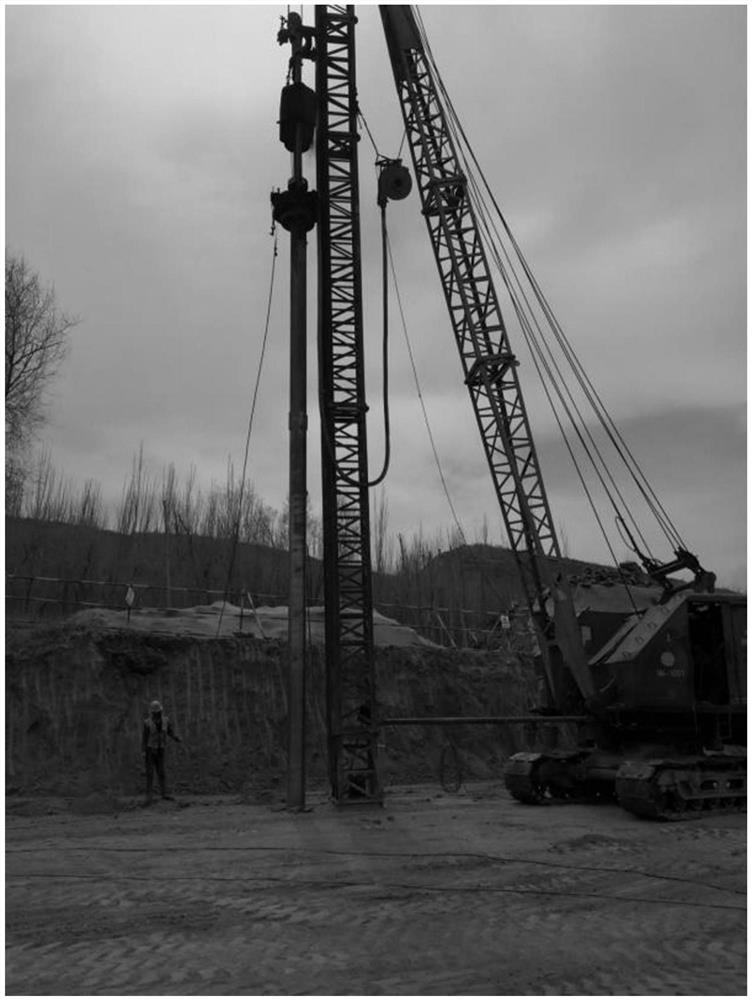

Boring-tamping lime-soil compacting pile construction process

InactiveCN1676762AConstruction noise is smallReduce vibrationBulkheads/pilesSoil preservationUltimate tensile strengthPile driver

The invention refers to a construction technique, which has a good effect for the drilling ram enlarge the gray soil and the stake. The concrete process is that perching the drill, vertical revising, drilling, milling the material, perching the pile driver, empty ram, filling in material, covering the top and moving the pile driver. The technique has the merits that it having small noisy, light vibration, can avoid the damp sinking efficiently, has a strong stake, the base can bear more weight, has the low cost of the project, project can be constructed in the city and has a broader application among the damp and sink loess areas.

Owner:祁春伟

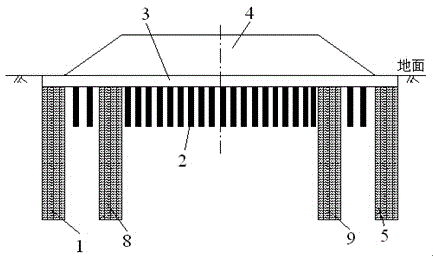

Collapsible loess wellpoint presoaking dynamic compaction replacement method

InactiveCN105735232AEliminate collapsibilityShorten the construction periodSoil preservationAfter treatmentDynamic compaction

The invention discloses a collapsible loess wellpoint presoaking dynamic compaction replacement method, and belongs to a deep collapsible loess foundation treatment method. The method comprises the steps that firstly, the treatment range and the treatment depth of a foundation are determined; secondly, within the foundation treatment range, a cushion material is laid on the whole surface; thirdly, according to the foundation treatment depth, a wellpoint hole is drilled out, a presoaking wellpoint pipe is vertically arranged in the wellpoint hole according to presoaking parameters, and water-pervious holes are evenly distributed in the wall of the pipe stretching into the foundation; fourthly, the presoaking wellpoint pipe is connected with a water injection pipe, and the foundation is subject to presoaking treatment; fifthly, the foundation is subject to dynamic compaction replacement treatment; and sixthly, the foundation quality is tested and is subject to acceptance check. The method is easy and convenient to construct, large in treatment depth, short in construction period and capable of effectively removing collapsibility of the deep collapsible loess foundation, and the bearing force of the foundation obtained after treatment is high.

Owner:HOHAI UNIV

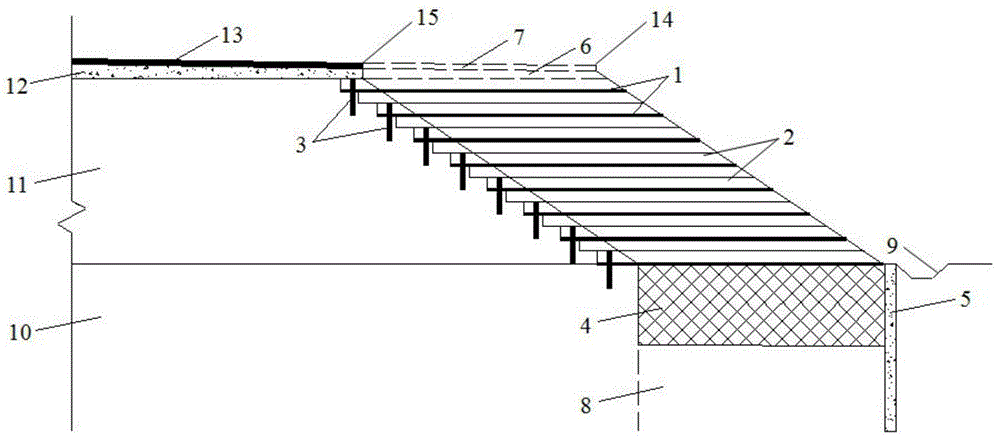

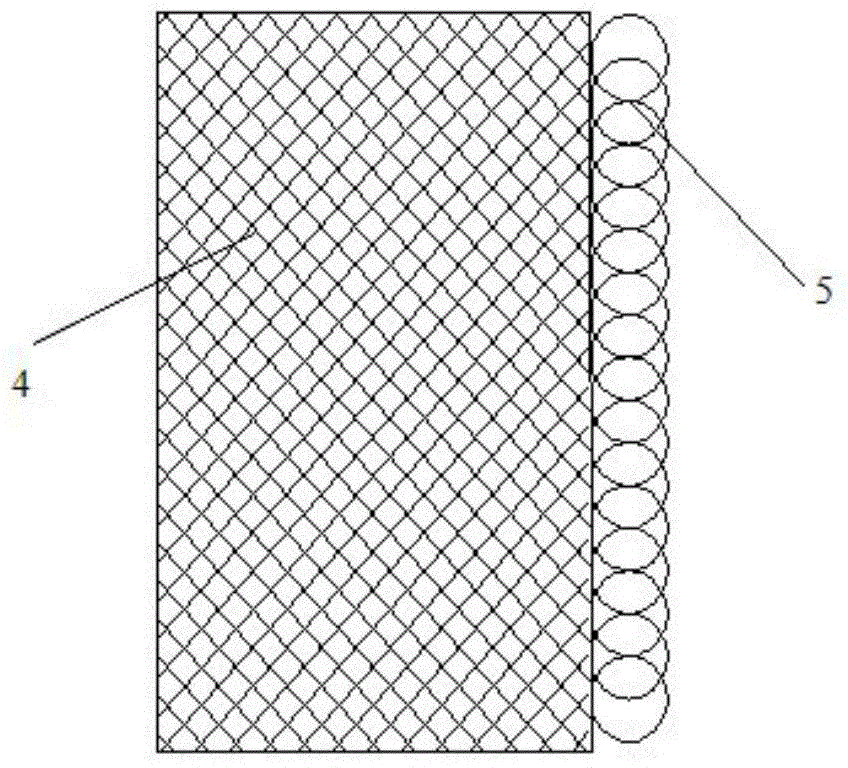

Road widening system and road widening method for collapsible yellow earth foundation layer

The invention discloses a road widening system and a road widening method for a collapsible yellow earth foundation layer. The road widening system for the collapsible yellow earth foundation layer comprises a collapsible yellow earth foundation layer, a lime earth changing and filling layer, filling layers, geogrids, a water stable layer of a to-be-widened road, a pavement of the to-be-widened road, micro rigid piles and a compacted cement soil pile wall. The collapsible yellow earth foundation layer, the lime earth changing and filling layer, the filling layers, the water stable layer of the to-be-widened road and the pavement of the to-be-widened road are sequentially distributed in a laminar manner from bottom to top; the compacted cement soil pile wall penetrates through the lime earth changing and filling layer and is longitudinally inserted into the collapsible yellow earth foundation layer; the one or more layers of geogrids are longitudinally paved in the filling layers; the micro rigid piles penetrate through the geogrids and are longitudinally inserted into an original embankment. The road widening system and the road widening method for the collapsible yellow earth foundation layer aim at implementing road widening for the collapsible yellow earth foundation layer, and the road widening system is reasonable in structural mechanical property, good in integrality and controllable in quality.

Owner:山西省交通科技研发有限公司

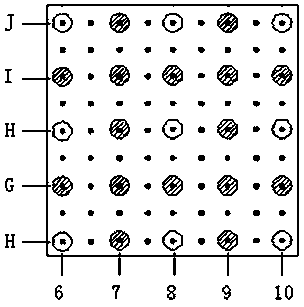

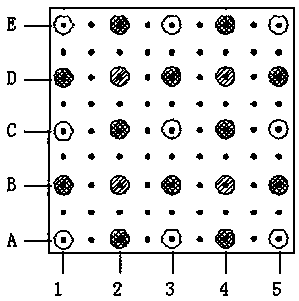

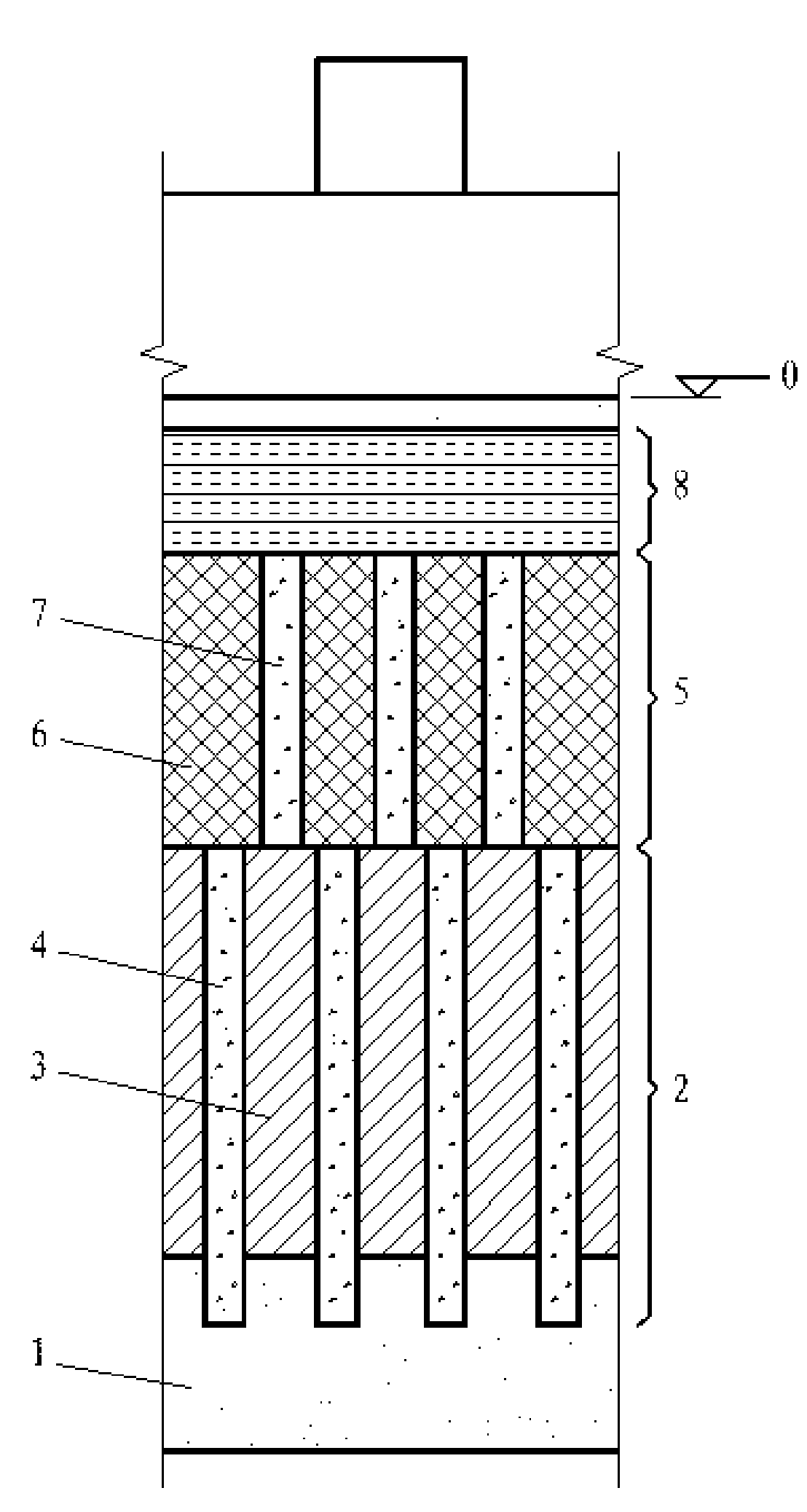

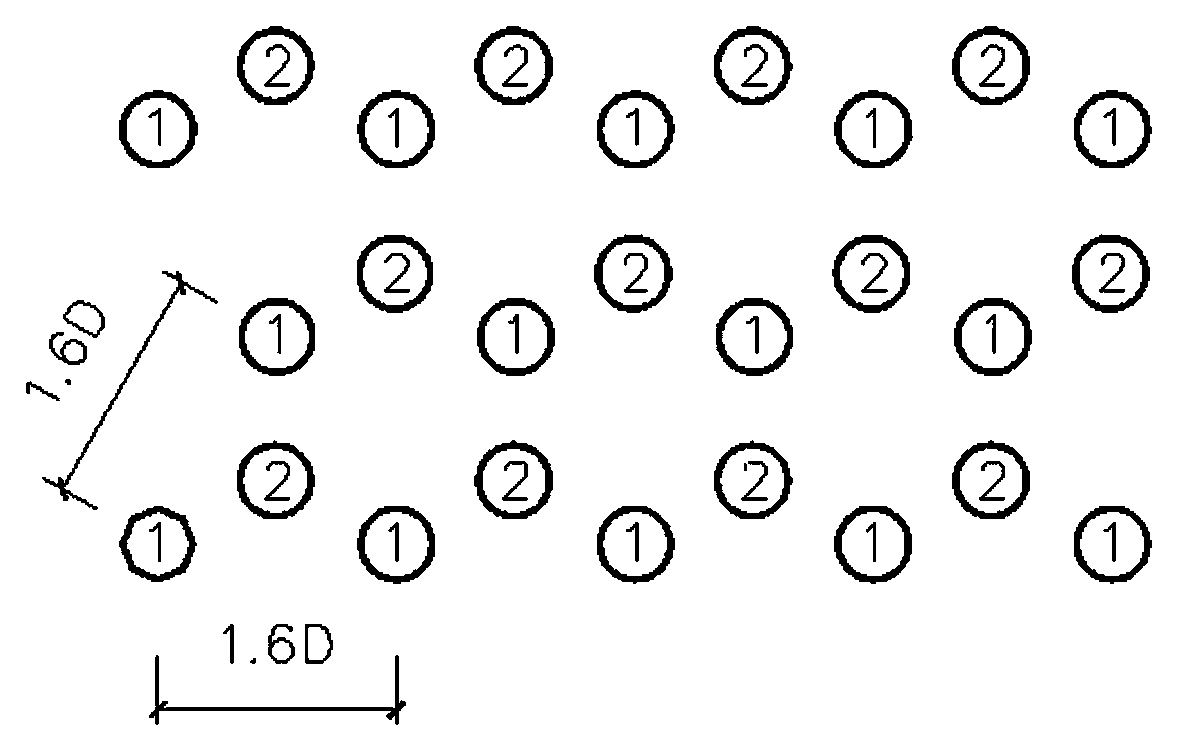

Vibration process of eliminating wet foundation falling for CFG pile

InactiveCN1740457AImprove bearing capacityEliminate collapsibilityBulkheads/pilesSoil preservationIsoetes triquetraBearing capacity

The present invention discloses vibration CFG pile process of eliminating wet foundation falling. The process includes first determining the vibration CFG pile positions in wet falling loess foundation with piles in equiangular triangle arrangement, the subsequent determining the pile interval equal to 3-5 times pile diameter, and final constructing piles in vibration sunken tube deposition method. The present invention can raise the bearing capacity of foundation and eliminating wet foundation falling, and has short construction period and low cost.

Owner:GUIYANG AL-MG DESIGN & RES INST

Secondary processing method of collapsibility foundation in loess region and composite foundation structure

InactiveCN101597897AEliminate collapsibilityImprove carrying capacityBulkheads/pilesSoil preservationEngineeringBearing capacity

The invention discloses a secondary processing method of collapsibility foundation in loess region and a composite foundation structure. The method comprises the following steps: a foundation is dug on an area, and the depth of the foundation is the thickness of collapsibility loess under foundation and the depth which can be processed by a lime-soil compacted column; the first-time lime-soil compacted column construction is carried out with a land extrusion method; after construction is finished and qualified by tests, original soil dug out is backfilled on the lime-soil compacted column foundation on the lower layer and is tamped, and the backfilling height is 0.6-1.6 meters below building foundation base elevation; then, the second-time lime-soil compacted column construction is carried out on the backfilled soil with the land extrusion method; after second construction is finished and qualified by tests, the lime-soil subcrust construction is carried out on the second-time lime-soil compacted column foundation, the thickness is 0.5-1.5 meters, and a complete composite foundation is formed. Under the condition of ensuring foundation bearing capacity, the invention can finish foundation processing construction by sections, and solves the problems that the existing construction machines can not finish foundation processing in which the construction depth is beyond mechanical construction ability thereof.

Owner:GUIYANG AL-MG DESIGN & RES INST

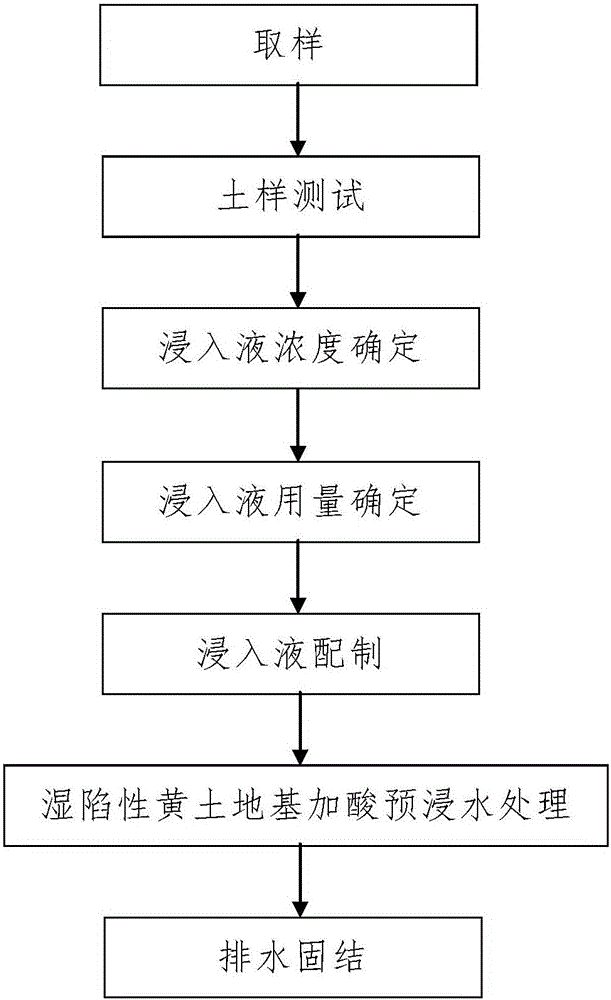

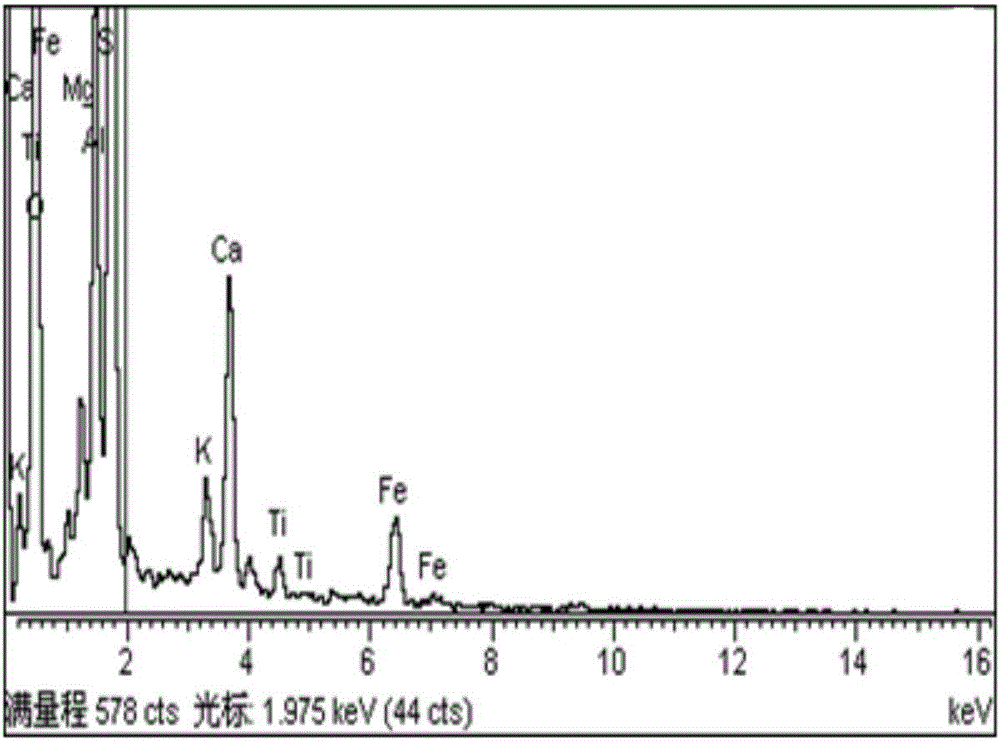

Method for treating collapsible loess foundation using acid-adding presoaking method

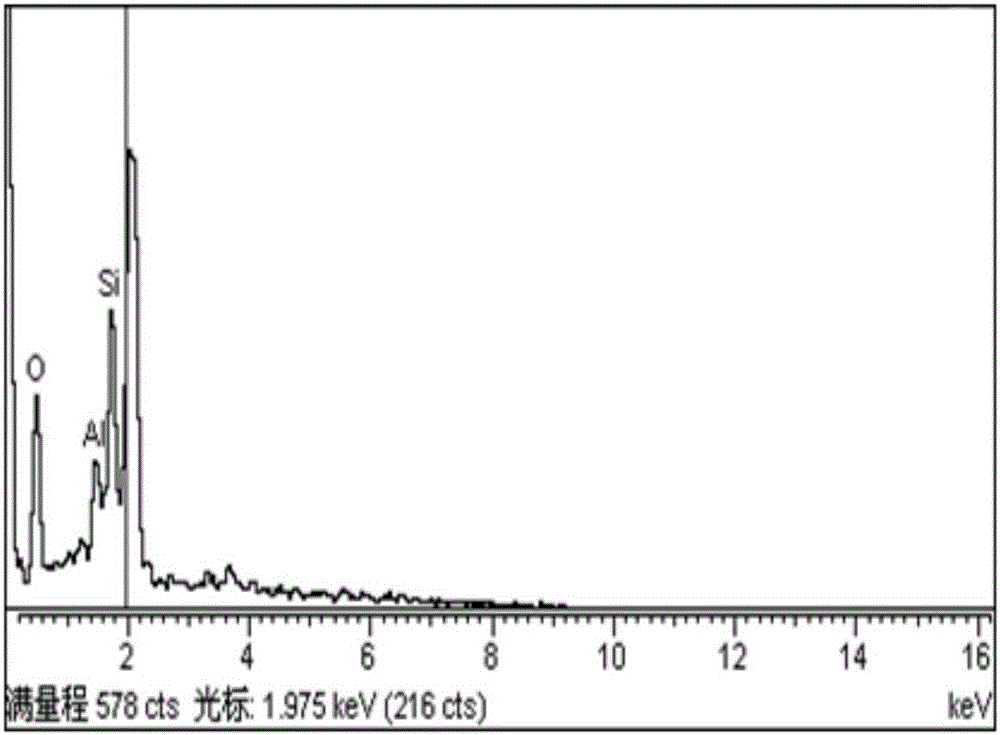

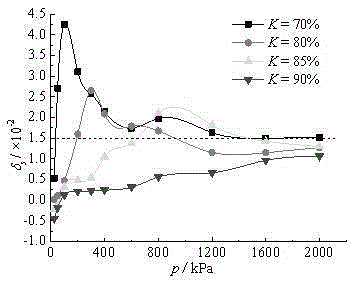

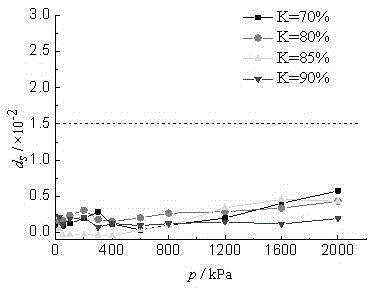

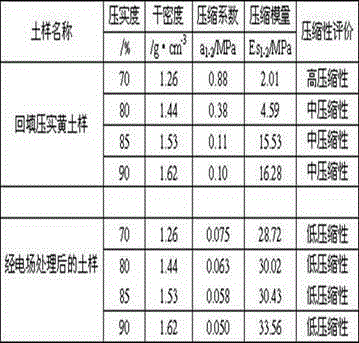

ActiveCN106049417AThe method steps are simpleReasonable designEarth material testingSoil preservationSoil scienceAqueous solution

The present invention discloses a method for treating a collapsible loess foundation using an acid-adding presoaking method. The method comprises a first step of sampling, which refers to using a soil sampler to cut to obtain a soil sample from a collapsible loess foundation to be treated; a second step of soil sample testing; a third step of determination of the concentration of a soaking liquid; a fourth step of determination of the usage amount of the soaking liquid; a fifth step of preparation of the soaking liquid according to the determined concentration and usage amount, the soaking liquid being an acid-added aqueous solution and being an acid solution formed by uniformly mixing water with acid; a sixth step of acid-adding presoaking treatment of the collapsible loess foundation, which refers to continuously adding the soaking liquid into the collapsible loess foundation to be treated, the adding time being 3-15 days; and a seventh step of drainage consolidation, which refers to carrying out drainage consolidation treatment on the collapsible loess foundation to be treated by using a drainage consolidation method. The method provided by the invention is simple in step, reasonable in design, convenient to construct, and excellent in using effect; and by using the method, a treatment process of the collapsible loess foundation can be easily, conveniently and rapidly completed, loess collapsibility can be effectively eliminated, the strength of the loess can be effectively enhanced, and the bearing capacity of the foundation can be raised.

Owner:张耀

Pressure hydro consolidation method of airtight vacuum membrane for loess foundation in collapsibility

InactiveCN1873108AEliminate collapsibilityEngineering practicabilitySoil preservationEngineeringLoess

A method for consolidating collapsible loess foundation includes laying out water-submerging holes on construction job site, sealing site by seal diaphragm and vacuuming sealed site to let soil be consolidated after is water fully injected in said holes.

Owner:CHINA SIXTH METALLURGICAL CONSTR

Treatment method for improving collapsible loess foundation

ActiveCN105421333AHigh strengthSimple construction processSoil preservationMass ratioMixed materials

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

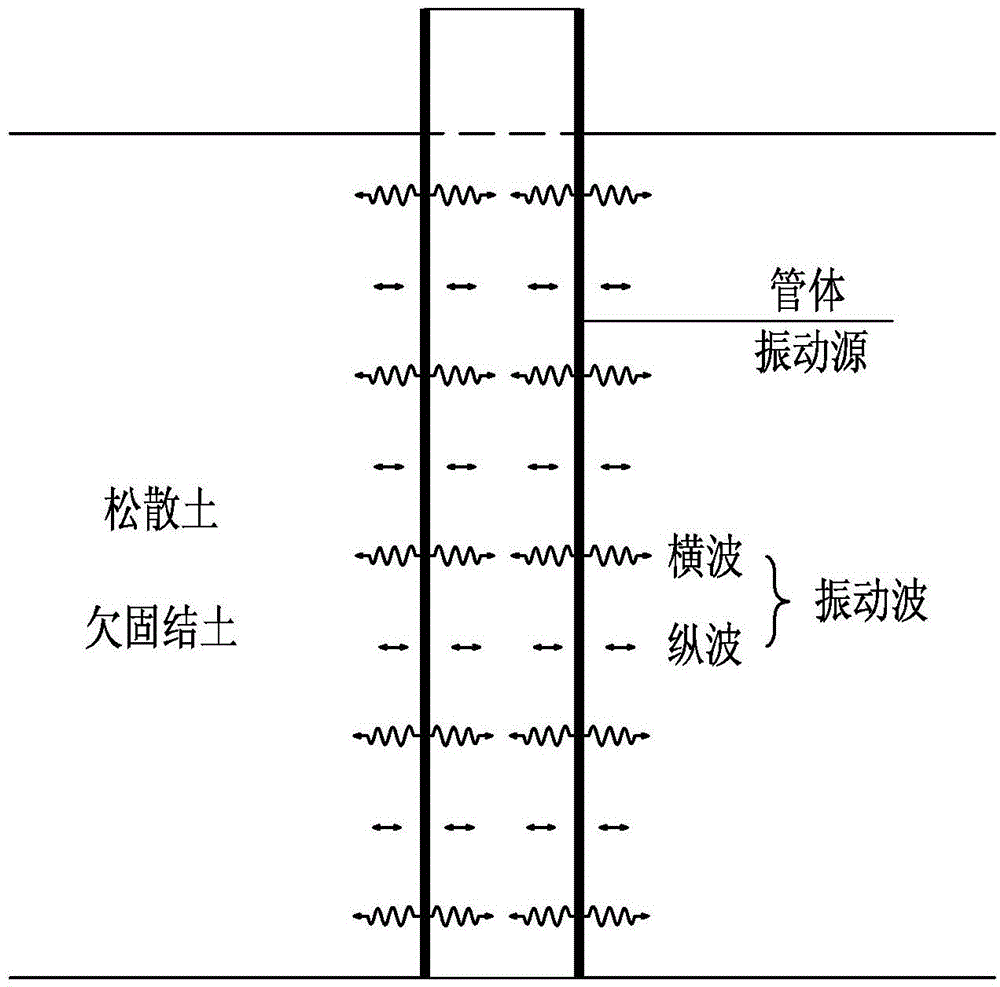

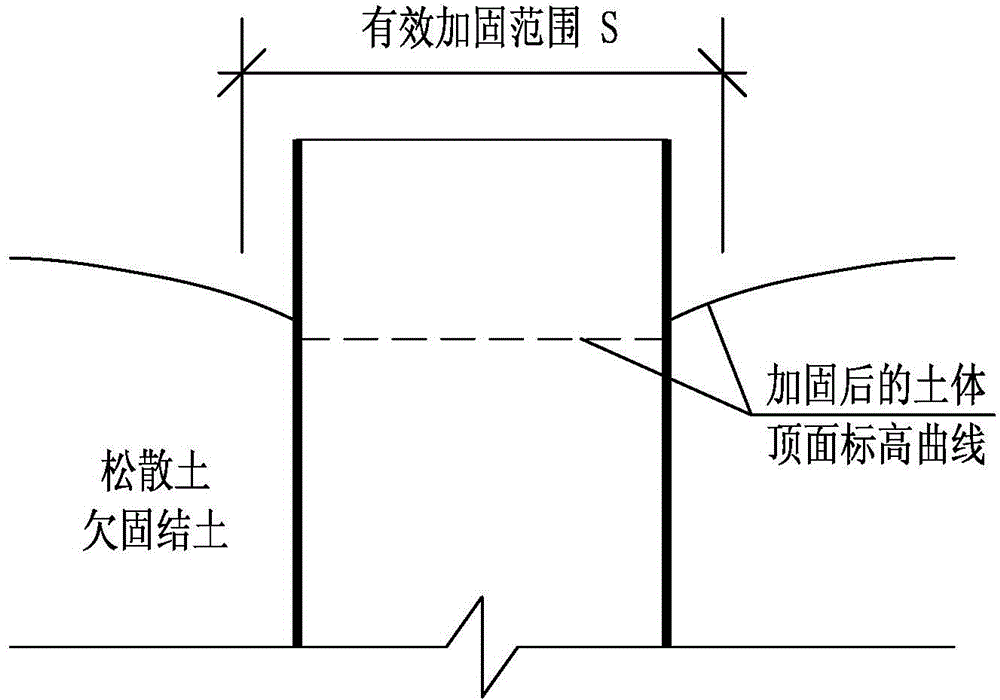

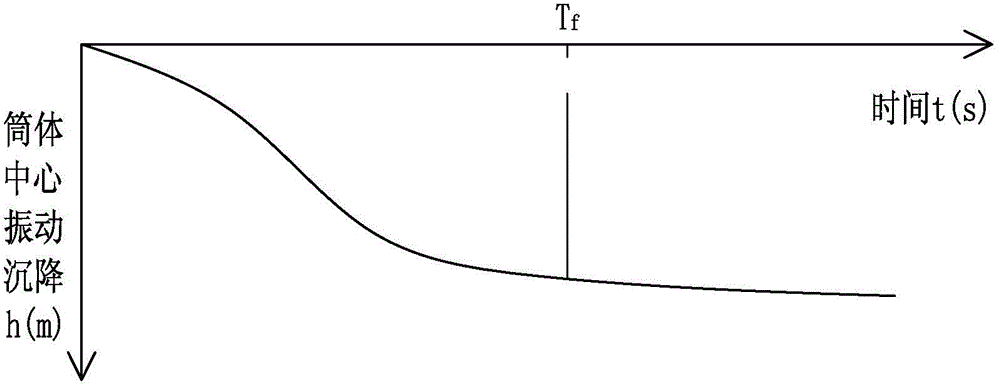

Tube sinking and excitation compacting method

ActiveCN104790373AEliminate collapsibilityImproves foundation stabilitySoil preservationBuilding materialPollutant

Provided is a tube sinking and excitation compacting method. By means of the method, foundation soil which is loose and needs to be reinforced can be rapidly and effectively reinforced. The method includes the following steps of firstly, measuring and placing point positions; secondly, conducting tube sinking and excitation; thirdly, keeping vibration; fourthly, pulling and moving tubes; fifthly, reinforcing surface soil; sixthly, leveling places. The method has the advantages that the foundation soil which is loose and needs to be reinforced can be effectively reinforced, the aims of eliminating collapsibility, liquidation and self-weight consolidation settlement of the foundation soil, improving foundation stability and foundation bearing capacity, reducing uneven settlement deformation and the like can be achieved, construction is convenient, rapid, effective and low in manufacturing cost, no building materials are needed, no pollutant is generated in the construction process, and the method is environmentally friendly.

Owner:CHINA ZHONGHUA GEOTECHN ENG

Comprehensive compacting method for highfill embankment in loess area

InactiveCN103993533AEliminate collapsibilityEliminate or minimize settlement deformationRoadwaysSoil scienceLoess

The invention relates to the technical field of geotechnical engineering construction, and in particular to a comprehensive compacting method for highfill embankment in a loess area. The method comprises the following steps: (1) clearing the surface of a soil foundation for 30cm and overbreaking for 2m, after overbreaking, compacting the foundation by using a heavy hammer, and processing a lower layer foundation, wherein the effective processing depth is no less than 1m; (2) paving 6% ash soil of 1m in thickness along the compacted soil foundation, and compacting; (3) after paving the ash soil, filling plain soil layer to layer, and compacting, wherein the filling thickness of each layer is not greater than 300mm, and a vibratory roller of 18t tons is adopted for compacting through rolling in a waling speed of 4km / h, and the compact coefficient is not less than 96%; (4) compacting to reinforce once by using the heavy hammer when every 3m of the plain soil is filled; and (5) refilling the plain soil till 1m below a roadbed, refilling 6% ash soil within 1m below the roadbed, and compacting. As the comprehensive compacting method for highfill embankment in the loess area is combined with a heavy hammer rammering construction process on the basis of a conventional vibratory roller compact process, a pre-compaction sinking period is shortened.

Owner:BEIJING MUNICIPAL CONSTR +1

Collapsible loess subgrade landslide treatment method

InactiveCN103015438AImprove stabilityReduce disturbanceFoundation testingExcavationsLandslideCrushed stone

The invention relates to the technical field of subgrade foundation treatment, in particular to a collapsible loess subgrade landslide treatment method which is characterized in that dry gravel is hammered into a pile by double pipes; the grain sizes of the gravel are 10mm to 30mm; the deviation between a pile pipe and the center of a hole site is no more than 2cm, the inclining degree of the pile pipe is no more than 1 / 400, the deviation of an effective pile length is no more than minus 10cm, and materials fed into a pile bottom are about 0.07m<3>; then hammering and compaction are carried out, an inner pipe is pulled out, and 0.14m<3> of gravel is added into an outer pipe; the hammering and the compaction step is repeated, until the pipe is pulled out and capping is carried out; and the ratio of piling and backfilling modified materials of loess to lime to water is 70: 20: 10. The collapsible loess subgrade landslide treatment method has the beneficial effects that the gravel pile can effectively eliminate the collapsibility of the loess foundation, a pile group and soil form the composite subgrade, so that the overall stability of the subgrade can be enhanced, the load bearing capability of the subgrade is improved, and settlement and uneven settlement are reduced.

Owner:李应芝

Environment-friendly type collapsible loess foundation structure and treatment method thereof

PendingCN108239989AAvoid pollutionEliminate collapsibilitySoil preservationStructure of the EarthSoil horizon

The invention discloses an environment-friendly type collapsible loess foundation structure and a treatment method thereof. The environment-friendly type collapsible loess foundation structure comprises undisturbed soil, a foundation pit and compaction piles. The undisturbed soil is arranged around the foundation pit, and the compaction piles are arranged in the undisturbed soil. The compaction piles are arranged in an equilateral triangle plum blossom shape in the undisturbed soil layer. A cushion layer is arranged at the lower portion of an independent foundation, and solid piles are arranged at the lower portion of the cushion layer. The compaction piles are arranged around the independent foundation and include the solid piles and virtual piles, wherein the solid piles are located at the lower portions of the virtual piles. The foundation treatment method comprises pile arranging, pile driving and excavating. The environment-friendly type collapsible loess foundation structure andthe treatment method thereof have the beneficial effects that the excavation amount is small, the environment friendliness effect is good, the construction period is short, and the manufacturing costis low.

Owner:陕西华邦建设工程有限公司

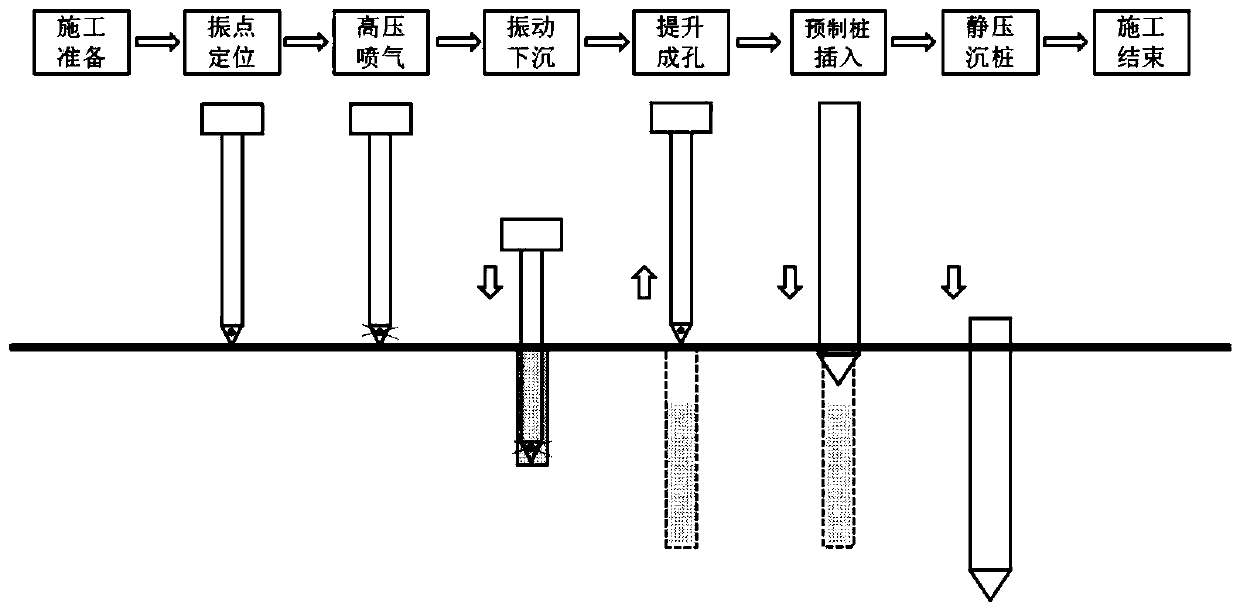

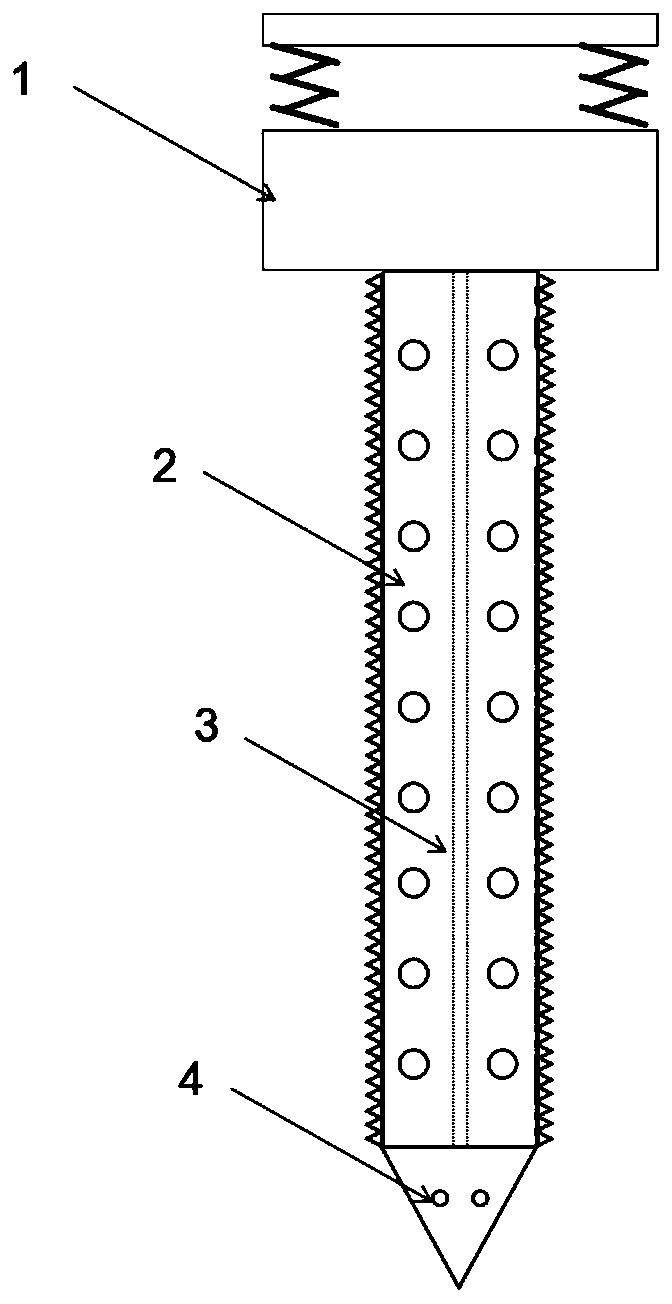

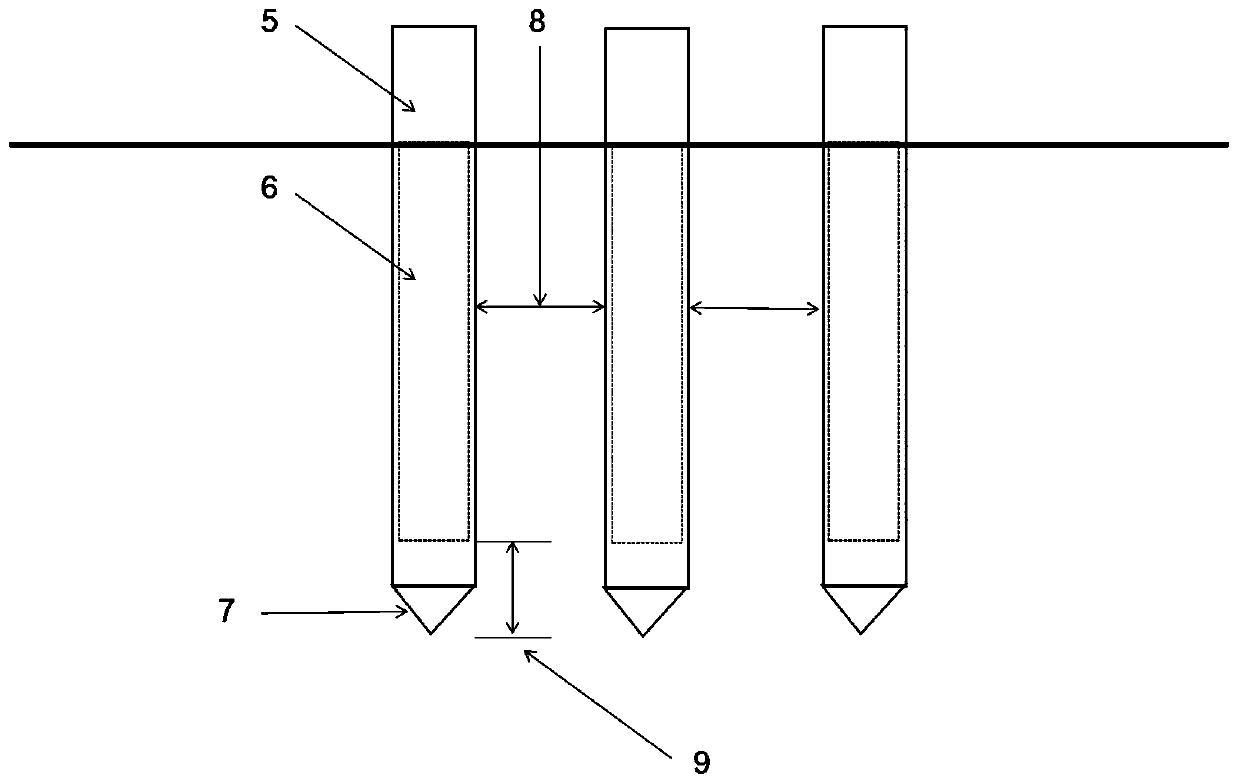

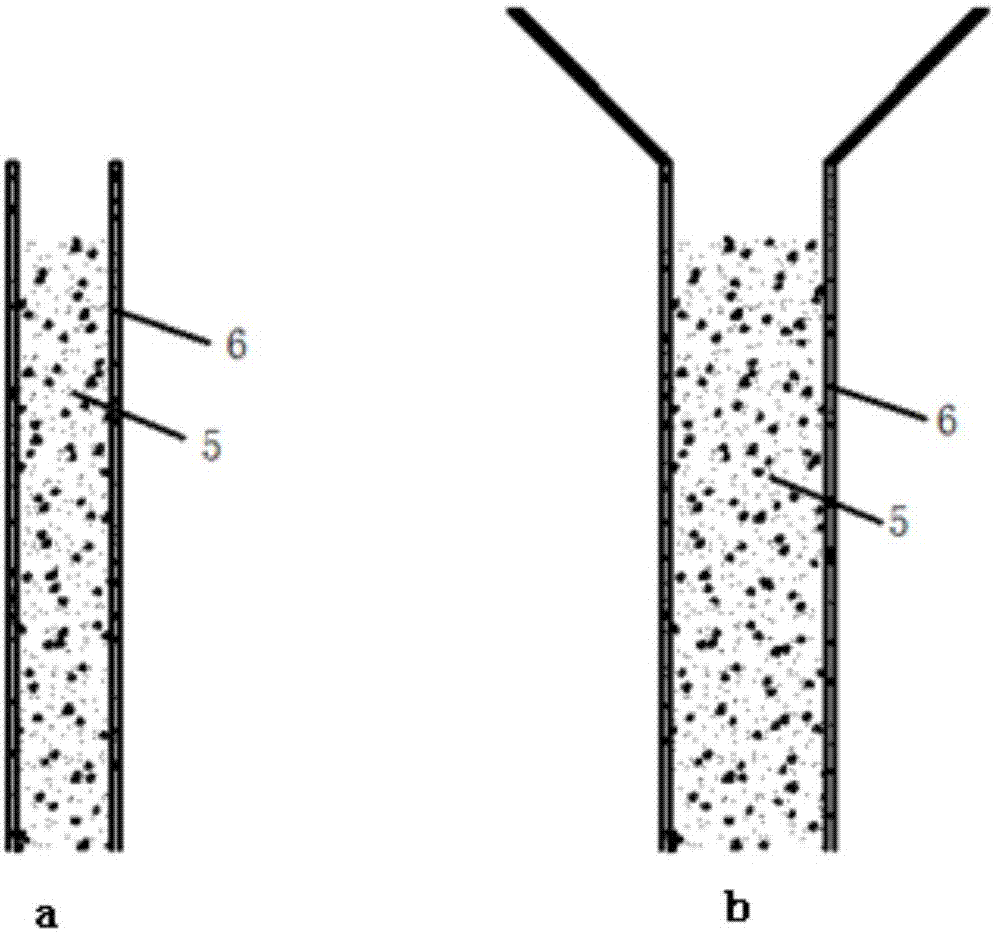

Construction method for precast pile composite foundation, applied to elimination of loess collapsibility

ActiveCN111058443AEliminate collapsibilityEfficient deliveryVibration drillingBulkheads/pilesStructural engineeringVibrational energy

The invention discloses a construction method for a precast pile composite foundation, applied to elimination of loess collapsibility. The method comprises the steps of (1) preparation for construction, (2) vibration point positioning, (3) high-pressure gas injection, (4) vibrating sinking, (5) lifting for pore formation, (6) insertion of a precast pile, (7) pile sinking, and (8) ending of construction. The construction method disclosed by the invention has the beneficial effects that based on a traditional construction method for the precast pile composite foundation, inter-pile loess is gradually compacted by vibration and collapsibility is eliminated through conveying of vibration energy aiming at the problem that collapsibility around a pile cannot be solved by a precast pile during processing of the collapsible loess foundation. In addition, during sinking of a vibration rod, high-pressure gas injection is added for quick pore formation, so the problem that the precast pile can hardly be sunk due to excessive side friction resistance in a loess area. The method is the economic and effective construction method for processing of the collapsible loess foundation.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD +1

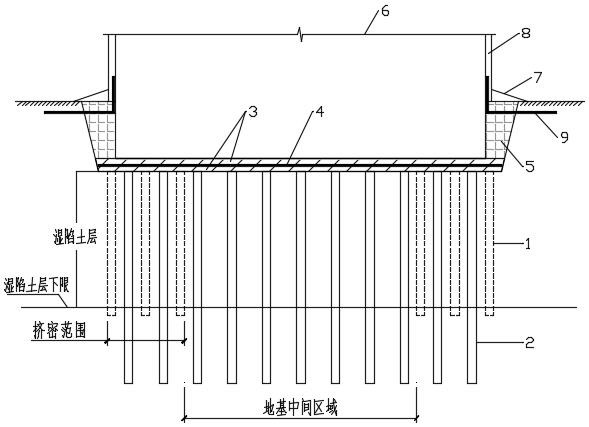

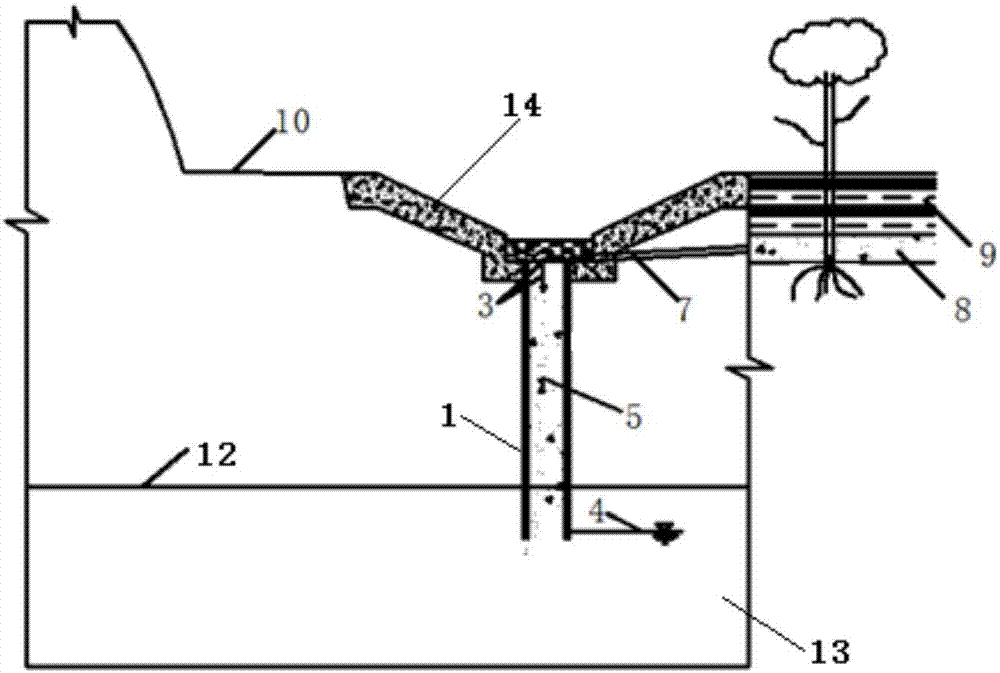

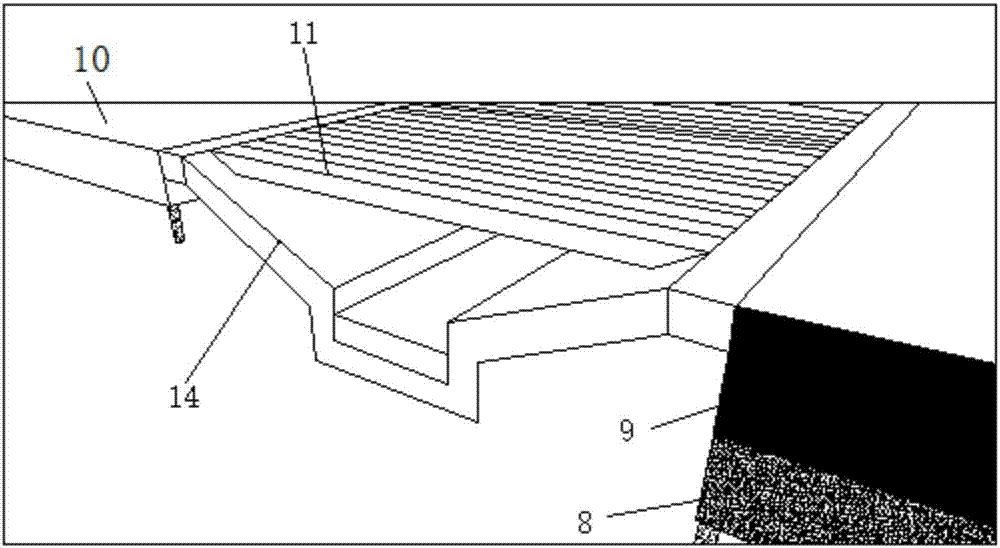

Method for treating high-rise building foundation in non-self-weight collapsible loess area

InactiveCN111648348AReduce construction costsGood economic benefitsProtective foundationBulkheads/pilesCushionGeotechnical engineering

The invention discloses a method for treating a high-rise building foundation in a non-self-weight collapsible loess area. The method comprises the following steps: step one, excavating a foundation pit to a designed elevation, and constructing and arranging compaction piles, wherein the compaction piles are arranged on the outer edge of the foundation within the range of not smaller than 1 / 2 thickness of a collapsible soil layer or within the range of not smaller than 5 m; and the pile diameter of the compaction piles is 300-400 mm, the pile length exceeds the lower limit of the collapsible soil layer by not less than 0.5 m, and the pile spacing of the compaction piles is 2-2.5 times of the pile diameter; step two, constructing and arranging CFG piles, wherein composite foundation of theCFG piles in the middle area of the foundation is designed and constructed according to general areas; step three, constructing and arranging an anti-seepage cushion layer on the top of the compositefoundation; and step four, tamping a foundation trench layer by layer and backfilling lime soil, and paving two pieces of L-shaped cloth and one film. According to the method, outdoor surface water infiltration can be cut off, the situation that the foundation is soaked in water, and consequently foundation collapsing cannot be conducted is avoided, then the composite foundation of CFG piles in the non-self-weight collapsible loess area can be designed according to the general areas, the collapsibility problem does not need to be considered any more, and a large amount of conventionally-adopted compaction pile construction cost is saved.

Owner:ZHONGYUN INTERNATIONAL ENGINEERING CO LTD

Sponge city sand drain drainage system

InactiveCN107975124AReduce collapsibilityHigh strengthSewerage structuresSewage drainingRebarReinforced concrete

The invention discloses a sponge city sand drain drainage system. The system comprises drainage channels located on the two sides of a road, multiple mutually parallel reinforced concrete blocks are horizontally arranged on the tops of the drainage channels, multiple sand drains are uniformly distributed at the bottoms of the discharge channels, and the side walls of the drainage channels are connected with greening units through PVC pipes. According to the sand drain drainage system, by means of combination of the drainage channels and the municipal drainage pipelines, the waterlogging problem of cities in northwest territories are solved; by arranging the sand drains in the drainage channels, the sand drains are filled with sand gravel, the collapsibility of city loess is relieved to a certain extent, the intensity of city foundations is enhanced, construction is simple, and the cost is low; rainwater collected in the drain channels is conveyed to the greening units on the two sidesof the road, the rainwater is collected, resources are reasonably allocated, the important role is achieved in city greening, and the system has the very good application value.

Owner:XIAN UNIV OF TECH

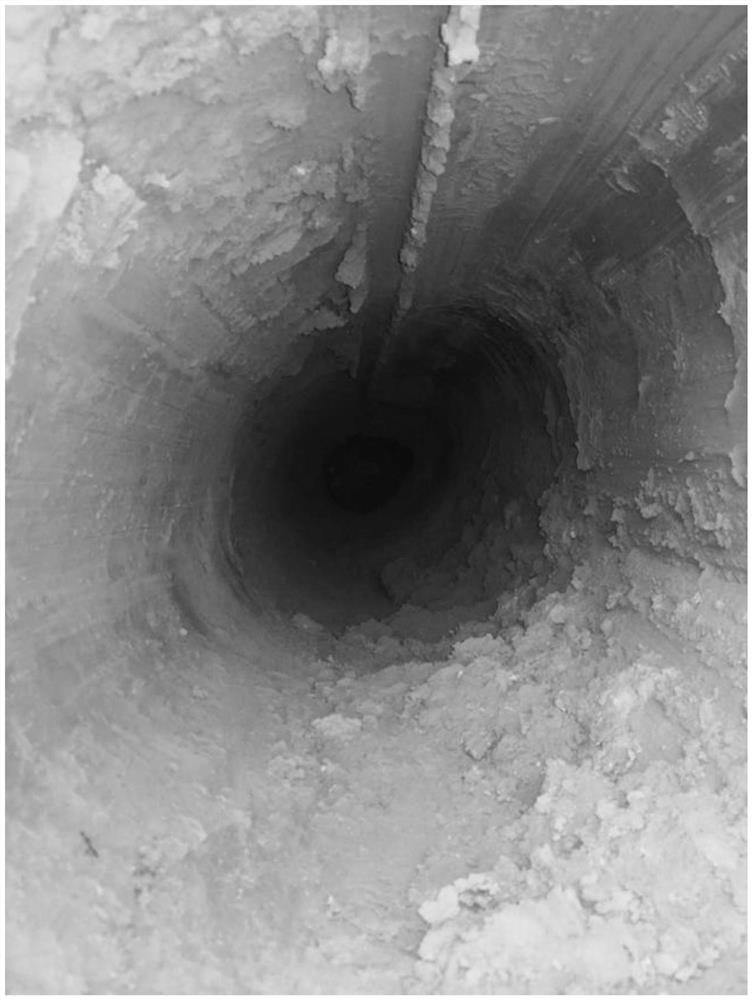

Method of treating collapsible loess foundation by two-way spiral drill compaction process

InactiveCN107489141AEliminate collapsibilityReduce the level of collapsibilitySoil preservationEngineeringDrill

The invention belongs to the field of foundation treatment, and discloses a method of treating a collapsible loess foundation by a two-way spiral drill compaction process, in order to solve the problem that the treatment depth of an existing method is shallow. The method comprises the following steps that (1) payoff location is carried out according to a pile position diagram, and the positions of piles are controlled; (2) a two-way spiral drill is adopted for drilling; (3) holes are filled with plain soil or ash soil, and ramming is carried out till the plain soil or the ash soil reaches the surface of a foundation; and (4) the step (2) and step (3) are repeated till field treatment is completed. The treatment depth can reach 30m by the method, the method is suitable for the foundation treatment of large-thickness collapsible loess, no soil is discharged in the hole-forming process, the effect of the compaction foundation is good, the loess collapsible level can be reduced effectively, and even the loess collapsibility can be eliminated.

Owner:LANZHOU ENG & RES INST OF NONFERROUS METALLURGY

Collapsibility soil or thaw collapsibility soil foundation treatment method

InactiveCN110409417ASatisfy the bearing capacity design requirementsReduce lossSoil preservationEngineeringBearing capacity

The invention relates to a collapsibility soil or thaw collapsibility soil foundation treatment method. Firstly, a water injection hole is formed in a foundation, after the water injection hole is formed, water is injected into the water injection hole, accordingly, collapsibility or thaw collapsibility of foundation soil is eliminated in a water injection manner, and the diameter of the water injection hole ranges from 380 mm to 2,000 mm; and secondly, after water injection is finished, pile foundation or foundation treatment is conducted on the foundation, and accordingly, the construction building foundation bearing capacity design requirement is met. Through the collapsibility soil or thaw collapsibility soil foundation treatment method, the construction period can be shortened, and the engineering quality is guaranteed.

Owner:王彦 +1

No-dumping vibrationless pore-forming compaction processing method for mollisol foundations

InactiveCN103015394AImprove compactnessImprove bearing capacityBulkheads/pilesSoil preservationPore diameterComputer science

The invention provides a self-propelled no-dumping vibrationless pore-forming compaction processing method for mollisol foundations, which comprises the following steps: determining arrangement method, diameters and intervals of pile pores and processing depth for compaction processing in the processing range of the mollisol foundations; performing pretreatment on the dead centers of all pile pore locations to form guide pores; and then adopting the self-propelled no-dumping vibrationless pore-forming compaction device to perform continuous transverse diameter reducing and vertical squeezing on the guide pores to enable the surrounding soil bodies to be continuously compacted to form compaction pores with designed pore diameter and pore depth. According to the invention, the method for processing the mollisol foundations is simple, vibration is avoided, the efficiency is high, and the quality is good; and the adopted self-propelled no-dumping vibrationless pore-forming compaction device is simple in structure, small in size, light and flexible, and is particularly suitable for pore-forming compaction processing for mollisol foundations such as loess, filling and the like in a construction field which has small space, is narrow and strictly controls the vibration.

Owner:NORTHWEST RES INST CO LTD OF C R E C +1

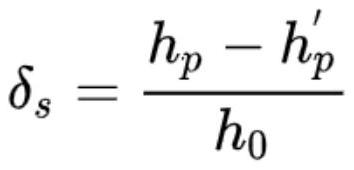

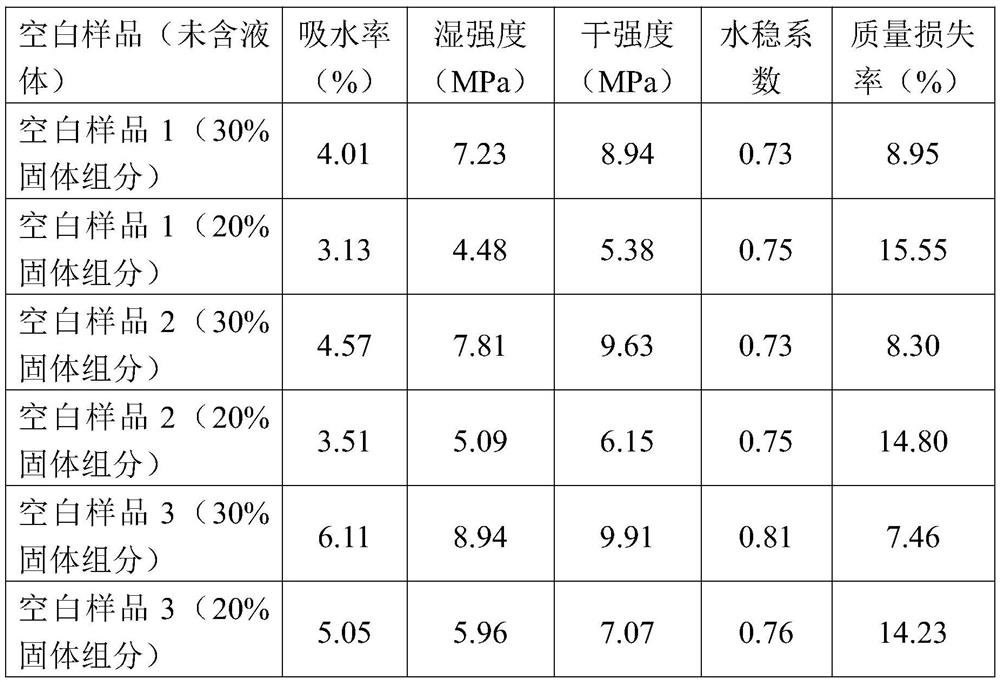

Hydrophobic anti-scouring loess solidifying agent

ActiveCN112812780AImprove toughnessImprove crack resistanceBuilding constructionsOrganic fertilisersCalcium hydroxideSulfate

The invention relates to a hydrophobic anti-scouring loess stabilizing agent. The hydrophobic anti-scouring loess stabilizing agent is composed of a powdery stabilizing component and a liquid waterproof component, wherein the powdery stabilizing component is composed of 50-70 parts of slag powder, 15-25 parts of cement, 5-25 parts of fly ash, 1-3 parts of synthetic fibers, 1-5 parts of calcium sulfate, 1-5 parts of calcium hydroxide and 1-2 parts of calcium chloride; and the liquid waterproof composition comprises the following components in parts by weight: 2-50 parts of a water repellent agent, 1-20 parts of an interface agent, 1-15 parts of a stabilizer and 20-90 parts of water. The unconfined compressive strength of a soil body solidified by the hydrophobic anti-scouring loess solidifying agent can reach 5 MPa or above, the toughness and crack resistance of the solidified soil body are improved through the fibers, and a high-strength high-toughness solidified soil material is formed. By adopting the prepared liquid waterproof component, the soil body has hydrophobicity, a large amount of external moisture can be effectively prevented from permeating, and the collapsibility of loess is reduced. Meanwhile, the anti-scouring performance of a loess sample doped with the solidifying agent is also enhanced.

Owner:YELLOW RIVER ENG CONSULTING

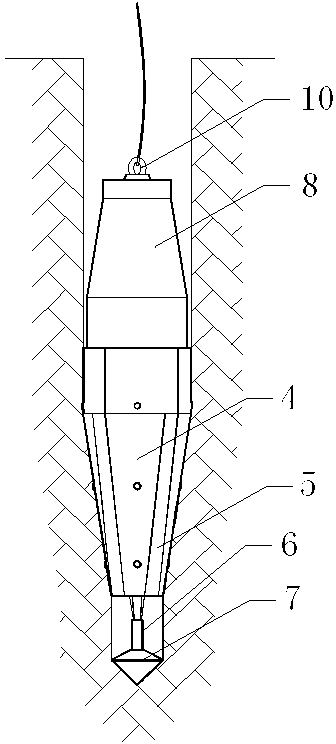

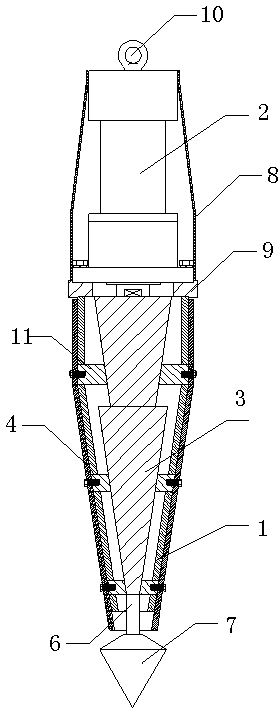

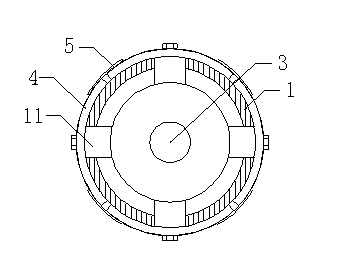

Device and method based on static pressure immersed tube hole forming heavy hammer tamping compaction pile

The invention discloses a device based on an immersed tube hole forming heavy hammer tamping compaction pile. The device comprises a static pressure pile machine, wherein the static pressure pile machine is connected with an immersed tube; and the front end of the immersed tube is a steel pile tip. The construction method comprises the steps of 1) flatting the site, removing barriers, measuring, paying off, and arranging pile positions according to the designed parameters; 2) moving the static pressure pile machine to one pile position, levelling the pile machine, aligning the immersed tube tip at the pile position through operating longitudinal and horizontal displacement systems, inserting the immersed tube, and arranging two theodolites or plumbing bobs in the vertical direction for adjusting the perpendicularity; 3) continuously observing the perpendicularity of the immersed tube in the first two strokes of the immersed tube, when the immersed tube reaches the designed elevation, stopping tube sinking, slowly pulling out the immersed tube, and moving the pile machine to the next pile position; and 4) before pile forming, measuring the drilling diameter and depth, placing a pile body in a pile hole, and carrying out layered compaction through heavy hammer tamping. The main purposes of guaranteeing the soil compaction effect, reducing the construction cost, reducing noise and causing no environmental pollution are achieved.

Owner:SHAANXI JUYUAN FOUND ENG CO LTD

A wind turbine pier foundation and its construction method

ActiveCN104594372BLarge diameterMake up for the lack of bending performanceFoundation engineeringPile capEngineering

The invention relates to a fan pile pier foundation and a construction method thereof, and discloses a fan pile pier foundation, which comprises a center pier foundation. The fan pile pier foundation is characterized in that an anchor rod pile is arranged at the bottom part of the center pier foundation, 8-12 inclined piles are arranged around the center pier foundation, a concrete pile cap is arranged at the top part of the center pier foundation, a reinforced bar at the top part of each inclined pile is connected with a reinforced bar of the concrete pile cap, the concrete pile cap is cast together with the inclined piles, and a prestressed anchor rod is arranged in the center pier foundation. The fan pile pier foundation has the advantages that the problems of insufficient bearing capacity and loess collapsibility of soft soil are solved; at the premise of meeting the domestic standard requirements, the material is saved, the construction period is shortened, the whole safety, stability and settling control property are sufficiently guaranteed, and the higher practicality is realized for the ground foundation reinforcing and foundation design of wind power generators in eastern coastal areas and northwestern collapsibility loess areas of China.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Collapsible foundation immersed tube pile forming treatment method

PendingCN113026716ASimple operation processImprove construction efficiencyFoundation testingSoil preservationWater contentSoil properties

The invention belongs to the technical field of foundation treatment construction, and relates to a collapsible foundation immersed tube pile forming treatment method. When a collapsible loess foundation is treated through immersed tube compaction piles, when shrinkage cavities occur after immersed tubes are pulled out, a long spiral drilling machine is adopted for conducting rotary excavating on retracted soil in holes for secondary soil discharging, and the beneficial effects of being good in hole forming effect and high in construction work efficiency are achieved. Meanwhile, due to secondary soil discharging after shrinkage cavity treatment, the compaction degree of soil between the piles is reduced, foundation soil is wet and soft and large in water content, and in order to make up for the compaction effect of the soil between the piles and improve the water content of the foundation soil, a filler ramming scheme of the next procedure is adjusted into a pile forming construction method including lime soil backfilling, heavy hammer ramming, layered filler filling and layered ramming. Due to the fact that lime is used for filler adding, the cost of the pile forming method is properly increased compared with a plain soil backfilling ramming pile forming scheme, the construction efficiency of the pile forming method is the same as that of the plain soil backfilling ramming pile forming scheme, and meanwhile the beneficial effects of being good in pile forming effect and effectively improving the foundation soil property are achieved. Compared with the scheme I, the scheme II and the scheme III in the prior art in the third part of the invention, the secondary hole forming and pile forming scheme has the beneficial effects of being economical, efficient, safe, environment-friendly and applicable.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com