Patents

Literature

34results about How to "Improve the bearing capacity of the foundation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

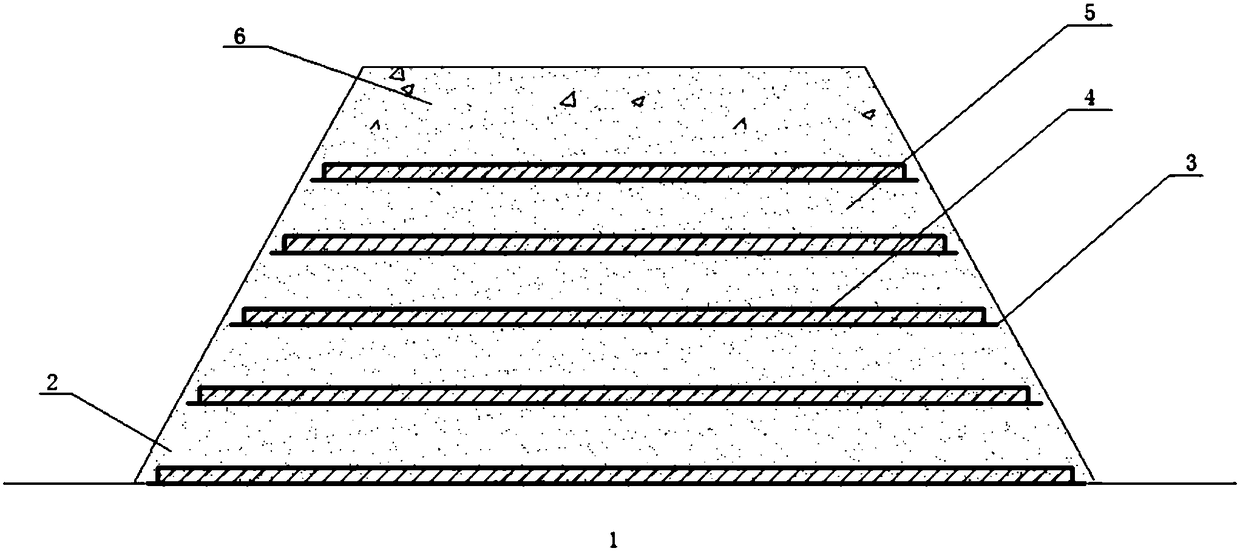

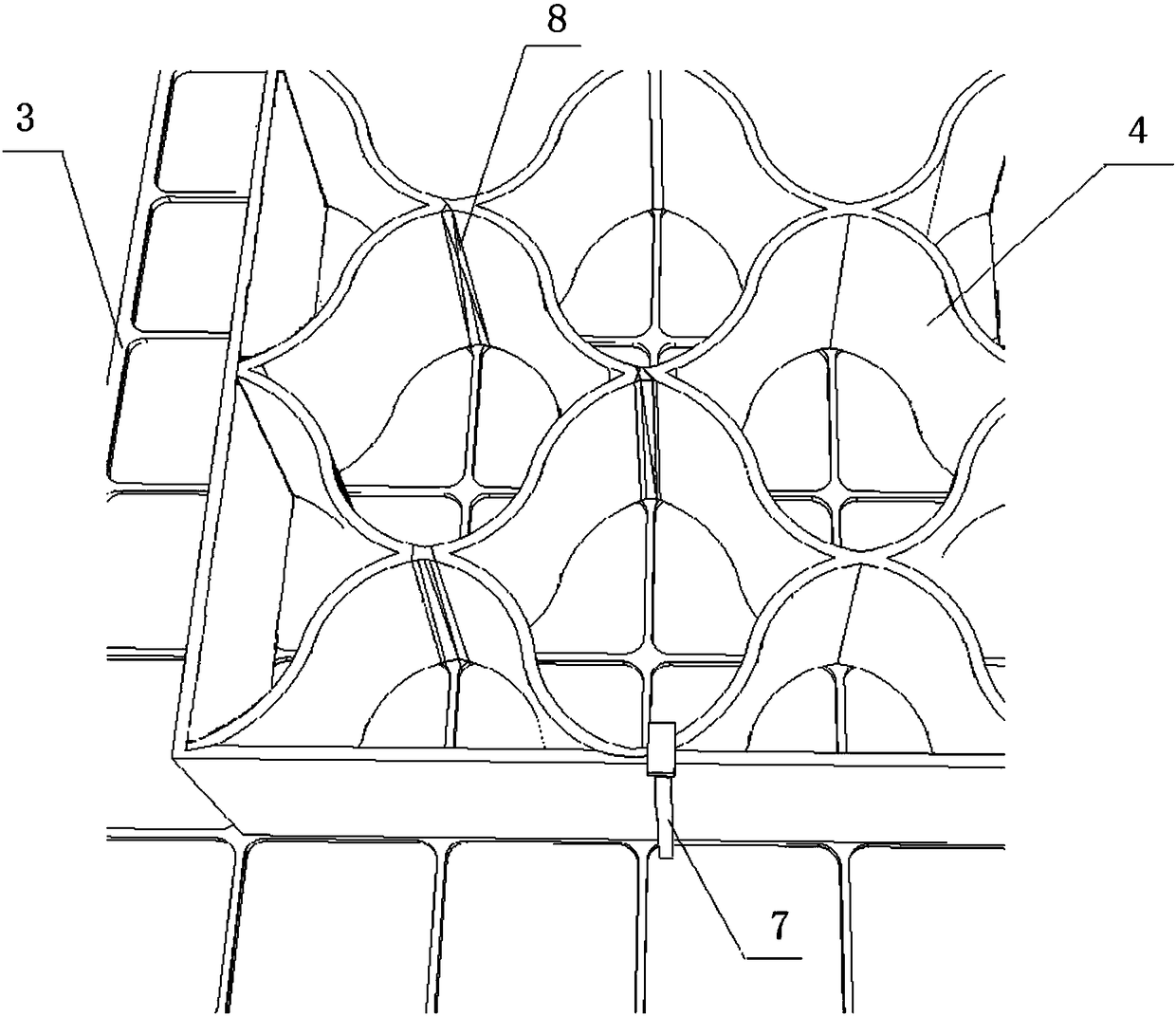

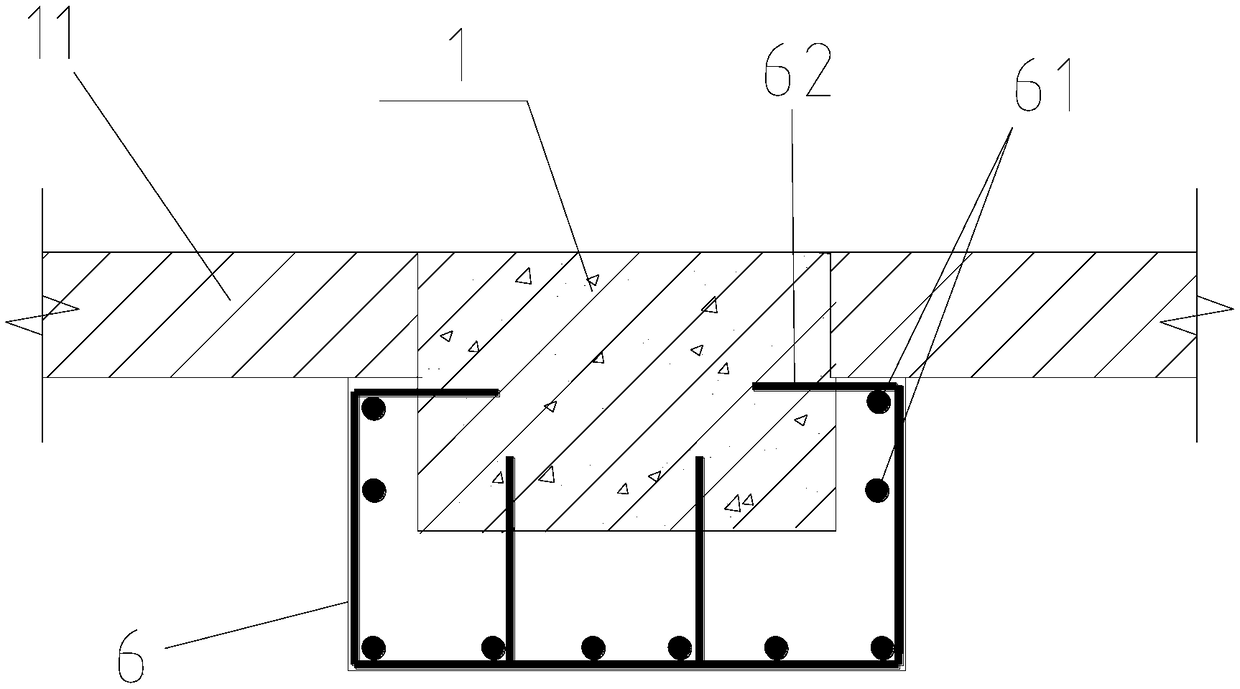

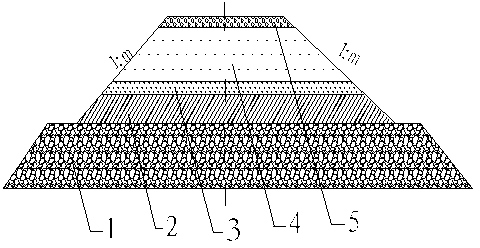

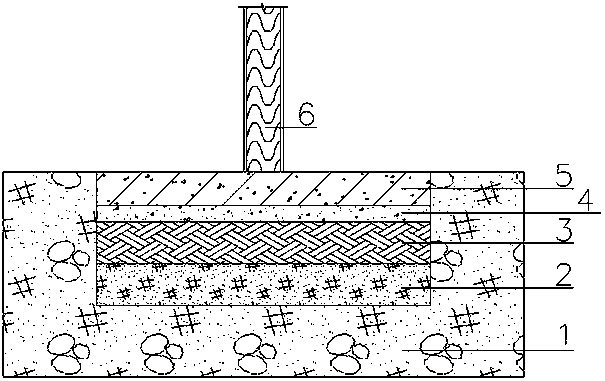

Domestic garbage incinerated ash and mixed soil composite reinforced subgrade and construction method thereof

ActiveCN108442200AImprove the bearing capacity of the foundationImprove stabilityRoadwaysGeocellsEngineering

The invention discloses a domestic garbage incinerated ash and mixed soil composite reinforced subgrade. The domestic garbage incinerated ash and mixed soil composite reinforced subgrade comprises a foundation layer, a subgrade layer paved on the top surface of the foundation layer and a road surface layer paved on the top surface of the subgrade layer, wherein the subgrade layer comprises a subgrade base body and a plurality of layers of reinforced structure layers; the subgrade base body is prepared from compacted filler and the filler is mainly prepared by mixing domestic garbage incinerated ash and clay; the reinforced structure layers are paved in the subgrade base body at intervals from bottom to top; the reinforced structure layer on the topmost layer is located on the bottom surface of the road surface layer; each reinforced structure layer is mainly composed of a geogrid and a geocell fixed at the top of the geogrid. According to the domestic garbage incinerated ash and mixedsoil composite reinforced subgrade disclosed by the invention, the urban domestic garbage incinerated ash is used as a filler component to be applied to subgrade construction, so that the environmentpollution is reduced, the land occupation problem caused by accumulation of garbage ash is alleviated and a novel way is provided for harmless and reclamation treatment on the ash; the domestic garbage incinerated ash and mixed soil composite reinforced subgrade disclosed by the invention has excellent strength and rigidity.

Owner:HUBEI UNIV OF TECH

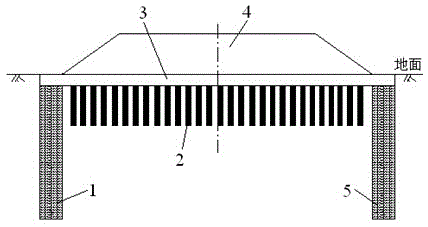

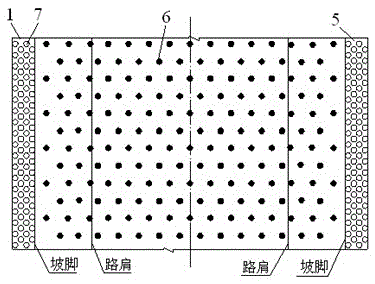

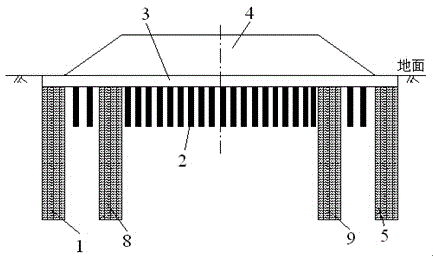

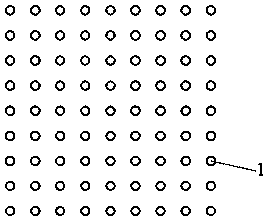

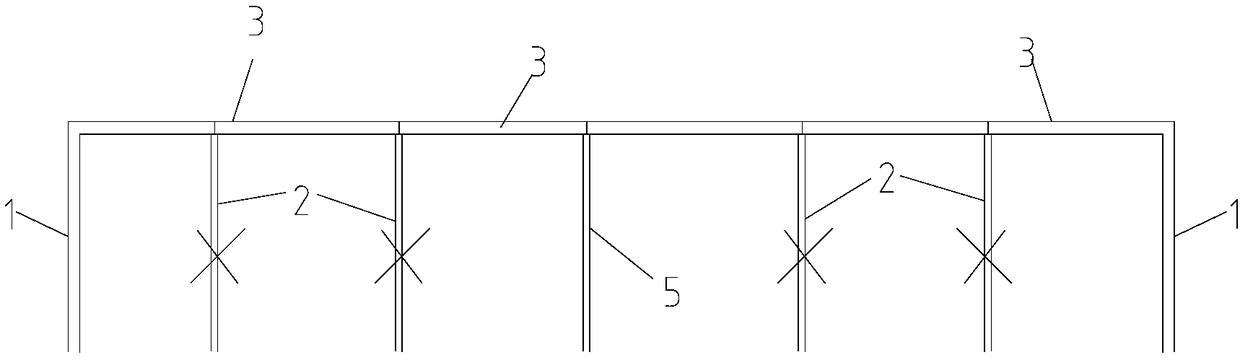

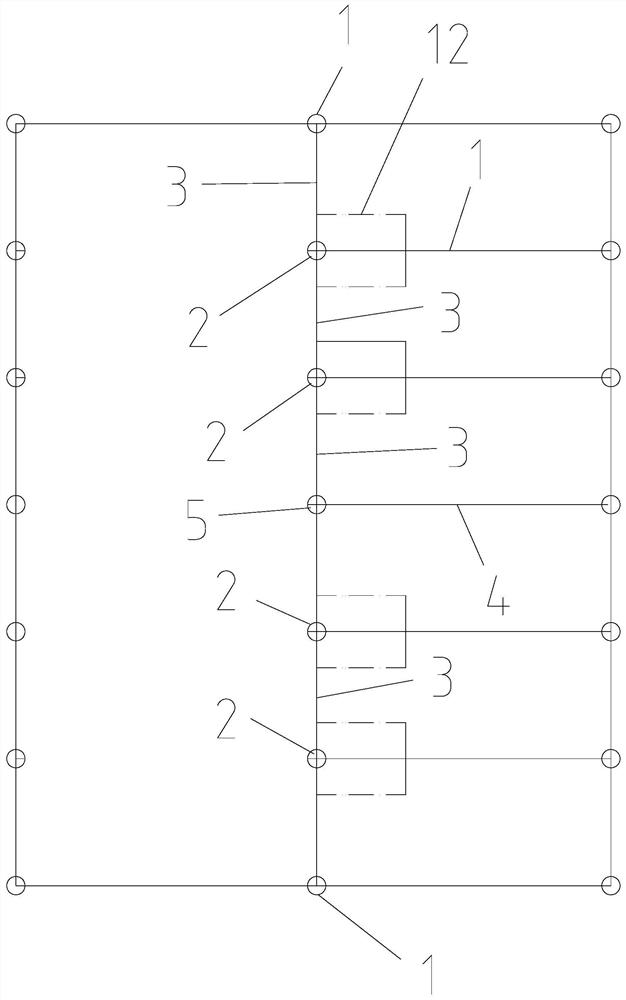

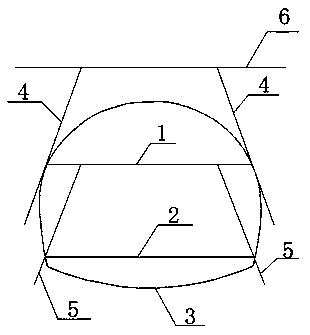

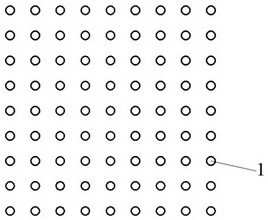

Novel long and short pile foundation treatment structure of collapsible loess area and construction method

ActiveCN105464068AEliminate collapsibilityImprove the bearing capacity of the foundationSoil preservationQuincunxSubgrade

The invention relates to a novel long and short pile foundation treatment structure of a collapsible loess area and a construction method. The structure comprises two rows of waterproof curtains and a plurality of rows of reinforcing row piles between the waterproof curtains. The interior of each of the two rows of waterproof curtains and one slope toe of a roadbed are located in the same vertical plane. Each waterproof curtain is composed of four rows of compact long piles, wherein every three adjacent compact long piles are located at the three vertexes of an equilateral triangle respectively. The reinforcing row piles are composed of a plurality of compact short piles, and the compact short piles are arranged in a quincunx shape. The waterproof curtains and the reinforcing row piles are covered with a waterproof cushion layer. A soil sample is subjected to indoor soil testing, and the height of the roadbed is determined; leveling, surveying and setting out are carried out; and the waterproof curtains and the reinforcing row piles are built on the outer sides of the slope toes of the roadbed according to the existing construction technology, the waterproof cushion layer is built on the waterproof curtains and the reinforcing row piles, and construction of the foundation treatment structure is completed. The foundation treatment structure is used in highway and railway projects of the collapsible loess area, the requirements of the projects of the roadbed for the bearing capacity and deformation of the foundation are met, the construction period is shortened, the project cost is reduced, and line operation safety is guaranteed.

Owner:NORTHWEST RES INST CO LTD OF C R E C

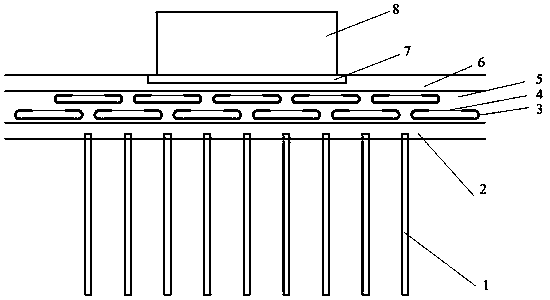

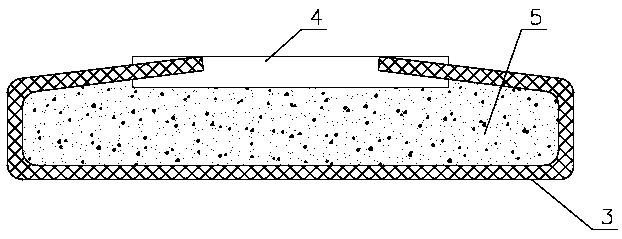

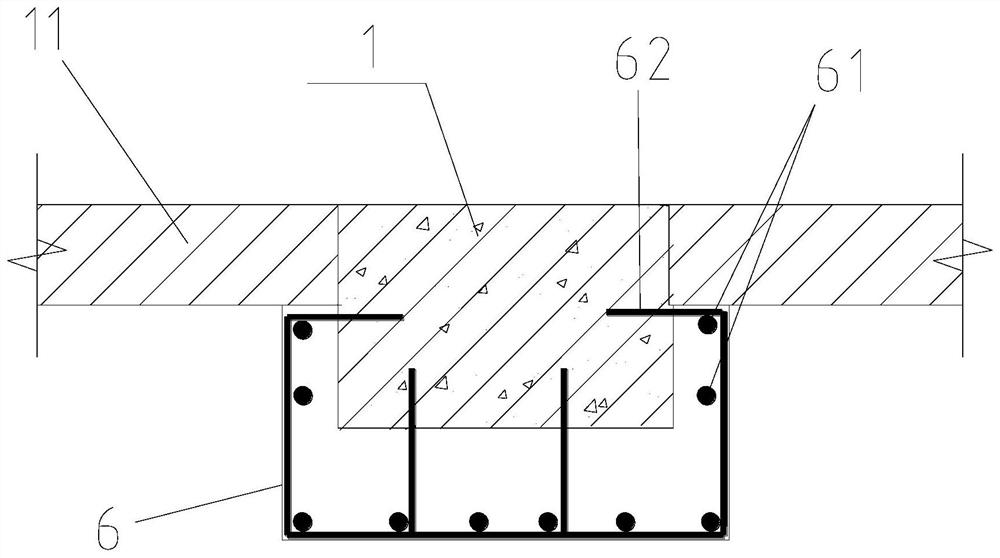

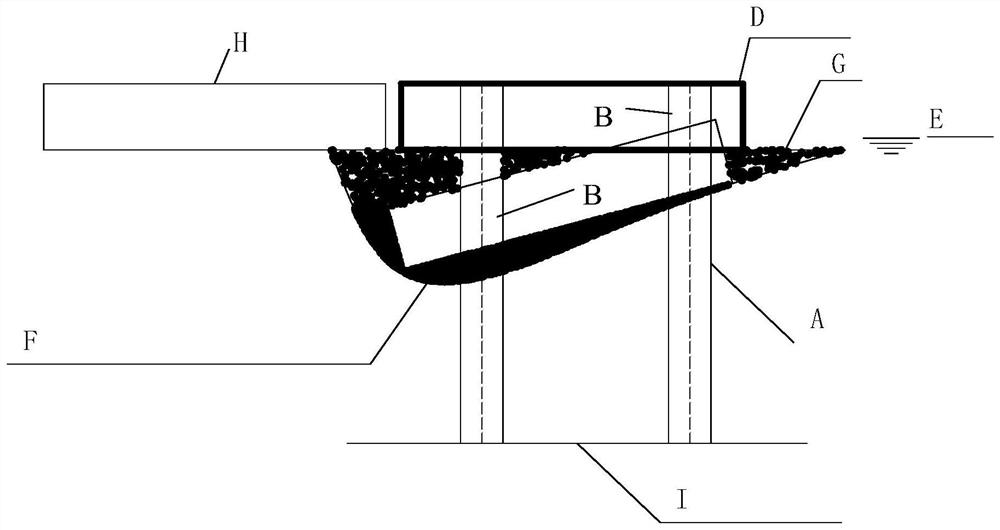

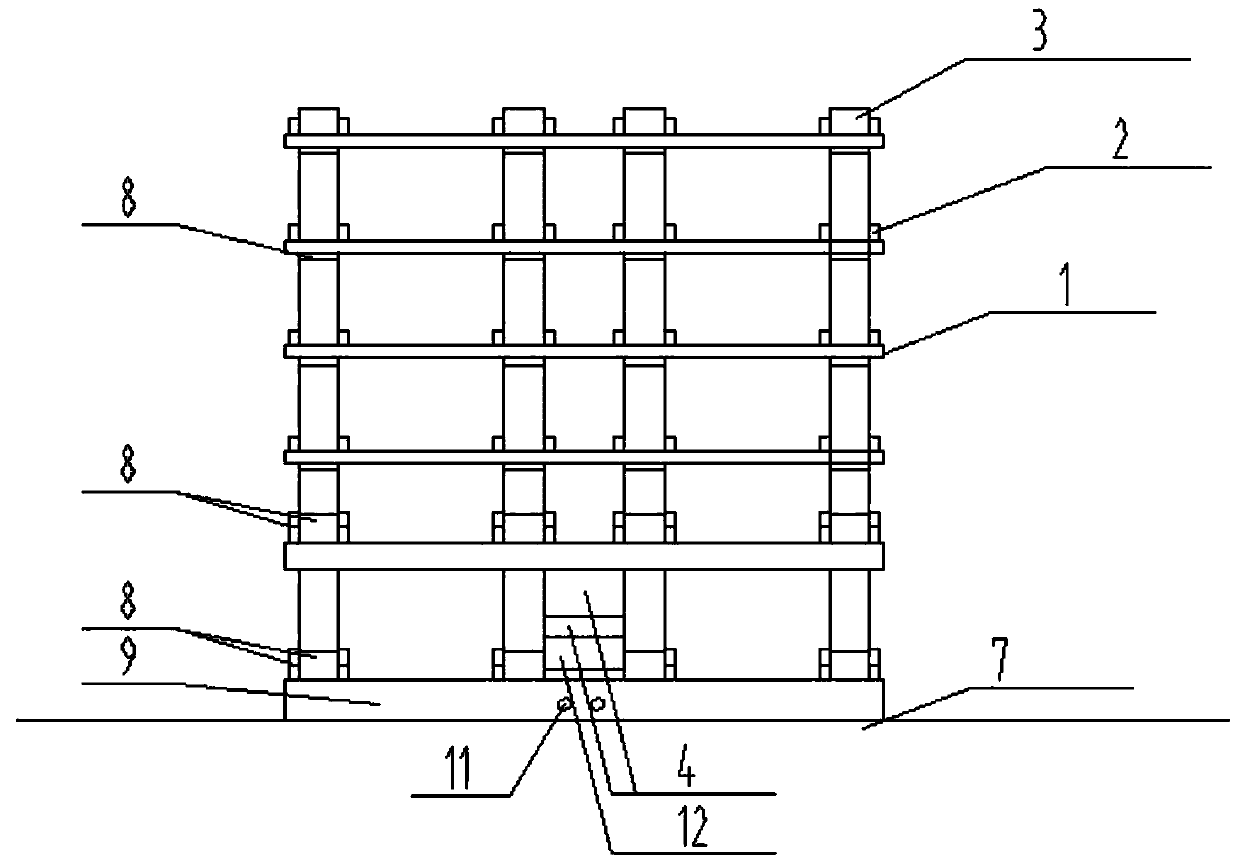

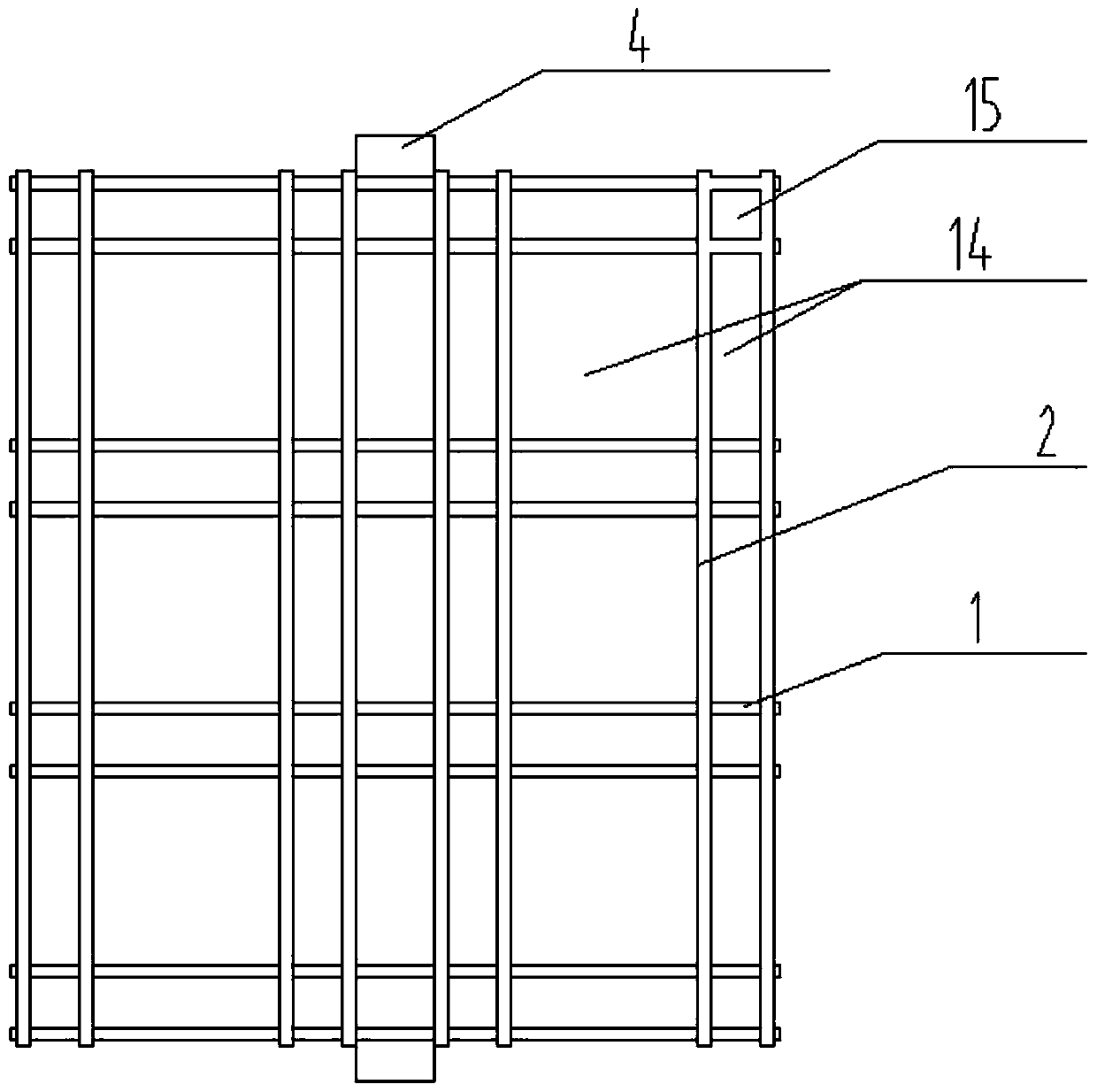

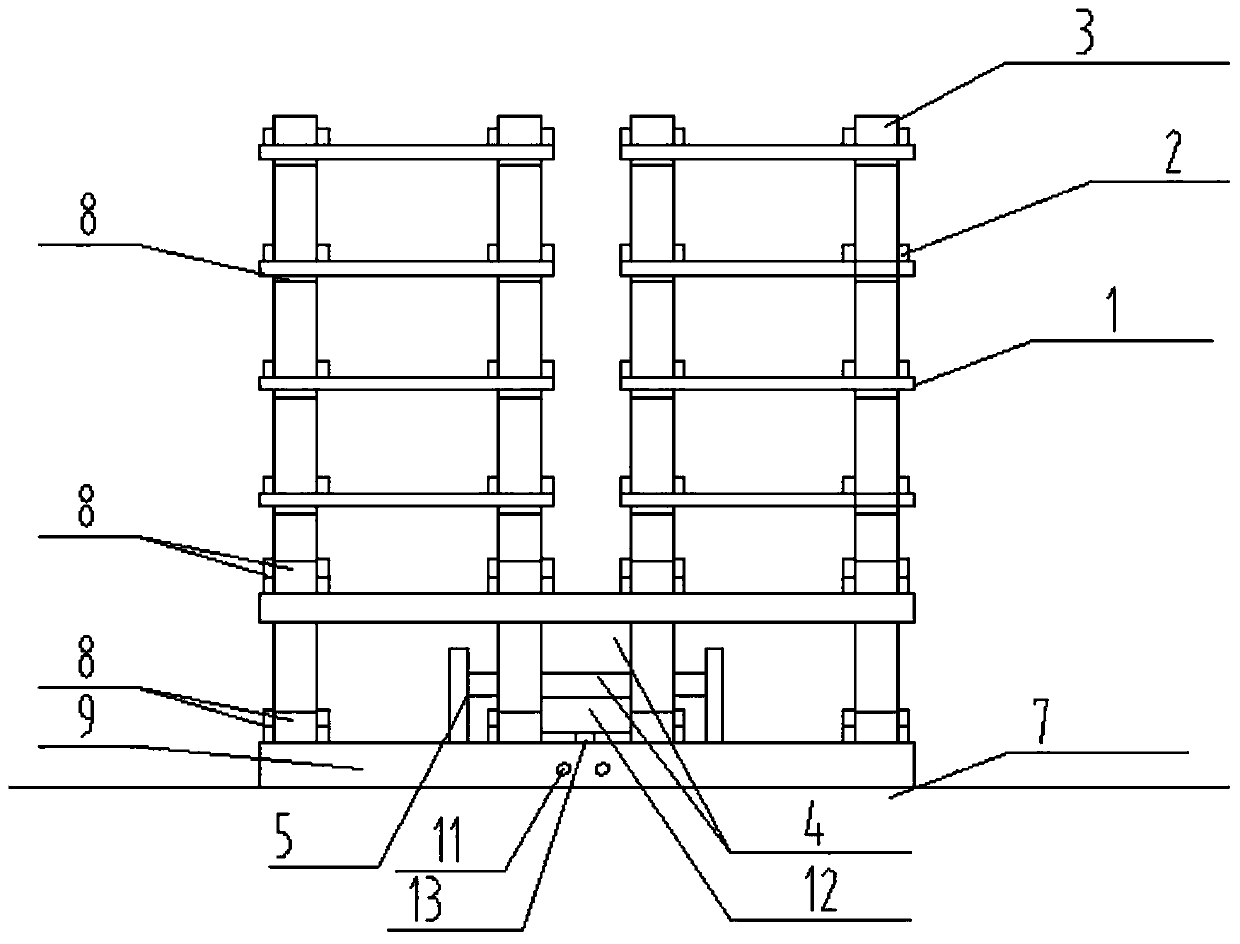

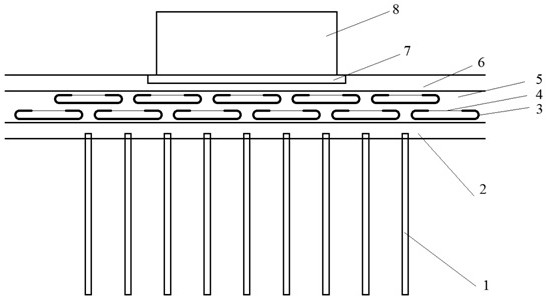

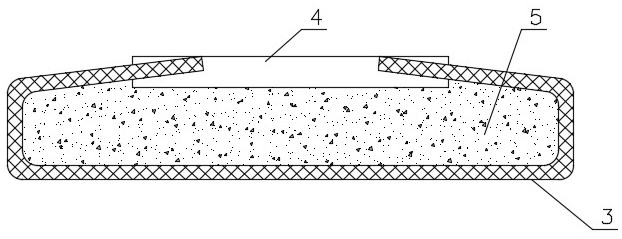

Novel seismic-isolation composite foundation and construction method thereof

ActiveCN110512637AGuaranteed resistanceIncrease resistanceProtective foundationSoil horizonWhole systems

The invention provides a novel seismic-isolation composite foundation and a construction method thereof. The novel seismic-isolation composite foundation comprises an upper structure, a raft board, afiber solidified soil layer, a double-layer wrapping type geotechnical composite broken stone layer, a solidified soil layer and piles sequentially from top to bottom, a segment is reserved at the topof each pile for being buried into the solidified soil layer, the reserving height accounts for 30-60% of the height of the solidified soil layer, the raft board is placed at the center of the grouped piles and buried into the fiber solidified soil layer, and fiber solidified soil is laid at the top of the raft board. The bearing capacity of the novel seismic-isolation composite foundation can beimproved, uneven settlement of a whole system is relieved, horizontal displacement is effectively prevented and controlled, piercing damage of the pile tops is prevented, seismic energy is absorbed and dissipated, and a novel and efficient anti-seismic and high-strength seismic-isolation composite foundation is constituted.

Owner:SOUTHEAST UNIV

Construction method of bagged rammed small-diameter soil-cement pile composite foundation

InactiveCN101899828AImprove the bearing capacity of the foundationReduce churnSoil preservationWeak fieldSoil horizon

The invention relates to a construction method of a bagged rammed small-diameter soil-cement pile composite foundation in a small-area weak and deep soft soil layer. The construction method is characterized in that a small-diameter soil engineering pipe bag is combined with the traditional soil-cement pile processing method to extrude surrounding soil bodies to be dense in a limiting way by utilizing the gluing reinforcement of cement and the restraint action of the soil engineering pipe bag so as to form high-density minitype pile group effect and enhance the bearing capability of the foundation. The diameter of the traditional soil-cement pile and the loss of soil-cement in the foundation are reduced by utilizing the packaging and restricting action of the soil engineering pipe bag, and the embedment depth of a pile body is reduced, thereby the reinforcement effect of a shallow-layer weak field soil composite foundation is achieved. Compared with construction method of the soil-cement pile large-area soft soil foundation, the invention has the advantages of simple process, fast construction, miniaturized construction equipment, material saving and low cost and can be popularized and used in the processing process of a small-area deep and weak field soil foundation.

Owner:HOHAI UNIV

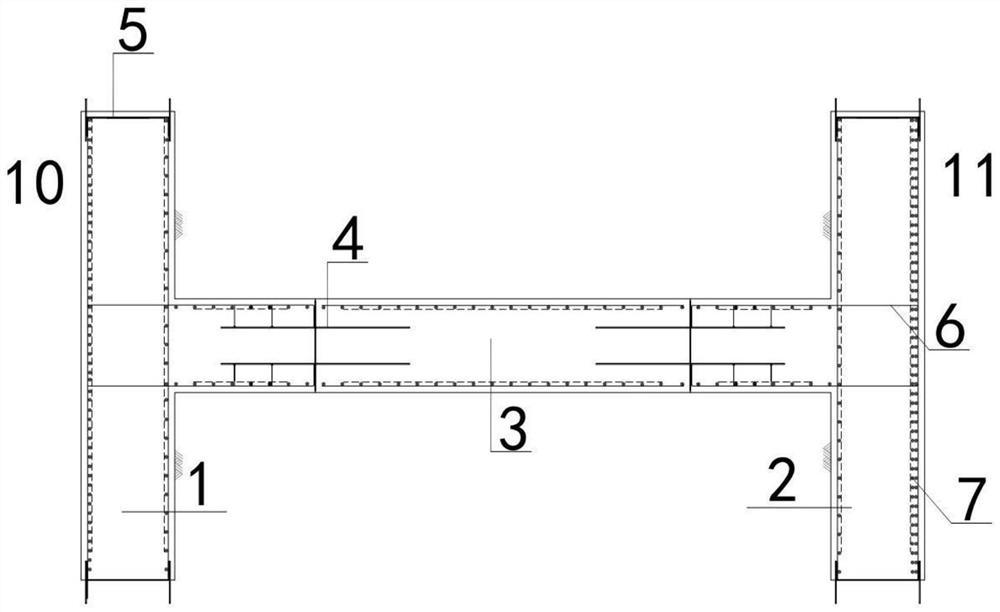

Underpinning reinforcement method for existing building structure

ActiveCN109403654AIncrease the sectionImprove the bearing capacity of the foundationBuilding repairsPipe supportUnderpinning

The invention discloses an underpinning reinforcement method for an existing building structure. Brackets are arranged and reinforced on an original supporting structure column, and a steel pipe supporting device is additionally arranged; enlarged section reinforcement is conducted on the basis of an original pre-reserved structural column, thus the purpose of improving the basic bearing capacityis achieved, and the design requirements of the basic bearing capacity after underpinning are met. Compared with an existing underpinning technology, the underpinning reinforcement method fully utilizes the original structure, damage is small, and the new structure is basically consistent with the original structure in form and coordinates with the original structure for common bearing; before theunderpinned column is removed, a foundation of the pre-reserved structural column is reinforced, reinforcement of the enlarged section and additionally arranged reinforcing bars is conducted, the bearing capacity is increased, and stiffness is improved; the overall economic adaptability is high, the cost is low, economic rationality is achieved, the construction period is short, and the influenceon adjacent surrounding shallow foundations is small; and the underpinning reinforcement method is suitable for application of underpinning transformation of buildings such as large powerhouse structures, gymnasium structures, large shopping mall structures, subway structures and various broken column transformation use spaces.

Owner:广东赛力克建筑技术工程有限公司

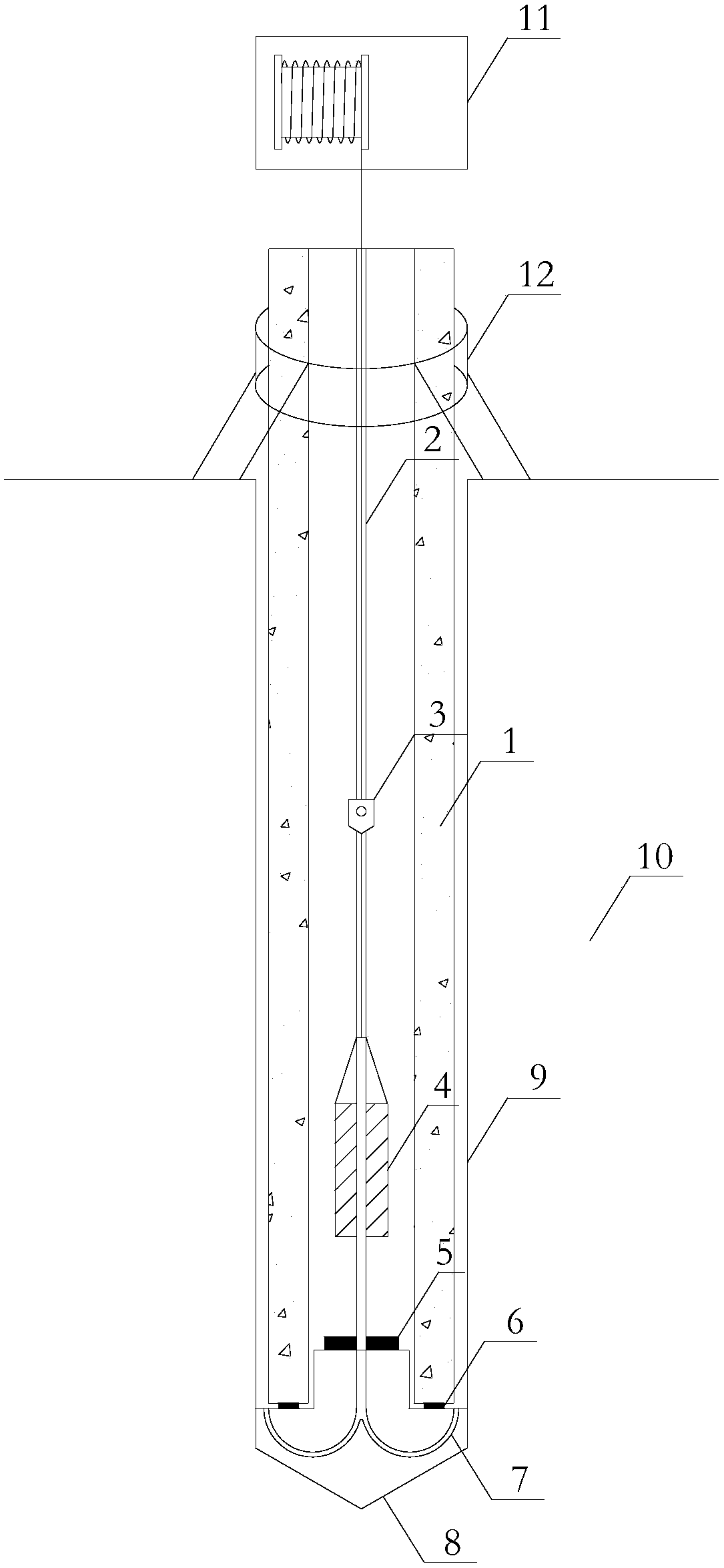

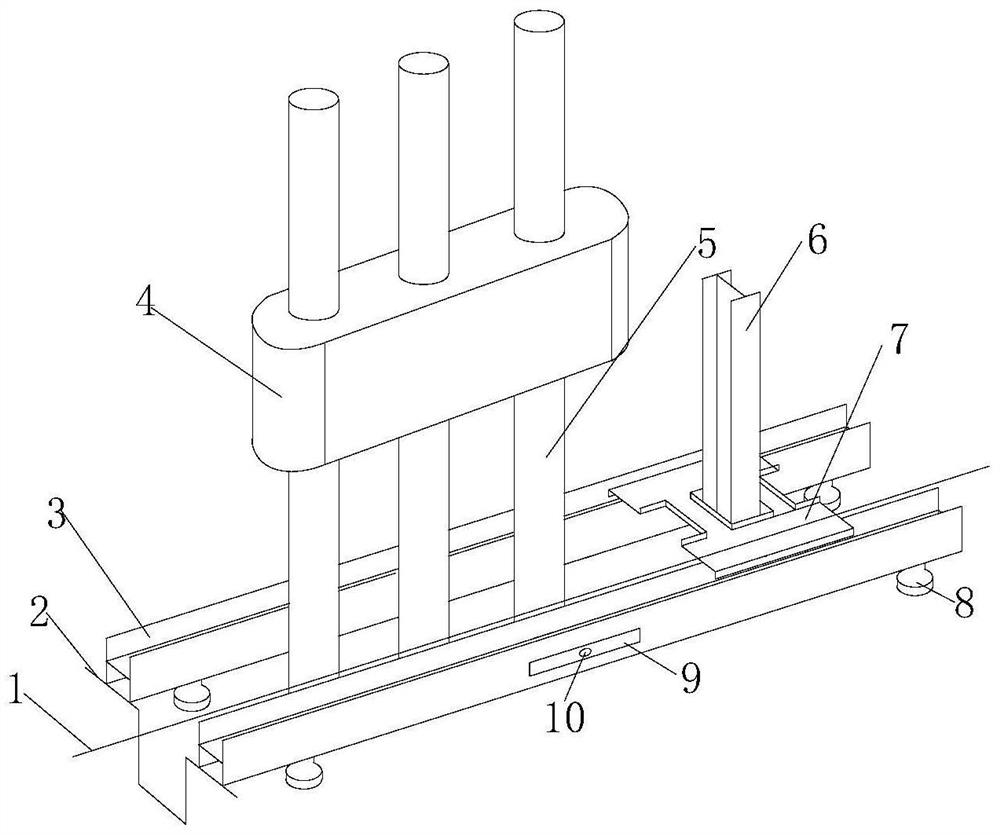

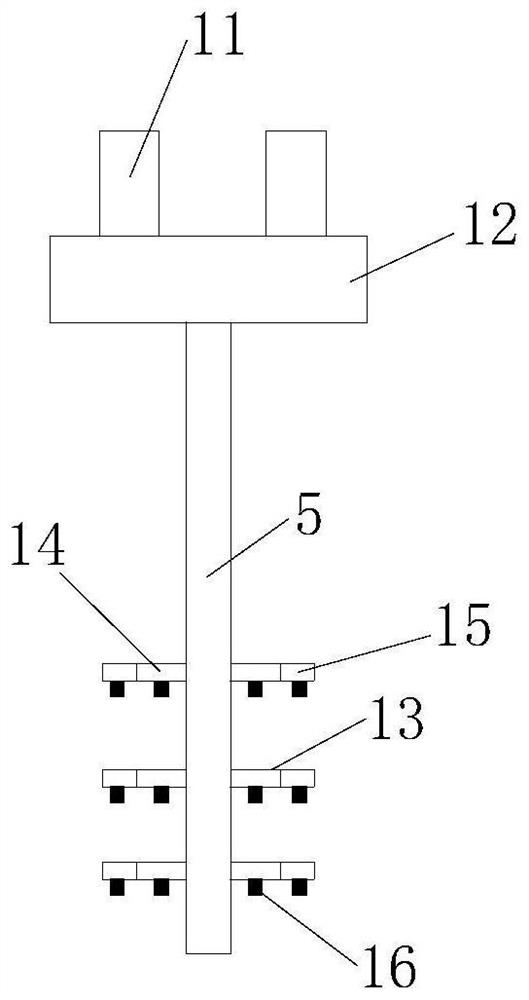

Hammering pile sinking and synchronous pile tip and side grouting structure and process in pile tip of pile shoe-provided pipe pile

ActiveCN107938666AReduce side frictionImproved hammer penetration abilityBulkheads/pilesPre stressPipe

The invention discloses a hammering pile sinking and synchronous pile tip and side grouting structure and a hammering pile sinking and synchronous pile tip and side grouting process in a pile tip of apile shoe-provided pipe pile, and belongs to the field of a construction method.. According to the grouting method, a center penetrating hammer is used for hammering the pile tip to expand a pile shoe so that the pile tip can be hit into the pile shoe; the pile tip sinks and takes a pre-stressed pipe pile to sink together; and the pile tip and the pile side are synchronously expanded to realize grouting treatment inside a grouting passage. The grouting structure disclosed by the invention is relatively high in hammering penetration capability; a synchronous grouting system can commendably play a lubrication effect in a pile sinking process and can reduce the friction resistance of the pile side; after pile sinking is ended, the strength improvement can provide a higher single pile bearingcapacity; a hammering process is performed under the ground; construction noises can be controlled commendably; and the height of an elevator is adjustable, namely the hammer drop journey can be corrected according to the geological conditions of the current pile sinking depth, so that higher pile sinking efficiency is achieved. The structure and the process disclosed by the invention have low requirements on equipment; the bearing capacity of an equipment platform generally needs not to be specially treated, all equipment can be recycled after the construction is ended, and good economicalbenefits are realized.

Owner:ZHEJIANG UNIV

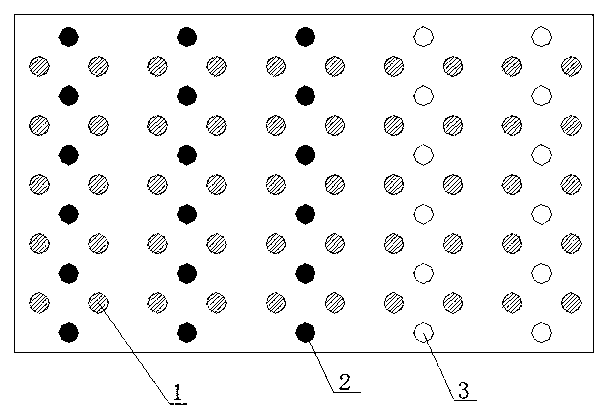

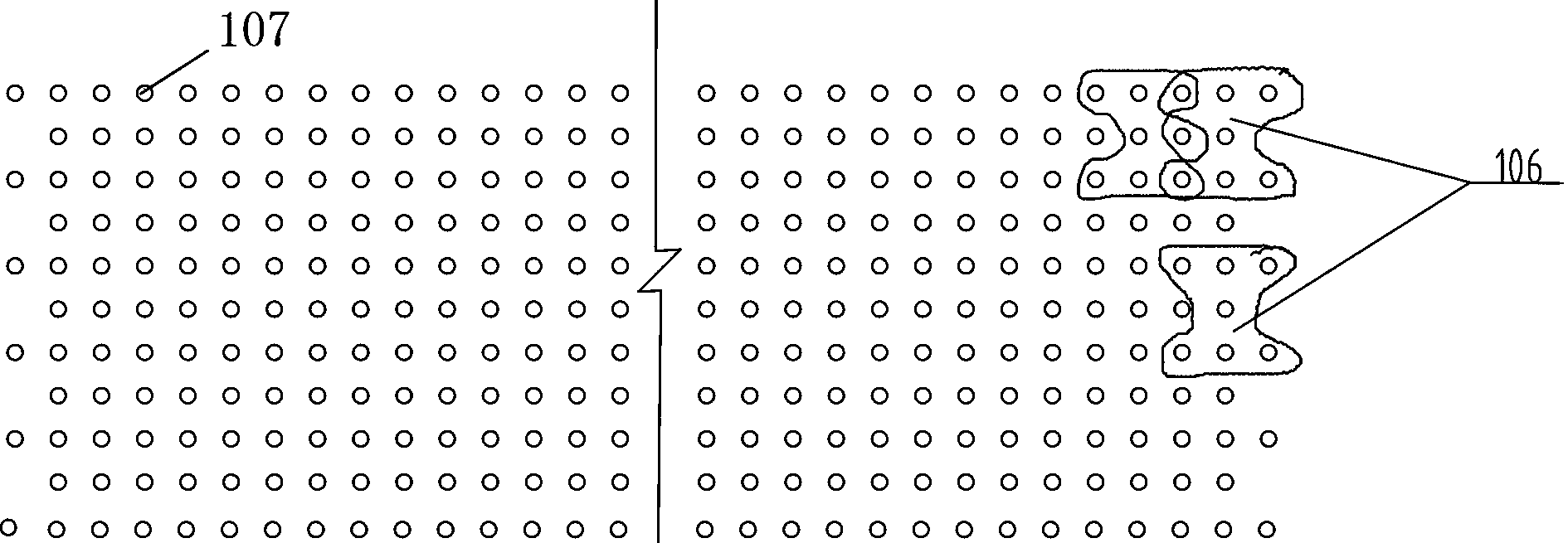

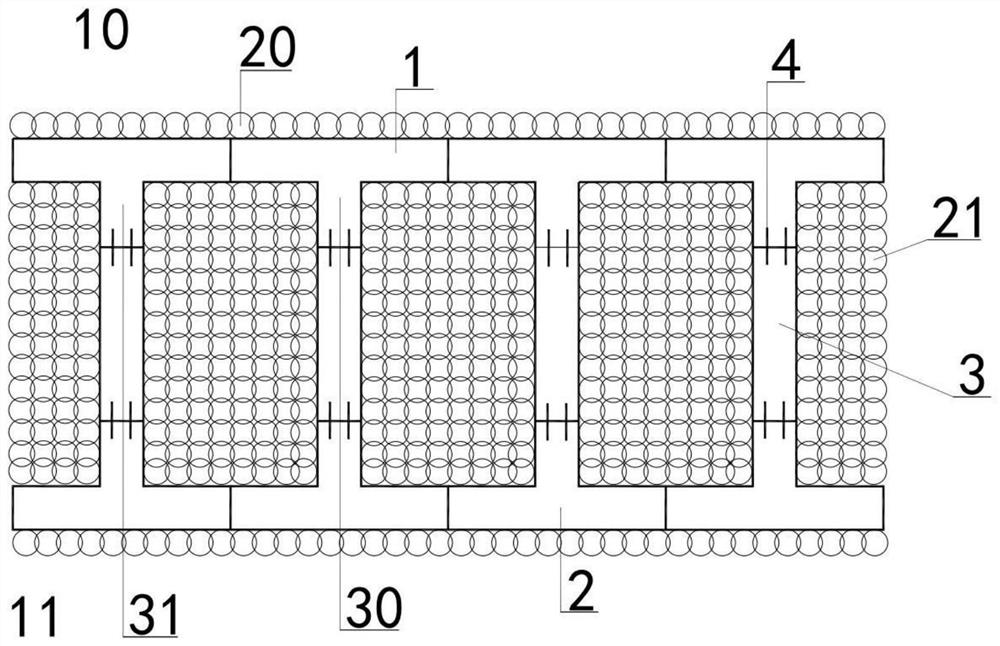

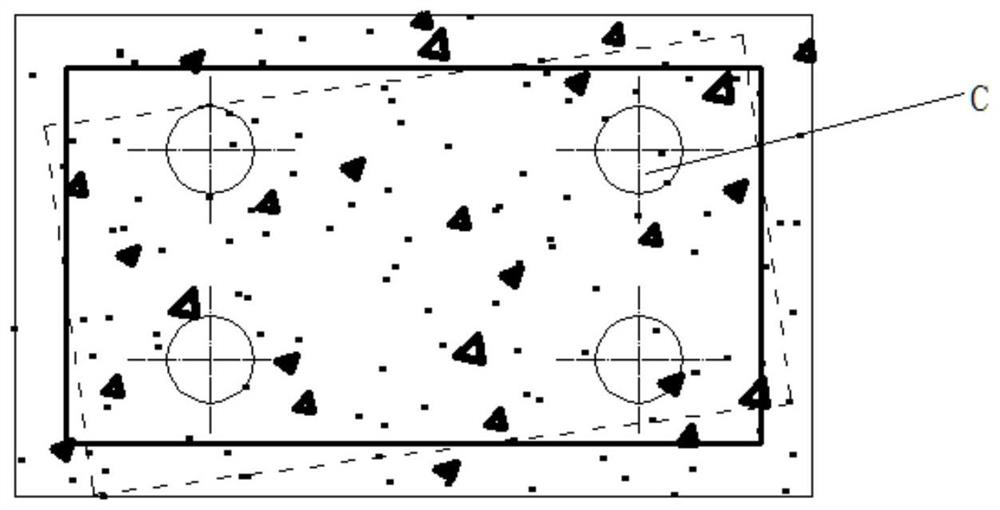

Composite treatment grouped piles for soft foundation

InactiveCN102704462AImprove the bearing capacity of the foundationImprove stabilitySoil preservationRebarBearing capacity

The invention relates to a treatment structure for a soft foundation, in particular to composite treatment grouped piles for the soft foundation. The composite treatment grouped piles comprise CFG (Cement Flyash Gravel Pile) piles, rotary drilled piles and pipe piles which are arranged in the foundation, wherein matrixes formed by the rotary drilled piles and matrixes formed by pipe piles are arranged at intervals; the CFG piles are also arranged in the form of a matrix and arranged in the matrixes formed by the rotary drilled piles and the matrixes formed by the pipe piles; pile caps are respectively connected above the piles, and the pile caps thereof are connected by reinforcing steel bars; and geogrids are supported on the pile caps thereof, and cotton-padded mattress cushion layers are arranged on the geogrids. Compared with the prior art, the CFG piles, the rotary drilled piles and the pipe piles are in the forms of matrixes and arranged in a staggered manner, so that stressed characteristics of the foundation under different working conditions in different periods are solved, and simultaneously, the bearing capacity of the foundation is greatly improved; the pile caps of the piles are connected, and the foundation load is transmitted through the cotton-padded mattress cushion layers, so that the bearing capacity of high-strength piles of the pile caps are effectively utilized, the stability of the foundation is improved, and the problem that the stress to the soft foundation in the treatment process is uneven is solved.

Owner:CHINA RAILWAY 16TH BUREAU GRP 5TH ENG

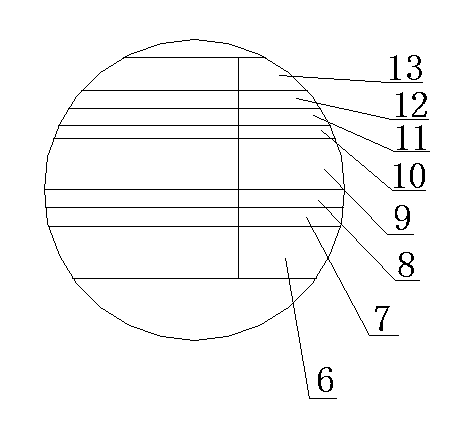

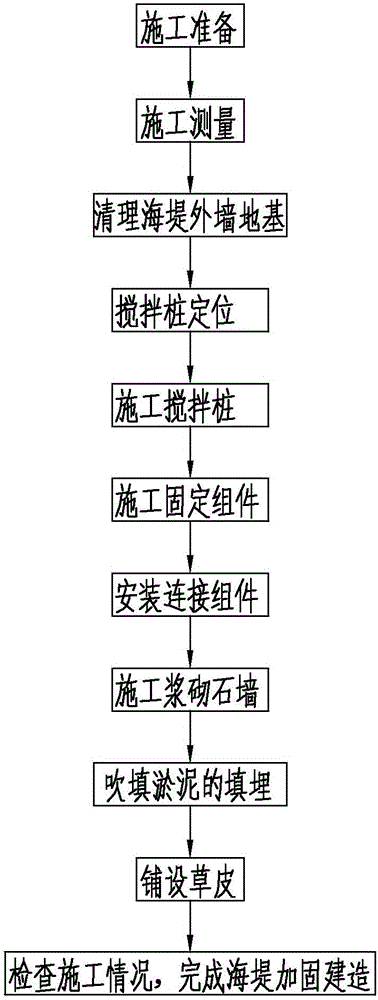

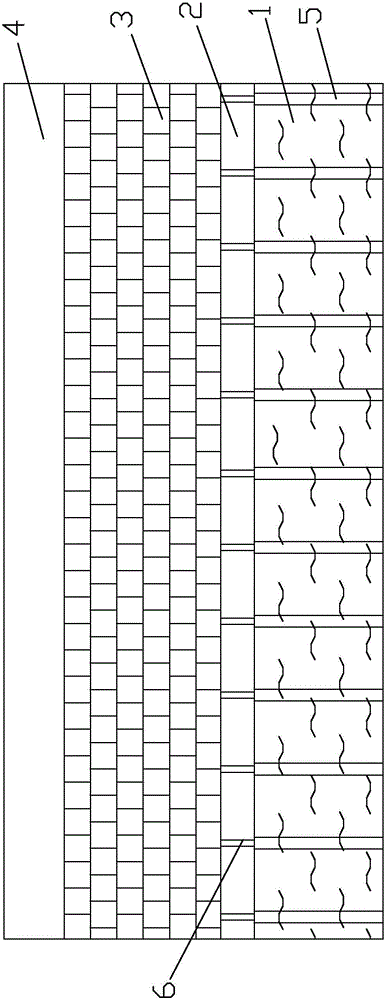

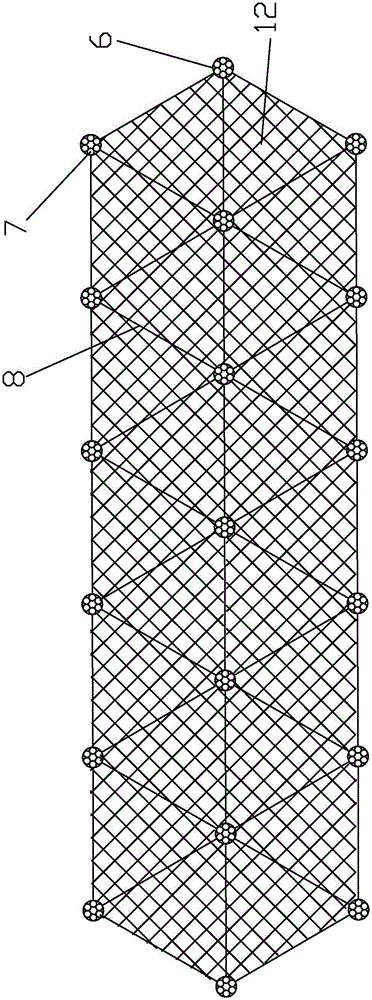

Construction method for improving bearing capacity of seawall armor foundation

ActiveCN105951670AImprove the bearing capacity of the foundationReduce foundation settlementClimate change adaptationCoastlines protectionSeawallLateral displacement

The invention discloses a construction method for improving the bearing capacity of a seawall armor foundation. The method comprises the following steps of construction preparation, construction measurement, cleaning of the foundation of an outer wall of a seawall, positioning of mixing piles, construction of the mixing piles, construction of fixing assemblies, mounting of connecting assemblies, construction of a wet masonry stone wall, laying of turfs and checks of construction conditions to complete reinforcing construction of the seawall. Under the condition that an original seawall is not dismantled, the outer wall of the original seawall is treated and reinforced, the mixing piles are constructed in a bidirectional mixing mode and are fixedly connected by constructing the fixing assemblies and mounting the connecting assemblies, and a composite foundation is formed by the cement mixing piles and sea mud on the sides of the piles, so that the bearing capacity of the foundation is improved, and settlement and lateral displacement amount of the foundation are reduced. The construction method is easy and feasible to operate, the construction cost is reduced, construction is convenient, the construction efficiency is high, project construction cost can be reduced, and the project construction period can be shortened, so that the project investment benefits are increased.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

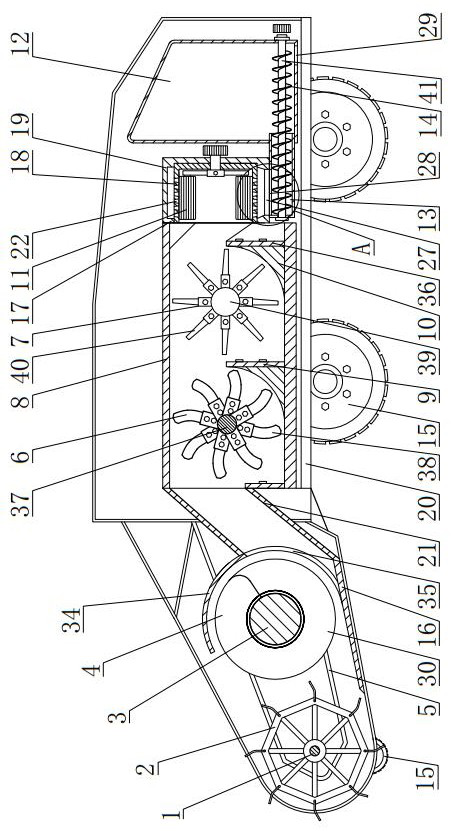

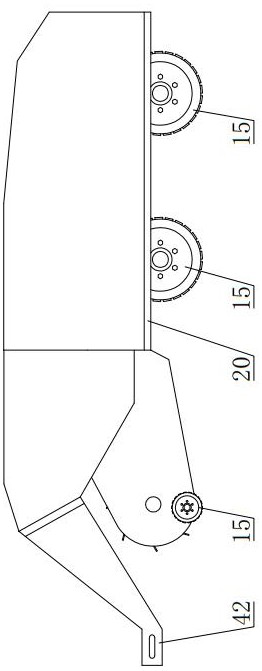

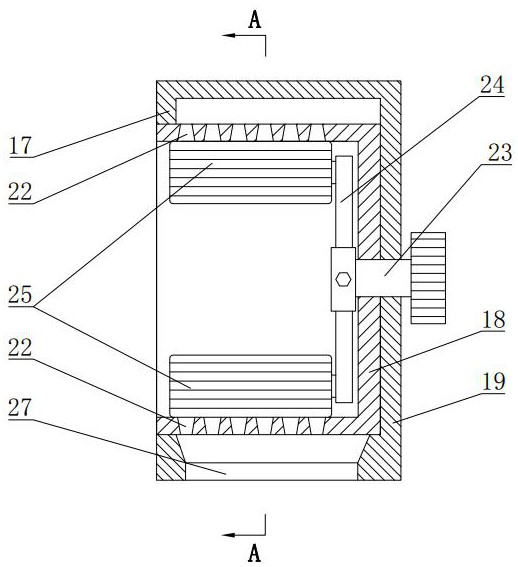

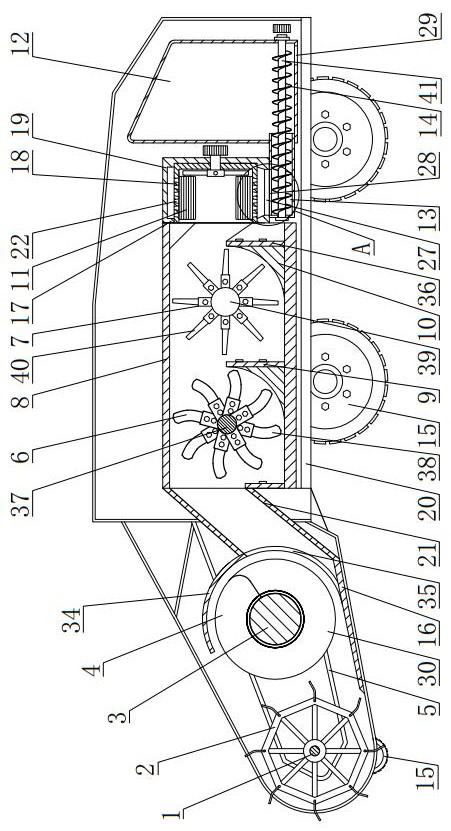

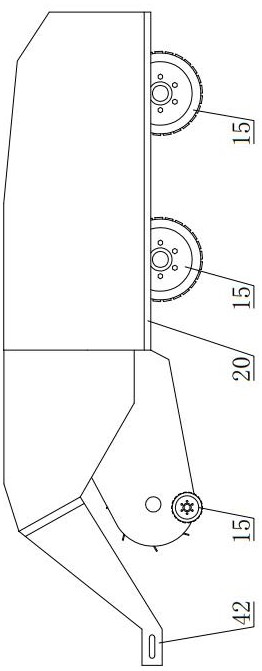

Straw smashing and forming equipment

ActiveCN112088666AHigh strengthImprove carrying capacitySolid waste managementLoadersSludgeAgricultural engineering

The invention relates to straw smashing and forming equipment. The equipment comprises a vehicle body, a supporting frame is mounted on the front side of the vehicle body, a grass raking frame is rotationally mounted on the supporting frame, straw gathering rotary blades are arranged on the rear side of the grass raking frame and rotationally mounted on the supporting frame, a material lifting barrel is arranged on the rear sides of the straw gathering rotary blades, and a smashing bin is fixedly mounted on the vehicle body. The other end of the material lifting barrel communicates with the smashing bin. A crushing frame and a smashing frame are mounted in the smashing cabin, the crushing frame is located on the front side of the smashing frame, a material bin is mounted at the tail of thesmashing cabin, the material bin communicates with the smashing cabin, a motor used for driving the grass raking frame, the straw gathering rotary blades, the crushing frame and the smashing frame torotate is mounted on the vehicle body, and a towing hook for towing a vehicle is mounted on the front side of the vehicle body. By means of the equipment, preparation materials can be provided for cement-straw solidified soil, straw particles can play a role in improving the strength of in-situ solidified sludge or soft soil, and construction machinery can conveniently and smoothly enter a site to carry out follow-up operation.

Owner:WEIFANG UNIVERSITY

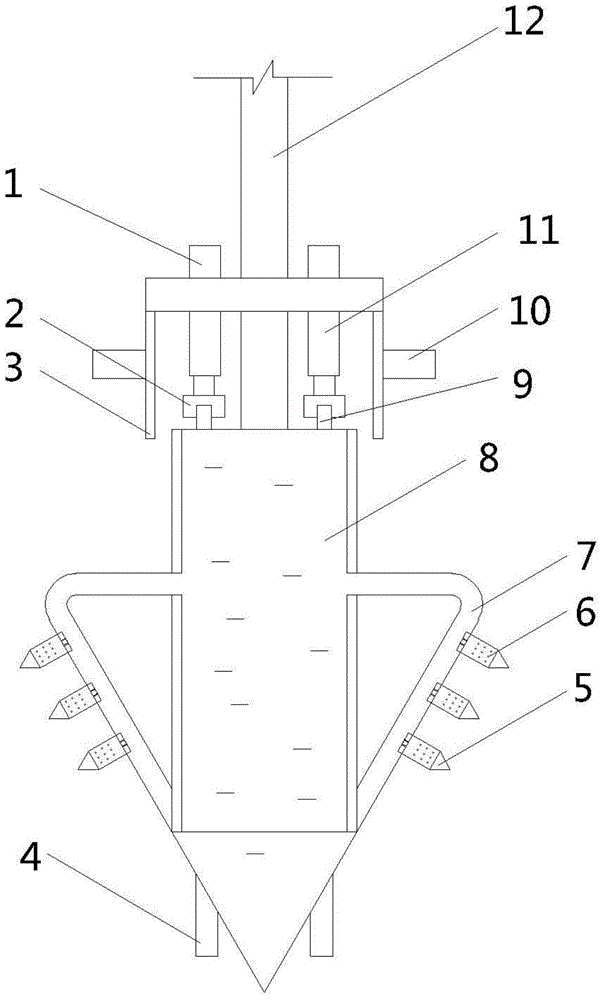

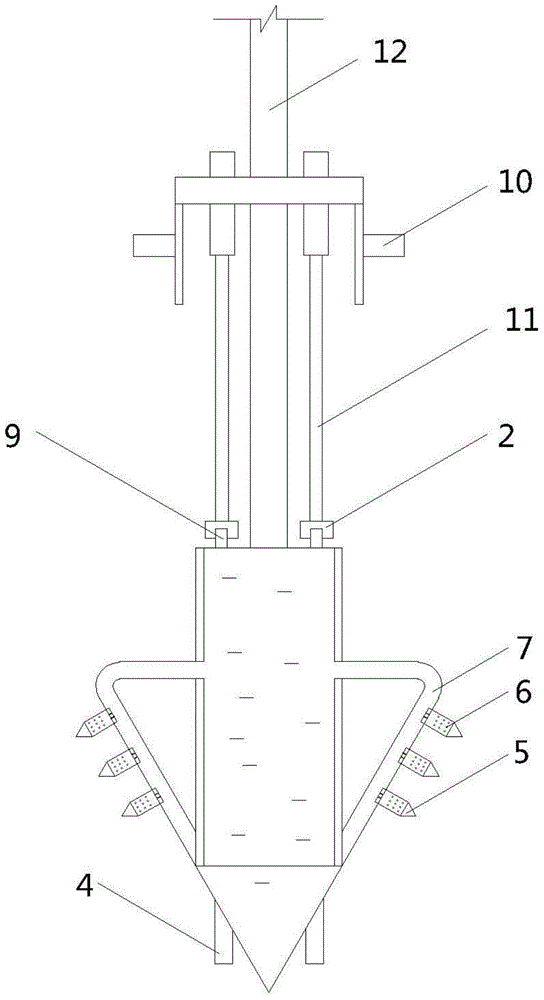

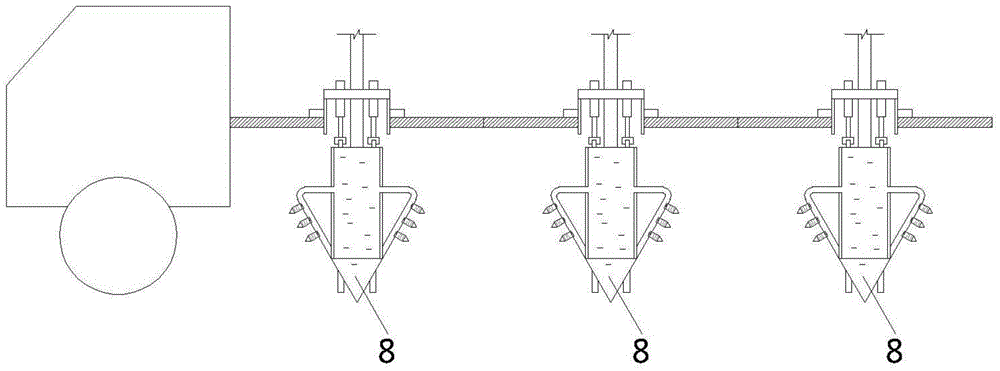

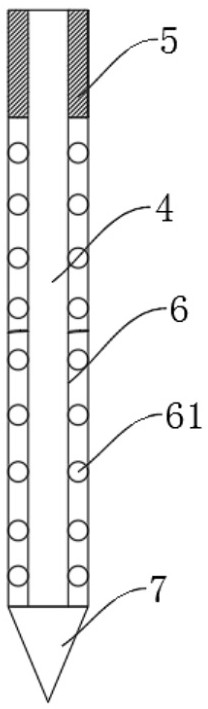

Guniting processing device for pavements on soft foundations

ActiveCN104790282AImprove the bearing capacity of the foundationReasonable institutional designRoads maintainenceSoil preservationEngineeringRoad surface

The invention discloses a guniting processing device for pavements on soft foundations. The device comprises a drill tank and an auxiliary wing, wherein the auxiliary wing is arranged below the drill tank; the device is characterized in that the drill tank is of a hollow structure, the top of the drill tank is provided with a joint, a movable chuck is arranged on the joint, the auxiliary wing is communicated with the hollow structure of the drill tank, a material spray head is arranged on the auxiliary wing, and the material spray head is provided with multiple material spray holes; a fencing cover is arranged above the drill tank, a grouting pipe is arranged on the fencing cover, a telescopic rod is arranged between the grouting pipe and the movable chuck, and the grouting pipe, the telescopic rod, the movable chuck and the joint are communicated in a penetrating mode; and a rotating column is connected with the top of the drill tank. The device is mechanically driven to enter soft soil to carry out material spray, so that a liquid curing agent and a soft soil foundation are mixed more uniformly, thereby increasing the bearing capacity of the foundation. The device disclosed by the invention is reasonable in design, high in construction speed, and suitable for being popularized and applied.

Owner:ZHEJIANG OCEAN UNIV

Soft soil foundation combined treatment method

ActiveCN104141295AImprove the bearing capacity of the foundationReduce construction costsSoil preservationGeomorphologyCushion

A soft soil foundation combined treatment method comprises the steps that (1) holes are drilled in a soft soil foundation, deep well tube wells are embedded in the drilled holes, holes are reserved in the walls of the deep well tube wells, and in the deep well tube wells, underground water in a ground aquifer is pumped and drained through a sinking pump; (2) base slot excavation is performed on the soft soil foundation; (3) the bottoms of base slots are evenly backfilled with sand cushion layers to be used as drainage channels; (4) plastic drainage plates are punched on the backfilled sand cushion layers vertically and downwards, the top ends of the drainage plates stretch out of the surfaces of the sand cushion layers by more than 30 cm, bottom elevations are punched on the drainage plates and at least stretch into the position below the foundation treatment thickness by 3 m, and therefore the underground water can be seeped through the drainage plates, then, the water flows to the tube wells together through the sand cushion layer drainage channels, and then the water is pumped and drained through the sinking pump; (5) when the underground water level is obviously reduced, layering backfilling and vibration grinding are carried out on the dust. According to the method, the foundation bearing force can be improved, the use function of a building is met, the construction cost is low, the construction period is short, and the effect is obvious.

Owner:上海交通建设总承包有限公司

Construction method for salty soil district railway roadbed with water content higher than liquid limit

InactiveCN103243625AImprove the bearing capacity of the foundationImprove stabilityRoadwaysSlurryEngineering

The invention discloses a construction method for a salty soil district railway roadbed with the water content higher than a liquid limit. The construction method comprises the working flow of checking salty soil, filling a sheet stone layer, filling a sand stone layer, filling a gravel reversed filter layer, filling a salty soil layer, and paving a sand cushion layer. By the construction method, soft roadbed soil is treated by throwing and filling sheet stones, so that the bearing capacity and the overall stability of the railway roadbed are improved, the cracking of edge slopes of the roadbed and other phenomena caused by settlement of the salty soil railway roadbed, mud exposure caused by slurry turning, salt expansion and the like are avoided, and the salty soil railway roadbed can be stably and normally used; the problem of lack of salty district roadbed fillings is solved, the materials are readily available, the cost is saved, and the construction method is economical and environmentally-friendly; and the two sides of the roadbed are widened, so that the roadbed can be protected, salination of a body of the railway roadbed is prevented, and the service life of the salty soil district railway roadbed is prolonged.

Owner:CHINA RAILWAY 21ST BUREAU GROUP THE FOURTH ENG

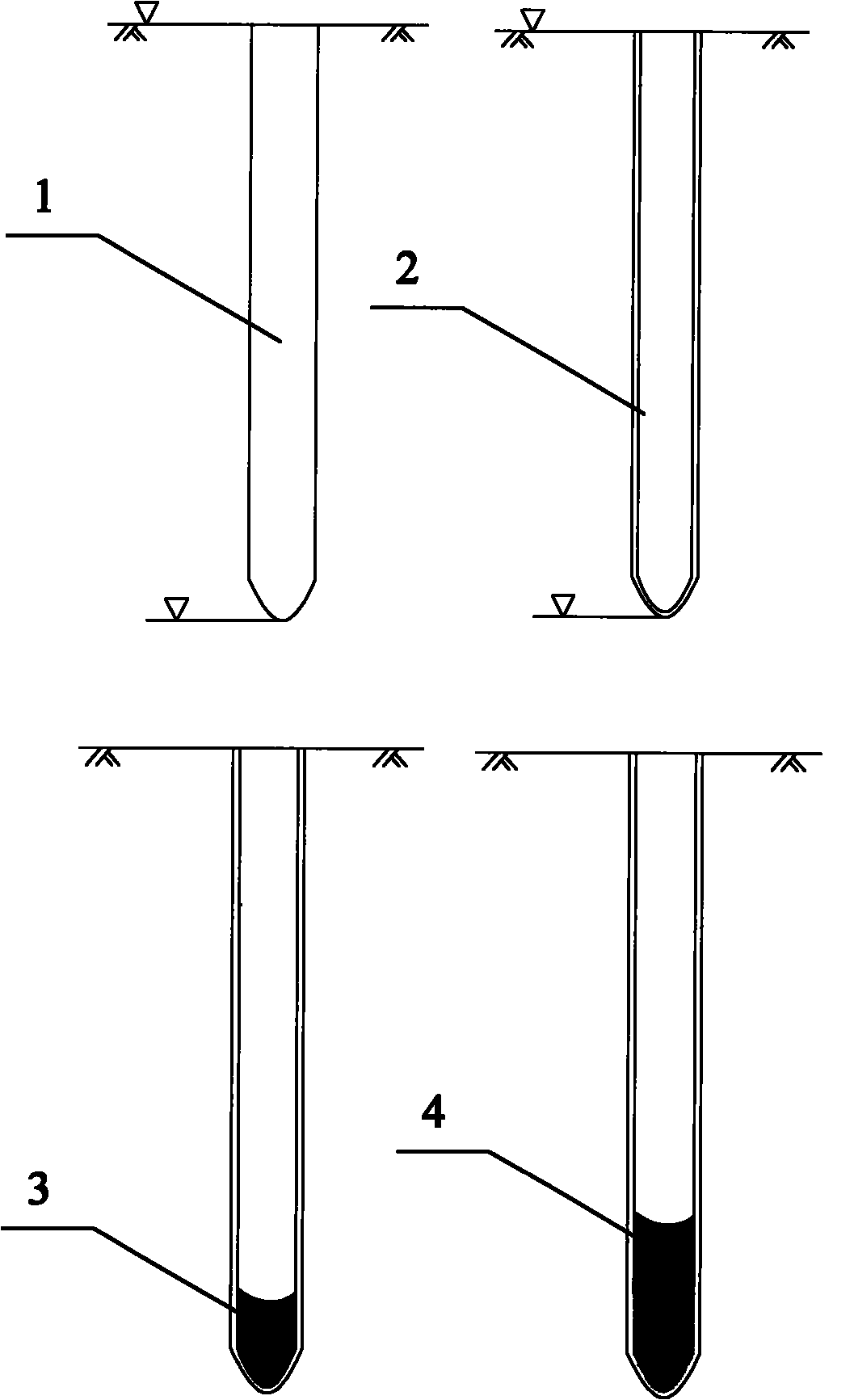

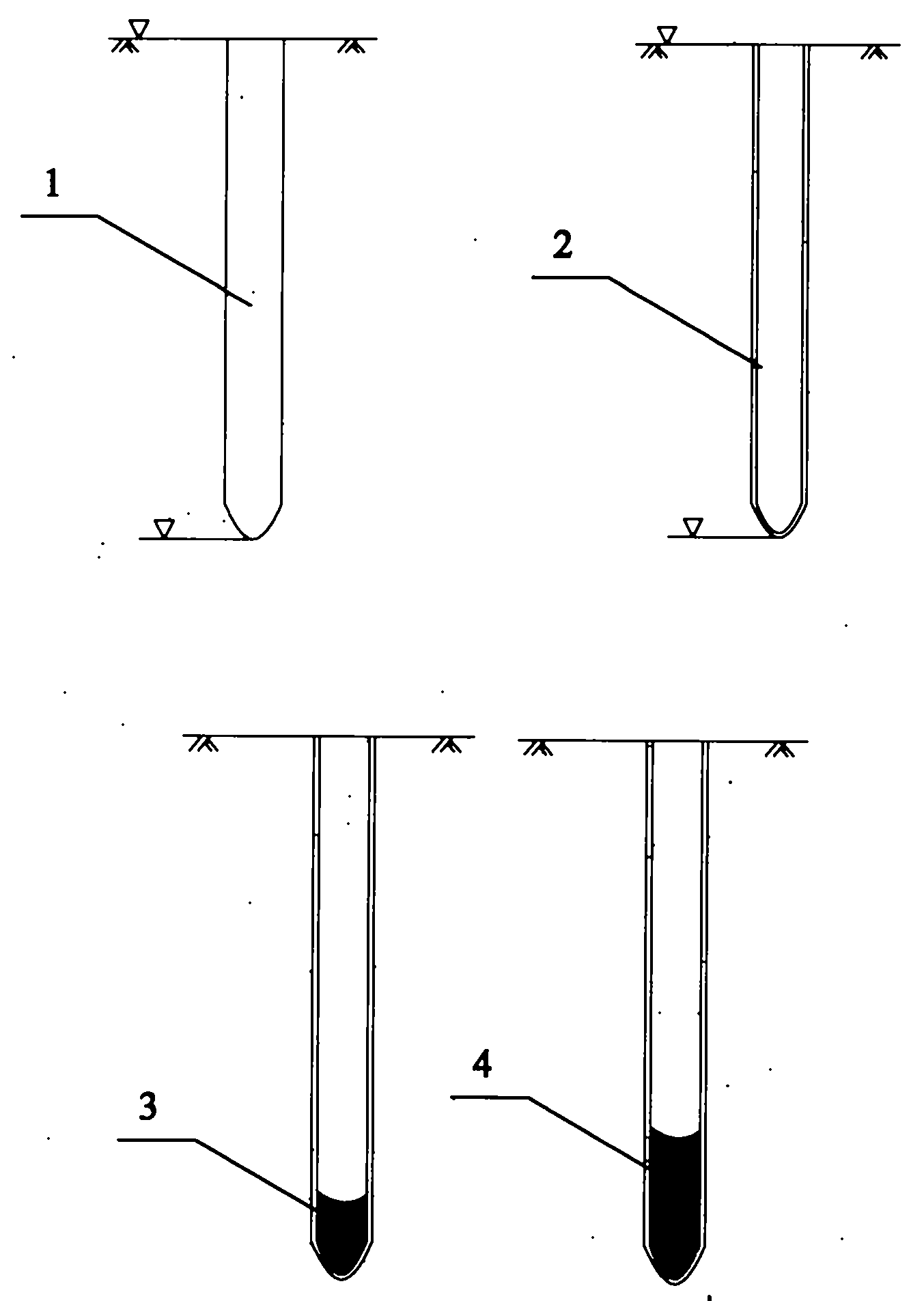

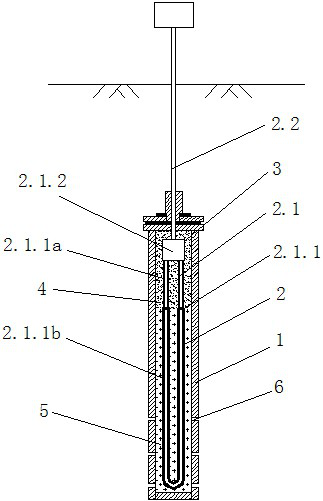

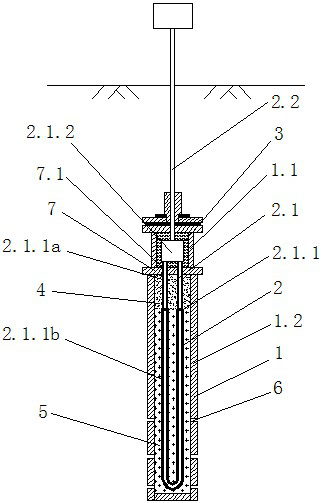

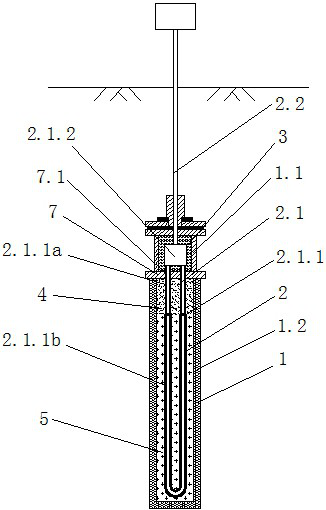

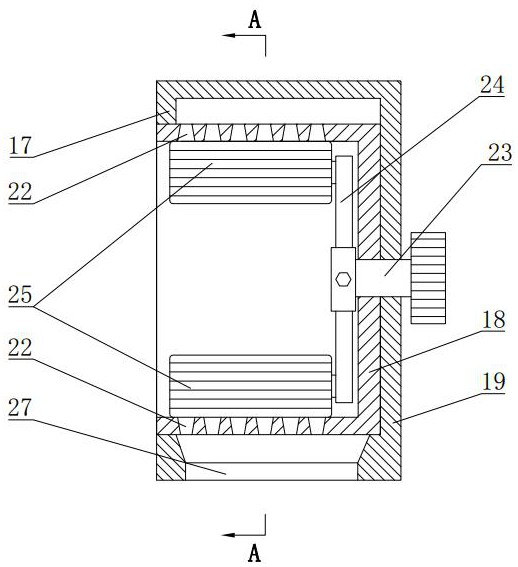

Pressurization thermosensitive vaporization phase change consolidation method and thermal desensitization intermittent evaporator therefor

ActiveCN112281807AAccelerated phase change consolidationImprove the bearing capacity of the foundationSteam generation heating methodsSoil preservationEvaporatorEngineering

The invention discloses a pressurization thermosensitive vaporization consolidation method. The method comprises the following steps that S1, a thermal desensitization intermittent evaporator is placed in a bottom area of a vacuum preloading drainage plate in a sludge consolidation area, heating is started, and during heating, the thermal desensitization intermittent evaporator jets high-pressuresteam; S2, heating is performed to 100-400 DEG C, the temperature is maintained for 3-120 minutes, heating is stopped for 6-240 minutes, and when the vacuumizing pressure is more than or equal to 80 kPa, the process is repeated; and S3, when the liquid limit index of a peripheral consolidated soil body is smaller than 0.98, heating is stopped, so that gasification and consolidation are completed.Intermittent heating and high-pressure steam jet can be achieved, the activity of water molecules is improved, the water molecules quickly flow to a low-temperature area, and the solidification efficiency is improved.

Owner:JIANGSU XINTAI GEOTECHNICAL TECH CO LTD

Construction method for improving bearing capacity of collapsible loess field foundation

InactiveCN105714766AEliminate collapsibilityImprove the bearing capacity of the foundationSoil preservationLoessBearing capacity

The invention belongs to the field of civil engineering foundations, and specifically relates to a construction method for improving the bearing capacity of a collapsible loess site foundation, which is characterized in that it includes the following steps: step 1, drilling pile holes; The sections are filled with the mixture of cement and soil, and tamped into sections to form soil-squeezing piles. The beneficial effect is that the soil collapsibility of the foundation soil can be eliminated by the compaction effect of the soil compaction pile formed by the mixture of cement and soil on the soil around the pile, and at the same time, the bearing capacity of the foundation of the collapsible loess site can be improved, which is simple and convenient. Reliable, it greatly simplifies the commonly used foundation treatment forms, and meets the needs of engineering construction.

Owner:LUOYANG URBAN PLANNING & ARCHITECTURE DESIGN RES INST CO LTD

Novel composite curing agent for heavy metal Cd contaminated soil and use method of novel composite curing agent

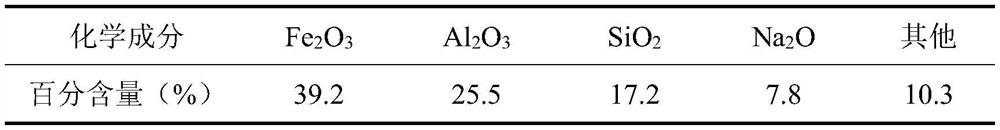

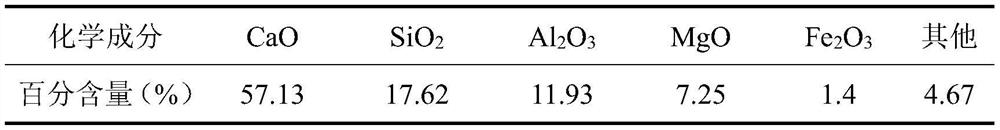

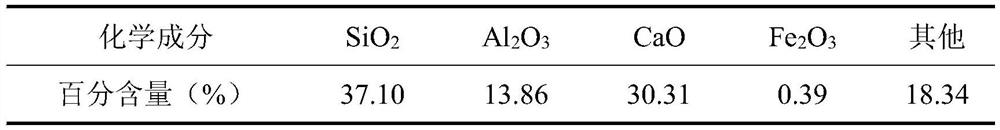

PendingCN114644929AReduce biological activityReduce contentContaminated soil reclamationOrganic fertilisersSoil scienceSlag

The invention provides a novel composite curing agent for heavy metal Cd contaminated soil and a use method thereof, the novel composite curing agent comprises red mud, blast furnace slag and an alkali activator or red mud, fly ash and an alkali activator, the mixing ratio of the red mud to the blast furnace slag is 7: 3, and the mixing ratio of the red mud to the fly ash is 1: 1. And the ratio of NaOH to Na2SiO3 in the alkaline exciting agent is 9: 1. Soil to be remediated is crushed and screened to obtain fine-grained soil, and the blast furnace slag mixture or the fly ash mixture and the fine-grained soil are fully mixed and evenly stirred to form the fine-grained soil compound. And uniformly spraying an aqueous solution of an alkaline activator into the fine-grained soil compound to enable the water content to reach 15-20%, and fully and uniformly mixing. And standing the mixed soil for 7-28 days to solidify the soil polluted by the heavy metal ions. The curing agent disclosed by the invention not only can remarkably reduce the content of heavy metals in soil, but also can improve the bearing capacity of a soil body, so that the effects of treating wastes with wastes and turning wastes into wealth are achieved.

Owner:HUBEI UNIV OF TECH

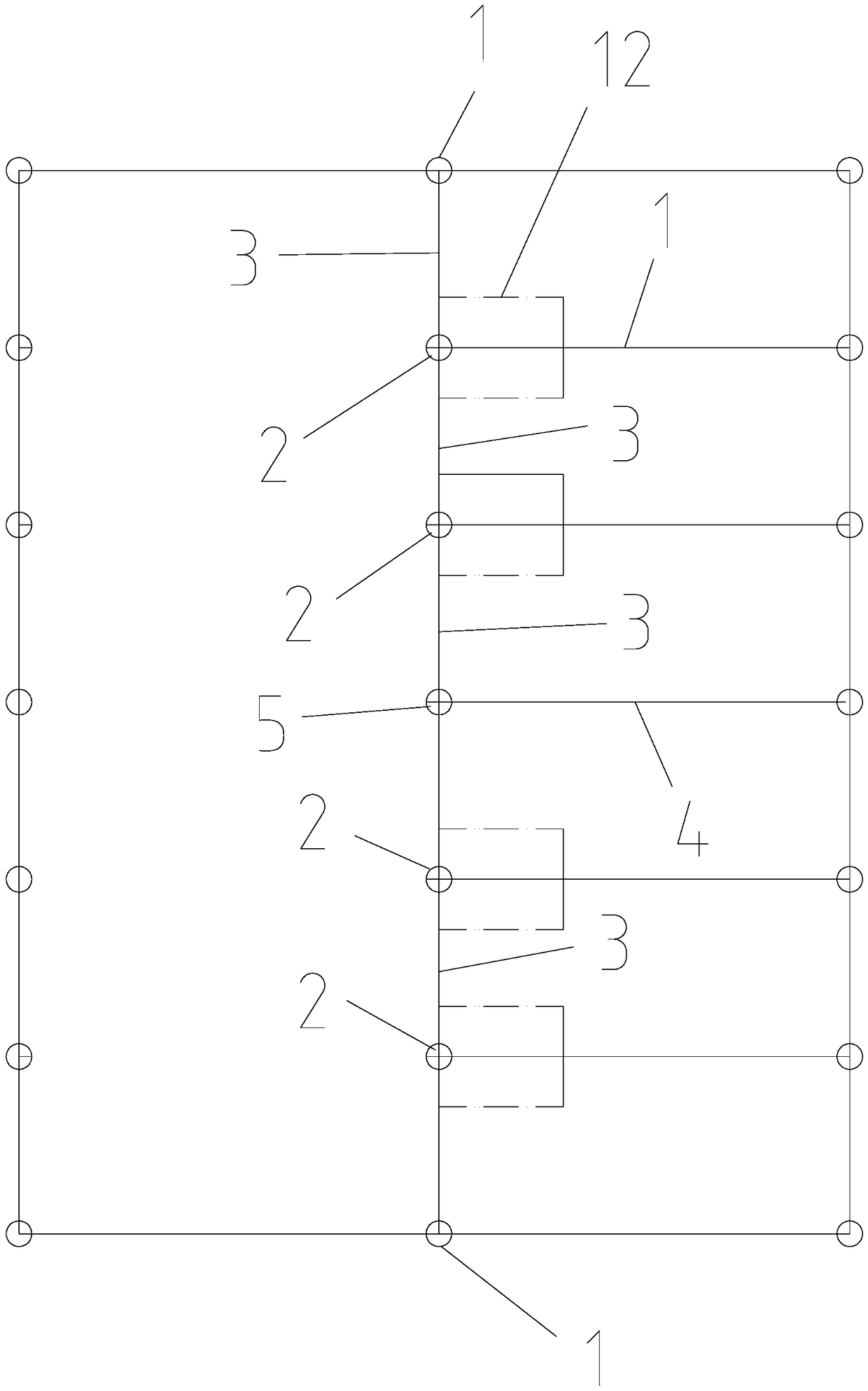

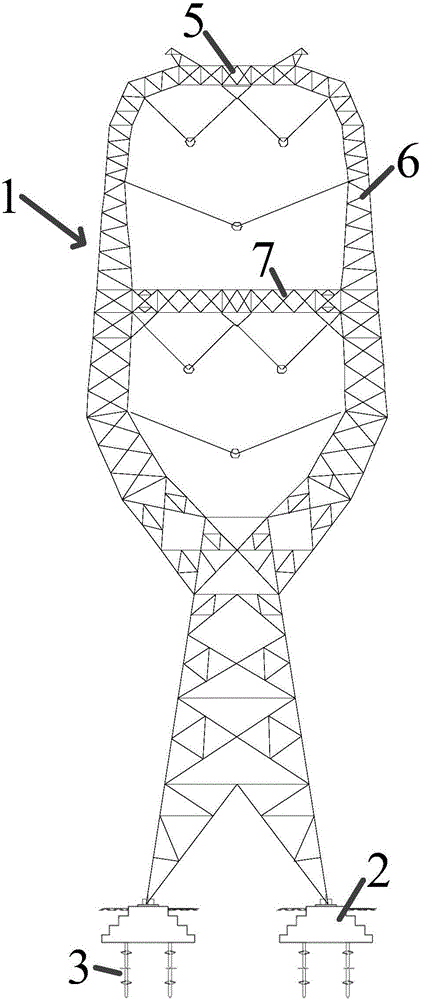

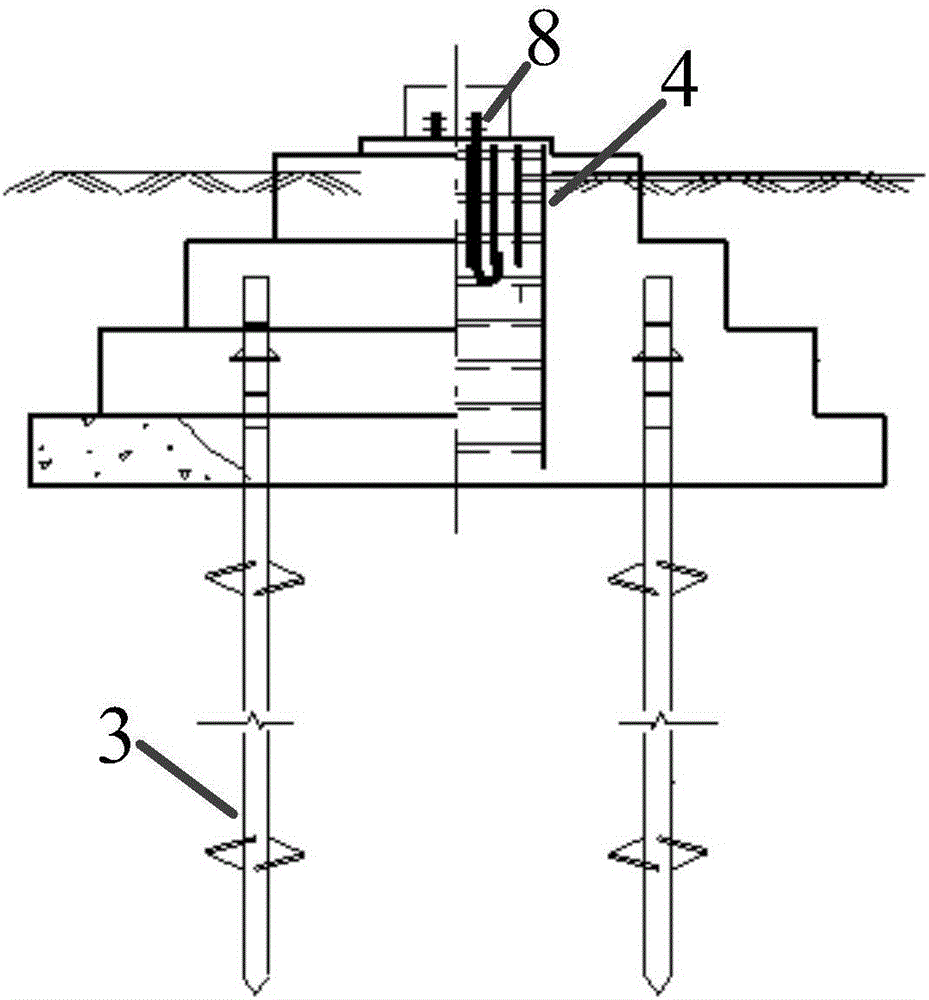

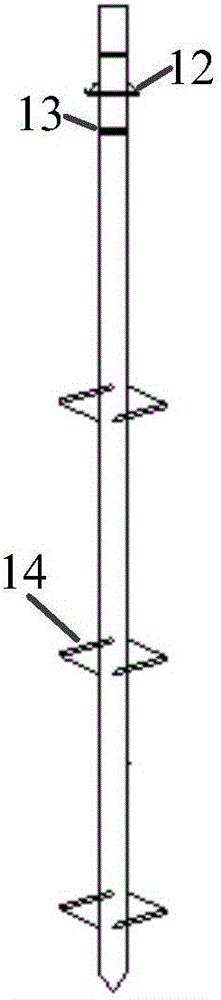

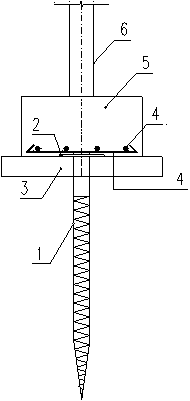

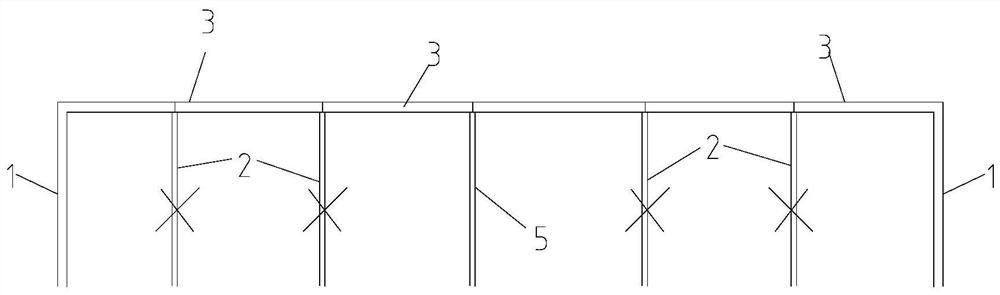

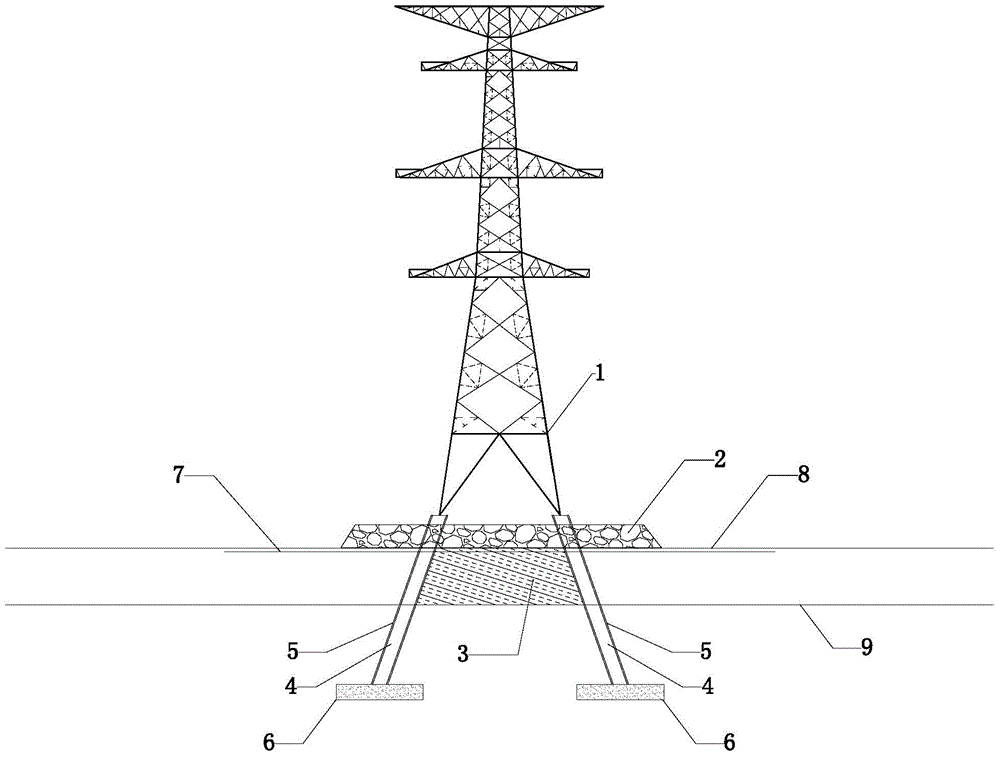

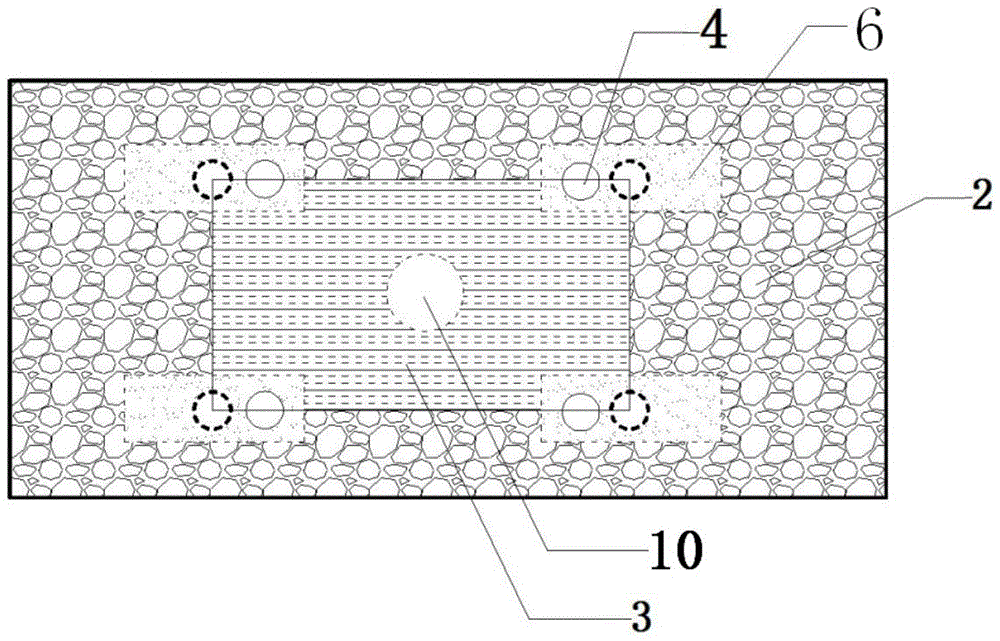

Compound foundation for power transmission tower

ActiveCN105714844AImprove the bearing capacity of the foundationReduce the difficulty of installation and maintenanceFoundation engineeringRebarPower transmission

The invention relates to a compound foundation for a power transmission tower. The power transmission tower comprises a tower body vertically arranged, and a tower window arranged at the upper end of the tower body; the compound foundation comprises a bearing table and spiral anchor rods arranged at the lower end of the bearing table; the bearing table is provided with a vertical reinforcement; and the spiral anchor rods are vertically arranged around the vertical reinforcement, and are provided with connecting components, connected with the bearing table, at the upper ends. The compound foundation, provided by the invention, is high in foundation bearing capacity, low in installation and maintenance difficulty and low in construction and maintenance costs.

Owner:CHINA ELECTRIC POWER RES INST +2

Thin-wall light steel structure steel pile strip-shaped foundation composite foundation technology

InactiveCN110835926ASettlement controlImprove integrityBulkheads/pilesArchitectural engineeringSettlement (structural)

The invention relates to a thin-wall light steel structure steel pile strip-shaped foundation composite foundation technology, and belongs to the technical field of constructional engineering. The technical problem to be solved by the invention is to supplement a spiral steel pile foundation to control building settlement and provide a part of foundation bearing capacity under the condition that astrip-shaped foundation under a concrete wall can meet or partially meet the building load requirement. The invention provides a composite foundation solution under a non-uniform soil layer, the foundation bearing capacity and settlement control problems of an existing fabricated thin-wall light steel structure in the non-uniform soil layer or a soft soil layer are solved, and a new solution is provided for structural safety and construction convenience.

Owner:YUNNAN ZHONGQIAN INTEGRATED HOUSING CO LTD

A kind of underpinning reinforcement method of existing building structure

ActiveCN109403654BIncrease the sectionImprove the bearing capacity of the foundationBuilding repairsArchitectural engineeringPipe support

The invention discloses an underpinning reinforcement method for an existing building structure. Brackets are arranged and reinforced on an original supporting structure column, and a steel pipe supporting device is additionally arranged; enlarged section reinforcement is conducted on the basis of an original pre-reserved structural column, thus the purpose of improving the basic bearing capacityis achieved, and the design requirements of the basic bearing capacity after underpinning are met. Compared with an existing underpinning technology, the underpinning reinforcement method fully utilizes the original structure, damage is small, and the new structure is basically consistent with the original structure in form and coordinates with the original structure for common bearing; before theunderpinned column is removed, a foundation of the pre-reserved structural column is reinforced, reinforcement of the enlarged section and additionally arranged reinforcing bars is conducted, the bearing capacity is increased, and stiffness is improved; the overall economic adaptability is high, the cost is low, economic rationality is achieved, the construction period is short, and the influenceon adjacent surrounding shallow foundations is small; and the underpinning reinforcement method is suitable for application of underpinning transformation of buildings such as large powerhouse structures, gymnasium structures, large shopping mall structures, subway structures and various broken column transformation use spaces.

Owner:广东赛力克建筑技术工程有限公司

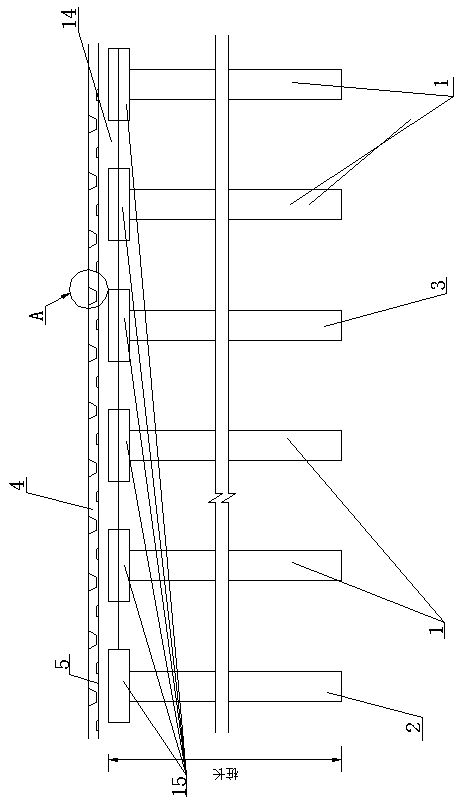

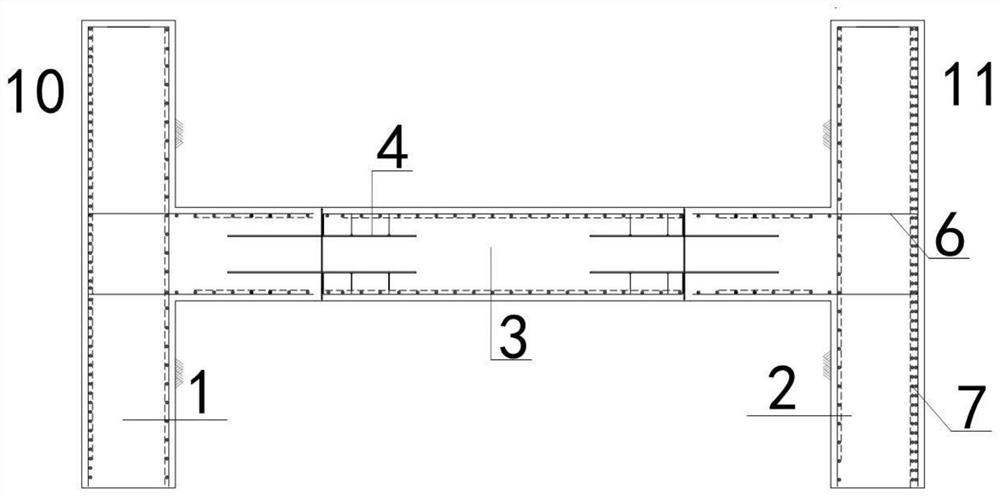

Construction method of revetment lattice diaphragm wall structure

PendingCN114855766AImprove the bearing capacity of the foundationAvoid Connector DisturbanceArtificial islandsClimate change adaptationRebarGeotechnical engineering

The invention discloses a construction method of a bank protection lattice type diaphragm wall structure, which comprises the following steps of: driving support piles in a set I-shaped lattice type diaphragm wall position and on the outer sides of the outer walls of a front wall and a rear wall of a diaphragm wall to be constructed respectively; full reinforcement cement mixing pile construction is conducted in a cavity between the left middle partition wall and the right middle partition wall, adjacent to each other, of the underground diaphragm wall to be constructed; underground diaphragm wall grooving construction is conducted; firstly, a reinforcement cage is installed in the I-shaped first open groove, and then a reinforcement cage is installed in the I-shaped closed groove; the two left-right adjacent T-shaped reinforcement cages at the front wall and the rear wall are fixedly connected through I-shaped connectors; the joint box is hoisted into the I-shaped joints of the front wall and the rear wall, and at least seven guide pipes are installed in the T-shaped reinforcement cage and the linear reinforcement cage; underwater concrete pouring is conducted at the grooving position of the underground diaphragm wall through a guide pipe at the same time; and the joint box at each I-shaped steel joint is jacked and pulled. The collapse probability of the groove section is effectively reduced, and the perpendicularity of the groove wall is guaranteed.

Owner:中铁十八局集团第五工程有限公司 +1

Hammering construction technology with pile shoe and pile body dead weight expanding function

ActiveCN114592517AAvoid defectsLess prone to problems such as inaccessibilityBulkheads/pilesPre stressPipe

The invention discloses a hammering construction technology with a pile shoe and pile body self-weight expanding function. The self gravity of the prestressed pipe pile is utilized, and the prestressed pipe pile is lifted and then freely falls, so that impact force for driving the expanded pile shoe into a soil layer is brought to the expanded pile shoe; and in the sinking process of the expanding pile shoe, a pile side gap channel is formed through the pile diameter expanding effect of the expanding pile shoe, and the resistance of layered soil around the pile to the pile body of the prestressed pipe pile in the pile sinking process is reduced. After the pile end of the prestressed pipe pile enters the ground surface, the impact process of the pipe pile occurs underground, the construction noise can be well controlled, and the advantages of the prestressed pipe pile in the construction process of the ultra-long pipe pile are more obvious. And the lifting height of the pipe pile can be adjusted, that is, the pile falling stroke can be corrected according to the geological condition of the current pile sinking depth, and the pile sinking efficiency is higher.

Owner:ZHEJIANG UNIV +1

Combined construction method for road bridge

PendingCN113957803AReduce cross-section settlement differenceReduce settlementBridge erection/assemblyRebarSoil horizon

The invention discloses a combined construction method for a road bridge, which comprises the following steps: S1, drilling a pile: after geological exploration and selection are carried out according to the construction position of a bridge, a pile casing is buried in a soil layer by adopting a corresponding rotary drilling rig and a circulating drilling rig, prepared slurry is used in a drilled hole, the drilling process comprises two steps of centering and drilling, and the drilling process comprises two steps of centering and drilling; wherein the slurry is used for the drilling step, finally, a drilled hole is cleared and checked, then the prepared reinforcement cage is put into the drilled hole, and concrete is poured and formed. During construction, the foundation bearing capacity of the widening bridge is improved, and the pile foundation bearing capacity of the widening bridge is improved by adopting a cast-in-place pile post-grouting technology; the integral cast-in-place layer is arranged at the splicing seam between the existing bridge superstructure and the widened bridge superstructure, so that the settlement of the newly-built widened bridge can be effectively reduced, and the pavement settlement difference of the road bridge is reduced.

Owner:方菱桥隧模架(福州)有限公司

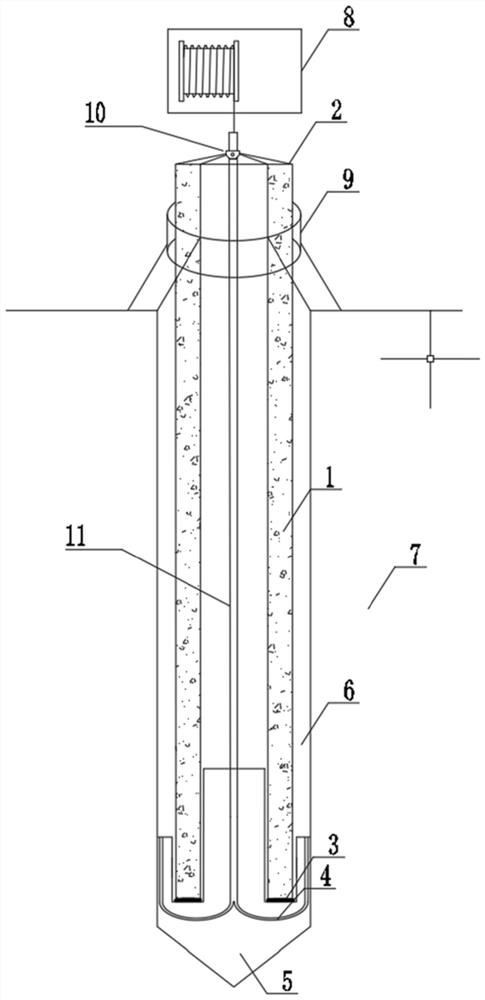

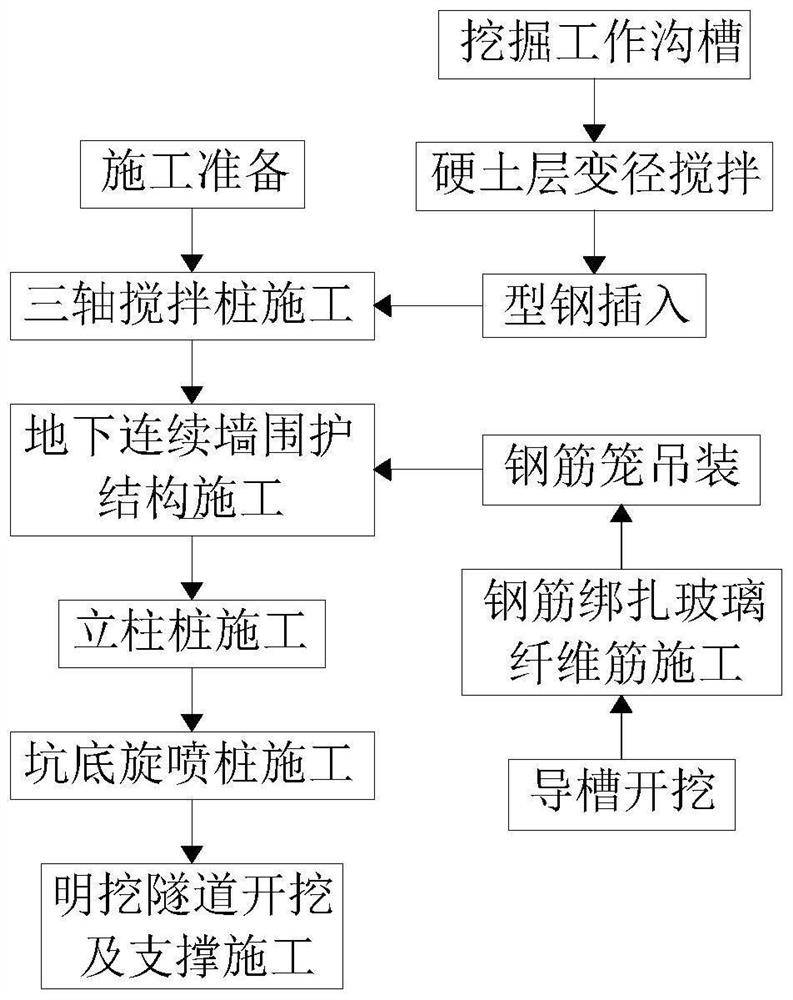

Pre-reinforcement system for overpass planned tunnel line of open cut tunnel foundation pit and construction method

PendingCN114703841AReduce construction costsImprove the bearing capacity of the foundationProtective foundationExcavationsRebarTunnel construction

According to the open cut tunnel foundation pit overpass planned tunnel line pre-reinforcement system and the construction method, in the construction process, firstly, three-shaft mixing pile blades are used for conducting hard soil layer variable-diameter mixing, and then a profile steel guiding and positioning technology is used for vertically inserting profile steel into the piles to form the three-shaft mixing piles; then, a guide groove is excavated through a hydraulic grab bucket and a hydraulic double-wheel slot milling machine, a glass fiber rib reinforcement cage is put down, main ribs and glass fiber ribs are connected through U-shaped buckles, longitudinal truss ribs and transverse truss ribs are installed for reinforcement, and an underground diaphragm wall is formed; and finally, jet grouting the consolidated body to form a jet grouting pile. The foundation bearing capacity is effectively improved, uneven deformation is reduced, the potential influence of planned tunnel construction on a built tunnel is avoided, the later maintenance cost of tunnel crack repair and the like is reduced, the method has the advantages of being high in construction safety, good in reinforcement quality, capable of saving energy, reducing emission and the like, smooth development of subsequent construction is effectively guaranteed, and the construction period is shortened. The influence of construction on the surrounding environment is reduced, and good indirect economic benefits and social benefits are generated.

Owner:浙江交工地下工程有限公司 +1

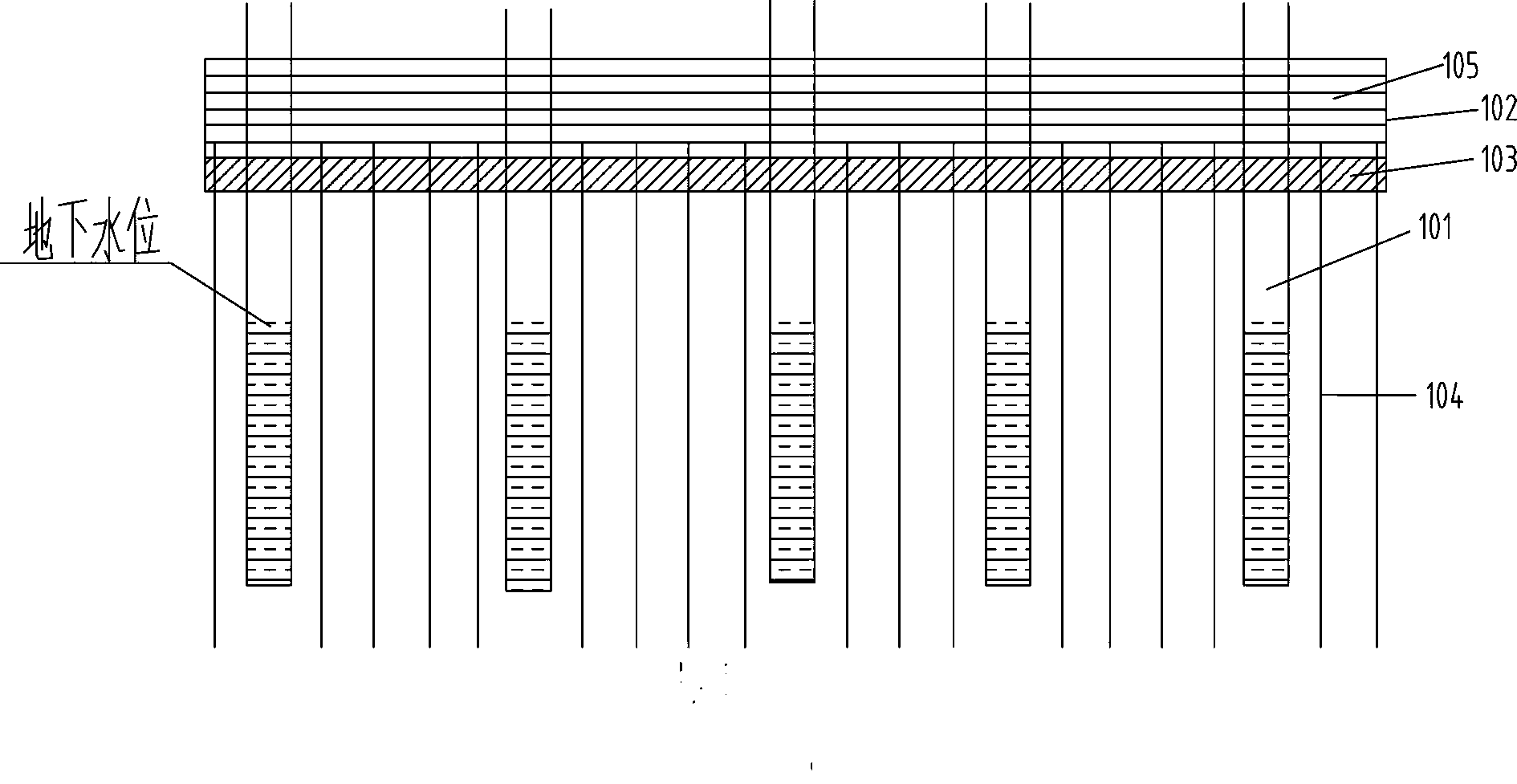

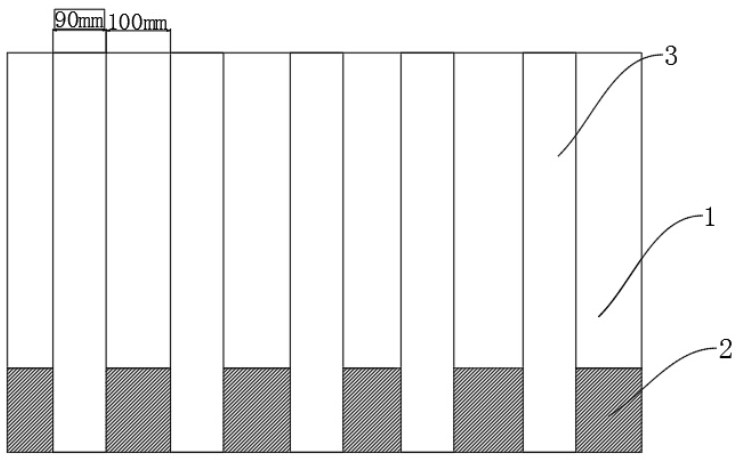

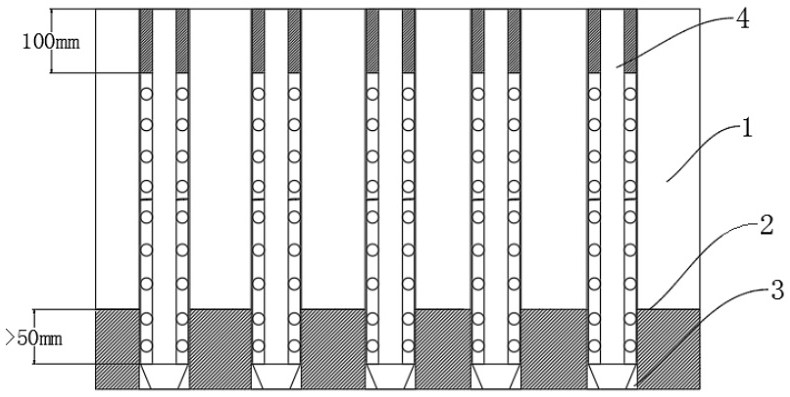

Construction method for grouting reinforcement of urban road roadbed in fly ash accumulation site

InactiveCN113502705AImprove the bearing capacity of the foundationImproved Engineering Instability featureRoadwaysSoil preservationPressure groutingDrill hole

The invention discloses a construction method for grouting reinforcement of an urban road roadbed in a fly ash accumulation site, which belongs to the technical field of roadbed reinforcement treatment of a fly ash accumulation site, and comprises the following steps of: determining a construction target position, cleaning the site, measuring and setting out to determine hole positions of grouting holes for piling and grouting, and manufacturing grouting pipes; forming holes by adopting a spiral drilling machine, wherein the depth range of the drilled holes penetrating through a fly ash soil layer to the position below an undisturbed soil layer is 0.4-0.6 m, the diameter length range of the grouting holes is 80-100 mm, and the distance between the grouting holes is 1 m, and cleaning the holes after the holes are formed; placing the grouting pipes into the cleaned grouting holes, filling evenly the space around the grouting pipes in the holes with sand, and sealing hole sealing pipes in the range of 1 m above the hole openings with blended cement mortar; 24h after grouting and hole sealing are conducted, using pure cement paste for pressure grouting and monitoring the grouting pressure value, wherein the grouting construction sequence is from the periphery to the middle, and hole separation construction is carried out. The purposes of improving the foundation bearing capacity and the deformation resistance and improving the engineering instability characteristic are achieved, the treatment time is shortened, and the treatment cost is reduced.

Owner:JINAN YELLOW RIVER CONSTR GRP CO LTD

Tunnel arch frame structure and process for reinforcing soft soil layer by driving locking feet in advance

PendingCN110905563ALarge operating spaceExtend working hoursUnderground chambersTunnel liningTunnel constructionSolum

The invention belongs to the technical field of tunnel construction, and particularly relates to a tunnel arch frame structure and process for reinforcing a soft soil layer by driving locking feet inadvance. According to the scheme that ground advanced locking foot guide pipes are driven on the ground in advance, and middle and lower step locking foot guide pipes are driven in an upper step holein advance, the time of locking foot construction is saved, the time of soil exposure after each step of excavation is shortened, and the anti-sedimentation capacity of a steel arch frame connected with the tunnel arch frame structure is improved.

Owner:JINAN URBAN CONSTR GRP +1

Fabricated thin-wall light steel structure soft soil curing composite foundation treatment technology

The invention relates to a fabricated thin-wall light steel structure soft soil curing composite foundation treatment technology, and belongs to the technical field of building engineering. The treatment technology aims to solve the technical problem that a basic bearing stratum of a fabricated thin-wall light steel structure does not reach a design value, and aims to solve the safety problems ofthe large settlement amount and non-uniform settlement of the fabricated thin-wall light steel structure. A composite foundation technology treatment scheme under the condition of a soft foundation soil layer is provided, the problem that an existing fabricated thin-wall light steel structure cannot adopt a natural foundation in a soft soil foundation is solved, and a new solution is provided forstructural safety and construction convenience.

Owner:YUNNAN ZHONGQIAN INTEGRATED HOUSING CO LTD

Reconstruction method of subsidence hydraulic structure

ActiveCN114837455APrevent ship from hittingImprove anti-seepage safetyBuilding repairsFoundation engineeringArchitectural engineeringCofferdam

The invention provides a method for rebuilding a sunk hydraulic structure. The method comprises the following steps: step 1, underwater exploration; 2, site treatment; 3, a construction platform is built; 4, designing a pile foundation scheme; 5, pile foundation construction is implemented according to the pile foundation scheme provided in the step 4; the pile foundations penetrate through the subsidence building and form a whole with the subsidence building; the pile foundation comprises a first-stage pile foundation and a second-stage pile foundation; 6, a foundation building surface is formed, specifically, the top of the subsidence building is cleaned, underwater self-leveling concrete is leveled, a plane is formed, and the foundation building surface is built on the top of the subsidence building in combination with a pile foundation and an upper load; in the whole process, large-range cofferdam construction, deep foundation pit construction, dismantling and other key steps of a traditional method are avoided, the subsidence building is changed into a favorable foundation, breakthrough is achieved, and the defects of a common traditional scheme are overcome.

Owner:NANJING HYDRAULIC RES INST +1

Composite slanted column expansion foundation structure applied to transmission lines in permafrost regions

ActiveCN105442626BFlat contact surfaceReduce direct freezing forceFoundation engineeringReinforced concreteEngineering

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

A straw crushing and forming equipment

ActiveCN112088666BHigh strengthImprove carrying capacitySolid waste managementLoadersAgricultural engineeringElectric machinery

The invention relates to a straw crushing and molding equipment, which includes a car body, a support frame is installed on the front side of the car body, a grass rake frame is rotatably installed on the support frame, and a straw gathering rotary blade is arranged on the rear side of the grass rake frame. The stalk gathering revolving blade is installed on the supporting frame for rotation. There is a lifting cylinder on the rear side of the straw gathering revolving blade, and a crushing cabin is fixed on the car body. A crushing frame and a crushing frame are installed. The crushing frame is located on the front side of the crushing frame. A silo is installed at the tail of the crushing cabin. leaves, crushing frame and the motor that the crushing frame rotates, and the front side of the car body is installed to connect the traction hook of the traction vehicle. The equipment can be used to provide preparation materials for cement-straw solidified soil, in which straw particles can play a role in improving the strength of in-situ solidified silt or soft soil, and facilitate the smooth entry of construction machinery into the site for subsequent operations.

Owner:WEIFANG UNIVERSITY

Integral type steel structural frame ballasting pile carrier and static load test method thereof

The invention discloses an integral type steel structural frame ballasting pile carrier. The characteristics of a steel structure frame building are used, the mode of being completely different form atraditional pile loading mode is adopted for pile loading, the pile carrier of an integral type steel structural frame is established, then solid ballasting filling or filling of liquid ballast is carried out filling of liquid ballast is carried out after a liquid container is mounted, so that super tonnage pile loading is realized.

Owner:张宗毅

A new type of seismic isolation composite foundation and its construction method

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com