Fabricated thin-wall light steel structure soft soil curing composite foundation treatment technology

A light steel structure and composite foundation technology, which is applied in infrastructure engineering, soil protection, construction, etc. The structure cannot use natural foundations, the large settlement of the assembled thin-walled light steel structure, etc., to achieve the effect of controlling uneven settlement, reducing the occupied area, and reducing the amount of earthwork excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

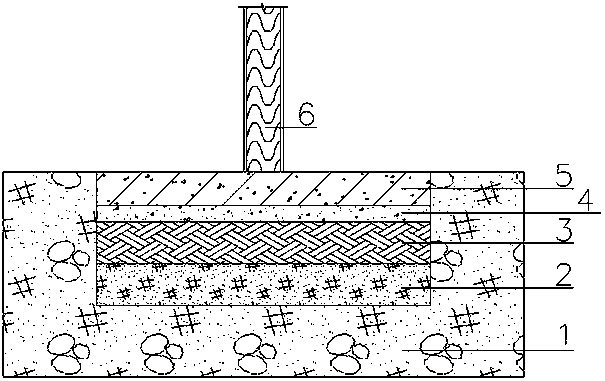

[0023] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

[0024] Step 1: Take the original soil 1 at the project site to conduct a geotechnical test, determine the physical parameters of the soil, and configure a special soil stabilizer;

[0025] Step 2: Excavate the foundation according to the drawings, over-excavate to a depth of about 500mm below the bottom of the foundation, and remove the original soil impurities 1;

[0026] Step 3: The over-excavation part under the base is solidified in layers with two layers of 250mm thick cushions. First, the lower solidified soil layer 2 is solidified and rolled with cement, curing agent, quicklime and original soil 1; then the upper layer of solidified soil Layer 3 is solidified and rolled with cement, curing agent, quicklime and original soil 1. The rolling weight is about 20 tons. The compressive strength of the cushion is expected to reach 1.0Mpa, and the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com