Patents

Literature

45results about How to "Fast backfill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

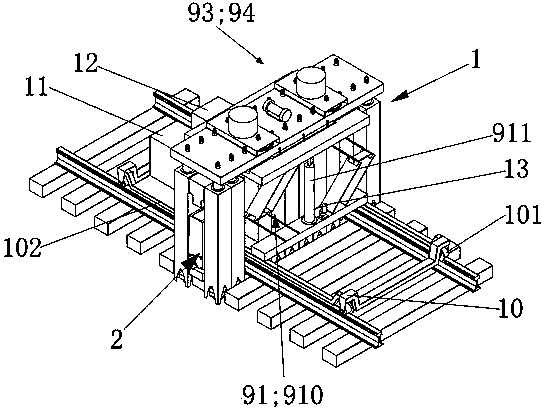

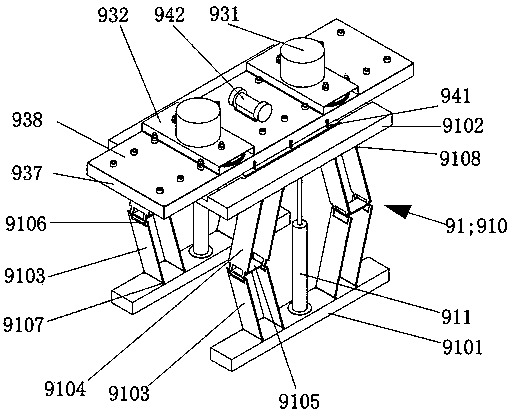

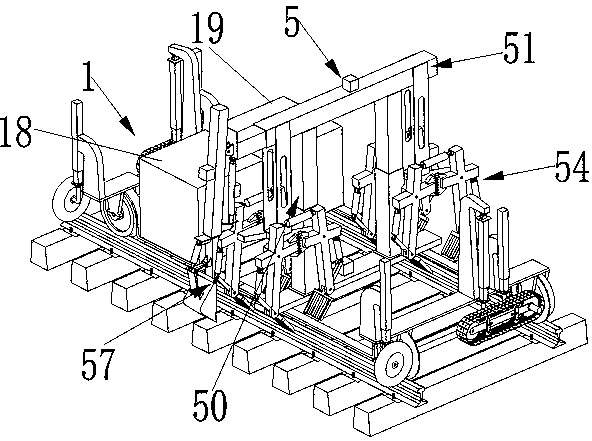

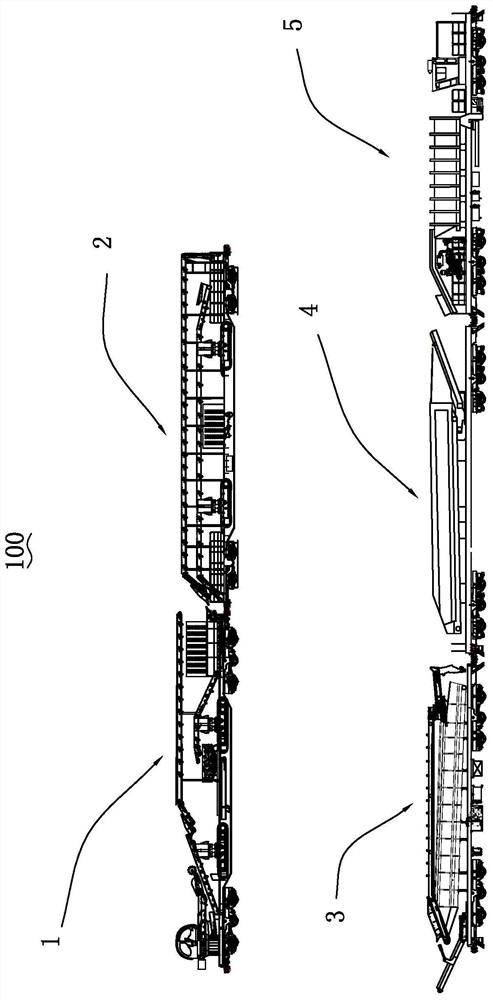

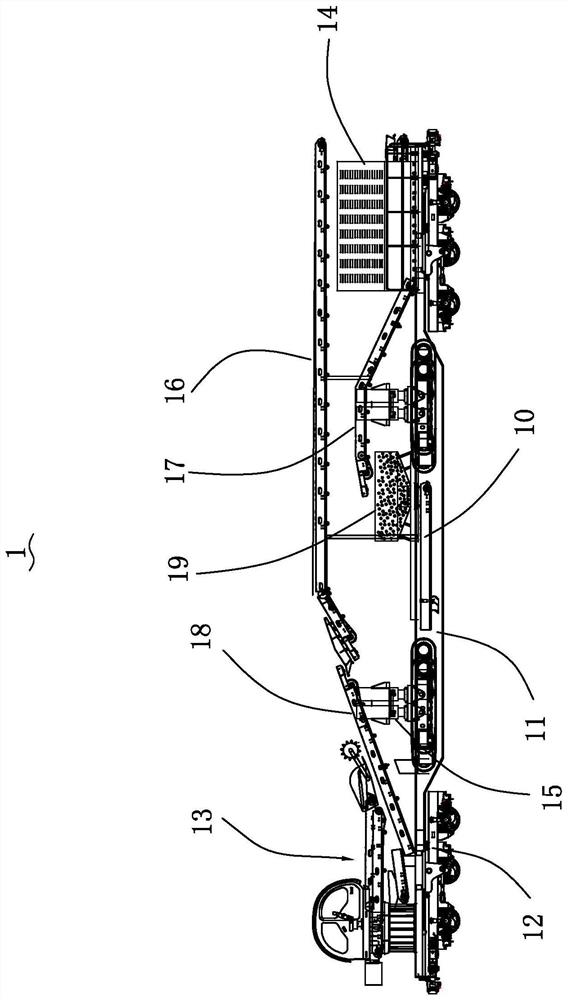

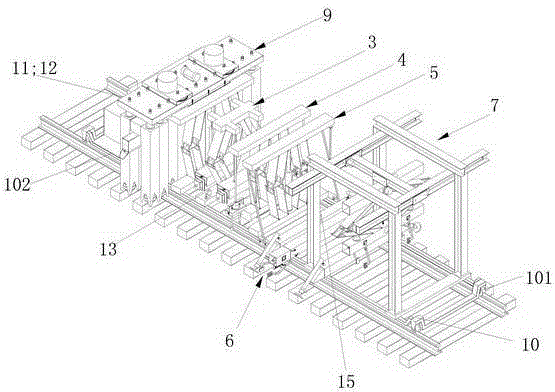

Full-mechanical rapid sleeper replacement machine

InactiveCN104195902AQuick alignmentAutomatic separation and dischargeBallastwayRailway track constructionPush and pullEngineering

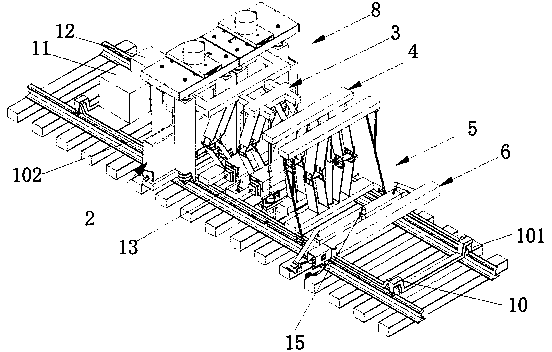

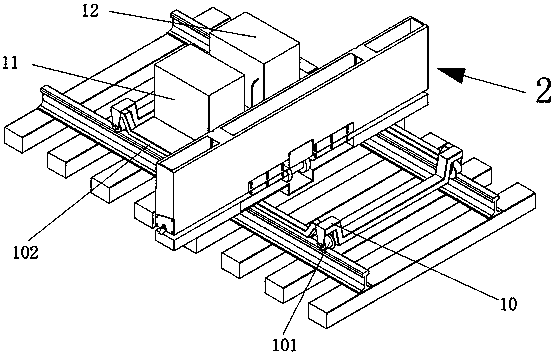

The invention discloses a full-mechanical rapid sleeper replacement machine which comprises a vibration rotary excavating and ballast removing device, a ballast collecting and discharging device, a vibration ballast pushing device, a four-nut synchronous assembly and disassembly device, a sleeper lifting and rotating device, a sleeper pushing and pulling device, a sleeper hoisting device, a rail car, a power generator, a hydraulic system box, a first camera assembly, a second camera assembly, a third camera assembly, a fourth camera assembly, a fifth camera assembly, a sixth camera assembly and a monitor. A plurality of casters and two longitudinal beams are arranged on the rail car, the vibration rotary excavating and ballast removing device, the ballast collecting and discharging device, the vibration ballast pushing device, the four-nut synchronous assembly and disassembly device, the sleeper lifting and rotating device, the sleeper pushing and pulling device, the sleeper hoisting device, the power generator and the hydraulic system box are arranged on the two longitudinal beams of the rail car, and the monitor is arranged in a cab of a tow tractor. The full-mechanical rapid sleeper replacement machine is suitable for rapid sleeper replacement on straight-line and curved rail rod segments, operating time in repairing skylight through limited line can be made full and reasonable use of, and full-mechanical sleeper replacement can be achieved.

Owner:KUNMING UNIV

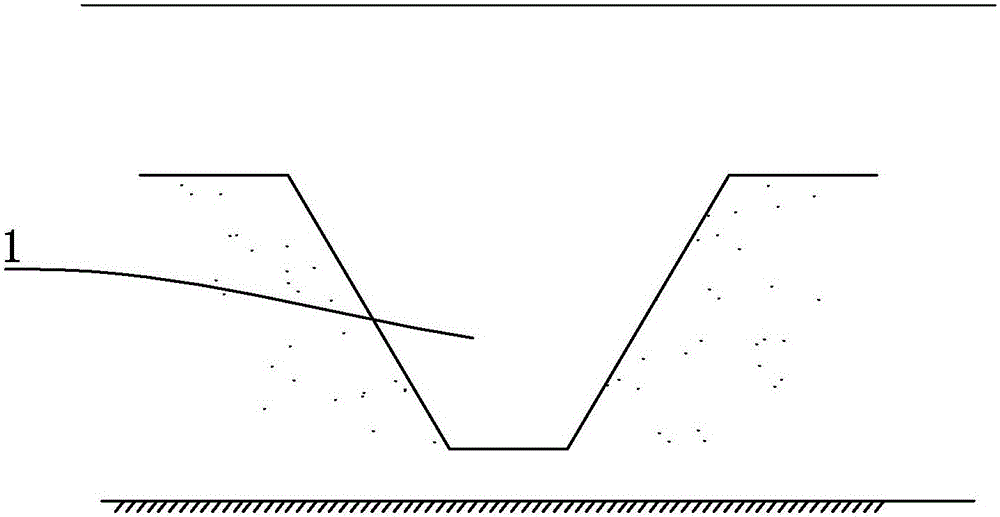

River crossing construction method of multi-pipe-segment sinking pipe

ActiveCN106120859ASave raw materialsFast backfillArtificial islandsPipe laying and repairArchitectural engineeringWelding

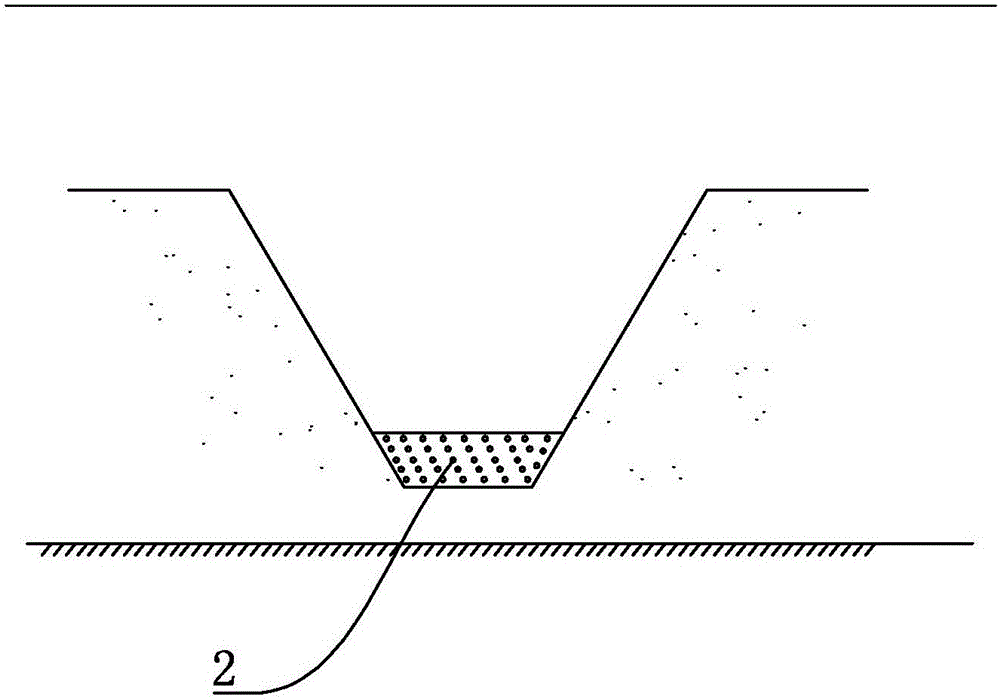

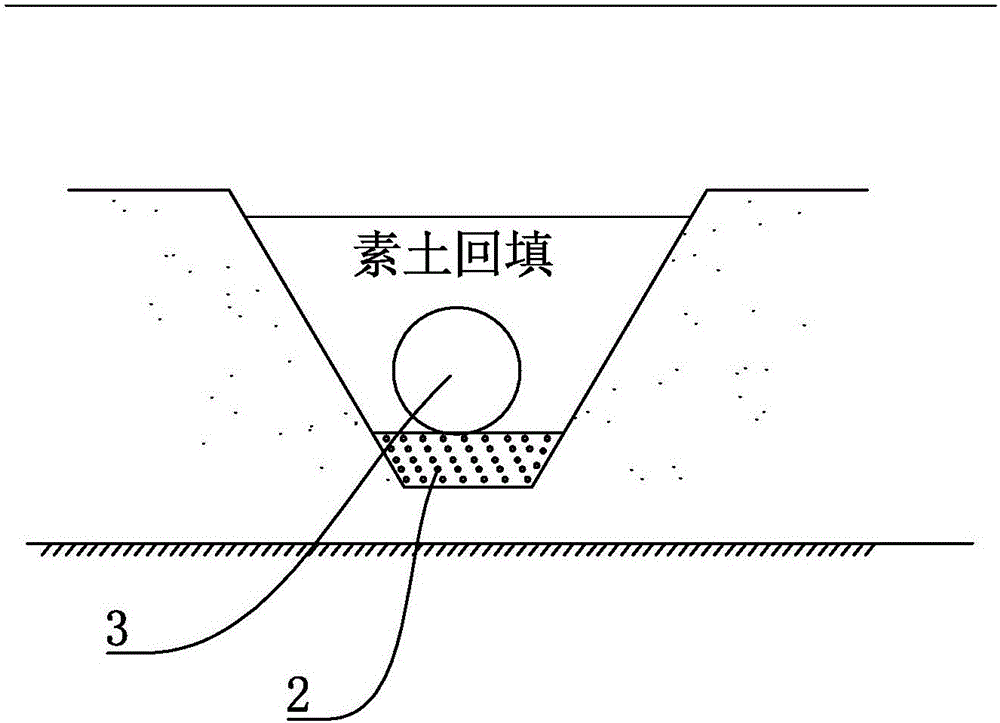

The invention discloses a river crossing construction method of a multi-pipe-segment sinking pipe. The method comprises the steps that A, underwater earthwork construction is carried out, and a groove used for sinking of a pipeline is excavated; B, a water area pipeline is assembled and jointed, afloat joining construction is carried out, and afloat water-free multi-pipe-segment welding is achieved; C, the water area sinking pipe is constructed, and the pipeline used for being spliced into a whole sinks into the groove; D, the underwater groove is subject to backfilling, the groove used for containing the pipeline is filled and leveled up, the pipeline is hidden, afloat water-free welding work is carried out, the construction difficulty is reduced, construction quality is improved, and whole pipeline sinking after the multiple pipe segments are welded is achieved.

Owner:天鸿建设集团有限公司

Soil remediation device used for municipal landscaping

InactiveCN109909288AFast backfillImprove repair effectSoil lifting machinesRotary stirring mixersSoil remediationLandscaping

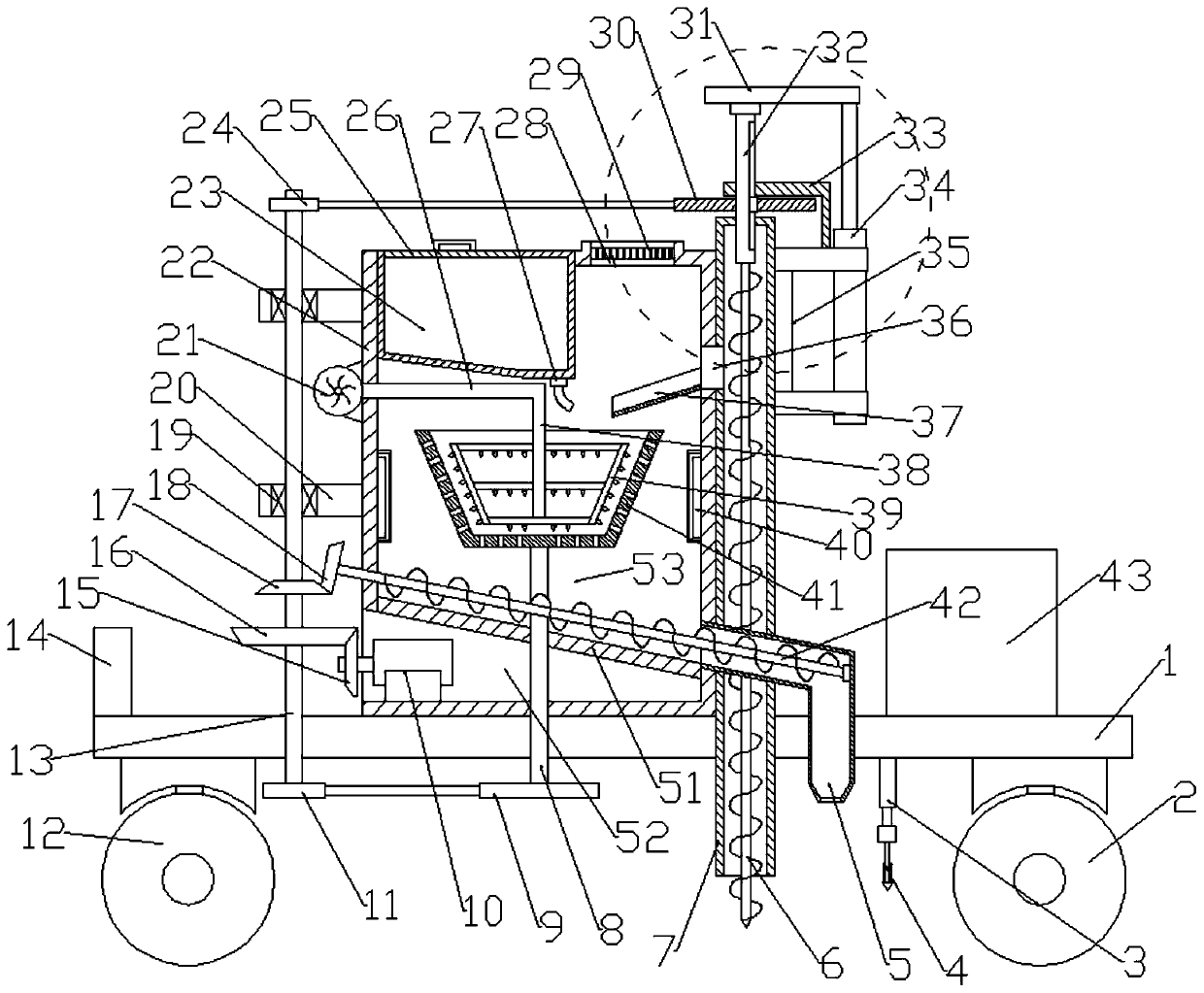

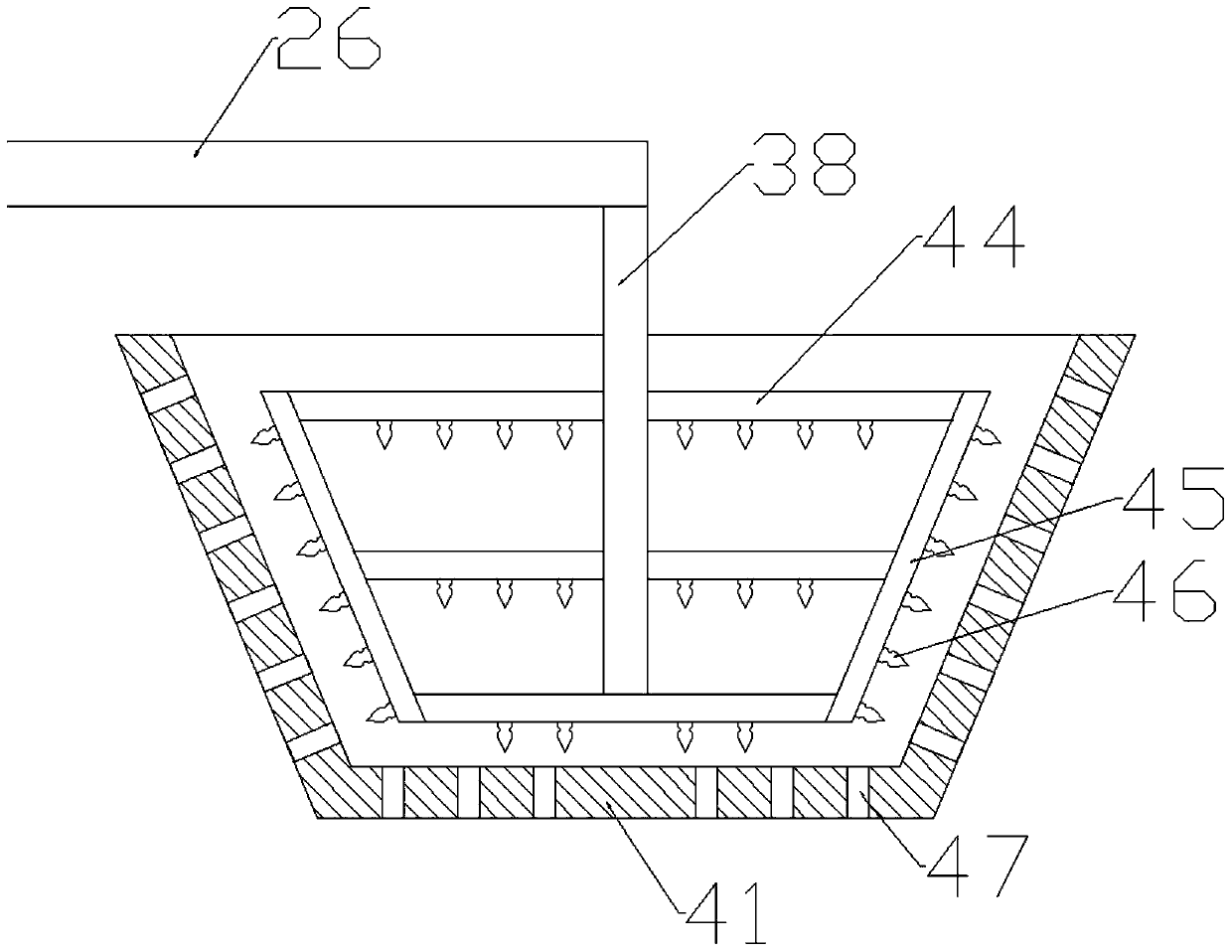

The invention discloses a soil remediation device used for municipal landscaping. The soil remediation device comprises a loading platform, wherein a soil remediation box is arranged in the middle ofthe upper side of the loading platform; a vertically arranged material lifting barrel is arranged on the right side of the soil remediation box; a spiral soil auger is arranged in the material liftingbarrel; a vertical transmission shaft is arranged on the left side of the soil remediation box; a soil feeding hole is formed between the top of the right side wall of the soil remediation box and the material lifting barrel; the interior of the soil remediation box is divided into a soil remediation cavity at the upper part and a motor chamber at the lower part by a partition board; a rotary drum is arranged in the middle of the soil remediation cavity; discharging holes are uniformly distributed in the side surface and the bottom surface of the rotary drum; a vertical rod is arranged in thecenter of the rotary drum; a stirring and smashing head is arranged on the vertical rod; an agent box filled with a soil remediation agent is arranged on the left of the inner top of the soil remediation cavity, and a gas outlet used for discharging inside gas is formed in the right of the inner top of the soil remediation cavity. According to the soil remediation device, soil is fed automatically, is smashed efficiently, is remedied by heating and is backfilled accurately.

Owner:泰顺县刘志威家庭农场

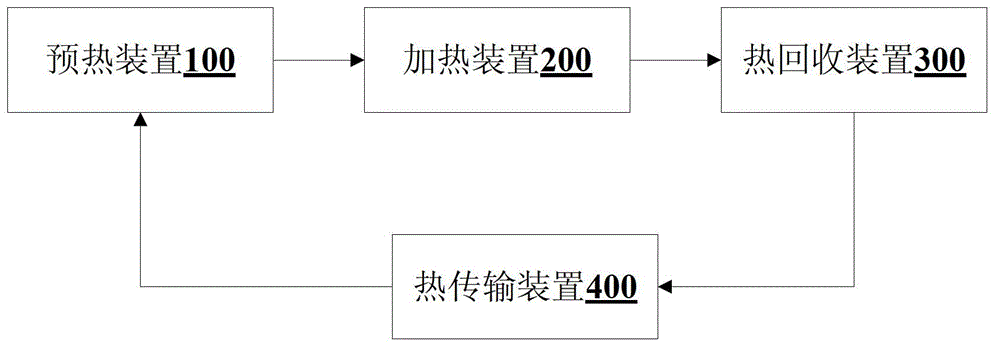

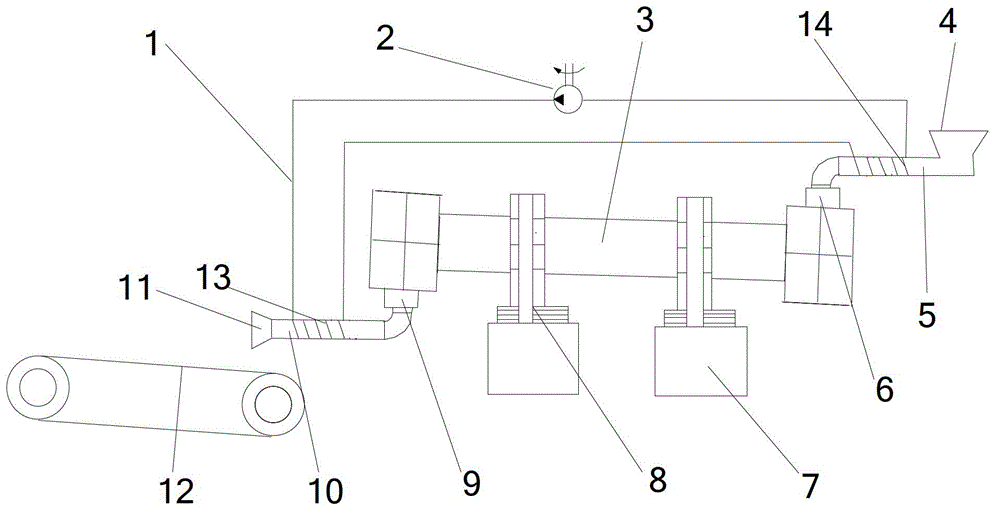

Soil repairing system and soil repairing method

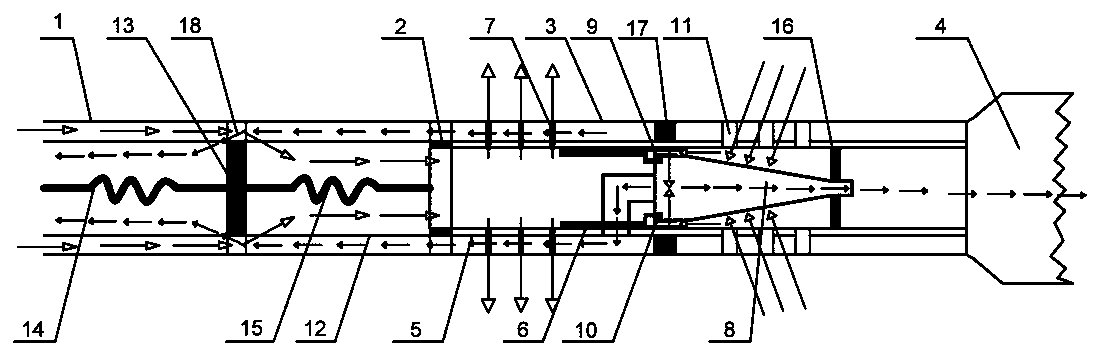

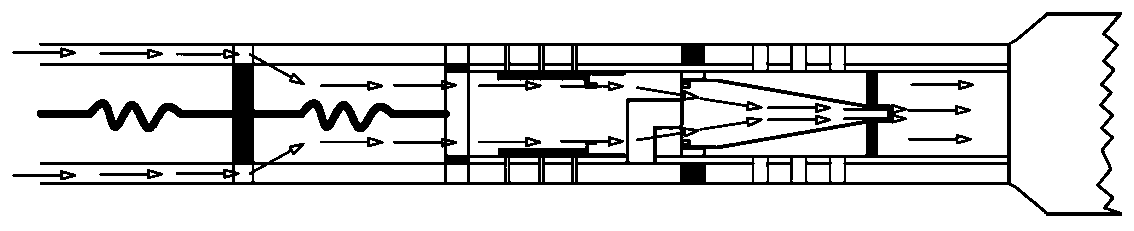

The invention discloses a soil repairing system and a soil repairing method. The soil repairing system comprises a preheating device, a heating device, a heat recycling device and a heat transmission device. The preheating device is used for preheating polluted soil. The heating device is connected with the preheating device and used for heating the preheated and polluted soil and separating pollutant in the soil. The heat recycling device is connected with the heating device and used for recycling heat of the polluted soil heated by the heating device. Further, the soil repairing system comprises a heat transmission device communicated with the preheating device through the heat transmission device to enable the heat recycling device to serve as a heat source of the preheating device. The soil repairing system and the soil repairing method effectively reduce cost of heat repairing of the polluted soil, and are favorable for quickly cooling the soil and apt to quick backfill of the soil.

Owner:BEIJING CHINA SCI GENERAL ENERGY & ENVIRONMENT CO LTD

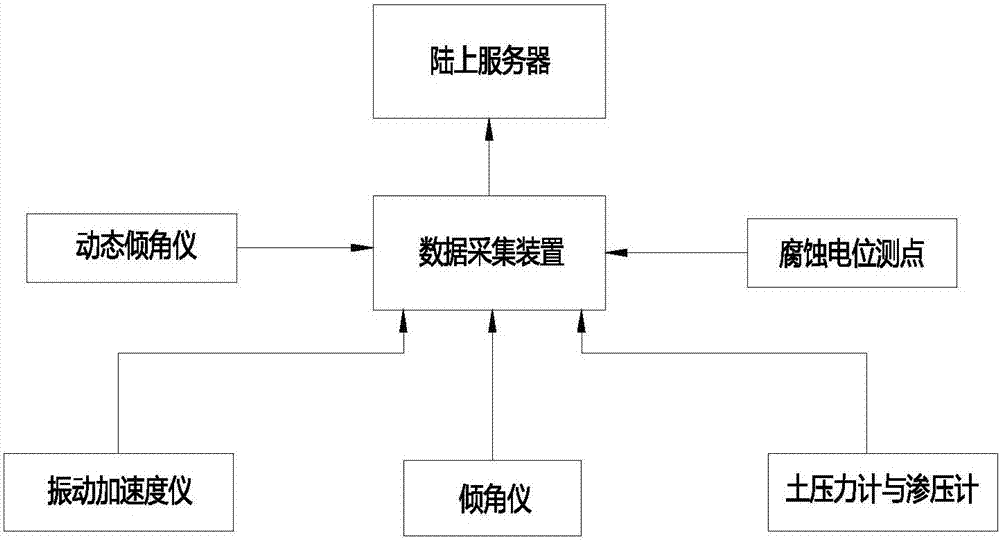

Offshore wind power single pile foundation pile monitoring device

PendingCN107386342AEffective protectionAvoid damageFoundation testingWind energy generationTechnical supportSteel tube

The invention discloses an offshore wind power single pile foundation pile monitoring device. The device comprises a single pile and the monitoring device arranged on the single pile, the monitoring device comprises a data collecting device, dynamic inclinometers, a vibration acceleration instrument, inclinometers, a earth pressure gauge and an osmometer, wherein the data collecting device is used for collecting monitoring data and transmitting the monitoring data to an onshore server, the dynamic inclinometers are arranged on the tops of the single pile and a draught fan, the vibration acceleration instrument is arranged on the inner wall of the pile body on the top of the single pile, the multiple inclinometers are arranged on the inner sides of towers at different elevations or the pile foundation in the prevailing wind direction respectively, and the earth pressure gauge and the osmometer are installed in the positions, at different elevations from the sludge surface, of the outer wall of the single pile in a pairing mode in the prevailing wind direction. According to the device, through monitoring of fault hidden troubles such as the stress-strain characteristics of the steel tube pile foundation, the resistance of pile-surrounding soil, the pore water pressure, the vibration acceleration of jacket steel, inclining, flexion, deformity and fracture of the towers, foundation uneven settlement and corrosion of the steel structure, automatic early warning can be conducted when the above hidden troubles happen, so that reliable technical support is provided for safety operation.

Owner:HUADIAN HEAVY IND CO LTD

Method for measuring soil water content on site

InactiveCN105510173AAvoid shock damagePrevent moisture lossWeighing by removing componentWithdrawing sample devicesField cropVegetation

The invention discloses a method for measuring soil water content on site. Soil is directly taken under field crops and weighed, and monitoring data is obtained through a formula. The method includes the step of calibrating the standard volume dry soil weight and the step of taking soil on site to measure the soil water content again. A special soil taking device is adopted, rotating soil taking is conducted under field crops in a drilling mode, vibration damage to undisturbed soil can be avoided, the influences of drilling on field vegetation and crops and soil structures are the lowest, and rapid backfill is facilitated. In addition, the depth between the centers of cutting rings and the ground can be precisely positioned by observing a sizestick, and soil samples can be precisely collected; by means of the on-site soil taking and weighing mode, soil moisture loss can be effectively avoided. The soil water content is precisely measured through the method, and various defects of an instrument detection method and a traditional manual soil taking and drying method can be avoided.

Owner:辽宁省水文局 +2

Soil organic restoration device and soil restoration method for smart agriculture

The invention discloses a soil organic restoration device for smart agriculture. A thermal stripping box is clamped to one side of the top end of a supporting frame, a movable roller is placed on the inner side of the thermal stripping box, a discharging hopper is installed on the inner side of the thermal stripping box, a separation limiting plate is connected to the inner side of the thermal stripping box, a concentration sleeve is welded to one end of the thermal stripping box, and a gas conveying pipe penetrates through one end of the concentration sleeve. A gas inlet end of the gas conveying pipe is installed at the top end of a concentration box in a penetrating mode, a gas outlet pipe penetrates through one end of the movable roller, and a gas outlet end of the gas inlet pipe is installed at the bottom end of a separation box in a penetrating mode. Through a conveying belt, the movable roller and the gas conveying pipe, generated steam is exhausted while soil is subjected to thermal stripping, the moisture content in the thermal stripping box is reduced, and meanwhile, heat is recycled for the second time, so that the movable roller is heated, the temperature of the movable roller is guaranteed, soil is heated while the conveying belt is dried, the soil is prevented from being attached to the surface of the conveying belt, and the treatment effect of the soil is guaranteed.

Owner:芷兰生态环境建设有限公司

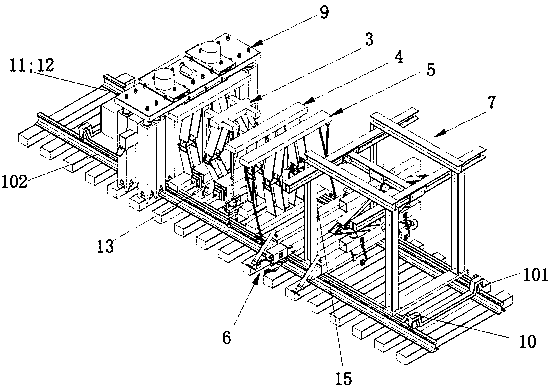

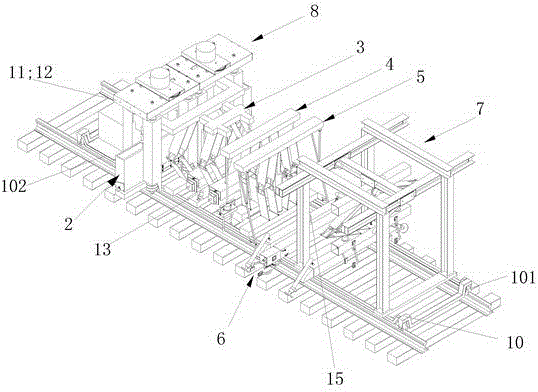

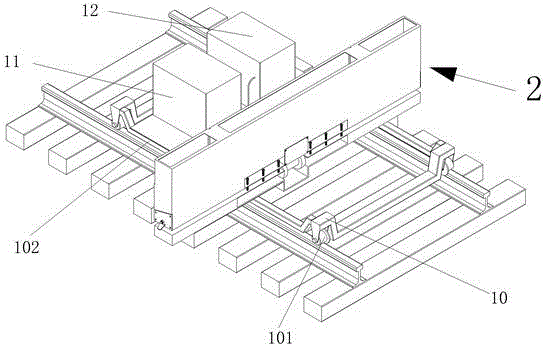

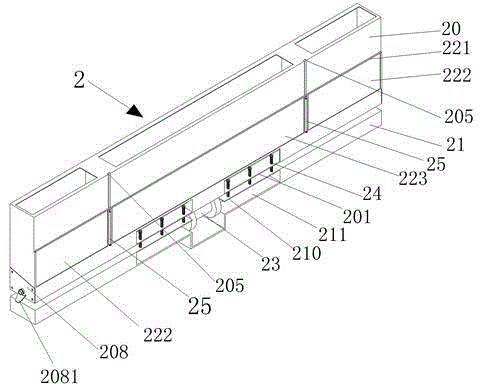

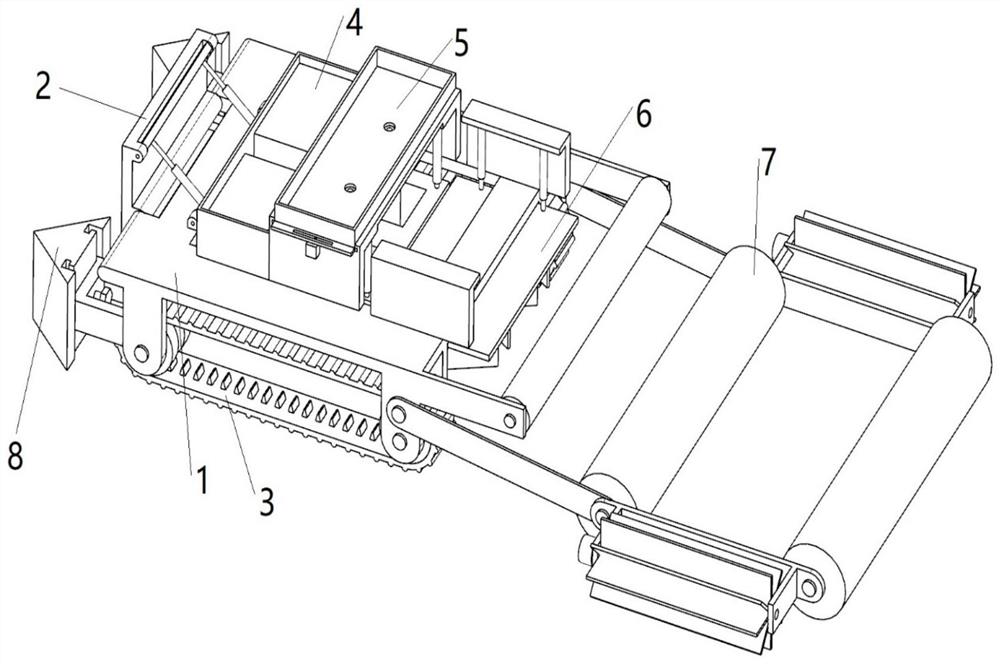

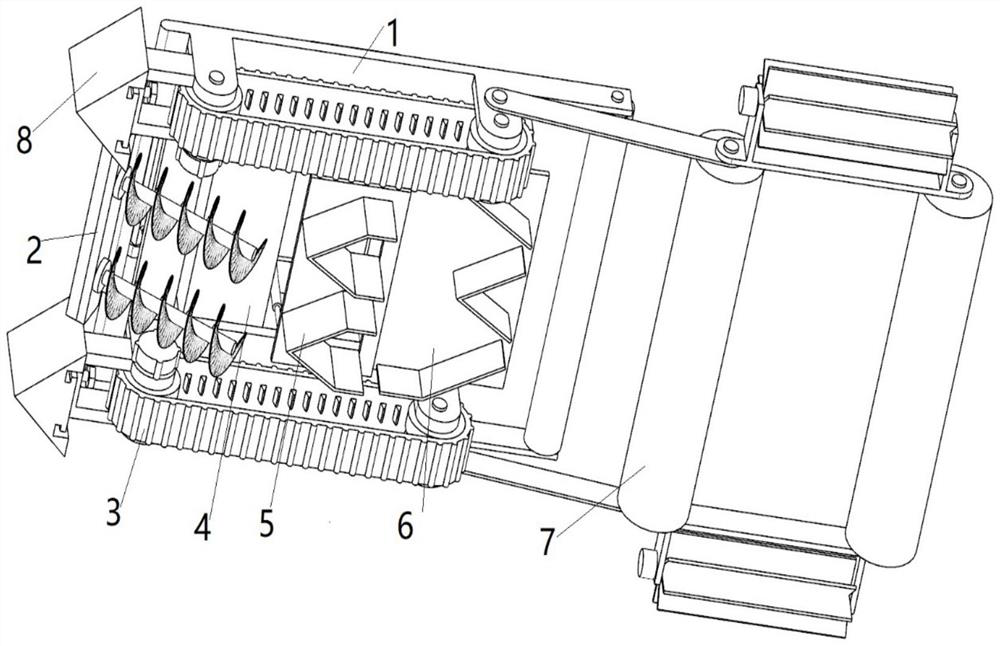

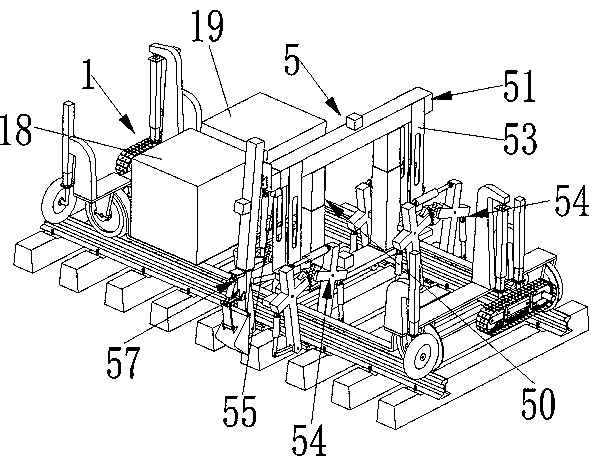

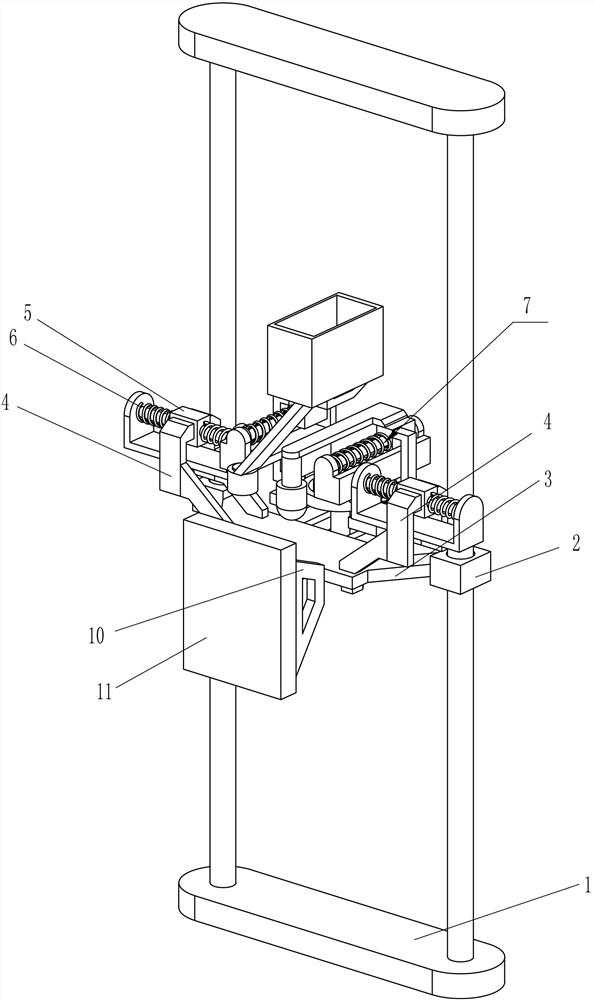

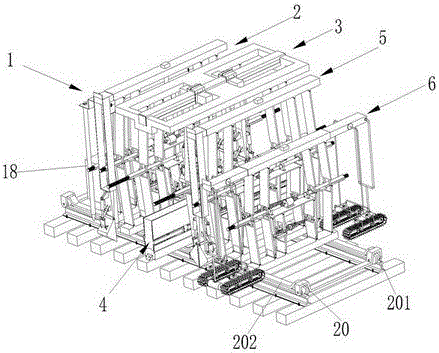

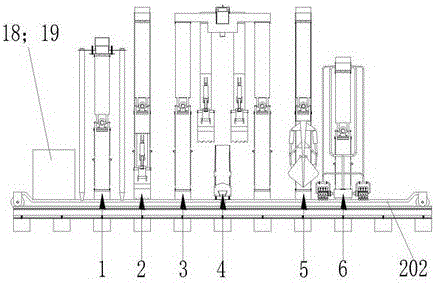

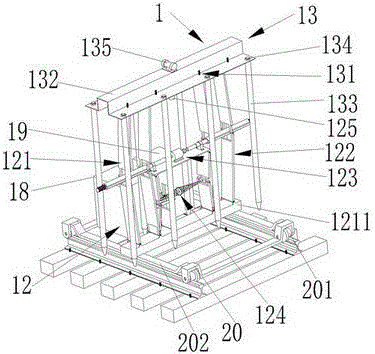

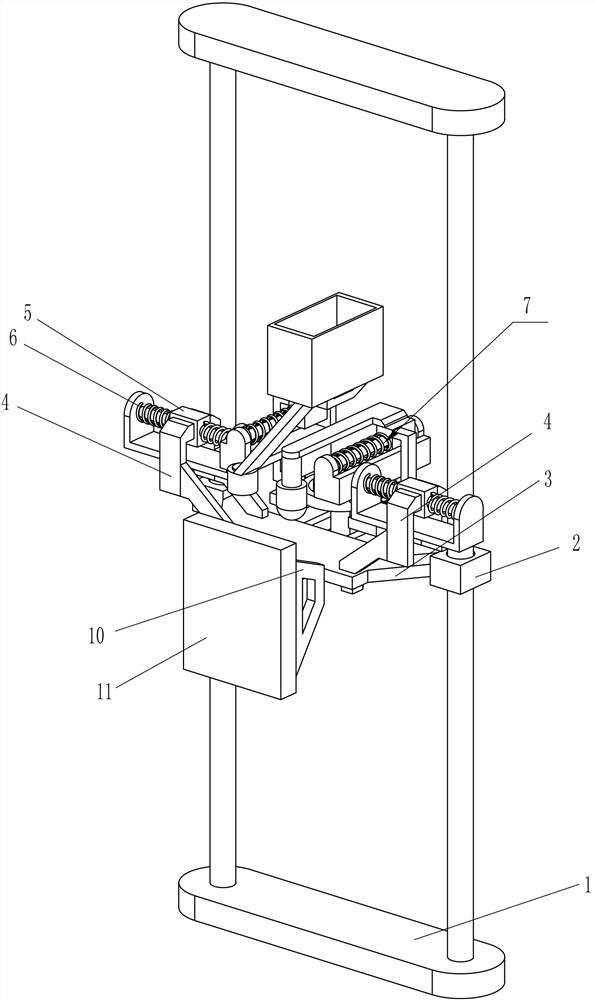

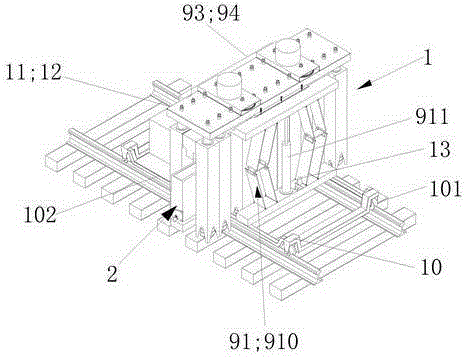

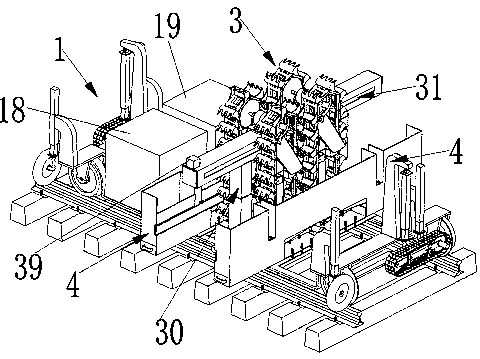

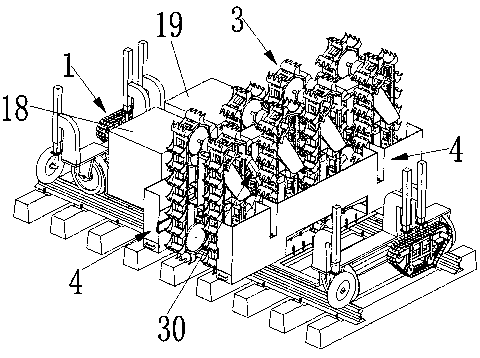

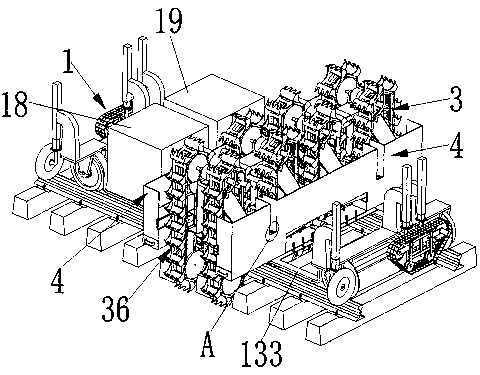

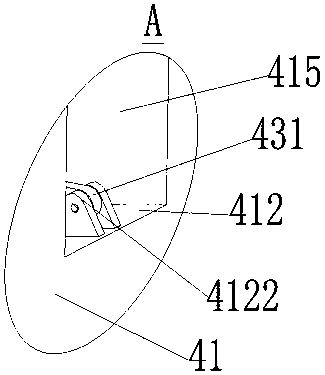

Mechanical sleeper replacing machine

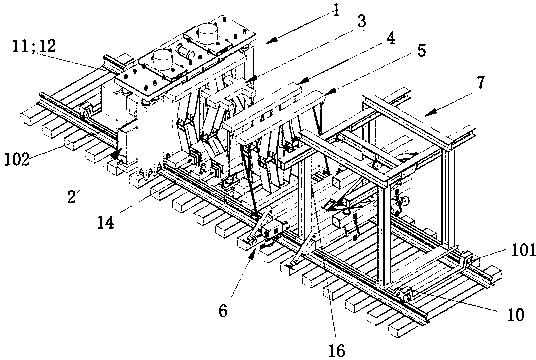

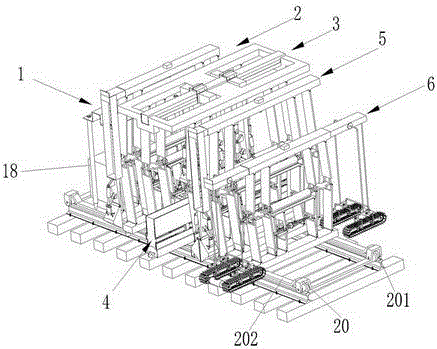

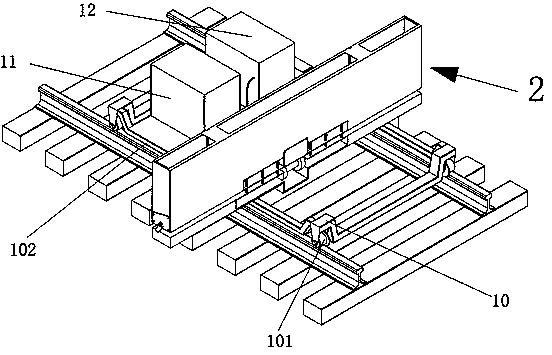

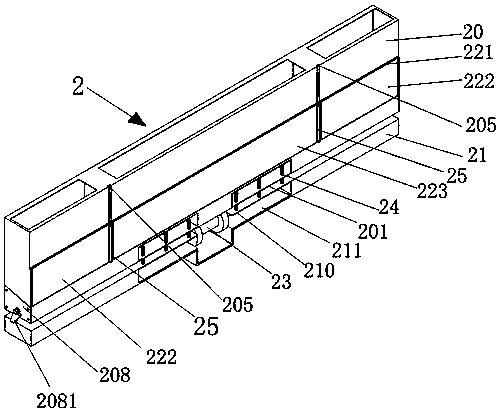

InactiveCN104195904AAutomatic separation and dischargeFor automatic dischargeBallastwayRailway track constructionAutomatic controlPush and pull

The invention discloses a mechanical sleeper replacing machine. The mechanical sleeper replacing machine is composed of a vibration stone pushing device, a four nut synchronous mounting and dismounting device, a rail lifting and sleeper rotating device, a sleeper pushing and pulling device, a sleeper hoisting device, a vibration rotary excavating type stone removing device, a rail car, a power generator, a hydraulic system box, a first camera shooting component, a second camera shooting component, a third camera shooting component, a fourth camera shooting component, a fifth camera shooting component, a sixth camera shooting component and a monitor, wherein the rail car is provided with multiple trundles and two longitudinal beams, the vibration stone pushing device, the four nut synchronous mounting and dismounting device, the rail lifting and sleeper rotating device, the sleeper pushing and pulling device, the sleeper hoisting device, the vibration rotary excavating type stone removing device, the power generator and the hydraulic system box are arranged on the two longitudinal beams of the rail car, and the monitor is arranged in a tractor cab. According to the mechanical sleeper replacing machine, a working device can be aligned with a working position quickly, requirements for quick sleeper replacement on linear and curve rail sections can be met, automatic program control can be achieved easily, and limited train passing gaps for track maintenance can be fully and reasonably utilized to achieve sleeper replacement.

Owner:KUNMING UNIV

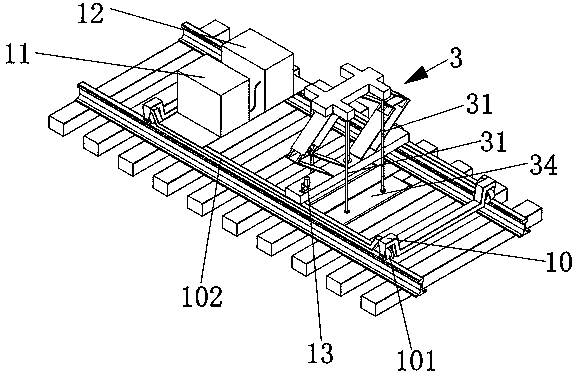

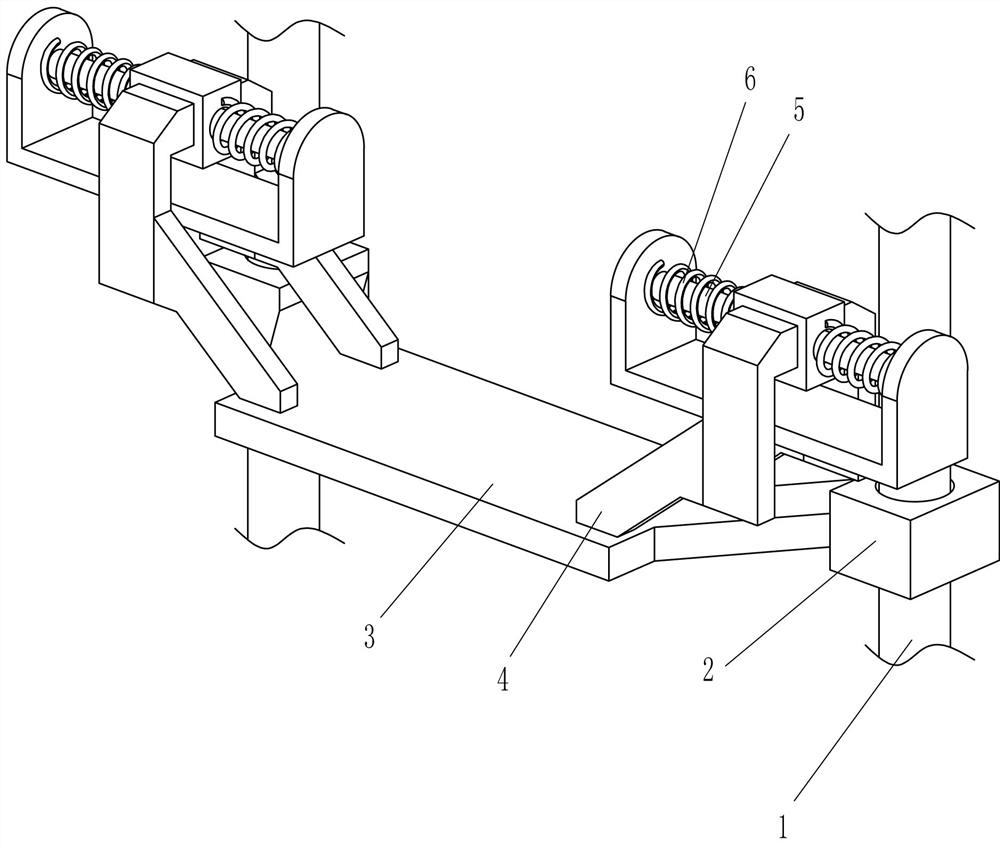

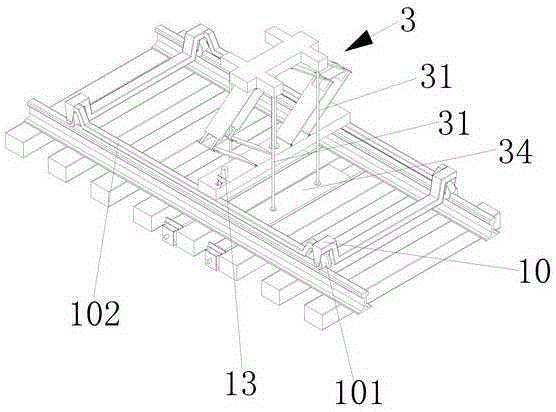

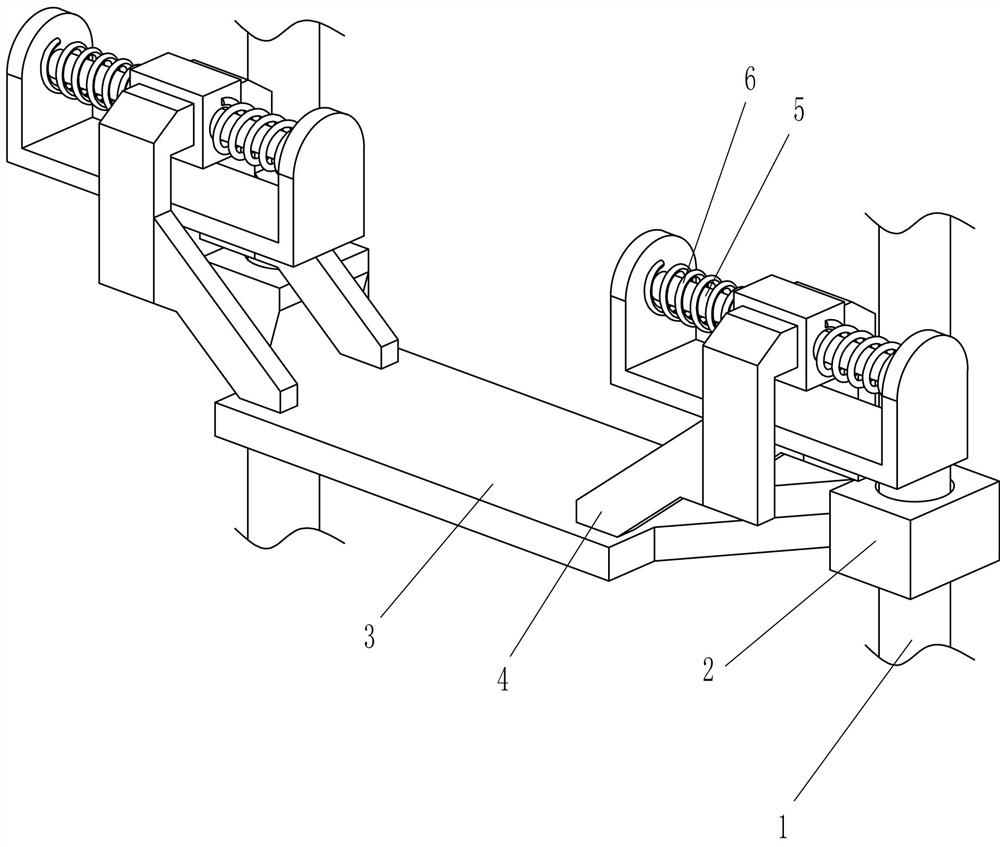

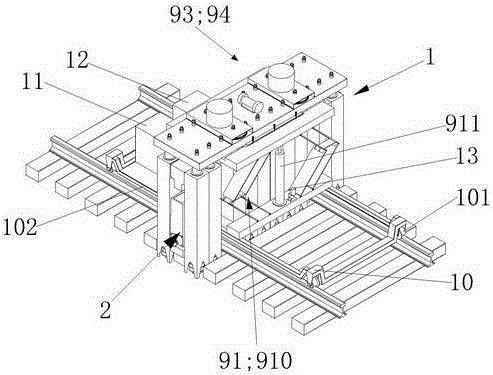

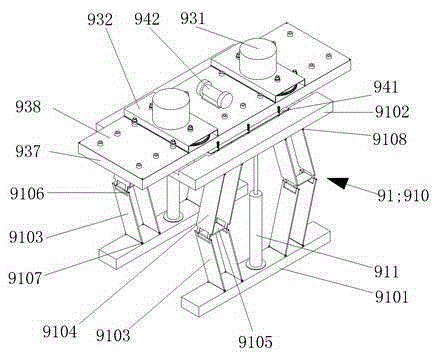

Mechanization sleeper replacement device

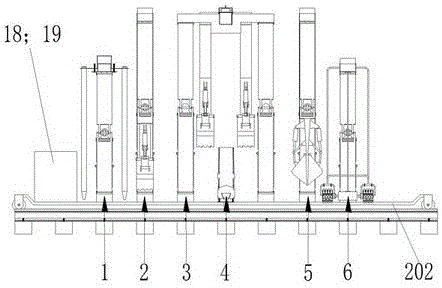

InactiveCN104179095AQuick alignmentAutomatic separation and dischargeBallastwayRailway track constructionPush and pullAutomatic control

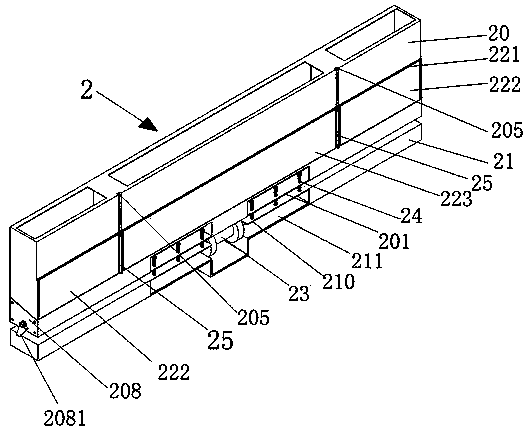

The invention discloses a mechanization sleeper replacement device. The mechanization sleeper replacement device is composed of a ballast collection and discharging device, a vibration stone pushing device, a four nut synchronization assembly and disassembly device, a rail lifting sleeper rotation device, a sleeper pushing and pulling device, a transverse moving vibration rotary excavating stone discharging device, a rail car, an electric generator, a hydraulic system case, a first camera component, a second camera component, a third camera component, a forth camera component and a monitor, wherein a plurality of trundles and two longitudinal beams are installed on the rail car, the ballast collection and discharging device, the vibration stone pushing device, the four nut synchronization assembly and disassembly device, the rail lifting sleeper rotation device, the sleeper pushing and pulling device, the transverse moving vibration rotary excavating stone discharging device, the electric generator and the hydraulic system case are arrange on the two longitudinal beams of the rail car, and the monitor is arranged in a cab of a tractor truck. The mechanization sleeper replacement device can rapidly align a working device to a position to be processed, can adapt to sleeper replacement work at straight and curve rail segments, easily achieves program automatic control, is convenient to operate, and can fully and reasonably use limited line repair skylight operation time to complete the sleeper replacement work.

Owner:KUNMING UNIV

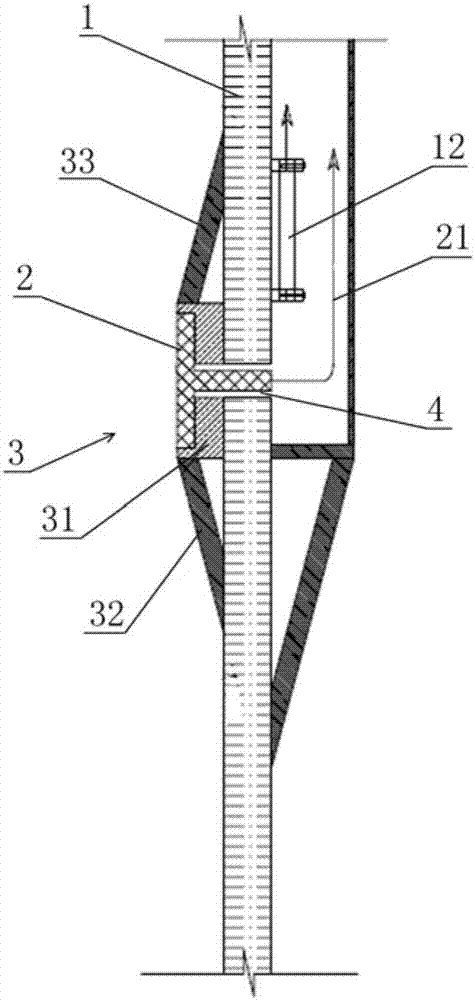

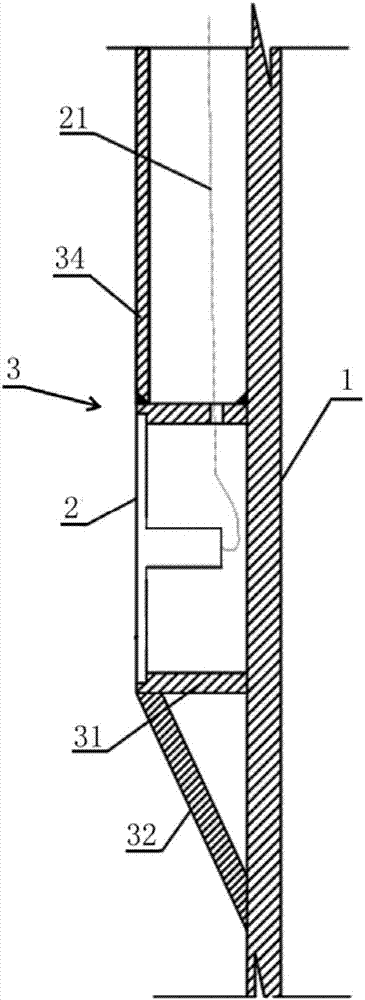

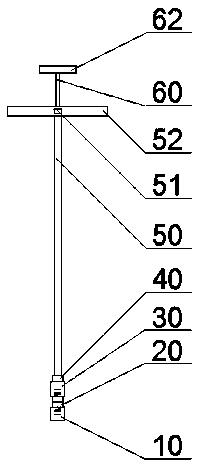

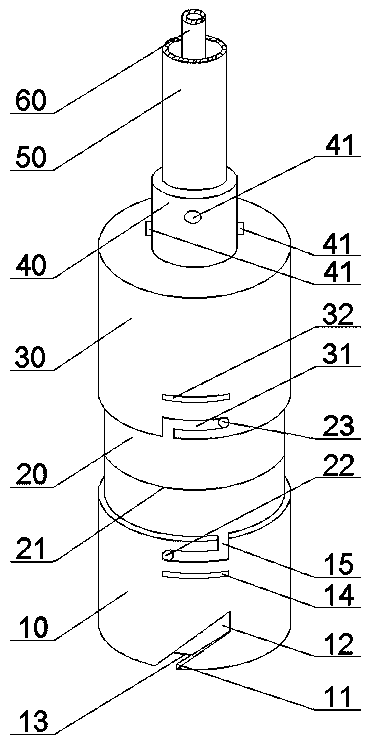

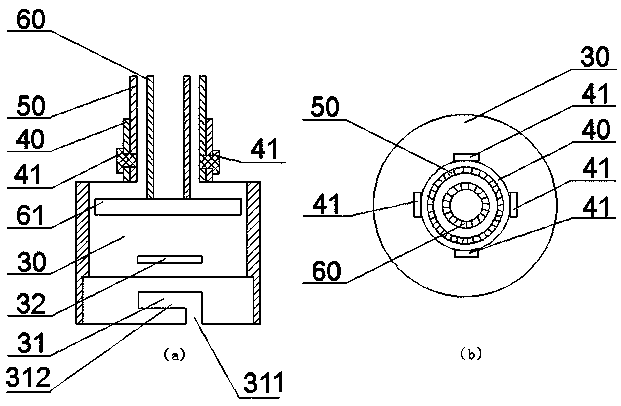

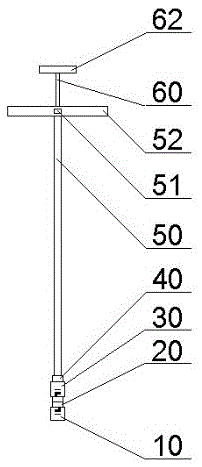

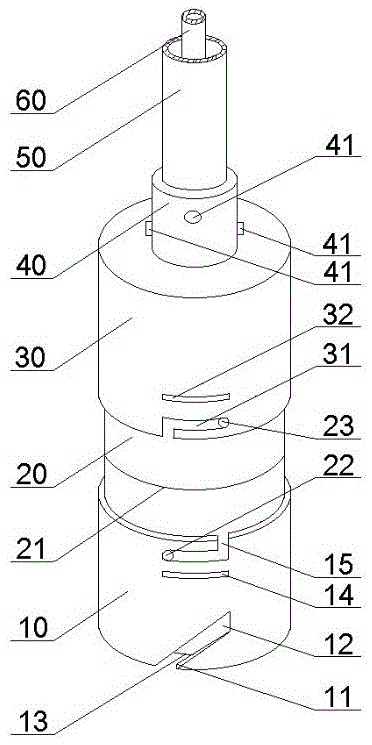

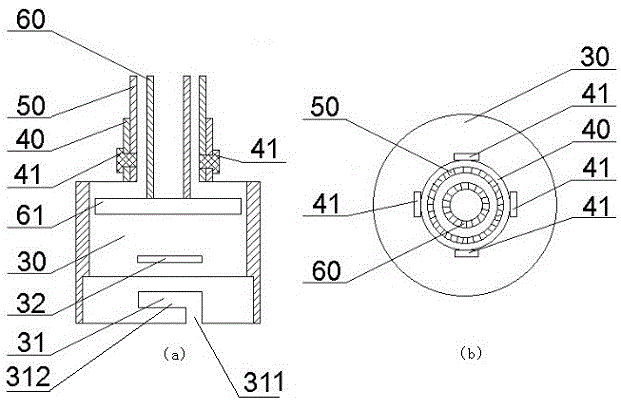

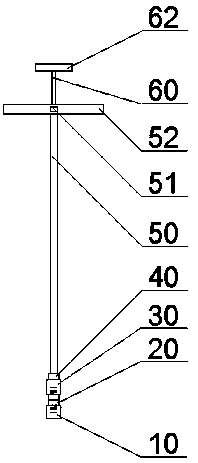

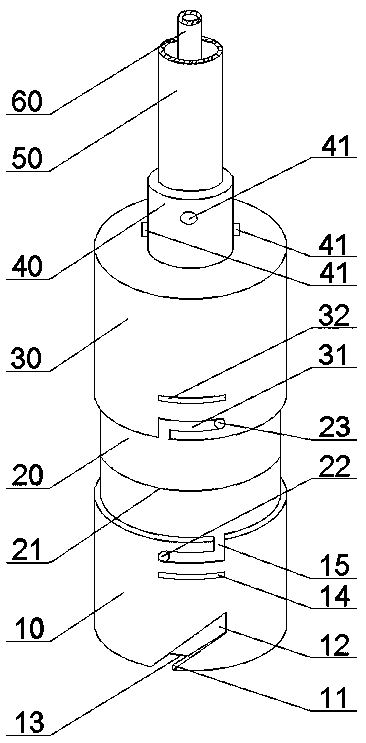

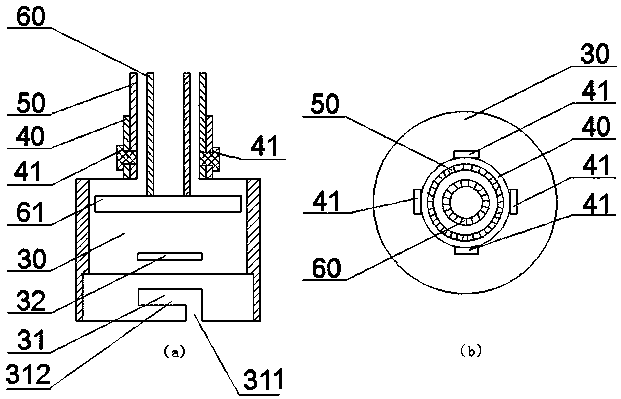

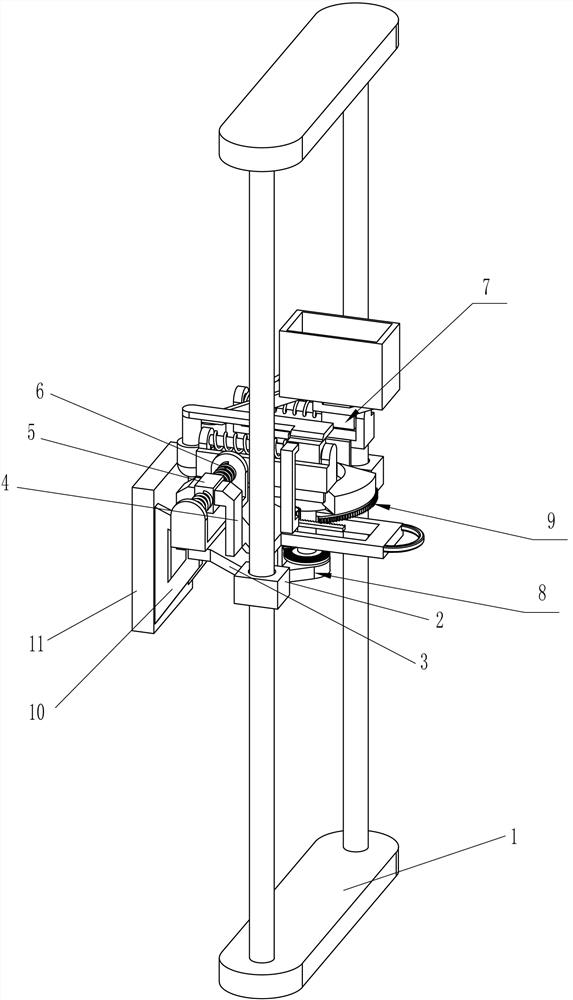

In-situ dynamic separation backfill device for submarine natural gas hydrate

ActiveCN108716361ARelieve stressIncrease productivityLiquid/gas jet drillingBorehole drivesButt jointEngineering

The invention discloses an in-situ dynamic separation backfill device for submarine natural gas hydrate. The device is mainly used for solving the problems in the prior art that static backfill devices are limited in disposal amount, poor in separation effect, low in backfill speed and small in backfill amount. The device includes a power device, a dynamic sealing connector, a dynamic separation backfill system and a drill, wherein one end of the power device is connected to other hydrate exploitation dual-layer pipes and equipment, the dynamic sealing connector is connected to the other end of the power device, the dynamic separation backfill system connected to the dynamic sealing connector is in butt joint with the power device and can be driven by the dynamic sealing connector to rotate, and the drill is connected to the dynamic separation backfill system. According to the scheme above, the purpose of fast in-situ backfill is achieved, and the device has a high practical value anda high popularization value.

Owner:SOUTHWEST PETROLEUM UNIV

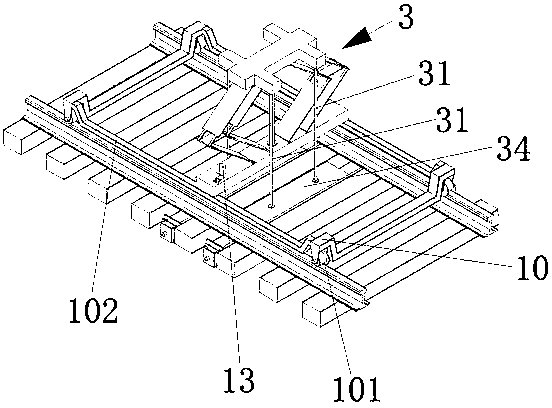

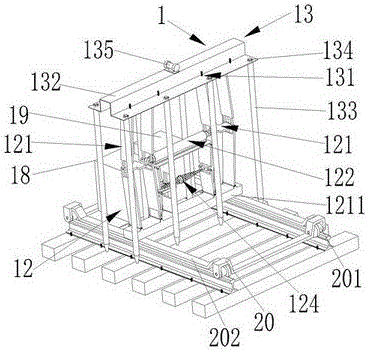

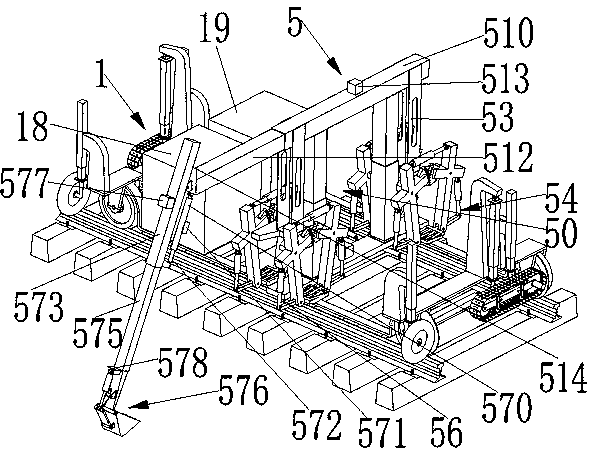

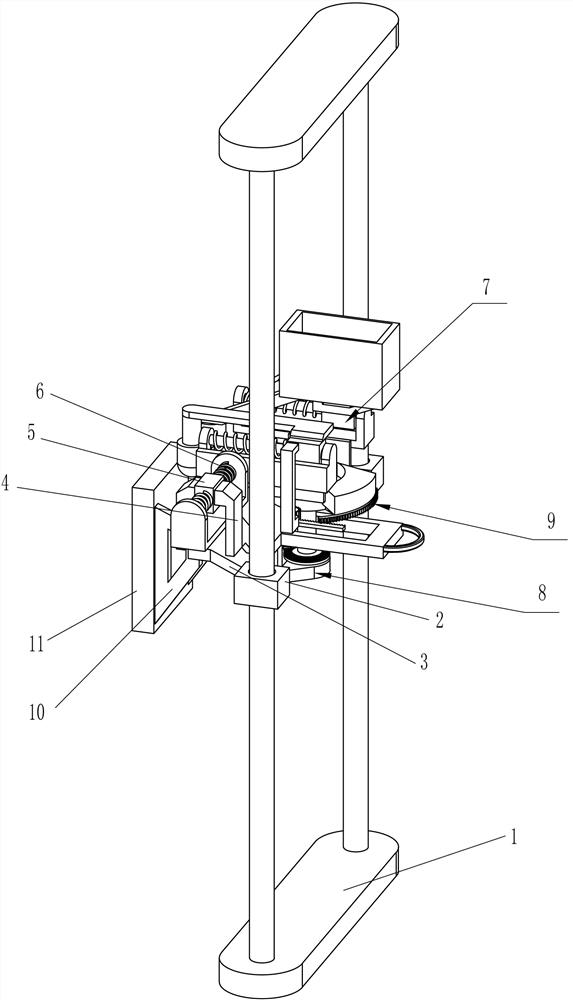

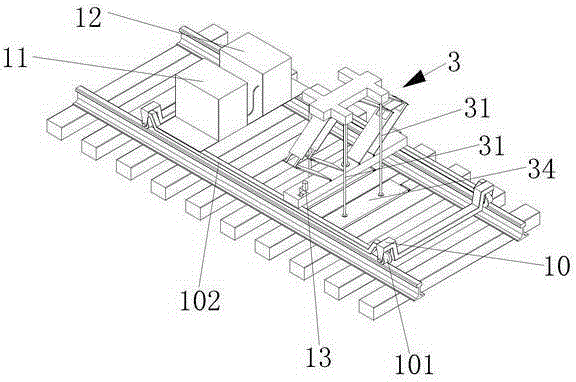

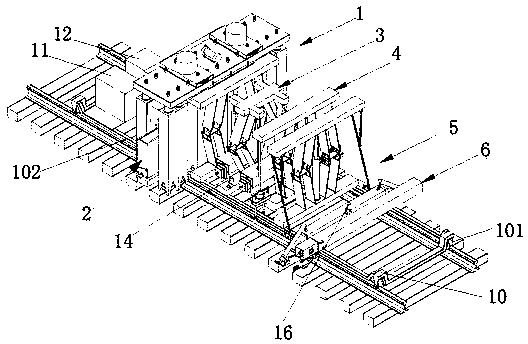

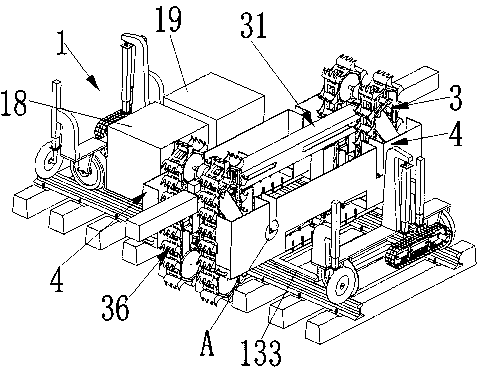

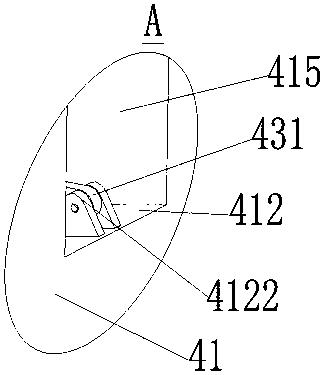

Rapid sleeper replacing machine

InactiveCN104153261AQuick alignmentAutomatic separation and dischargeRailway track constructionPush and pullAutomatic control

The invention discloses a rapid sleeper replacing machine which is composed of a ballast collecting and removing device, a vibration stone pushing device, a four-nut synchronous mounting and dismounting device, a rail lifting and sleeper rotating device, a sleeper push-and-pull device, a sleeper lifting device, a transversely moving vibration rotary excavating and stone removing device, a railcar, a generator, a hydraulic system box, a first photographing assembly, a second photographing assembly, a third photographing assembly, a fourth photographing assembly, a fifth photographing assembly, a sixth photographing assembly and a monitor. The railcar is provided with a plurality of trundles and two longitudinal beams, the ballast collecting and removing device, the vibration stone pushing device, the four-nut synchronous mounting and dismounting device, the rail lifting and sleeper rotating device, the sleeper push-and-pull device, the sleeper lifting device, the transversely moving vibration rotary excavating and stone removing device, the generator and the hydraulic system box are arranged on the two longitudinal beams of the railcar, and the monitor is arranged in a cab of a tractor. The rapid sleeper replacing machine enables a working device to be aligned to a working position rapidly and can be adapted to the work of rapid sleeper replacement of linear and curve rail sections, automatic program control is achieved easily, and operation is convenient.

Owner:KUNMING UNIV

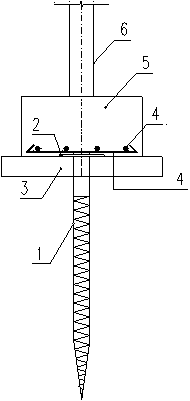

Soil sampling equipment for drilling standard volume of undisturbed soil

InactiveCN105651545AAvoid shock damageReduce the impactWithdrawing sample devicesVegetationEngineering

The invention discloses soil sampling equipment for drilling standard volume of undisturbed soil. The equipment includes a drill, a cutting ring, a positioning seat and a scale bar. The cutting ring is removably attached to the bottom of the positioning seat; the drill is removably connected at the bottom of the cutting ring; the positioning seat is connected to the bottom of the scale bar; the scale bar, positioning seat, cutting ring and drill are each provided with a cavity, and the cavities are communicating with each other; a bulldozing bar is within the scale bar; the bottom of the bulldozing bar is connected to a bulldozing bolt; the bulldozing bar can move up and down within the cavity; the bulldozing bar and scale bar can be by connected a fixing device; side a plurality of lower soil cut ports are arranged on the side of the drill; the height of the lower soil cut ports is less than or equal to the height of the lower edge of the cutting ring; the side of the positioning seat is provided with a plurality of upper soil cut ports; and the height of the upper soil cut ports is equal to or greater than the height of the upper edge of the cutting ring. The equipment can accurately position the depth from the center of the cutting ring to the ground; for soil sampling, a drilling mode is used to avoid shock damage to the undisturbed soil; the drilling hole has minimal impact on the field crops and the vegetation and soil structure, and is convenient for quick backfilling.

Owner:辽宁省水文局 +2

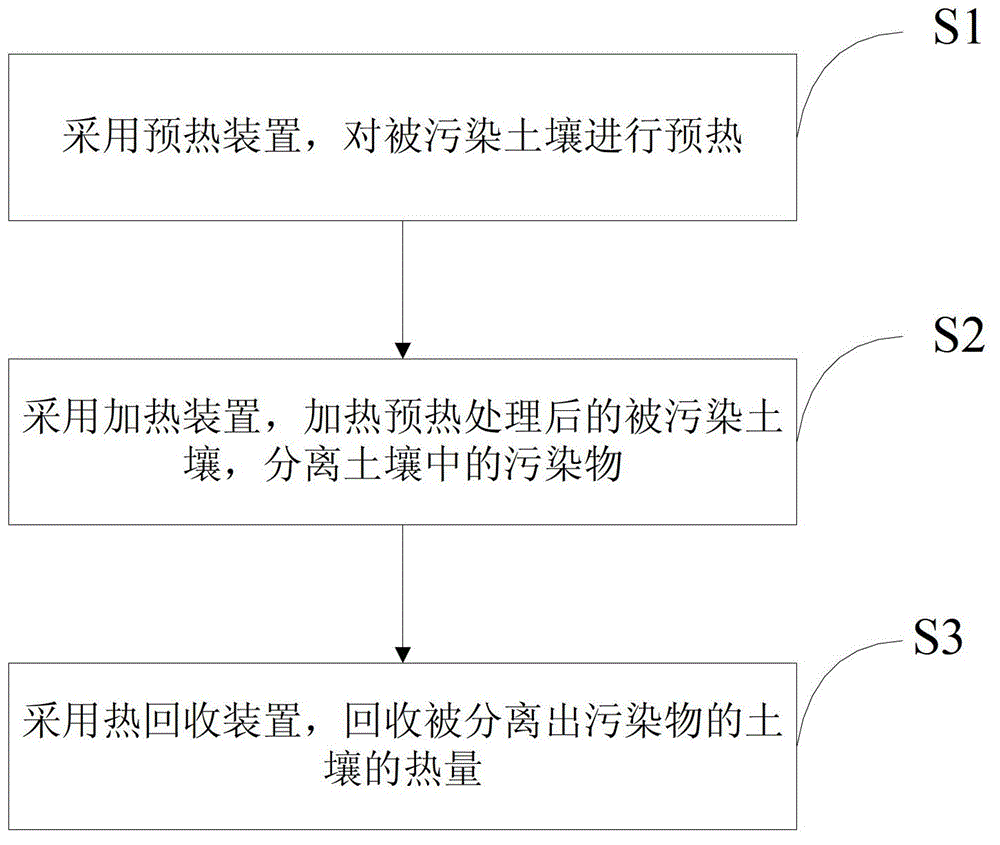

Method for remediating soil by using thermal desorption and microbial technology

InactiveCN106311733ARemove pollutantsKeep moistureContaminated soil reclamationSoil scienceSoil remediation

The invention discloses a method for remediating soil by using thermal desorption and a microbial technology. The soil is remediated by utilizing a thermal desorption soil remediating system, and the method comprises the following steps: firstly, preheating contaminated soil by adopting a preheating device, then, heating the preheated contaminated soil by adopting a heating device to separate contaminants in the soil, and finally, recovering heat of the soil from which the contaminants are separated by adopting a heat recovery device; remediating the soil by utilizing the microbial technology; applying organic fertilizer to the soil treated by thermal desorption per mu, and plowing the organic fertilizer under the soil by a rotary cultivator; then, sprinkling the soil to keep soil humidity, and then, evenly spraying microbial soil remediating inoculant; and evenly spraying the microbial soil remediating inoculant once after two months to finish soil remediation after three months. According to the method disclosed by the invention, by adopting thermal desorption and the microbial technology, a breeding condition in favor of microbial strains is created by utilizing a physical and biological method, and the soil is remediated in manner of nature, return and equilibrium.

Owner:上海松沅环境修复技术有限公司

Saline-alkali soil peanut sowing mulch applicator and operation method

InactiveCN113228884AMaintain stabilityIncrease frictionPlantingSeed depositing seeder partsAlkali soilAgricultural engineering

The invention relates to the field of agricultural equipment, in particular to a saline-alkali soil peanut sowing mulch applicator and an operation method. The saline-alkali soil peanut sowing mulch applicator comprises a machine frame, the machine frame is used for supporting the whole device, a ditching device is arranged in front of the machine frame and can perform ditch digging, driving devices are arranged on the two sides of the lower part of the machine frame and can drive the device to move, and the driving devices are arranged below the machine frame so that a large ground clearance can be formed between the machine frame and the ground. A control box is arranged above the machine frame and used for controlling all power facilities, a sowing device is arranged above the machine frame and located behind the ditching device and can sow seeds into dug ditches, and a soil covering device is arranged above the machine frame and located behind the sowing device and can bury seeds in soil; and a film mulching device is arranged behind the machine frame and can cover the planted seeds with a mulching film. Peanut sowing and film mulching work can be easily and rapidly carried out.

Owner:WEIFANG UNIVERSITY

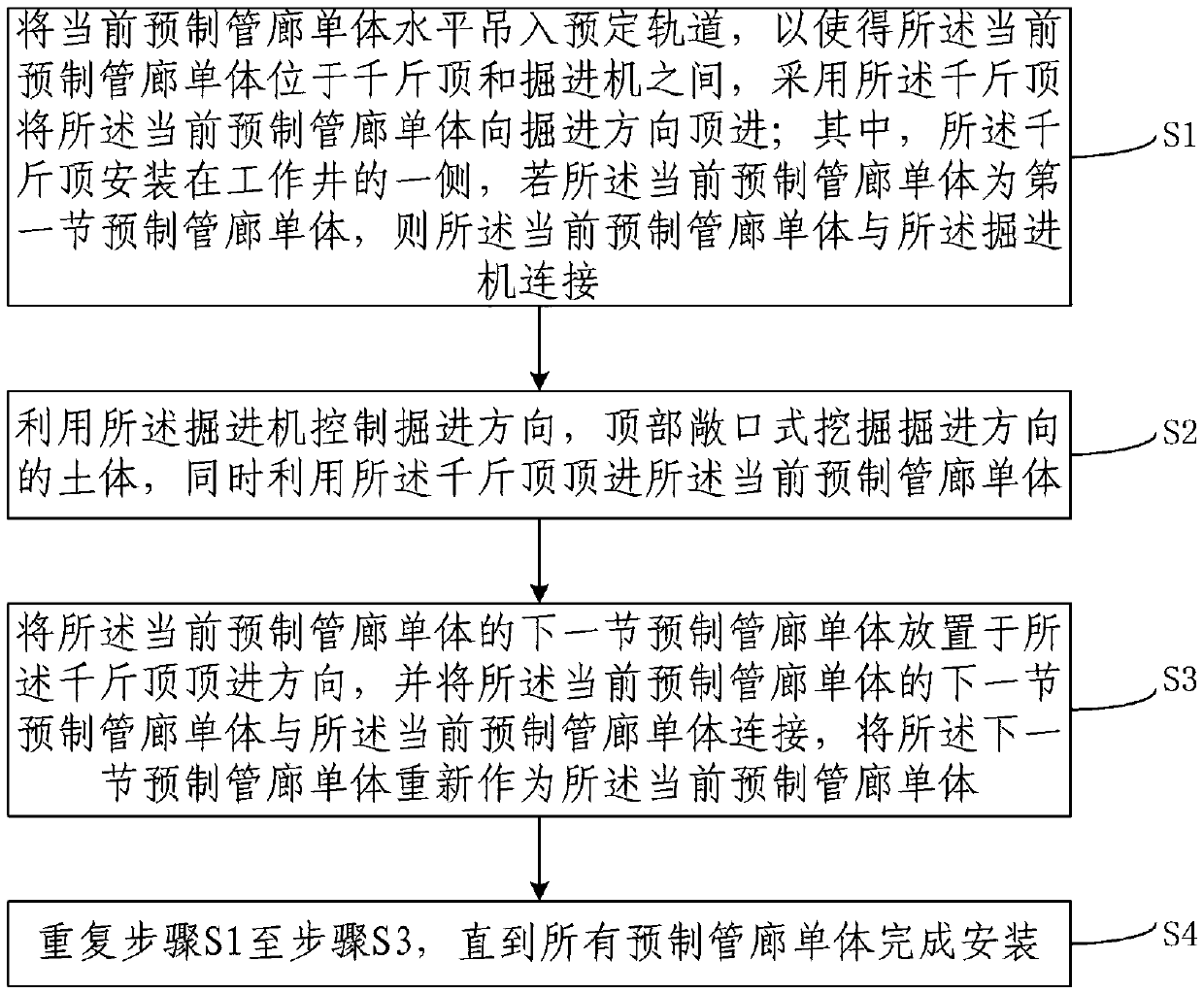

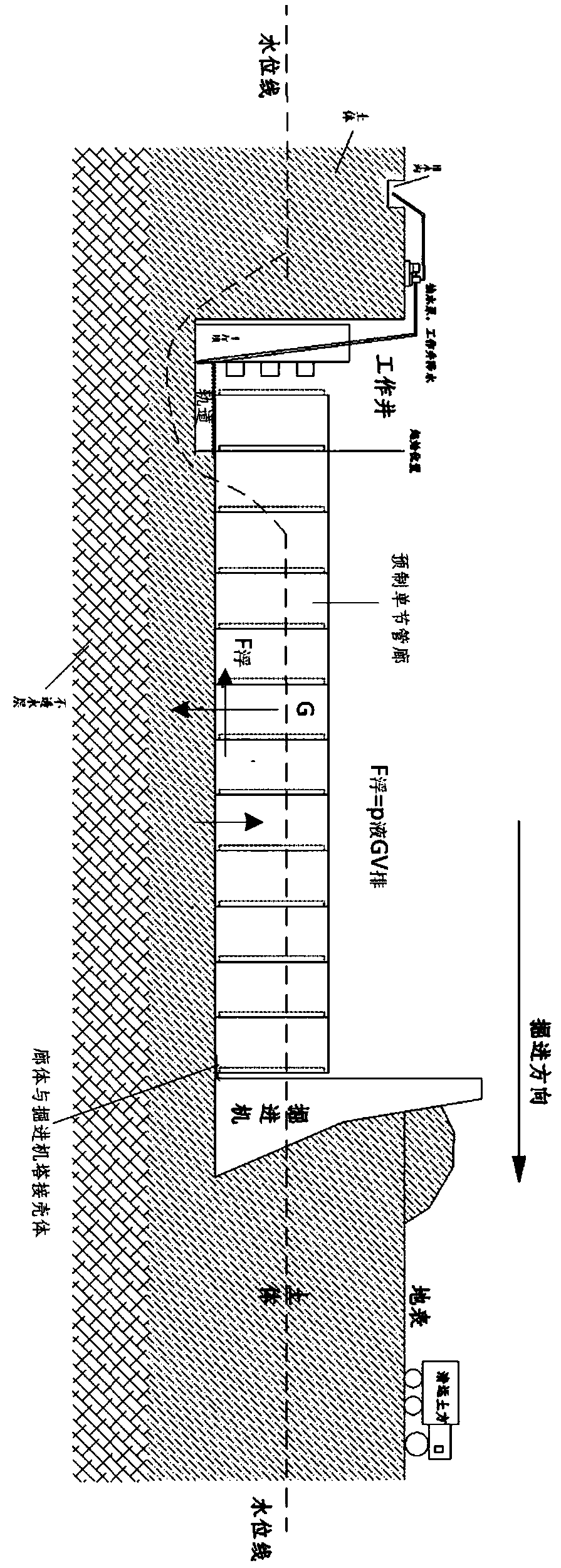

Mounting method of prefabricated pipe gallery

InactiveCN109610503AReduce construction costsReduce noiseArtificial islandsUnderwater structuresEngineeringFrictional resistance

The embodiment of the invention provides a mounting method of a prefabricated pipe gallery. The mounting method comprises the steps: after a current prefabricated pipe gallery single body is horizontally hoisted into a predetermined rail through a hoisting system to enable the current prefabricated pipe gallery single body to be located between a jack and a roadheader, the current prefabricated pipe gallery single body is jacked in the heading direction through the jack; the heading direction is controlled through the roadheader, a soil body in the heading direction is excavated in a top openmode and meanwhile jacked into the current prefabricated pipe gallery single body through the jack, and the position, between the roadheader and a working well, of the outer side of the pipe gallery is filled with liquid to reduce frictional resistance; a single body of the next section and the current prefabricated pipe gallery single body are connected in the jacking direction of the jack, and thus the single body of the next section serves as the current prefabricated pipe gallery single body again; and the steps are repeated till all the prefabricated pipe gallery single bodies are mounted. According to the mounting method of the prefabricated pipe gallery, the construction cost is low, noise is small, pollution is small, the destroyed soil body face is narrow, rainfall and support work is reduced, the construction speed is high, and quick backfill can be achieved.

Owner:中煤建工集团有限公司

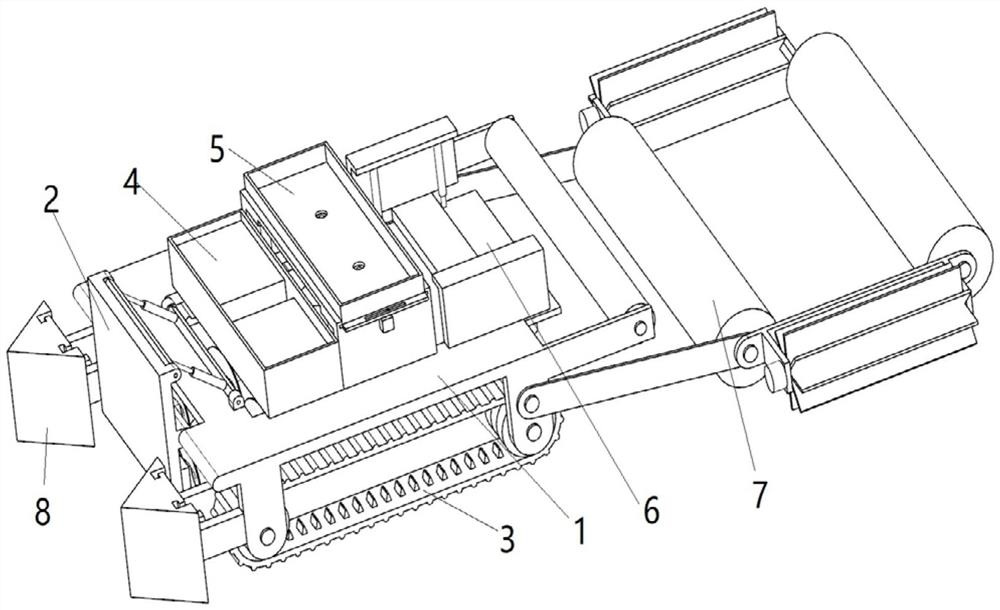

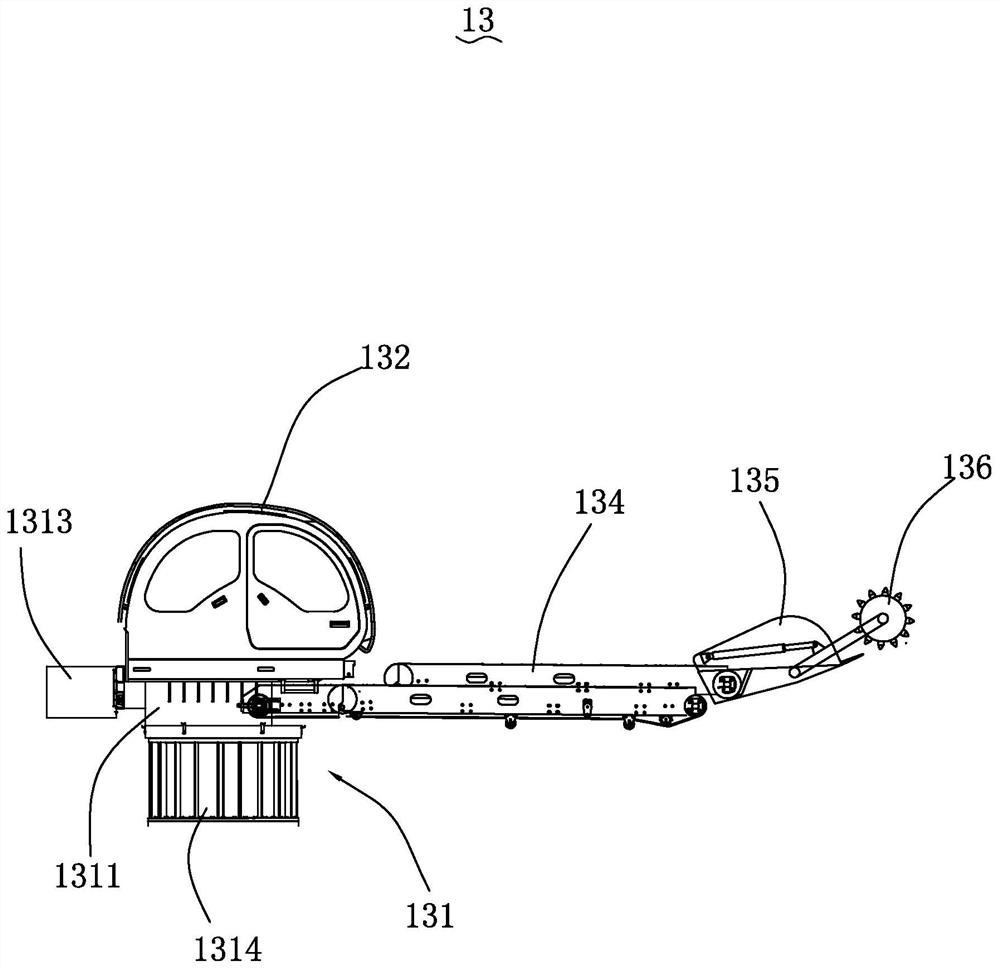

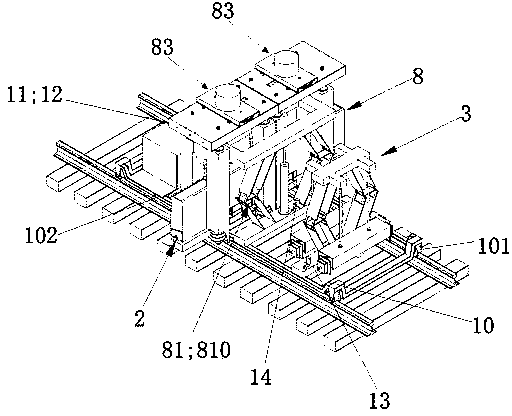

Small railway maintenance equipment capable of removing and backfilling ballast

InactiveCN106283977AQuickly align to working positionEasy dischargeBallastwayAutomatic controlSprocket

The invention discloses small railway maintenance equipment capable of removing and backfilling ballast. The equipment is composed of a tamping and blast leveling device, a runway shoulder and ballast bed shape correction device, a grab bucket stone removal device, a ballast centralized removal device, a sleeper end stone removal device, a sprocket stone removal device and a rail car. A working device can be aligned with a working position quickly, ballast between sleepers can be removed quickly, and sandy soil in ballast can be automatically removed at the same time; ballast on a ballast bed outside a sleeper end can be quickly removed; ballast on a ballast bed below a rail can be quickly removed; ballast can be quickly backfilled in the space between replaced sleepers on two sides; the shape of a runway shoulder and a ballast bed can be quickly corrected; ballast backfilled in the space between the replaced sleepers can be quickly tamped and leveled; the equipment can be adapted to linear and bent rail sections for ballast removal and backfilling; automatic control can be achieved, operation is convenient, and ballast removing and backfilling efficiency is high.

Owner:KUNMING UNIV

Stone pulling-discharging multi-functional intelligent device

The invention discloses a stone pulling-discharging multi-functional intelligent device. The stone pulling-discharging multi-functional intelligent device is composed of a self-propelled track car, astone pulling-discharging multi-functional device, a charging battery pack, an inverter and a hydraulic system and control system box, wherein the charging battery pack and the inverter provides powerfor an oil pump and a control system, and the hydraulic system and control system box is internally provided with an oil tank, the oil pump, a hydraulic control system and an automatic control system; an self-propelled track car is composed of a drive device, a driven wheel assembly, a round-trip track device, a car frame, four first constant-strength cantilevel beams and two second constant-strength cantilevel beams; the working position can be automatically and quickly aligned, stone ballast under steel rails between the two sides of a damaged sleeper can be quickly pulled out, and stone ballast of the outer side of the sleeper end is discharged; and the stone ballast of the outer side of the sleeper end can be quickly refilled, and thus the shape of the road shoulder of a road bed canbe repaired. The track car can arrive and depart railway tracks in a self-propelled mode, the influence on normal traffic of a train is avoided, the center of gravity of the track car is not raised when the track car moves up and down the tracks, and thus damping is avoided.

Owner:KUNMING UNIV

Ballast replacing vehicle set for ballast replacing operation in turnout replacing process

PendingCN113403894AImprove work efficiencyQuick collectionBallastwayMarine engineeringMaterial transport

The invention discloses a ballast replacing vehicle set for ballast replacing operation in a turnout replacing process, which comprises a ballast replacing vehicle, a highway-railway dual-purpose railway ballast conveying vehicle, a rail-mounted railway ballast conveying vehicle, a belt type material conveying vehicle and a ballast supplementing vehicle which are connected in sequence, the ballast replacing vehicle, the highway-railway dual-purpose ballast conveying vehicle, the rail-mounted ballast conveying vehicle and the belt type material conveying vehicle are grouped to complete excavation of stone ballast and bottom ballast backfilling operation after an old turnout is dismantled, and the ballast supplementing vehicle completes stone ballast backfilling and shaping operation after a new turnout is installed. According to the ballast replacing vehicle set for ballast replacing operation in the turnout replacing process, dependence on manpower is reduced, the working efficiency is high, safety and reliability are achieved, and meanwhile the ballast replacing vehicle set can adapt to ballast replacing operation after old turnouts are dismantled in the turnout replacing process.

Owner:BAOJI CSR TIMES ENG MACHINERY

A Method for Measuring Soil Moisture Content on Site

InactiveCN105510173BAvoid shock damagePrevent moisture lossWeighing by removing componentWithdrawing sample devicesVegetationField crop

The invention discloses a method for measuring soil water content on site. Soil is directly taken under field crops and weighed, and monitoring data is obtained through a formula. The method includes the step of calibrating the standard volume dry soil weight and the step of taking soil on site to measure the soil water content again. A special soil taking device is adopted, rotating soil taking is conducted under field crops in a drilling mode, vibration damage to undisturbed soil can be avoided, the influences of drilling on field vegetation and crops and soil structures are the lowest, and rapid backfill is facilitated. In addition, the depth between the centers of cutting rings and the ground can be precisely positioned by observing a sizestick, and soil samples can be precisely collected; by means of the on-site soil taking and weighing mode, soil moisture loss can be effectively avoided. The soil water content is precisely measured through the method, and various defects of an instrument detection method and a traditional manual soil taking and drying method can be avoided.

Owner:辽宁省水文局 +2

Wiring groove concrete backfilling equipment for building decoration

ActiveCN112049425AFast backfillLiberate manpowerBuilding material handlingMoving partsGeotechnical engineering

The invention relates to building decoration equipment, in particular to wiring groove concrete backfilling equipment for building decoration. According to the equipment, concrete backfilling steps can be simplified, the working efficiency can be improved, backfilled concrete is vibrated to decrease gaps of the backfilled concrete. The wiring groove concrete backfilling equipment for building decoration comprises two sets of mounting frames; a first moving pair is arranged between the mounting frames; and a fixing frame is arranged on a moving part of the first moving pair. By adopting a modethat concrete is placed in a concrete box and flows into a wiring groove through an electric control valve, and a mode that a vibration block vibrates the backfilled concrete, so that the backfillingprocess of the concrete can be conducted without manually holding a cement shovel, the backfilling speed can be increased, and manpower is saved.

Owner:安徽新城建设有限公司

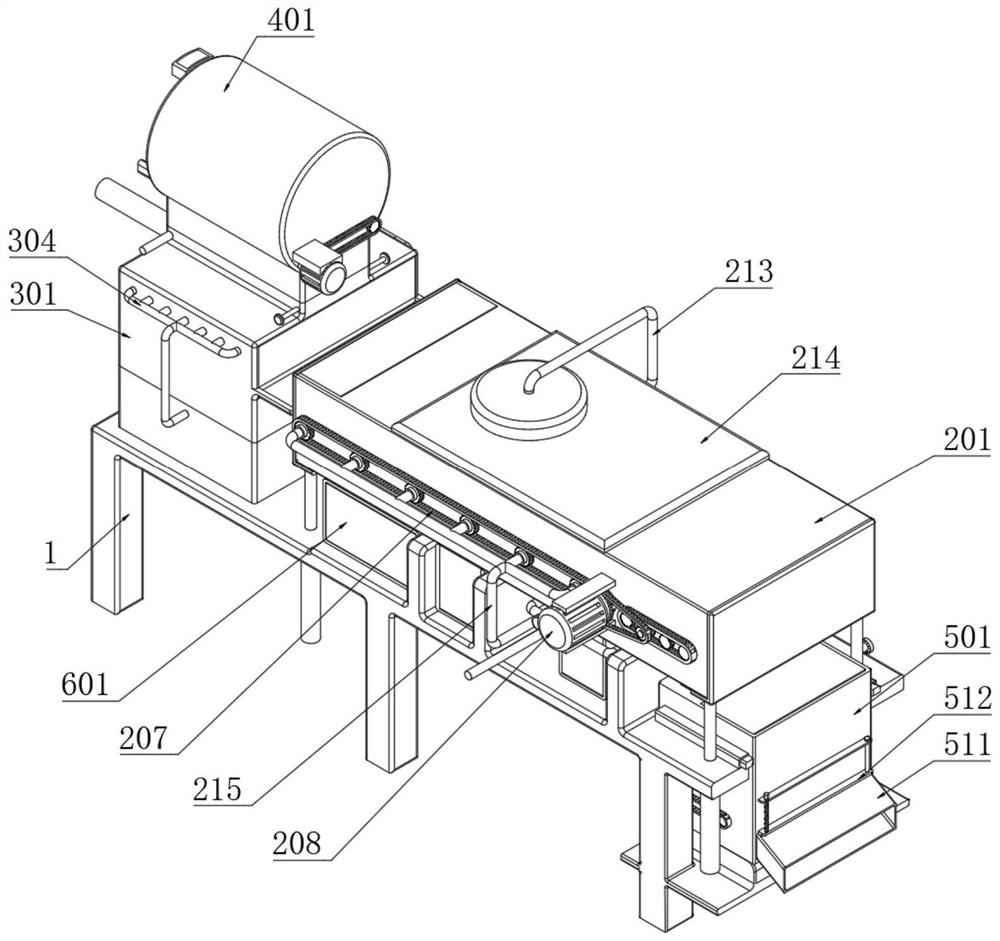

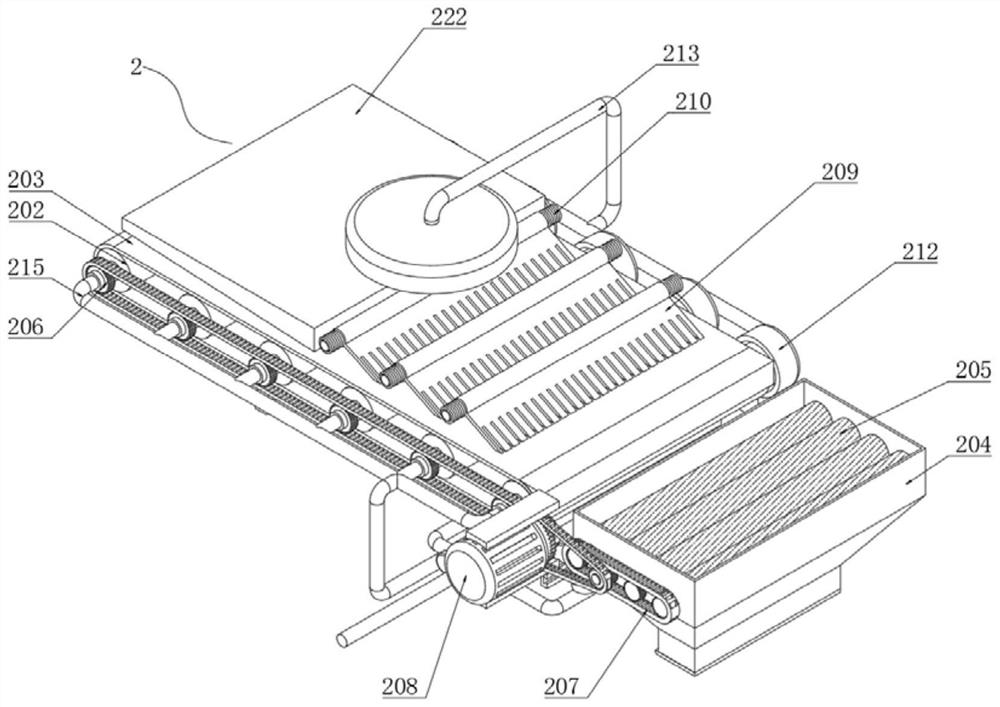

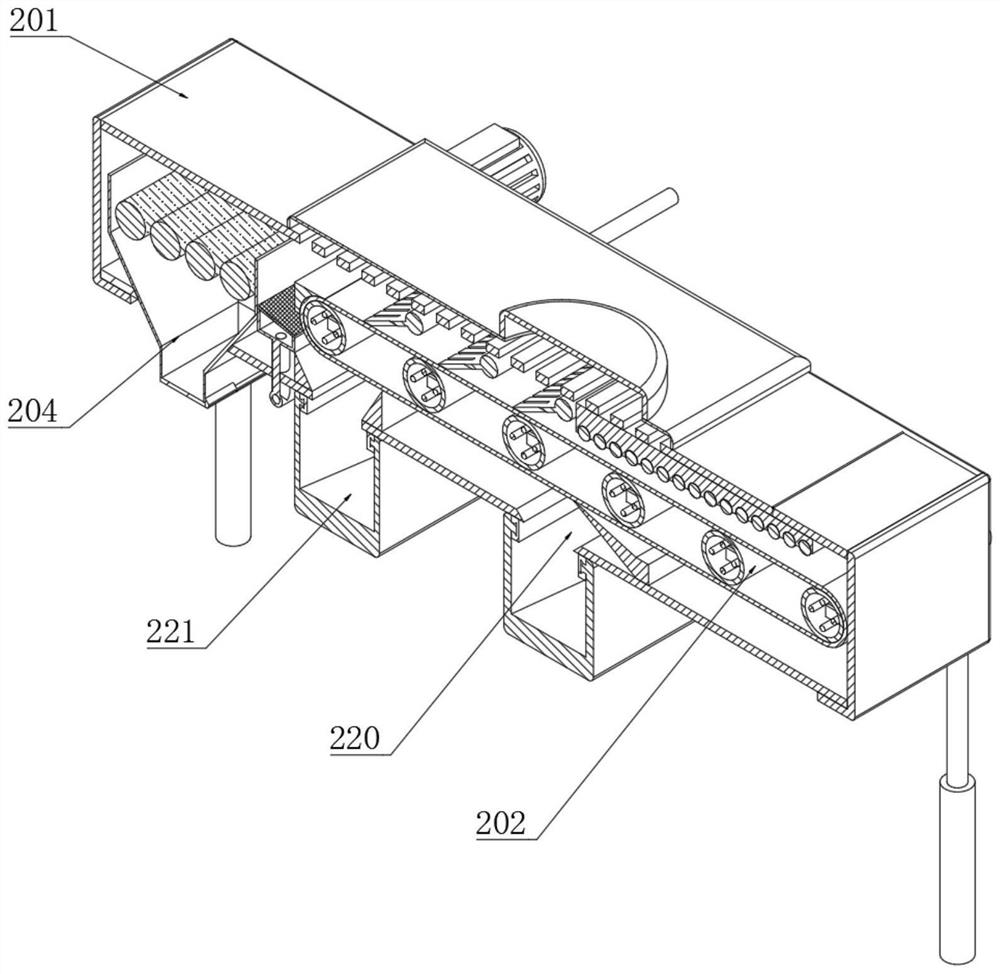

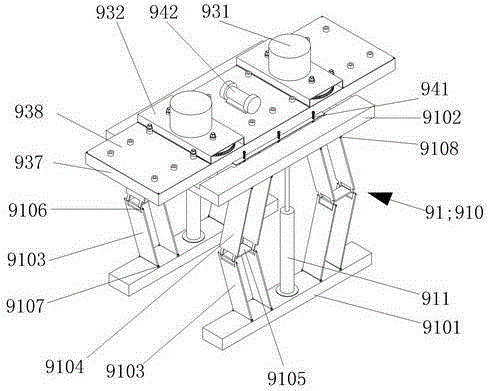

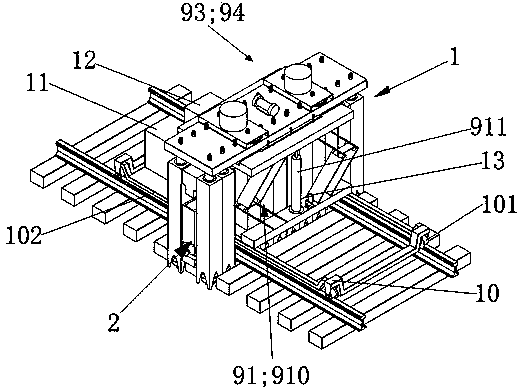

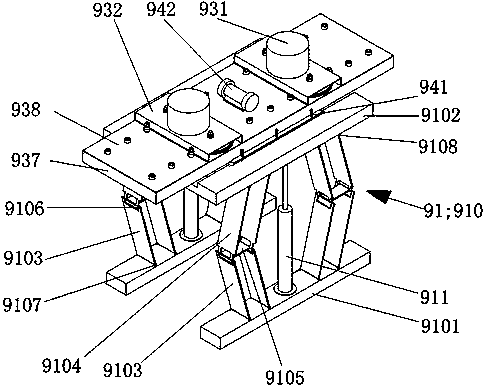

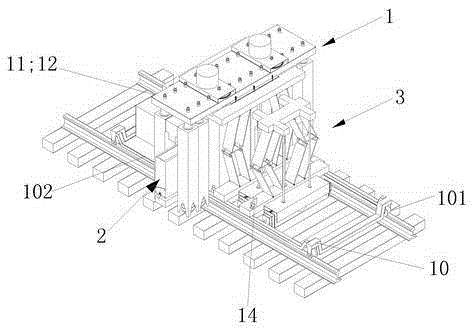

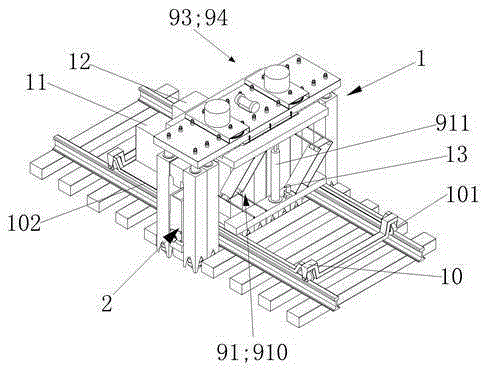

Mechanization rapid ballast discharging and filling machine used among sleepers

The invention discloses a mechanization rapid ballast discharging and filling machine used among sleepers. The mechanization rapid ballast discharging and filling machine used among the sleepers is composed of a ballast collection and discharging device, a vibration stone pushing device, a traverse moving vibration rotary excavating stone discharging device, a rail car, an electric generator, a hydraulic system case, a first camera component, a second camera component and a monitor, wherein four trundles and two longitudinal beams are installed in the rail car, the ballast collection and discharging device, the vibration stone pushing device, the traverse moving vibration rotary excavating stone discharging device, the electric generator and the hydraulic system case are arranged on the two longitudinal beams of the rail car, the rail car is dragged by an engineering truck, the monitor is arranged in a cab of a tractor truck, and the electric generator provides power to an oil pump and a motor. The mechanization rapid ballast discharging and filling machine used among the sleepers can rapidly align a working device to a position to be processed, can rapidly discharge ballast among the sleepers into a stone collection box, can automatically separate sandy soil from the ballast and discharge the sandy soil, can rapidly backfill two sides of a sleeper which replaces a previous sleeper with the ballast in the stone collection box, can adapt to stone discharging work of straight and curve rail segments, and can fully and reasonably use limited line repair skylight operation time to complete ballast cleaning work.

Owner:KUNMING UNIV

A mechanized pillow changing machine

InactiveCN104195904BQuick alignmentAutomatic separation and dischargeBallastwayRailway track constructionPush and pullAutomatic control

Owner:KUNMING UNIV

Ballast discharging and filling mechanized device

InactiveCN106223135AQuickly align to working positionEasy dischargeBallastwayTrack superstructureAutomatic controlSprocket

The invention discloses a ballast discharging and filling mechanized device. The ballast discharging and filling mechanized device is composed of a ballast tamping and flattening device, a road shoulder and road bed shape repairing device, a grab bucket stone clearing device, a ballast concentrated discharging device, a sleeper end stone clearing device, a sprocket stone discharging device and a rail vehicle. According to the ballast discharging and filling mechanized device, a working device can be quickly aligned with a working position; ballast located between sleepers, can be quickly discharged, and meanwhile sandy soil in the ballast is automatically removed; ballast in the positions, on the outer sides of the ends of the sleepers, of a road bed can be quickly removed; ballast in the position, under a steel rail, of the road bed can be quickly removed; ballast can be quickly backfilled between sleepers on the two sides of replaced sleepers, and the shape of a road shoulder and the shape of the road bed can be quickly repaired; the ballast backfilled to the position between the replaced sleepers can be quickly tamped and flattened in a vibration mode; the ballast discharging and filling mechanized device can adapt to ballast discharging and filling work of linear and curved rail sections; and automatic control can be achieved, operation is convenient, and the working efficiency of ballast discharging and filling is high.

Owner:KUNMING UNIV

Concrete backfilling equipment for wiring grooves for building decoration

The invention relates to building decoration equipment, in particular to a concrete backfilling equipment for wiring grooves used for building decoration. Provided is a wiring groove concrete backfilling device for building decoration that can simplify concrete backfilling steps, improve work efficiency, and vibrate the backfilled concrete to reduce the voids. The utility model relates to a concrete backfilling equipment for wiring grooves for building decoration, which includes installation frames, the number of which is two groups, and a first moving pair is arranged between the mounting frames, and a fixed frame is arranged on the moving part of the first moving pair. The invention adopts the method of placing the concrete in the concrete box and flowing out into the wiring groove through the electric control valve, and adds the vibrating block to vibrate the backfilled concrete, so that the concrete backfilling process can be carried out without manual hand-held cement shovel, and can make Backfilling speed is increased and manpower is liberated.

Owner:安徽新城建设有限公司

Thin-wall light steel structure steel pile strip-shaped foundation composite foundation technology

InactiveCN110835926ASettlement controlImprove integrityBulkheads/pilesArchitectural engineeringSettlement (structural)

The invention relates to a thin-wall light steel structure steel pile strip-shaped foundation composite foundation technology, and belongs to the technical field of constructional engineering. The technical problem to be solved by the invention is to supplement a spiral steel pile foundation to control building settlement and provide a part of foundation bearing capacity under the condition that astrip-shaped foundation under a concrete wall can meet or partially meet the building load requirement. The invention provides a composite foundation solution under a non-uniform soil layer, the foundation bearing capacity and settlement control problems of an existing fabricated thin-wall light steel structure in the non-uniform soil layer or a soft soil layer are solved, and a new solution is provided for structural safety and construction convenience.

Owner:YUNNAN ZHONGQIAN INTEGRATED HOUSING CO LTD

A vibrating rotary excavation and ballast filling machine between sleepers

The invention discloses a vibration rotary excavating ballast discharging and filling machine used among sleepers. The vibration rotary excavating ballast discharging and filling machine used among the sleepers is composed of a vibration rotary excavating stone discharging device, a ballast collection and discharging device, a rail car, an electric generator, a hydraulic system case, a camera component and a monitor, wherein four trundles and two longitudinal beams are installed on the rail car, the vibration rotary excavating stone discharging device, the ballast collection and discharging device, the electric generator and the hydraulic system case are arranged on the two longitudinal beams of the rail car, the rail car is dragged by an engineering truck, the monitor is arranged in a cab of a tractor truck, and the electric generator provides power to an oil pump and a motor. The vibration rotary excavating ballast discharging and filling machine used among the sleepers can rapidly align a working device to a position to be processed, can rapidly discharge ballast among the sleepers into a stone collection box, can automatically separate sandy soil from the ballast and discharge the sandy soil, can rapidly backfill two sides of a sleeper which replaces a previous sleeper with the ballast in the stone collection box, can adapt to stone discharging work at straight and curve rail segments, easily achieves program automatic control, is convenient to operate, simple in structure, reliable in performance and high in mechanization operation rate, and can fully and reasonably use limited line repair skylight operation time to complete macadam cleaning work.

Owner:KUNMING UNIV

Quick sleeper-changing machine

InactiveCN104179093AQuick alignmentAutomatic separation and dischargeRailway track constructionPush and pullBallast

The invention discloses a quick sleeper-changing machine. The quick sleeper-changing machine consists of a vibration rotary excavating stone discharging device, a stone ballast collecting and discharging device, a vibration stone pushing device, a four-nut synchronous assembling and disassembling device, a rail lifting sleeper-rotating device, a sleeper pushing and pulling device, a rail car, a generator, a hydraulic system box, a first video component, a second video component, a third video component, a fourth video component and a monitor; a plurality of trundles and two longitudinal beams are mounted on the rail car, the vibration rotary excavating stone discharging device, the stone ballast collecting and discharging device, the vibration stone pushing device, the four-nut synchronous assembling and disassembling device, the rail lifting sleeper-rotating device, the sleeper pushing and pulling device, the generator and the hydraulic system box are arranged on the two longitudinal beams of the rail car, and the monitor is arranged in a motor tractor cab. According to the quick sleeper-changing machine, stone ballast among the sleepers is quickly discharged in a stone collection box and is automatically separated to discharge sand in the stone ballast; the quick sleeper-changing machine can be suitable for straight-line and curve rail road sleeper-changing work; limited circuit repair skylight work time can be fully and reasonably utilized, so that the sleeper-changing work is completed.

Owner:KUNMING UNIV

A Mechanized Ballast Discharging Machine Between Sleepers

The invention discloses a mechanization ballast discharging and filling machine used among sleepers. The mechanization ballast discharging and filling machine used among the sleepers is composed of a vibration rotary excavating stone discharging device, a ballast collection and discharging device, a vibration stone pushing device, a rail car, an electric generator, a hydraulic system case, a first camera component, a second camera component and a monitor, wherein four trundles and two longitudinal beams are installed on the rail car, the vibration rotary excavating stone discharging device, the ballast collection and discharging device, the vibration stone pushing device, the electric generator and the hydraulic system case are arranged on the two longitudinal beams of the rail car, the rail car is dragged by an engineering truck, the monitor is arranged in a cab of a tractor truck, and the electric generator provides power to an oil pump and a motor. The mechanization ballast discharging and filling machine used among the sleepers can rapidly align a working device to a position to be processed, can rapidly discharge ballast among the sleepers into a stone collection box, can automatically separate sandy soil from the ballast and discharge the sandy soil, can rapidly backfill two sides of a sleeper which replaces a previous sleeper with the ballast in the stone collection box, can adapt to stone discharging work of straight and curve rail segments, easily achieves program automatic control, and is convenient to operate, simple in structure and high in mechanization operation rate.

Owner:KUNMING UNIV

Stone discharging-filling multi-functional intelligent device

The invention discloses a stone discharging-filling multi-functional intelligent device. The stone discharging-filling multi-functional intelligent device is composed of a self-propelled track car, atransverse-moving chain bucket stone discharging device, two stone ballast collecting-discharging multi-functional devices, a charging battery pack, an inverter and a hydraulic system and control system box, wherein the charging battery pack and the inverter provides power for an oil pump and a control system, and the hydraulic system and control system box is internally provided with an oil tank,the oil pump, a hydraulic control system and an automatic control system; the self-propelled track car is composed of a drive device, a driven wheel assembly, a round-trip track device, a car frame,four first constant strength cantilevel beams and two second constant strength cantilevel beams; and the working position can be automatically and quickly aligned, stone ballast between the two sidesof a damaged sleeper is automatically discharged, sandy soil is screened, refilling is conducted between the two sides of the damaged sleeper, the track car can arrive and depart railway tracks in a self-propelled mode, the situation that normal traffic of a train is influenced is avoided, the center of gravity of the track car is not raised when the track car moves up and down the tracks, and damping is avoided.

Owner:KUNMING UNIV

Multifunctional automatic device for chain bucket stone discharging

The invention discloses a multifunctional automatic device for chain bucket stone discharging. The multifunctional automatic device for chain bucket stone discharging is composed of a self-driving rail vehicle, a chain bucket stone discharging device, two ballast collecting and discharging multifunctional devices, a charging battery pack, an inverter, a hydraulic system and a control system box. The charging battery pack and the inverter provide power for an oil pump and a control system. The hydraulic system and the control system box are internally provided with an oil tank, the oil pump, ahydraulic control system and an automatic control system. The self-driving rail vehicle is composed of a driving device, a driven wheel assembly, a round-trip track device, a vehicle frame, a laser displacement sensor and six cantilever beams of equal strength. The working position can be automatically and quickly aligned, ballast between sleepers on the two sides of a damaged sleeper automatically discharges and screens sand and soil and backfill the sleepers on the two sides of a replaced sleeper, and the rail vehicle can travel to and from a railway track automatically so as to avoid affecting the normal passage of a train; and the operation is convenient, automatic control is easy to realize, the working efficiency of stone discharging, screening, backfilling of the ballast and the like is high.

Owner:KUNMING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com