Patents

Literature

983results about "Track superstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

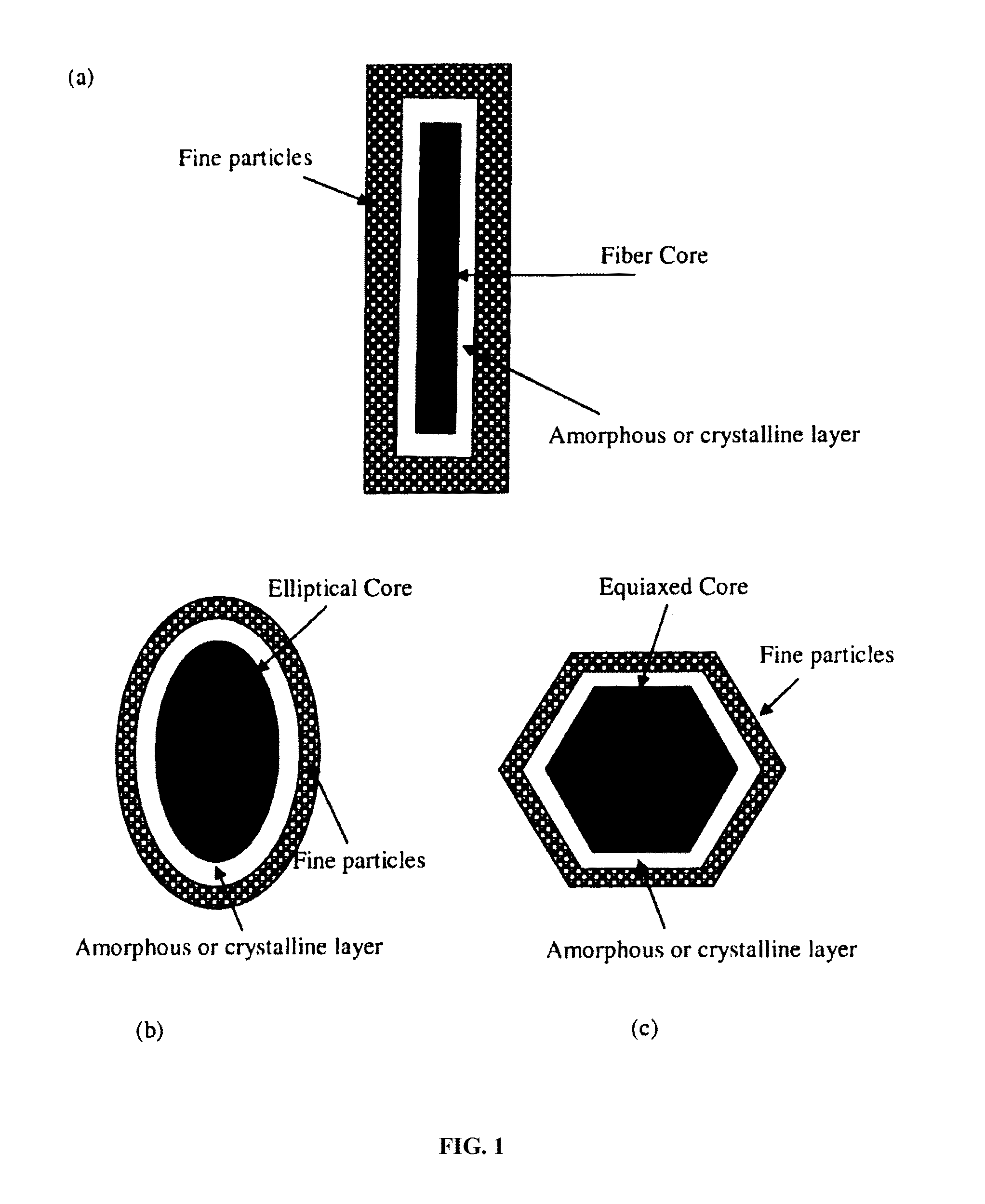

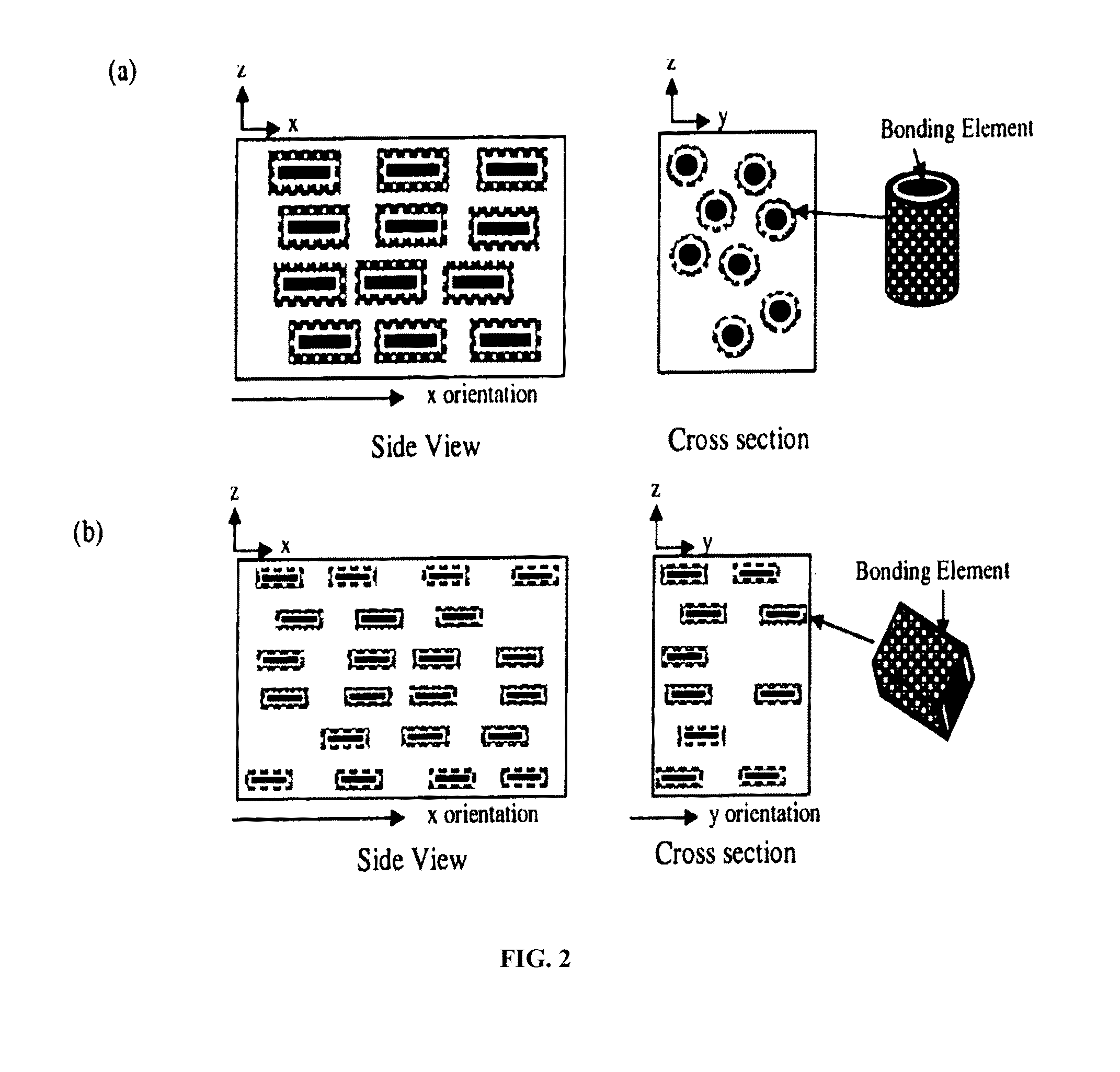

Composite railroad ties and methods of production and uses thereof

ActiveUS20140263683A1Excellent physical and performance characteristicExcellent weatherability and performance characteristicBallastwayCeramic shaping apparatusCarbon footprintMethods of production

The invention provides novel railroad ties manufactured from novel composite materials that possess excellent physical and performance characteristics matching or exceeding existing concrete RRTs. The RRTs of the invention can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production with improved energy consumption and more desirable carbon footprint and minimal environmental impact.

Owner:SOLIDIA TECH

Composite railway crosstie, shaped like an I beam

InactiveUS6247651B1The implementation process is simpleBallastwayPlastic recyclingElectrical and Electronics engineeringEngineering

A railway crosstie is adapted for use in a track system having a pair of rails supported on longitudinally spaced crossties. The railway crosstie includes an I-beam member made of a combination of recycled materials.

Owner:FLANNER JR GEORGE C

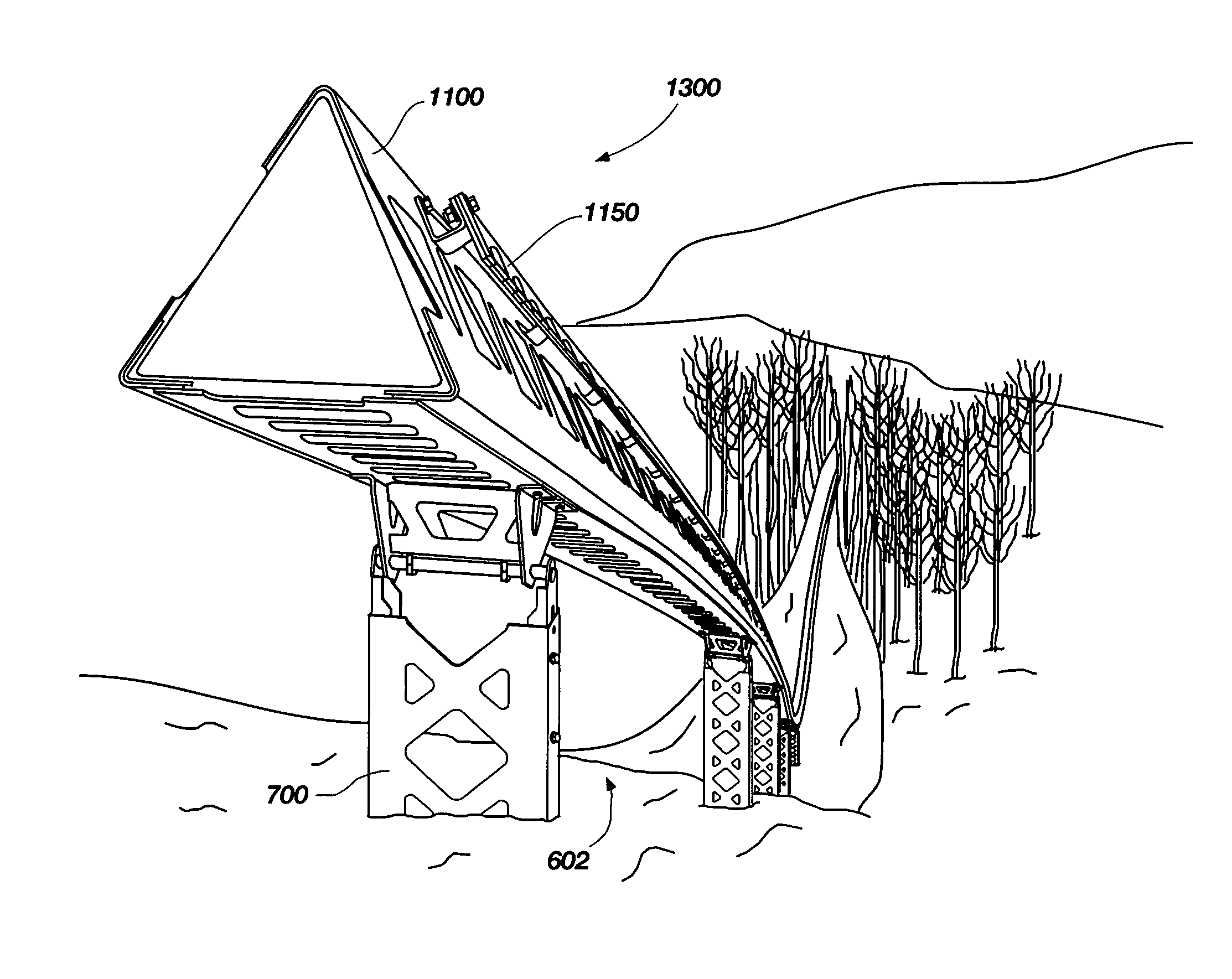

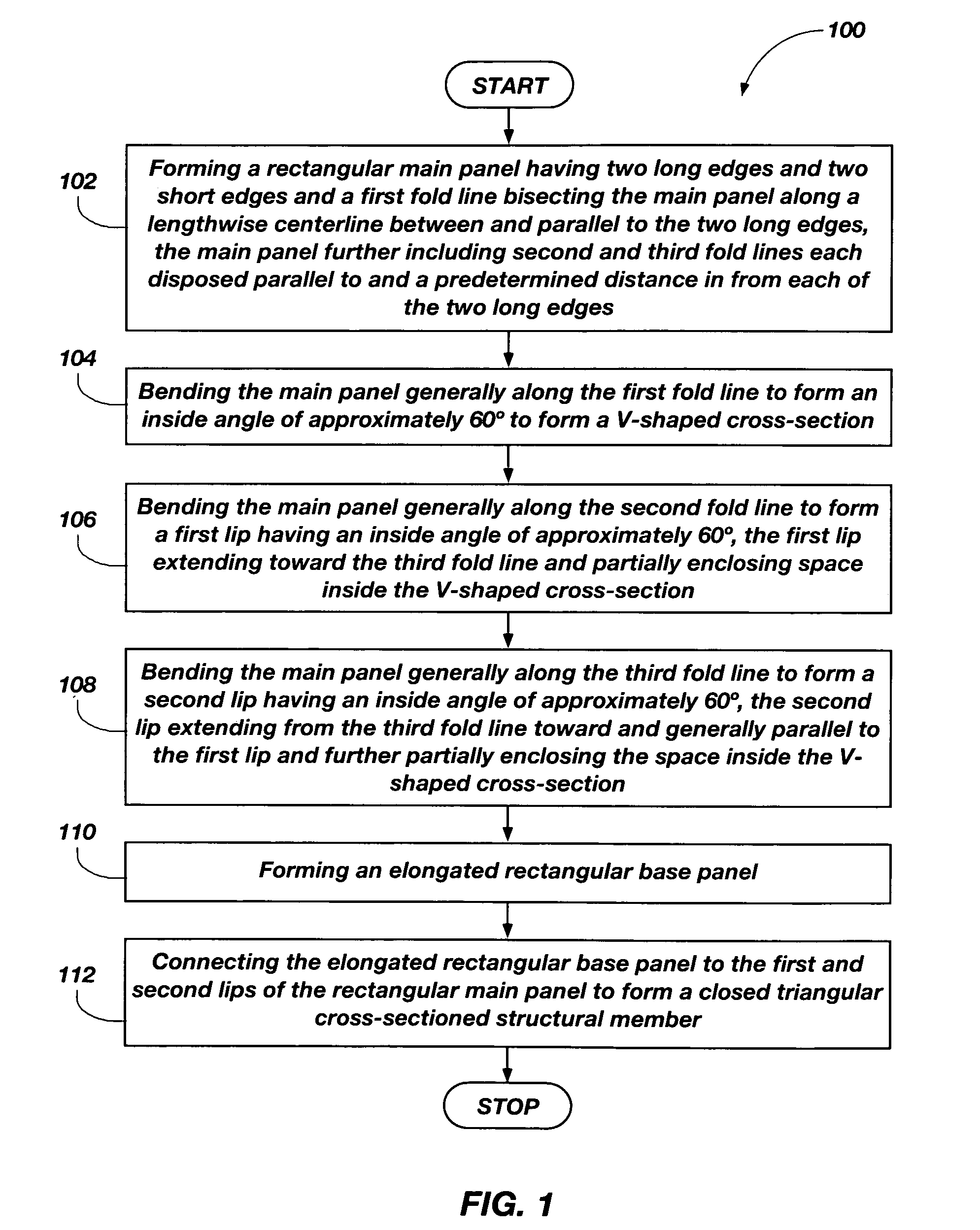

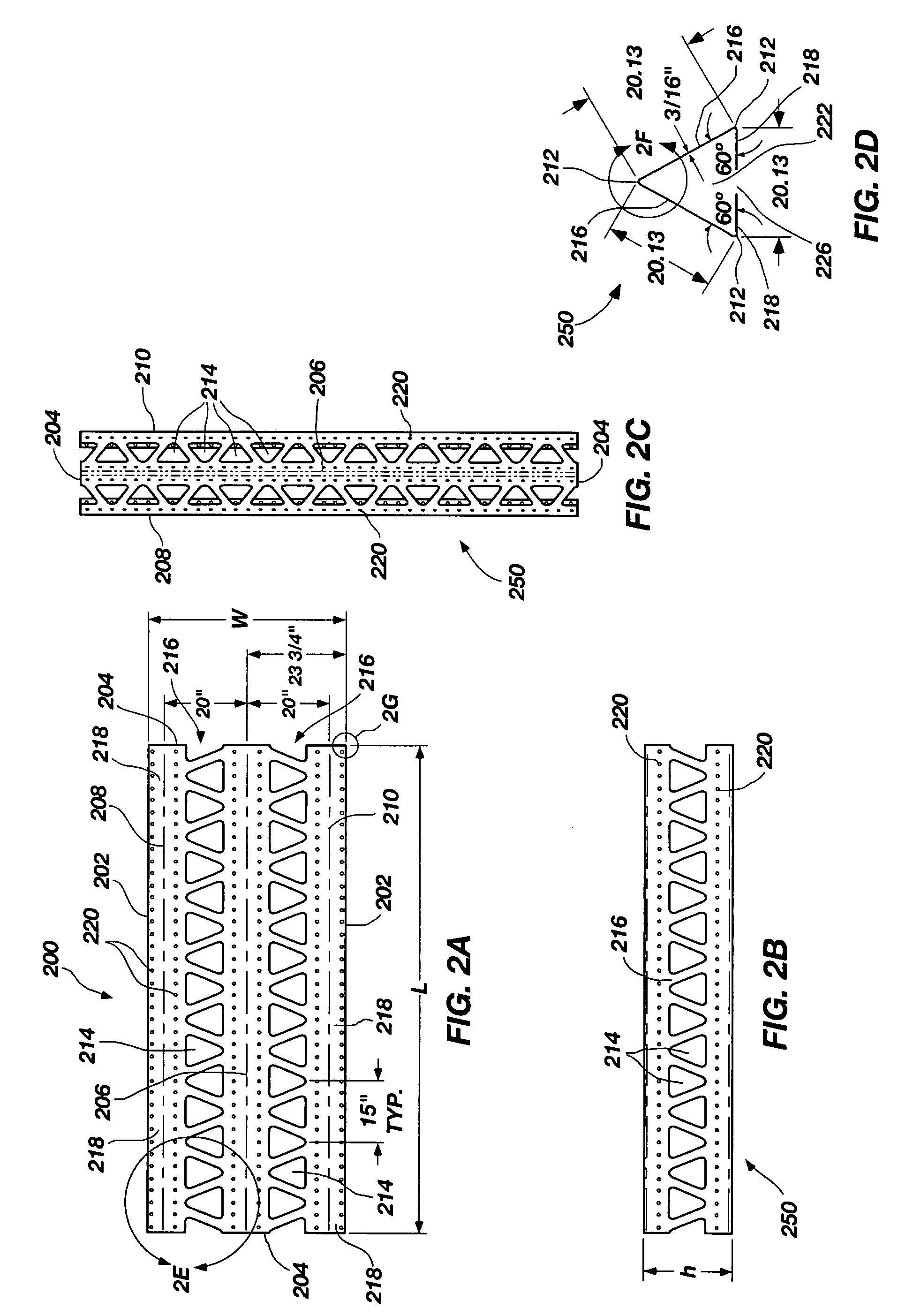

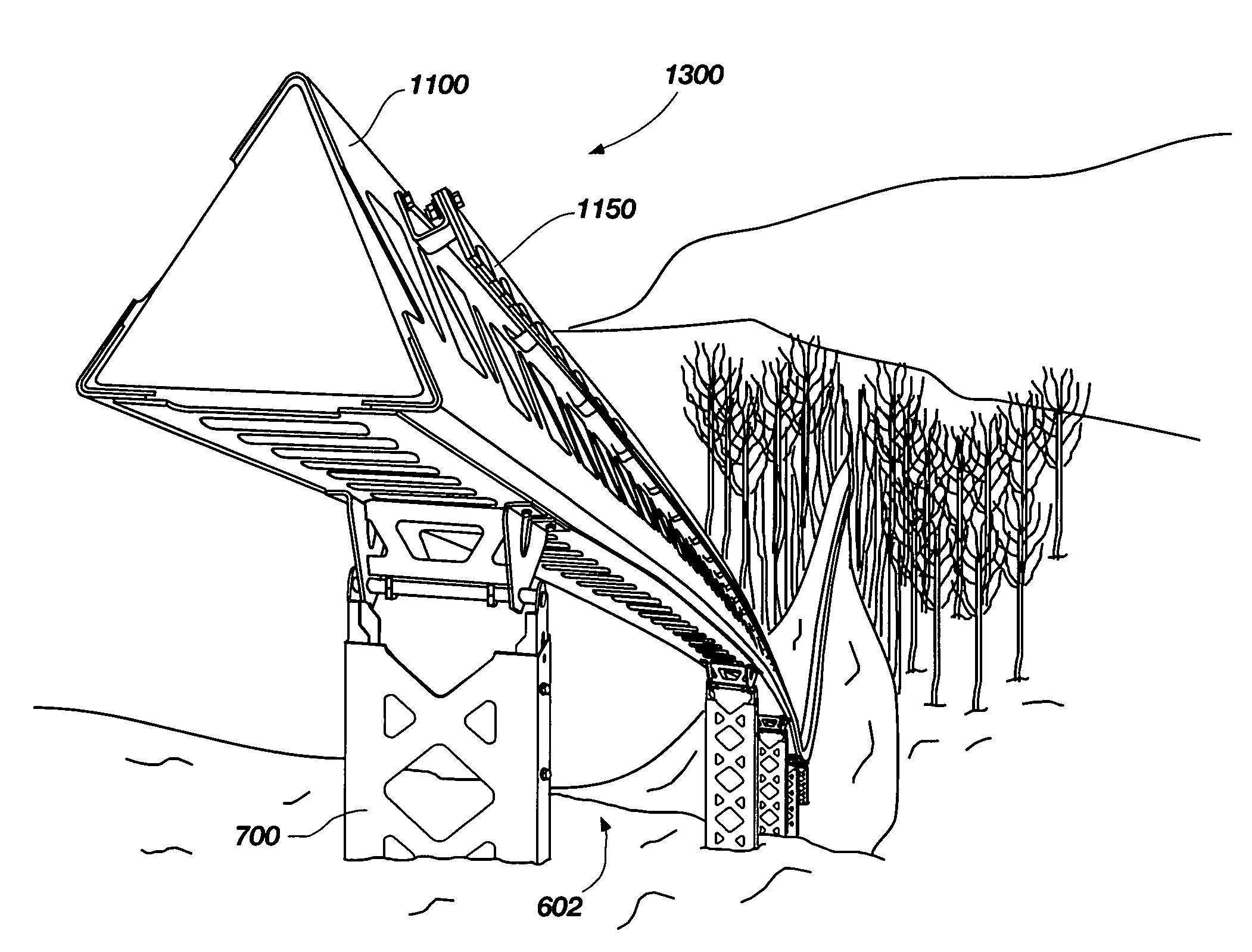

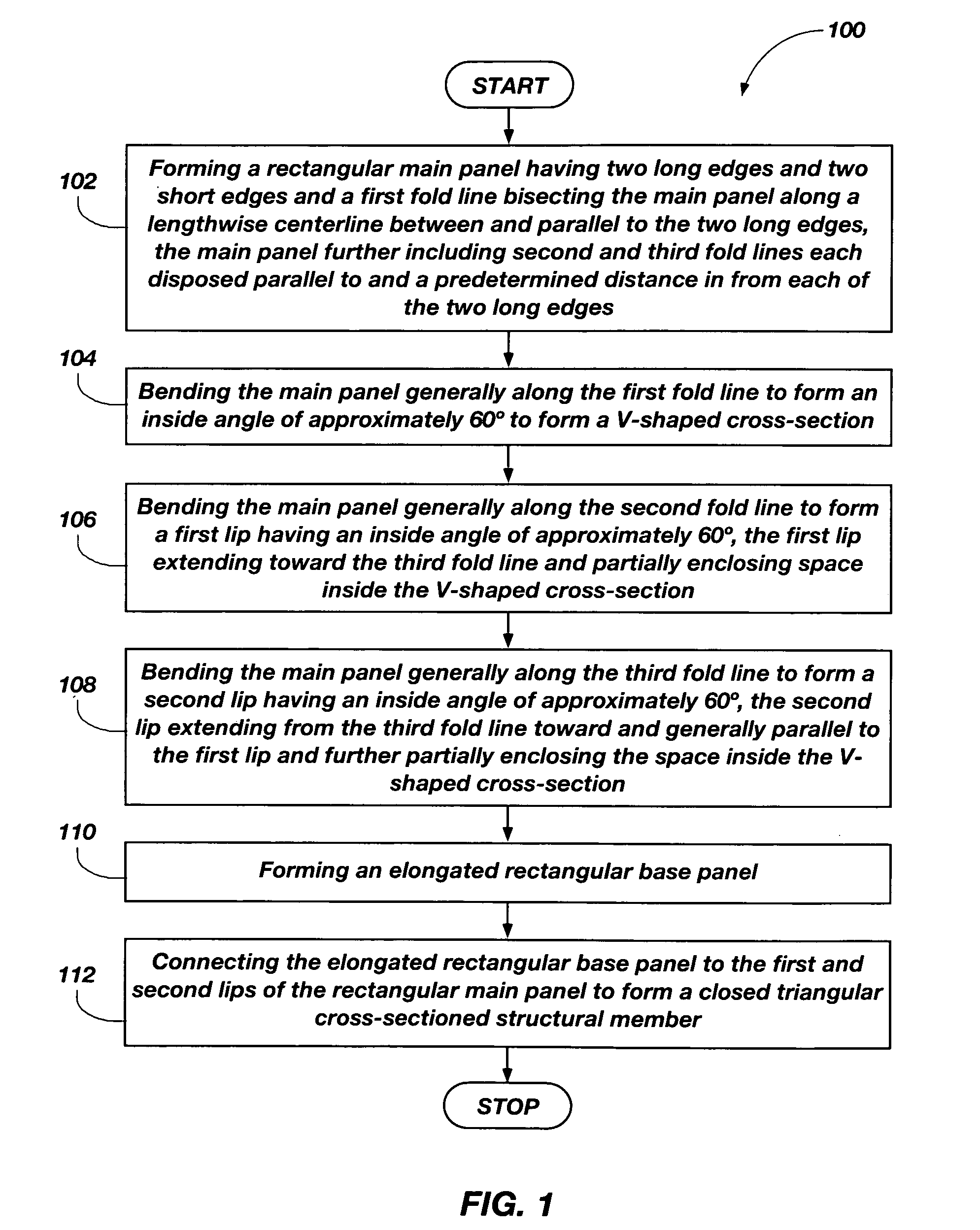

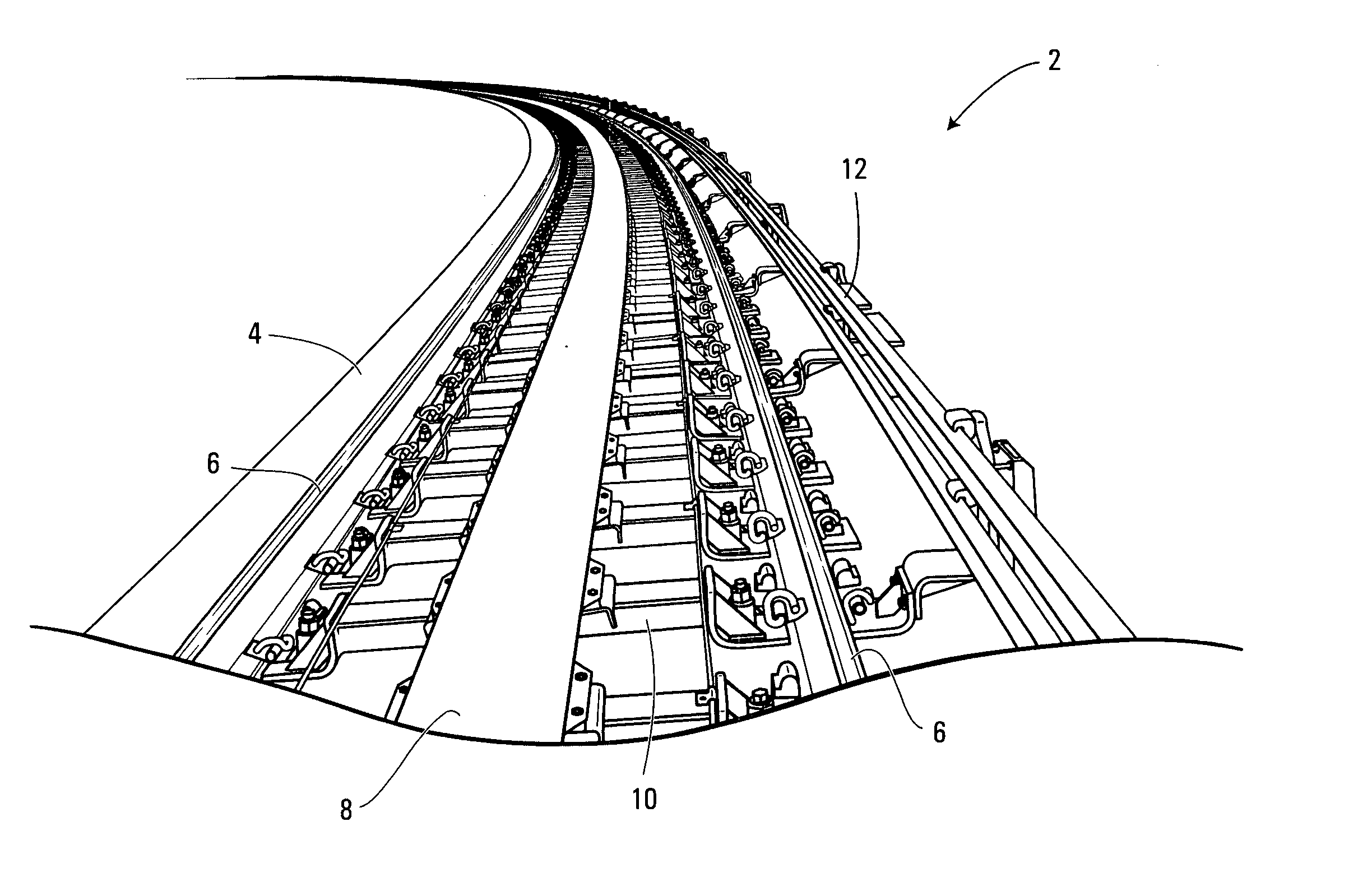

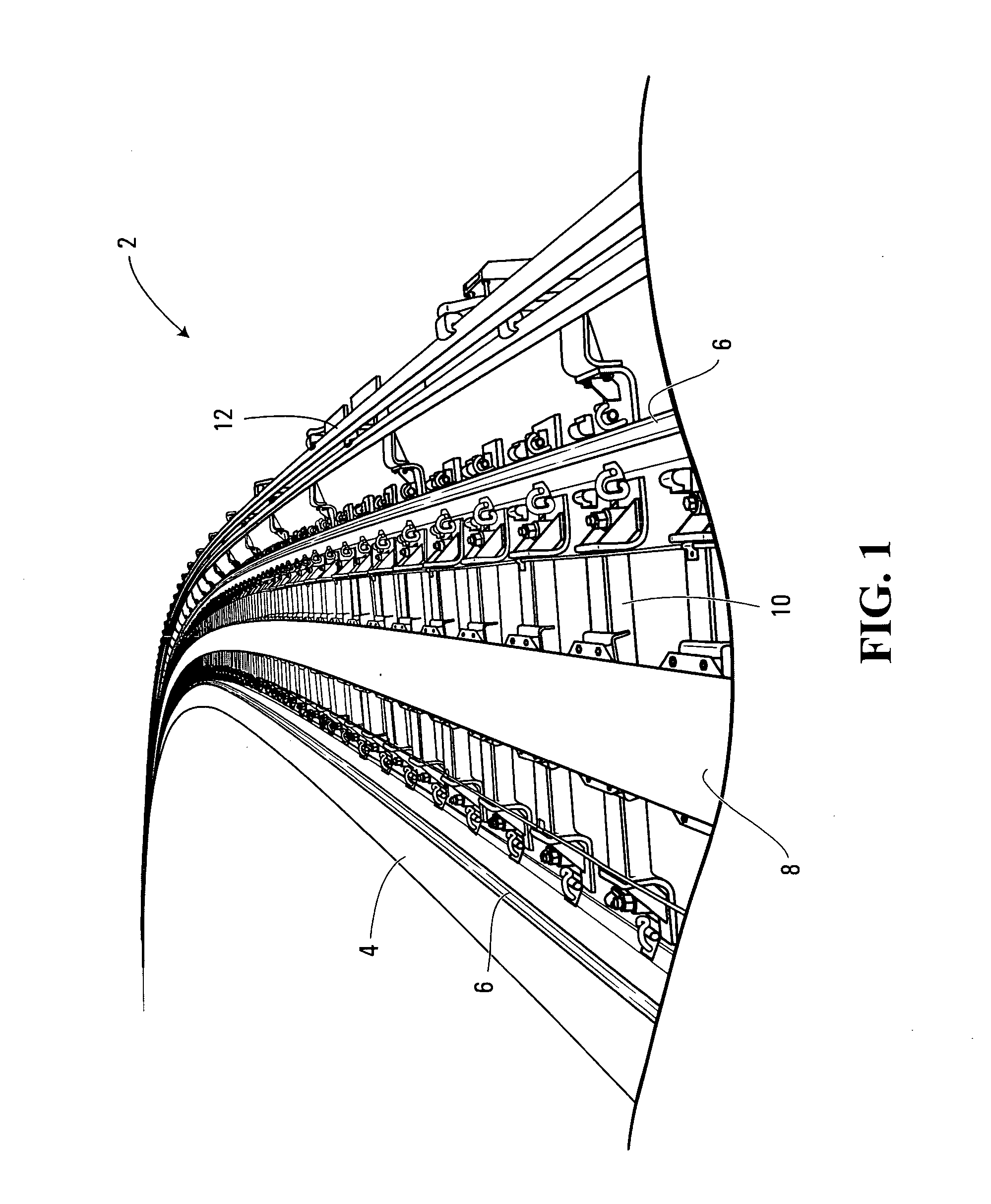

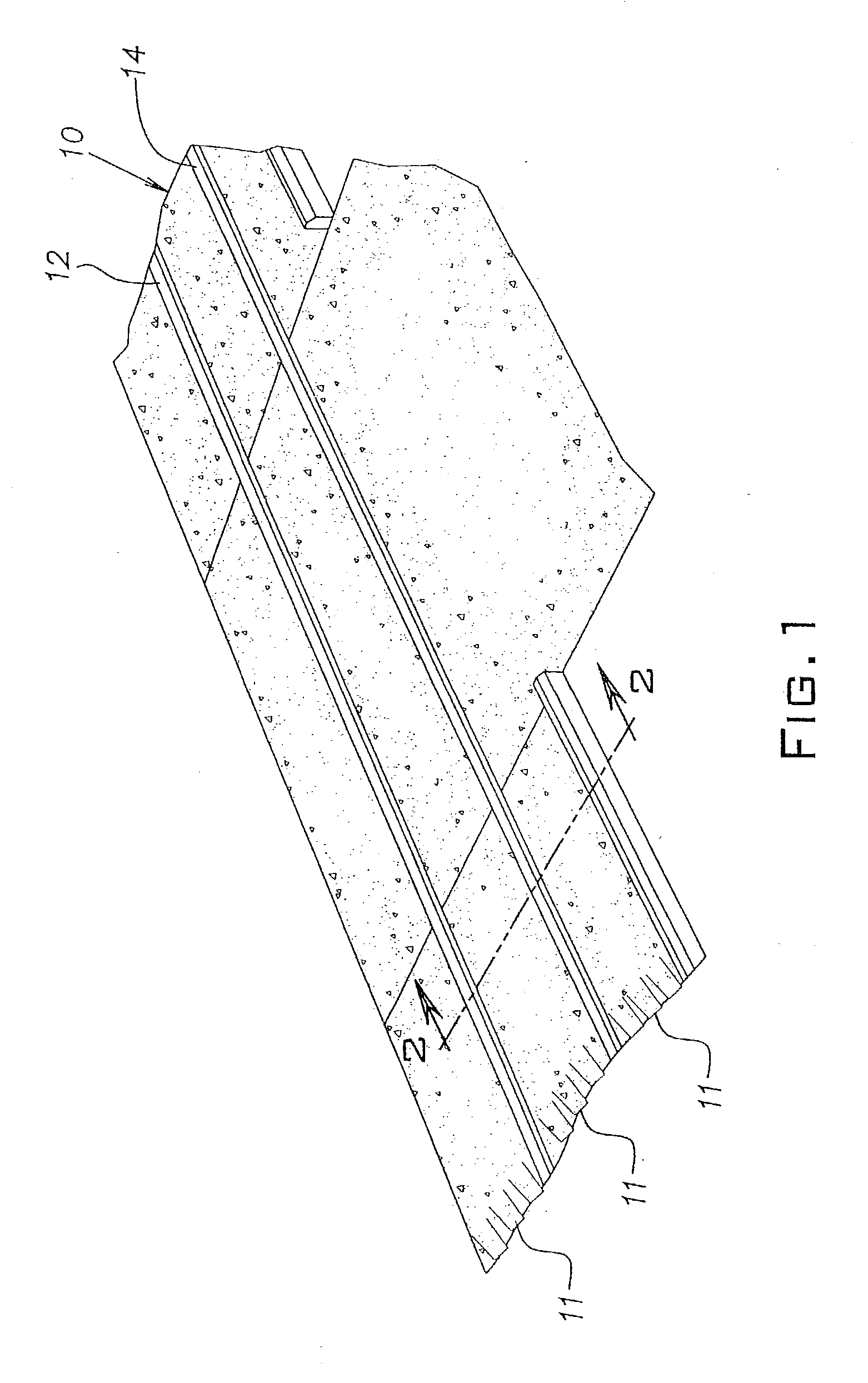

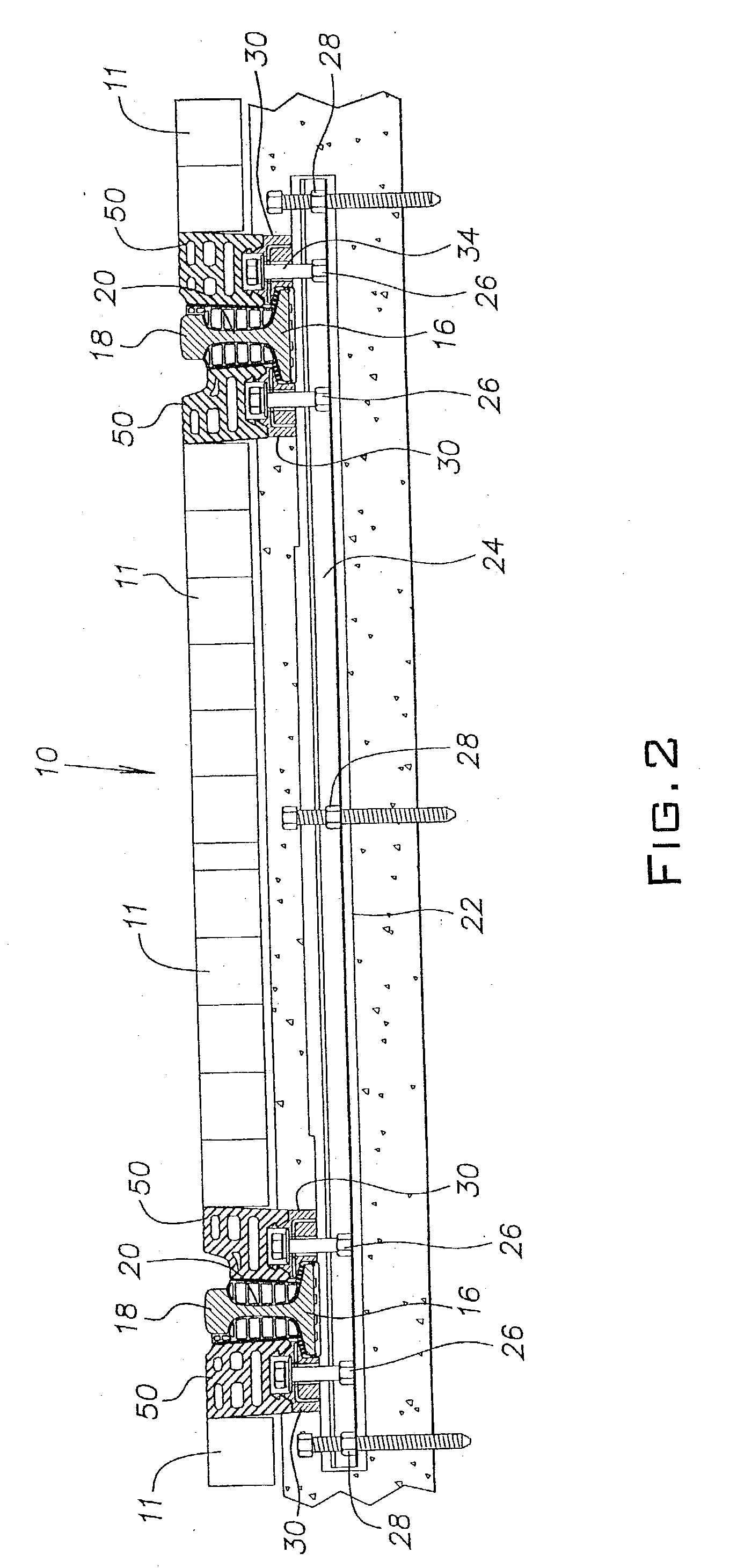

Hollow structural members, a rail system and methods of manufacturing

The invention is hollow structural members, a rail system based thereon and method of manufacturing such hollow structural members. Embodiments of the structural members may be hollow triangular prism-shaped with a cross-section that is triangular, isosceles, hexagonal or otherwise. Embodiments of rail systems based on hollow structural members are also disclosed. Embodiments of the rail systems disclosed herein may also include reaction assemblies for local dissipation of stresses due to thermal expansion of track materials.

Owner:HILLTRAC

Hollow structural members, a rail system and methods of manufacturing

The invention is hollow structural members, a rail system based thereon and method of manufacturing such hollow structural members. Embodiments of the structural members may be hollow triangular prism-shaped with a cross-section that is triangular, isosceles, hexagonal or otherwise. Embodiments of rail systems based on hollow structural members are also disclosed. Embodiments of the rail systems disclosed herein may also include reaction assemblies for local dissipation of stresses due to thermal expansion of track materials.

Owner:HILLTRAC

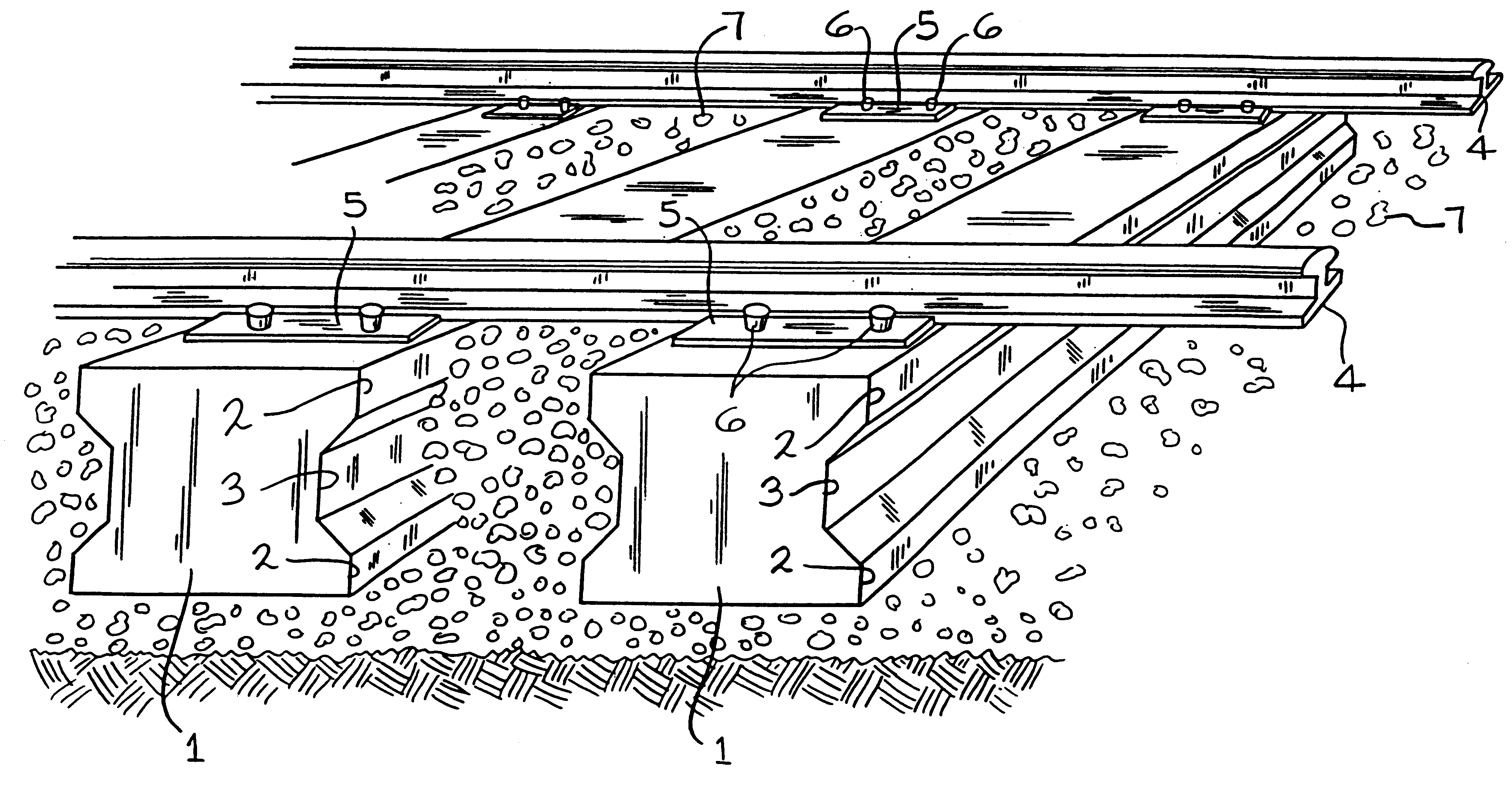

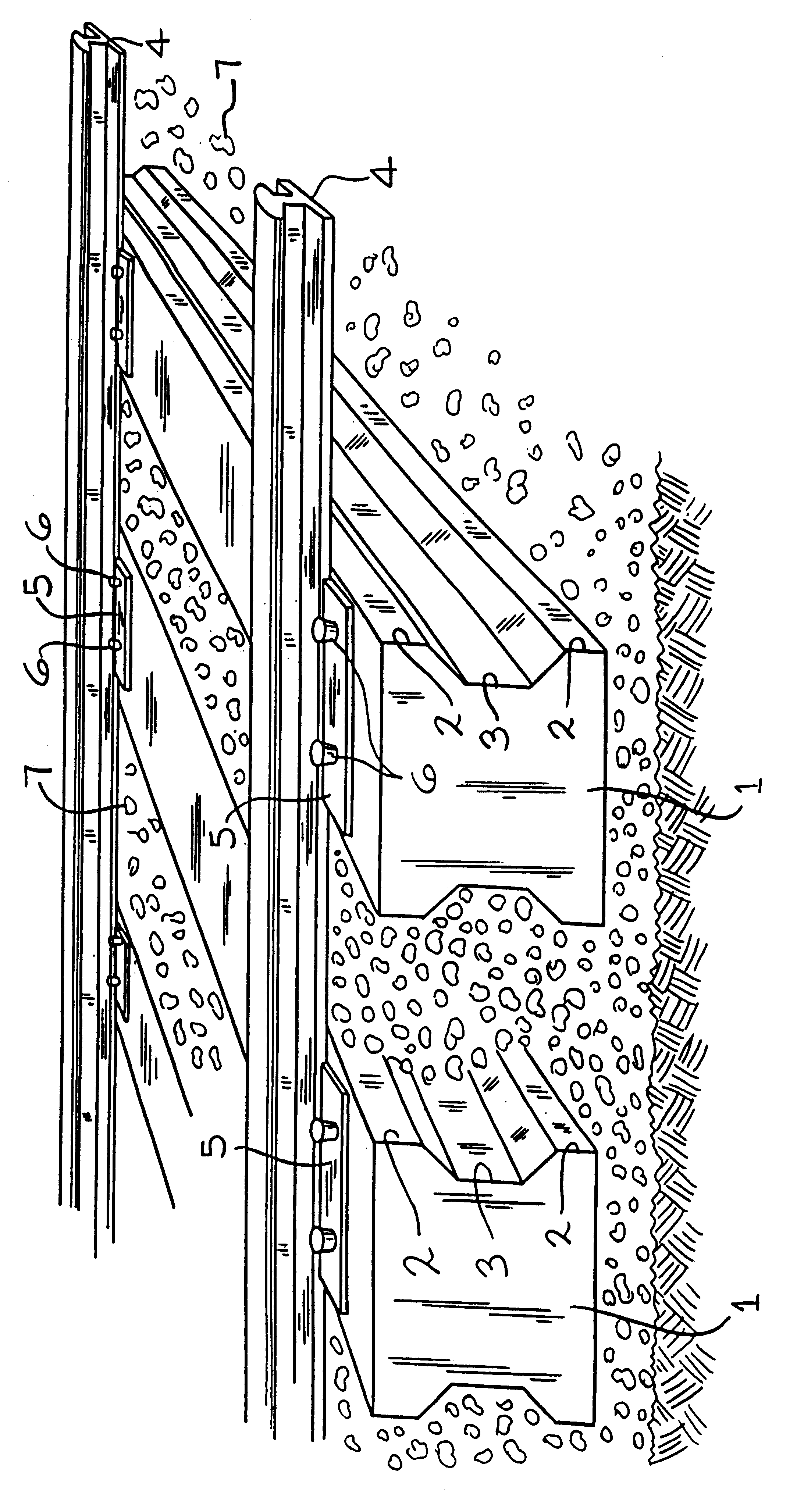

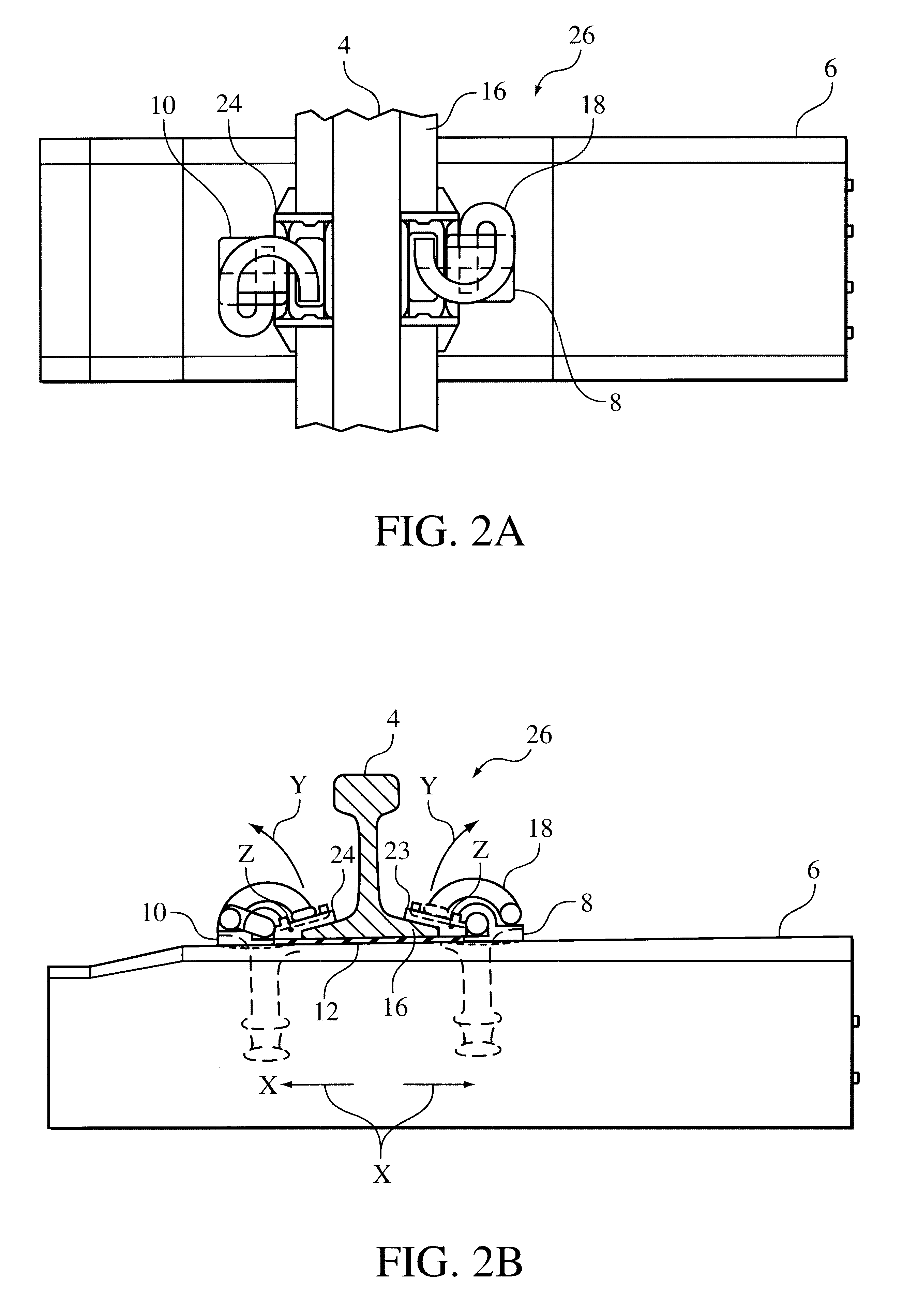

Rail track tie

InactiveUS20080083835A1Improve vibration damping effectControl stressBallastwayRail fastenersDynamic stiffnessEngineering

The rail track tie including: a rigid block presenting a bottom face, and a top face for receiving at least one longitudinal rail; a cover for receiving the rigid block and in the form of a rigid shell including a bottom and a peripheral rim around the bottom; and a resilient soleplate disposed between the bottom face of the rigid block and the bottom of the cover. The resilient soleplate has dynamic stiffness k2 lying in the range of 6 kN / mm to 10 kN / mm, and preferably in the range of 6 kN / mm to 8 kN / mm.

Owner:ALSTOM TRANSPORT SA

Cross-tie

Owner:BOMBARDIER TRANSPORTATION GMBH

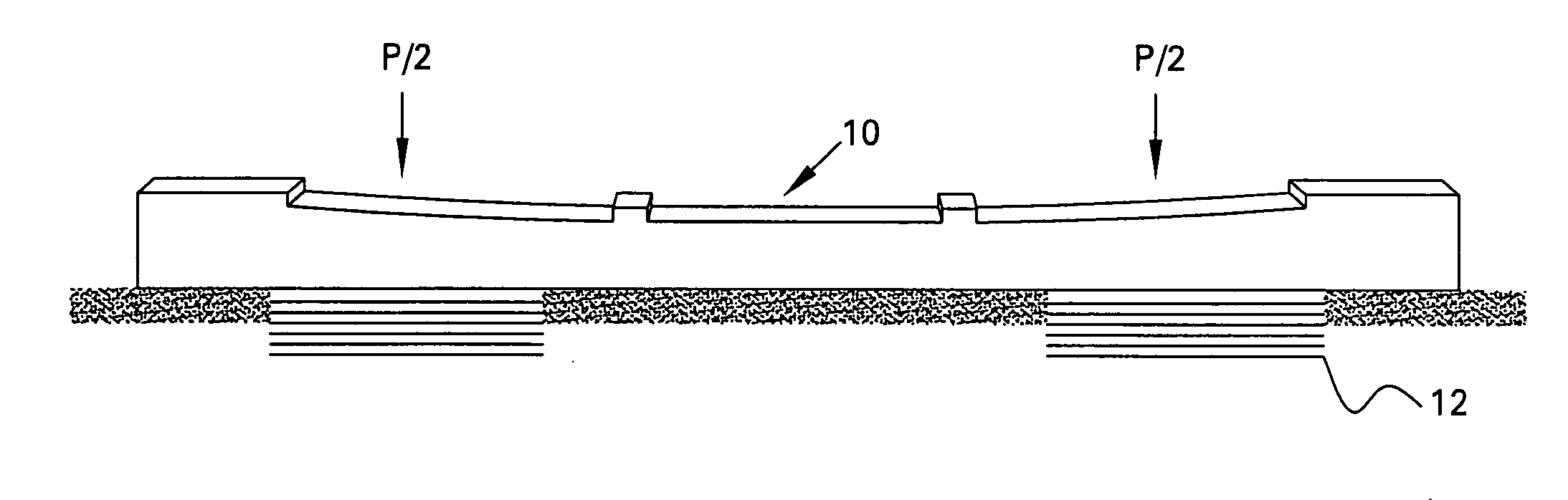

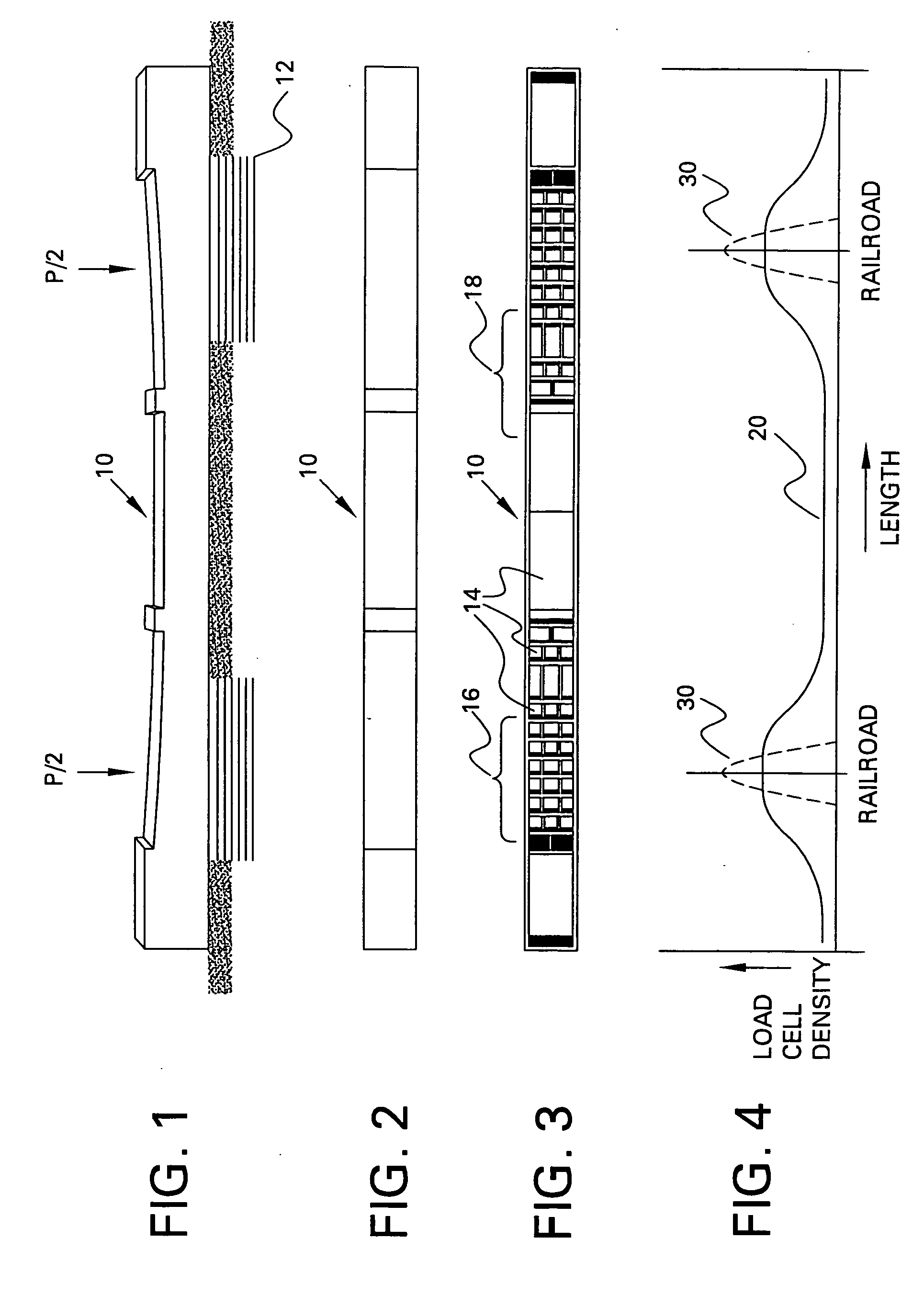

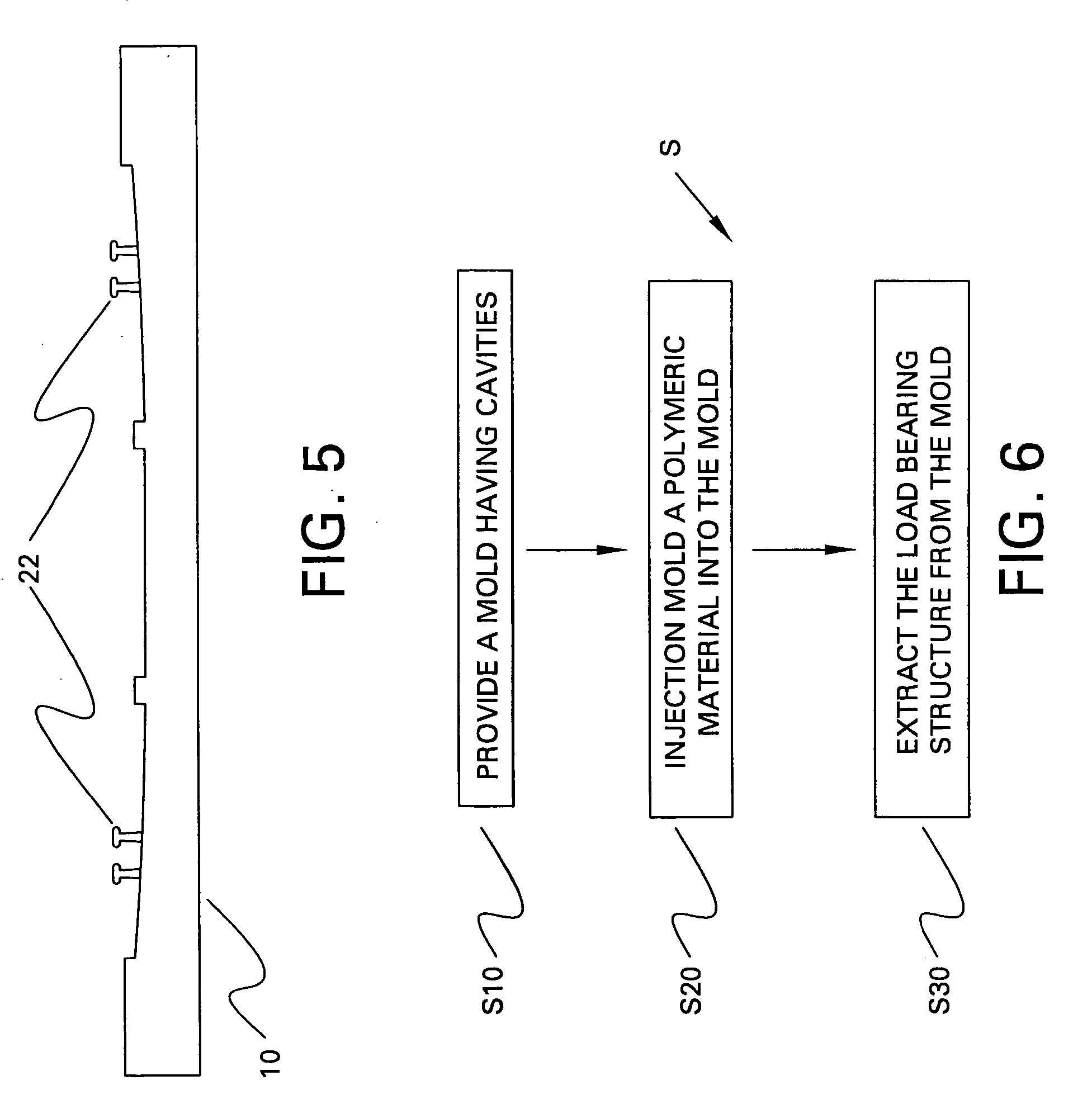

Load bearing structure and method of manufacture thereof

A load bearing structure configured to bear a load, the structure comprising a multiple cells. The load bearing structure has a length, a center, and a cell density, which varies at least along the length of the load bearing structure, which weighs at least 6 kg.

Owner:GENERAL ELECTRIC CO

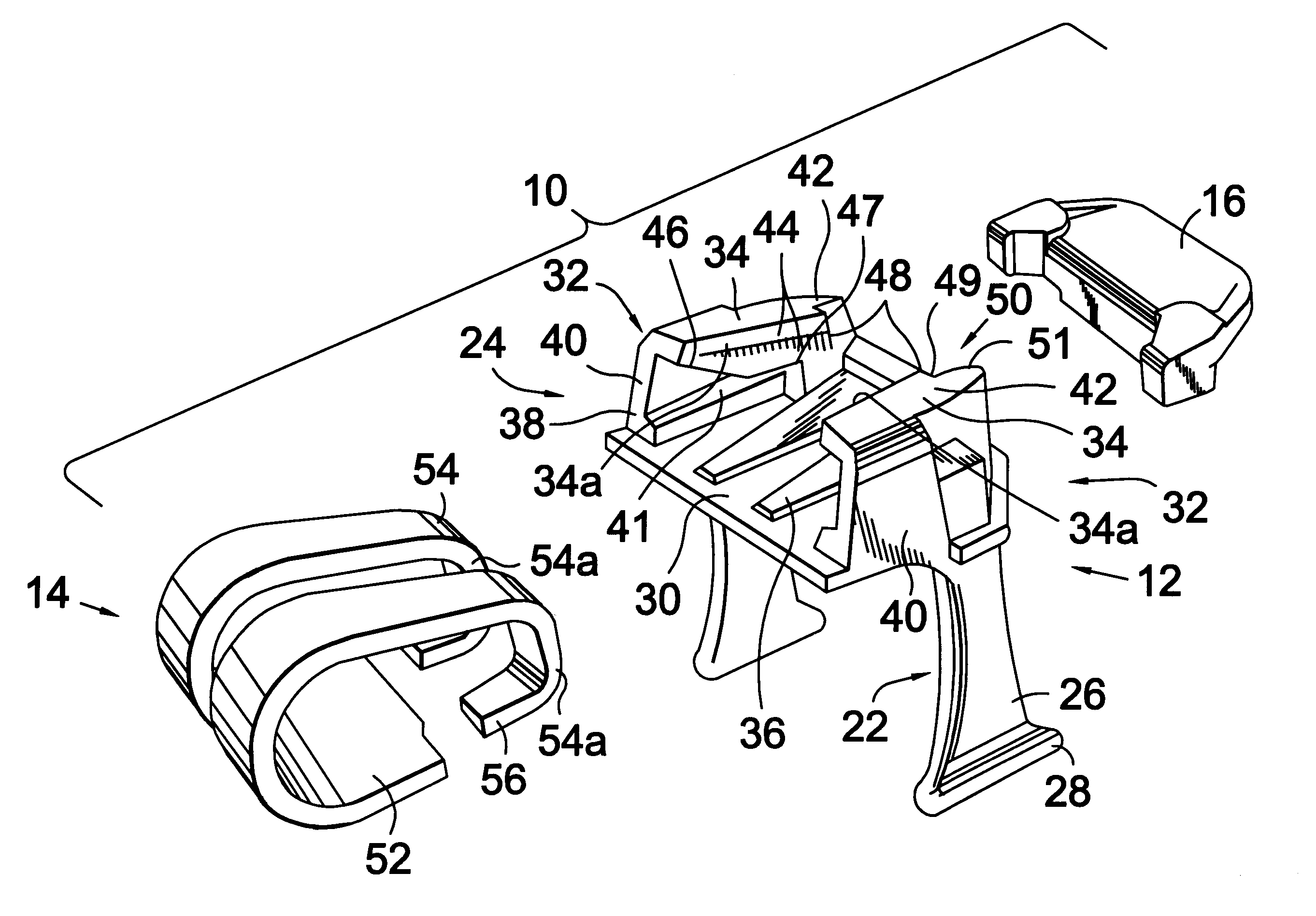

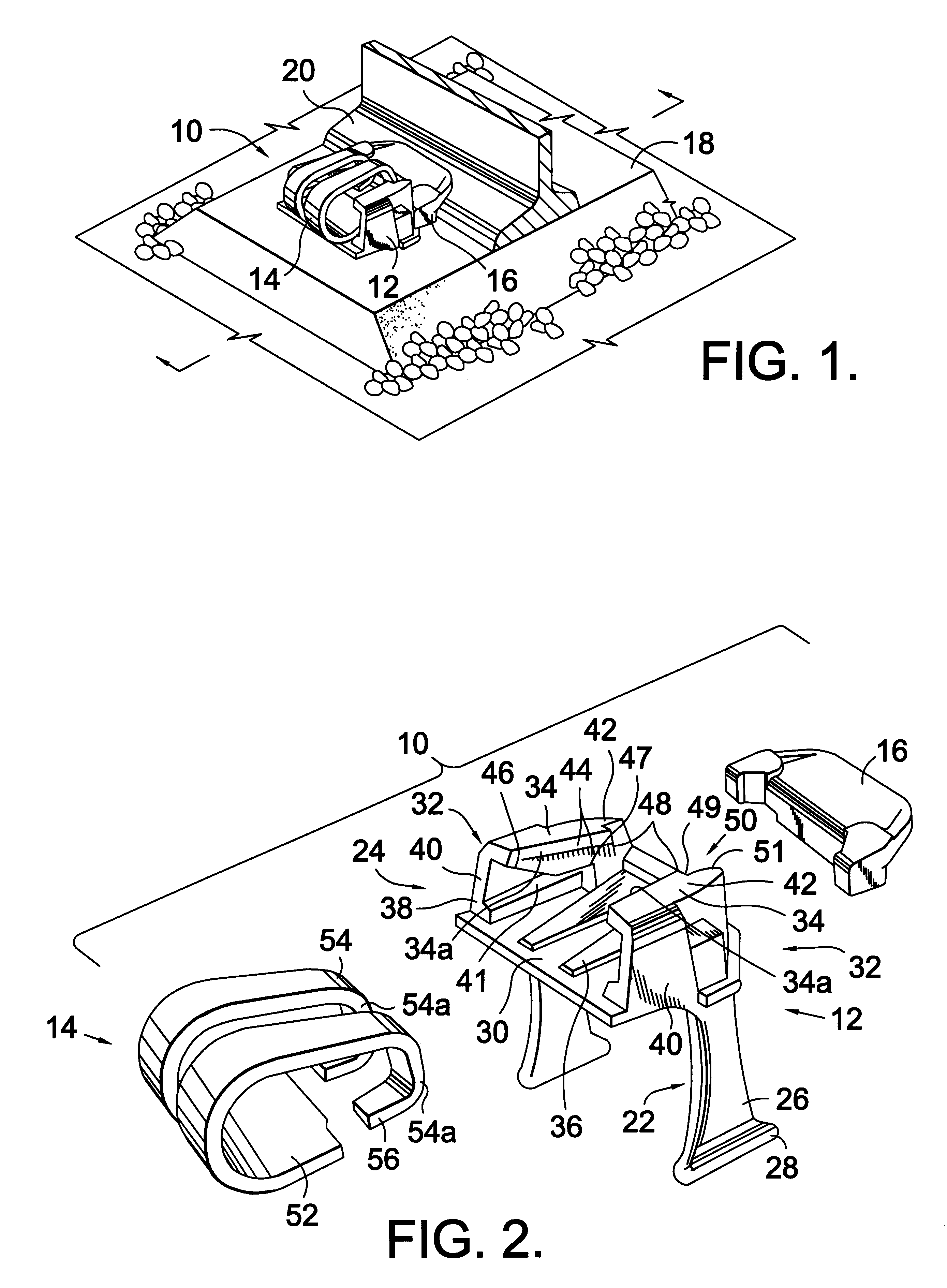

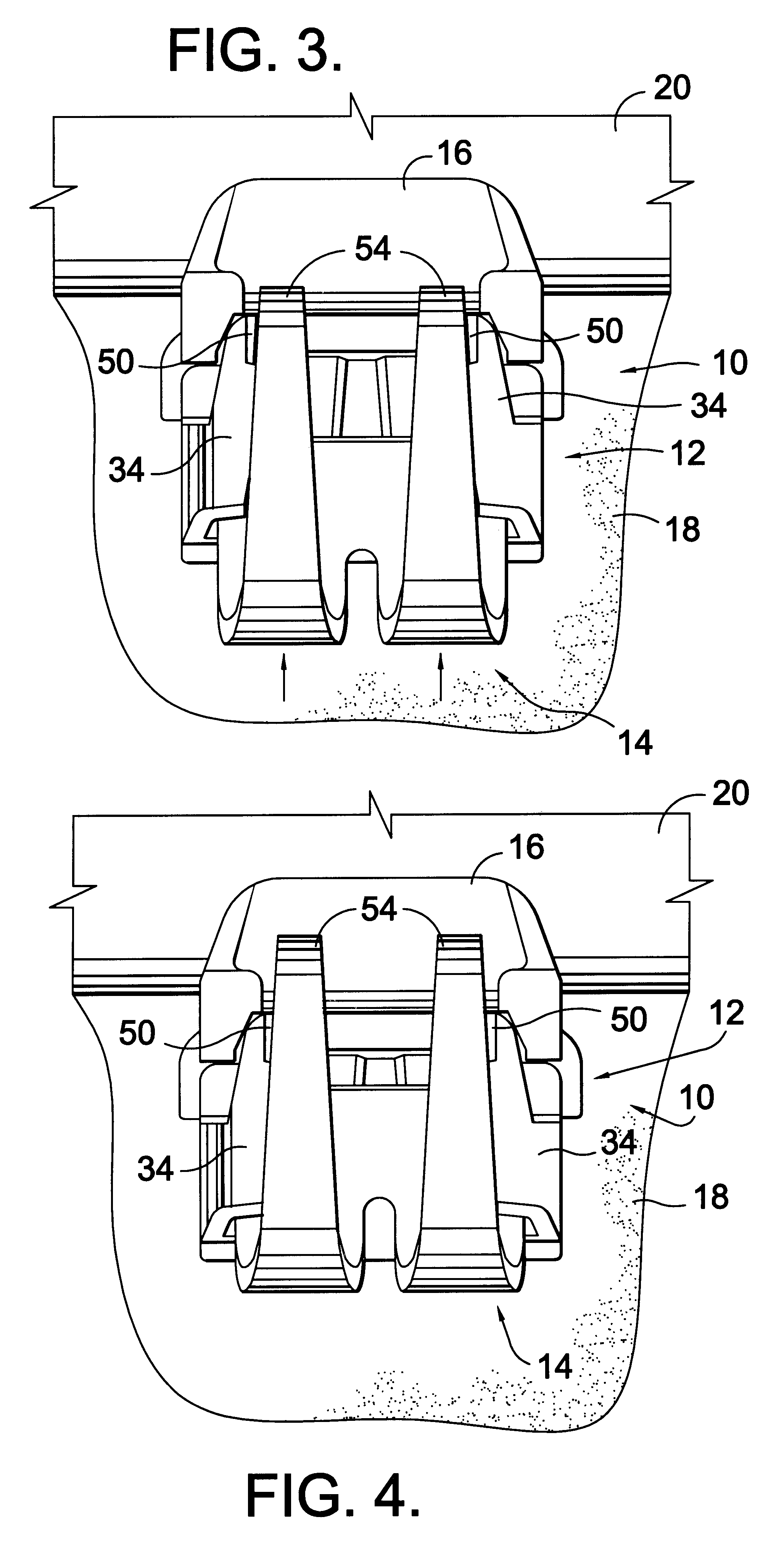

Rail fastening system constructed to allow pre-assembly of a rail clip and shoulder

A rail fastening system including a cast shoulder and an elastic rail spring clip for applying a holding force to an insulator and a rail. The spring clip includes a pair of compressible arms for exerting a rail hold down force and a substantially horizontal base portion for application to the cast shoulder. The cast shoulder includes an anchoring portion, a receiving portion including converging opposing sides angled to define a throat having a width less than a decompressed width of the spring clip arms, and notches on the sides adjacent to the throat. In practice, the spring clip is applied to the cast shoulder such that two spring clip arms contact and move along the converging sides causing the spring clip arms to be compressed by the sides. When the arms move beyond the throat, the arms spring outwardly into the notch. The notch provides a catch that prevents any backward migration such that the elastic rail spring clip and the cast shoulder can be pre-assembled at a remote location, requiring less labor at the rail installation site.

Owner:PROGRESS RAIL SERVICES

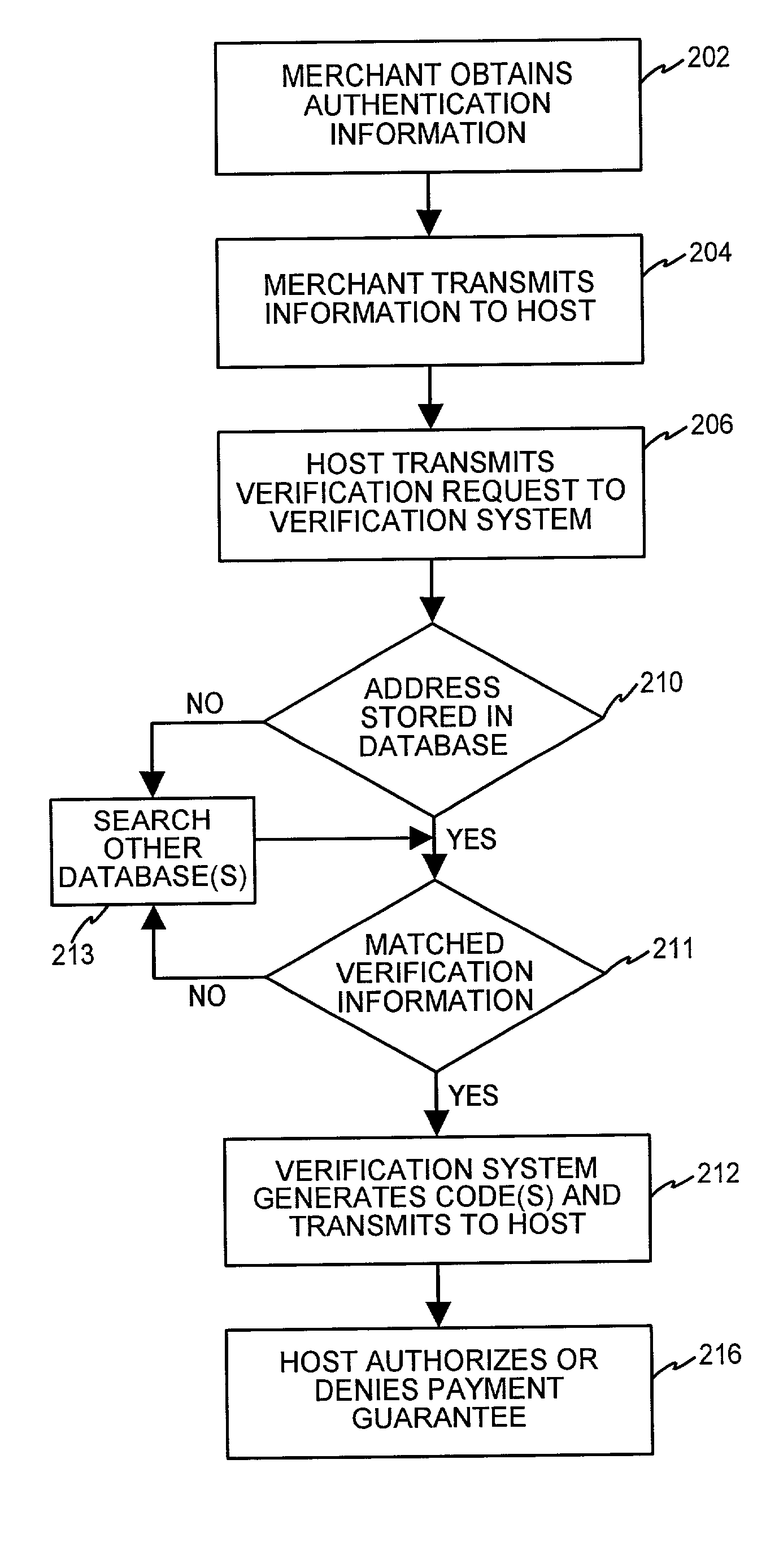

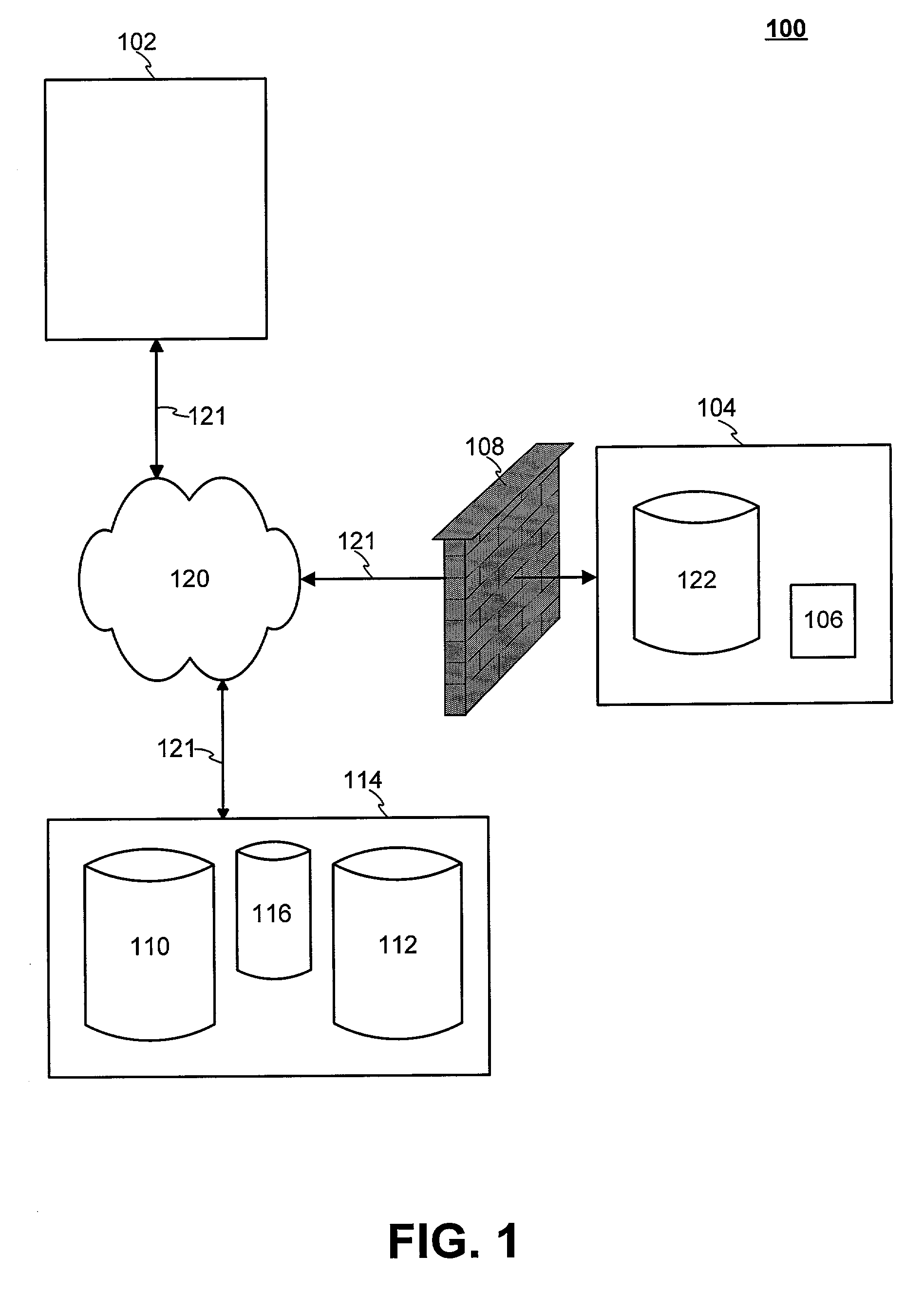

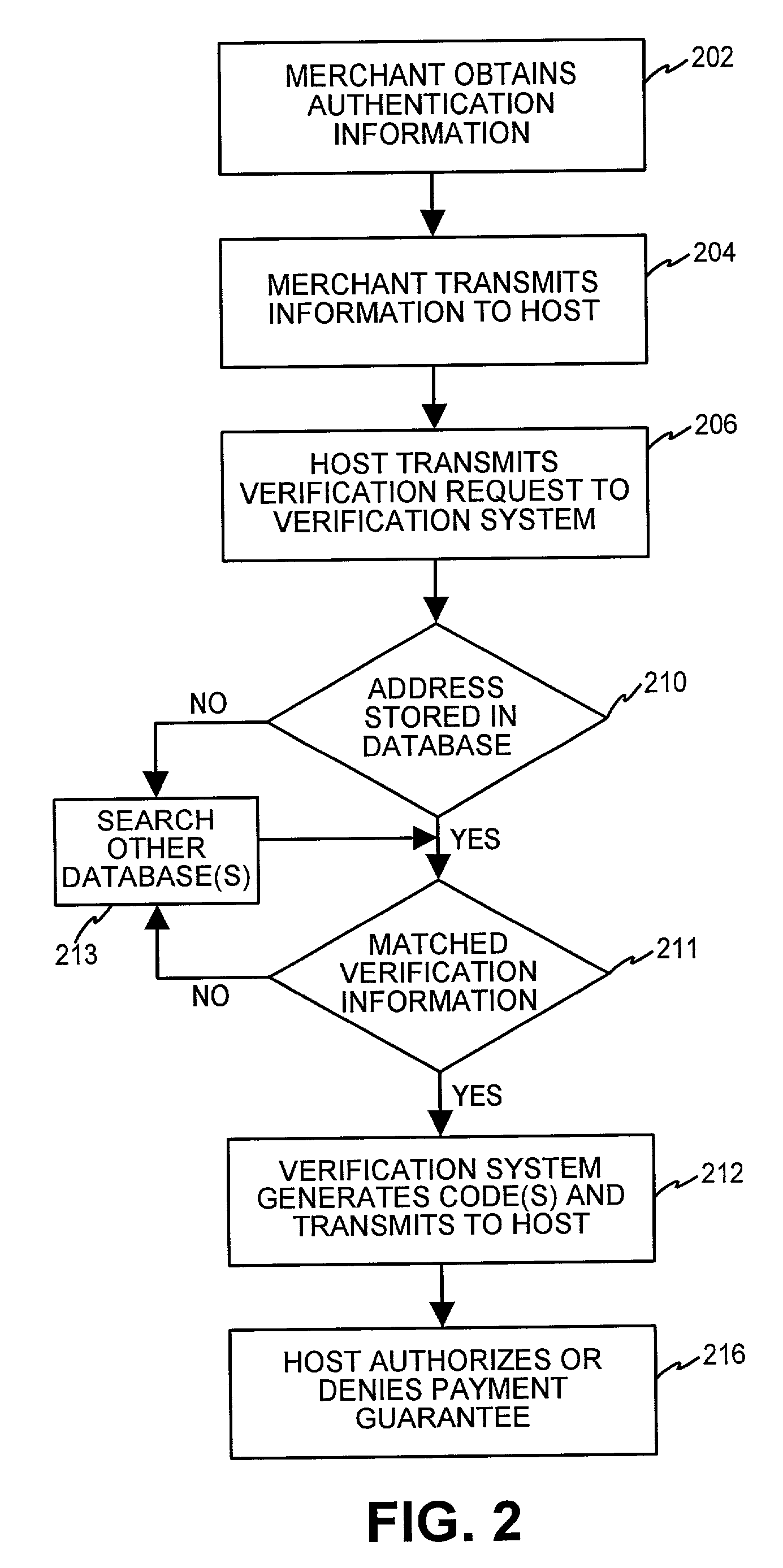

System and method for global automated address verification

The present invention provides systems and methods for global address verification of a transaction, such as a transaction card purchase. In accordance with an exemplary embodiment of the present invention, the system verifies a billing address and / or an alternate address (e.g., shipping address) in a single transaction. The billing address and / or the alternate address are associated with a transaction card purchaser. If the billing and / or alternate addresses are verified, then the transaction card issuer may offer a payment guarantee to the merchant. The merchant may choose to ship the purchased item to either a billing address or an alternate address. If the address is not verified, then the transaction card issuer may choose not to offer a payment guarantee to the merchant, and the merchant may choose not to ship the item to the alternate address.

Owner:LIBERTY PEAK VENTURES LLC

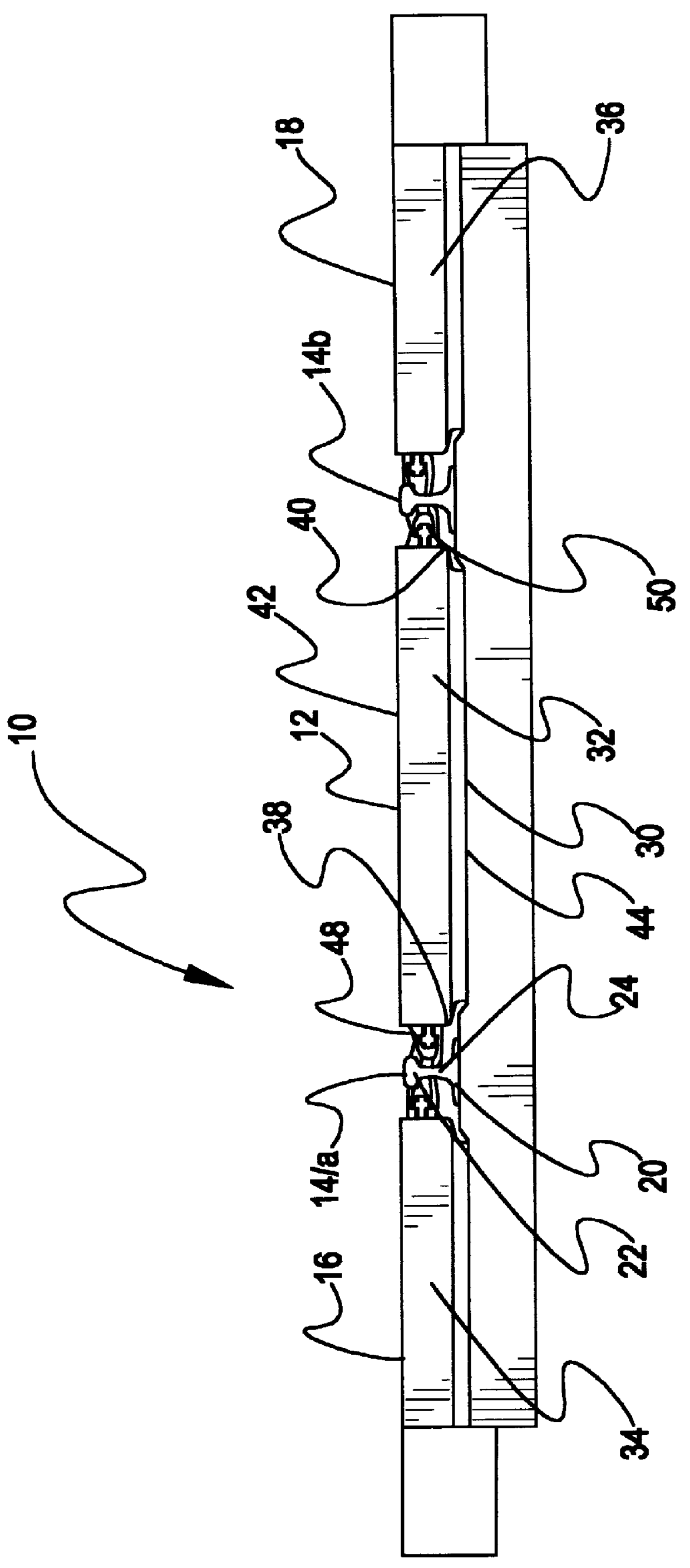

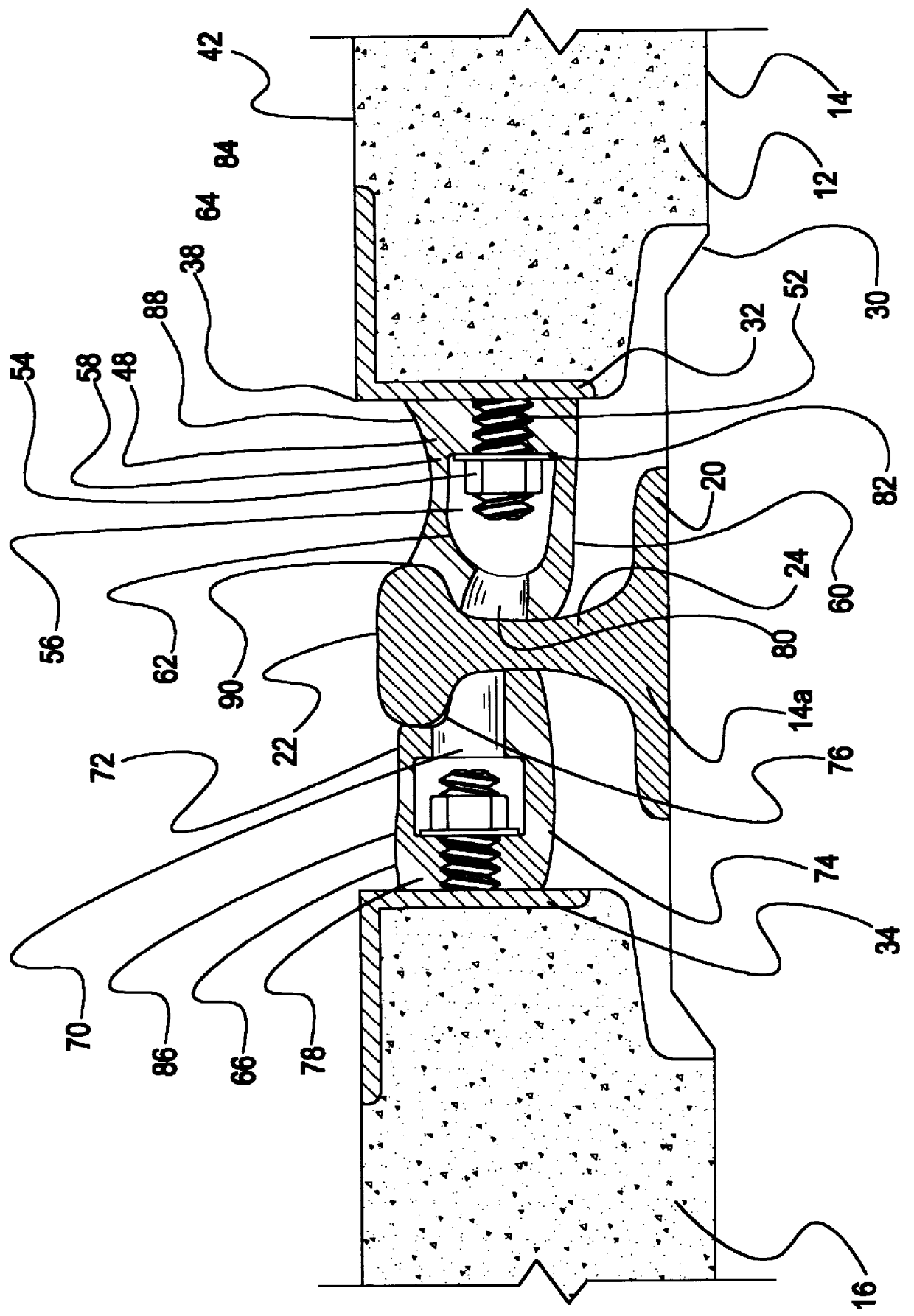

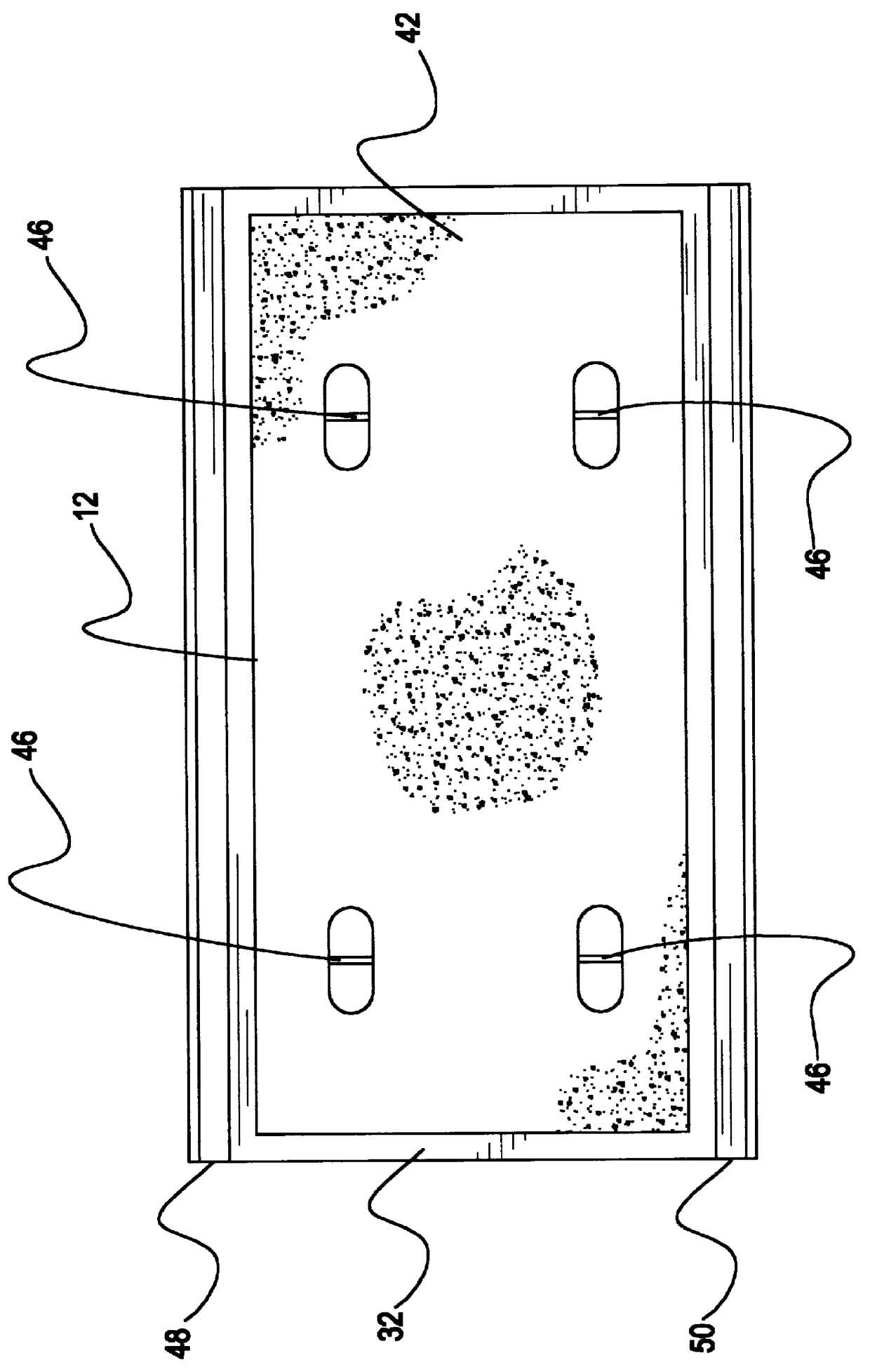

Railway grade crossing apparatus and method of installation

A railway grade crossing apparatus comprises at least one rectangular gauge panel of precast concrete with resilient bumpers on opposing sides for closely fitting between the rails and rectangular field panels of precast concrete, each having a resilient bumpers on one side for placement between the outside of each rail and the adjacent road abutment, the gauge and field panels having means for attaching lifting a device to the top surface of the panel, and the method of installing said apparatus comprising lifting the panels into place with a bumper abutting the side of a rail, and exerting a lateral force on the panel toward the rail to compress the bumper whereby the opposite side may be urged downward into place and releasing the lateral force to allow the resilience of the compressed bumper to adjust the lateral position of the panel to a final position between the rails or rail and road abutment.

Owner:SCHROEDER RICK A

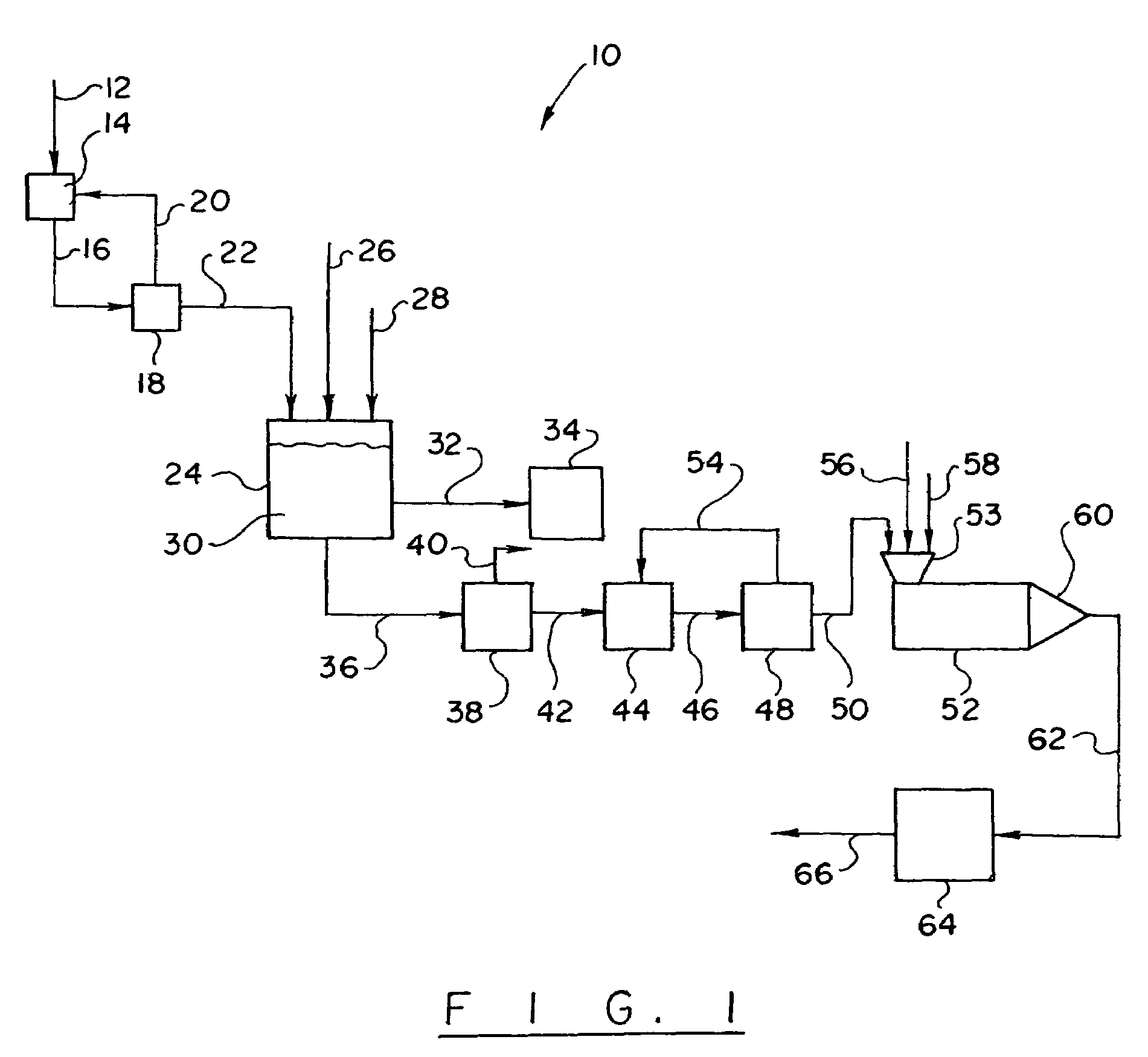

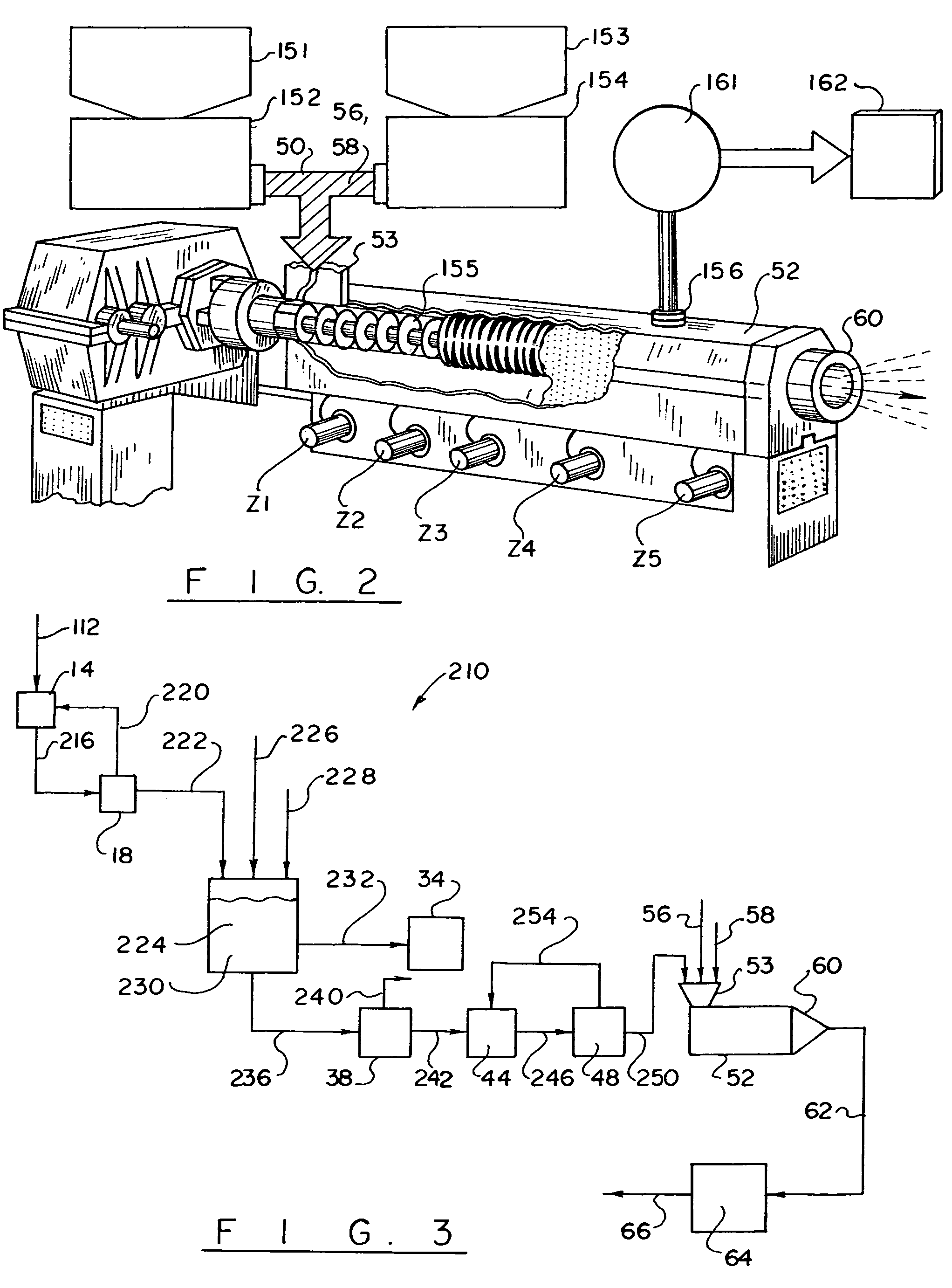

Thermoplastic railroad cross-ties

InactiveUS7331533B2Avoid accumulationIncrease awarenessBallastwayPlastic recyclingPolyolefinRoof tile

A process is provided for making thermoplastic-composites from recycled thermoplastics (polyolefins) together with phosphogypsum waste by-product from the phosphate fertilizer wet process or, in an equally preferred embodiment with fluorogypsum waste by-product from fluorine production wet process to produce lumber profiles. The process involves (a) admixing phosphogypsum (calcium sulfate) and / or fluorogypsum (calcium fluoride) waste byproduct and / or Flue Gas Desulfurization (FGD) gypsum and / or crude gypsum and / or calcined gypsum with thermoplastics and a functionalized compound with or without coupling agents to produce a filled thermoplastic-composite composition, and (b) melt processing the composition to produce a filled thermoplastic-composite article. The articles are preferably in the form of railroad cross ties or construction articles such as common lumber profiles, panels, tiles, poles, utility poles, crossarms for utility poles, roofing tiles, pipeline skids, pilings, marine fender-piles (including light emitting piles), bulkheads, revetments, and are useful for constructing various structures, such as oilfield board roads and equipment mats. The process avoids the accumulation of undesired phosphogypsum / fluorogypsum “stacks” and provides environmentally friendly useful products which require no chemical preservatives to prevent insect infestation or decay from the elements. Tailings from ore processing can also be used as a filler.

Owner:COMPOSITECH

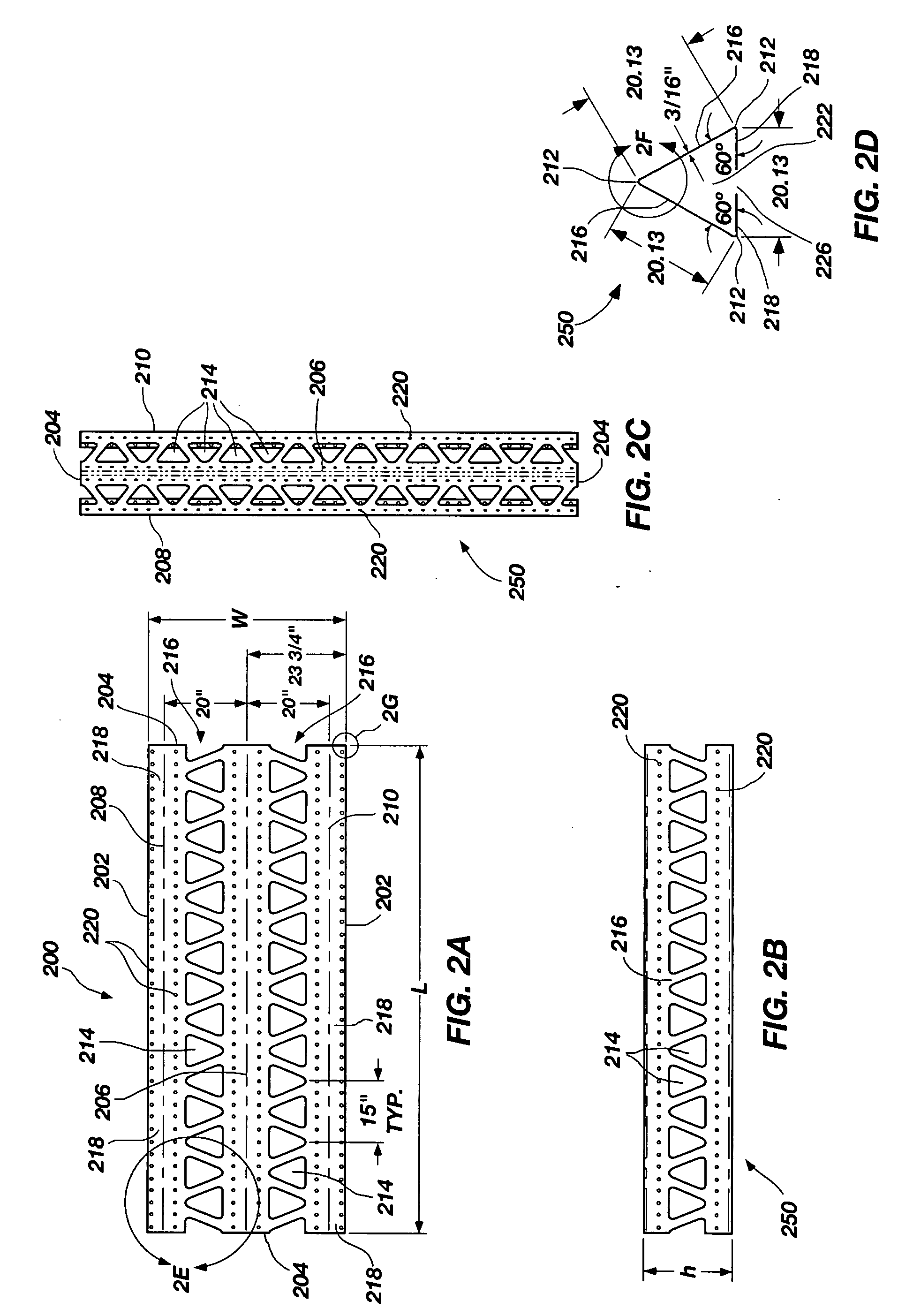

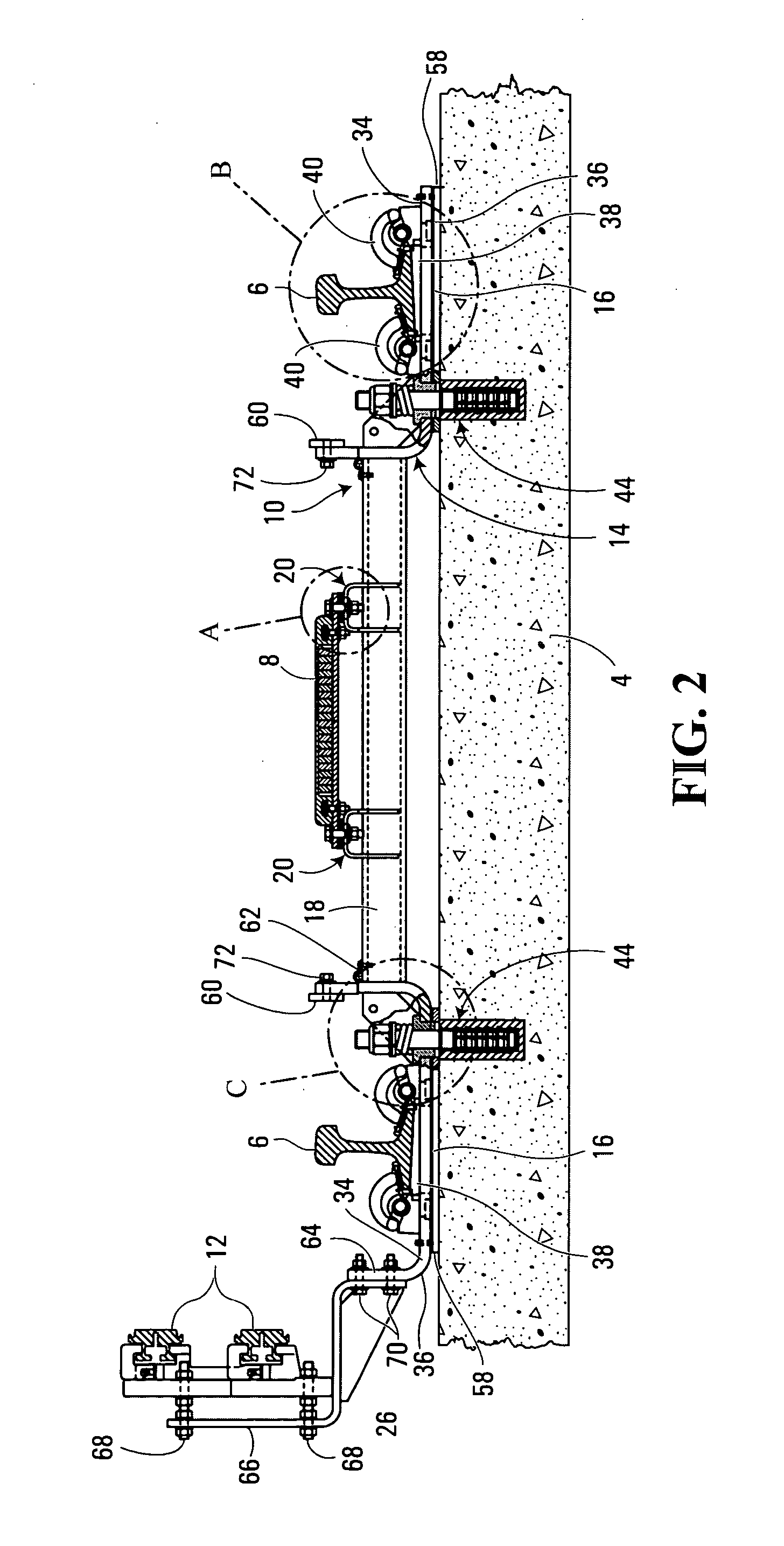

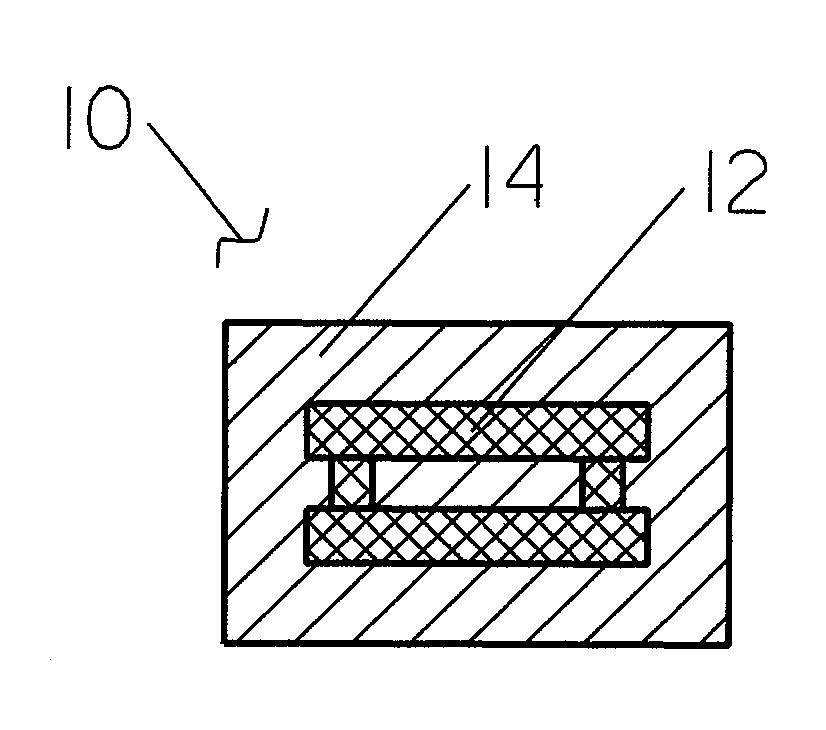

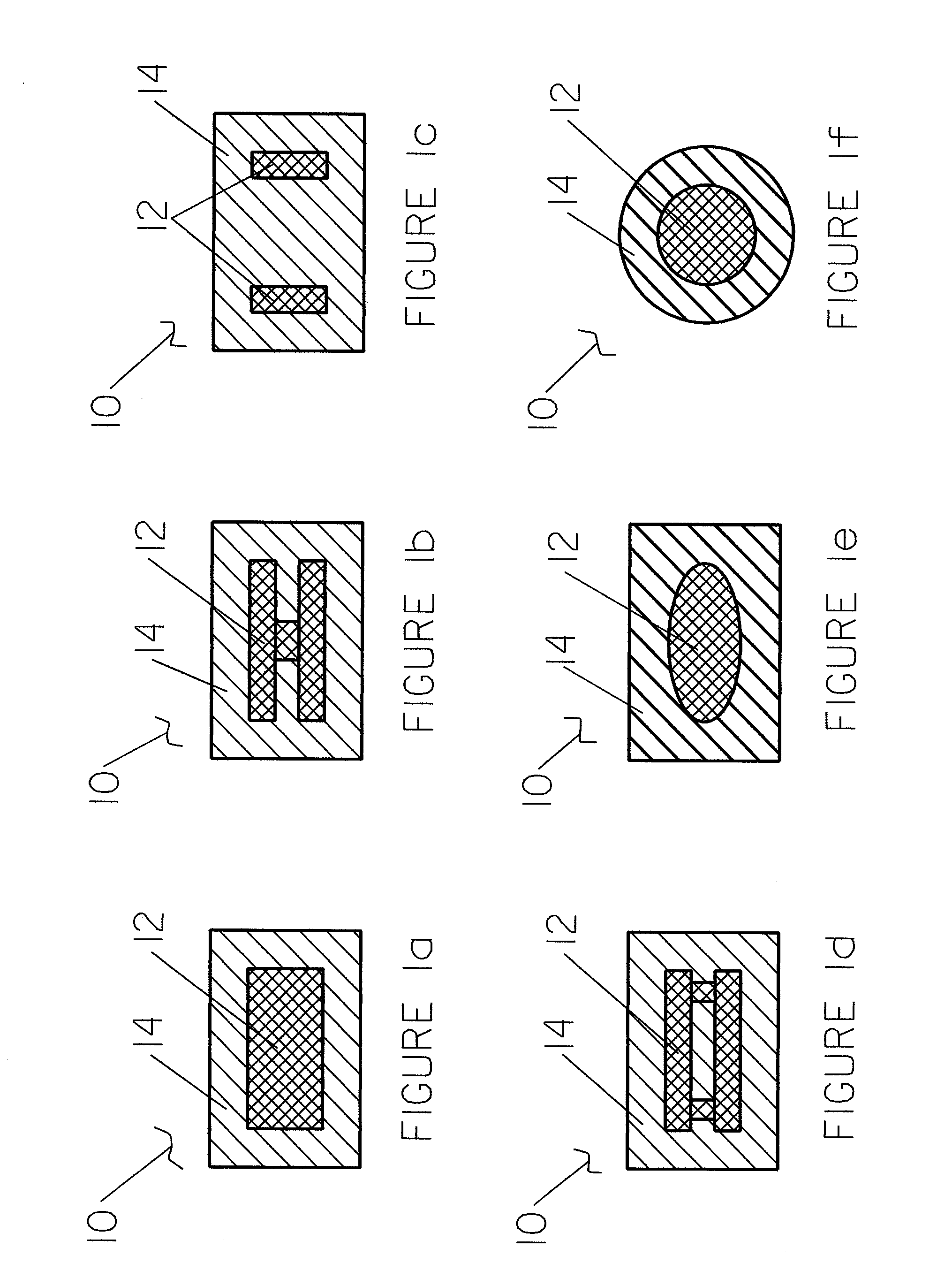

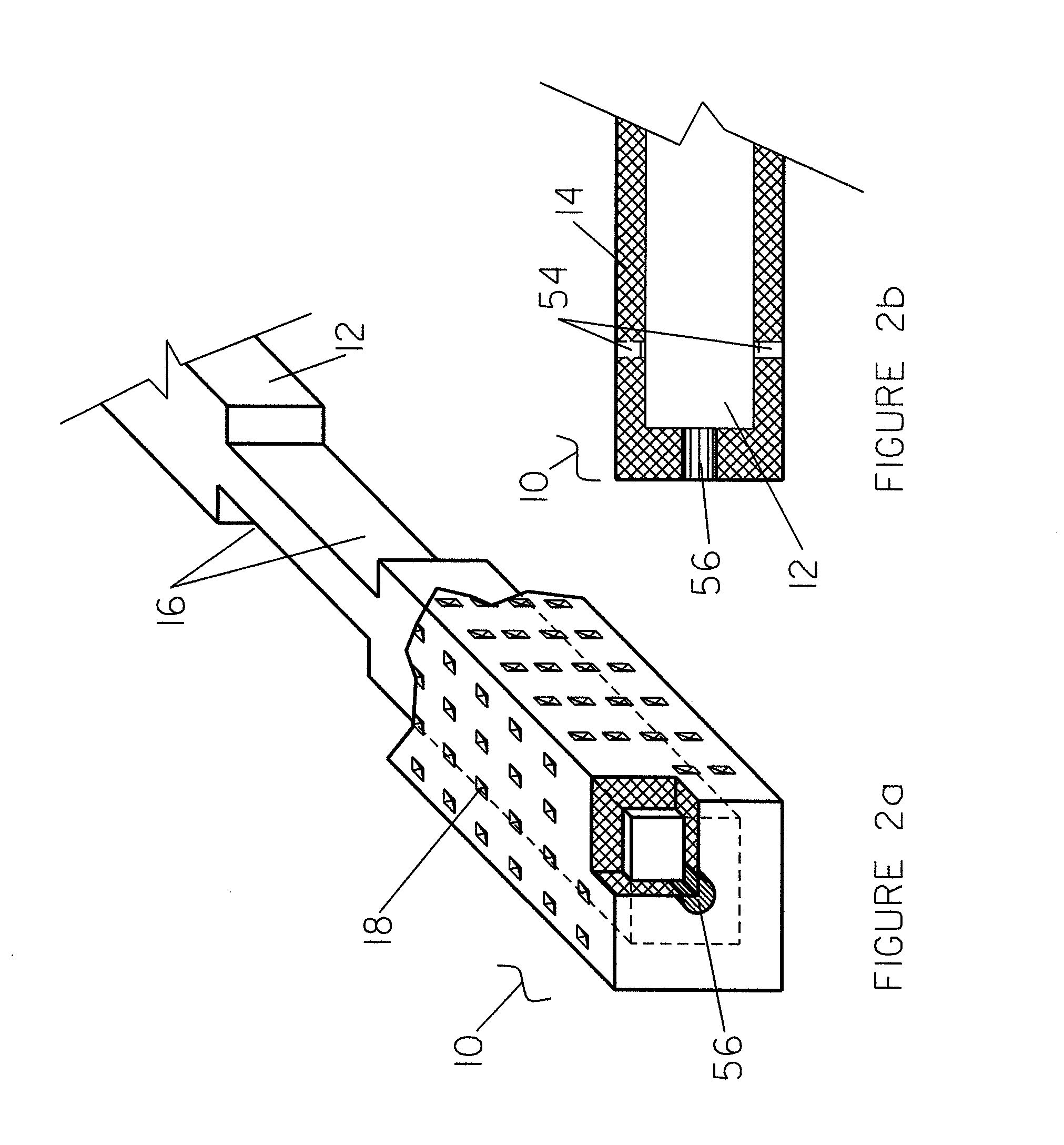

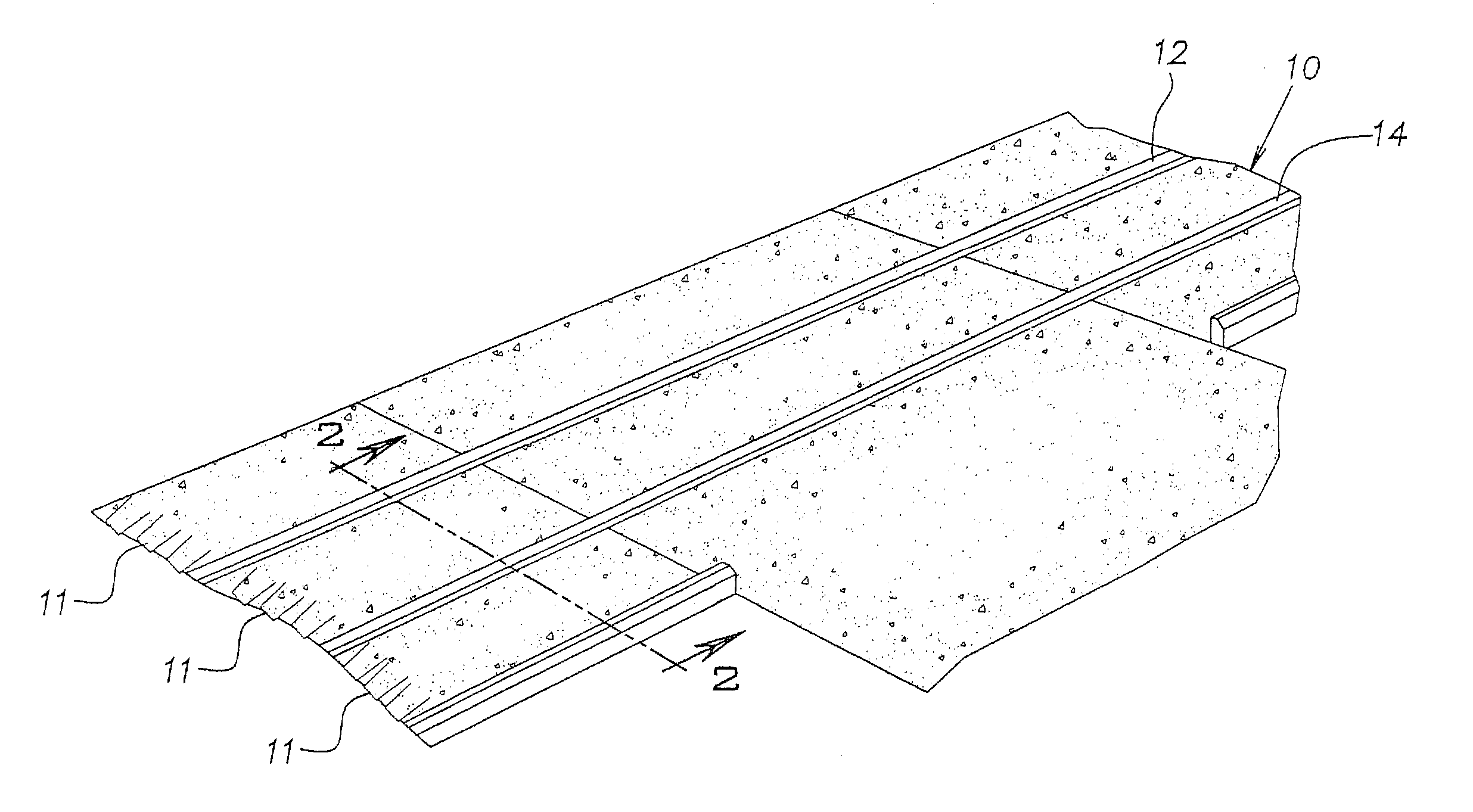

Composite load bearing structure

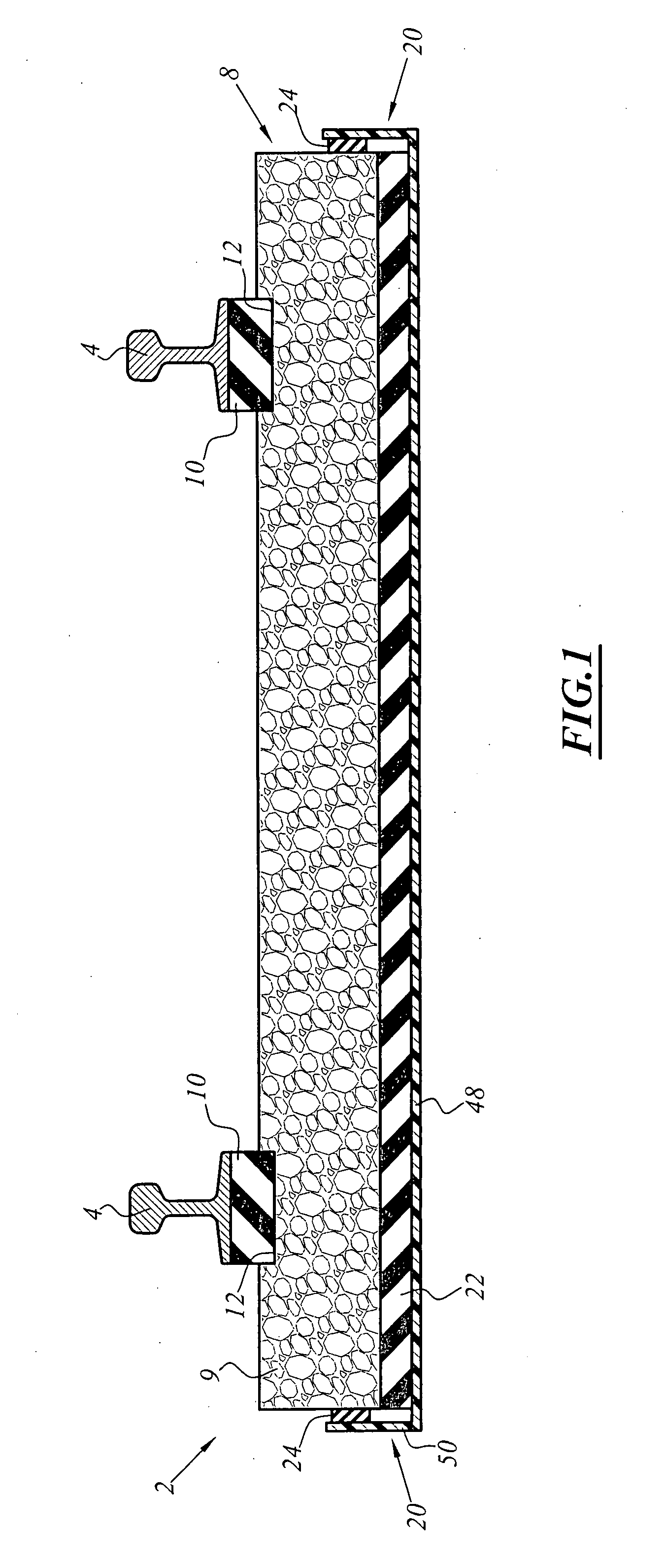

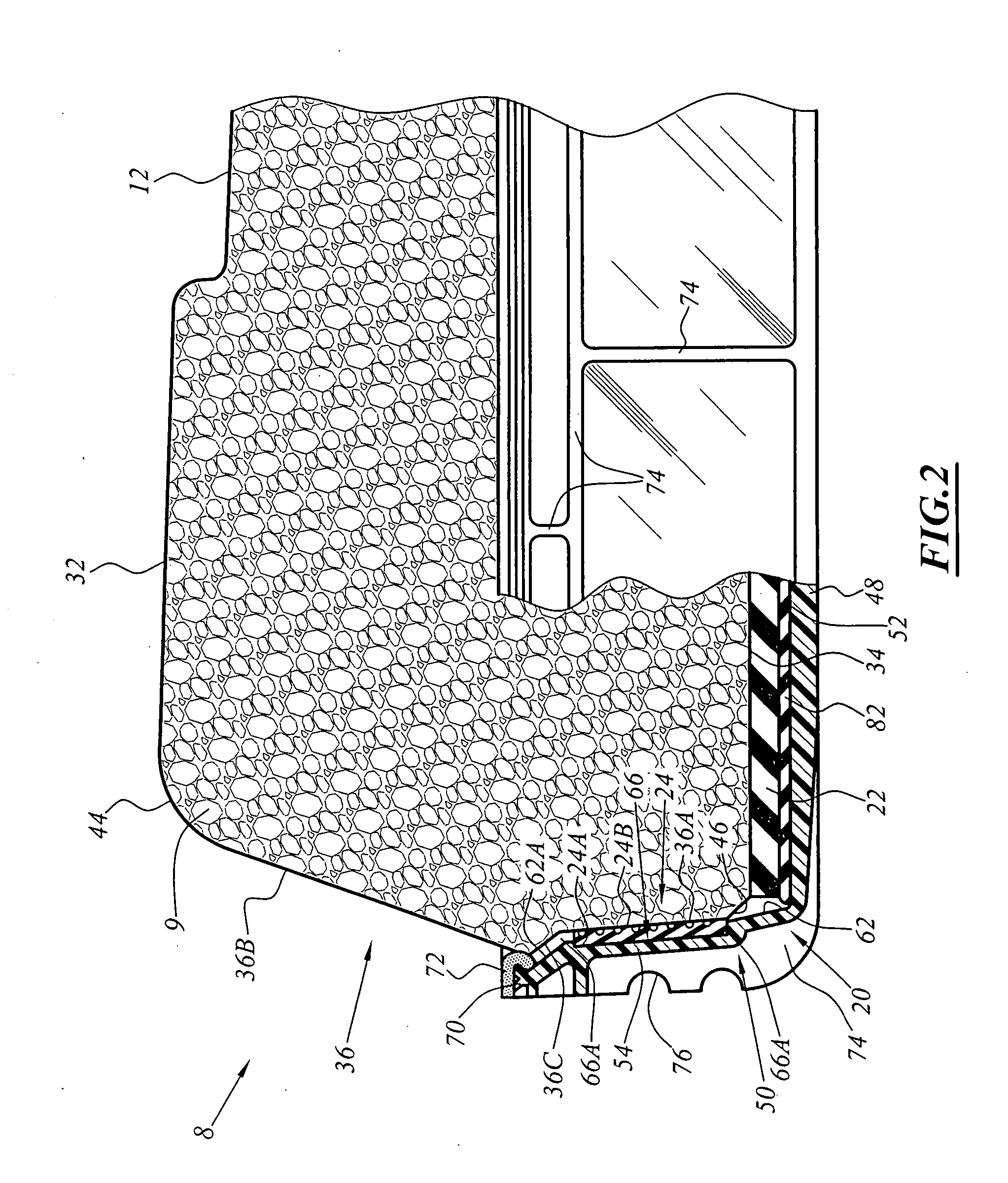

InactiveUS20080179418A1Easy to copyStrengthBallastwayRail fastenersEngineeringMechanical engineering

A composite load bearing member is provided comprising an elongated inner structural member and a thick polymeric composite outer member. An apparatus for producing the composite load bearing member is provided including devices for suspending the inner structural member within a mold cavity prior to and during injection of the polymeric composite outer member. A method of using the apparatus to produce the composite load bearing member is provided.

Owner:INTEGRICO COMPOSITES LLC

Forcibly spread frame for a rail vehicle and rail vehicle with such a frame

Owner:VOSSLOH HIGH SPEED GRINDING

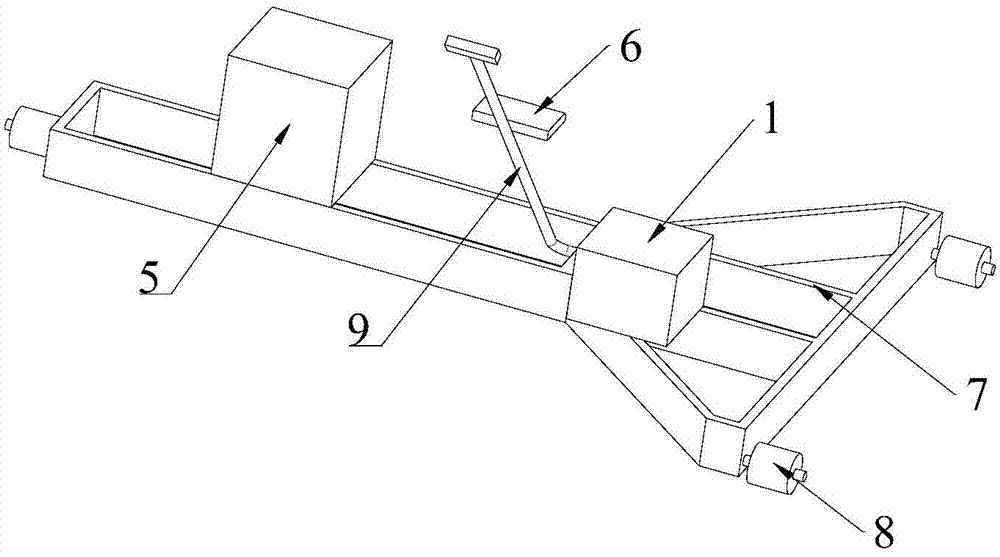

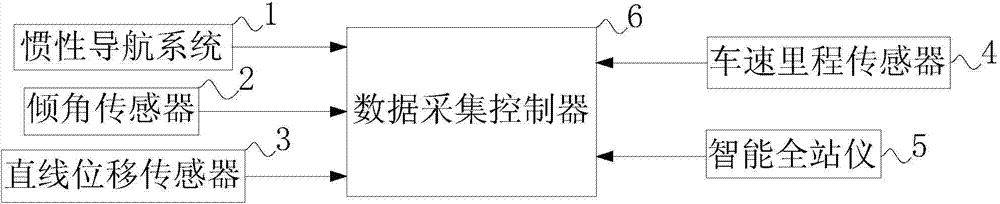

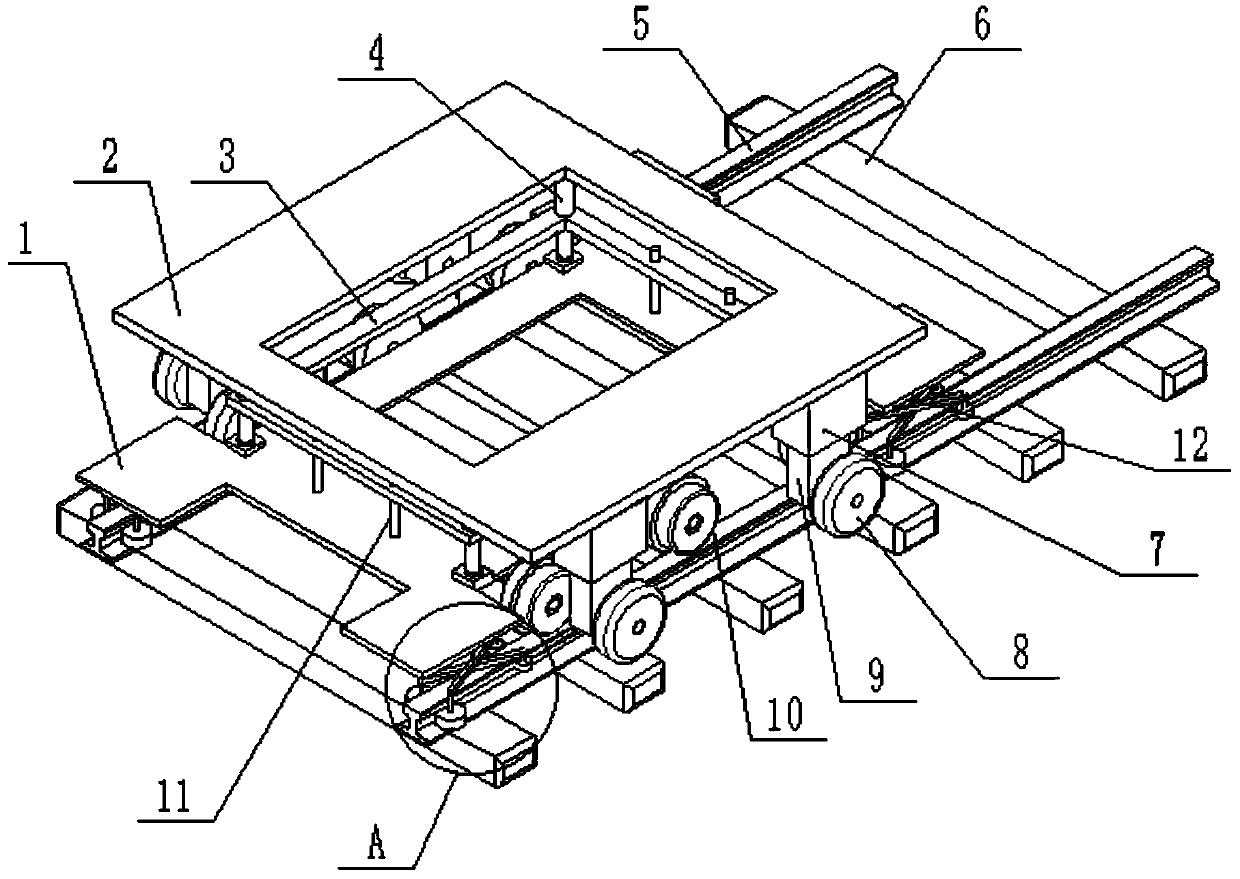

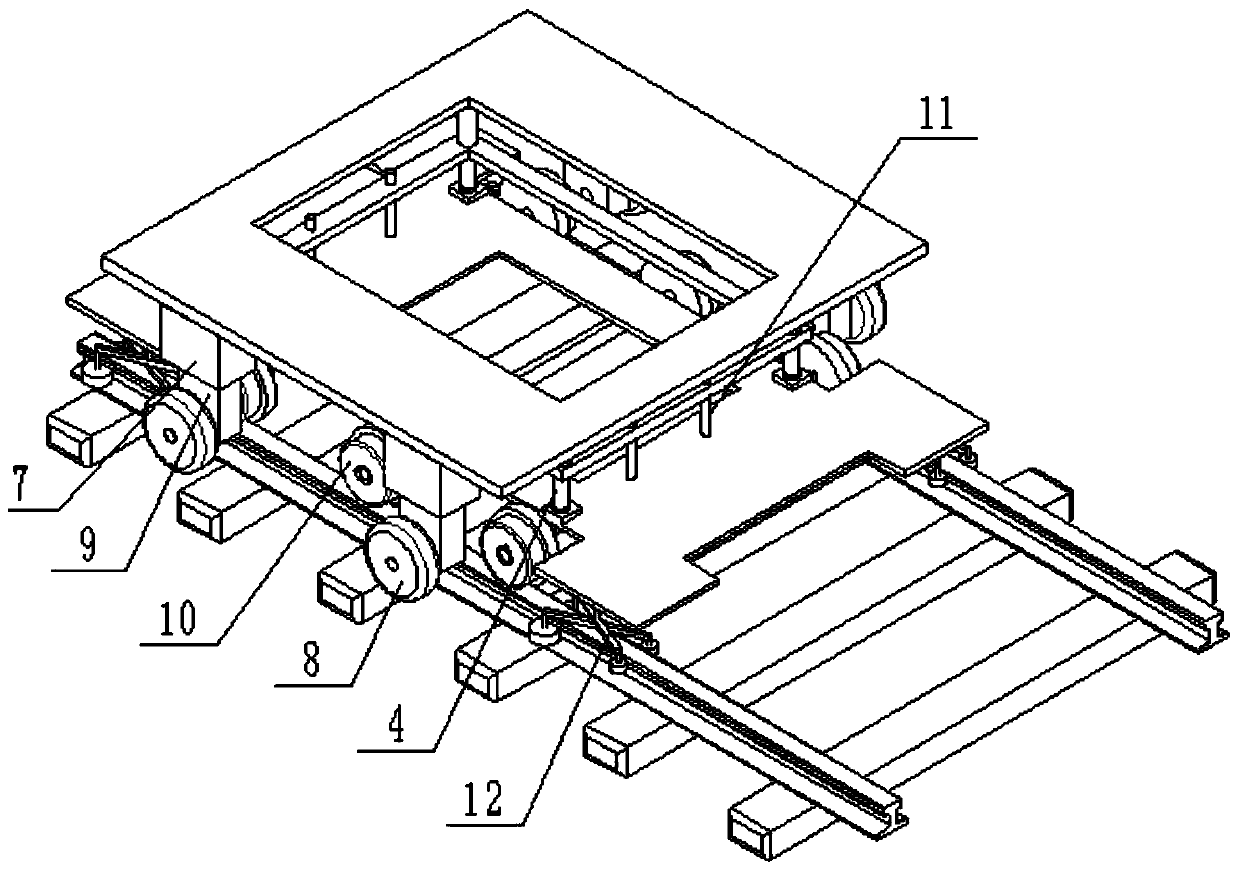

Quick geometrical state measuring instrument for track

InactiveCN104775342AMileage real-time detectionTrack gauge real-time detectionTrack superstructureMeasuring apparatusFast measurementEnvironment effect

The invention discloses a quick geometrical state measuring instrument for a track. The quick geometrical state measuring instrument for the track comprises a hand-propelled track inspection trolley, an inertial navigation system, an inclination angle sensor, a linear displacement sensor, a speed and mileage sensor, an intelligent total station and a data acquisition controller, wherein a main body of the quick geometrical state measuring instrument for the track is the hand-propelled track inspection trolley which can walk along the track; sensors for detecting a speed, mileage, a track space, an inclination angle and the like, the inertial navigation system, the intelligent total station and the data acquisition controller are integrated on the hand-propelled track inspection trolley. The quick geometrical state measuring instrument for the track is based on the principle of combining absolute measurement with relative measurement, the geometrical ride comfort evaluation parameters, such as the mileage, the track space, the levelness, the twist warp, the track direction and the height of the track, and the absolute deviations of the plane and the elevation of the track can be detected in real time. By using the quick geometrical state measuring instrument for the track, the detection of the parameters of the track is realized through the inertial navigation system; the absolute constraint is carried out through the intelligent total station; the quick geometrical state measuring instrument for the track is high in precision and quick in speed, and is influenced less by an external environment.

Owner:北京力铁轨道交通设备有限公司

Wholly wrapped railroad crosstie and its manufacturing method

Owner:6732667 MANITOBA

Railway crossing structure

An insulation system for an embedded track construction for a transit railway having spaced parallel railway rails includes a rail boot for substantially enclosing each of the rails along its length, rail clips extending on each side of each of the rails for securing the rails to supporting ties, and fillers extending on each side of each of the rails, frictionally engaging and removably mounting the rails to an associated one of said rail clips. The fillers cooperate to provide a coplanar roadway with said rails.

Owner:IHEC ACQUISITION

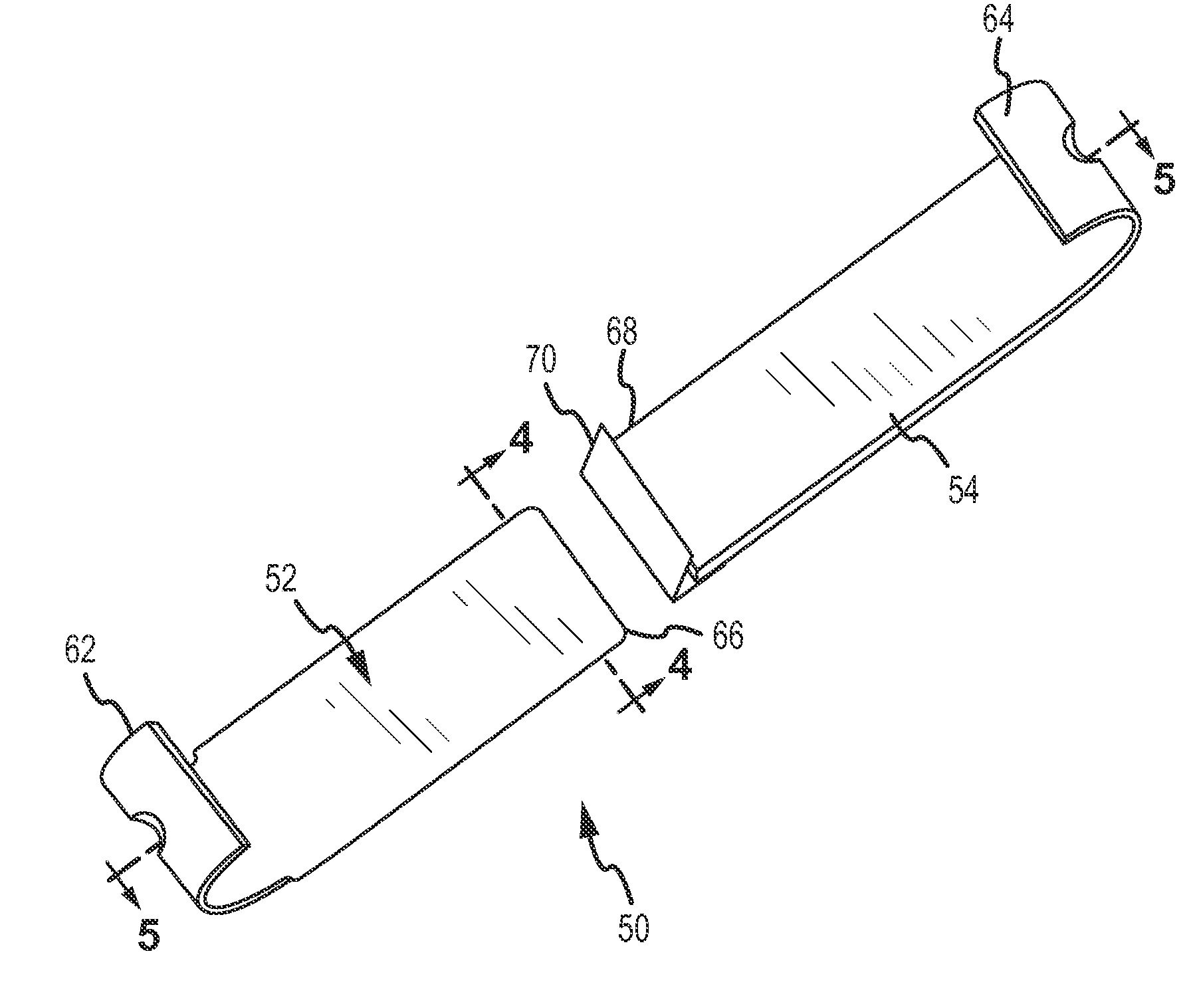

Rail anchor isolator

The present invention provides an isolator particularly adapted for use with a rail anchor utilized in an application where railroad rail is installed on concrete ties. The isolator protects the concrete tie from contact with the rail anchor caused by longitudinal movement of the rail due to train acceleration of deceleration or expansion and contraction due to temperature changes. In one embodiment, the isolator is comprised of a structural plastic material and includes a front face section and a rear face section. The front face section and rear face section each comprise a generally rectangular structure, having a top edge, bottom edge, and side edges. A center section joins the front face section and rear face section and forms part of the top of the isolator. In another embodiment, the front face section includes a top section and bottom section, with the top section having a lower edge projecting laterally at an acute angle from the bottom section. Similarly, the rear face section includes a top section and a bottom section, with the top section having a lower edge projecting laterally at an acute angle from the bottom section.

Owner:PROGRESS RAIL SERVICES

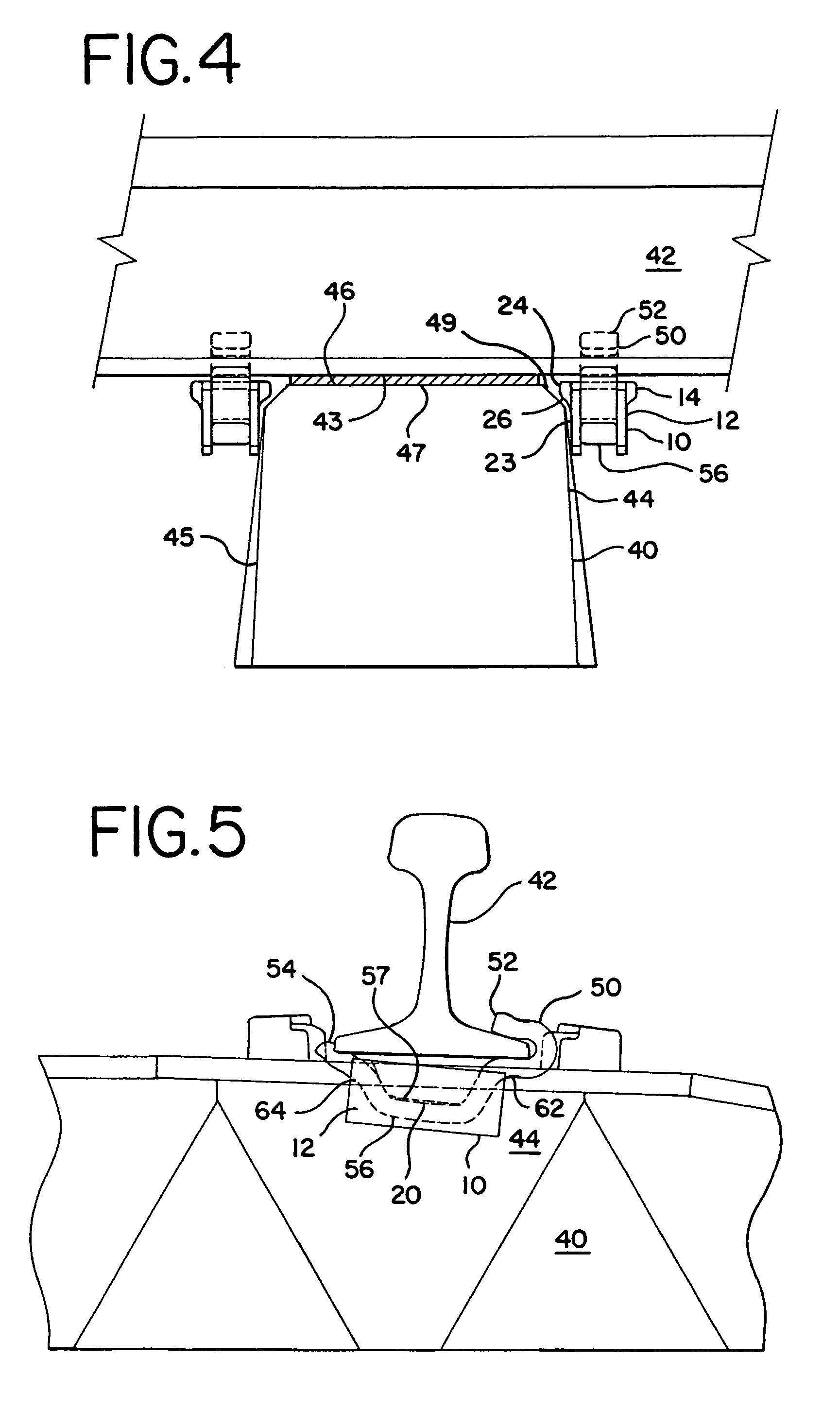

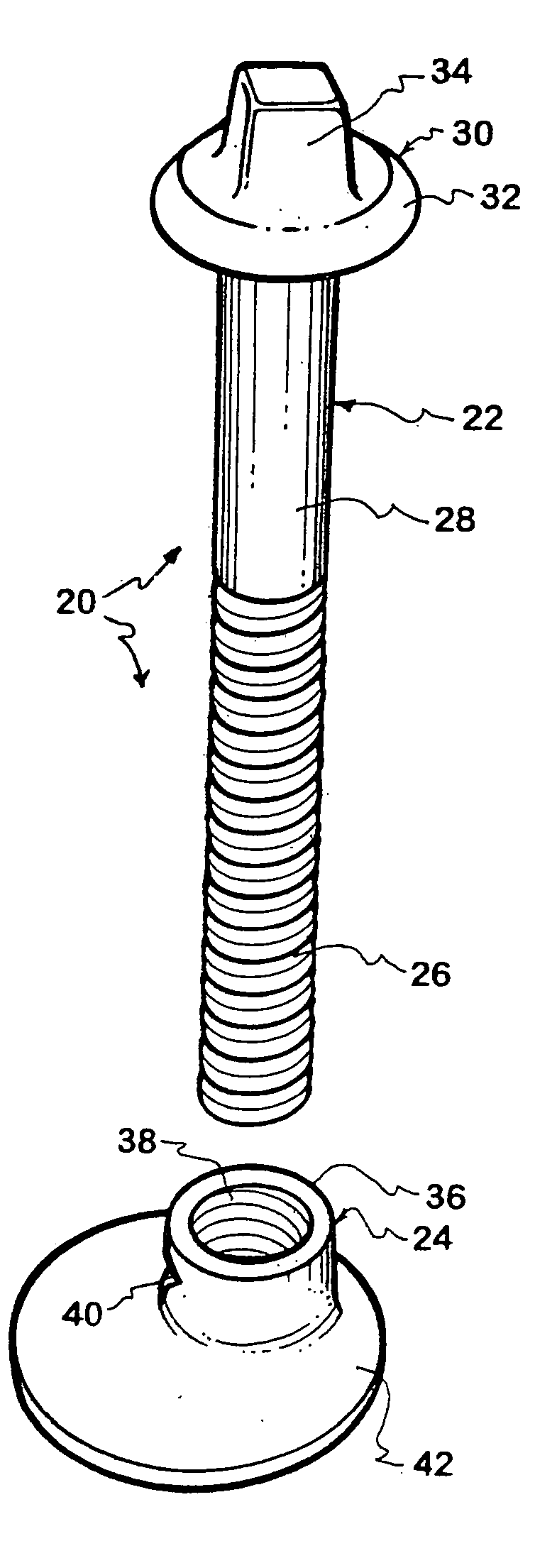

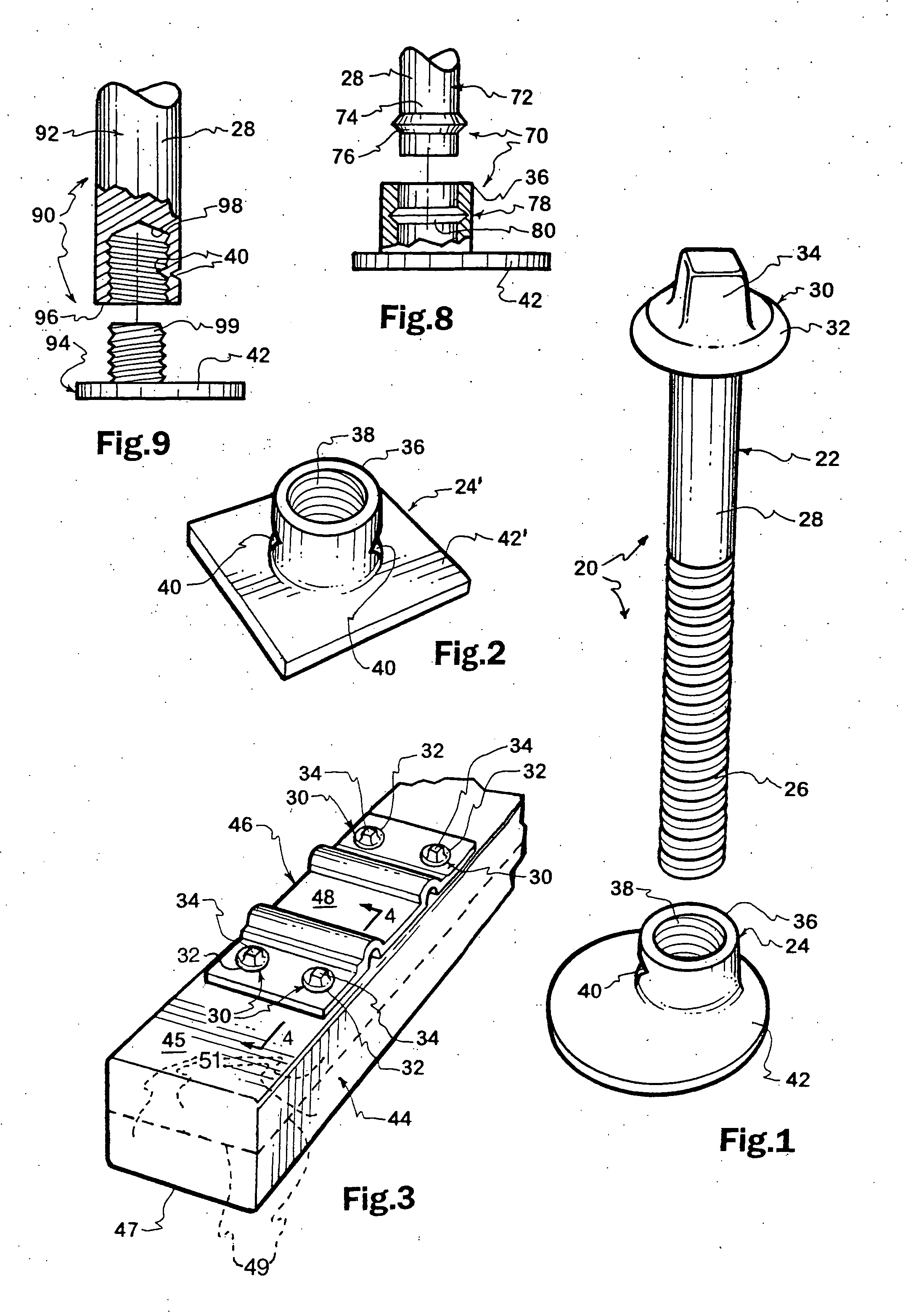

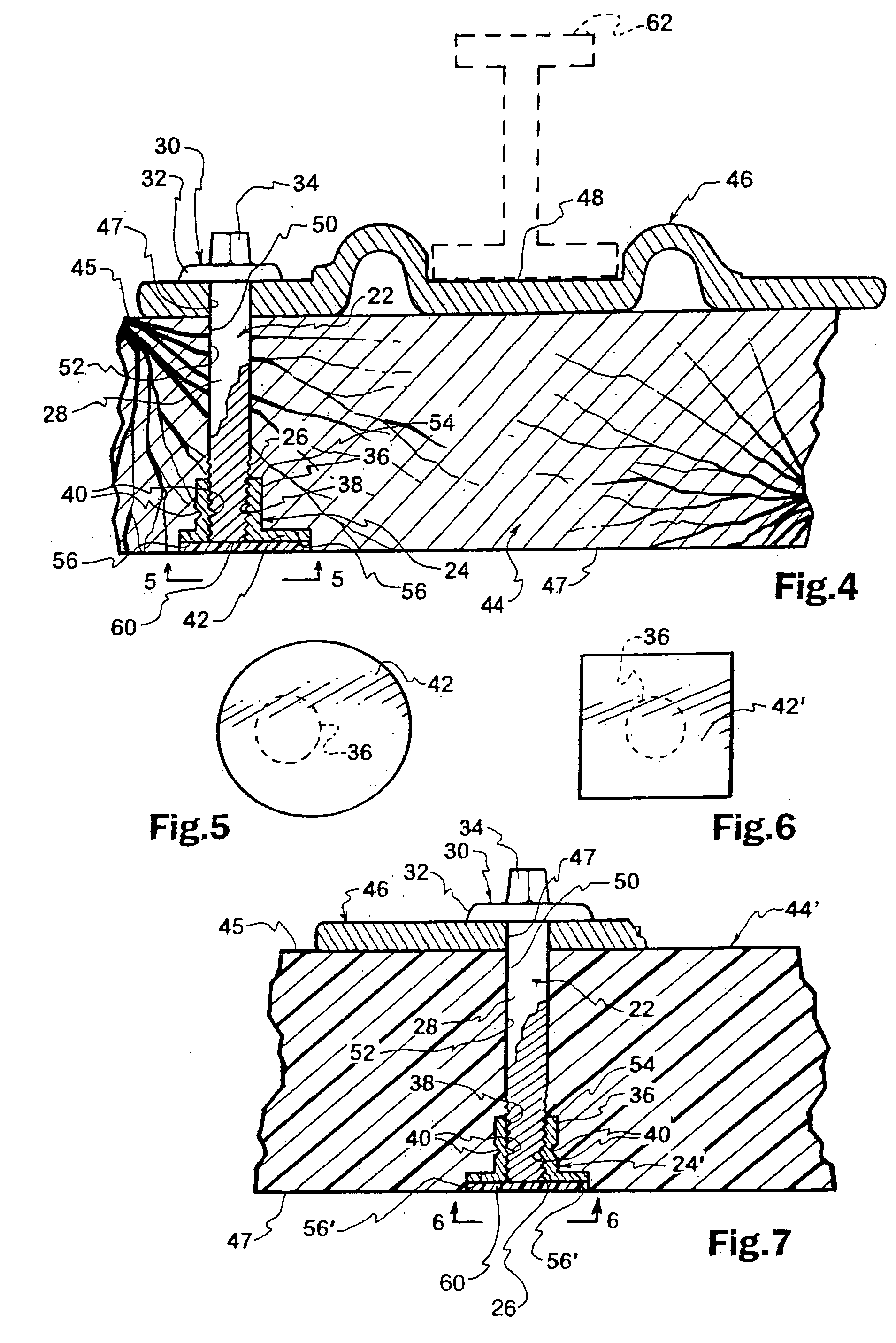

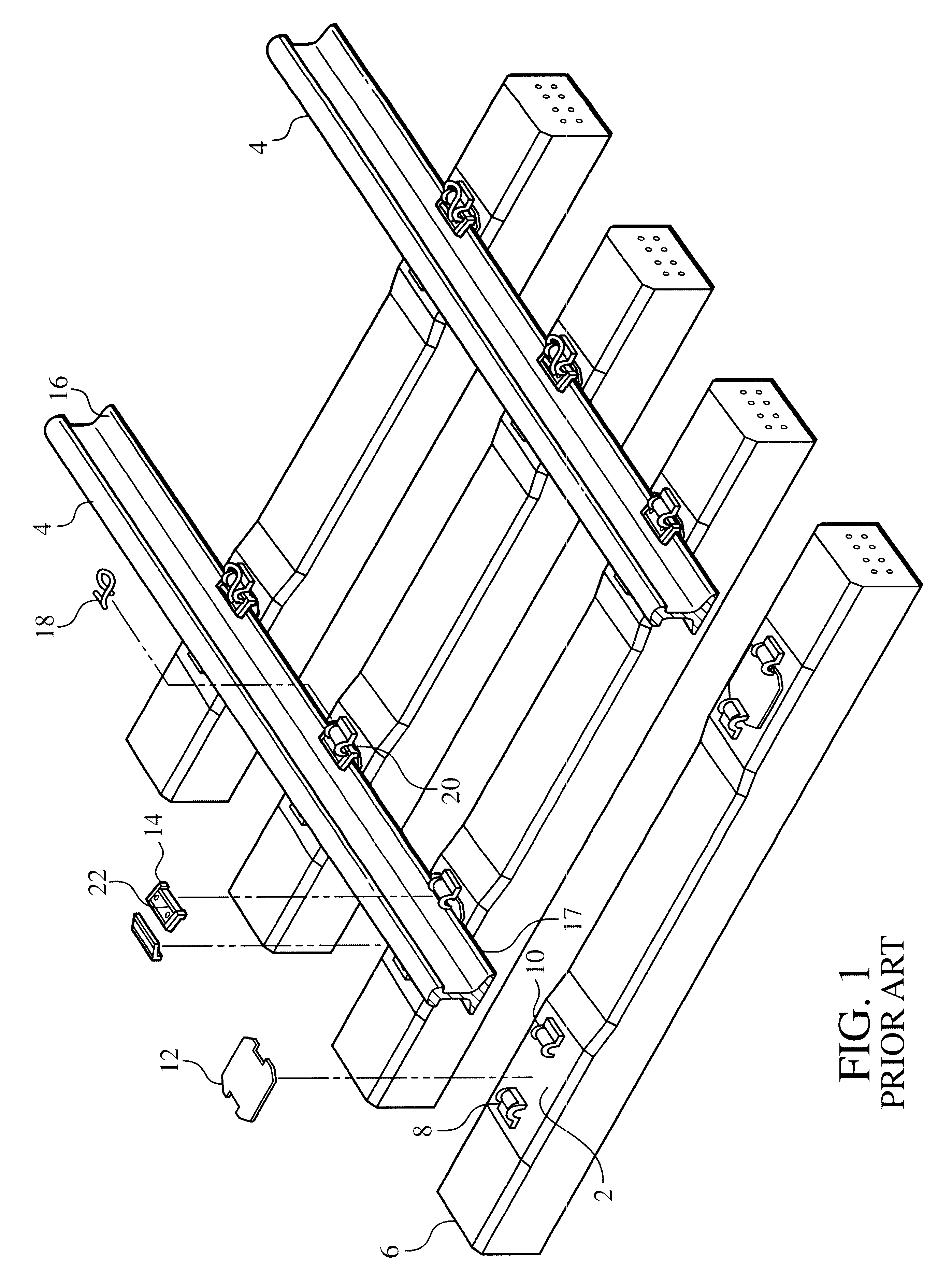

Spikeless tie plate fasteners, pre-plated railroad ties and related assemblies and methods

InactiveUS20060214019A1Prevent and alleviate layer separation and layerPrevent and alleviate layer and layer shiftingBallastwayRail fastenersEngineeringScrew joint

Railroad tie plates secured collectively by spikeless fasteners to a tie with railroad spikes securing the rails to the ties and related methodology are disclosed wherein two-part fasteners are used in respect to sets of aligned tie and tie plate apertures such that the two fastener parts are joined together against inadvertent separation within each tie aperture at a connection or union site, which includes but is not limited to force fit unions and threaded unions, and spikes are driven into the ties through other tie plate apertures.

Owner:OLLENDICK DAVID

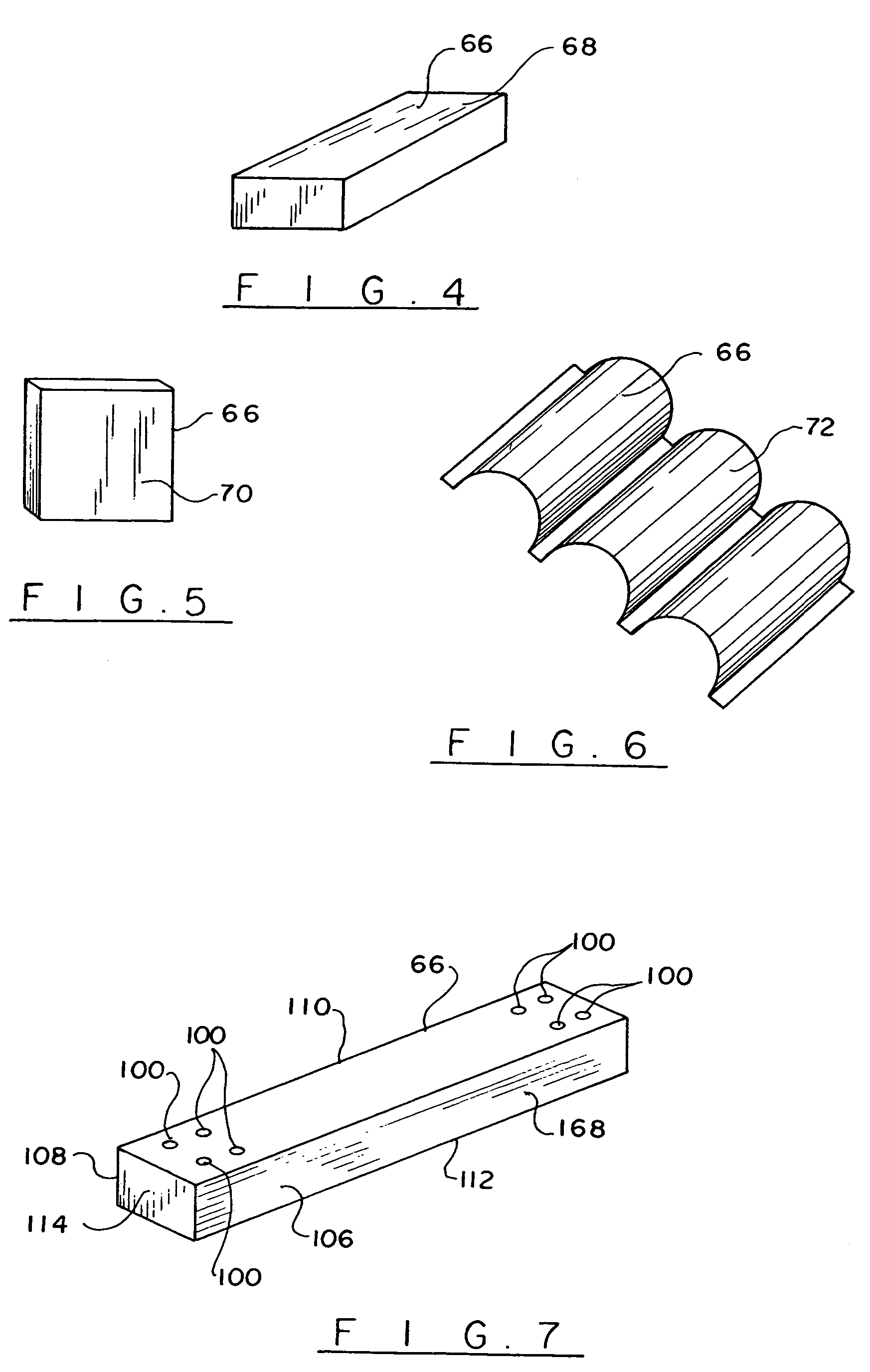

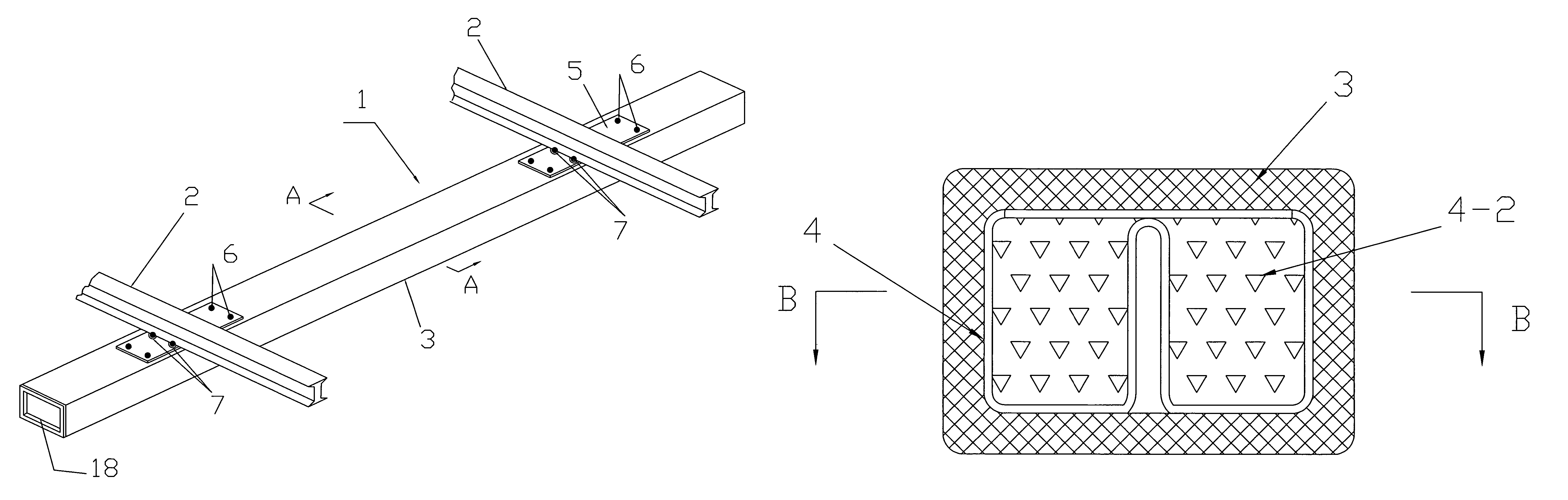

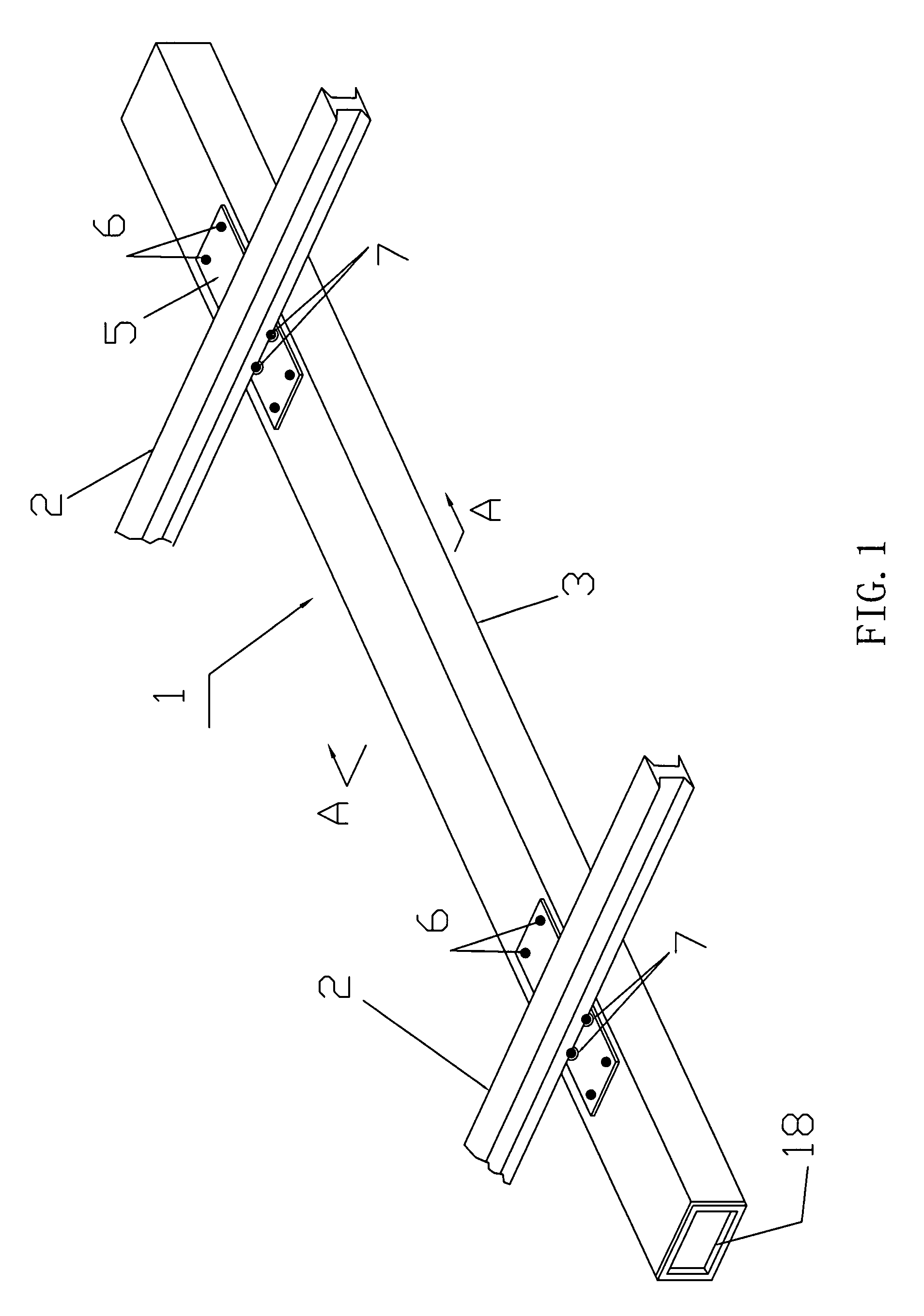

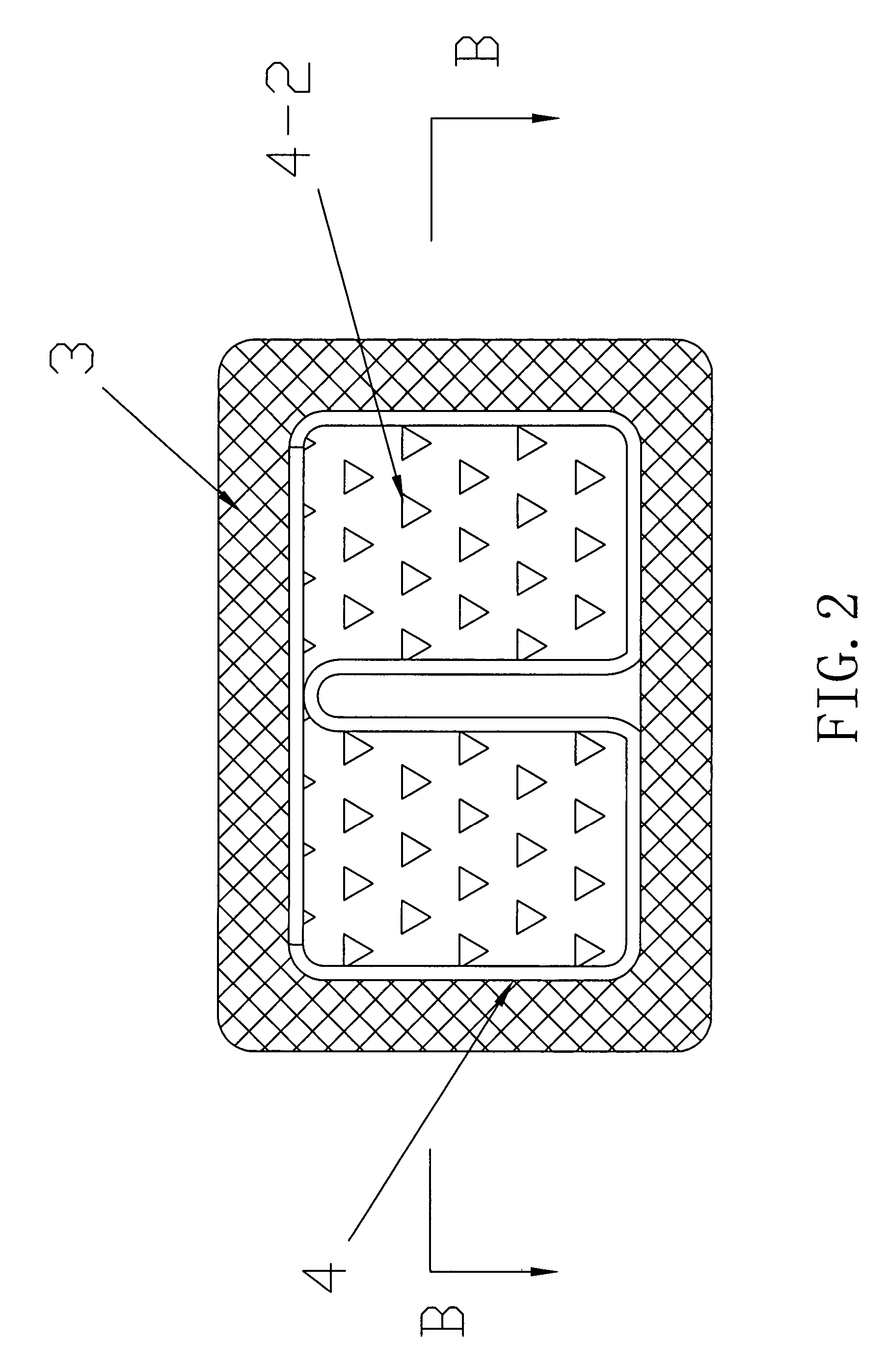

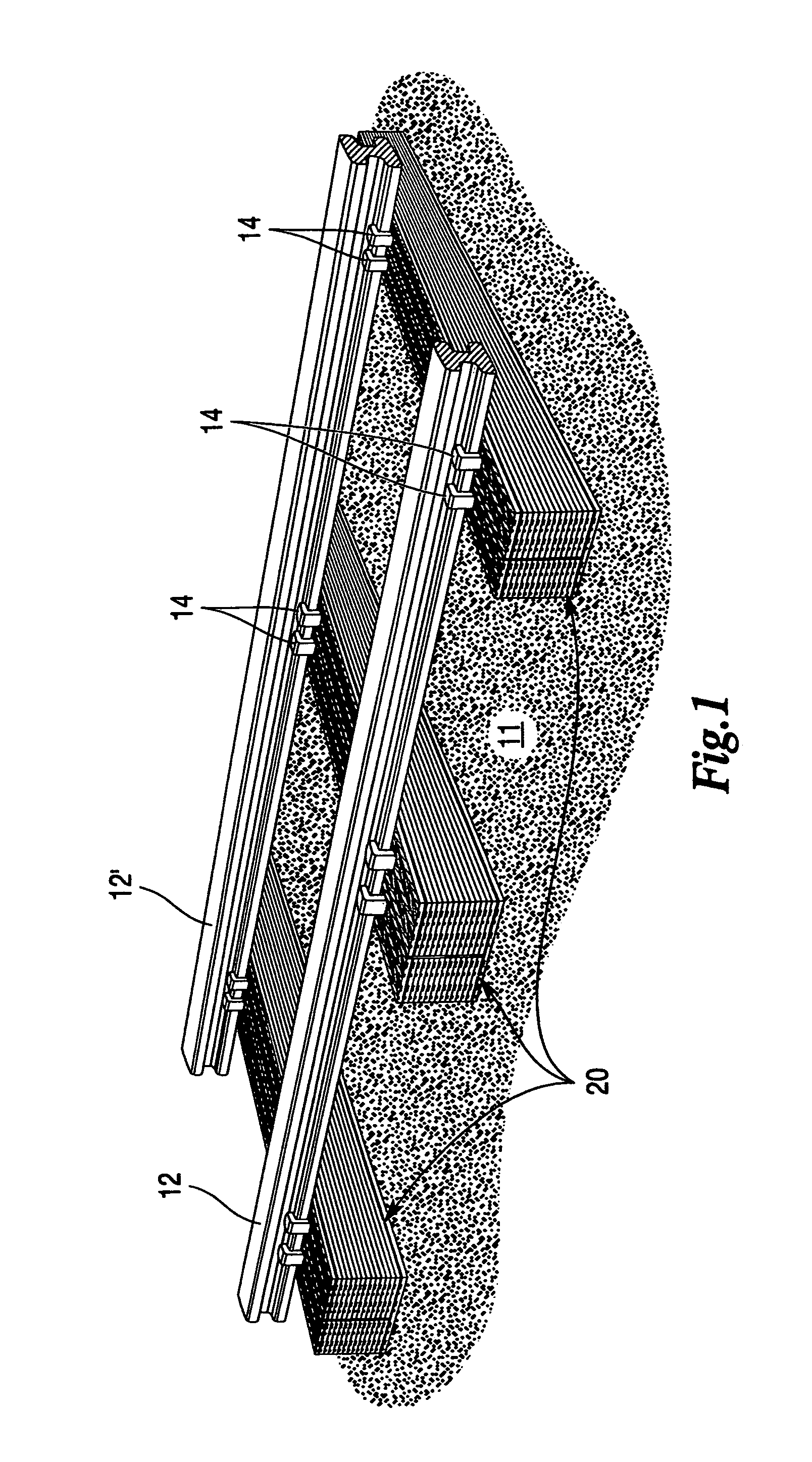

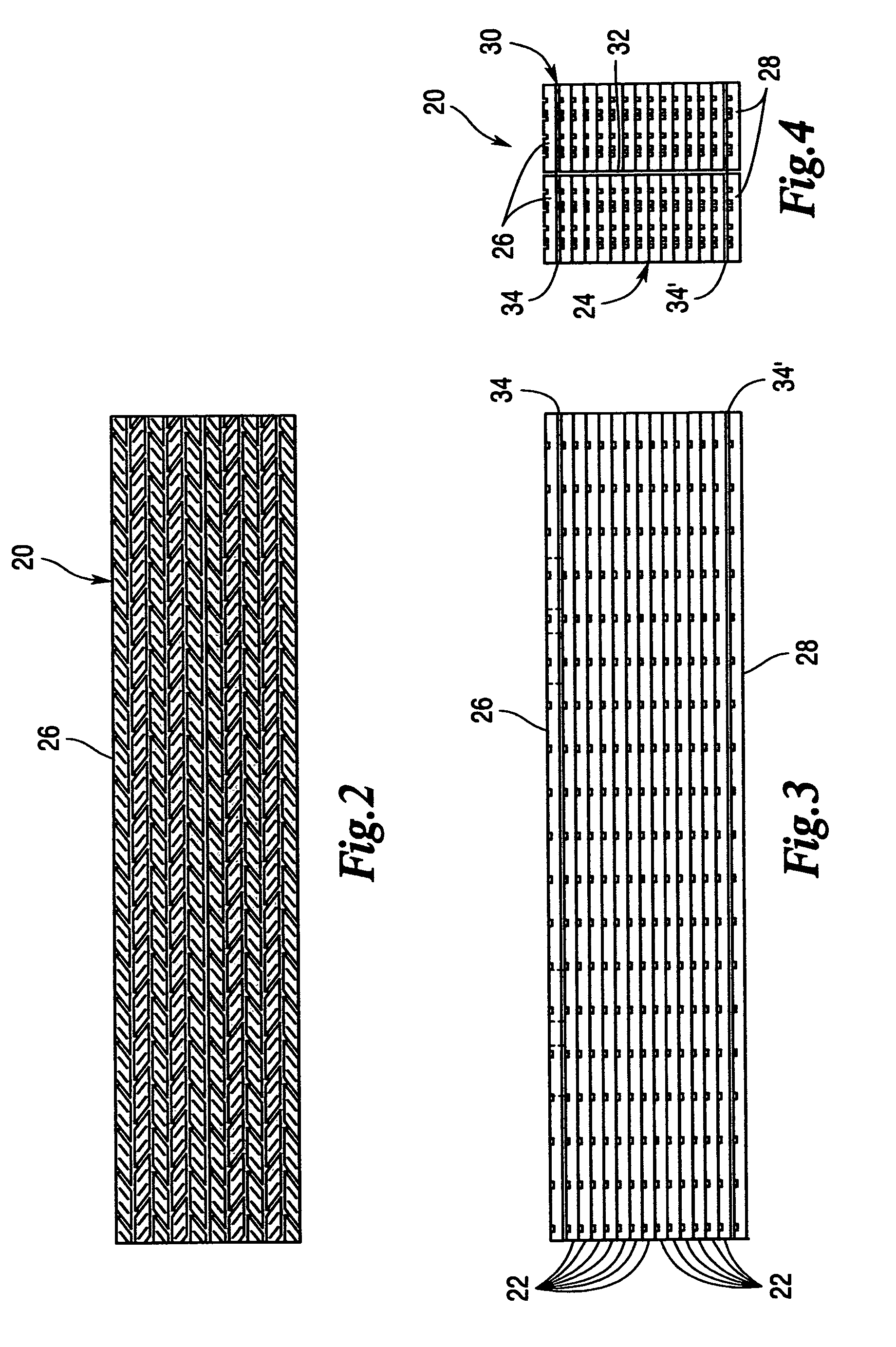

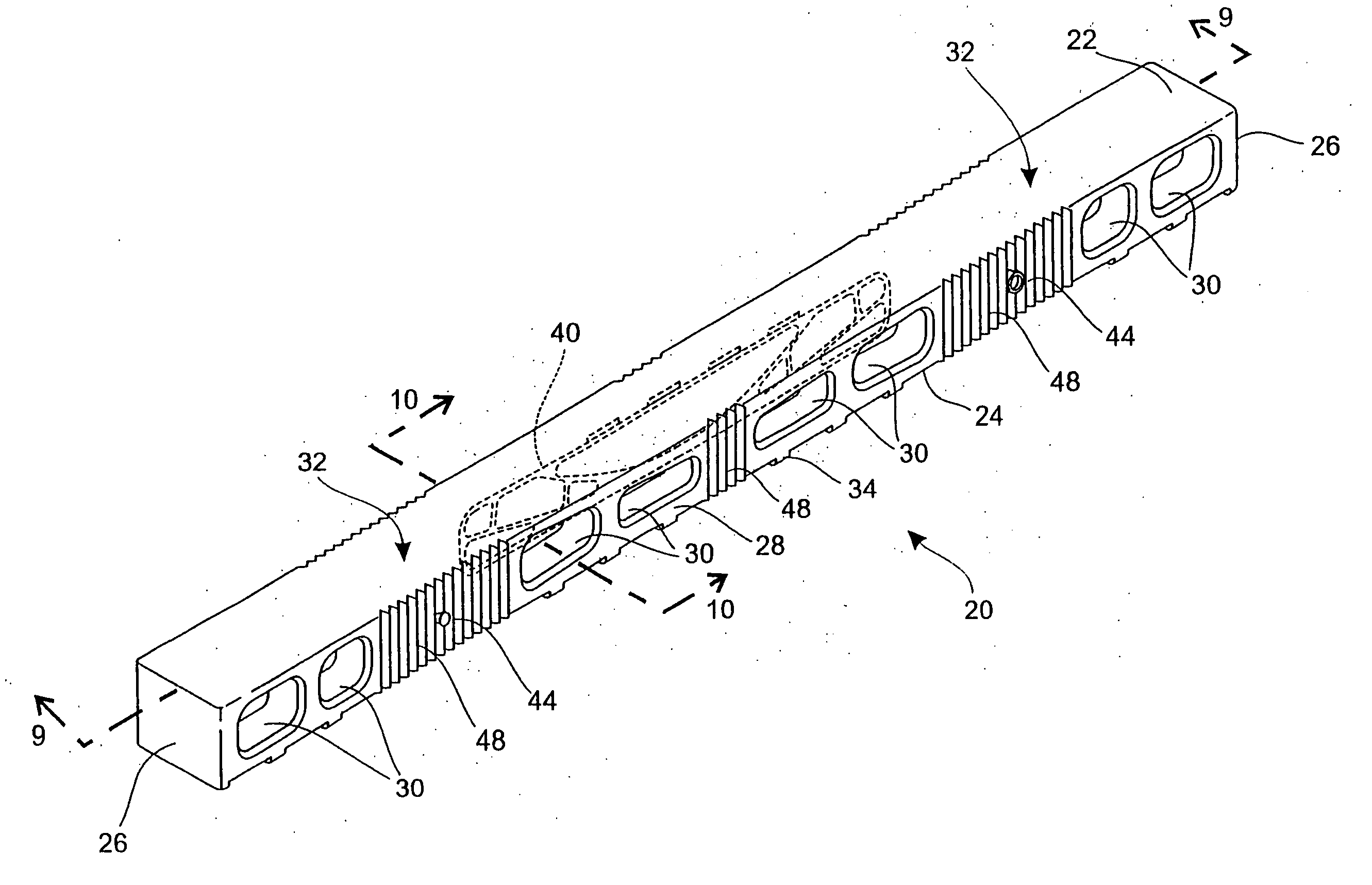

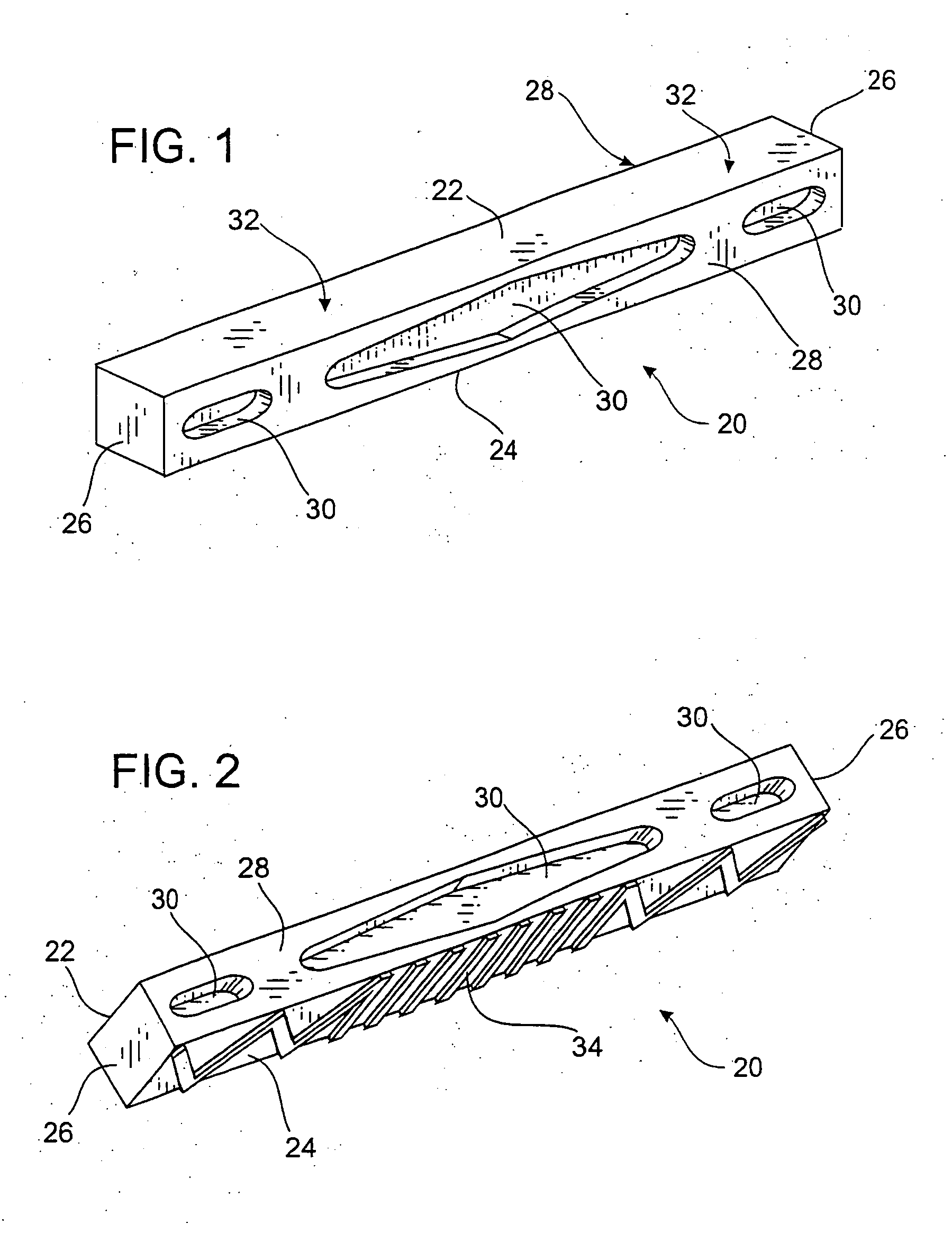

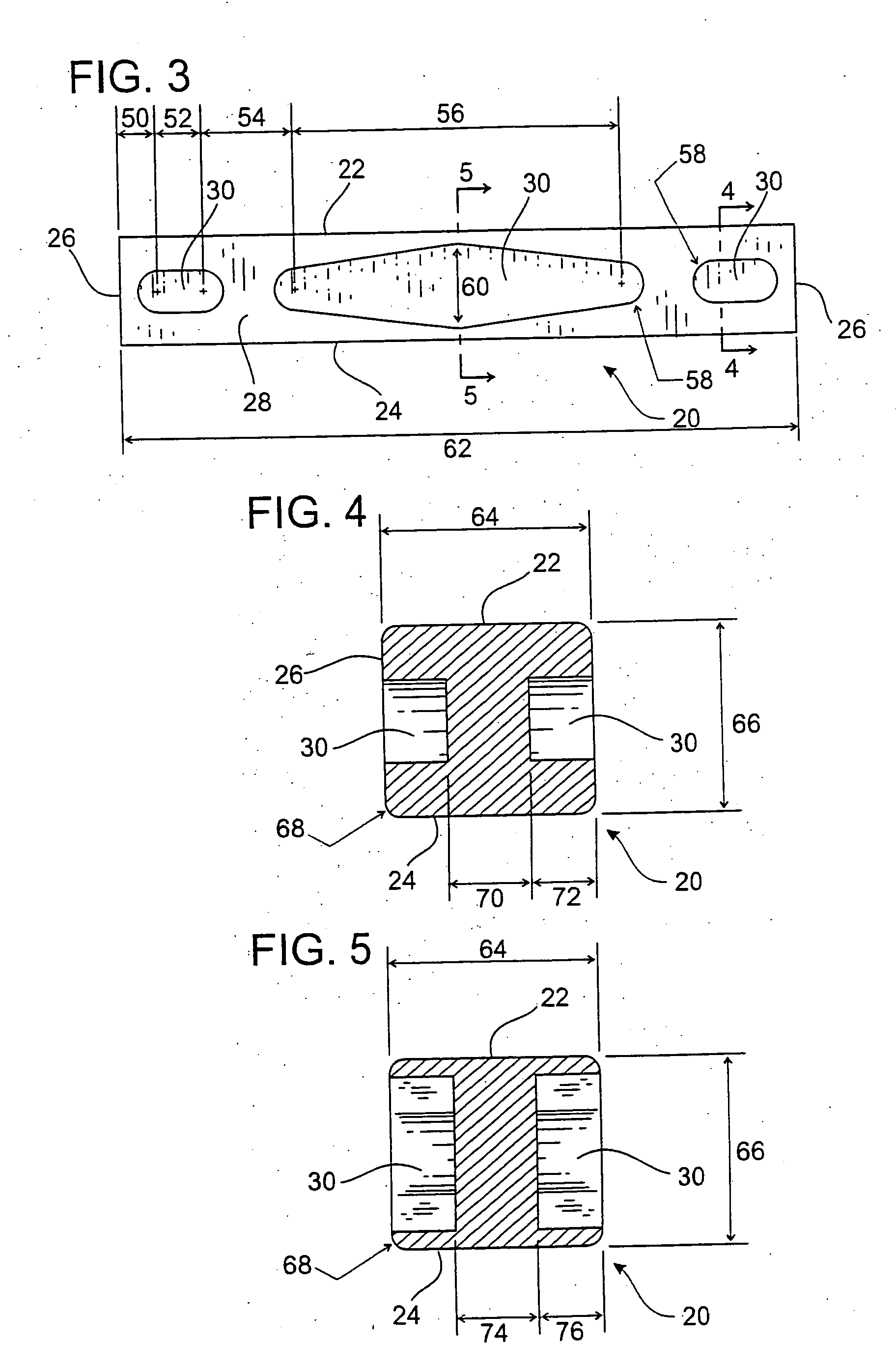

Tire tread railroad tie

ActiveUS7931210B1High compressive strengthIncrease stiffnessBallastwayRail fastenersFlexural strengthEngineering

Re-cycled tire treads are laminated into stacks and attached to a reinforcement element which has a first portion which provides increased compressive strength and a second portion which provides increased torsional and bending strength. Several embodiments with reinforcing elements ranging from T-bars, to I-beams to box beams, with variations including corrugated flanges. Pre-drilled holes can be provided in the flanges to facilitate insertion of the spikes. While steel-belted tires are preferred for use in creating stacks, provisions are made to ensure electrical isolation of the two rails to permit transmission of data thereby. The railroad tie can have electronic signaling hardware built-in by placing sensors and related circuitry between adjacent plies in a laminated stack.

Owner:NP&G INNOVATIONS

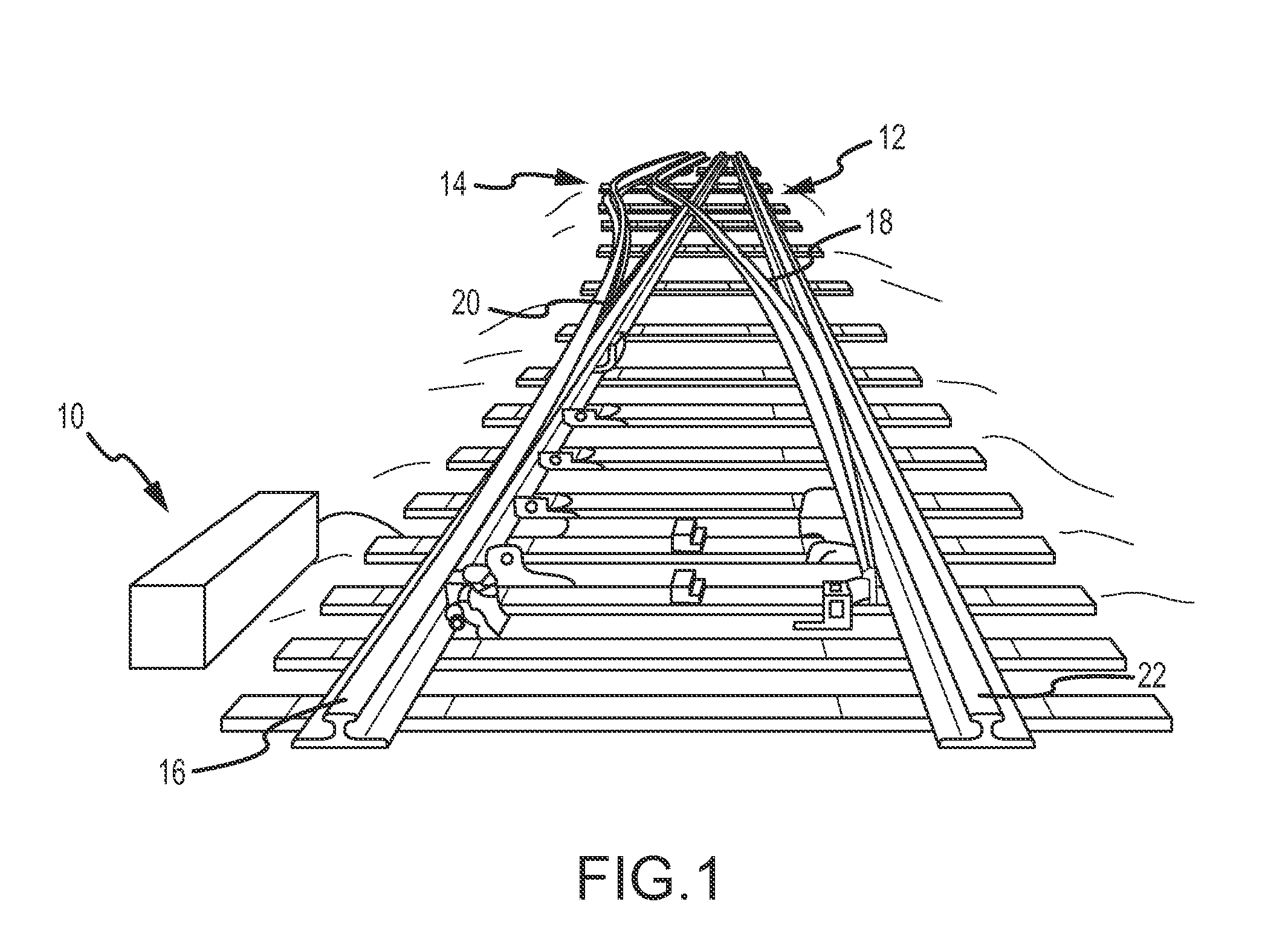

Railroad signal line attachment clip

InactiveUS20080257973A1Avoid corrosionAvoid accidentsRail fastenersTrack superstructureNon invasiveRailway signalling

The present disclosure relates to a system and method for non-invasively attaching components to railroad track rails. More specifically, an anchor is provided that securely fastens to the track rail in a non-invasive manner for holding one or more signal lines to a surface of the track rail. In one embodiment, the non-invasive anchor utilizes a compressive force to clamp to a flange portion of the track rail. In this regard, first and second body members of the anchor may be advanced toward the toward opposing surfaces of track rail to compress the component between a portion of the anchor and a surface of the track rail. In one embodiment, a pawl prevents the withdrawal of these body members from one another such that the compressive force may be maintained once the anchor is applied to the track rail.

Owner:CCI THERMAL TECH INC

Railway track cleaning and maintaining device

ActiveCN110886270AAvoid safety accidentsRealize distance adjustmentTrack superstructureRailway track constructionVehicle frameTrackway

The invention relates to a railway track cleaning and maintaining device, including a vehicle frame, wherein the vehicle frame comprises a first vehicle frame and a second vehicle frame which are connected with each other; the first vehicle frame is arranged under the second vehicle frame; track wheels are installed on the lower portion of the first vehicle frame; walking wheels are installed on the lower portion of the second vehicle frame; the track wheels can drive the vehicle frame to travel along a railway track, and the walking wheels can drive the vehicle frame to travel along the ground; and the distance value of the first vehicle frame and the second vehicle frame in the vertical direction can be adjusted, so that the distance between the lowest point of the track wheels and the lowest point of the walking wheels in the vertical direction is changed by the same value.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

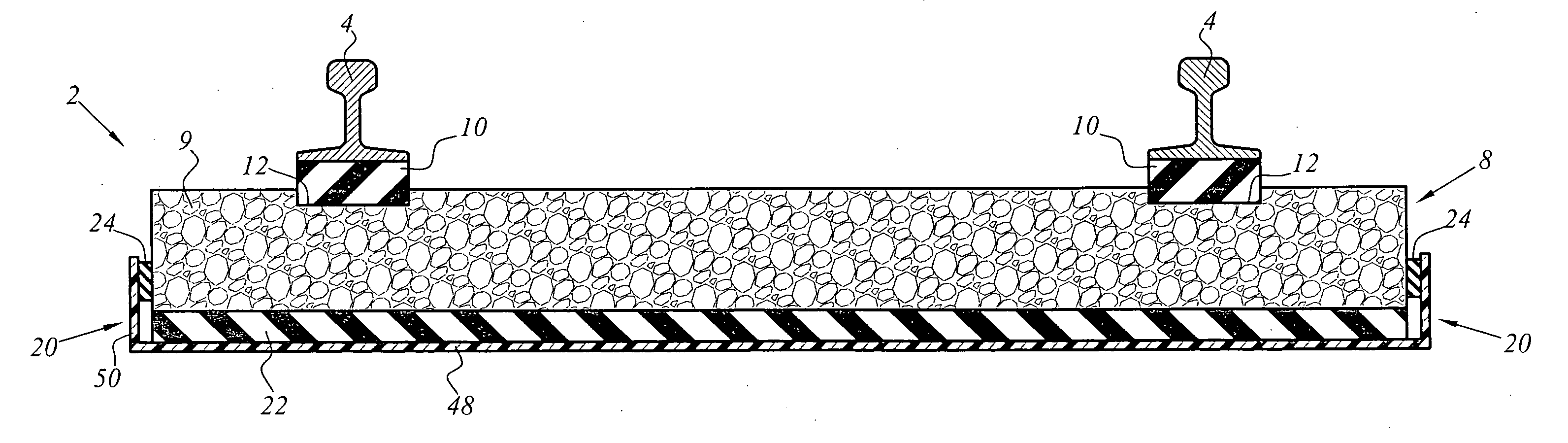

Composite railroad tie and method of manufacture

An improved mold and method of manufacture for an improved railroad tie or other structural member. The improved railroad tie or structural member being fabricated using an injection molding process with various thermoplastic resins and fillers. The improved mold used has a cooling cavity which helps cool the structural member while still in the mold. The improved insert allows an automated molding system to be used for greater production rates.

Owner:FORCEPRO L L C

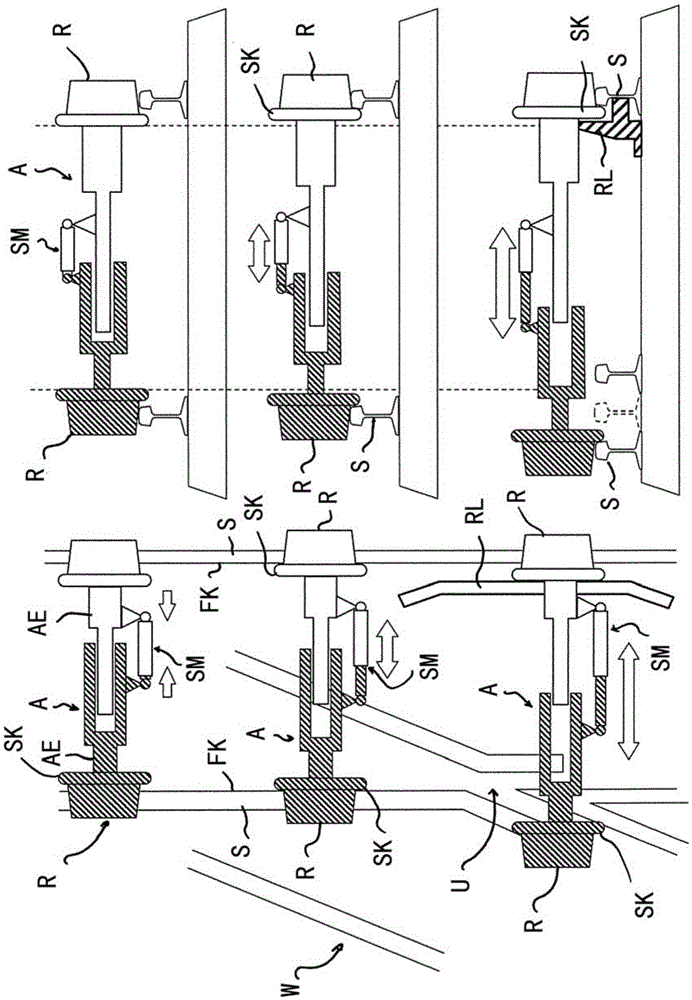

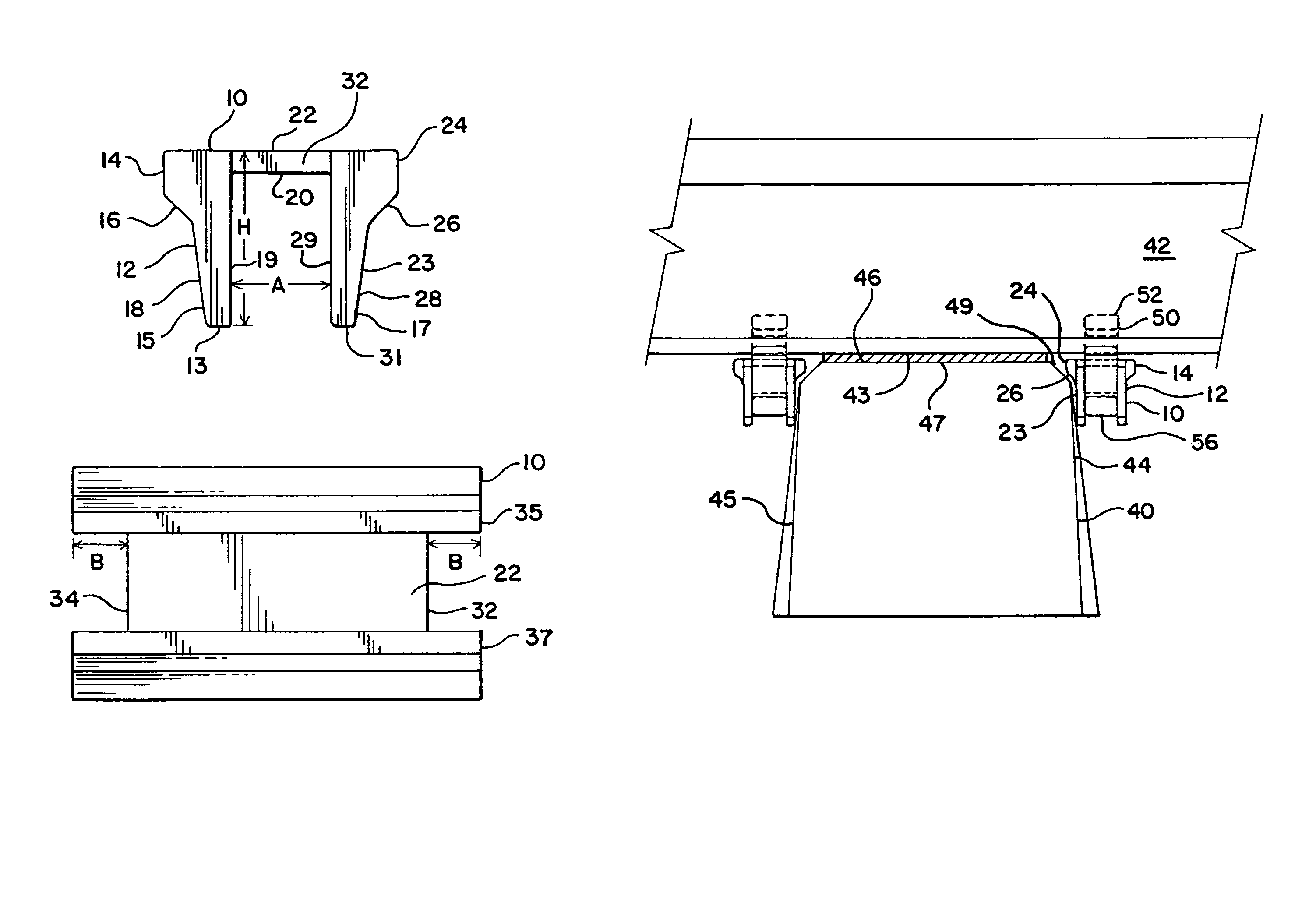

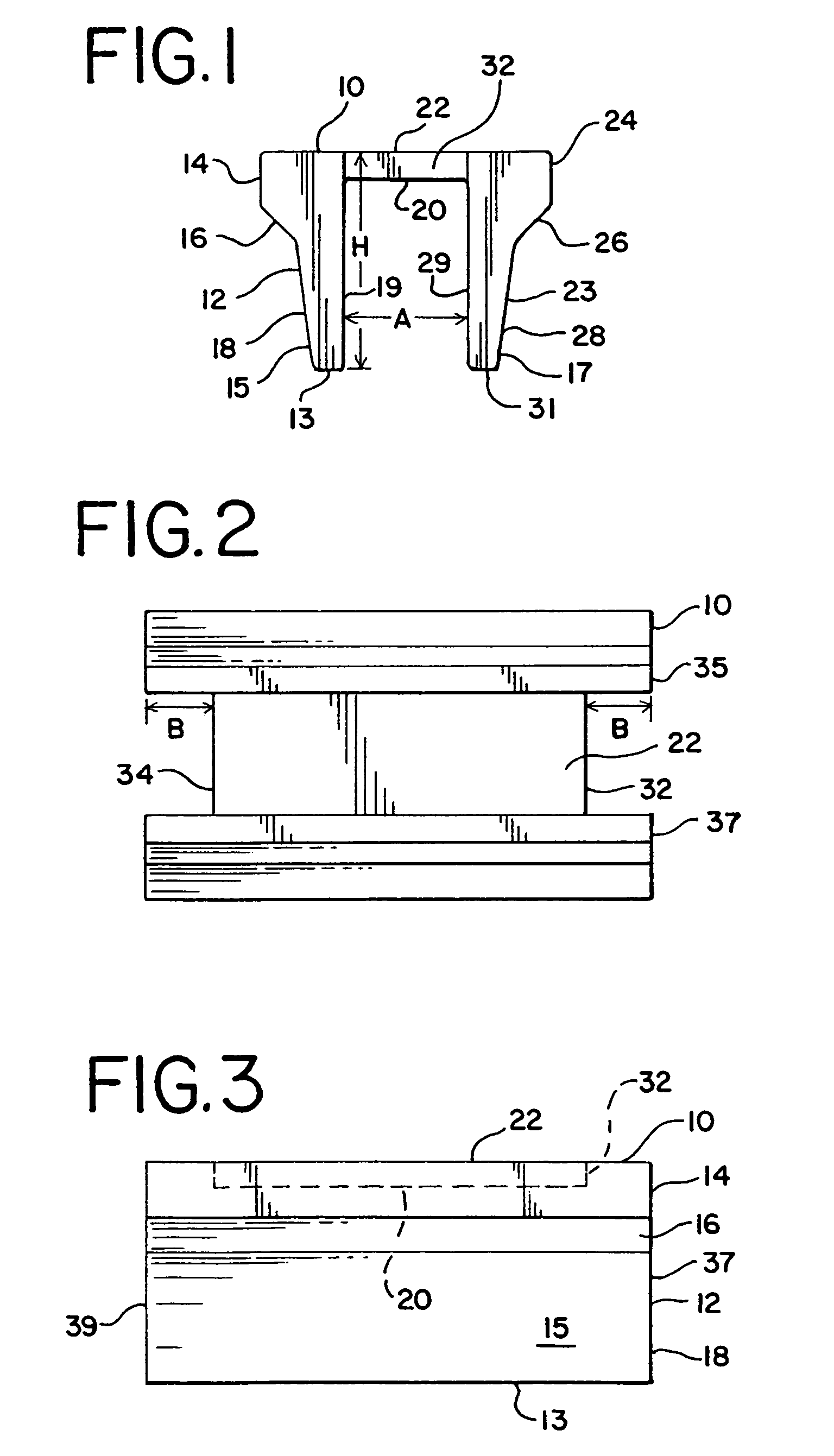

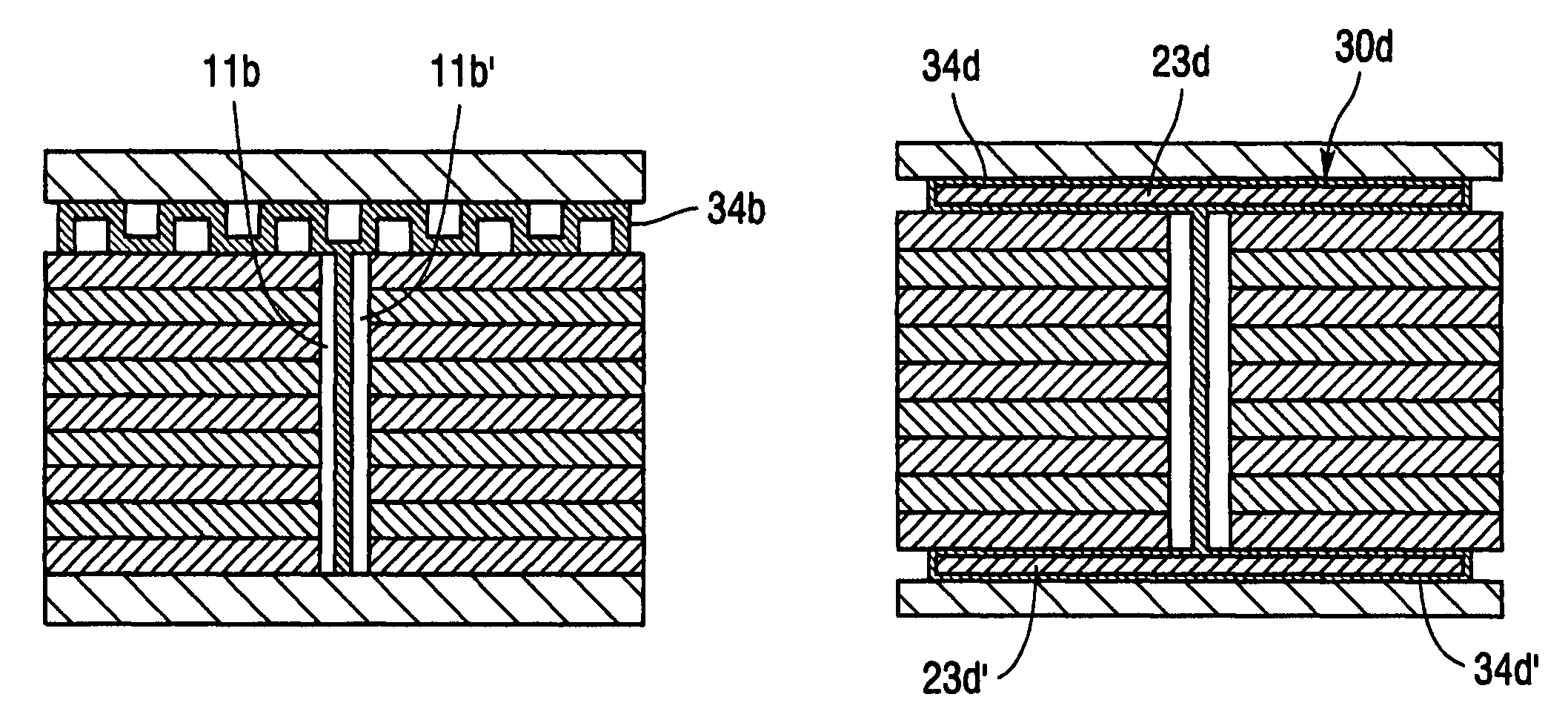

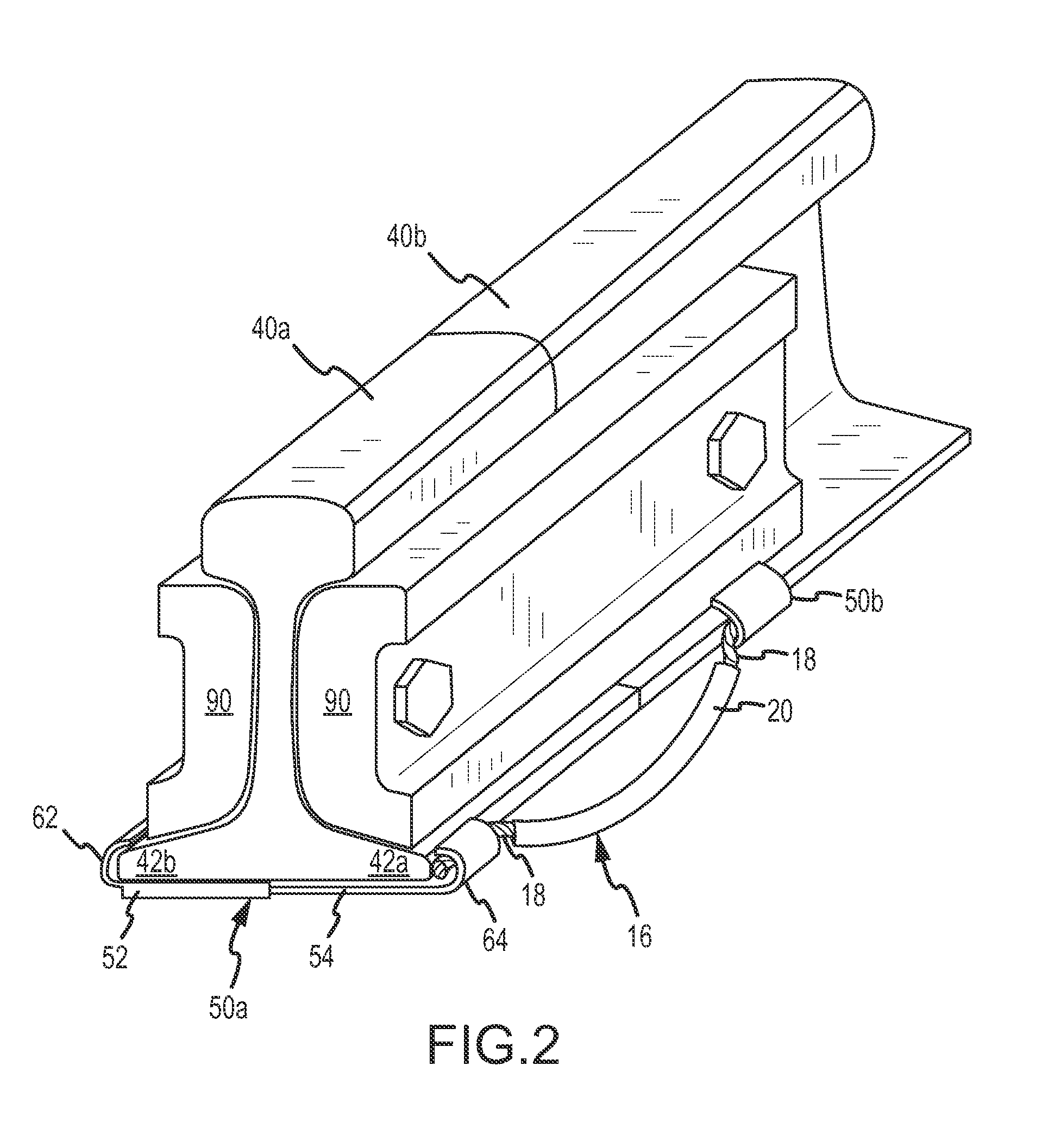

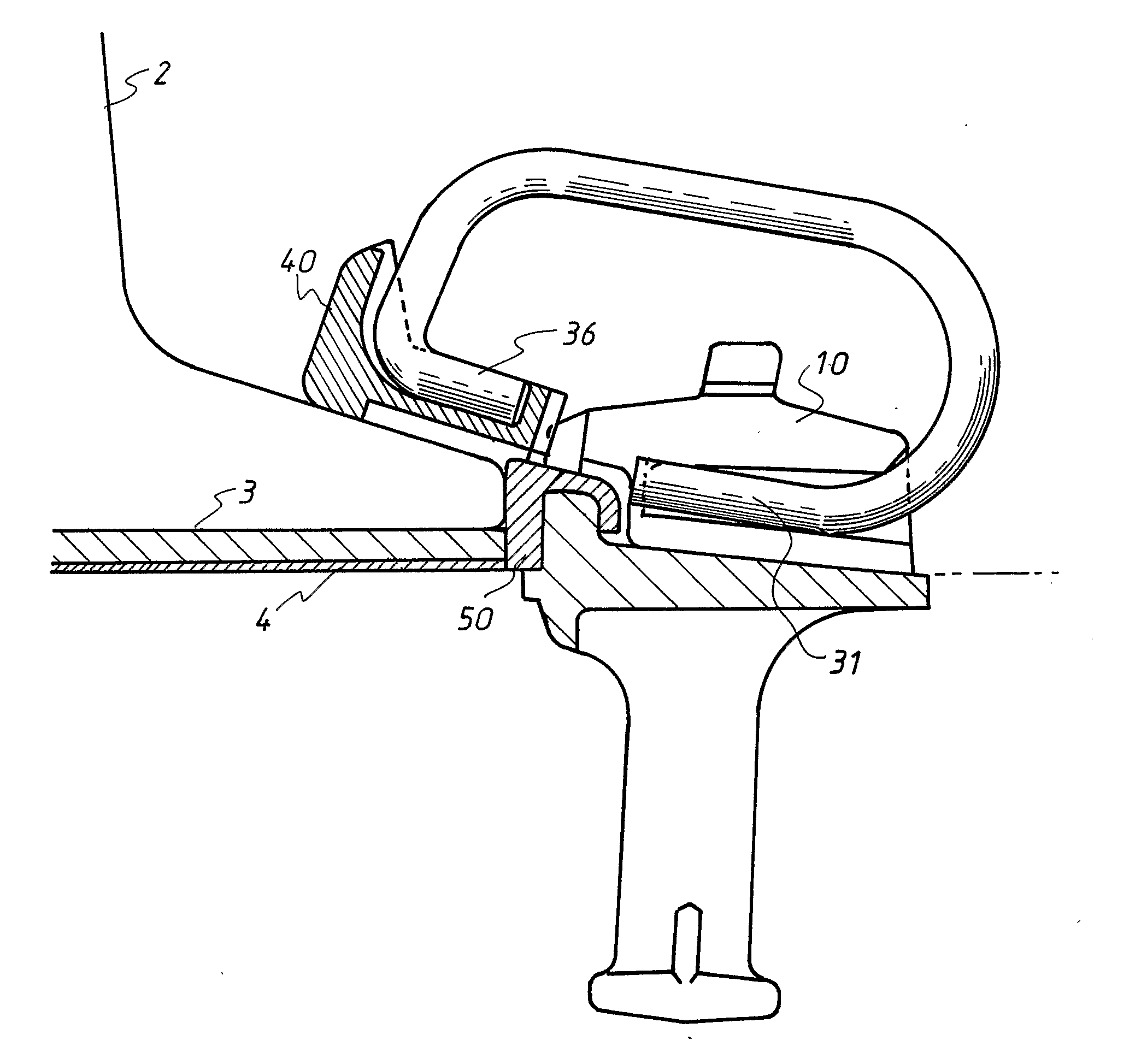

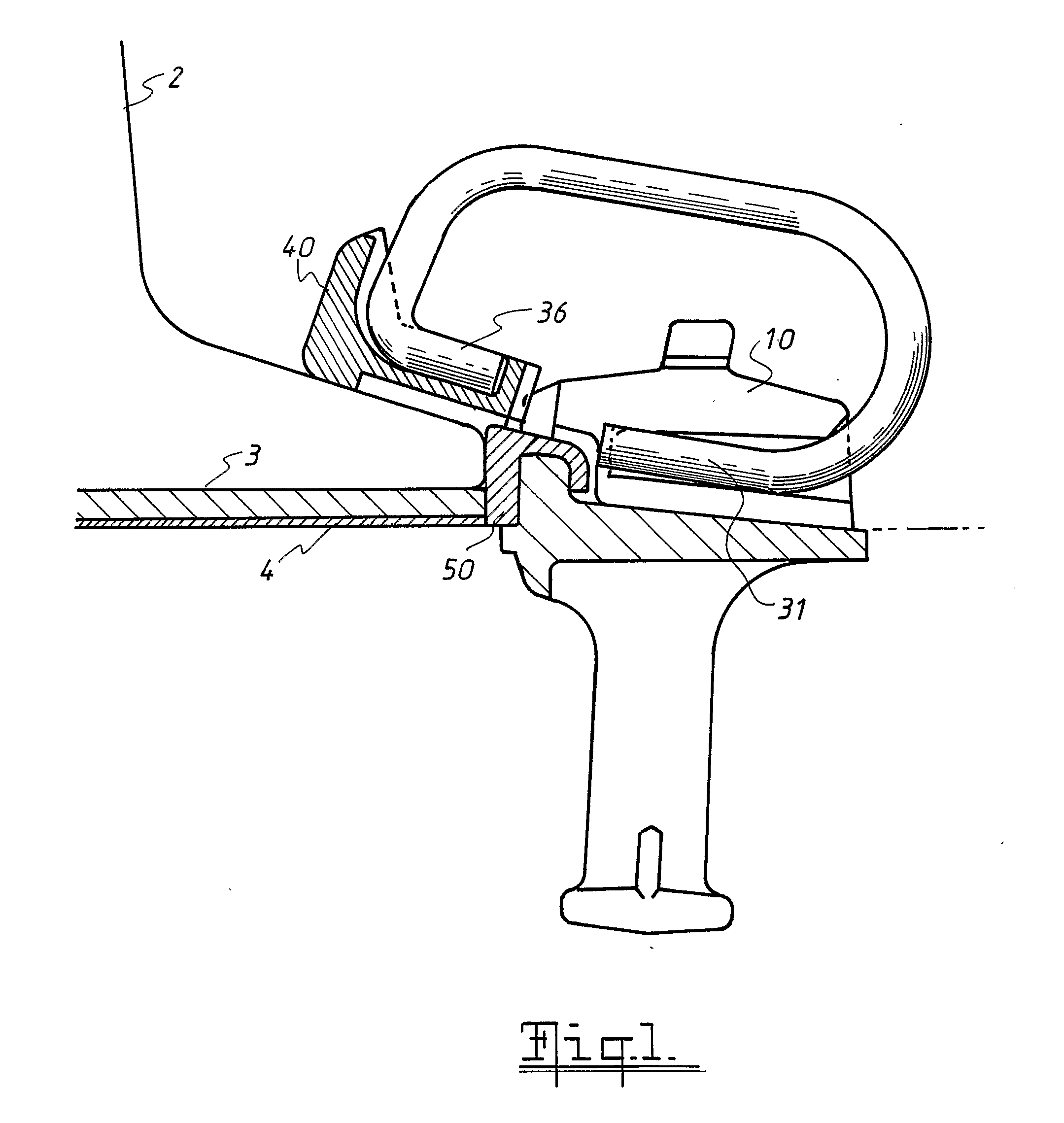

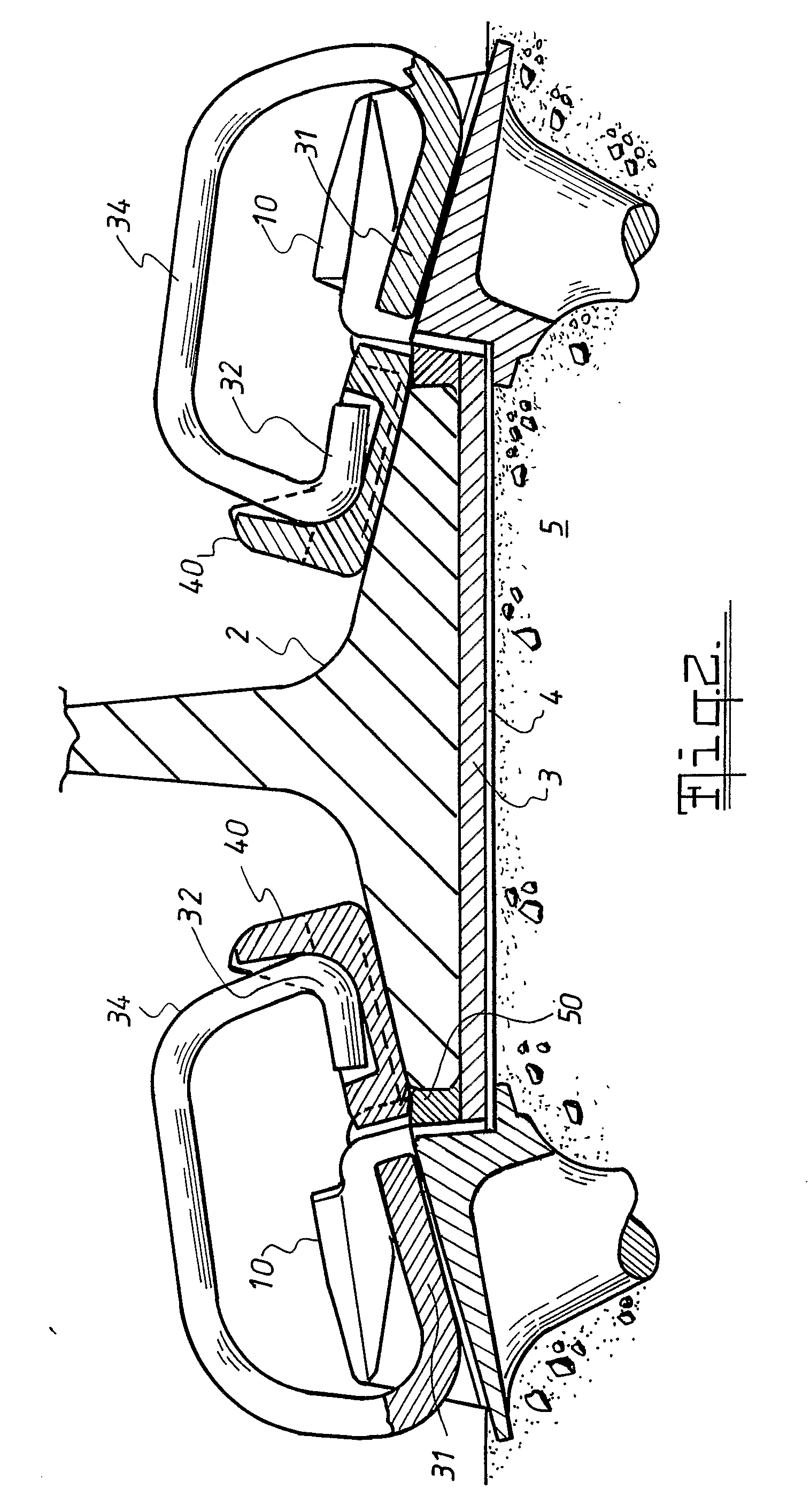

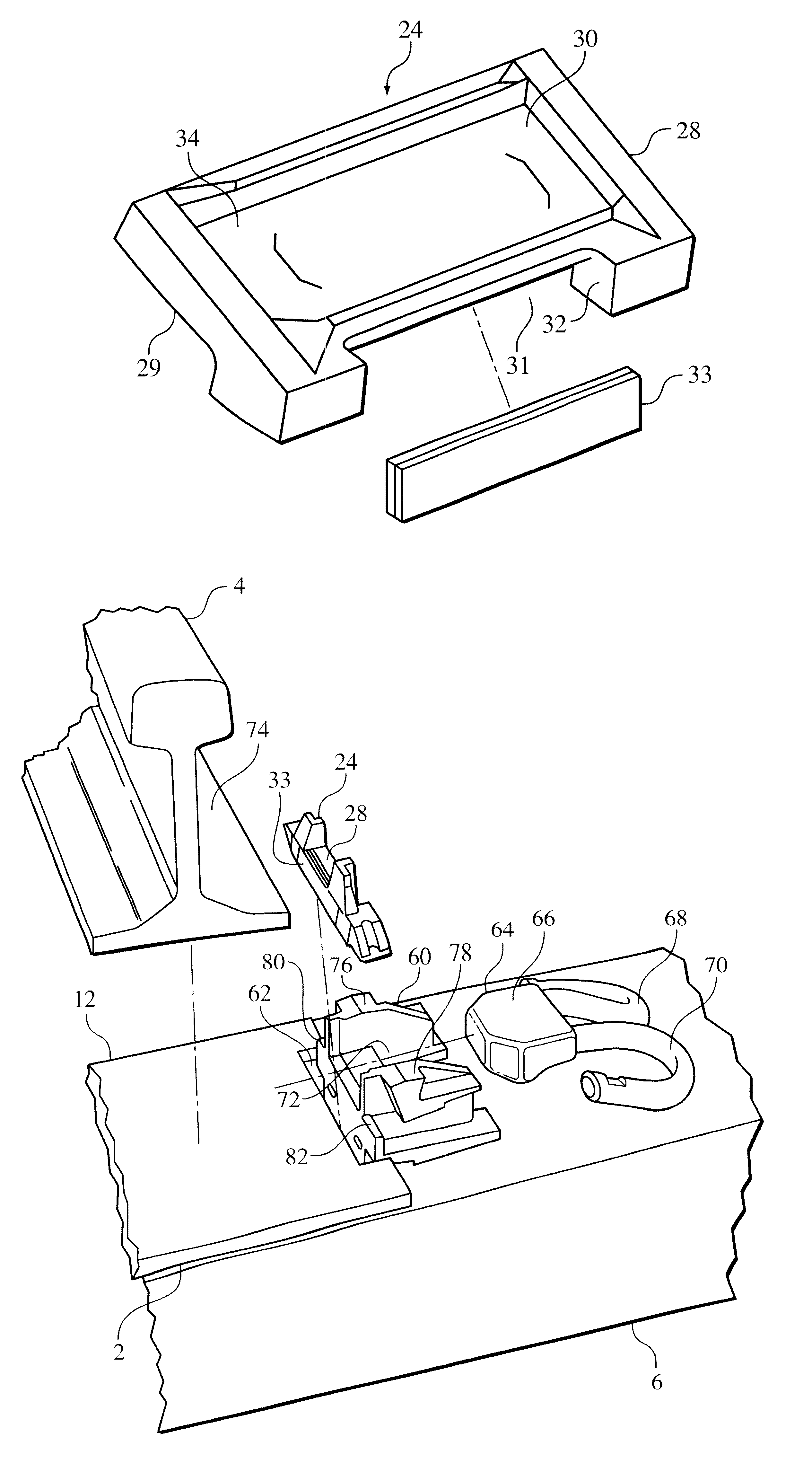

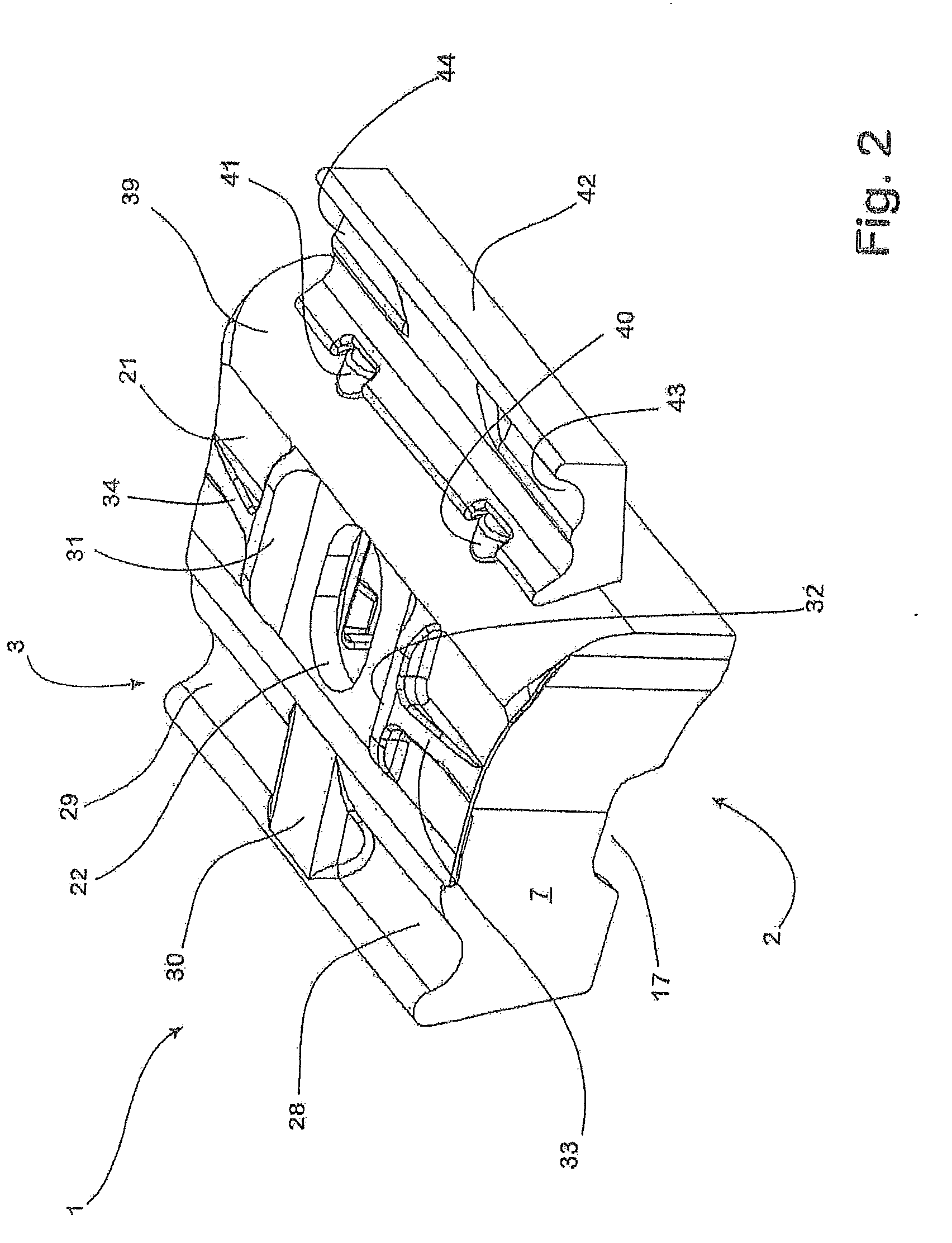

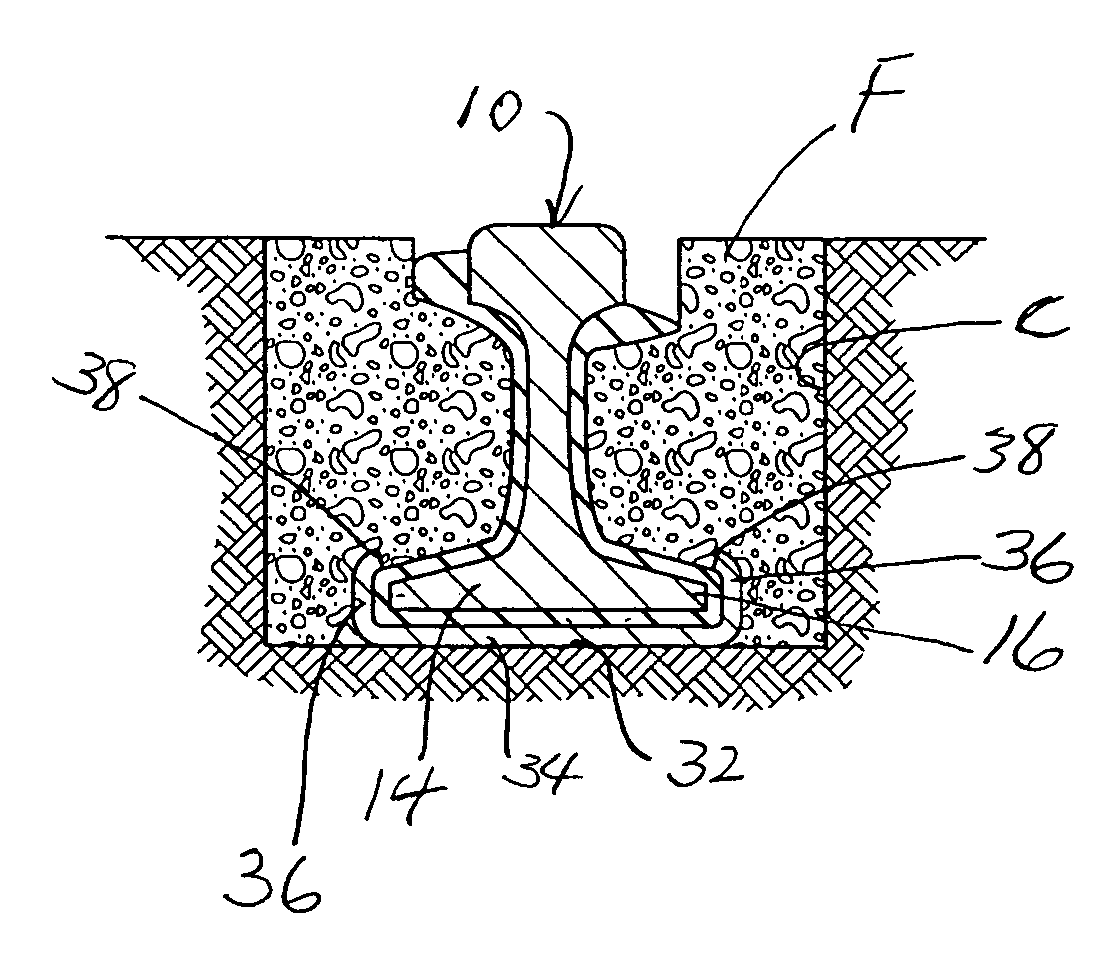

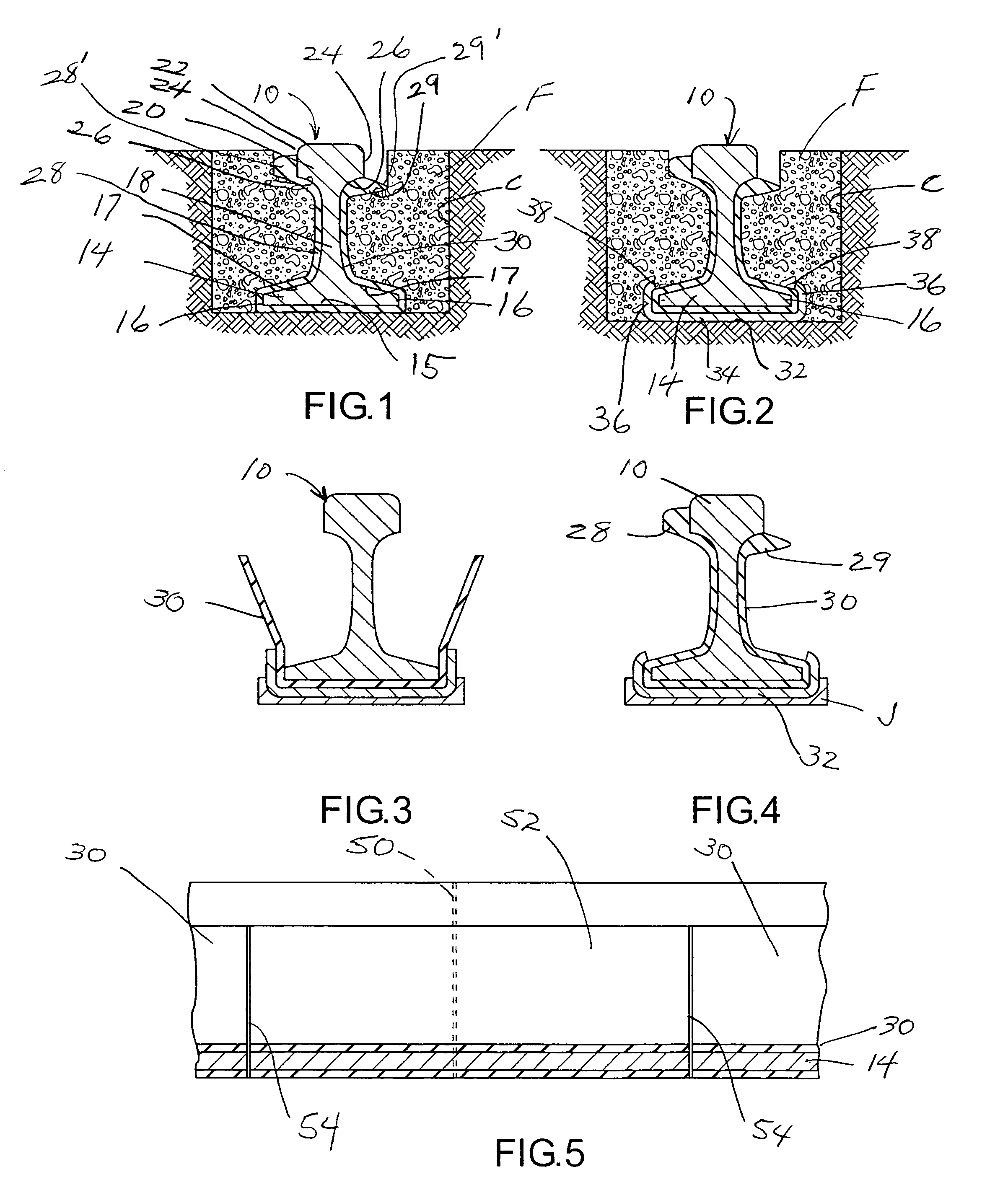

Rail Clip Insulator

ActiveUS20080203181A1Solve the lack of spaceAvoid excessive forceRail fastenersTrack superstructureEngineeringMechanical engineering

A two-part rail clip insulator (40, 50) for a tie and rail seat assembly that enables the seat to be pre-assembled at the rail tie fabrication plant into a preloaded position where a rail (2) may be laid on the tie (5) on site, the clips (30) being movable to the loaded position after the rail is placed in position. The rail seat includes a concrete rail tie (5), a pair of rail clip support shoulders (10) cast in place in the tie (5), each shoulder (10) having a rail face between its external sides, a pair of shoulder insulators (50) each shaped to lie against the rail face of the rail shoulder, a pair of rail clips (30) each having a base section (31) adapted to seat within the support shoulder (10) and a toe section adapted to seat on the rail base; the arrangement being such that when the rail clip is in the preloaded position, the toe insulator (40) and the toe (36) of the clips do not project beyond the face of the shoulder insulator (50), so that a rail (2) can be laid between the rail shoulders and their associated insulators (50). The toe insulator (40) is shaped to facilitate loading of the rail clip (30) and resist movement of the clip or the rail during use.

Owner:PROGRESS RAIL SERVICES

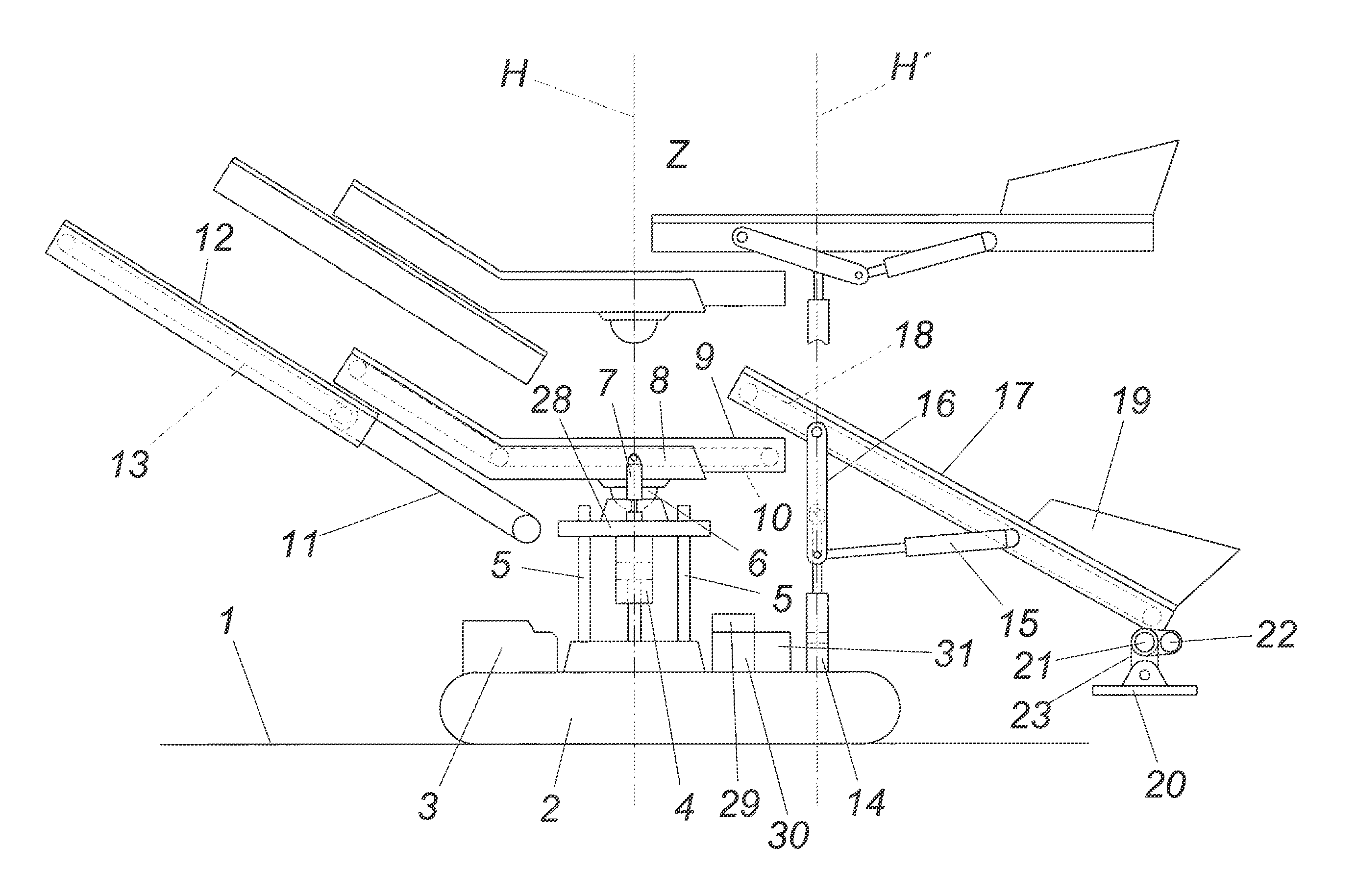

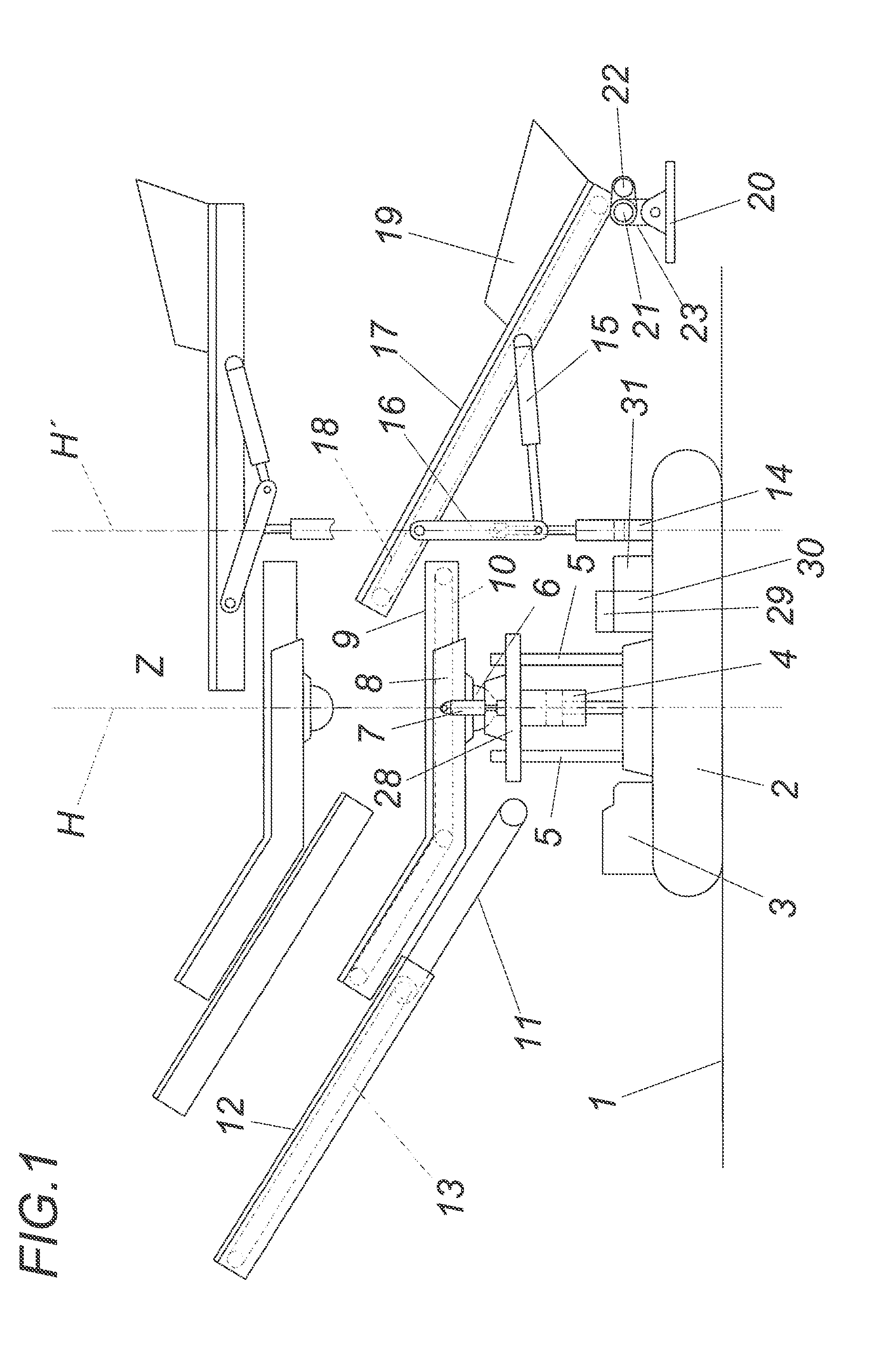

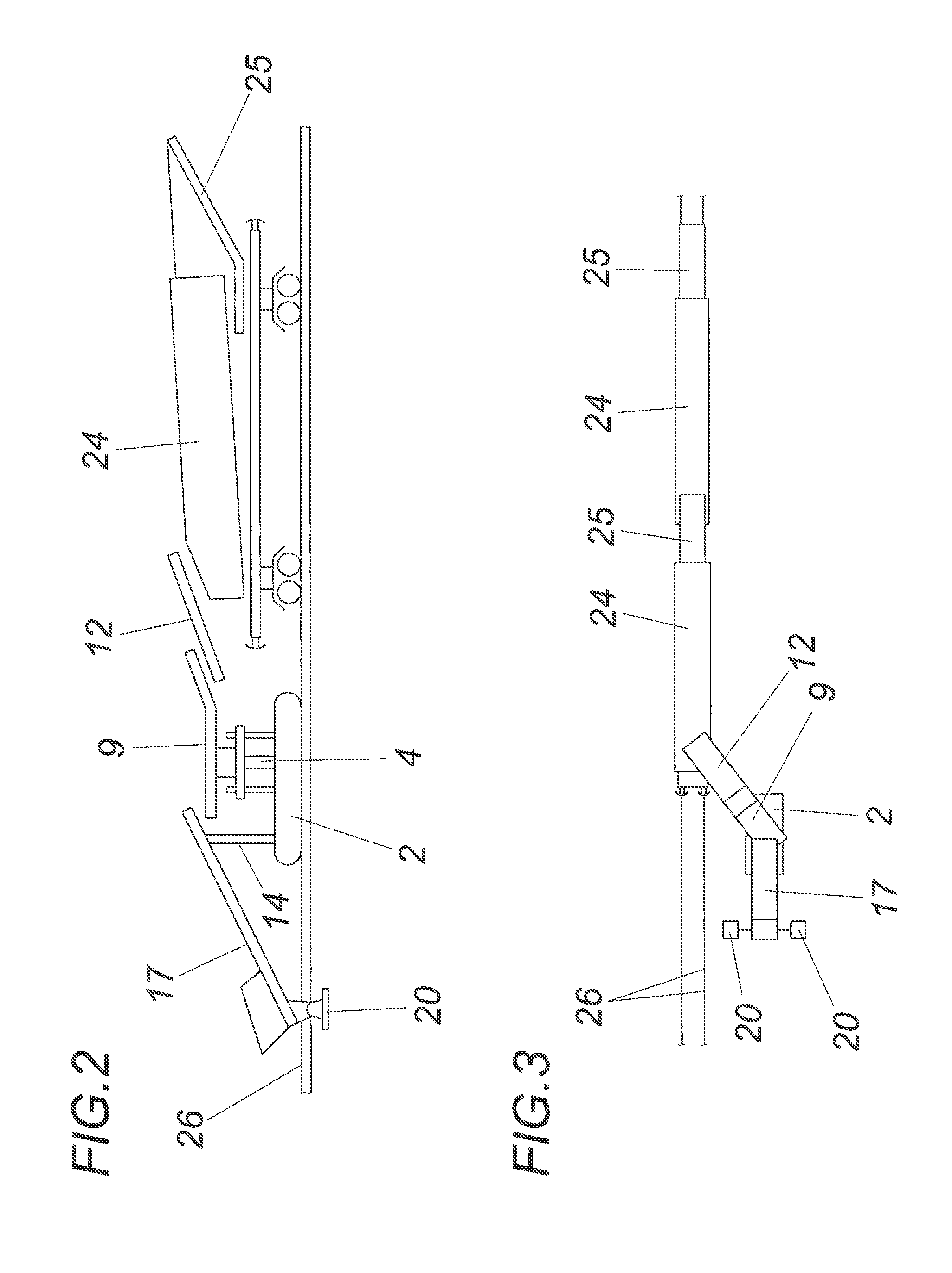

Apparatus for conveying material for railway construction

An apparatus for conveying material for railway construction comprising a material loading device which is movable on a chassis, in particular a crawler chassis (2) having at least one receiving conveyor belt (17) each for receiving material and having a transfer conveyor belt (9, 12) for transferring material is described. In order to create advantageous transfer conditions, it is proposed that the transfer conveyor belt (9,12) is rotatable about a chassis vertical axis by means of a rotary drive and can be adjusted in height along the chassis vertical axis by means of a lifting drive (4).

Owner:HP3 REAL GMBH

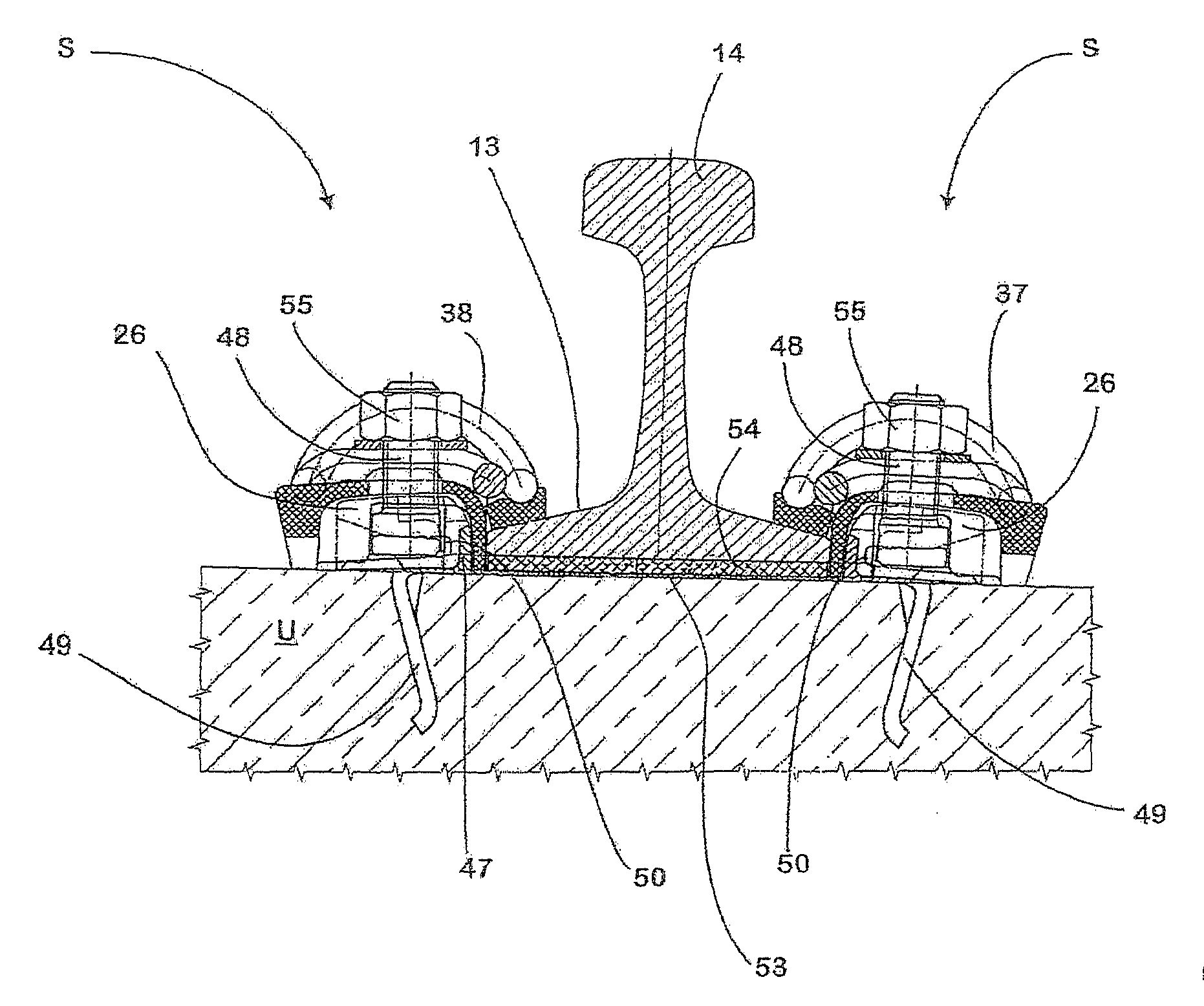

Concrete railroad tie two-piece insulator spacer and fastening system

A system for securing a rail to a concrete railroad tie employing a two-piece insulator spacer that improves the resistance of the insulator spacer to the crushing deterioration induced by laterally-directed compressive forces during service. The insulator spacer comprises an upper member and a post member. The post member is subjected to high compressive loads in service and consists of composite material that is sufficiently electrically insulating to operably electrically insulate the rail with which the insulator spacer is in contact from the shoulder insert with which the improved insulator spacer is also in contact.

Owner:KSA PARTNERSHIP

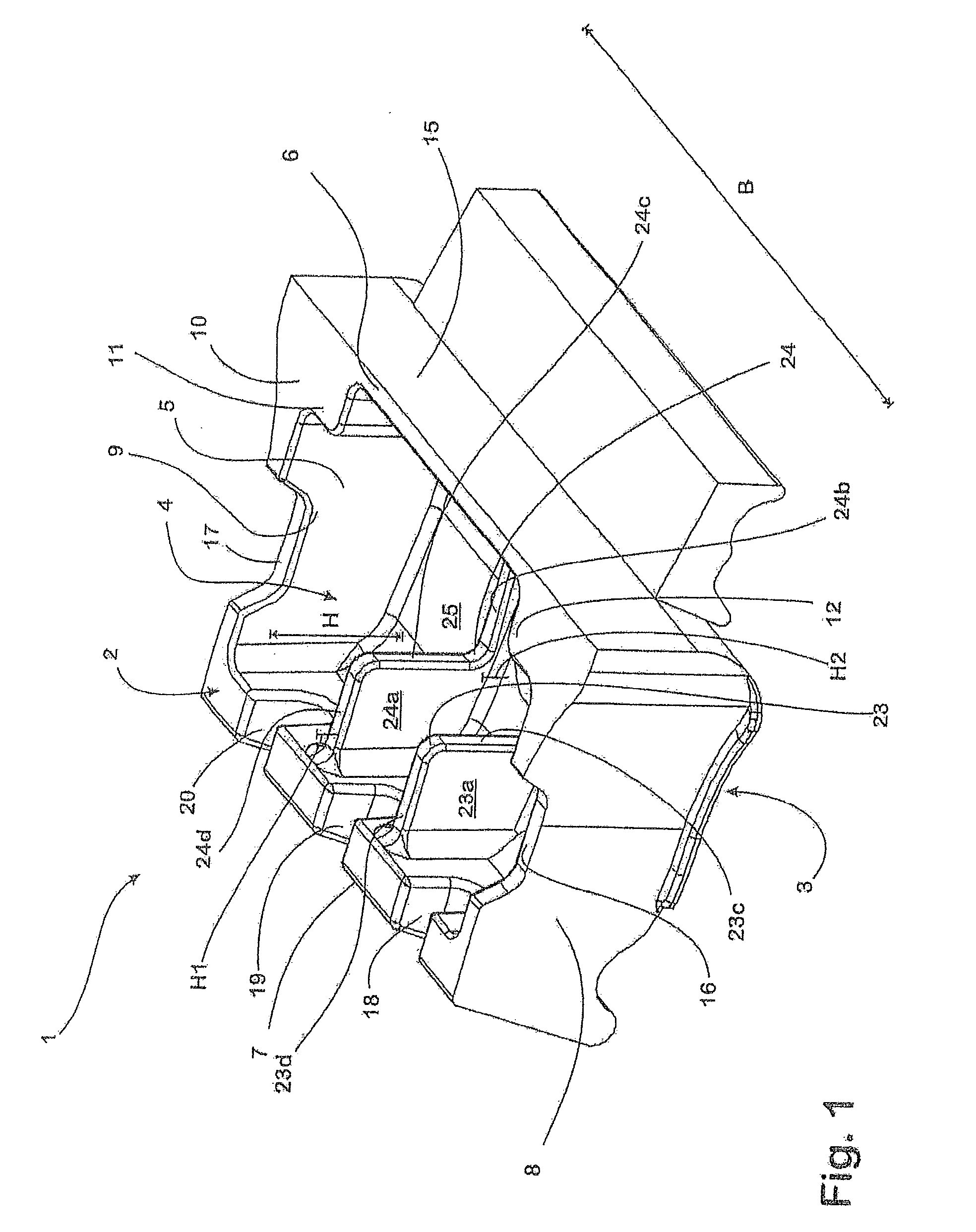

Guide plate for a system for fastening a rail to a substrate, and a system comprising a guide plate of this type

ActiveUS20100200666A1Meet the requirementsReliable loadRail fastenersTrack superstructureEngineeringMechanical engineering

The invention relates to a guide plate for a system for fastening a rail to a substrate on which there is provided, laterally of the railway track, a shoulder, which absorbs the forces occurring when the rail is traveled on by a rail vehicle, the guide plate having an underside which is associated with the substrate and an upper side which is exposed in the installation position, is remote from the underside and on which it is possible to support a spring element provided for applying resiliently elastic holding-down forces to the rail to be fastened.

Owner:VOSSLOH WERKE GMBH

Insulated rail for electric transit systems and method of making same

InactiveUS7484669B2Eliminating resultingEasy to installBallastwayTemporary pavingsElectricityTransit system

A rail cover and support for mounting and insulating the rails of an electric transit system in which the rail cover is vulcanized both to the rail and outer skid support at the manufacturing site prior to delivery to the field and a rail cover completely surrounds both the base flange and web portion of each rail and terminates along the undersides of the top flange. In one form, the upper free ends of the rail cover are increased in thickness to form bumpers along opposite sides of the rail to cushion it against undue shifting or vibration. In fabricating the rail, a sheet dielectric material is vulcanized to the rail with or without a skid plate.

Owner:METROSHIELD

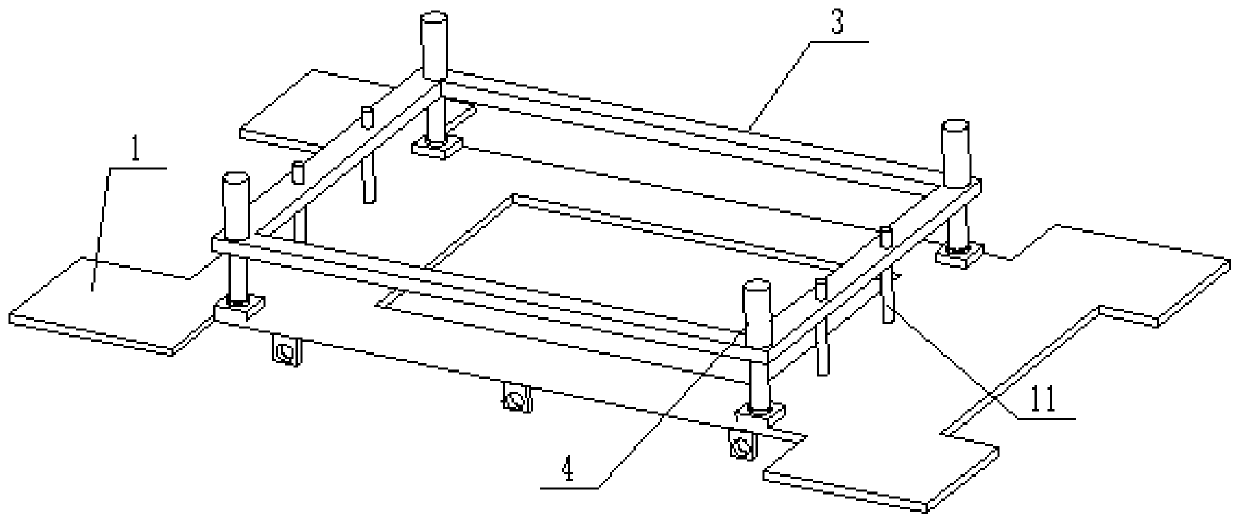

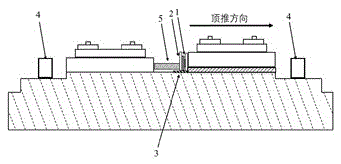

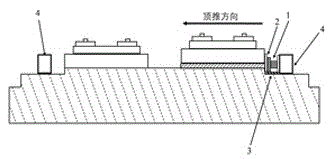

Midline deviation rectifying method for sedimentary offset ballastless track

InactiveCN106702834AReduce constraintsReduce settingsTrack superstructureRailway track constructionFilling materialsHigh pressure

The invention discloses a midline deviation rectifying method for a sedimentary offset ballastless track. The midline deviation rectifying method comprises the following steps that (1) the uplifting quantity and the offset quantity of the sedimentary offset ballastless track line are determined; (2) the track structure characteristics are combined, a grouting uplifting hole is formed in the top surface of the ballastless track structure, and grouting uplifting material is injected into a ballastless track supporting layer or under a base plate through a grouting pipe installed in the grouting hole by adopting high-pressure grouting equipment under a certain grouting pressure according to the determined equipment parameters and the grouting steps, so that an overall ballast bed and the upper structure of the ballastless track are uplifted; (3) a jacking and pushing point is arranged on the side surface of the ballastless track structure, a jacking and pushing device is installed, and the ballastless track line is rectified to the designed position through the jacking and pushing process of grouping loading and jacking and pushing step by step; and (4) after the midline is rectified, the line recovery work is timely conducted, a lower gap of the overall ballast bed of the ballastless track is filled with a filling material, a fastener system is finely adjusted, and the line smoothness is recovered.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

Rail heater clip

A rail clip for securing a strip heater to a rail that resists removal when subjected to intense vibration, such as when rail cars are passing overhead. The rail clip is configured with a U-shaped rail flange receiving area wherein the opposite sides of this receiving area are configured with at least one tooth each for securing the rail therebetween. For greater securement, multiple teeth on each side of this U-shaped receiving area would be employed and with at least one tooth on each side thereof being in alignment with the other. Furthermore, the teeth on at least one side of this receiving area would include multiple teeth, both pointed and elongated.

Owner:THOMAS & BETTS INT INC

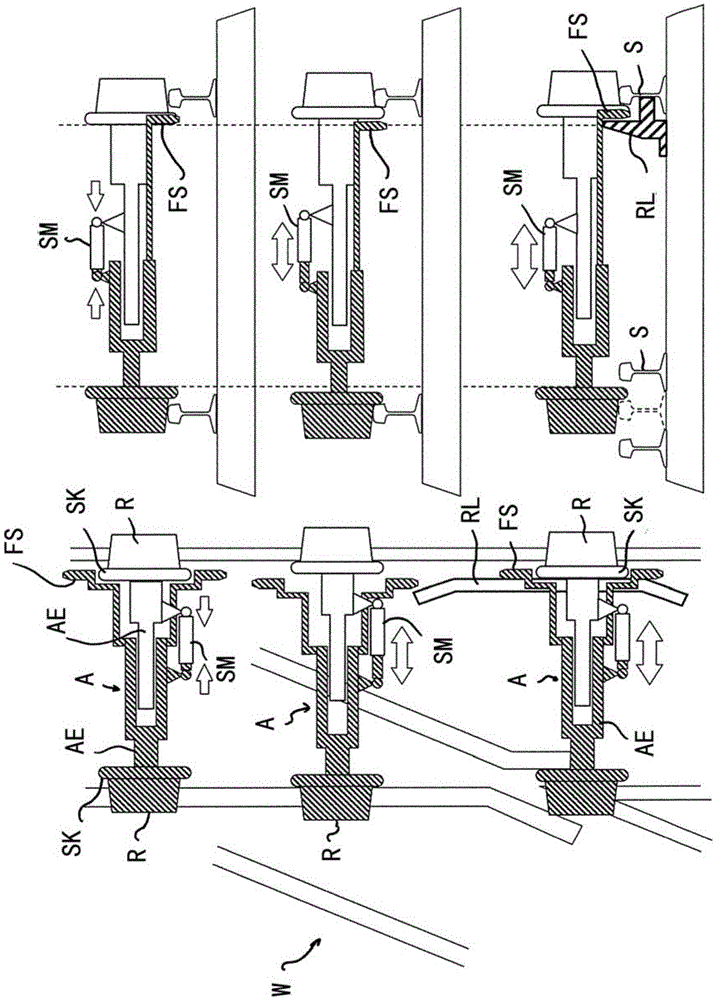

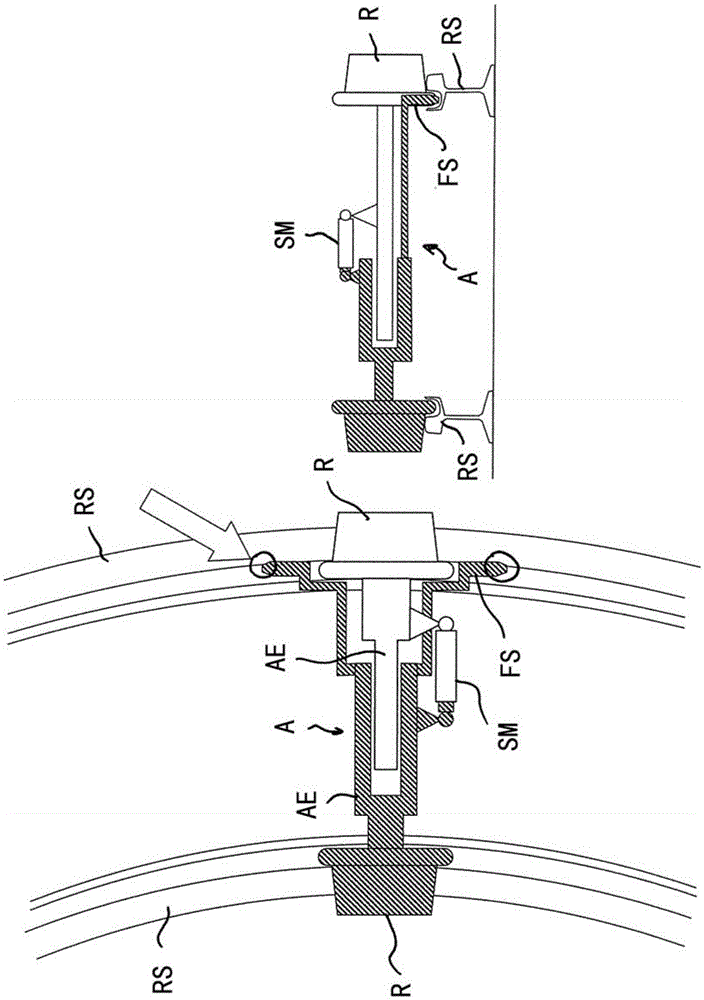

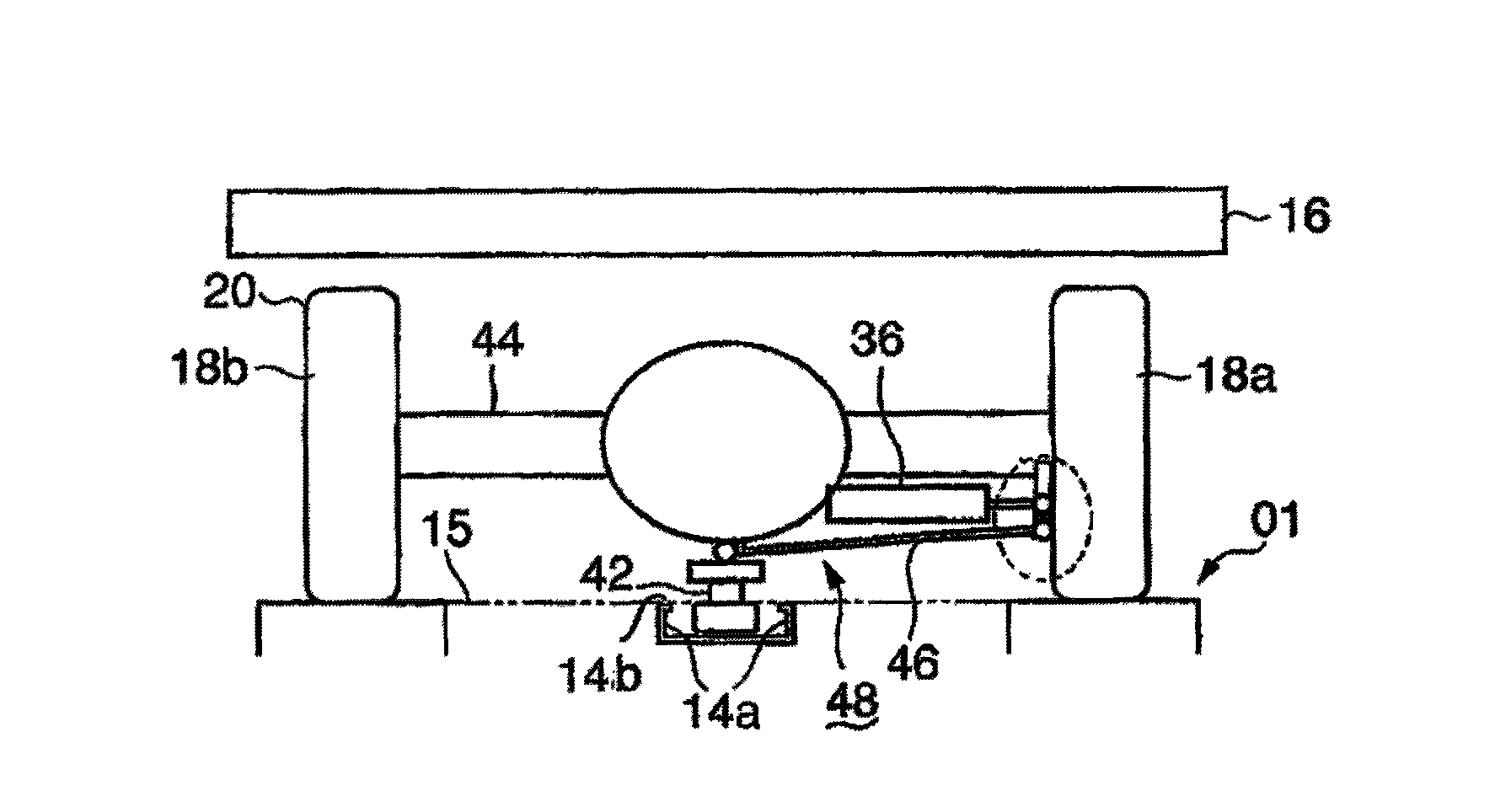

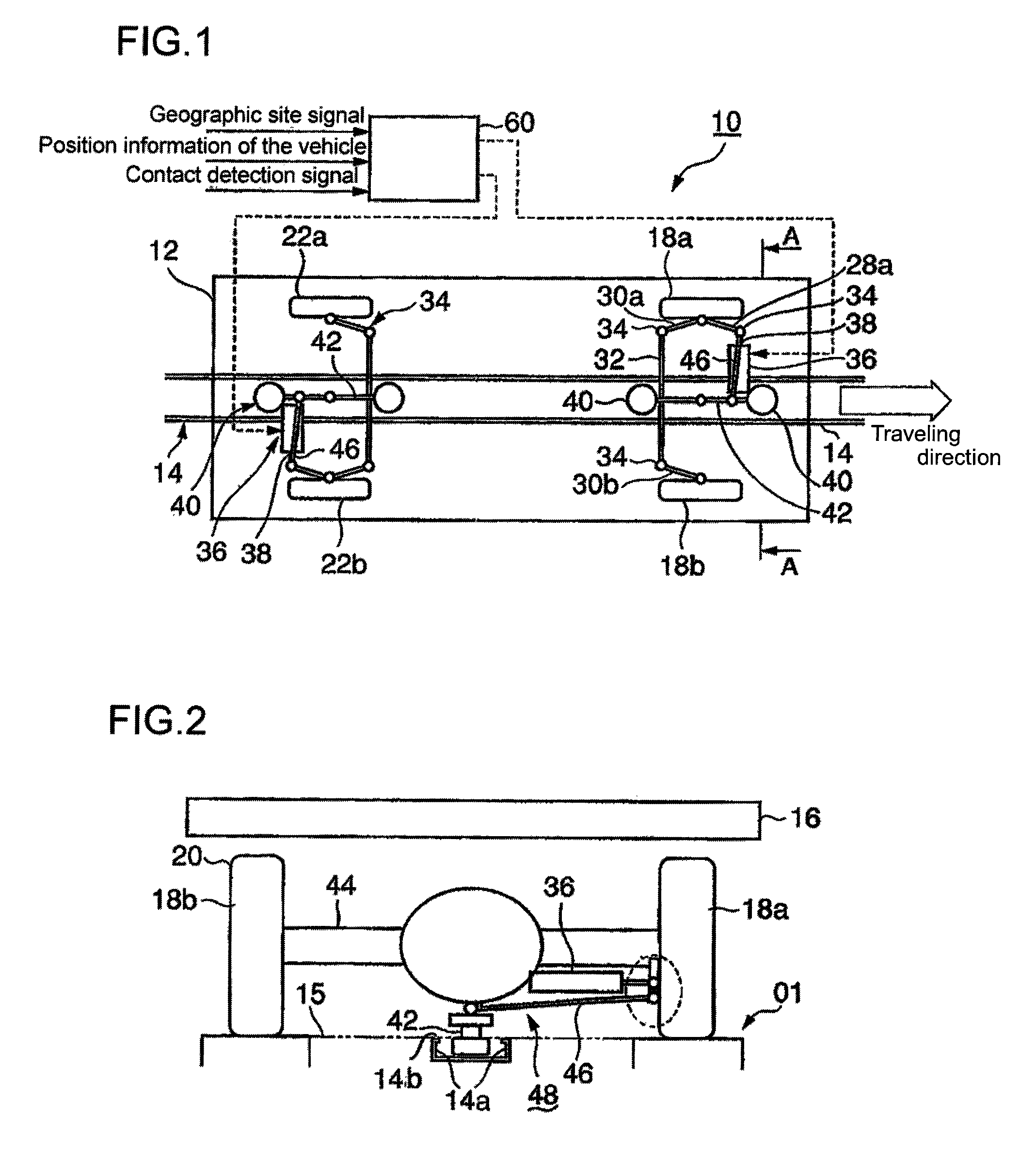

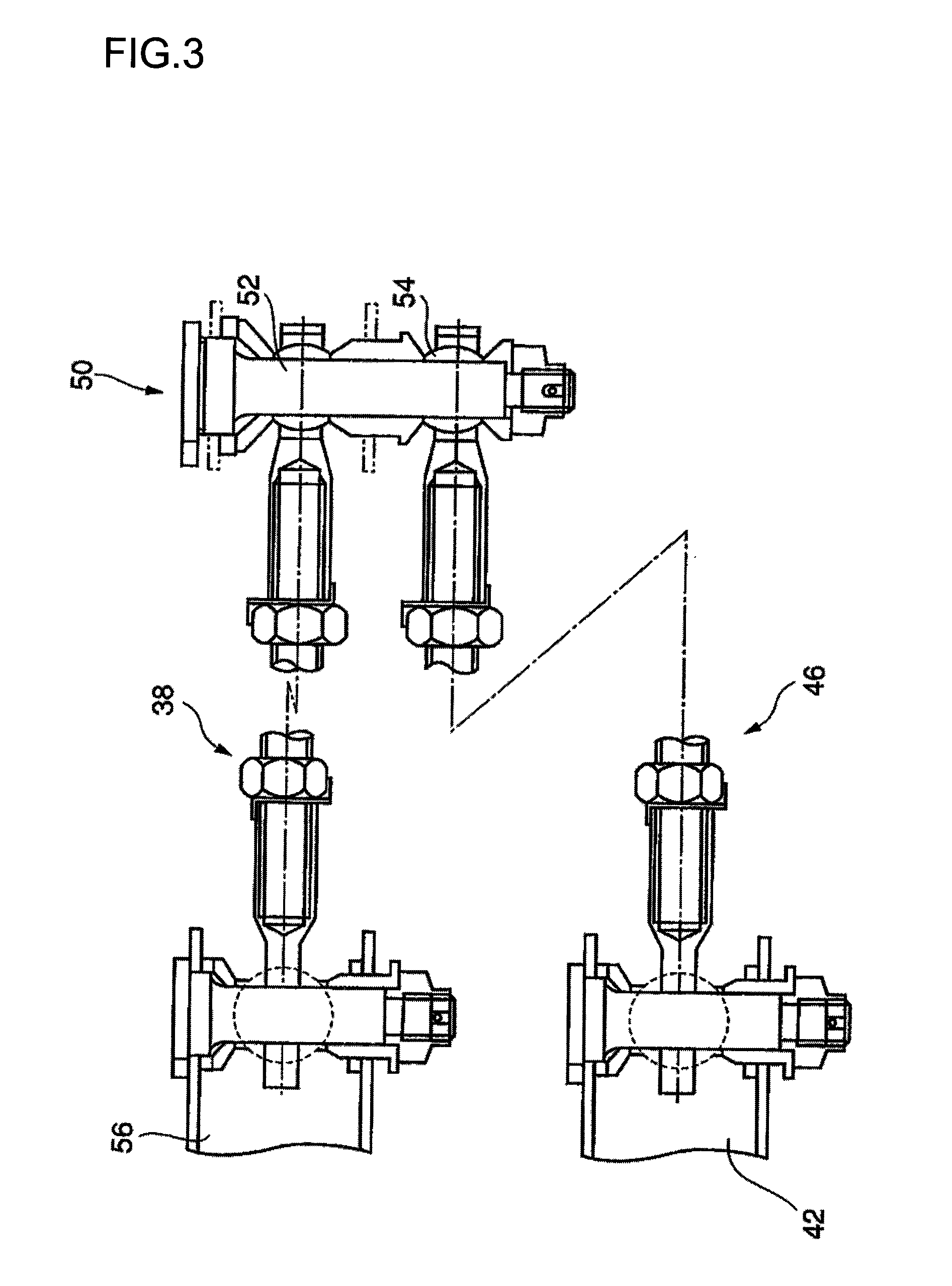

Structure of bifurvation and crossover site of guideway in guided vehicle transportation system

Structure of a bifurcation site and crossover site of a guideway in a guided vehicle transportation system; in which the guideway consists of left and right roadbeds, a depression between the roadbeds, and a guard rail having a U-shaped groove laid down on the depression; and a fail-safe mechanism is constituted by the guard rail and guard wheels attached to the vehicle; is proposed. The vehicle is equipped with automatic steering mechanisms for steering front and rear wheels and guard wheels supported laterally rotatably by front and rear supporting arms which are supported laterally rotatably underside the vehicle. The guard wheels are received in the groove of the guard rail. A movable guard plate and driving means thereof are provided to switch connection of the groove of the guard rail at a bifurcation thereof, and a movable plate and driving means thereof are provided to be able to plug or cover each of openings of grooves of guard rails in a region where the guard rail crosses a roadbed so that the movable plate is moved to plug or cover the groove thereby preparing a flat surface level with the roadbed.

Owner:MITSUBISHI HEAVY IND ENG LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com