Railway track cleaning and maintaining device

A technology of railway track and maintenance device, applied in track cleaning, track maintenance, track and other directions, can solve the problems of inability to convert, waste a lot of time, and tedious operation, and achieve the effect of saving wasted time, avoiding motion interference, and quickly switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

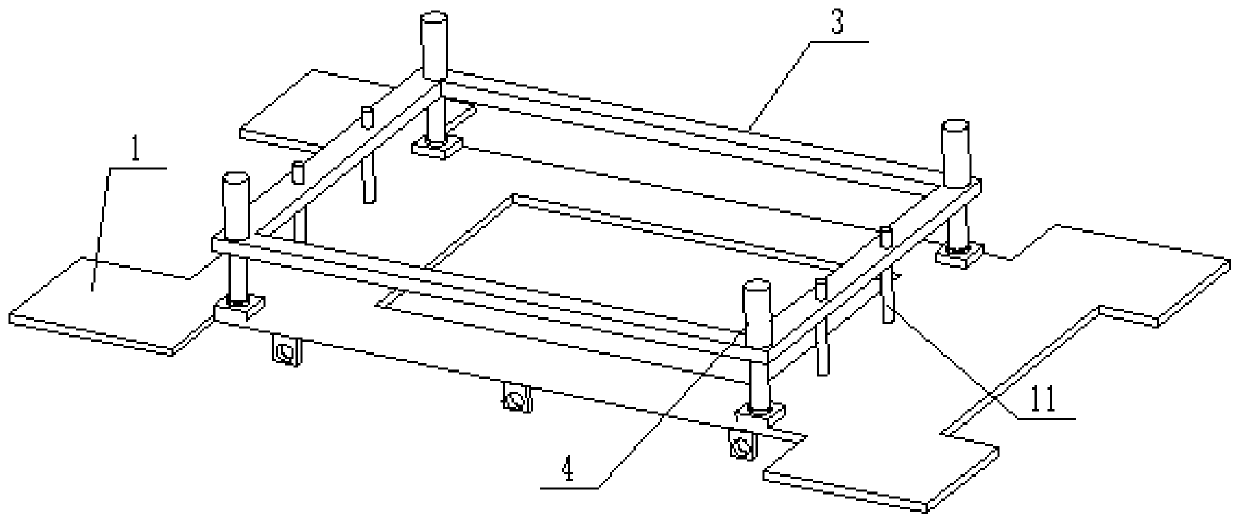

[0054] In other embodiments, the linear telescoping unit can also adopt structures such as electric push rods and cylinders, which can be selected by those skilled in the art, provided that the usage requirements can be met.

[0055] Of course, those skilled in the art can also use other technical means than the linear telescopic unit to adjust and fix the distance between the first frame 1 and the second frame 2 in the vertical direction, so I won’t go into details here. .

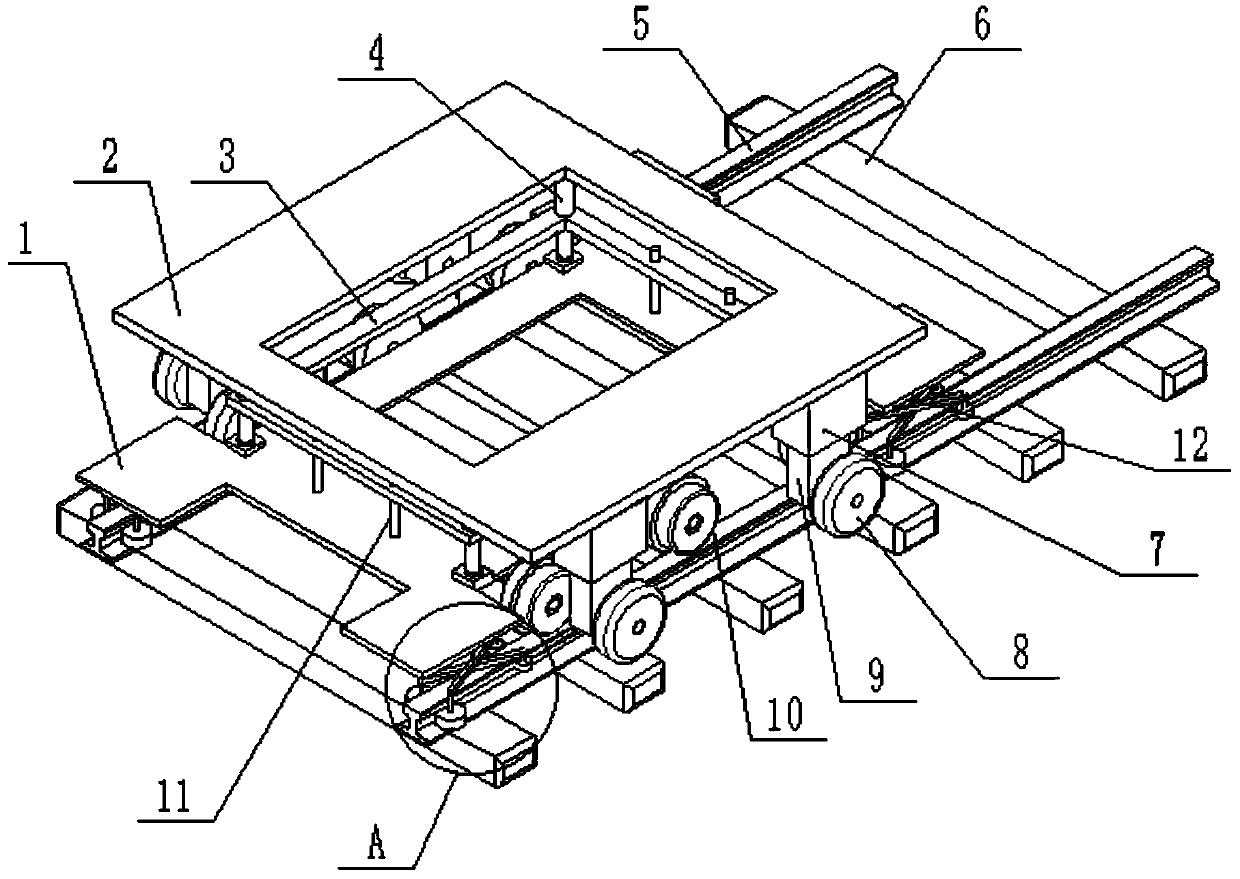

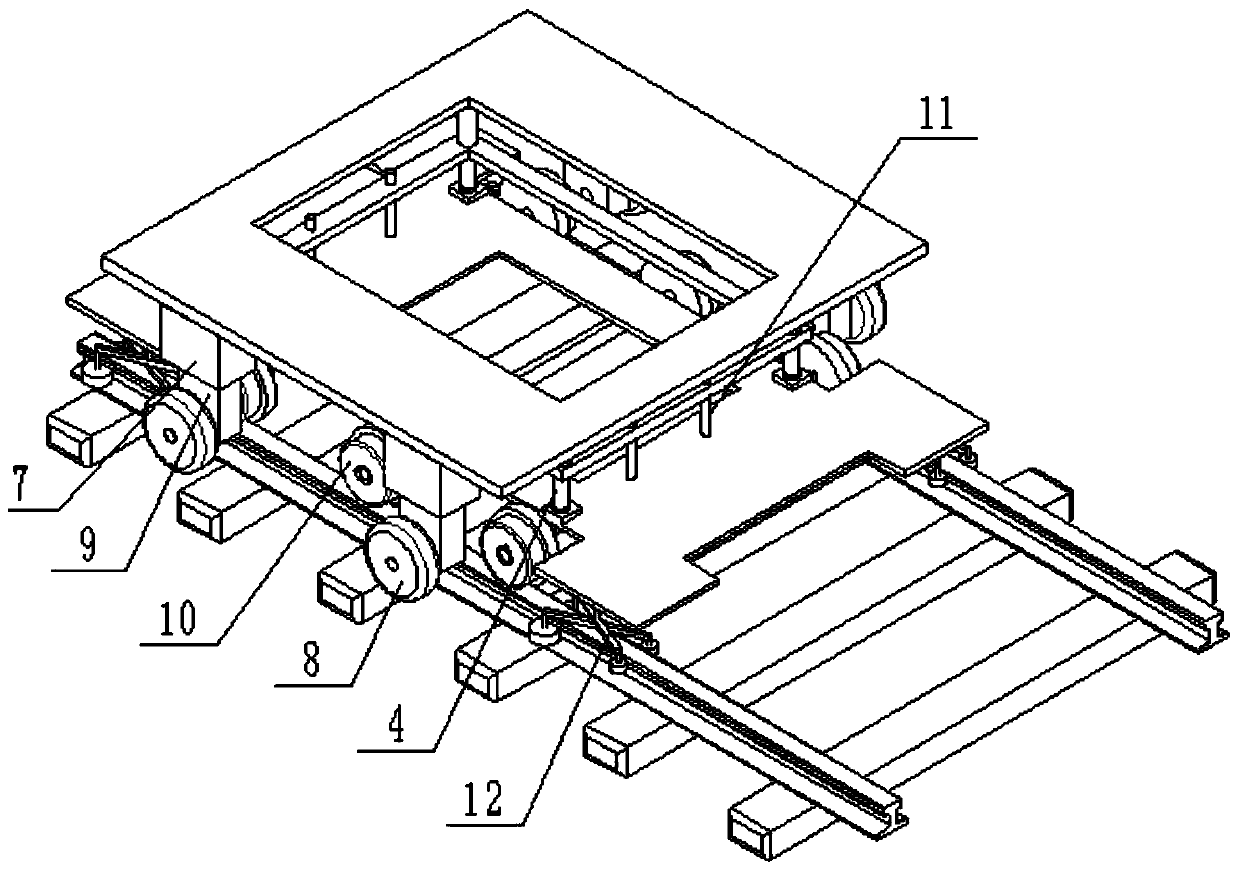

[0056] In order to realize the walking function of the vehicle frame on the railway track and the ground, the present embodiment sets track wheels 10 and road wheels 8, and the number of the track wheels 10 and the road wheels 8 is multiple, and the walking direction of the road wheels 8 It can be adjusted to realize steering when the vehicle frame walks along the ground, and the rail wheel 10 and the road wheel 8 are driven by a power mechanism to realize rotation.

[0057] Specifically, the structural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com