Patents

Literature

309results about How to "Avoid motion interference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gear pump for micro-miniature turbojet engine

ActiveCN101403382BReduce weightReduce leakageRotary piston pumpsRotary piston liquid enginesMicrocontrollerJet engine

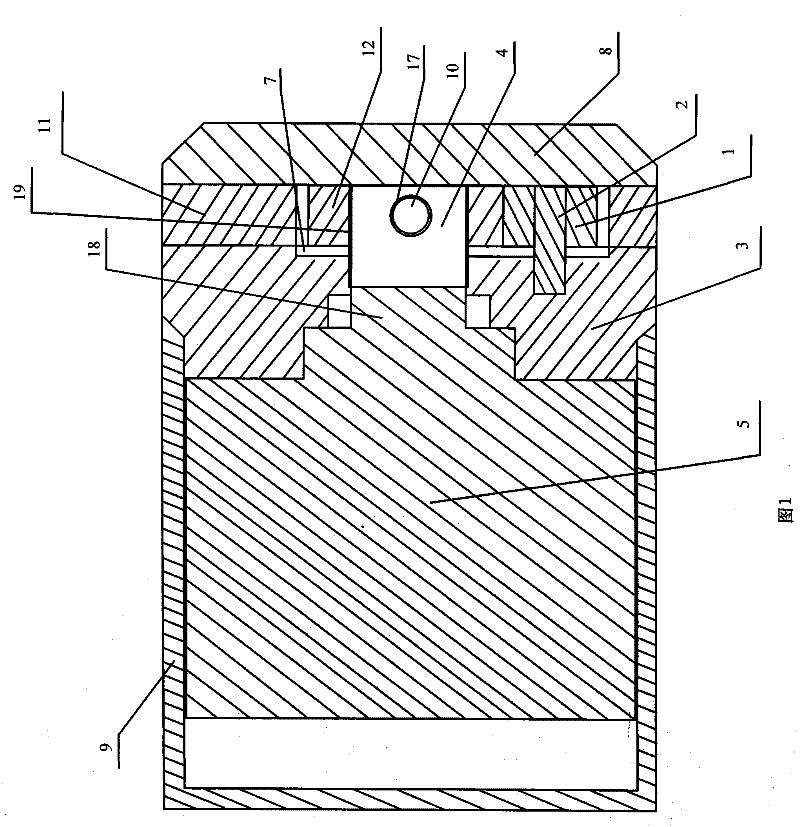

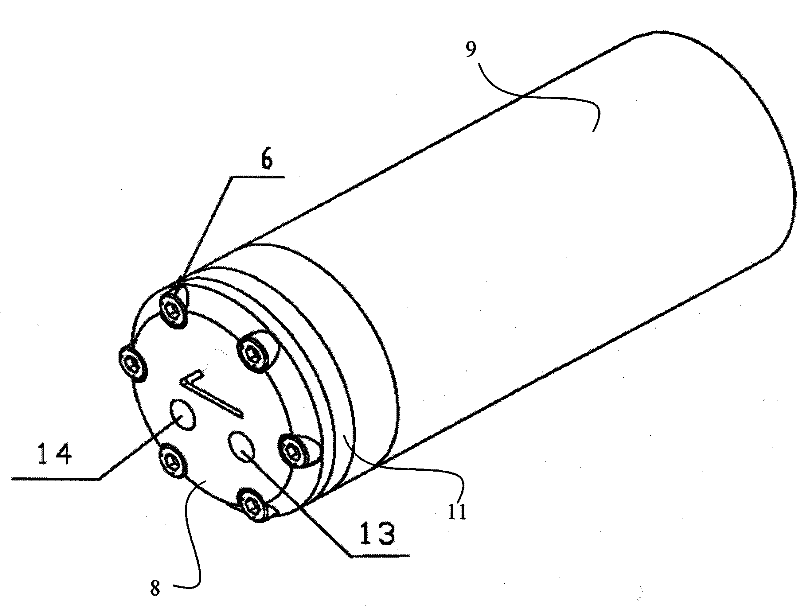

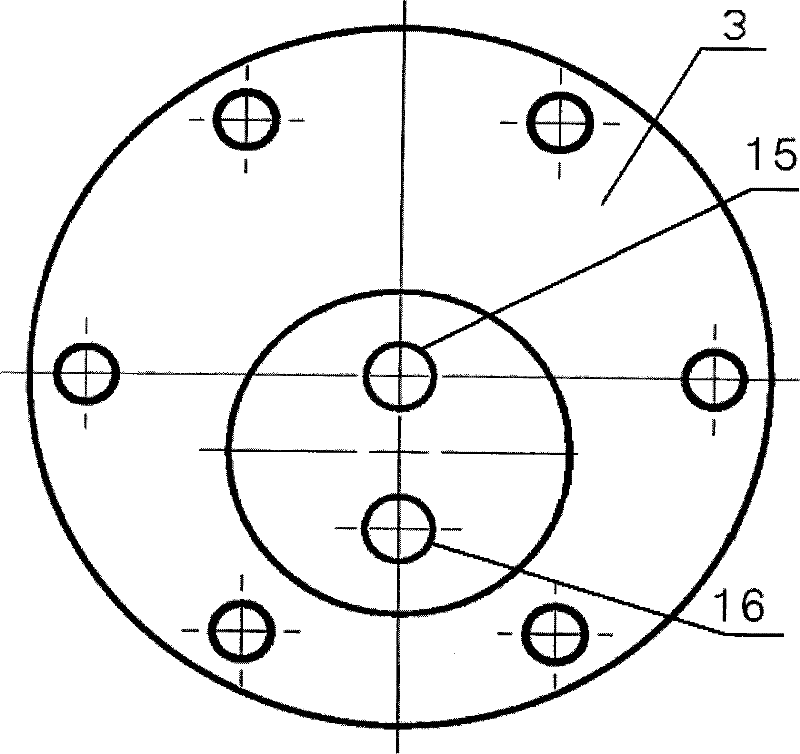

The invention discloses a gear pump used for a microminiature turbo-jet engine, comprising a direct current motor, a pump body, an upper pump cover, a lower pump cover, a shell, a pair of driving and driven gears which are meshed and a driving shaft and a driven shaft. The driving gear is arranged on the driving shaft; the driven gear is arranged on the driven shaft and is aligned and meshed withthe driving gear; the lower pump cover is fixed on the direct current motor, the upper pump cover is connected to the lower pump cover and the plane of the pump body is pressed tightly and sealed so as to lead the structure to be simple; the shell is sleeved at the outside of the lower pump cover; the driving gear and the driving shaft adopt a method of combining clearance fit and a transmission pin to eliminate the installation error of an output shaft of the direct current motor; and an antifriction material is embedded at the positions on the lower pump cover and the upper pump cover corresponding to the driving gear and the driven gear so as to increase the reliability and durability of the gear pump. Most parts of the gear pump adopt aluminium alloy so as to reduce the weight furthest. The gear pump can control the rotating speed of the direct current motor by pulse-width modulation of a single-chip microcontroller and control the flow rate of the gear pump precisely.

Owner:北京领动国创科技有限公司

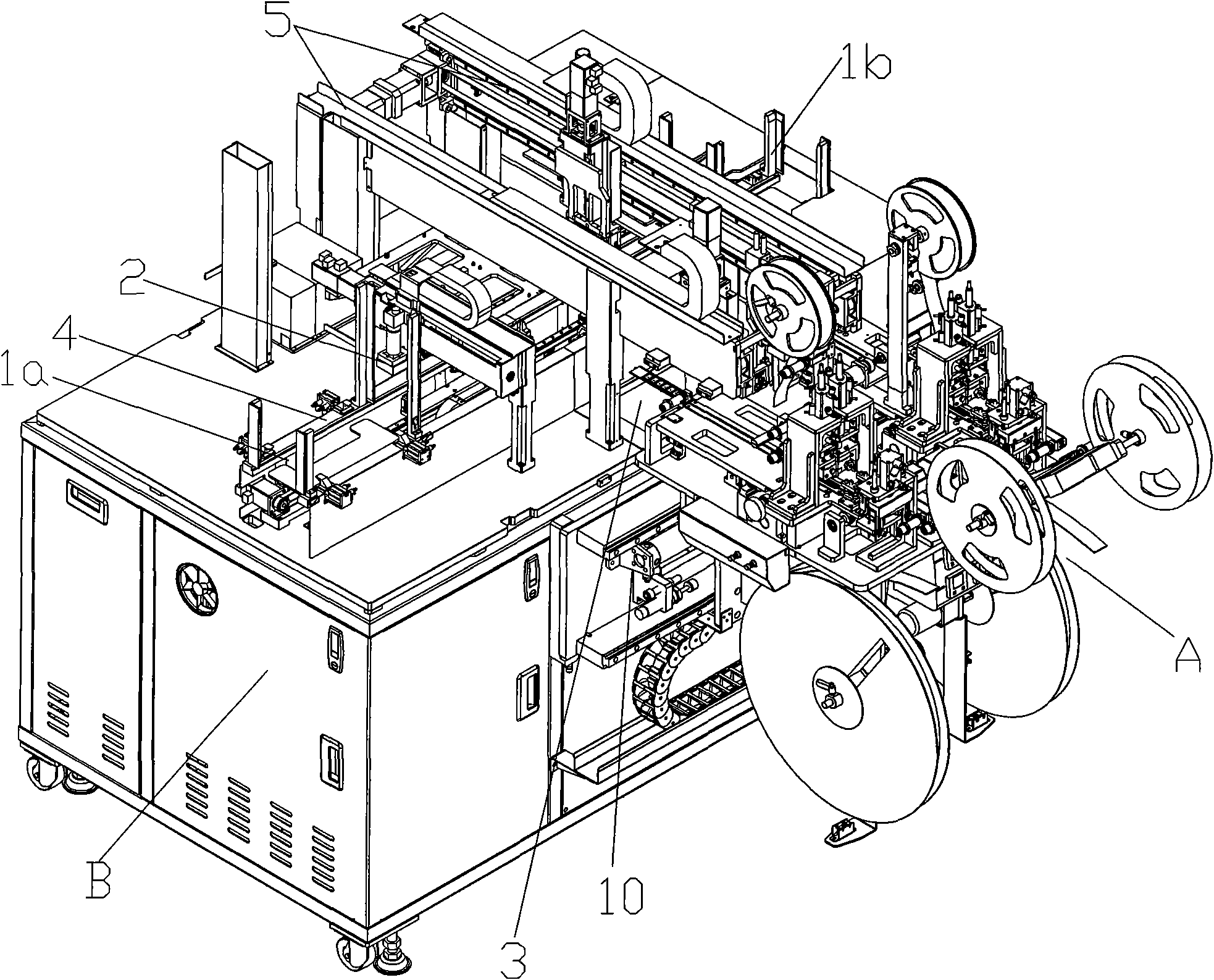

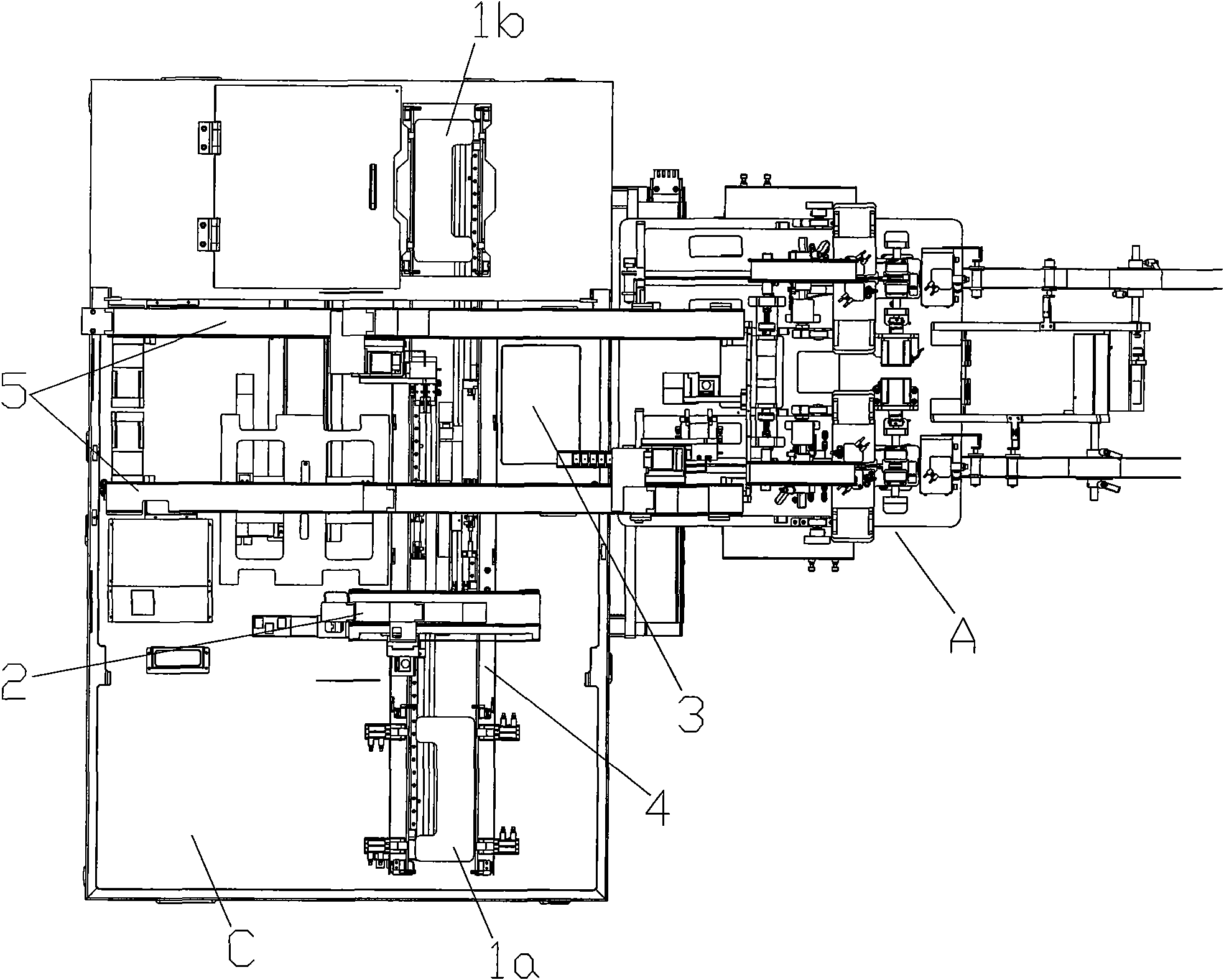

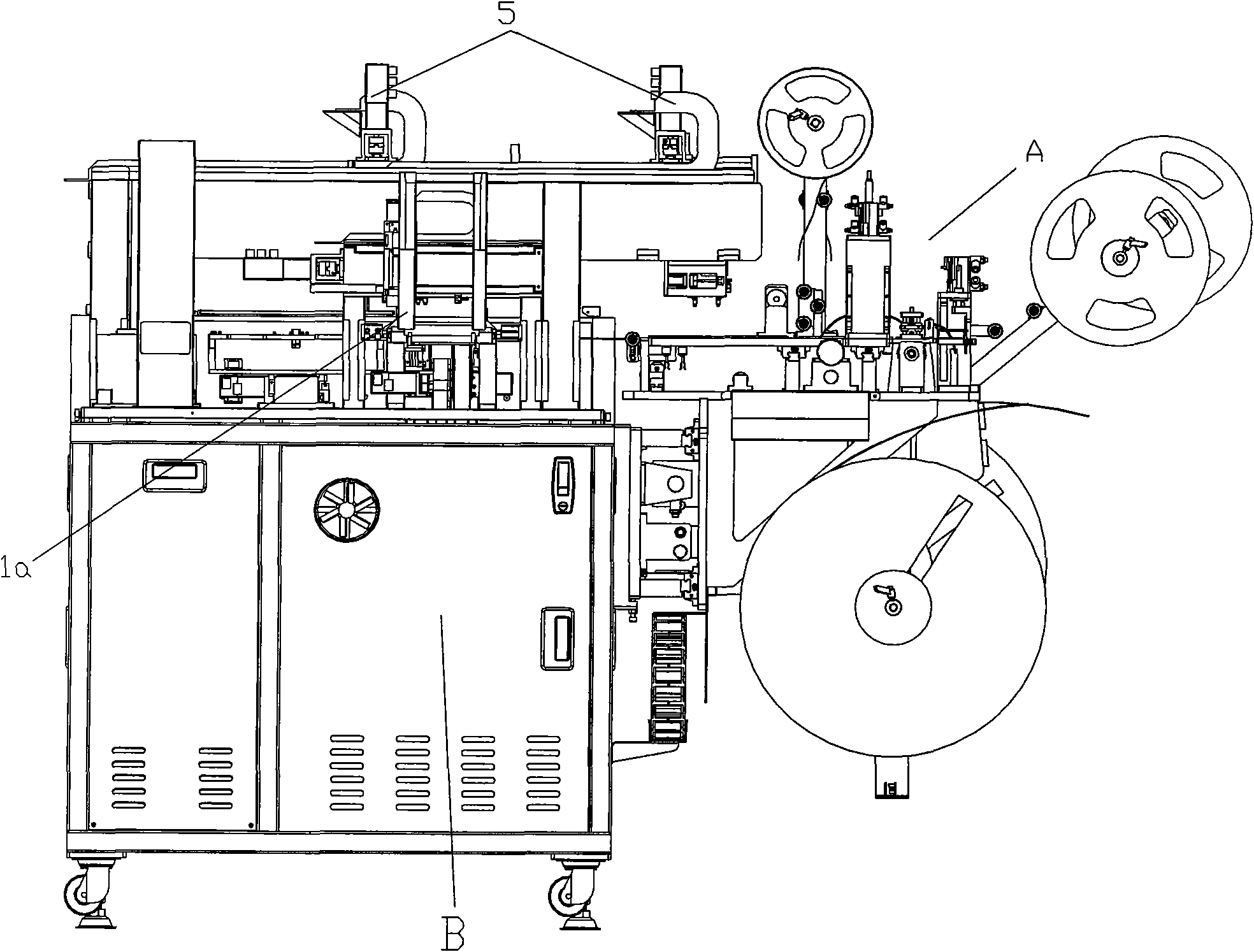

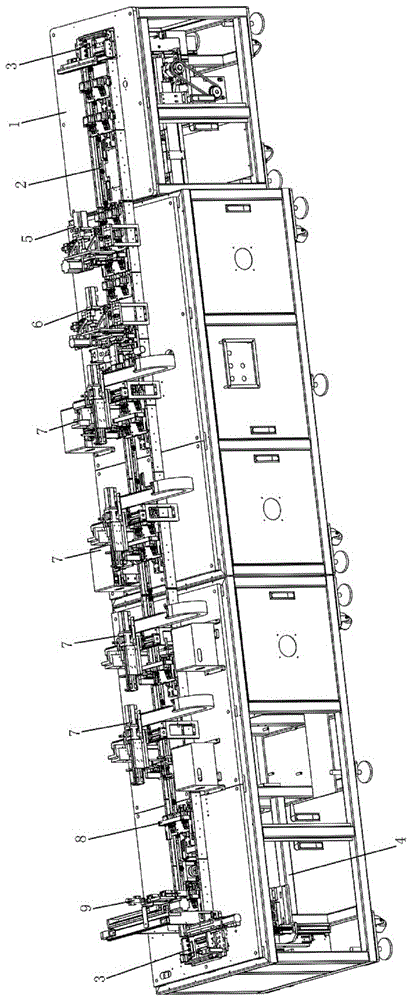

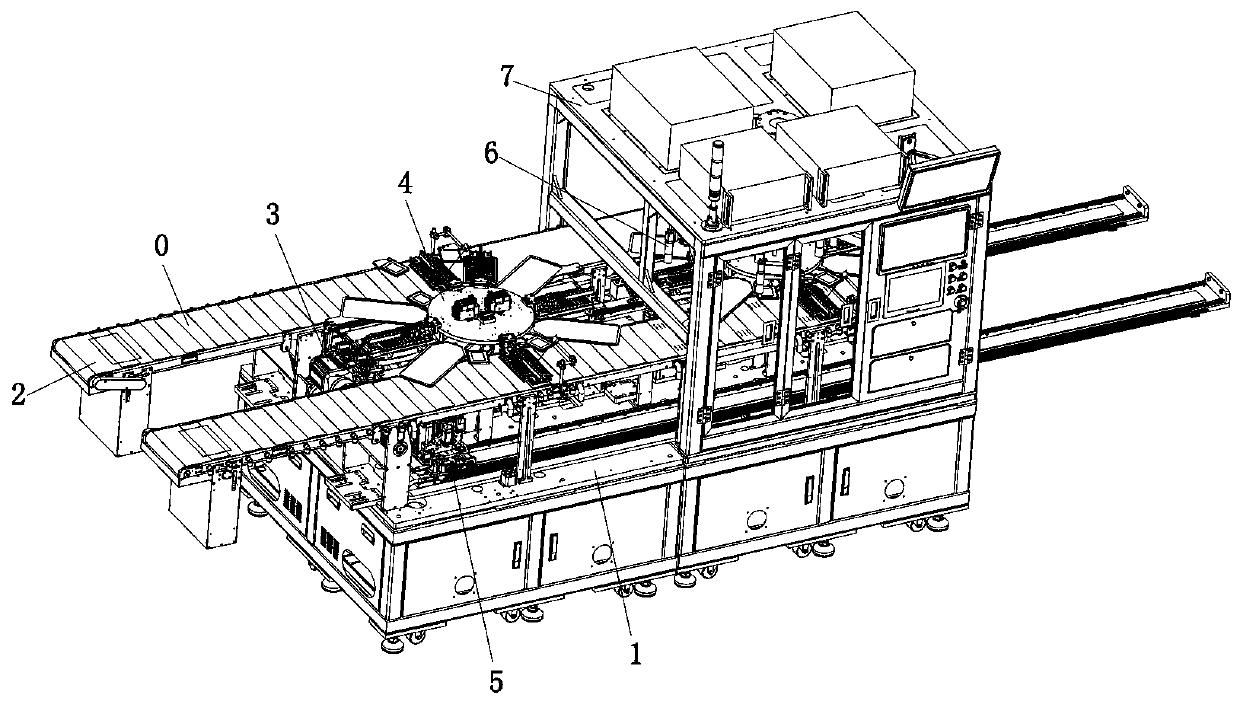

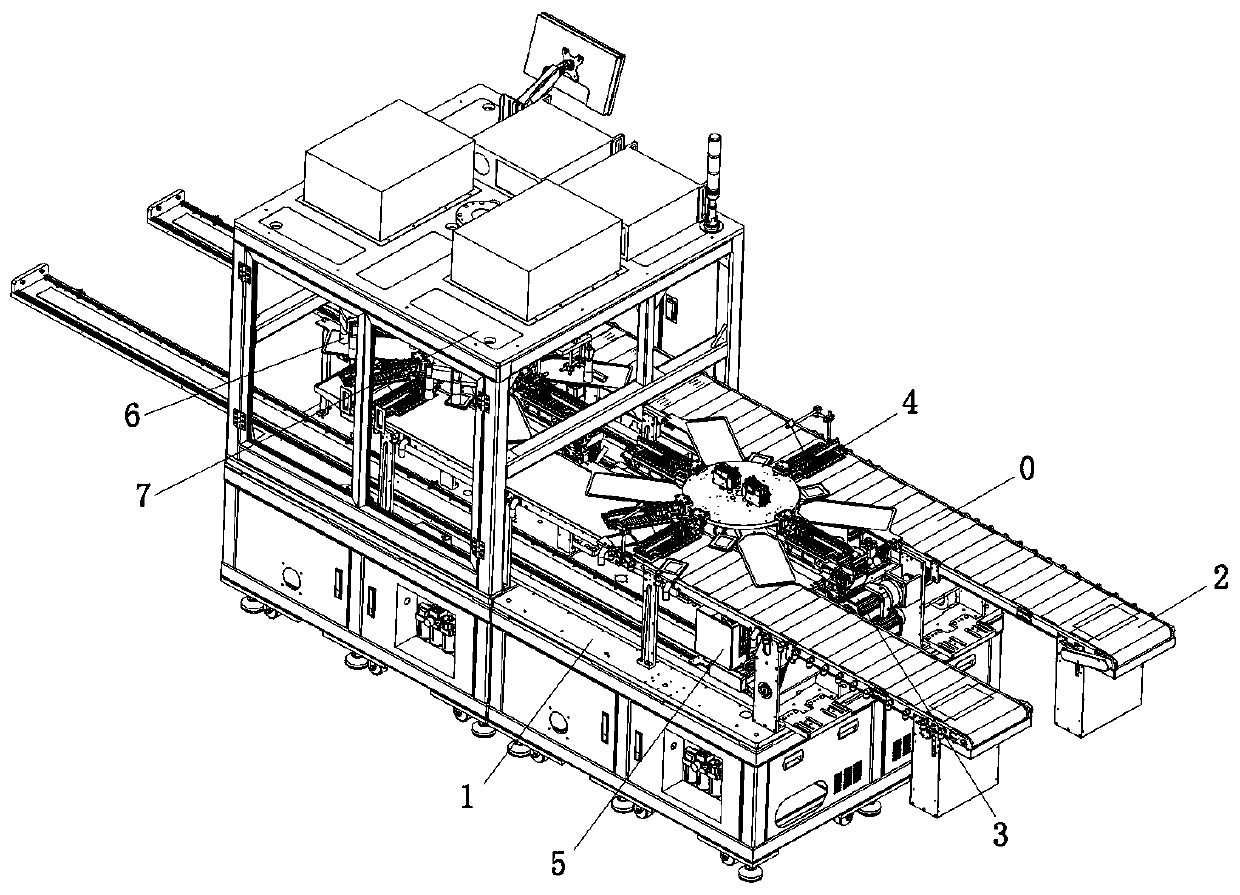

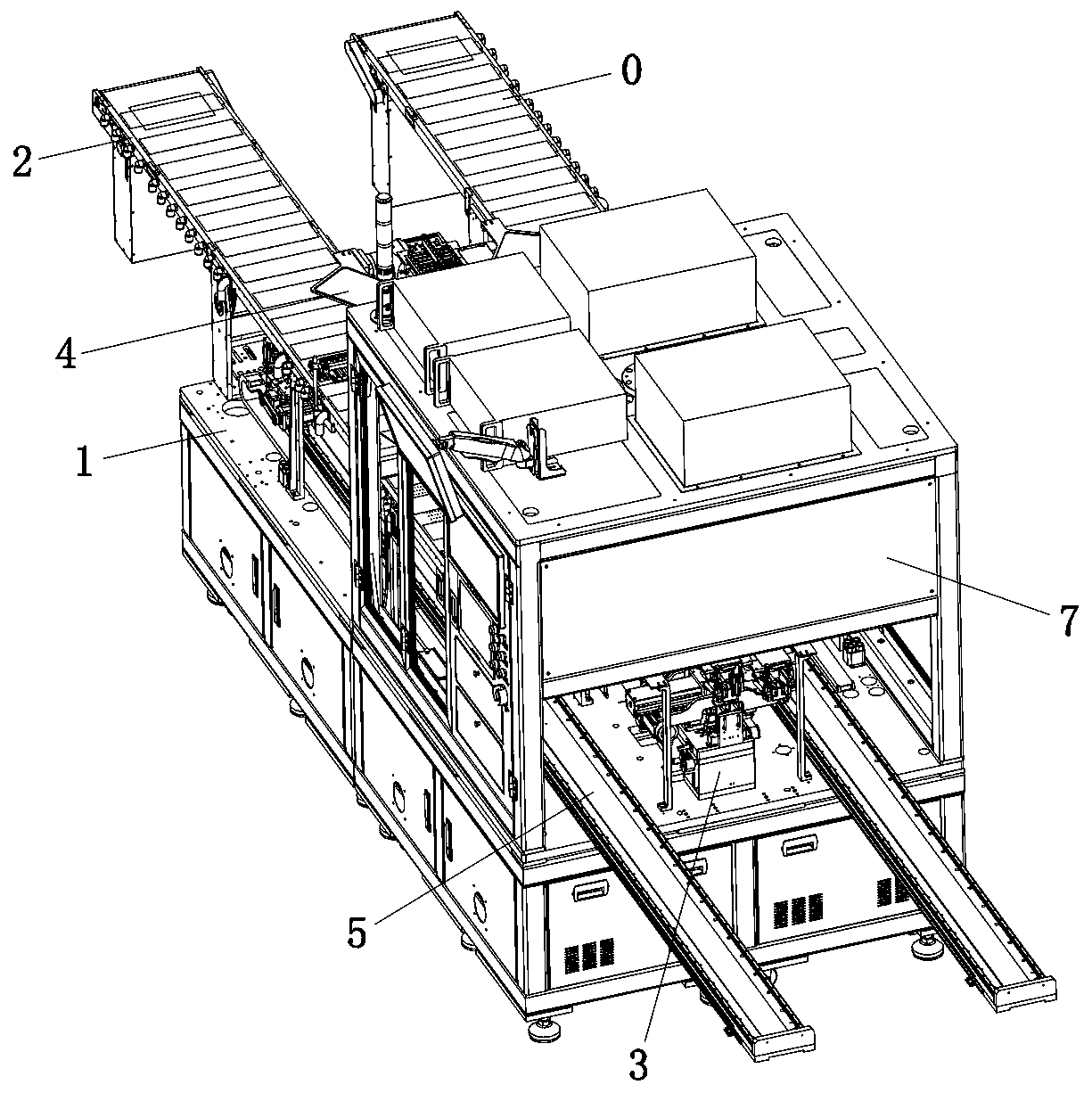

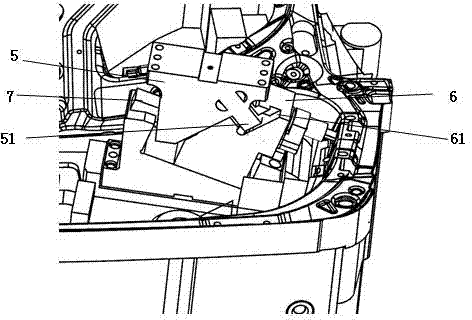

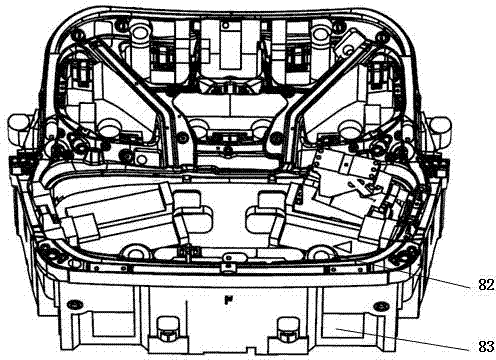

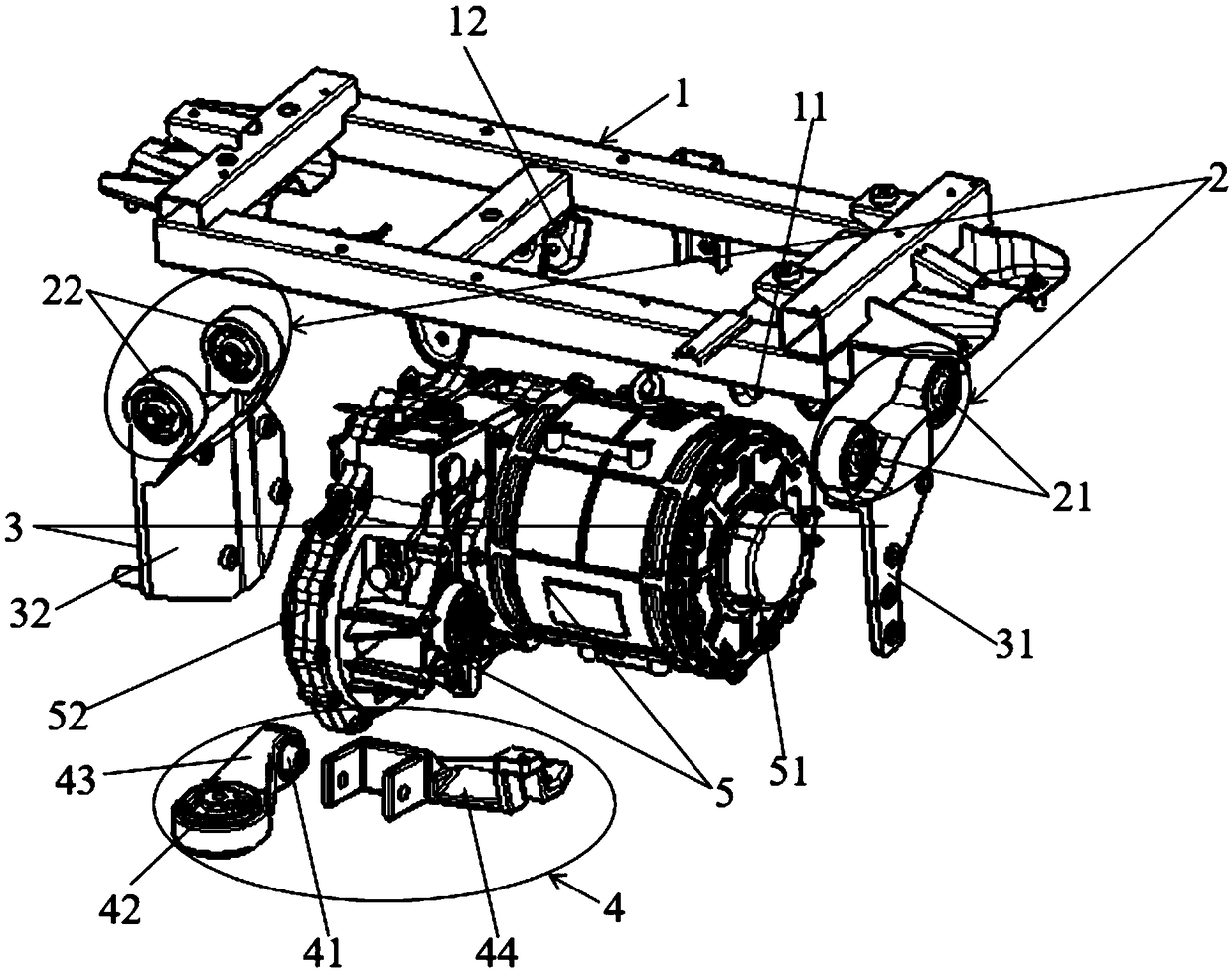

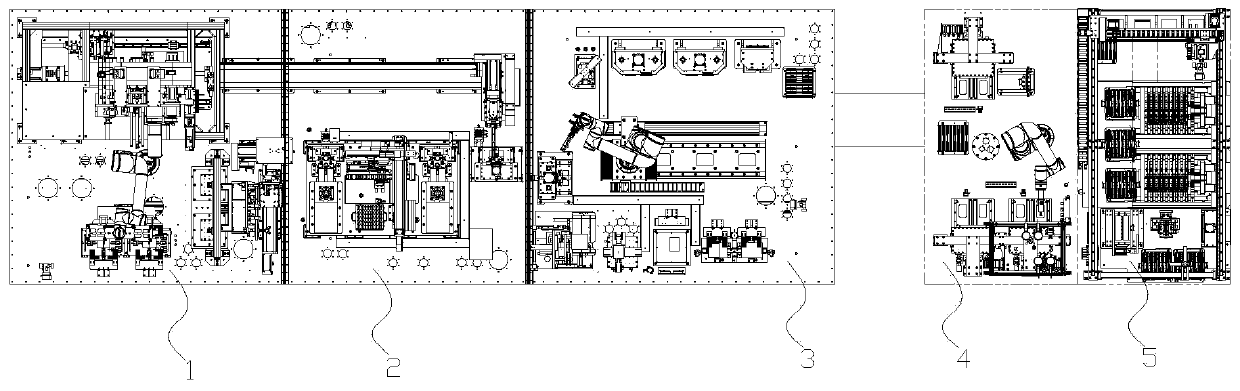

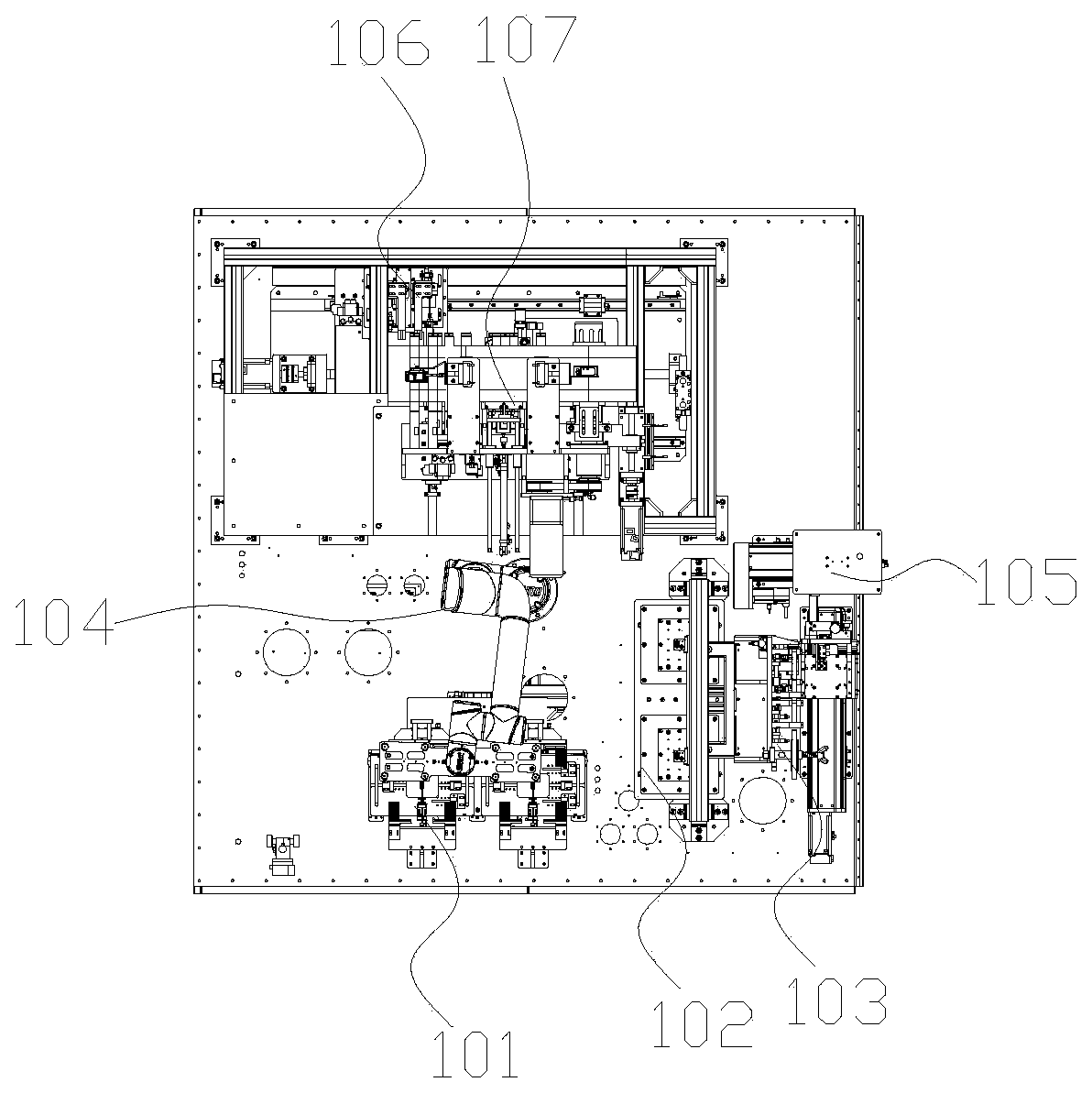

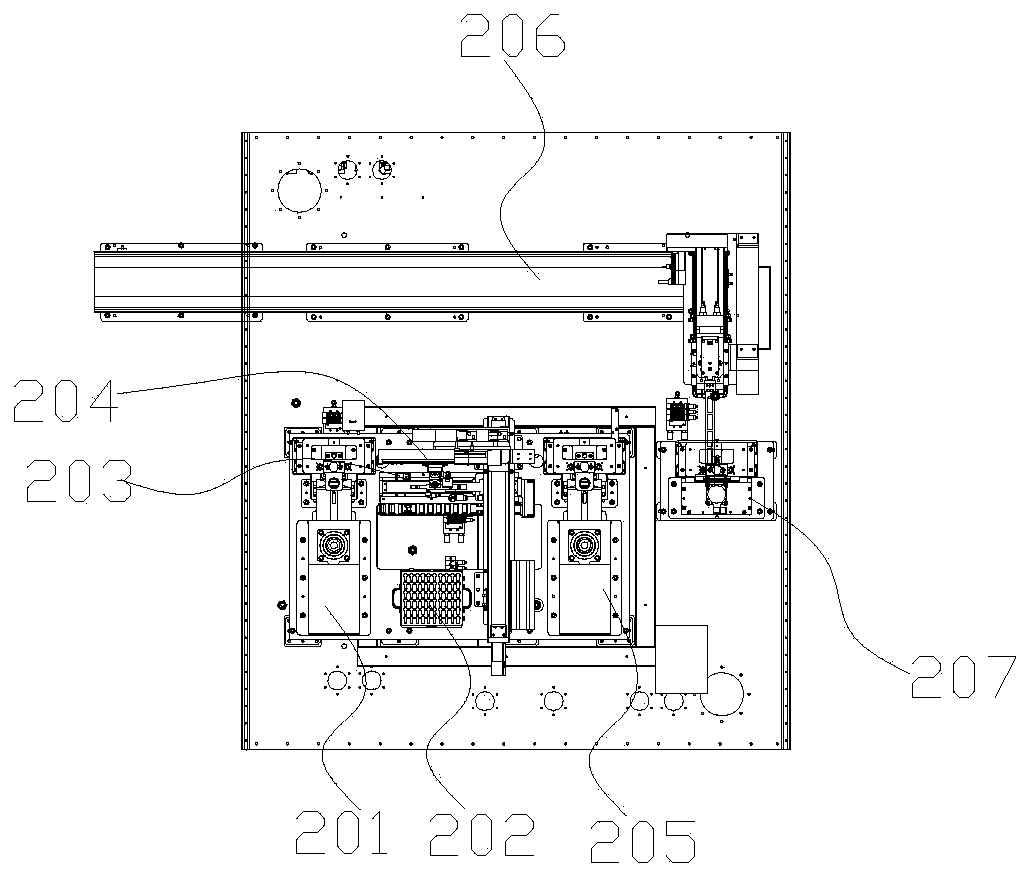

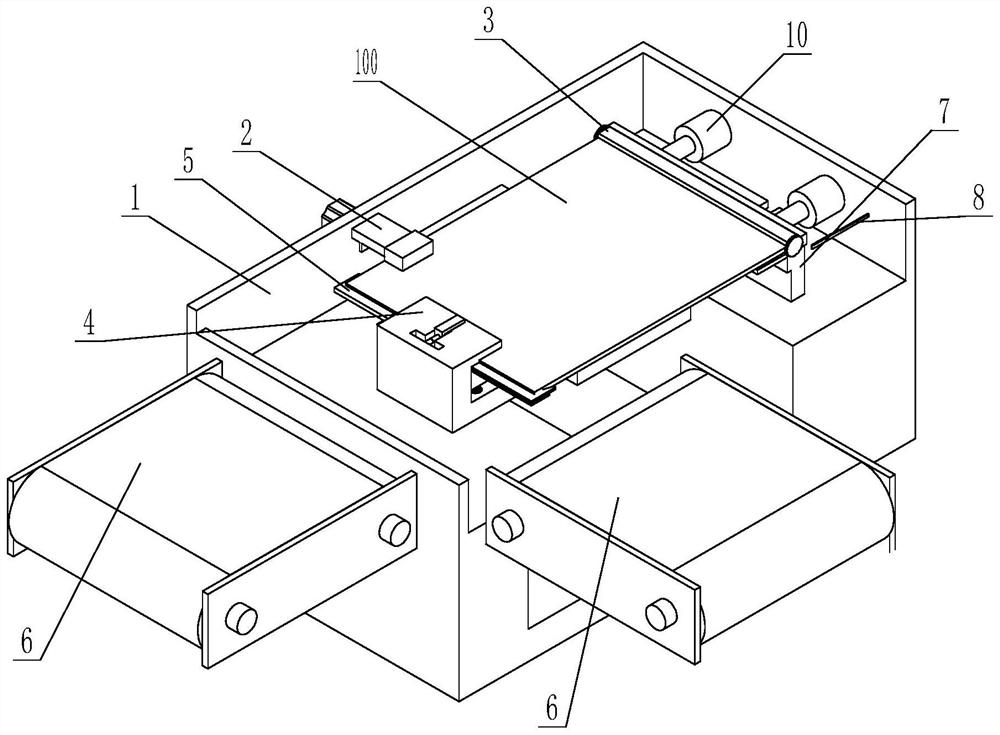

Disk-feeding braider and classified gripping method thereof

InactiveCN101920795AAvoid motion interferenceImprove pick and place efficiencyWrapping material feeding apparatusWrapper twisting/gatheringMechanical engineeringIntegrated circuit

The invention discloses a disk-feeding braider and a classified gripping method thereof. The braider comprises a tray conveying device, a tray separating device, a top surface scanning surface, a three-dimensionally scanning device, a double-gripper classified gripping device, an unaccepted product collecting device, a hollow tray stacking device and a braid packaging device, wherein the tray conveying device is used for conveying a tray; the tray separating device is used for separating the tray onto the tray conveying device; the top surface scanning surface is used for scanning the top surface of an integrated circuit block in the conveyed tray; the three-dimensionally scanning device is used for three-dimensionally scanning the bottom surface and the side face of the integrated circuit board; the double-gripper classified gripping device is used for gripping the top surface-scanned and / or three-dimensionally scanned integrated circuit board in a classified way and comprises a first classified gripping device and a second classified gripping device; the unaccepted product collecting device is used for receiving the integrated circuit board of which the scanning result is unqualified; the hollow tray stacking device is used for stacking a conveyed hollow tray on which classified gripping is finished; and the braid packaging device is used for packaging and winding the integrated circuit board of which the top surface scanning and three-dimensionally scanning results are qualified. The disk-feeding braider and the corresponding classified gripping method have the characteristic of high work efficiency.

Owner:GRAND TECH SHENZHEN

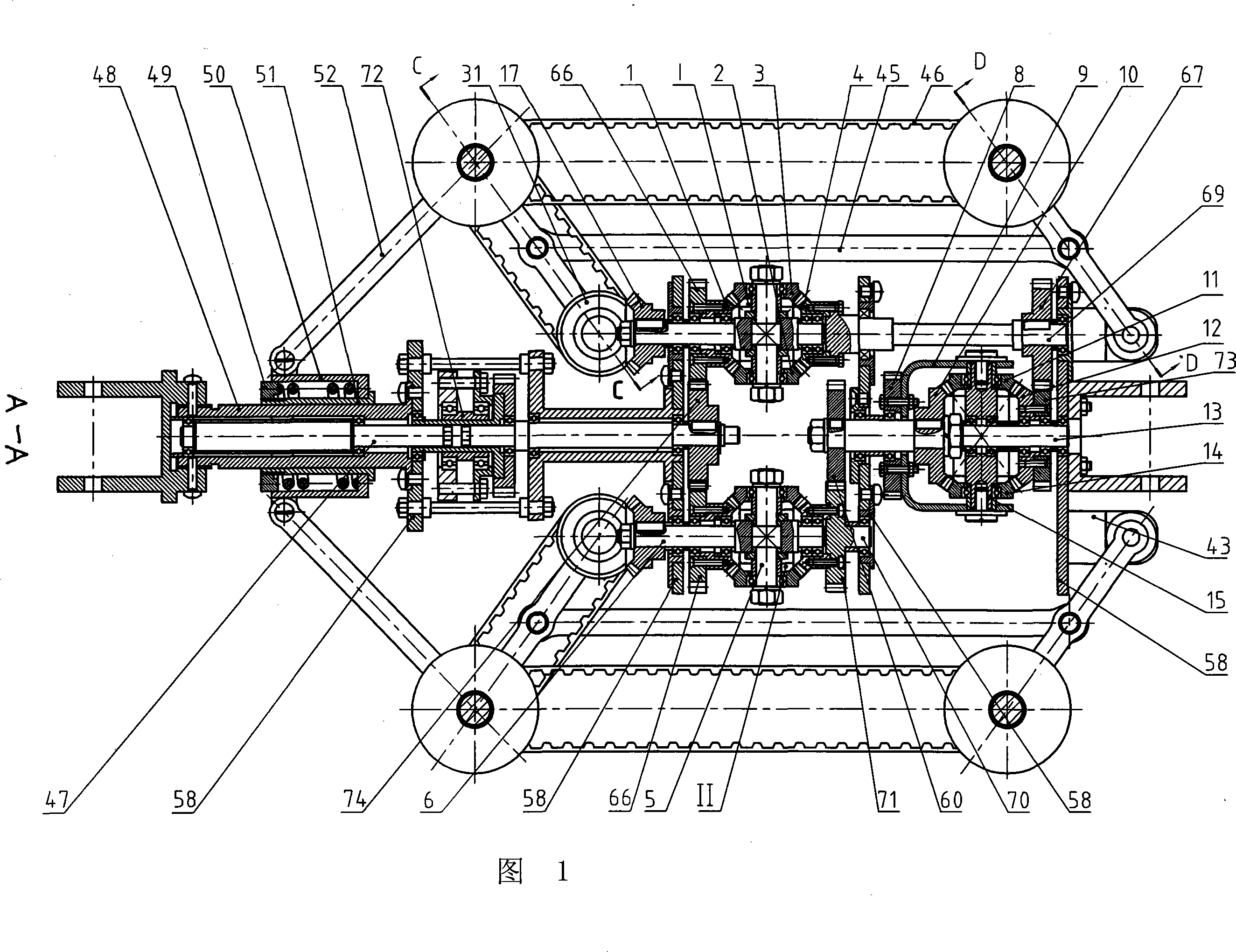

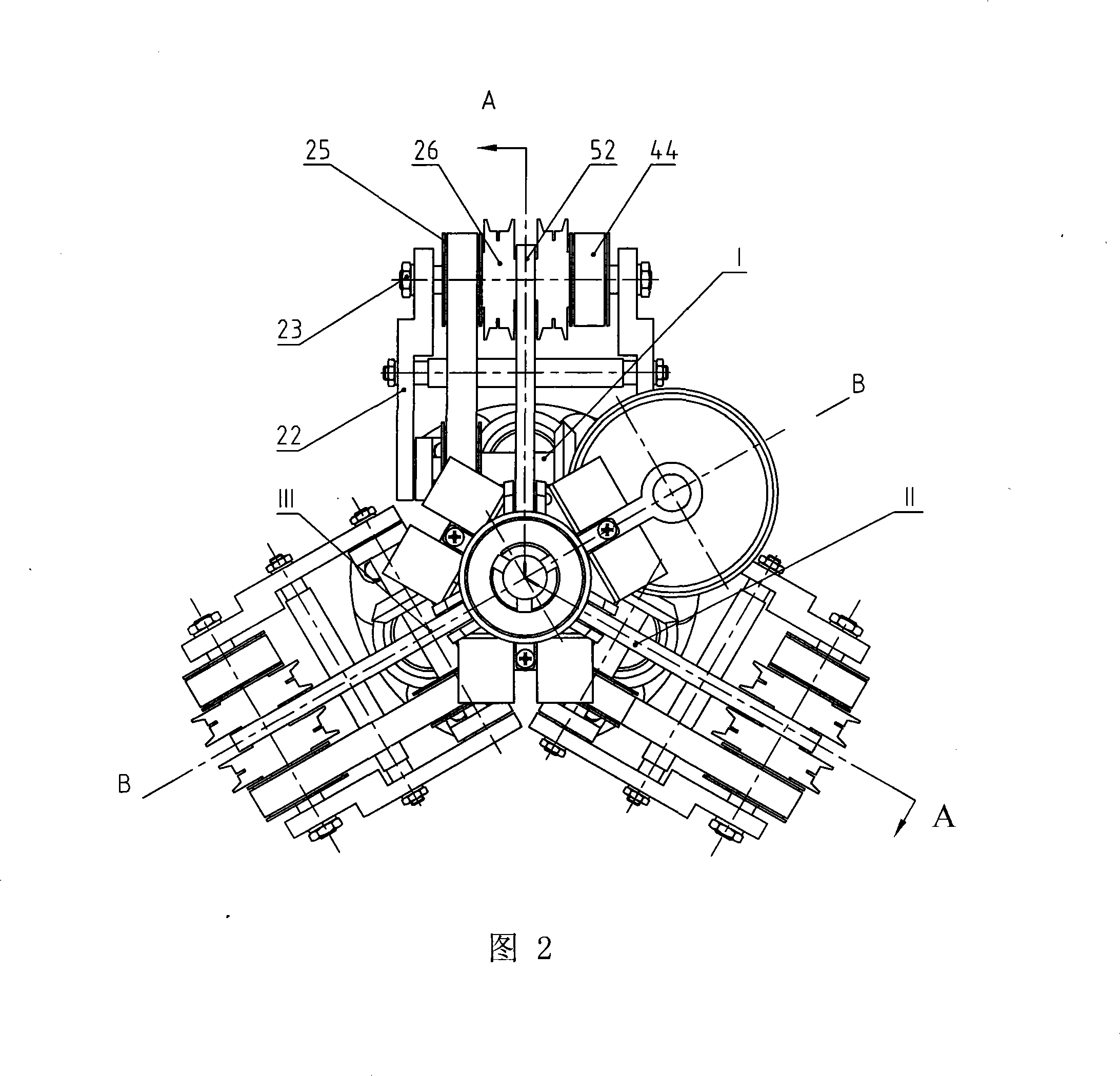

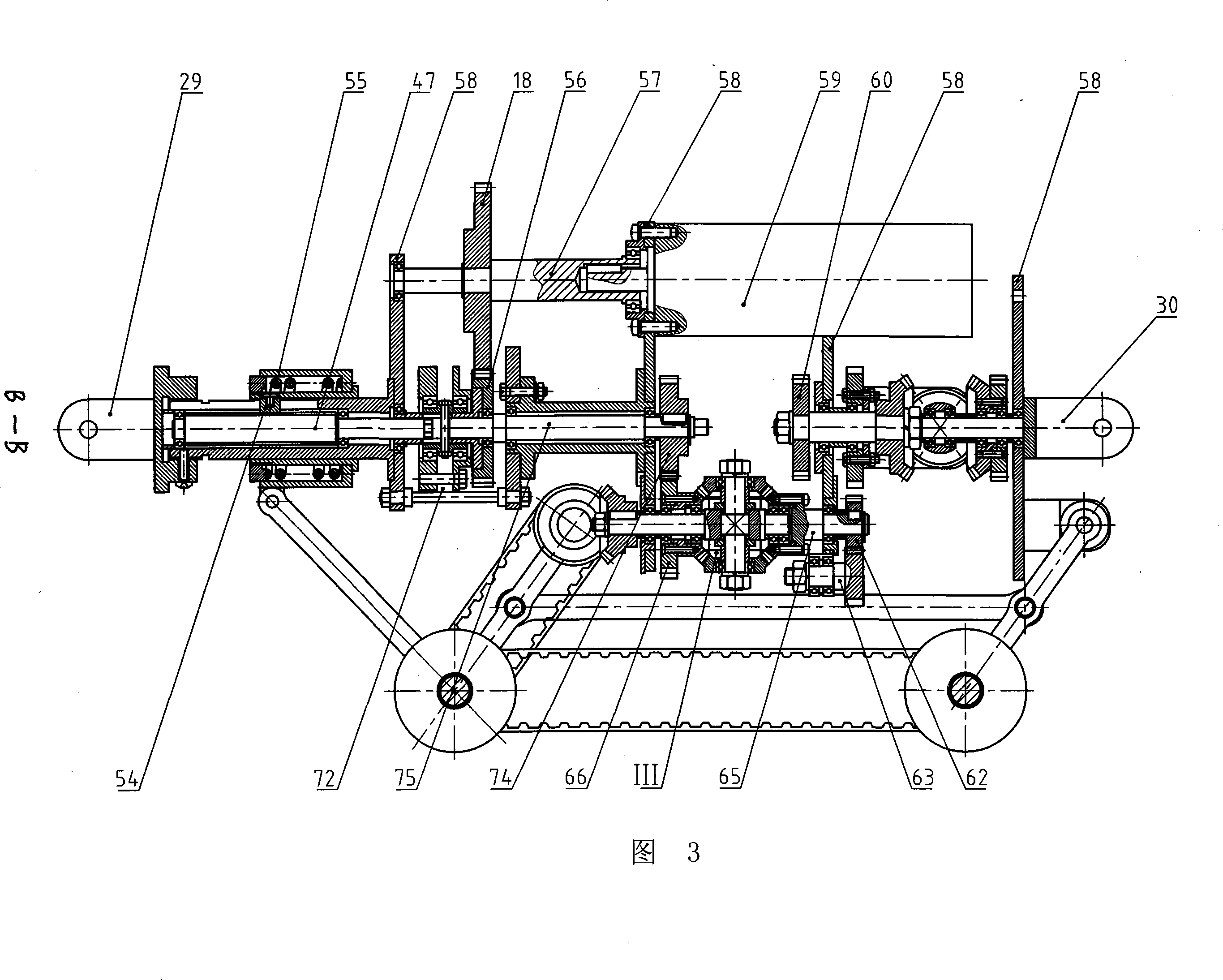

Triaxial differential type pipe creeping device

The invention relates to a three- shaft differential type pipe creeper, which is characterized in that the invention comprises three differential gears with same structure I, II, III, a transfer gear, three creeping wheel servomechanisms with same structure, a preloaded reducing mechanism, and a driving mechanism, the invention can connect with various pipe operation devices which are matched with the invention to proceed creeping operation along to the inner walls of the pipe, the creep speed of each creeping wheel is real-time regulated according to the self-attitude and pipe environment condition in order to realize self-regulation, and to avoid the phenomenon of motion interference which is generated at the moment that the current wheel type pipe creeper passes through the pipe or passes through the pipe whose inner physical dimension is changed, thereby increasing driving efficiency and traction ability, and reducing input power and the friction and abrasion of the a driving pair in the process of motion. The creeping wheel can realize the total main drive through a driving mechanism of a motor, and the invention has the advantages of simple structure, high driving efficiency, small power volume, low cost, long service life, spreading application range, etc.

Owner:HARBIN INST OF TECH +1

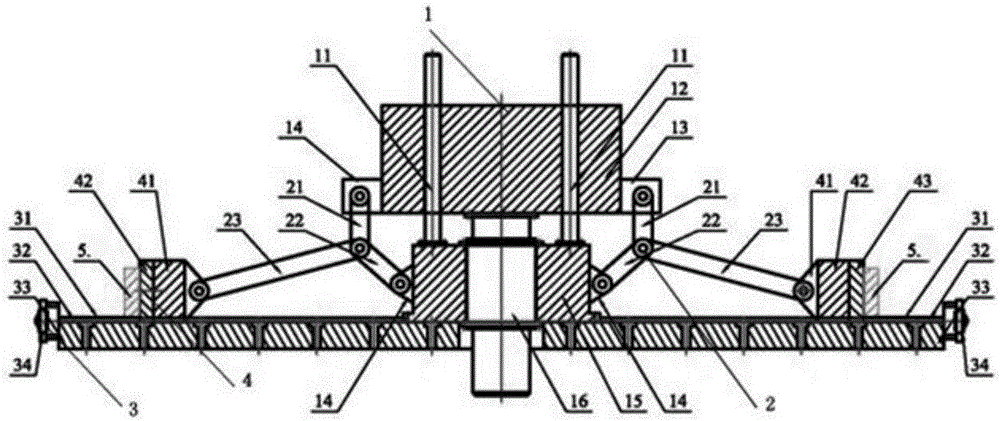

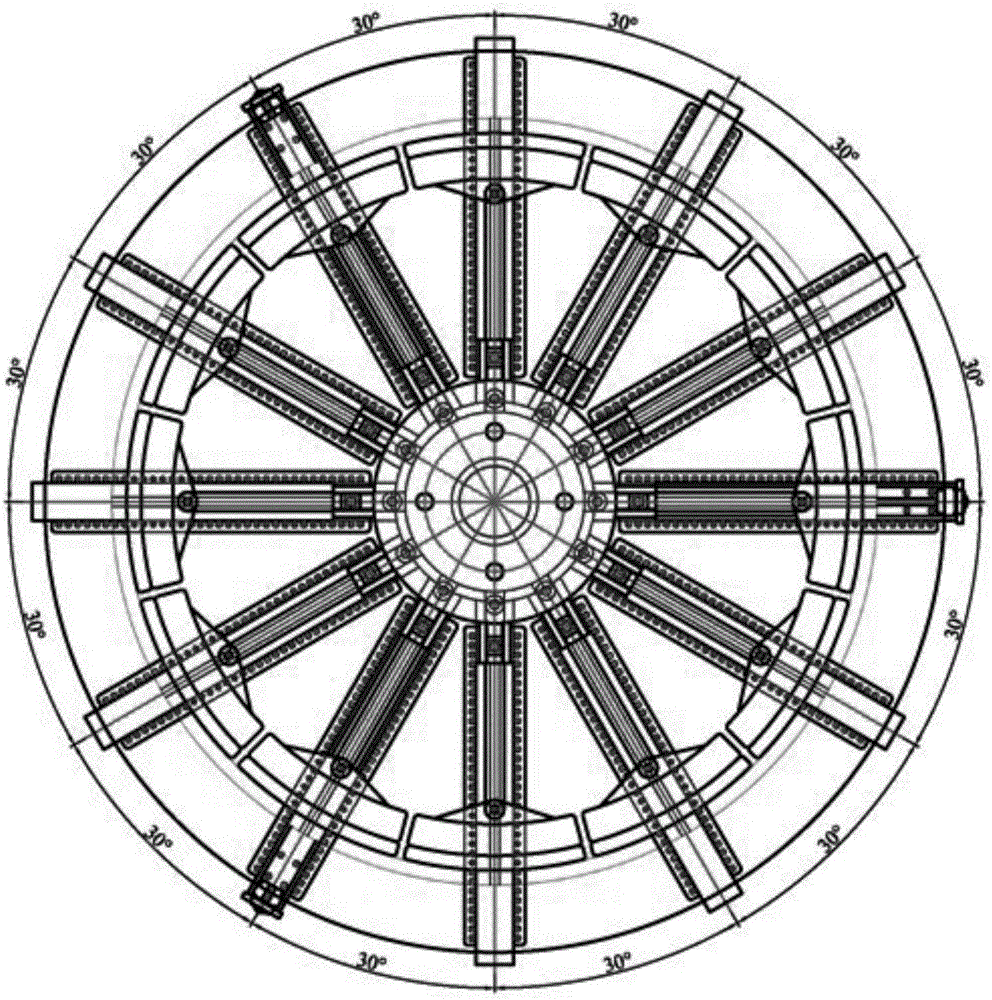

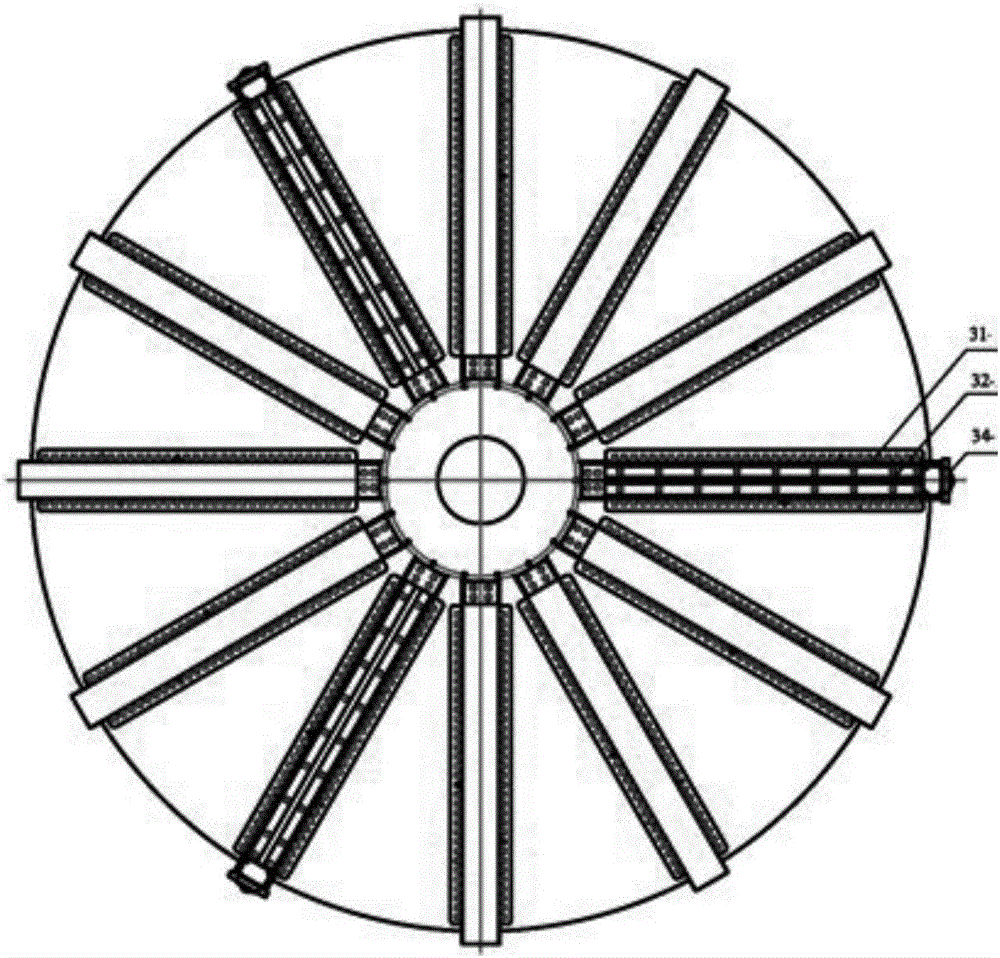

Mechanical expanding machine for large-diameter ring piece

ActiveCN106216538AEasy to useMeet the needs of expanding forceShaping toolsHydraulic cylinderEngineering

The invention discloses a mechanical expanding machine for a large-diameter ring piece. The mechanical expanding machine for the large-diameter ring piece comprises a piston cylinder, a supporting disk, a fixed workbench and a sliding block. The fixed workbench is arranged at the center of the upper surface of the supporting disk. The piston cylinder is installed in the fixed workbench and is connected with the lower end face of the fixed workbench through a piston rod. At least two hinged rod force amplifying devices are evenly arranged in the circumferential direction of the fixed workbench. Sectioned male dies corresponding to the hinged rod force amplifying devices are evenly distributed on the supporting disk in the circumferential direction of the fixed workbench. The bottom of each sectioned male die is provided with a guide groove, and each sectioned male die slides in a radial guide rail on the supporting disk under the action of the corresponding hinged rod force amplifying device. According to the mechanical expanding machine for the large-diameter ring piece, a hinged rod force amplifying mechanism is adopted, force exerted by the hydraulic cylinder on the sliding block is amplified, and therefore the mechanical expanding machine can obtain large output force. The mechanical expanding machine for the large-diameter ring piece is particularly suitable for expanding of the large-diameter ring piece with the diameter larger than 5 m. In addition, the hinged rod force amplifying mechanism is convenient to use and maintain, accessories of the hinged rod force amplifying mechanism are convenient to replace, and the production and manufacturing cost of the hinged rod force amplifying mechanism is low.

Owner:CENT SOUTH UNIV

Railway track cleaning and maintaining device

ActiveCN110886270AAvoid safety accidentsRealize distance adjustmentTrack superstructureRailway track constructionVehicle frameTrackway

The invention relates to a railway track cleaning and maintaining device, including a vehicle frame, wherein the vehicle frame comprises a first vehicle frame and a second vehicle frame which are connected with each other; the first vehicle frame is arranged under the second vehicle frame; track wheels are installed on the lower portion of the first vehicle frame; walking wheels are installed on the lower portion of the second vehicle frame; the track wheels can drive the vehicle frame to travel along a railway track, and the walking wheels can drive the vehicle frame to travel along the ground; and the distance value of the first vehicle frame and the second vehicle frame in the vertical direction can be adjusted, so that the distance between the lowest point of the track wheels and the lowest point of the walking wheels in the vertical direction is changed by the same value.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

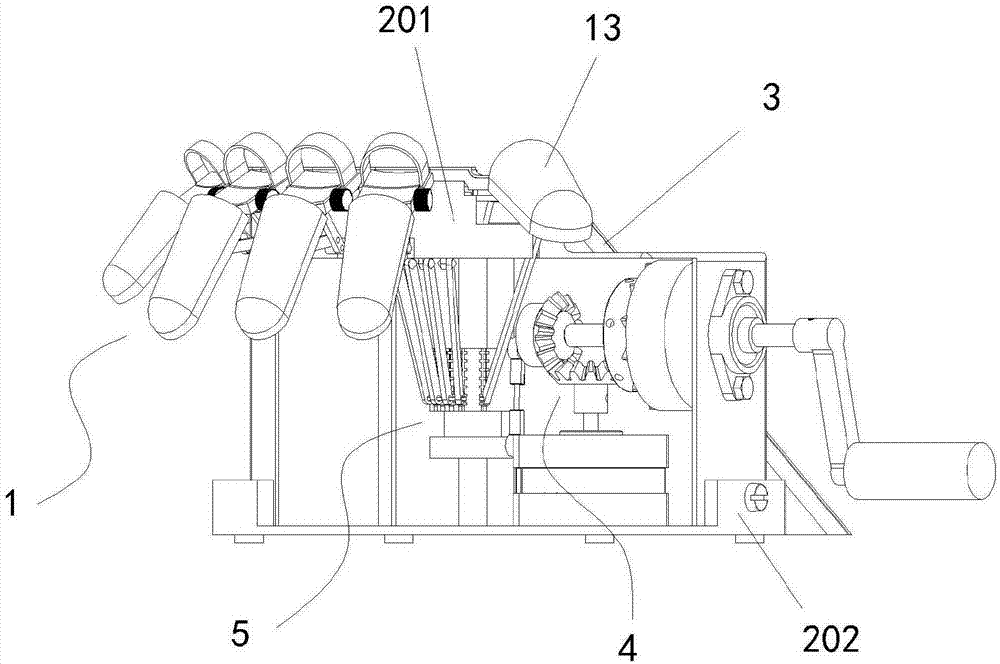

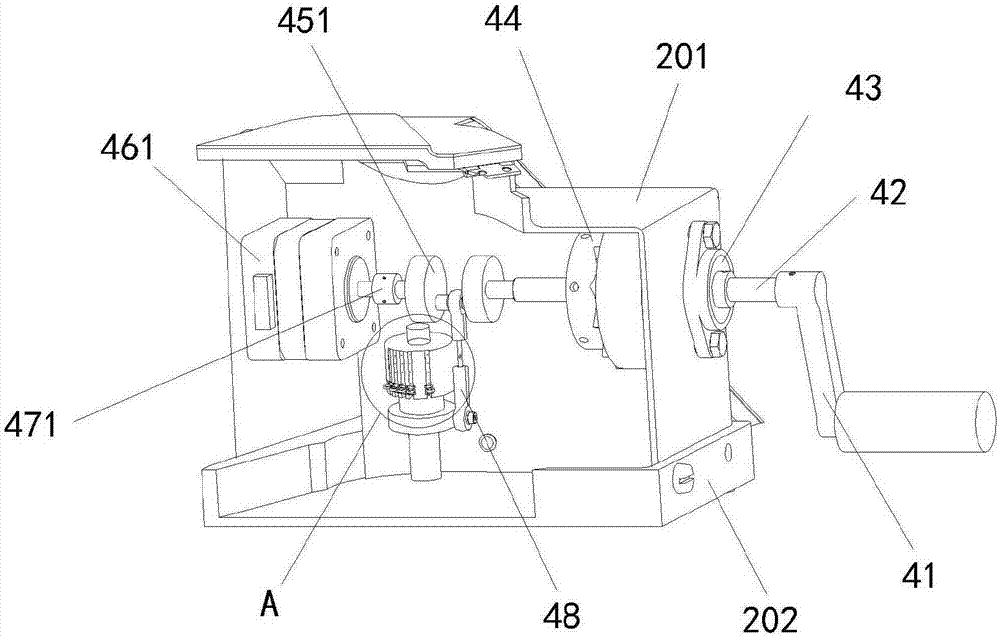

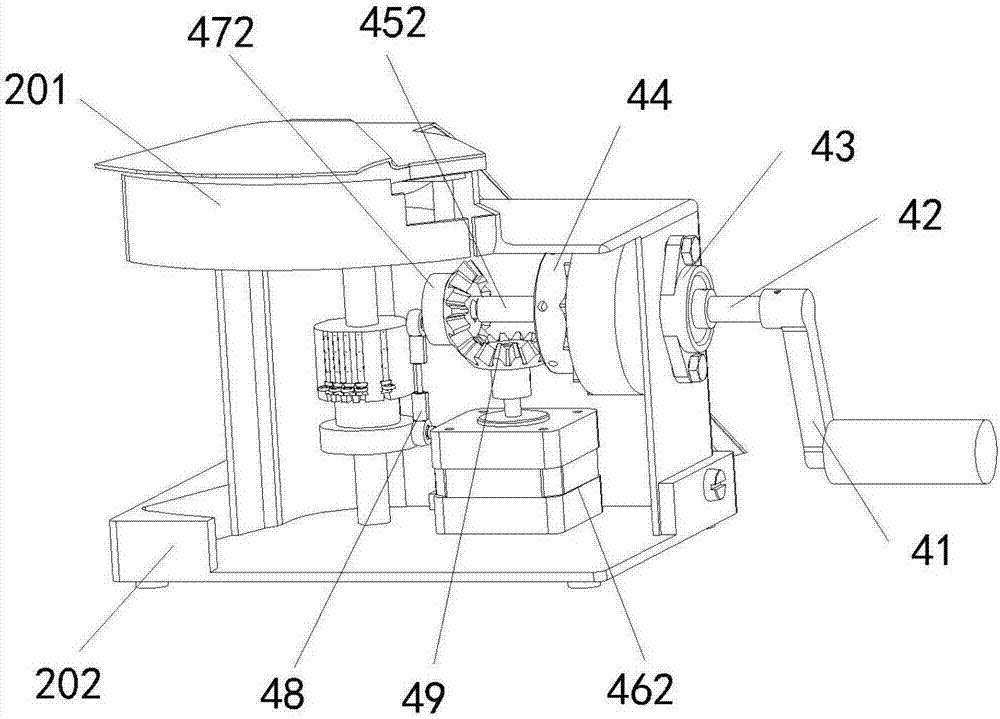

Hand five-finger rehabilitation training and correction device

ActiveCN107184370AMeet rehabilitation training needsReal-time adjustmentChiropractic devicesEngineeringRehabilitation training

The invention discloses a hand five-finger rehabilitation training and correction device and relates to the technical field of rehabilitation devices. An upper box body and a lower box body are connected in a matched mode, a containing cavity is formed in the inside, a hand training mechanism is fixed to the upper box body, prime mover mechanisms are arranged in the containing cavity and transfer power to the hand training mechanism through a transmission mechanism, the hands are driven to perform rehabilitation training. The hand five-finger rehabilitation training and correction device is provided with two different prime mover mechanisms, adopts hand-cranking and motor hybrid drive and provides active, passive and cooperated training modes, the designed hand-cranking drive is used for healthy limb training and promoting rehabilitation of a hand nerve function and a double-side cooperated function, a more simplified parallel six-rod mechanism is adopted, and the actual holding rule of the hands is greatly recovered. Quick and convenient dismounting of a drive rod and adjustment of a drive rod installing position are achieved through exercise and limiting of a secondary slide block, thus the exercise angles of knuckles are adjusted in a certain range, and the hand five-finger rehabilitation training and correction device achieves the purposes of meeting different rehabilitation training demands and achieving personalized training.

Owner:HEFEI UNIV OF TECH

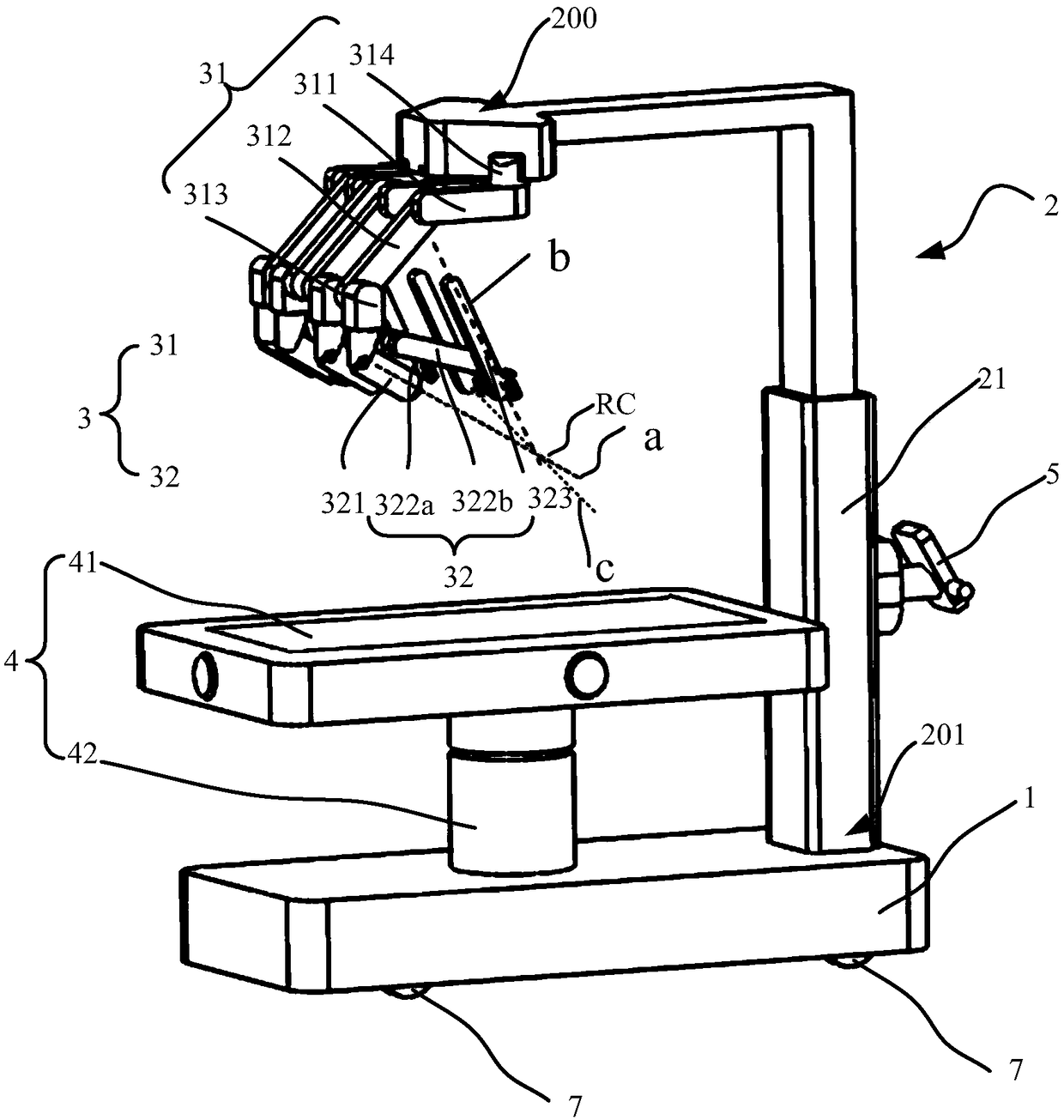

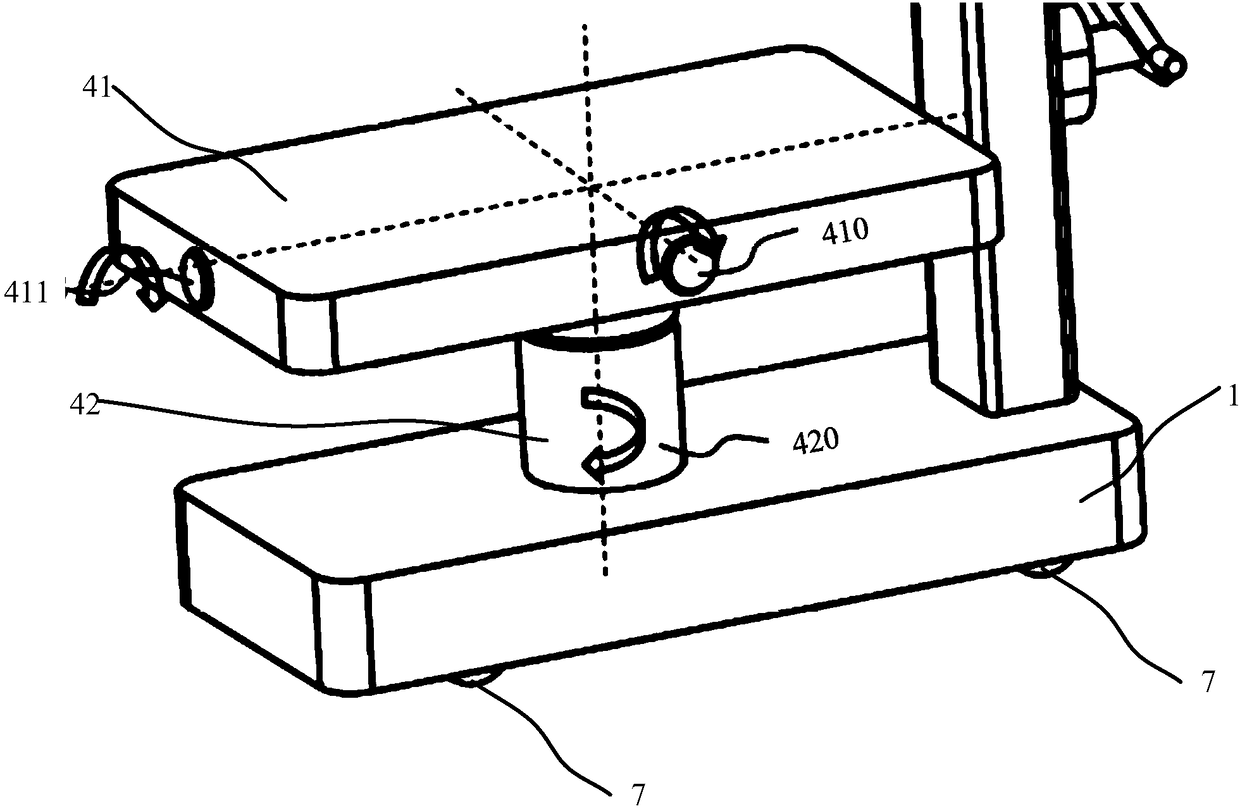

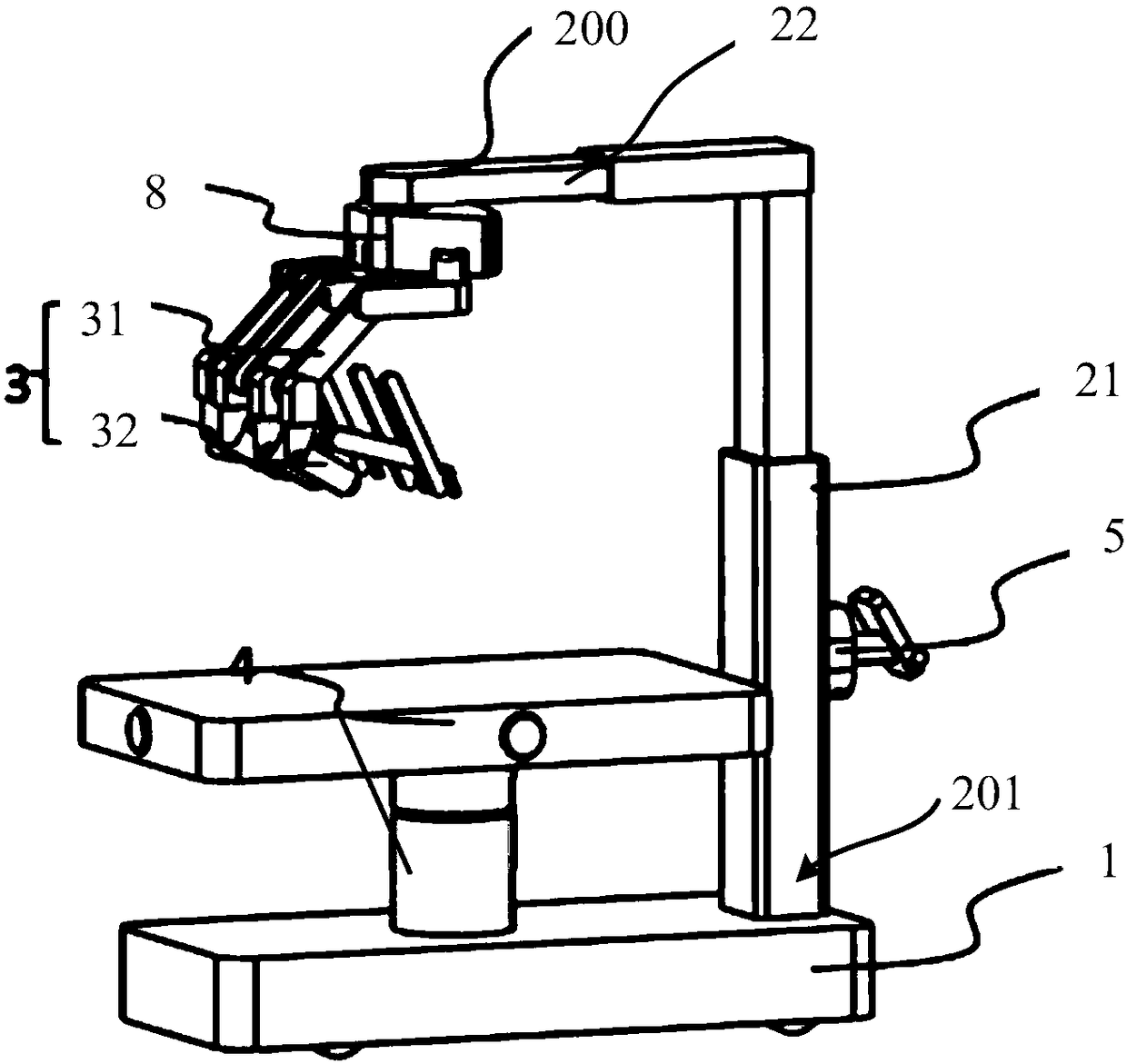

Surgical robot terminal

ActiveCN108186120ASimple structureSimplified qualityOperating tablesDiagnosticsSurgical robotMedical robot

The invention provides a surgical robot terminal. According to the surgical robot terminal, a sickbed is designed to comprise a plurality of rotating joints, so that the position, relative to a mechanical arm, of the sickbed is adjusted, then the mechanical arm moves around a fixed point, the position, relative to the mechanical arm, of the sickbed makes up the limited range for adjustment of themechanical arm, based on the matched adjustment of the rotating joints on the sickbed, the surgical robot terminal can be adjusted to any work position, the overall structure and quality of the surgical robot terminal are simplified, and then the surgical robot terminal well accords with the requirements of light weight and concise structure of the medical robot.

Owner:SHANGHAI MICROPORT MEDBOT (GRP) CO LTD

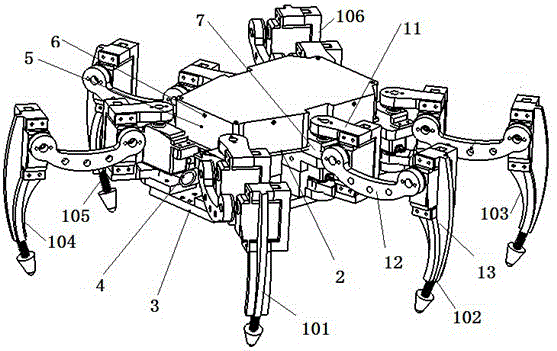

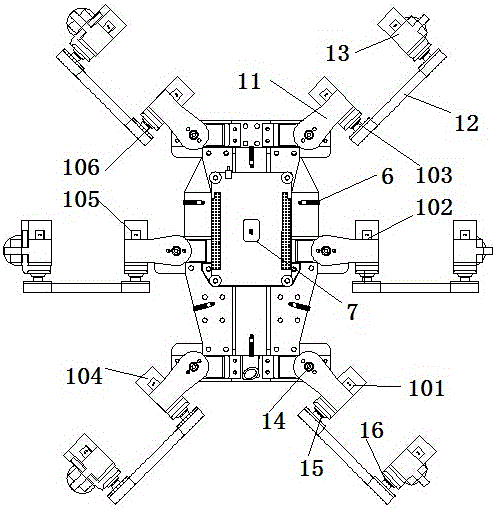

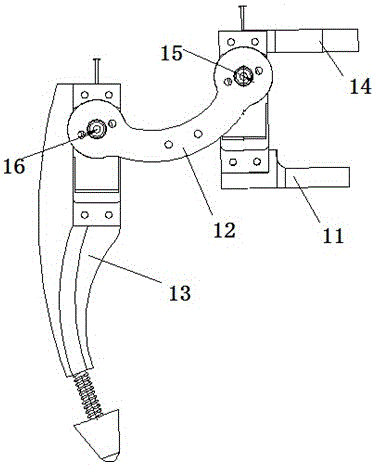

Hexapod bionic robot

The invention relates to a robot, in particular to a hexapod bionic robot. The hexapod bionic robot comprises an upper bottom plate, a lower bottom plate, a fire extinguisher, an upper cover, obstacle avoidance sensors, a controller and six legs, wherein a robot body is formed by the upper bottom plate and the lower bottom plate; the upper cover is mounted on the upper bottom plate; the controller is mounted in the upper cover; the robot body is octagonal; a pair of opposite edges of the robot body are two tips respectively, and the other six edges are respectively positioned on two sides so as to form side waists; the first leg is mounted at one end of one side waist, the second leg is mounted in the middle of the side waist, and the third leg is mounted at the other end of the side waist; the fourth leg is mounted on the other side waist and symmetrical to the first leg, the fifth leg is mounted on the side waist and symmetrical to the second leg, and the sixth leg is mounted on the side waist and symmetrical to the third leg; the fire extinguisher is mounted at one tip of the robot body; each obstacle avoidance sensor is mounted between every two adjacent legs. The hexapod bionic robot provided by the invention has high adaptive capability to environment, can realize real-time obstacle avoidance and can reasonably plan walking routes; the robot body is stable, and legs are flexible and varied to move; the hexapod bionic robot can be adapted to various terrains, different speeds and different load requirements.

Owner:NANJING FORESTRY UNIV

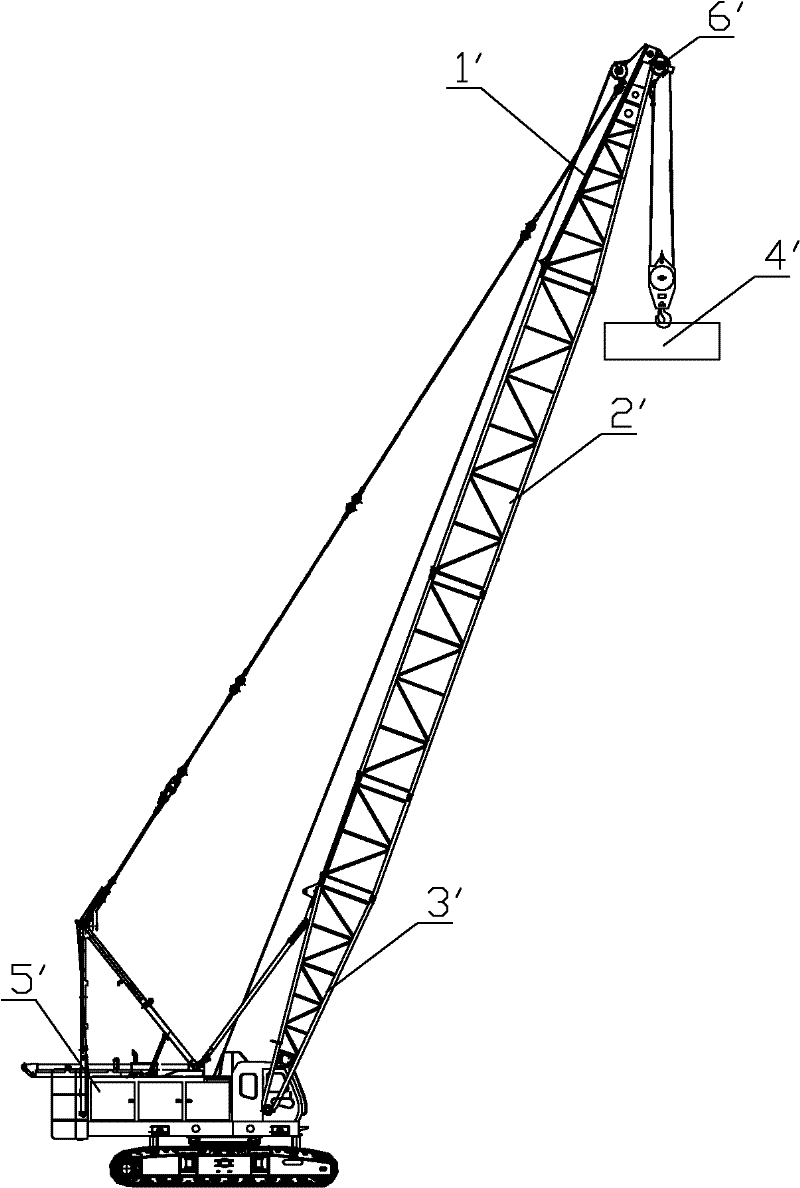

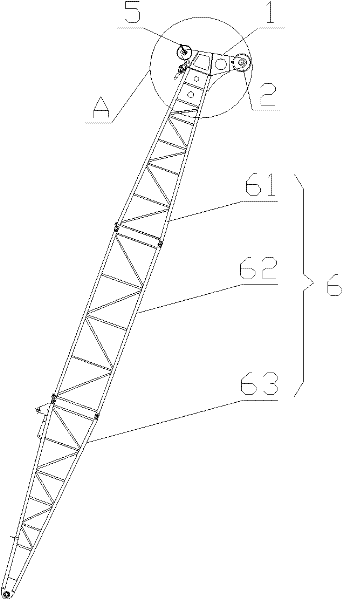

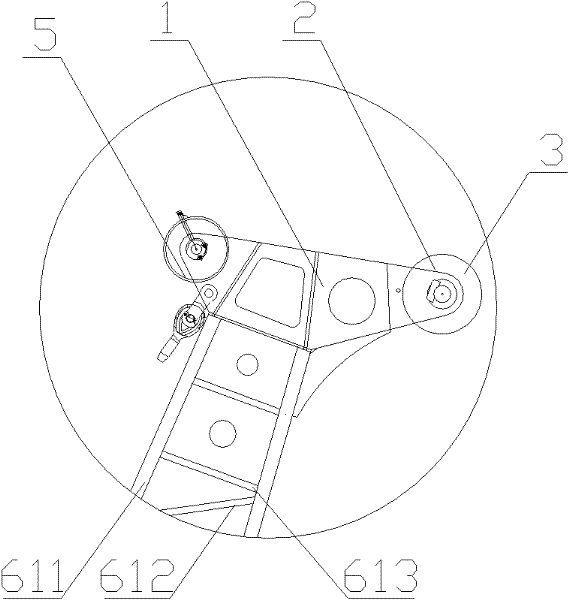

Dynamic compaction machine and arm rack device thereof

InactiveCN102251511ALarge working spaceAvoid motion interferenceSoil preservationDynamic compactionEngineering

The invention discloses an arm rack device of a dynamic compaction machine. The arm rack device comprises a supporting arm rack (6), the bottom of which is connected with the body of the dynamic compaction machine; the arm rack device also comprises a front stretching arm head device (1) arranged at the top of the supporting arm rack (6), and a fixed pulley (2) for lifting a rammer (7) of the dynamic compaction machine is arranged at the front end of the front stretching arm head device (1); the rammer (7) is relatively far from the supporting arm rack (6), so the operating space of the rammer (7) in the horizontal direction is enlarged, movement interference between the rammer (7) and the supporting arm rack (6) is avoided, and the operating safety is increased; and the rammer (7) of the same diameter can be lifted to a greater height, so that the operating performance of the dynamic compaction machine is fully exerted, and the work efficiency of the dynamic compaction machine is improved. Moreover, the invention also provides the dynamic compaction machine comprising the arm rack device.

Owner:BEIJING CSR TIMES LOCOMOTIVE & ROLLING STOCK MECHANICS

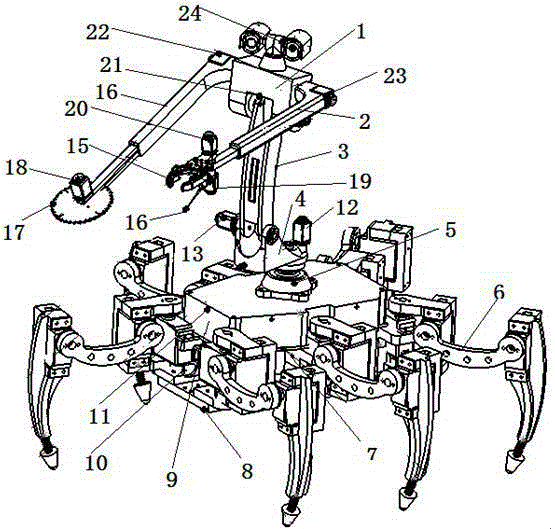

Six-leg two-arm bionic robot

InactiveCN105128016AEasy to moveGuaranteed to move normallyManipulatorVehiclesControl systemHand arm

The invention relates to robots and in particular relates to a six-leg two-arm bionic robot. A robot body comprises an upper bottom plate and a lower bottom plate; a fire extinguisher is arranged on the robot body; six legs are also arranged on the robot body; an upper cover is arranged on the upper bottom plate; obstacle avoidance sensors are arranged at the periphery of the upper cover and are connected with a control system in the upper cover; a base is connected on the upper cover; a rotation arm waist part is arranged on the base and rotates around the center line vertical to the base; the top of the rotation arm waist part is hinged with a stretching arm trunk; the top of the stretching arm trunk is hinged with an upper arm shoulder part; the upper arm shoulder part is respectively hinged with a left arm and a right arm; a camera is also arranged on the upper arm shoulder part; a temperature sensor and a mechanical claw are arranged on the left arm; and a saw blade is arranged on the right arm. According to the six-leg two-arm bionic robot, the robot body is stable, the rotation space of the legs is large, many functions are integrated on the two arms, obstacles in the advance process can be removed, simultaneously remaining fire can be cleared, and the personnel and material rescue in various disasters can be completed by replacing a tail end actuator.

Owner:ZHENJIANG SKY ROBOT TECH CO LTD

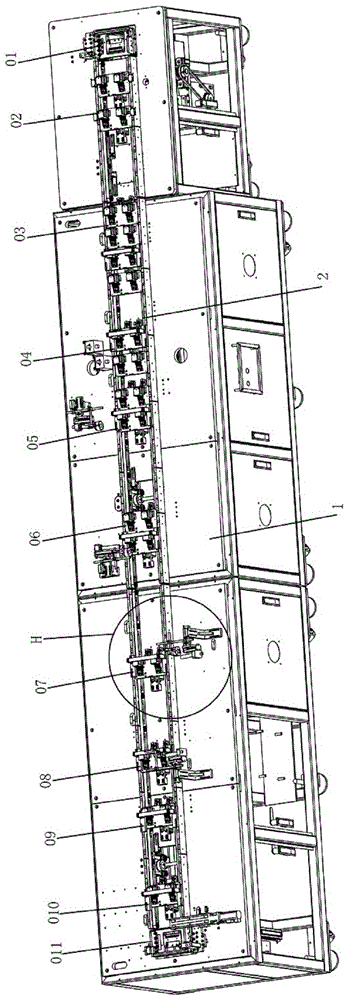

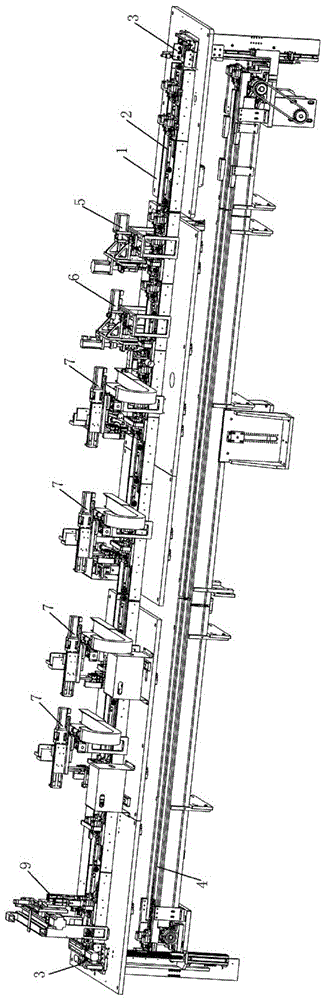

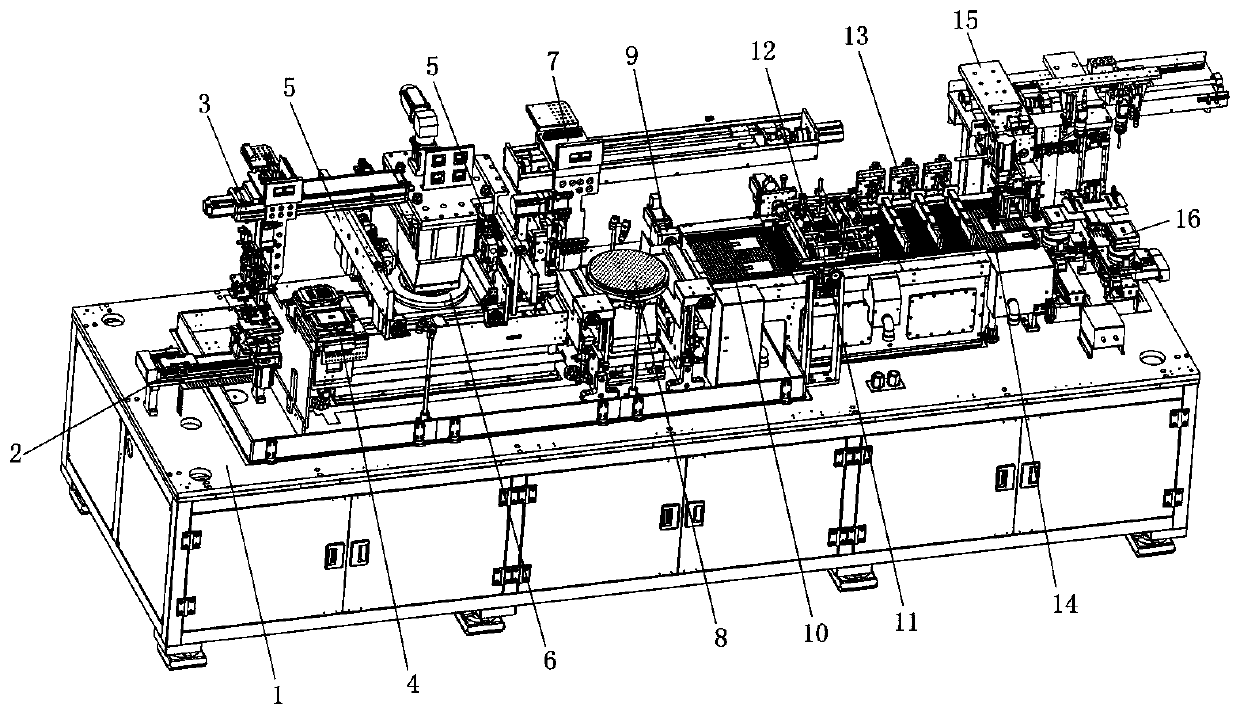

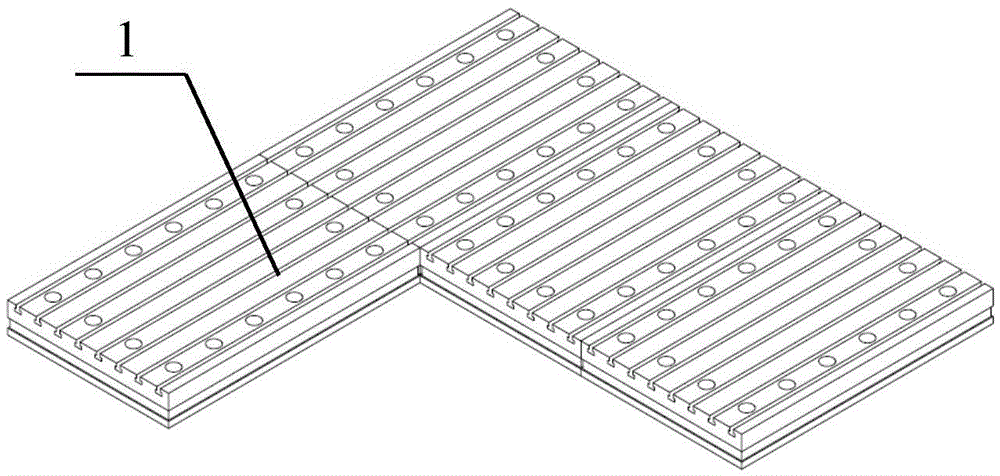

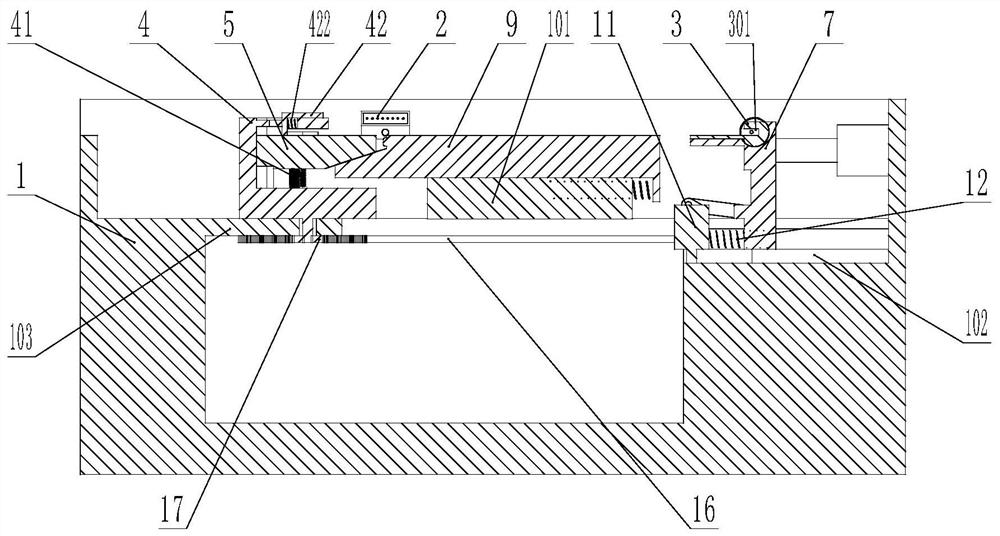

Production line for automatic wire threading and trimming and production process thereof

ActiveCN105811224AAchieve circular flowPrevent slidingLine/current collector detailsProduction lineWire cutting

The invention discloses a production line for automatic wire threading and trimming and a production process thereof. The production line comprises a rack, an upper-layer material strip, jig lifting mechanisms, a lower-layer material strip, a wire trimming mechanism, a wire cutting mechanism, a wire threading mechanism, a wire embedding and clamping mechanism and a discharging mechanism, wherein the upper-layer material strip and the lower-layer material strip are separately arranged at the upper part and the lower part of the rack, the jig lifting mechanisms are arranged at the two ends of the upper-layer material strip and the lower-layer material strip, jigs are circulated and flown between the upper-layer material strip and the lower-layer material strip by the jig lifting mechanisms, and an upper jig station, a loading station, a wire trimming station, a wire cutting station, a wire threading station, a wire embedding and clamping station, a discharging station and a lower jig station are sequentially arranged along the direction of the upper-layer material strip of the rack so as to gradually complete process steps of jig loading, feeding, wire embedding, wire cutting, first wire threading, second wire threading, third wire threading, fourth wire threading, wire embedding and clamping, discharging and jig unloading. The production line integrates multiple automatic wire threading and processing actions, the structural design is compact, the yield is high, and the product quality and the automatic degree are high.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

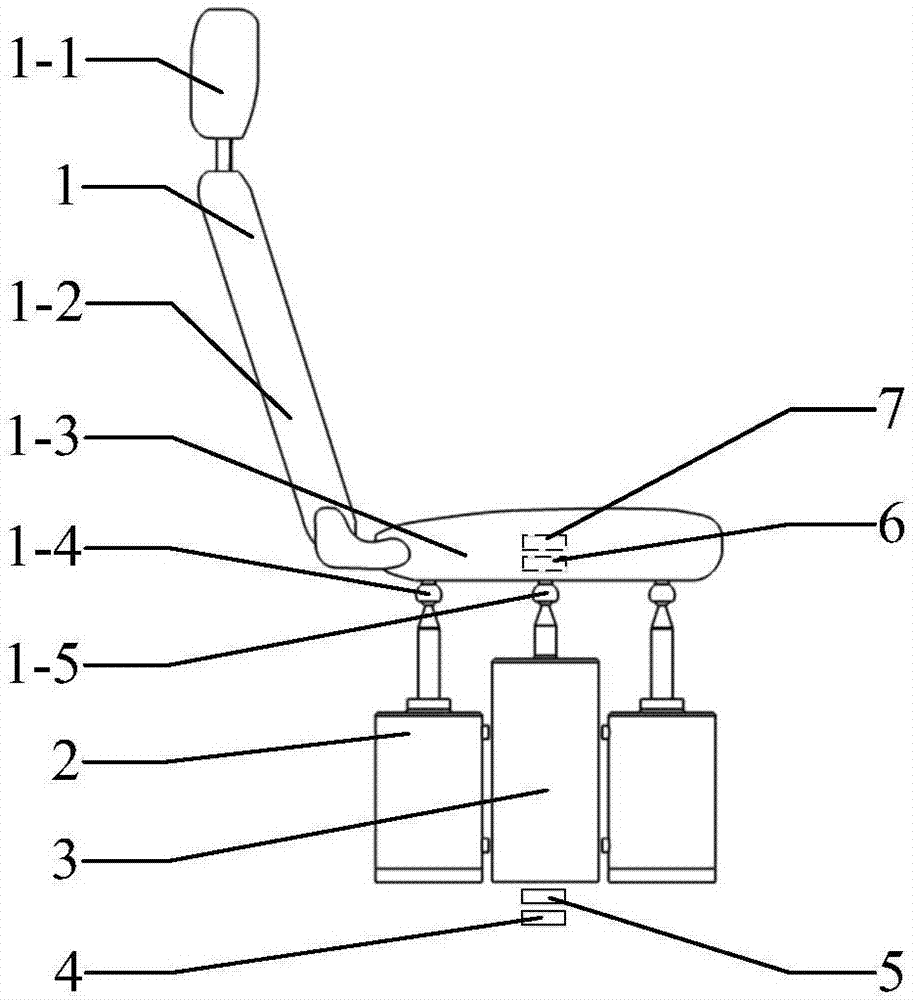

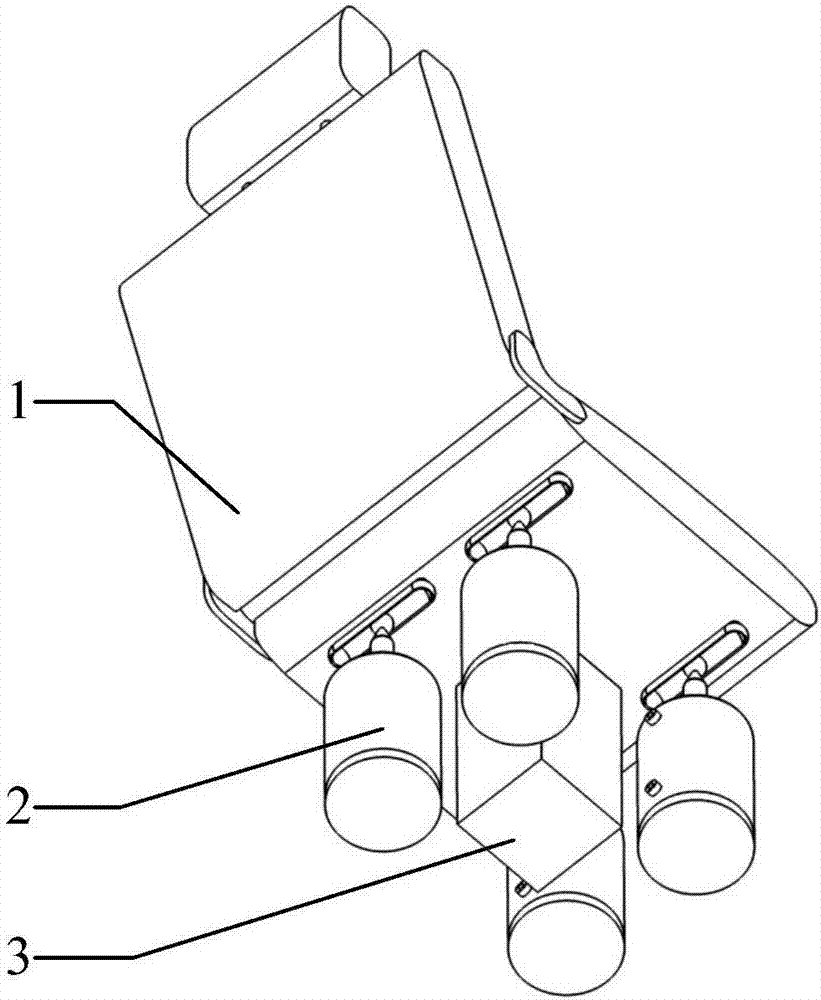

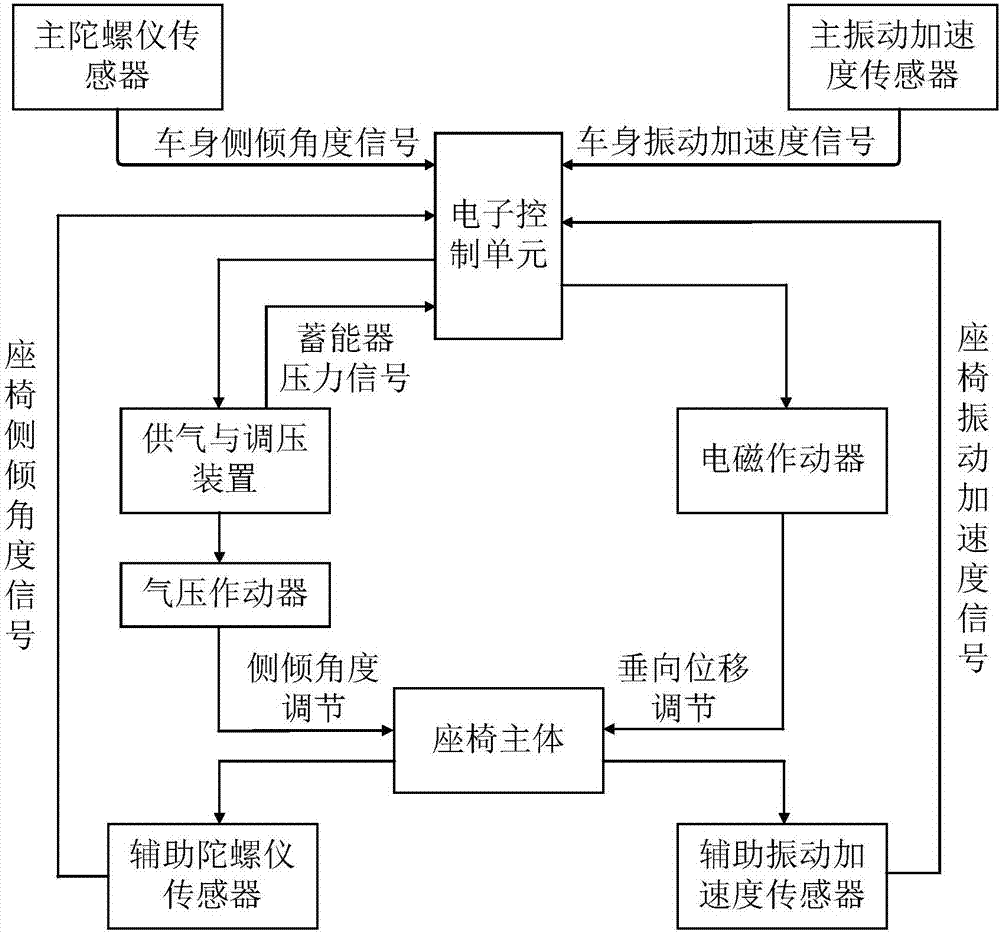

Self-adaptive adjusting active vibration-reducing auto seat

ActiveCN107310438ARealize functionLess discomfortMovable seatsSeat suspension devicesGyroscopeVibration acceleration

The invention relates to automobile parts, in particular to a self-adaptive adjusting active vibration-reducing auto seat. The seat is installed in a carriage of an automobile, and comprises a seat body, four air-pressure actuators, a magnetic actuator, a main gyroscope sensor, a main vibration accelerated speed sensor, an auxiliary gyroscope sensor, an auxiliary vibration accelerated speed sensor, four air supplying and pressure regulating devices and an electronic control unit. According to the seat, the riding comfort of the automobile and the accuracy of posture control of the seat are improved; a self-adaptive posture adjusting function of the seat is achieved by the gyroscope sensors, the electronic control unit, the air supplying and pressure regulating devices and the air-pressure actuators, an active vibration-reducing function of the seat is achieved by the vibration accelerated speed sensor, the electronic control unit and the magnetic actuator, and the two functions can work simultaneously and separately to form a whole in structure without affecting each other on functions, so that the reliability of a system is improved; the structure is compact, the stability is good, the cost is low, and motion interference is avoided.

Owner:SHANDONG UNIV

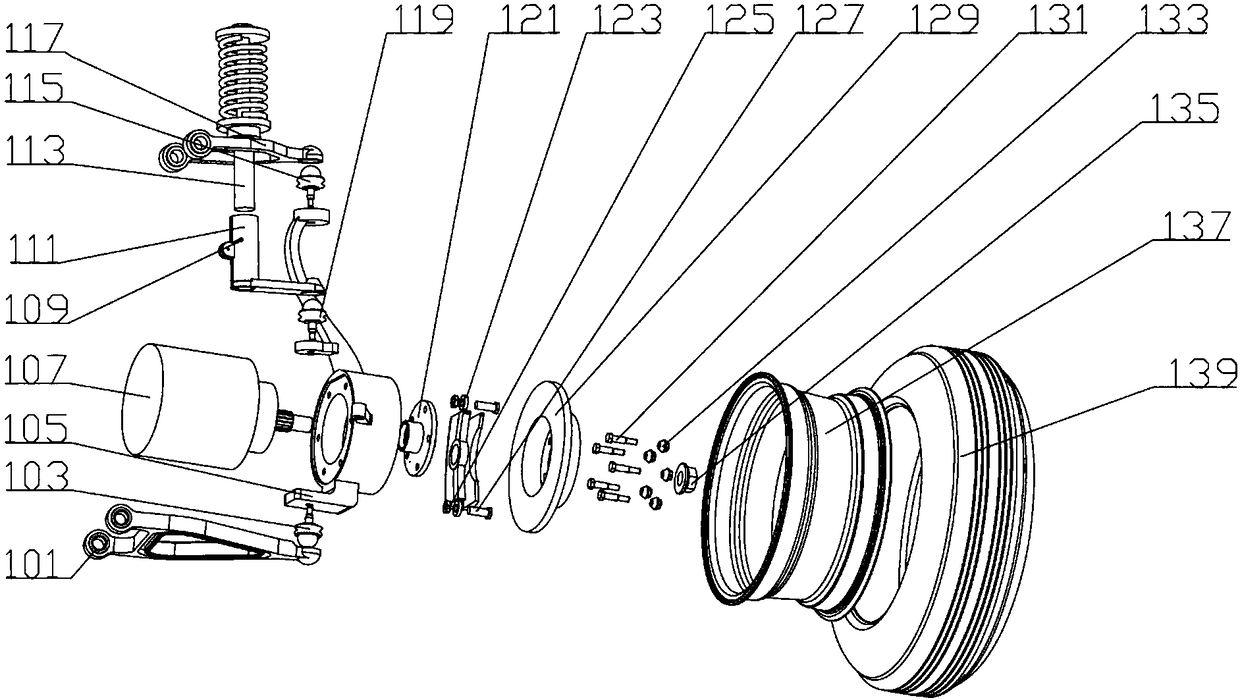

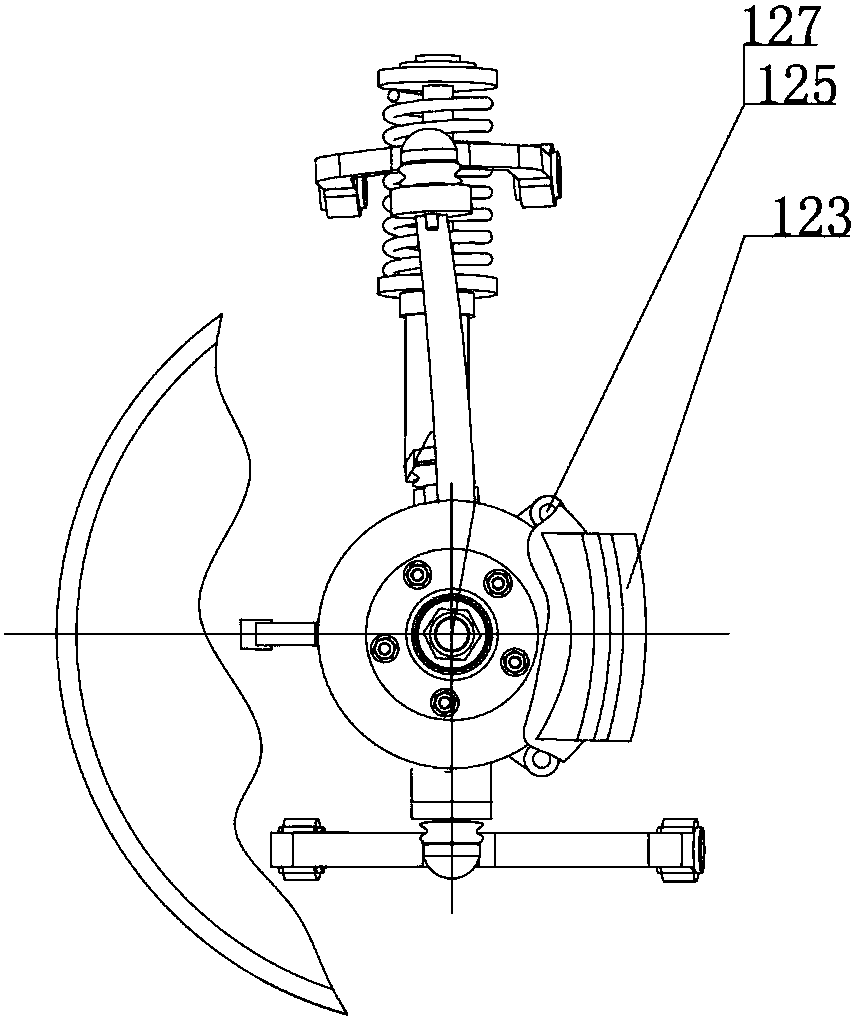

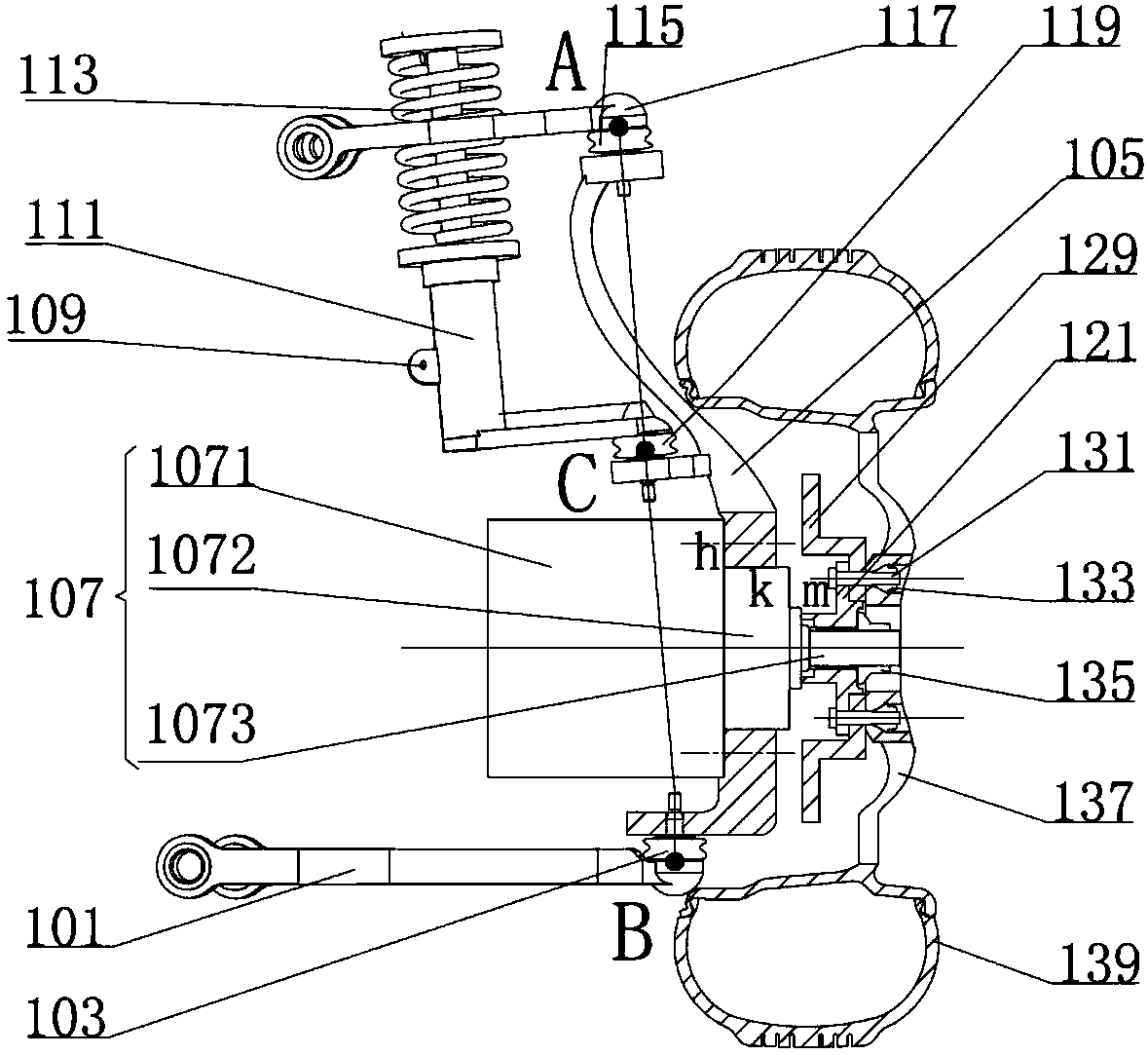

Double-wishbone front-suspension system applied to driving of inner rotor hub motor

PendingCN108312839AGuaranteed ride comfortLittle structural changeSteering linkagesMotor depositionHollow cylinderKnuckle

The invention discloses a double-wishbone front-suspension system applied to driving of an inner rotor hub motor. The double-wishbone front-suspension system comprises a steering knuckle, an upper control arm, a lower control arm, a shock absorber spherical hinge lower supporting arm, a spring damper assembly, and the inner rotor hub motor. The steering knuckle is provided with an upward extendingsupporting arm, the upper control arm is hinged to the top end of the supporting arm to form a first hinge point, and the lower control arm is hinged to the lower end of the steering knuckle to forma second hinge point. The shock absorber spherical hinge lower supporting arm comprises a hollow cylinder with a side opening in one side and a rectangular flat plate vertically placed with the hollowcylinder, wherein the extended end of the rectangular flat plate is connected with the middle part of the supporting arm through a ball head pin to form a third hinge point. The upper end of the spring damper assembly is supported on a vehicle body, and a cylinder barrel at the lower part of the spring damper assembly is fixed in the hollow cylinder, the inner rotor hub motor is matched with thehollow cylinder of the steering knuckle, wherein the third hinge point is located on a connecting line between the first hinge point and the second hinge point. The double-wishbone front-suspension system solves the problem of interference of the wheel hub motor on the arrangement of suspension components and various components during wheel steering and up and down movement.

Owner:JILIN UNIV

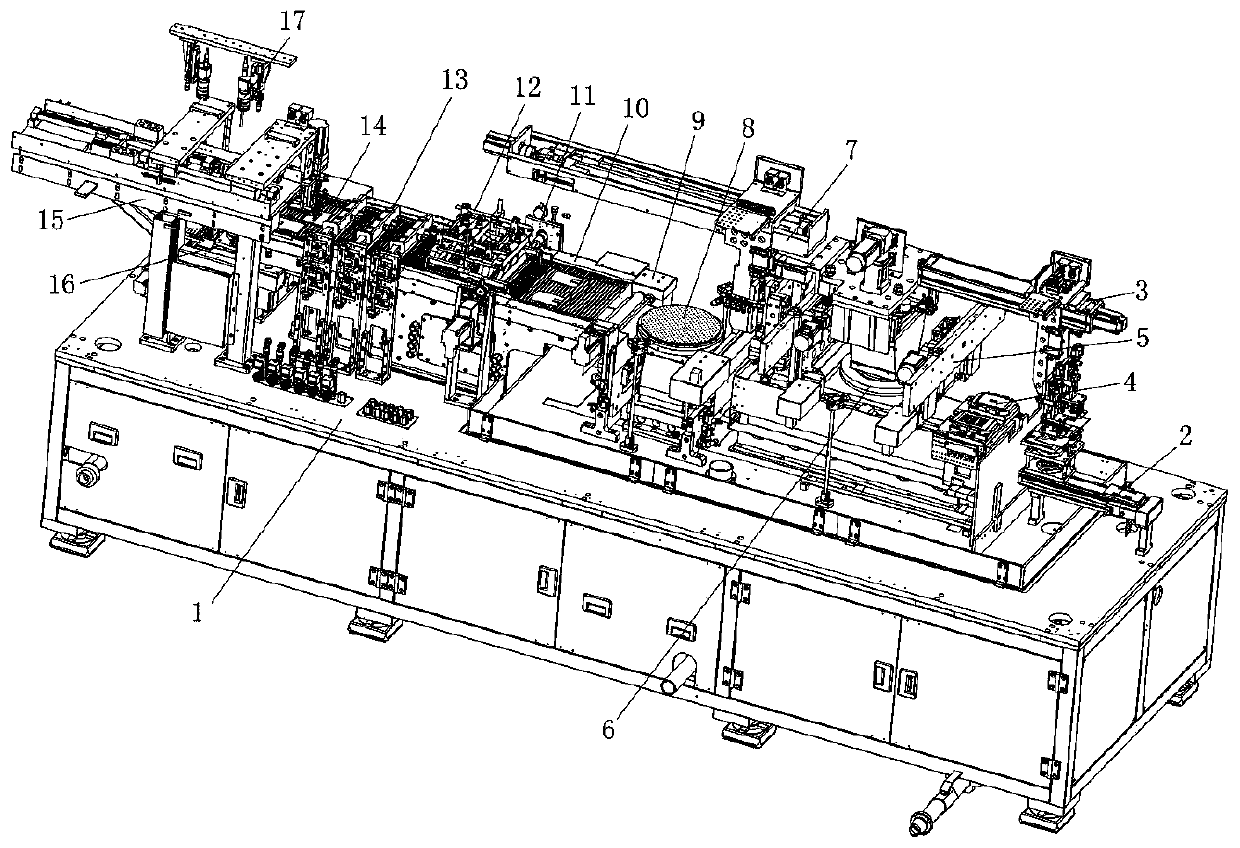

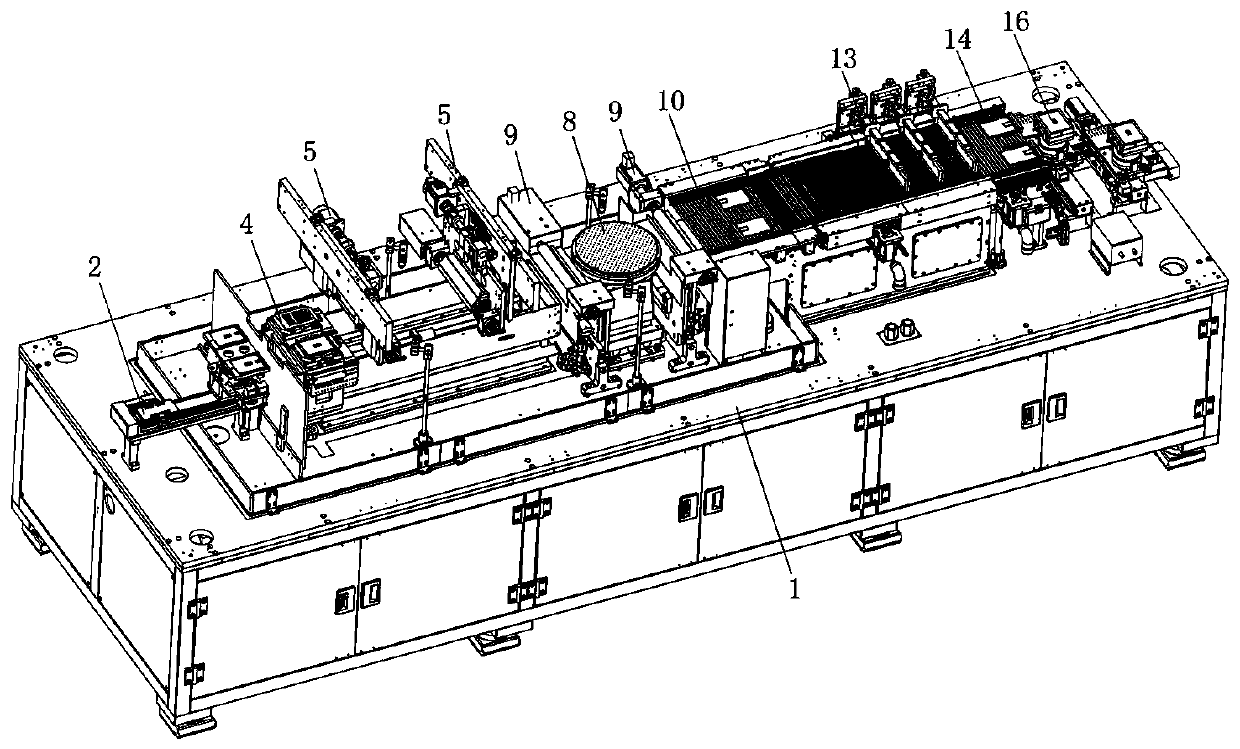

Full-automatic grinding and cleaning machine and grinding and cleaning technology thereof

ActiveCN109955145AAvoid position shiftAvoid positionLapping machinesFlexible article cleaningTransmission channelManipulator

The invention discloses a full-automatic grinding and cleaning machine and a grinding and cleaning technology thereof. The full-automatic grinding and cleaning machine comprises a feeding part, a CF cleaning part, a TFT cleaning part, a two-fluid cleaning and drying part, and a discharging part, wherein the feeding part, the CF cleaning part, the TFT cleaning part, the two-fluid cleaning and drying part and the discharging part are sequentially arranged on a machine table in the flow direction of glass pieces; the to-be-cleaned glass pieces are sequentially transported from the feeding part tothe CF cleaning part, a CF surface is cleaned through the CF cleaning part, the TFR surface is cleaned through the TFT cleaning part, and the CF surface and the TFT surface are cleaned by the two-fluid cleaning and drying part simultaneously and then dried, and the dried glass pieces are discharged and exported through the discharging part. According to the full-automatic grinding and cleaning machine and the grinding and cleaning technology thereof, transmission of the small and micro-sized glass pieces is effectively realized, and the problems of positional displacement and motion interference of the glass pieces in the two-fluid cleaning and drying process are effectively avoided; and rotating, material splitting, and exporting of the glass pieces are realized through cooperation of adouble-glass transmission channel formed by a gap between adjacent conveying rollers in an upward extending mode and a discharging mechanical arm, the height of a brush can be controlled in real time,displacement of the glass pieces is avoided, and the cleaning efficiency of the brush and the real-time cleaning versatility of the brush are effectively improved.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

Turret type automatic lamination production line and lamination process thereof

PendingCN110350253AAvoid displacement deviationImprove lamination efficiencyFinal product manufactureLi-accumulatorsProduction lineEngineering

The invention discloses a turret type automatic lamination production line and a lamination process thereof. The turret type automatic lamination production line comprises a rack, feeding vacuum pullbodies, lamination mechanisms, turret mechanisms, material discharging mechanical arms and CCD mechanisms; two feeding vacuum pull bodies are provided; the two feeding vacuum pull bodies are parallelly arranged on the rack at intervals; two turret mechanisms are provided; the two turret mechanisms are arranged at two lamination stations respectively; four lamination mechanisms are provided; two groups of lamination mechanisms are arranged to two sides of the two turret mechanisms respectively, wherein each group of lamination mechanisms includes two lamination mechanisms; two material discharging mechanical arms are provided; the two material discharging mechanical arms are sequentially arranged below the two feeding vacuum pull bodies respectively; two CCD mechanisms are provided; and thetwo CCD mechanisms are arranged above the two lamination stations respectively. With the turret type automatic lamination production line and the lamination process thereof of the invention adopted,the sequential alternating lamination of the two lamination mechanisms is realized in the same rotation cycle, so that lamination efficiency is improved; the continuous lamination of a platform is realized, and the problem of movement interference during material discharging is avoided; and pole sheets are pressed uninterruptedly, so that the displacement deviation of the pole sheets is effectively avoided.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

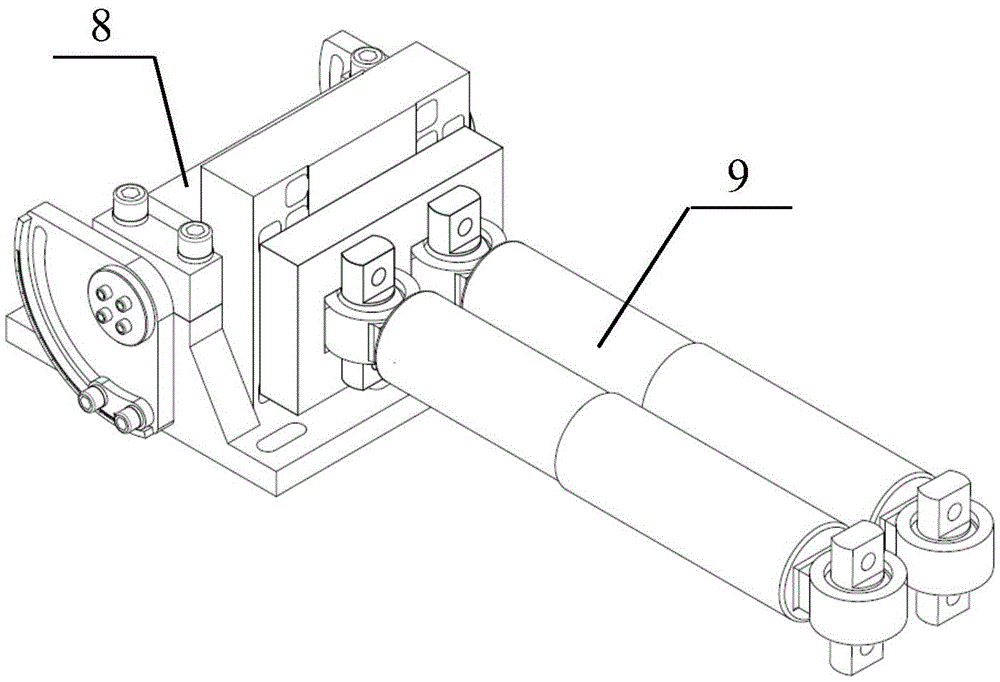

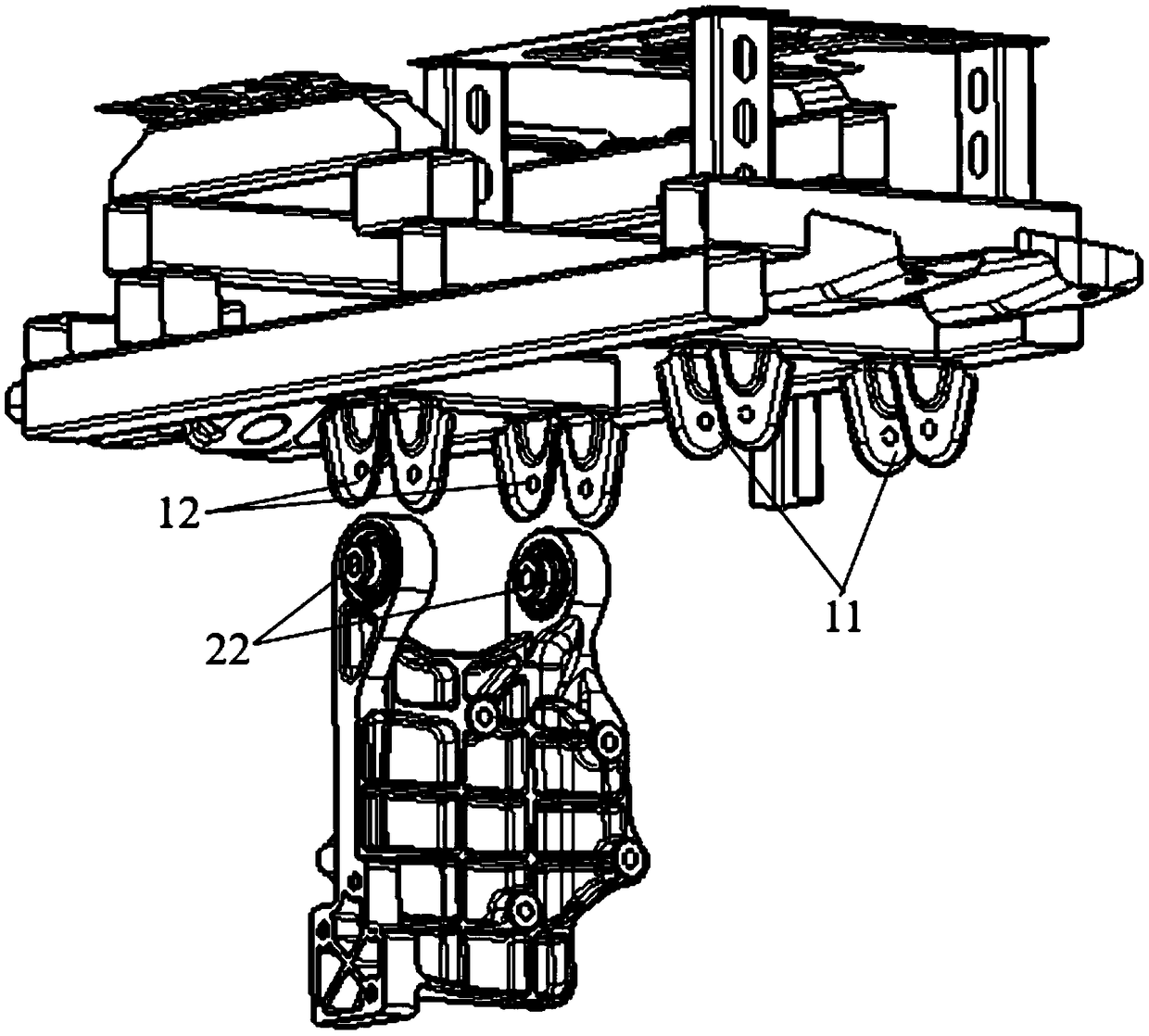

Universal test bench for high-speed train damper

ActiveCN105651532ARealistically reproduce the state of motionEasy to installRailway vehicle testingVibration testingControl systemActuator

The invention discloses a universal test bench for a high-speed train damper. The universal test bench for the high-speed train damper aims to solve the problems that an existing test bench of the damper is poor in performance, low in precision and high in cost. The test bench mainly comprises a mounting platform, a damper universal supporting assembling body, a vertical actuator assembling body, a bearing stand column, a transverse actuator assembling body, a damper variable angle mounting assembly and a longitudinal actuator assembling body; in the universal test bench for the high-speed train damper, the damper variable angle mounting assembly is connected with the vertical actuator assembling body, the transverse actuator assembling body and the longitudinal actuator assembling body; meanwhile, one end of the test damper is fixed, and the other end of the test damper is connected with the damper variable angle mounting assembly. The three actuators act under the control of a control system, the work state of the damper is represented truly, and meanwhile signals collected by a sensor are transferred to a detection system.

Owner:JILIN UNIV

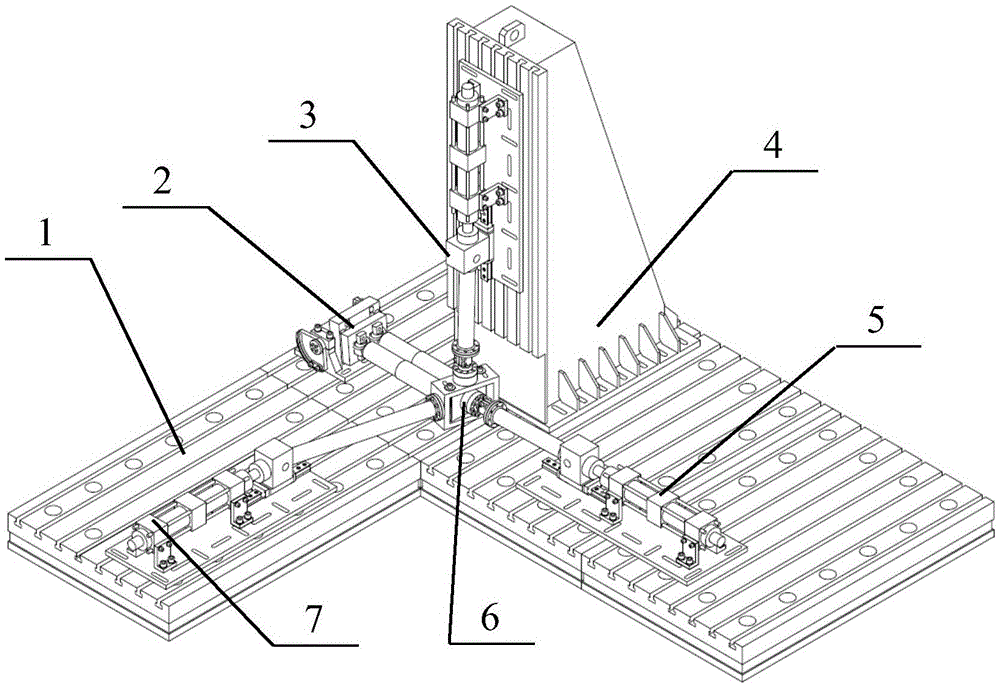

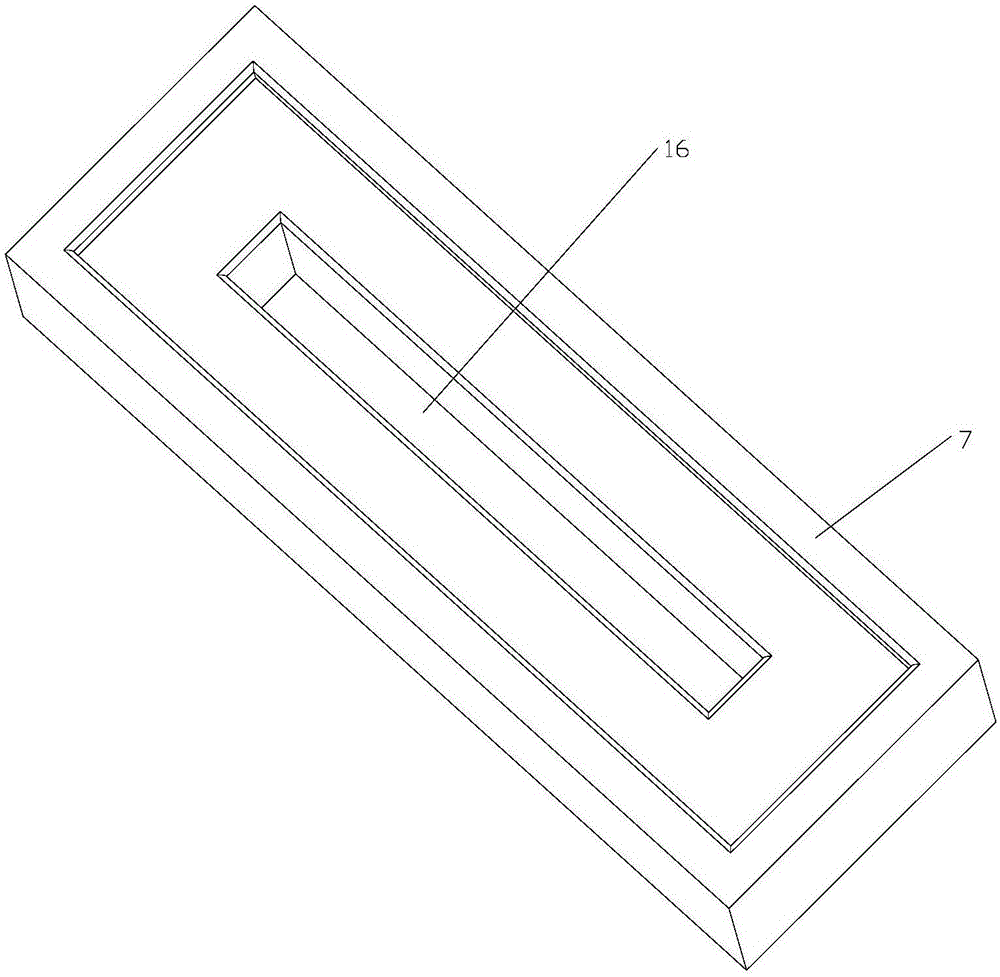

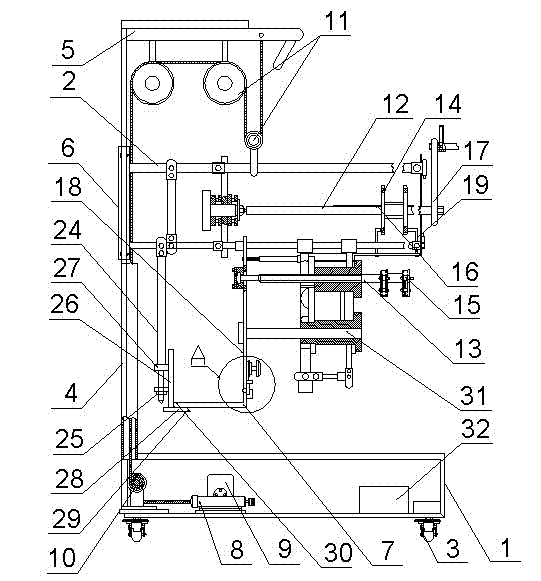

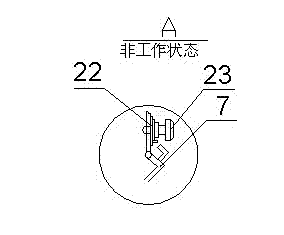

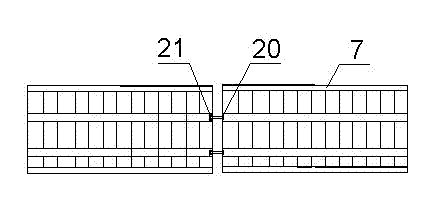

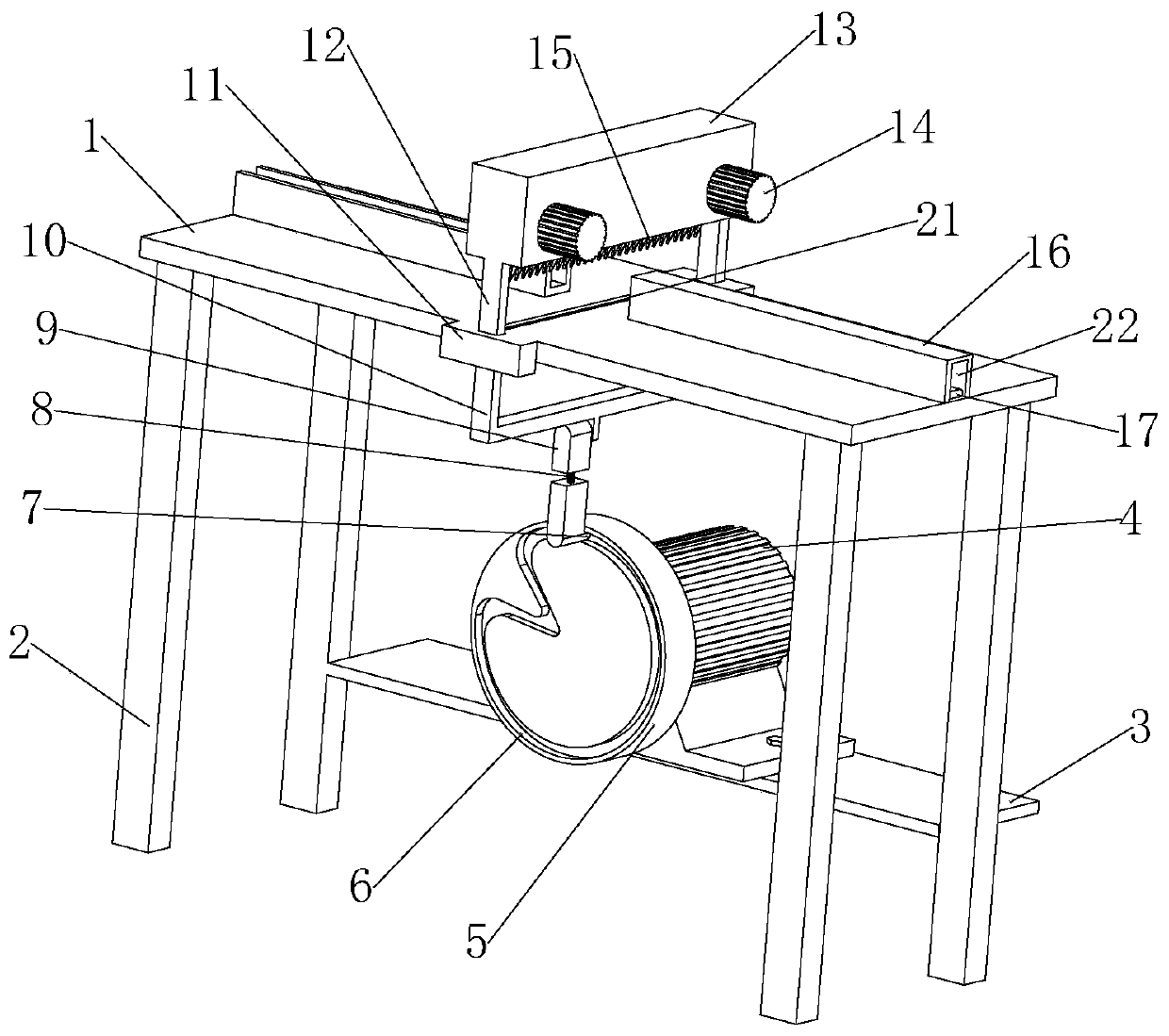

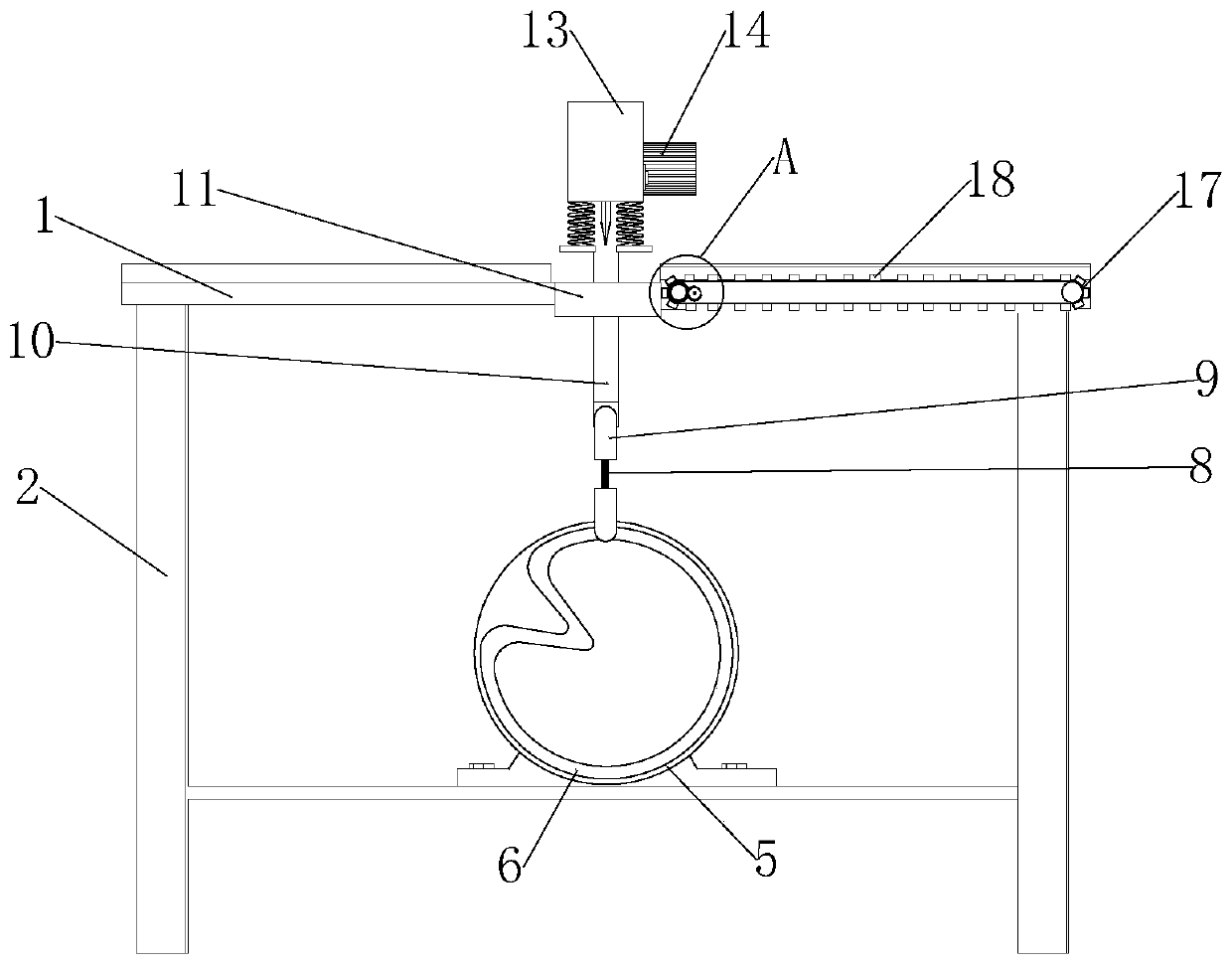

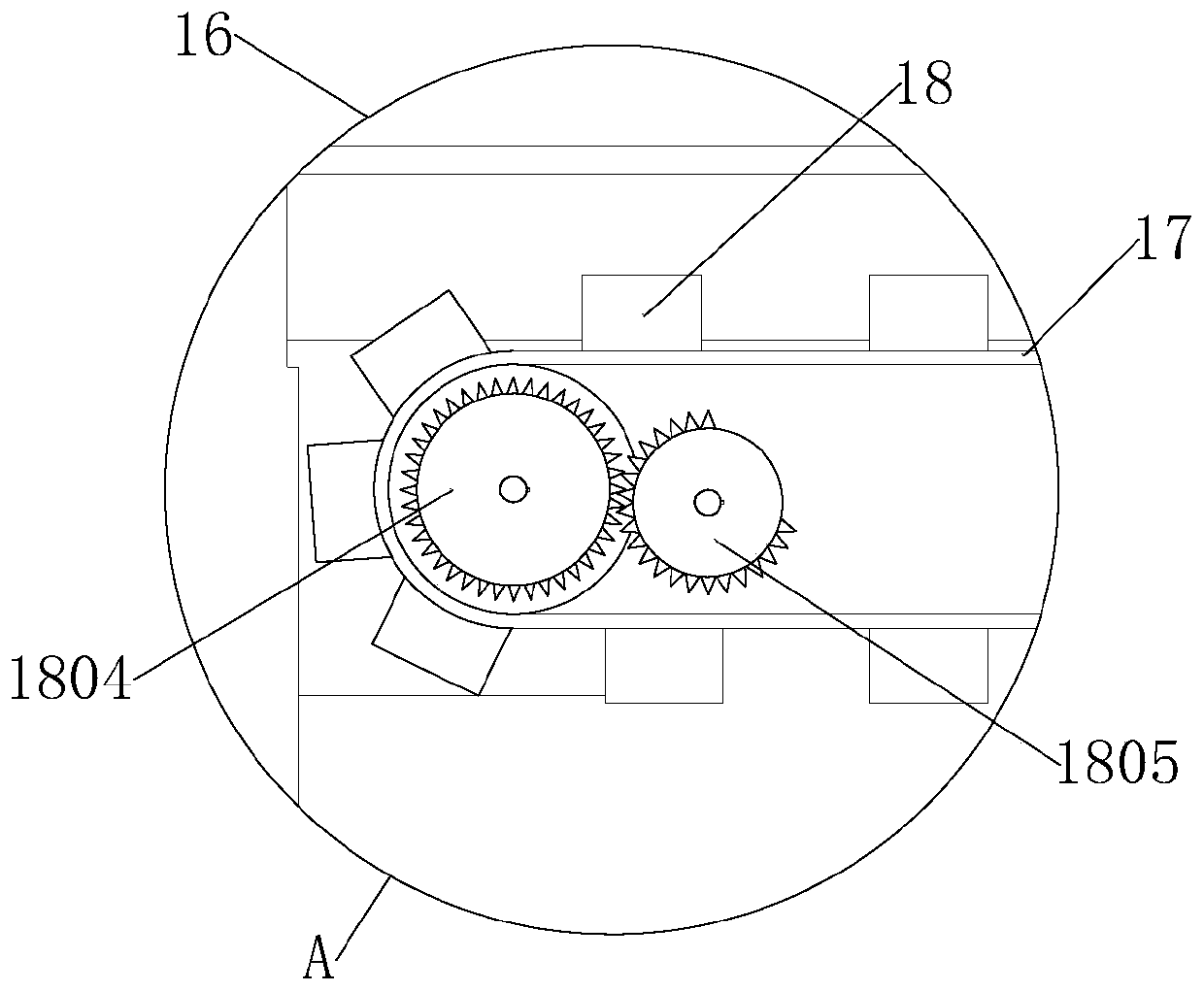

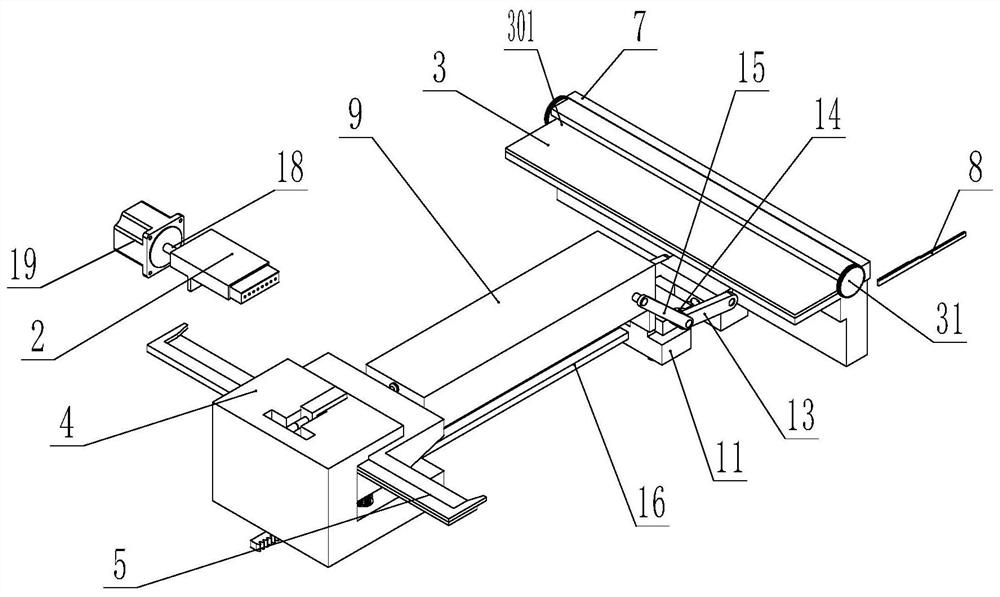

Mechanism for continuously punching workpieces

ActiveCN106238775AAvoid motion interferenceGuaranteed reliabilityFeeding apparatusBoring/drilling componentsEngineeringMechanical engineering

The invention discloses a mechanism for continuously punching workpieces. The mechanism comprises a base (1) which is rotatably connected with a guide rod (3) through a rotating shaft (2), the guide rod (3) is slidably connected with a first linear rack (4) through a dovetail groove, and a drilling machine (6) used for punching a workpiece (5) placed on the base (1) is arranged on the first linear rack (4); a platform (7) is arranged on the base (1) and slidably connected with a slider (8) through the dovetail groove, and a connecting rod (9) is obliquely arranged on the slider (8). The mechanism is higher in punching accuracy and capable of guaranteeing included angles among multiple holes when the holes are processed at the same time.

Owner:创客帮(山东)科技服务有限公司

Cantilever-type lifting medical stretcher

InactiveCN102784042AChieve progressImplement backward movementNursing bedsWorking pressureEngineering

The invention discloses a cantilever-type lifting medical stretcher which comprises a bed stand, a lifting frame and a lead screw feeding mechanism. Casters are arranged at four bottom corners of the bed stand, a support frame is arranged on one side of the bed stand, a cantilever connected with the lifting frame is arranged on the upper portion of the support frame, a sleeve connected with the lifting frame is arranged in the middle of the support frame, the lifting frame is provided with a power mechanism, the lead screw feeding mechanism is positioned in the front of the lifting frame, and the front end of the lead screw feeding mechanism is connected with a bed board. The lifting frame together with the sleeve can vertically move along the supporting frame and is applicable to sickbeds with different heights, and the lead screw feeding mechanism can effectively advance and draw back the bed board. By the aid of the cantilever-type lifting medical stretcher, a patient can be effectively shifted to another bed and transferred, the pain of the patient is relieved, and the working pressure of medical workers is relieved. The cantilever-type lifting medical stretcher is unique in creation, convenient to use and easy to popularize.

Owner:HENAN POLYTECHNIC INST +2

Automatic cutting machining system for bridge-cutoff aluminum alloy

InactiveCN111482653AImprove cutting efficiencyEasy to swing back and forthMetal sawing devicesStructural engineeringMachining system

The invention discloses an automatic cutting machining system for a bridge cutoff aluminum alloy, and relates to the technical field of machining. The automatic cutting machining system involves a horizontally-fixed workbench, wherein supporting legs erected at the bottom end of the workbench are arranged at the bottom end of the workbench, fixing frames are symmetrically arranged on the front side wall and the rear side wall of the workbench, and downwards-through through holes are formed in the middle parts of the top ends of the fixing frames on the two sides; and a cutting machine is arranged in the middle part of the top end of the workbench, downwards-vertical side supporting rods are symmetrically arranged on the front side and the rear side of the bottom end of the cutting machine,and the side supporting rods on the two sides penetrate through the through holes of the fixing frames in a sliding fit mode and stretch out towards the bottom end of the workbench. According to theautomatic cutting machining system for the bridge cutoff aluminum alloy, a shaftless idler wheel is arranged inside the cutting machine, the two ends of the shaftless idler wheel drive two cutting blades to swing back and forth below the cutting machine through second pin rods which are arranged in a staggered mode, and the surface of aluminum alloy is rapidly cut through the two cutting blades swinging back and forth, so that the cutting efficiency of the aluminum alloy is improved.

Owner:南通市荣力达铝业有限公司

Flanging and punching die

The invention provides a flanging and punching die. The flanging and punching die comprises an upper die base and a lower die base, wherein the upper die base is connected with an upper die pressing core, the lower die base is connected with a lower die pressing core, the upper die base is connected with an upper die lateral punching driving block, the upper die lateral punching driving block is provided with a lateral punching wedge forced rollback hook, the lower die pressing core is respectively connected with an upper flanging cutter block, a lower die lateral punching female die insert, a lateral punching wedge and a lateral punching wedge guide pillar, the lateral punching wedge and the lateral punching wedge guide pillar is a moving pair, the lateral punching wedge is provided with a lateral punching wedge forced rollback groove, the lateral punching wedge forced rollback hook is arranged in the lateral punching wedge forced rollback groove, the lateral punching wedge is connected with a lower die lateral punching male die insert, and the lower die lateral punching male die insert and the lower die lateral punching female die insert are matched with each other. The flanging and punching die has the advantages of achieving the purpose of simultaneously flanging and punching, and reducing work procedures.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

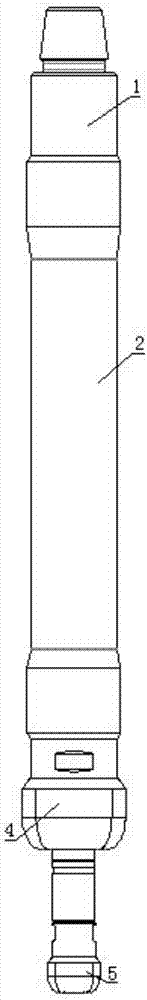

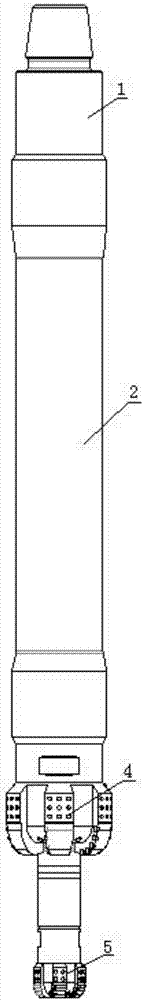

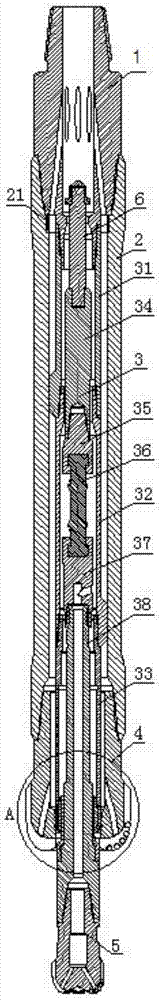

Drilling speed increasing device with composite drill bit

The invention relates to the field of petroleum and natural gas drilling equipment, in particular to a drilling speed increasing device with a composite drill bit. According to the technical scheme, the drilling speed increasing device with the composite drill bit comprises a multifunctional connector, the multifunctional connector is connected with a shell and a screw driving assembly, and the screw driving assembly is sleeved with the shell; the end, away from the multifunctional connector, of the shell is connected with a reaming drill bit body, and the end, away from the multifunctional connector, of the screw driving assembly is connected with a pilot drill bit body; water holes are formed in the reaming drill bit body and the pilot bit body; and the reaming drill bit body is a diamond drill bit or a roller bit, and the pilot bit body is a diamond drill bit or a roller bit. According to the drilling speed increasing device, the pilot bit body can achieve two-stage speed increasing, accordingly the overall drilling speed is increased, and the problems that a pilot bit of an existing two-stage drilling device is low in rotation speed and not obvious in drilling speed increasing are solved.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

A suspension system of a suspension electric vehicle and a method for using the same

PendingCN109130818AConsistent spatial locationConsistent positionSpringsElectric propulsion mountingVehicle frameEngineering

A suspension system of a suspension electric vehicle comprises a mounting beam, a vibration damping mechanism, a load bearing mechanism and a torsion resistance mechanism, wherein the vibration damping mechanism is integrally mounted on one end of the load bearing mechanism, the other end of the load bearing mechanism is connected to the power system, the vibration damping mechanism is connected to the mounting beam, one end of the torsion resistance mechanism is connected to the power system, and the other end of the torsion resistance mechanism is connected to the subframe. The load-bearingelement skeleton I and skeleton II are arranged on both sides of the power system, the damping element I is arranged on the skeleton I, and the damping element II is arranged on the skeleton II, so that the mounting beam is more force-bearing and the structure is more stable. By adjusting the direction of the rubber bushings in the damping element I and the damping element II, the stiffness of theentire suspension system in all directions is more reasonable, the limit capacity of the suspension system to the dynamic system is improved. The vibration damping element I is arranged on the frameI and the vibration damping element II is arranged on the frame II, so that the force on the mounting beam is more reasonable and the structure is more stable. The design of the anti-torsion mechanismimproves the anti-torsion ability of the whole system. The invention also discloses a method for using the suspension system of the suspension electric vehicle.

Owner:CHERY COMML VEHICLE ANHUI

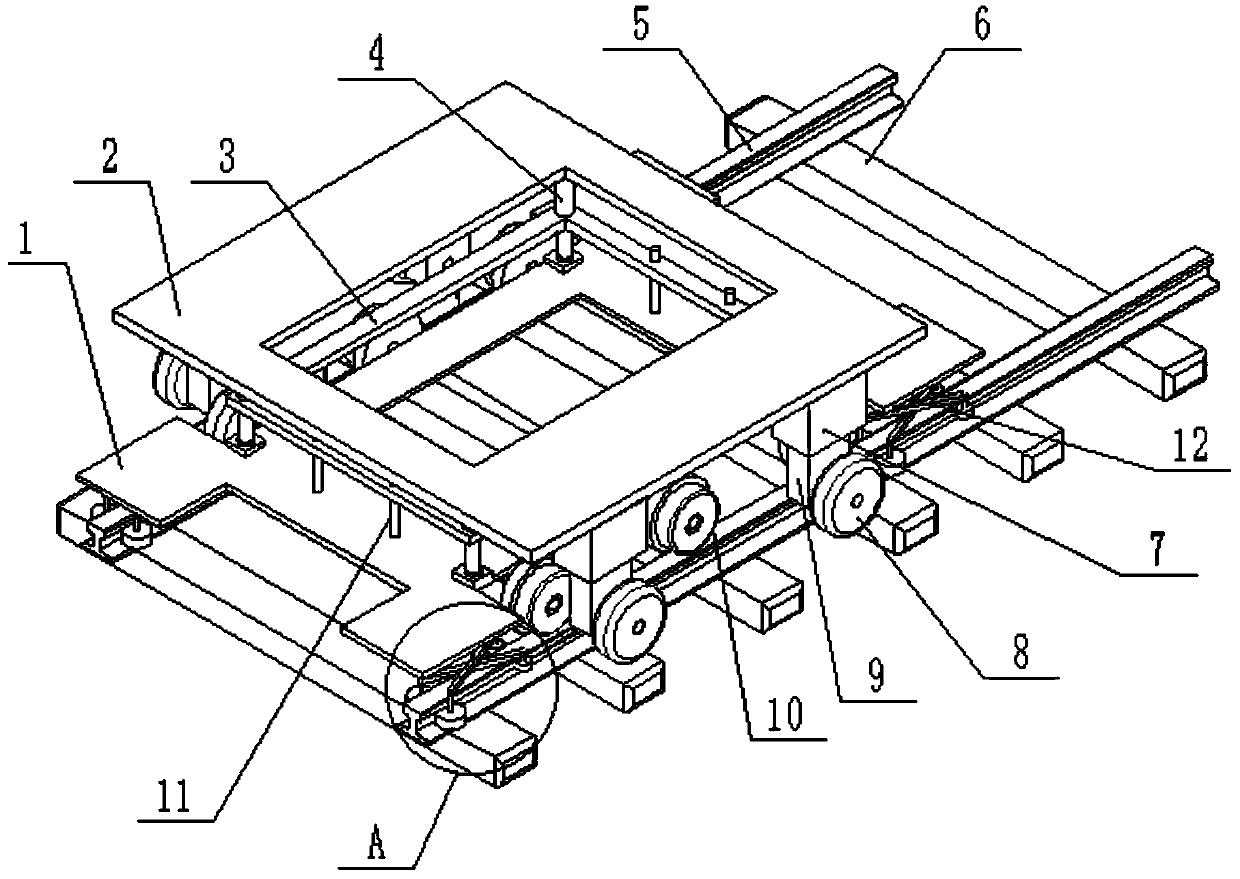

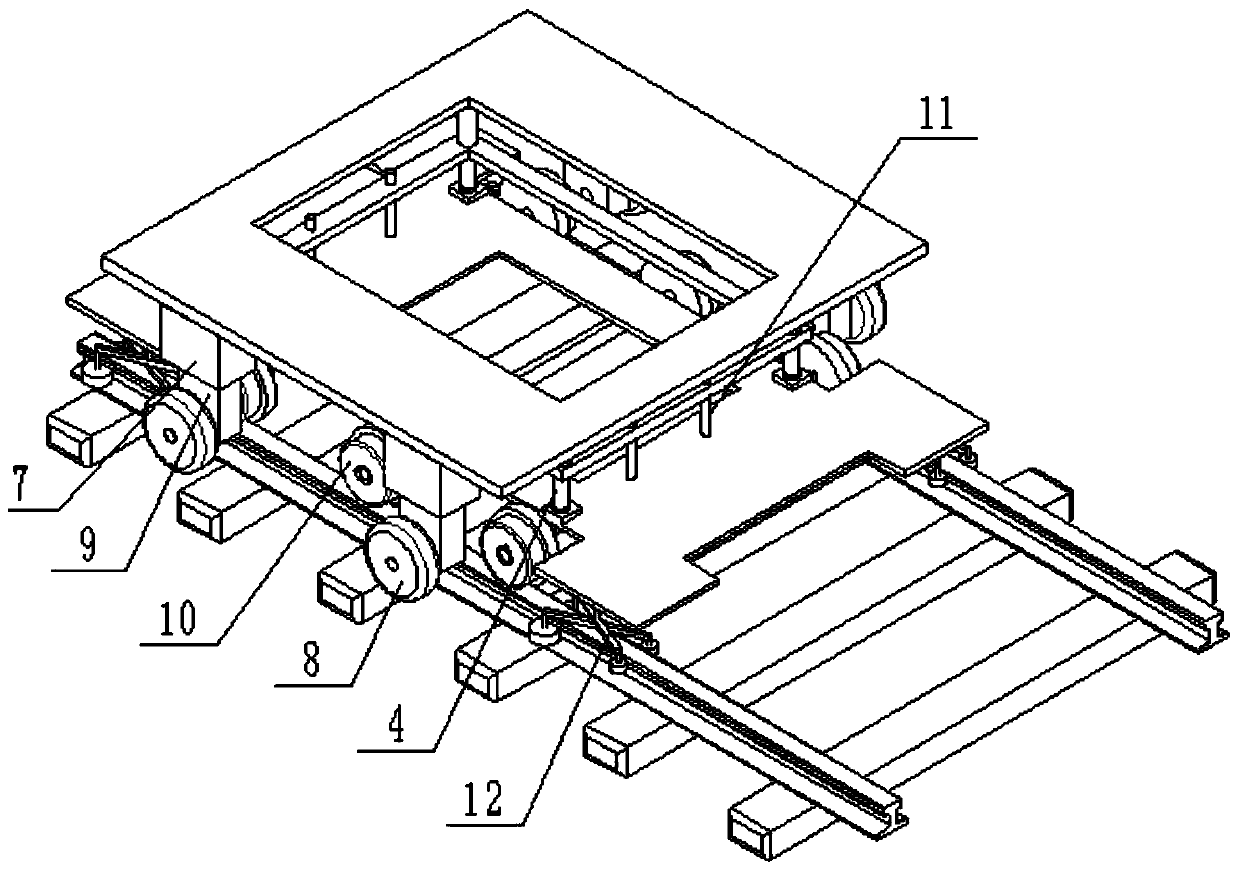

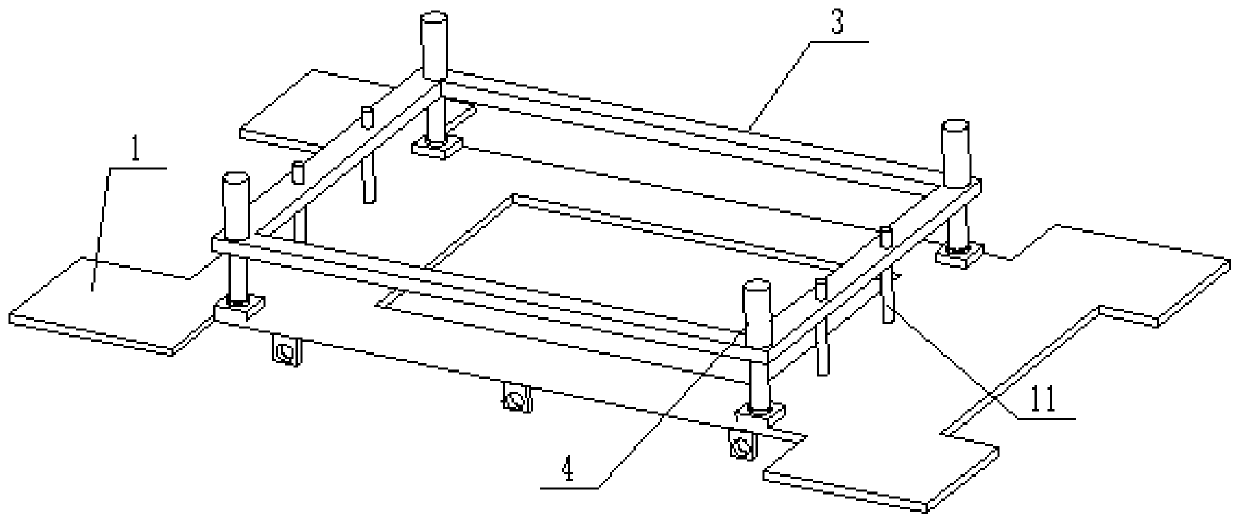

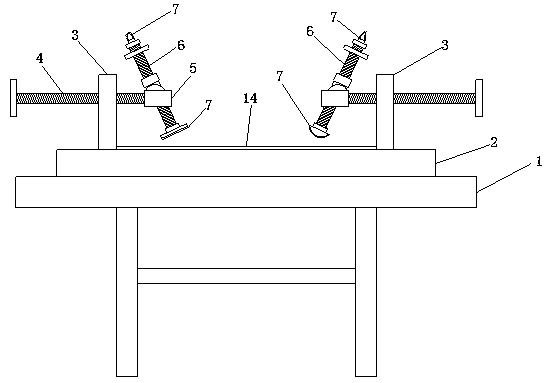

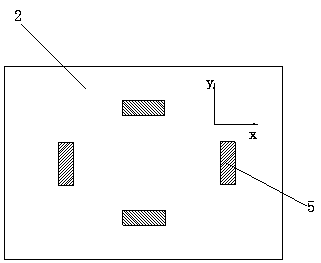

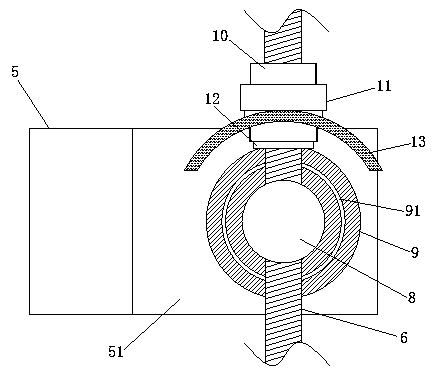

Special-shaped part clamping table and special-shaped part machining method

InactiveCN108838958ASimple structureWith self-locking abilityWork benchesLocking mechanismSelf locking

The invention discloses a special-shaped part clamping table and further discloses a special-shaped part machining method. The special-shaped part clamping table comprises a table body and an operating panel arranged on the top face of the table body. Four or more supporting seats are distributed on the panel surface of the operating panel around the same central point, wherein two or more of thesupporting seats are symmetric with respect to the y-axis, and two or more of the supporting seat are symmetric with respect to the x-axis; a horizontal telescopic rod is arranged on each supporting seat, wherein the horizontal telescopic rod faces the direction of the central point and can be self-locked; and the end, facing the central point, of each horizontal telescopic rod is the inner end, the inner end of each horizontal telescopic rod is connected with a telescopic jacking rod with a self-locking function through an angle-adjusting locking mechanism which can adjust the angle in the z-axis direction, and thus the telescopic jacking rods can conduct angle adjusting and length adjusting simultaneously. The special-shaped part clamping table is adopted for clamping. The clamping distance and angle can be adjusted according to the sizes and shapes of the parts, and the special-shaped part clamping table can be applied to clamping and fixing of the special-shaped parts with irregular surface shapes.

Owner:YANGTZE NORMAL UNIVERSITY

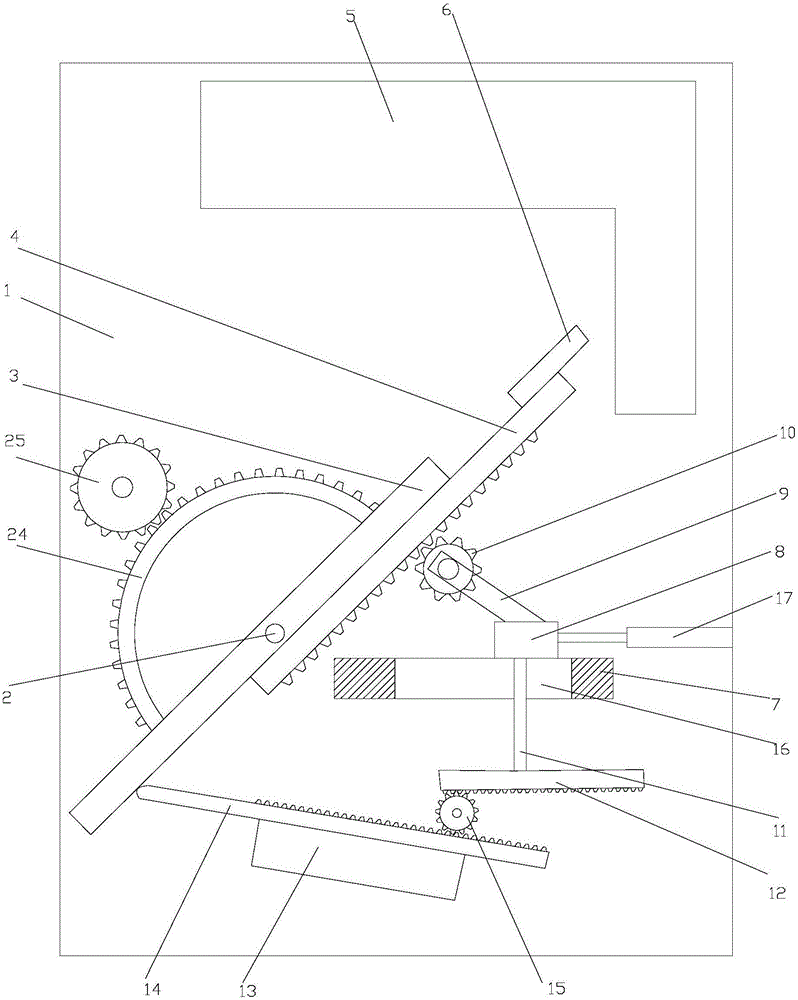

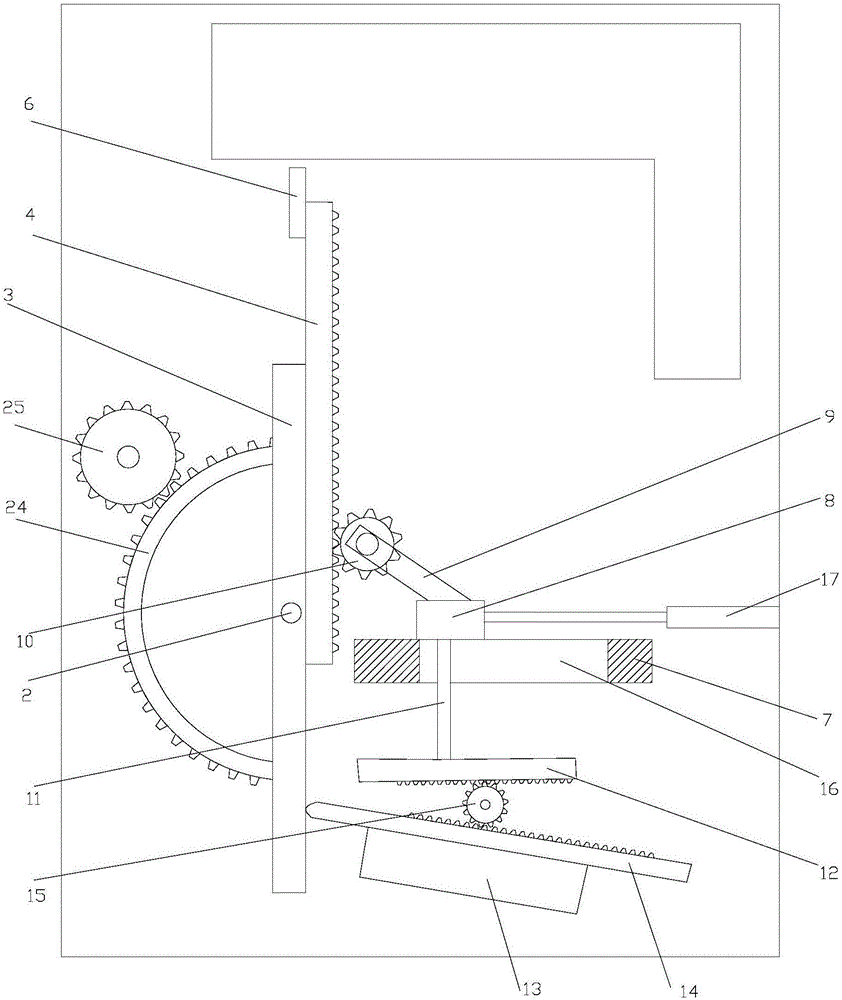

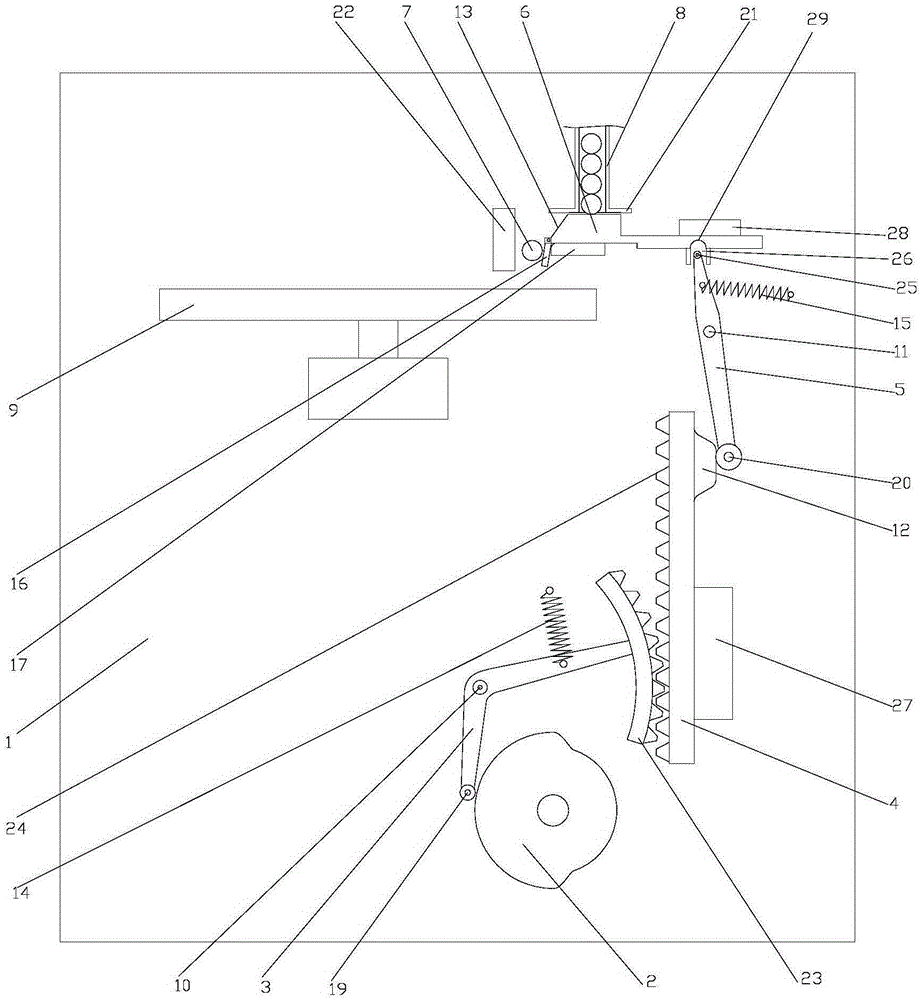

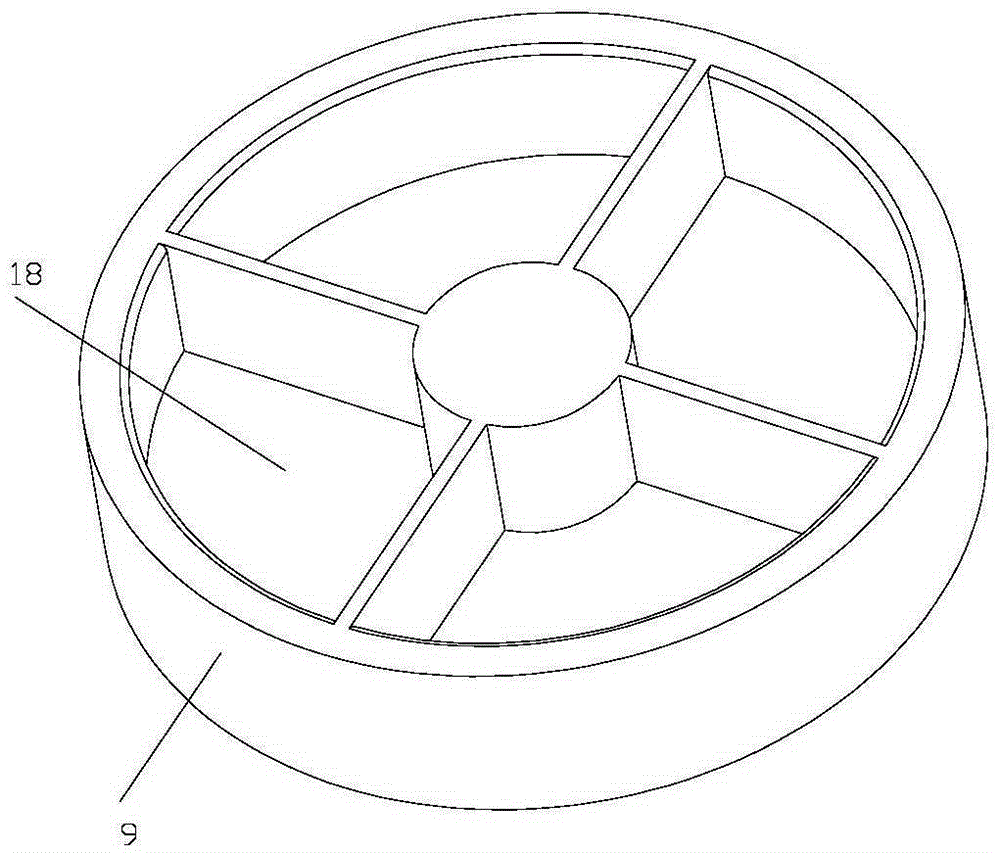

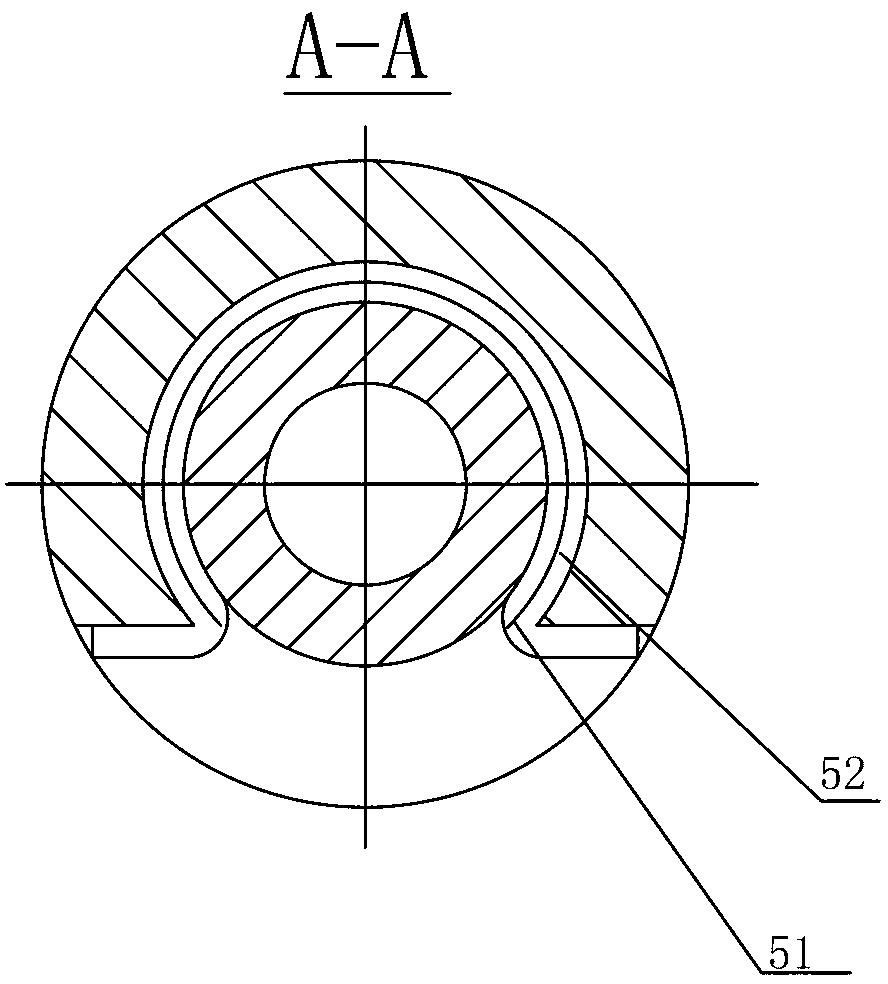

Ball automatic grouping device

The invention discloses a ball automatic grouping device. The ball automatic grouping device comprises a base (1), a cam (2), a transmission rod (3), a vertical plate (4), a swing rod (5), a push block (6), a charging barrel (8) for accommodating balls (7), and a turntable (9) for receiving the balls (7) rolling from the charging barrel (8), wherein the cam (2) is rotationally connected to the base (1); a first motor for driving the cam (2) to rotate is arranged on the base (1); the middle part of the transmission rod (3) is rotationally connected to the base (1) through a first hinge point (10); one end of the transmission rod (3) is butted against the outer contour of the cam (2), and the other end is provided with an arc rack (23); and a first tension spring (14) is arranged between the transmission rod (3) and the base (1). The ball automatic grouping device is accurate in ball counting and low in labor intensity of operators.

Owner:NEWSUN NINGBO AUTO BEARING MFG

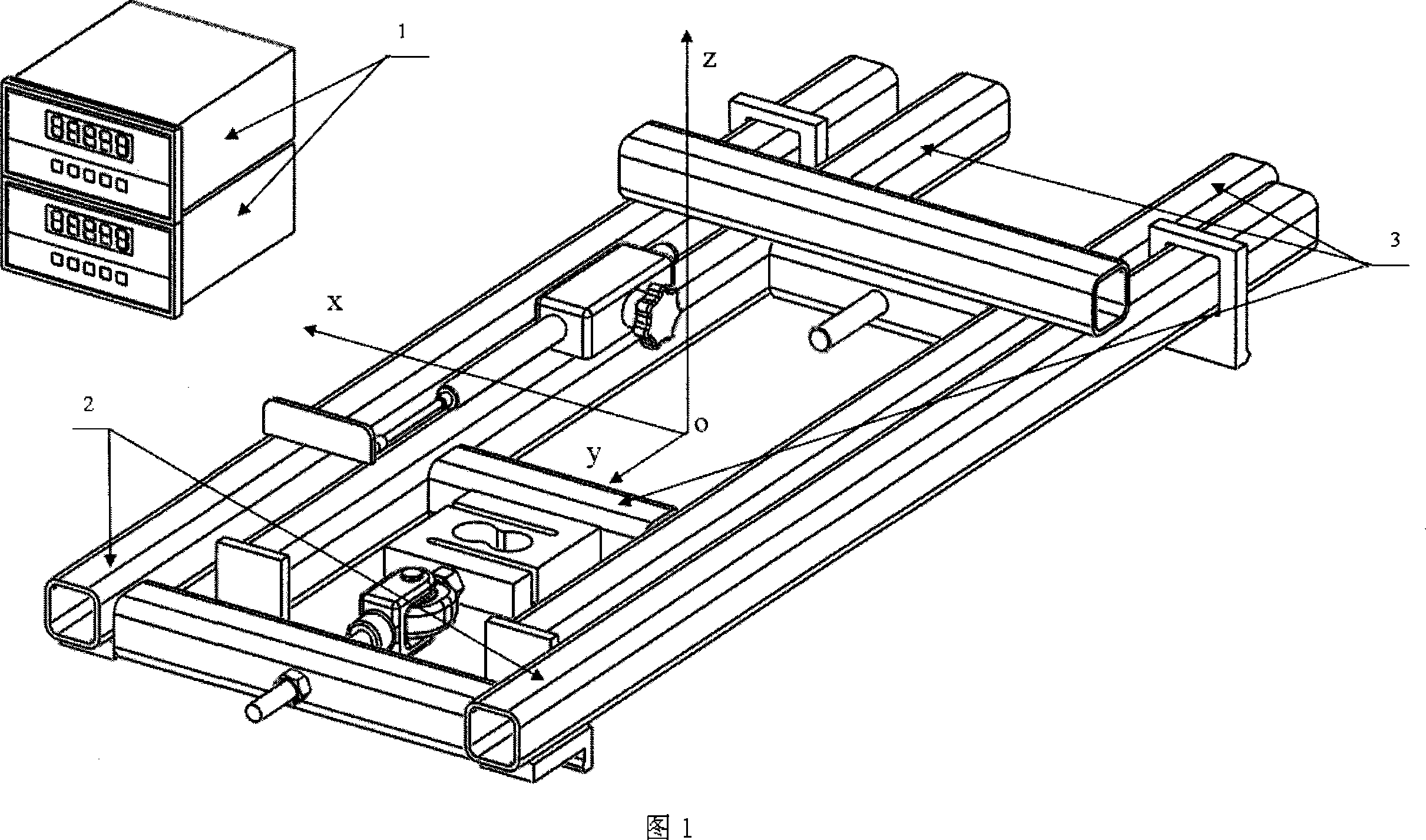

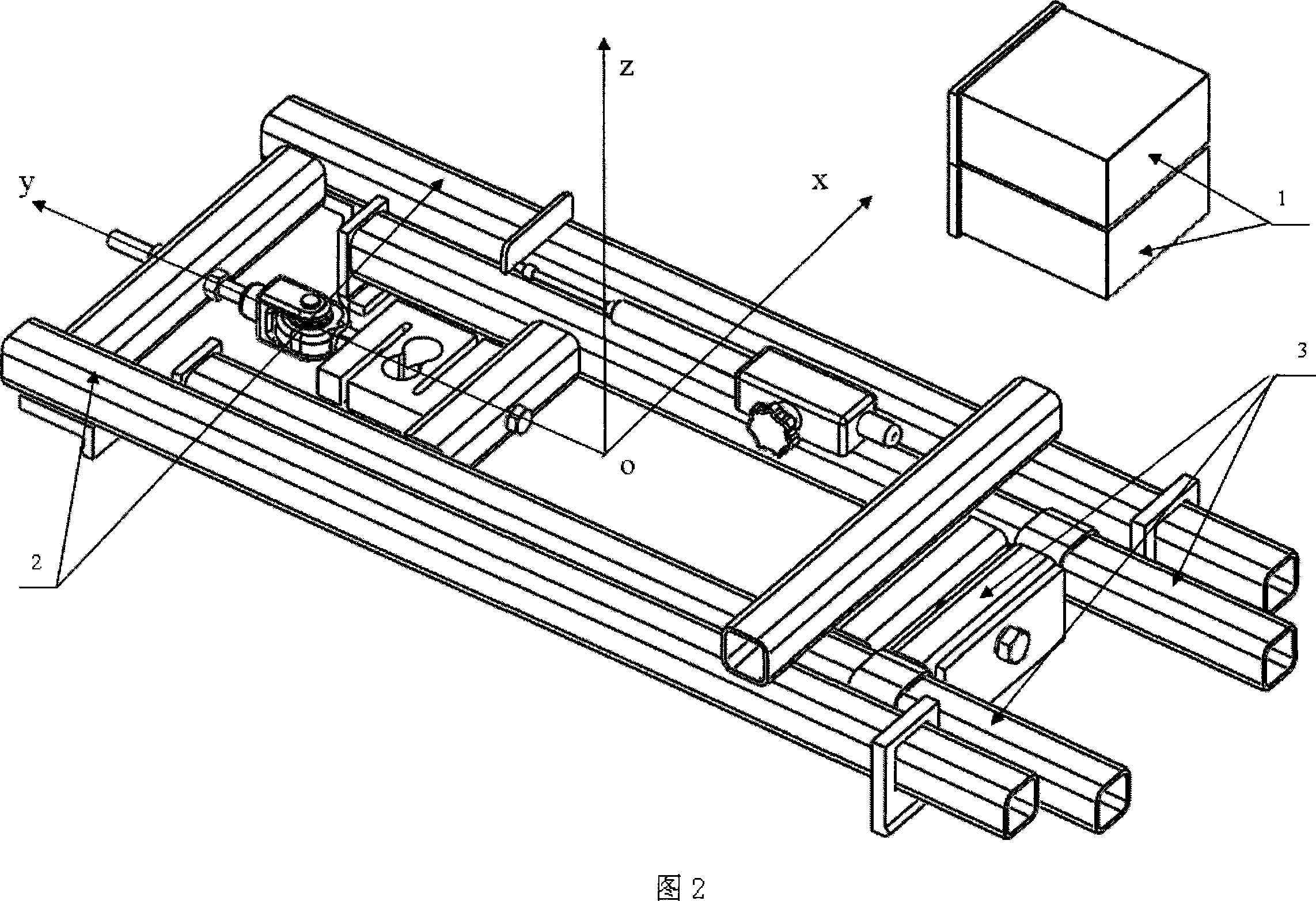

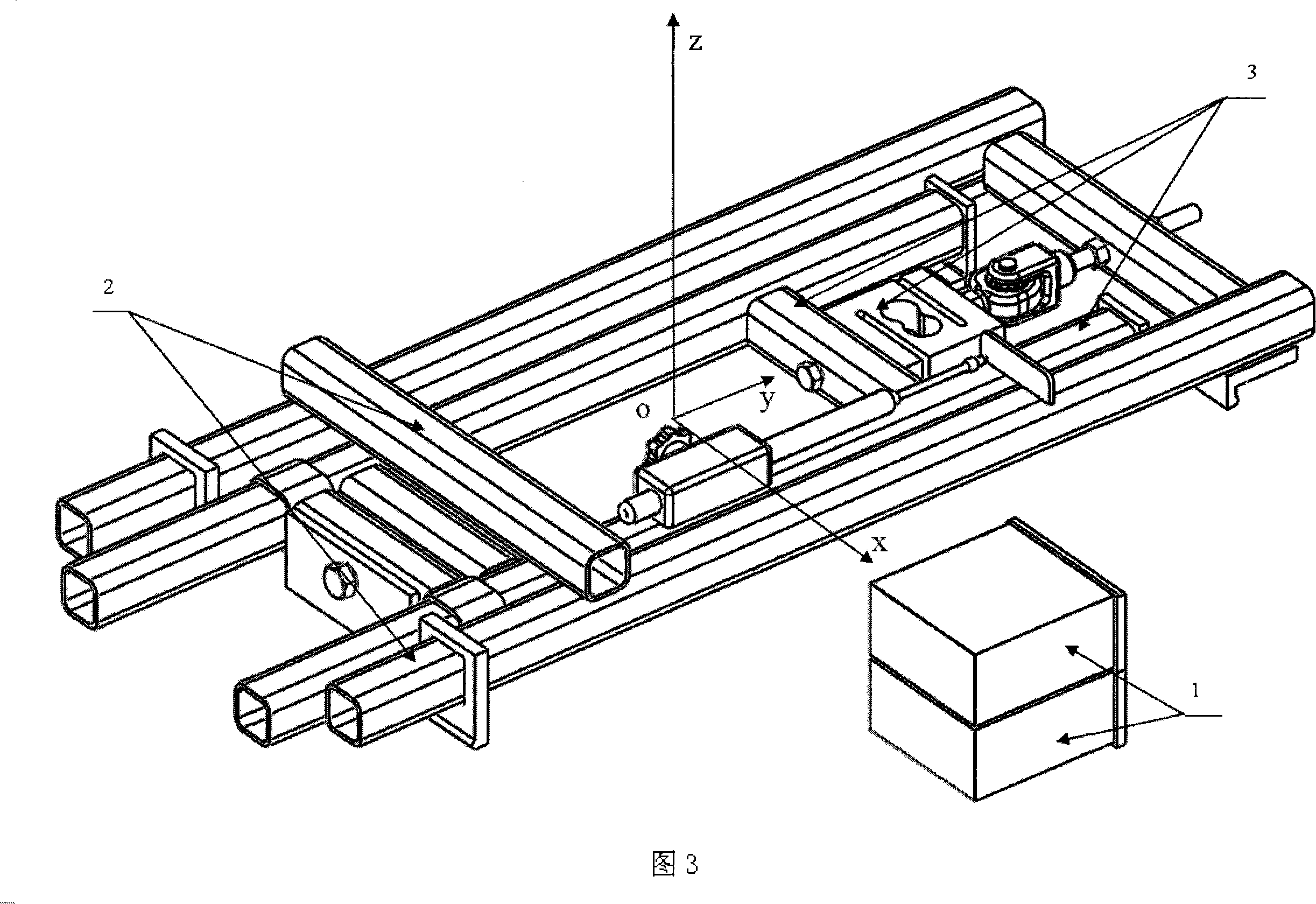

Portable digital display automotive suspension clearance test stand calibrating apparatus

InactiveCN101241047AReduce weightLow machining accuracy requirementsVehicle testingUsing electrical meansEngineeringSynchronous detection

The invention discloses a detecting device for portable digital display vehicle suspension clearance test table so as to provide a detecting device for portable digital display suspension clearance test table to fulfill blank of device of this aspect. The detecting device is composed of a digital meter (1), an outer layer gripper part (2) and an inner layer gripper part (3). The inner layer gripper part (3) is mounted in the outer layer gripper part (2), connected actively to the outer layer gripper part (2). The outer layer gripper part (2) is fixed on groundwork. Lower surface of the inner layer rectangular frame (13) in the inner layer gripper part (3) is placed on upper surface of the vehicle suspension clearance test table. The digital meter (1) is mounted outside of the outer layer gripper part (2). An interface of the digital meter (1) is connected to an interface line of a force sensor (9) and a displacement sensor (10) mounted on the inner layer gripper part (3). The invention is applied to synchronous detection of force and displacement of the vehicle suspension clearance test table.

Owner:JILIN UNIV

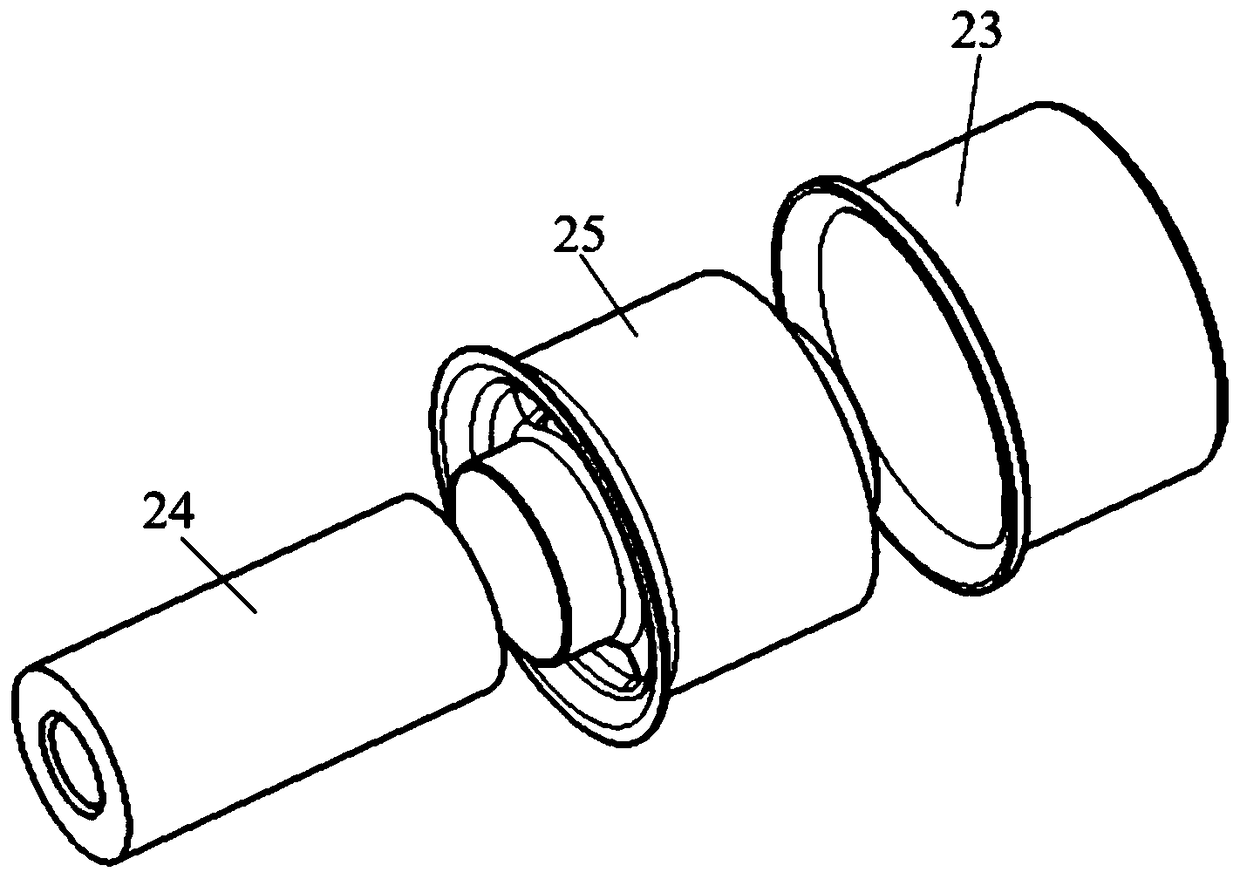

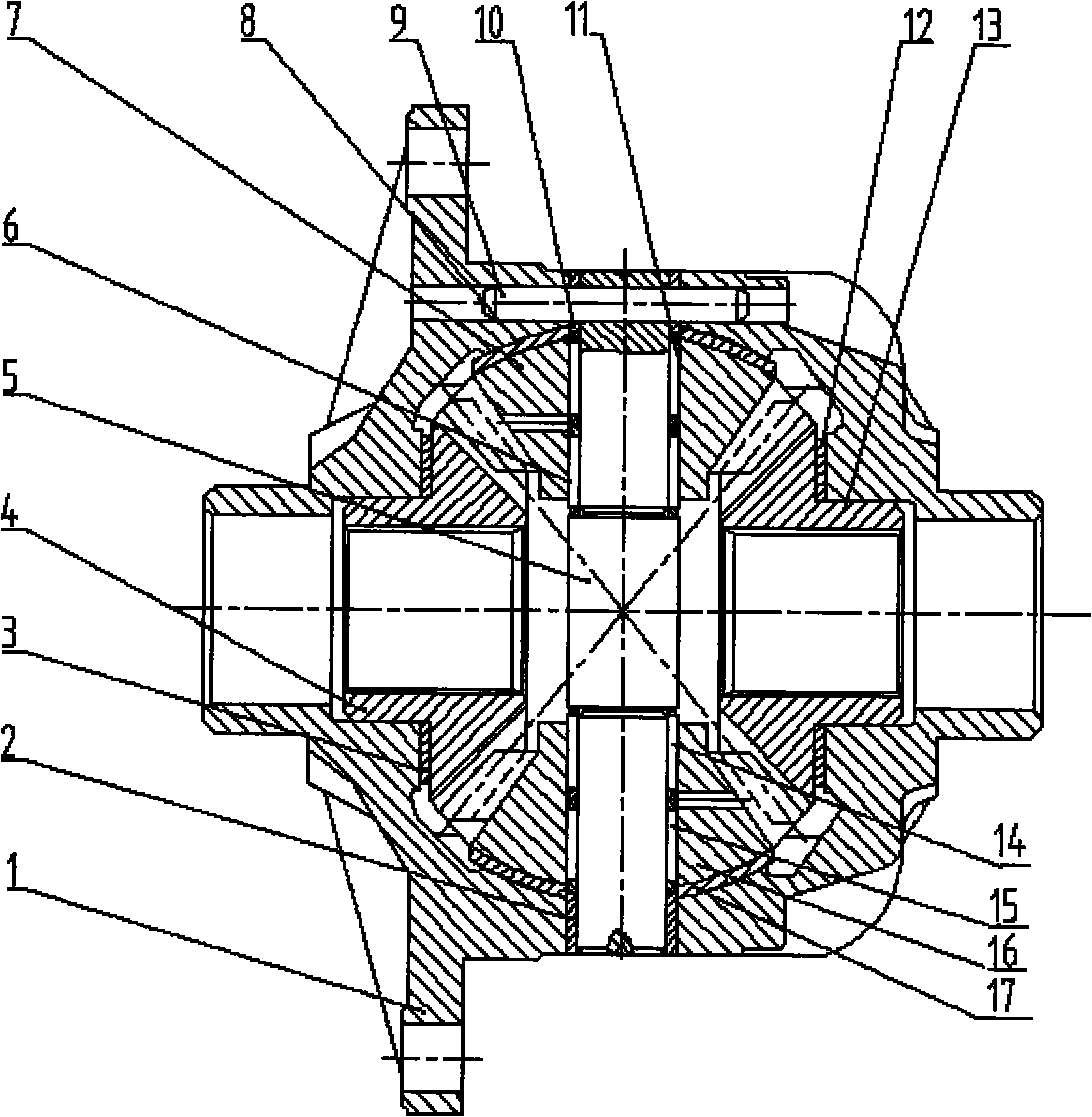

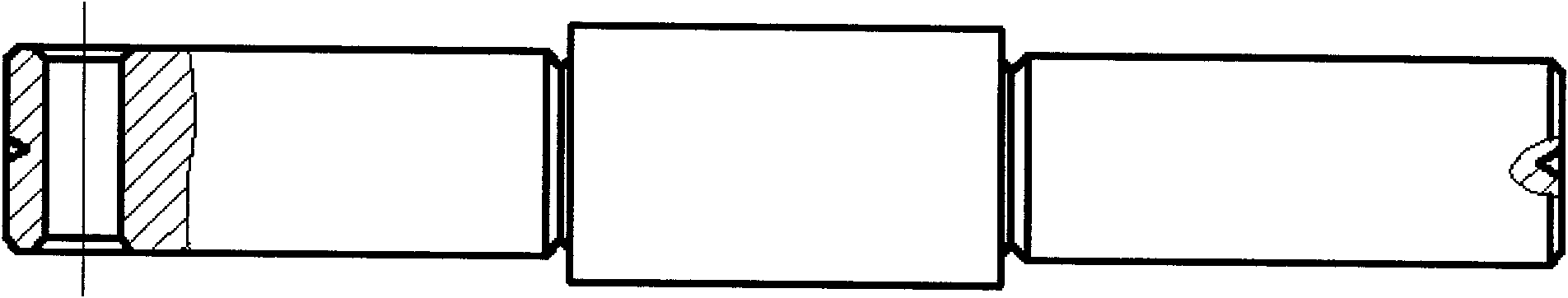

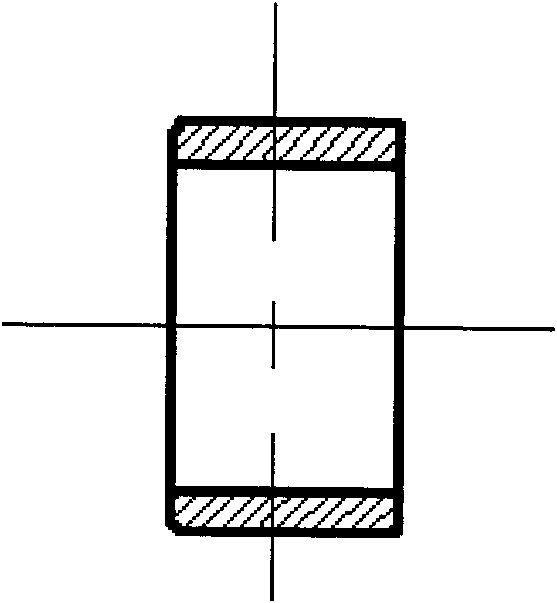

Differential-speed dynamic coupling device

InactiveCN101893077AGuaranteed uptimeSolve the problem of severe sliding wearShaftsDifferential gearingsInterference fitNeedle roller bearing

The invention discloses a differential-speed dynamic coupling device, aiming at solving the problem of sliding friction between a planetary gear and a planetary gear shaft in a traditional differential mechanism. The differential-speed dynamic coupling device comprises a differential mechanism casing, a left half shaft gear, an upper planetary gear, a right half shaft gear, a lower planetary gear, a circular sleeve without a hole, a planetary gear shaft, an upper needle bearing No. 1, an upper needle bearing No. 2, a circular sleeve with a hole, a lower needle bearing No. 1, a lower needle bearing No. 2 and the like, wherein the upper needle bearing No. 1, the upper needle bearing No. 2, the circular sleeve with a hole, and the lower needle bearing No. 1, the lower needle bearing No. 2 and the circular sleeve without a hole are sleeved on the upper end and the lower end of the planetary gear shaft in sequence, the planetary gear shaft which is sleeved with the circular sleeve with a hole and the circular sleeve without a hole is installed in an upper end hole and a lower end hole of the differential mechanism casing, and the circular sleeve without a hole and the lower inner hole of the differential casing form the interference fit. The upper planetary gear and the lower planetary gear which are installed on the upper end and the lower end of the planetary gear shaft are respectively and simultaneously meshed with the left half shaft gear and the right half shaft gear which are arranged in the left end hole and the right end hole of the differential mechanism casing.

Owner:JILIN UNIV

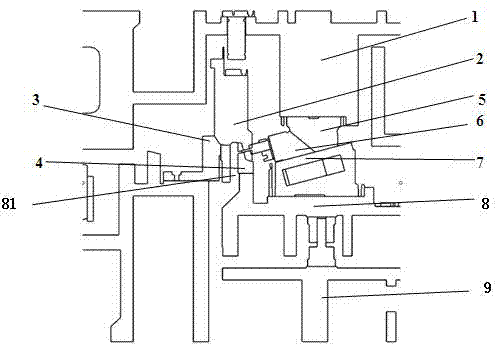

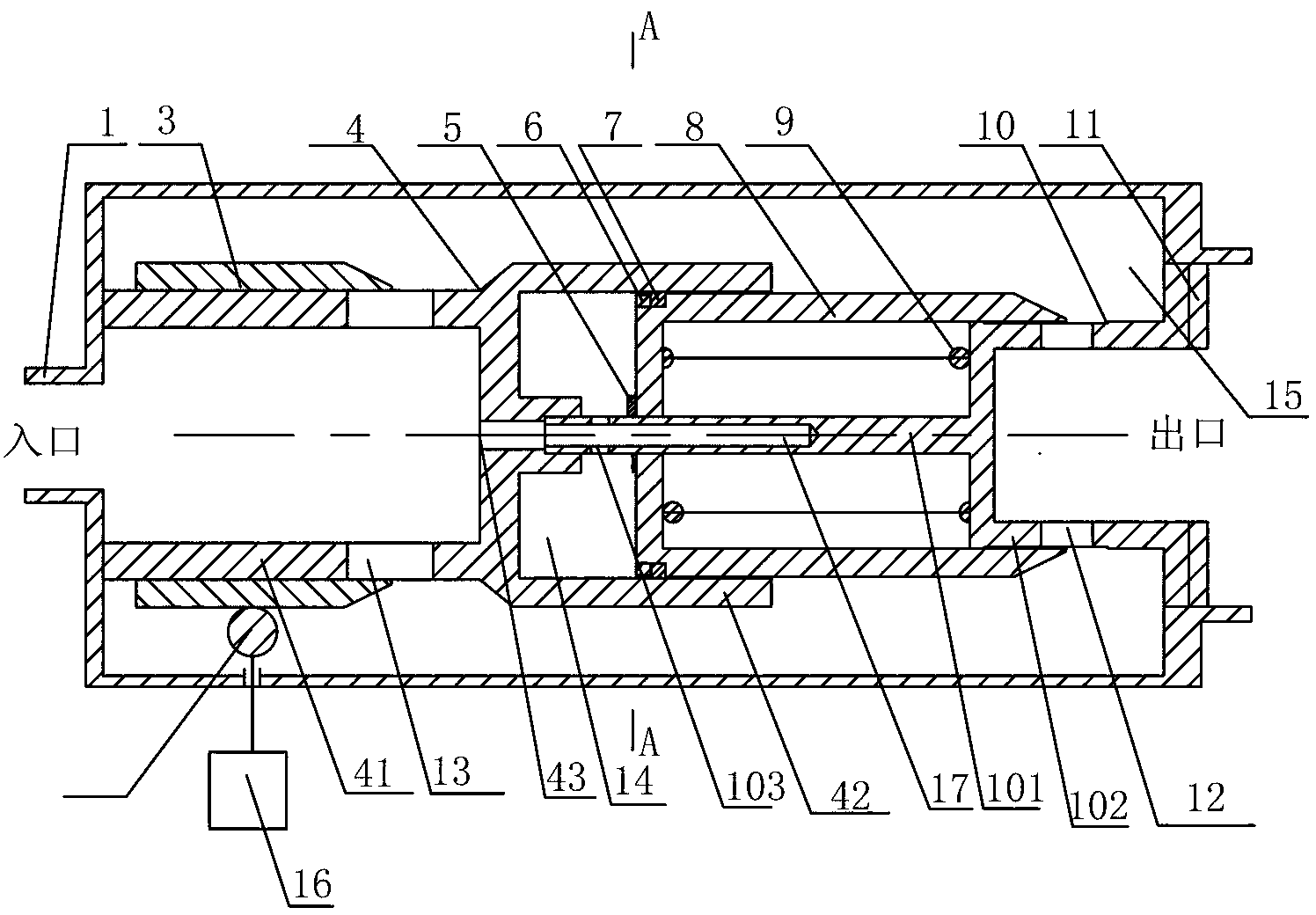

Integral high-pressure small-flow adjuster

InactiveCN103016769ASimple structureReduce structural weightOperating means/releasing devices for valvesSlide valveLiquid mediumControl system

The invention relates to an integral high-pressure small-flow regulator which comprises a shell, a pressure difference regulation component, a power regulation component, a slide valve seat and a supporting sleeve, wherein the supporting sleeve is arranged at the inlet of the shell; the supporting sleeve comprises an inlet diversion sleeve and a spacing seat which are sequentially and fixedly connected; the inlet diversion sleeve is provided with an inlet throttling hole; the slide valve seat comprises a fixed barrel and an outlet diversion sleeve which are sequentially and fixedly connected; the other end of the fixed barrel is fixedly connected with the support sleeve; the other end of the outlet diversion sleeve is fixed on the shell; and the outlet diversion sleeve is provided with an outlet throttling hole. The integral high-pressure small-flow adjuster is used for solving the technical problems of low precision and poor stability of an existing medium flow regulating system, can be used for controlling the flow of a liquid medium in a liquid control system, and is stable in flow and high in precision under the operating conditions of high pressure and great pressure changes.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

Multi-module composite complete machine linkage soft package lithium battery intelligent manufacturing control system and method

ActiveCN111258286AAvoid motion interferenceImprove product qualityAssembling battery machinesFinal product manufactureControl signalEngineering

The invention discloses a multi-module composite complete machine linkage soft package lithium battery intelligent manufacturing control system and method, and relates to the technical field of lithium battery intelligent manufacturing. The method is used for controlling the soft package lithium battery intelligent manufacturing system. The soft package lithium battery intelligent manufacturing system comprises a lamination device, a welding device, a heat sealing device, a liquid injection device and a formation device, and comprises a cloud network, an upper computer and a PLC main station which are in control connection, and the PLC main station is in control signal connection with a battery cell manufacturing control module, an aluminum plastic film heat sealing control module and a liquid injection formation control module. According to the control system, mechanical overall linkage and multi-channel information interaction, data analysis and intelligent process parameter optimization in electrical control are achieved, all the modules achieve whole-line linkage in the mechanical aspect and the control aspect, and all the modules and an intelligent system of an execution layerachieve information data interaction through a switch.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

Computer main board automatic detection device and detection method thereof

The invention discloses a computer main board automatic detection device and a detection method thereof, and relates to the technical field of computer detection. The computer main board automatic detection device comprises a workbench, the middle of the workbench is hollowed to be in a concave shape, a partition plate is arranged above an opening in one side and used for bearing a positioning clamping mechanism, and a feeding mechanism is arranged on the side, away from the partition plate, of the top end of the workbench; the feeding mechanism reciprocates in the direction of the clamping mechanism and is matched with the clamping mechanism to clamp and position main boards, and a detector connector is further arranged on the workbench and used for connecting the main boards and a detector; the positioning and clamping mechanism is rotationally connected with the partition plate, the positioning and clamping mechanism rotates by 90-180 degrees under driving mechanism, and conveying belts are arranged in the 90-degree direction and the 180-degree direction correspondingly and used for sorting and warehousing the main boards; and when the feeding mechanism moves in the direction of the clamping mechanism, the clamping mechanism is sequentially driven to rotate and perform clamping and closing actions through the connecting assembly. According to the computer main board automatic detection device, automatic feeding, positioning clamping, detection and sorting warehousing of the main boards are realized, the detection efficiency of the main boards is improved, and the personnel cost is reduced.

Owner:NANJING AUDIT UNIV

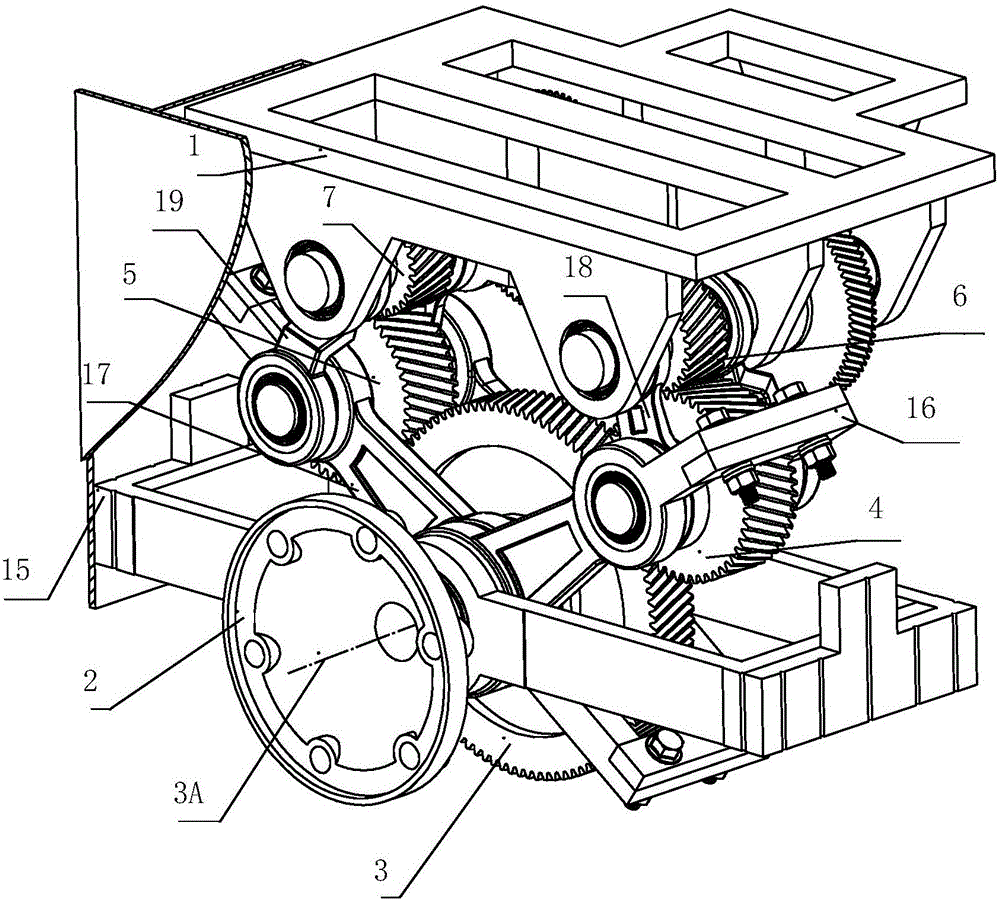

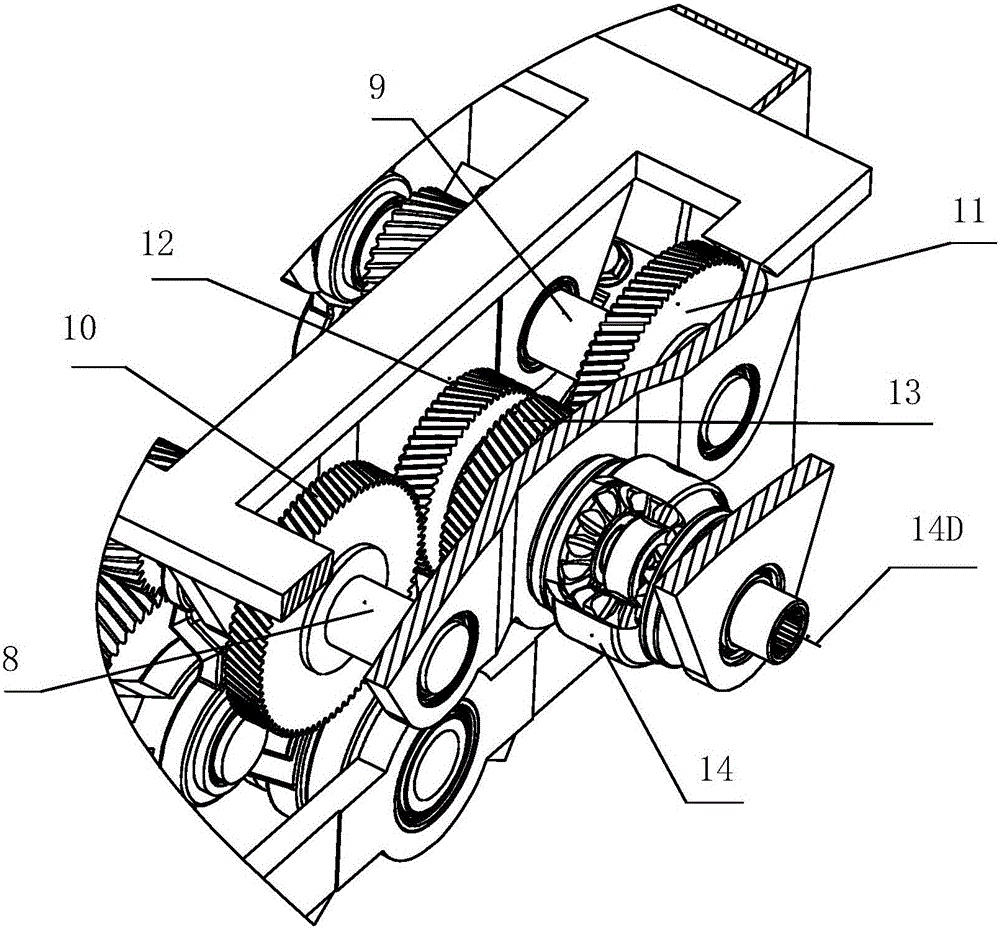

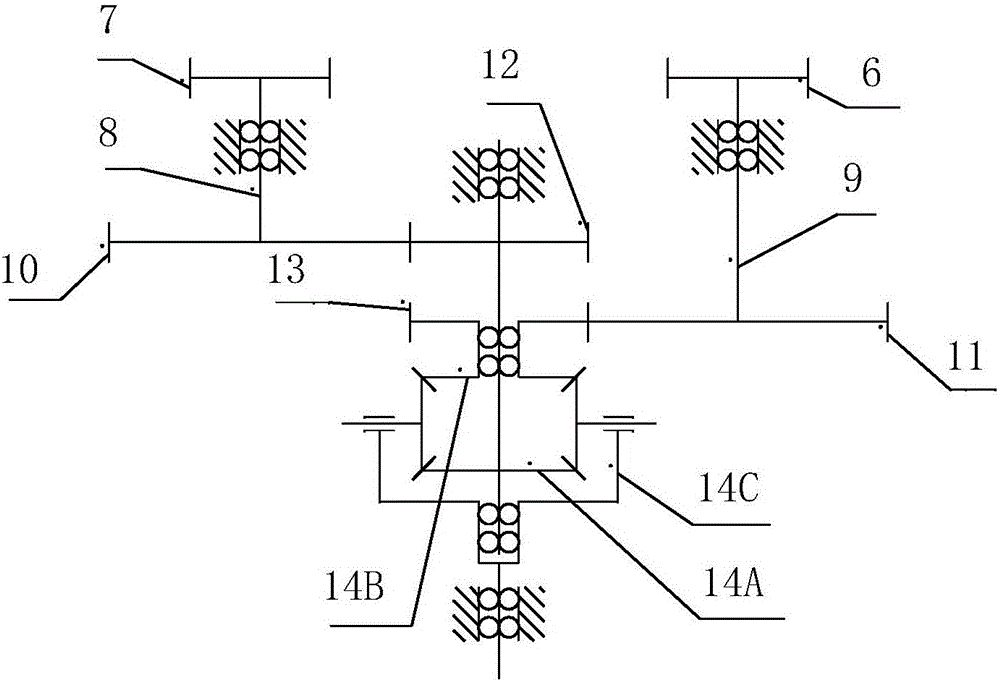

Two-degree-of-freedom decoupling reducing mechanism

ActiveCN105774450ASmall inertia forceSmall sizeResilient suspensionsControl devicesEngineeringTwo degrees of freedom

The invention provides a two-degree-of-freedom decoupling reducing mechanism, and aims to solve the problem of contradiction between irregular forced vibration and stable driving force transmission at a power output end, and output stable power while reducing inertia force at the power output end. The two-degree-of-freedom decoupling reducing mechanism comprises a frame (1), a power output shaft (2), a power output wheel (3), idle wheels I and II (4, 5), secondary reduction gears I and II (6, 7), shafts I and II (8, 9), primary reduction gears I and II (10, 11), transfer gears I and II (12, 13), a differential assembly (14), a linear guide mechanism (15), and connecting rod bearing assemblies I, II, III and IV (16, 17, 18, 19). By adopting the two-degree-of-freedom decoupling reducing mechanism, decoupling of linear movement and rotation at the power output end can be realized, and a power source does not translate along with the power output end, so that the inertial force at the power output end is reduced, and stable output power is kept. The mechanism is small in overall size, is short in transmission chain, and is convenient to install and apply.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com