Double-wishbone front-suspension system applied to driving of inner rotor hub motor

A hub motor and inner rotor technology, applied in the direction of suspension, elastic suspension, steering mechanism, etc., can solve the problems of affecting the force transmission, the impact of the damping effect of the shock absorber, and the swing of the shock absorber, so as to ensure the ride comfort , Small changes in hard point parameters, and good process integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

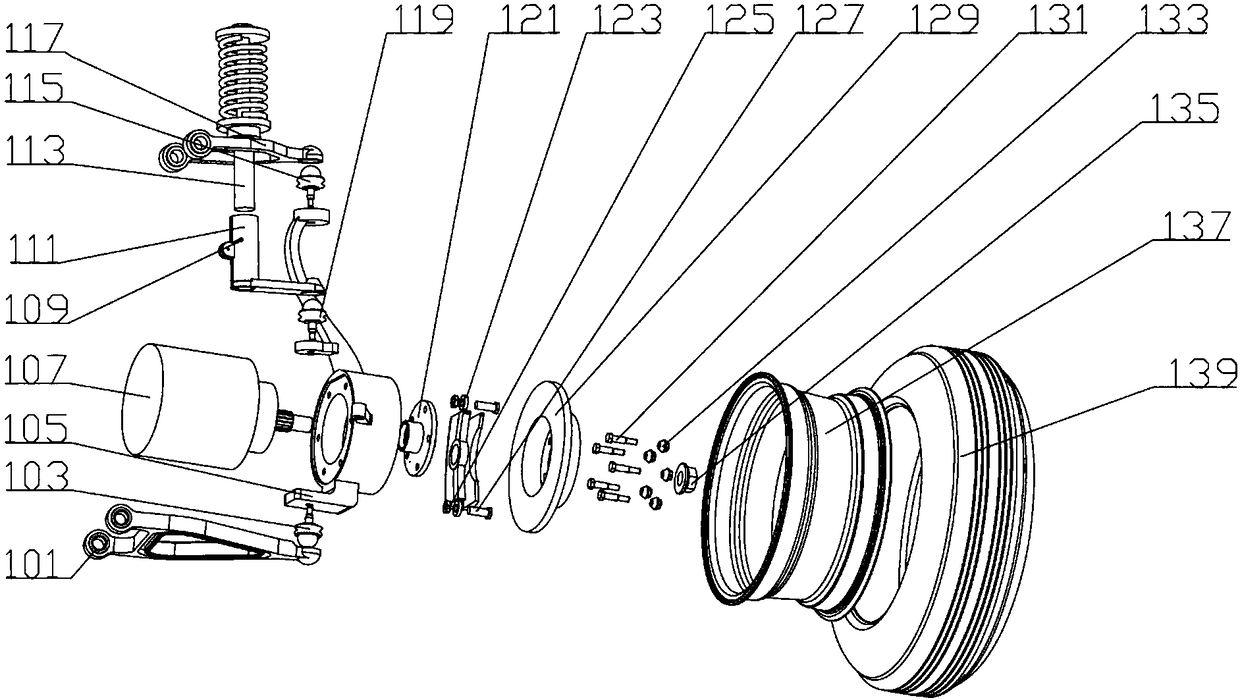

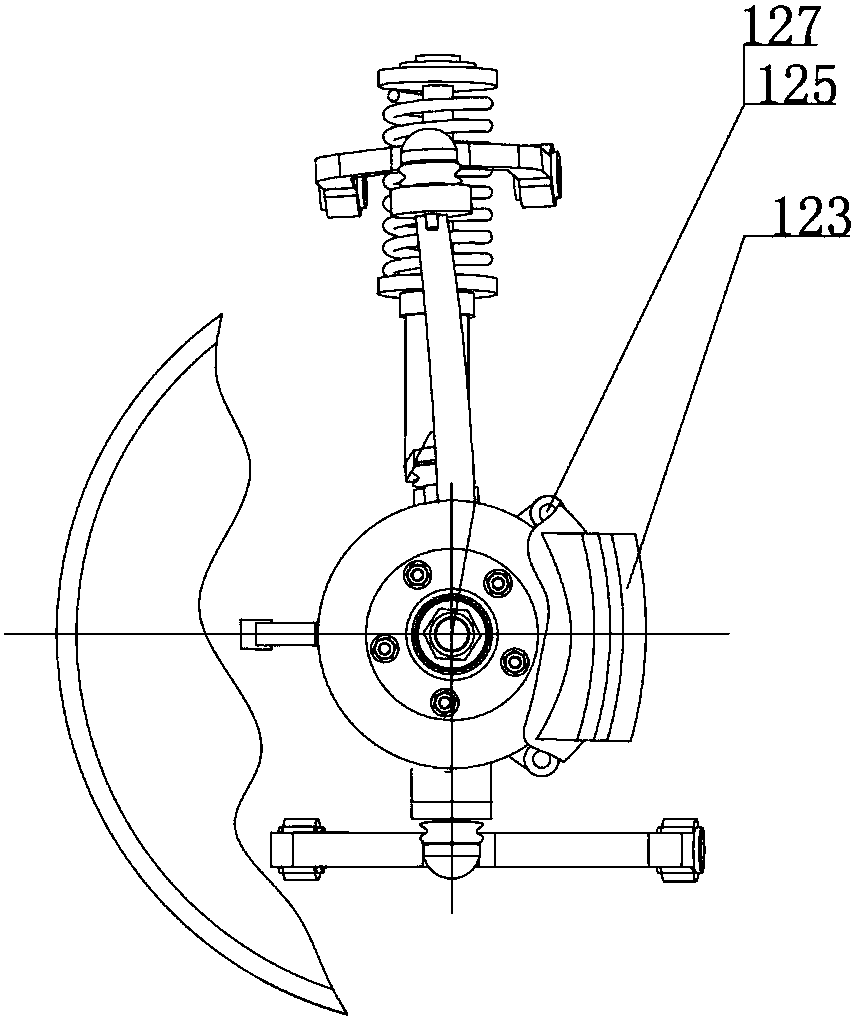

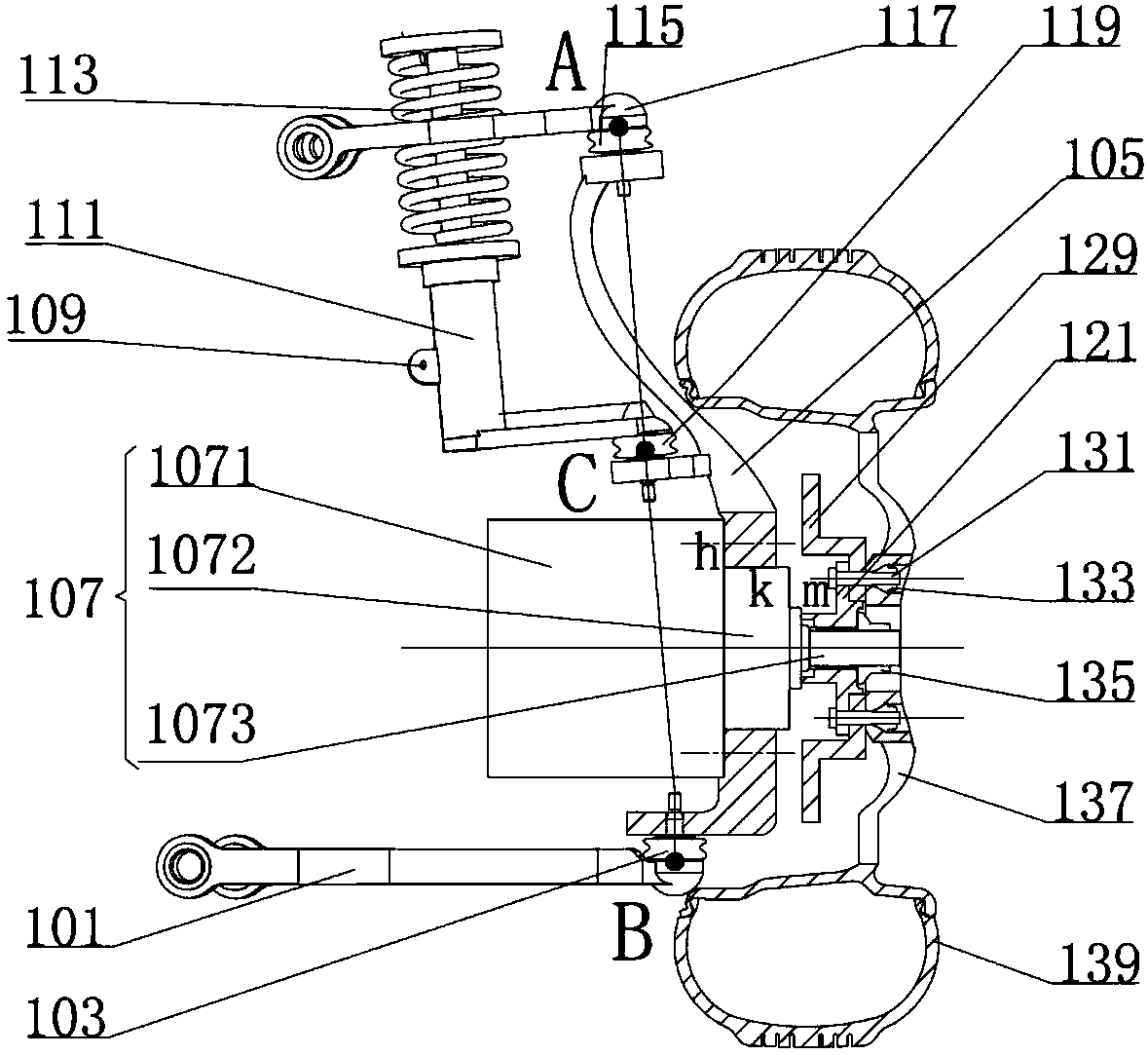

[0043] Such as figure 1 , image 3 As shown, the double-wishbone front suspension system applied to the drive of the inner rotor hub motor according to the present invention mainly includes three parts, the suspension, the hub motor 107 and the wheels.

[0044] The hub motor 107 includes a drive motor and a reducer, and adopts an integrated design. The drive motor adopts a high-speed and low-torque inner rotor permanent magnet synchronous motor. The reducer of the driving motor adopts a coaxial large reduction ratio planetary gear reduction mechanism (not shown separately in the figure), and its specific structure is not limited. The output torque of the driving motor is amplified by the large reduction ratio reducer and then output. The shape of the hub motor 107 is divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com