Patents

Literature

4414results about "Pivoted suspension arms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

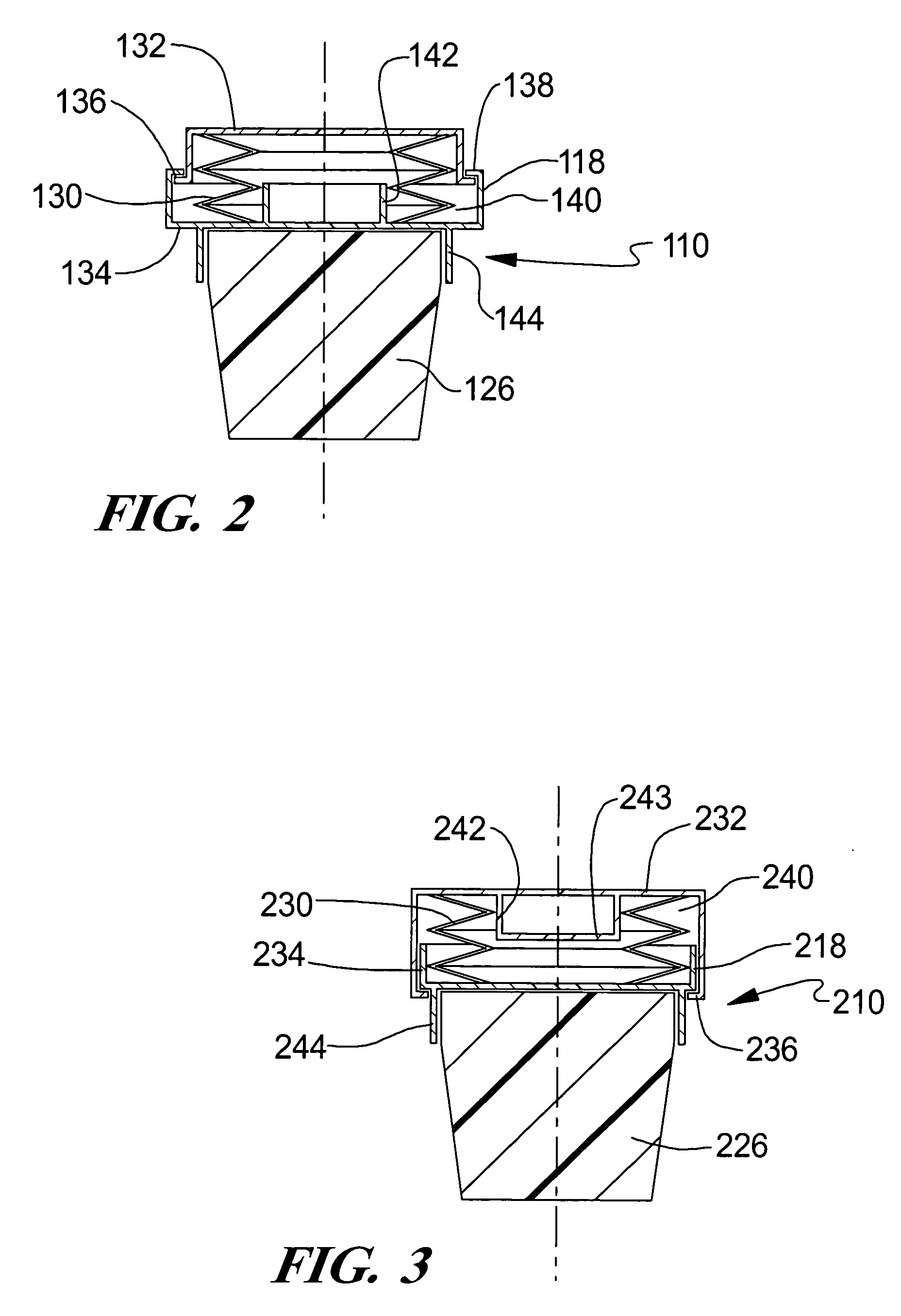

Multiple shaft diameter flexible coupling system

Compression exerted by a clamp collar integral to a molded plastic flexible shaft coupling accommodating angular shaft misalignment upon the circumferential outward surface of a radially compressible molded sleeve insert located in a shaft bore of the flexible coupling facilitates engagement of a reduced diameter shaft located within the sleeve insert. Use of a sleeve insert having a different internal diameter similarly accommodates flexible coupling to another diameter shaft. Utilization of sleeve inserts selected from a plurality of different reduced internal diameters and exterior diameters sized to fit either shaft bore enables flexible coupling of both multiple matched shaft diameters and an exponential number of differing opposed shaft diameter combinations within a range limited by the flexible coupling shaft bores. Radial compressibility of the sleeve insert is facilitated by the utilization of resilient material, interruption of the circumferential extension by a longitudinal slot, or both. Utilization of congruent longitudinally uniform, radially non-uniform, flexible coupling shaft bore and insert sleeve outward surfaces provides additional torque transmission capacity.

Owner:SHINOZUKA KINZOU

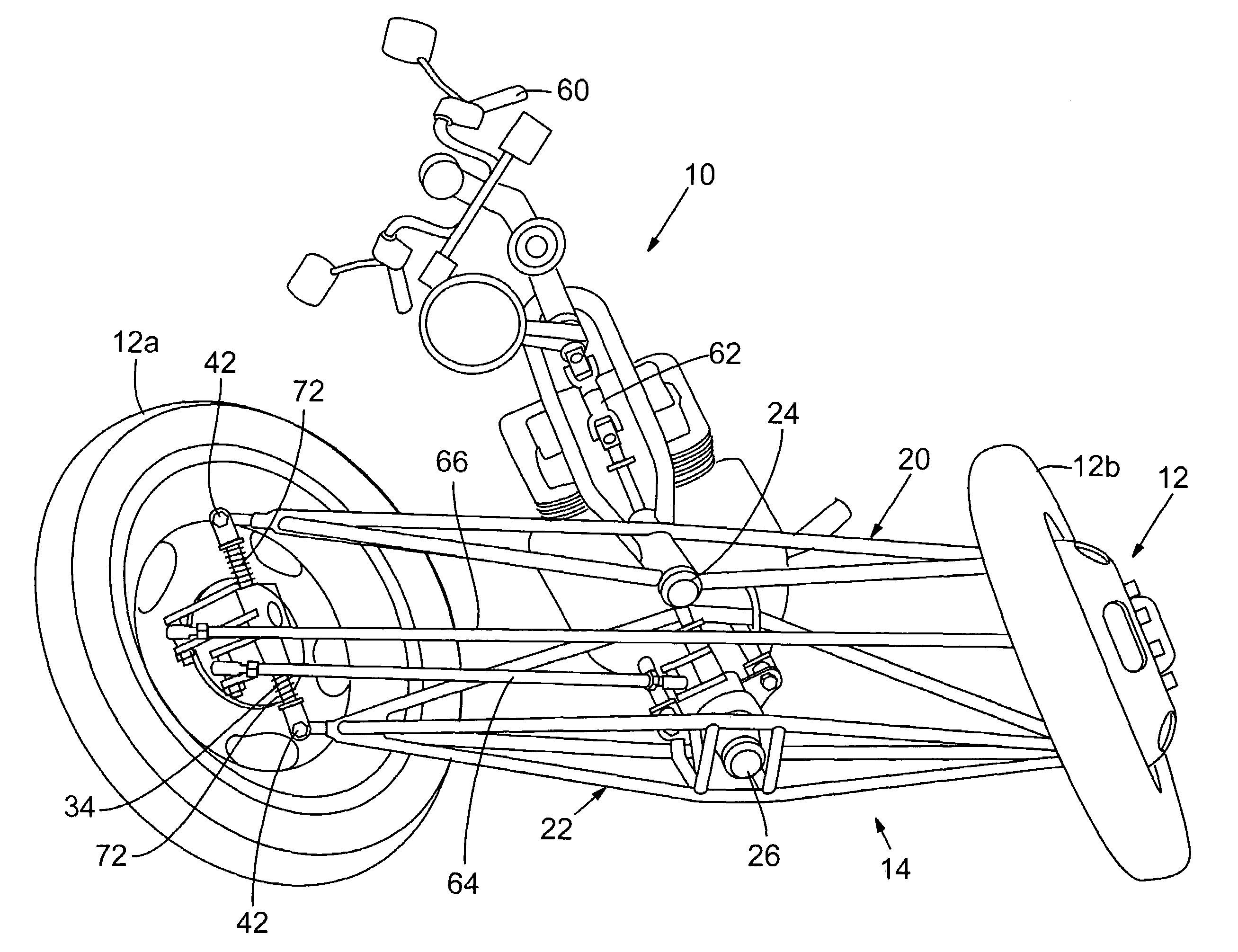

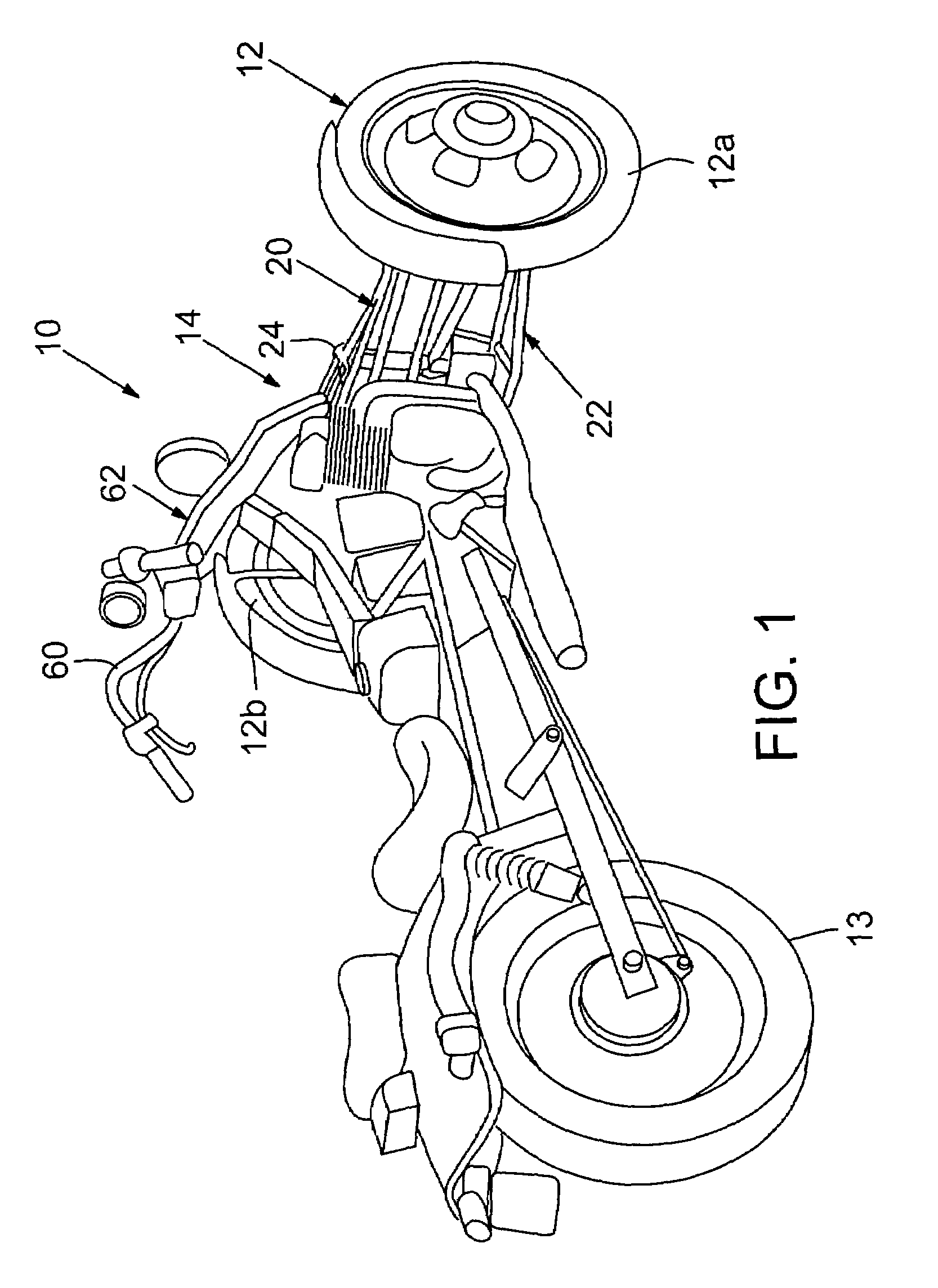

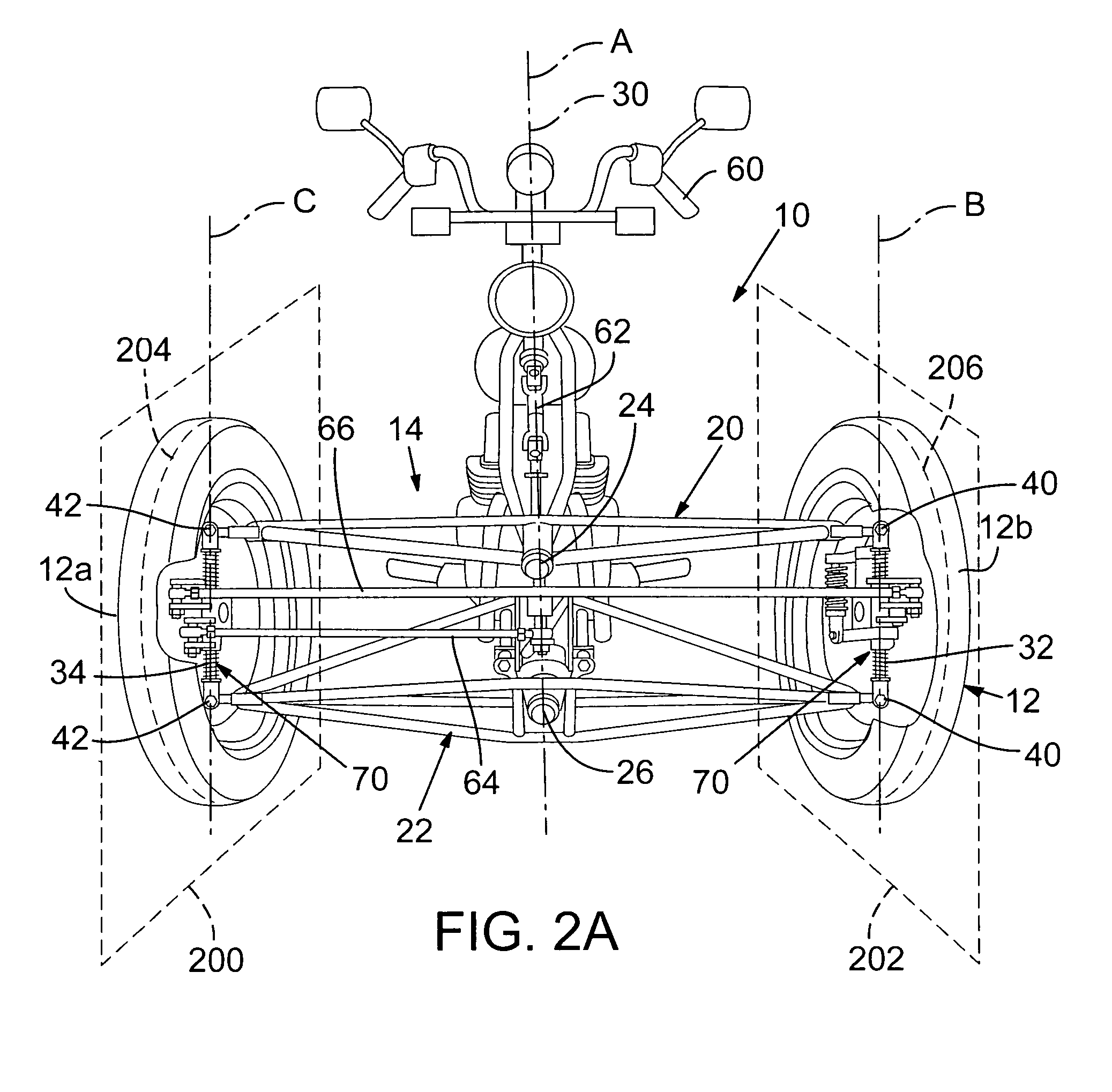

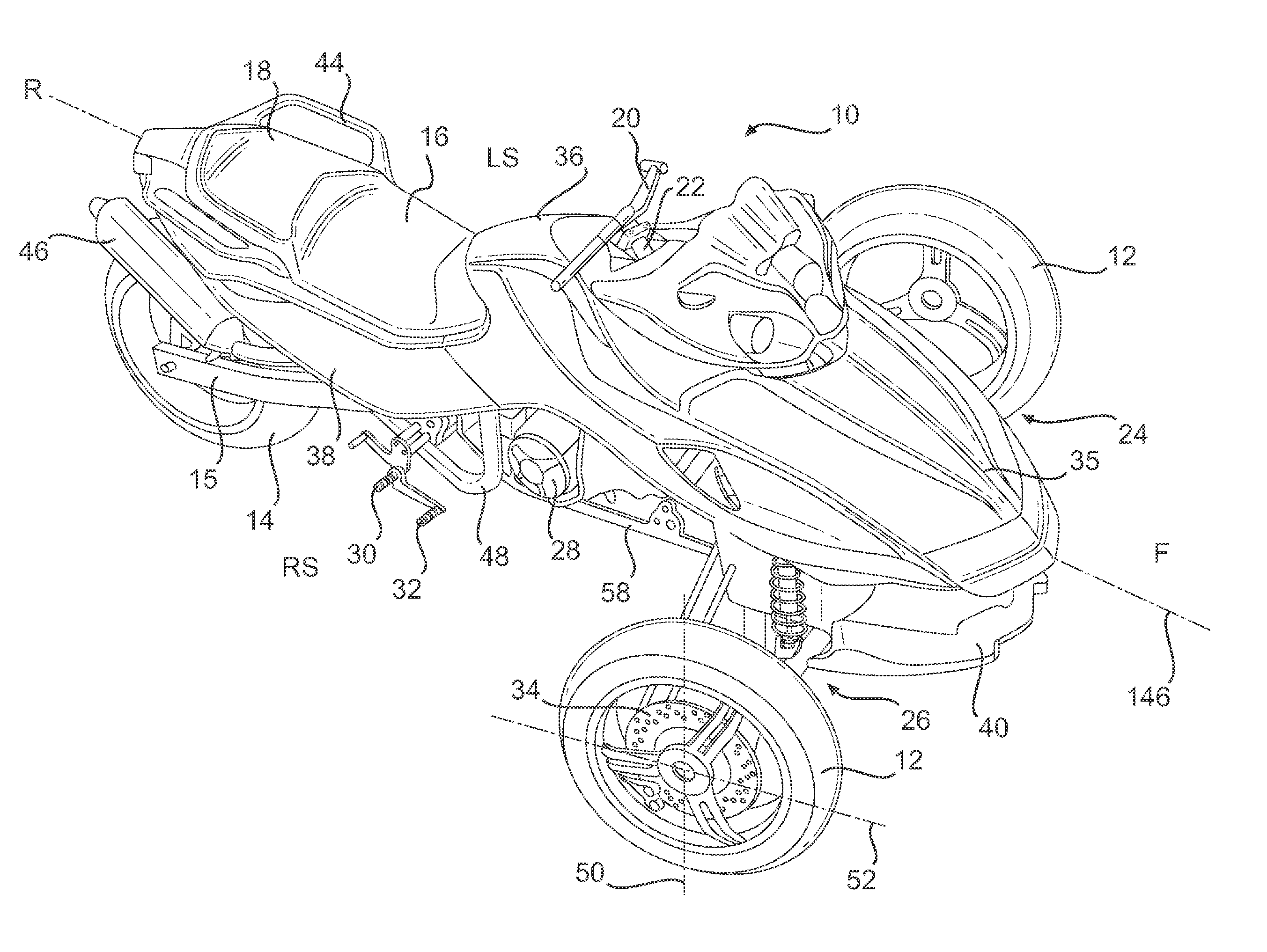

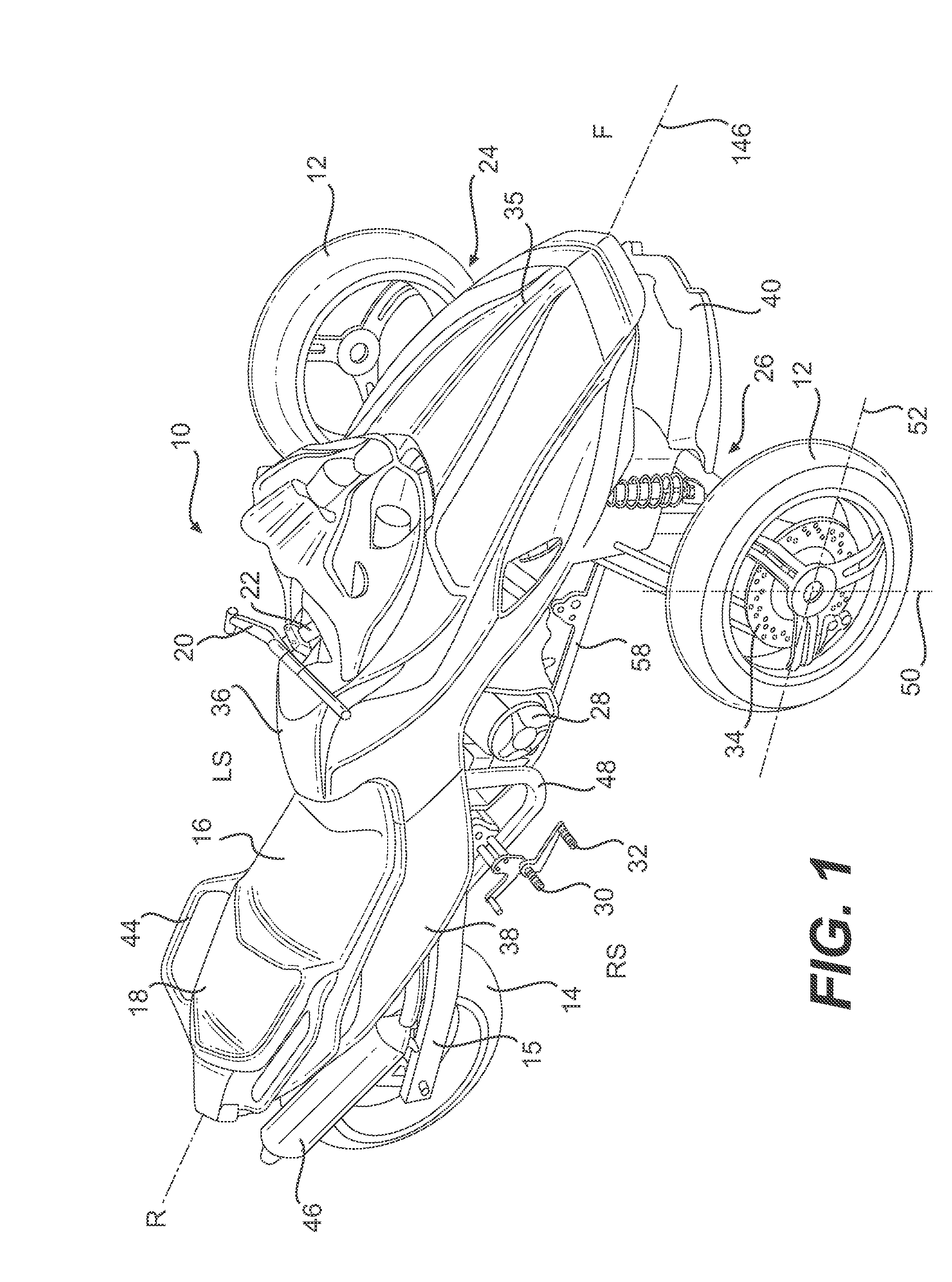

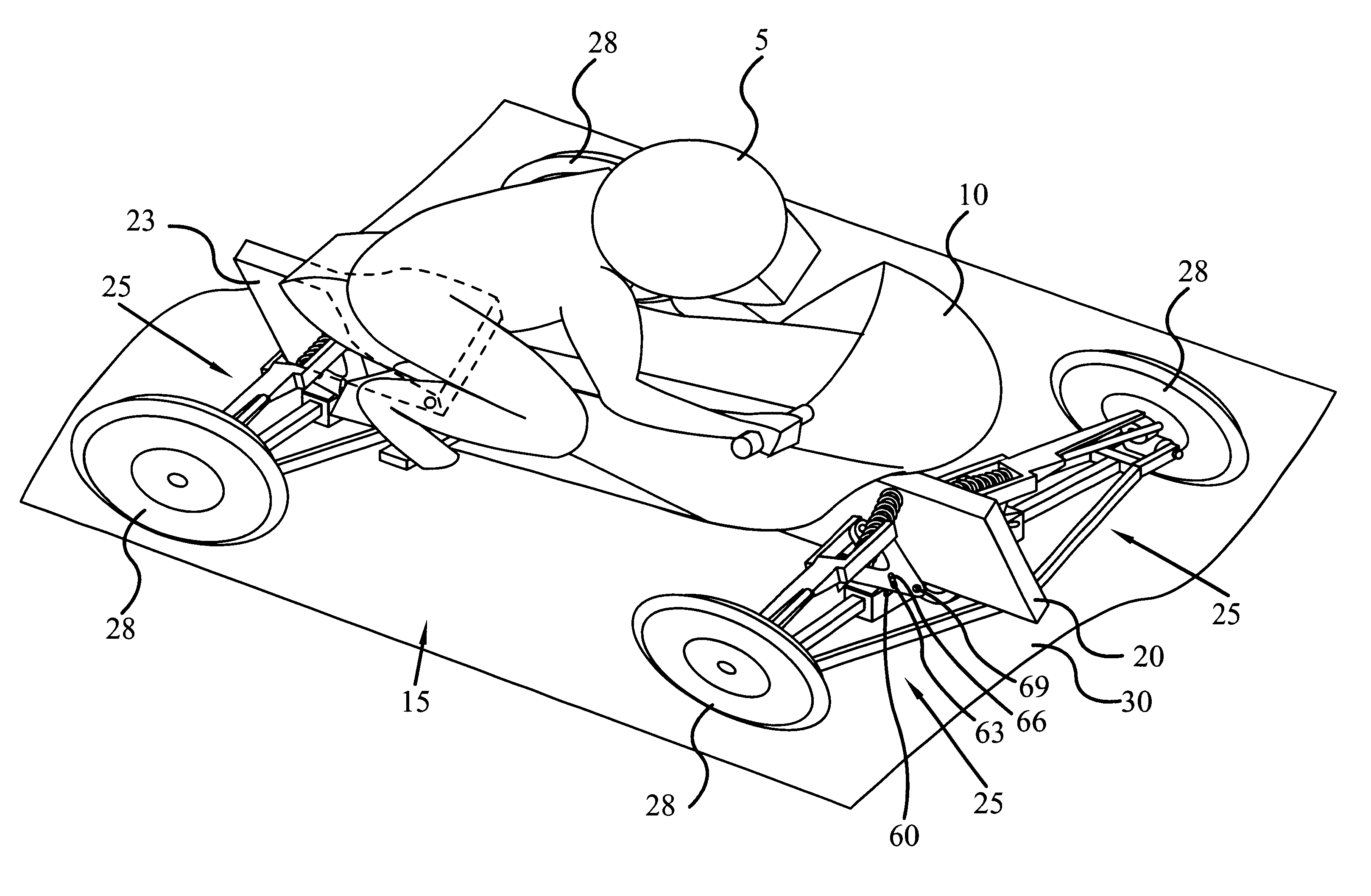

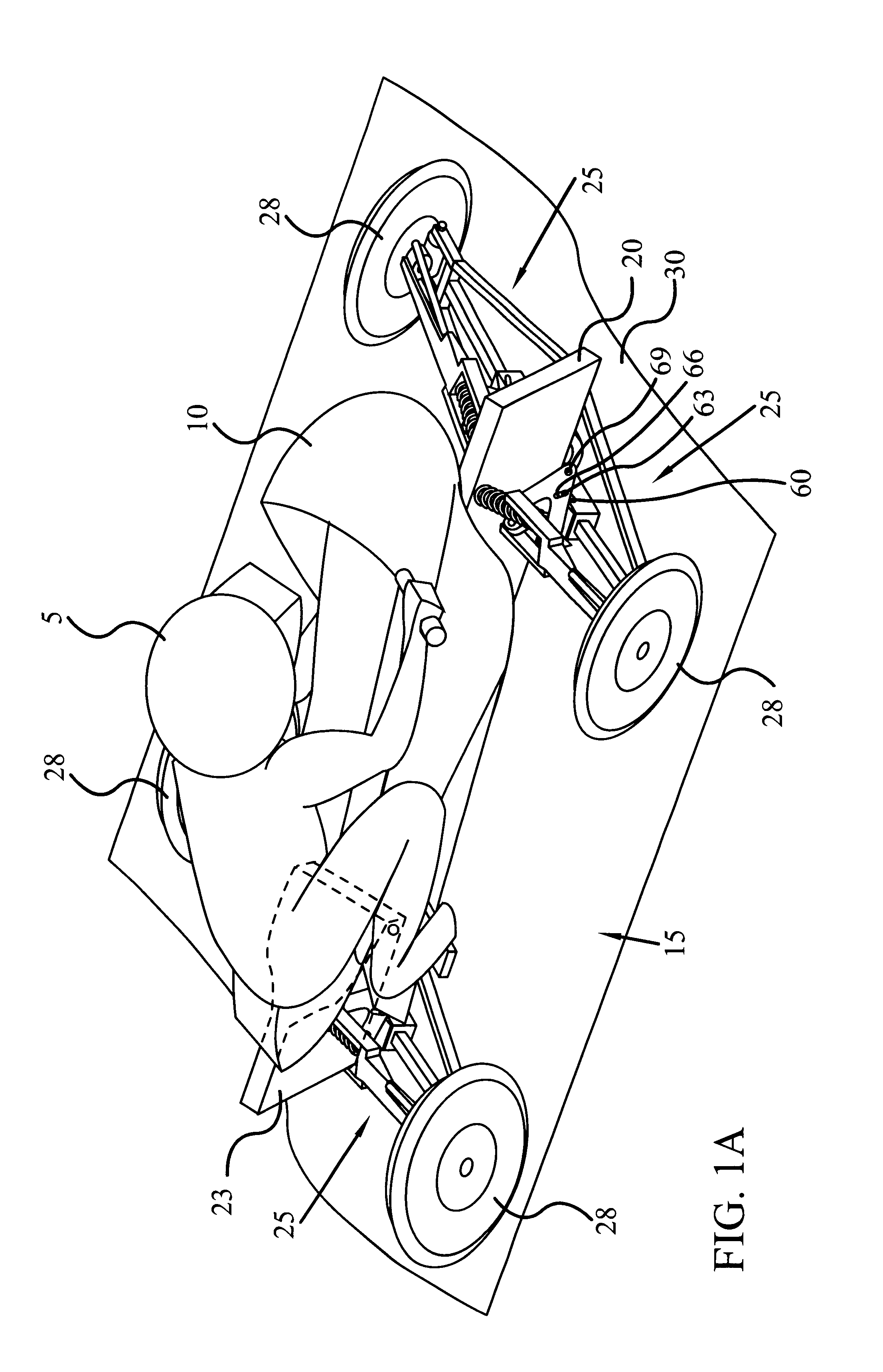

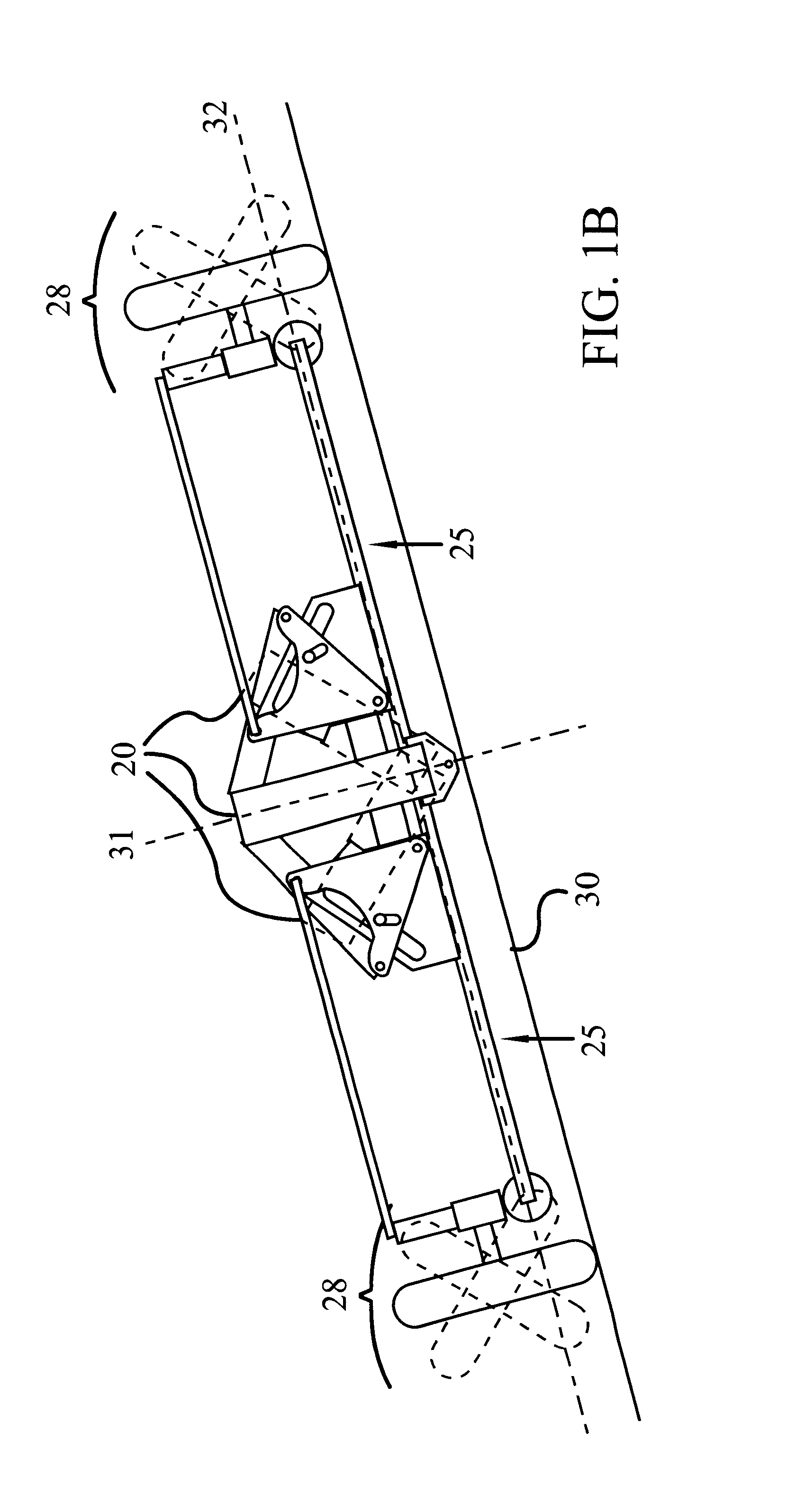

Tilting wheeled vehicle

ActiveUS7487985B1Complex control systemWheel based transmissionFrictional rollers based transmissionControl systemCaster angle

A tilting, preferably three-wheeled, vehicle is disclosed that has a tilting mechanism that allows the vehicle to have leaning characteristics substantially similar to those offered by an in-line two-wheeled vehicle, but that does not require complex linkages and / or control systems to operate effectively. A tilting linkage is operably secured to a frame to allow a pair of spaced apart wheels to remain substantially aligned with the plane of the vehicle throughout its range of movement while still allowing the steering axes of each wheel to intersect the substantially vertical centerline of each wheel. The linkage also allows the caster angle of each wheel's pivot axis can be optimized independently of the angle of the vehicle's handlebar steering shaft.

Owner:ARCIMOTO

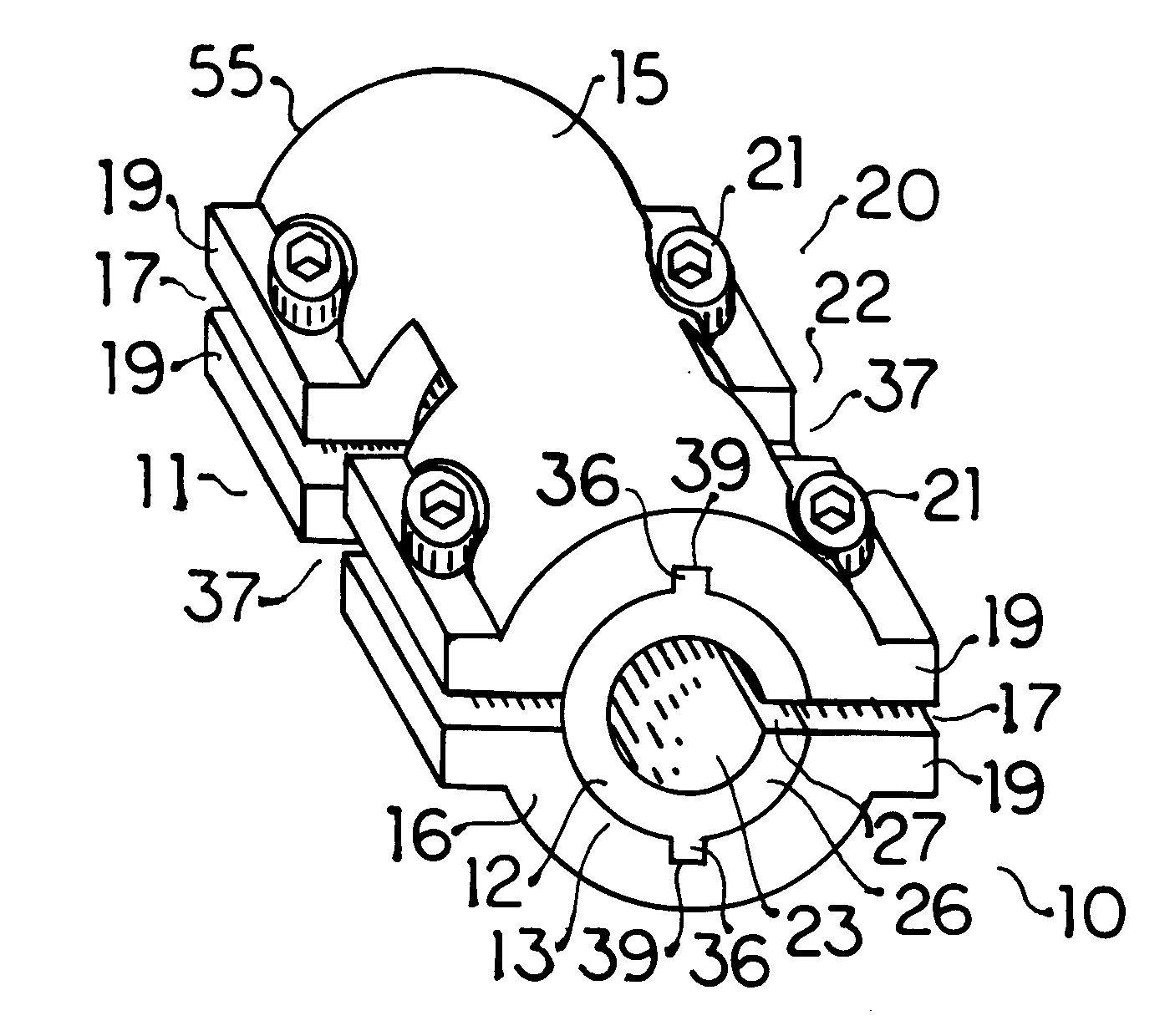

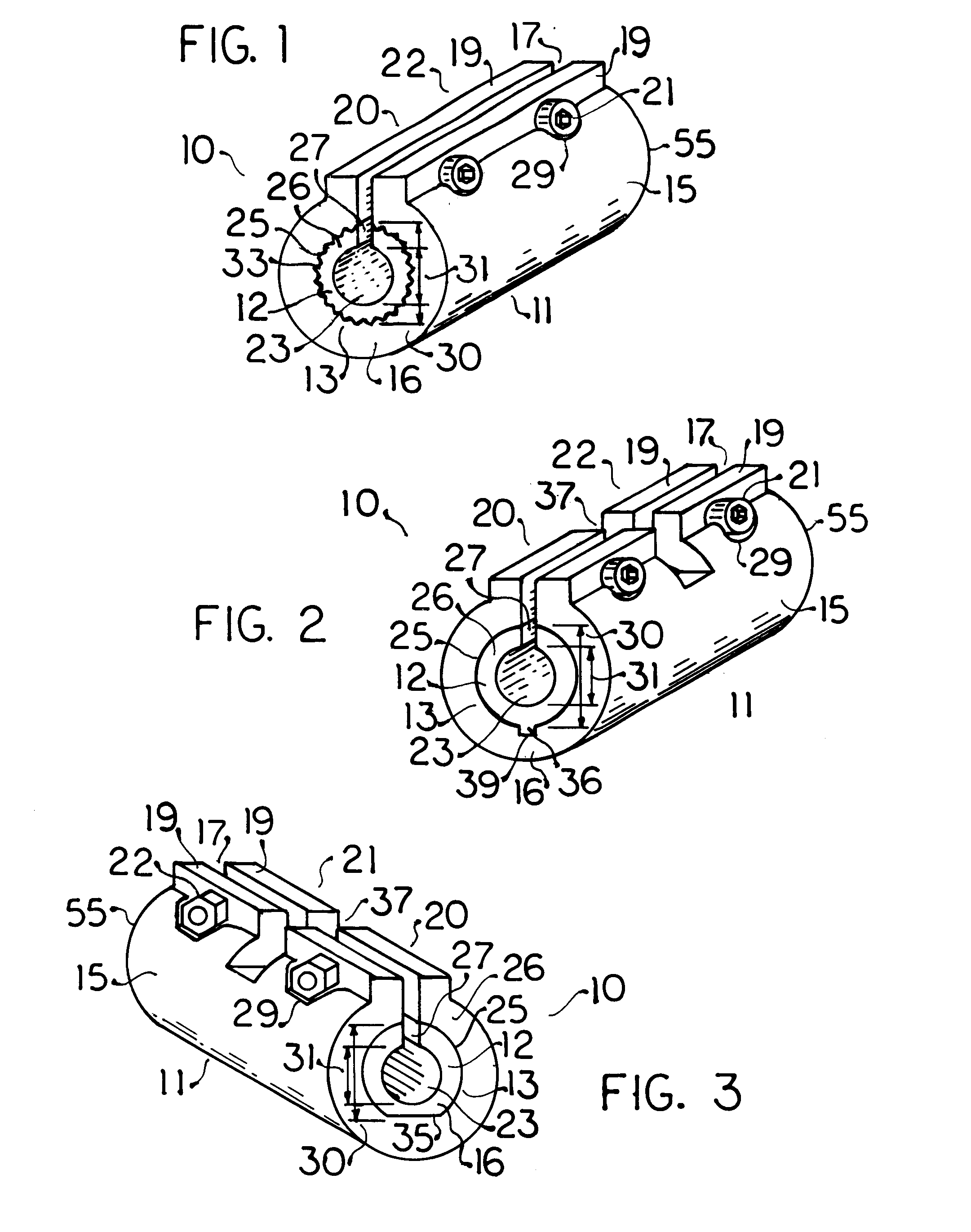

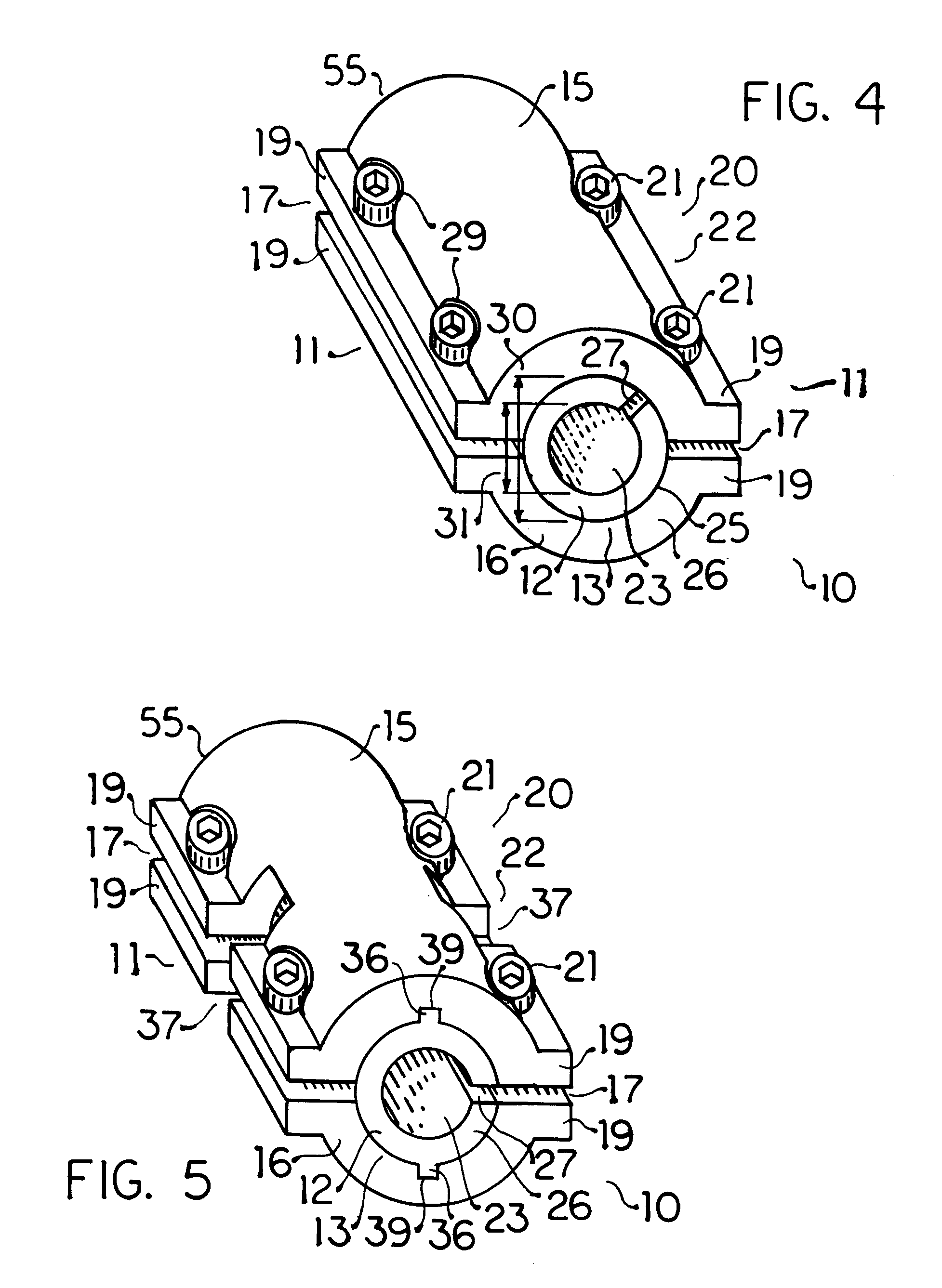

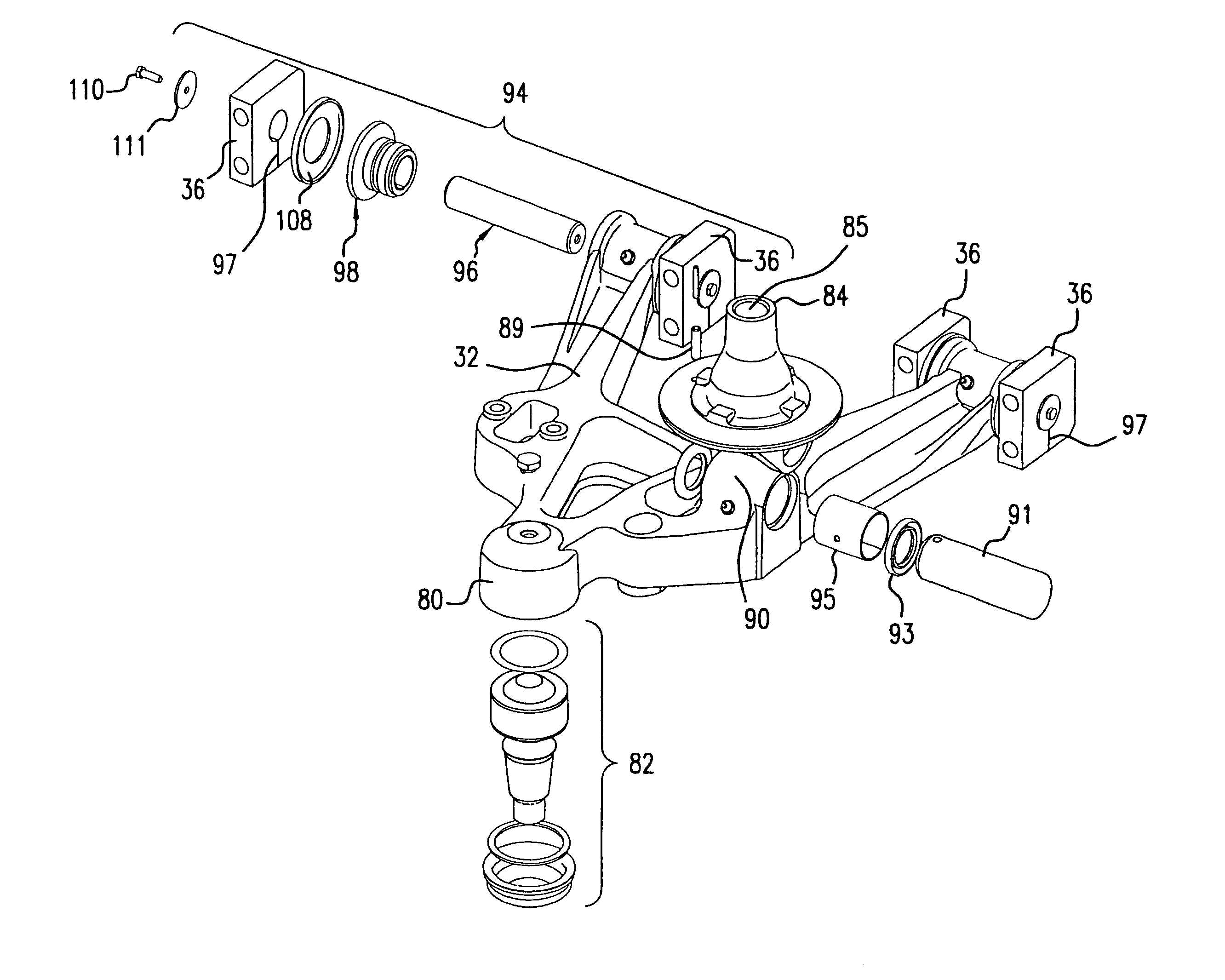

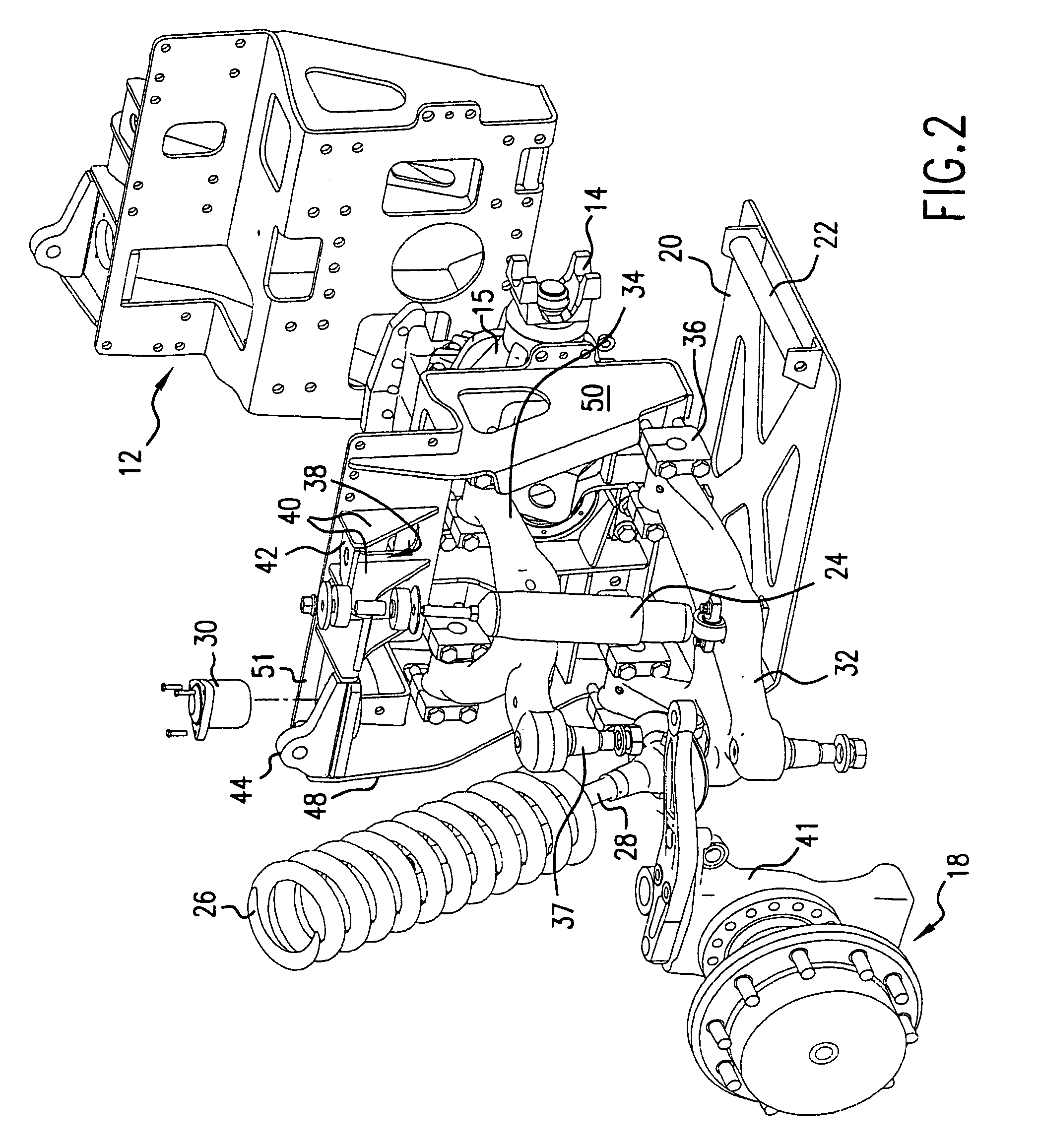

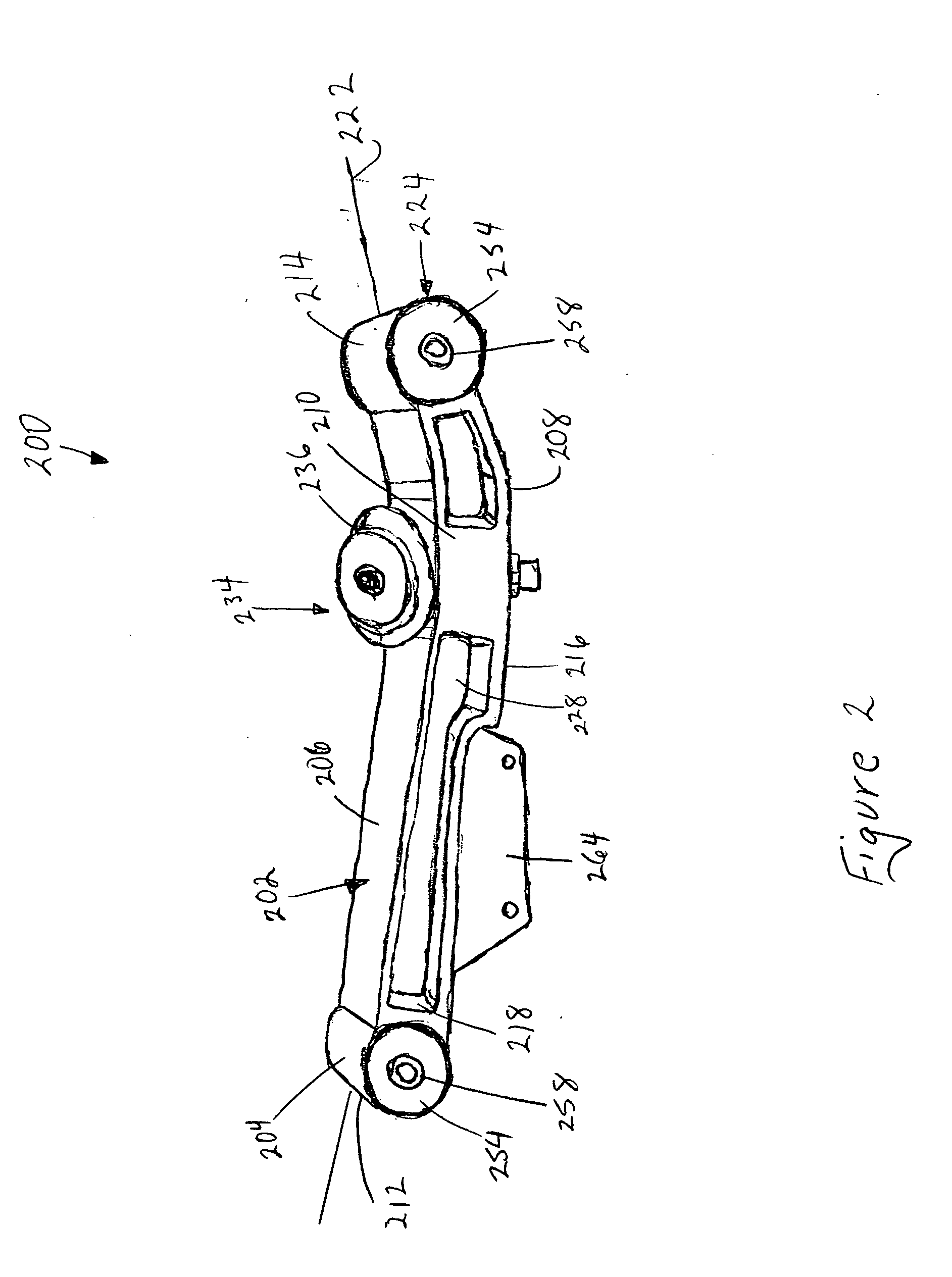

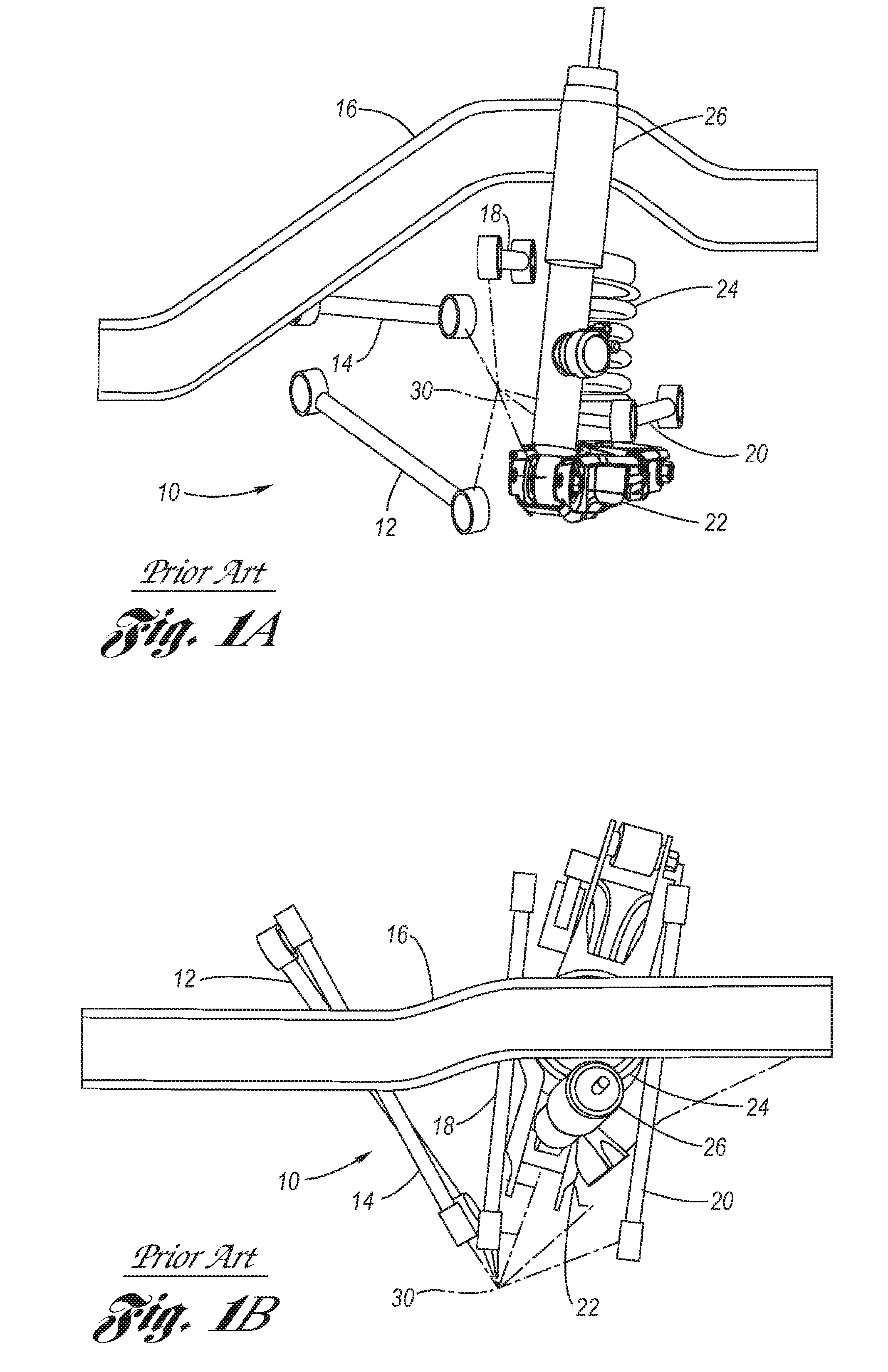

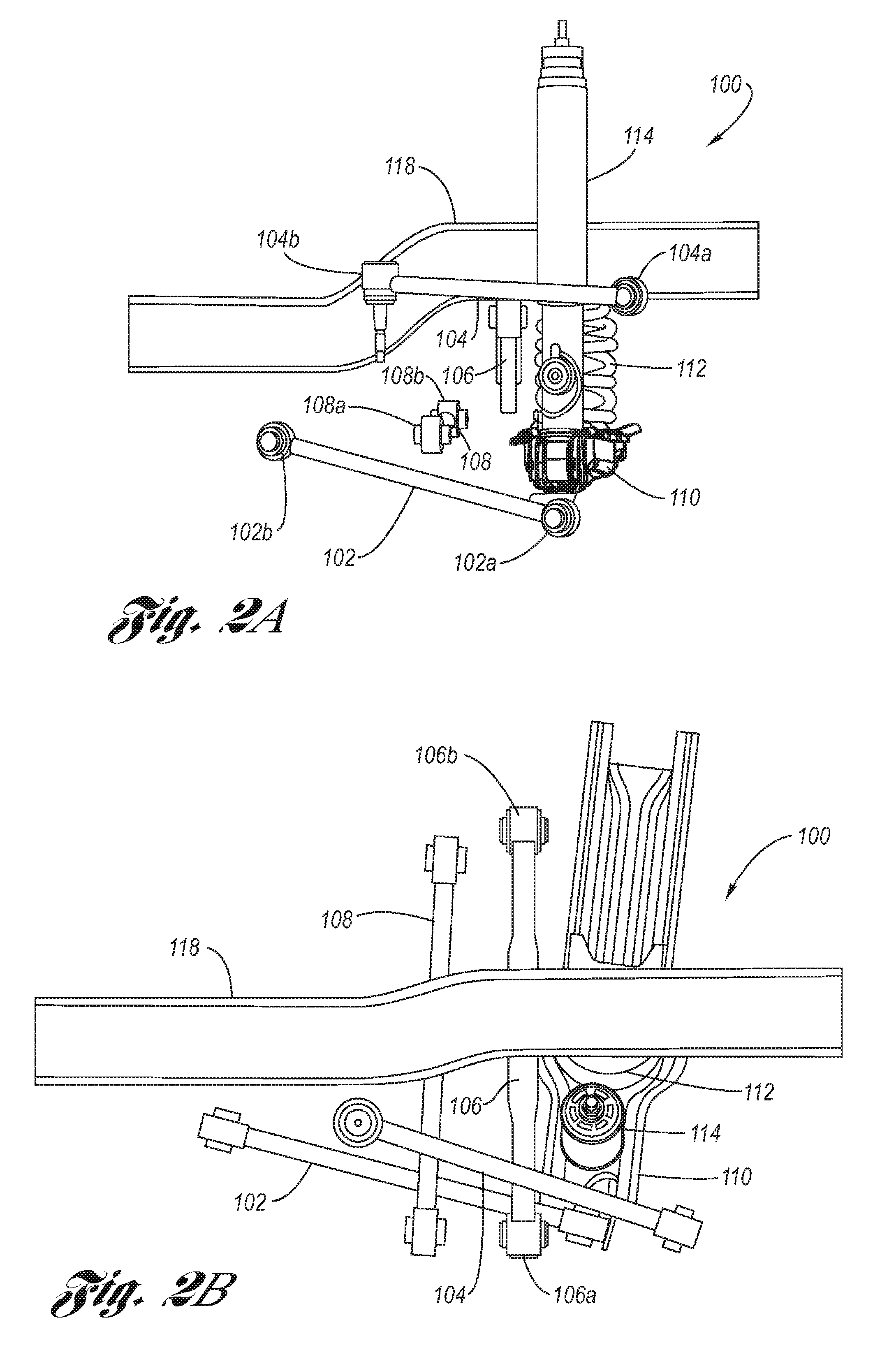

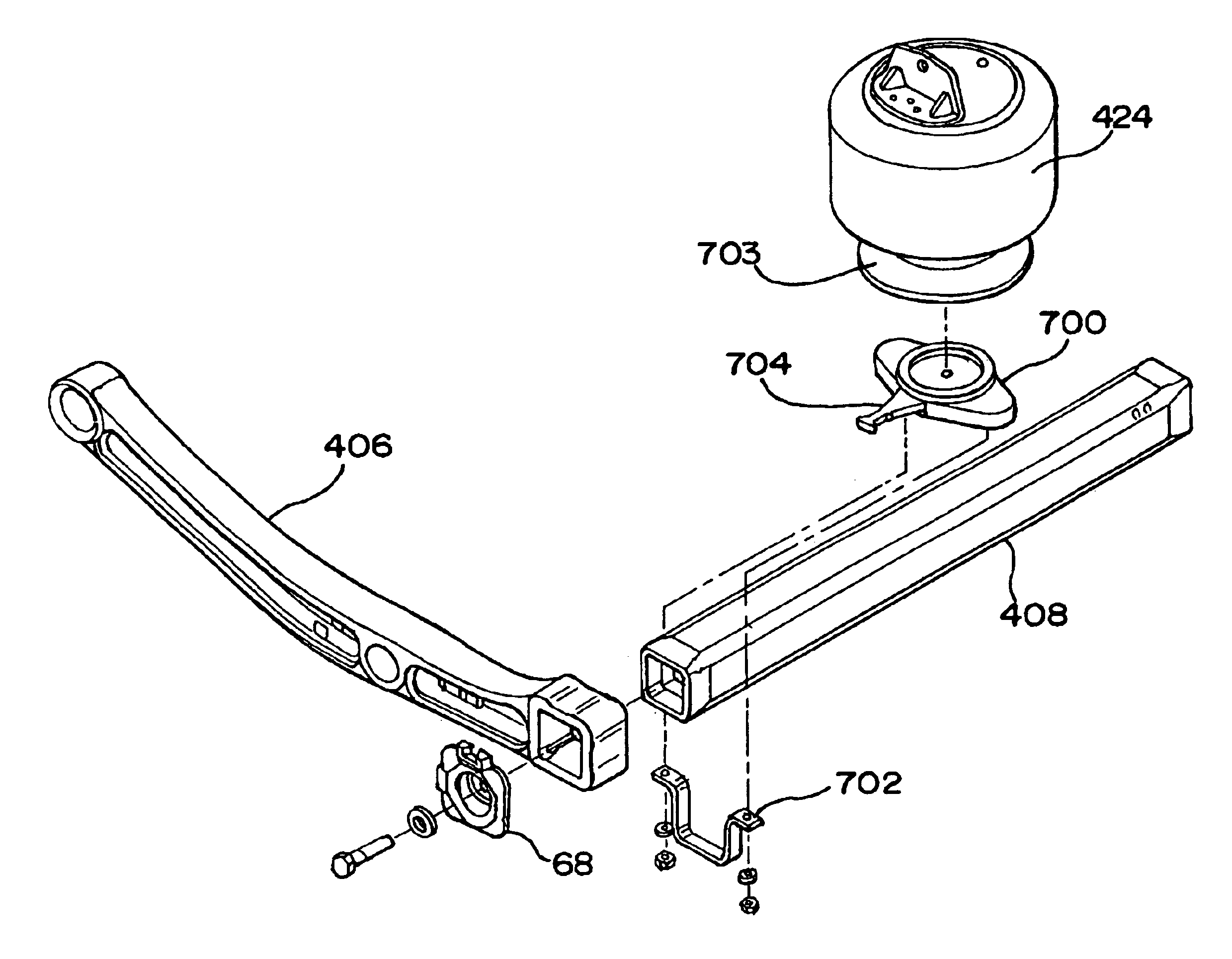

Mounting assembly for a vehicle suspension arm

A mounting assembly for use with a mounting surface includes an arm, a pin, a pair of clamping blocks and a fastener. The arm has a cylindrical bore at one end. The pin extends through the bore. Each block of the pair of clamping blocks includes a central opening and is circumferentially discontinuous about the central opening. Each clamping block further includes a slot defined by portions of the block. The slot is dimensioned to allow the pin to pass through the slot when the block is in an unclamped position and to tightly grip the pin when the block is in a clamped position. The fasteners extend across the slots and are configured to engage the mounting surface to mount the blocks to the mounting surface.

Owner:OSHKOSH CORPORATION

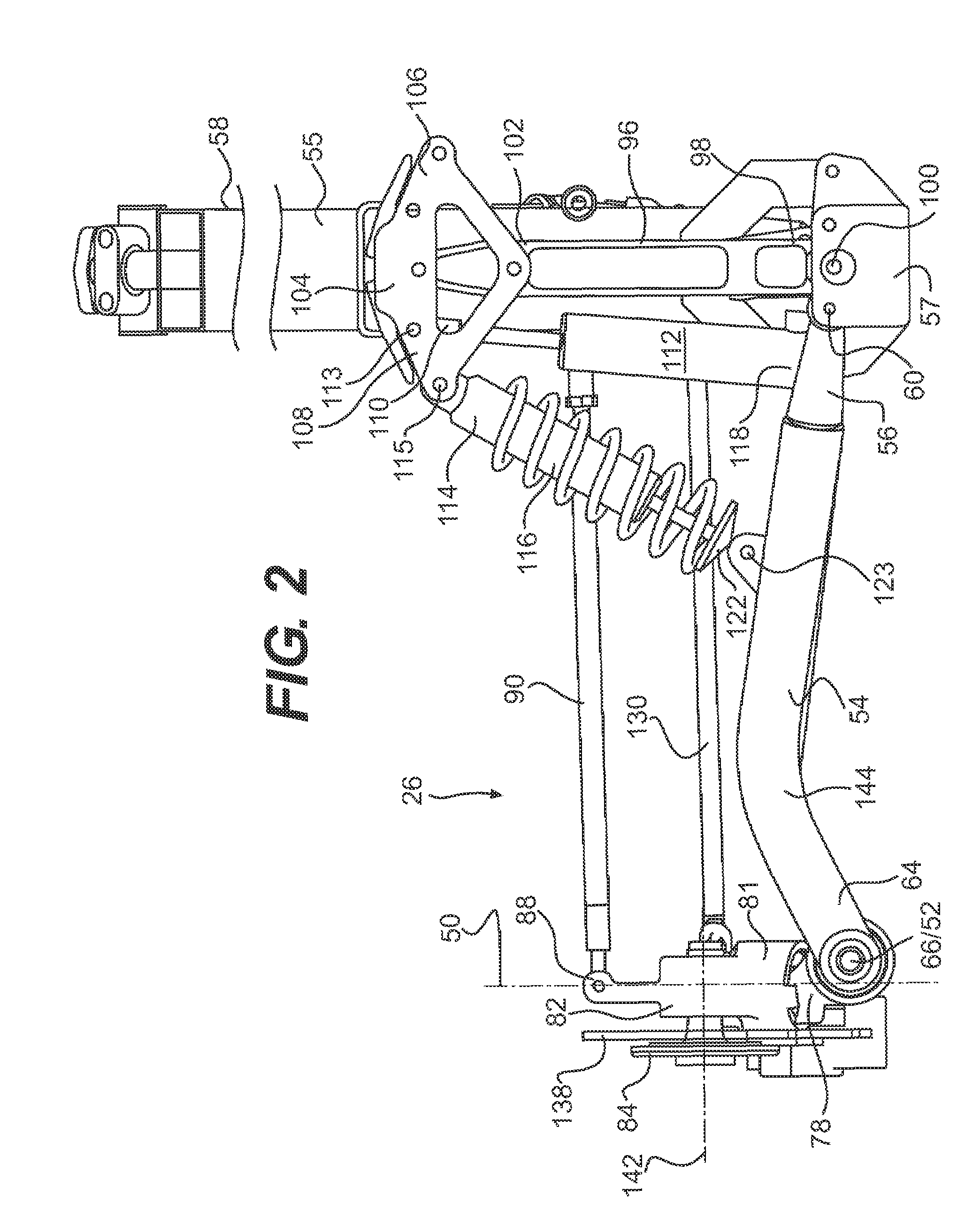

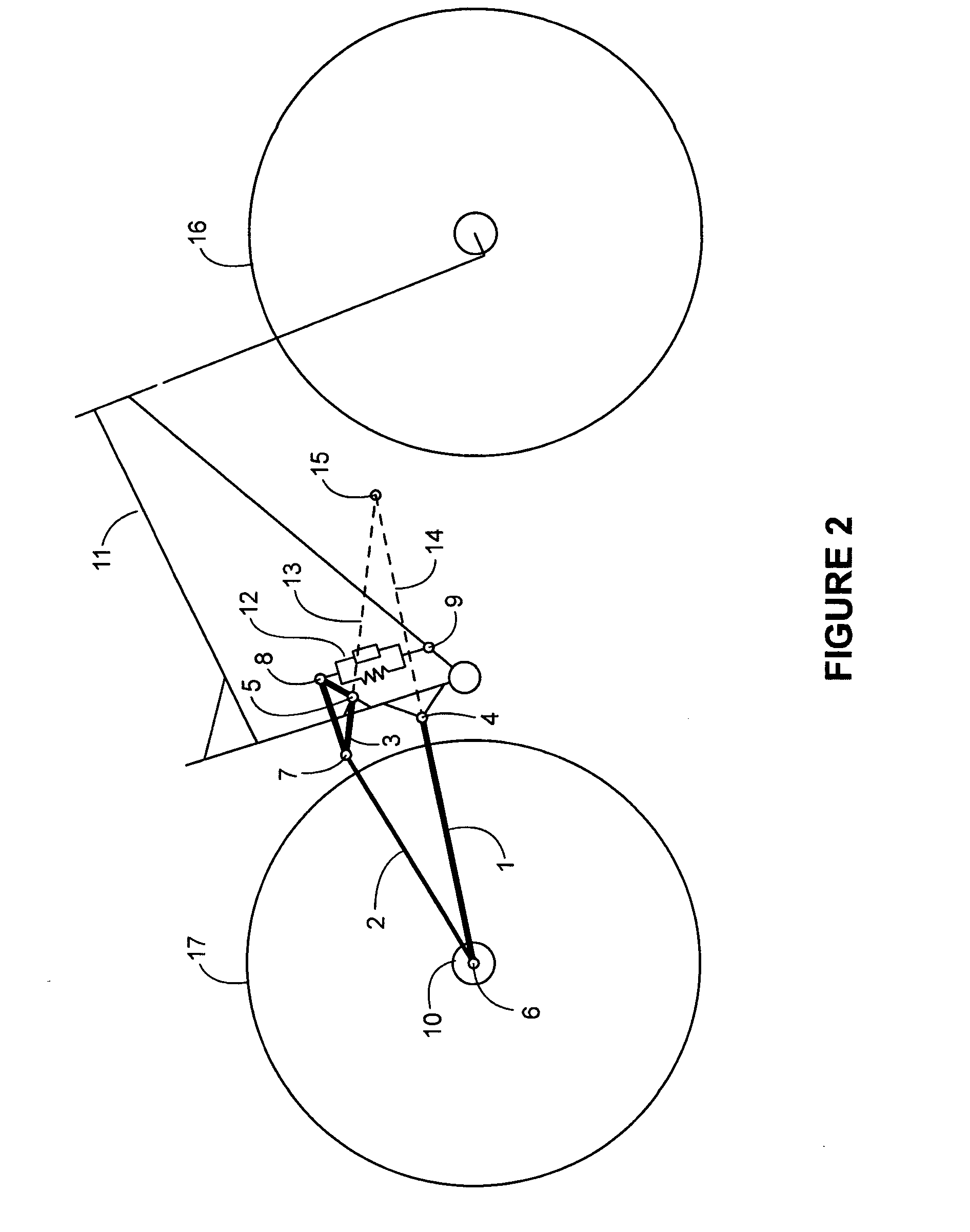

Leaning vehicle with tilting front wheels and suspension therefor

A leaning vehicle has a frame pivotally connected to the lower end of a shock tower, the pivotal connection defining a frame leaning axis wherein the frame is adapted to lean to a right side and to a left side relative to the shock tower about the frame leaning axis. The leaning vehicle includes an actuator operatively connected to the frame and to the shock tower which is adapted to impart a leaning motion to the frame relative to the shock tower about the frame leaning axis.

Owner:BOMBARDIER RECREATIONAL PROD INC

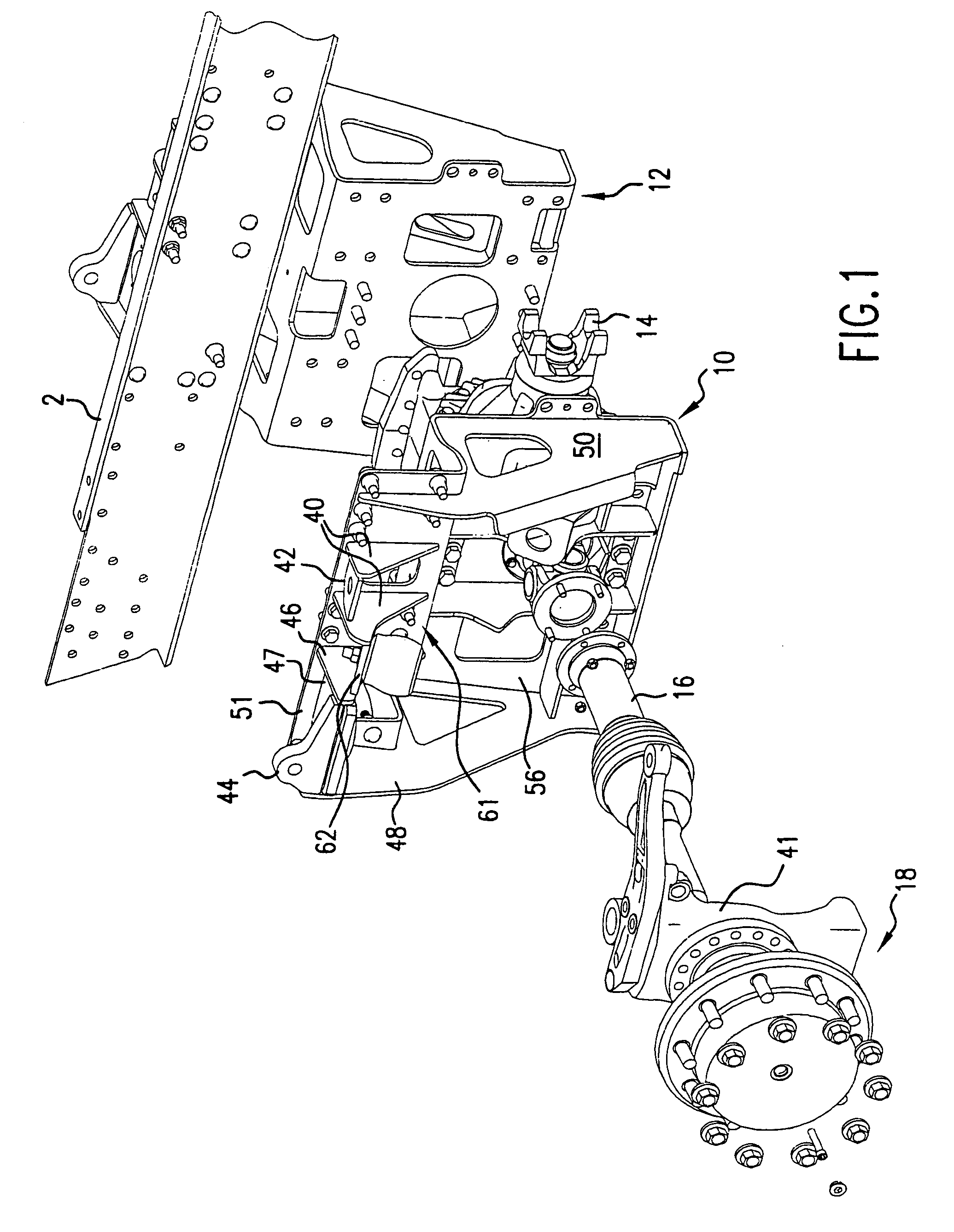

Front vehicle body structure

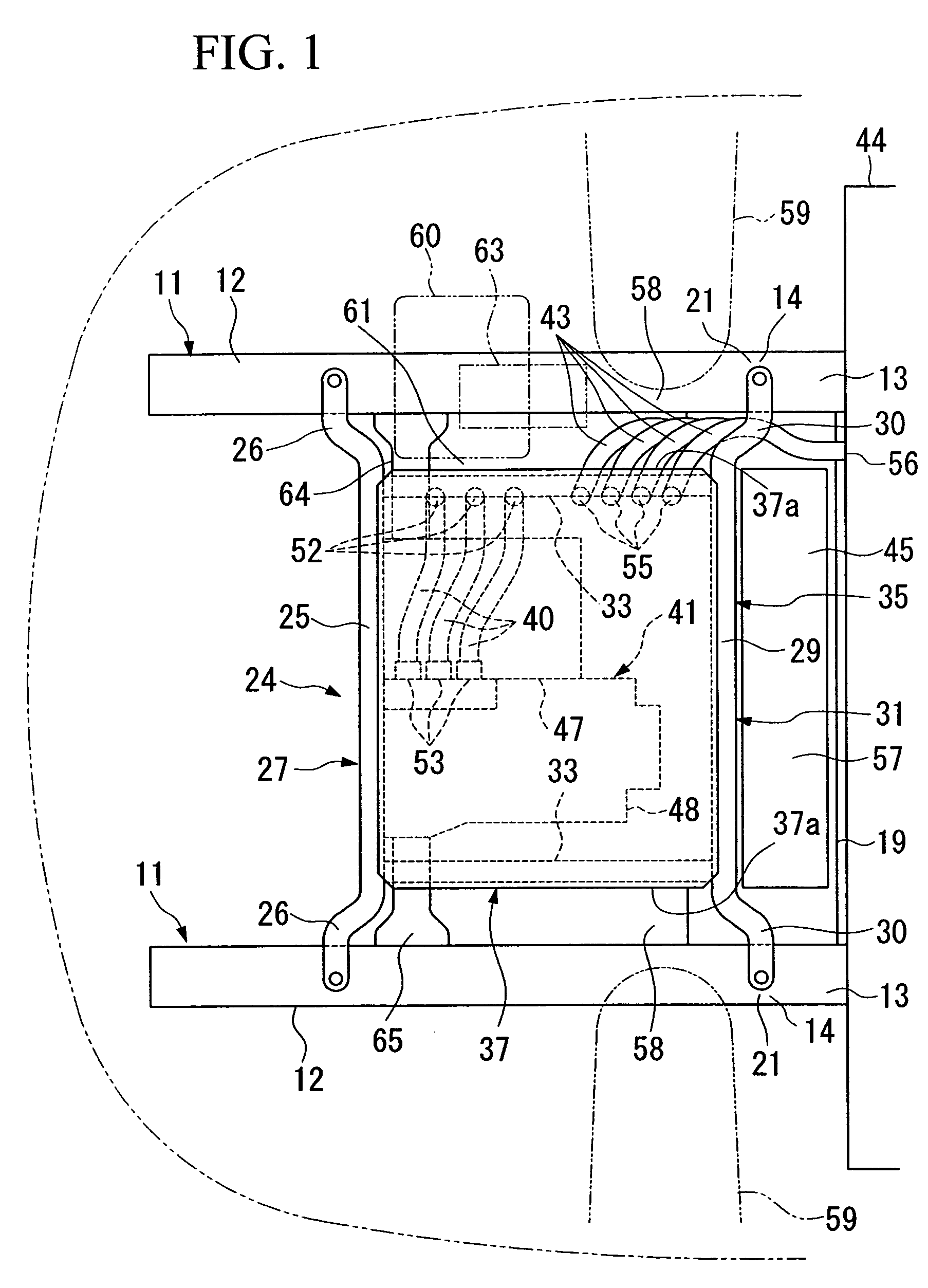

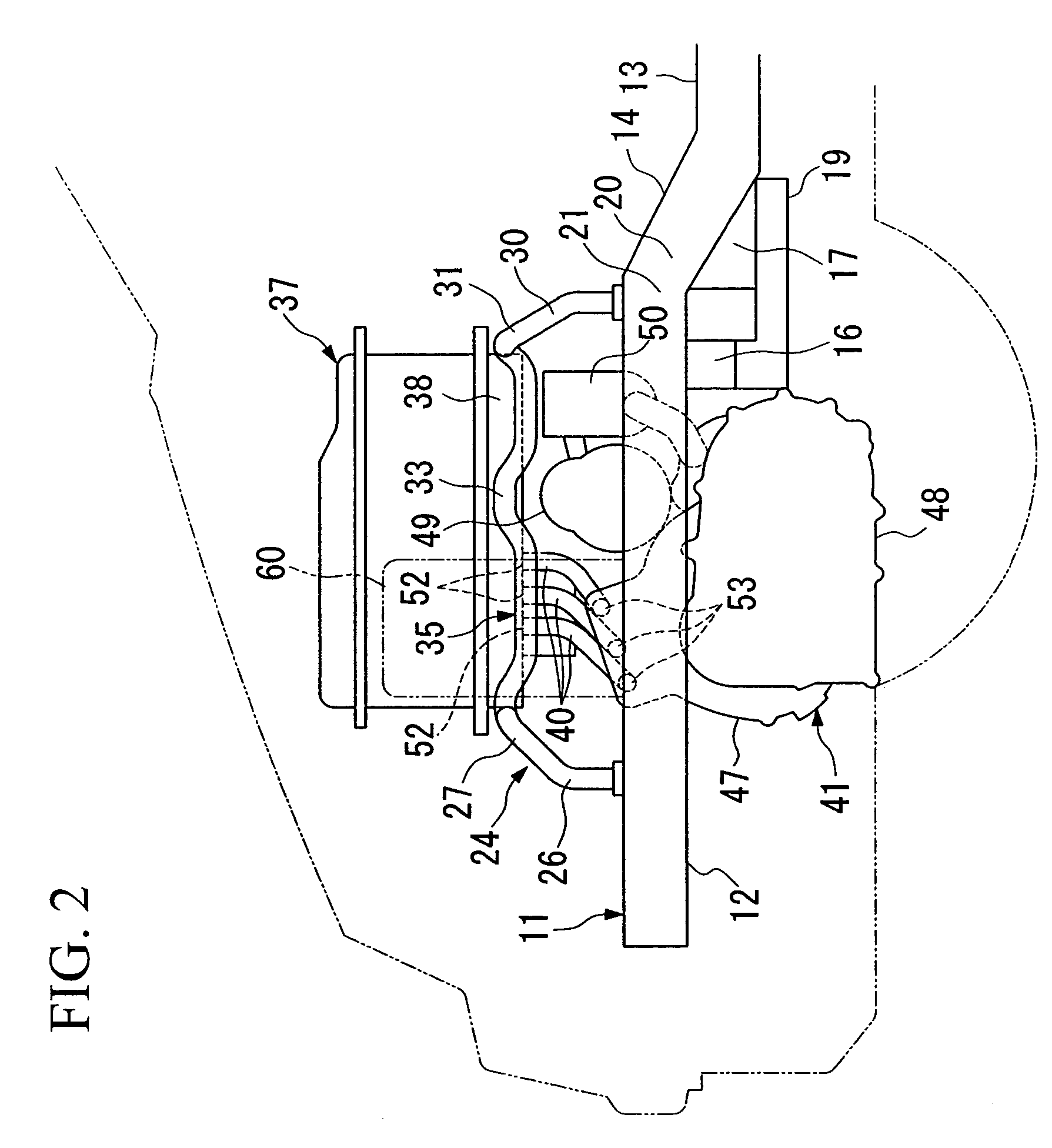

InactiveUS7393016B2Reliable absorptionAvoid displacementVehicle seatsUnderstructuresVehicle frameEngineering

Front vehicle body structure includes left and right front side frames, a subframe provided on the undersides of the side frames, and left and right mounting brackets for connecting the side frames and subframe. Engine-transmission unit is mounted on the subframe. Respective rear half portions of the side frames extend toward the rear of the vehicle body while gradually approaching the centerline of the vehicle body. Left and right mounting brackets are provided, on the respective rear half portions, to project toward the centerline. The left and right mounting brackets are detachably connected to the subframe. When an impact load greater than a predetermined intensity has been applied, the left and right mounting brackets are detached from the subframe and then squashed by the engine-transmission unit while effectively absorbing the impact.

Owner:HONDA MOTOR CO LTD

Vehicle front body structure

ActiveUS7144039B2Easy to transformAvoid displacementVehicle seatsFuel cell auxillariesMechanical engineeringEngineering

Owner:HONDA MOTOR CO LTD

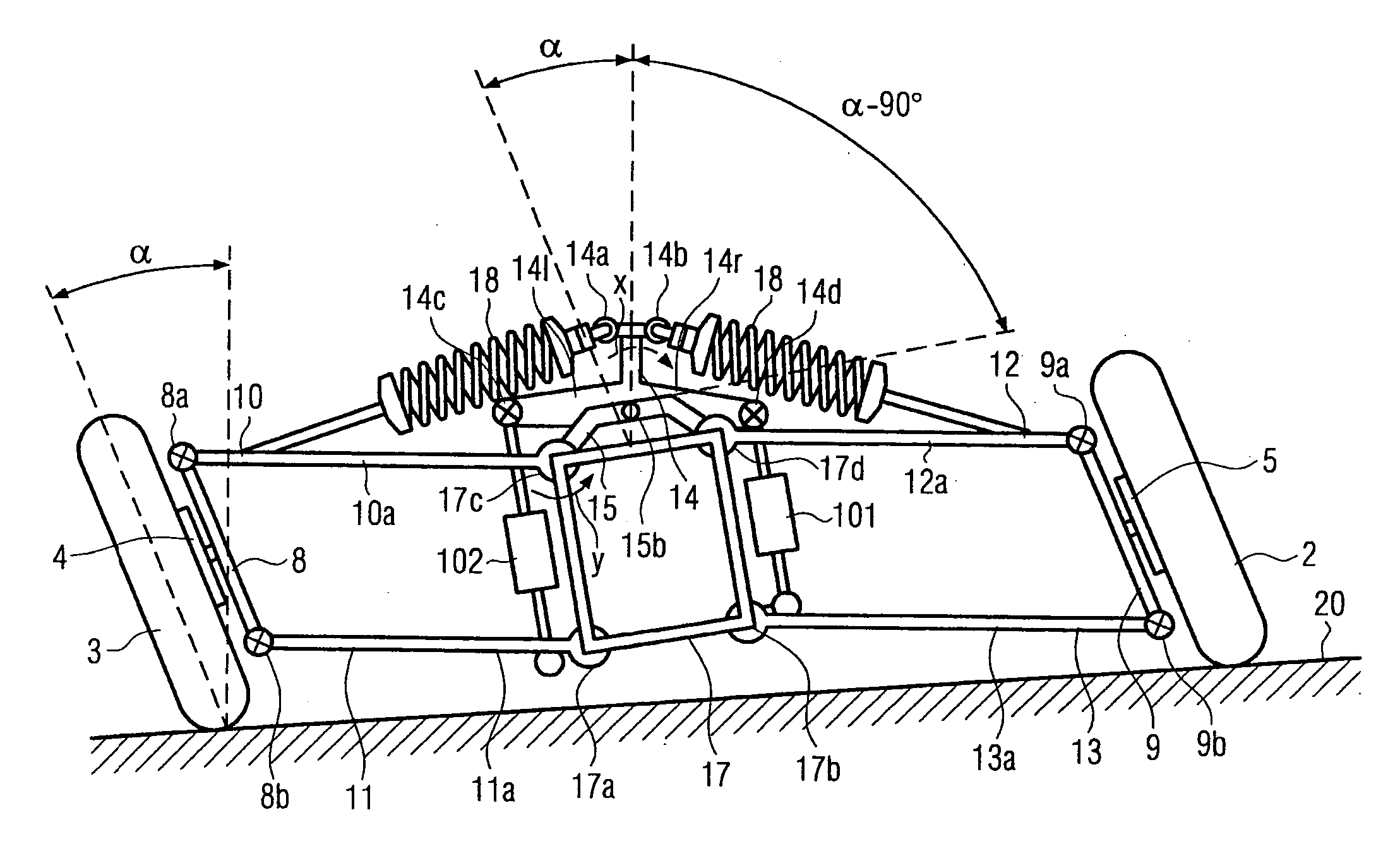

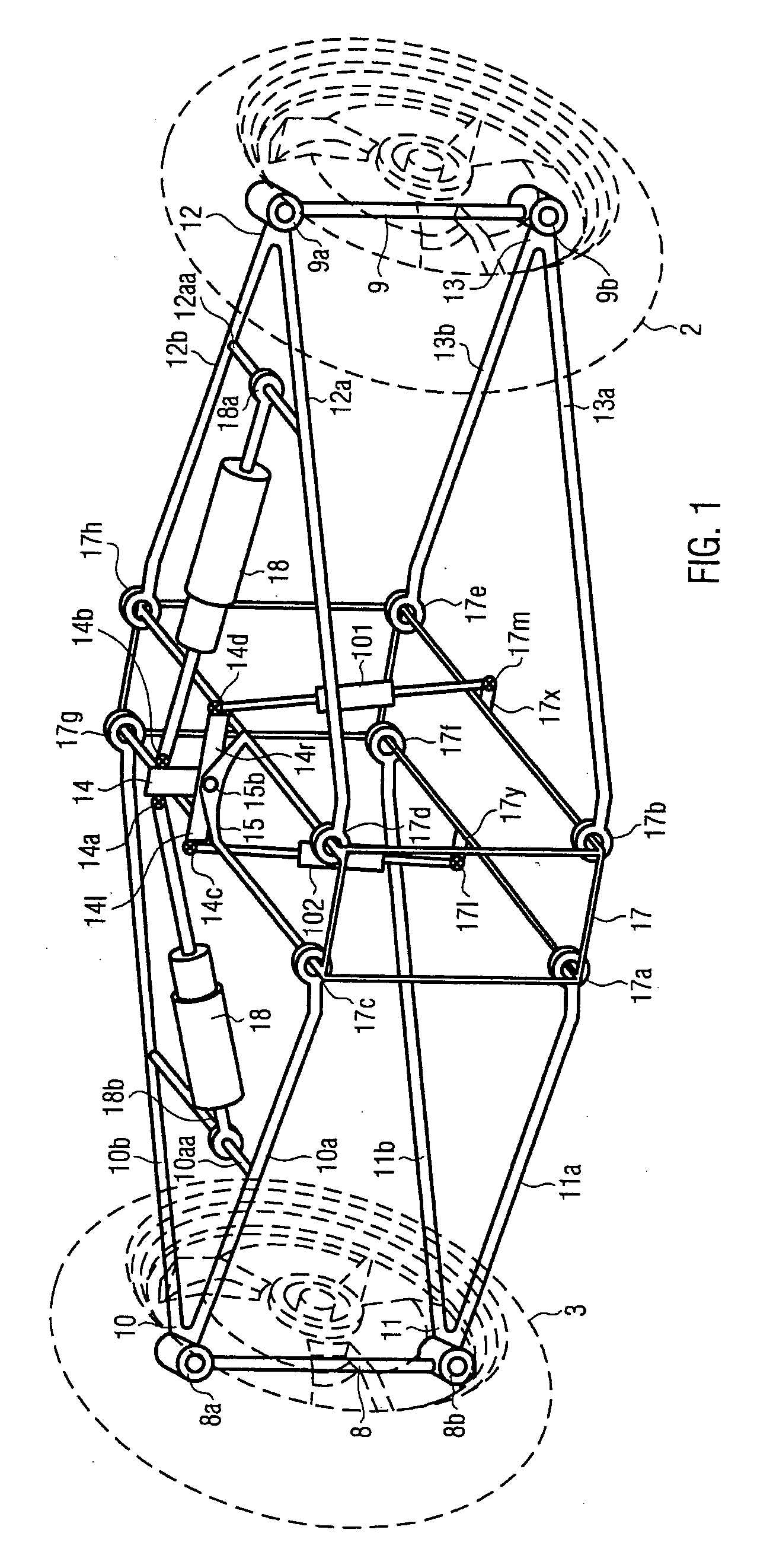

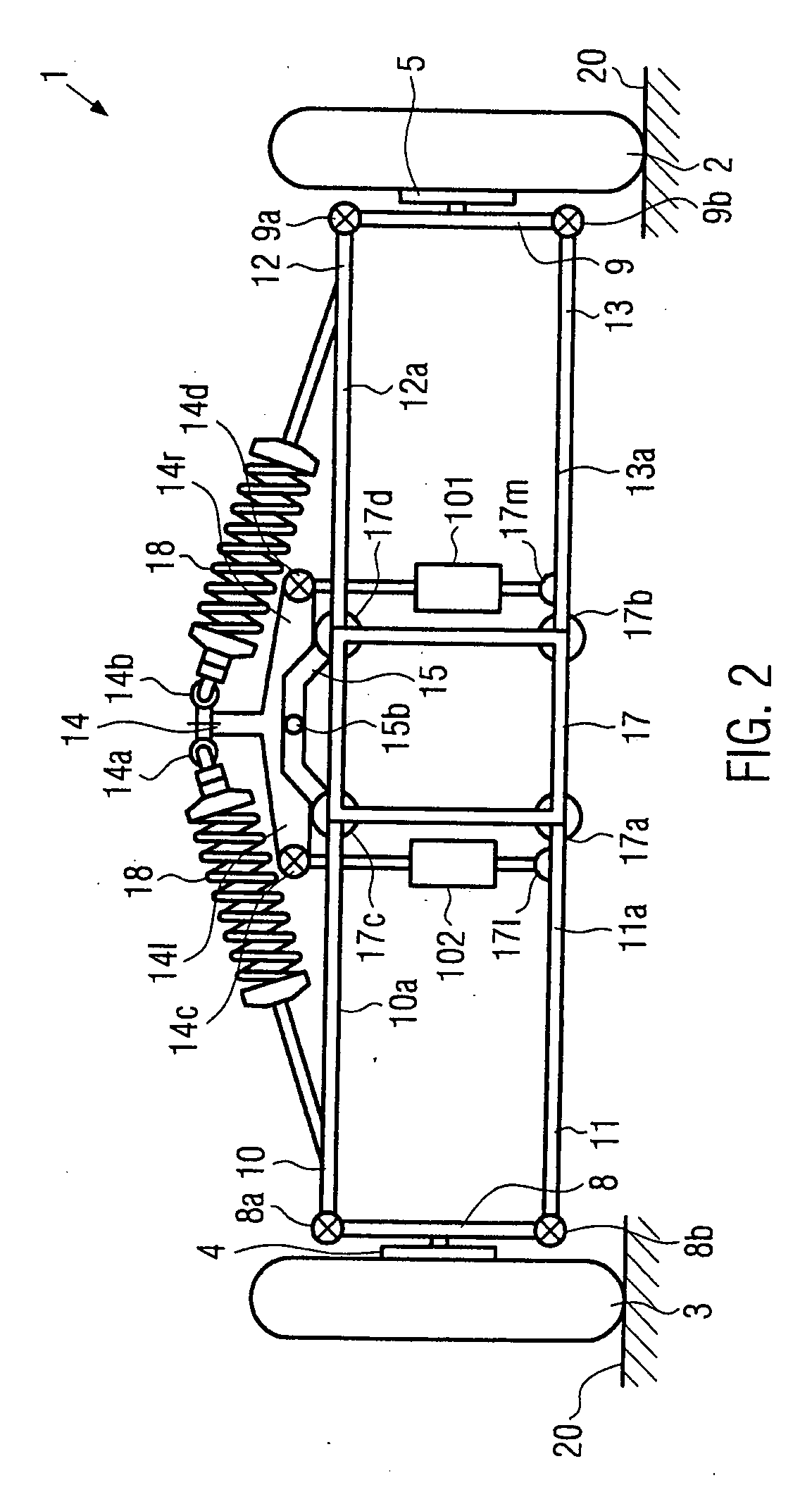

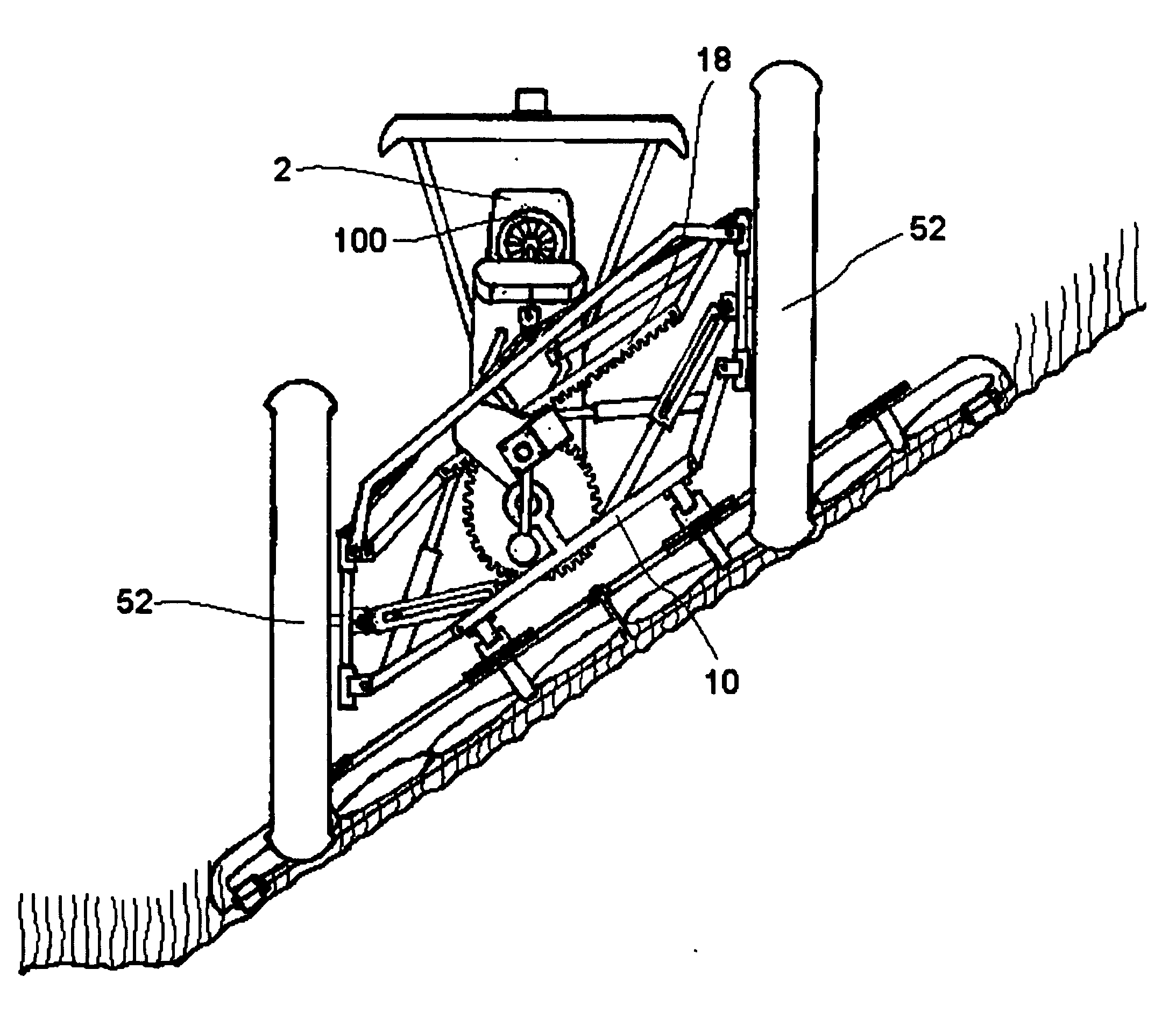

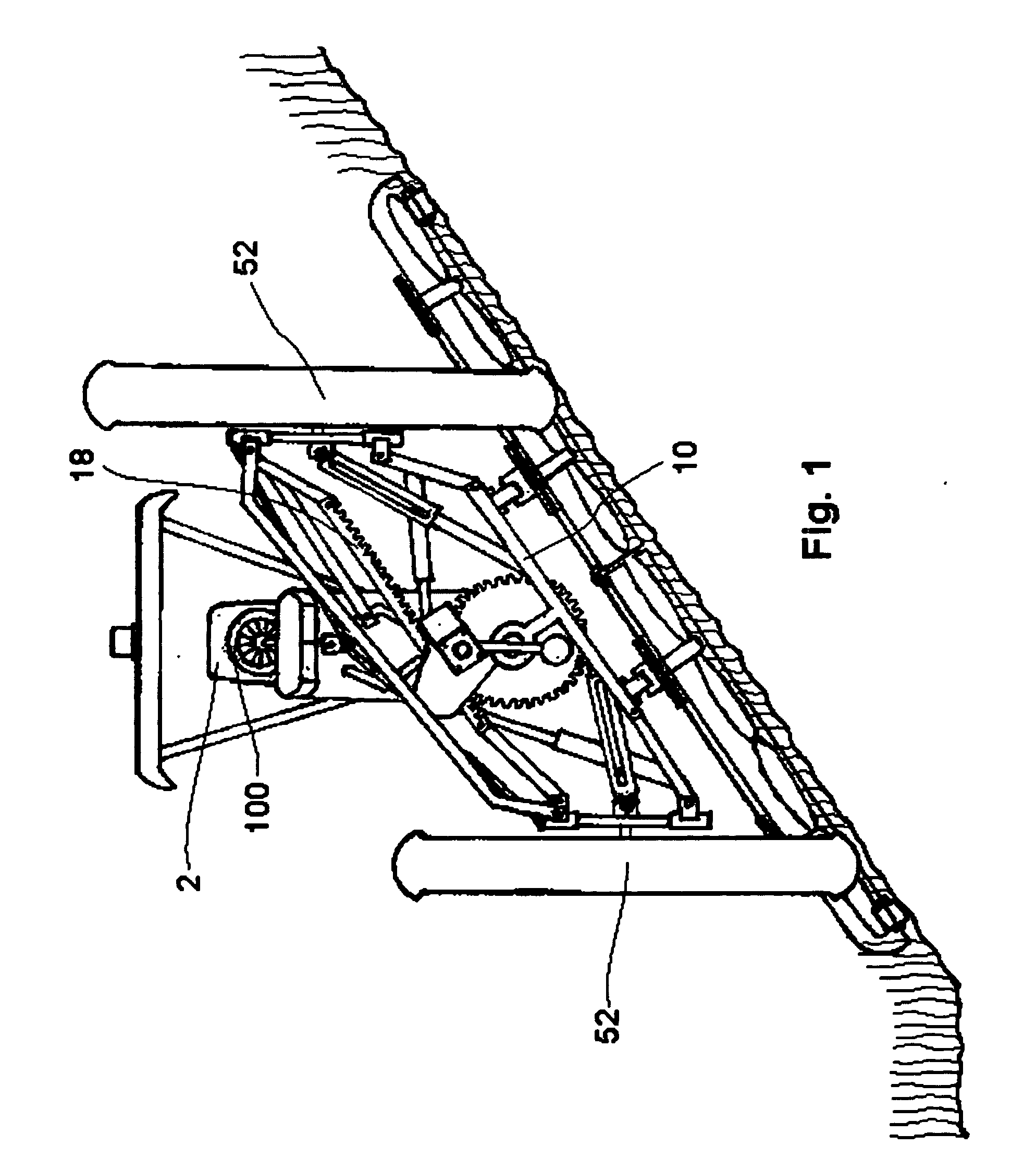

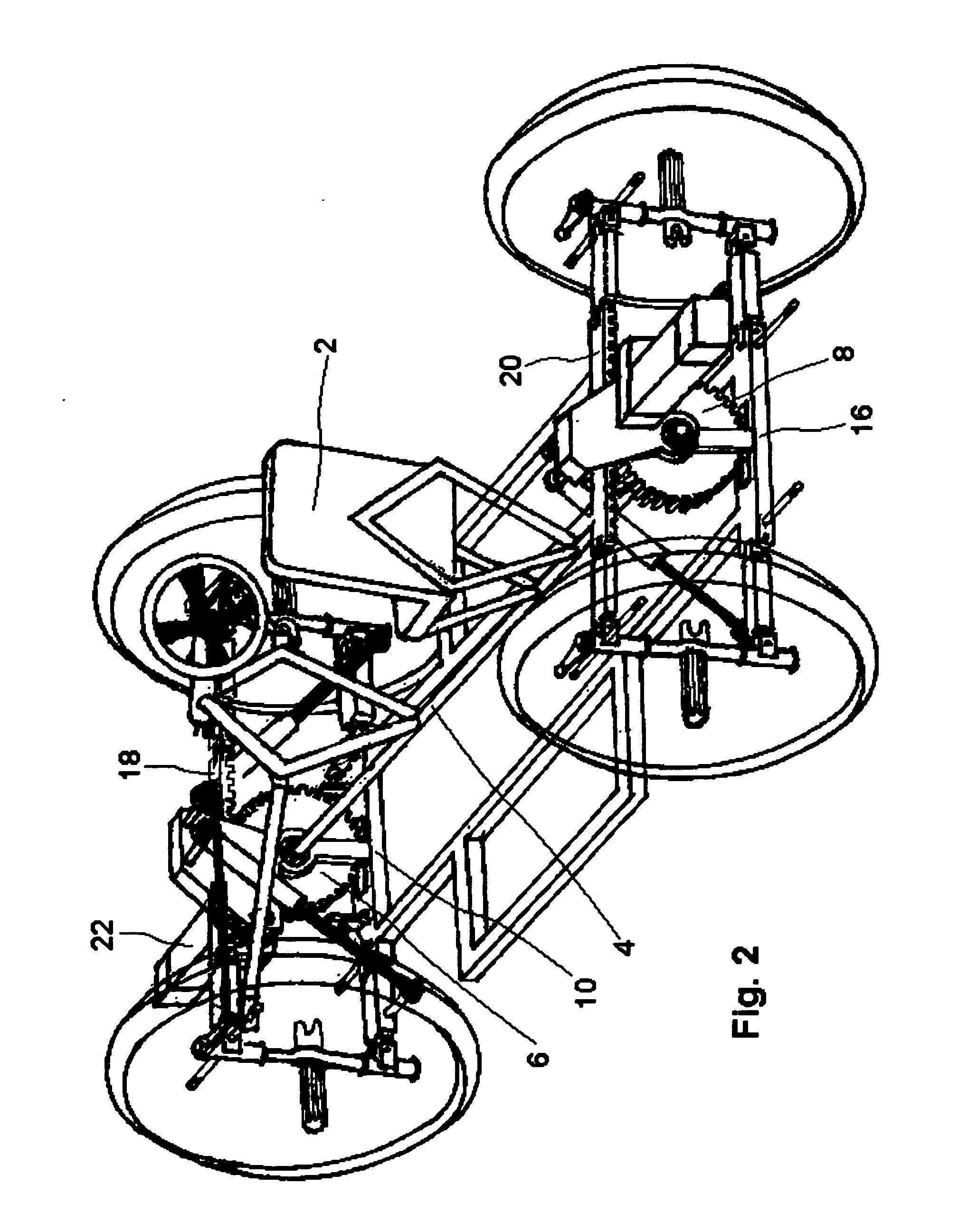

Suspension tilting module for a wheeled vehicle and a wheeled vehicle equipped with said suspension tilting module

A tilting suspension system is provided for two wheels (2, 3) of a vehicle (200) disposed on a common axle with the module comprising a rigid frame (17) adapted to be firmly fixed to the chassis of the vehicle so as to be tilted together with the whole vehicle and a tilting arm (14) pivotally linked to the rigid frame. The tilting of the rigid frame is obtained as a result of the counter torque arising when activating hydraulic actuating means (101, 102) pivotally interposed between the tilting arm (14) and the rigid frame (17), with the tilting arm being pivotally connected to shock absorbers (18). The tilting module further comprises suspension arms (10, 11, 12, 13) pivotally connected to the rigid frame, with the suspension arms supporting, in cooperation with supporting uprights, the two wheels thus allowing both tilting and steering of the two wheels. The hydraulic actuating means (101, 102) are actuated by a hydraulic pump (112) driven by an electric motor (108).

Owner:FONDAZIONE TORINO WIRELESS

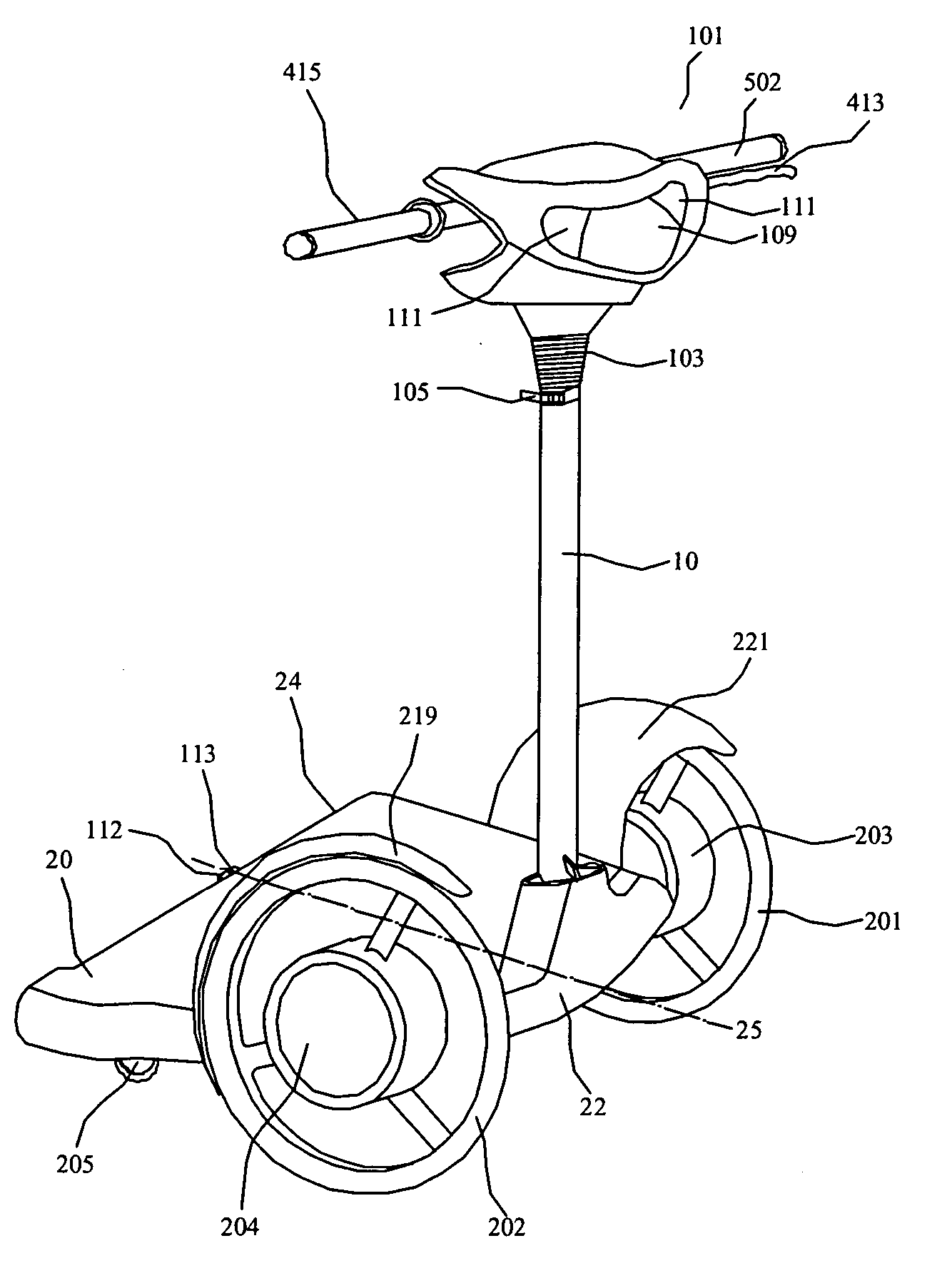

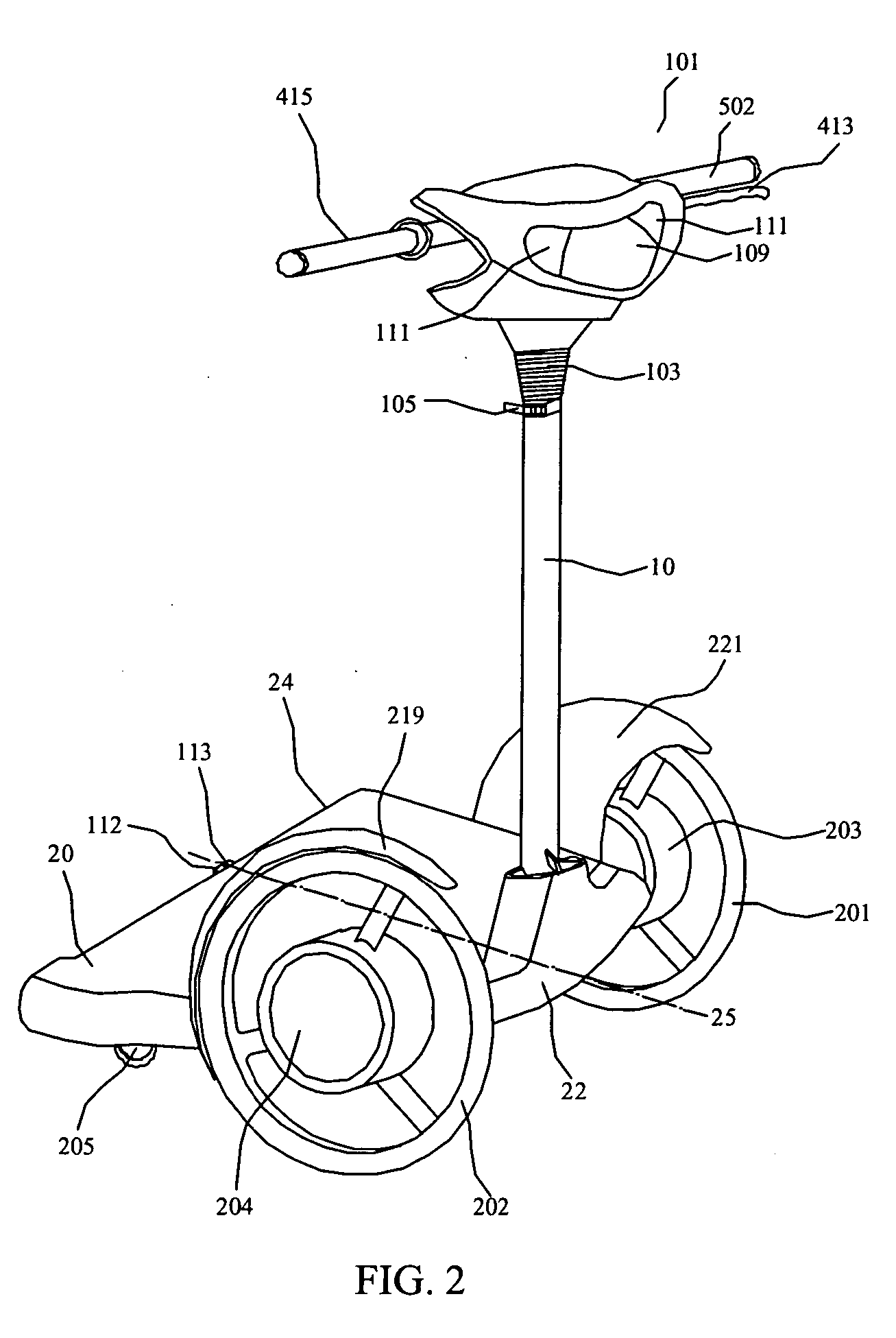

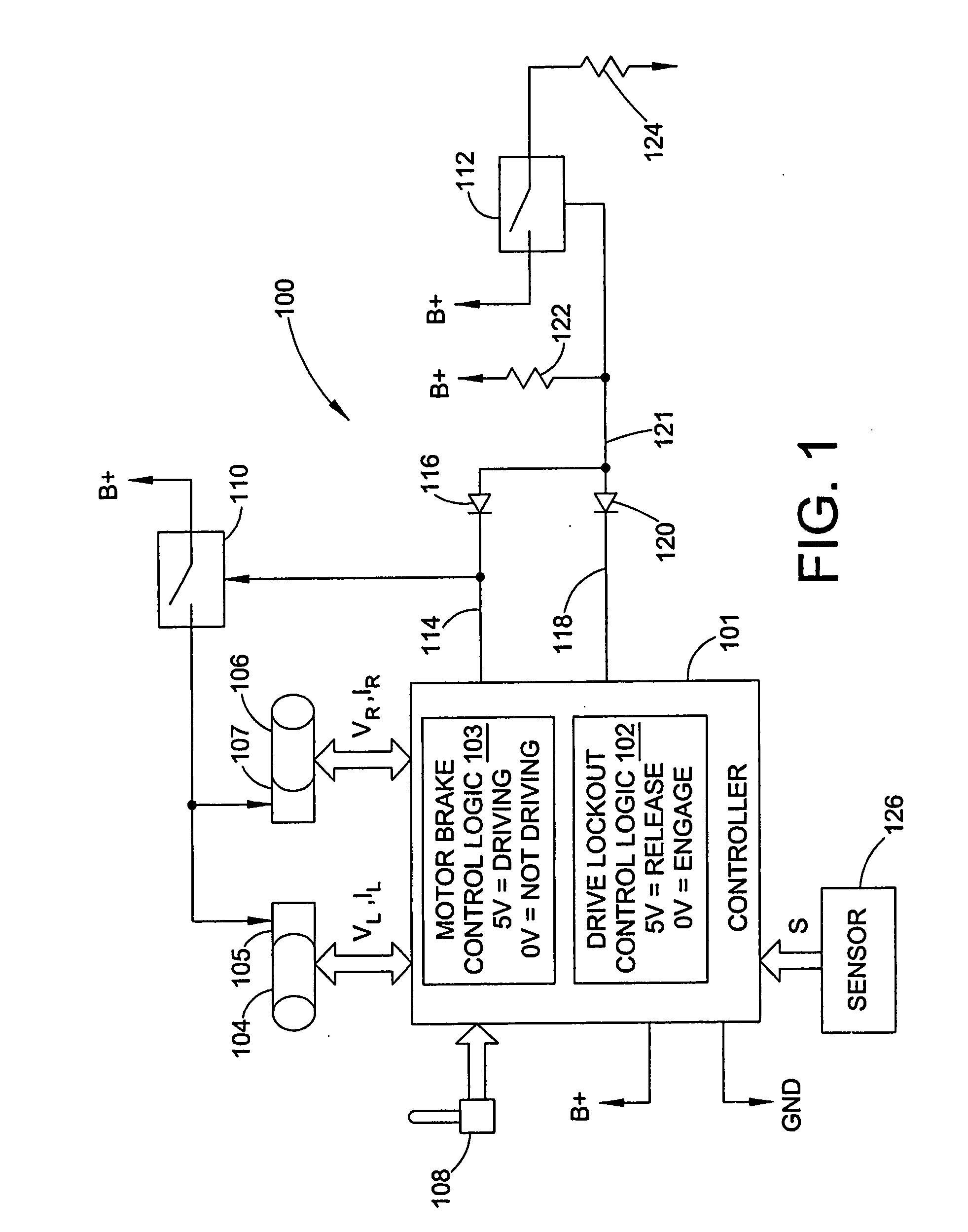

Drive mechanism for vehicle

InactiveUS20050134014A1Simple structureImprove stabilitySteering linkagesFluid steeringSteering wheelDrive wheel

The present invention provides an electric-driven vehicle, which comprises a supporting platform and an upright tube, wherein the supporting platform has first and second ends and a longitudinal axis perpendicular to the first and second ends, the upright tube is fitted at the first end of the supporting platform and operatively connected with the supporting platform, a handle frame is provided on a top end of the upright tube. The electric-driven vehicle further includes two driving wheels operatively mounted at opposite sides of the first end of the supporting platform, at least one steering wheel operatively mounted on a bottom of the second end of the supporting platform, a driving means for the driving wheels, and a power supply means mounted on the bottom of the supporting platform and electrically connected with the driving means. The present invention also provides a support platform structure for an electric-driven vehicle, which comprises a first portion and a second portion, wherein the first portion having sleeves for operatively mounting the driving wheels, and a first side; the second portion having a steering knuckle for operatively mounting the steering wheels, and a second side corresponding to the first side; the first side and the second side are connected via a connecting member, and at least one of the first side and the second side can rotate about the bond-linkage element.

Owner:XIE SHOUCHUN

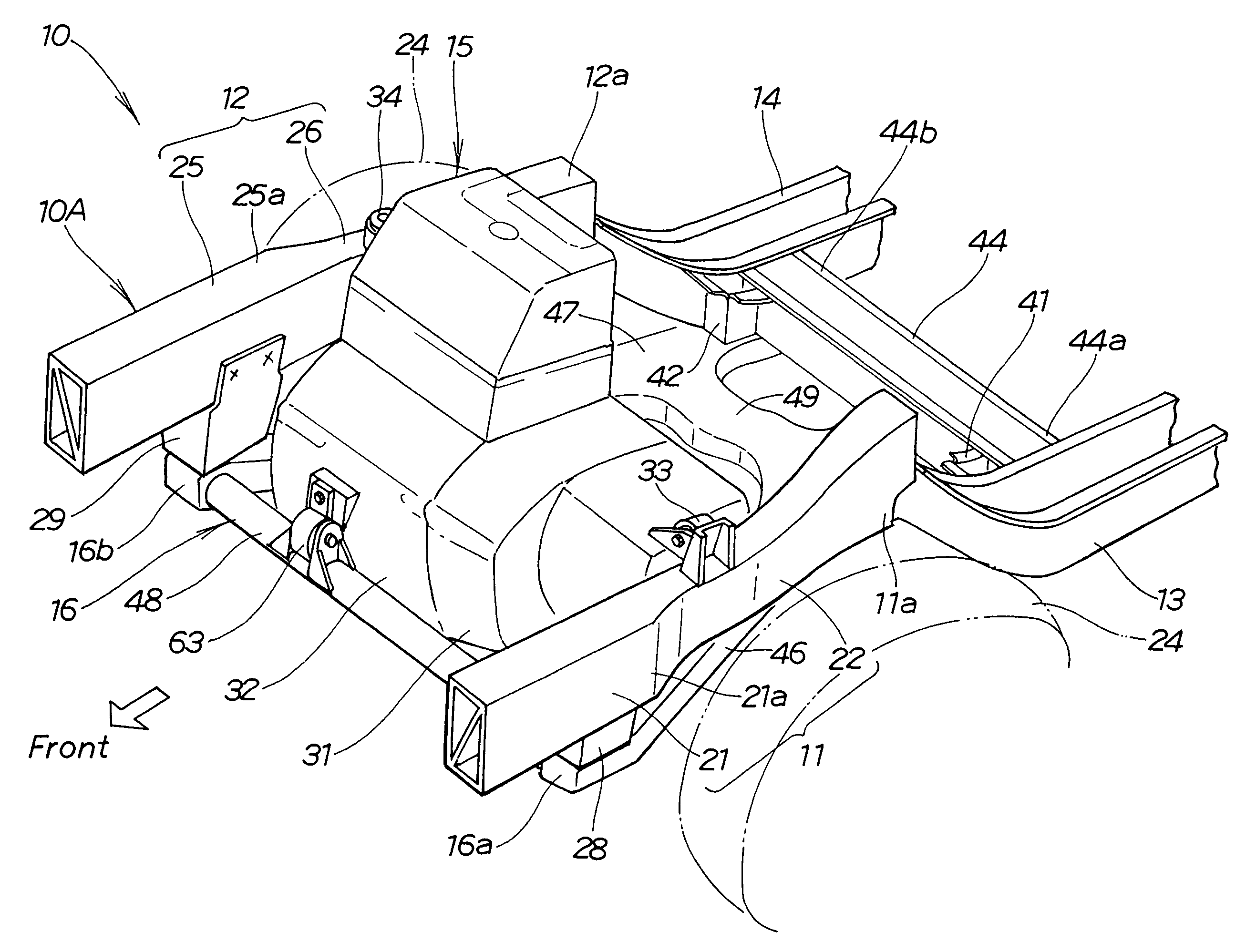

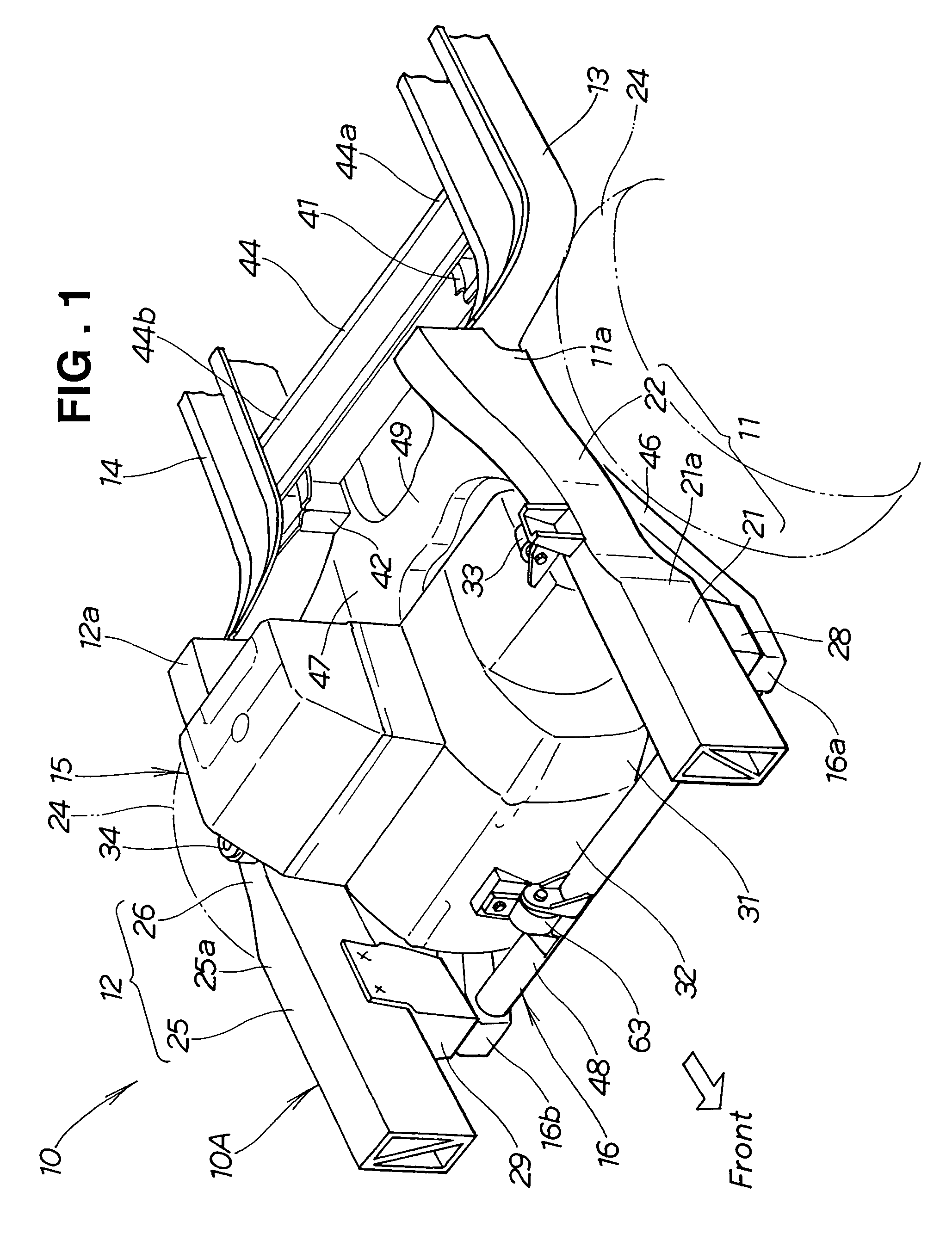

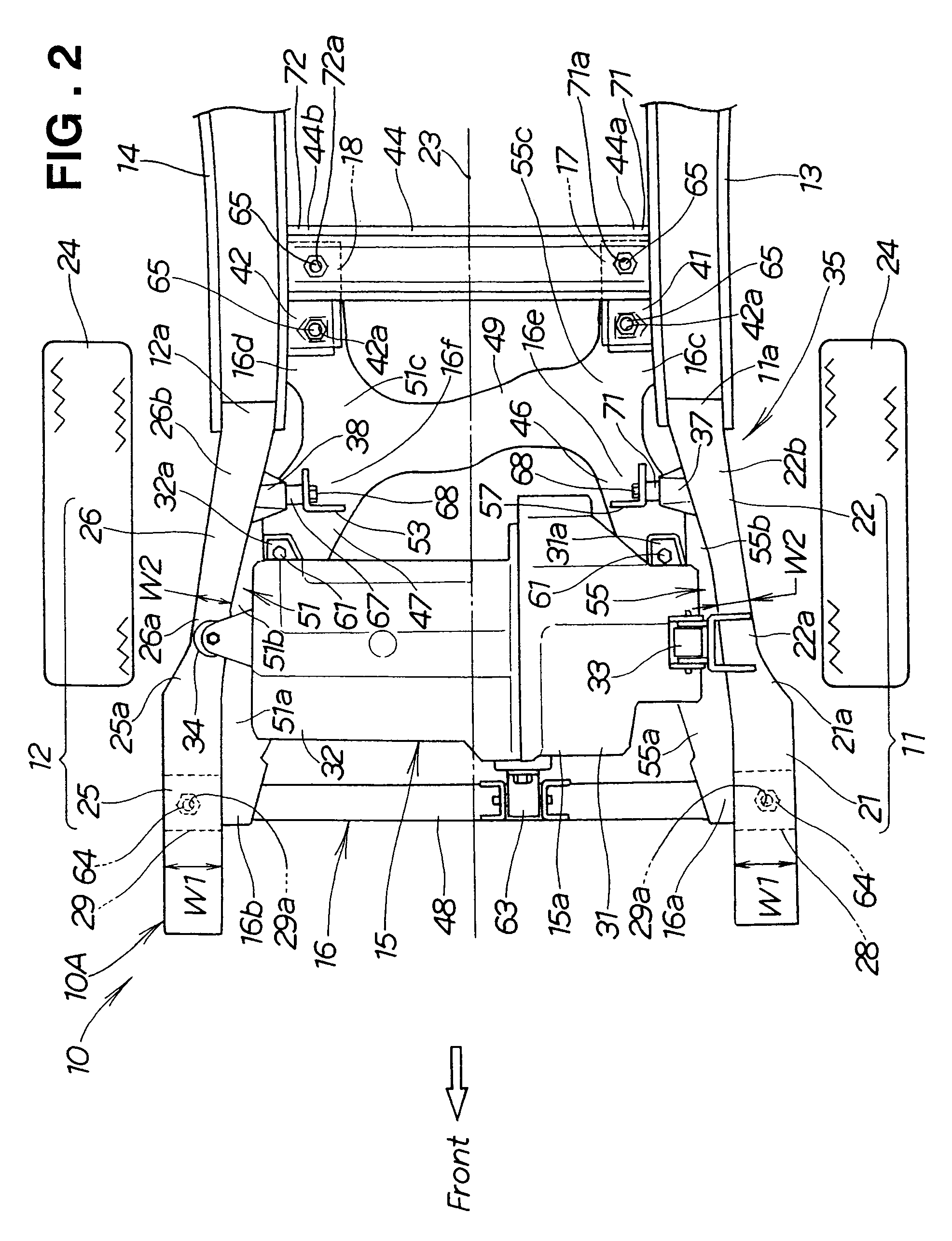

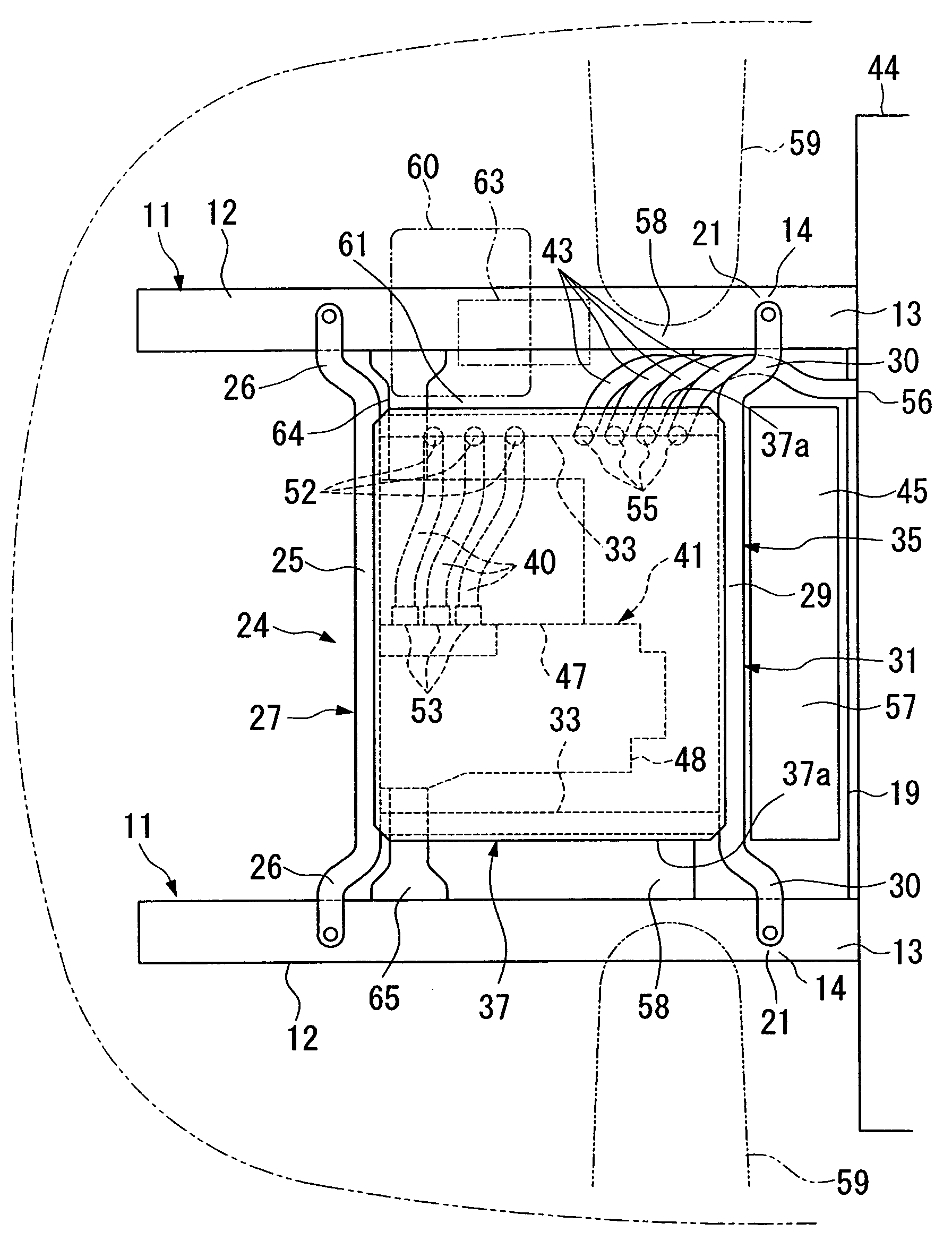

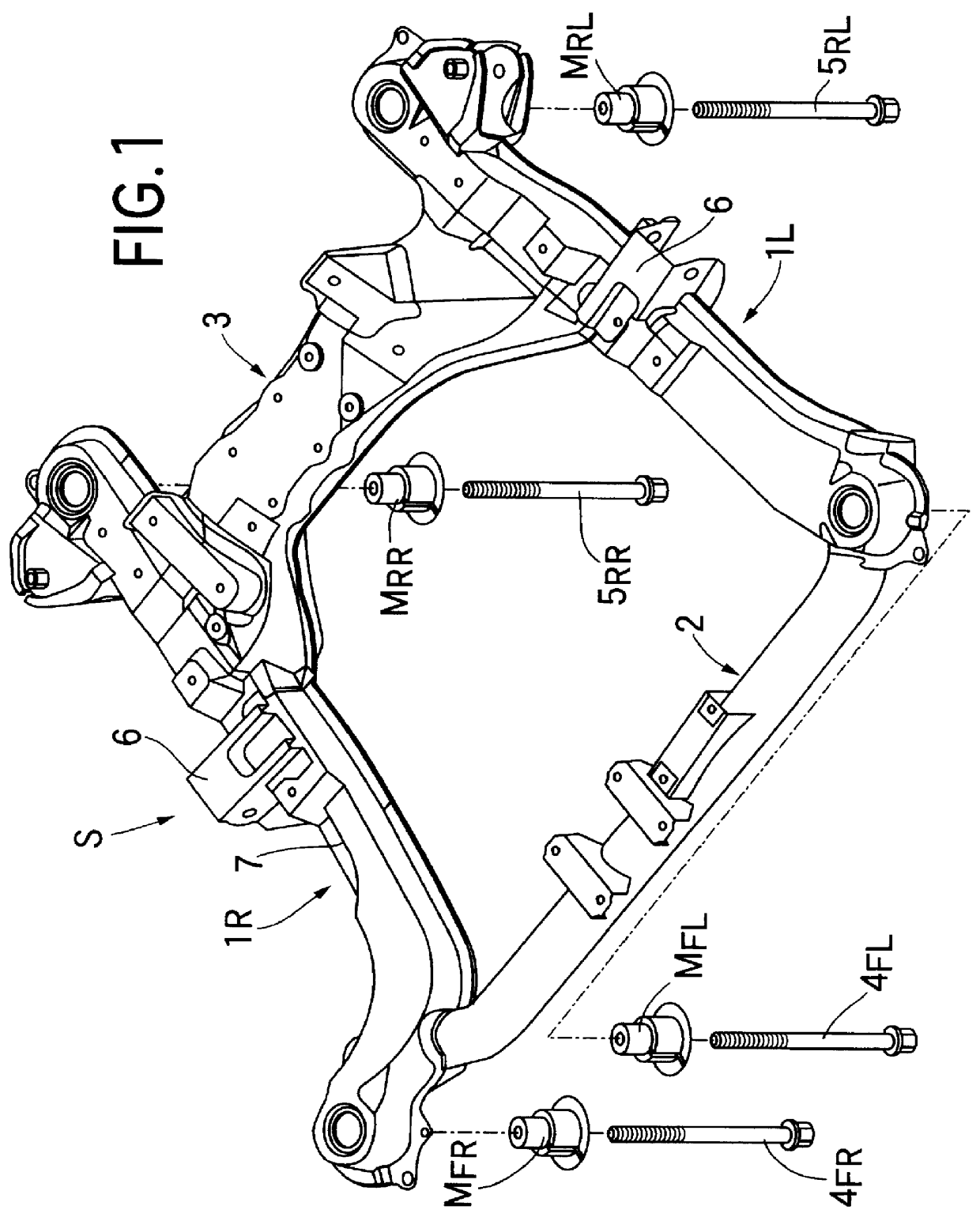

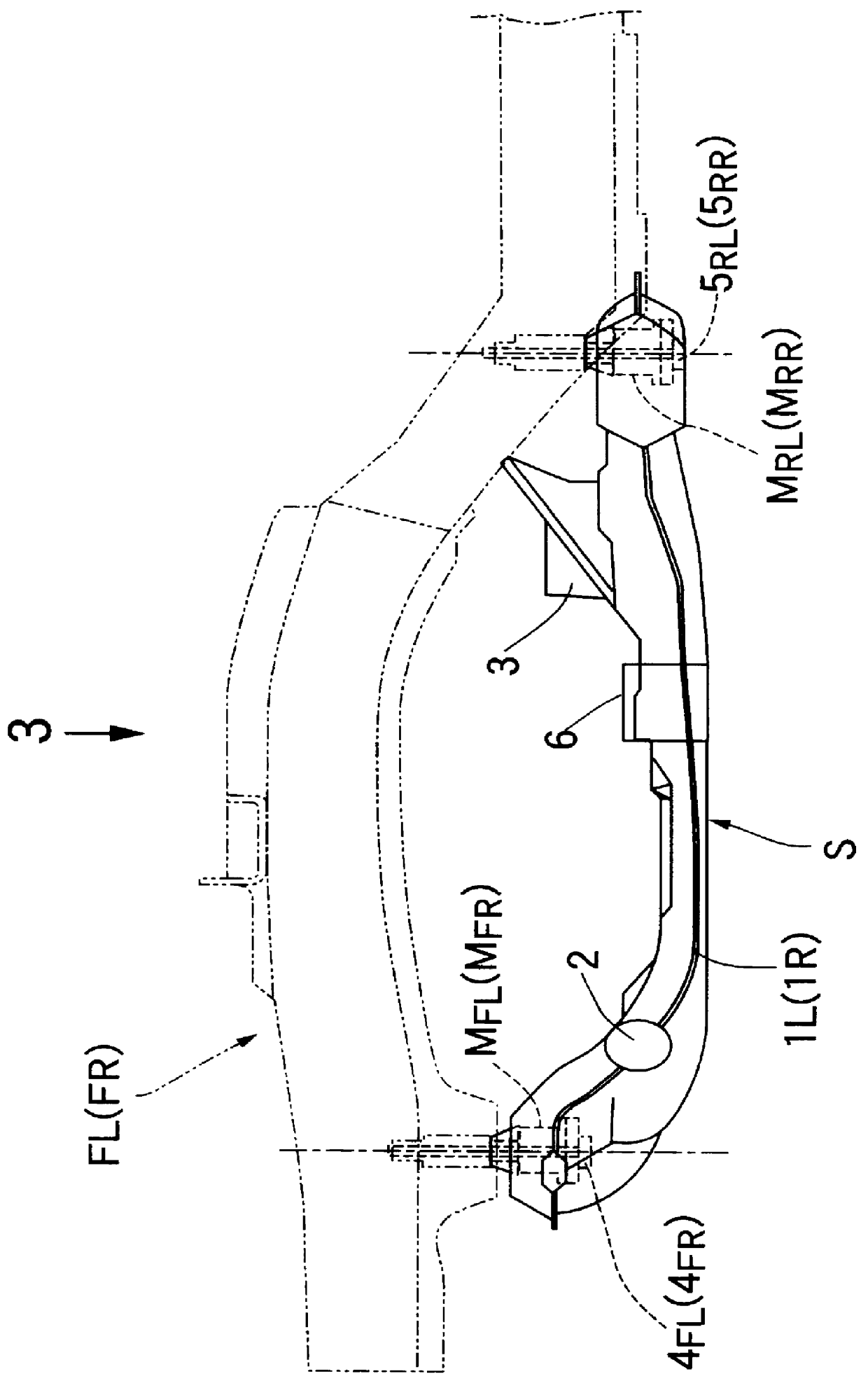

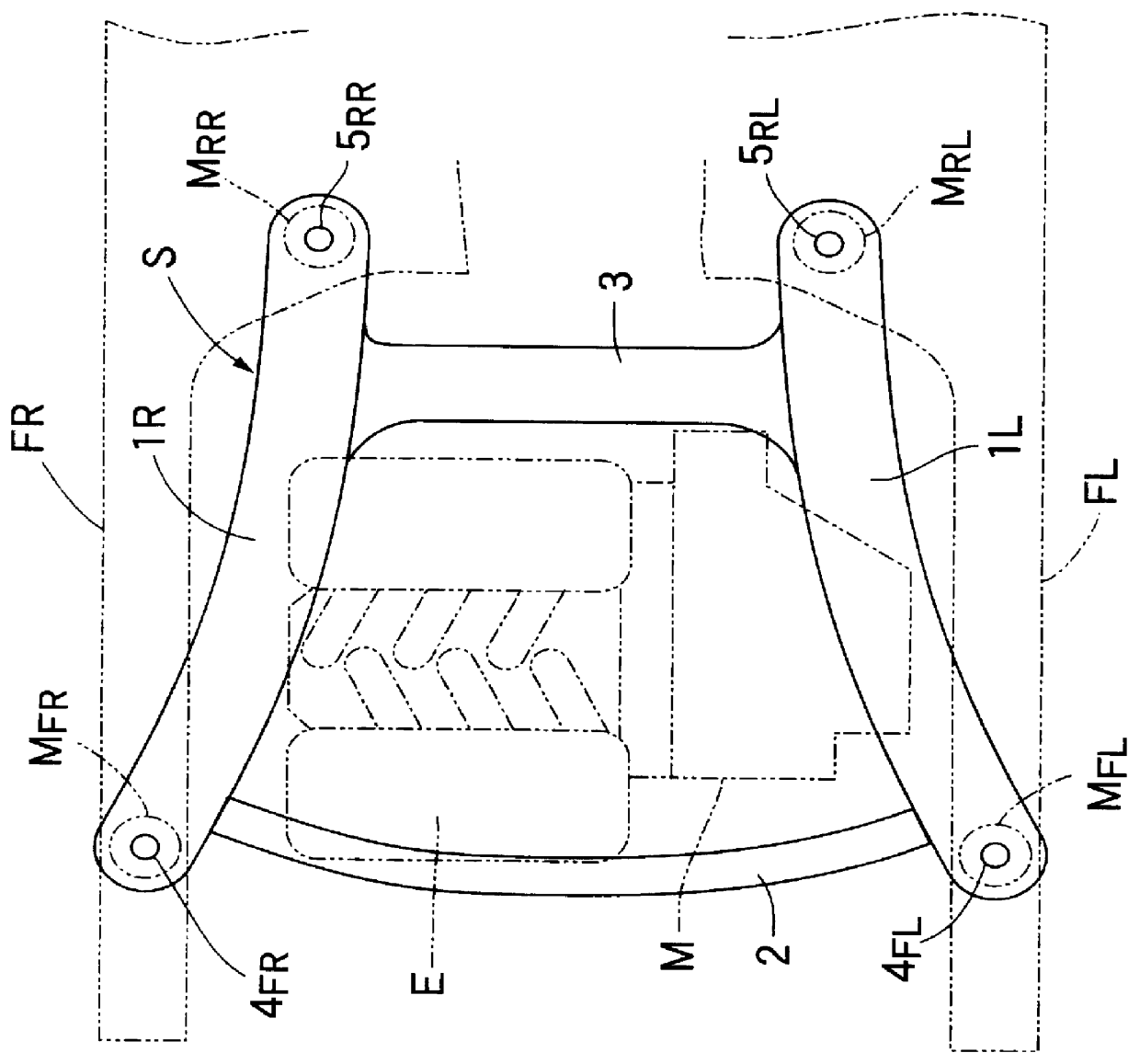

Shock absorbing vehicle body structure

InactiveUS6109654AReduce stiffnessDifference in rigidityPedestrian/occupant safety arrangementSteering linkagesVehicle frameTime lag

A shock absorbing vehicle body structure in a vehicle includes a substantially quadrilateral front subsidiary frame comprised of left and right side members extending in a longitudinal direction of a vehicle body and connected at their front and rear ends to each other by a front cross member and a rear cross member. The front subsidiary frame is supported at its four corners on main frames for the vehicle body through rubber mounts and bolts. Upon full-lap collision of the vehicle, the left rear bolt is first broken, whereby the rear end of the left side member is separated from the main frame and then, the right rear bolt is broken, whereby the rear end of the right side member is separated from the main frame. The right and left side members are formed with different rigidities to a longitudinal load applied thereto, which causes the right and left rear bolts to break at different times, or with a time lag therebetween. Such a time lag decreases the peak value of deceleration of the vehicle at a time when the front subsidiary frame is separated from the main frames due to a full-lap collision of the vehicle.

Owner:HONDA MOTOR CO LTD

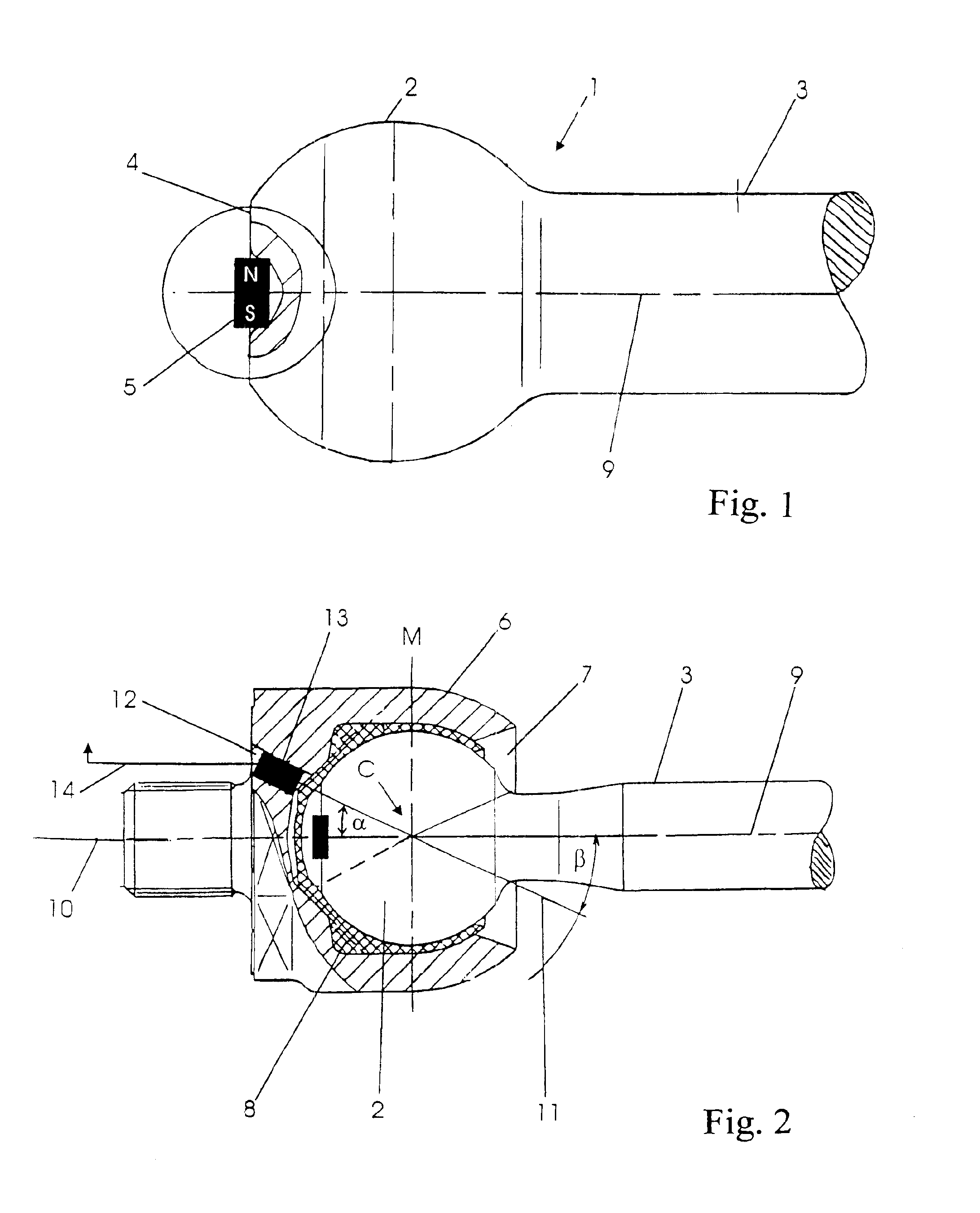

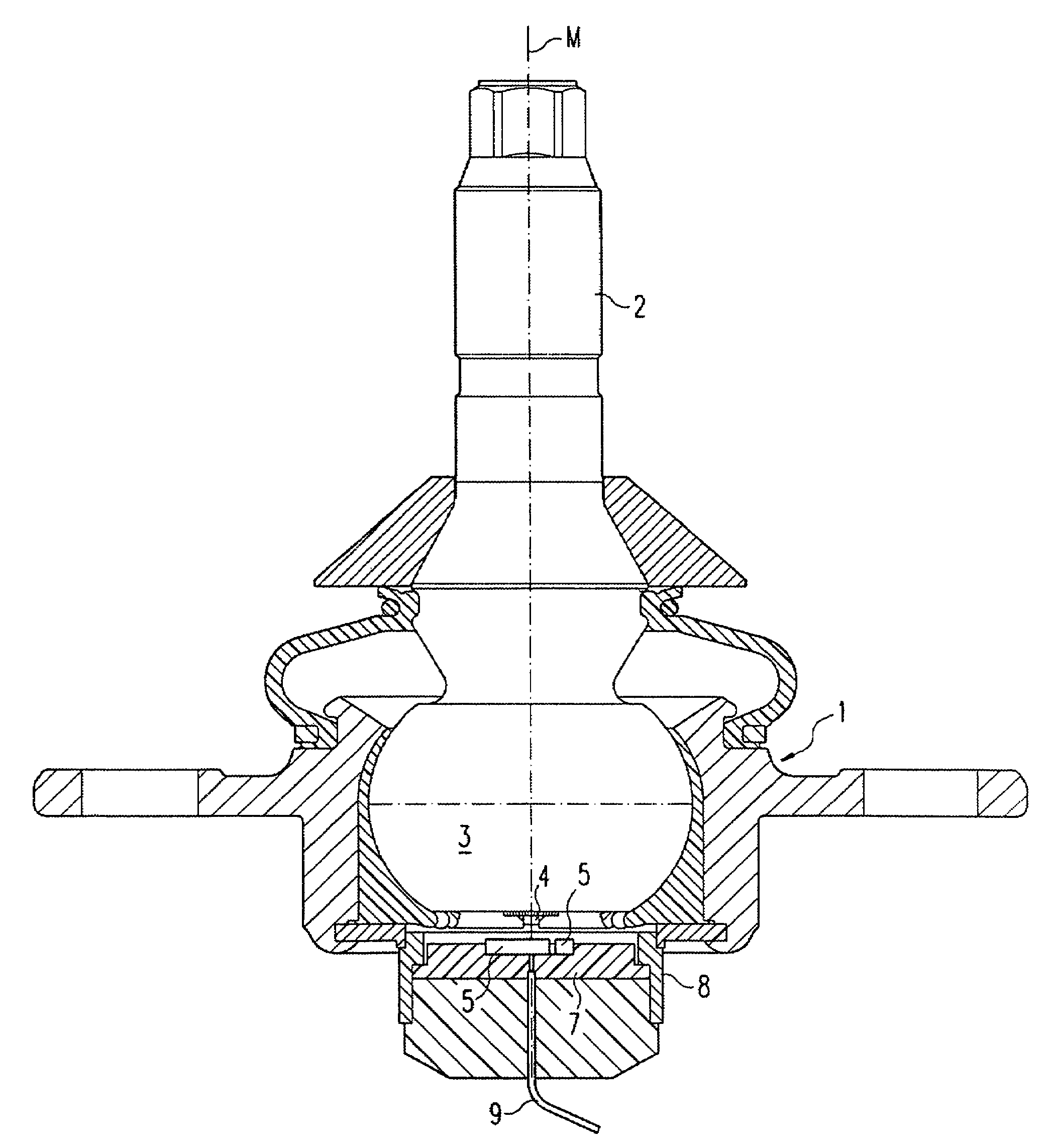

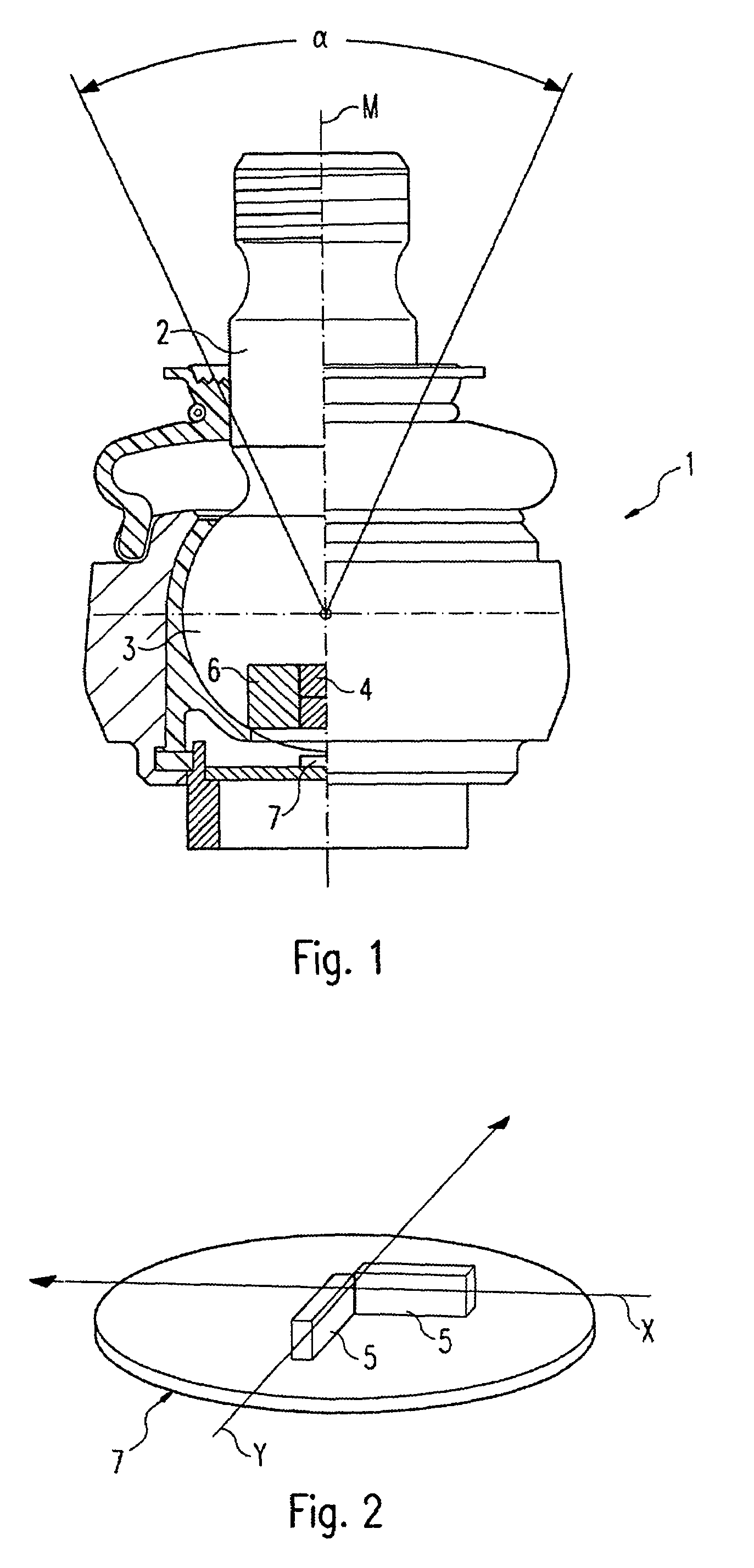

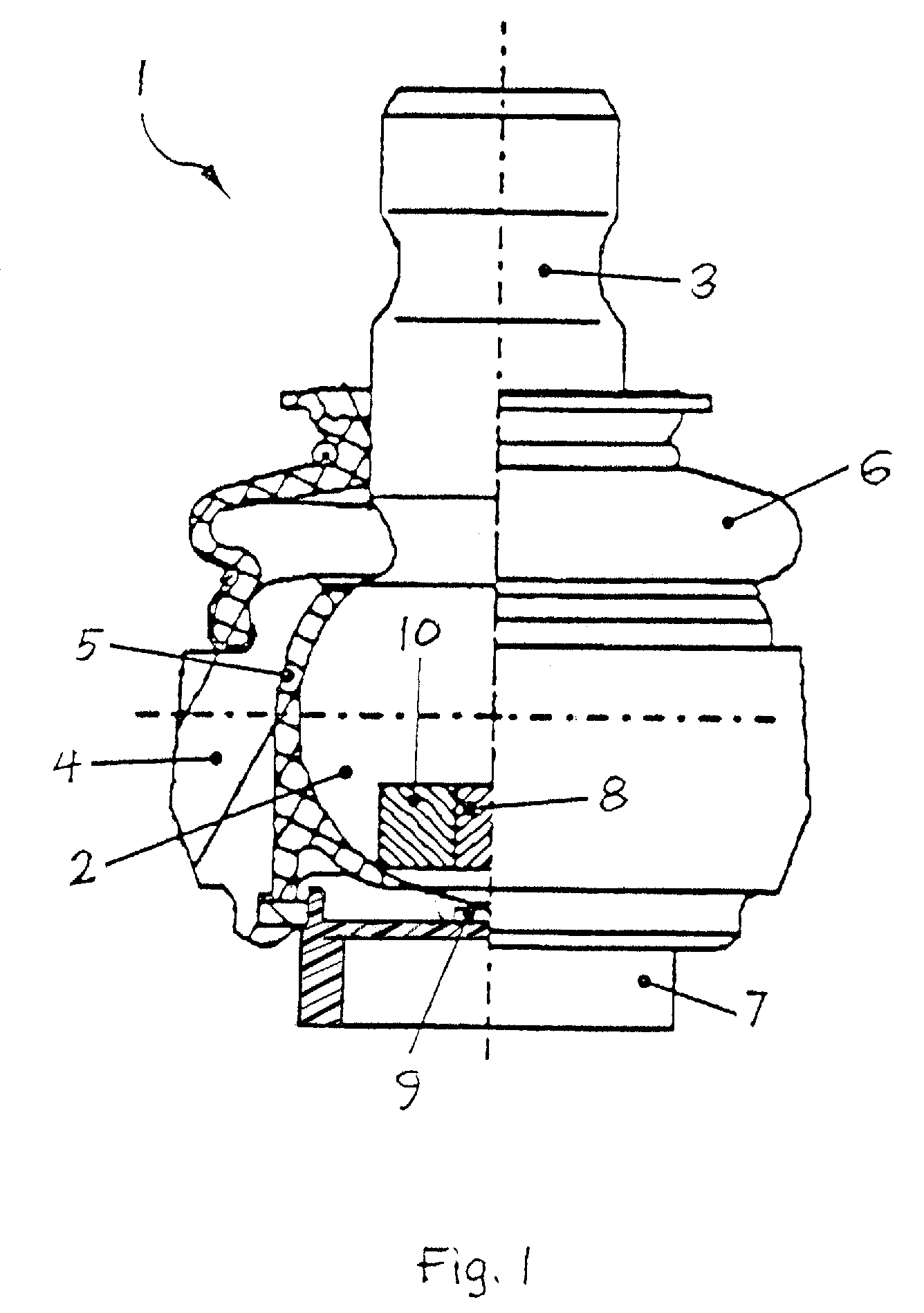

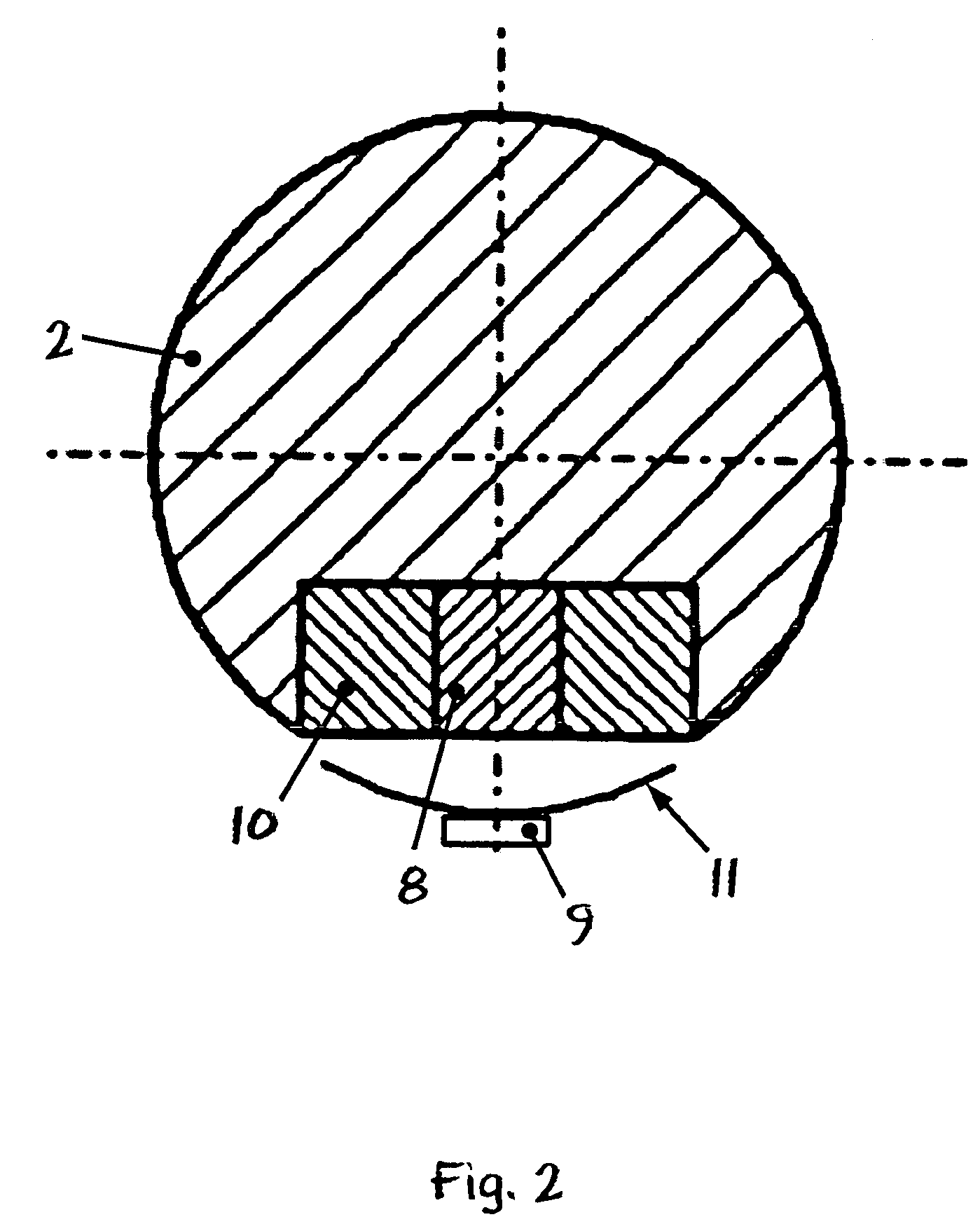

Ball joint with integrated angle sensor

InactiveUS6879240B2Improve accuracyDetect any spatial positionBearing assemblyShaftsTransducerEngineering

A ball-and-socket joint with integrated angle sensor for a motor vehicle, especially for the chassis of the motor vehicle is created. The ball-and-socket joint has a ball-and-socket joint housing (6) provided with a joint opening (7), a ball pivot (1) having a joint ball (2) and a pin (3), which is mounted, with its joint ball (2), rotatably and pivotably in a hollow-ball-shaped bearing surface in the ball-and-socket joint housing (6), and projects, with its pin (3), through the joint opening (7) out of the ball-and-socket joint housing (6). A two-pole field transducer (5) is provided at the end of the joint ball (2) facing away from the pin (3). The poles of the field transducer (5) are arranged on the ball surface. In this case, at least two field sensors (13) are arranged at a distance from one another with respect to the meridian plane defined by the large circle on the hollow-ball-shaped bearing surface running at right angles to the bearing longitudinal axis in the area or on the ball-and-socket joint housing (6) facing away from the joint opening, and interact with the field produced by the field transducer (5).

Owner:ZF LEMFOERDER METALLWAREN AG

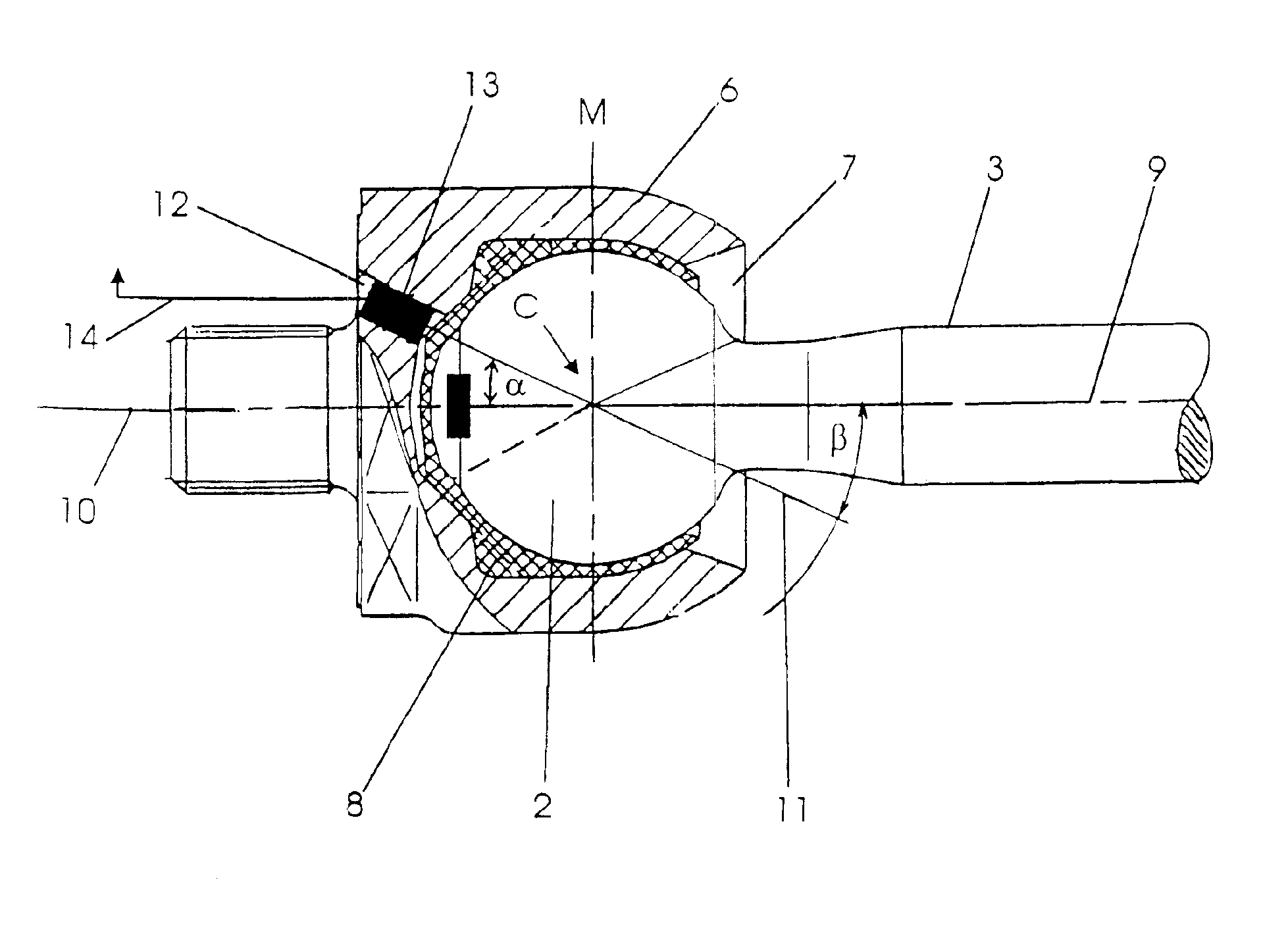

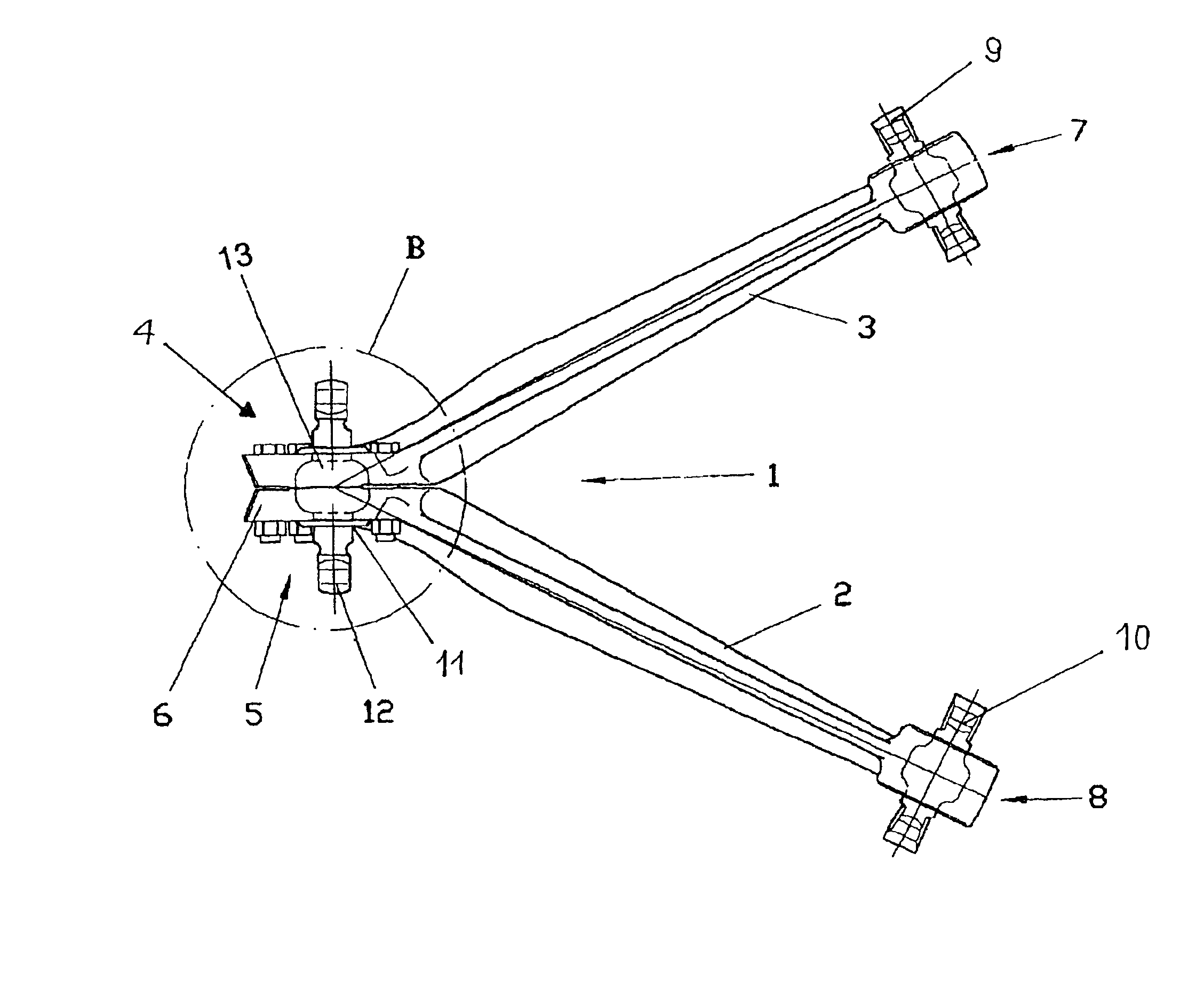

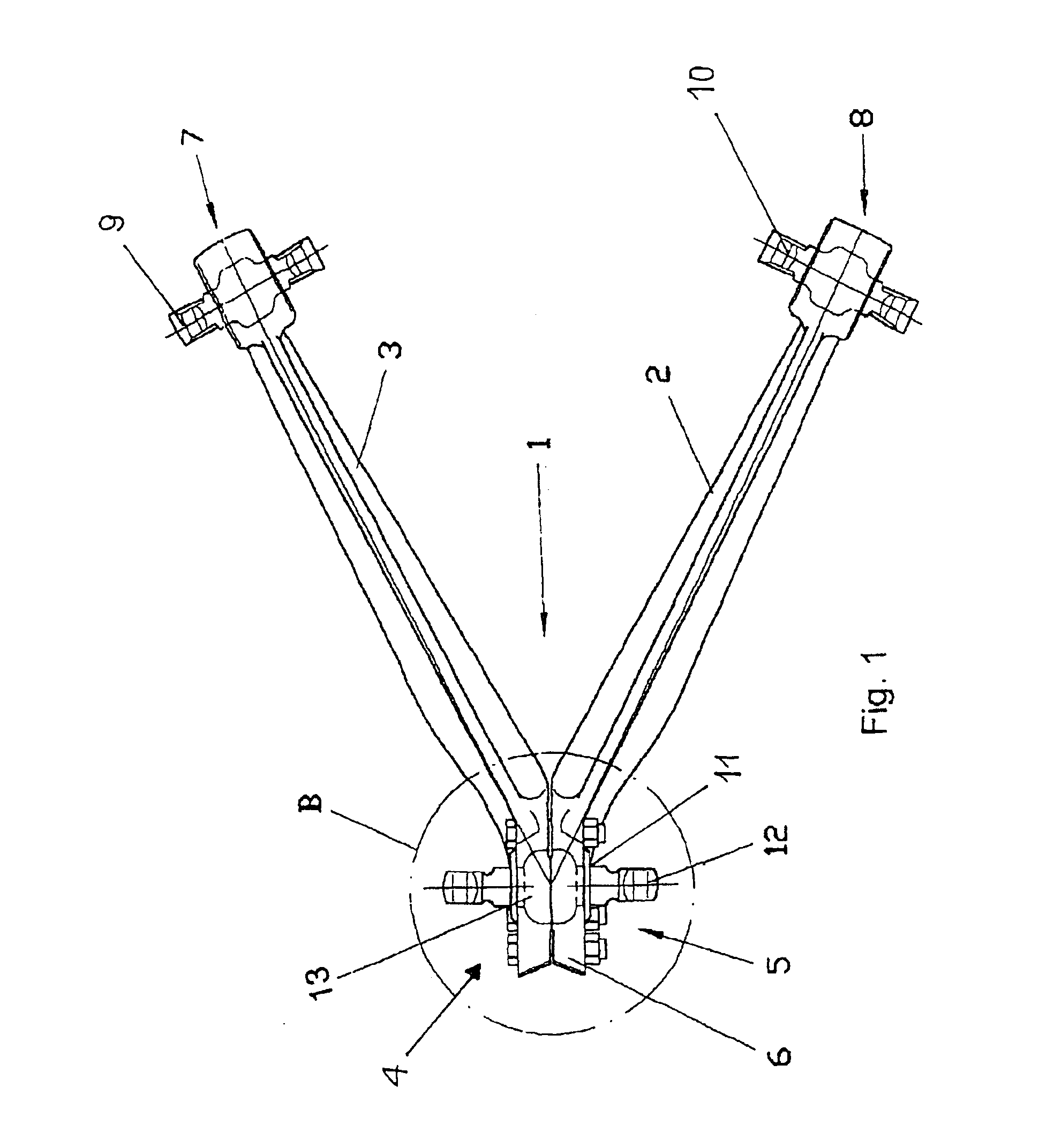

Steering triangle

InactiveUS6959935B2Simple designReduce shear forceNon-rotating vibration suppressionRigid suspensionsElastomerControl arm

A steering triangle (1) is provided for the axle suspension of motor vehicles for the articulated connection of a vehicle axle with a vehicle chassis with two control arms (2, 3). The control arms are connected to each other in a joint housing (6) formed by the control arms (2, 3) together for a rubber-metal bearing (11) for fixing the steering triangle (1) on the vehicle axle. The rubber-metal bearing (11) has a pivot axis (12) provided with a spherical surface and an elastomer body (14), which extends around the pivot axis (12) at least in the area of the spherical surface and which is accommodated in a recess (16) located within the joint housing (6), in which steering triangle two pressing rings (17, 18) are arranged within the recess (16) of the joint housing (6) on the axial outer sides of the elastomer body (14). The pressing rings can be moved toward each other by a tensioning device via the intermediary of stop faces (22) of the joint housing (6). The stop faces are in contact with the outer sides of the pressing rings (17, 18), which outer sides face away from each other. The rubber-metal bearing can be pretensioned both in the axial direction and in the radial direction, so that stronger forces can be absorbed due to the higher rigidity achieved as a result.

Owner:ZF FRIEDRICHSHAFEN AG

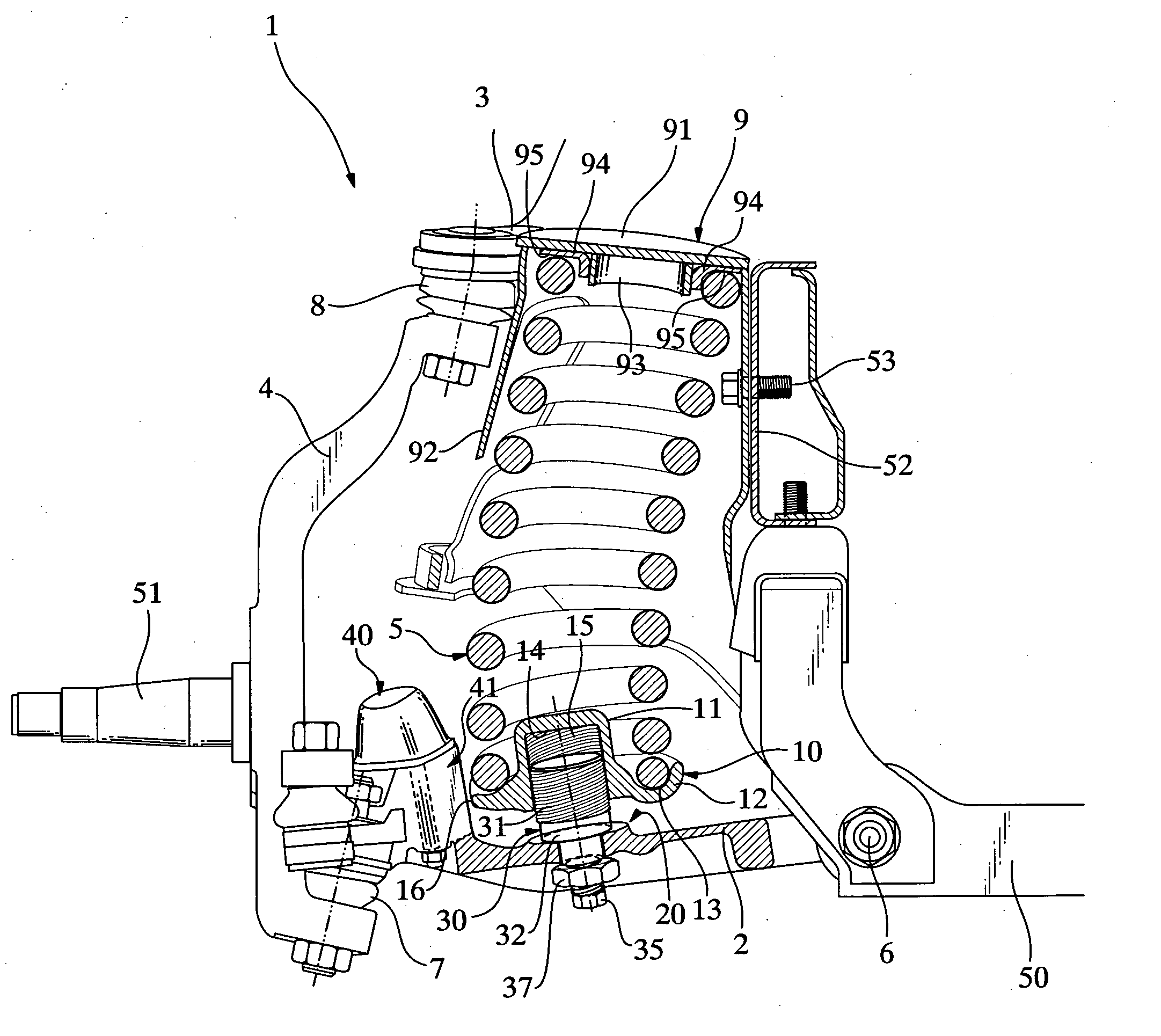

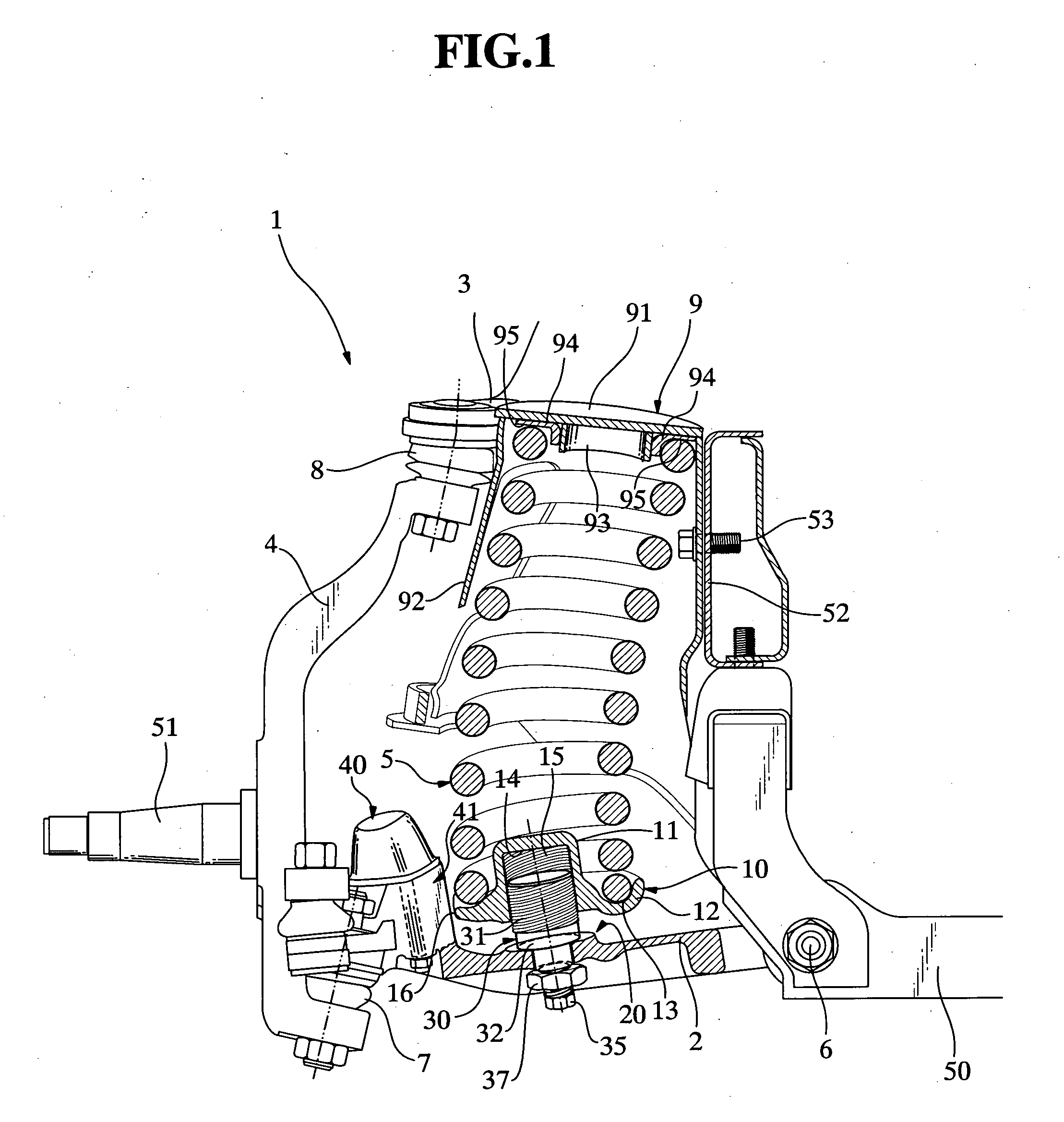

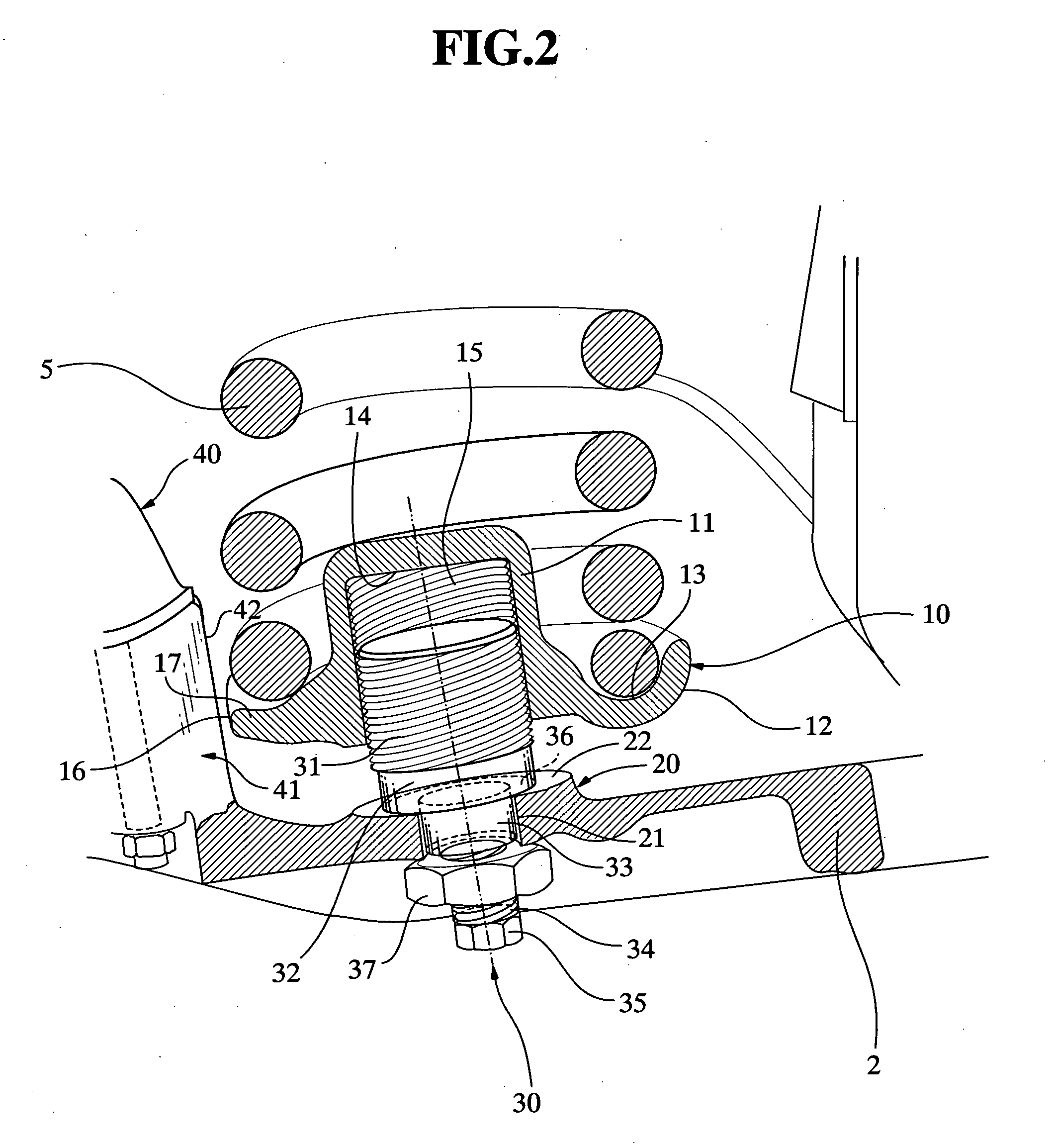

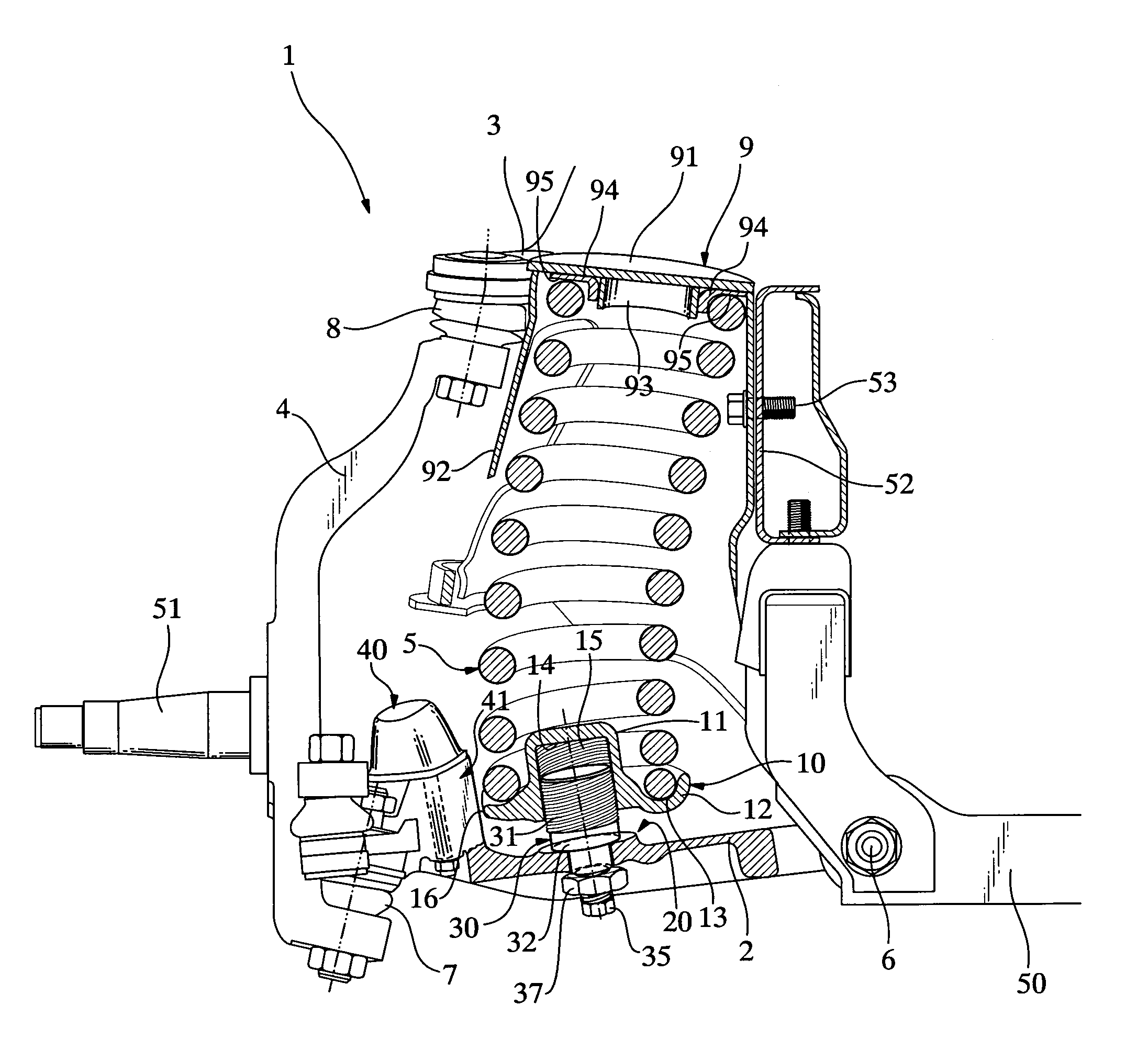

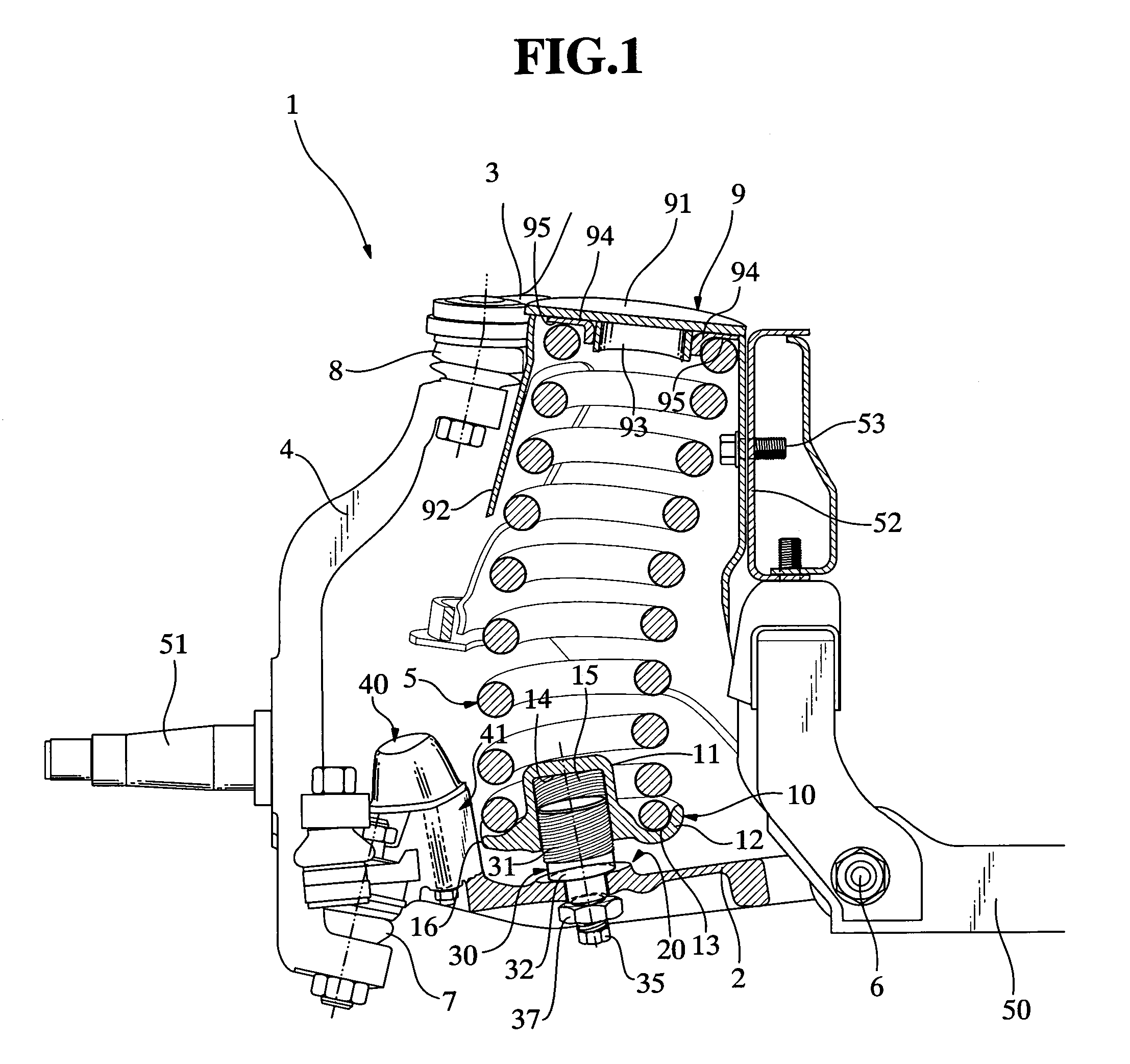

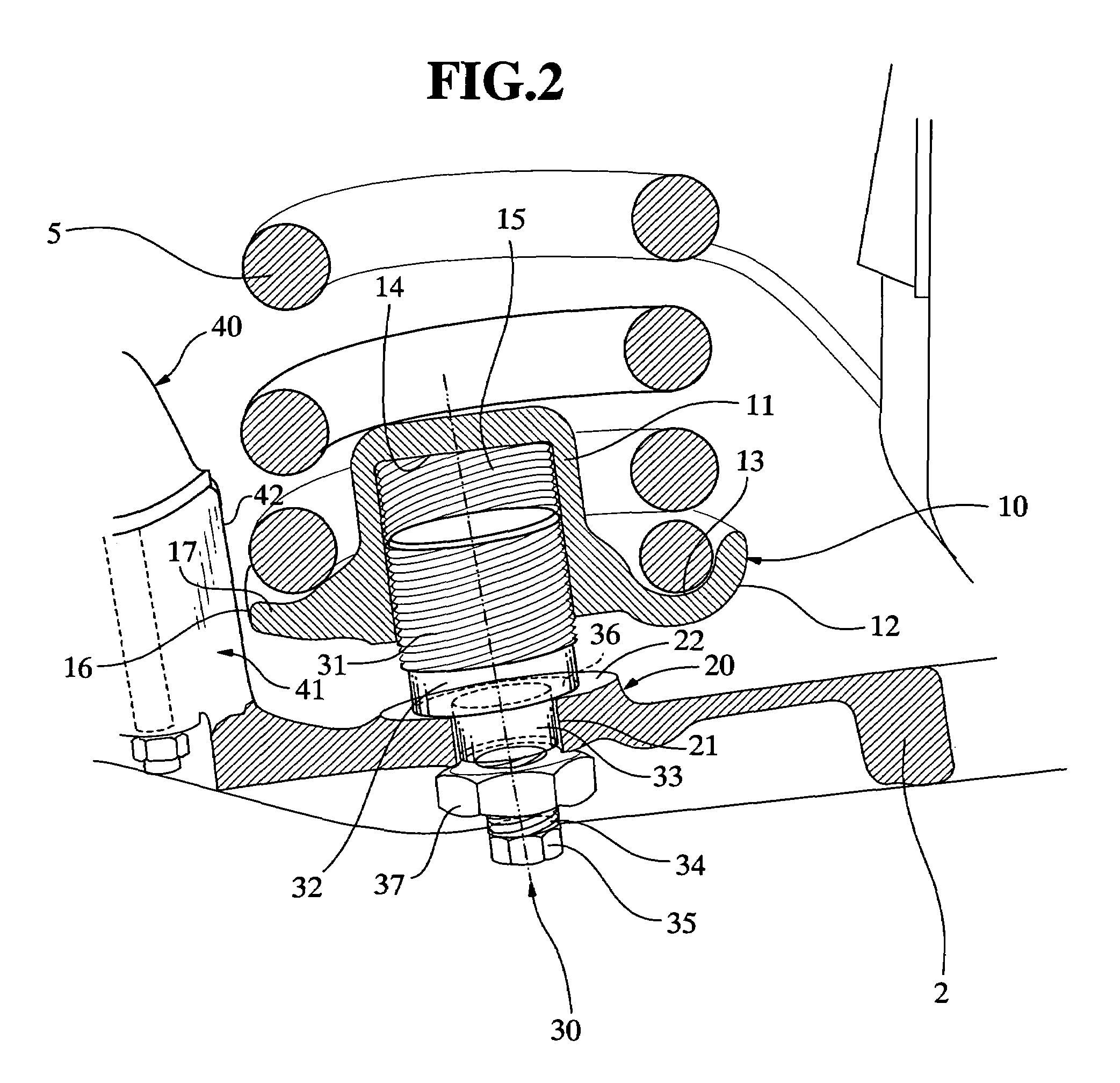

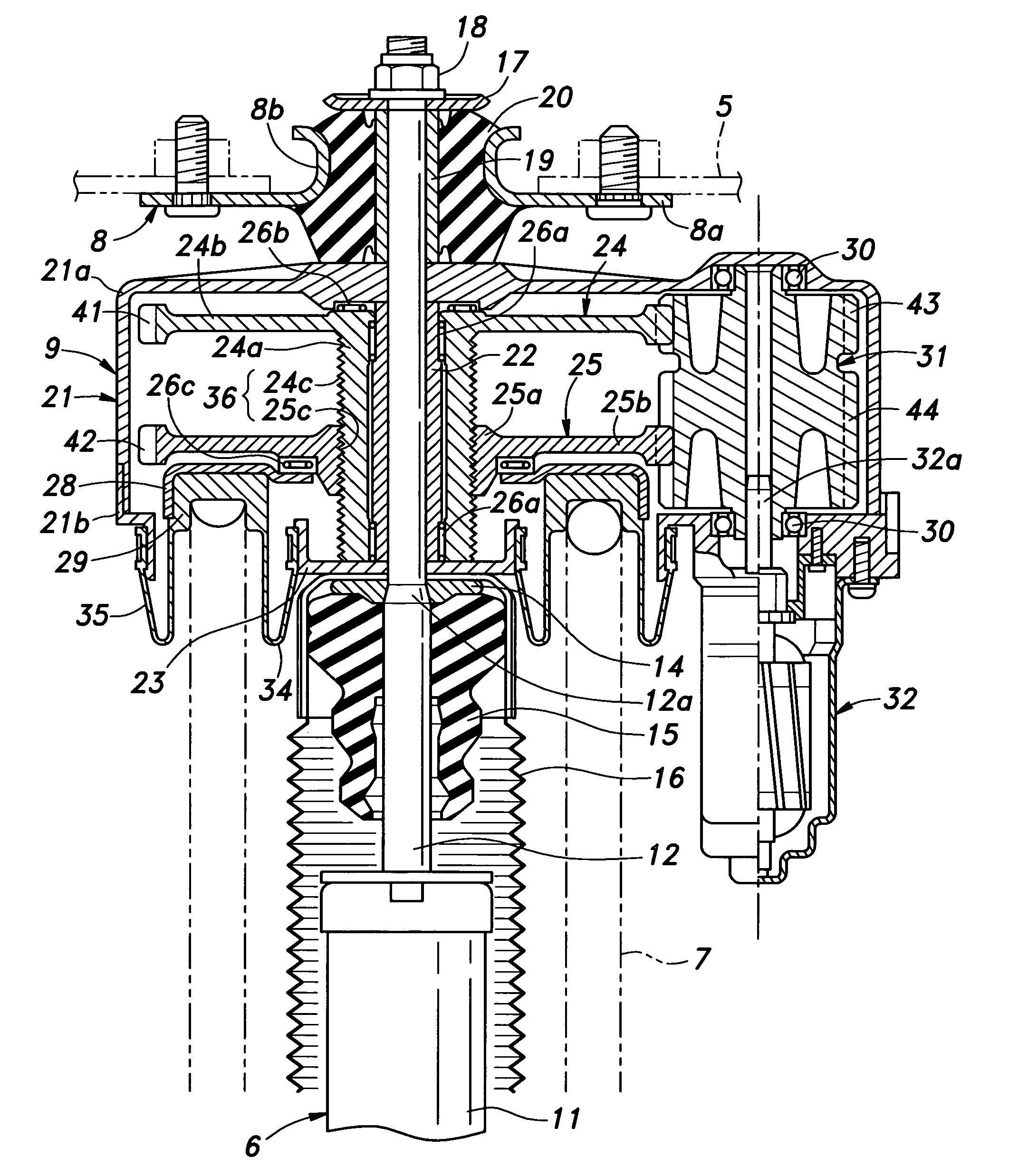

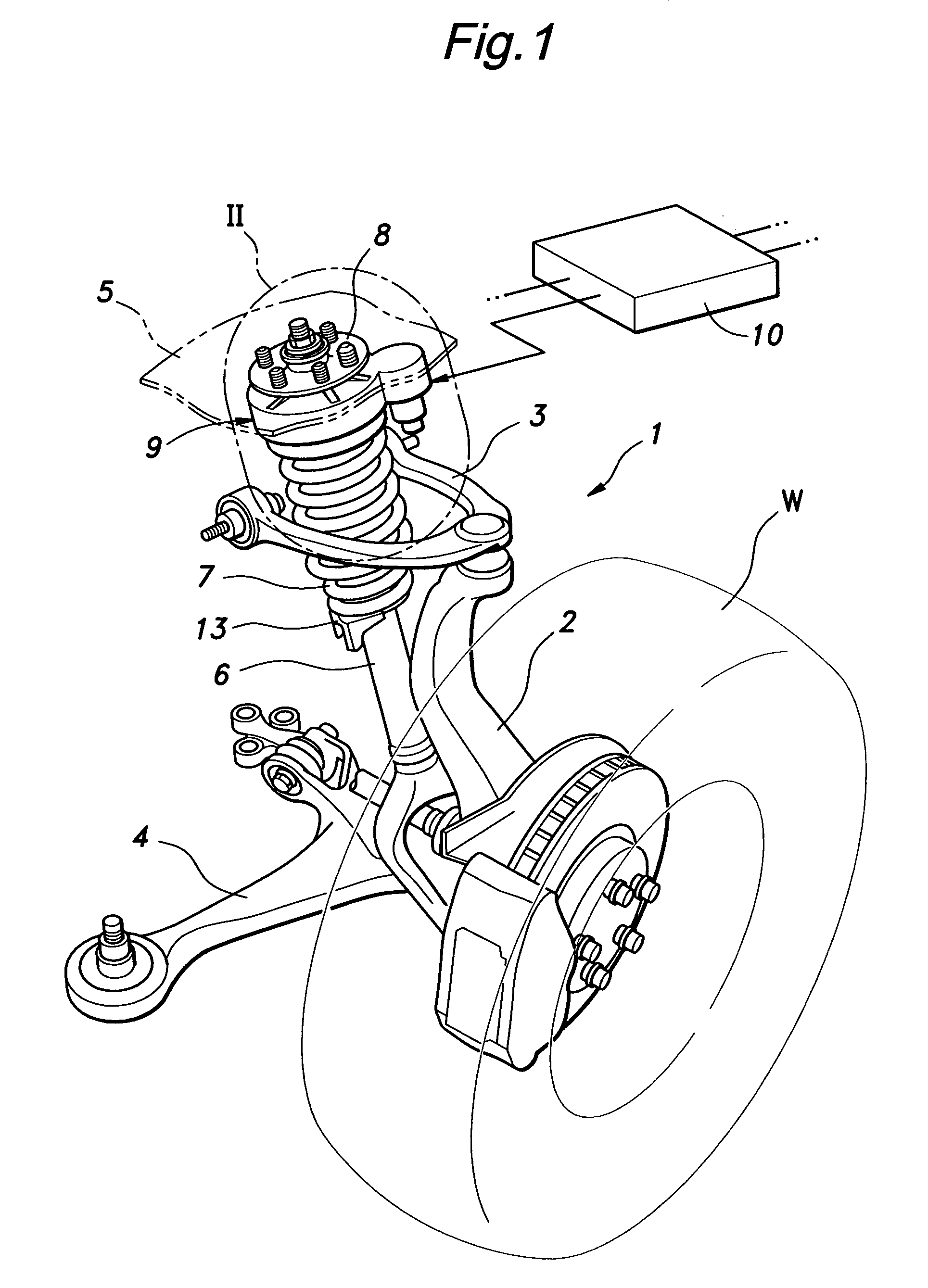

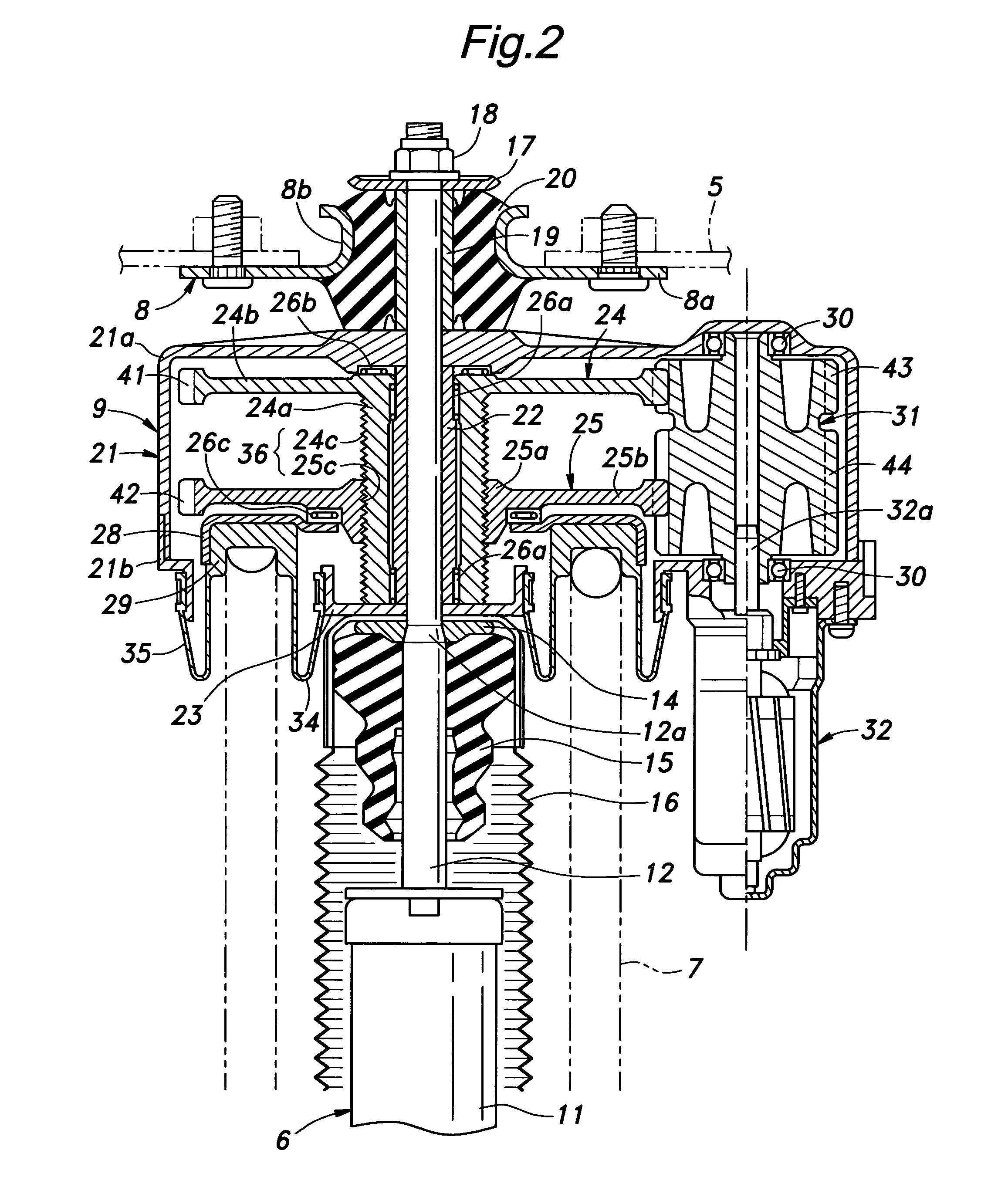

Vehicle Height Adjustment Device And Vehicle Height Adjustment Method

InactiveUS20080018065A1Easy constructionReduce the number of partsSteering linkagesVehicle cleaning apparatusCoil springEngineering

A vehicle height adjustment device has an adjustment bolt (30) rotatably supported by or fixed to a wheel-side member or a vehicle-body member, and a spring seat member (10) threadedly engaging with the adjustment bolt. Rotation of the spring seat member is limited by a bump rubber pedestal (41) (or a coil spring bracket (9)). Displacement of the spring seat member occurs in an axial direction of rotation of the bolt, in accordance with rotation of the bolt. According to the present invention, rotation of the spring seat involved in rotation of the bolt for adjusting the vehicle height can be restricted, and a construction of a vehicle height adjustment mechanism can be simplified so that the number of parts or members of the device is reduced.

Owner:ISUZU MOTORS LTD

Vehicle height adjustment device and vehicle height adjustment method

InactiveUS7631882B2Easy constructionReduce the number of partsSteering linkagesVehicle cleaning apparatusCoil springEngineering

A vehicle height adjustment device has an adjustment bolt (30) rotatably supported by or fixed to a wheel-side member or a vehicle-body member, and a spring seat member (10) threadedly engaging with the adjustment bolt. Rotation of the spring seat member is limited by a bump rubber pedestal (41) (or a coil spring bracket (9)). Displacement of the spring seat member occurs in an axial direction of rotation of the bolt, in accordance with rotation of the bolt. According to the present invention, rotation of the spring seat involved in rotation of the bolt for adjusting the vehicle height can be restricted, and a construction of a vehicle height adjustment mechanism can be simplified so that the number of parts or members of the device is reduced.

Owner:ISUZU MOTORS LTD

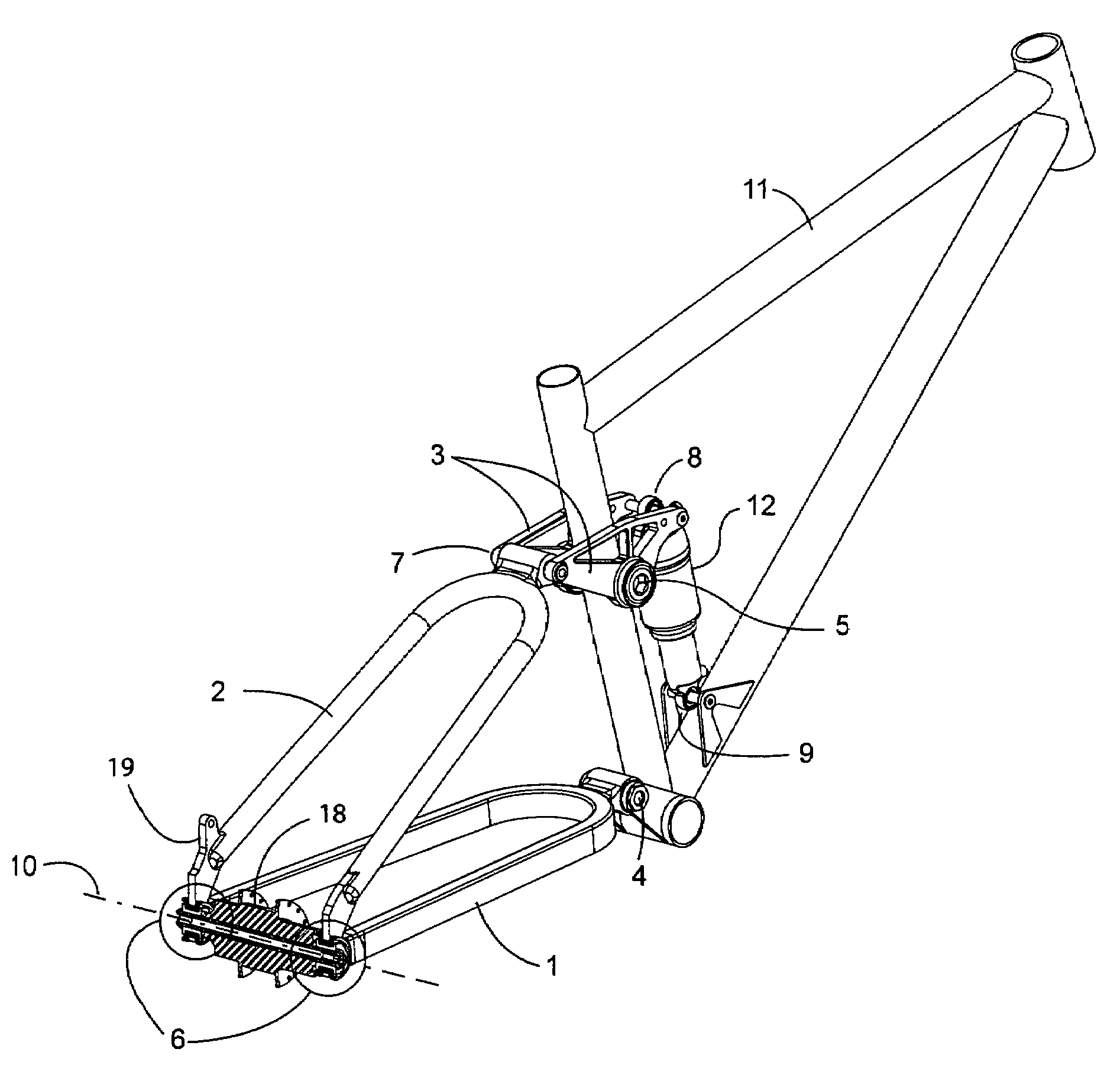

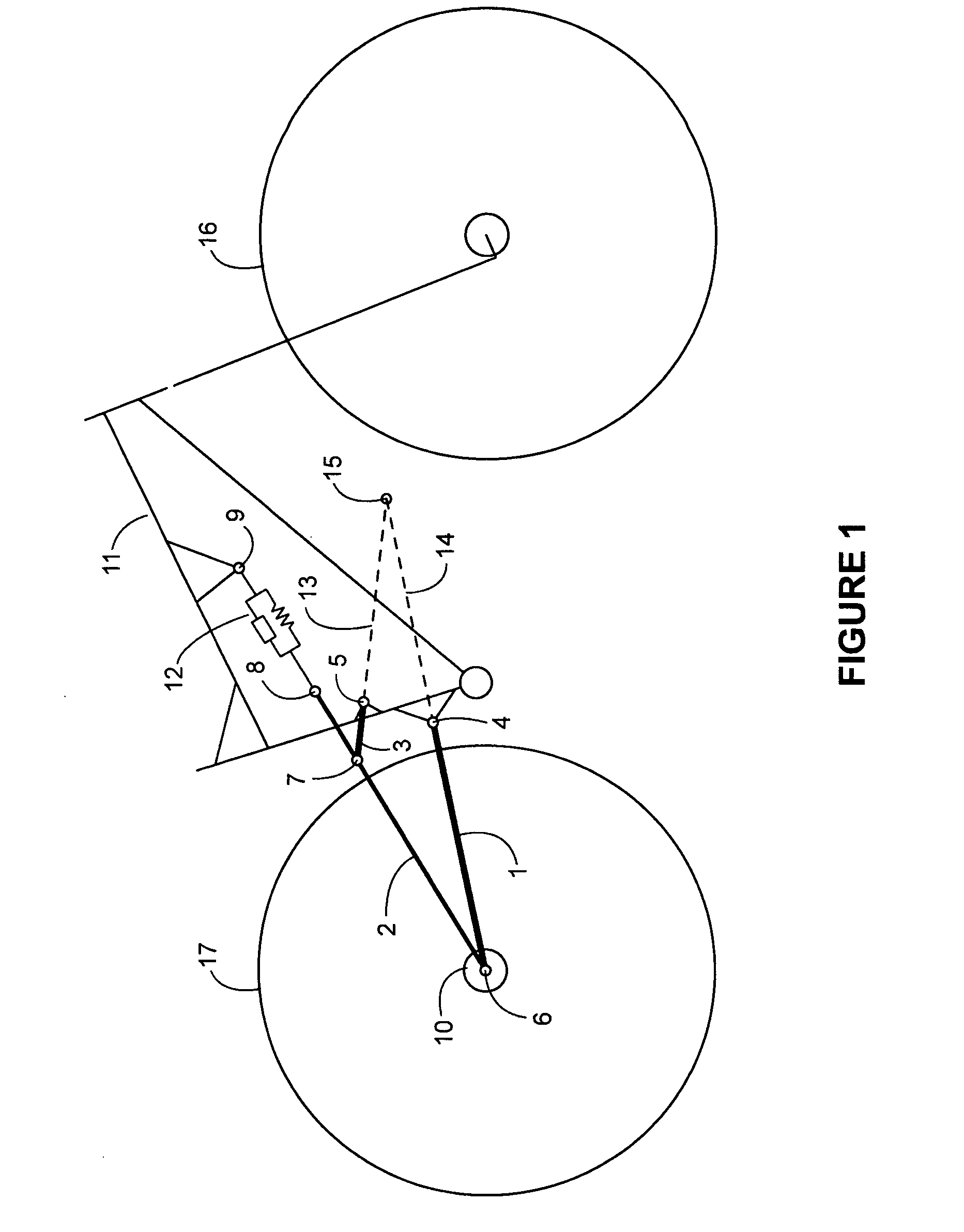

Vehicle suspension systems for seperated acceleration responses

InactiveUS20080067772A1Lower performance requirementsPassenger cyclesChildren cyclesEngineeringBrake force

Owner:SPLIT PIVOT

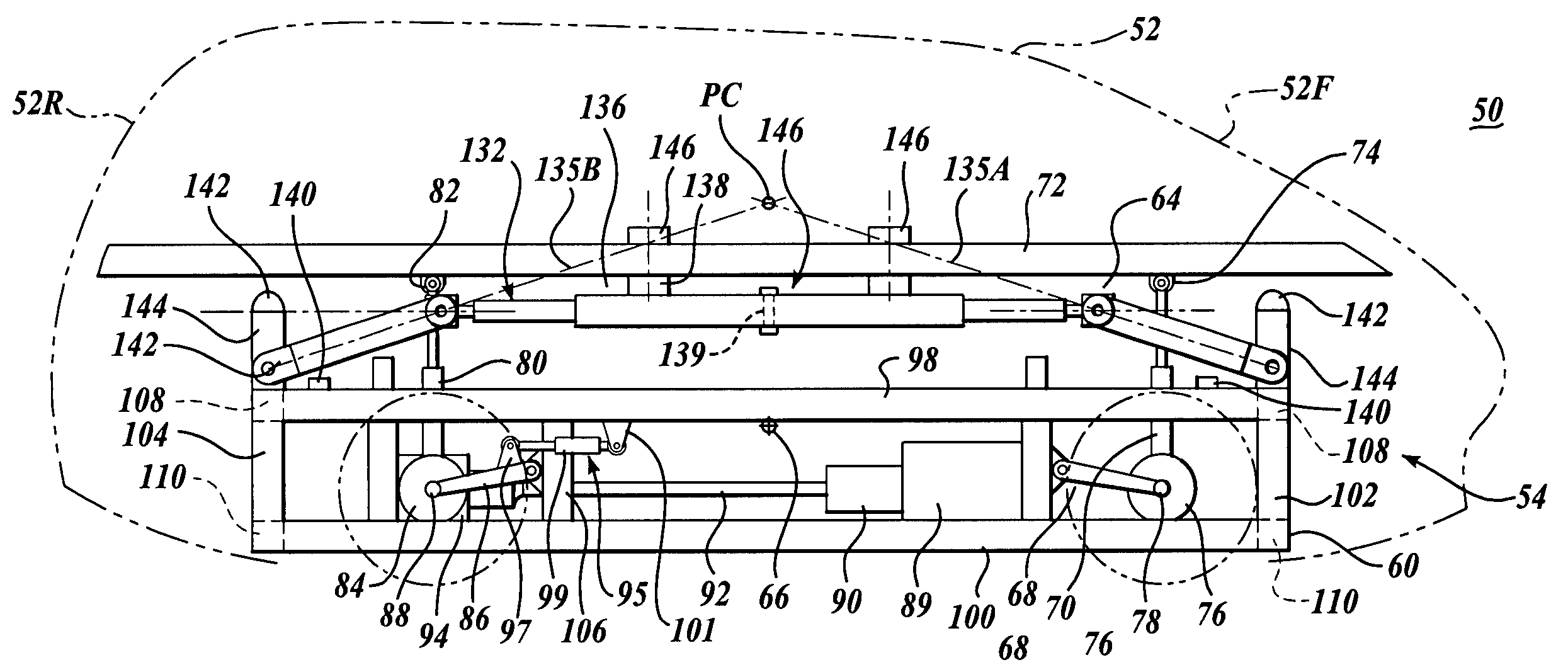

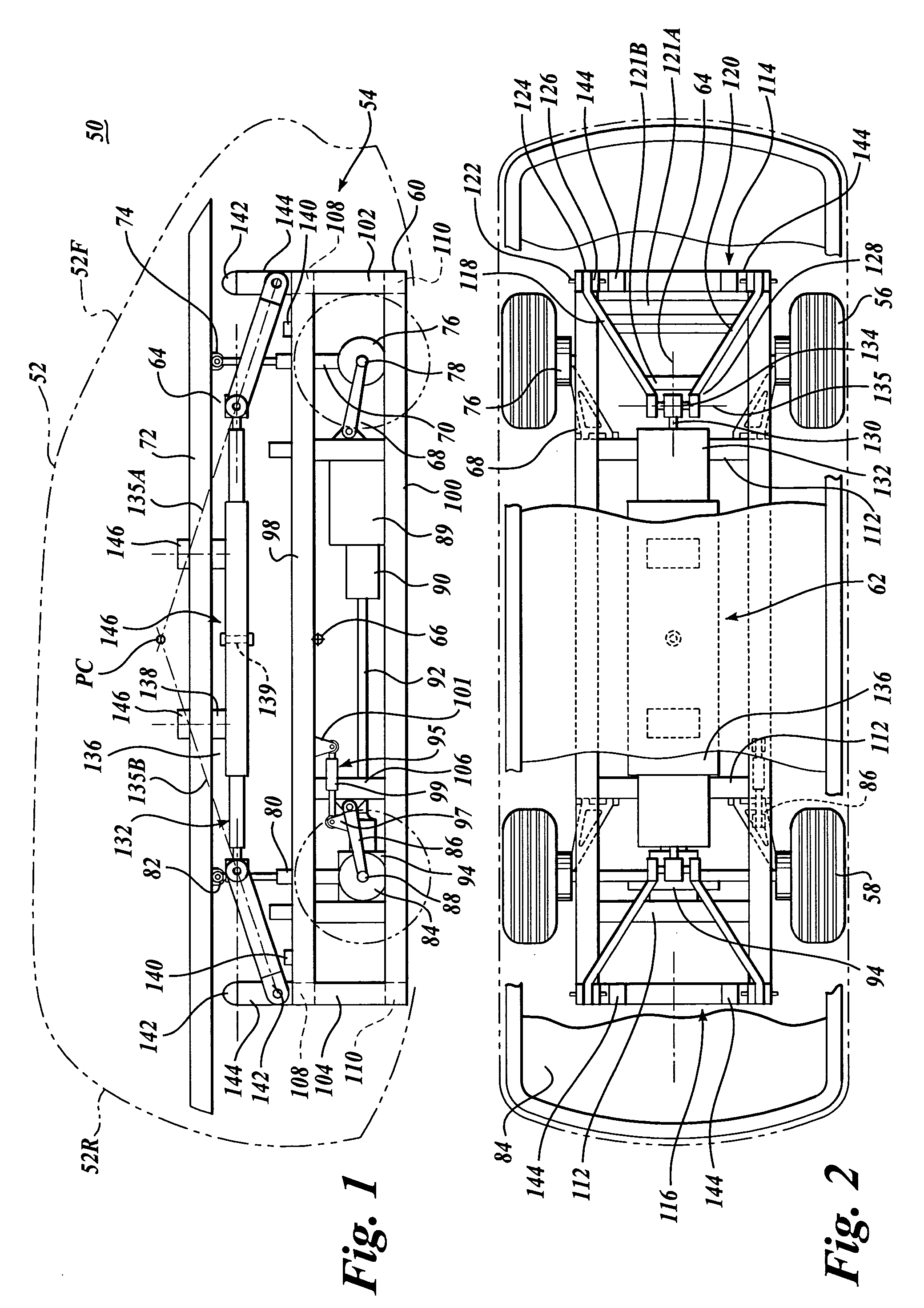

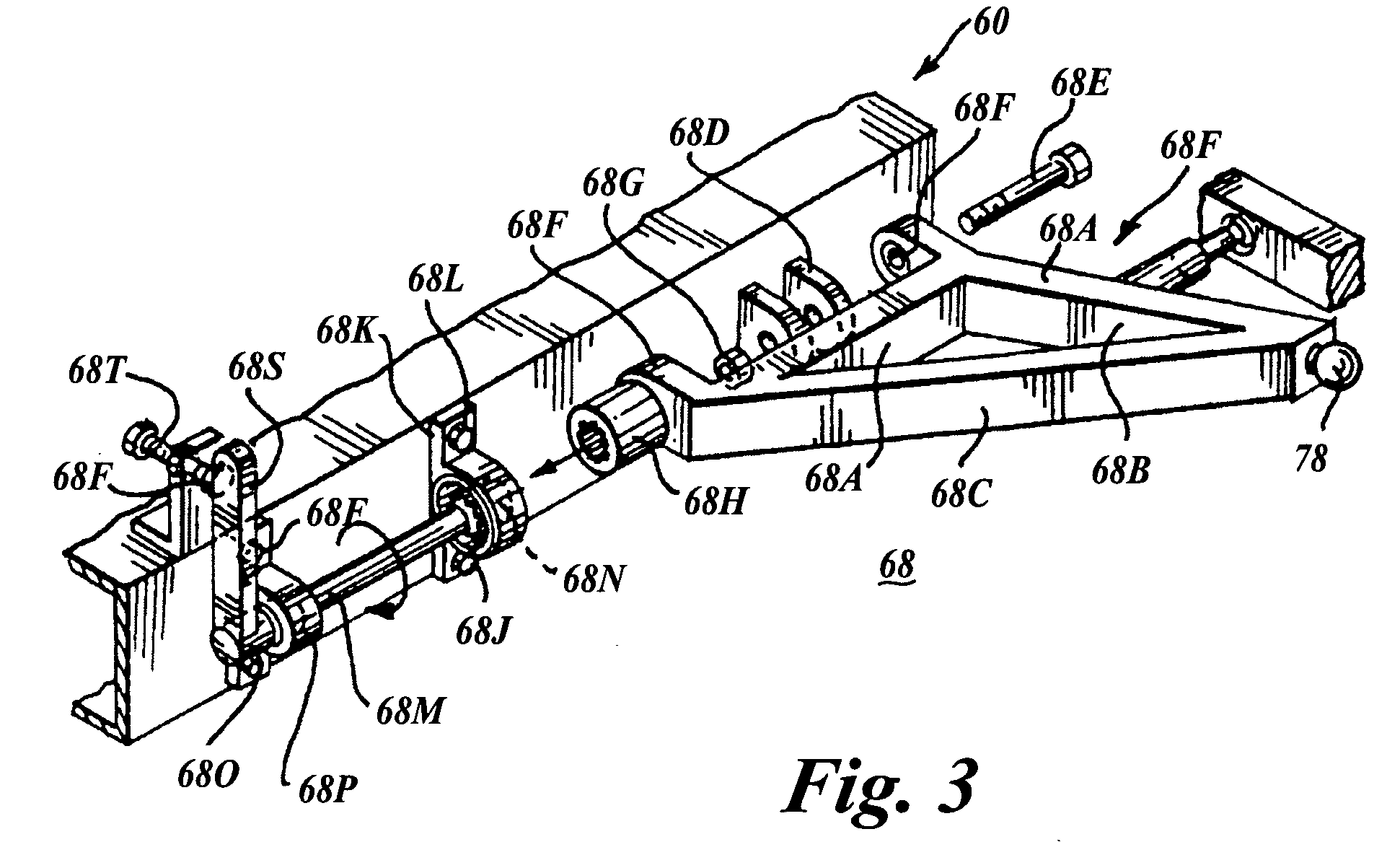

Vehicle with movable and inwardly tilting safety body

ActiveUS20050275181A1Reduce the detrimental effects on vehicle handlingImprove vehicle handlingVehicle body stabilisationVehicle cleaning apparatusEngineeringInterconnection

A suspension system for a vehicle (50c) having a body (52c) and a plurality of wheel support assemblies (56c, 58c) includes a tie structure (60c) interposed between the body and the wheel support assemblies. A first interconnection system (68c) interconnects the tie structure to the wheel support assemblies, and the second interconnection system (302) interconnects the tie structure and the body. The second interconnection system includes a plurality of link structures (304, 320) pivotally connected at one end to the tie structure, and pivotally connected at the opposite end to the body. Such link structures are oriented relative to the tie structure to extend towards a common point along a longitudinal axis (33B) of the tie structure.

Owner:MACISAAC WILLIAM L

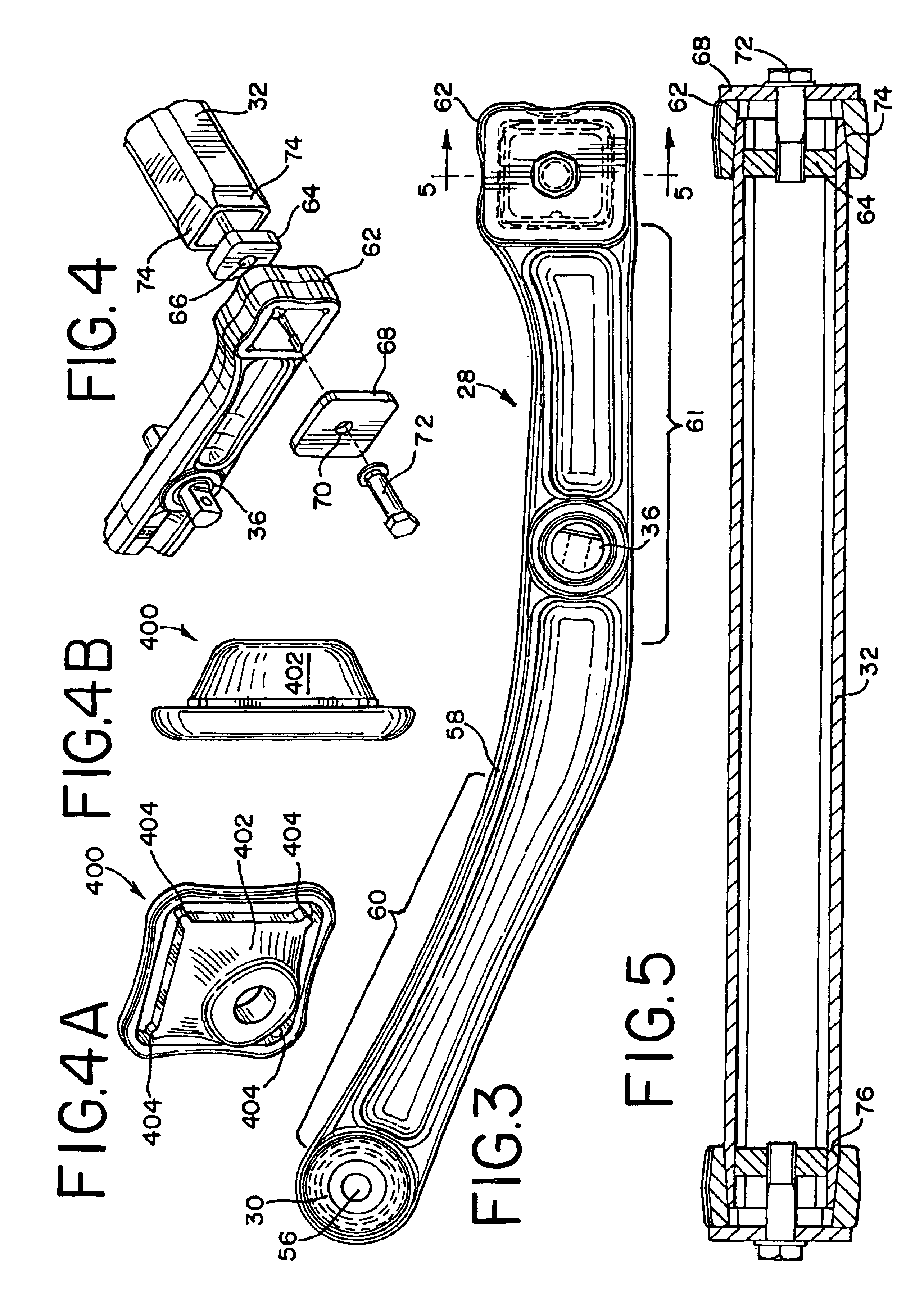

Lower control arm kit for vehicle with four link rear suspension

InactiveUS20060071441A1Reduce unsprung weightEasy to bendInterconnection systemsResilient suspensionsSpherical bearingControl arm

The present invention provides a suspension tuning device and kit for vehicles with four link rear suspensions. More specifically, the suspension tuning device generally comprises a pair of billet aluminum lower control arms each having a spring platform rotatably secured to a weight jacking bolt and a removable / replaceable sway bar attachment plate. Each end of the control arms include a transverse thru-bore adapted to accept a three part urethane bushing or a spherical bearing. The lower control arms are constructed to mount within a standard four link rear suspension, such as that supplied on a FORD MUSTANG, to permit quick suspension alterations throughout a predetermined range.

Owner:STEEDA AUTOSPORTS

Vehicle height adjusting system

ActiveUS20070210539A1Stable supportCompact designVehicle cleaning apparatusToothed gearingsLinear motionDrive shaft

A first rotor (24; 124) and a second rotor (25; 125) are arranged in a coaxial and mutually rotatable relationship and are provided with a first driven gear (41; 141) and a second driven gear (42; 142), respectively. A drive shaft (31; 131) is also provided with a first drive gear (43; 143) and a second drive gear (44; 144) which are commonly connected to an output shaft of an electric motor (32; 132), and mesh with the first and second driven gears, respectively, at slightly different gear ratios. The first and second rotors are connected via a thread feed mechanism (36; 136) that converts a relative rotation between the first and second rotors into an axial linear movement between the first and second rotors that is used for changing a distance between a vehicle body part and a corresponding end of a suspension spring in a vehicle height adjusting system (9; 109). Owing to a differential rotation of a high gear ratio between the first and second rotors, a significant torque amplification is possible with a compact arrangement. The use of spur gears instead of a worm gear mechanism minimizes torque loss.

Owner:HONDA MOTOR CO LTD

Four wheel drive stationary body vehicle having controlled wheel and passenger compartment lateral lean with independent steering

InactiveUS20050206101A1Comfortable independent lateral leanIncrease speedVehicle cleaning apparatusLoading/unloading vehicle arrangmentGear wheelControl theory

In this vehicular chassis system, the vehicle's passenger compartment and wheels incline toward the turning center side in such a manner, that the wheels can be tilted independently from steering. This vehicle has a steering apparatus controlling the steering, and a separate apparatus controlling the lateral leaning. The lean is controlled mechanically using a pendulum, and forced lateral leaned using a control unit, or manually with the transfer of body weight using several pinions with a set ratio to control the passenger compartment lateral lean in conjunction with the wheel lateral lean. An electric DC servo gear motor can be used to control the lateral lean, that intern moves a pinion, which moves a rack and lateral movable cross member, while controlling the lateral leaning wheels and pulling the tilt support bar pivotally attached to a passenger compartment in the same leaning direction.

Owner:BOUTON TODD RICHARD

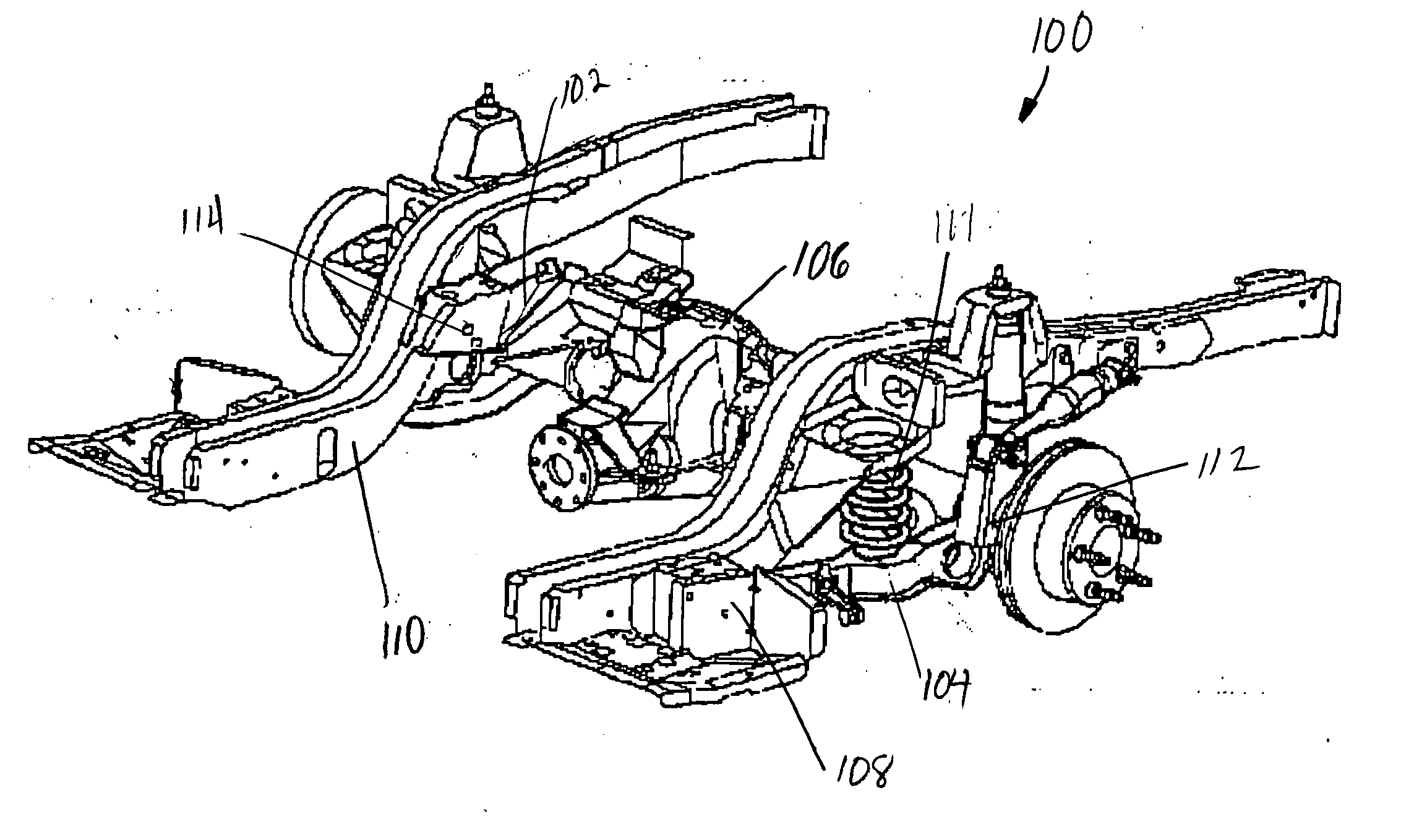

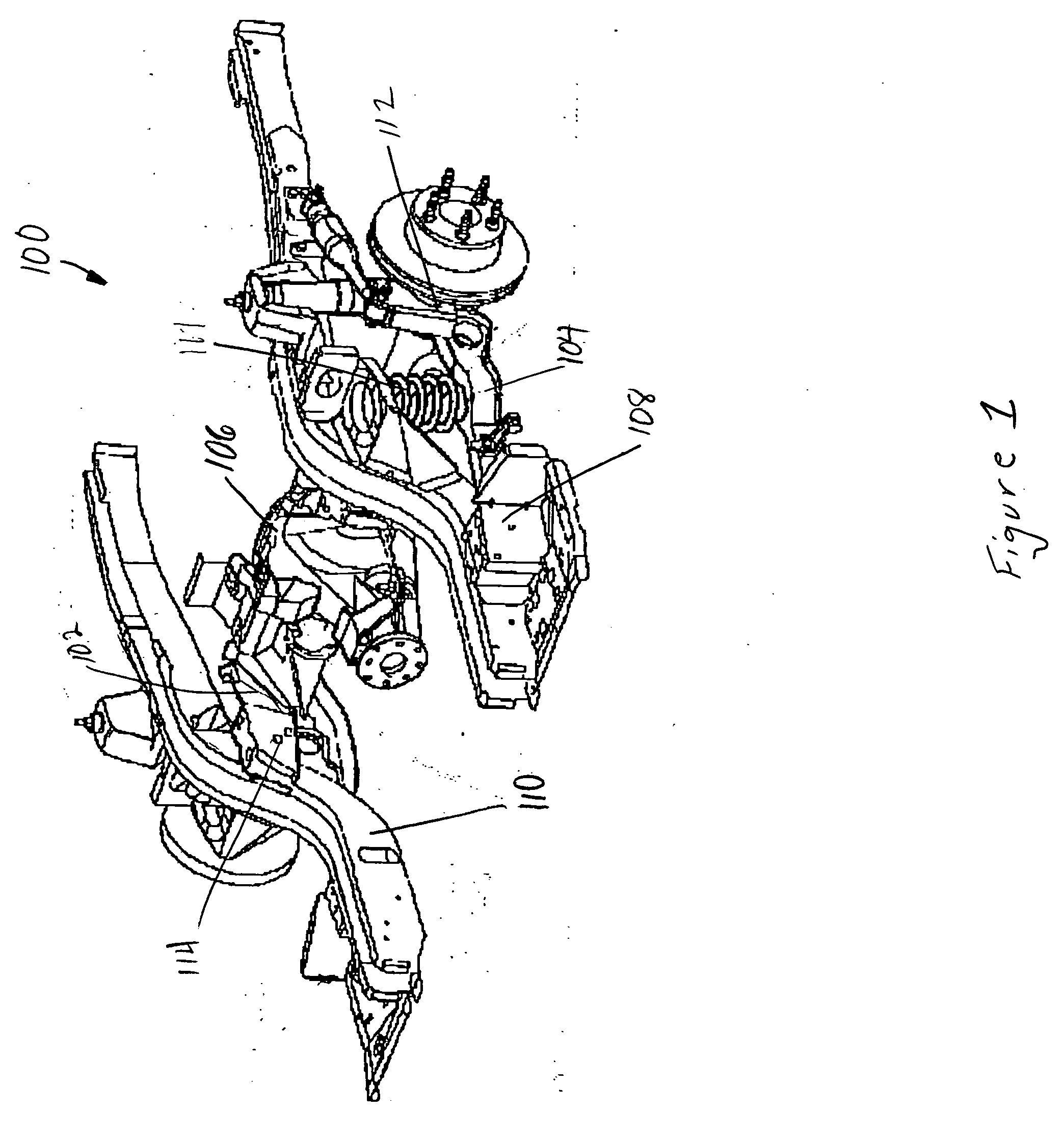

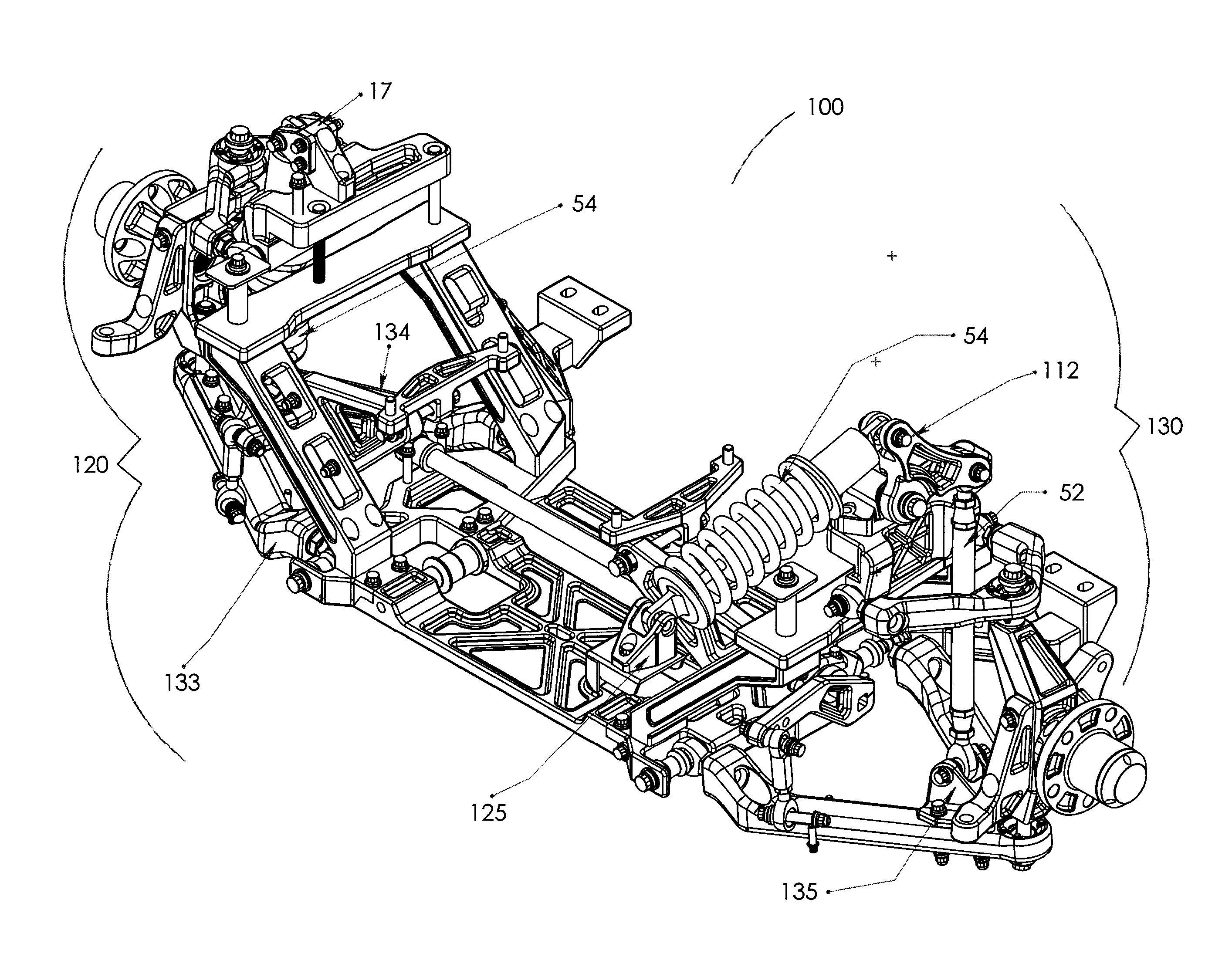

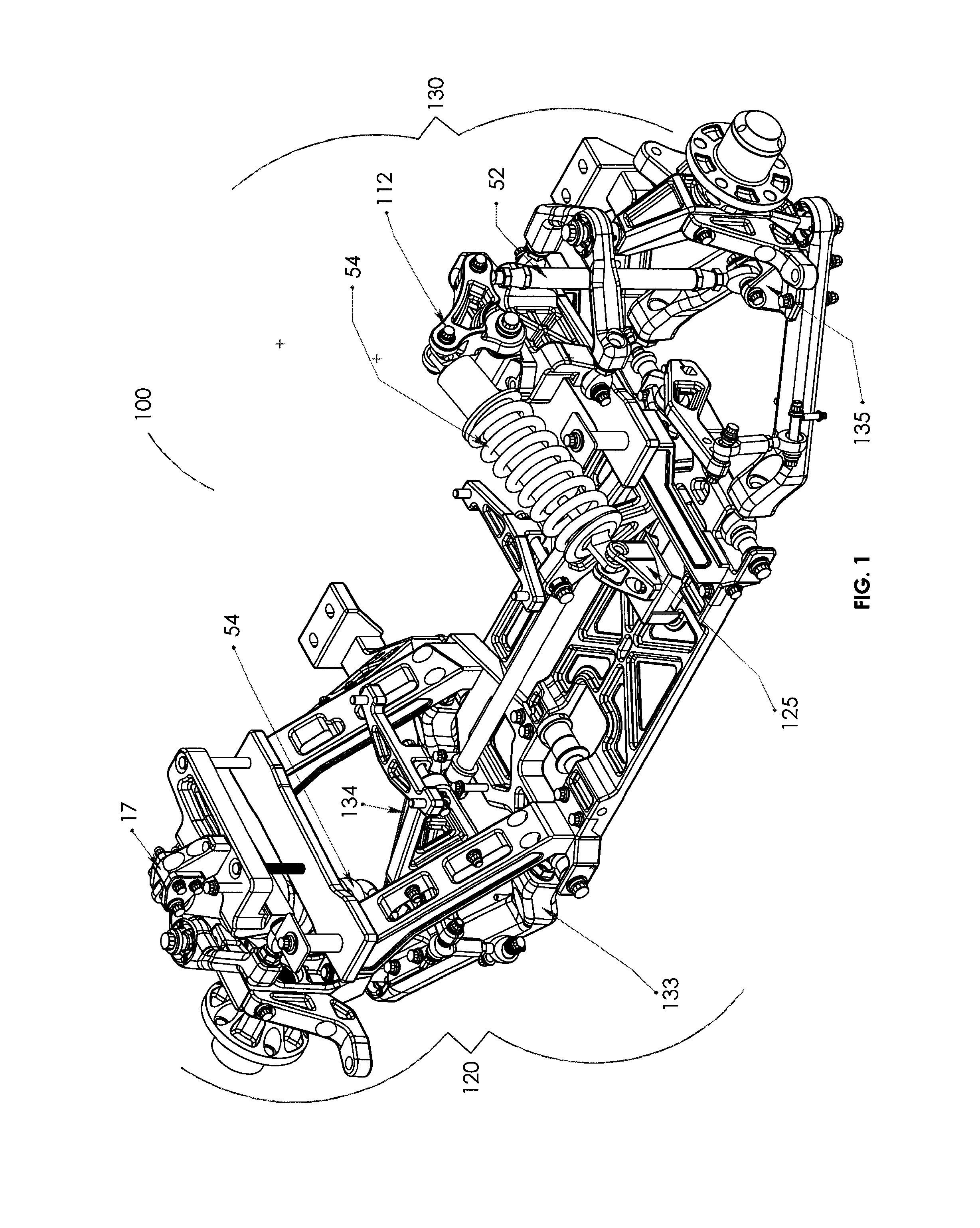

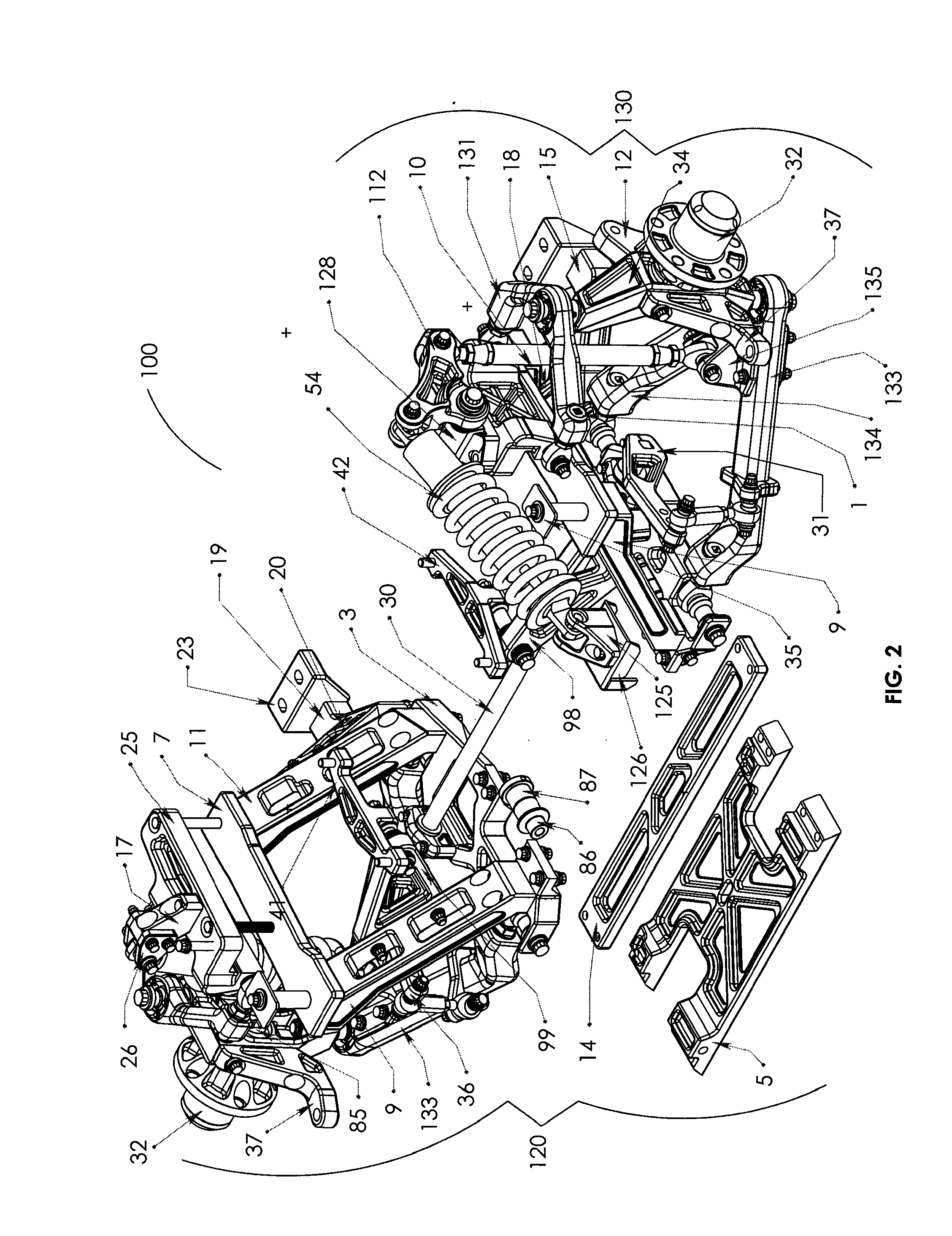

Modular suspension system

InactiveUS20090230650A1Improve performanceReduce maintenanceSpringsResilient suspensionsModularityTruck

A modular suspension system for automobiles and trucks. The present invention relates to a suspension system which is both modular in design and specifically manufactured for high performance wheeled vehicles. This system has multiple modular parts which enable the system to function in various makes and models of vehicles. The modular aspects of this system also enable the cradle to be removable so that the engine and transmission of the vehicle can be easily reached. The modular aspects also allow this system to be set-up with a traditional shock configuration or with a rocker set-up shock system.

Owner:JME ENTERPRISES

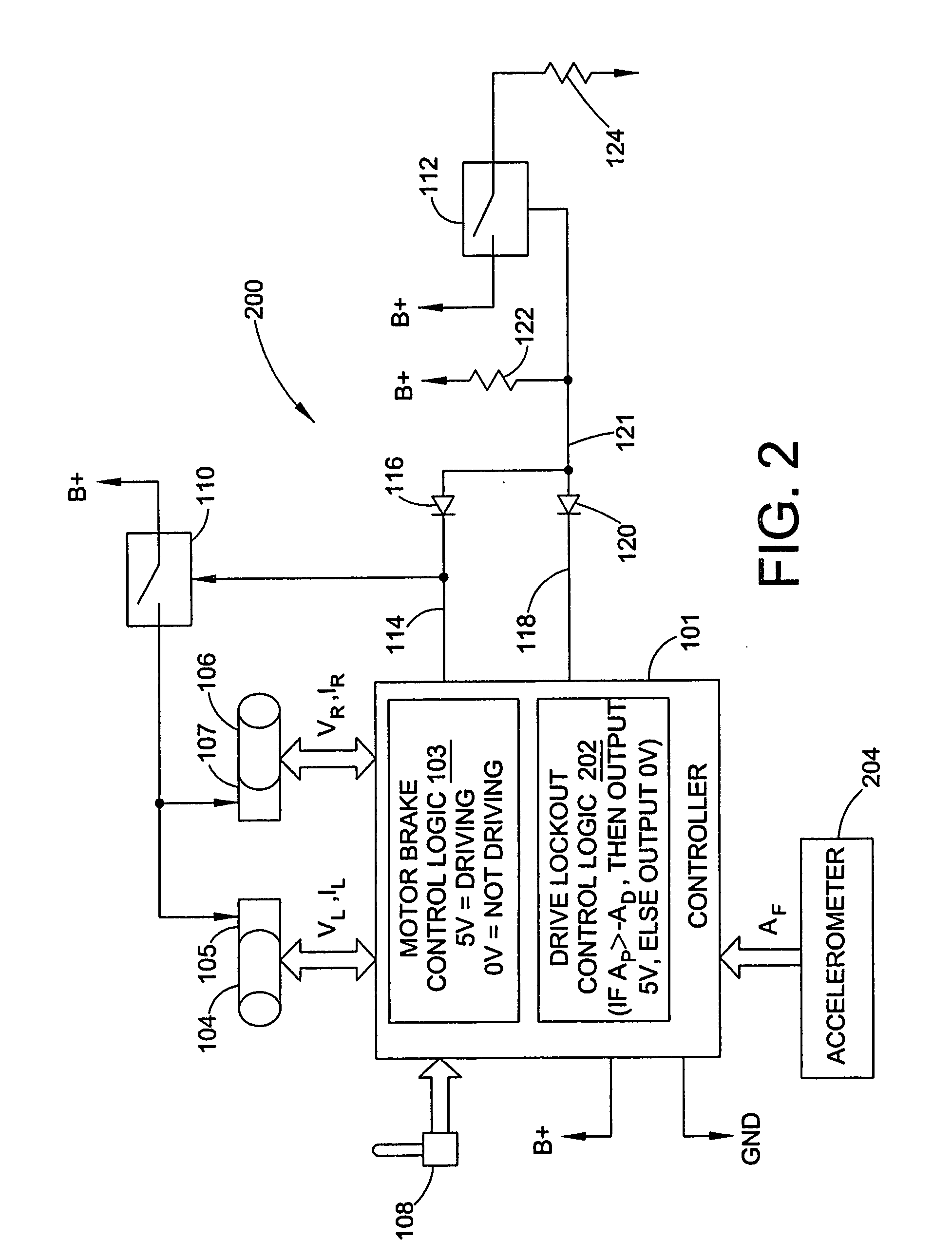

Vehicle lean and alignment control system

The amount of lean to be provided is determined by force sensors, the speed, and / or the angle of turn. Then the vehicle is leaned by actuators in the suspension in accordance with a predetermined protocol in an electronic control unit (ECU). The protocol also provides shock absorption by rapidly tracking a contour of a surface on which the vehicle rides. The suspension is provided by a plurality of arm assemblies each including a lower arm, an upper control arm, and an actuator motively connected to the lower arm and to the upper control arm. The arm assemblies are pivotally connected to the frame on a common axis. The arm assemblies generally form parallelograms and are actuated in concert to remain generally parallel to each other through a range of angles to adjust the lean of the vehicle. The arm assemblies are also actuated independently of each other to accommodate variations in the contour. In one aspect, an actuator controlled by an ECU can be replaced by a mechanical actuator that can be activated manually such as by a driver's own leaning weight.

Owner:MELCHER THOMAS WESLEY

Ball-and-socket joint with an angle sensor

InactiveUS7405557B2Improve accuracyAccurate measurementMagnetic measurementsBearing assemblyTransducerEngineering

A ball and socket joint with integrated angle sensor, especially for use as a vehicle level control in the chassis of a motor vehicle. The ball and socket joint has a ball and socket joint housing (1), a ball pivot (2) mounted in the ball and socket joint housing (1), a bipolar field transducer (4) arranged at the joint ball (3) of the ball pivot (2), and at least one magnetic field direction sensor (5), which is arranged at the ball and socket joint housing (1) and interacts with the magnetic field generated by the field transducer (4), wherein only one pole of the bipolar field transducer (4) is arranged on the surface of the ball.

Owner:ZF FRIEDRICHSHAFEN AG +1

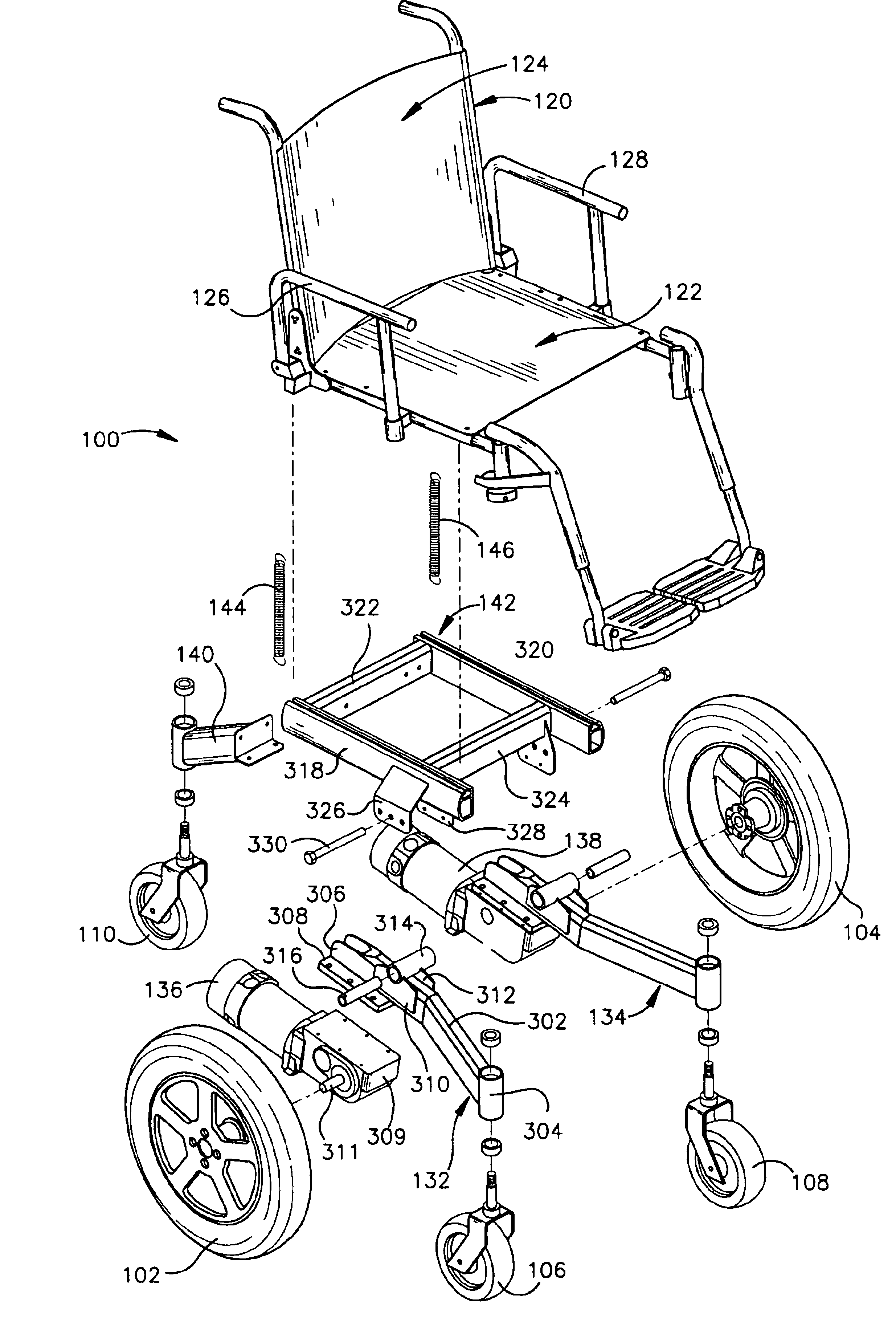

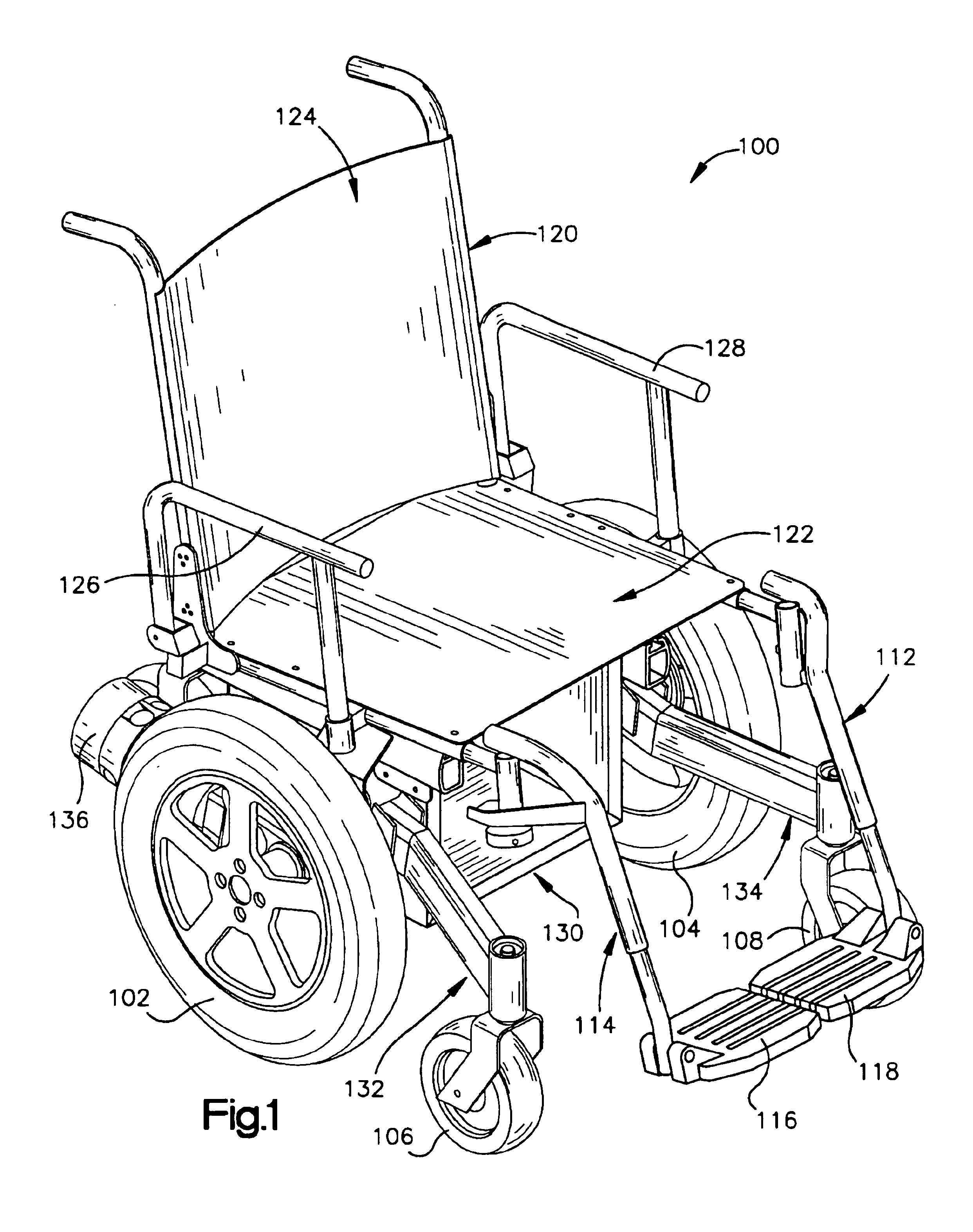

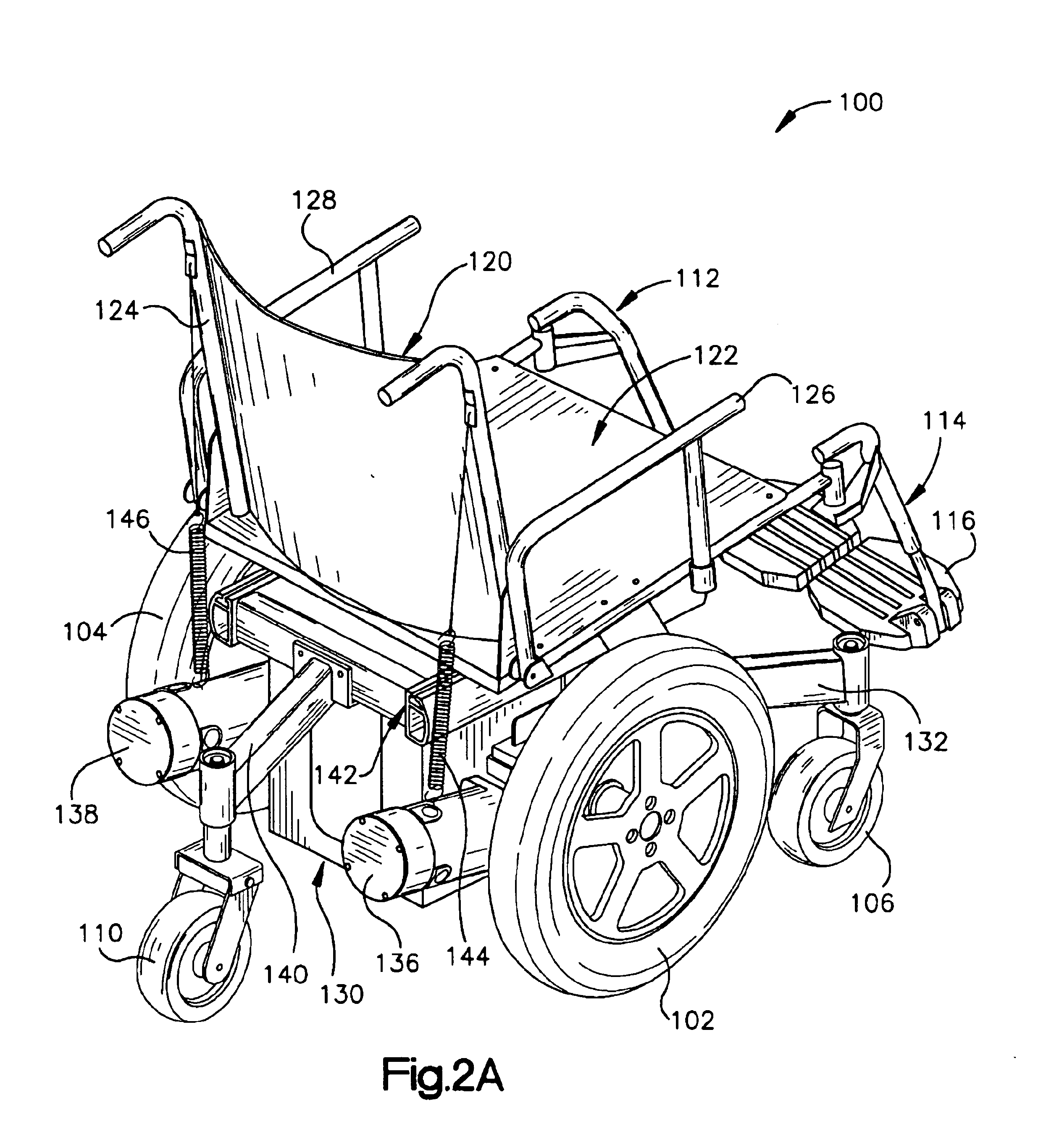

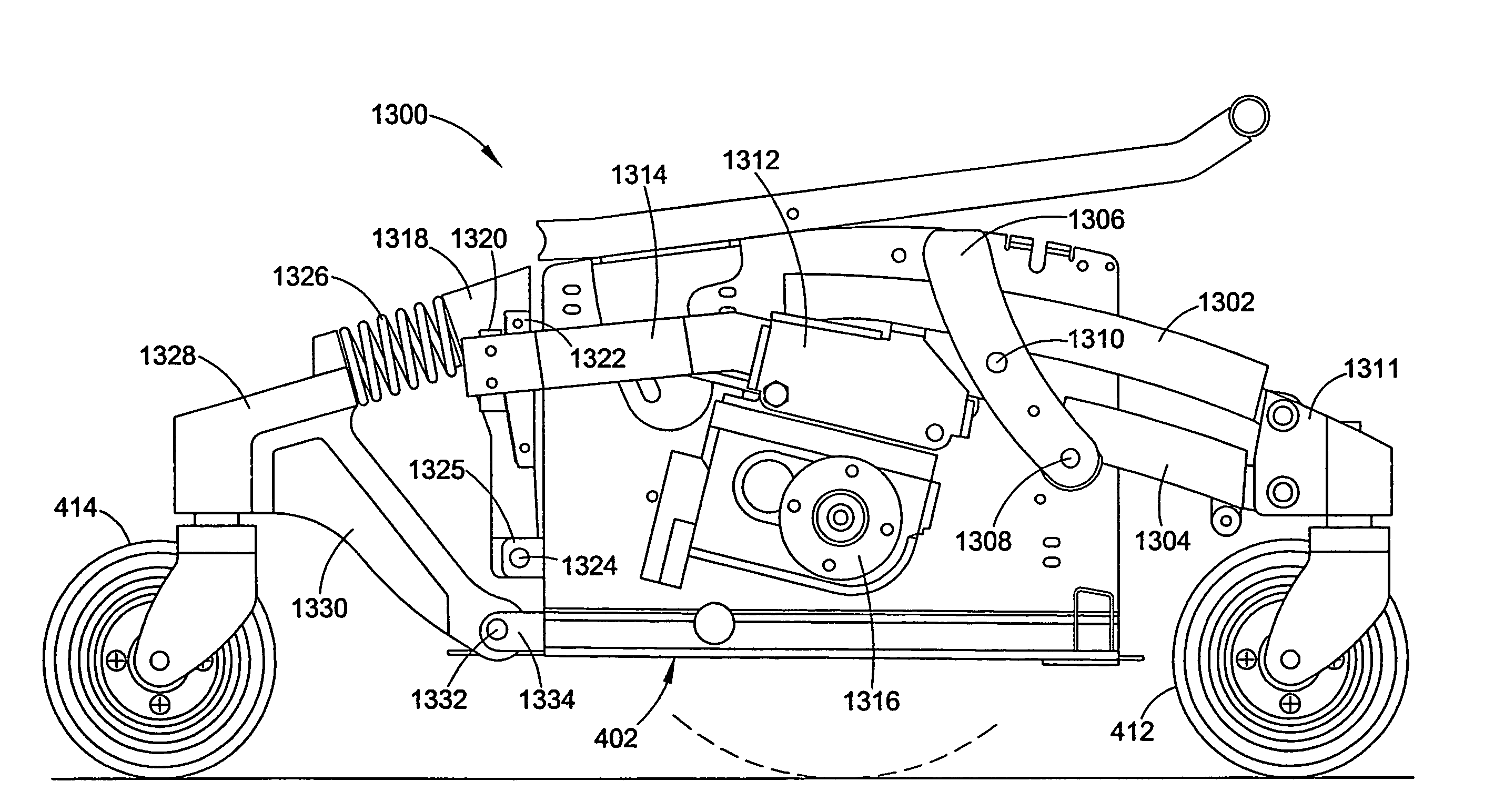

Obstacle traversing wheelchair

Owner:INVACARE CORP

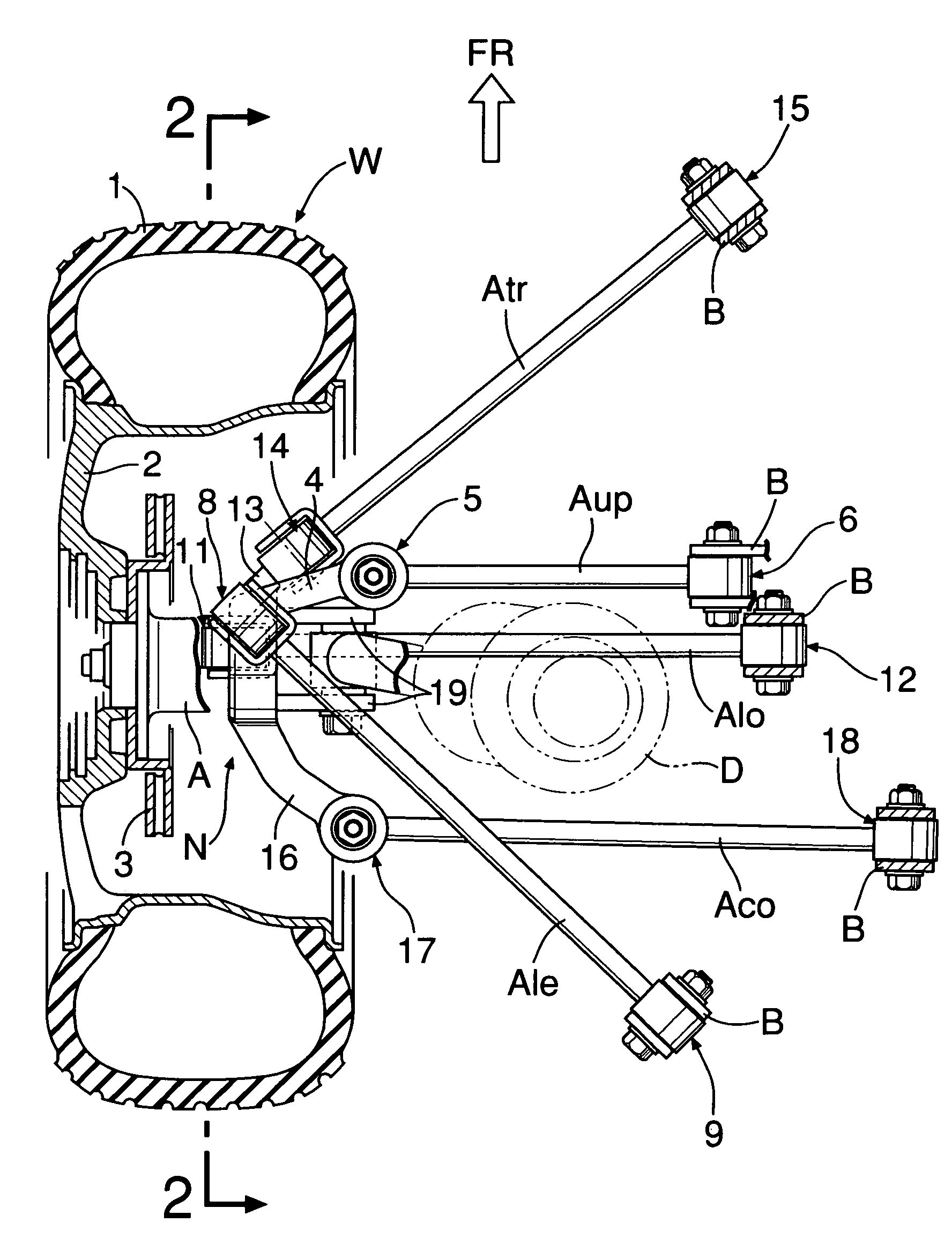

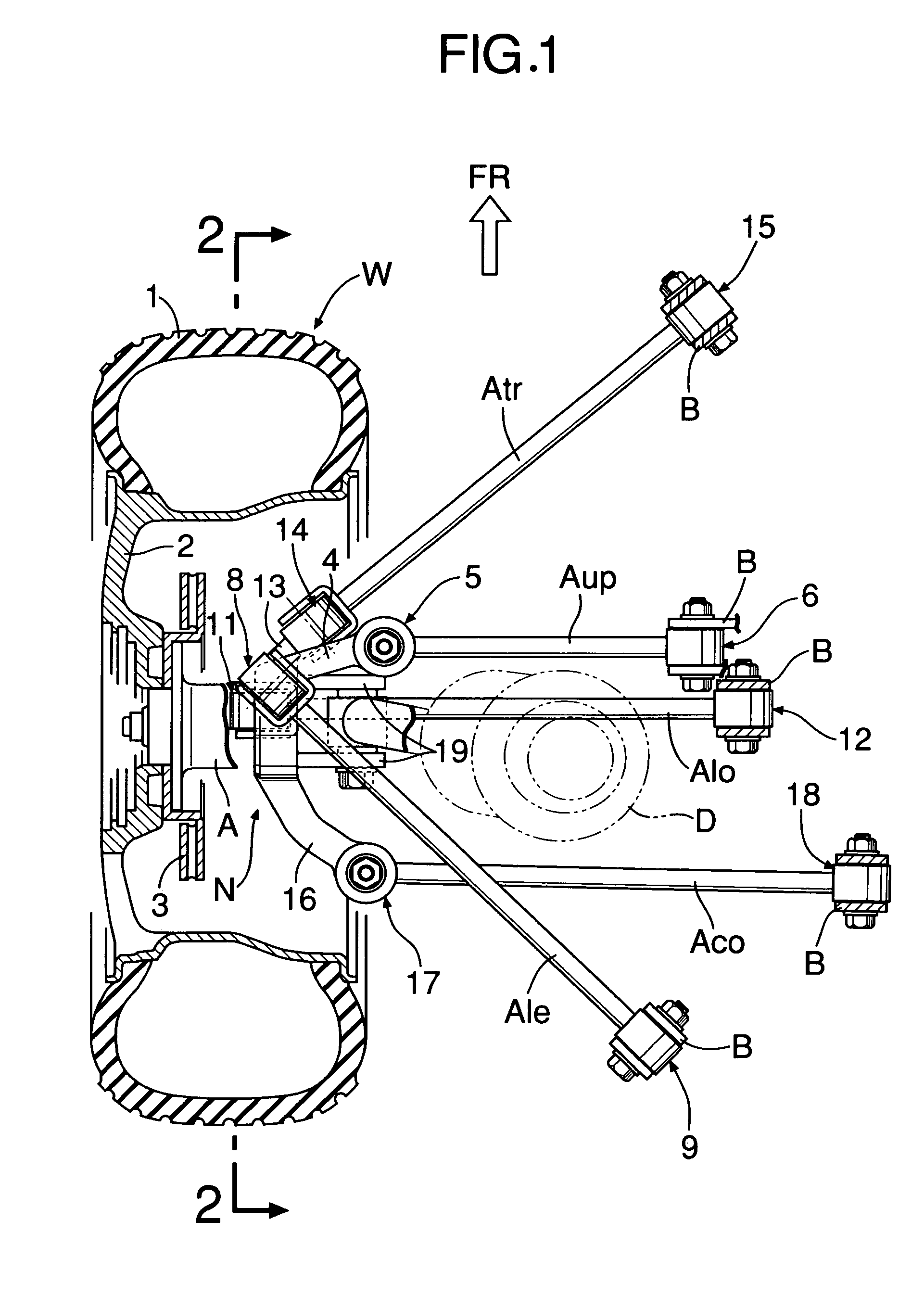

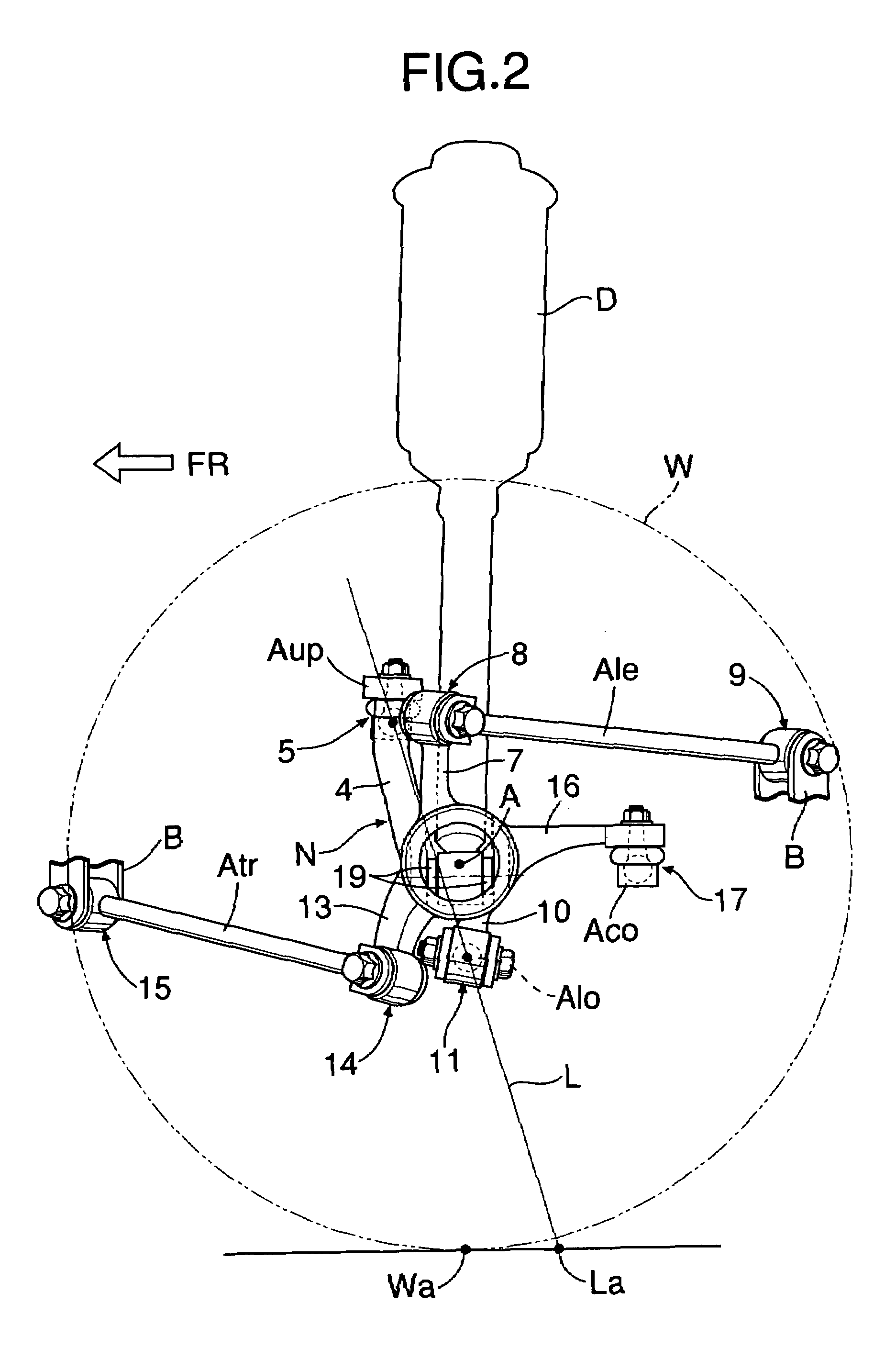

Vehicular rear suspension system

InactiveUS7258355B2Improve vehicle stabilityIncrease lateral stiffnessInterconnection systemsResilient suspensionsGround contactControl arm

A vehicular rear suspension system includes an upper arm, a lower arm, and a control arm, each of which is connected to a knuckle. A straight line passing through a ball joint and a rubber bushing joint intersects the road surface at an intersection point that is positioned behind a ground contact point of the rear wheel in the longitudinal direction of the vehicle body. The ball joint connects the upper arm to the knuckle, and the rubber bushing joint connects the lower arm to the knuckle. Longitudinal elastic coefficients of the three arms are set in a predetermined relationship. Therefore, the intersection point at which an elastic kingpin intersects the road surface is positioned without fail behind a point of action of a lateral force when turning in the longitudinal direction of the vehicle body to achieve a lateral force toe-in and enhanced steering stability of the vehicle.

Owner:HONDA MOTOR CO LTD

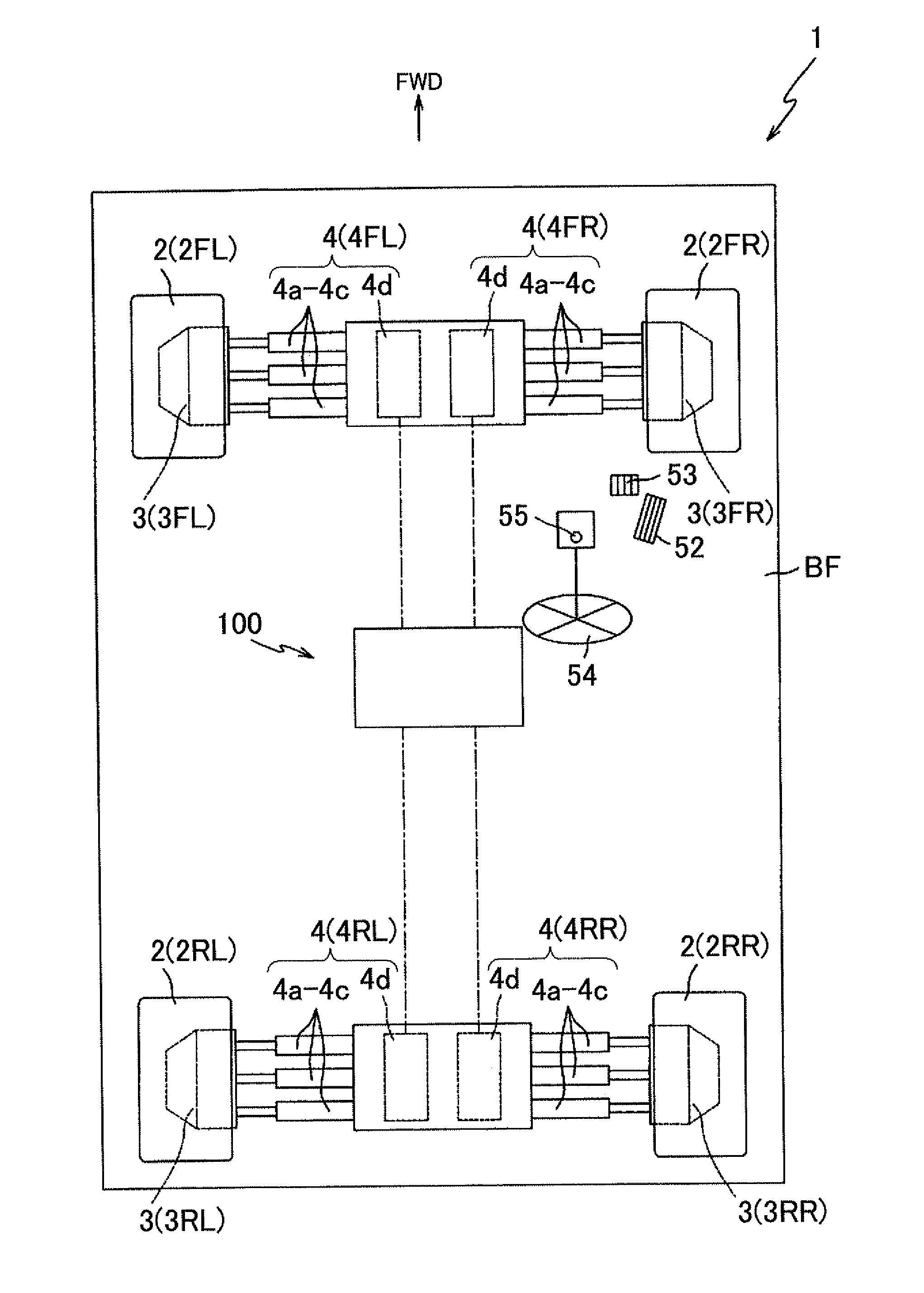

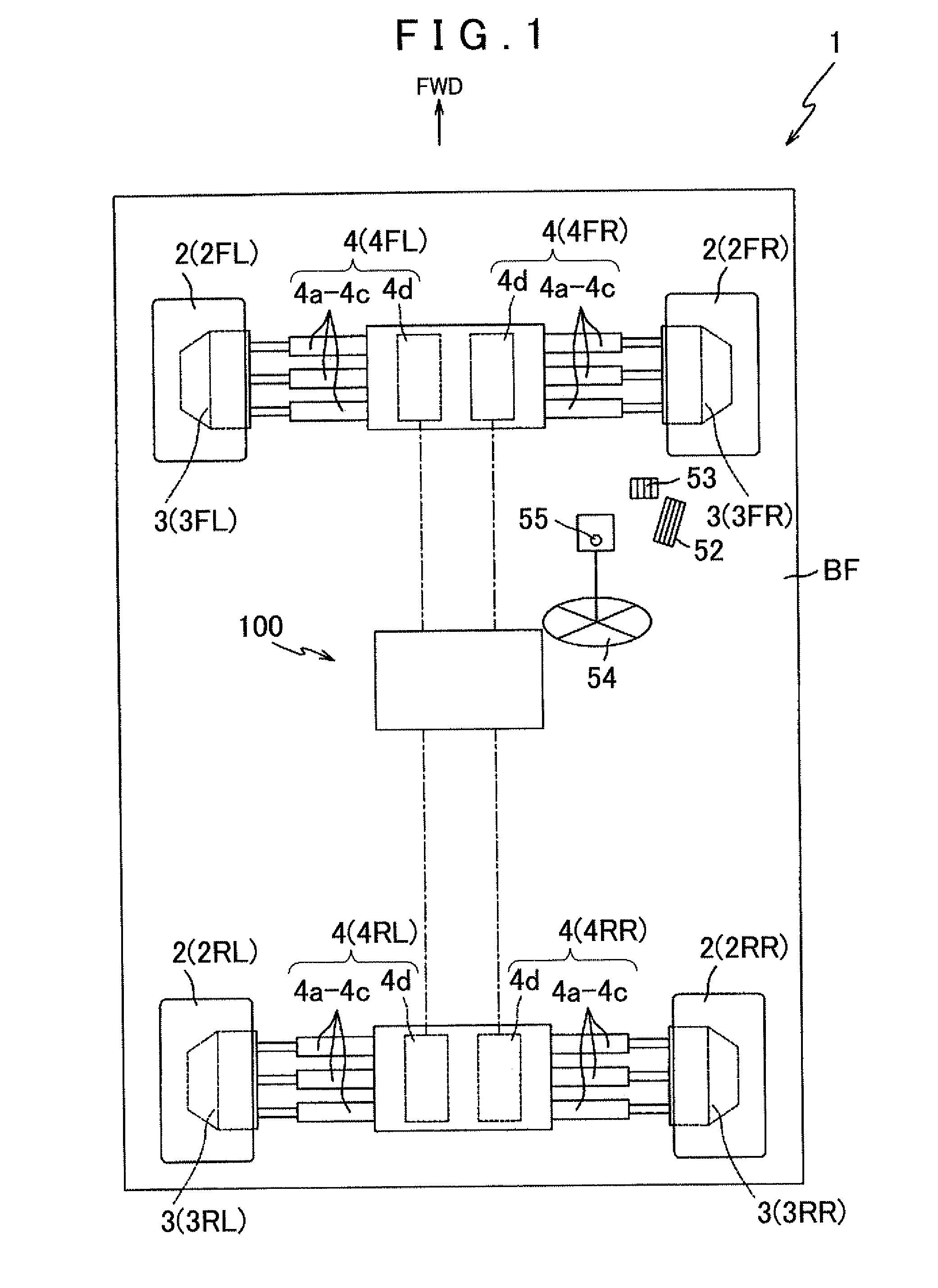

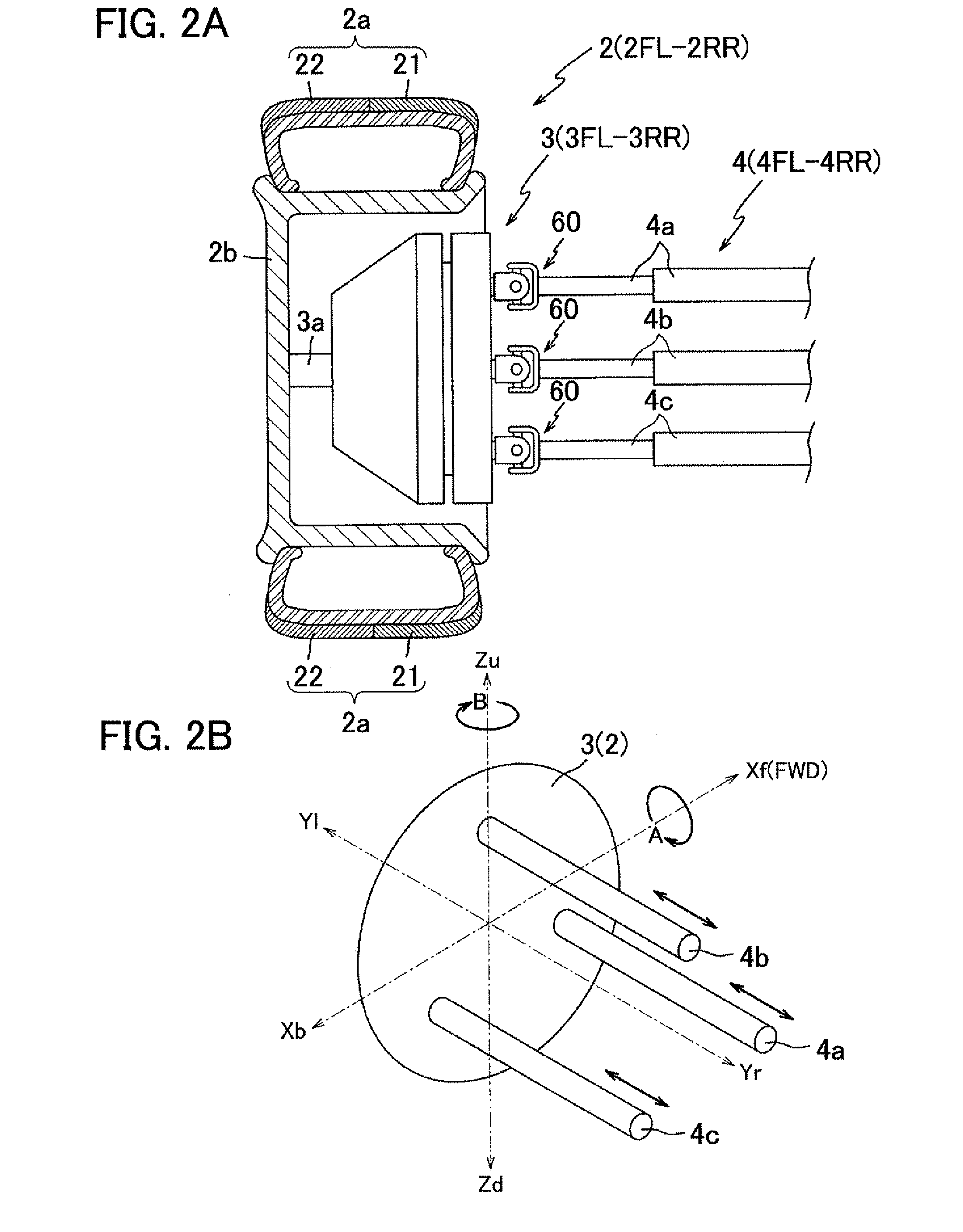

Camber angle controlling device

InactiveUS20100217491A1Improve gripIncrease clamping forceDigital data processing detailsSpecial tyresRolling resistanceCamber angle

A camber angle applying device is controlled to adjust the camber angle of wheels to a predetermined value. Therefore, the characteristics (or a high gripping property) of a high gripping force and the characteristic (or a low rolling resistance) of a small rolling resistance can be separately used as the performance of the wheels. By utilizing the high gripping property of the wheels, therefore, a vehicle is enabled to reduce its energy consumption, while retaining its running characteristics (such as a turning performance, an accelerating performance or a braking performance), by utilizing the rolling resistance of the wheels. Moreover, the camber angle applying device is controlled to reduce the rolling resistance of the wheels, so that the energy loss to occur in the wheels during running can be reduced to further reduce the energy consumption of the vehicle.

Owner:EQUOS RES

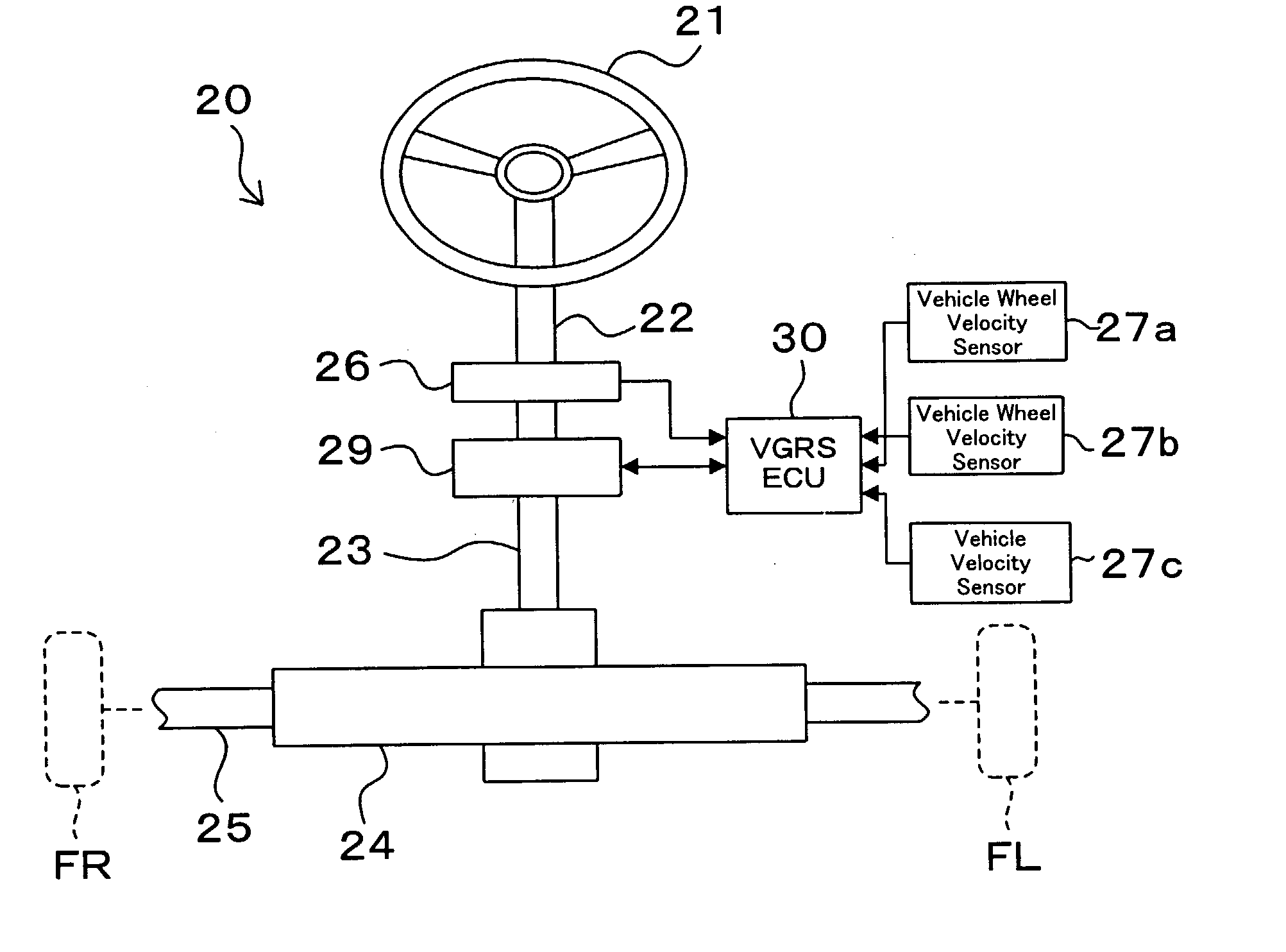

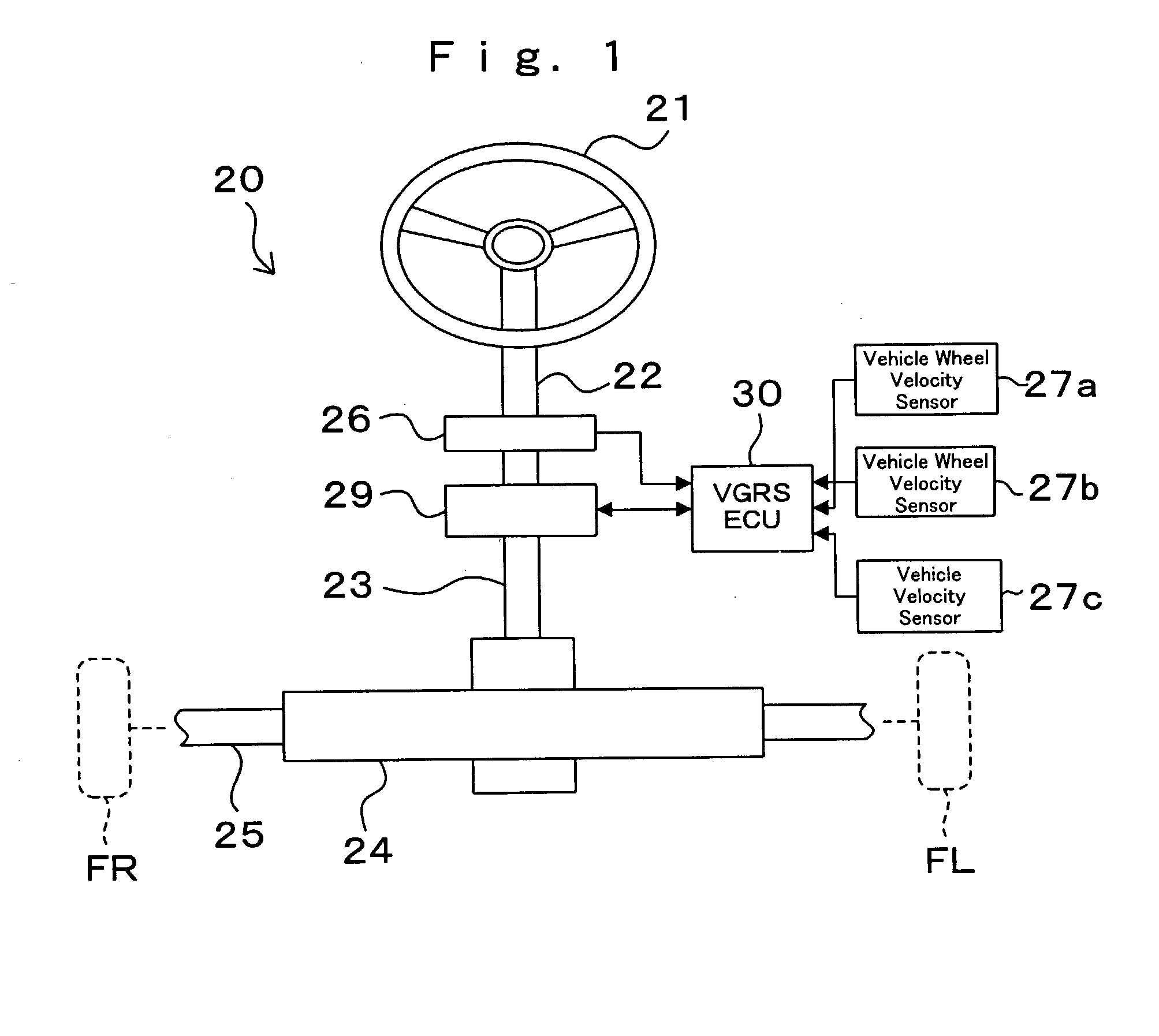

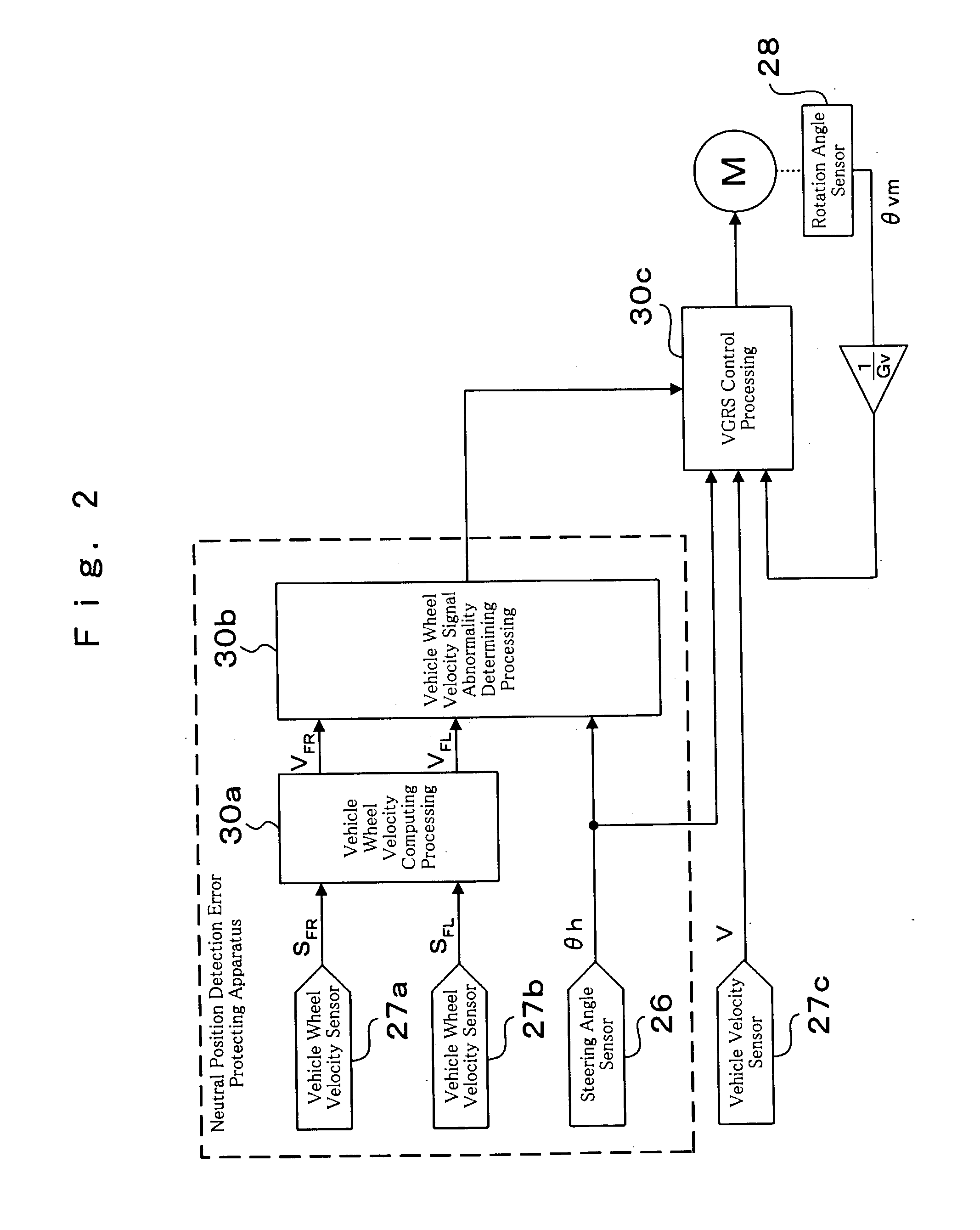

Steering angle neutral position detection error protecting method and detection error protecting apparatus

InactiveUS20040046346A1Detection errorAvoid detectionVehicle testingRegistering/indicating working of vehiclesLocation detectionDrive wheel

In a neutral position detection error protecting apparatus, vehicle wheel velocities SFR, SFL of right / left driven wheels FR, FL are detected by vehicle wheel sensors 27a, 27b and a right / left wheel velocity difference VFD is obtained from vehicle wheel velocities VFR, VFL of the driven wheels FR, FL through vehicle wheel velocity signal abnormality determining processing 30b so as to detect steering angle information thetah from the steering wheel 21. Then, when a condition that a right / left wheel velocity difference VFD is less than a predetermined velocity V1, a condition that a rotation angle of steering angle information thetah is more than a predetermined value thetak and a condition that a vehicle wheel velocity is more than a predetermined velocity V2 according to vehicle wheel velocities VFR, VFL of the driven wheels FR, FL are all satisfied in a predetermined period T, it is determined that there is any abnormality in the vehicle wheel velocities SFR, SFL (VFR, VFL) of the driven wheels FR, FL through vehicle wheel velocity signal abnormality determining processing 30b.

Owner:TOYODA MASCH WORKS LTD

Suspension for wheeled vehicles

A wheelchair suspension comprises a frame, at least one pivot arm, at least one front caster, at least one rear caster, a stabilizing system, and a sensor. The pivot arm is coupled to the frame. The front caster is coupled to the pivot arm. The rear caster is coupled to the frame. The stabilizing system is coupled to the frame and the pivot arm. The sensor is arranged such that movement of the frame relative to the rear castor causes actuation of the stabilizing system to at least partially resist further movement of the frame.

Owner:INVACARE CORP

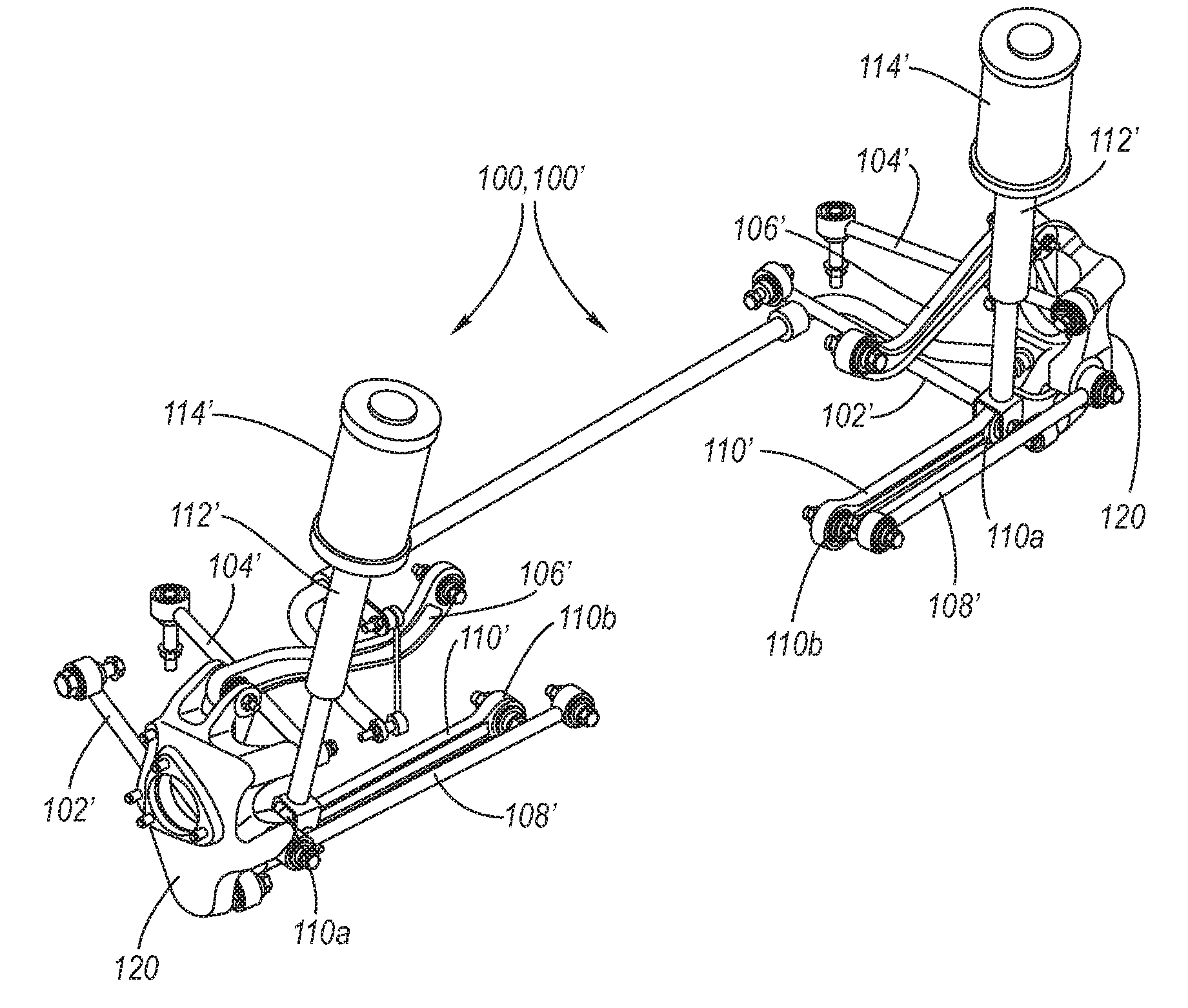

Decoupled 5-link independent rear suspension

InactiveUS7891684B1Easy to manageIncrease spacingInterconnection systemsResilient suspensionsBrake torqueMobile vehicle

A decoupled 5-link independent rear suspension system (IRS) for motor vehicles. Three lateral linkages, the toe, camber and spring links, establish the wheel plane orientation and react to vertical and lateral loads, and two longitudinal links, the upper and lower trailing links, react to tractive loads and brake torques. The upper and lower trailing links are longitudinally orientated and disposed outboard of the body rail, thus allowing for improved load reactions of the suspension system, as well as optimization of the body rail configuration and space accommodation for other vehicle components, such as for example fuel, batteries and exhaust.

Owner:GM GLOBAL TECH OPERATIONS LLC

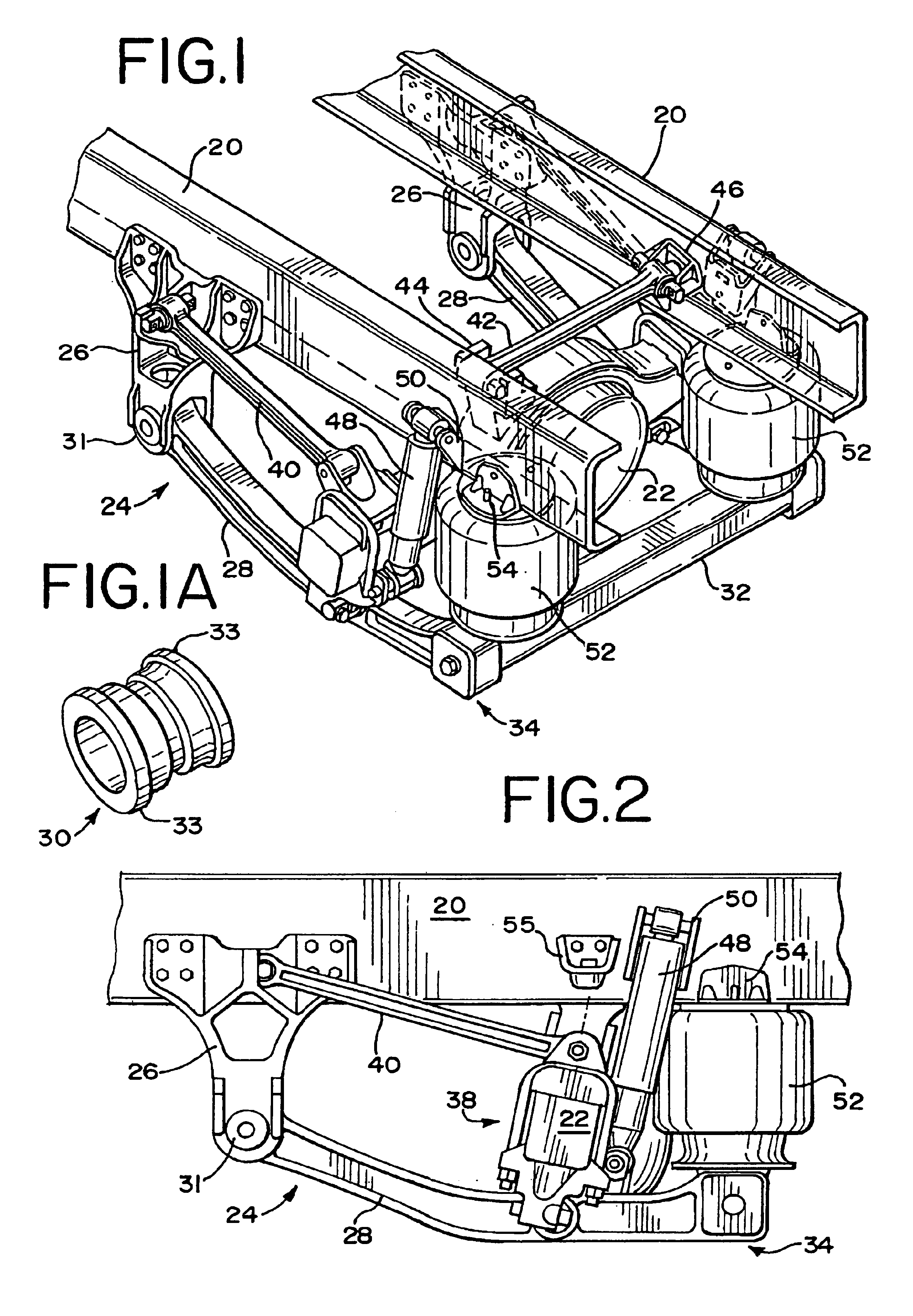

Air spring and air spring mounting assembly

InactiveUS6945548B2Easy to adjustImprove featuresRigid suspensionsLiquid springsVehicle frameAir spring

A non-torque reactive air suspension exhibiting excellent roll stability characteristics is shown to include frame hangers mounted to frame rails extending longitudinally on opposite sides of a vehicle. Longitudinally extending beams are connected to the frame hangers at one end and extend parallel to the frame rails. At their other ends, the beams are joined by a crossbrace extending laterally across the vehicle centerline. In a central portion thereof, the beams have an axle pivot bore to which an axle clamp assembly is connected, the axle clamp assembly clamping a drive axle housing for the vehicle. The axle pivot bore is generally aligned with the drive axle. A control rod assembly is connected to suspension or frame components. Together with the beams, the control rod assembly forms a parallelogram configuration wherein the beams form the lower linkages of that configuration and the control rods included within the control rod assembly form the upper linkages of that configuration.

Owner:THE BOLER

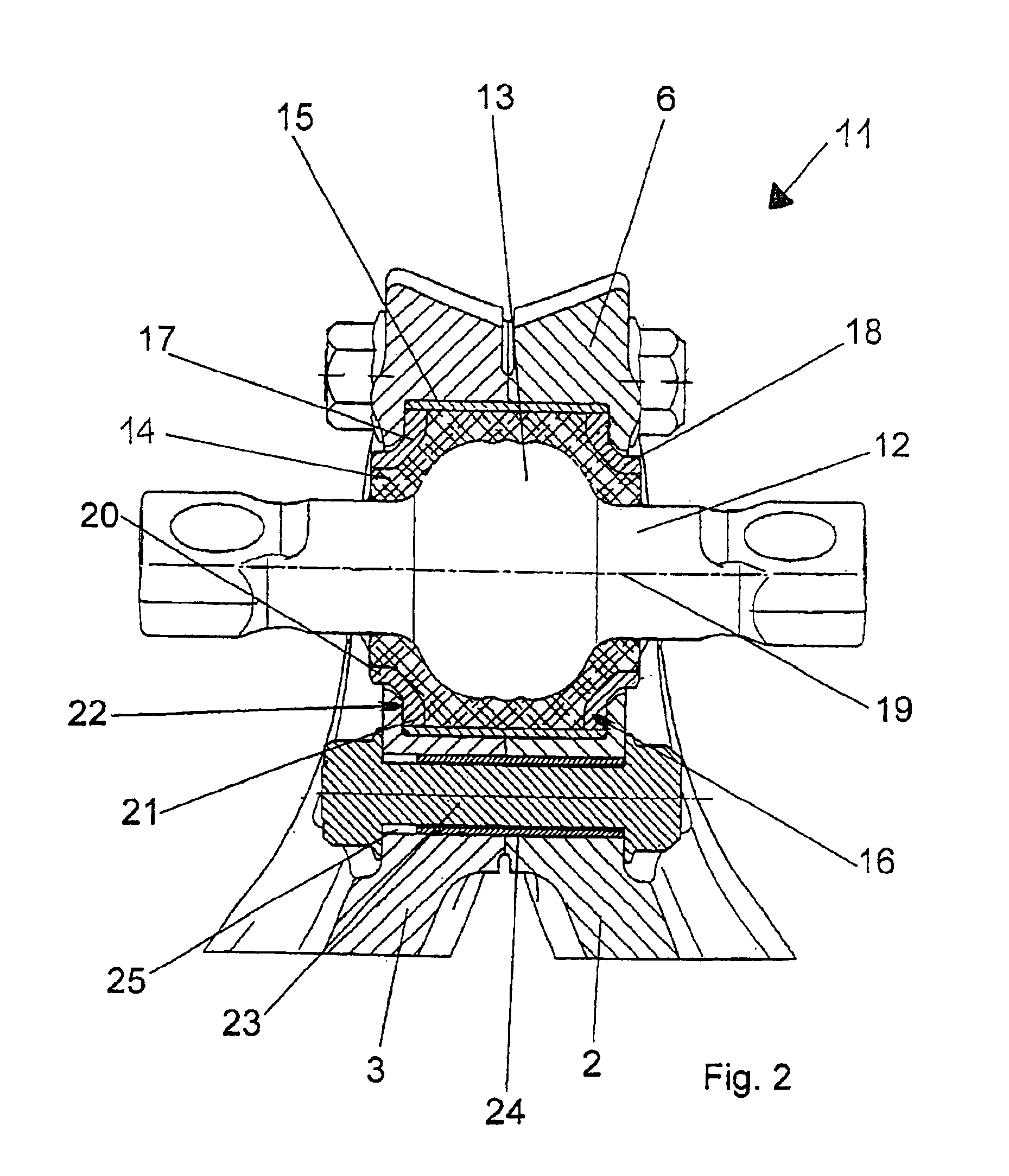

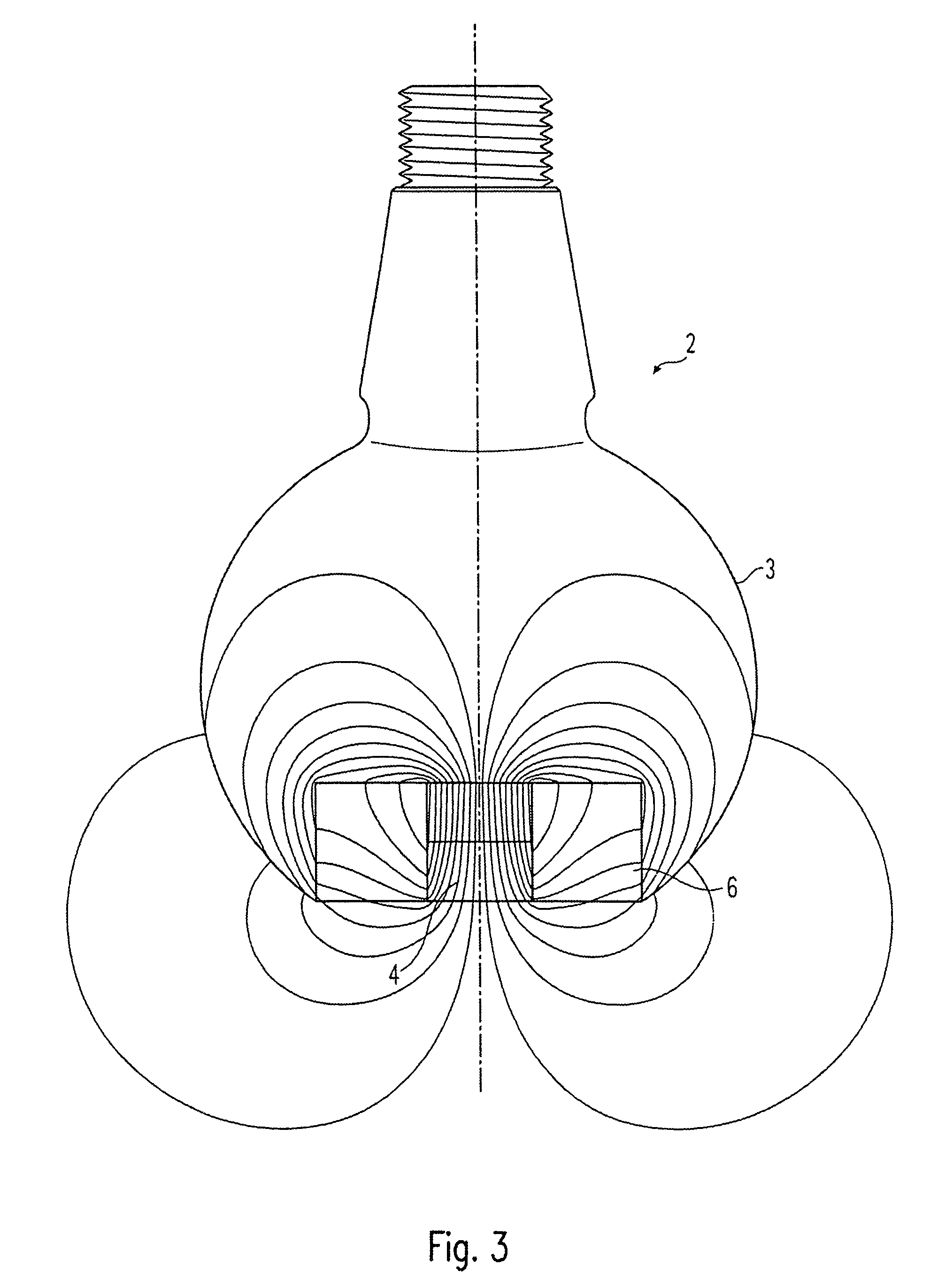

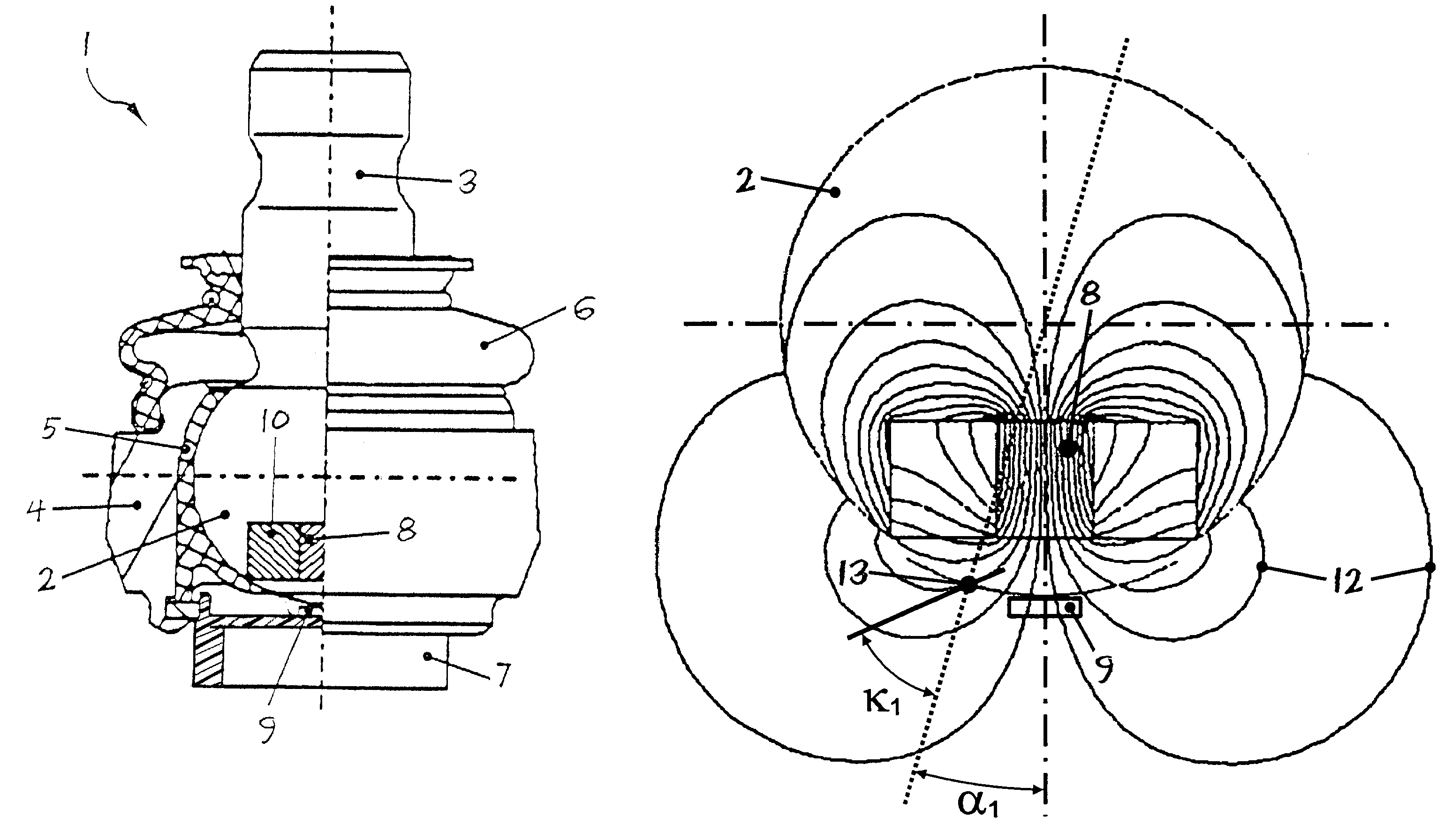

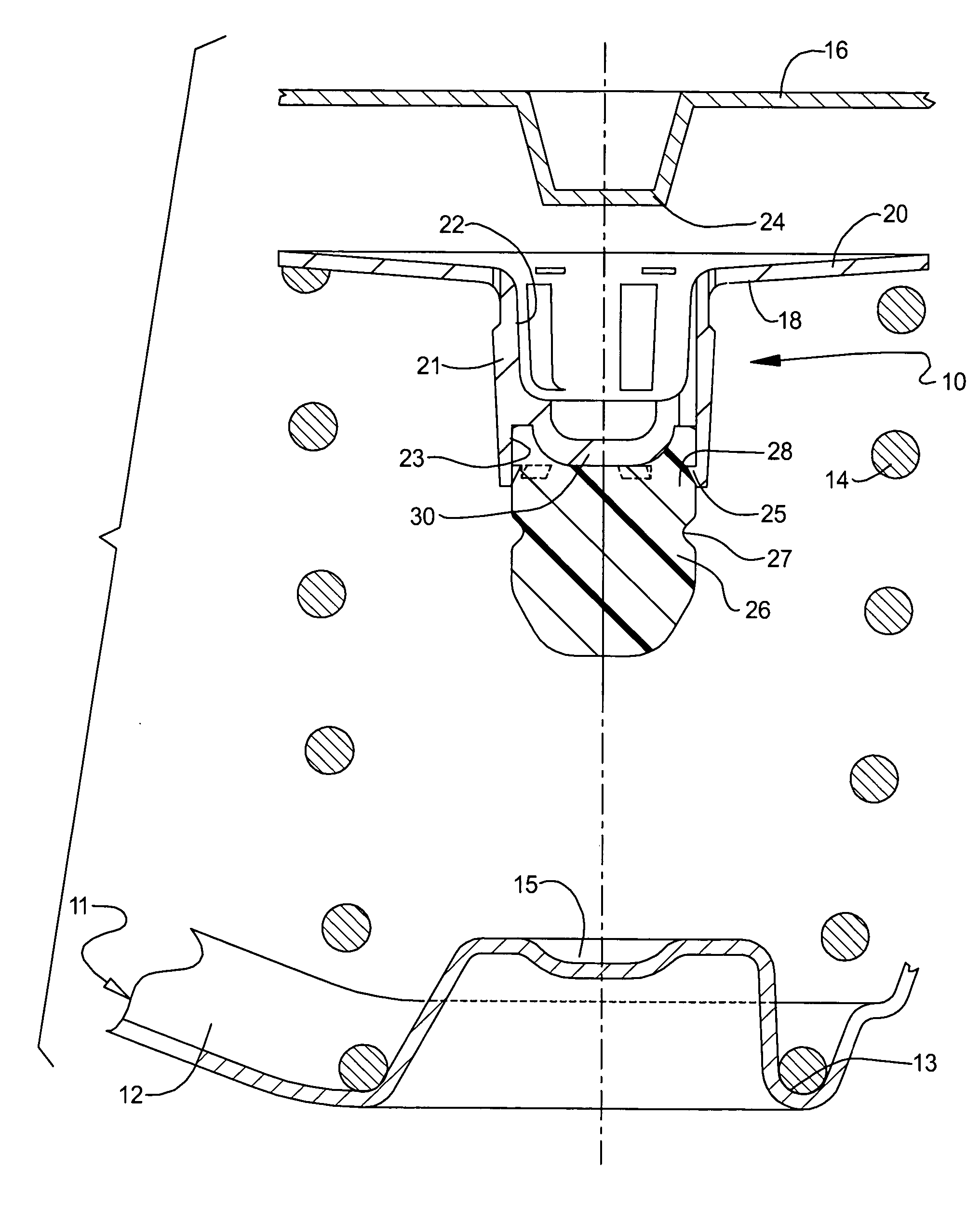

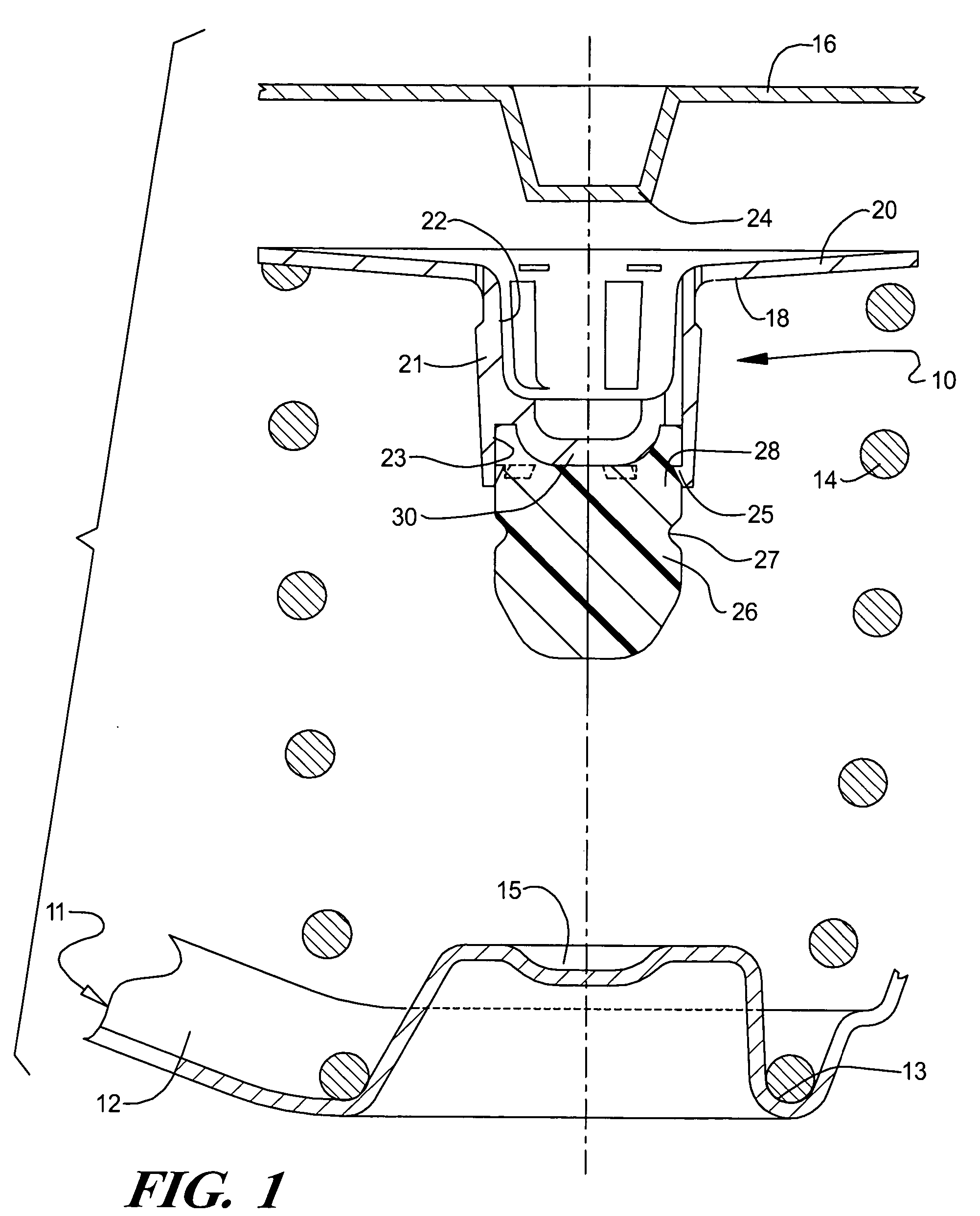

Ball and socket joint with pivoting angle sensor for detecting the relative angular position of the joint housing and the ball pivot

InactiveUS7170285B2Reduce effortLow costBearing assemblyMagnetic-field-controlled resistorsEngineeringSacroiliac joint

A ball and socket joint (1) is provided with a pivoting angle sensor (9) for detecting the relative angular position of the joint housing (4) and the ball pivot (3). The pivoting angle α of the joint ball (2) is detected by a measuring means comprising a magnet (8) and a magnetic field sensor (9). The position and the size of the magnet (8) as well as the position and the size of the recess of the joint ball (2) are selected for each type of ball and socket joint from one series such that when the particular nominal pivoting angle αm of the ball and socket joint (1) is reached, the angle κ of the magnetic field lines (12) passing through the magnetic field sensor (9) approximately equals a constant κm, which applies to the entire series. As a result, one and the same magnetic field sensor (9) can be used within the entire series of ball and socket joints for a plurality of types and it can be arranged in one and the same sensor housing (7) as well as at one and the same location at the ball and socket joint (1) for a plurality of types. Among other things, considerable cost savings are achieved because of the resulting reduction in the number of parts and the simplification of the design of the series of ball and socket joints.

Owner:ZF FRIEDRICHSHAFEN AG

Dual spring jounce bumper assembly

InactiveUS20060043659A1Increase load capacityReduce peak loadSpringsResilient suspensionsEngineeringSnubber

Owner:GENERAL MOTORS COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com