Patents

Literature

2634 results about "Air suspension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air suspension is a type of vehicle suspension powered by an electric or engine-driven air pump or compressor. This compressor pumps the air into a flexible bellows, usually made from textile-reinforced rubber. Unlike hydropneumatic suspension, which offers many similar features, air suspension does not use pressurized liquid, but pressurized air. The air pressure inflates the bellows, and raises the chassis from the axle.

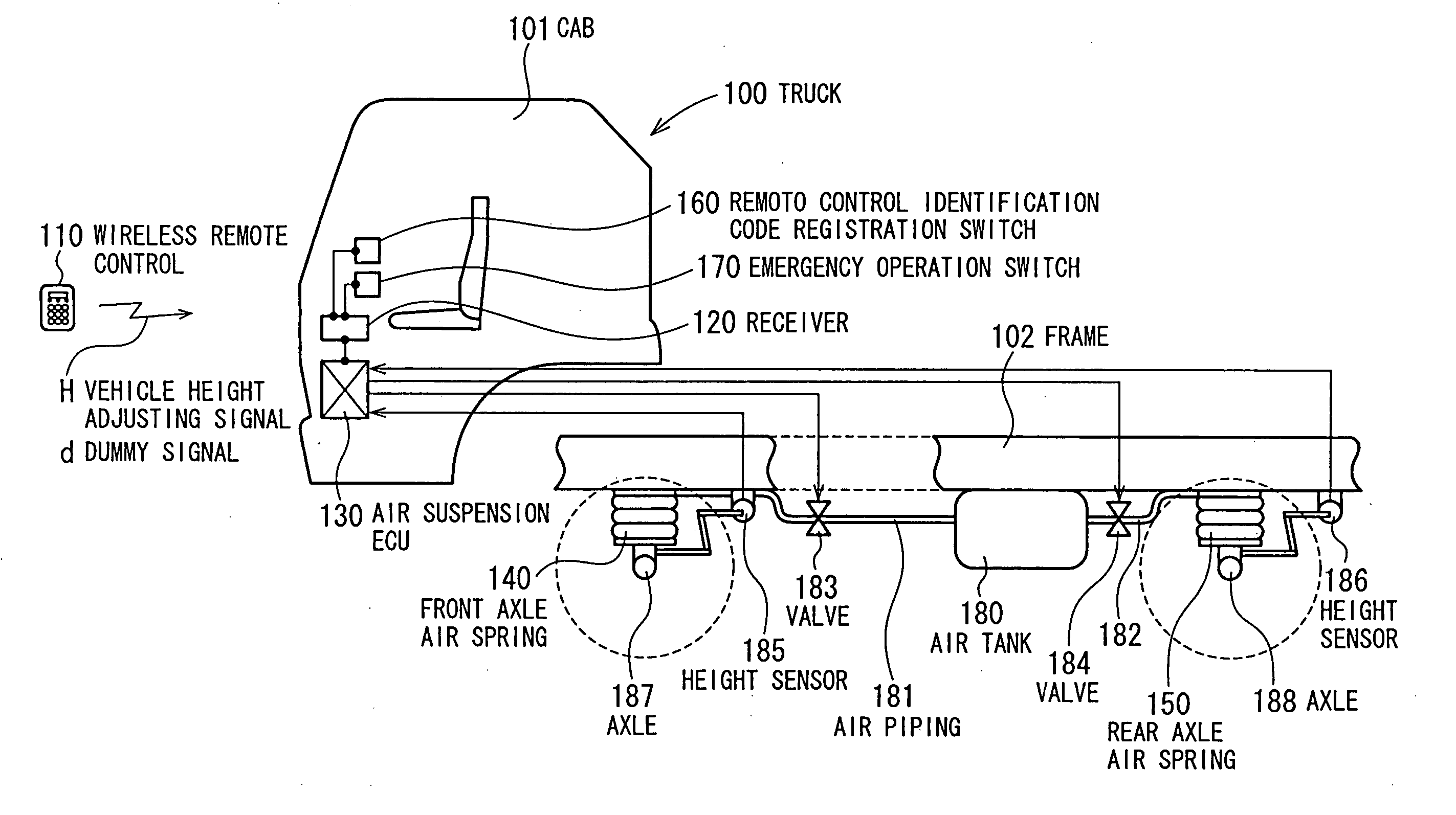

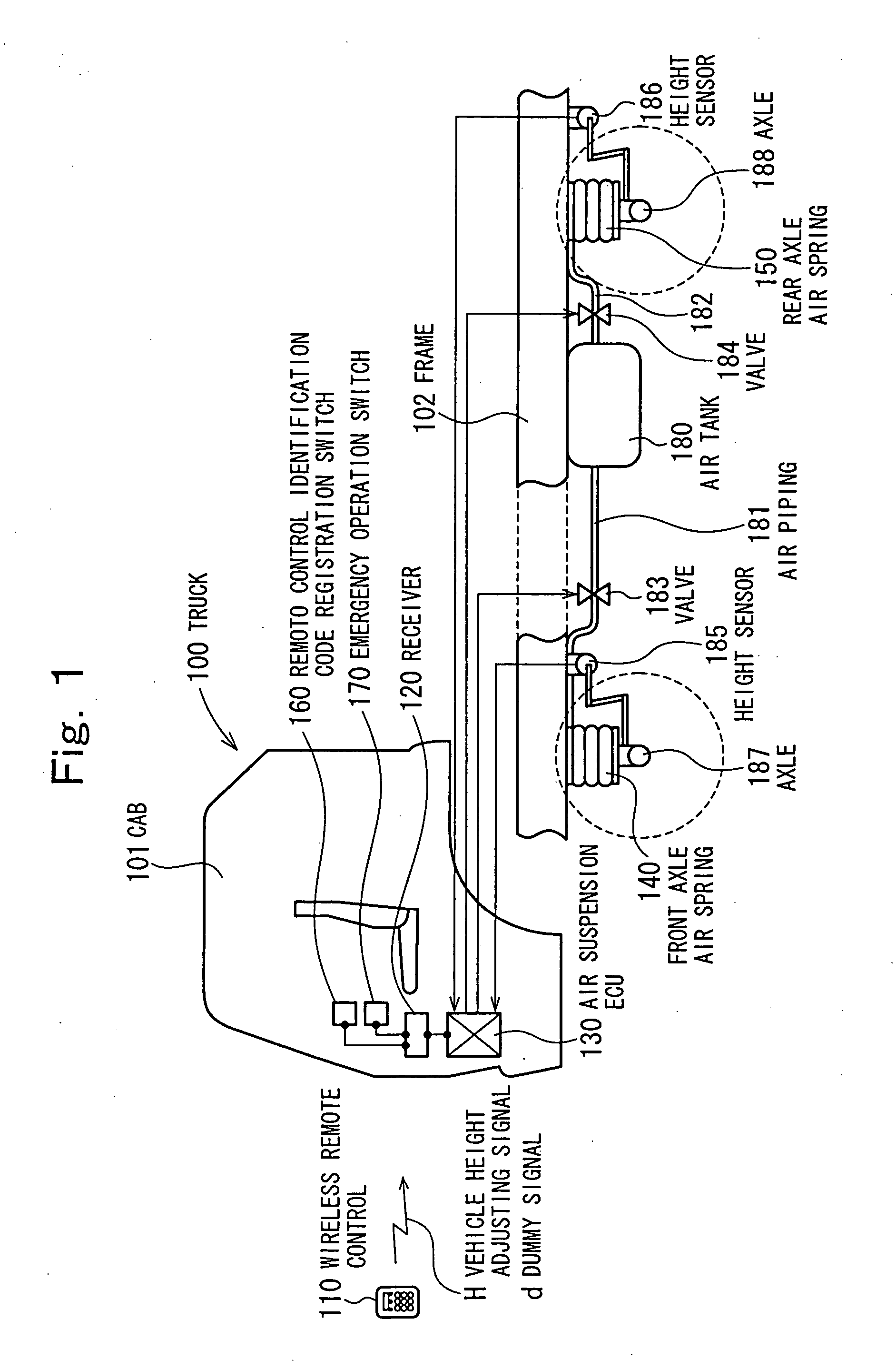

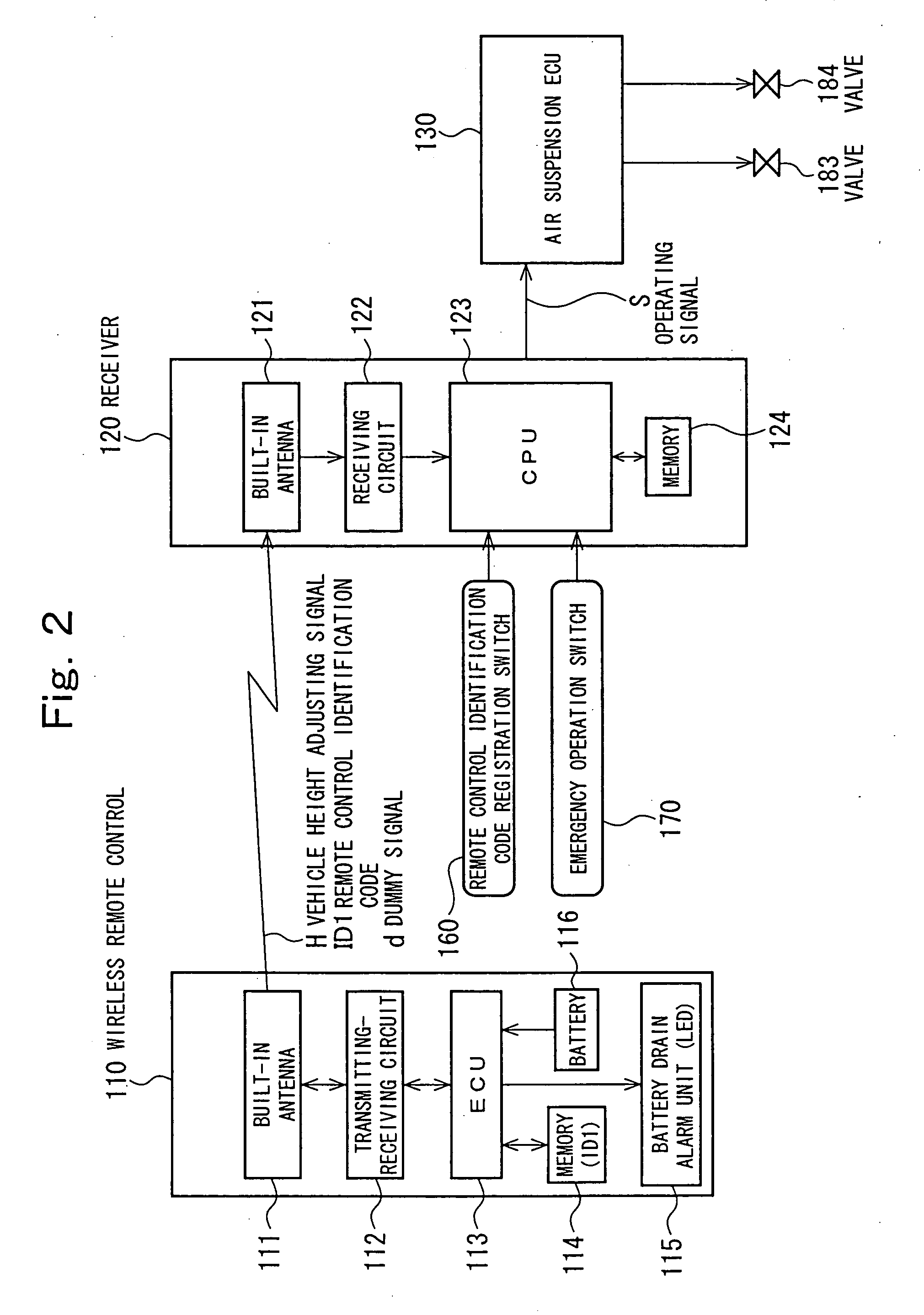

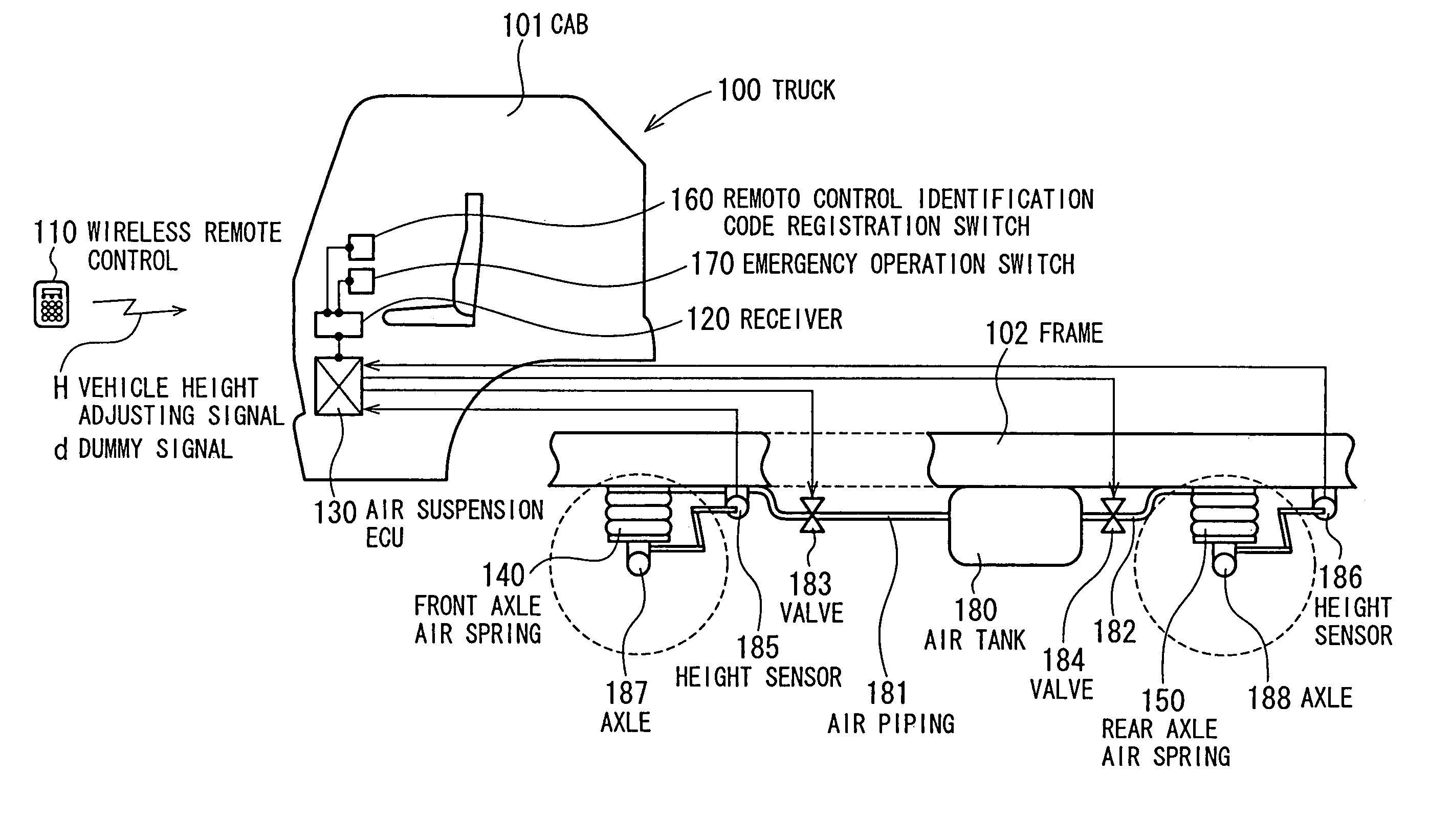

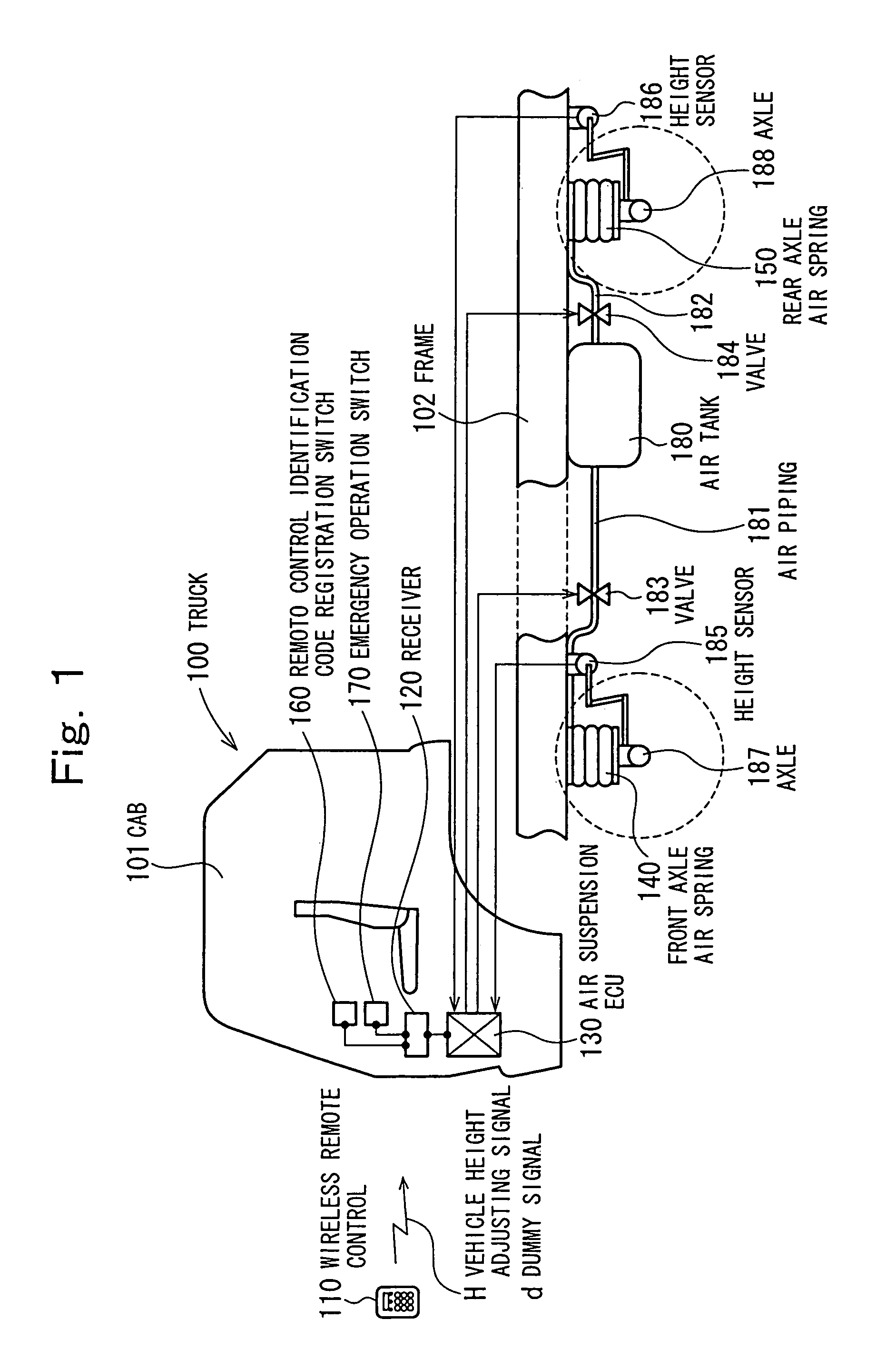

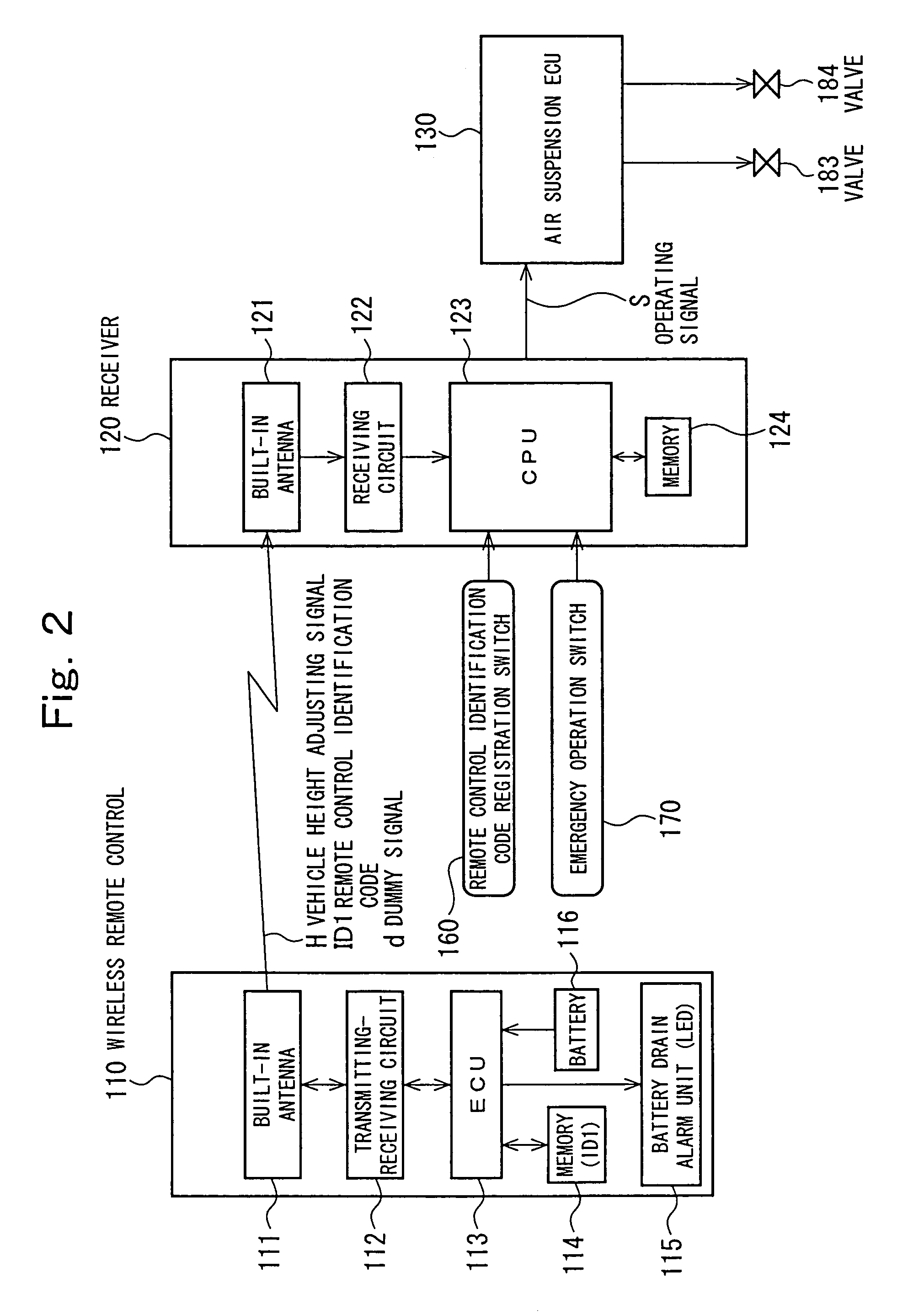

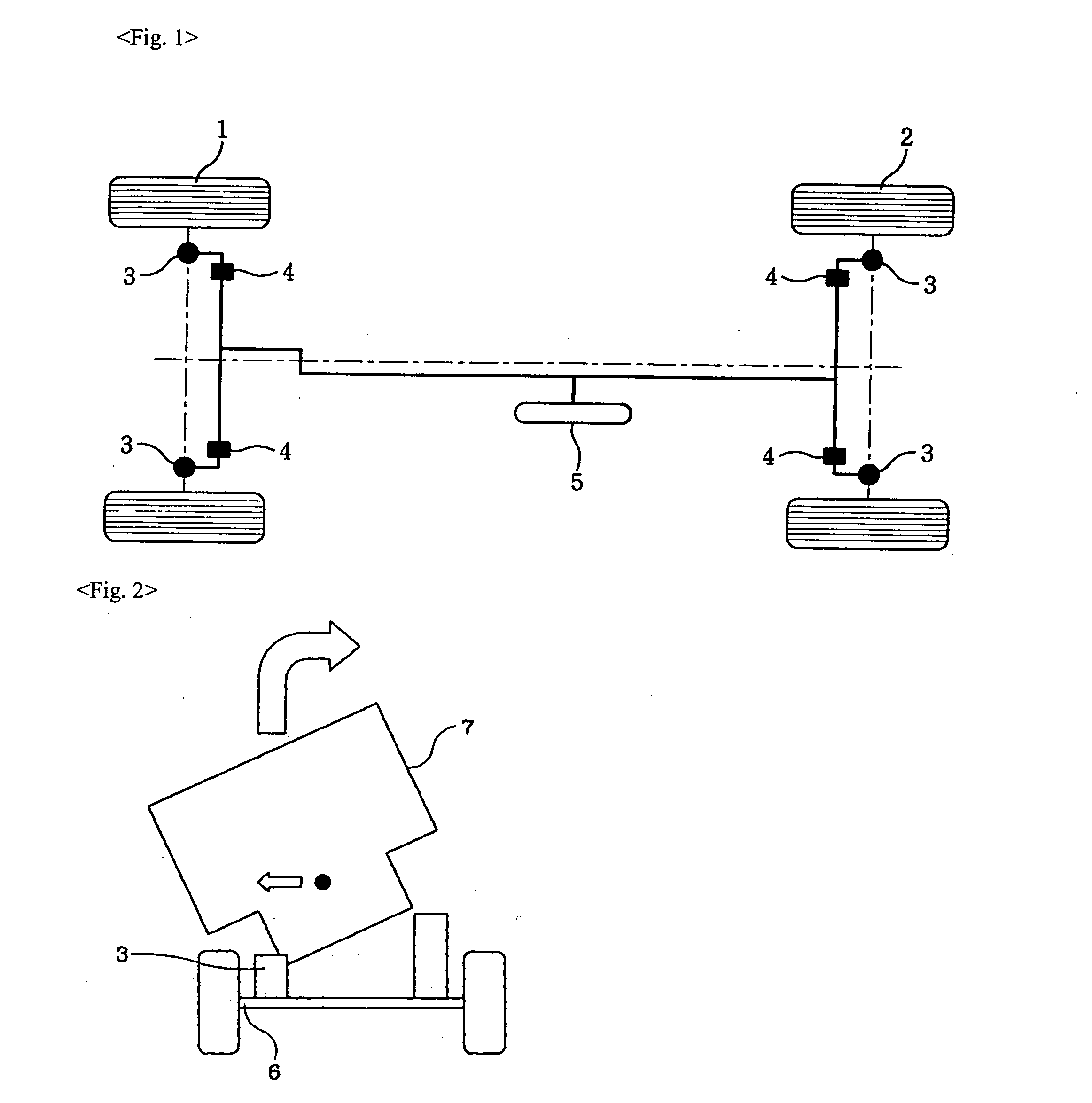

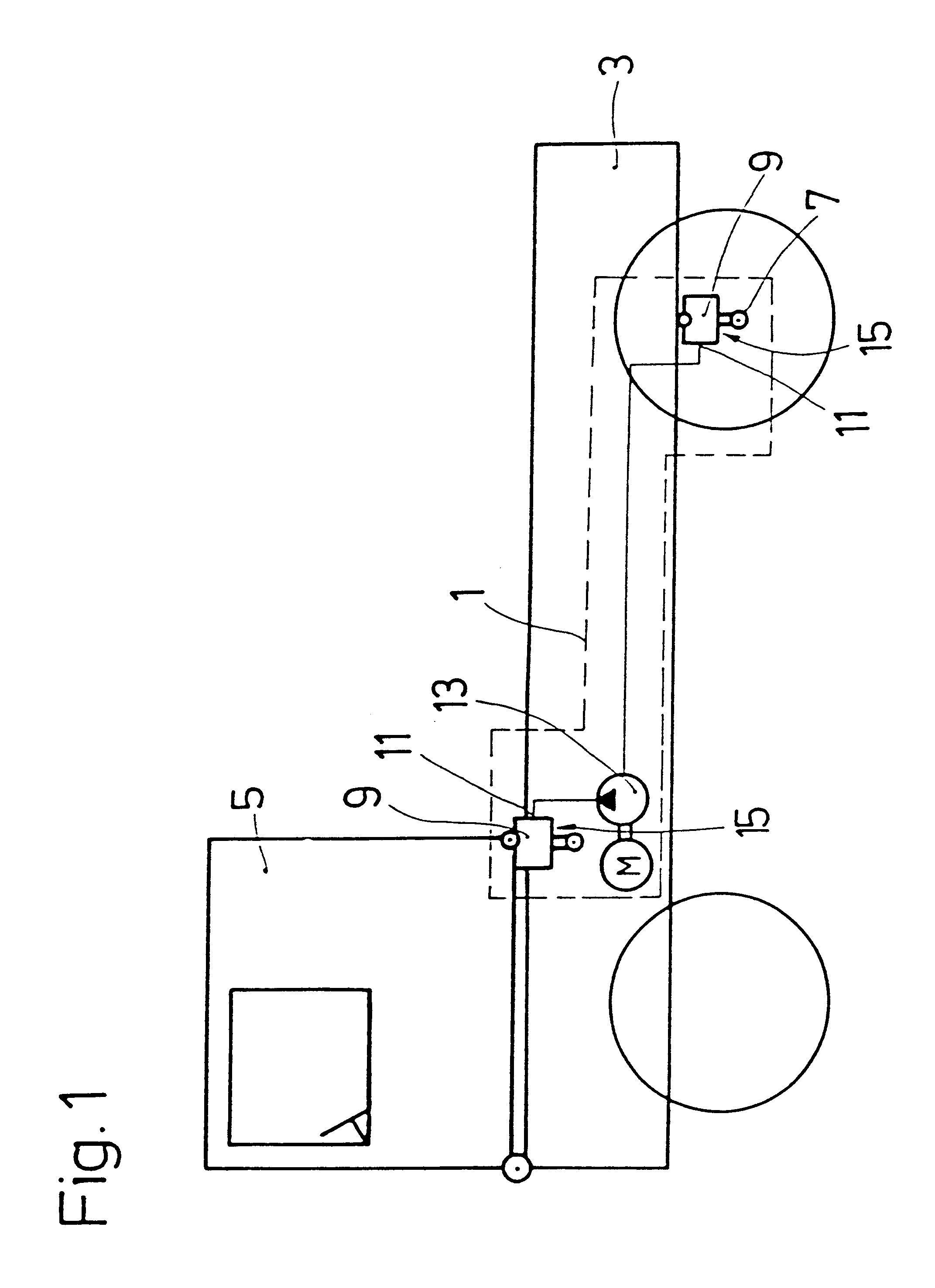

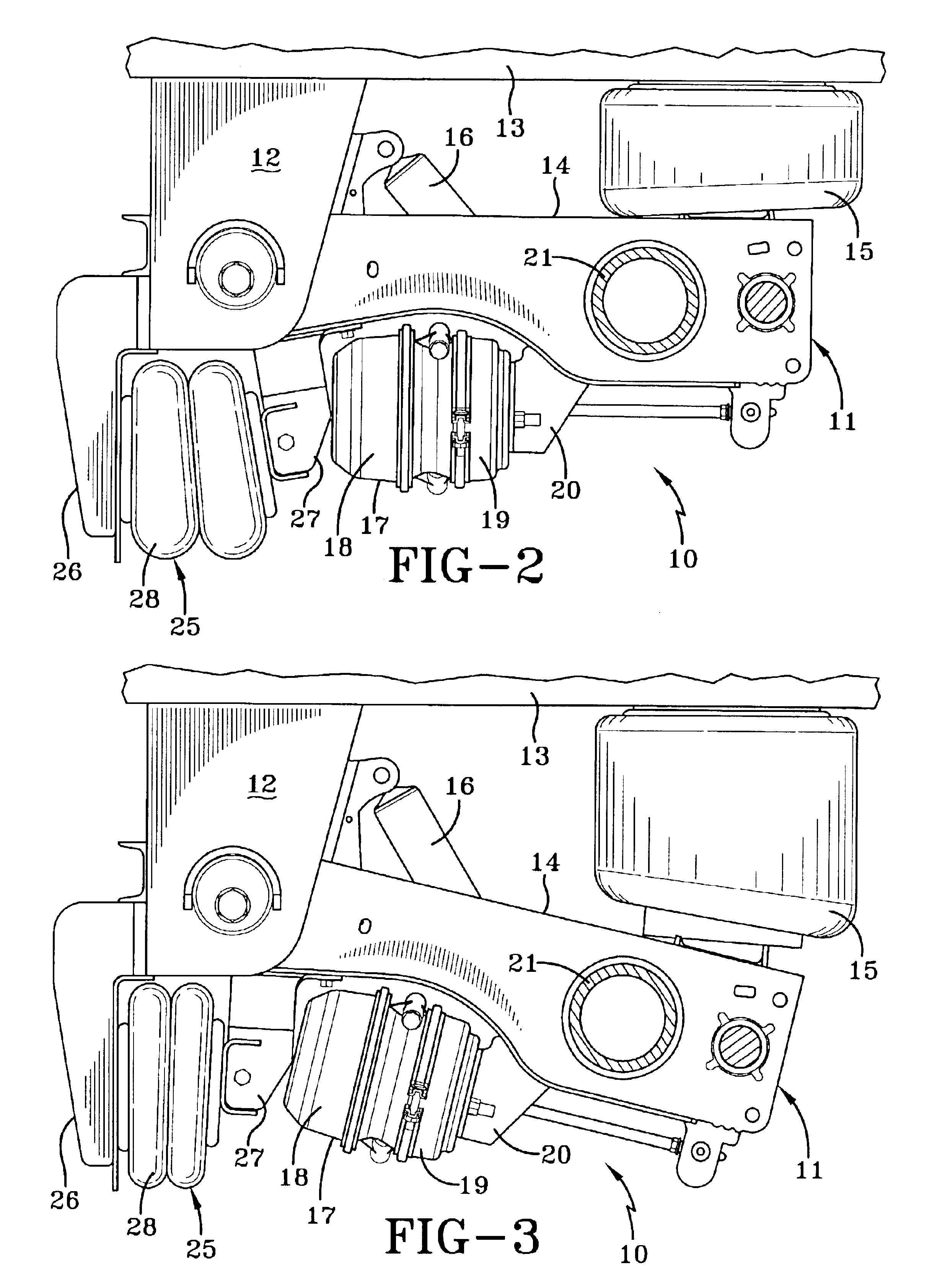

Vehicle height adjusting apparatus

InactiveUS20050110229A1Improve efficiencyReduce riskDigital data processing detailsAnimal undercarriagesRemote controlAir spring

To improve operability for vehicle height adjustment, while ensuring safety, in a vehicle such as a truck, a wireless remote control radio-transmits a vehicle height adjusting signal tagged with a remote control identification code. The remote control identification code is preregistered in a receiver, which, upon receipt of the vehicle height adjusting signal tagged with the remote control identification code, takes in the vehicle height adjusting signal. According to information contained in the received vehicle height adjusting signal, an air suspension ECU controls supply and discharge of compressed air for air springs to adjust the vehicle height. When an emergency operation switch is operated, the vehicle height adjusting signal from the wireless remote control is disabled, and vehicle height adjustment is preferentially made based on a switching signal from the emergency operation switch.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

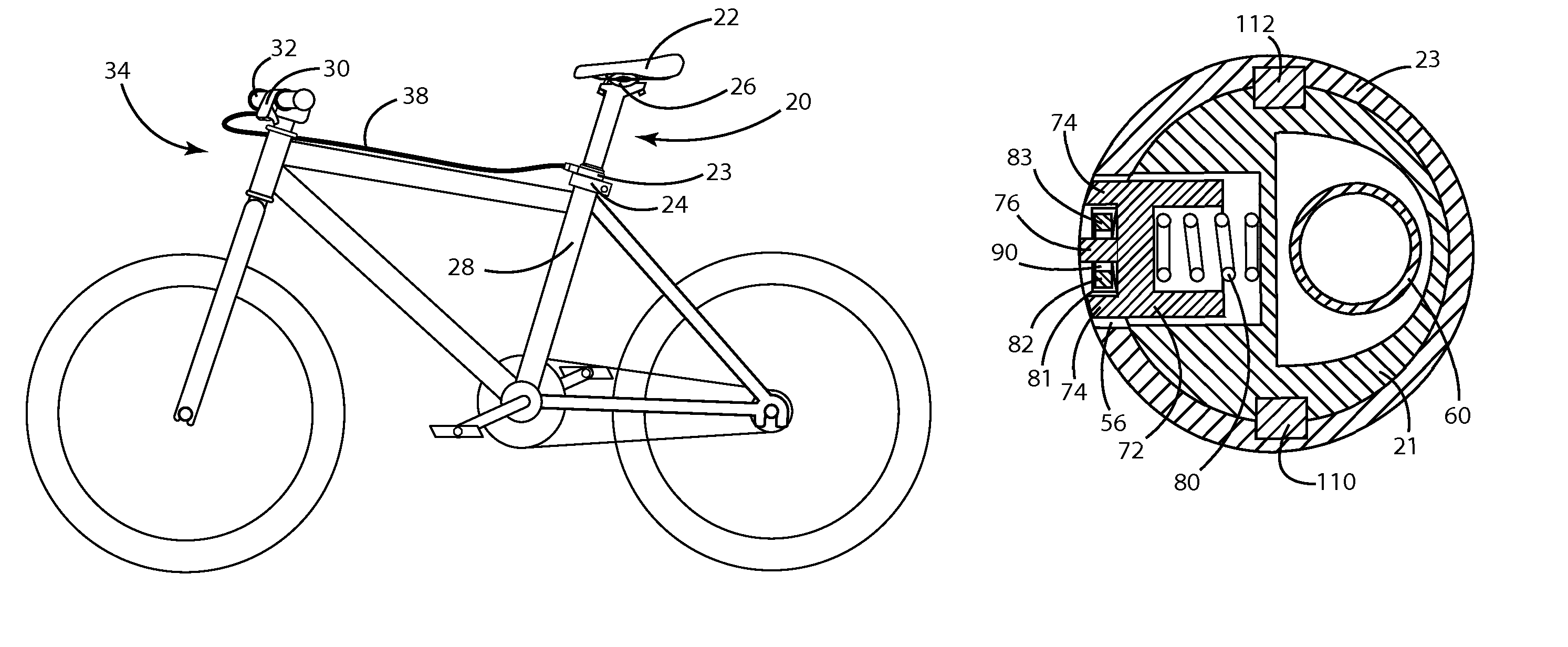

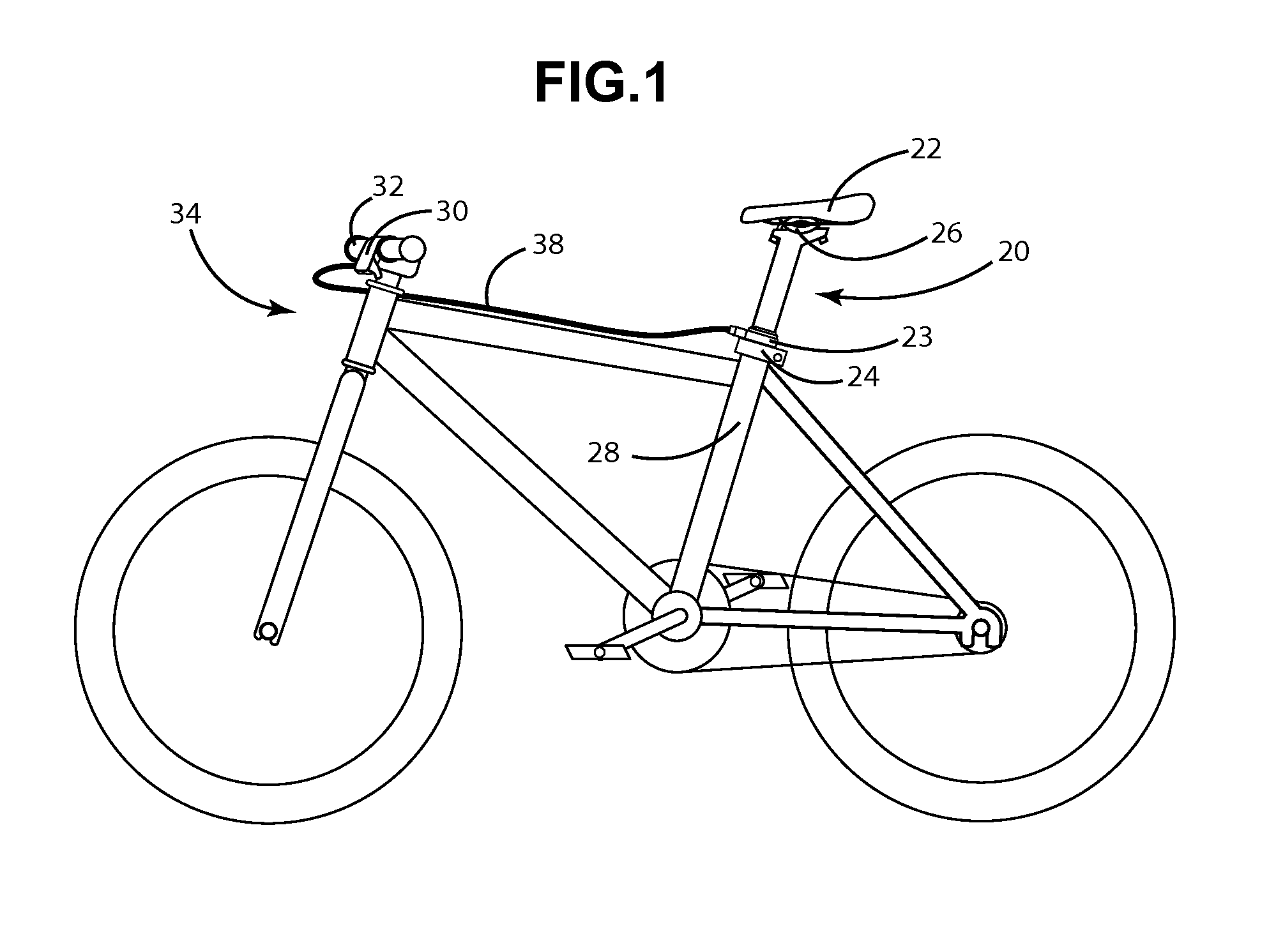

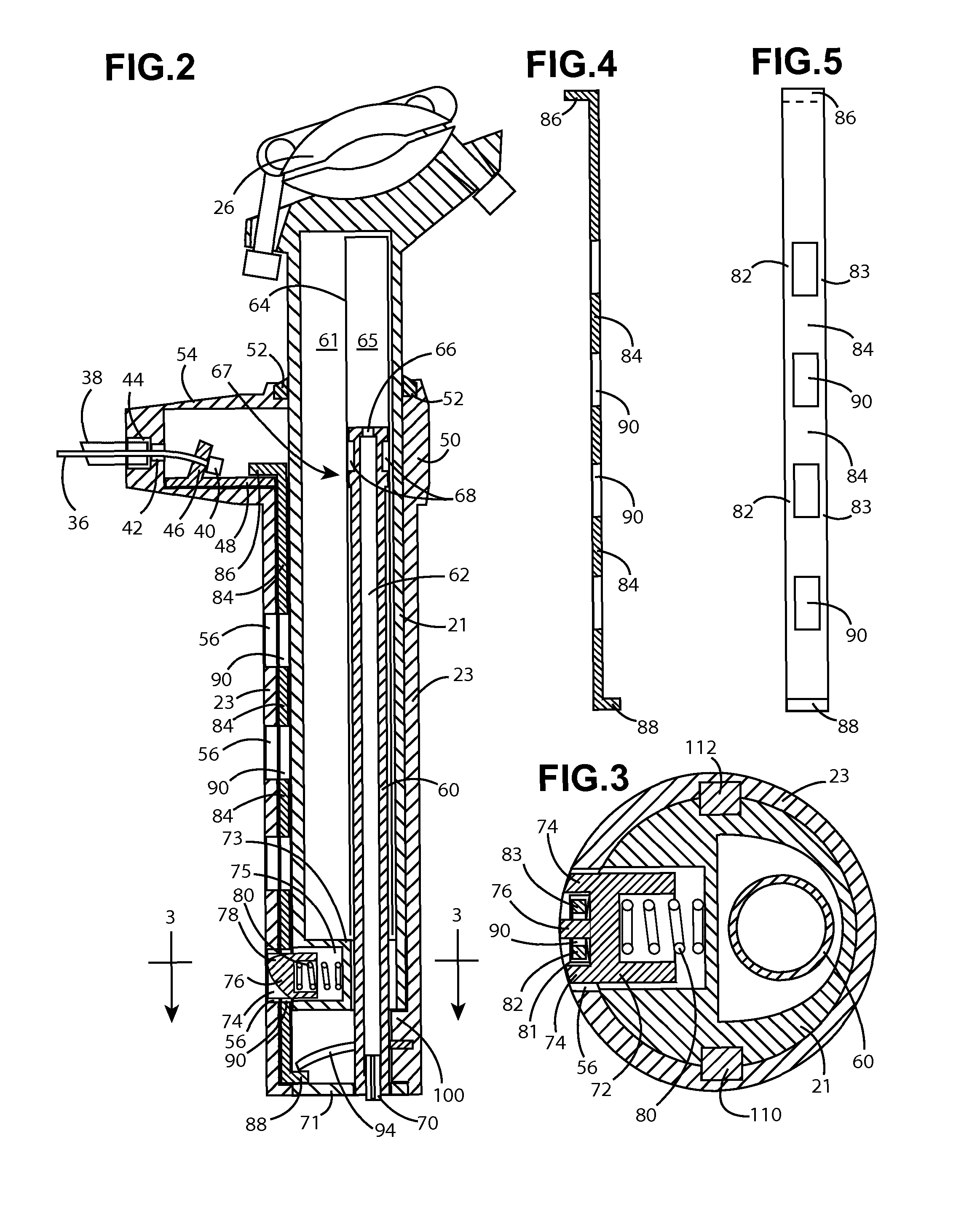

Bicycle seat height adjusting assembly

Owner:WALSH AUSTIN A

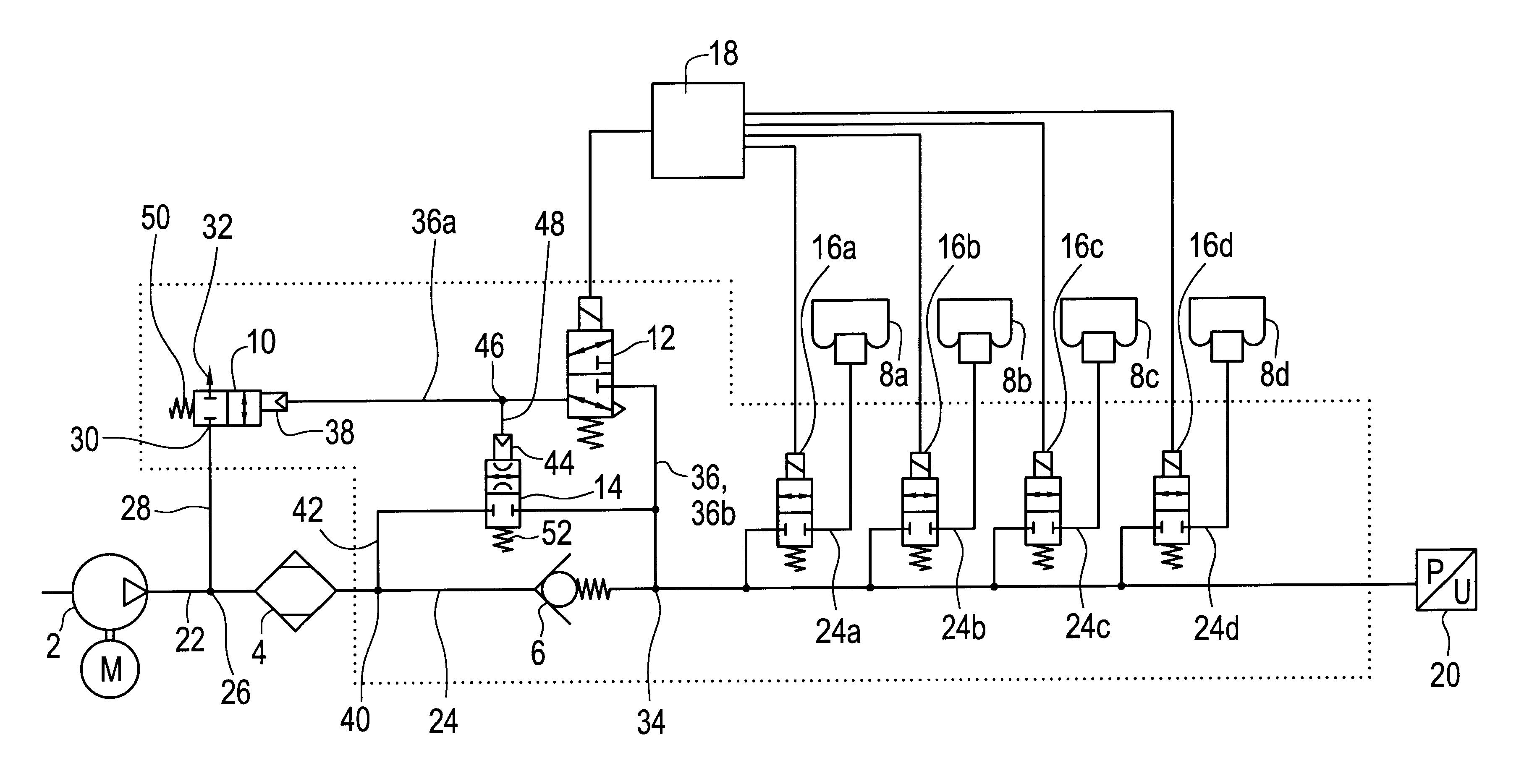

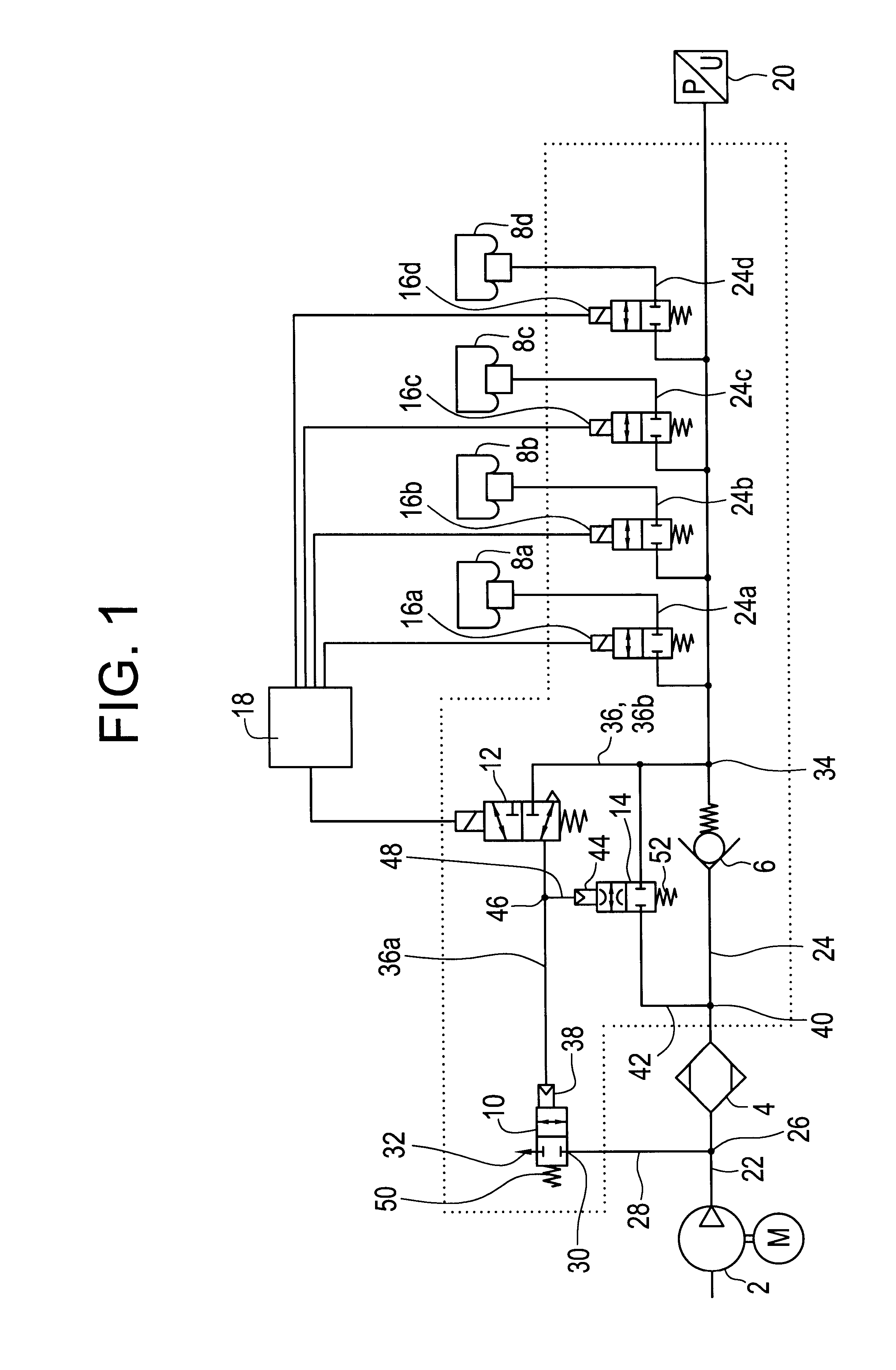

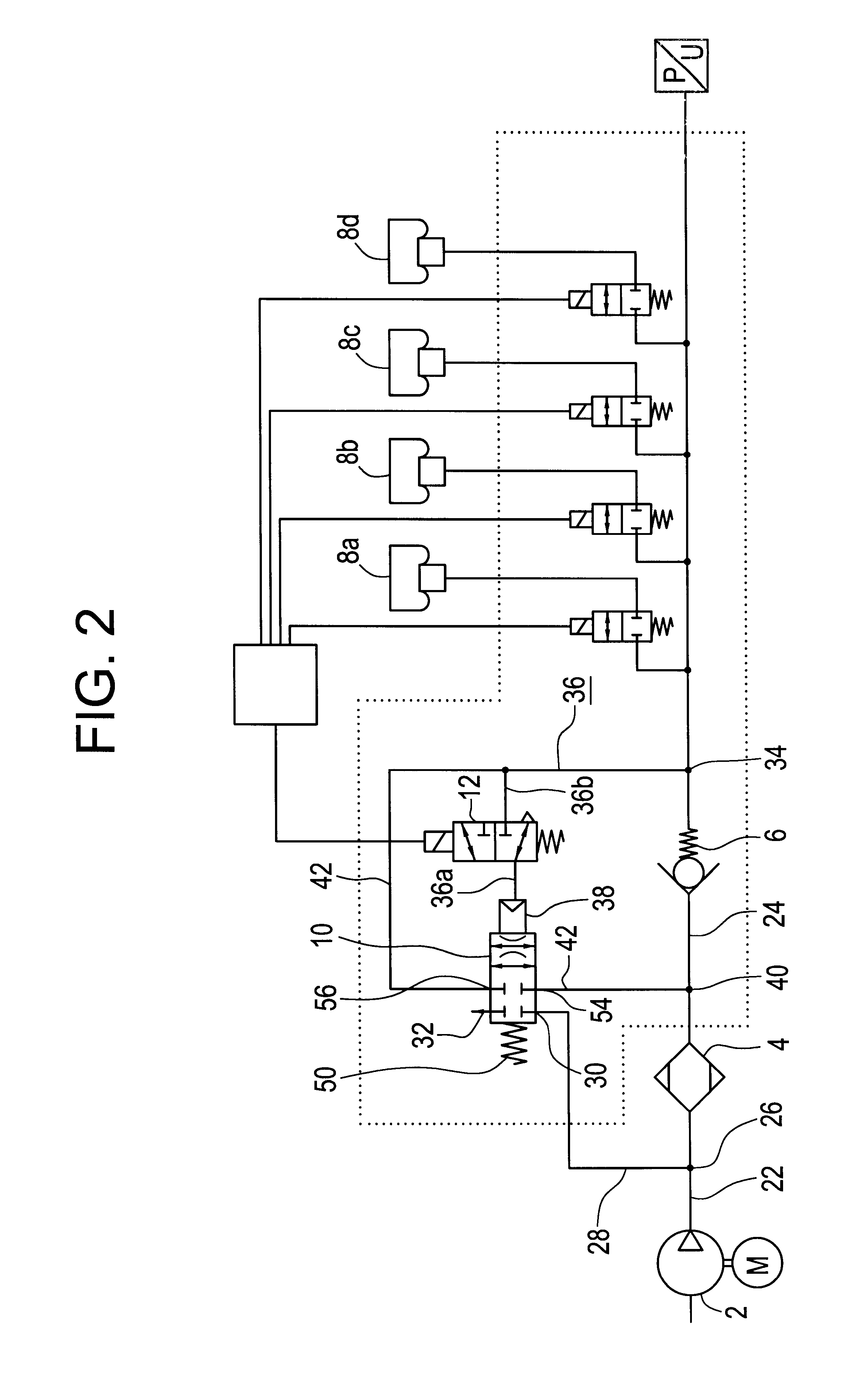

Level adjustment device for vehicles with air springs

InactiveUS6332623B1Fast emptyingLarge flowVehicle body stabilisationVehicle cleaning apparatusAir springAtmospheric air

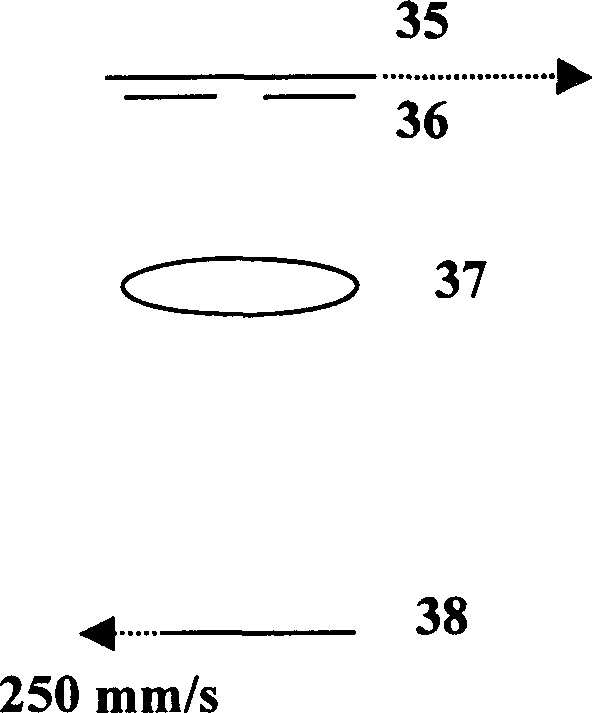

Level adjustment device for vehicles with air springs 8a through 8d, by which a vehicle body is furnished with suspension on at least one vehicle axle, which includes the following:a source of compressed air 2, which, for the purpose of filling air springs 8a through 8d, can be connected to air springs 8a through 8d via an air dryer 4, the air dryer 4, for the purpose of filling the air springs, is connected on one side to air springs 8a through 8d through a check valve 6 that is open to air springs 8a through 8d, each air spring 8a through 8d, for the purpose of emptying them, can be connected through the air dryer 4 and through a pneumatically controlled first distribution valve 10 to the atmosphere, wherein the pneumatic control input 38 of this distribution valve 10 is then impinged through a second controllable distribution valve 12 with the pressure in air springs 8a through 8d against a restoring force 50 acting on the pneumatic control input 38, the pneumatic control input 38 of the pneumatically controlled first distribution valve 10, for the purpose of ending the emptying process, can be connected to the atmosphere, wherein the air dryer 4 is connected on the other side to air springs 8a through 8d through a pneumatically controlled third distribution valve 14, wherein the pneumatic control input 44 of this distribution valve is then impinged with the pressure of air springs 8a through 8d against a restoring force 52 acting on the pneumatic control input 44.

Owner:CONTINENTAL AG

Vehicle height adjusting apparatus

InactiveUS7316406B2Improve efficiencyReduce riskDigital data processing detailsAnimal undercarriagesRemote controlAir spring

A wireless remote control radio-transmits a vehicle height adjusting signal tagged with a remote control identification code in order to improve vehicle height adjustment operability in a vehicle such as a truck. The remote control identification code is pre-registered in a receiver, which, upon receipt of the vehicle height adjusting signal tagged with the remote control identification code, takes in the vehicle height adjusting signal. According to information contained in the received vehicle height adjusting signal, an air suspension ECU controls the supply and discharge of compressed air for air springs to adjust the vehicle height. When an emergency operation switch is operated, the vehicle height adjusting signal from the wireless remote control is disabled, and vehicle height adjustment is preferentially made based on a switching signal from the emergency operation switch.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

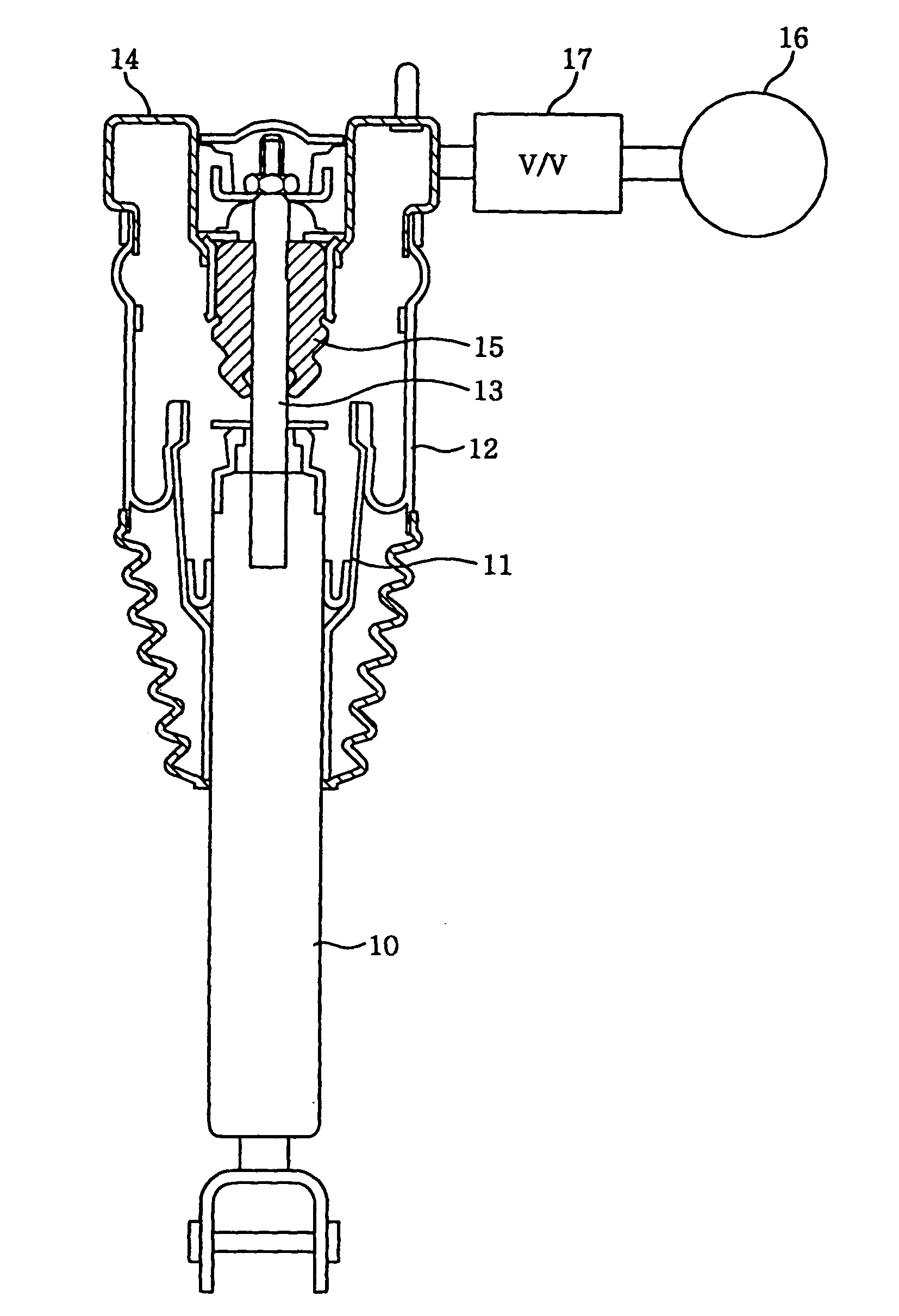

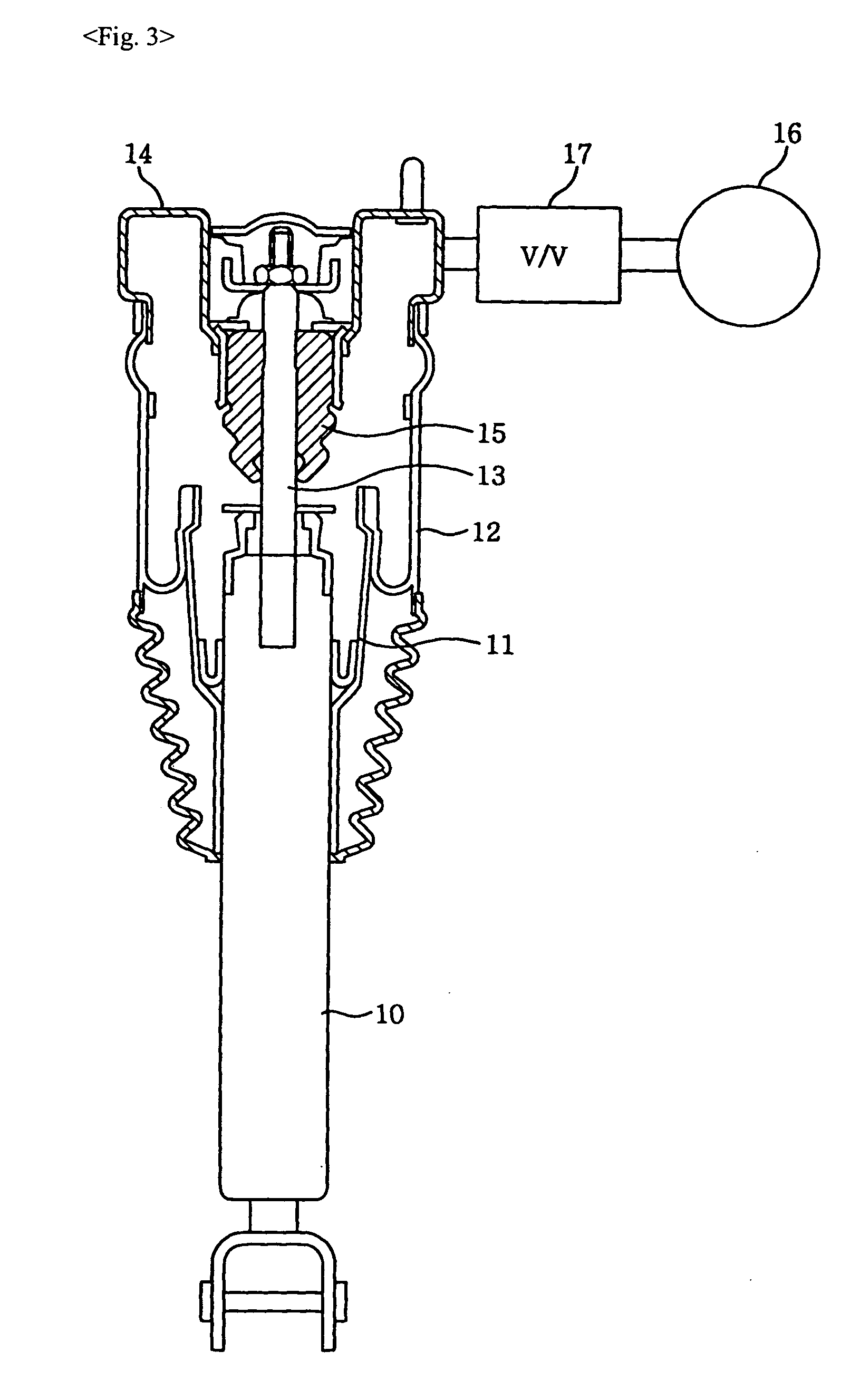

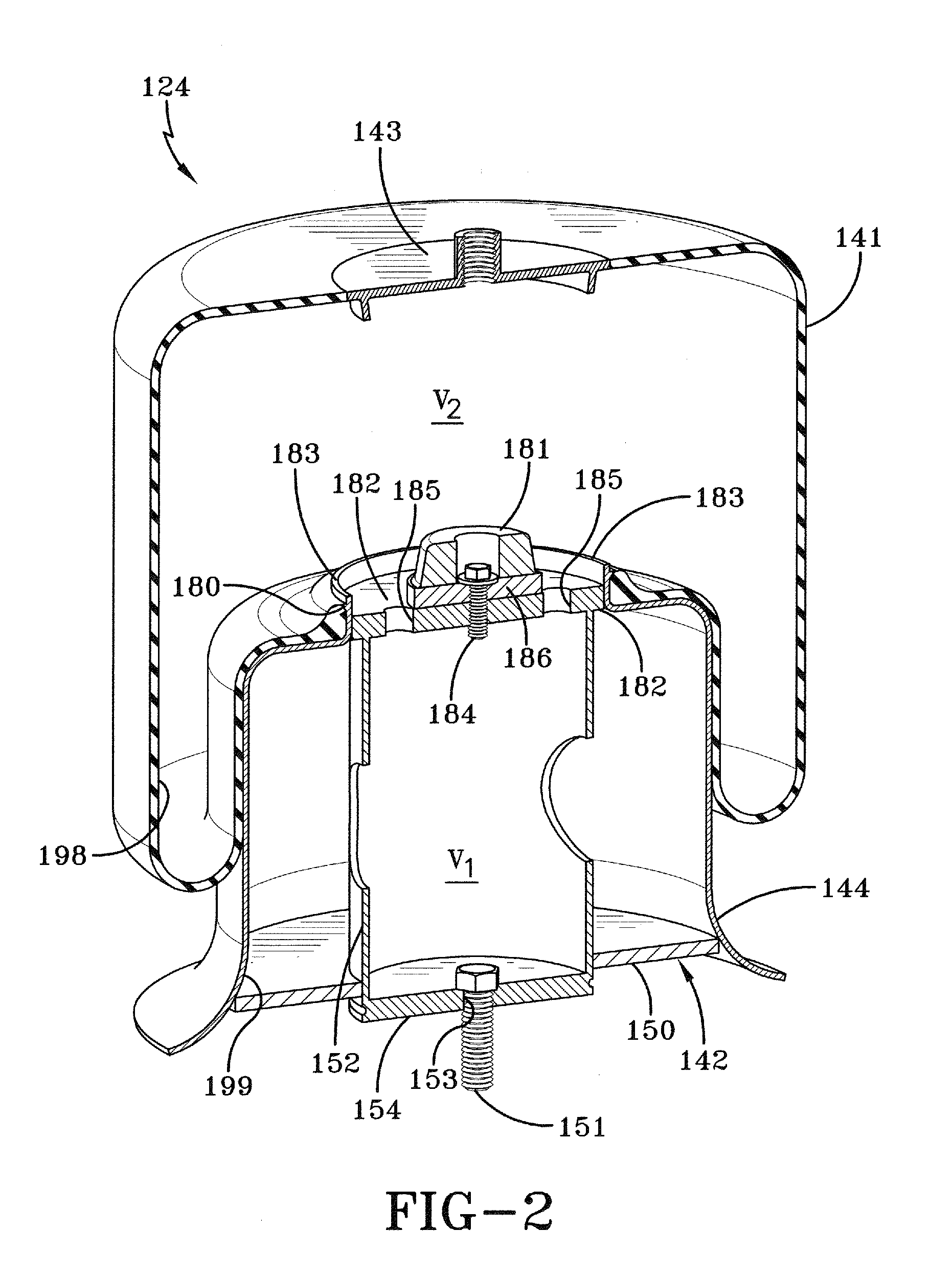

Air suspension and electronically controlled suspension system

InactiveUS20060219503A1Rapidly and efficiently stabilize movement of vehiclePipe supportsSpringsDriver/operatorControl signal

The present invention relates to an air suspension and an electronically controlled suspension system. An electronically controlled suspension system of the present invention comprises an air suspension including a volume expander connected to a pressure acting volume of an air spring to expand the pressure acting volume, and a volume control valve for opening or closing the connection between the pressure acting volume and the volume expander; a mode-changing switch for applying a mode-setting key signal according to a driver's button operation; an electronic control unit for outputting a valve control signal for use in exhibiting a suspension characteristic of the vehicle in response to the mode-setting key signal from the mode-changing switch; and an air spring volume adjustor for controlling a spring rate of the air spring through adjustment of the pressure acting volume of the air spring by opening or closing the volume control valve in response to the valve control signal from the electronic control valve, thereby forcibly setting the suspension characteristic of the vehicle. The present invention is to control a spring rate of an air spring employed in an air suspension to a range of damping force characteristics of a relevant mode by selectively controlling a pressure acting volume of the air spring using a fast response valve in response to a signal corresponding to a driver's mode-changing operation. Thus, during sudden braking, rapid acceleration or cornering, a driver can conveniently change characteristics of a vehicle mounted with the air suspension by operating a button within the vehicle, resulting in maximization of consumers' satisfaction.

Owner:HL MANDO CORP

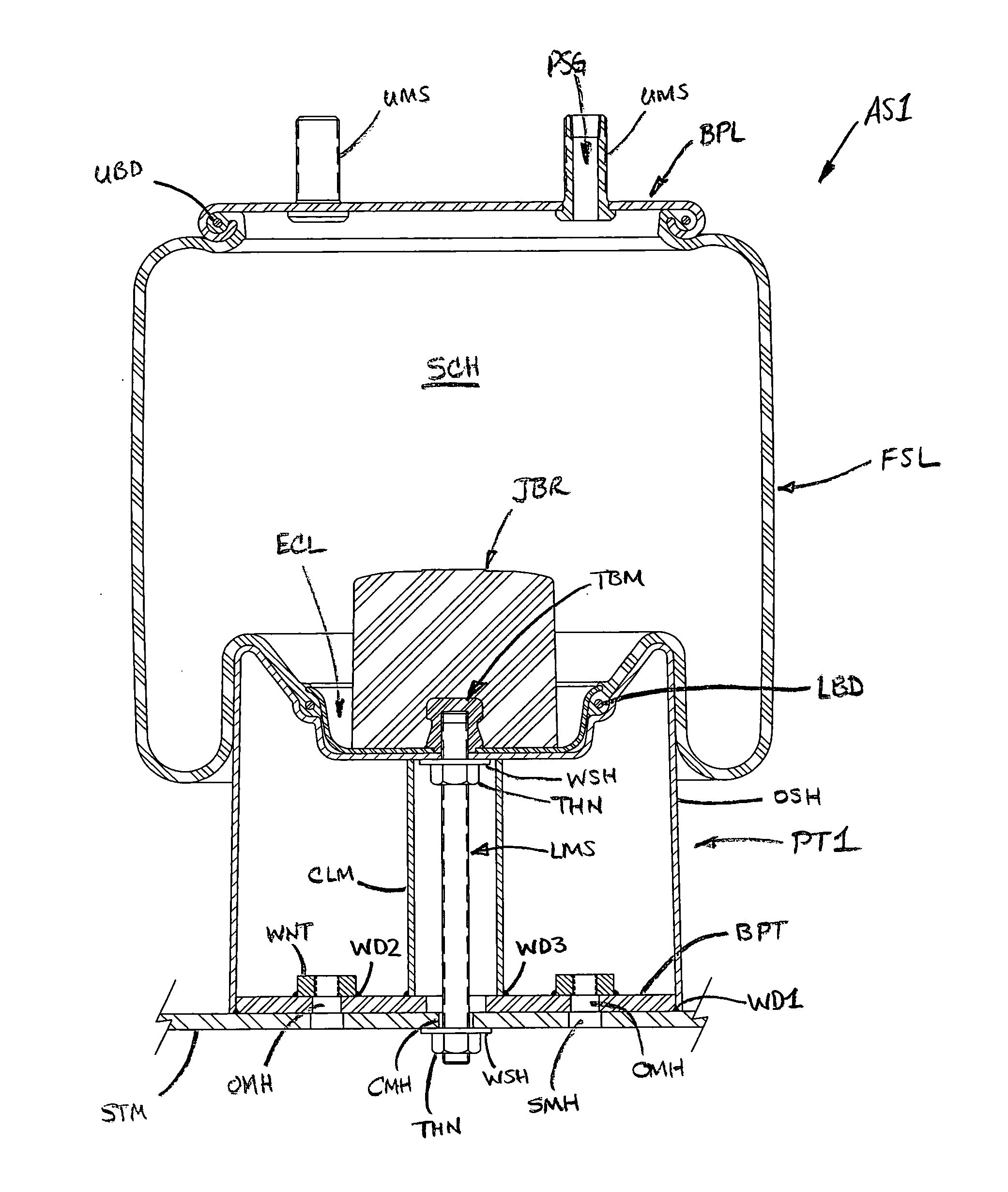

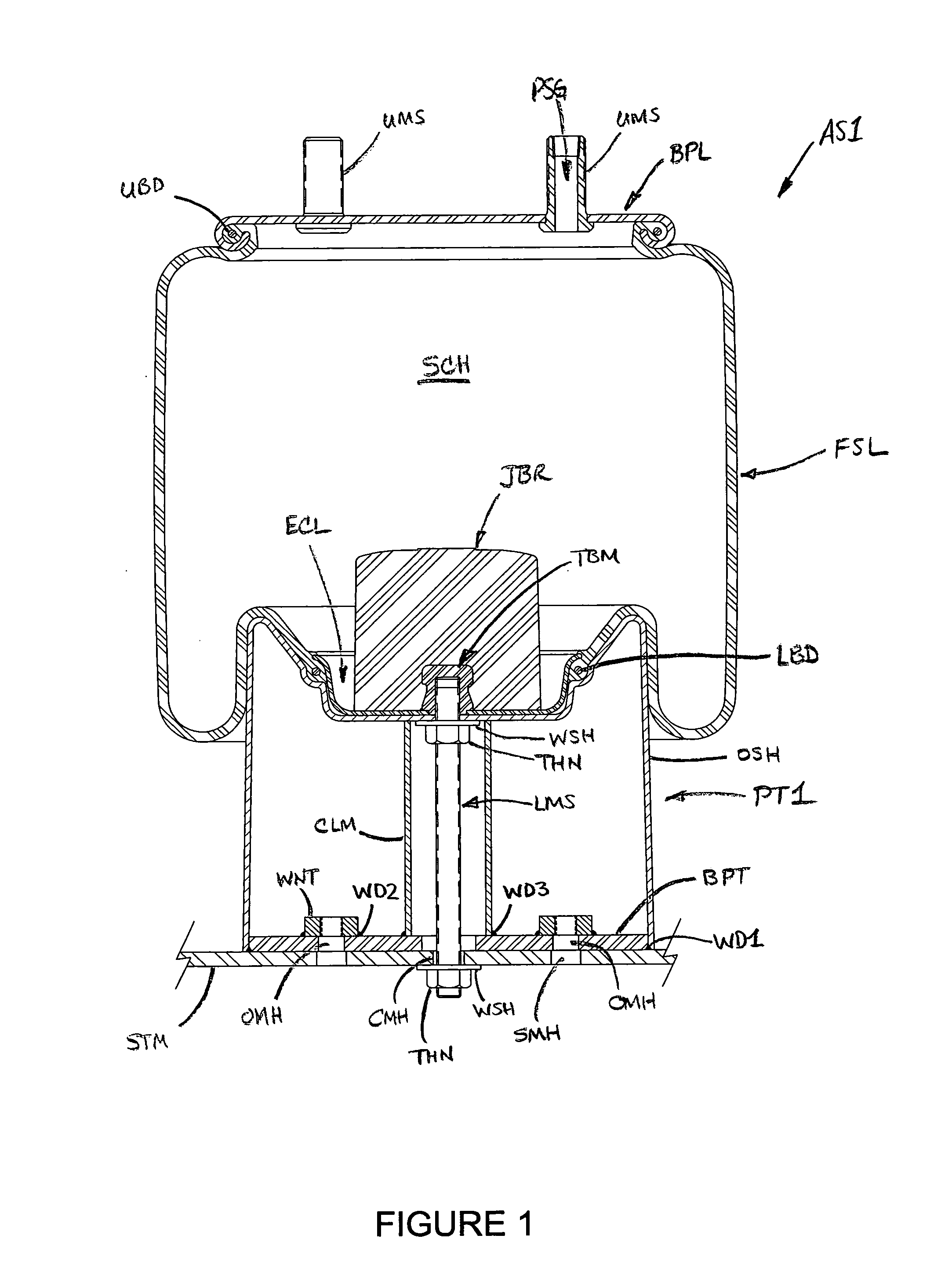

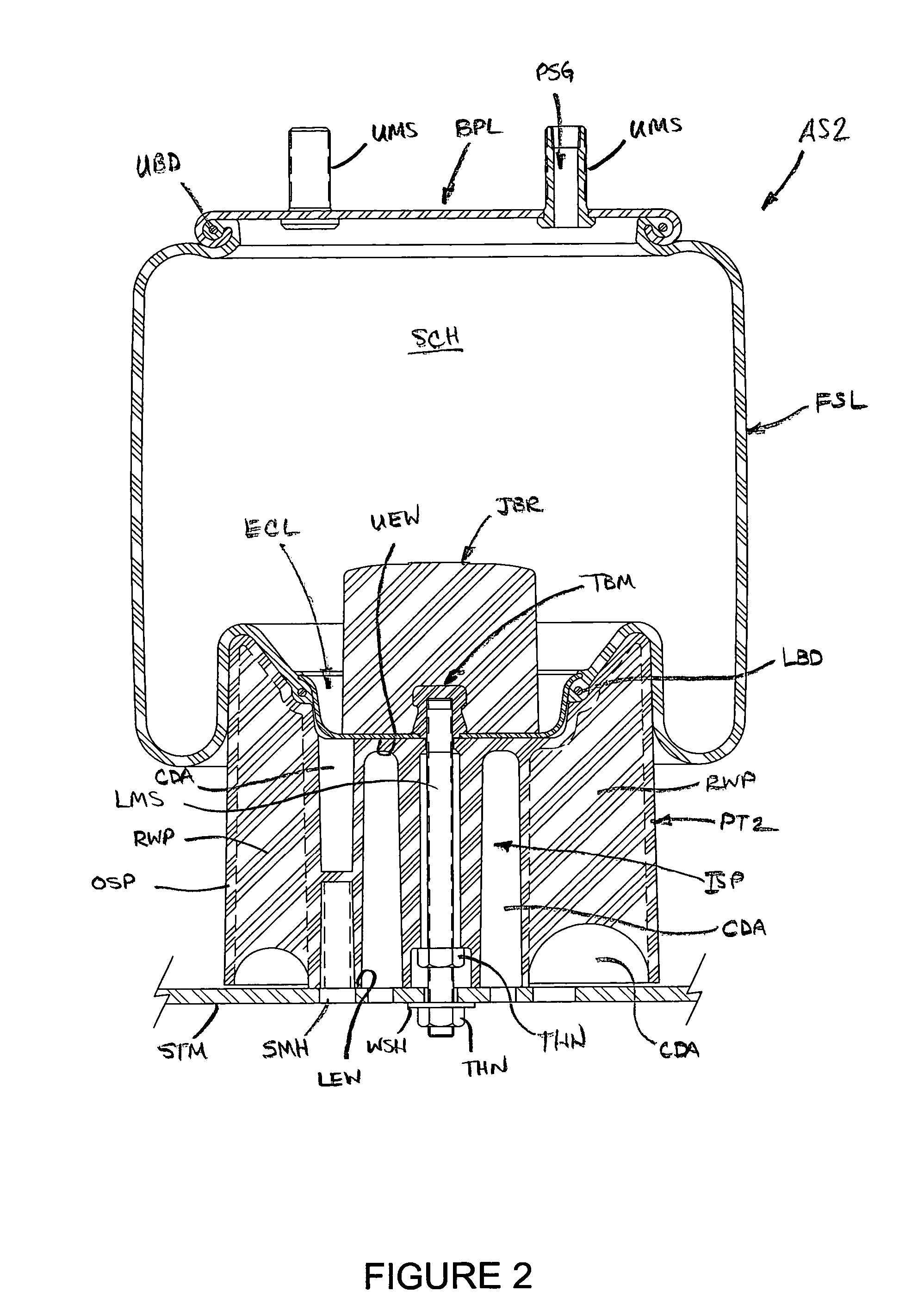

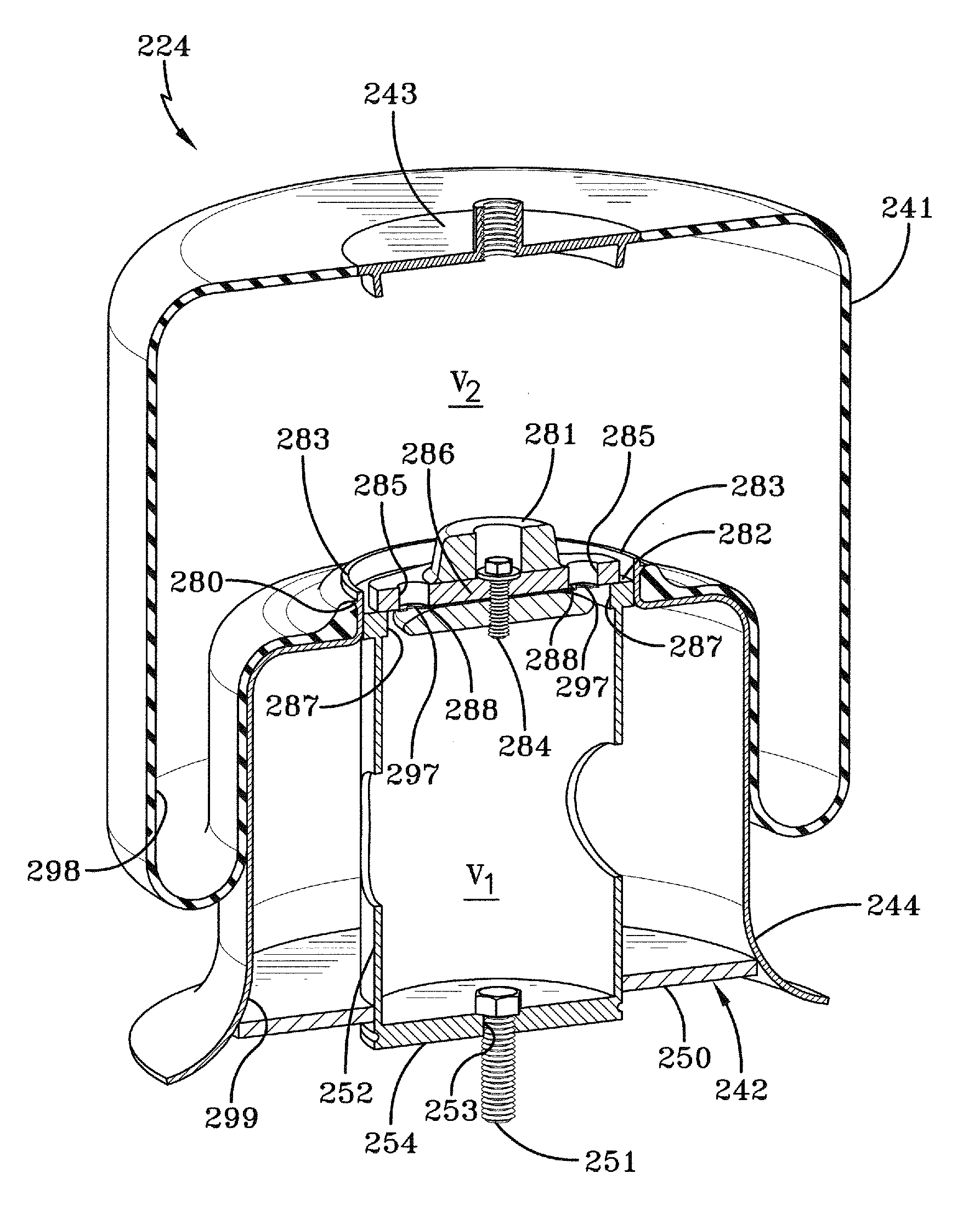

Air spring assembly and method

A piston assembly for an air spring includes an outer shell and a structural insert. The outer shell includes a side wall and an end wall at least partially defining a shell cavity having an open end. The structural insert is received in the shell cavity and includes a central portion and a plurality of support walls extending outwardly from the central portion toward the side wall of the outer shell. The central portion includes first and second opposing ends with the first end disposed toward the end wall of the outer shell and the second end disposed toward the open end of the outer shell. An air spring assembly includes such a piston assembly. A method of manufacturing an air spring assembly is also included.

Owner:FIRESTONE IND PROD COMPANY

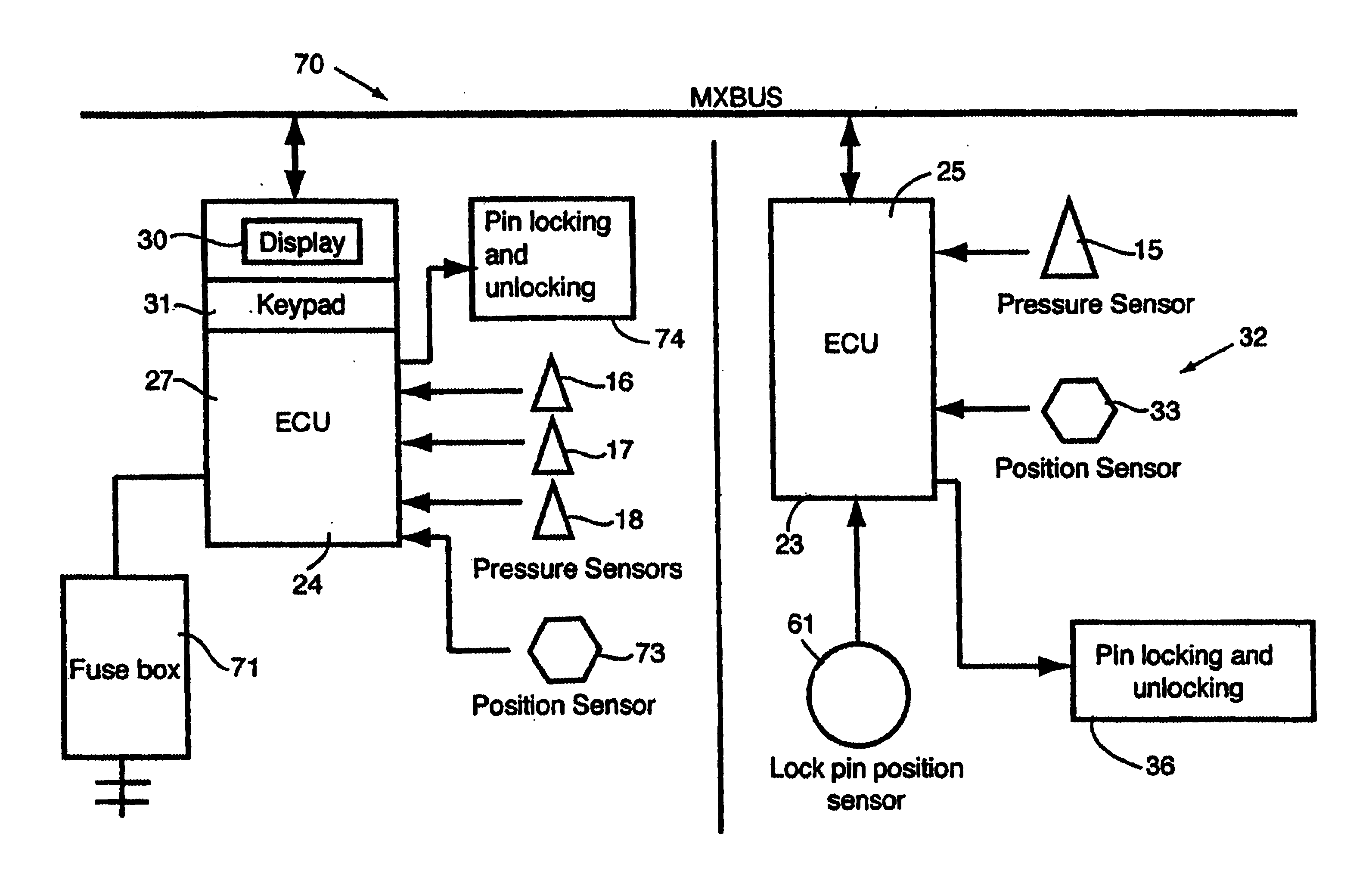

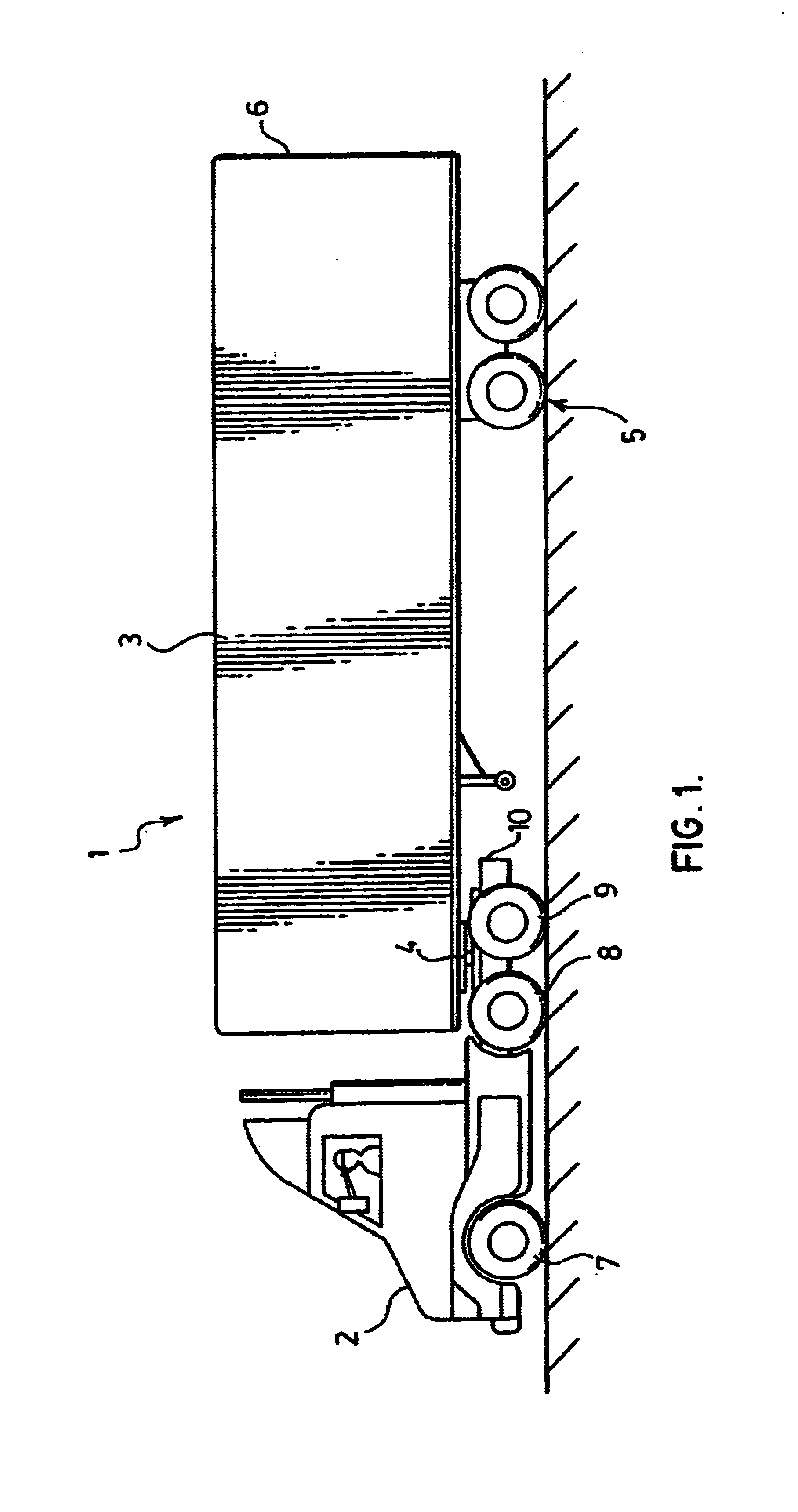

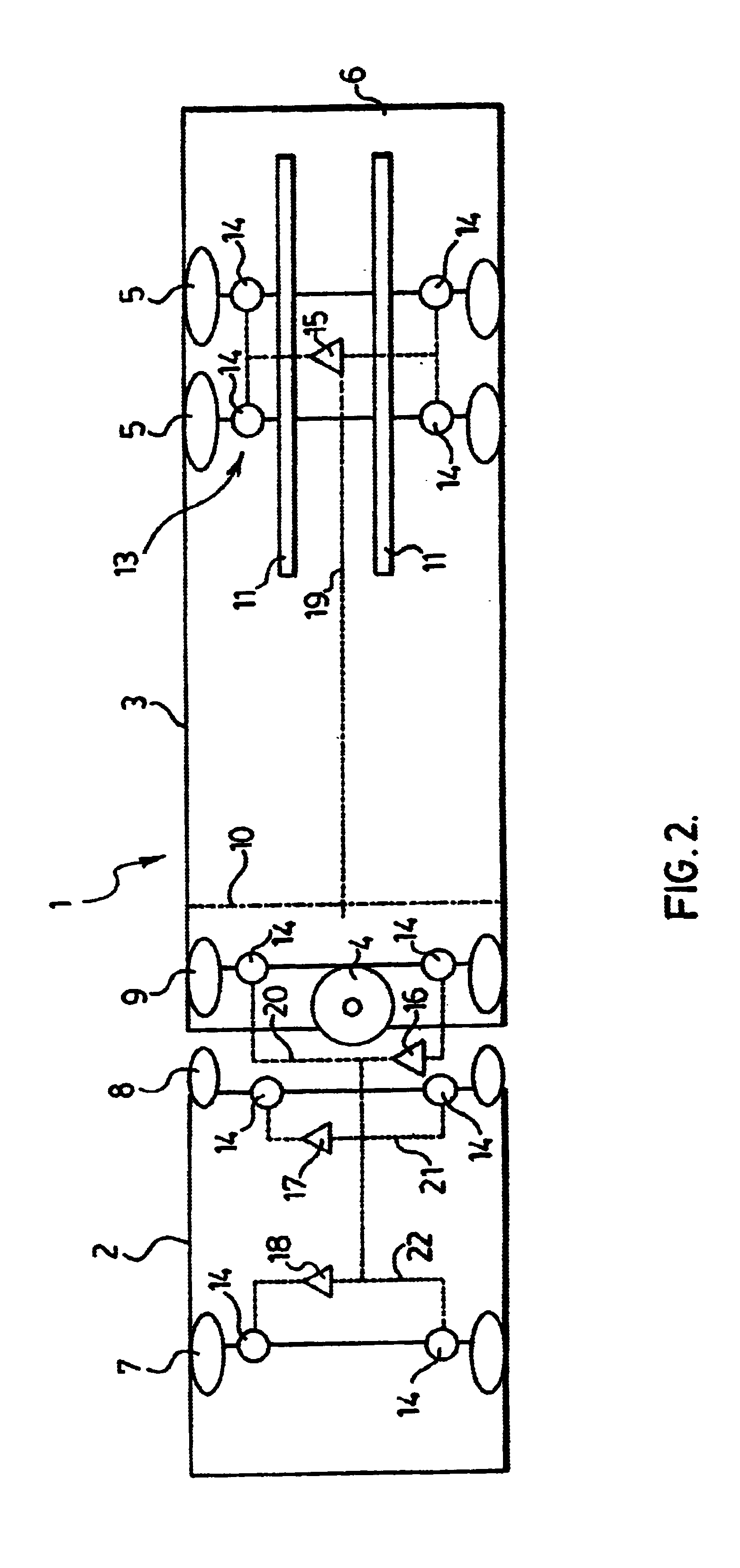

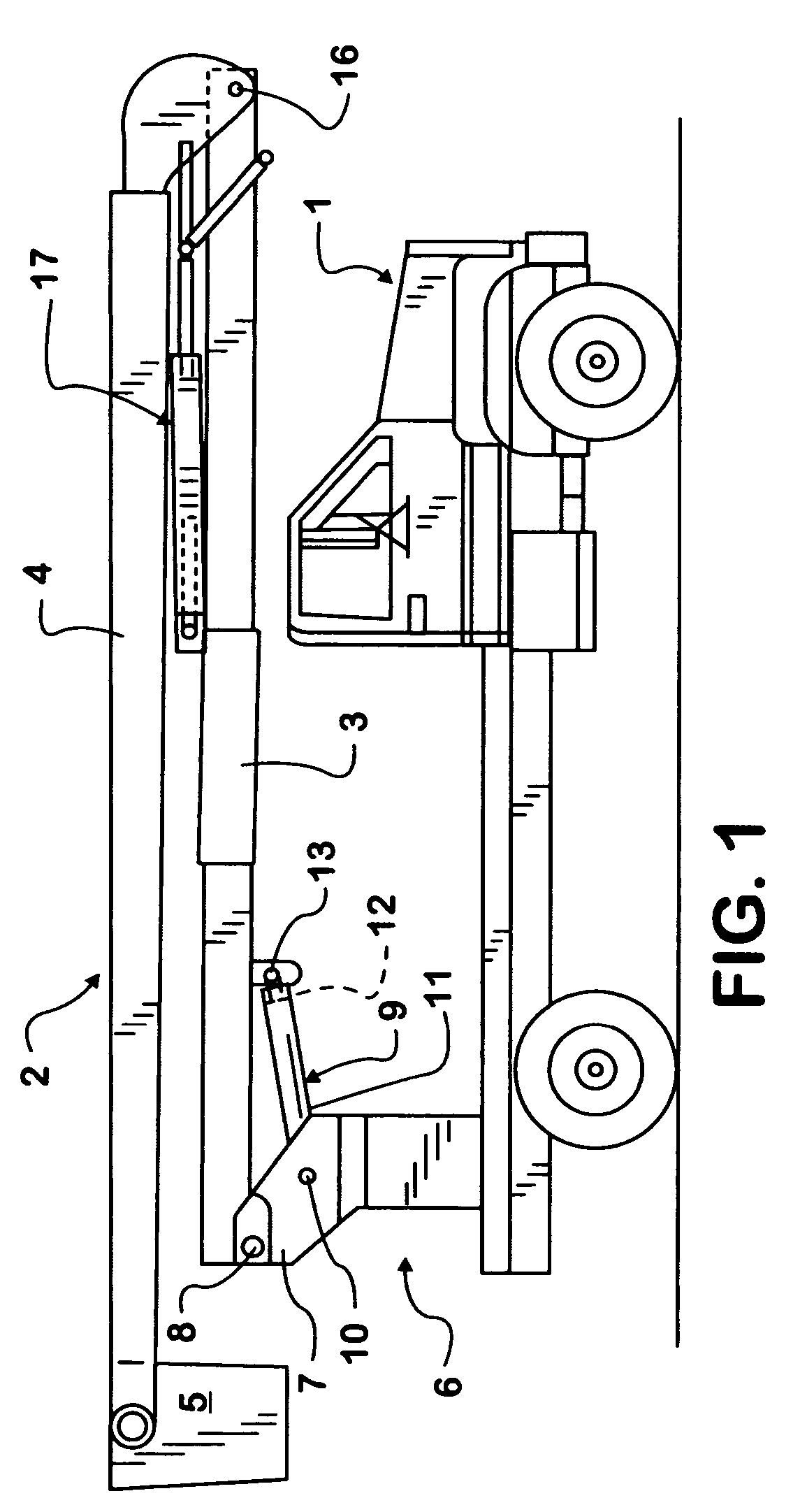

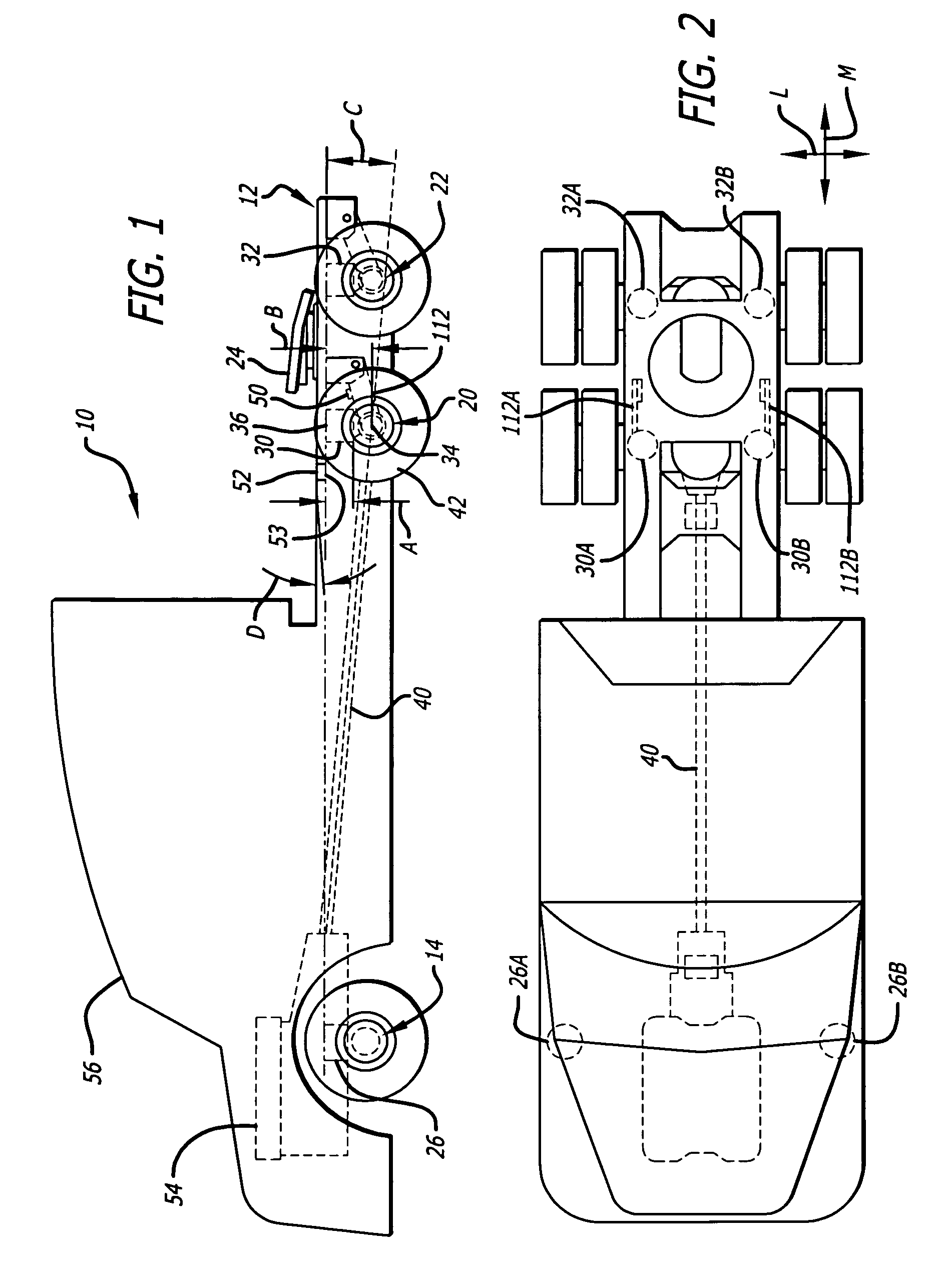

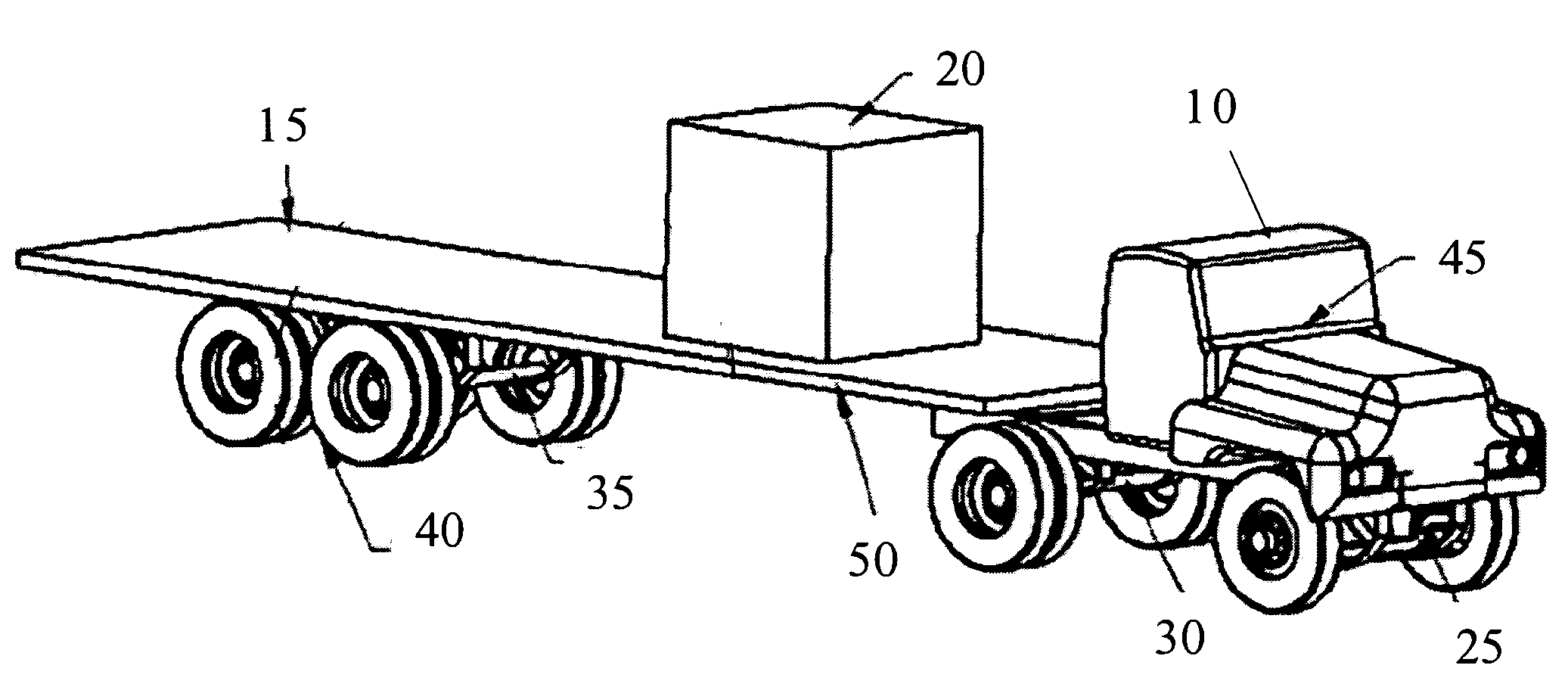

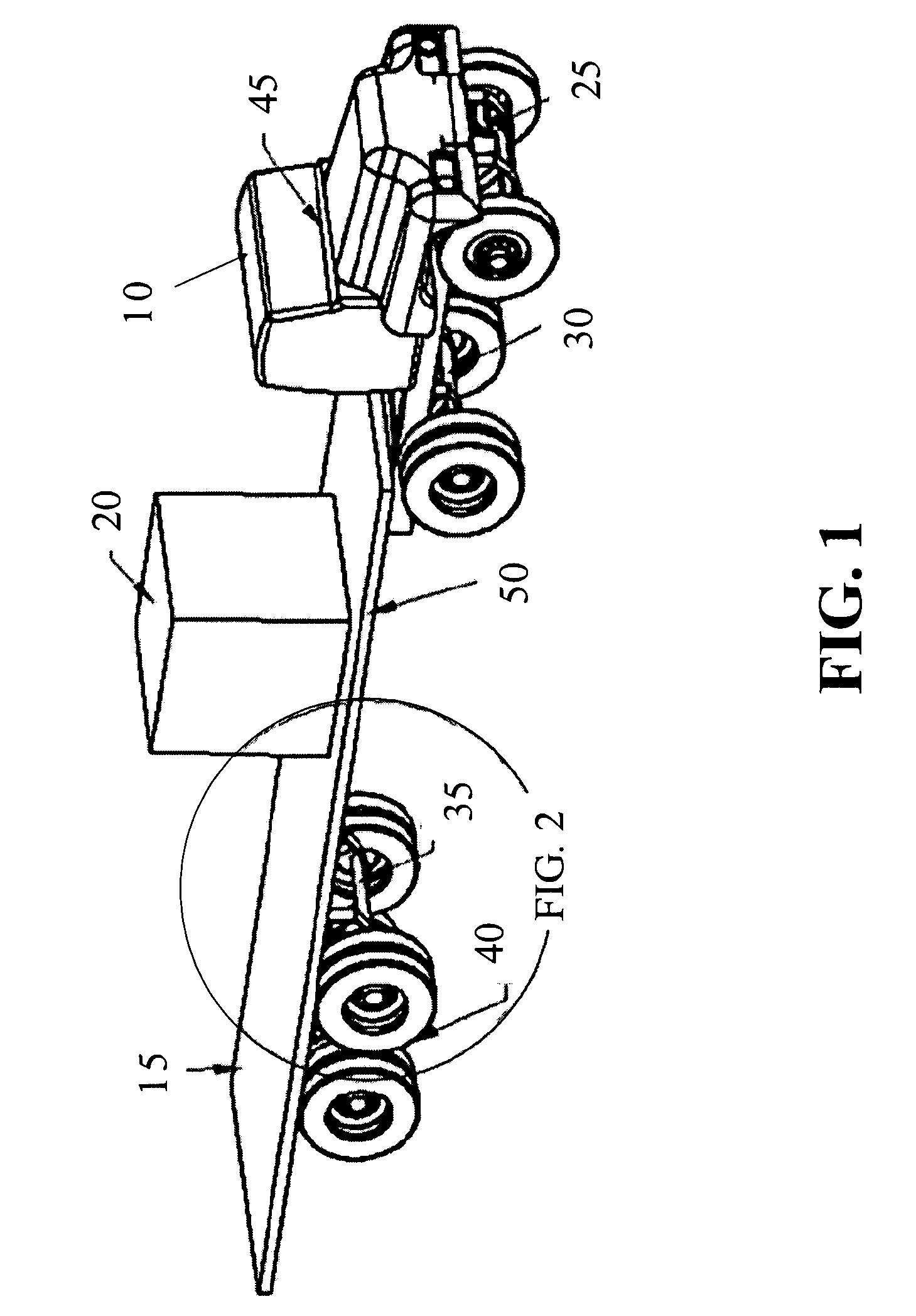

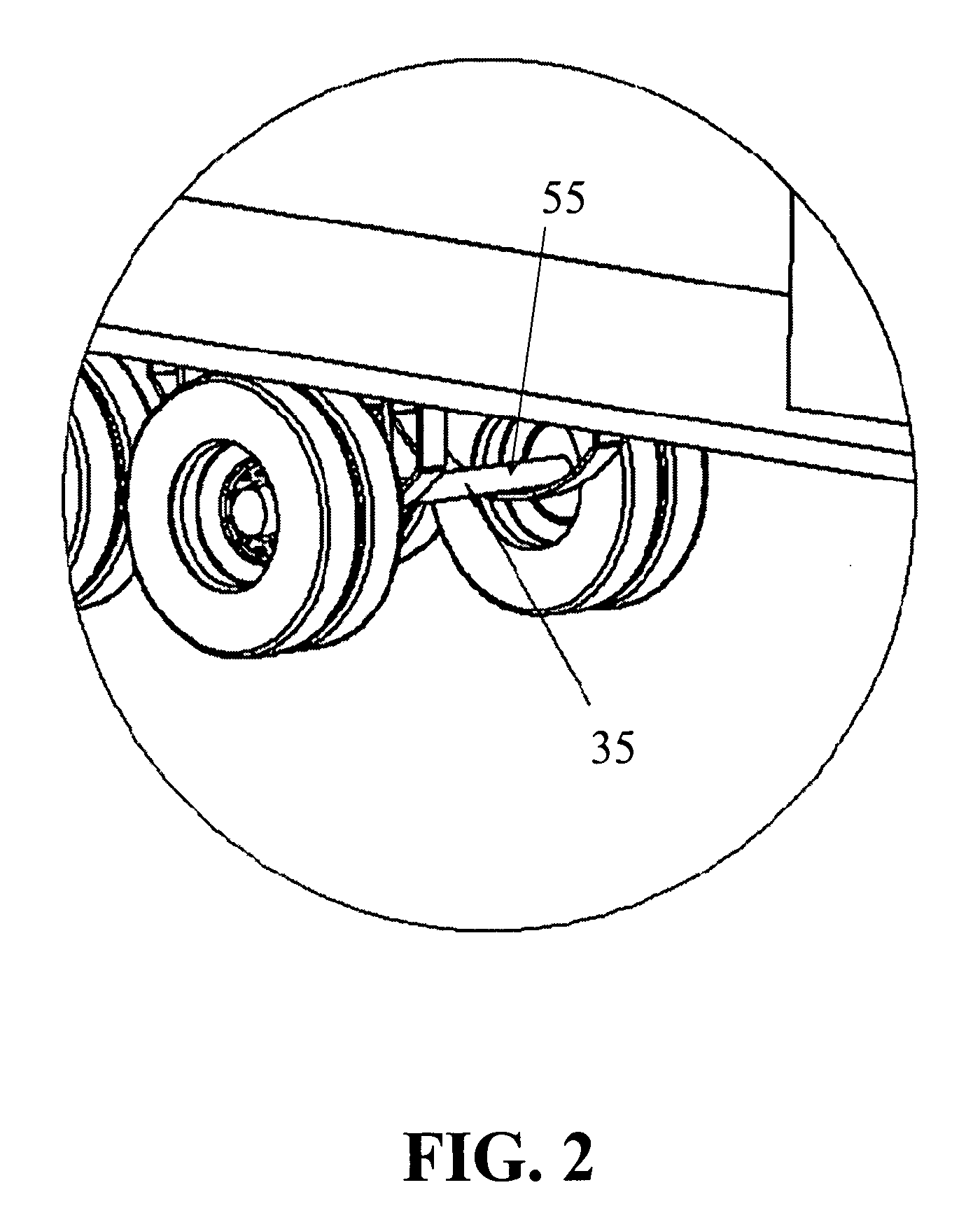

Axle weight distribution system

InactiveUS6921100B2Improve securityConvertible cyclesOptical signallingCommunication interfaceDisplay device

The present invention relates to a system for adjusting weight distribution throughout all axle groups of the truck and trailer. The trailer has at least one axle group mounted on a pair of rails attached to the frame of the trailer. These axle groups are locked in position on the rails by locking pins. The system for adjusting weight distribution according to the present invention measures the weight on every axle group on the truck and trailer. The measurement may be of weight directly by load cells etc. or indirectly, by taking measurements from the air suspension system to calculate weight. The measurements are delivered as an electrical signal to one or more microprocessors capable of receiving the electrical signals and calculating the optimum position of the axle group on the trailer. The position of the trailer axle groups relative to the rails is also determined and the position delivered to the microprocessor(s). The microprocessor(s) is programmed to calculate the weight on each axle group and determine any change in position of the trailer axle group(s) on the rails to optimize the weight distribution. The information is presented to the driver on a display located in the cab of the truck. The system further includes apparatus to lock and unlock the locking pins that lock the trailer axle group(s) in position on the rails. The system also includes a communication interface between the truck and the trailer.

Owner:WHEEL MONITOR

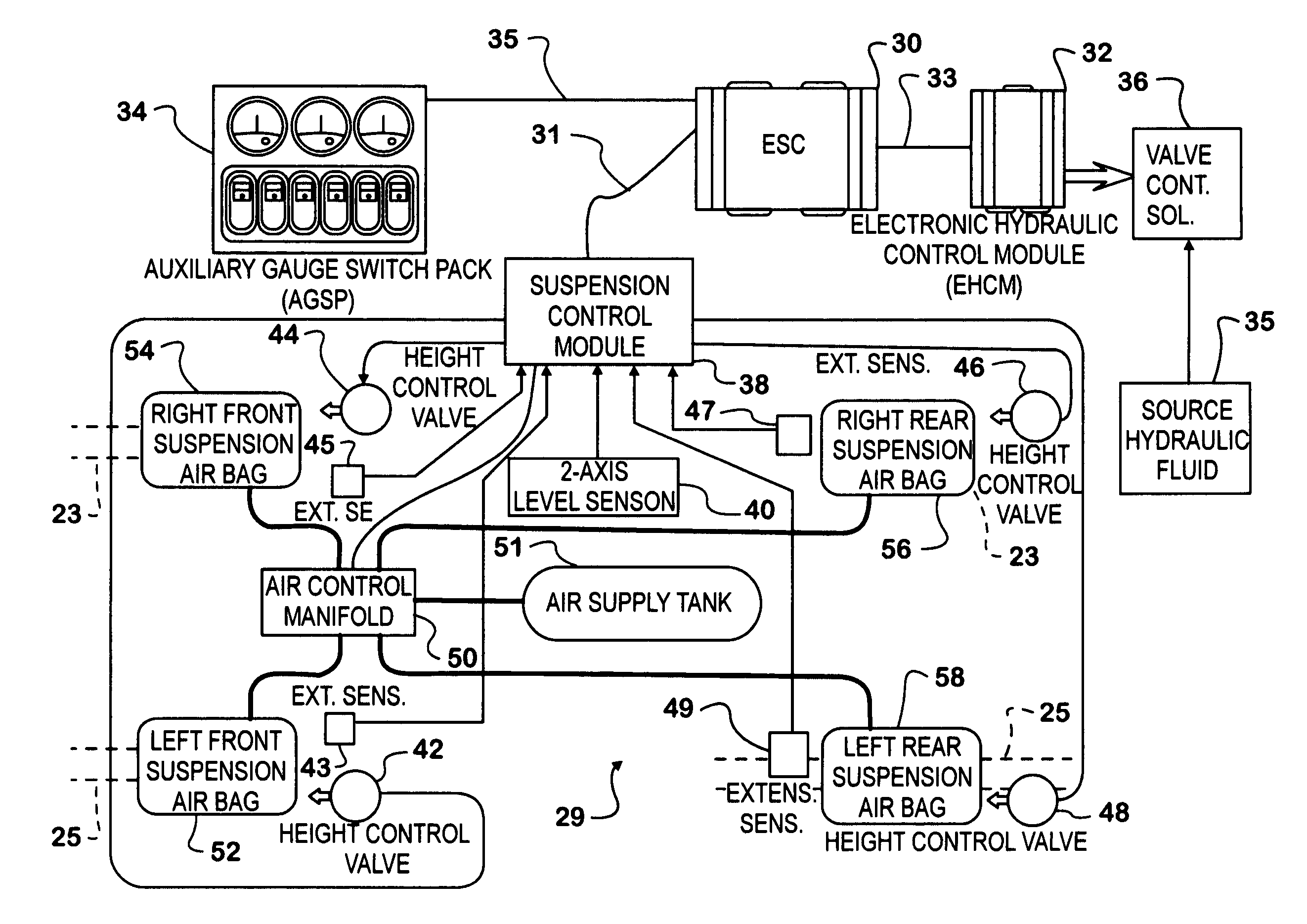

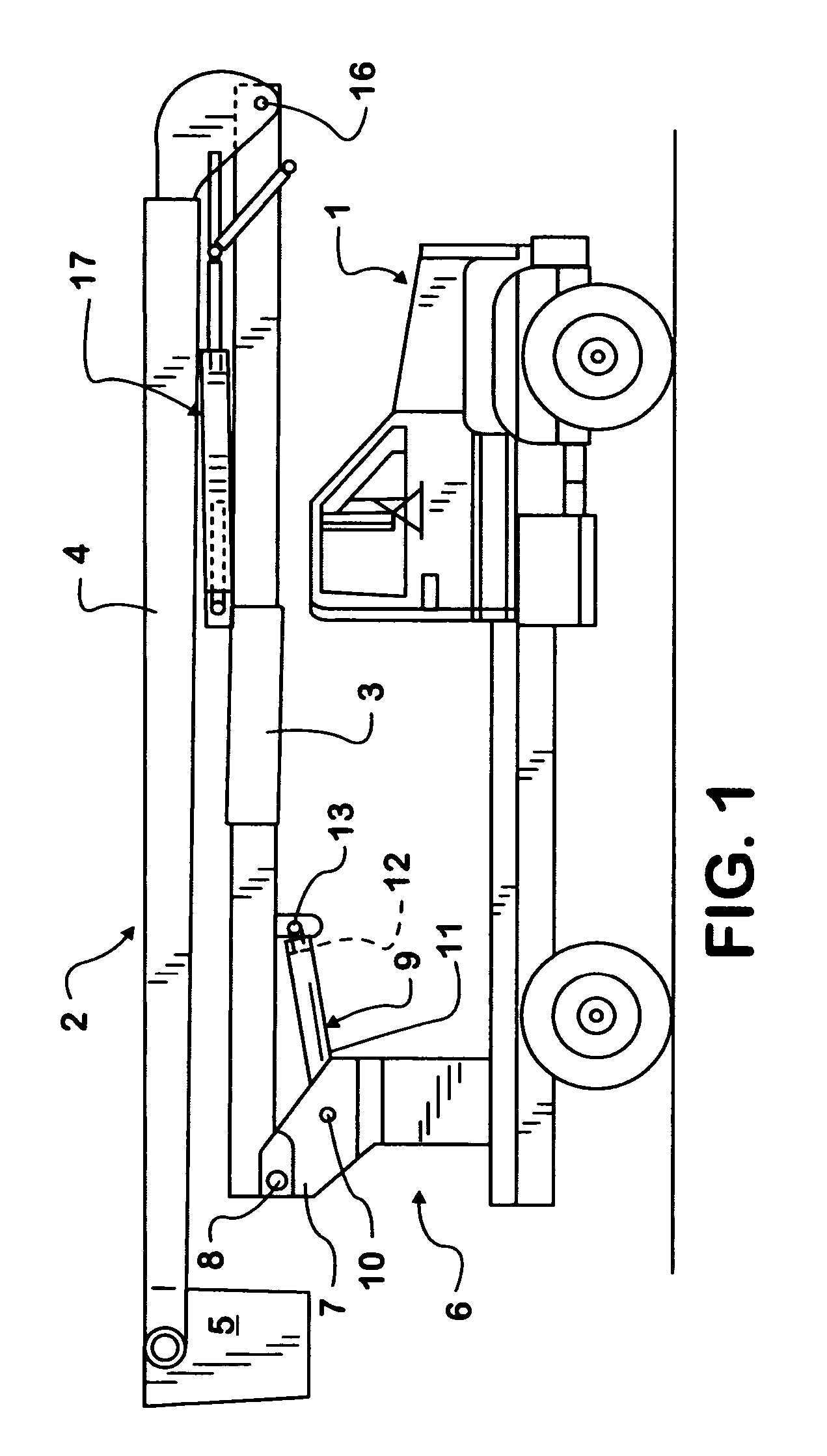

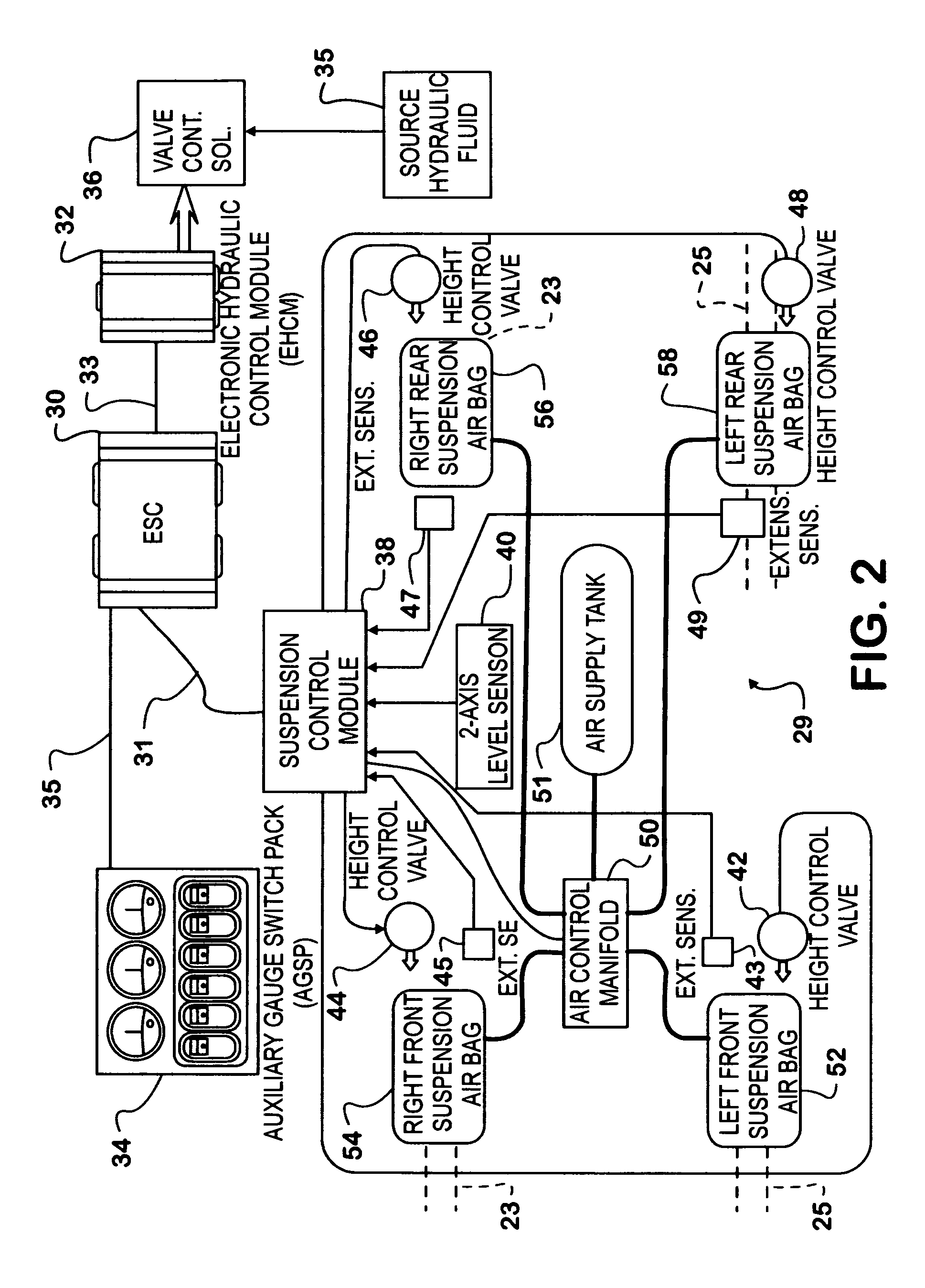

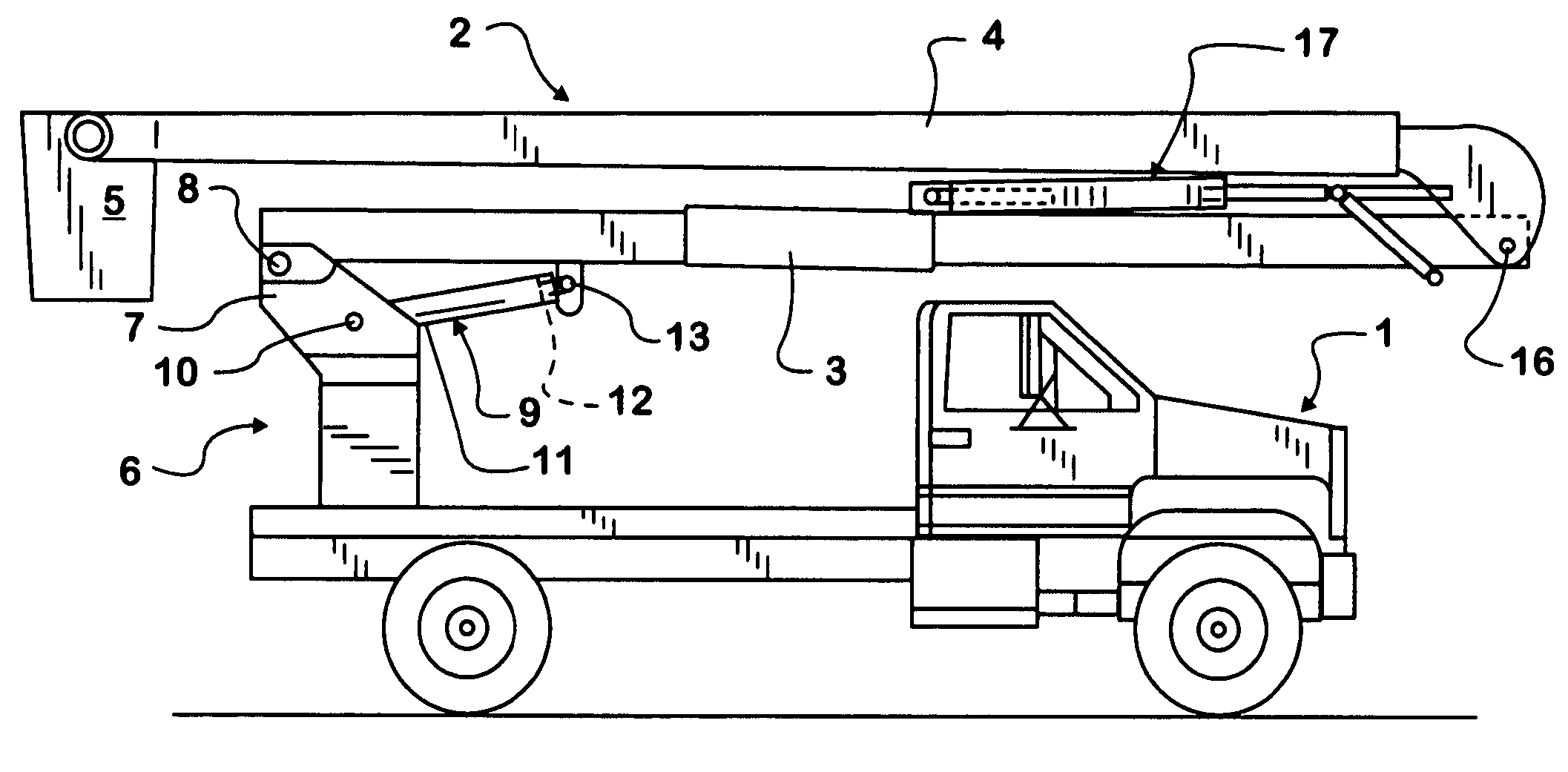

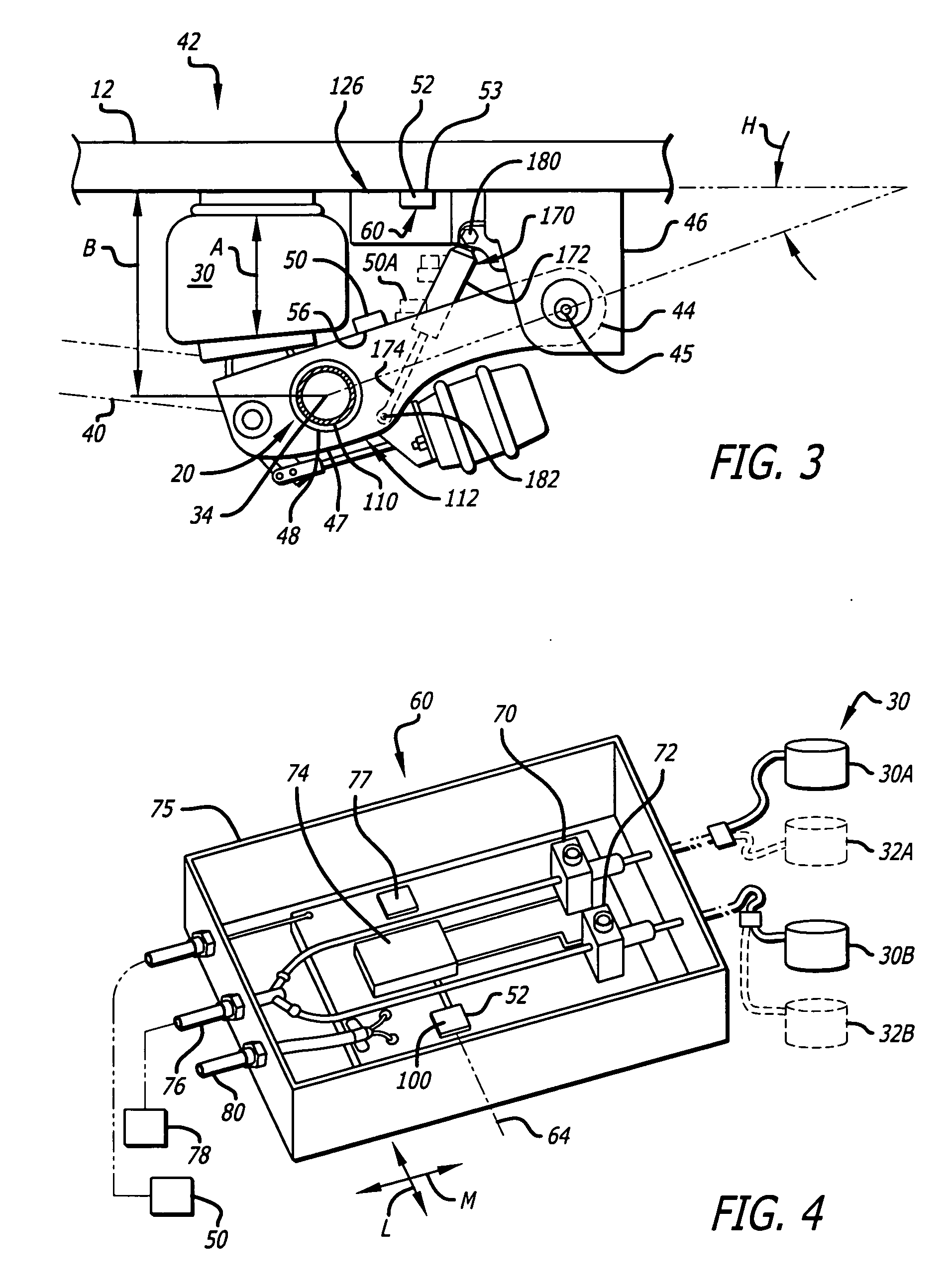

Pneumatic vehicle stabilization system

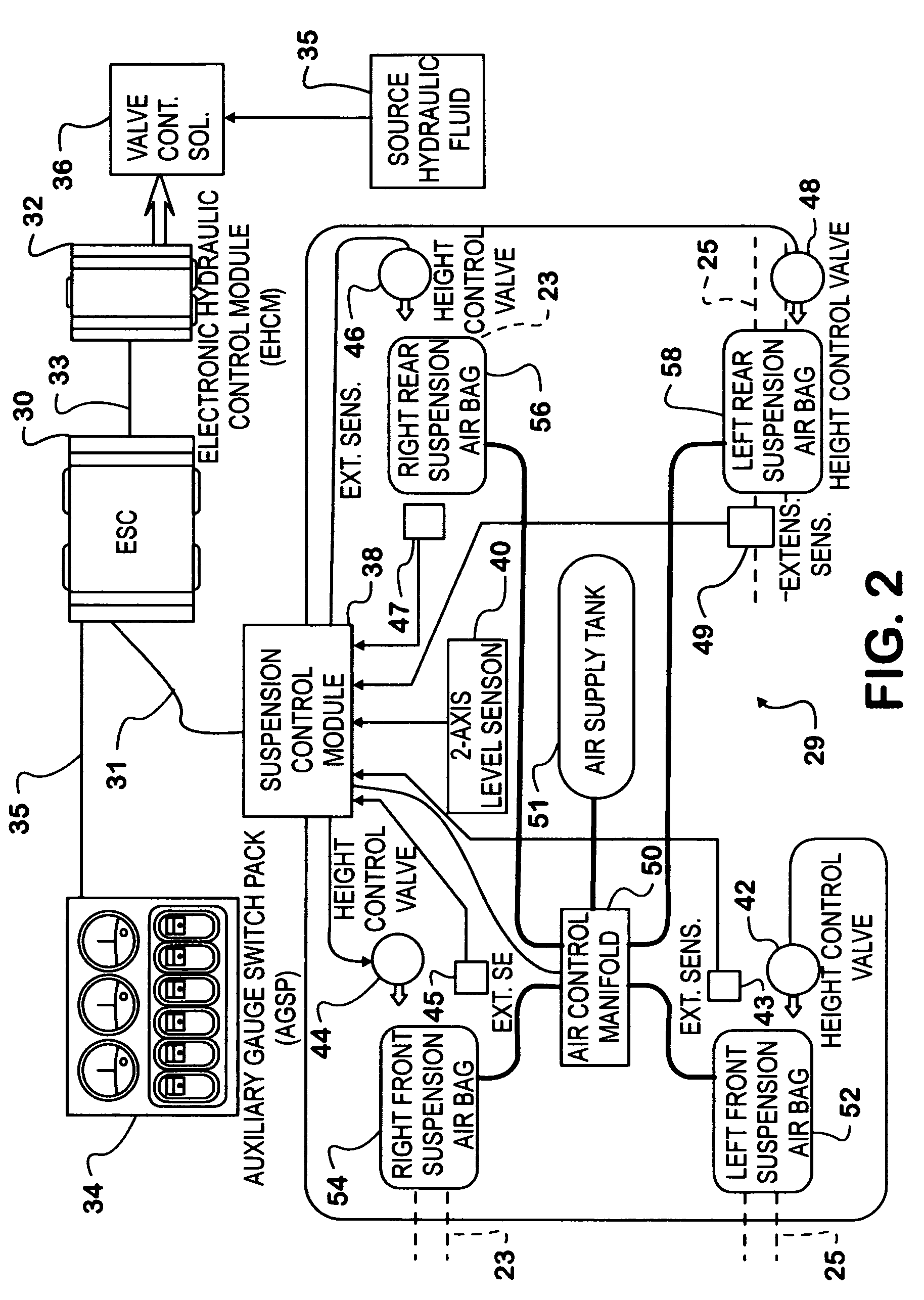

ActiveUS20070158920A1Best possible stabilityImprove stabilityAuxillary drivesVehicle body stabilisationControl systemEngineering

An electronic height control system for a vehicle chassis air suspension is modified to provide bimodal operation. In the second mode of operation the chassis air suspension system is maintain a stationary in a stable, level position to serve as a base for a mobile aerial lift unit installed on the vehicle. Operation of the suspension system in its stabilization and leveling mode is triggered by activation of a vehicle power take-off unit (“PTO”) used to position the aerial lift unit.

Owner:INT TRUCK INTPROP LLC

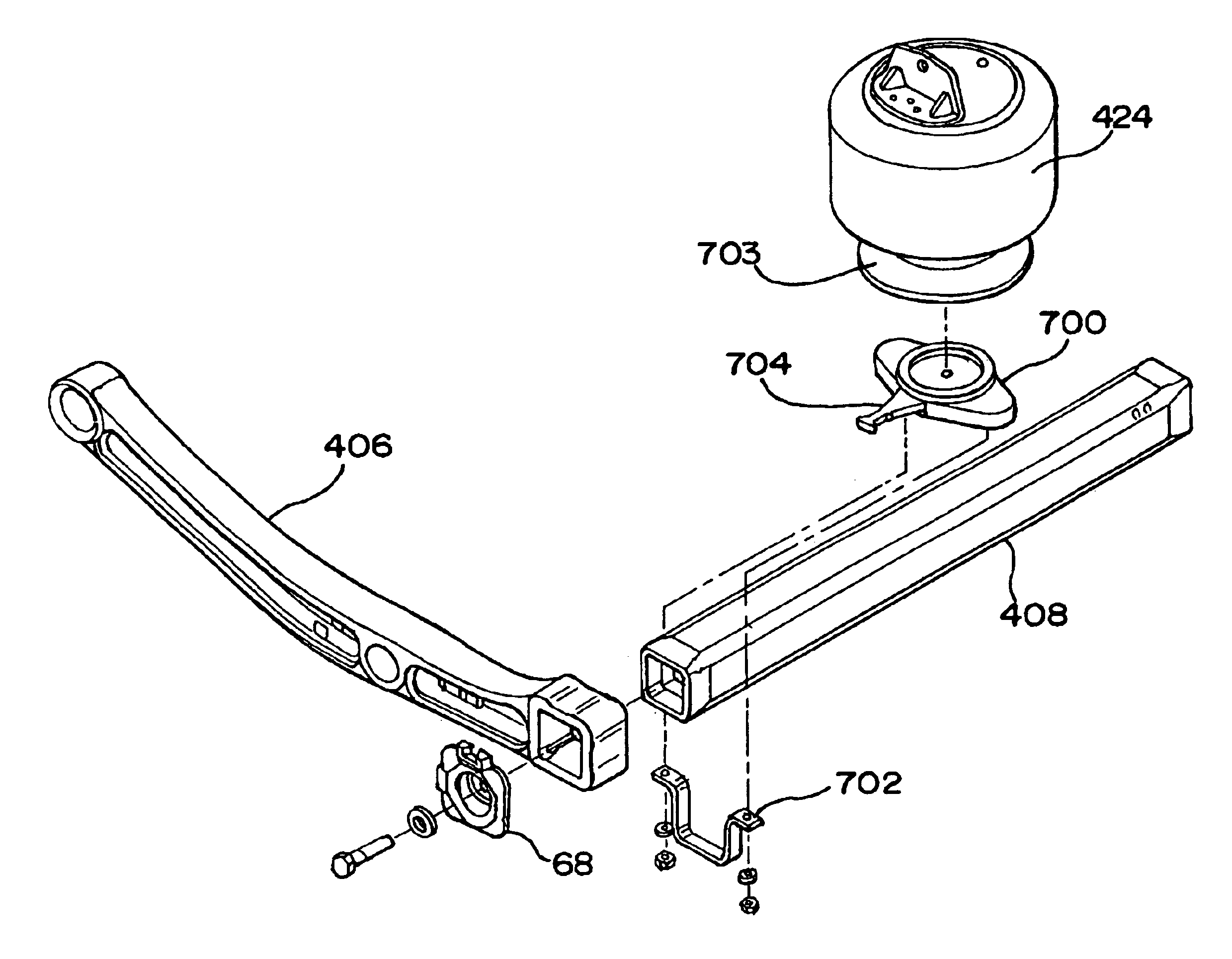

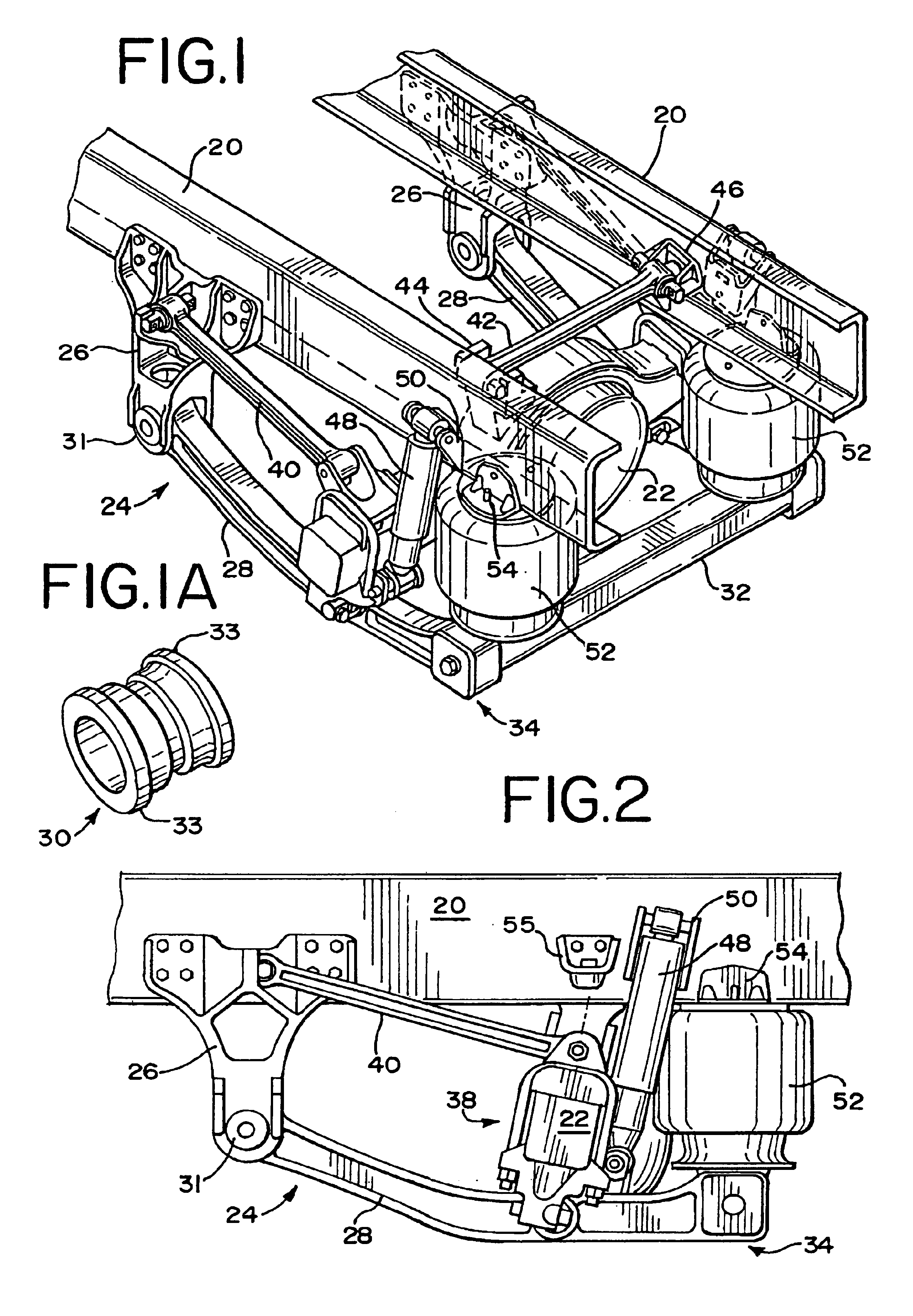

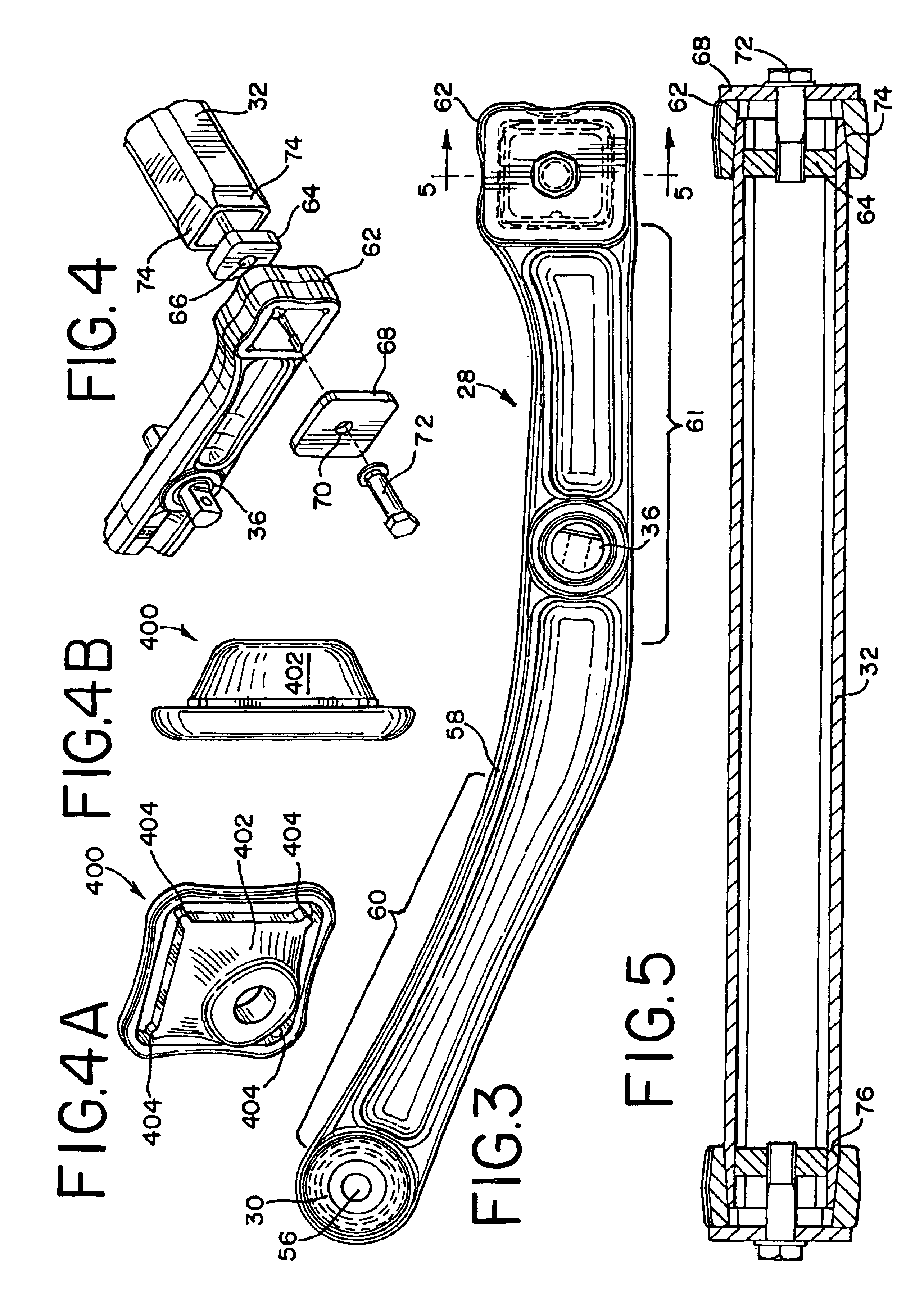

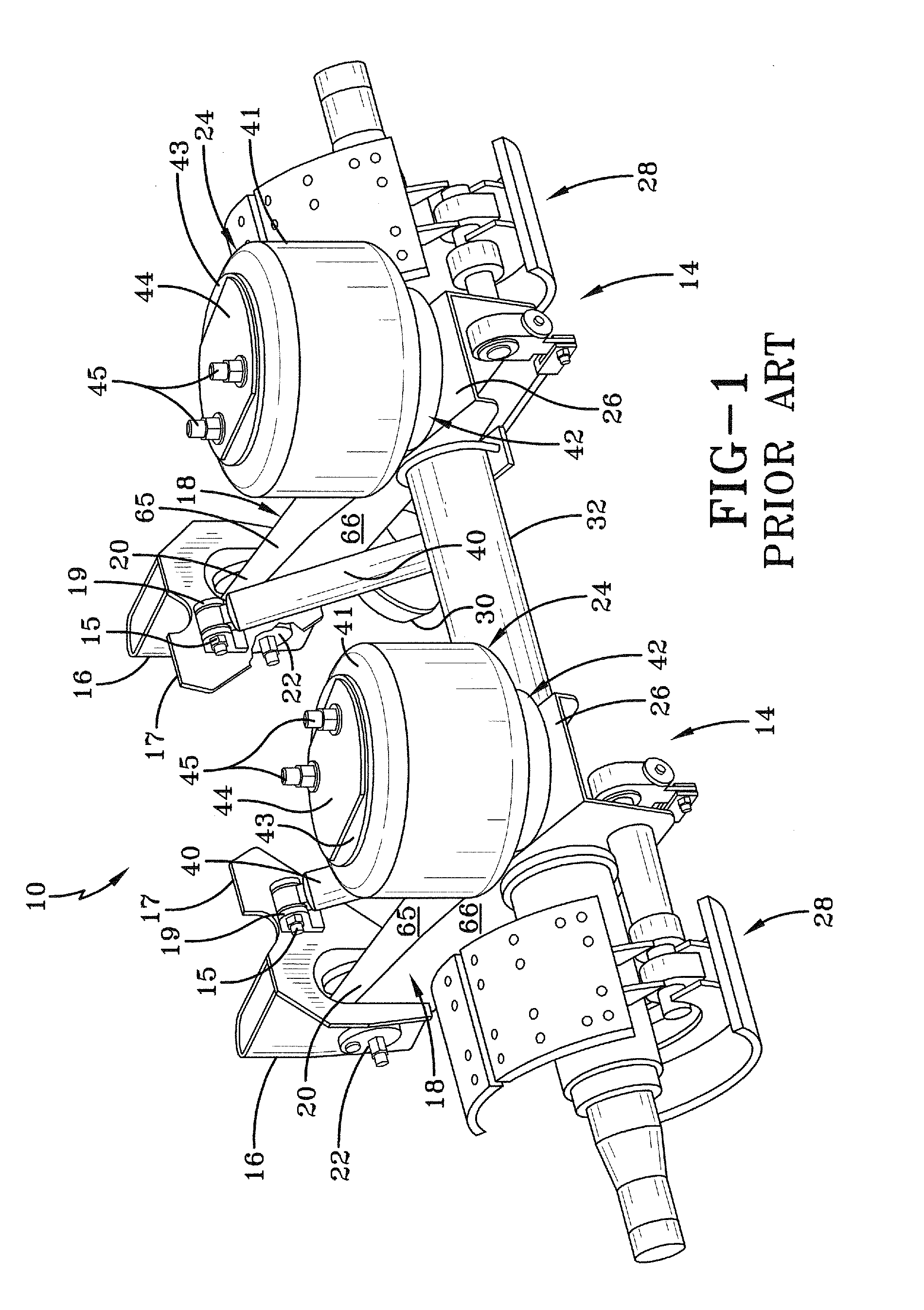

Air spring and air spring mounting assembly

InactiveUS6945548B2Easy to adjustImprove featuresRigid suspensionsLiquid springsVehicle frameAir spring

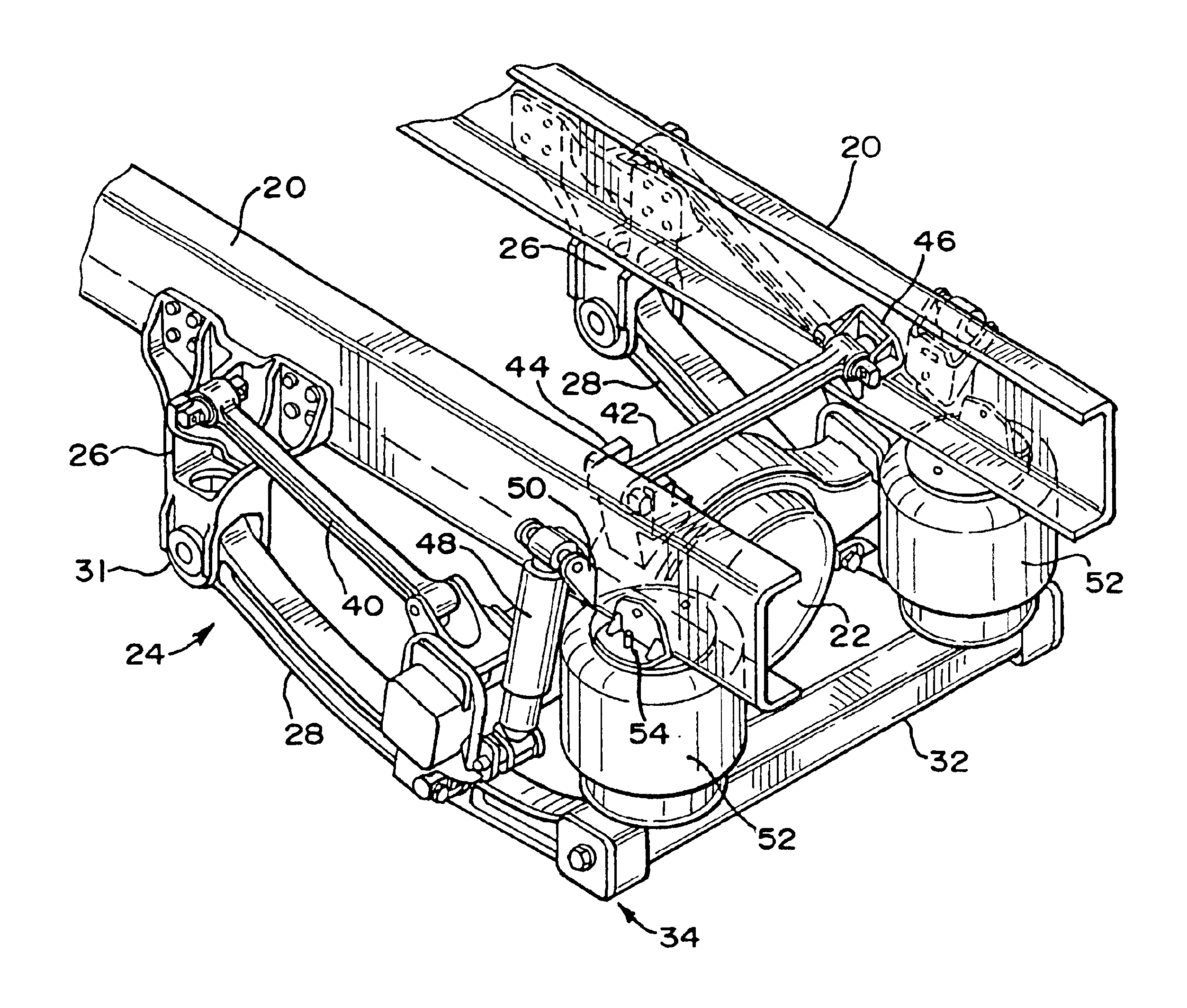

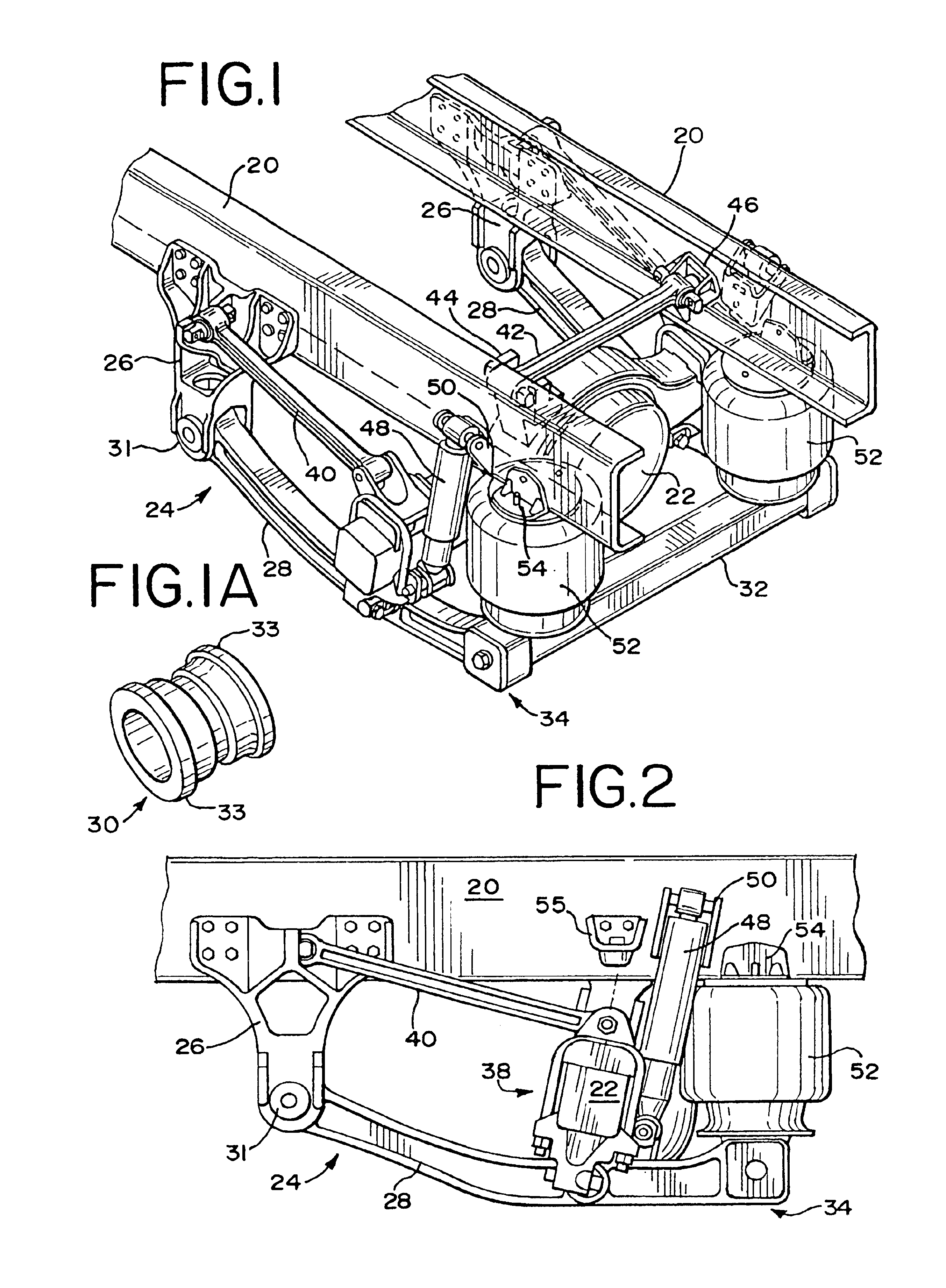

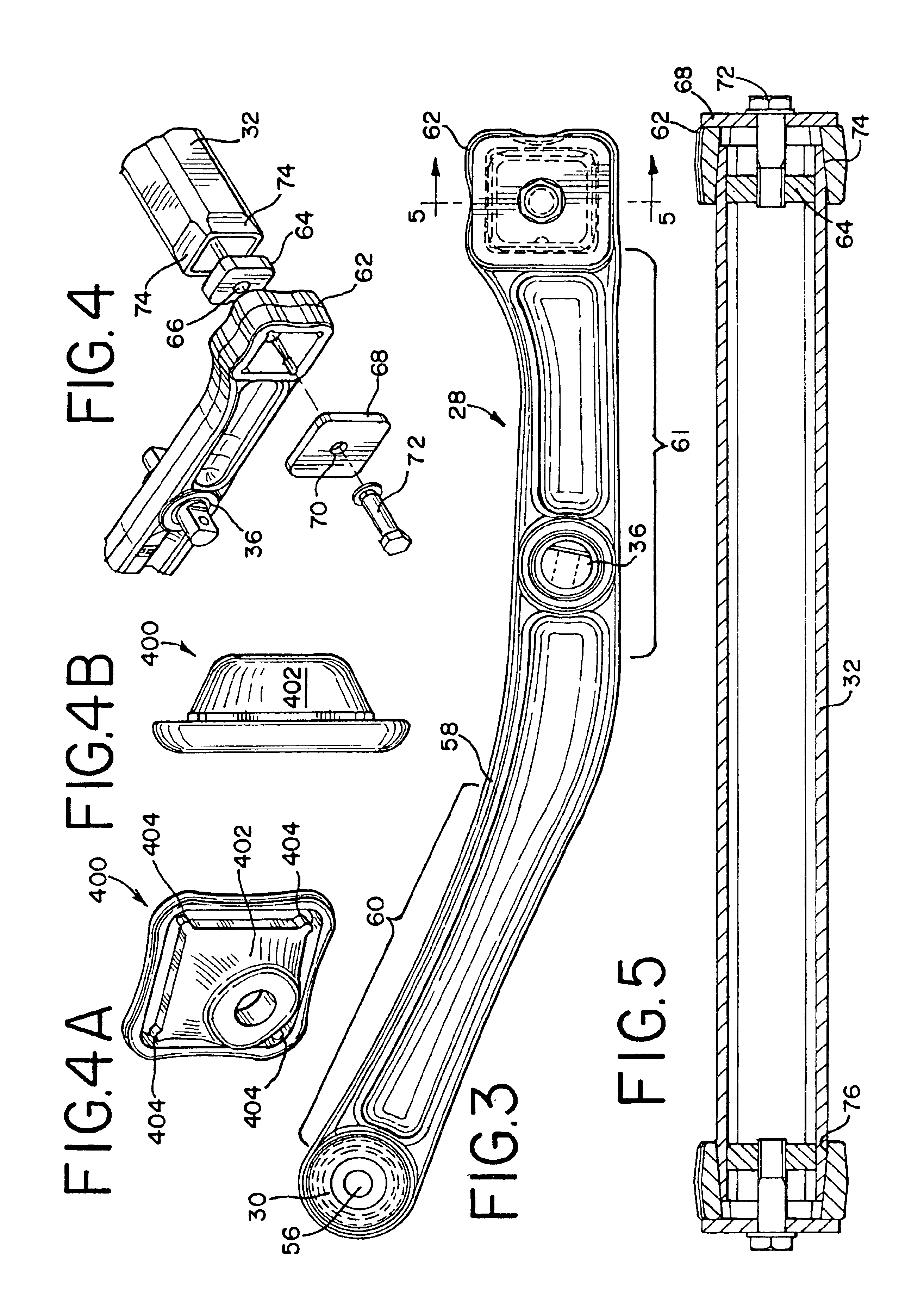

A non-torque reactive air suspension exhibiting excellent roll stability characteristics is shown to include frame hangers mounted to frame rails extending longitudinally on opposite sides of a vehicle. Longitudinally extending beams are connected to the frame hangers at one end and extend parallel to the frame rails. At their other ends, the beams are joined by a crossbrace extending laterally across the vehicle centerline. In a central portion thereof, the beams have an axle pivot bore to which an axle clamp assembly is connected, the axle clamp assembly clamping a drive axle housing for the vehicle. The axle pivot bore is generally aligned with the drive axle. A control rod assembly is connected to suspension or frame components. Together with the beams, the control rod assembly forms a parallelogram configuration wherein the beams form the lower linkages of that configuration and the control rods included within the control rod assembly form the upper linkages of that configuration.

Owner:THE BOLER

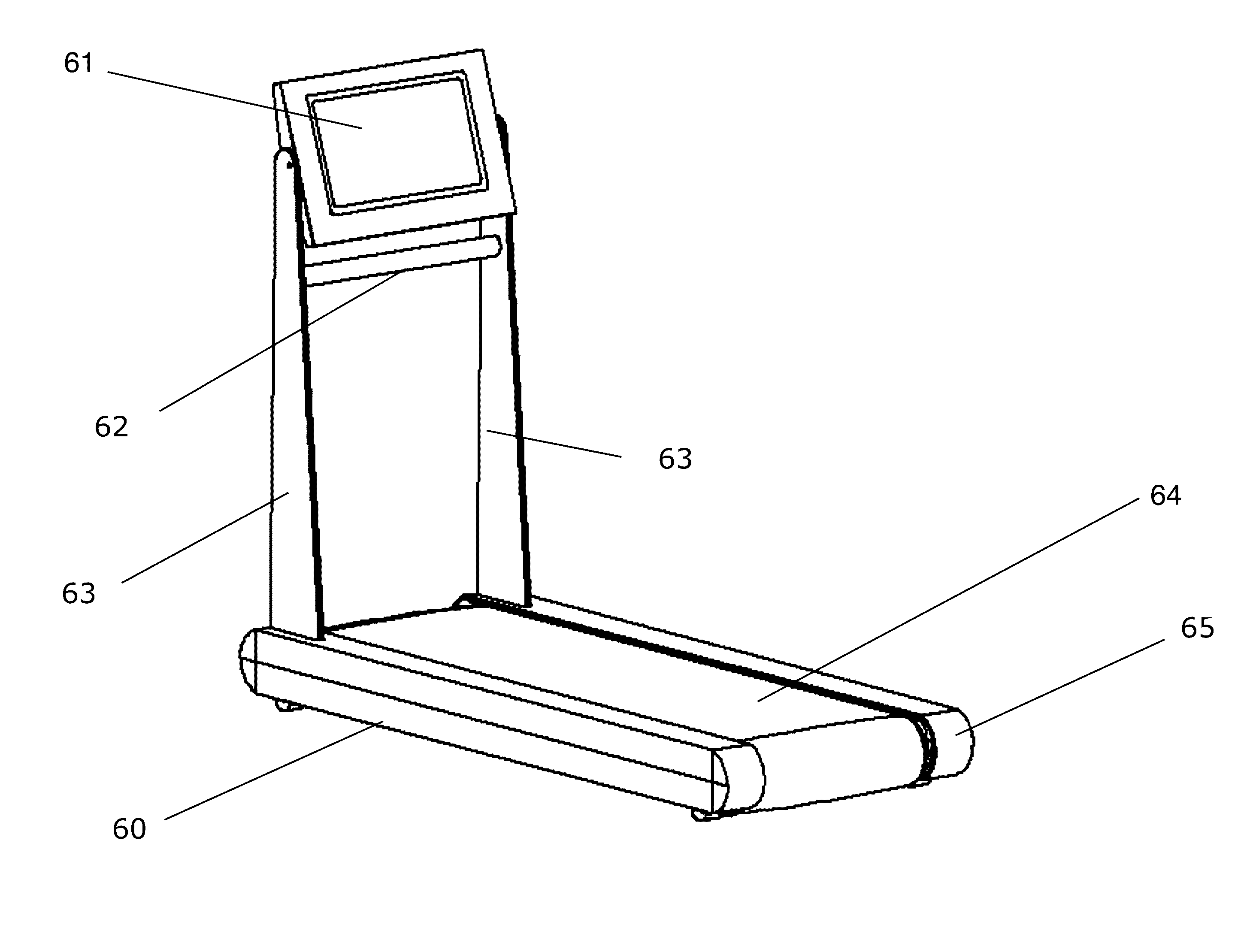

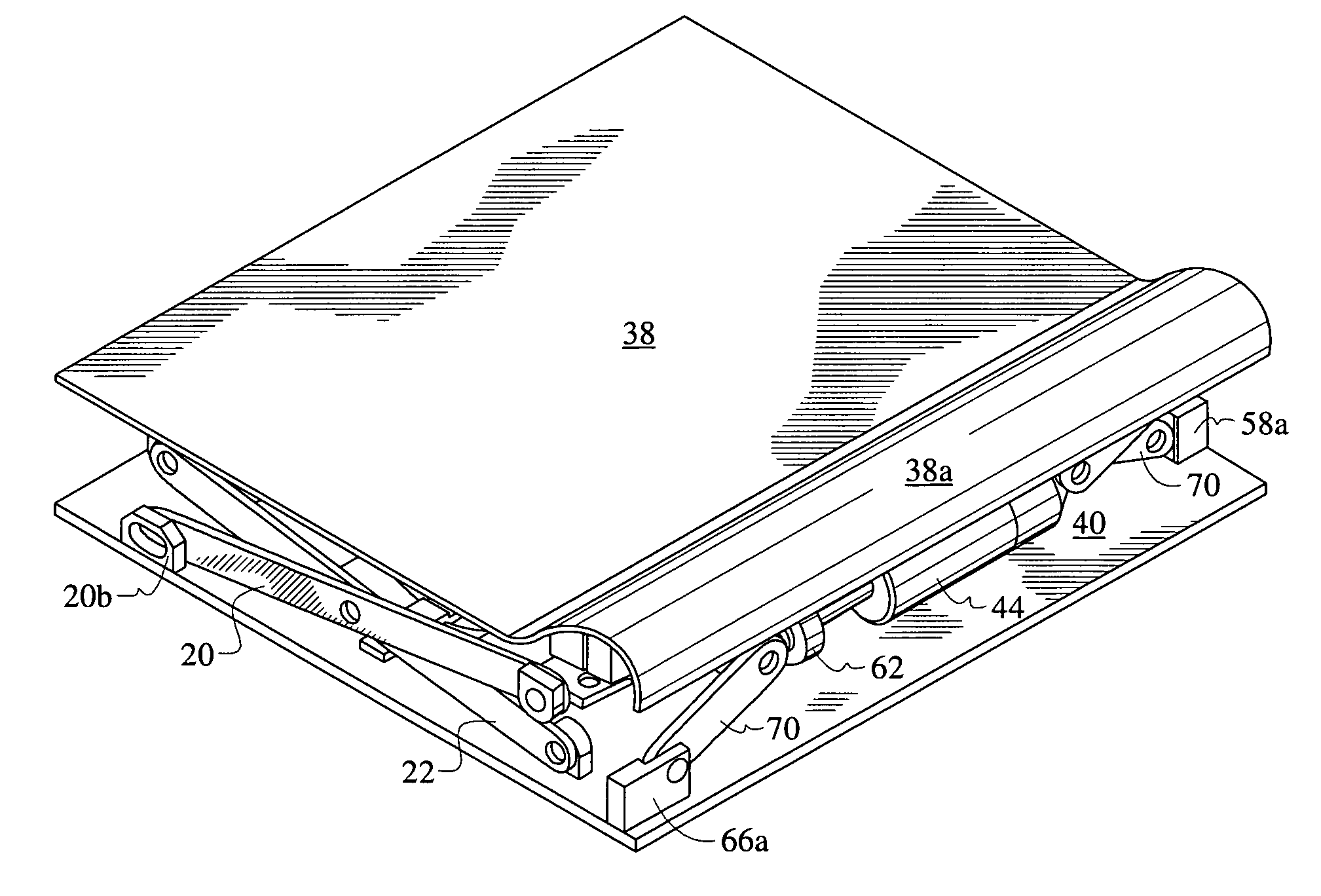

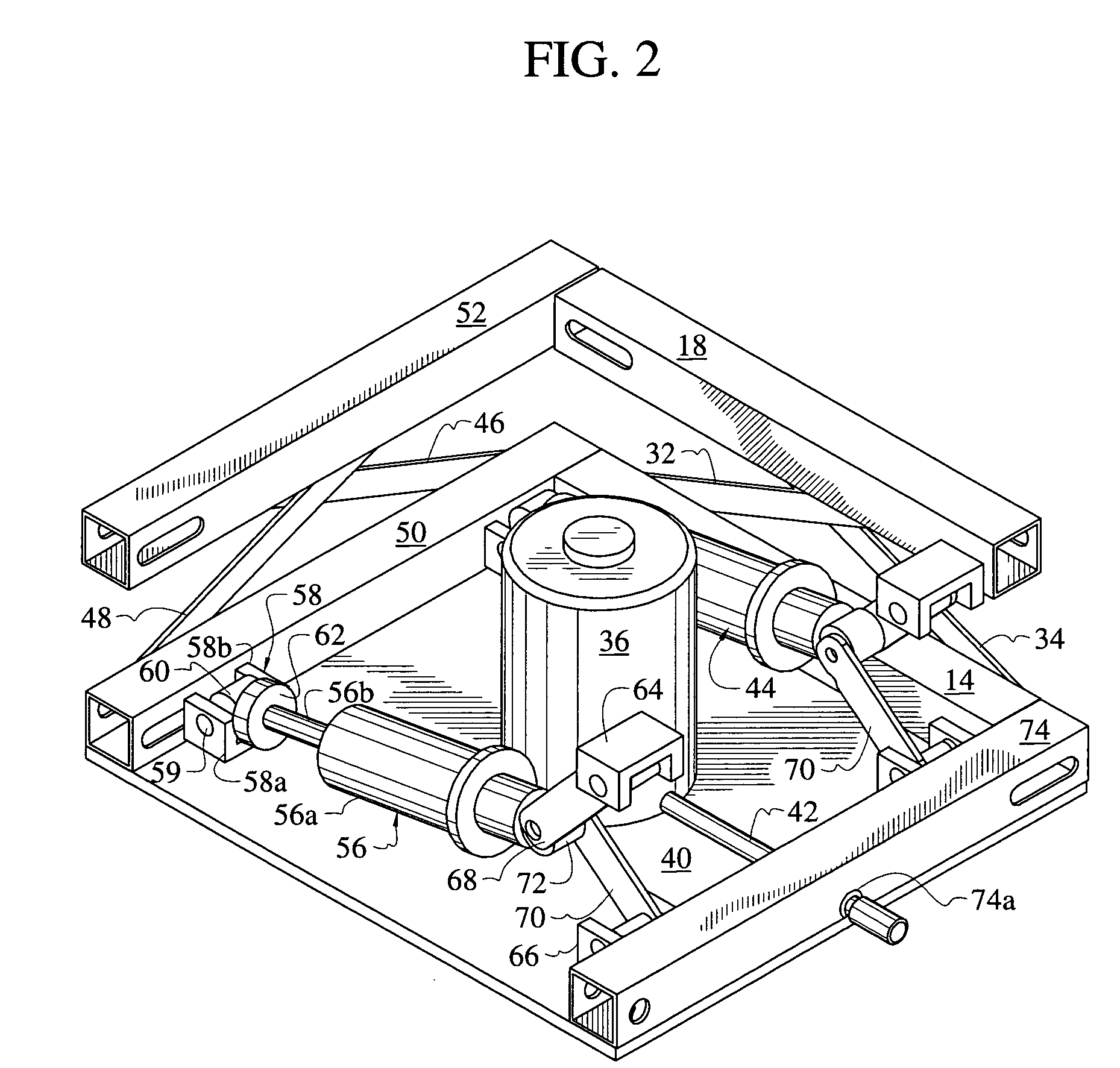

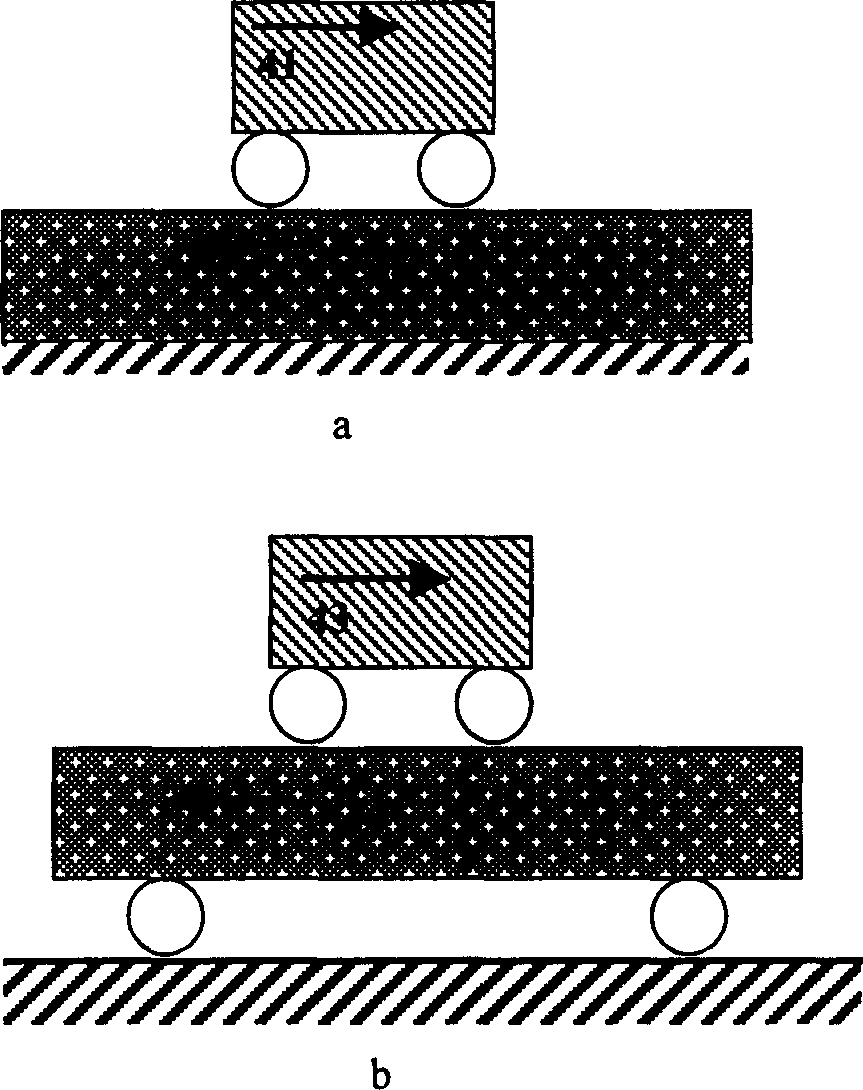

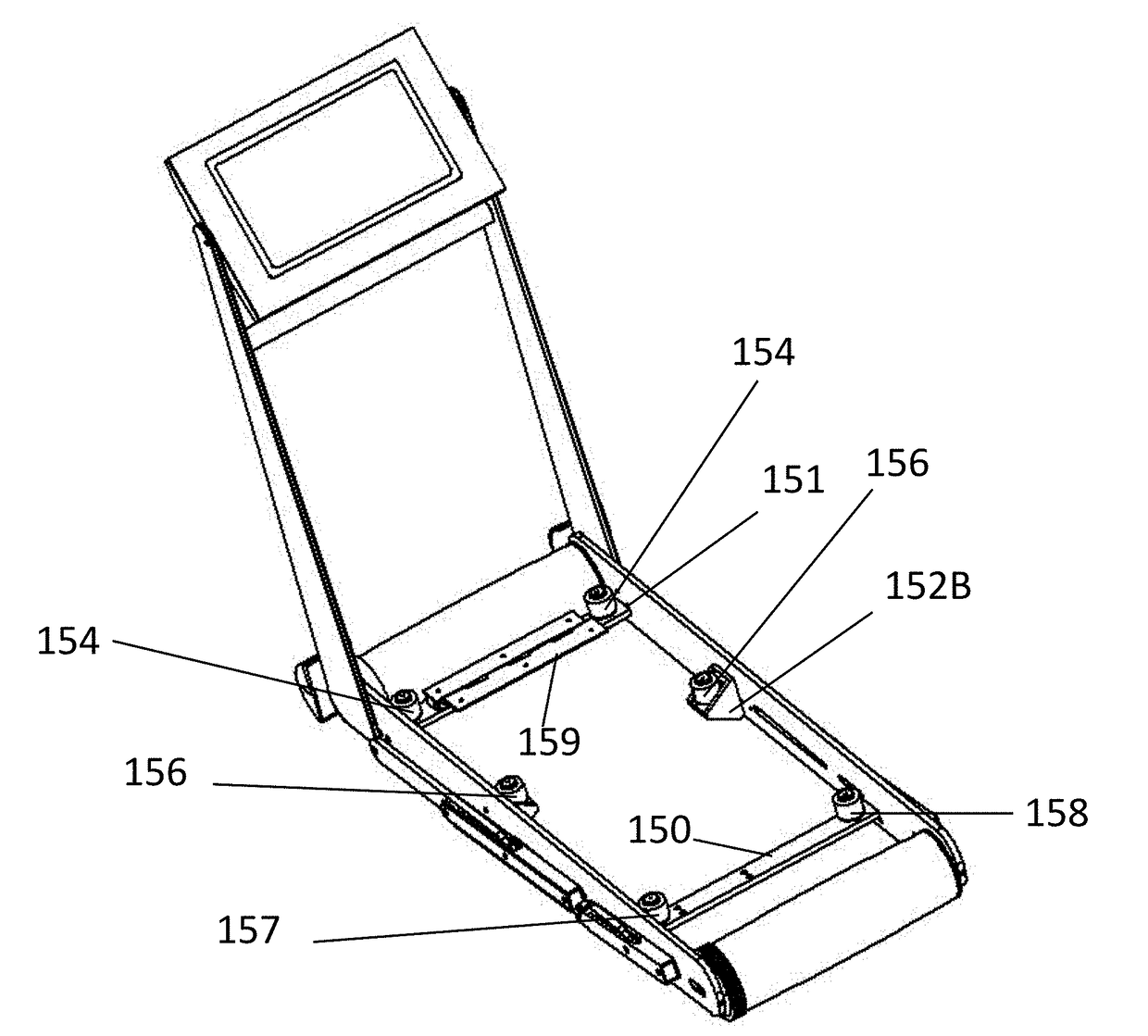

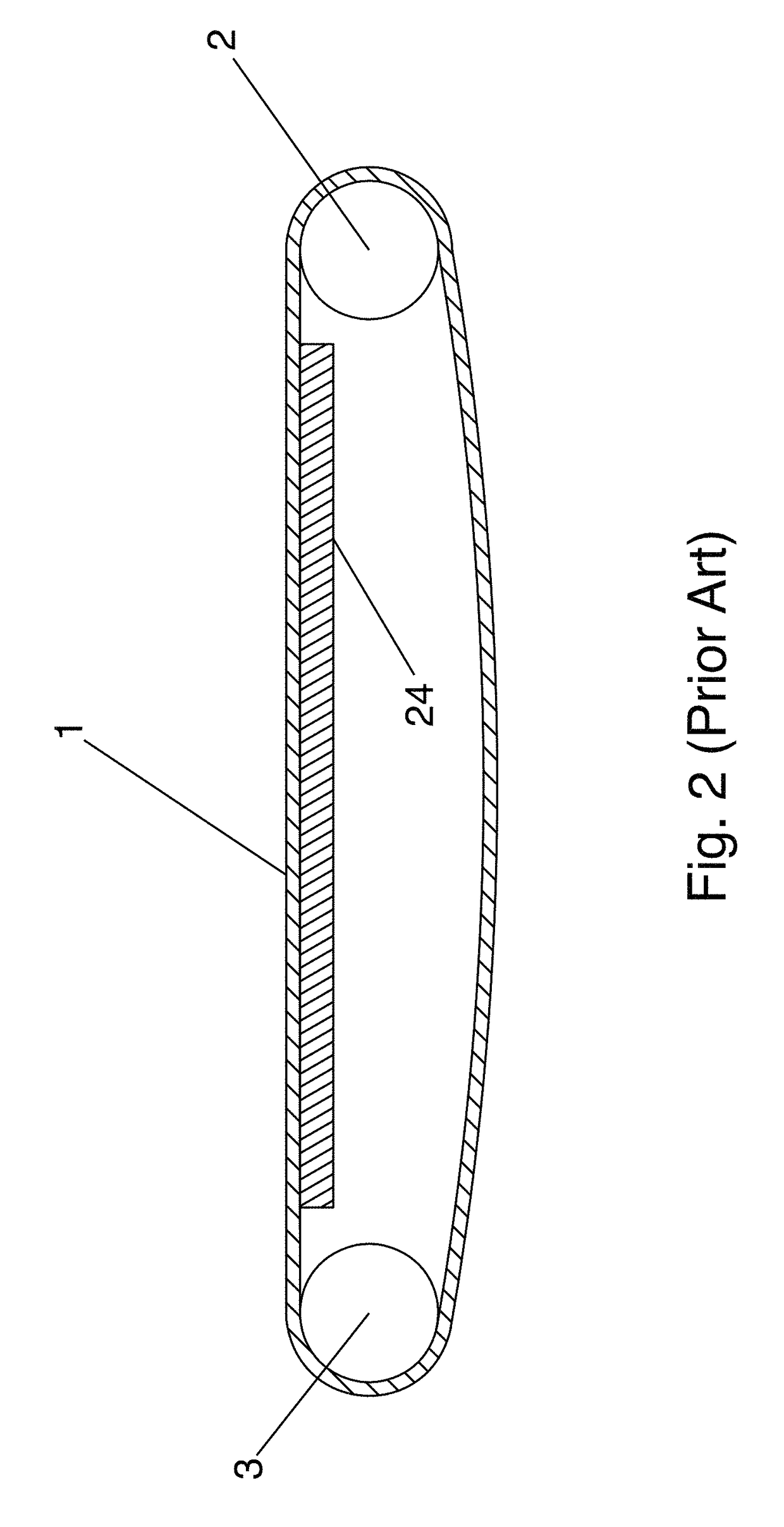

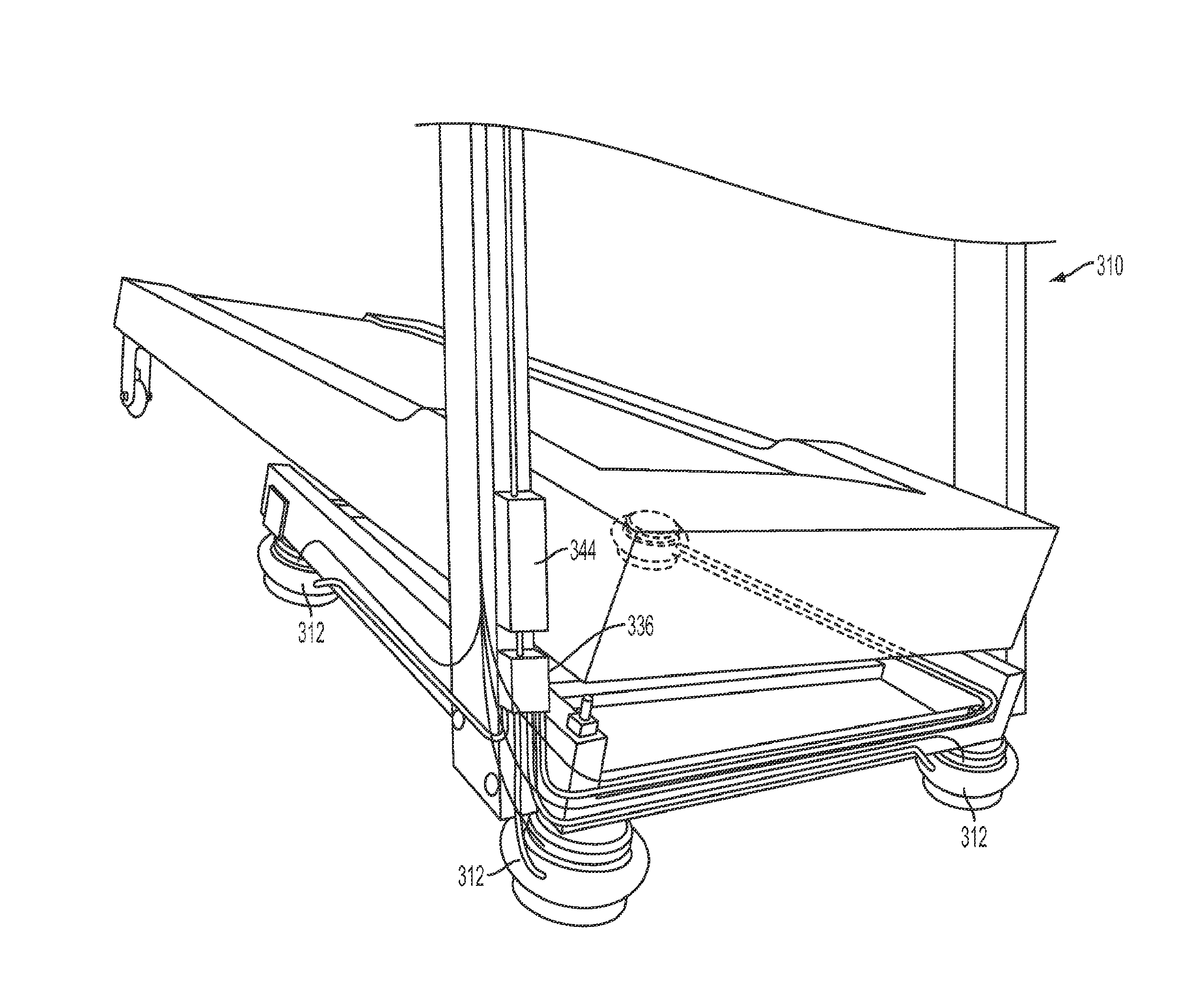

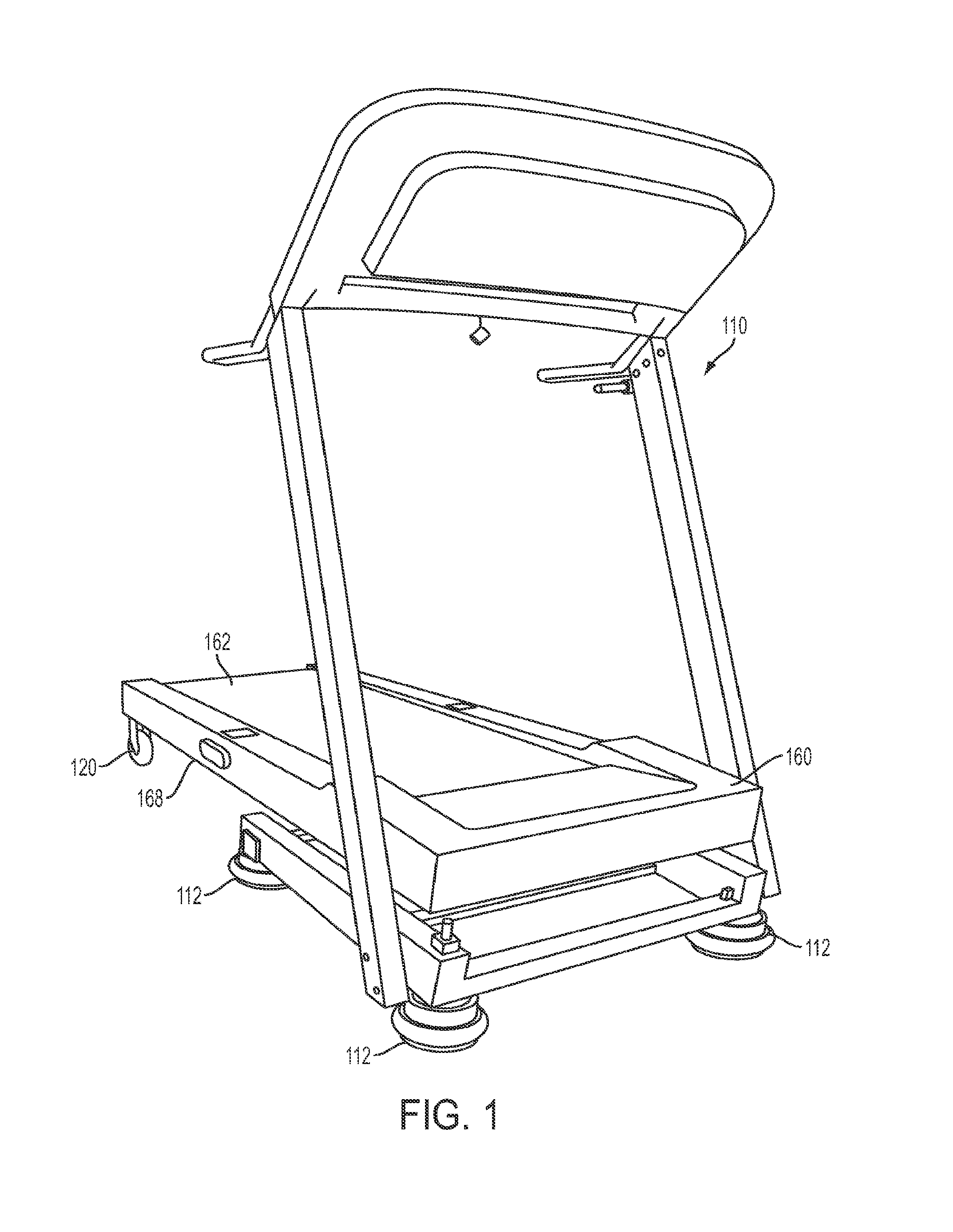

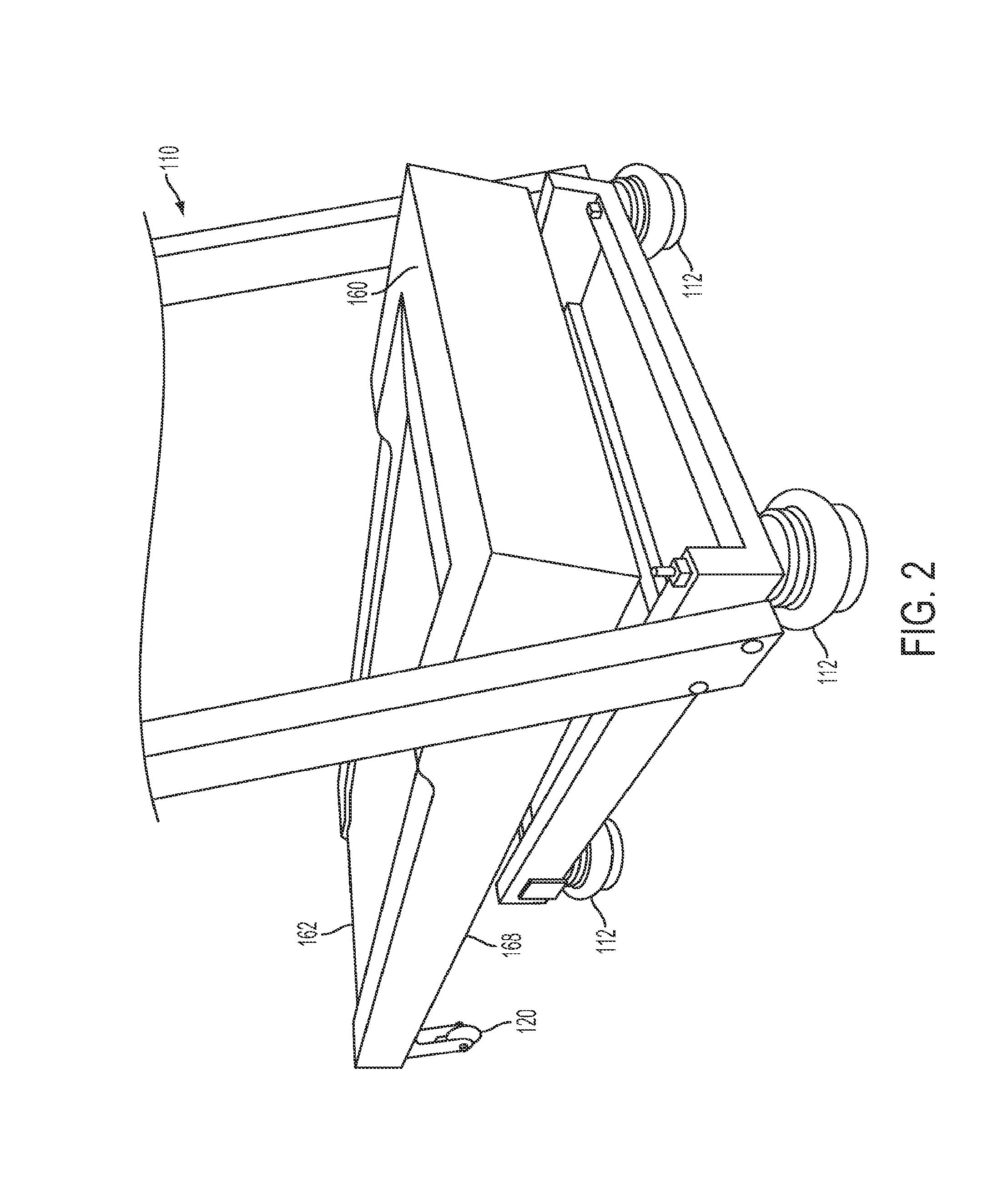

Treadmill

A computerized treadmill is provided. The treadmill deck may be fully suspended by a plurality of air suspension elements, such as bellows. The bellows may be pressurized by a computer-controlled compressor feeding a central air reservoir to which each bellows is connected via air hose. The bellows may be dampened to control expansion. A double hinge connecting the deck with frame may control lateral movement and reduce lateral load on the bellows. Incline and decline mechanisms facilitate a variety of deck angles. Control of the treadmill may be by computer, whether integrated or modular, whether traditional, laptop, tablet or smart phone. Control of the treadmill and conveyance of information associated with treadmill operation may be integrated with computer or smart phone applications, whether dedicated or third party.

Owner:MOSER GEORGE

Shock absorbing platform with dampening means

A shock-absorbing platform includes a bottom plate and a top plate joined to one another along at least two sides by elongate rigid links that enable the plates to remain in parallel relation to one another as the plates are displaced responsive to externally-imparted forces. An air spring resists relative vertical motion between the bottom and top plates as external forces are applied to the platform. A shock-absorbing damper damps the natural oscillation of the air spring. The resistance presented by the air spring is adjustable through an inlet and outlet port in fluid communication with a remote source of air under pressure. In a second embodiment, a seat bottom includes arched leaf springs that supplant the air spring to increase the range of relative movement between the top and bottom plates and to lower the profile of the seat bottom.

Owner:BURER PETER J

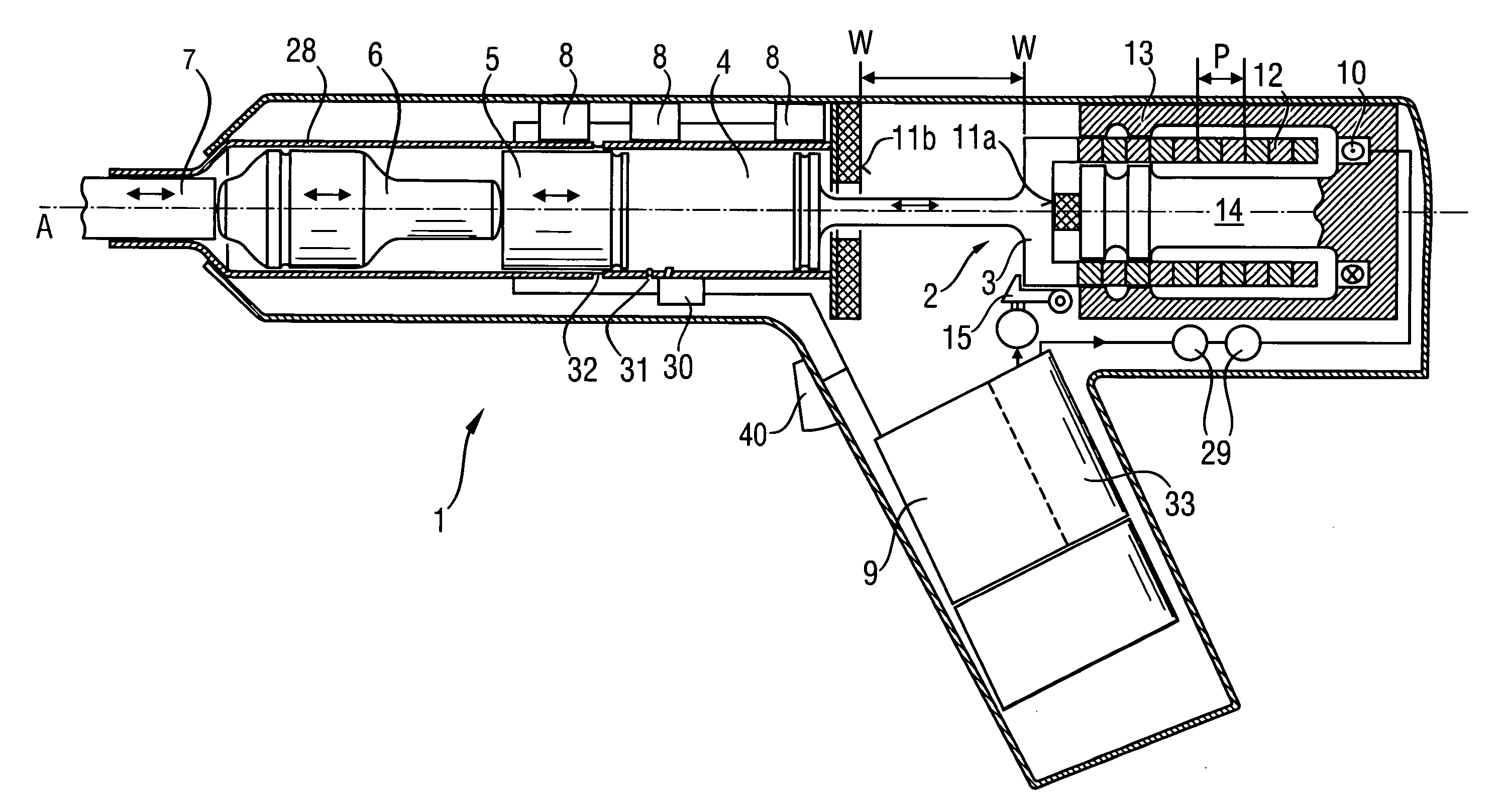

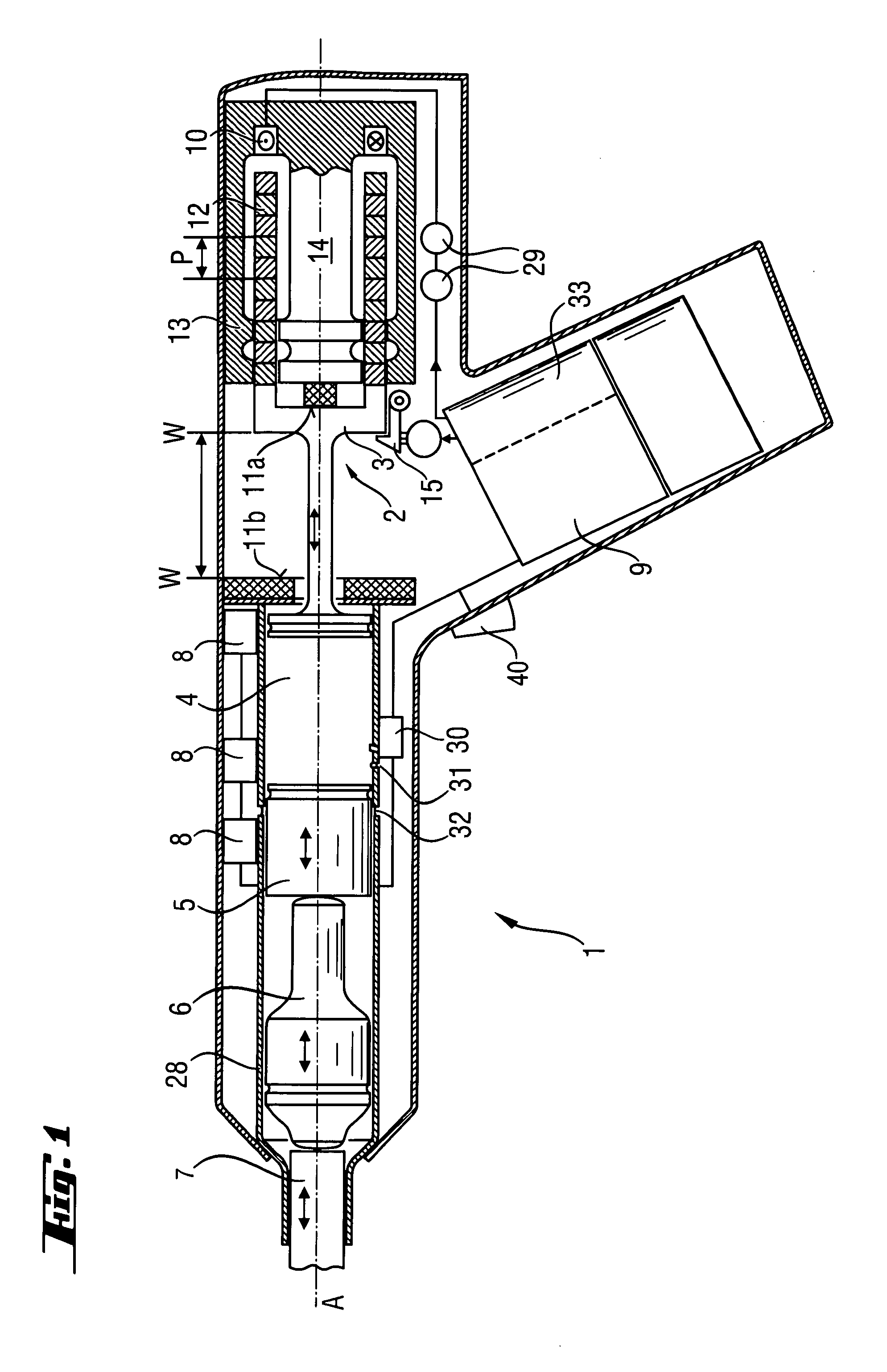

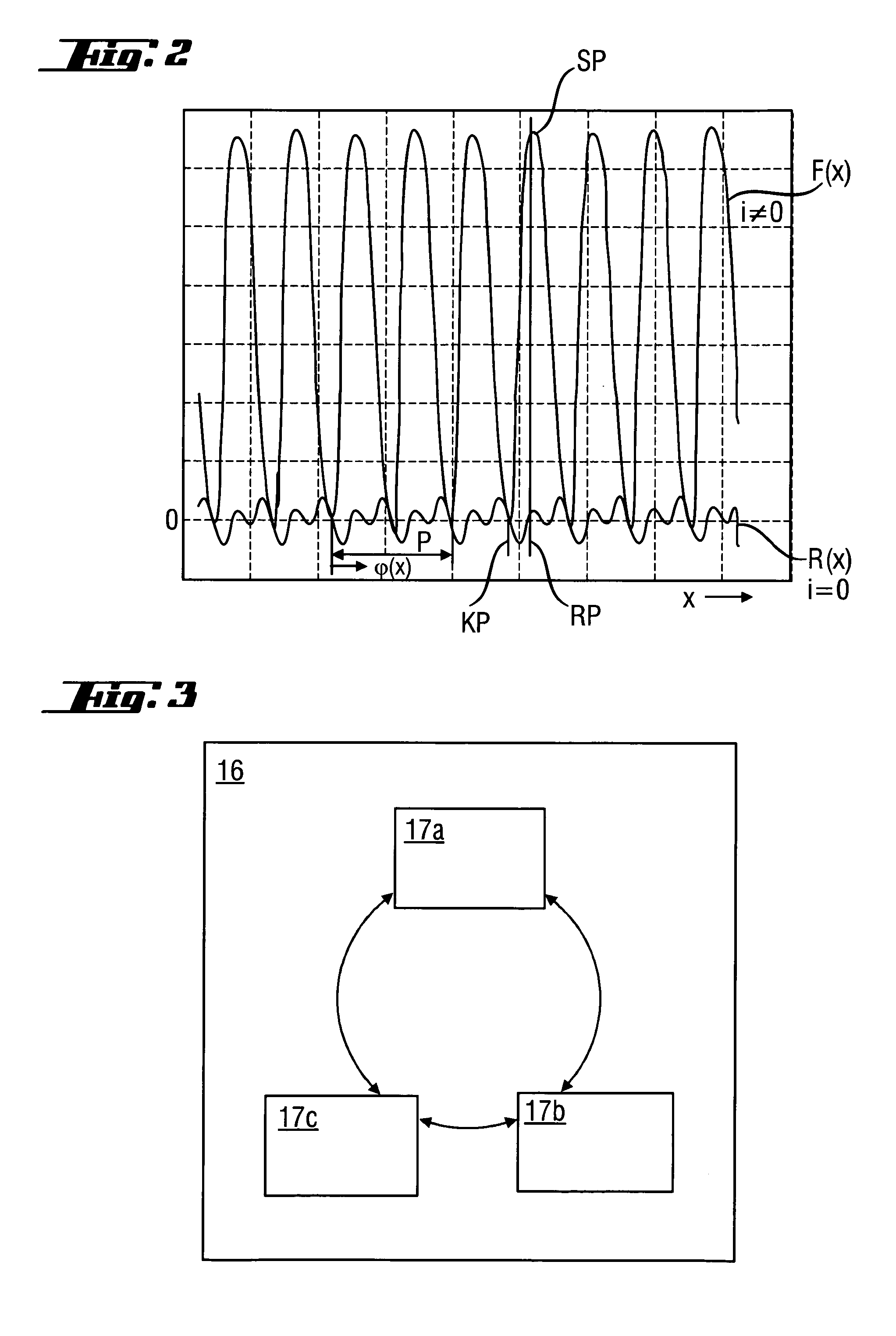

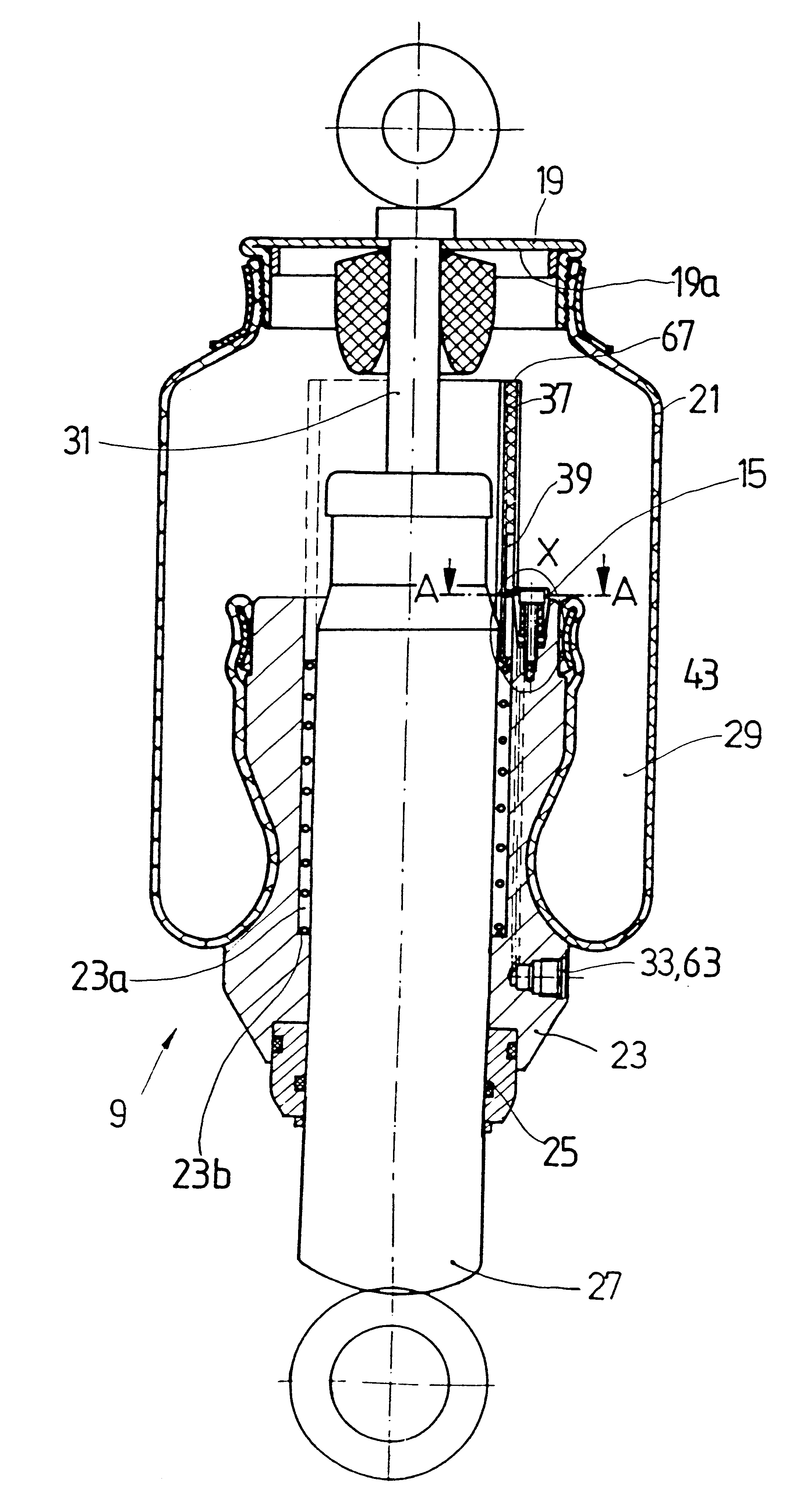

Hand-held power tool with air spring percussion mechanism, linear motor, and control process

ActiveUS20090065226A1Reduce dataHigh impact frequencyAssociation with control/drive circuitsAC motor controlAir springHand held

A hand-held power tool (1) includes a linear motor (2) having a rotor (3) which is movable along a percussion axis (A) in an axially limited manner between two reversal points (W) and which can be driven by the striking piston (5) of the power tool with the intermediary of an air spring (4), sensors designed for determining the actual state of the rotor (3) and connected to a computer (9) connected via power electronics (33) to at least one field coil (10) of the linear motor (2), with the rotor (3) being displaced against a contact element (11a, 11b) at least at one reversal point (W) and being pressed against the contact element electromagnetically; and a control process for the hand-held power tool.

Owner:HILTI AG

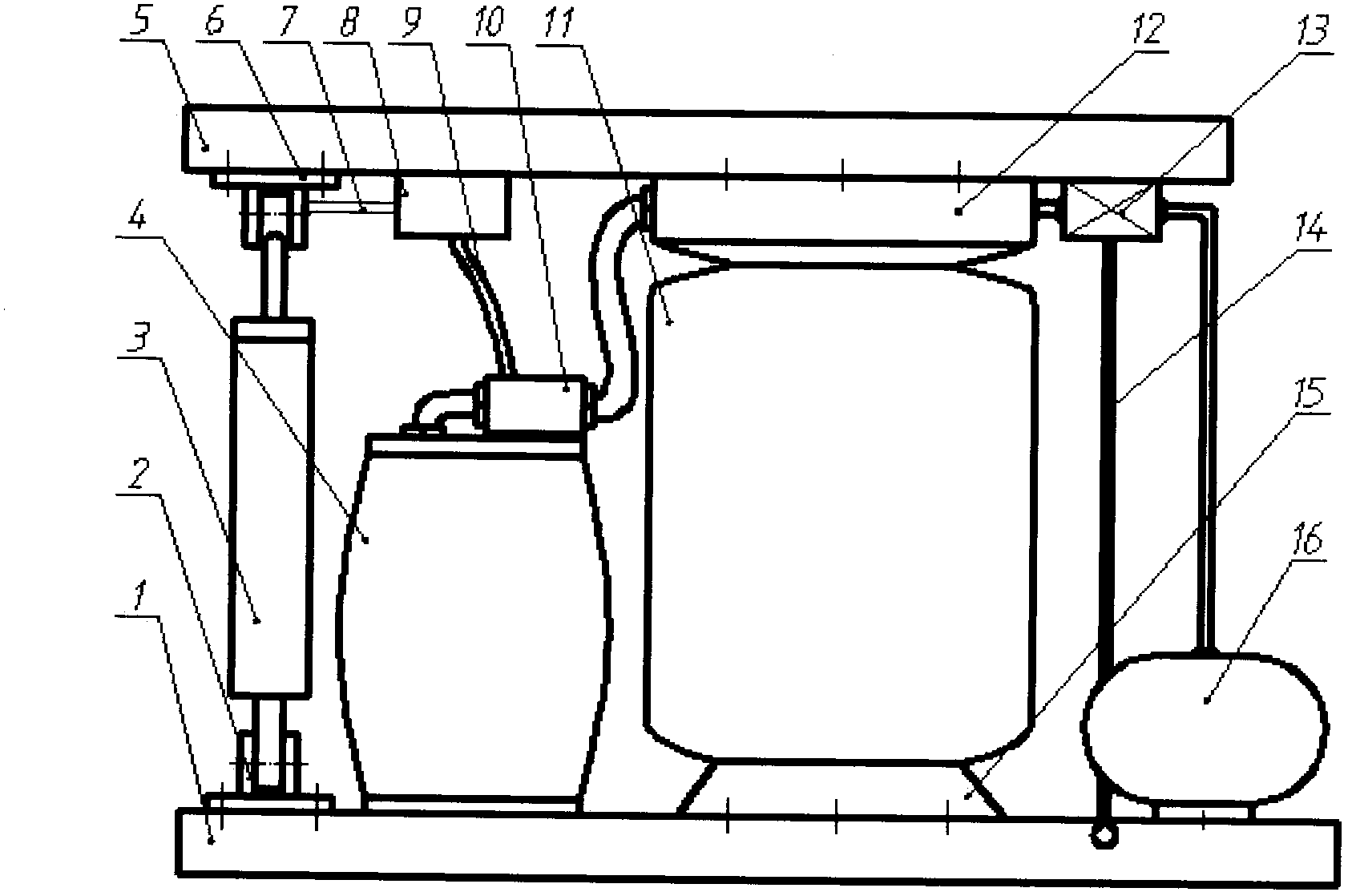

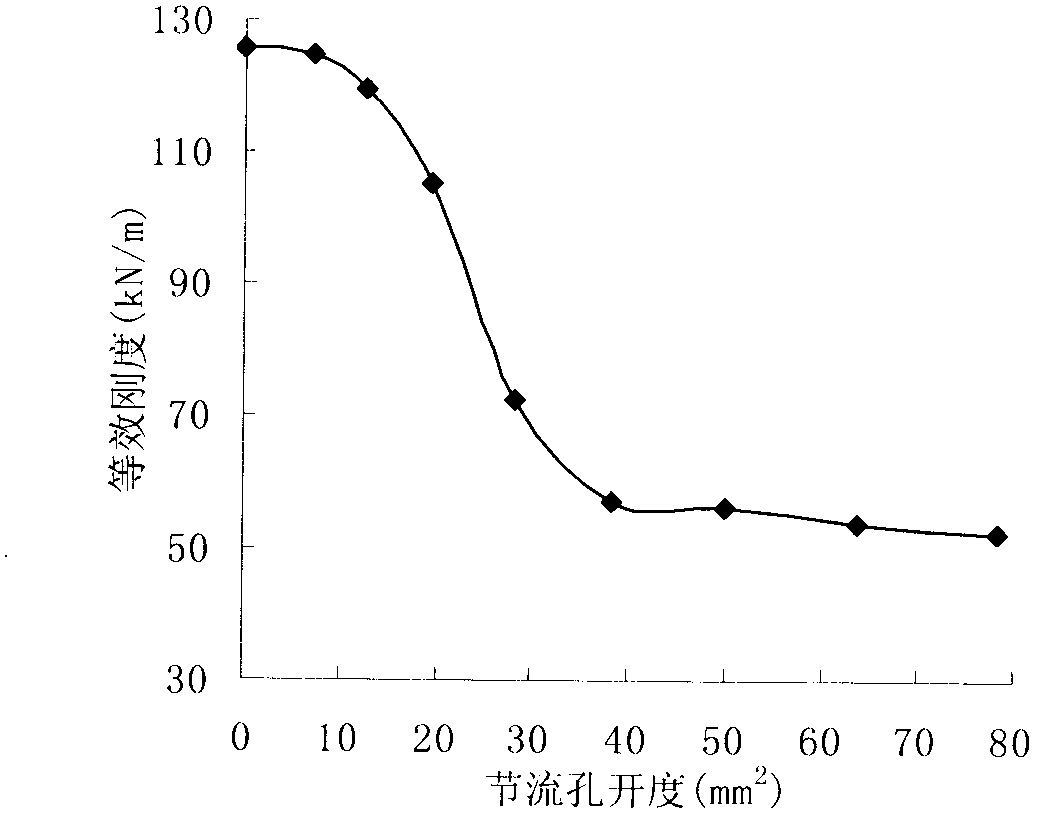

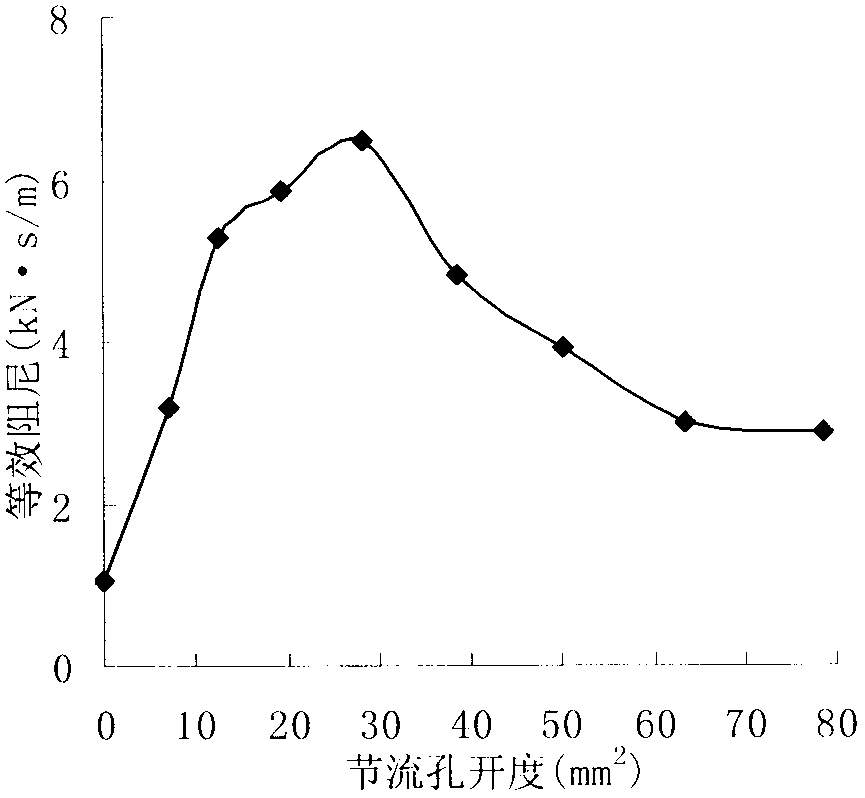

Shock absorbing system with combined rigidity and damping adjusting function and shock absorbing method

InactiveCN102678808AChange the stiffnessExcitation frequency to avoidSpringsNon-rotating vibration suppressionTime domainControl signal

Owner:NANJING AGRICULTURAL UNIVERSITY

Pneumatic vehicle stabilization system

An electronic height control system for a vehicle chassis air suspension is modified to provide bimodal operation. In the second mode of operation the chassis air suspension system is maintain a stationary in a stable, level position to serve as a base for a mobile aerial lift unit installed on the vehicle. Operation of the suspension system in its stabilization and leveling mode is triggered by activation of a vehicle power take-off unit (“PTO”) used to position the aerial lift unit.

Owner:INT TRUCK INTPROP LLC

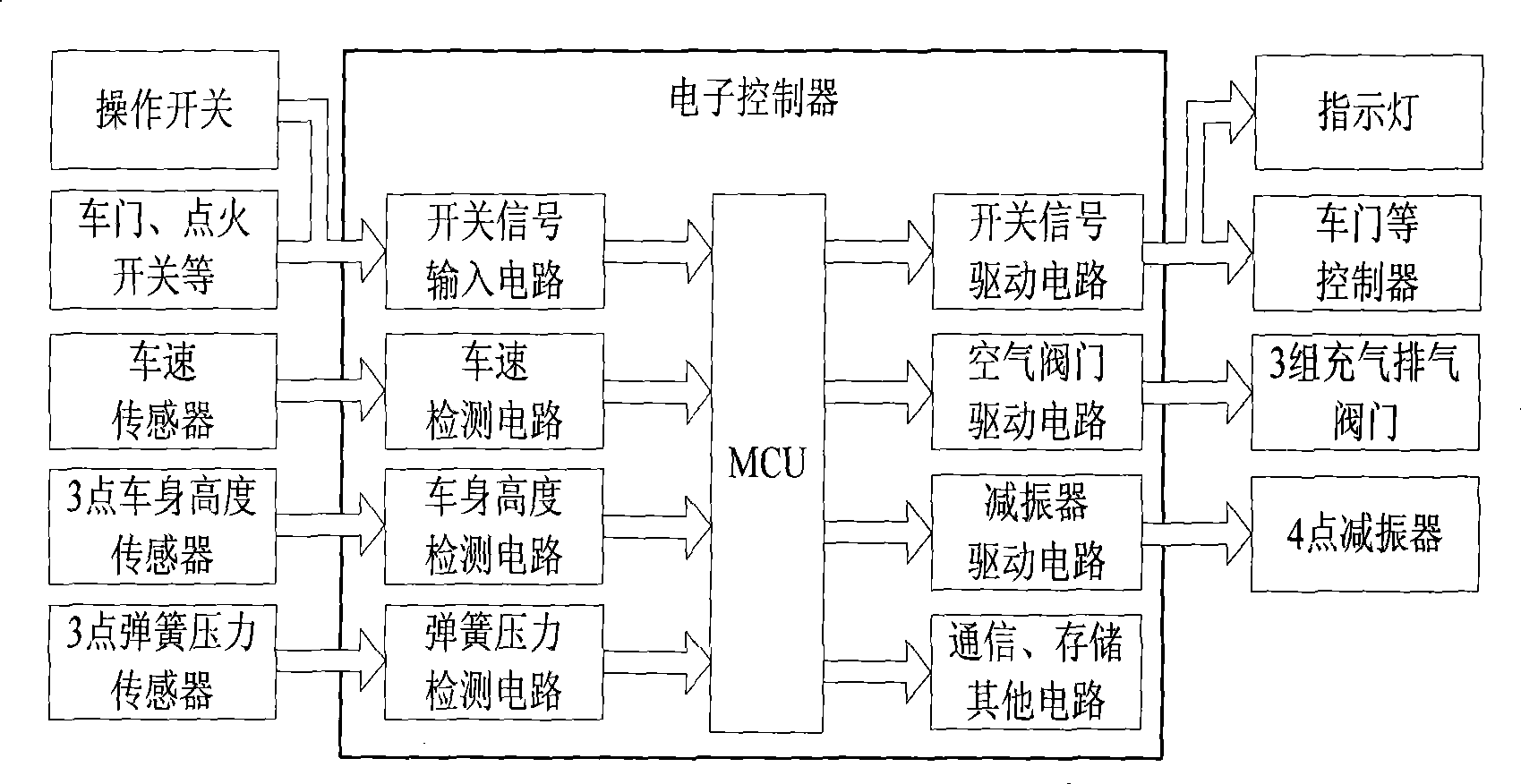

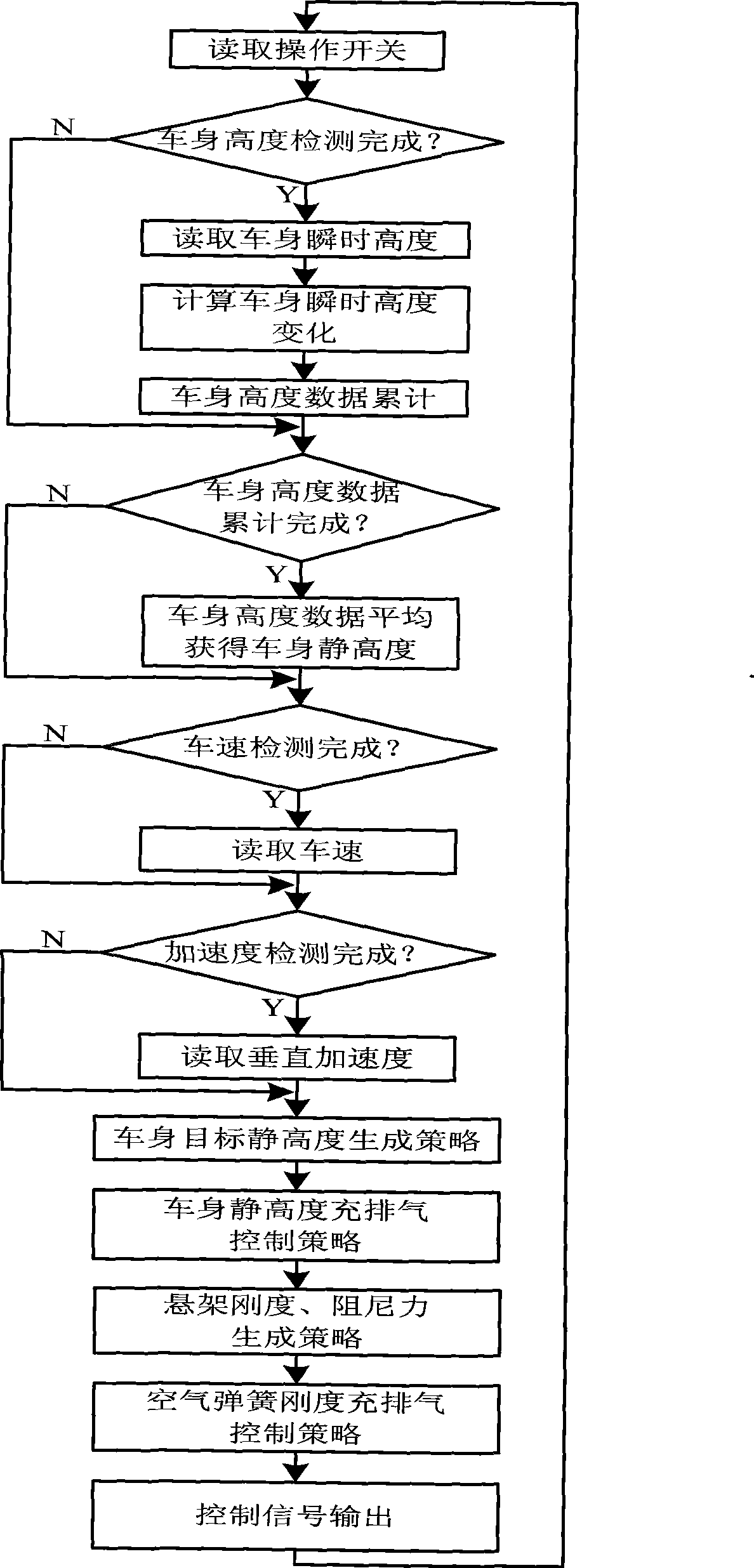

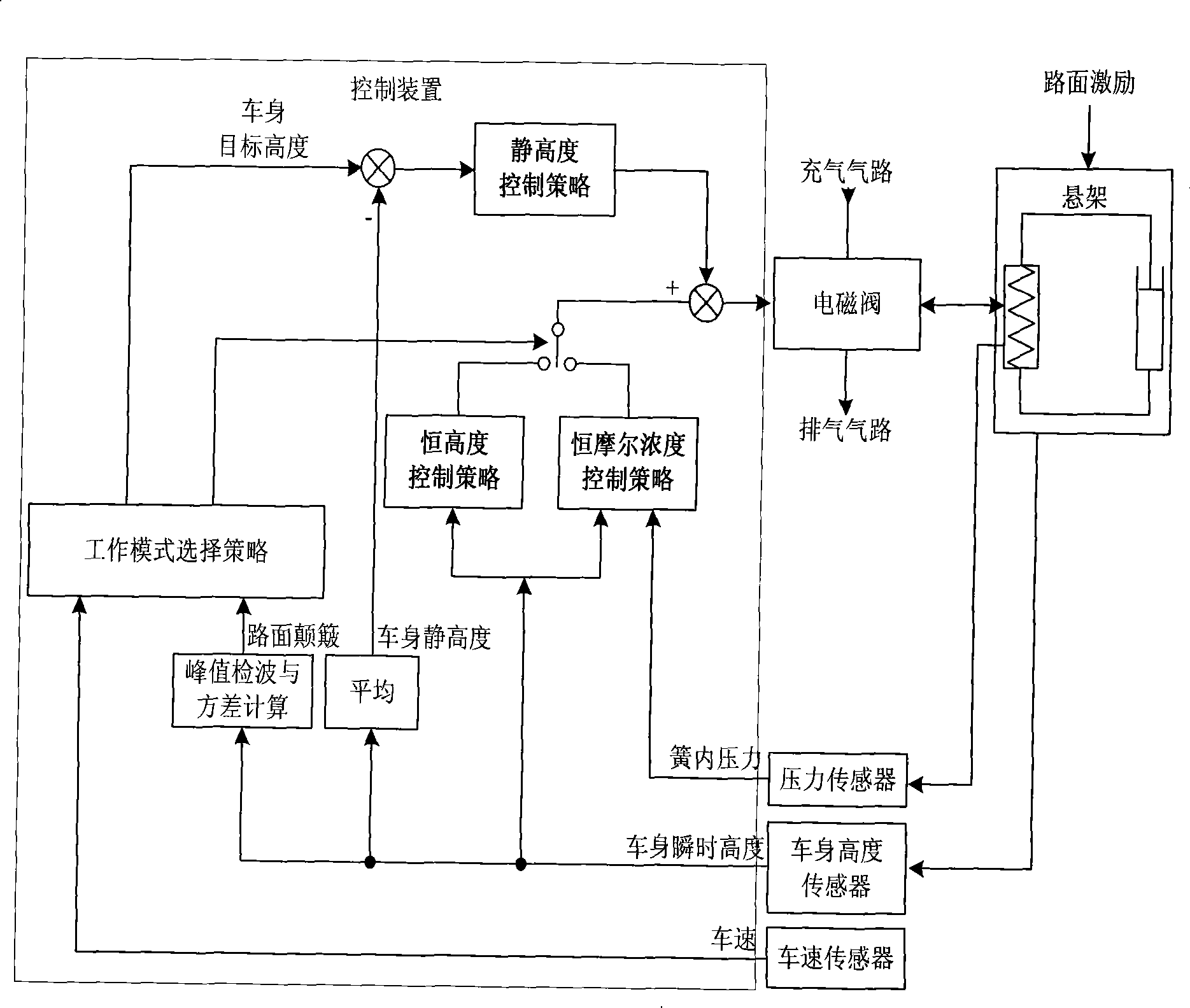

Control method of automobile air suspension

The invention discloses a control method for a vehicle air suspension; the invention takes the electric control device of a hardware part as the core and is configured with components such as various external sensors, an air spring, an air valve, and an adjustable shock absorber, and the like; the software part comprises signal detection, data processing and secondary calculation, a control method and control output; and firstly different working models are judged by calculating the variance of the input vehicle body height and the vehicle speed; open-loop control and a neural network are used for realizing online self-correction function; the electric control device controls the implementation of the air valve according to the air charge and discharge time which is obtained by the neural network, and then the air molar concentration and the deviation quantity in the spring are obtained by calculation; and finally a detail control signal is obtained. The control method causes the vehicles to be controlled flexibly under different pavement conditions, has appropriate flexibility and damping performance under various road conditions, effectively solves the conflicts when parameters are matched to be suitable for various road conditions, and improves the handling performance, the safety, the comfort and the off-road performance of the vehicles.

Owner:JIANGSU UNIV +1

Air spring for a heavy-duty vehicle with damping features

ActiveUS20120061887A1Reduce and eliminate sizeReduce complexityLiquid springsResilient suspensionsAir springEngineering

An air spring for a heavy-duty vehicle axle / suspension system includes a bellows chamber operatively connected to a piston chamber. An opening is disposed between the bellows chamber and the piston chamber in order to allow fluid to communicate between the bellows chamber and the piston chamber. The cross-sectional area of the opening and the volumes of the bellows chamber and the piston chamber are tuned in order to optimize the damping characteristics of the air spring.

Owner:HENDRICKSON USA L L C

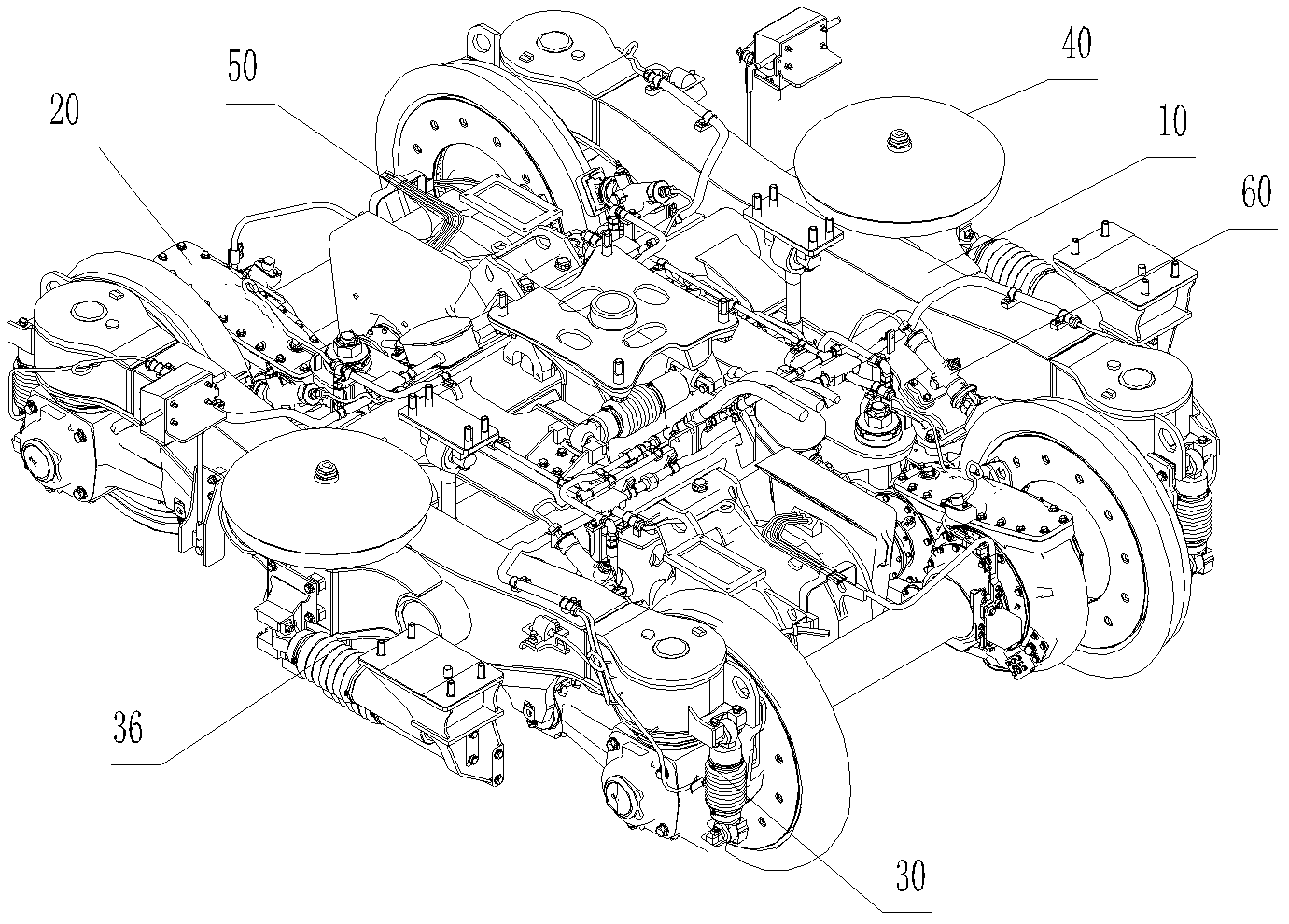

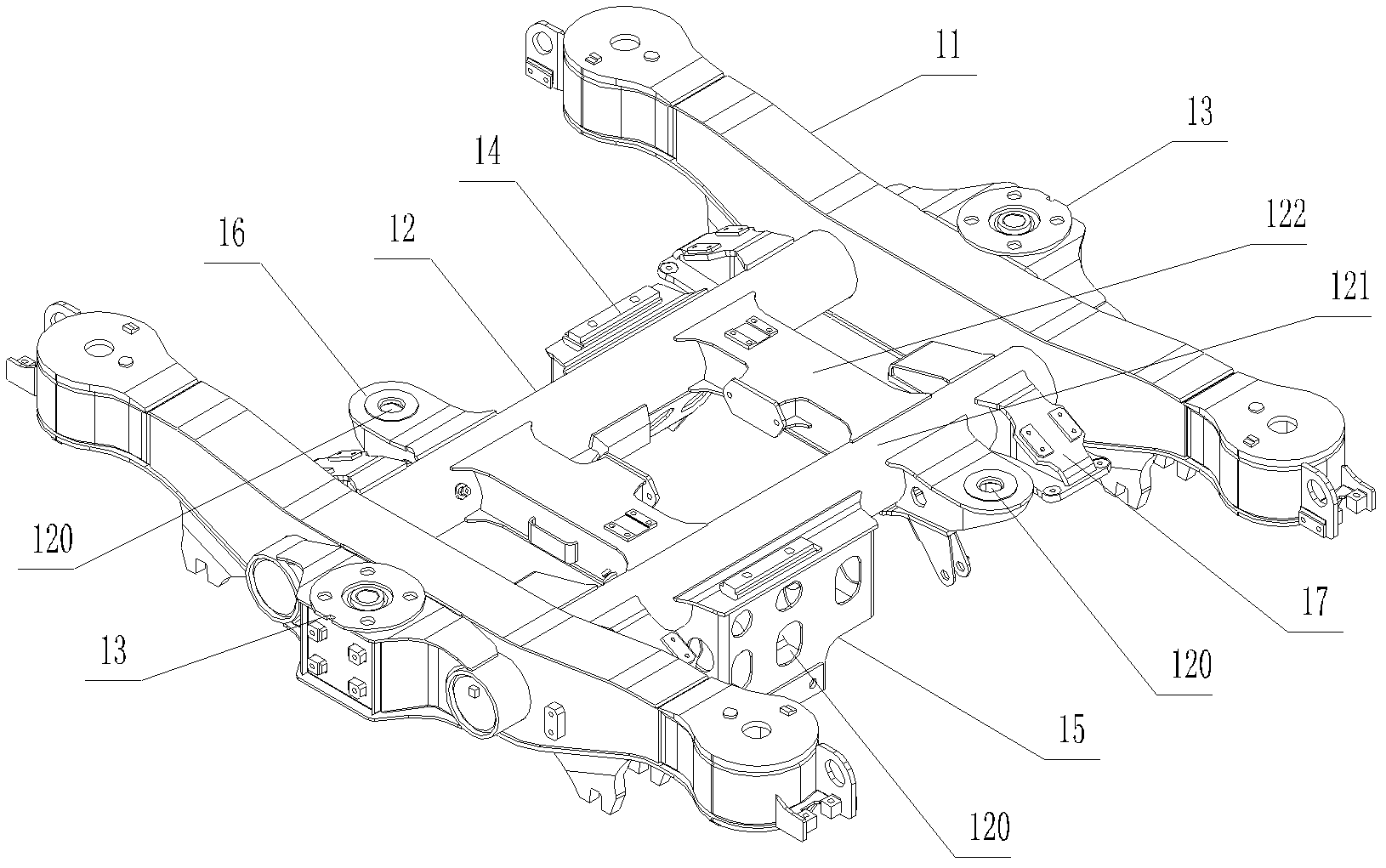

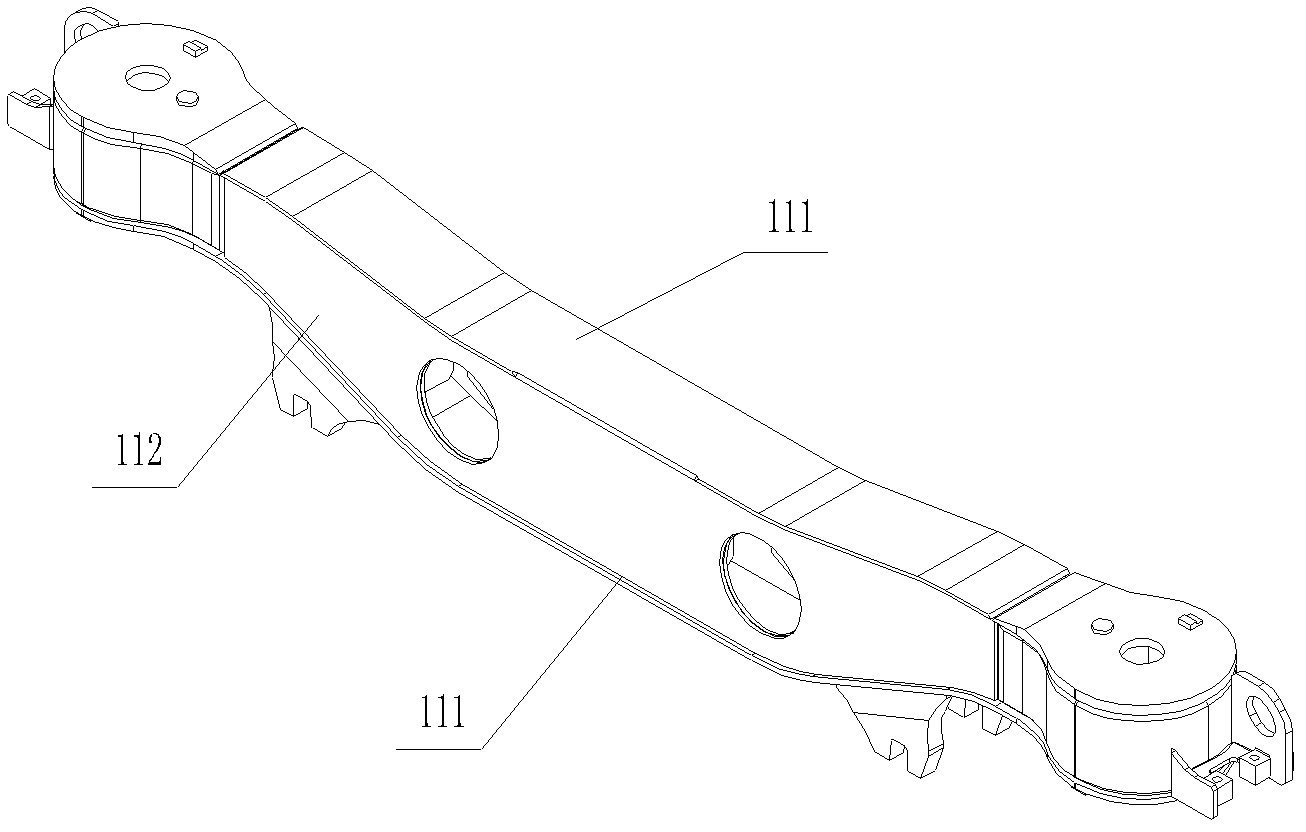

Bogie of high-speed motor train unit

InactiveCN102923153AAchieve lightweight designGuaranteed stabilityBogiesWheel-axle combinationsBogieAir spring

The invention discloses a bogie of a high-speed motor train unit. By adopting a brand-new bogie structure and a hanging connection and traction mode, overall lightweight design is realized, the unsprung weight of the bogie is reduced, and the hanging parameter between the bogie and a body is optimized. On the basis that the high-speed running speed is met, stability when the bogie passes through a big corner and good traction and braking performance are expected. The bogie comprises a framework, two groups of wheel set travelling devices, a linear motor, a first hanging device, a second hanging device, a traction device and a foundation brake device. The framework comprises a pair of side beam assemblies and a pair of cross beam assemblies which are connected with each other; each side beam assembly has a hollow box body structure, and comprises a pair of upper and lower cover plates and a pair of lateral web plates which are welded; each cross beam assembly comprises a pair of hollow steel pipes penetrating the lateral web plates and welded with the lateral web plates; and a pair of air spring supporting beams is welded at two ends of a steel pipe and outside the lateral web plates.

Owner:CRRC QINGDAO SIFANG CO LTD

Ultra-precise silicon wafer positioning system with balance weight damping apparatus

ActiveCN1595299ALimited rotational freedomReduce positioning accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusMomentumThree degrees of freedom

It is ultra-fine silicon pad position system with balance damping apparatus, which uses conservation of momentum principle and put the silicon pad supporting apparatus and its guide apparatus on a balance block with X, Y freedom degree supported by a float axis. When the silicon supporting apparatus moves along one direction, the balance block moves oppositely and eliminates the vibration caused by move reaction. The system also has a momentum wheel system used to eliminate the vibration caused by the momentum distance non-conservation in the moving surface of the silicon pad supporting apparatus. The whole system is supported by three air elastic spring and absorbs the remaining vibration of rest three freedom degrees and further improves the moving accuracy of the silicon pad position system.

Owner:TSINGHUA UNIV +1

Treadmill

A computerized treadmill is provided. The treadmill deck may be fully suspended by a plurality of air suspension elements, such as bellows. The bellows may be pressurized by a computer-controlled compressor feeding a central air reservoir to which each bellows is connected via air hose. The bellows may be dampened to control expansion. A double hinge connecting the deck with frame may control lateral movement and reduce lateral load on the bellows. Incline and decline mechanisms facilitate a variety of deck angles. Control of the treadmill may be by computer, whether integrated or modular, whether traditional, laptop, tablet or smart phone. Control of the treadmill and conveyance of information associated with treadmill operation may be integrated with computer or smart phone applications, whether dedicated or third party.

Owner:MOSER GEORGE

Vehicle suspension

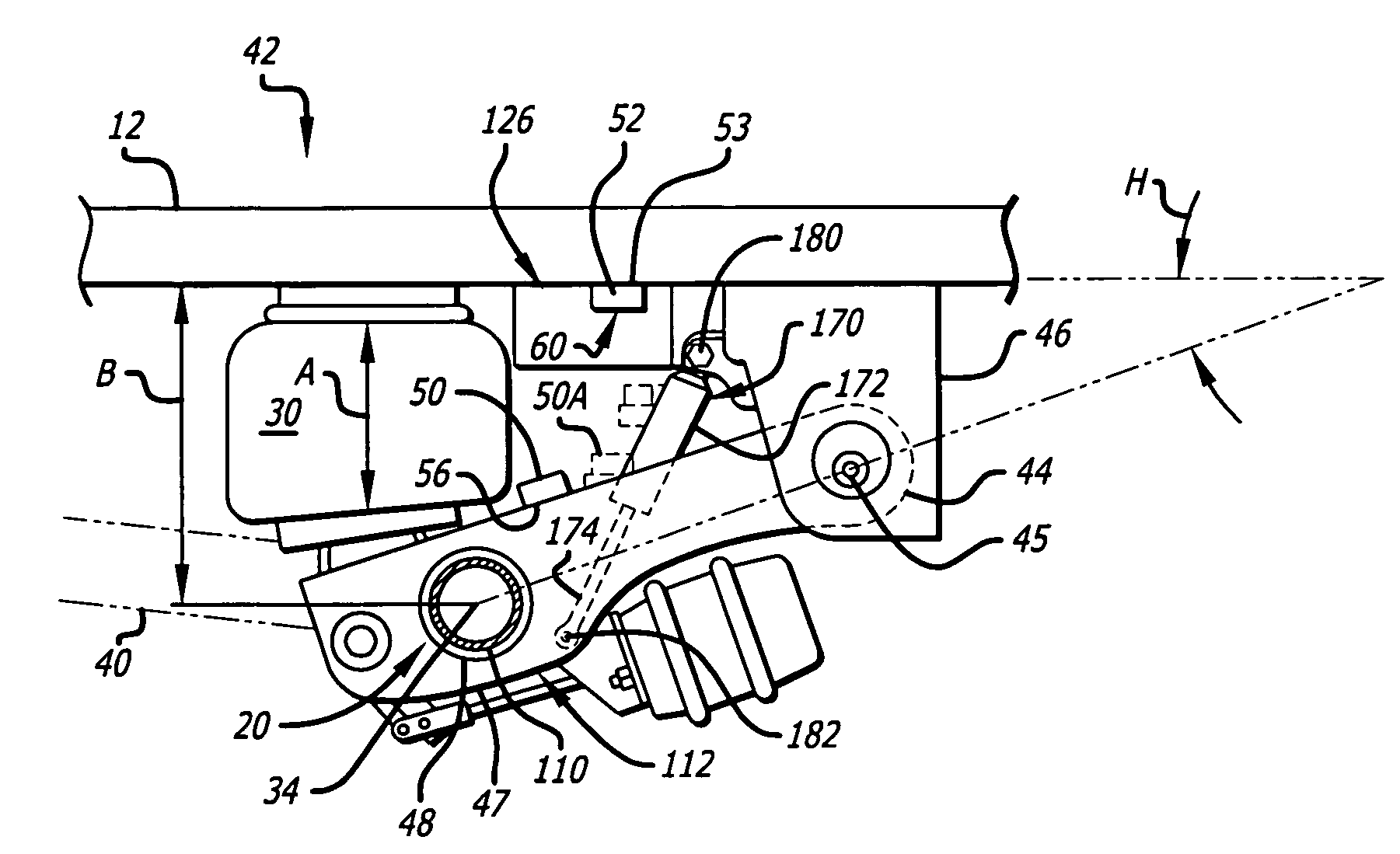

InactiveUS6851689B2Facilitate installation and assemblyEasy to adjustVehicle cleaning apparatusLoading/unloading vehicle arrangmentVehicle frameEngineering

A non-torque reactive air suspension exhibiting excellent roll stability characteristics is shown to include frame hangers mounted to frame rails extending longitudinally on opposite sides of a vehicle. Longitudinally extending beams are connected to the frame hangers at one end and extend parallel to the frame rails. At their other ends, the beams are joined by a crossbrace extending laterally across the vehicle centerline. In a central portion thereof, the beams have an axle pivot bore to which an axle clamp assembly is connected, the axle clamp assembly clamping a drive axle housing for the vehicle. The axle pivot bore is generally aligned with the drive axle. A control rod assembly is connected to suspension or frame components. Together with the beams, the control rod assembly forms a parallelogram configuration wherein the beams form the lower linkages of that configuration and the control rods included within the control rod assembly form the upper linkages of that configuration.

Owner:HENDRICKSON USA L L C

Electronic control of vehicle air suspension

InactiveUS20060267296A1Prolong lifeReduce the amount requiredSpringsResilient suspensionsMotion detectorVehicle frame

A system is provided for use on large vehicles of the type wherein the vehicle frame is supported on vehicle axle assemblies through air bags, and each air bag has a lower end coupled to the lower end of an arm such as a swing arm whose upper end is pivotally mounted on the frame. The height of the air bag is sensed by a pair of tilt sensors, sensing tilt of its location with respect to gravity, and the difference in tilt indicates air bag height. The output of the tilt sensors may be filtered, and a motion detector allows rapid filling or dumping of air bags independent of filtering of tilt sensor signals. Control of the vehicle air suspension can also be based upon inputs from one or more air bag pressure sensors.

Owner:BARKSDALE

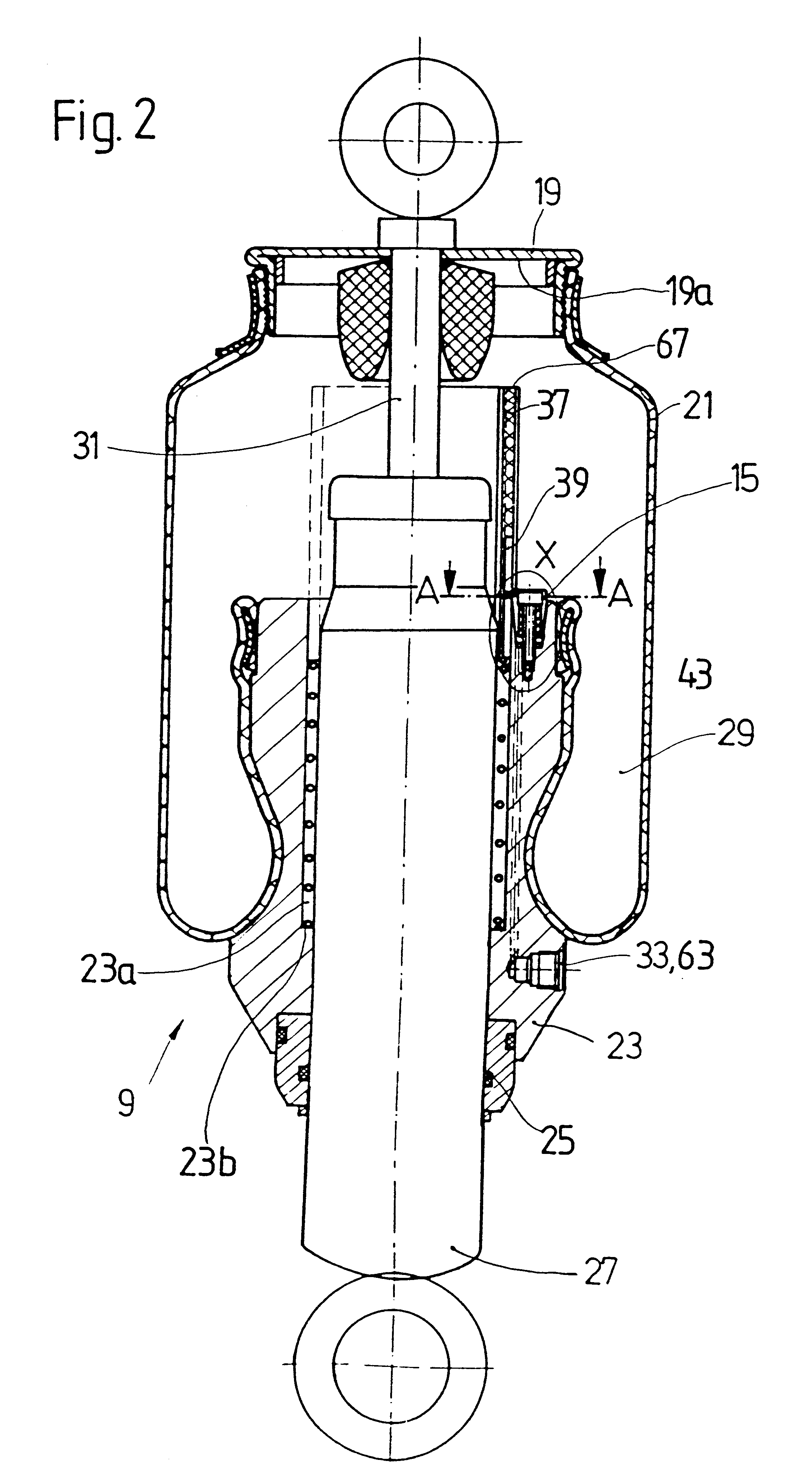

Air-suspension system

An air-suspension system has at least one air spring arranged between a chassis and a vehicle component mounted relative to said chassis for movement along an oscillatory path. A control valve is arranged inside the air spring and has control positions for feeding, blocking and discharging compressed air in the air spring. The control valve is activated via a control element also arranged inside the air spring. A guideway of the control element acts on one of an outer tube air-spring subassembly and a rolling tube air-spring subassembly which are movable relative to one another. The control valve is designed as a rotary-slide valve and is activated via the guideway and a rotary-slide valve body. The guideway of the control element is shorter than the stroke length of the air spring, the one of the subassemblies which actuates the control element being in releasable operative connection with the control element. The releasable operative connection is restricted only to a section of the stroke travel between the two air-spring subassemblies of outer tube or rolling tube.

Owner:ZF FRIEDRICHSHAFEN AG

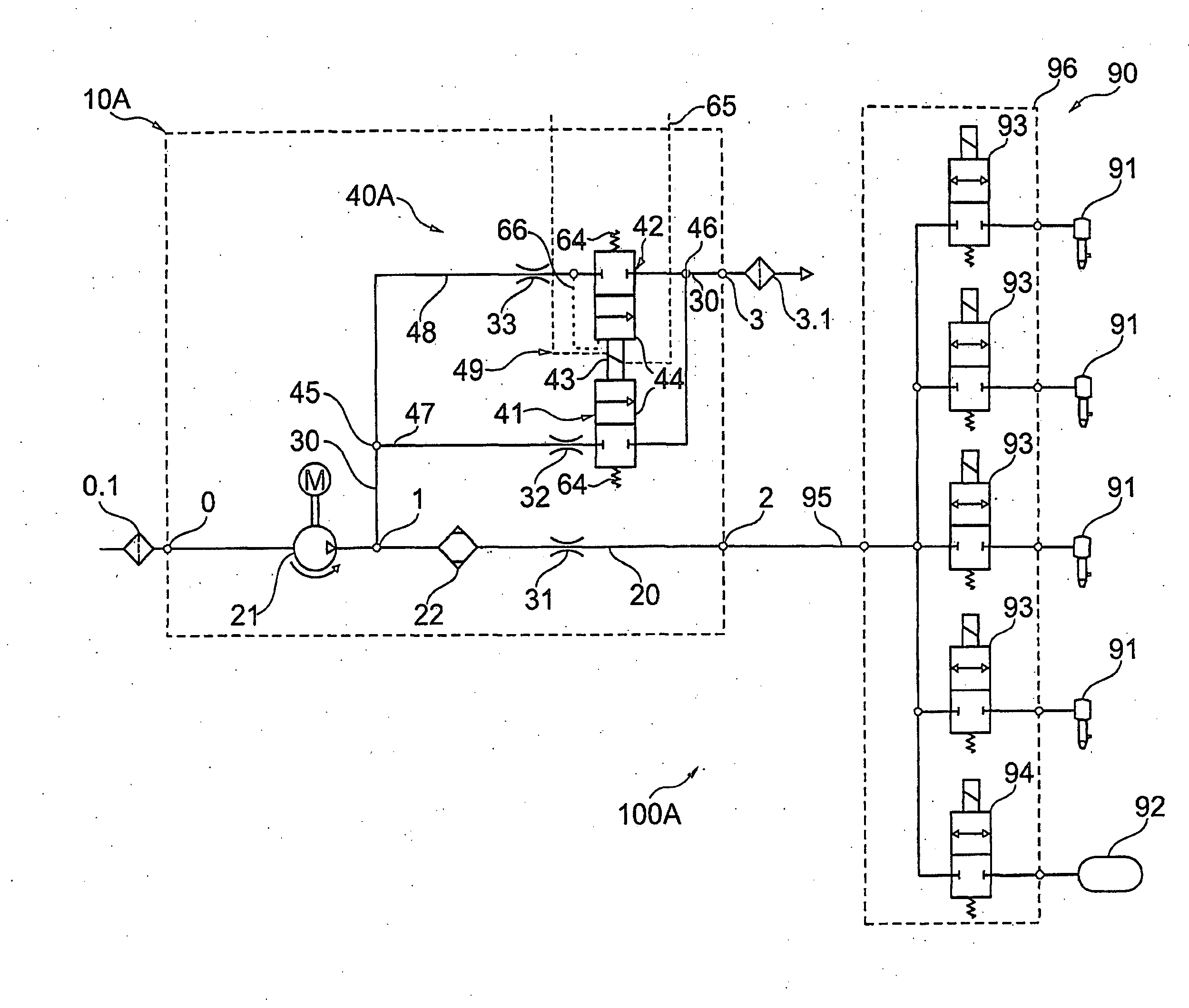

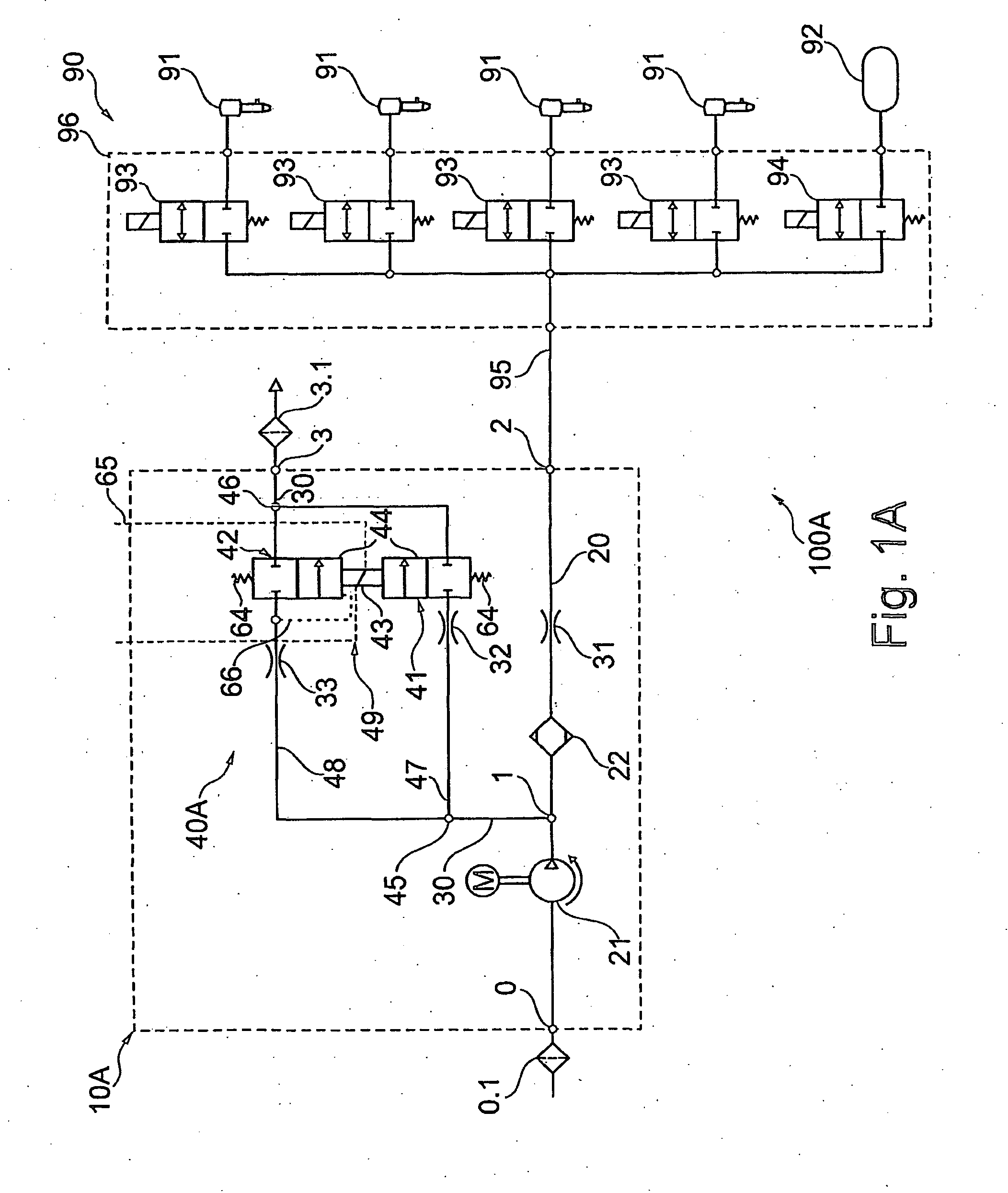

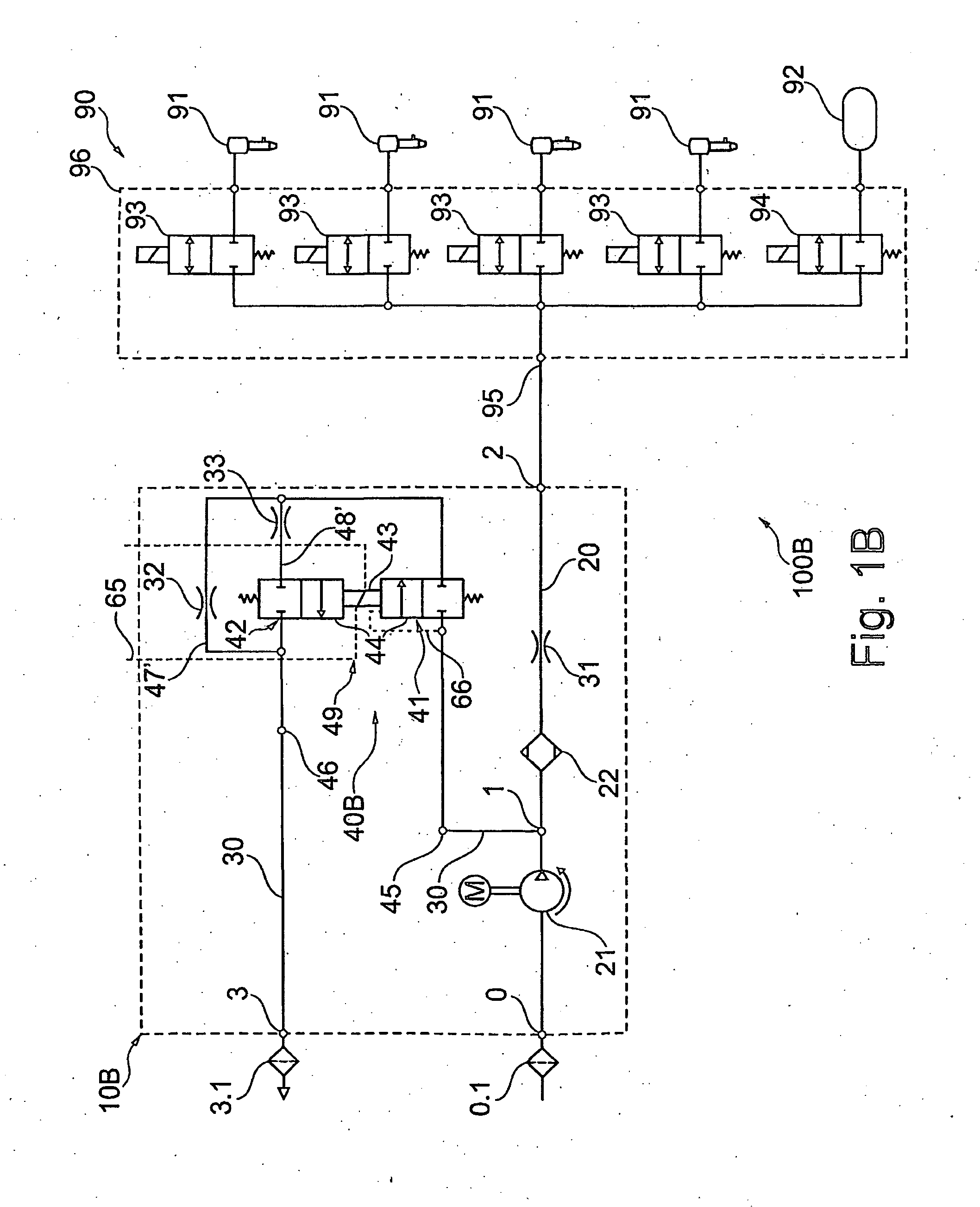

Compressed Air Supply Installation, Pneumatic System and Method

ActiveUS20130318954A1Reliable and yet flexibleFast principle of operationRotary clutchesResilient suspensionsAir compressionSolenoid valve

A compressed air supply installation for operating a pneumatic installation, especially an air suspension installation of a vehicle, includes: an air supply unit and an air compression unit for supplying a compressed air supply unit with compressed air, a pneumatic connection, especially a bleeding line, comprising a bleeding valve system in the form of a controllable solenoid valve system and a bleeding port for bleeding air, and a pneumatic connection, especially a compressed air supply line, comprising an air drier and a compressed air port for supplying the compressed air. The solenoid valve system comprises a primary valve and a secondary valve, which are actuatable by a controller of the solenoid valve system that is common to both valves and acts upon both valves.

Owner:ZF CV SYST EURO BV

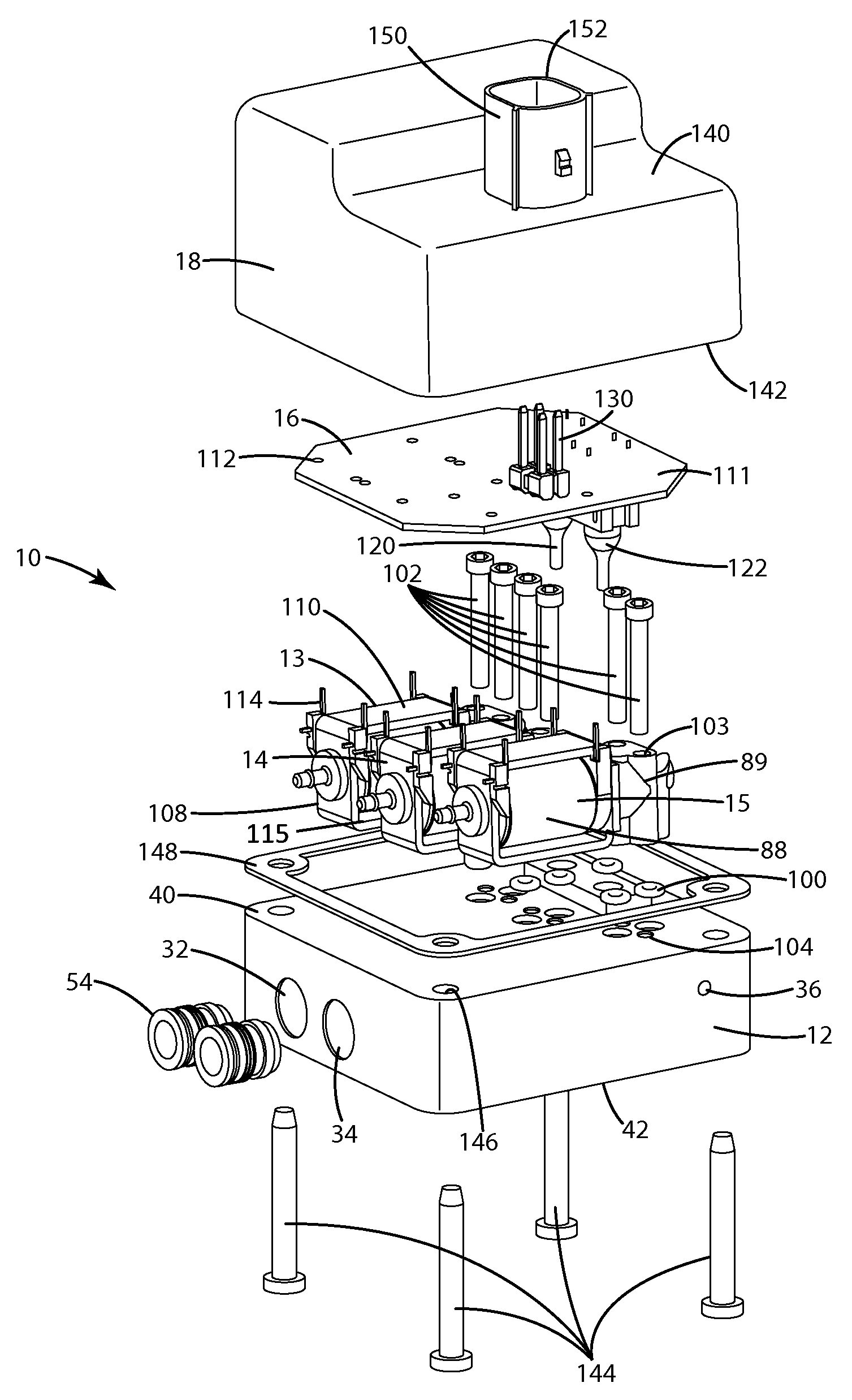

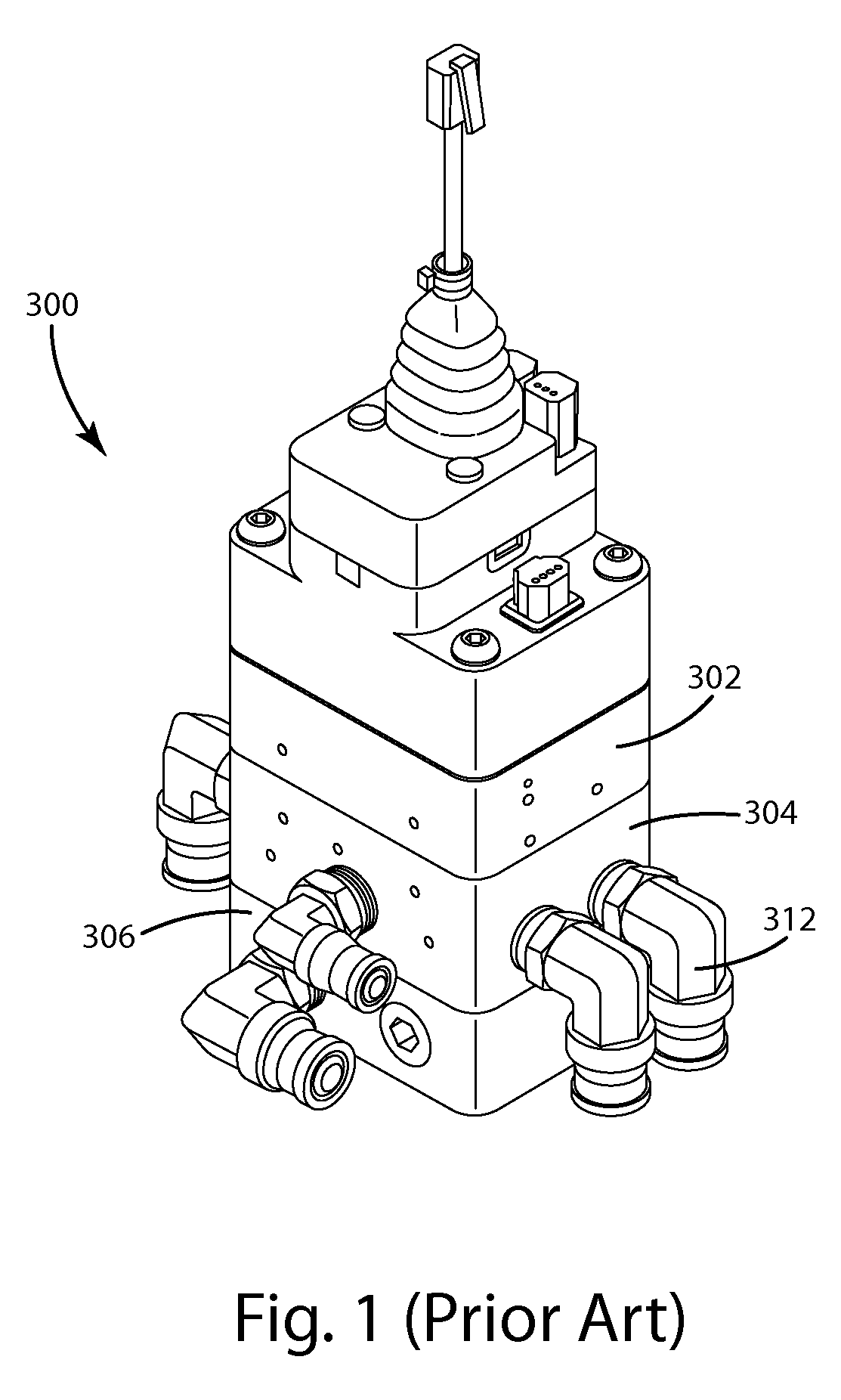

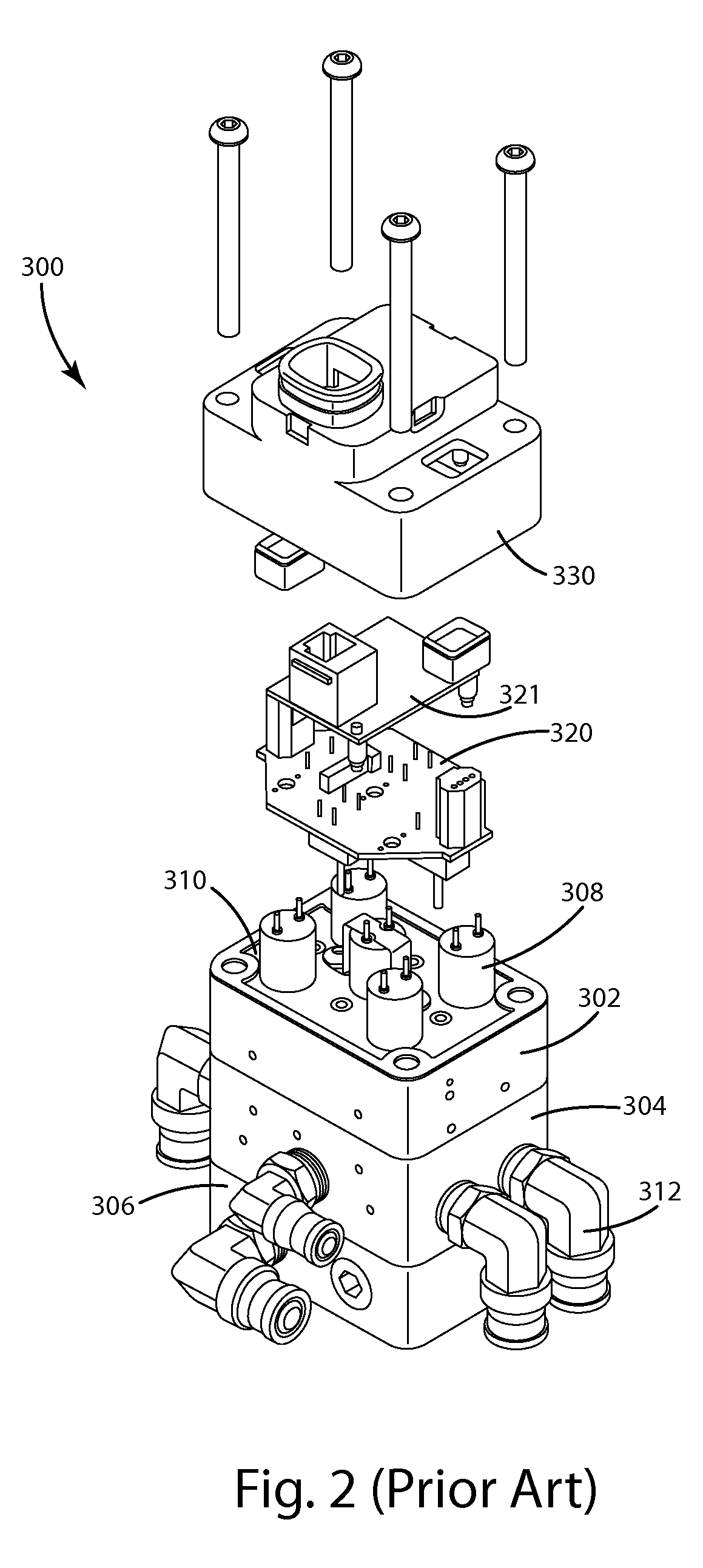

Integrated manifold system for controlling an air suspension

ActiveUS8905071B2Space maximizationEffective controlWave amplification devicesEngine diaphragmsSolenoid valveAir spring

Owner:AIR ELEVATOR

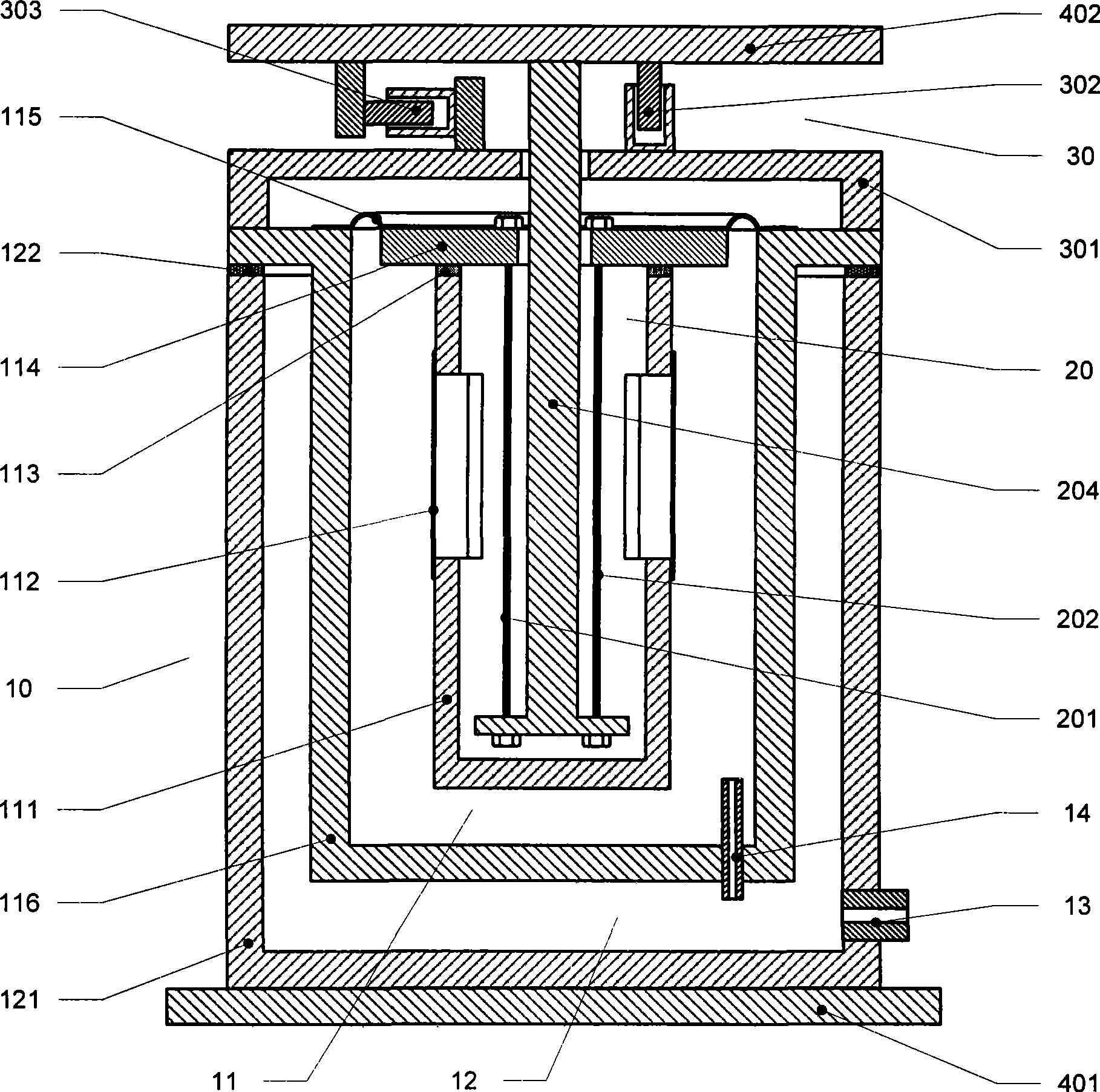

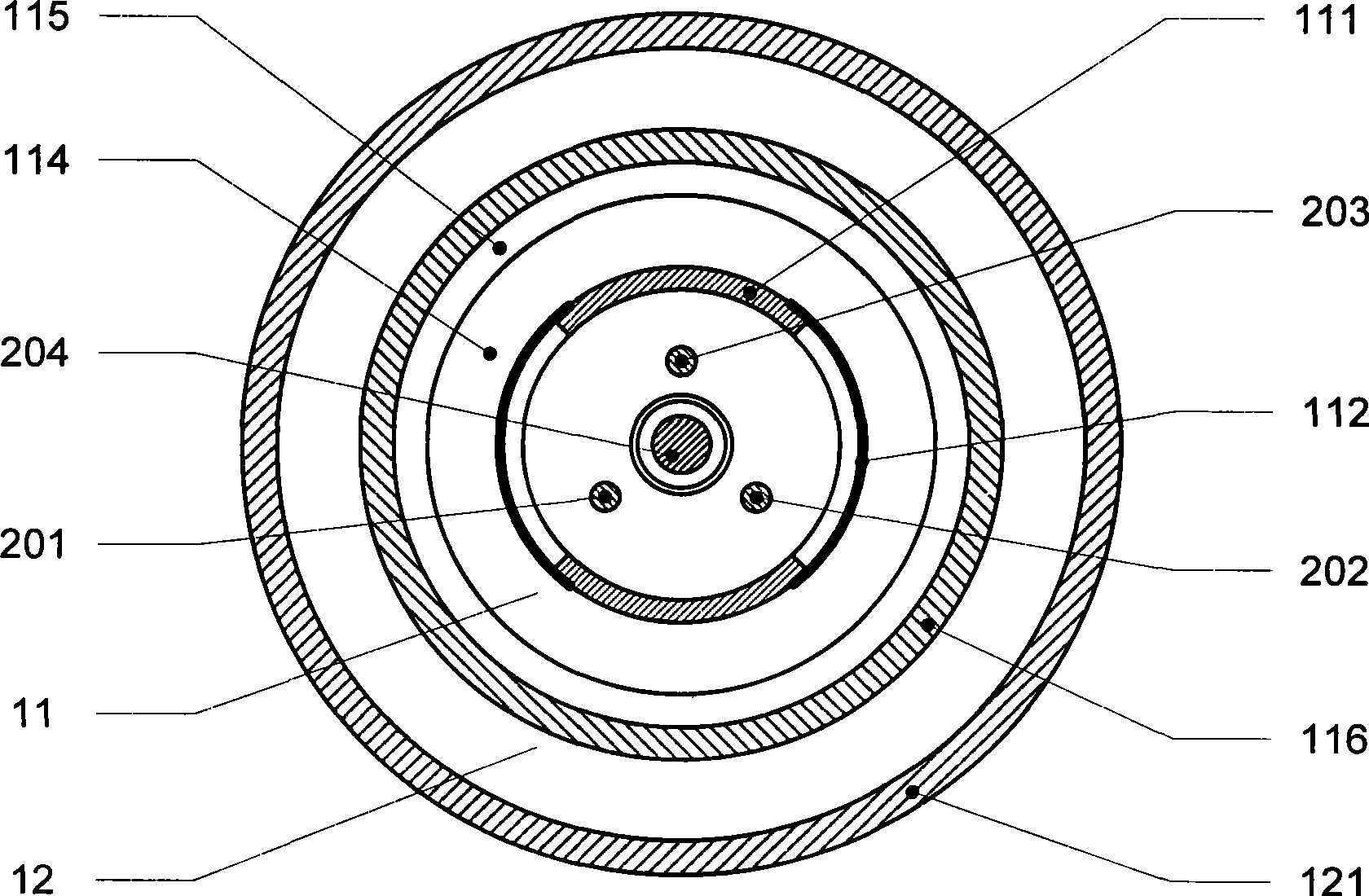

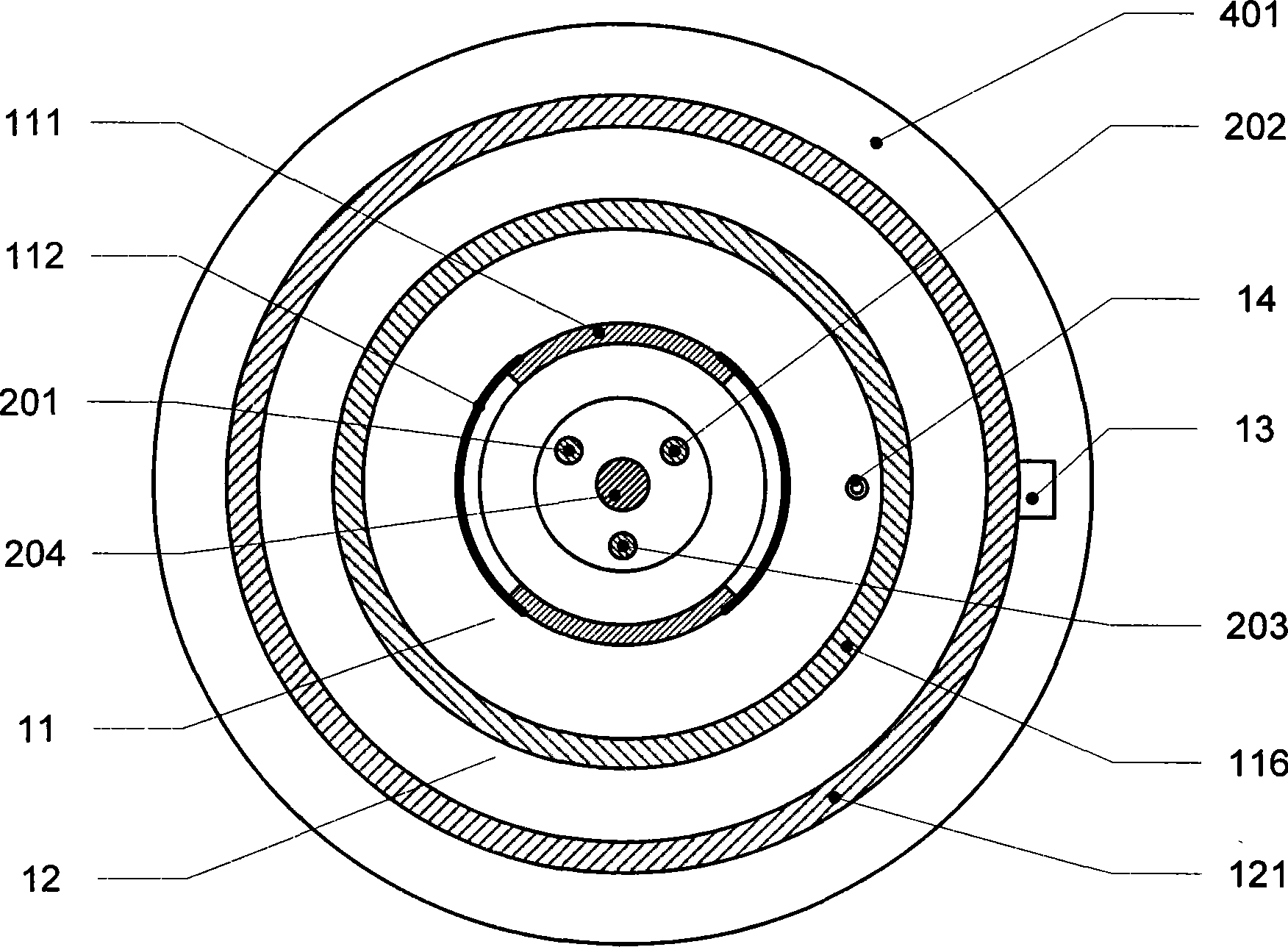

Heavy load precision damper and vibration reduction system formed thereby

InactiveCN101398052AMany degrees of freedomMulti-subwooferGas based dampersVibration suppression adjustmentsEngineeringActuator

The invention pertains to the technical field of precision damping, and is a heavy-load precision damper and a damping system comprising thereof. The damper comprises a low-rigidity air spring with variable damp, an inverted-pendulum structure with low horizontal rigidity and a group of three-degree-of-freedom active damping actuators. The structure of the air spring is external-internal annularity double air chambers communicated with a throttling hole; the inverted-pendulum structure comprises a main supporting rod and at least two flexible swing rods and is located in an annular air chamber; and the active damping actuator comprises three linear motors arranged in an orthogonal manner. The heavy-load precision damper vertically generates large bearing force by the air spring, respectively separates vertical and horizontal vibration transmission by the air spring and the inverted-pendulum structure, and actively controls the damp vibration by acting force of the vertical and horizontal linear motors. The damping system comprises at least three heavy-load precision dampers arranged in the shape of a polygon, and realizes six-degree-of-freedom precision damping of a vibration-isolation device by the mutual action of every heavy-load precision dampers.

Owner:HUAZHONG UNIV OF SCI & TECH

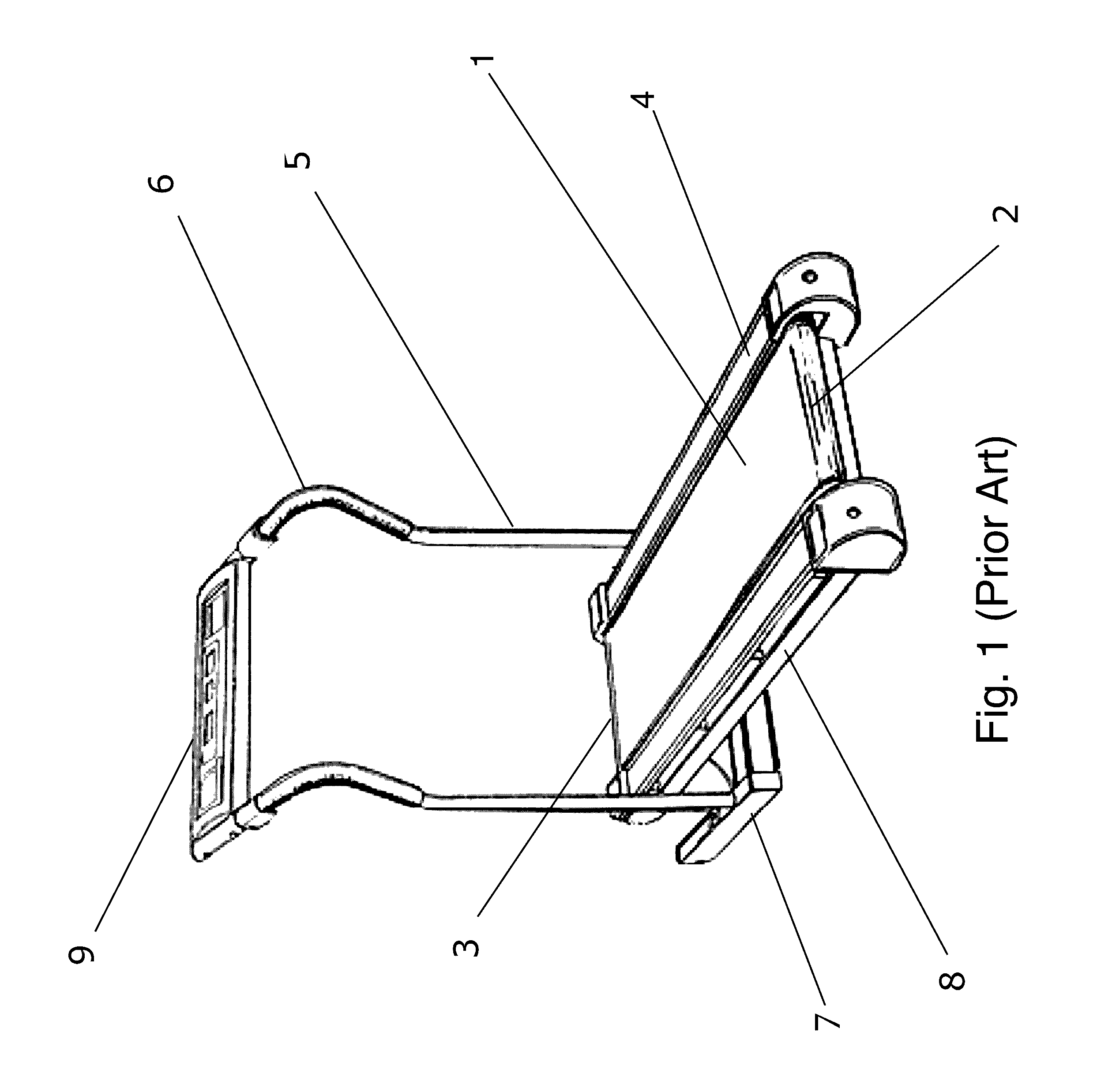

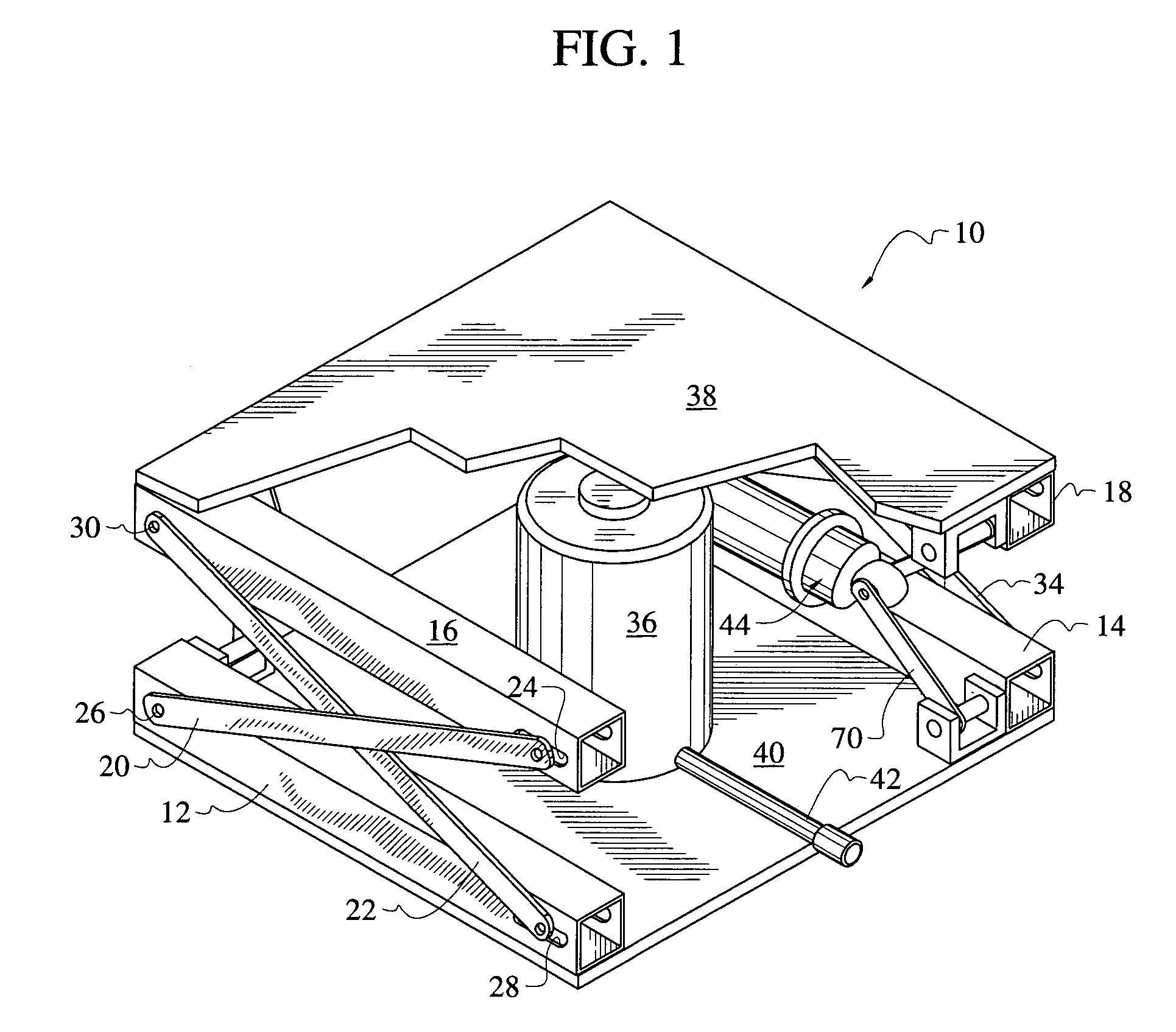

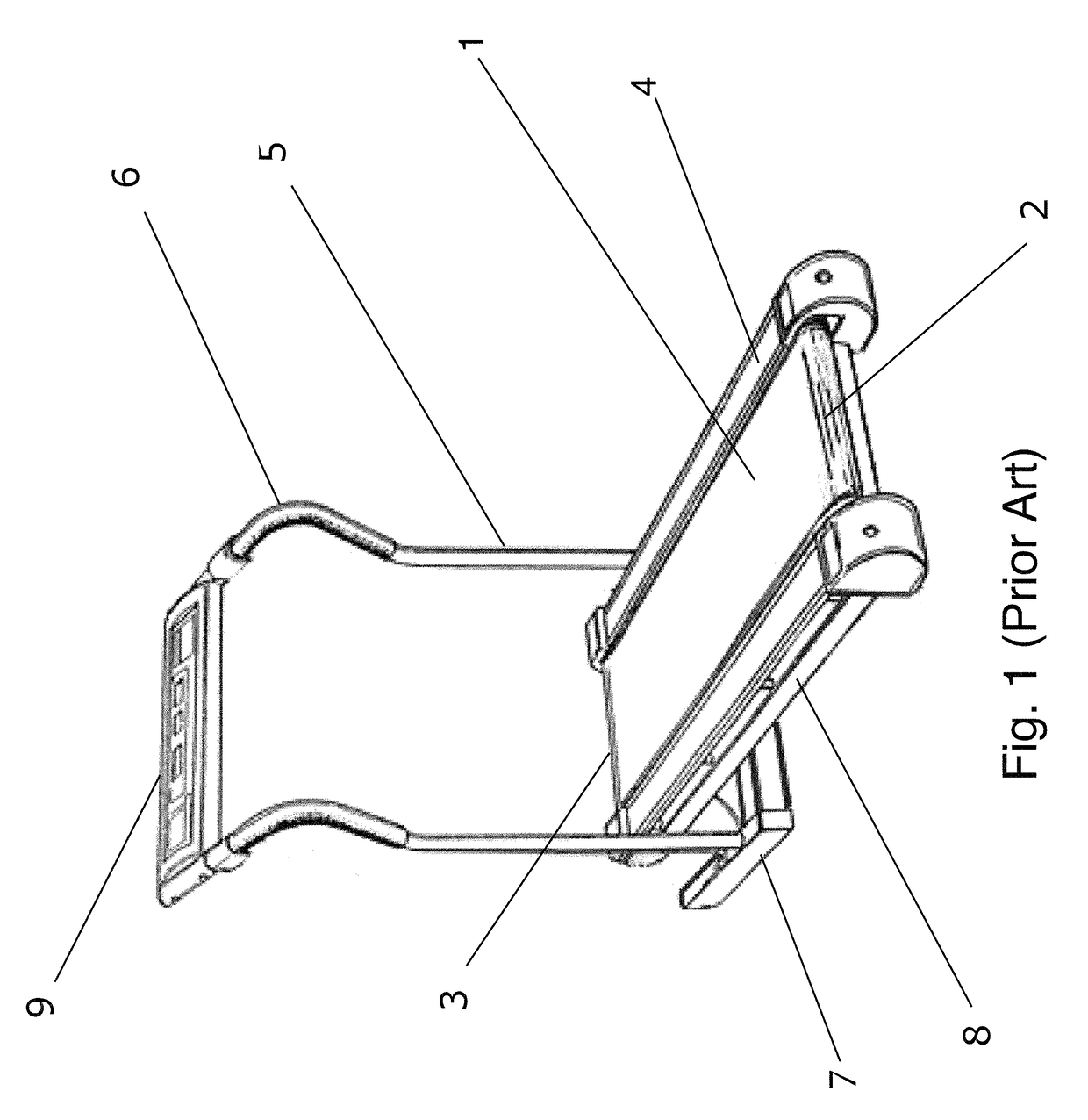

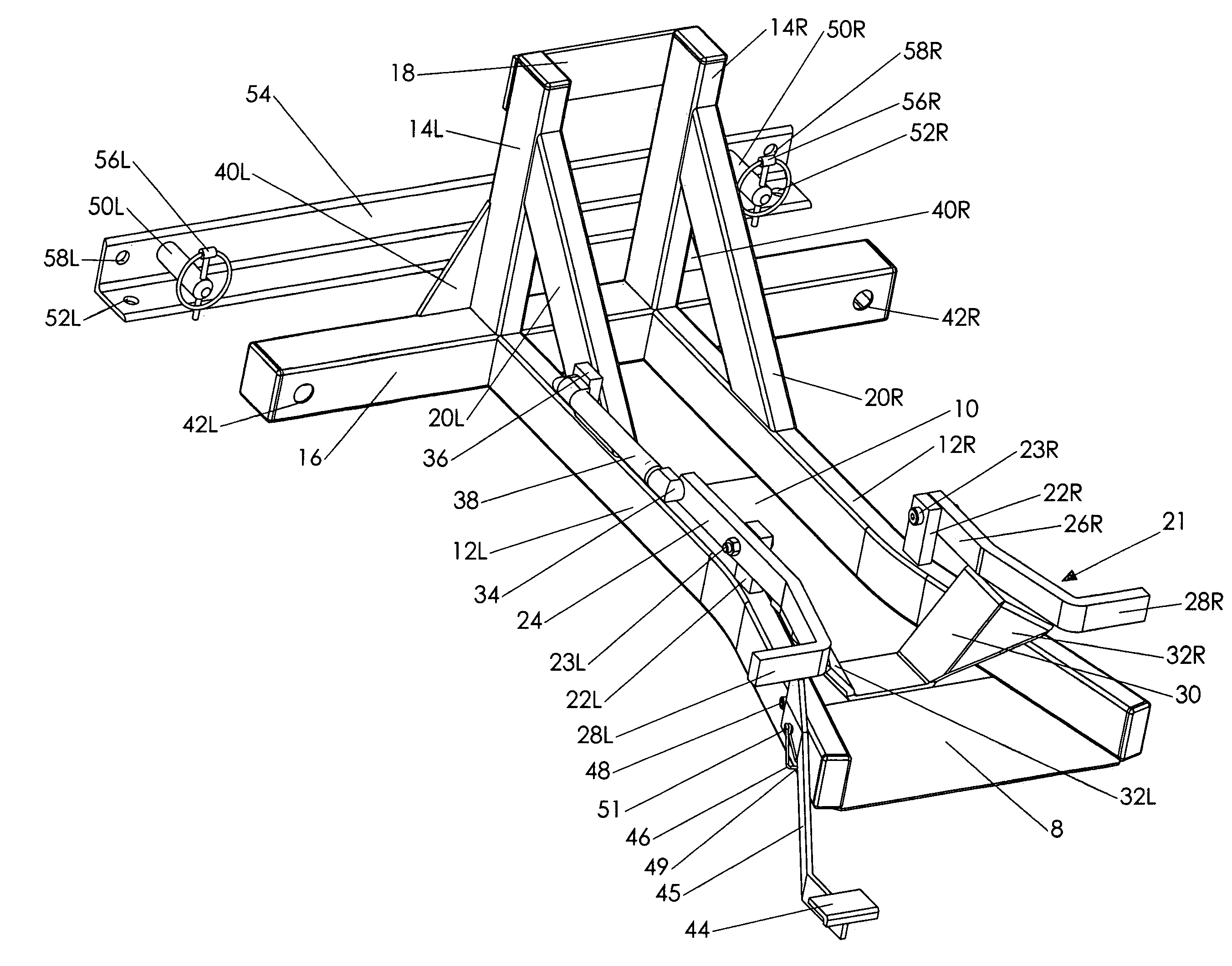

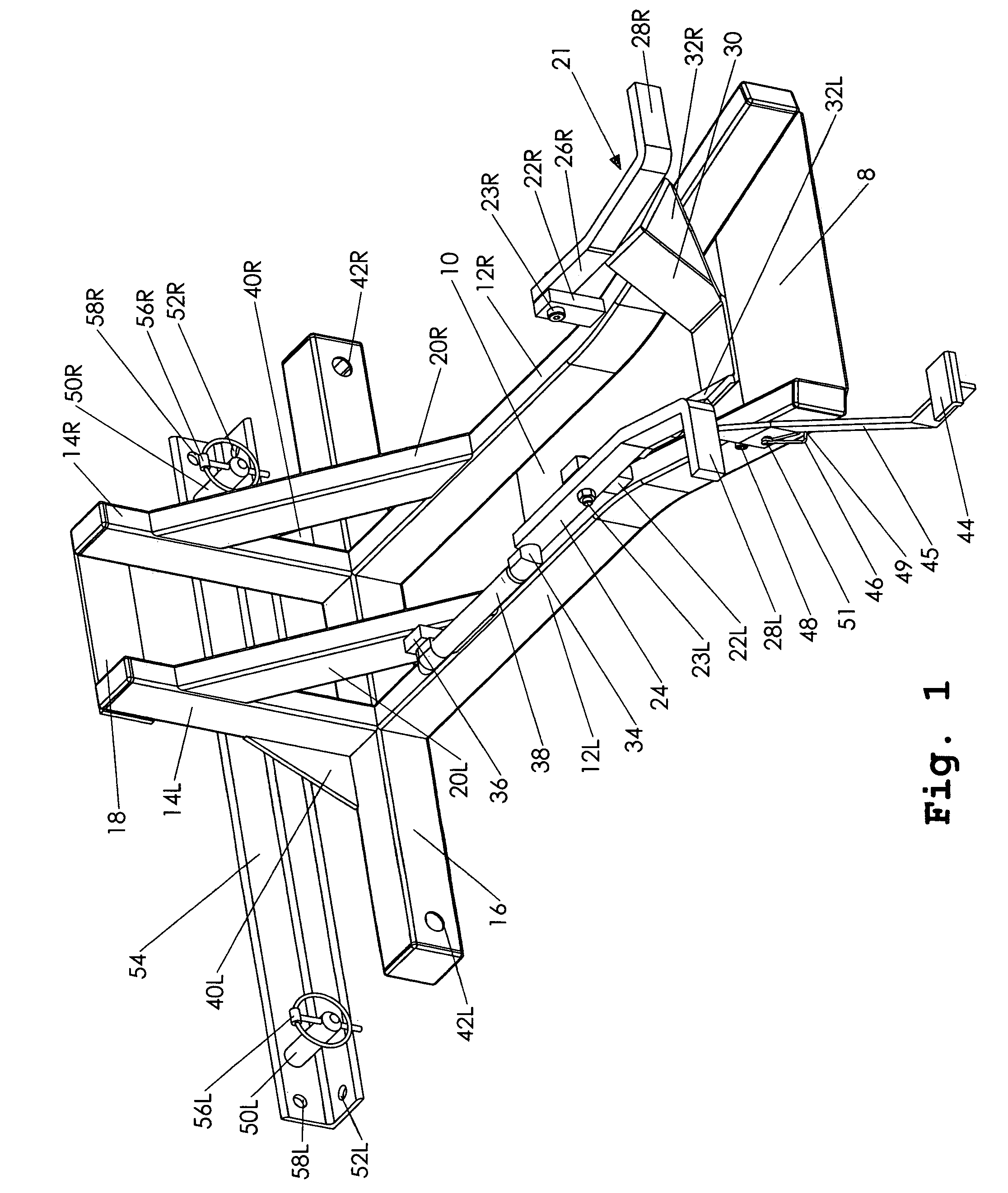

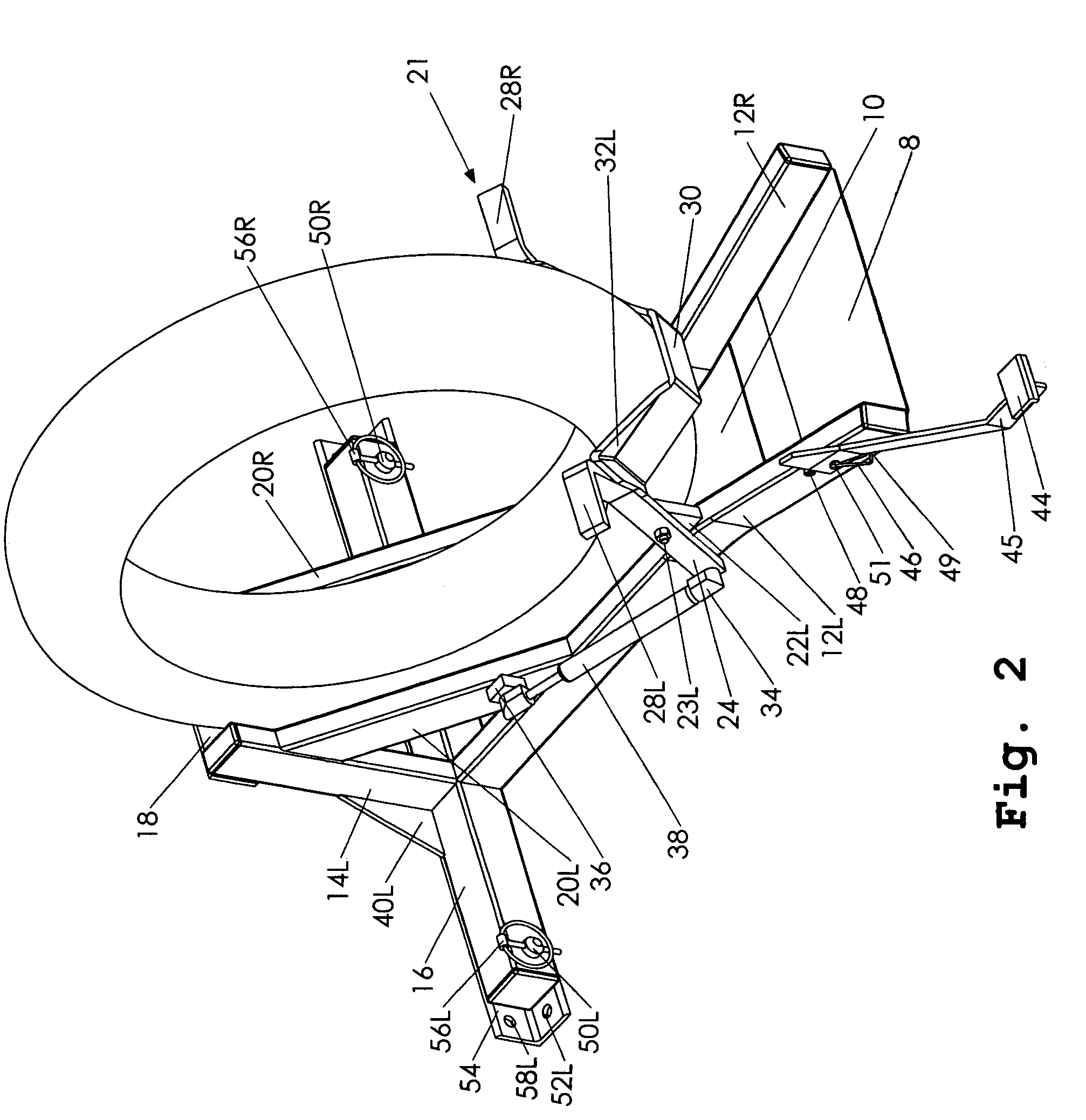

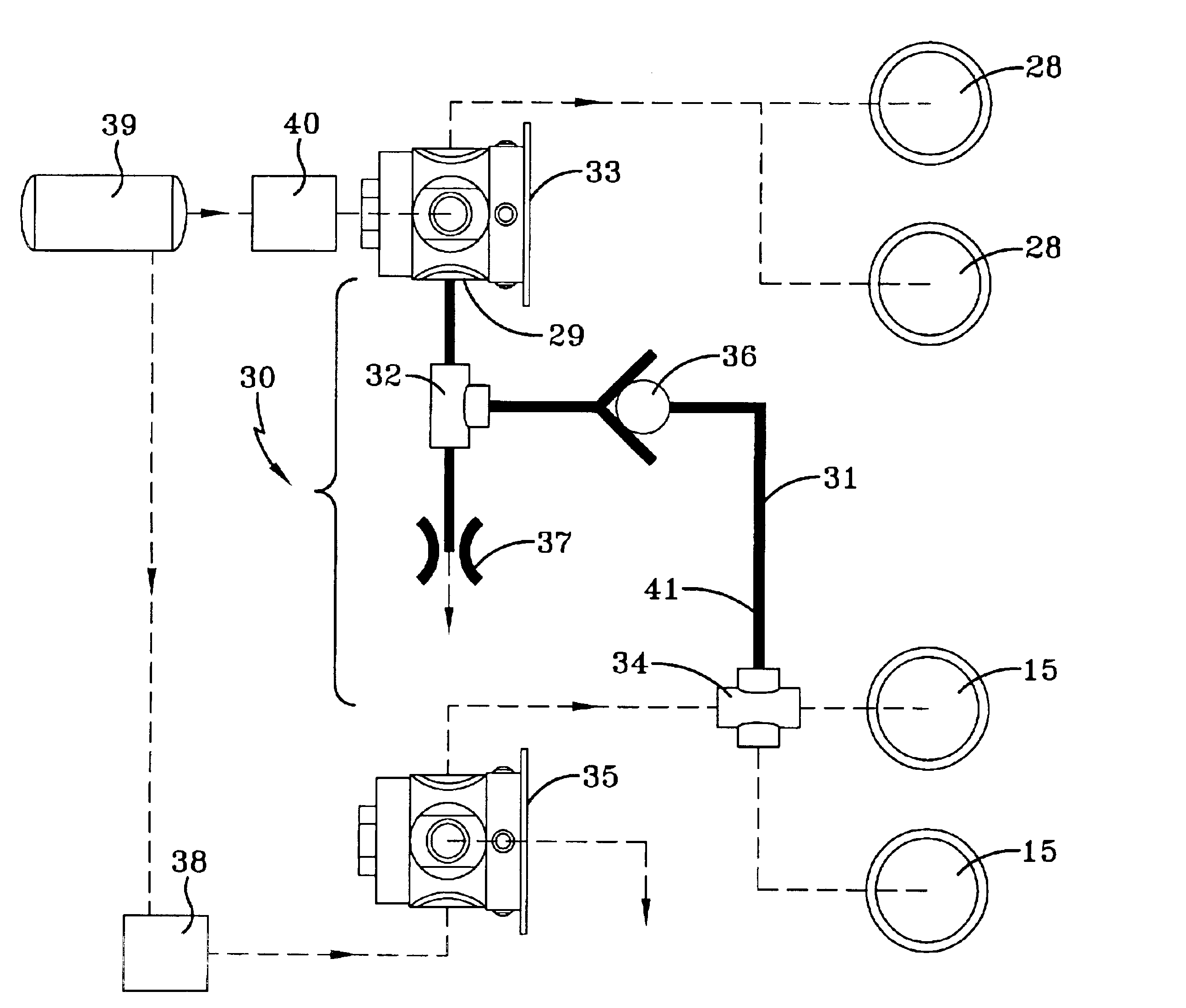

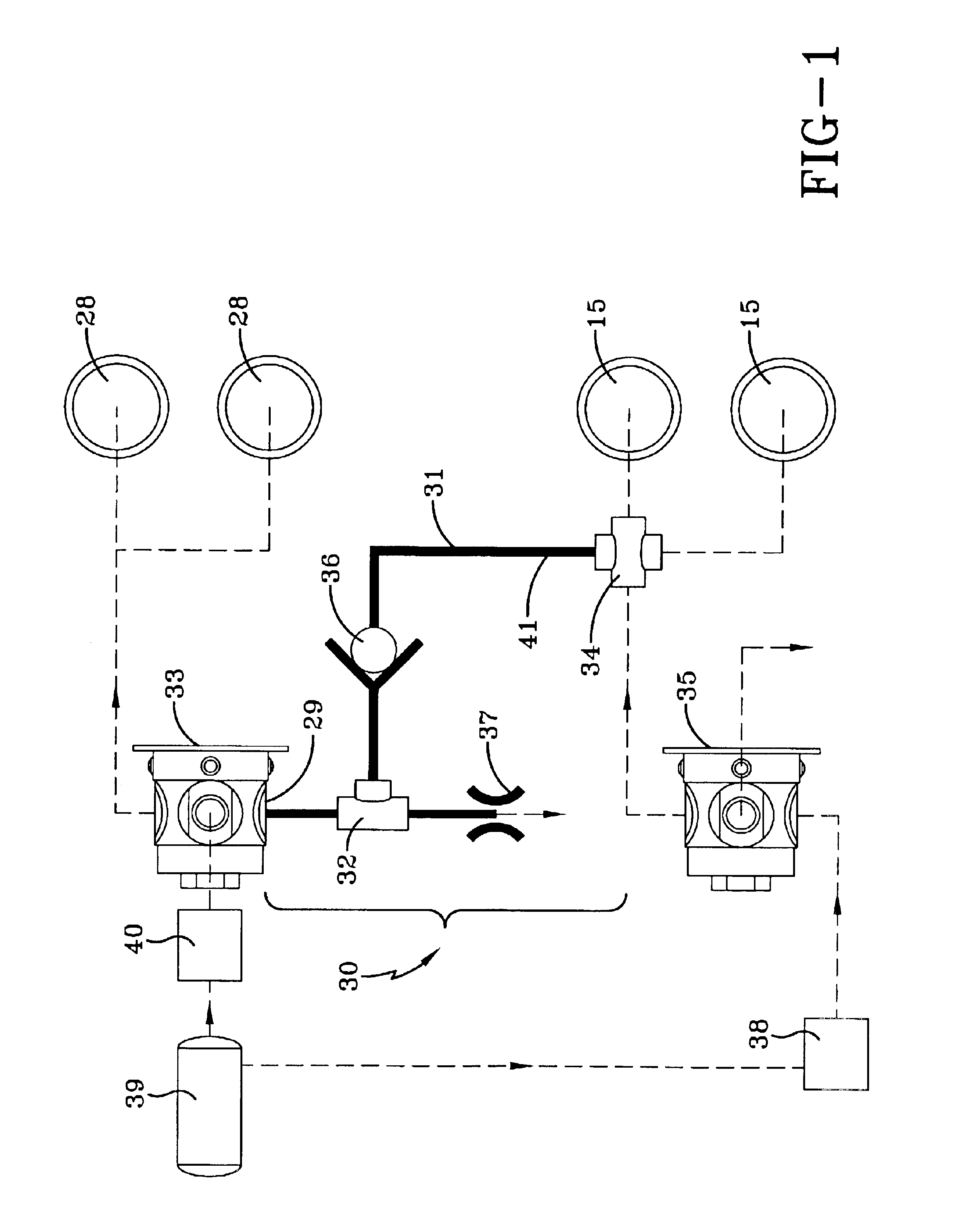

Motorcycle wheel stand for parking and transport

An improved motorcycle wheel stand having a set of guide rails (12), a set of vertical supports (14), a positive stop (18), and a perpendicular stabilizing tube (16). The wheel is clamped by pressure supplied by an air spring (38) acting upon a pivoting lever (24) attached to a rotating shoe assembly (21) which rotates up and forward against the rear of the wheel, thus pushing the motorcycle into the stand. Removal of the motorcycle is accomplished by the pressing and cocking of assembly (21) by foot and rolling the motorcycle backwards. Assembly (21) is held down by virtue of the center line of spring (38) being out of line relative to spring mounting points (36) and (34) and the pivot point of lever (24).

Owner:WHEEL DOCK

Lift axle air pressure transfer control apparatus

InactiveUS6845989B2Sufficient pressureLower overall vehicle requirementVehicle cleaning apparatusLoading/unloading vehicle arrangmentOperational systemAir spring

A lift-type axle / suspension system of a heavy-duty vehicle includes ride air springs for providing vehicle load support when the system is lowered, and one or more lift air springs for selectively raising the system when such additional load support is unnecessary or when greater vehicle maneuverability is desired. An apparatus integrates and simultaneously controls the operating systems for the lift and ride air springs. The control apparatus includes a plurality of conduits and valves which enable pressurized air from the lift air springs to be rapidly provided to the ride air springs when the system is being lowered. The additional air supplements the normal source of air from the vehicle compressed air source to ensure sufficient and timely air for smooth and efficient operation of the ride air springs without excessive buckling or folding, thus maintaining adequate overall vehicle air pressure needed for operating other vehicle components.

Owner:HENDRICKSON USA L L C

On-board truck scale

InactiveUS20070181350A1Weighing auxillary devicesSpecial purpose weighing apparatusMicrocontrollerOn board

A system and method that can provide a measurement of the weight on a trailer or vehicle, e.g., a truck or rig. The system and method can be implemented on systems that are equipped with air suspension, as well as those without air suspension, unlike conventional systems that require air suspension systems for installation. Additionally, the system and method can yield gross trailer weight, even if the truck is not instrumented. Further, the system and method can provide axle weight on properly equipped axles. A system for measuring weight on a trailer of a vehicle has a sensor system having a plurality of sensors, wherein each sensor is attached to an axle of the trailer or the vehicle. A microcontroller receives a transmission of strain change from a sensor. A display unit displays a calculated weight on the trailer from the microcontroller.

Owner:STEMCO LP

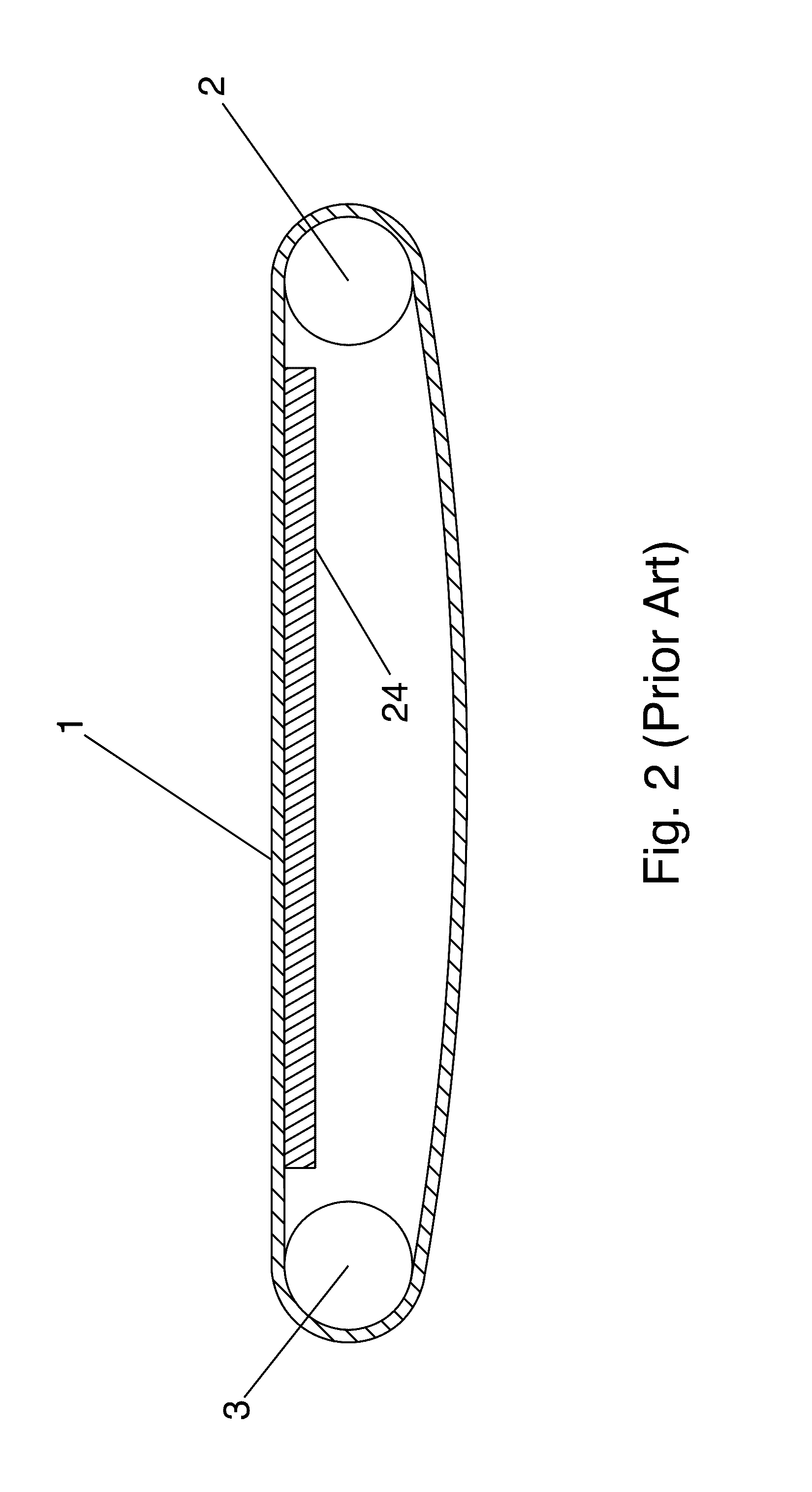

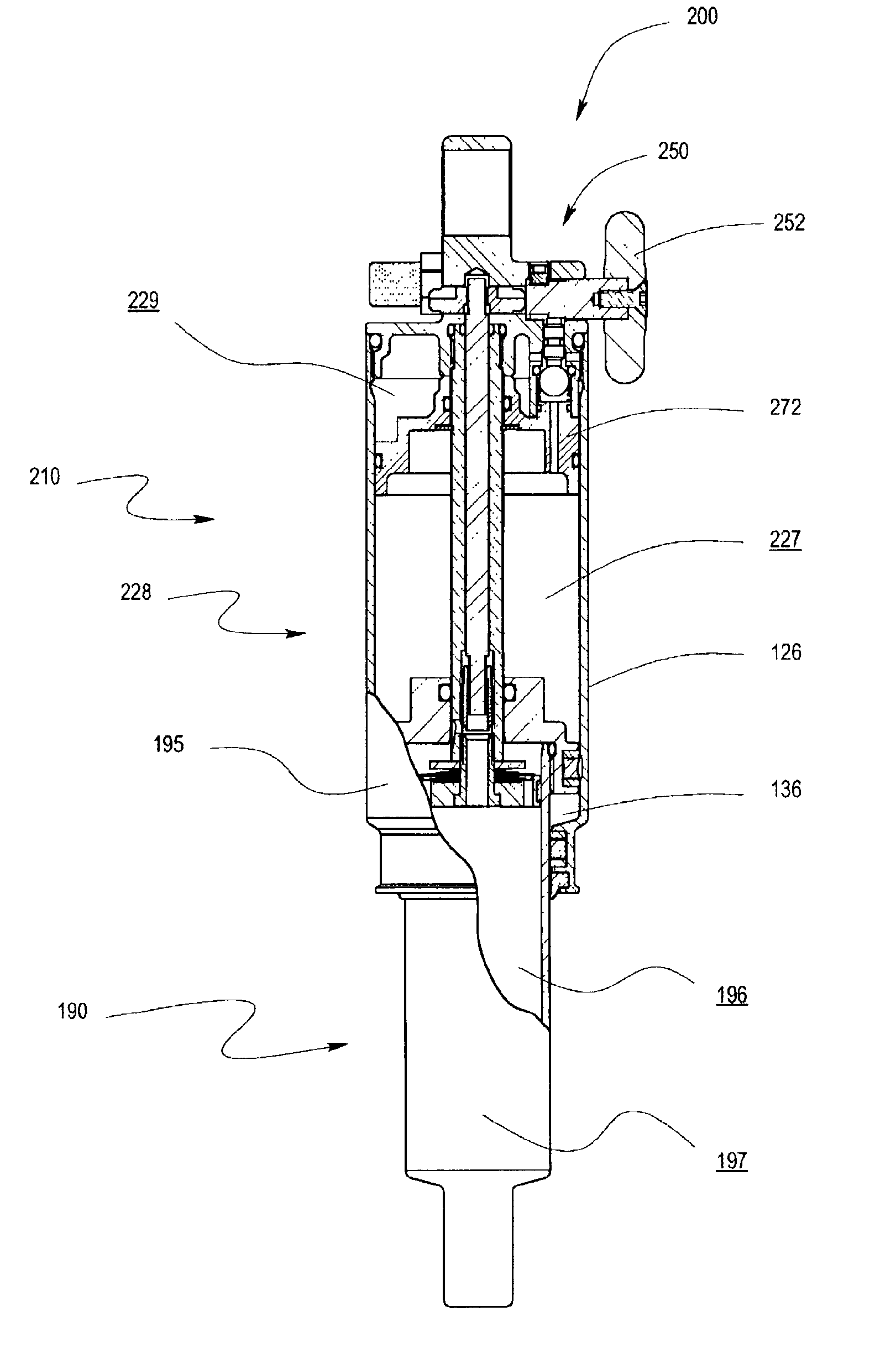

Shock-absorbing treadmill

ActiveUS8435160B1Movement coordination devicesCardiovascular exercising devicesAir springEngineering

A treadmill having one or more air springs attached to the underside of the treadmill and one or more wheels on the underside of the treadmill near the back end of the treadmill, to provide increased shock-absorption over conventional treadmills. Other embodiments disclosed herein include treadmills with the above-discussed components as well as one or more air compressors, pressure sensors, and / or weight sensors for adjusting the level of pressure in the one or more air springs, based on the weight of a person using such a treadmill.

Owner:DH2PM2 LLC

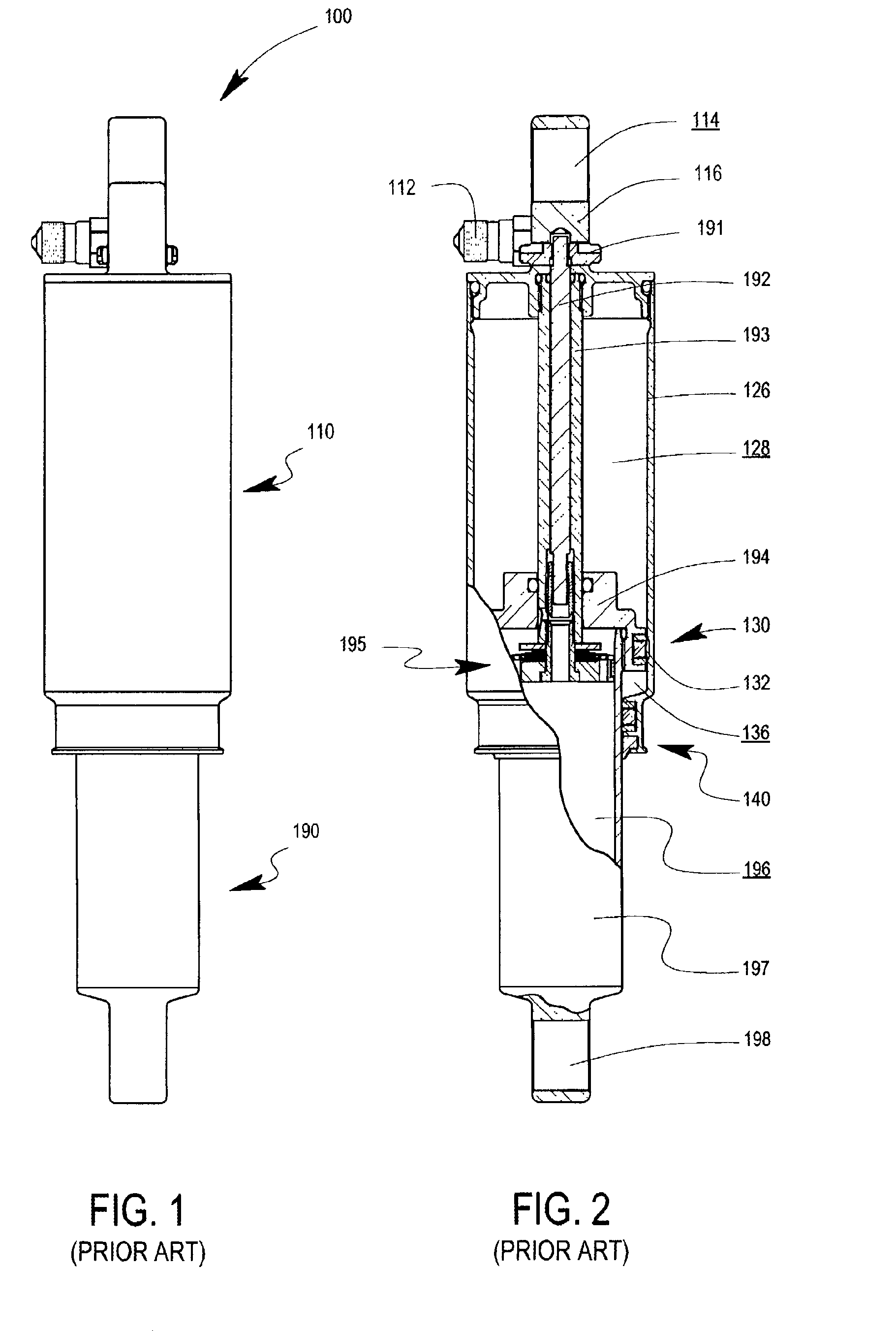

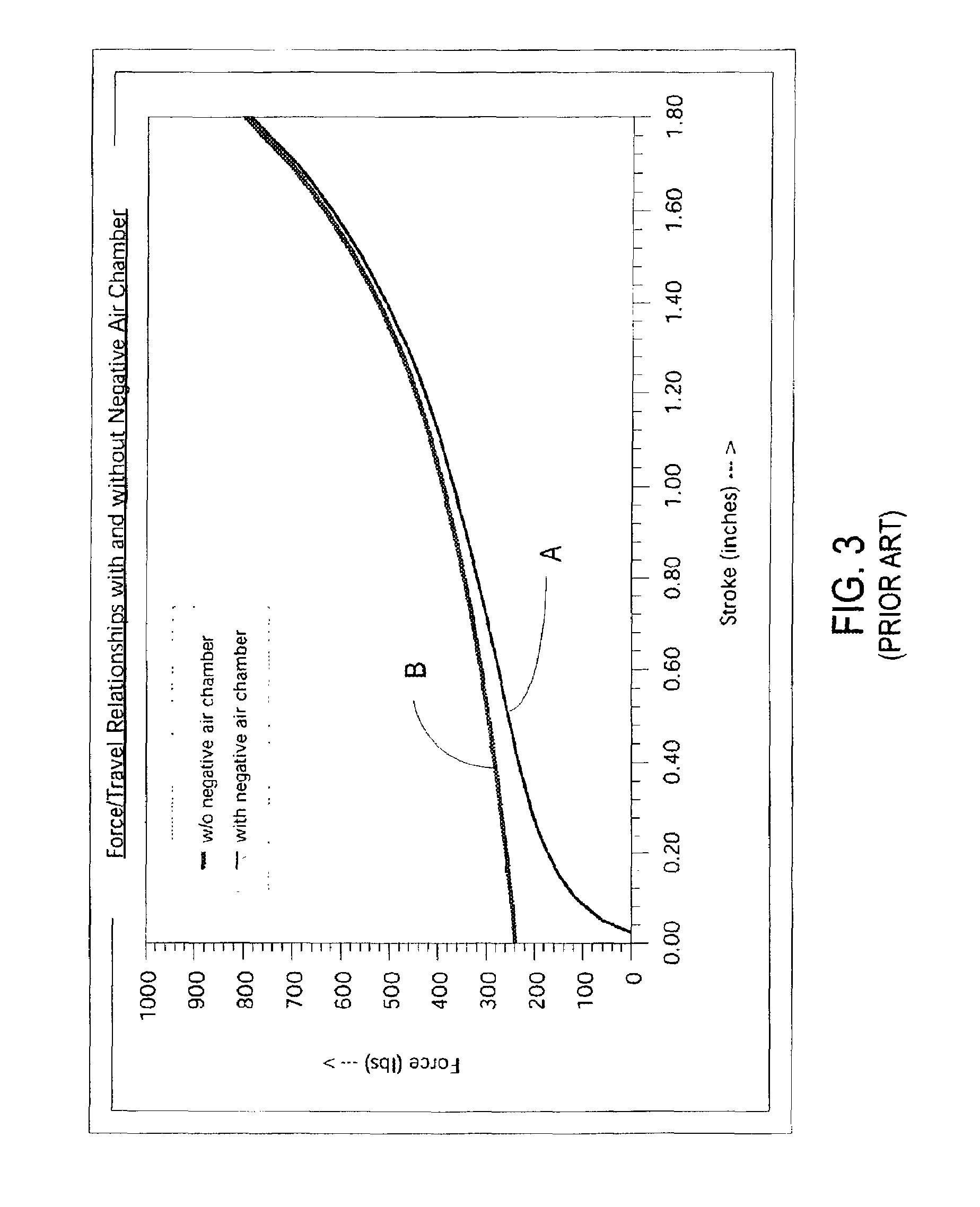

Integrated and self-contained suspension assembly having an on-the-fly adjustable air spring

InactiveUS7641028B2The process is convenient and fastThe process is simple and fastCycle springsSprings/dampers functional characteristicsElectricityGas cylinder

An integrated and self-contained suspension assembly having a gas spring integrated with a shock absorber (damper) is described. The rigid gas cylinder of the air spring is divided into a first gas chamber and a second gas chamber. A flow port connects the first and second gas chambers, and can be manually opened or closed by valve and a simple one-quarter turn rotation of an external knob to instantly switch the gas spring between two different spring rates. The different spring rates are functions of the separate or combined volumes of the two gas chambers. The integrated suspension assembly is compactly packaged and self-contained, i.e., does not require any externalities, such as gas sources or electricity, to operate.

Owner:FOX FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com