Bogie of high-speed motor train unit

A high-speed EMU and bogie technology, which is applied in the direction of the lateral relative movement between the bogie, the underframe and the bogie, the wheels, etc. Dynamic performance, optimized design platform, structural improvement and performance optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

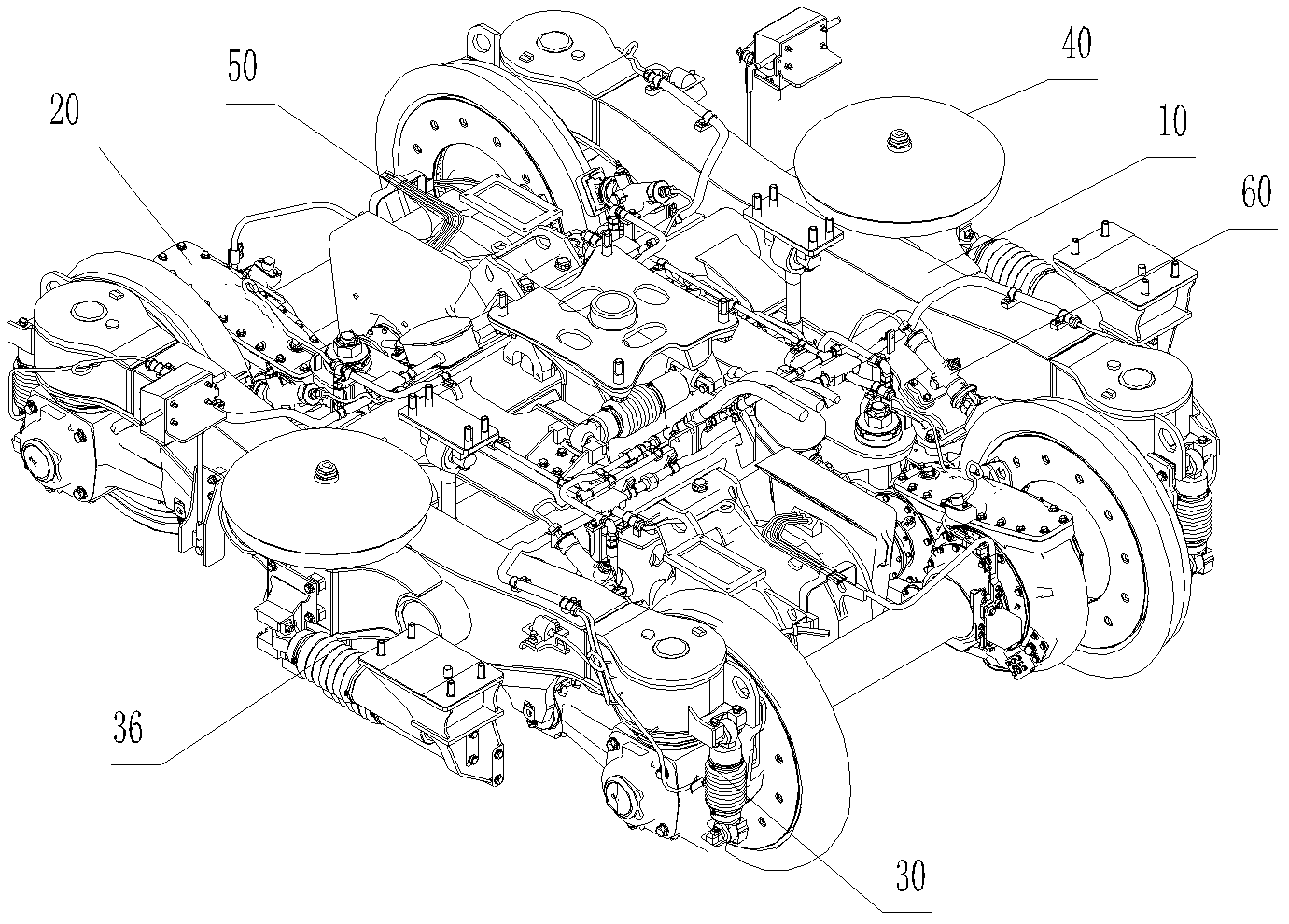

[0081] Example 1, such as figure 1 and Figure 17 As shown, the high-speed EMU bogie mainly includes a frame 10, a wheel set running device 20, a primary suspension device 30, a secondary suspension device 40, a driving motor 26, a traction device 50, and a foundation braking device 60. in,

[0082] A foundation braking device 60 is installed and fixed on the outer side of the frame 10, which includes a pair of side beams 11 and a pair of cross beams 12 connected to each other;

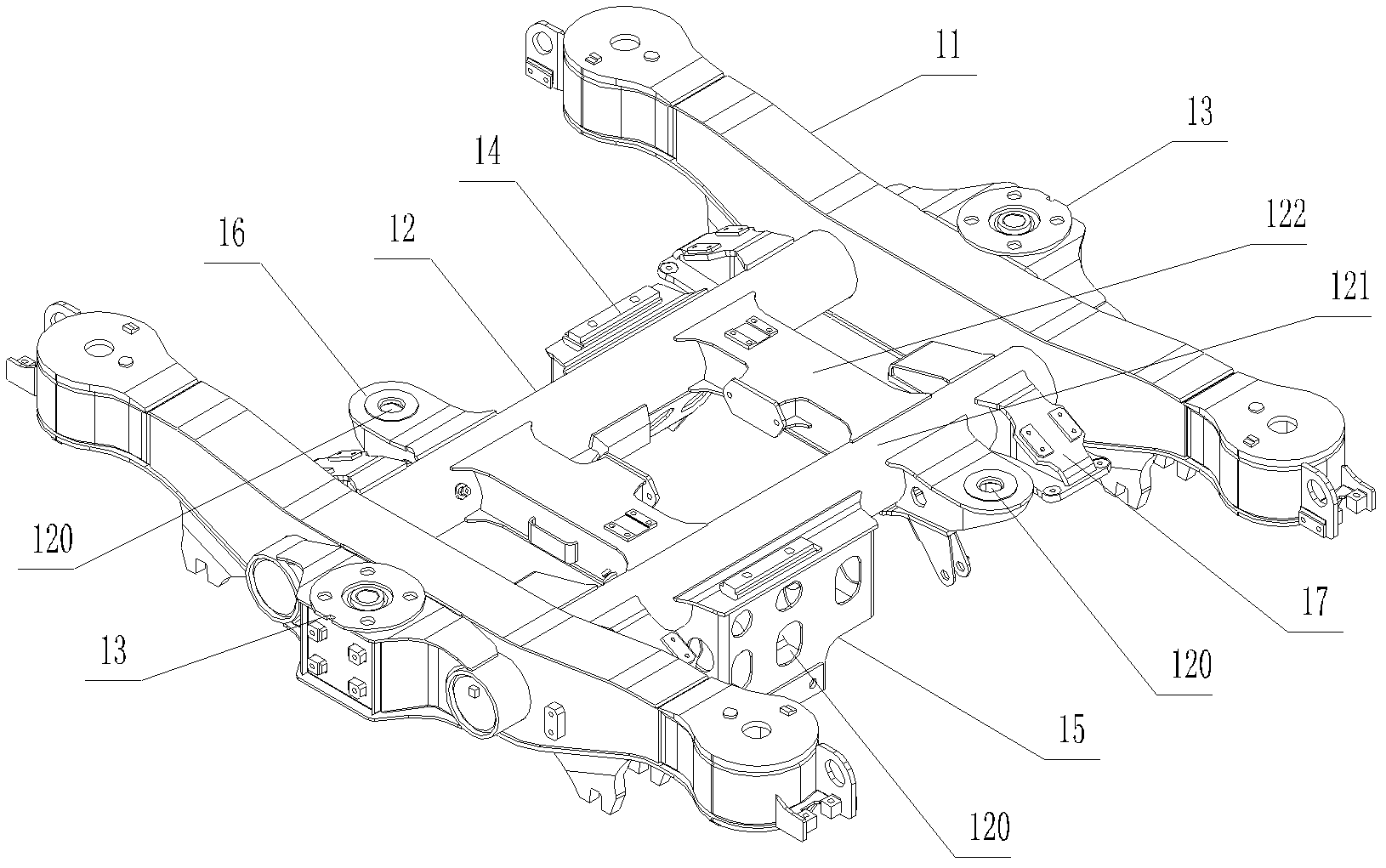

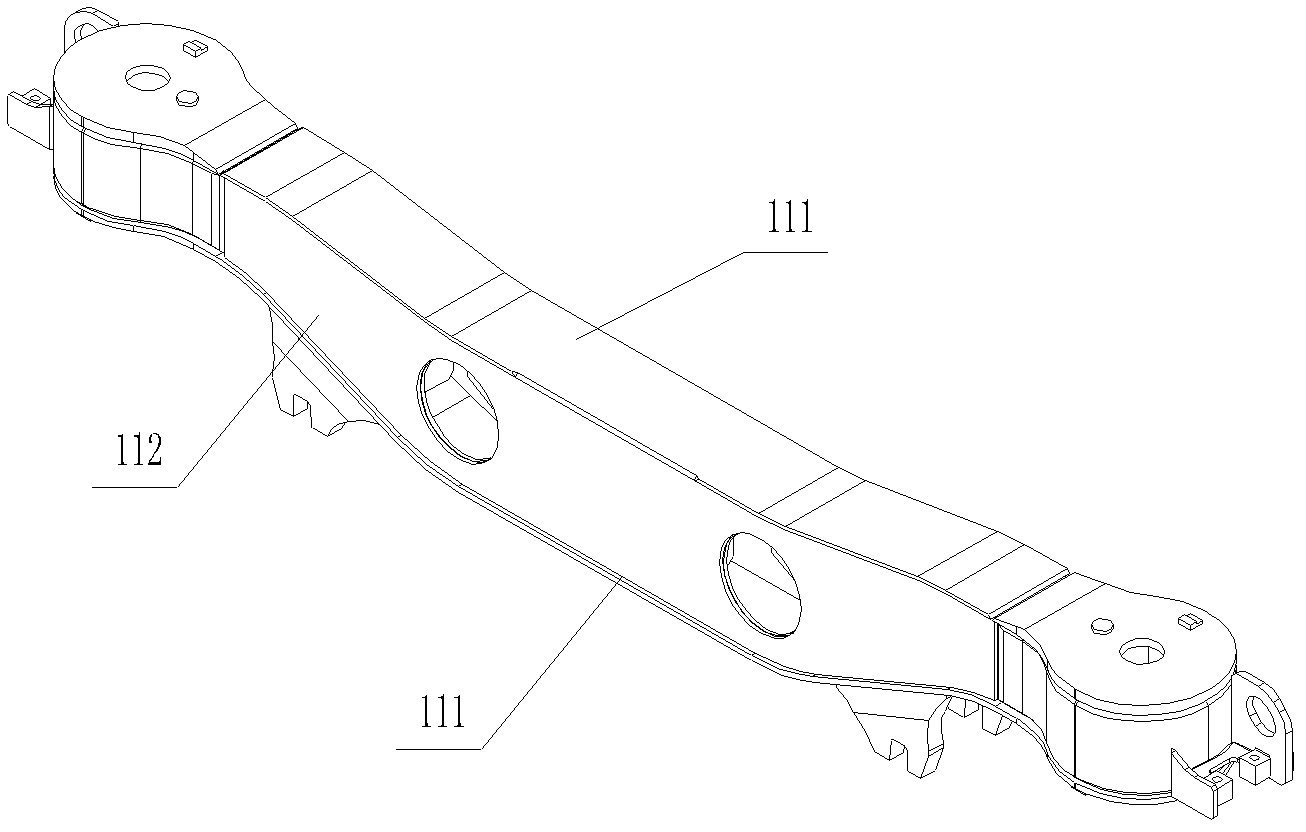

[0083] The side beam composition 11 has a hollow box structure, including a pair of upper and lower cover plates 111 and a pair of side webs 112 formed by welding; A pair of welded hollow steel pipes 121; a pair of air spring support beams 13 are welded and installed on both ends of the steel pipes 121 and outside the side webs 112, and the air spring support beams 13 have a hollow box structure. The beam composition 12, at least one longitudinal auxiliary beam 122 is welded between a pair of steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com