Patents

Literature

385results about "Brake arrangement with braking member" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

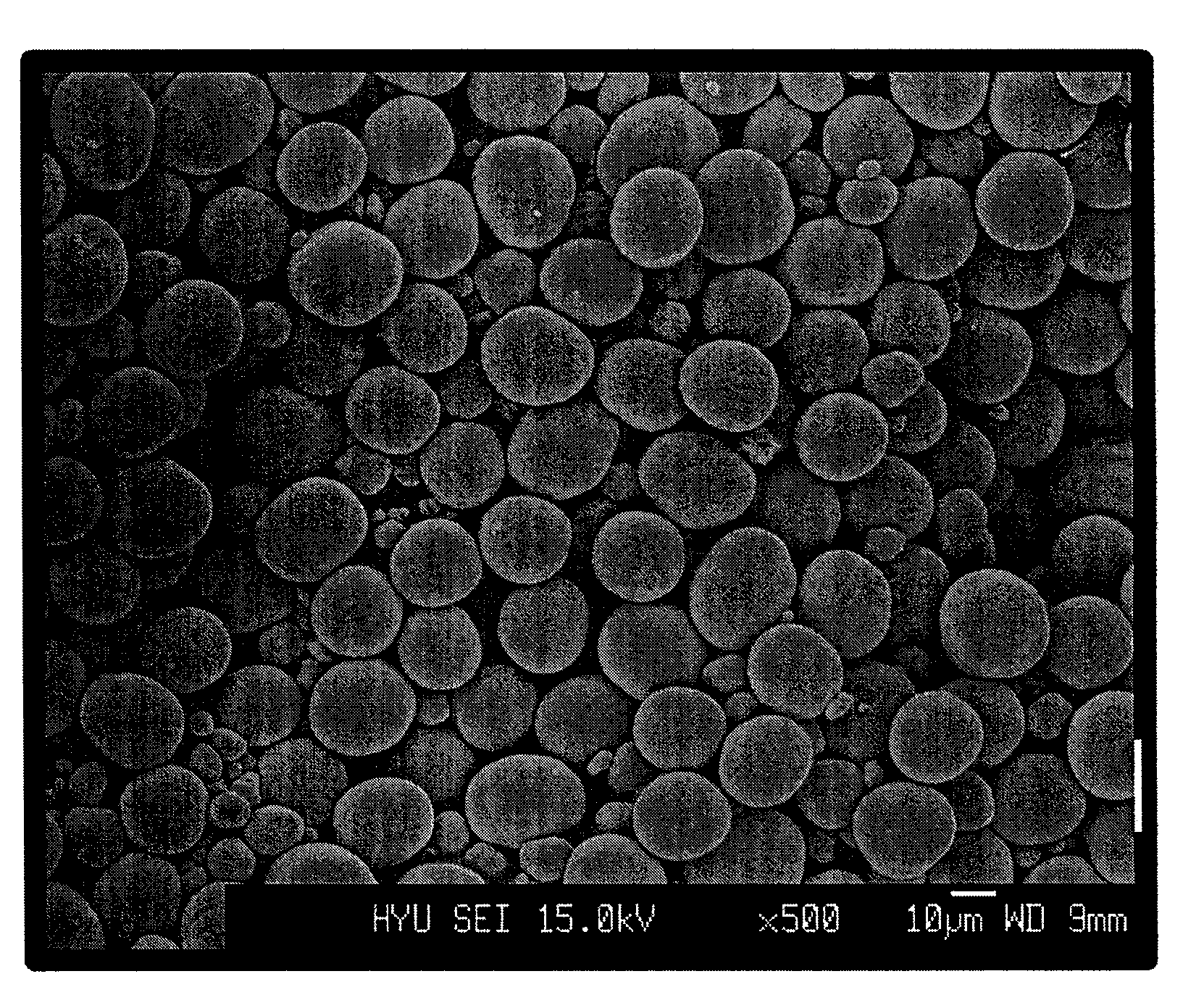

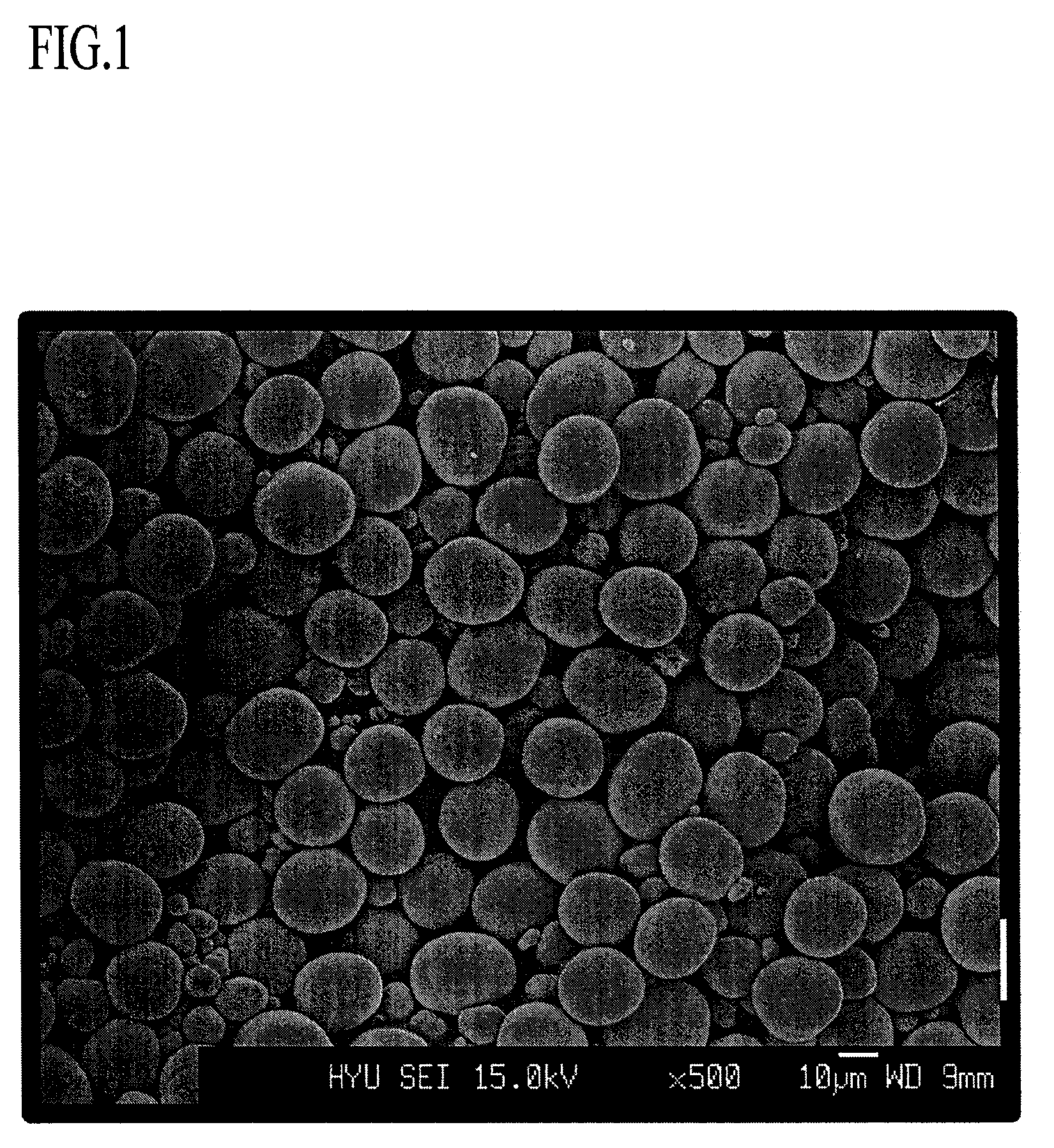

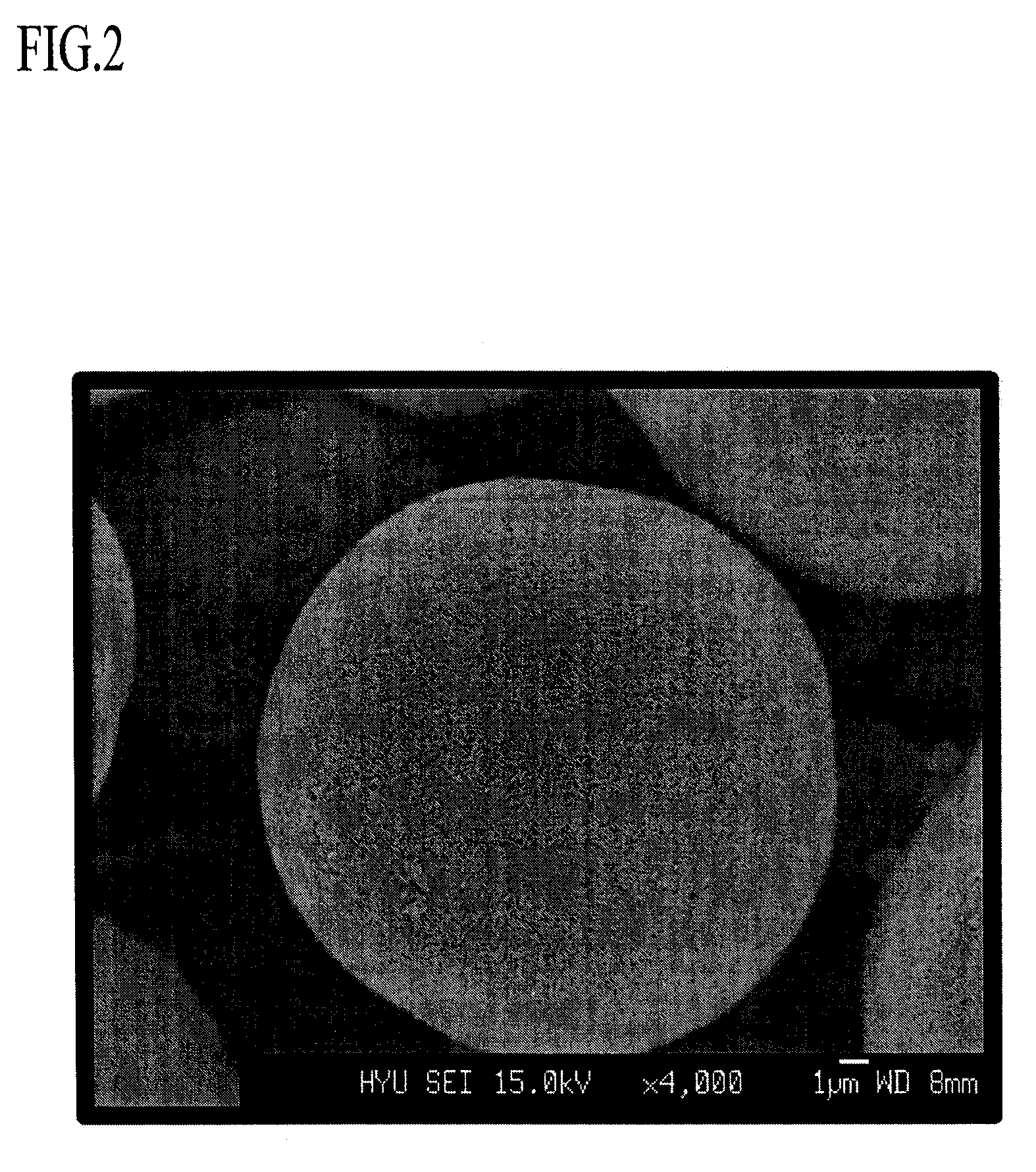

Positive active material for lithium battery, method of preparing the same, and lithium battery including the same

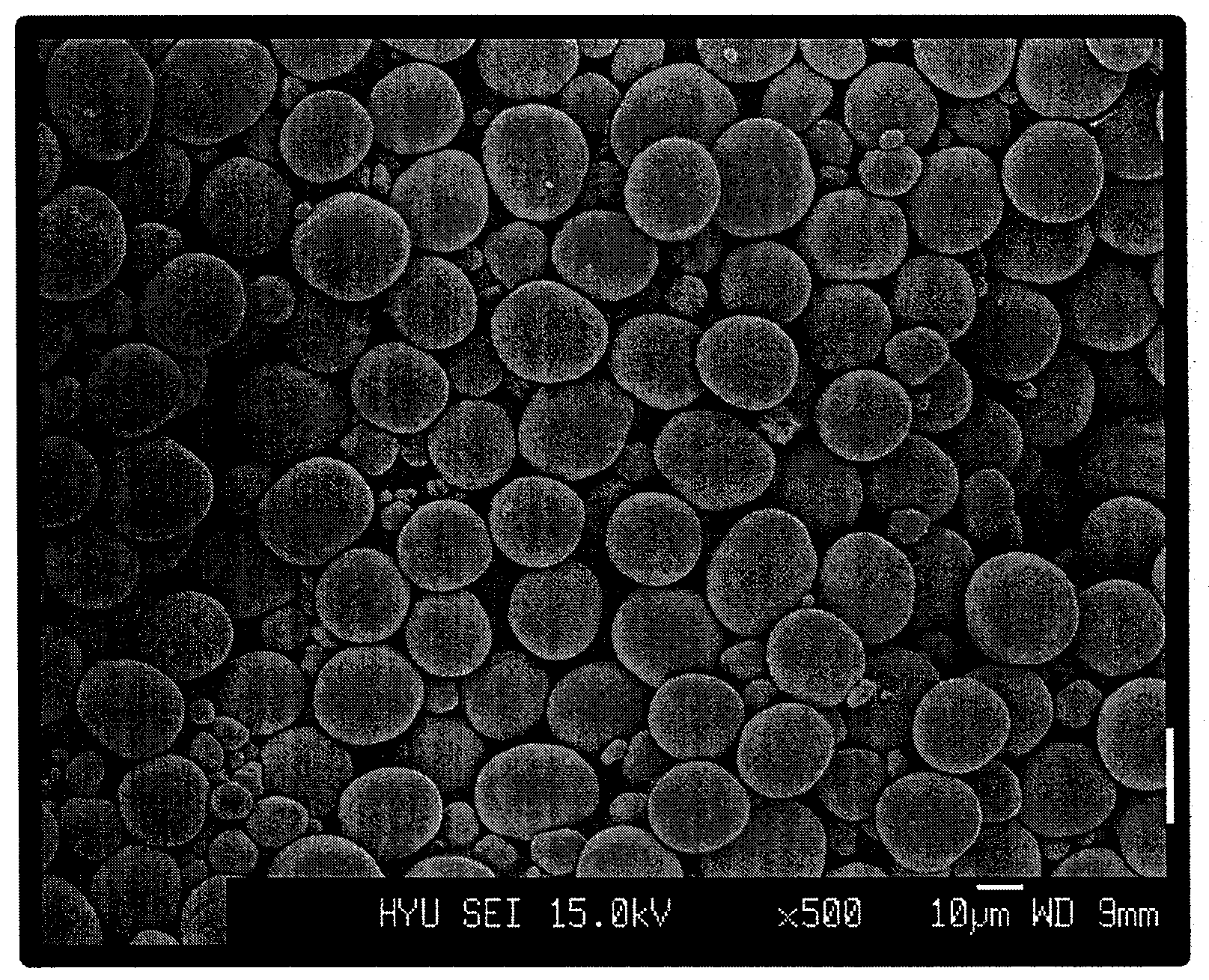

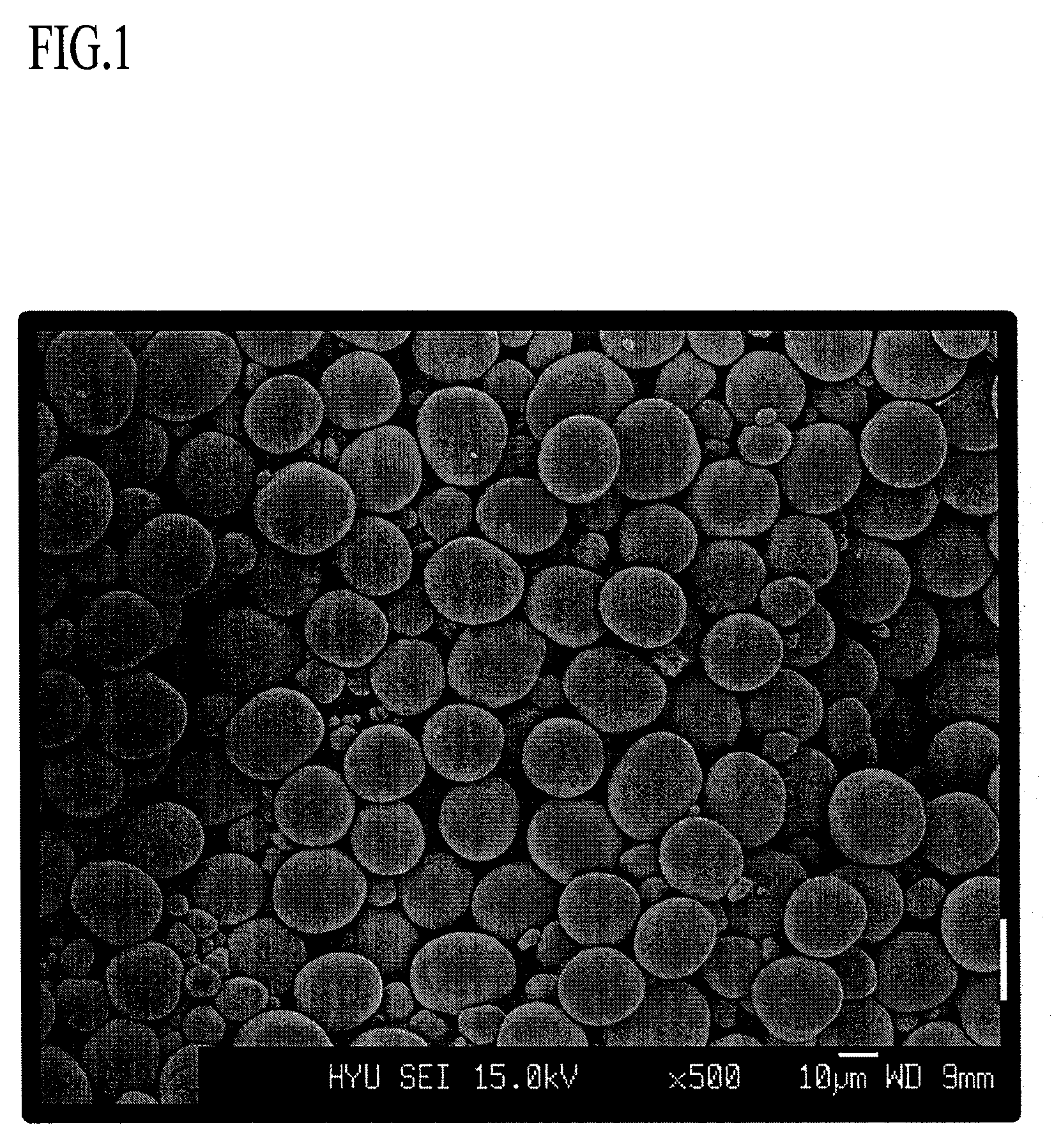

ActiveUS20090068561A1Conductive materialActive material electrodesConcentration gradientThermal stability

A positive active material according to one embodiment of the present invention includes an internal bulk part and an external bulk part surrounding the internal bulk part and has a continuous concentration gradient of the metal composition from an interface between the internal bulk part and the external bulk part to the surface of the active material. The provided positive active material in which the metal composition is distributed in a continuous concentration gradient has excellent electrochemical characteristics such as a cycle life, capacity, and thermal stability.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

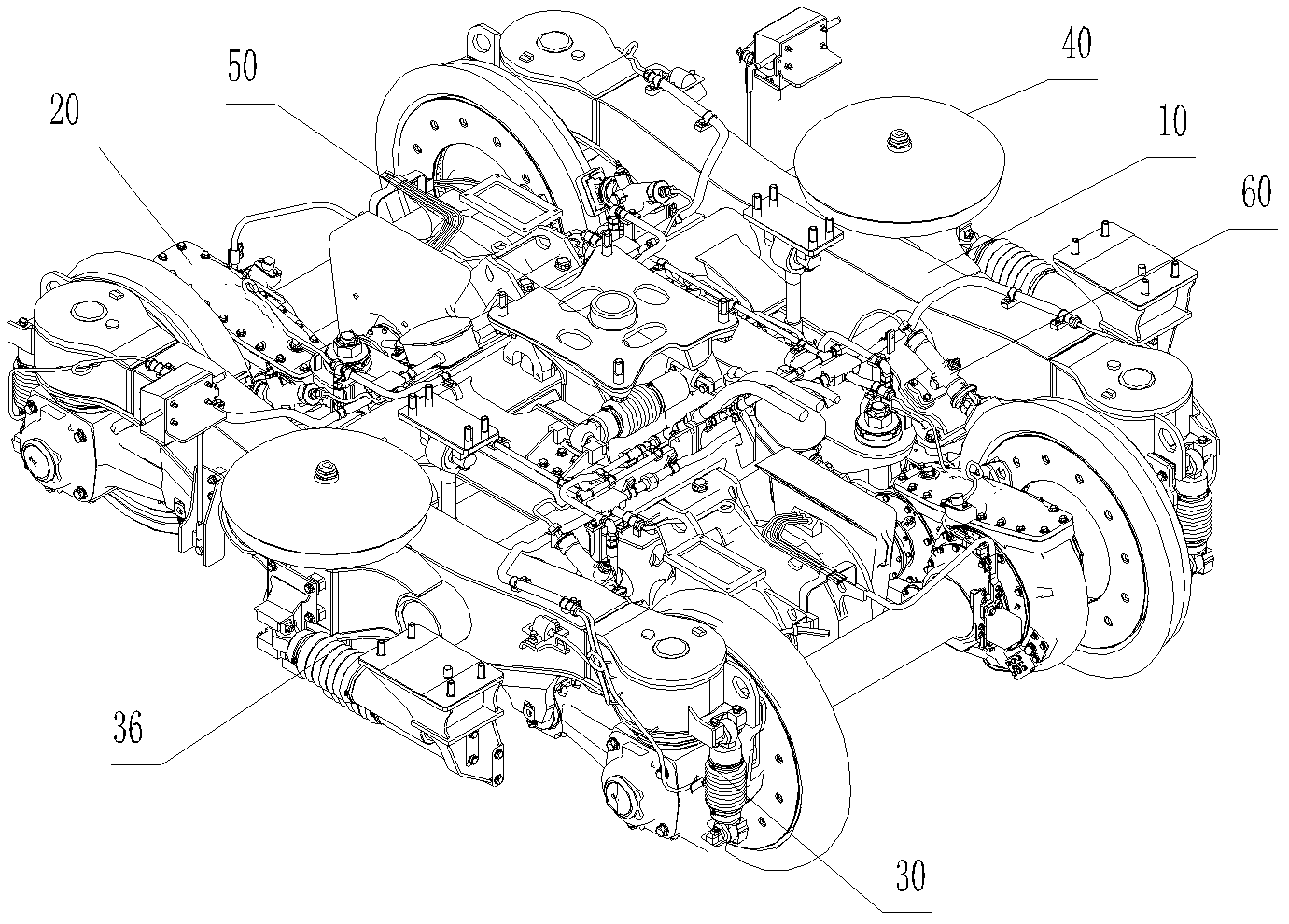

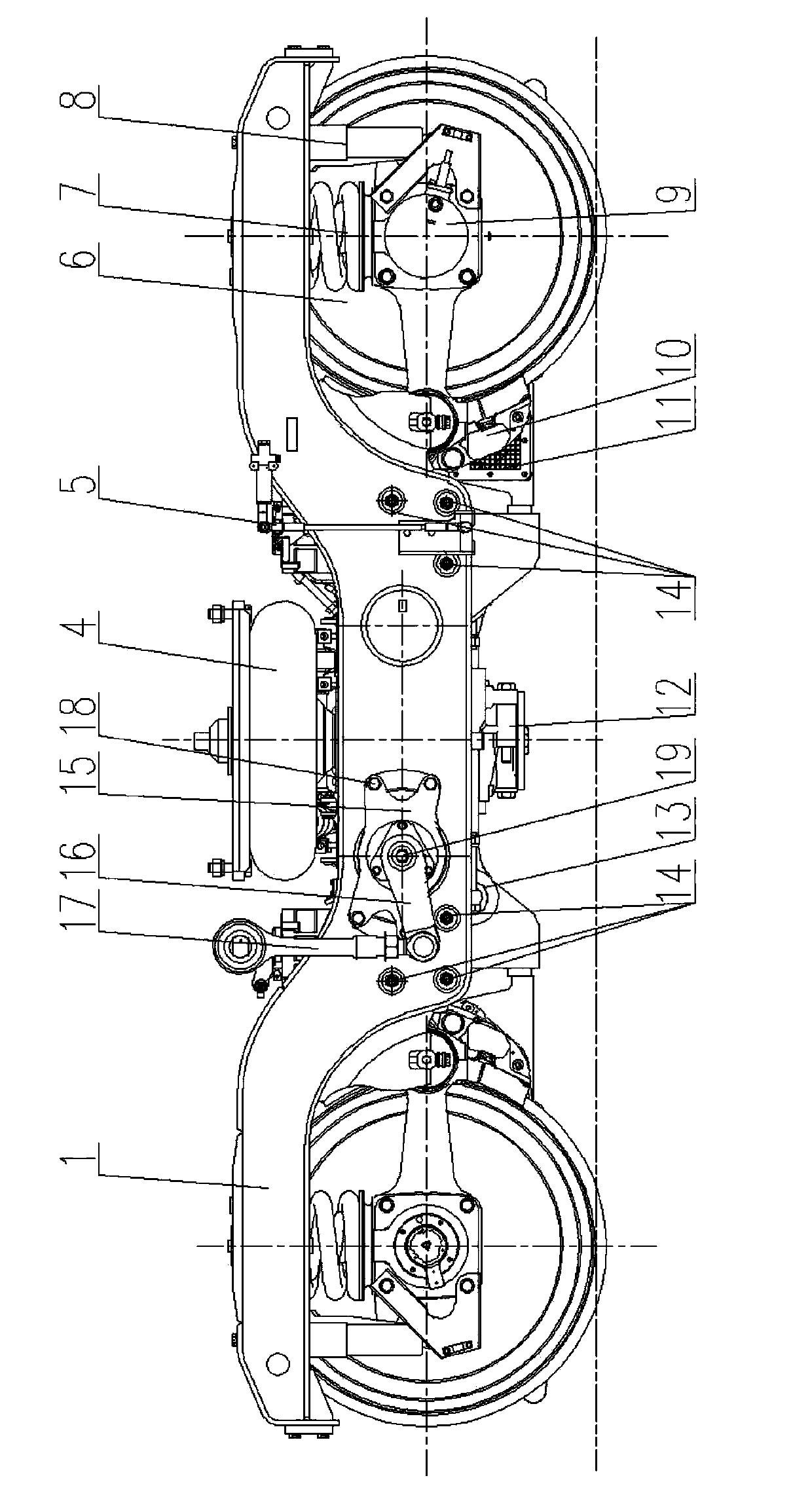

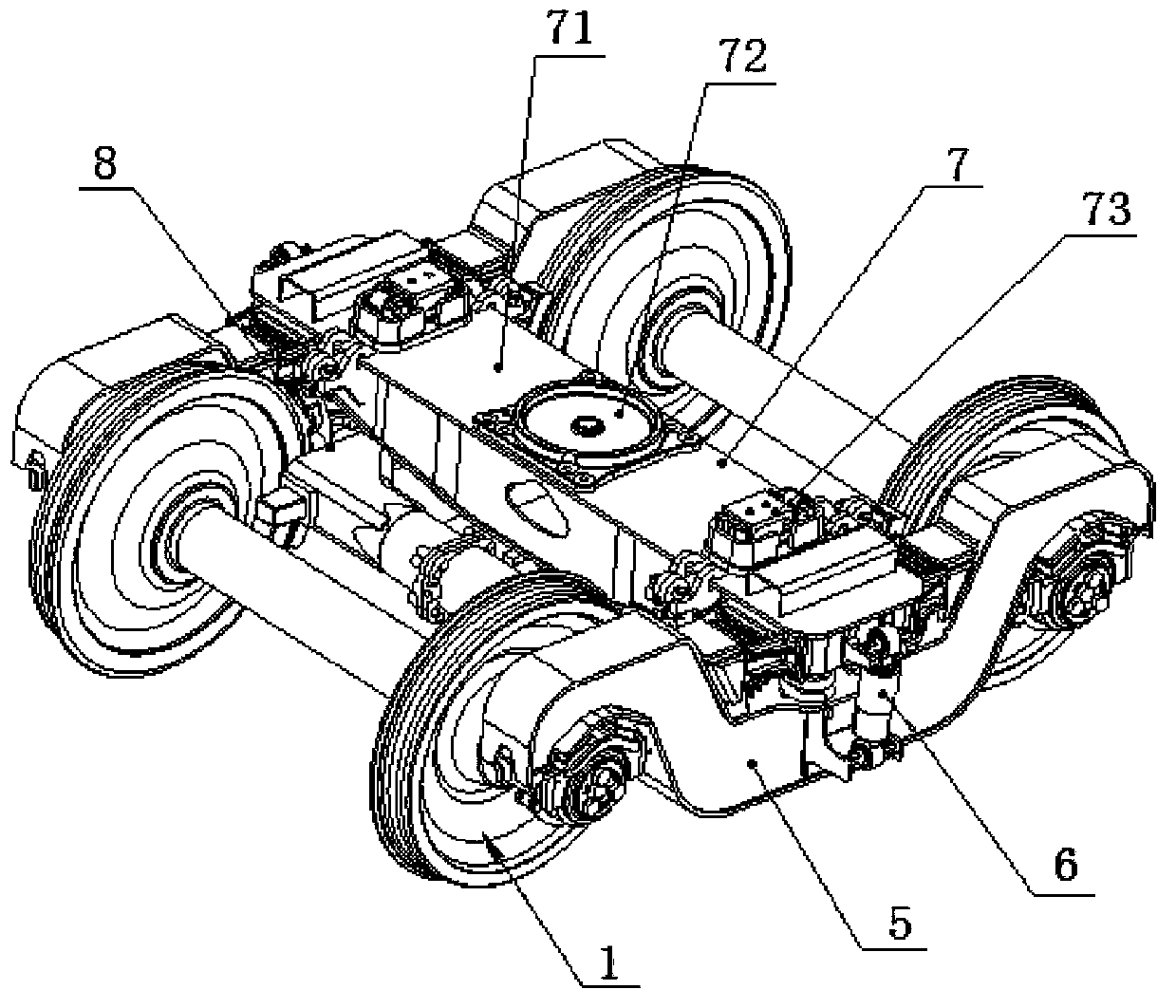

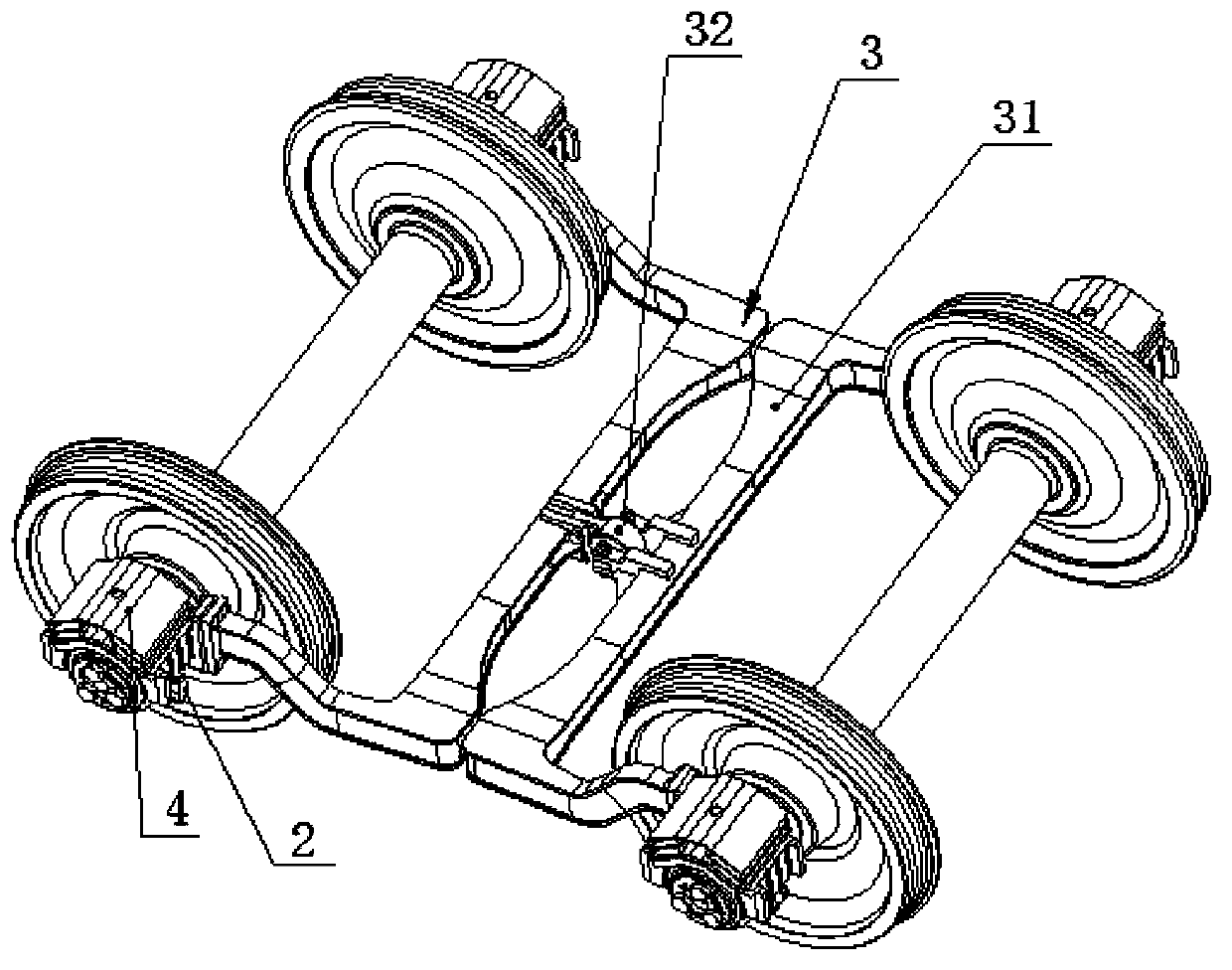

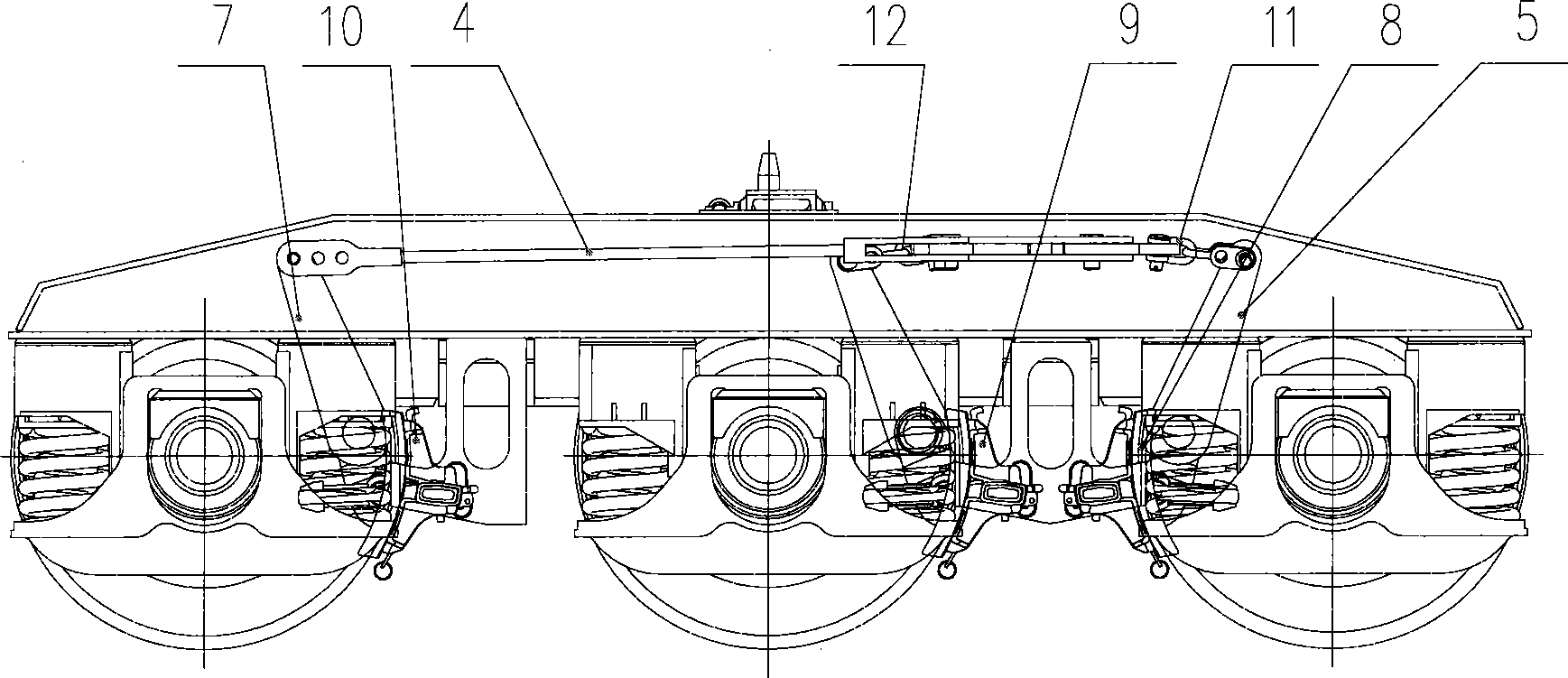

Bogie of high-speed motor train unit

InactiveCN102923153AAchieve lightweight designGuaranteed stabilityBogiesWheel-axle combinationsBogieAir spring

The invention discloses a bogie of a high-speed motor train unit. By adopting a brand-new bogie structure and a hanging connection and traction mode, overall lightweight design is realized, the unsprung weight of the bogie is reduced, and the hanging parameter between the bogie and a body is optimized. On the basis that the high-speed running speed is met, stability when the bogie passes through a big corner and good traction and braking performance are expected. The bogie comprises a framework, two groups of wheel set travelling devices, a linear motor, a first hanging device, a second hanging device, a traction device and a foundation brake device. The framework comprises a pair of side beam assemblies and a pair of cross beam assemblies which are connected with each other; each side beam assembly has a hollow box body structure, and comprises a pair of upper and lower cover plates and a pair of lateral web plates which are welded; each cross beam assembly comprises a pair of hollow steel pipes penetrating the lateral web plates and welded with the lateral web plates; and a pair of air spring supporting beams is welded at two ends of a steel pipe and outside the lateral web plates.

Owner:CRRC QINGDAO SIFANG CO LTD

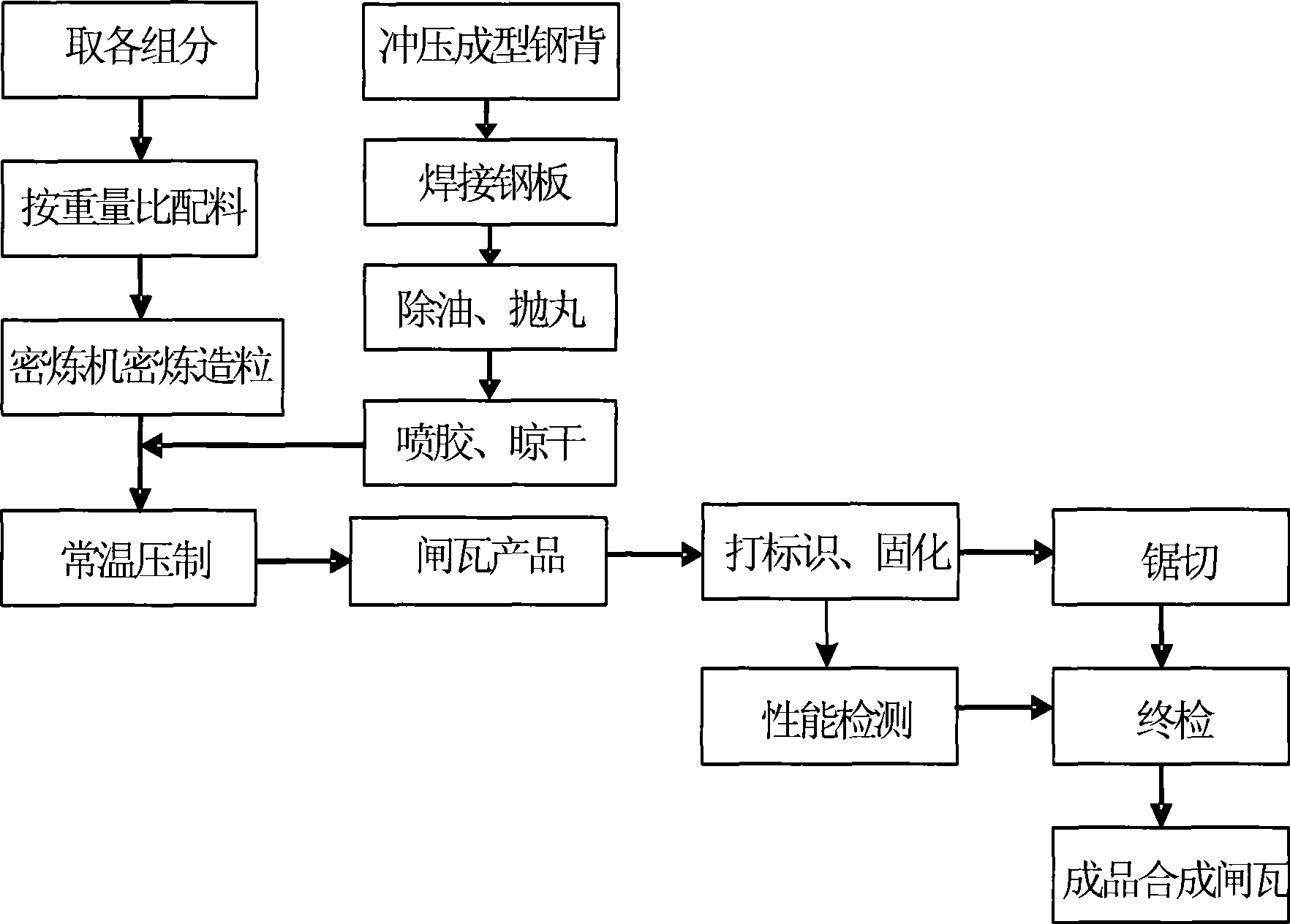

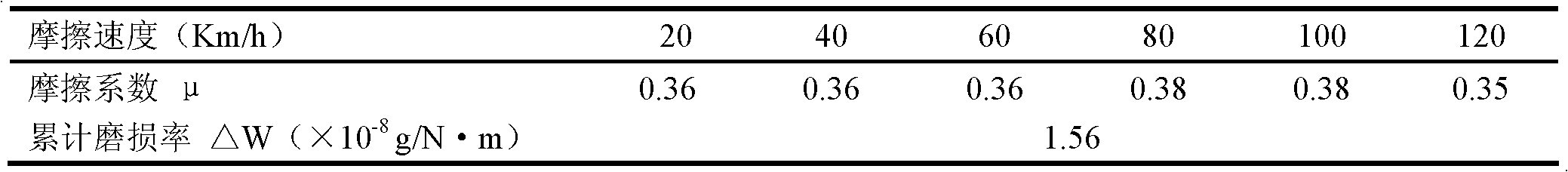

High friction composite brake shoe for railway freight car and manufacture method thereof

ActiveCN101391611AHigh compressive strengthHigh impact strengthBraking membersBrake arrangement with braking memberFiberEngineering

The invention discloses a high friction composite brake shoe for a railway wagon and a manufacturing method thereof. The composite brake shoe comprises: a steel back and a brake shoe body which is fixed on the steel back, wherein, the brake shoe body is prepared by materials which are synthesized by various components with the following weight ratio: 8 to13 parts of nitrile butadiene rubber, 2 to10 parts of styrene butasiene rubber, 5 to10 parts of cresol modified A-stage phenolic resin, 15 to 30 parts of steel fiber, 10 to 15 parts of magnesium oxide, 5 to 10 parts of calcined petroleum coke, 2 to 5 parts of silicon carbide, 10 to25 parts of mineral fiber, 5 to 10 parts of calcium hydride, 10 to 20 parts of barium sulfate, 5 to 10 parts of graphite, 1 to 5 parts of molybdenum disulfide, 1 to 5 parts of carbon black, 1 to 3 parts of sulfur and 1 to 3 parts of enhancer. The brake shoe can be used in the railway heavy-duty high-speed wagon and has stable friction performance and better wear resistance; the brake shoe can effectively inhibit the phenomena of metal inlay, cracks, dropping blocks and the like and reduce the damages on wheels; and the brake shoe is characterized by better impact resistance performance and good weatherability.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

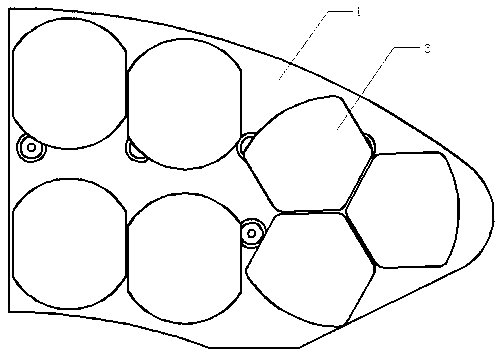

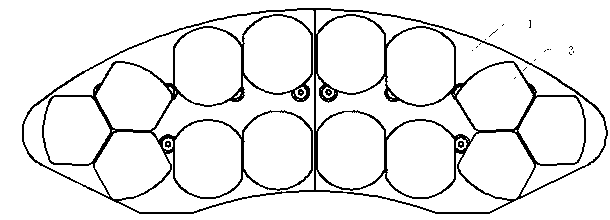

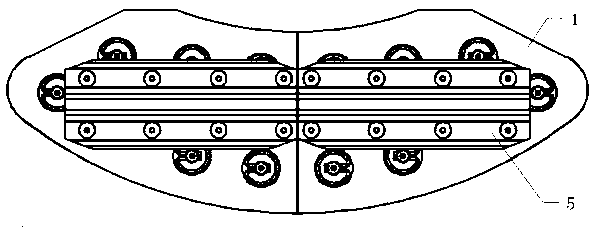

Copper-based powder metallurgy high speed brake lining

InactiveCN101493127AComply with work performance requirementsEffect of small friction propertiesBraking membersFriction liningBoron nitrideSilicon dioxide

The invention provides a copper based powder metallurgy high speed brake lining, which comprises a steel backing, a brake block, a framework, a spring washer and a swollen tail block. In the course of braking, the brake lining has smaller abrasion loss and can effectively prevent the edge dropping, angle dropping and camber wear of the brake block. The brake block uses copper based powder metallurgy friction material; copper powder, iron powder, tin powder, chromium powder, titanium powder, nickel powder, bismuth meal, graphite, boron nitride, aluminum oxide, silicon dioxide, zirconite and the like are well blended according to the proportion, stamped and sintered on the framework after cold pressing. The copper based powder metallurgy high speed brake lining has the characteristics of high mechanical strength, good thermal conduction, good thermal stability, strong heat-resistant fade performance, long service life, small abrasion on a retarding disc and stable friction performance and the like, and can effectively control very high way trains with 200-300km / h per hour.

Owner:贵州新安航空机械有限责任公司

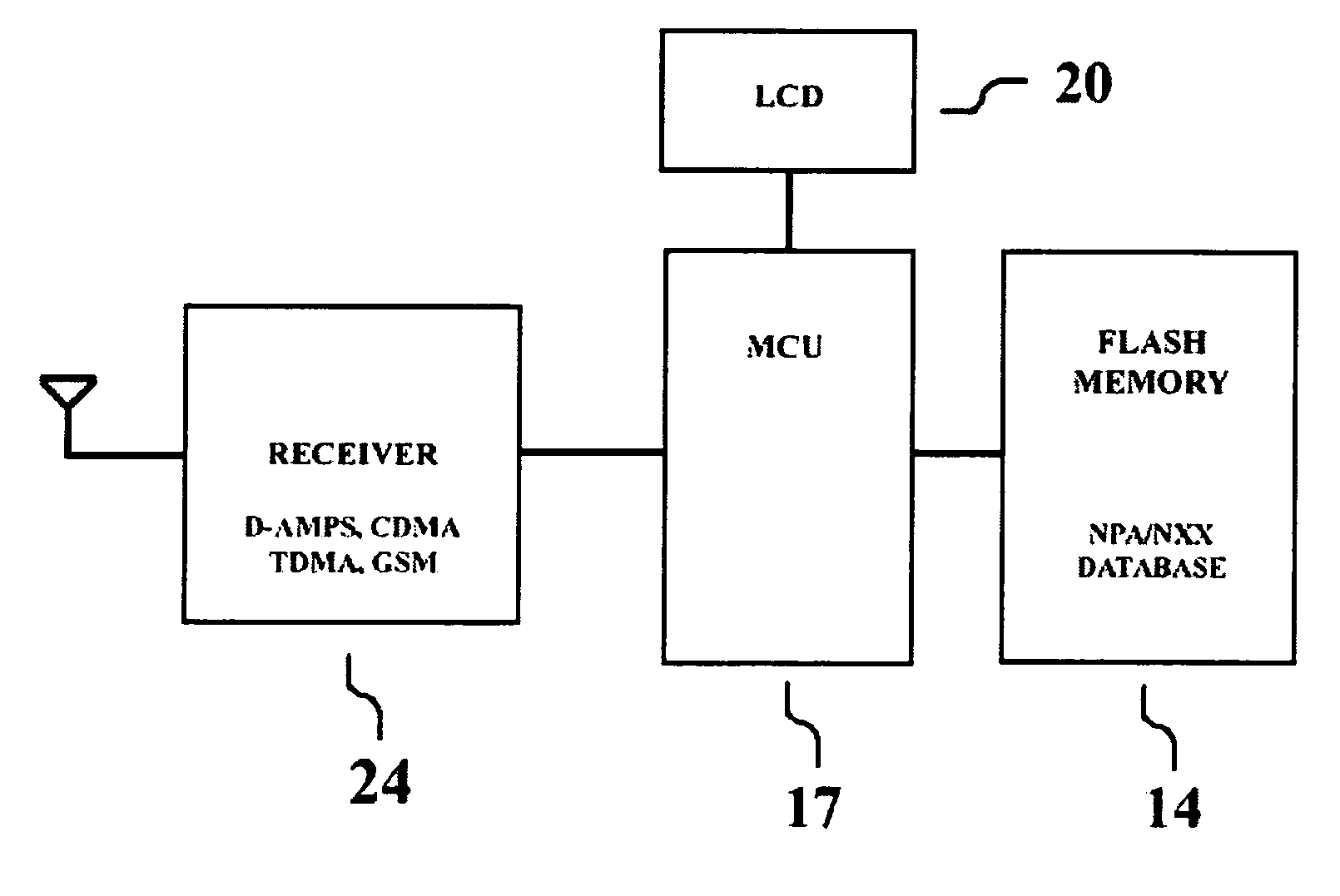

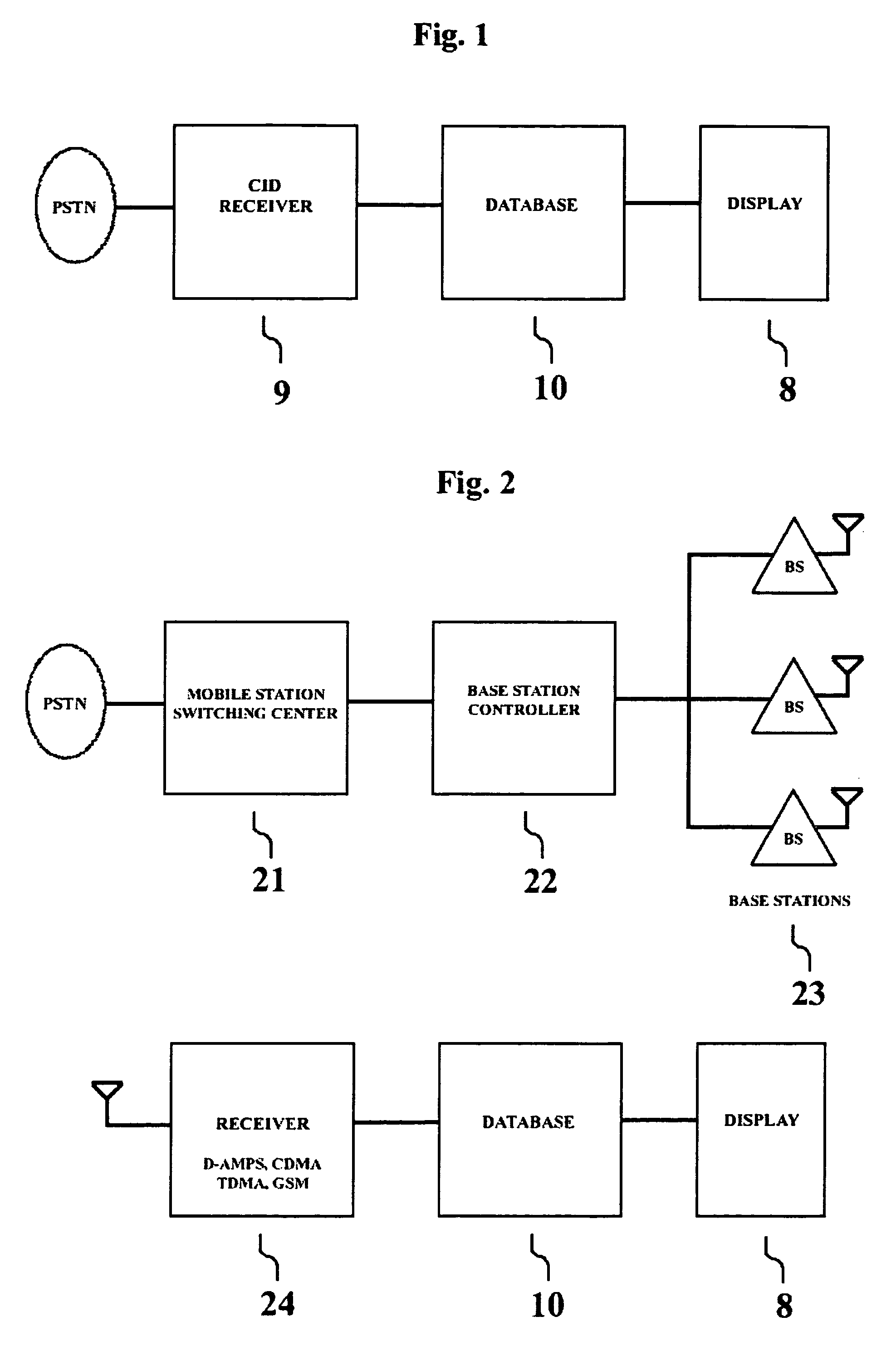

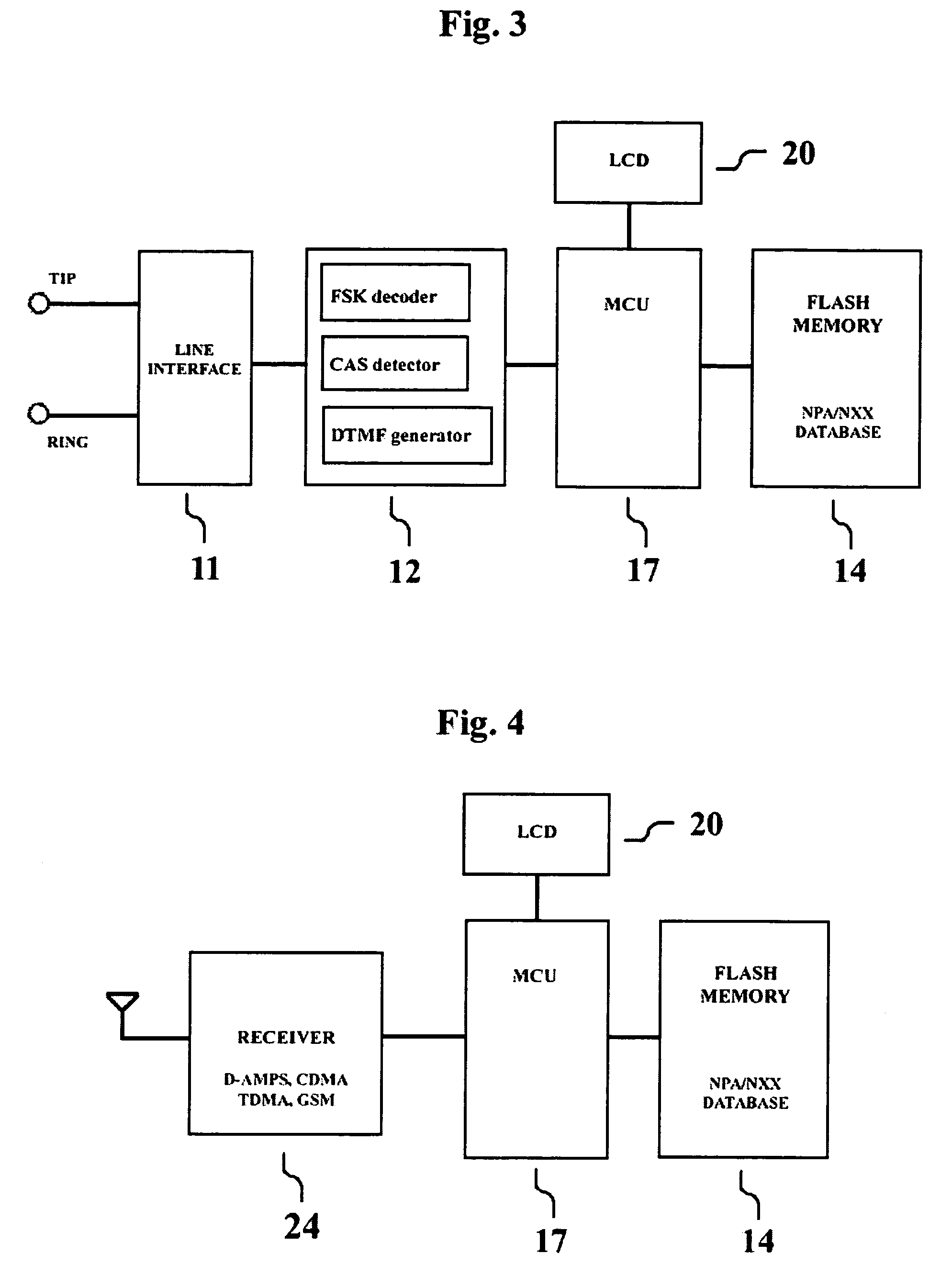

Decoding and processing system for advanced determination and display of city and state caller information

InactiveUS7200212B2Convenient and efficient displayEver-increasing numberSpecial service for subscribersServices signallingMicrocontrollerCall origination

An improved decoding and processing system is provided for advanced determination and display of geographic information to a called party relating to the call origination party. The improved system comprises a receiving means to receive the calling number delivery (CND) message from a local central office (CO) switch or mobile station switching center; a microcontroller storage and retrieval device containing a data base library for selectively determining the corresponding geographic information such as city and / or state by matching the area code and / or local exchange number received from the call origination party; and a readout device for displaying the city and / or state of the incoming call. Preferably, the system includes capability to automatically update the data base library of the storage and retrieval device as new area codes and / or local exchanges are subsequently assigned. Accordingly, the improved system provides the user with convenient and efficient display of geographic information related to caller identification that is capable of determining an ever-increasing number of area code and local telephone exchange numbers.

Owner:CEQUINT INC

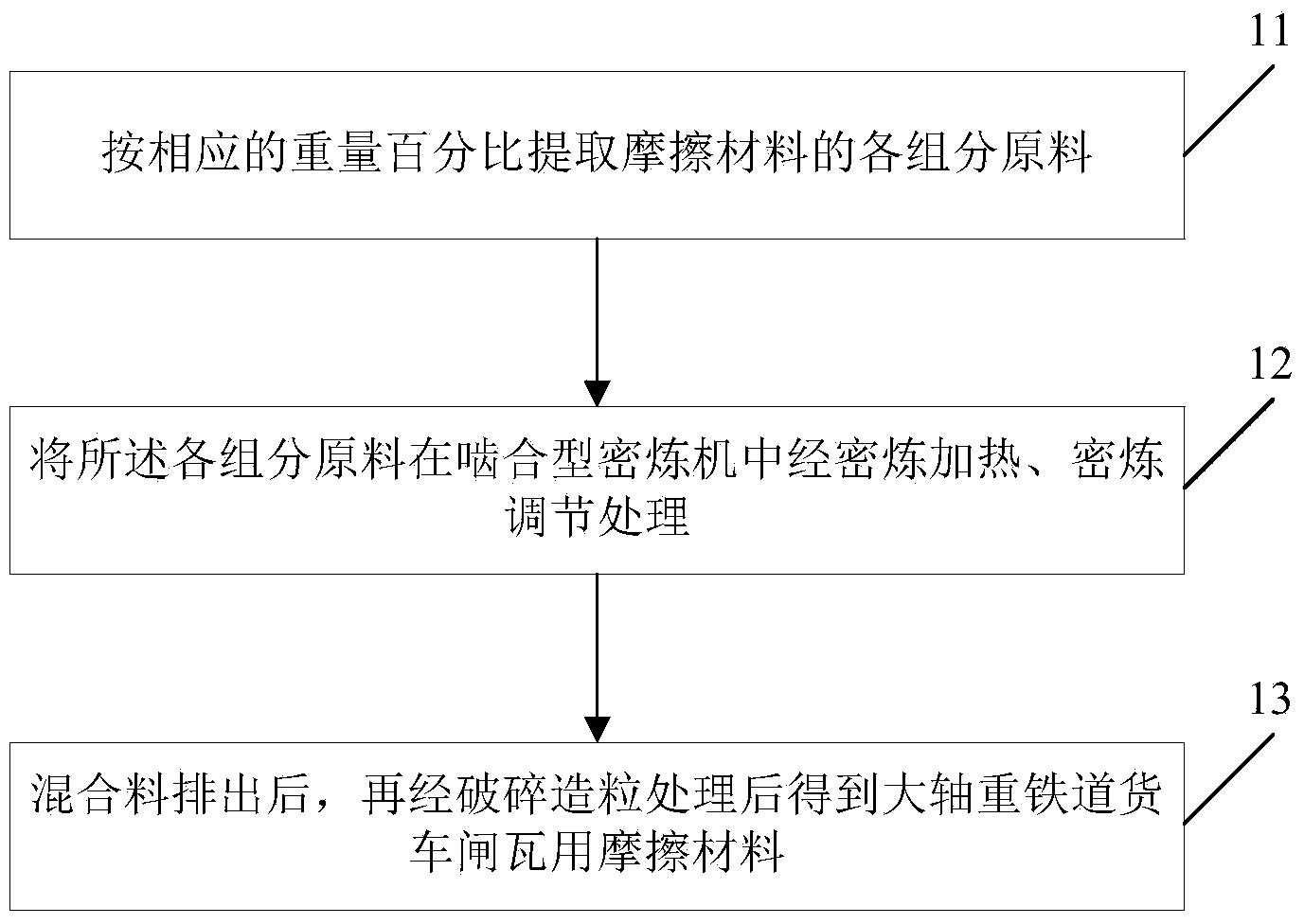

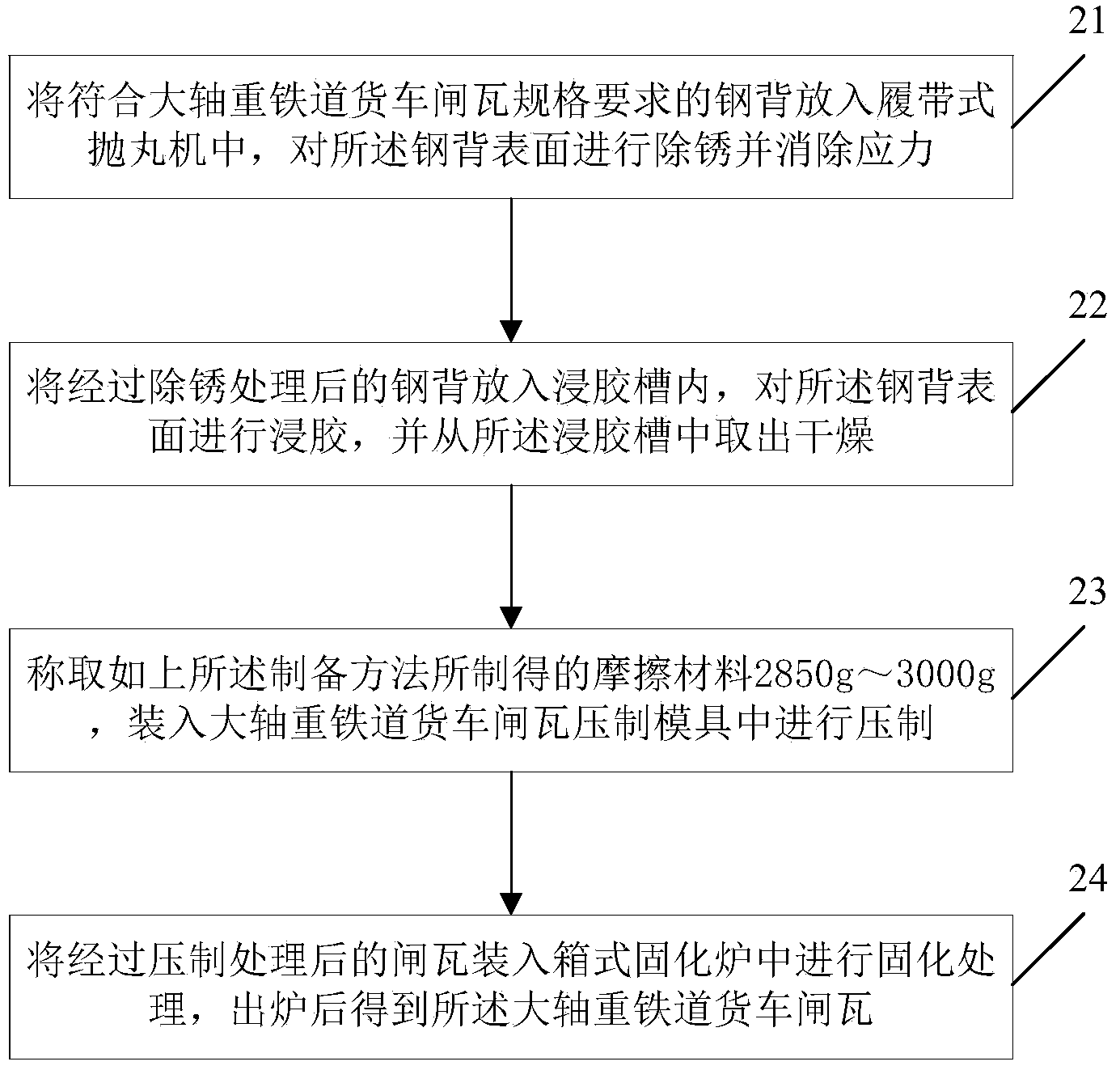

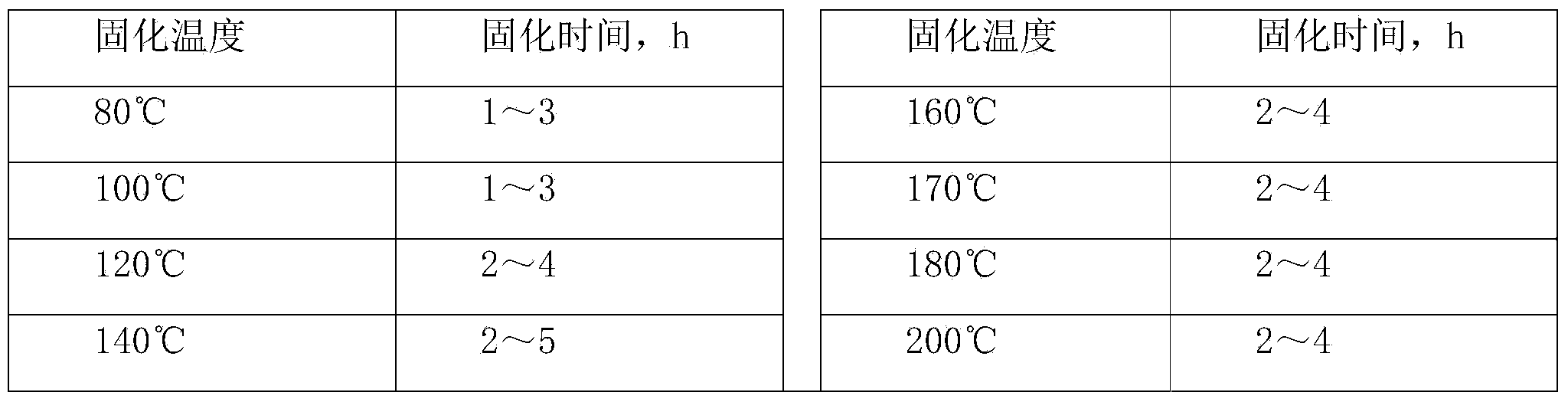

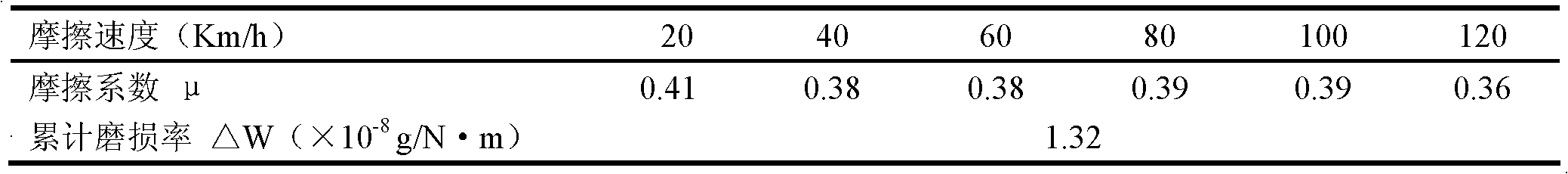

Friction material for brake-shoe of heavy axle-load wagon, and preparation method of wagon brake-shoe

ActiveCN103819765AFrictionally stableImprove wear resistanceBrake arrangement with braking memberWear resistantTruck

The invention discloses a friction material for brake-shoe of heavy axle-load wagon, and a preparation method of a brake-shoe of heavy axle-load wagon. The preparation method of the friction material comprises the following steps: preparing raw materials of the friction material according to corresponding weight ratio of each raw material; adding the prepared raw materials into a meshing-type internal mixer to carry out an internal heating treatment and an internal modulating treatment; discharging the processed raw materials, grinding, and finally granulating so as to obtain the friction material. The method can obtain a friction material having a stable friction performance and good wear resistant property; and at the same time the friction material can be used to manufacture braking parts which can meet the application requirements of heavy axle-load wagon.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

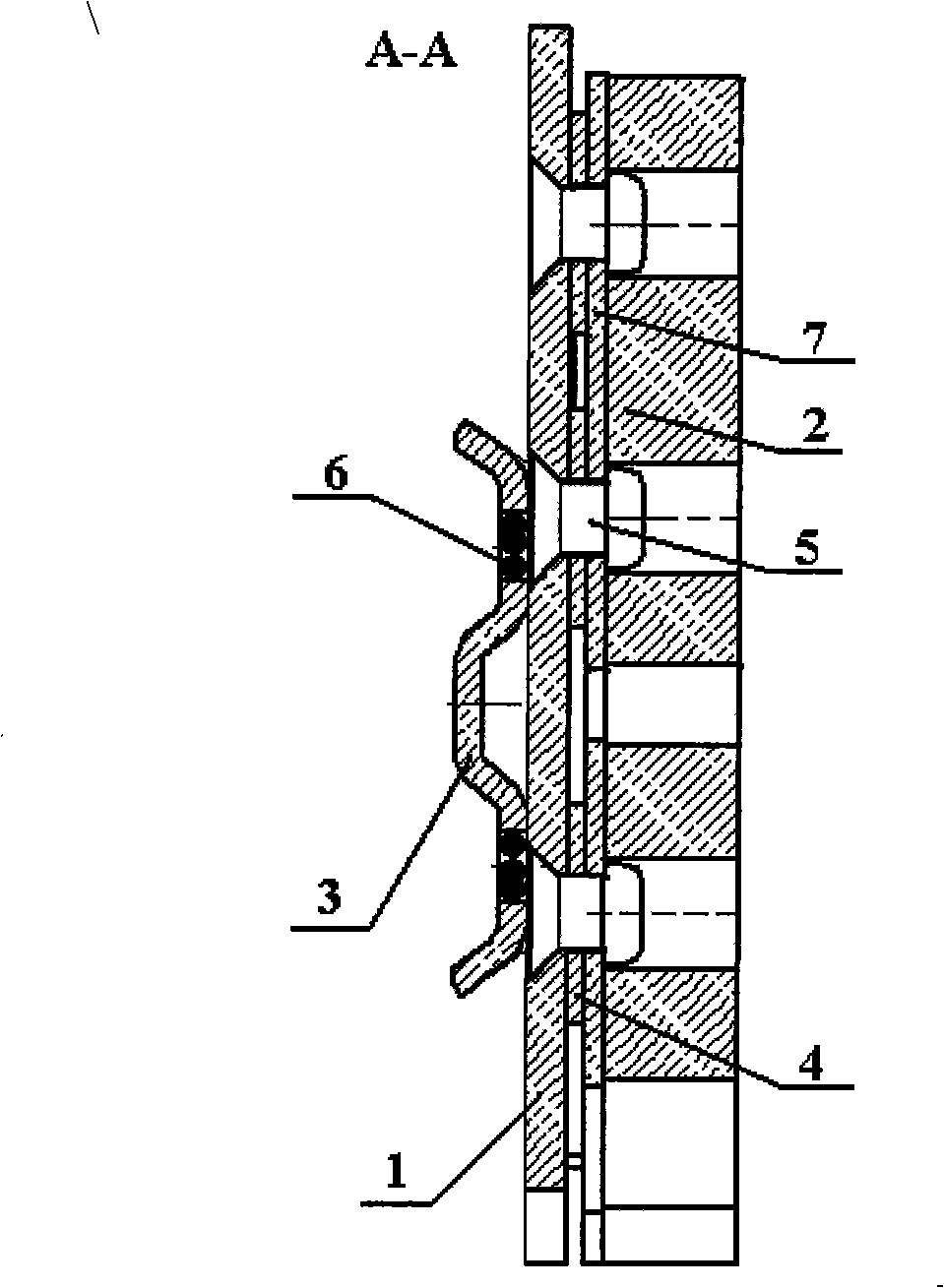

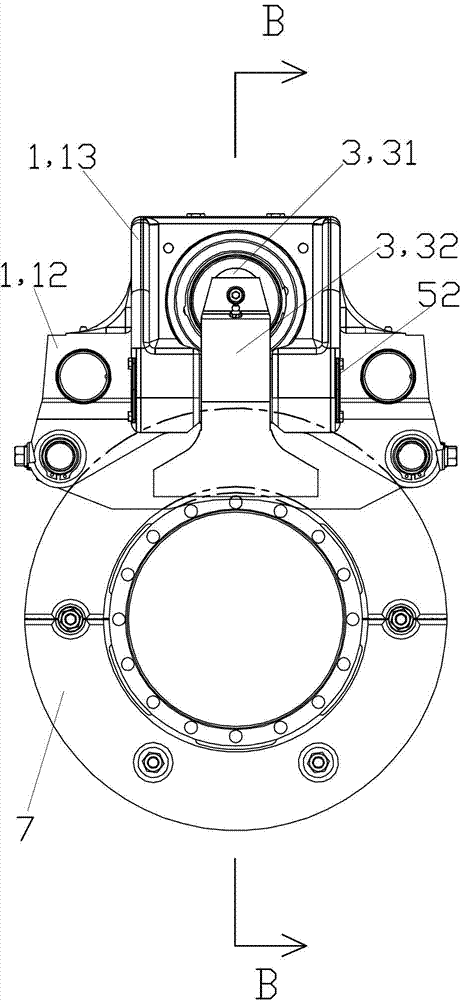

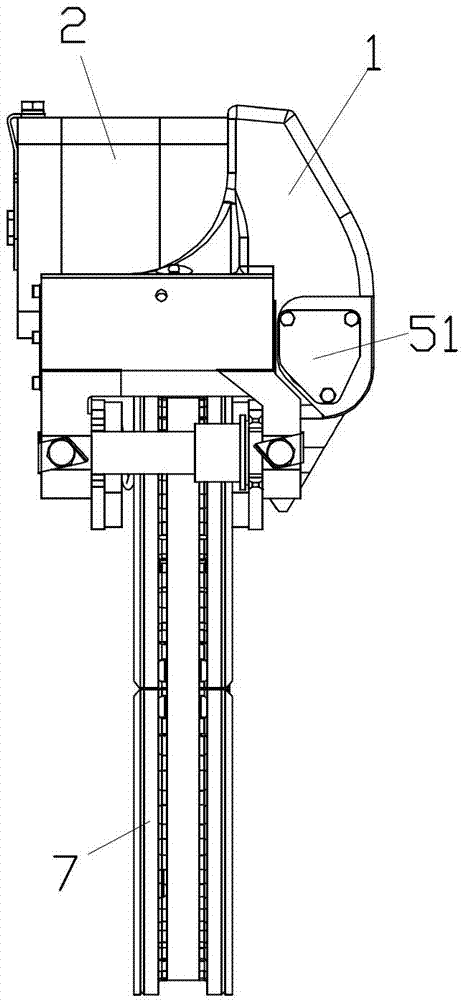

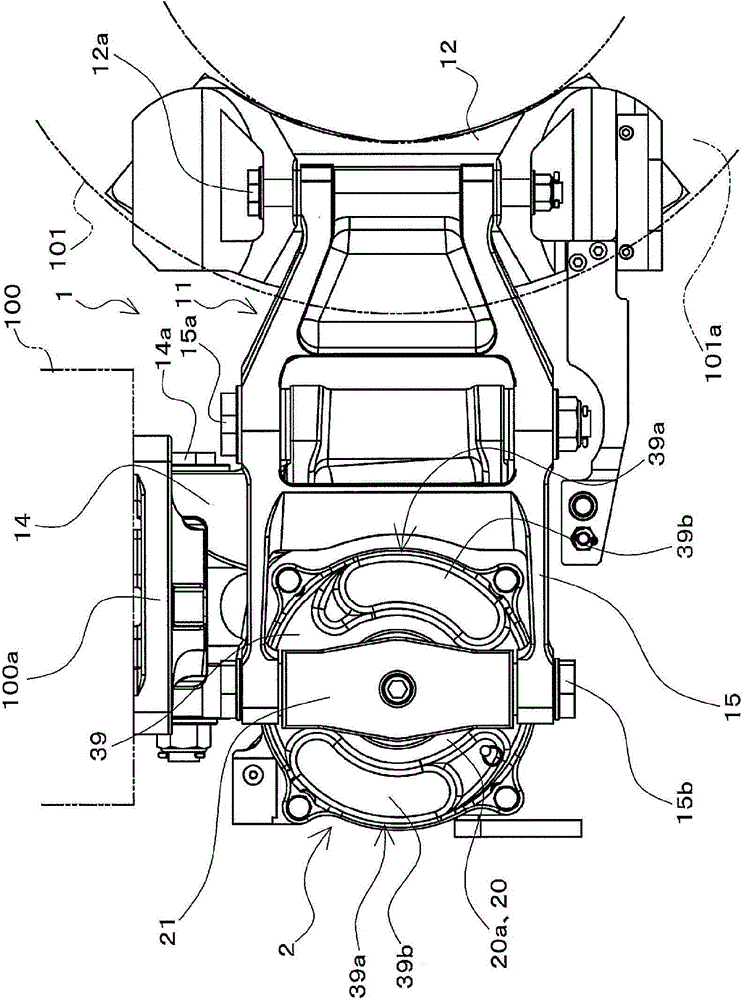

Hydraulic pressure braking clamp device

ActiveCN103112472AEasy to replaceShorten maintenance timeBrake arrangement with braking memberMechanical engineeringPiston

The invention provides a hydraulic pressure braking clamp device which comprises a clamp base, a brake cylinder, a lever member, a lever pin and a clamp assembly. The brake cylinder mainly comprises a piston member, a push rod assembly, a gate adjustment assembly, a disc spring assembly and a manual adjustment shaft assembly. The clamp assembly mainly comprises a clamp left assembly, a clamp right assembly, a front gate piece and a rear gate piece. The clamp assembly and the brake cylinder are fixedly arranged on the clamp base. The brake cylinder brakes and remits a train brake disc by means of driving of the lever member to the clamp assembly. The hydraulic pressure braking clamp device can automatically adjust braking gaps between the gate pieces of a hydraulic pressure clamp and wheels, is good in adjustment accuracy, high in adjustment efficiency, safe, reliable, and compact in structure, meets railway vehicle installation requirements of lower floor boards, is convenient and fast in replacement of the expendable gate pieces, and saves maintenance time and cost.

Owner:华伍轨道交通装备(上海)有限责任公司

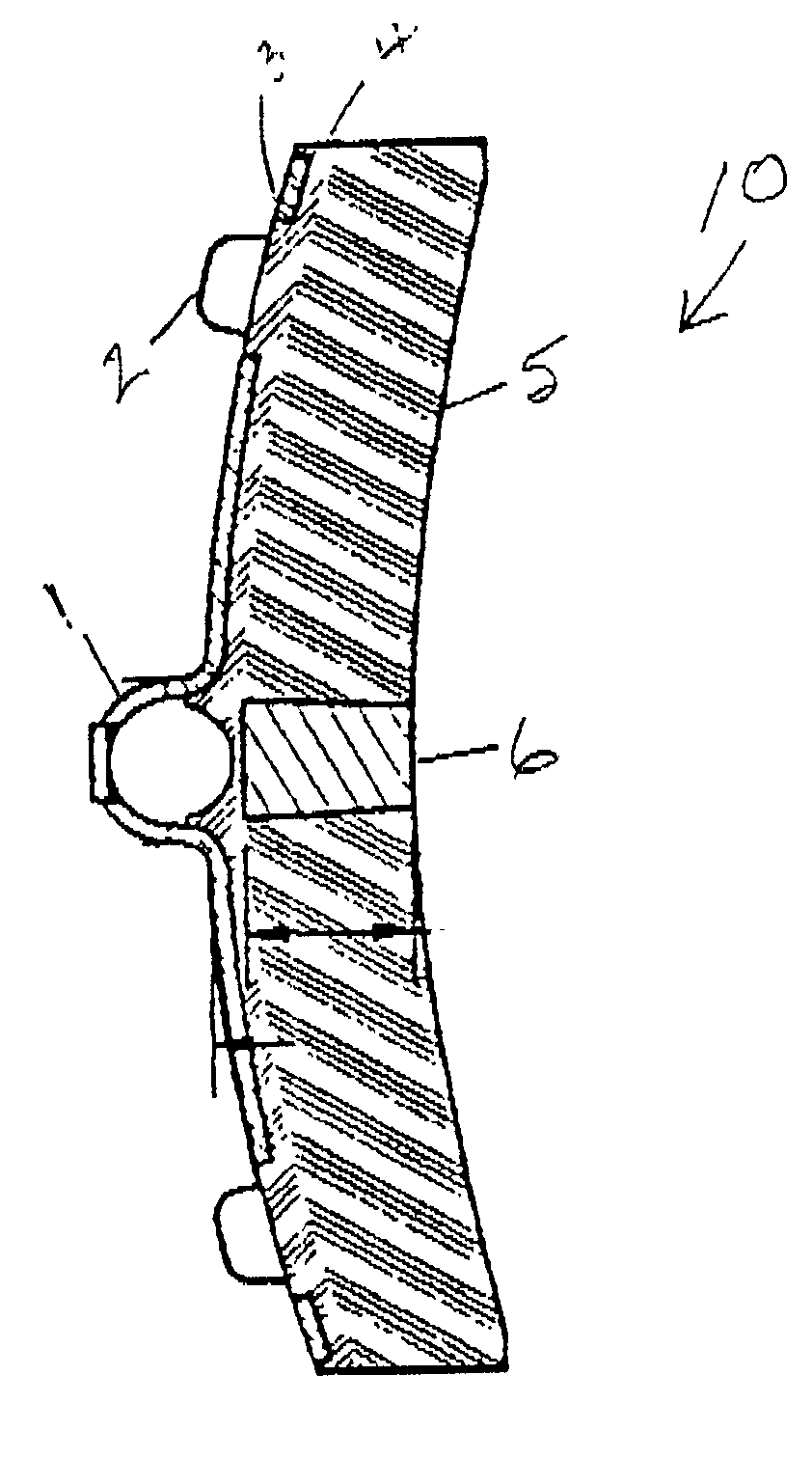

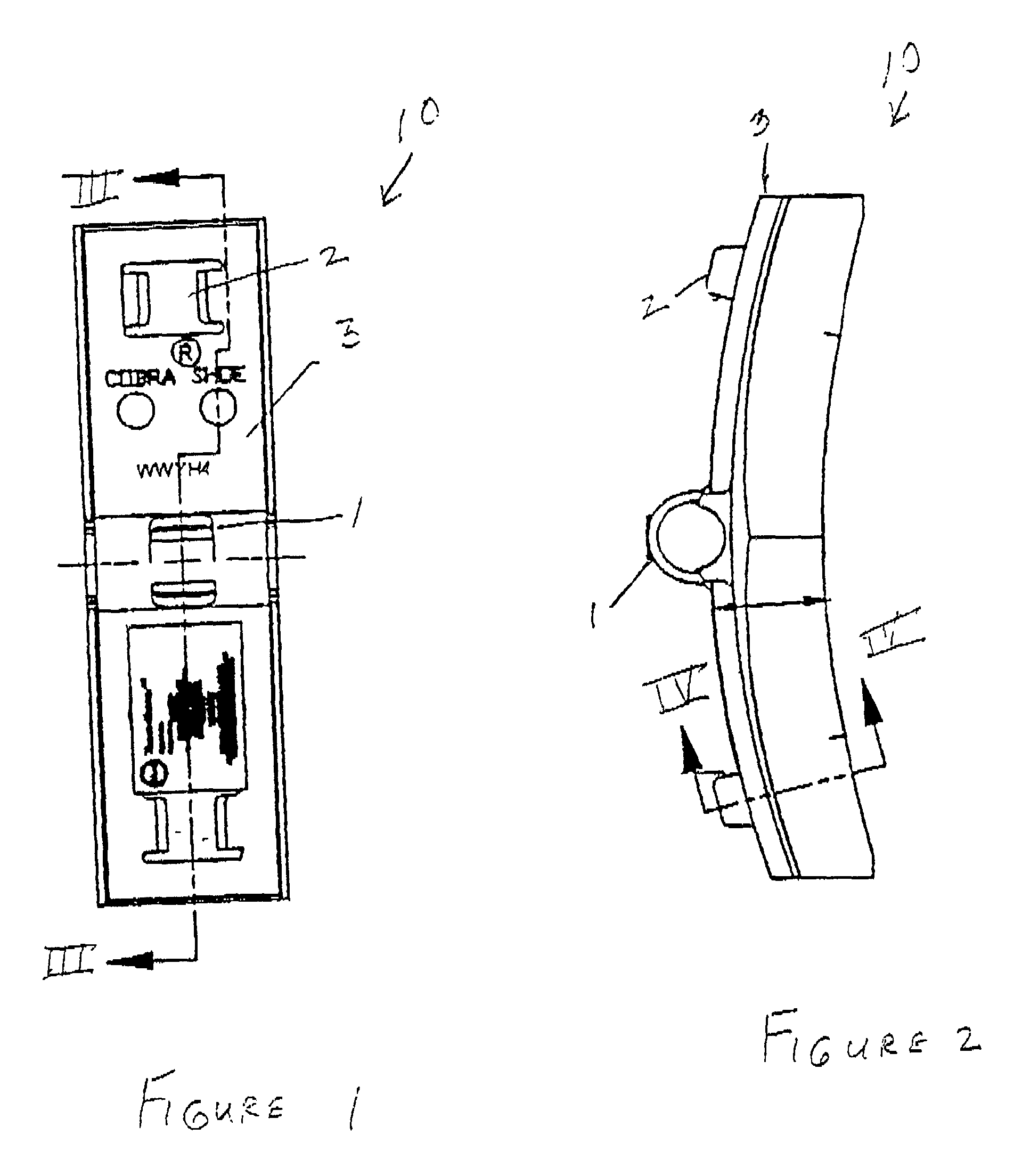

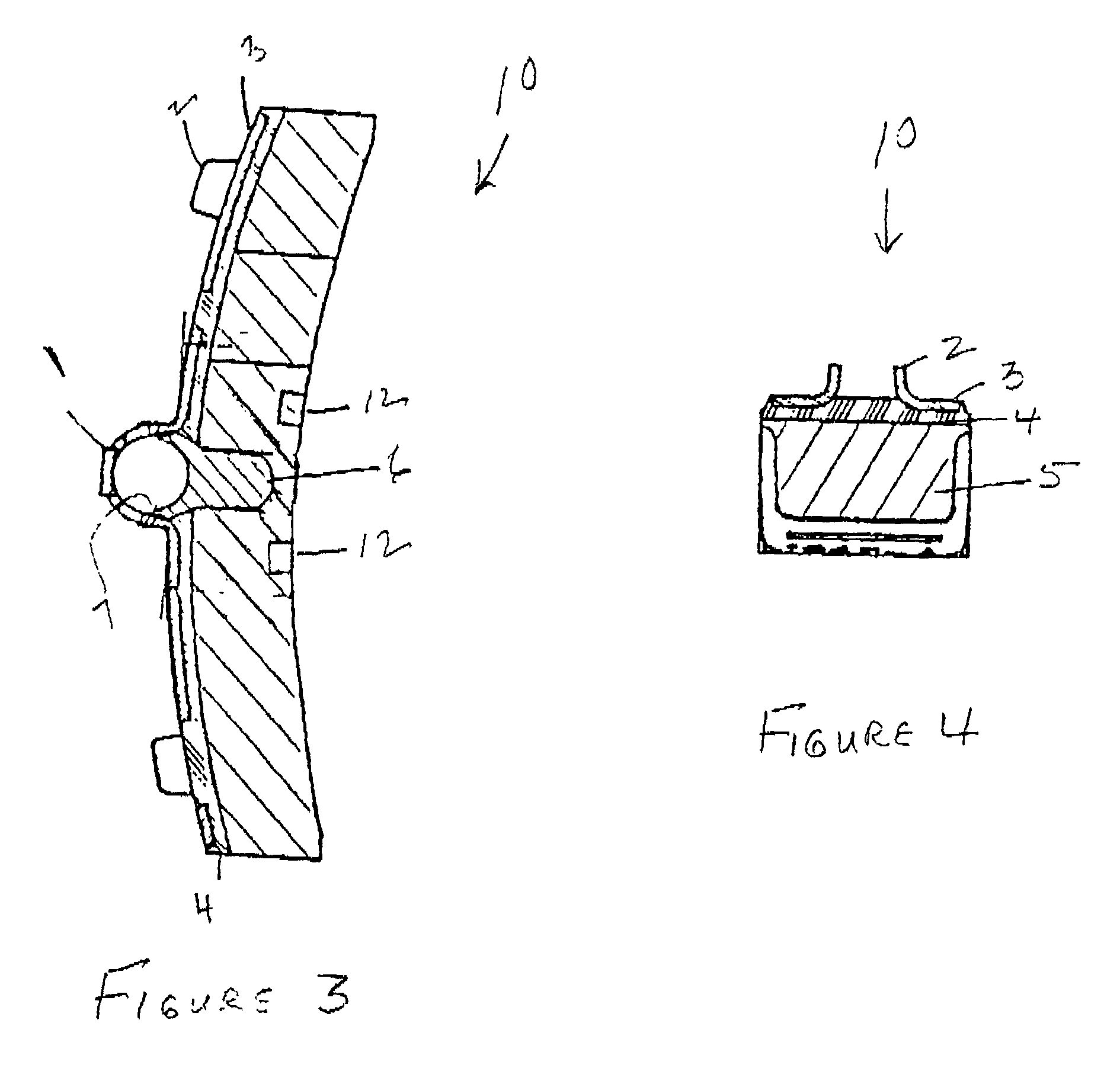

Suspended inserts to provide wheel conditioning

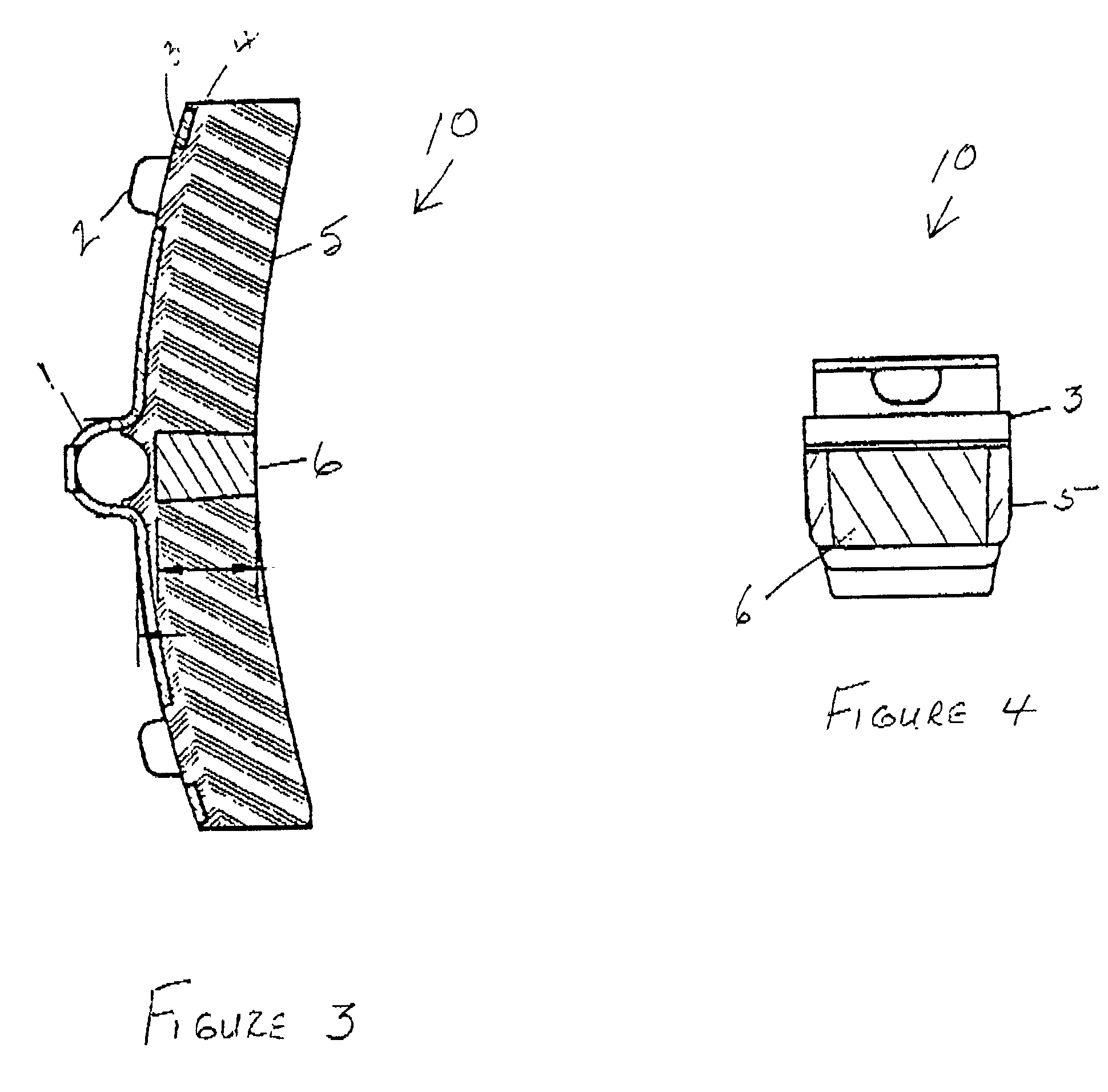

InactiveUS20030234143A1Reduce defectsLightweight productionBraking membersFriction liningControl theoryBrake shoe

A brake shoe is used on a railway vehicle for both applying a braking force and simultaneously reconditioning a wheel tread surface of a wheel disposed on such railway vehicle during a normal braking application on such vehicle. The brake shoe comprises a backing plate having a predetermined configuration and a first friction type material formed into a brake shoe and having a predetermined shape. There is a brake surface for engaging a wheel tread having a predetermined configuration and having a predetermined surface area. A second friction type material is formed as a discrete insert, having a predetermined shape and a predetermined width, and molded into first friction type material. One surface of the discrete insert being disposed coincidently as part of the brake surface of the brake shoe. The second friction type material exhibits greater abrasive properties than does the first friction type material.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

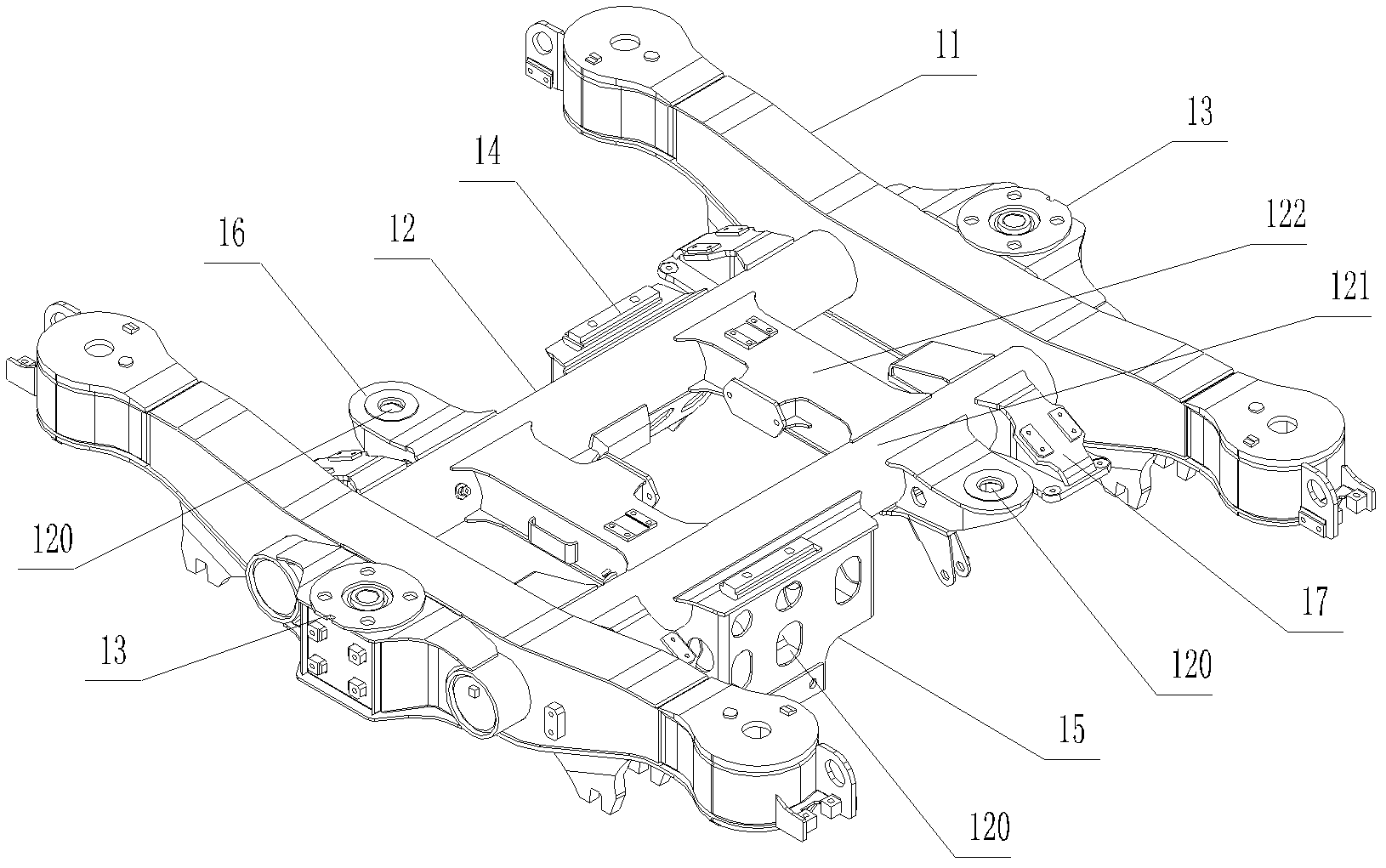

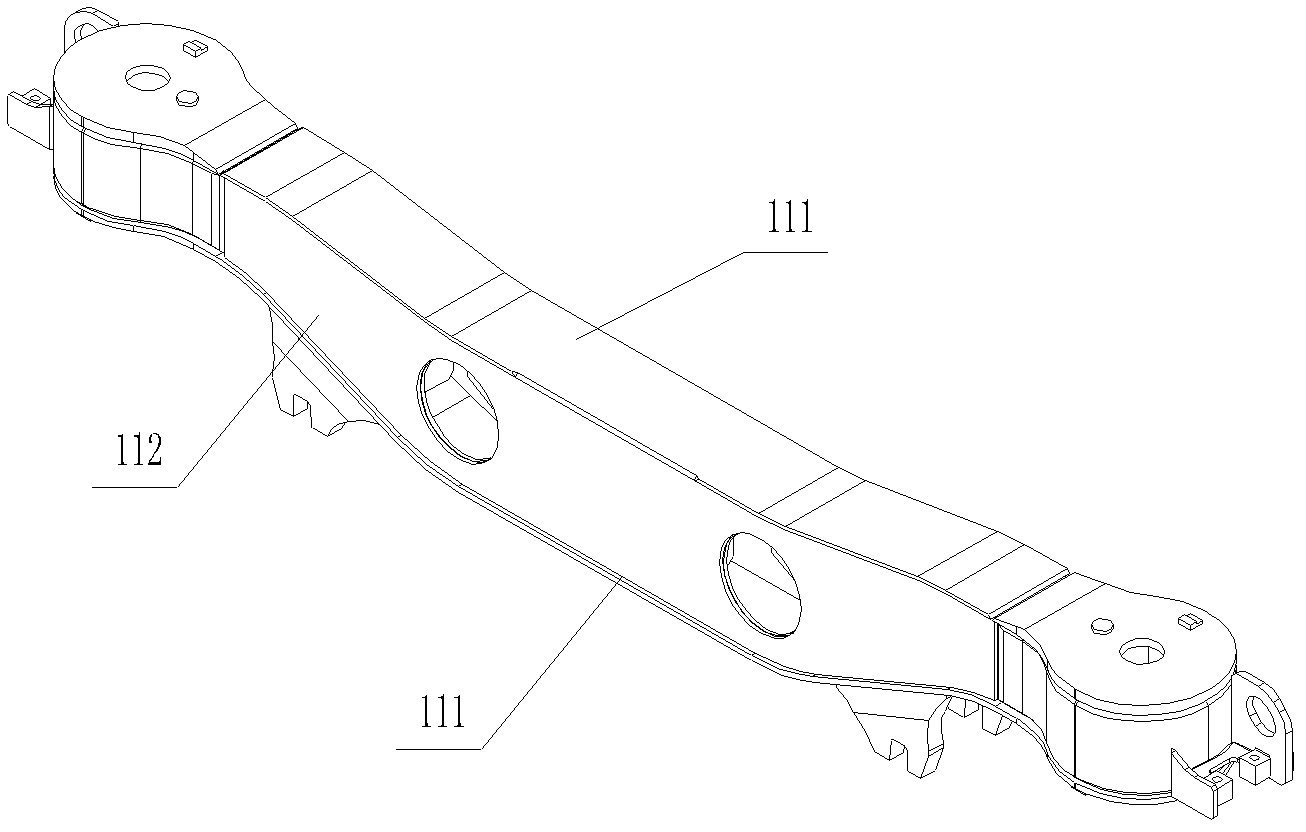

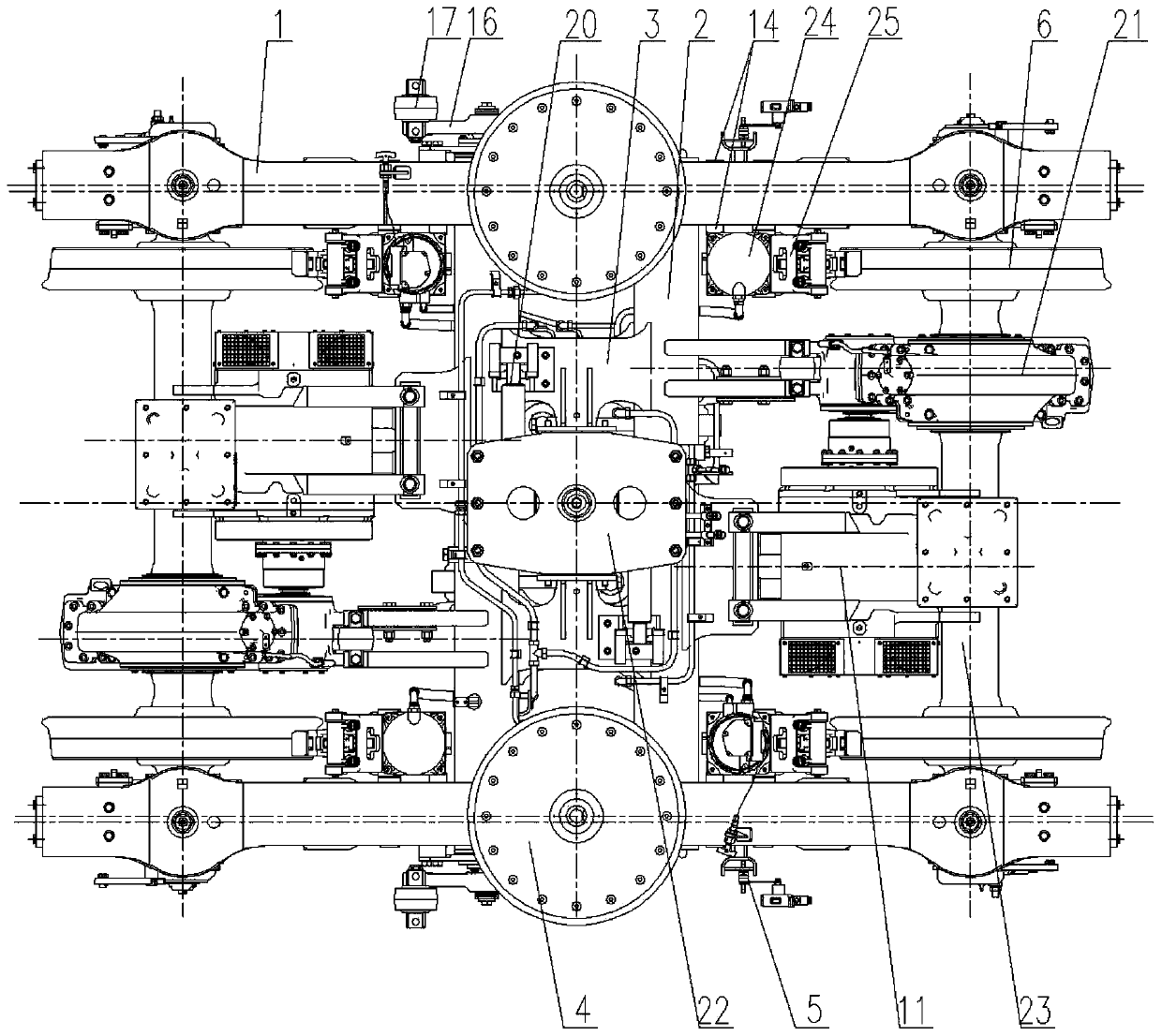

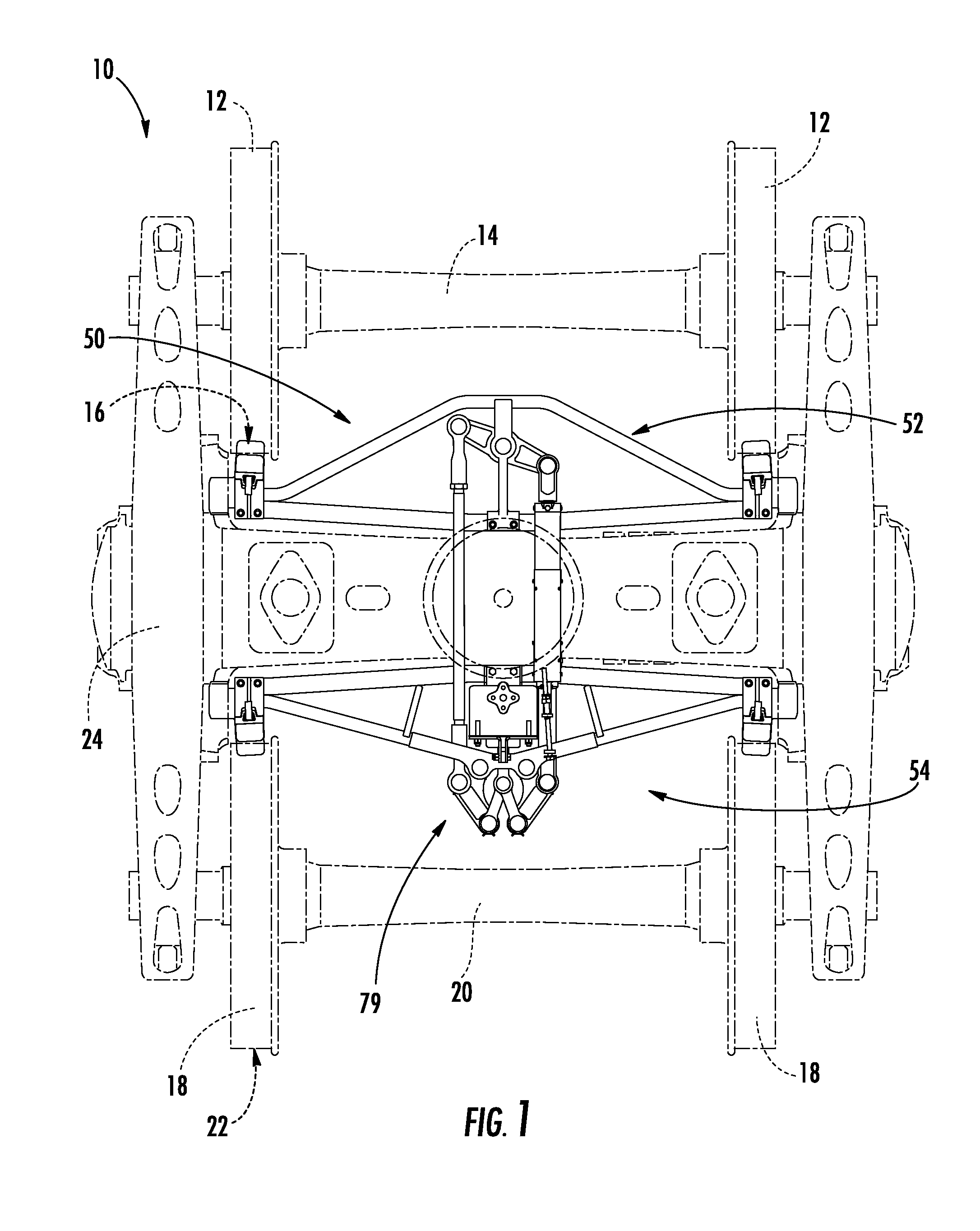

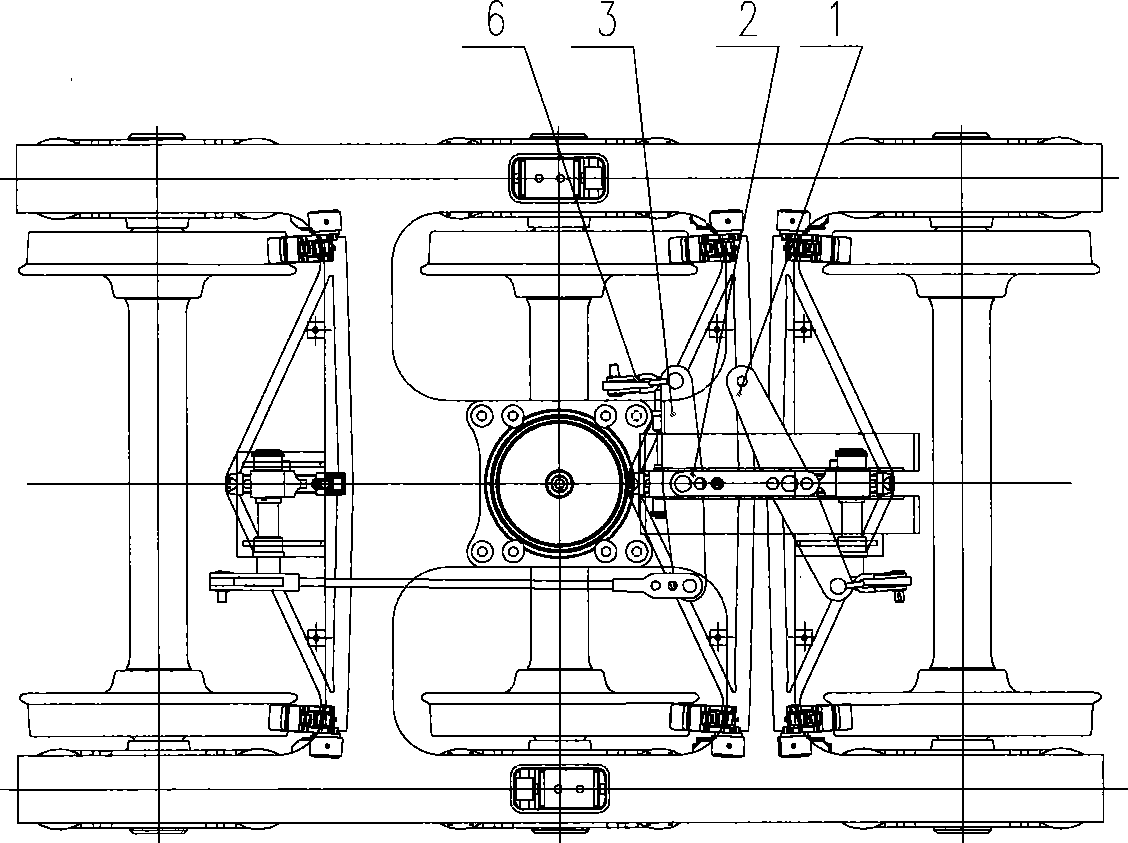

Large-axle-load railway vehicle bogie

ActiveCN103625493AImprove flexural strengthIncreased torsional strengthBogiesBogie-underframe connectionsBogieAir spring

The invention relates to a large-axle-load railway vehicle bogie which comprises a framework. The framework is composed of side beams, a cross beam, an auxiliary beam, two wheel pairs, a primary suspension device, a secondary suspension, a traction device, a foundation brake device, a traction motor and a gearbox. The primary suspension device is composed of a steel spring and a rotating arm shaft box, and the rotating arm shaft box is connected with the framework through the steel spring. The wheel pairs comprise wheel shafts and wheels fixed at the two ends of each wheel shaft, and the wheel shafts are connected with the rotating arm shaft box. The secondary suspension device comprises an air spring, a side-rolling preventing torsion bar and a height control device which all are arranged on the framework. The height of side beam vertical plates and the outer radius and the thickness of the cross beam are increased, the overall bending strength and the torsional strength of the bogie are greatly improved, the load bearing ability of a motor lifting seat and a gearbox lifting seat is greatly improved, the vertical load bearing ability of the side beams is greatly improved, and 17 tons of axle load can be met.

Owner:CRRC QINGDAO SIFANG CO LTD

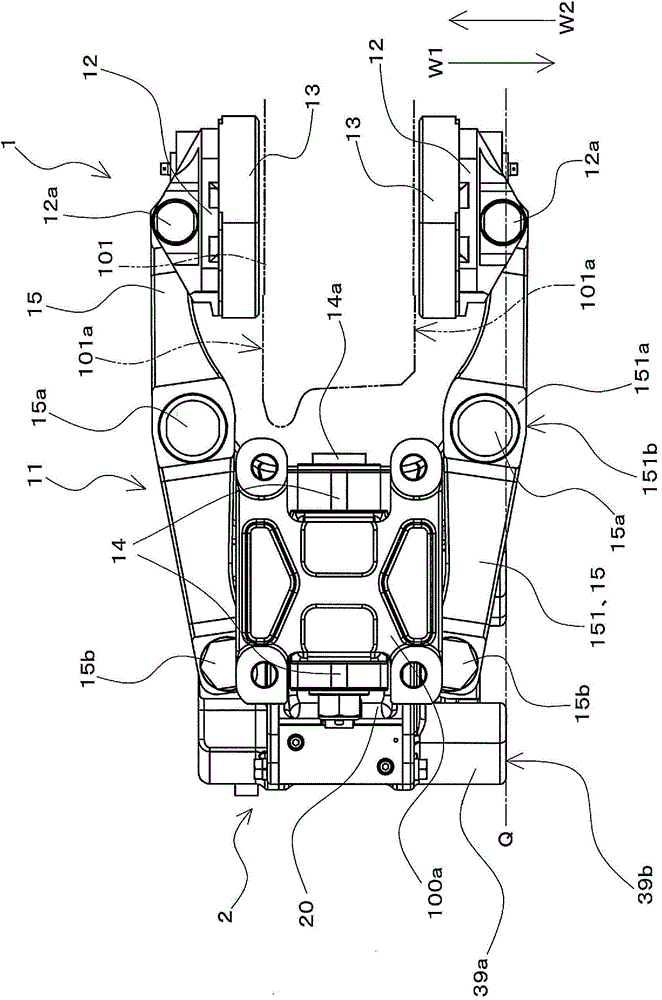

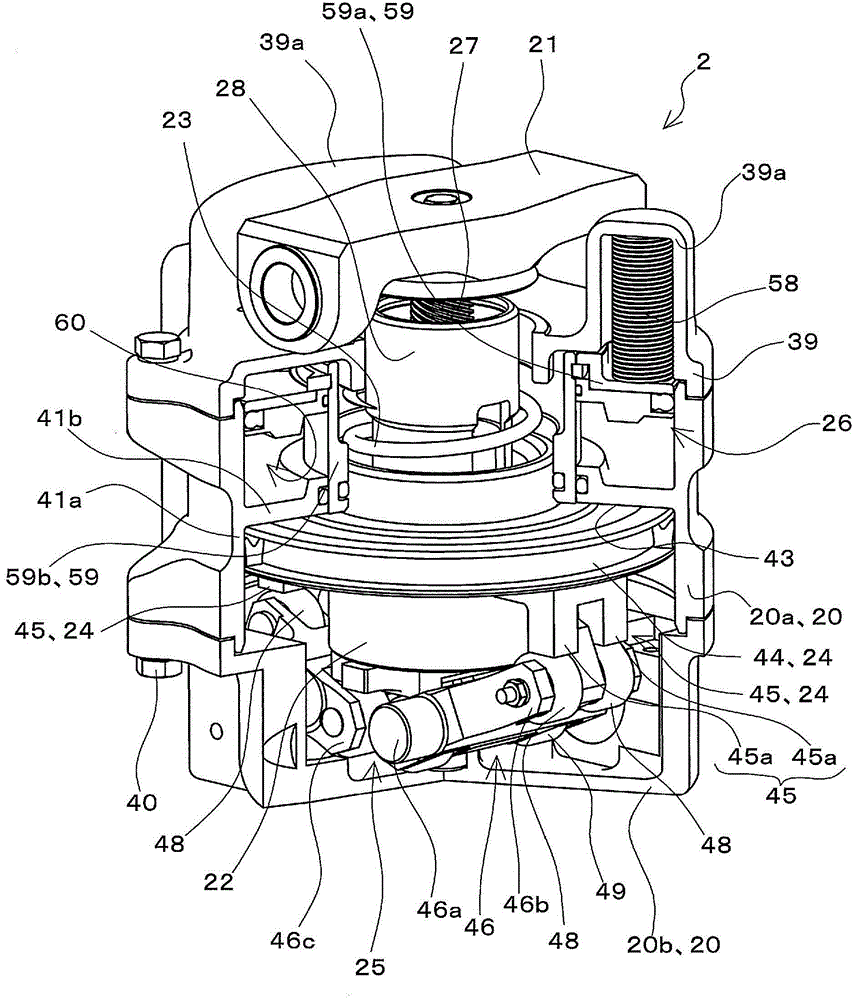

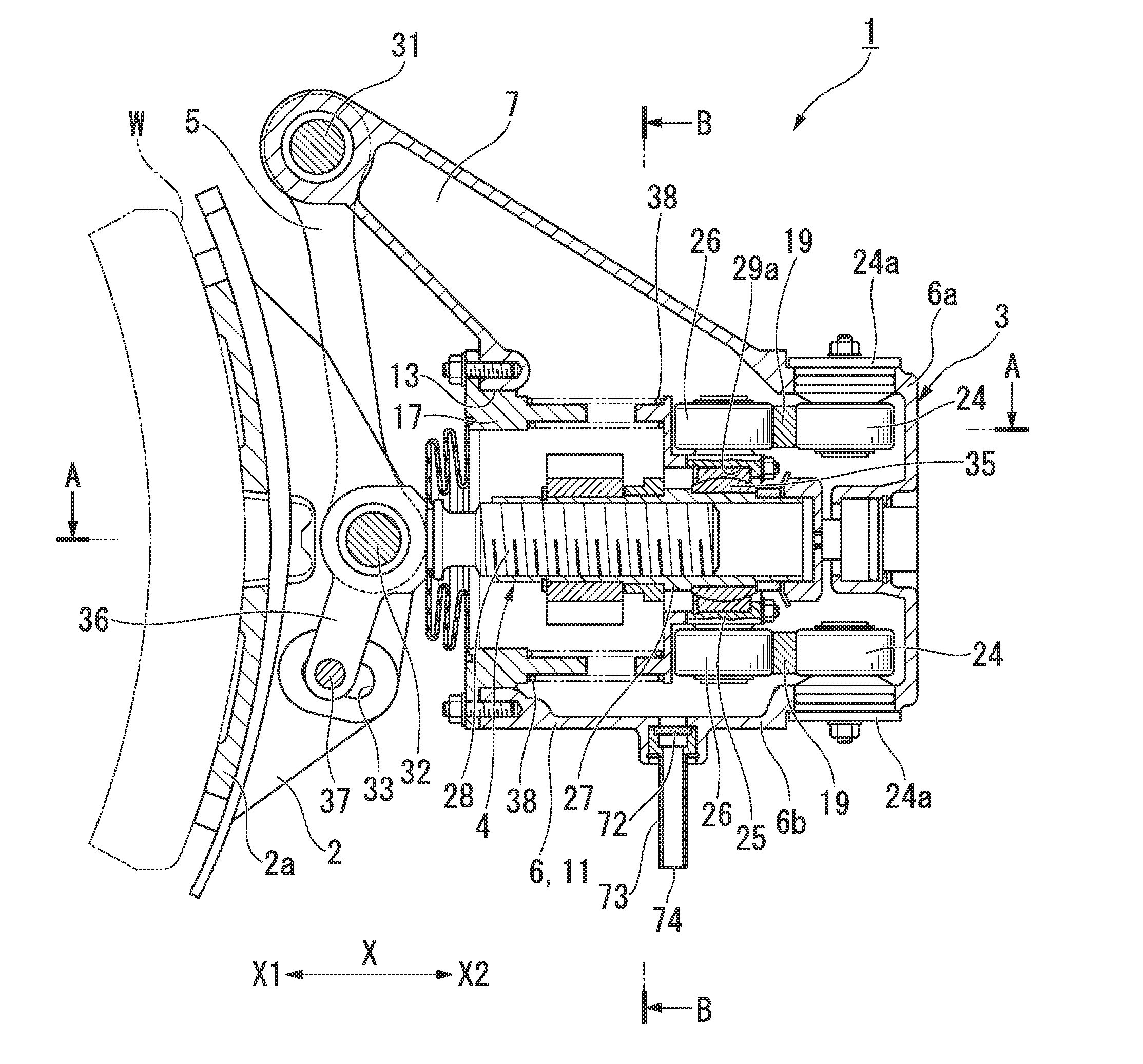

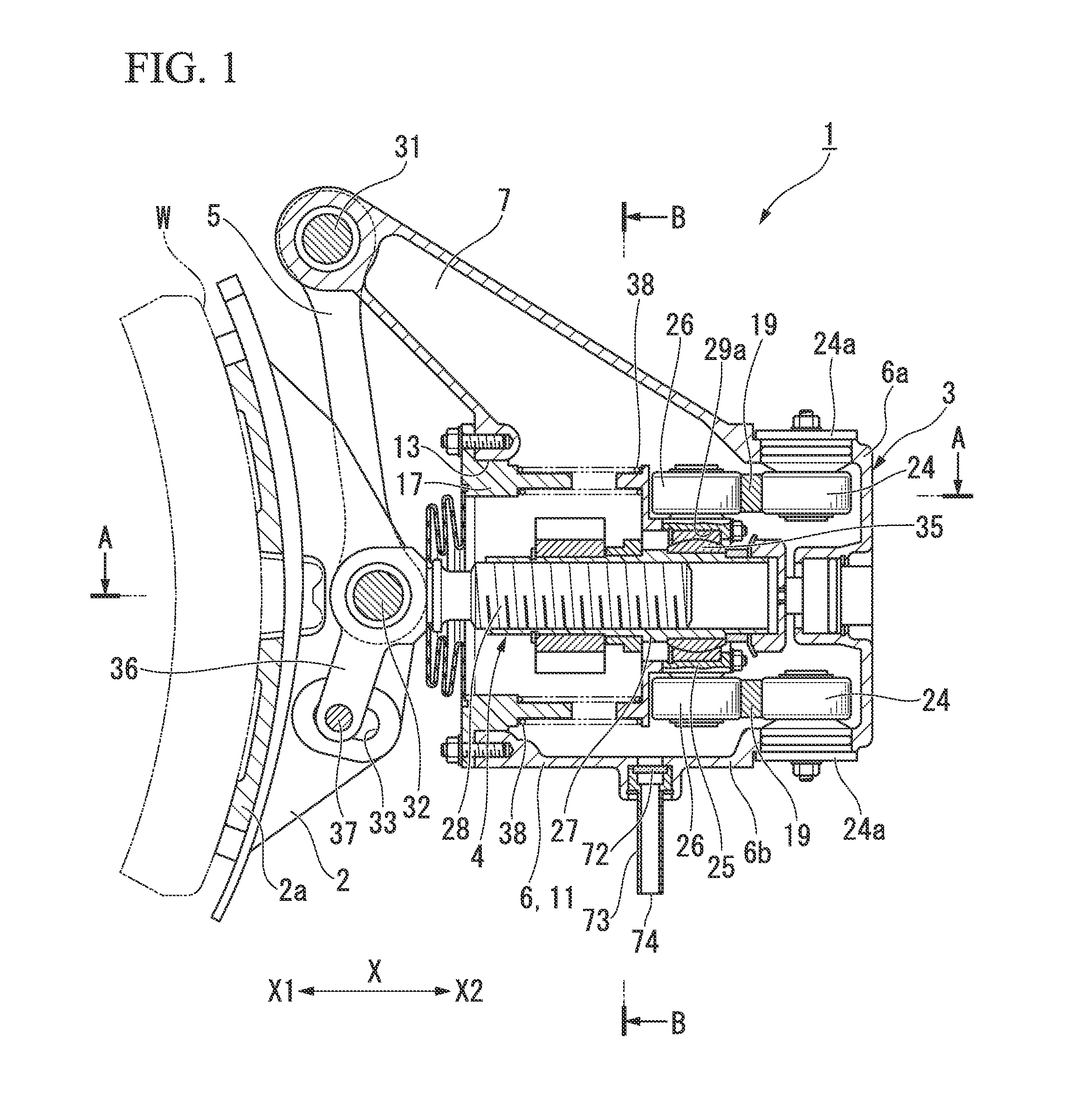

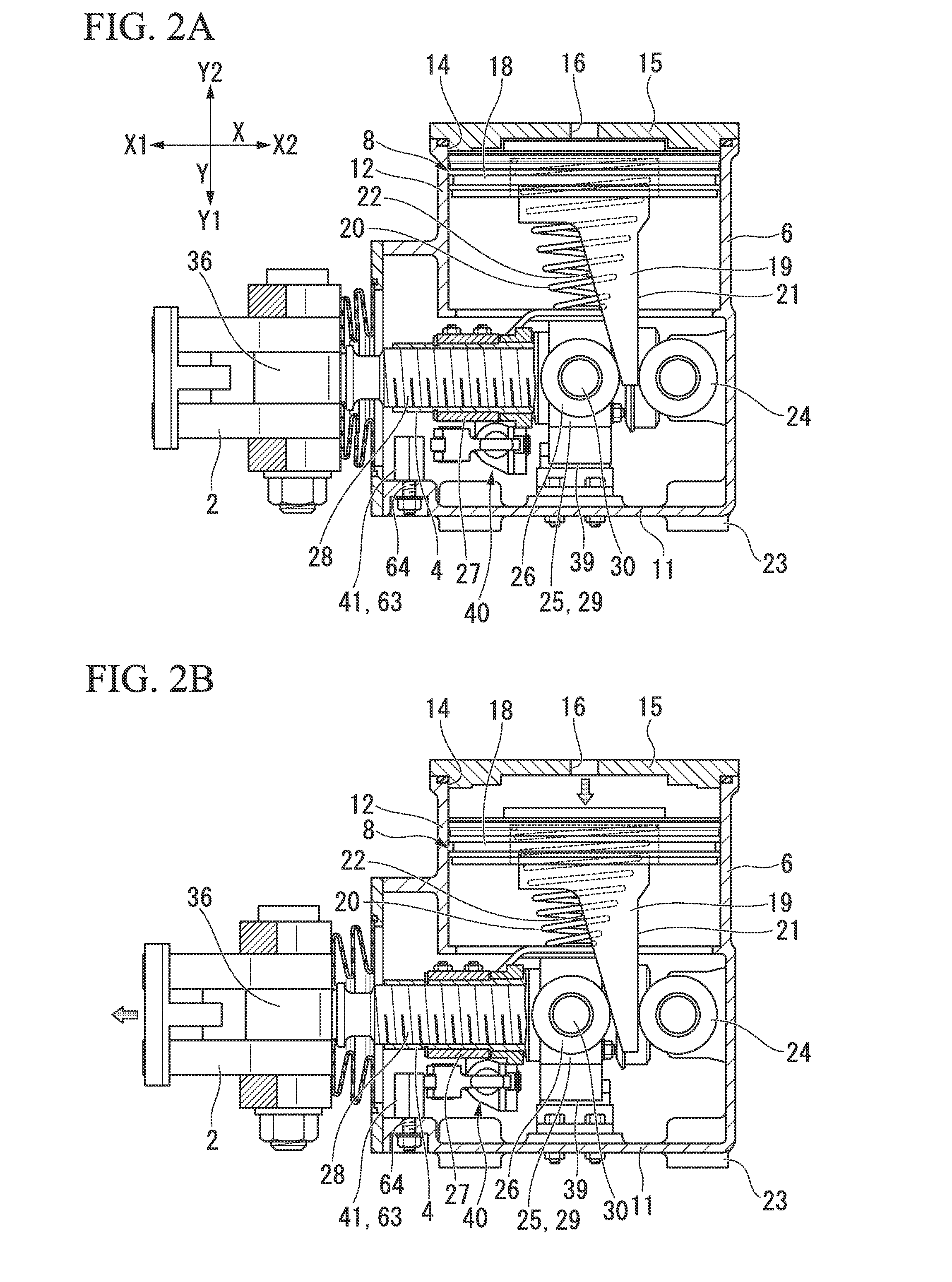

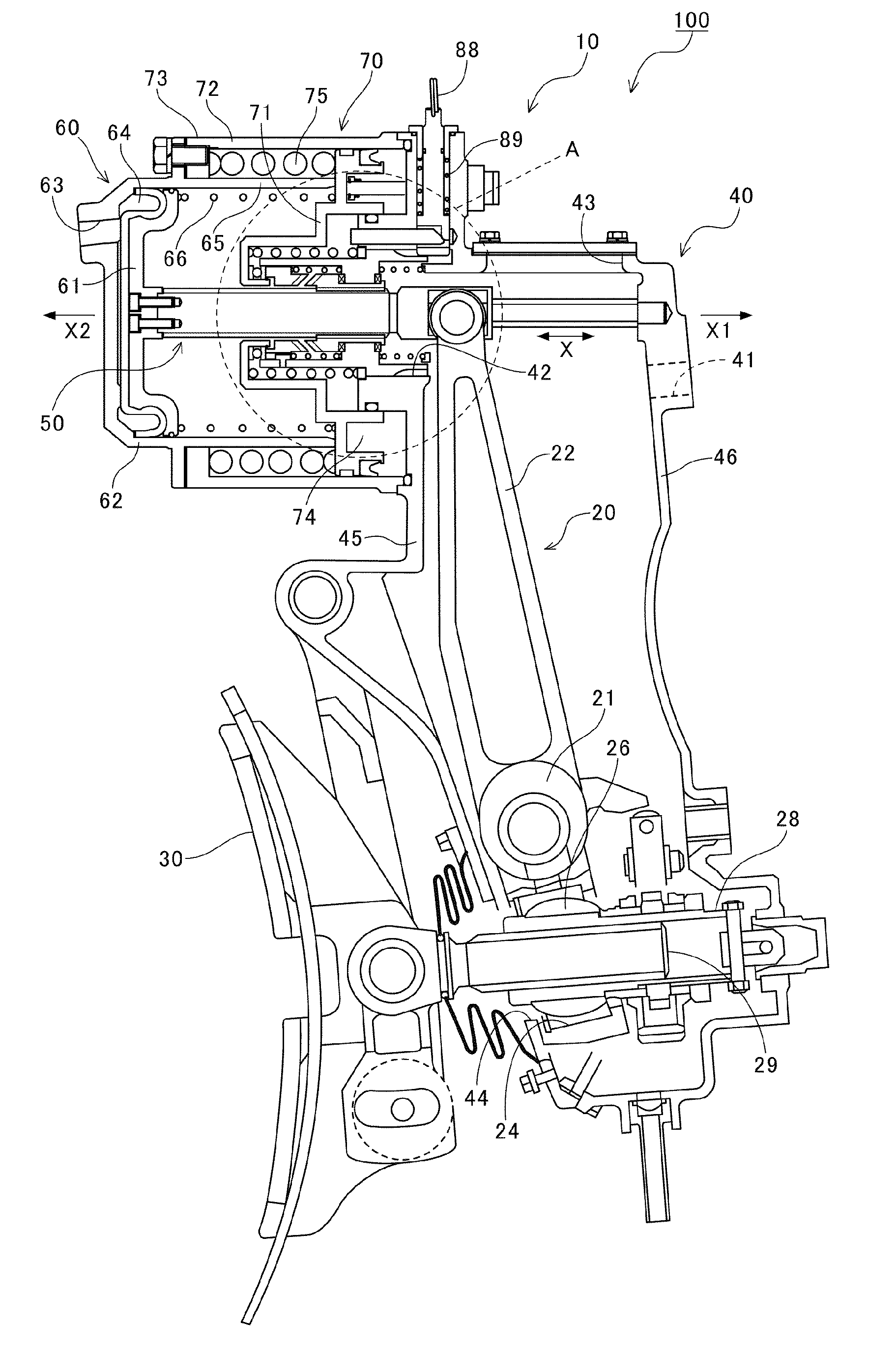

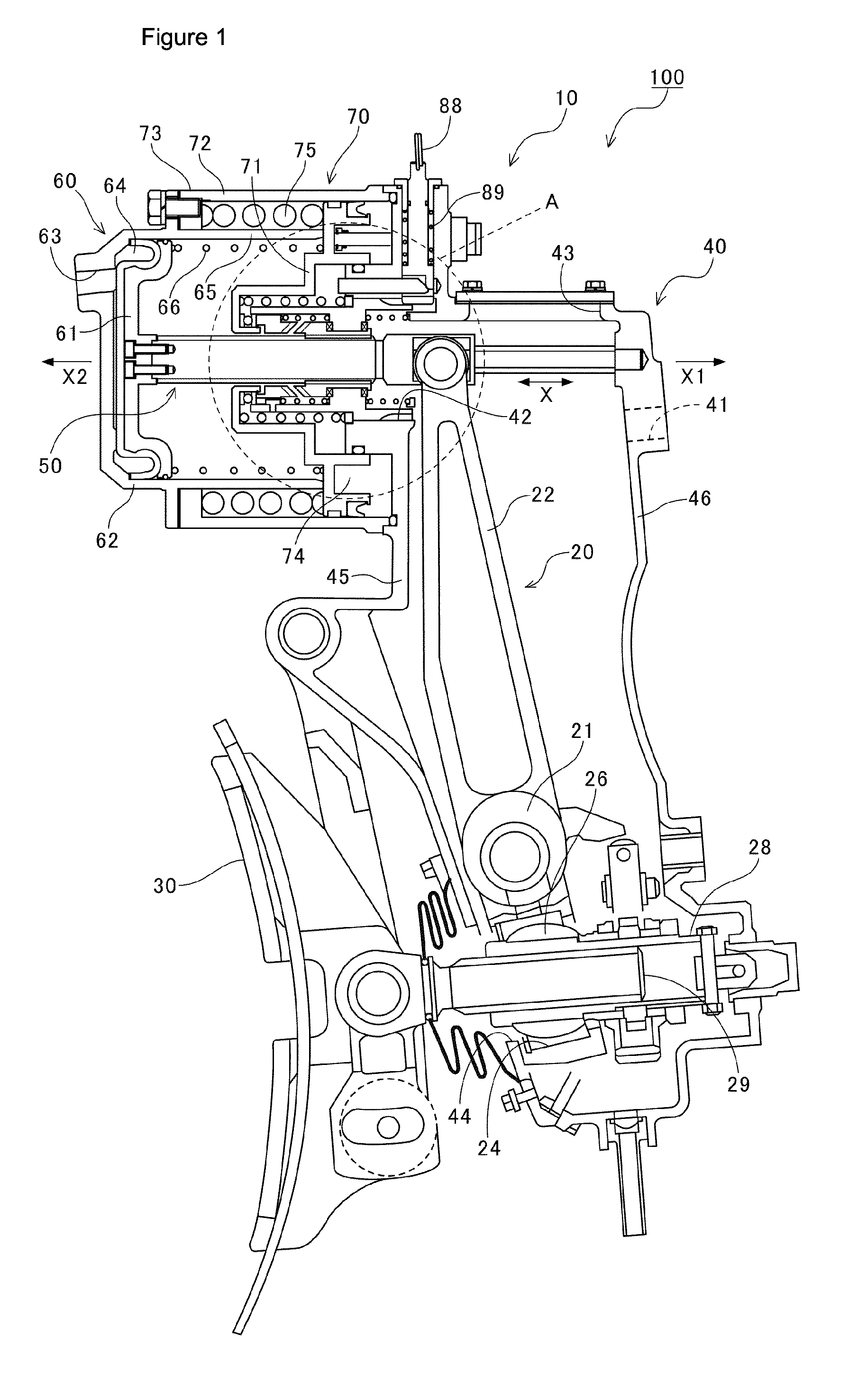

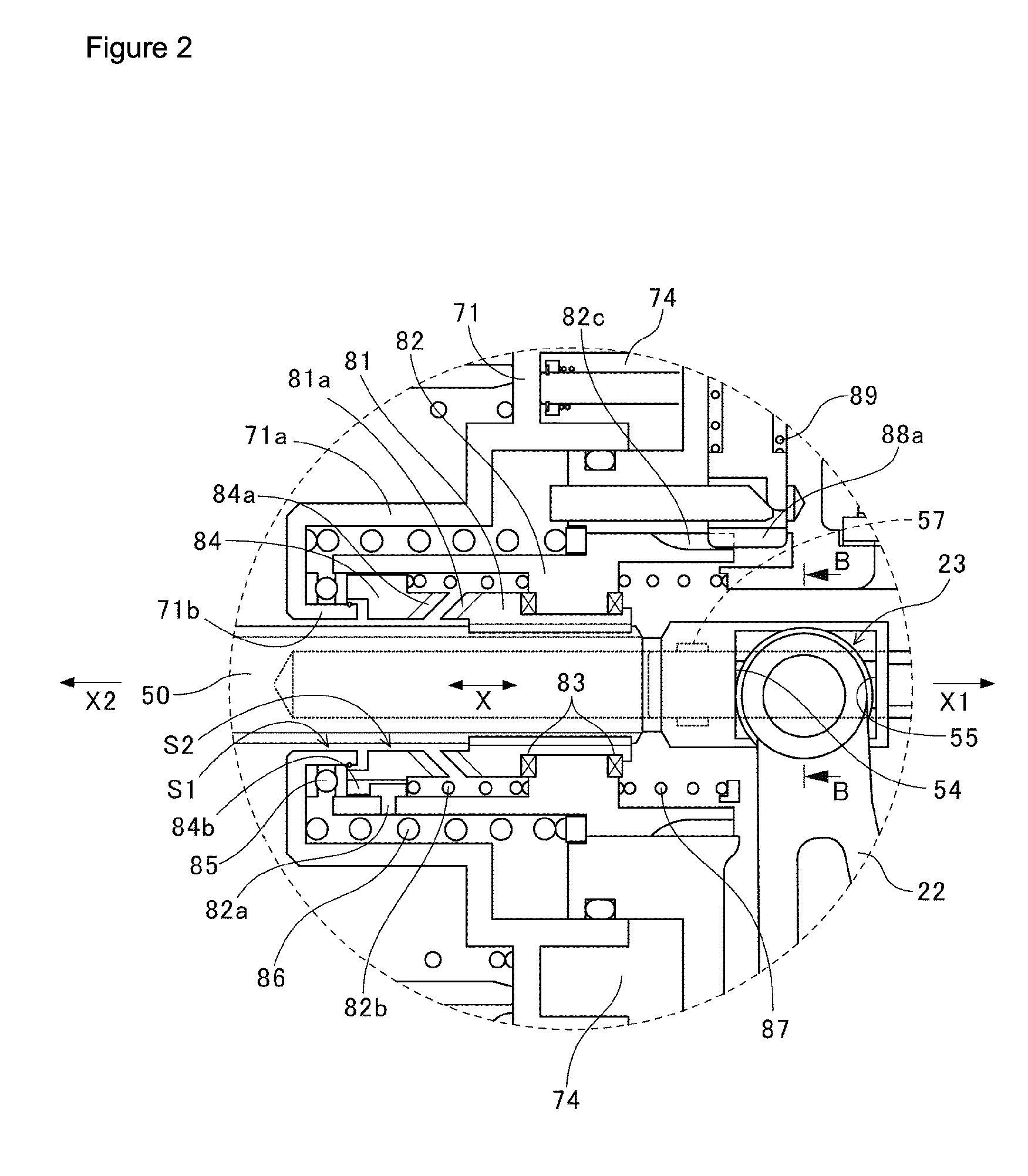

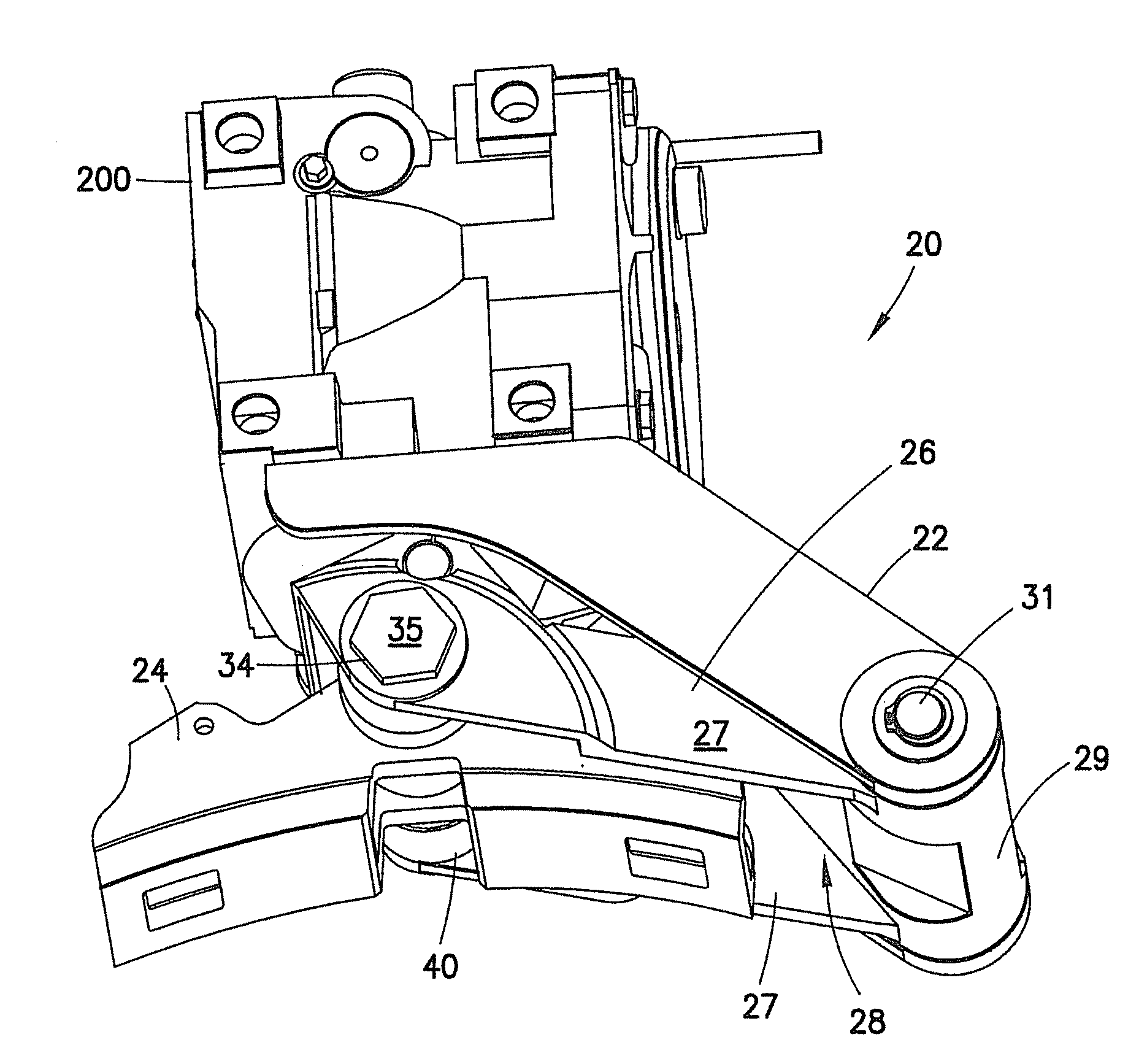

Brake cylinder device and disk brake device

ActiveCN103958916ASuppression of upsizingLarge braking forceAxially engaging brakesBrake wear compensation mechanismEngineeringMechanical engineering

Provided is a compact brake cylinder device capable of increasing the brake force output from a brake output unit that moves along with a rod, without requiring the device to be made larger. A piston (24) sections off a pressure chamber (43) within a main cylinder (20a), surrounds the axial periphery of a rod (22), and moves in a direct line parallel with the direction of motion of the rod (22). With the supply of a pressure fluid to the pressure chamber (43) the piston (24) moves outward relative to the main cylinder (20a) in opposition to the biasing force of a rod-biasing spring (23). An oscillating member (46) of a force-multiplying mechanism (25) is biased by the piston (24) moving in the outward direction, oscillates, and biases the rod (22), causing the rod (22) to move in the forward direction. In this way, the force-multiplying mechanism (25) multiplies the drive force from the piston (24) so as to act on the rod (22). The brake output unit (21) moves in the forward direction along with the rod (22) and outputs brake force.

Owner:NABLESCO CORP

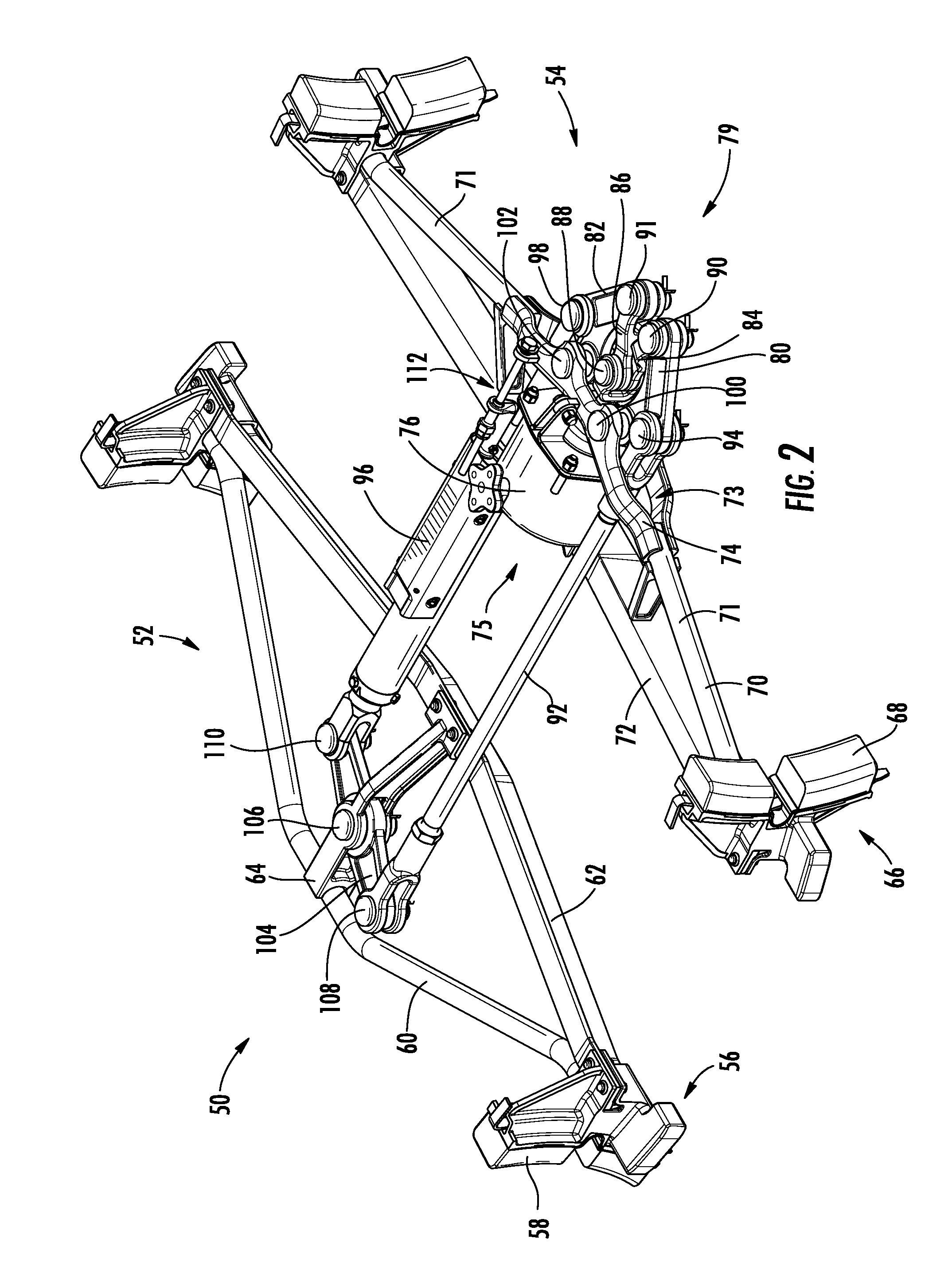

Braking system for a railway car

The present invention includes a braking system for a railway car generally including a brake cylinder having a cylinder rod. The cylinder rod is in mechanical communication with a lever transfer assembly and is configured to articulate said lever transfer assembly. The lever transfer assembly may be rotatably connected to a first brake assembly and connected to a rear brake assembly through respective connection rods. Actuating the lever transfer assembly with the cylinder rod generates a divergent braking force between the first and second brake assemblies for slowing and / or stopping the railway car.

Owner:AMSTED RAIL CO INC

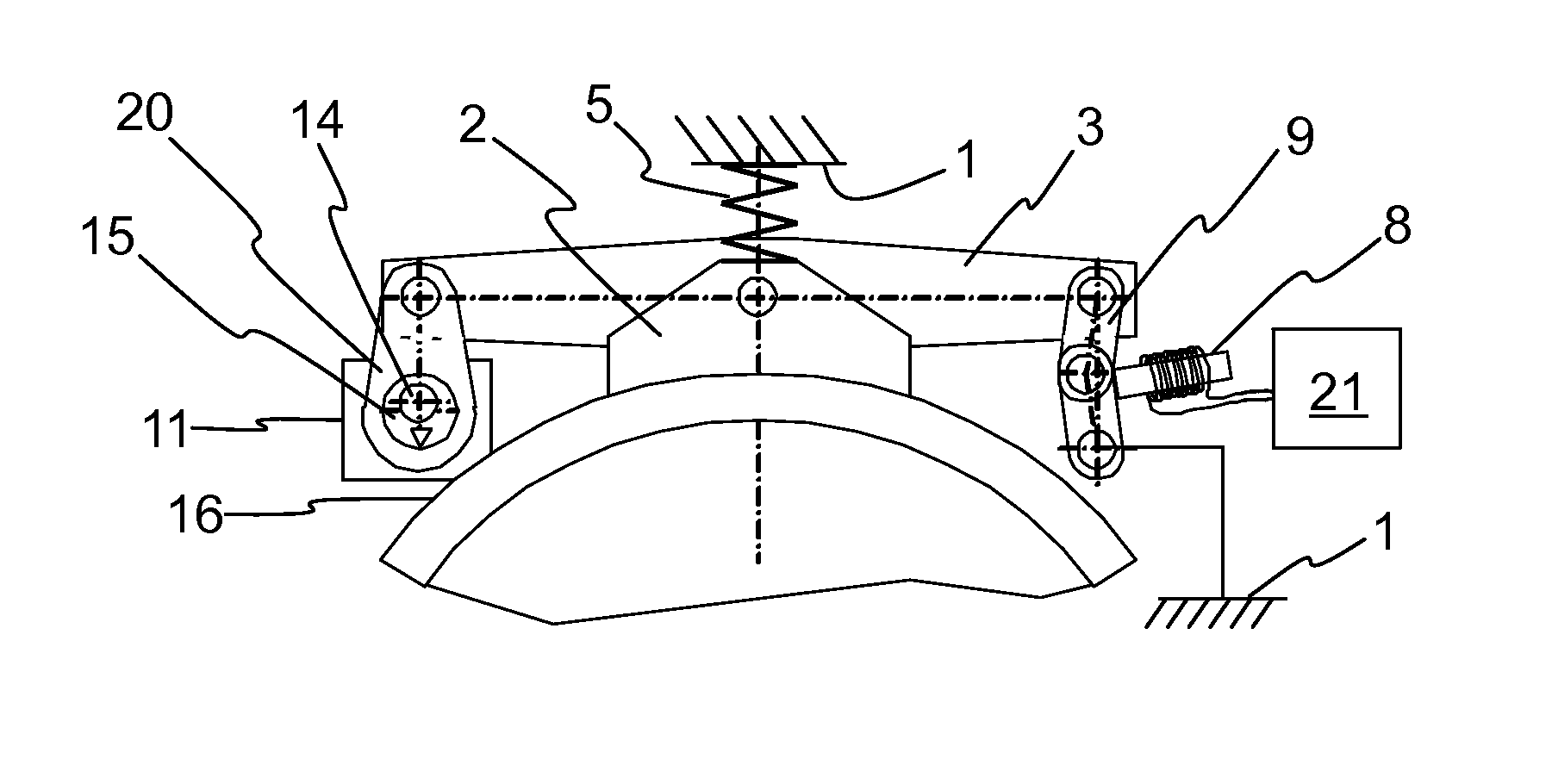

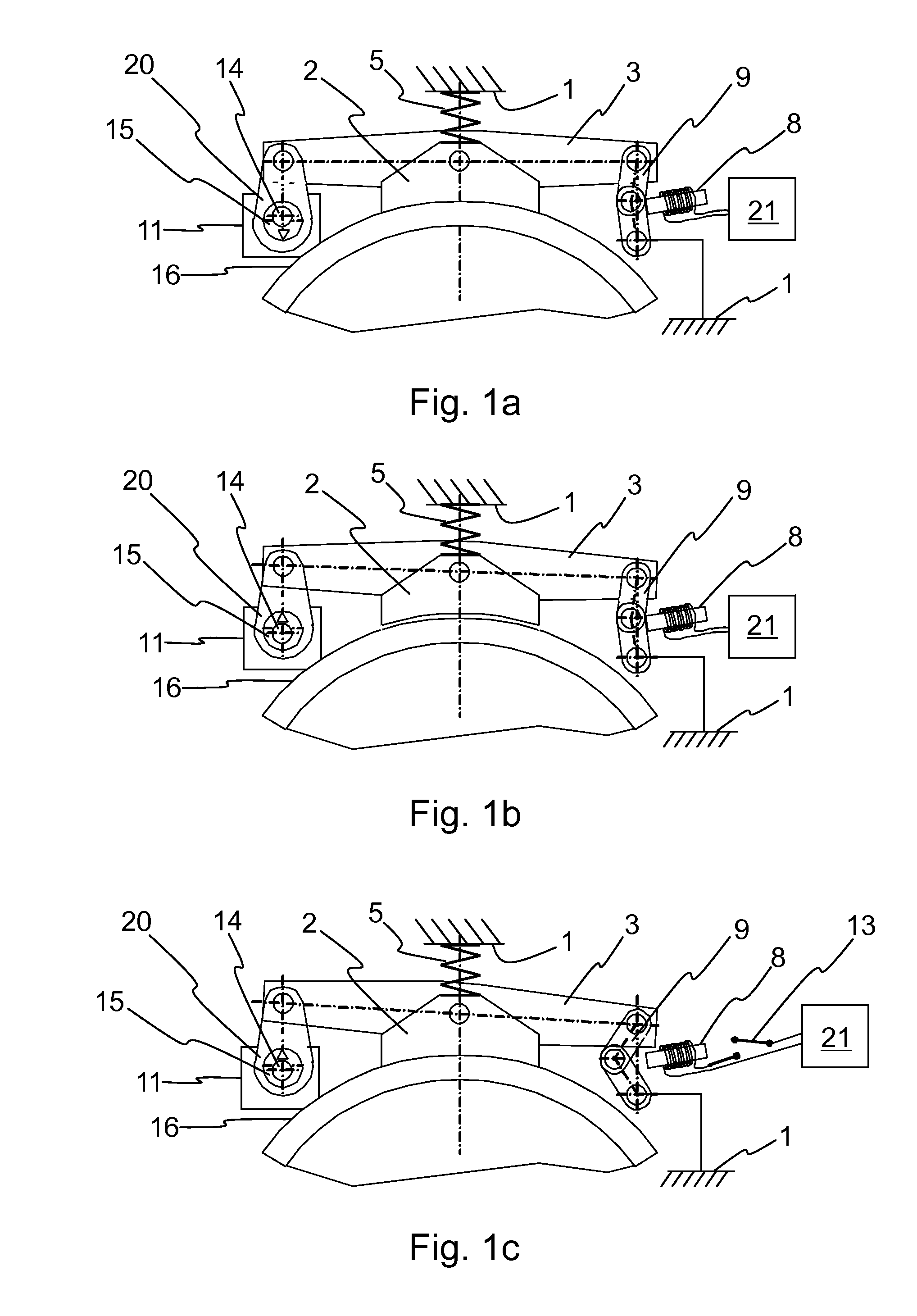

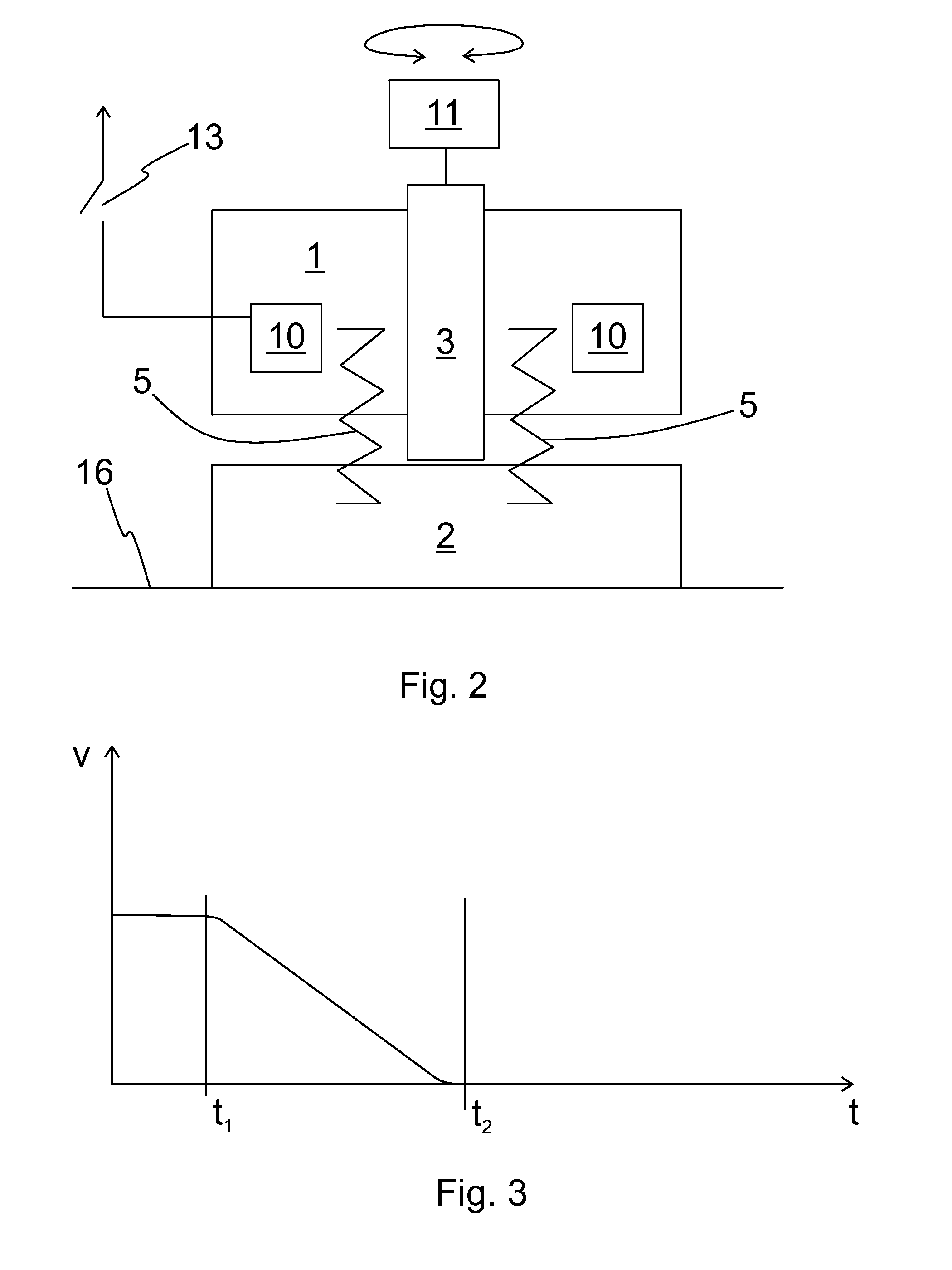

Brake

ActiveUS20150129365A1Avoid noiseAvoid disturbing noiseBraking element arrangementsNoise/vibration controlSpring forceEngineering

The invention relates to a brake and to a method for controlling the brake. The brake comprises a base part, a braking piece movably supported on the base part, which braking piece is configured to be moved between a braking position and a releasing position, a spring, with the spring force of which the braking piece can be dropped into a braking position, a support member for limiting the initial position of the drop-out movement of the braking piece and also a controllable actuator, which is mechanically connected to the aforementioned support member and configured to displace the initial position of the drop-out movement of the braking piece with respect to the braking position.

Owner:KONE CORP

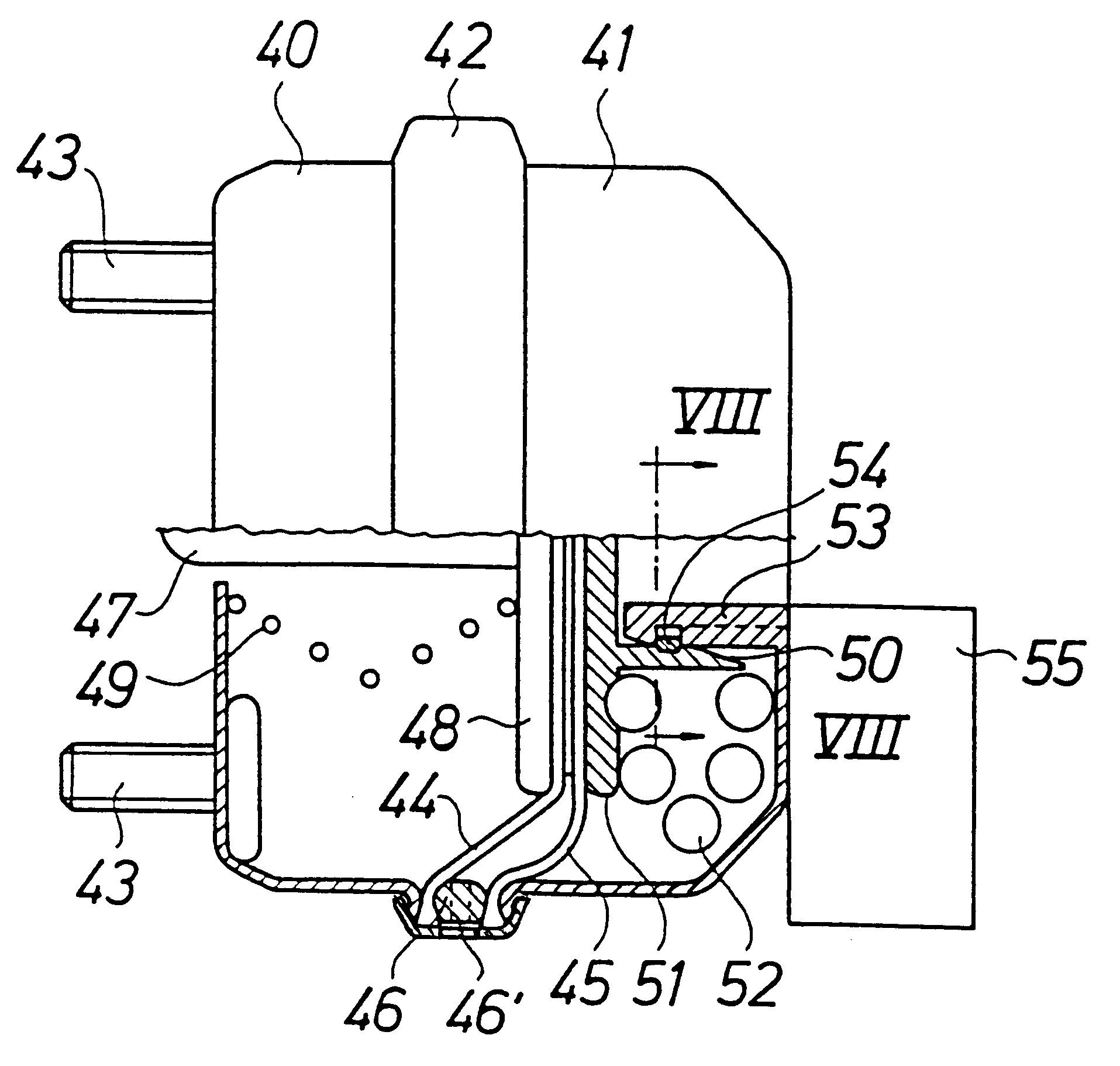

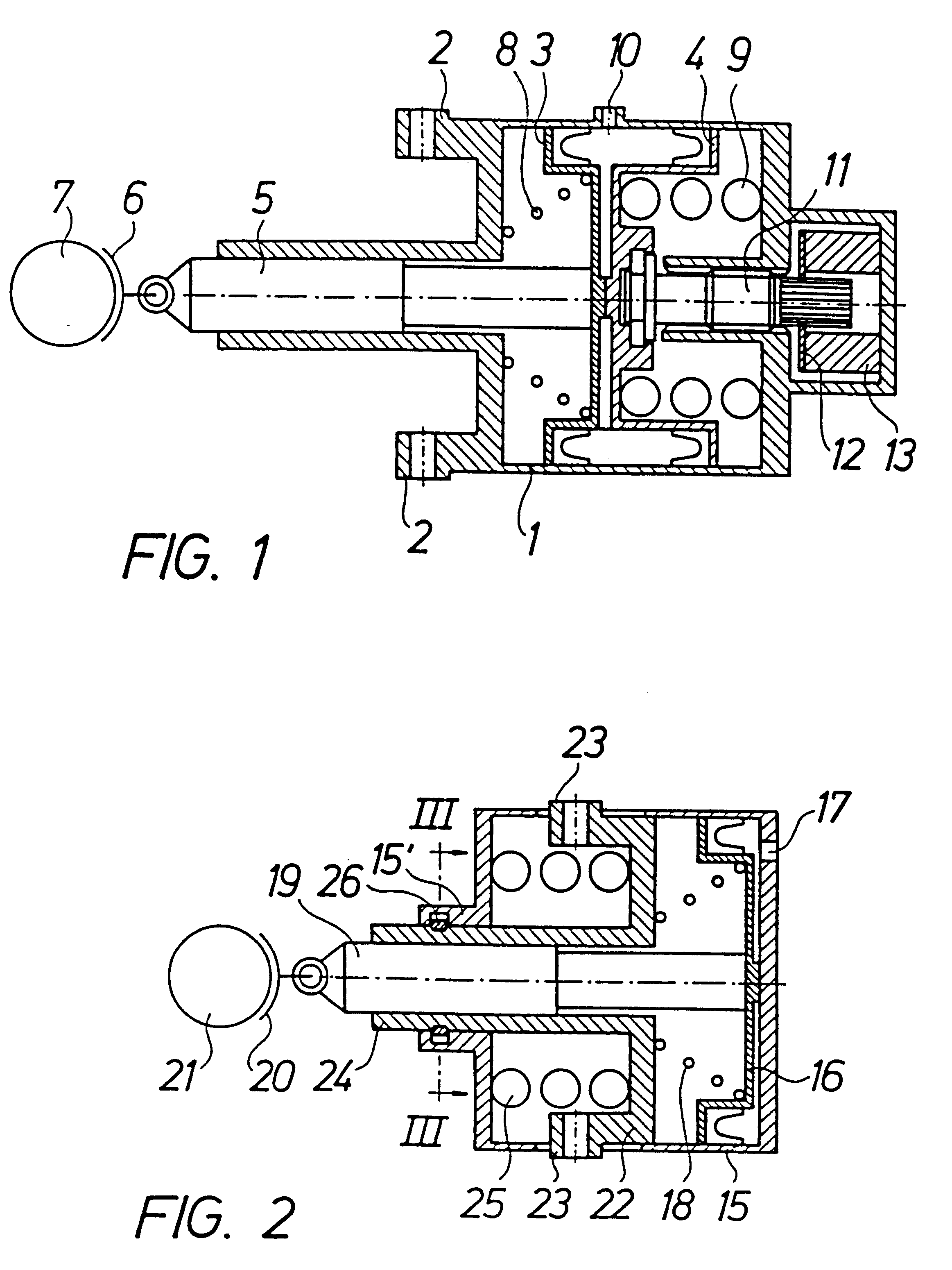

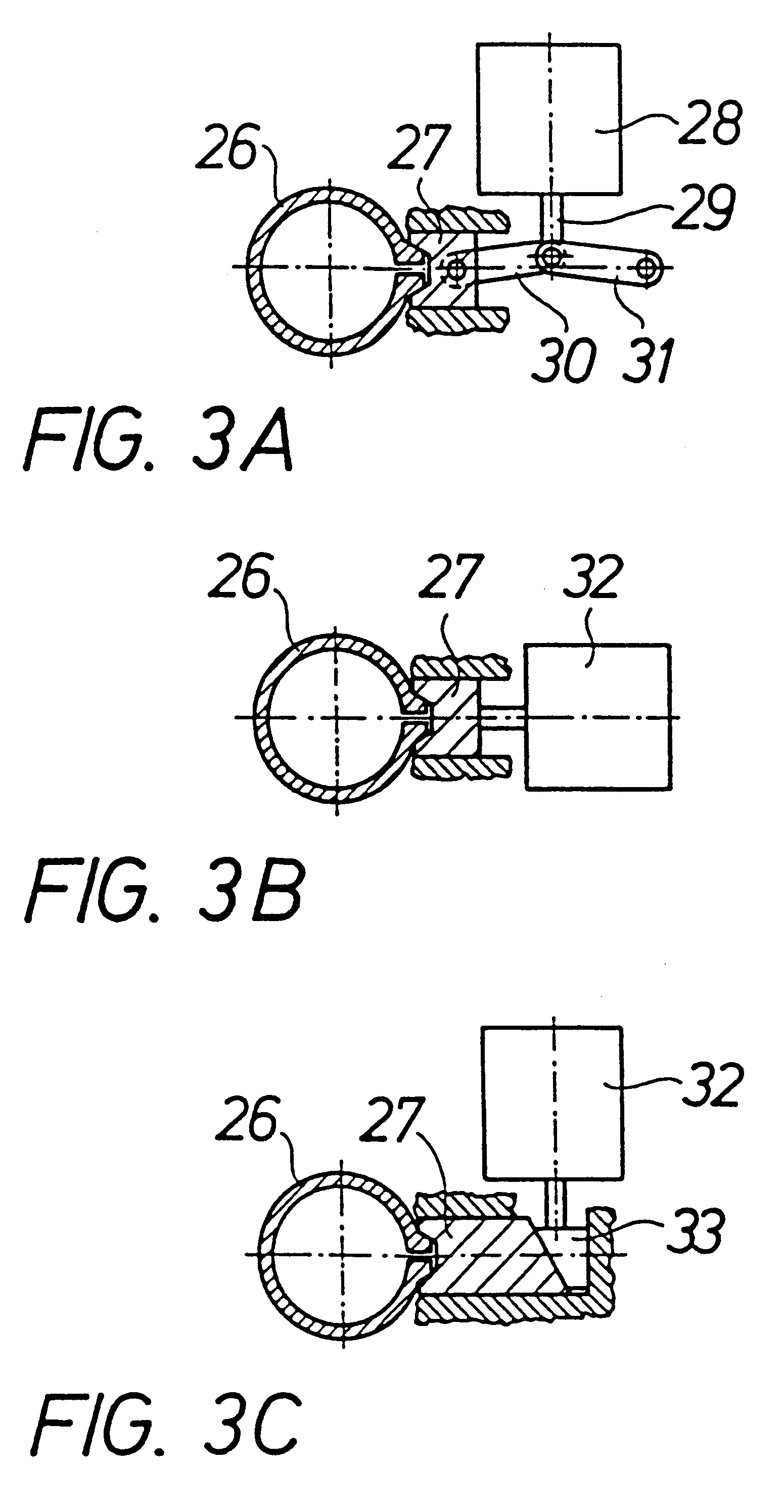

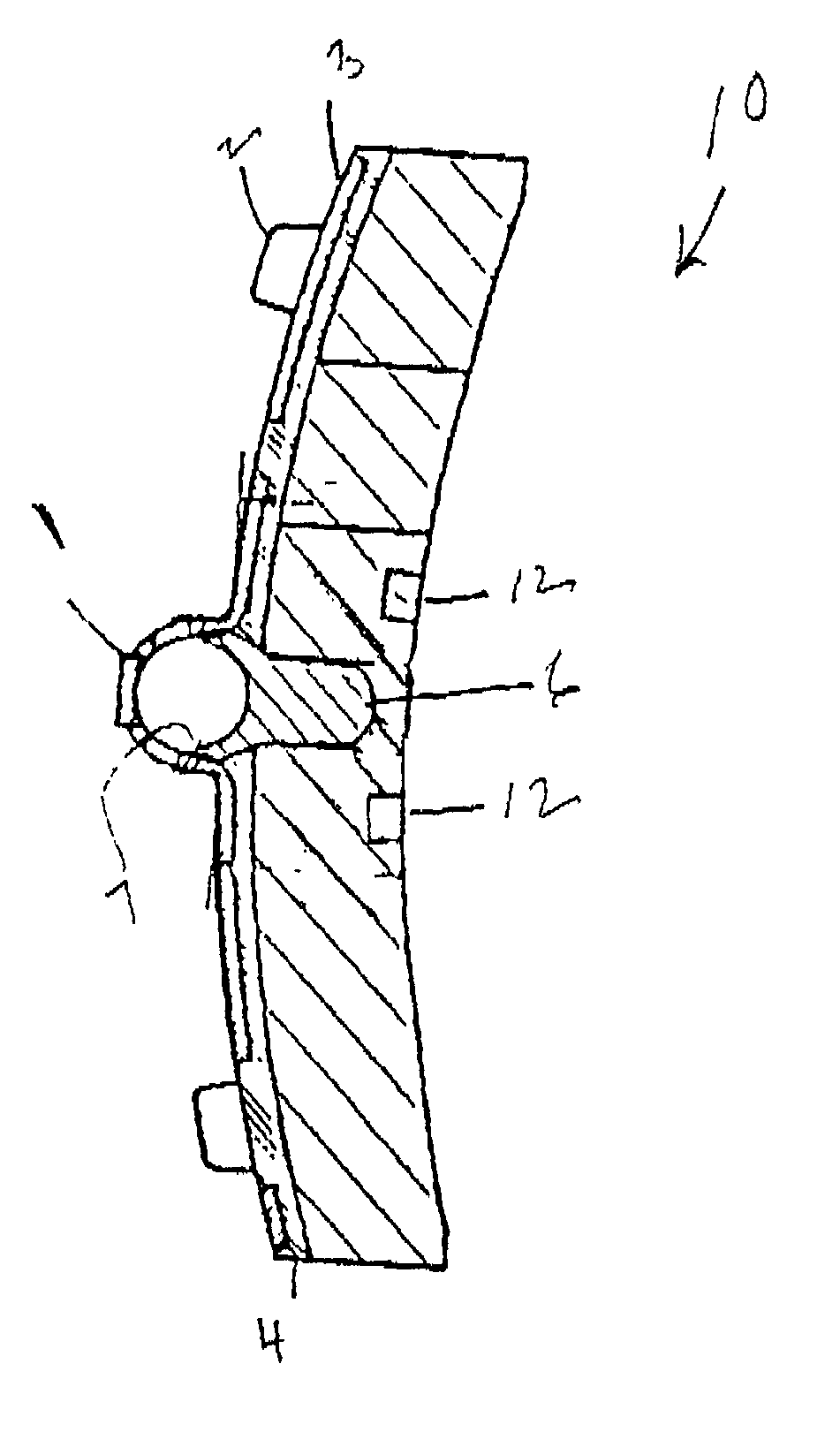

Safety brake arrangement in a brake actuator

A brake actuator for delivering a brake force through a brake block or br pad to a wheel or disc to be braked comprises in a housing (1) a service brake arrangement (3, 5). The actuator also comprises a safety brake arrangement (4, 9) including at least one powerful spring (9), acting in the brake application direction, means for tensioning the spring by the reaction force at a service brake application, and mechanical means (11, 12, 13) for locking the spring to the housing in a tension state. These locking means can be released at will for accomplishing a safety brake application.

Owner:SAB WABCO SA

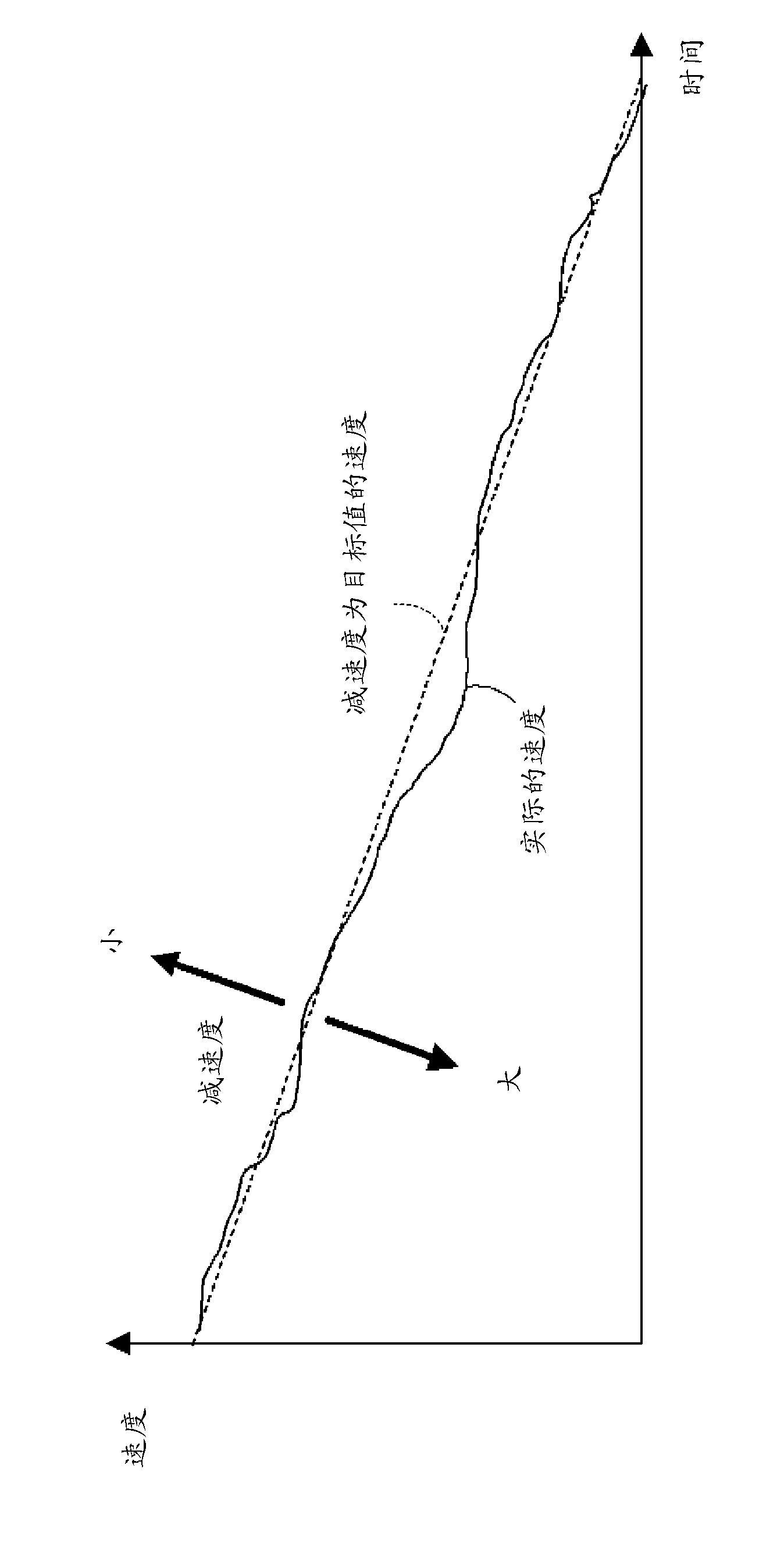

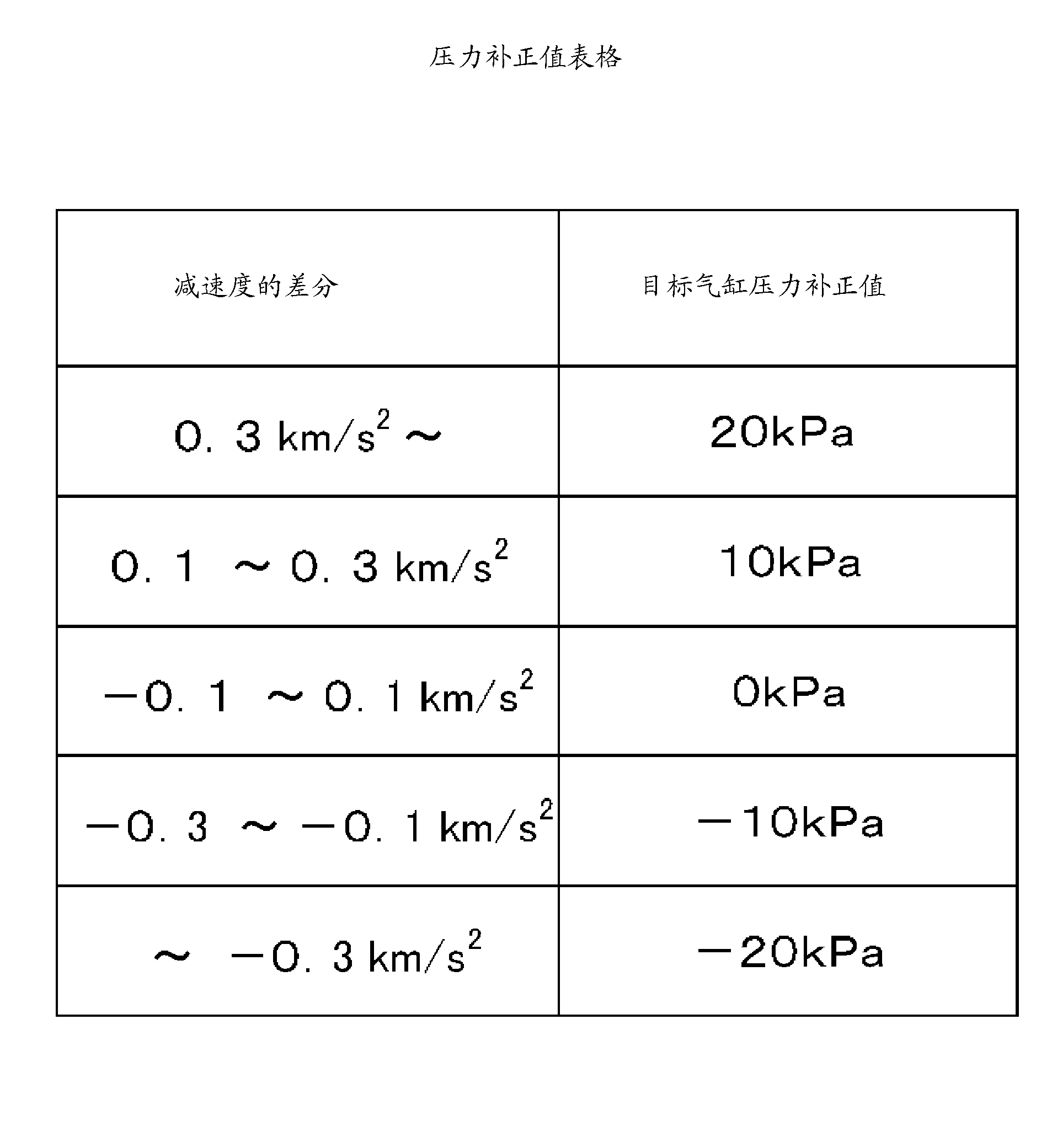

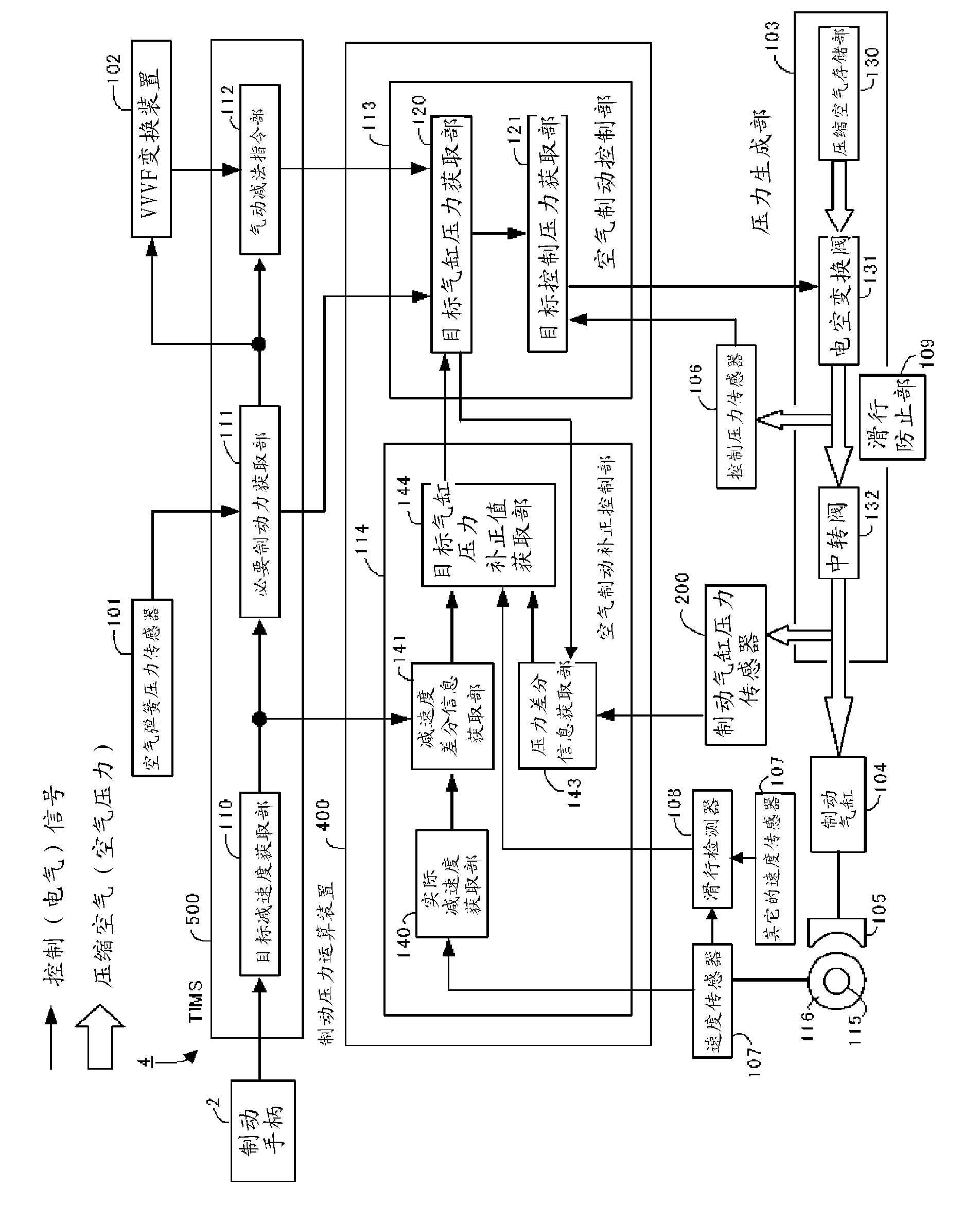

Brake pressure calculation device, brake control system and program

A brake pressure calculation device (100) acquires target cylinder pressure that is the target value of pressure within a brake cylinder (104) of an air brake, and is provided with a target cylinder pressure acquisition unit (120), a deceleration difference information acquisition unit (141), and a target cylinder pressure correction value acquisition unit (142). The target cylinder pressure acquisition unit (120) acquires the target cylinder pressure on the basis of required brake force and a target cylinder pressure correction value. The deceleration difference information acquisition unit (141) acquires deceleration difference information indicating the difference between the target value of deceleration and the actual value of deceleration. The target cylinder pressure correction value acquisition unit (142) acquires the target cylinder pressure correction value on the basis of the deceleration difference information.

Owner:MITSUBISHI ELECTRIC CORP

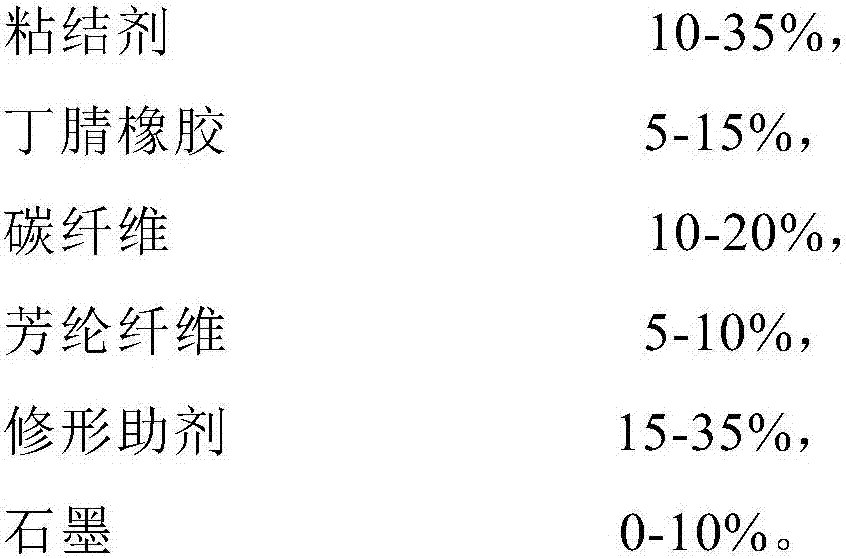

Motor car wheel tread sweeper shape-repair grinding device and preparation method thereof

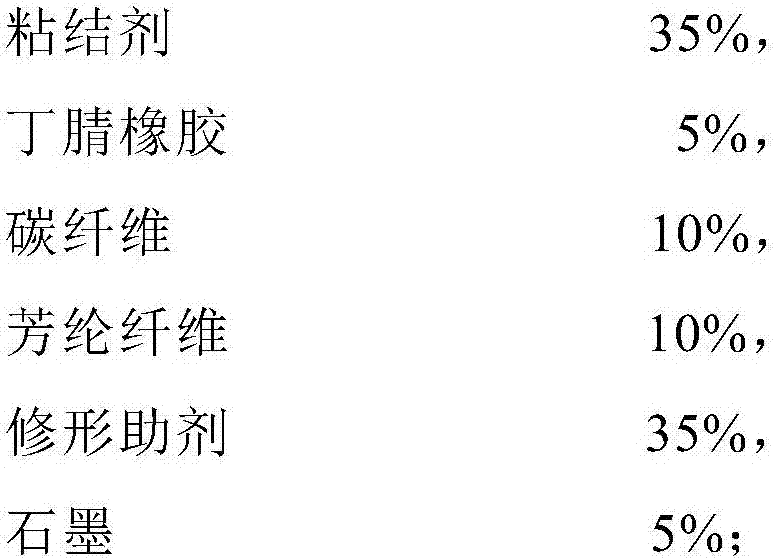

ActiveCN107188456ANo damageVisibly repairs wheel surface imperfectionsVehicle cleaningBrake arrangement with braking memberRoom temperatureGraphite

The invention relates to a motor car wheel tread sweeper shape-repair grinding device and a preparation method thereof. The preparation method comprises: preparing the following raw materials by weight: 10-35% of a binder, 5-15% of nitrile butadiene rubber, 10-20% of carbon fiber, 5-10% of aramid fiber, 15-35% of a shape-repair aid, and 0-10% of graphite; adding the raw materials to a high speed plow harrow type material mixer in steps according to a certain ratio, mixing for 5-10 min, carrying out a reaction for 200-500 s in a molding mold at a temperature of room temperature to 150 DEG C under a pressure of 200-600 kg / cm<2>, and carrying out high temperature sintering on the molded grinding device for 5-20 h at a sintering temperature of 100-140 DEG C so as to obtain the motor car wheel tread sweeper shape-repair grinding device. Compared to the grinding device in the prior art, the grinding device of the present invention is used in the Changke standard multiple units, can significantly repair the wheel surface defects and the non-roundness, has characteristics of no undesirable phenomena such as cracks, hot spots, sparks, metal embedding, layering, shedding and the like, no damage to the dual, and good effect.

Owner:SHANGHAI REINPHEN NEW MATERIAL TECH CO LTD

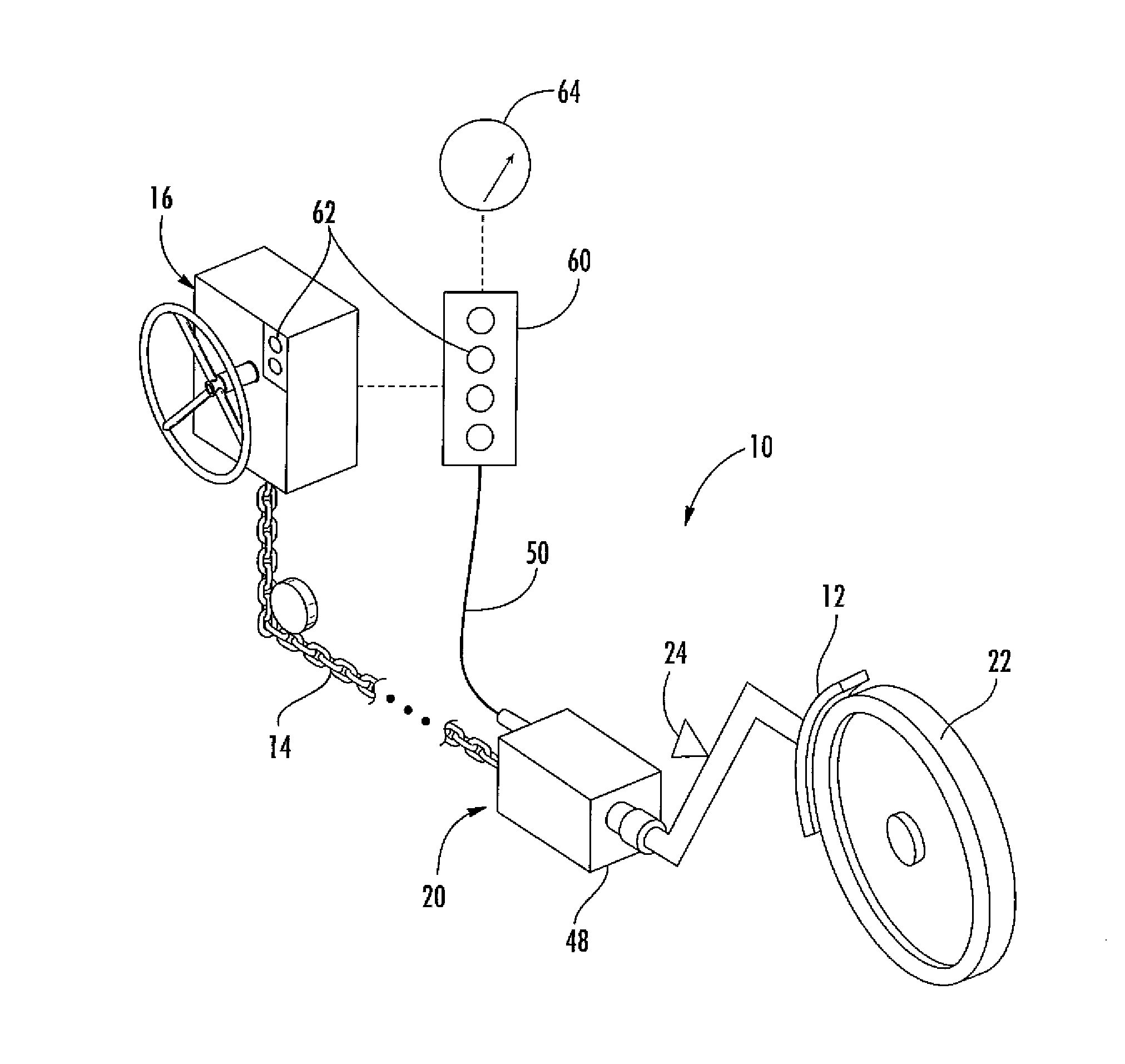

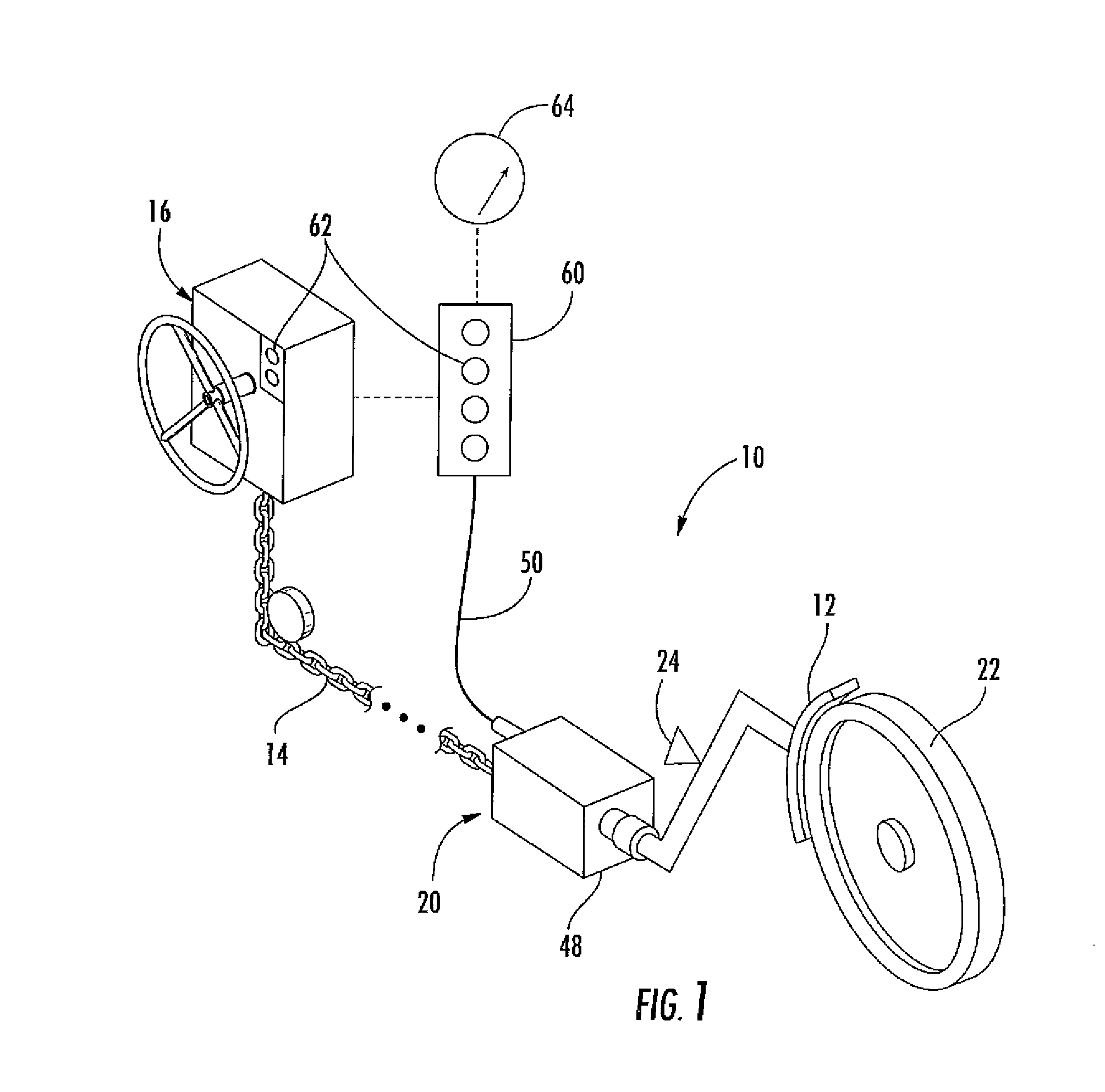

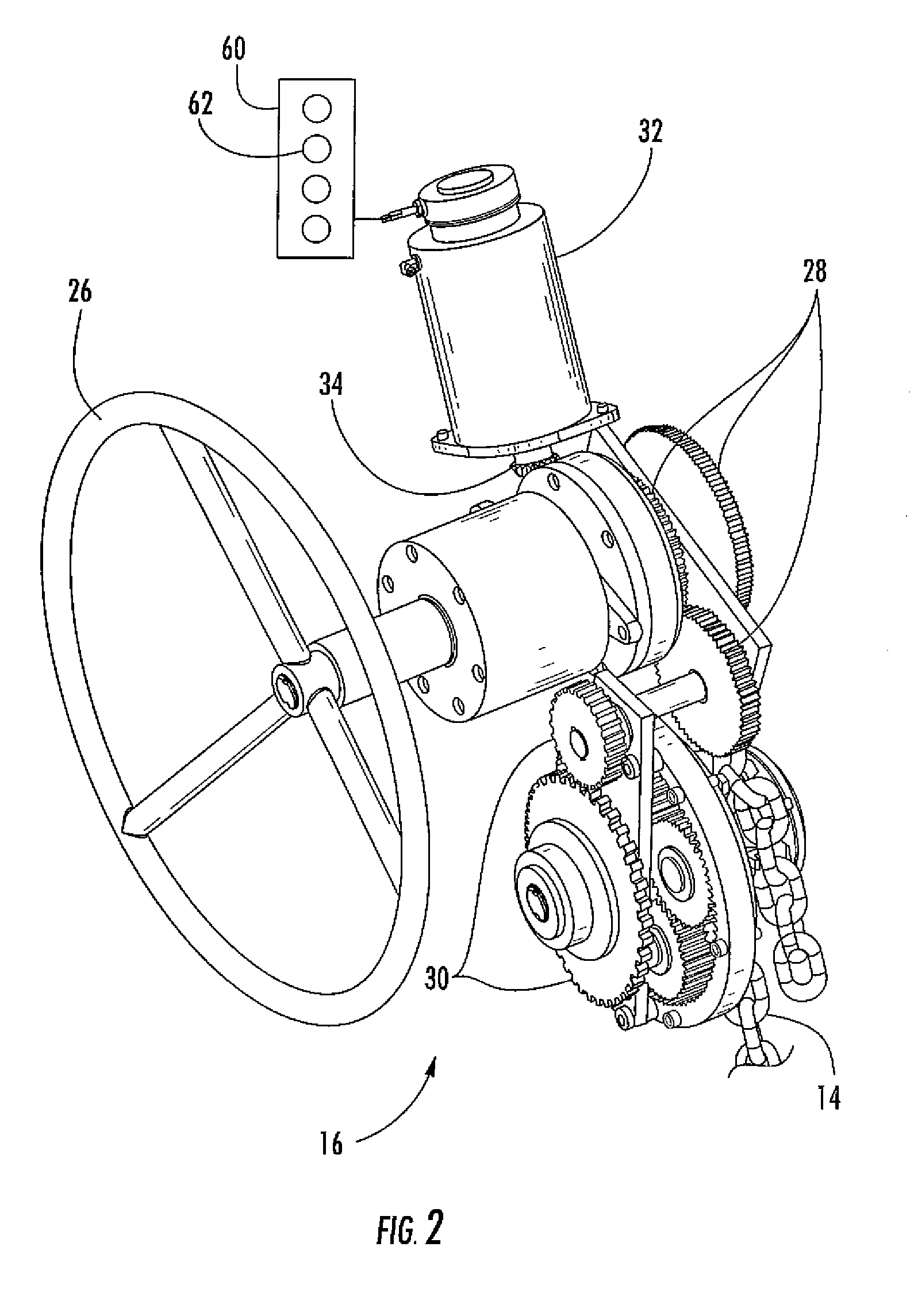

System and method for operating a locomotive parking brake

A system for operating a locomotive parking brake includes a wheel brake, a coupling connected to the wheel brake, and means for applying force to the coupling. A sensor connected to the coupling measures a force applied to the coupling and generates a signal reflective of the force applied to the coupling. A method for operating a locomotive parking brake includes applying a force to a coupling connected to a wheel brake, measuring the force applied to the coupling, and comparing the force applied to the coupling to a first predetermined limit. The method further includes indicating that the force applied to the coupling is equal to or greater than the first predetermined limit.

Owner:GRAHAM WHITE MFG

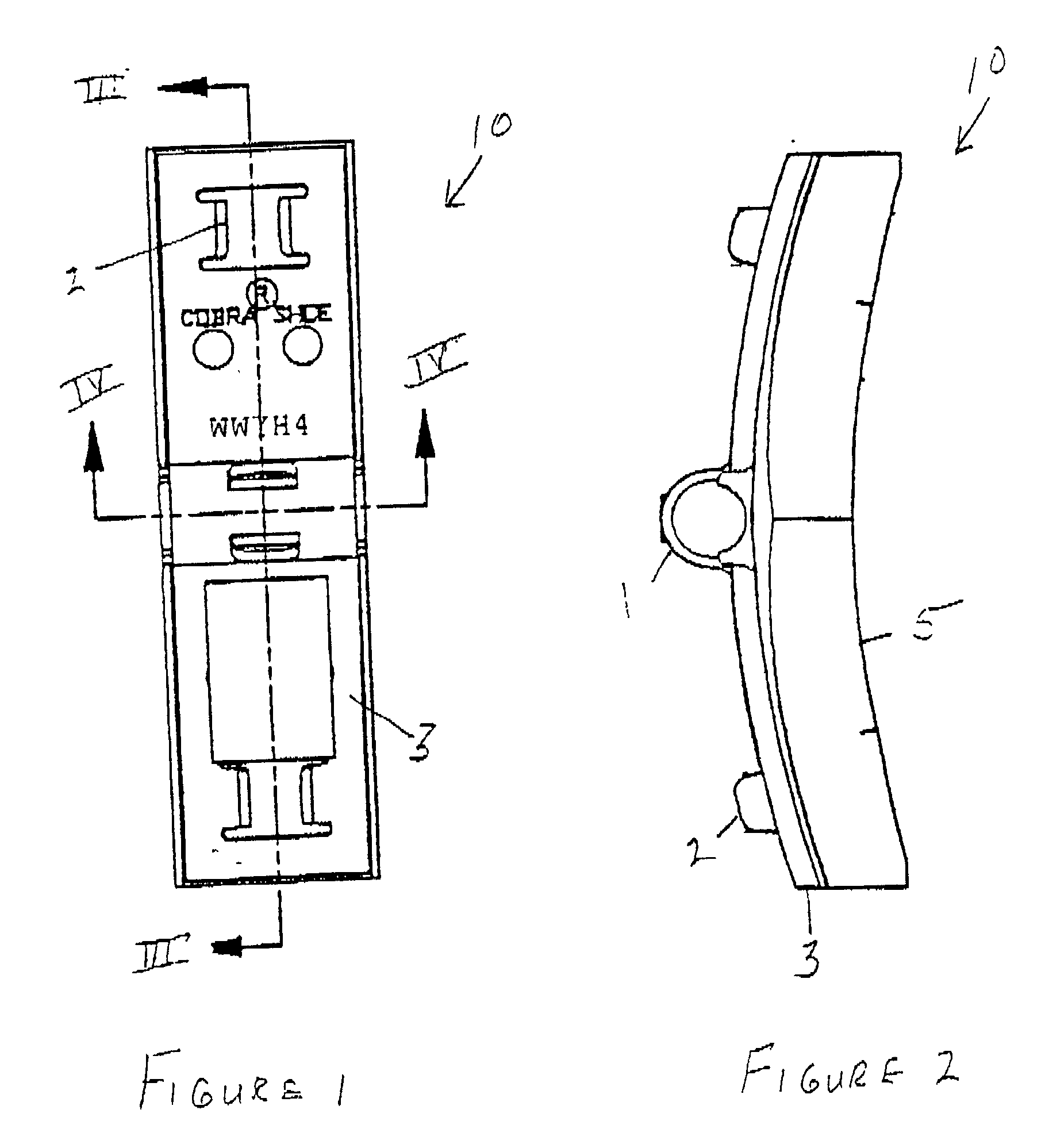

Supplemental inserts to improve wheel conditioning

InactiveUS20030234142A1Reduce defectsLightweight productionBraking membersFriction liningEngineeringBrake shoe

A brake shoe for use on a railway vehicle for reconditioning a wheel tread surface during a normal braking application including a backing plate and a first friction material extending over the brake surface of such brake shoe. It further contains a second friction material, formed as a discrete insert molded into such first friction material. Such second friction material initially is completely embedded. One surface of the insert is incrementally exposed as the first friction type material is eroded away. Such second friction material exhibits abrasive properties and is bonded to such backing plate. A third friction material is disposed as another discrete insert imbedded in the first friction type material. One surface of the abrasive third friction material being disposed as part of the brake surface of the brake shoe.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

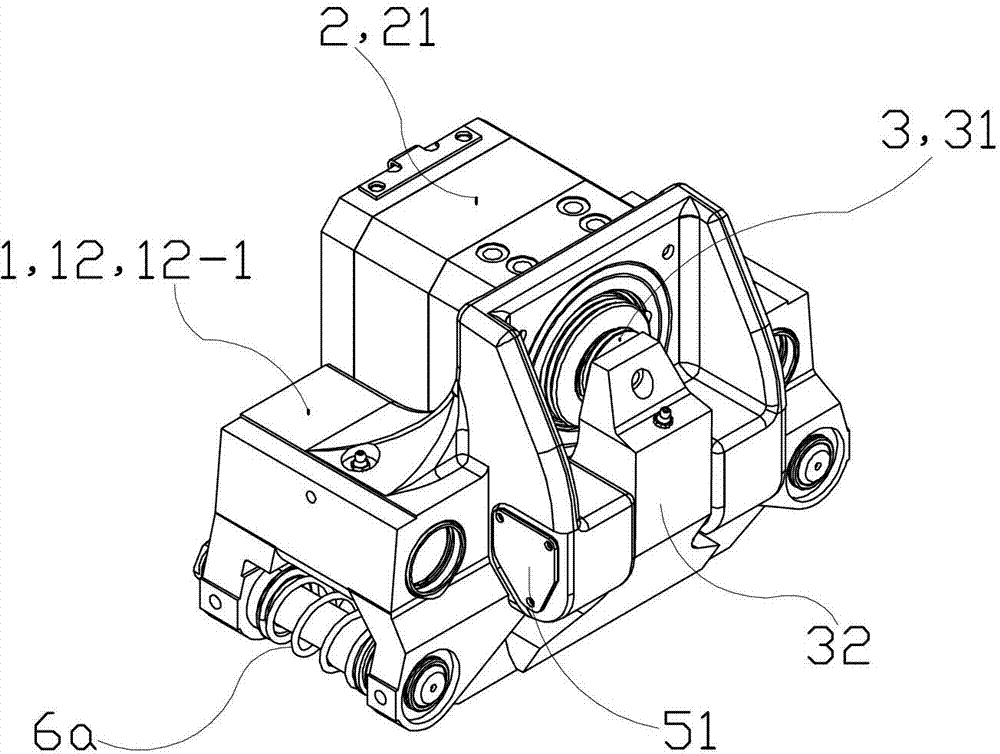

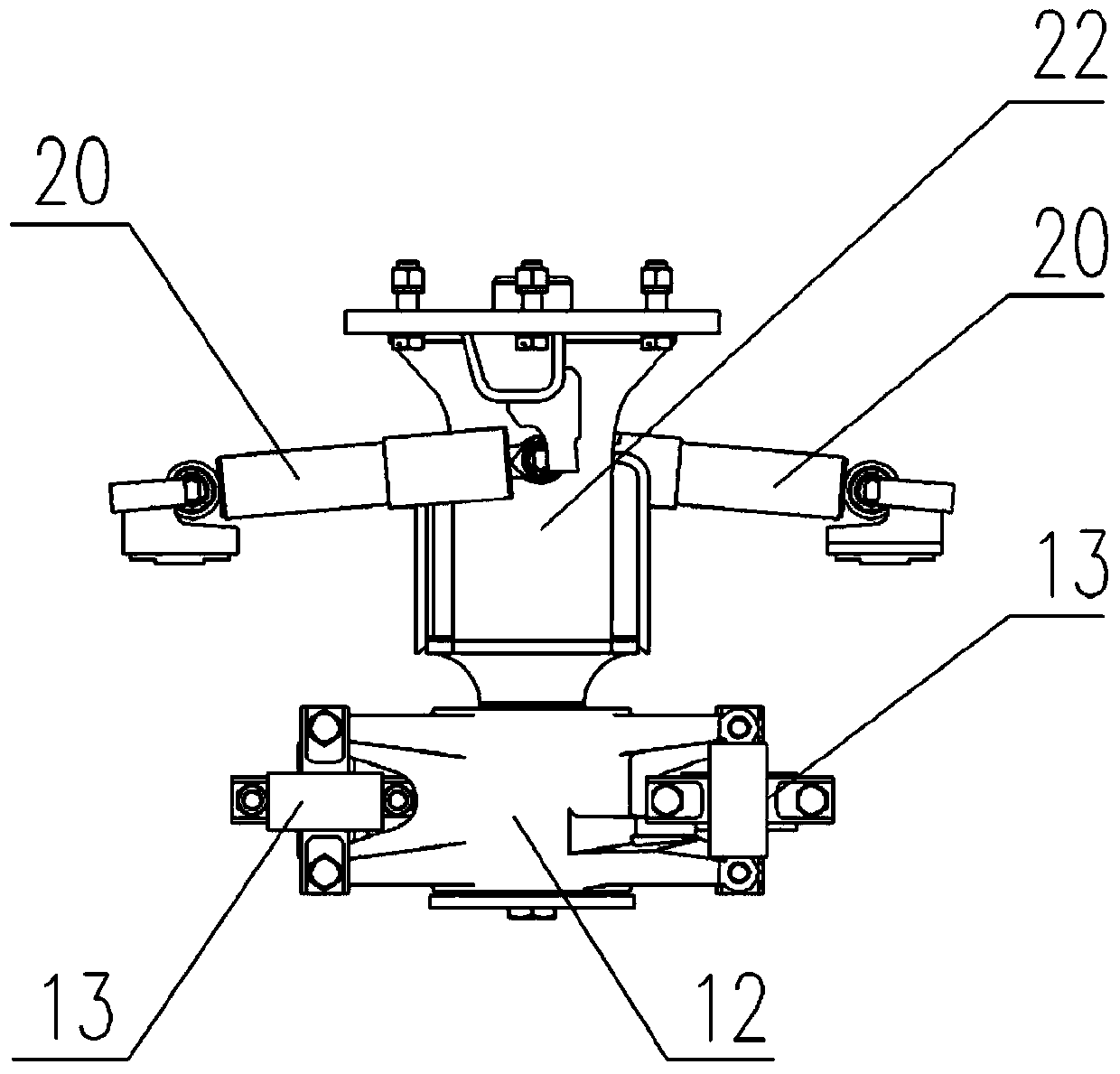

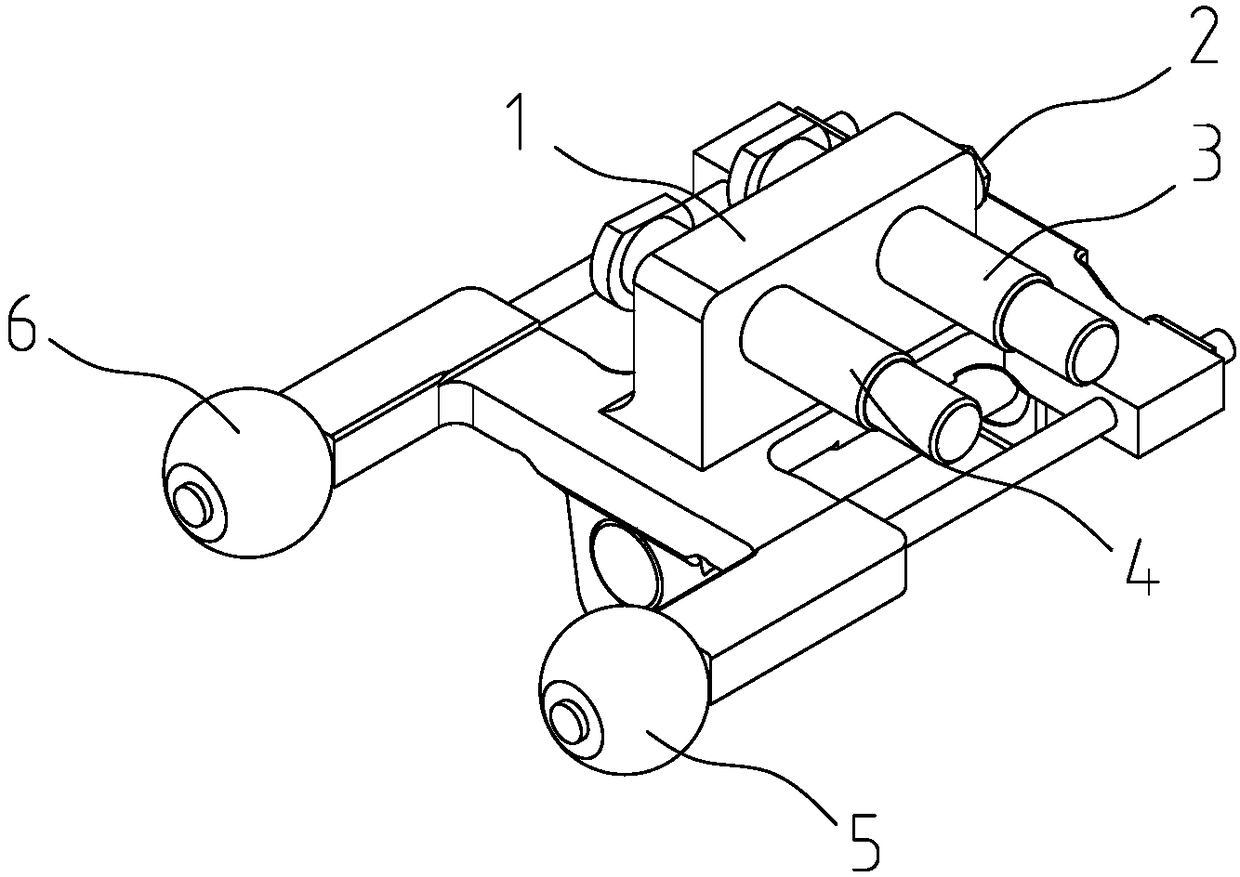

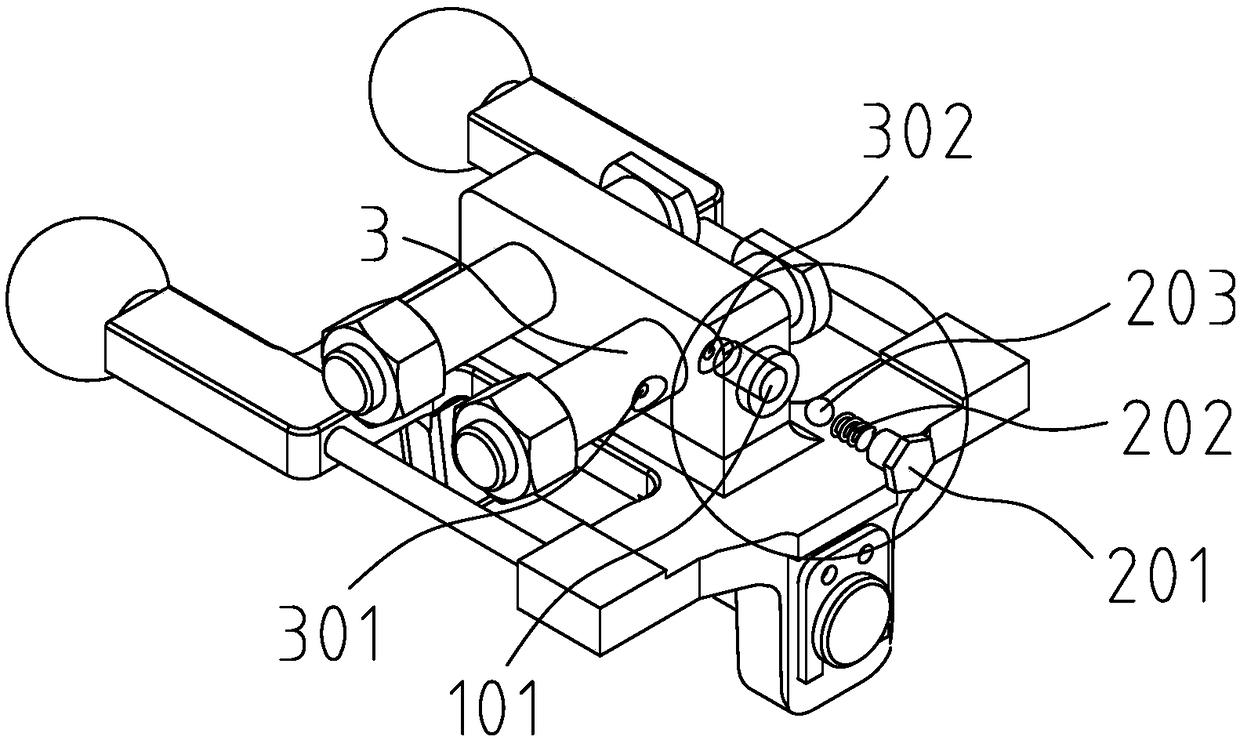

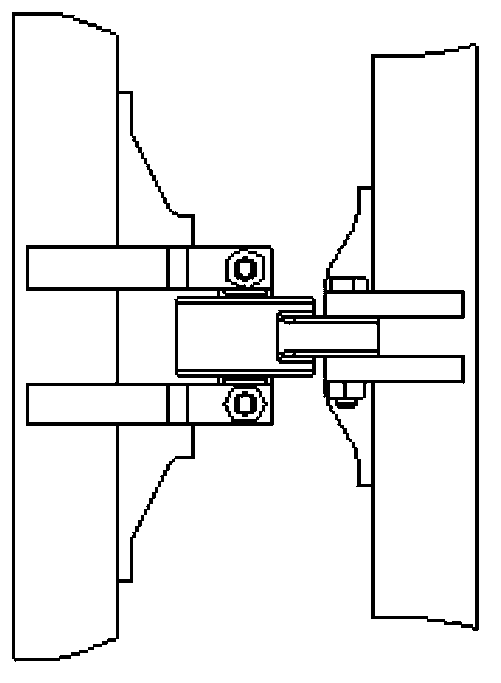

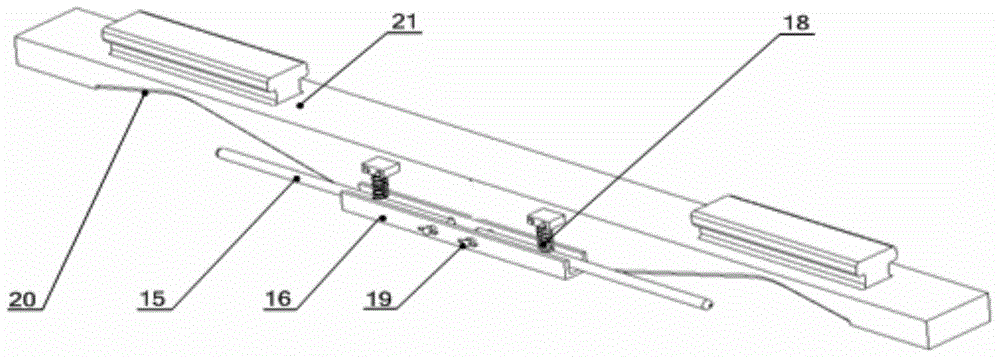

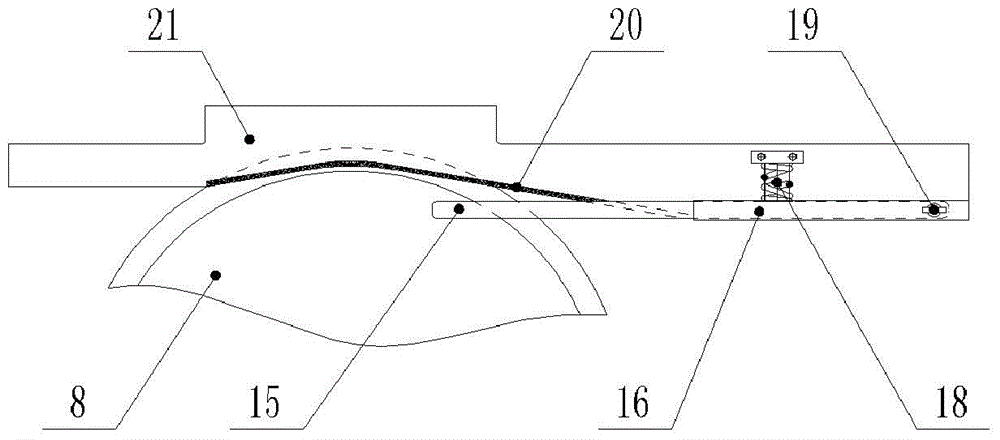

Rigid following mechanism and brake clamp unit for variable-gauge bogie

ActiveCN108482415ASimple structureIncrease flexibilityBogiesBrake arrangement with pressed braking surfaceBogieEngineering

The invention relates to a rigid following mechanism and a brake clamp unit for a variable-gauge bogie. The rigid following mechanism comprises a following connecting part, a positioning device and atleast two fixed parts, wherein the positioning device is mounted on the following connecting part; and the fixed parts are parallel to each other. The following connecting part and the fixed parts are installed in a sliding fit mode. The positioning device is connected with a first fixed part in a contact mode. Contact sliding parts are separately installed on two supporting arms of the followingconnecting part. The brake clamp unit comprises a mounting bracket and a brake actuator and a rigid follower mechanism, wherein the brake actuator is mounted on the mounting bracket. The following connecting part and the brake actuator are installed in a fit mode. The positioning device is tightly attached to the mounting bracket, and the fixed parts are fixedly installed on the mounting bracket.The rigid following mechanism and the brake clamp unit for the variable-gauge bogie can change the position along with wheels, the position on a target gauge position is automatically found, and thechange of the position is achieved.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Positive active material comprising a continuous concentration gradient of a metal composition for lithium battery, method of preparing the same, and lithium battery including the same

ActiveUS8865348B2Conductive materialActive material electrodesConcentration gradientElectrochemistry

A positive active material according to one embodiment of the present invention includes an internal bulk part and an external bulk part surrounding the internal bulk part and has a continuous concentration gradient of the metal composition from an interface between the internal bulk part and the external bulk part to the surface of the active material. The provided positive active material in which the metal composition is distributed in a continuous concentration gradient has excellent electrochemical characteristics such as a cycle life, capacity, and thermal stability.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

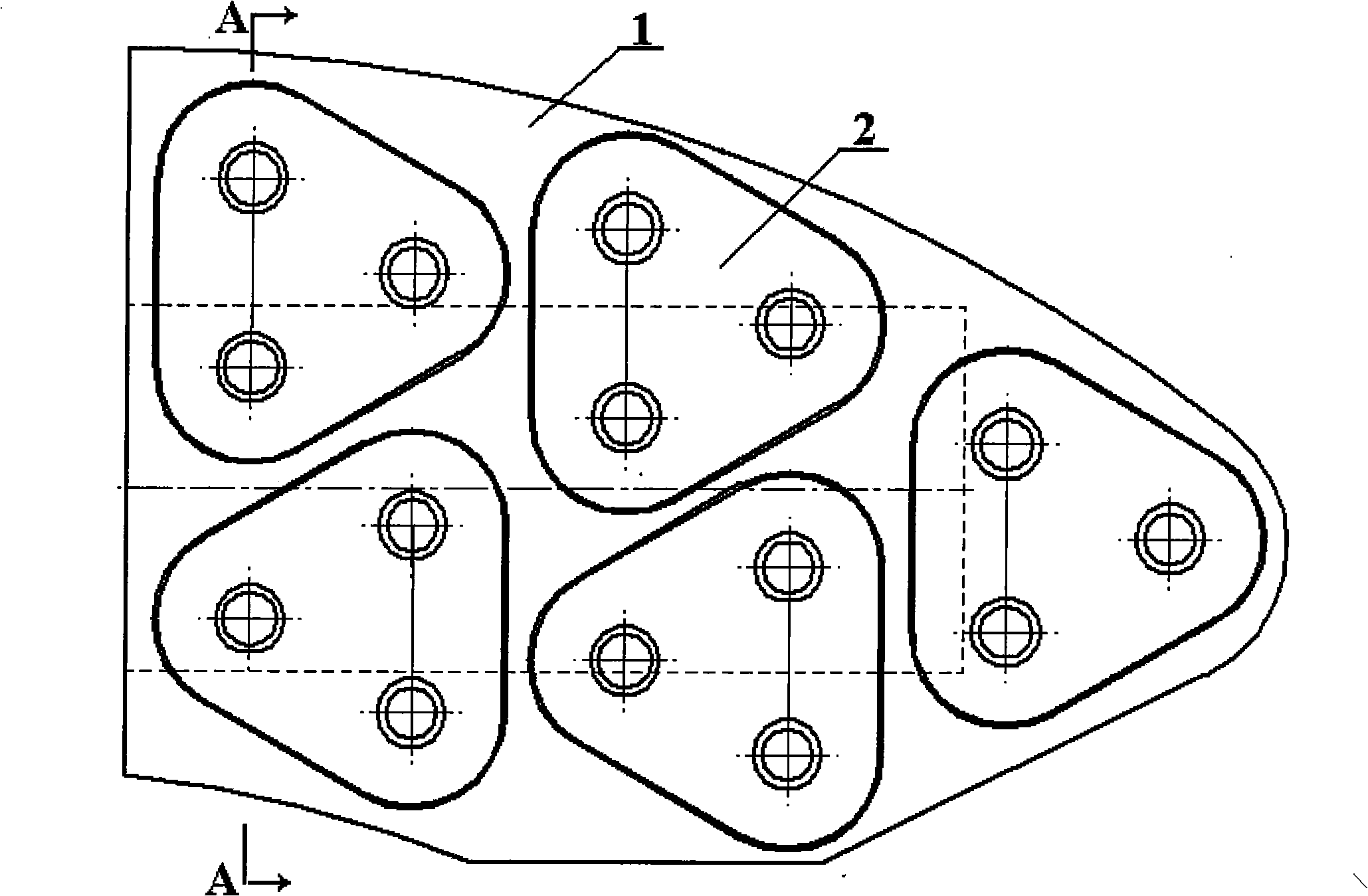

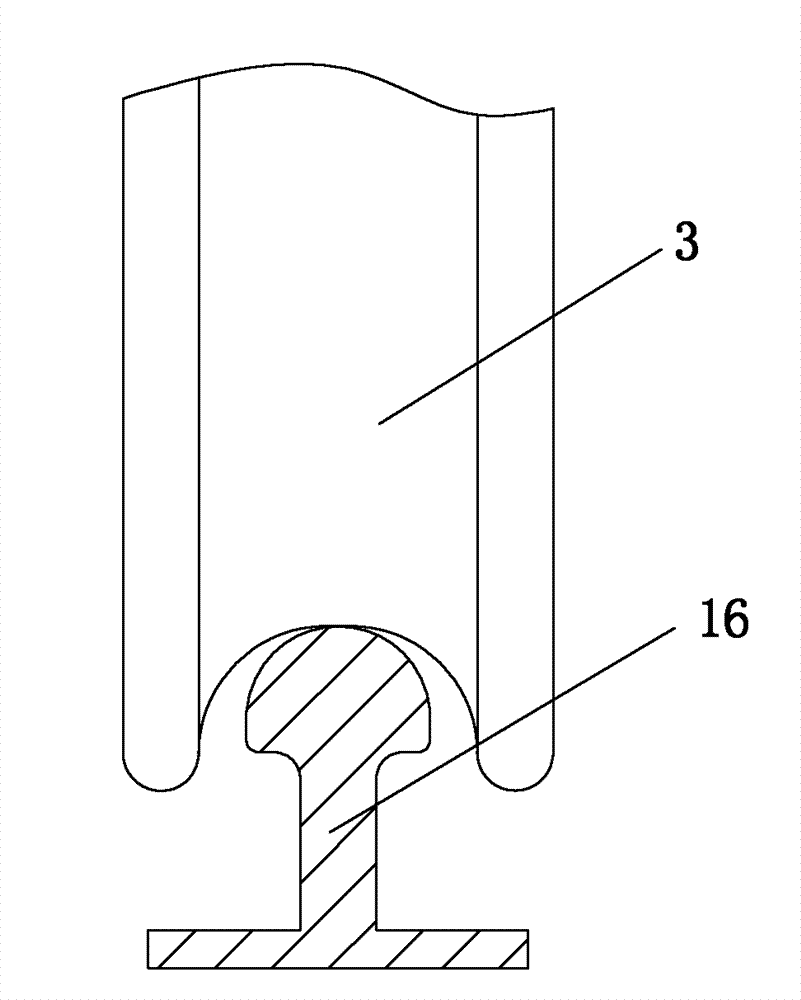

Floating type brake pad for train

ActiveCN103133571AStress averagingNo local breakageBraking membersFriction liningClassical mechanicsMechanical engineering

The invention relates to a floating type brake pad for a train. The floating type brake pad comprises a rear panel, a friction block, a clamping spring and an elastic supporting plate arranged between the friction block and the real panel. The elastic supporting plate comprises a ball supporting face and a supporting pawl arranged outside the ball supporting face. The ball supporting face is attached to a ball supporting portion of the friction block. A guiding hole suitable for a locating portion of the friction block to penetrate through is molded at the center of the bottom of the ball supporting face. The supporting pawl extends from the edge of the ball supporting face to the bottom of the ball supporting face and tends to a direction away from the guiding hole. A connecting edge of the supporting pawl and an edge of the ball supporting face are connected through a smooth transition section, and the supporting pawl and a supporting edge extend to exceed the bottom of the ball supporting face. The floating type brake pad for the train solves the problem that a pawl of an elastic supporting piece portion of the brake pad does not stretch outwards and is bent inwards, the elastic supporting plate can be stretched outwards along the direction of the supporting pawl during stress, and supporting failure of a corresponding portion is avoided.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

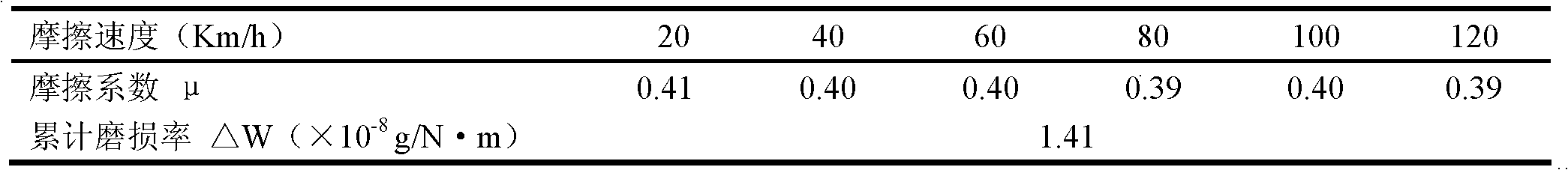

Synthetic brake shoe for urban railway vehicle and preparation method thereof

InactiveCN102134397AImprove basic performanceHigh temperature and high basic performanceFriction liningBrake arrangement with braking memberLow noiseWeather resistance

The invention discloses a synthetic brake shoe for an urban railway vehicle and a preparation method thereof. The synthetic brake shoe for an urban railway vehicle is prepared from acicular wollastonite used as a reinforcing material, polybismaleimide resin used as a base material, and a filling and frictional property regulator by a hot pressing technique. The synthetic brake shoe for an urban railway vehicle is prepared from 8-16% of polybismaleimide resin, 6-14% of nitrile-butadiene rubber, 12-24% of graphite, 4-16% of iron powder, 4-12% of wollastonite, 6-14% of friction powder, 21-39% ofbarite and 0-6% of coupling agent. The synthetic brake shoe for an urban railway vehicle has the advantages of stable friction factor, wear resistance, low abrasion, no cracking or metal inlay, favorable weather resistance and low noise, does not damage wheels, does not pollute the city, and can satisfy the operational requirements for urban railway trains.

Owner:DALIAN JIAOTONG UNIVERSITY

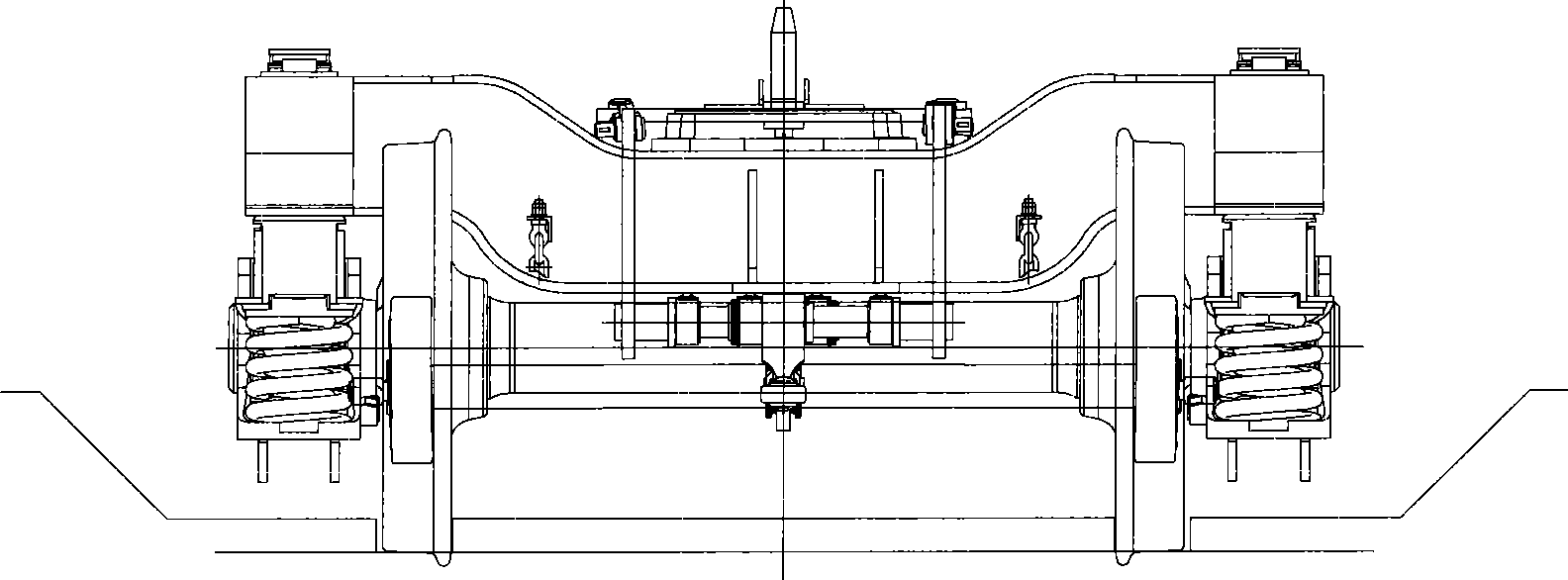

Low-power radial welding bogie

The invention provides a low-power radial welding bogie comprising two wheel sets, a three-piece side welding beam and a crossbeam. Two ends of the side beam are connected with the wheel sets through primary rubber-metal pads and bearing saddles respectively. The wheel sets are connected with a wheel set connecting device through the bearing saddles. A crossbeam assembly is connected with the side beam through two secondary suspension systems. A foundation brake gear is suspended on the crossbeam assembly or the side beam. The secondary suspension systems have multiple structural styles, and the wheel sets are of variable- gauge structures. Compared with conventional freight car bogies, the low-power radial welding bogie has the advantages that the bogie is good in uniform load performance; defects of cast structure swing bolsters and side frame casting are avoided; wheeltrack acting force is reduced, and wear parts of the suspension systems are reduced; the variable-gauge wheel sets meet requirements on variable-gauge performance of the bogie; high-speed operation stability of the bogie is improved, and rim wear generated when the bogie passes curves is reduced; the bogie can meet the requirements on maximum axle load of 30t and highest running speed of 200km / h.

Owner:CRRC SHANDONG CO LTD

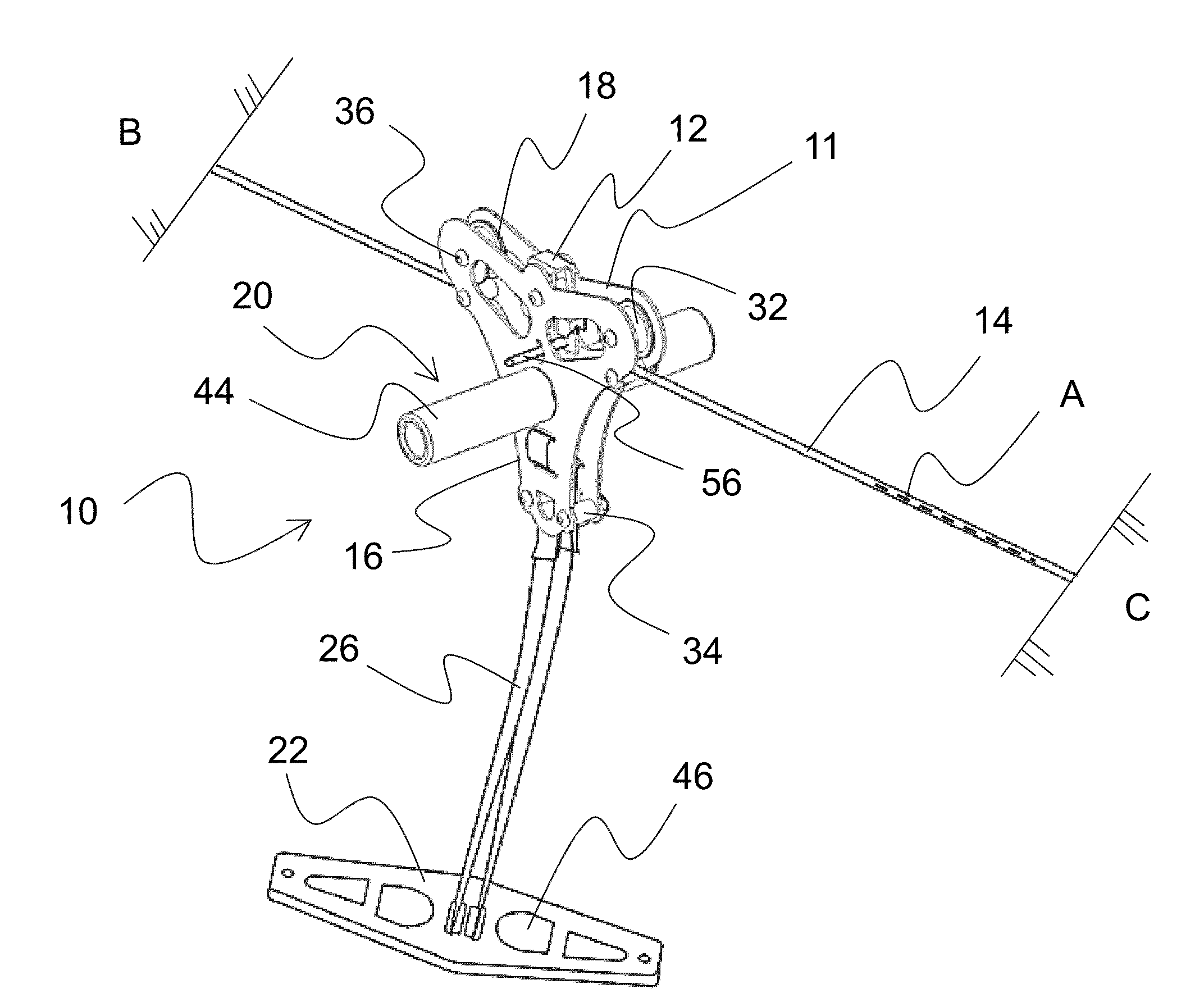

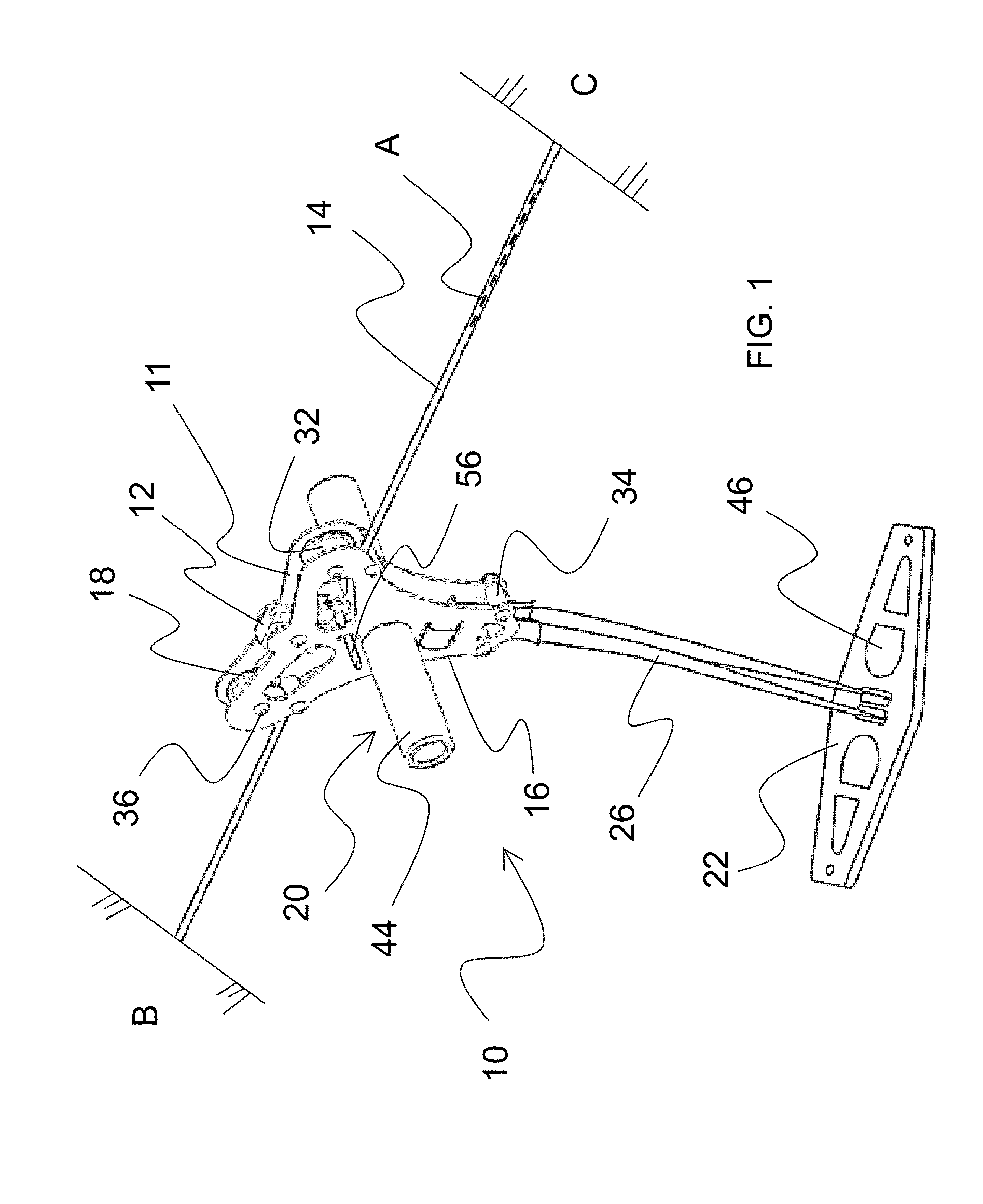

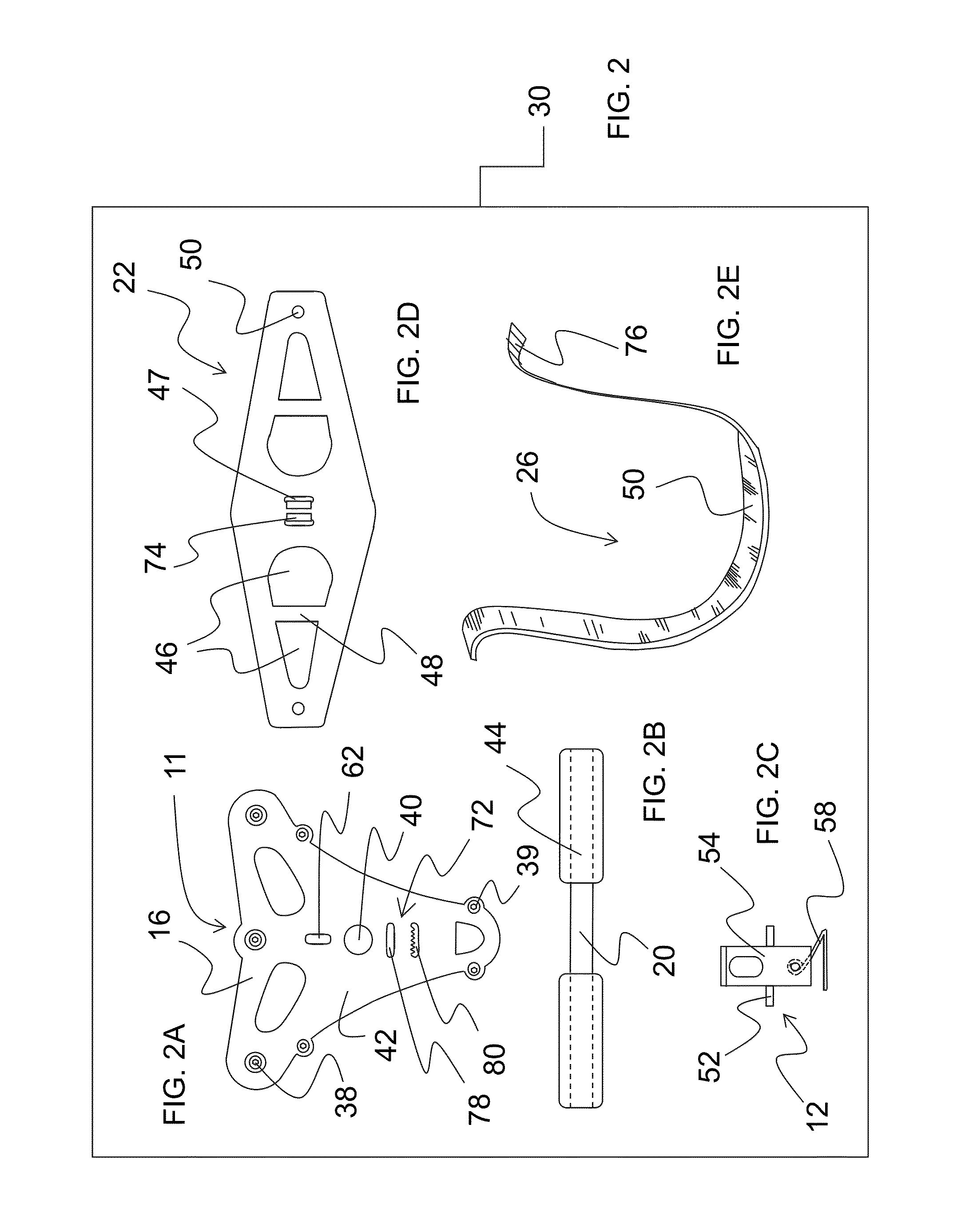

Zip line apparatus

Embodiments of the present invention generally relate to a zip line or trolley system kit for propelling a person or an object using gravity along an extended cable line suspended between two trees or towers. The zip line or trolley system may include an easily installable support harness assembly, a braking system and a removable seat fixture to provide for the zip line system to be completely portable to be carried, installed and taken down in remote locations.

Owner:NORTH STAY LLC

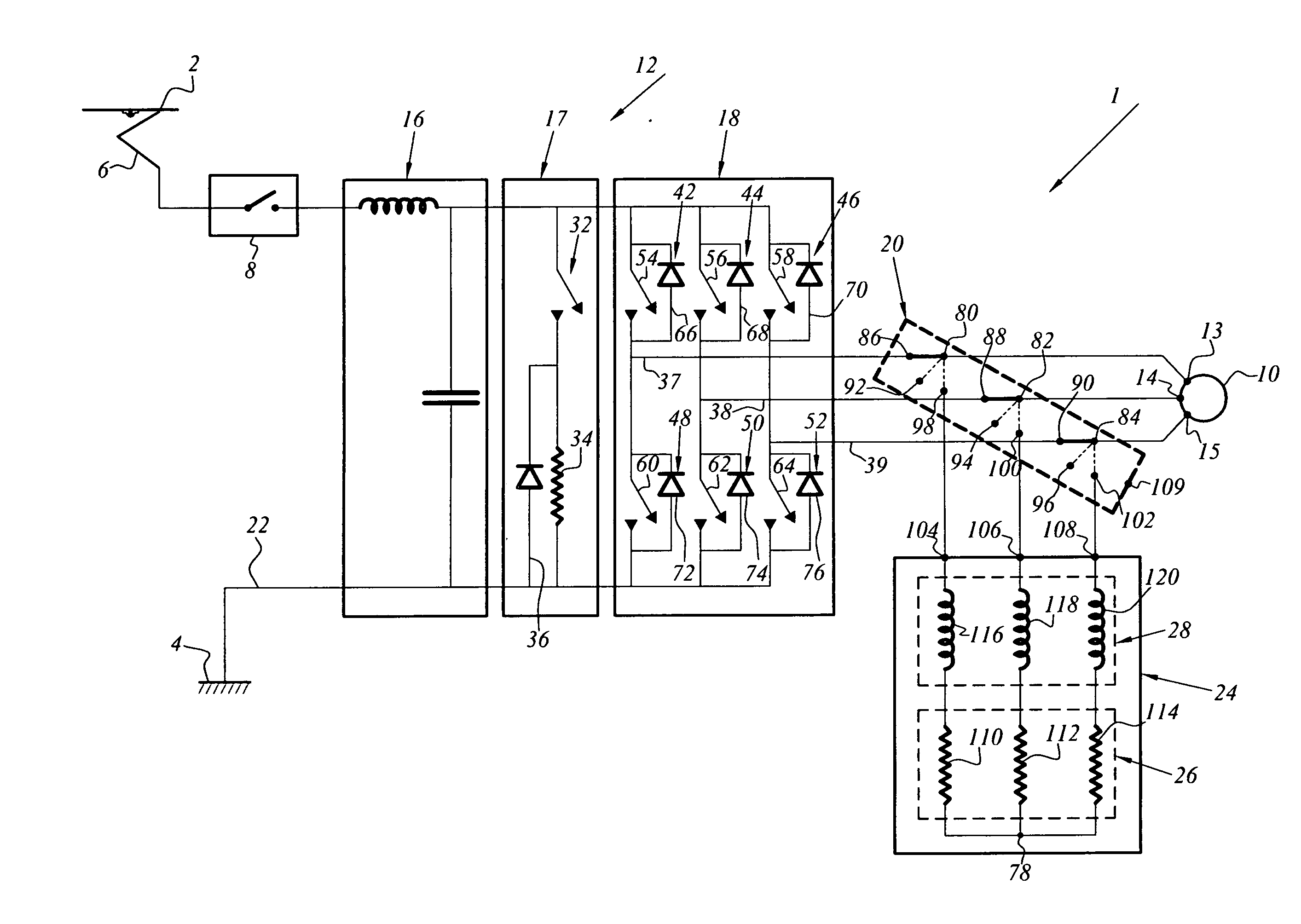

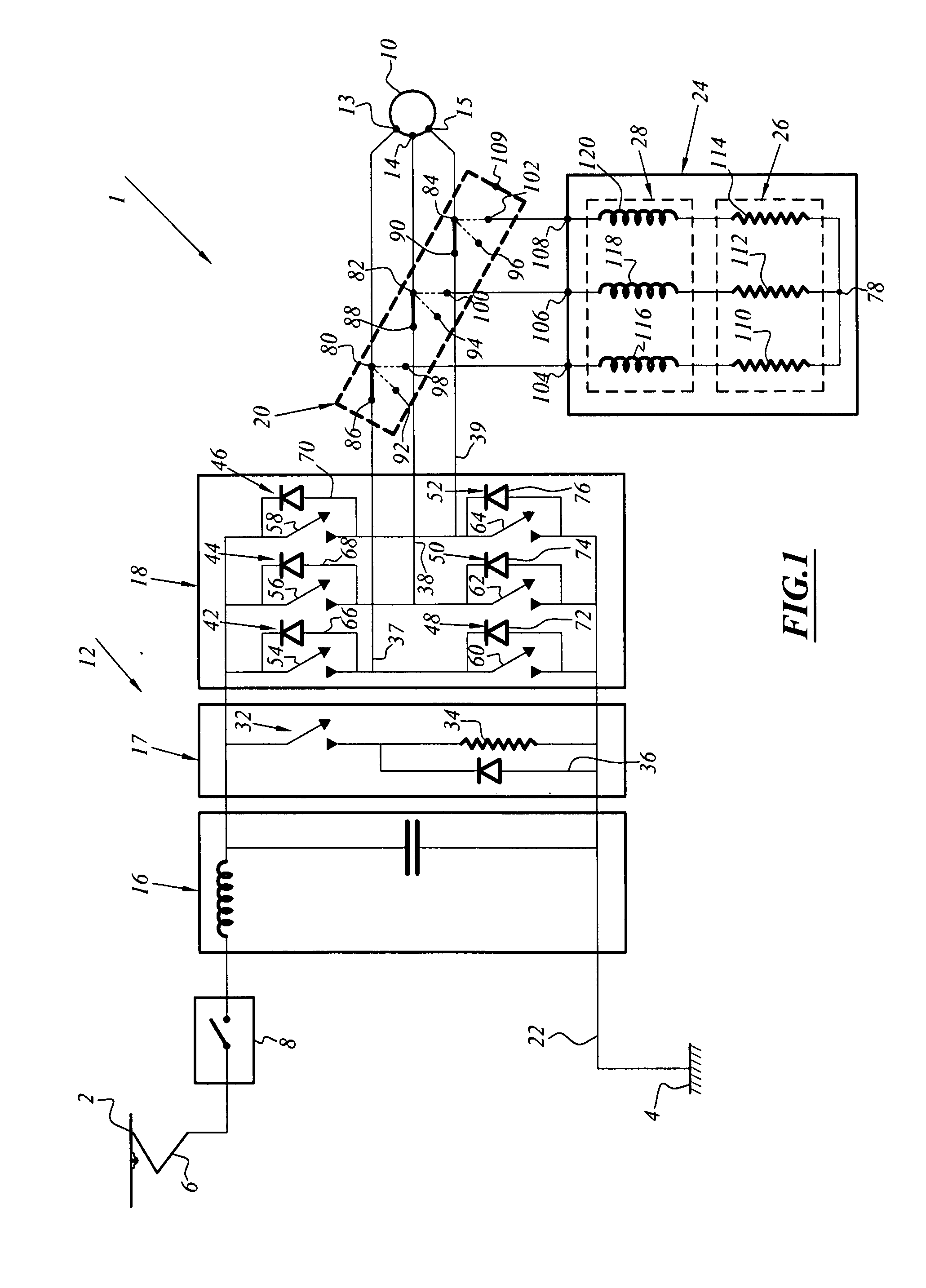

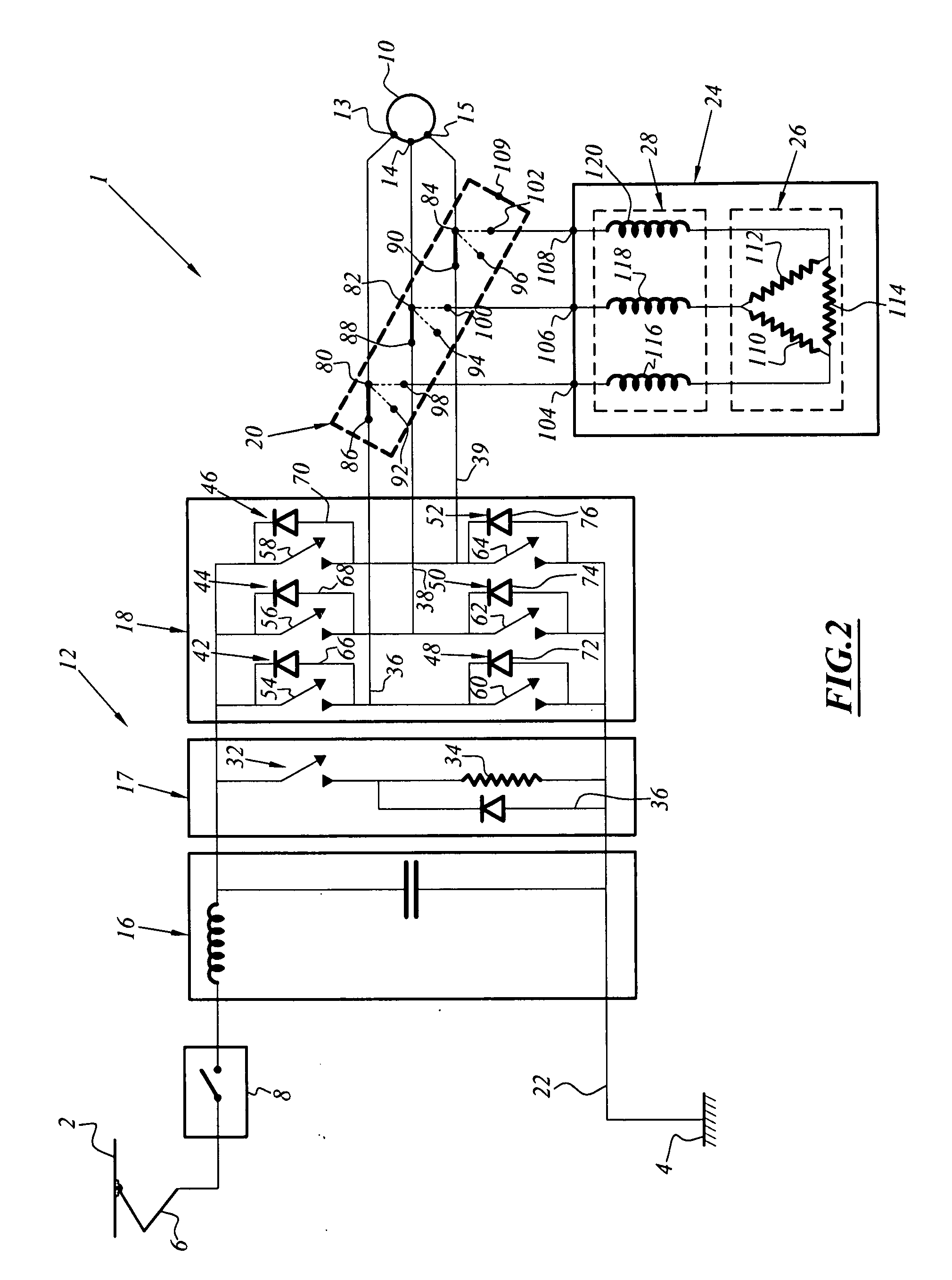

Electric safety braking device with permanent magnet motor and breaking torque control

ActiveUS20090066272A1Efficient electric safetyRailway vehiclesDc motor stoppersBrake torqueElectricity

This electric safety braking device for an electric traction vehicle may allow the force / speed characteristic of the vehicle to be improved and includes a rotating electromechanical machine with permanent magnets which has at least one coil with electric terminals, a rheostatic electric braking torque production device, and a commutation device which are capable of connecting the electric terminals of the electromechanical machine to the braking torque production device. The electric safety braking device includes at least one inductor is connected in series between the braking torque production device and the electromechanical machine.

Owner:ALSTOM TRANSPORT TECH SAS

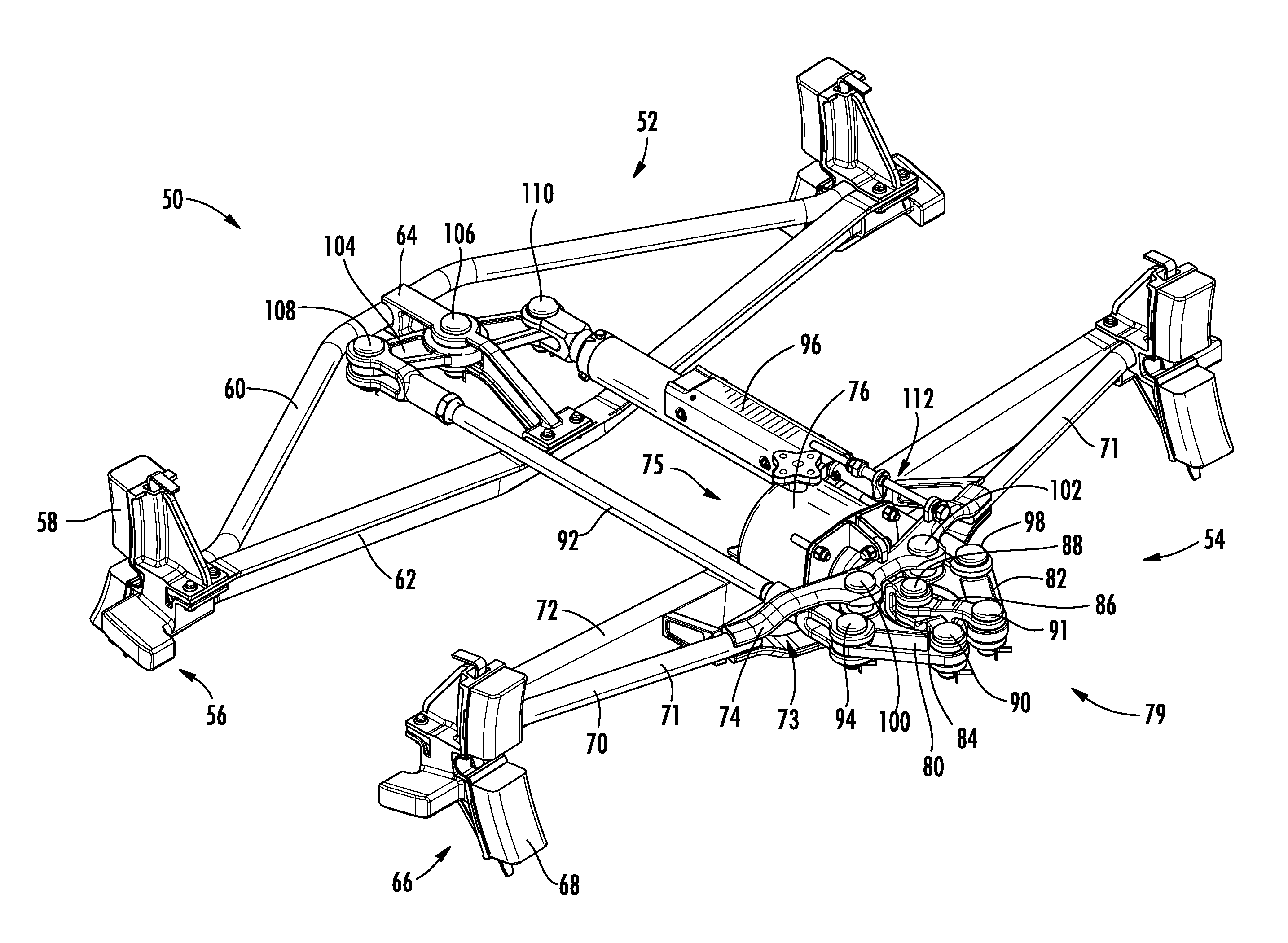

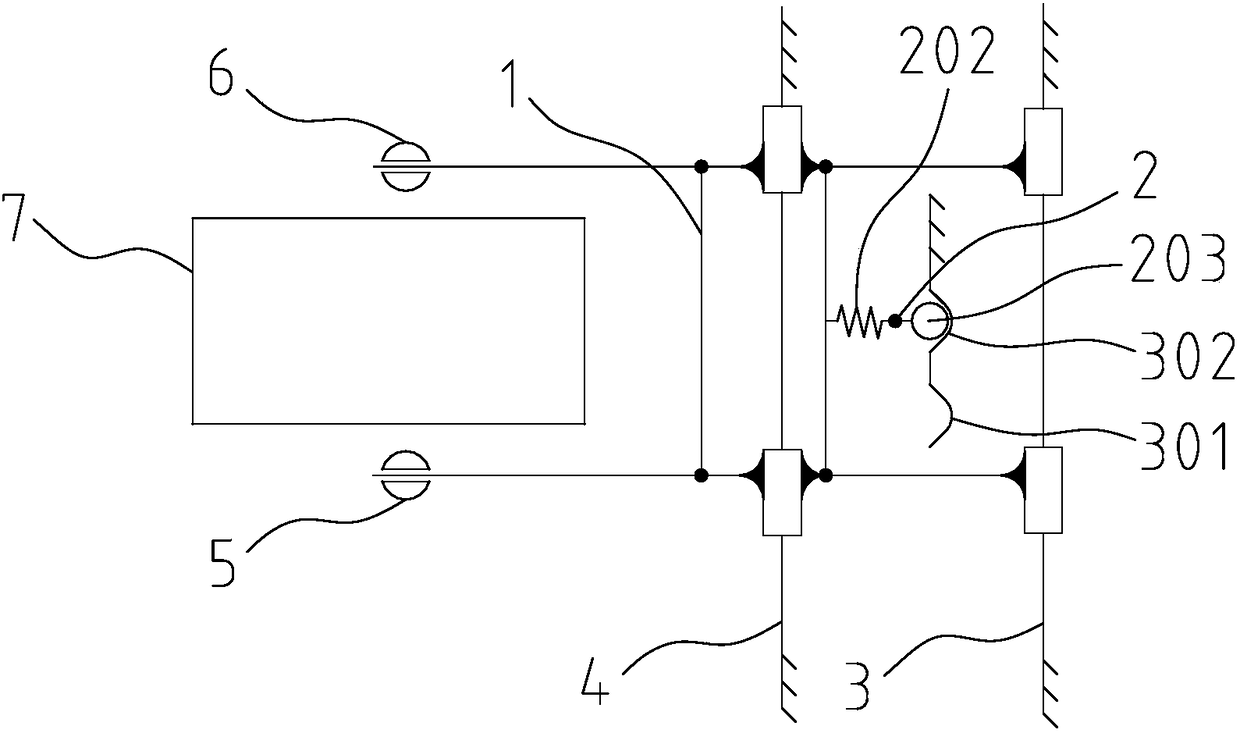

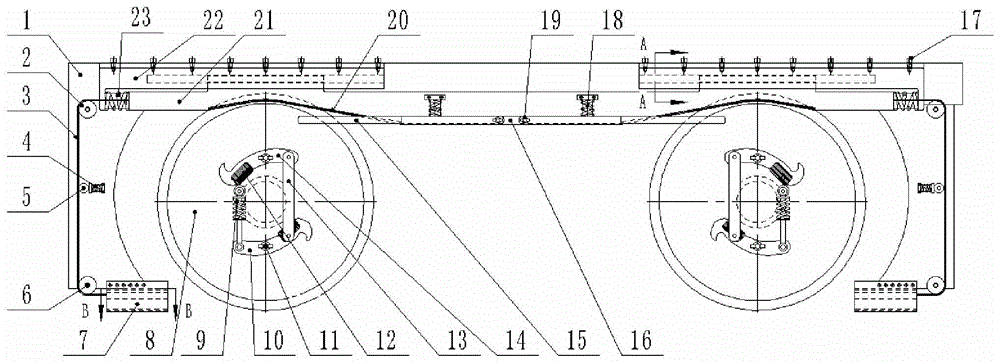

Triaxial bogie brake rigging apparatus and triaxial bogie

ActiveCN101412402AReduced braking ratioImprove braking efficiencyBogiesBrake arrangement with braking memberBogieTruck

The invention relates to the technical field of lorry braking, and provides a three-axle truck foundation braking device. The device comprises a brake force transmission mechanism, a first rocker composition, a second rocker composition, a third rocker composition, a first assembled type braking beam, a second assembled type braking beam and a third assembled type braking beam. Wherein each wheel pair composition of the three-axle truck corresponds to a group of rocker compositions, the brake force transmission mechanism is arranged above the truck frame and connected with the rocker compositions together corresponding to the tree wheel pair compositions, so that an activity endpoint of a horizontal traveling lever and the highest point of the rocker composition are higher than that of the truck frame, and the activity space of the activity endpoint of the traveling lever is not limited by the truck frame structure, and the braking leverage of the truck frame can be reduced, the braking efficiency is high. The invention also provides a three-axle truck.

Owner:CRRC QIQIHAR ROLLING CO LTD

Rope breakage safety protection device for mining car of inclined shaft

ActiveCN104590307AQuick responseFast brakingTrack-braking member co-operationBrake arrangement with braking memberArresting gearAutomotive engineering

The invention discloses a rope breakage safety protection device for a mining car of an inclined shaft. The device consists of two sets of braking devices with the same structure, wherein the two sets of braking devices correspond to front and rear wheels of the mining car respectively, and each set of braking device consists of a speed control device, a wheel quioning device and a rail quioning device; the speed control devices consist of braking pawls controlled by the speed of the wheels through centrifugal flail blocks; the wheel quioning devices consist of brake levers controlled by the braking pawls and braking wedge blocks; the rail quioning device consist of rail encircling blocks pulled by the braking wedge blocks through braking triggering ropes. The safety protection device has the advantages that the speed of the mining car is used as a starting signal, and the device can quickly response; in case of rope breakage, the wheel quioning devices and the rail quioning devices simultaneously act, so that double safety is provided; the device also has a safety protection function for the leftward and rightward movement rope breakage of the mining car and disconnection between mining cars; the device is compact in structure, light in weight and small in size.

Owner:LIAONING TECHNICAL UNIVERSITY

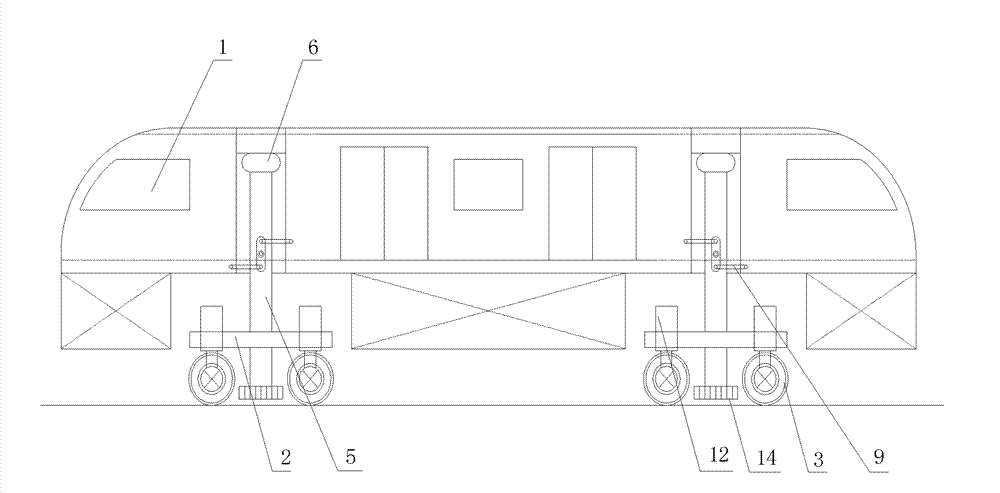

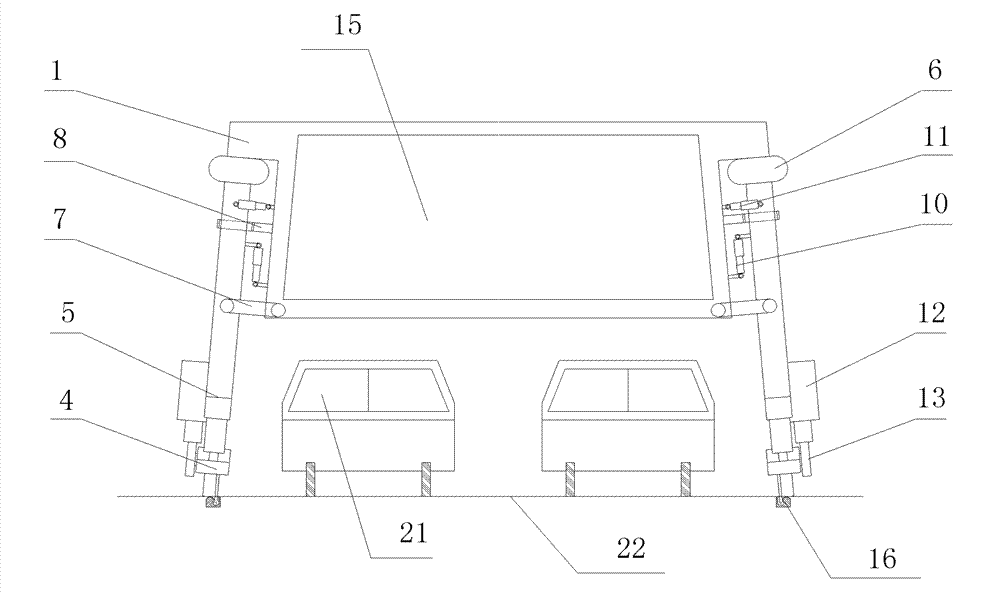

Stereo tramcar

InactiveCN102765395AStrong orientationImprove lateral stabilityRail-engaging wheelsElectric locomotivesAir springEngineering

The invention relates to a stereo tramcar which operates across 1-2 tracks. The tracks are provided with steel rails which fit with the tramcar. The distance from an underframe of the tramcar body to the ground is greater than the height of a car. The tramcar comprises four independent walking parts connected with the tramcar body. The walking parts incline inwardly and are connected with the tramcar body to form a trapezoid structure. The top of the walking parts is connected with the upper portion of the tramcar body through air springs. The gravity center of the tramcar body is lower than the contact surface of the air springs and the tramcar body. The central portion of the walking parts is connected with the lower portion of the tramcar body through a transverse pull bar. A Z-shaped draw gear is arranged between the walking parts and the tramcar body. In comparison with the prior art, the stereo tramcar provided by the invention has advantages of good steering ability, good lateral stability, strong road adaptability, safety, reliability and the like.

Owner:TONGJI UNIV

Brake device

ActiveUS20130098719A1Easy to changeAdjust in timeBraking element arrangementsBrake wear compensation mechanismMechanical engineeringEngineering

A brake device includes: a damper; an advancing and retreating member; and a gap adjustment mechanism. The gap adjustment mechanism has: a control section having a control surface facing an opposite side to a braking direction; an operation member whose movement is controlled by contacting the control surface as the advancing and retreating member advances towards the braking side in the braking direction, thereby enabling relative movement with respect to the advancing and retreating member towards the opposite side to the braking direction; and a position adjustment section which, when the advancing and retreating member advances towards the braking side in the braking direction, and the operation member relatively moves with respect to the advancing and retreating member, changes an initial position of the advancing and retreating member according to the relative movement amount of the operation member.

Owner:MITSUBISHI HEAVY IND ENG LTD

Unit brake

ActiveUS20140231192A1Prevent unintentional relaxation of brake forcePrevent disengagementBraking element arrangementsRail brake actuationEngineeringClutch

Disclosed is unit brake, which is equipped with a cylinder apparatus in which a clutch mechanism that switches between transmitting or cutting off a biasing force of a spring brake part is disposed, is capable of preventing a braking force due to the spring brake part from unintentionally decreasing due to a meshing section of the clutch mechanism disengaging, and is of a size that can replace an existing unit brake, and maintains the performance of bearings in the clutch mechanism even with long-term use. The clutch mechanism of the unit brake includes: a nut member that rotatably screws on a spindle that is positioned in an area that communicates with the atmosphere, and is movably supported in a direction opposite to braking; a clutch that is disposed in a direction opposite to braking with respect to the nut member, and faces the nut member in the vicinity of the spindle; a clutch box that is formed in a cylinder shape, and houses the nut member and clutch on the inside; and bearings that rotatably support the nut member on the inside of the clutch box.

Owner:NABLESCO CORP

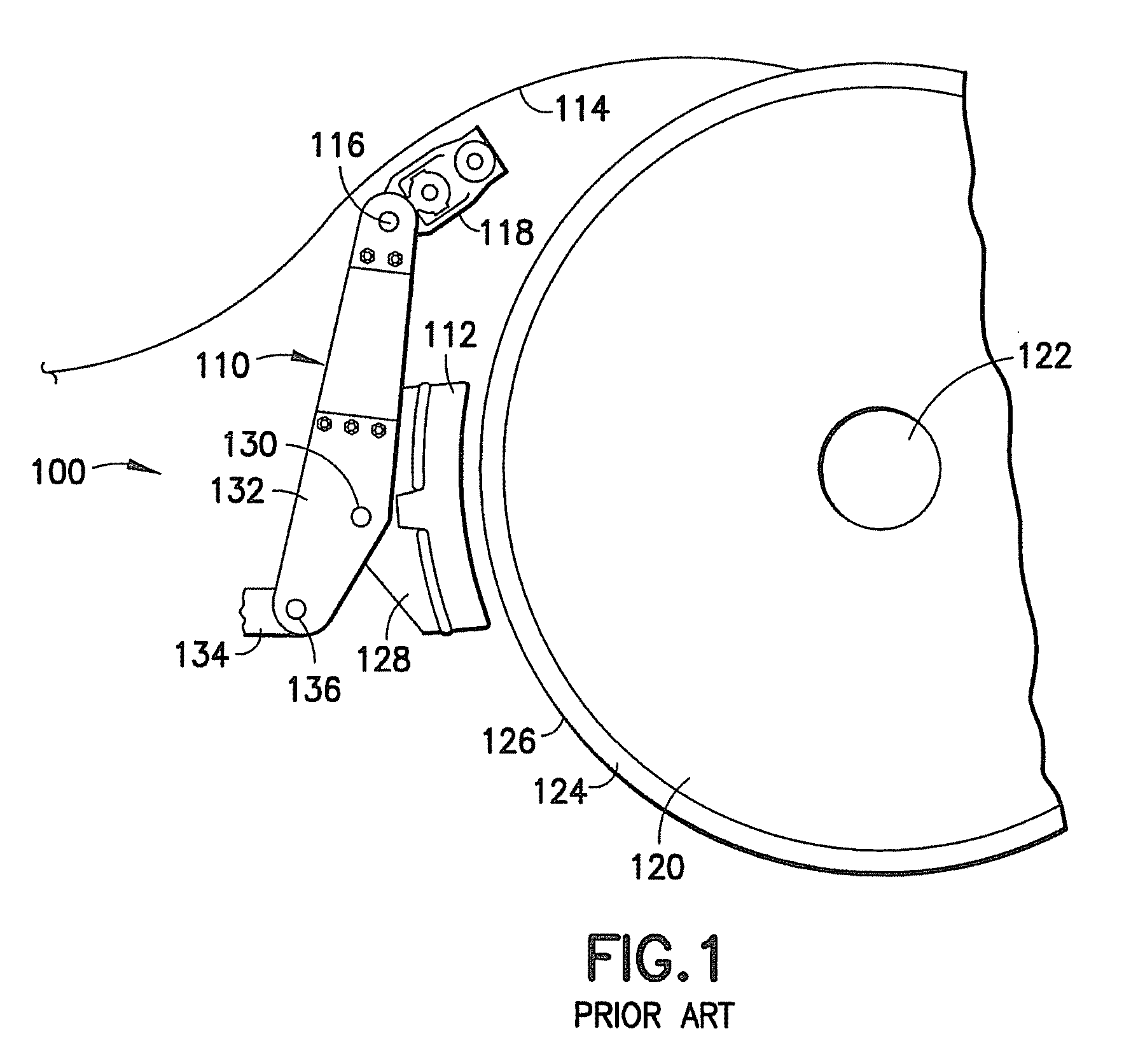

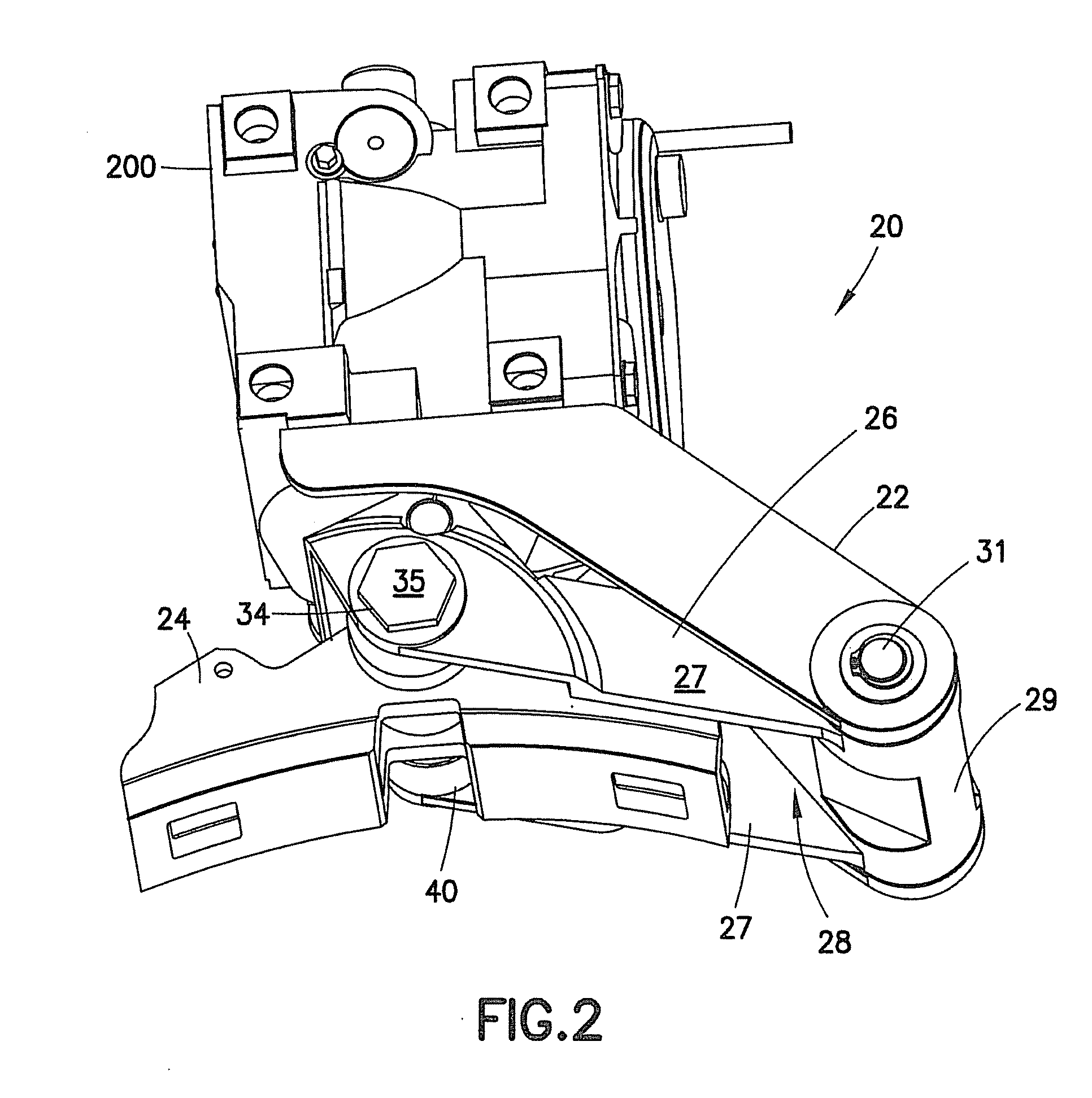

Brake Shoe Support Assembly and Method

InactiveUS20100258393A1Preventing shoe ride-offPrevent intrusionRail brake actuationBraking membersBrake shoeTruck

The brake shoe support assembly is able to track the lateral movement of a wheel, typically a wheel on an axle truck that allows lateral wheel movement. In operation, a flange of the wheel pushes on one side of the brake shoe support assembly, pushing it along a pin, and compressing a resilient biasing structure. As the wheel returns to a center or neutral position, the compressed resilient biasing structure expands pushing the brake shoe support assembly back to an original or neutral position. The resilient biasing structure also minimizes the lateral movement of the brake shoe support assembly down the wheel taper under normal braking loads thus preventing shoe ride-off. The resilient biasing structure may be enclosed in a housing adapted to prevent the intrusion of contaminants.

Owner:WABTEC HLDG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com