Patents

Literature

479results about How to "Suppression of upsizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

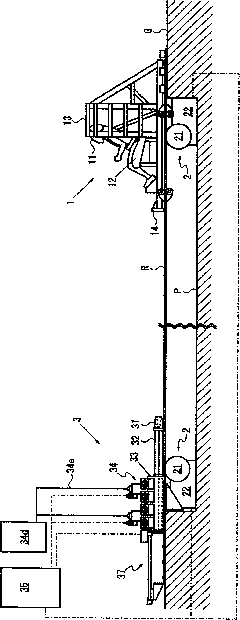

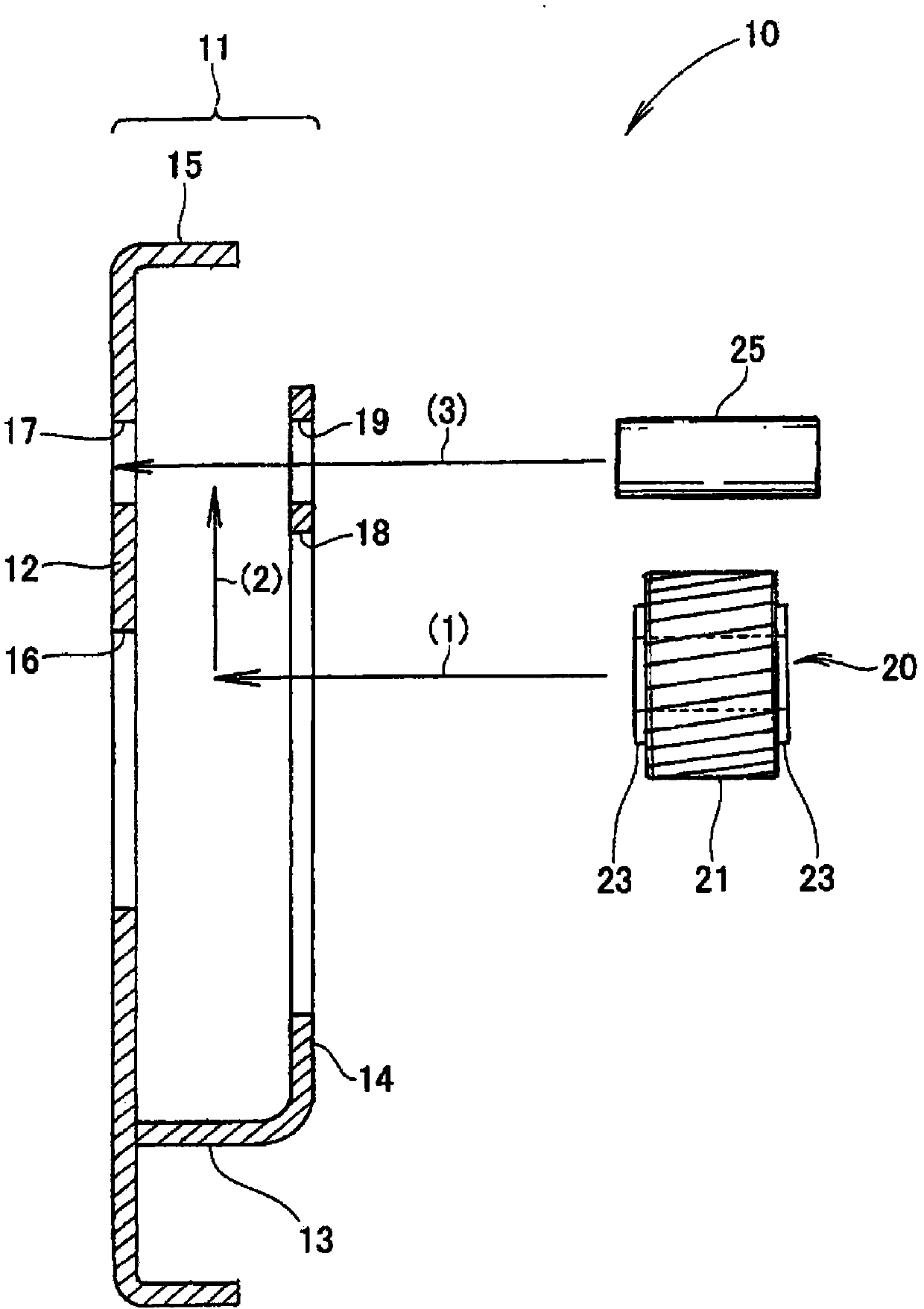

Impact test device and impact test method

InactiveCN102192827AControl decelerationCollision-prone reproductionShock testingEmbedded systemSpeed reduction

The present invention provides an impact test device and an impact test method which can easily reproduce impact. The impact test device of the invention is provided with the following components: a test member (1) which carries dummies (11) for simulating passengers, a driving device (2) which causes the test member (1) to advance, and a speed reduction device (3) which causes the impact of the test member (1) for reducing speed. The speed reduction device (3) is provided with the following components: a buffer part (31) which impacts with the test member (1), a shaft part (32) which is provided with the buffer part (31) at the front end and extends along the advancing direction of the test member (1), a body part (33) which supports the shaft part (32), a brake device (34) which is configured at the body part (33) and applies the load in a direction which is approximately same with the advancing direction of the test member (1) on an external surface of the shaft part (32), and a control device (35) which controls the load that is applied by the brake device (34).

Owner:JOYSON SAFETY SYST JAPAN KK

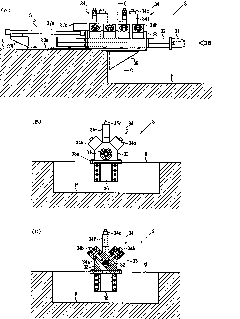

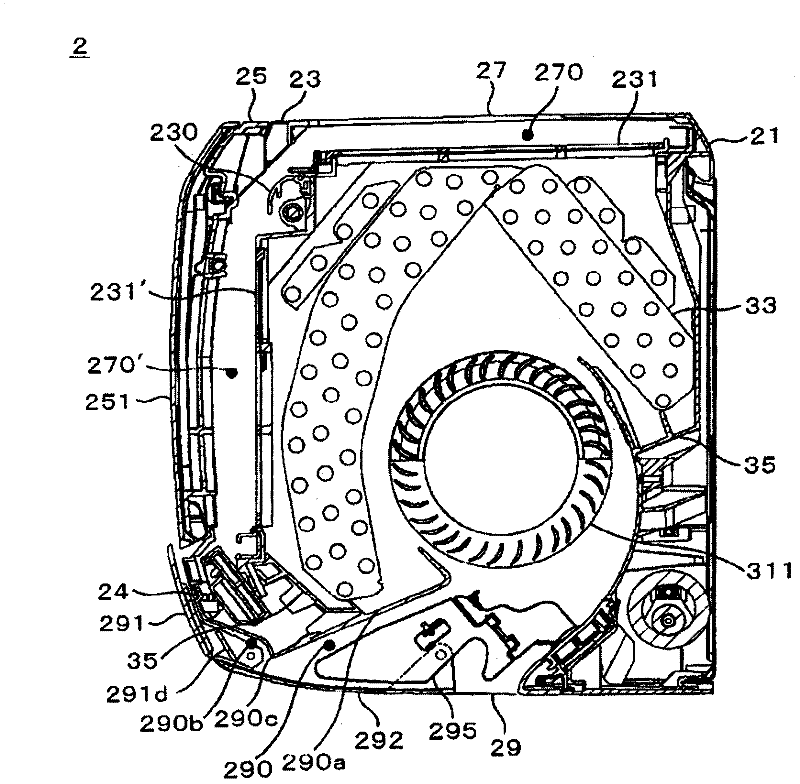

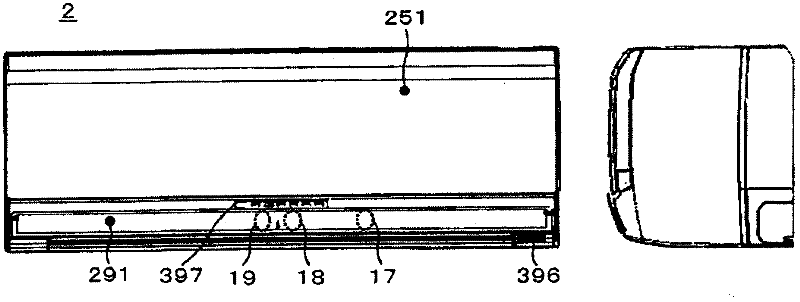

Air conditioner

ActiveCN102455036AAccurate detectionEasy to detectMechanical apparatusSpace heating and ventilation safety systemsEngineeringElectric power

The present invention provides an air conditioner which has advantages of high comfort and electric power reduction and is provided with a sound sensor. The air conditioner of the invention comprises the following components: a sound sensor; communicating holes which are provided closer to the inside part than two ends of a blowing outlet and are between a downmost end of an upper wall of a blowout air channel and a suction inlet, wherein the communicating holes are used for communicating the sound sensor with the indoor space; a filter which is provided the suction inlet; and an automatic cleaning device which is used for cleaning the filter. Therefore, the air conditioner which has the advantages of high comfort and electric power reduction and is provided with the sound sensor can be provided.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

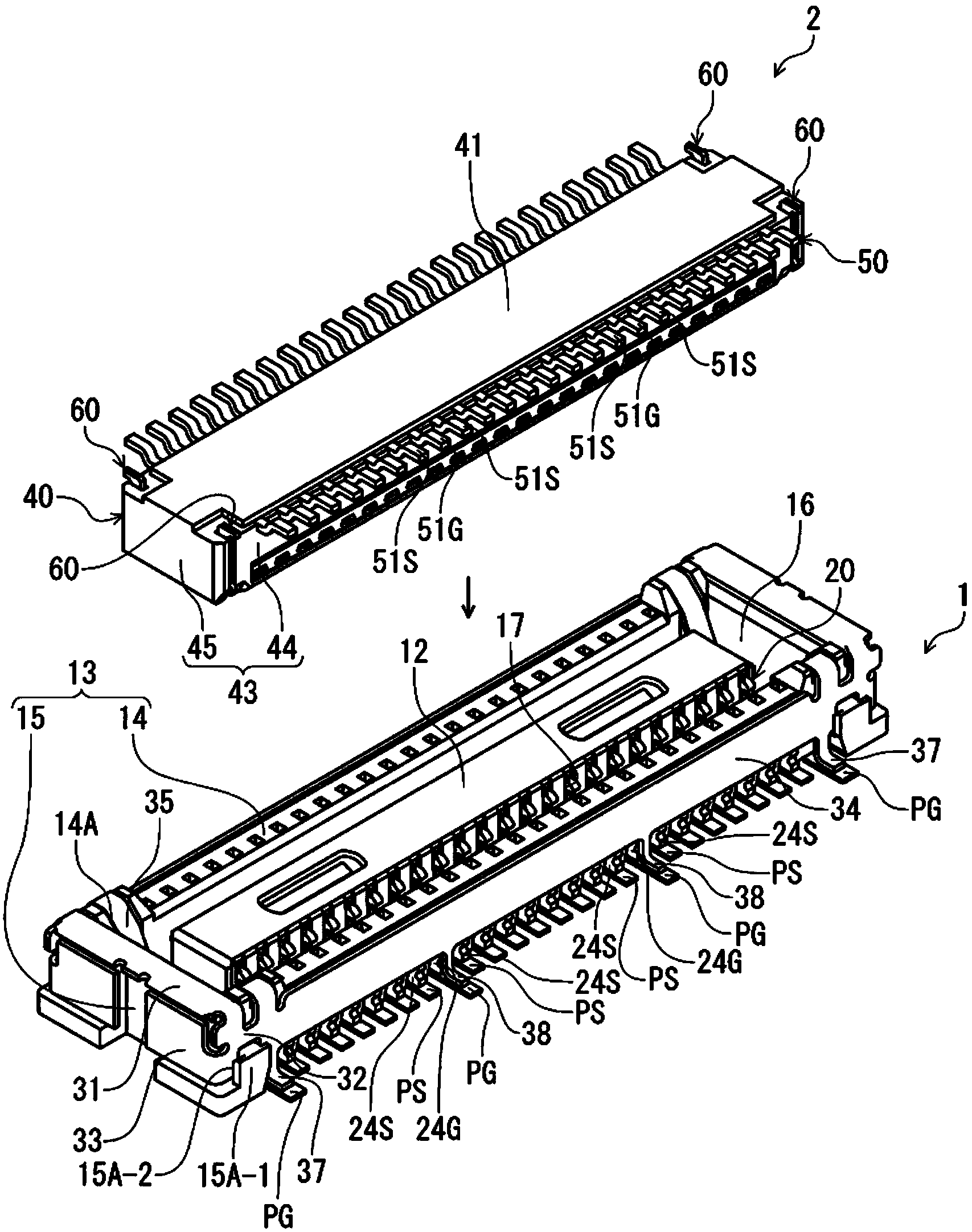

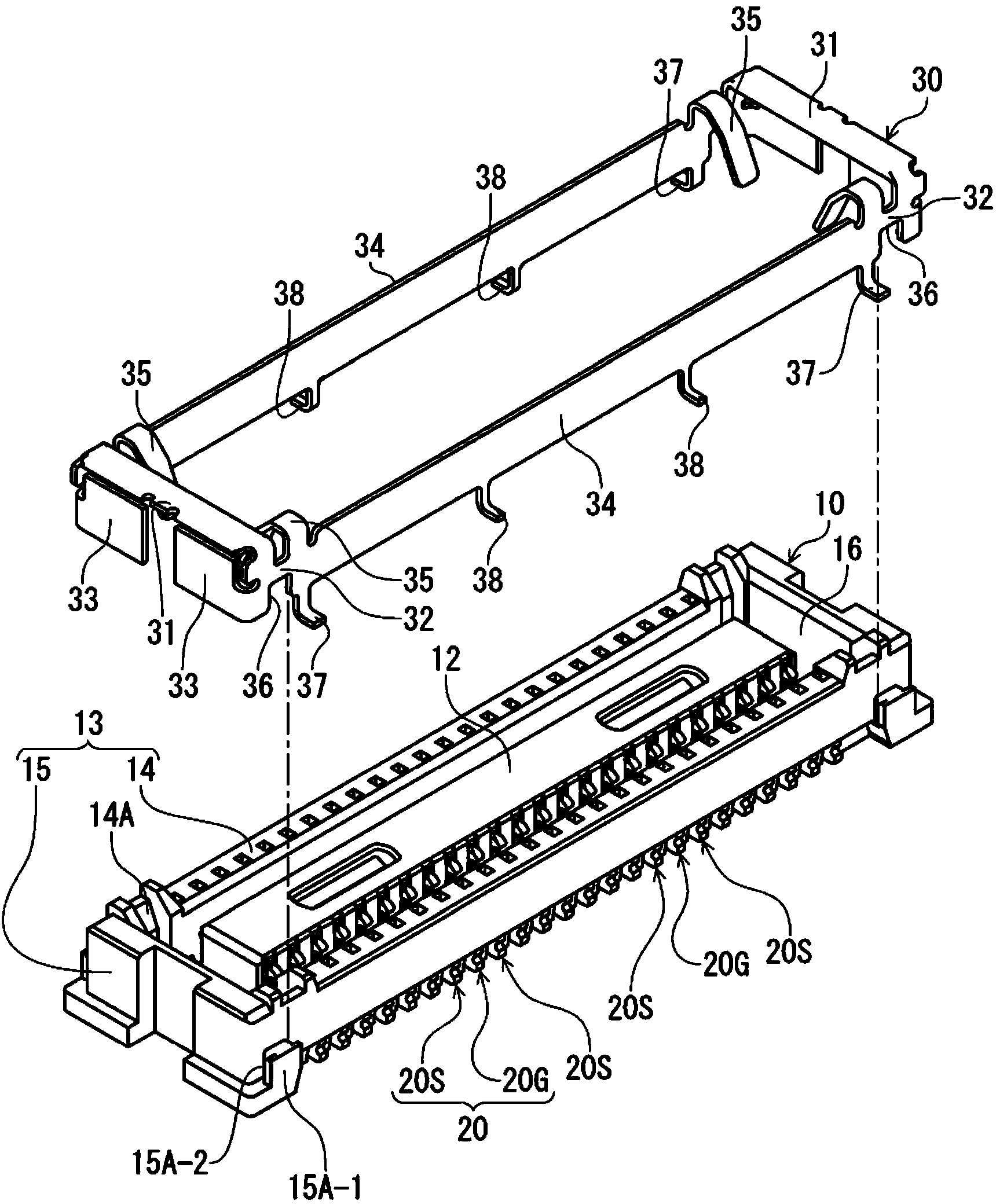

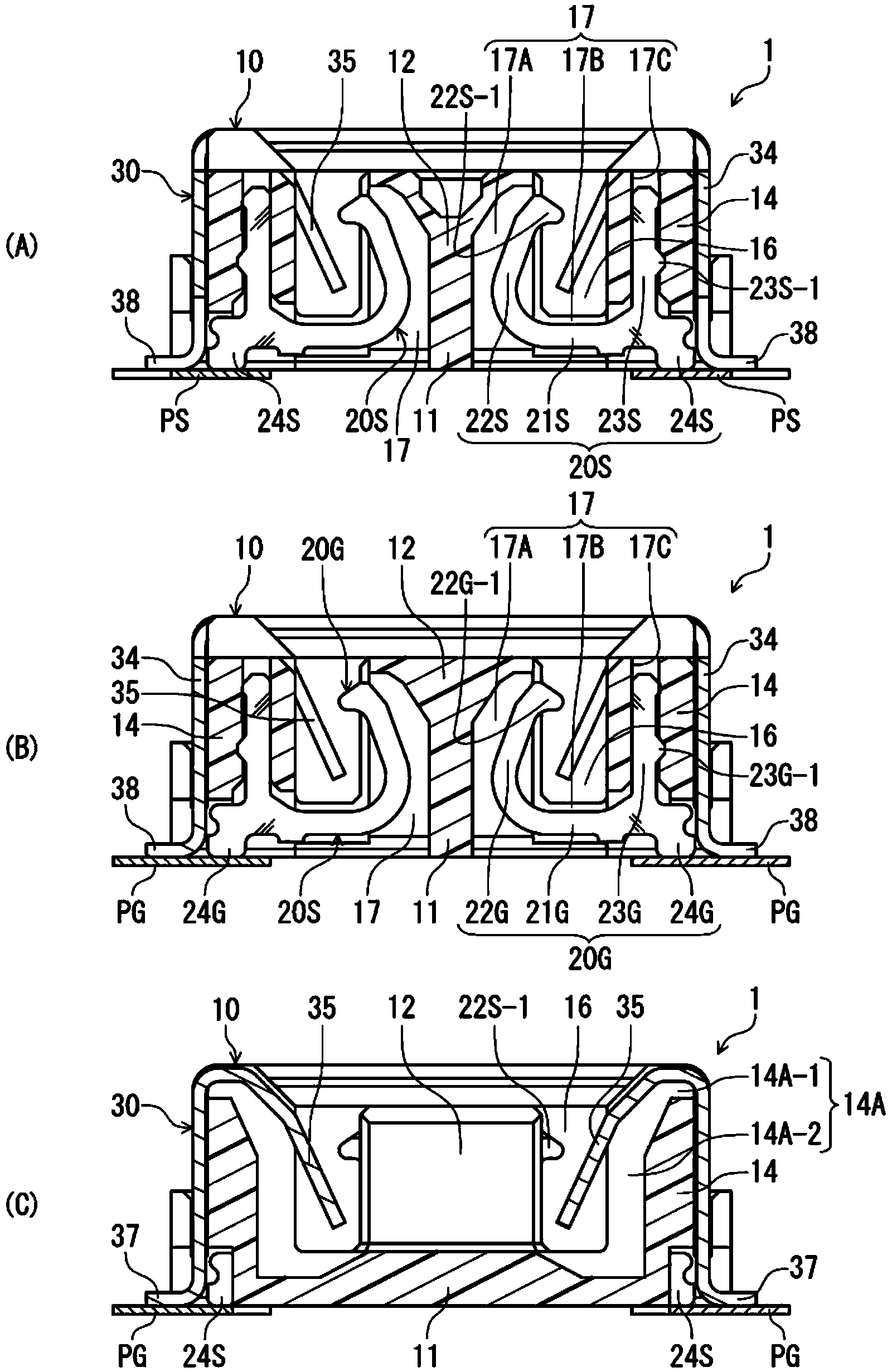

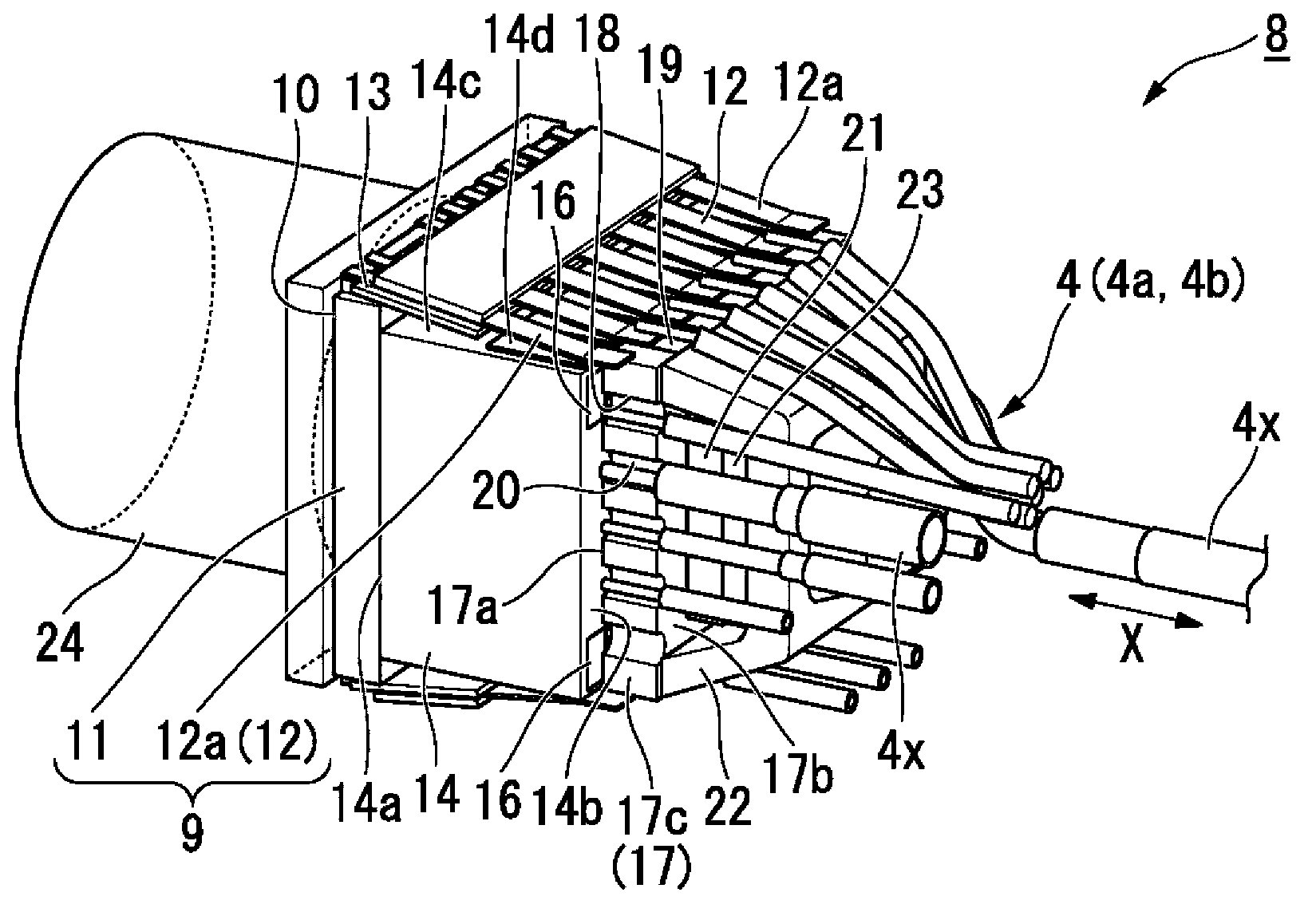

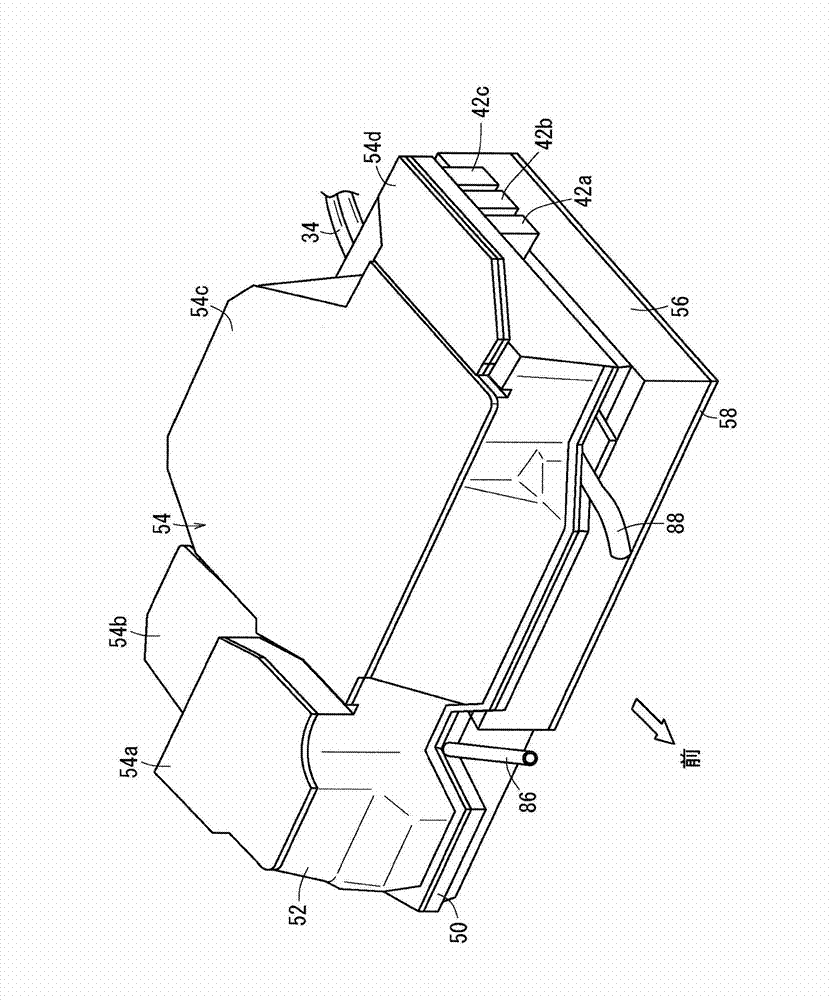

Electrical connector for circuit board and electrical connector installation body

ActiveCN104241972AClosely spacedIncrease the number ofFixed connectionsCoupling protective earth/shielding arrangementsEngineeringElectrical and Electronics engineering

The invention provides an electrical connector for a circuit board and an electrical connector installation body. The electrical connector cannot be enlarged in a terminal arrangement direction and can carry out reliable connection of a connection section of each terminal and a grounding pin section of a shield section with corresponding bonding pads. A grounding connection section (24G) of a grounding terminal (20G) is located between the signal connection sections (24S) of two adjacent signal terminals (20) in the terminal arrangement direction. The grounding pin section (38) of the shield section (30) is connected with a bonding pad for grounding and of the circuit board in a position closer than the above signal connection section (24S) and the above grounding section (24) in the connector width direction, is located in a region between the signal connection sections (24S) at two sides of the grounding connection section (24G) corresponding to the grounding pin section (38), and has an overlapping range with the grounding connection section (24G) in the terminal arrangement direction.

Owner:HIROSE ELECTRIC GROUP

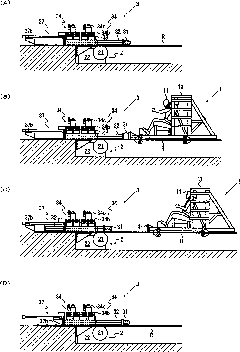

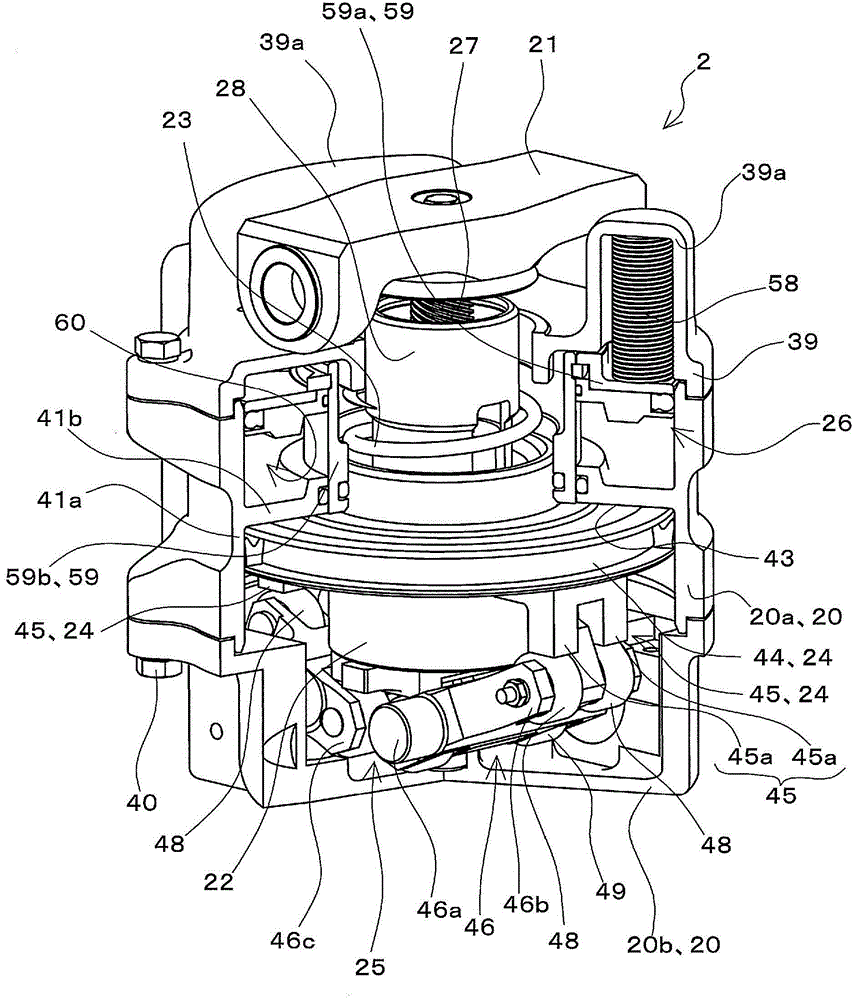

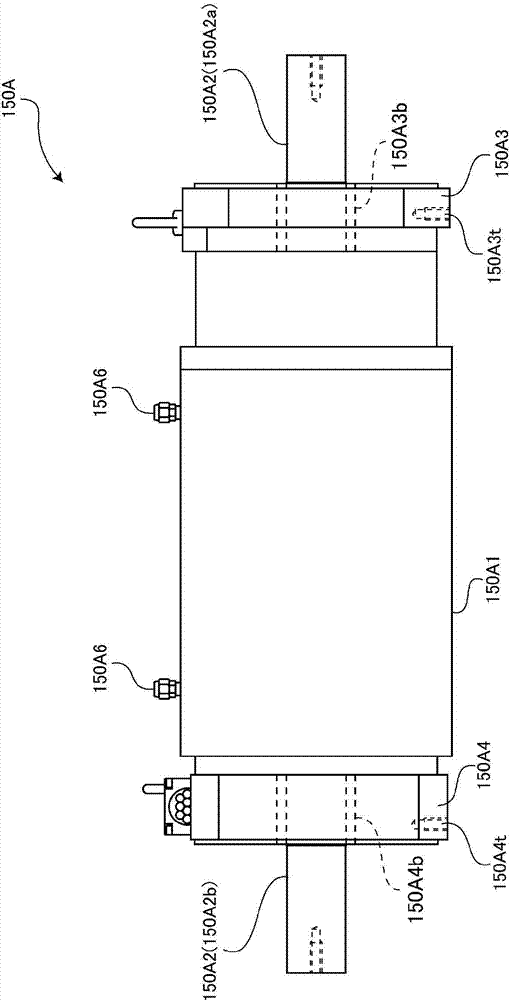

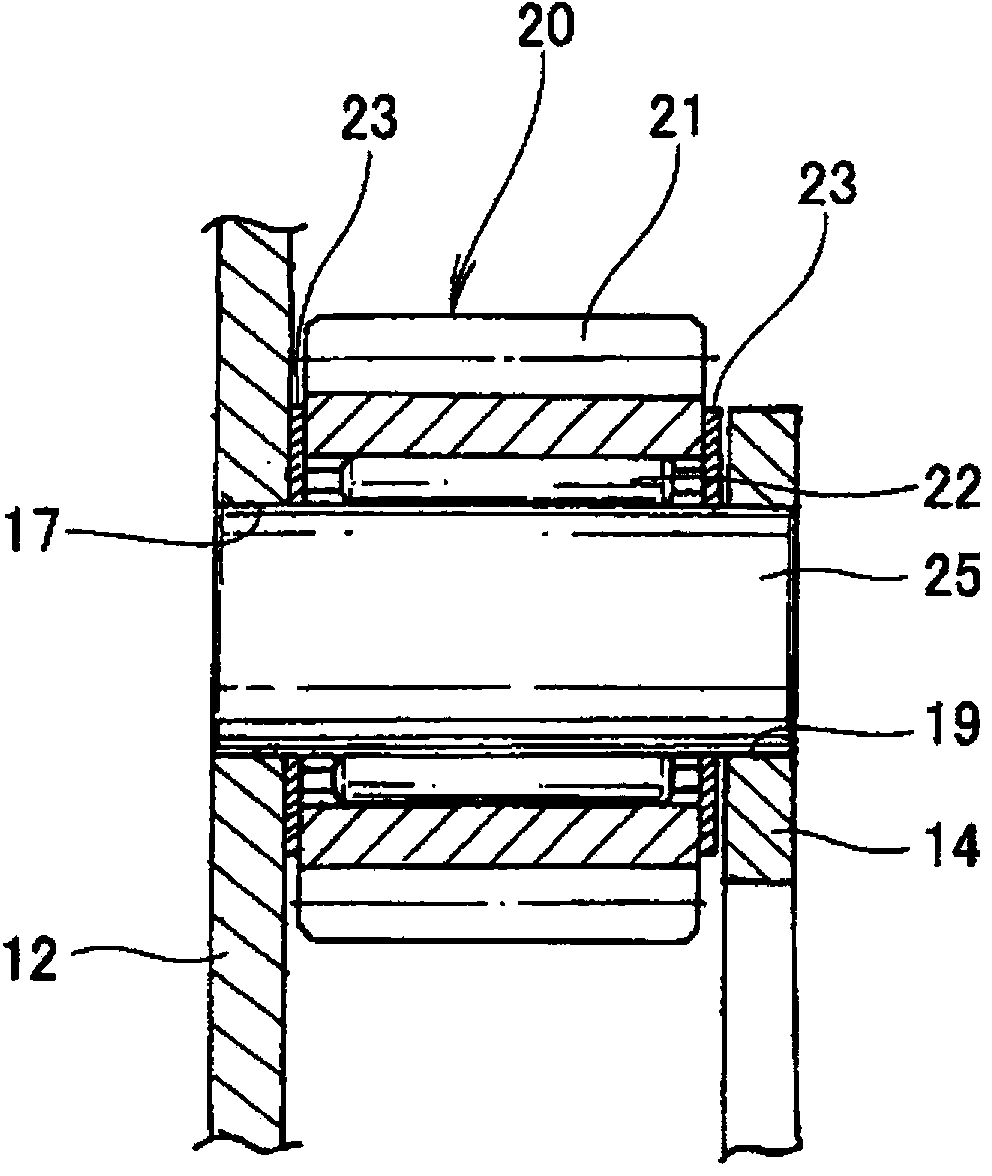

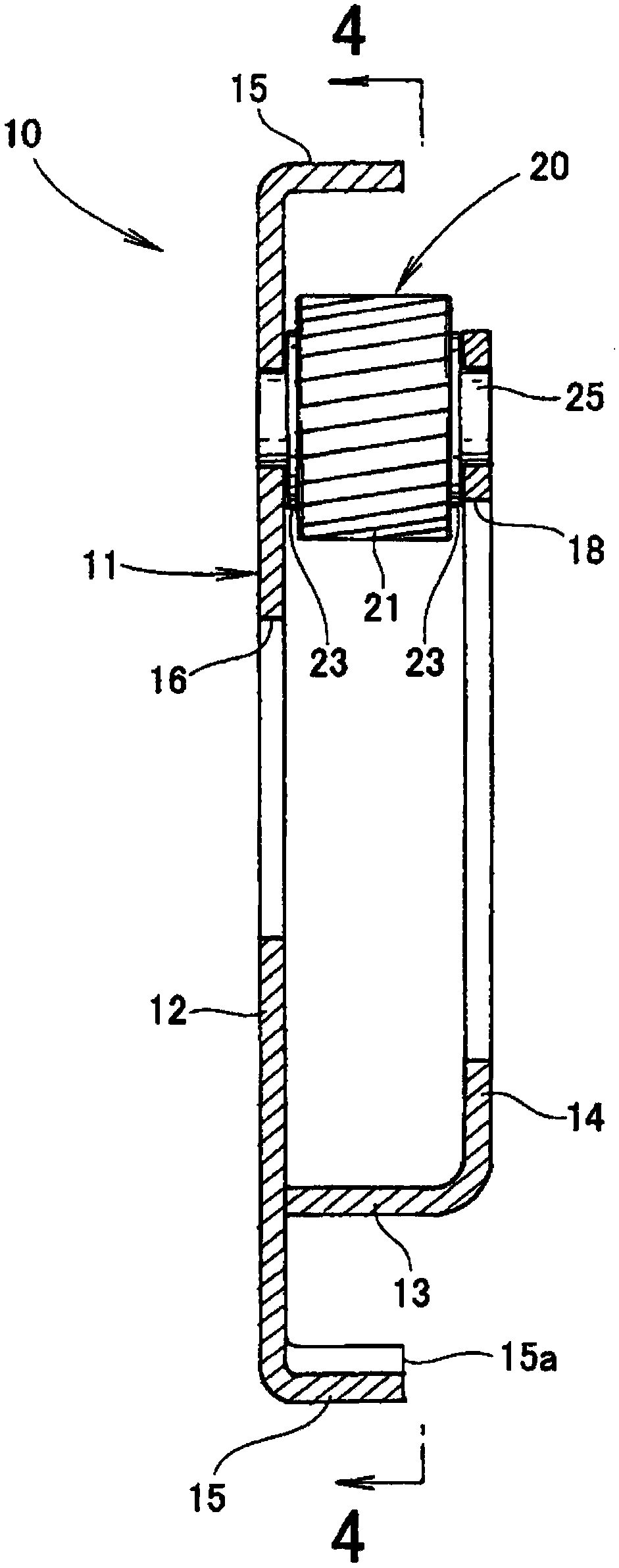

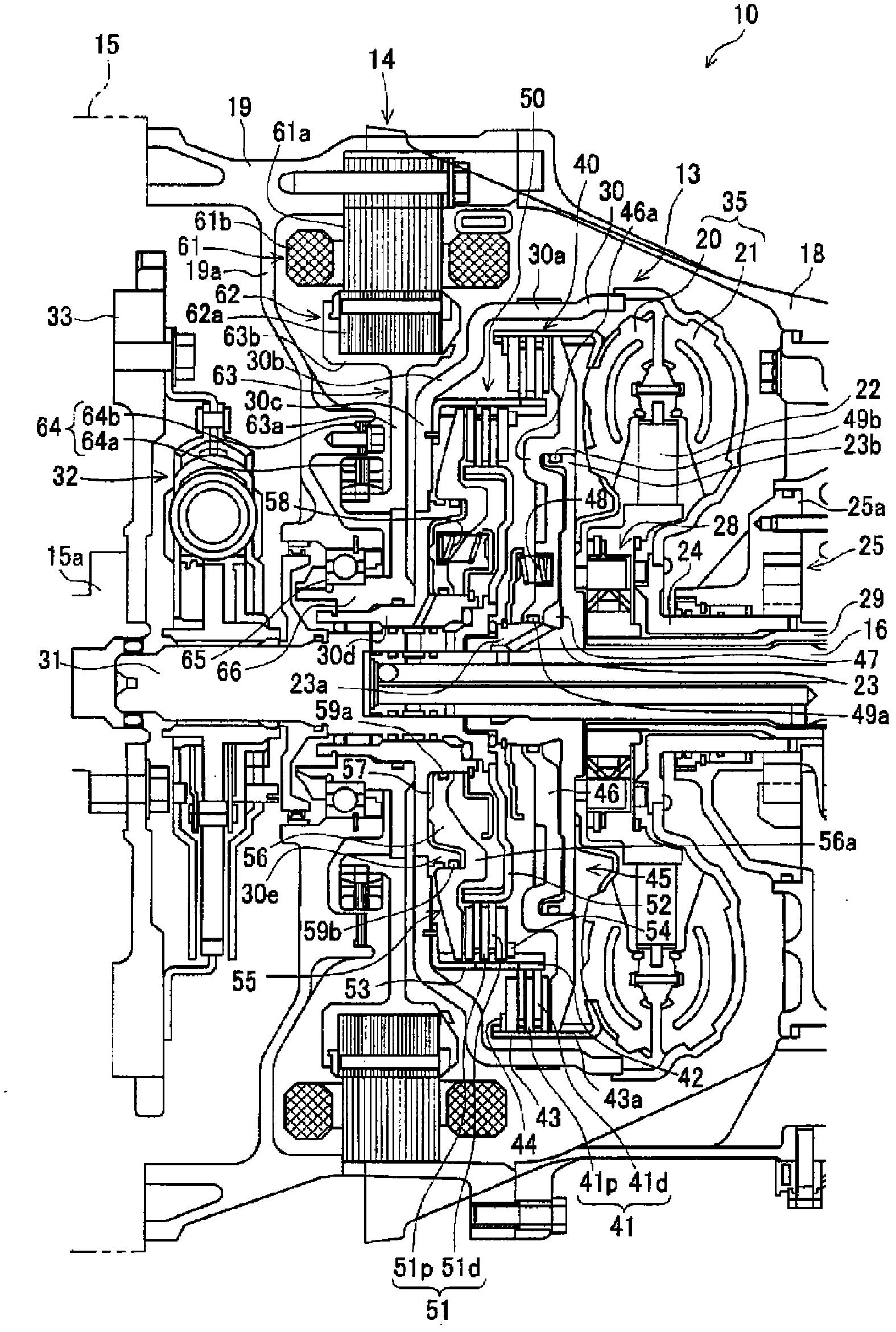

Brake cylinder device and disk brake device

ActiveCN103958916ASuppression of upsizingLarge braking forceAxially engaging brakesBrake wear compensation mechanismEngineeringMechanical engineering

Provided is a compact brake cylinder device capable of increasing the brake force output from a brake output unit that moves along with a rod, without requiring the device to be made larger. A piston (24) sections off a pressure chamber (43) within a main cylinder (20a), surrounds the axial periphery of a rod (22), and moves in a direct line parallel with the direction of motion of the rod (22). With the supply of a pressure fluid to the pressure chamber (43) the piston (24) moves outward relative to the main cylinder (20a) in opposition to the biasing force of a rod-biasing spring (23). An oscillating member (46) of a force-multiplying mechanism (25) is biased by the piston (24) moving in the outward direction, oscillates, and biases the rod (22), causing the rod (22) to move in the forward direction. In this way, the force-multiplying mechanism (25) multiplies the drive force from the piston (24) so as to act on the rod (22). The brake output unit (21) moves in the forward direction along with the rod (22) and outputs brake force.

Owner:NABLESCO CORP

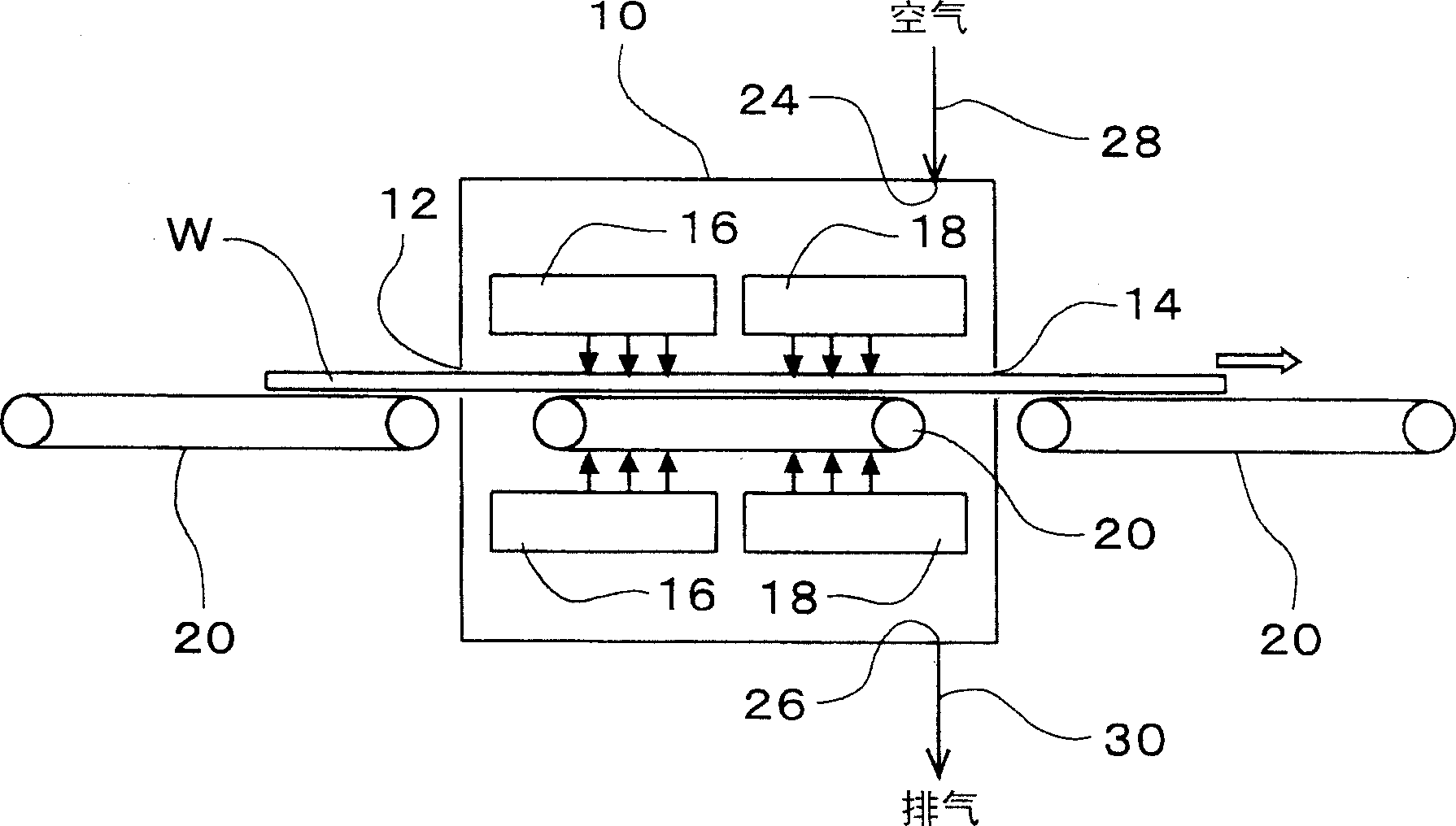

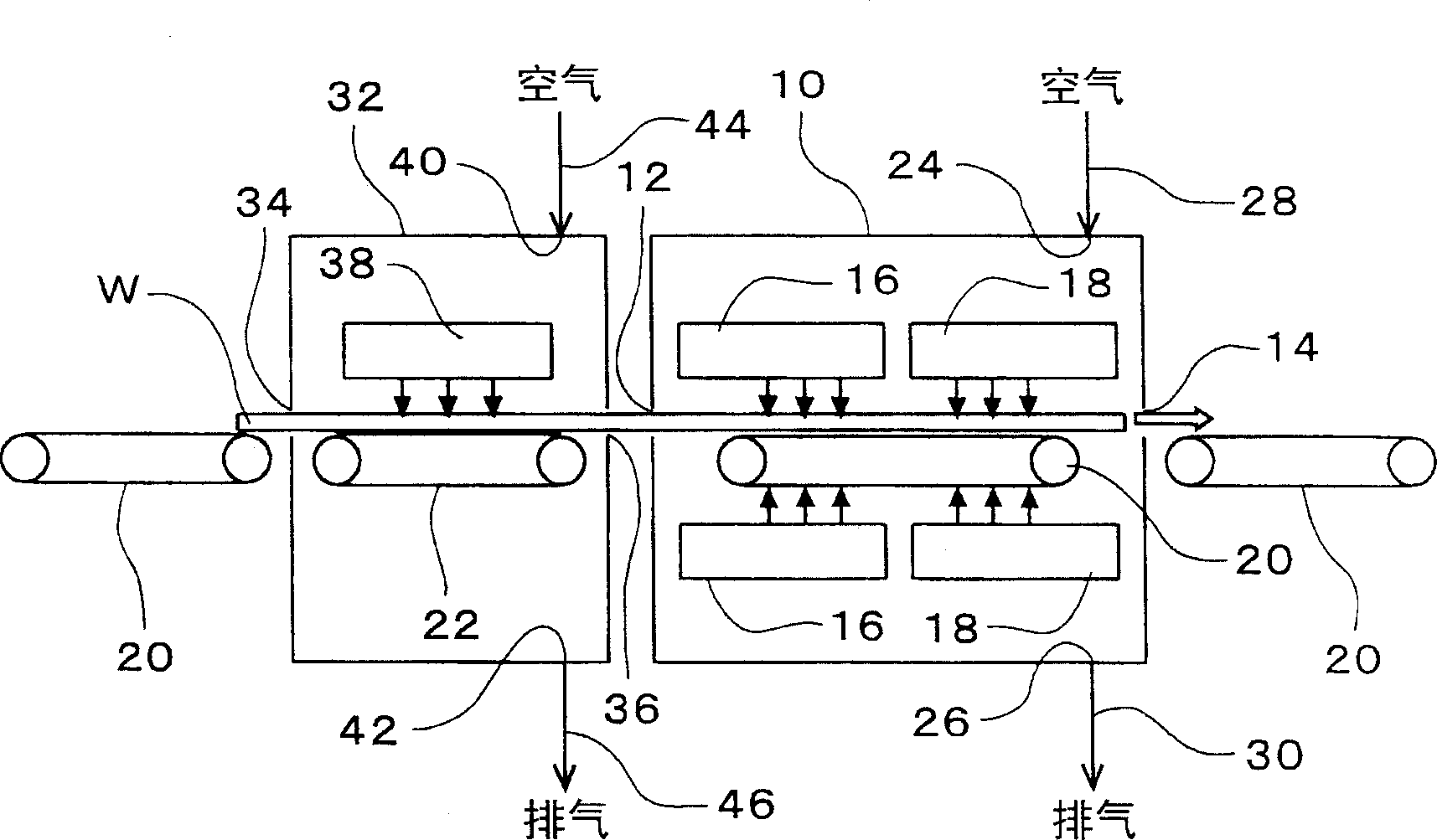

Substrate processing apparatus

InactiveCN1638033APrevent outflowAvoid flyingSemiconductor/solid-state device manufacturingCharge manipulationMiniaturizationExhaust pipe

PROBLEM TO BE SOLVED: To provide equipment wherein the equipment can be miniaturized, while the configuration equipped with a chamber in which treatment tools are arranged in the inside, and consumption of treatment liquid can be also reduced. SOLUTION: The chamber 10 of a tightly closed type, which has a substrate carry-in port 12 and a substrate taking out port 14, the processing tools 16, 18 arranged inside the chamber, and a roller transfer 20 which transfers a substrate W are installed. The length of the chamber is made smaller than the dimensions in the substrate transfer direction. An air supply pipe 28 for supplying air for purging into the chamber, and an exhaust pipe 30 for exhausting air for purging, from the inside of the chamber are installed, and internal atmosphere and external atmosphere of the chamber are isolated from each other.

Owner:DAINIPPON SCREEN MTG CO LTD

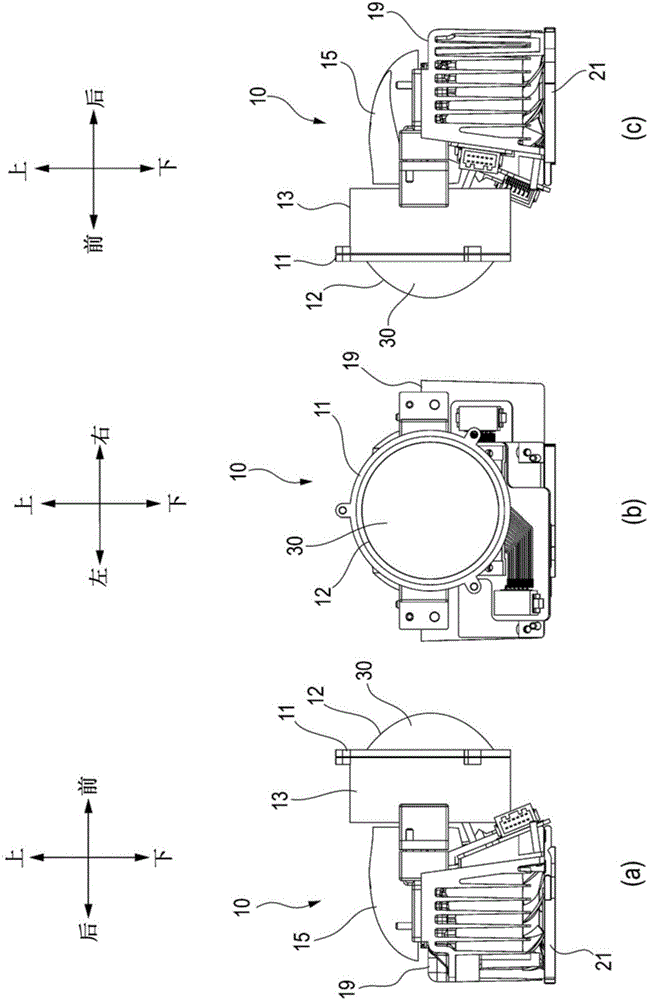

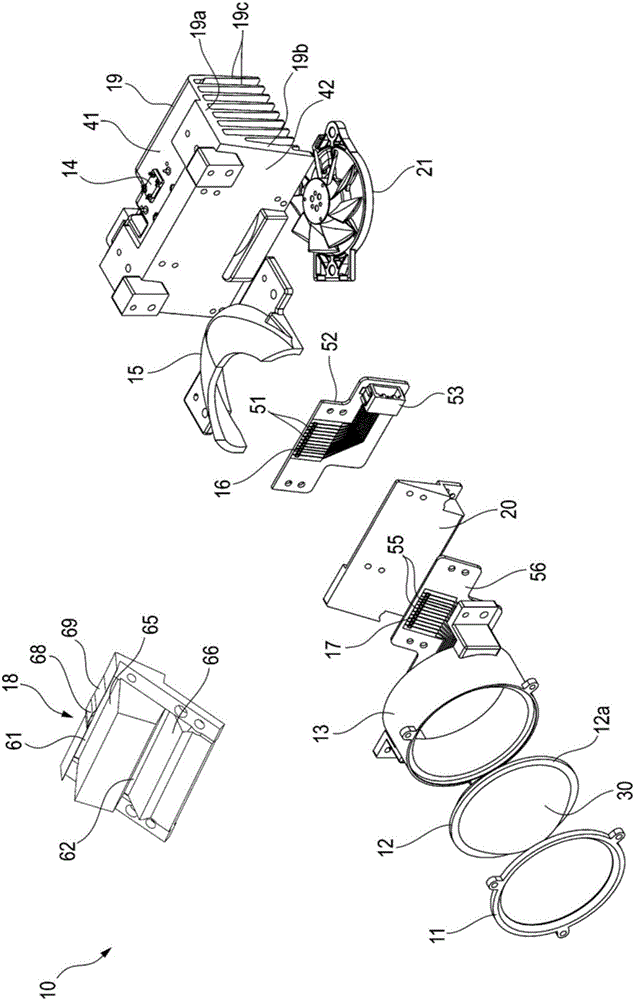

Imaging mechanism and endoscope apparatus

ActiveCN103185960ASuppression of upsizingTelevision system detailsEndoscopesEndoscopeBiomedical engineering

An imaging mechanism and an endoscope apparatus include: an image sensor including a sensor face and a plurality of input / output leads, a holding member having a sensor contact face contacted with one face of an opposite side of the image sensor to the sensor face, a circuit board that is secured to an outer face of an opposite side of the holding member to the sensor contact face and has a mounting surface in parallel to the sensor face, and a contact-point part disposed on a side face of the circuit board intersecting with a mount face, and in a region where the outline of the circuit board is inside the outline of the holding member. At least one of the holding member and the circuit board includes a relay wiring part which the contact-point part and at least one of the input / output leads are electrically connected to.

Owner:EVIDENT CORP

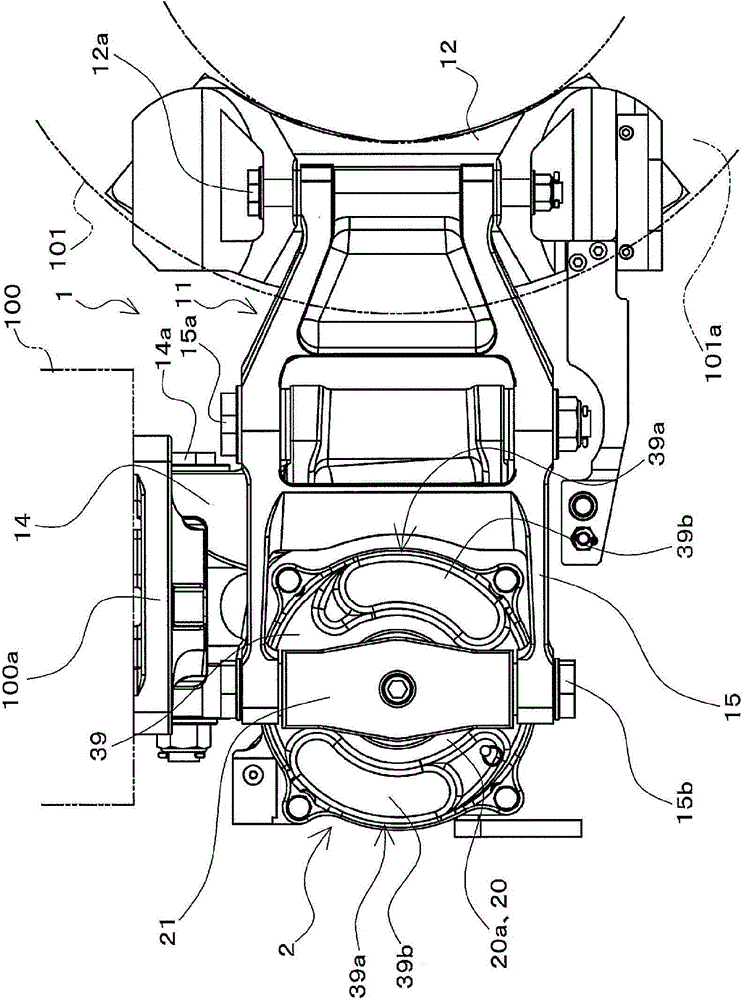

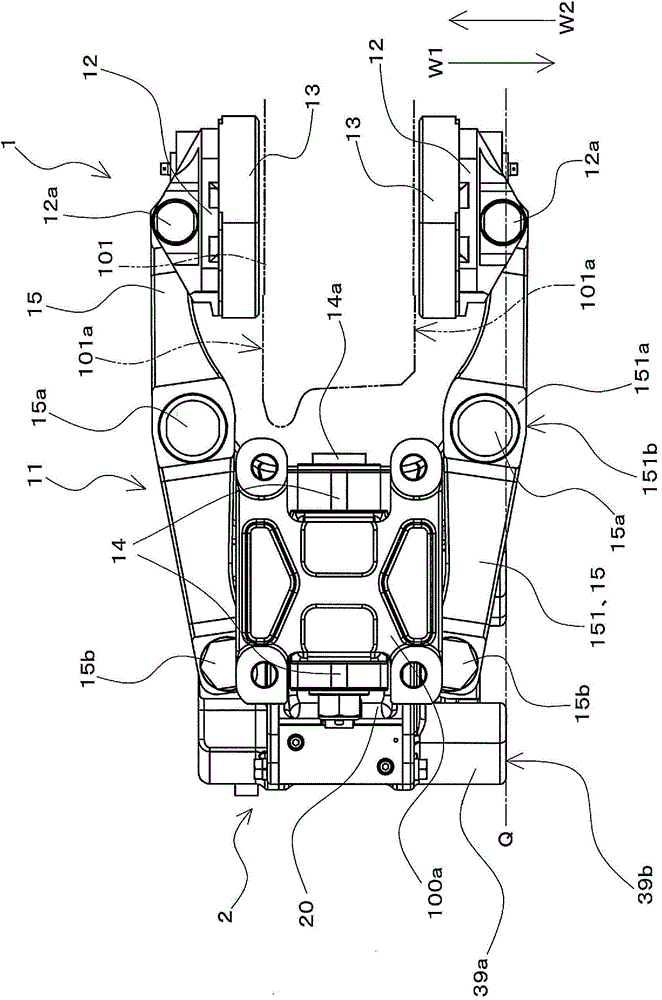

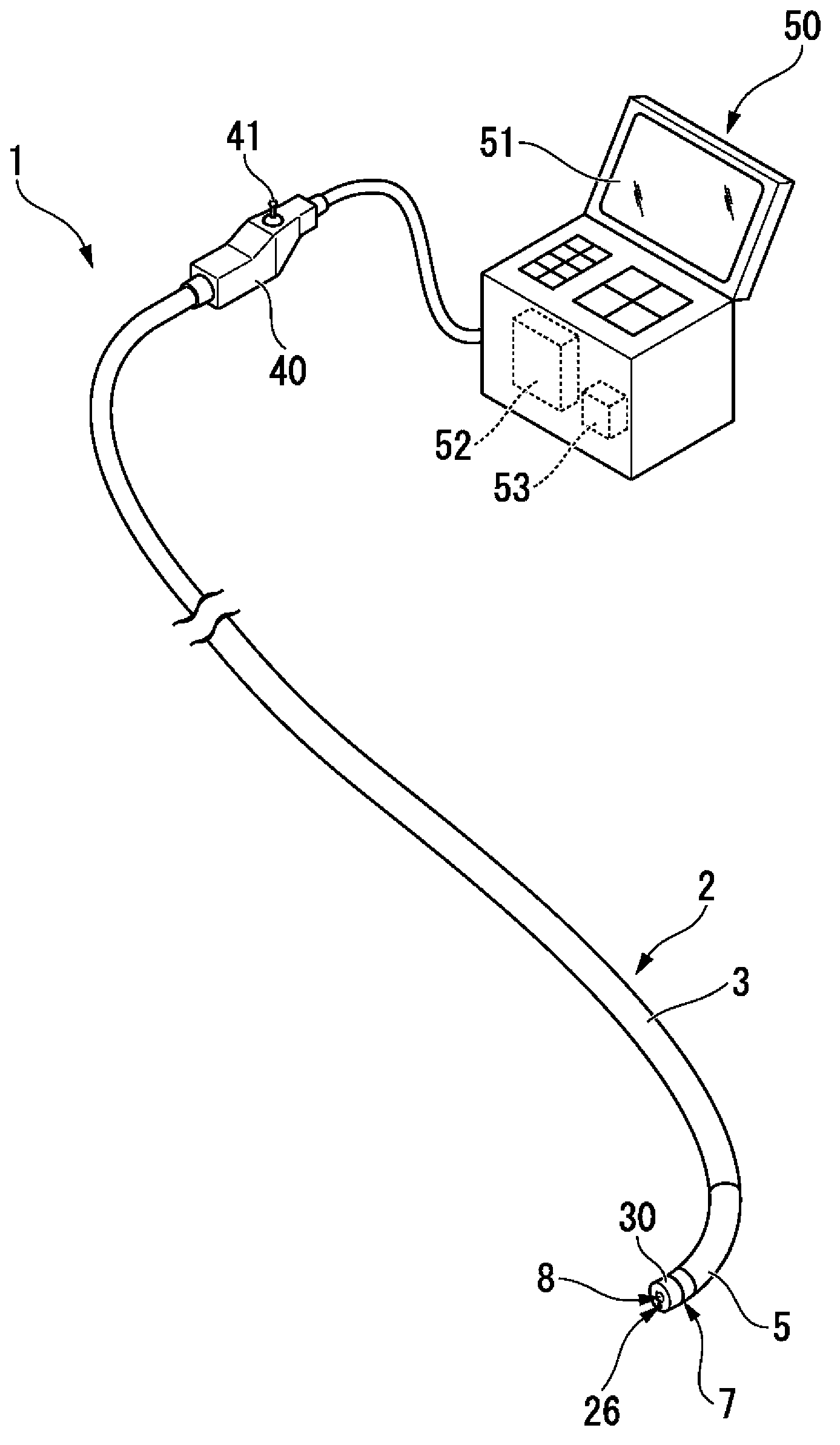

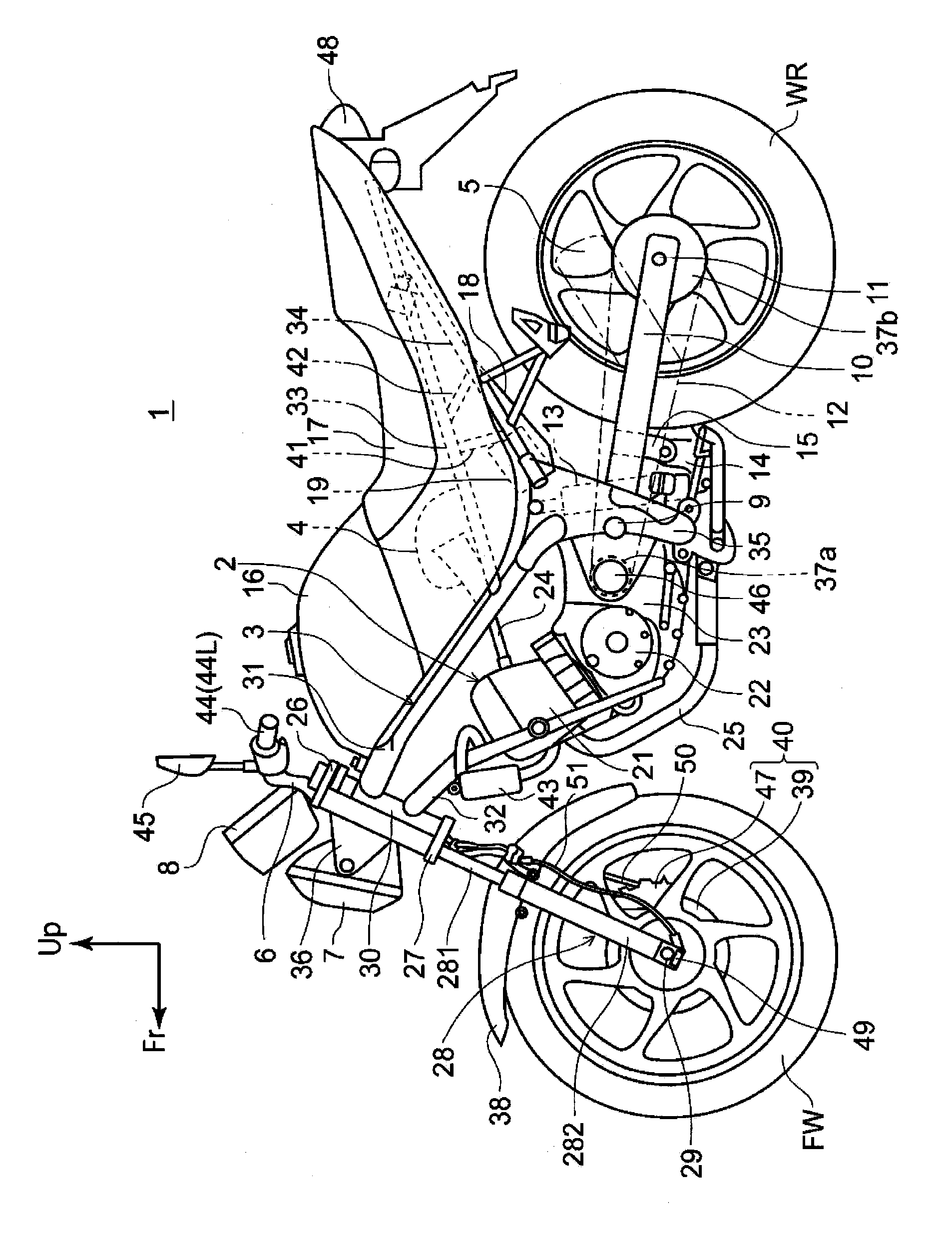

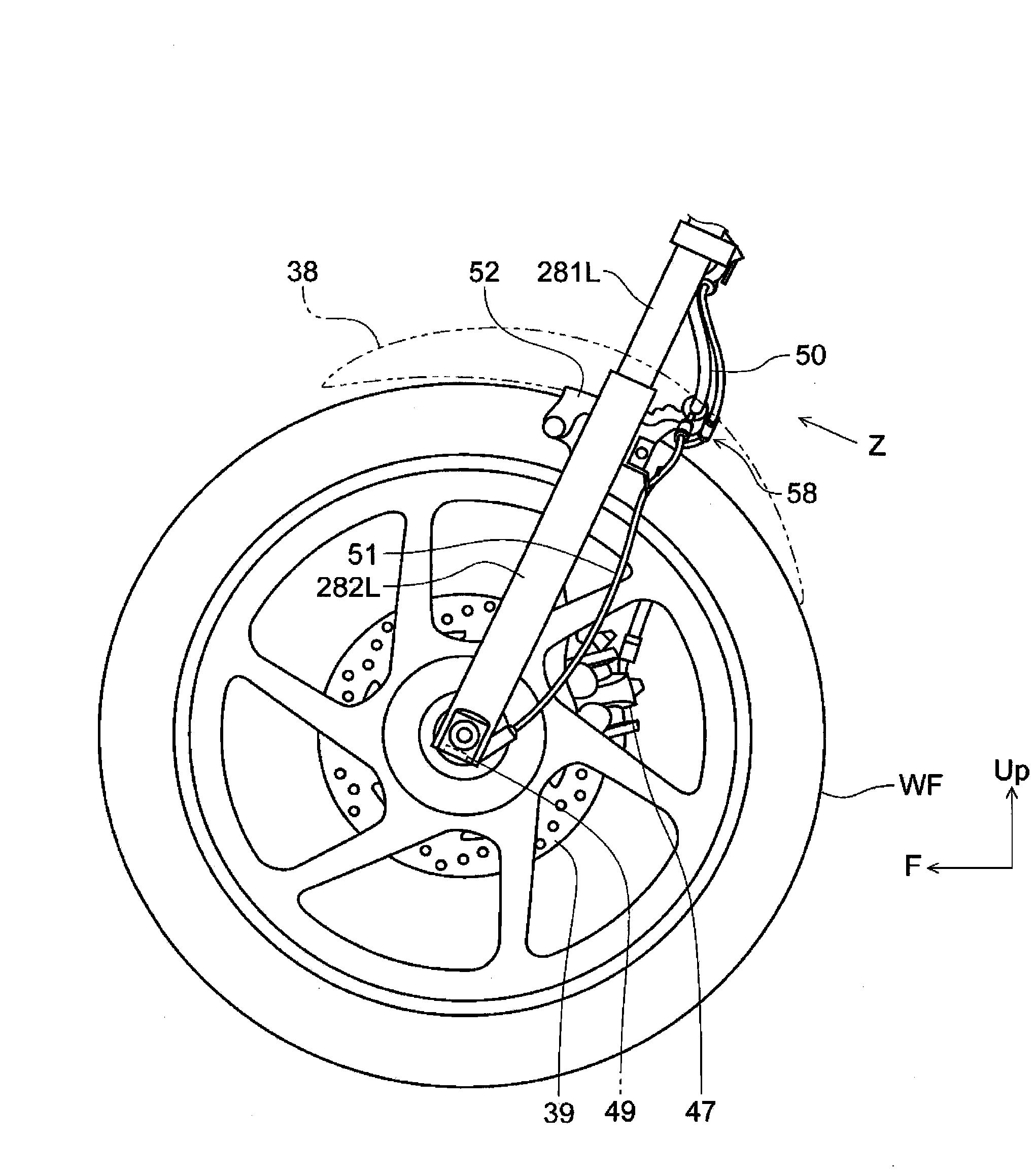

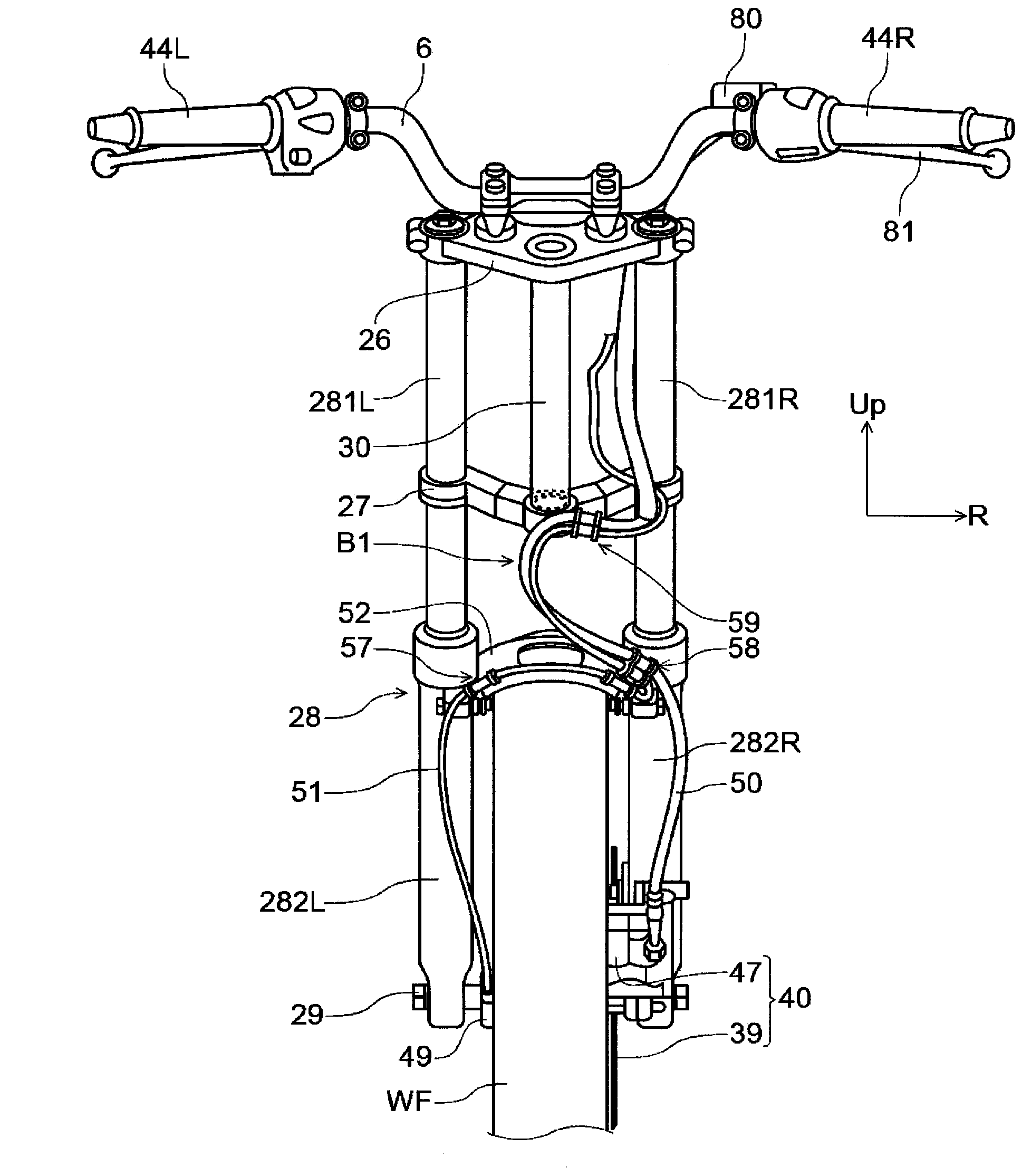

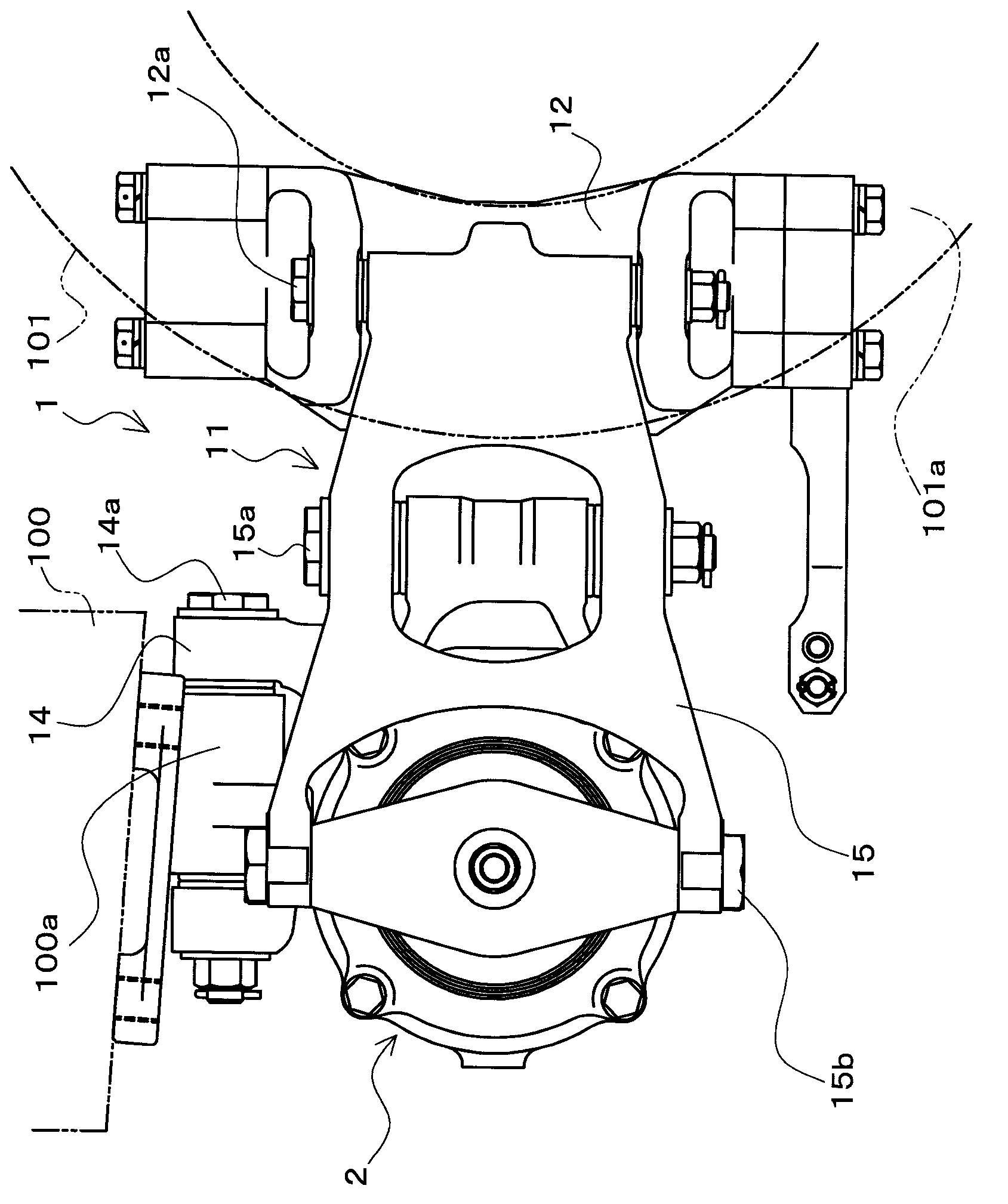

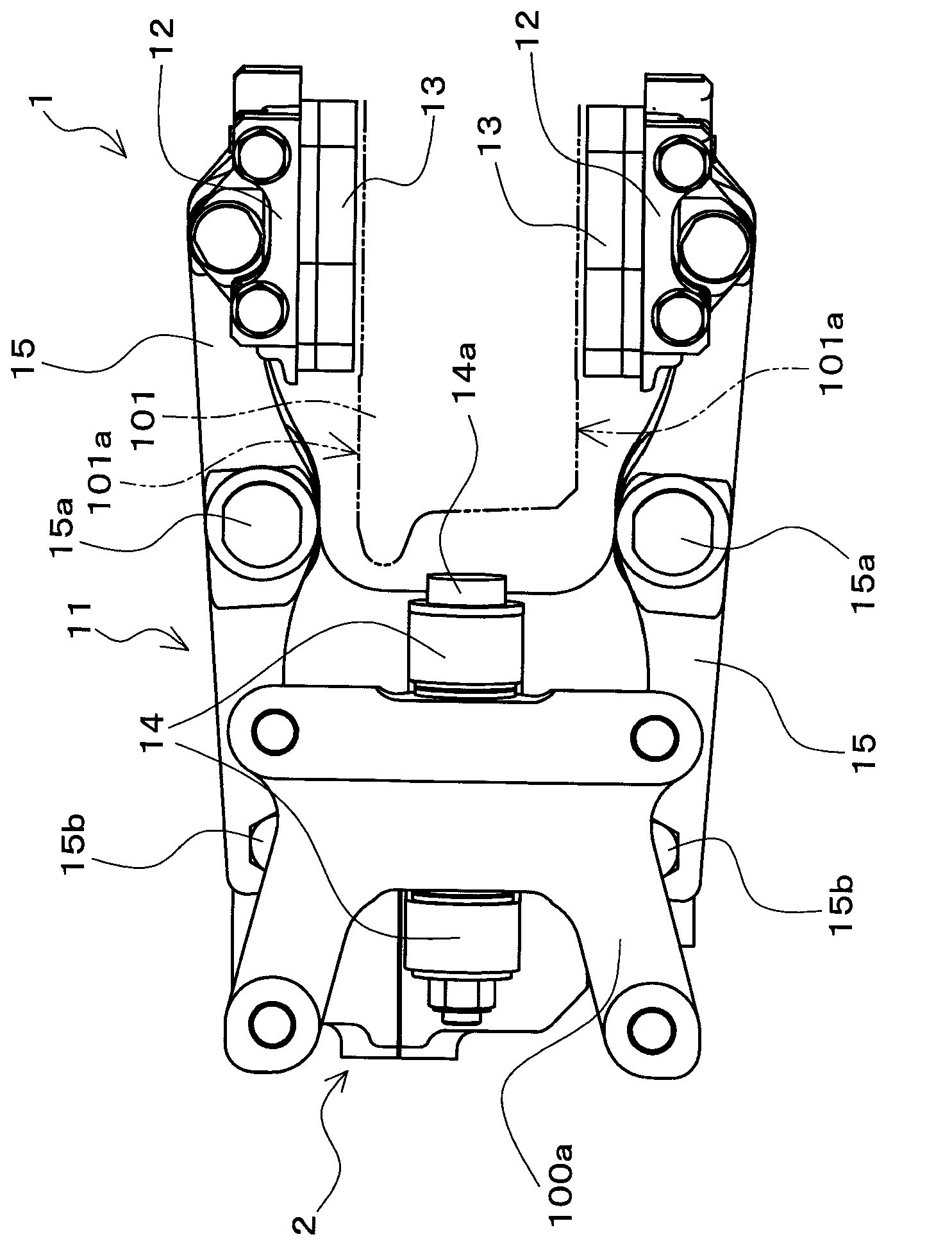

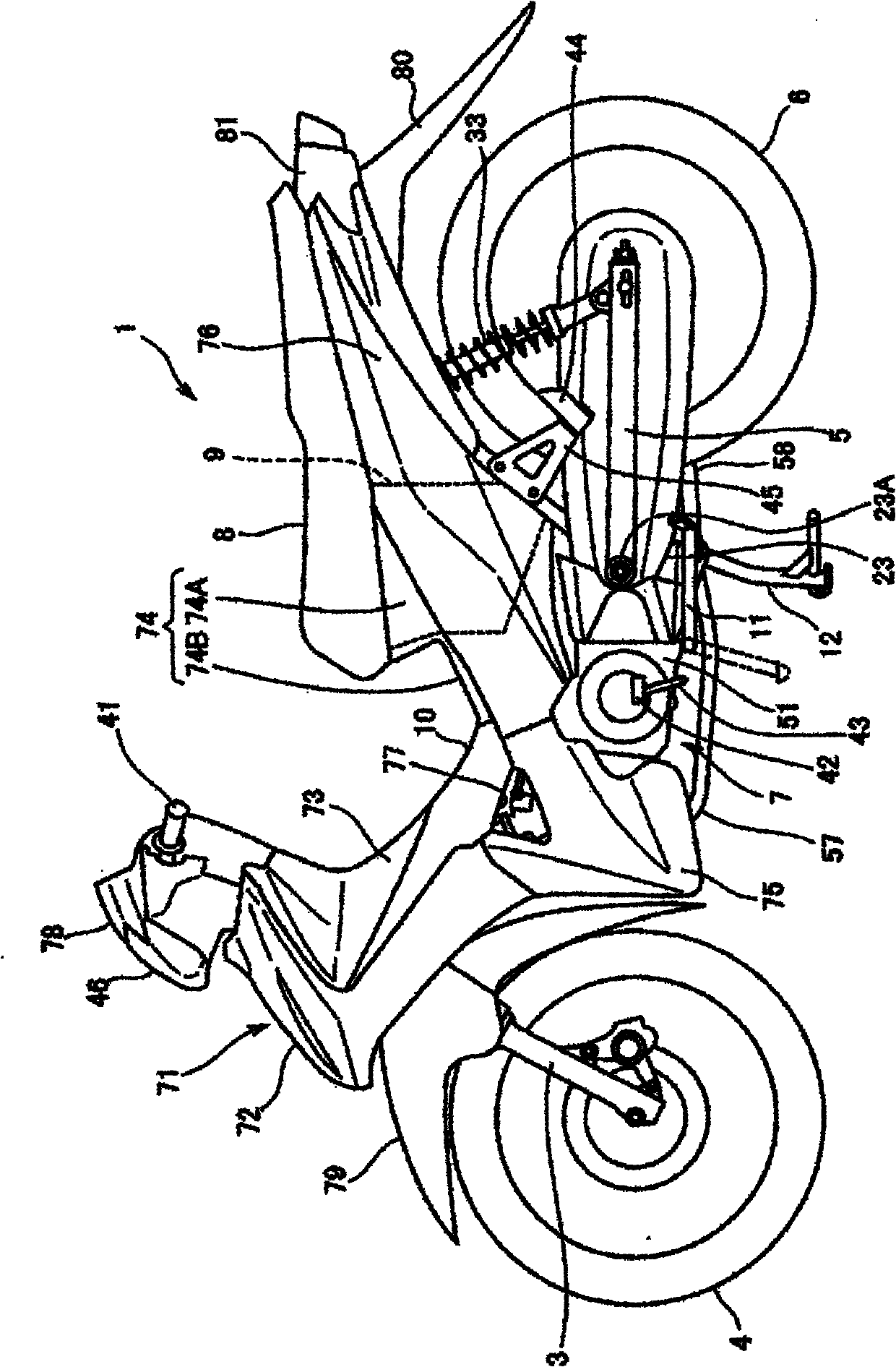

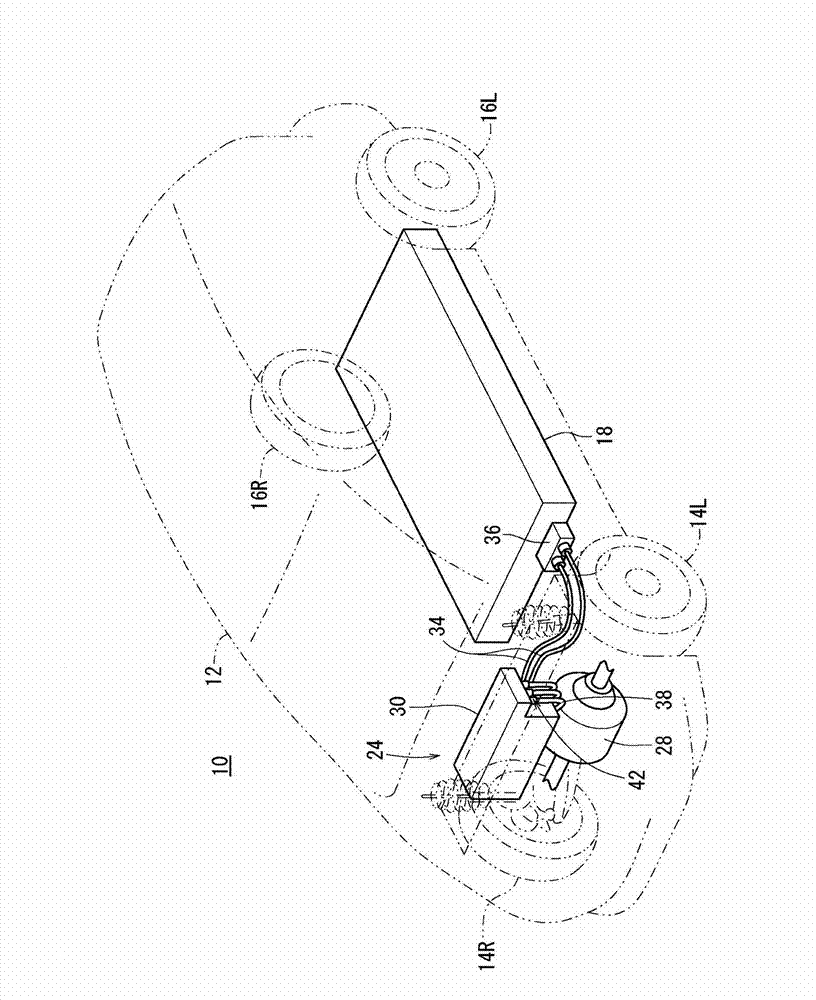

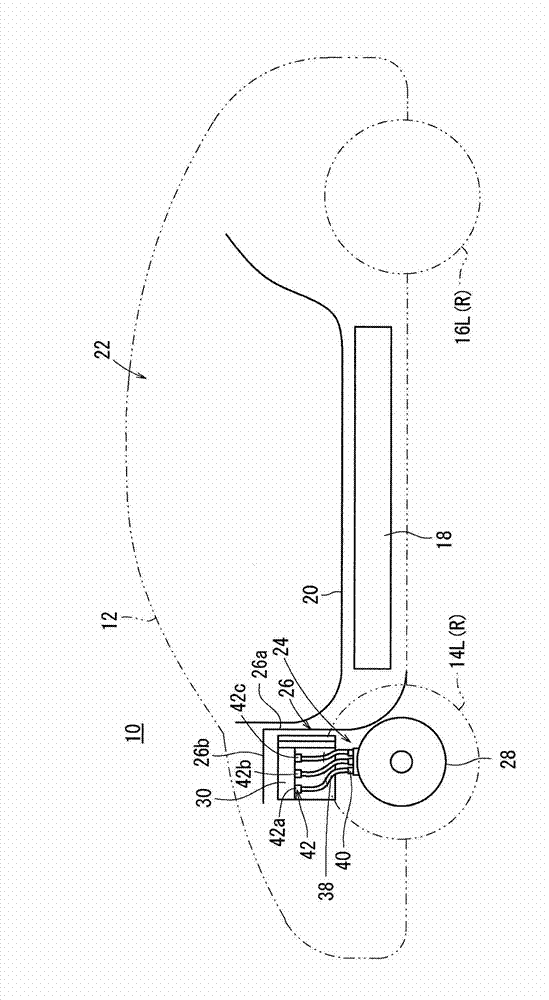

Saddled vehicle

ActiveCN104203737AIncrease the lengthEasy to ensure bendingPipe supportsOptical signalWheel speed sensorEngineering

Provided is a saddled vehicle having a wire routing structure which can efficiently bundle a brake hose and a harness which are divided to the left and right relative to the front wheel. A saddled vehicle is provided with a first clamp section (57) which affixes a harness (51) for a wheel speed sensor (49) at a position above an outer tube (282L) located on the side to which the wheel speed sensor (49) is provided. The saddled vehicle is also provided with a second clamp section (58) which bundles the harness (51) and the brake hose (50) and allows the harness (51) and the brake hose (50) to extend further upward, the harness (51) and the brake hose (50) being bundled at substantially the same height as the first clamp section (57) at a position above an outer tube (282R) located on the side to which a caliper (47) is provided. The second clamp section (58) includes a second harness holding section (641) for affixing the harness (51) and also includes a third harness holding section (642) which changes the direction of the harness (51) and which affixes the harness (51) in such a manner that the harness (51) is oriented to extend along the brake hose (50). The harness (51) and the brake hose (50) form a pivotable section (B1) bent in the left-right direction between the second clamp section (58) and a bottom bridge (27).

Owner:HONDA MOTOR CO LTD

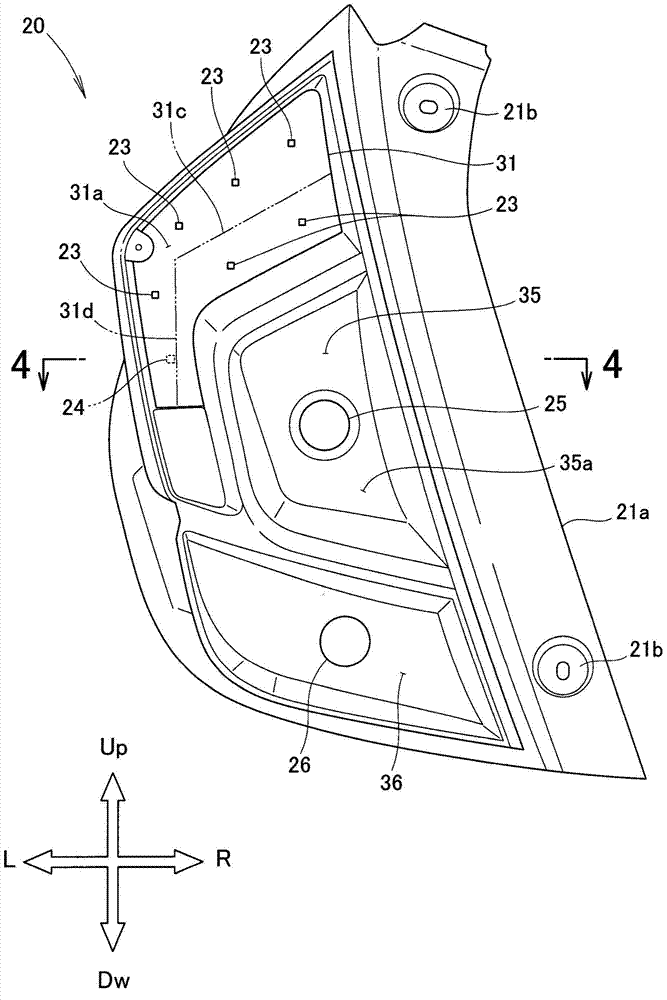

Vehicle lamp

ActiveCN107435884ASuppression of upsizingIncreased Design FreedomVehicle headlampsLight fasteningsDistribution patternOptoelectronics

The invention provides a vehicle lamp capable of preventing a large size of a lamp and improving design freedom of distribution patterns added to a regulated distribution patther. The vehicle lamp comprises a projection lens (2), a predetermined light source (14) arranged at a rear of the projection lens (12) and configured to emit light for forming a predetermined light distribution pattern (P), a reflector (15) configured to reflect the light (l) emitted from the predetermined light source (14) towards a first back focus (F1) of the projection lens (12), a first array light source (16) arranged at the rear of the projection lens (12) and including a plurality of semiconductor light emitting elements (51) aligned in at least one row, and a second array light source (17) arranged at the rear of the projection lens (12) and including a plurality of semiconductor light emitting elements (55) aligned in at least one row. The first array light source (16) and the second array light source (17) are arranged in an upper-lower direction.

Owner:KOITO MFG CO LTD

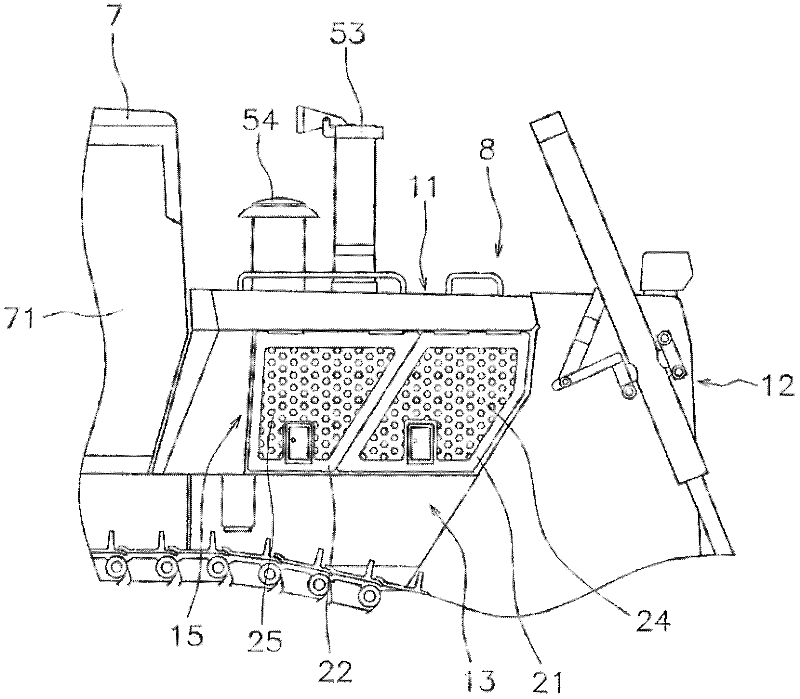

Work vehicle

ActiveCN102666174AReduce cooling efficiencyGreat accessExhaust apparatusSilencing apparatusEngineeringHeat spreader

In a work vehicle, an engine compartment is disposed forwards of a cab. An exhaust gas treatment device is disposed over an engine in the engine compartment. A radiator is disposed forwards of the exhaust gas treatment device (33) in the engine compartment. A blower is configured to generate an airflow passing through the radiator from back to front of the radiator. The exhaust gas treatment device is slanted with respect to a vehicle width direction for increasing a distance between the exhaust gas treatment device and the radiator towards a first lateral face portion. Further, the first lateral face portion includes air inlets facing a space between the exhaust gas treatment device and the radiator.

Owner:KOMATSU LTD

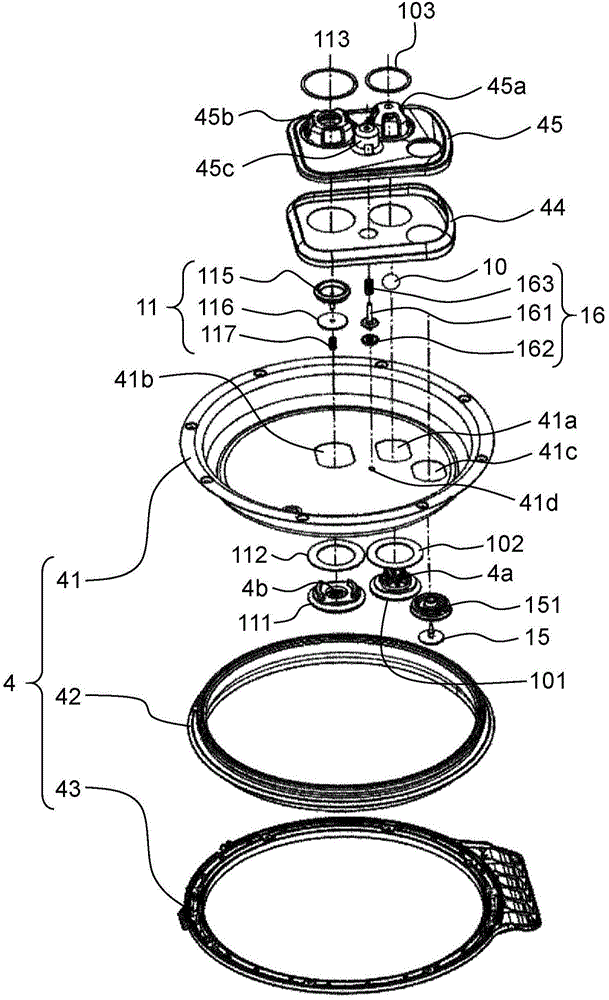

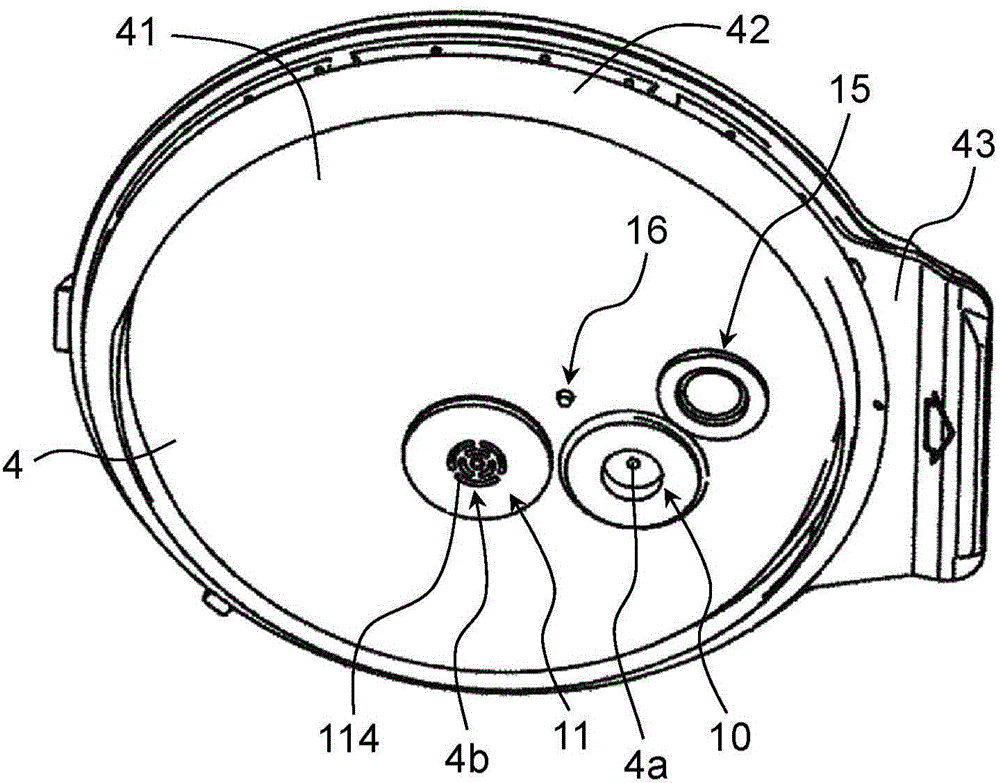

Pressure-type rice cooker

ActiveCN105030054ASuppression of upsizingIncrease the opening areaPressure-cookersEngineeringPressure controlled ventilation

The present invention provides a pressure-type rice cooker. A pressure control valve (10) may be configured to be a first vapour discharge hole (4a) which is capable of opening and closing and is arranged at a cover body. A reducing valve (11) may be configured to a second vapour discharge hole (4b), arranged at the cover body, upwards elastically applied by power, moved along the thickness direction of the cover body and being capable of opening and closing. A reducing valve travel mechanism (12) comprises a reducing valve drive rod disposed within the cover body and moved along the direction vertical to the thickness direction of the cover direction; and an inclined surface configured to move along the thickness direction of the cover body in a movement link of the reducing valve drive rod mode via the inclined surface. The reducing valve is moved along the thickness direction of the cover body in a movement link of the reducing valve drive rod mode. According to the structure, openings of the vapour discharge hole may be enlarged while the large scale of the rice cooker is restrained, and the pressure in a pot may be more accurately adjusted to the specified value higher than the barometric pressure.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

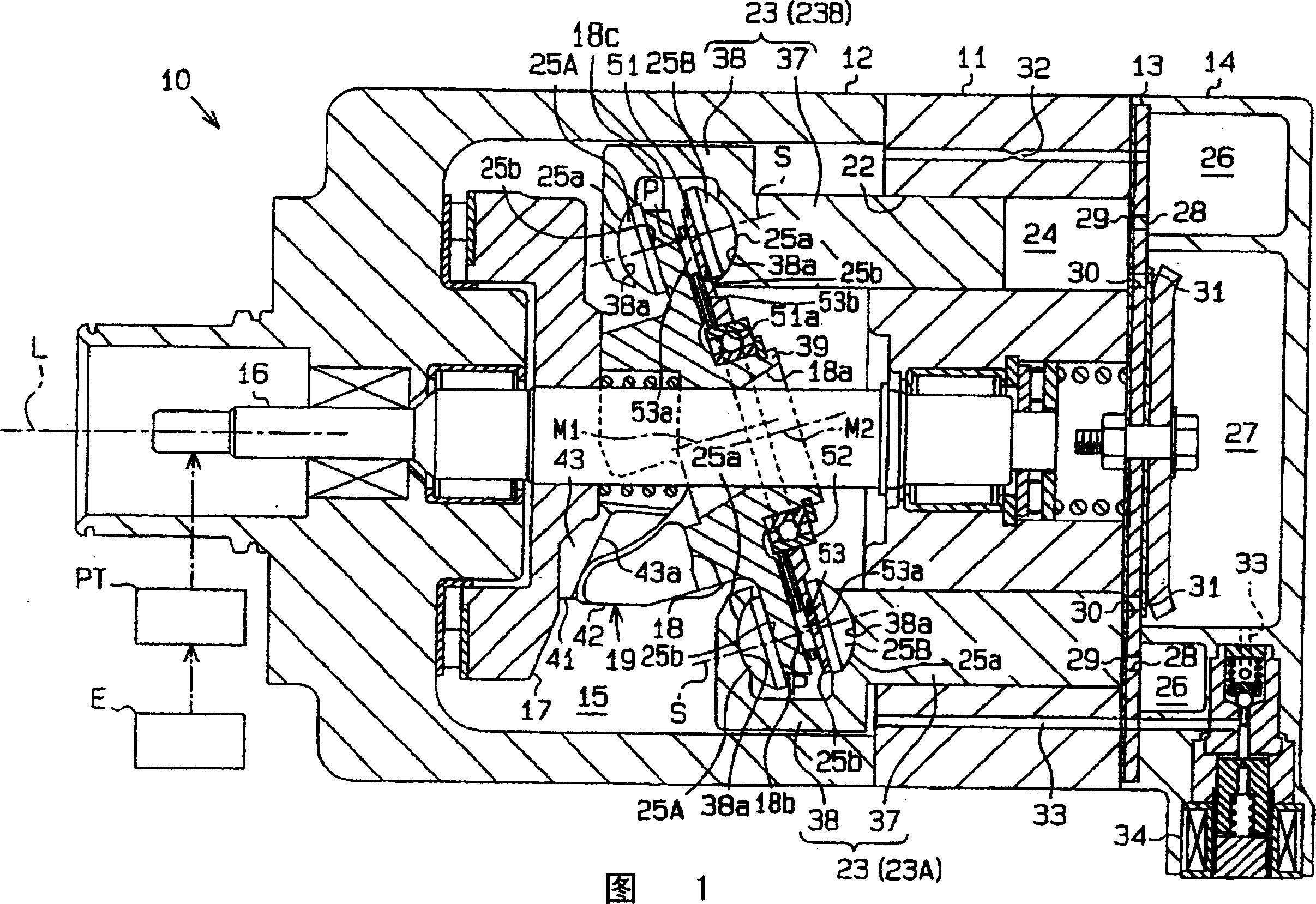

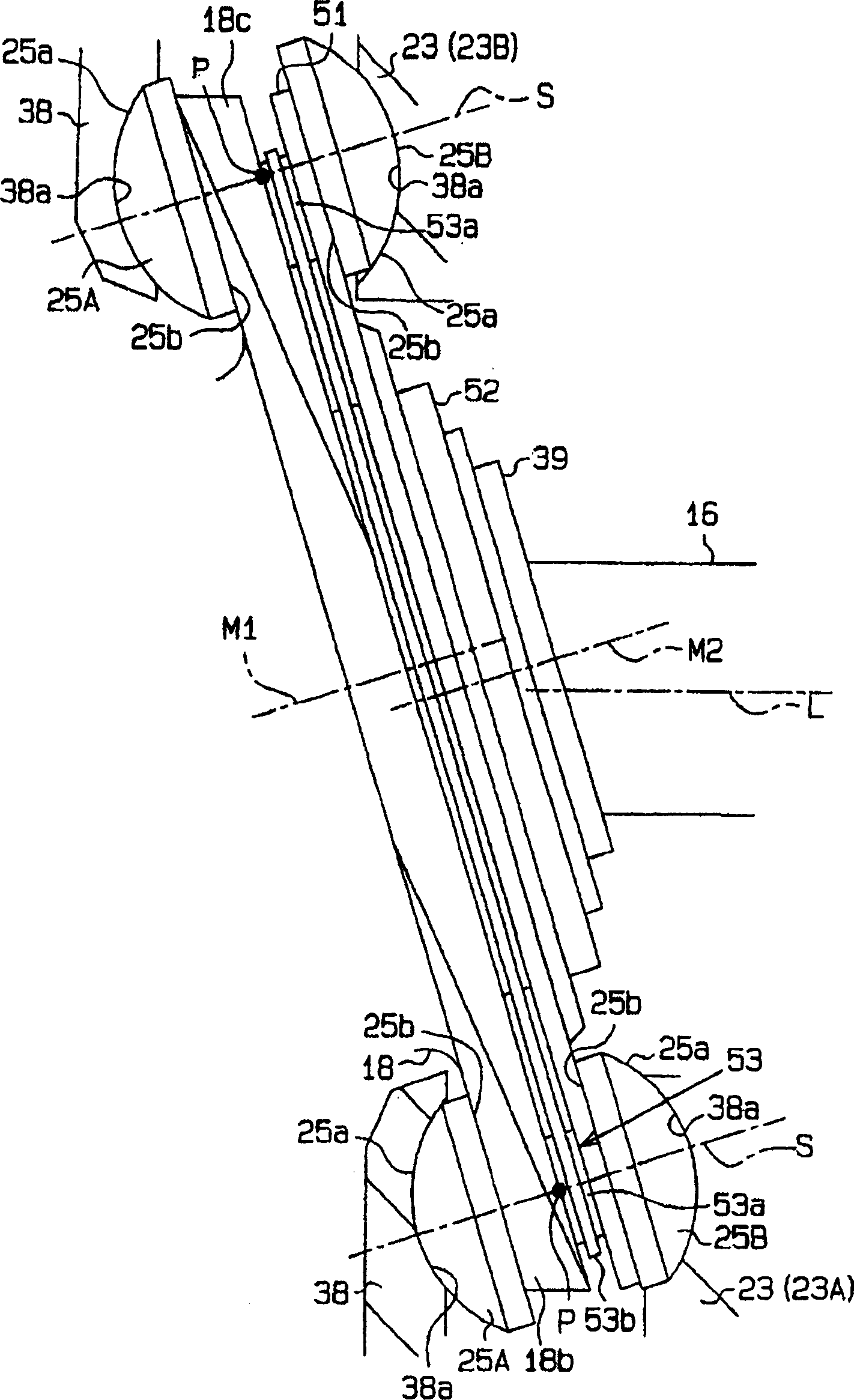

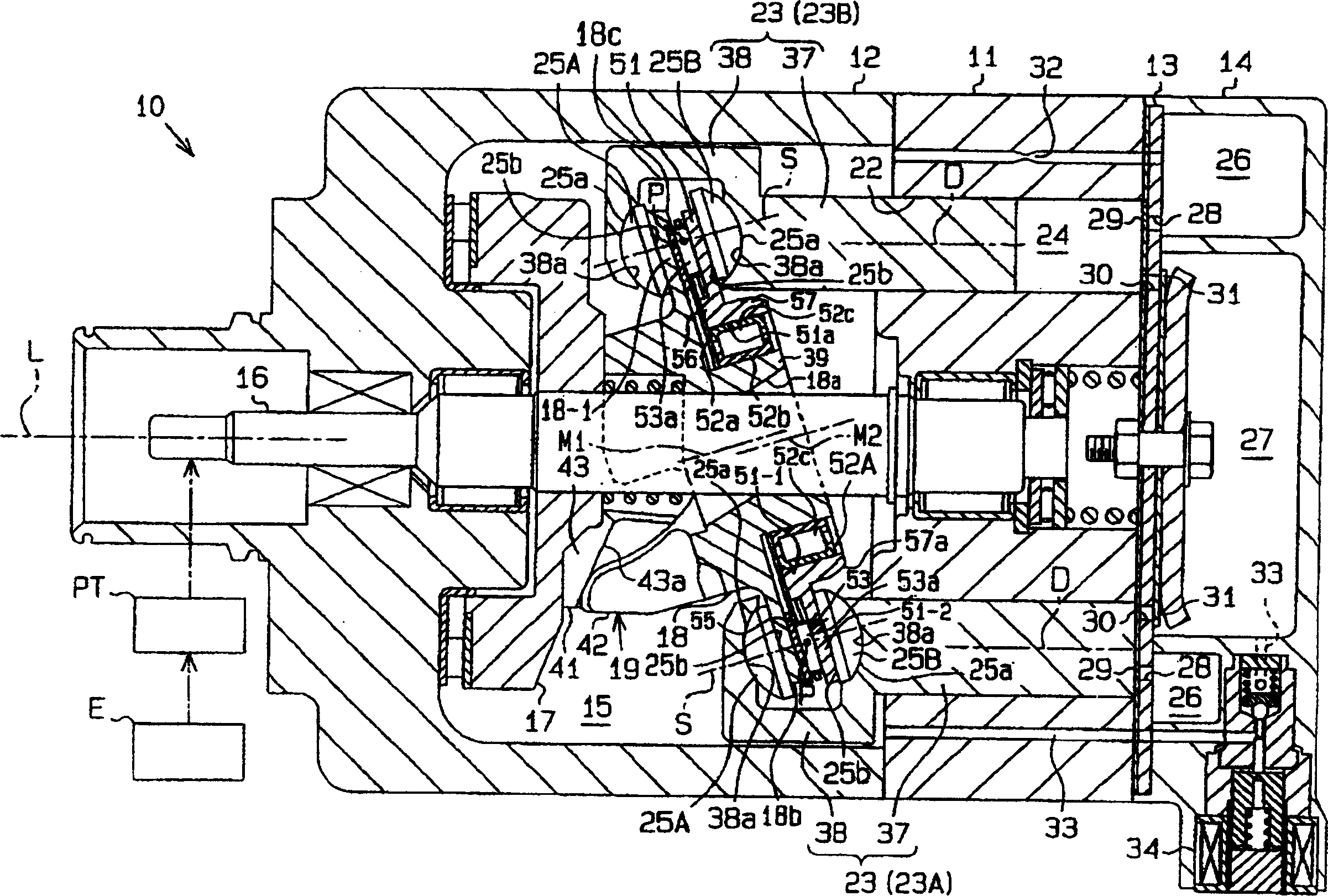

Variable displacement swash plate type compressor

InactiveCN1878955AStrong crimping forceReduced durabilityMulti-stage pumpsPositive-displacement liquid enginesBall bearingDrive shaft

A variable displacement swash plate type compressor, wherein a first swash plate (18) is connected to a drive shaft (16) so as to be rotated integrally with each other and double-head pistons (23) are anchored to the first swash plate (18) through shoes (25A) and (25B). The pistons (23) are reciprocatingly moved in the linear direction by the rotation of the first swash plate (18) according to the rotation of the drive shaft (16) to compress refrigerant gas. An annular second swash plate (51) is supported on the first swash plate (18) rotatably relative to each other through a ball bearing (52). The second swash plate (51) is disposed between the first swash plate (18) and the shoes (25B) on a compressive load receiving side slidably on the first swash plate (18) and the shoes (25B). Sloped faces (chamfered parts) are formed at the projected corner parts (18b) and (18c) of the first swash plate (18). Accordingly, the durability of the swash plates and the shoes can be increased.

Owner:TOYOTA IND CORP

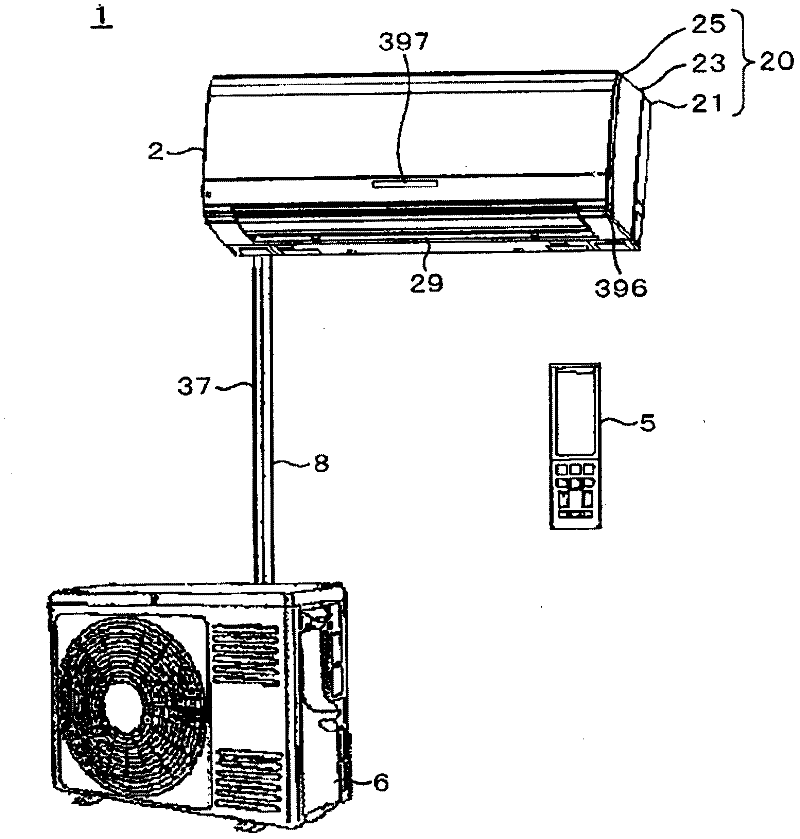

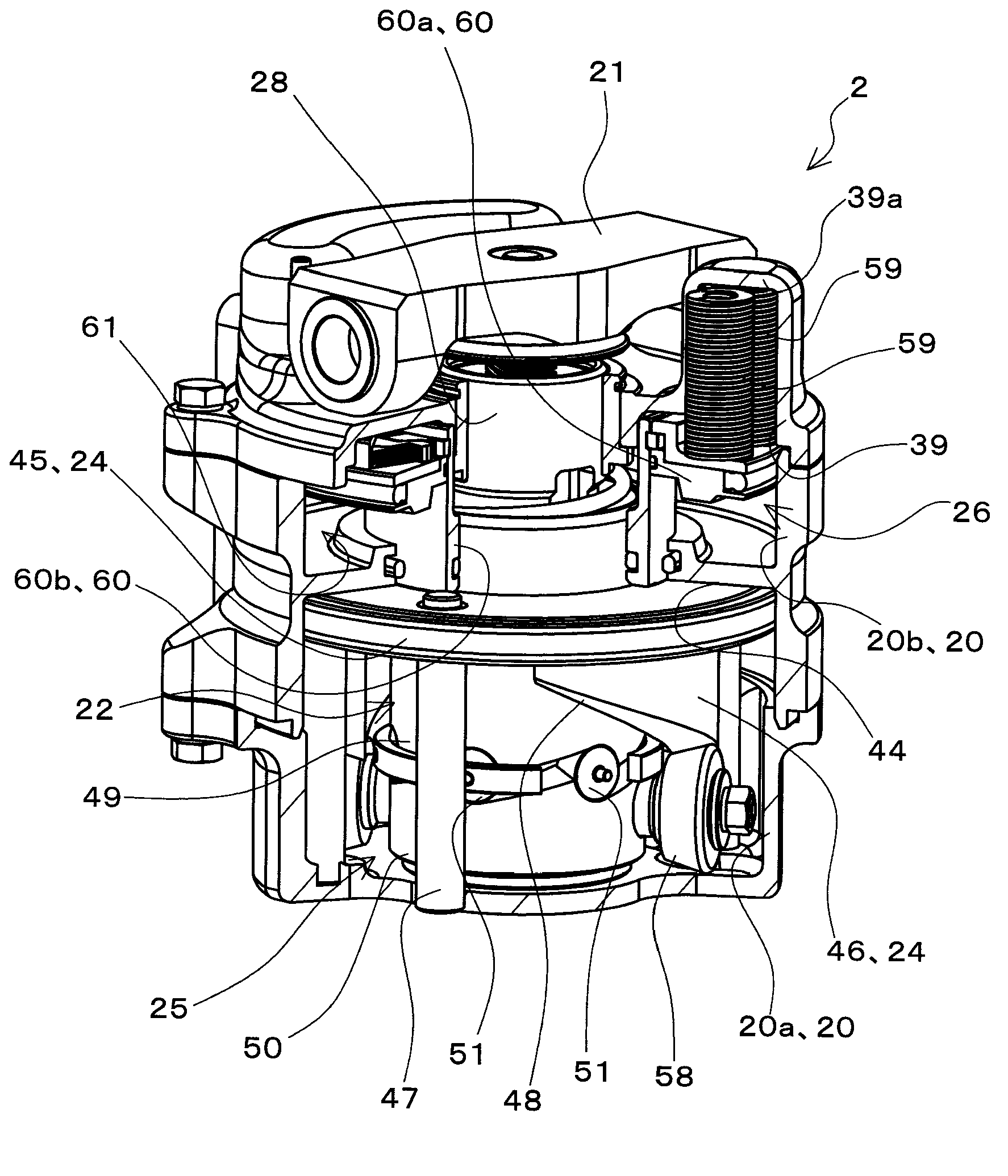

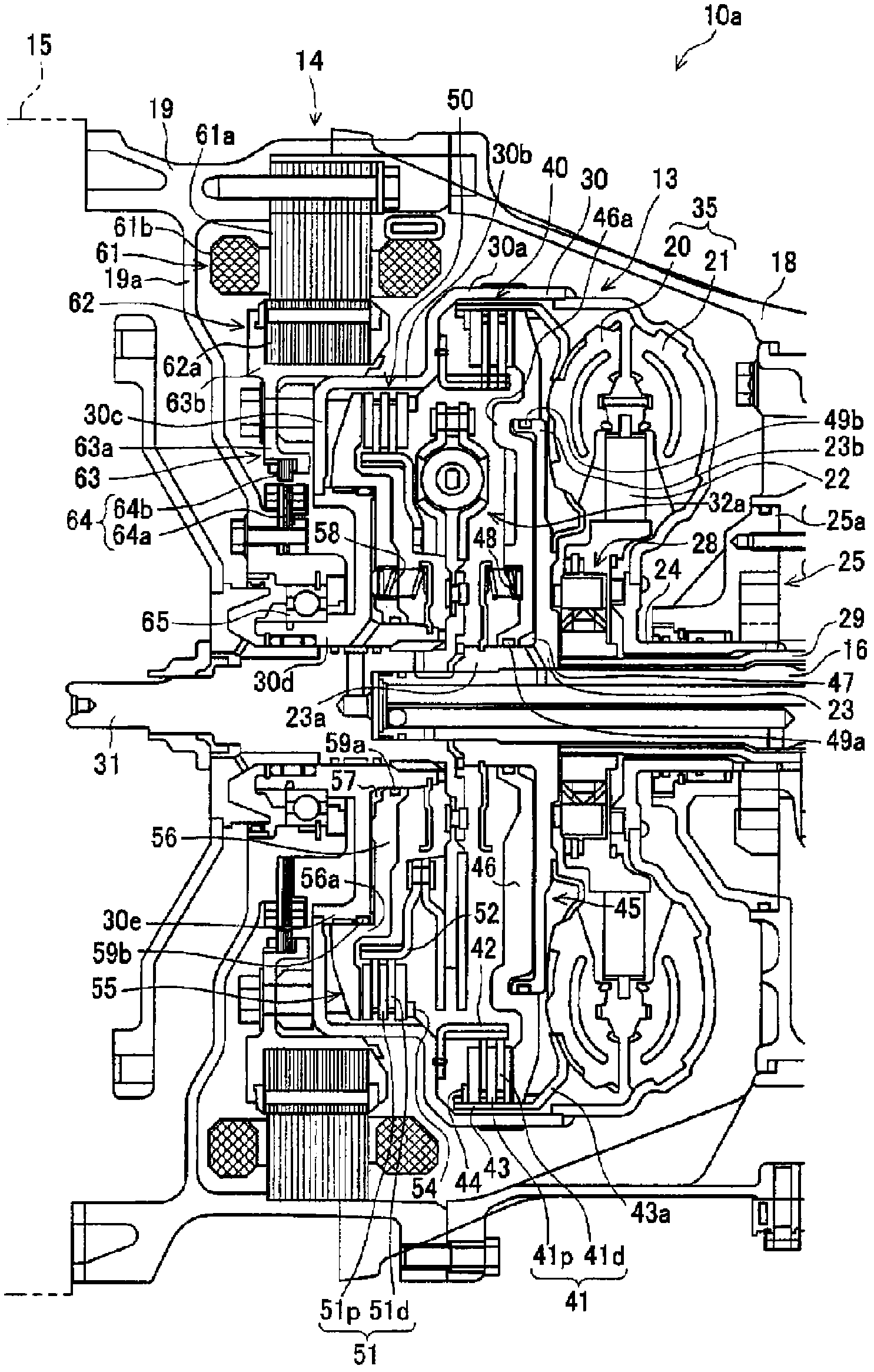

Brake cylinder device and disc brake device

InactiveCN102985718ASave configuration spaceGreat driving forceAxially engaging brakesBrake actuating mechanismsEngineeringMechanical engineering

Disclosed is a compact brake cylinder device which, while avoiding increases in the size of the device, is capable of increasing the braking force outputted from a brake output unit which moves together with a rod. A rod (22) is provided inside of a cylinder body (20) so as to freely move in the advancing and retracting directions of the cylinder shaft direction. A piston (24) partitions a pressure chamber (44) inside of the cylinder body (20), surrounding the circumference of the rod (22), and moves in a linear direction parallel to the movement direction of the rod (22). By supplying a pressure fluid to the pressure chamber (44), the piston (24) resists the biasing force of a biasing spring (23) and moves in the retracting direction relative to the cylinder body (20). At that time, a force-multiplication mechanism (25) converts the linear direction drive force generated by the piston (24) to a rotational direction, moves the rod (22) in the advancing direction, and multiplies the drive force from the piston (24) to act on the rod (22). A brake output unit (21) moves together with the rod (22) in the advancing direction and outputs a braking force.

Owner:NABLESCO CORP

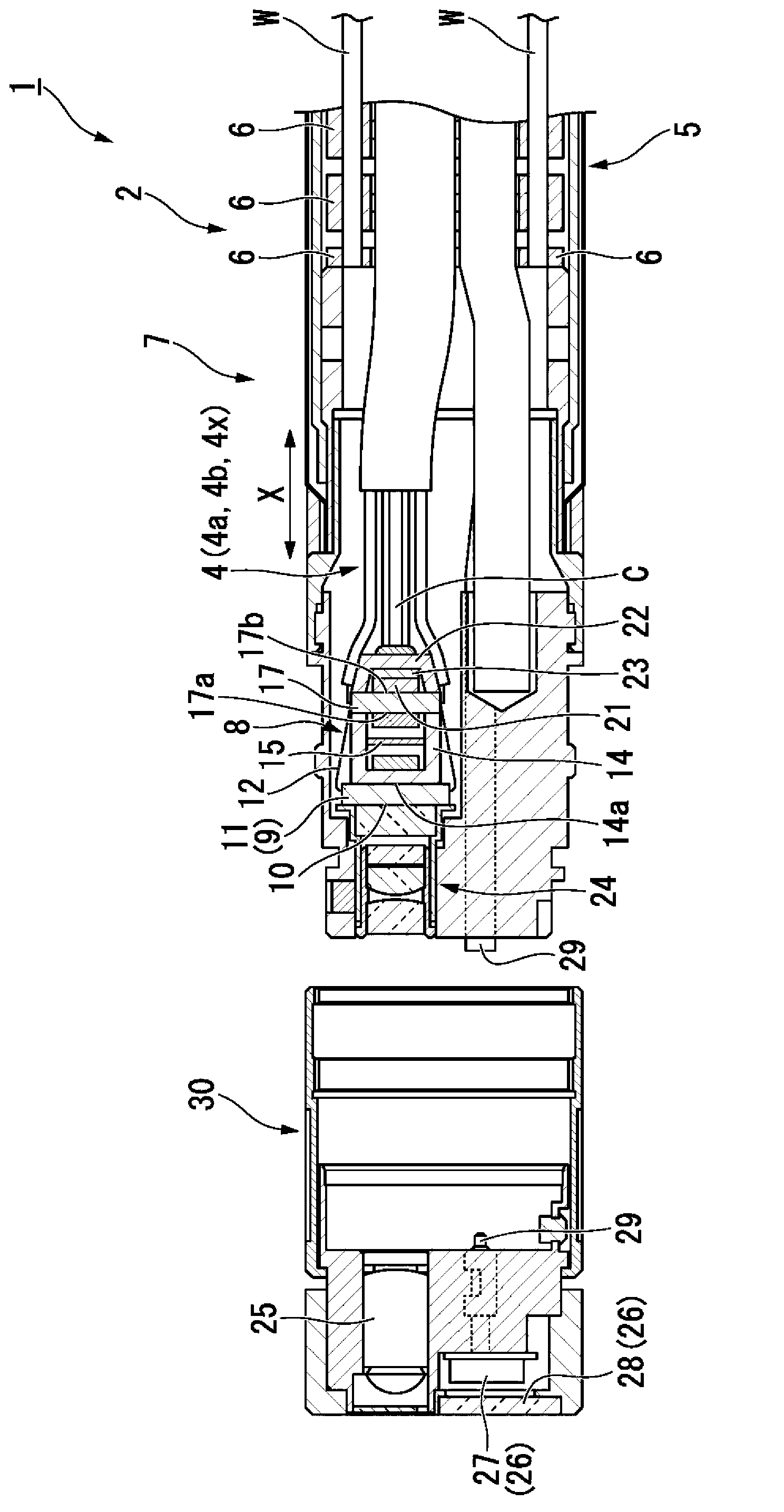

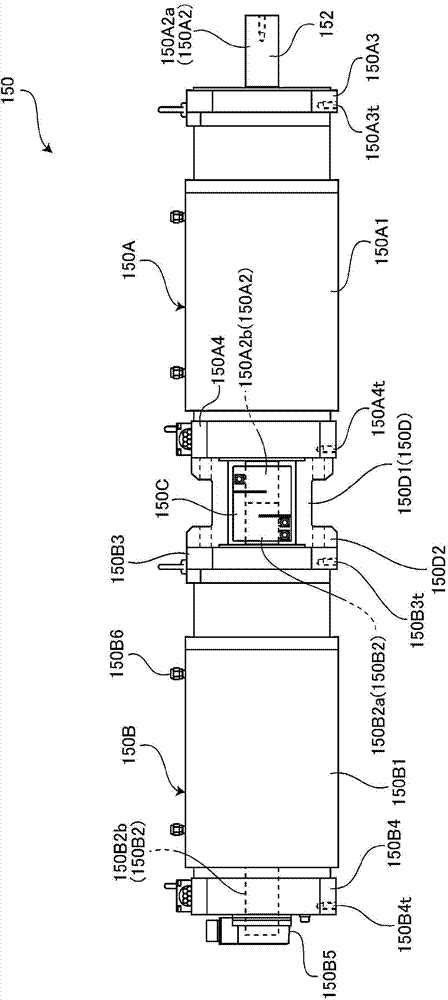

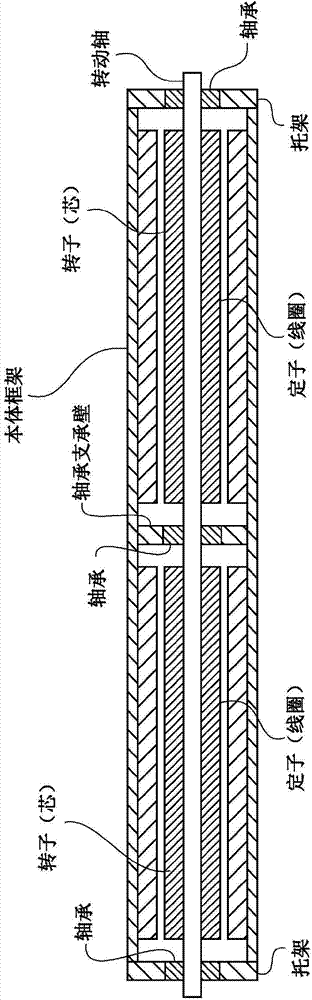

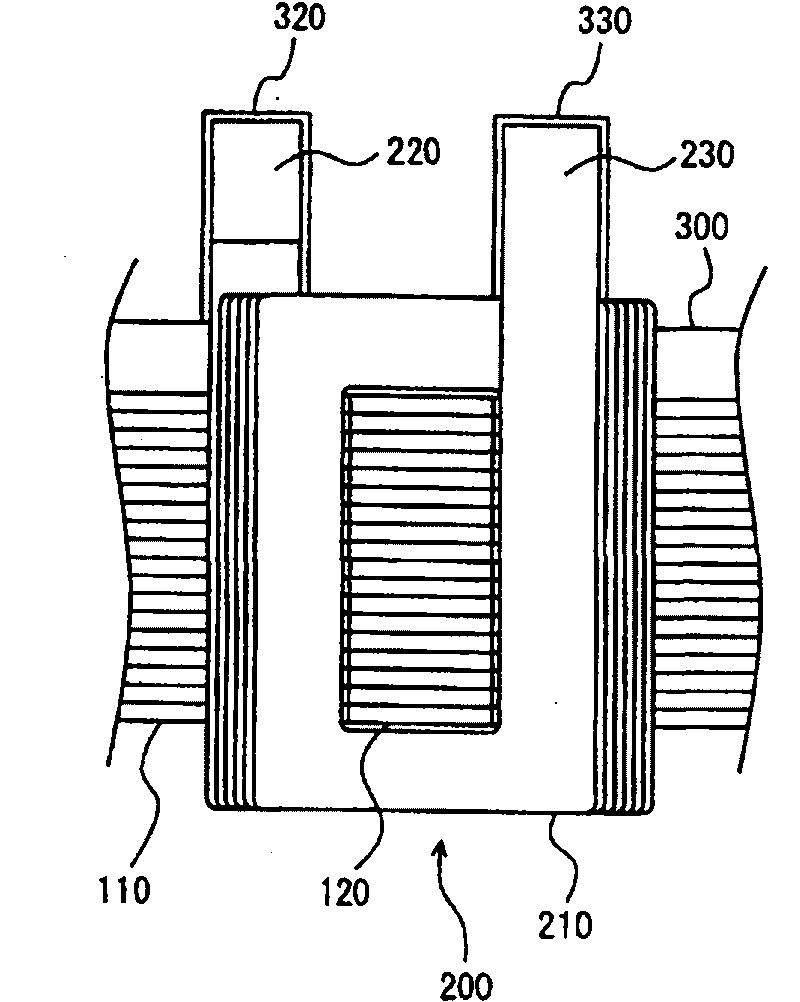

Two-output-shaft motor, motor unit, power simulator, torsion testing device, rotational torsion testing device, tire testing device, linear actuator and vibration device

ActiveCN104737423AReduce power lossReduce operating costsMachine part testingEngine testingDrive shaftLinear actuator

This two-output-shaft motor is equipped with: a cylindrical main frame; a substantially plate-like first bracket that is attached to one axial end of the main frame; a substantially plate-like second bracket that is attached to the other axial end of the main frame; and a drive shaft that runs through the hollow part of the main frame, penetrates through the first bracket and the second bracket, and is rotatably supported by bearings provided in the first bracket and the second bracket. One end of the drive shaft protrudes to the outside from the first bracket and forms a first output shaft for outputting a driving force to the outside, and the other end of the drive shaft protrudes to the outside from the second bracket and forms a second output shaft for outputting the driving force to the outside.

Owner:KOKUSAI KEISOKUKI KK

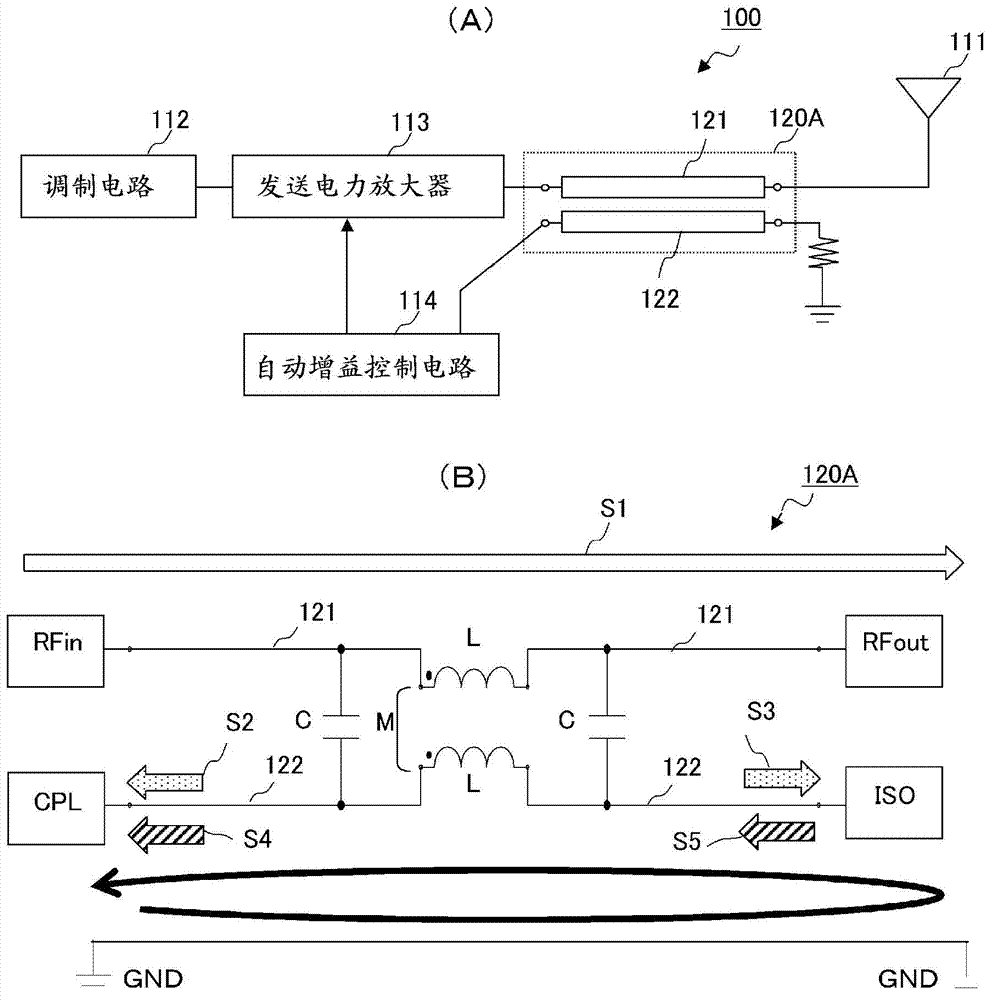

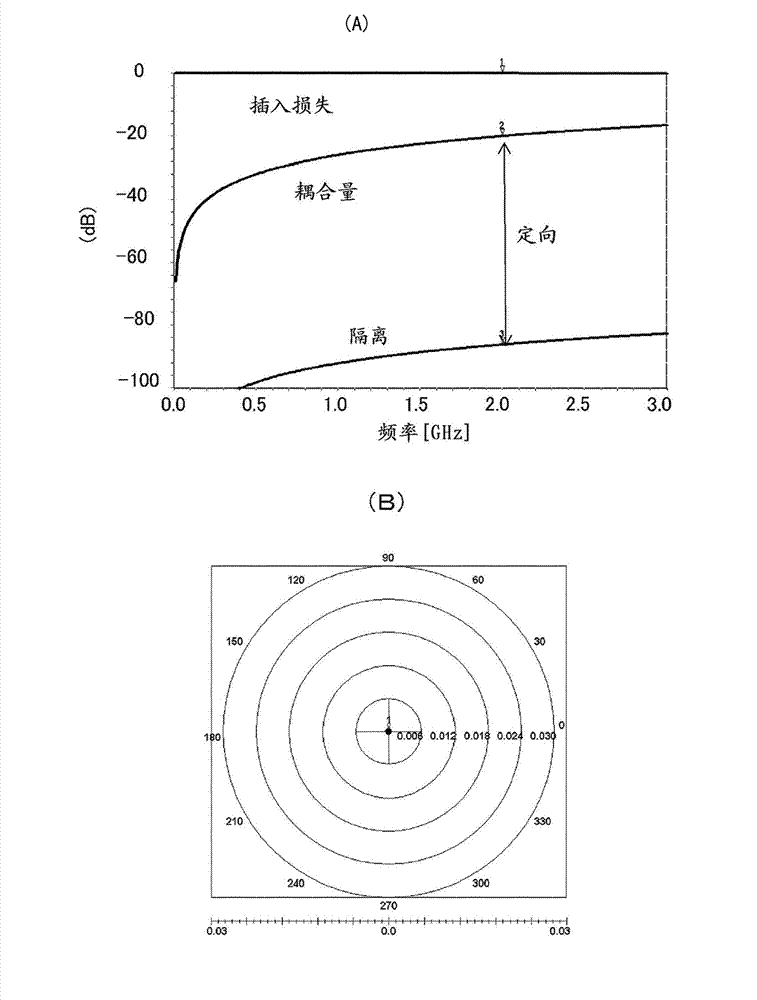

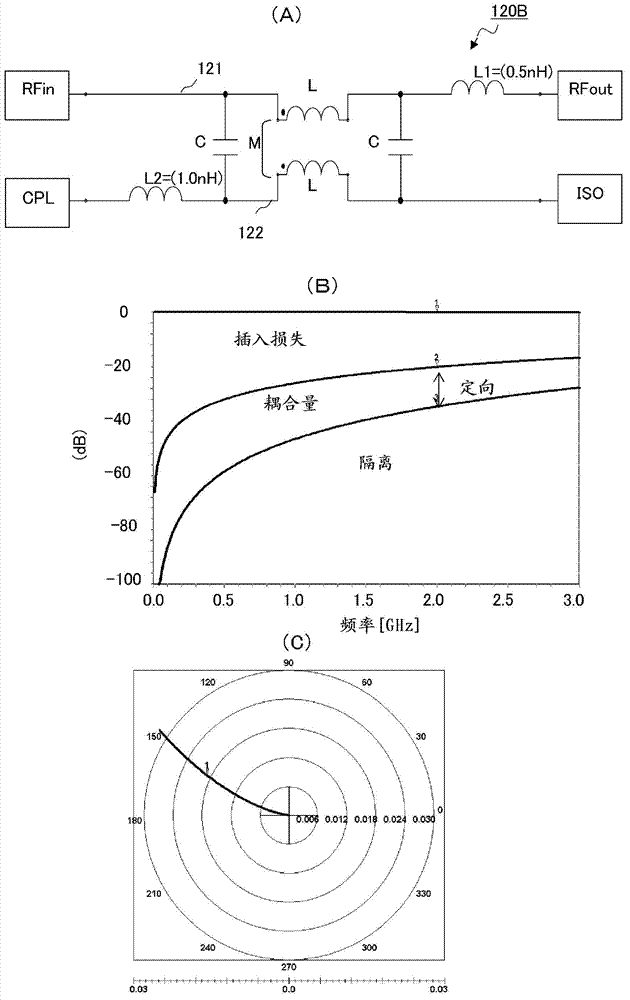

Directional coupler

ActiveCN103201899ASuppression of upsizingImprove isolation characteristicsCoupling devicesCapacitanceMagnetic field coupling

In the present invention, while minimizing increases in the size of a directional coupler, said directional coupler is provided with good isolation characteristics even in the presence of parasitic impedance. A transmission-line directional coupler (20A) is provided with a main line (21) and a coupled line (22) that is coupled to the main line (21) by electric-field coupling and magnetic-field coupling. The main line (21) has a signal-input port (RFin) and a signal-output port (RFout), and the coupled line (22) has a coupling port (CPL) and an isolation port (ISO). A series capacitance is connected to either the signal-output port (RFout) or the coupling port (CPL), but not both.

Owner:MURATA MFG CO LTD

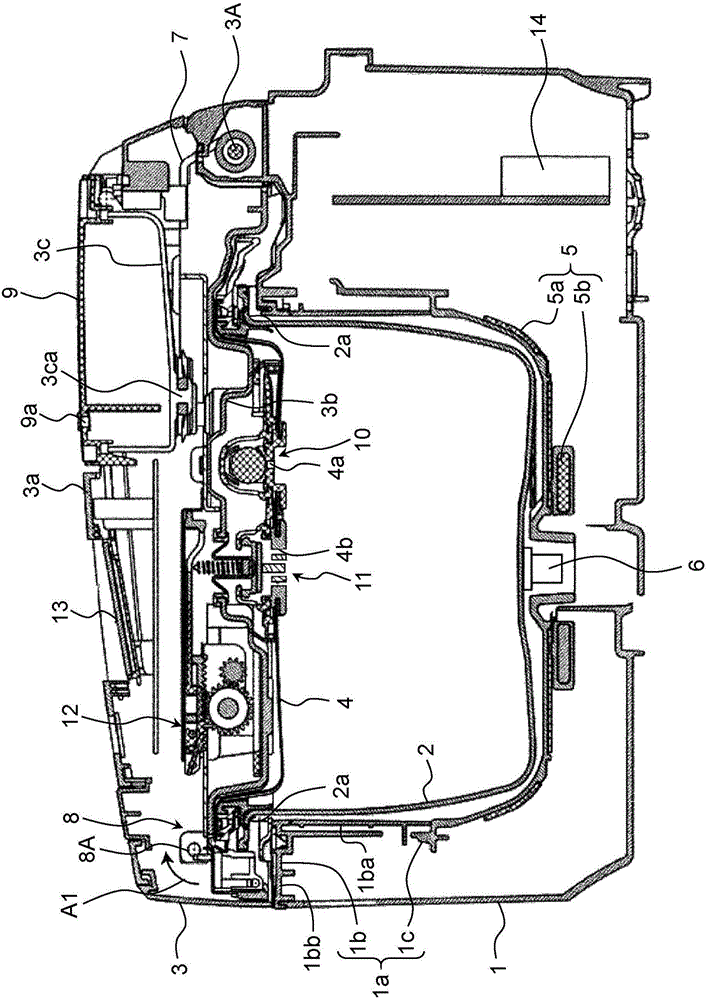

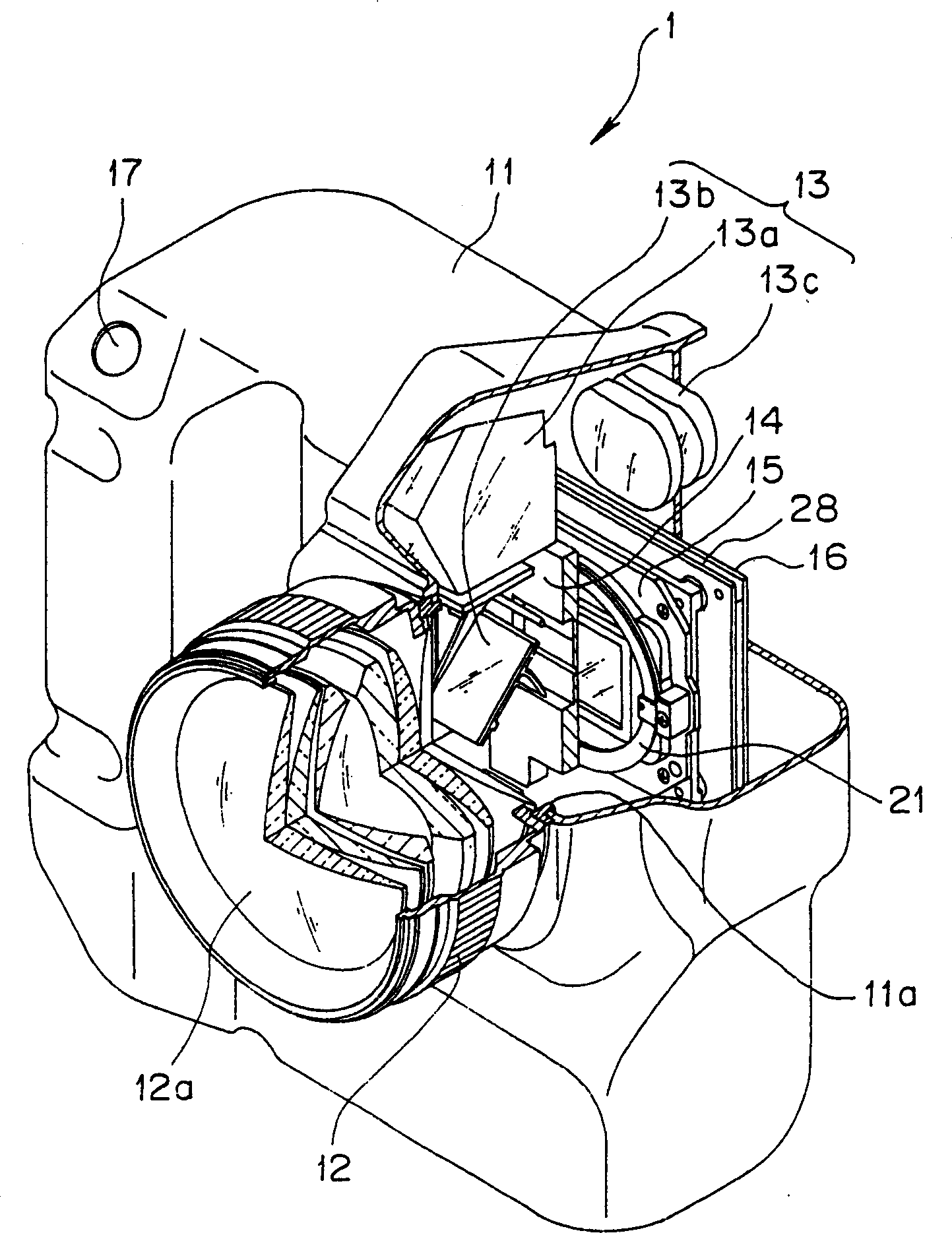

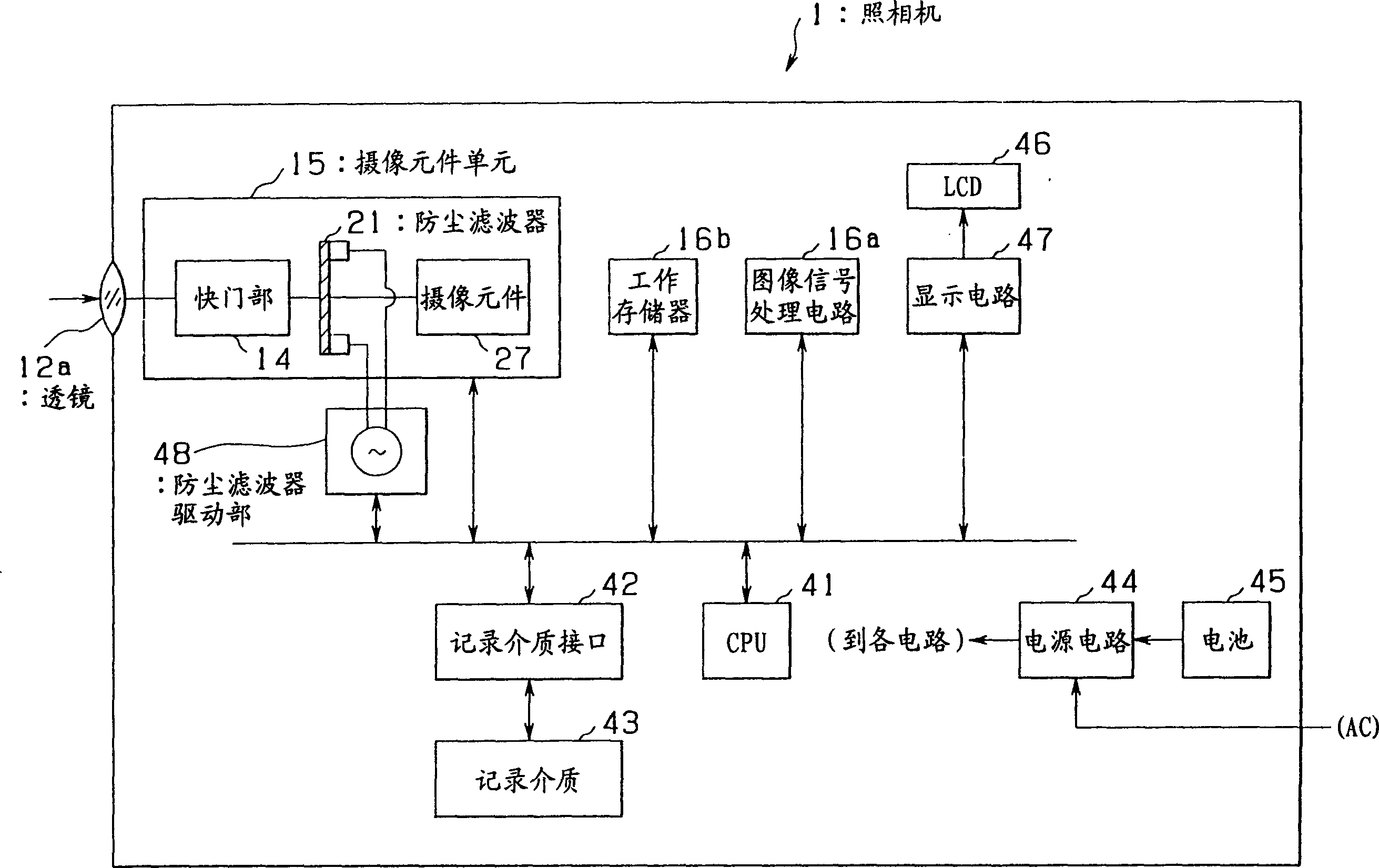

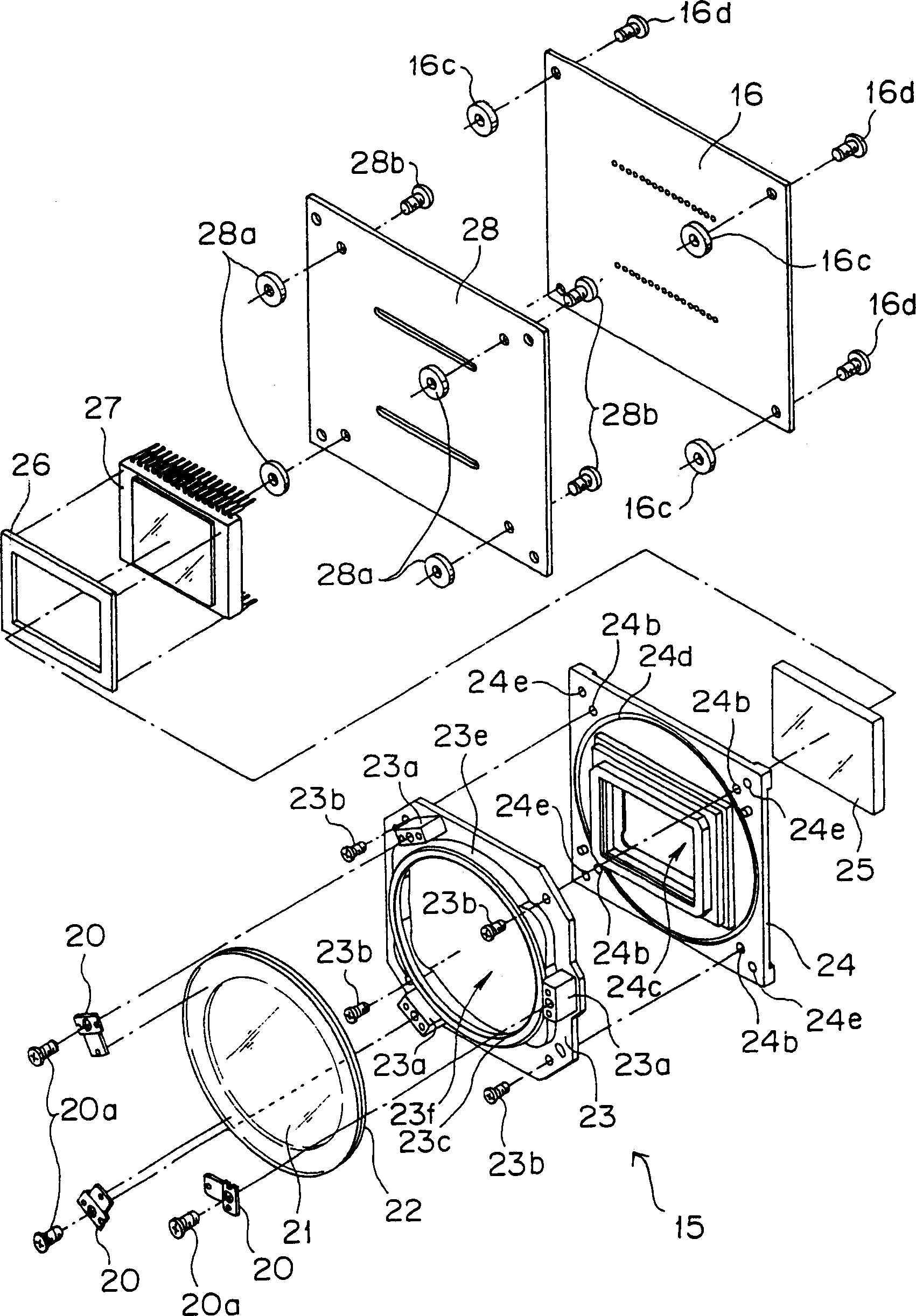

Camera and camera element unit

InactiveCN1460890AImprove accuracySimple structureTelevision system detailsColor television detailsSignal processing circuitsImage signal

Camera and camera element unit are provided in the invention. The camera includes an image pick-up device which obtains an image signal corresponding to beams irradiated onto a photoelectrically converting surface thereof; a dust-proofing member with a circular or polygonal plate-shape as a whole, including a transparent portion at an area having at least a predetermined extensity in a radial direction from the center thereof, opposed to the front of the optical device at a predetermined interval; a member for vibration annularly arranged at a peripheral portion of the dust-proofing member, which applies vibrations to the dust-proofing member; a sealing structure arranged to constitute a space portion that is substantially sealed at a portion formed by opposing the image pick-up device and the dust-proofing member by sealing the space portion at peripheral portions of the image pick-up device and the dust-proofing member; and an image signal processing circuit which converts an image signal obtained from the image pick-up device, corresponding to an image formed onto the photoelectrically converting surface of the image pick-up device, into a signal suitable to recording.

Owner:OM DIGITAL SOLUTIONS CORP

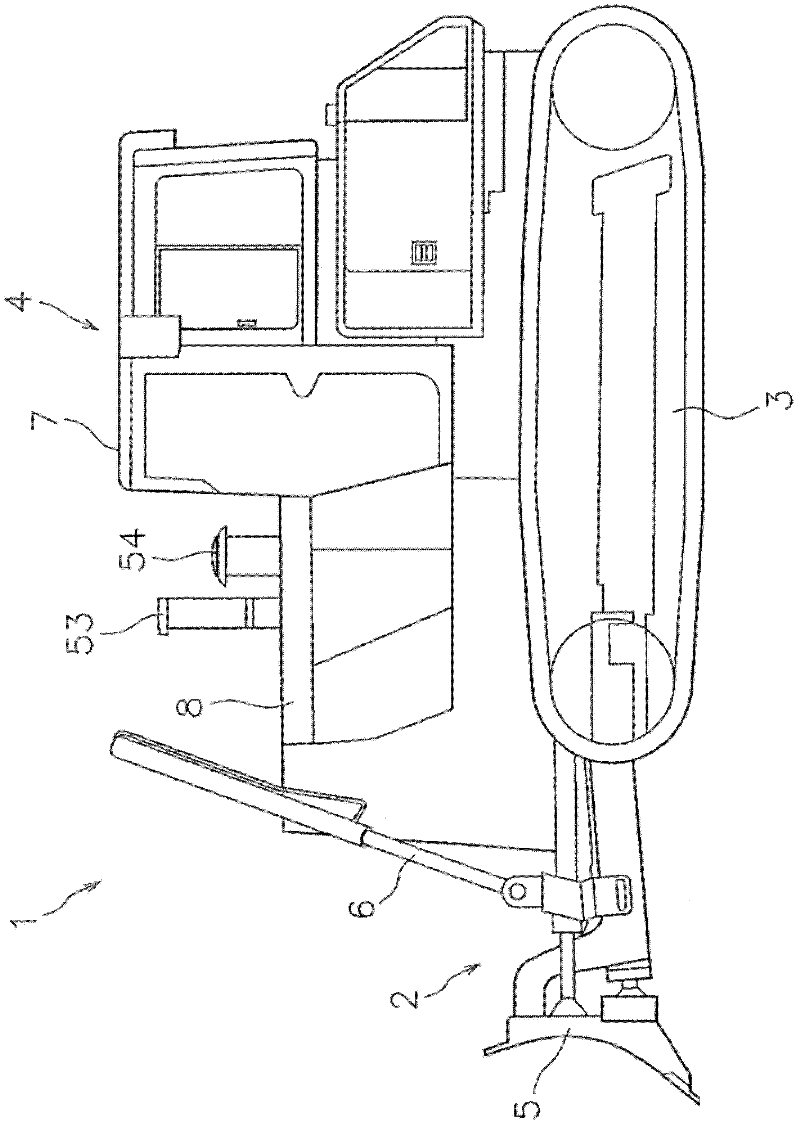

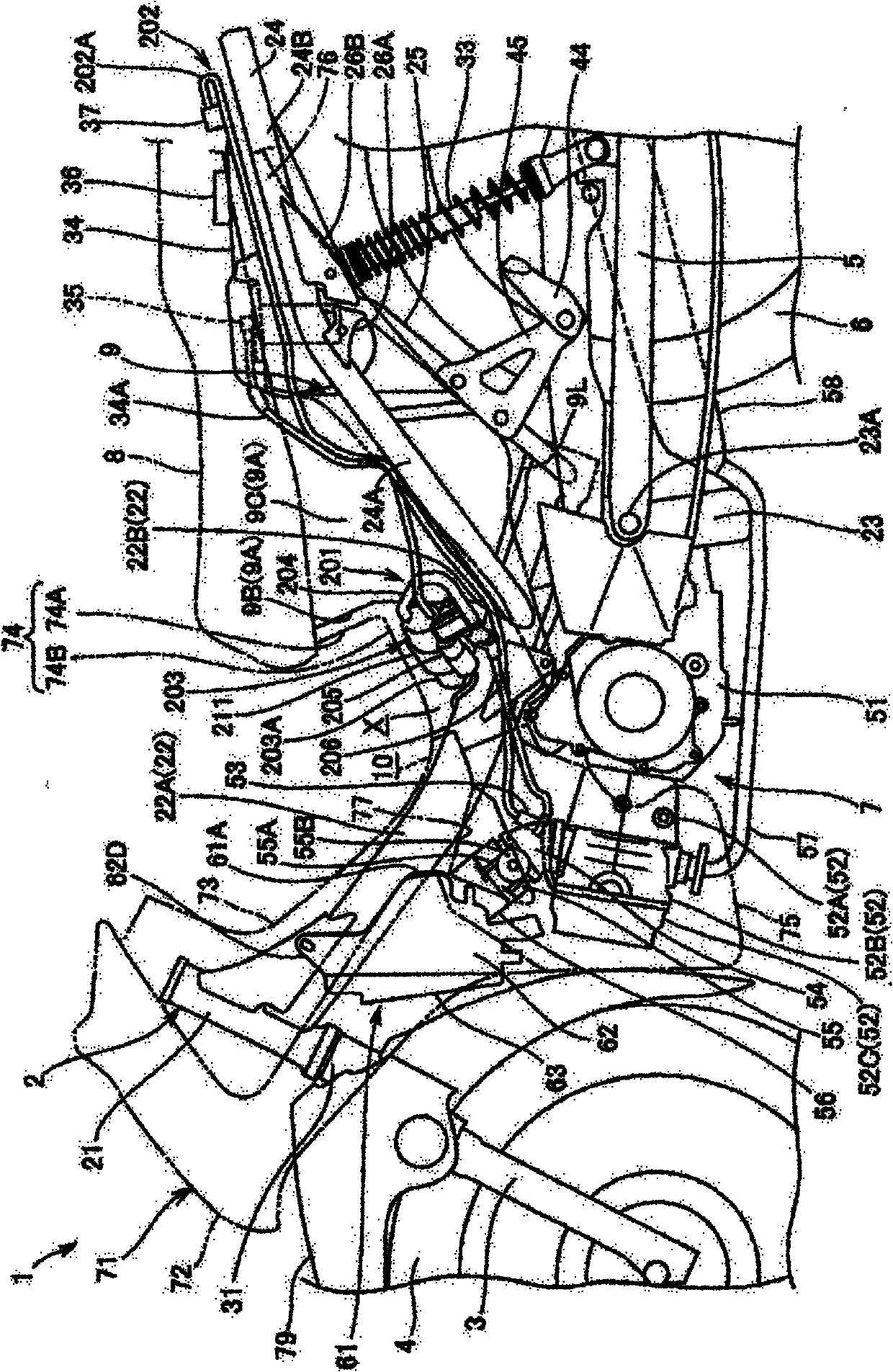

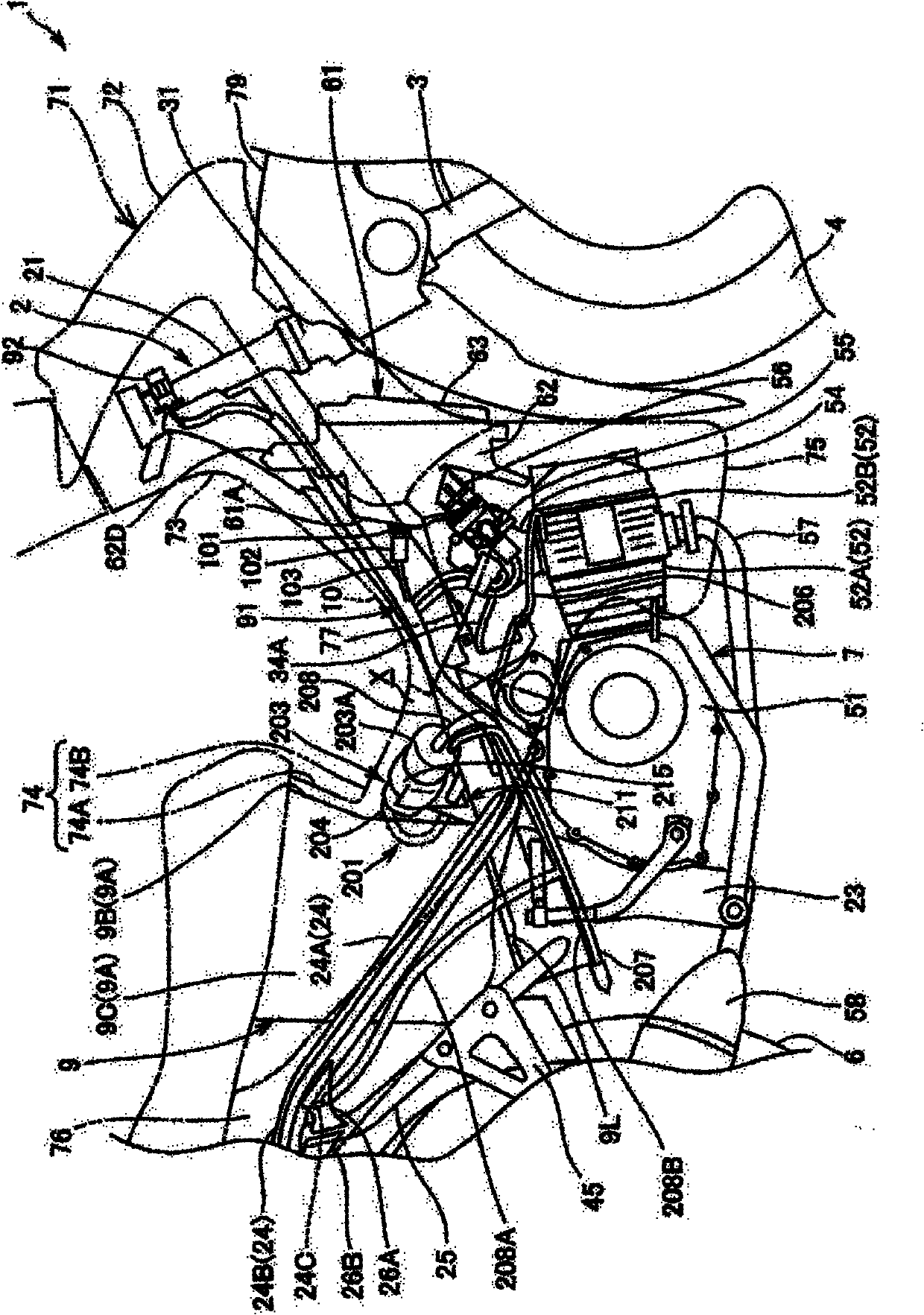

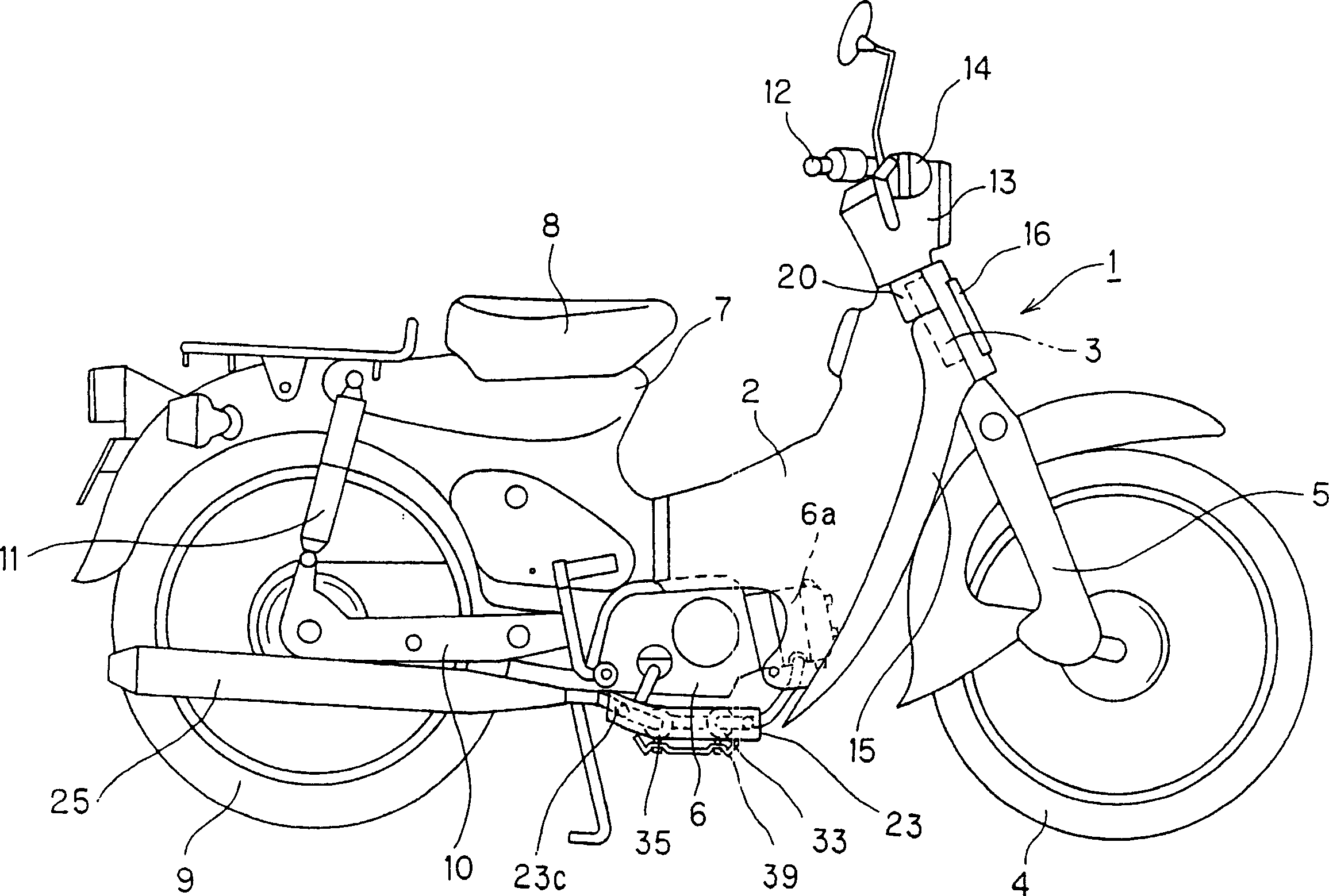

Evaporated fuel processing apparatus of motor-driven cart

ActiveCN102167112AReduce widthSuppression of upsizingNon-fuel substance addition to fuelMachines/enginesMotor driveVehicle frame

The invention provides an evaporated fuel processing apparatus of a motor-driven cart which can prevent the large scale of vehicle width due to an absorption tank. The motor-driven cart (1) comprises an engine (7) supported by a vehicle frame (2), a fuel tank (34) storing fuel transmitted to the engine (7), a receiving casing (9) disposed at the lower side of a seat (8) and the absorption tank (203) which is disposed at the periphery of the receiving casing (9) and absorbs the evaporated fuel from the fuel tank (34). In the motor-driven cart (1), the length direction of the absorption tank (203) tilts with respect to the width direction of a vehicle.

Owner:HONDA MOTOR CO LTD

Electric vehicle

InactiveCN103129364ASuppression of upsizingIncrease the number ofSpeed controllerElectric propulsion mountingEngineeringBattery electric vehicle

The invention provides an electric vehicle restricting large development of an electric compressor. The electric vehicle (10) is provided with a power control unit (30) using a battery (18) to carry out driving control to a driven motor, an air-conditioned compressor (118), a conductive component (180) provided with branch points (181-185), so that one end is connected with the battery (18) side and the other end is respectively connected with a power conversion module (60) and the air-conditioned compressor (118). The power conversion module (60) is disposed in the power control unit (30) and is used for converting DC of the battery (18) to AC. Coils (117,200) are arranged between the branch points (181-185) and the air-conditioned compressor (118). The conductive component (180) and the coils (117,200) are arranged in the power control unit (30).

Owner:HONDA MOTOR CO LTD

Pinion assembling tray and pinion assembling device

InactiveCN103727211AShort cycleImprove productivityAssembly machinesGearing detailsEngineeringPinion

The invention provides a pinion assembling tray and a pinion assembling device, which can assemble a pinion to a planet carrier for operation with high efficiency so as to raise assembling productivity. The pinion assembling device (60) is composed of a conveyor (61) for conveying a pinion assembling tray (30) and a first station (S1), a second station (S2) and a third station (S3) configured along the conveyor (61). At the first station (S1), a pinion module is inserted into the planet carrier and moves, is inserted into a shaft at the second station (S2) and is in pivot joint with the shaft at the third station (S3). The pinion assembling device can independently perform pinion module positioning and shaft inserting, shorten a period and increase productivity.

Owner:MUSA PRECISION IND CO LTD

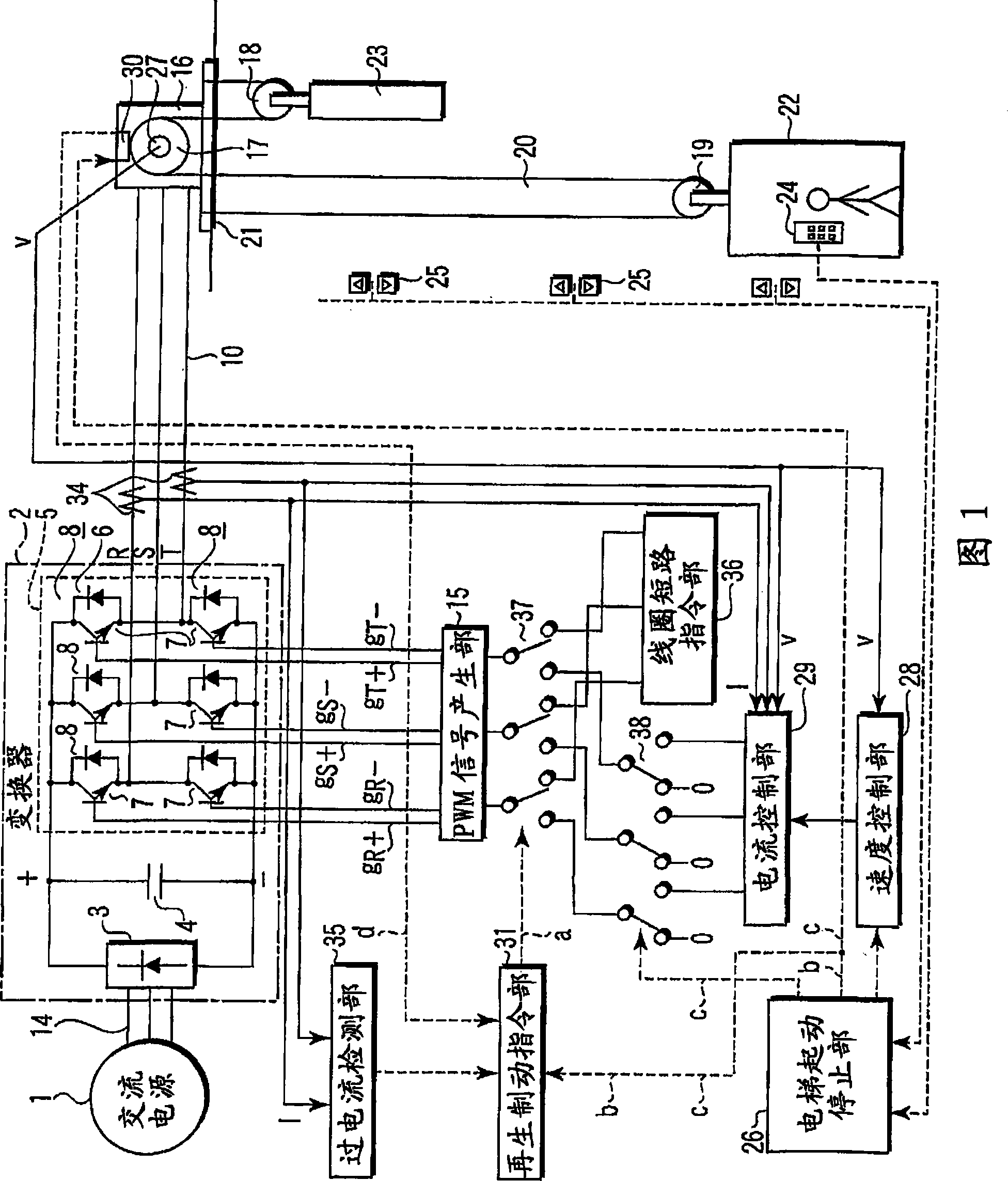

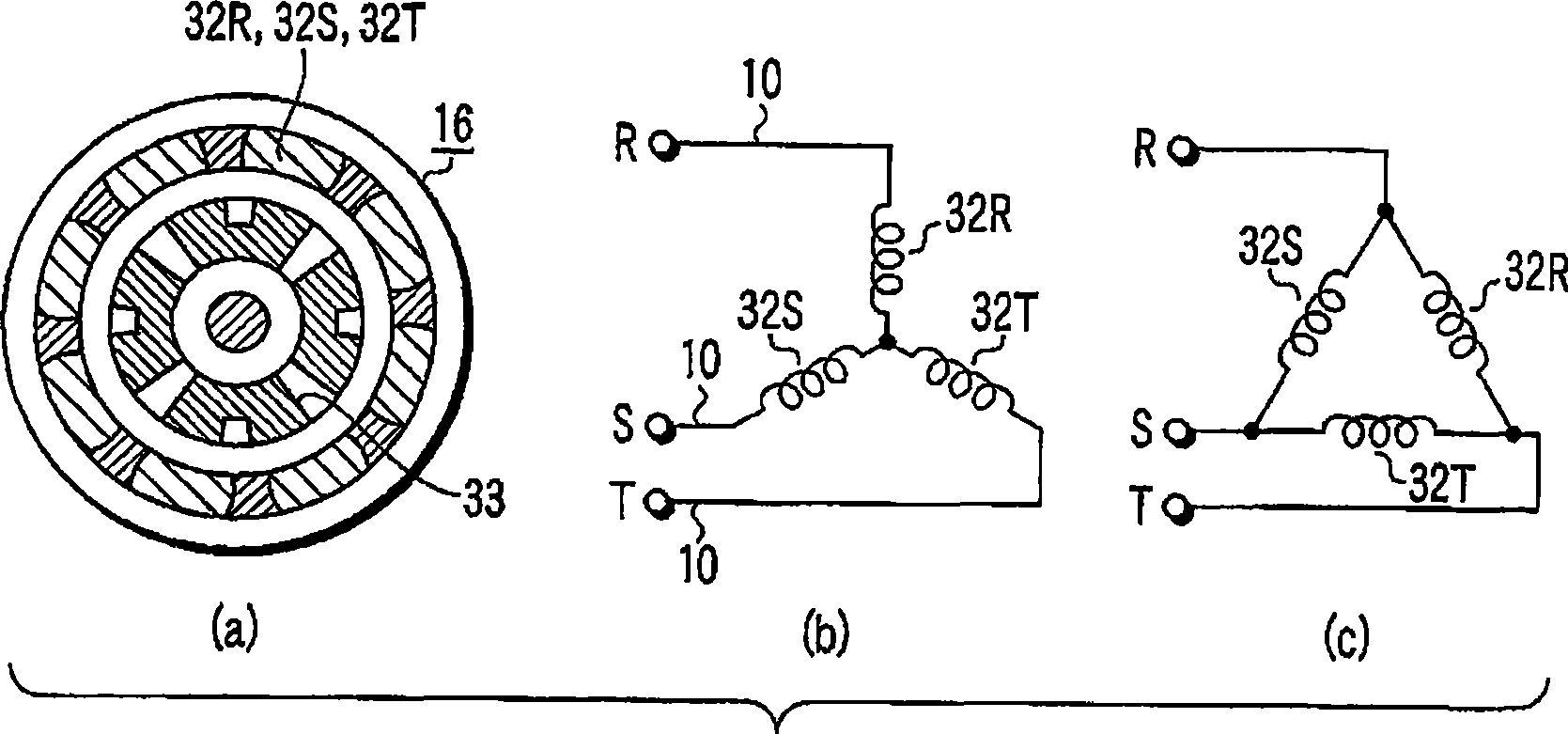

Elevator controller

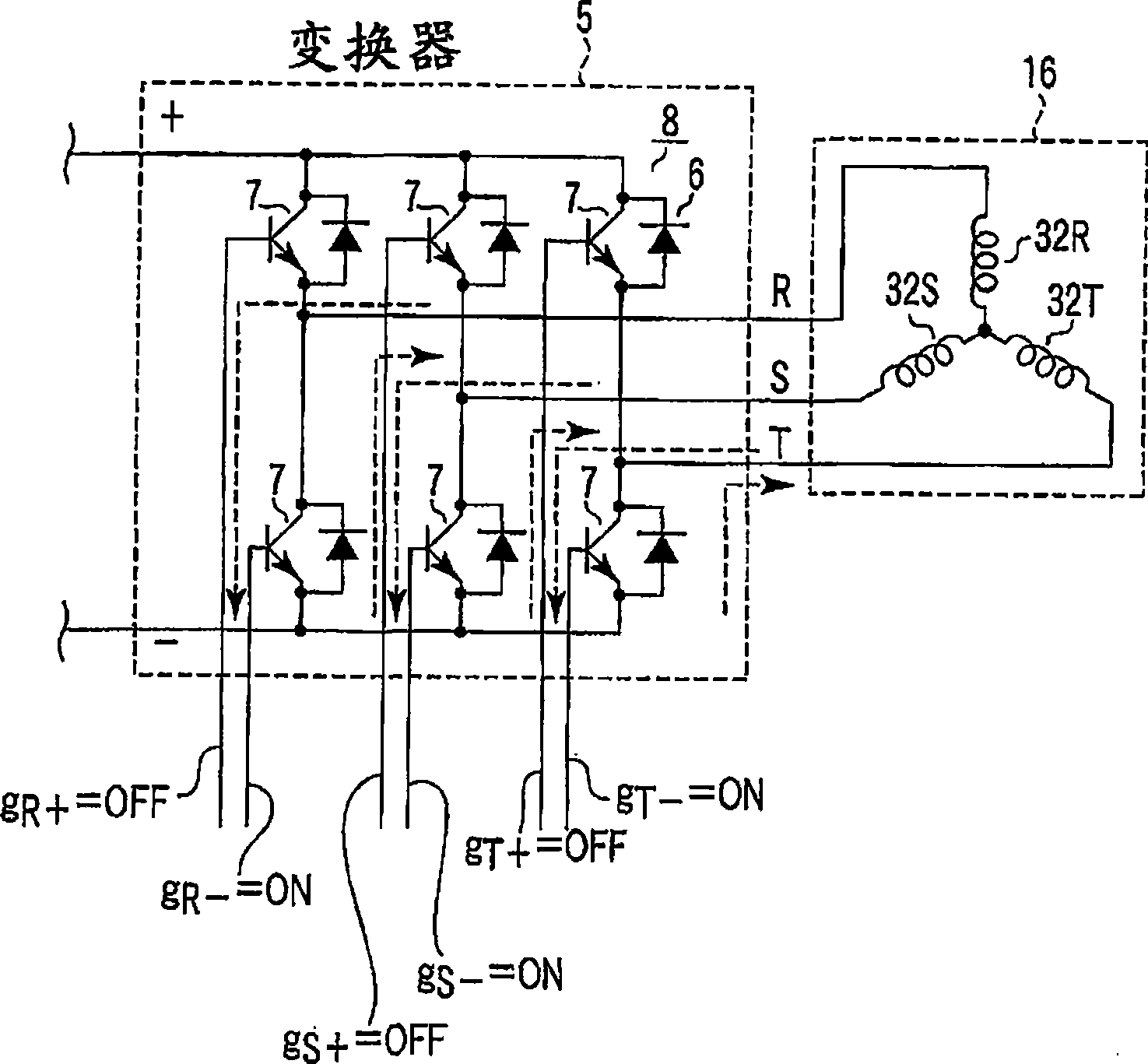

InactiveCN101389560AIncrease manufacturing costSuppression of upsizingMotor/generator/converter stoppersDynamo-electric converter controlEngineeringAlternating current

An elevator control device converts an AC power into a DC power by a rectifier (3), converts it into AC power by an inverter (5), and supplied the AC power via a power line (10) to field windings (32R, 32S, 32T) of a motor (16) synchronized with a permanent magnet. When deactivating the motor (16) synchronized with a permanent magnet, a switching element (7) of the inverter (5) is maintained in a closed state and a closed circuit is formed by the switching element (7), the power line (10), and the field windings (32R, 32S, 32T) of the motor so that a regenerative current flows into the closed circuit and a regenerative energy is consumed by the field windings, thereby effectively performing regenerative braking of the motor.

Owner:TOSHIBA ELEVATOR KK

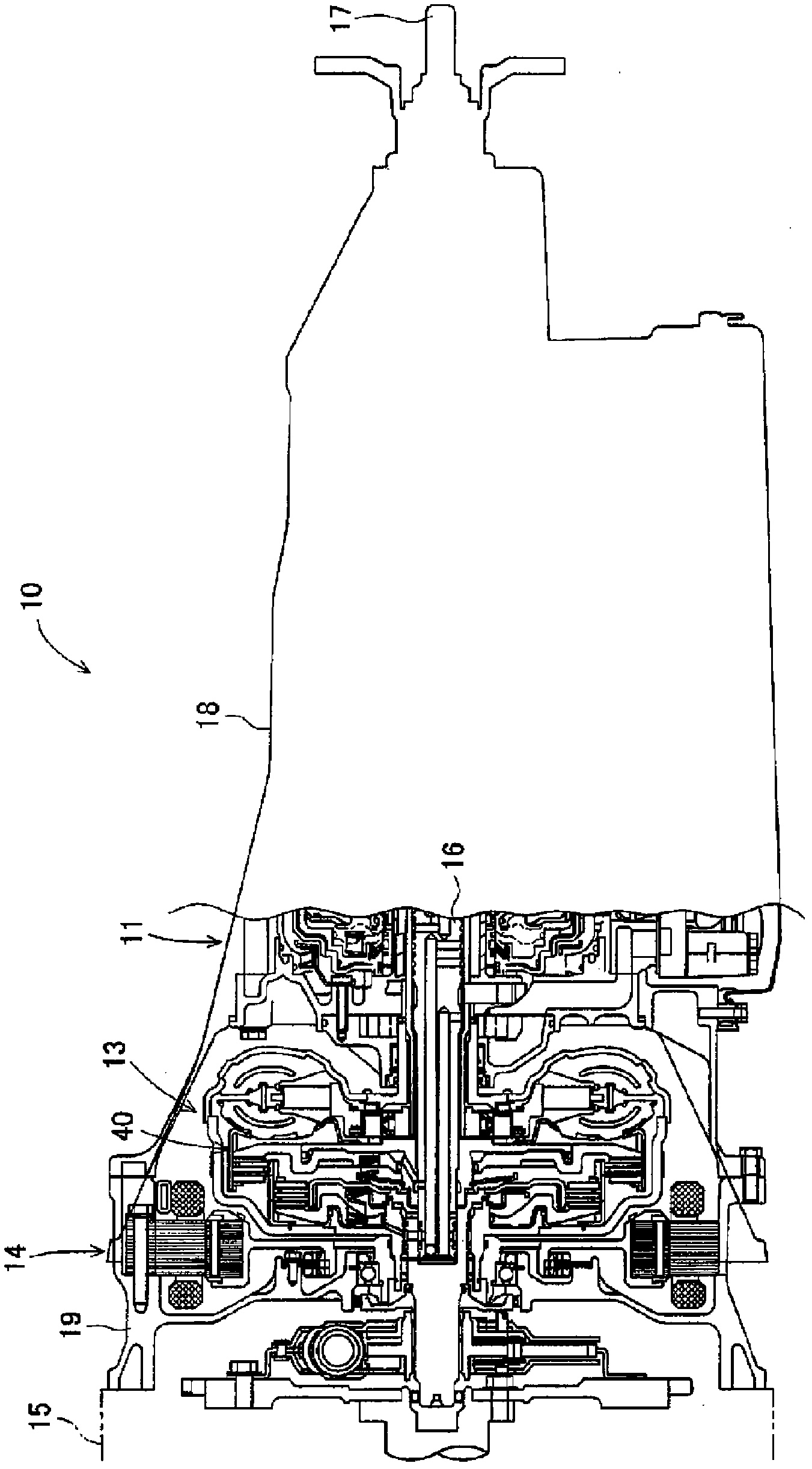

Vehicle drive device

InactiveCN102007012ASmall heat releaseImprove controllabilityGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingTorque transmissionEngineering

A drive device for a vehicle, having an engine power disengaging clutch mounted in a lockup clutch-equipped fluid power transmitting device, wherein controllability and torque transmission capacities of both the clutches are increased, the amount of heat generation of friction materials when the clutches are engaged is reduced, the drive device allows a fluid drive device to be configured withoutan increase in the size thereof, and the drive device is configured without an increase in the size thereof. The lockup clutch and the engine power disengaging clutch are respectively formed as multi-plate clutches having actuators. Friction plates of the lockup clutch are provided on the outer diameter side of a torus. The engine power disengaging clutch is formed to have a smaller diameter thanthe lockup clutch. The engine power disengaging clutch is provided in a torque converter. On the outer diameter side of the engine power disengaging clutch, a motor generator is mounted overlapping axially the friction plates of the engine power disengaging clutch.

Owner:AISIN AW CO LTD

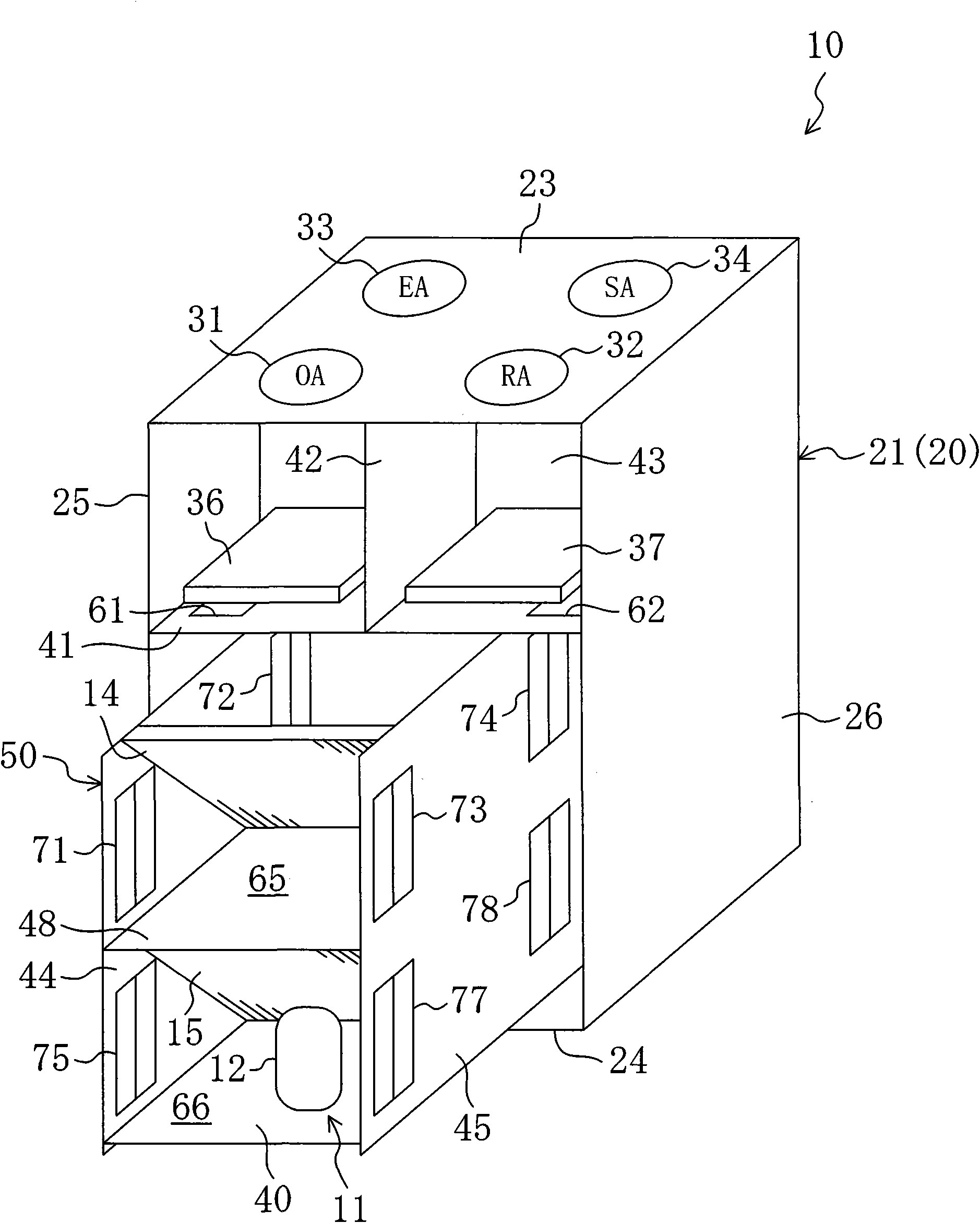

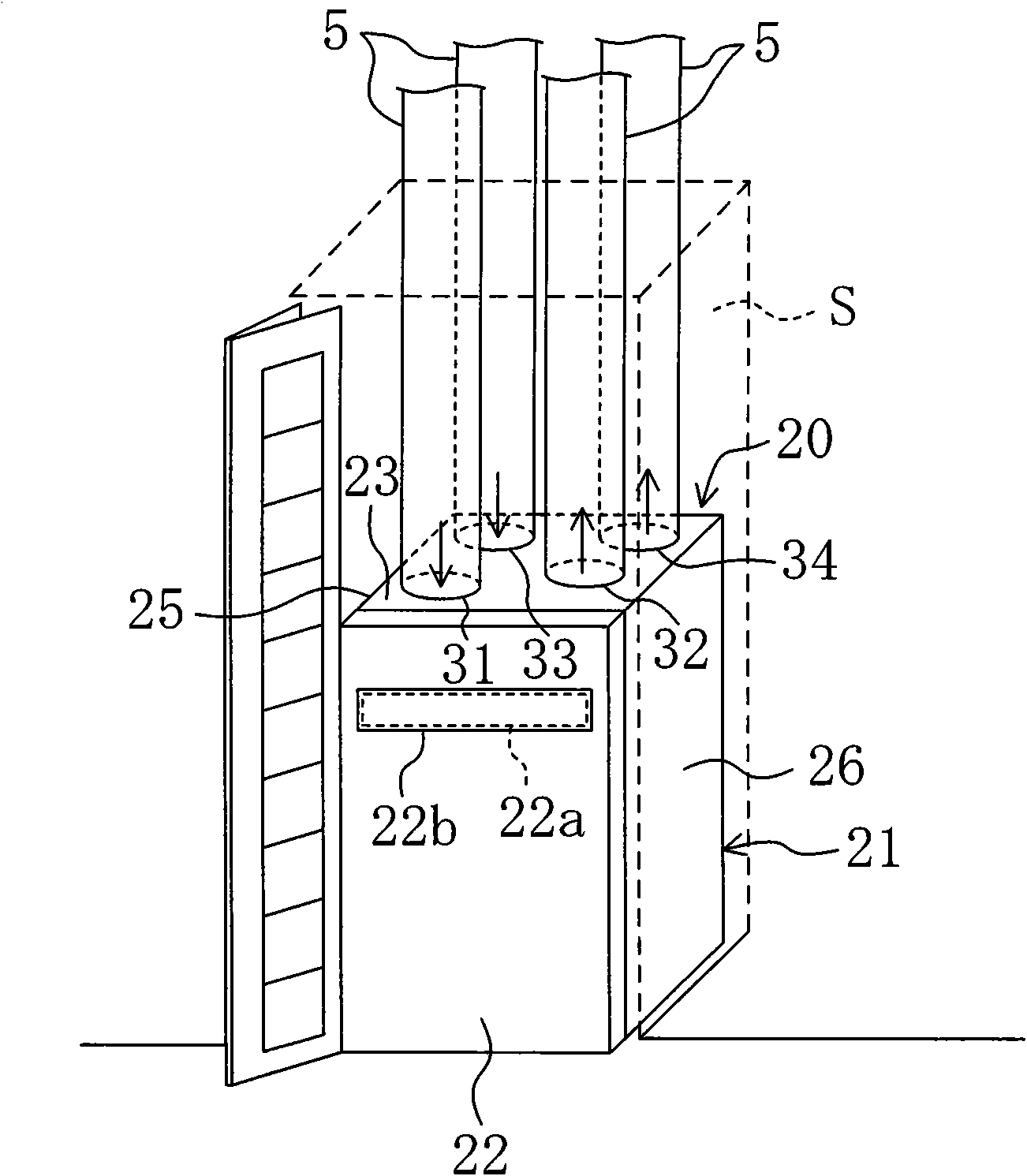

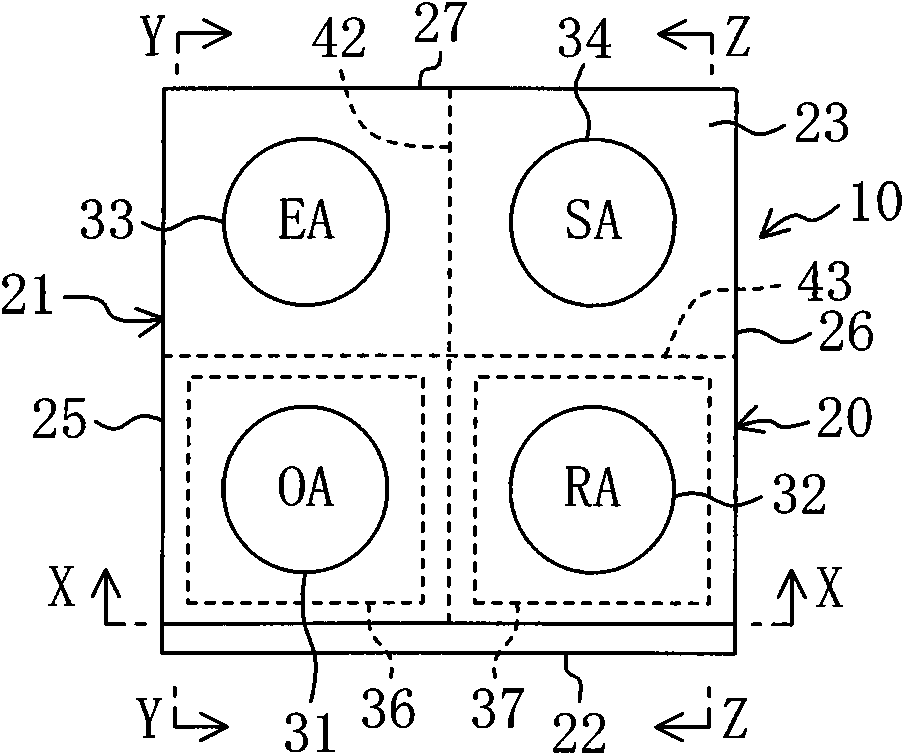

Humidity control device and ventilation device

InactiveCN101815906AImprove maintainabilityEasy to take outEnergy recovery in ventilation and heatingGas treatmentMoistureElectrical and Electronics engineering

Owner:DAIKIN IND LTD

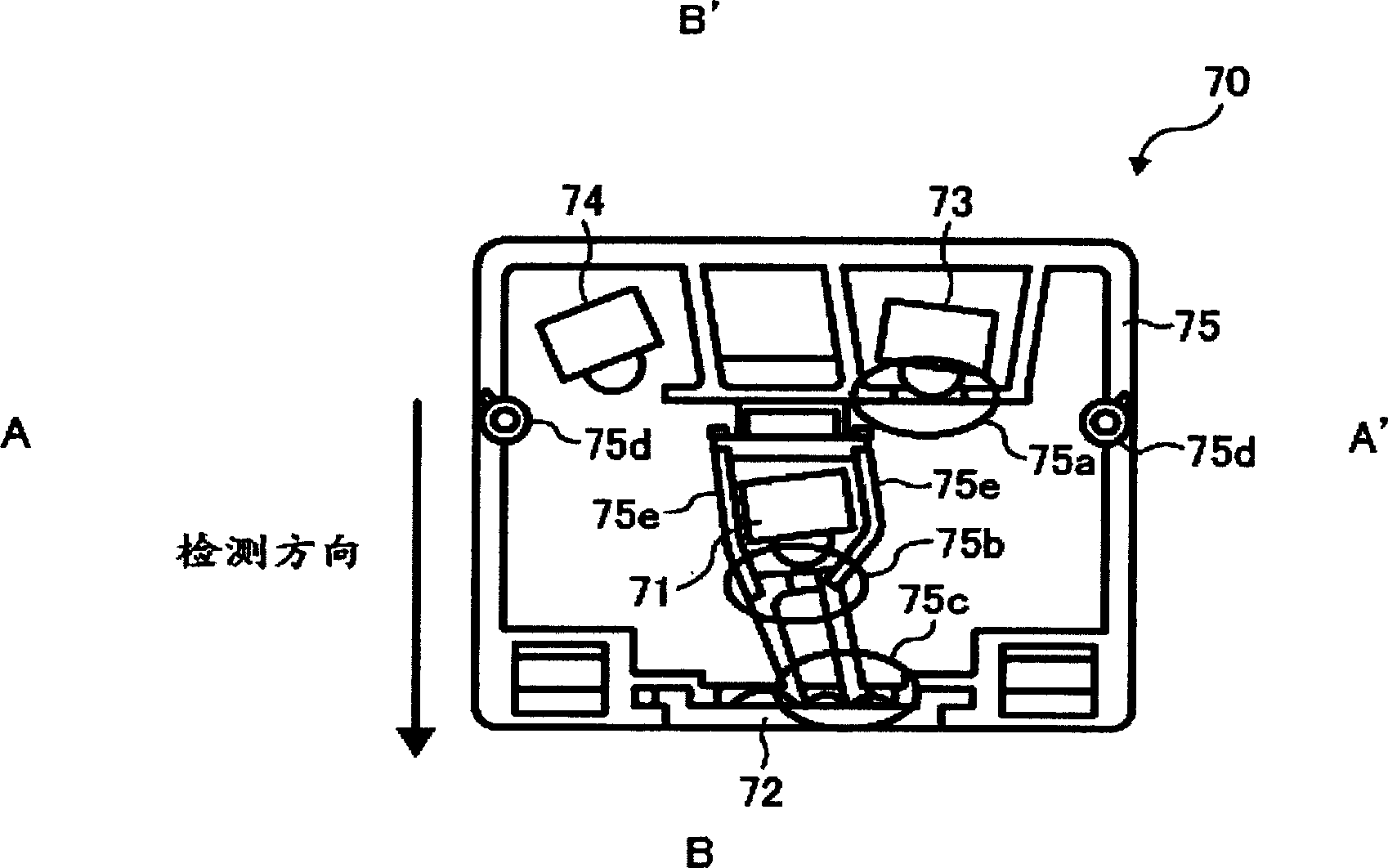

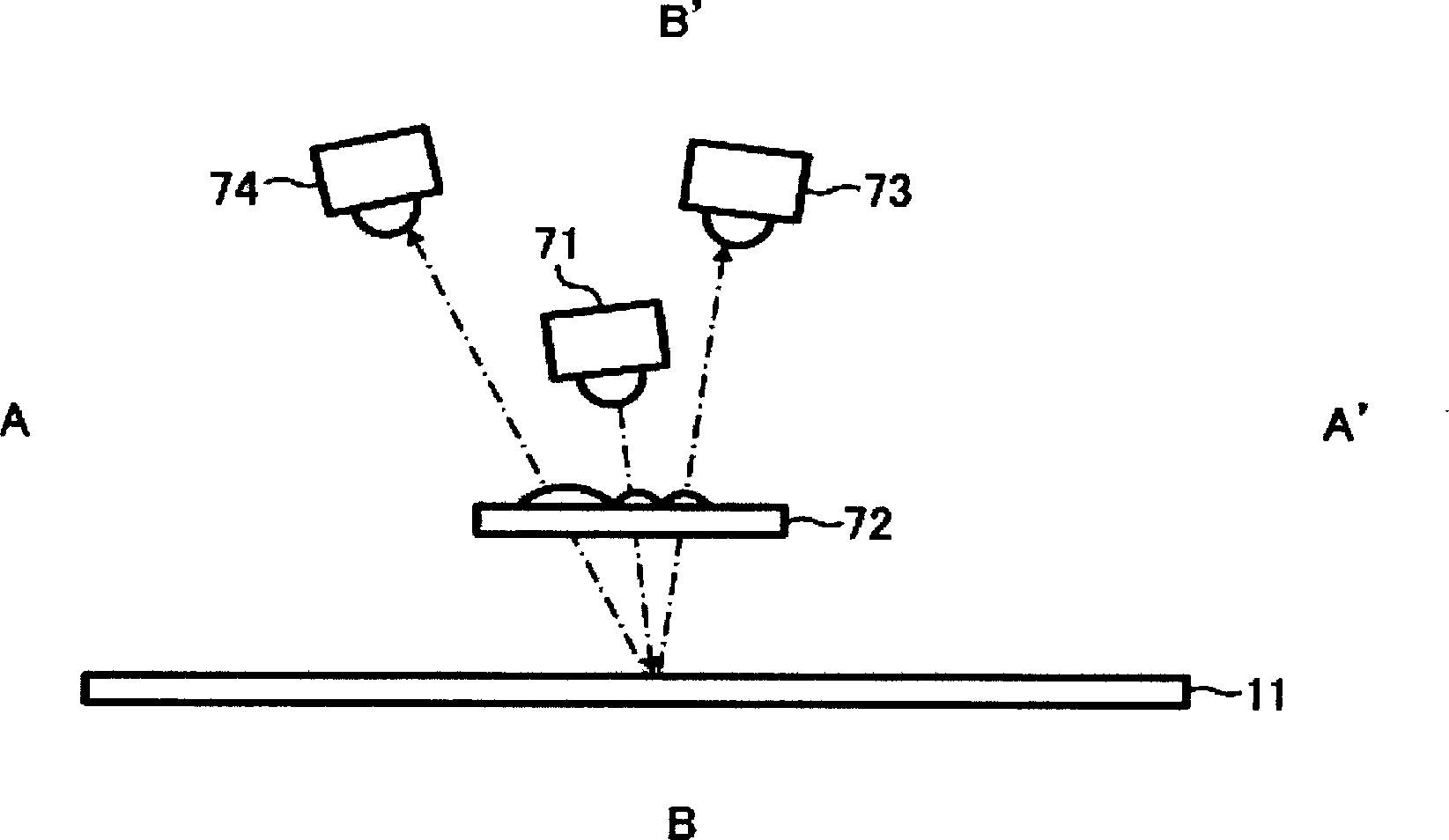

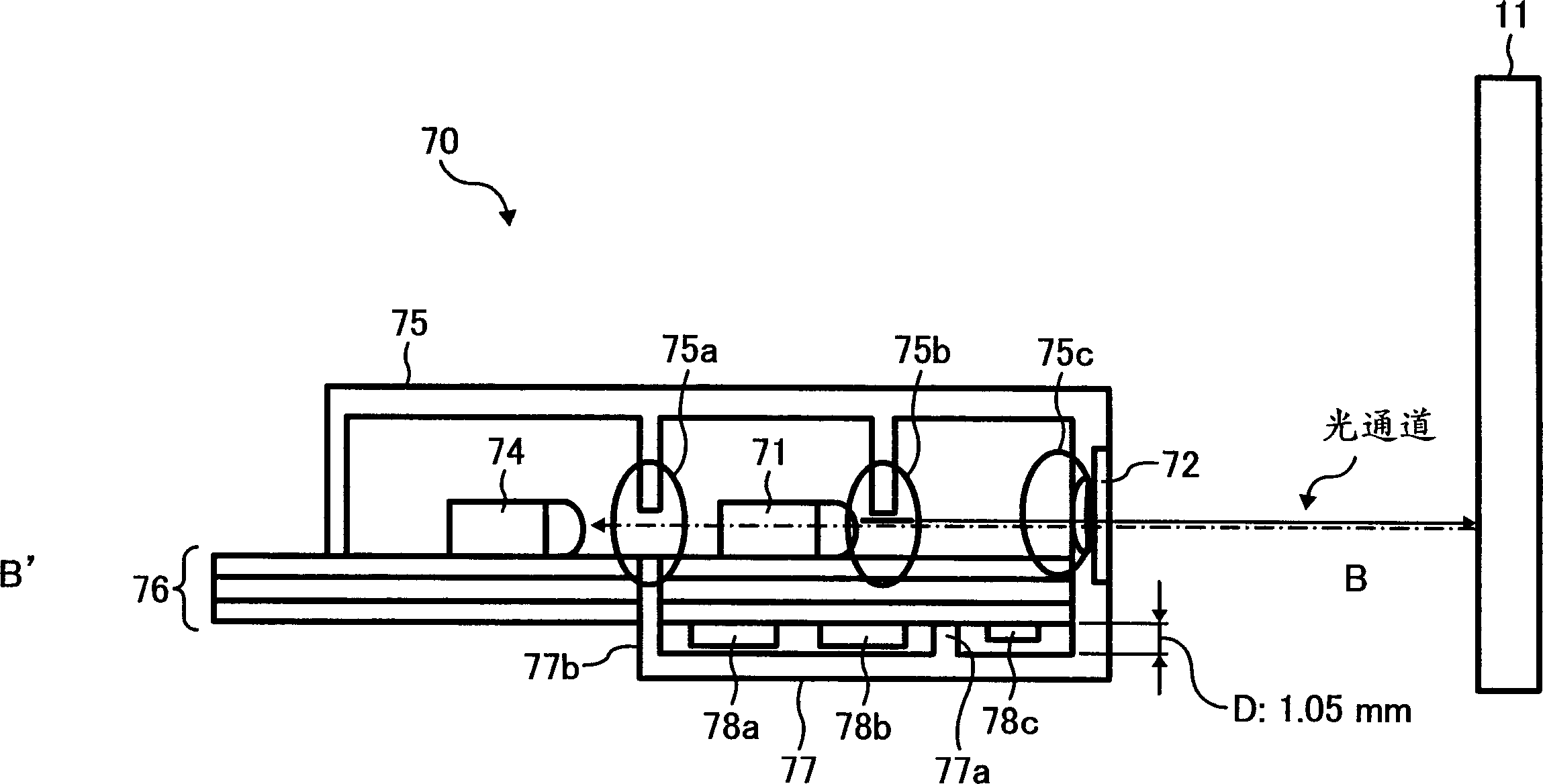

Optical detecting device and apparatus for image forming

InactiveCN1862414ASuppression of upsizingGuaranteed performanceElectrographic process apparatusOptical propertyImage formation

Provided is an optical detection device capable of suppressing increase in size, capable of being arranged at a suitable place in an image forming device with many space constraints, and capable of eliminating adverse effects on optical characteristics. In the optical detection device of the "toner image pattern" formed on the detection object, there is at least a printed circuit board 76, a light emitting element 71 and a light receiving element 74 mounted on the printed circuit board, and light shielding members 75 and 77. sensor. In order to detect the surface of the aforementioned detection object, at least one optical sensor will be disposed on the above-mentioned printed circuit board 76, and a part of the optical sensor circuit components 78a, 78b and 78c on the printed circuit board is housed in the aforementioned light shielding member 75 and 77 in.

Owner:RICOH KK

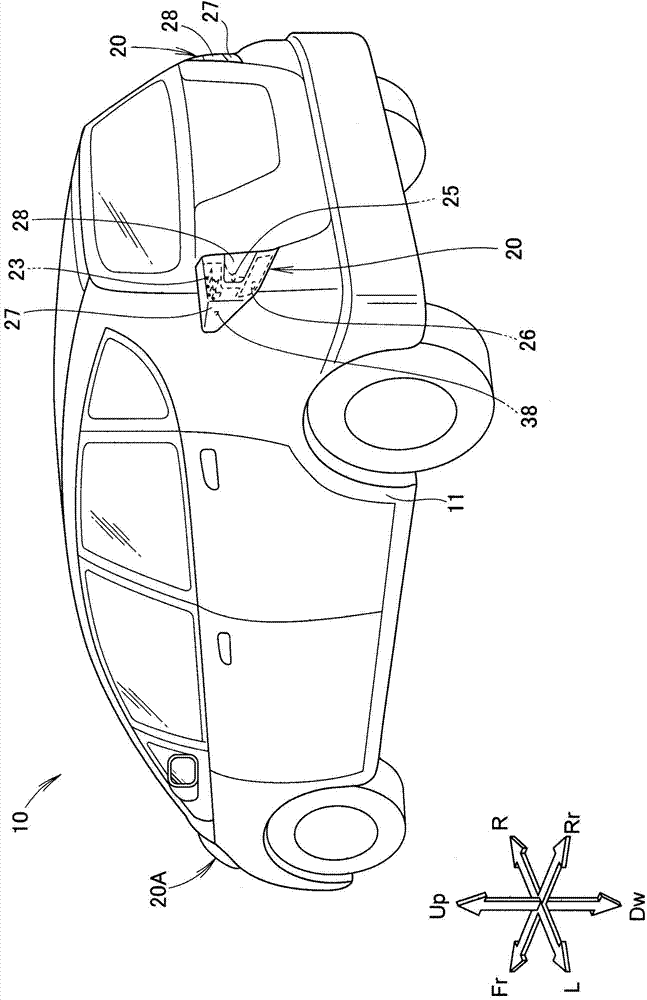

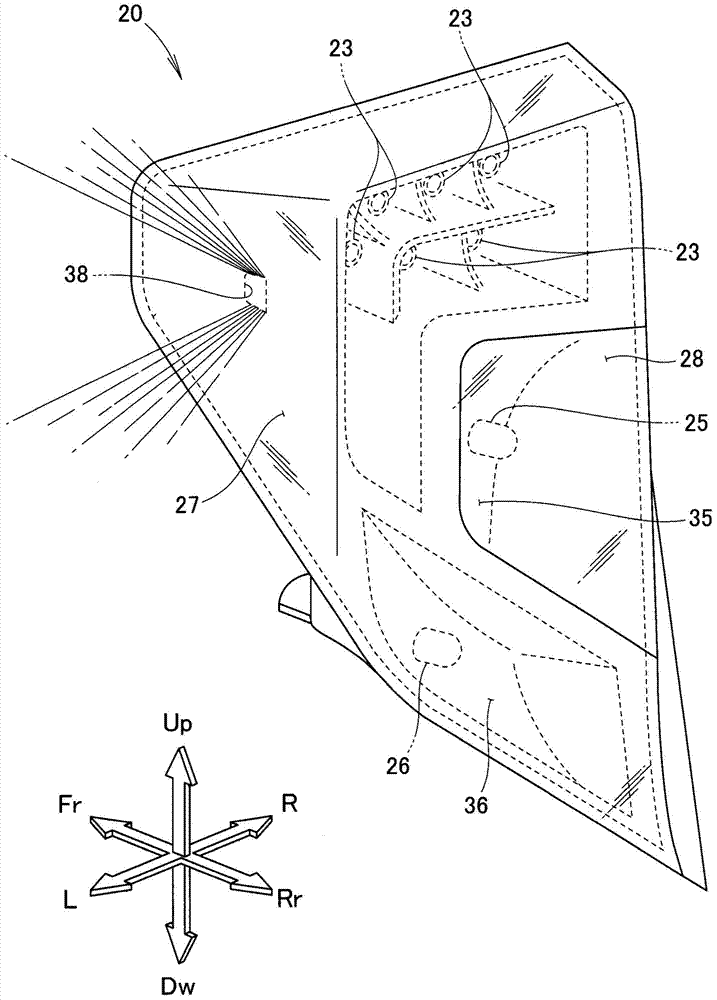

Vehicular lighting unit

ActiveCN104279484AAvoid oversizingSuppression of upsizingPoint-like light sourceOptical signallingEngineeringMaterials science

A vehicular lighting unit includes: a first light source in the form of an LED for providing illumination forward or rearward of a vehicle body, the first light source being mounted on one surface of a base plate in an orientation corresponding to the direction of the illumination; a second light source in the form of an LED for providing illumination laterally outward of the vehicle body, the second light source being mounted on another surface of the base plate; and a reflection section provided near the second light source for reflecting light emitted from the second light source laterally outward of the vehicle body

Owner:HONDA MOTOR CO LTD

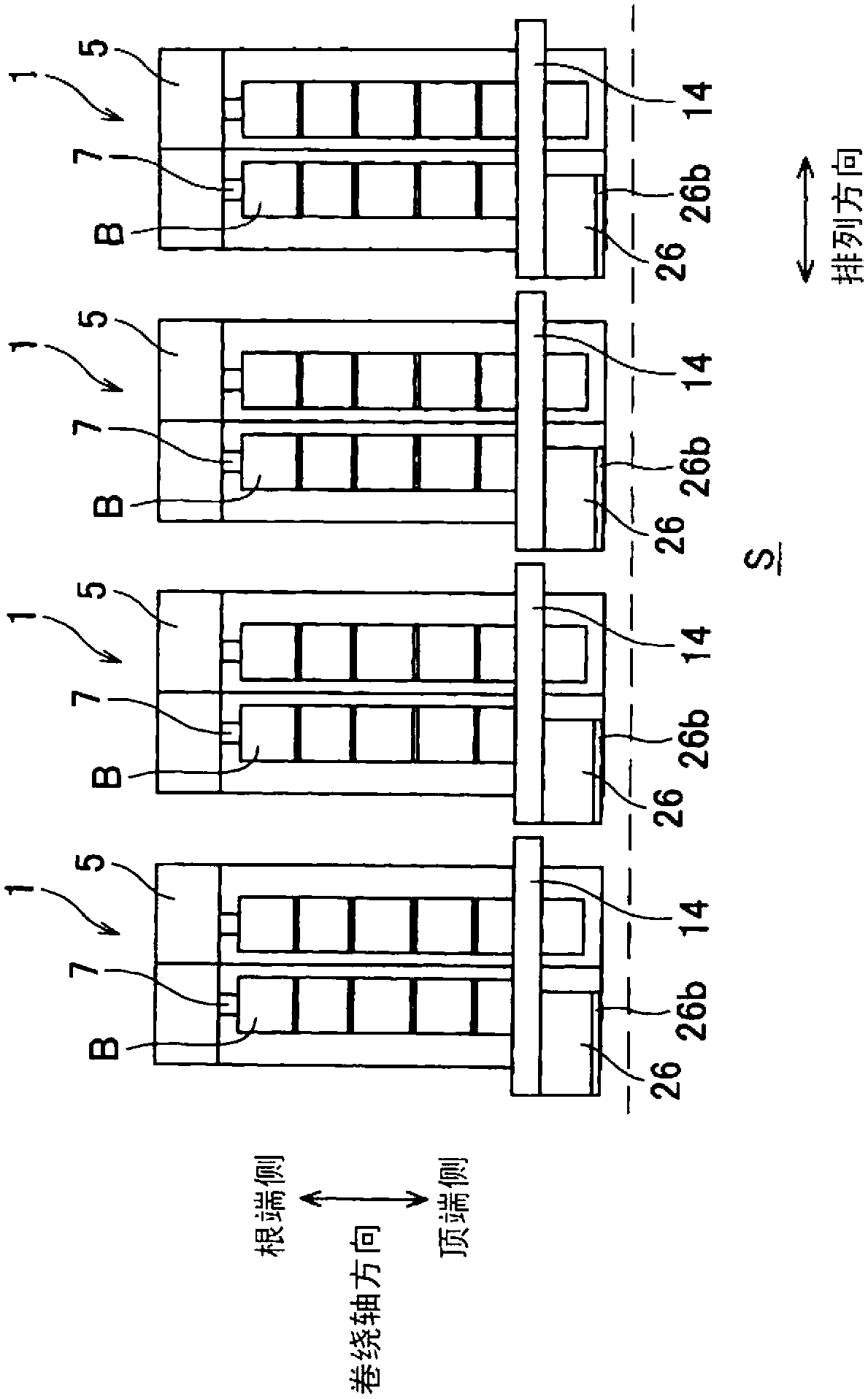

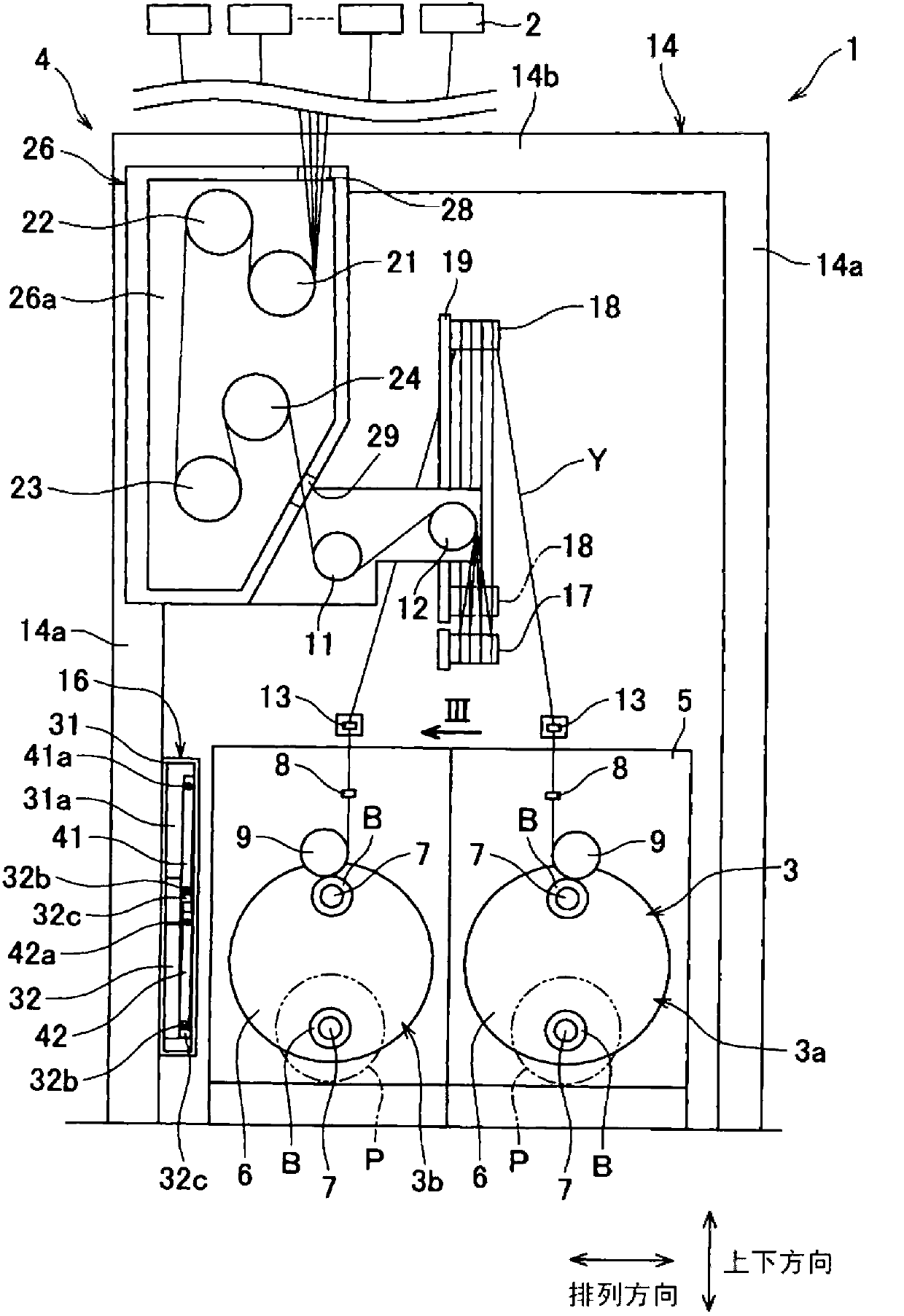

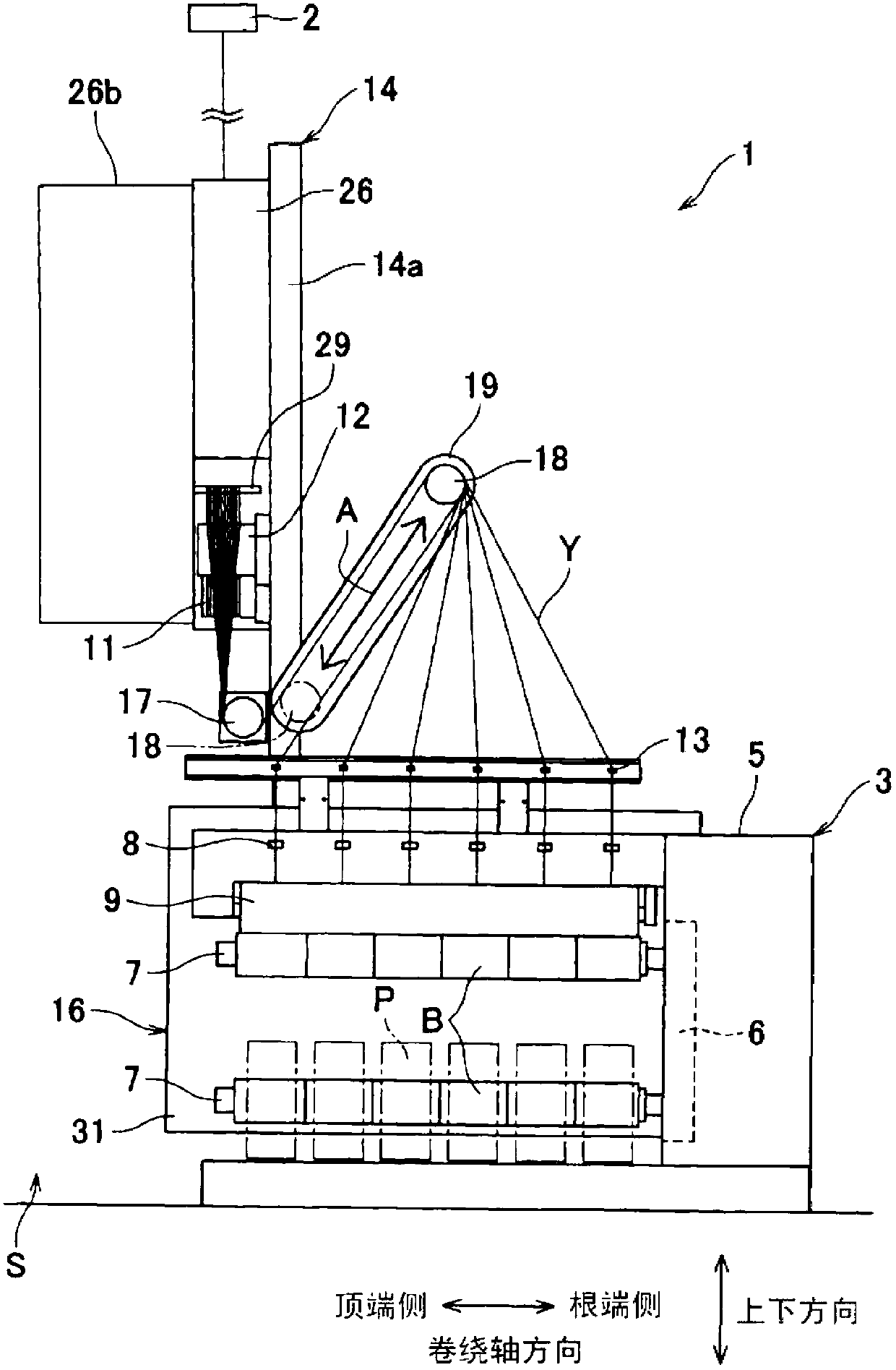

Spun yarn take-up apparatus

ActiveCN103305944AAvoid obstaclesSuppression of upsizingNew-spun product collectionArtificial thread manufacturing machinesYarnEngineering

The present invention relates to a spun yarn take-up apparatus. In the case that the godet rollers are godet rollers, a working platform used for performing yam threading operation on the godet rollers does not obstruct the attachment and removal of bobbins on the bobbin holder and increases space efficiency. Onto godet rollers (21 to 24) arranged in parallel with a bobbin holder (7), a yam threading operation can be performed from the leading end side of the bobbin holder (7). A working platform (33) is able to selectively take any one of an operation posture in which footboards (41 and 42) extend in the horizontal direction and a retracted posture in which the footboards (41 and 42) extend in the vertical direction. In the operation posture, the working platform (33) is located on the leading end side of the bobbin holder (7). The retracted posture is deviated from a yarn winding device (3) with respect to an alignment direction. A storage (31) having a slidable component (32) stored therein is provided laterally to the yarn winding device (3). The working platform (33) is attached to the slidable component (32). Moving the slidable component (32) in the winding axis direction with the working platform (33) taking the retracted posture causes the working platform (33) to be stored into the storage (31).

Owner:TMT MACHINERY INC

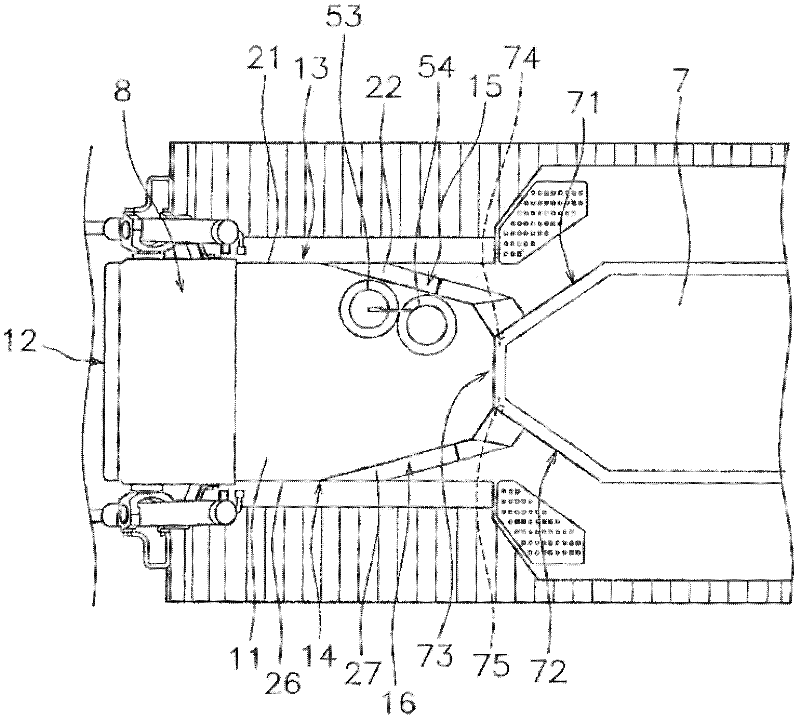

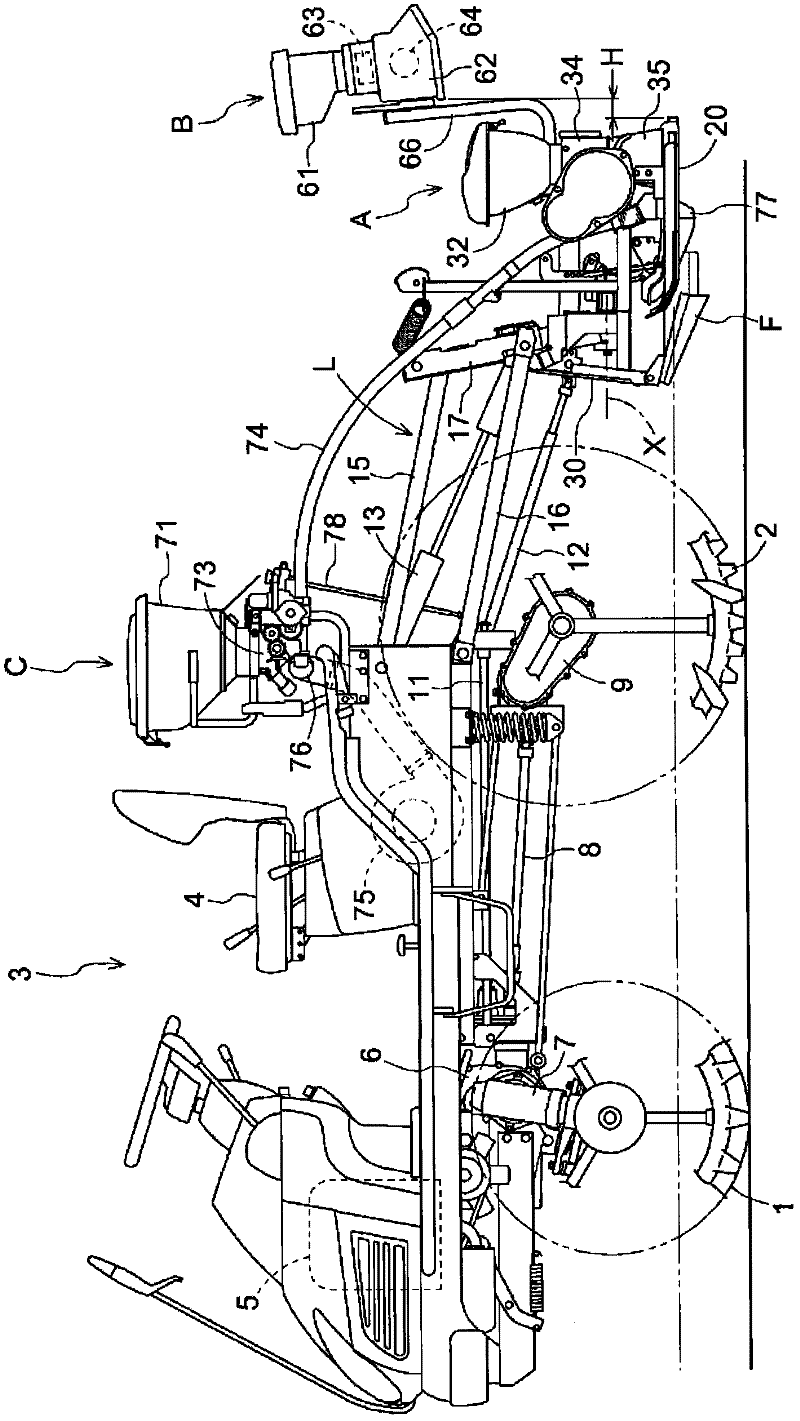

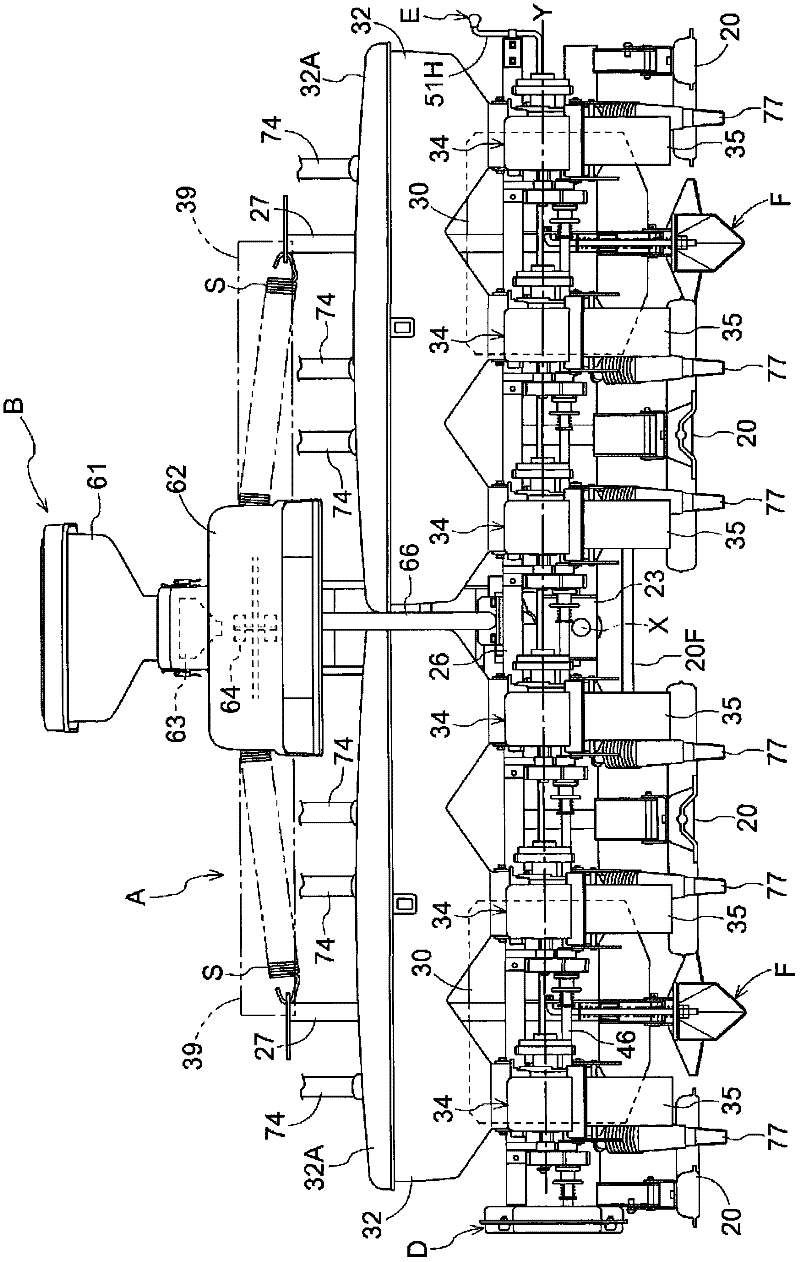

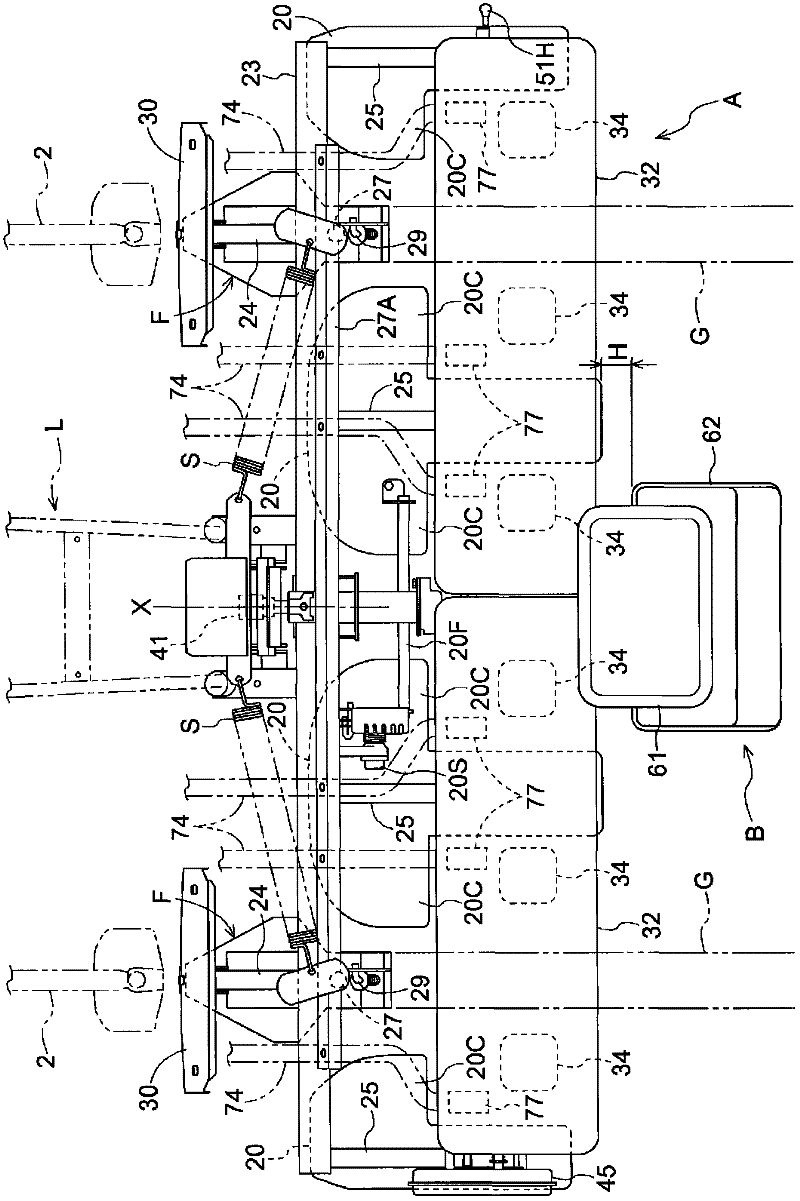

Operation machine for paddy field

ActiveCN102124845ASuppression of upsizingRestrain droopingPlantingAgriculture gas emission reductionEngineeringPaddy field

The present invention provides an operation machine for paddy field, which seldom causes scattering when point-shaped seedling is performed. The operation device for the paddy field is connected with a back end of a driving machine body. The operation device for paddy field can freely lift through a connecting rod mechanism (L), and can freely swing around a swinging shaft core (X). The operation machine for the paddy field performs point-shaped seedling that the rice seeds in a seed bucket (32) directly drop to the field through driving a feeding-out roller (33) around a roller shaft core (Y) in a transverse gesture. A height grade of the roller shaft core (Y) is set to a height grade which is approximately same with that of the swinging shaft core (X).

Owner:KUBOTA LTD

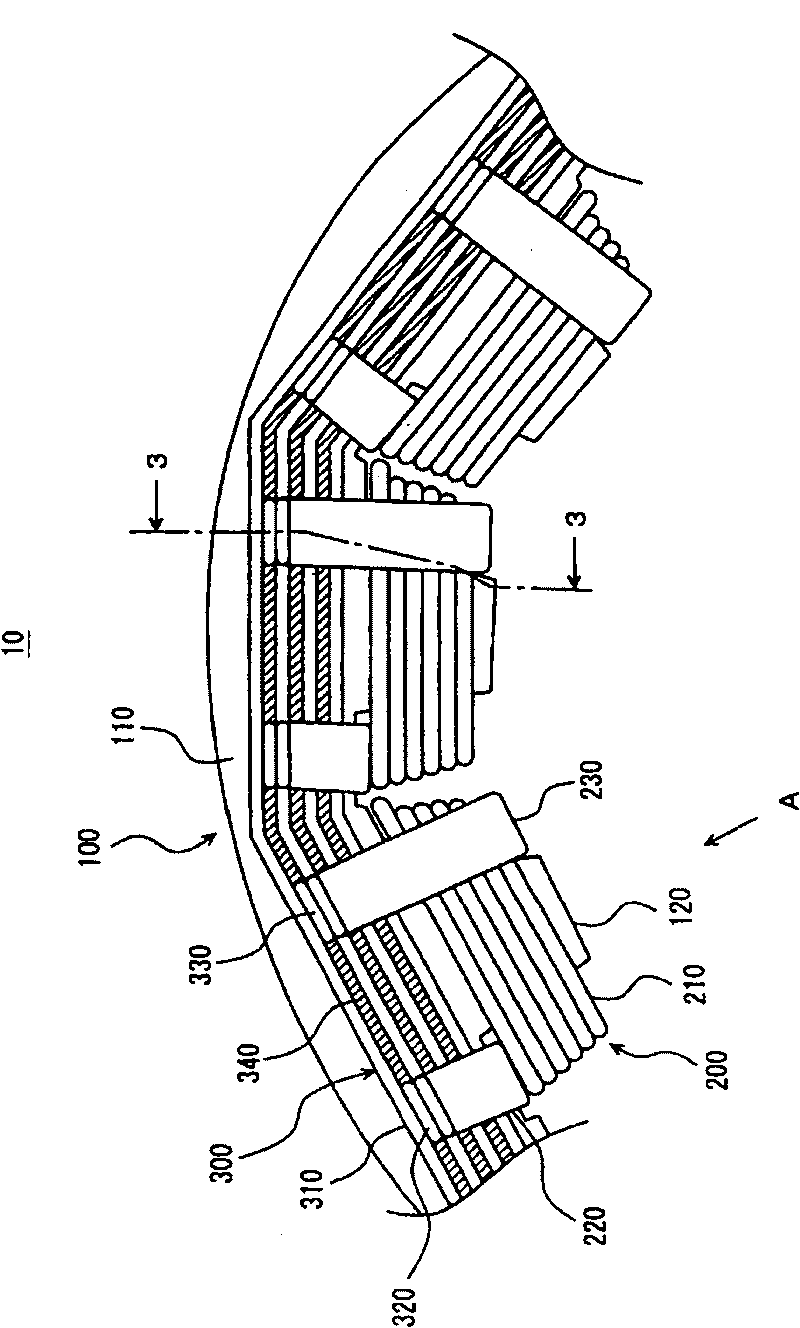

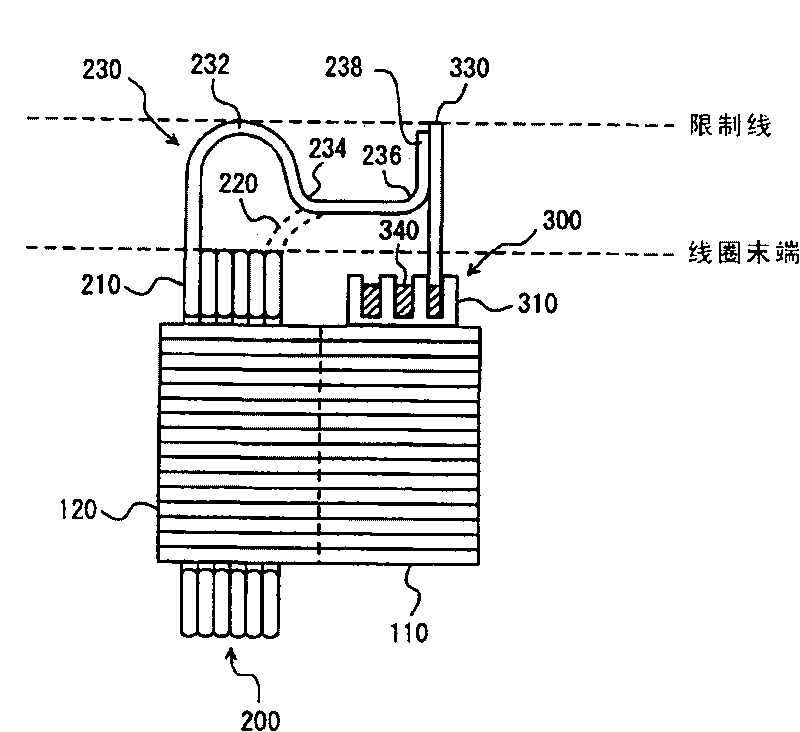

Connecting wire used in stator of electric motor, stator having the connecting wire and bending method of the connecting wire

ActiveCN101743680ASuppression of upsizingSecure spaceManufacturing dynamo-electric machinesWindings conductor shape/form/constructionElectric motorStator

A connecting wire (230) is bent toward a coil main body (210) at a first bending section (232) near a limit line of a length along an axis of a stator core. Furthermore, the connecting wire (230) is bent toward a direction away from the coil main body (210) at a second bending section (234) which is located closer to the coil main body (210) than the first bending section (232). The connecting wire (230) is further bent at a third bending section (236) in a direction away from the coil main body (210) so that a connecting portion (238) comes into contact with, and extends along an end surface of a terminal member (330) substantially in parallel thereto.

Owner:TOYOTA JIDOSHA KK

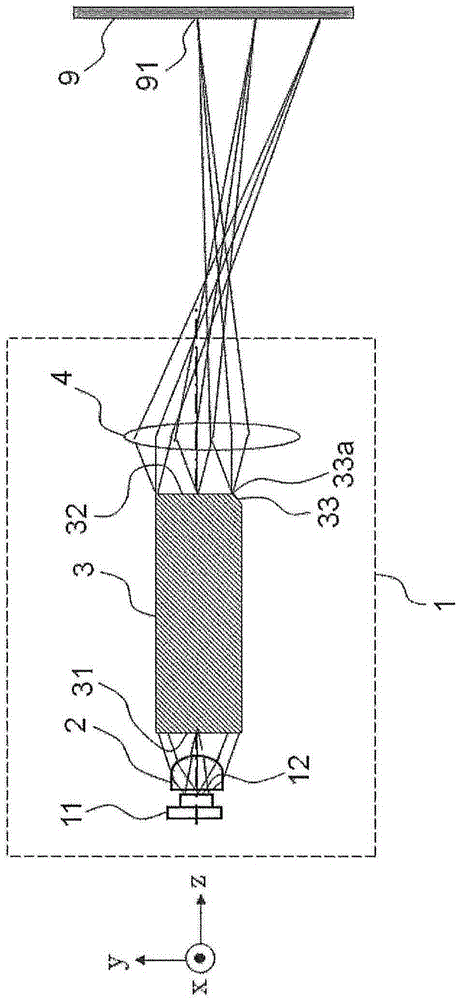

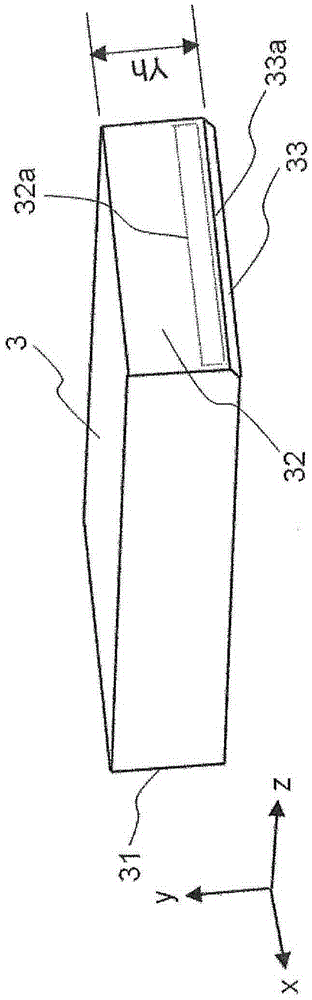

Headlight module for vehicle, headlight unit for vehicle, and headlight device for vehicle

ActiveCN105358900ASuppression of upsizingDecreased light use efficiencyVehicle headlampsOptical signalLight guideOptoelectronics

This headlight module for the vehicle is provided with a light source (11), a light guiding component (3), and a projection lens (4). The light source (11) emits light that forms illumination light. The light guiding component (3) has light emitted by the light source (11) incident thereto from an incident surface (31) as incident light and the incident light is superimposed by reflecting the incident light at side surfaces and emitted from an emission surface (32). The projection lens (4) projects the light emitted by the emission surface (32). The light guiding component (3) has an inclined surface (33) on a side surface. The brightness of part of a region is made brighter than other regions by superimposing incident light in which incident light has been reflected by the inclined surface (33) on incident light that has not been reflected by the inclined surface (33) in part of a region on the emission surface (32).

Owner:MITSUBISHI ELECTRIC CORP

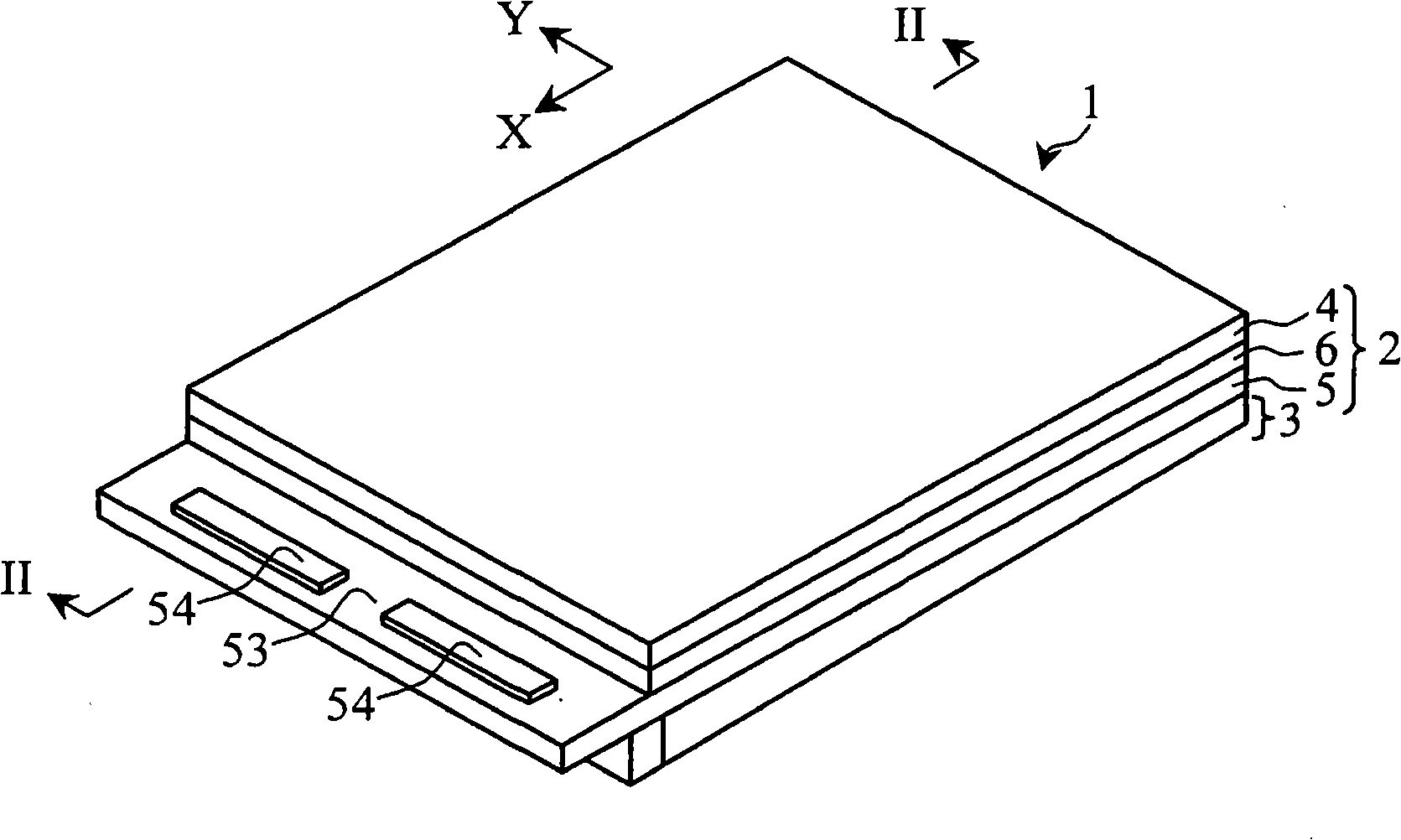

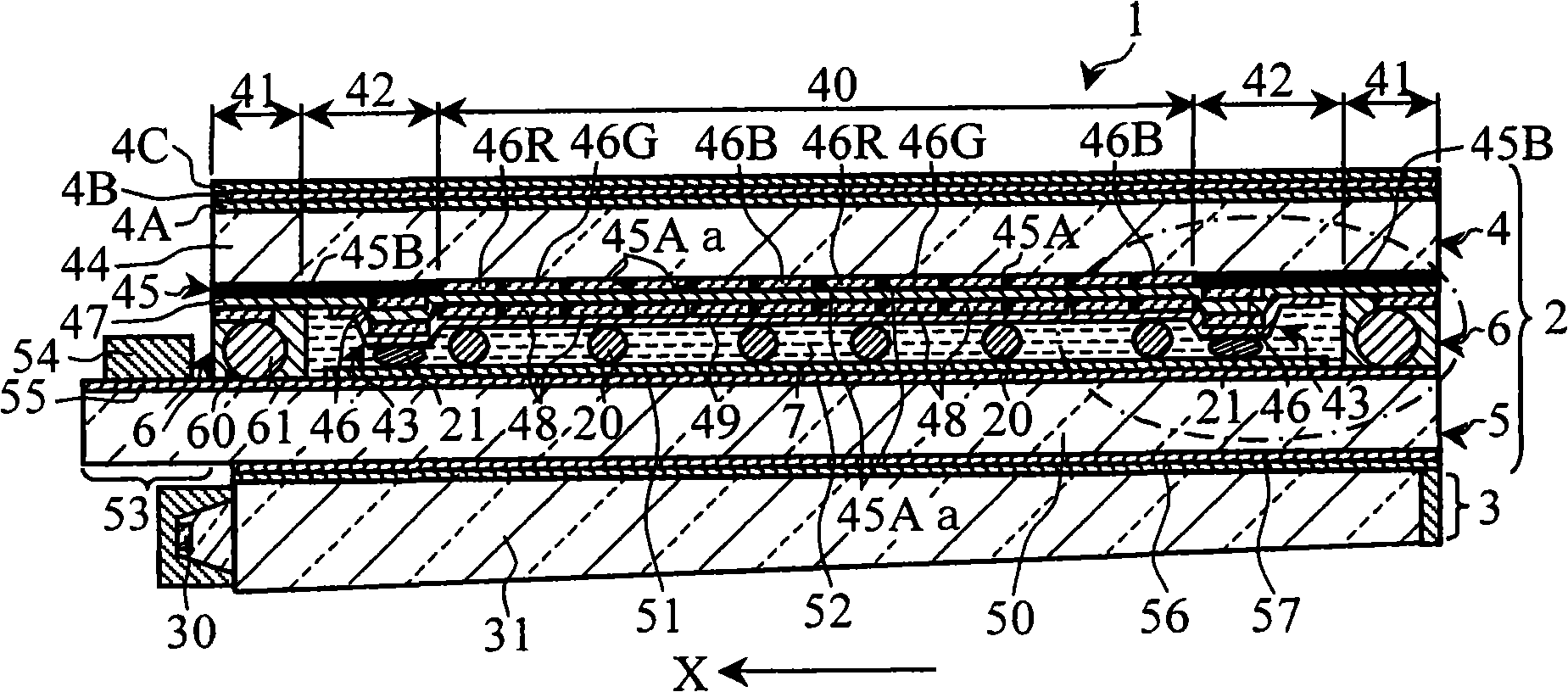

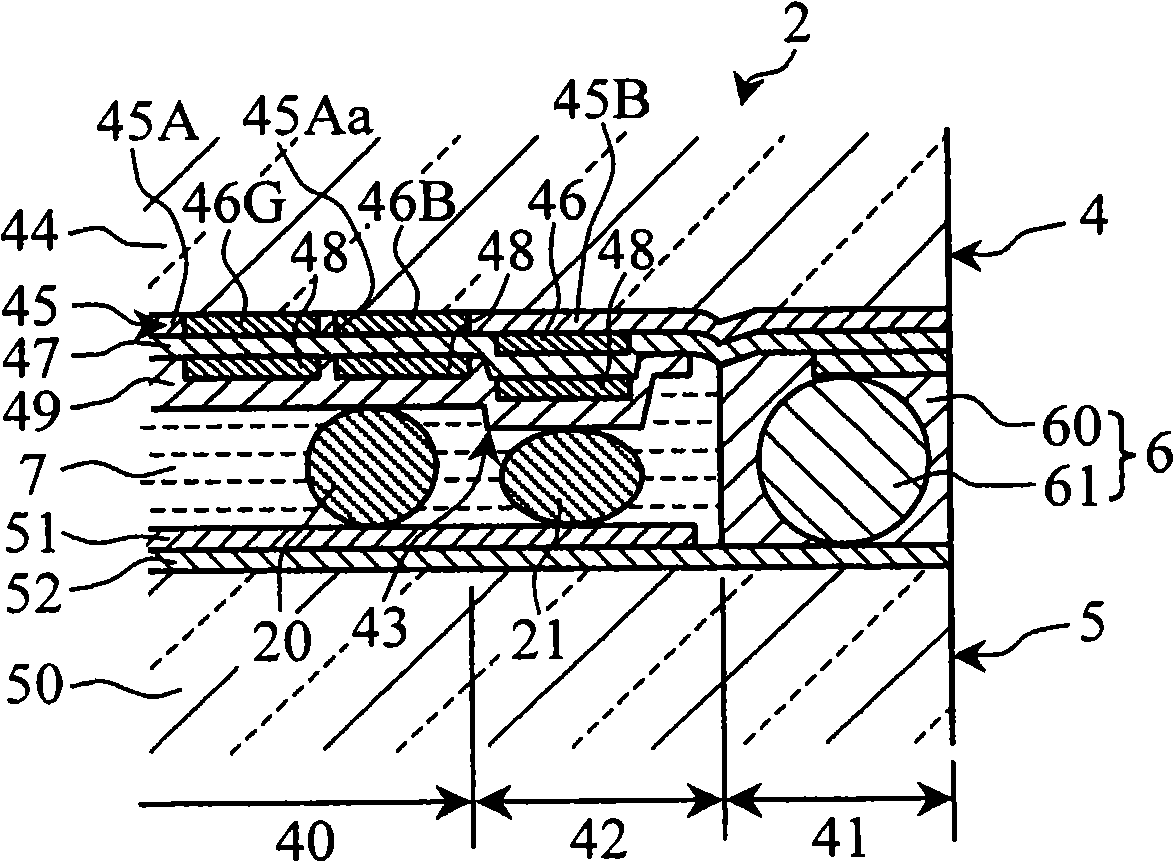

Liquid crystal display panel, liquid crystal display device provided with same, and bonding substrate for liquid crystal display panel

InactiveCN101278228AWill not be enlargedUniform thicknessNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display panel (2) is provided with a first substrate (4) having a light blocking film (45), a plurality of color filters (46R, 46G, 46B, 46) and a display electrode (48) formed on a first transparent substrate (44); a second substrate (5) having a display electrode (51) formed on a second transparent substrate (50); a plurality of spacers (20, 21) for maintaining a distance between the first substrate (4) and the second substrate (5); and a sealing member (6) for sealing a liquid crystal between the first substrate (4) and the second substrate (5). At least the first substrate (4) or the second substrate (5) is provided with a protruding section (43) formed to surround a display area (40) in a peripheral region (42) between a display area (40) including a plurality of display pixels and a sealing area (41) sealed by the sealing member (6). The spacers (20, 21) include the first spacer (20) positioned in the display area (40) and the second spacer (21) positioned at the protruding section.

Owner:KYOCERA CORP

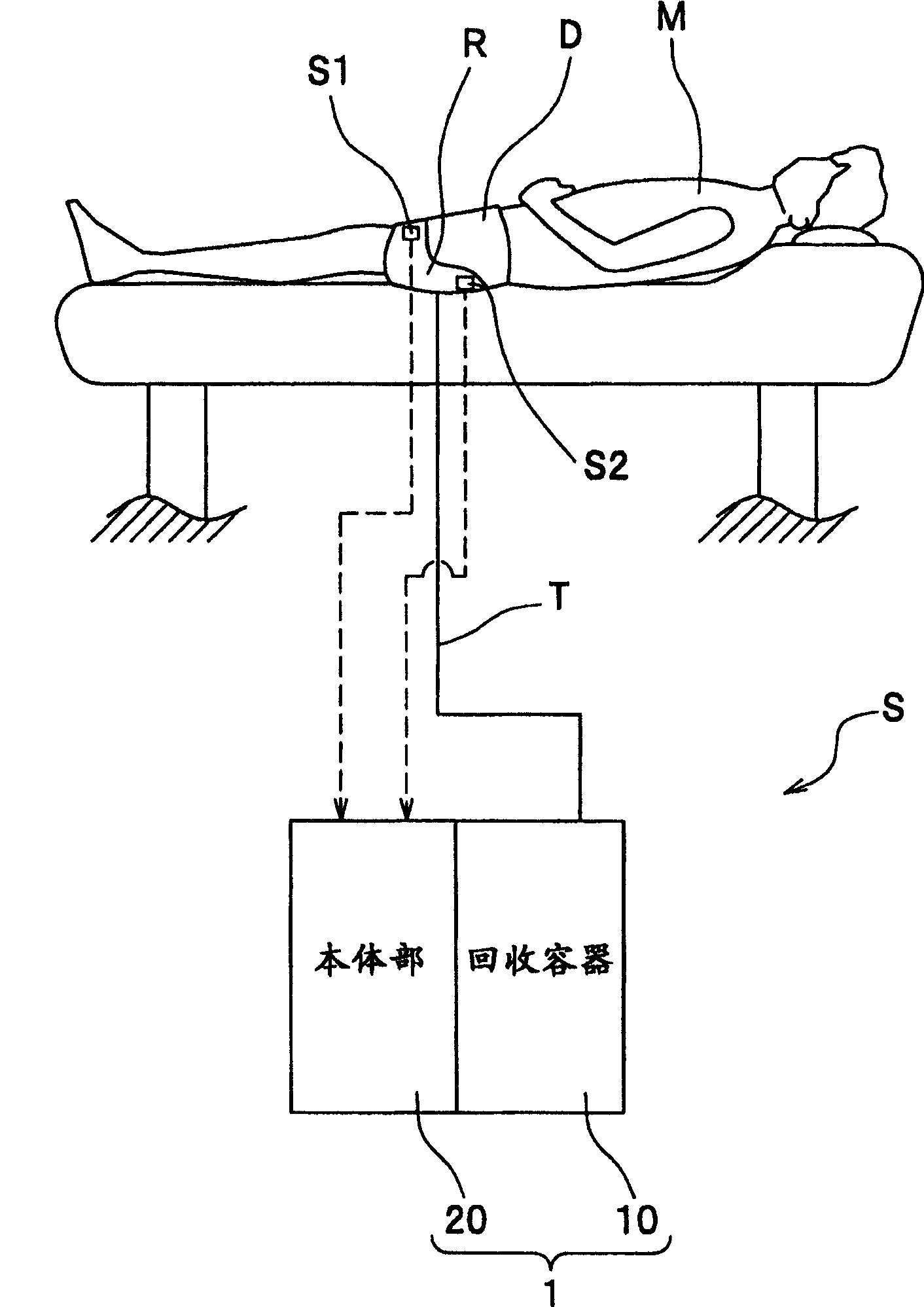

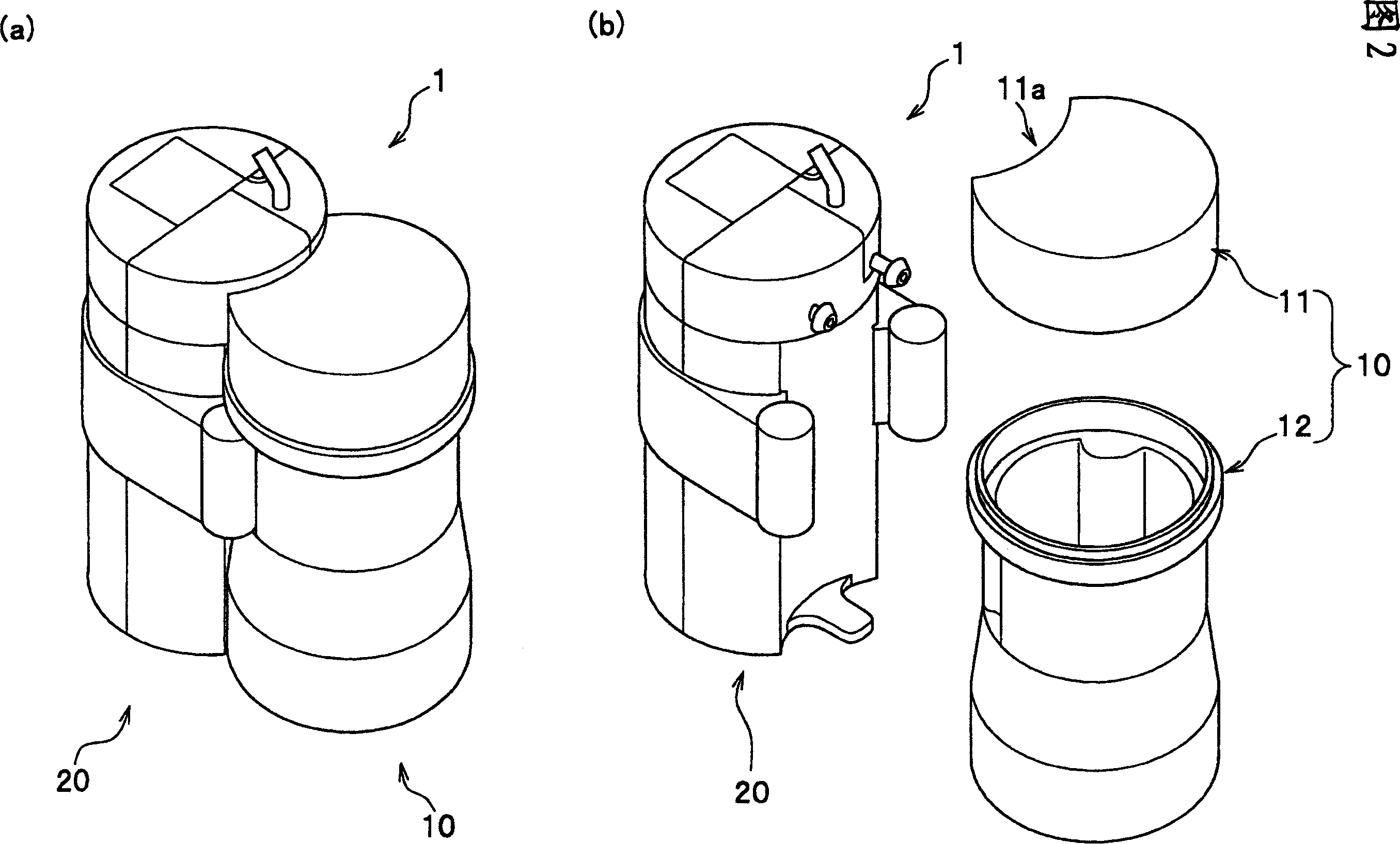

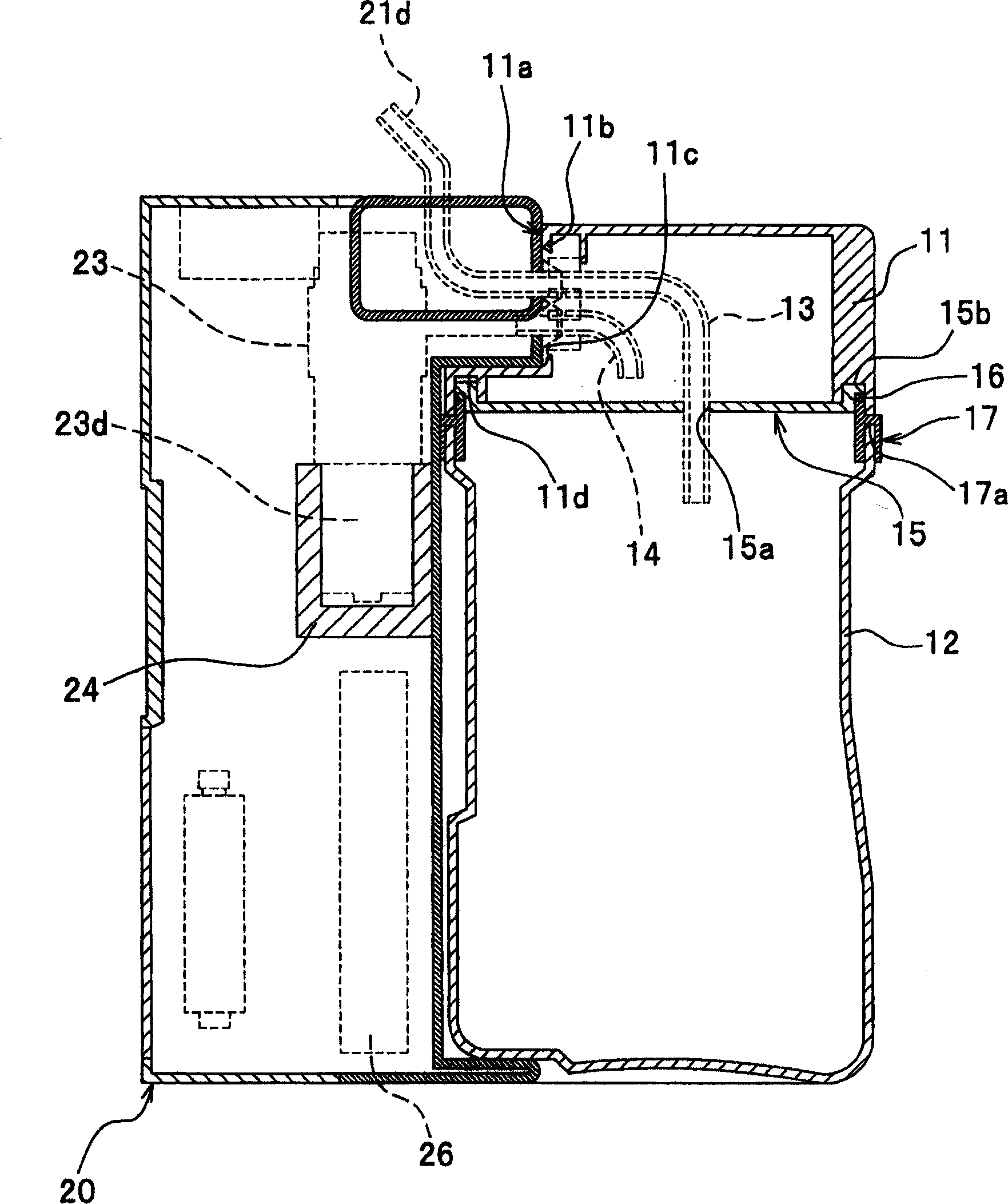

Automatic urine collecting apparatus

InactiveCN1762312ASuppression of upsizingSuppress noiseMedical transportBodily discharge devicesRotary pumpEngineering

It is an object of the present invention to provide an automatic urine recovery device capable of increasing the suction capacity of a suction pump while suppressing an increase in the overall size of the device or loud noise generated by the device. The automatic urine recovery device (1) has a recovery container (10) for storing urine delivered from a urine receiver through a hose, and a main body (20) that is freely detachable to the recovery container (10). And, in the main body (20), as a suction pump for sucking the urine received by the urine receiver (R) and transporting it to the recovery container (10), a suction pump with small size, large suction force and quiet noise is provided. The characteristics of the rotary pump (23).

Owner:HITACHI LTD

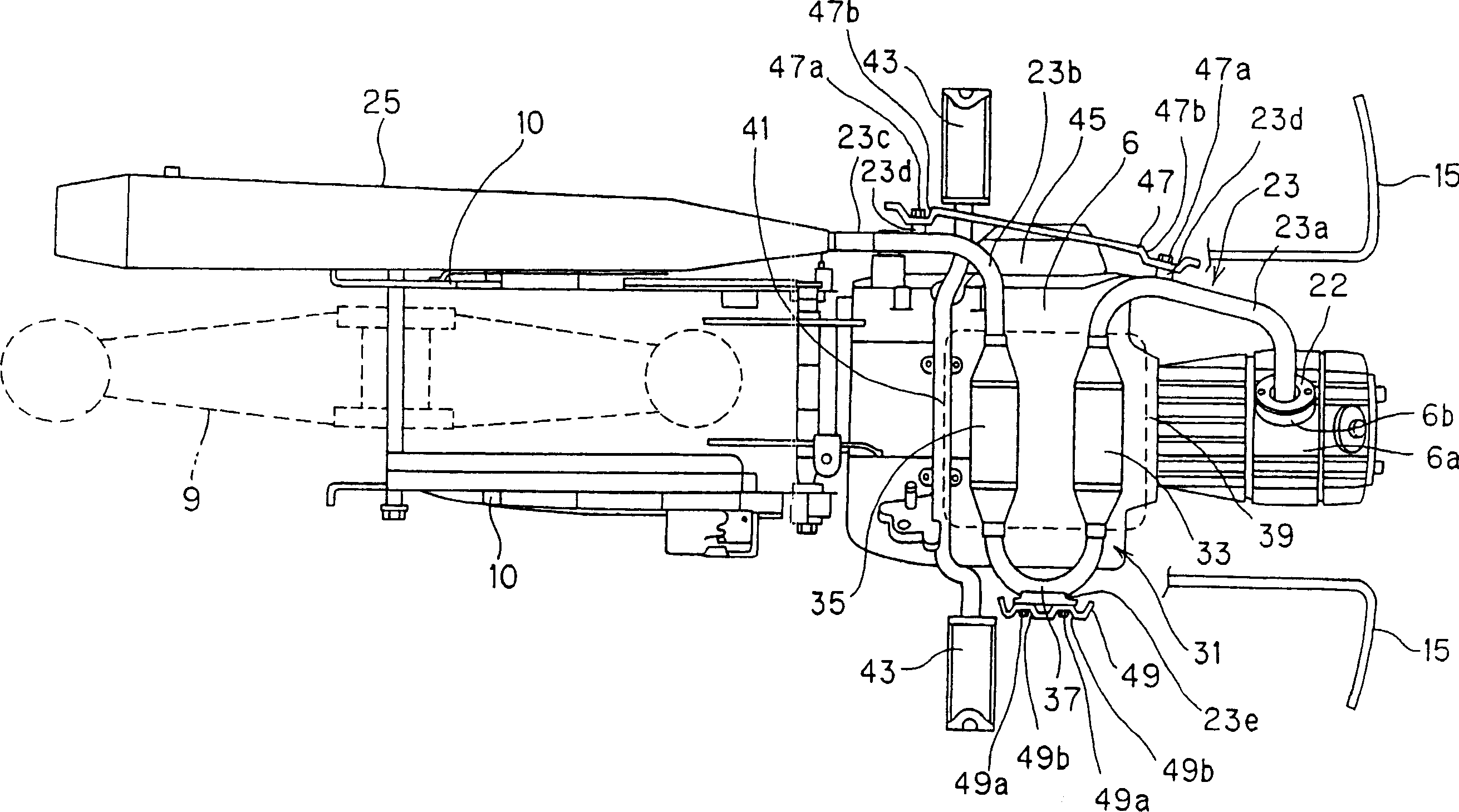

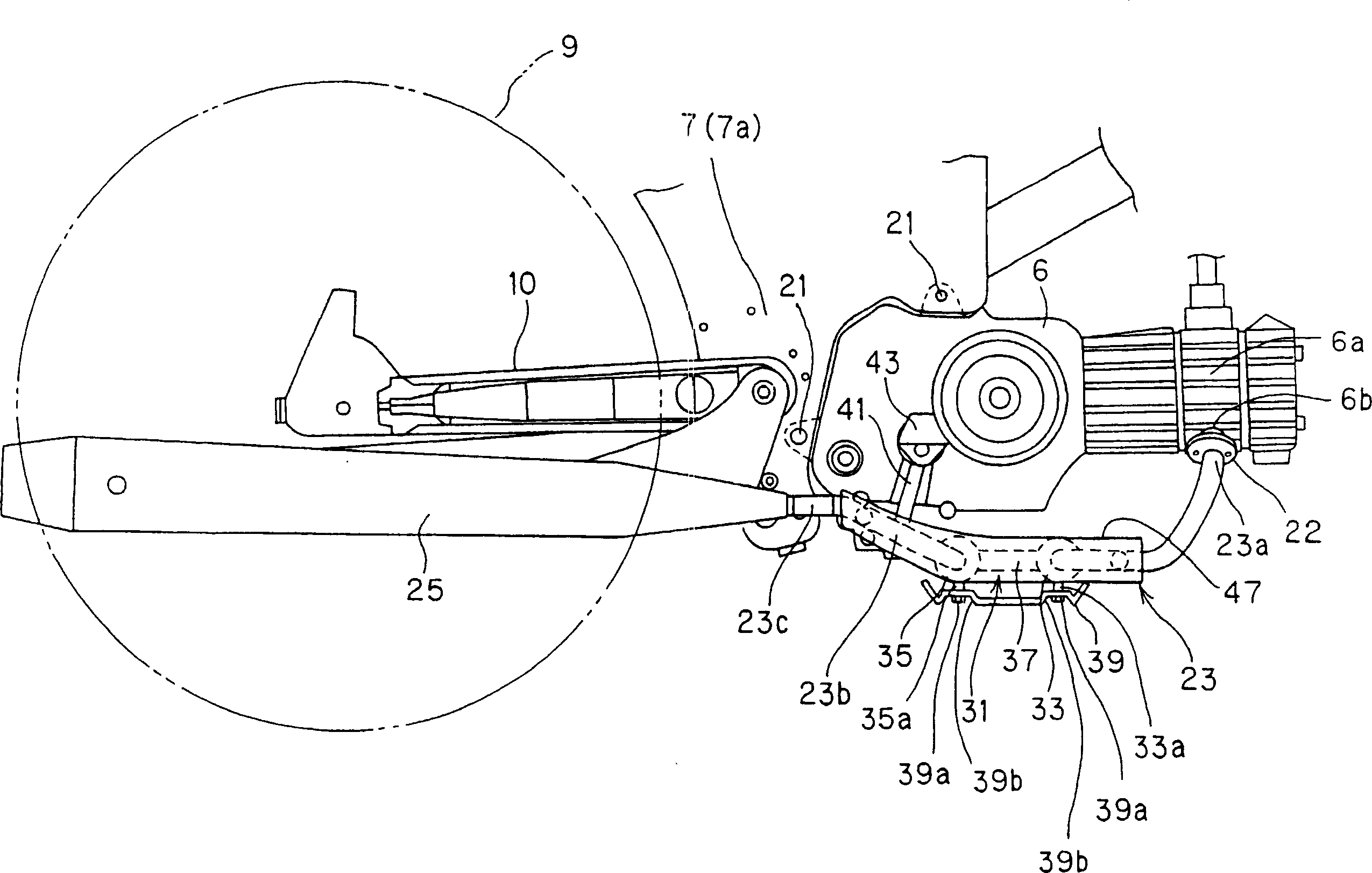

Exhaust apparatus of vehicles

InactiveCN1796733ASuppression of upsizingEasy to set upExhaust apparatusSilencing apparatusBiological activationExhaust pipe

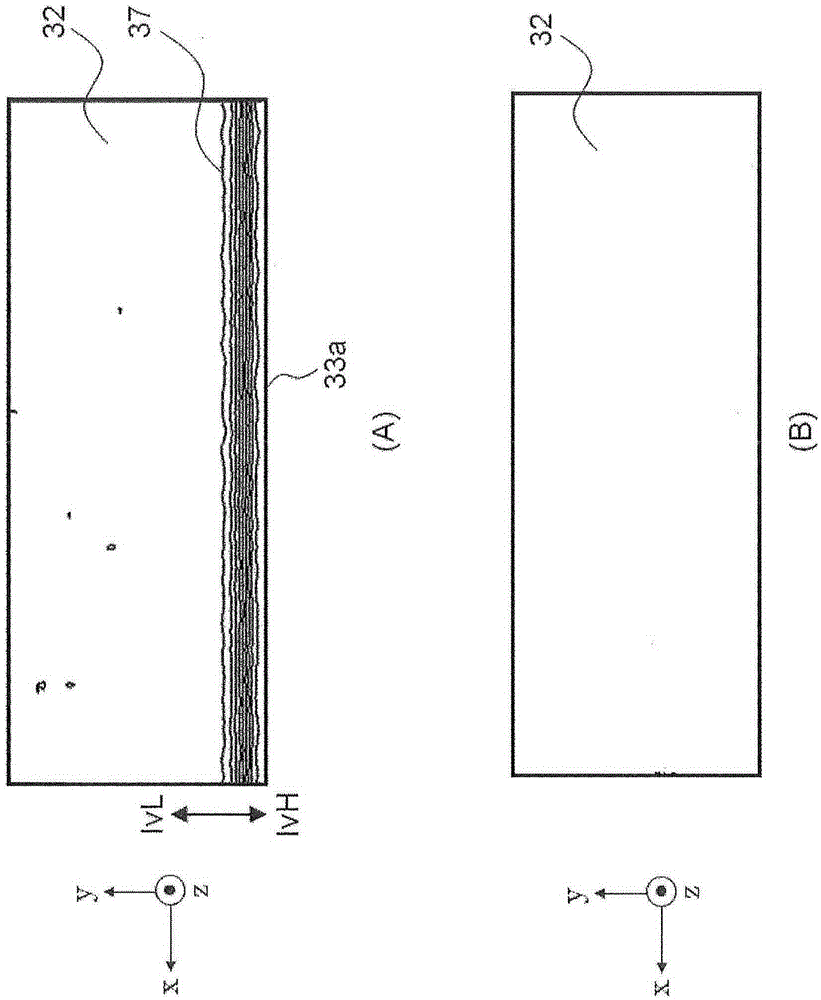

To provide an exhaust device for a vehicle capable of promoting catalyst activation in a cold state without enlarging a muffler connected to an exhaust pipe. In the exhaust device for the vehicle, the muffler 25 is connected to the exhaust pipe 23 extending from an engine 6, and a plurality of catalysts are provided. A bent part 31 having an upstream side catalyst converter 33, a downstream side catalyst converter 35, and a bent pipe 37 connecting the respective catalyst converters 33 and 35 in series is formed in a part of the exhaust pipe 23 positioned near the engine 6 and extending to the muffler 25.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com