Spun yarn take-up apparatus

A pulling device and spinning technology, which is applied in the directions of transportation and packaging, textile and papermaking, and transportation of filamentous materials, etc., can solve problems such as troublesome and complicated initial threading operations, and achieve the effect of restraining large-scale growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

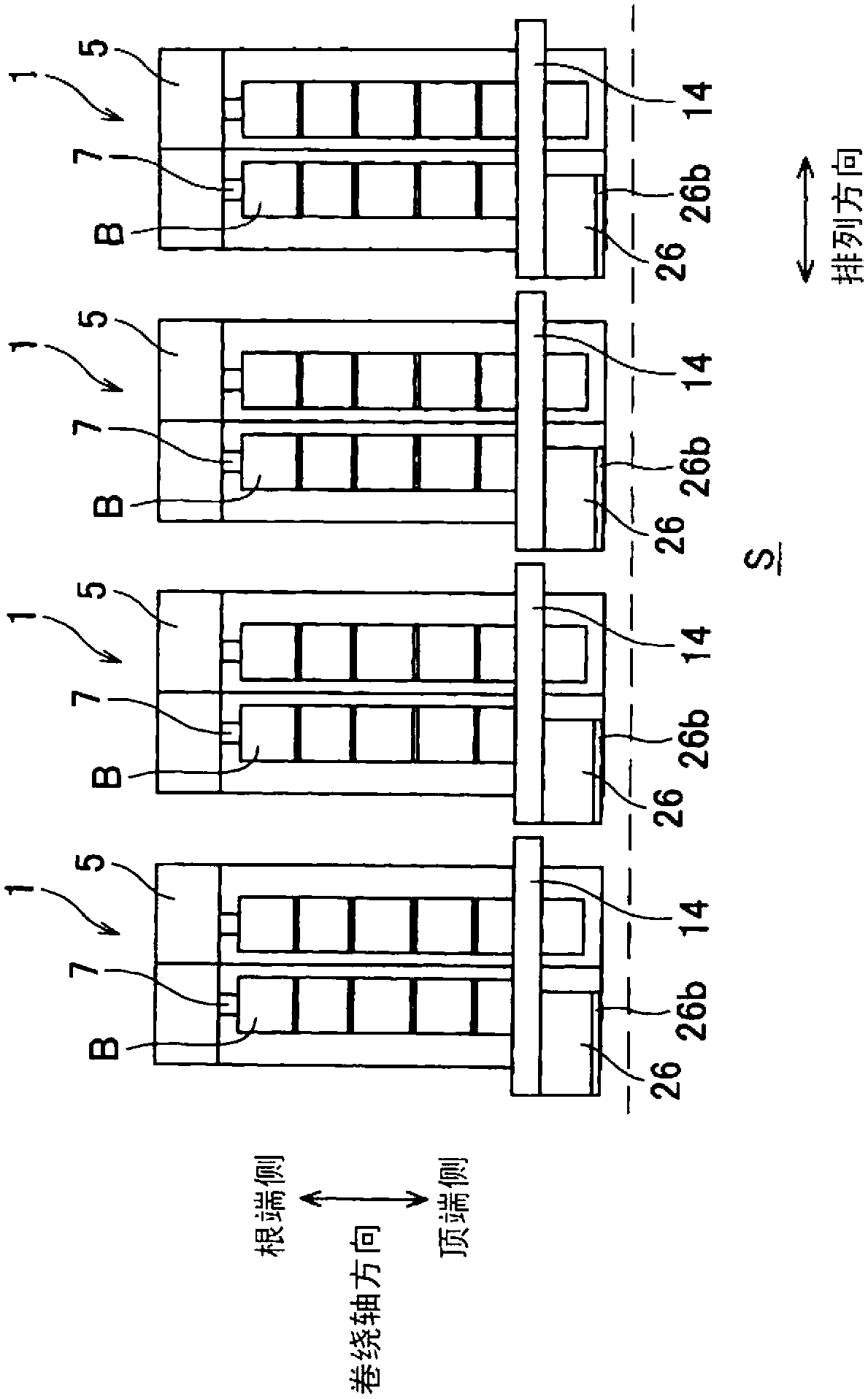

[0032] Preferred embodiments of the present invention will be described below.

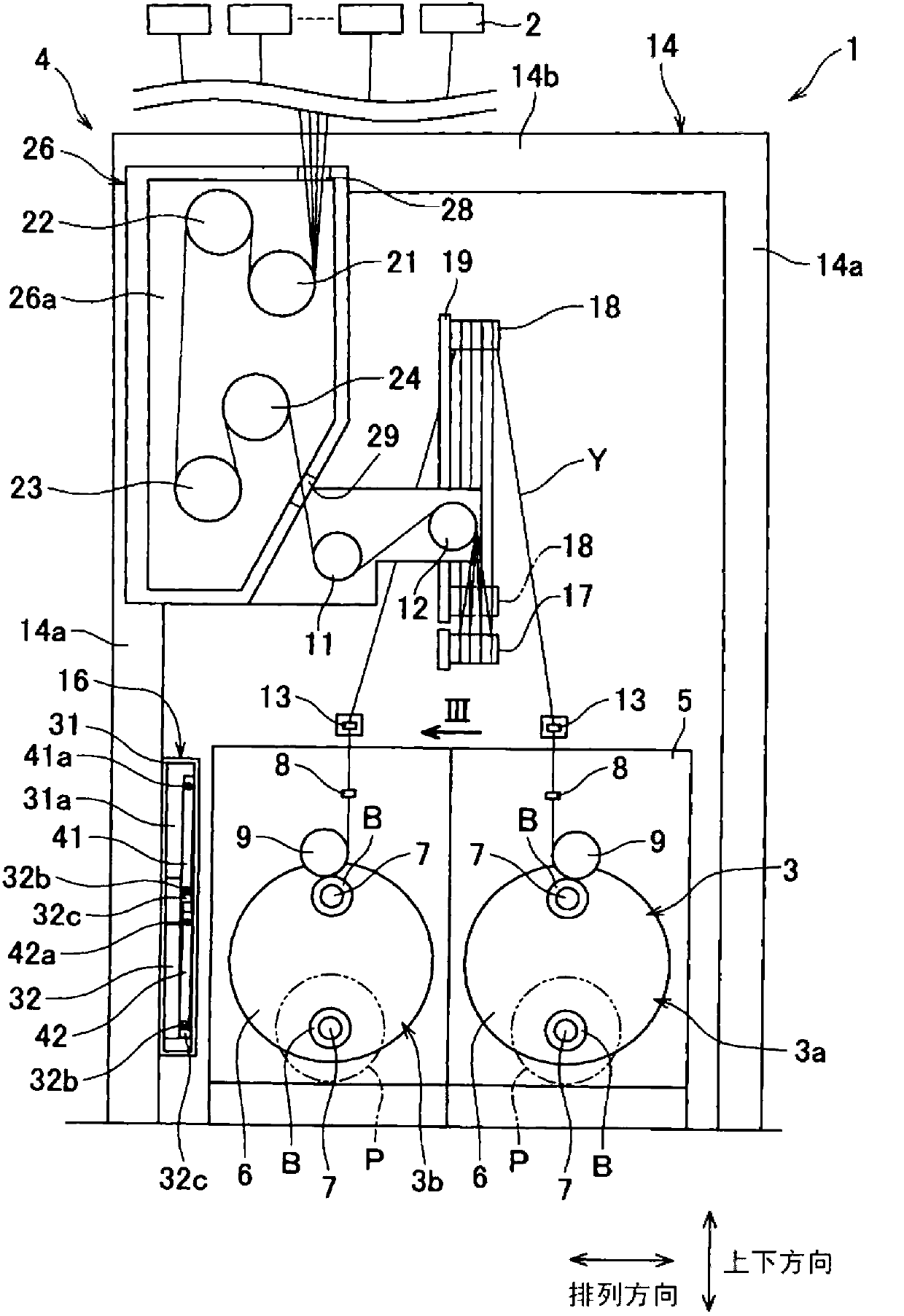

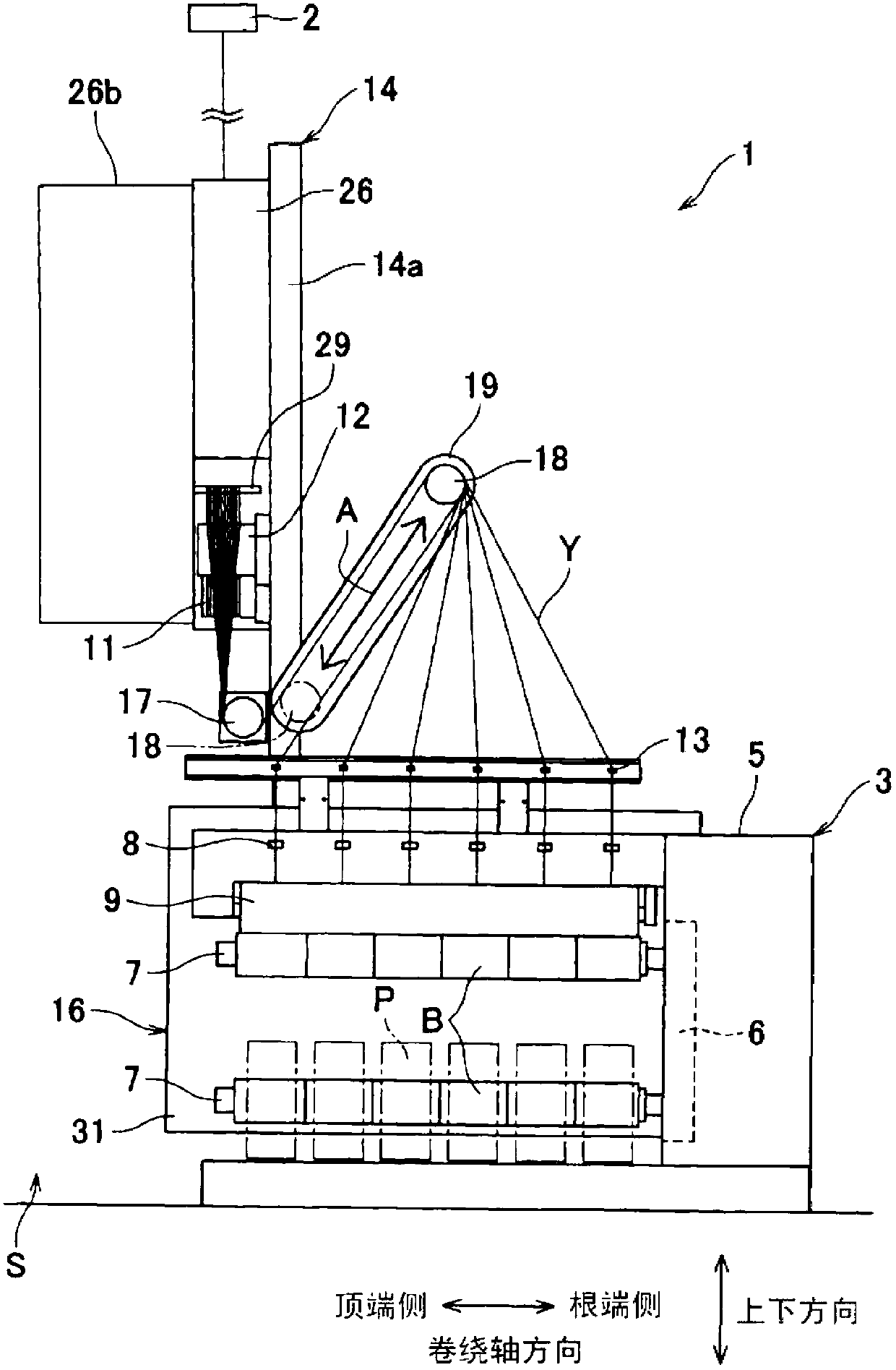

[0033] Such as figure 1 As shown, the spinning machine 1 (spinning machine) according to the present embodiment is considered to be, for example, the spinning machine 2 (see figure 2 ) for the arrangement of a plurality of spinnerets that spun a plurality of yarns Y or after loading and unloading a plurality of bobbins B from the top side of the bobbin base 7 that is supported by a cantilever described later, in order to be effective in a limited space A plurality of spinning drawing machines 1 are arranged in a plan view direction in an arrangement direction (horizontal and perpendicular to the axial direction of the bobbin base 7) ), and the top end side of the bobbin holder 7 becomes the work space S for the operator to perform work.

[0034] Each spinning traction machine 1 such as Figure 2 ~ Figure 6As shown, the plurality of yarns Y spun from the spinning machine 2 located above and sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com