Pinion assembling tray and pinion assembling device

A technology for assembling devices and assembling trays, which is applied in the directions of assembling machines, transmission parts, belts/chains/gears, etc., which can solve the problems of cycle shortening, limitation of productivity, time-consuming, etc., so as to reduce the possibility of falling off, The effect of shortening cycle time and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Hereinafter, embodiments of the present invention will be described based on the drawings. Also, the drawings are viewed from the directions of the reference numerals.

[0059] 【Example】

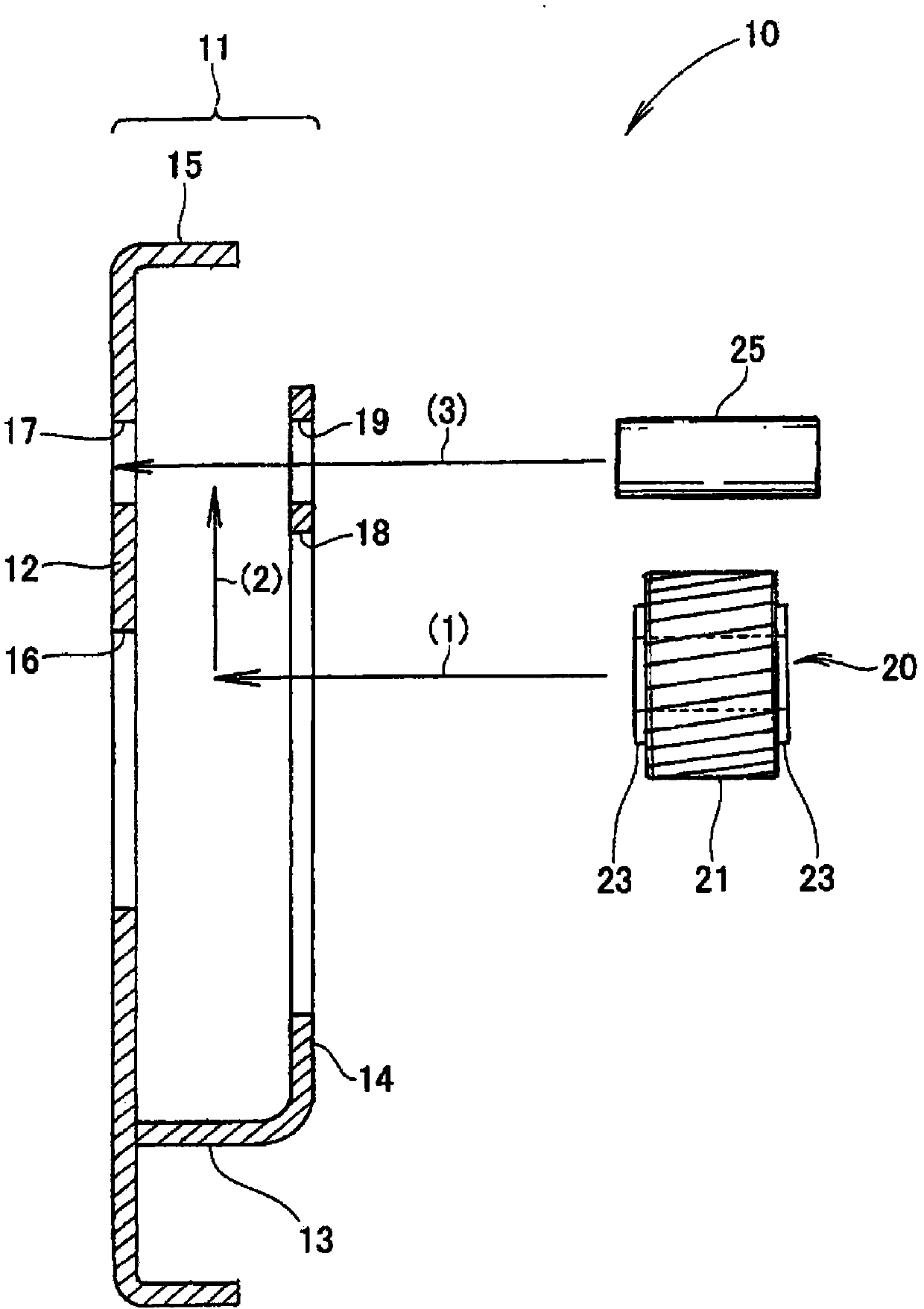

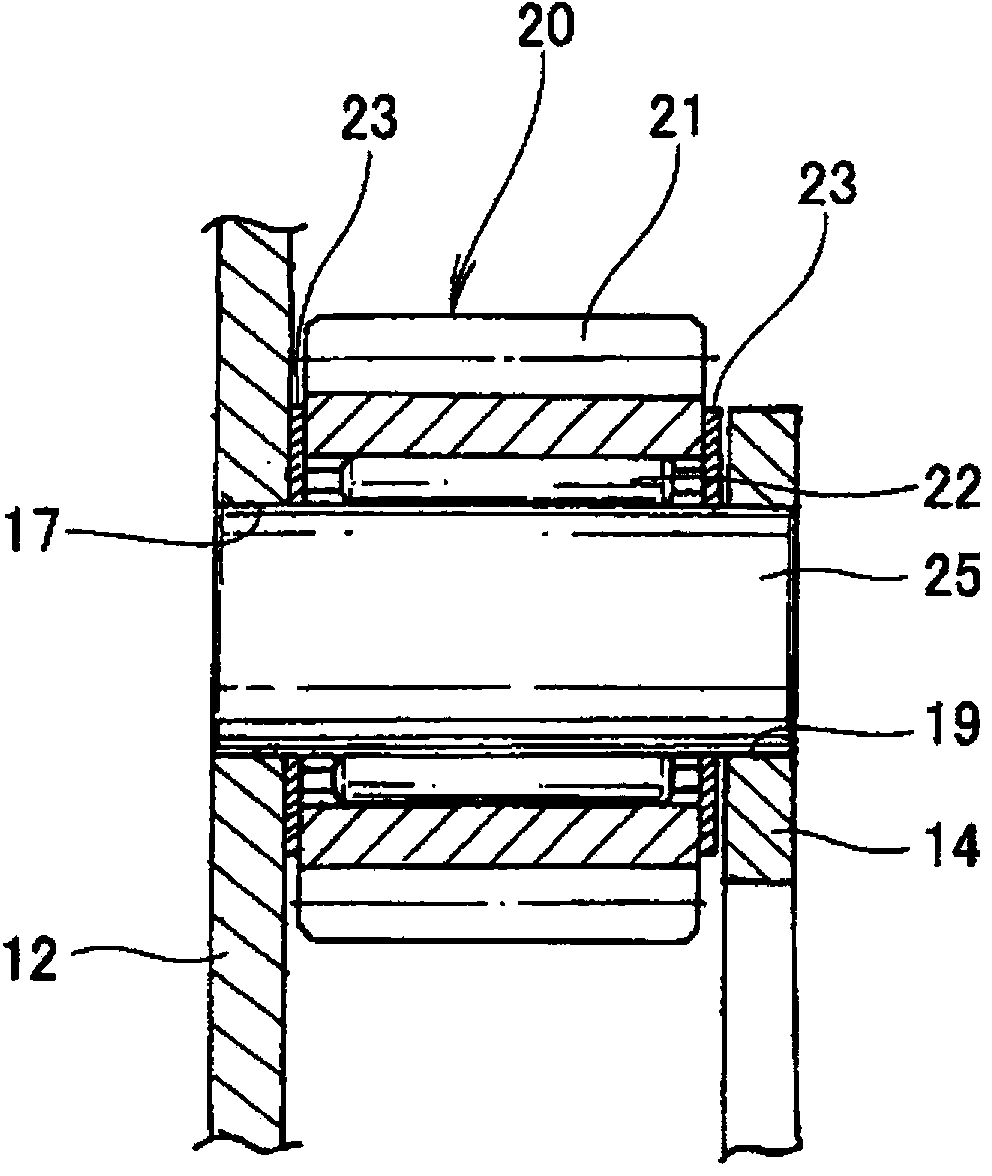

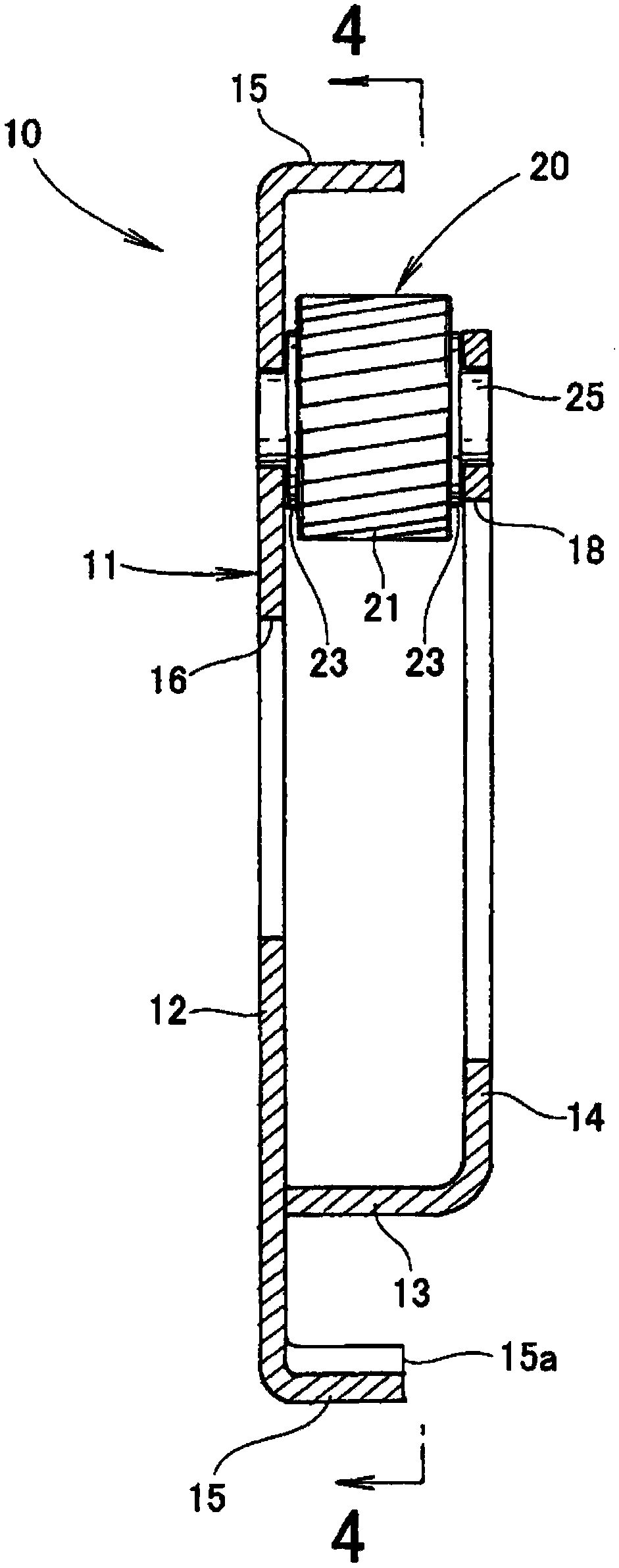

[0060] like figure 1 As shown, the planet carrier assembly 10 is composed of the planet carrier 11 , the pinion assembly 20 and the shaft 25 .

[0061] Further, the carrier 11 is composed of a carrier base 12 extending from the carrier base 12 in the longitudinal direction (including substantially the longitudinal direction) of the shaft 25 , an arm portion 13 , and a circular plate portion 14 . The plate portion 14 extends from the distal end of the arm portion 13 in parallel with the carrier base 12 .

[0062] In this example, the peripheral wall portion 15 stands up from the outer edge of the carrier base 12 toward the disc portion 14 .

[0063] The carrier base 12 is provided with a first center hole 16 and a first shaft insertion hole 17 into which the shaft 25 is inserted. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com