Patents

Literature

2280 results about "Nylon 6" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nylon 6 or polycaprolactam is a polymer developed by Paul Schlack at IG Farben to reproduce the properties of nylon 6,6 without violating the patent on its production. (Around the same time, Kohei Hoshino at Toray also succeeded in synthesizing nylon 6.) It is a semicrystalline polyamide. Unlike most other nylons, nylon 6 is not a condensation polymer, but instead is formed by ring-opening polymerization; this makes it a special case in the comparison between condensation and addition polymers. Its competition with nylon 6,6 and the example it set have also shaped the economics of the synthetic fiber industry. It is sold under numerous trade names including Perlon (Germany), Dederon (former East Germany), Nylatron, Capron, Ultramid, Akulon, Kapron (former Soviet Union and satellite states), and Durethan.

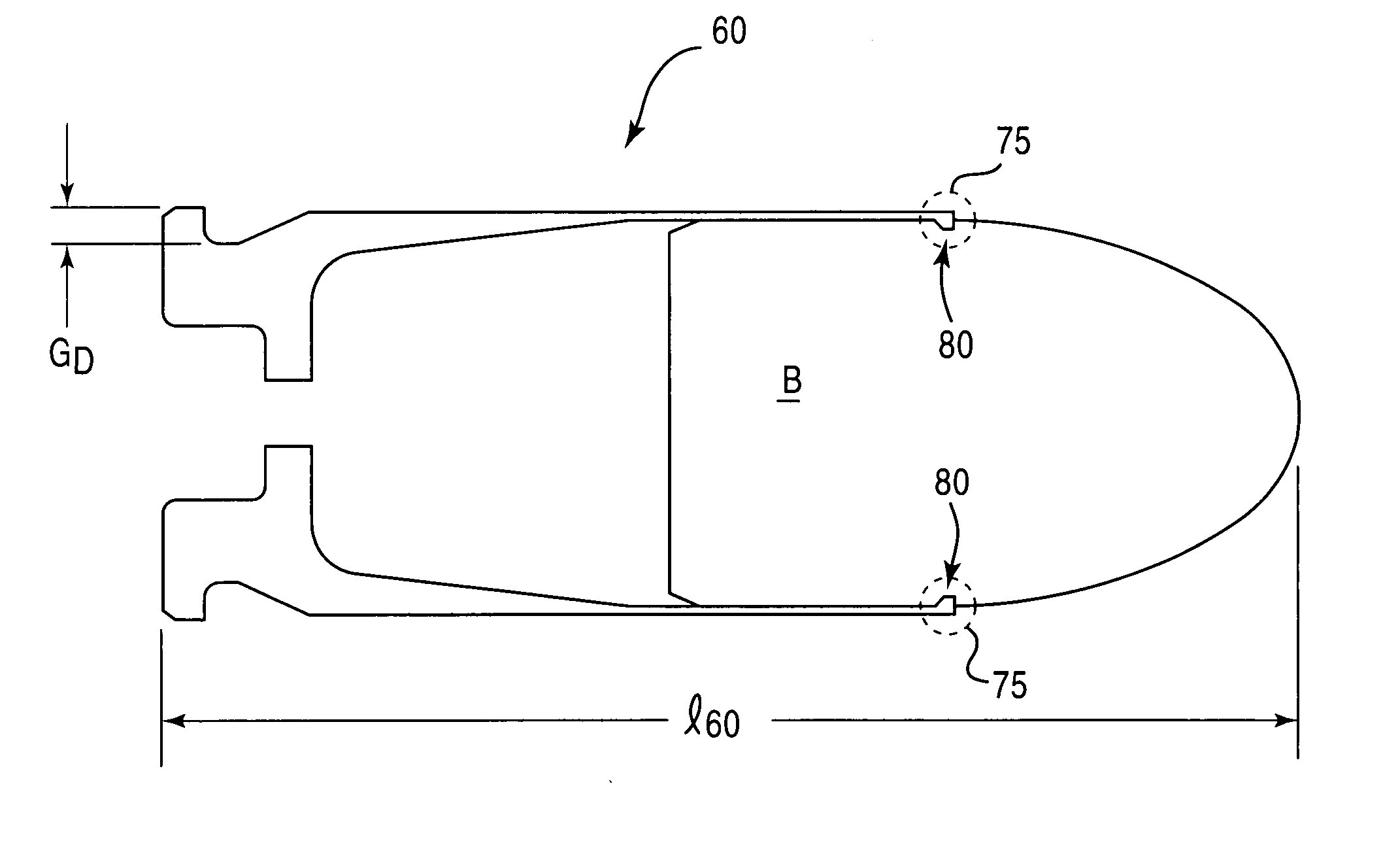

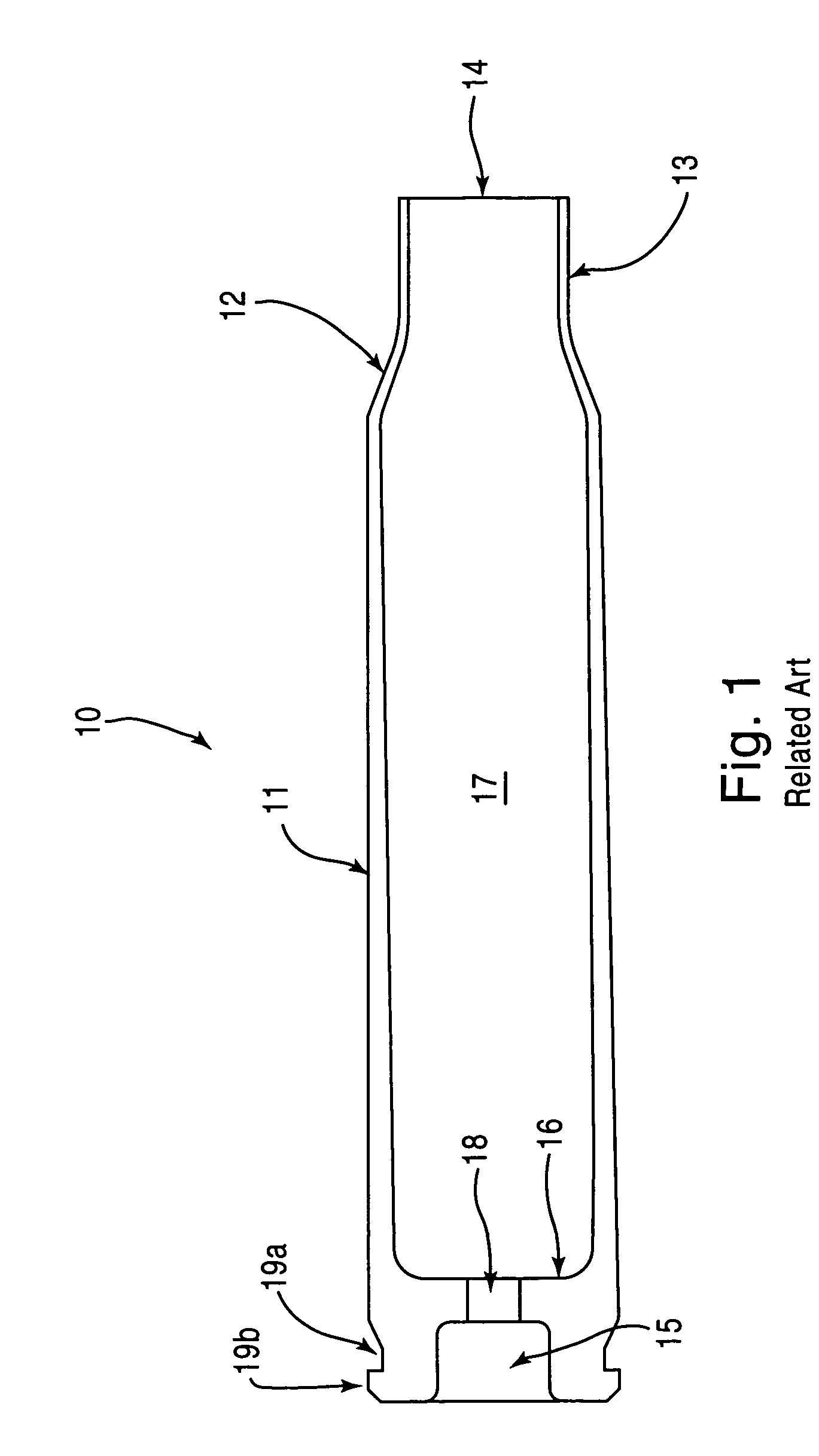

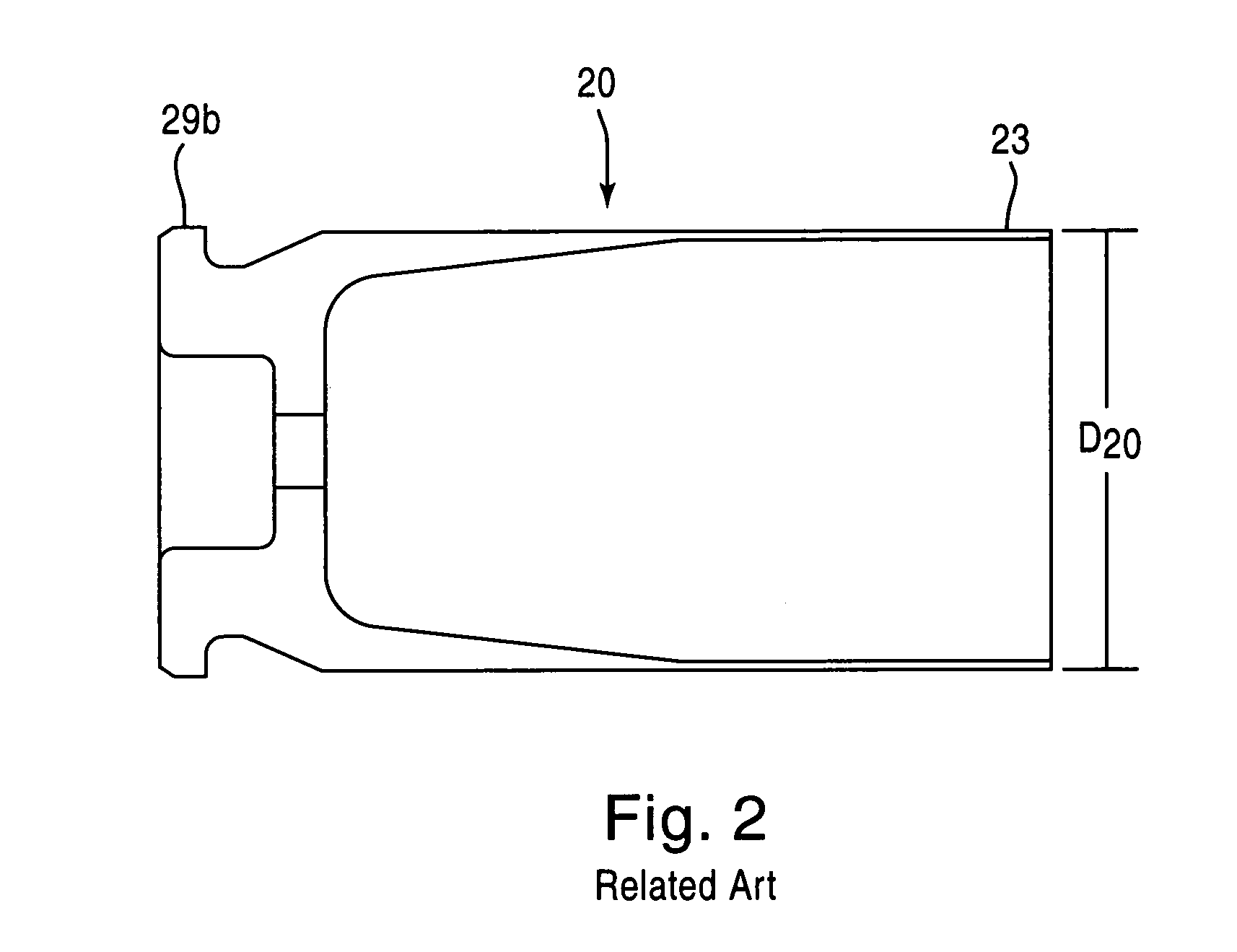

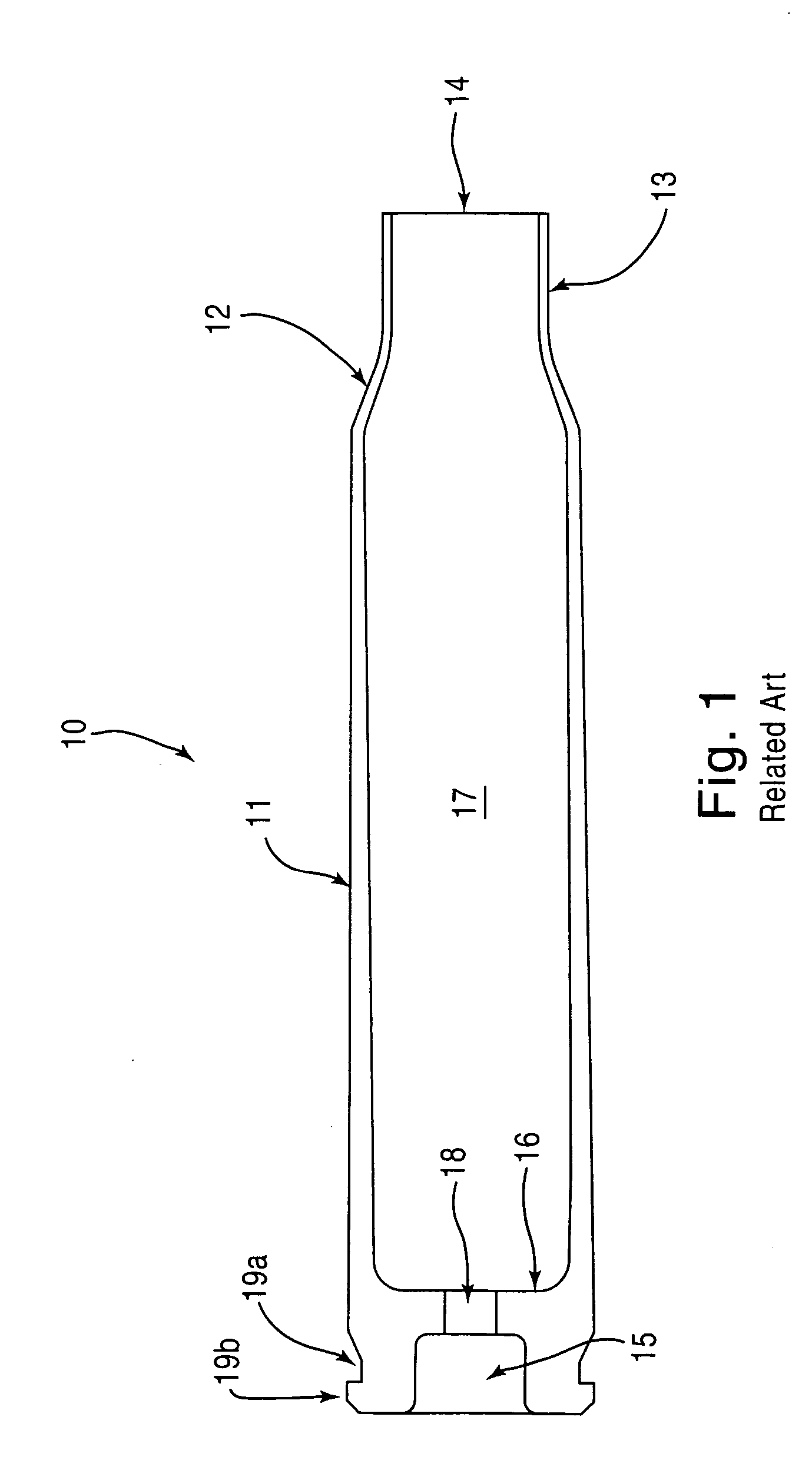

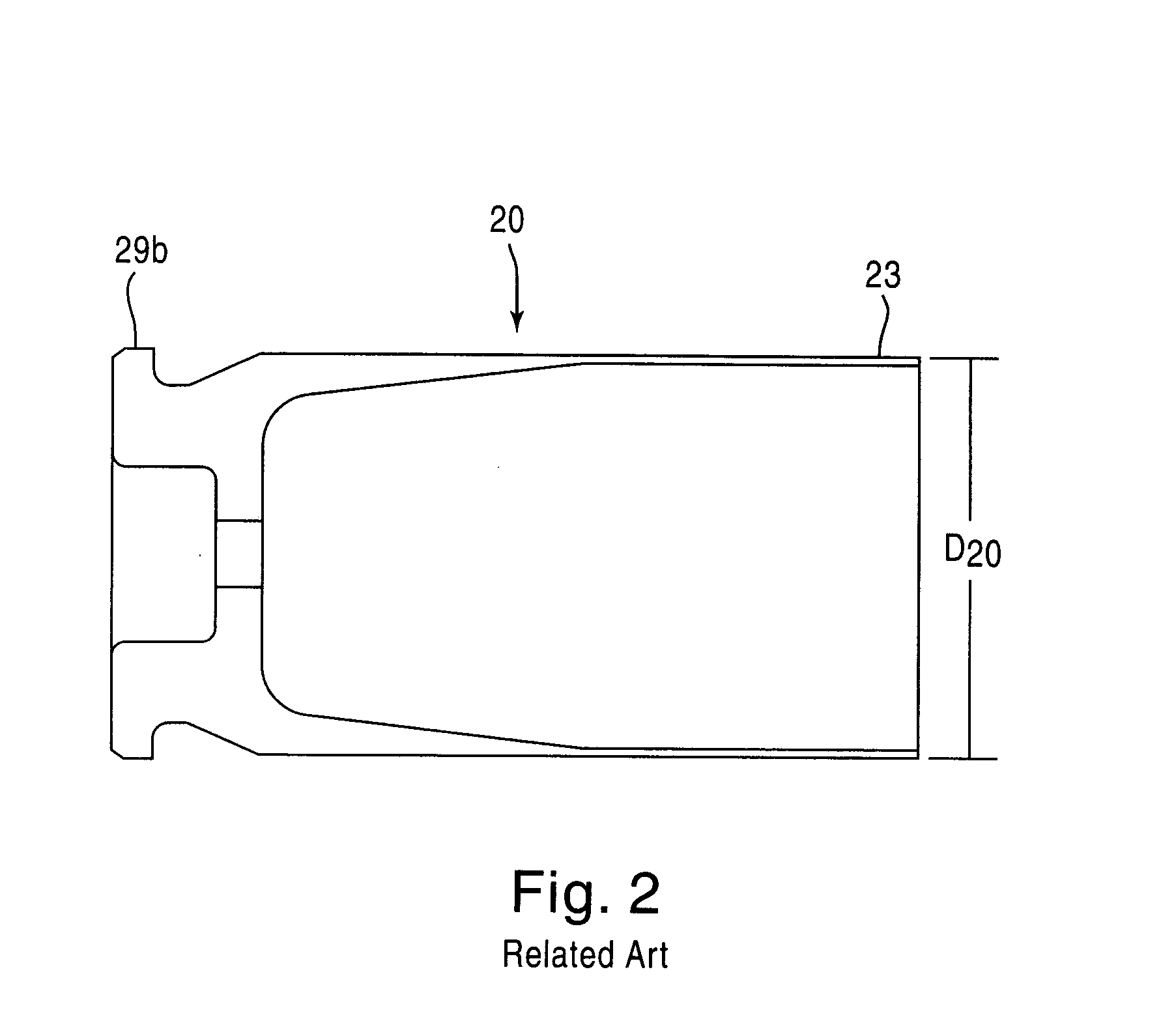

Lead free, composite polymer based bullet and cartridge case, and method of manufacturing

A lead-free, composite polymer based bullet and cartridge case and methods of manufacturing the same, wherein the composite polymer material includes a tungsten metal powder, nylon 6 / 6, nylon 6, short glass fibers, as well as additives and stabilizers. The cartridge case includes a lip lock configured to matingly engage a cannelure formed along an outer circumferential surface of the bullet. The cartridge case also includes resilient walls wherein the case may snap fit onto the bullet. The bullet and cartridge case may be formed in a single step process by injection molding or a two step process including injection molding and a welding process.

Owner:POLYTECH AMMUNITION

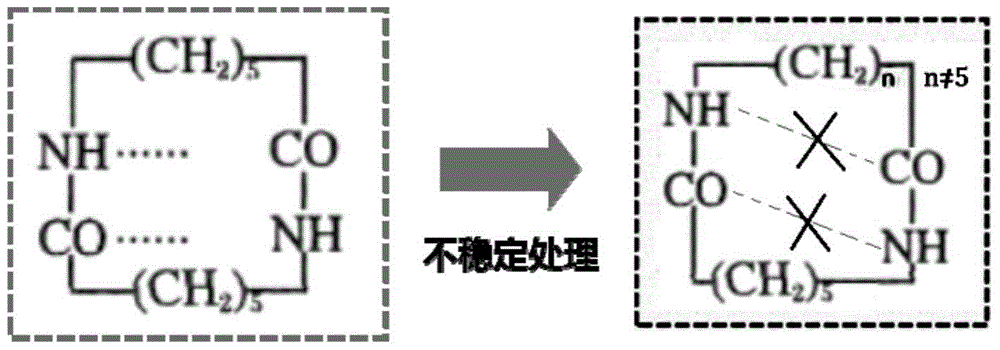

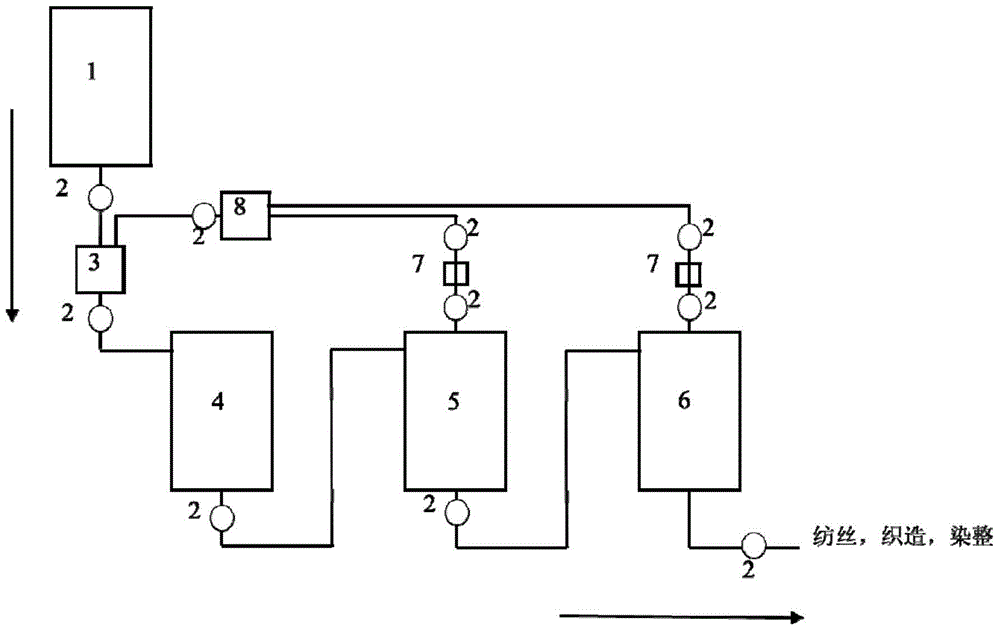

Nylon 6 polymerization method and direct spinning method of melt of polymer obtained with nylon 6 polymerization method

ActiveCN105669969AIncrease profitReduce manufacturing costFlame-proof filament manufactureHollow filament manufacturePolymer sciencePolyamide

The invention relates a nylon 6 polymerization method and a direct spinning method of a melt of a polymer obtained with the nylon 6 polymerization method. A polyamide 6 prepolymer is prepared at the low temperature, the content of oligomers in the melt is controlled in advance, polymerization is completed before a large quantity of cyclic oligomers are generated with a condensation polymerization dynamic strengthening method, a nylon 6 polymer melt with certain molecular weight is acquired, the content of extracts in the product is smaller than or equal to 1.5 wt%, and the content of cyclic dipolymers is smaller than or equal to 0.2wt%; then, direct melt spinning forming is performed after condensation polymerization dynamic strengthening ends. The process is simple, energy consumption is further reduced while the utilization rate of caprolactam is increased, the obtained melt can be directly used for melt spinning, high-capacity large-scale production is easy to realize, a modifier can be added in the polymerization process, flexible production of nylon 6 is realized, and the nylon 6 can be applied to fibers for clothes, industrial filaments, engineering plastics and other fields.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

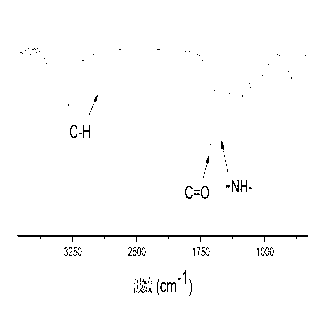

Preparation method of graphene modified nylon 6 fiber

ActiveCN103215689AImprove performanceImprove interfacial bond strengthMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberNylon 6

The invention relates to a preparation method of a graphene modified nylon 6 fiber and belongs to the technical field of a functional fiber material. The preparation method comprises the following steps of: carrying out carboxylation and acylating chlorination treatment on graphene; then carrying out diamine treatment to obtain graphene oxide with an active amino on the surface; carrying out polymerization reaction by utilizing the aminated graphene and caprolactam through an initiator 6-aminocaproic acid to prepare a modified nylon 6 melt of the graphene; and carrying out spinning and stretching through a fusion and spinning process to obtain the graphene modified nylon 6 fiber. The technical scheme of the invention utilizes aminated graphene enhanced 6 to improve the interface bonding strength with a base resin, so as to be good for improving the whole performance of the graphene modified nylon 6 fiber. A fiber material prepared by the preparation method provided by the invention can be widely applied to the technical fields of aerospace, cars and ships, communication and transportation, mechano-electronics and the like.

Owner:SUZHOU UNIV

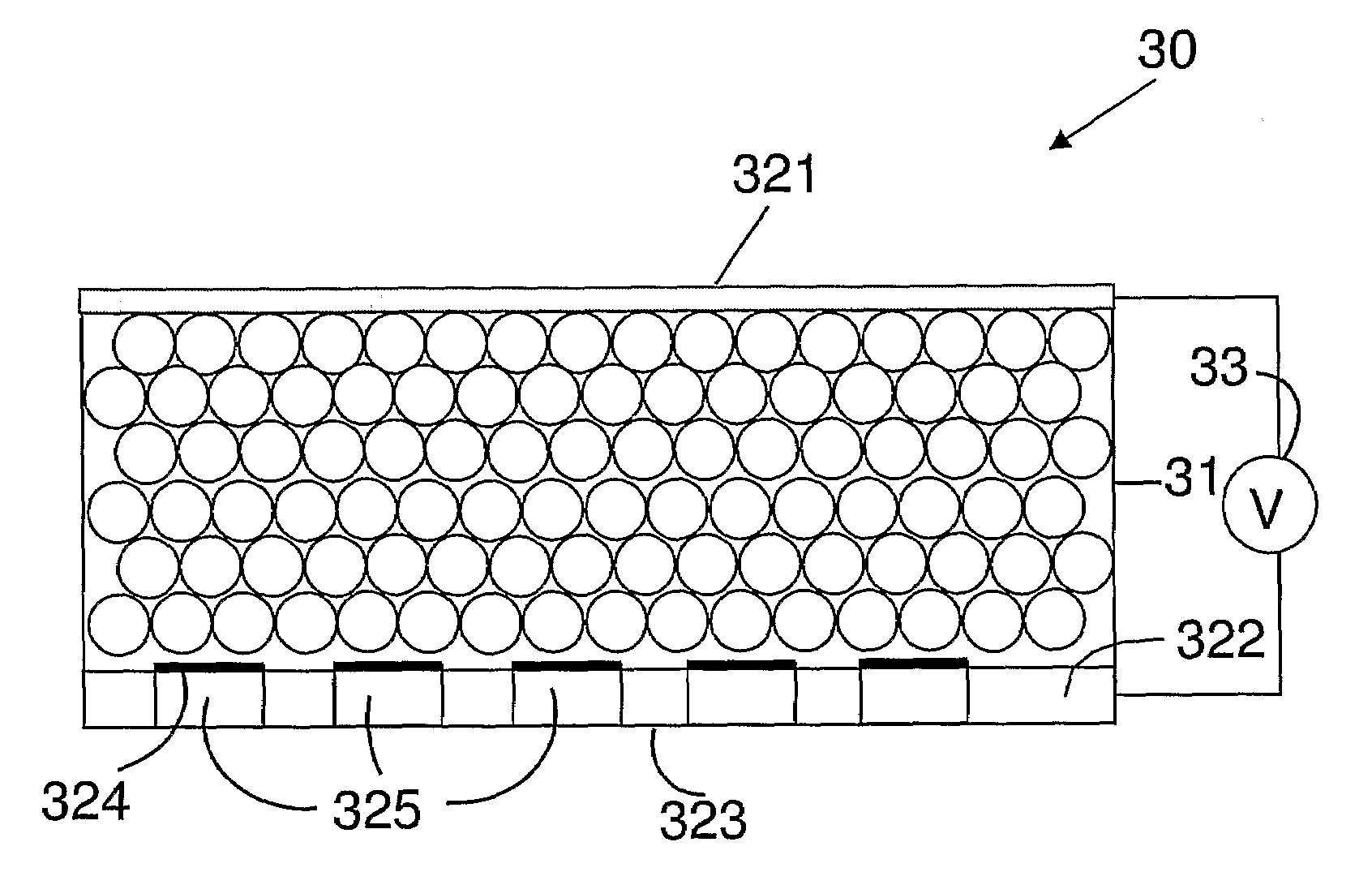

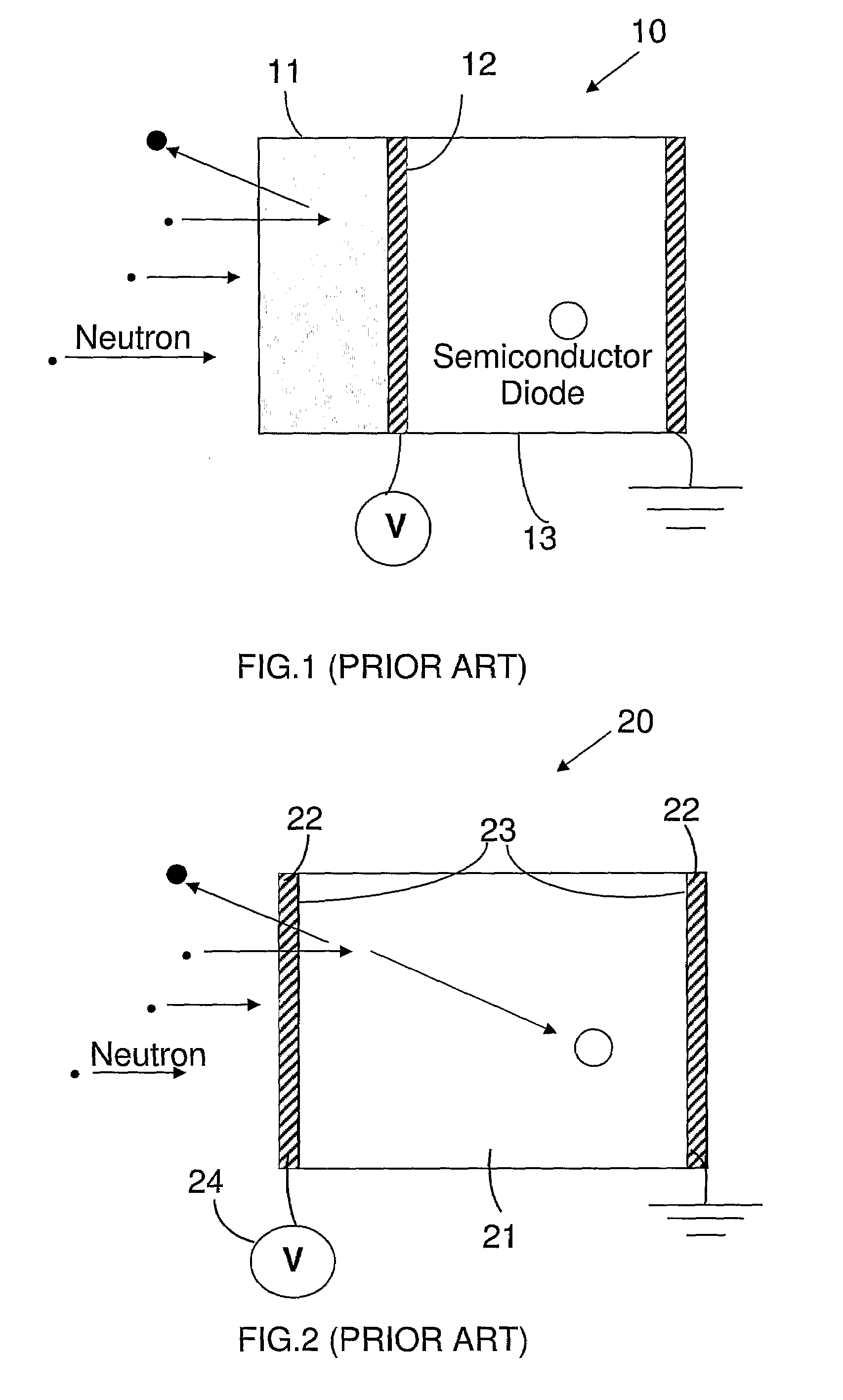

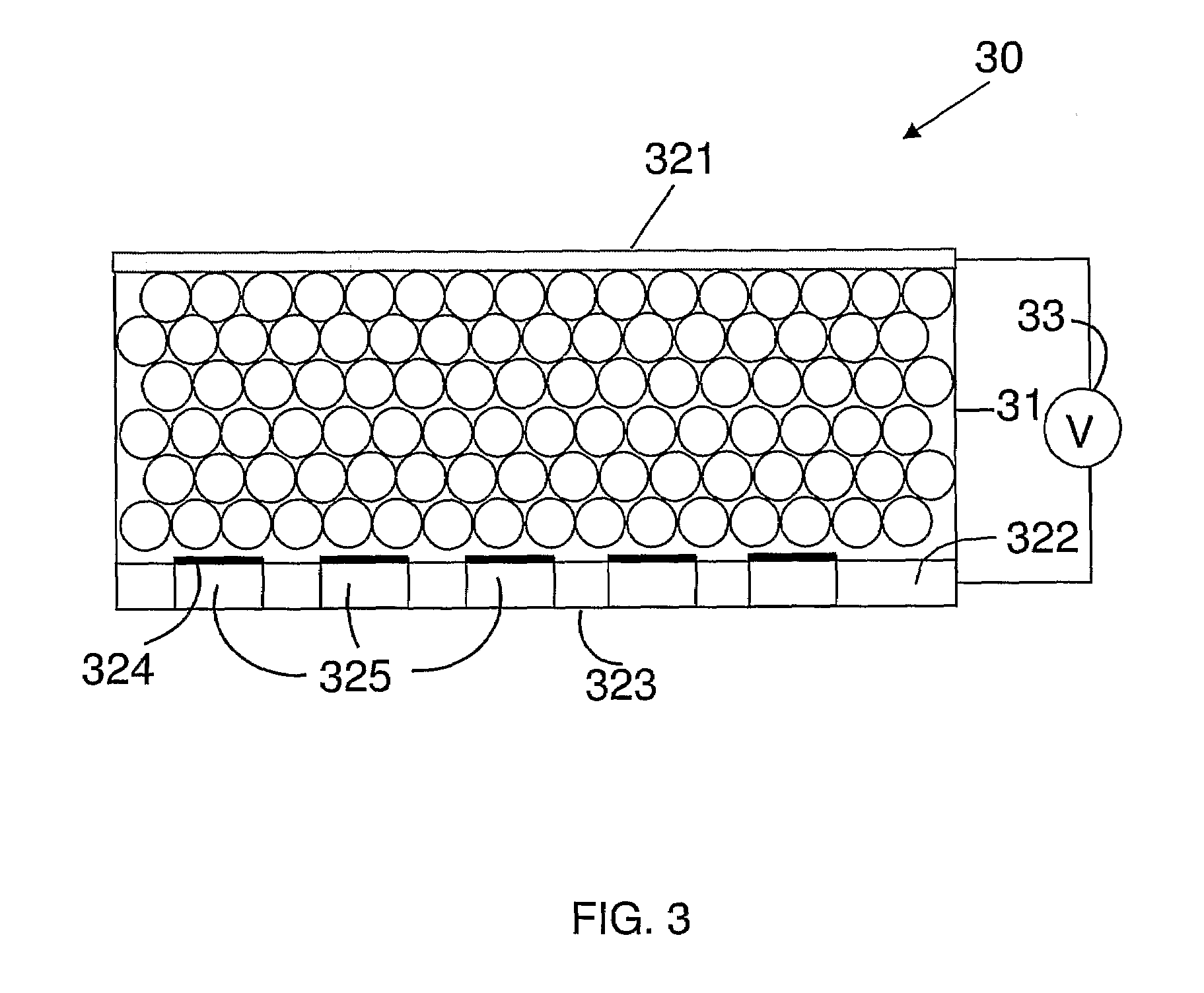

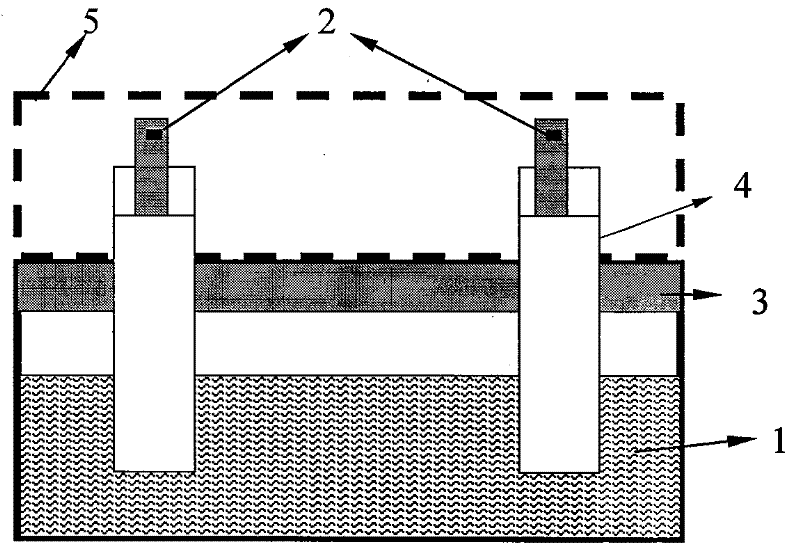

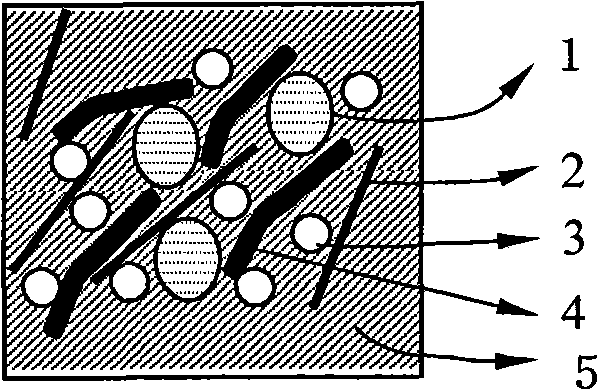

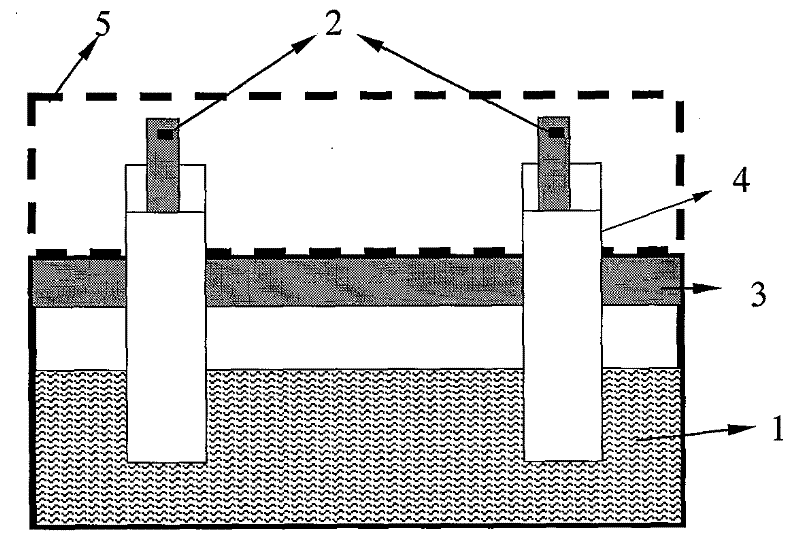

Solid-state neutron and alpha particles detector and methods for manufacturing and use thereof

InactiveUS20090302226A1Optimize detection resultsMeasurement with semiconductor devicesSolid-state devicesParticulatesSemiconductor materials

A solid-state detector for detection of neutron and alpha particles detector and methods for manufacturing and use thereof are described. The detector has an active region formed of a polycrystalline semiconductor compound comprising a particulate semiconductor material sensitive to neutron and alpha particles radiation imbedded in a binder. The particulate semiconductor material contains at least one element sensitive to neutron and alpha particles radiation, selected from a group including 10Boron, 6Lithium, 113Cadmium, 157Gadolinium and 199Mercury. The semiconductor compound is sandwiched between an electrode assembly configured to detect the neutron and alpha particles interacting with the bulk of the active region. The binder can be either an organic polymer binder or inorganic binder. The organic polymer binder comprises at least one polymer that can be selected from the group comprising polystyrene, polypropylene, Humiseal™ and Nylon-6. The inorganic binder can be selected from B2O3, PbO / B2O3 / , Bi2O3 / PbO, Borax glass, Bismuth Borate glass and Boron Oxide based glass.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

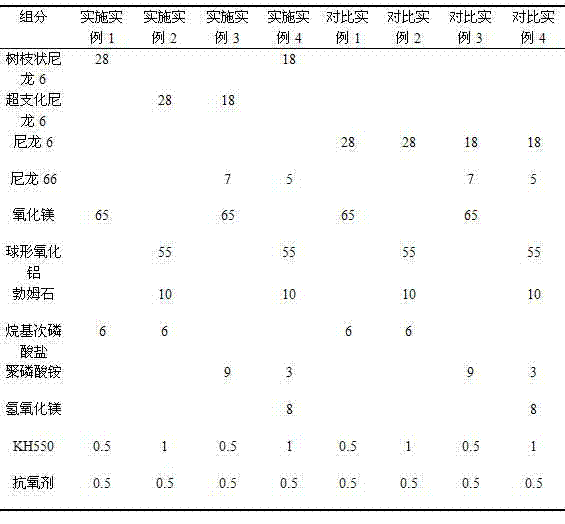

A high flame retardant high thermal conductivity composite material component and its manufacturing method

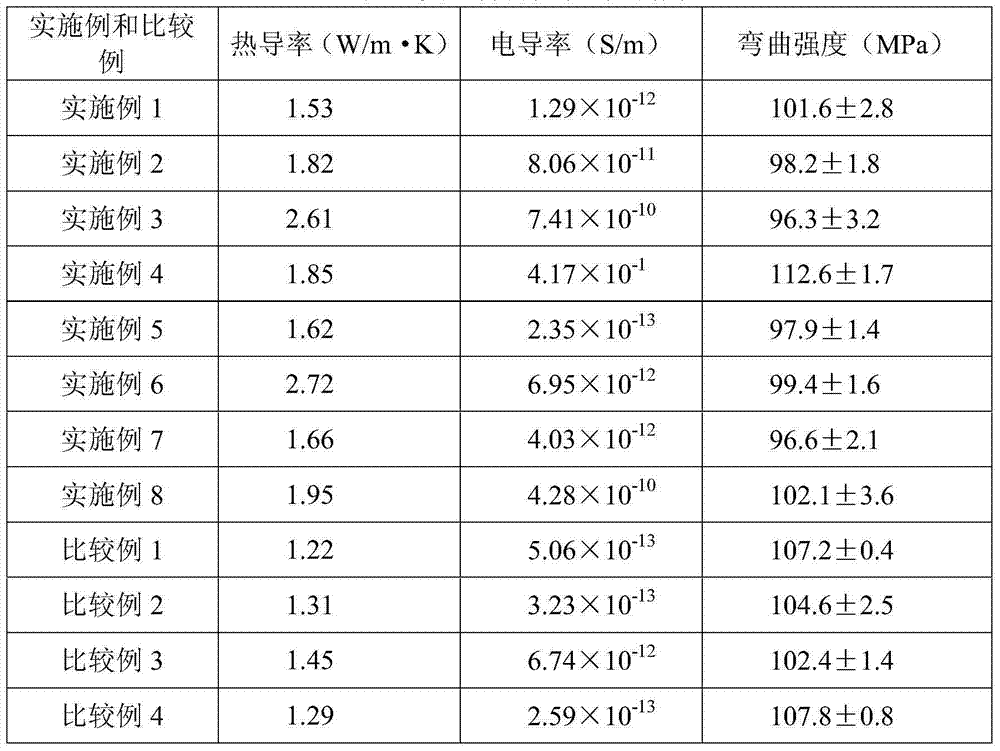

InactiveCN102260413AImprove thermal conductivityImprove flame retardant performancePolymer sciencePhenol formaldehyde resin

The invention relates to a high-molecular composite material having performances of high heat conduction and high flame retardation, the invention is characterized in that the composite material does not contain any halogen or a non environmentally-friendly heavy metal fire retardant, the flame resistance is capable of reaching a UL94 V0 standard, simultaneously, the composite material has good heat conducting performance, the heat conduction coefficient is more than 0.5 W / m. DEG C. The composite material provided in the invention has good injection moulding performance, extruding performance and hot pressing performance. The composite material comprises the following basic components: 1) one or a plurality of metal hydroxides, such as aluminum hydroxide, magnesium hydroxide, zinc hydroxide and the like, wherein the weight content is 10-70%, 2) about 0.2%-60% of the weight content of expandable graphite flaky powder, the lamina size is more than 10 um, and the expandable coefficient is more than or equal to 20 times; 3) 15%-70% of the weight content of matrix resins, such as epoxy resin, organic silicone resin, phenolic resin, thermosetting polyester resin and thermoplastic resins of nylon 6, nylon 66, PBT, PP, HDP and the like. The composite material component of the invention can be directly used for radiators such as LED, electric appliances and electronic components, the heat can be radiated into colder environment so that the operating temperature of the electronic device can be reduced.

Owner:HEFU NEW MATERIAL TECH WUXI

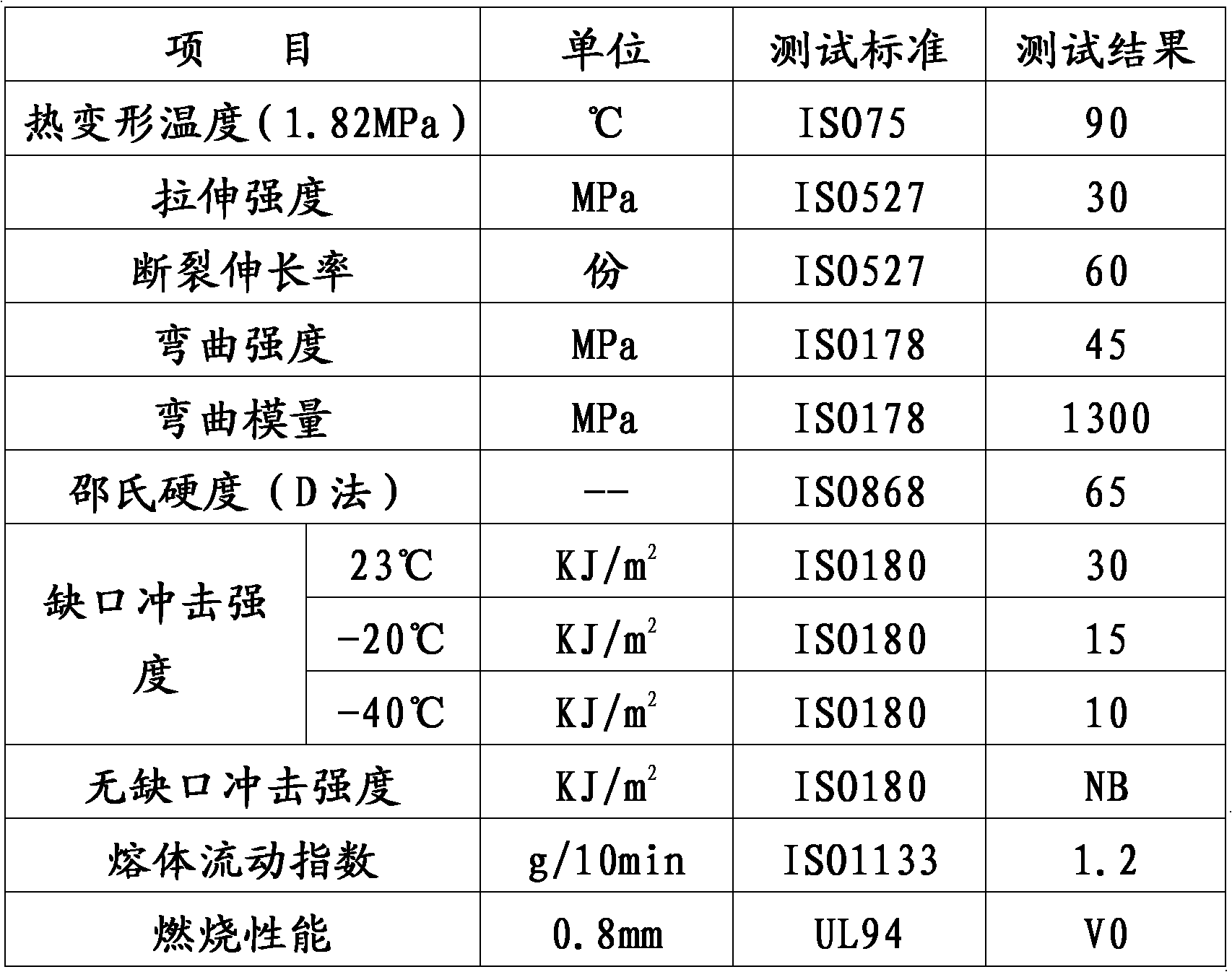

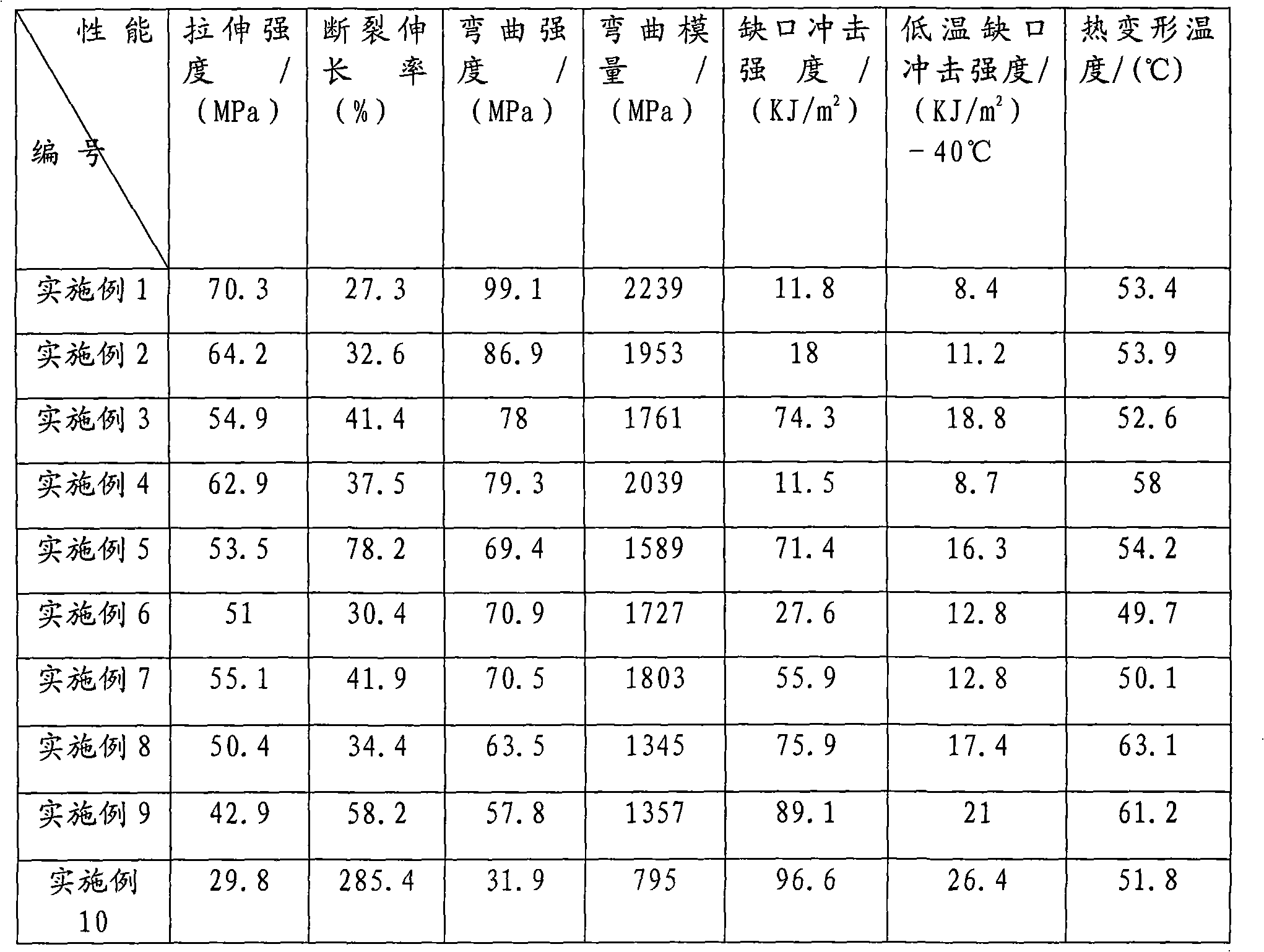

Halogen free flame retardant nylon 6 composite with high CTI value and preparation method thereof

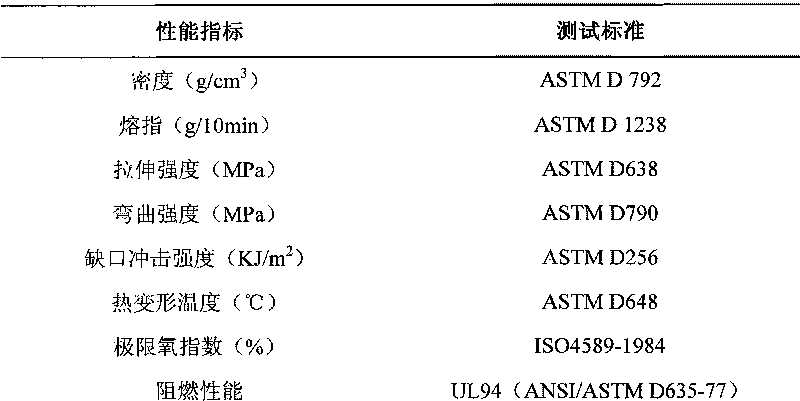

InactiveCN101812231AHigh CTI valueImprove flame retardant performancePolymer scienceFlexural strength

The invention discloses a halogen free flame retardant nylon 6 composite with high CTI value and a preparation method thereof. The composite comprises the following components by mass percent: 643.5-68.8wt.% of nylon, 10-12wt.% of fire retardant, 7-19wt.% of fire retardant synergetic inorganic packing, 8-12% wt.% of toughening agent, 1-3wt.% of bulking agent, 5-10% wt.% of enhance inorganic filler and 0.2-0.5wt.% of anti-oxygen which are prepared into the compound by a high speed premixing dispersing primary extrusion processing. The disclosed composite has as high as 550V CTI value and UL 94V-0 level excellent fire resistance; simultaneously, the polymer has good mechanical property by a comprehensive modified technique, wherein the tensile strength reaches 70.5Mpa, the bending strength reaches 90.7MPa and the impacting strength of a gap reaches 28.1kJ / m2. The invention solves the problem that the flaming resistant and high CTI value are difficult to satisfy simultaneously; the inventive 6 nylon compound is very suitable for preparing a low-pressure vacuum contactor, a transformer coil framework, a high-temperature resistant relay, a breaker, a high voltage electrical apparatus, a handle and a thin wall electronic and electrical appliance elements, and the like.

Owner:BEIJING UNIV OF CHEM TECH

Flame-retardant PP/nylon corrugated tube composite material and preparation method thereof

ActiveCN102050993AImprove flame retardant performanceImprove high temperature resistanceProcedure AgentsManufacturing technology

The invention relates to a corrugated tube material and particularly discloses a flame-retardant PP (Polypropylene) / nylon corrugated tube composite material and a preparation method thereof, aiming to overcome the shortcomings in the prior art that the mechanical property of the PP corrugated tube is bad, the nylon corrugated tube is not flame-retardant, the stability is bad, and the service lifeis short. The material disclosed by the invention comprises the following substances by weight percentage: 47-75 of PP, 3-40 of nylon, 5-30 of flame retardant, 5-20 of compatilizer, 1-40 of flexibilizer, 0-10 of filling master batches, 0.2-1.5 of heat stabilizer, and 0.2-1.5 of processing agent. The preparation method comprises the steps as follows: the filling master batches are firstly preparedand then added into a twin-screw extruder to melt and mix with other materials, and pelletings are extruded out to prepare the flame-retardant PP / nylon composite material. The invention has the advantages of favorable flame-retardant property, excellent high-temperature resistance, friction resistance, chemical corrosion resistance, long service life, high surface glossiness, high electrical insulativity, simple manufacturing technology, and low cost.

Owner:SHANGHAI KINGFA SCI & TECH +1

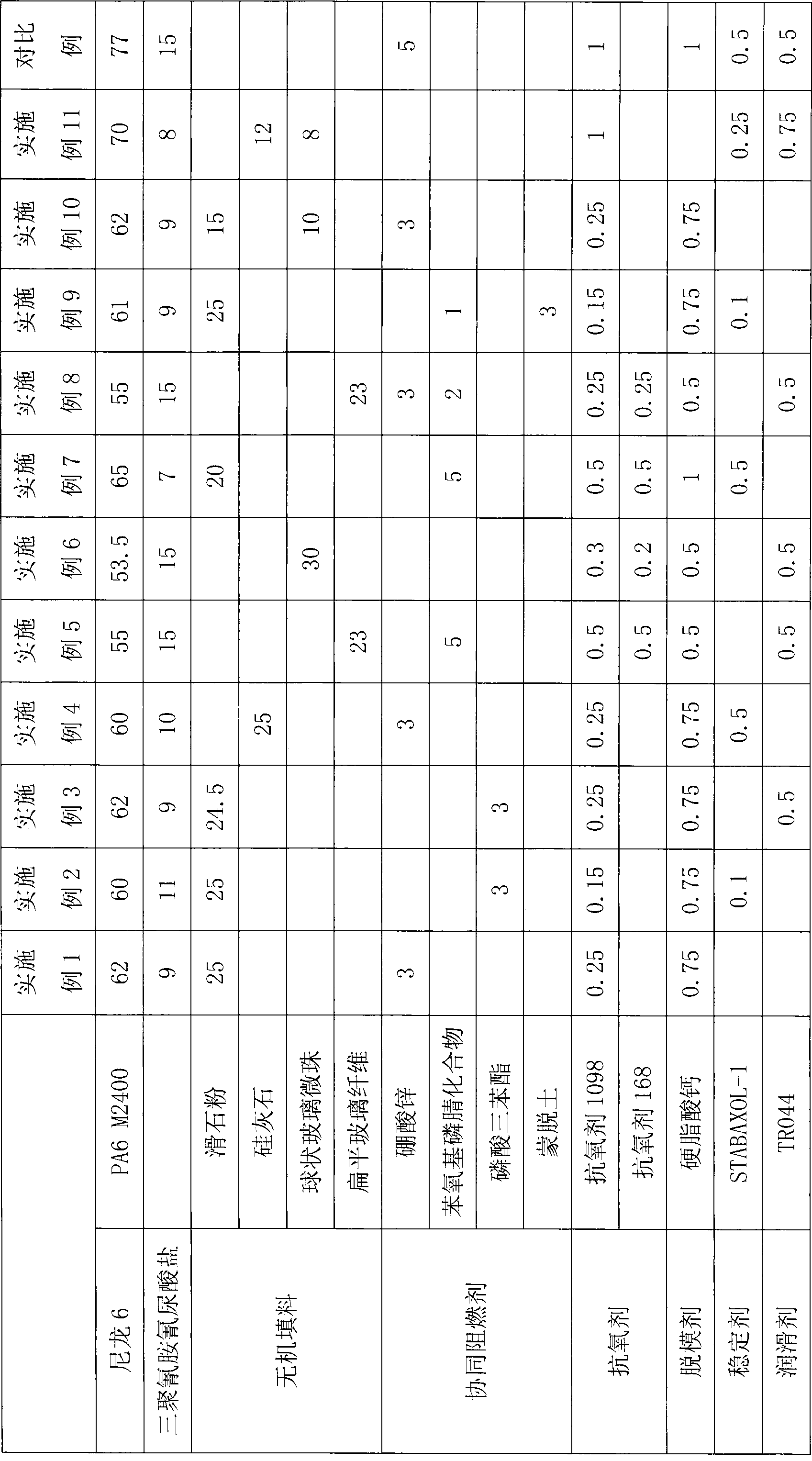

Halogen-free filling flame-retardant nylon 6 composite material and preparation method thereof

The invention provides a halogen-free filling flame-retardant nylon 6 composite material and a preparation method thereof. The halogen-free filling flame-retardant nylon 6 composite material provided by the invention is characterized by being prepared from the following raw materials: 53-70 parts by weight of nylon 6 resin, 7-15 parts by weight of melamine cyanurate, 20-30 parts by weight of inorganic filling material, 0-5 parts by weight of synergistic flame retardant, and 1-5 parts by weight of processing agent. Compared with the prior art, the halogen-free filling flame-retardant nylon 6 composite material provided by the invention has the beneficial effects the halogen-free filling flame-retardant nylon 6 composite material is capable of passing the GWFI (Glow Wire Flammability Index) test at 960 DEG C, also has the characteristics of being low in cost, high in modulus and strength, excellent size stability, environment-friendly, flame-retardant and the like, and has good application prospect.

Owner:SHANGHAI KINGFA SCI & TECH +1

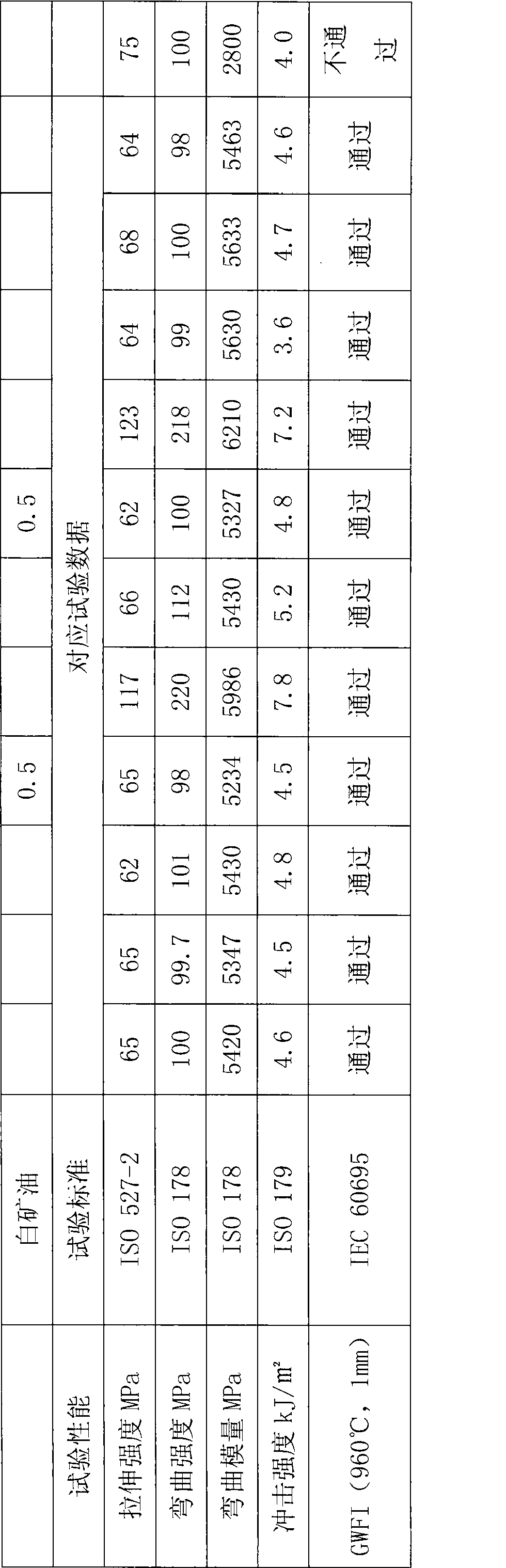

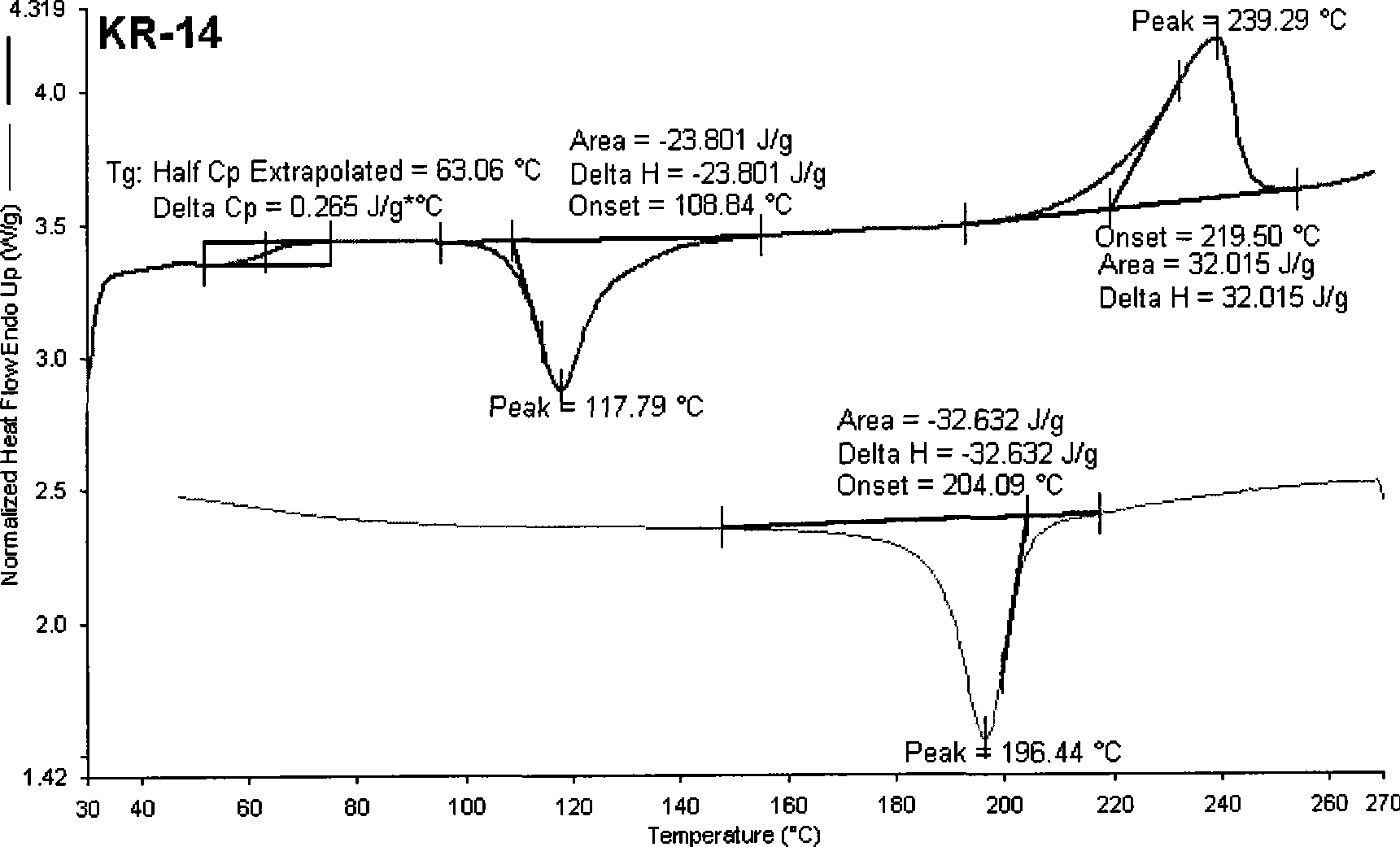

Nylon 6/graphene nanometer composite material with high thermal conductivity and preparation method thereof

The invention relates to a nylon 6 / graphene nanometer composite material with high thermal conductivity and a preparation method thereof. The composite material is composed of a nylon 6 matrix and nanometer graphene and is prepared by carrying out in situ polymerization and melt blending and banburying on obtained master batches and pure nylon 6. The nanometer graphene oxide adopted in the preparation method has a high radius-thickness ratio, a small amount of nanometer graphene oxide is added and is thermally reduced to form heat-conducting master batches, and an effective graphene heat conducting path can be formed effectively in the nylon 6. The small amount of nanometer graphene oxide heat conducting fillers and the master batches are added into the pure nylon 6 to be mixed and compounded so as to keep the good mechanical properties of the nylon 6 in the heat-conducting composite material. The nylon 6 / graphene nanometer composite material with high thermal conductivity, provided by the invention, is excellent in heat conducting property, simple in preparation process and low in cost, thereby being capable of being widely applied in the field of heat dissipation of automobiles, computers, LEDs (Light Emitting Diode), etc.

Owner:SHANGHAI UNIV

High-fluidity halogen-free flame retardant reinforced nylon composite material and preparation method thereof

The invention discloses a high-fluidity halogen-free flame retardant reinforced nylon composite material and a preparation method thereof. According to the invention, high-fluidity nylon resin containing chain structural nylon 6 is adopted as matrix resin; 4.9 to 29.5 parts of halogen-free flame retardant and 0.1 to 0.5 part of antioxidant are added in a mixing machine for evenly mixing; the obtained mixture is melted and extruded through a screw extruder; a reinforcement component is added in the extruding process; and finally, a novel halogen-free flame retardant reinforced nylon composite material of the high-fluidity halogen-free flame retardant reinforced nylon composite material is obtained through drawing, cooling and pelletizing. The flame retardant reinforced nylon composite material has the characteristics of high melt fluidity, good environmental friendliness and flame retardance, good electric performance, excellent mechanical performance and the like; and obtained products have excellent surface performance, low warpage and high smoothness. The material can be widely applied in the field of electric plastic parts, such as casings, breakers, wire connection boxes, socket switches and the like of semiconductor devices such as IGBT (Insulated Gate Bipolar Transistor) and the like.

Owner:株洲时代工程塑料实业有限公司

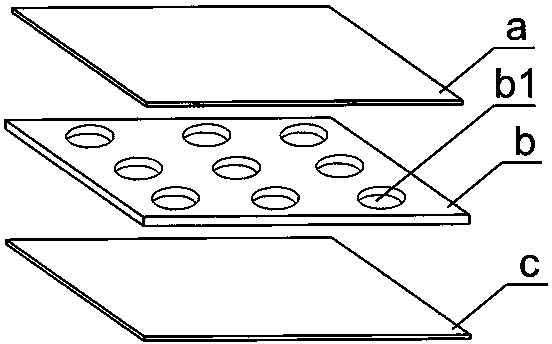

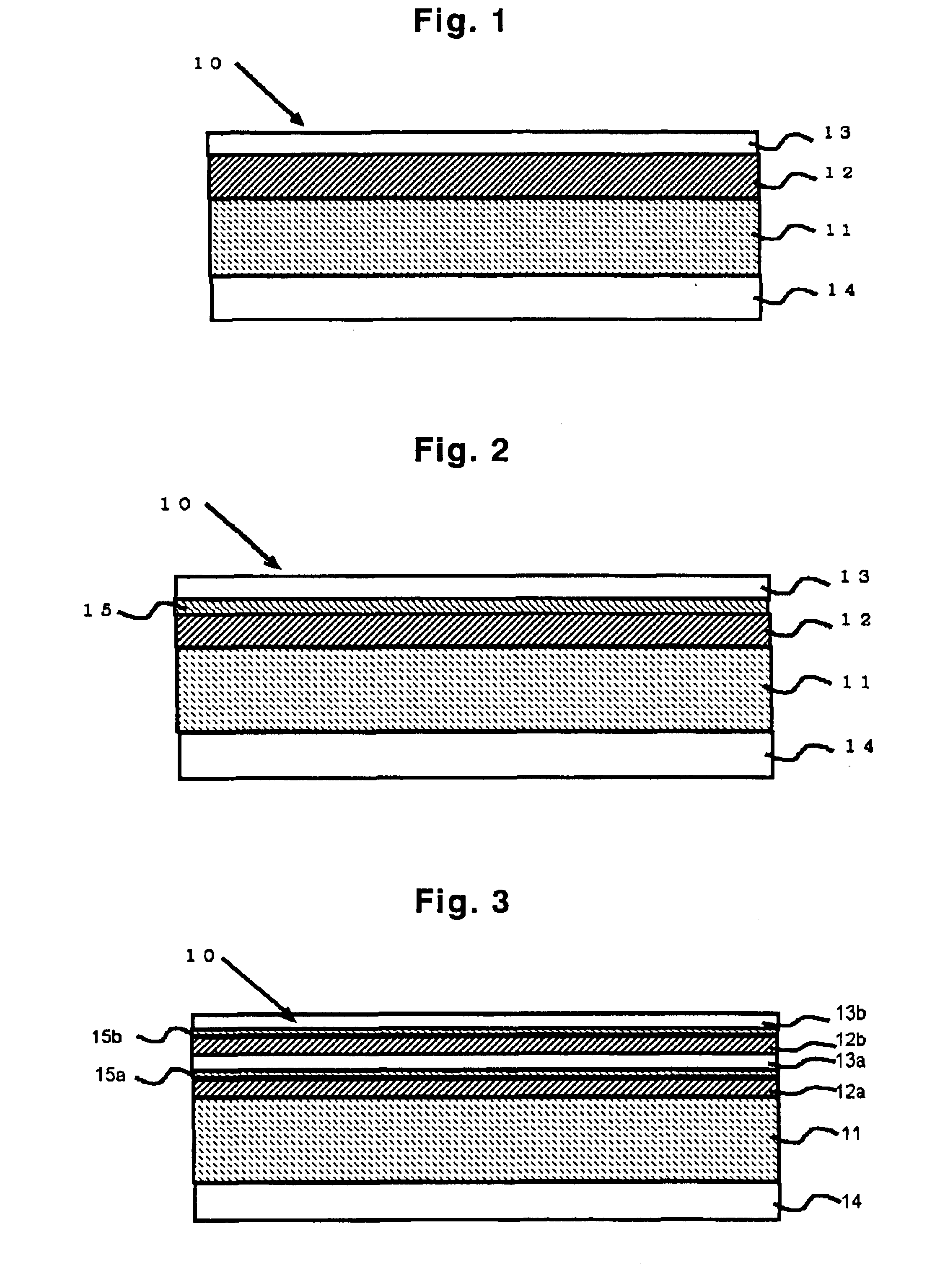

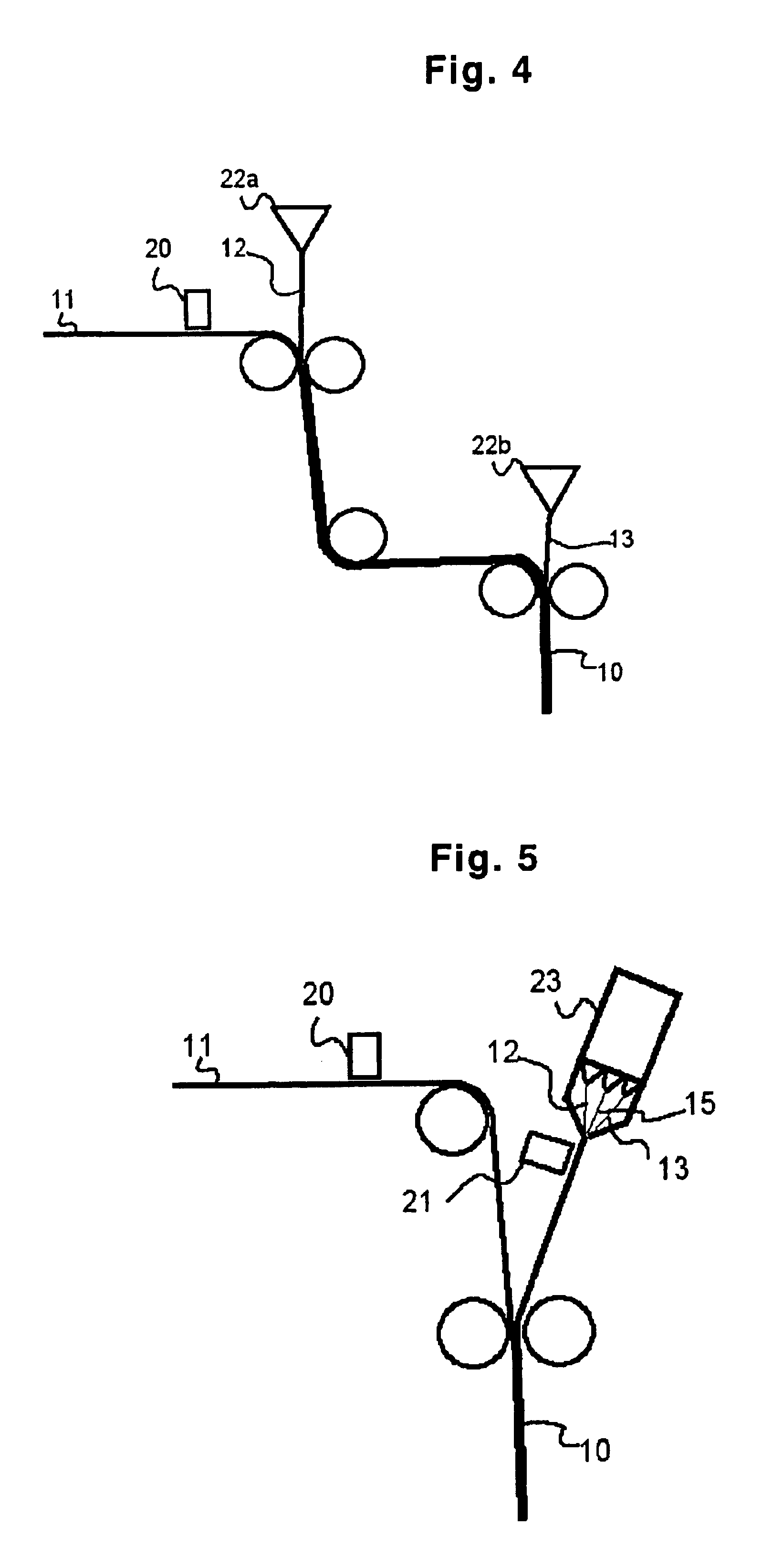

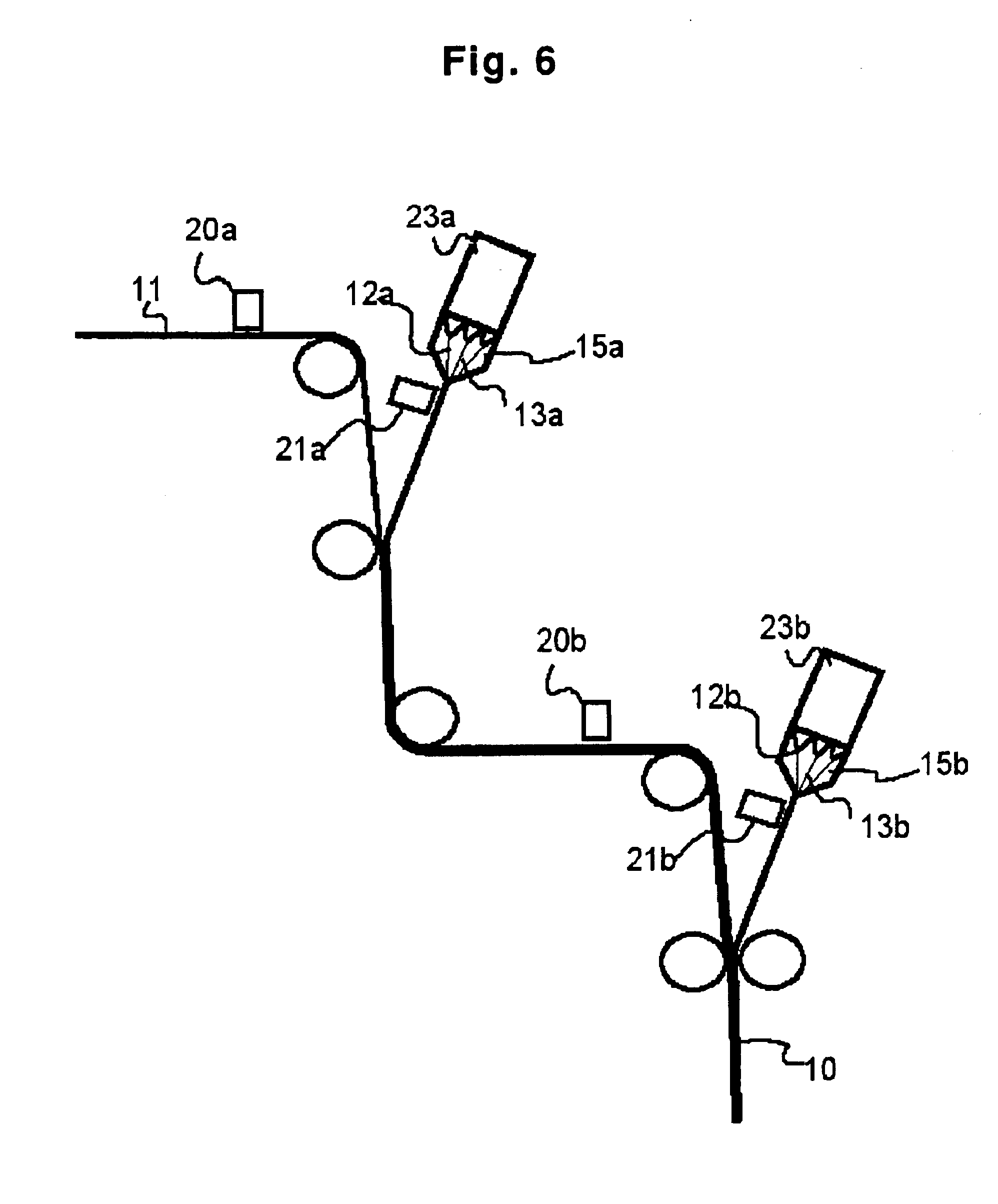

Laminated packaging material and method for producing the same

InactiveUS6872459B1Valid conversionExcellent in non-scalping and gas barrierLamination ancillary operationsLayered product treatmentLinear low-density polyethyleneSwelling ratio

This invention relates to the laminated material for food packaging, and its manufacturing process. The laminated material (10) consists of the quality keeping intermediate layer (12) laminated inside the paper core layer (11) and the core layer and the heat sealable innermost layer (13). The quality keeping intermediate layer comprises of an extrusion coatable blend polymer consisting of polymer component A 50-95% of nylon-MXD6 or EVOH and, polymer component B 5-50% of nylon 6, nylon 6, the blends or PET. The quality keeping intermediate layer is extruded and laminated directly in the core layer, the innermost layer contains at least the linear low density polyethylene which has a narrow molecular weight distribution, and has the properties parameter of mean density of 0.910-0.925, 100-122 degrees C. peak melting point, melt flow index of 5-20, swelling ratio (SR) of 1.4-1.6, and 5-50 micrometer layer thickness.The hardness, production efficiency, and cost performance of the barrier packaging container formed by the packaging material are improved.

Owner:TETRA LAVAL HLDG & FINANCE SA

Lead free, composite polymer based bullet and method of manufacturing

Owner:TRUE VELOCITY IP HLDG LLC

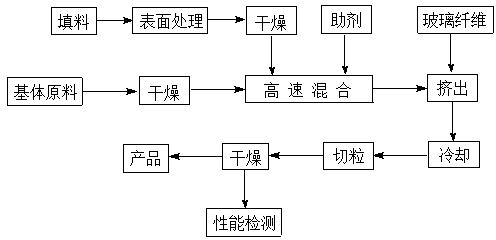

Glass fiber-reinforced nylon 6-polypropylene alloy material

The invention relates to glass fiber reinforcing nylon 6-polypropylene alloy material. The invention is characterized in that the invention adopts nylon 6 and polypropylene as the matrix resin, and under the condition that the addition level of plasticizer is not changed, the invention can achieve and is preferable to the mechanical property of the unilateral enforced nylon 6 material without polypropylene added, in particular to the impact property. The matrix resin, the plasticizer as well as the antioxidant are evenly mixed and then enter into a double screw extruder, simultaneously glass fiber is added from the special glass fiber opening of the double screw extruder, and the matrix resin, the plasticizer, the antioxidant and the glass fiber are cooled, dried and palletized to be produced into finished products after being mixed together and extruded. The invention has the advantages that the plasticizer can be self made, the cost of the alloy material is low, the invention has good impact property, and the other mechanical properties are kept unchanged basically.

Owner:SHANGHAI KINGFA SCI & TECH +1

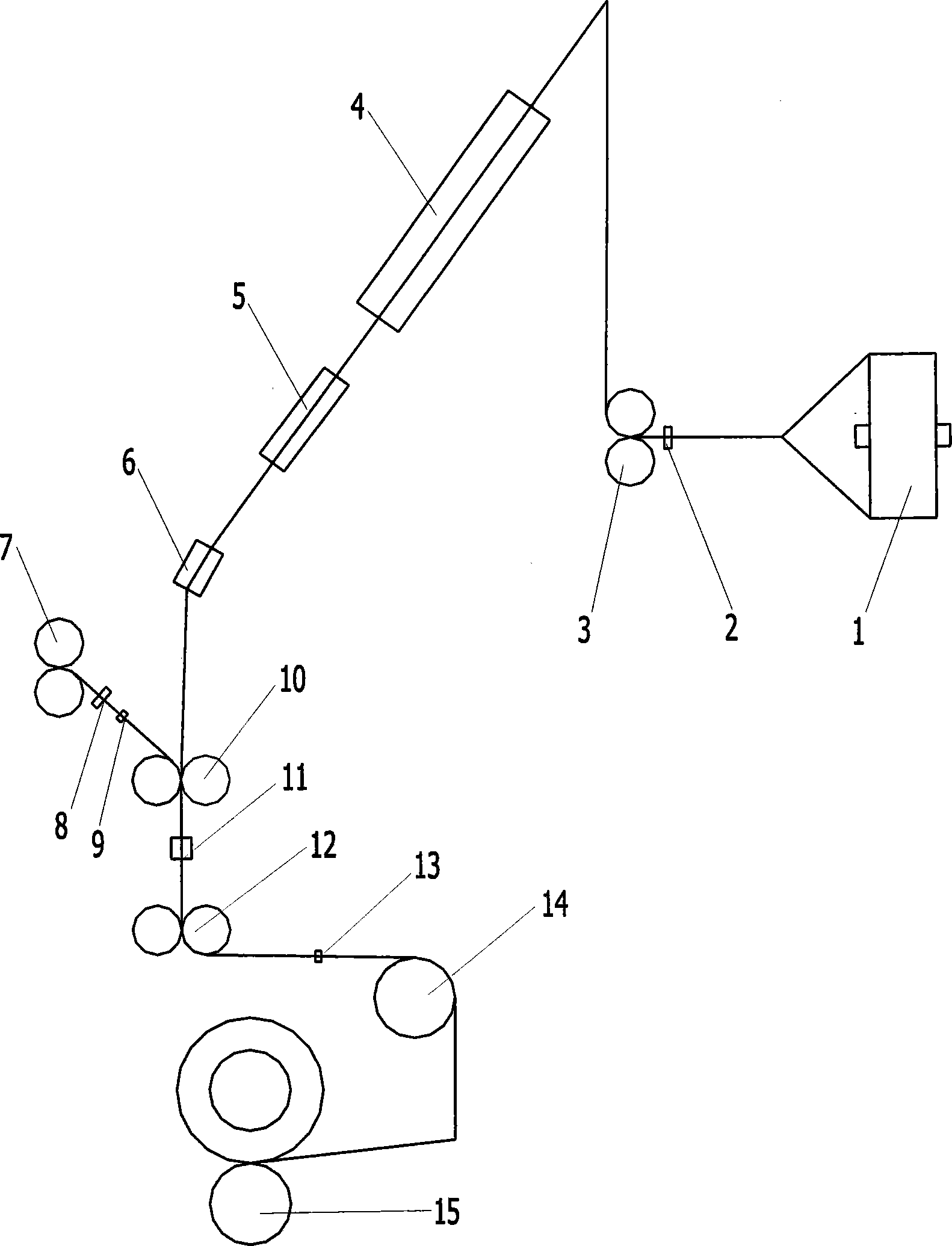

Method for manufacturing nylon/spandex air-textured yarn by false twist texturing machine one-step method

The present invention provides a method for making nylon-polyurethane fiber blended yarn by utilizing false-twist texturing machine and adopting one-step process. Said method includes the following steps: (A), making nylon raw yarn be drawn out from raw yarn frame, and making said nylon raw yarn be fed into first roller by means of first yam-cutting device of false-twist texturing machine, then fed into a texturing hot-box, and passed through a cooling device and a false-twister, then attracted by suction gun; (B), making polyurethane fiber yarn be drawn out from polyurethane fiber roller, and making said polyurethane fiber yarn be passed through second yarn-cutting device and second yarn-detector, then be attracted by suction gun, then combined with nylon yarn; and (C), making the combined two yarns be passed through intermediate roller, air-entanglement jet device, second auxiliary roller and first yarn detector, and be reached to oiling roller, finally passed through winding roller and winding to make formation.

Owner:WUXI HONGYUAN ELECTROMECHANICAL TECH

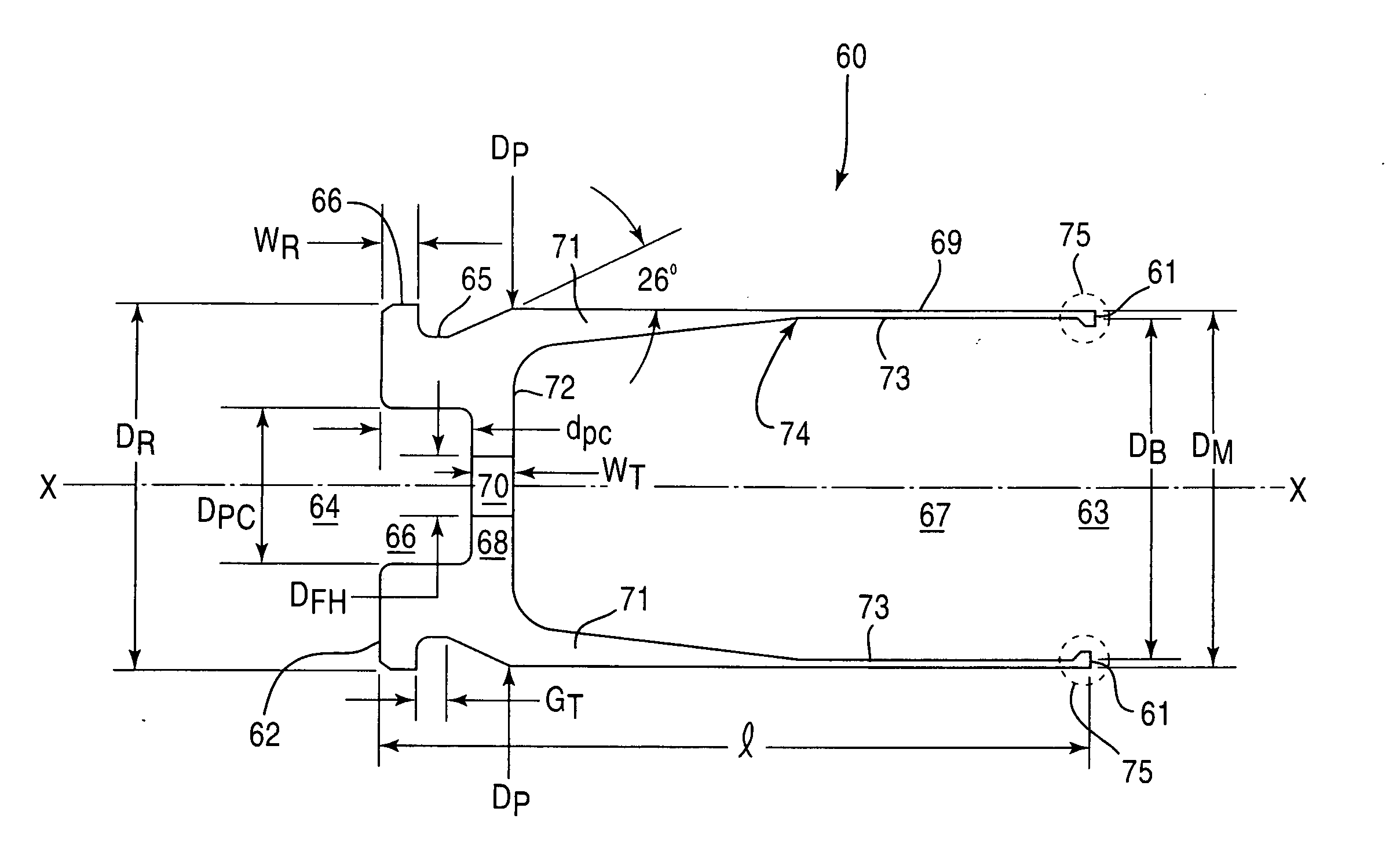

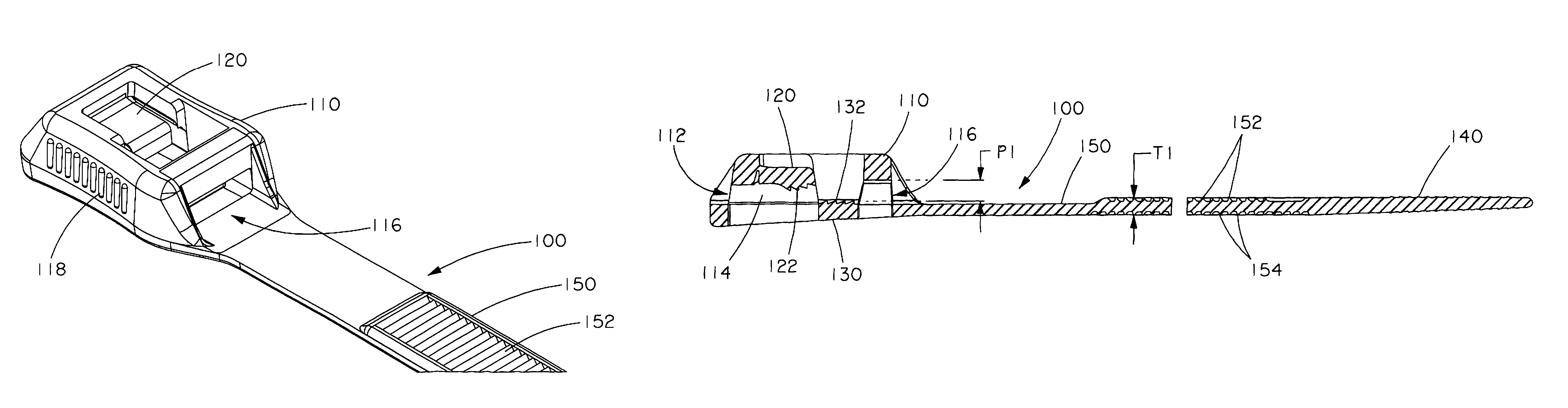

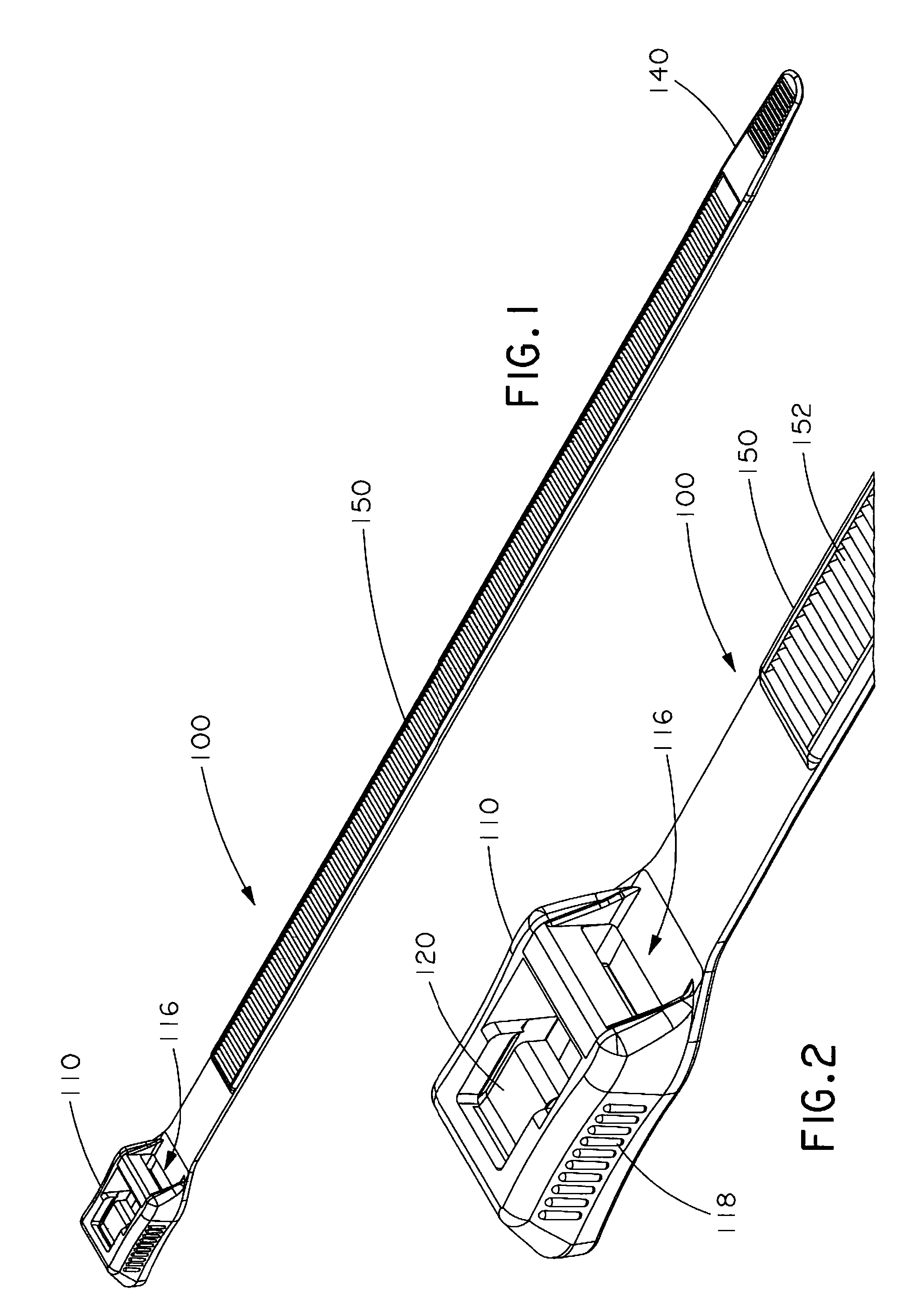

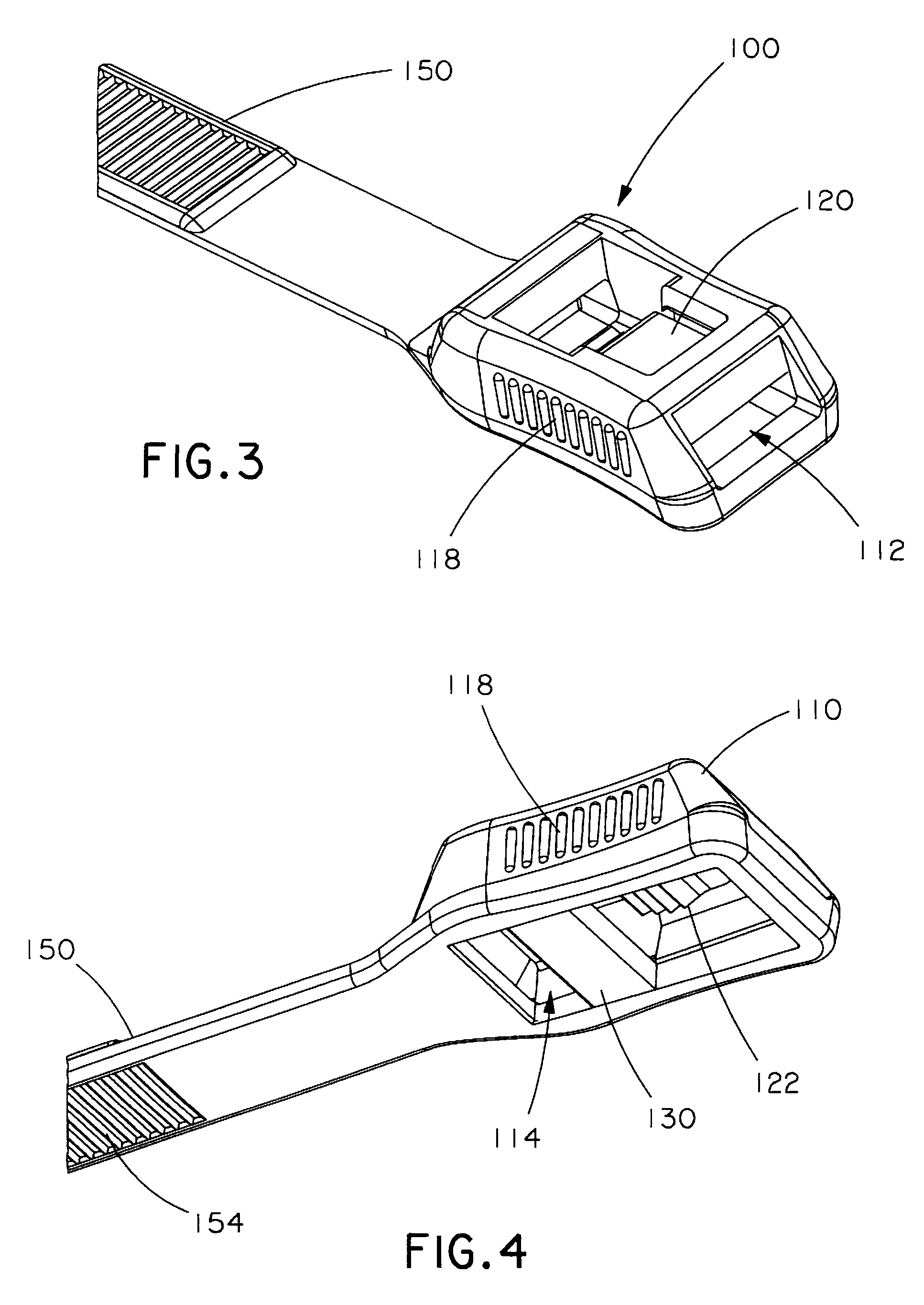

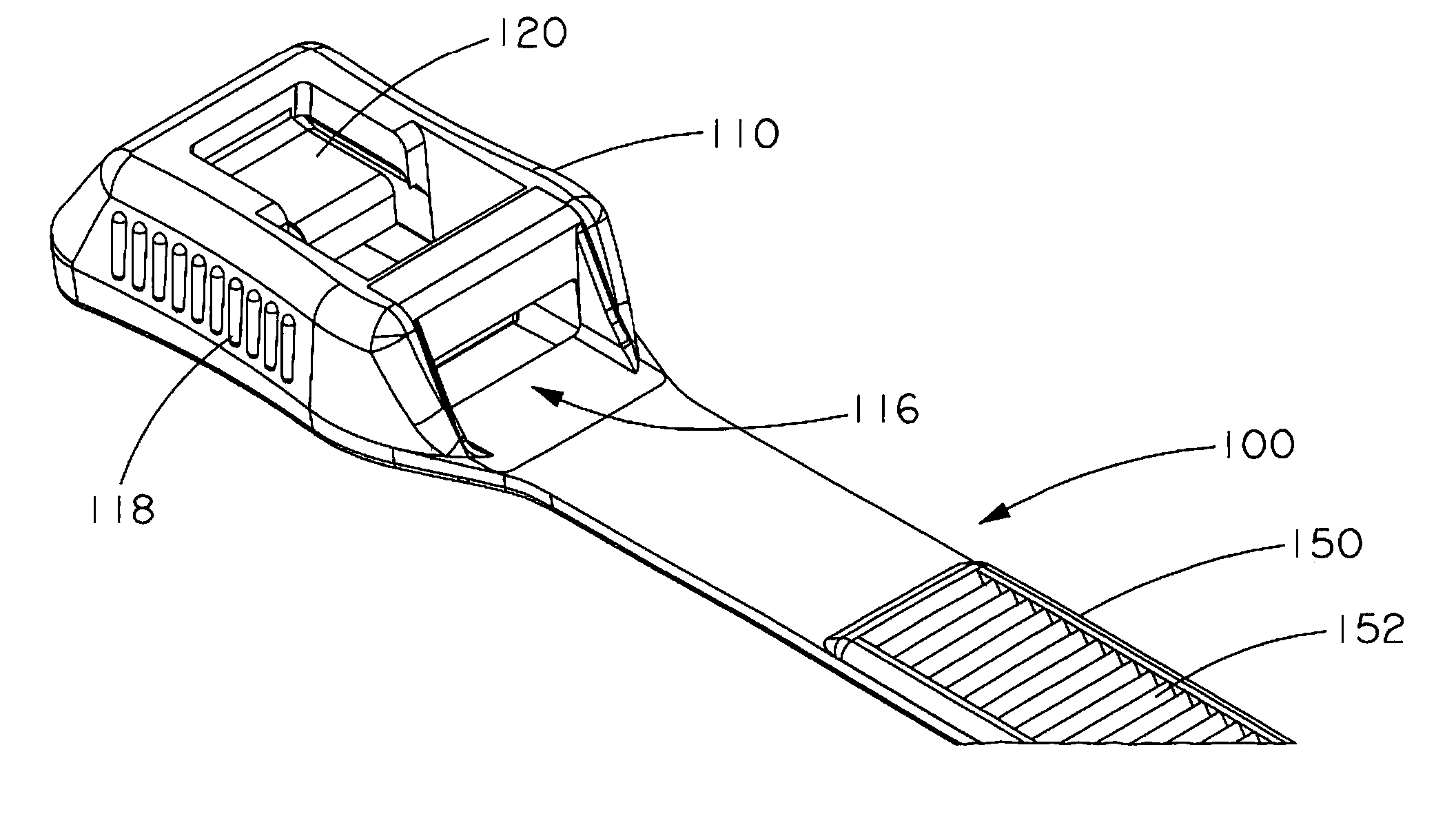

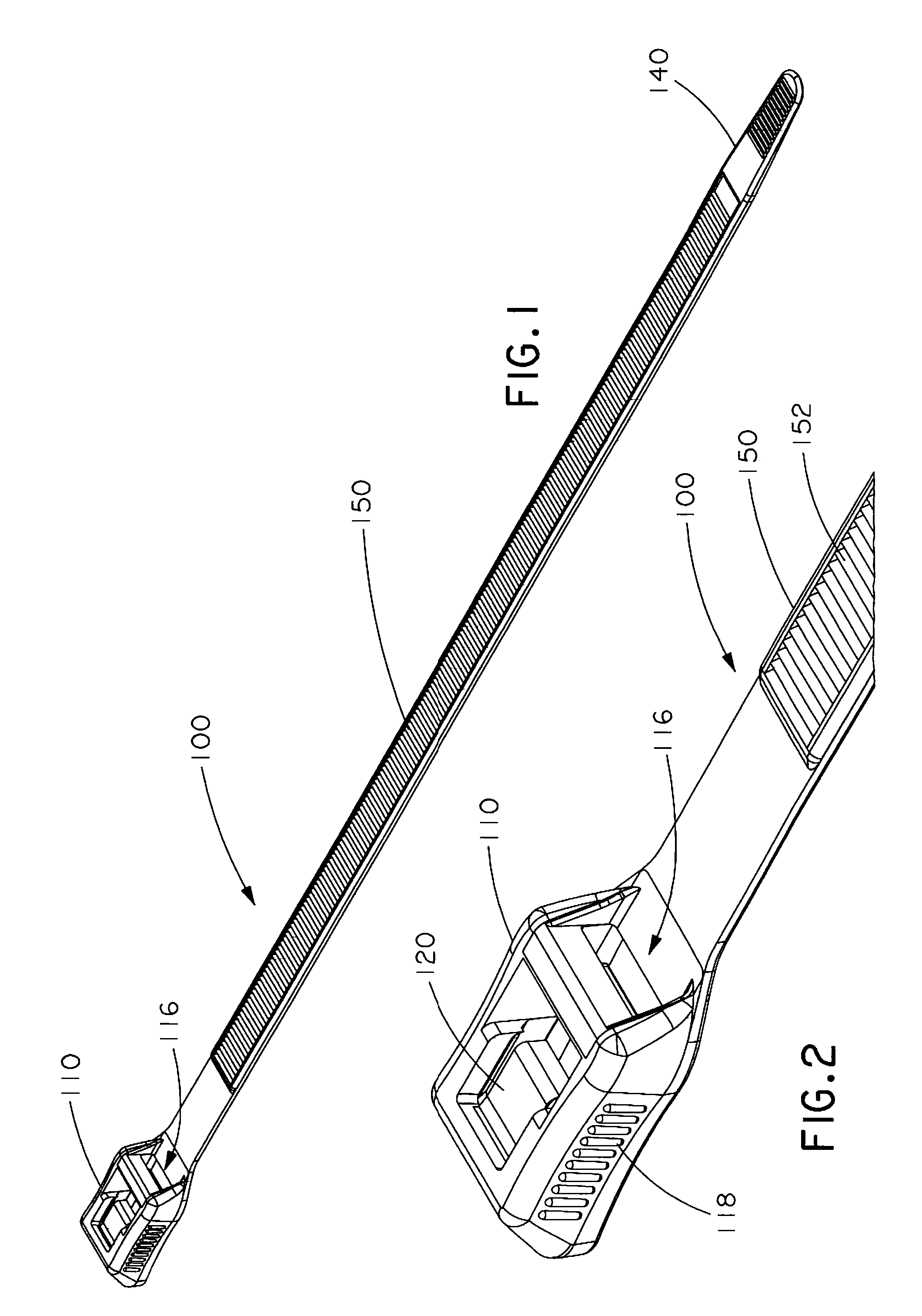

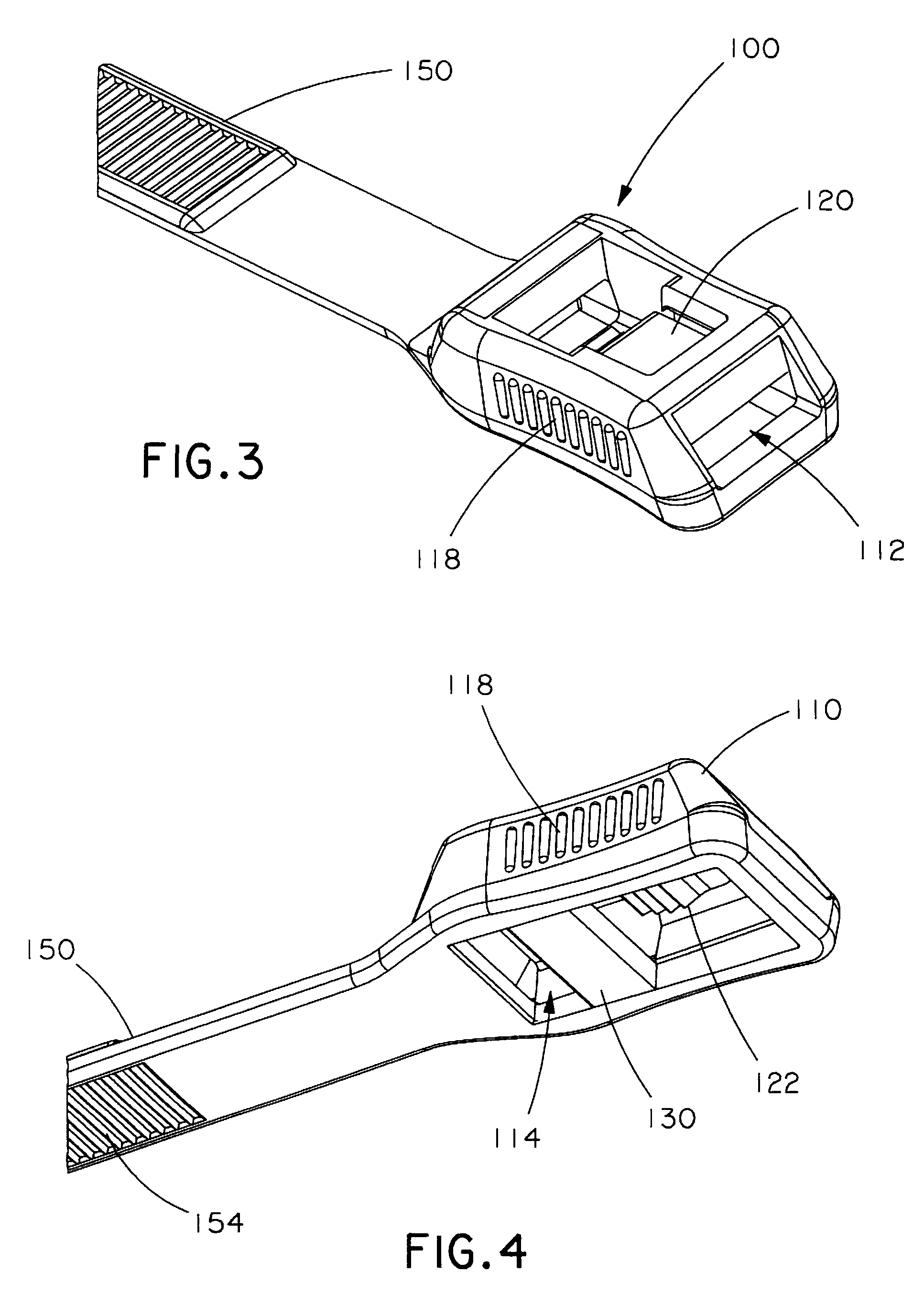

In-line cable tie with fixed and hinged locking mechanisms

A one-piece cable tie, such as an in-line cable tie, includes a hybrid locking mechanism including both a fixed locking wedge and a hinged locking wedge. The hinged locking wedge may be laterally offset from the fixed locking wedge along a longitudinal axis of an internal passageway of the cable tie head. Preferably, the hinged locking wedge is located on a top surface of the passageway while the fixed locking wedge is located on a bottom surface of the passageway. The hinged locking wedge may be located close to the strap ingress. The cable tie is preferably made of Nylon 6.6, yet can achieve both a low thread insertion force and a high loop tensile strength suitable for demanding applications. Maximized strength is achieved through use of multiple teeth on each of the hinged and fixed locking wedges.

Owner:PANDUIT

Processing method of high-strength low-shrinkage nylon 6 fine denier filament

InactiveCN102181951ALow dry heat shrinkageArtificial filament heat treatmentStretch-spinning methodsBreaking strengthNitrogen

The invention discloses a processing method of a high-strength low-shrinkage nylon 6 fine denier filament, belonging to the technical field of nylon filament processing. The method comprises the following steps: preparing materials: adding the nylon 6 slices into a bin of nitrogen protective gas to obtain a material to be melted; melting: introducing the material to be melted into a screw extruder for melting to obtain a melt; forming: introducing the melt from the upper part of a spinning box, and ejecting from a spinneret orifice of a spinneret plate to obtain a filament bundle; cooling: introducing the filament bundle into a slow-cooling area for slow cooling, forming through side-blowing air cooling, and further cooling through a channel; oiling and pre-interlacing: oiling the cooling-formed filament bundle through an oil lip or oil wheel, and pre-interlacing; drafting: feeding the filament bundle to be drafted through a feeding roller, drafting through a heat roller, and then performing relax-type setting to obtain the drafting-set filament; and re-interlacing and re-oiling: re-interlacing and re-oiling the drafting-set filament before packaging to obtain the high-strength low-shrinkage nylon 6 fine denier filament. The method can adapt to different purposes of products, and can be applied to the occasions having rigorous requirements on the breaking strength and dry heat shrinkage.

Owner:CHANGSHU POLYESTER

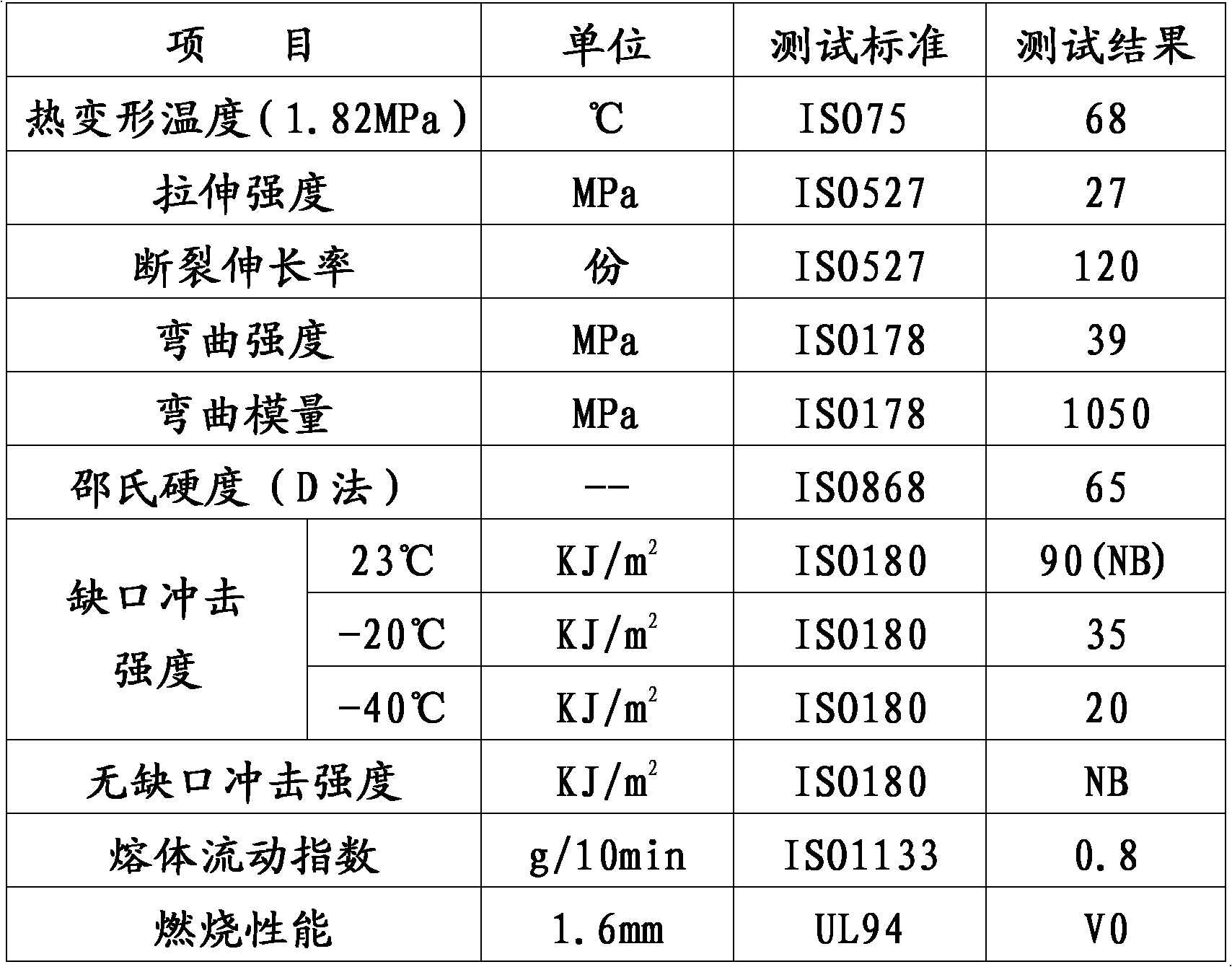

Low-smell toughening polyamide (PA) 6 material and preparation method thereof

The invention discloses a low-smell toughening polyamide (PA)6 material. The low-smell tougheningPA6 material comprises the following raw materials in part by weight: 60 to 95 parts of nylon 6 resin, 5 to 40 parts of polyolefin, 0.5 to 5 parts of maleic anhydride, 0.1 to 0.5 part of peroxide and 0.2 to 5 parts of other additive. By the preparation method, the processing step of preparing toughening polyamide (PA)6 material is simplified, namely the primary two steps are combined into one step, and the preparation of the toughening polyamide (PA)6 material is realized by controlling a processing temperature. The production cost is reduced by the method; the prepared toughening polyamide (PA)6 material is excellent in performance and low in smell, has a certain practicability and commercial value and can be applied in fields, such as vehicles, electronics / electrical appliances and the like.

Owner:SHANGHAI PRET COMPOSITES

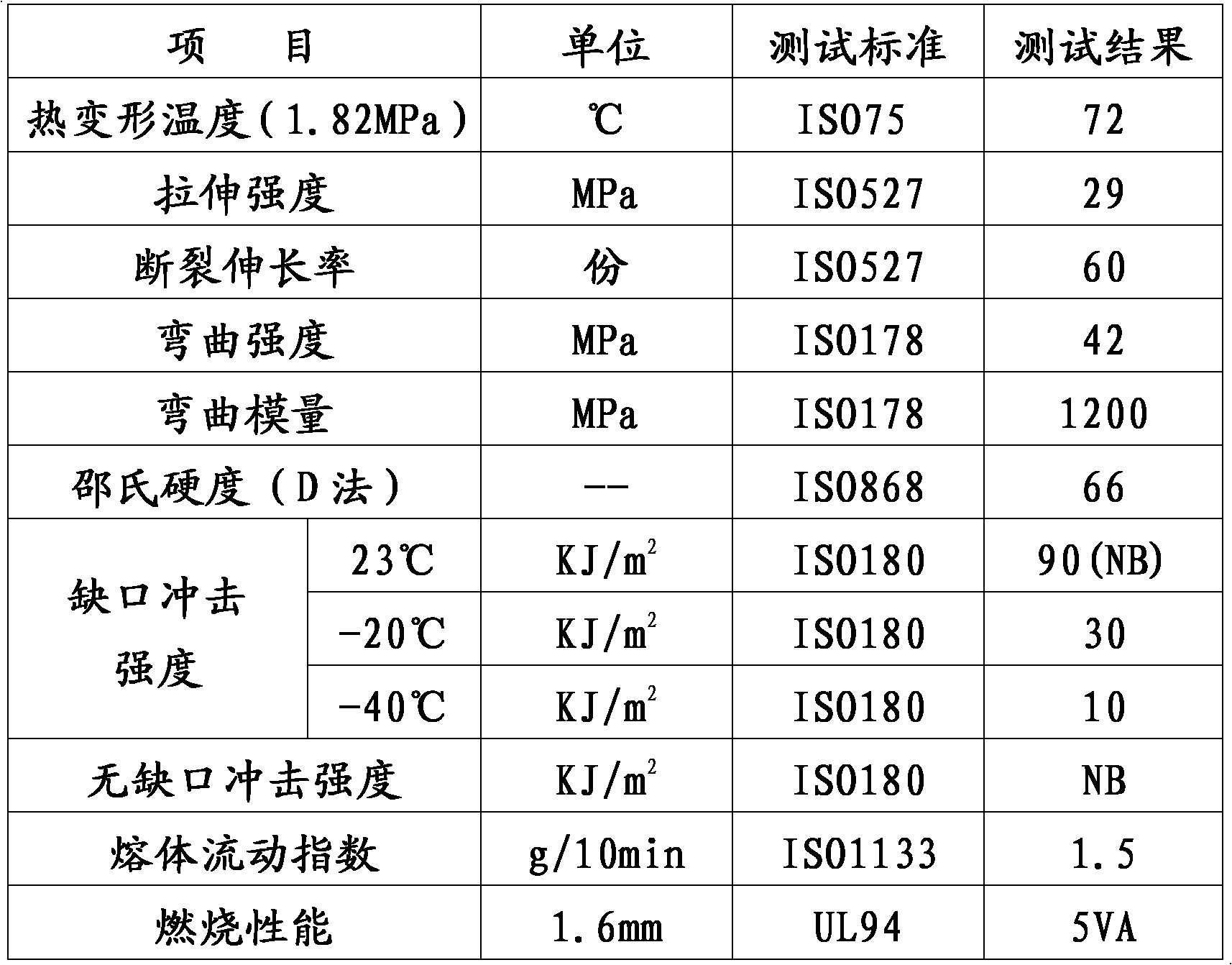

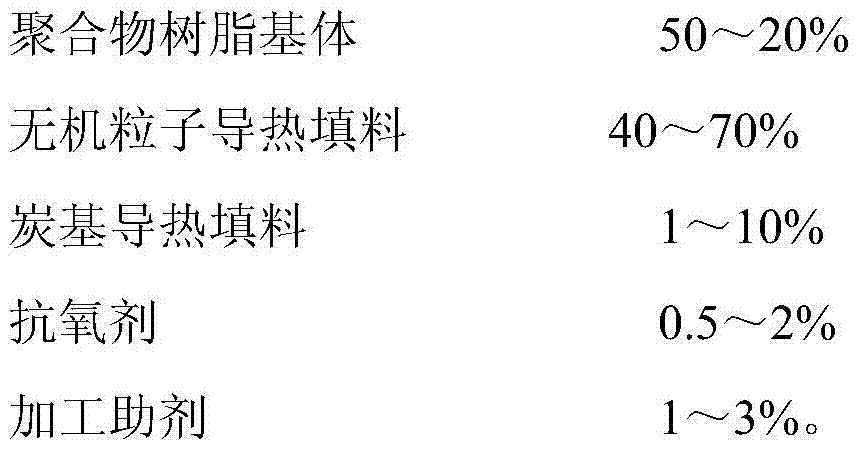

High-flowability polyamide based halogen-free flame-retardant heat-conducting composite material and preparation method thereof

The invention discloses a high-flowability polyamide halogen-free flame-retardant heat-conducting composite material and a preparation method thereof. A novel halogen-free flame-retardant heat-conducting composite material is prepared by using high-flowability nylon 6 resin with a branch chain structure as a base body, adding additives such as heat-conducting fillers, a halogen-free flame retardant, an antioxidant and a coupler, and preparing the material through a double-screw melt blending technology. The halogen-free flame-retardant heat-conducting composite material has the characteristics of good heat conductivity, high melt flowability, good environment-friendly and flame-retardant performances, excellent insulation and mechanical comprehensive performances and the like; an obtained product is high in heat-radiating speed, high in strength, low in warping degree and resistant to high temperature and ageing; the composite material can be widely applied to the field of electric plastic parts with higher heat-radiating requirements such as locomotive compartment illumination lamp covers, auto and civil LED heat radiators, household appliance motor shells, notebook power, micro-projector shells, transformer coil frameworks and the like.

Owner:株洲时代工程塑料制品有限责任公司

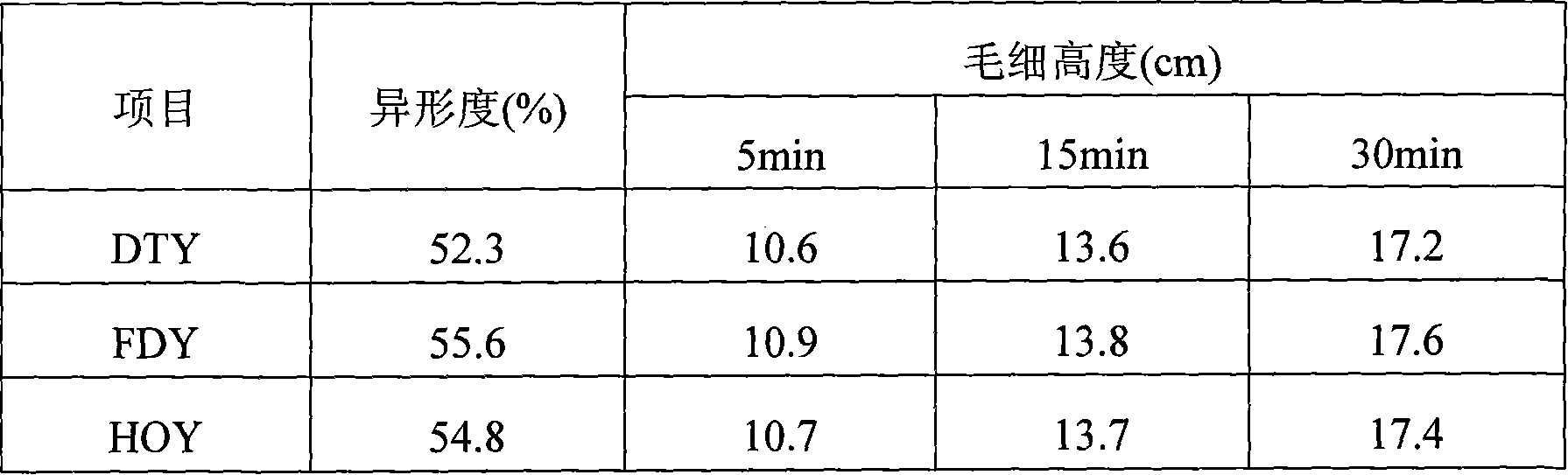

Method for producing polyamide moisture-absorption perspiration fibre and product

InactiveCN101158056AImprove hygroscopic propertiesSoft touchFilament/thread formingMonocomponent polyamides artificial filamentFiberPerspiration

The invention discloses a production method and a product of moisture absorption and sweat exhaust fiber of chinlon 6. The method is that dried slices of nylon 6 are put into a screw extruder to form melts of chinlon 6, which are then spun by a spinneret with an irregular section arranged in a spinning box body. After processes of slow cooling, cross air blowing, oiling and following high speed winding, the moisture absorption and sweat exhaust fiber of chinlon 6 is made.

Owner:GAOYAO XINDA FIBERS

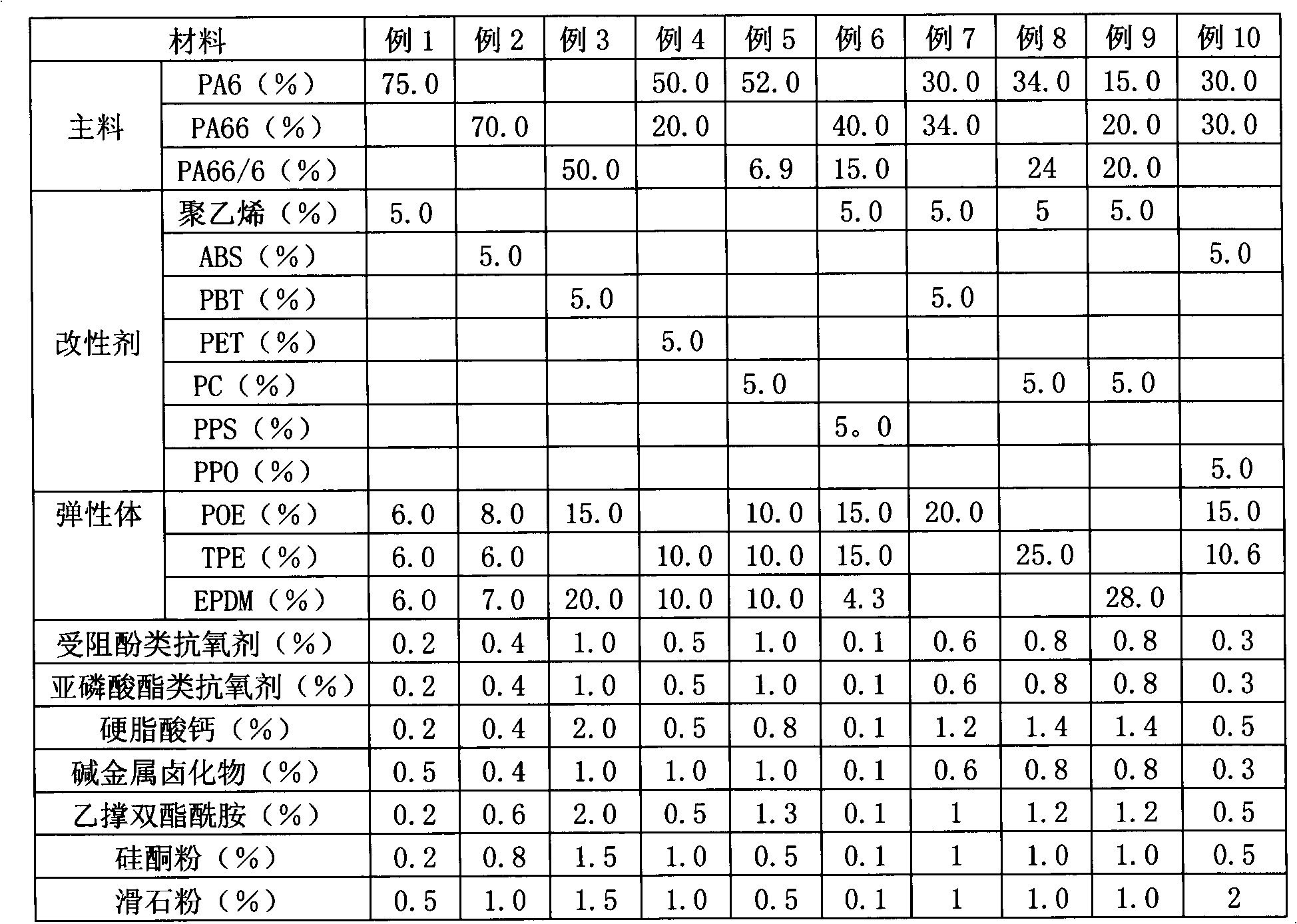

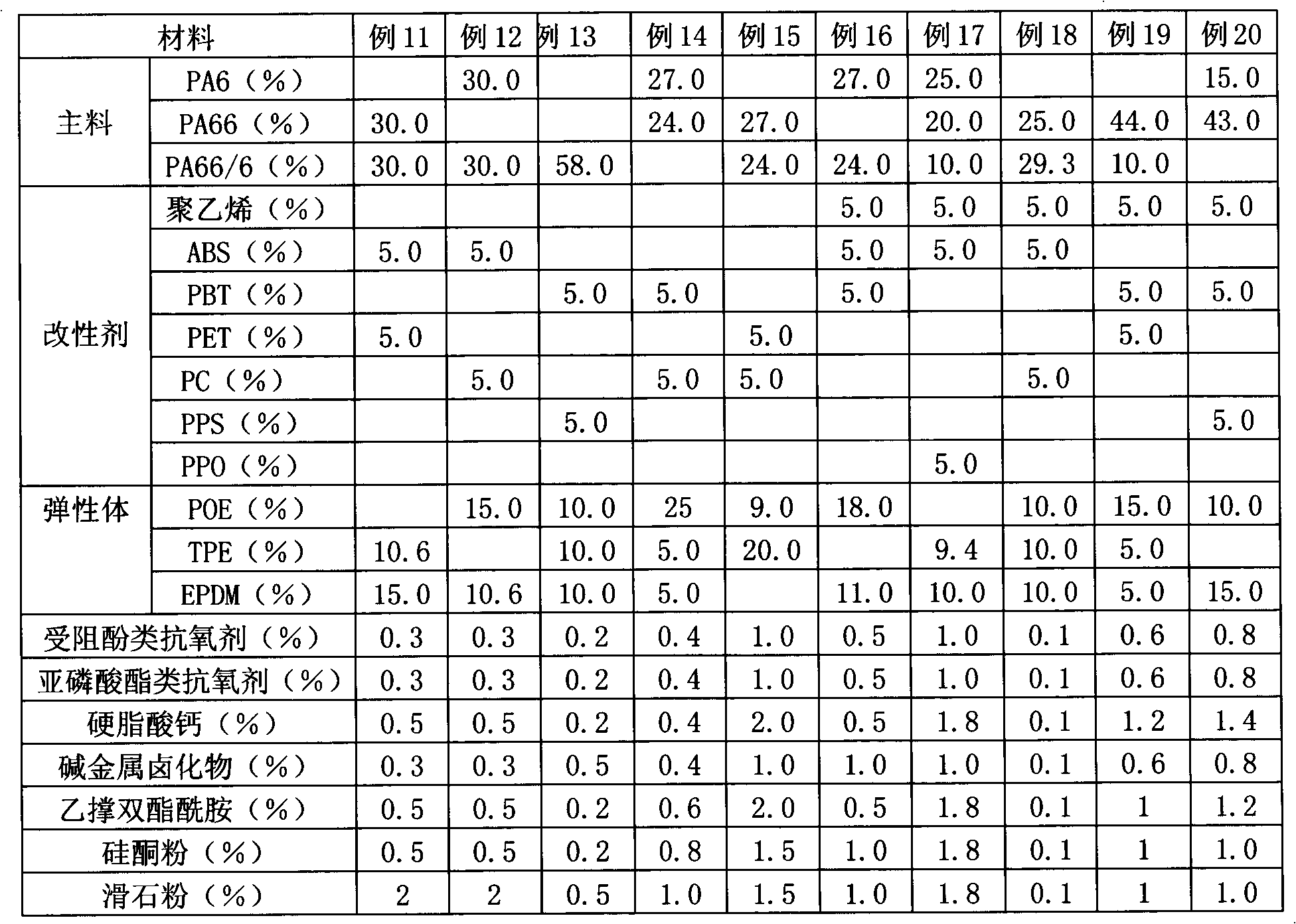

Nylon composite material with low fuel oil permeability rate used for fuel oil tank and preparation method thereof

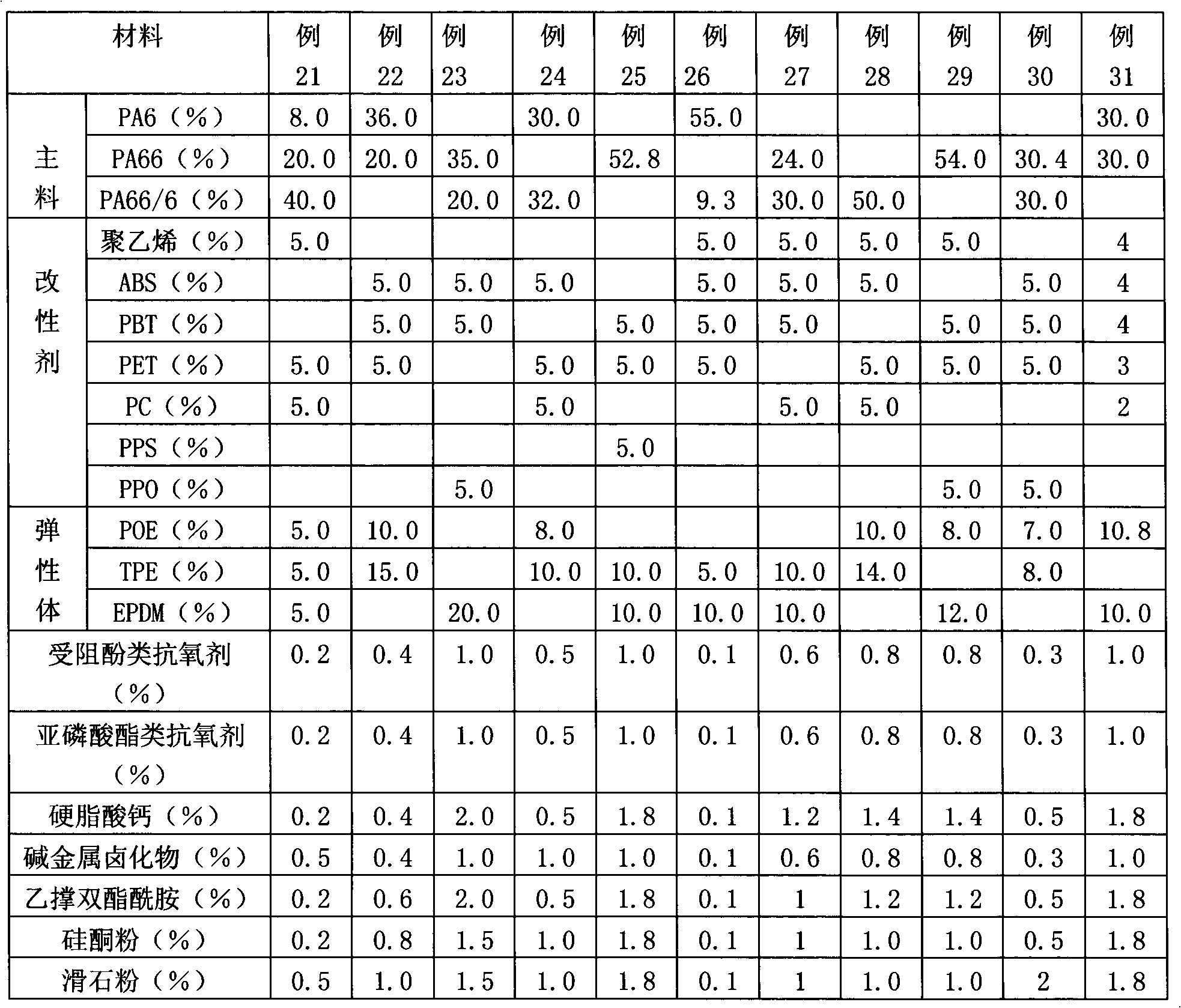

The invention provides a nylon composite material with low fuel oil permeability rate used for a fuel oil tank, which is characterized by containing a main material, a modifier, an elastomer and an auxiliary agent, wherein the main material is selected from a nylon 6 copolymer, a nylon 66 copolymer, a nylon 6 / 66 copolymer or a random mixture thereof, the modifier is selected from ABS, polyethylene, PC, PPS, PPO, PBT, PET or a random mixture thereof, the elastomer is selected from POE, TPE, EPDM or a random mixture thereof, and the auxiliary agent contains a temperature-resistant anti-aging agent, a lubricant and a nucleating agent. The nylon composite material with low fuel oil permeability rate used for the fuel oil tank, which is provided by the invention, has favorable blow-molding forming performance and very large market value, the fuel oil permeability rate is below 1.7g / m<2>*24h, and the shock-resistance strength at low temperature (negative 40 DEG C) reaches 65-95kJ / m<2>.

Owner:辰东意普万新材料(广东)有限公司

Flame-retardant antistatic reinforced nylon 6 composition and preparation

InactiveCN101469129AHigh strengthImprove flame retardant performanceOther chemical processesTO-18Glass fiber

The invention relates to a flame retardant antistatic reinforced nylon 6 composition and a method for preparing the same. 45 to 60 weight percent of nylon 6 slice, 10 to 40 percent of fiberglass, 15 to 18 percent of flame retardant, 2 to 4 percent of flame retardant boosting agent, 2 to 5 percent of anlistatig, 0.1 to 0.5 percent of antioxidant and 0.1 to 1 percent of lubricant by weight percentage are put in a high mixing machine, are mixed for 2 to 5 minutes and are discharged; the mixed raw materials and fiberglass are put to a screw extruder and is subjected to extrusion and pelletization; the rotational speed of the screw extruder is between 180 and 600 revolutions / minute; and the temperature is between 160 and 250 DEG C. Compared with the prior art, the flame retardant antistatic reinforced nylon 6 composition has the characteristics of high strength, excellent flame retardance, lasting antistatic property, easy processing and the like.

Owner:HEFEI GENIUS NEW MATERIALS

High heat conducting nylon composite material and preparation method thereof

The invention discloses a high heat conducting nylon composite material and a preparation method thereof. The high heat conducting nylon composite material belongs to one of functional high molecules. The composite material is prepared from a thermoplastic nylon resin base body, heat conducting filler and other processing agents. The heat conducting coefficient is greater than 2.7W / m.K. The resin base body can be nylon 6 or a compound of nylon 6, nylon 9, nylon 66, nylon 610 and nylon 1010. The heat conducting filler can be one or more of magnesium oxide, aluminum oxide, aluminum nitride, boron nitride, silicon nitride, a multiwalled carbon nanotube and a graphite flake layer. The processing agents can be octadecanamide, polyethylene wax, liquid paraffin and the like. The method disclosed by the invention is simple to operate and low in cost, and can prepare the heat conducting composite material with excellent comprehensive performance by one step. The method is easy to realize industrialized production and can be widely applied to the fields of automobiles, household appliances, meter cases, circuit elements and the like.

Owner:BEIJING UNIV OF CHEM TECH

In-Line Cable Tie with Fixed and Hinged Locking Mechanisms

ActiveUS20070266531A1High strengthLower insertion forceSilencing apparatusFlexible elementsLocking mechanismNylon 6

A one-piece cable tie, such as an in-line cable tie, includes a hybrid locking mechanism including both a fixed locking wedge and a hinged locking wedge. The hinged locking wedge may be laterally offset from the fixed locking wedge along a longitudinal axis of an internal passageway of the cable tie head. Preferably, the hinged locking wedge is located on a top surface of the passageway while the fixed locking wedge is located on a bottom surface of the passageway. The hinged locking wedge may be located close to the strap ingress. The cable tie is preferably made of Nylon 6.6, yet can achieve both a low thread insertion force and a high loop tensile strength suitable for demanding applications. Maximized strength is achieved through use of multiple teeth on each of the hinged and fixed locking wedges.

Owner:PANDUIT

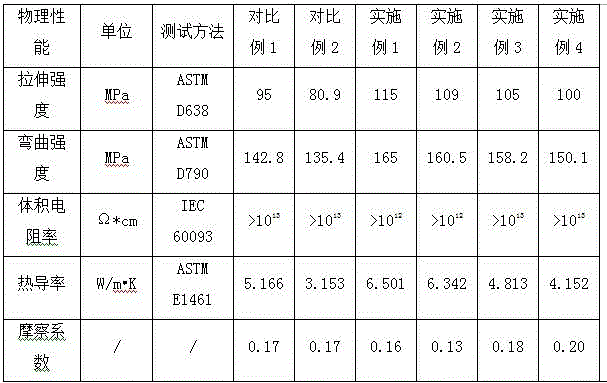

Heat-conducting, wear-resistant and insulated nylon 6 composite material and preparation method thereof

The invention relates to a heat-conducting, wear-resistant and insulated nylon 6 composite material and a preparation method thereof. The material is composed of the following raw materials in percentage by weight: 20-50% of PA 6, 10-30% of fibrous heat-conducting fillers, 15-30% of insulated heat-conducting powder A, 5-10% of insulated heat-conducting powder B, 5-15% of heat-conducting wear-resistant powder, 0.75-1.5% of coupling agent, 3-10% of compatibilizer, 0.2-0.5% of antioxidant and 0.2-0.5% of lubricant. According to the heat-conducting, wear-resistant and insulated nylon 6 composite material provided by the invention, heat-conducting fillers with different particle sizes, different shapes and different draw ratios are compounded so that the fillers are more uniformly distributed in a plastic matrix so as to form a heat-conducting network more easily. Since a low-feeding high-shearing extrusion process is used in the invention, an extruder is at a hungry state to achieve an effect of dispersing the fillers more uniformly. When the fibrous heat conducting fillers are added, a single screw extruder is used, so that the fibers can be sheared into smaller size, the damage is smaller, and meanwhile, the fillers are dispersed more uniformly by extruding the fillers by the extruder for the second time; and the heat-conducting, wear-resistant and insulated nylon 6 composite material provided by the invention has the advantages of good heat conducting effect, excellent wear resistance, easy workability, etc.

Owner:SHANGHAI UNIV

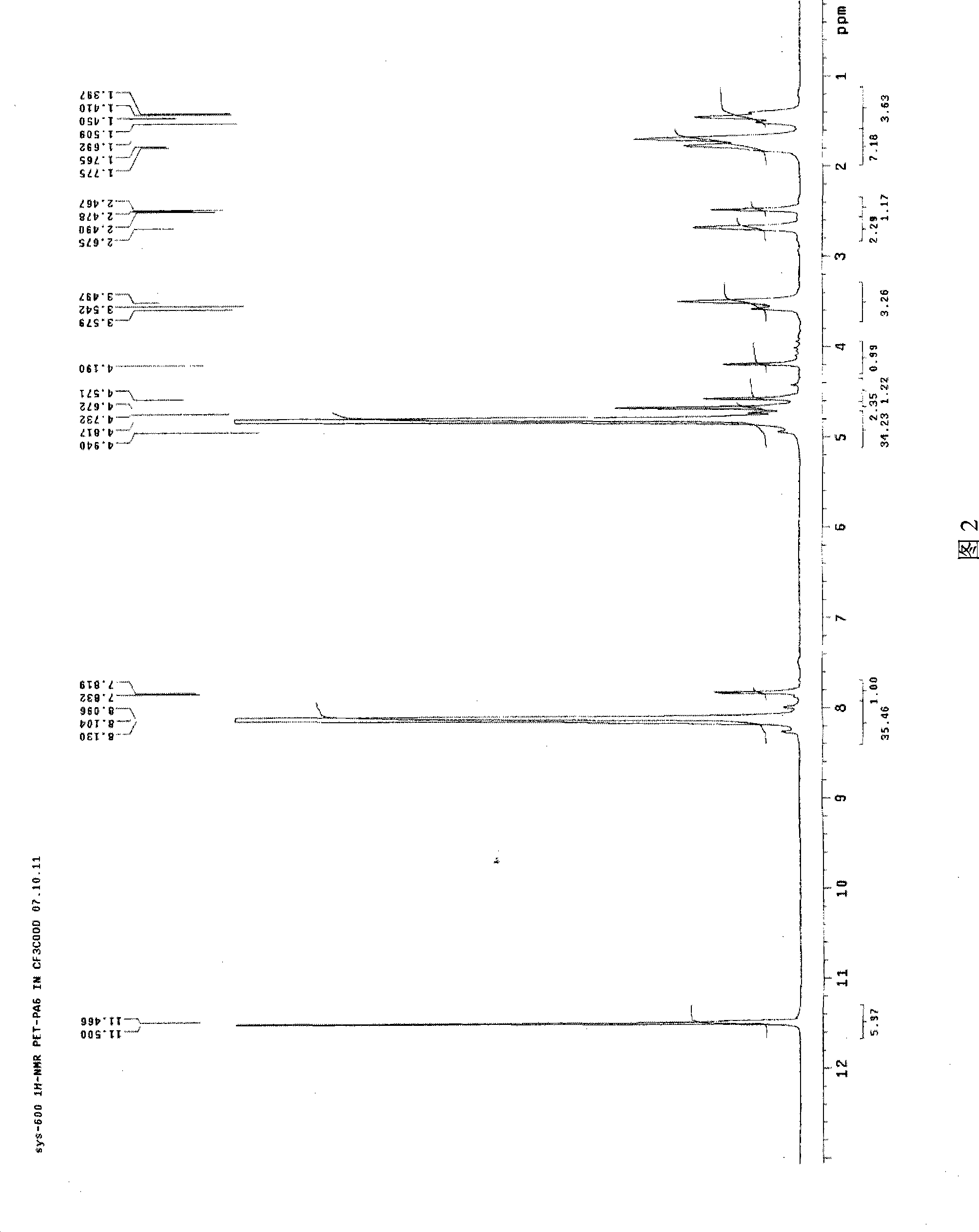

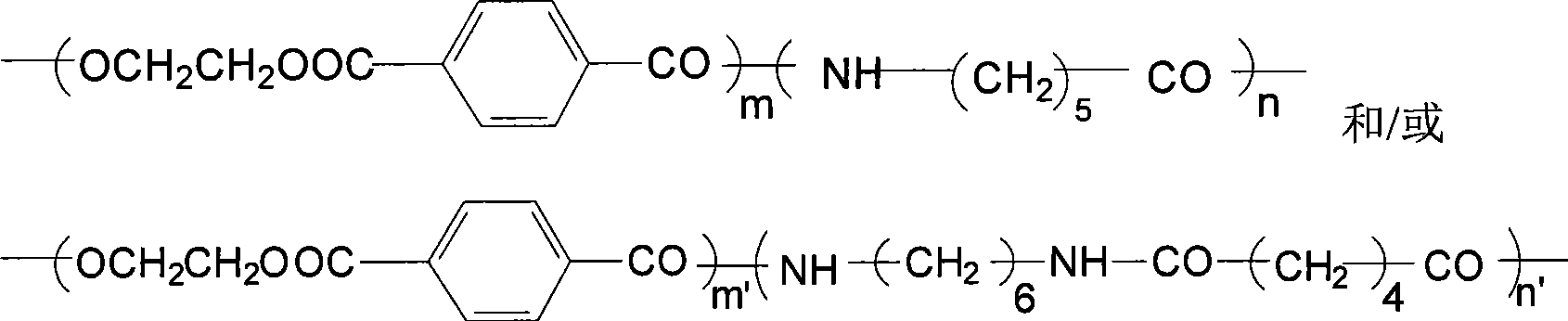

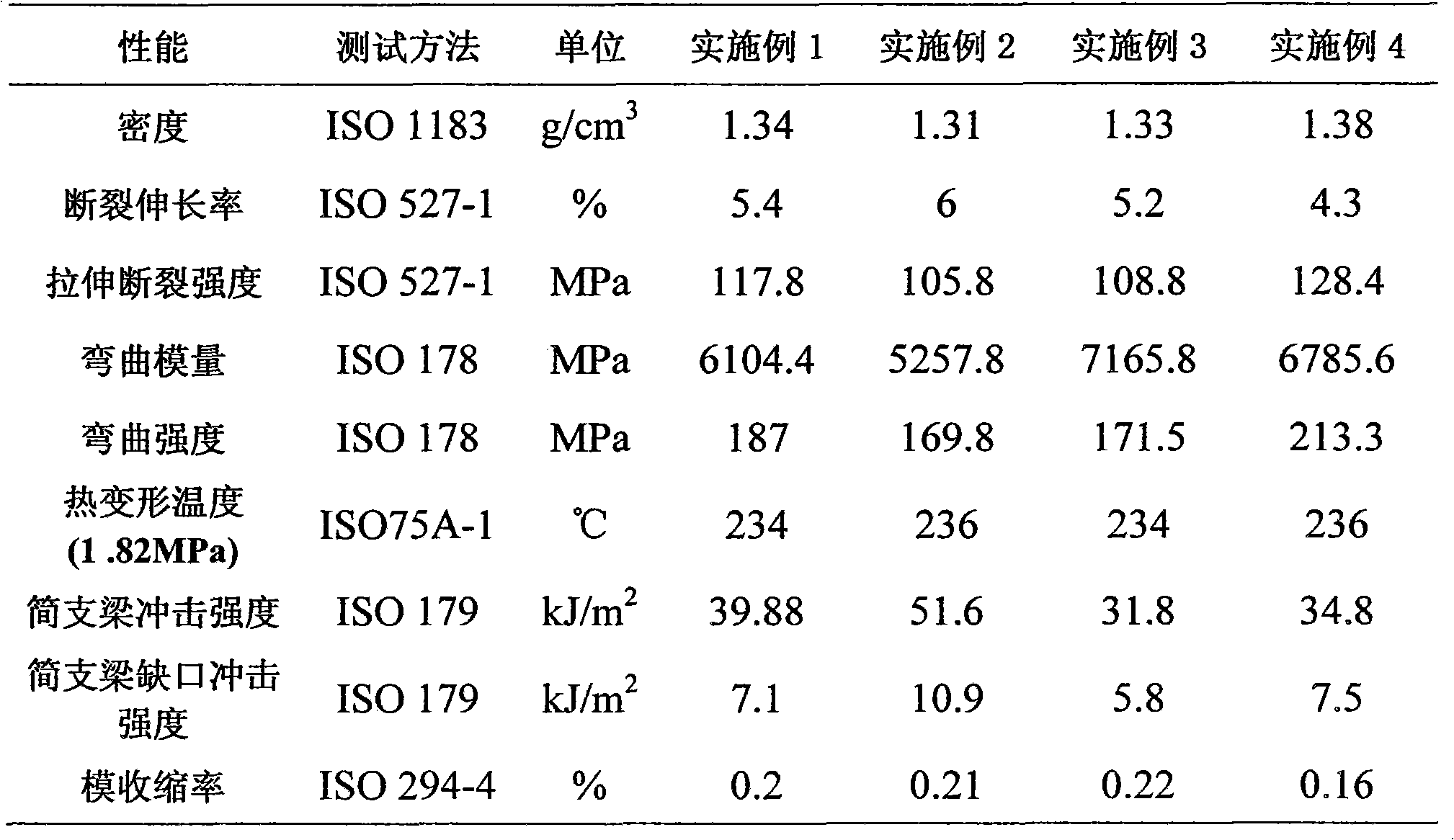

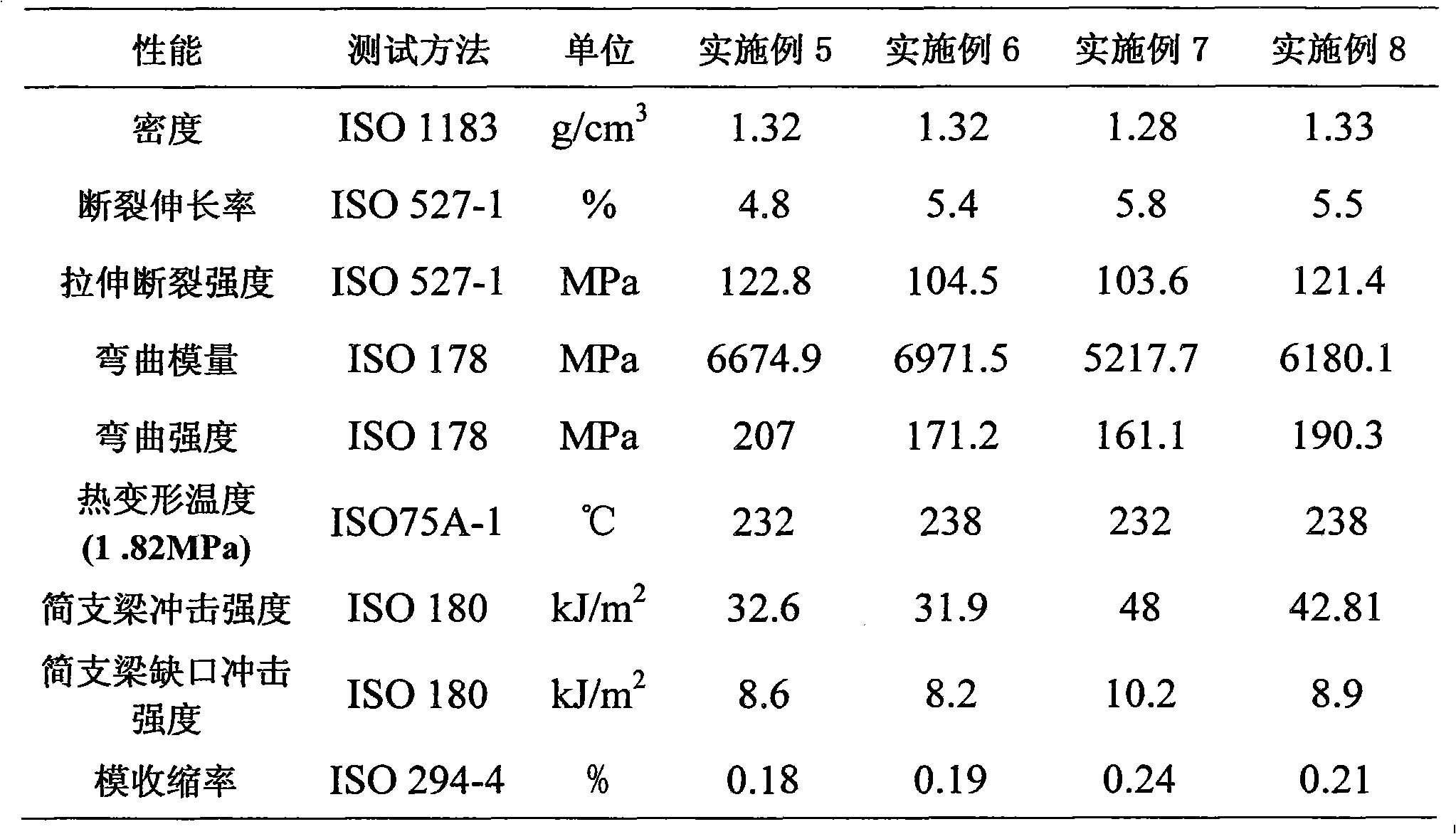

Acidic dyeable polyester and method for preparing acidic dyeable polyester and fiber thereof

ActiveCN101450990AUniform dyeingAffinityMonocomponent copolyesters artificial filamentDyeing processFiberFormate

The invention relates to acidic dyeable polyester and a method for preparing acidic dyeable polyester chip and fiber. The method comprises the steps of performing transesterification or esterification to p-phenyl dimethyl formate or p-phenyl dicarboxylic acid and glycol, adding polyamide such as nylon 6 and / or nylon 66 during polyester polymerization so as to prepare polyester chip, drying the polyester chip and using a conventional spinning machine to spin so as to prepare the polyester fiber used for the dyeing of acid dye. The polyester fiber thoroughly solves the problem that polyester and polyamide are not compatible, ensures uniform dyeing of acid dye, and enables spinning workstage to proceed smoothly. In addition, as the preparation of the polymer adopts a process similar to polyester polymerization for polymerization on a common polyester polymerization device, the method is simple to operate, easy to perform industrial production and low in cost.

Owner:CHINESE TEXTILE ACAD

Warpage resistance nylon 6 composite material for vehicle air conditioning air door and preparation method thereof

InactiveCN101580636AHigh impact strengthImprove liquidityAir-flow control membersGlass fiberFlexural modulus

The invention discloses a warpage resistance nylon 6 composite material for a vehicle air conditioning air door and a preparation method thereof. The composite material is composed of nylon 6 chips, fiberglass, glass microballoons, compatilizer, antioxidizer, a coupling agent and a lubricating agent. The preparation method includes the following steps: (1) after being uniformly mixed, the nylon 6 chips, the compatilizer, the antioxidizer, the coupling agent and the lubricating agent are added into a double screw extruder on the first segment of a barrel, the glass microballoons are added by a side feeding machine on the fourth segment of the barrel, and the fiberglass is added by the side feeding machine on the sixth segment of the barrel; and (2) after being extruded outside, the prepared particles are dried and cooled, and finally the warpage resistance nylon 6 composite material for the vehicle air conditioning air door can be obtained. The warpage resistance nylon 6 composite material prepared by the invention has the advantages of extremely high flexural modulus, high fluidity and favorable dimension stability, solves the problem of warpage of a large finished piece caused by material shrinkage, and guarantees the assembly of the finished piece.

Owner:合诚技术股份有限公司

Multi-component compound modified nylon 6 composite material for carrier roller and preparation method thereof

The invention belongs to the field of high-molecular composite materials, and provides a high-performance multi-component compound modified nylon 6 composite material for a conventional carrier roller. The composite material consists of 100 parts of mixed nylon 6, 10-40 parts of alkali-free glass fiber, 5-30 parts of talcum powder, 0.01-1 part of nano silicon dioxide, 1-5 parts of solid lubricant, 0.01-3 parts of wear-resistant agent, 0.05-1 part of anti-aging agent, 0.2-1 part of dispersing agent and 0.01-0.5 part of silane coupling agent. After being uniformly mixed, the material system is extruded by a twin-screw extruder and granulated to obtain a high-performance composite material. By adopting the composite material provided by the invention, the prepared carrier roller has the characteristics of high strength, abrasion resistance, high-temperature resistance, light weight, low noise, long service life, appropriate price, convenience in maintenance and the like, and can be widely applied to the places such as mines except coal mines, wharfs, grain depots, cement plants, power plants, chemical plants, salt fields and the like.

Owner:HUNAN UNIV OF TECH

Method for preparing nylon 6/graphite oxide nanocomposite

The invention relates to a method for preparing a nylon 6 / graphite oxide nanocomposite. In the method, caprolactam is adopted for in situ hydrolysis and ring-opening polymerization to prepare the nylon 6 / graphite oxide nanocomposite, so that caprolactam monomers are easy to perform in-situ intercalative polymerization to dissociate a graphite oxide lamella, and the dispersing uniformity of the graphite oxide lamella in a polymer substrate is improved; and the composite prepared has better conductivity and high-efficiency flame retardancy. The nylon 6 substrate is converted from an insulator to a semiconductor and the flame retardant rating can reach V-0 rating of a UL94 standard, and the integral good mechanical property of the material per se is maintained simultaneously. The method has the advantage of simple and effective process; the conductivity and flame retardancy of the obtained composite are obviously improved; the material has good secondary-working character; an additive graphite oxide does not pollute the environment; and the nylon 6 / graphite oxide nanocomposite has wide application range.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

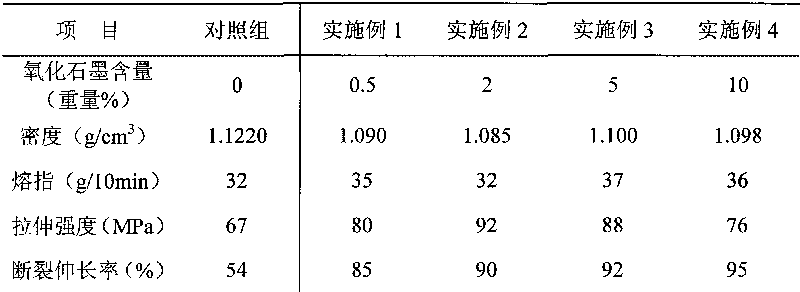

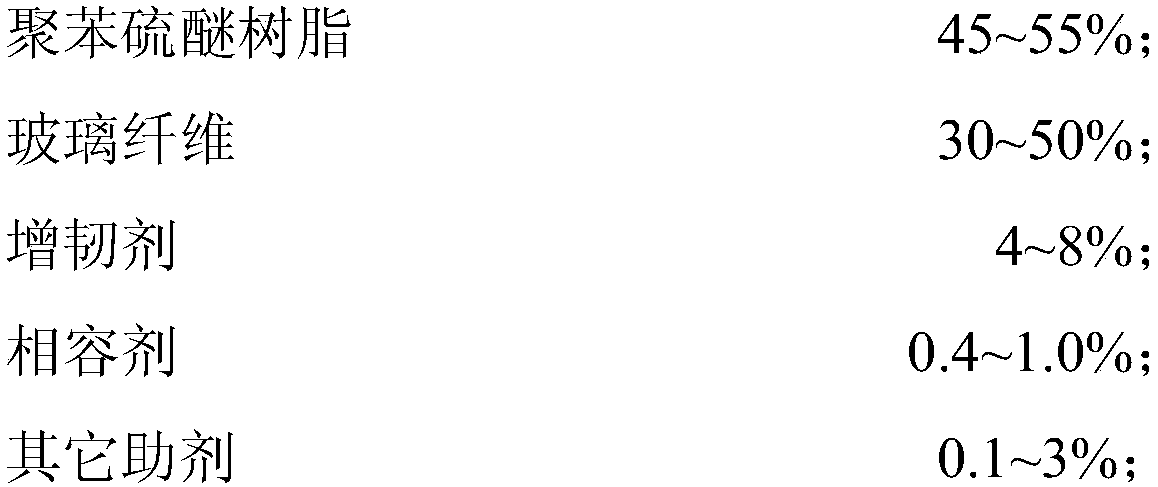

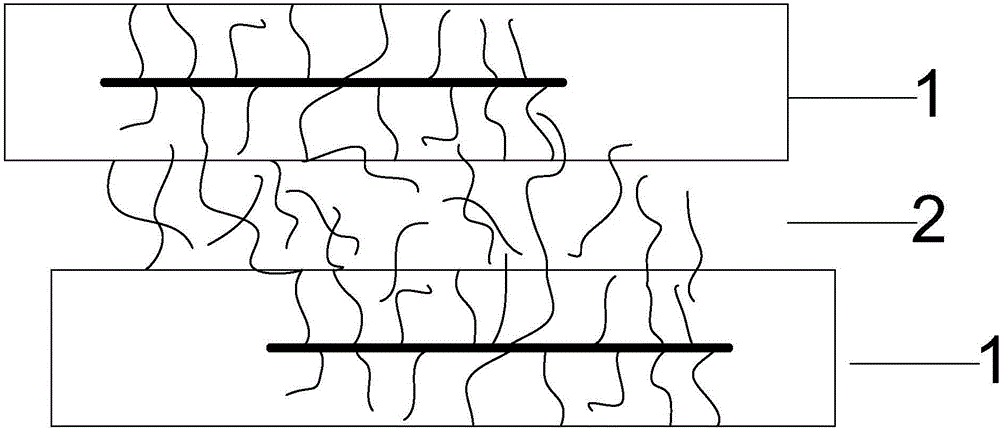

High strengthening and toughening type polyphenylene sulfide composite material and preparation method thereof

The invention discloses a high strengthening and toughening type polyphenylene sulfide composite material. 100 wt% of the composite material comprises 45-55 wt% of polyphenylene sulfide resin, 30-50 wt% of glass fibers, 4-8 wt% of a toughening agent, 0.4-1.0 wt% of a compatibilizer and 0.1-3 wt% of other additives; the surface of the glass fibers is impregnated with a silane coupling agent; the toughening agent is at least one selected from nylon 6, nylon 66, ethylene-methyl acrylate-glycidyl methacrylate and a maleic anhydride grafted styrene-ethylene-butadiene-styrene block copolymer elastomer; and the compatibilizer is selected from epoxy resins. The polyphenylene sulfide composite material disclosed in the invention has the advantage of high rigidity, high toughness and high flame retardation property, is especially suitable for producing small parts and ultrathin parts which have high requirements for the impact performance, and greatly broadens the application range of a phenyl sulfide material.

Owner:CGN JUNER NEW MATERIALS +1

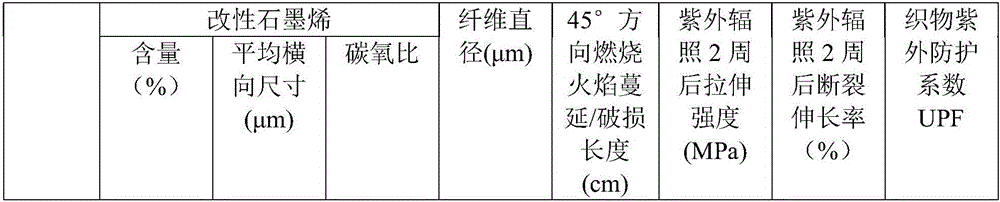

Graphene/nylon 6 fiber with flame-retarding and ultraviolet-proof properties and preparation method of graphene/nylon 6 fiber

ActiveCN106835333AAvoid cloggingImprove bindingFlame-proof filament manufactureMonocomponent polyamides artificial filamentGraphene nanocompositesNylon 6

The invention discloses a graphene / nylon 6 fiber with flame-retarding and ultraviolet-proof properties and a preparation method of the graphene / nylon 6 fiber and belongs to the technical field of functional high molecular materials. The graphene / nylon 6 fiber with the flame-retarding and ultraviolet-proof properties is prepared through high-speed melting spinning of a graphene / nylon 6 nano composite material; the graphene / nylon 6 nano composite material is prepared by compounding modified graphene, caprolactam and various auxiliary agents. The graphene / nylon 6 nano composite material obtained by the invention can continuously pass through a melting spinning hole at a high speed and continuous high-speed spinning is realized; the diameter of the fiber is 5mum to 50mum; compared with a pure nylon 6 fiber, the prepared graphene modified nylon 6 fiber has excellent flame-retarding, melt-dripping-resisting and ultraviolet-proof performances and the like.

Owner:HANGZHOU GAOXI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com