Multi-component compound modified nylon 6 composite material for carrier roller and preparation method thereof

A multi-component composite and modified nylon technology is applied in the field of manufacturing a low-cost, environment-friendly, high-performance nylon 6 composite material for conventional idlers, which can solve problems such as different performance requirements, high prices, and defects in promotion, and achieve Excellent wear resistance, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

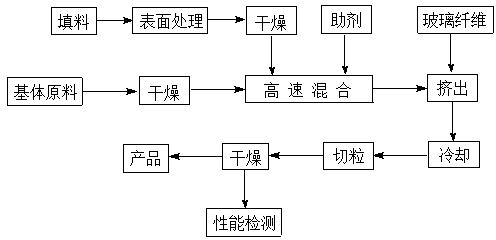

Method used

Image

Examples

Embodiment 1

[0052] Multi-component composite modified nylon 6 composite materials for idlers in ports, grain depots and salt fields:

[0053] The composition of raw material mass parts is: mixed nylon 6: non-alkali glass fiber: talcum powder: nano silicon dioxide: solid lubricant (graphite powder): wear-resistant agent (molybdenum disulfide): antiaging agent (antioxidant 1098): hard Fatty acid monoglyceride: silane coupling agent KH-550 = 100: 15: 18: 0.3: 1: 0.05: 0.1: 0.2: 0.1, wherein the composition of mixed nylon 6 is medium viscosity nylon 6 (relative viscosity 2.8 ~ 3.4) : Low-viscosity nylon 6 (relative viscosity 2.2-2.7) = 90:10 (mass ratio); the matching ratio of talcum powder particle size is 1000 mesh: 1800 mesh = 1:1.

[0054] Preparation:

[0055] (1) Raw material pretreatment:

[0056] Drying treatment: Dry the mixed nylon 6, alkali-free glass fiber, talcum powder, solid lubricant, wear-resistant agent, and nano-silica for 12 hours respectively;

[0057] Surface modifica...

Embodiment 2

[0069] Multi-component modified nylon 6 composite materials for idlers in ports, grain depots and salt fields:

[0070] The composition of raw material parts by mass is: mixed nylon 6: alkali-free glass fiber: talcum powder: nano silicon dioxide: solid lubricant (graphite fluoride): wear-resistant agent (molybdenum disulfide): anti-aging agent (antioxidant 168): Stearic acid monoglyceride: coupling agent KH-560 = 100: 20: 20: 0.3: 1: 0.1: 0.1: 0.3: 0.12, wherein the composition of mixed nylon 6 is medium viscosity nylon 6 (relative viscosity 2.8 ~ 3.4) : Low-viscosity nylon 6 (relative viscosity 2.2-2.7) = 85:15 (mass ratio); talcum powder is composed of 1000 mesh and 1500 mesh, and its mass ratio is 1:1.

[0071] Preparation:

[0072] (1) Raw material pretreatment

[0073] Drying treatment: Dry the mixed nylon 6, alkali-free glass fiber, talcum powder, solid lubricant, wear-resistant agent, and nano-silica for 12 hours respectively;

[0074] Surface modification treatment:...

Embodiment 3

[0084] The multi-component composite modified nylon 6 composite material used for rollers in mines, cement plants and power plants other than coal mines is composed of: mixed nylon 6: alkali-free glass fiber: talcum powder: nano silicon dioxide: solid Lubricant (boron nitride): anti-wear agent (molybdenum disulfide): anti-aging agent (antioxidant 168): monoglyceride stearate: coupling agent KH-570=100:25:20:0.3:1.2: 0.5: 0.3: 0.6: 0.4, wherein the mixed nylon 6 is medium-viscosity nylon 6: low-viscosity nylon 6=80:40; talcum powder is composed of 800 mesh and 1500 mesh, and the mass ratio is 1:1.

[0085] Preparation:

[0086] (1) Raw material pretreatment

[0087] Drying treatment: Dry the mixed nylon 6, alkali-free glass fiber, talcum powder, solid lubricant, wear-resistant agent, and nano-silica for 12 hours respectively;

[0088] Surface modification treatment:

[0089] a. Add the silane coupling agent to ethanol to prepare a solution with a weight concentration of 4%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com