Patents

Literature

183 results about "Medium viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medium Viscosity Silicone Fluids are used in a wide range of instruments, gauges, sensors and meters to monitor and control temperature, pressure, vibration, motion & humidity. Their thermal properties and high damping action help to ensure the most accurate reading in the gauges/instruments/meters, switches and sensors,...

Method for preparing medium-viscosity PET slice by recycled low-viscosity polyester yarn

InactiveCN101659757ASimple processing methodSlicing performance is similarPlastic recyclingMonocomponent polyesters artificial filamentFiberYarn

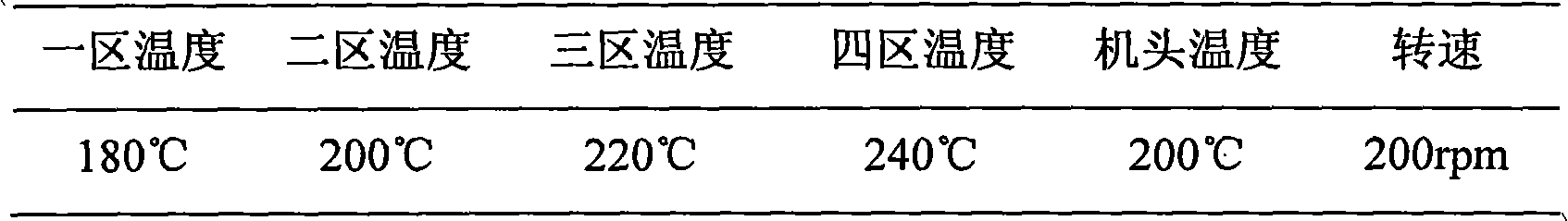

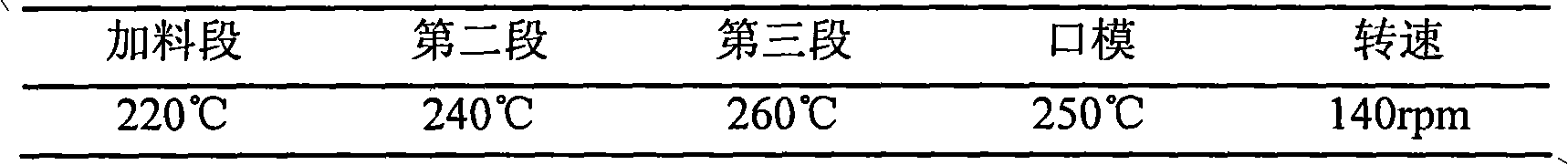

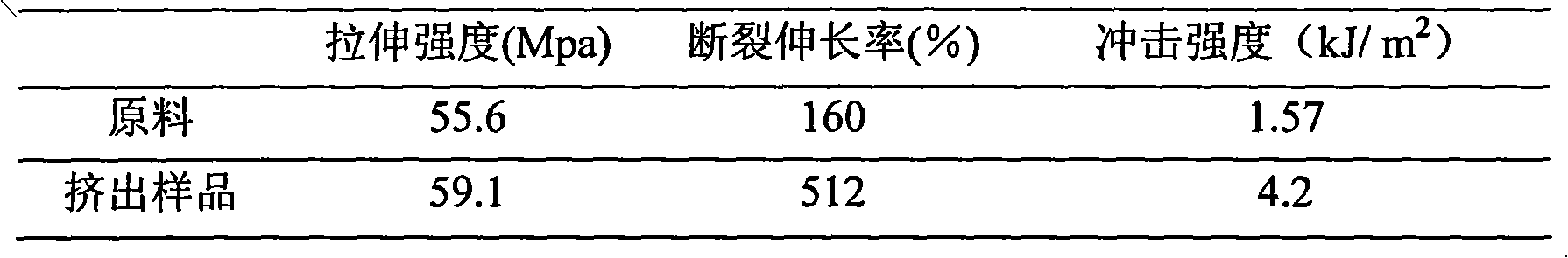

The invention provides a method for preparing a medium-viscosity PET slice through adding a viscosified chain extender during the process that a double-screw extruder smelts and extrudes recycled low-viscosity polyester fiber or polyester fabric fragments to carry out smelting, chain extension and extrusion reaction. The method enables the viscosity of PET to be enhanced through the following steps: taking the recycled low-viscosity terylene fiber or the polyester fabric fragments as a raw material, adding the viscosified chain extender, enabling the raw material and the chain extender to react in the extruder, and then extruding the reaction products to increase the viscosity of the PET. Through changing processing conditions and reaction proportion, the PET slices with different viscosity can be obtained. The products obtained by the invention can be used for industrial yarns, such as carpets, filature and the like and can serve as the raw materials of textile fabrics.

Owner:EAST CHINA UNIV OF SCI & TECH

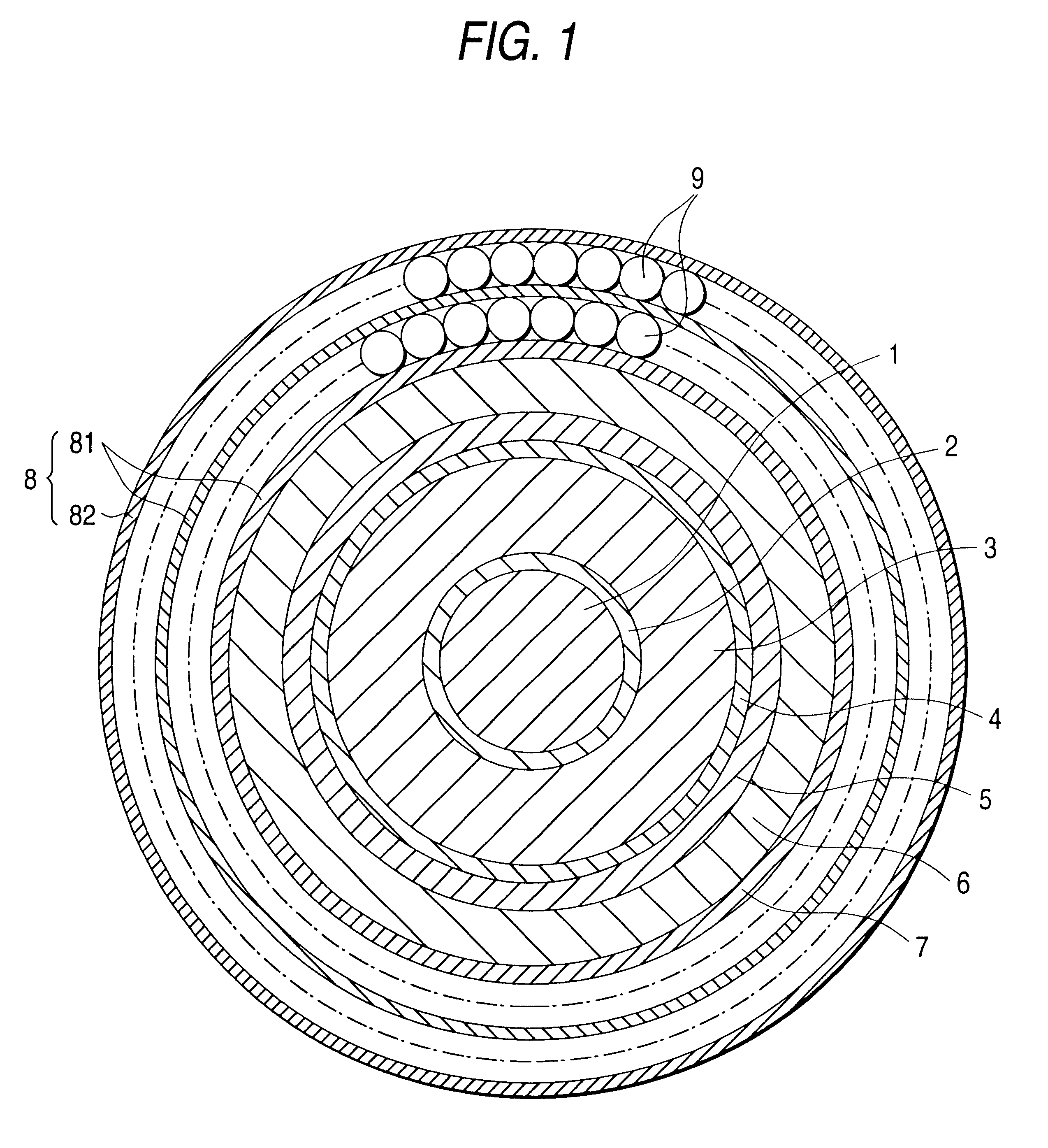

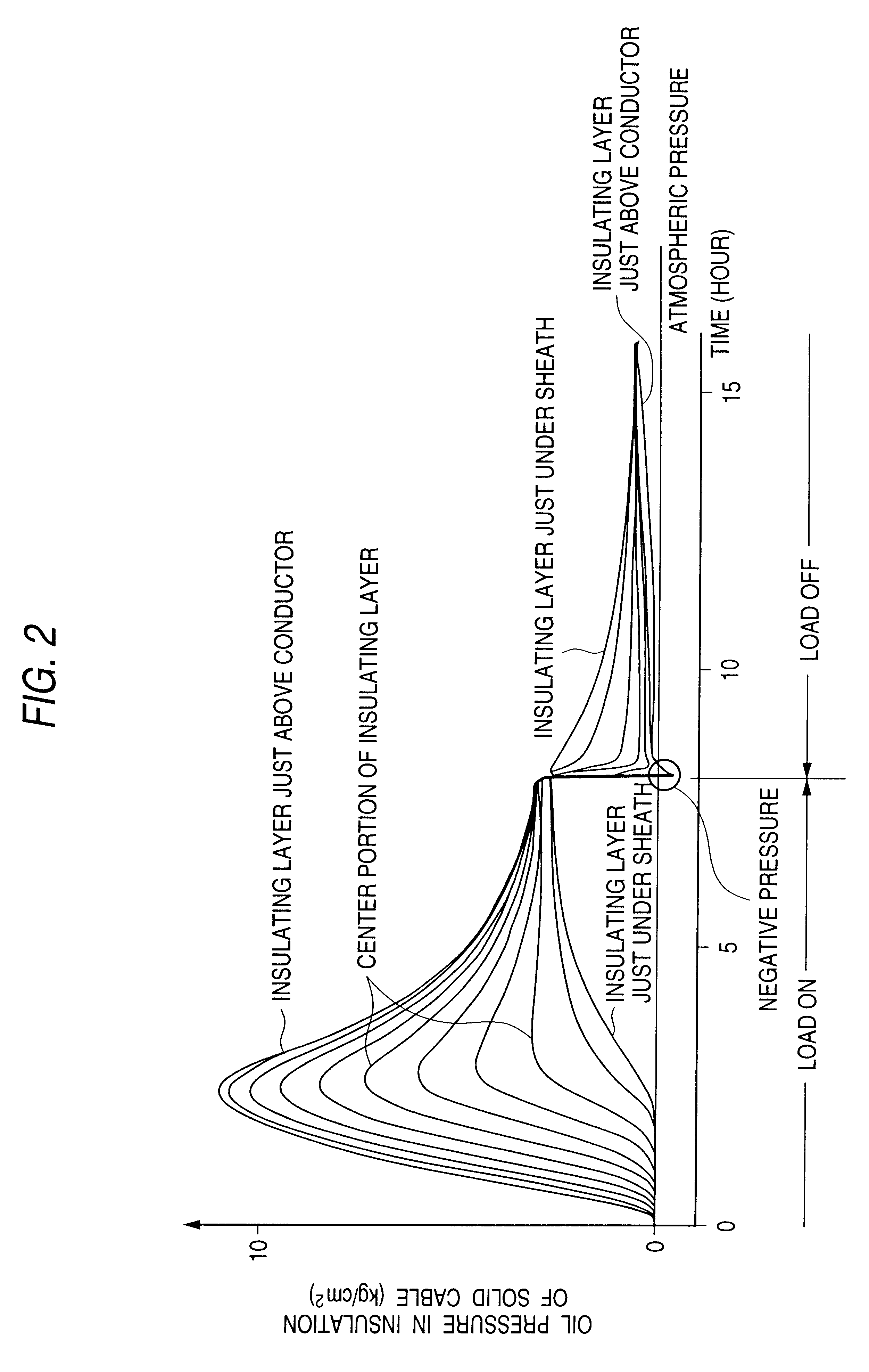

Solid cable, manufacturing method thereof, and transmission line therewith

InactiveUS20010042635A1High tensile strengthRubber insulatorsOil-pressure cablesInsulation layerElectrical conductor

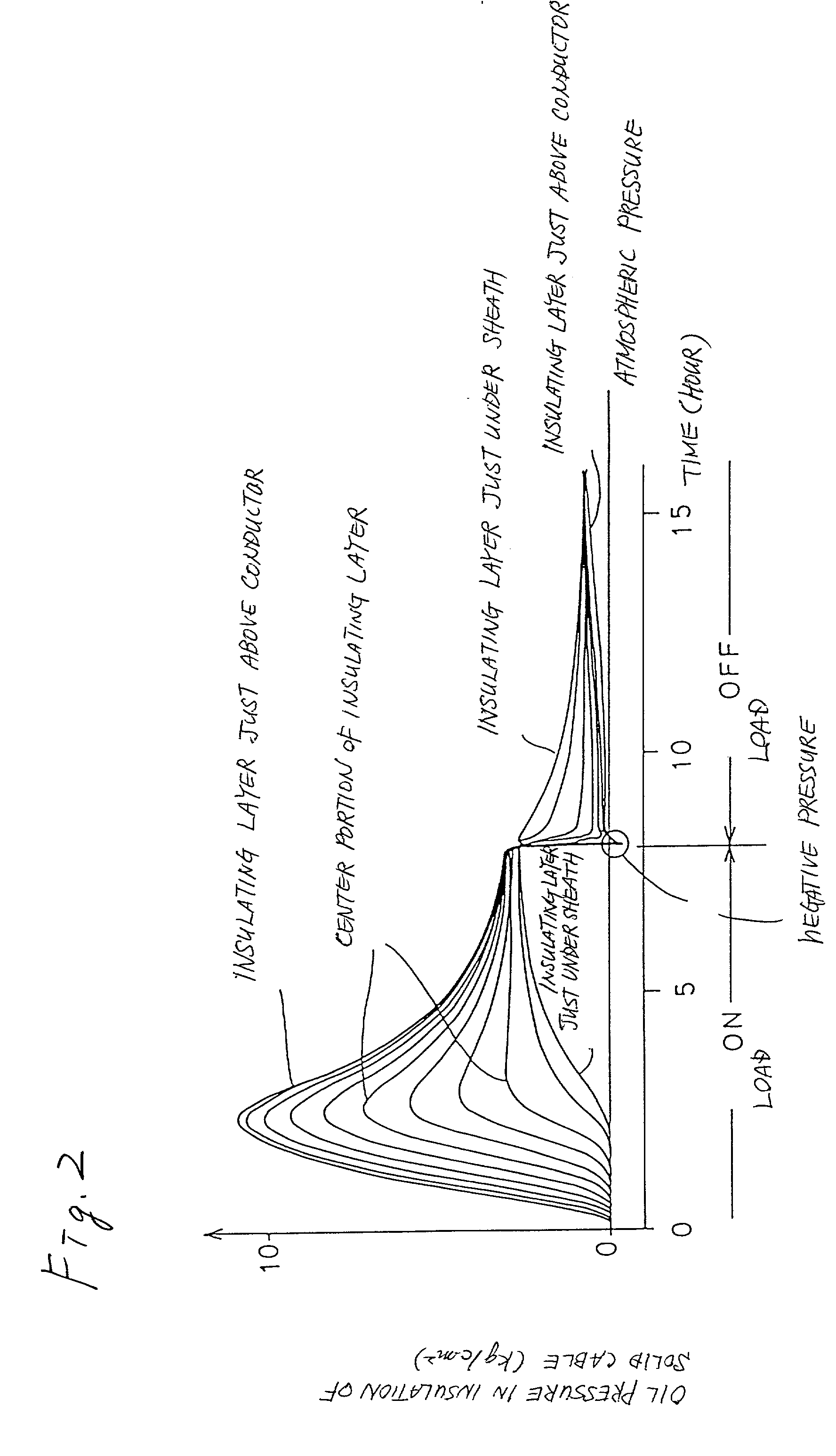

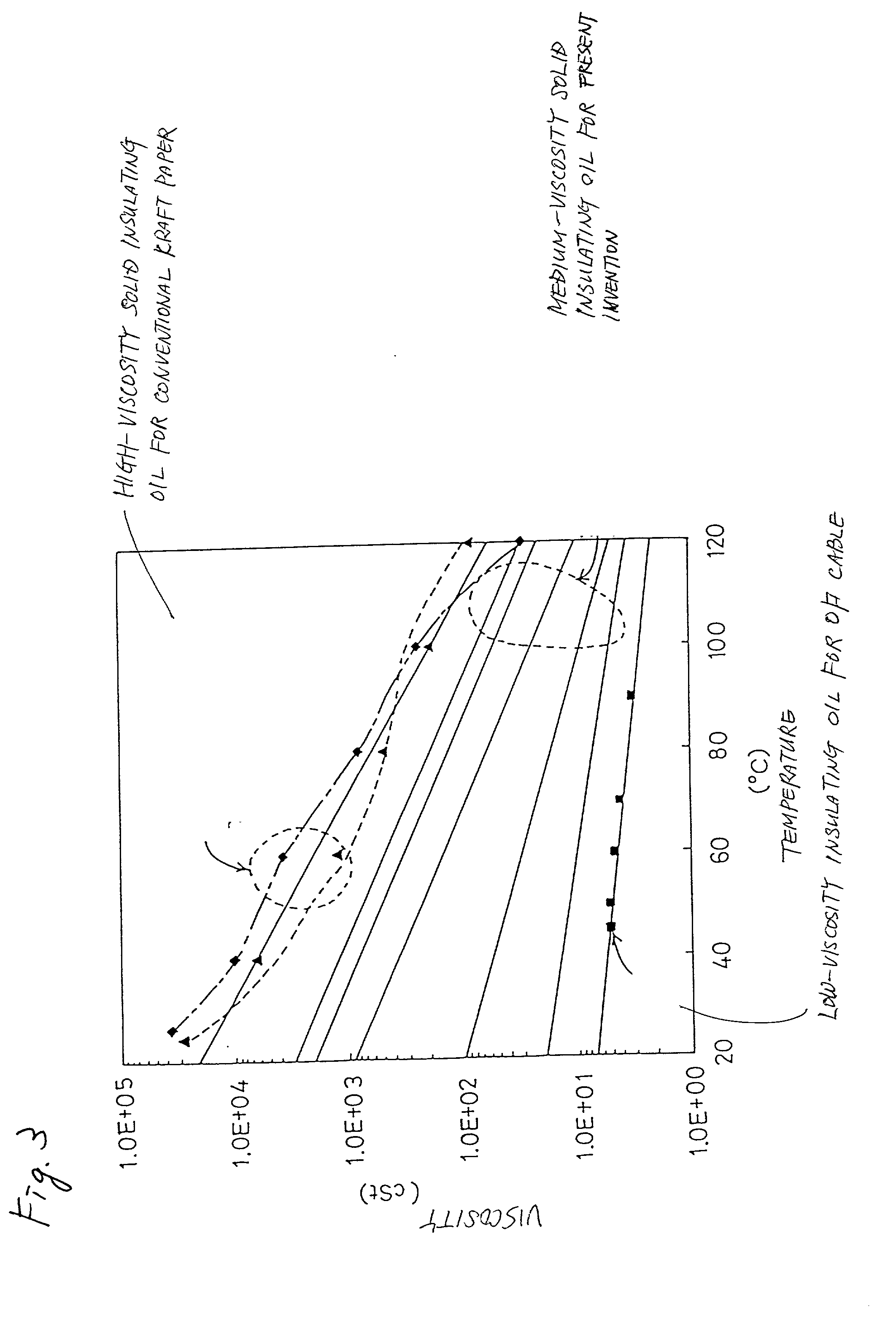

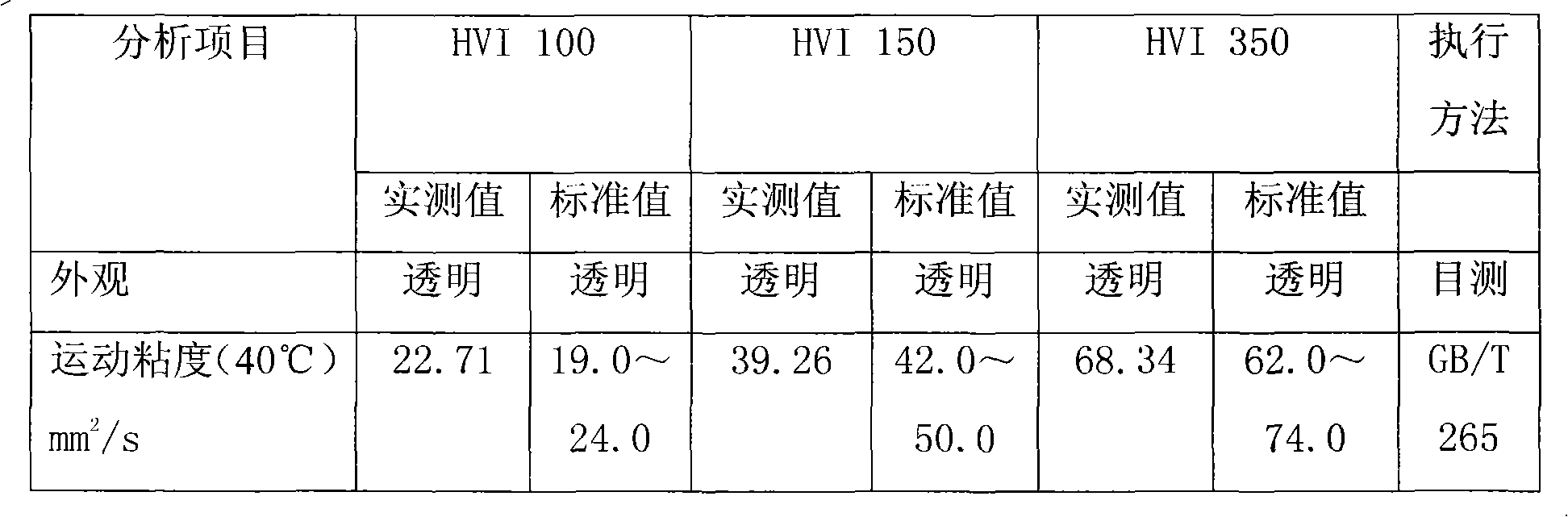

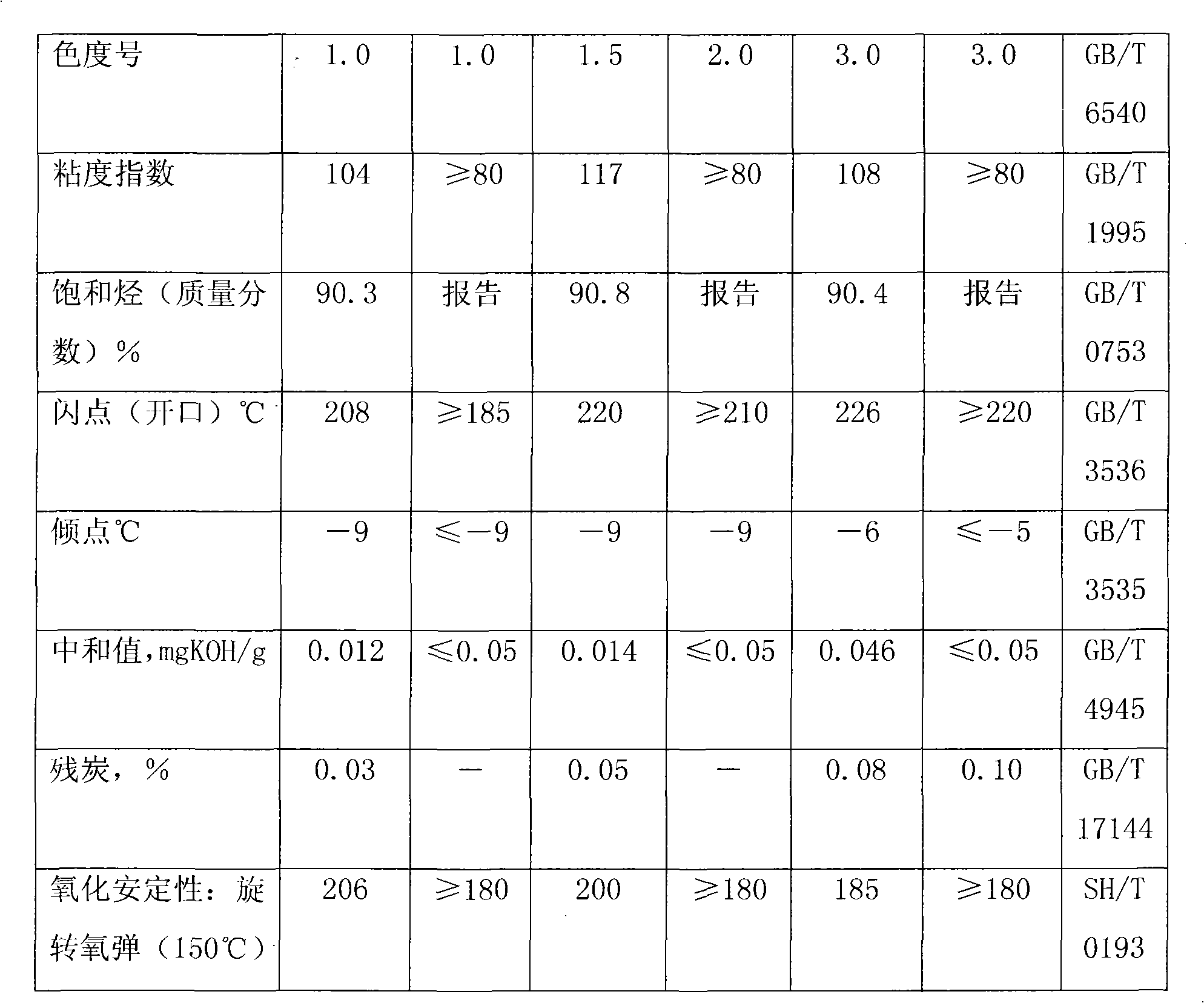

A solid cable provided with an insulation layer on the outer circumference of a conductor, and impregnated with insulating oil in this insulation layer. Medium-viscosity insulating oil the viscosity of which is between not less than 10 cst and less than 500 cst at 60° C. is used as the insulating oil.

Owner:SUMITOMO ELECTRIC IND LTD

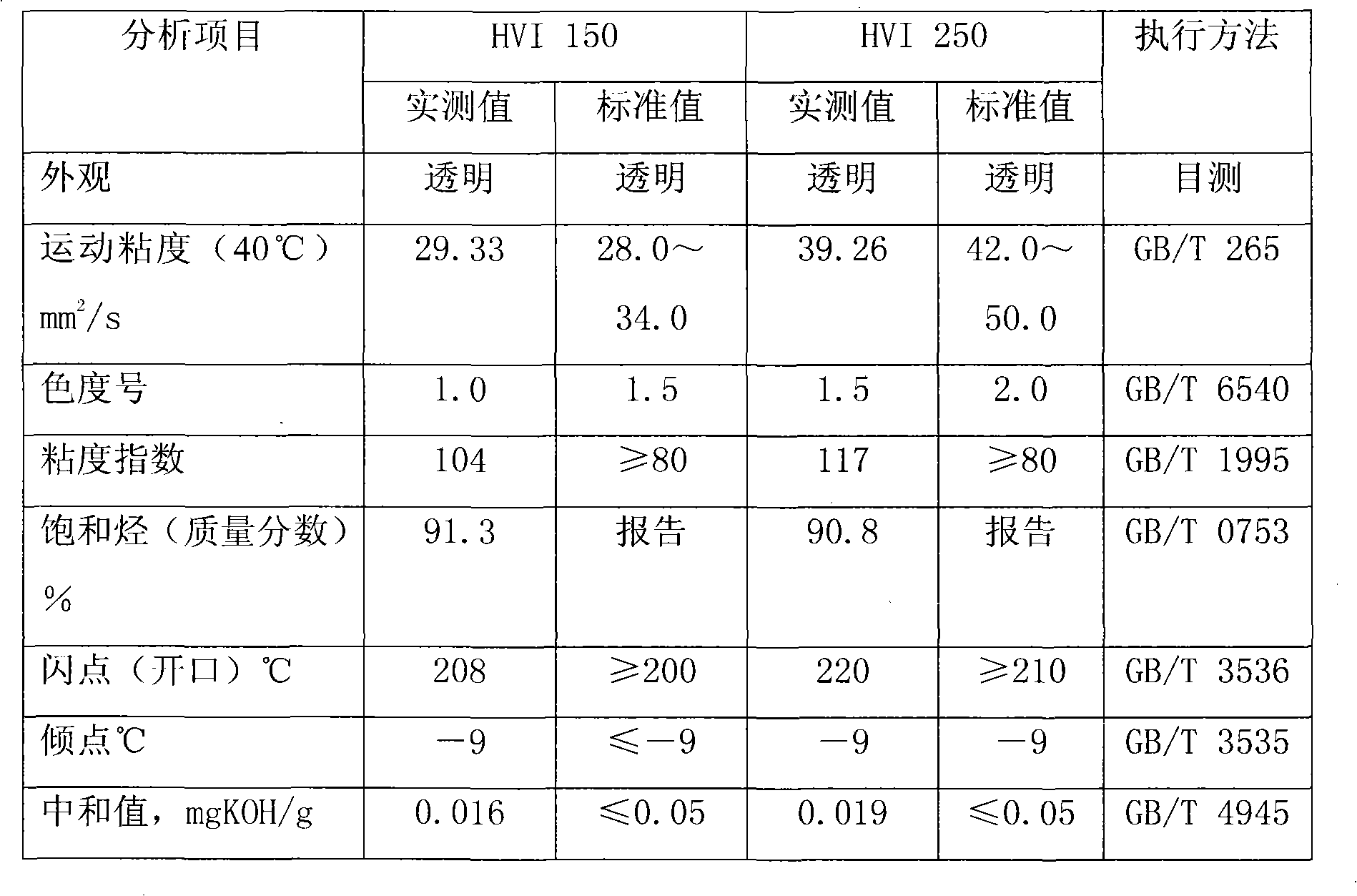

Process method for producing base oil by regenerating waste lubricating oil

ActiveCN102373108AShort stayImprove qualityTreatment with plural serial refining stagesLubricant compositionDistillationEconomic benefits

The invention discloses a process method for producing base oil by regenerating waste lubricating oil, realized by the steps of pretreatment of waste lubricating oil, thin film evaporation, molecular distillation, clay refining and degasification with flash evaporation. The use of the process can regenerate any waste lubricating oil collected from markets. According to different quality of the waste lubricating oil, the base oil yield is 50-90 %. The process can be flexibly adjusted, particularly, the process can be used for producing base oil with single specification of low and medium viscosity in parallel to maximize the production and processing capacity of devices, and can be used for producing base oil with three specifications of low, medium and high viscosity in series to separatethe base oil fraction from the waste lubricating oil completely according to different quality and values, so that the maximum economic benefit is achieved.

Owner:BEIJING JINYU MANGROVE ENVIRONMENTAL PROTECTION TECH

Foaming agent and circulation microvesicle drilling fluids and drilling technique

InactiveCN101244372AGood leakage prevention and plugging effectImprove the lubrication effectTransportation and packagingMixingCelluloseMicrovesicle

The invention discloses a foaming agent and circulative micro-foam drilling fluid as well as well-drilling technological method; wherein, the foaming agent comprises 30% neopelex ABS, and 70% lauryl sodium sulfate SDS; the circulative micro-foam drilling fluid is produced through adding 0.1% sodium hydroxide, 0.2 to 0.3% xanthan gum XC, 0.2 to 0.3% medium viscosity flocculent cellulose CMC and 0.1 to 0.3% foaming agent; during well drilling construction, the circulative micro-foam drilling fluid is first to be prepared, and then is used to perform the wet drilling. With the foaming agent added to the circulative micro-foam drilling fluid, the formed micro-foam slurry has the advantages of good leakage proof and plugging effect, great lubrication performance, good rheology, obvious improved drilling quality and drilling efficiency.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +1

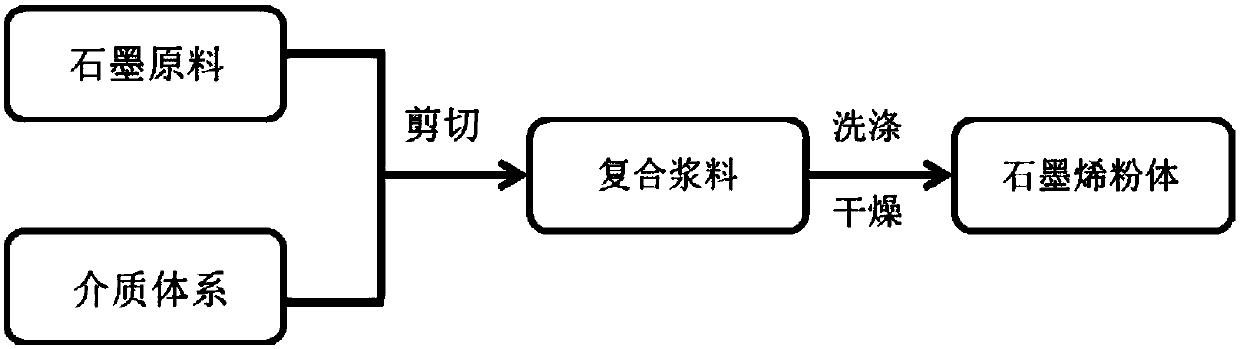

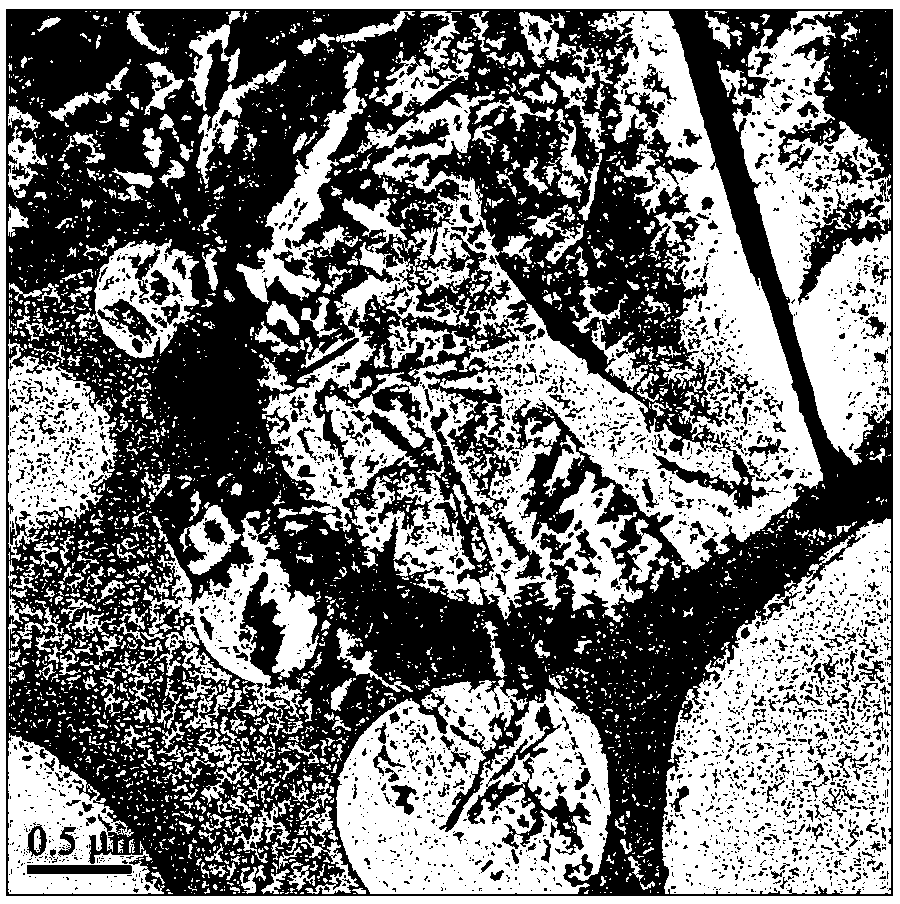

Method for preparing graphene from graphite through HPLC (high performance liquid chromatography) stripping

The invention provides a method for preparing graphene from graphite through HPLC (high performance liquid chromatography) stripping. The method comprises steps as follows: 1), preparation of a medium system: a), the medium system is prepared from macromolecules and an organic solvent which are polymerized; or b), the medium system is prepared from macromolecule prepolymers; 2), shearing and stripping: graphite raw materials are uniformly dispersed in the prepared medium system, a mixture is formed and then is sheared, graphite stripping is realized, and composite slurry is obtained; 3), separation: the composite slurry is separated, and graphene powder can be obtained. According to the method, the stripping efficiency is substantially improved by the aid of medium viscosity, wettability between graphite and medium is improved through matching with interface energy, and the problem of dispersion of the graphene is solved. The stripping efficiency of a common solvent is far lower than 1%, but the stripping efficiency of the invention can reach 100%. The method is simple and efficient, and high-yield and large-scale industrial production of high-quality graphene can be realized with the method.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

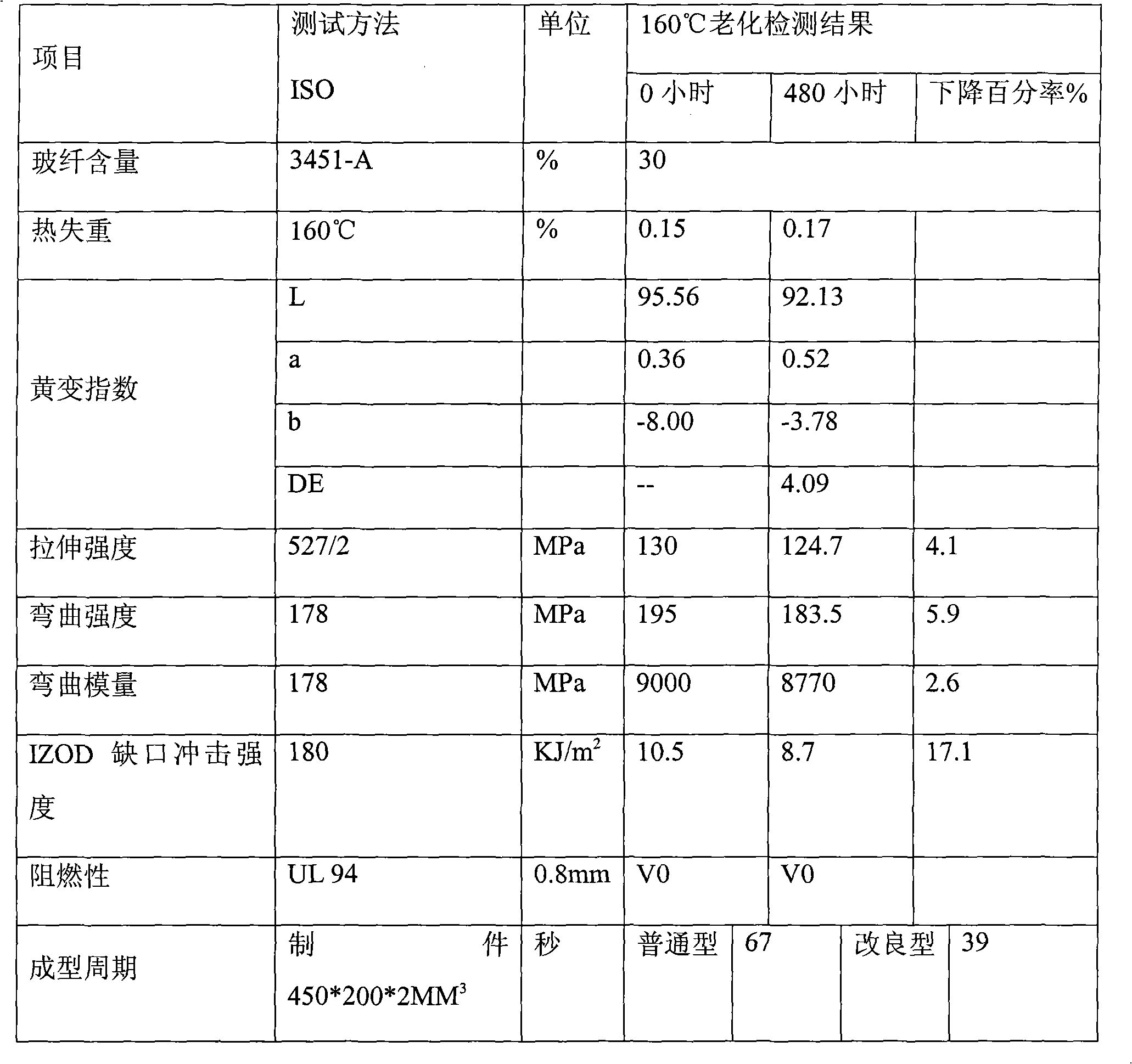

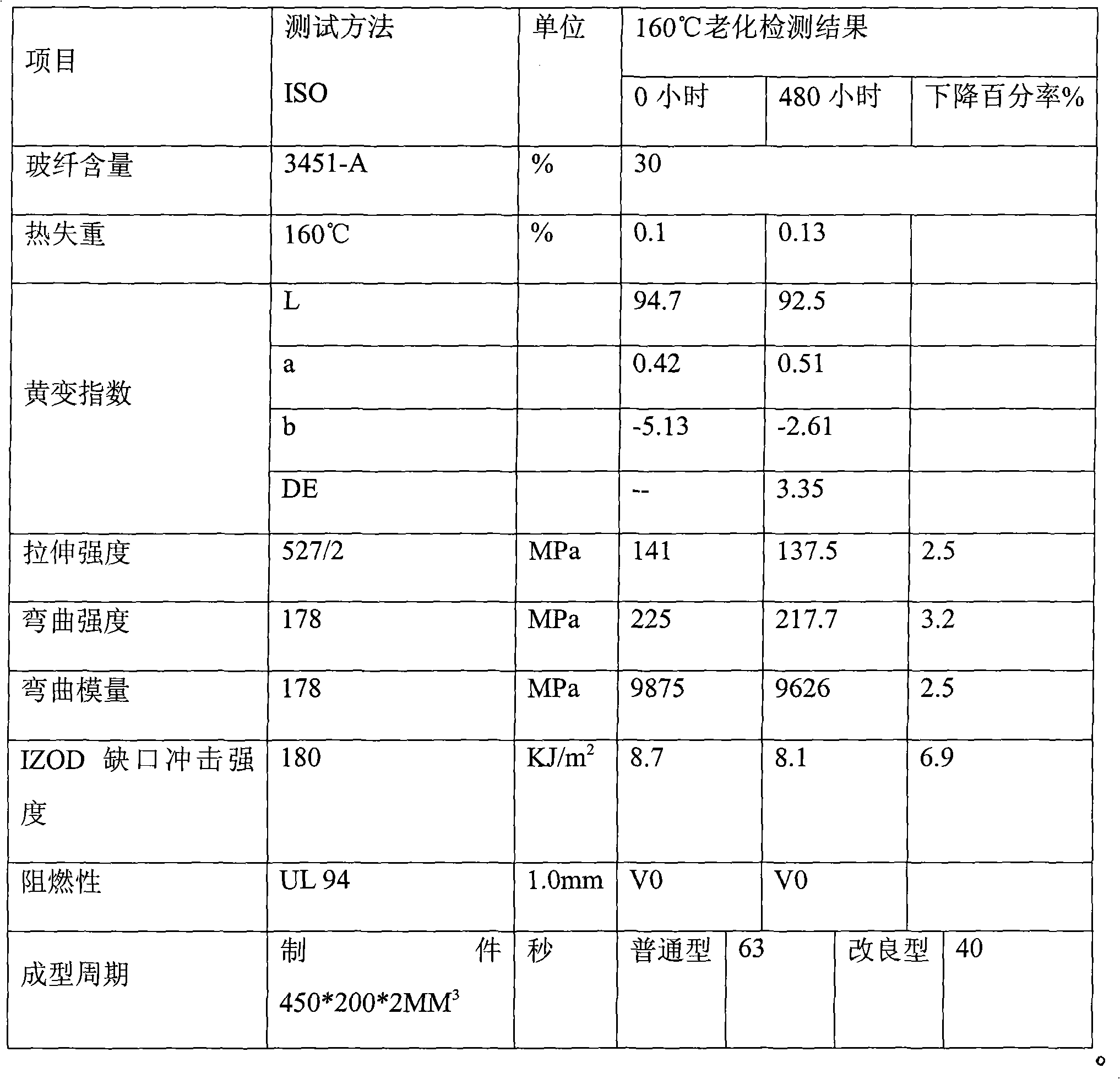

Flame-proof reinforced Valox compound and preparation thereof

InactiveCN101275010ANot easy to change colorGood thermal and oxygen aging stabilityPolytetramethylene terephthalateGlass fiber

The invention discloses a flame retardant intensified polybutylene terephthalate composite and a preparation method thereof; weight portions of the compositions for preparing the flame retardant intensified polybutylene terephthalate composite are: 100 portions of medium viscosity PBT resin, 15 to 30 portions of brominated flame retardants, 10 to 30 portions of composite mother particles, and 15 to 150 portions of fiber glass. The product of the invention has good stability of heat resistance and oxygen aging in the treatment process and good stability of heat resistance and oxygen aging in long-term use at high temperature, so light color and bright color products are difficult to change color during the processing period, and difficult to turn yellow or black under long-term use at high temperature, which can satisfy the application in long-term use at high temperature for electronic and electrical components and appearance parts and large power energy-saving light.

Owner:SHANGHAI KINGFA SCI & TECH +1

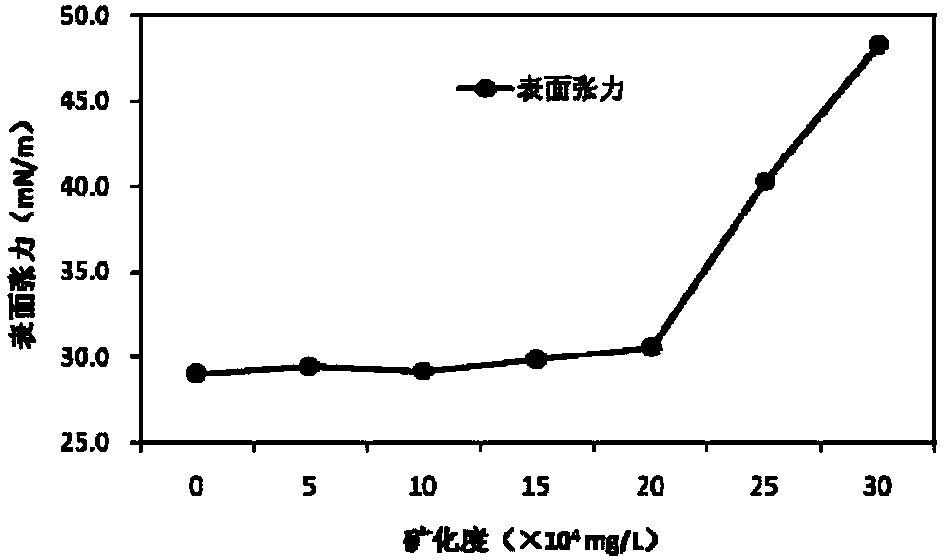

Biochemical anti-salt anti-high temperature oil displacement viscosity reducer and preparation method thereof

ActiveCN103614131AImprove temperature resistanceHigh resistance to mineralizationDrilling compositionDistilled waterReducer

Owner:DALIAN OPUS BIOENG

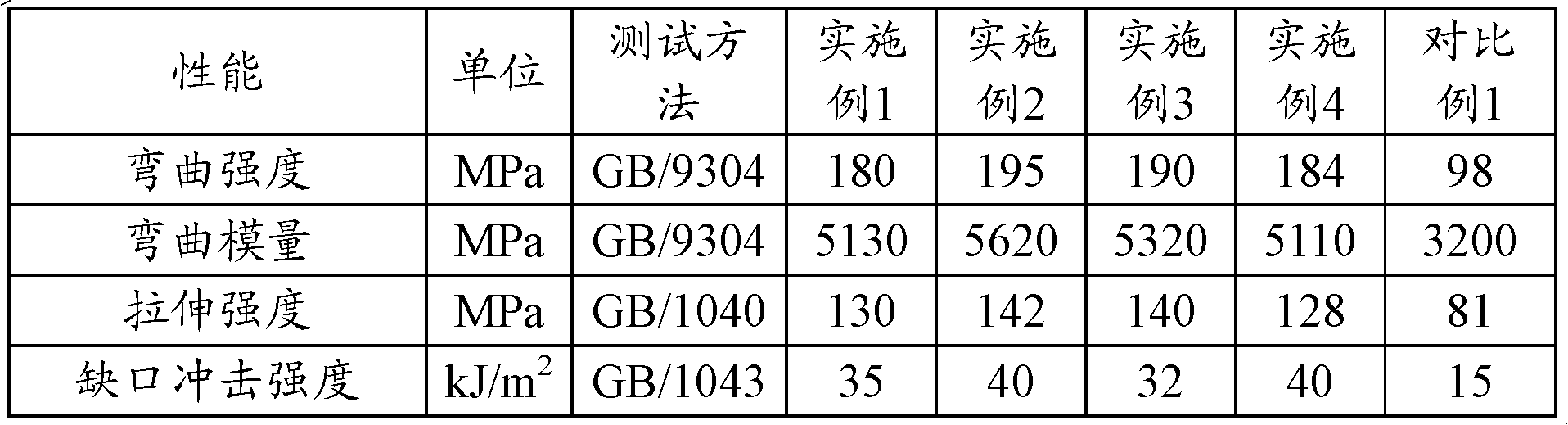

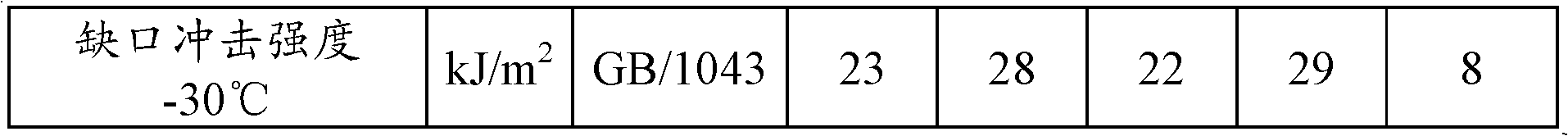

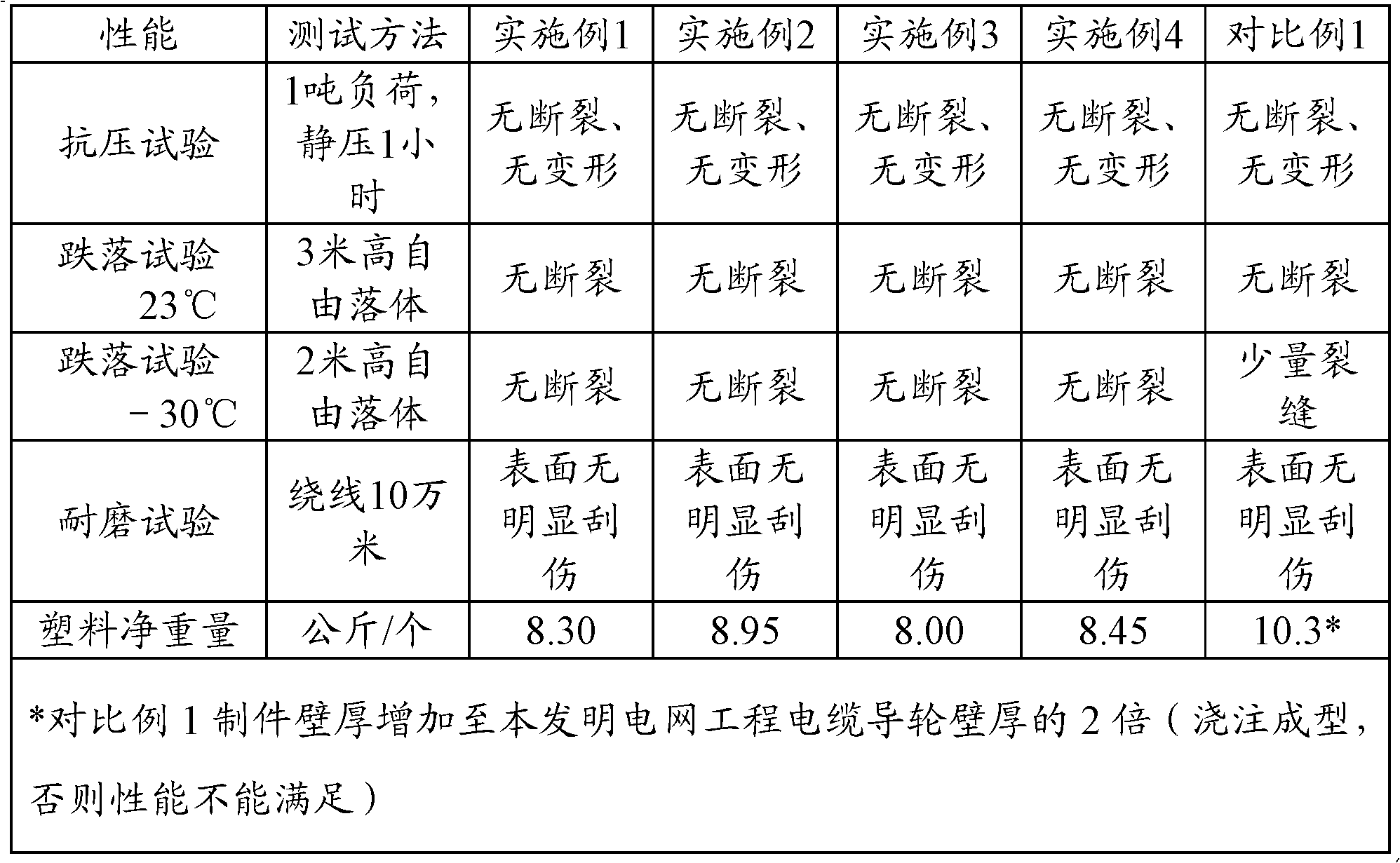

Polyamide composite material and its preparation method and application

The invention discloses a polyamide composite material which comprises, by weight, 20.0% to 40.0% of polyamide 6 with a low viscosity, 10.0% to 30.0% of polyamide 6 with a medium viscosity, 5.0% to 20.0% of a polar low temperature impact modifier, 1.0% to 8.0% of a wear-resisting agent, 0.2% to 5.0% of a heat stabilizer, 0.5% to 5.0% of a lubricant and 20.0% to 45.0% of a reinforcing component. The material has excellent performance and is especially applicable to preparation of cable rollers. The invention also discloses a preparation method for the polyamide composite material. According tothe method, polyamide 6 with a low viscosity, polyamide 6 with a medium viscosity, the low temperature impact modifier, the wear-resisting agent, the heat stabilizer and the lubricant are stirred anduniformly mixed; an obtained mixture is added into a double-screw extruder, and the reinforcing component is added into the double-screw extruder to prepare the polyamide composite material. The method has the advantages of simple operation and suitability to industrial production.

Owner:CGN JUNER NEW MATERIALS +1

Preparation method of medium-viscosity poly alpha-olefin base oil

ActiveCN103666552AEasy to separateReduce pollutionTreatment with polymerisationOligomerDistilled water

The invention relates to a preparation method of medium-viscosity poly alpha-olefin base oil. The preparation method comprises the following steps: under conditions with a temperature of 20 DEG C-120 DEG C, reaction pressure of 0.1 MPa-1.4 MPa and a volume ratio of alpha-olefin / a solvent of (1:0)-(1:3), catalyzing 1-decene or 1-decene and alpha-olefin of C8-C12 for oligomerization for 2 hours-12 hours by using an alkaline-modified AlCl3 / Al2O3 immobilized catalyst; and filtering the catalyst after stopping reaction, washing by distilled water, distilling under the normal pressure to remove the solvent, distilling under reduced pressure to remove un-reacted alpha-olefin to obtain alpha-olefin oligomer base oil, wherein the yield of the poly alpha-olefin is greater than 60 omega%, the movement viscosity of the oligomer at 100 DEG C is 10.0mm<2> / s-25.0mm<2> / s, and the chlorine content of the oligomer is less than 2.0 omega%.

Owner:PETROCHINA CO LTD +1

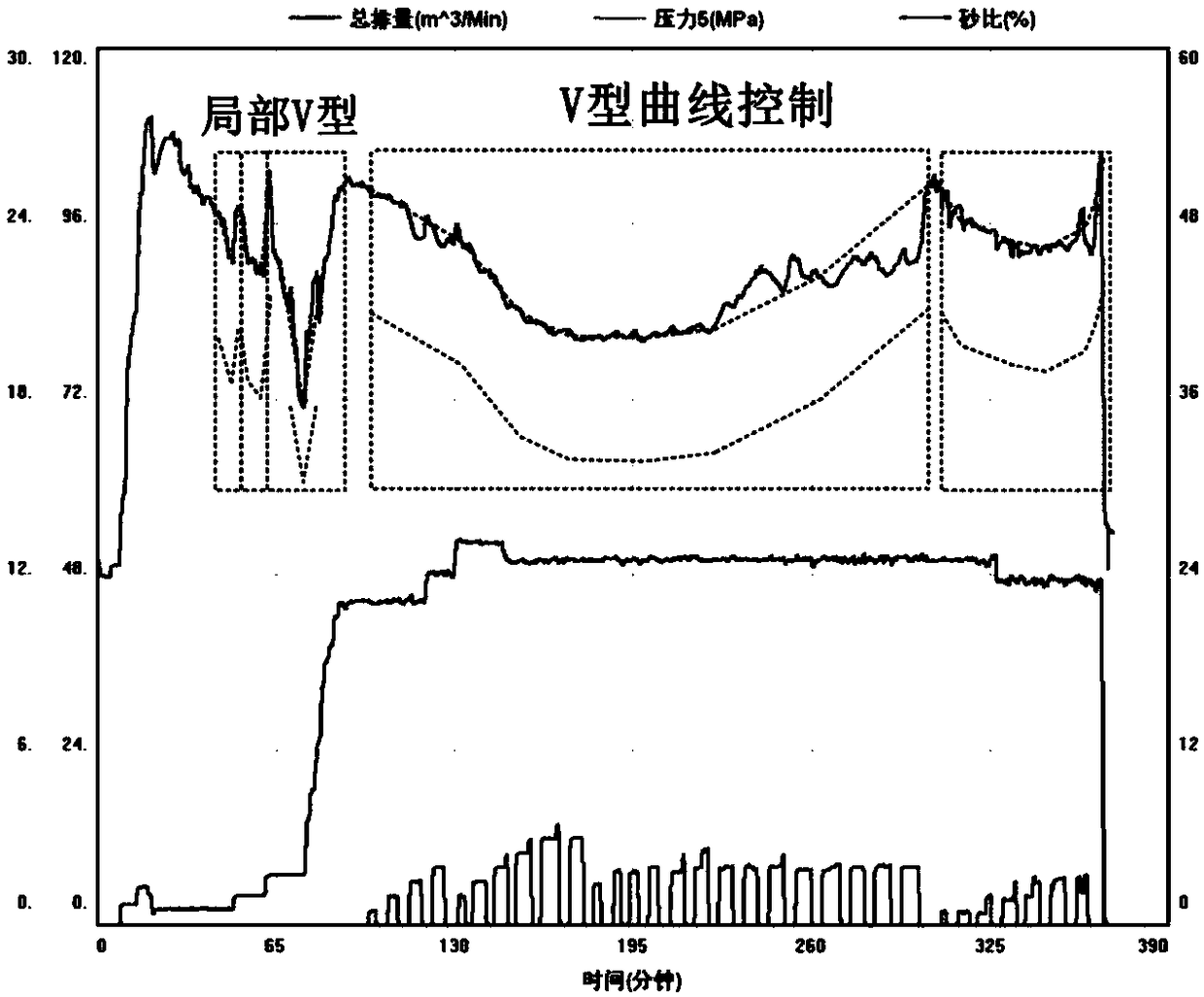

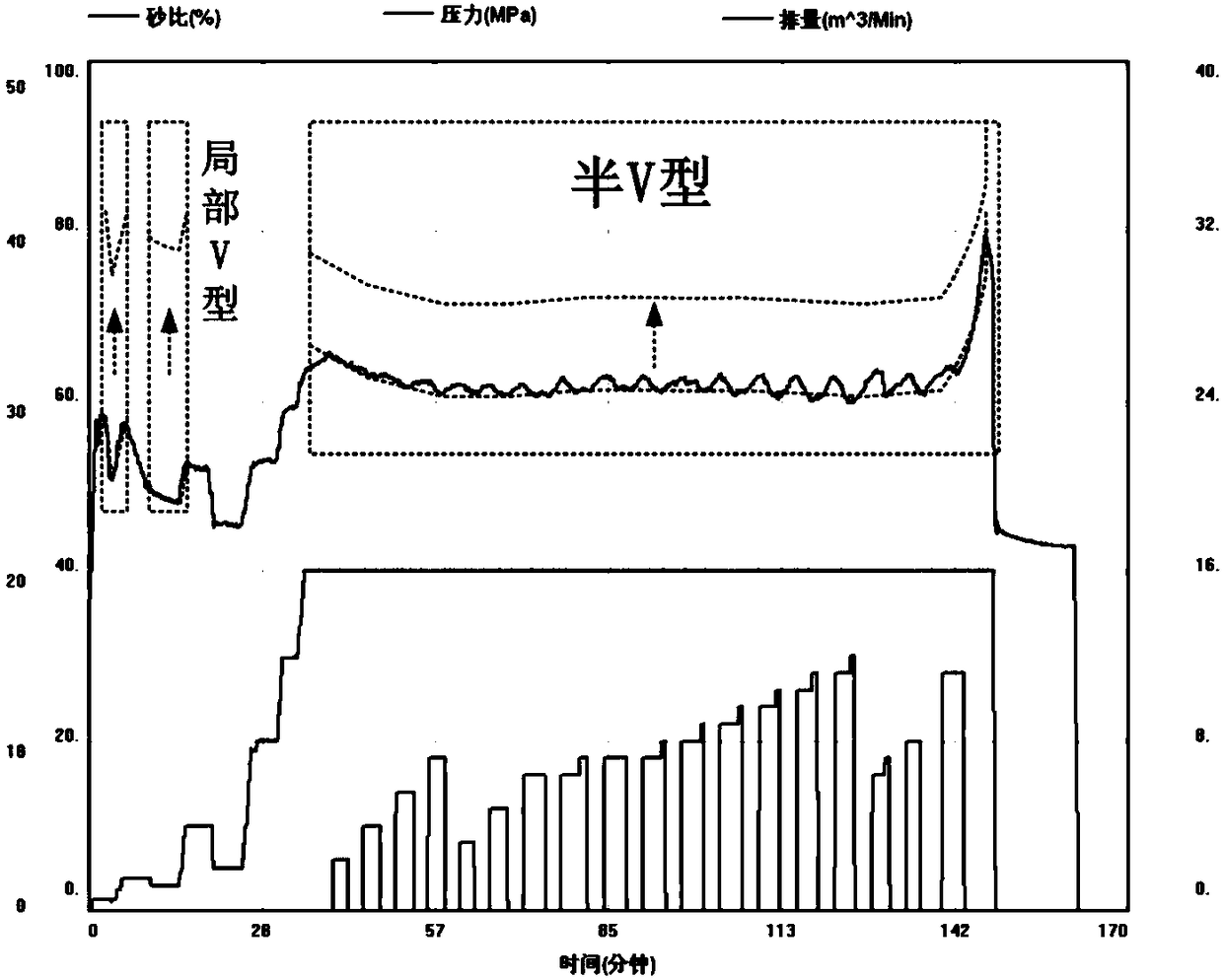

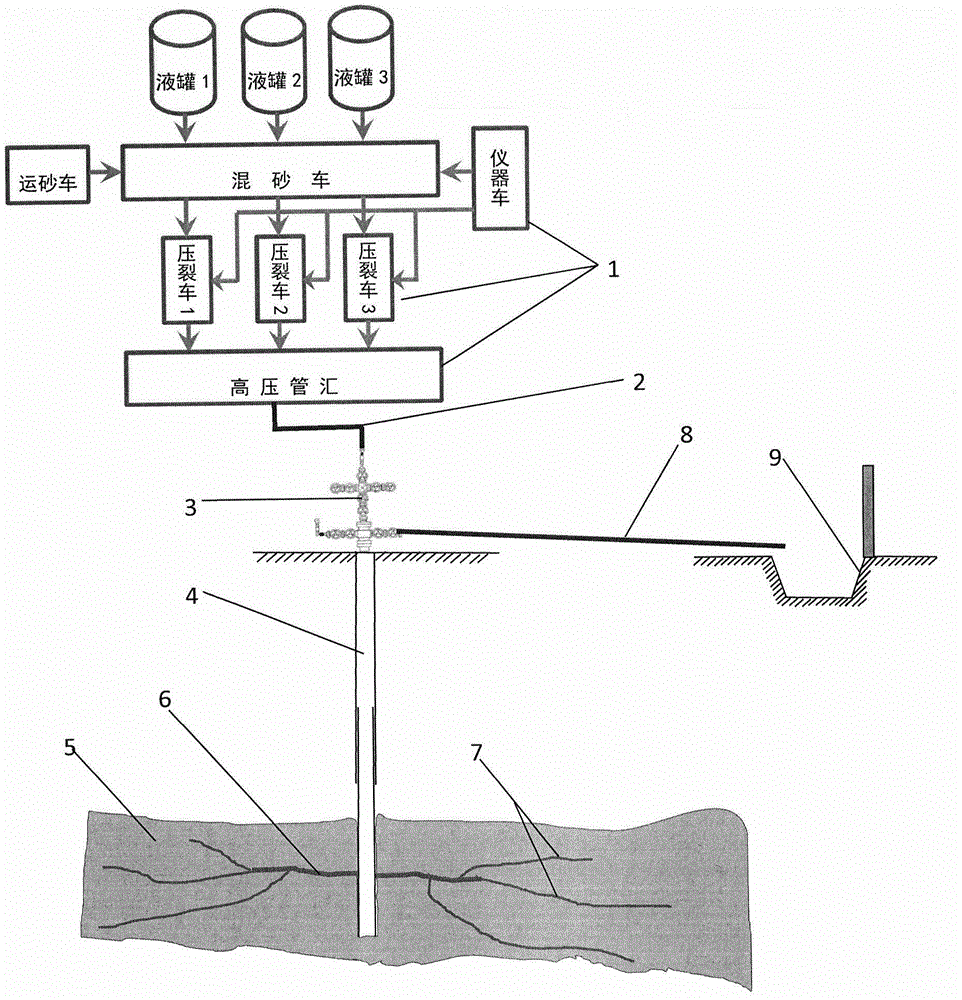

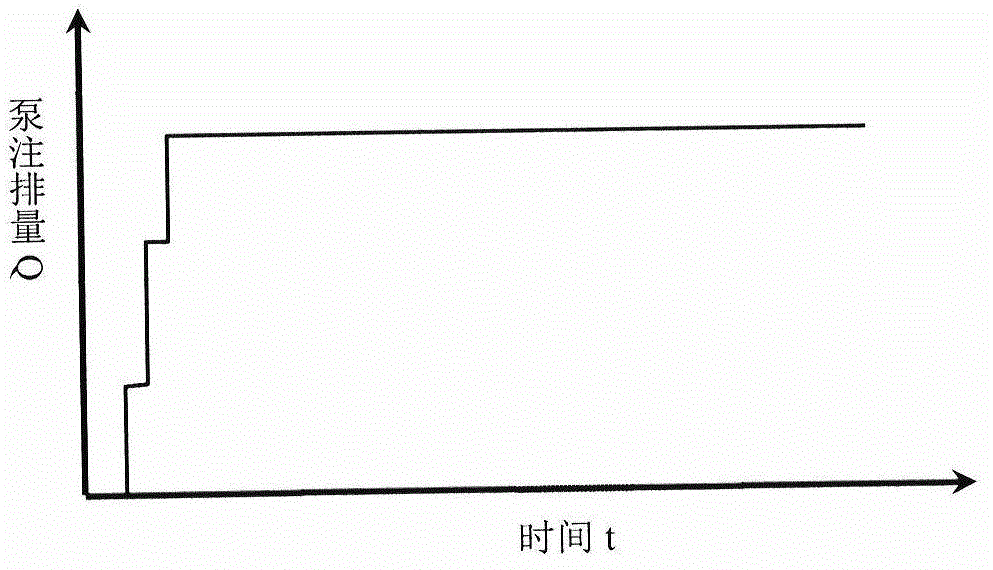

Fracturing method for deep shale gas through V-shaped pressure curve

ActiveCN109113703AIncrease the effective transformation volumeImprove fill rateFluid removalLiquid ratioPressure curve

The invention discloses a fracturing method for deep shale gas through a V-shaped pressure curve. The fracturing method comprises the steps of (1) key reservoir parameter evaluation, (2) optimizationof fracture parameters and fracturing construction parameters, (3) perforation position determination and perforation operation, (4) acid pretreatment, (5) variable-displacement and low-viscosity slick water joint forming construction, (6) powder pottery construction for adding different sand liquid ratios into low-viscosity slick water, (7) medium-particle-size proppant construction for adding different sand liquid ratios into medium-viscosity slick water, (8) high-viscosity gel and large-particle-size carrying proppant construction, and (9) displacing operation. According to the fracturing method, complexity of fracturing fractures of the deep shale gas is improved, the filling ratios of systems with different scales of fractures such as near wells, far wells, main fractures and micro-fractures are increased, the effective stimulation volume of the deep shale gas is increased, and the yield increasing and stabilizing effects after pressure are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fracturing method applicable to thin layer

The invention provides a fracturing method applicable to a thin layer. The method comprises the steps that 1) comprehensive characteristic evaluation of a reservoir and a compartment is carried out to acquire the information of the lithology, the physical property, the rock mechanics, the crustal stress and the sensibility characteristic of the reservoir and the compartment; 2) at the acid liquid pretreatment phase, acid liquid is injected into the reservoir; 3) at the pre-liquid phase, low viscosity fracturing liquid is injected into the reservoir; 4) at the sand adding phase of sand-carrying liquid, a medium viscosity fracturing liquid system mixed with a propping agent is injected into the reservoir; 5) at the replacement phase, a less replacement technology is used. According to the invention, the fracturing degree of the reservoir of the class, the effective support degree of the propping agent and the support efficiency of a long shaft crack can be improved; the post-pressing long-term diversion ability is improved; the post-pressing effect is ensured; the stable yield period is prolonged; and the fracturing reforestation effect of the reservoir of the class and the reservoir utilization are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

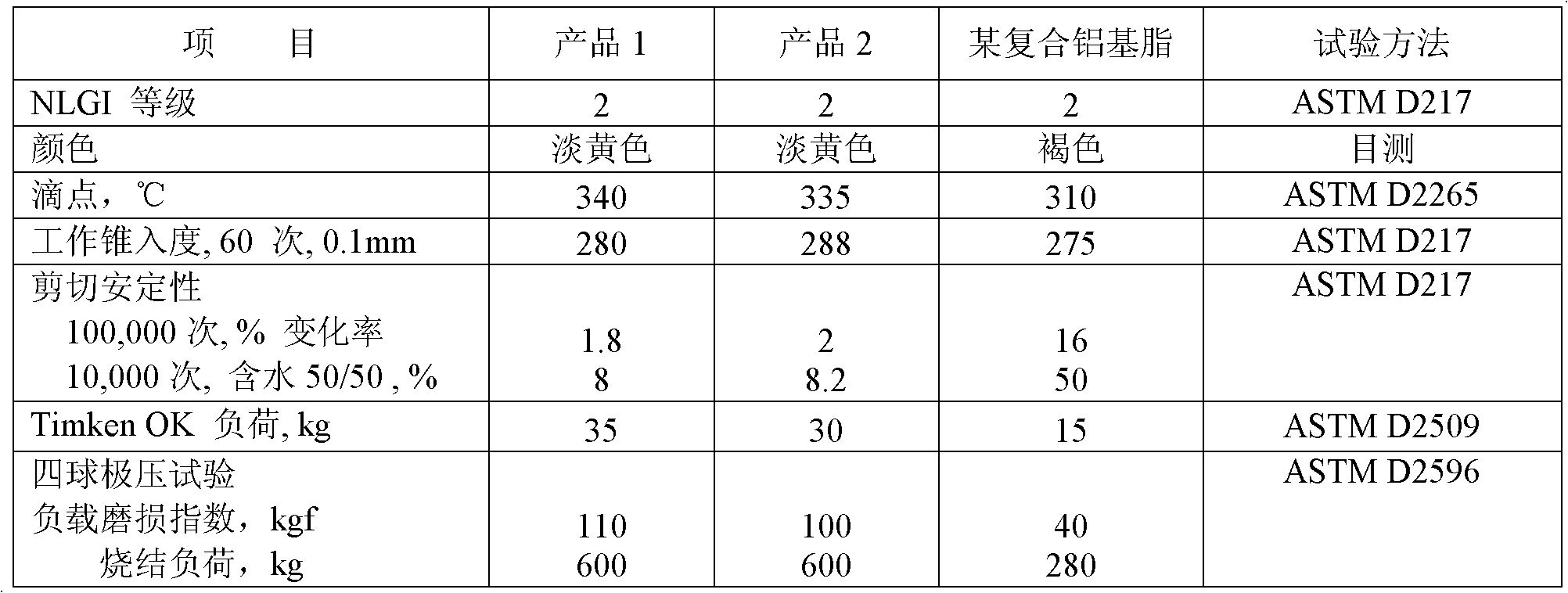

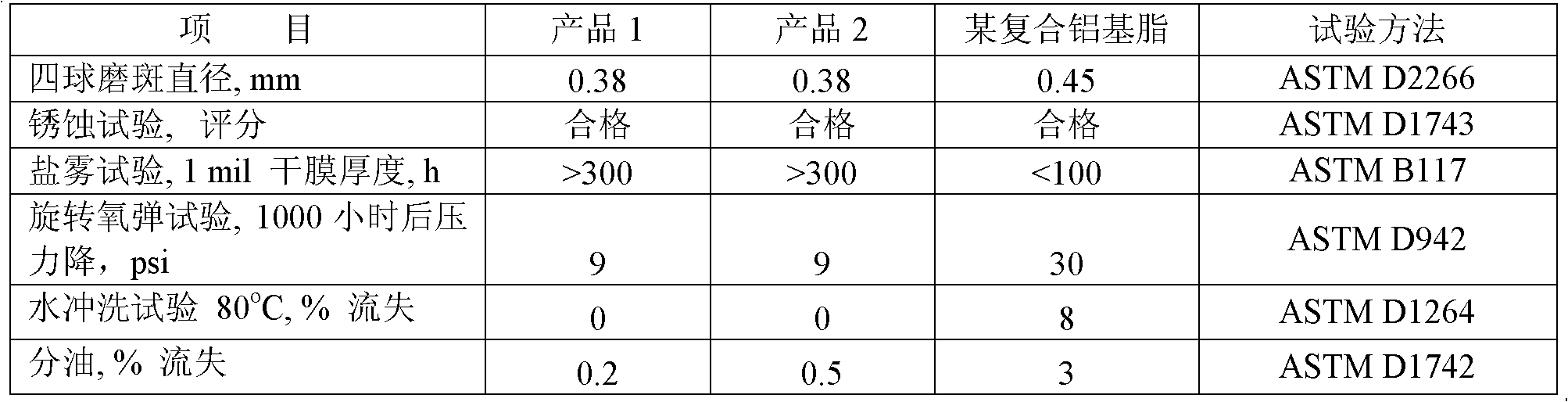

Multifunctional superstrong extreme pressure antiwear lubricating grease and preparation method thereof

InactiveCN102690716AStrong extreme pressureWear scar diameter is smallLubricant compositionAcetic acidCalcium hydroxide

The invention relates to superstrong extreme pressure antiwear lubricating grease and a preparation method thereof; particularly, a densifier is generated by calcium sulfonate with a high base number through a phase inversion reaction, and the lubricating grease is prepared by combining base oil with other functional additives, wherein the base oil is combined by base oil with high viscosity and medium viscosity. The method comprises the following steps: stirring and mixing the composite base oil and the calcium sulfonate in a reaction vessel, heating, adding a phase inversion promoter, glacial acetic acid, and water, heating and reacting at a constant temperature, adding calcium hydrate, aliphatic acid and boric acid after the phase inversion is completed, reacting at a constant temperature, heating and dehydrating, adding an anti-oxidant, refining, transferring the materials into a blending vessel, adding an eutectic rolling additive and an adhesion improver, dispersing and homogenizing the mixture, filtering, and degassing to obtain the finished product. The lubricating grease of the invention has excellent water sprinkling resistance, excellent high and low temperature performance, superstrong extreme pressure antiwear performance, excellent pumping performance, outstanding shearing stability, and antirust performance.

Owner:超美科技(深圳)有限公司

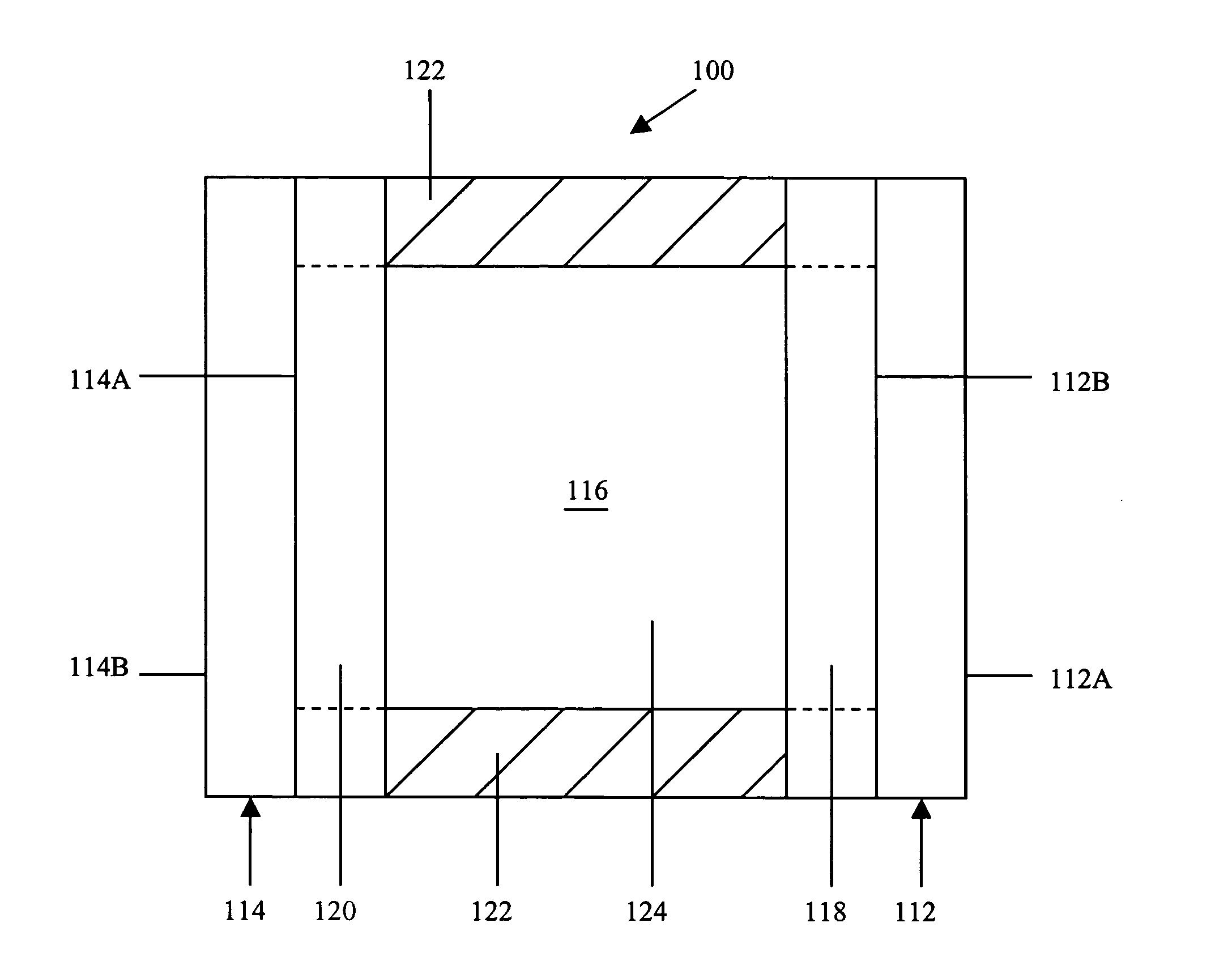

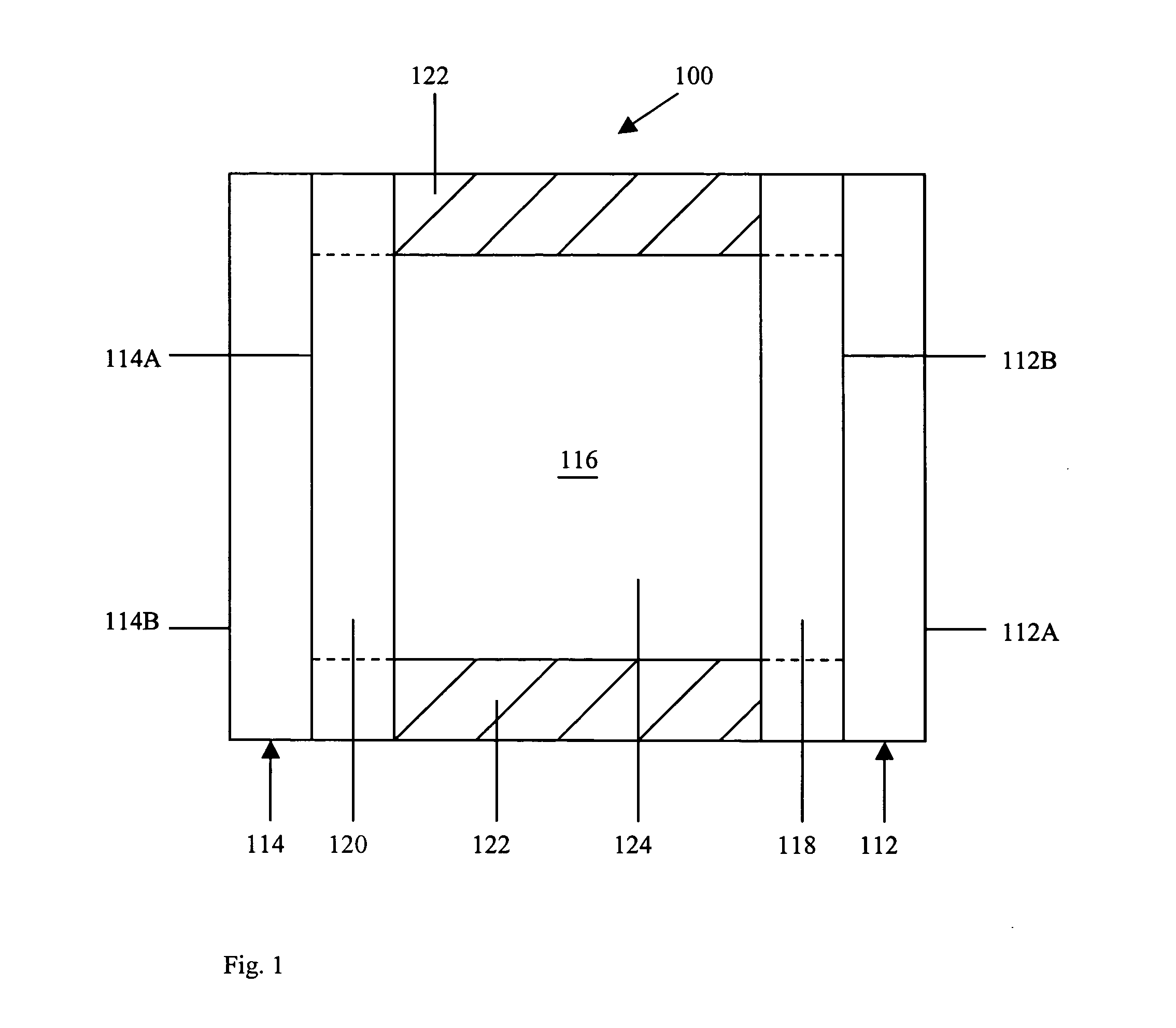

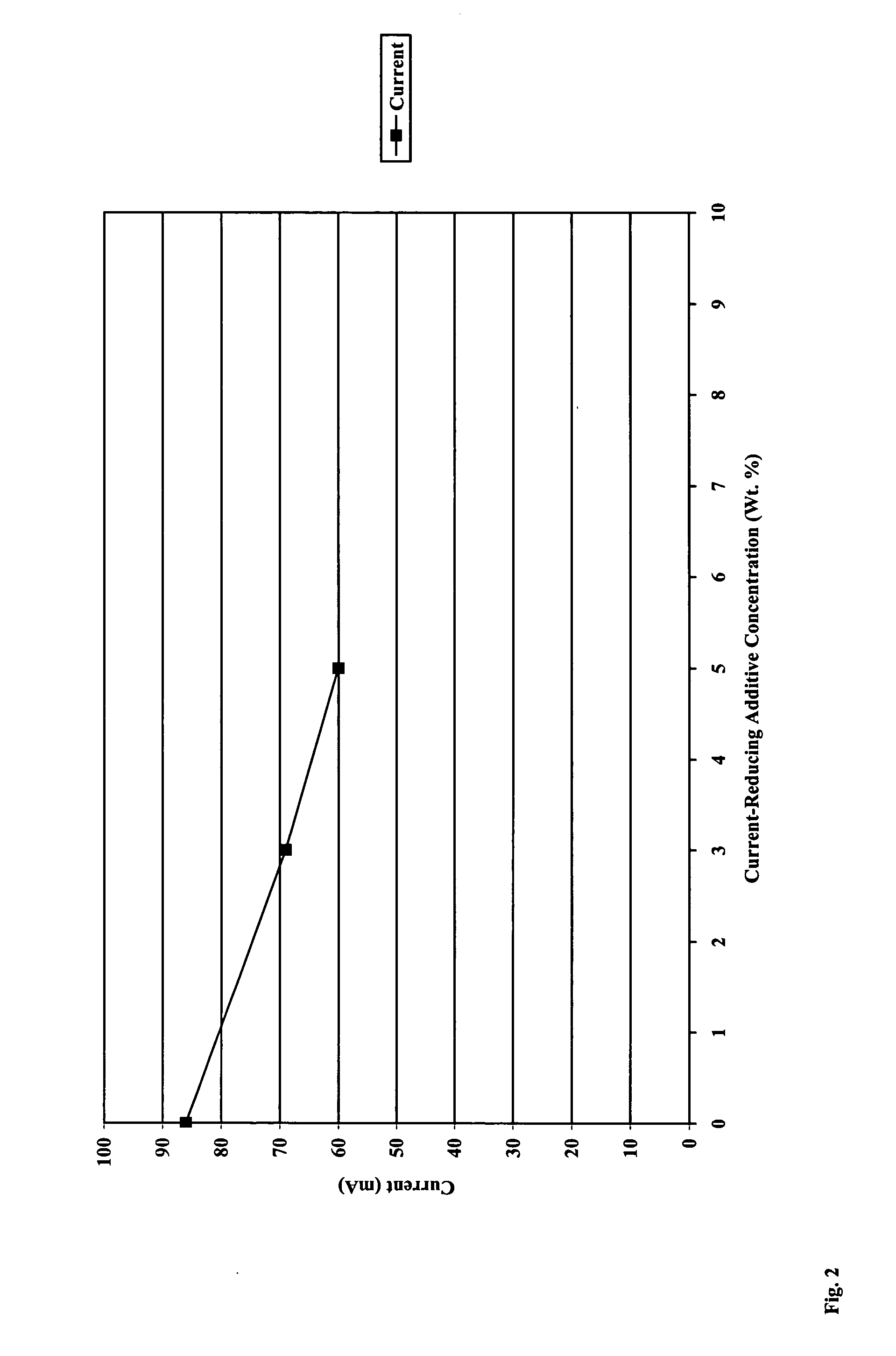

Electrochromic device having a current-reducing additive

InactiveUS20050012079A1Low viscosityFacilitate acceptable production ratesConductive materialOrganic conductorsProduction rateElectricity

An electrochromic medium for use in an electrochromic device comprising: at least one solvent; an anodic electroactive material; a cathodic electroactive material, wherein at least one of the anodic and cathodic electroactive materials is electrochromic; and a current-reducing additive, wherein the current-reducing additive comprises a polymer present in an effective concentration to materially reduce the current of the electrochromic medium upon application of an electrical potential, relative to an electrochromic medium without the current-reducing additive, while maintaining an electrochromic medium viscosity which facilitates acceptable production rates without a problematic degree of seal or other device component failure.

Owner:GENTEX CORP

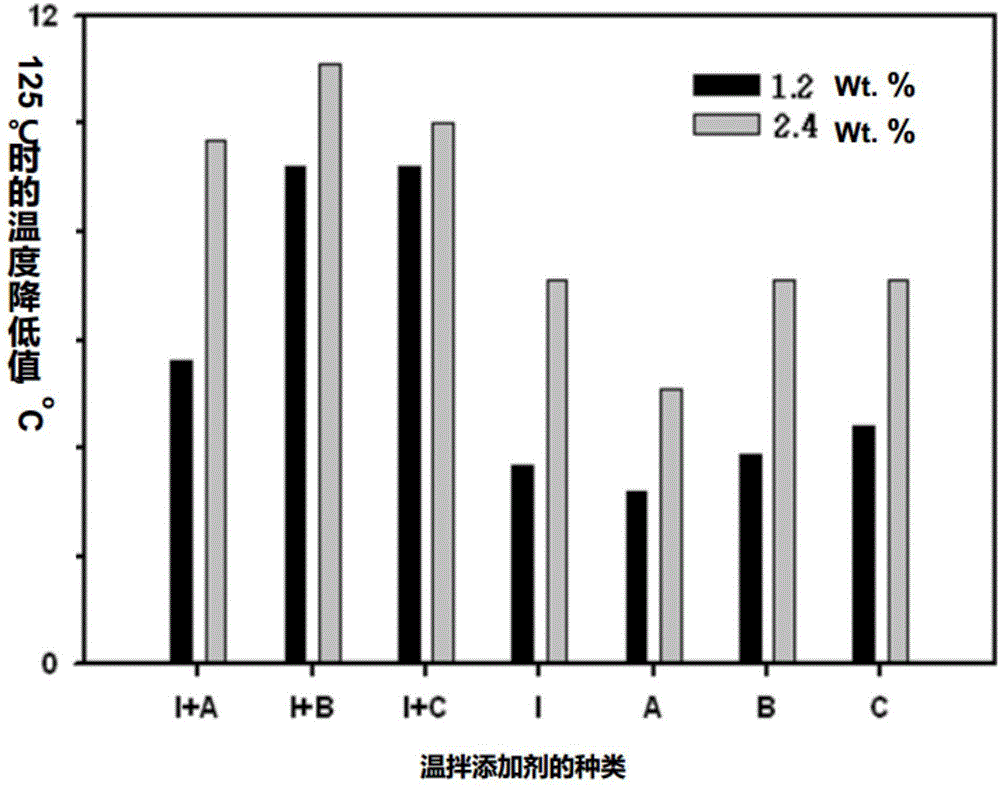

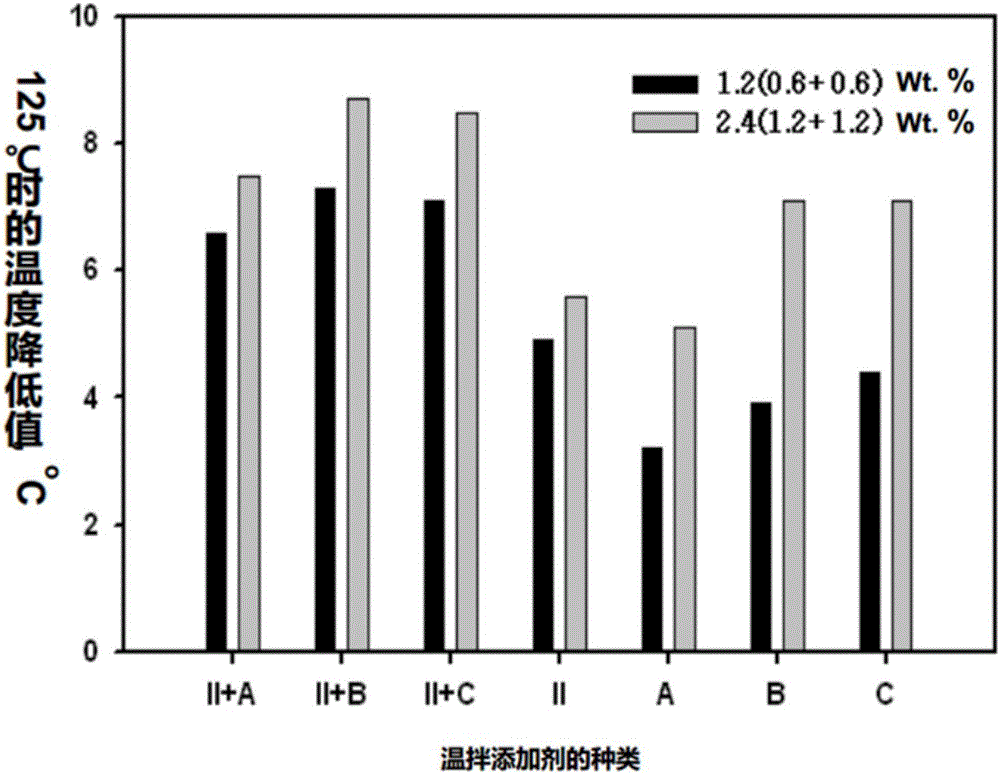

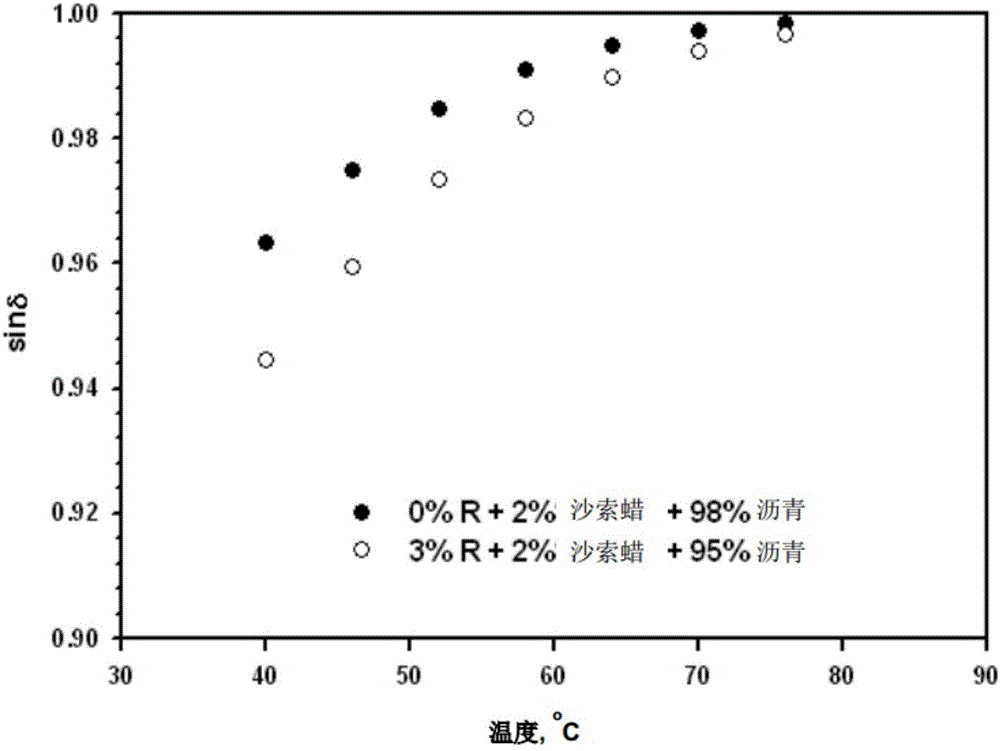

High visco-elastic warming mixing modifying agent for asphalt road and production method and application of high visco-elastic warming mixing modifying agent

InactiveCN105110685AEasy to layImproved performance characteristicsClimate change adaptationPolymer scienceRoad surface

The invention discloses a high visco-elastic warming mixing modifying agent for an asphalt road and a production method and application of the high visco-elastic warming mixing modifying agent. The high visco-elastic warming mixing modifying agent comprises a high visco-elastic modifying agent, a warm mixing additive component and a reactant. The high visco-elastic modifying agent comprises, by mass, 10-90% of mixed-viscosity polymer and 10-90% of high elastomeric polymer, and the mixed-viscosity polymers comprise at least one high-viscosity polymer and at least one medium-viscosity polymer. The warm mixing additive component comprises a mixture formed by at least two warm mixing additives. The high visco-elastic warming mixing modifying agent can be used for preparing a warm mixing asphalt concrete mixture and can be used for producing all modified asphalt concrete mixtures under the warm mixing temperature, and the modified asphalt road high in durability can be conveniently paved. The high visco-elastic warming mixing modifying agent has the advantages that air pollution is reduced, fuel is saved, material oxidizing and aging are reduced, and the opening time frame of the road is shortened; the high visco-elastic warming mixing modifying agent can further improve the road performance feature, and the service life of the road is prolonged.

Owner:许政道

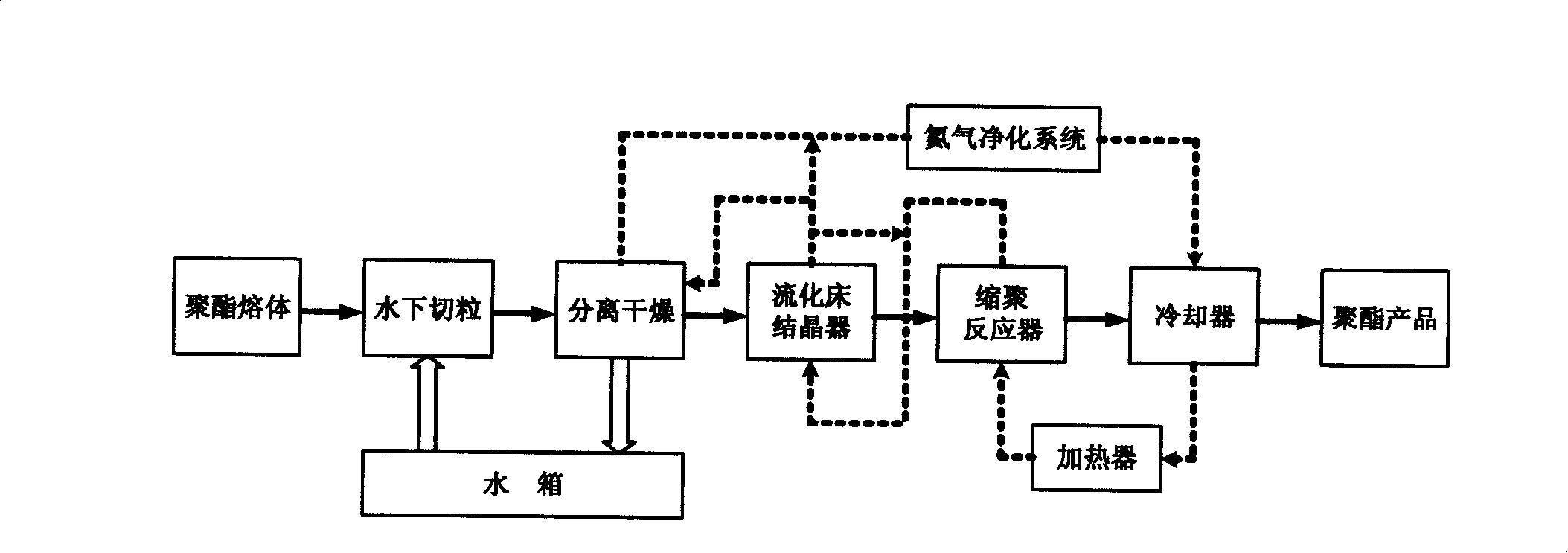

Polyethylene terephthalate solid-state polycondensation technique

The invention relates to a technique for further generating high viscosity polyester through solid phase polycondensation by using a PET polymer obtained through melt polycondensation. Firstly, medium viscosity polyester is used for granulation in warm water at 80 to 97 DEG C, the formed polyester granules and water are delivered to solid-liquid separation and drying equipment to ensure the granules to be separated from the water, the separated water flows into a water tank and is then delivered to a granule cutting room for periodic operation, the granules enter into crystallization equipment to be crystallized in inert gas atmosphere, the crystallized granules enter into a solid phase polycondensation reactor for reaction, the inherent viscosity is further improved, and the granules after the reaction enter into a cooler to be cooled down. The process of the technique is short, the chip bunker of a PET melt polymerization device, the raw material bin of a solid phase polycondensation device, and a delivery device can be saved, and crystallization is only required to be performed once during the solid phase polycondensation step; the energy saving effect is very remarkable, in each kilogram of polyester pellets, the energy can be saved by 69.1 kcal, the heating energy can be saved by 75.23 kcal, therefore, the economic efficiency is very remarkable.

Owner:SINOPEC OILFIELD SERVICE CORPORATION

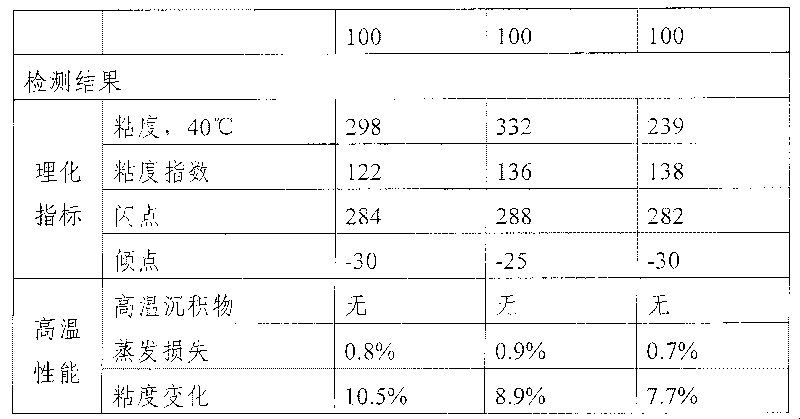

Parifying and regenerating process for high and medium viscosity waste oils

The present invention relates to the utilization of waste resource, and especially the regeneration and utilization of mixed waste oil of high and medium viscosity. The purification and regeneration process of waste oil of high and medium viscosity includes the following steps: natural deposition and rough filtration; heating for flocculation and deposition; three stages of pre-treatment including the secondary filtering; low temperature and high vacuum dewatering and fine filtering; inspection, etc. Through the purification and regeneration process, the produced oil product may reach the standard of new oil product.

Owner:上海宝钢废旧油处理有限公司

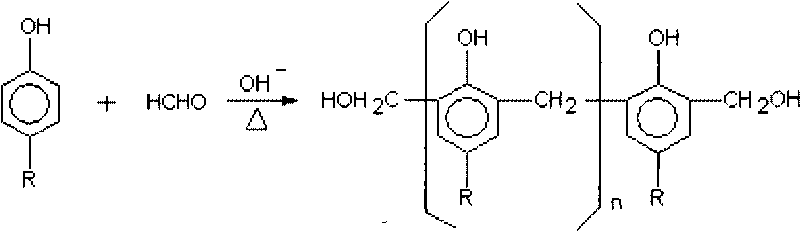

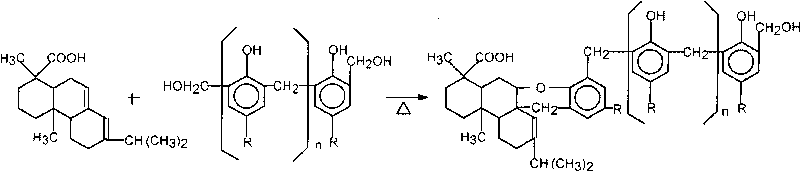

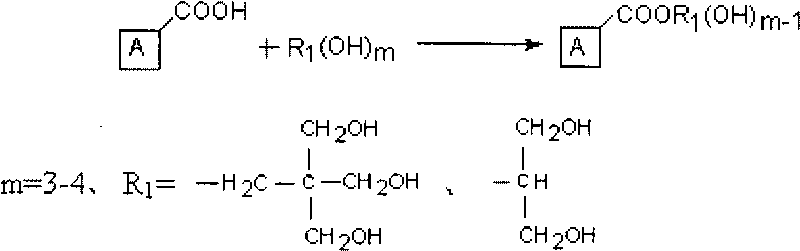

Preparation method of rosin modified phenolic resin

The invention relates to a preparation method of a rosin modified phenolic resin. The method comprises the following three steps of reactions: 1. performing condensation of tert-butylphenol, bisphenol A, tung oil and solid formaldehyde under the action of catalyst magnesium acetate and lime to generate polymer of hydroxymethyl tert-butylphenol; 2. performing an addition reaction with rosin to generate an addition product; and 3. performing esterification of the addition product, pentaerythritol and glycerin under the action of catalyst zinc chloride to generate the rosin modified phenolic resin. The preparation method adopts proper raw material proportioning, reaction temperature, reaction time, catalyst and other technical conditions, thus during the production process, the resin viscosity can be effectively controlled, and the operation is simple and flexible and has good effect. The quality of the product is increased, the oil solubility of resin is good, the oil medium viscosity is high, the normal heptane capacity is 4.5ml / g or more; and the prepared paint film ink has good water resistance and alkali resistance, high hardness, excellent anti-after-binding performance, quick-drying performance, lightness and strong adhesive force. Therefore, the preparation method of the invention is applicable to industrial production.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

High shine, stick-shaped cosmetic products

The present invention provides a cosmetic composition having a gloss of at least about 85 gloss units (gu), as well as sufficient shape retention properties for forming a stick-shaped cosmetic product. Specifically, the cosmetic composition contains: (a) a high viscosity oil component; (b) a medium viscosity oil component; (c) a low viscosity oil component; and (d) an oily gelling agent comprising an ester of glycerol or polyglycerin with an aliphatic or hydroxyl aliphatic acid and a dibasic acid. A stick-shaped cosmetic product formed by the cosmetic composition of the present invention exhibits a high-shine that is not available in conventional stick-shaped cosmetic products and yet retains the high make-up coverage typically provided by conventional stick-shaped cosmetic products.

Owner:ELC MANAGEMENT LLC

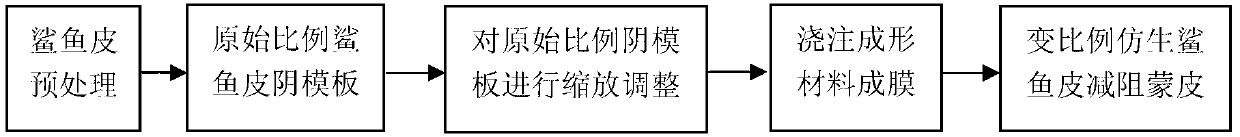

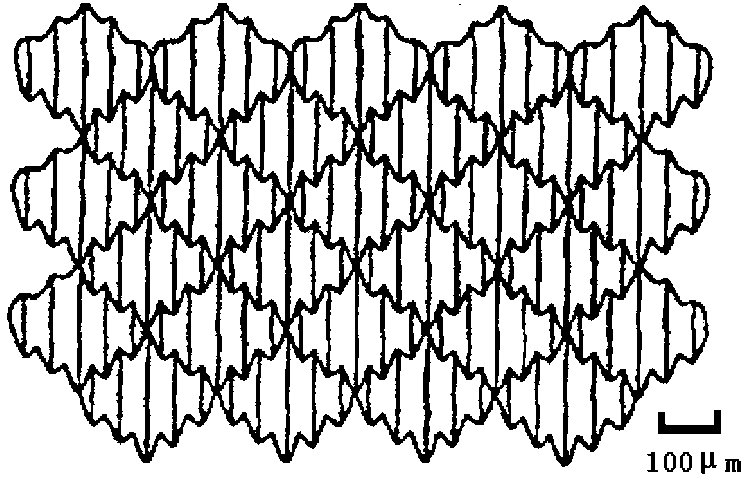

Controlled manufacturing method for shark imitated drag reduction surface structure under variable environment

ActiveCN102849205AImprove production efficiencyLow costFuselage bulkheadsEngineeringApplication object

The invention discloses a controlled manufacturing method for a shark imitated drag reduction surface structure under a variable environment. The method comprises the following steps of: 1, preparing an original-ratio sharkskin biological female template; 2, designing shape parameters of a deformed imitated shark required to be manufactured according to the requirement of an application environment; and 3, preparing a variable-proportion bionic drag reduction skin according to the application environment. The variable-proportion bionic sharkskin shaped drag reduction skin prepared by using the method has a functional structure completely in accordance with the original sharkskin shape, but has different shape parameters. By using the method for making the bionic drag reduction skin, the size of the surface shape of the skin can be adjusted according to the parameters such as common speed, different parts of the outer surface and the medium viscosity of an application object, so that the drag reduction effect of the shark imitated drag reduction skin is in an optimal state. The method has high practical value and broad application prospect in the technical field of bionic manufacturing.

Owner:BEIHANG UNIV

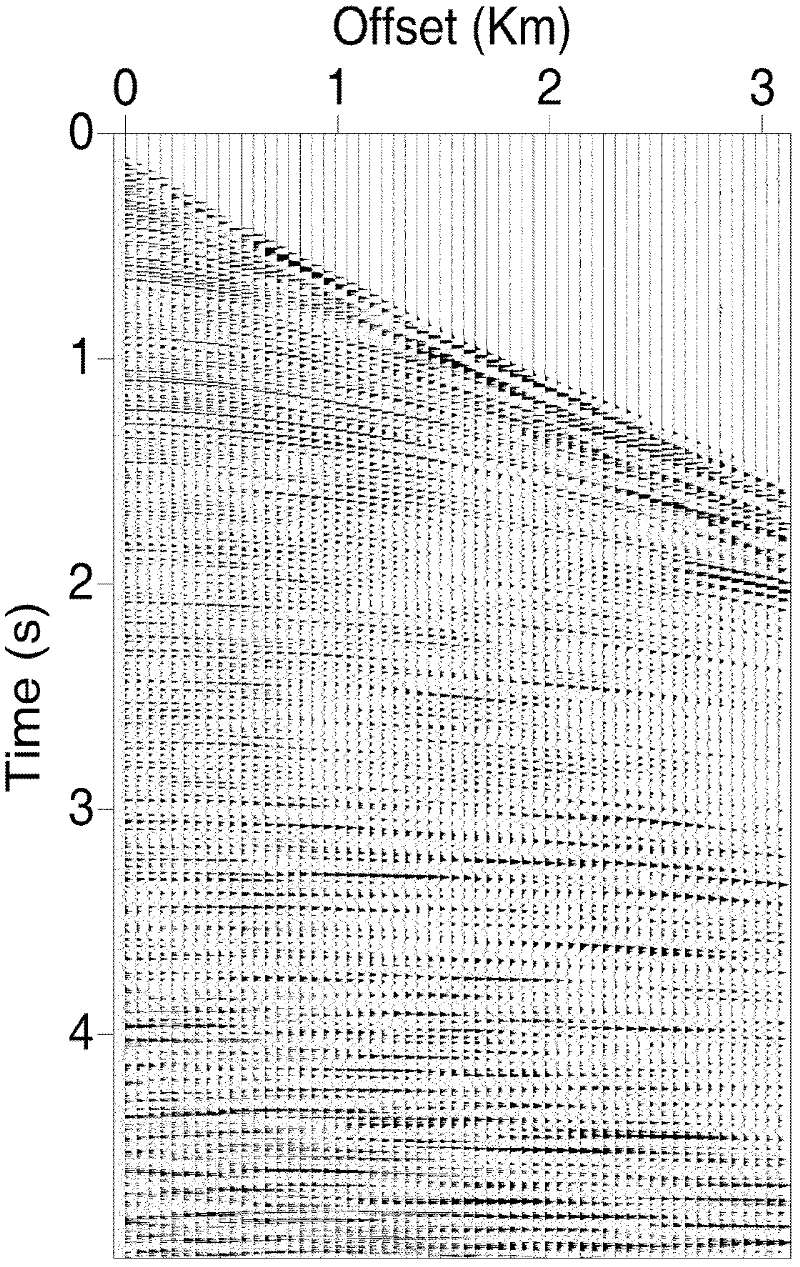

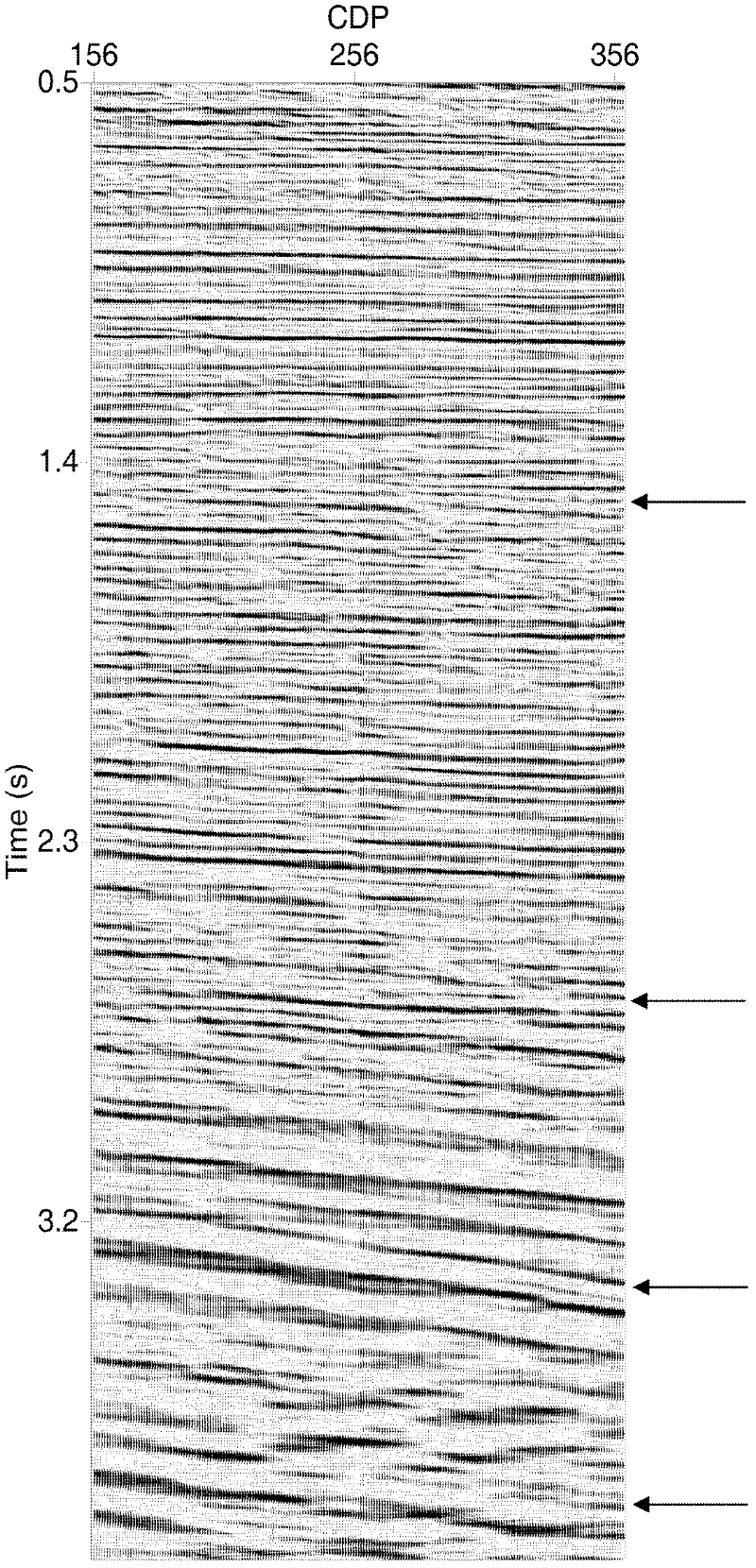

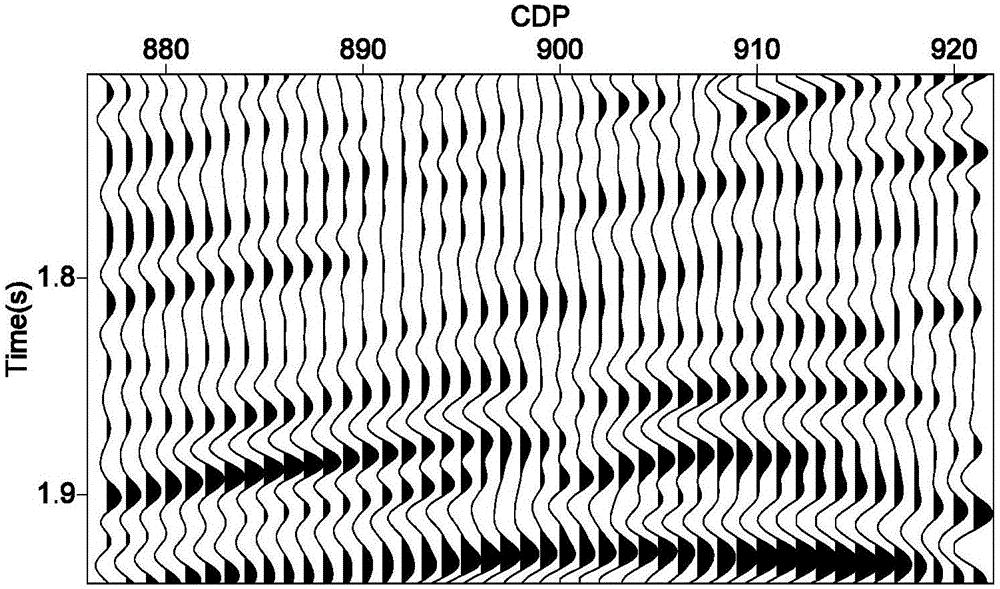

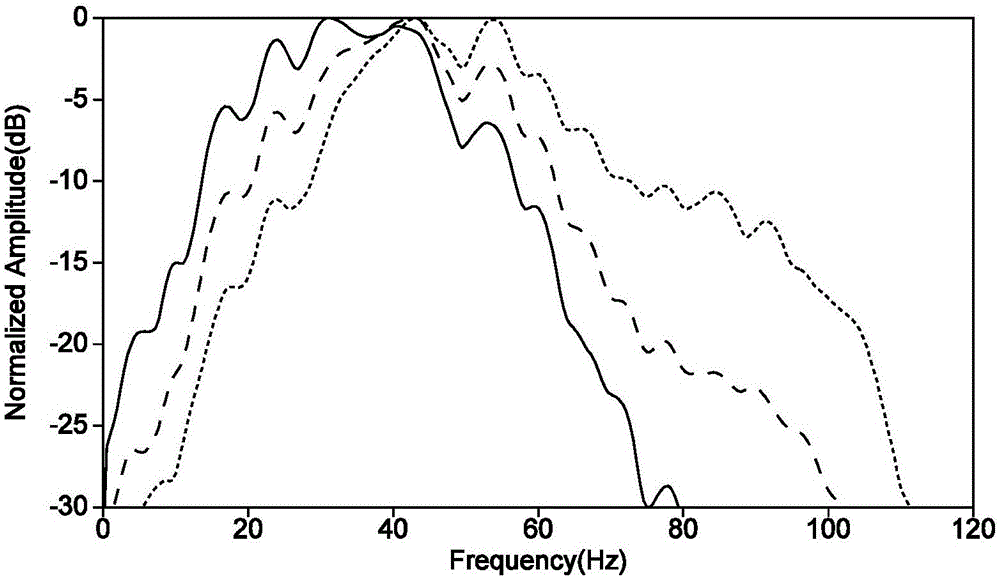

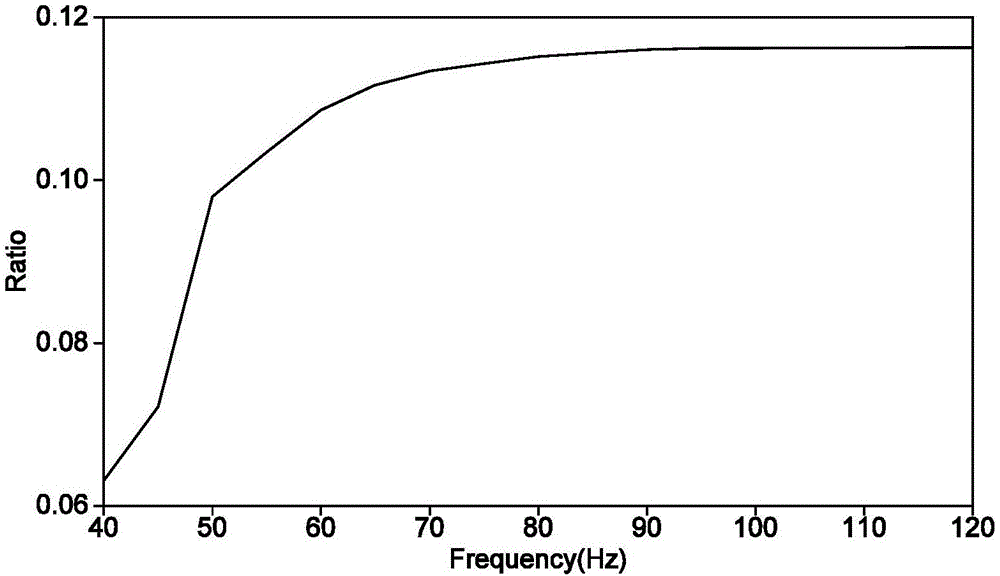

Prestack time migration method for compensating absorptive attenuation

ActiveCN102590862AHigh resolutionEasy to identifySeismic signal processingUltrasound attenuationHypothesis

A prestack time migration method for compensating absorptive attenuation is applied to the processing of reflex seismic data in seismic prospecting. According to the method, attenuation of amplitude of high frequency seism, caused by earth medium viscosity and thin layer scattering, is compensated in the migration process, the attenuated high frequency component is restored, so that the image resolution ratio of intermediate and deep constructions reaches up to the degree approximately to the shallow construction, and the stability is guaranteed and the noise amplification is avoided. No hypothesis is made on lamination or uniformity of a Q-value space distribution, and by introducing an equivalent Q-value describing absorptive attenuation of the seismic amplitude, the compensation of absorptive attenuation and prestack time migration are effectively combined together. The method can determine the equivalent Q-value on the basis of reflex seismic data collected on the ground, so that the difficulty in determining the Q-value by the existing various absorptive attenuation compensation methods is avoided. The method can better indicate rupture and stratum deposition patterns of the intermediate and deep constructions and is of great application value for the exploration of oil gas and mineral resources.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Universal industrial gear oil additive composition

The invention provides an additive composite for general industrial gear lubricants, comprising (A) at least one type of extreme pressure and anti-wear additive with sulfurs, (B) at least one type of multi-functional anti-wear additive with phosphors, and (C) at least one type of anti-rusting agent. The composite has the advantages of lower levels of additive, simple formula, strong universality and excellent performance. By adding the additive composite into base oil with medium viscosity index or high viscosity index or into a mixture of the base oil according to weight percentage between 0.6 and 1.0, a medium-duty industrial gear oil up to the indexes of GB5903-95 standards, such as the number 100, 220,320, 460,680 and1000, is prepared. By adding the additive composite into base oil with medium viscosity index or high viscosity index or into the mixture of the base oil according to the weight percentage between 1.0 and 1.4, a heavy-duty industrial gear oil up to the indexes of GB5903-95 standards, such as the number 100, 220,320, 460,680 and1000, is prepared.

Owner:PETROCHINA CO LTD

Production method of pure Shengma fiber fabric

The invention relates to a production method of a pure Shengma fiber fabric. Shengma fibers are woven together with wefts through warping, sizing and denting, wherein the process of warping takes the standards of medium speed, small tension, low elongation and maintained elasticity as a principle for controlling; the process of sizing adopts the process routes of low viscosity, low temperature, small tension and maintained elongation; in a size formula, medium-viscosity and low-viscosity modified starch is used as a main material, and low-polymerization PVA (Polyvinyl Acetate) and polyacrylate are used as auxiliary materials; the process of weaving adopts a loom hands-on craft with small tension, small opening, low rear beam and proper back move of the rear beam; and the loom has the requirements that a rubber roll temple is used, the temperature and the humidity are lower, the warp knot tail length is short, and the cropping is timely. The pure Shengma fiber fabric is an environmentally friendly and healthy novel shell fabric, has the advantages of environmental protection, ventilation, smoothness, flexibility, comfort, washing resistance and good dropping feel, also has the effects of bacteriostasis and strong mite suppression and is particularly suitable for manufacturing bedclothes, infant gertrudes, medical textiles, towels, handkerchieves, decorative fabrics, process shell fabrics, and the like.

Owner:JIHUA 3509 TEXTILE

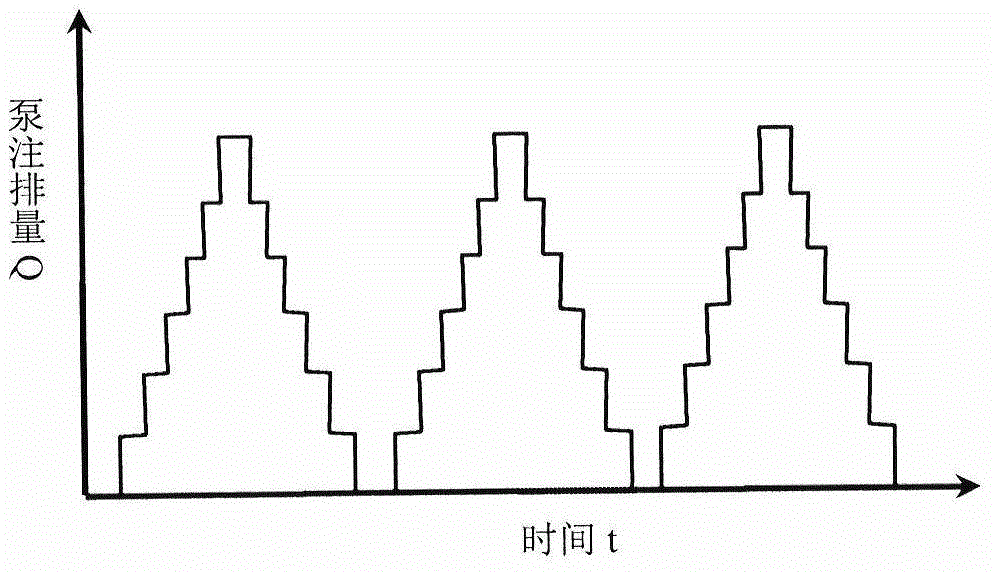

Novel fracturing pump-injection method

The invention provides a novel fracturing pump-injection method. The novel fracturing pump-injection method specifically comprises the following several stages that 1, a main crack formation stage, namely a high-viscosity fracturing fluid is adopted to conduct conventional pump-injection fracturing on a reservoir and is in coordination with an end screening-out technology to form a main crack definite in crack length and crack width; 2, a branch crack initiation stage, namely a low-viscosity clear water or slick water fracturing liquid system is used for initiating and forming multiple branch cracks at the ends of the main crack and around the main crack in a periodic pulsing pump-injection fracturing mode; 3, a branch crack extending stage, namely a medium-viscosity fracturing liquid system is adopted to enable the crack lengths and the crack heights of the multiple branch cracks to be further increased in a large-displacement conventional pump-injection mode. By means of the novel fracturing pump-injection method, a crack network system formed by the main crack and multiple branch cracks at the tail ends can be formed in the tight reservoir, and an optimal seepage channel is provided for oil gas to flow into a shaft.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method of heat conduction paster adopting fiber glass mesh as supporting structure

ActiveCN102153955AThe overall thickness is thinGood chemical stabilityNon-macromolecular adhesive additivesFilm/foil adhesivesGlass fiberFiberglass mesh

The invention discloses a preparation method of heat conduction paster, adopting a fiber glass mesh as a supporting structure. The preparation method comprises the steps of dissolving and formulating silicon rubber into silicon rubber solution, and sequentially adding vulcanizer, heat conduction filler and a silane coupling agent to formulate size with medium viscosity and fine coating performance by ultrasonic dispersion and ball-milling uniform mixing; and uniformly coating the size on the pretreated glass fiber mesh and obtaining the heat conduction paster through solvent volatilization, drying, moulding curing and trimming. The heat conduction paster has a high heat conduction rate and a small thermal expansion coefficient, is high in heat stability and soft, meets the requirement on an insulating property, and is convenient to use and disassemble since the surface of the paster has certain viscosity that can be adjusted within a certain range.

Owner:GUANGDONG UNIV OF TECH

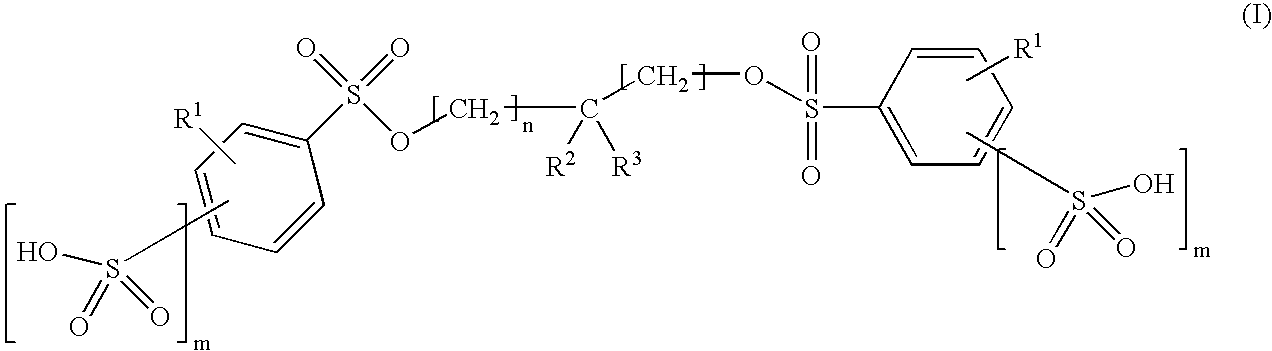

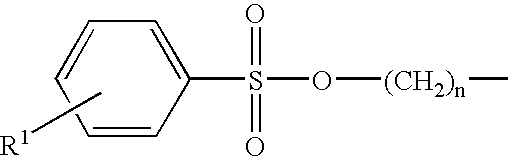

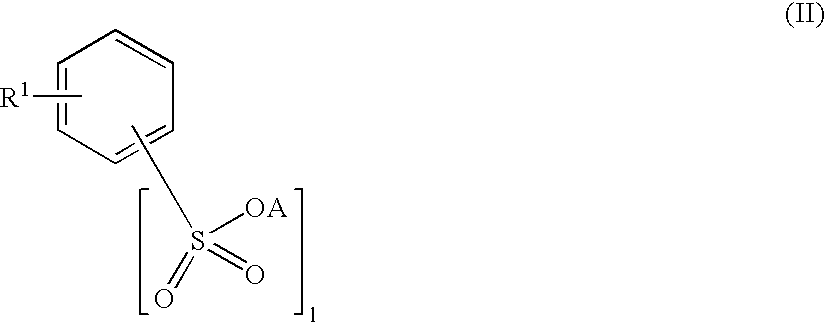

Inhibition of catalytically active impurities in polycarbonate by the melt transesterification process

ActiveUS7250483B2DisadvantagePrevent particle and metal cation and deficiencyCombination devicesSulfur-dioxide/sulfurous-acidTransesterificationPolycarbonate

An improvement to the melt transesterification process for the preparation of polycarbonate is disclosed. The improvement entails adding to the process between its medium viscosity reactor and a high viscosity reactor at least one bridged ester of organic sulphur-containing acid.

Owner:COVESTRO DEUTSCHLAND AG

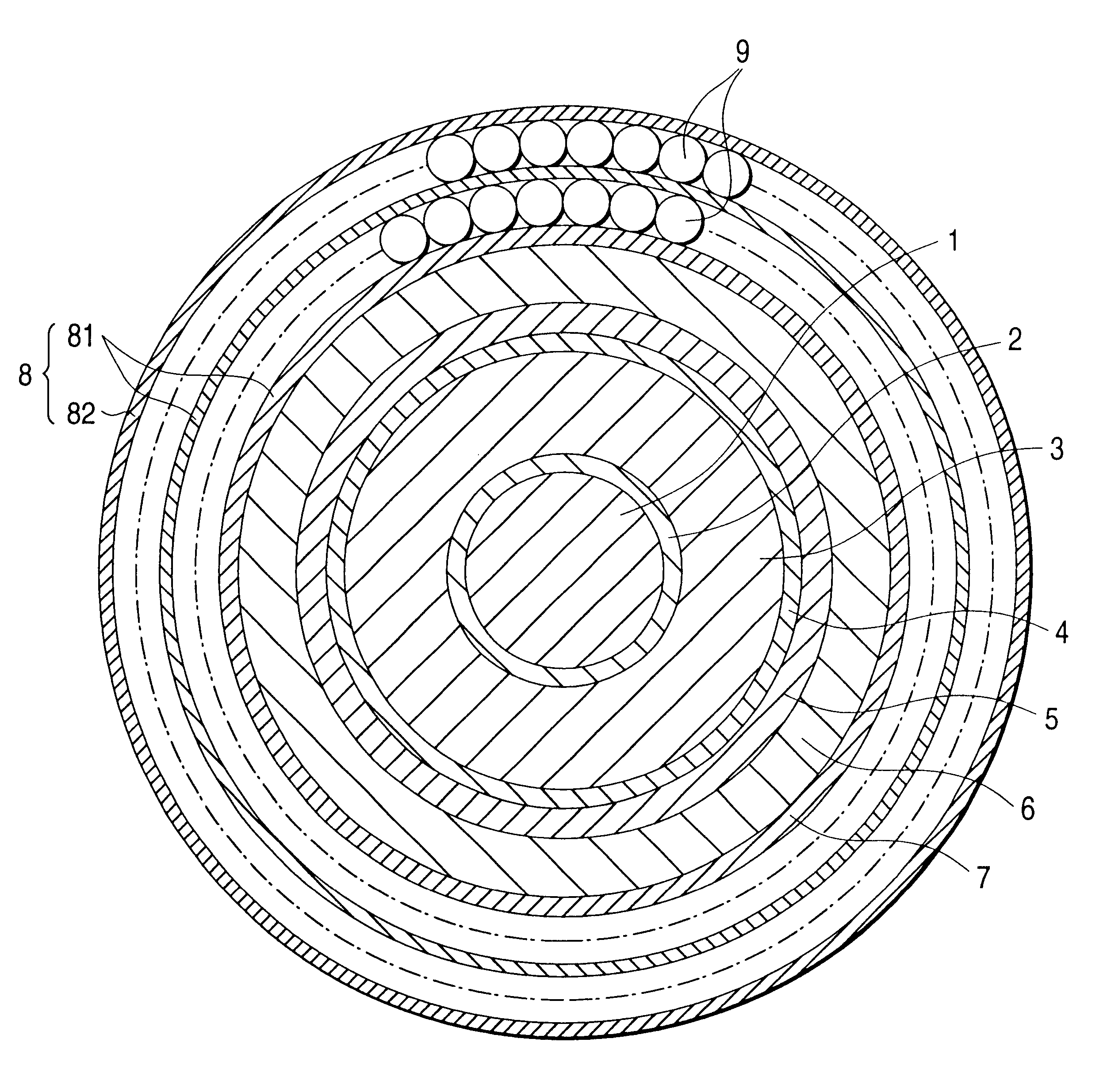

Solid cable, manufacturing method thereof, and transmission line therewith

InactiveUS6399878B2High tensile strengthRubber insulatorsOil-pressure cablesPolyolefinElectrical conductor

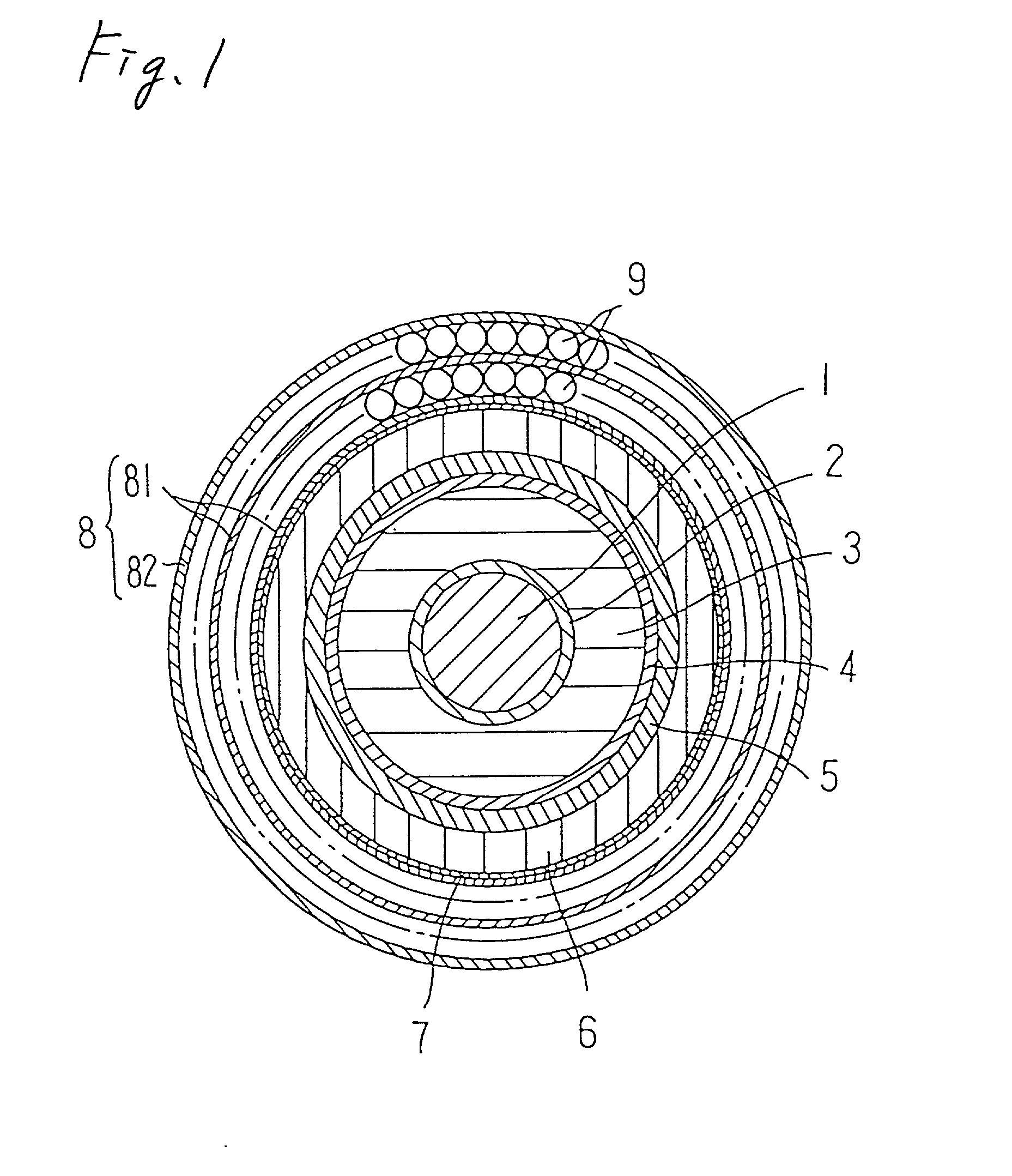

A cable and cable system is provided having a conductor and an insulation layer on an outer circumference of a conductor. The insulation layer is impregnated with a medium-viscosity insulating oil that has a viscosity of 10 centistokes (cst) to less than 500 cst at 60° C. The insulation layer includes an insulating tape that may be one or a combination of composite tape having a polyolefin resin film laminated with a kraft paper on both its sides and an insulating tape including a polyolefin resin film. The cable includes a metal sheath provided on an outer circumference of the insulation layer, and a reinforcing layer formed on an outer circumference of the metal sheath. The reinforcing layer reinforces the metal sheath by absorbing hoop stress exerted on the metal sheath. The cable system includes a submarine-portion cable and a land-portion cable, an oil stop joint box, and an oil feeding tank. The oil stop joint box connects the submarine-portion cable to the land-portion cable, and the oil feeding tank is connected to the land-portion cable which feeds the medium-viscosity insulating oil to the land-portion cable.

Owner:SUMITOMO ELECTRIC IND LTD

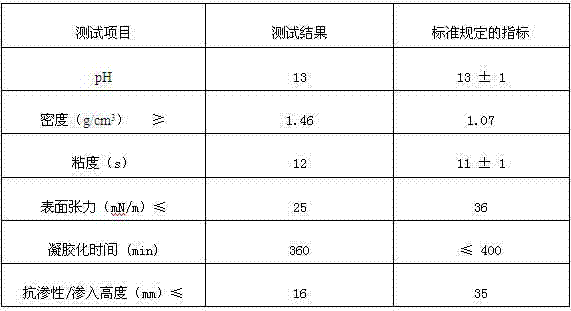

Inorganic silicate waterproof agent with depth permeability and filling property and preparation method of waterproof agent

The invention belongs to the field of building materials, particularly relates to an inorganic silicate waterproof agent with depth permeability and filling property and a preparation method of the waterproof agent, and aims to provide a concrete waterproof agent with the depth permeability, excellent filling property and excellent waterproof performance. Soluble sodium silicate water solution serves as a reaction active substance, deionized water serves as a thinning agent, inert silica solution serves as a filling substance, and a catalyst and an ultra-high active fluorocarbon surfactant serves as auxiliary materials. The concrete waterproof agent has high active substance contents, appropriate inert fillers, medium viscosity and low surface tension, so that the concrete waterproof agent is high in permeation capacity and micro-pore filling capacity and can furthest close concrete surfaces, inner micro pores and micro cracks. When the waterproof agent is used, concrete and cement mortar surfaces are treated in a spraying manner, and the pressure-resistant strength and the anti-permeability performance of the waterproof agent can be remarkably improved.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Slurry forretaining wall in use for not excavating drilling

This invention discloses slurry for protecting the walls during nonexcavating drilling. The slurry comprises: water 100 parts, bentonite 3-10 parts, and slurry-treating agent 0.75-2.5 parts. When the bentonite is calcium soil, the slurry-treating agent comprises sodium carbonate, Na-CMC and biotreating agent, and the proportions are: calcium soil 5-10 parts, sodium carbonate 0.25-0.5 part, Na-CMC 0.25-1 part, and biotreating agent 0.25-1 part. When the bentonite is sodium soil, the slurry-treating agent comprises Na-CMC and biotreating agent, and the proportions are: sodium soil 3-8 parts, Na-CMC 0.3-0.6 part, and biotreating agent 0.6-1.5 parts. The biotreating agent is Marchilus pauhoi gum, and Na-CMC is medium viscosity sodium carboxymethylcellulose. The slurry can avoid the difficulties in drilling and expanding the holes, as well as hole caving and pipe sticking.

Owner:彭良 +3

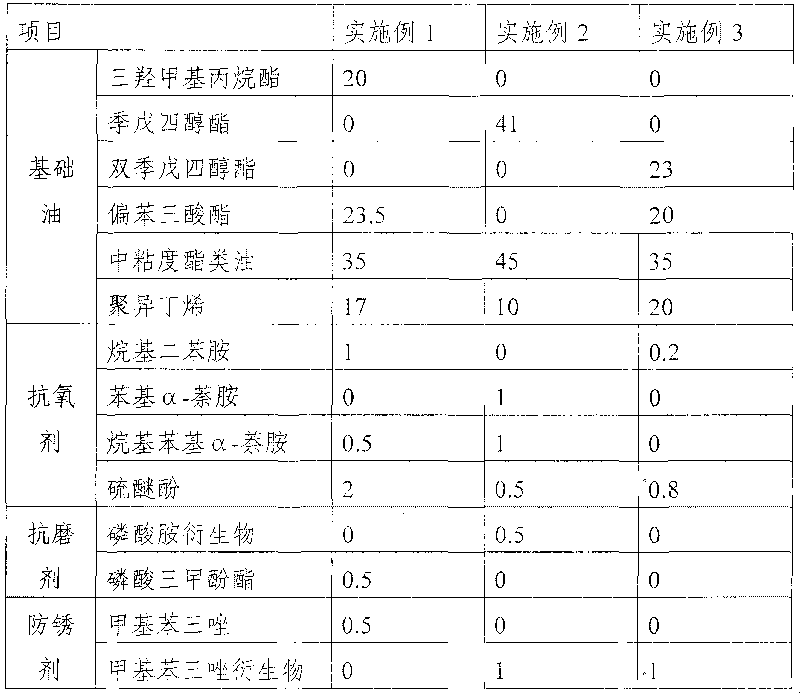

High-temperature chain oil composition

The invention relates to high-temperature chain oil taking ester oil as base oil, wherein the chain oil comprises: (1) 30 to 50 percent of low-viscosity ester oil; (2) 30 to 50 percent of medium-viscosity ester oil; (3) 10 to 20 percent of polyisobutylene in specific molecular weight; and (4) 1.5 to 3.5 percent of antioxidants, 0 to 3 percent of antiwear agent and 0 to 1 percent of antirust agent. The viscosity of the high-temperature chain oil is 150 to 320 cst at 40 DEG C and is small in increasing trend at high temperature.

Owner:益田润石(北京)化工有限公司

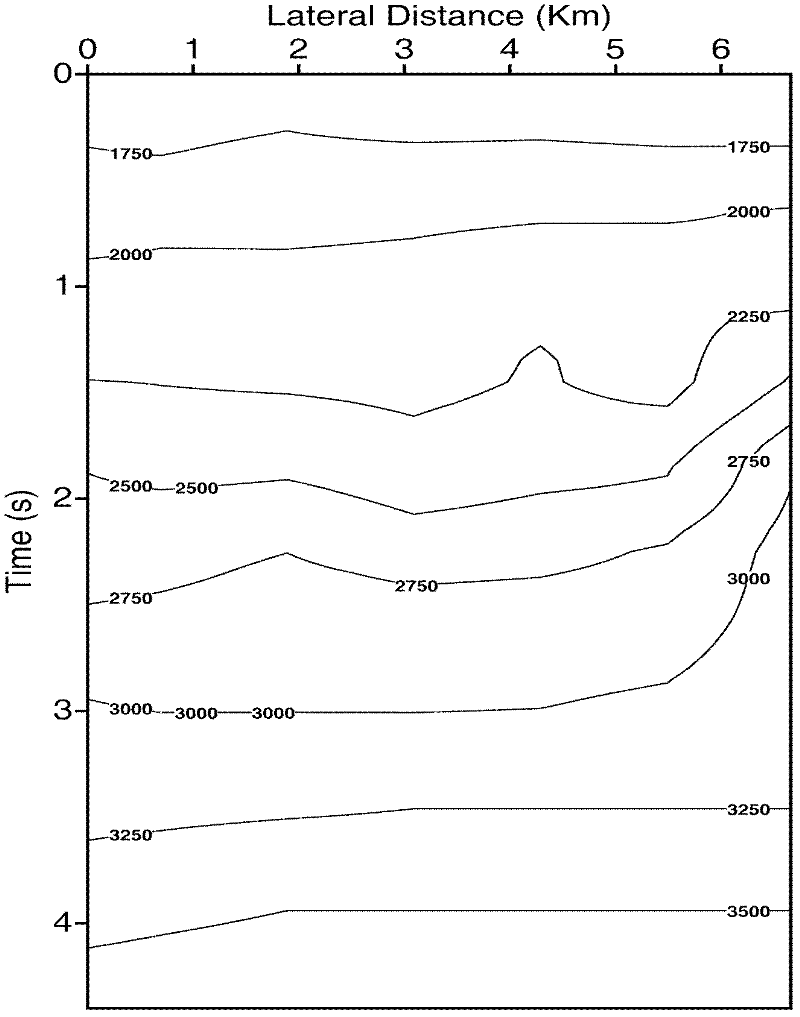

Ground receiving-based Q-value field modeling method of reflection seismic data

ActiveCN106443786AHigh resolutionSolve key difficultiesSeismic signal processingUltrasound attenuationMineral Sources

The invention discloses a ground receiving-based Q-value field modeling method of reflection seismic data, and the method is used for improving the resolution of seismic imaging in seismic exploration. According to the method disclosed by the invention, the Q value for describing the absorption attenuation of a seismic wave propagated through the earth medium is obtained by use of the ground-acquired reflection seismic data, and the problem of difficulty in modeling a non-uniform Q-value field in seismic exploration is solved. With the obtained three-dimensional Q-value field, the amplitude attenuation of a high-frequency seismic wave caused by the earth medium viscosity and thin-layer scattering in the migration imaging of seismic data can be compensated, the attenuated high-frequency component is recovered, and a subsurface structure image with resolution higher than that of a subsurface image obtained by a conventional migration method is obtained. The method has important application value in the exploration of oil-gas and mineral resources.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com