Patents

Literature

95 results about "Centistokes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A unit of viscosity

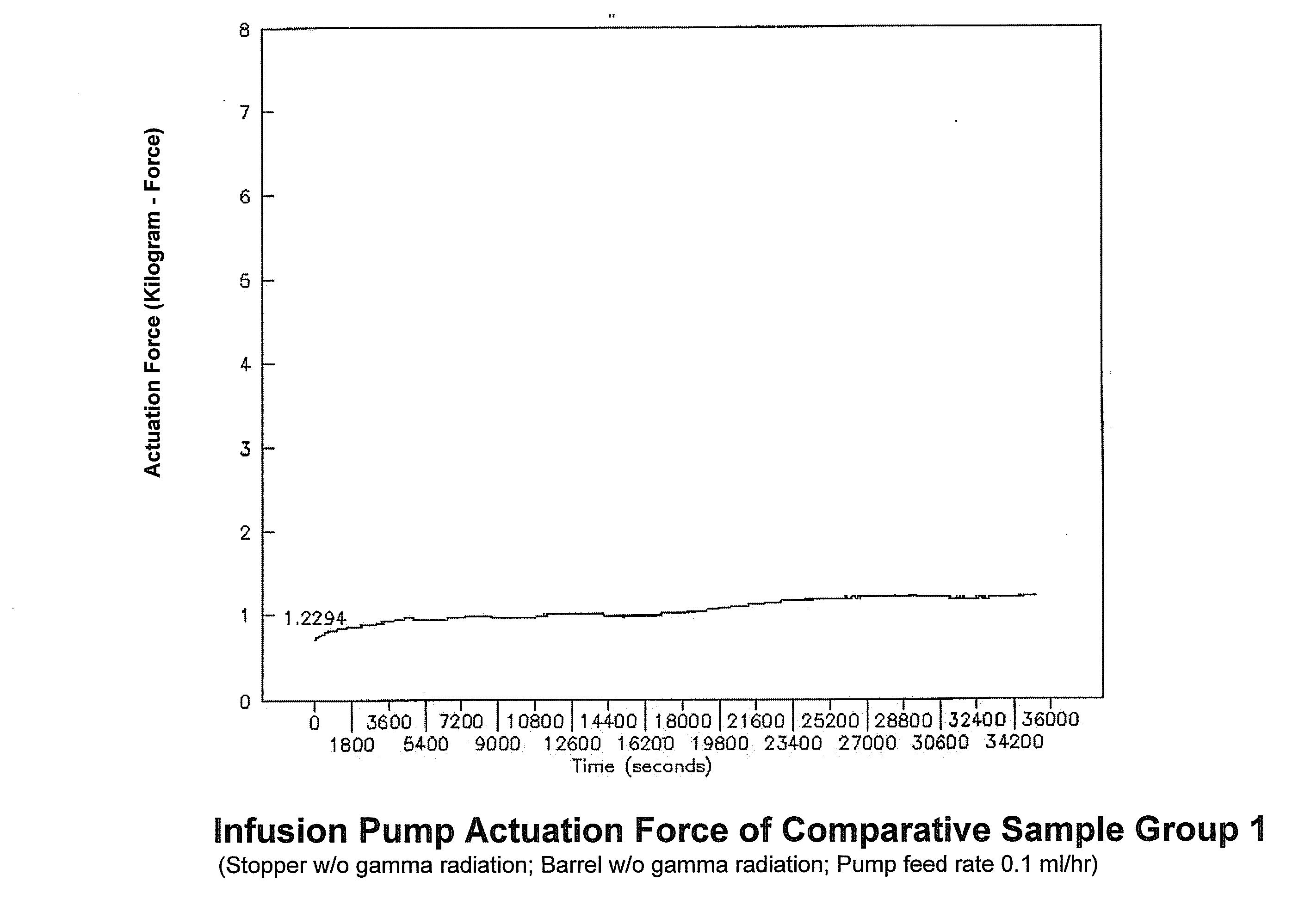

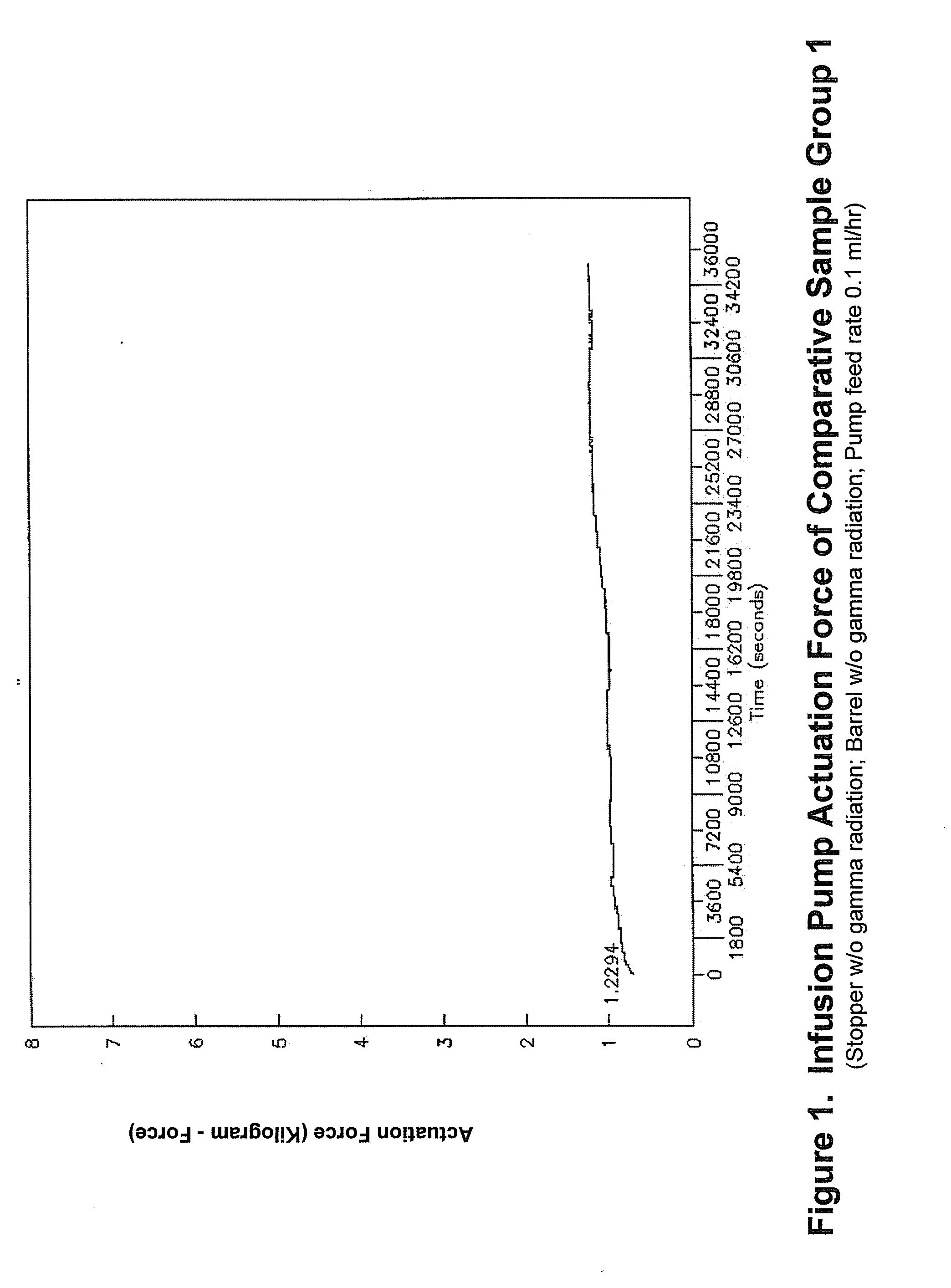

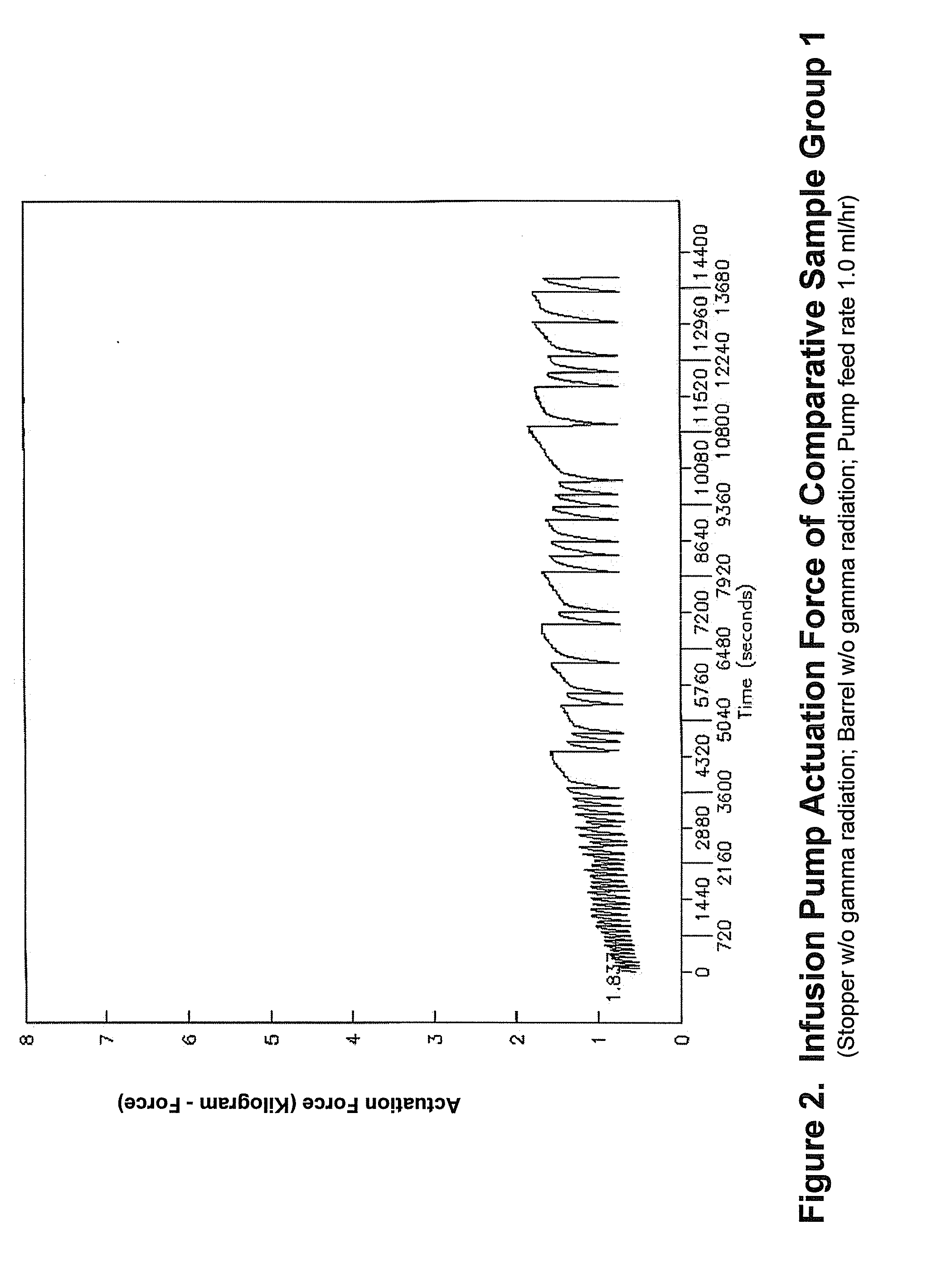

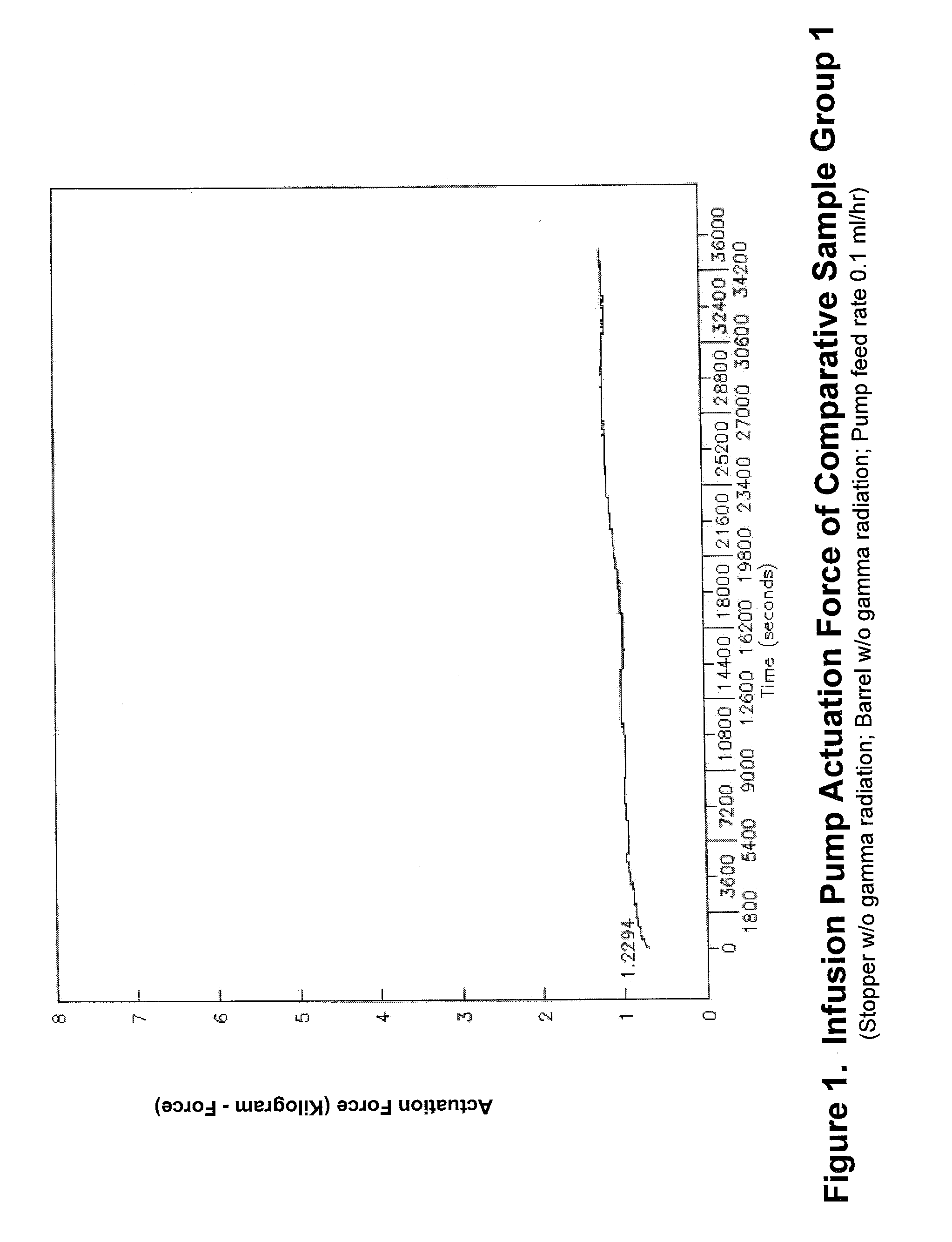

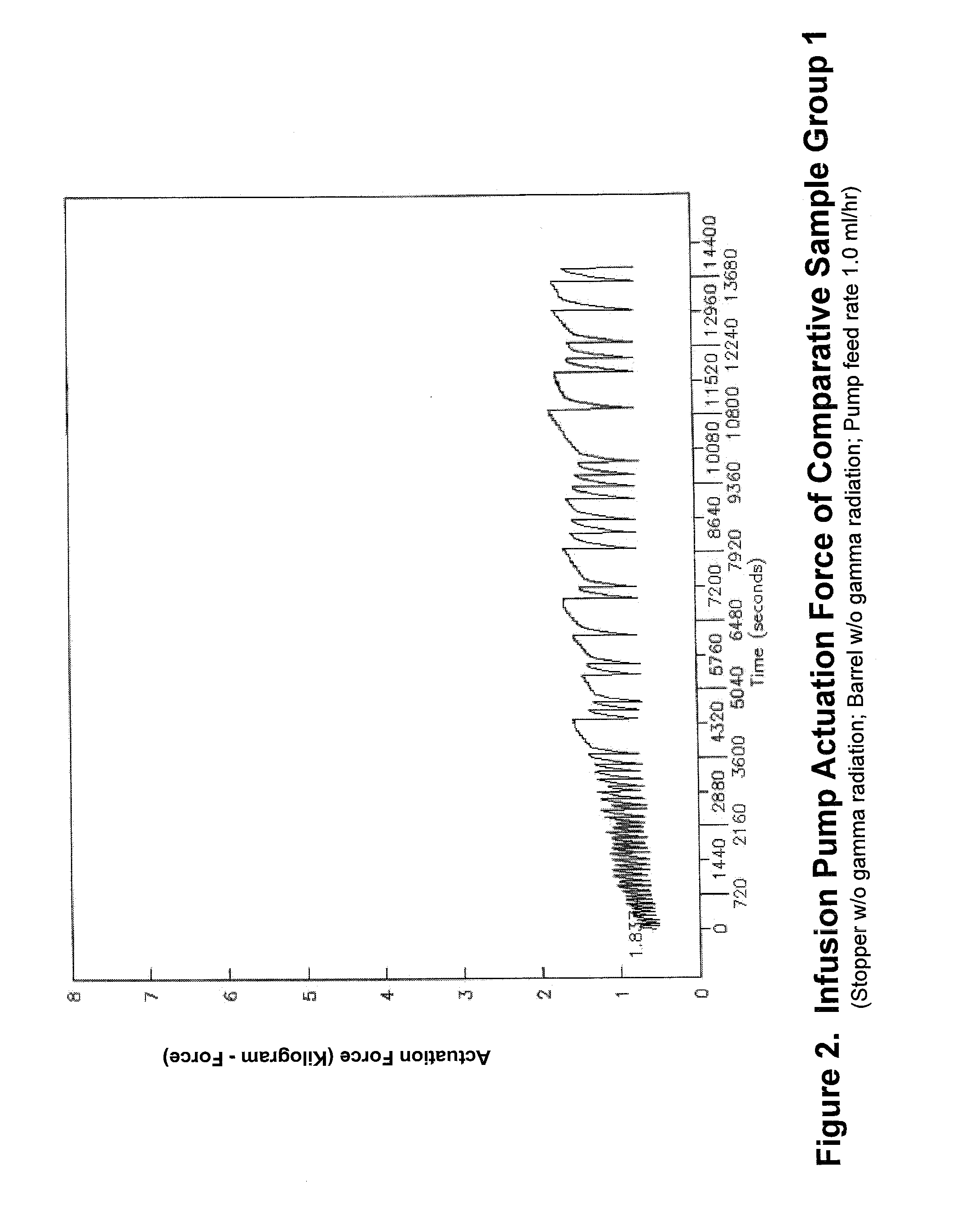

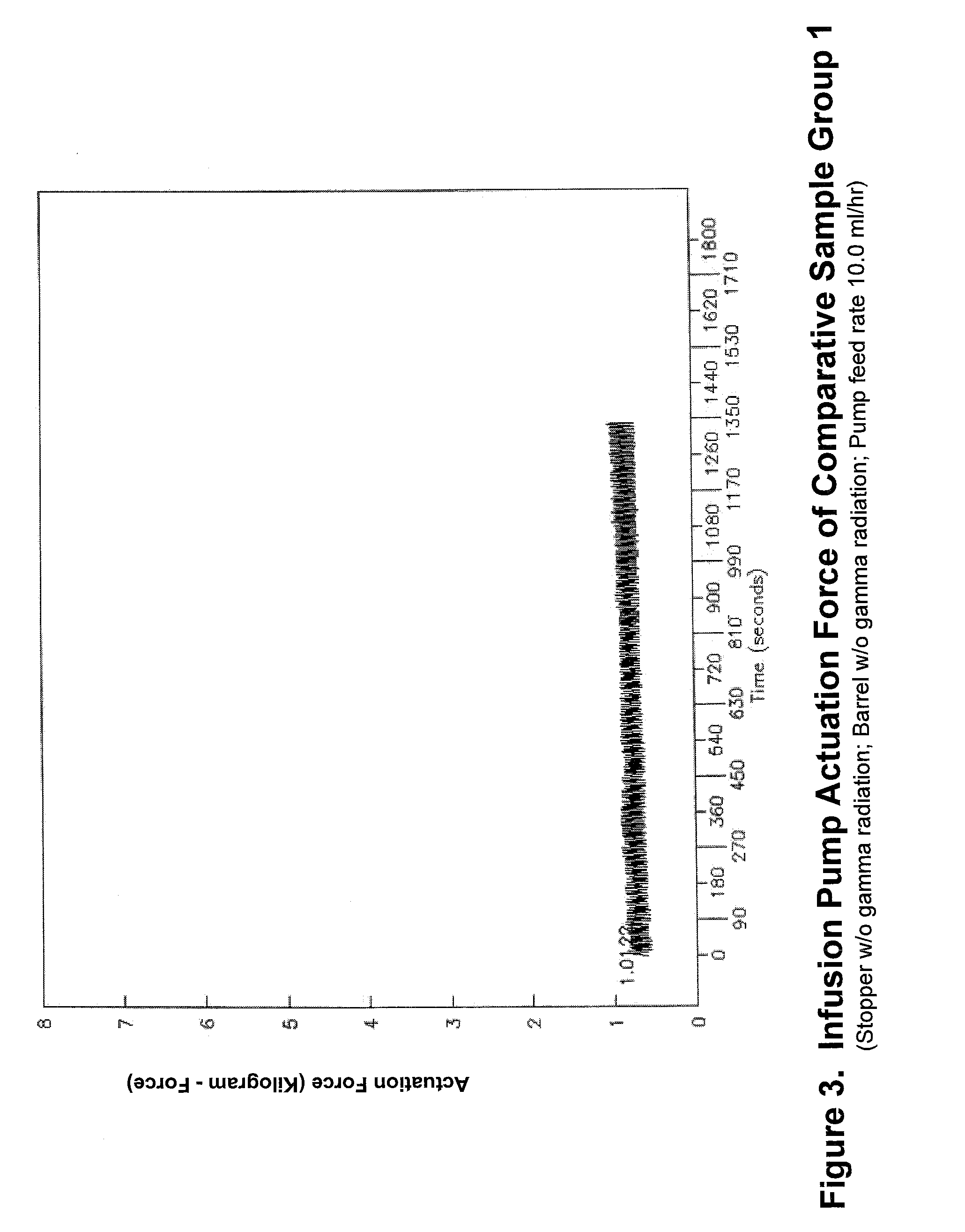

Medical Components Having Coated Surfaces Exhibiting Low Friction and Methods of Reducing Sticktion

InactiveUS20080069970A1Reducing breakloose forceReduce supportRadiation applicationsInfusion syringesCoated surfaceCentistokes

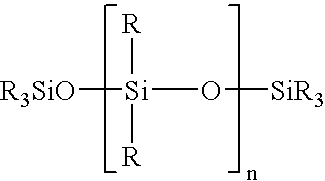

A medical article is provided including a chamber formed from a cyclic polyolefin having an inner surface in sliding engagement with an exterior surface of a sealing member, the inner surface of the chamber being coated with a first organopolysiloxane having a viscosity ranging from about 5,000 centistokes to about 100,000 centistokes; and a sealing member having an exterior surface coated with a second organopolysiloxane having a viscosity ranging from about 10,000 centistokes to about 500,000 centistokes, the coatings being adhered to the surfaces by crosslinking induced by irradiation with an isotope, electron beam, or ultraviolet radiation, as well as methods of reducing breakloose force, sustaining force, and / or sticktion between engaging surfaces in such articles.

Owner:BECTON DICKINSON & CO

Non-volatile lubricant system for medical devices

ActiveUS7332227B2Low viscosityEfficient deliverySilicon organic compoundsLayered productsPolymer chemistryMedical treatment

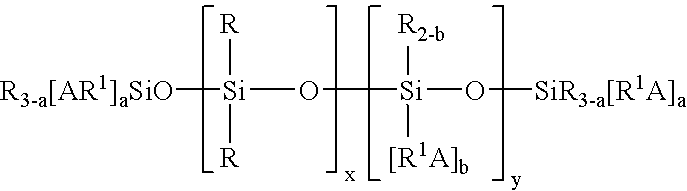

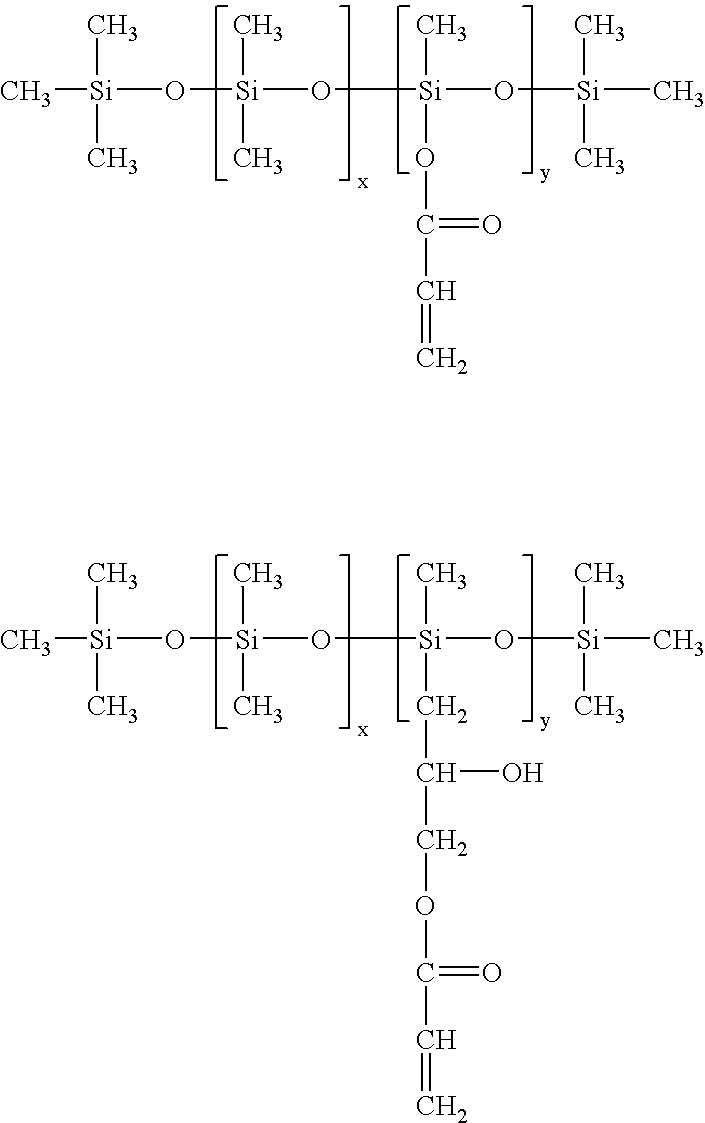

A non-volatile lubricious coating composition is provided for use with medical devices, such as hypodermic needles, catheters, and the like. The coating composition includes a first siloxane polymer having a very low viscosity less than about 50 centistokes, a second siloxane polymer having a high viscosity greater than about 1,000 centistokes, a reactive silicone polymer which is capable of crosslinking upon exposure to radiation, such as a UV curable silicone acrylate, and a photoinitiator to accelerate cross-linking of the reactive silicone polymer. The coating composition may further include an aminofunctional siloxane polymer to promote adhesion to metal surfaces when used with needles. The coating composition provides flowability without the need for any volatile organic solvent, and is capable of curing to provide adhesion and lubricity.

Owner:BECTON DICKINSON & CO

Silicone polymer contact lens compositions and methods of use

InactiveUS20050288196A1Low vapor pressureImprove the immunitySenses disorderPharmaceutical delivery mechanismAlcoholCentistokes

The present invention is an eye preparation comprising a hydrophobic composition adapted for use on a contact lens inserted into a patient's eye and having a viscosity of 1 to 15,000 centistokes. The composition includes a silicone polymer, fluorinated silicone polymer, fluorocarbon polymer, fluorinated alcohol, or perfluorinated polyether composition, singly or blended, adapted to coat at least a portion of a contact lens inserted in a patient's eye. Silicone polymers for use in the invention include dimethicone, cyclomethicone, and silicone gums.

Owner:OCULARIS PHARMA

Topical anti-microbial compositions

Topical anti-microbial compositions, and more particularly anti-bacterial and anti-fungal compositions, comprising a therapeutically effective amount of an anti-microbial agent, a starch, a hydroalcoholic solvent, and a volatile silicone compound having a viscosity of about 0.1 to about 50 centistokes. These compositions are capable of temporarily or permanently reducing, inhibiting, treating, ameliorating, or preventing microbial skin infections, as well as other related skin conditions. These compositions are further capable of restoring or repairing a skin lipid barrier of a mammal.

Owner:STIEFEL LABORATORIES

Asphalt composition and method

A paving asphalt composition for improving the durability and longevity of asphalt road surfaces is disclosed. The paving asphalt composition includes asphalt base stock, heavy residuum of re-refined motor oil, and a chemical modifier. The heavy residuum of re-refined motor oil preferably has an API gravity of at least about 12, a kinematic viscosity greater than about 400 centistokes at 140 DEG F., a flash point greater than about 400 DEG F. and a mass loss less than about 3%. The paving asphalt composition may also include a polymer. A method of forming the paving asphalt composition and a method of paving roads are also disclosed.

Owner:CROWN ASPHALT DISTRIBUTION L L C

Photoconductor member with bound silicone oil

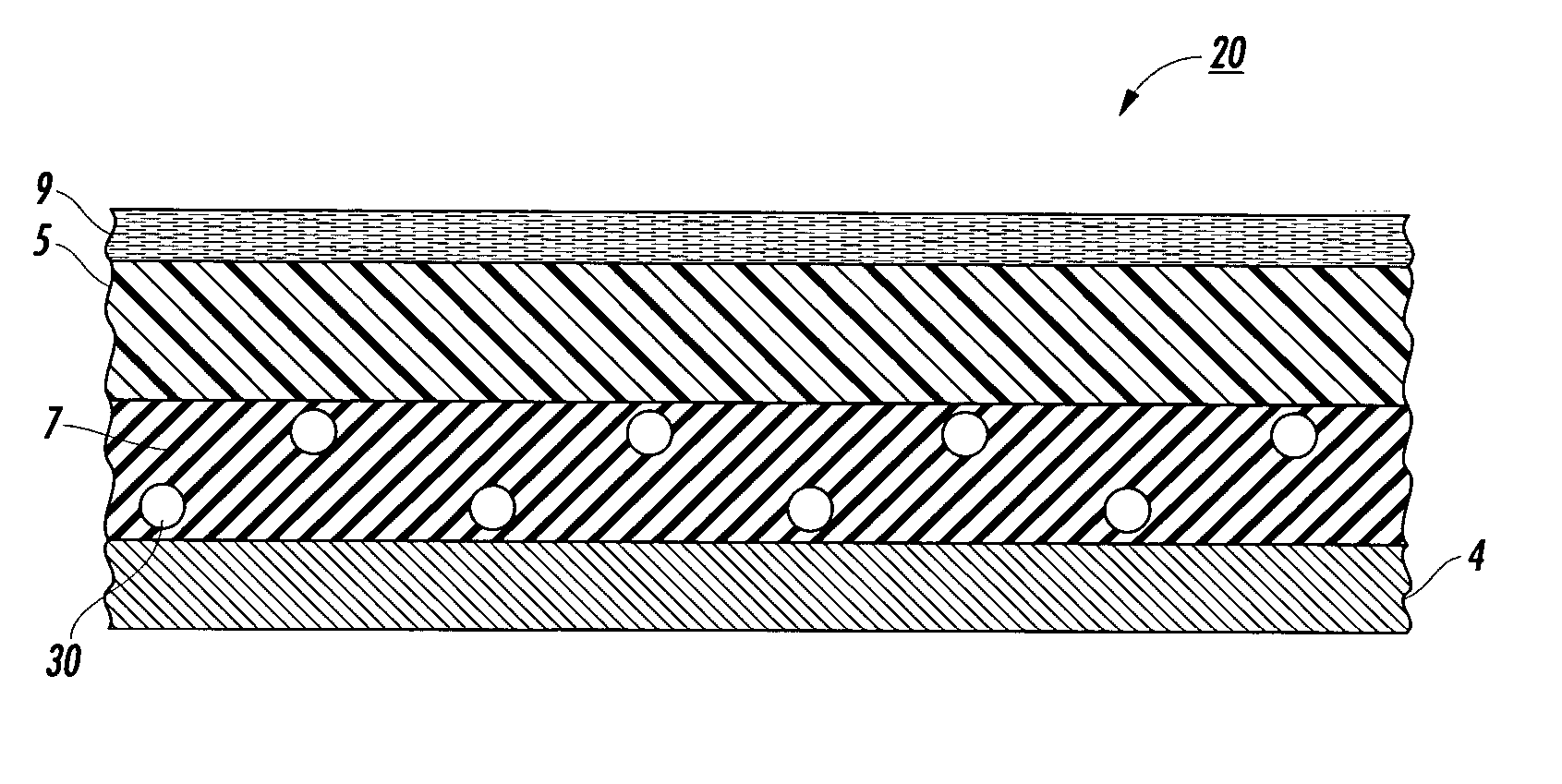

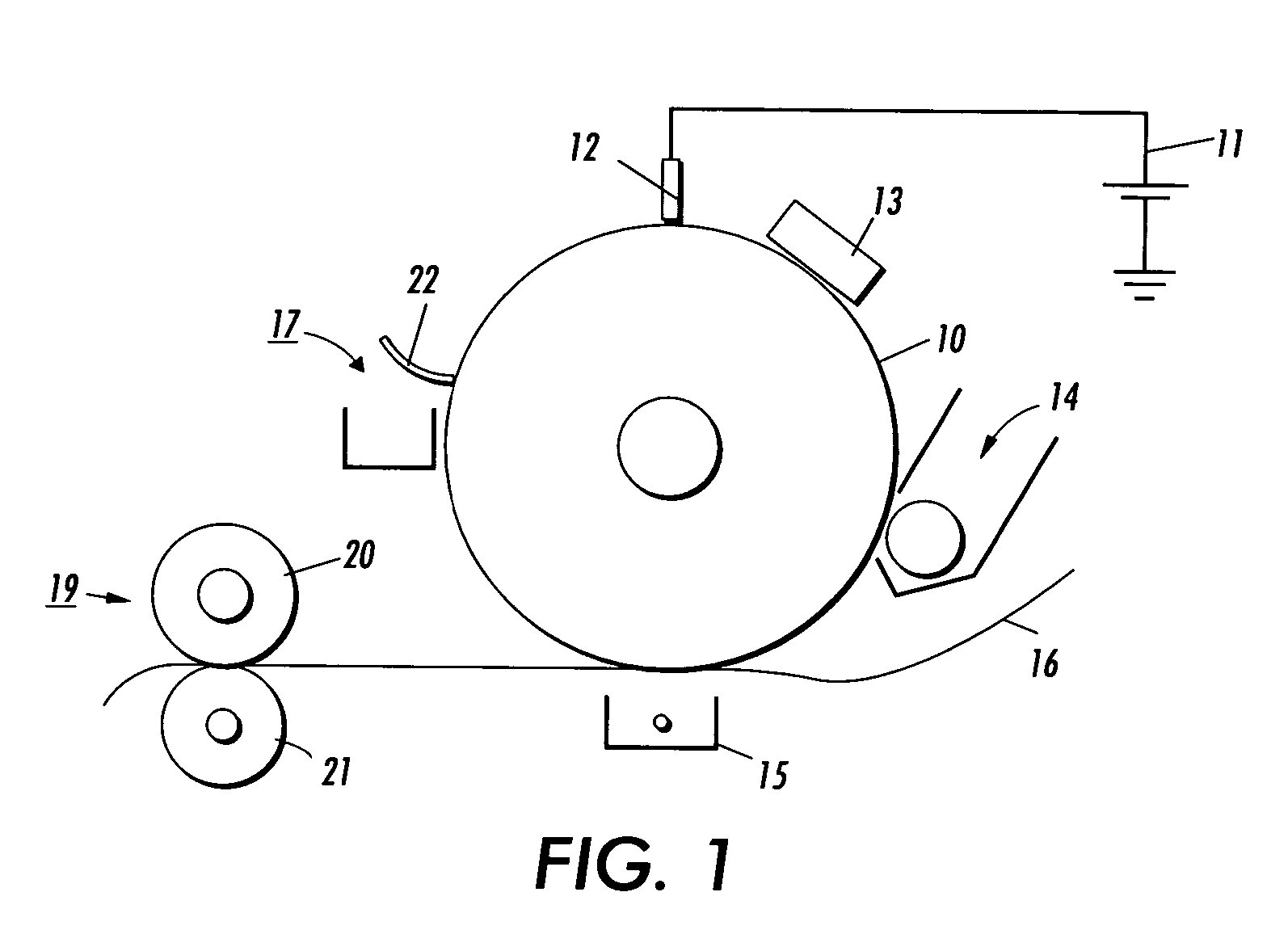

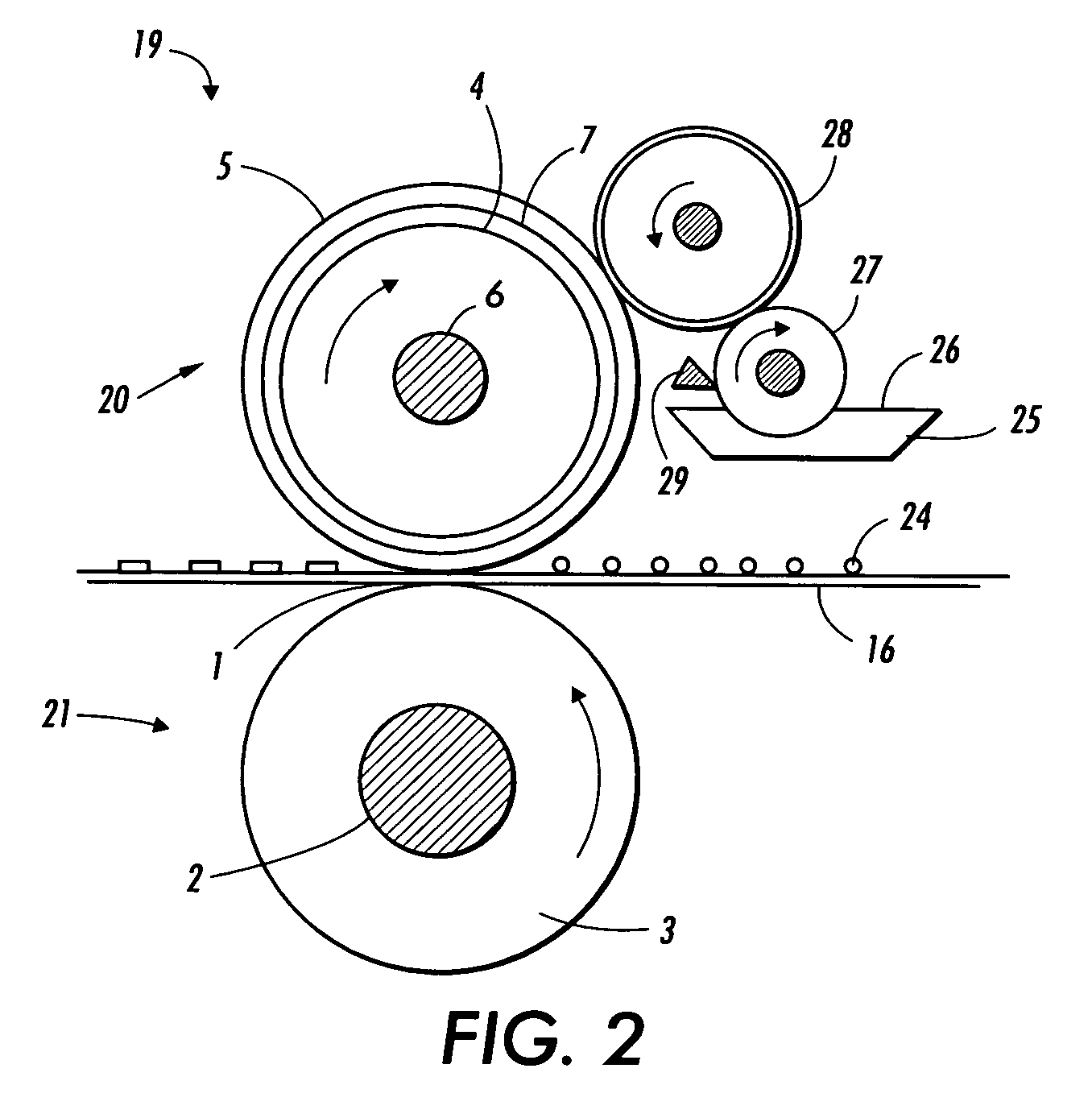

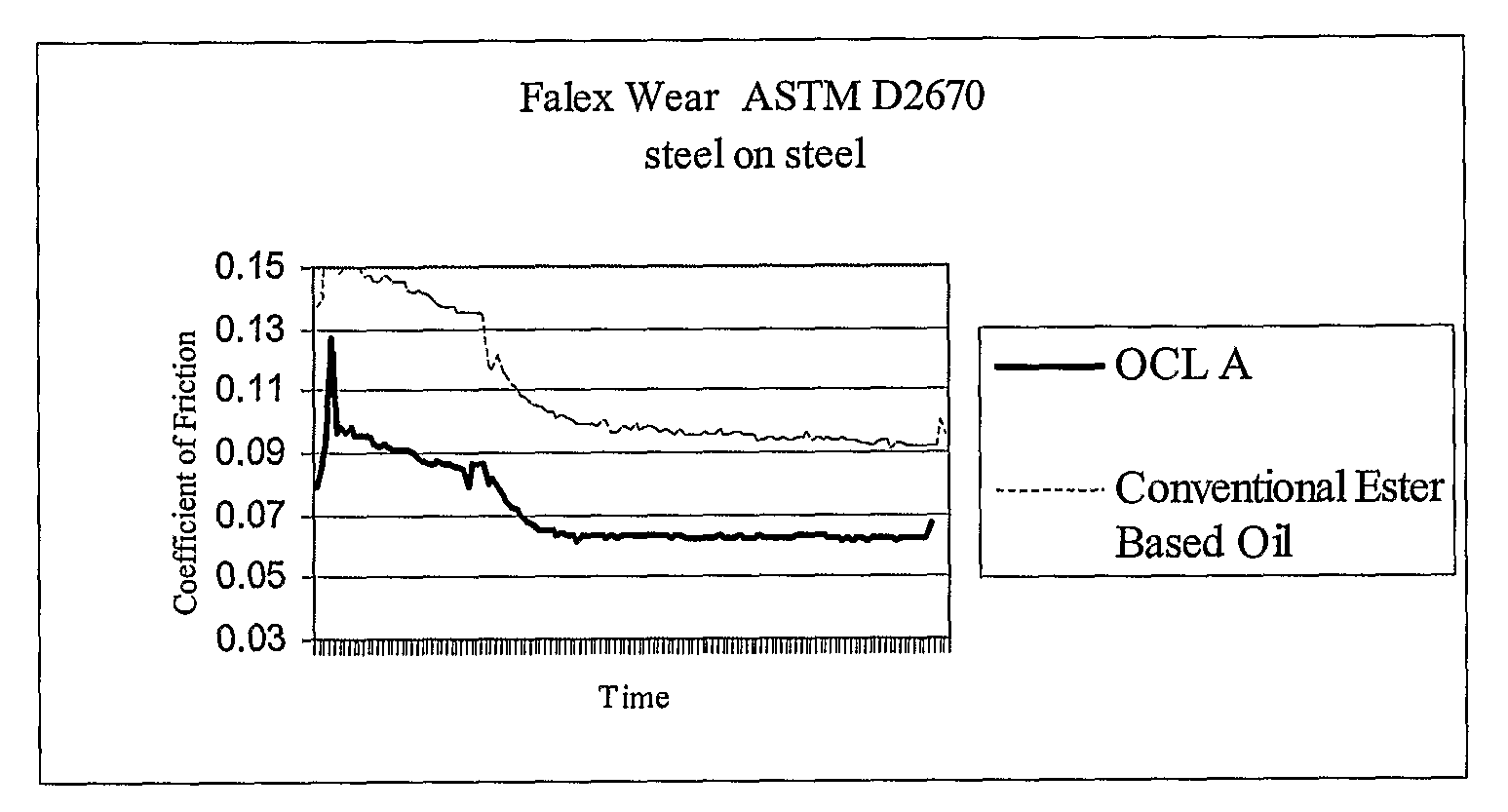

ActiveUS20060183041A1Improve the lubrication effectImprove wear resistanceElectrographic process apparatusCorona dischargeElectrical conductorMicrosphere

A charge transfer layer system that encapsulates or surrounds high viscosity silicone oils (polysiloxanes) using silicone microspheres, fluoropolymers such as polytetrafluoroethylene or inorganic particles such as silica, or metal soaps (zinc stearate). The encapsulation of the silicone oil results in aggregation or agglomeration of the silicone microspheres, fluoropolymers, or inorganic particles. The silicone oils have viscosity greater than 10,000 centistokes (cs) and the particles are about 6 μm or less.

Owner:LEXMARK INT INC

Medical Components Having Coated Surfaces Exhibiting Low Friction and Methods of Reducing Sticktion

InactiveUS20130190695A1Reduce forceReduce supportInfusion syringesIntravenous devicesCoated surfaceCentistokes

Owner:BECTON DICKINSON & CO

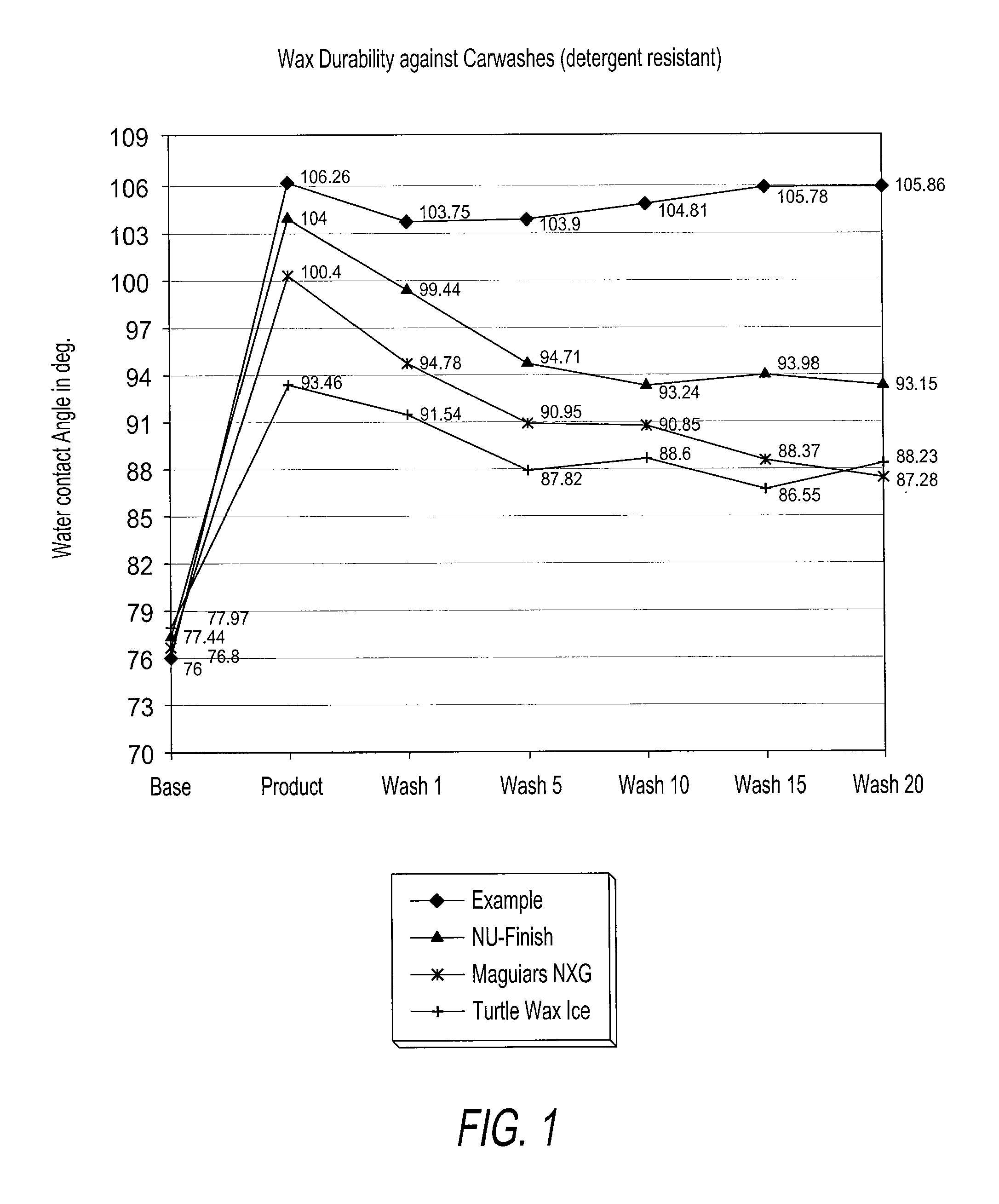

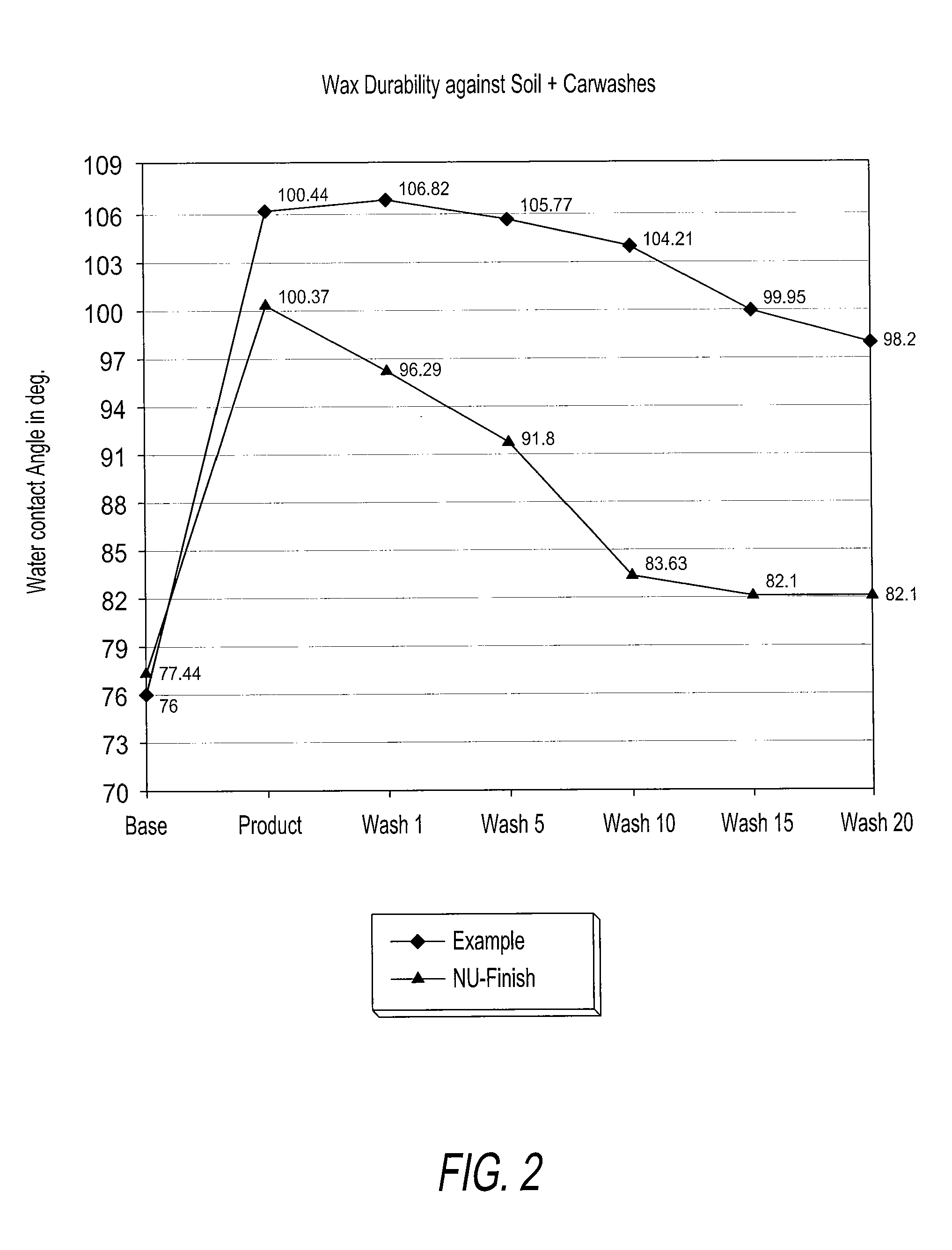

Compositions and methods for treating automotive surfaces

This disclosure relates to compositions containing a) a silicone resin, b) a first silicone fluid having a viscosity from about 1 to about 15,000 centistokes at 25° C.; c) a second silicone fluid having a viscosity from about 1 to about 30,000 centistokes at 25° C.; d) an acrylic polymer; e) a hydrocarbon solvent; and f) water. The compositions of this disclosure provide long lasting hydrophobic coatings with high water contact angles for automotive surfaces, in which the hydrophobic automotive surfaces possess self-cleaning functions, e.g., water and dirt repellency. This disclosure also relates to methods for treating automotive surfaces and to automotive surfaces coated with the compositions.

Owner:ENERGIZER AUTO INC

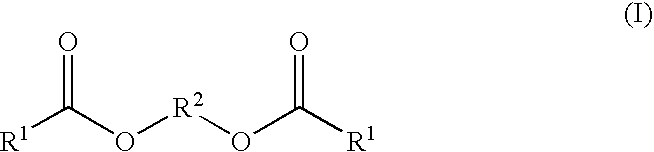

Polyol polyester-containing personal care products that do not contain low viscosity silicone fluids

The invention provides a personal care product that does not contain a lower viscosity silicone fluid; the personal care product includes at least one polyol polyester that is the esterification reaction product of a polyol having three to six carbons atoms and a carboxylic acid having three to six carbon atoms and a personal care formulation. Also provided are replacement compositions for use in personal care products that are at least one polyol polyester that is the esterification reaction product of a polyol having three to six carbons atoms and a carboxylic acid having three to six carbon atoms and having a kinematic viscosity of about 2 to about 20 centistokes at 25° C. and wherein the replacement composition does not contain a low viscosity silicone fluid. Related methods are also described.

Owner:INOLEX INVESTMENT CORP

Sprayable dry wash and wax composition comprising a silicone blend and acrylic-based polymer

ActiveUS7399738B1Equal and good performanceGood colorInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWaxCentistokes

A composition for simultaneously cleaning and waxing non-porous surfaces without the need for additional rinsing of the treated surface with water, has a pH of from about 6 to about 7 and contains by weight: (a) from about 0.04 to about 0.12% of an acrylic-based polymer, wherein the acrylic-based polymer is a hydrophobically modified, crosslinked polyacrylate powder which has been crosslinked with a polyalkenyl polyether or is an acrylic polymer containing acid groups and which dissolves and swells immediately when neutralized with an alkali salt (b) from about 0.5 to about 5.0% of a silicone blend composed of: (i) from about 70 to about 95% of a first polydiorganosiloxane fluid having a viscosity of from about 0.65 to about 60,000 centistokes at 25° C., and (ii) from about 5 to about 30% of a polydiorganosiloxane fluid mixture having a viscosity of from about 500 to about 2000 centistokes at 25° C., the polydiorganosiloxane fluid mixture being composed of a second polydiorganosiloxane fluid and a silicone resin; (c) wax; and (d) water. The composition can be used to simultaneously clean and wax non-porous surfaces such as the exterior surfaces of automobiles and other vehicles, windows, and the like.

Owner:ENERGIZER AUTO INC

Fuel Additive and Fuel Treatment Process

InactiveUS20070015656A1Improve solubilityHighly effectiveNon-fuel substance addition to fuelOrganic-compounds/hydrides/coordination-complexes catalystsCentistokesOn board

Disclosed is a fuel additive concentrate having a high flash point which is characterized by a viscosity controlled for dosing in a Bernoulli feed device. The concentrate is high temperature stable and is in a form suitable for on-board dosing of fuel which can provide predictable feed rates from a feed device. It comprises a fuel soluble platinum group metal composition and / or a fuel soluble or dispersible cerium composition and / or a fuel soluble or dispersible iron compound and a high flash aromatic solvent. The solvent and the metal composition or compositions are present in relative amounts to provide a FBC concentrate having a flash point (ASTM D93-85) of greater than 140° F. and, a preferred kinematic viscosity within the range of from 7 to 25 centistokes, as measured by ASTM D445 at 105° F.

Owner:CLEAN DIESEL TECHNOLOGIES

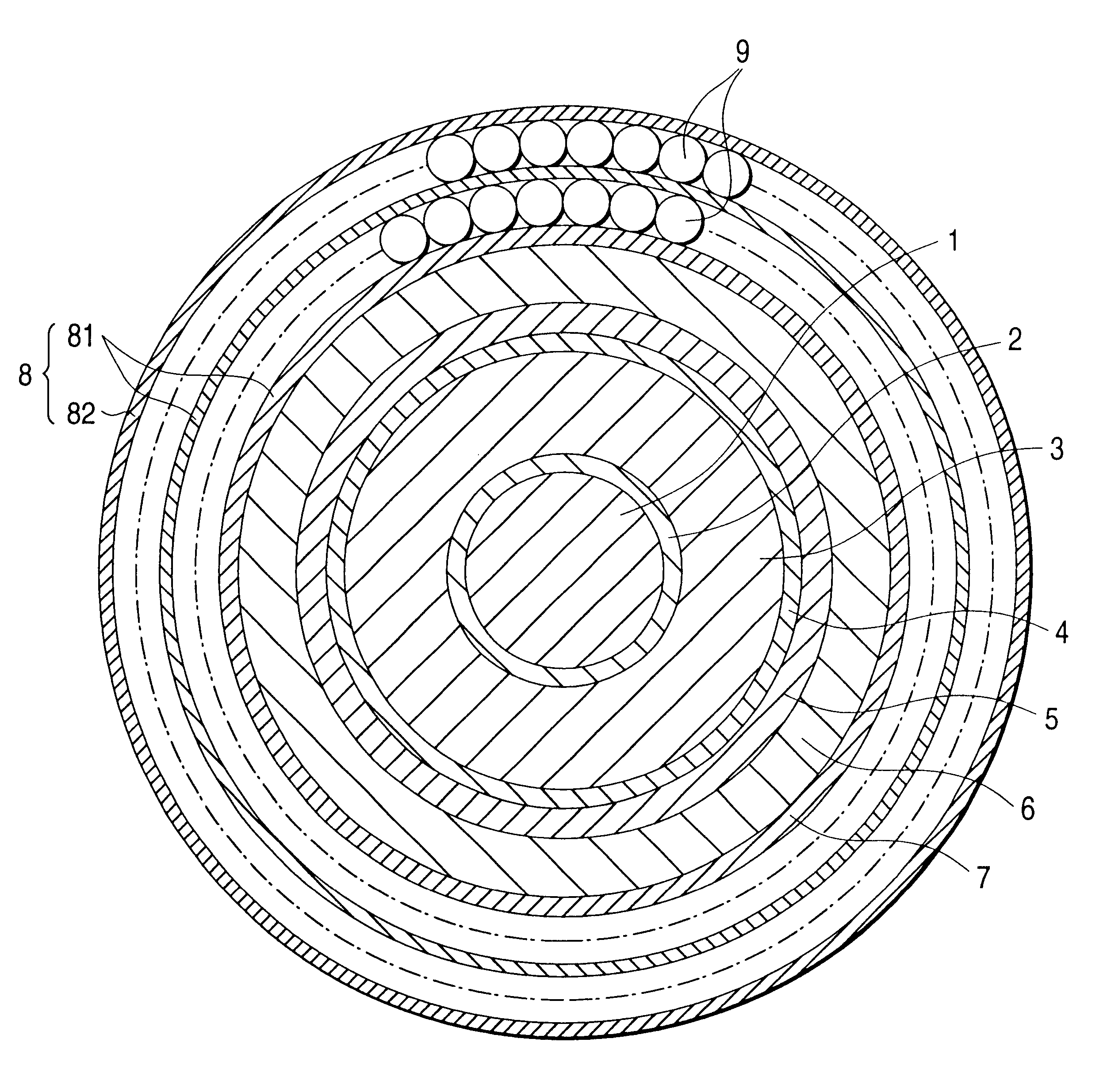

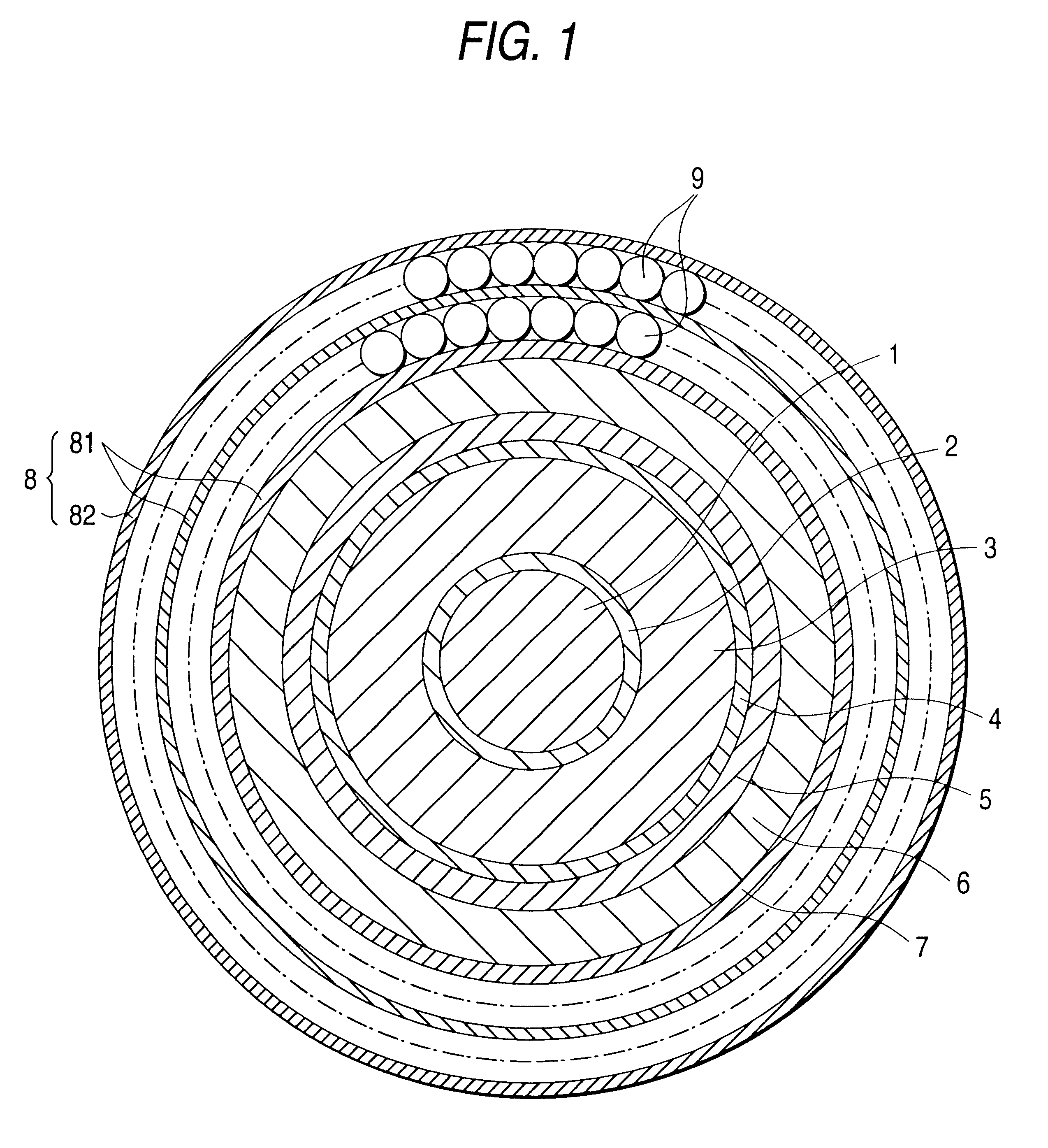

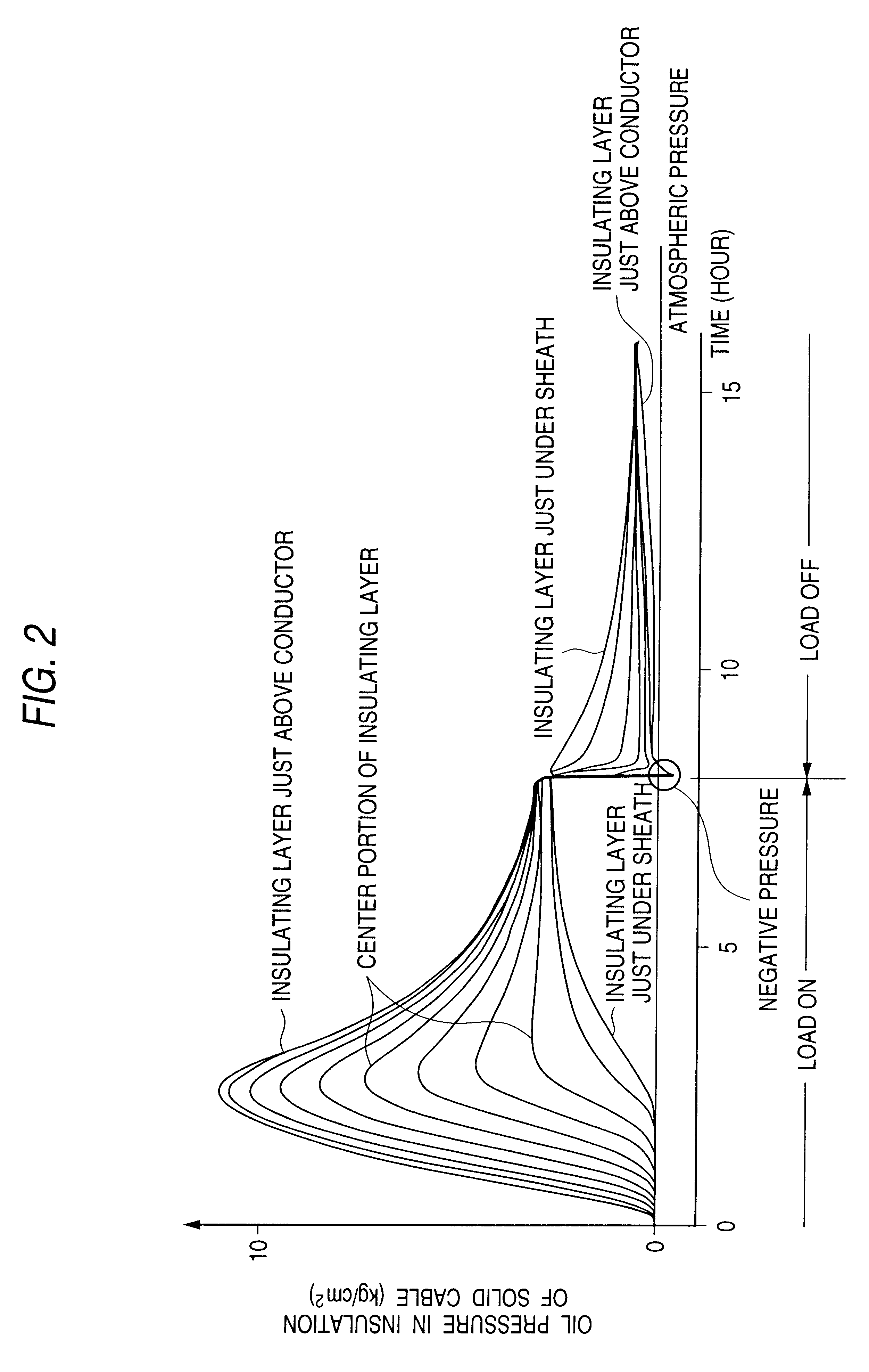

Solid cable, manufacturing method thereof, and transmission line therewith

InactiveUS6399878B2High tensile strengthRubber insulatorsOil-pressure cablesPolyolefinElectrical conductor

A cable and cable system is provided having a conductor and an insulation layer on an outer circumference of a conductor. The insulation layer is impregnated with a medium-viscosity insulating oil that has a viscosity of 10 centistokes (cst) to less than 500 cst at 60° C. The insulation layer includes an insulating tape that may be one or a combination of composite tape having a polyolefin resin film laminated with a kraft paper on both its sides and an insulating tape including a polyolefin resin film. The cable includes a metal sheath provided on an outer circumference of the insulation layer, and a reinforcing layer formed on an outer circumference of the metal sheath. The reinforcing layer reinforces the metal sheath by absorbing hoop stress exerted on the metal sheath. The cable system includes a submarine-portion cable and a land-portion cable, an oil stop joint box, and an oil feeding tank. The oil stop joint box connects the submarine-portion cable to the land-portion cable, and the oil feeding tank is connected to the land-portion cable which feeds the medium-viscosity insulating oil to the land-portion cable.

Owner:SUMITOMO ELECTRIC IND LTD

Room-temperature-curable polyorganosiloxane composition

InactiveUS20100249308A1Without deteriorating physical propertySuppress surface glossPigment pastesResin acidCentistokes

The present invention provides a room-temperature-curable polyorganosiloxane composition which can become a silicone rubber with matte surface and is free from deterioration in physical properties. Specifically, the room-temperature-curable polyorganosiloxane composition comprises:(A) 100 parts by weight of a substantially straight-chain polyorganosiloxane having a viscosity of 20 to 1,000,000 centistokes at 25° C., and having a molecular chain terminal being sealed with a silanol group or a silicon atom-bonded hydrolyzable group;(B) 0.1 to 15 parts by weight of an organic silicon compound having 3 or more silicon atom-bonded hydrolyzable groups in a single molecule;(C) 0 to 15 parts by weight of a condensation reaction catalyst;(D) 100 to 400 parts by weight of a non-treated ground calcium carbonate or a ground calcium carbonate surface-treated with resin acid; and(E) 1 to 200 parts by weight of a non-treated precipitated calcium carbonate or a precipitated calcium carbonate surface-treated with resin acid,wherein at least one of (D) component and (E) component is required to be treated with resin acid, andwherein the amount of (D) component relative to the sum of (D) component and (E) component is within the range of 50 to 99.9% by weight.

Owner:MOMENTIVE PERFORMANCE MATERIALS JAPAN LLC

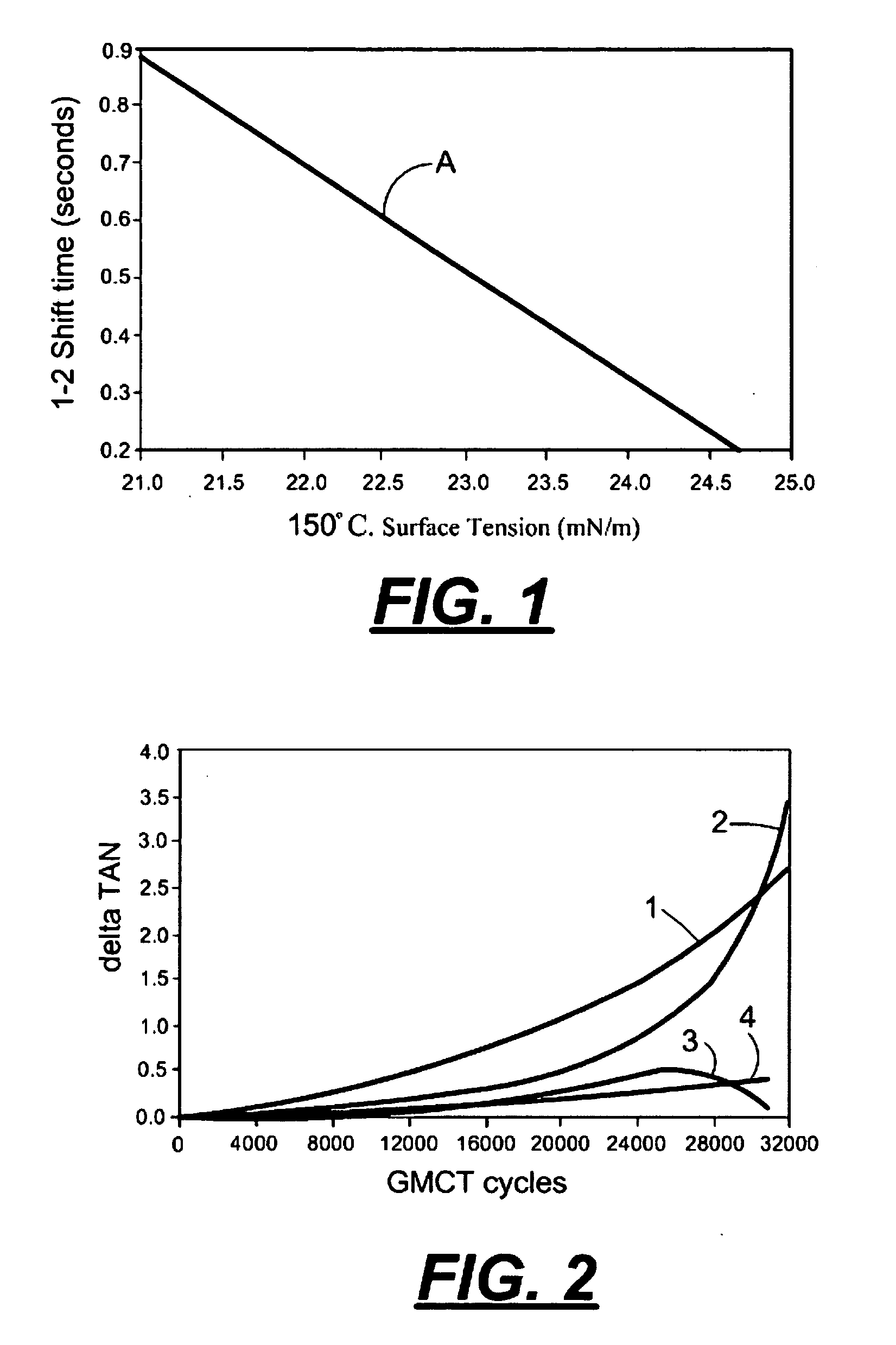

Power transmission fluids with enhanced lifetime characteristics

InactiveUS20060264339A1Reduce surface tensionDecrease foaming tendencyGear lubrication/coolingAdditivesCentistokesShift time

A power transmission fluid having improved characteristics, a method of lubricating a transmission, and a vehicle containing the transmission fluid is disclosed. The transmission fluid includes an amount of silicon-containing antifoam agent having a kinematic viscosity of greater than about 20,000 centistokes at 25° C. that is effective to provide gear shifting times of no more than about 0.75 seconds over a useful lifetime of the transmission fluid.

Owner:DEVLIN MARK T +3

Lubricating oil for rotary kiln wheel belts and method for preparing same

The invention discloses lubricating oil for rotary kiln wheel belts and a method for preparing the same. The lubricating oil can be used to solve the problem that the lubricating performance of the rotary kiln wheel belts is undesirable in severe environments, has high wear resistance and high temperature resistance. The maximum use temperature of the lubricating oil can reach 600 DEG C, and therefore the lubricating oil can form a high-strength high-temperature protective lubricating firm to prevent vibration, distortion and deformation of rotary kilns and falling of flame-retarding bricks and to prolong the service life of the rotary kilns. The easy method for preparing the lubricating oil can improve working efficiency and product quality obviously and save lots of energy, and is convenient to promote. The lubricating oil for rotary kiln wheel belts comprises the following components in percentage by mass: 49 to 69 percent of poly-alpha-olefin, 10 to 30 percent of composite calcium-base grease, 10 to 40 percent of composite metal soap, 2 to 5 percent of nano colloidal molybdenum disulfide powder, 2 to 4 percent of colloidal graphite powder, 1.5 to 3 percent nano soft metal powder and 5 to 6 percent of flame retarder, wherein the total percentage of the components is 100 percent. The kinematic viscosity of poly-alpha-olefin synthetic oil at 100 DEG C is 40 to 80 centistokes, and the open flash point of the poly-alpha-olefin synthetic oil is not less than 320 DEG C.

Owner:洛阳正本润滑材料有限公司

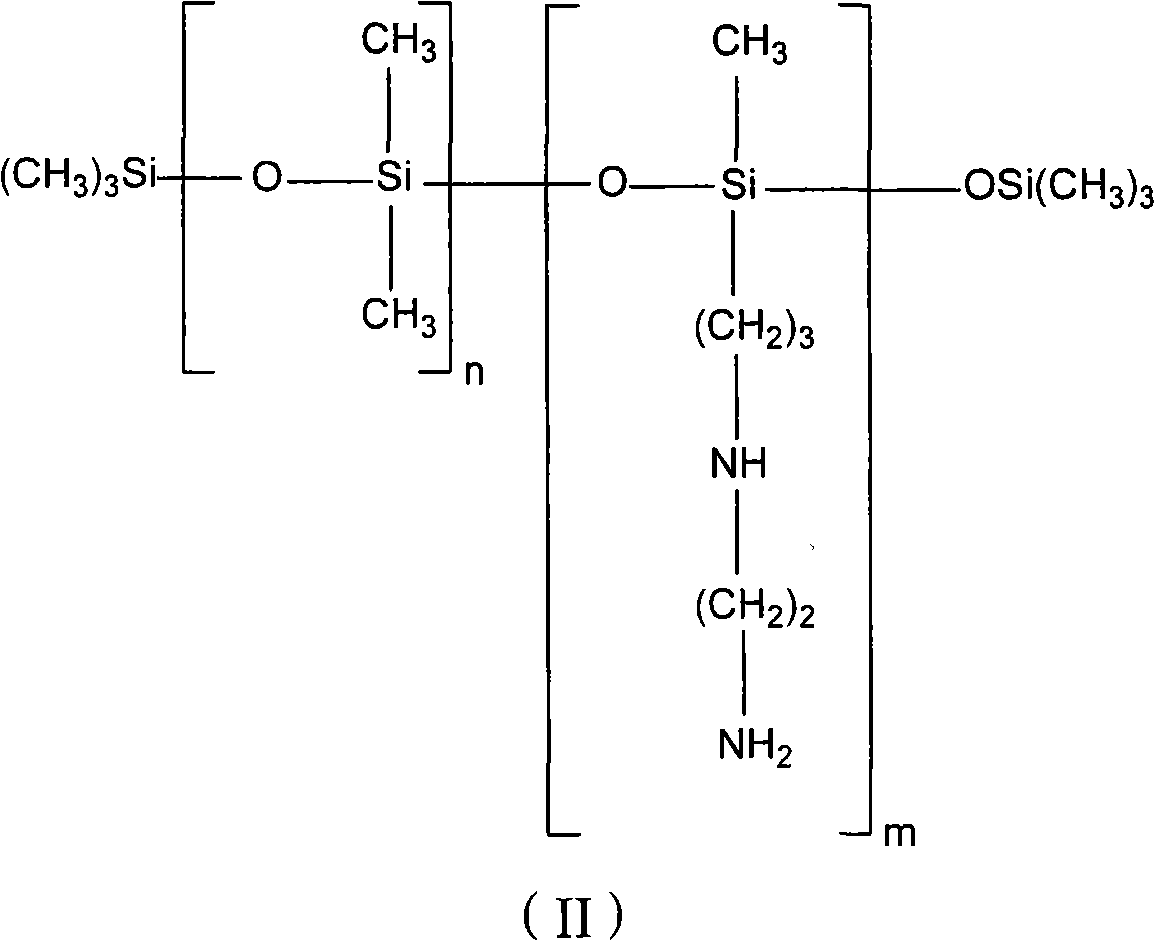

Amino-functional fusing agent

A fuser member having a substrate, a layer thereover including a polymer, and, on the polymeric layer, a coating of a release agent having a mixture of (a) an organosiloxane polymer concentrate containing amino-substituted organosiloxane polymers, wherein there are amino functional groups on at least some of the polymer molecules of the concentrate, the concentrate has a degree of functionality of from about 0.3 to about 0.4 mole percent, the concentrate has a viscosity of from about 800 to about 1,300 centistokes; and (b) a nonfunctional organosiloxane polymer diluent, the diluent has a viscosity of from about 100 to about 2,000 centistokes; the mixture has a degree of functionality of from about 0.05 to about 0.3 mole percent, wherein the mixture has a viscosity of from about 550 to about 1,300 centistokes, and wherein the ratio by weight of concentrate to diluent is from about 1:2 to about 1:30, and an image forming apparatus having the fuser member.

Owner:XEROX CORP

High Temperature Lubricant Compositions and Methods of Making the Same

InactiveUS20080317964A1Low deposit formation tendencyHigh viscosityLiquid carbonaceous fuelsLiquid/solution decomposition chemical coatingHigh resistancePolyester

A high temperature lubricant composition for lubricating conveyored oven chains and other high temperature applications comprises at least one polyol polyester polymer and optionally at least one additive. The polyol polyester polymer can be made from esterification of at least one polyol, at least one dicarboxylic acid and at least one monocarboxylic acid. Optionally, at least one polyol polyester, at least one extreme pressure / antiwear agent and / or at least one metal deactivator is added to the final lubricant composition. The lubricant has a kinematic viscosity @40° C. of from about 50 to about 1,000 centistokes, a viscosity index of at least about 140, and a flash point of at least about 270° C. The lubricants have low evaporation loss, high resistance to oxidation, and provide reduction of friction when used in high temperature lubricant applications. Methods of applying the composition to conveyored oven chains include, but are not limited to, spraying, dipping, brushing, manually applying and combinations thereof.

Owner:INOLEX INVESTMENT CORP

Non-buffing wax emulsion composition

Disclosed herein is a composition comprising a formula emulsion wherein the formula emulsion comprises a cationic or amphoteric surfactant, a wax emulsion, a thickener, and at least two silicone oils having different viscosities, wherein the composition is free of abrasives and organic solvents. The weighted average viscosity of the silicone oils is 2200 to 2400 centistokes (cSt).

Owner:PRESTONE PROD CORP

Sprayable Dry Wash and Wax Composition and Method of Using Same

ActiveUS20090035451A1Equal and good performanceGood colorInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWaxCentistokes

A composition for simultaneously cleaning and waxing non-porous surfaces without the need for additional rinsing of the treated surface with water, has a pH of from about 6 to about 7 and contains by weight: (a) from about 0.04 to about 0.12% of an acrylic-based polymer, wherein the acrylic-based polymer is a hydrophobically modified, crosslinked polyacrylate powder which has been crosslinked with a polyalkenyl polyether or is an acrylic polymer containing acid groups and which dissolves and swells immediately when neutralized with an alkali salt (b) from about 0.5 to about 5.0% of a silicone blend composed of: (i) from about 70 to about 95% of a first polydiorganosiloxane fluid having a viscosity of from about 0.65 to about 60,000 centistokes at 25° C., and (ii) from about 5 to about 30% of a polydiorganosiloxane fluid mixture having a viscosity of from about 500 to about 2000 centistokes at 25° C., the polydiorganosiloxane fluid mixture being composed of a second polydiorganosiloxane fluid and a silicone resin; (c) wax; and (d) water. The composition can be used to simultaneously clean and wax non-porous surfaces such as the exterior surfaces of automobiles and other vehicles, windows, and the like.

Owner:ENERGIZER AUTO INC

Hair care composition comprising an aminosilicone and a high viscosity silicone copolymer emulsion

Hair care composition comprising an aminosilicone having a viscosity of from about 1,000 centistokes to about 1,000,000 centistokes, and less than about 0.5% nitrogen by weight of the aminosilicone; a silicone copolymer emulsion with an internal phase viscosity of greater than about 120 x 106 centistokes, as measured at 25 DEG C; and a gel matrix comprising a cationic surfactant; a high melting point fatty compound; and an aqueous carrier.

Owner:THE PROCTER & GAMBLE COMPANY

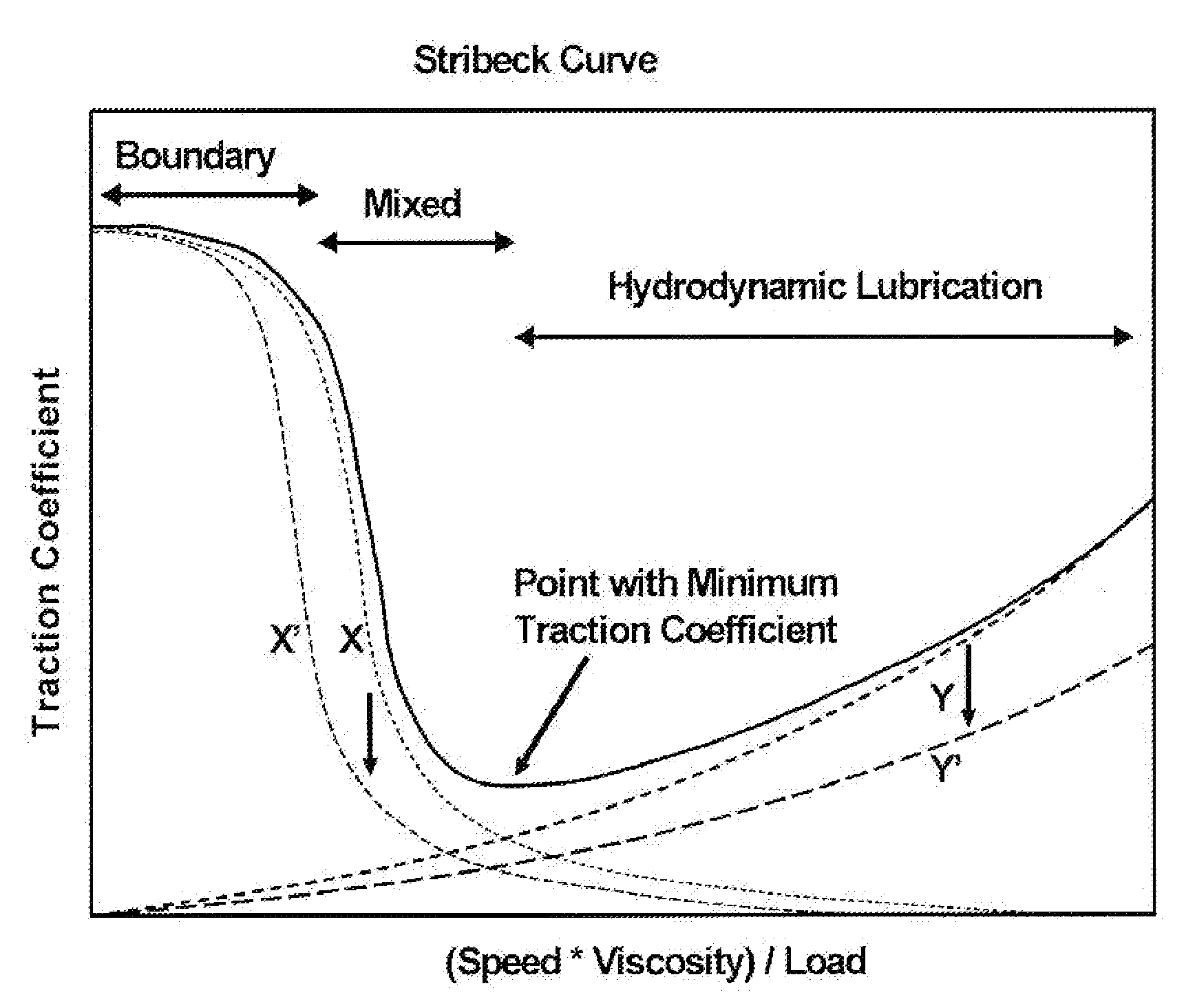

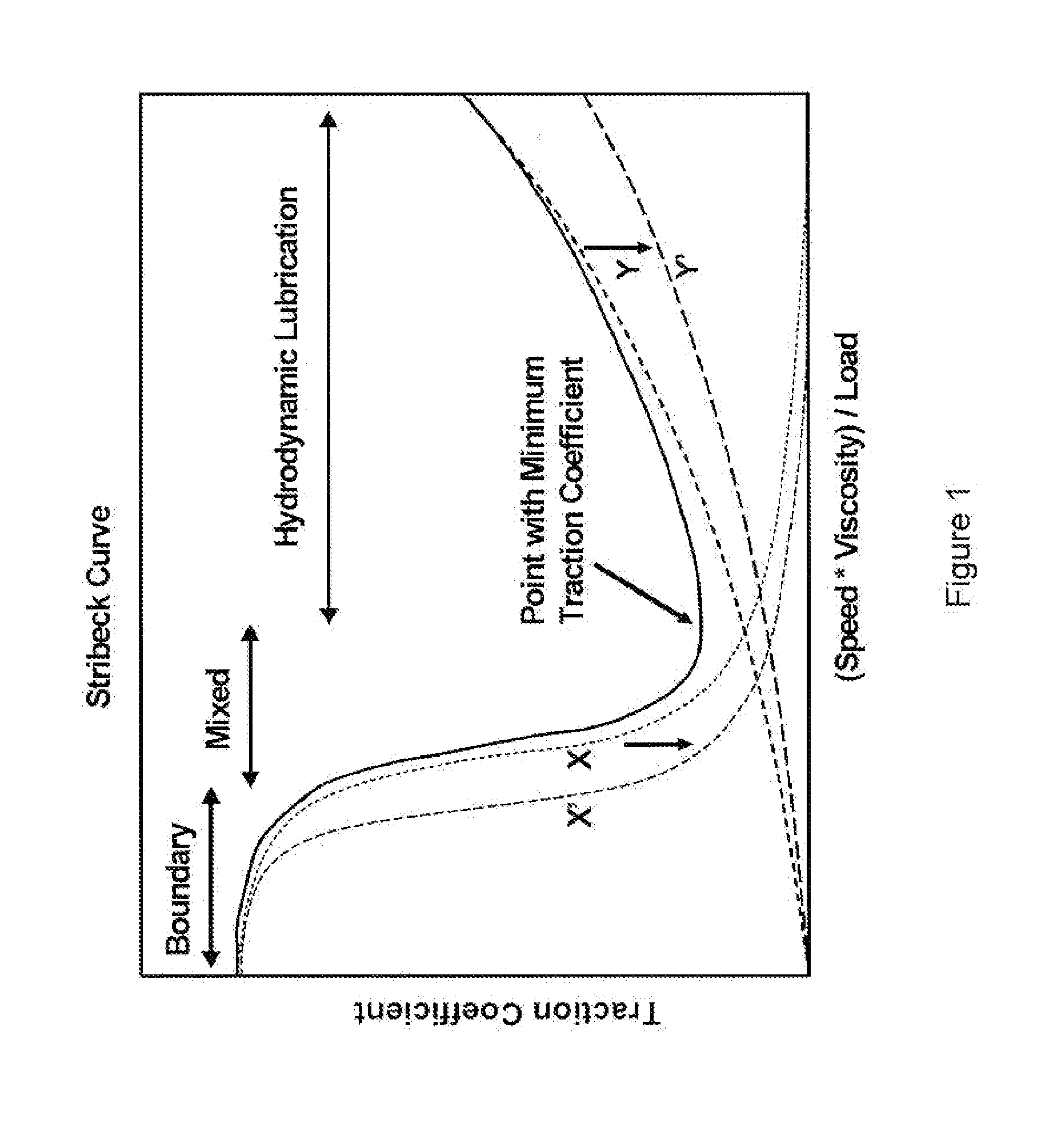

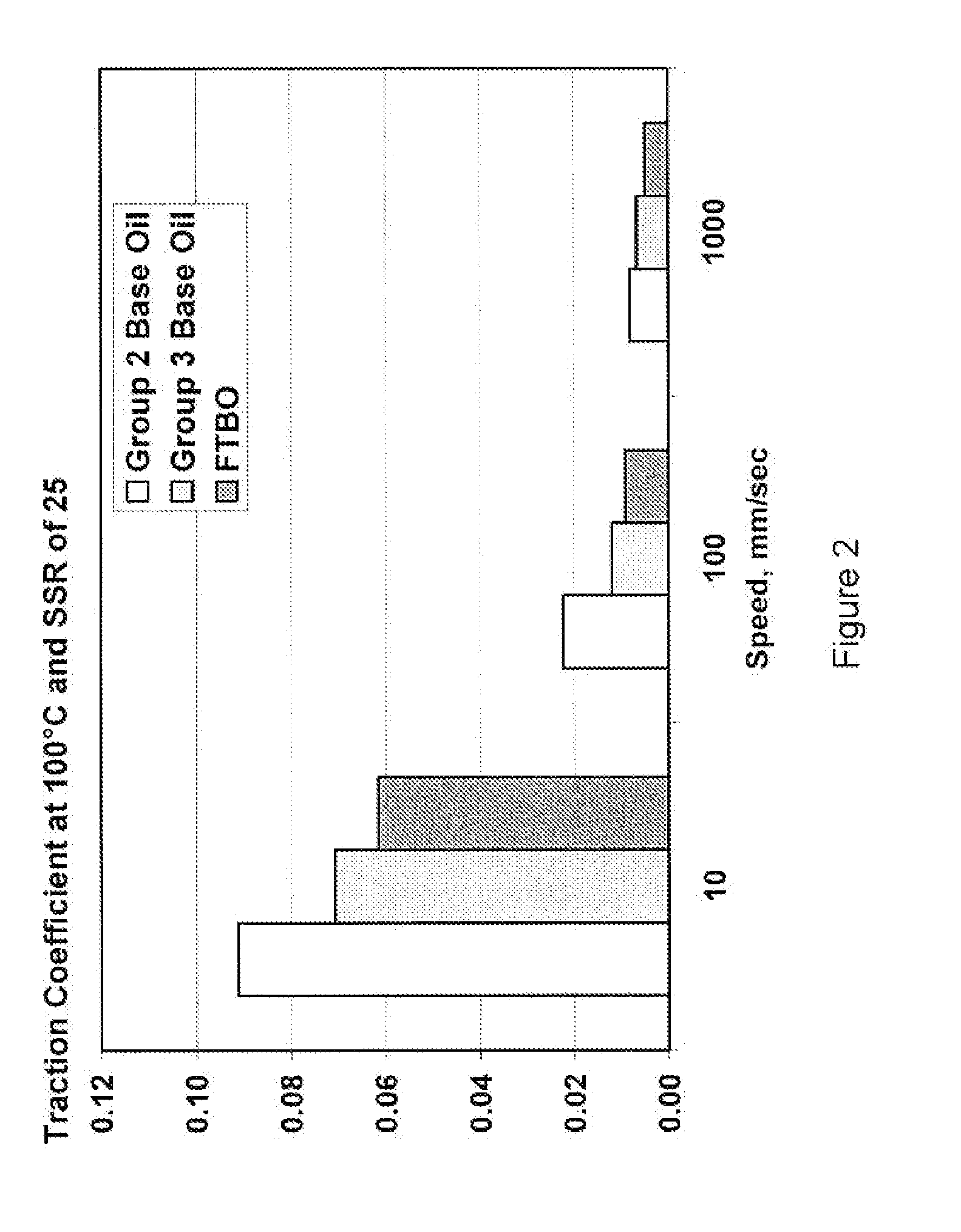

Traction coefficient reducing lubricating oil composition

InactiveUS20080128322A1Reducing traction coefficientReduction factorAdditivesBase-materialsCombustionCentistokes

The present invention is directed to a traction coefficient reducing lubricating oil composition comprising (a) a major amount of an oil of lubricating viscosity comprising a blend of two or more isomerized Fischer-Tropsch derived base oils wherein the kinematic viscosity of the blend is in a range from about 2 to about 14 centistokes at 100° C., and (b) one or more lubricating oil additives wherein the lubricating oil composition is essentially free of friction modifiers. The present invention is also directed to a method for reducing the traction coefficient in internal combustion engines comprising lubricating the internal combustion engines with a lubricating oil composition comprising (a) a major amount of an oil of lubricating viscosity comprising a blend of two or more isomerized Fischer-Tropsch derived base oils wherein the kinematic viscosity of the blend is in a range from about 2 to about 14 centistokes at 100° C., and (b) one or more lubricating oil additives wherein the lubricating oil composition is essentially free of friction modifiers.

Owner:CHEVRON ORONITE CO LLC

Operating a turbo charged diesel engine

InactiveUS20090165760A1Improve acceleration performanceInternal combustion piston enginesNon-fuel substance addition to fuelCentistokesTurbocharger

A method of operating a turbo charged diesel engine is provided where a viscosity increasing component in a diesel fuel composition is used, to improve the acceleration performance, at low engine speeds (for example up to 2200 rpm). This method may be used for reducing the engine speed at which the turbo charger reaches its maximum speed when accelerating at low engine speeds, or reducing the time taken for the turbo charger to reach its maximum speed. It may mitigate a deterioration in the acceleration performance of the engine due to another cause. The VK 40 of the resultant fuel composition is suitably 2.8 mm2 / s (centistokes) or greater. The viscosity increasing component may in particular be a Fischer-Tropsch derived fuel component, an oil or a fatty acid alkyl ester. A density increasing component may be used in the fuel composition together with the viscosity increasing component.

Owner:SHELL OIL CO

Emulsions and products thereof

InactiveUS20060270569A1Improve emulsion stabilityImprove anti-corrosion performanceBase-materialsEmulsionCentistokes

Owner:CHEMTOOL

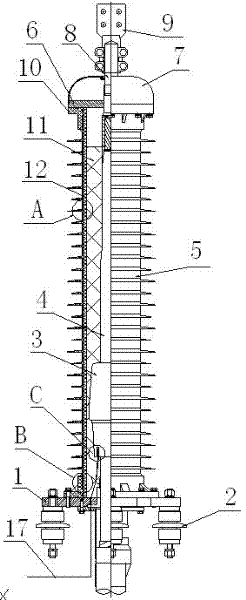

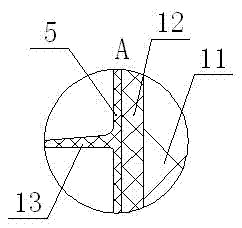

Online monitoring dry type cable terminal with composite external casing and on-site assembling method thereof

ActiveCN102208794ARealize real-time observationRealize the alarm functionCable terminationsGratingCentistokes

The invention discloses an online monitoring dry type cable terminal with a composite external casing and an on-site assembling method thereof. The assembling method comprises the following steps of: making the end part of a cable pass through a base and sectioning the external layer of a cable core; assembling an outlet hardware at the end part of the cable core, and sleeving a silicon rubber stress cone on a cut-off position of main insulation and external shielding of the cable; assembling a photoelectric grating sensor in a preset installation space of the stress cone, and making a transmission optical fiber, connected with the photoelectric grating sensor, pass through the base and stretch to the external side of the cable terminal; enabling the end part of the cable to be penetratedin the silicon rubber casing and the stress cone to be located in the cashing, and filling vulcanized silicone rubber with viscosity of 1,500-1500,000 centistokes into a gap between the cable and thecasing; after the surface of the liquid vulcanized silicone rubber is cured, assembling a cover plate and a shielding hood. After the liquid vulcanized silicone rubber is cured completely, the cover plate and the shielding hood are assembled, and the outlet hardware and the wiring hardware are assembled at the core end part, the dry type cable terminal is formed.

Owner:上海永锦电气技术股份有限公司

Self-lubricated bearing compositions and methods of making the same

ActiveUS20160348720A1Improve performanceEasy to useShaftsBearing componentsCentistokesSliding contact

A self-lubricated bearing contains a first member, a second member configured to slide against the first member, and a lubricating liner disposed in a sliding contact area between the first member and the second member. The lubricating liner contains at least one structural polymer and at least one lubricant with viscosity less than 5100 centistokes. A method is also provided for making the bearings, which includes adding the at least one lubricant with viscosity less than about 5100 centistokes to one or more components of the lubricating liner during the process of making the liner or bearing. The self-lubricated bearing compositions of the invention have surprisingly long service lives versus prior art self-lubricated bearings.

Owner:NEW HAMPSHIRE BALL BEARINGS

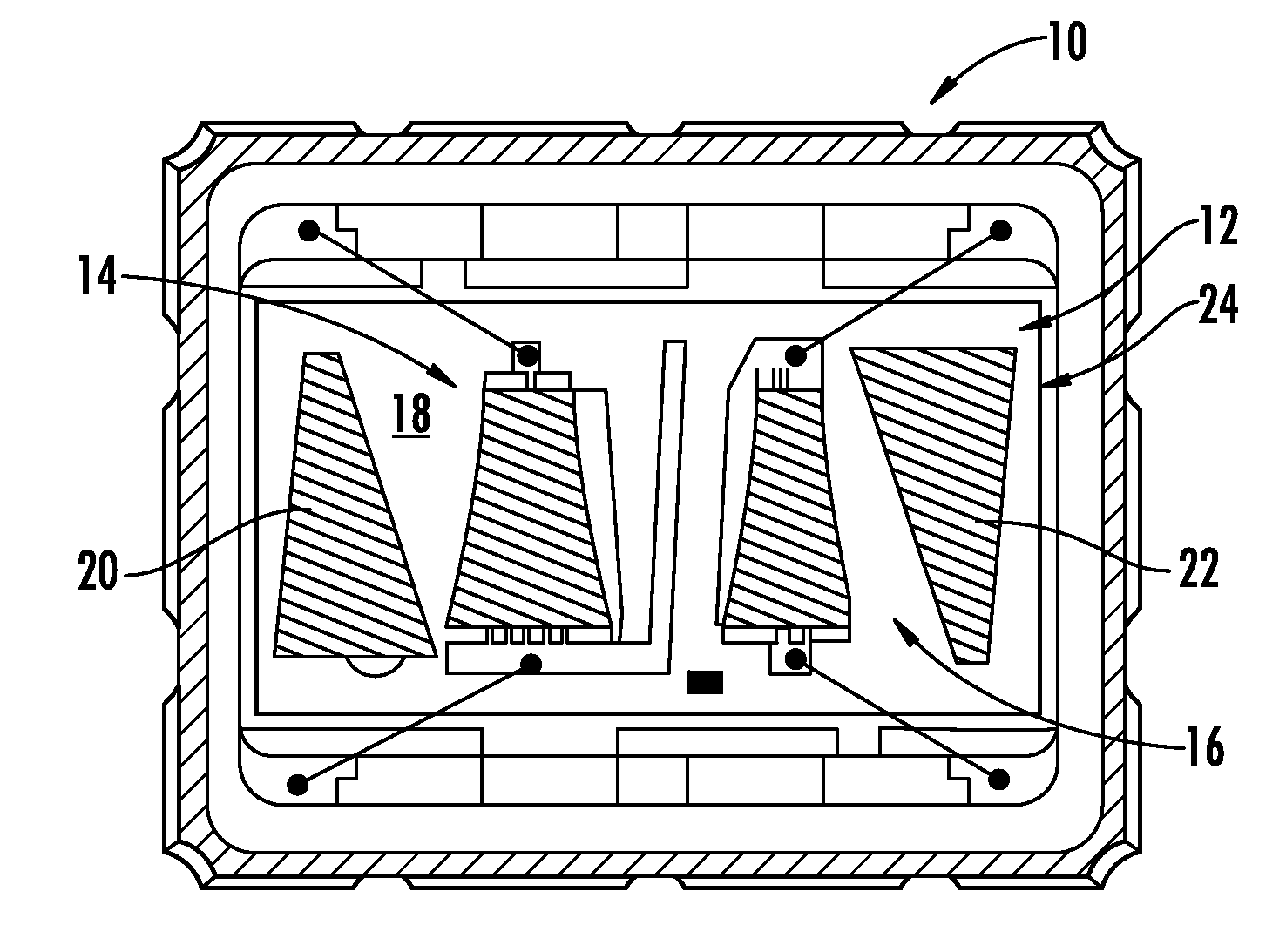

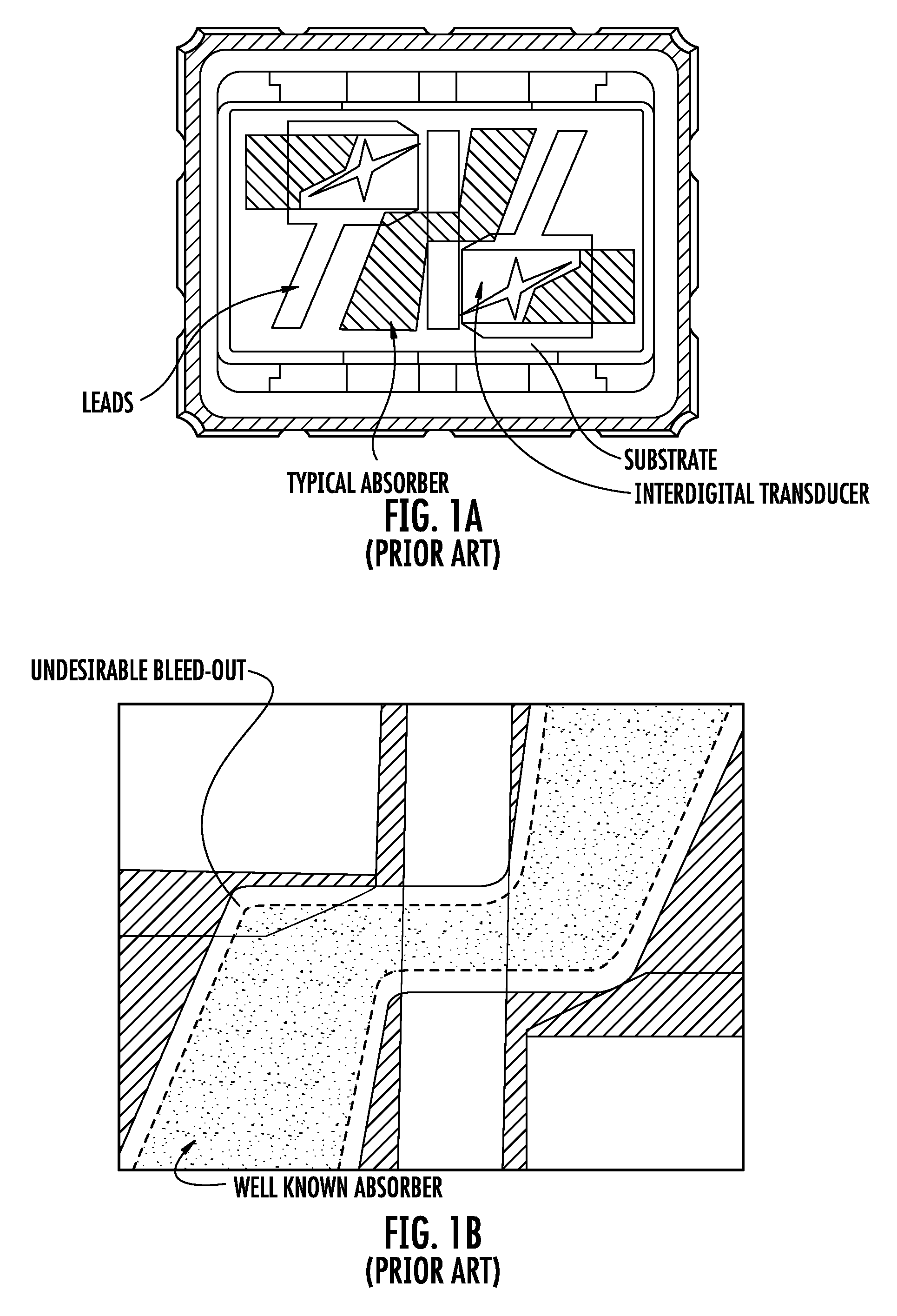

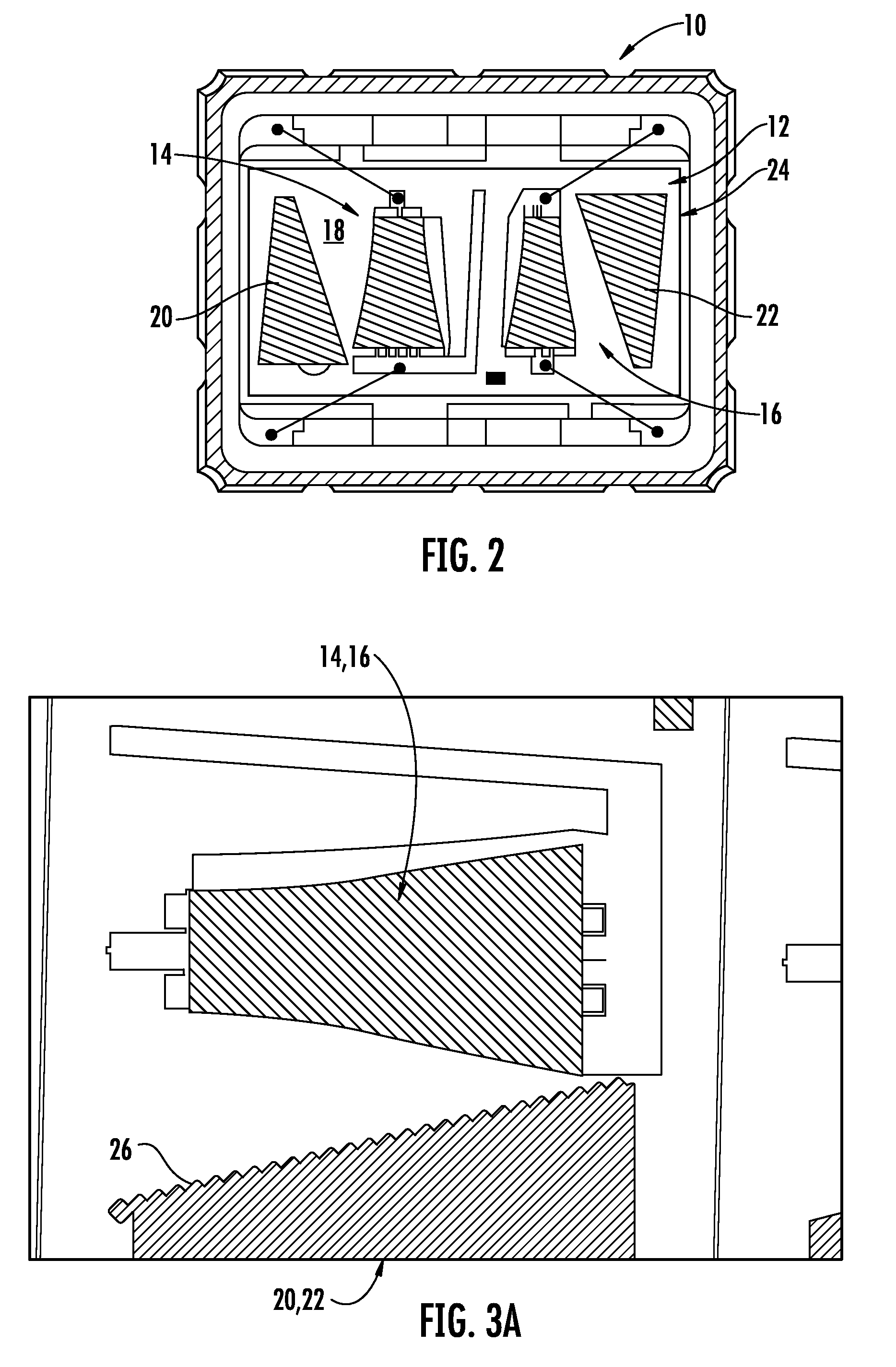

Acoustic wave filters using photo-definable epoxy for suppression of unwanted acoustic energy

ActiveUS7800281B1Desirable transmission capabilityImprove fidelityImpedence networksPiezoelectric/electrostriction/magnetostriction machinesEpoxyCentistokes

A SAW filter comprising an input transducer and an output transducer fabricated on a piezoelectric substrate and an epoxy based photo-definable acoustic absorber on the substrate for suppressing unwanted acoustic waves. The photo-definable acoustic absorber has a viscosity in a range from about 50 centistokes to 12000 centistokes and a thickness from about 10 microns to 120 microns. One acoustic absorber includes an SU-8 family member epoxy.

Owner:QORVO US INC

Lubricating oil and uses thereof

InactiveUS20140305146A1Growth inhibitionImprove propertiesDirect voltage acceleratorsHeat-exchange elementsCentistokesRefrigerant

Herein disclosed is a lubricant oil or lubricant for the compressor of a refrigeration system which operates with a refrigerant comprising at least one component of the hydrocarbon (HC) group of refrigerants, (a) whereby the lubricant consists of at least 85 weight % of alkylbenzene having an average molecular weight of ≧160 g / mol and exhibiting a viscosity of 2.2-3.0 centistokes (cSt) at 40 deg C.; optionally wherein the alkylbenzene consists of at least 85 wt % of linear (straight chain) alkylbenzene, having an average molecular weight of ≧160 g / mol and exhibiting a viscosity of 2.2-3.0 centistokes (cSt) at 40 deg C.; (b) or alternatively whereby the lubricant consists of at least 85 weight % of alkylbenzene having an average molecular weight of ≧190 g / mol and having a viscosity of 2.5-3.5 cSt at 40 deg C.; optionally wherein the alkylbenzene consists of at least 85 wt % of linear (straight chain) alkylbenzene, having an average molecular weight of ≧190 g / mol and exhibiting a viscosity of 2.5-3.5 centistokes (cSt) at 40 deg C.

Owner:SHRIEVE CHEM PRODS

Anhydrous Antiperspirant Compositions

An anhydrous aerosol antiperspirant composition comprising a concentrate comprising at least about 40%, by weight of the concentrate, of an alcohol; an antiperspirant active dissolved in the alcohol; and at least one volatile silicone oil that is miscible in the alcohol and antiperspirant active solution and that has a viscosity of less than 10 centistokes at 25° C.

Owner:THE PROCTER & GAMBLE COMPANY

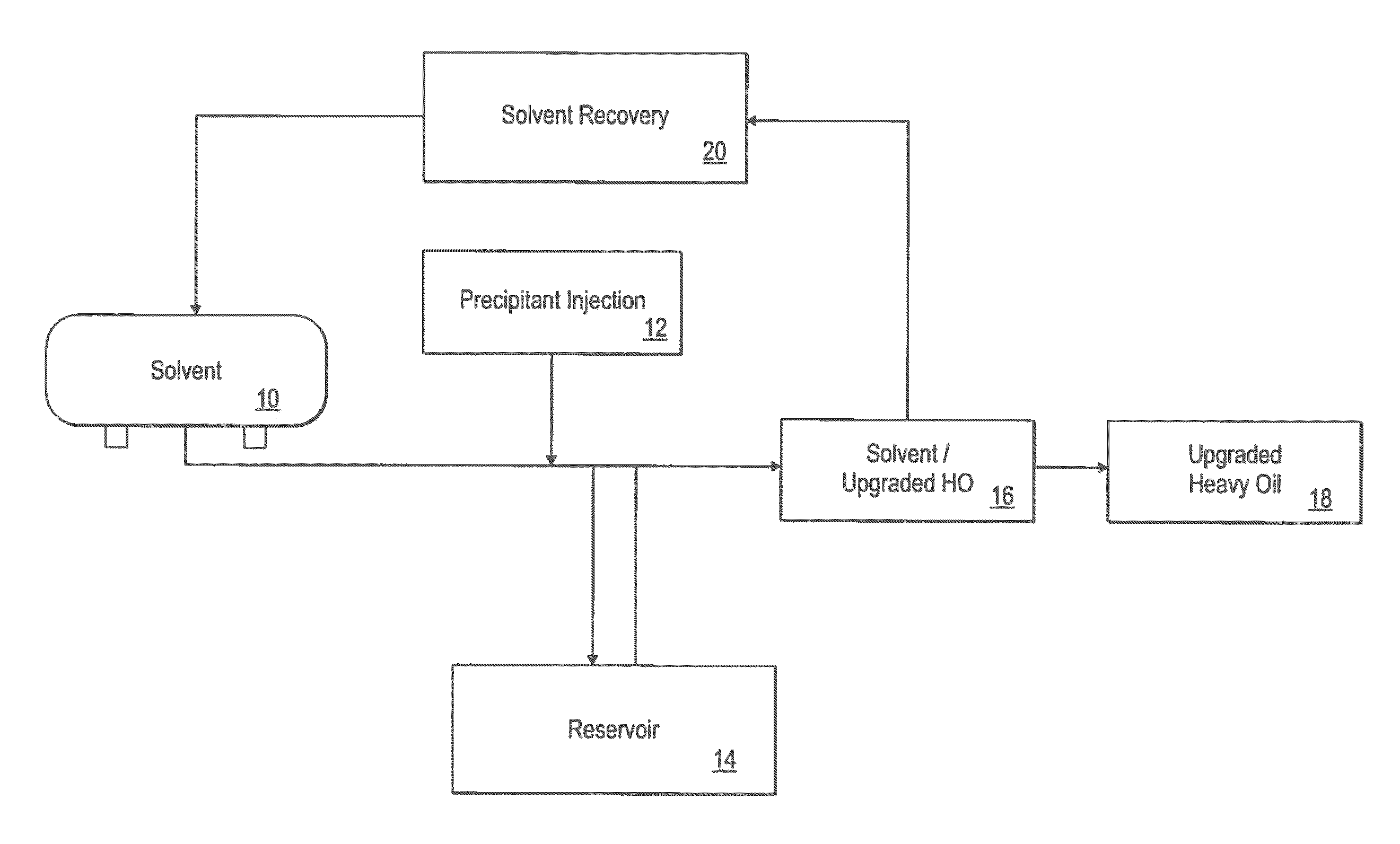

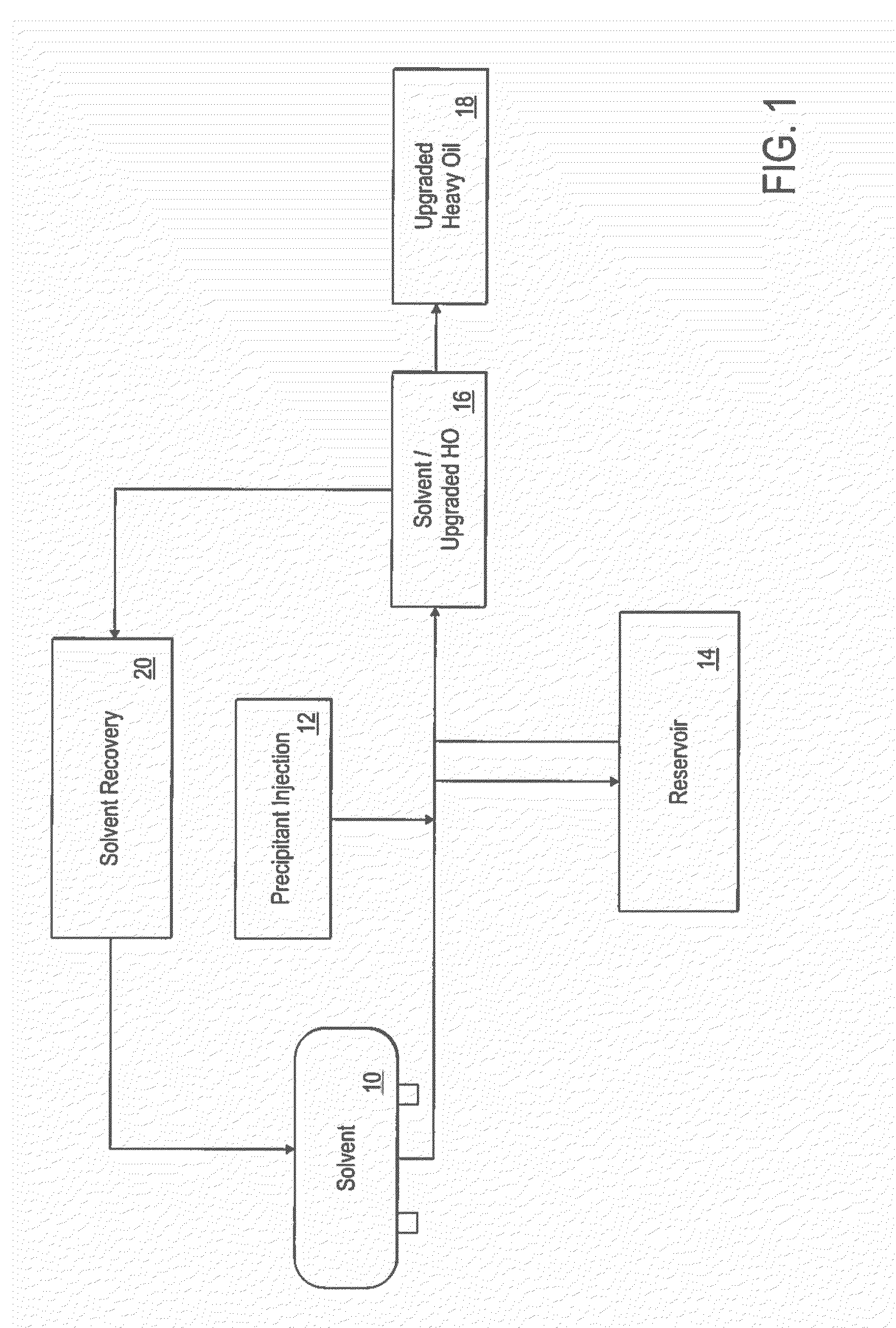

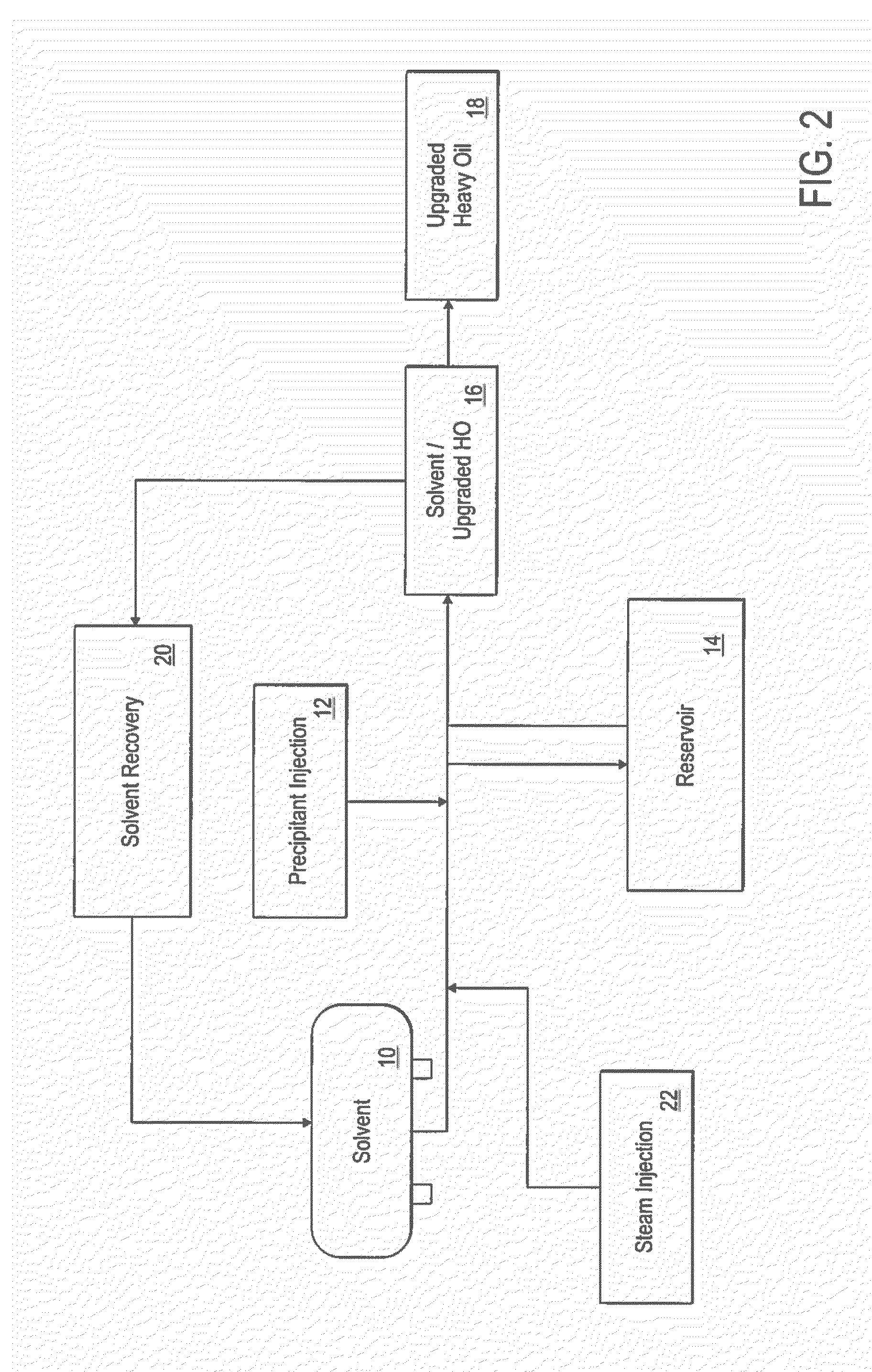

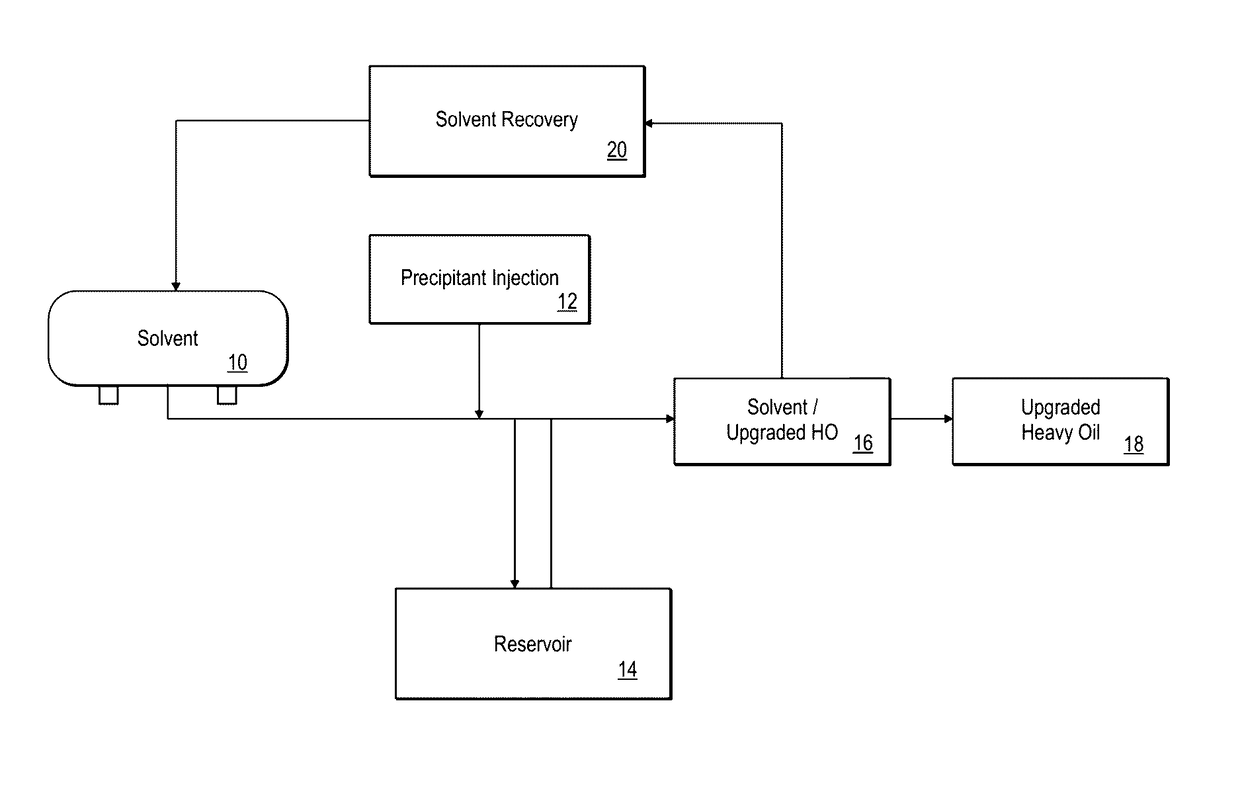

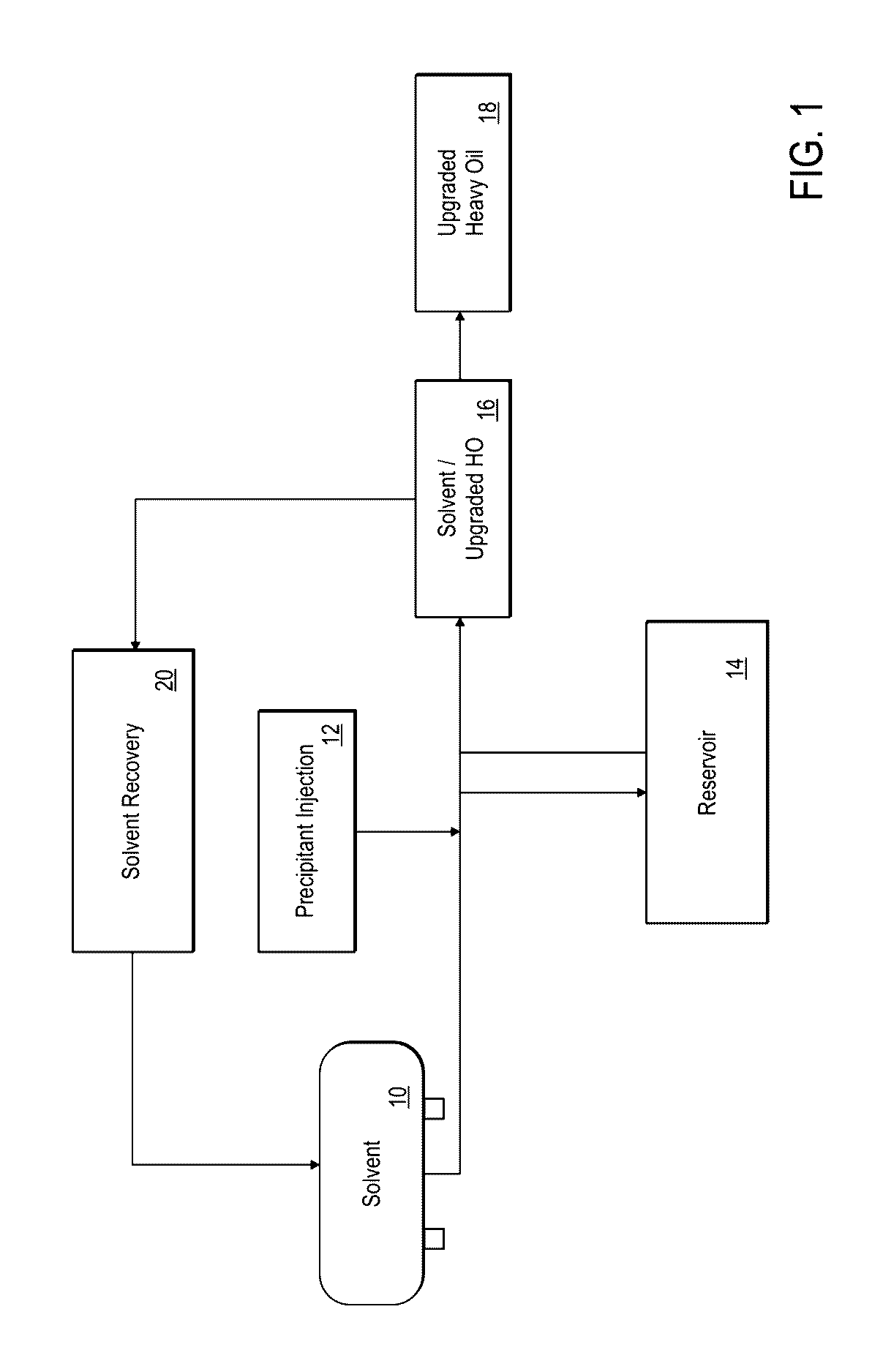

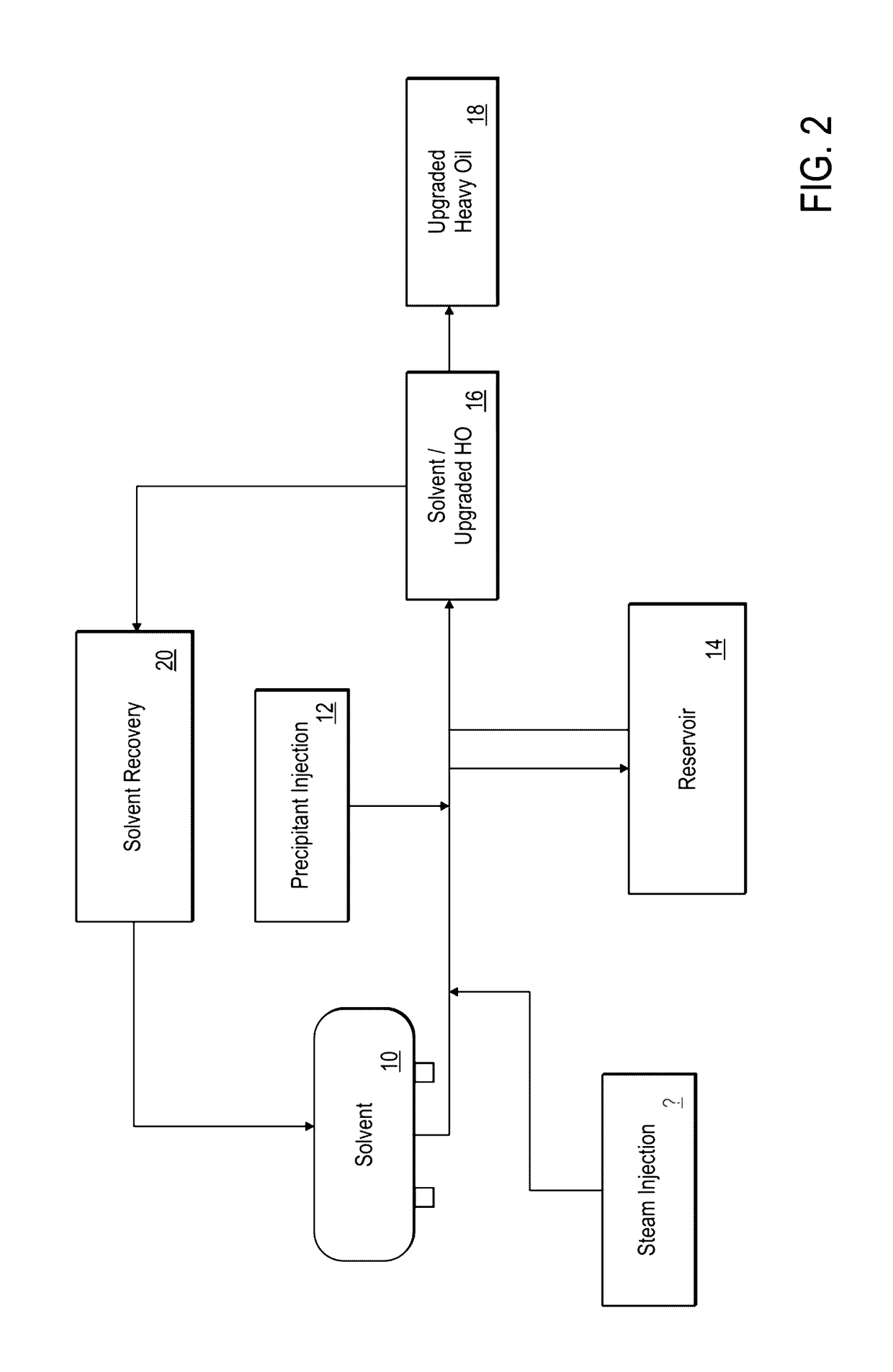

Process for in situ upgrading of a heavy hydrocarbon using asphaltene precipitant additives

ActiveUS20150114635A1Improved APIIncrease gravityFluid removalDrilling compositionHydrocarbon solventsCentistokes

Disclosed is a process for in situ upgrading of a heavy hydrocarbon comprising the steps of: (a) positioning a well in a reservoir containing a heavy hydrocarbon having an initial API gravity of less than or equal to about 20, an n-heptane asphaltene content as measured by the ASTM D-6560 of at least about 1 wt. %, and a viscosity at 35° C. greater than about 350 centistokes (cSt); (b) injecting one or more hydrocarbon solvents and one or more asphaltene precipitant additives into the well in any order at a ratio by volume of the solvent to the heavy hydrocarbon of at least from about 0.1:1 to about 20:1 under reservoir conditions so as to provide an upgraded hydrocarbon in the reservoir, wherein the upgraded hydrocarbon has an improved API gravity greater than the initial API gravity, a reduction in the asphaltene content, and a lower viscosity; and (c) producing the upgraded hydrocarbon from the well. The process of the present invention can be also carried out at higher temperatures such as by injecting steam with the one or more hydrocarbon solvents and the one or more asphaltene precipitant additives into the well in any order.

Owner:CHEVROU USA INC

Process for in situ upgrading of a heavy hydrocarbon using asphaltene precipitant additives

ActiveUS9670760B2Improved APIIncrease gravityFluid removalDrilling compositionHydrocarbon solventsCentistokes

Owner:CHEVROU USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com