Online monitoring dry type cable terminal with composite external casing and on-site assembling method thereof

A cable terminal and dry composite technology, which is applied in the installation of cable terminals, cable accessories, cables, etc., can solve the problems of inability to monitor the quality of online operation, the verticality of the product cannot be guaranteed, and the product is easy to sway with the wind. Achieve the effects of shortening the maintenance time of power outages, excellent water repellency, and saving time for troubleshooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

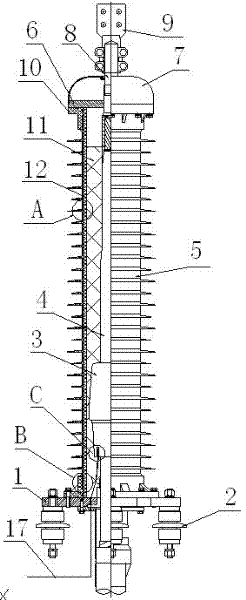

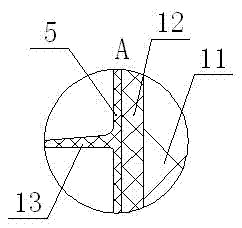

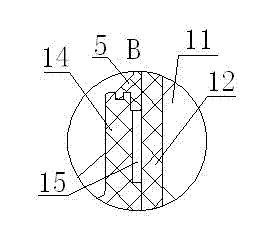

[0026] As shown in the figure, the structure of the cable terminal for on-line monitoring of the present invention includes an aluminum alloy base 1, an aluminum alloy shield 7, a silicon rubber stress cone 3, a silicon rubber sleeve 5, and a cable 4. The base 1 and the shielding cover 7 are arranged on both ends of the sleeve 5 , the end of the cable 4 is inserted into the sleeve 5 , the stress cone 3 is located in the sleeve 5 , and the stress cone 3 is sleeved on the cable 4 at the same time. Vulcanized silicone rubber 11 liquid with a viscosity between 1,500 and 1,500,000 centistokes is poured into the interval between the cable 4 and the casing 5, and the vulcanized silicone rubber 11 can connect the base 1, the cable 4 and the casing 5 after curing. together to form a dry cable termination.

[0027]An installation space is reserved when the stress cone 3 is manufactured, and a fiber grating sensor 16 that can detect and transmit the temperature information of the stress ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com