Patents

Literature

5085 results about "Electron bunches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

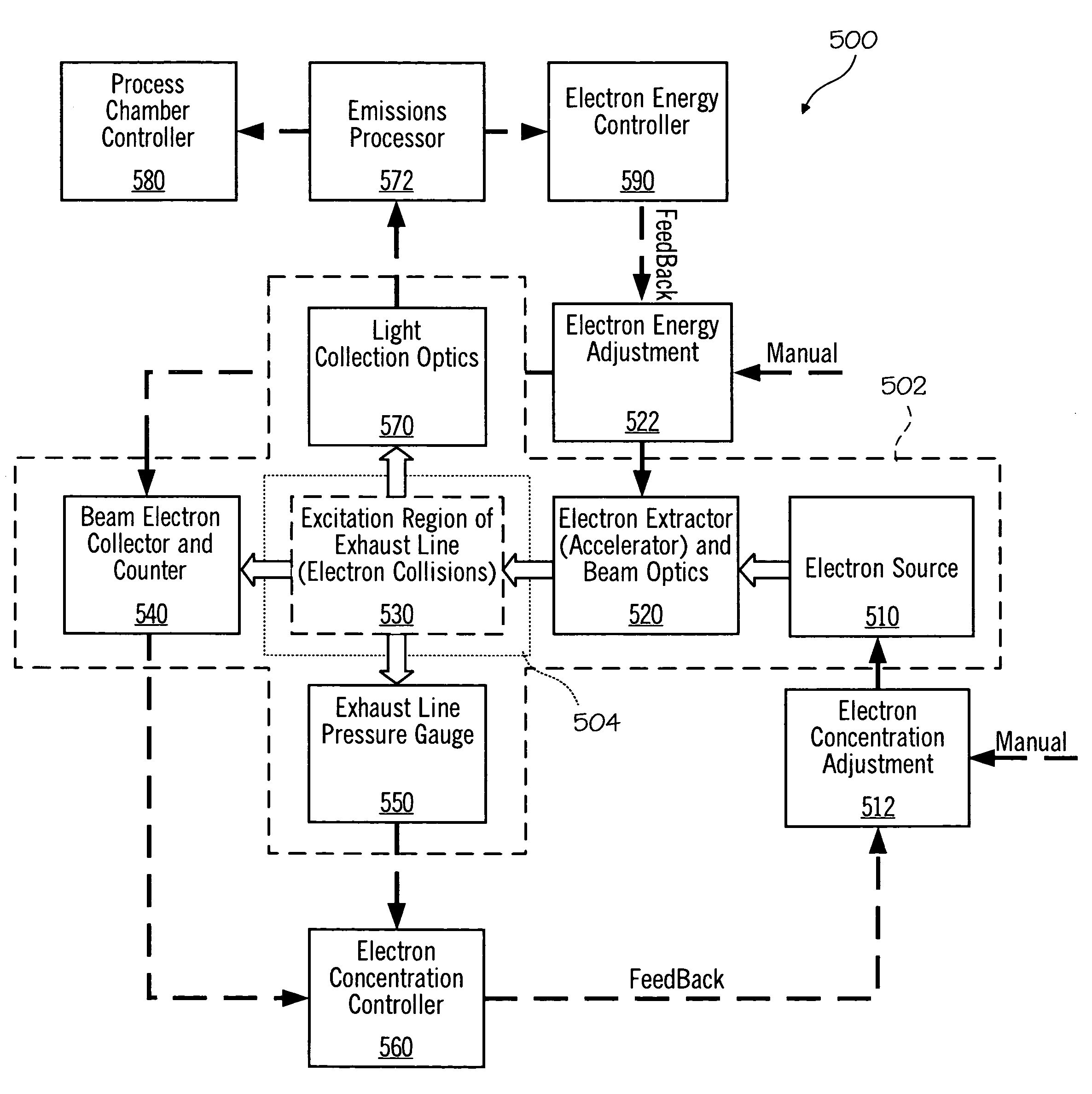

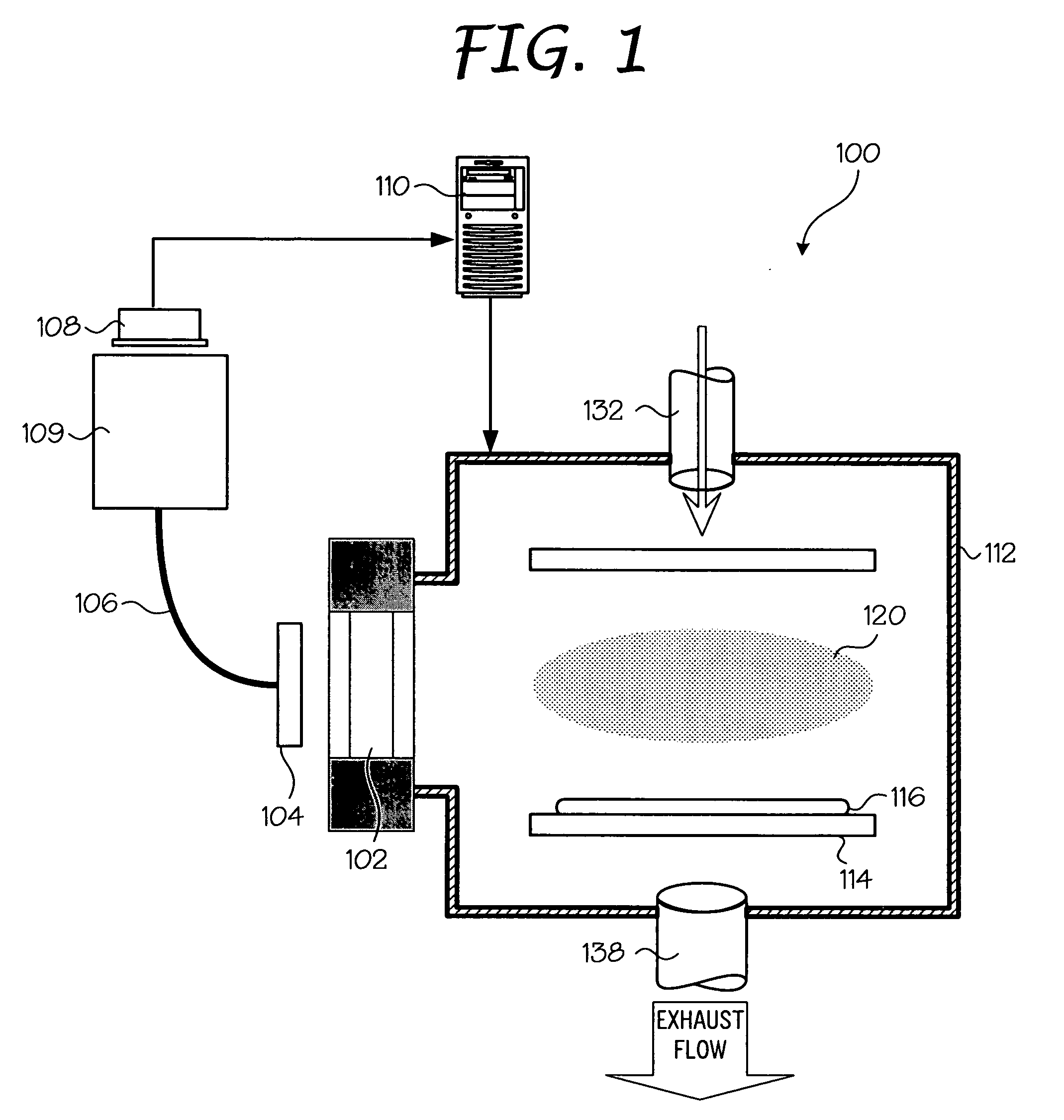

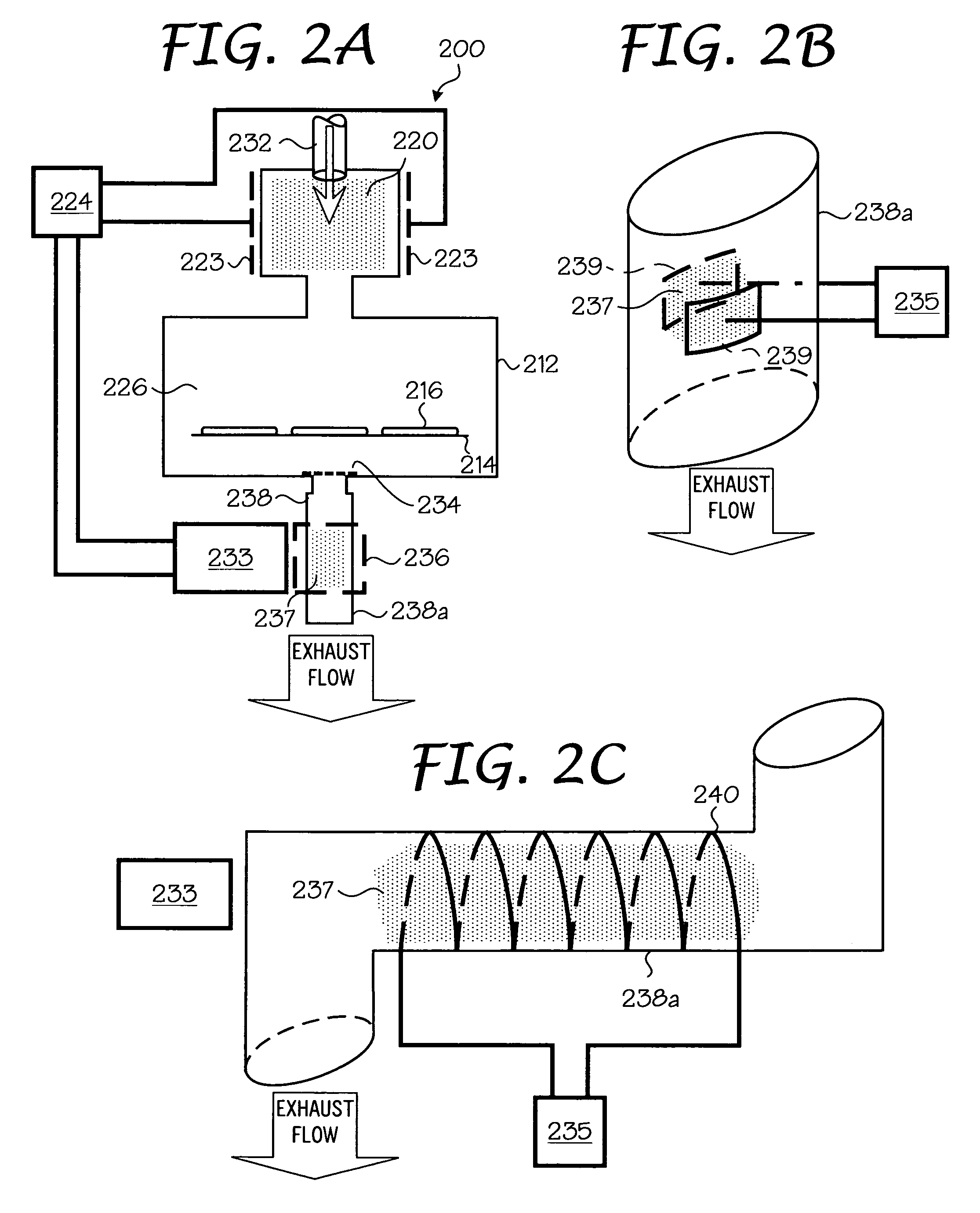

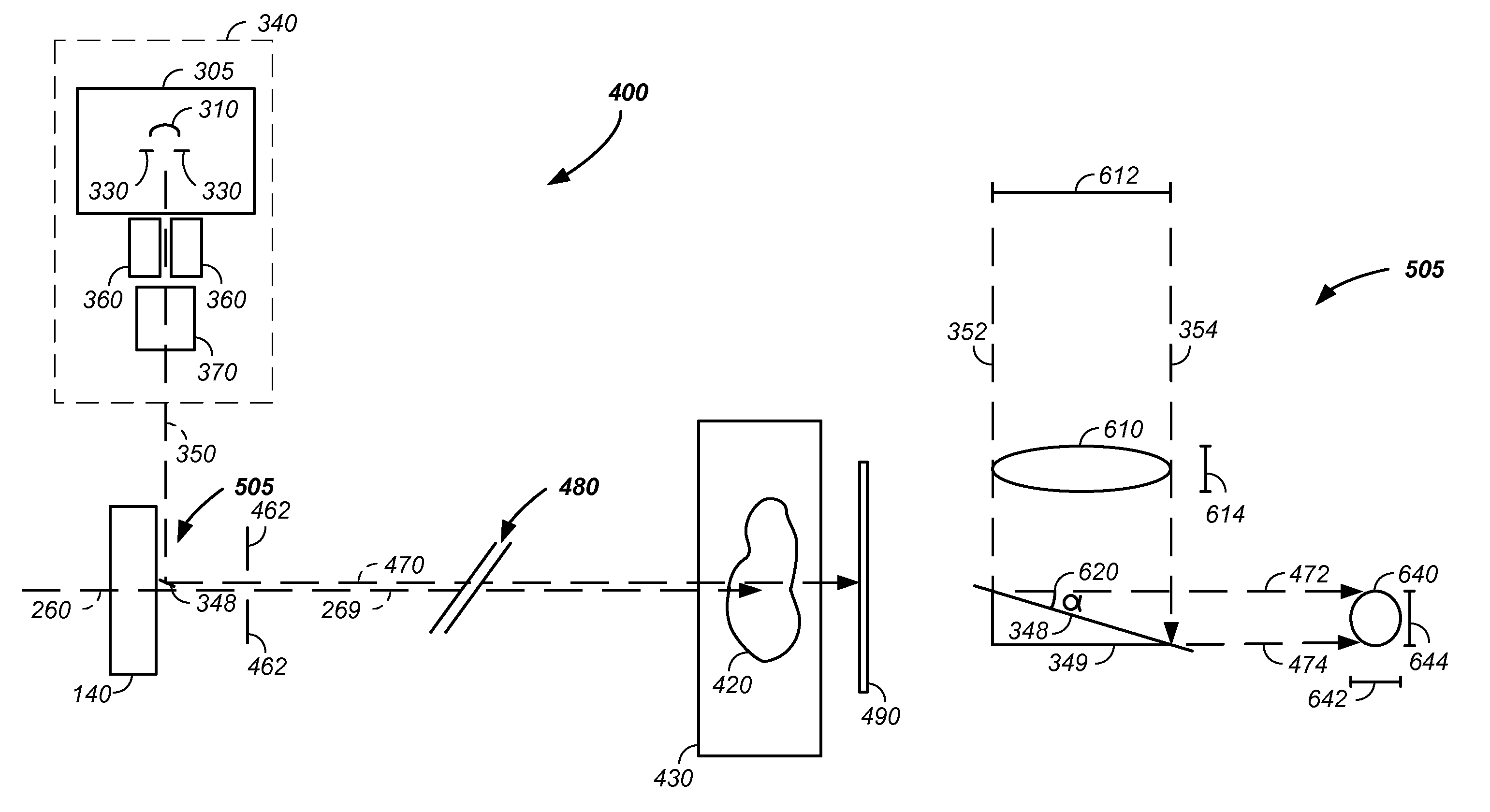

Electron beam exciter for use in chemical analysis in processing systems

ActiveUS20100032587A1Disparity will become so greatHigh electron energyCathode ray tubes/electron beam tubesRadiation therapyElectron sourceFluorescence

The present invention is directed to a gas line electron beam exciter, gas line electron beam excitation system and method for exciting a gas using an electron beam exciter. The electron beam exciter generally comprises a variable density electron source for generating a cloud of electrons in an electron chamber and a variable energy electron extractor for accelerating electrons from the electron chamber as an electron beam and into an effluent stream for fluorescing species in the effluent. The electron density of the electron beam is variably controlled by adjusting the excitation power applied to the variable density electron source. The electrons in the electron chamber reside at a reference electrical potential of the chamber, typically near ground electrical potential. The electron energy of the electron beam is variably controlled by adjusting an electrical potential across the variable energy electron extractor, which energizes the electrons through an extraction hole of the chamber and toward the extractor. The greater the difference in the electrical potential between the electron extractor and the electron source, the higher the energy imparted to the electrons in the electron beam. The excitation power applied to the electron source can be adjusted independently from the electron energy of the electron beam, thereby altering the electron density of the electron beam without changing the energy level of the electrons of the electron beam.

Owner:VERITY INSTR +1

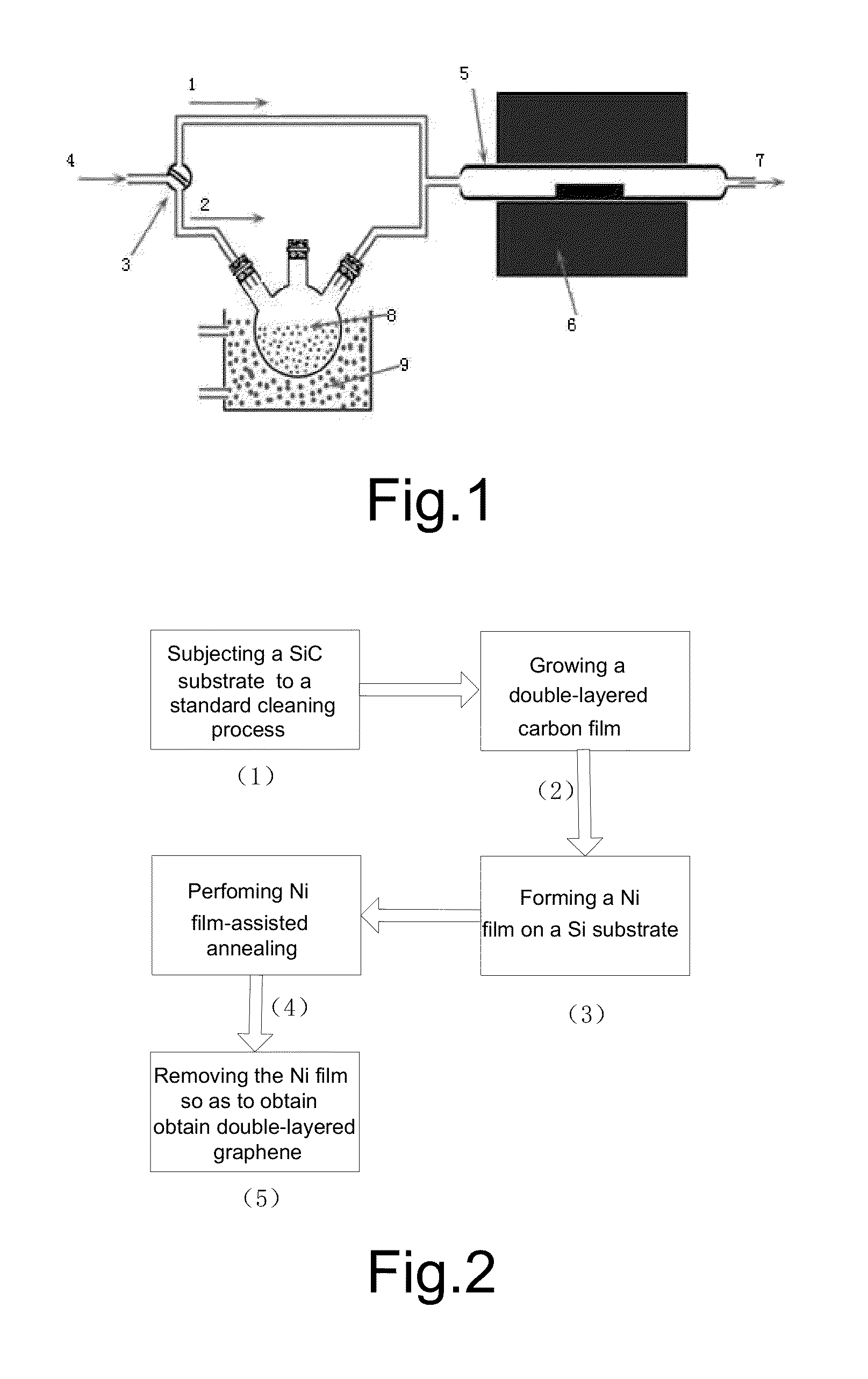

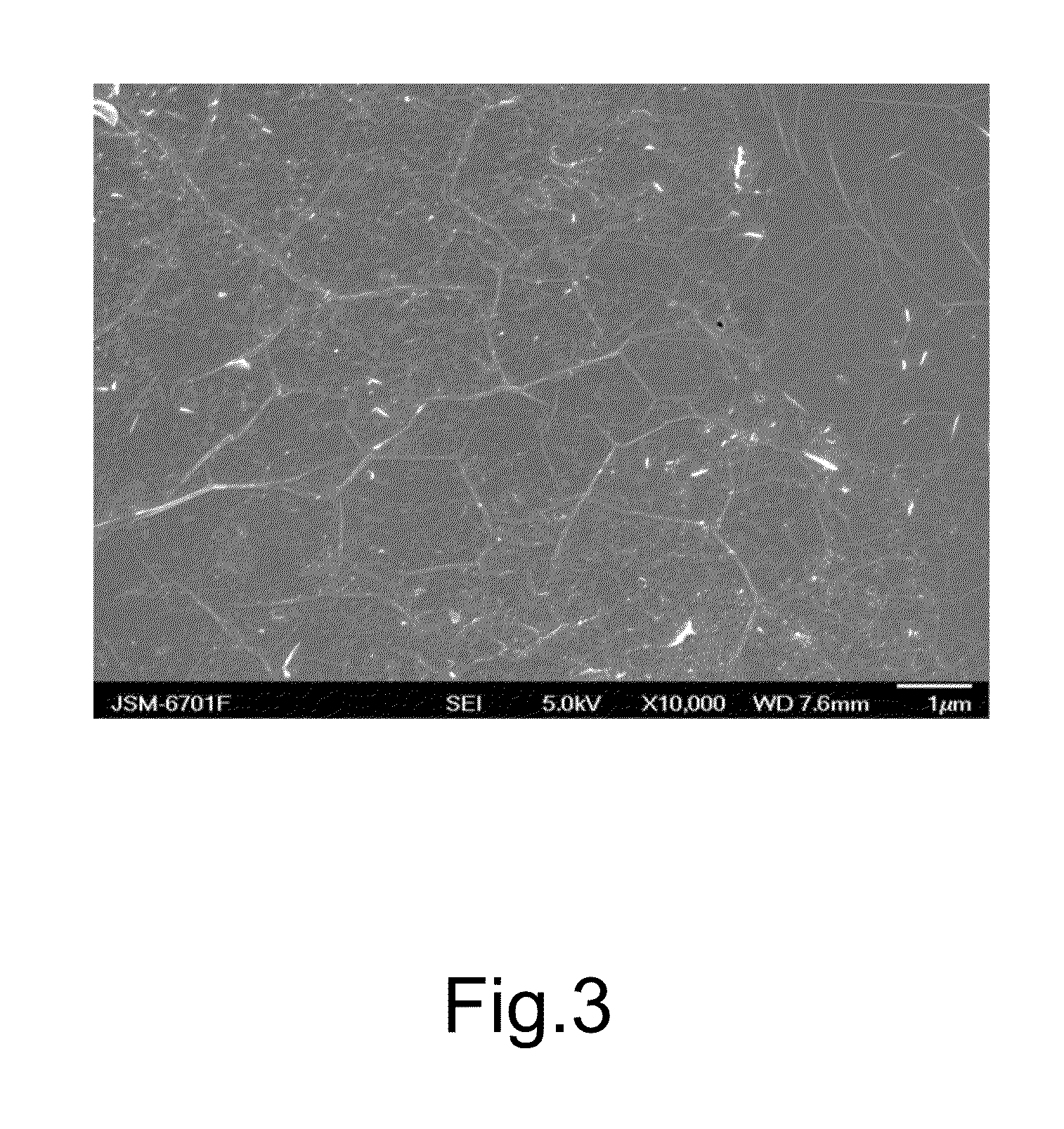

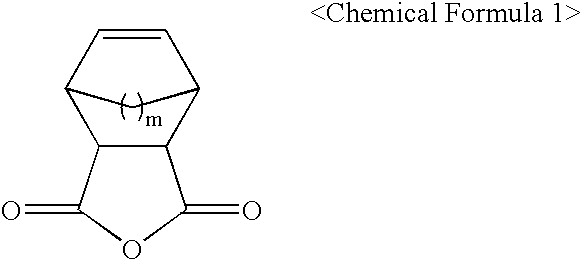

Process for Preparing Graphene on a SiC Substrate Based on Metal Film-Assisted Annealing

ActiveUS20140367642A1Simply and energy-efficientFlat surfaceMaterial nanotechnologyVacuum evaporation coatingCarbon filmElectron beam deposition

Provided is a process for preparing graphene on a SiC substrate, based on metal film-assisted annealing, comprising the following steps: subjecting a SiC substrate to a standard cleaning process; placing the cleaned SiC substrate into a quartz tube and heating the quartz tube up to a temperature of 750 to 1150° C.; introducing CCl4vapor into the quartz tube to react with SiC for a period of 20 to 100 minutes so as to generate a double-layered carbon film, wherein the CCl4 vapor is carried by Ar gas; forming a metal film with a thickness of 350 to 600 nm on a Si substrate by electron beam deposition; placing the obtained double-layered carbon film sample onto the metal film; subsequently annealing them in an Ar atmosphere at a temperature of 900 to 1100° C. for 10-30 minutes so as to reconstitute the double-layered carbon film into double-layered graphene; and removing the metal film from the double-layered graphene, thereby obtaining double-layered graphene. Also provided is double-layered graphene prepared by said process.

Owner:XIDIAN UNIV

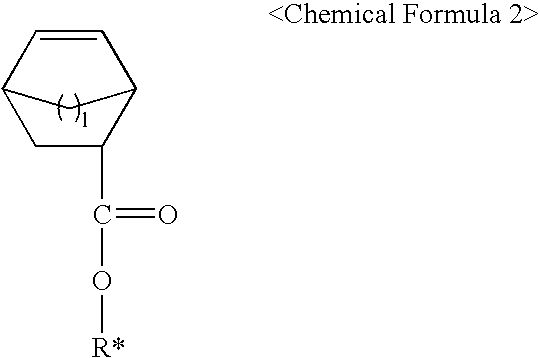

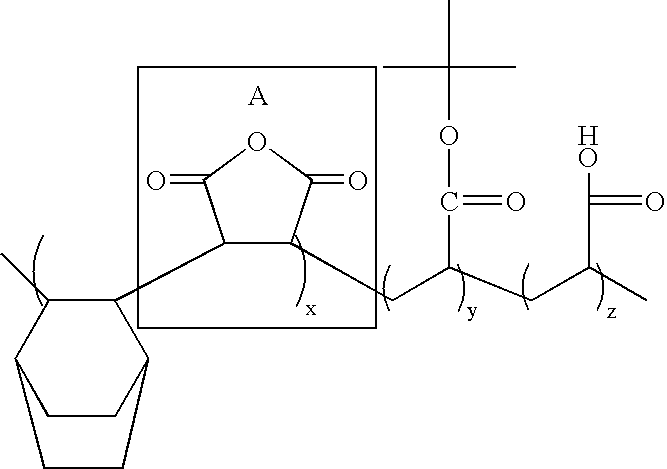

Polymers for photoresist and photoresist compositions using the same

InactiveUS6987155B2Improve the immunityExcellent etching resistance and adhesiveness and photosensitivityElectric discharge tubesPhotomechanical exposure apparatusResistX-ray

The present invention relates to photoresist monomers, polymers formed therefrom and photoresist compositions suitable for photolithography processes employing a DUV light source, such as KrF (249 nm) and ArF(193 nm); EUV; VUV; E-beam; ion-beam; and X-ray. Photoresist monomers of the present invention are represented by the following Chemical Formula 1: wherein, m is 1 or 2.Polymers of the present invention comprise repeating units derived from the comonomer of Chemical Formula 1, preferably together with monomers of the following Chemical Formula 2: wherein,R* is an acid-labile group, andl is 1 or 2.

Owner:HYUNDAI ELECTRONICS IND CO LTD

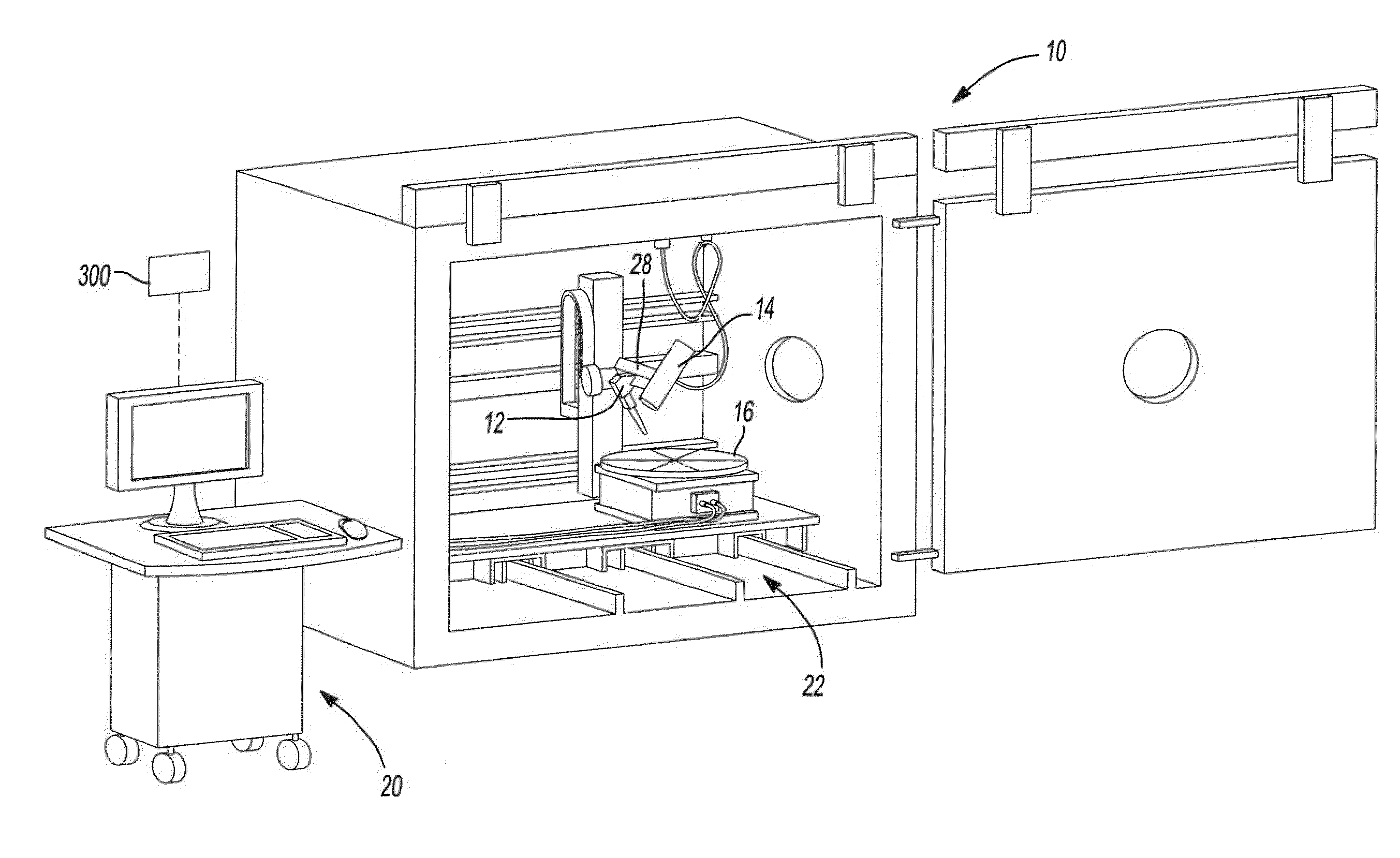

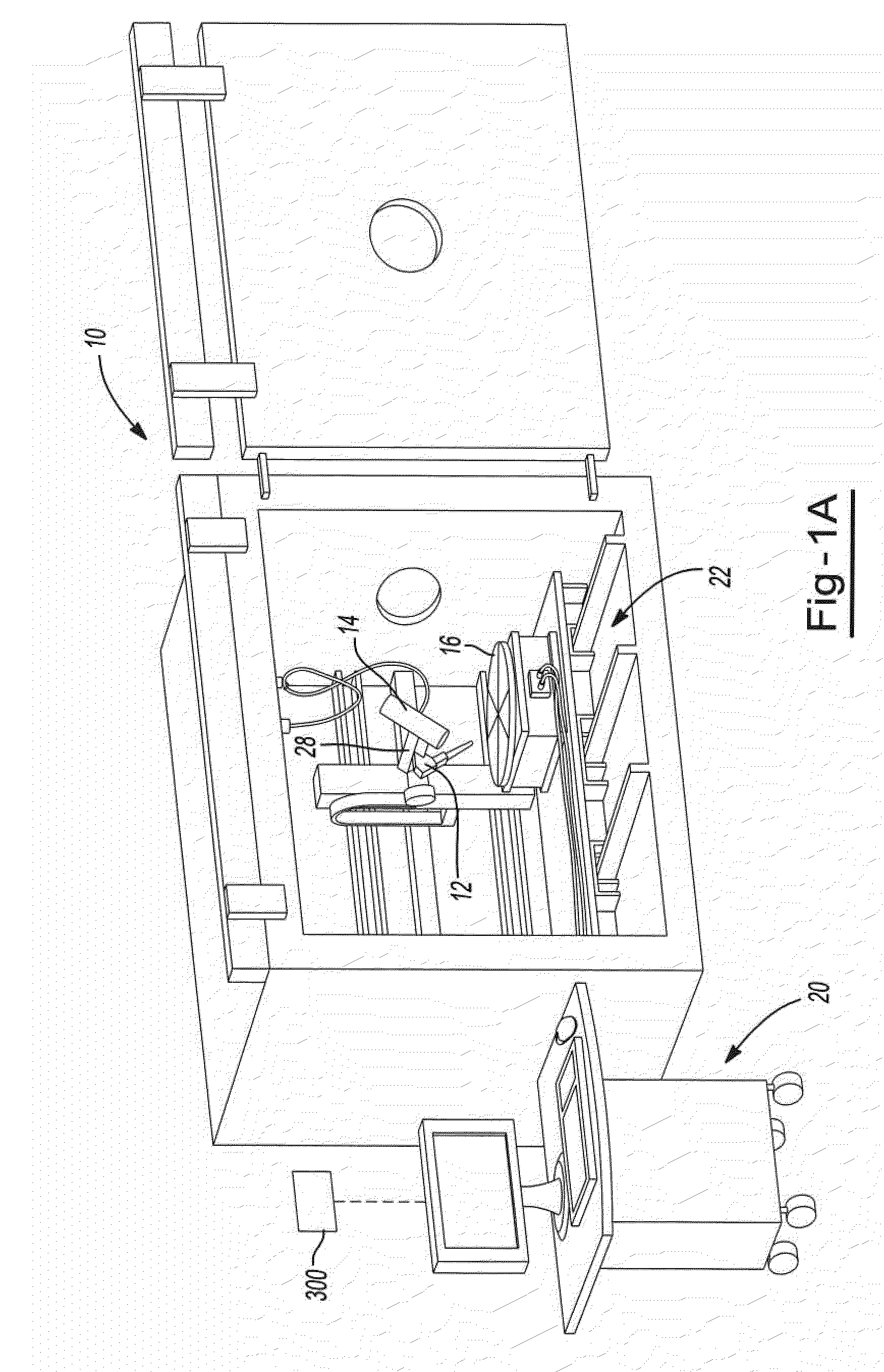

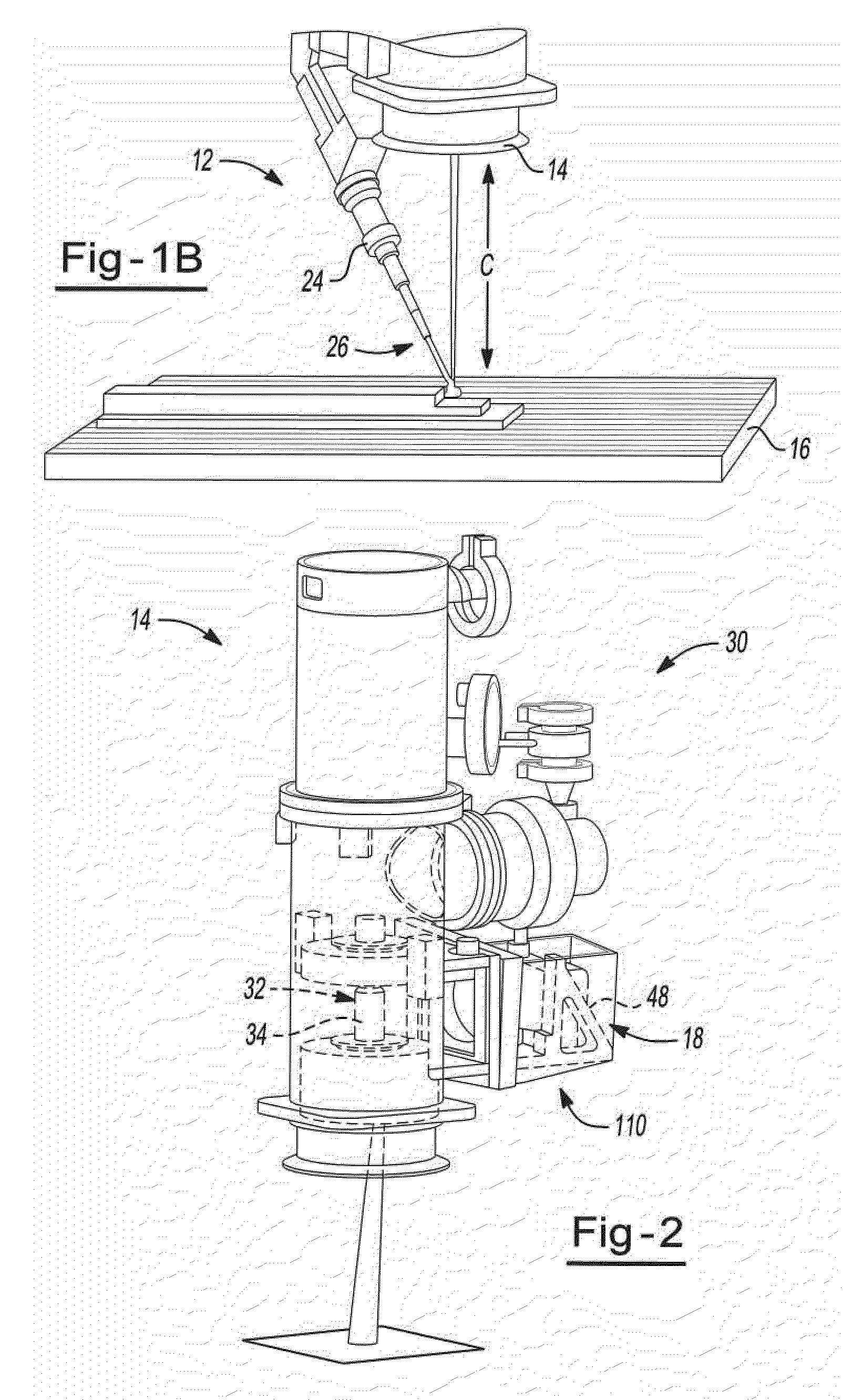

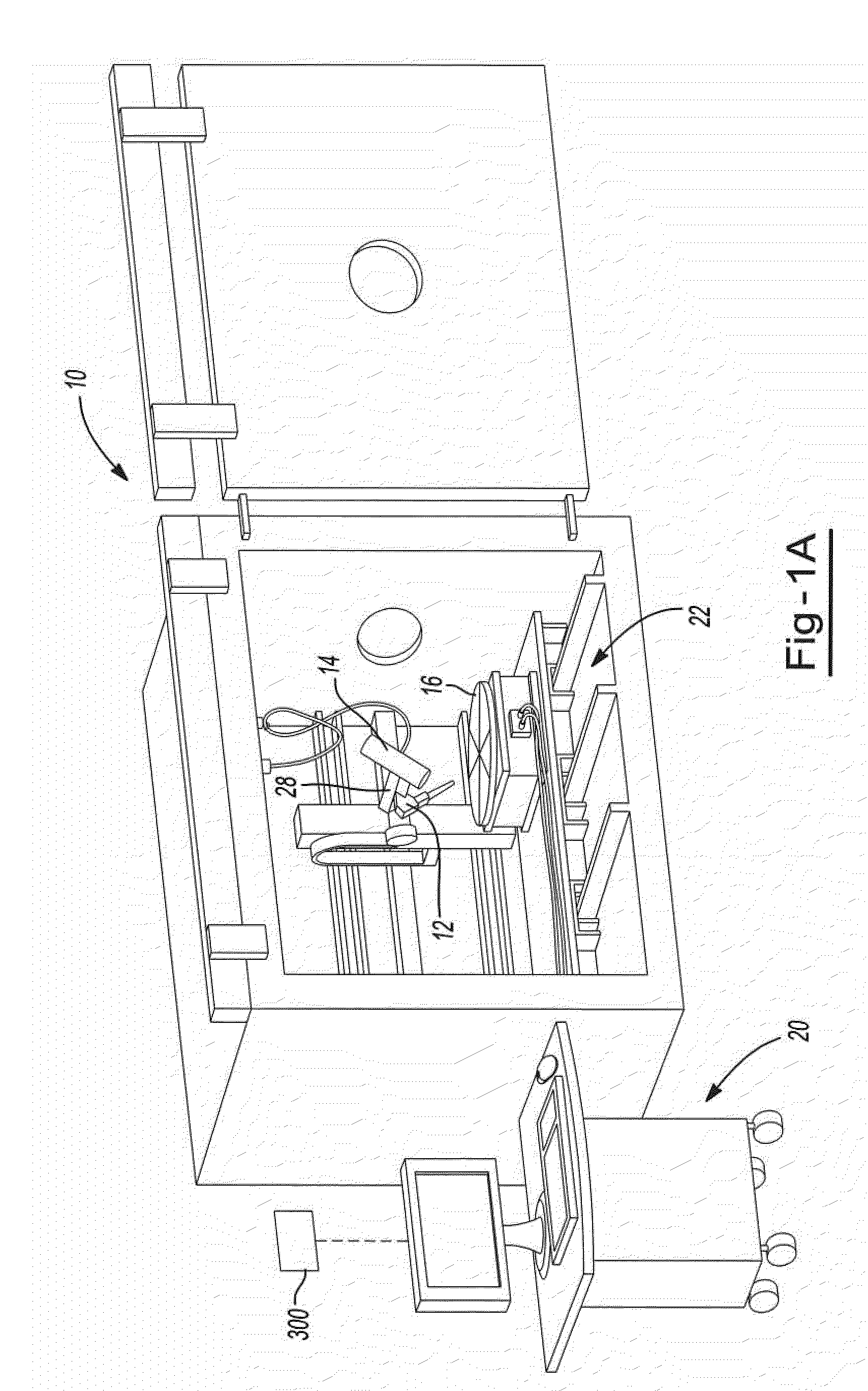

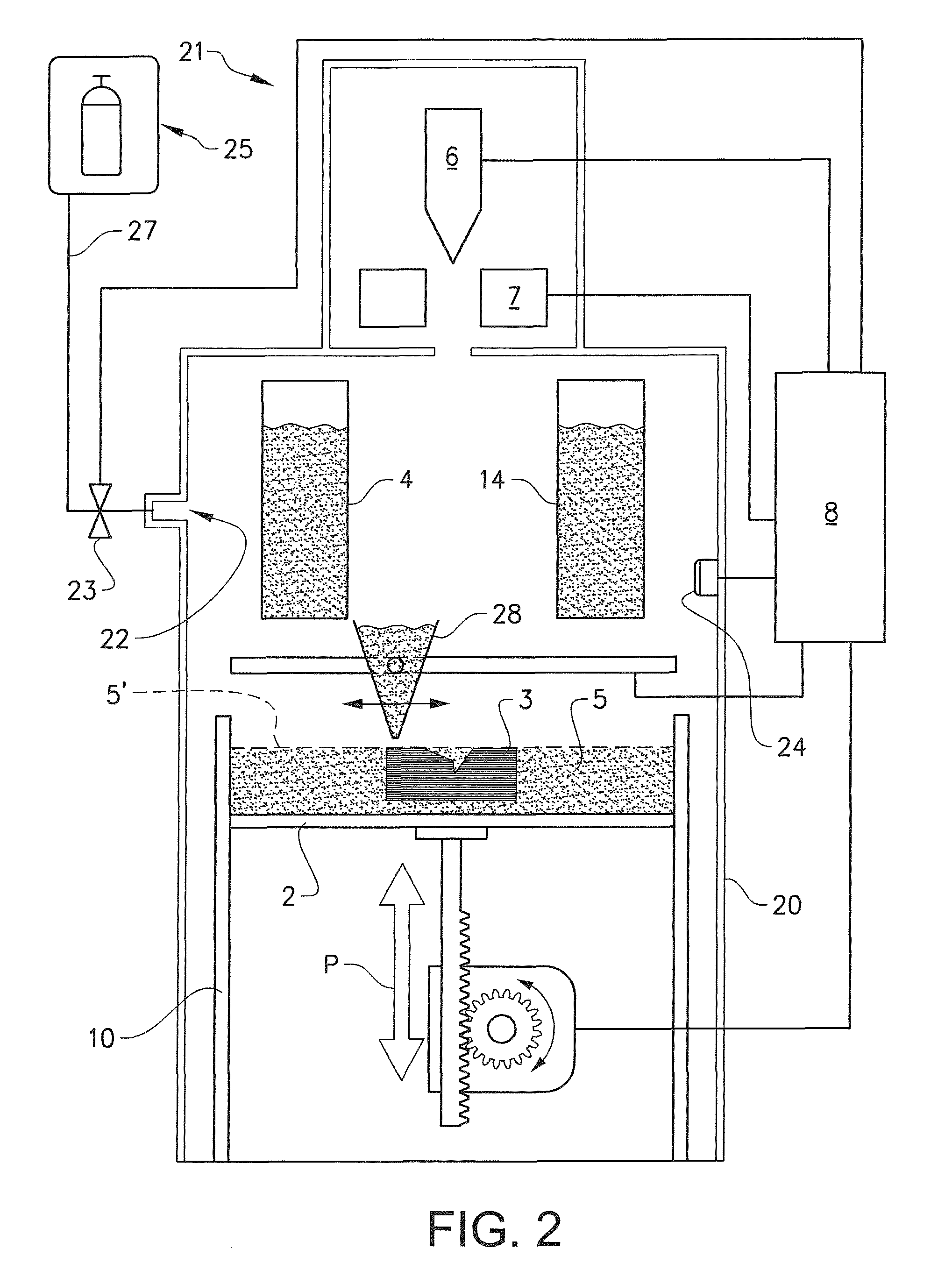

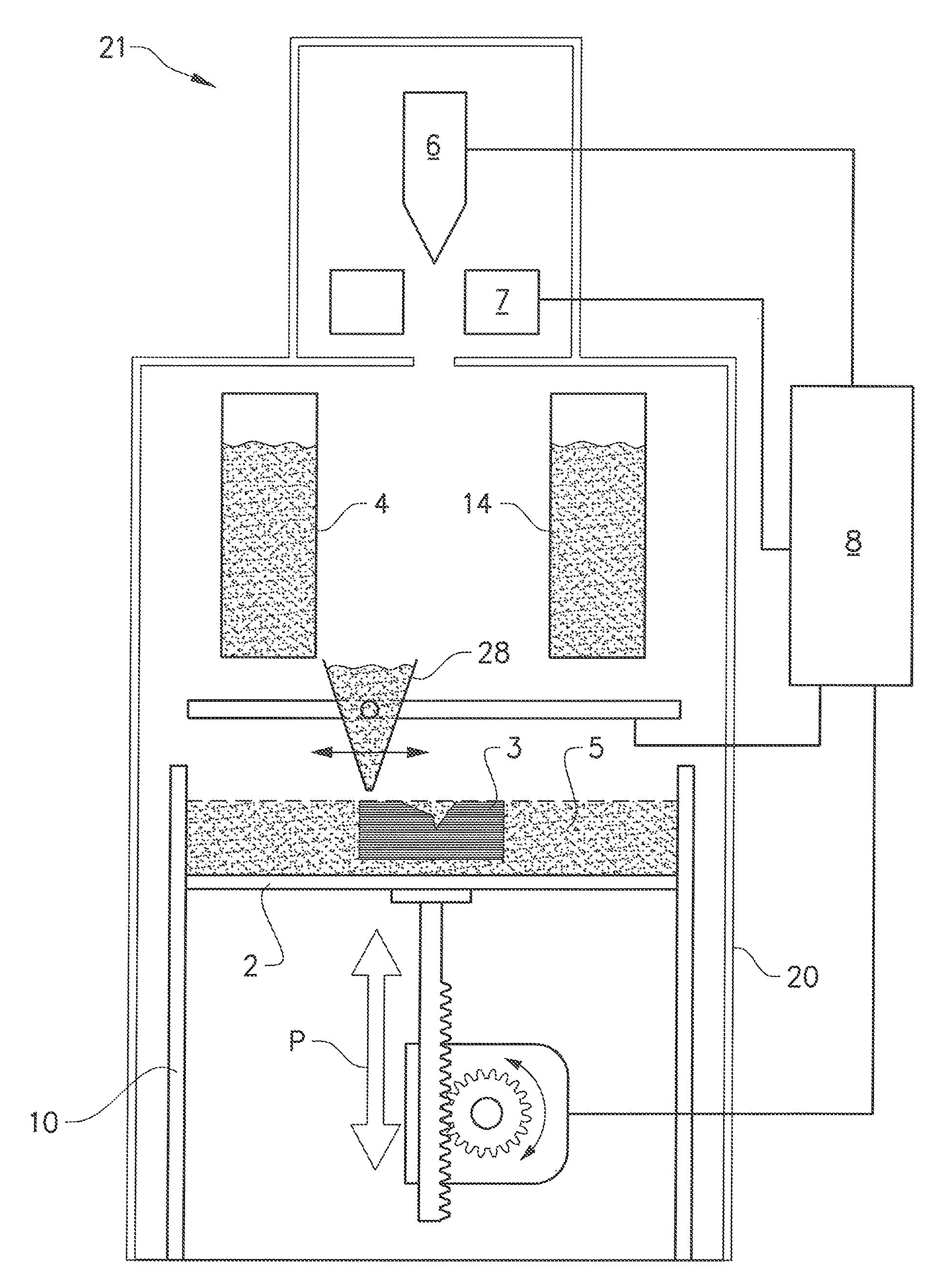

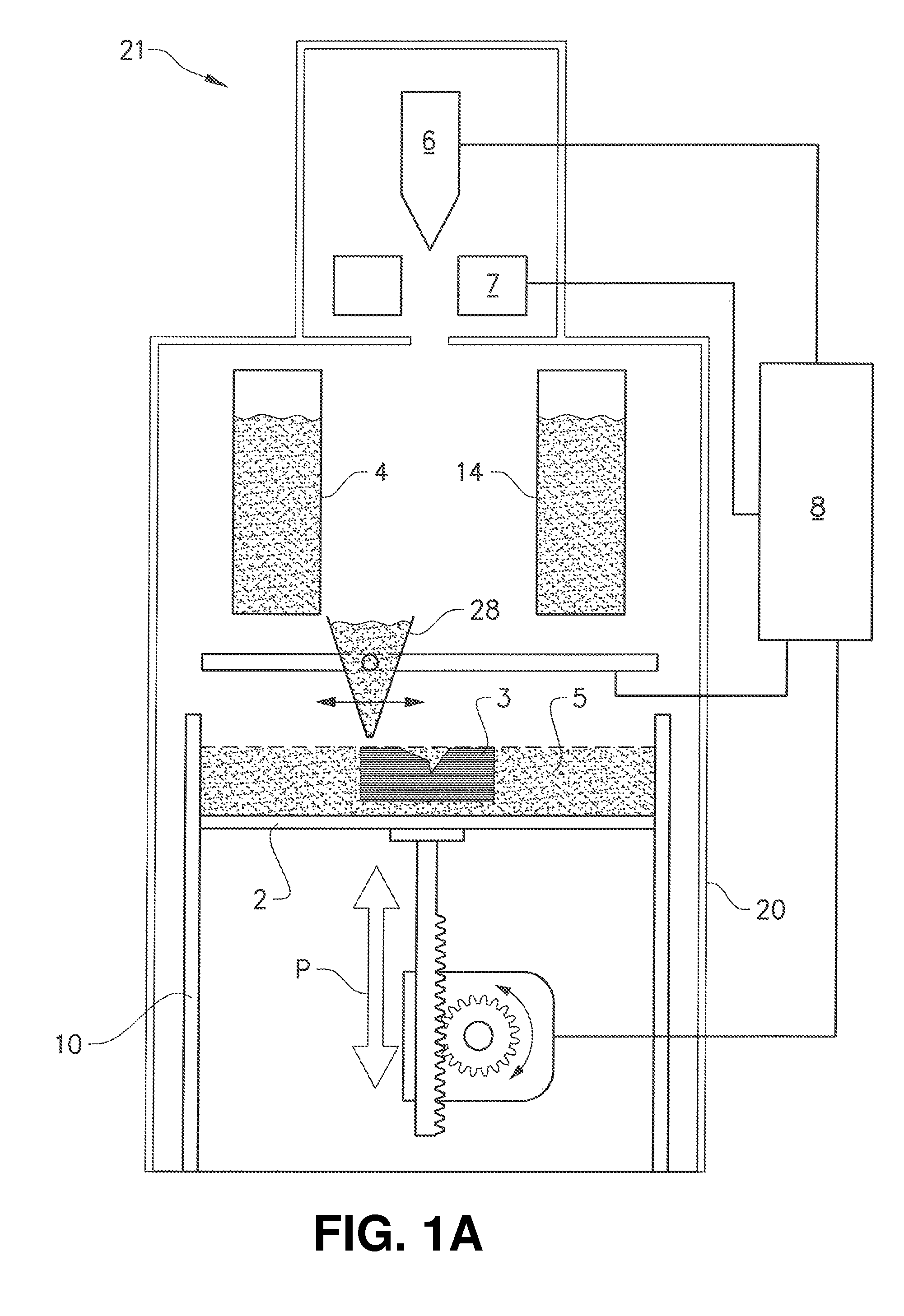

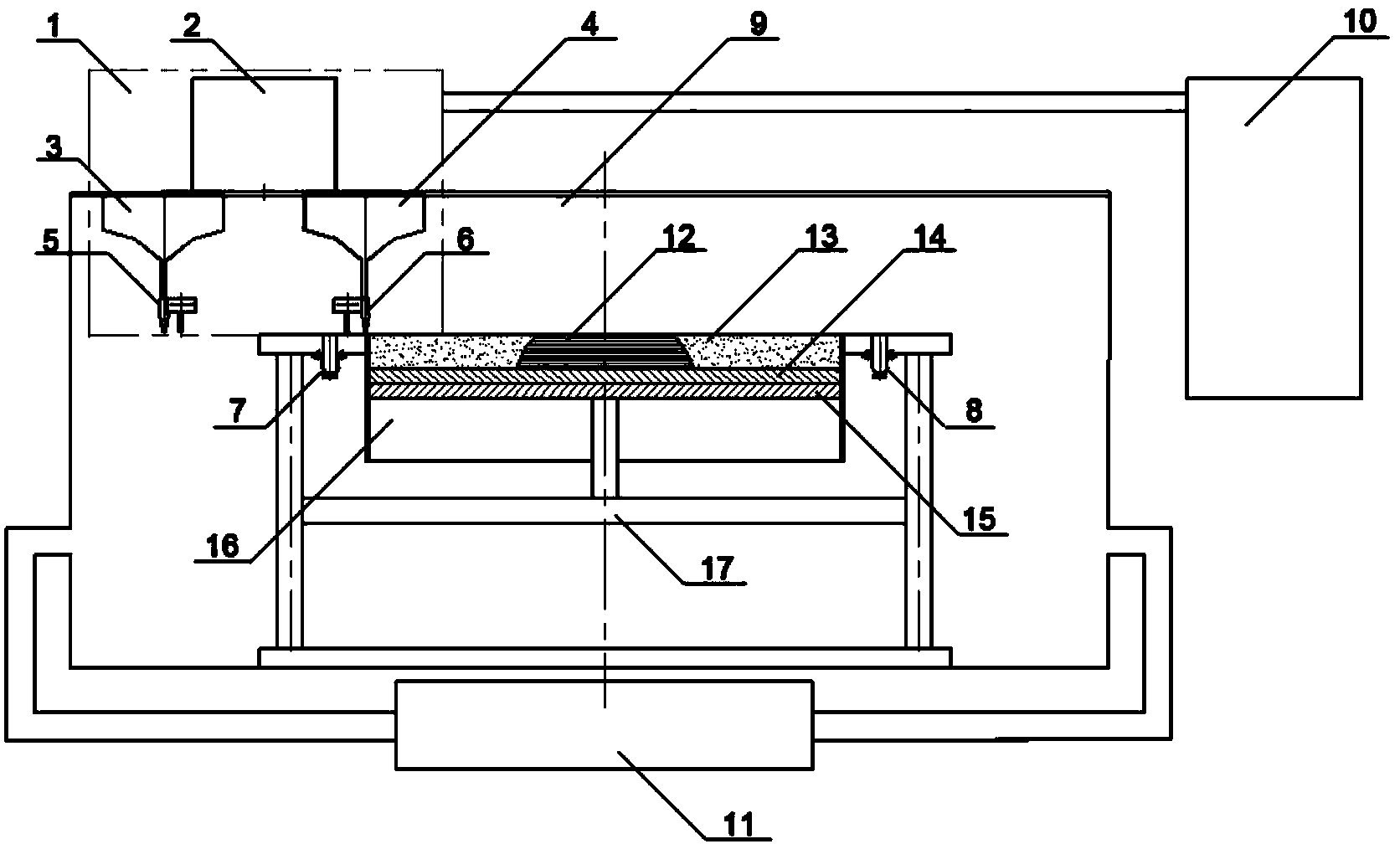

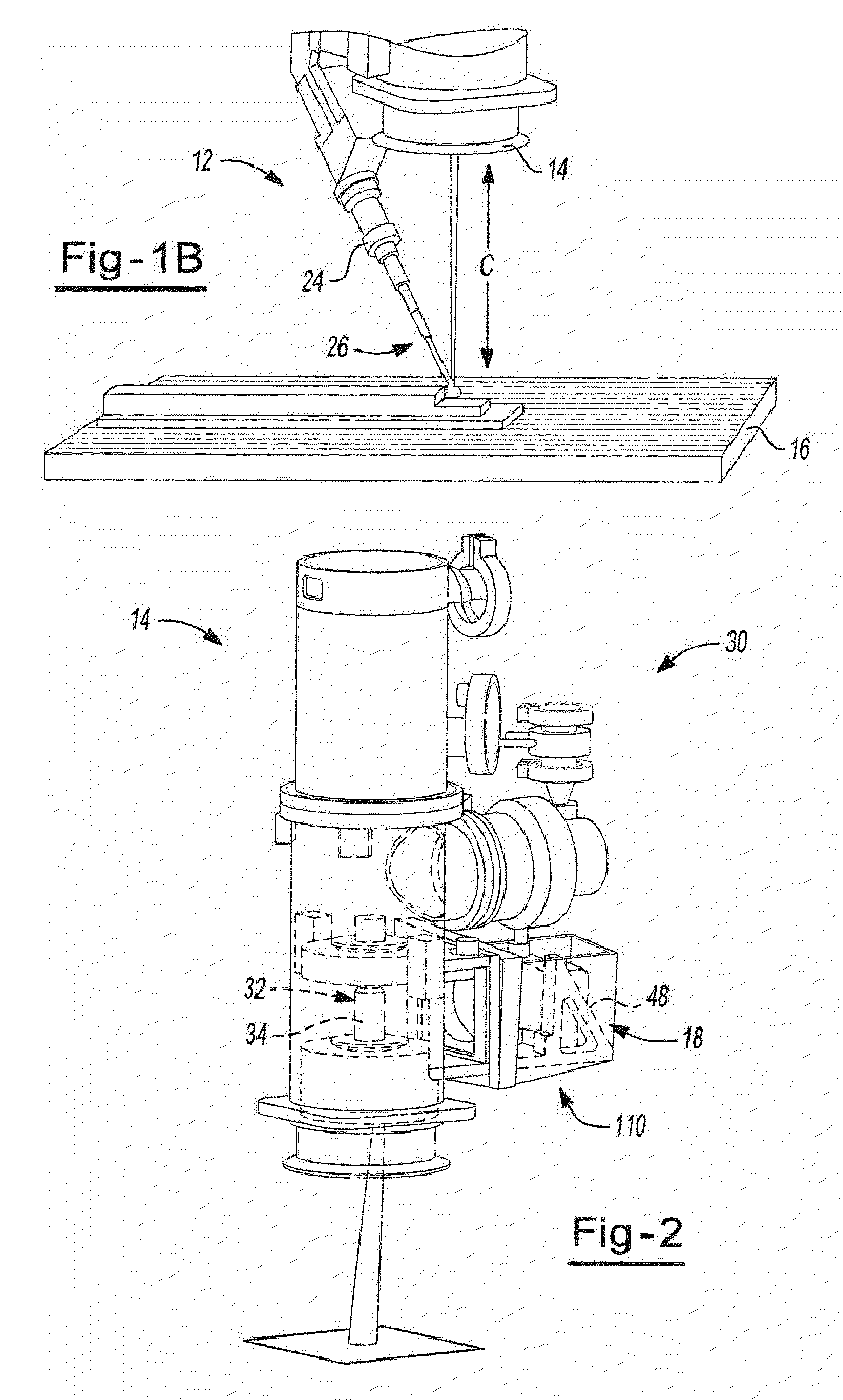

Electron beam layer manufacturing

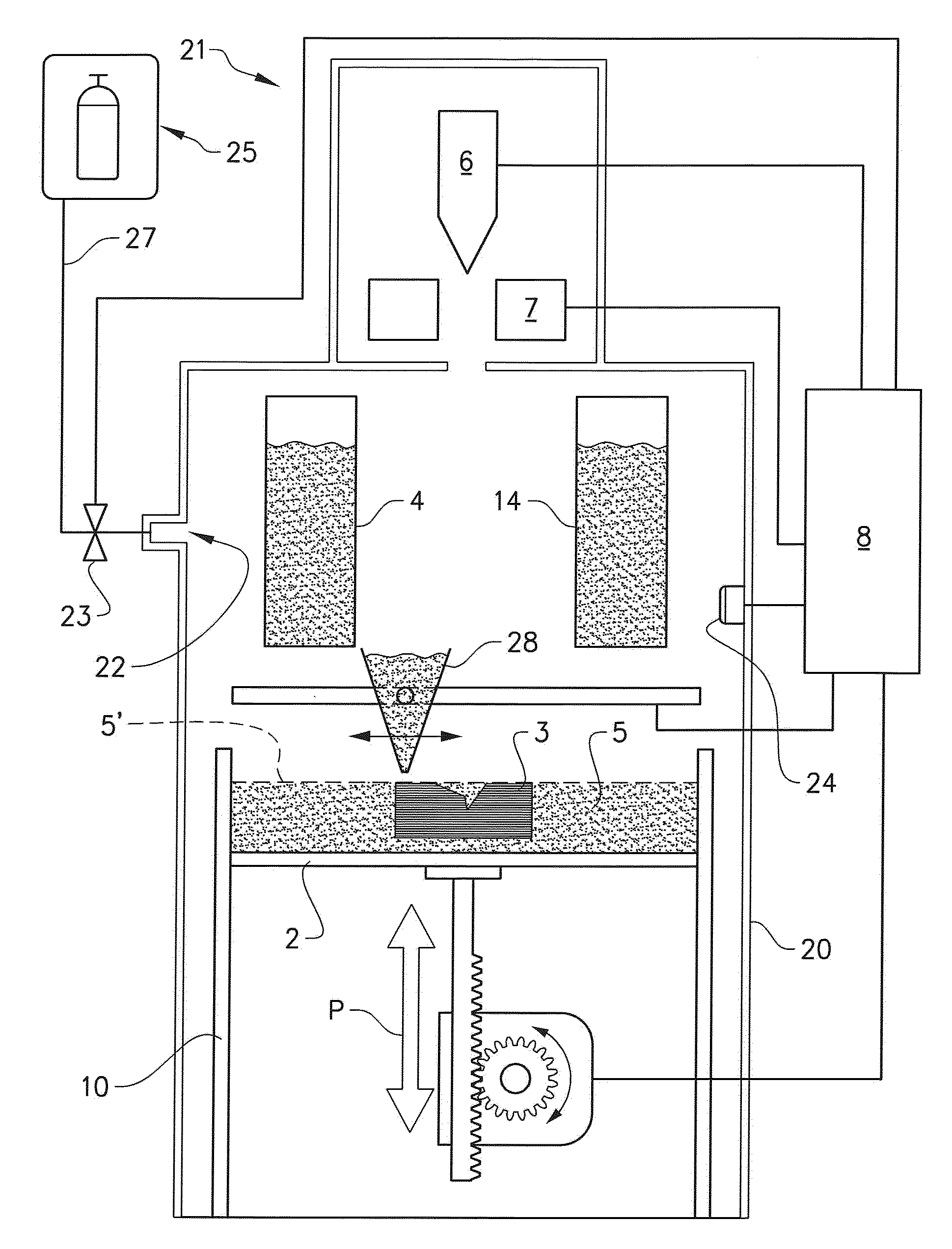

ActiveUS20110061591A1Obstruct passageProgramme controlAdditive manufacturing apparatusFree formClosed loop

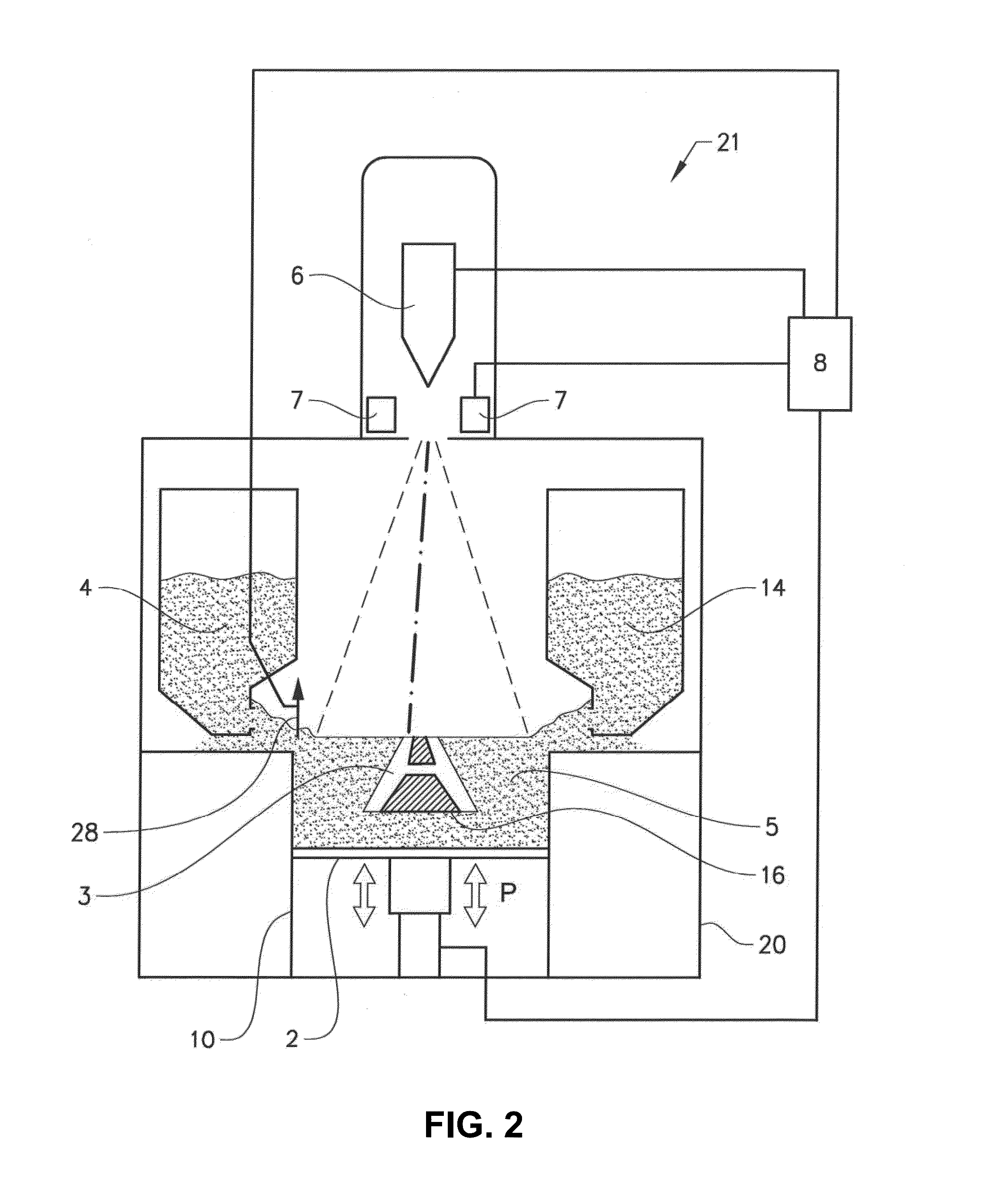

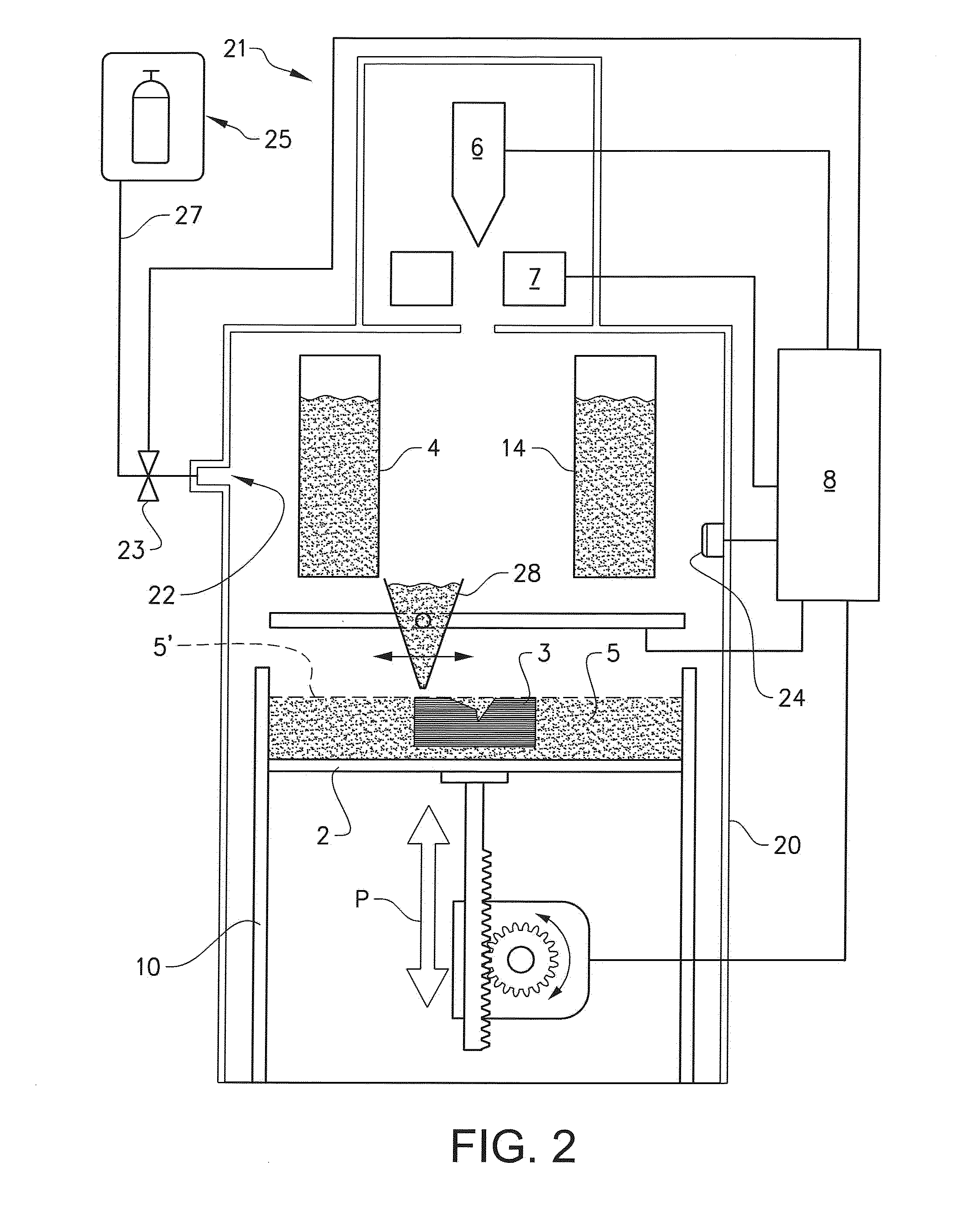

A process and apparatus for free form fabrication of a three-dimensional work piece comprising (a) feeding raw material in a solid state to a first predetermined location; (b) depositing the raw material onto a substrate as a molten pool deposit under a first processing condition; (c) monitoring the molten pool deposit for a preselected condition; (d) comparing information about the preselected condition of the monitored molten pool deposit with a predetermined desired value for the preselected condition of the monitored molten pool deposit; (e) solidifying the molten pool deposit; (f) automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step (d); and repeating steps (a) through (f) at one or more second locations for building up layer by layer a three-dimensional work piece. The apparatus is characterized by a detector that monitors a preselected condition of the deposited material and a closed loop electronic control device for controlling operation of one or more components of the apparatus in response to a detected condition by the detector.

Owner:SCIAKY SA

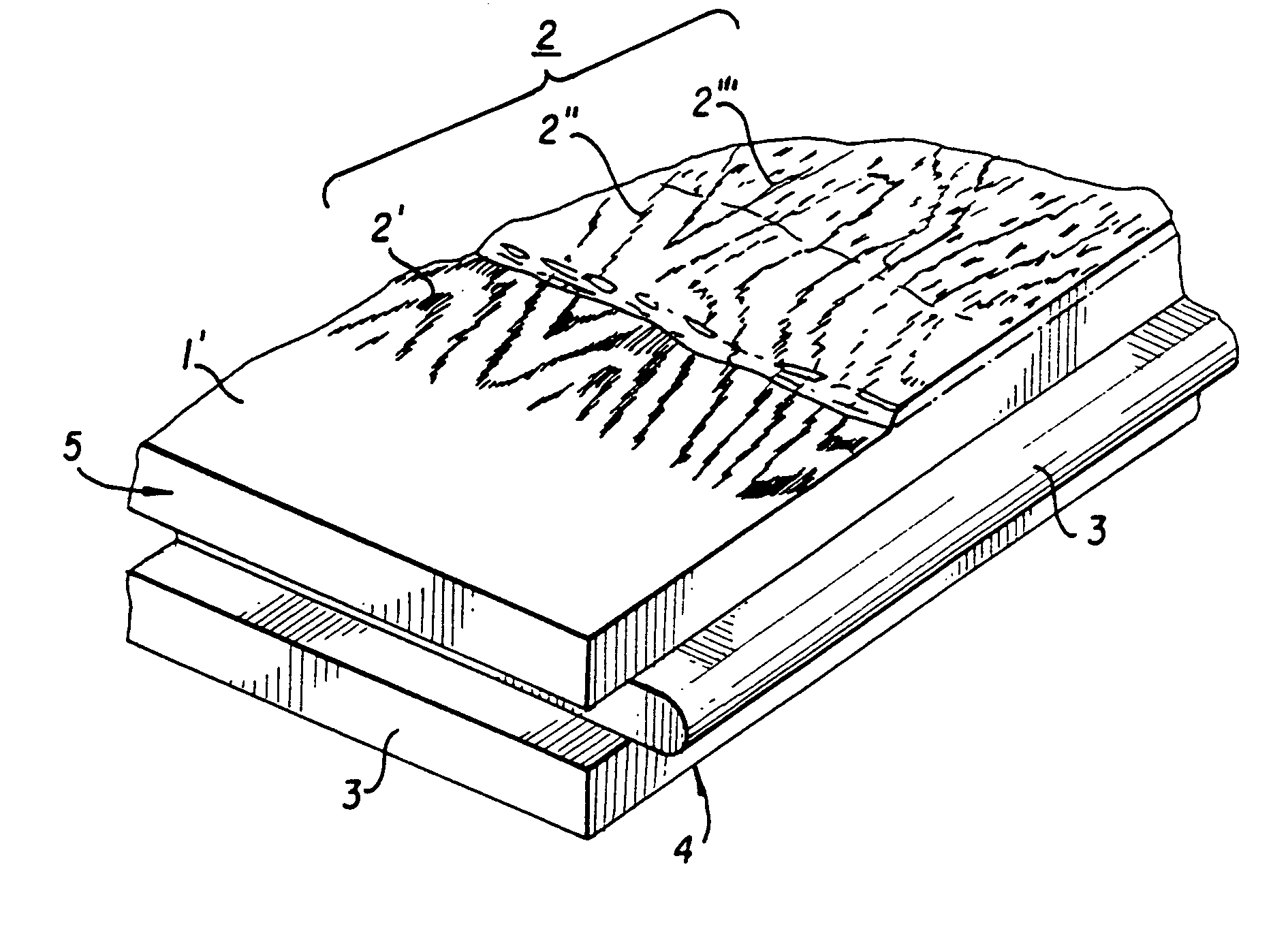

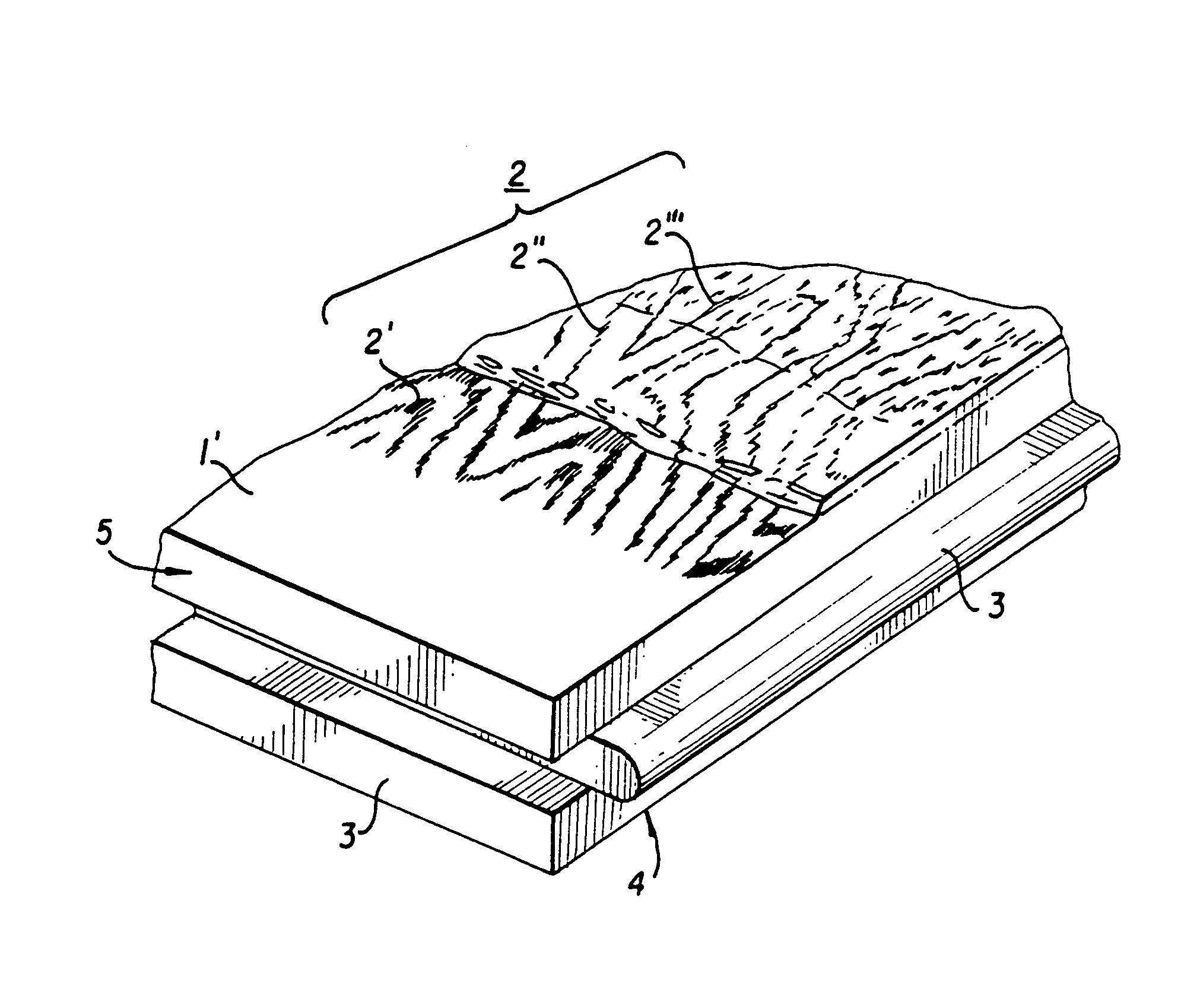

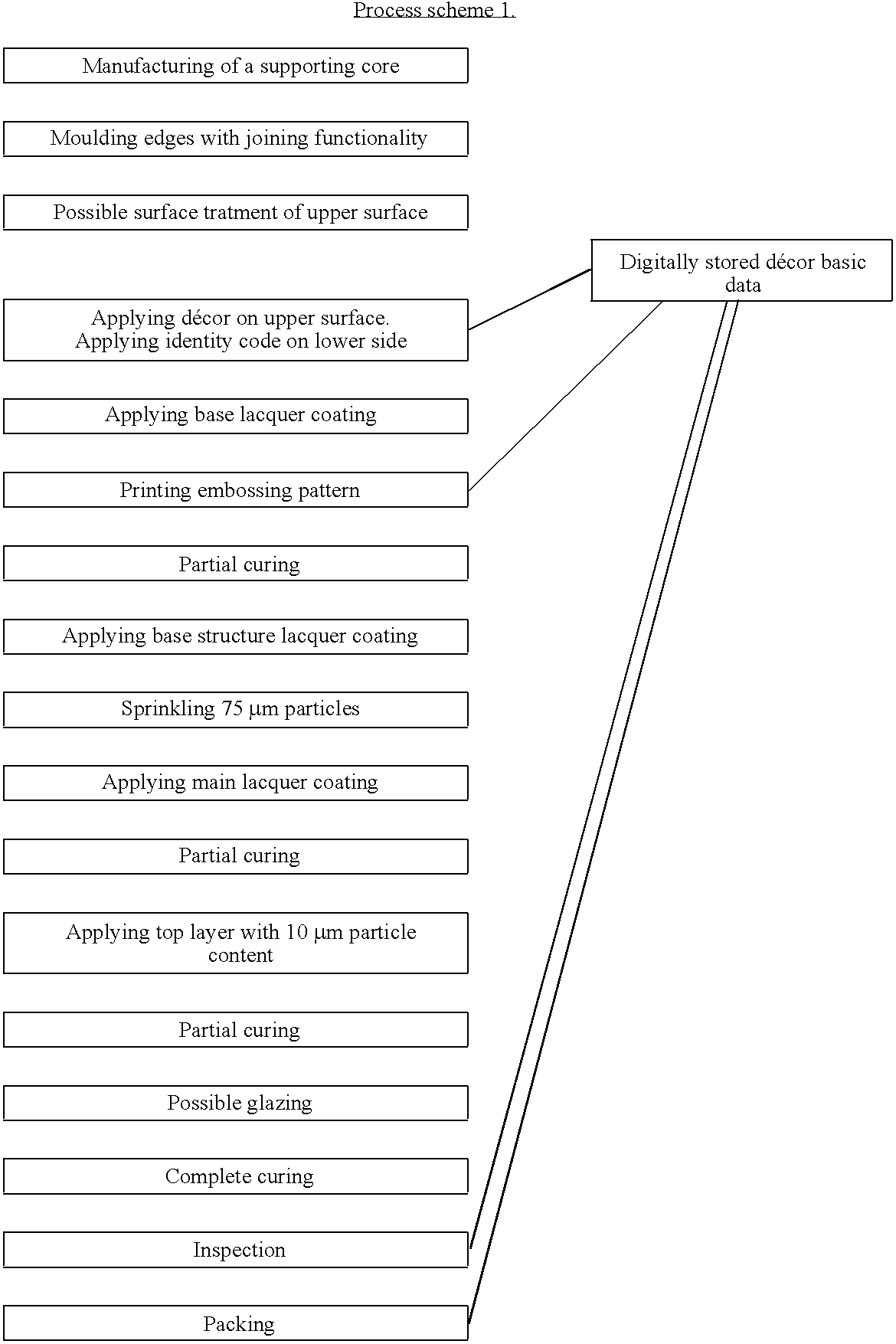

Process for the manufacturing of surface elements with a structured upper surface

InactiveUS6991830B1High resolutionRearrange décorCovering/liningsOrnamental structuresLacquerEngineering

A process for the manufacturing of a decorative surface element, which element comprises a base layer and a decorative upper surface. A wetting repellent lacquer is printed in a predetermined pattern on the decorative upper surface. The wetting repellent lacquer covers only parts of the decorative upper surface. A wear layer of a UV or electron beam curing lacquer is then applied on top of the decorative upper surface which UV or electron beam curing lacquer is repelled from the parts of the surface being covered by the wetting repellent lacquer whereby a surface structure is achieved.

Owner:UNILIN NORDIC AB

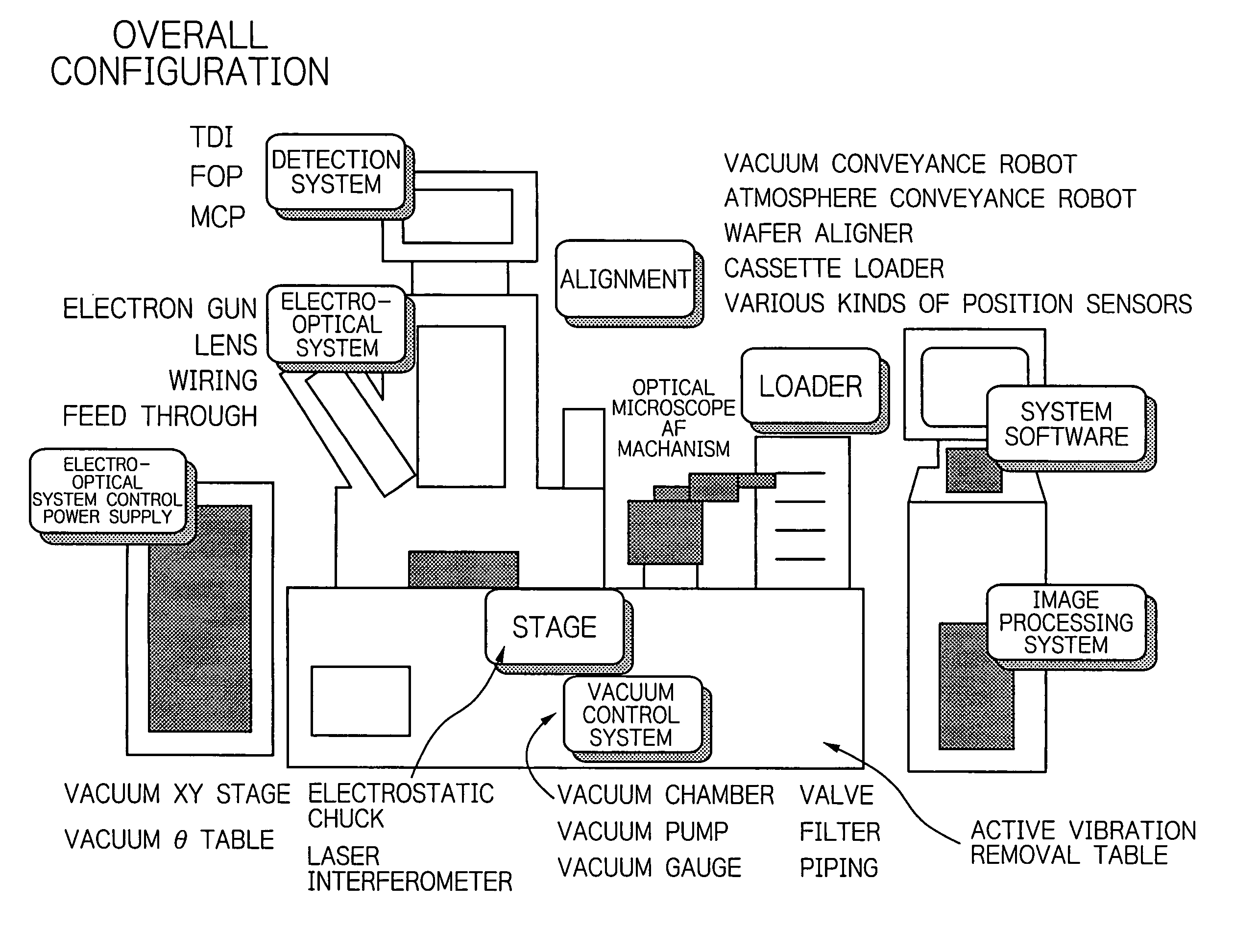

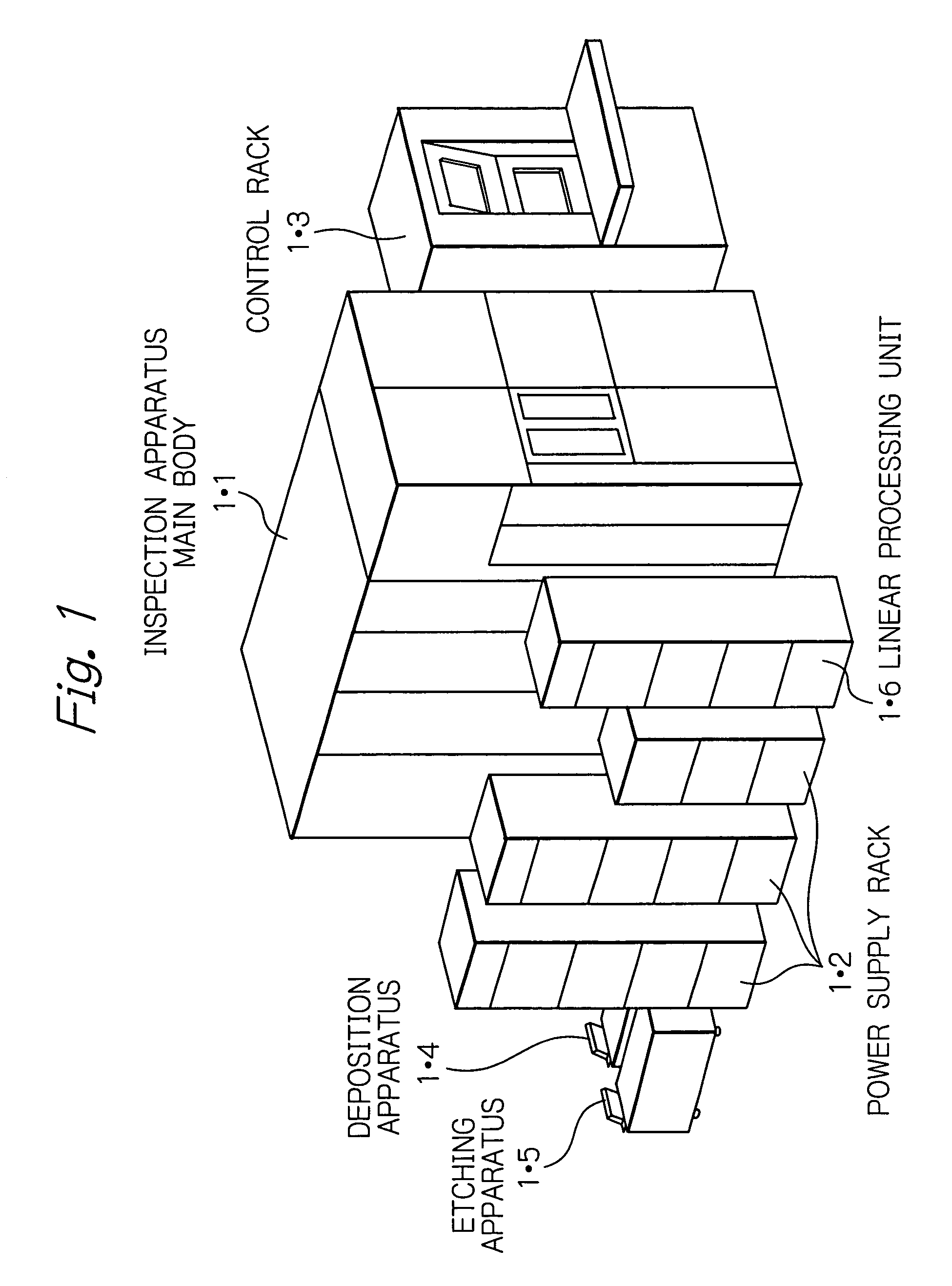

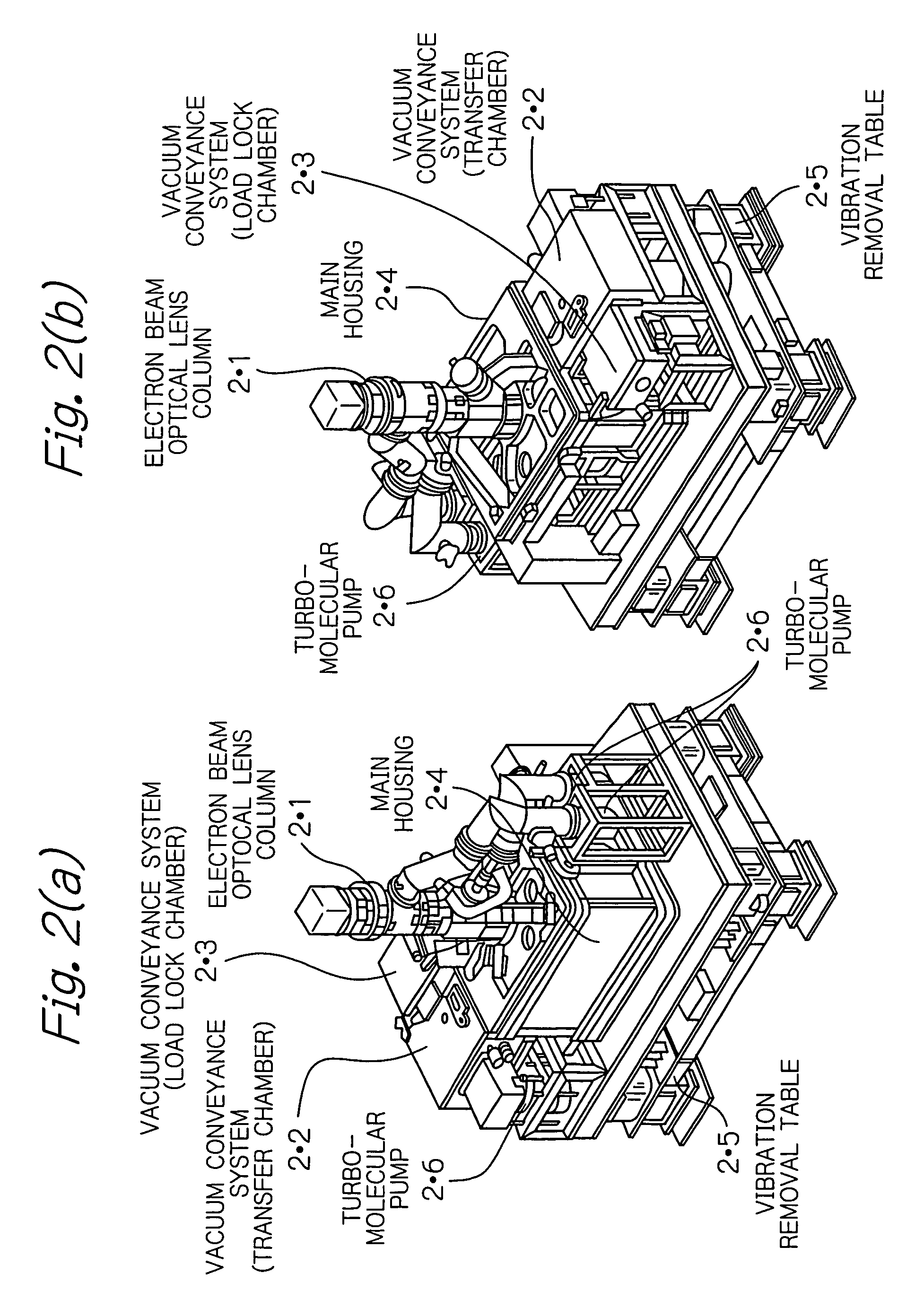

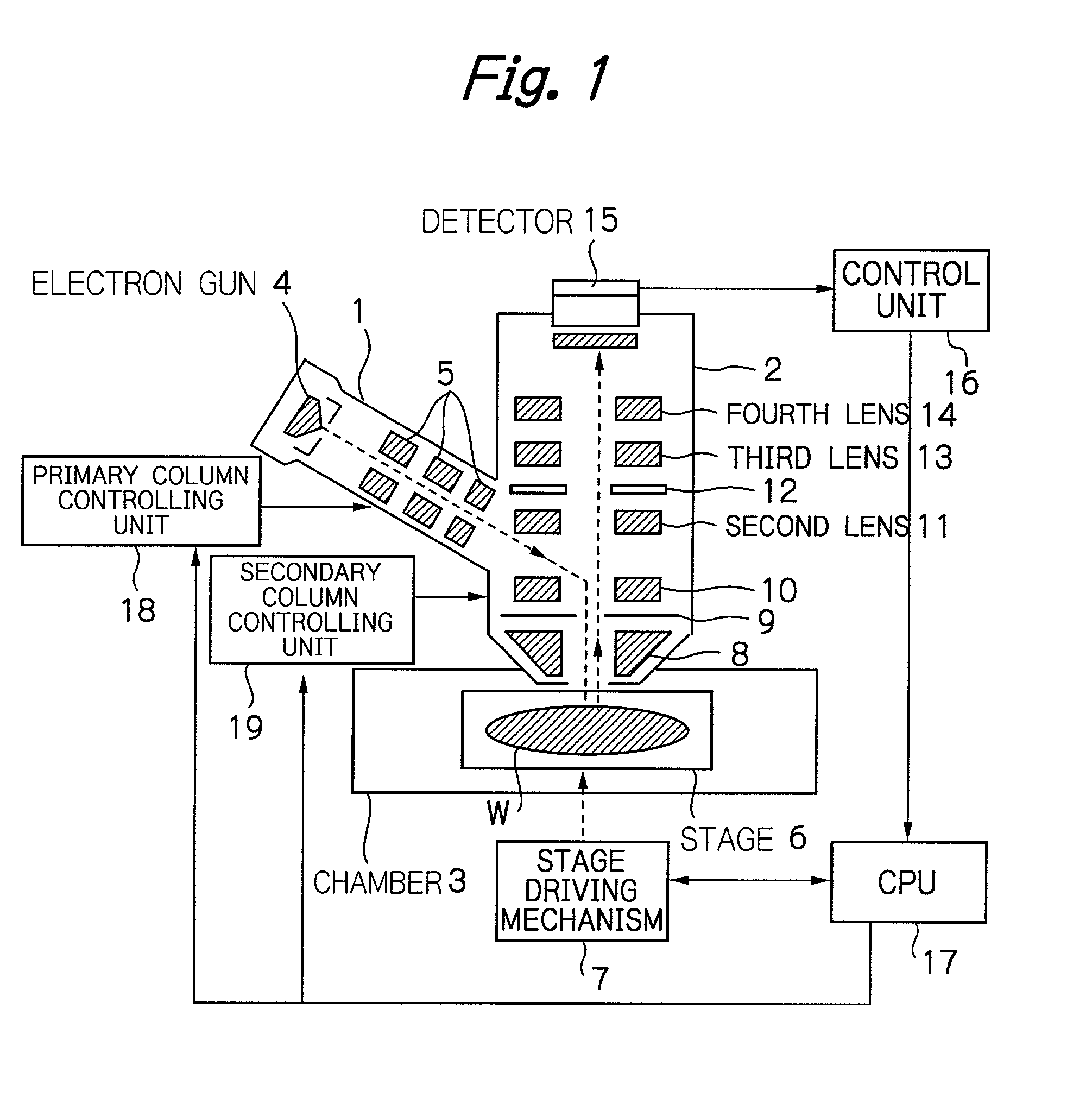

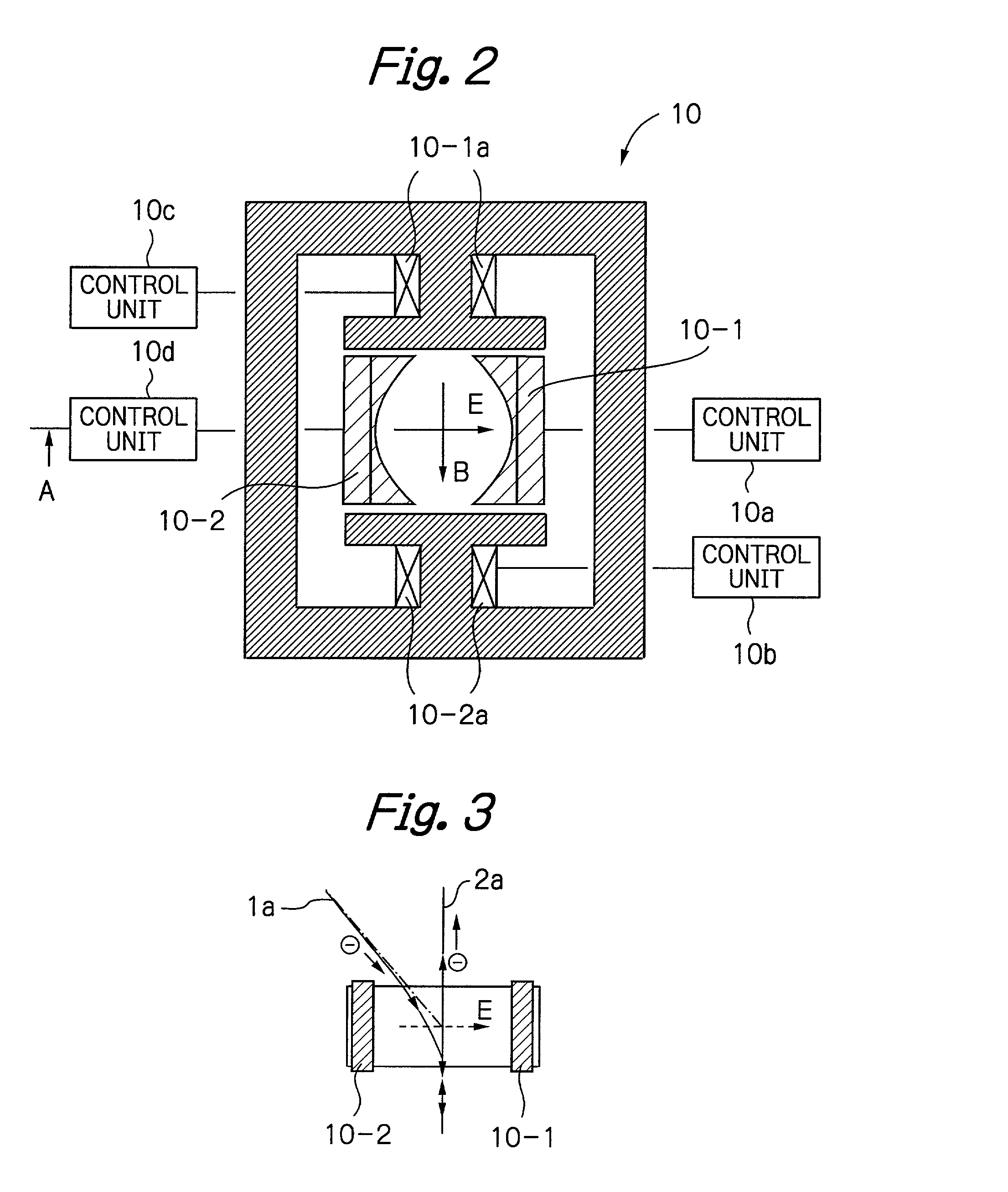

Testing apparatus using charged particles and device manufacturing method using the testing apparatus

ActiveUS7138629B2Material analysis using wave/particle radiationElectric discharge tubesIlluminanceBeam source

Owner:EBARA CORP

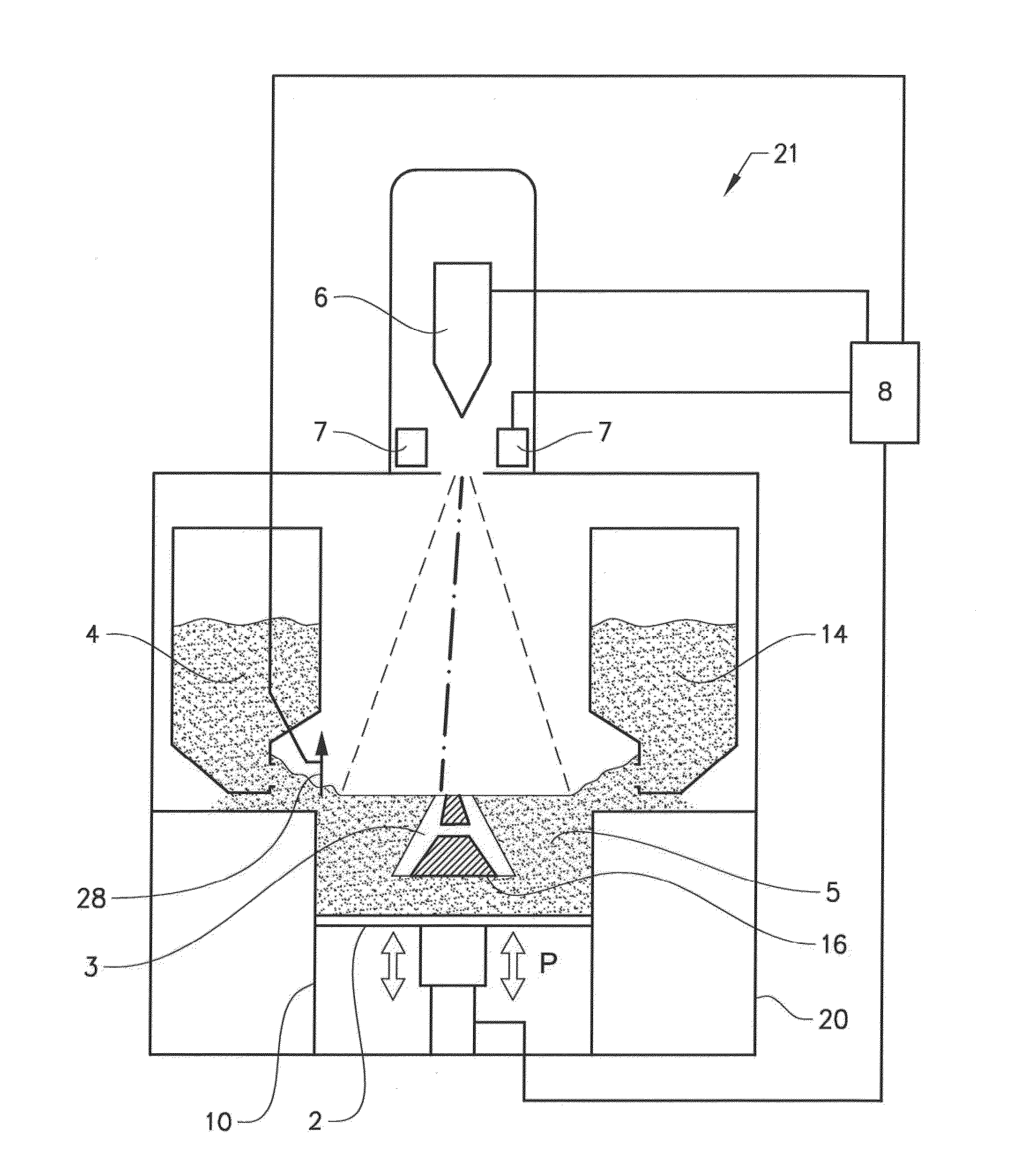

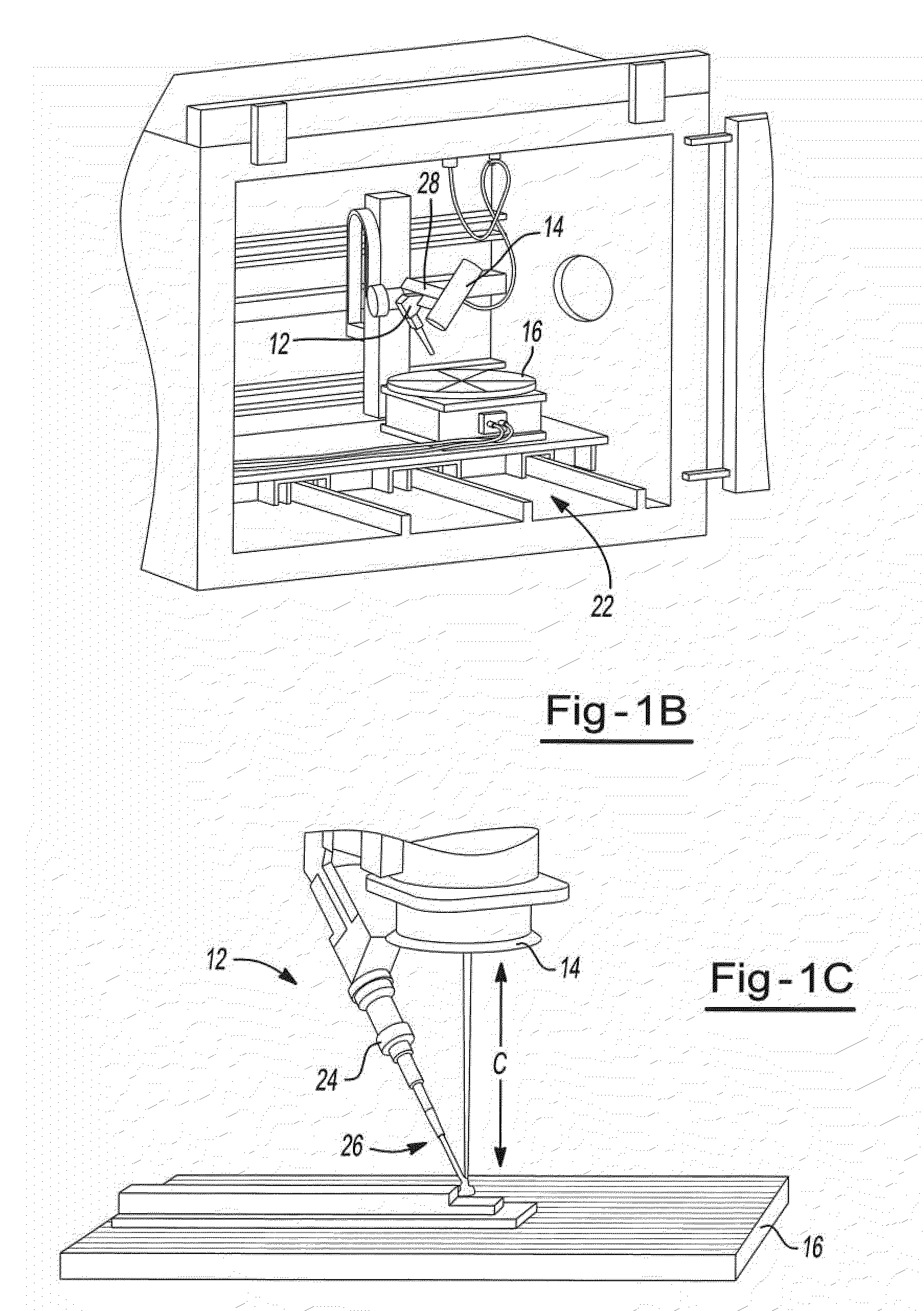

Additive manufacturing of three-dimensional articles

ActiveUS20150165525A1Improve material characteristicImprove material propertiesAdditive manufacturing apparatusArc welding apparatusBeam sourcePower flow

The present invention relates to a method for forming a three-dimensional article through successively depositing individual layers of powder material that are fused together so as to form the article, said method comprising the steps of: providing at least one electron beam source emitting an electron beam for heating and / or fusing said powder material. Controlling the electron beam source in a first mode when said formation of said three dimensional article is in a first process step. Controlling said electron beam in a second mode when said formation of said three dimensional article is in a second process step, wherein in said first mode an electron beam current from said electron beam source is controlled in a feed-forward mode and in said second mode said electron beam current is controlled in a feed-back mode.

Owner:ARCAM AB

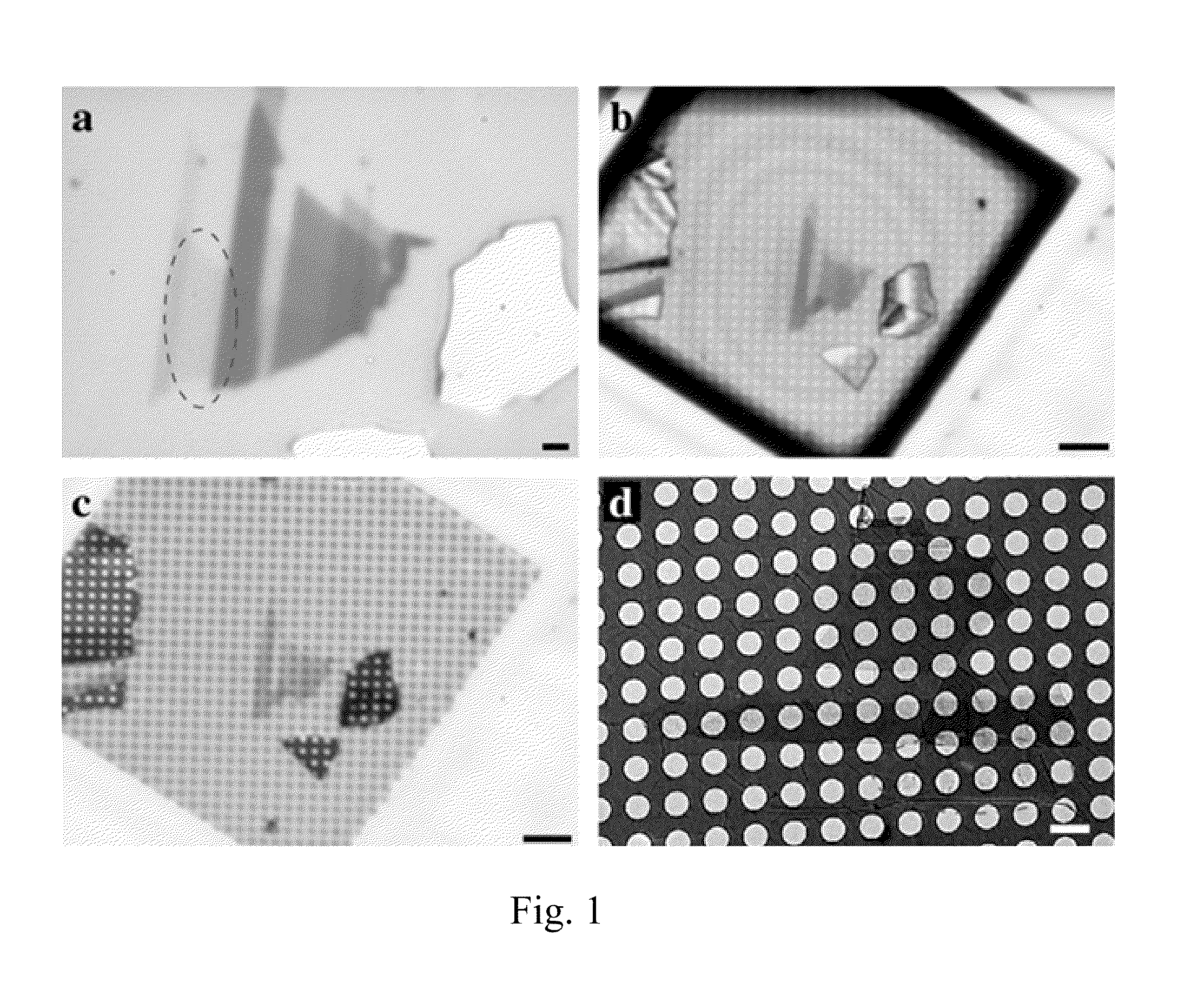

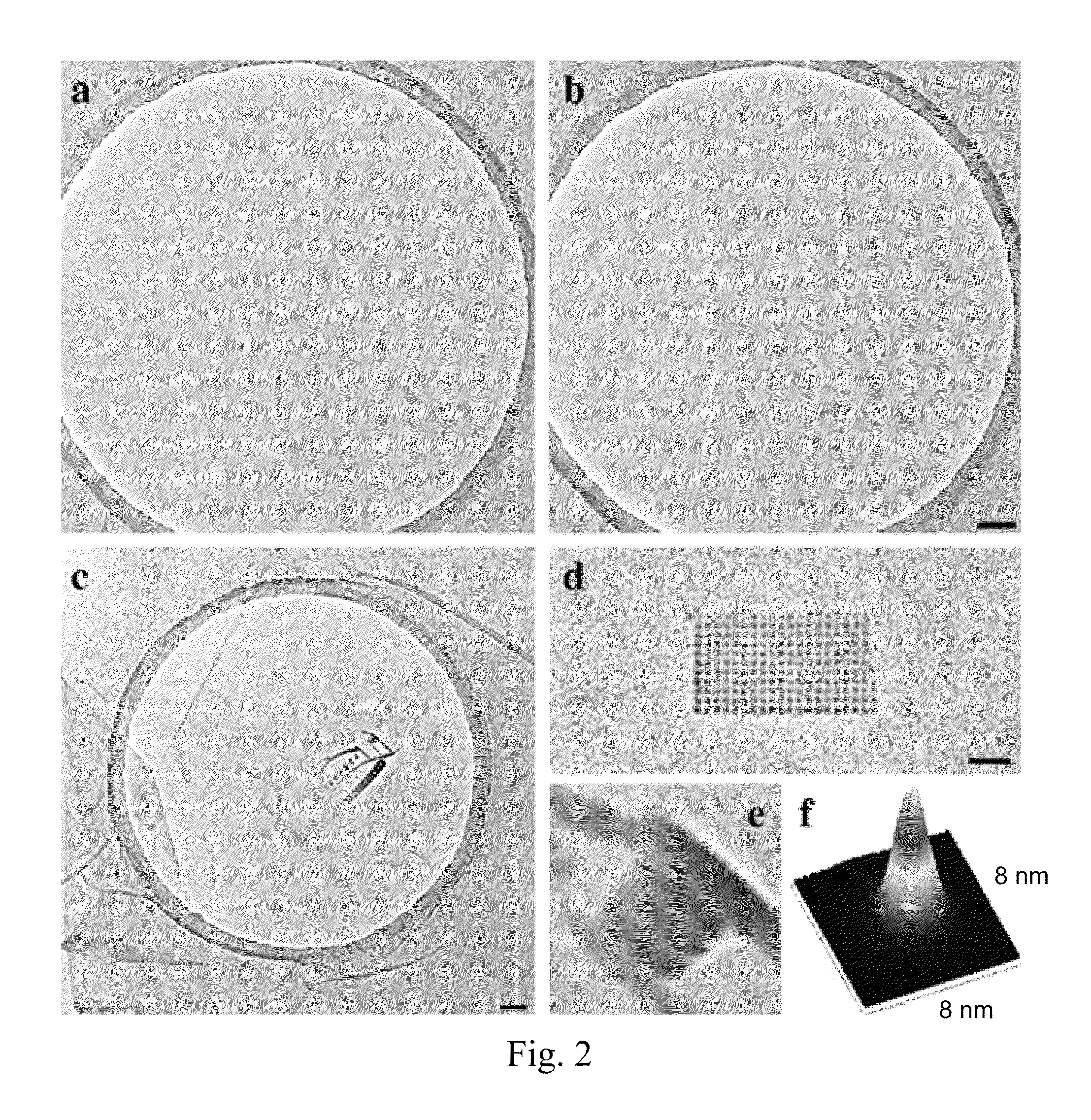

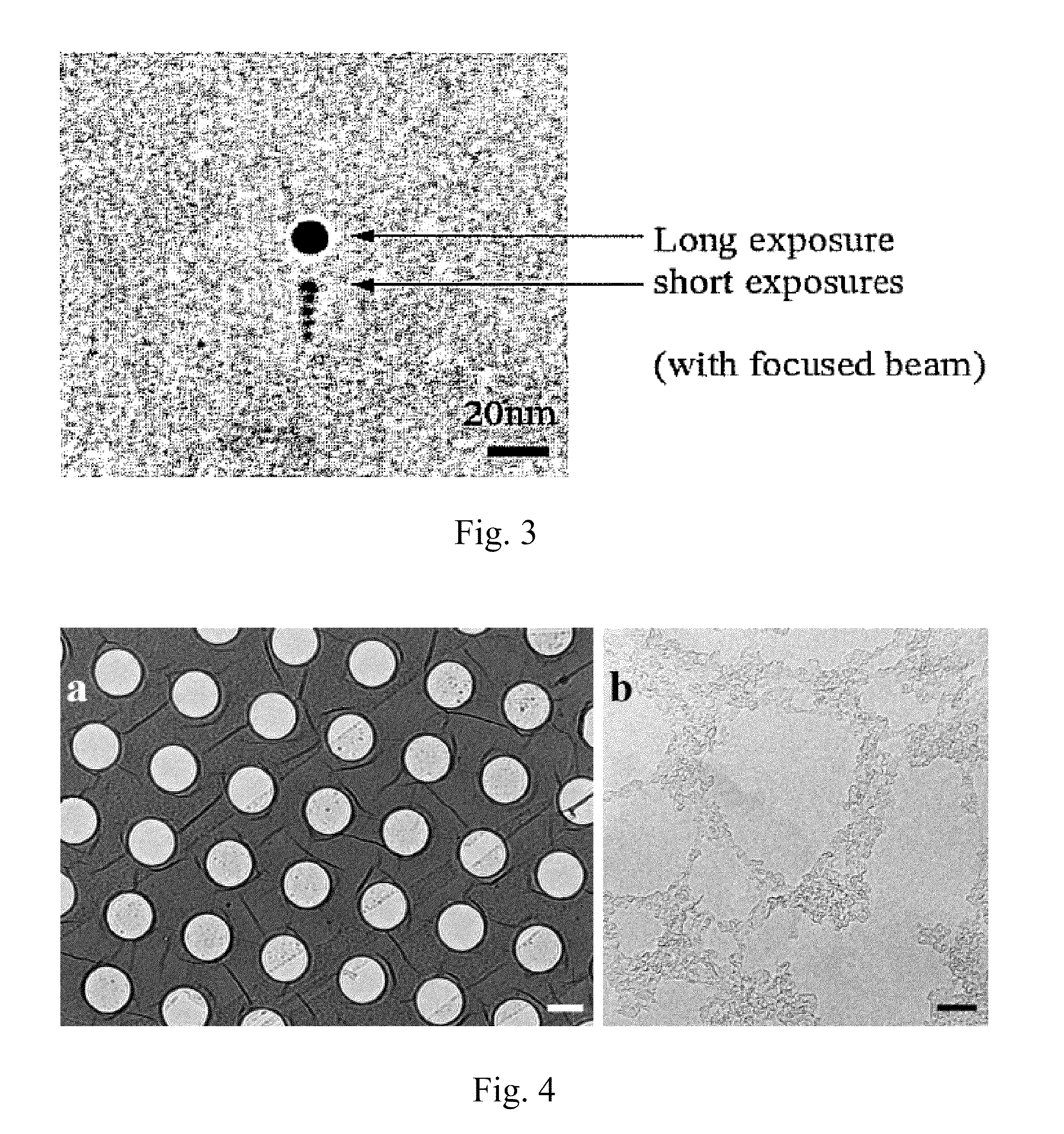

Graphene-based structure, method of suspending graphene membrane, and method of depositing material onto graphene membrane

An embodiment of a method of suspending a graphene membrane across a gap in a support structure includes attaching graphene to a substrate. A pre-fabricated support structure having the gap is attached to the graphene. The graphene and the pre-fabricated support structure are then separated from the substrate which leaves the graphene membrane suspended across the gap in the pre-fabricated support structure. An embodiment of a method of depositing material includes placing a support structure having a graphene membrane suspended across a gap under vacuum. A precursor is adsorbed to a surface of the graphene membrane. A portion of the graphene membrane is exposed to a focused electron beam which deposits a material from the precursor onto the graphene membrane. An embodiment of a graphene-based structure includes a support structure having a gap, a graphene membrane suspended across the gap, and a material deposited in a pattern on the graphene membrane.

Owner:RGT UNIV OF CALIFORNIA

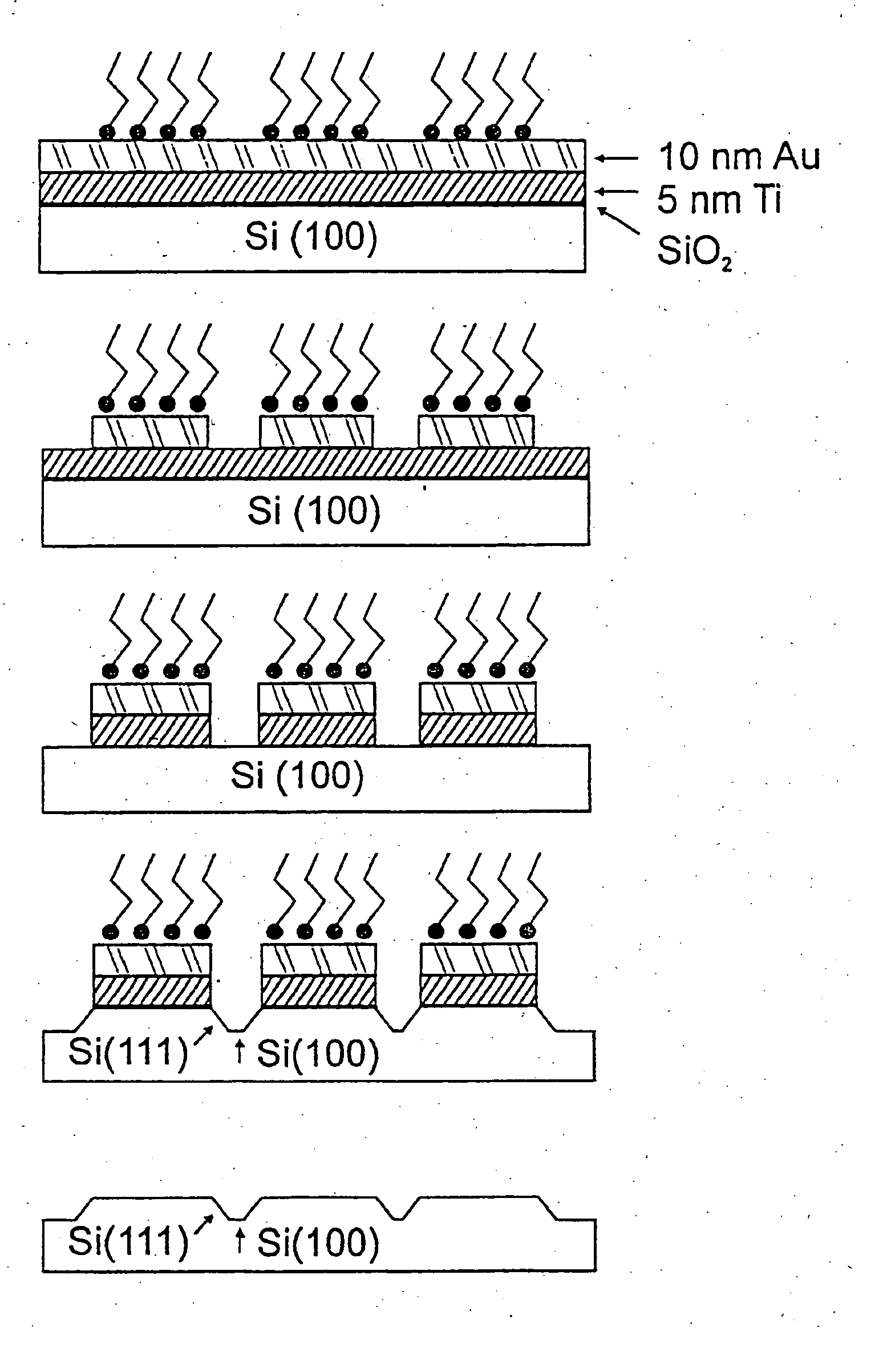

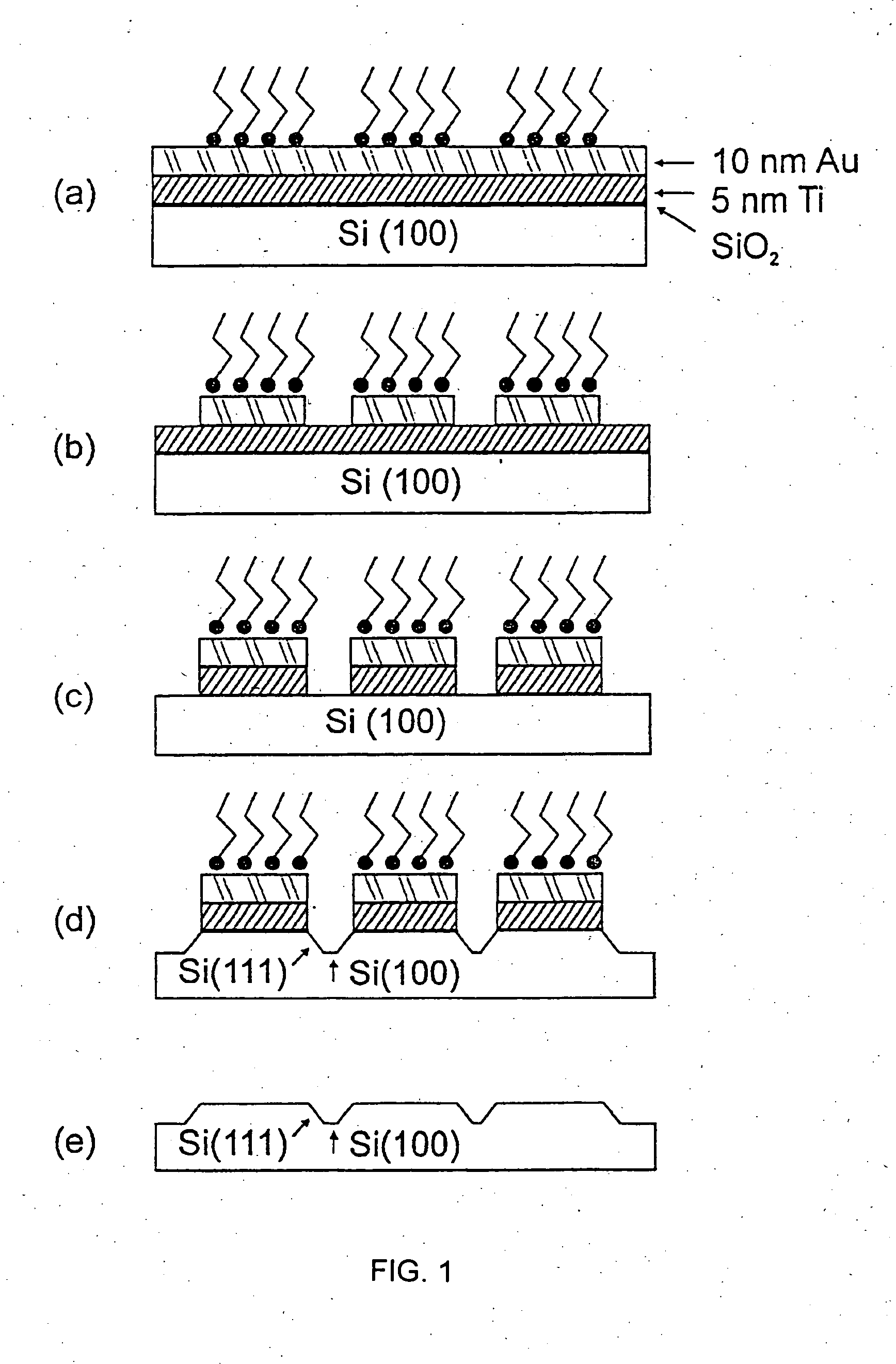

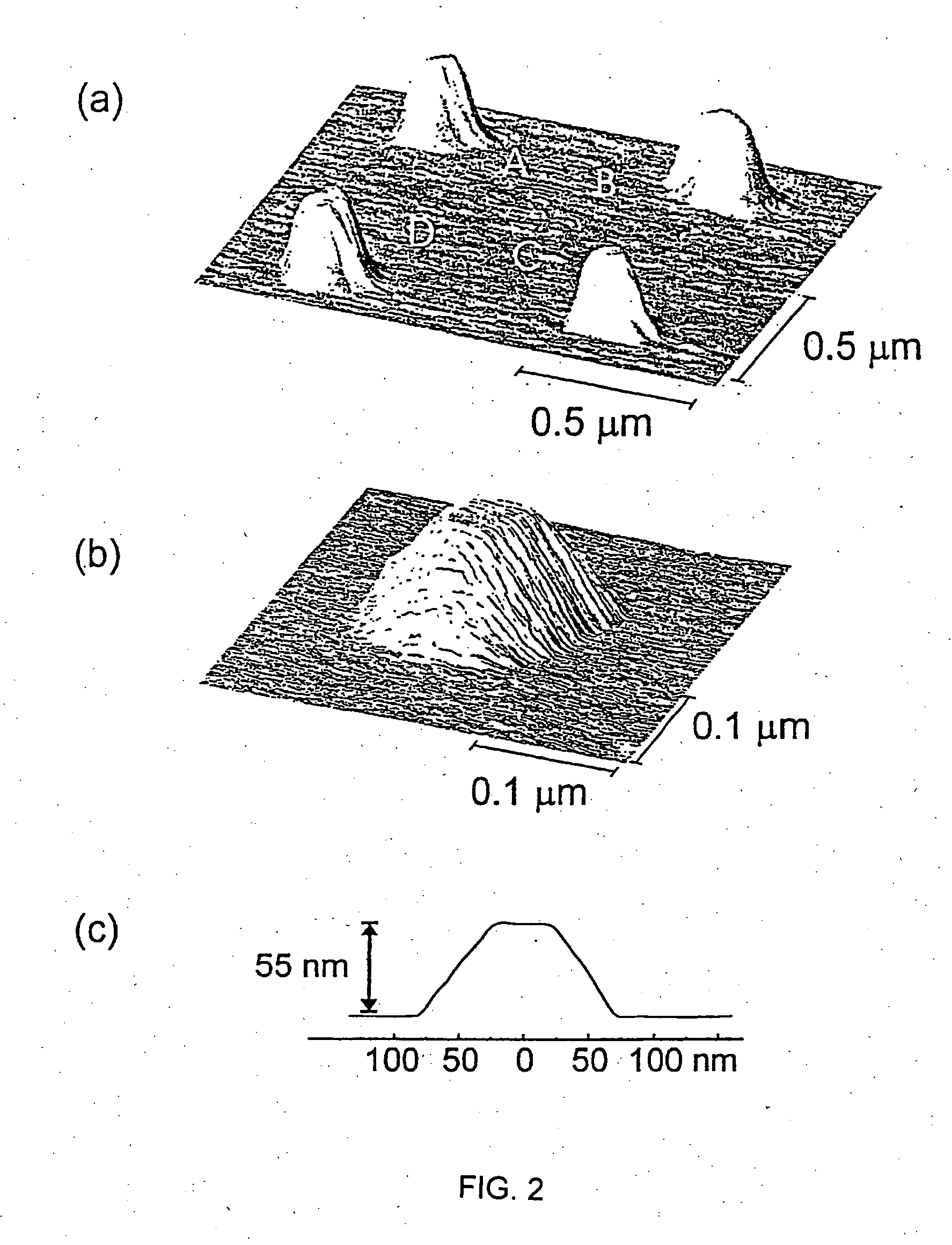

Fabrication of sub-50 nm solid-state nanostructures based on nanolithography

InactiveUS20060014001A1High resolutionMaterial nanotechnologyDecorative surface effectsResistDip-pen nanolithography

Combination of nanolithography and wet chemical etching including the fabrication of nanoarrays of sub-50 nm gold dots and line structures with deliberately designed approximately 12-100 nm gaps. These structures were made by initially using direct write nanolithography to pattern the etch resist, 16-mercaptohexadecanoic acid (MHA), on Au / Ti / SiOx / Si substrates and then wet chemical etching to remove the exposed gold. These are the smallest Au structures prepared by a wet chemical etching strategy. Also, Dip-Pen Nanolithography (DPN) has been used to generate resist layers on Au, Ag, and Pd that when combined with wet chemical etching can lead to nanostructures with deliberately designed shapes and sizes. Monolayers of mercaptohexadecanoic acid (MHA) or octadecanethiol (ODT), patterned by DPN, were explored as etch resists. They work comparably well on Au and Ag, but ODT is the superior material for Pd. MHA seems to attract the FeCl3 etchant and results in nonuniform etching of the underlying Pd substrate. Dots, lines, triangles and circles, ranging in size from sub-100 to several hundred nm have been fabricated on these substrates. These results show how one can use DPN as an alternative to more complex and costly procedures like electron beam lithography to generate nanostructures from inorganic materials.

Owner:NORTHWESTERN UNIV

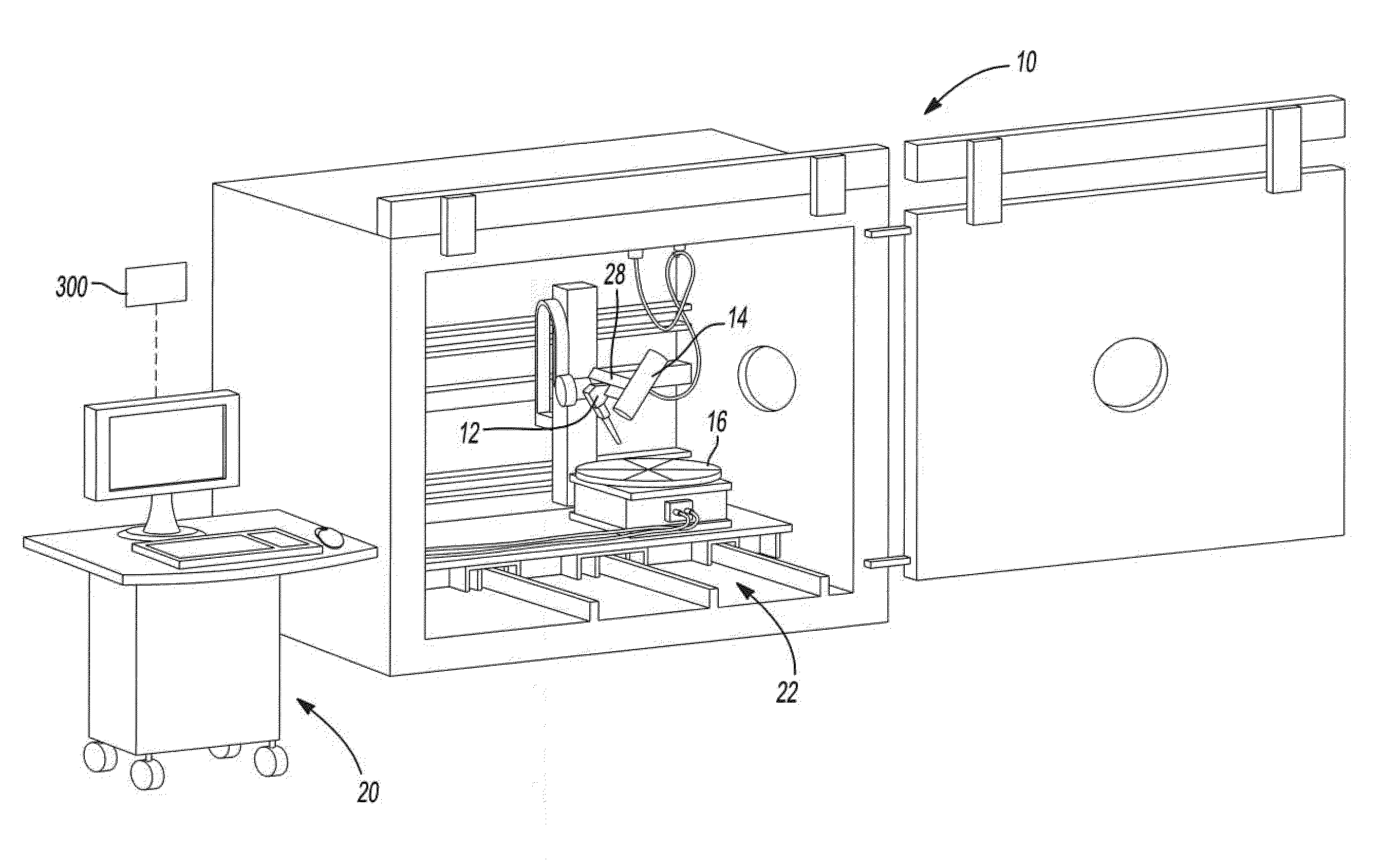

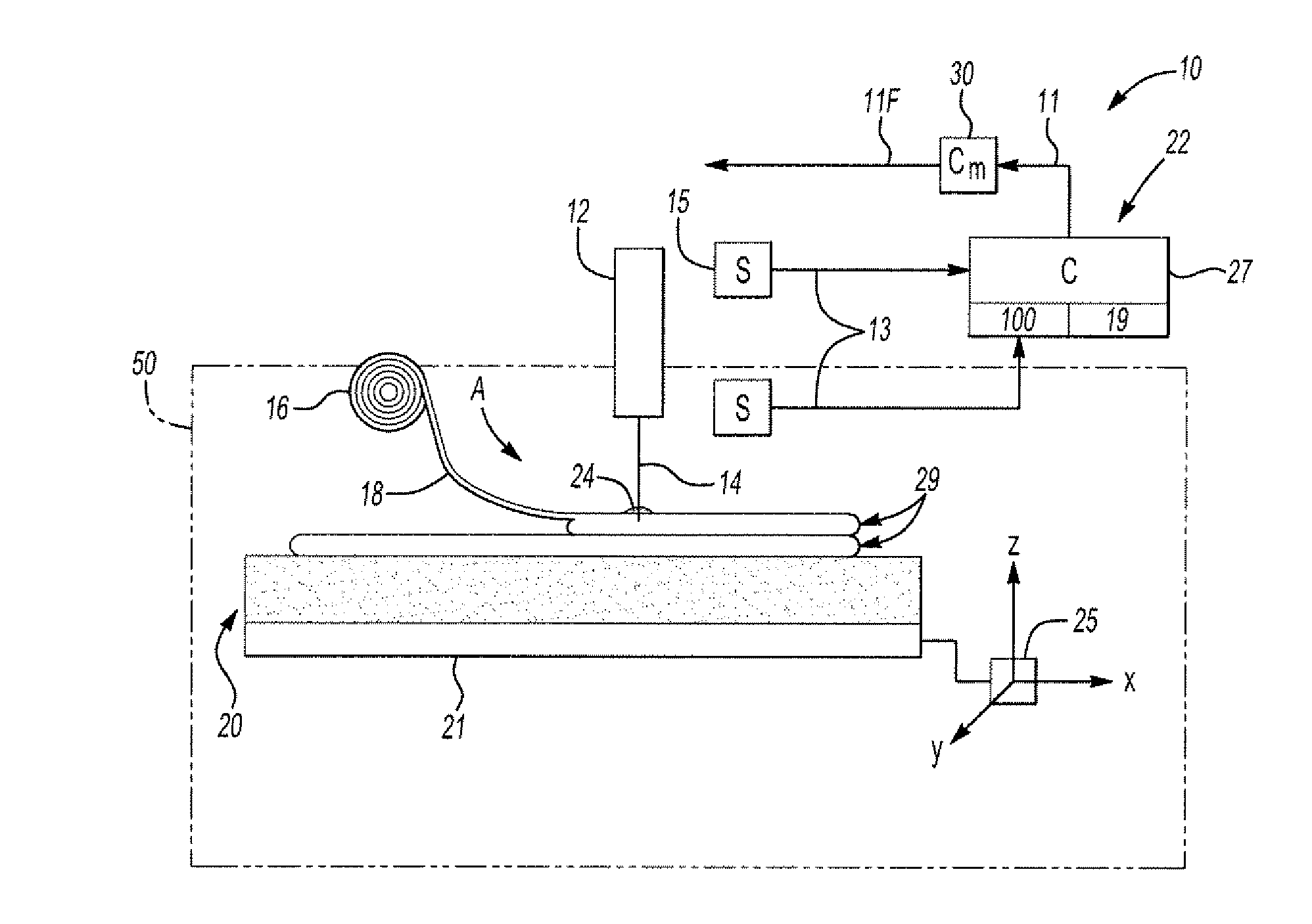

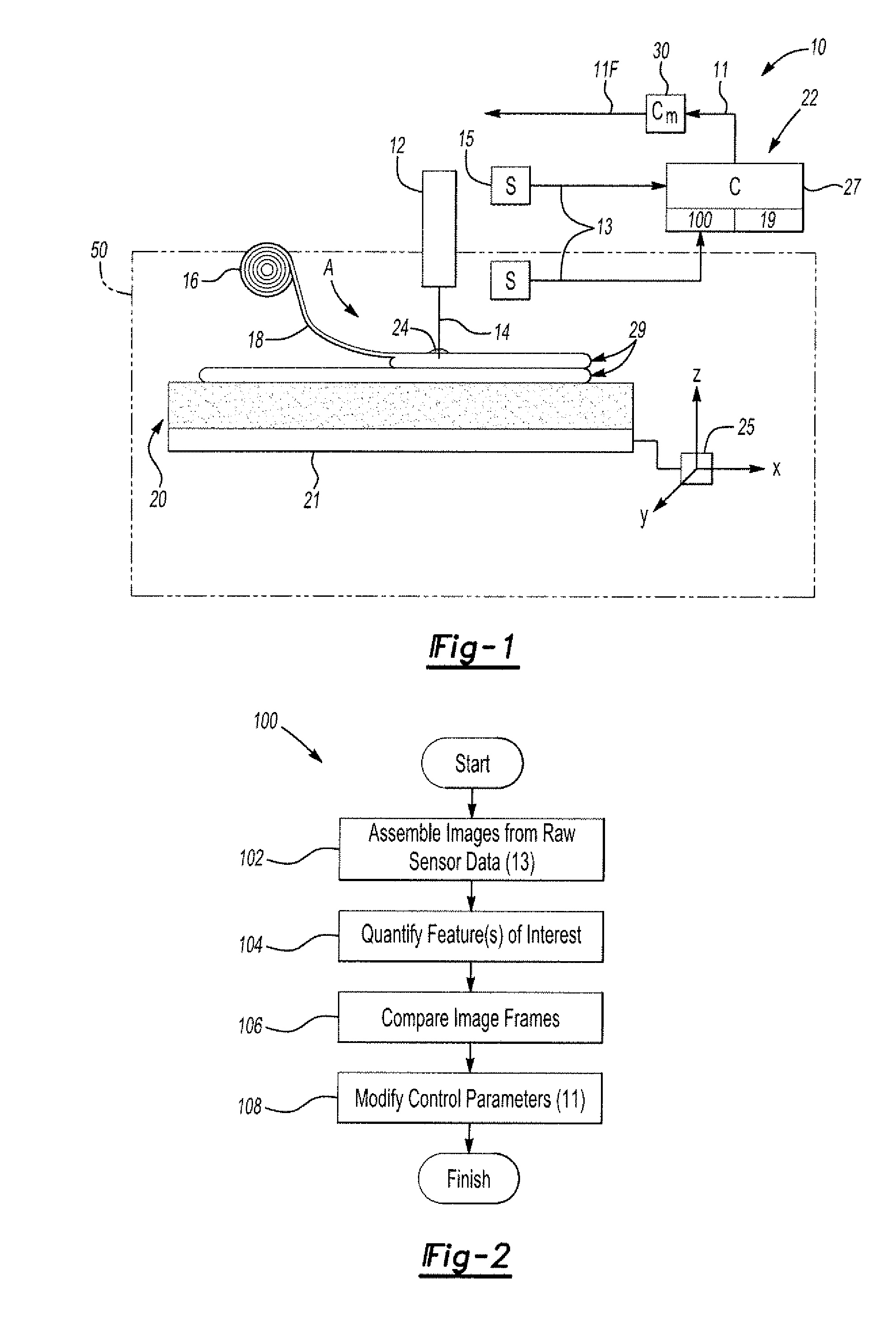

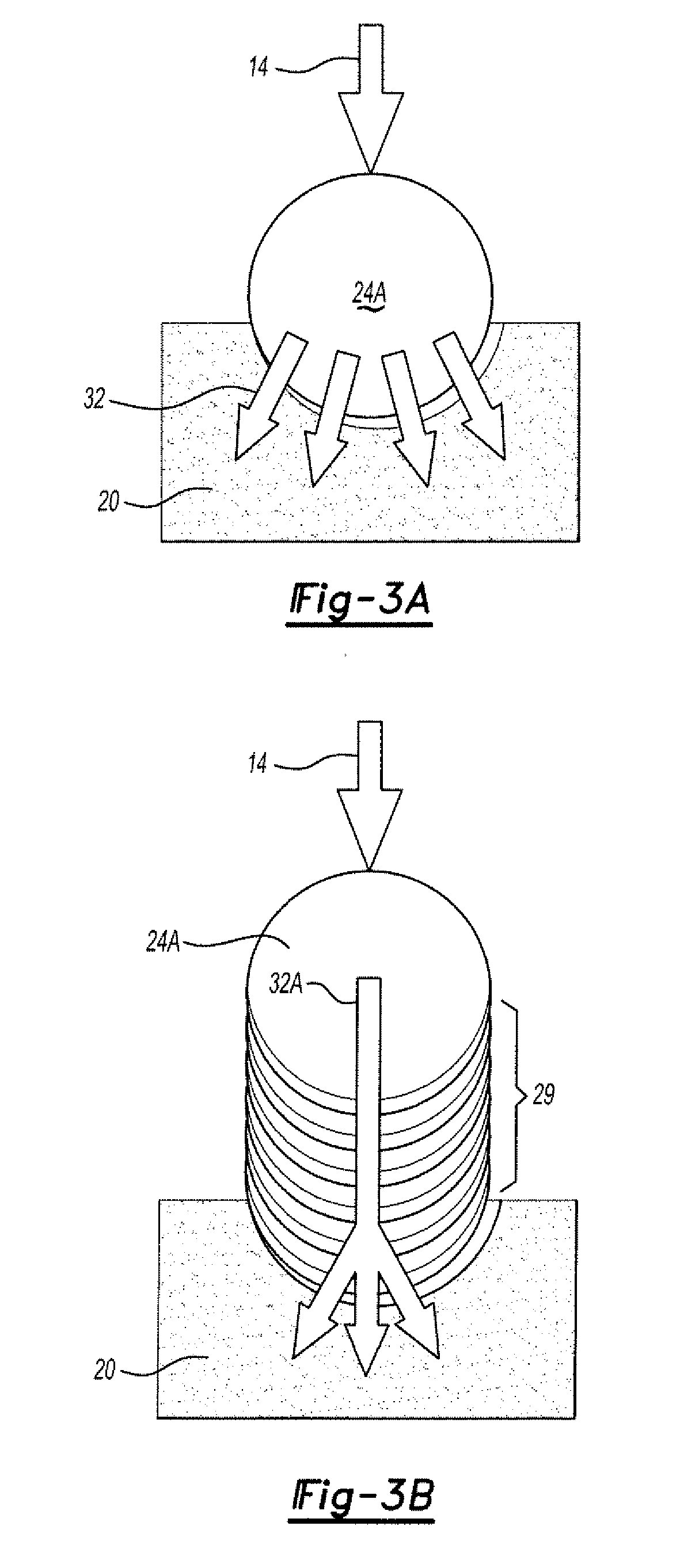

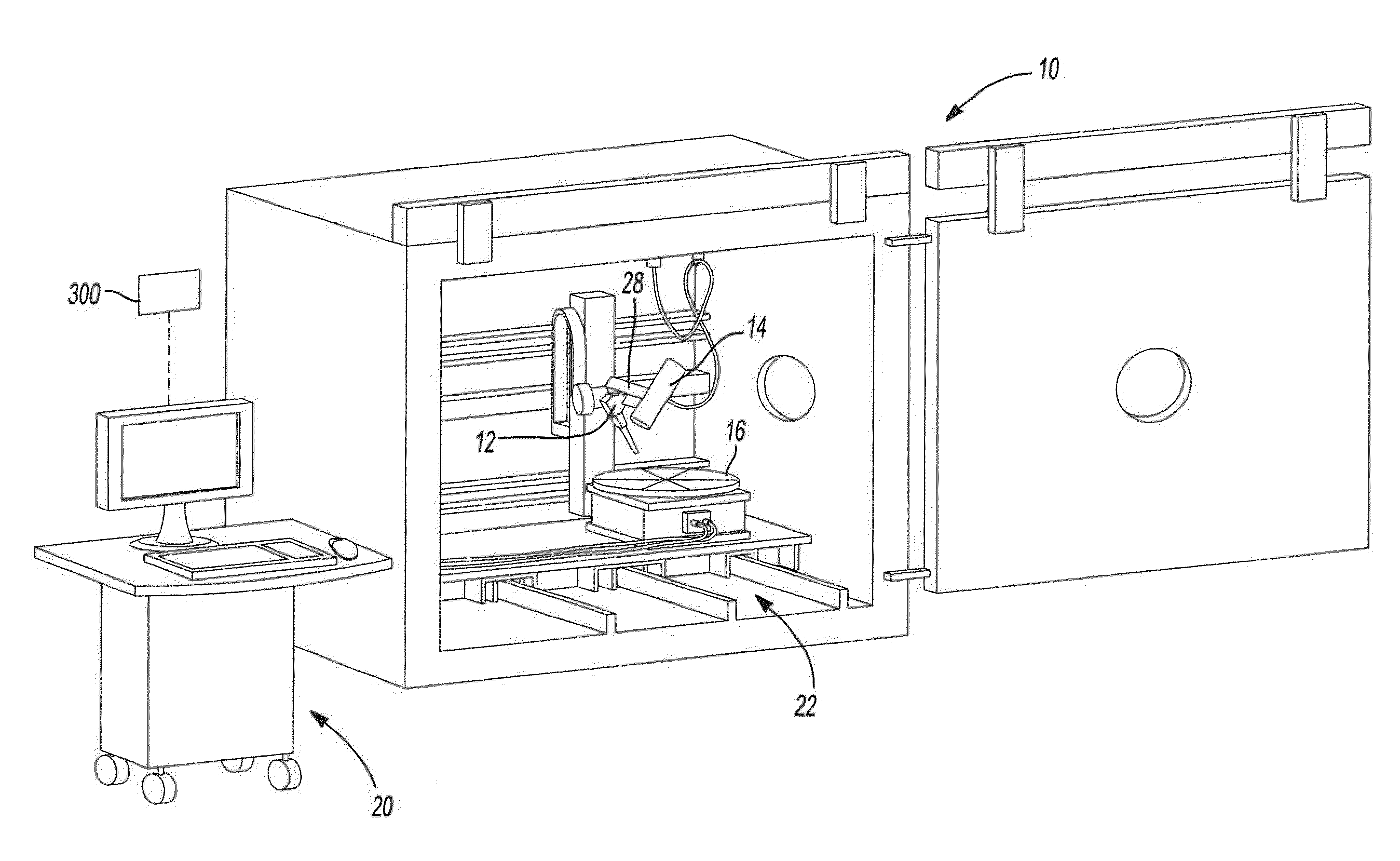

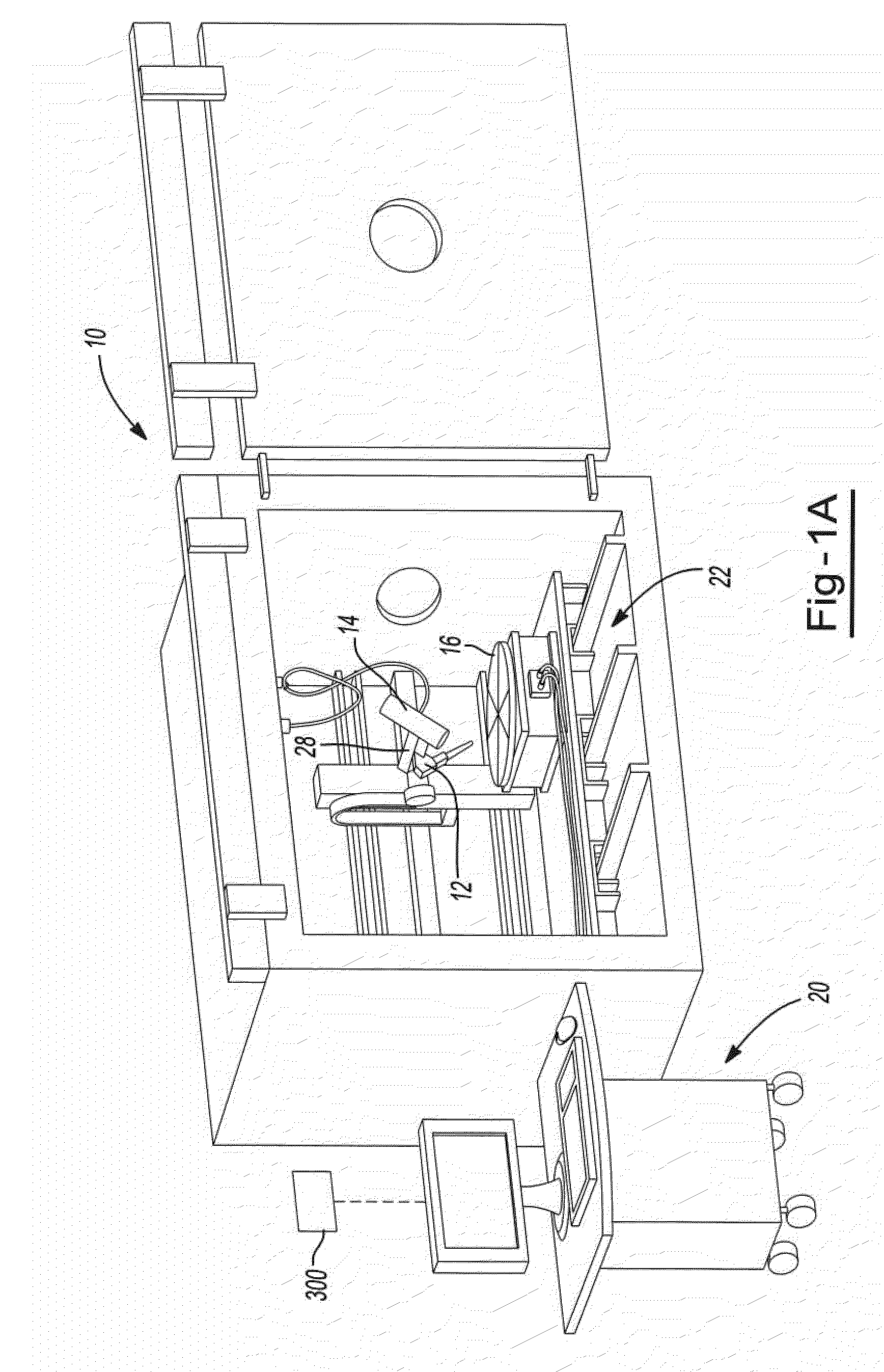

Electron beam layer manufacturing using scanning electron monitored closed loop control

ActiveUS20110114839A1Speed up the processQuick buildAdditive manufacturing apparatusMaterial analysis using wave/particle radiationClosed loopTrailing edge

A process (and apparatus for performing the process) for layer manufacturing a three-dimensional work piece comprising the steps of; feeding raw material in a solid state to a first predetermined location; exposing the raw material to an electron beam to liquefy the raw material; depositing the raw material onto a substrate as a molten pool deposit, the deposit having a forward edge region in an x-y plane with a forward edge region width and a trailing edge region in the x-y plane with a trailing edge region width, under at least one first processing condition; monitoring the molten pool deposit for at least one preselected condition using detecting of scatter from a scanning electron beam contemporaneously with the depositing step; solidifying the molten pool deposit; automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step; and repeating steps at one or more second locations for building up layer by layer, generally along a z-axis that is orthogonal to the x-y plane, a three-dimensional work piece.

Owner:SCIAKY SA

Method and apparatus for increasing the resolution in additively manufactured three-dimensional articles

ActiveUS9079248B2High resolutionHigh pressure levelAdditive manufacturing apparatusIncreasing energy efficiencyPowder bedImage resolution

Owner:ARCAM AB

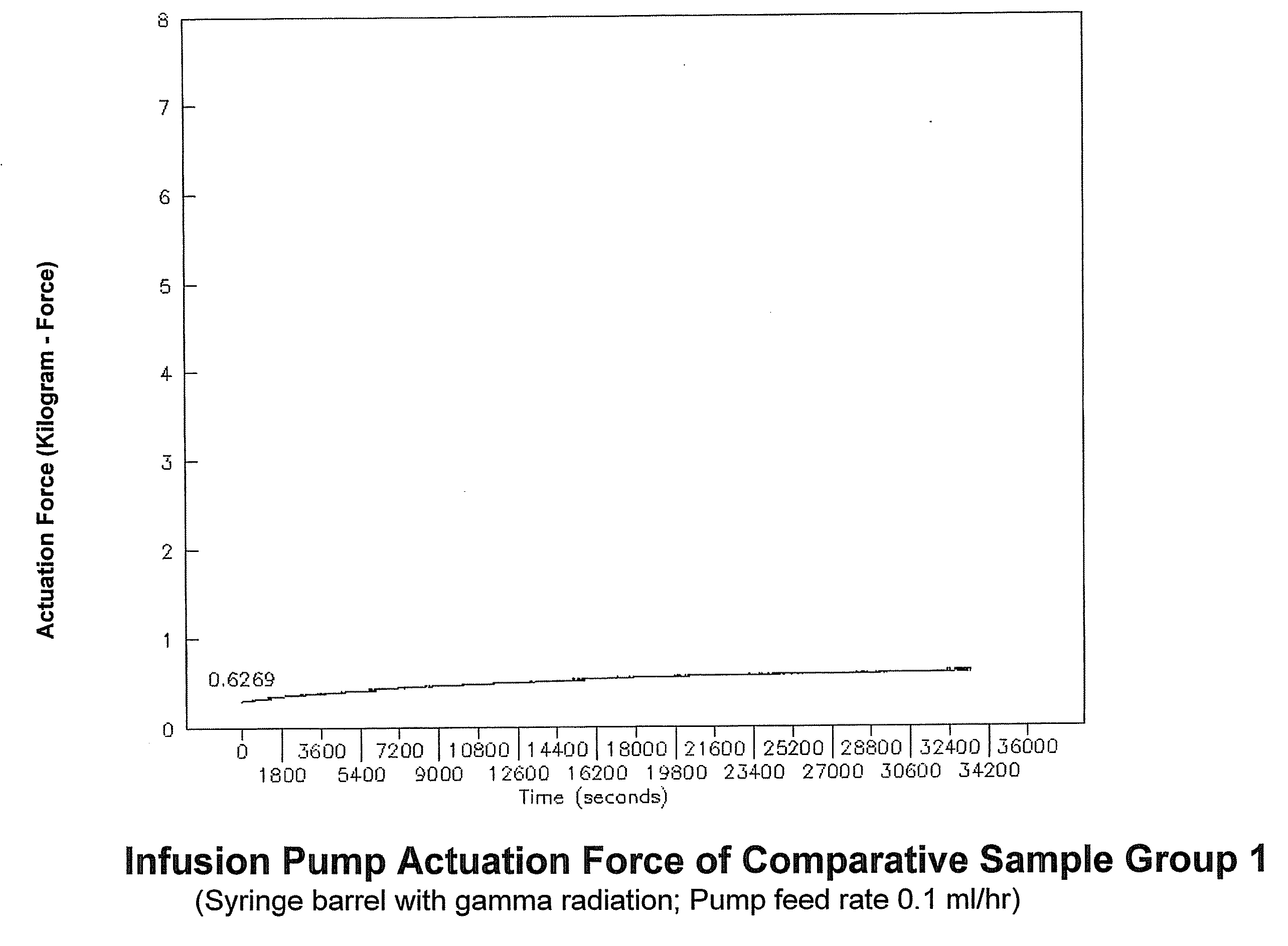

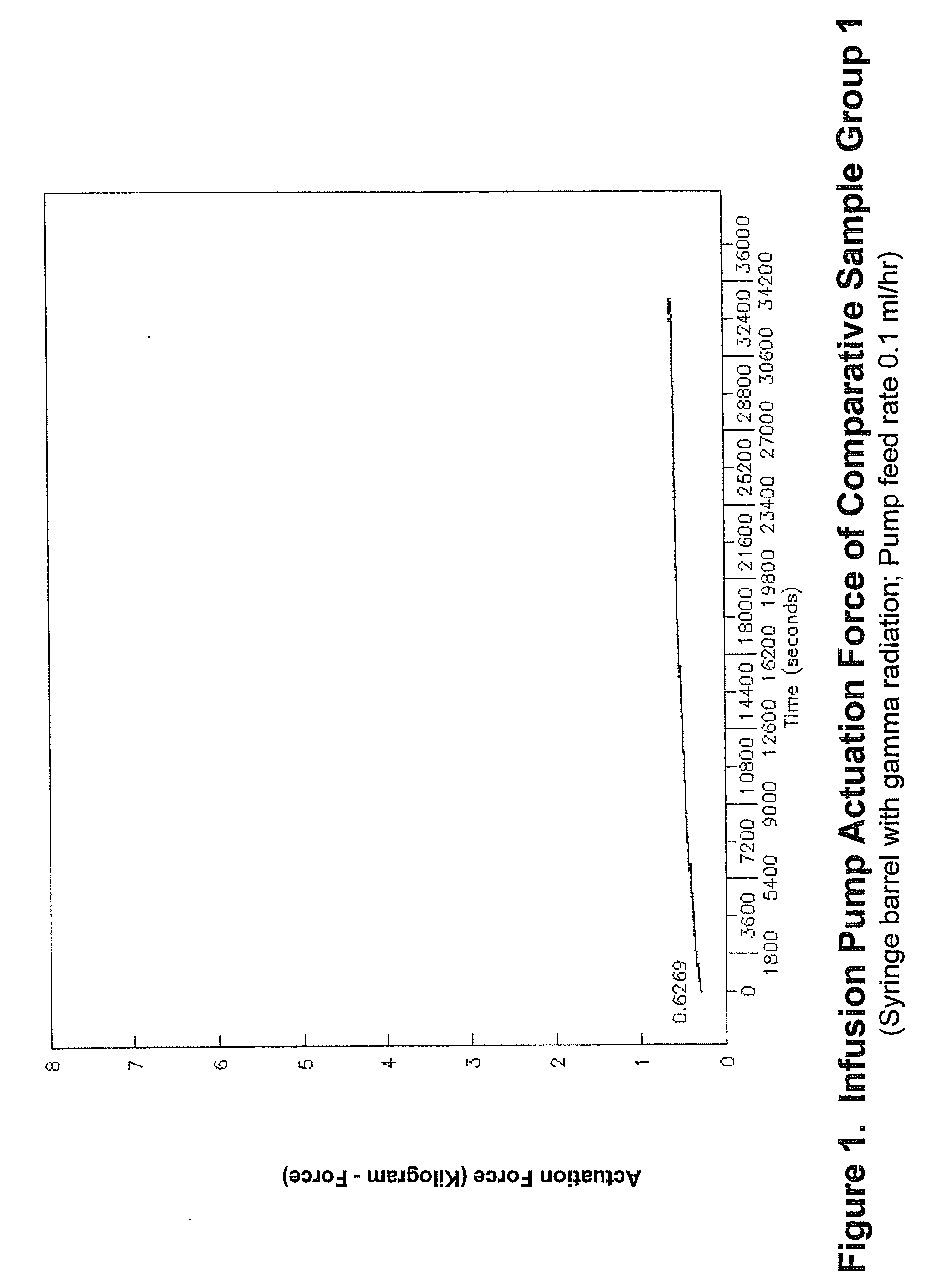

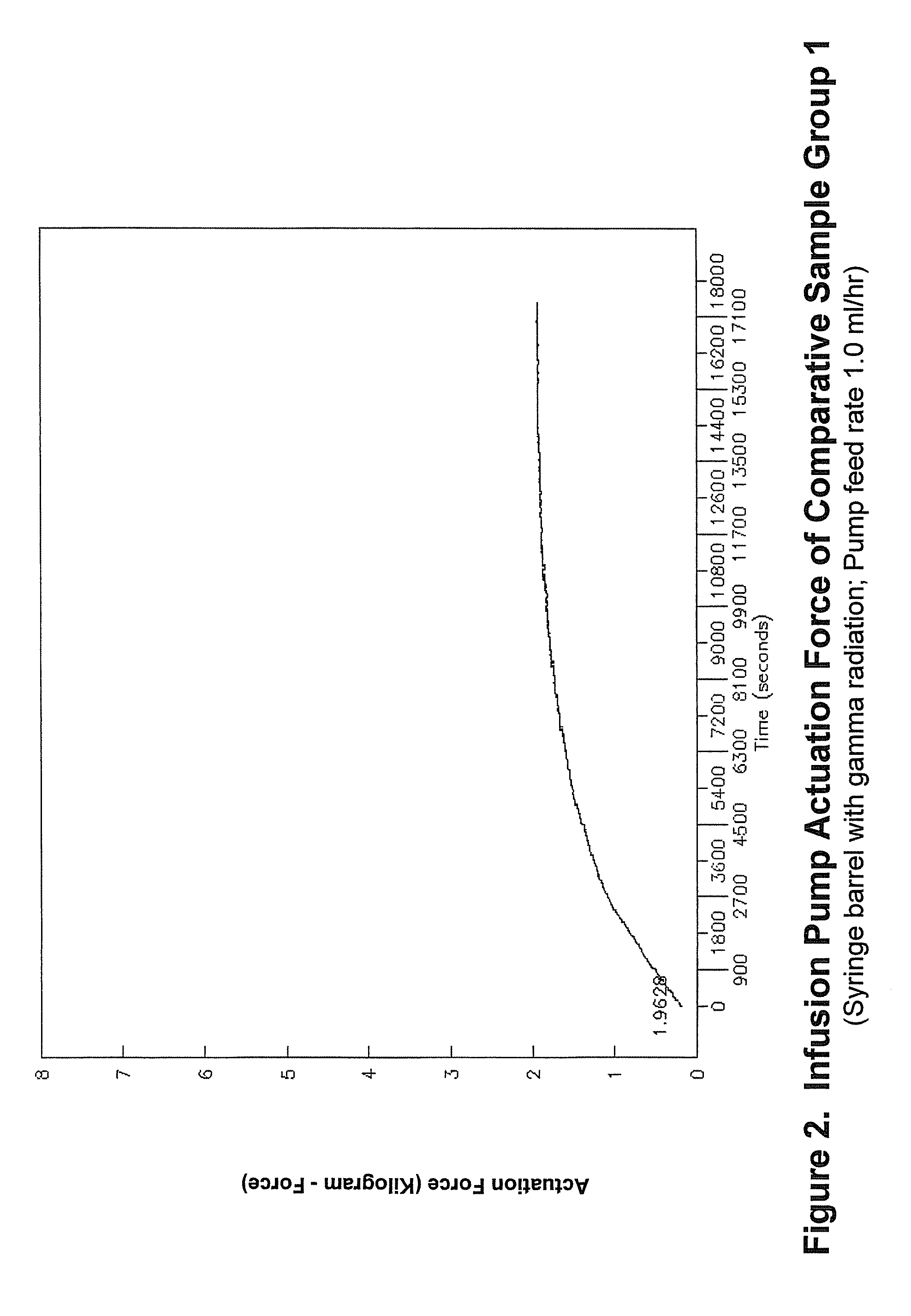

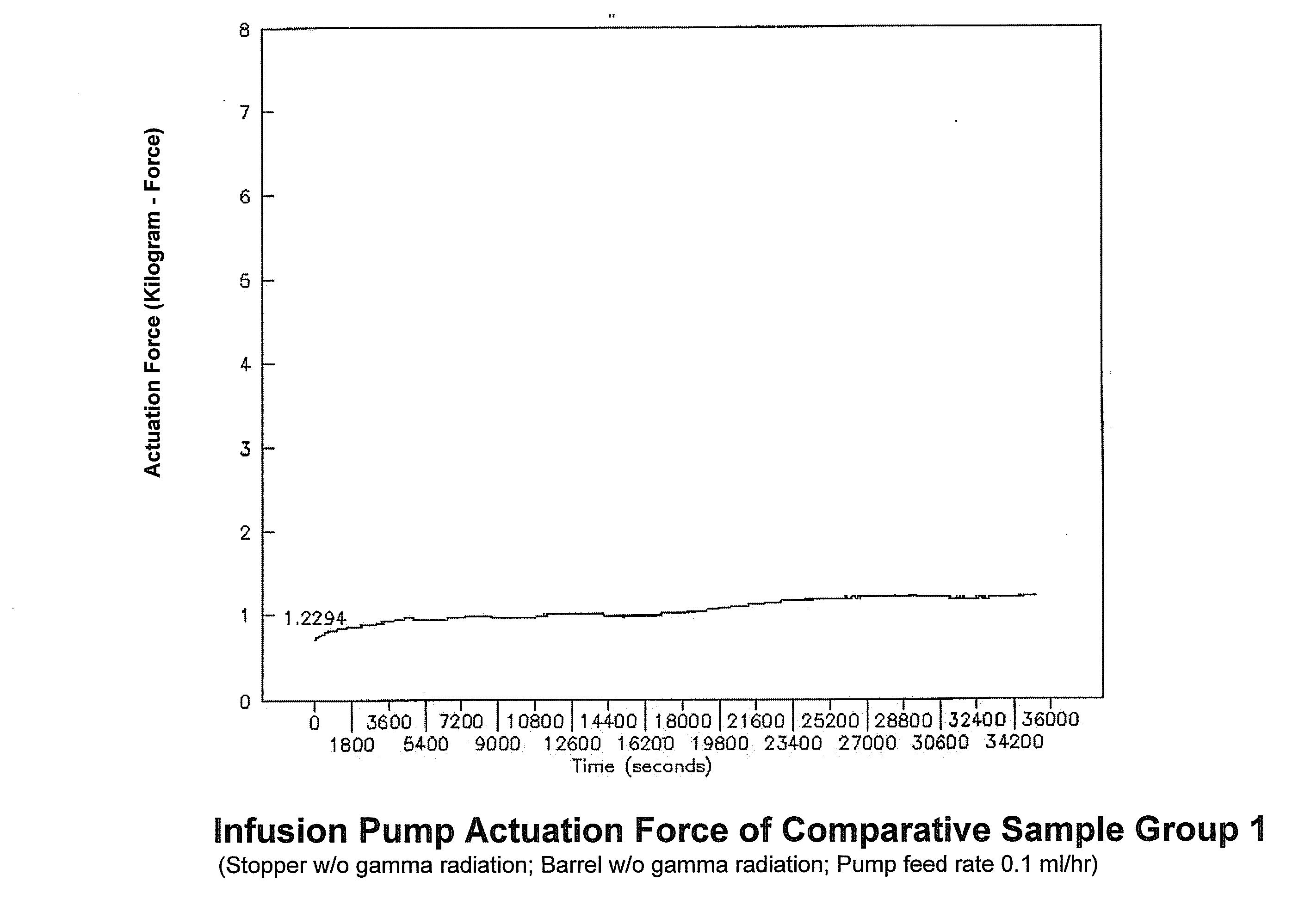

Medical Components Having Coated Surfaces Exhibiting Low Friction and Methods of Reducing Sticktion

This invention relates to components useful for medical articles, such as a syringe assembly, having sliding surface(s) coated with a composition including organopolysiloxane(s), the coating being adhered to the surface(s) of the component by crosslinking induced by oxidative treatment and irradiation with an isotope, electron beam or ultraviolet radiation or heat treatment; medical articles including the same; methods to reduce static and kinetic friction between slidable surfaces; and articles of low friction prepared thereby.

Owner:BECTON DICKINSON & CO

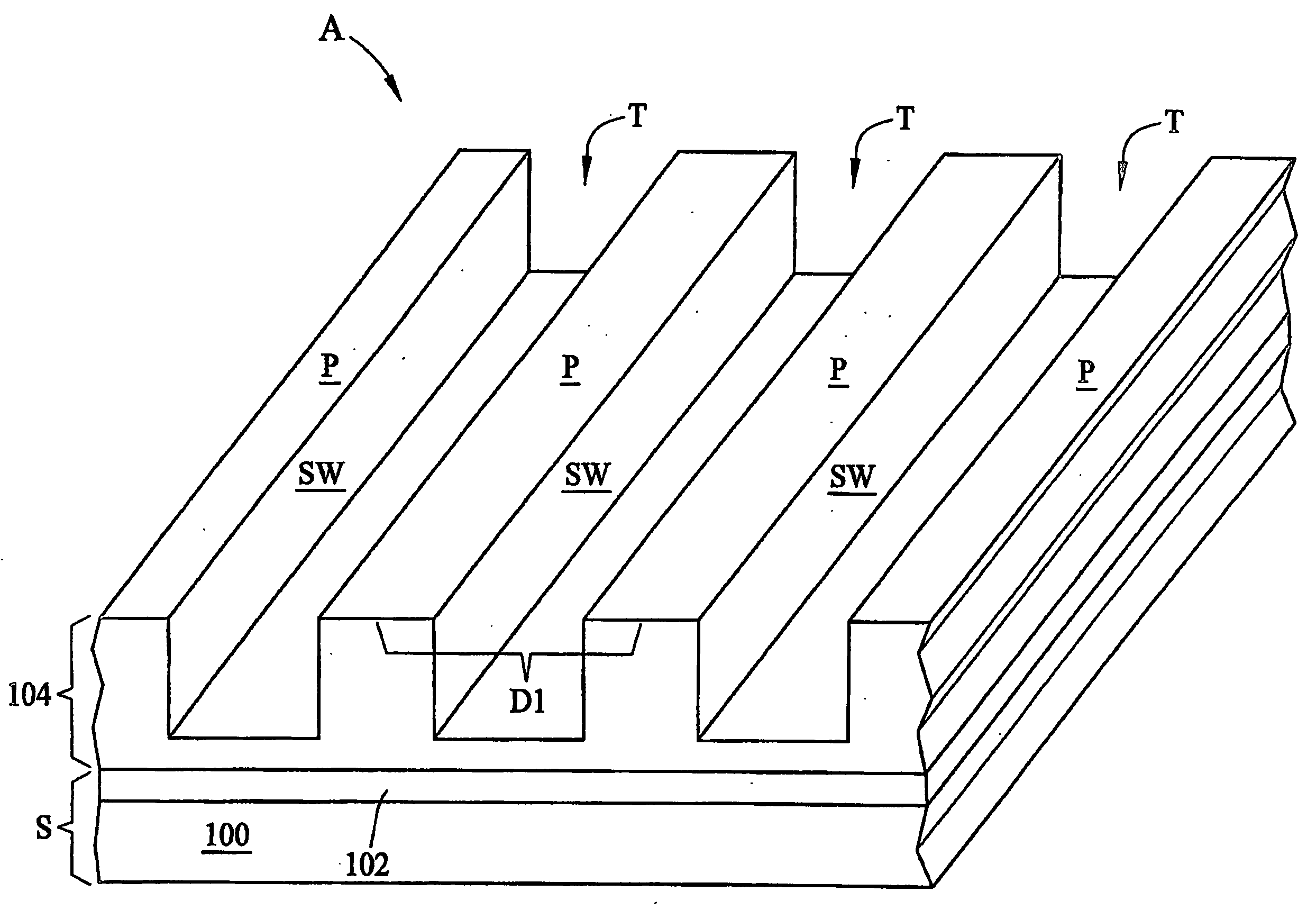

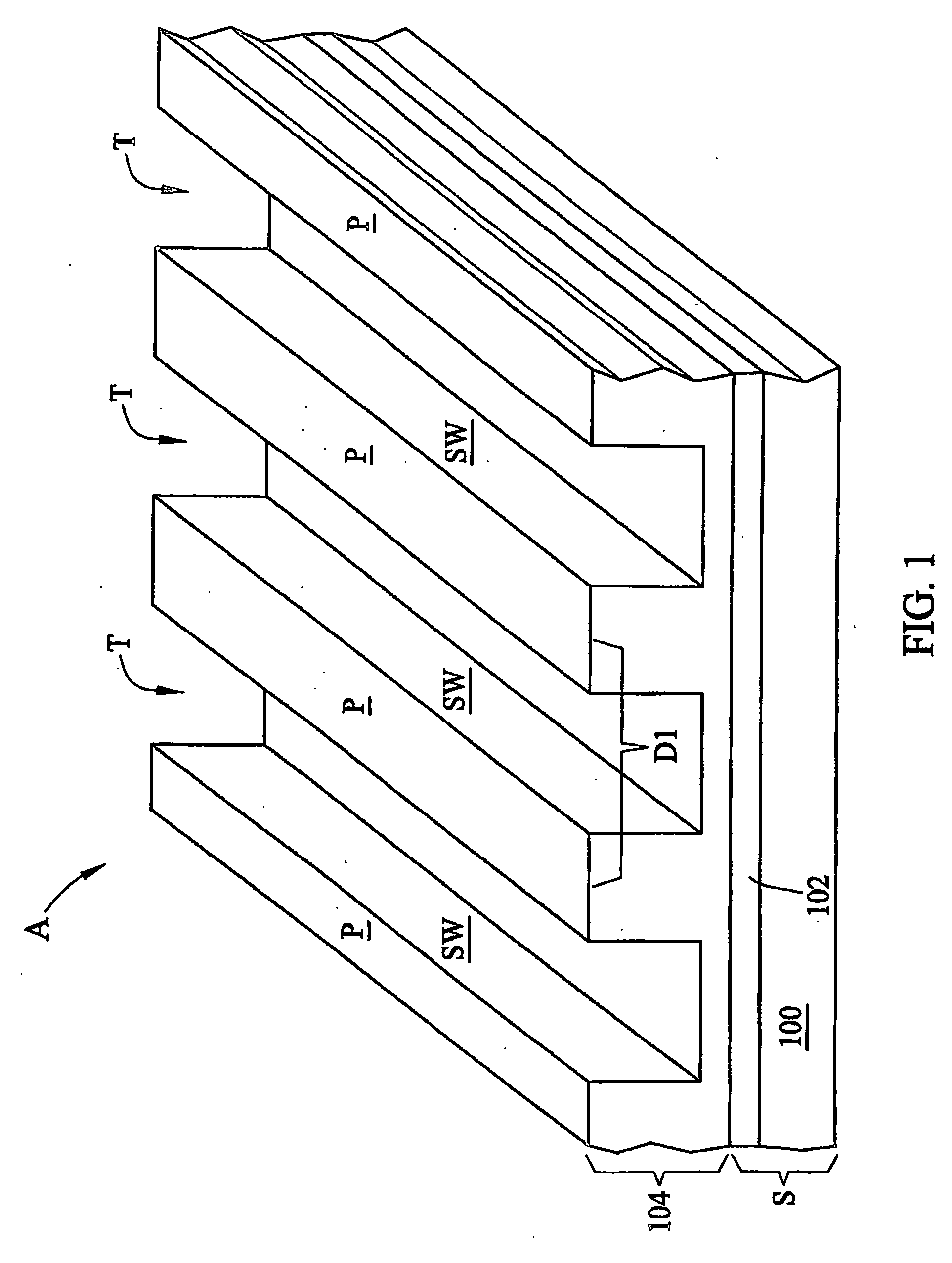

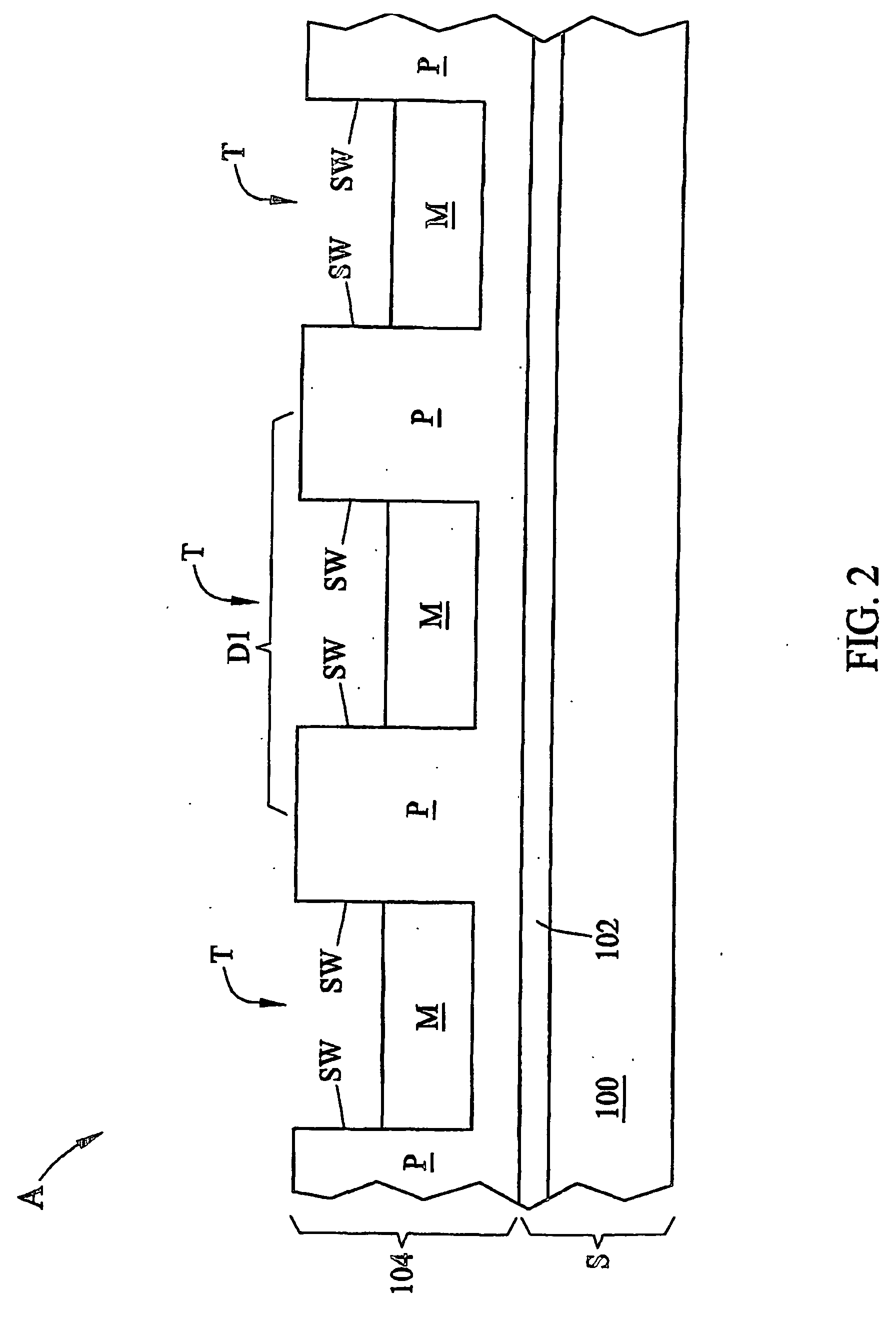

Methods for nanoscale structures from optical lithography and subsequent lateral growth

InactiveUS20070029643A1Reduce defect densityReduce dislocationMaterial nanotechnologyDecorative surface effectsLithographic artistPhotonics

Methods, and structures formed thereby, are disclosed for forming laterally grown structures with nanoscale dimensions from nanoscale arrays which can be patterned from nanoscale lithography. The structures and methods disclosed herein have applications with electronic, photonic, molecular electronic, spintronic, microfluidic or nano-mechanical (NEMS) technologies. The spacing between laterally grown structures can be a nanoscale measurement, for example with a spacing distance which can be approximately 1-50 nm, and more particularly can be from approximately 3-5 nm. This spacing is appropriate for integration of molecular electronic devices. The pitch between posts can be less than the average distance characteristic between dislocation defects for example in GaN (ρ=1010 / cm2→d=0.1 μm) resulting an overall reduction in defect density. Large-scale integration of nanoscale devices can be achieved using lithographic equipment that is orders of magnitude less expensive that that used for advanced lithographic techniques, such as electron beam lithography.

Owner:NORTH CAROLINA STATE UNIV

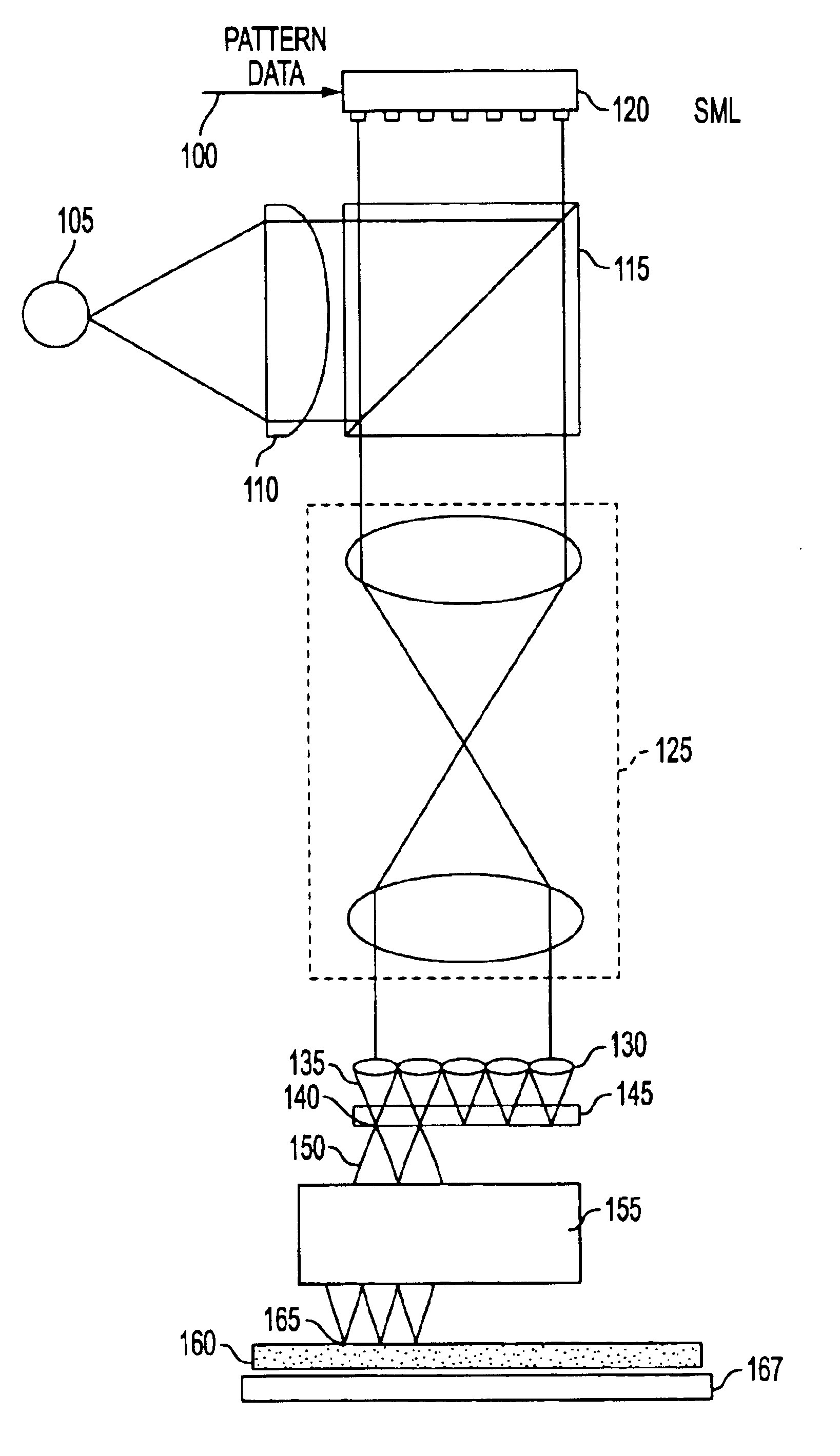

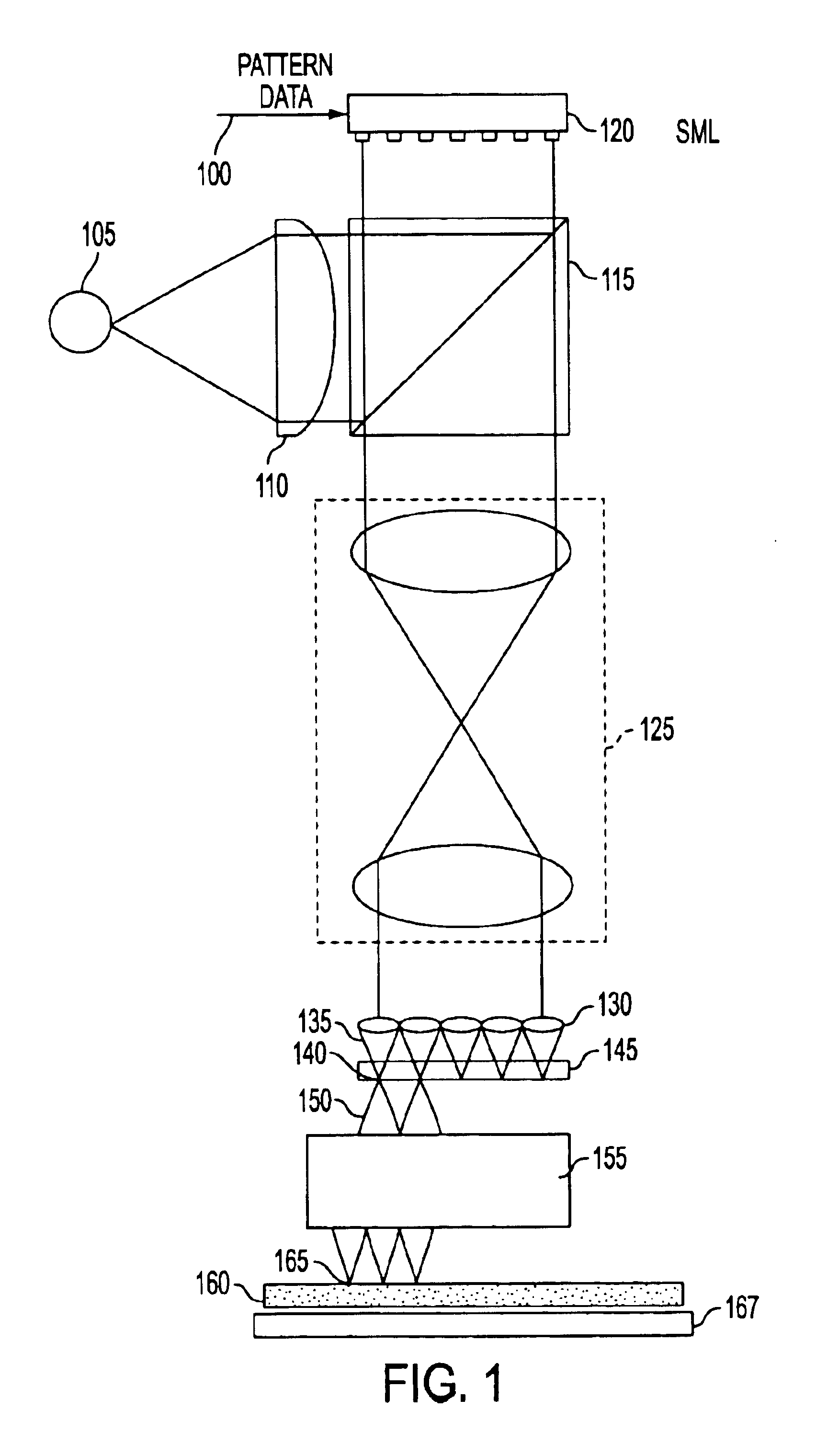

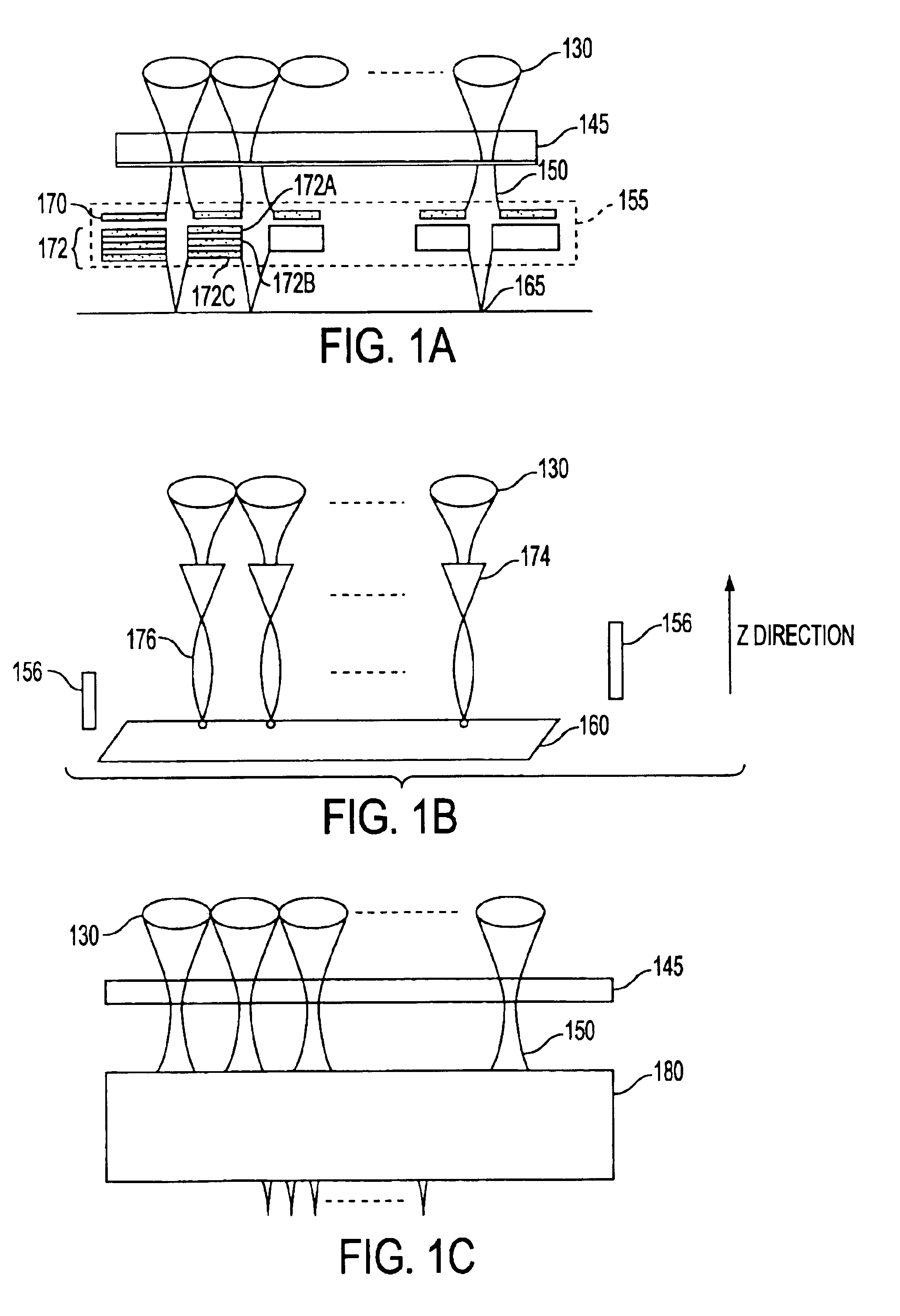

Maskless photon-electron spot-grid array printer

InactiveUS6841787B2Readily apparentElectric discharge tubesNanoinformaticsOptical radiationIntermediate image

A high resolution and high data rate spot grid array printer system is provided, wherein an image representative of patterns to be recorded on a reticle or on a layer of a semiconductor die is formed by scanning a substrate with electron beams. Embodiments include a printer comprising an optical radiation source for irradiating a photon-electron converter with a plurality of substantially parallel optical beams, the optical beams being individually modulated to correspond to an image to be recorded on the substrate. The photon-electron converter produces an intermediate image composed of an array of electron beams corresponding to the modulated optical beams. A de-magnifier is interposed between the photon-electron converter and the substrate, for reducing the size of the intermediate image. A movable stage introduces a relative movement between the substrate and the photon-electron converter, such that the substrate is scanned by the electron beams.

Owner:APPLIED MATERIALS INC

Method and apparatus for additive manufacturing

ActiveUS9550207B2Improve conductivityReduce probabilityAdditive manufacturing apparatusTransportation and packagingPowder bedEngineering

Various embodiments provide a method and apparatus for forming a three-dimensional article through successive fusion of parts of at least one layer of a powder bed provided on a work table in an additive manufacturing machine, which parts corresponds to successive cross sections of the three-dimensional article. The method comprises the steps of: applying a layer of predetermined thickness of powder particles on the work table, applying a coating on at least a portion of the powder particles, which coating is at least partially covering the powder particles, and fusing the powder particles on the work table with an electron beam.

Owner:ARCAM AB

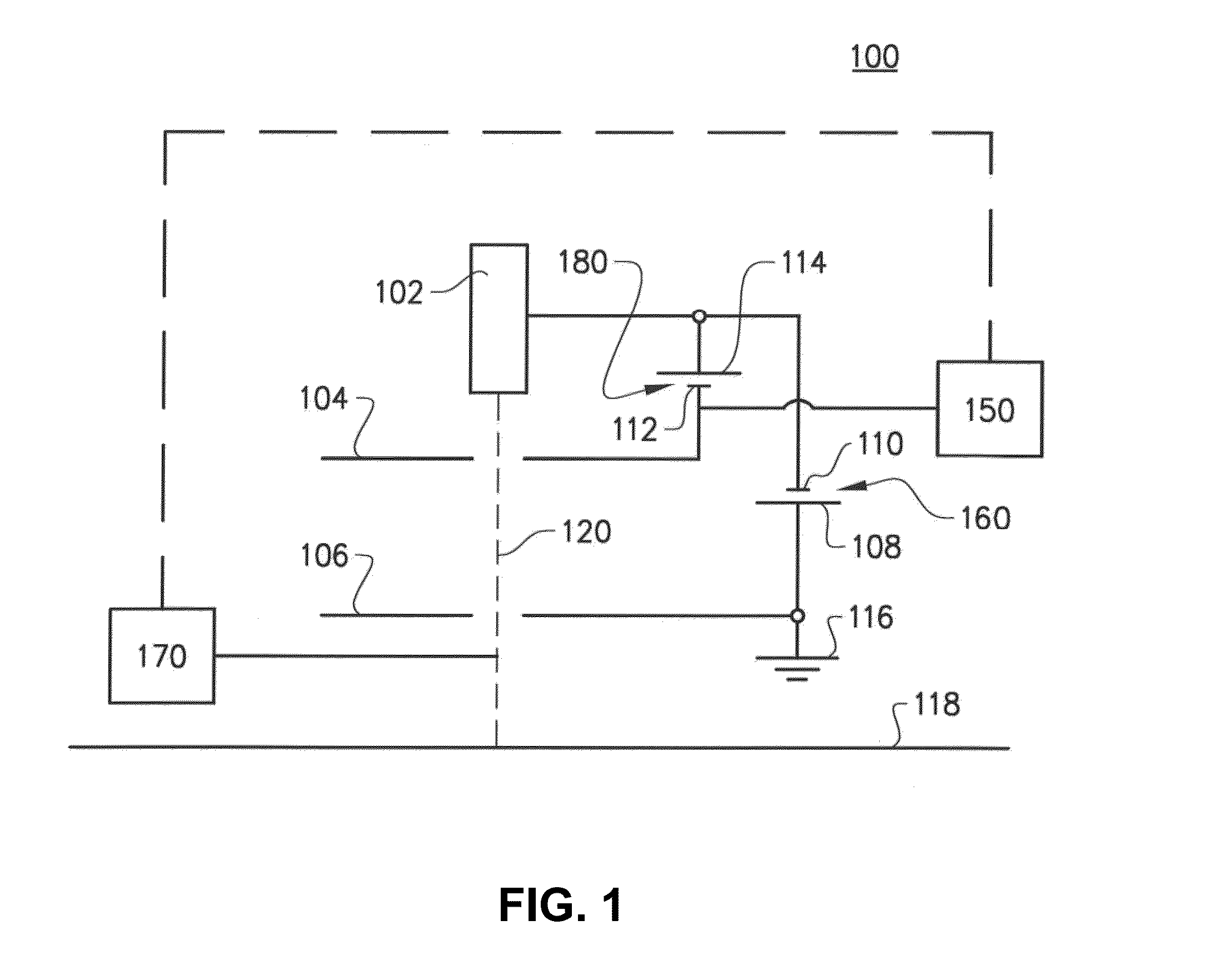

Closed-Loop Process Control for Electron Beam Freeform Fabrication and Deposition Processes

InactiveUS20100260410A1Electric discharge tubesCharacter and pattern recognitionClosed loopEngineering

A closed-loop control method for an electron beam freeform fabrication (EBF3) process includes detecting a feature of interest during the process using a sensor(s), continuously evaluating the feature of interest to determine, in real time, a change occurring therein, and automatically modifying control parameters to control the EBF3 process. An apparatus provides closed-loop control method of the process, and includes an electron gun for generating an electron beam, a wire feeder for feeding a wire toward a substrate, wherein the wire is melted and progressively deposited in layers onto the substrate, a sensor(s), and a host machine. The sensor(s) measure the feature of interest during the process, and the host machine continuously evaluates the feature of interest to determine, in real time, a change occurring therein. The host machine automatically modifies control parameters to the EBF3 apparatus to control the EBF3 process in a closed-loop manner.

Owner:NASA

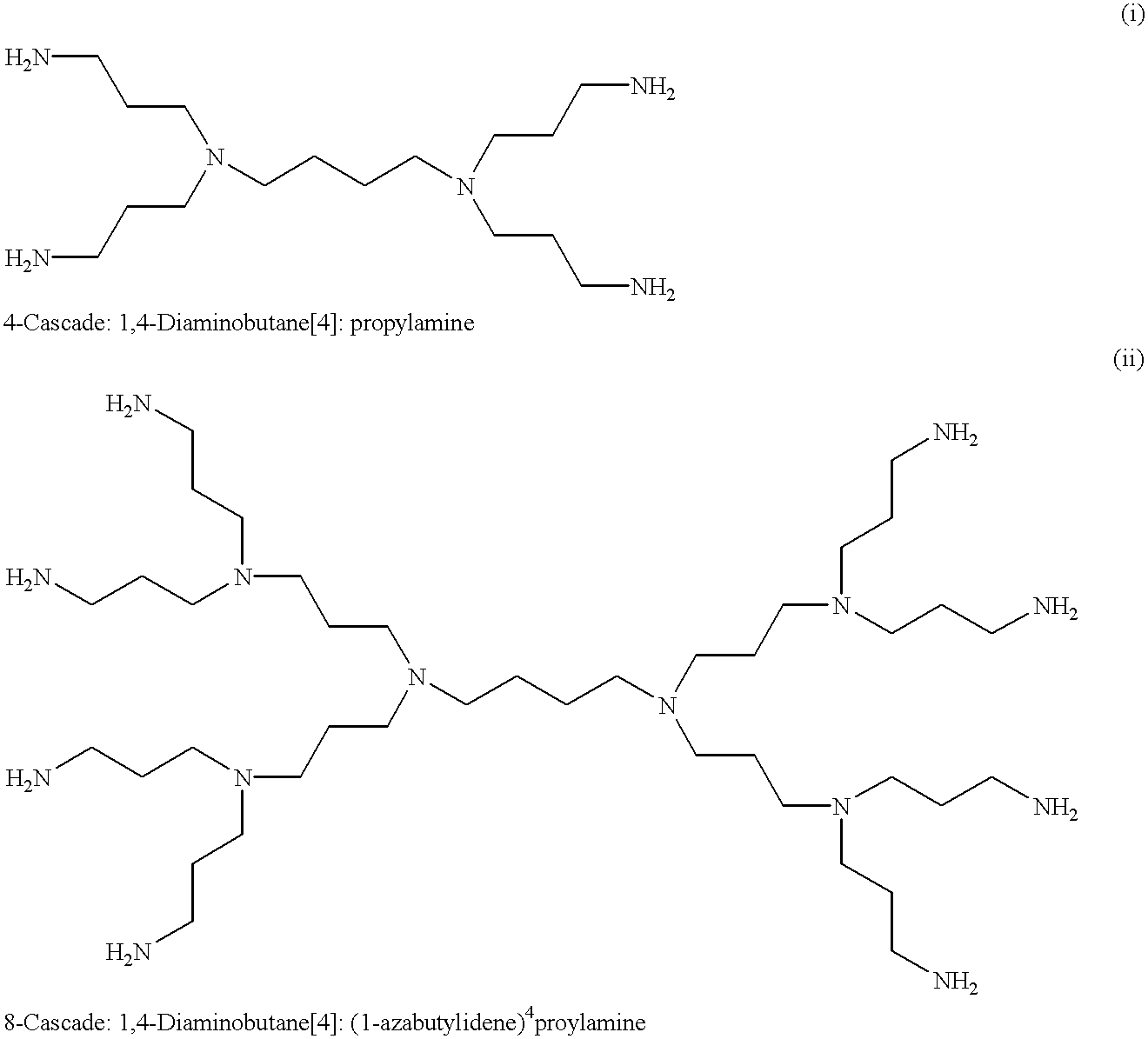

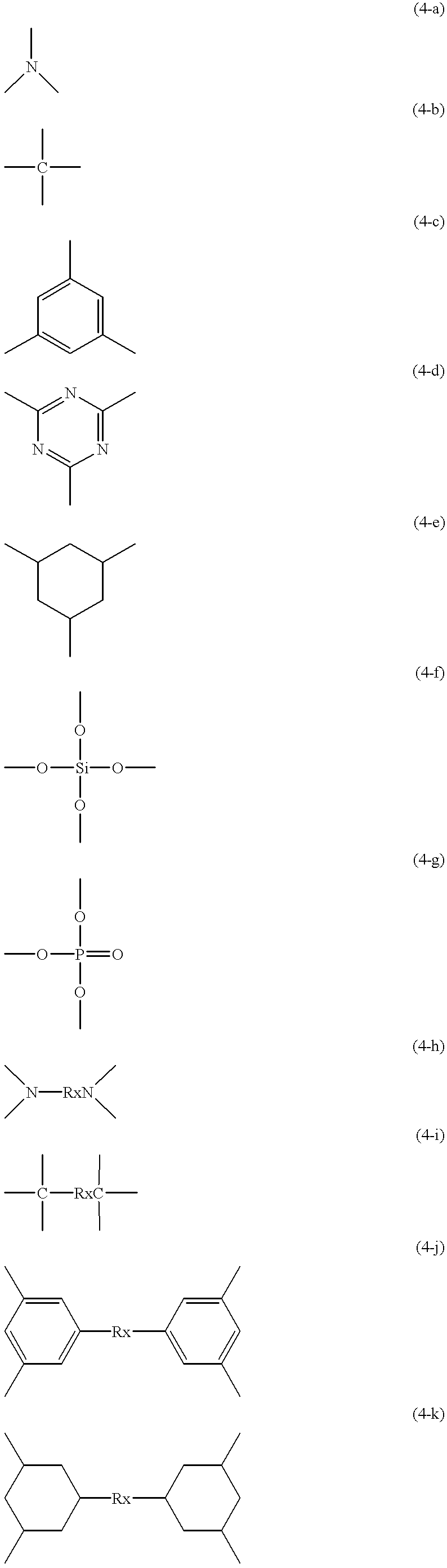

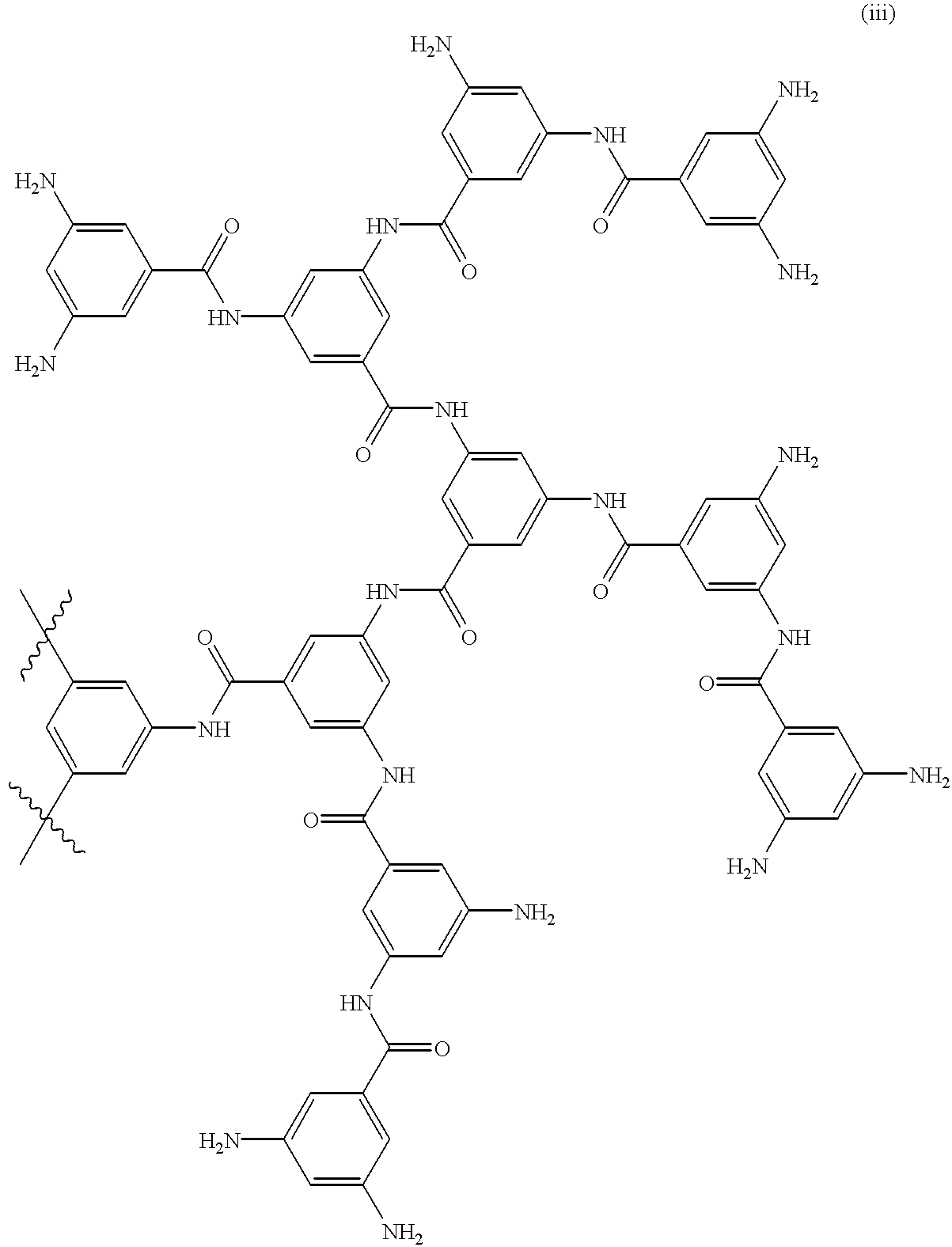

Vinyl-group-containing dendrimer and curable composition

A vinyl-group-containing dendrimer useful in coating and printing and is curable by any one of conventional triggers such as heating, ultraviolet light, infrared light, electron beams and gamma rays, the composition comprising a vinyl-group-containing dendrimer (A) comprising a core portion, branching portions, branches and at least 4 terminal portions and having a vinyl group as a terminal portion and a long-chain group and a curable unsaturated-group-containing compound (B), and the composition comprising a vinyl-group-containing dendrimer (A) obtained by reacting a polyfunctional compound (a) having at least three active-hydrogen-containing groups in a terminal per molecule and having at least five active hydrogen atoms per molecule with a long-chain-group-containing compound (b) having a functional group reactive with an active hydrogen atom so as to leave part of the active hydrogen atoms, thereby obtaining a long-chain-group-containing multi-branched compound (X), and reacting the long-chain-containing multi-branched compound (X) with a vinyl-group-containing compound (c) having a functional group reactive with an active hydrogen atom and a curable unsaturated-group-containing compound (B).

Owner:TOYO INK SC HOLD CO LTD

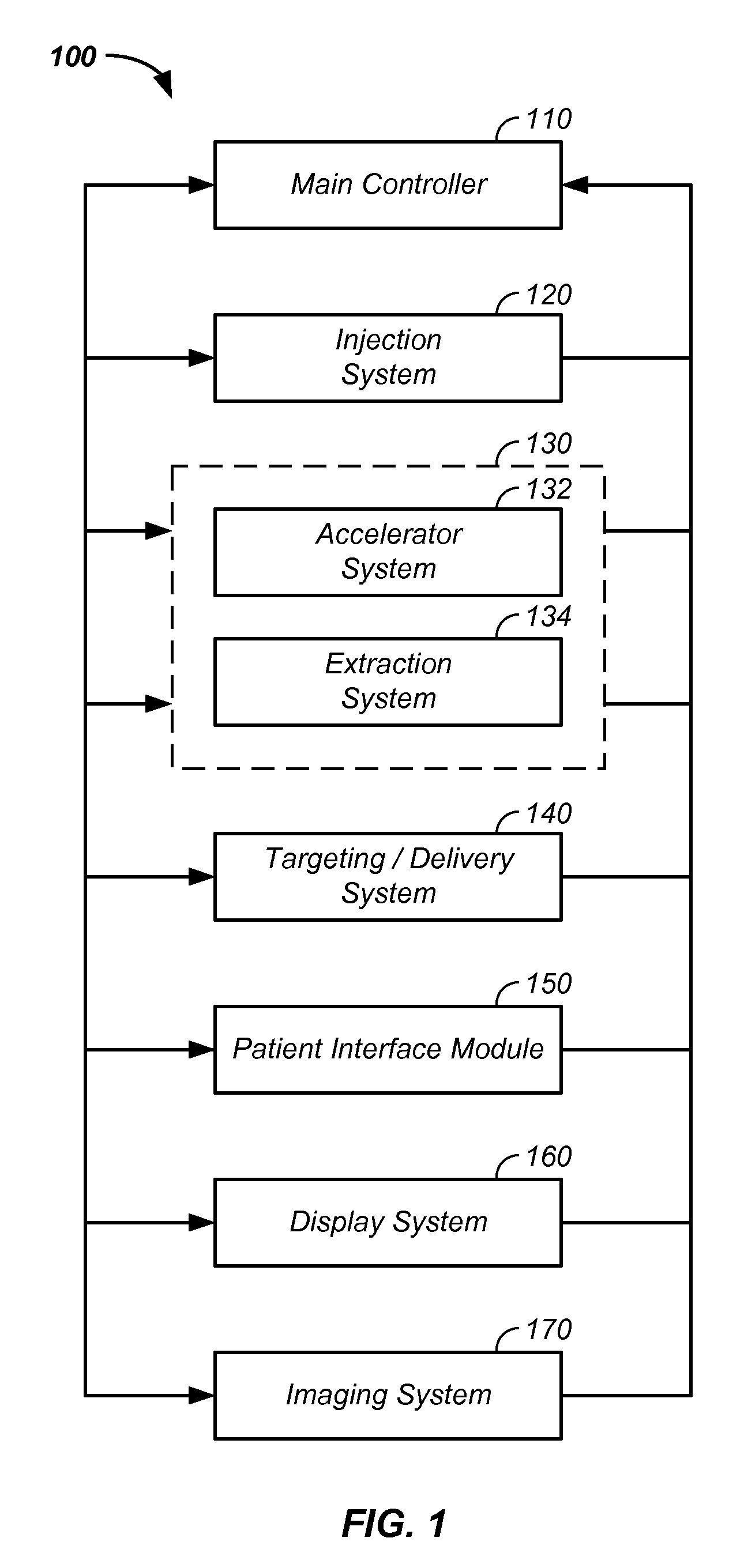

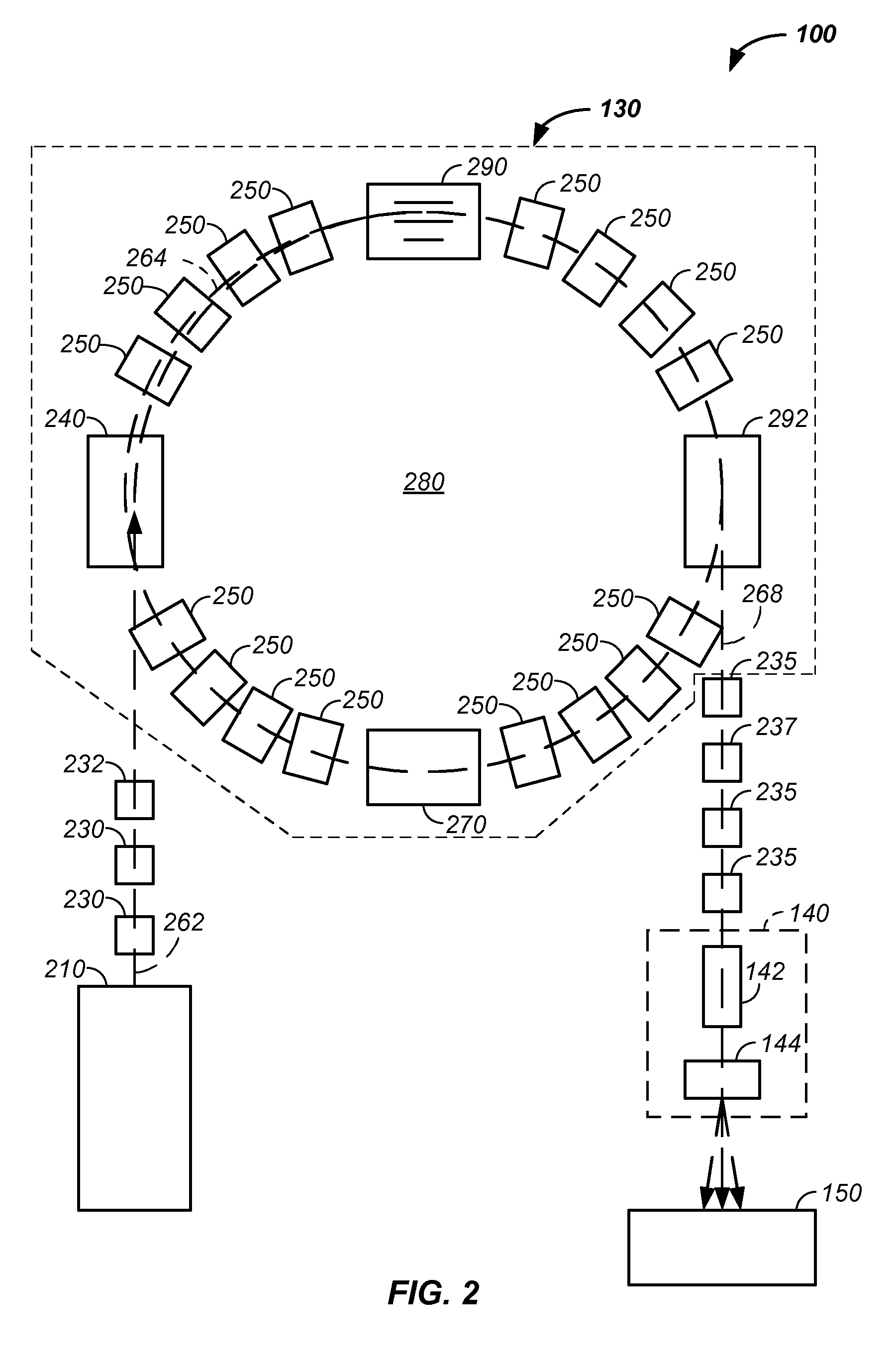

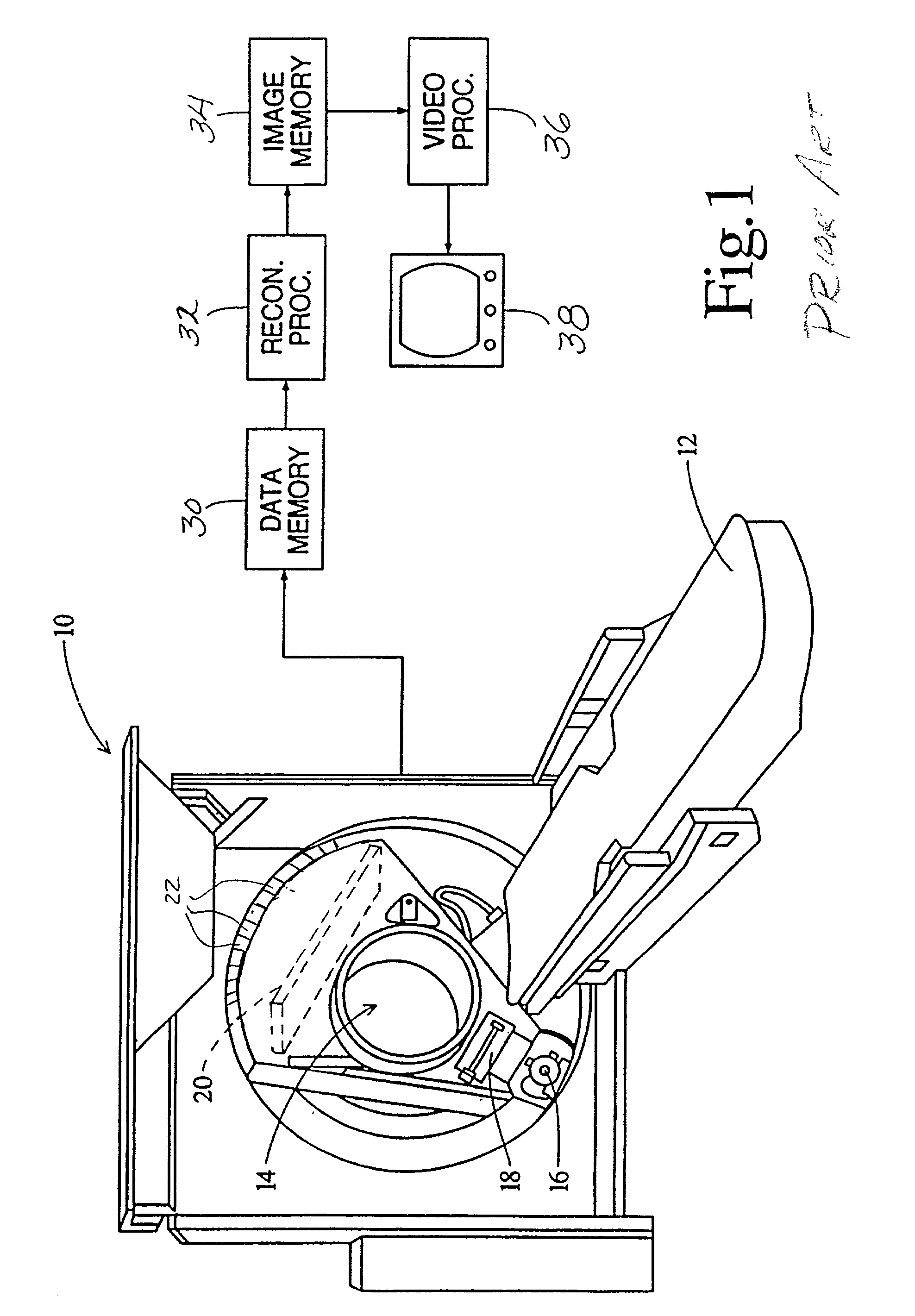

Elongated lifetime X-ray method and apparatus used in conjunction with a charged particle cancer therapy system

ActiveUS7940894B2Beam/ray focussing/reflecting arrangementsX-ray tube electrodesSoft x rayParticle beam

The system uses an X-ray imaging system having an elongated lifetime. Further, the system uses an X-ray beam that lies in substantially the same path as a charged particle beam path of a particle beam cancer therapy system. The system creates an electron beam that strikes an X-ray generation source located proximate to the charged particle beam path. By generating the X-rays near the charged particle beam path, an X-ray path running collinear, in parallel with, and / or substantially in contact with the charged particle beam path is created. The system then collects X-ray images of localized body tissue region about a cancerous tumor. Since, the X-ray path is essentially the charged particle beam path, the generated image is usable for precisely target the tumor with a charged particle beam.

Owner:BALAKIN ANDREY VLADIMIROVICH +1

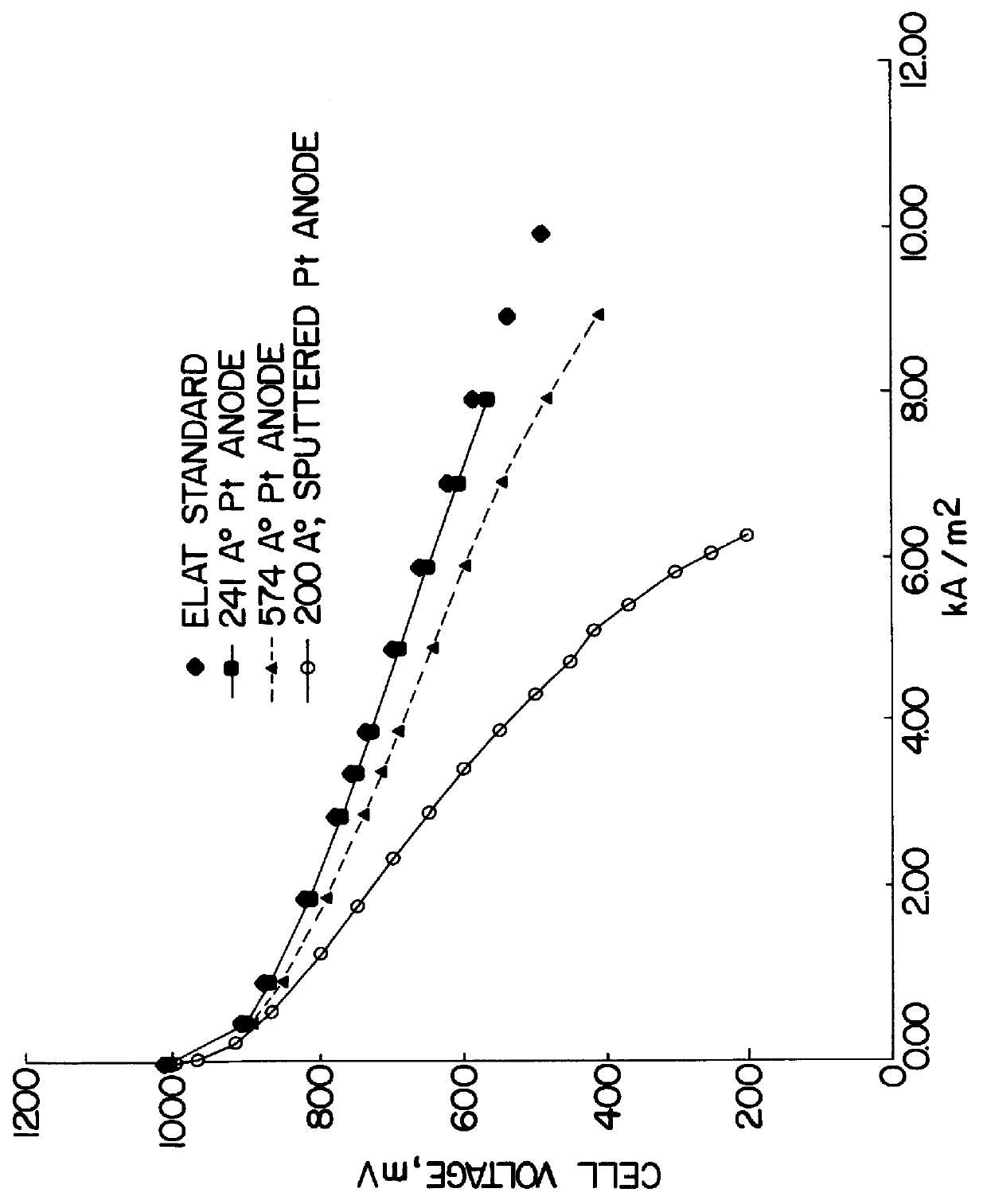

Method of forming robust metal, metal oxide, and metal alloy layers on ion-conductive polymer membranes

InactiveUS6077621AShort development timeLow costFinal product manufactureVacuum evaporation coatingConductive polymerElectron bunches

The invention is to a dual beam process for providing an ion-conducting membrane with a thin metal or metal-oxide film. The process includes the cleaning of a membrane surface with a low energy electron beam followed by the deposition of the metal or metal-oxide film by a high energy electron beam of ions.

Owner:BASF FUEL CELL

Method of making electron beam polymerized emulsion-based acrylate pressure sensitive adhesives

InactiveUS6103316AImprove adhesionHigh polymerizable contentFilm/foil adhesivesVacuum evaporation coatingEmulsionElectron

A one-step process using electron beam radiation to polymerize pressure sensitive adhesives on web from acrylate emulsions is disclosed. The radiation may be supplied in a single or multiple dose. Products using such pressure sensitive adhesives are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

Medical Components Having Coated Surfaces Exhibiting Low Friction and Methods of Reducing Sticktion

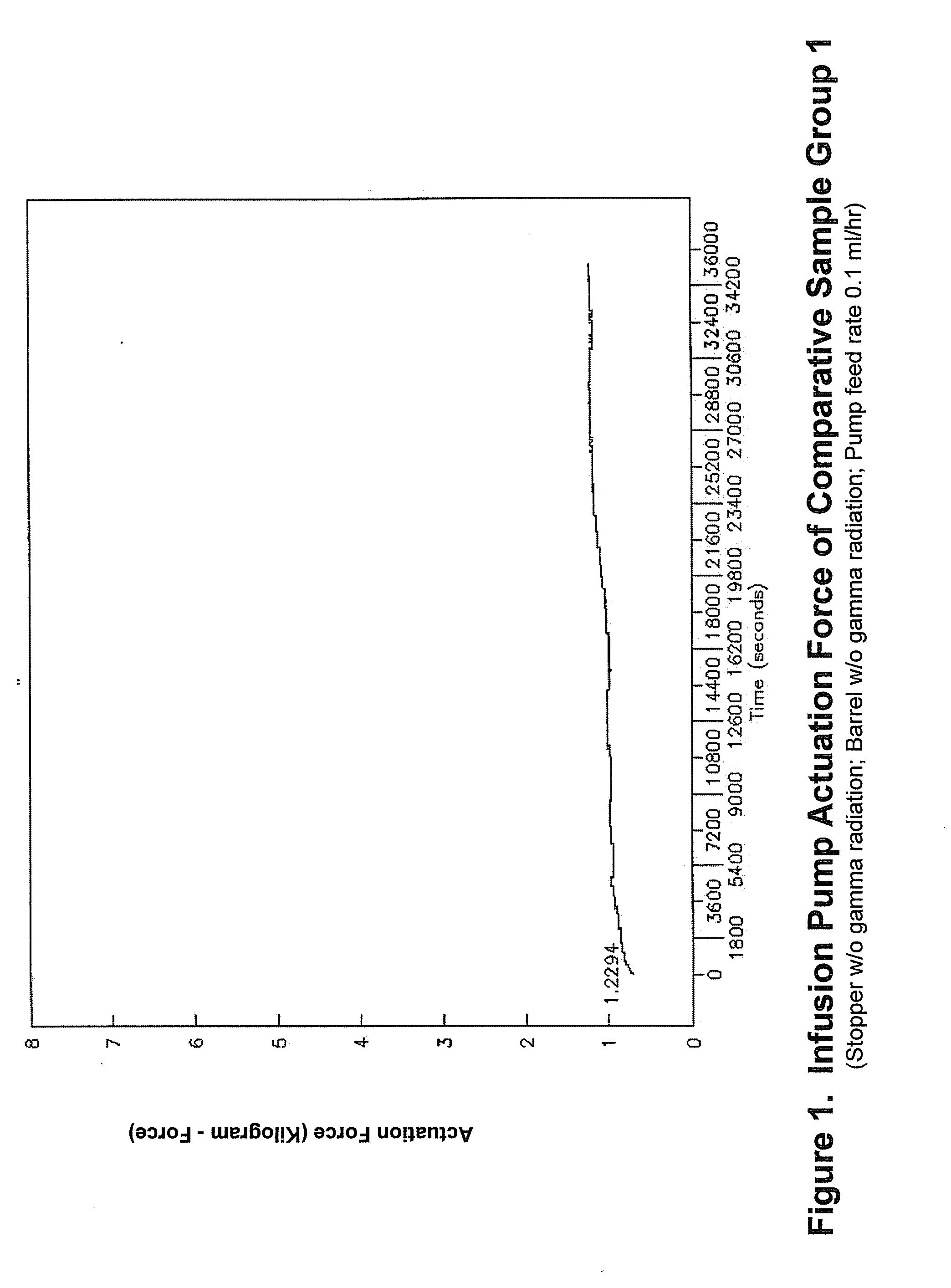

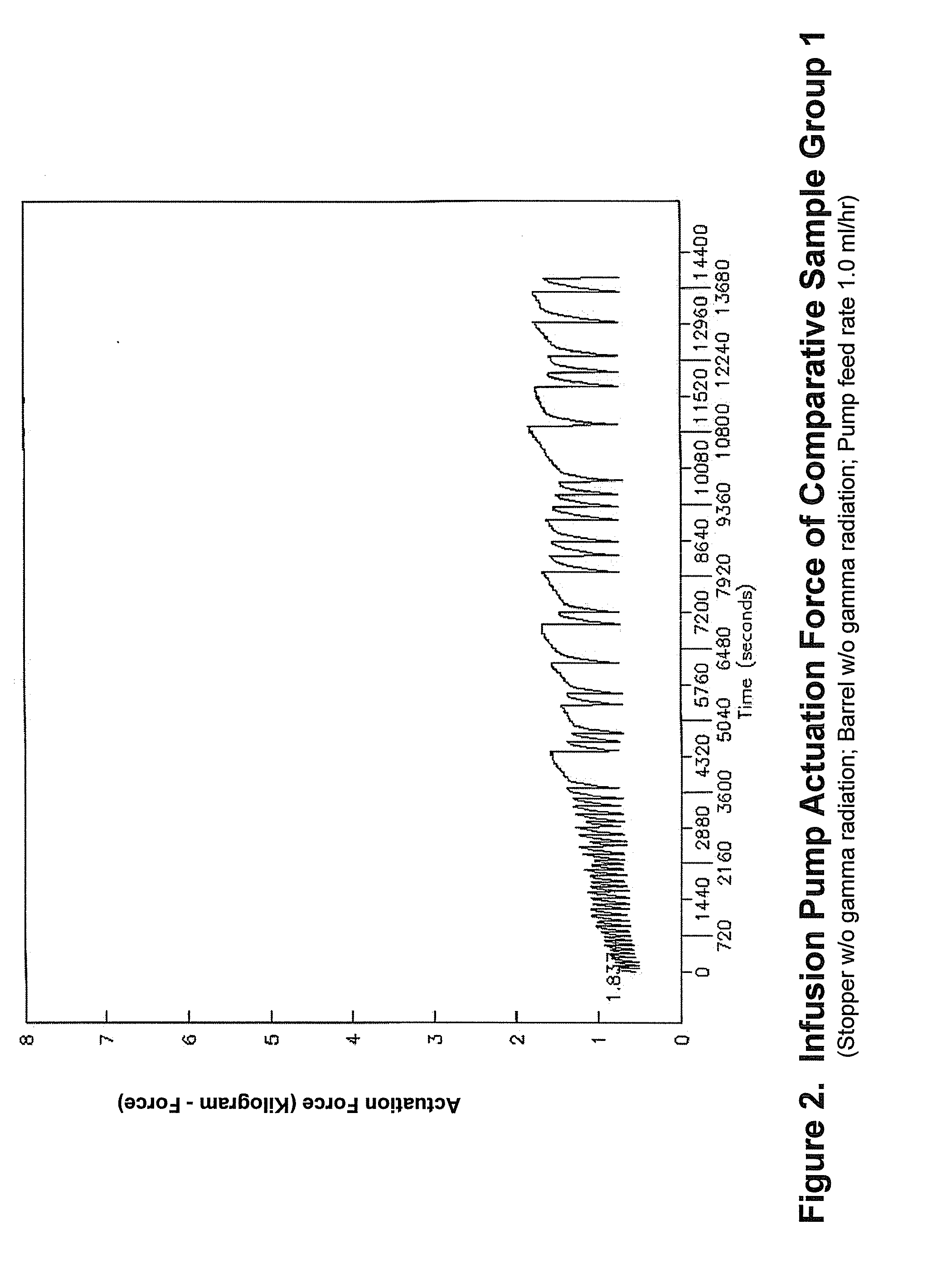

InactiveUS20080069970A1Reducing breakloose forceReduce supportRadiation applicationsInfusion syringesCoated surfaceCentistokes

A medical article is provided including a chamber formed from a cyclic polyolefin having an inner surface in sliding engagement with an exterior surface of a sealing member, the inner surface of the chamber being coated with a first organopolysiloxane having a viscosity ranging from about 5,000 centistokes to about 100,000 centistokes; and a sealing member having an exterior surface coated with a second organopolysiloxane having a viscosity ranging from about 10,000 centistokes to about 500,000 centistokes, the coatings being adhered to the surfaces by crosslinking induced by irradiation with an isotope, electron beam, or ultraviolet radiation, as well as methods of reducing breakloose force, sustaining force, and / or sticktion between engaging surfaces in such articles.

Owner:BECTON DICKINSON & CO

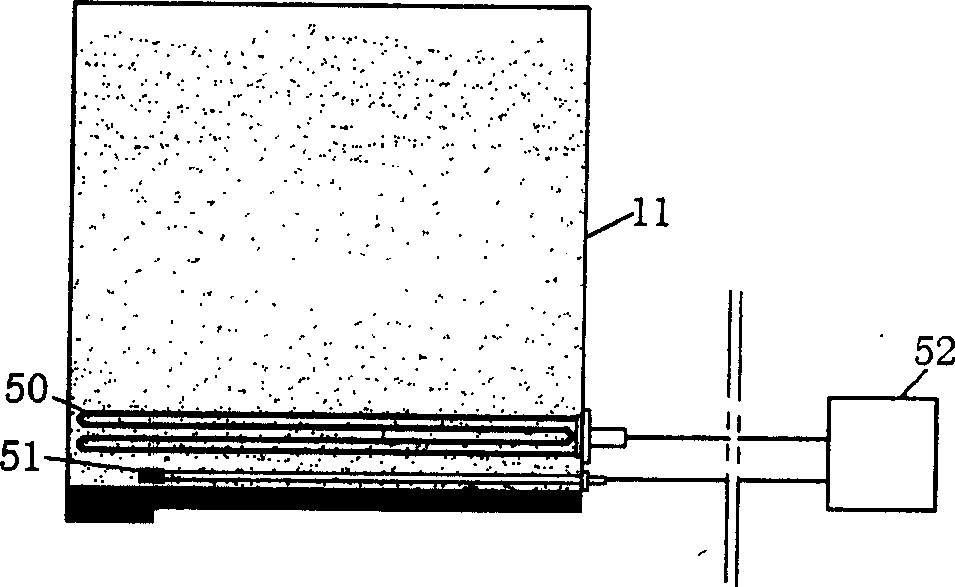

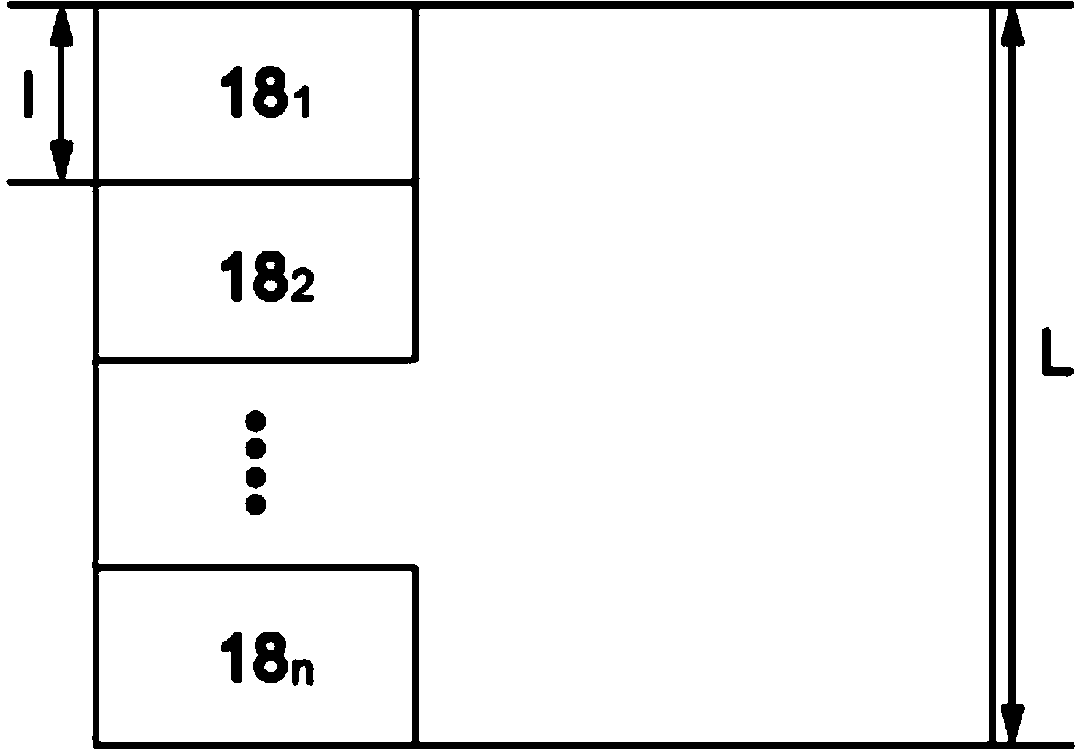

Method and apparatus for increasing the resolution in additively manufactured three-dimensional articles

ActiveUS20140370323A1High pressure levelHigh beam qualityAdditive manufacturing apparatusIncreasing energy efficiencyImage resolutionVacuum chamber

A method for increasing the resolution when forming a three-dimensional article through successive fusion of parts of a powder bed, said method comprising providing a vacuum chamber, providing an electron gun, providing a first powder layer on a work table inside said vacuum chamber, directing an electron beam from said electron gun over said work table causing the powder layer to fuse in selected locations to form a first cross section of said three-dimensional article, providing a second powder layer on said work table, directing the electron beam over said work table causing said second powder layer to fuse in selected locations to form a second cross section of said three-dimensional article, reducing the pressure in the vacuum chamber from a first pressure level to a second pressure level between the providing of said first powder layer and said second powder layer.

Owner:ARCAM AB

Sterile filling machine having needle filling station within e-beam chamber

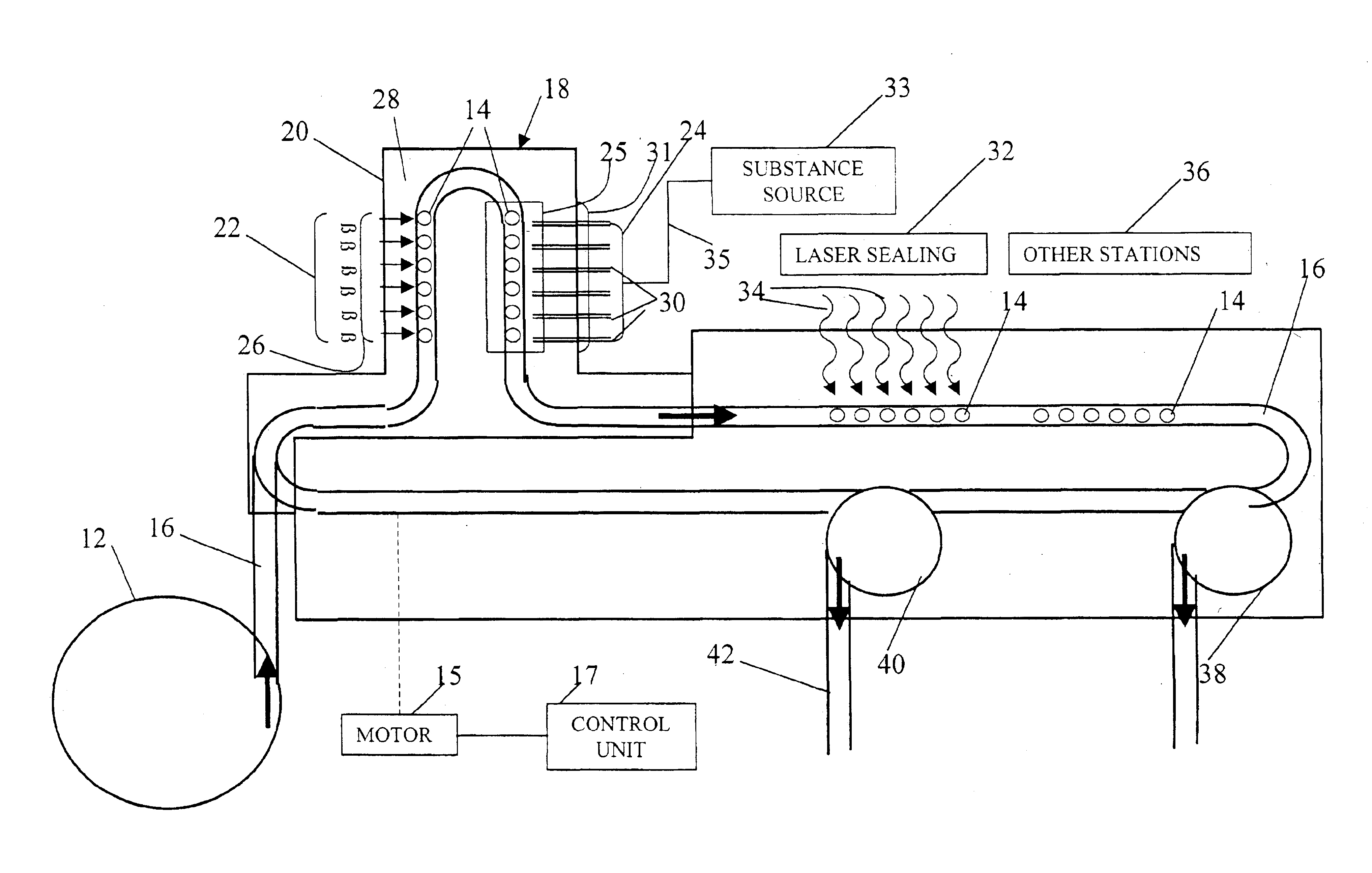

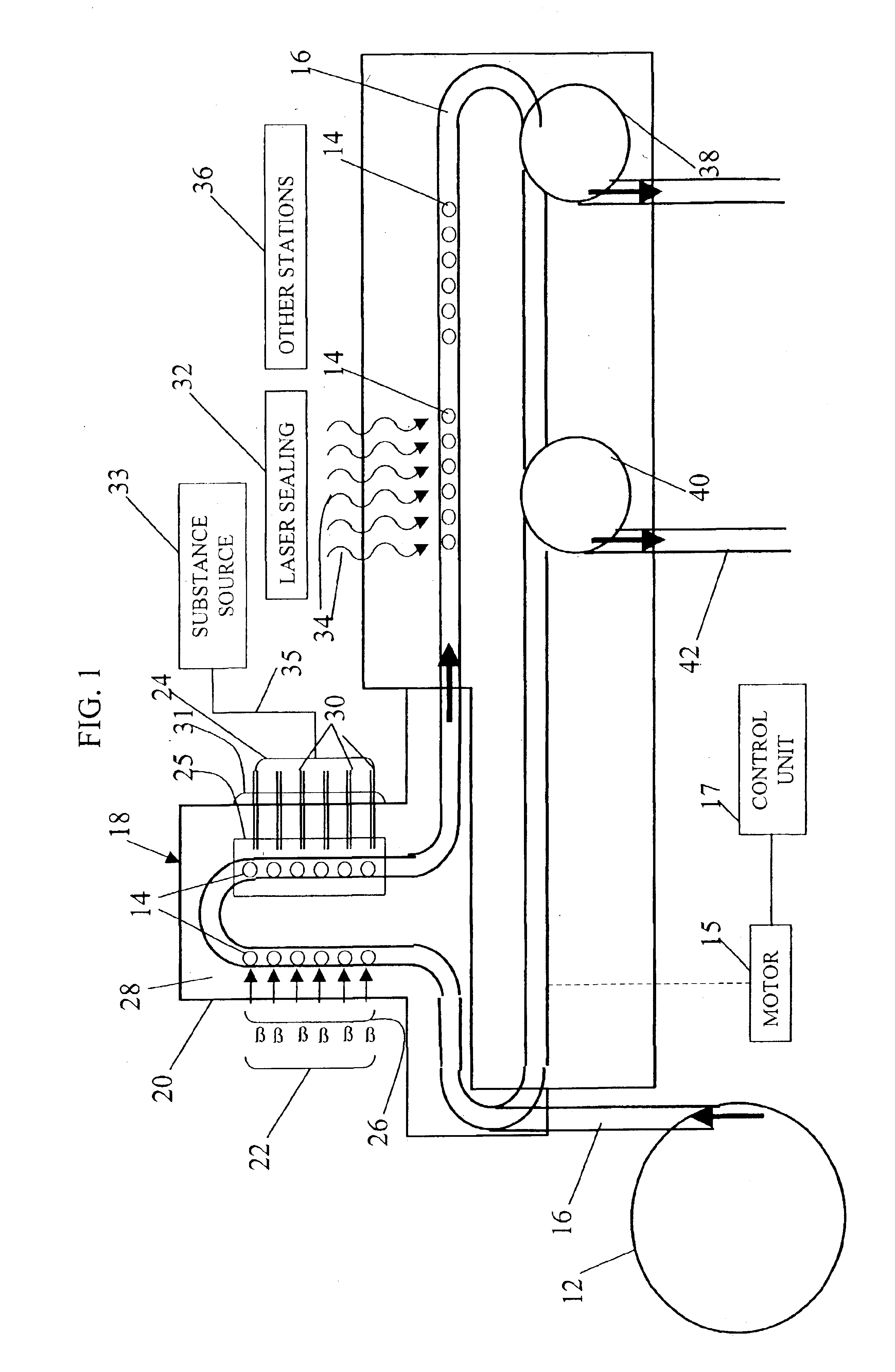

InactiveUS6929040B2Obstruct passageEliminate the risk of contaminationLiquid fillingPackage sterilisationEngineeringSyringe needle

A sterile filling machine and related method are provided for sterile filling a container with a substance. The container includes a heat resealable stopper and a chamber for receiving the substance therein. The sealed, empty containers are subjected to radiation capable of penetrating through the stopper and chamber for sterilizing the container. The previously sterilized containers are then transported through an e-beam chamber, wherein an electron beam is directed onto a penetrable surface of the stopper to sterilize the penetrable surface. A needle is mounted within the e-beam chamber and moved into engagement with the stopper to pierce the sterilized penetrable surface of the stopper and inject the substance through the needle and into the chamber of the container. The needle is then withdrawn from the stopper and the filled container is transported outside of the e-beam chamber. Laser energy is then transmitted onto the penetrated surface of the stopper to fuse the stopper material and hermetically re-seal the stopper.

Owner:MEDINSTILL DEV

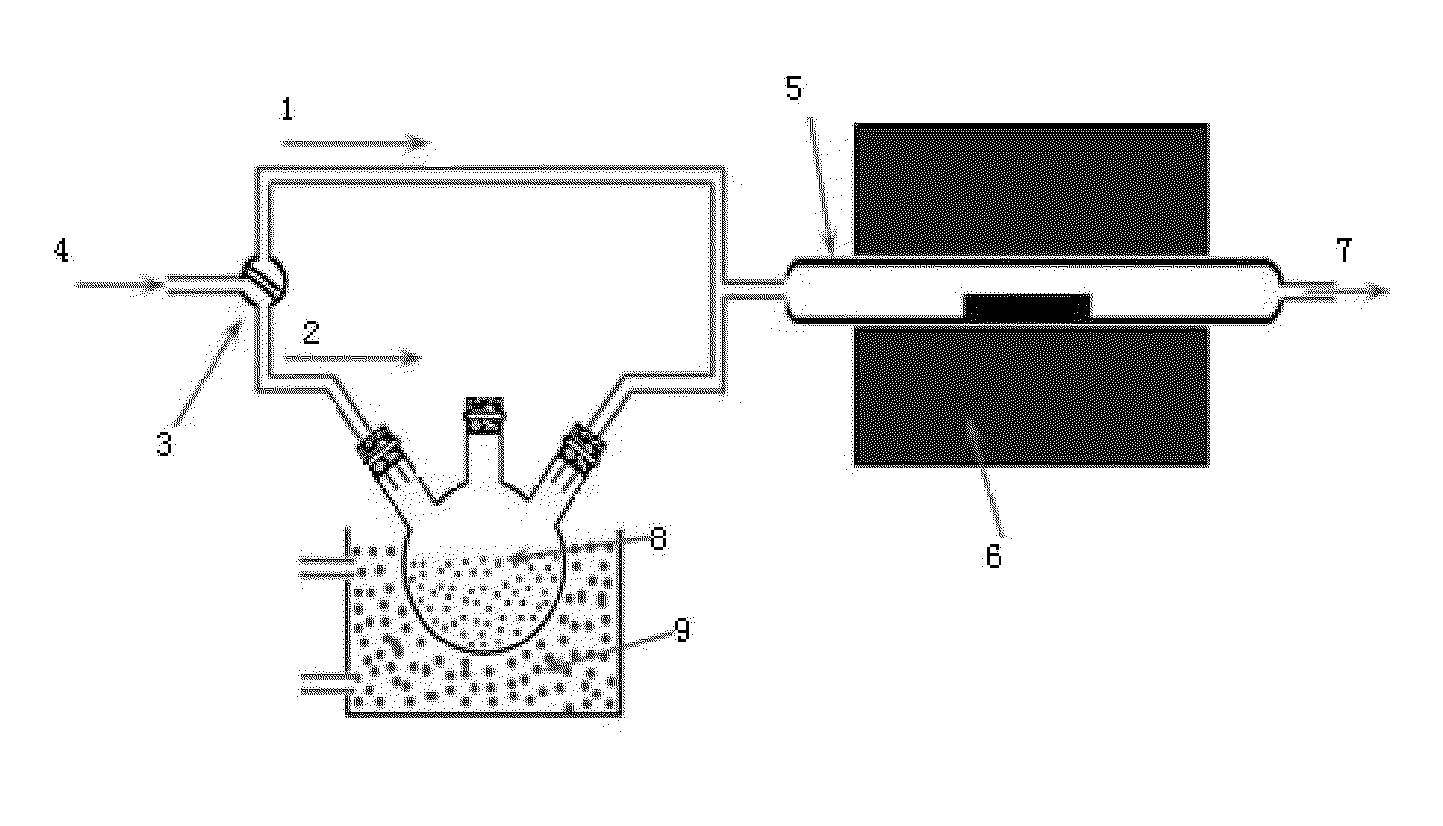

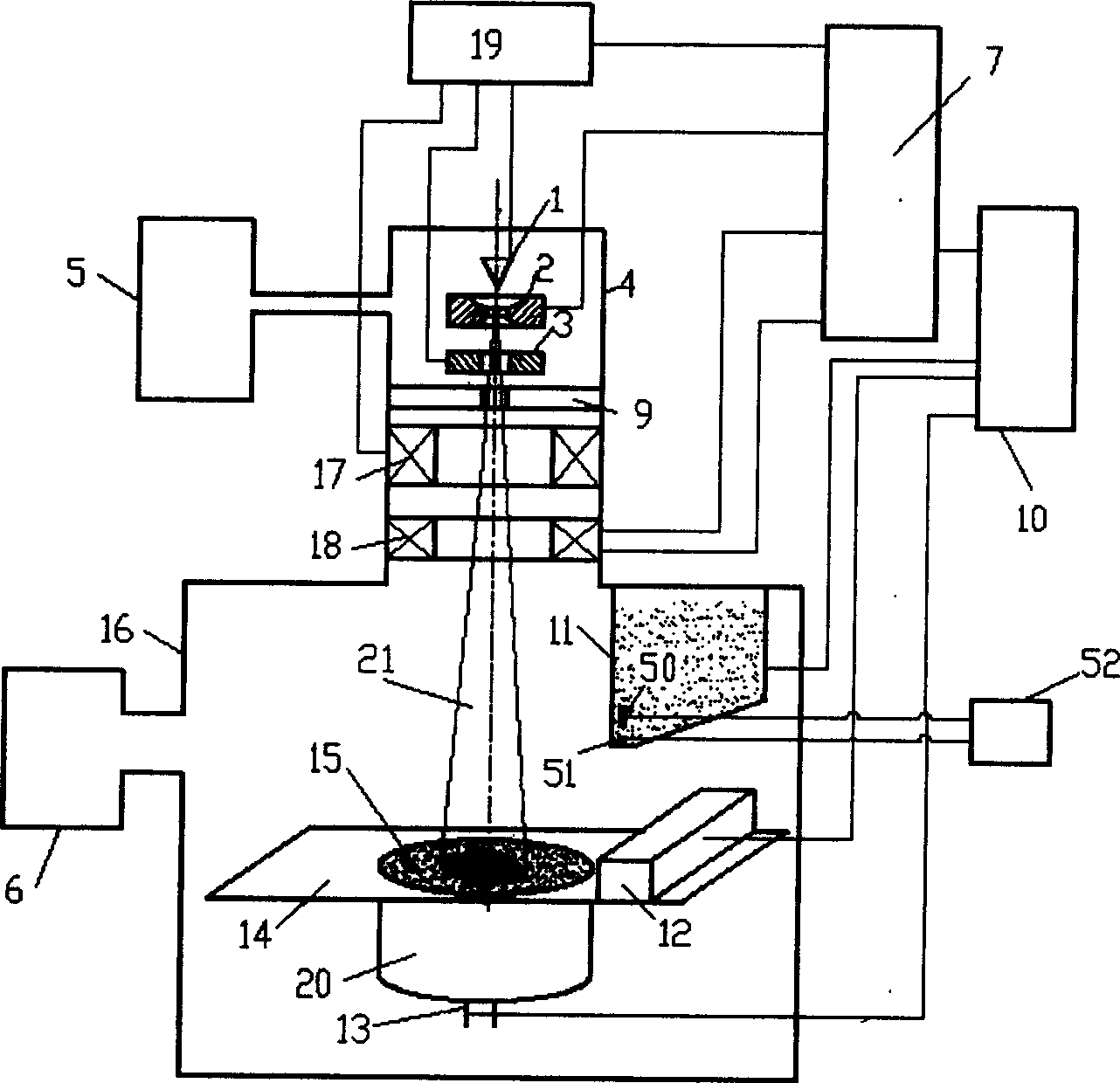

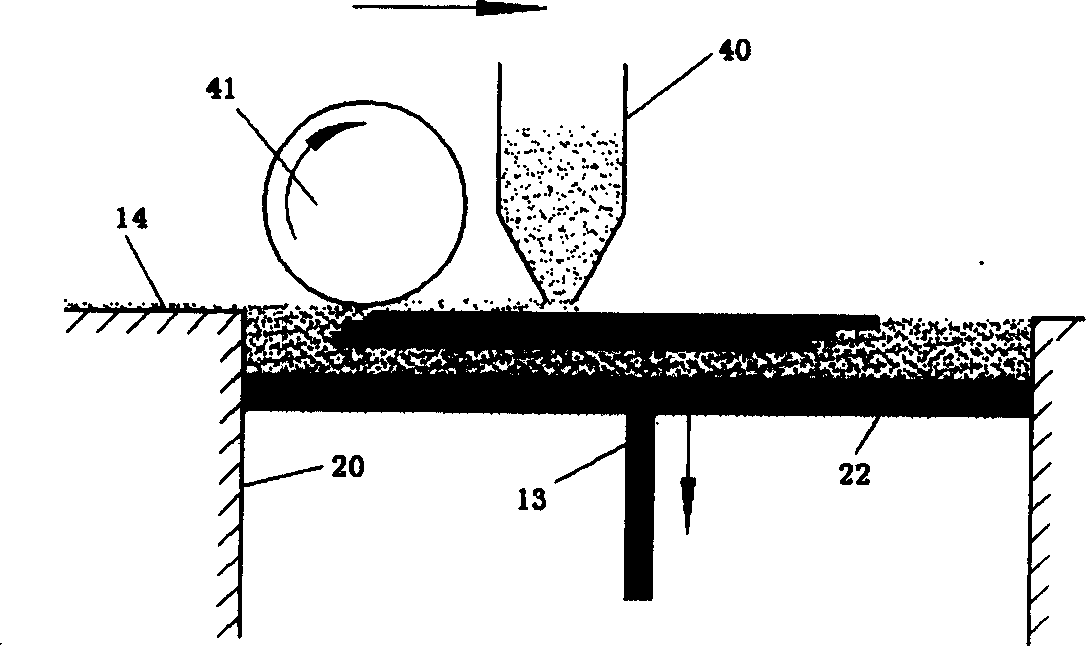

Synchronous sintering process for electronic beam selection zone and three dimension layered producing device

ActiveCN1648802AHigh speedHigh precisionComputer controlElectron beam welding apparatusRapid scanHeat stress

The present invention relates to technology and apparatus with high energy beam to sinter or melt and deposit material successively to realize laminated solid manufacture. The present invention features that the electronic beam scan controller controls the electronic beam to scan fast in pattern projection mode for heating powder homogeneously. Each scanning of the electronic beam has short time in the selected area, so that the scan initiating point has no great temperature change generated during the whole scanning course. Through one or several frames of scanning, the material in the forming area has temperature synchronously raised to reach the sintering or re-melting temperature for deposition onto the forming area before synchronous cooling. The present invention has greatly reduced heat stress and raised forming precision and quality.

Owner:TSINGHUA UNIV

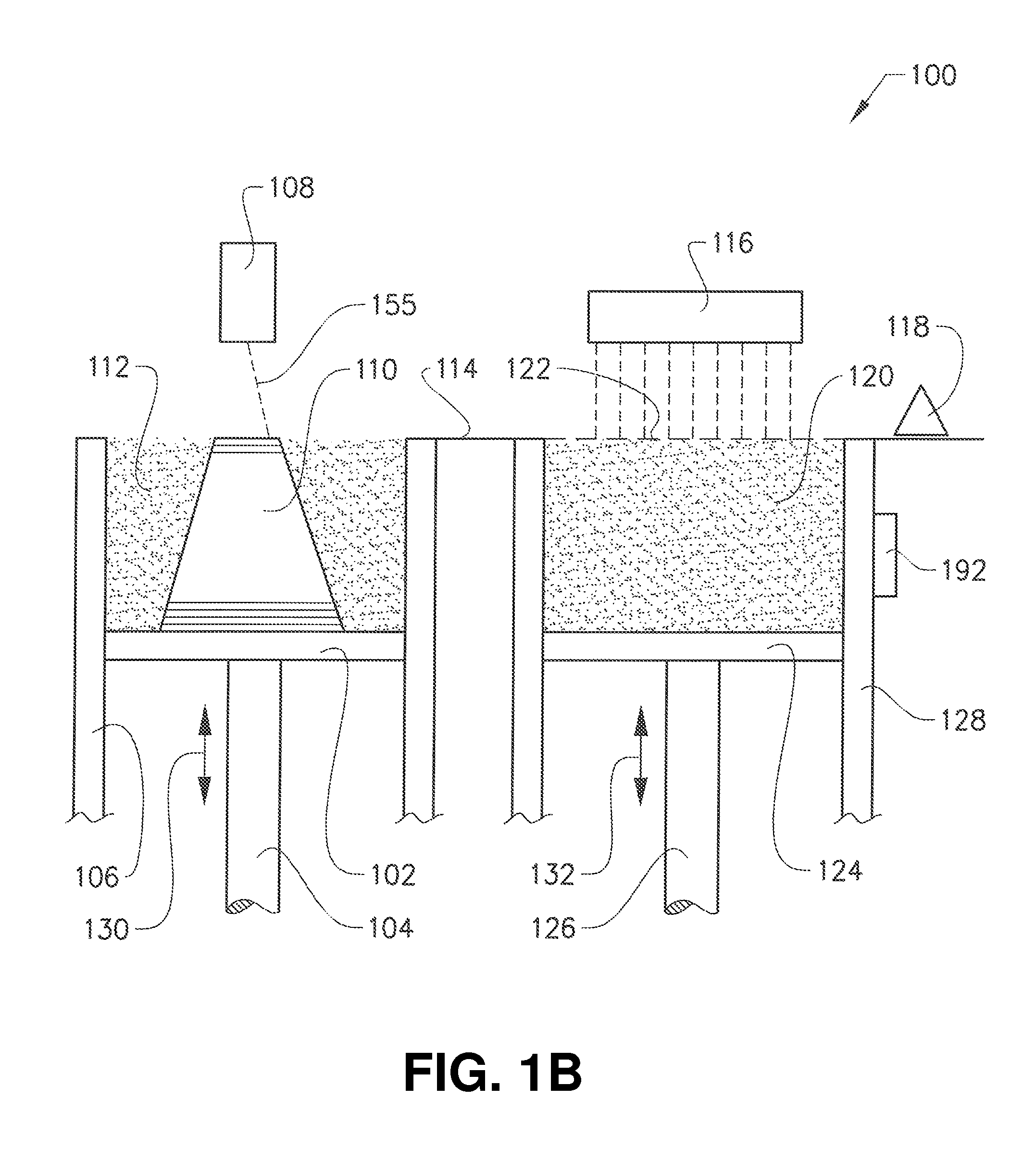

Equipment for manufacturing large-size metal part in high energy beam additive manufacturing mode and control method of equipment

ActiveCN104001915AImprove forming efficiencyShorten the "waiting time"Increasing energy efficiencyControl systemEngineering

The invention discloses equipment for manufacturing a large-size metal part in a high energy beam additive manufacturing mode and a control method of the equipment. The equipment comprises a work cavity, a worktable, a control system, a high energy beam scanning generator, a powder storage hopper, a powder laying device and a gas purification module, wherein the worktable is composed of a forming cylinder and a powder recycling cylinder, and the upper surface of the forming cylinder and the upper surface of the powder recycling cylinder are coplanar and form a work plane. The control system controls the high energy beam scanning generator and the powder laying device to move opposite to the worktable in the powder laying direction. The equipment for manufacturing the large-size metal part in the high energy beam additive manufacturing mode and the control method of the equipment largely shorten the waiting time caused by pre-installation of a powder bed when a common laser / electron beam selective melting technology is used for processing a part, thereby obviously improving the forming efficiency of high energy beam additive manufacturing. Through the application of the equipment for manufacturing the large-size metal part in the high energy beam additive manufacturing mode and the control method of the equipment, a metal part with a meter-grade size, high performance, high accuracy and a complex structure can be manufactured efficiently and rapidly.

Owner:TECH LASER TECH SHANGHAI CO LTD

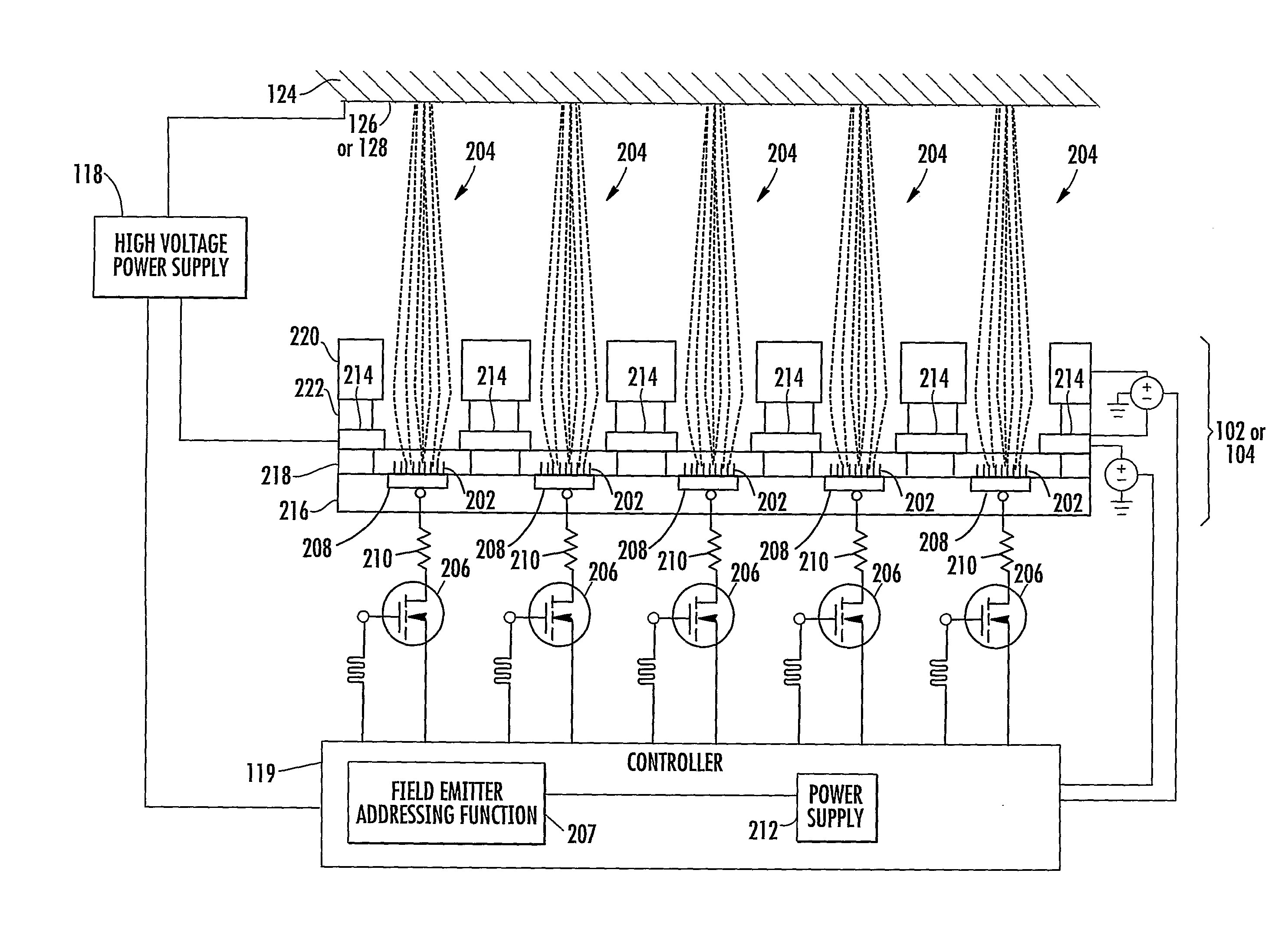

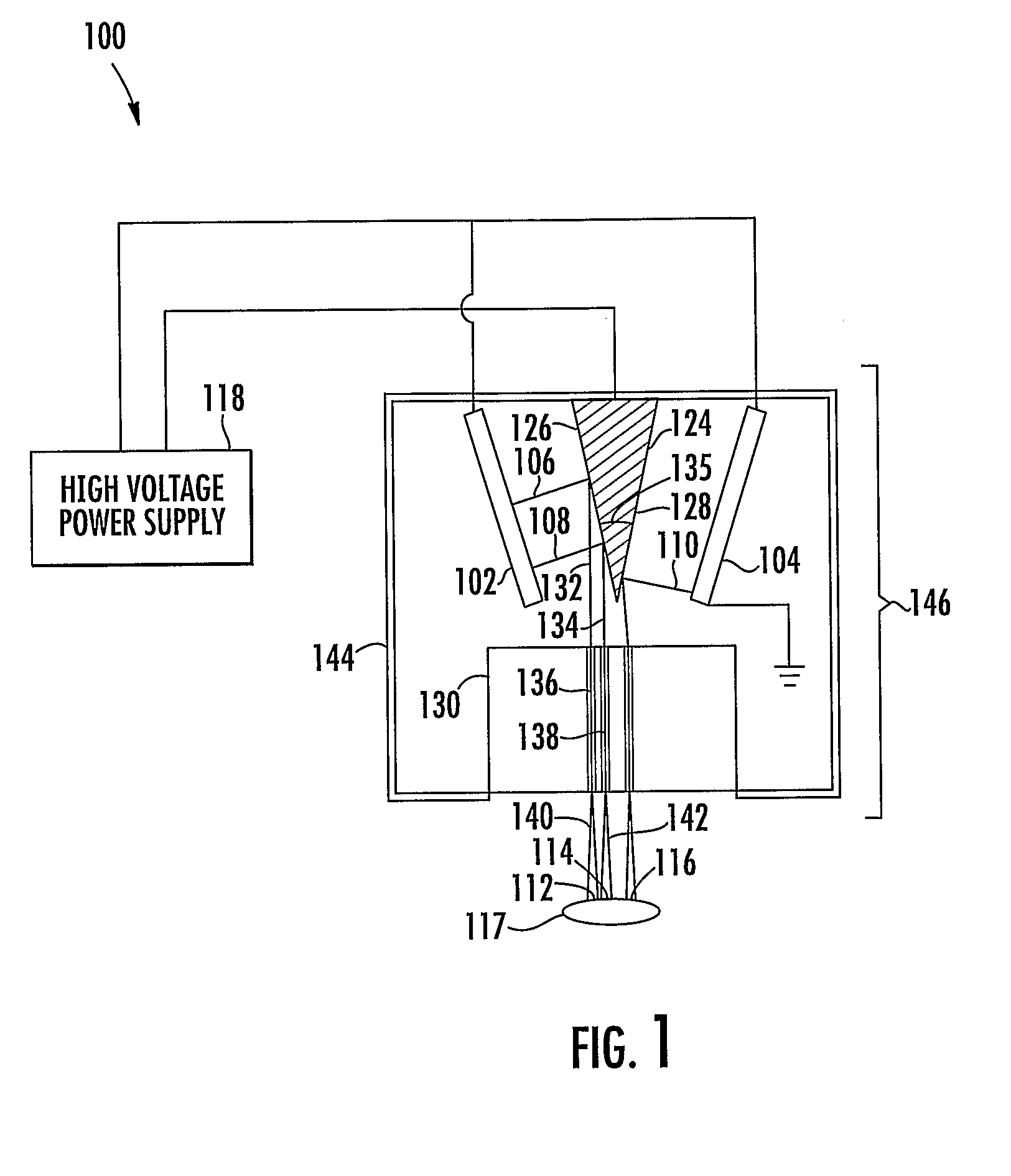

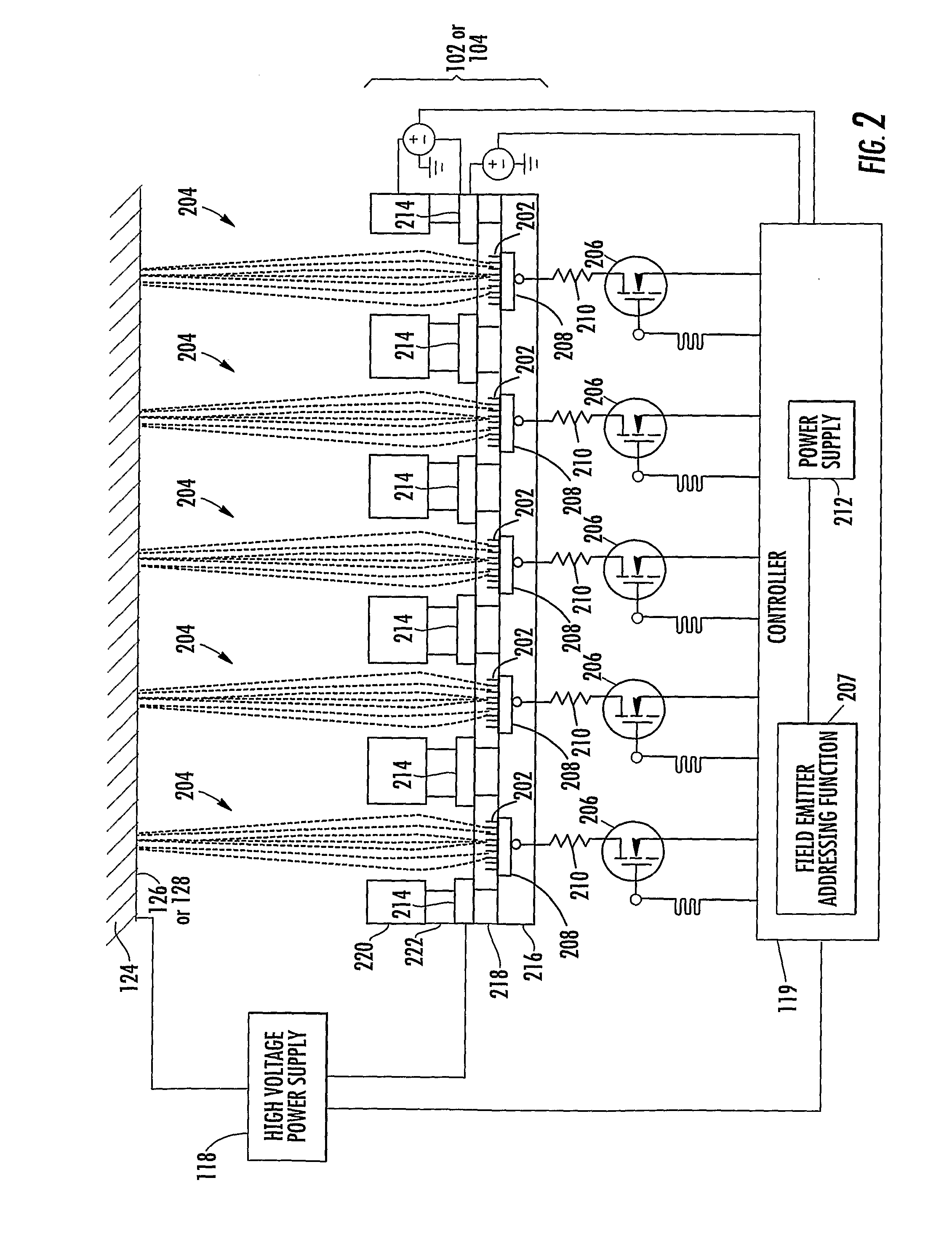

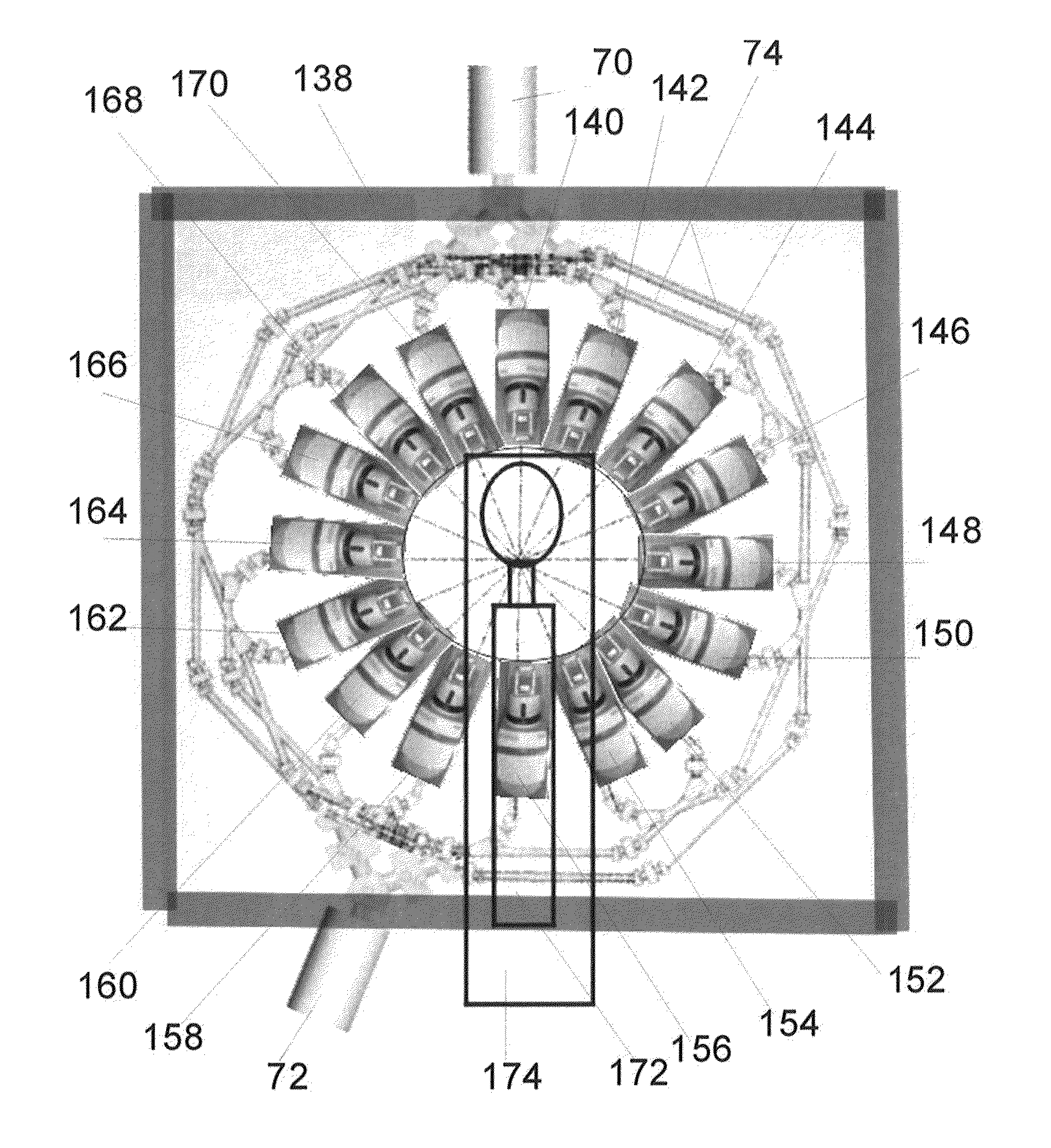

X-ray pixel beam array systems and methods for electronically shaping radiation fields and modulation radiation field intensity patterns for radiotherapy

ActiveUS20100260317A1Handling using diaphragms/collimetersX-ray tube with very high currentSoft x rayElectron source

X-ray pixel beam array systems and methods for electronically shaping radiation fields and modulating radiation field intensity patterns for radiotherapy are disclosed. One exemplary pre-clinical system may include addressable electron field emitters (102, 104) that are operable to emit a plurality of electron pixel beams (106, 108, 110). Each electron pixel beam may correspond to an x-ray target (124) and x-ray pixel beam collimation aperture (136, 138) to convert a portion of energy associated with the electron pixel beam to a corresponding x-ray pixel beam (140, 142). Further, the x-ray pixel beam array collimator (130) forms a one-to-one correspondence between individual electron pixel beam and its corresponding x-ray pixel beam. One exemplary clinical system may include a high-energy electron source (1203), an n-stage scanning system (1210), x-ray pixel beam targets (1212), and an x-ray pixel beam array collimator (1214). A controller (1206) may sequentially direct electron beam pulses to predetermined x-ray pixel targets and produce an electronically controlled radiation field direction, pattern; and intensity pattern.

Owner:DUKE UNIV +1

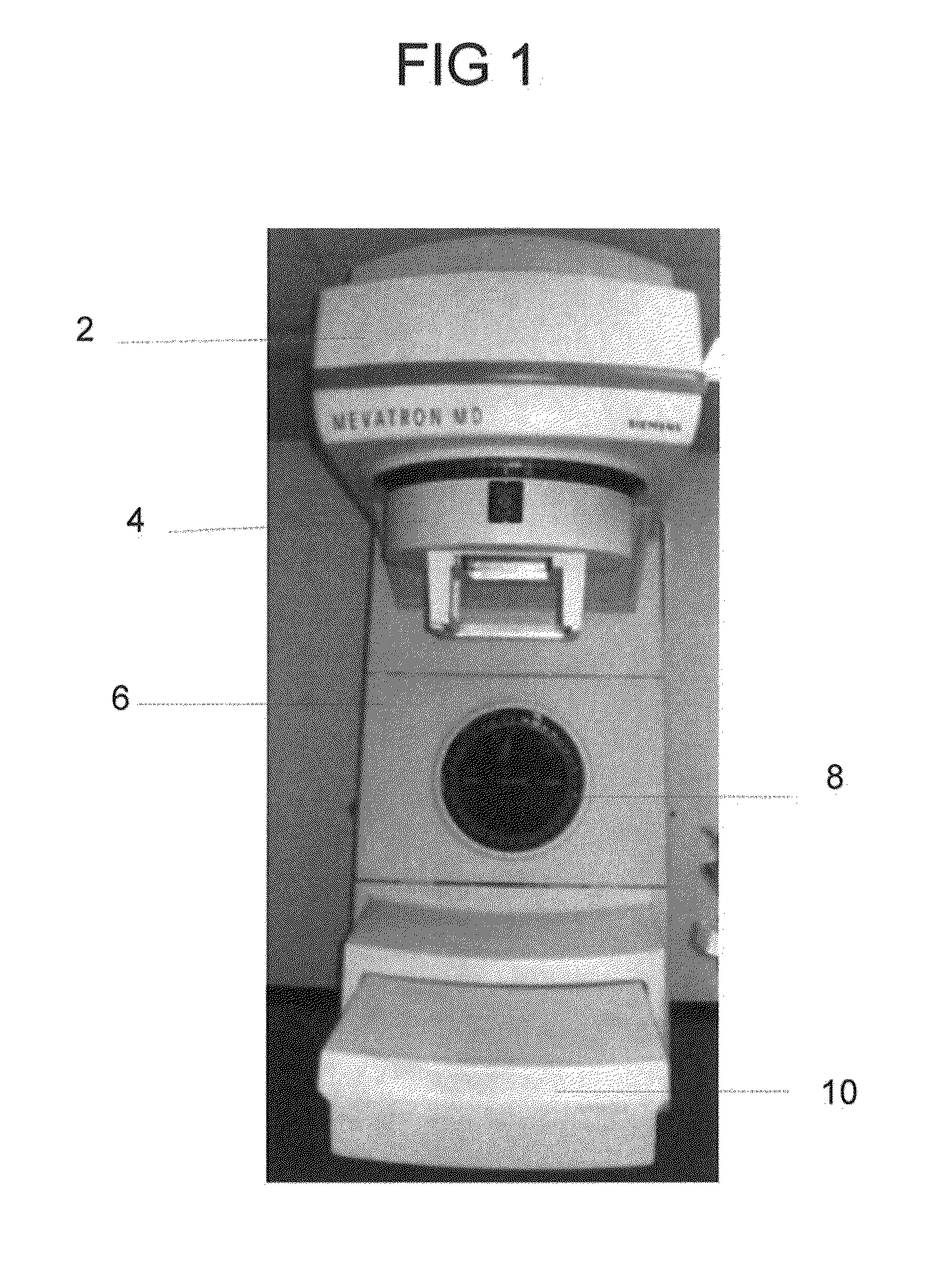

Lethal and sublethal damage repair inhibiting image guided simultaneous all field divergent and pencil beam photon and electron radiation therapy and radiosurgery

InactiveUS7835492B1Improve modulationIncrease radiation intensityIrradiation devicesX-ray/gamma-ray/particle-irradiation therapyRadiosurgeryC banding

A medical accelerator system is provided for simultaneous radiation therapy to all treatment fields. It provides the single dose effect of radiation on cell survival. It eliminates the inter-field interrupted, subfractionated fractionated radiation therapy. Single or four beams S-band, C-band or X-band accelerators are connected to treatment heads through connecting beam lines. It is placed in a radiation shielding vault which minimizes the leakage and scattered radiation and the size and weight of the treatment head. In one version, treatment heads are arranged circularly and connected with the beam line. In another version, a pair of treatment heads is mounted to each ends of narrow gantries and multiple such treatment heads mounted gantries are assembled together. Electron beam is steered to all the treatment heads simultaneously to treat all the fields simultaneously. Radiating beam's intensity in a treatment field is modulated with combined divergent and pencil beam, selective beam's energy, dose rate and weight and not with MLC and similar devices. Since all the treatment fields are treated simultaneously the dose rate at the tumor site is the sum of each of the converging beam's dose rate at depth. It represents the biological dose rate. The dose rate at d-max for a given field is the individual machine dose rate. Its treatment options includes divergent or pencil beam modes. It enables to treat a tumor with lesser radiation toxicities to normal tissue and higher tumor cure and control.

Owner:SAHADEVAN VELAYUDHAN

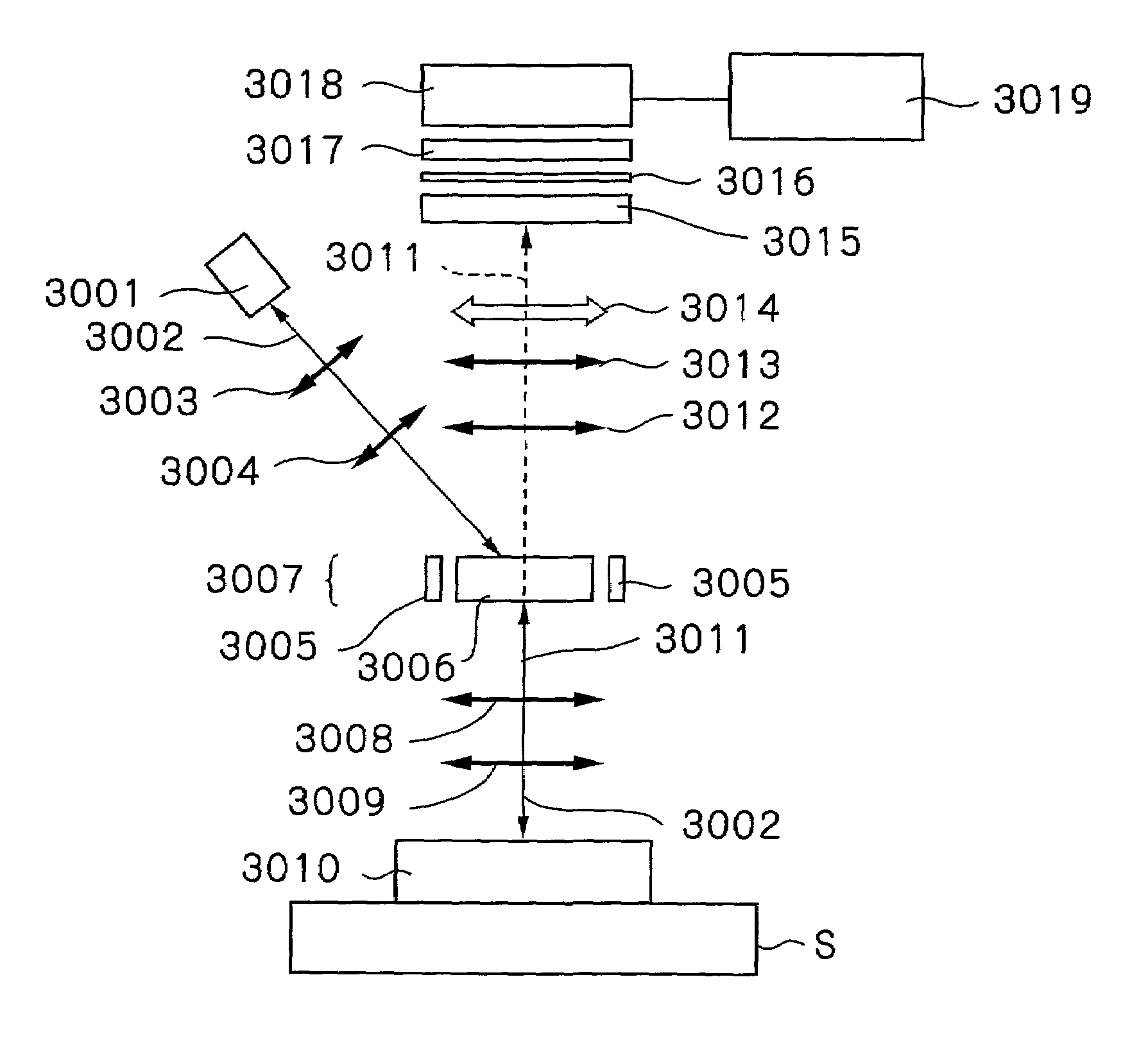

Electron beam inspection system and inspection method and method of manufacturing devices using the system

InactiveUS6992290B2Inspection speed is fastImprove inspection speedMaterial analysis using wave/particle radiationElectric discharge tubesLine sensorSecondary electrons

An electron beam inspection system of the image projection type includes a primary electron optical system for shaping an electron beam emitted from an electron gun into a rectangular configuration and applying the shaped electron beam to a sample surface to be inspected. A secondary electron optical system converges secondary electrons emitted from the sample. A detector converts the converged secondary electrons into an optical image through a fluorescent screen and focuses the image to a line sensor. A controller controls the charge transfer time of the line sensor at which the picked-up line image is transferred between each pair of adjacent pixel rows provided in the line sensor in association with the moving speed of a stage for moving the sample.

Owner:EBARA CORP

Electron beam layer manufacturing

ActiveUS8546717B2Obstruct passageProgramme controlAdditive manufacturing apparatusFree formClosed loop

A process and apparatus for free form fabrication of a three-dimensional work piece comprising (a) feeding raw material in a solid state to a first predetermined location; (b) depositing the raw material onto a substrate as a molten pool deposit under a first processing condition; (c) monitoring the molten pool deposit for a preselected condition; (d) comparing information about the preselected condition of the monitored molten pool deposit with a predetermined desired value for the preselected condition of the monitored molten pool deposit; (e) solidifying the molten pool deposit; (f) automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step (d); and repeating steps (a) through (f) at one or more second locations for building up layer by layer a three-dimensional work piece. The apparatus is characterized by a detector that monitors a preselected condition of the deposited material and a closed loop electronic control device for controlling operation of one or more components of the apparatus in response to a detected condition by the detector.

Owner:SCIAKY SA

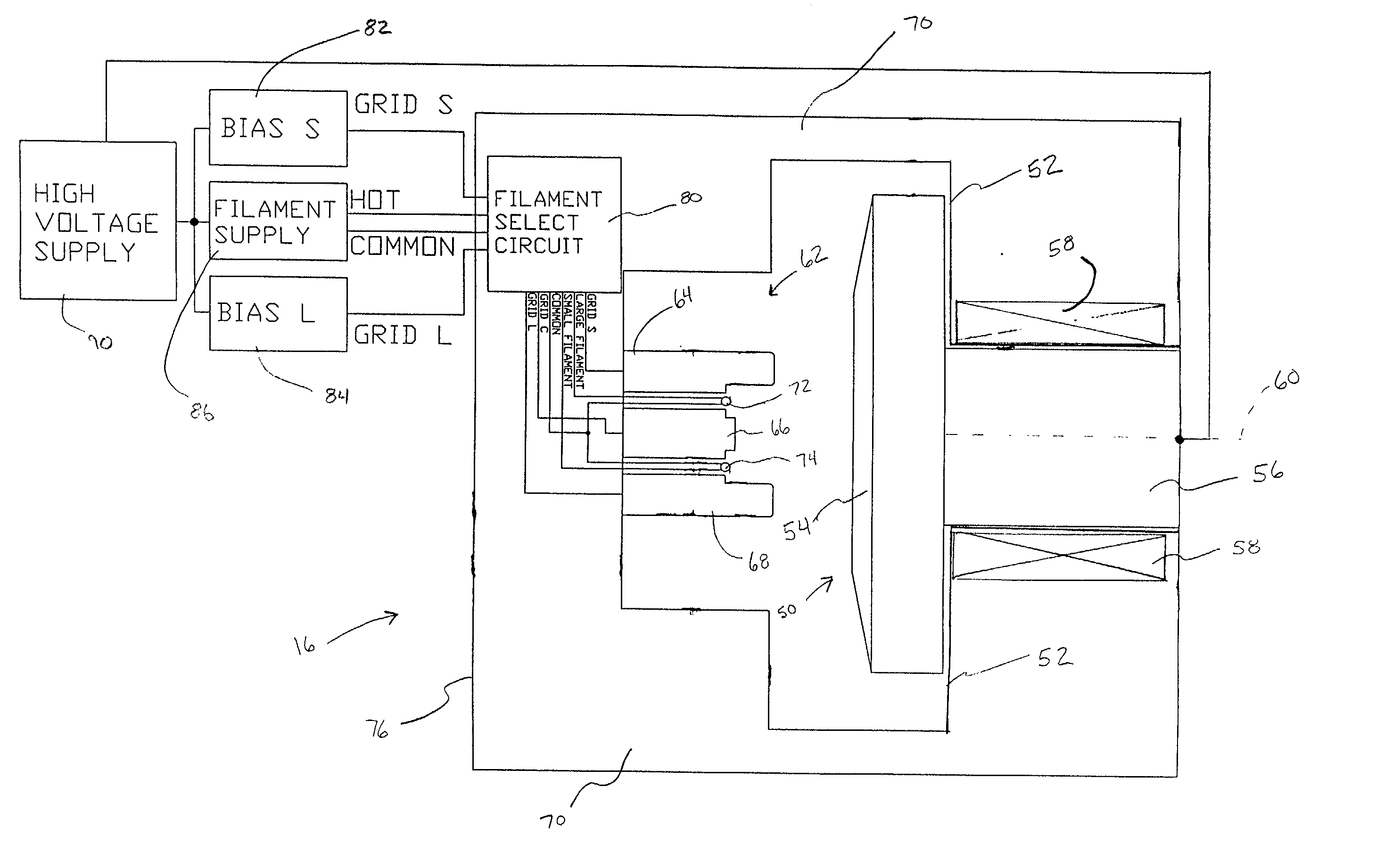

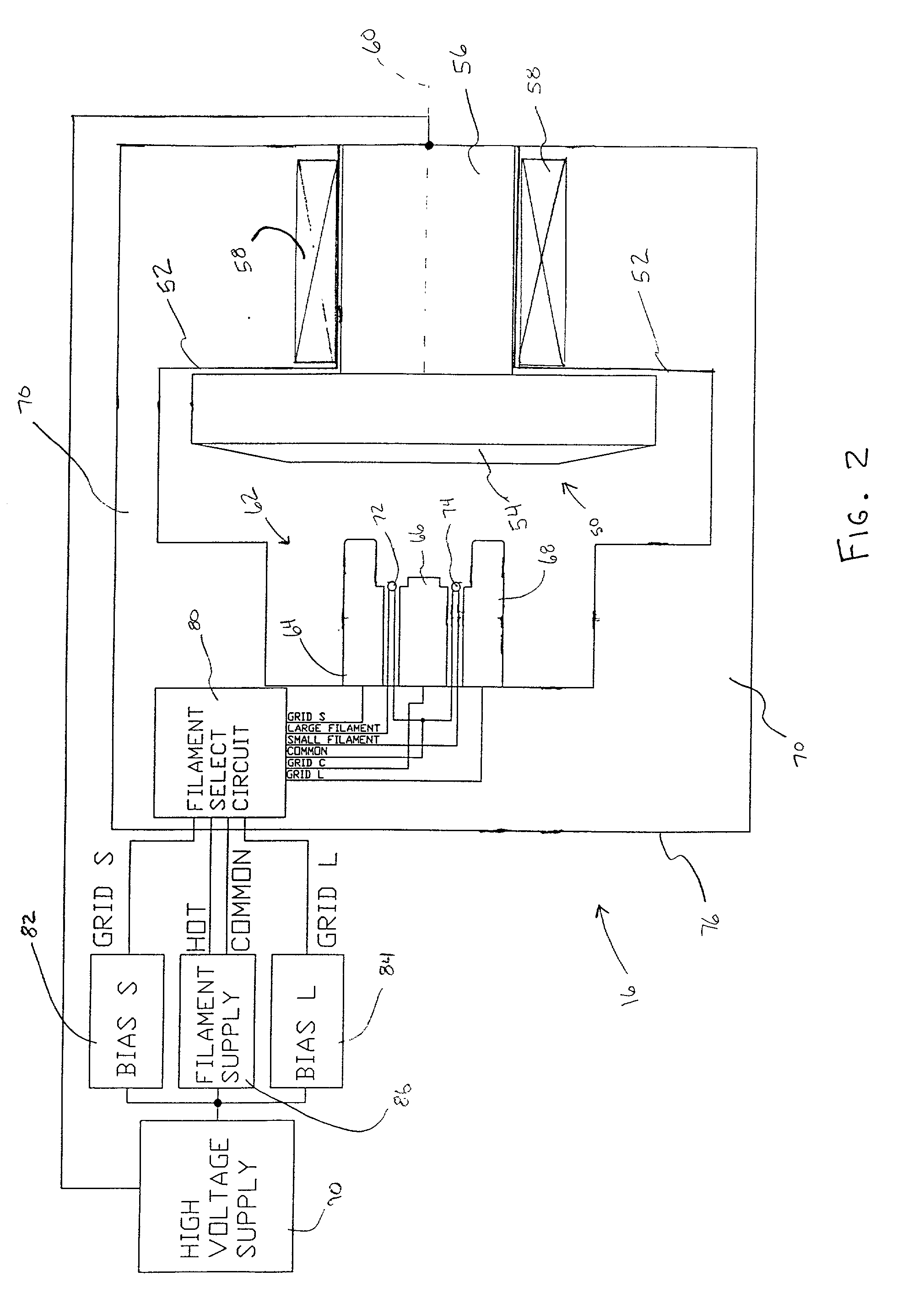

Dual filament, electrostatically controlled focal spot for x-ray tubes

InactiveUS20020126798A1High x-ray fluxIncrease sampling densityX-ray tube electrodesCathode ray concentrating/focusing/directingX-rayVariable length

A dual filament x-ray tube assembly (16) includes an evacuated envelope (52) having an anode (54) disposed at a first end of the evacuated envelope (52) and a cathode assembly (62) disposed at a second end of the evacuated envelope (52). The cathode assembly includes a variable-length filament assembly (72, 74; 100) which emits electron beams for impingement on the anode (54) at focal spots having varying lengths. The cathode assembly (62) further includes a cathode cup (64, 66, 68; 110, 112) which is subdivided into a plurality of electrically insulated deflection electrodes (64, 66, 68; 110, 112). A filament select circuit (80) selectively and individually heats a portion of the variable-length filament assembly (72, 74). Electron beams emitted from the filament assembly (72, 74) are electrostatically focused and controlled by applying potentials to different ones of the deflection electrodes (64, 66, 68; 110, 112). The x-ray tube assembly (16) provides longer focal spots for thick-slice scanning applications and shorter focal spots for thin-slice scanning applications along with the benefit of electrostatic focusing and control.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com