Synchronous sintering process for electronic beam selection zone and three dimension layered producing device

A three-dimensional layering, manufacturing equipment technology, applied in electron beam welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of low efficiency, can only be sintered and deposited point by point or partition, and can only be sintered and deposited point by point or partition. Heating etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

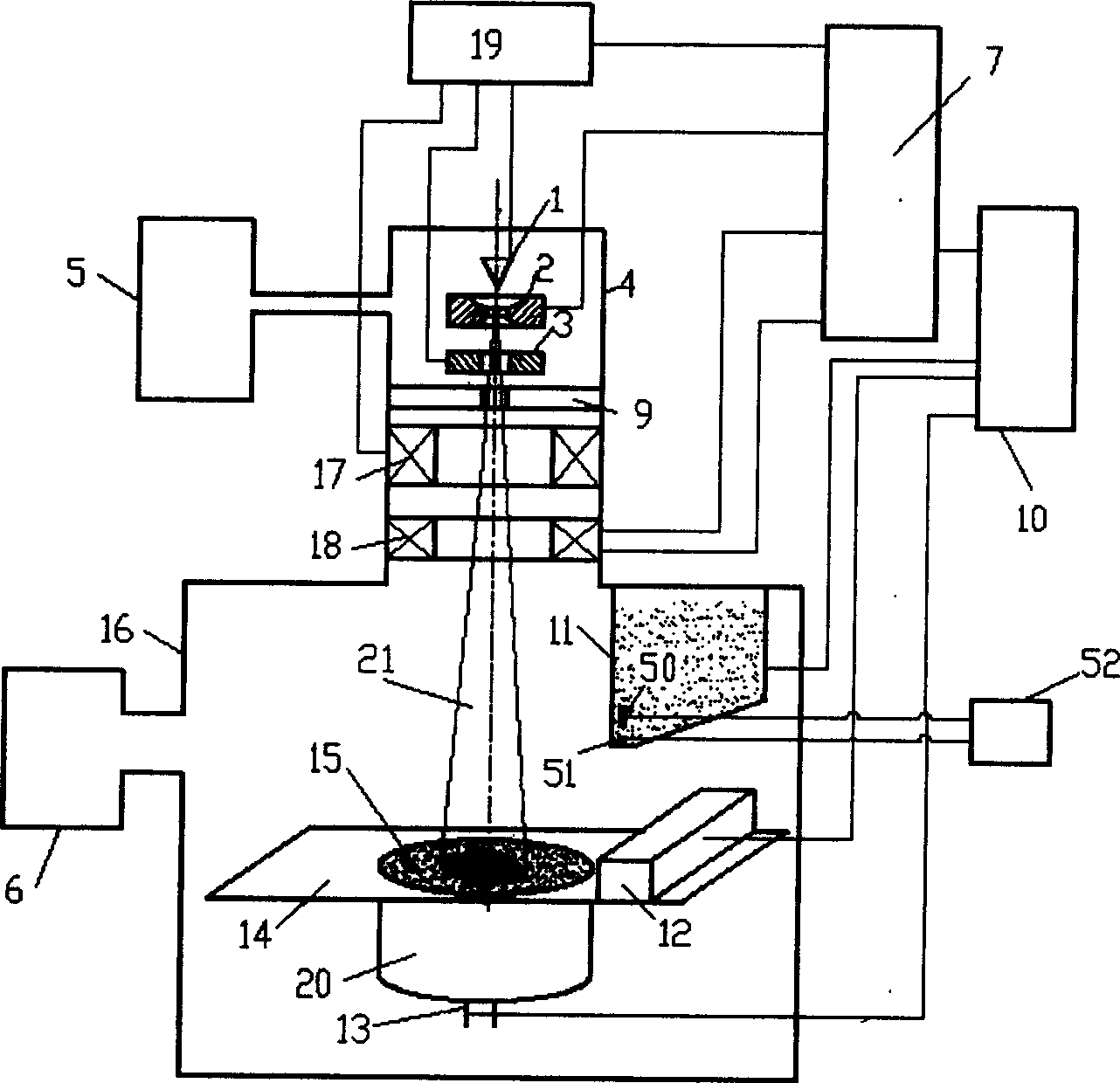

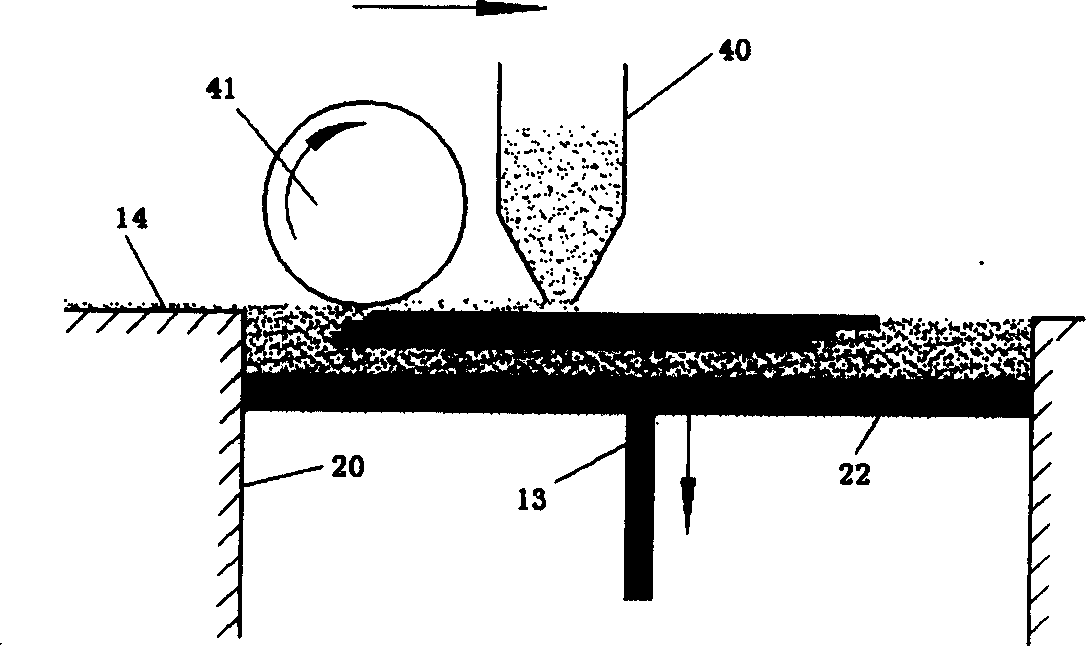

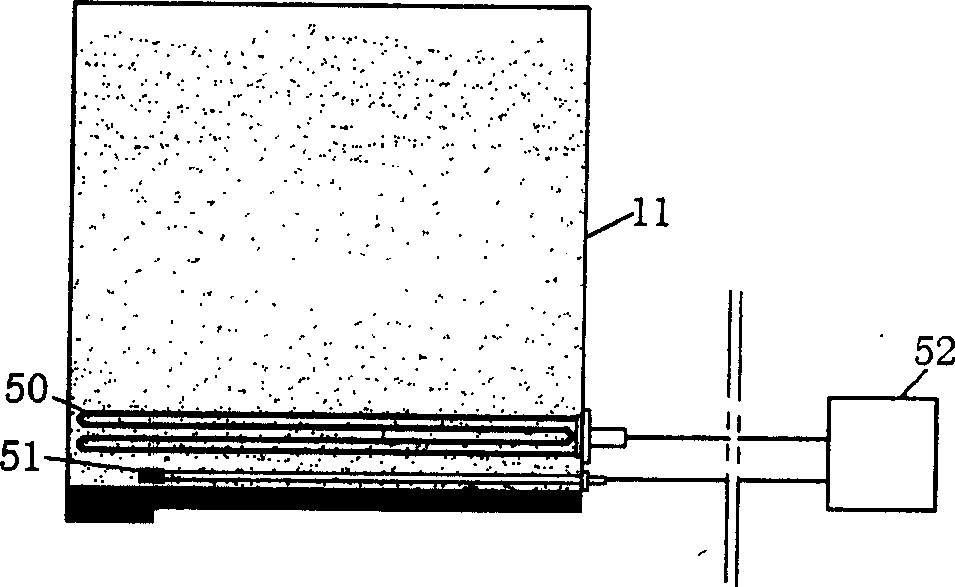

[0027]The three-dimensional layered manufacturing equipment provided by the present invention mainly includes the following parts: a powder spreading platform 14, which is used to constrain the powder in the powder spreading process; After the piston falls to a preset height relative to the powder spreading platform, a narrow space with a set height is formed on the upper part of the forming cylinder; the height of the space is equal to the thickness of the layer to be constructed; the powder spreading and pressing device 12 is located at On the powder spreading platform, the powder spreading platform can be swept horizontally to fill the carried powder in the upper space of the molding cylinder and flatten and compact it, and send the excess powder to the residual material recovery device; the powder supply device 11, It is installed above the powder spreading platform for storing and supplying powder; the powder recovery device is suspended at both ends of the powder spreadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com