Patents

Literature

877 results about "Material recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material recovery. Resource recovery method in which emphasis is on separating and processing waste products to reclaim usable material.

Method for determining the extent of recovery of materials injected into oil wells during oil and gas exploration and production

Disclosed is a method of determining the extent of recovery of materials injected into a oil well comprising the steps of: a) preparing a material to be injected into an oil well; b) admixing therewith a chemical tracer compound at a predetermined concentration; c) injecting the admixture into an oil well; d) recovering from the oil well a production fluid; e) analyzing the production fluid for the concentration of the chemical tracer present in the production fluid; and f) calculating the amount of admixture recovered from the oil well using the concentration of the chemical tracer present in the production fluid as a basis for the calculation. Fluorinated benzoic acids are disclosed as a preferred tracer.

Owner:CORE LAB LP

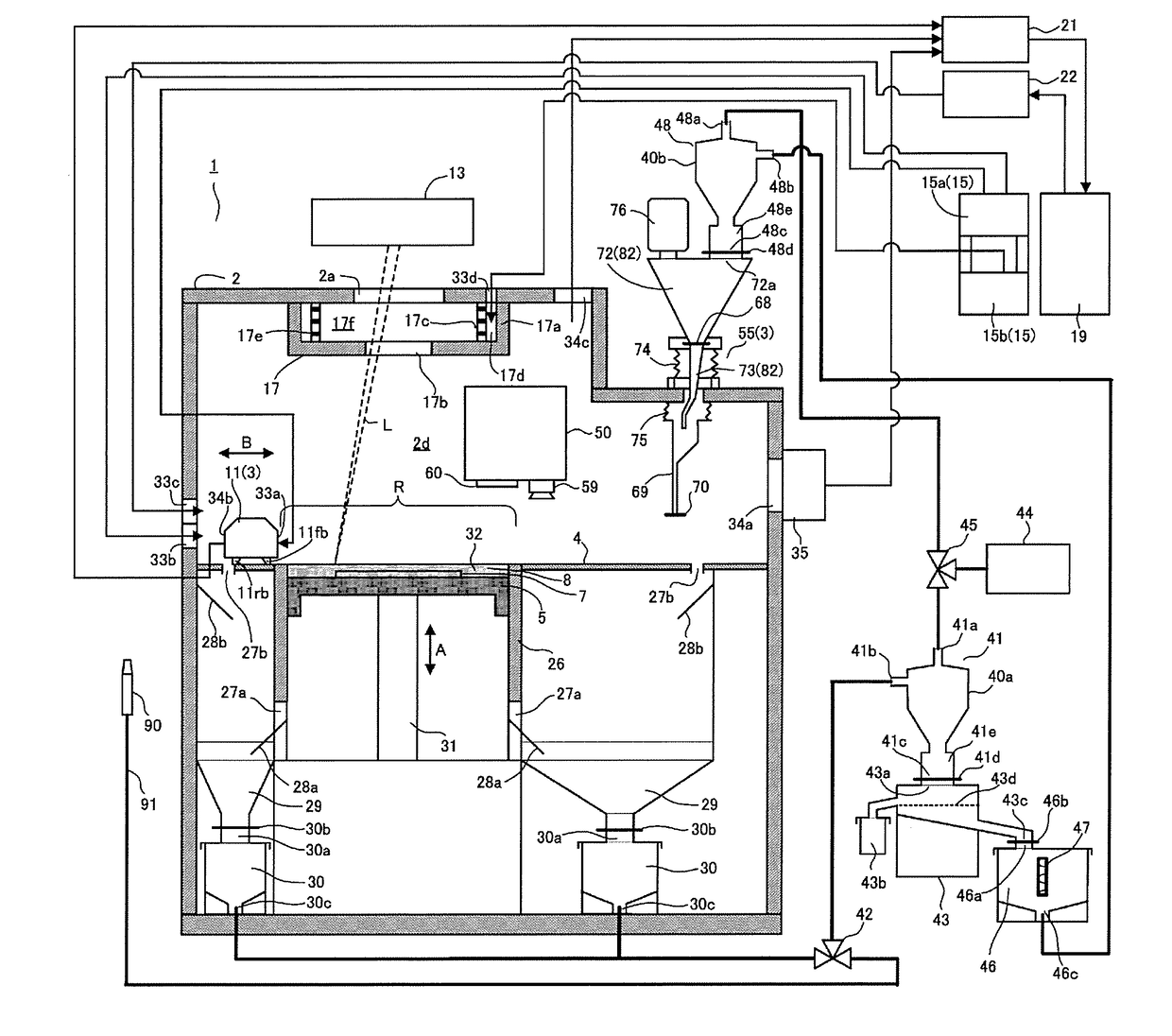

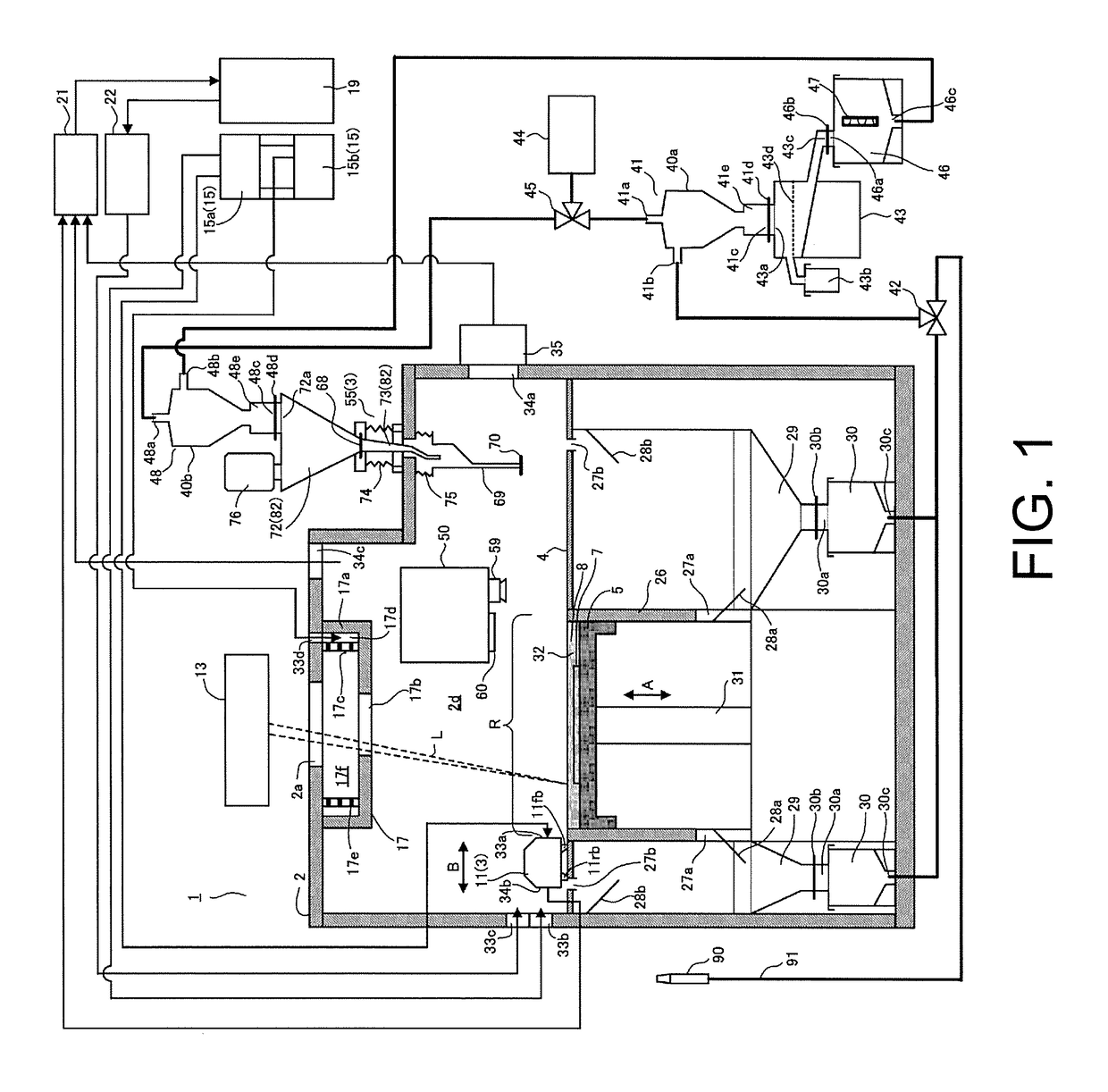

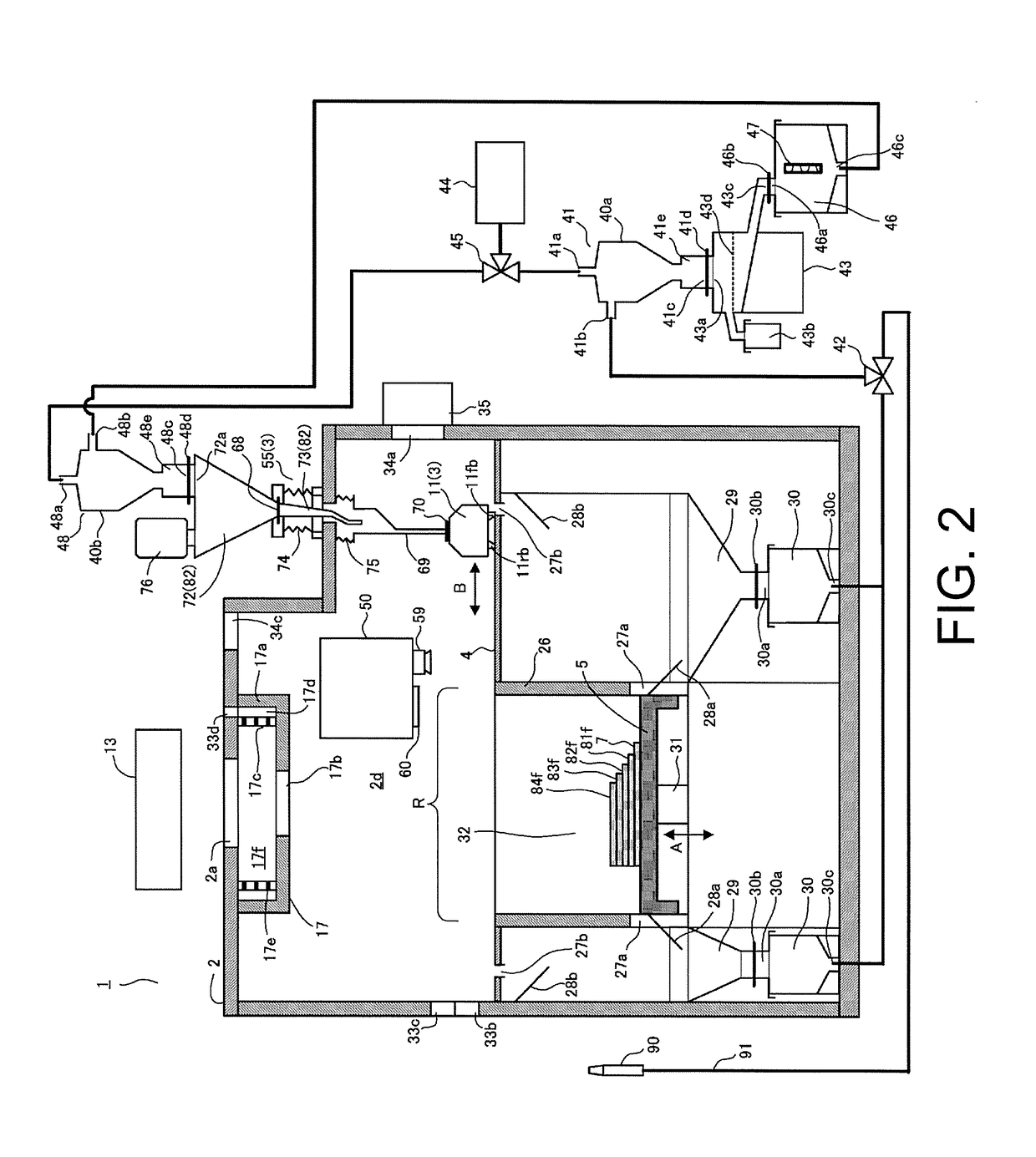

Three-dimensional printer

ActiveUS20170348771A1Form evenlyLong automationManufacturing enclosuresManufacturing material handlingMaterial supplyRetaining wall

A three-dimensional printer (1) includes a material supply device (3) that supplies material powder to a table which is movable vertically, a powder retaining wall (26) that surrounds the table and retains the material powder, a material-recovery bucket (30) that accommodates excess material powder and impurities discharged from the powder retaining wall, an impurity removing device (43) that removes the impurities from the material powder, and a material drying device (47) that dries the material powder. The material powder from which the impurities have been removed and which has been dried is returned and recycled to the material supply device.

Owner:SODICK CO LTD

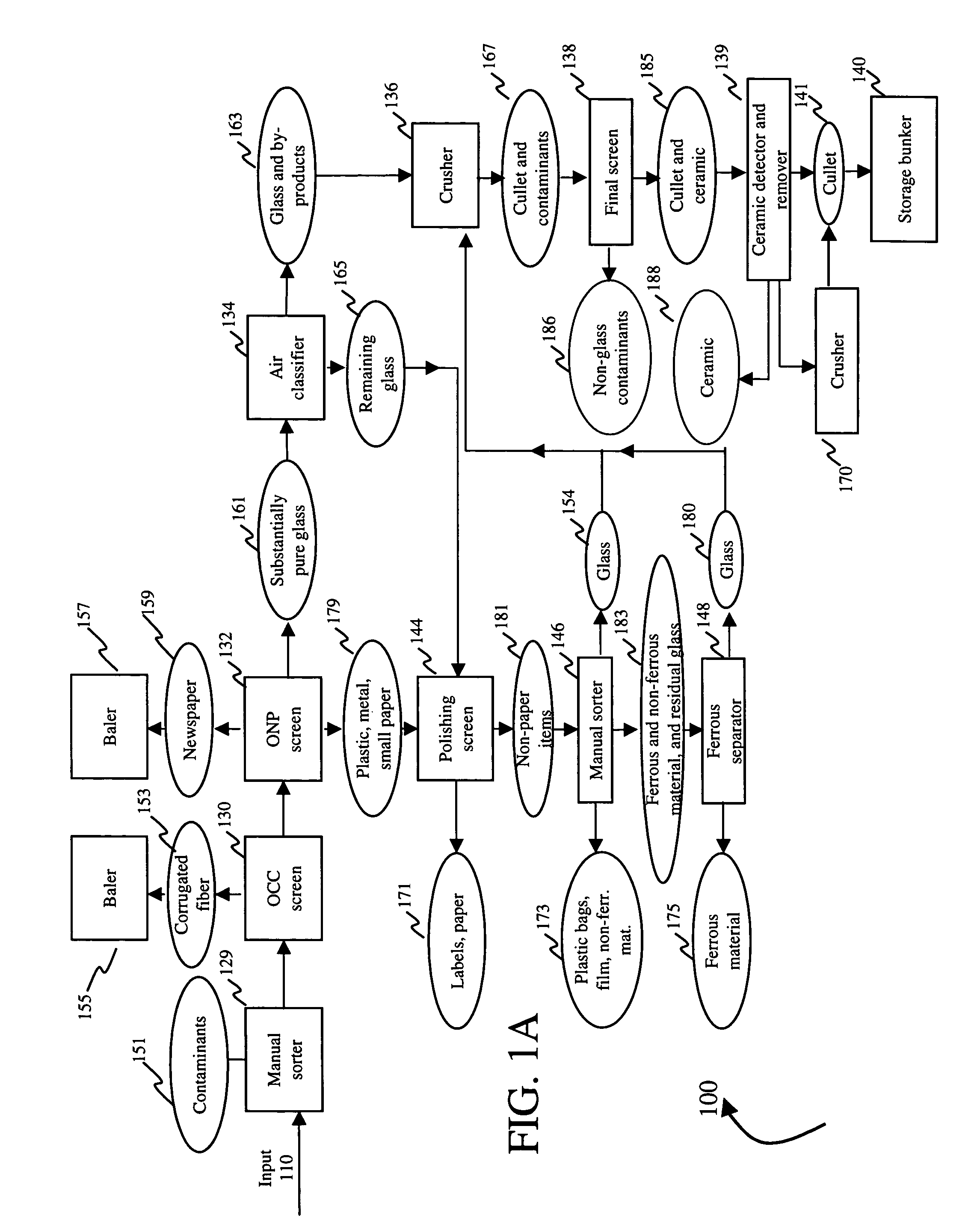

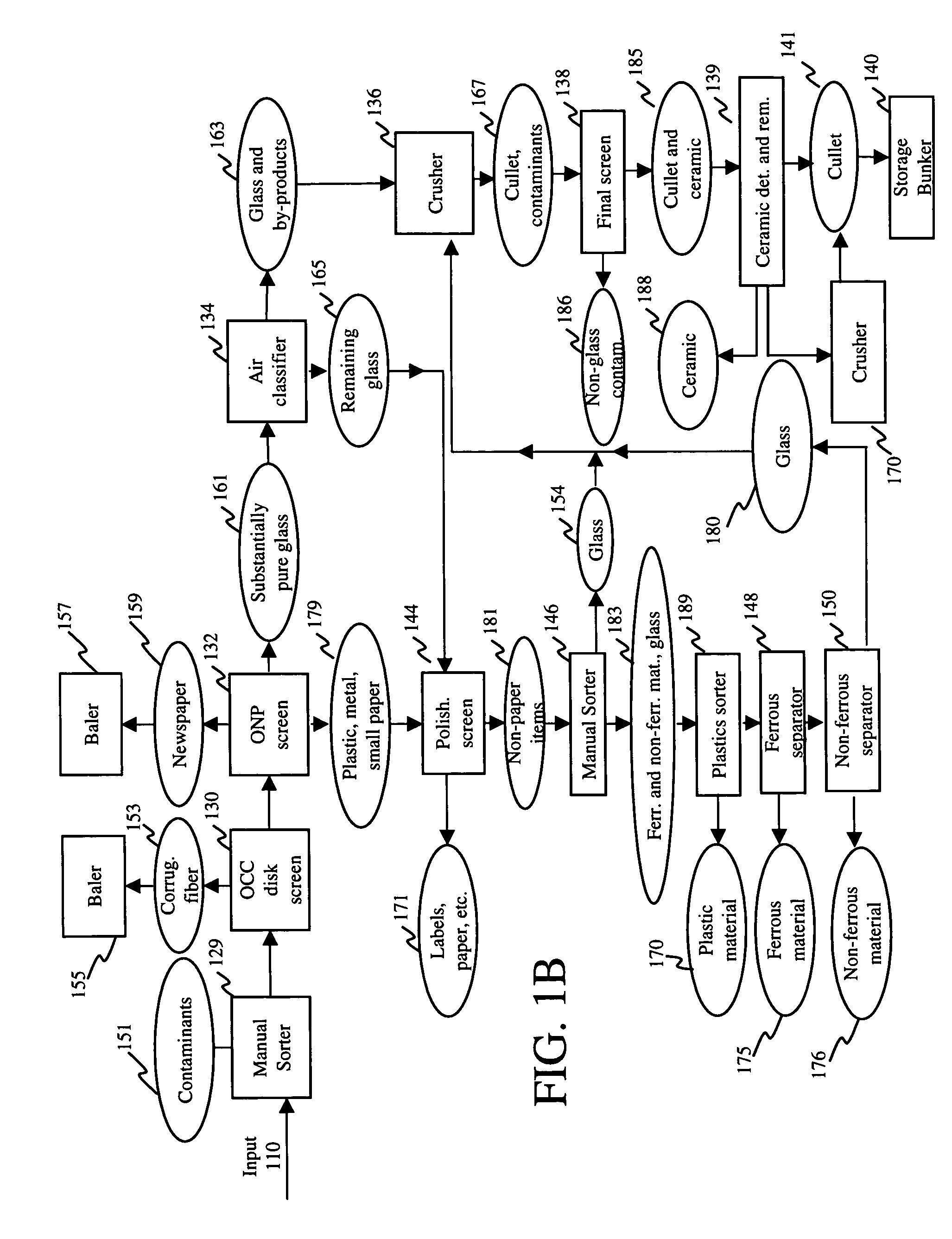

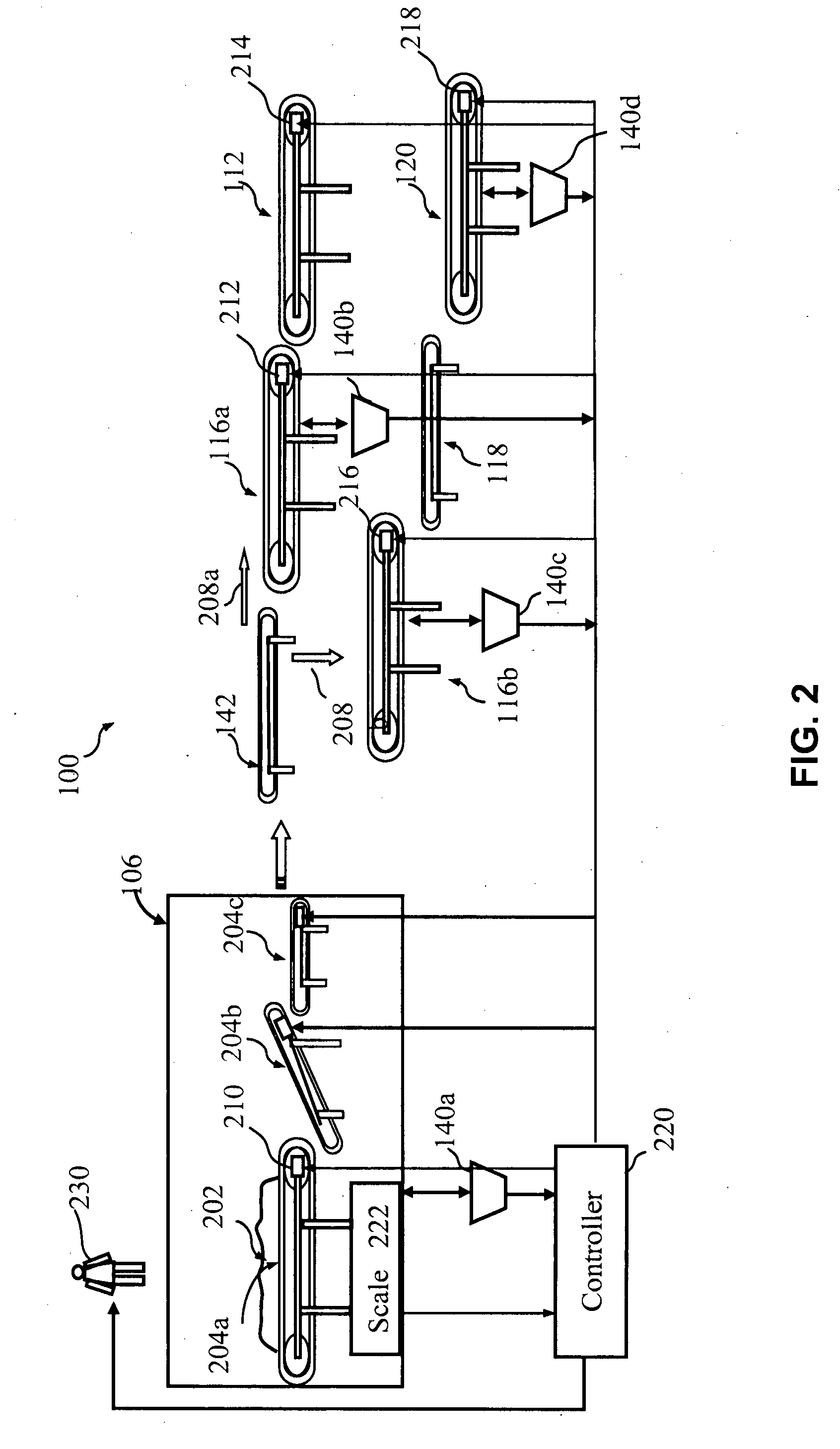

Systems and methods for sorting, collecting data pertaining to and certifying recyclables at a material recovery facility

Systems and methods for collecting data pertaining to glass, plastic and / or paper composition within an input stream that includes recyclable material. The data collected can pertain, for example, to the weight and / or volume of the glass, plastic and / or paper within the input stream. The data can be certified for use a third party.

Owner:THE CLOROX CO +1

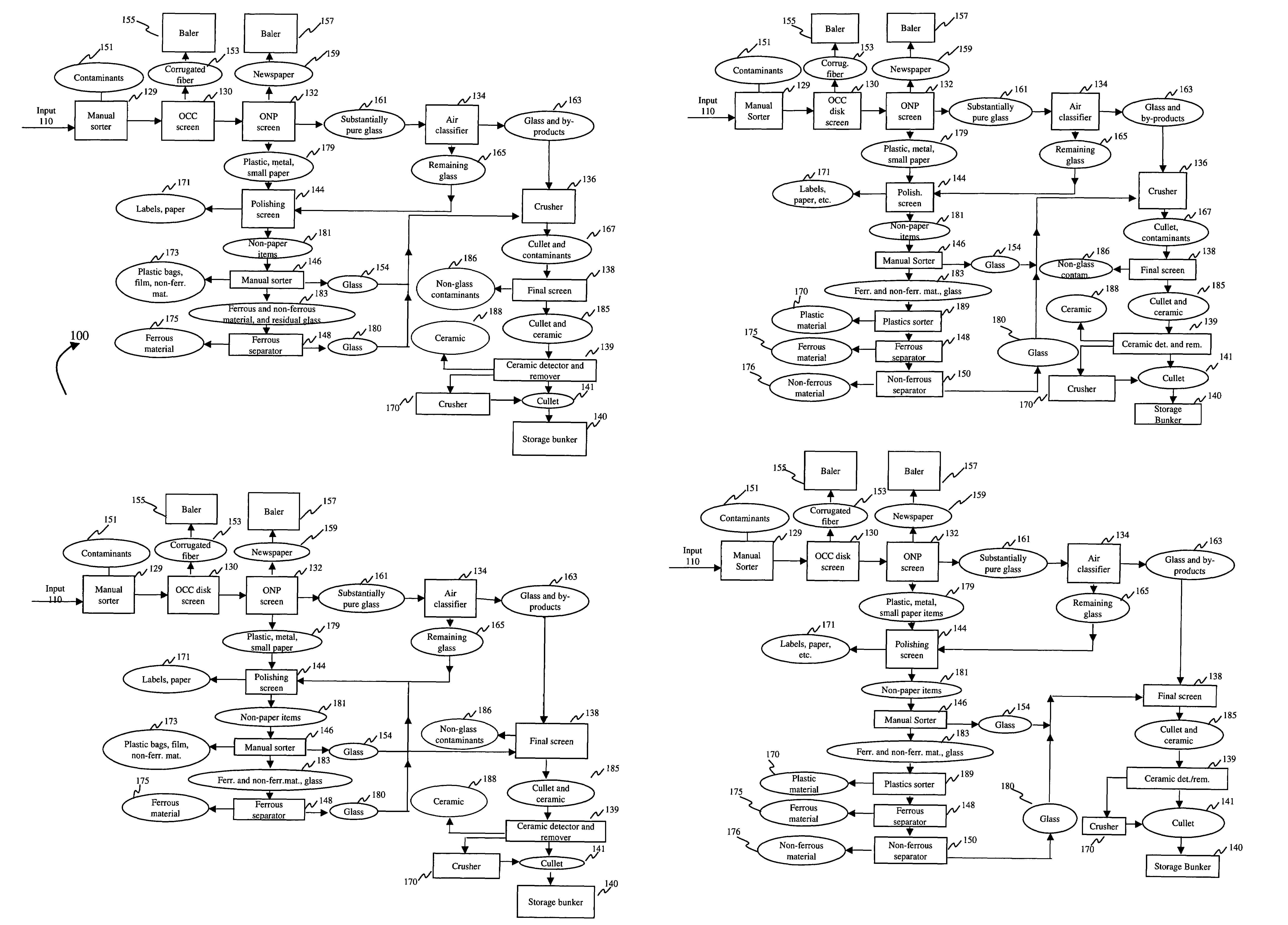

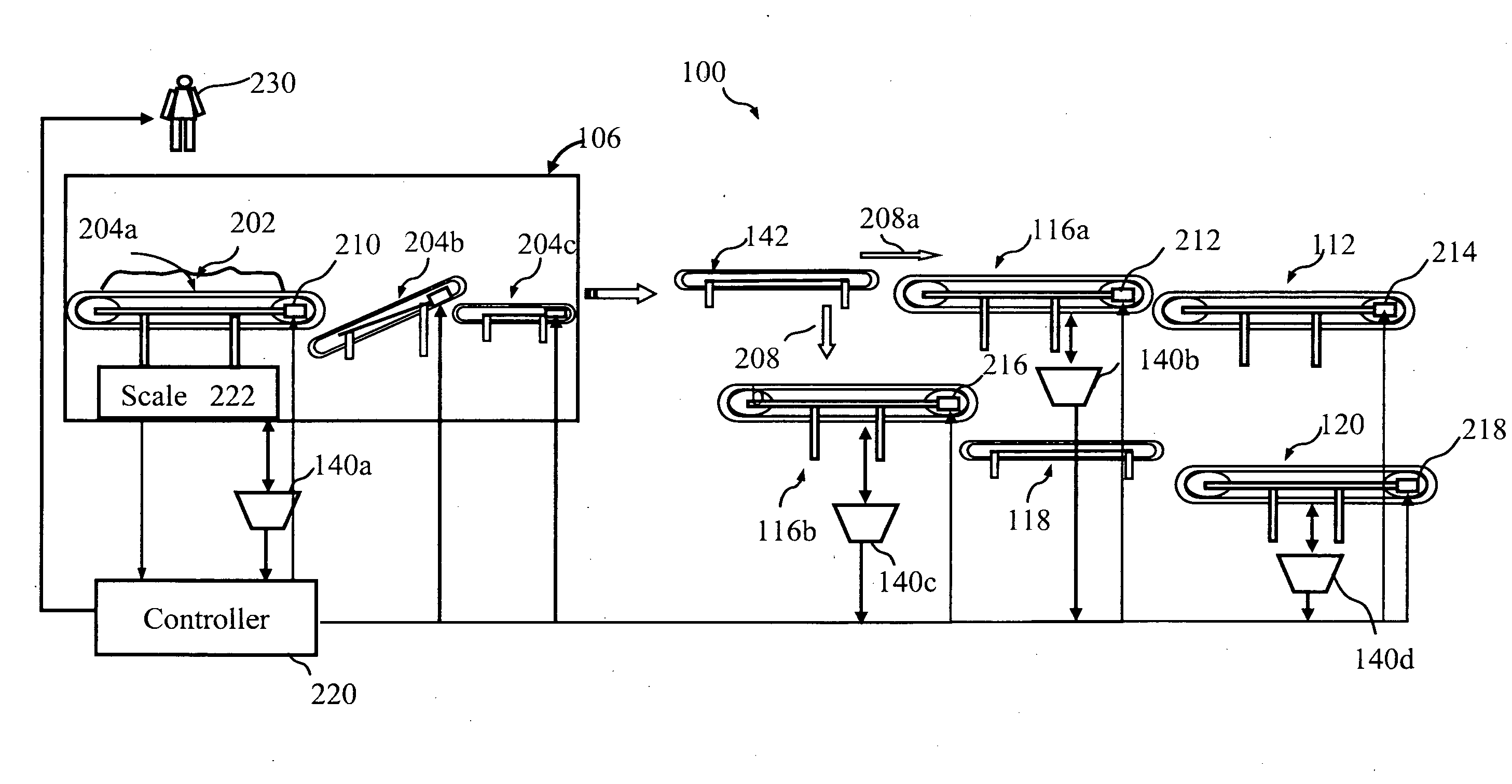

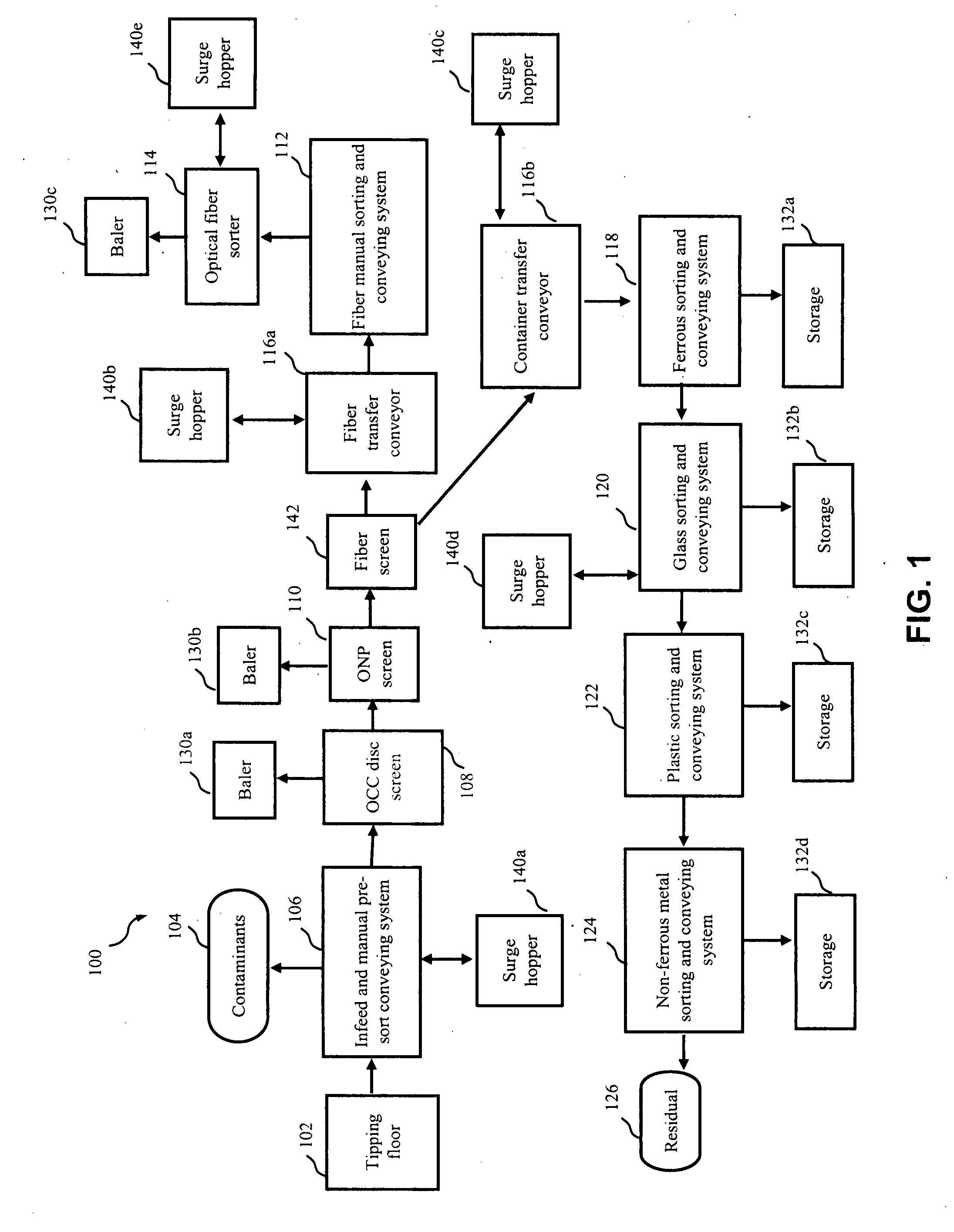

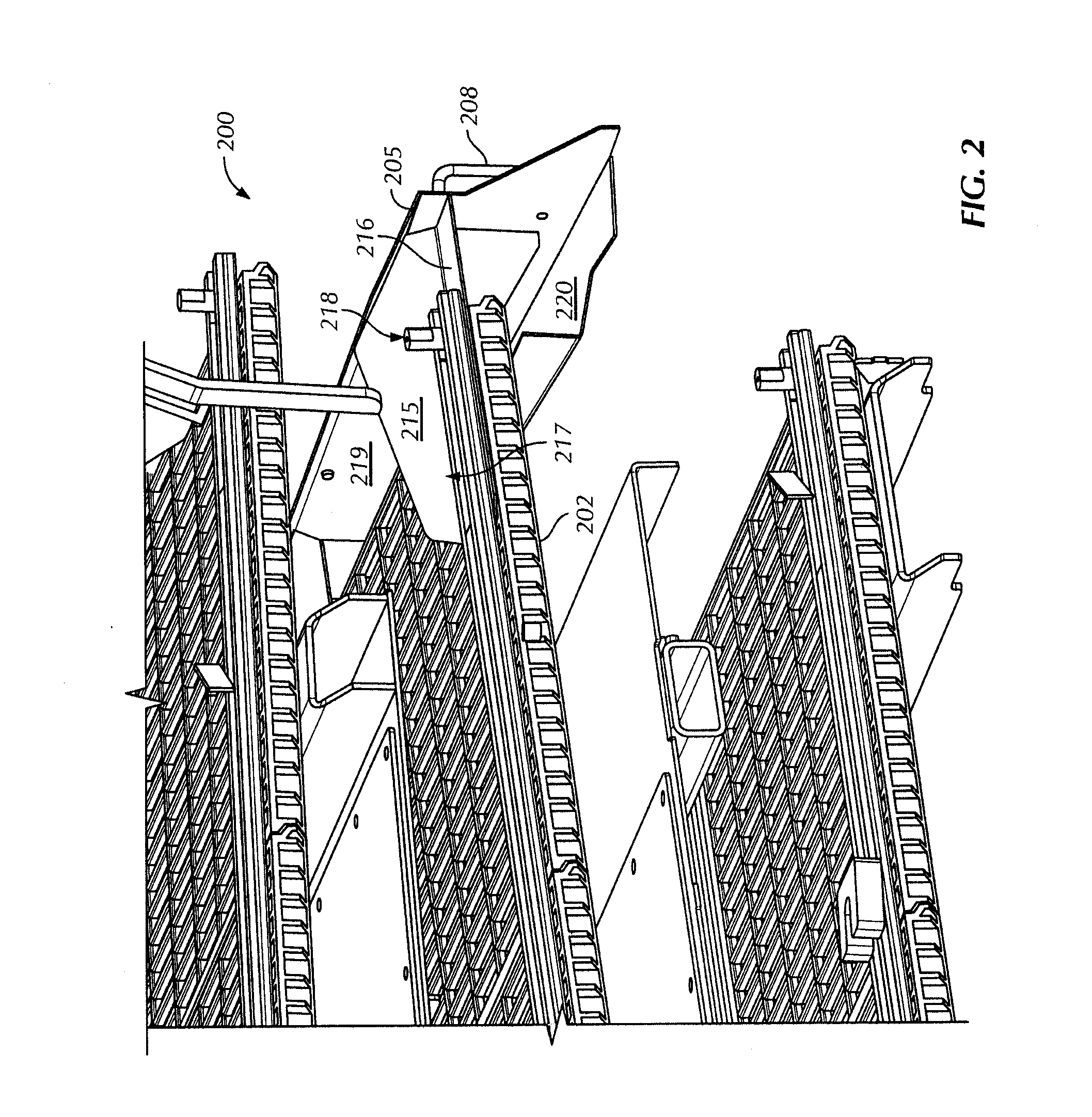

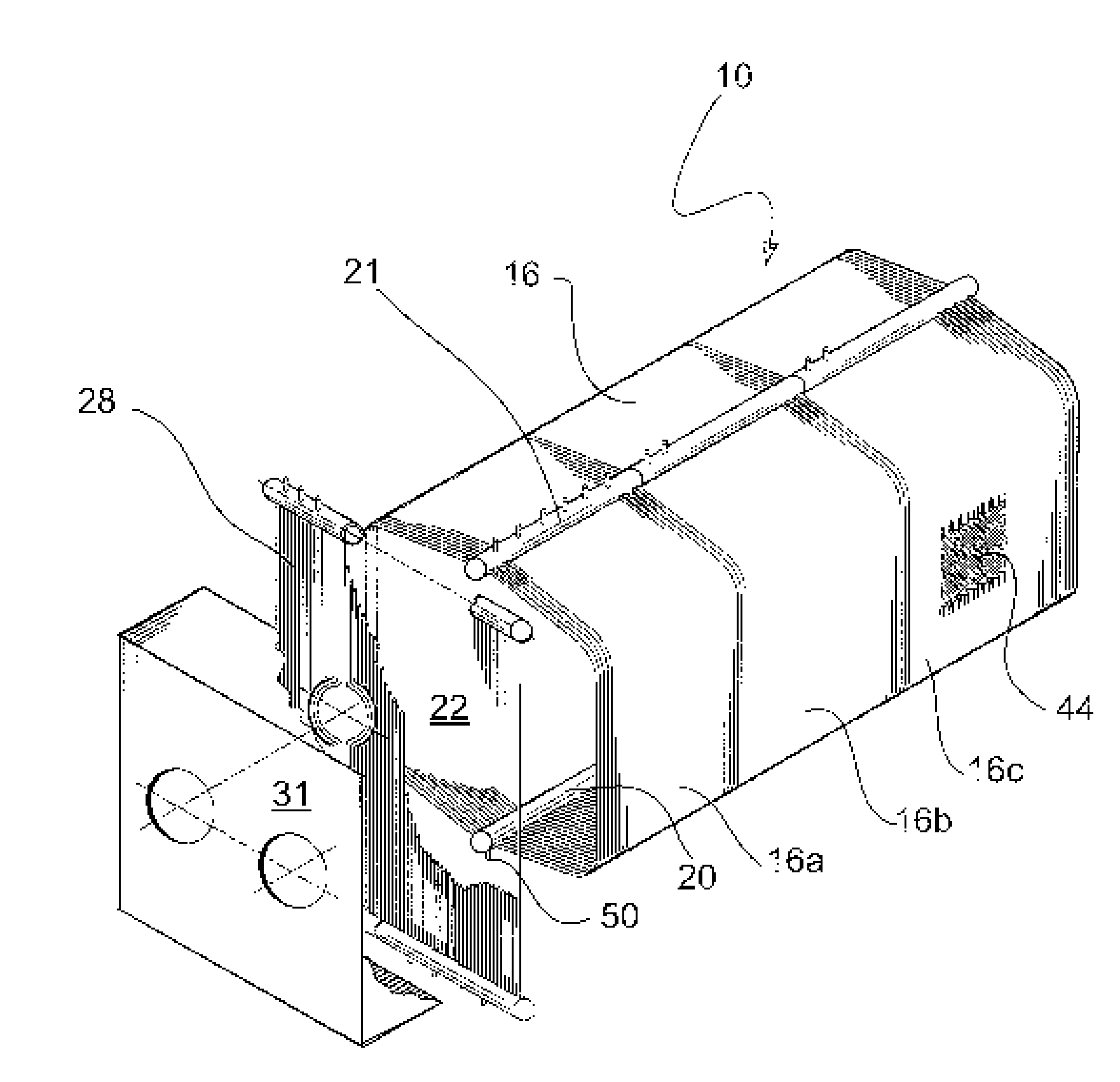

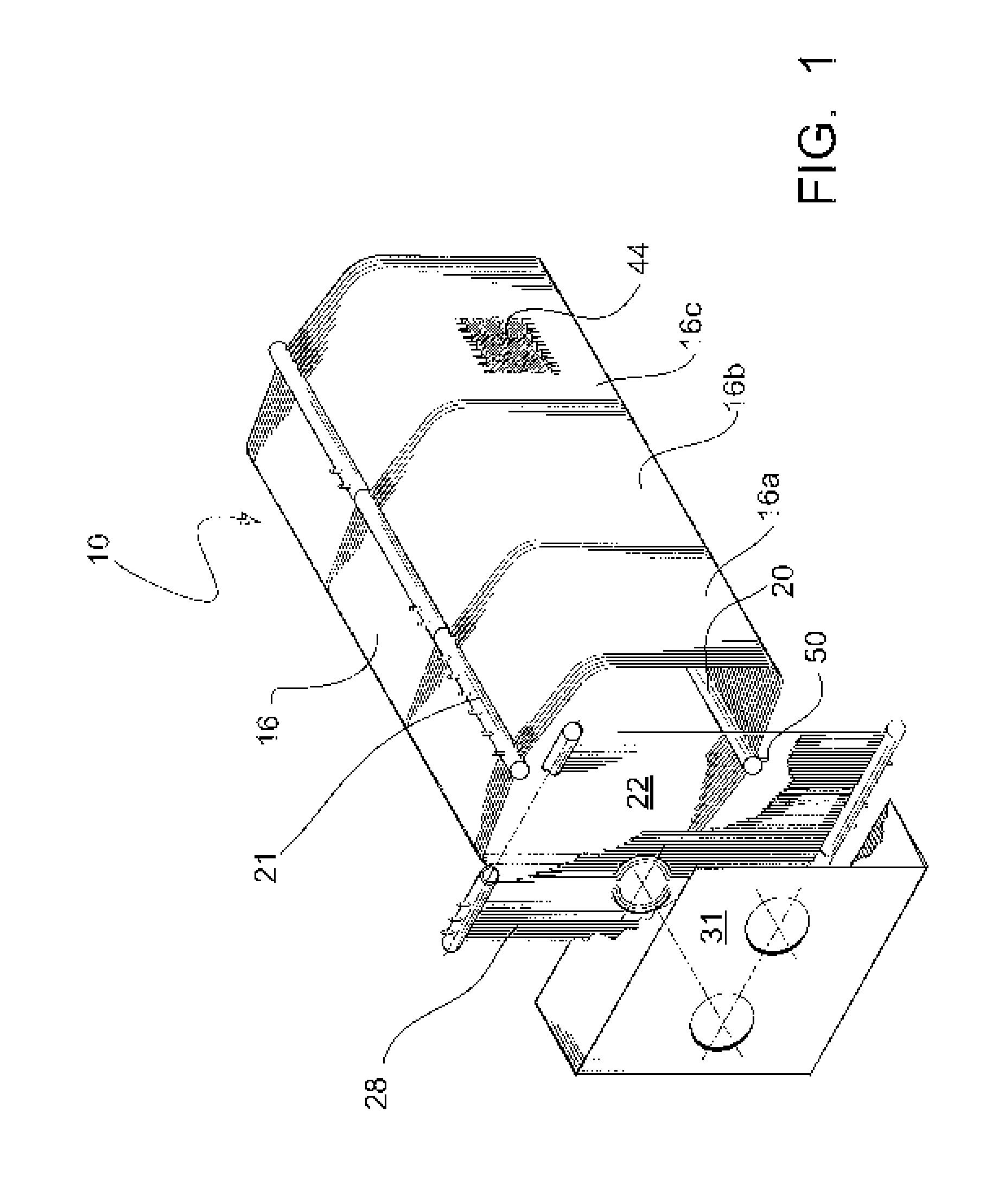

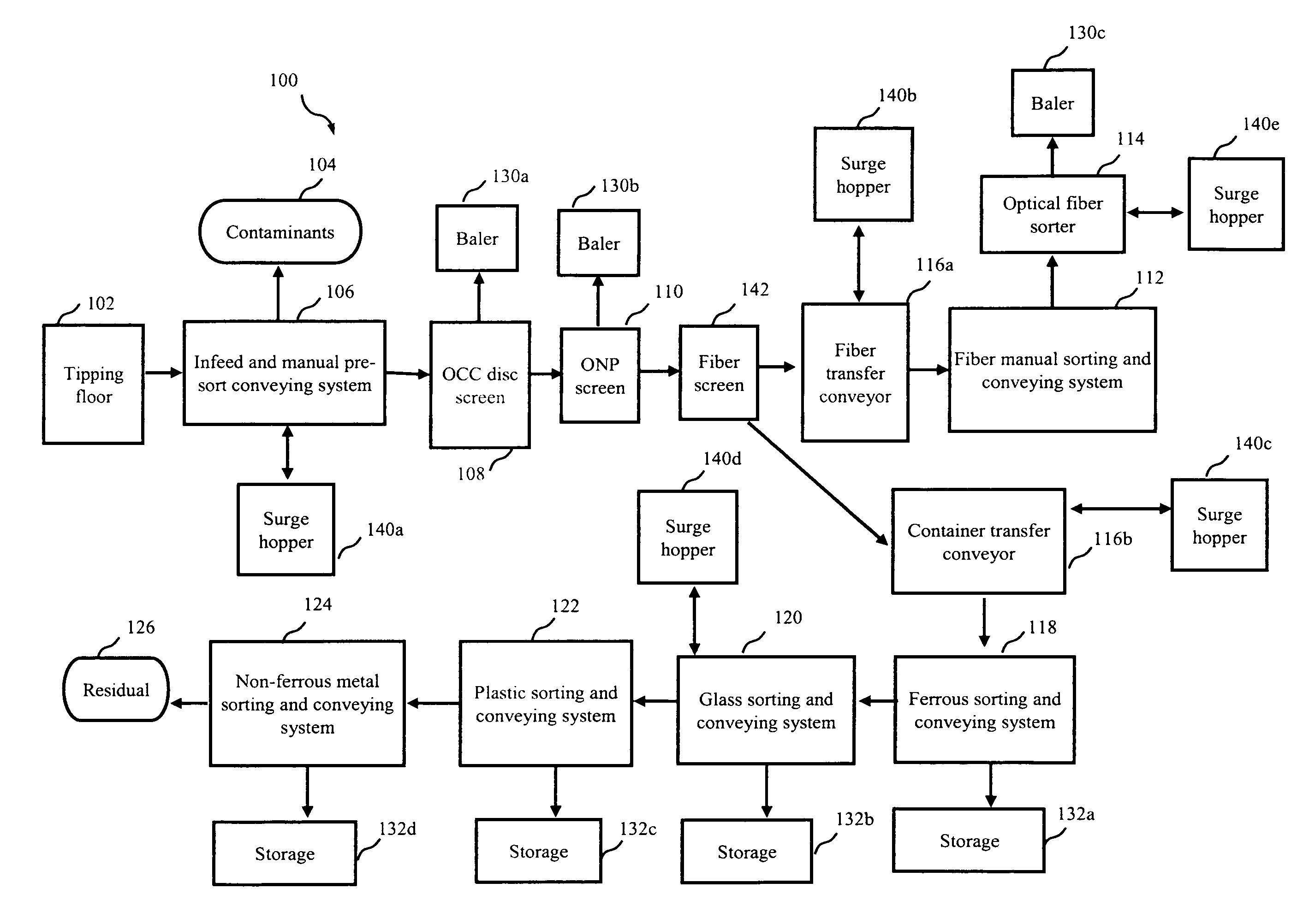

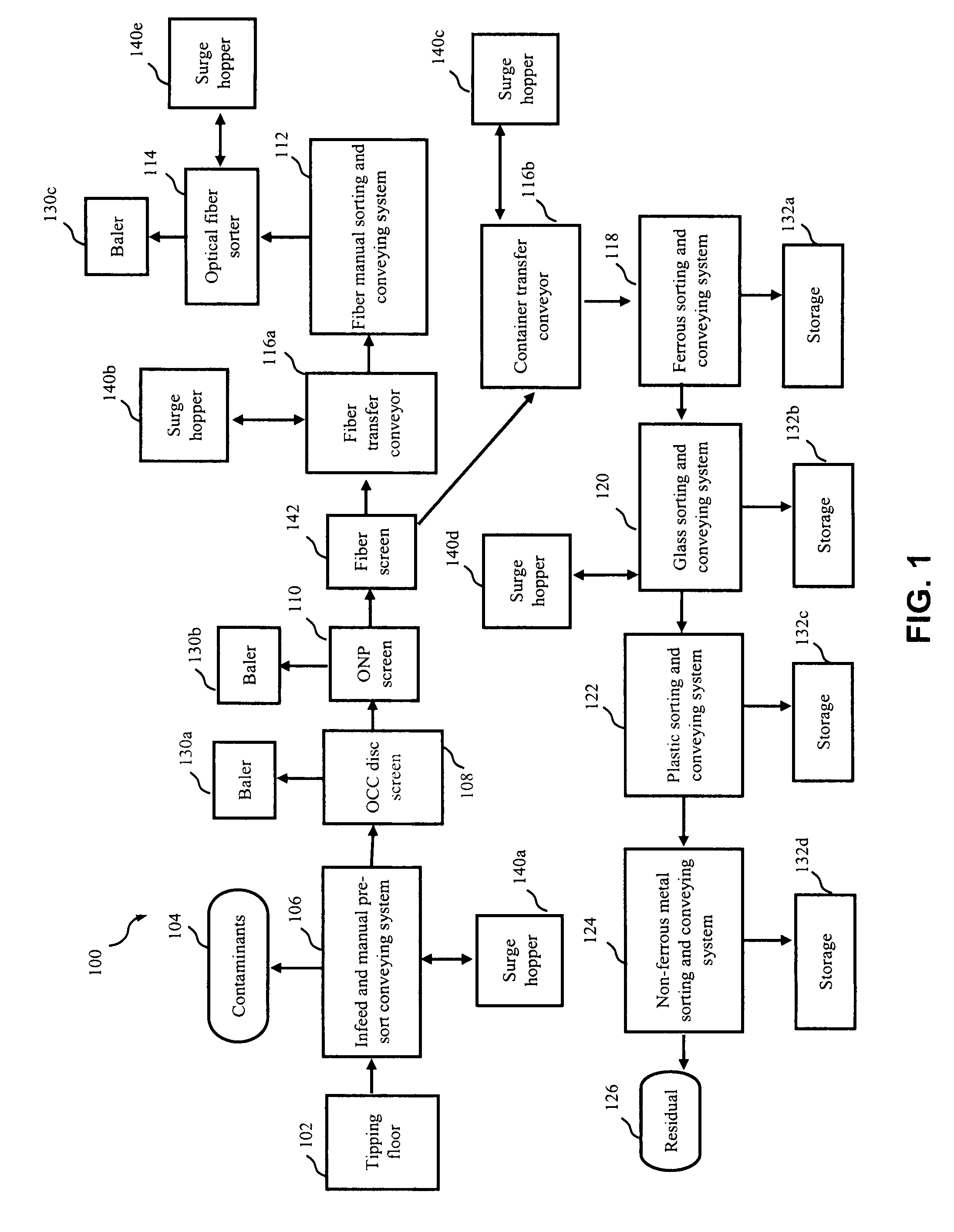

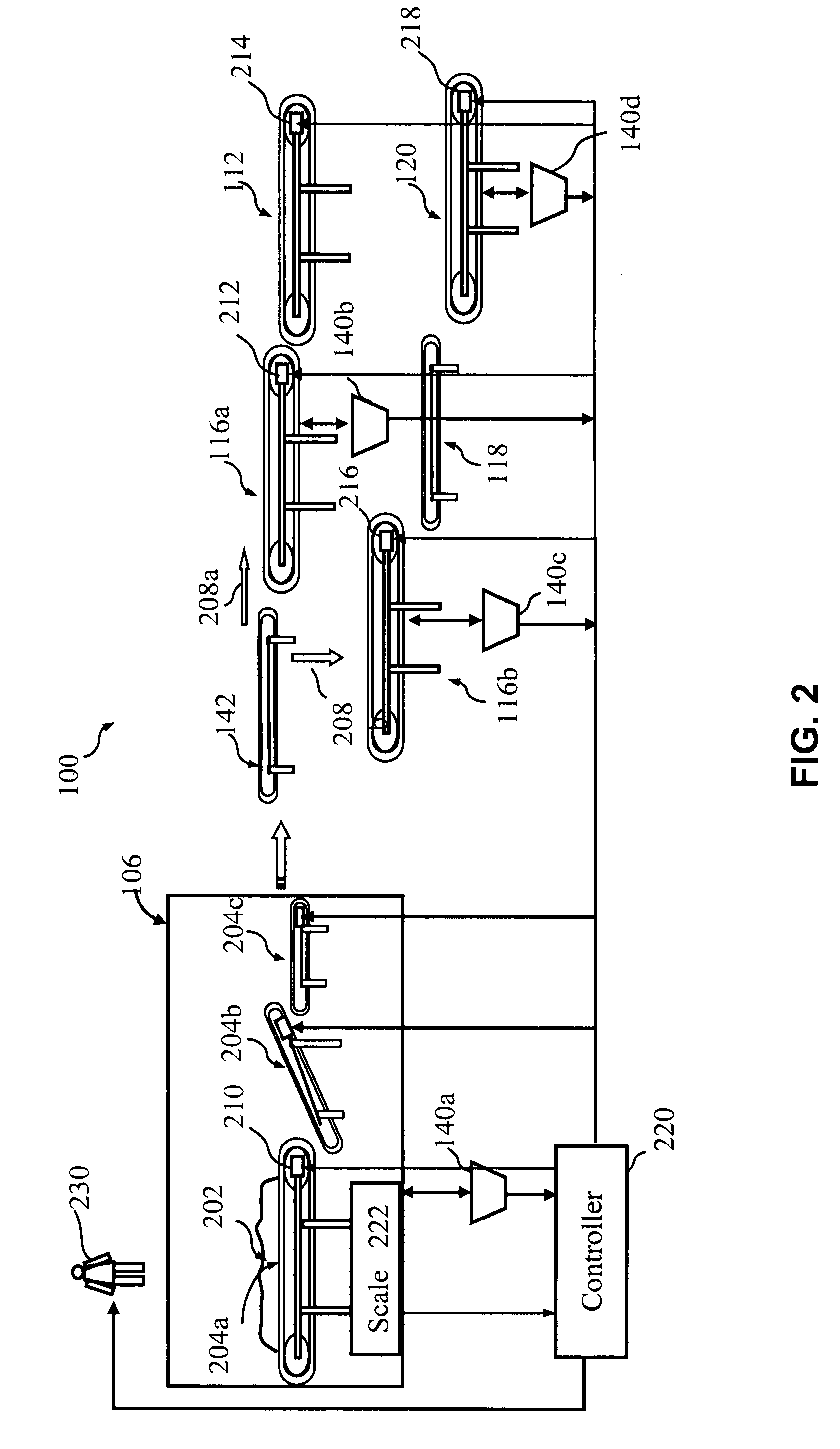

Systems and methods for optimizing a single-stream materials recovery facility

ActiveUS20080290006A1Facilitate manualFacilitate automated removalGlass recyclingCentrifugesFiberControl theory

Systems and methods for sorting a plurality of recyclable items in a single-stream materials recovery facility (SSMRF) are provided. In some embodiments, a system includes an infeed conveying system, a fiber transfer conveyor, a container transfer conveyor, and a glass sorting and conveying system. The system further includes a controller configured to obtain total weight and volume of recyclable items at the infeed conveying system. The controller estimates a percent weight of fiber items and a percent weight of non-fiber items relative to the total weight. Based on the estimates, the controller controls speed of at least one of the infeed conveying system, the fiber transfer conveyor, the container transfer conveyor, and the glass sorting and conveying system.

Owner:RE COMMUNITY HLDG II INC

Method for determining the extent of recovery of materials injected into oil wells during oil and gas exploration and production

Disclosed is a method of determining the extent of recovery of materials injected into a oil well comprising the steps of: a) preparing a material to be injected into an oil well; b) admixing therewith a chemical tracer compound at a predetermined concentration; c) injecting the admixture into an oil well; d) recovering from the oil well a production fluid; e) analyzing the production fluid for the concentration of the chemical tracer present in the production fluid; and f) calculating the amount of admixture recovered from the oil well using the concentration of the chemical tracer present in the production fluid as a basis for the calculation. Fluorinated benzoic acids are disclosed as a preferred tracer.

Owner:CORE LAB LP

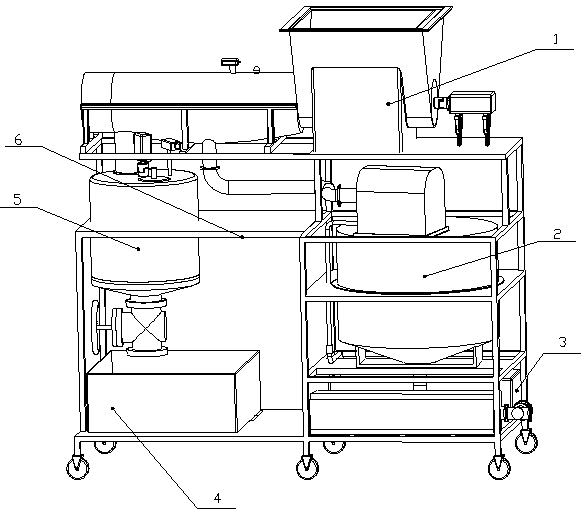

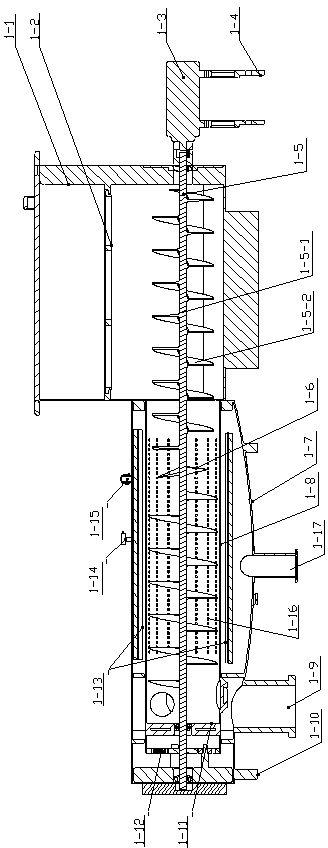

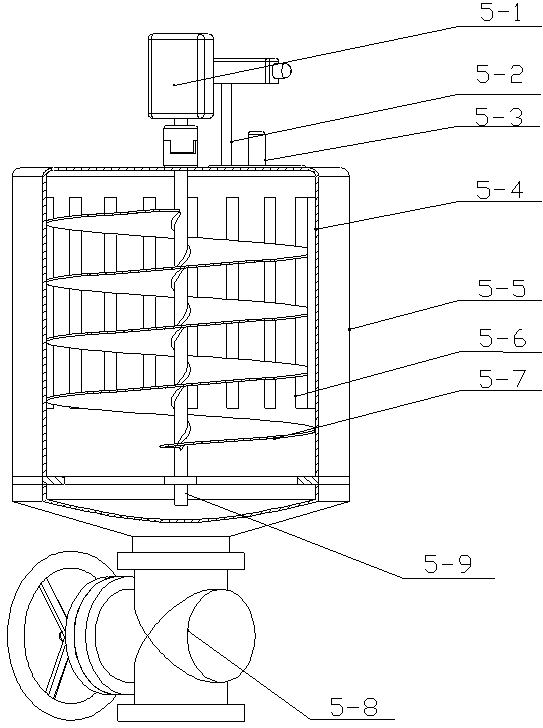

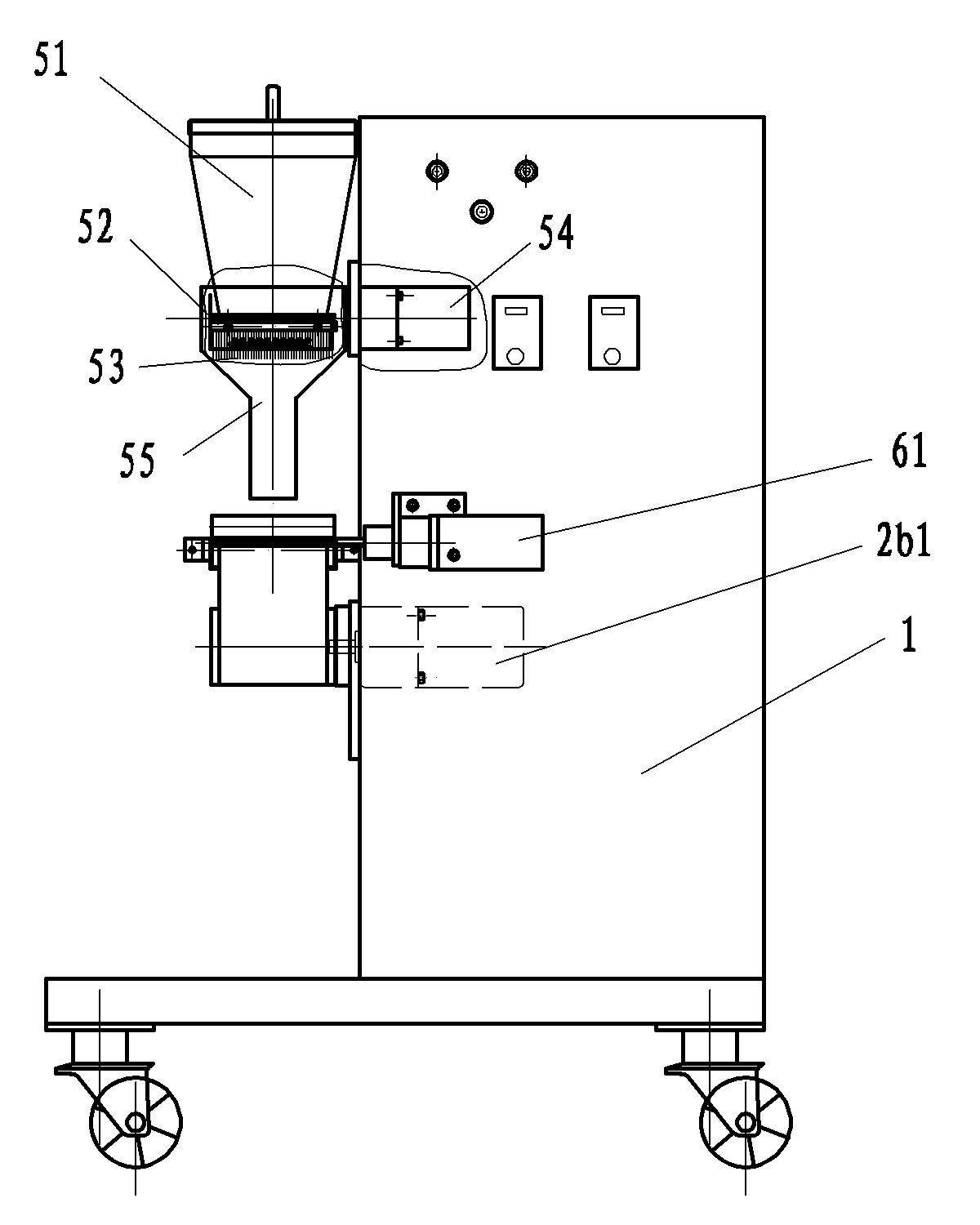

Multifunctional kitchen waste integrated processor

InactiveCN103357648AEasy to handleThe process is stable and reliableSolid waste disposalOil and greaseResource utilization

A disclosed multifunctional kitchen waste integrated processor comprises a rack, a dewatering smashing molding device disposed at the upper part of the rack, a drying disinfection device and an oil-water separation device both disposed on the rack; the drying disinfection device (5) and the oil-water separation device are both connected with the dewatering smashing molding device; a material recovery tank is disposed under the drying disinfection device; and an oil sump tank and a waste-water purifying groove are disposed under the oil-water separation device. The beneficial effects of the integrated processor comprise: kitchen waste enters into the dewatering smashing molding device through a feed hopper, and is subjected to dewatering, smashing and molding, drying and disinfection; and an oil-water mixture is separated into oil and waste water through the oil-water separation device; and the whole process is automatically controlled by an operating system, and the integrated processor is convenient to use and labor-saving. The integrated processor helps to effectively change operation conditions of waste classified processing, and is capable of recovering the processed solid residue and oil for resource utilization, and is good in practicality.

Owner:ANHUI SCI & TECH UNIV

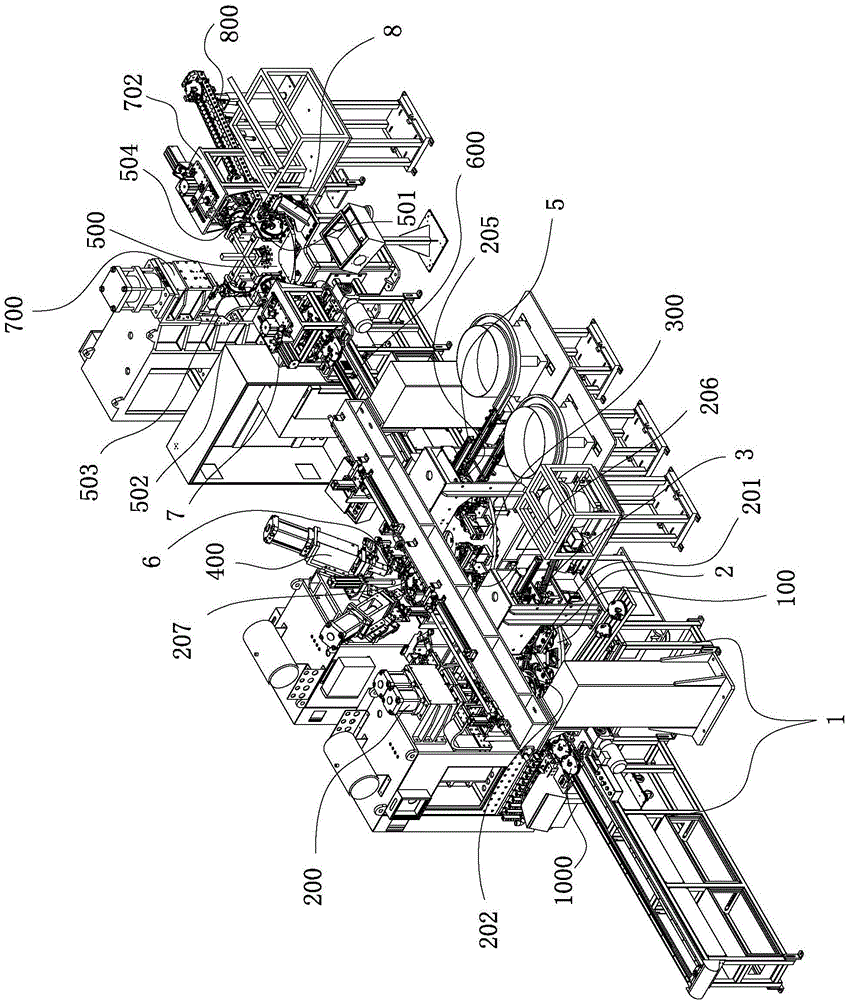

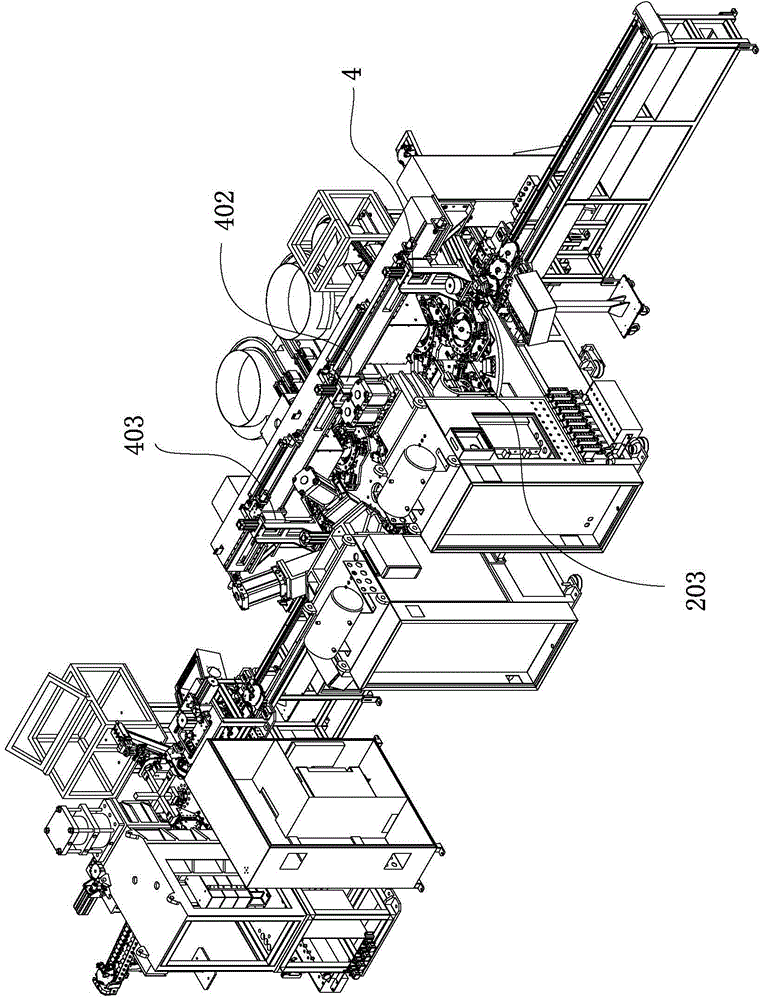

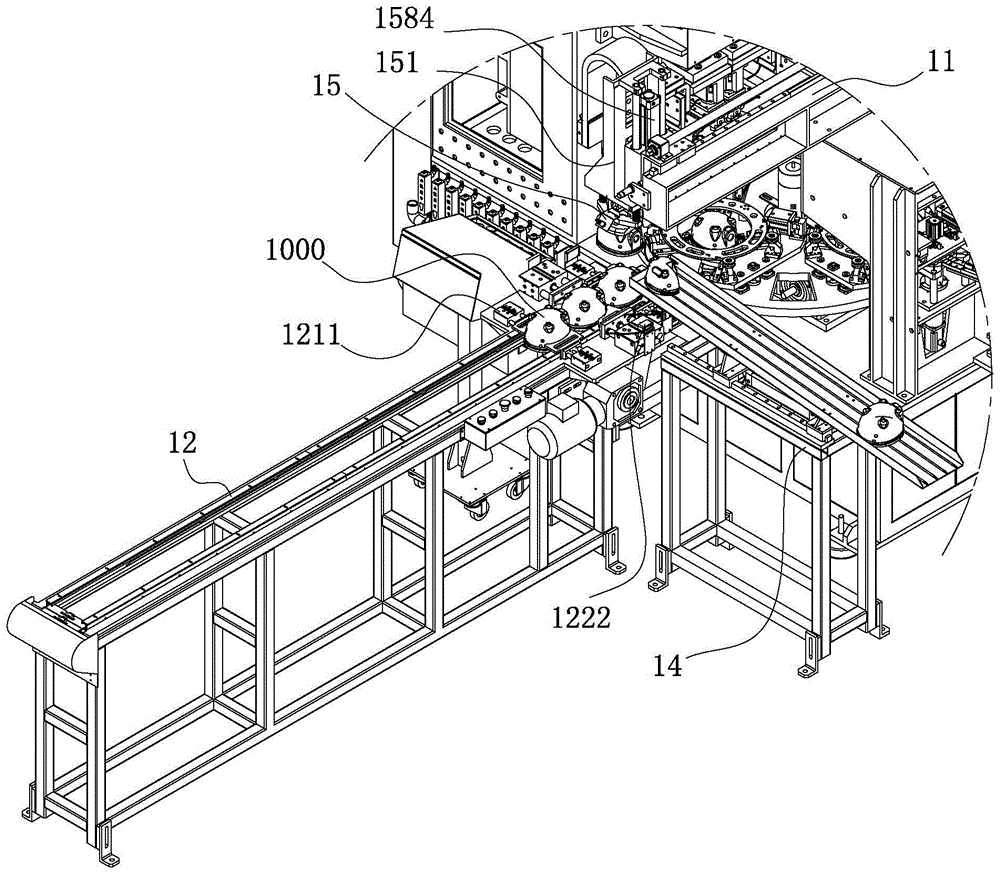

Production equipment of refrigeration compressor casing

ActiveCN104353943ARealize automated productionQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesRefrigeration compressorTechnical standard

The invention discloses production equipment of a refrigeration compressor casing. The production equipment comprises a false material recovery mechanism, a first calibration mechanism, a pin feeding device, a first material fetching device, a machine leg automatic feeding mechanism, a machine leg clamping device, a first casing fetching and placing mechanism, a glass terminal fetching mechanism, a first rotary table, a pin welding machine, a second rotary table, a machine leg welding machine, a third rotary table, a conveying belt, a glass terminal electric welding machine and a material conveying frame. The production equipment has the advantage that the false material recovery mechanism, the first calibration mechanism, the pin feeding device, the first material fetching device, the machine leg automatic feeding mechanism, the machine leg clamping device, the first casing fetching and placing mechanism, the glass terminal fetching mechanism, the first rotary table, the pin welding machine, the second rotary table, the machine leg welding machine and the conveying frame are welded into the automatic production equipment, so the uniformity of technical standards of one product in the production process is realized, the automation degree is high, the production efficiency is greatly improved, and the production cost is reduced.

Owner:东莞市鹏煜威科技有限公司

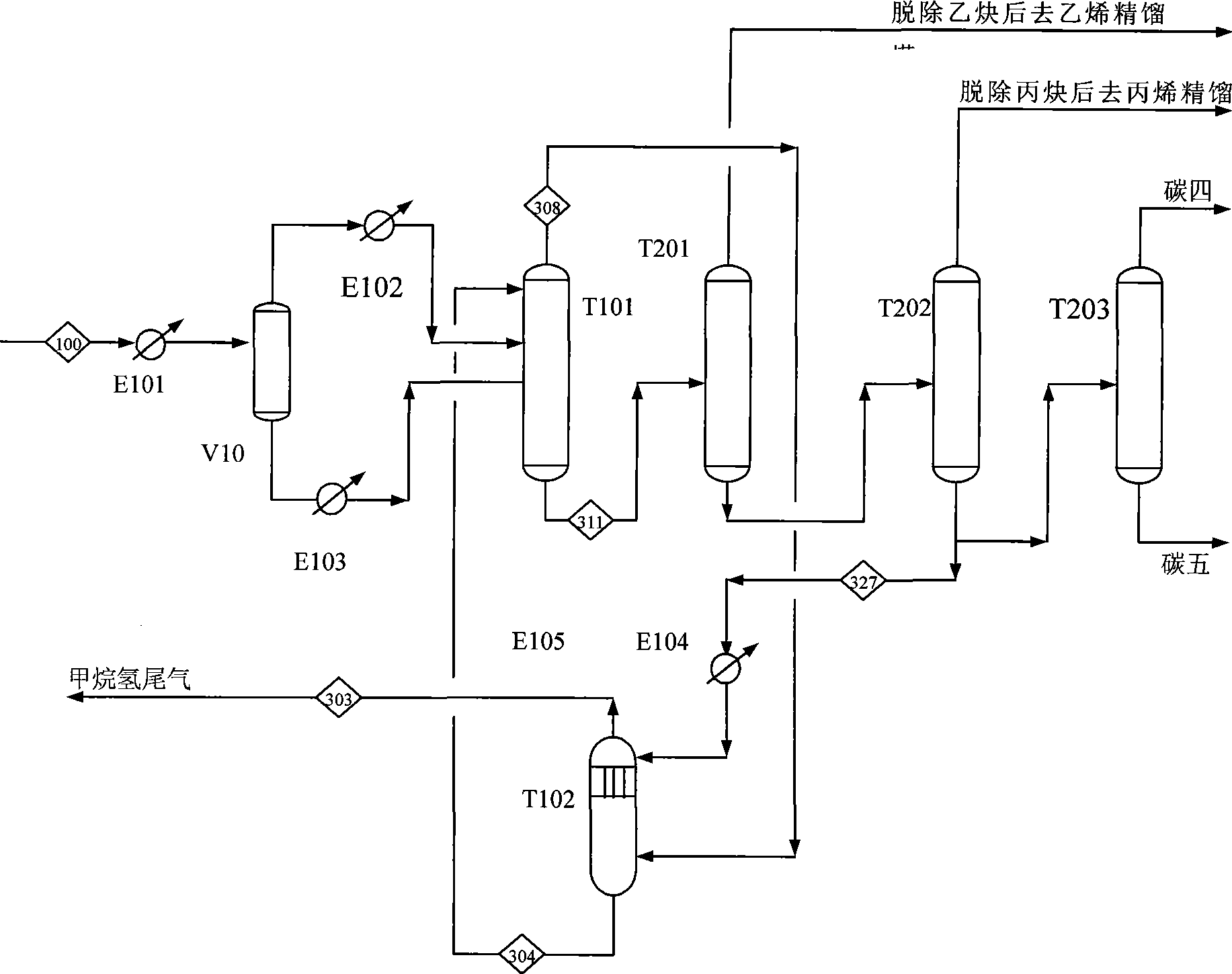

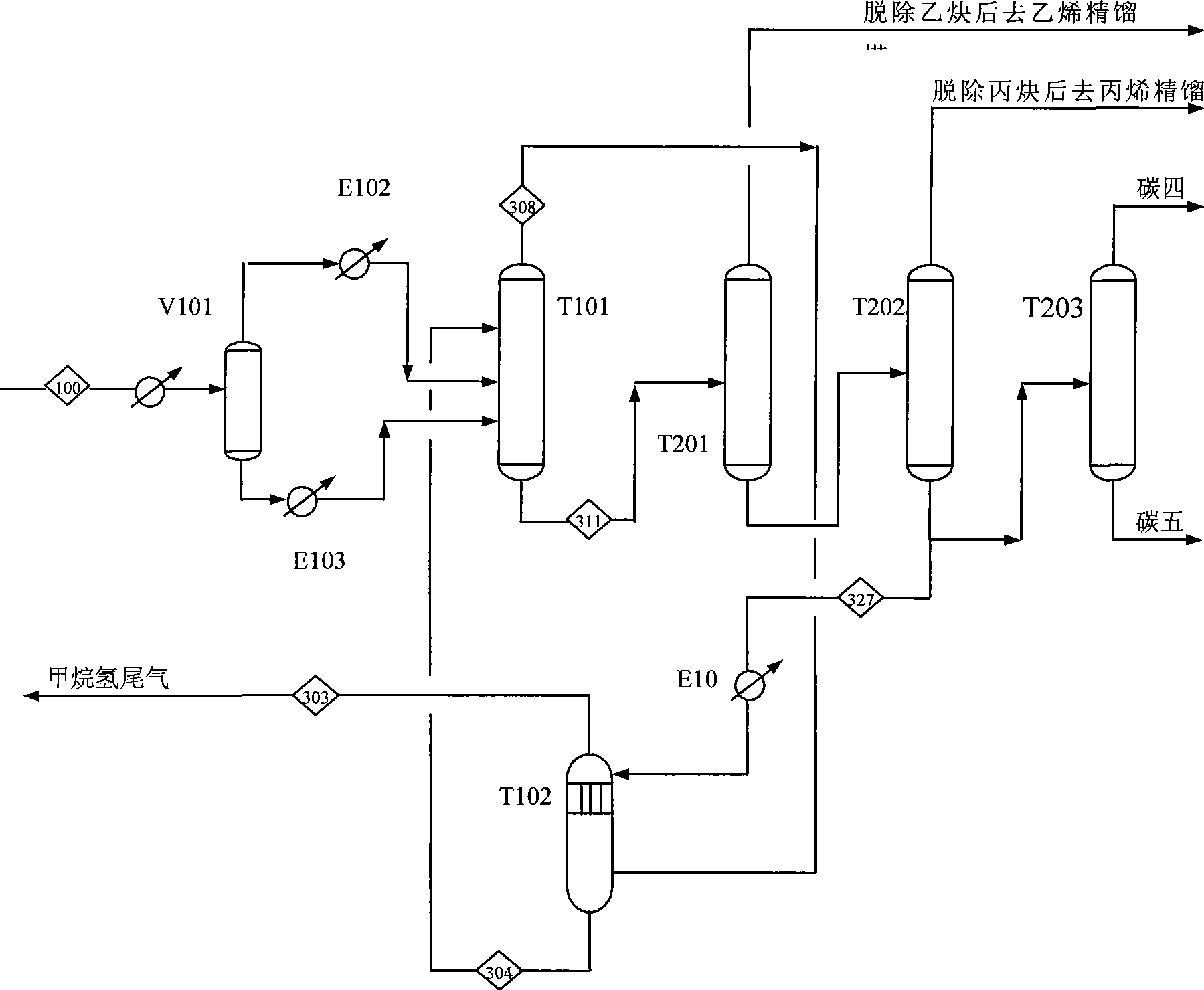

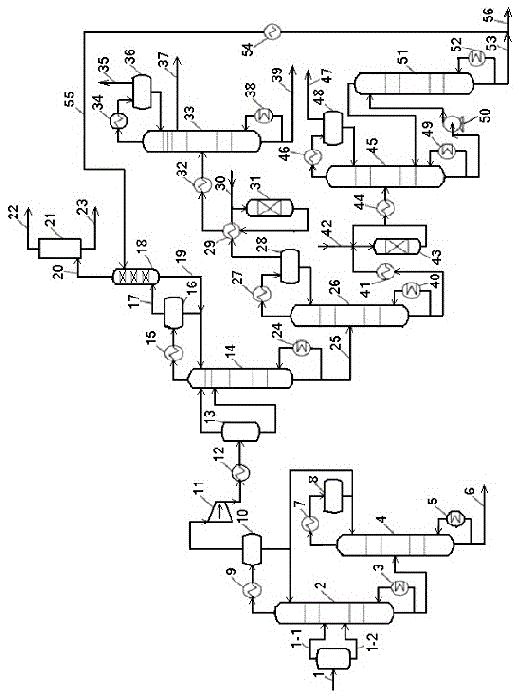

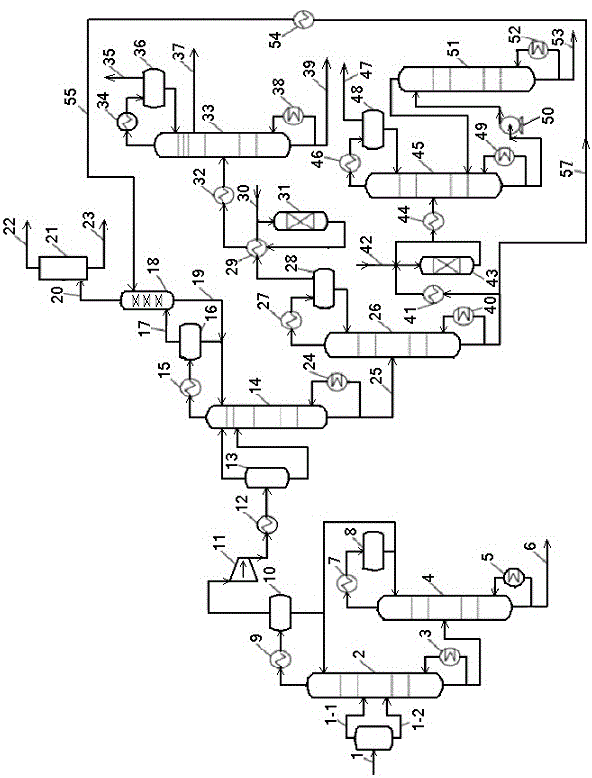

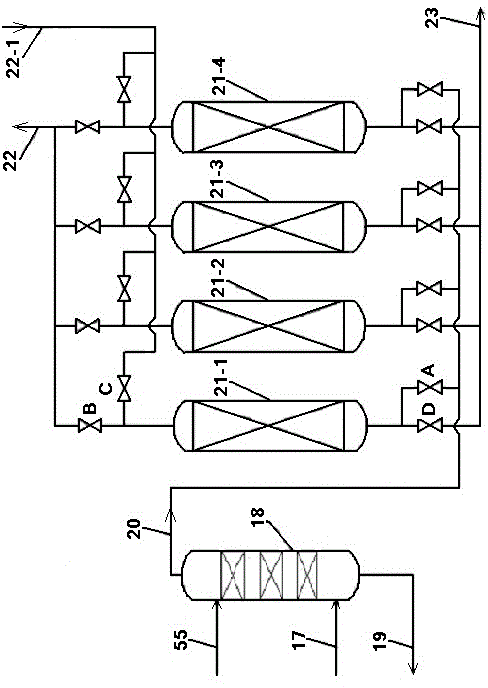

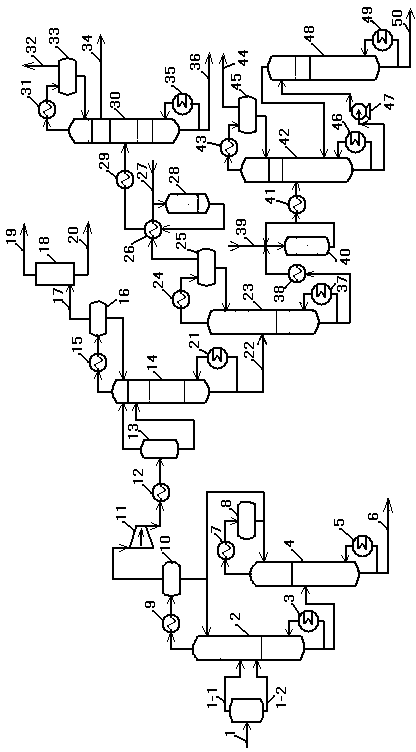

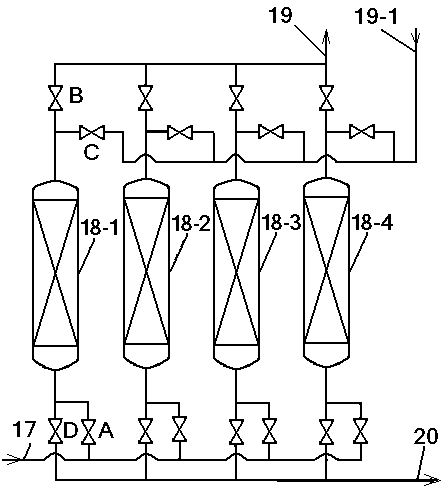

Method for separating lower hydrocarbon containing light gas by combining distillation and solvent absorption

ActiveCN101445419AHigh recovery rateLess investmentDistillation purification/separationAbsorption purification/separationHydrocarbon mixturesDistillation

The invention relates to a method for separating lower hydrocarbon containing light gas by combining distillation and solvent absorption, comprising the steps as follows: (1) pre-disposed gas at the outlet of a reactor is cooled to the temperature ranging from 10 DEG C to -37 DEG C and sent to a pre-cutting tower; (2) the gas at the outlet of the pre-cutting tower is sent to an absorption tower and C1 and C2 in the gas are separated by taking C3 or C4 or C5 or C6 or hydrocarbon mixtures as absorbent; (3) outcomes generated at the bottom of the absorption tower are sent to the pre-cutting tower; with C2 distillate further absorbed and methane and lighter components removed in the pre-cutting tower, the outcome is sent to a deethanizer so that the C2 and C3 are clearly cut. Compared with the prior art, the method has the advantages of little investment, low energy dissipation, high material recovery rate, simple operation, small maintenance quantity, reliable running, requiring no ethane refrigerant compressor, and the like.

Owner:WISON ENG

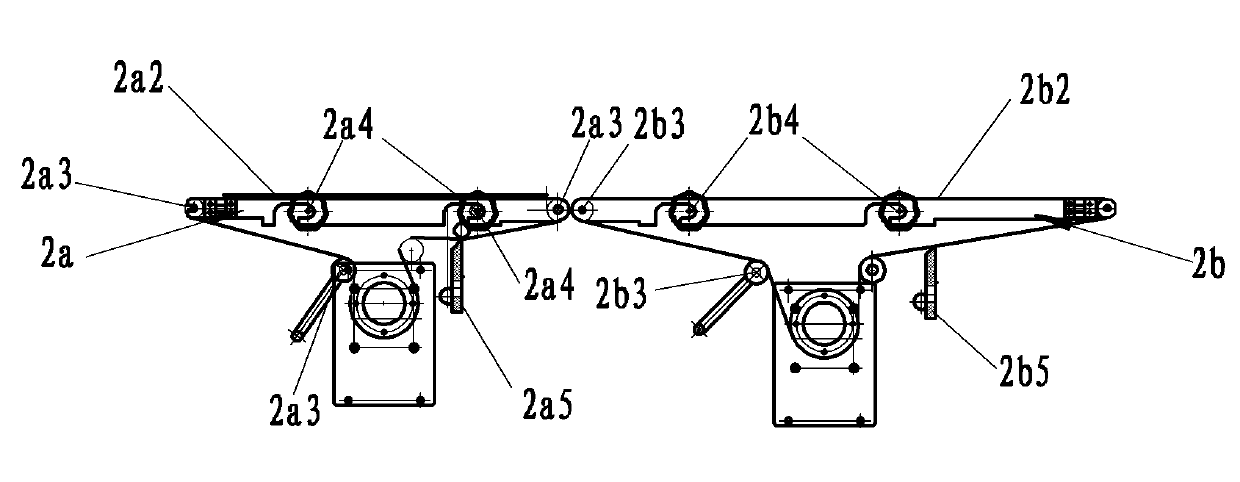

Cake surface sesame scattering machine

The invention relates to a sesame scattering machine. The sesame scattering machine comprises a machine body, a cake introduction conveying mechanism, a cake surface syrup spraying mechanism, a syrup mist suction-removal mechanism and a cake surface sesame scattering mechanism, wherein the cake introduction conveying mechanism is formed by motors, conveyor belts, tension rollers and transmission rollers; the cake surface syrup spraying mechanism is formed by a syrup storage tank, a syrup conveying tube and a nozzle; the syrup mist suction-removal mechanism is formed by a syrup mist suction tube, a filter and a vacuum pump; and the cake surface sesame scattering mechanism is composed of a sesame storage bucket, a sesame distributor, a hairbrush and a sesame catching bucket. The syrup is sprayed on the surfaces of cakes in a pressurization mode, and the granule distributor with the surface fully distributed with pits is used for scattering sesames, so the syrup spray distribution and the sesame distribution are fast and uniform; the syrup mist suction-removal mechanism is arranged, so the splash of the sprayed syrup and the suffusion of the syrup in air are controlled; the cake introduction conveying mechanism is provided with conveyor cleaning scrapers, so it is benefit for cleaning, and material recovery can be realized; a cake passing and pressing apparatus is arranged at the stroke tail end, so the granules are firmly viscous after the rolling, and blocking and clamping phenomena at the junctions of the conveyor belts to where the cakes are transmitted are eliminated. The sesame scattering machine has the characteristics of reliable operation, automation and fastness, less material loss, environment cleaning, and suitableness for line production.

Owner:江苏裕铭铜业有限公司

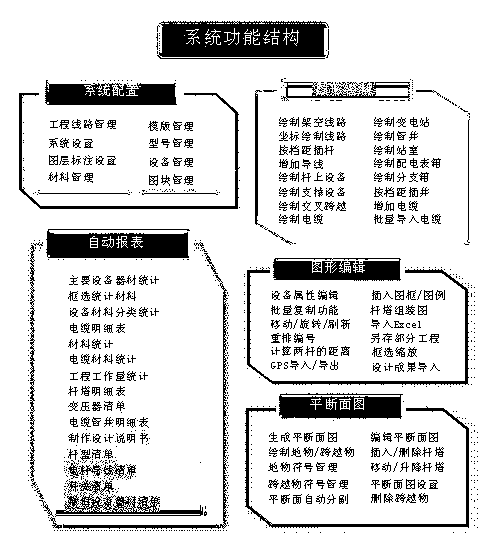

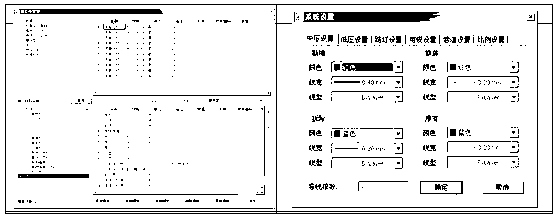

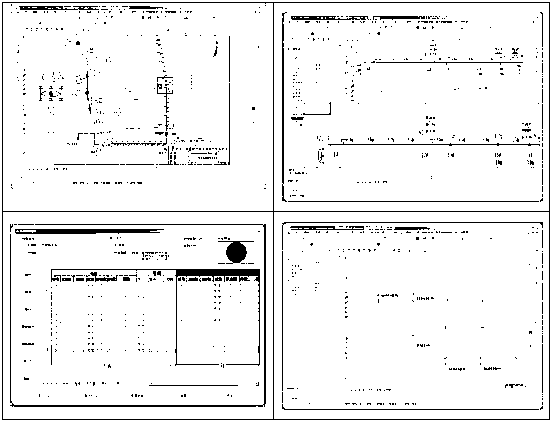

Computer design method of standard distribution network line

ActiveCN102999671ARealize the designPrecise designSpecial data processing applicationsGraphicsEnterprise resource planning

The invention discloses a computer design method of a standard distribution network line. The computer design method of the standard distribution network line comprises the steps of drawing construction diagrams of overhead power distribution lines and cable lines according to distribution line design requirements and a standard diagram, accurately counting materials required by a project, and automatically generating various kinds of report forms. According to the computer design method of the standard distribution network line, the ERP (Enterprise Resource Planning) material entering process can be greatly optimized, and moreover, a preliminary budget of the material part can be automatically embedded into a rural network project preliminary budget template, and the differences between the construction diagram and an as-constructed diagram are analyzed to generate a material balance sheet after the construction diagram and the as-constructed diagram are accomplished, so that a data support is provided for the material recovery, the project auditing and the construction cost, the project materials can be managed and controlled, and create favorable conditions are created for the fixed-assets management, the base data management and the distribution network operation and maintenance management of the post-stage project.

Owner:XUYI POWER SUPPLY OF JIANGSU ELECTRIC POWER +2

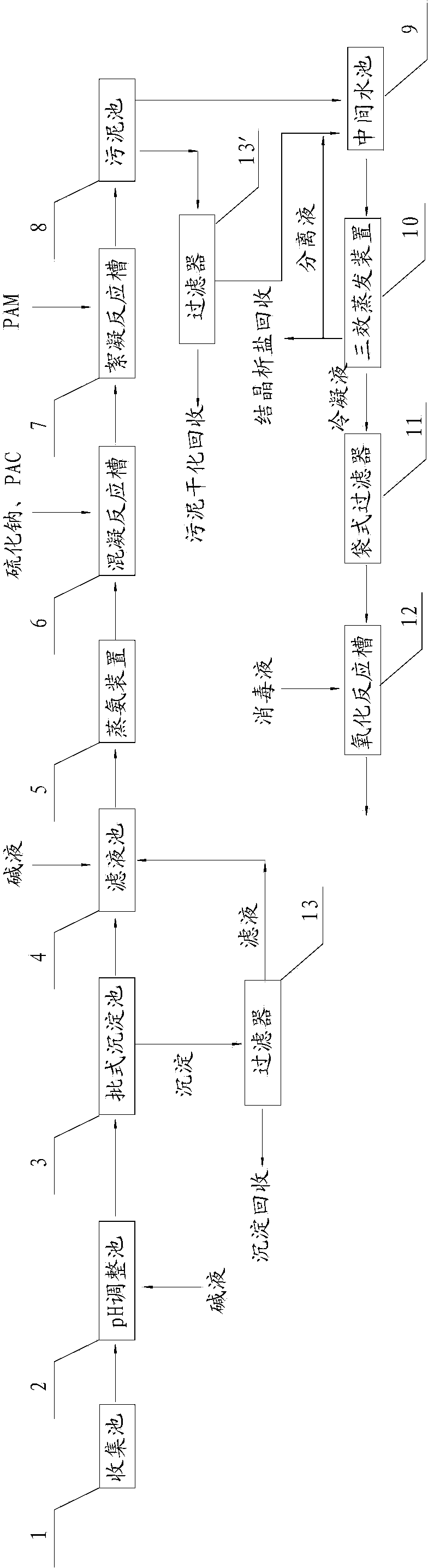

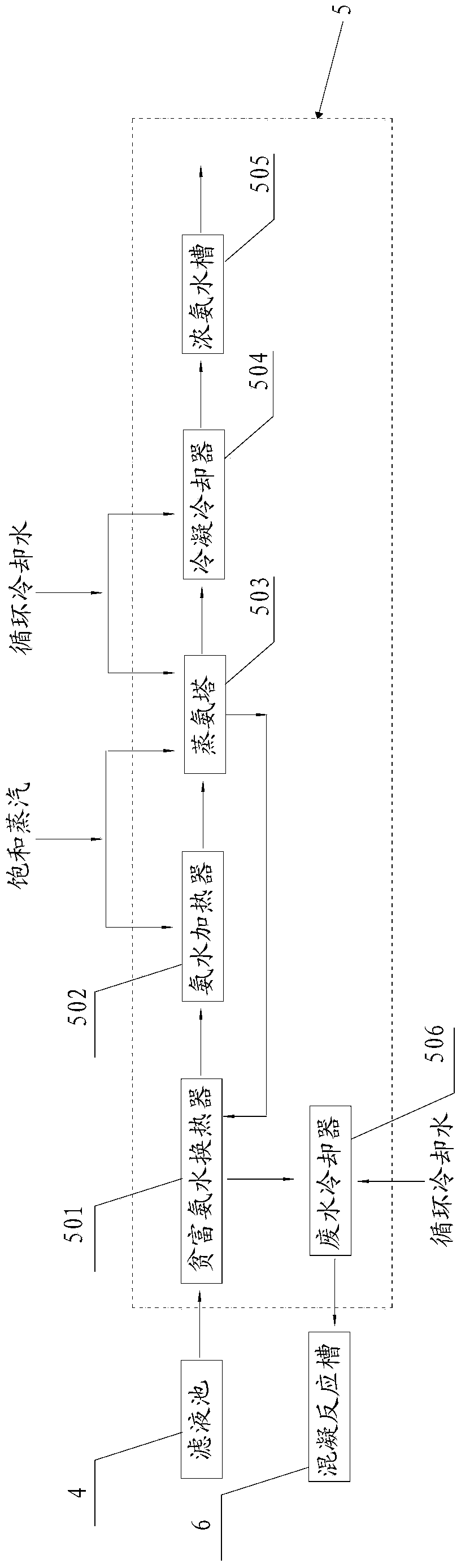

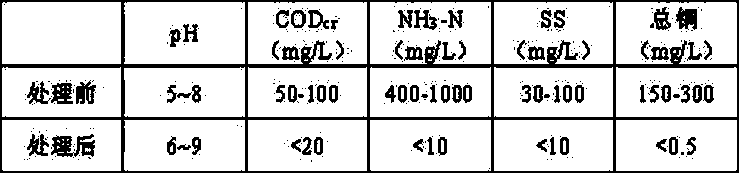

Material recovery method of wastewater containing high-concentration ammonia-nitrogen and heavy metal ions and treatment system

InactiveCN103466870AHarm reductionMeet emission standardsMultistage water/sewage treatmentAmmonia preparation/separationRecovery methodHigh concentration

The invention relates to a material recovery method of wastewater containing high-concentration ammonia-nitrogen and heavy metal ions and a wastewater treatment system. The material recovery method comprises the following steps: regulating the pH value, ammonia stilling, precipitating, evaporating and the like. The invention further relates to the corresponding treatment system. After the adoption of alkali liquor to precipitate metal ions, sodium sulfide is continuously added to further remove the metal ions left in the waste liquor to reach the emission standard; stronger ammonia water, solid precipitates and the like produced during the wastewater treatment process are recovered to reduce the environmental harm effectively and produce certain economic benefits.

Owner:SUZHOU SUJING ENVIRONMENTAL ENG

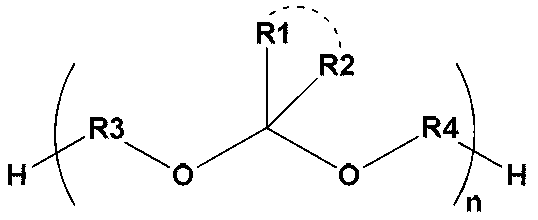

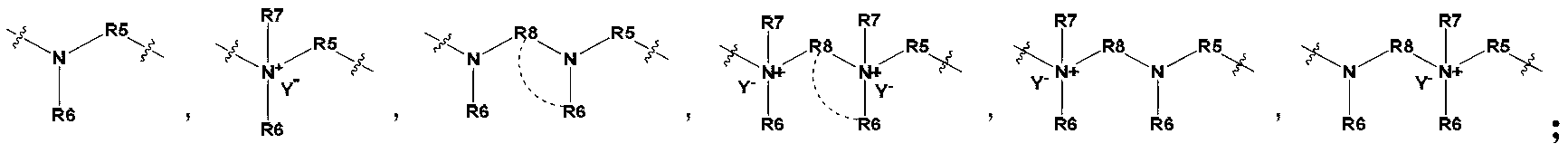

Degradable mixed polyamine epoxy resin curing agent, and preparation and composite material recovery thereof

The invention provides a novel degradable oligomer (polymer) mixed polyamine epoxy resin curing agent and a synthesis method thereof. The curing agent can react with an epoxy resin system to generate a polymerized substance which can be recovered through degradation; the curing agent, the epoxy resin system, reinforcing materials and auxiliary materials can be prepared into a reinforced composite material; and the material can be recovered through degradation. The synthesis method of the degradable oligomer (polymer) mixed polyamine curing agent provided by the invention is mild in reaction conditions, short in production cycle and suitable for industrial mass production; and the cured substance and the reinforced composite material generated by the reaction of the degradable oligomer (polymer) mixed polyamine curing agent and the epoxy resin can be degraded under normal-pressure mild but specific conditions, the degradation process is simple to operate, and industrial mass recovery can be easily realized.

Owner:ADESSO ADVANCED MATERIALS WUXI CO LTD

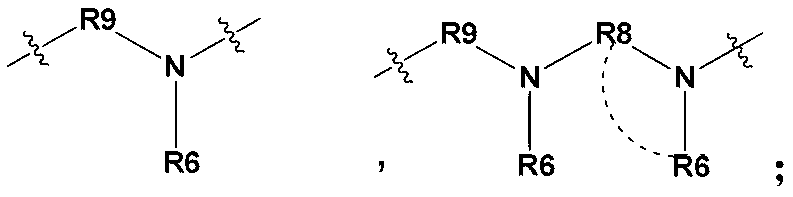

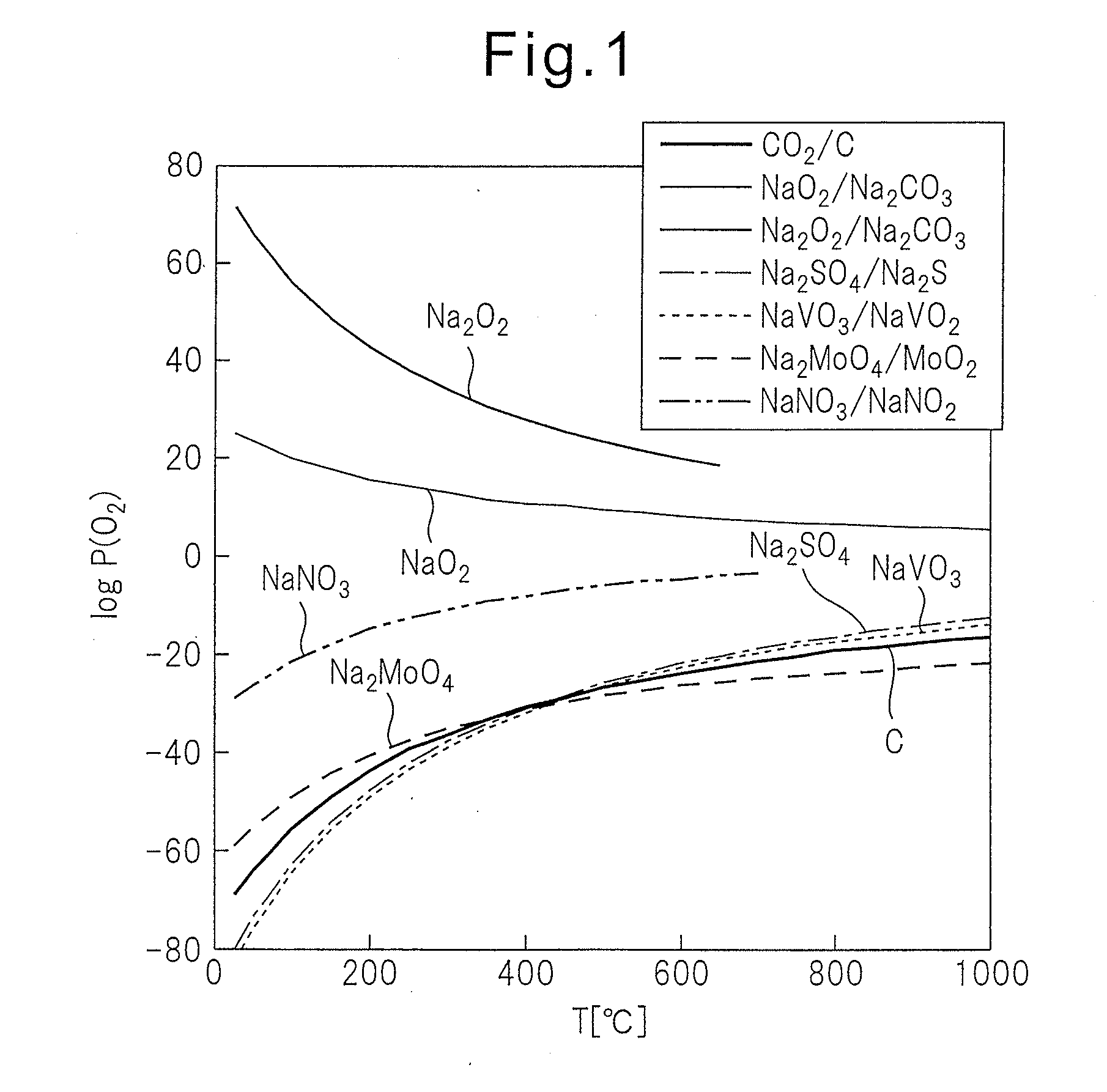

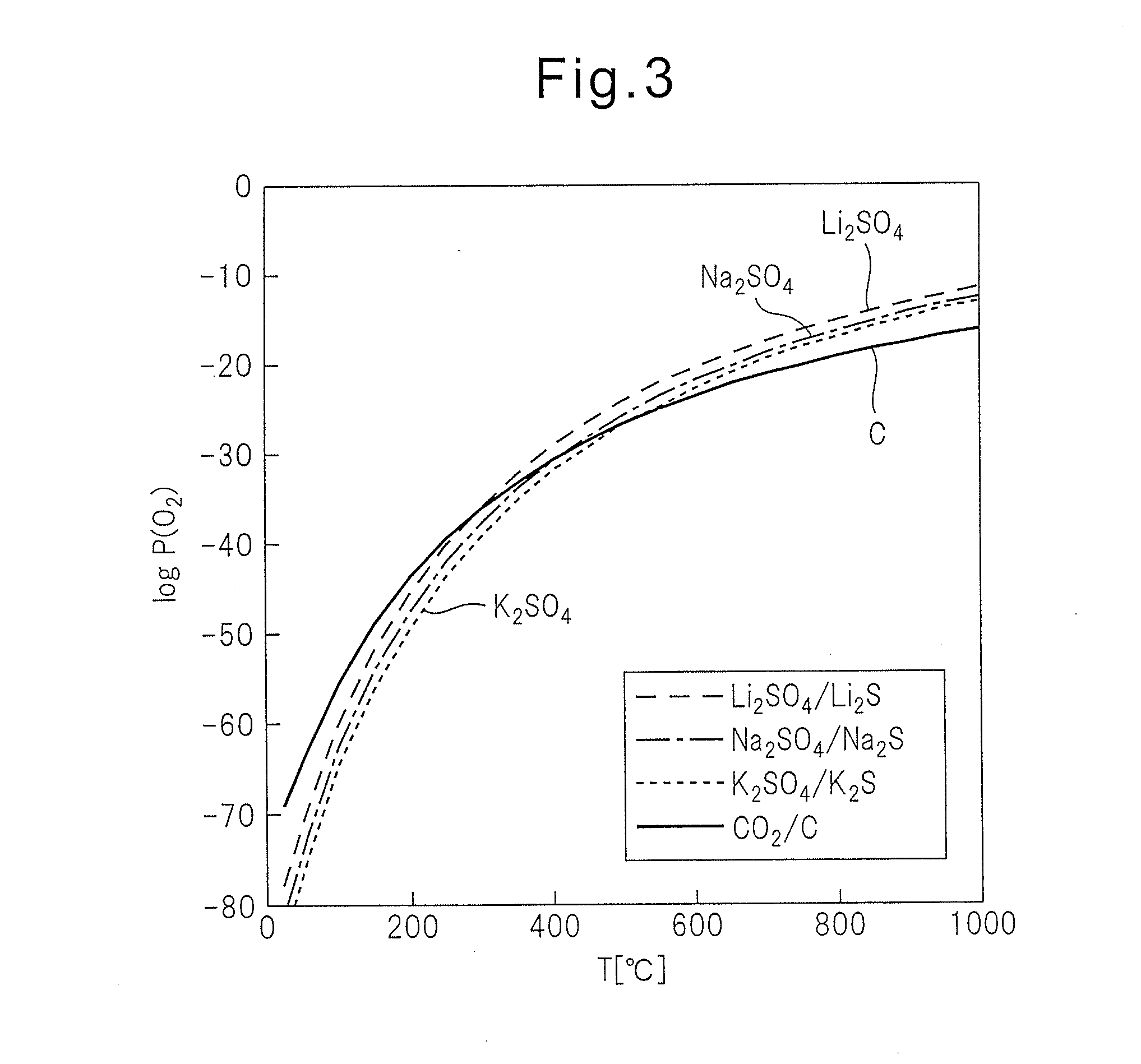

Method for recovering active material from waste battery material

ActiveUS20130323142A1Electrode thermal treatmentWaste accumulators reclaimingConductive materialsBiological activation

Method of recovering active material from waste battery materials comprises: (1) an electrode material mixture recovery step of separating an electrode from the waste battery material to recover an electrode material mixture including the active material, a conductive material, and a binder from the electrode; (2) an activation agent mixing step of mixing an activation agent including one or more alkali metal compounds with the recovered electrode material mixture; (3) an activation step of heating the obtained mixture to a retention temperature not less than a melting start temperature of the activation agent to activate the active material included in the mixture; and (4) an active material recovery step of recovering the activated active material from a mixture obtained as a result of cooling after the activation step.

Owner:SUMITOMO CHEM CO LTD

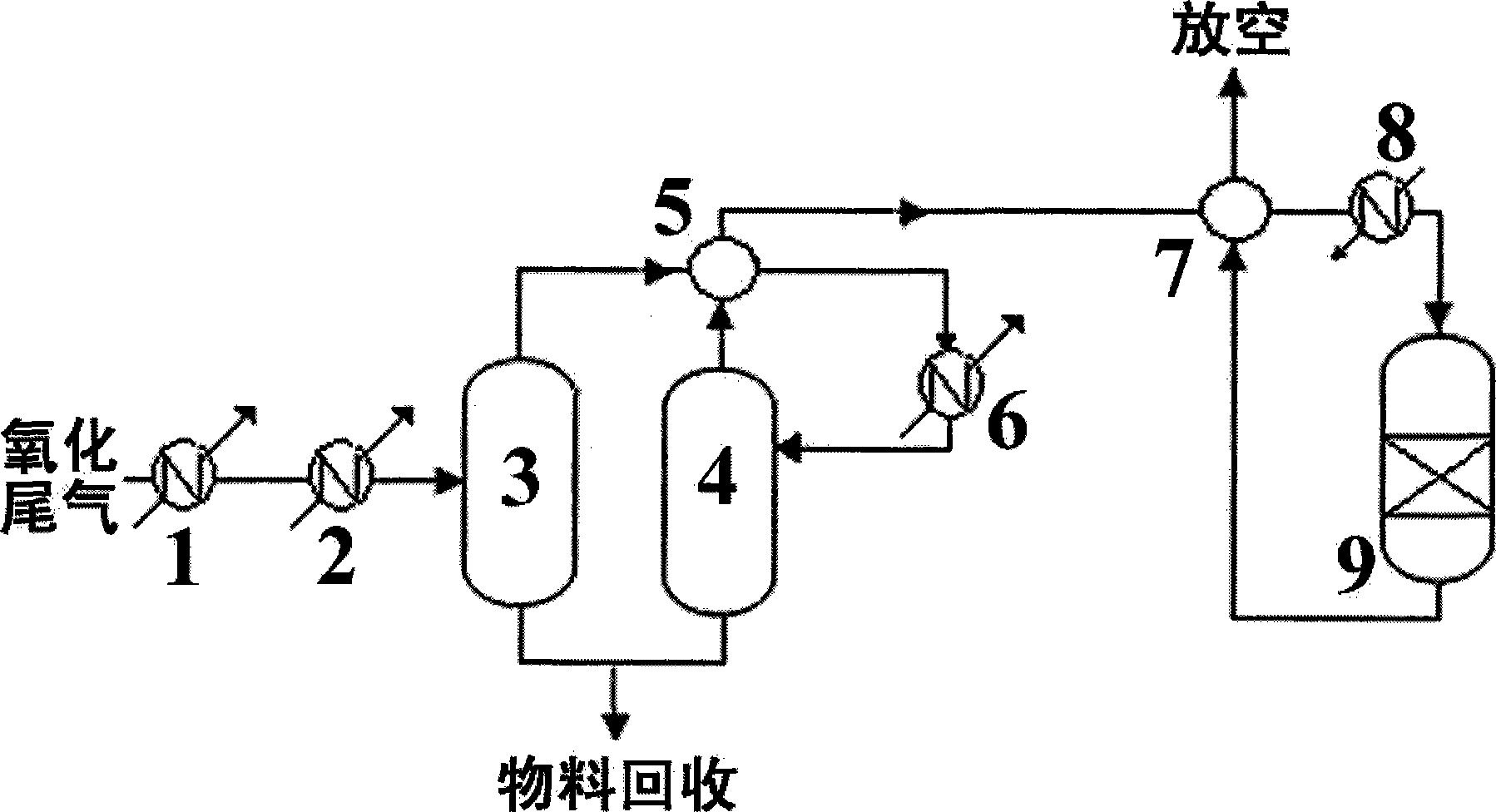

Process for treating oxidized exhaust gas

ActiveCN101543684AReduce the temperatureAchieve reuseOrganic compound preparationChemical industryLoss rateDevice material

The invention discloses a novel method for recovering and treating oxidized exhaust gas generated in phenol production, which comprises the following steps: adopting deep cooling to achieve liquefaction separation of organic matters by reducing the temperature of the exhaust gas to below 5 DEG C, wherein the material recovery rate reaches more than 95 percent; and adopting a Pt catalyst to decompose residual total hydrocarbons and cumene in the exhaust gas at a temperature of between 220 and 450 DEG C to achieve emission after reaching standards. The method can improve the exhaust emission quality, recover effective components in the exhaust gas, and reduce the device loss rate and the device material consumption on the basis of raw water cooling and activated carbon adsorption.

Owner:CHINA PETROLEUM & CHEM CORP

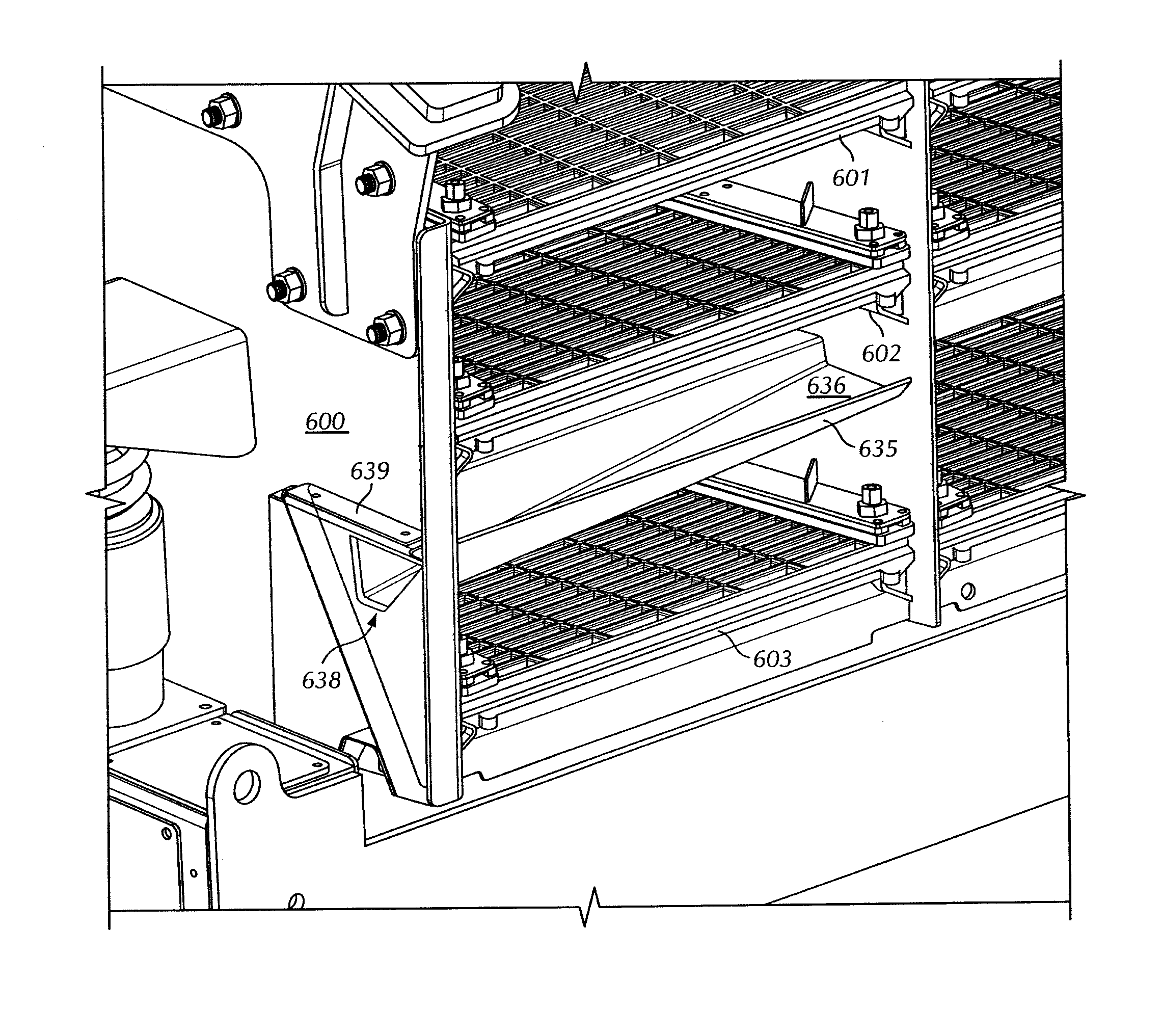

Wellbore strengthening material recovery

A wellbore strengthening material collection system including a vibratory separator having a top deck, a middle deck, and a bottom deck, and also including a collection trough coupled to at least one of the decks and configured to receive wellbore strengthening materials from the at least one of the decks. Additionally, a collection trough including a body having an inlet and an outlet, an angled surface disposed within the body and at least on extension surface extending form the body and configured to secure the collection trough to a vibratory separator.

Owner:MI

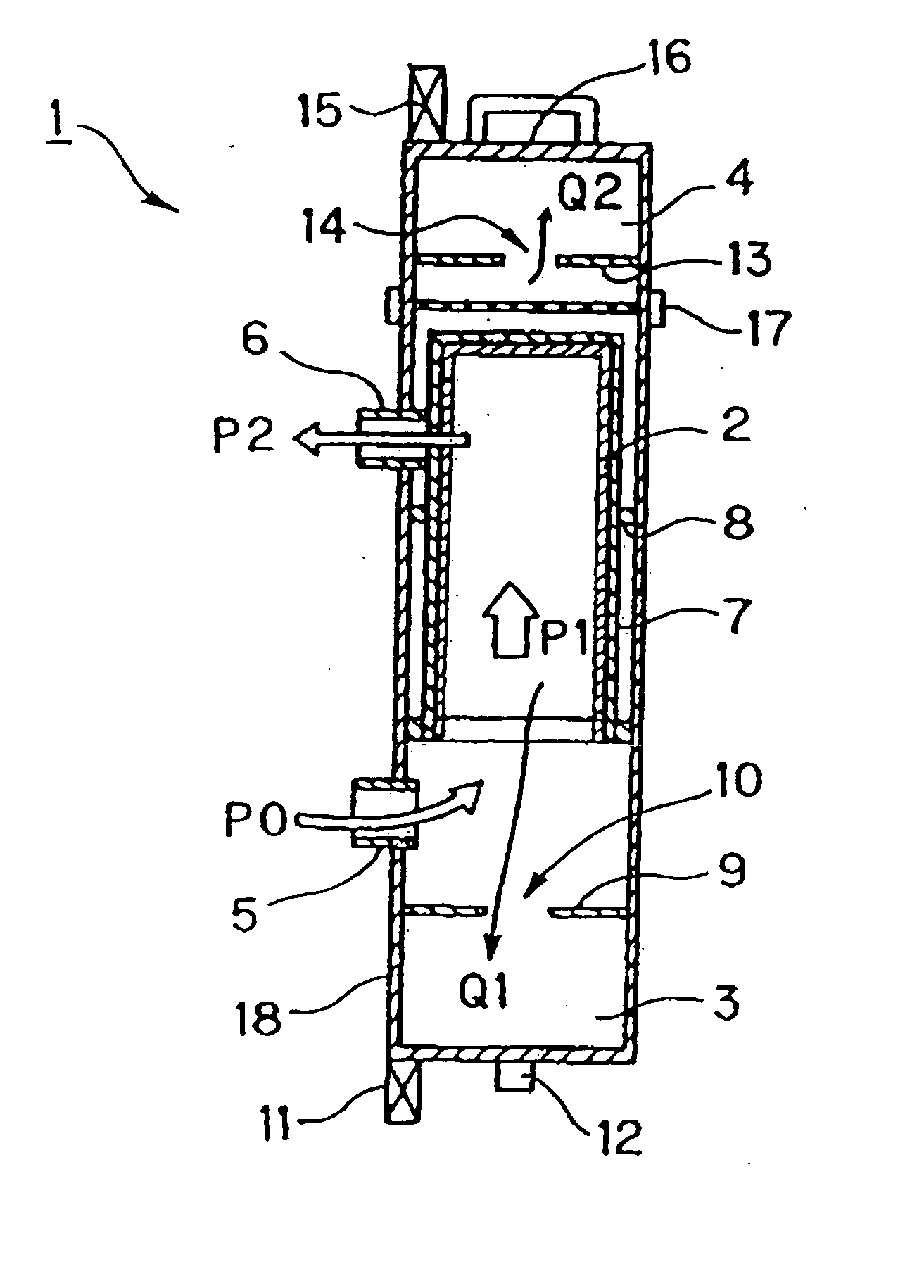

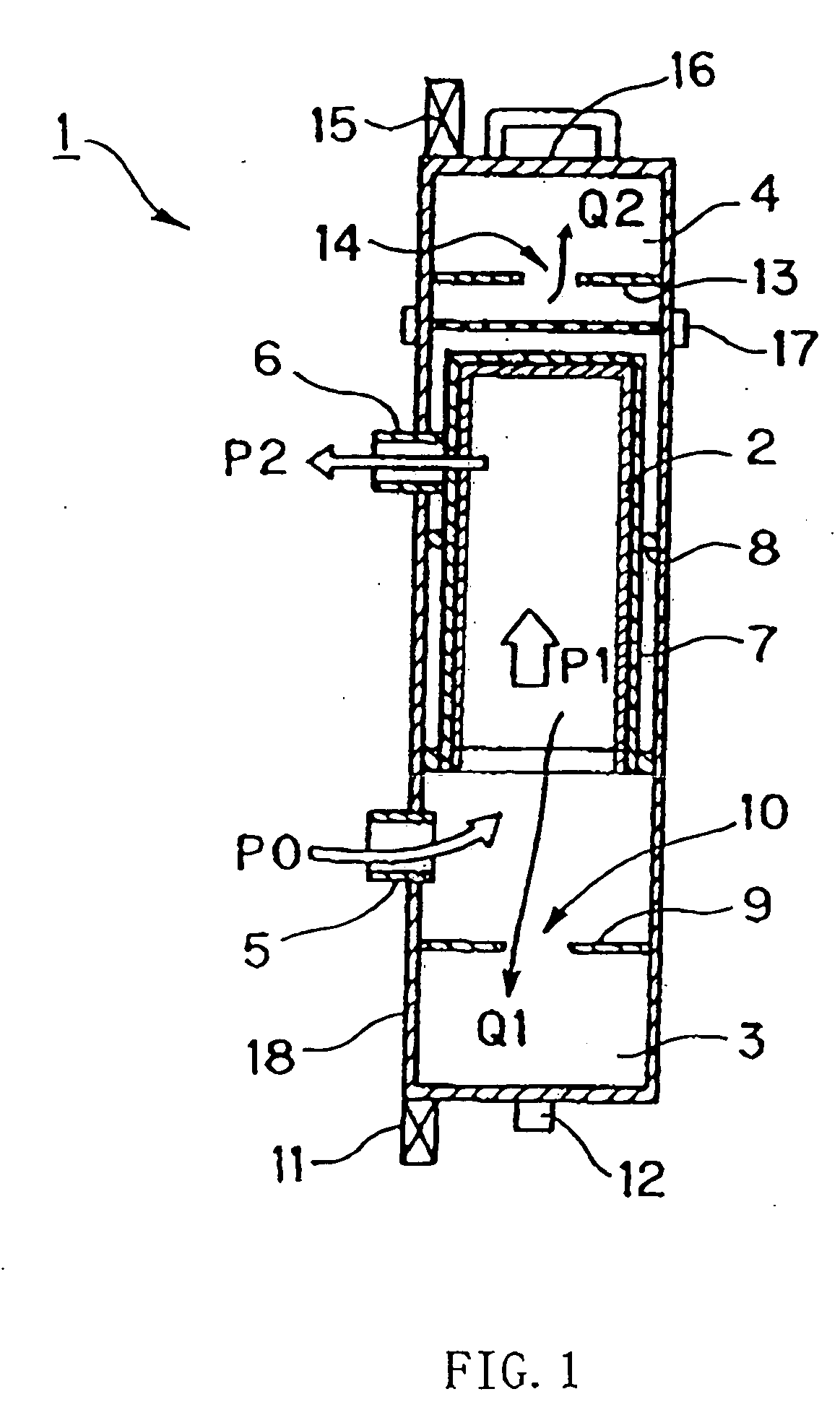

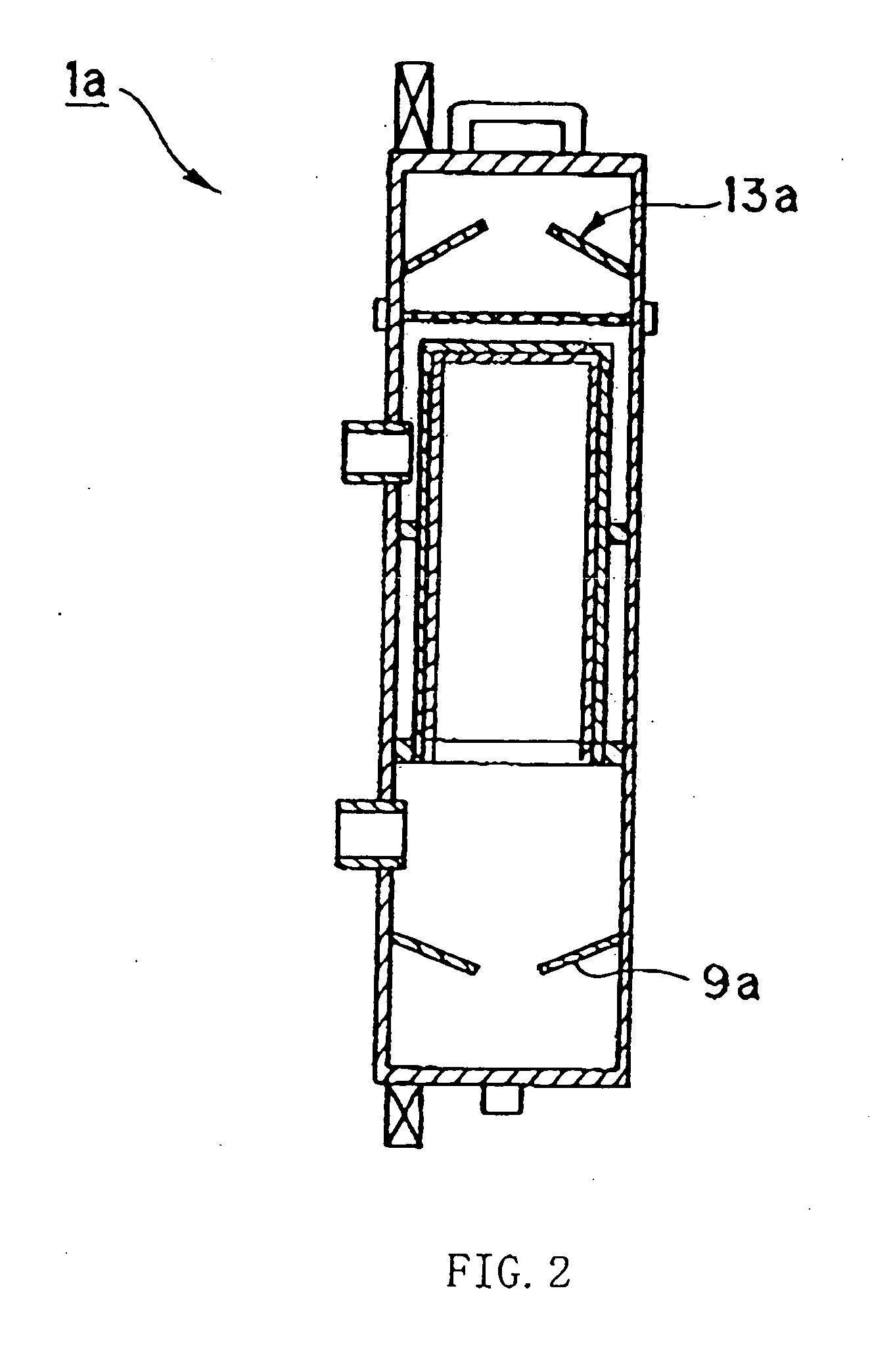

Filter device

InactiveUS20050103700A1Avoid agitationInhibit deteriorationWater/sewage treatmentSedimentation separationFiltrationSediment

The present invention relates to a filter device for removing impurities contained in liquid. A filter housing 18 is provided with a container for accommodating a filter bag 2 therein, a deposit recovery tank 3 for recovering a deposit and a floating material recovery tank 4 for recovering a floating material. Thus, it is possible to prevent any deterioration of filtration performance caused by filtered and separated impurities, and to achieve both of filtration and specific gravity difference separation by a single device.

Owner:NOK CORP

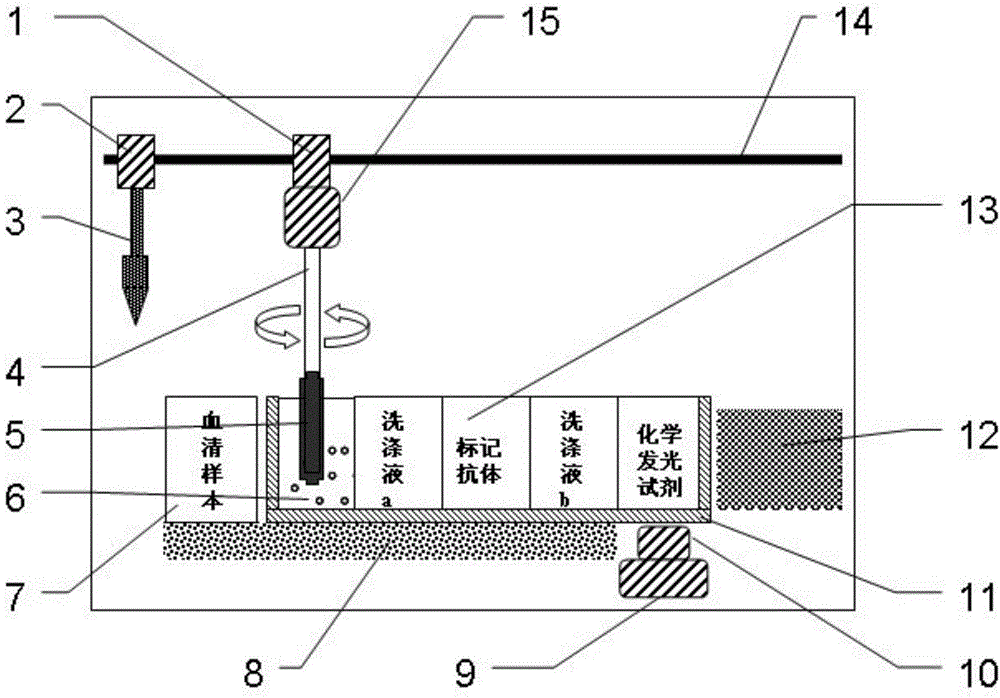

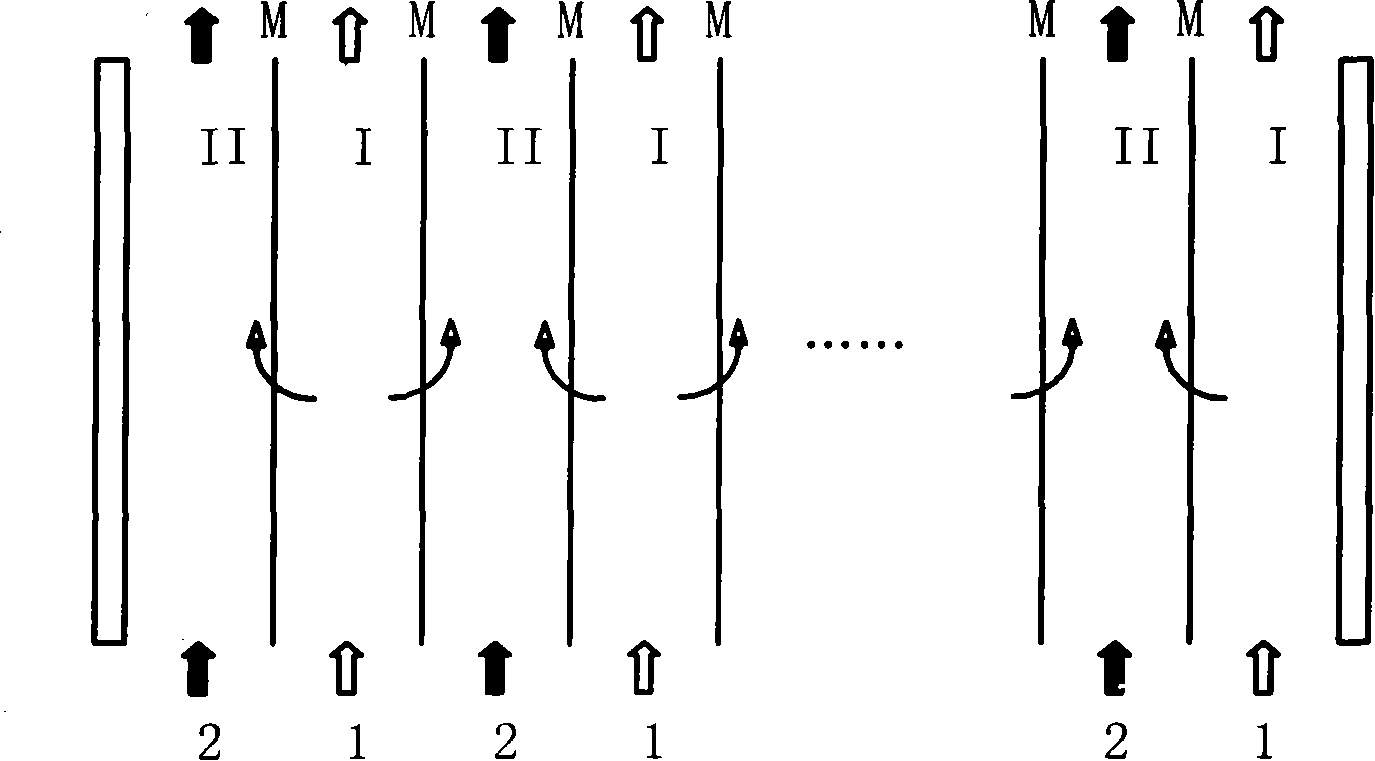

Full-automatic luminescent immunoassay system based on micronano-magnetic bead electromagnetic transfer technique

The invention provides a full-automatic luminescent immunoassay system based on a micronano-magnetic bead electromagnetic transfer technique. The system includes a computer and a detection box. The detection box is a sealable lightproof box, and comprises a first motor, a second motor, a membrane rupture device, an electromagnetic stirring rod, a Teflon coating or a disposable plastic jacket, immunomagnetic beads, a sample pool, a temperature control device, a photoelectric conversion device, a bottom reading light path, a waste consumable material recovery area or ultrasonic cleaning equipment, a reagent bin consumable material and a consumable material adapter, a guide rail and an electromagnet. The system provided by the invention is based on a magnetic bead transfer method, simplifies the detection steps, integrates the detection module, avoids a complex liquid path system, saves the detection time while realizing full automation and miniaturization of the immunodetection system, and also lowers the system cost at the same time.

Owner:THE SECOND AFFILIATED HOSPITAL OF NANJING MEDICAL UNIV

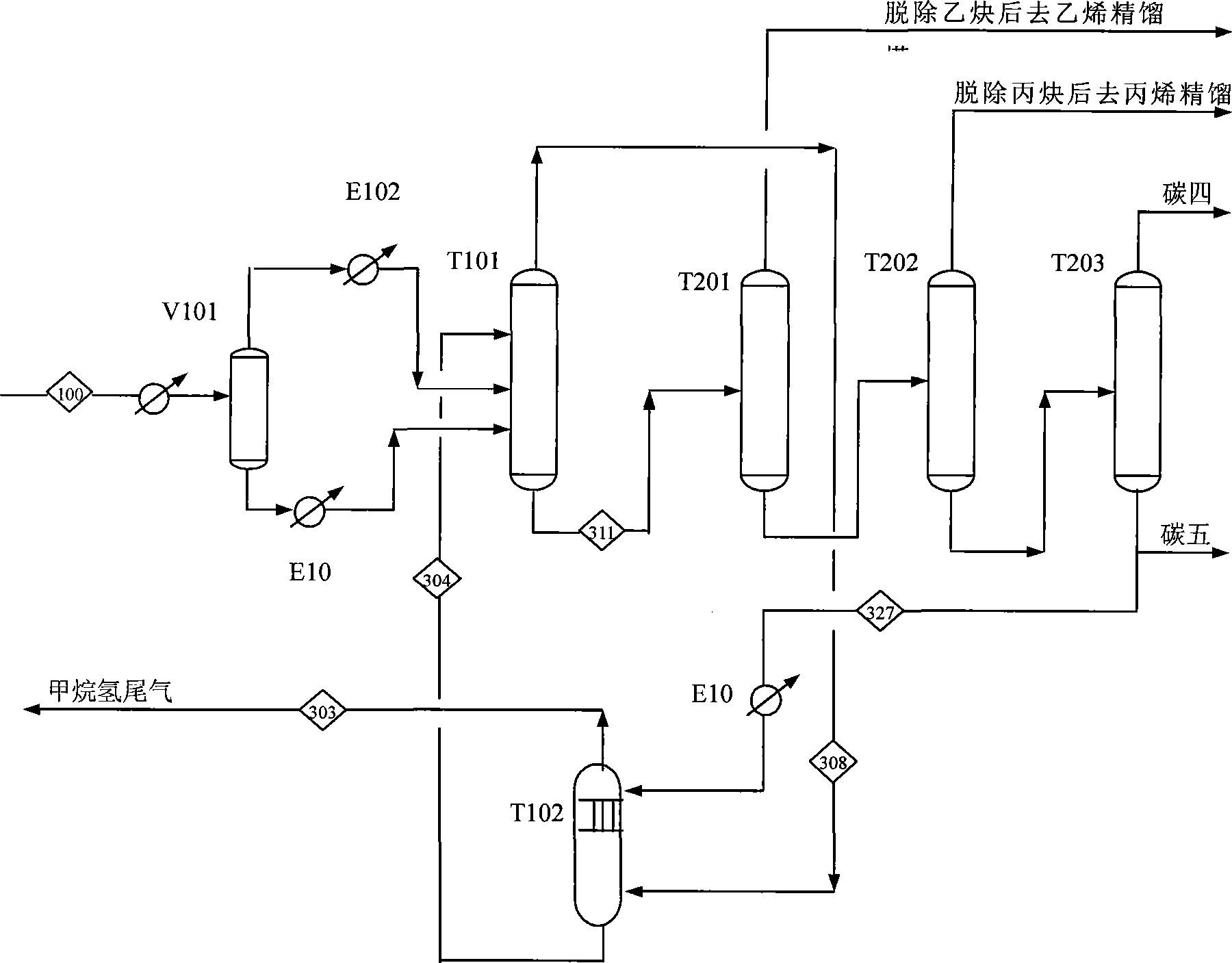

Lightweight alkene separation method reducing absorbent usage amount and device thereof

ActiveCN103333039AHigh operating temperatureAvoid explosionDistillation purification/separationAdsorption purification/separationCooling towerGas phase

The invention discloses a lightweight alkene separation method reducing absorbent usage amount and a device thereof. Lightweight alkene reaction gas converted from oxygen-containing compound is subjected to a pre-treatment and then induced to a double-tower depropanization system. The product in the top of the towers of the depropanization system cools and is transported to a demethanation tower, in the top of the demethanation tower only propylene cooler is used to cool materials, the gas phase in the top of the tower is transported to a tower, which is provided with a heat exchanger in the middle or in the top, to absorb carbon dihydrocarbon, the gas discharged from the absorption tower is induced into a pressure swing absorption device to further recycle ethylene, recycled coarse ethylene gas mixes with lightweight ethylene reaction gas before returning to a section of compressor. The invention provides a non-deep-cold lightweight alkene separation method, which has the advantages of small investment, low energy consumption, small absorbent circulation volume and high material recovery rate.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD +1

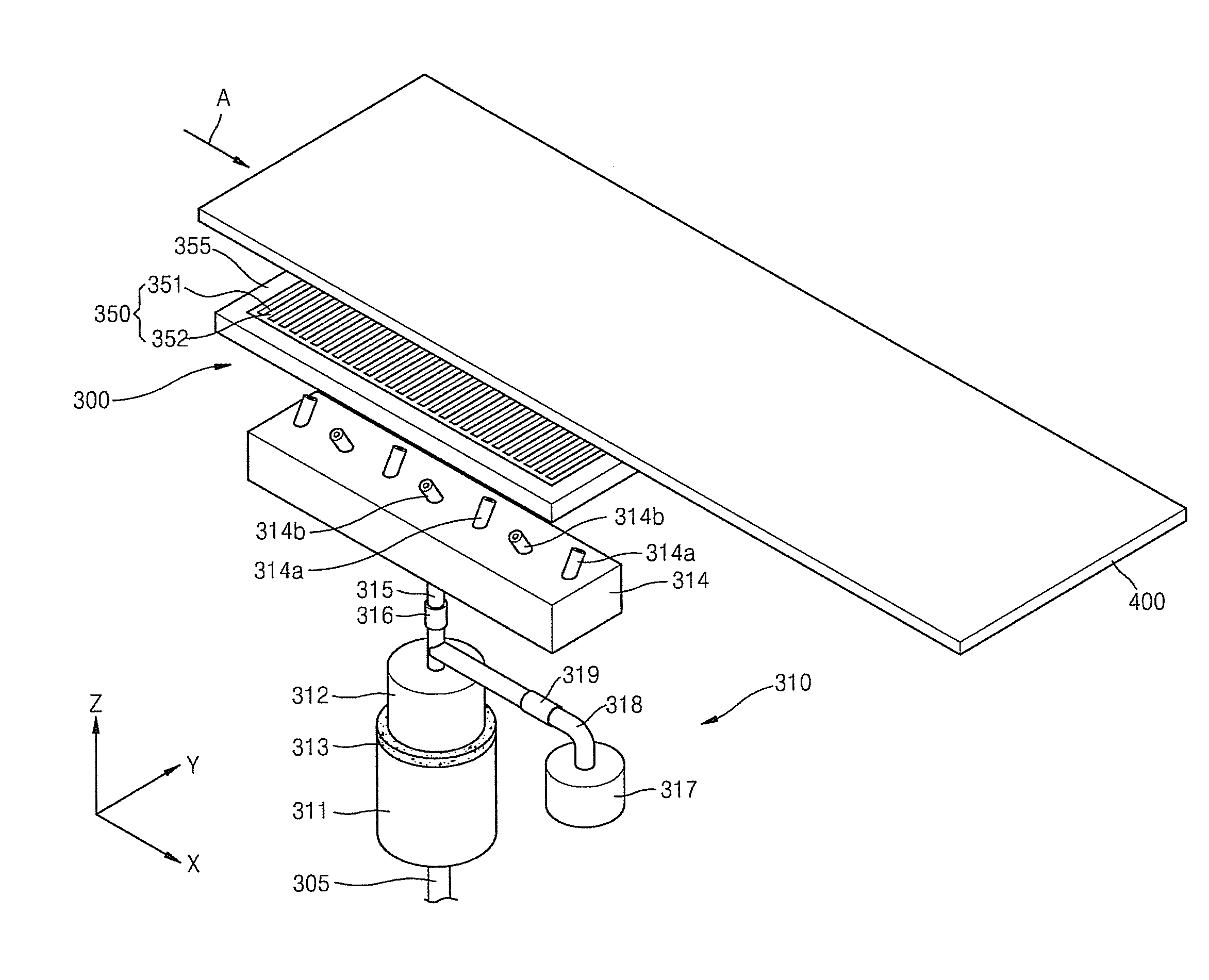

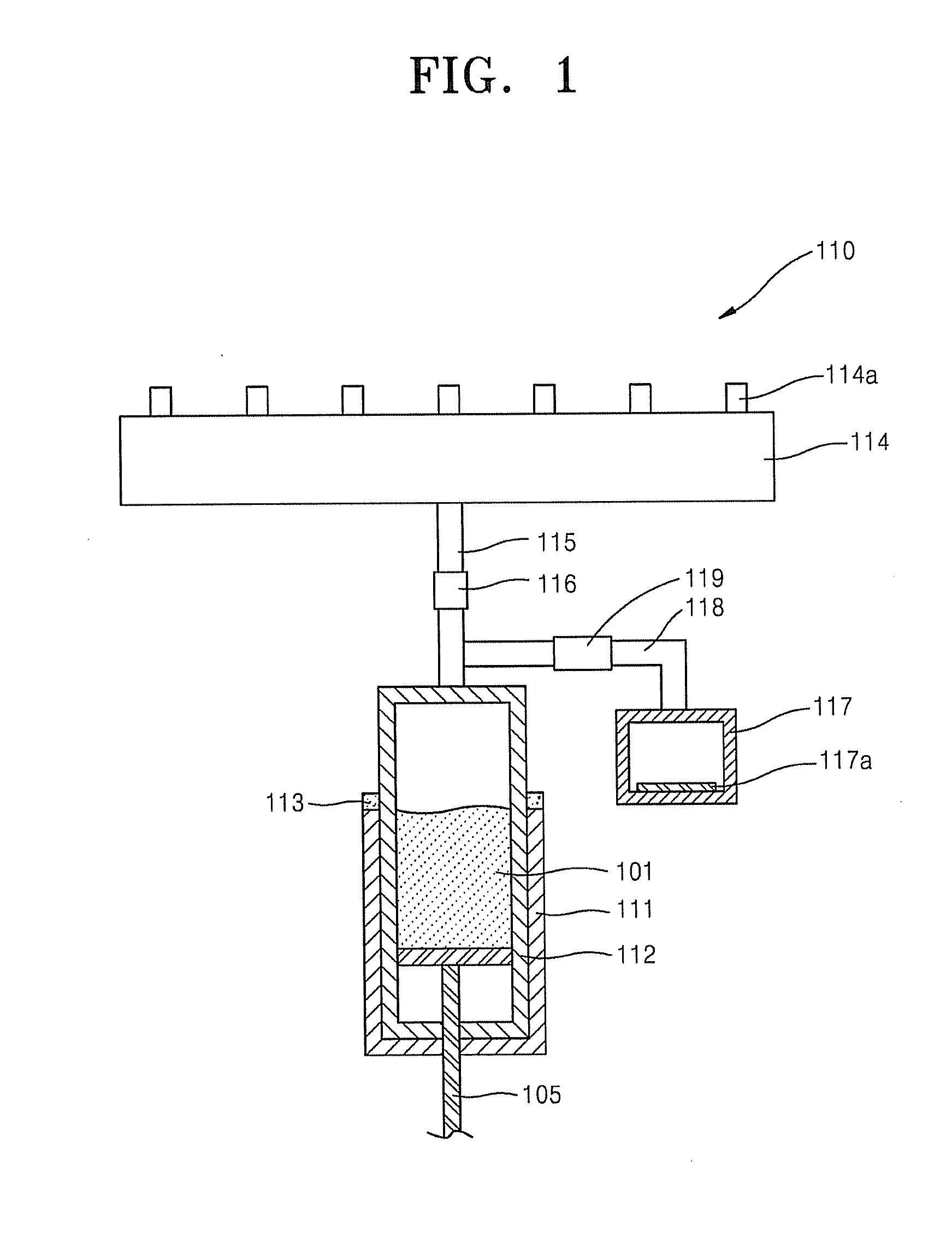

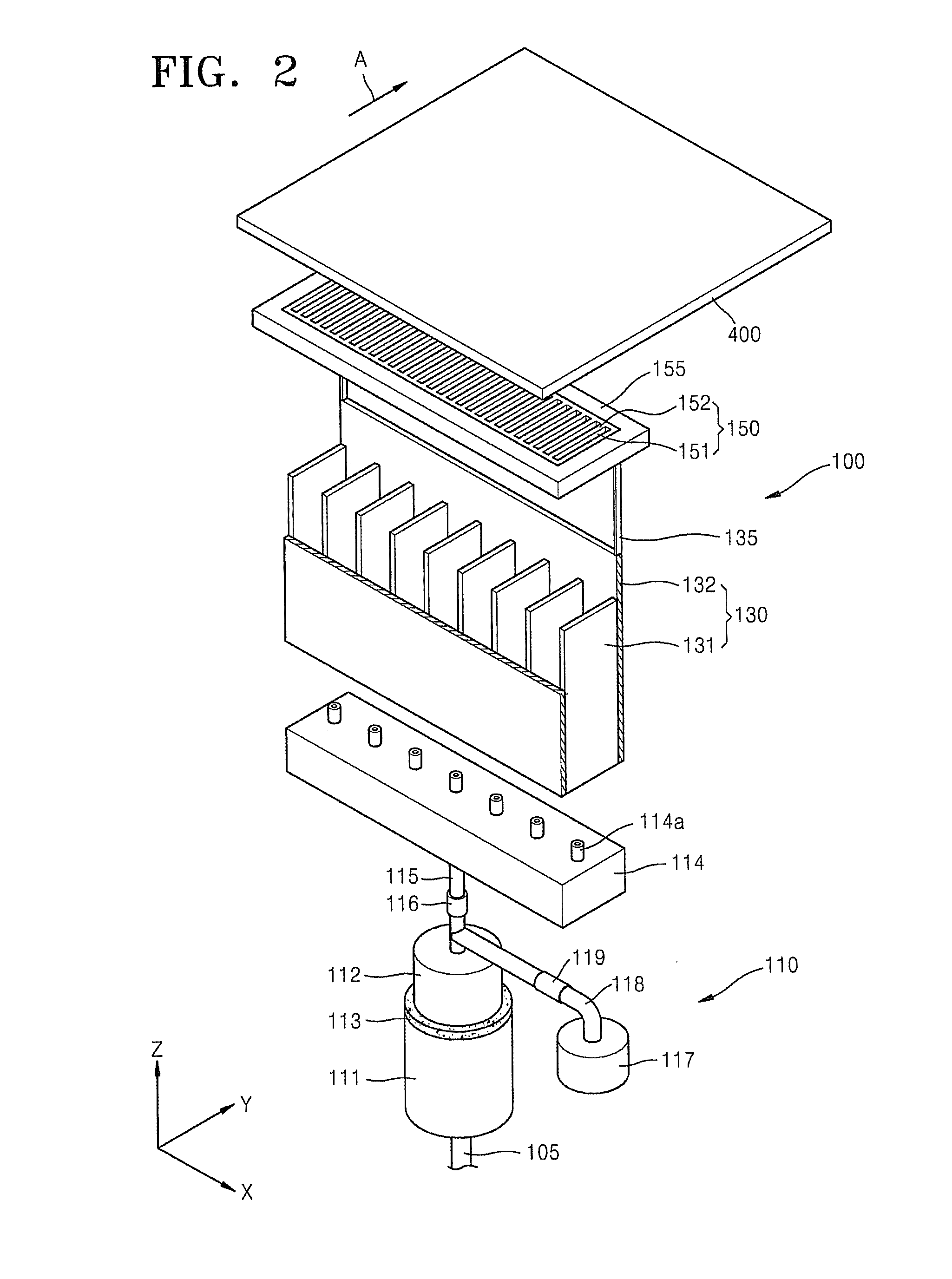

Deposition source, thin film deposition apparatus and method of manufacturing organic light-emitting display apparatus

InactiveUS20110165320A1Inhibition of denaturationEasily improve characteristicVacuum evaporation coatingSolid-state devicesCrucibleMaterial recovery

A deposition source, a thin film deposition apparatus, and a method of manufacturing an organic light-emitting display apparatus, the deposition source including: a crucible to hold a deposition material; a heater to heat the deposition material; a nozzle unit disposed at a side of the crucible; a first connector disposed between the crucible and the nozzle unit; a first valve disposed on the first connector to control the flow of the deposition material to the nozzle unit; a deposition material recovery unit to collect the deposition material; a second connector to connect the first connector to the deposition material recovery unit; and a second valve to control the flow of the deposition material through the second connector.

Owner:SAMSUNG DISPLAY CO LTD

Separating method and equipment of low-carbon olefins beneficial to product recovery

ActiveCN103304358AHigh operating temperatureAvoid explosionHydrocarbonsAdsorption purification/separationRefrigeration compressorCooling tower

The invention discloses a separating method and corresponding equipment of low-carbon olefins beneficial to product recovery. The separating method comprises the steps of: pretreating and delivering oxygenated chemical-converted low-carbon olefin flow into a depropanization system, cooling and delivering top products of the depropanization system into a demethanizing tower, cooling the top of the demethanizing tower only with a propylene refrigerant, delivering vapor phase at the tower top into a pressure swing adsorption device for recovering ethylene, returning the recovered crude ethylene gas back before a segment of compressor to be mixed with low-carbon olefin reaction gas flow, so that a copious cooling cold box and an ethylene refrigeration compressor are omitted, and the fixed investment and energy consumption can be reduced. Compared with the prior art, the separating method and corresponding equipment have the advantages of being low in separating energy consumption, high in material recovery rate, small in influence on the following ethylene and propylene separation, and the like.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD +1

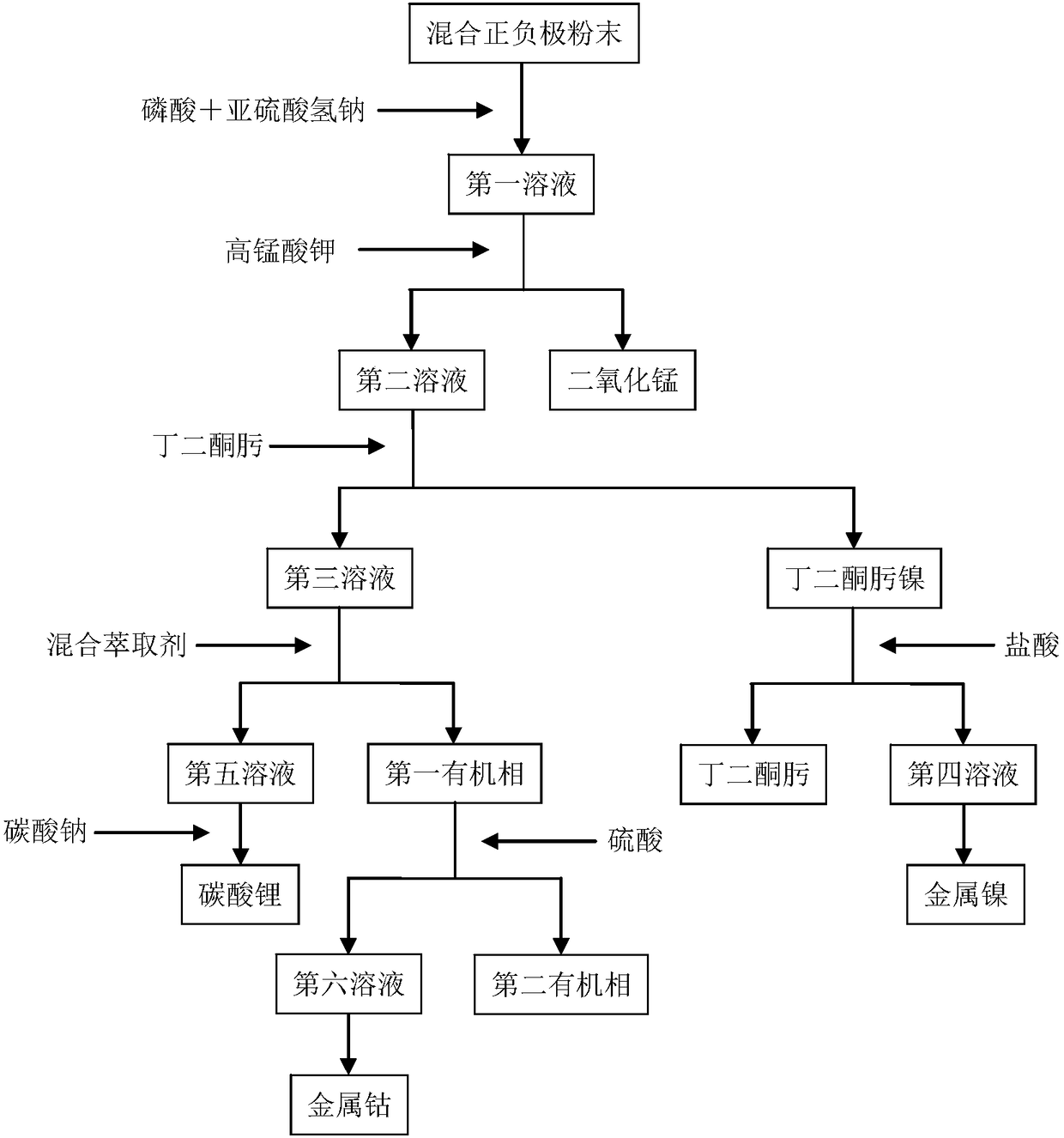

Method for recovering metal materials in waste ternary power batteries

ActiveCN108193050AImprove reducibilityReduce corrosionPhotography auxillary processesWaste accumulators reclaimingPurification methodsPhosphoric acid

The invention relates to a method for recovering metal materials in waste ternary power batteries, and belongs to the technical field of battery material recovery and cyclic utilization. The method comprises the steps that positive and negative electrode mixed powder, phosphoric acid solution and the like react with each other, filtering is conducted to obtain a first solution; a potassium permanganate solution is added into the first solution for recovering manganese dioxide, a second solution is obtained, a butanone oxime solution is added into the second solution, butanone oxime nickel precipitation and a third solution are obtained, butanone oxime nickel is dissolved in hydrochloric acid, separating is conducted to obtain a fourth solution, and the fourth solution is subjected to electrodeposition to recover metal nickel; then mixed extractant is used for extracting cobalt ions in the third solution, separating is conducted to obtain an organic phase and a fifth solution, cobalt inthe organic phase is extracted by using sulfuric acid, a sixth solution is obtained, and the sixth solution is subjected to electrodeposition to recover metal cobalt; and a sodium carbonate solutionis added to the fifth solution, and lithium carbonate is recovered. The method for recovering the metal materials in the waste ternary power batteries adopts a mild and stable phosphoric acid-sodium bisulfite system; the multiple purification methods of precipitation, extraction and electrodeposition are used without interference to each other, and the separation effect is good; and the recoveredproducts have many types, and application is wide.

Owner:中国人民解放军陆军防化学院

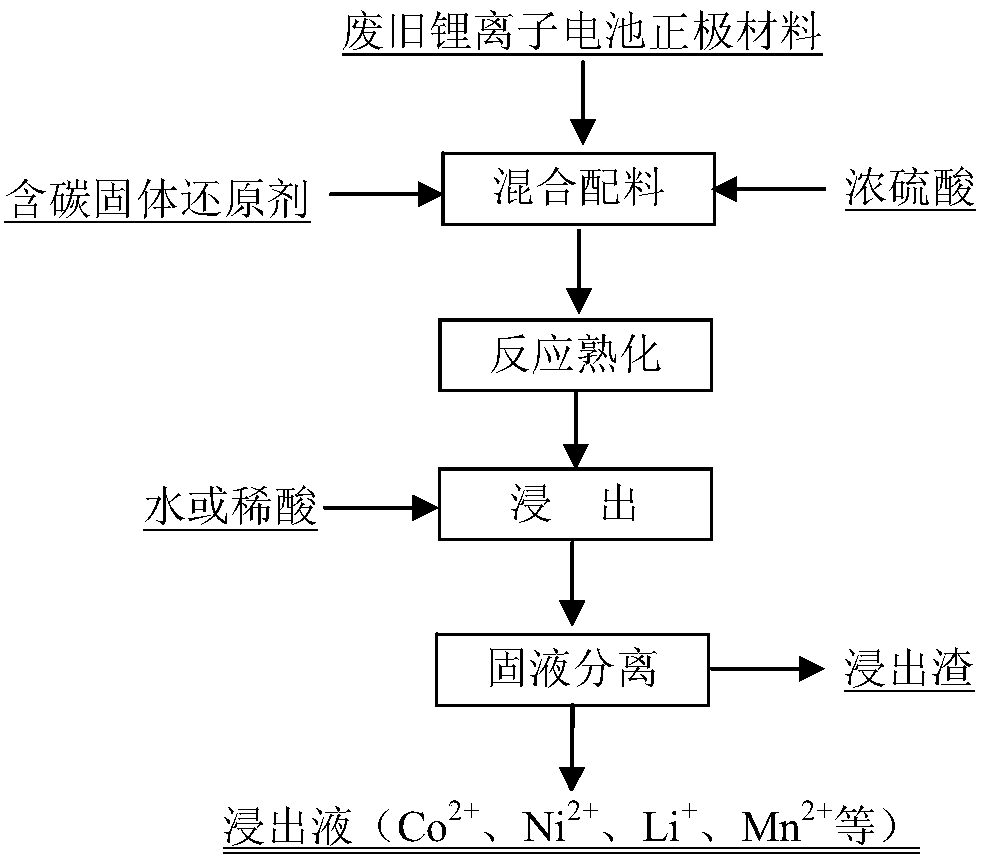

Method for comprehensively recovering anode materials of waste lithium ion batteries

ActiveCN108559846AIncrease profitHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementBiological activationLithium-ion battery

The invention discloses a method for comprehensively recovering anode materials of waste lithium ion batteries and belongs to the technical field of lithium ion battery material recovery. The method comprises the steps that firstly, anode material powder obtained by splitting, crushing and screening the waste lithium ion batteries is evenly mixed with a certain number of carbon-containing solid reductants such as coal dust and coke powder and an appropriate amount of concentrated sulfuric acid, and then, after reaction curing is conducted in a period of time under the condition of the temperature of 100-300 DEG C, a solid clinker is obtained; and the solid clinker is subjected to slurrying leaching through water or dilute sulfuric acid, thus a leaching agent containing useful elements is obtained, and lithium, cobalt, nickel, manganese, vanadium and the like are recovered from the leaching agent. According to the method for comprehensively recovering the anode materials of the waste lithium ion batteries, the roasting activation process is not needed, thus energy consumption is low, and environment pollution is little; reagents which are wide in source and low in price are used, and thus the cost is low; and the concentrated sulfuric acid curing reaction condition is adopted, and thus the useful element recovery rate is high.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

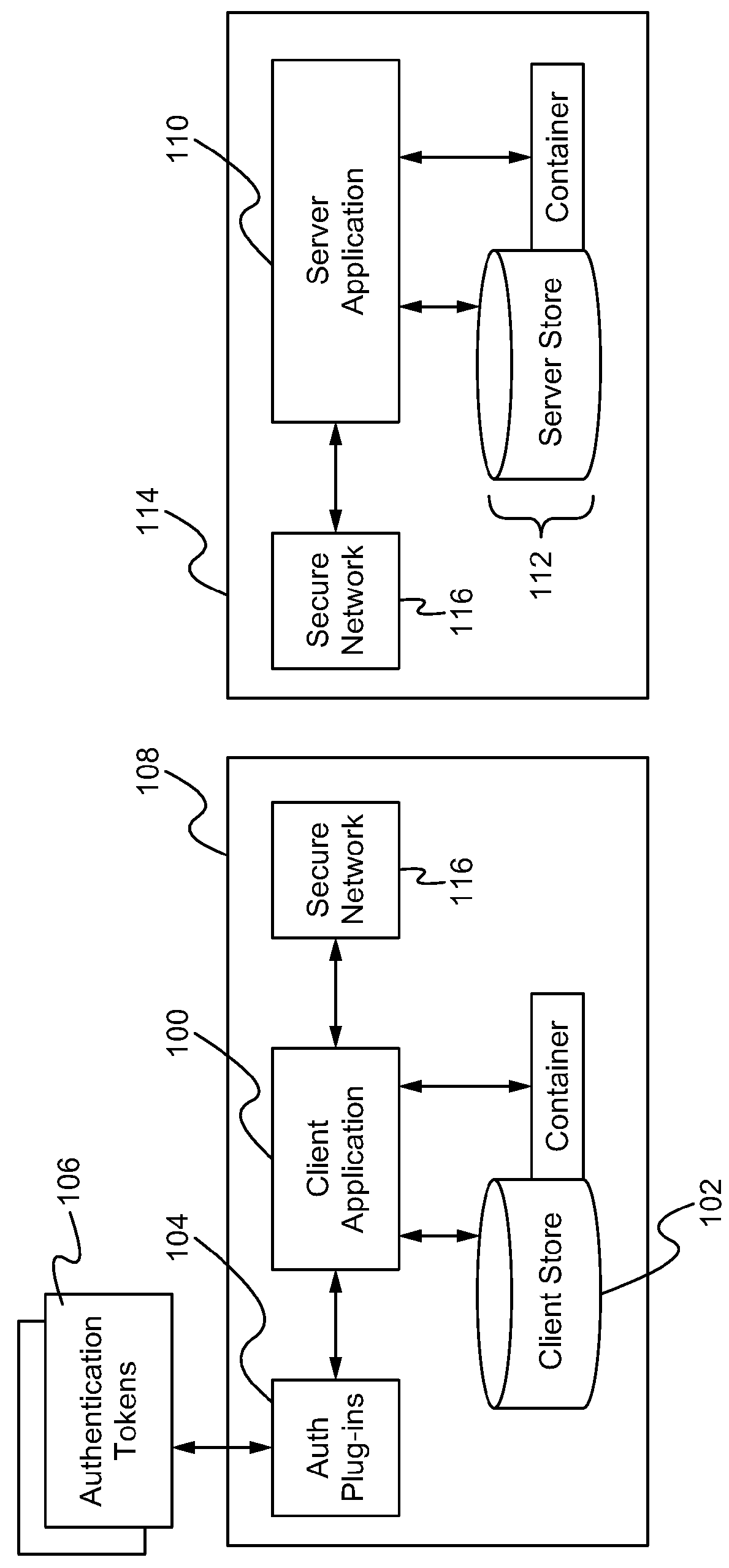

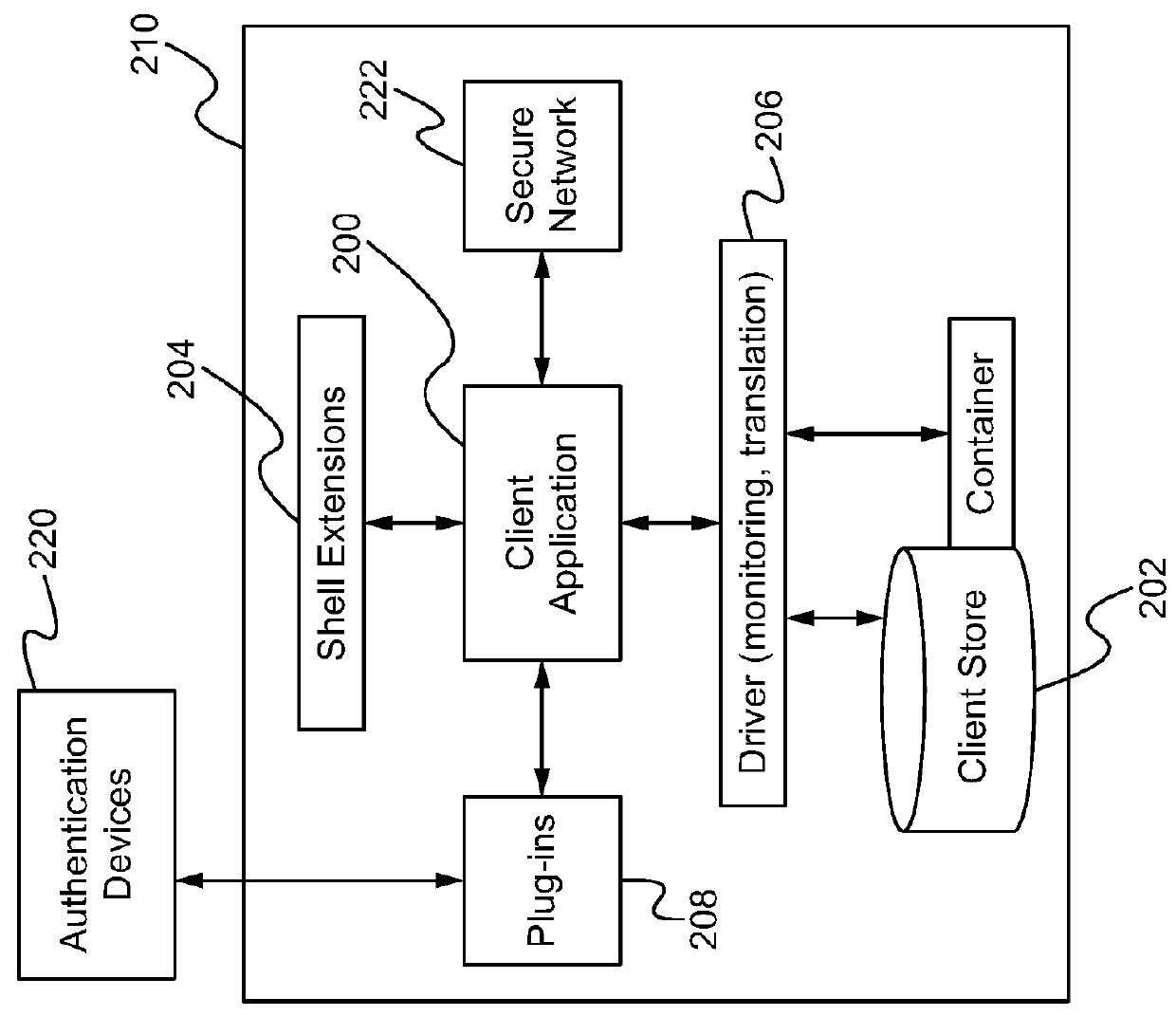

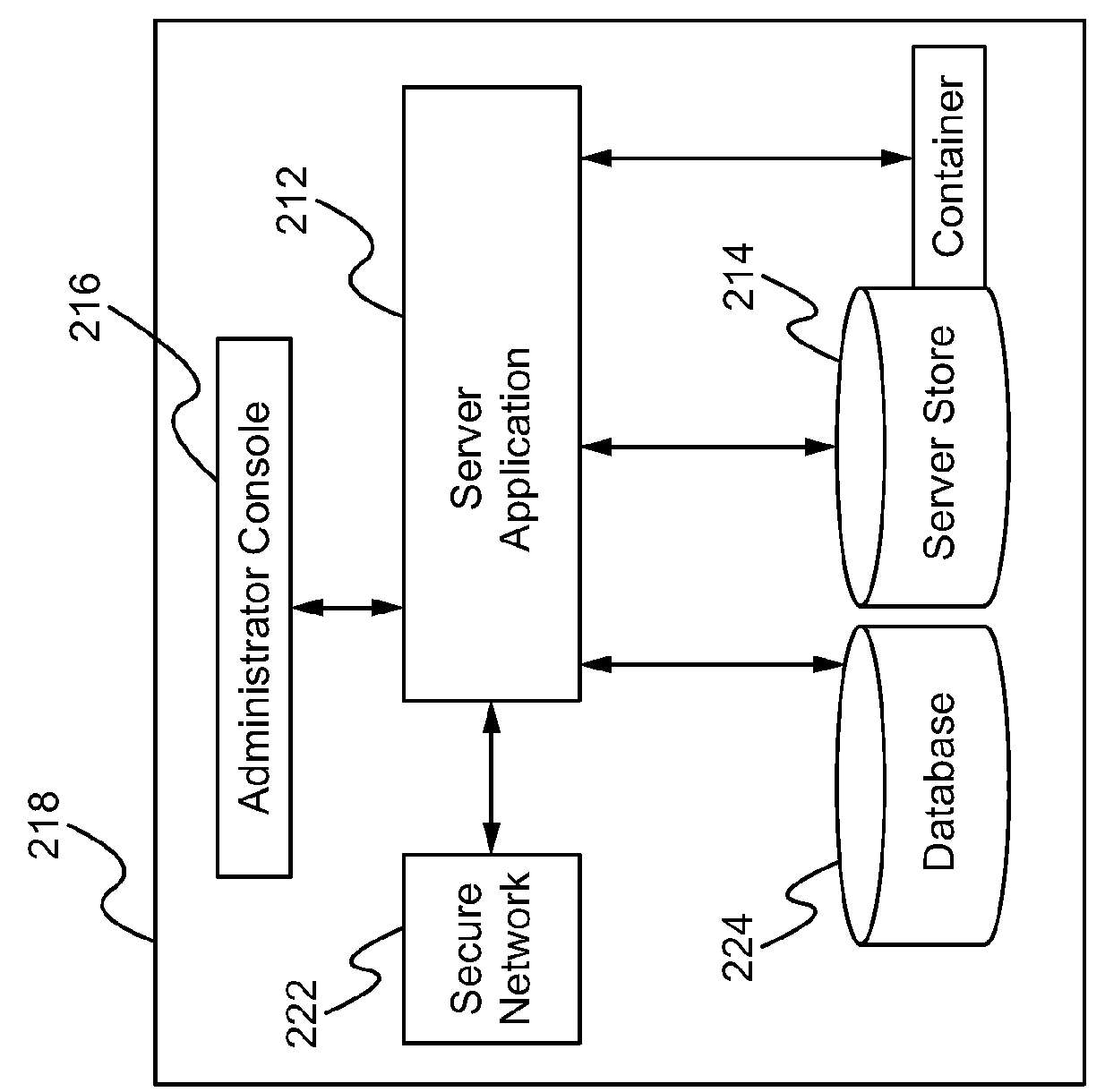

System and associated software for providing advanced data protections in a defense-in-depth system by integrating multi-factor authentication with cryptographic offloading

ActiveUS20180109504A1Minimize disruptionKey distribution for secure communicationEncryption apparatus with shift registers/memoriesClient dataApplication software

The advanced data protection system is implemented by distributing data encryption across multiple isolated computing systems and using multi-factor authentication to access remote, protected decryption material. Architectural components include: Client application software reading / writing from / to a client data store executing on a client host computer, client application plug-ins communicating with external authentication devices, server application software reading / write data from / to a server data store executing on a host computer which is physically or virtually isolated from the client host computer, authentication devices, components, or systems integrated with or connected to the client computer and exposing programmatic interfaces to client application software, and secure networking components executing on both hosts that provide secure data exchange. The system employs certain associated software that incrementally encrypts client data on both the client and server, storing portions of the results on each computer, and requiring multi-factor authentication for distributed decryption material recovery.

Owner:DEFINITIVE DATA SECURITY INC

Method for construction of bridge cast-in-situ pre-stressed concrete continuous beam

ActiveCN101824800AHigh recovery rateShorten the construction periodForms/shuttering/falseworksBridge erection/assemblyBridge engineeringPre stress

The invention belongs to the technical field of bridge engineering construction, particularly relates to a method for the construction of a bridge cast-in-situ pre-stressed concrete continuous beam, which solves the problems that the existing construction method is incapable of meeting the requirements for construction period, imposes strict requirements for the bearing capacity and operation space of a foundation, and has high-workload and uneconomic foundation reinforcement. The method comprises the following steps: building a tied-arch support below the position where the concrete continuous beam is arranged; arranging a vertical supporting structure below the position of the tip of the concrete continuous beam; then, building a formwork system above the tied-arch support; and sequentially constructing the beam 'from middle to two sides', and reserving closure segments at two sides of the beam, wherein the tied-arch support comprises an arch part and a tie bar connected in a hinged way, and a support is arranged at the bottom of the tie bar. Accordingly, the invention has the following beneficial effects: the method which is not restricted by the construction environment and conditions can reduce the construction period, save the construction cost, meet the requirements for cast-in-situ construction and prevent the existing structure from being damaged by the stress system; and the method has the advantages of wide applicable range, high material recovery rate and obvious economic benefit.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

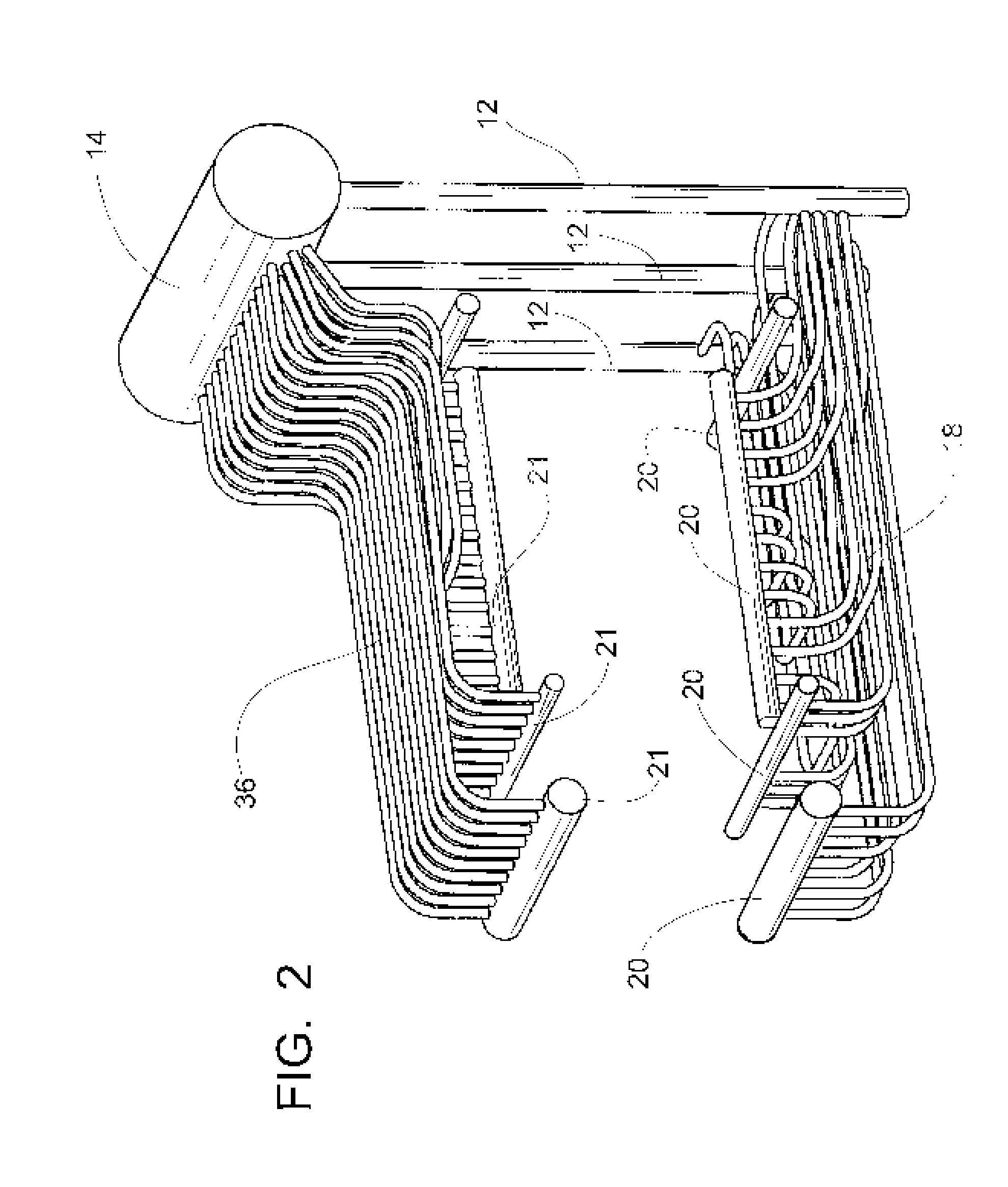

Natural Circulation Industrial Boiler for Steam Assisted Gravity Drainage (SAGD) Process

A gravity feed, natural circulation boiler for an SAGD process using low quality feedwater for carbonatious material recovery, has a large diameter steam drum with downcomers. A furnace of the boiler has individually replaceable membrane wall modules, each with upper and lower headers and membrane roof, wall and floor parts connected to the drum and defining a fire box having an inlet end and an outlet end. The furnace includes a membrane front wall connected to the drum with a windbox upstream of the front wall. Burners at the inlet end of the firebox heat the firebox and riser pipes are connected between the steam drum and the upper header for supplying steam to the steam drum when the firebox in heated, the downcomer pipes being connected to the lower header for supplying water from the stream drum under gravity feed so that each module defines a single circuit. Furnace outlet screen bank and subsequent generating banks each with upper and lower headers and associated feeder and riser tubes complete the boiler.

Owner:BABCOCK & WILCOX CANADA LIMITED

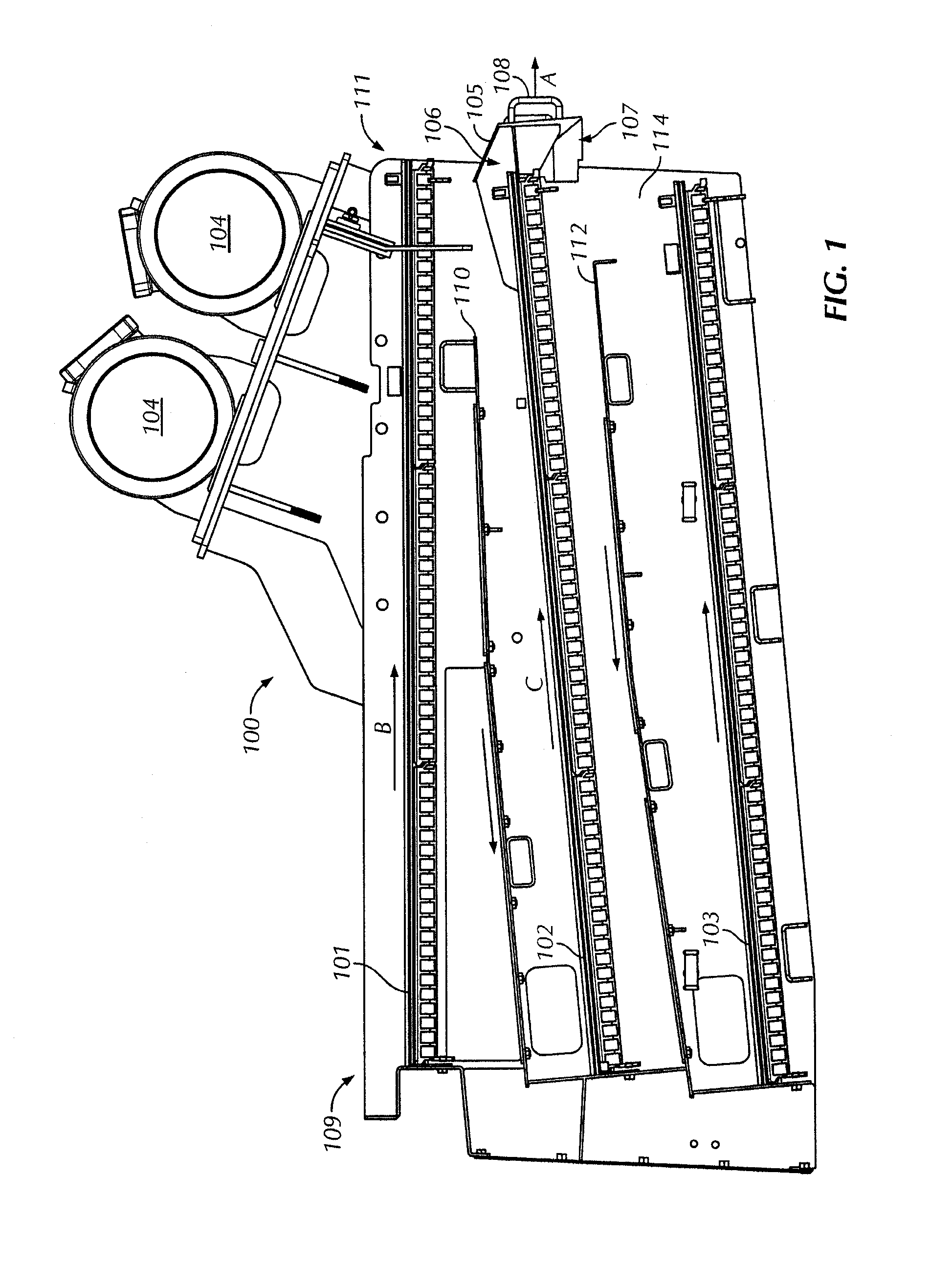

Systems and methods for optimizing a single-stream materials recovery facility

ActiveUS8459466B2Facilitate manual and automated removalShorten speedGlass recyclingCentrifugesFiberControl theory

Systems and methods for sorting a plurality of recyclable items in a single-stream materials recovery facility (SSMRF) are provided. In some embodiments, a system includes an infeed conveying system, a fiber transfer conveyor, a container transfer conveyor, and a glass sorting and conveying system. The system further includes a controller configured to obtain total weight and volume of recyclable items at the infeed conveying system. The controller estimates a percent weight of fiber items and a percent weight of non-fiber items relative to the total weight. Based on the estimates, the controller controls speed of at least one of the infeed conveying system, the fiber transfer conveyor, the container transfer conveyor, and the glass sorting and conveying system.

Owner:RE COMMUNITY HLDG II INC

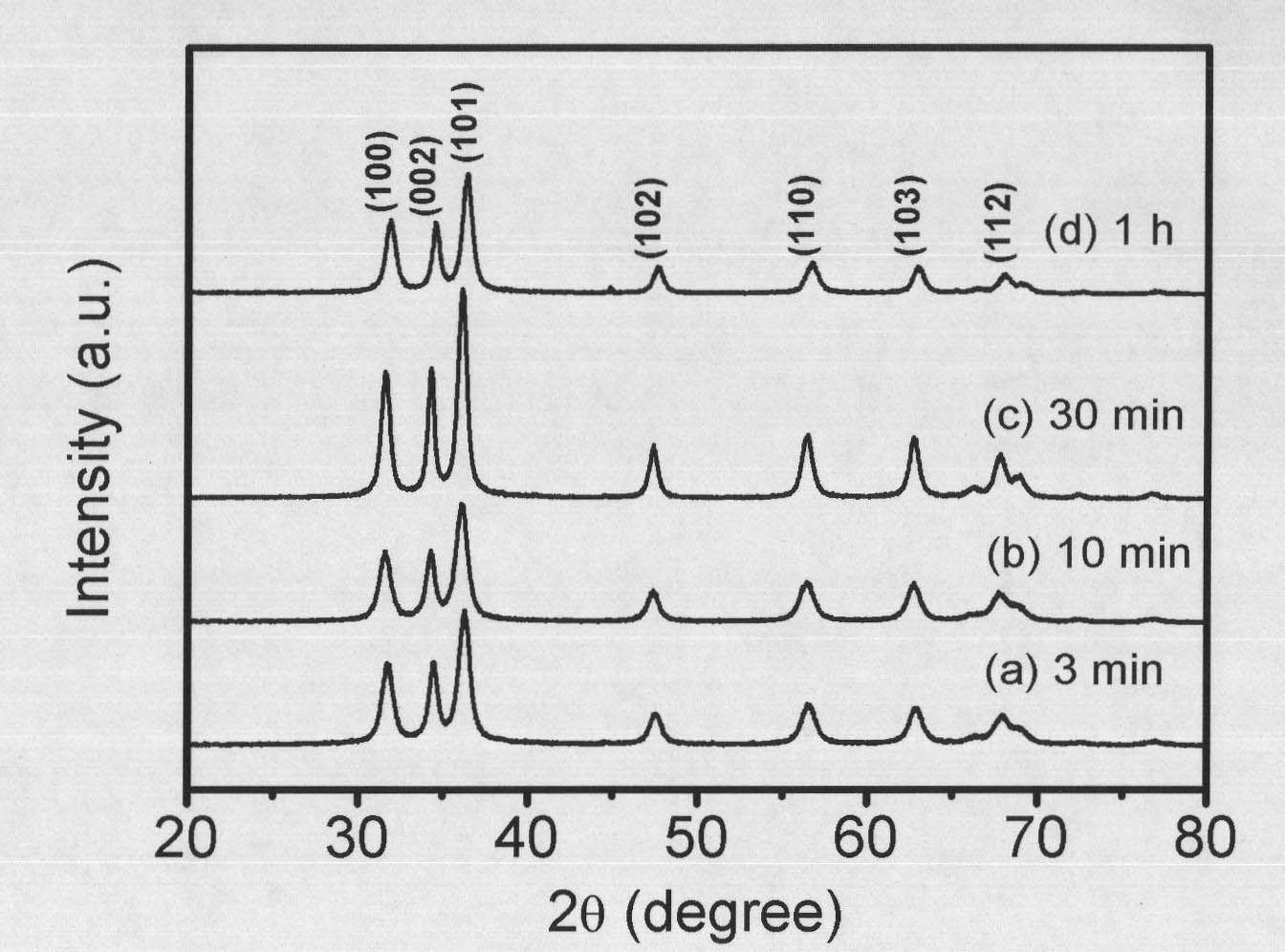

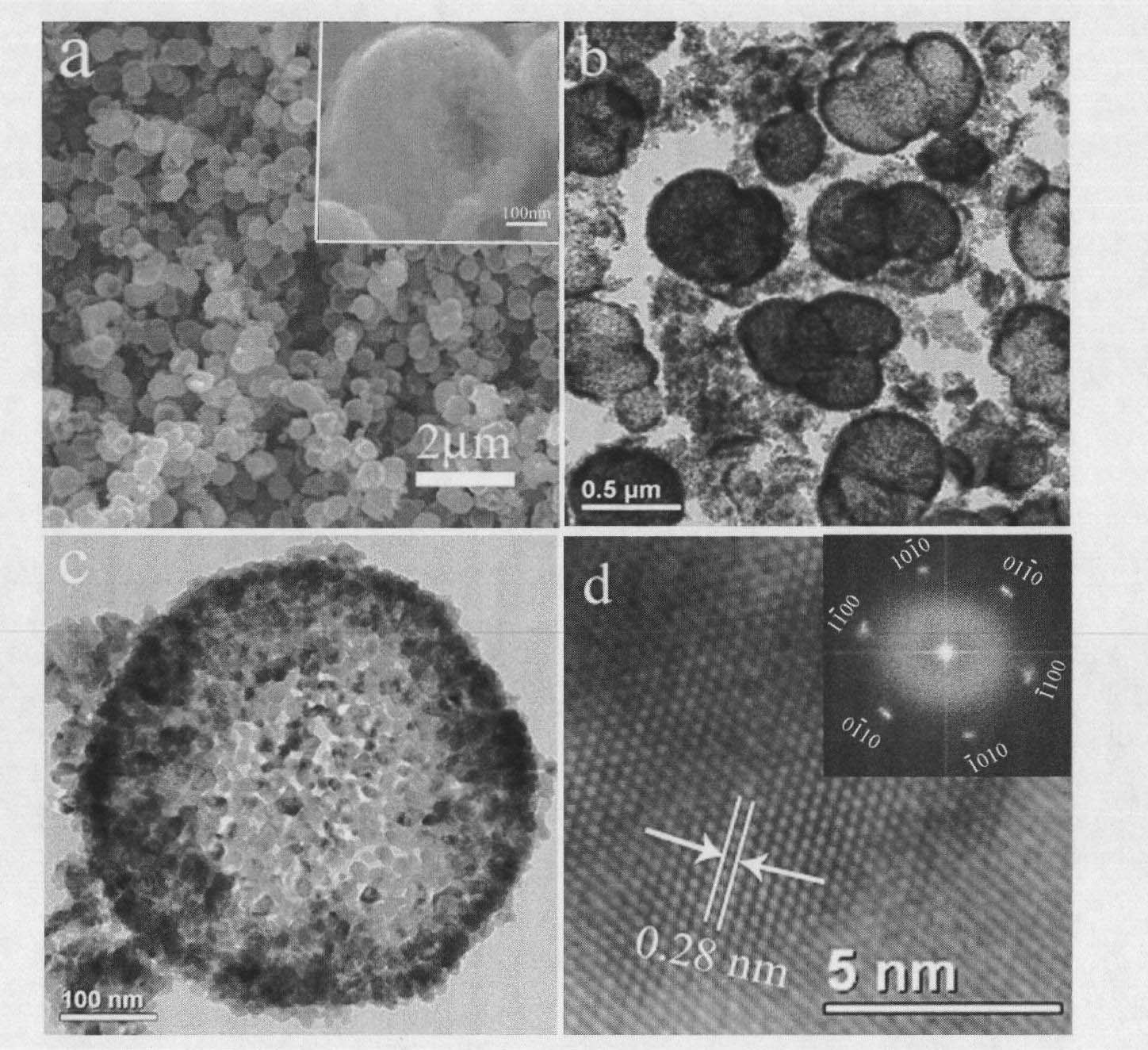

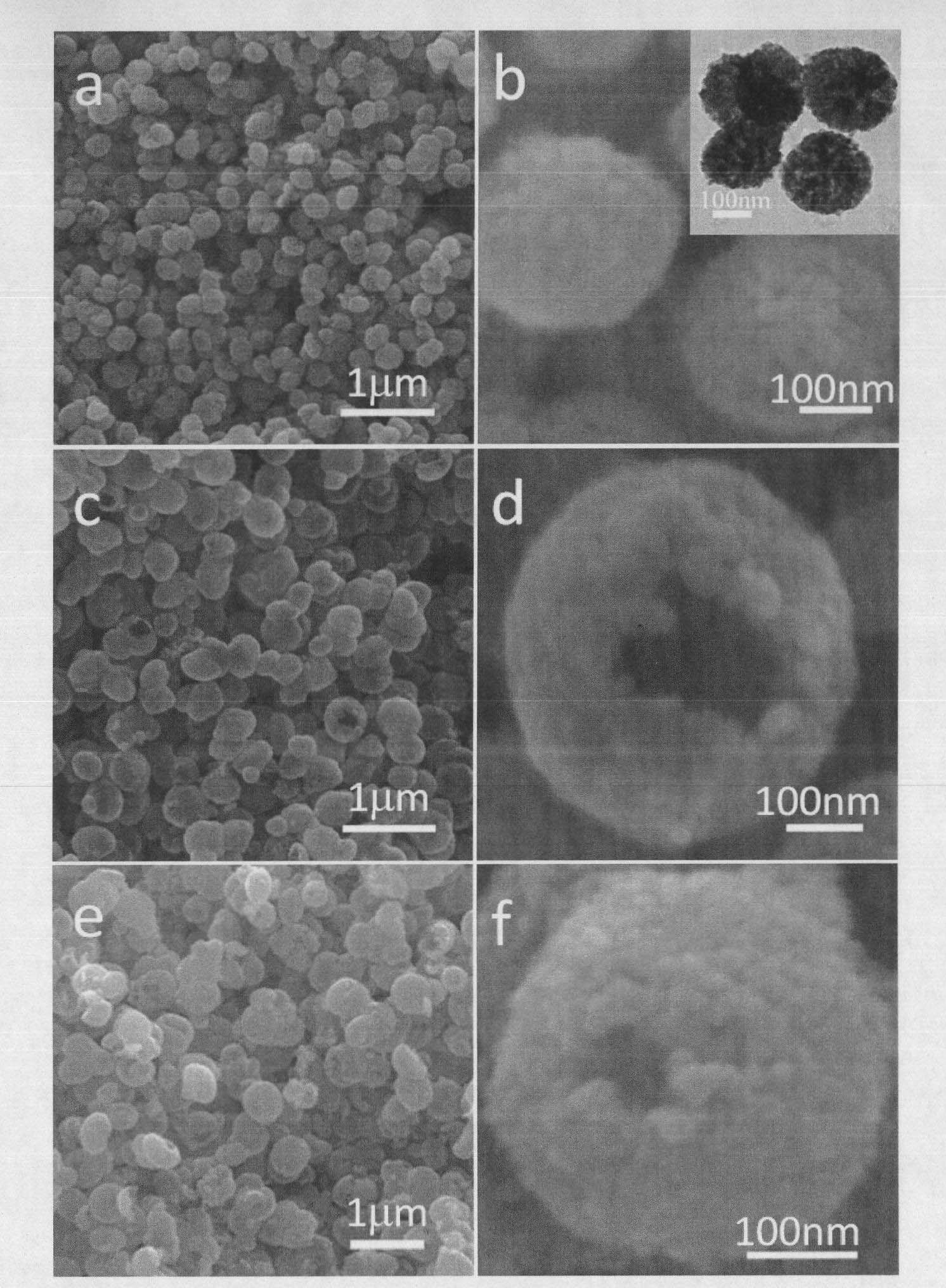

Method for preparing zinc oxide hollow spheres

InactiveCN101817548AThe synthesis method is simpleGood reproducibilityZinc oxides/hydroxidesChemical reactionSolvent

The invention discloses a method for preparing zinc oxide hollow spheres. The method of the invention is an ultrasonic method and comprises the following steps of: (1) dissolving a zinc salt in a mixed solvent of an organic solvent and water to perform an ultrasonic reaction; and (2) centrifugally separating the product of the reaction, washing the product by water and alcohol in turn and drying the product to obtain the zinc oxide hollow spheres. The method of the invention is simple, convenient, quick, high in repeatability; and the prepared zinc oxide hollow spheres can be widely used in fields of catalysis, chemical reaction carriers, medicament transport, cosmetics, paints, solar cells and the like. Dye-sensitized solar cells prepared by using the zinc oxide hollow spheres have the advantages of low cost, rich raw materials, toxicity and pollution elimination, partial material recovery and the like, have a great significance for environmental protection, and enjoy immerse advantages in large-scale industrial production.

Owner:SUN YAT SEN UNIV

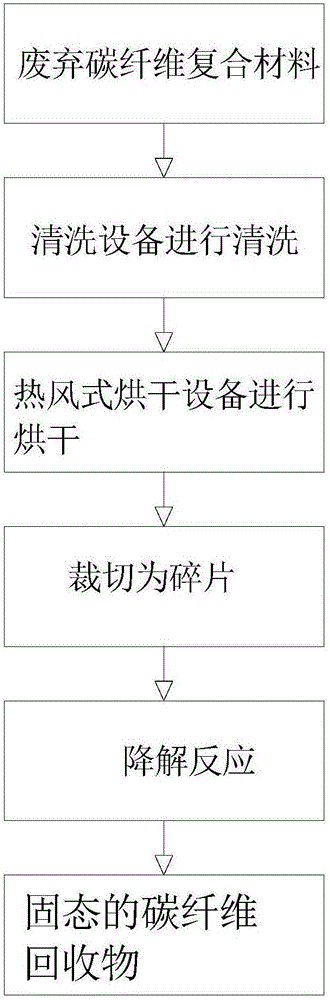

Carbon fiber composite material recovery method

InactiveCN105199139AHigh recovery rateImprove recycling efficiencyPlastic recyclingRecovery methodMicrowave oven

The invention relates to a carbon fiber composite material recovery method. The method comprises the following steps: putting a waste carbon fiber composite material in stirring cleaning equipment to be cleaned, spreading fragments on a tray, putting the tray in a microwave oven, carrying out radiation heating treatment on the carbon fiber composite material fragments in the tray, filling an inert gas in the microwave oven to protect the carbon fiber composite material when the carbon fiber composite material undergoes degradation reaction in the microwave oven and obtaining a solid recovered carbon fiber material after degradation of the carbon fiber composite material is completed. The method has the beneficial effects that the impurities on the surface of the carbon fiber composite material can be removed and the recovery rate of the carbon fibers in the carbon fiber composite material can be increased by cleaning the carbon fiber composite material; meanwhile, the degradation reaction efficiency of the carbon fiber composite material in the microwave oven is further improved by cutting the carbon fiber composite material into the fragments; and the recovery rate of the carbon fibers can be greatly increased, the recovery time can be shortened and waste of the carbon fiber material can be avoided by adopting the recovery method.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

Method for collaborative treatment of positive and negative active materials of waste lithium-ion batteries

ActiveCN110835682AHigh reactivityAchieving auto-redoxWaste accumulators reclaimingBattery recyclingPhysical chemistryManganese

The invention discloses a method for collaborative treatment of positive and negative active materials of waste lithium-ion batteries, and belongs to the technical field of lithium-ion battery material recovery. Appropriate amount of concentrated sulfuric acids are added into a mixture of positive active materials and negative active materials obtained by crushing and separating the waste lithium-ion batteries for reaction and maturation to obtain solidified clinker, the obtained solidified clinker is leached with water or dilute acids, a leached solution containing cobalt, lithium, nickel, titanium and other useful metal elements is obtained from leached pulp through sedimentation and separation, high-quality graphite and residues are obtained from leached residues through centrifugal classification to achieve collaborative intensified treatment of the positive and negative active materials of the waste lithium-ion batteries, nickel, cobalt, manganese, lithium, graphite powder and other components can be recovered comprehensively, the recovery process of active materials in waste batteries is conducive to simplifying, the recovery rate of useful elements is high, and the purity ofrecovered graphite products is high. Main consumption agents of the method are sulfuric acids, and the cost is low.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

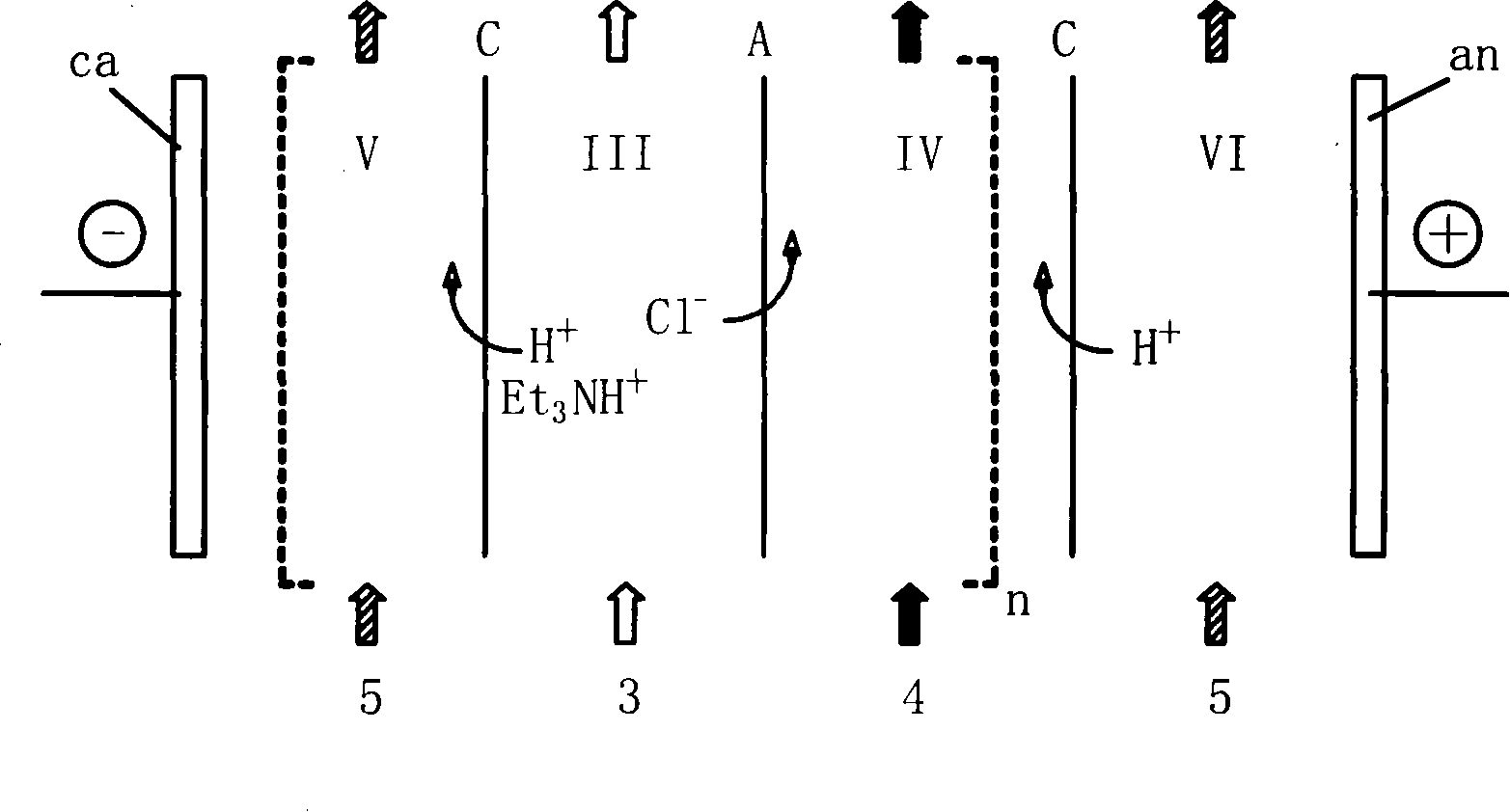

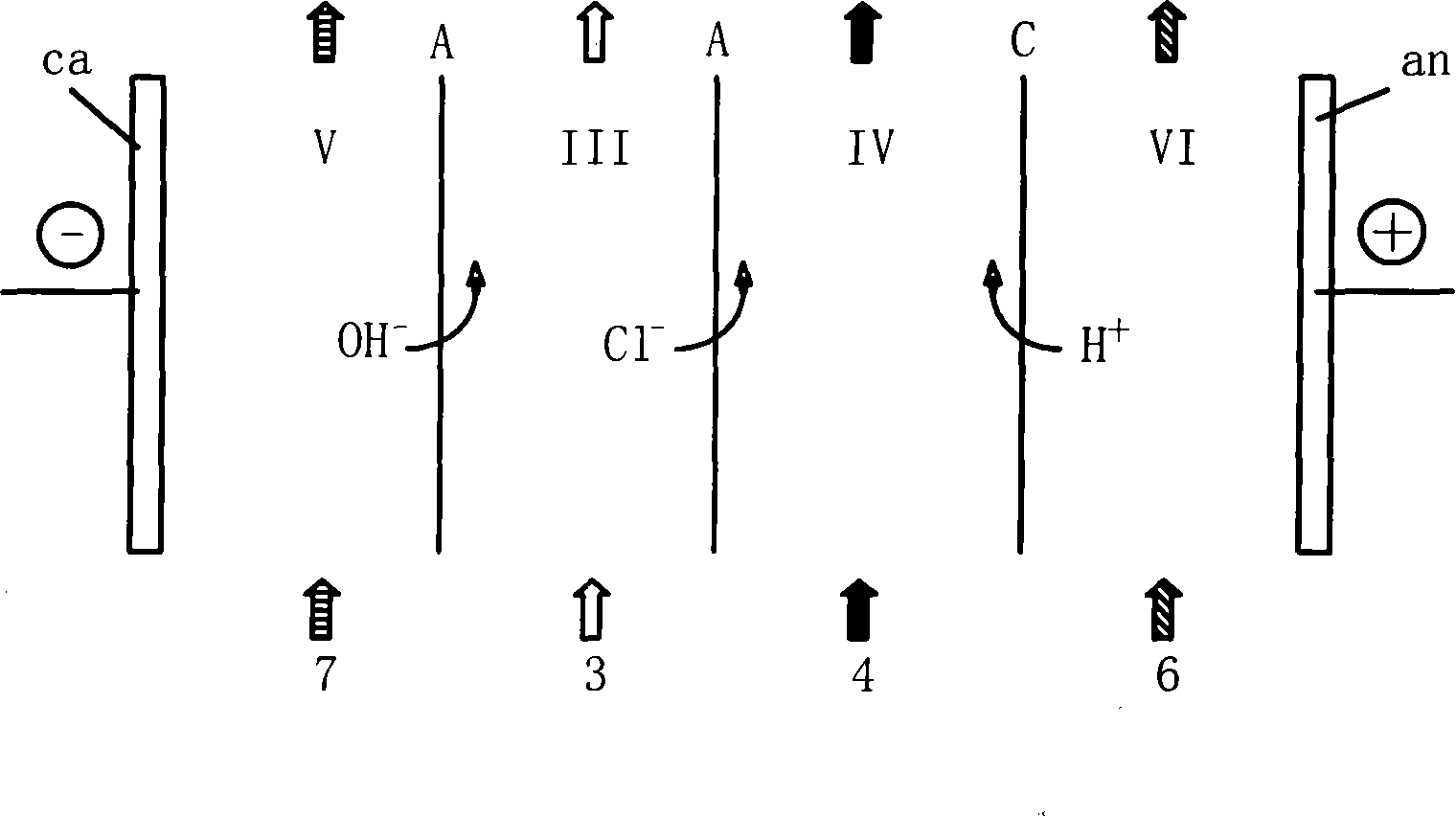

Method for processing mother solution of glyphosate

The invention relates to a treatment method of glyphosate mother liquid, with high useful material recovery rate, low cost and low pollution, which uses diffusion dialysis electrodialysis or diffusion dialysis, and electrodialysis to recover at least one of alcaine, triethylamine, and glyphosate of mother liquid, wherein the mother liquid is treated via diffusion dialysis first to recover some alcaine, then treated via electrodialysis to recover most alcaine and triethylamine, therefore, the invention realizes the synchronous recovery of alcaine and triethylamine, the glyphosate of the mother liquid can be recovered as 7% or 10% glyphosate sodium salt, ammonium salt or isopropyl amine salt, or be recovered by as glyphosate raw pesticide. The invention is suitable for treating glyphosate mother liquid in the glyphosate production of dialkyl phosphate method.

Owner:莫一平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com