Lightweight alkene separation method reducing absorbent usage amount and device thereof

A technology for light olefins and separation methods, which is applied in the directions of absorption purification/separation, adsorption purification/separation, distillation purification/separation, etc., and can solve problems such as the reduction of propylene content, the reduction of the use value of absorbents, and the increase of energy consumption for separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

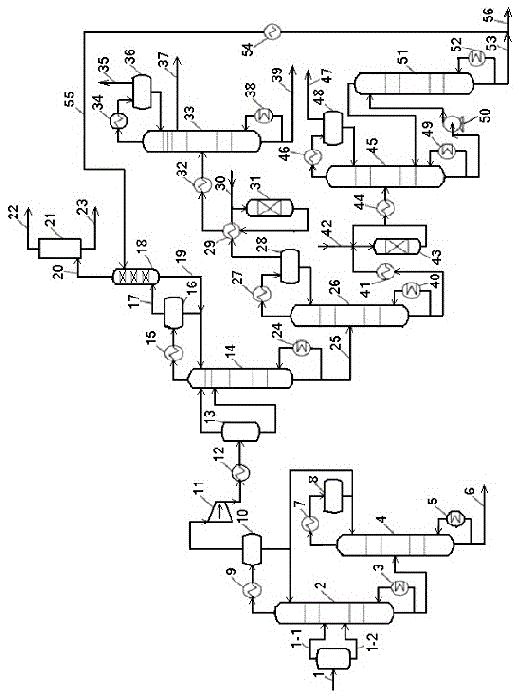

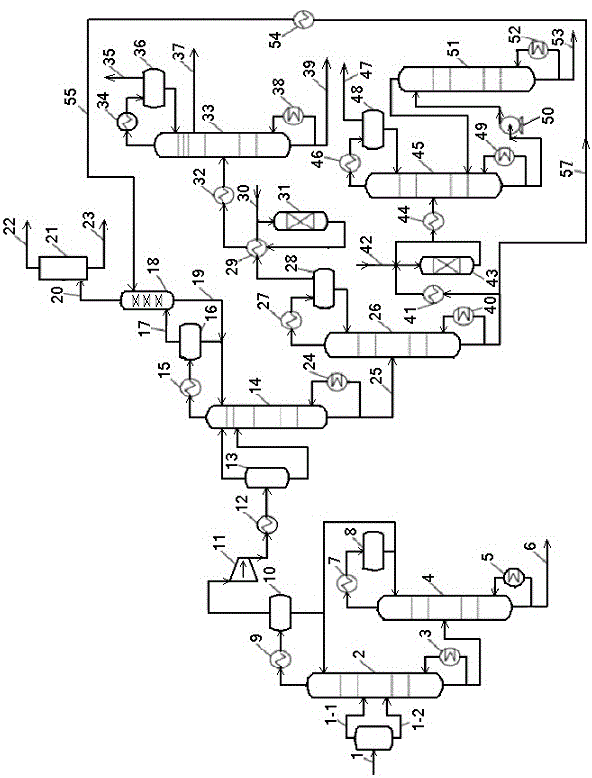

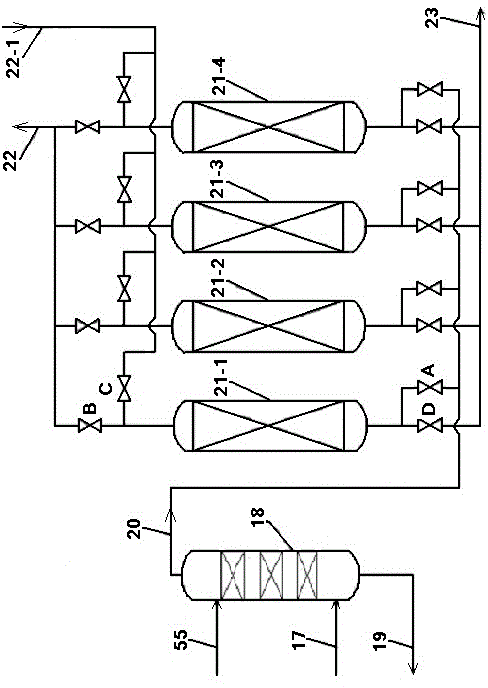

[0080] like figure 1 and image 3 In the lighting method of a light olefin that reduces the amount of absorption agent, the converter of oxidation compounds is converted to remove the light olefin hybrid gases. After removing the oxidation compounds and water during pre -treatment, in addition to including ethylene and acrylia, in addition to including ethylene and acrylic, in addition to including ethylene and acrylic, in addition to including ethylene and acrylic, in addition to including ethylene and acrylic, in addition to including ethylene and acrylic, in addition to including ethylene and acrylic, it is included.It also includes hydrogen, oxygen, nitrogen, carbon dioxide, carbon dioxide, methane, ethylene, ethylene, acetylene, propionide, propane, propane, and propane.After the mixed material is compressed and the heat changes are used as a light olefin logistics 1, it is divided into two phases of steam liquid, of which the steam phase is 1-1 through the pipeline, and the l...

Embodiment 2

[0096] like figure 2 and image 3 The difference between the embodiment and Example 1 is that the absorption tower uses the propane 57 produced by the deoxane tower bottom as the absorbent, and the method described in the example of this embodiment.After mixing the rough ethylene gas obtained from the transformer in front of the machine, press it to be pressed to 2.0MPa after the pre -processing and removed impurities. After cooling to 15 ° C, the raw material for the olefin separation system is sent to the deoxane tower system.The low-voltage deoxane tower bottom product is sent to the deoxane tower, and the high-voltage decarcular tower product is pressed to 3.2 MPA to cool to -37 ° C after being cooled to -37 ° C.The products of the deoxyne tower are entered into the deoxyne tower and subsequently separated. The ethylene products are obtained from the side line of the ethylene refined tower.The refrigerant refrigerate, non -condensed hydrogen, methane, and some ethylene are dist...

Embodiment 3

[0100] The difference between Example 3 and Example 1 is that the numerical parameters involved are: the operating pressure of the high -voltage deoxane tower is 1.8MPa, and the temperature of the high -pressure deoxane tower bottom is 100 ° C;The operating pressure of the tower top is 0.5MPa, and the temperature of the low-pressure deoxane tower tower is 100 ° C; the operating pressure of the tower tower top of the tower tower is 3.5MPa;The temperature of the tower bottom is -5 ° C, and the tower kettle is heated in circulating water; the temperature of the absorbent in the absorption tower is -40 ° C, and the operating pressure of the absorption tower is 4.0MPa;Sexual activation carbon, adsorption pressure is 3.5MPa, and adsorption temperature is -15 ° C; the operating pressure of the pendulum tower tower is 2.0MPa;The operating pressure is 1.0MPa; the temperature of the moisty-refined tower bottom temperature is -30 ° C; the ethylene refined tower kettle is heated with circulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com