Patents

Literature

753results about "Absorption purification/separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

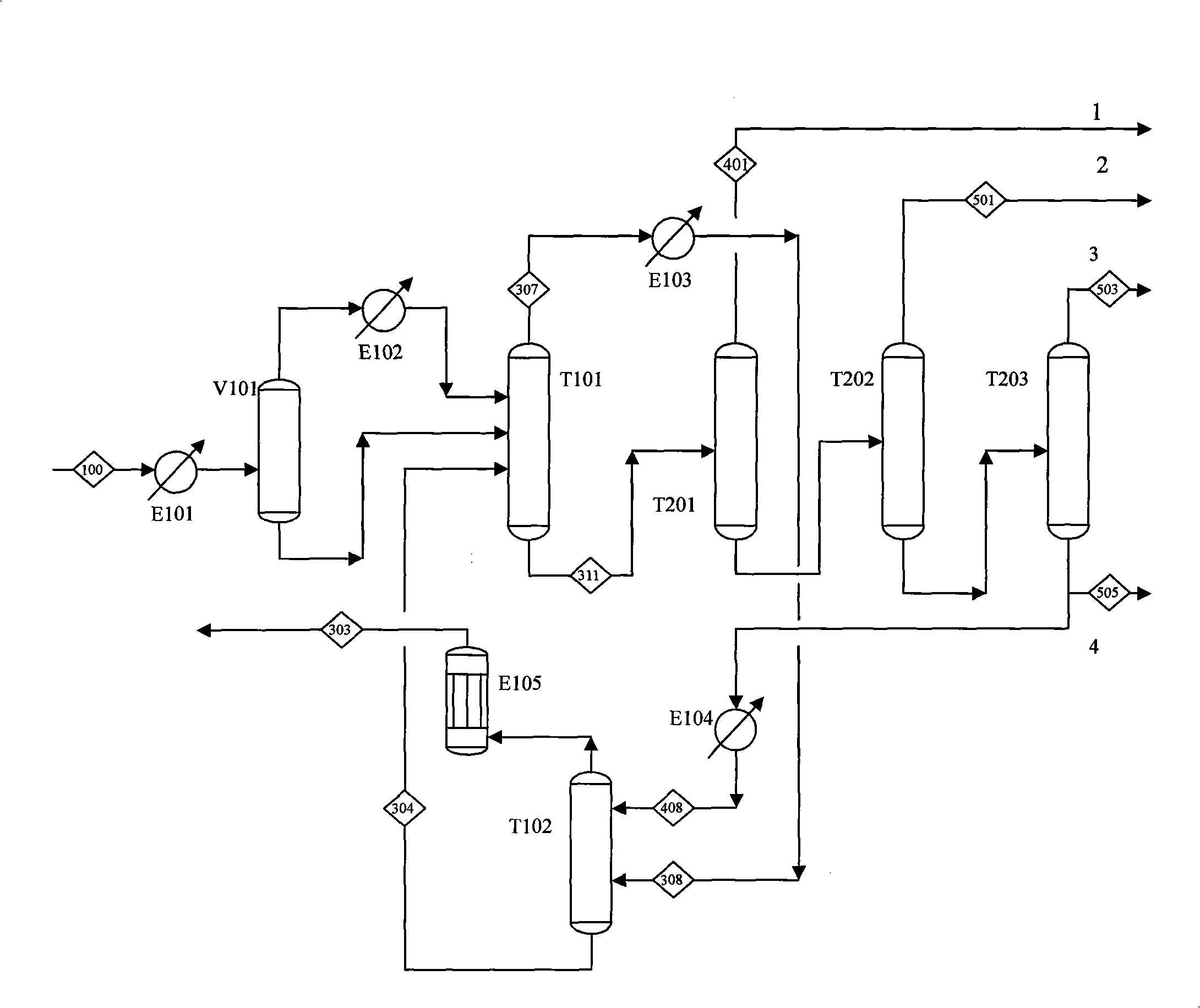

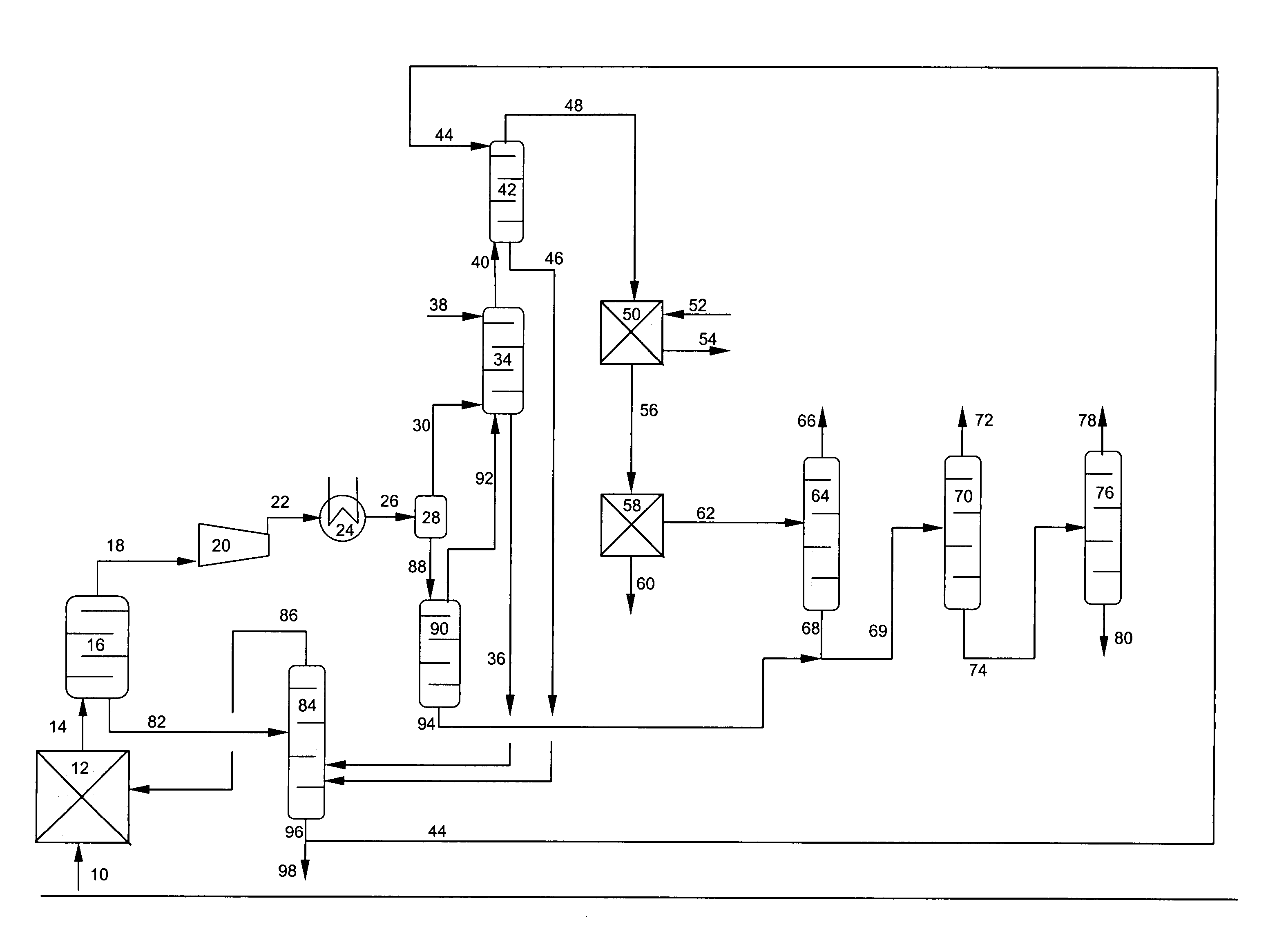

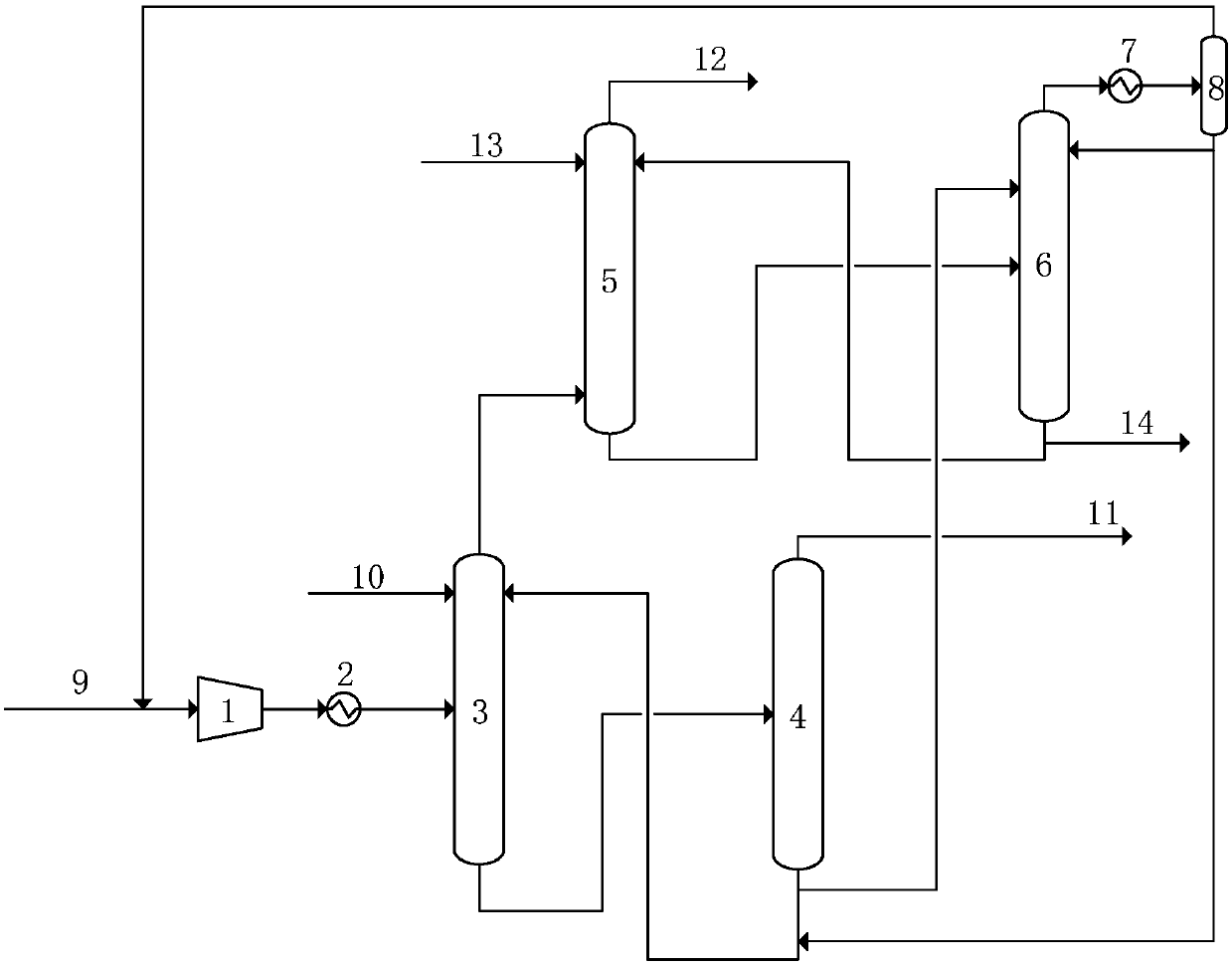

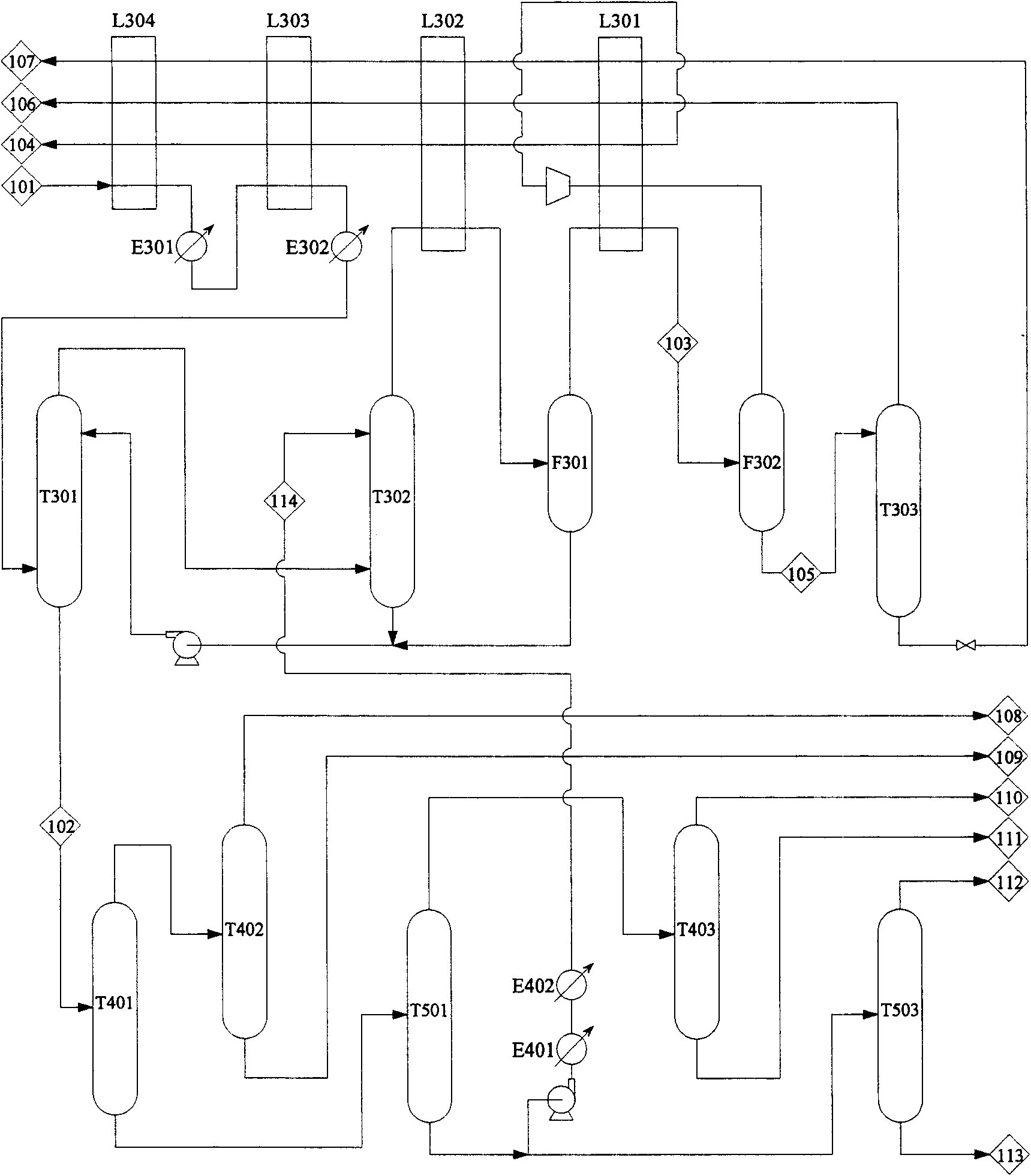

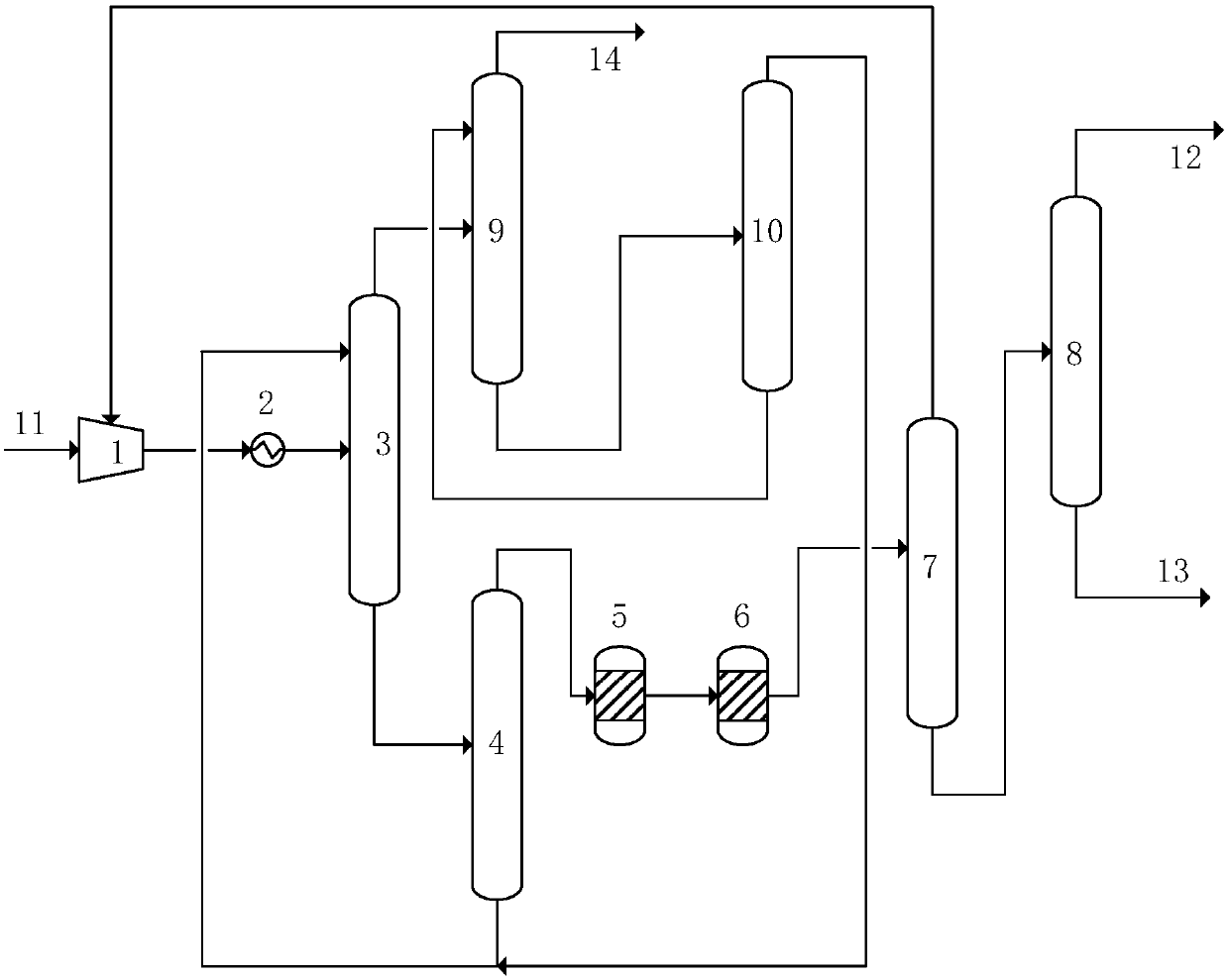

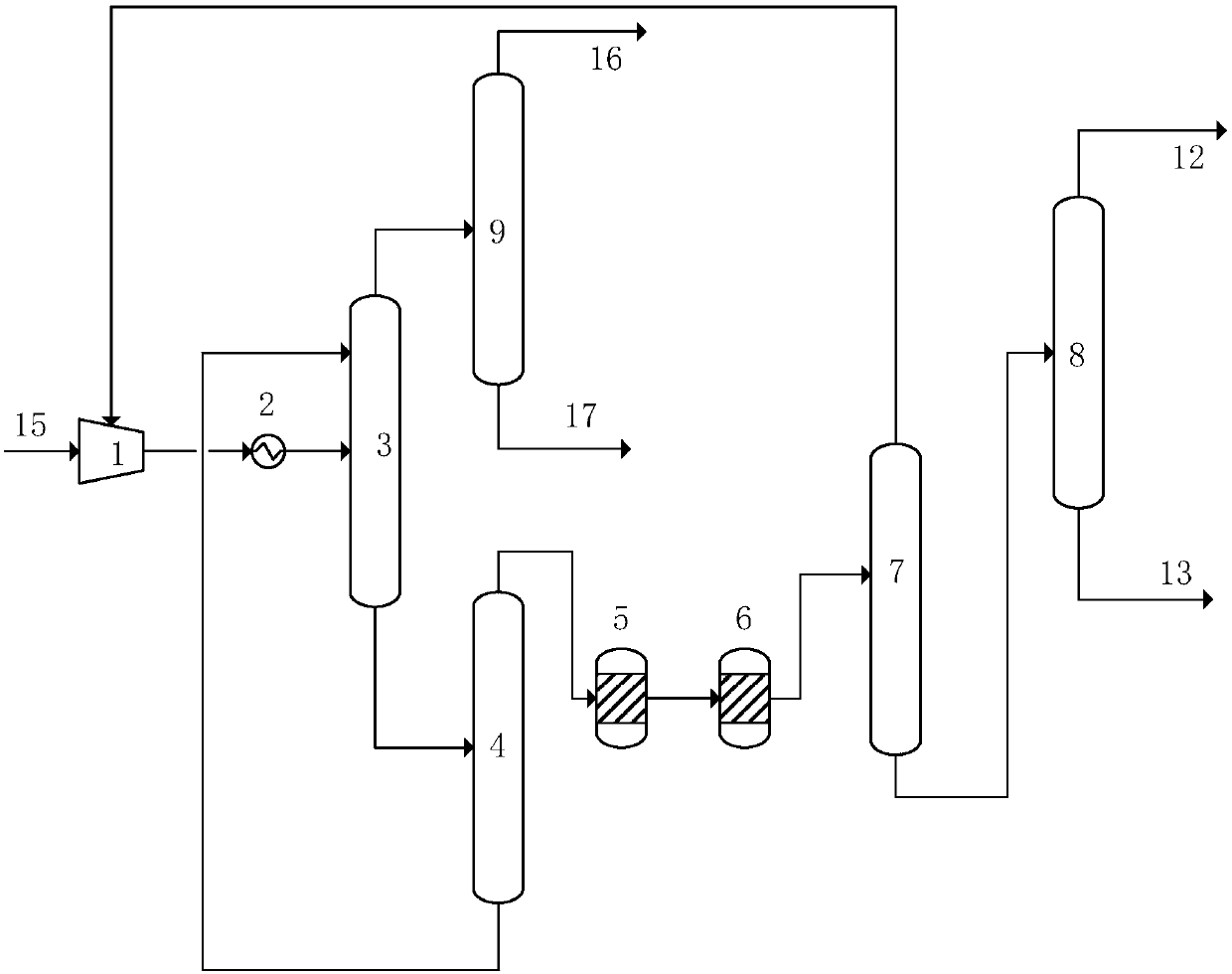

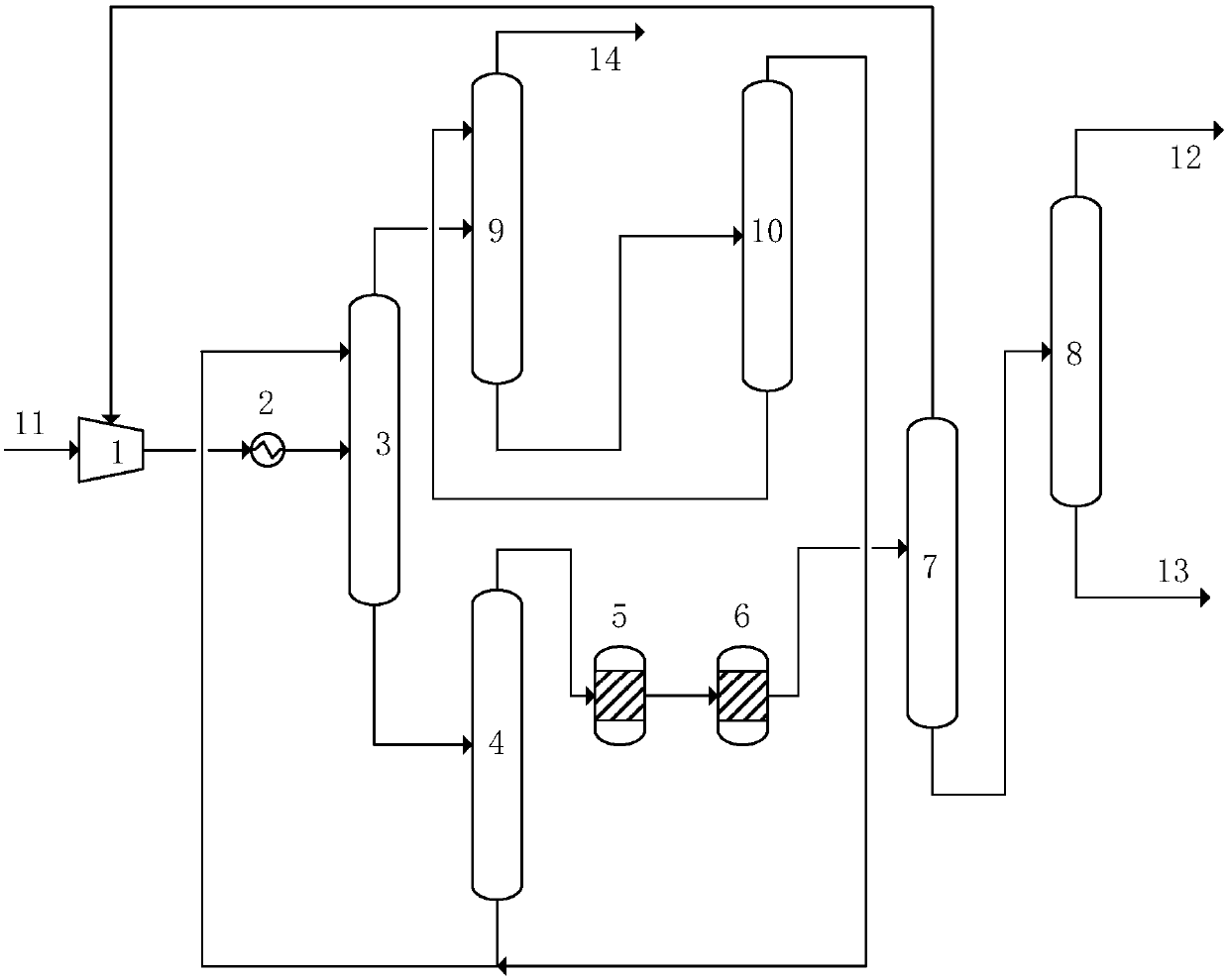

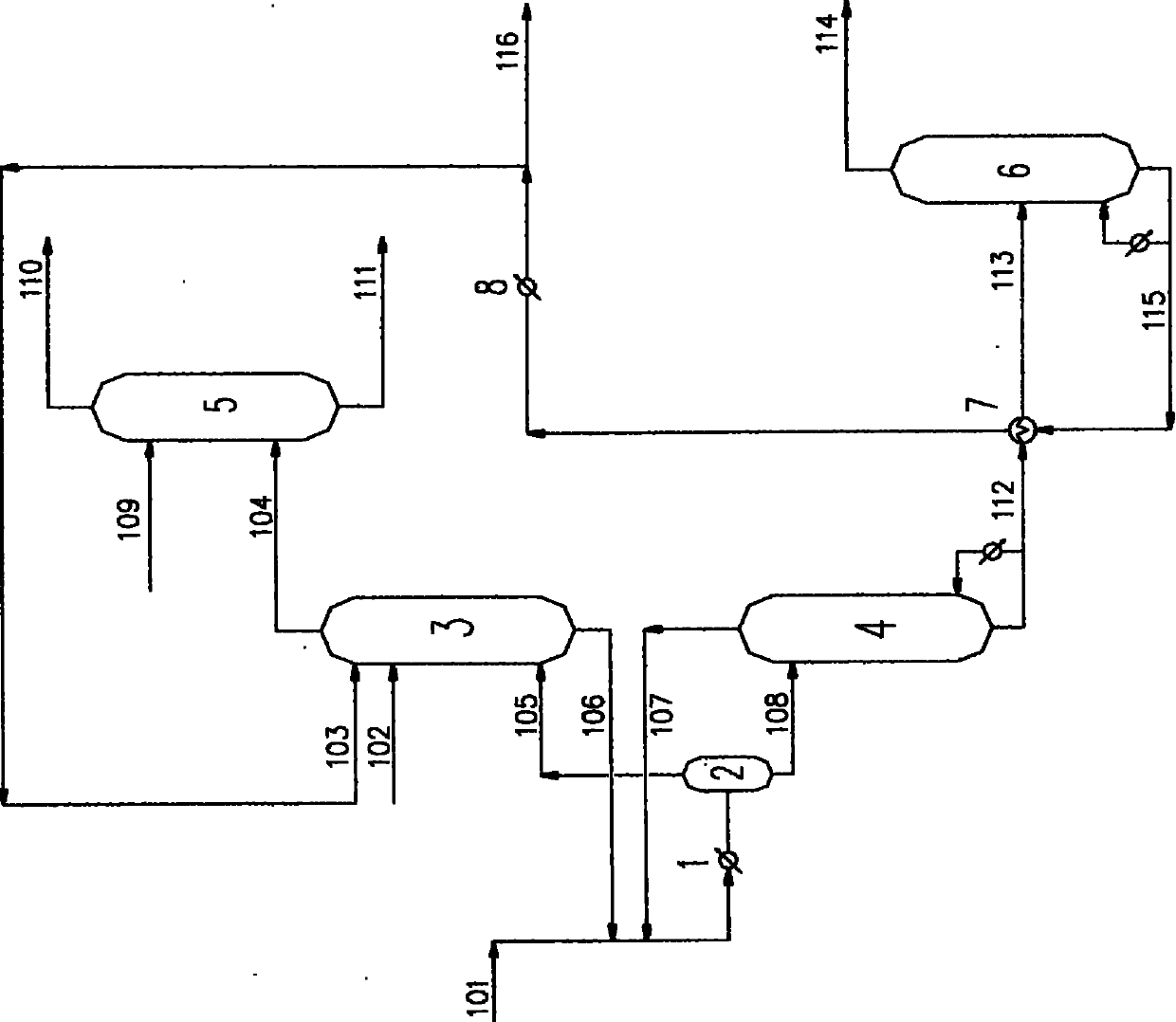

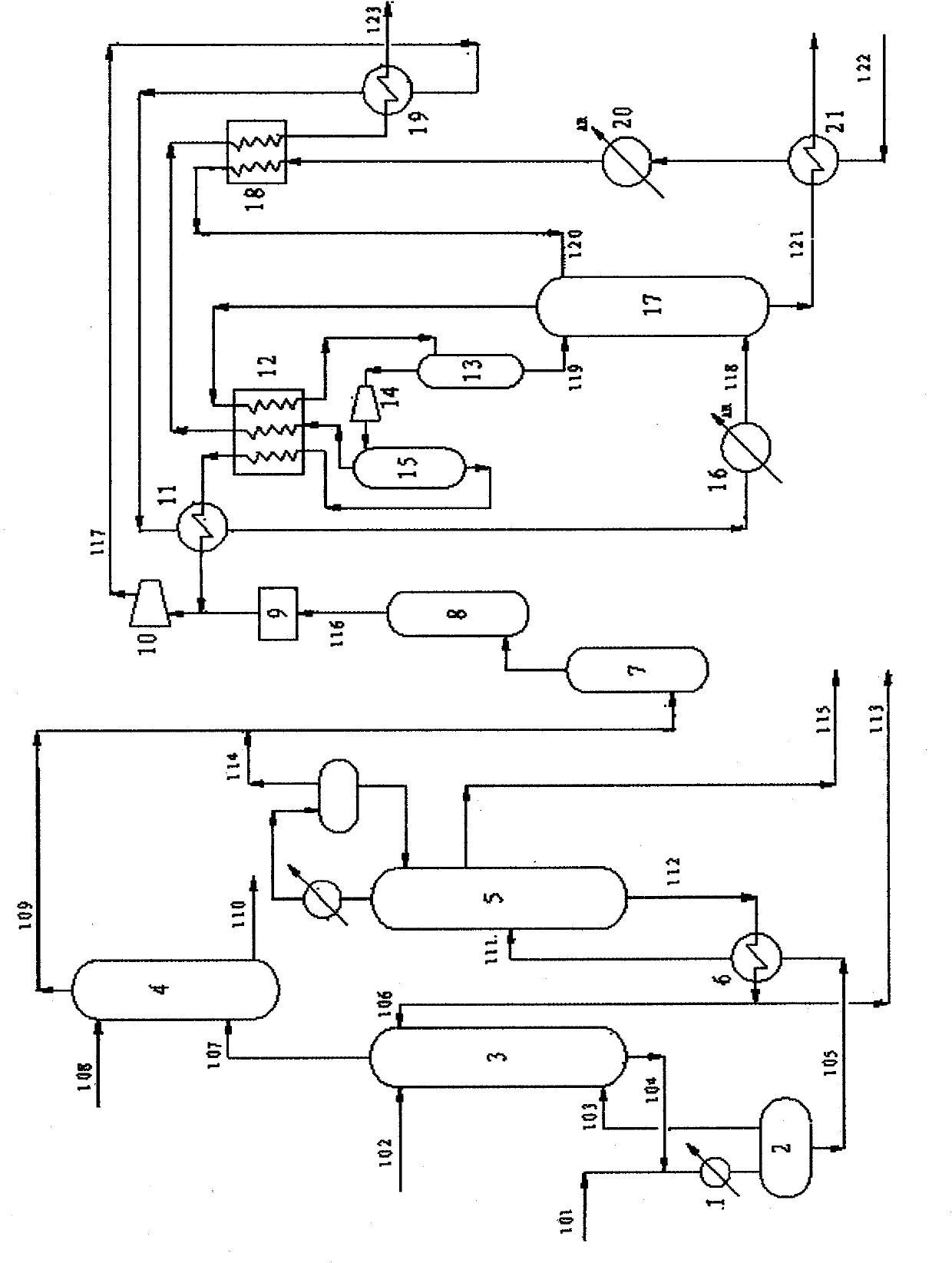

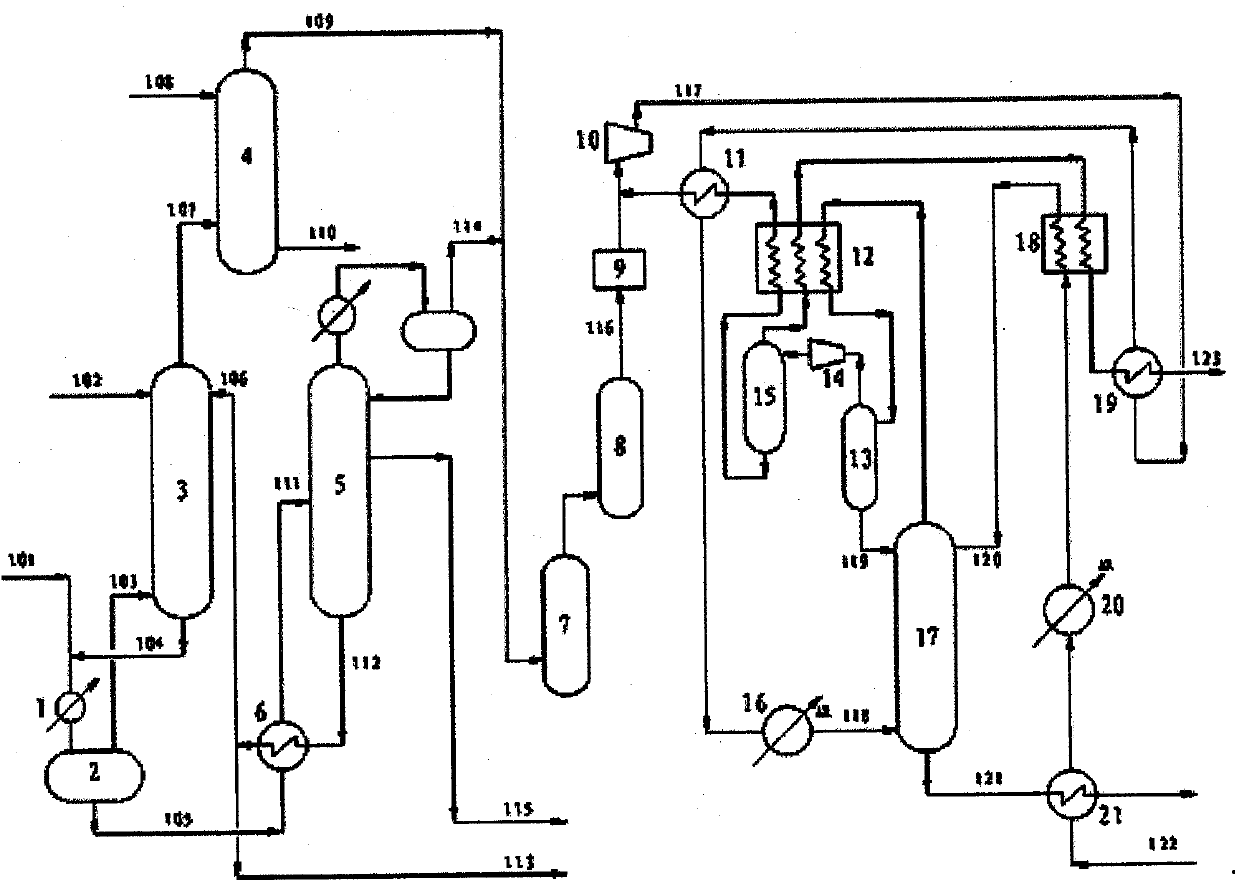

System and process for preparing aromatic hydrocarbon by converting methanol or dimethyl ether

ActiveCN101823929AHigh yieldHigh selectivityHydrogen separation using liquid contactHydrocarbon from oxygen organic compoundsAromatizationAromatic hydrocarbon

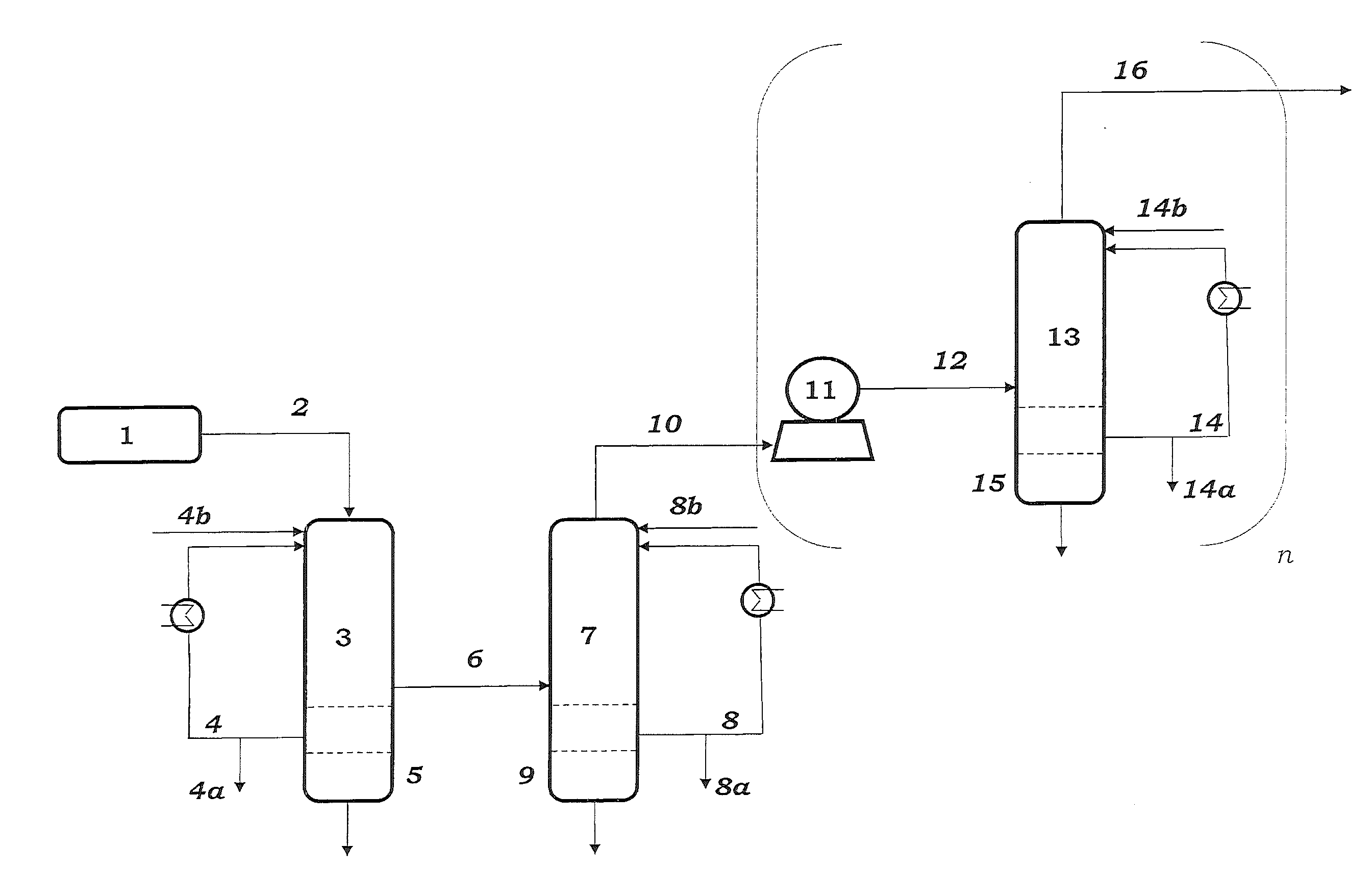

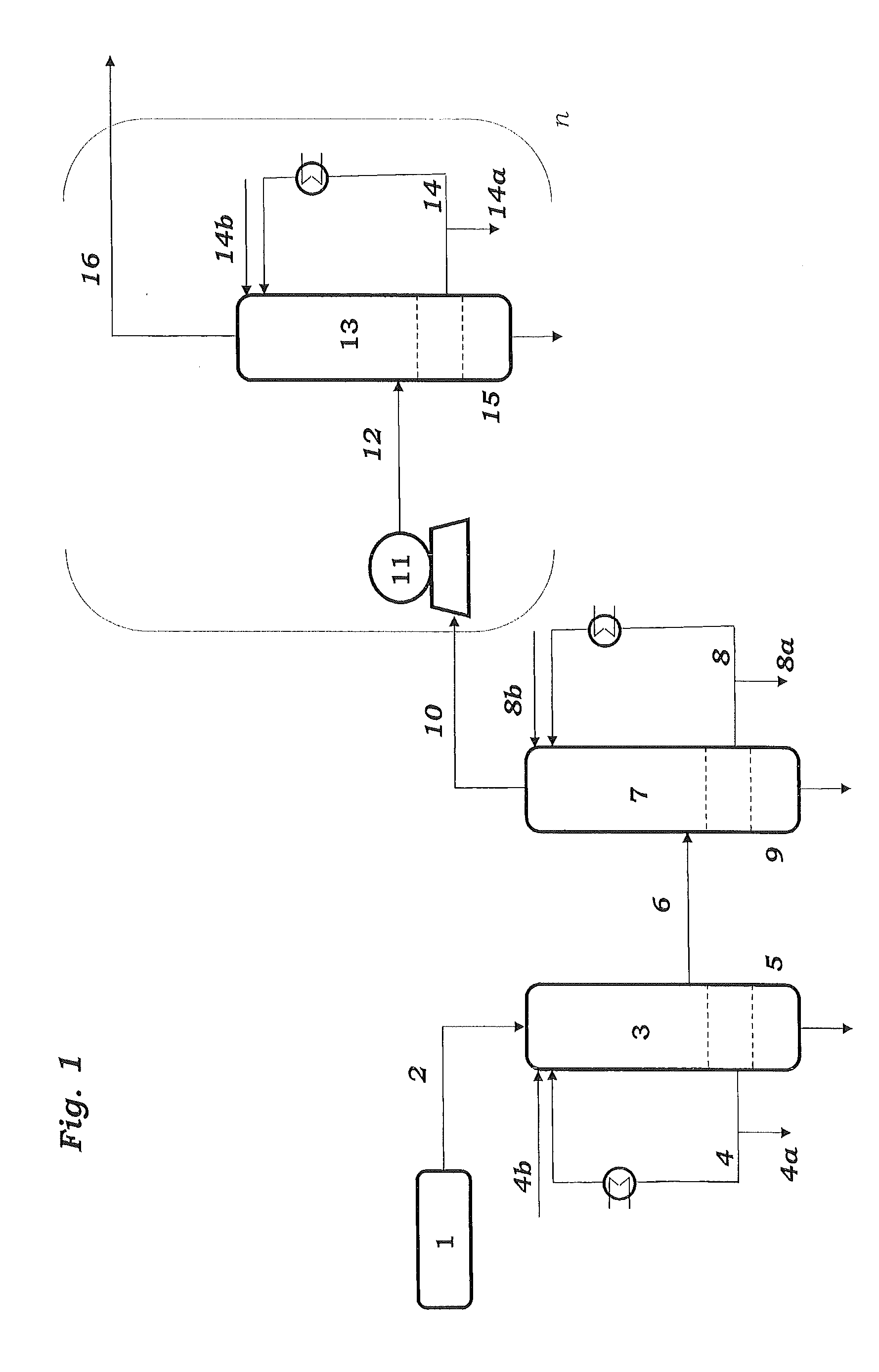

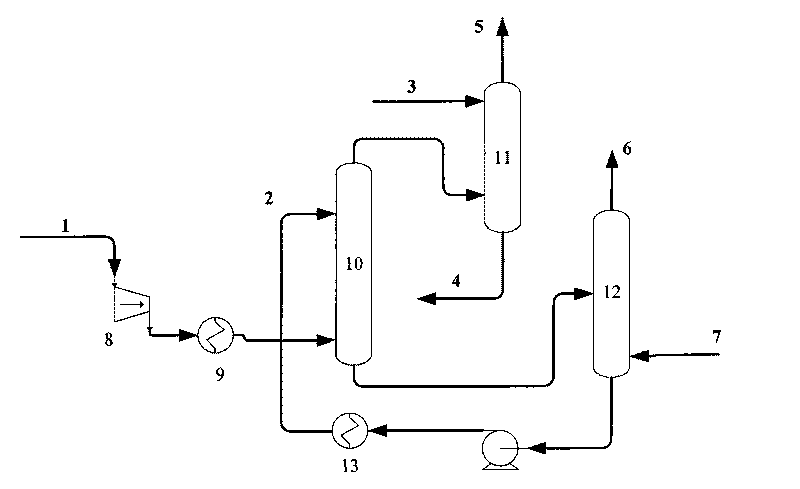

The invention relates to a system and a process for preparing aromatic hydrocarbon by converting methanol or dimethyl ether and belongs to the technical field of aromatic hydrocarbon production. The methanol or the dimethyl ether serving as a raw material firstly reacts in an aromatization reactor; a reaction product is separated; H2, methane, mixed C8 aromatic hydrocarbon and partial C9s + hydrocarbons serving as products are output from the system; and C2+ non-aromatic hydrocarbon and aromatic hydrocarbons except the mixed C8 aromatic hydrocarbon and the partial C9s + hydrocarbons are take as a circular material flow and return to corresponding reactors for further aromatization reaction. By separating and recycling the product obtained in the process of aromizing the methanol or the dimethyl ether, the system and the process improve the yield and selectivity of the aromatic hydrocarbon; and moreover, the process is flexible, and target products can be changed according to market demands.

Owner:TSINGHUA UNIV

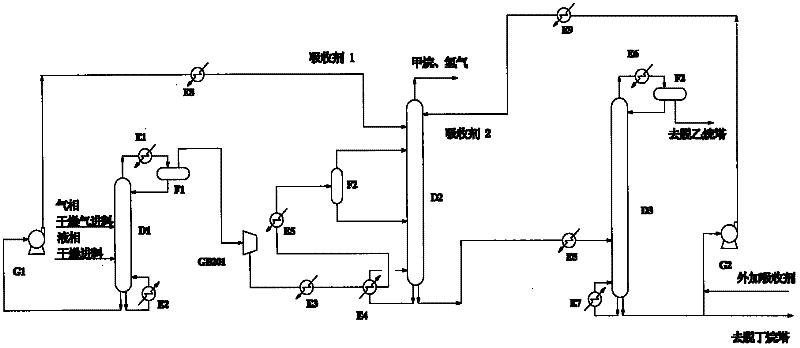

Process for Preparing Butadiene by Oxidative Dehydrogenation of N-Butenes with Monitoring of the Peroxide Content During Work-Up of the Product

InactiveUS20140200381A1Analysis using chemical indicatorsHydrocarbon by hydrogenationWater vaporDesorption

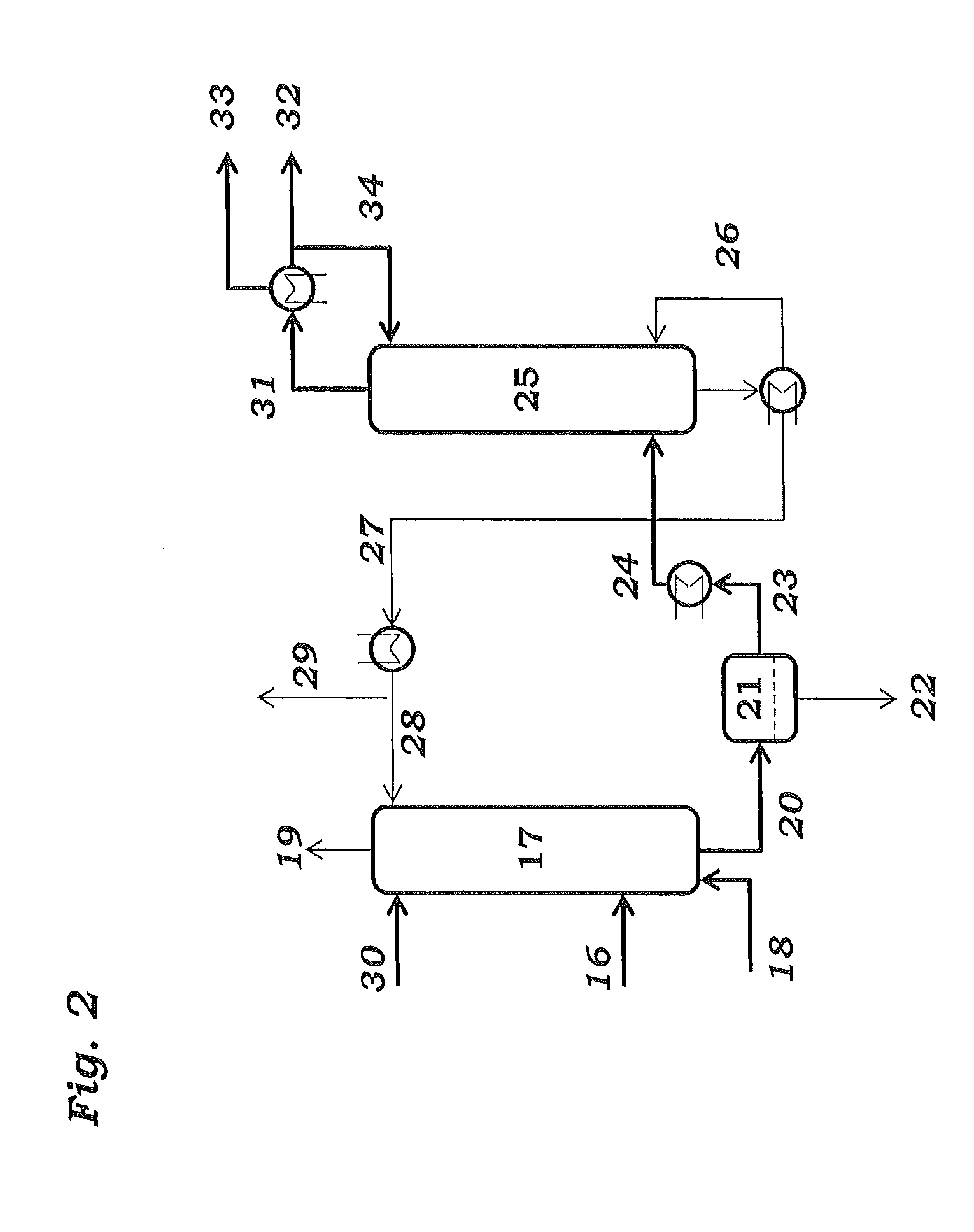

The invention relates to a process for preparing butadiene from n-butenes, which comprises the following steps:A) provision of a feed gas stream a comprising n-butenes;B) introduction of the feed gas stream a comprising n-butenes and an oxygen-comprising gas into at least one dehydrogenation zone and oxidative dehydrogenation of n-butenes to butadiene, giving a product gas stream b comprising butadiene, unreacted n-butenes, water vapor, oxygen, low-boiling hydrocarbons, possibly carbon oxides and possibly inert gases;C) cooling and compression of the product gas stream b in at least one cooling stage and at least one compression stage, with the product gas stream b being brought into contact with a circulated coolant to give at least one condensate stream c1 comprising water and a gas stream c2 comprising butadiene, n-butenes, water vapor, oxygen, low-boiling hydrocarbons, possibly carbon oxides and possibly inert gases;D) separation of incondensable and low-boiling gas constituents comprising oxygen, low-boiling hydrocarbons, possibly carbon oxides and possibly inert gases as gas stream d2 from the gas stream c2 by absorption of the C4-hydrocarbons comprising butadiene and n-butenes in a circulated absorption medium, giving an absorption medium stream loaded with C4-hydrocarbons and the gas stream d2, and subsequent desorption of the C4-hydrocarbons from the loaded absorption medium stream to give a C4 product gas stream d1;E) separation of the C4 product stream d1 by extractive distillation using a solvent which is selective for butadiene into a stream e1 comprising butadiene and the selective solvent and a stream e2 comprising n-butenes;F) distillation of the stream e1 comprising butadiene and the selective solvent to give a stream f1 consisting essentially of the selective solvent and a stream f2 comprising butadiene;where samples are taken from the circulated coolant in step C) and / or the circulated absorption medium in step D) and the peroxide content of the samples taken is determined by means of iodometry, differential scanning calorimetry (DSC) or microcalorimetry.

Owner:BASF AG

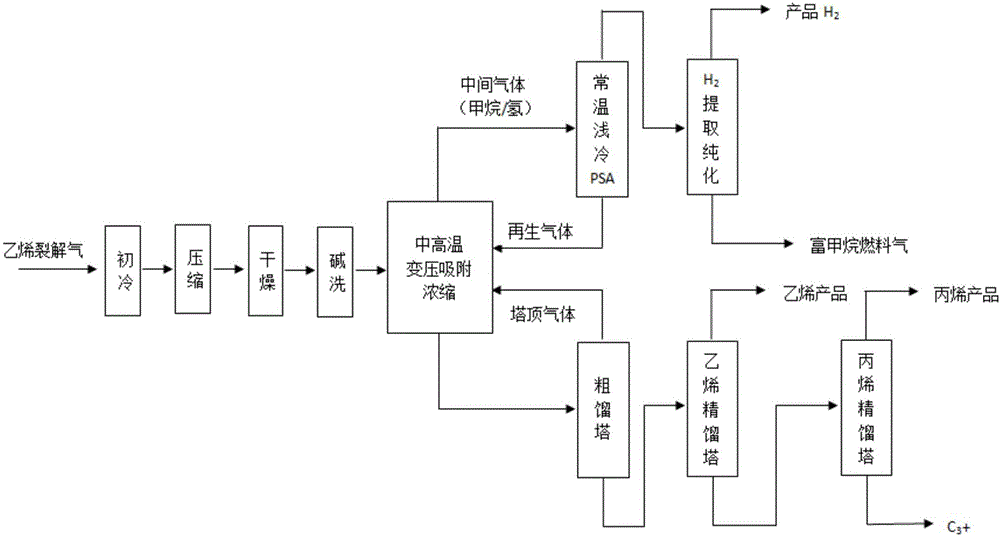

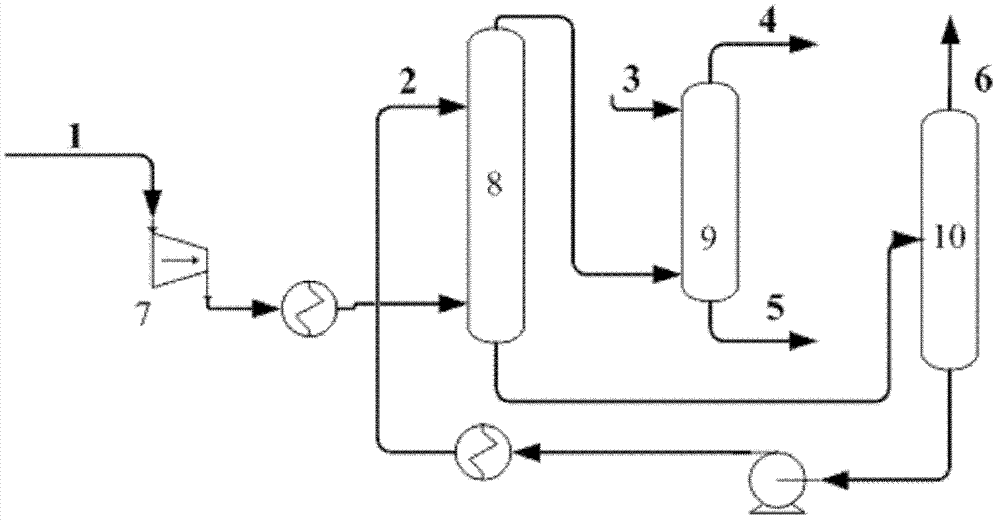

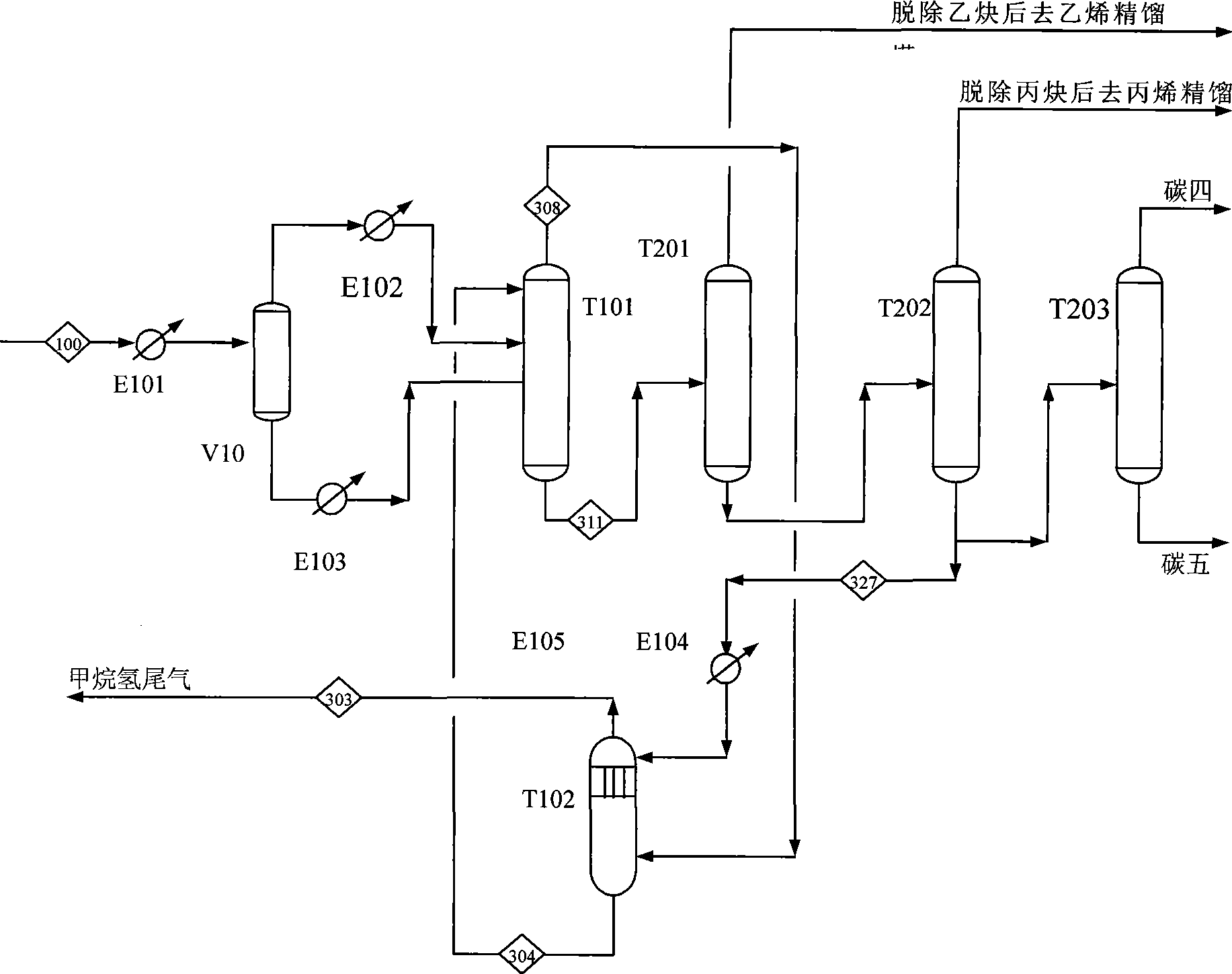

Non-copious cooling lower carbon number hydrocarbons separation method containing light gas

ActiveCN101353286AHigh ethylene contentHigh recovery rateFractional condensation purification/separationHydrocarbonsCarbon numberProduct gas

The invention relates to a separation method for non-cryogenic low-carbon hydrocarbon containing light gases. The method comprise the steps as follows: (1) pre-treated gas at the outlet of a reactor is cooled to the temperature of 10-37 DEG C and sent to a pre-cutting tower; (2) a product at the top of the pre-cutting tower is cooled and sent to an absorption tower, and C2 hydrocarbons in the product at the top of the pre-cutting tower are absorbed by an absorbent consisting of C3, C4, C5 or the mixture of hydrocarbons thereof; and (3) tower kettle products of the pre-cutting tower are sent to a deethanizing column for clearly cutting the C2 and the C3 to obtain C2 distillate at the top of the tower; the tower kettle products are C3 and heavier components. Compared with the prior art, the method has the advantages of lower investment, lower energy consumption, higher recycling rate of materials, simpler operation, less maintenance workload, reliable operation, etc.

Owner:WISON ENG

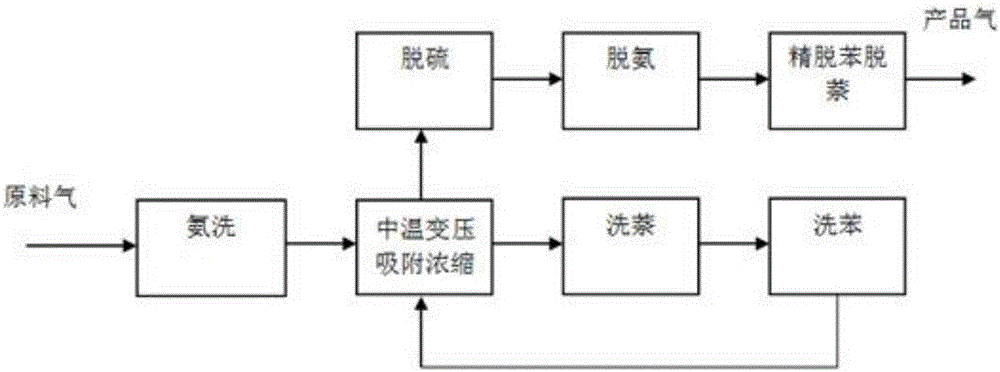

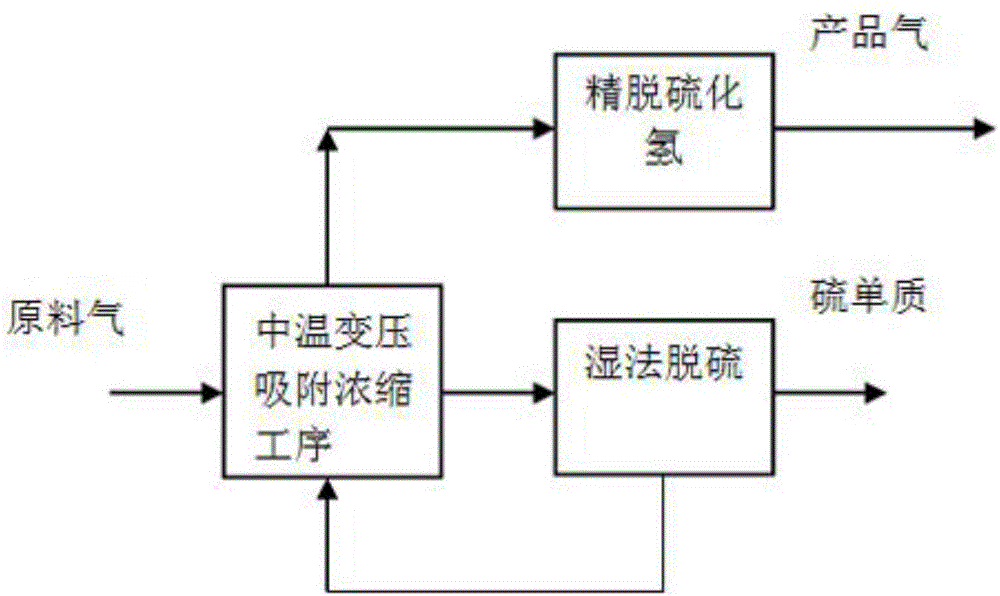

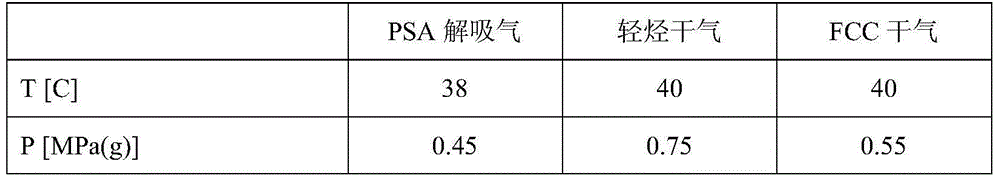

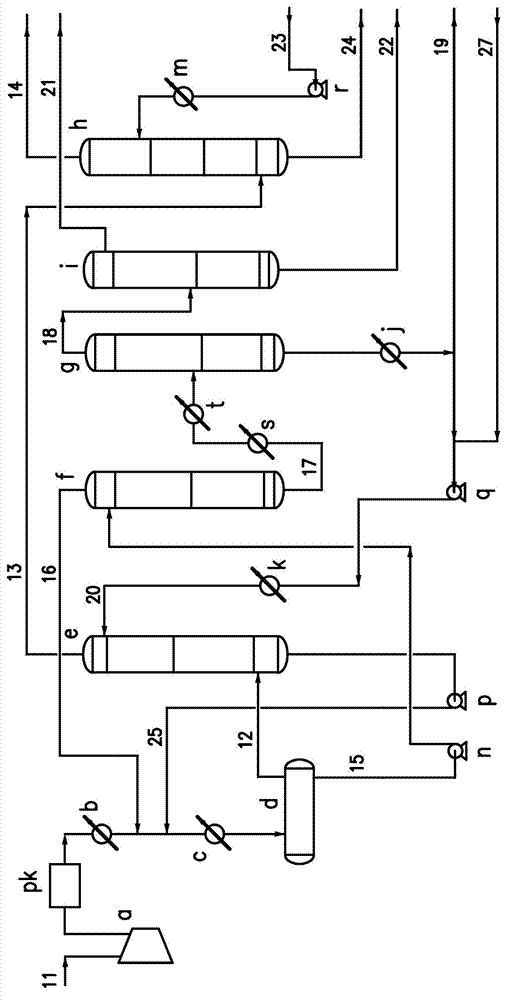

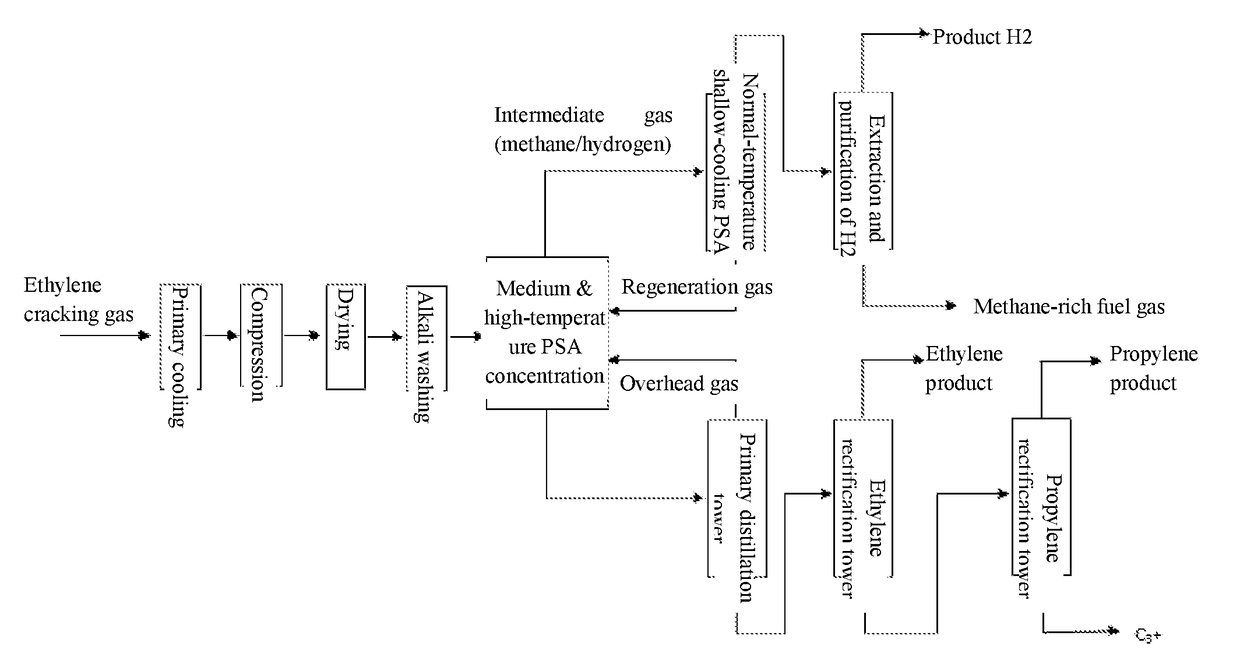

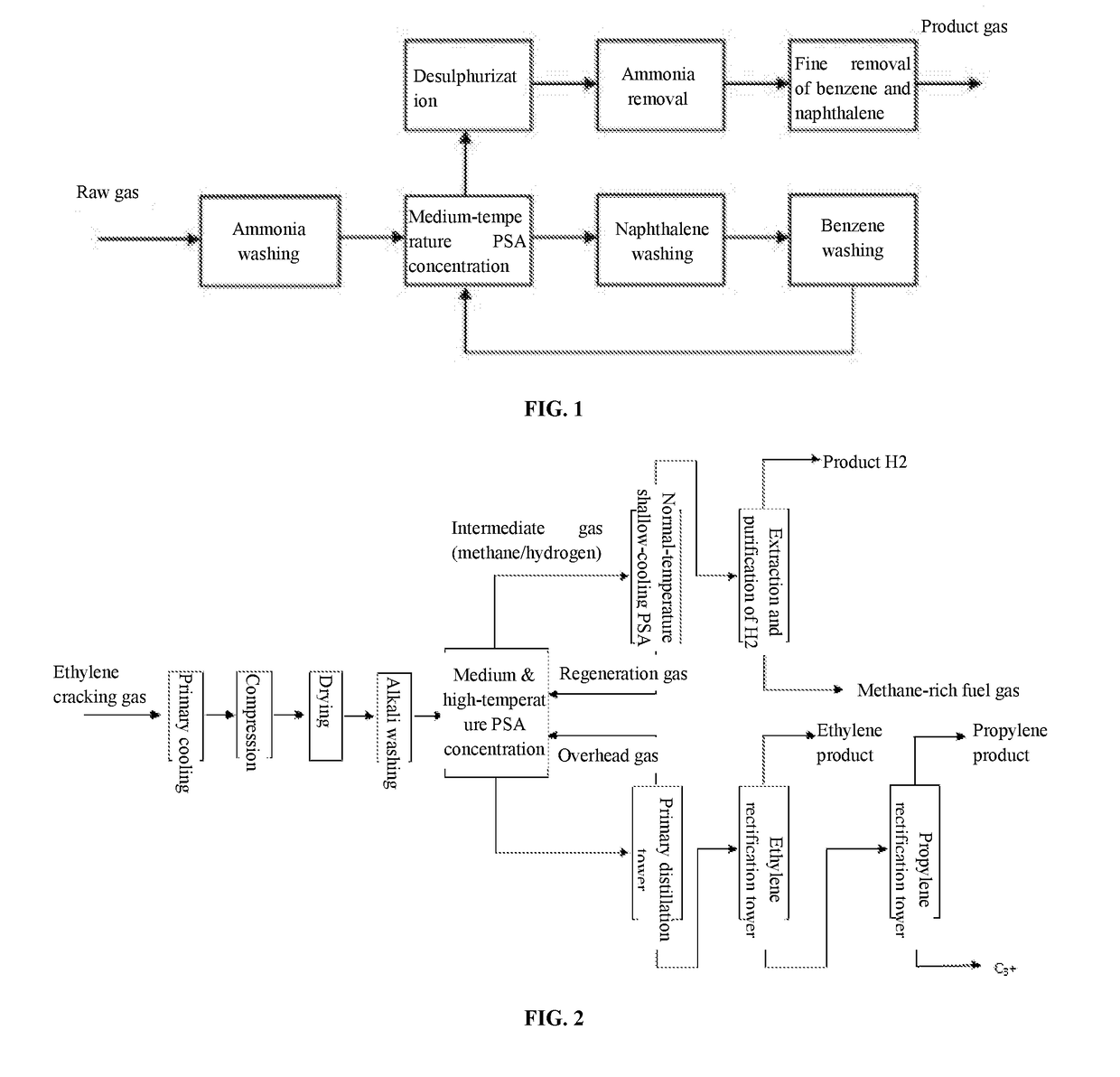

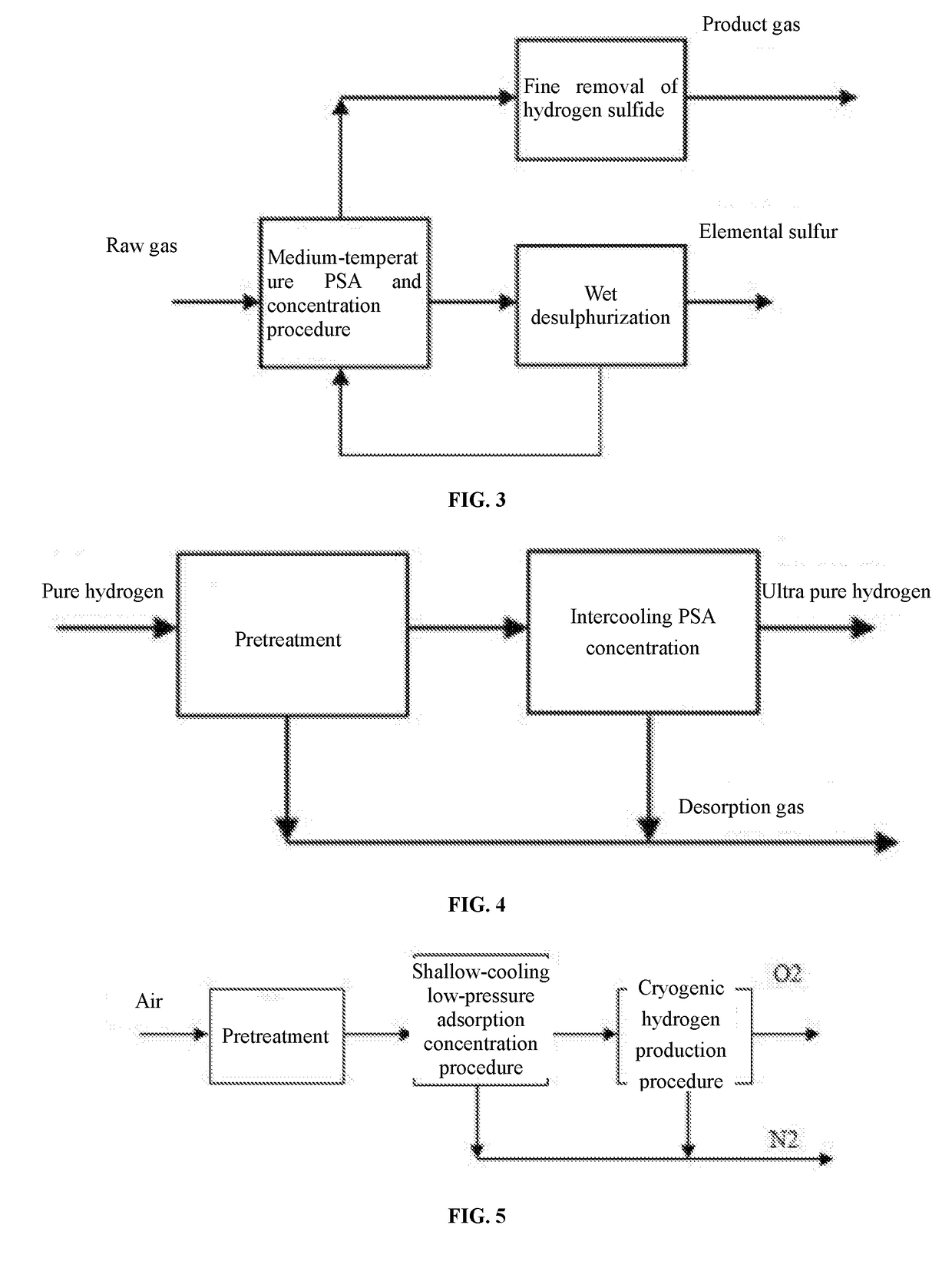

Full-temperature-range pressure swing adsorption gas separation, refinement and purification method

ActiveCN105749699AReduce energy consumptionBroaden the scope of adsorption separation applicationsSolidificationLiquefactionEnergy gradientPurification methods

The invention discloses a full-temperature-range pressure swing adsorption gas separation, refinement and purification method.By means of the difference of the temperatures and pressures of different raw material gases and the difference of the adsorption separation coefficients and physical chemistry properties of all components in the raw material gases in the temperature range of 80-200 DEG C and the pressure range of 0.03-4.0 MPa, the adsorption or desorption regeneration operation of the pressure swing adsorption circulation process is adjusted by coupling all separation methods, the adsorption theory that the pressure or temperature swing adsorption separation process is only limited to the adsorption and desorption regeneration circulation operation through pressure or temperature changes is expanded, and therefore all raw material gases are separated, refined and purified by achieving the energy gradient utilization in the gas separation, refinement and purification process and achieving the circulation operation, where adsorption, desorption and regeneration are easily matched and balanced, in the moderate to low cold and moderate to high temperature pressure swing adsorption separation process, and it is changed that a traditional adsorption method is only limited to the auxiliary effect of refinement and purification, and adsorption becomes the basic separation unit operation just as important as refinement, absorption and extraction separation.

Owner:SICHUAN TECHAIRS

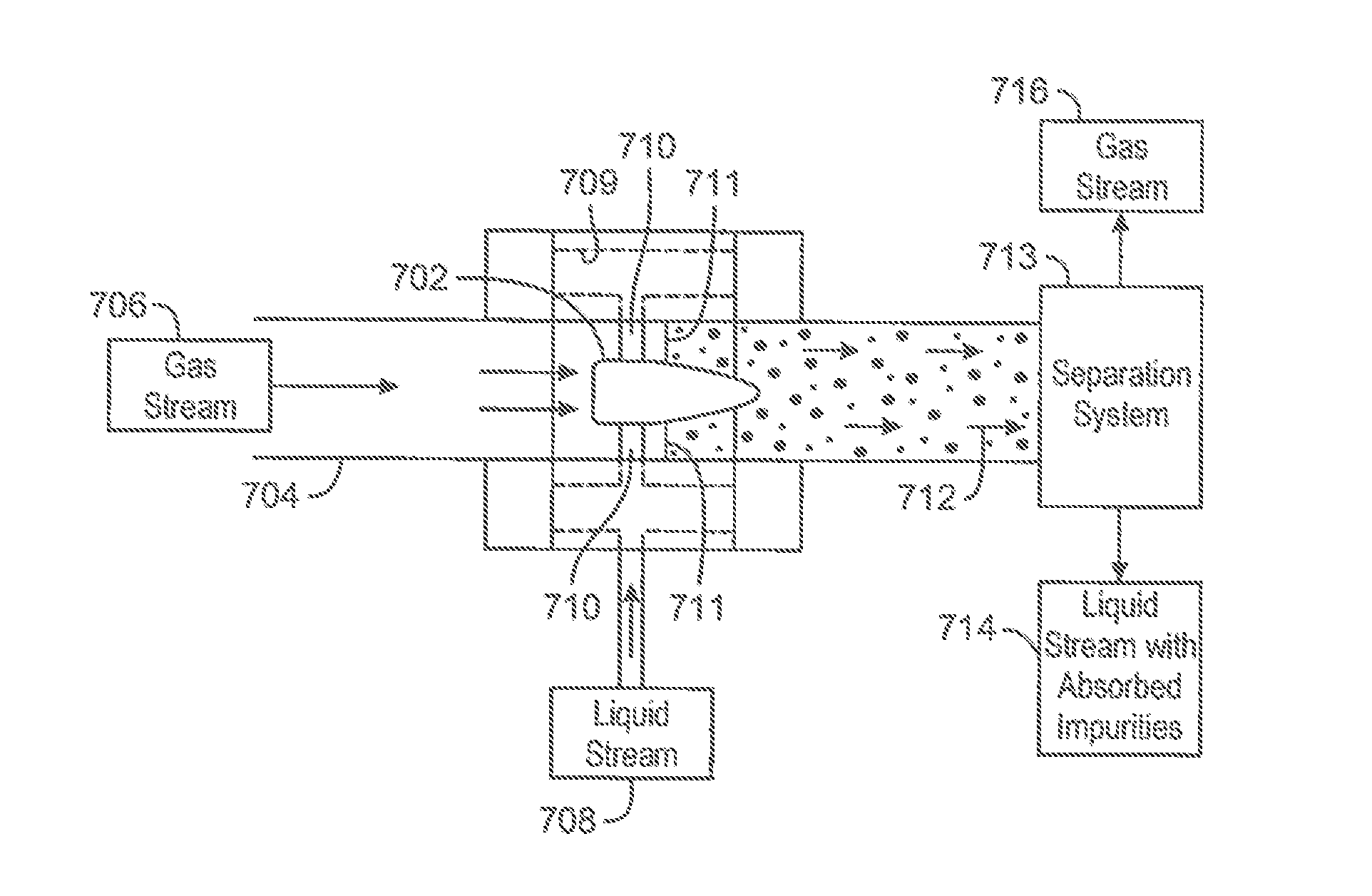

Contacting A Gas Stream With A Liquid Stream

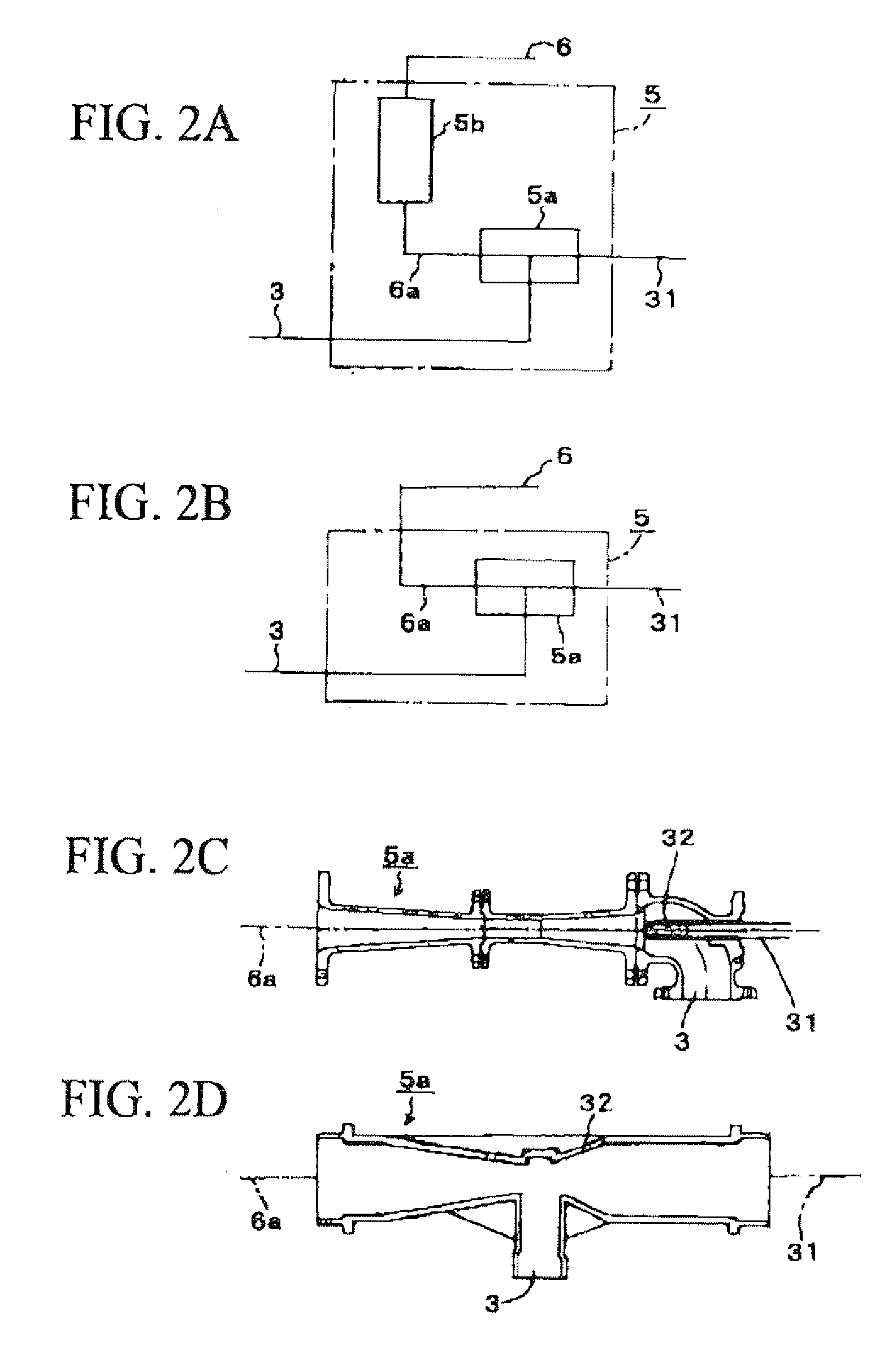

ActiveUS20150352463A1Effective mergerOrganic compound preparationLighting and heating apparatusEngineeringContact system

A co-current contacting system is described herein. The co-current contacting system includes a co-current contactor located in-line within a pipe. The co-current contactor includes an annular support ring configured to maintain the co-current contactor within the pipe and a number of radial blades configured to allow a liquid stream to flow into the co-current contactor. The co-current contacts also includes a central gas entry cone configured to allow a gas stream to flow through a hollow section within the co-current contactor, wherein the co-current contactor provides for efficient incorporation of liquid droplets formed from the liquid stream into the gas stream. The co-current contacting system also includes a separation system configured to remove the liquid droplets from the gas stream.

Owner:EXXONMOBIL UPSTREAM RES CO

Device and method for separating refinery dry gas through oil absorption

InactiveCN103087772AEasy to getLow costGaseous mixture working upAbsorption purification/separationDesorptionGasoline

The invention discloses a device and a method for separating refinery dry gas through oil absorption. The device comprises a C4 absorption tower and a C4 desorption tower. A gasoline absorption tower is arranged after the C4 absorption tower. A top outlet of the C4 absorption tower is connected to the lower part of the gasoline absorption tower. The bottom and the top of the gasoline absorption tower respectively communicate with the outside world. The method comprises the steps that: catalytic dry gas is subjected to compression and cooling, and is delivered into the C4 absorption tower and is absorbed by using a C4 absorption agent; the tower kettle material of the C4 absorption tower is delivered into the C4 desorption tower; the tower kettle material of the C4 desorption tower is delivered back to the C4 absorption tower; tower top gas of the C4 absorption tower is delivered into the gasoline absorption tower and is absorbed by a gasoline absorption agent. According to the invention, no equipment such as ethylene cooling machine, expansion machine, or cold box is needed, such that investment and energy consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for refining catalysis drying gas by using oil absorption extraction

The invention discloses a method for refining catalysis drying gas by using oil absorption extraction. The method comprises the steps of using the carbon five-hydrocarbon containing pentane as absorbent, absorbing the C2 distillate and more important components in the compressed and cooled catalysis drying gas in a main absorbing tower, sending the matter in the main absorbing tower to a desorbing tower, and recycling the C2 concentrated gas from the top of the desorbing tower. The method of the invention has high absorbing temperature and needs no ethylene, propylene cooling compressor and de-compressor so the energy consumption is less, the investment is low and the operation is simple.

Owner:CHINA PETROLEUM & CHEM CORP +1

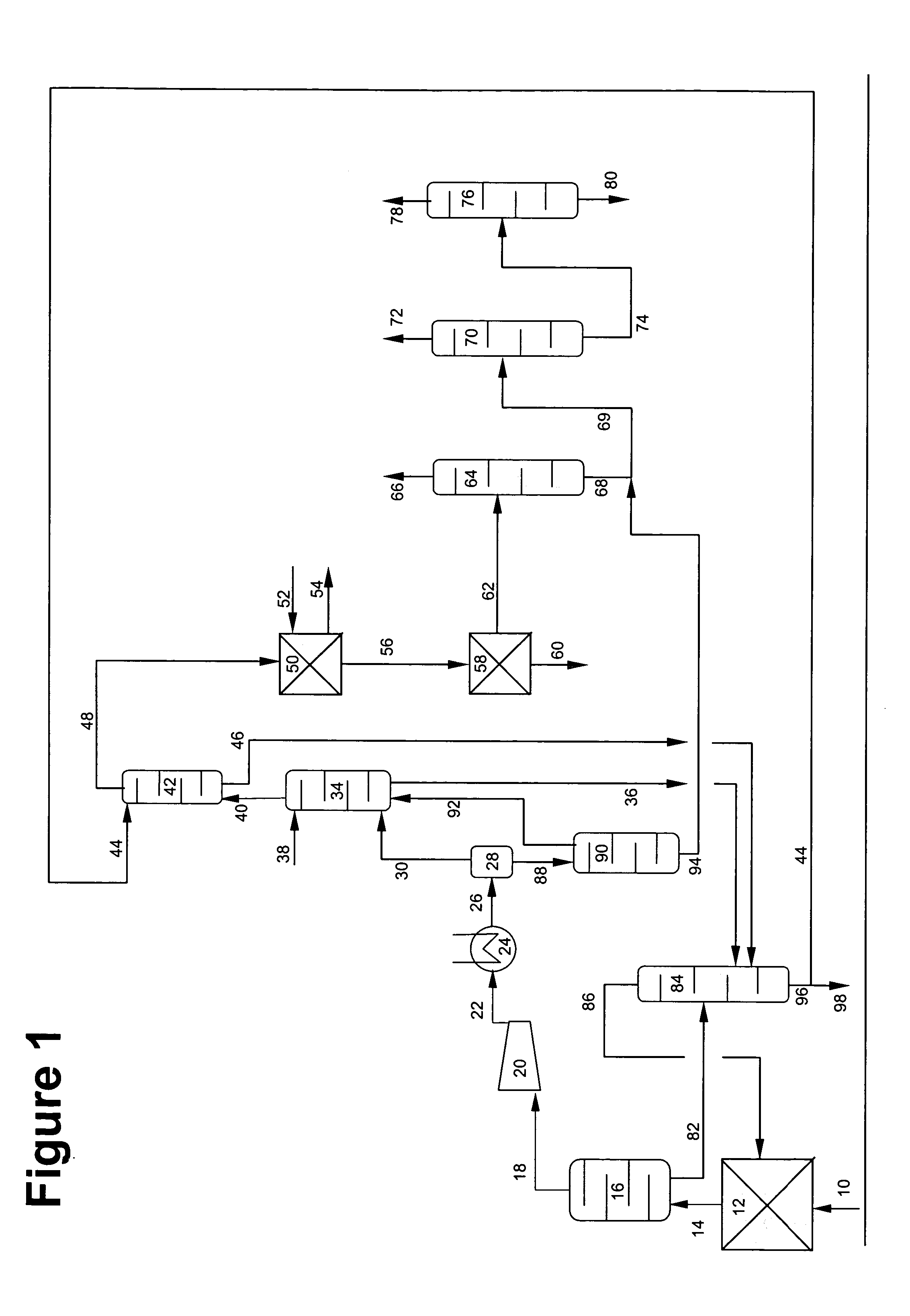

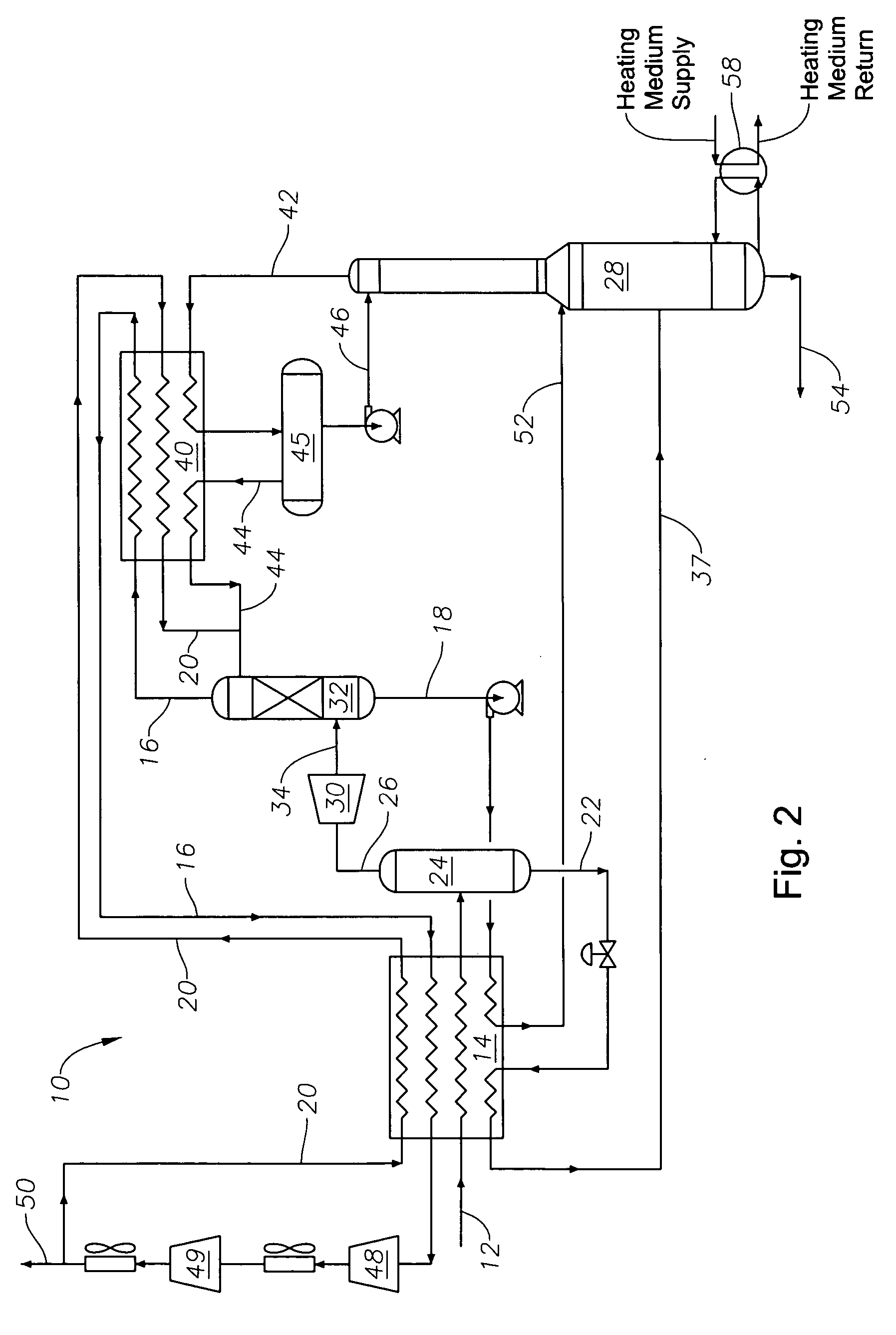

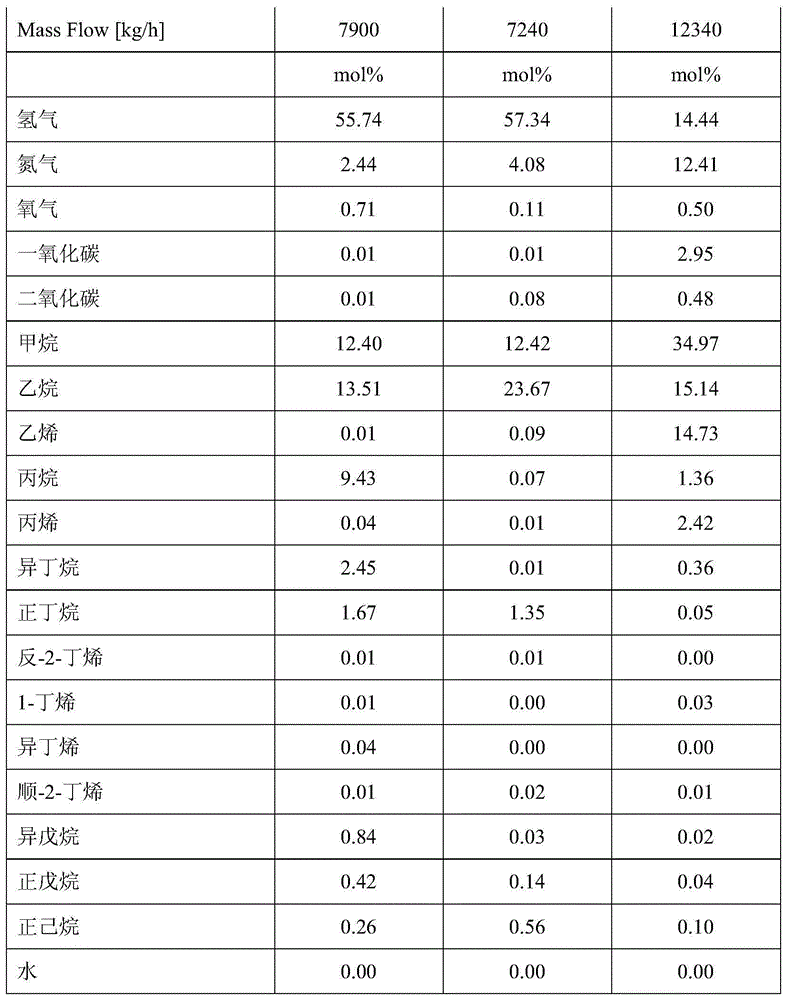

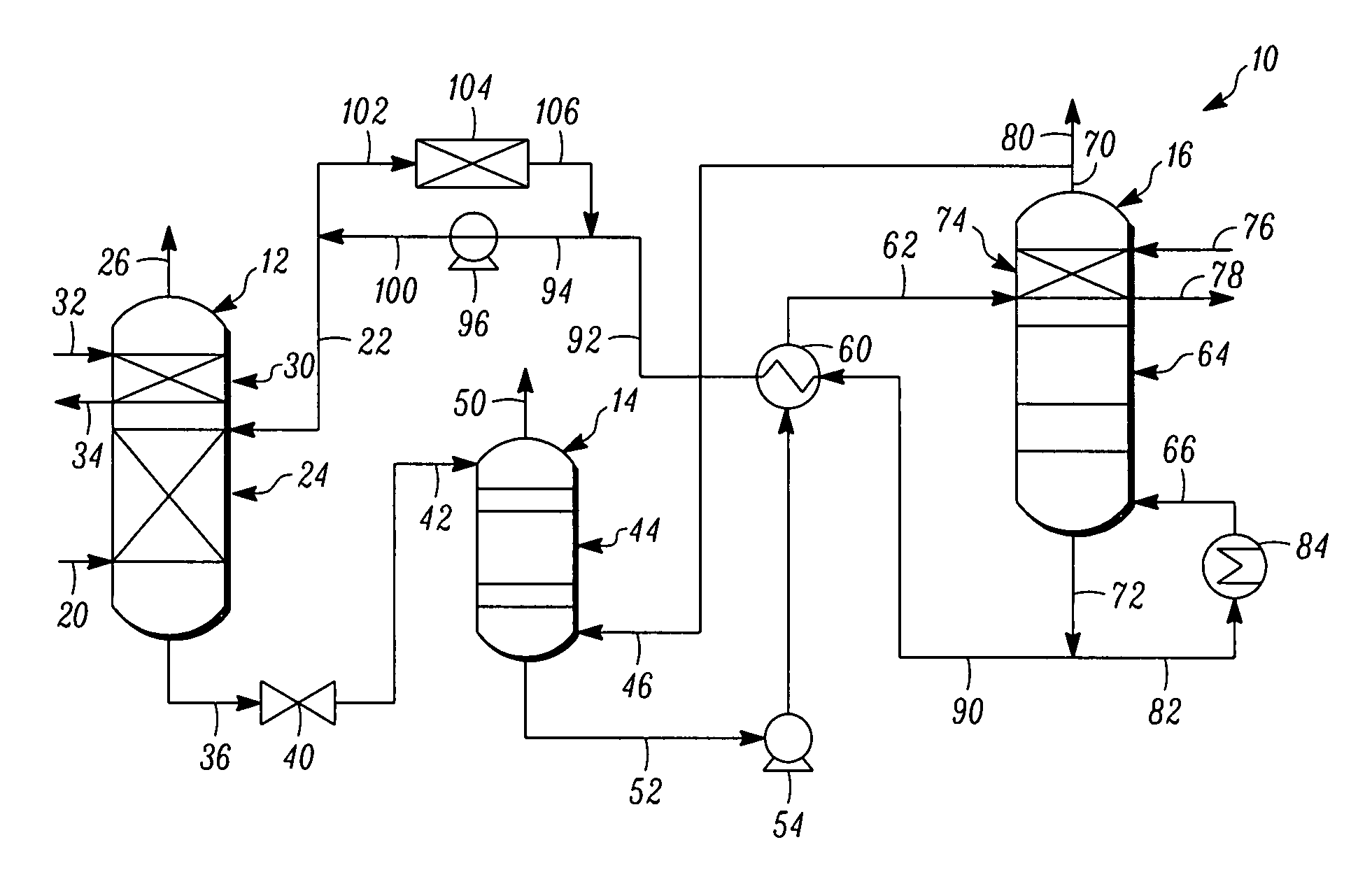

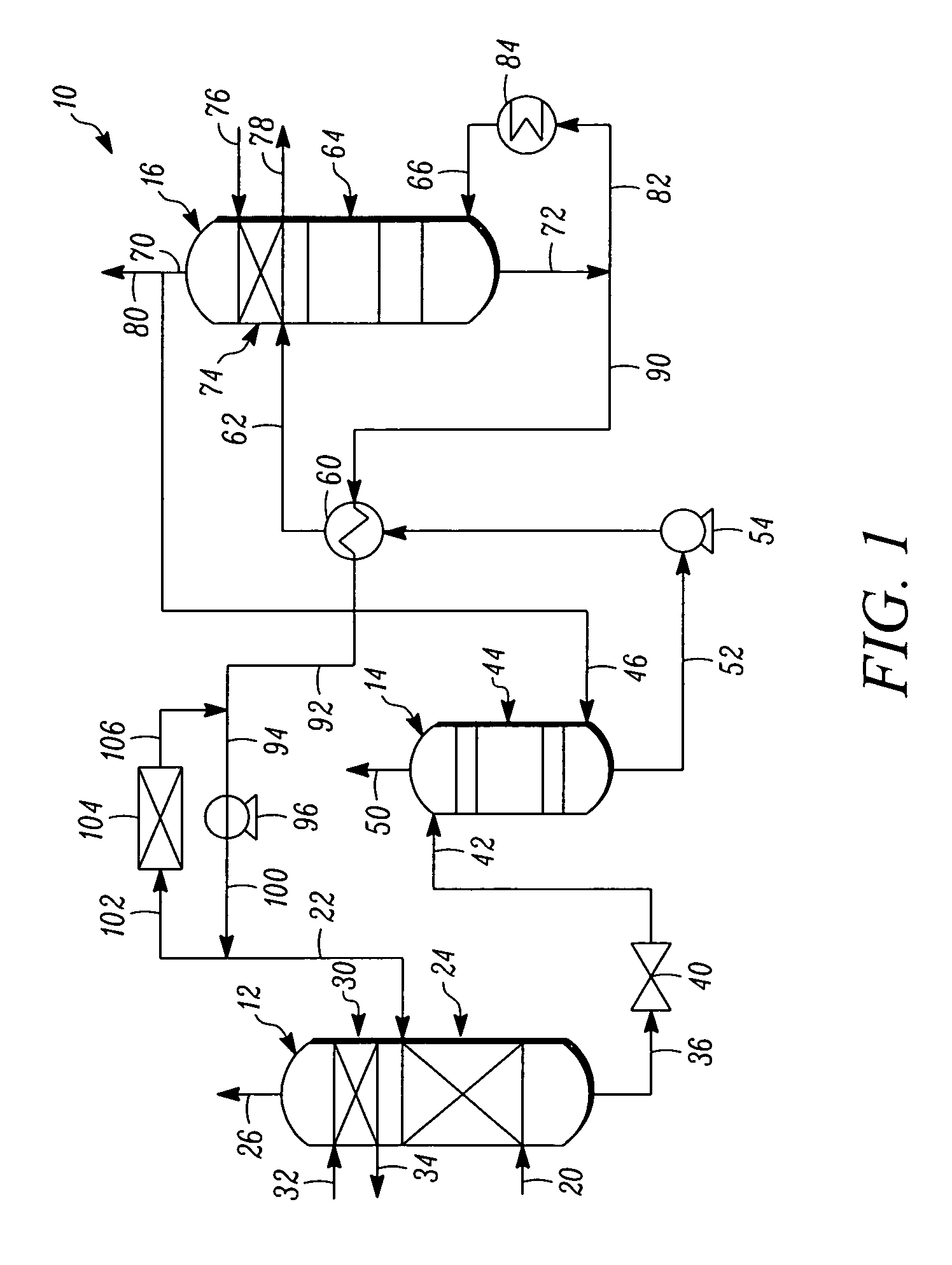

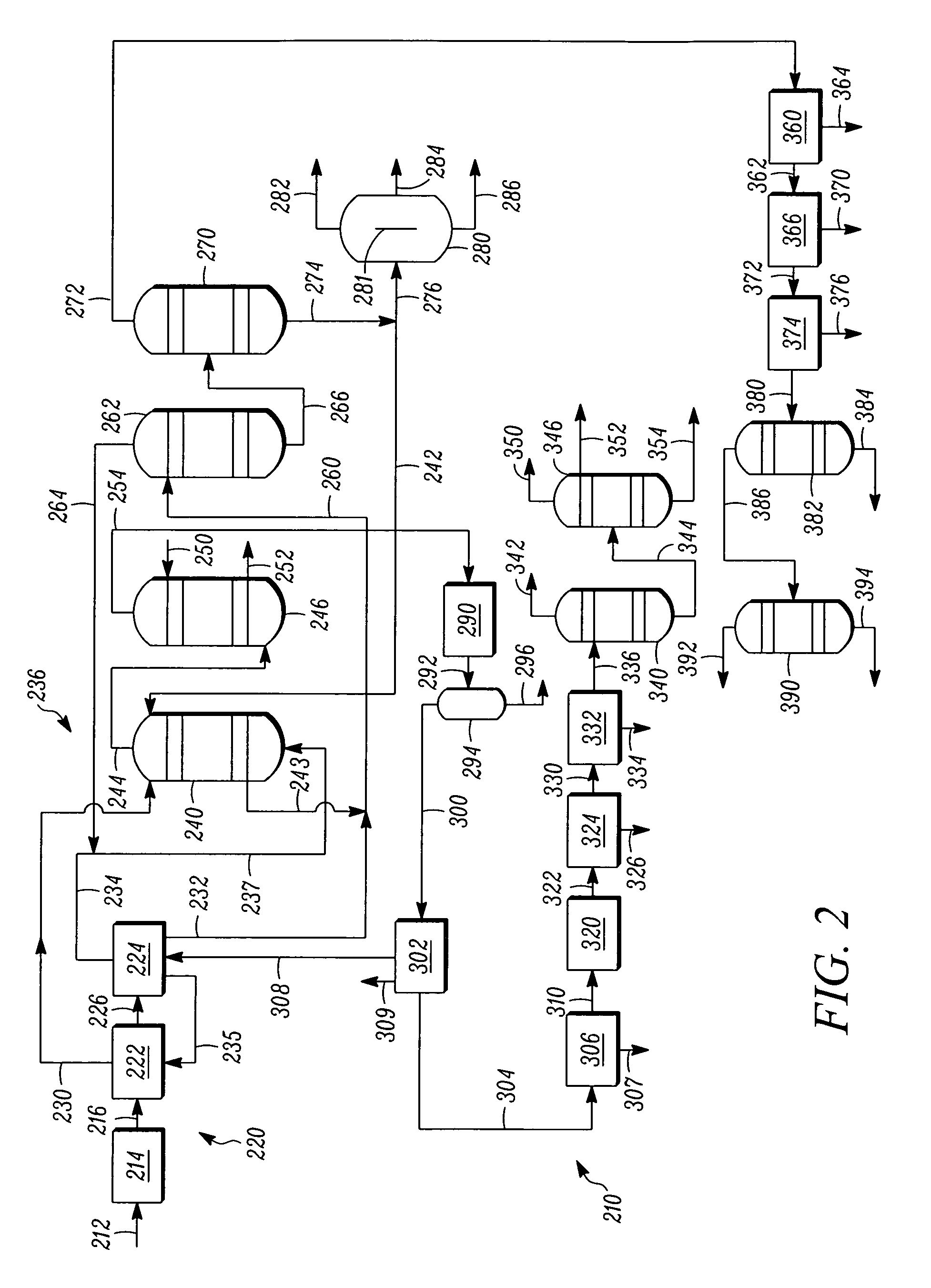

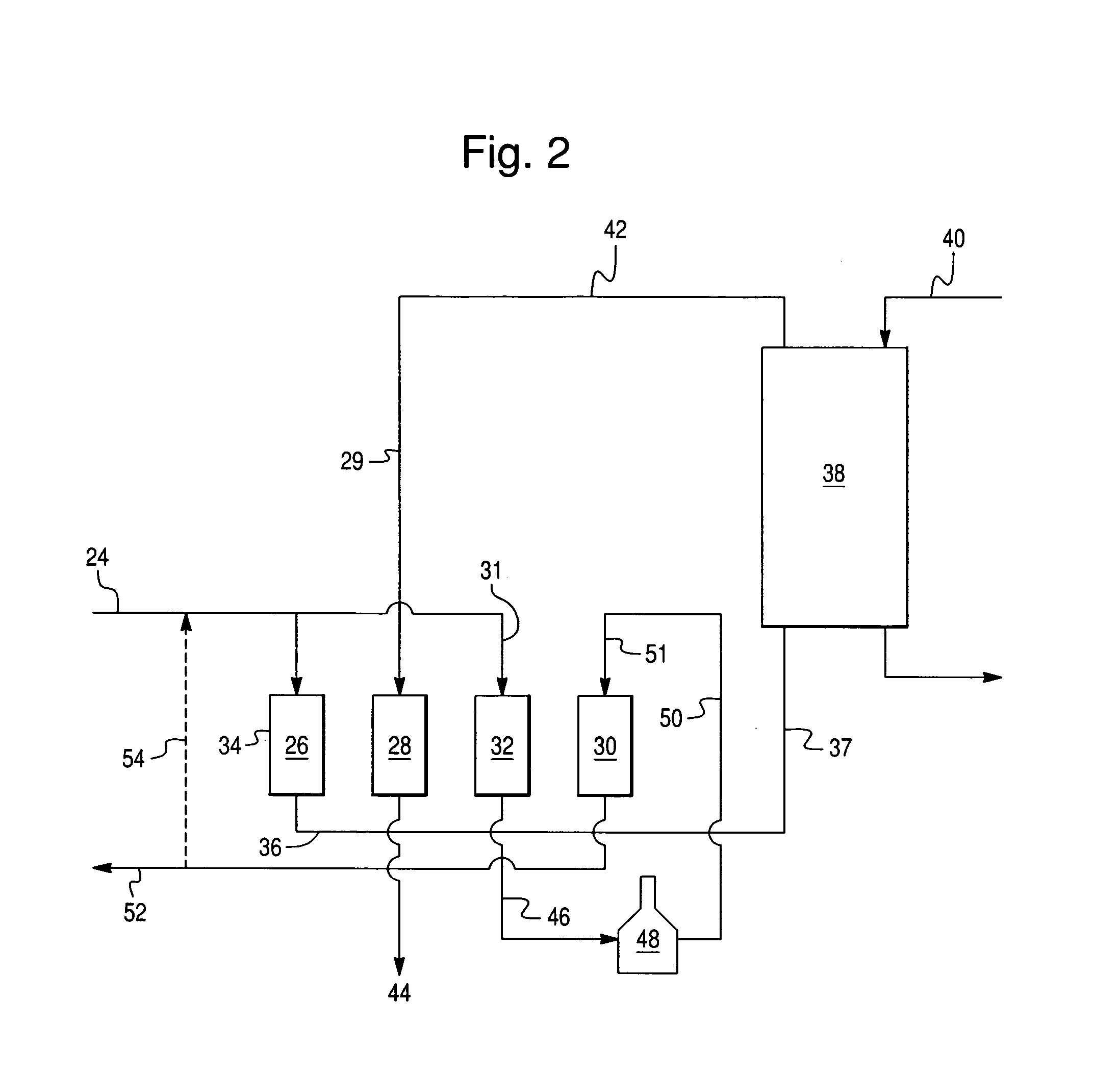

Recovery of ethylene and propylene from a methanol to olefin reaction system

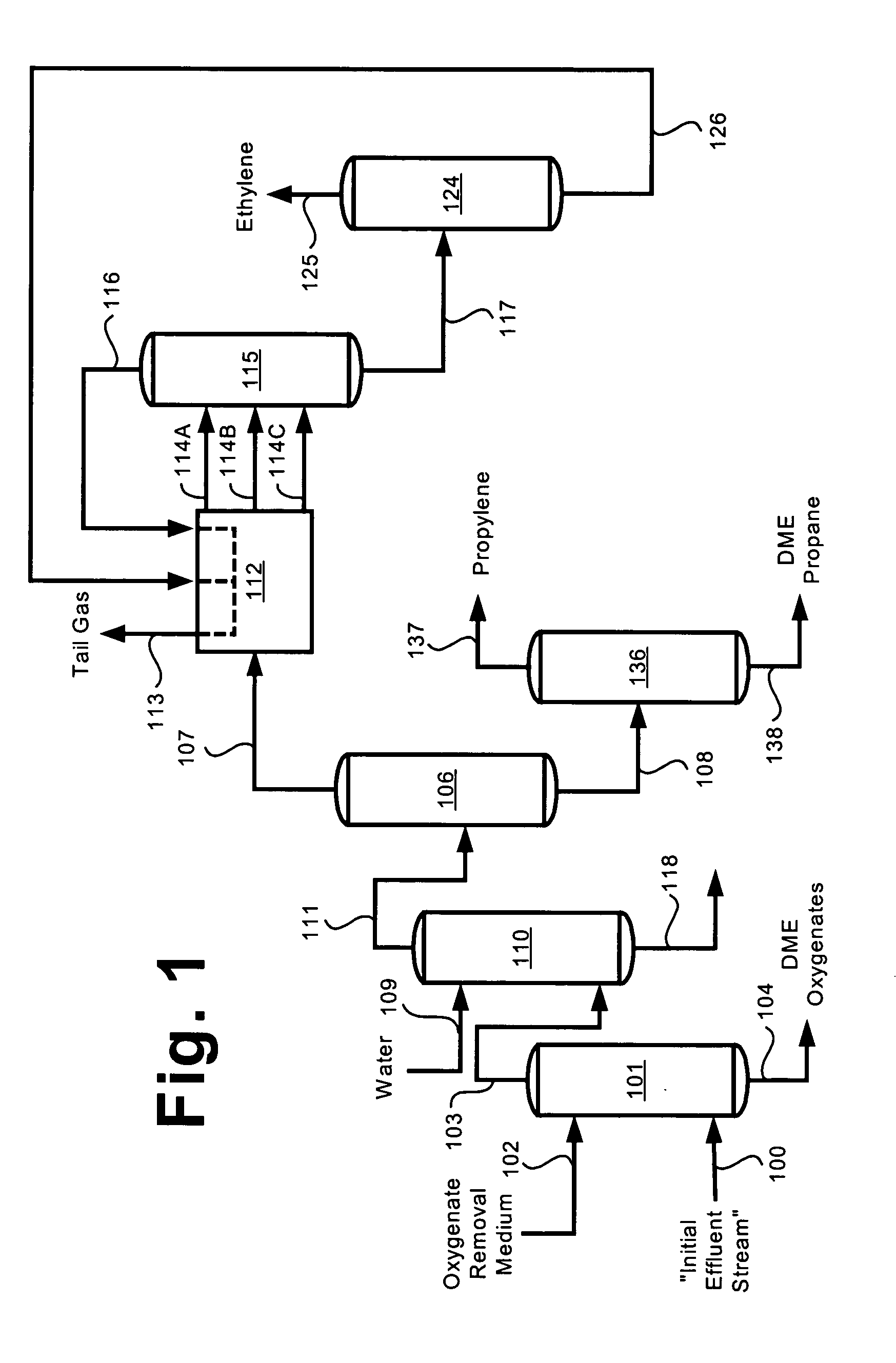

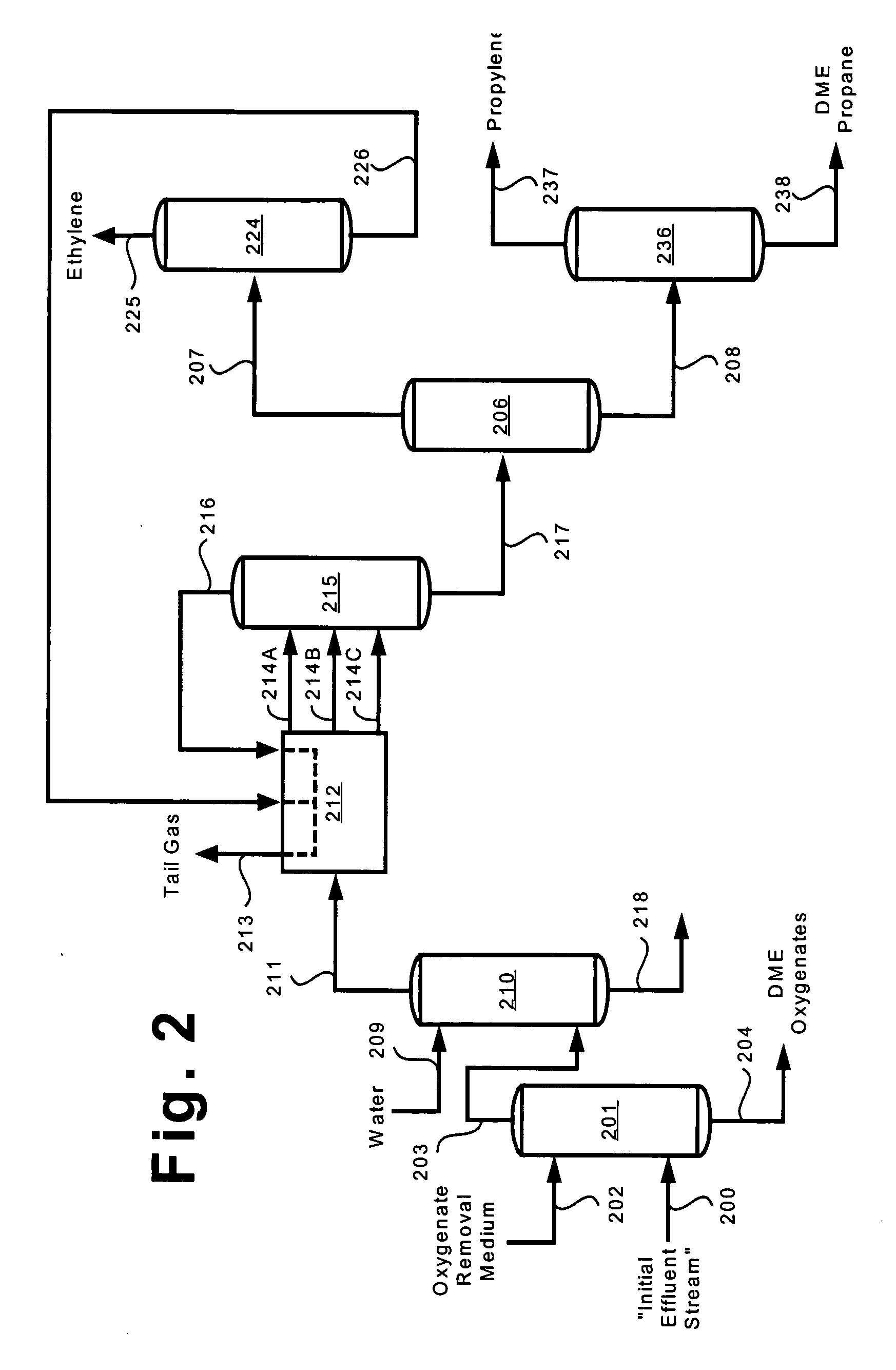

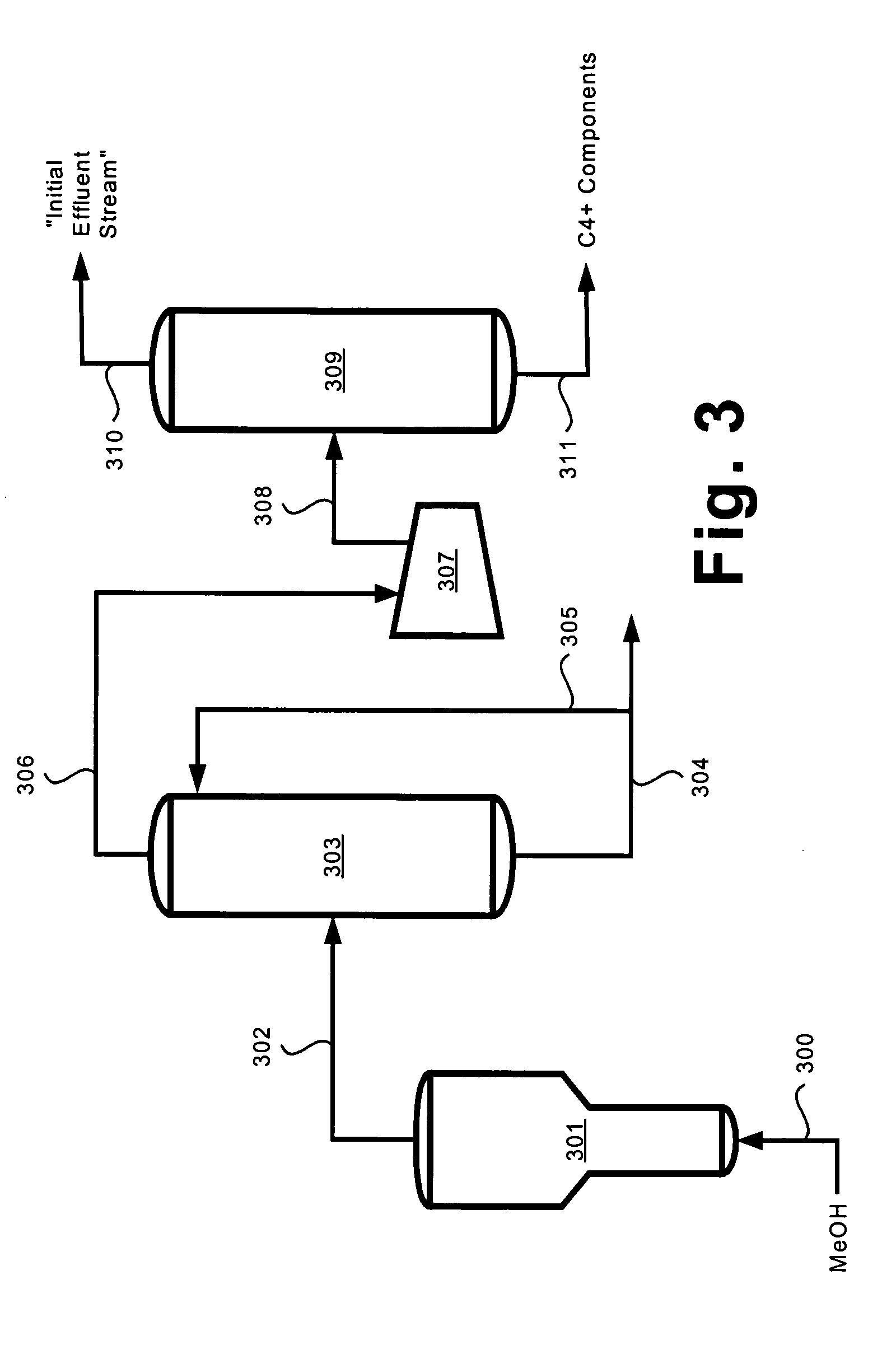

InactiveUS20050033104A1Efficient removalMinimizing equipment countHydrocarbon by hydrogenationLiquid hydrocarbon mixture productionPropadieneDimethyl ether

The present invention provides new highly-efficient separation processes and systems for separating polymerization-grade ethylene and propylene from an initial effluent stream comprising ethane, ethylene, propylene, dimethyl ether, and one or more of propane, acetylene, methyl acetylene, propadiene, methane, hydrogen, carbon monoxide, carbon dioxide and C4+ components. In one embodiment, the initial effluent stream is provided from a methanol-to-olefin reaction system. It has been discovered that an efficient separation of these components is realized when DME is partially removed in a first separation step comprising methanol and water washing steps, followed by separation of the remaining components in additional separation steps.

Owner:EXXONMOBIL CHEM PAT INC

Process for producing olefins

A process is described for producing an olefins stream from a first vapor effluent stream from an oxygenate to olefin conversion reaction, said first vapor effluent stream comprising C2 and C3 olefins, C4 hydrocarbons, and C2 to C6 carbonyl compounds. In the process, the temperature and pressure of the first vapor effluent stream are adjusted to produce a second vapor effluent stream having a pressure ranging from about 100 psig to about 350 psig (790 to 2514 kPa) and a temperature ranging from about 70° F. to about 120° F. (21 to 49° C.), said second vapor effluent stream containing about 50 wt. % or more C4 hydrocarbons based upon the total weight of C4 hydrocarbons in the first vapor effluent stream. The second vapor effluent stream is then washed with a liquid alcohol-containing stream to produce a third vapor effluent stream, whereafter the third vapor effluent stream is washed with liquid water to provide a fourth vapor effluent stream comprising the C2 and C3 olefins and about 1.0 wt. % or less C2 to C6 carbonyl compounds.

Owner:EXXONMOBIL CHEM PAT INC

Lean reflux-high hydrocarbon recovery process

A two-tower scheme process for the recovery of propane and heavier components from a hydrocarbon gas stream is provided. Feed gas is cooled, partially condensed, and then separated to give a first liquid stream and a first vapor stream. First liquid stream is sent to a distillation tower that recovers at the bottoms a major portion of propane and heavier components and produces an overhead gas stream. First vapor stream is expanded and sent as bottom feed to the absorber. Absorber produces an absorber overhead stream containing essentially all the ethane and lighter components and an absorber bottoms stream. Absorber bottoms stream is heated and sent to the distillation tower as middle feed. Absorber overhead stream is warmed and optionally compressed. A part of the compressed stream is substantially condensed and sent to absorber as top feed. The process and apparatus can be used to recover ethane and heavier hydrocarbons.

Owner:LUMMUS TECH INC

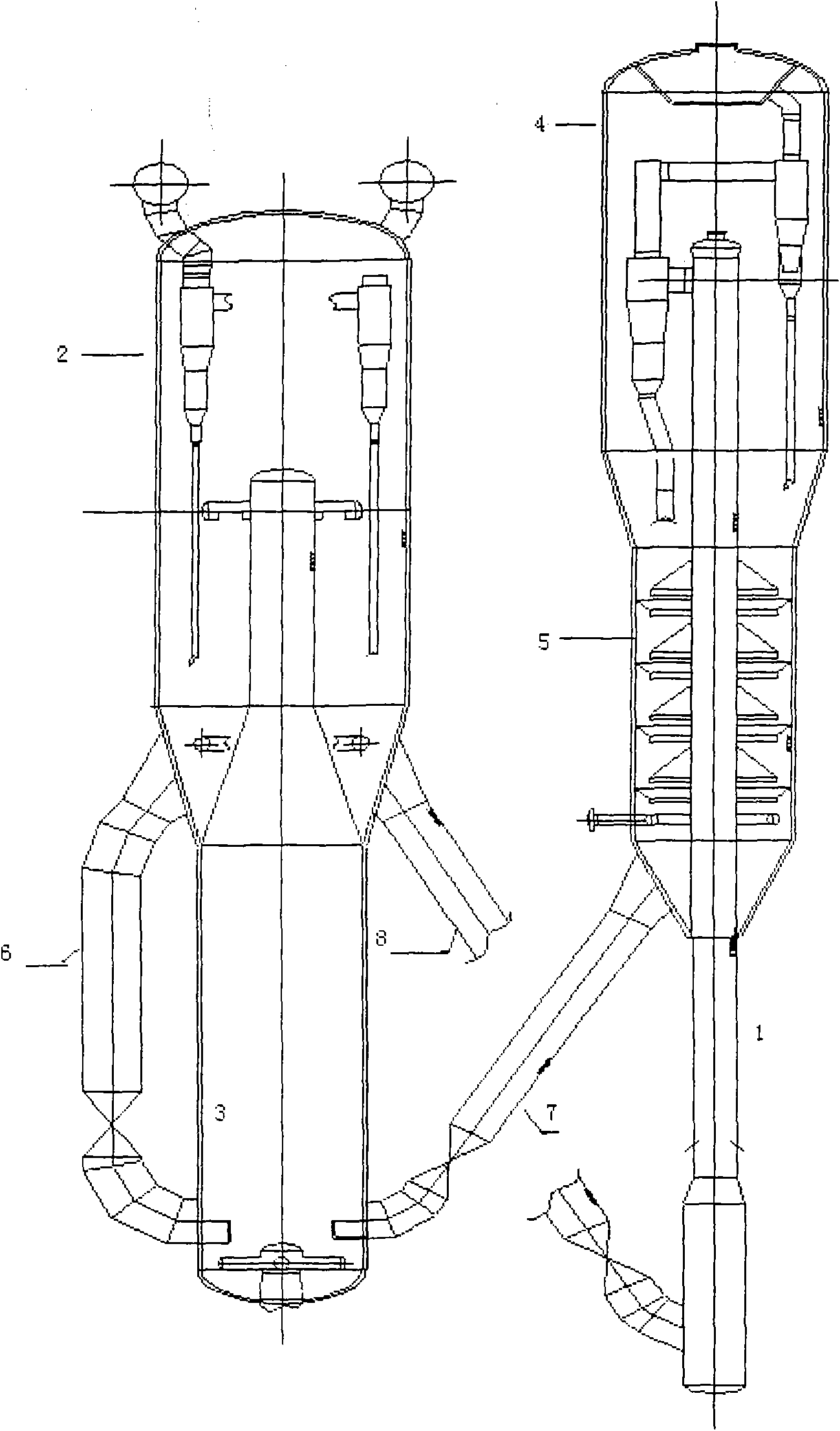

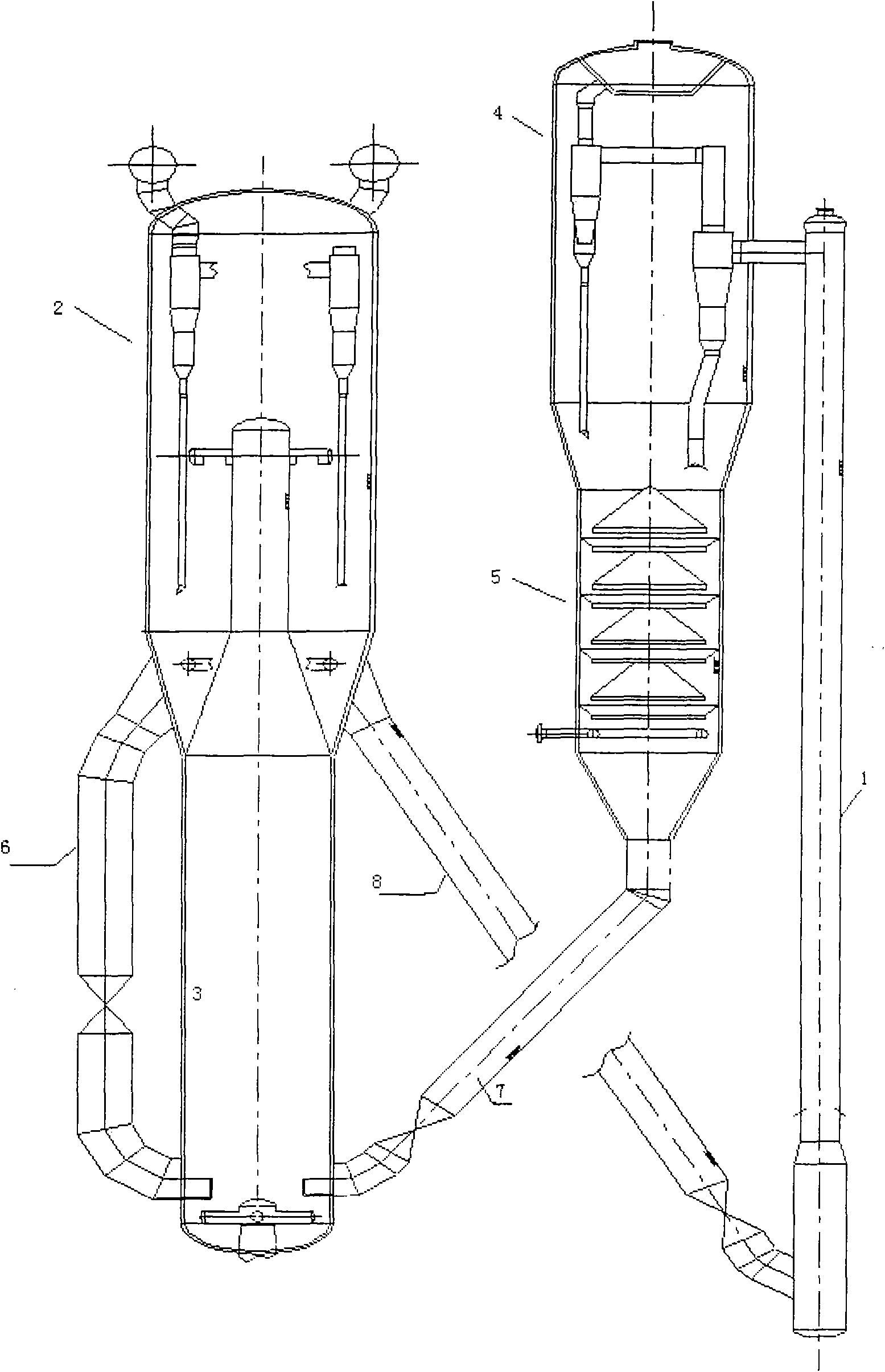

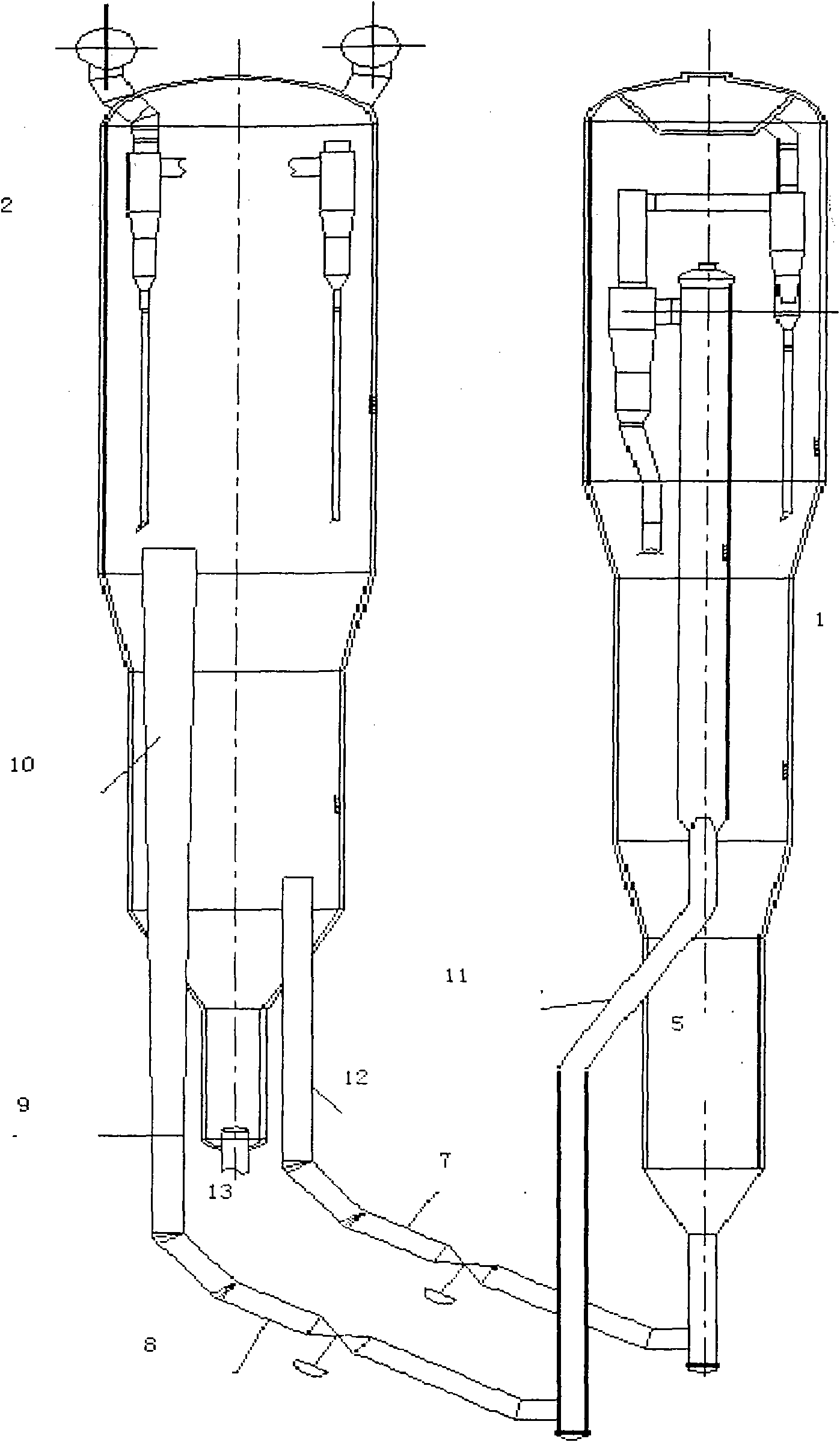

Technology device and method for preparing propylene by dehydrogenating propane or propane-enriched low carbon hydrocarbon

ActiveCN102040445AReduce energy consumptionLow unit priceHydrogen separationDistillation purification/separationGas phaseAlkali metal oxide

The invention provides a technology device and method for preparing propylene by dehydrogenating propane or propane-enriching low carbon hydrocarbon. The device comprises a reacting / regenerating part and a product fractionating part. A reacting / regenerating system is divided into a parallel type arrangement scheme and a coaxial type arrangement scheme by a fluidized bed reacting / regenerating technology, wherein a raising pipe of the parallel type reacting / regenerating system is an internal or external raising pipe, and a raising pipe of the coaxial type reacting / regenerating system is an external raising pipe. The method comprises the steps: leading raw materials and reaction products to enter into a raising pipe reactor after heat exchange; performing a dehydrogenating conversion reaction under the conditions that the reaction temperature is 500-700 DEG C, the pressure is 0.1-0.4MPa, and the ratio of a microspherical catalyst to oil is 5-60, wherein the microspherical catalyst consists of chromium, rare earth oxides, alkali metal oxides and a gamma-Al2O3 carrier, preferably, the temperature is 550-670 DEG C, the pressure is 0.1-0.15MPa, and the ratio of the microspherical catalyst to oil is 6-14; leading the reaction products and the raw materials to enter into a gas-oil separator to separate a gas phase, a liquid phase from a water phase after heat exchange and cooling; leading the separated gas to enter into a gas compressor to be compressed and be transported to an absorbing / stabilizing part; pumping the liquid to an absorbing tower; transporting the liquefied gas from a return tank at the top of a stabilizing tower to a propylene / propane separating tower by a charging pump of a propylene tower; discharging the fine propylene separated from the top of the tower out of the device as a product; discharging the separated byproduct hydrogen out of the device; and returning products at bottom of the tower to the reacting / regenerating part to be recycled.

Owner:卓润生 +1

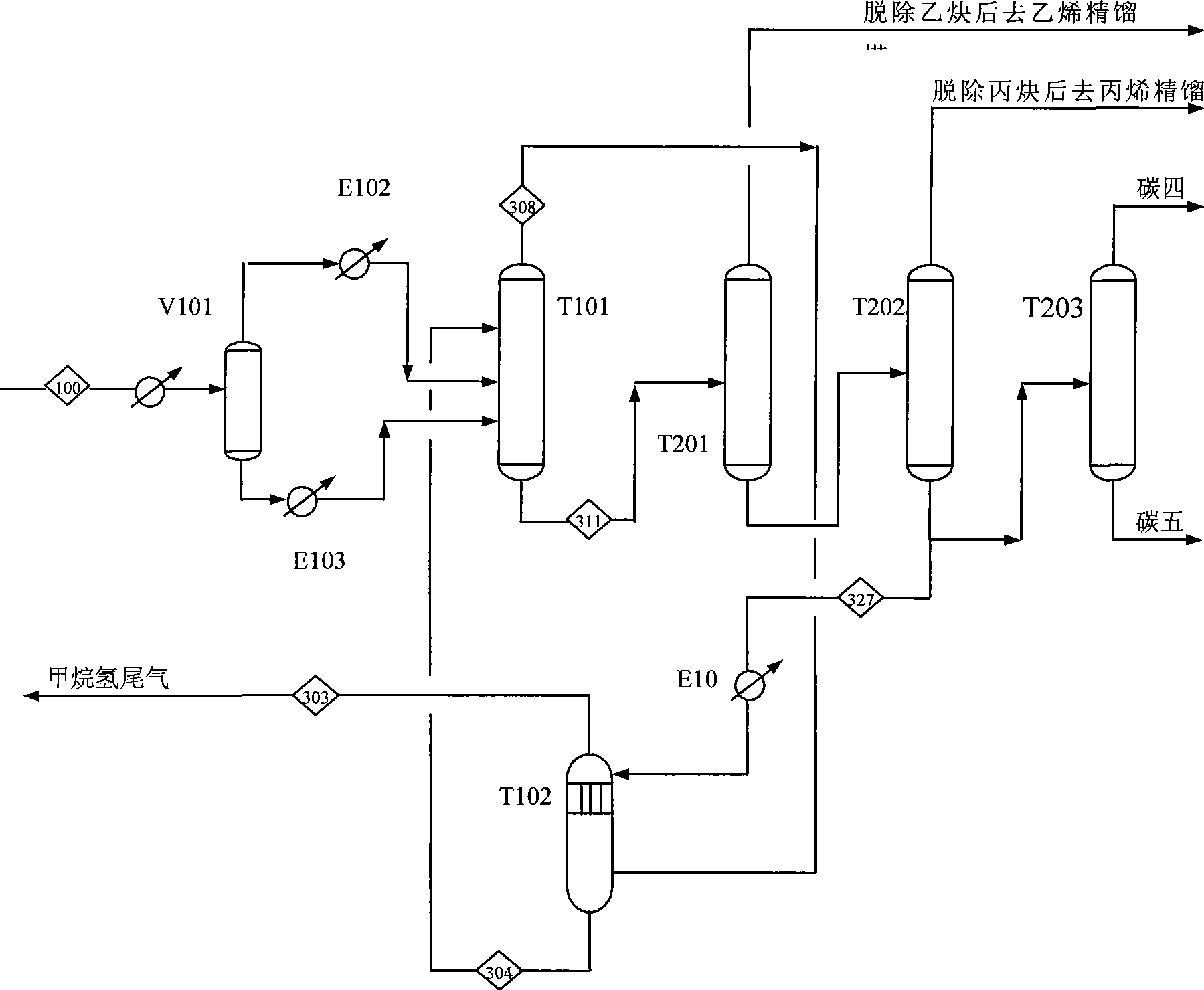

Method for separating lower hydrocarbon containing light gas by combining distillation and solvent absorption

ActiveCN101445419AHigh recovery rateLess investmentDistillation purification/separationAbsorption purification/separationHydrocarbon mixturesDistillation

The invention relates to a method for separating lower hydrocarbon containing light gas by combining distillation and solvent absorption, comprising the steps as follows: (1) pre-disposed gas at the outlet of a reactor is cooled to the temperature ranging from 10 DEG C to -37 DEG C and sent to a pre-cutting tower; (2) the gas at the outlet of the pre-cutting tower is sent to an absorption tower and C1 and C2 in the gas are separated by taking C3 or C4 or C5 or C6 or hydrocarbon mixtures as absorbent; (3) outcomes generated at the bottom of the absorption tower are sent to the pre-cutting tower; with C2 distillate further absorbed and methane and lighter components removed in the pre-cutting tower, the outcome is sent to a deethanizer so that the C2 and C3 are clearly cut. Compared with the prior art, the method has the advantages of little investment, low energy dissipation, high material recovery rate, simple operation, small maintenance quantity, reliable running, requiring no ethane refrigerant compressor, and the like.

Owner:WISON ENG

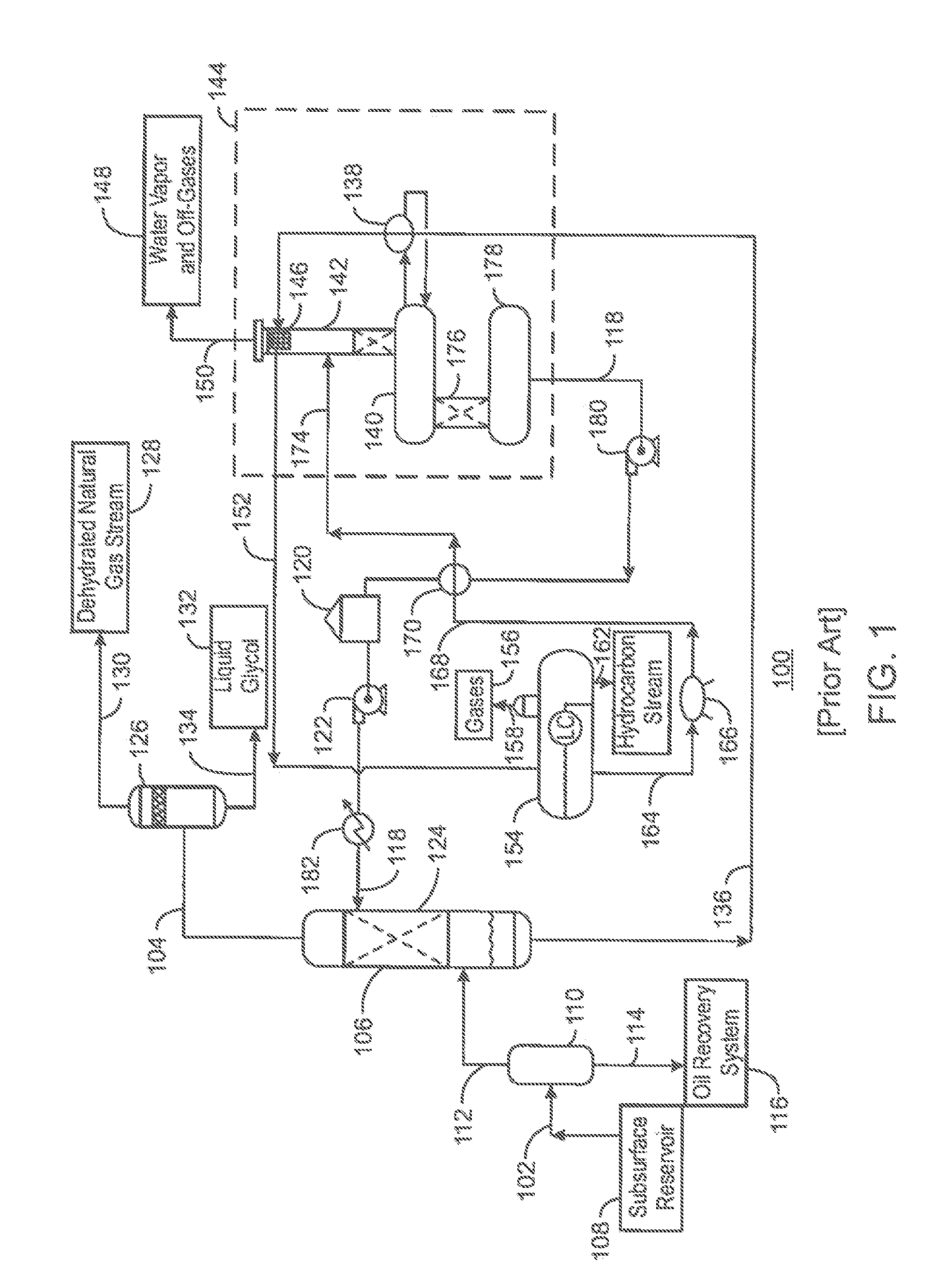

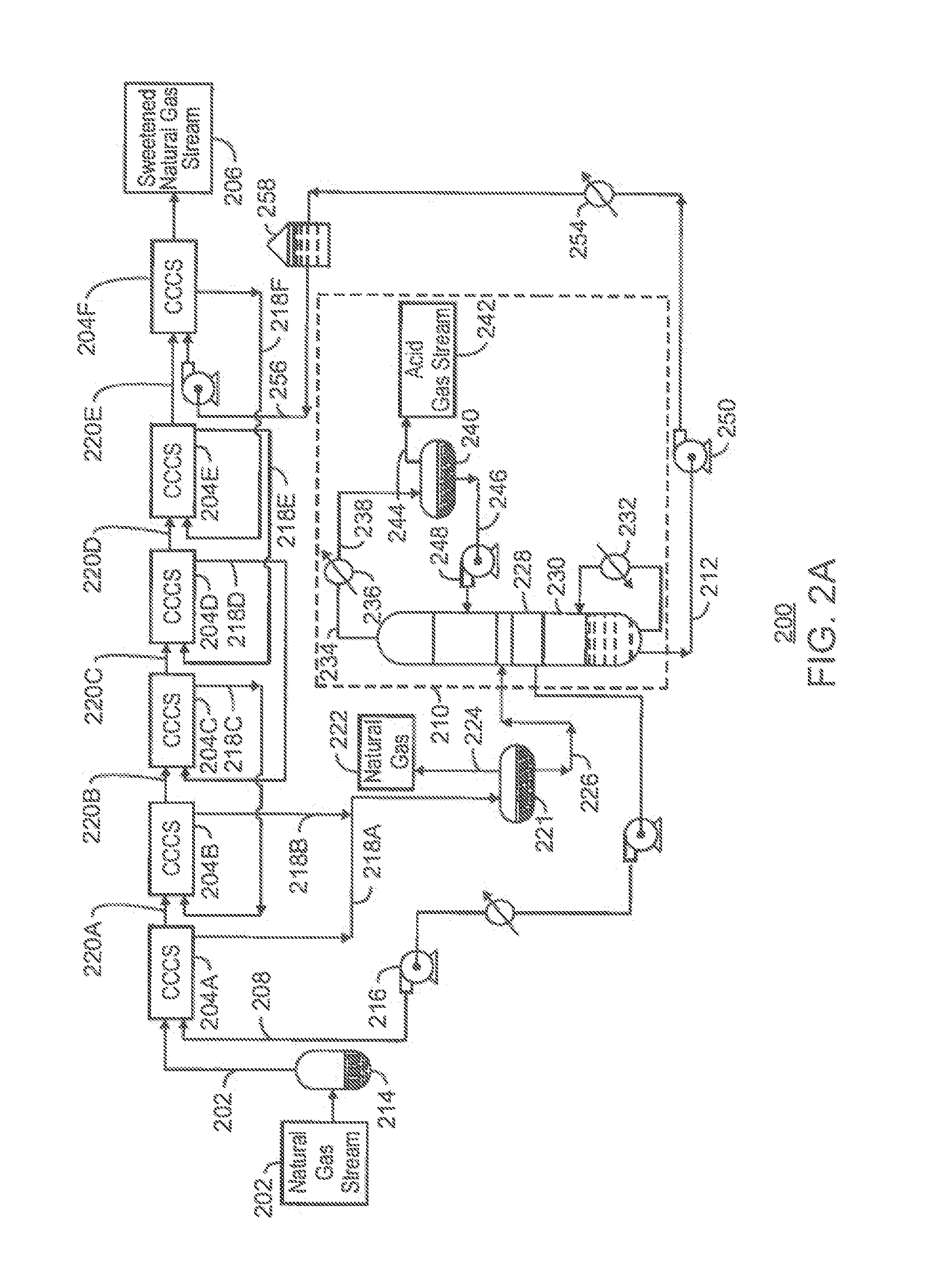

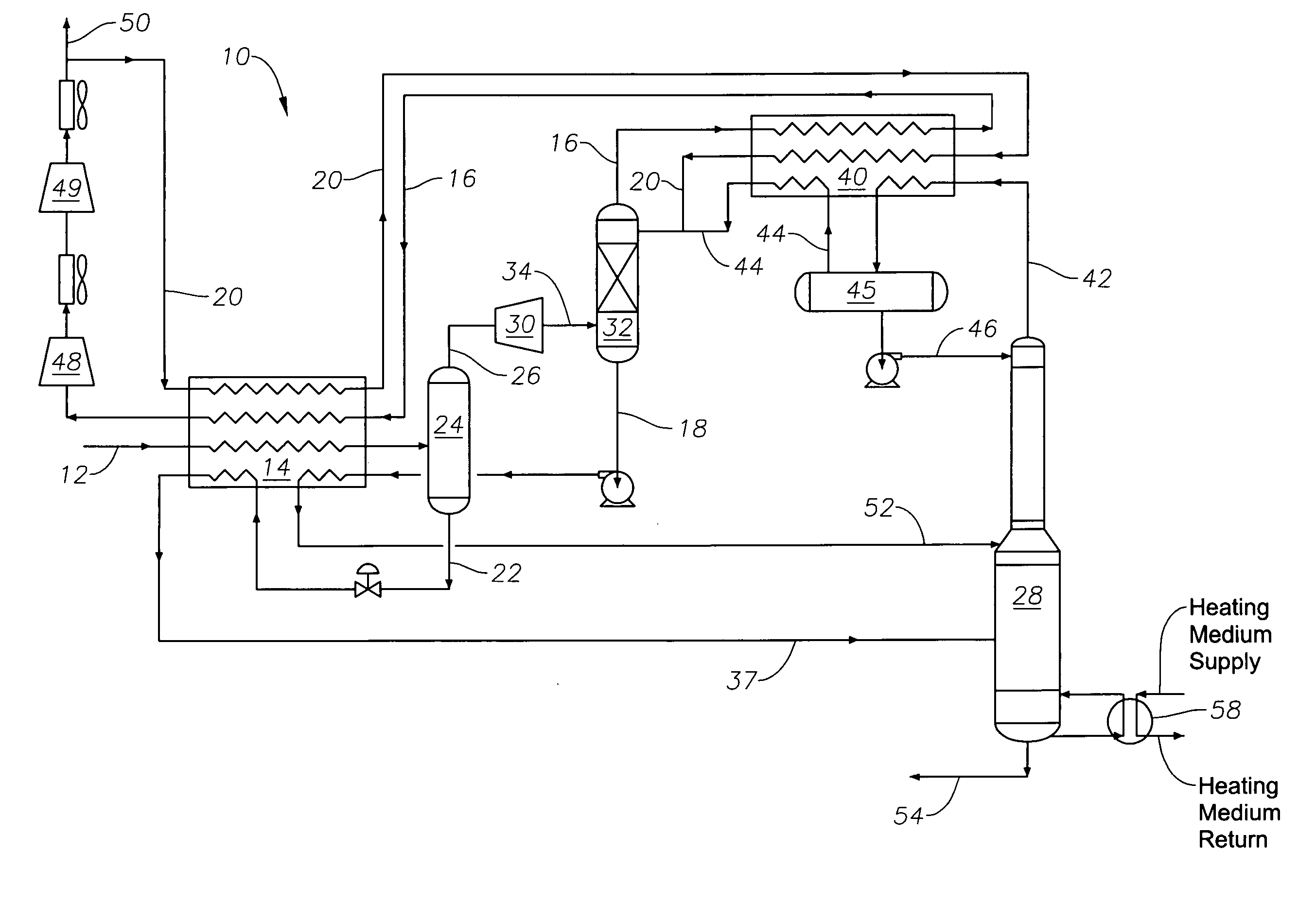

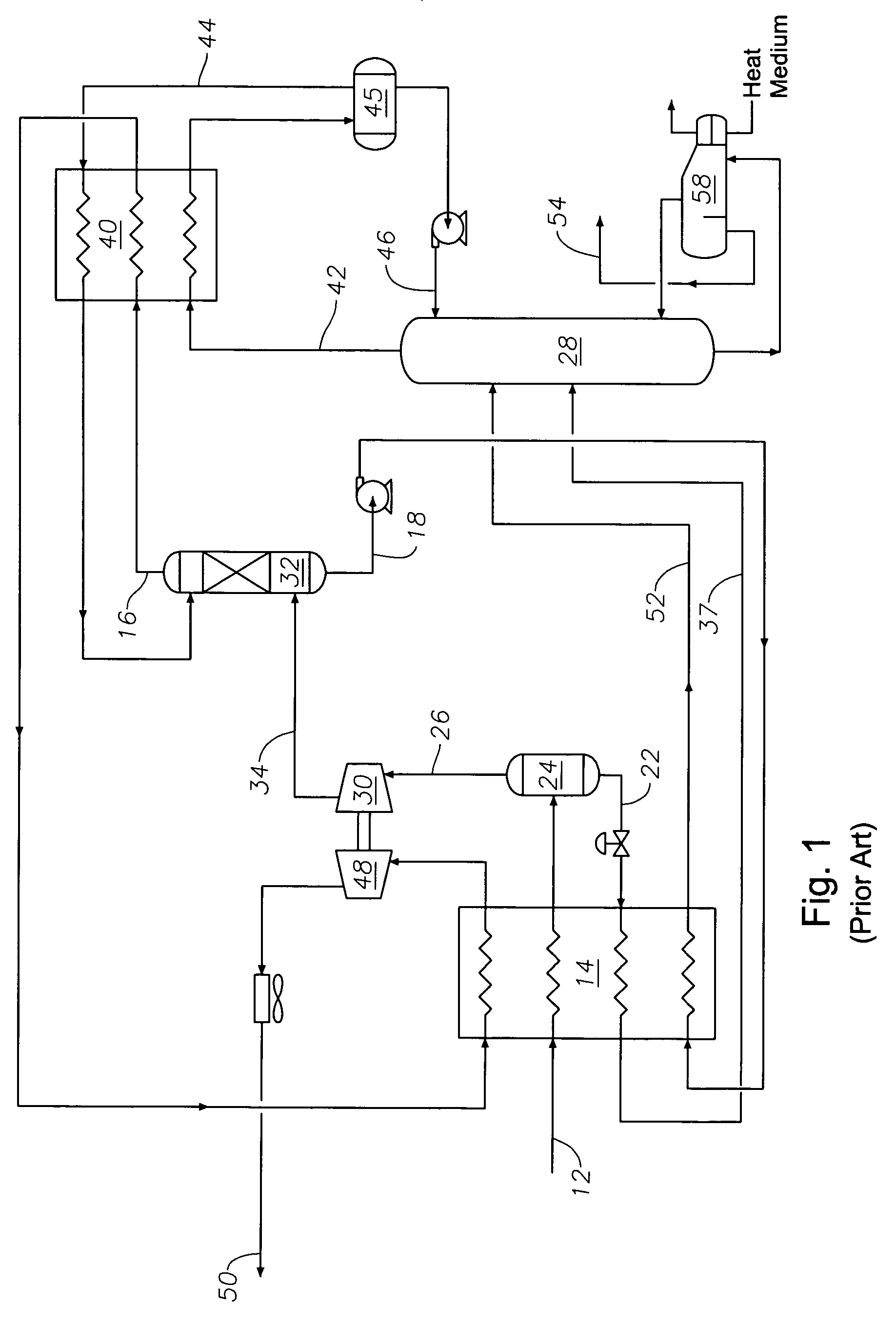

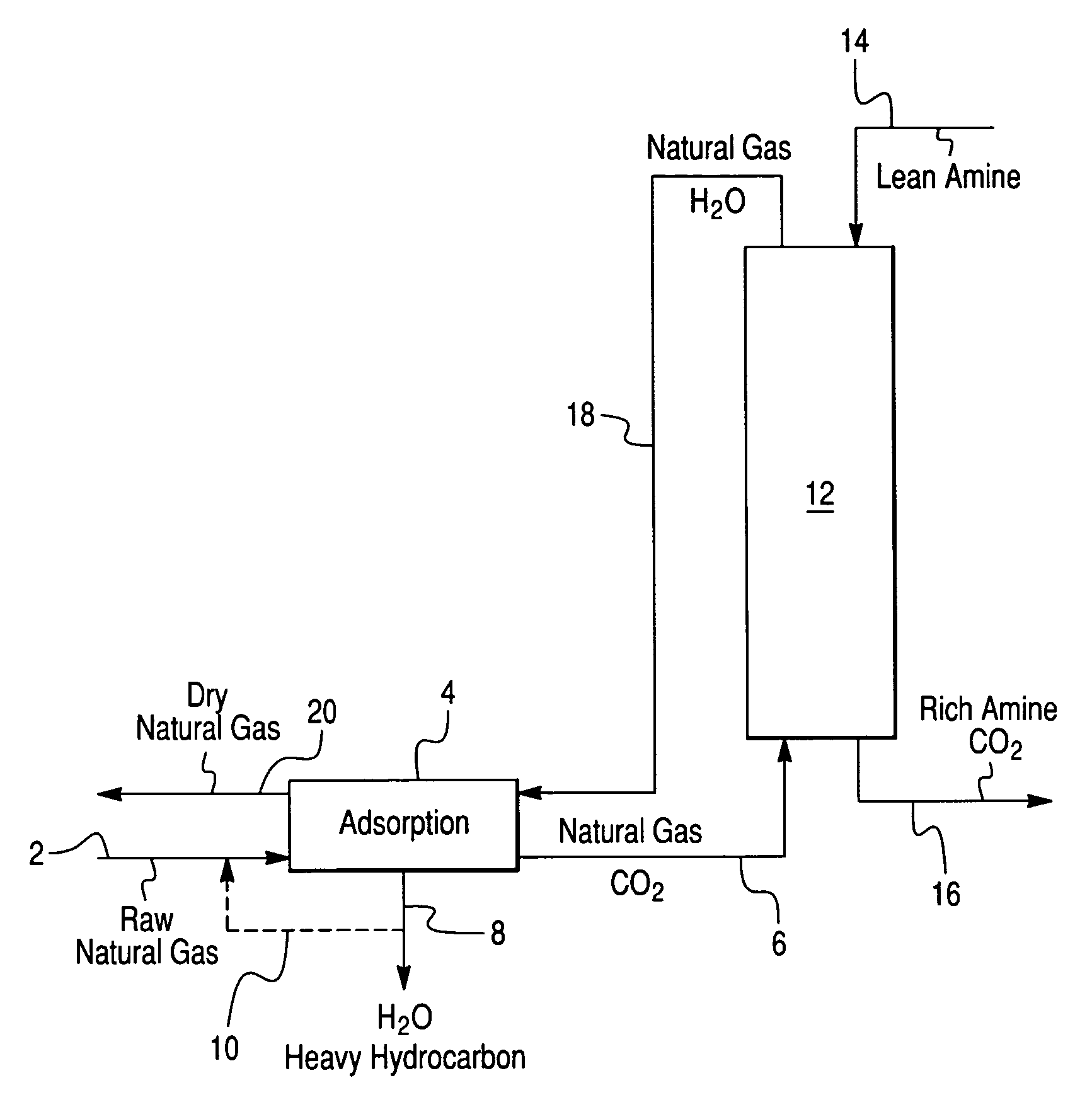

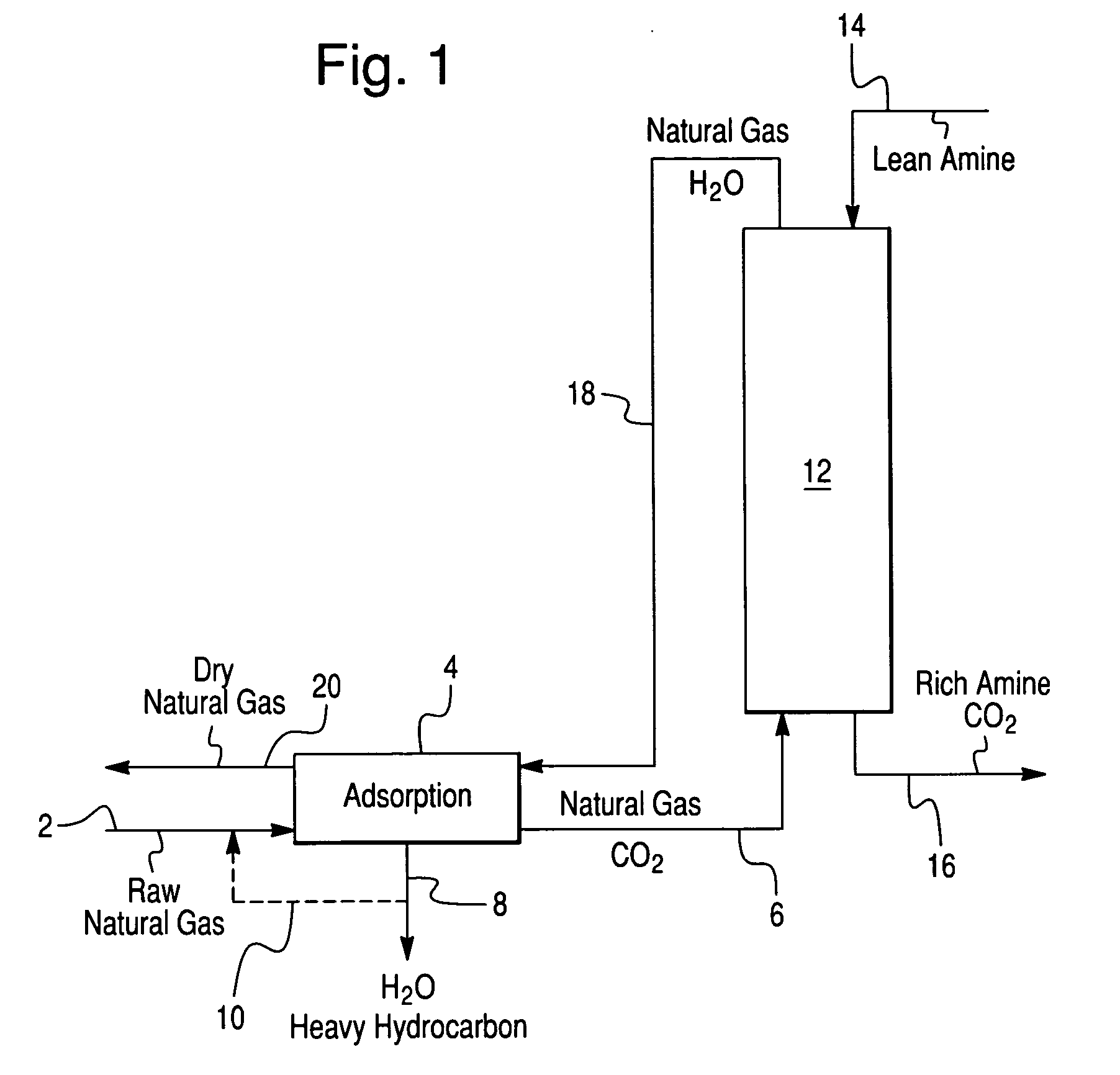

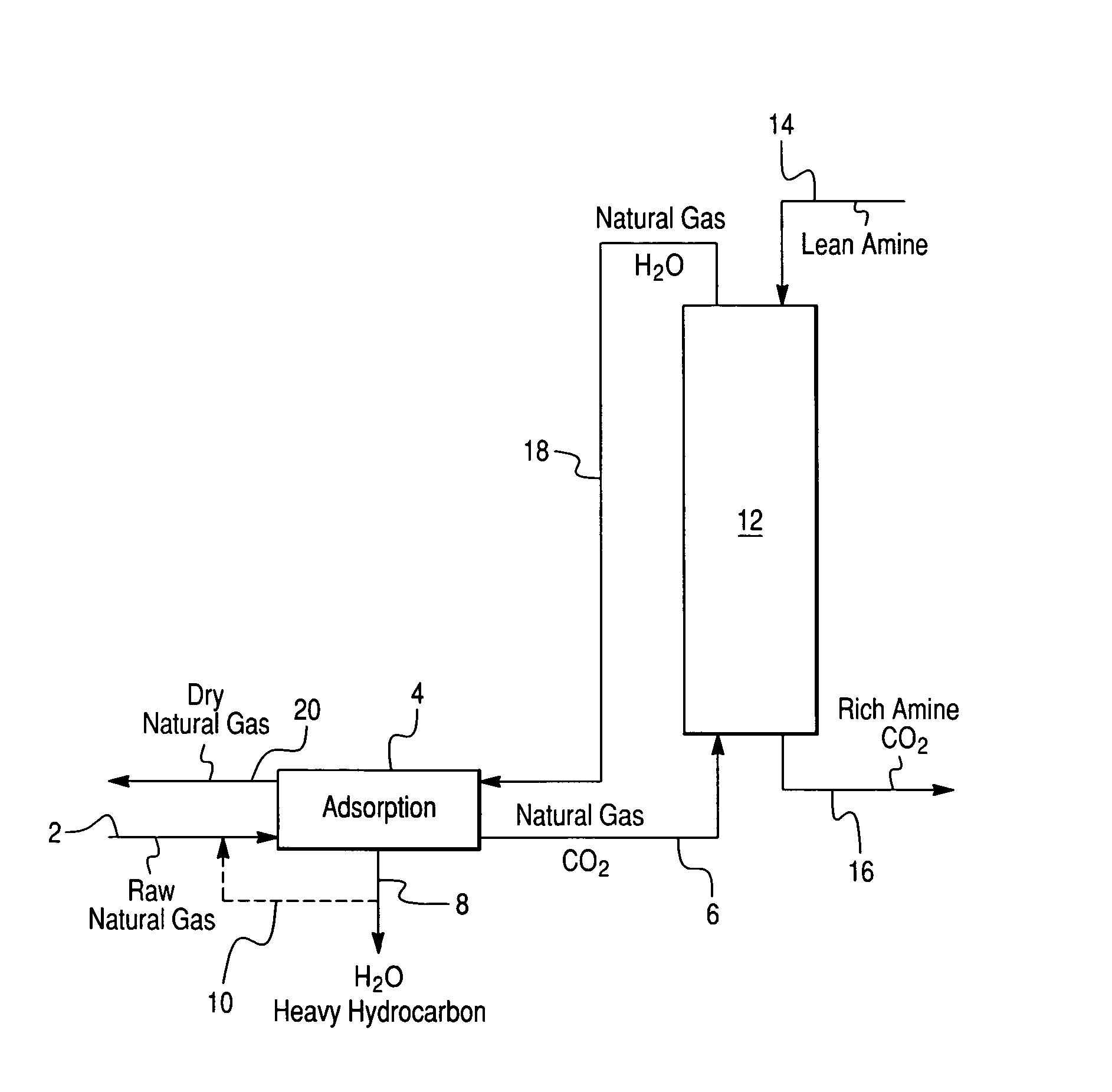

Integrated heavy hydrocarbon removal, amine treating and dehydration

The present invention is directed to an improved integrated process for the removal of heavy hydrocarbons, carbon dioxide, hydrogen sulfide, and water from a raw natural gas feed stream. More specifically, the integrated process of the present invention comprises a three step process involving the adsorption of heavy hydrocarbons and water on an adsorbent bed selective for the same, a subsequent aqueous lean amine treatment for the absorptive removal of acid gases, such as carbon dioxide and hydrogen sulfide, and an adsorptive removal of water. The process of the present invention results in a highly purified dry natural gas product stream.

Owner:BASF CATALYSTS LLC

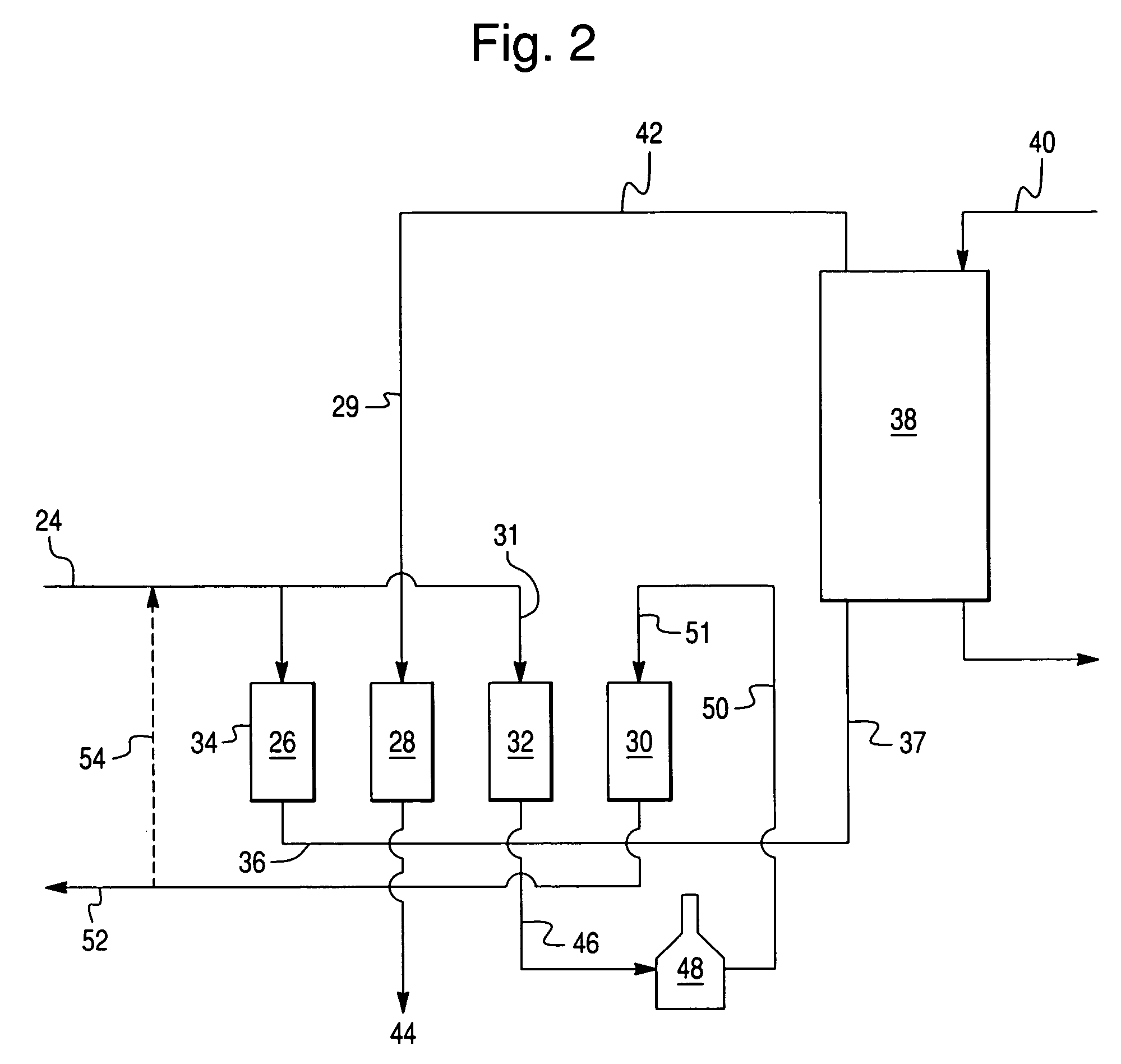

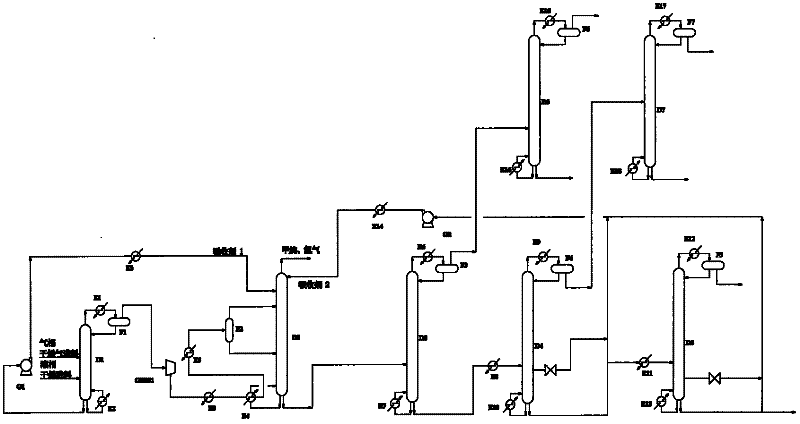

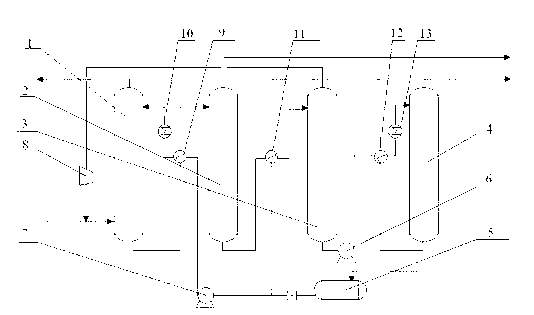

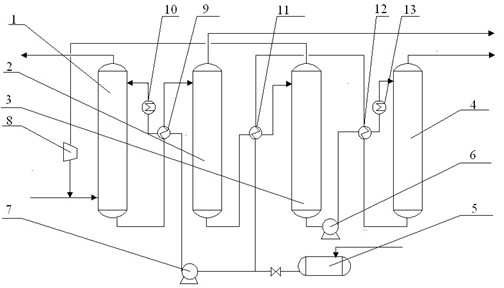

Refinery mixed dry gas recovery system and recovery method

ActiveCN104557387AReduce total usageReduce lossesHydrocarbonsGaseous mixture working upUnsaturated hydrocarbonGasoline

The invention discloses a refinery mixed dry gas recovery system and a recovery method. The system comprises an absorption tower, a desorption tower, a rough separation tower, a purification device, a gasoline absorption tower and a gasoline desorption tower, wherein a compressor is connected with a heat exchanger and then is connected with the absorption tower, the top of the absorption tower is connected with the gasoline absorption tower, and the bottom of the absorption tower is connected with the desorption tower; the top of the desorption tower is connected with the purification device and then is connected with the rough separation tower, the bottom of the gasoline absorption tower is connected with the gasoline desorption tower, the top of the gasoline desorption tower is connected with the upper part of the absorption tower, and the bottom of the gasoline desorption tower is connected with the upper part of the gasoline absorption tower. According to the recovery system, a C2 component is recovered from dry gas through one set of absorption-desorption, a tower top gas phase of the desorption tower enters the rough separation tower, and an entrained absorbent is recovered through another set of absorption-desorption; ethylene-rich gas is recovered from the tower top of the rough separation tower and is delivered to an ethylene unit demethanizer, and ethane-rich gas is recovered from a reactor of the rough separation tower and is delivered to an ethylene unit cracking furnace. According to the recovery method disclosed by the invention, the flow is simple, the recovery rate is high, saturated hydrocarbons and unsaturated hydrocarbons are treated separately, and the operation of an ethylene unit is hardly affected.

Owner:CHINA PETROLEUM & CHEM CORP +1

Amine treatment in light olefin processing

Processing schemes and arrangements for the amine treatment of high olefin content (e.g., ethylene-rich) carbon dioxide-containing streams such as for the effective separation and removal of carbon dioxide therefrom are provided. Corresponding or associated processing schemes and arrangements for the catalytic cracking of a heavy hydrocarbon feedstock and obtaining light olefins substantially free of carbon dioxide via absorption-based product recovery are also provided.

Owner:UOP LLC

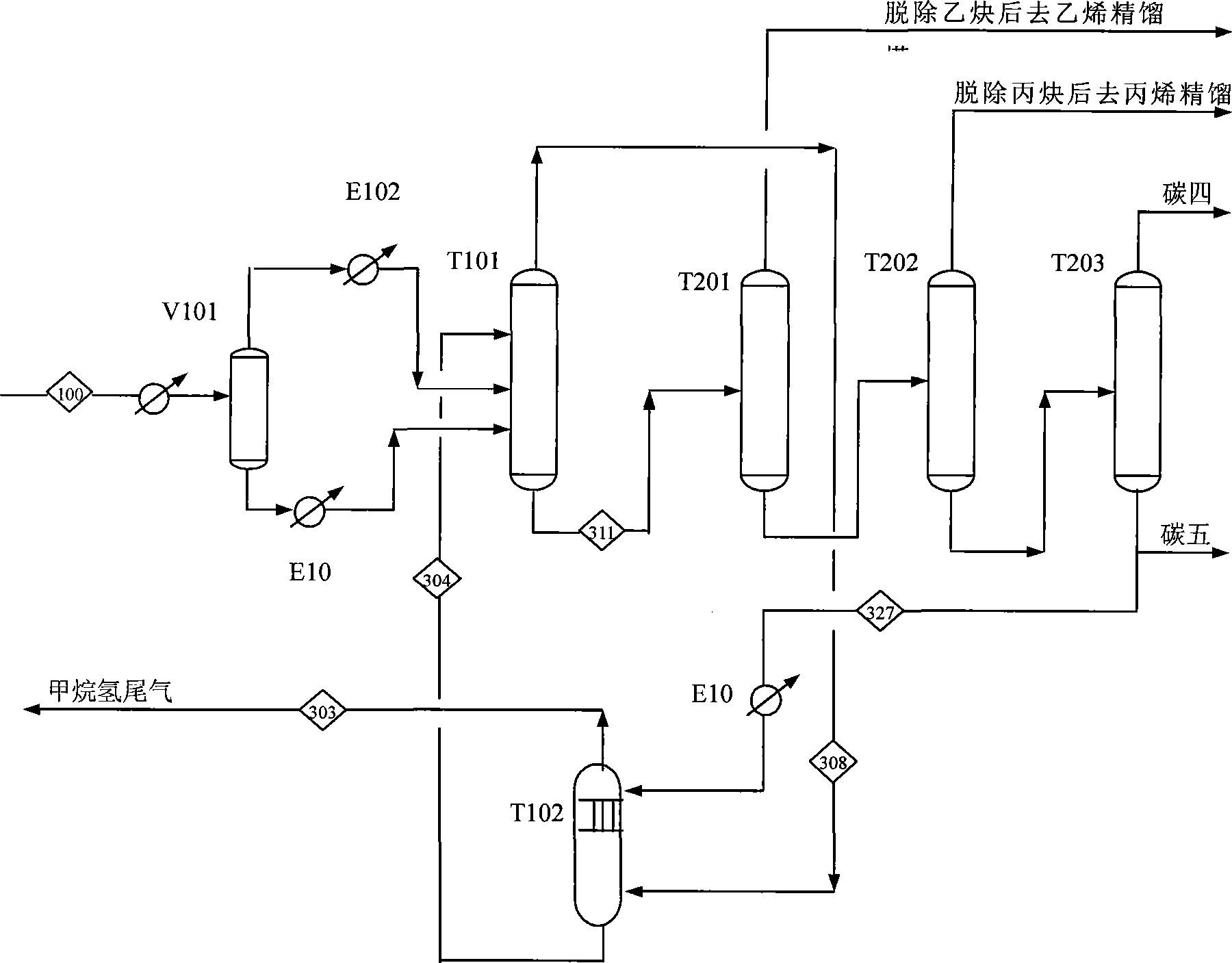

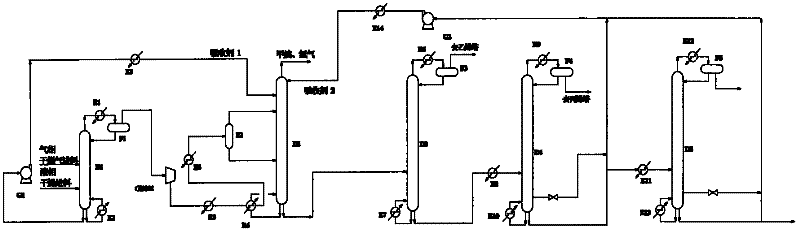

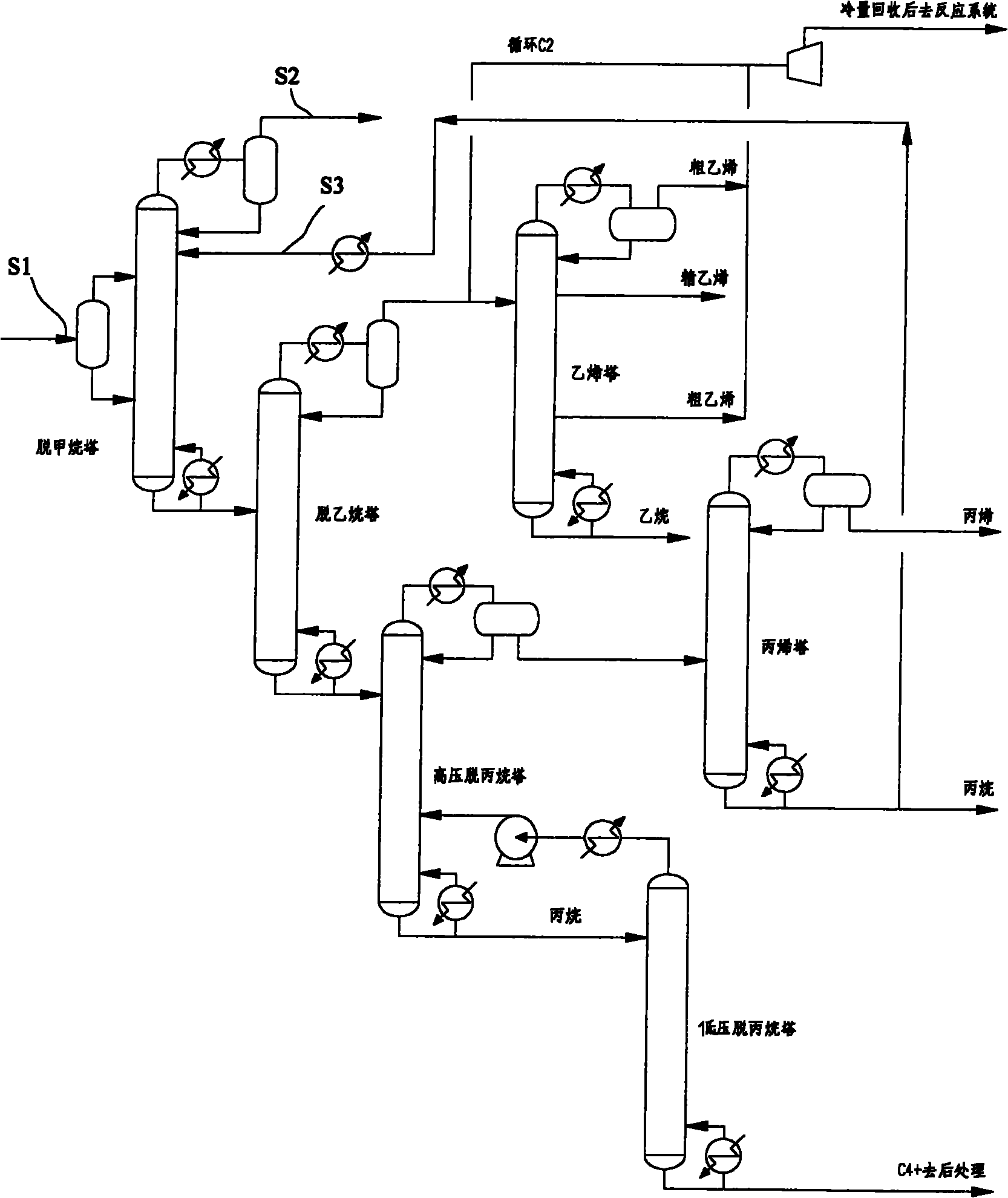

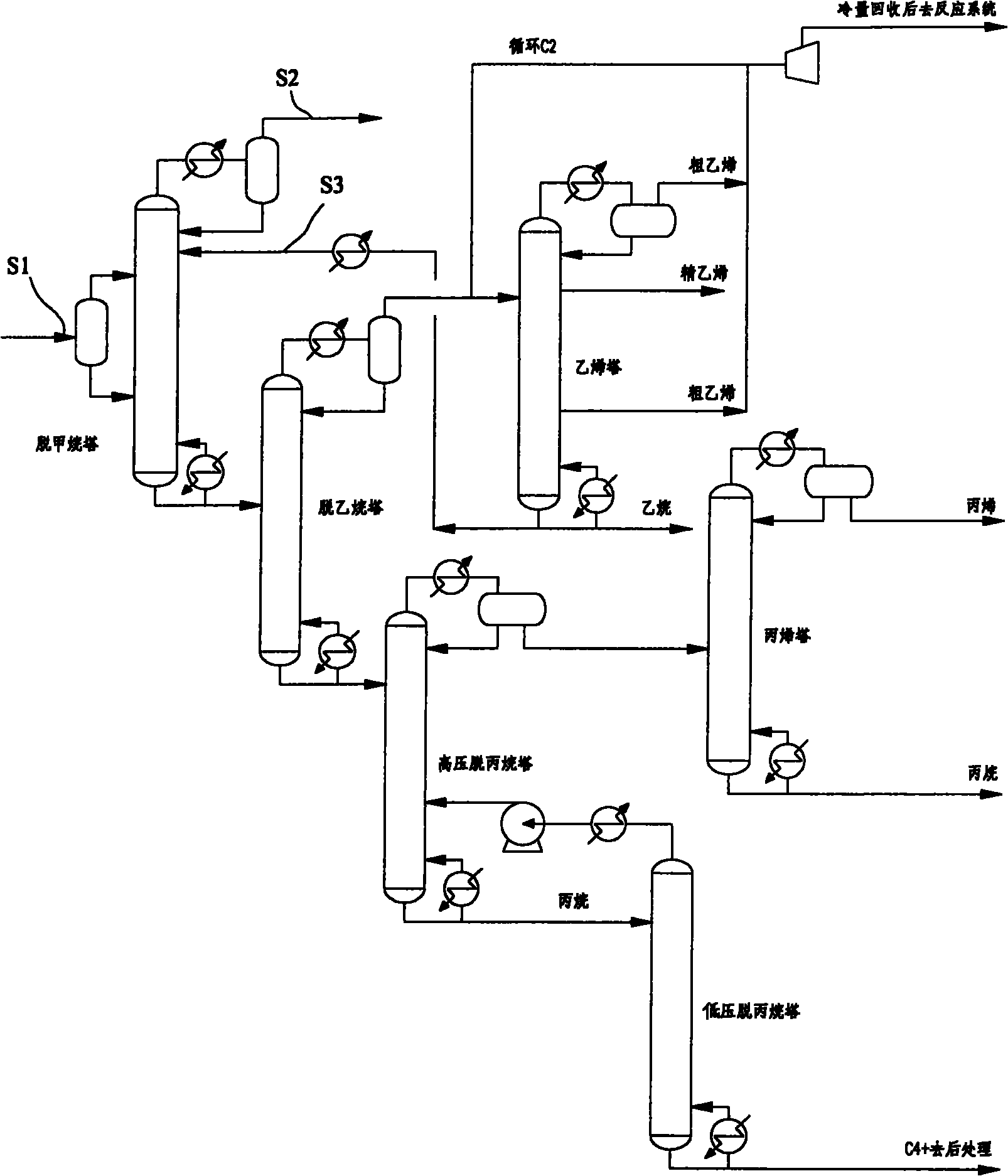

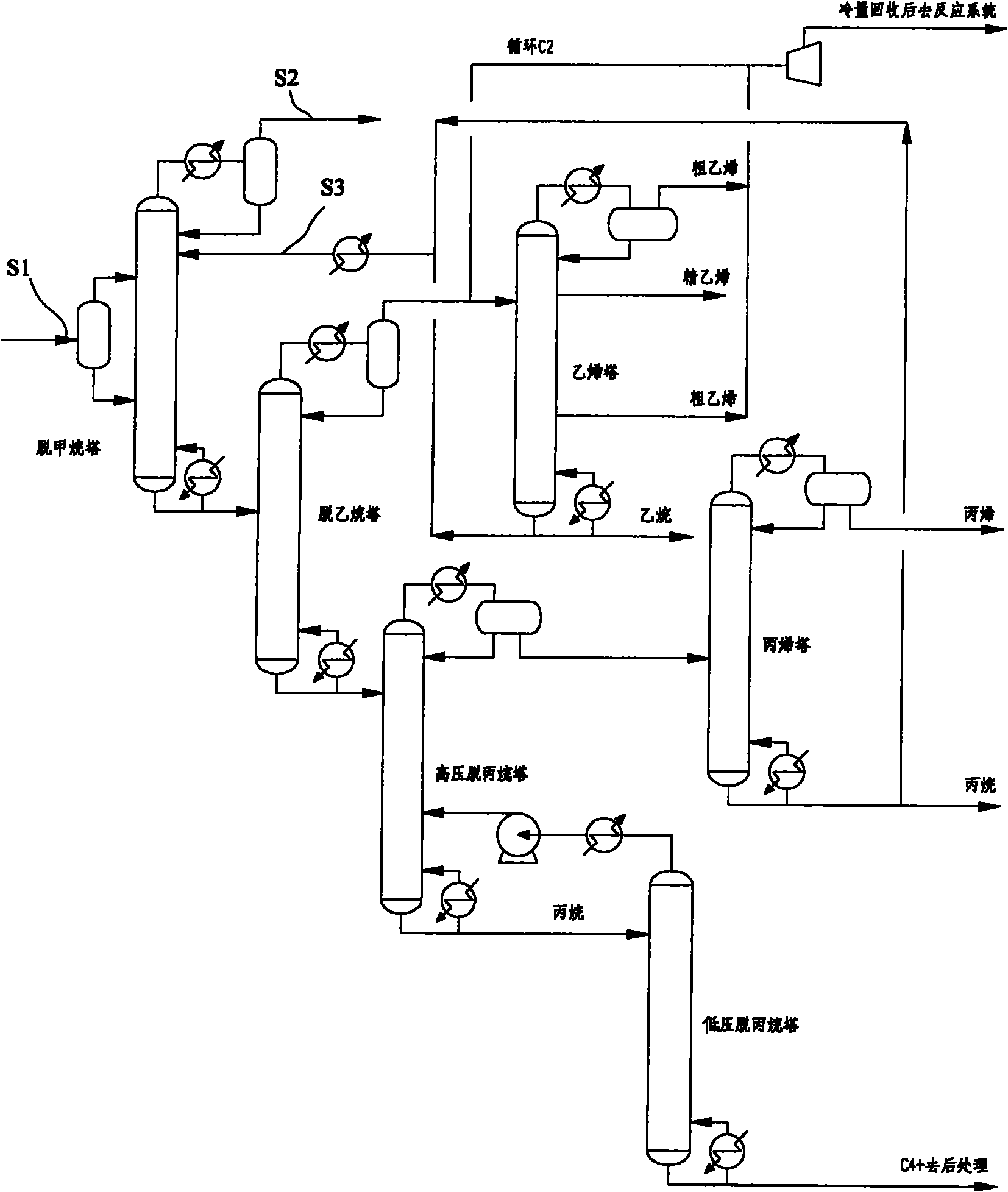

Process flow for separating low-carbon hydrocarbons and separating gas during production of olefins (M-OS/MTO) from methanol

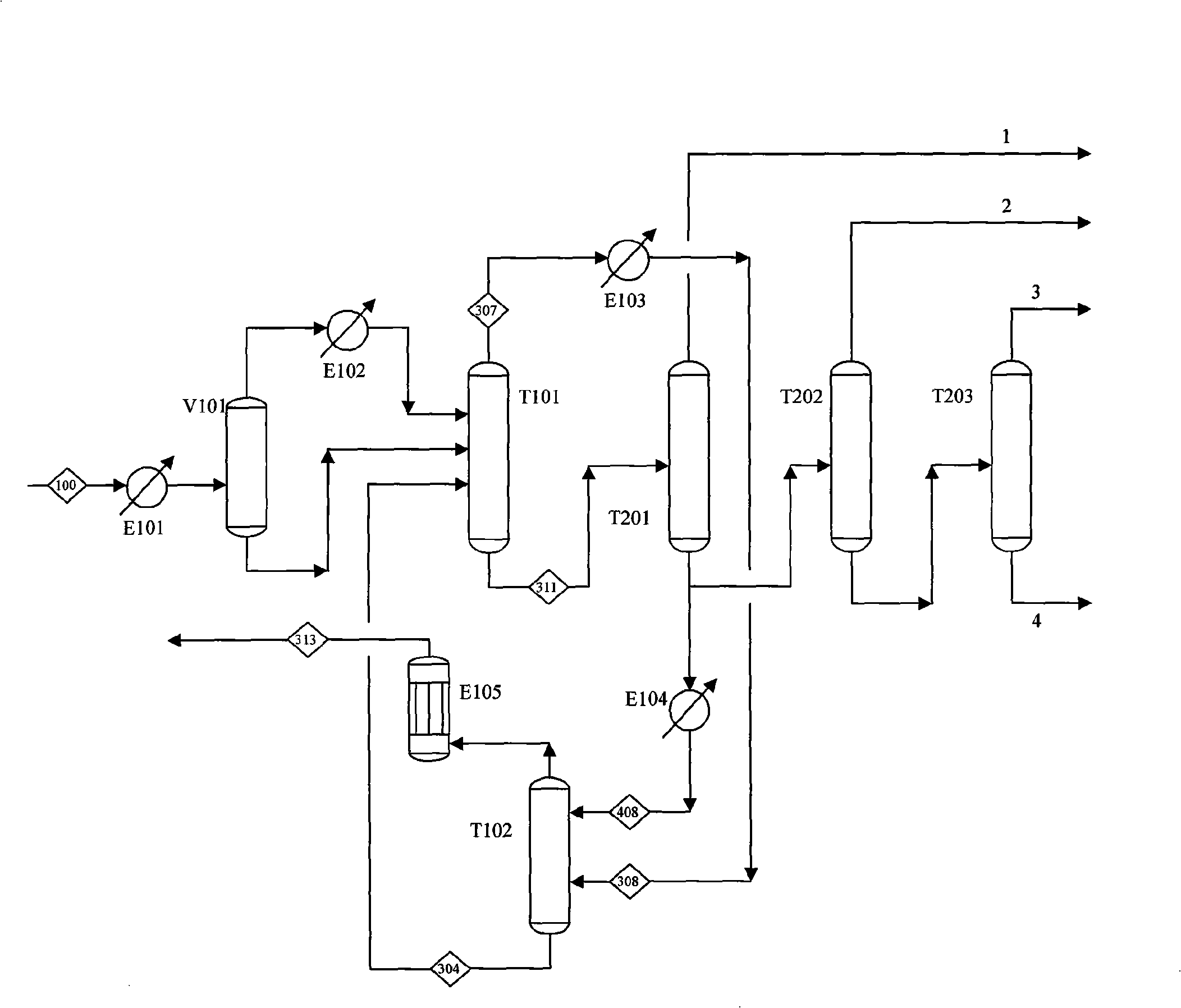

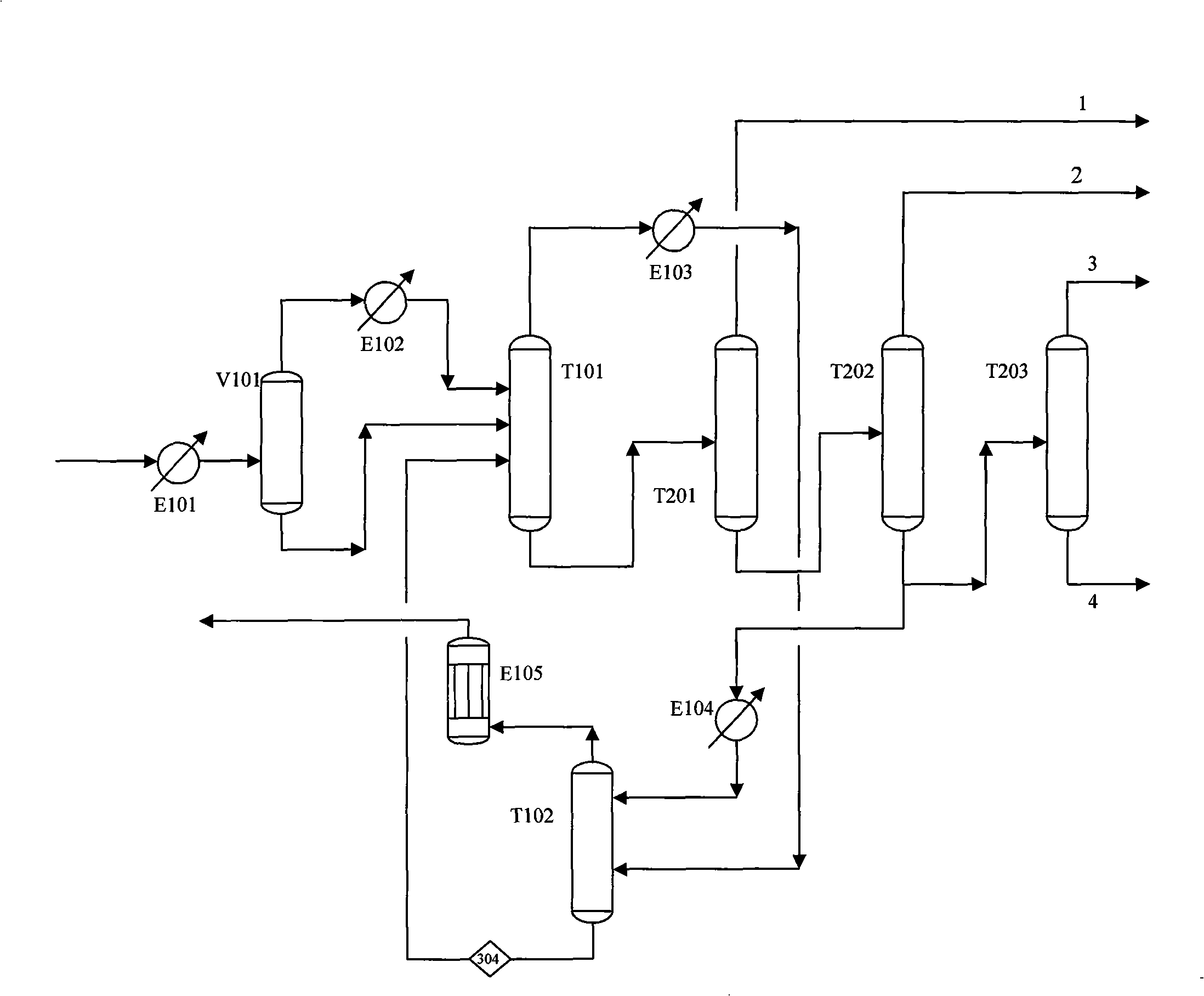

ActiveCN102503757ALess investmentReduce energy consumptionDistillation purification/separationEthylene productionOlefiant gasAbsorption effect

The invention provides a non-cryogenic oil absorption separation method for a mixture of low-carbon hydrocarbons, which is used for separating the mixture of the hydrocarbons from gas during production of olefins from methanol. Methane / hydrogen can be separated from heavy components, namely C2 and above by absorbing fractions of the C2 and above by adopting two or more strands of absorbing agents. According to the method disclosed by the invention, an absorbing agent separating tower is increased before a demethanization tower, one strand of material flow, which is separated from the tower is taken as a main absorbing agent of the demethanization tower for absorbing the C2 and C3, the strand of the absorbing agent is the mixture of the fractions, which is from the former system and needs to be separated, and circulation is not required. The second strand of the absorbing agent of the demethanization tower is from a system including a depropanization tower and a debutanization tower, and the absorption effect is further enhanced. Compared with the prior art, the method can greatly reduce the using quantity of the circulating absorbing agents; moreover, the multiple strands of the absorbing agents are adopted, equipment investment and energy consumption are significantly reduced, the recovery rate of ethylene and propylene is further improved; and furthermore, the flow is simple, the operation cost is low, and the operation is safe and reliable.

Owner:SINOPEC SHANGHAI ENG +1

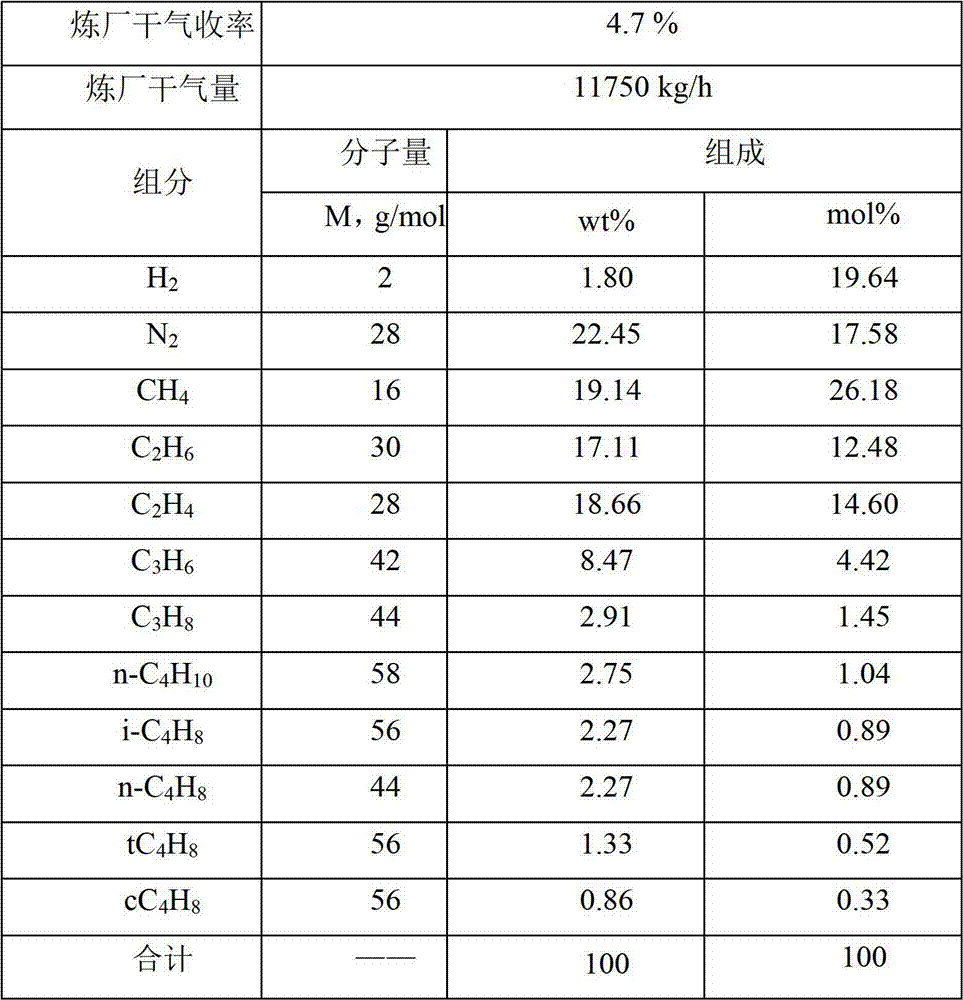

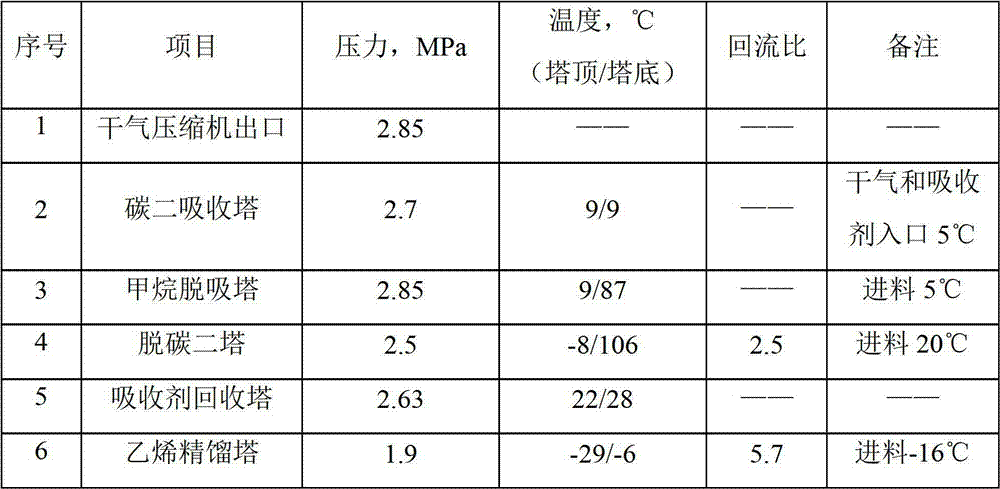

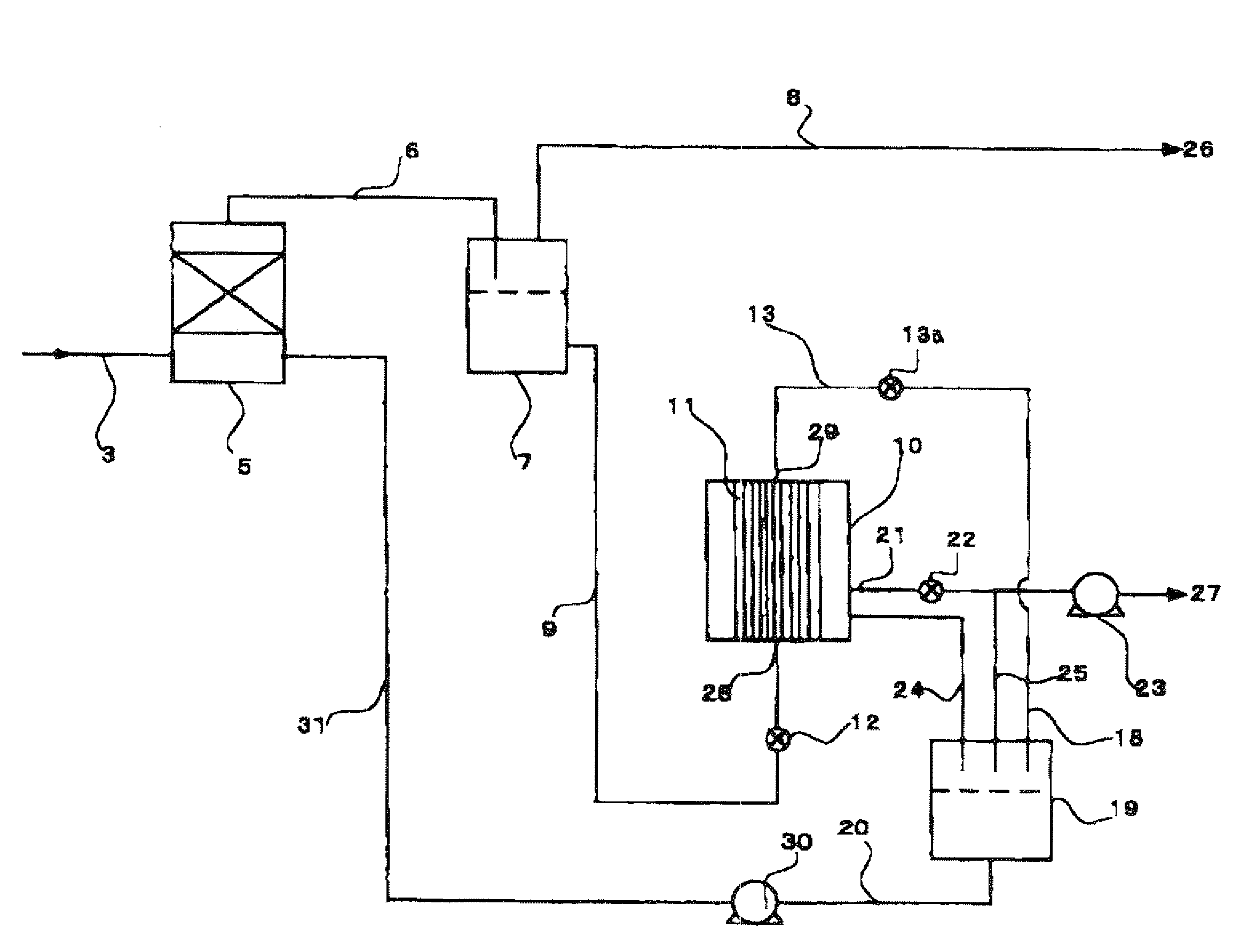

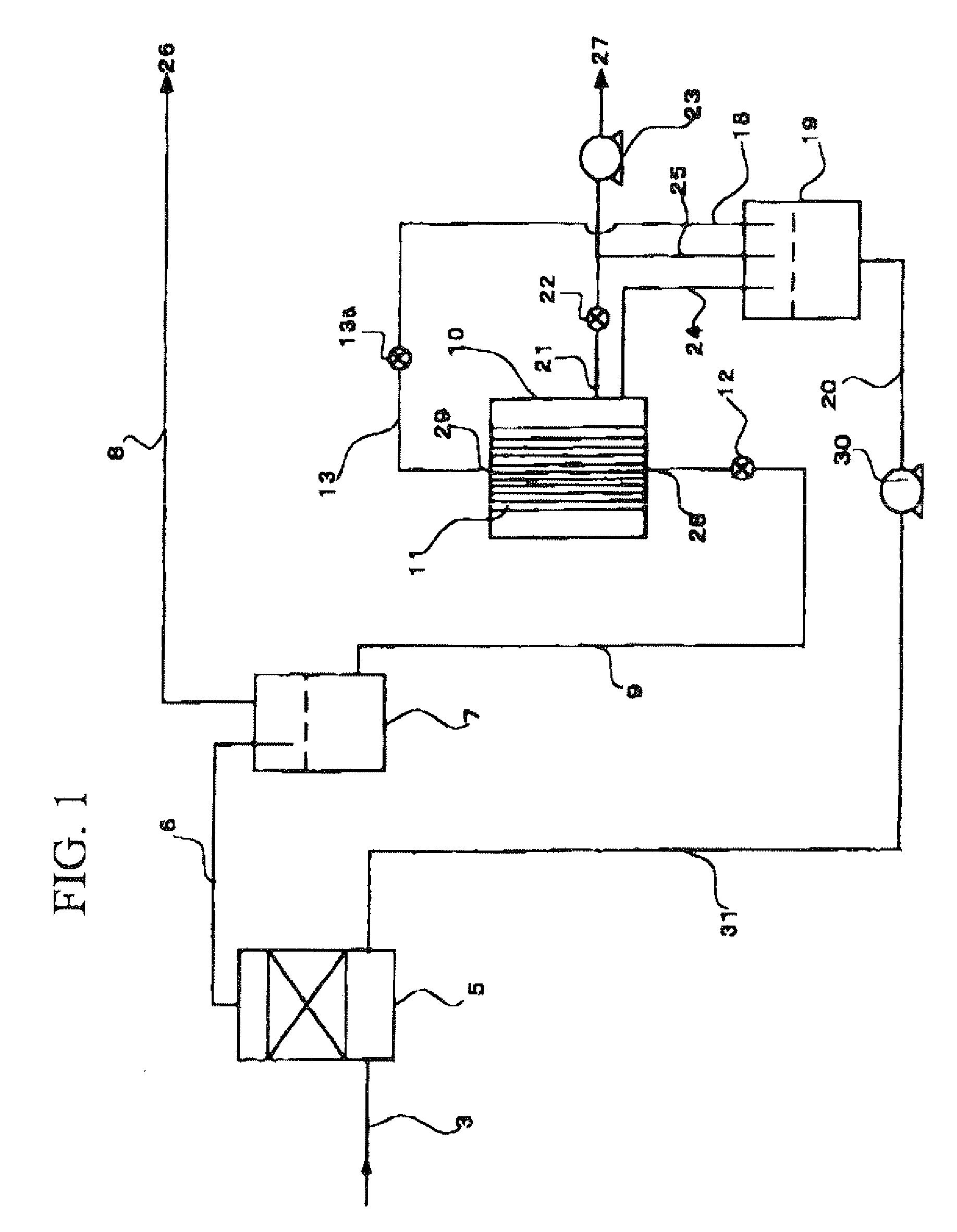

Recovering system and method of C2 in refinery dry gas by compound adsorption method

ActiveCN103588604AModerate operating conditionsGuaranteed RecoveryEthylene productionAbsorption purification/separationFluid phaseProcess engineering

The invention provides a recovering system and a method of C2 in refinery dry gas by a compound adsorption method. The recovering system comprises a compressor, a pretreatment unit, a refinery dry gas cooling unit, a compound adsorption unit and a rectification unit. The adsorption unit comprises a gas-liquid separating tank, a C2 adsorption tower, and a methane desorption tower. The rectification unit comprises a C2 removing tower and an ethylene rectification tower. The refinery dry gas, after being compressed, pretreated and cooled, is subjected to gas-liquid separation to obtain a gas phase and a liquid phase. The gas phase is fed into the C2 adsorption tower and subjected to C2 adsorption by using a C4 mixture or a C5 mixture as an absorbent. The liquid phase is fed into the methane desorption tower, and subjected to methane desorption through stripping. The mixed adsorption oil at the bottom of the C2 adsorption tower and desorption gas at the top of the methane desorption tower are returned to the gas-liquid separation tank after being mixed and cold with the refinery dry gas. Tower bottom of the methane desorption tower is cooled and fed into the C2 removing tower and the ethane rectification tower to be rectified to obtain an ethylene product and an ethane product. The method provided by the invention adopts moderate operating conditions. The ethylene and the ethane both have the high recovering rate and the high purity.

Owner:CHINA PETROCHEMICAL CORP +1

Methane separation method, methane separation apparatus, and methane utilization system

InactiveUS20090156875A1Improve efficiencyReduce module costSemi-permeable membranesGas treatmentFiberLiquid phase

A methane separation method of the present invention at least includes: mixing the biogas and an absorbing liquid that absorbs carbon dioxide in a mixer so as to form a mixed fluid of a gas-liquid mixed phase; introducing the mixed fluid into a first gas / liquid separator so as to separate the mixed fluid through gas / liquid separation into methane and a CO2-absorbed liquid formed due to an absorption of the carbon dioxide by the absorbing liquid; recovering methane separated in the first gas / liquid separator; and supplying the CO2-absorbed liquid through a supply port of a membrane module comprised of a container and a plurality of hollow fiber permeable membranes built therein to inside of the membranes so as to make the CO2-absorbed liquid permeate the permeable membranes, and lowering a pressure outside the permeable membranes to a level lower than that inside the permeable membranes.

Owner:TAIYO NIPPON SANSO CORP +1

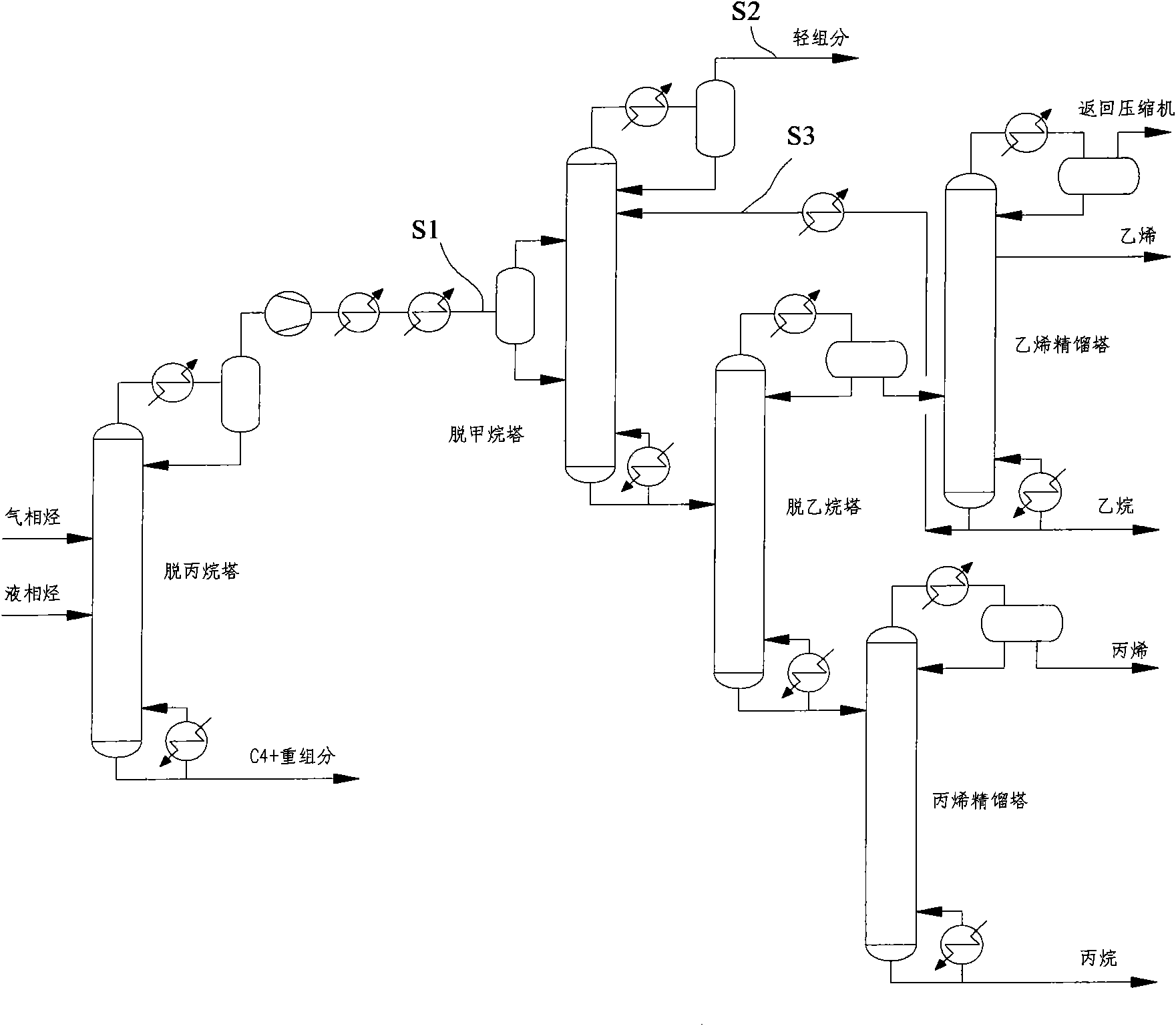

Separation method for producing light olefins from oxygenated chemicals

InactiveCN101973831AReduce investmentReduce the difficulty of operationGaseous fuelsEthylene productionGas phaseMethane

The invention discloses a separation method for producing light olefins from oxygenated chemicals. In the method, a product from a reactor for producing the light olefins from the oxygenated chemicals and / or a product generated from olefins catalytic cracking are mixed, and the mixture is treated by a series of pretreatment steps of heat recovery, compression, purification, cooling and the like and is separated into gas-phase hydrocarbon and liquid-phase hydrocarbon; the gas-phase hydrocarbon and the liquid-phase hydrocarbon respectively enter different column plates of a depropanizing column to be in (C3-)-(C4+) separation; after being subjected to further compressing and cooling, light components of C3 and below on the top of the depropanizing column enter the depropanizing column, and ethane is used as an absorbent on the top of the depropanizing column to enhance the recovery rate of the ethane; C2-C3 at the bottom of the depropanizing column enter a deethanizing column to separate C2 and C3; the C2 enters an ethylene rectifying column, ethylene is produced through side drawing, noncondensable gas on the top of the ethylene rectifying column returns to a compressor, after totally cooling, the ethane at the bottom of the column is recovered as an absorbent of a demethanizing column or partly as fuel gas; and C3 enters a propylene rectification tower, propylene is recovered on the tower top, and propane is recovered at the tower bottom, as an LPG (Liquid Petroleum Gas) byproduct. The invention has the advantages of high ethylene yield, low energy consumption, little investment and the like, and the byproduct can be effectively utilized.

Owner:EAST CHINA ENG SCI & TECH

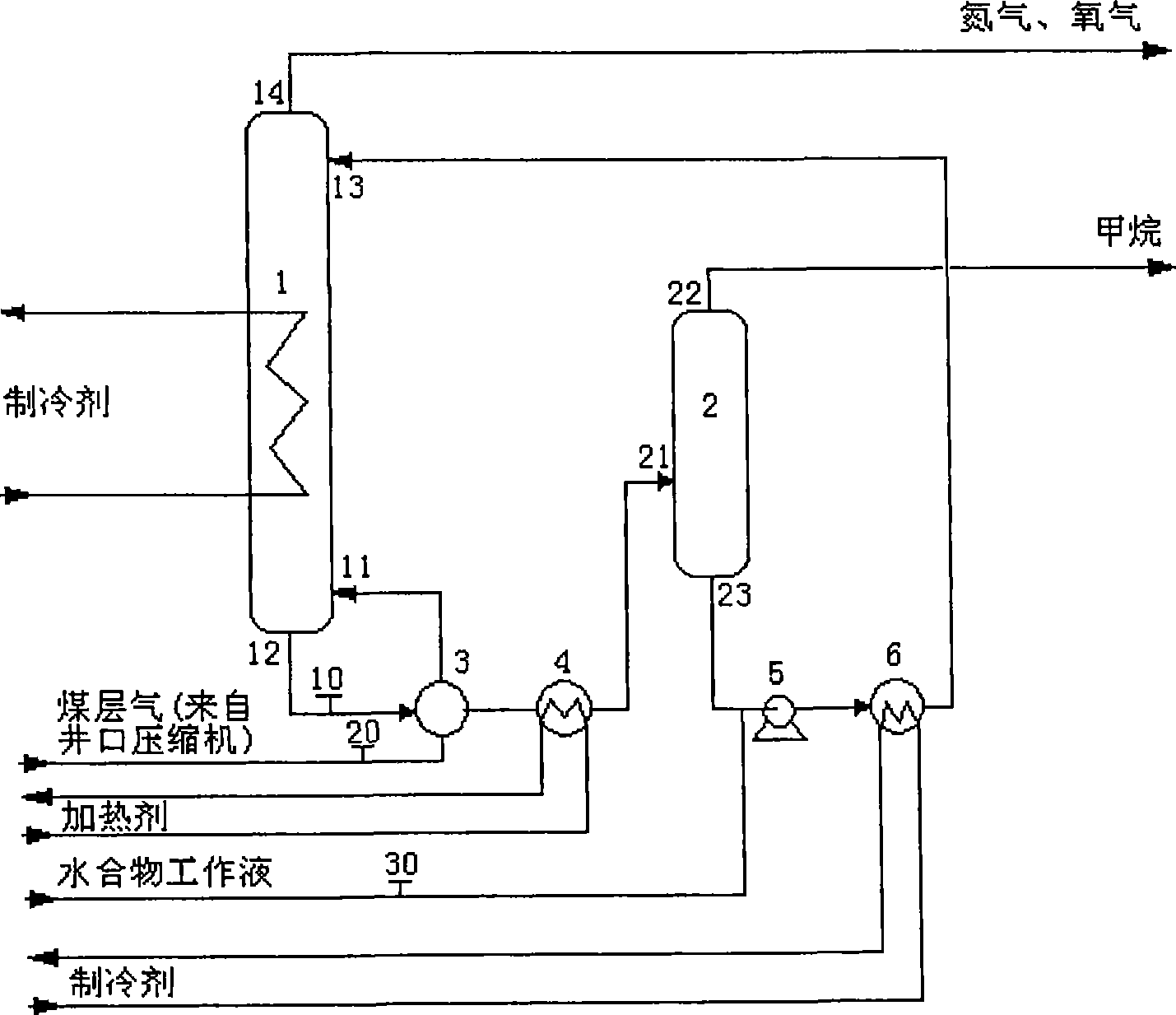

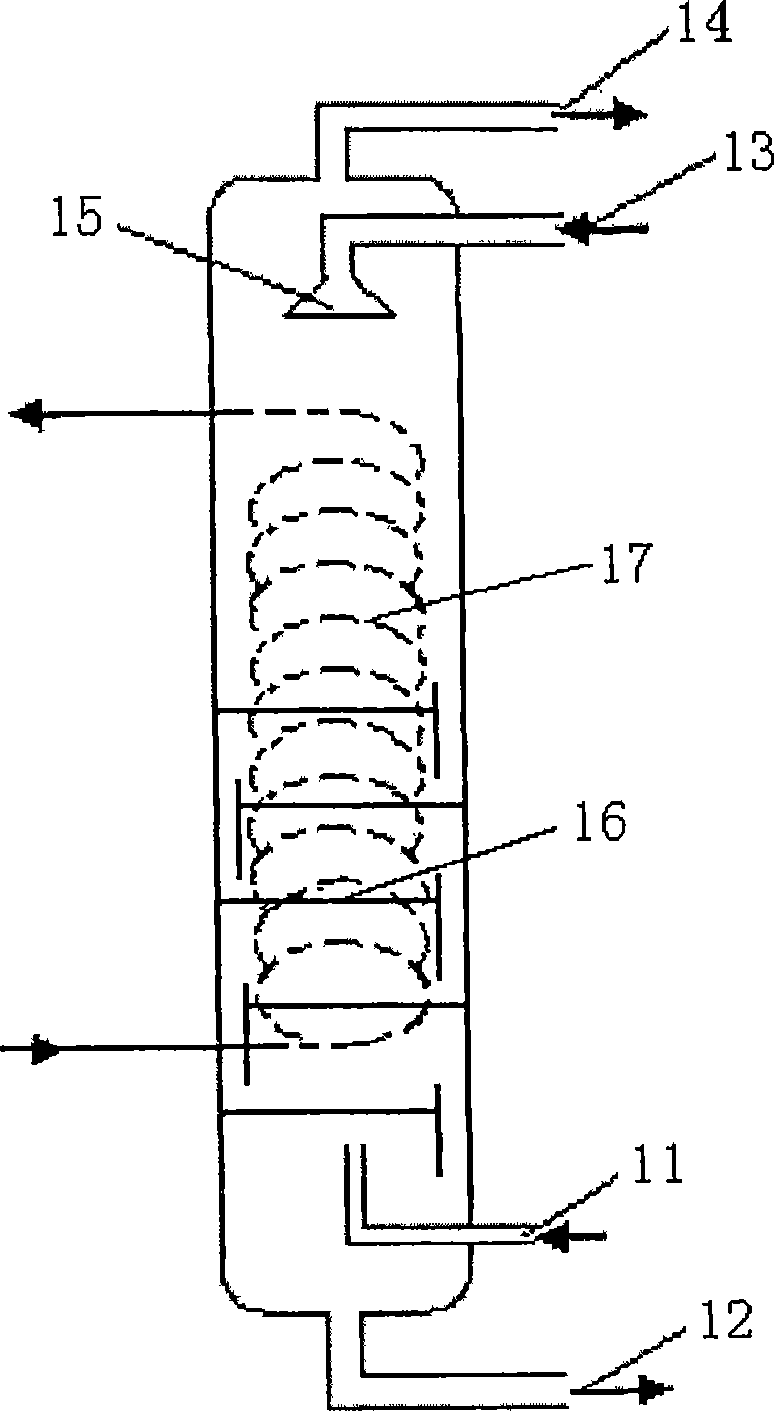

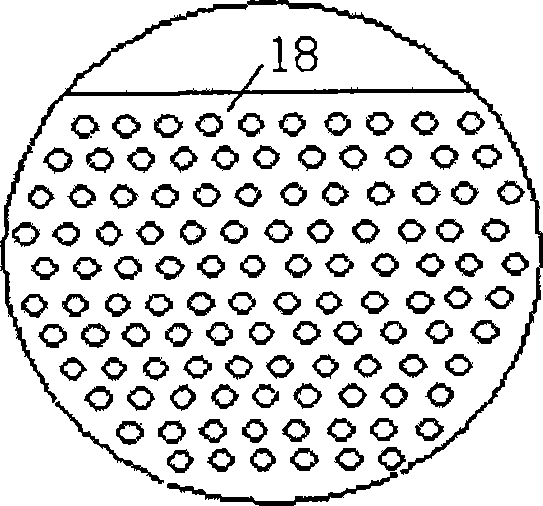

Method and device for low-pressure processing of coal bed gas

InactiveCN101530719AReduce concentrationEmission reductionDispersed particle separationAbsorption purification/separationHydration reactionHigh concentration

The invention relates to a method for low-pressure processing of coal bed gas, comprising the steps of: introducing the coal bed gas into a hydration reactor from the bottom part of a hydration reactor so as to be contacted with hydrate working liquid in the hydration reactor, leading methane contained in the coal bed gas and water in the hydrate working liquid to generate hydration reaction to form a hydrate which is removed from the coal bed gas; meanwhile, the purified gas is obtained after the methane in the coal bed gas is removed; wherein the operation pressure of the hydration reactor is 0.11-0.85MPa, and the temperature is 3-18 DEG C. The formed hydrate can be further introduced into a hydrate decomposition device for decomposition, thereby obtaining the methane with high concentration. The invention simultaneously relates to a device for realizing the method for low-pressure processing of the coal bed gas. The invention can safely purify the oxygen-containing coal bed gas under lower pressure and remove the contained methane to be lower than 0.05 molar fraction, thereby reducing the emission of the methane, reducing the greenhouse effect and simultaneously avoiding the risk of explosion.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

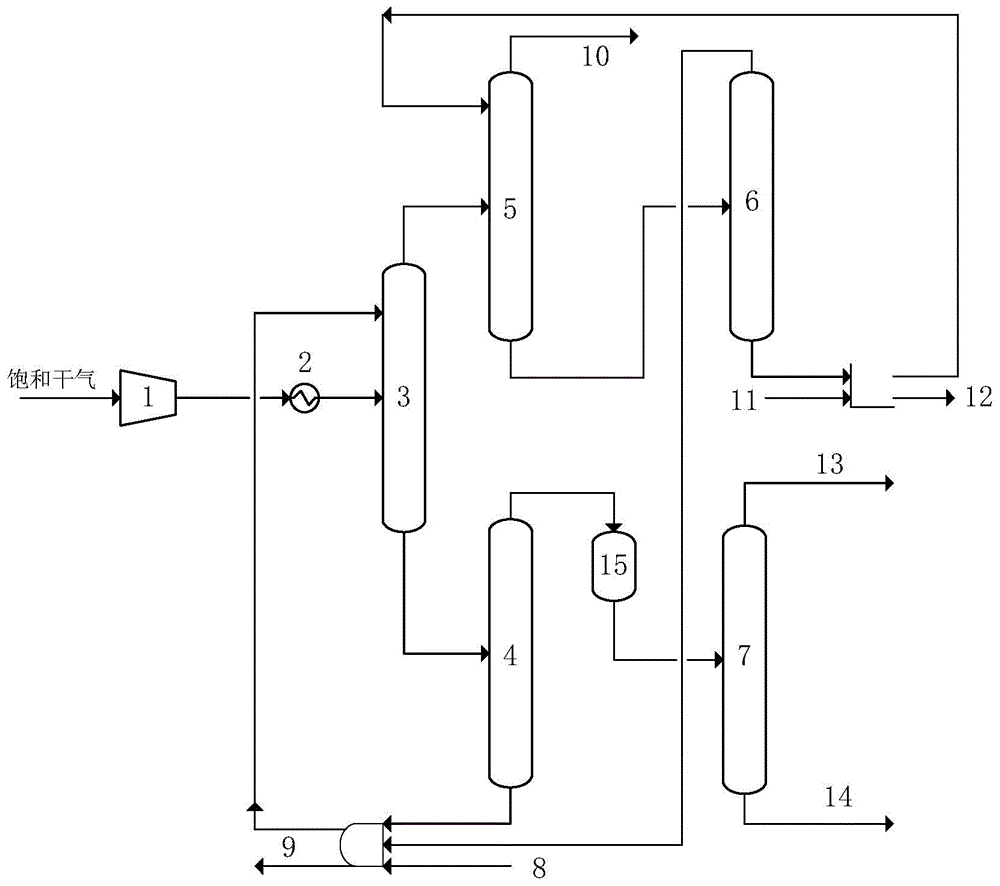

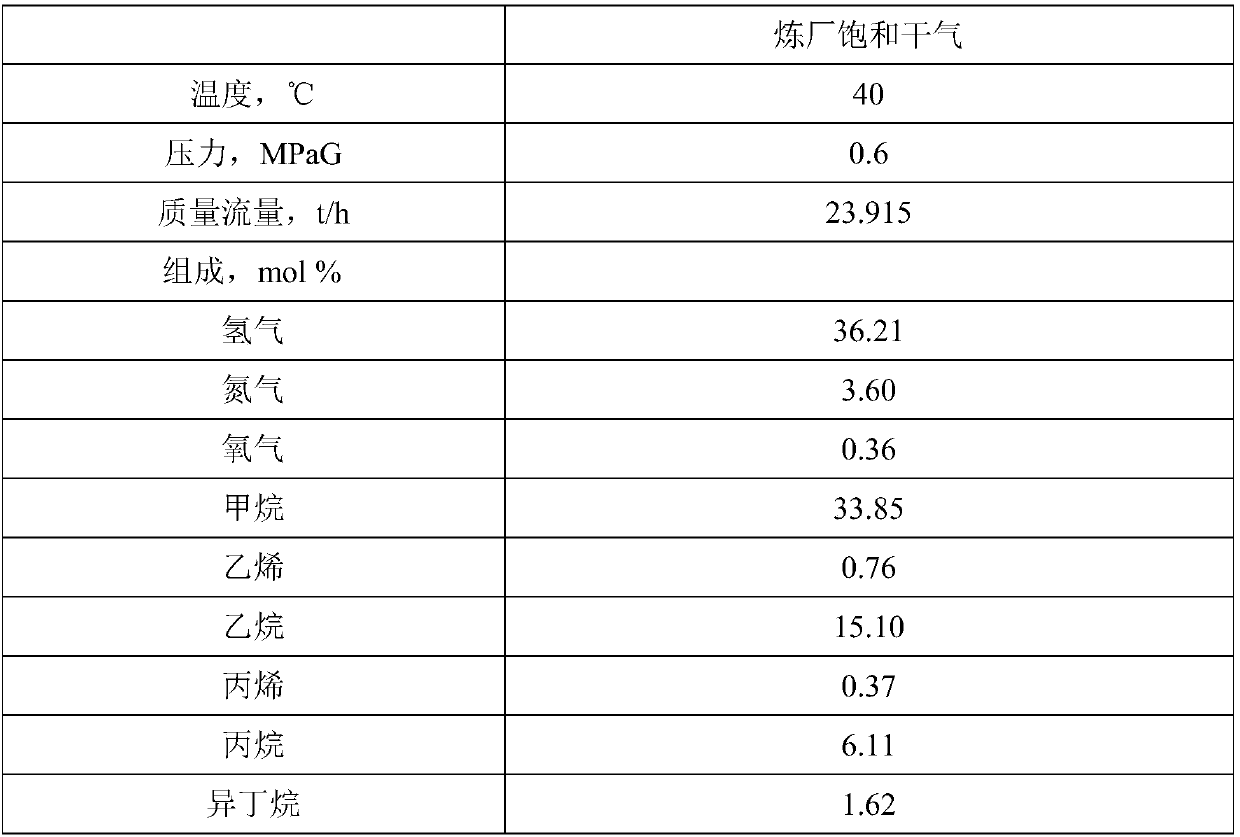

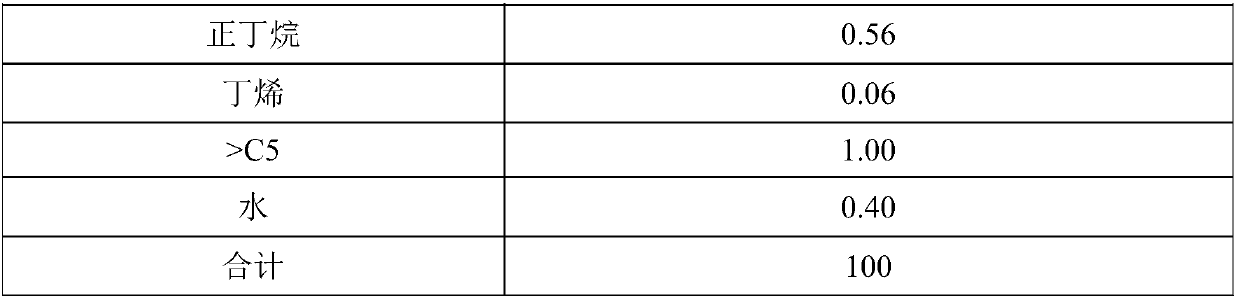

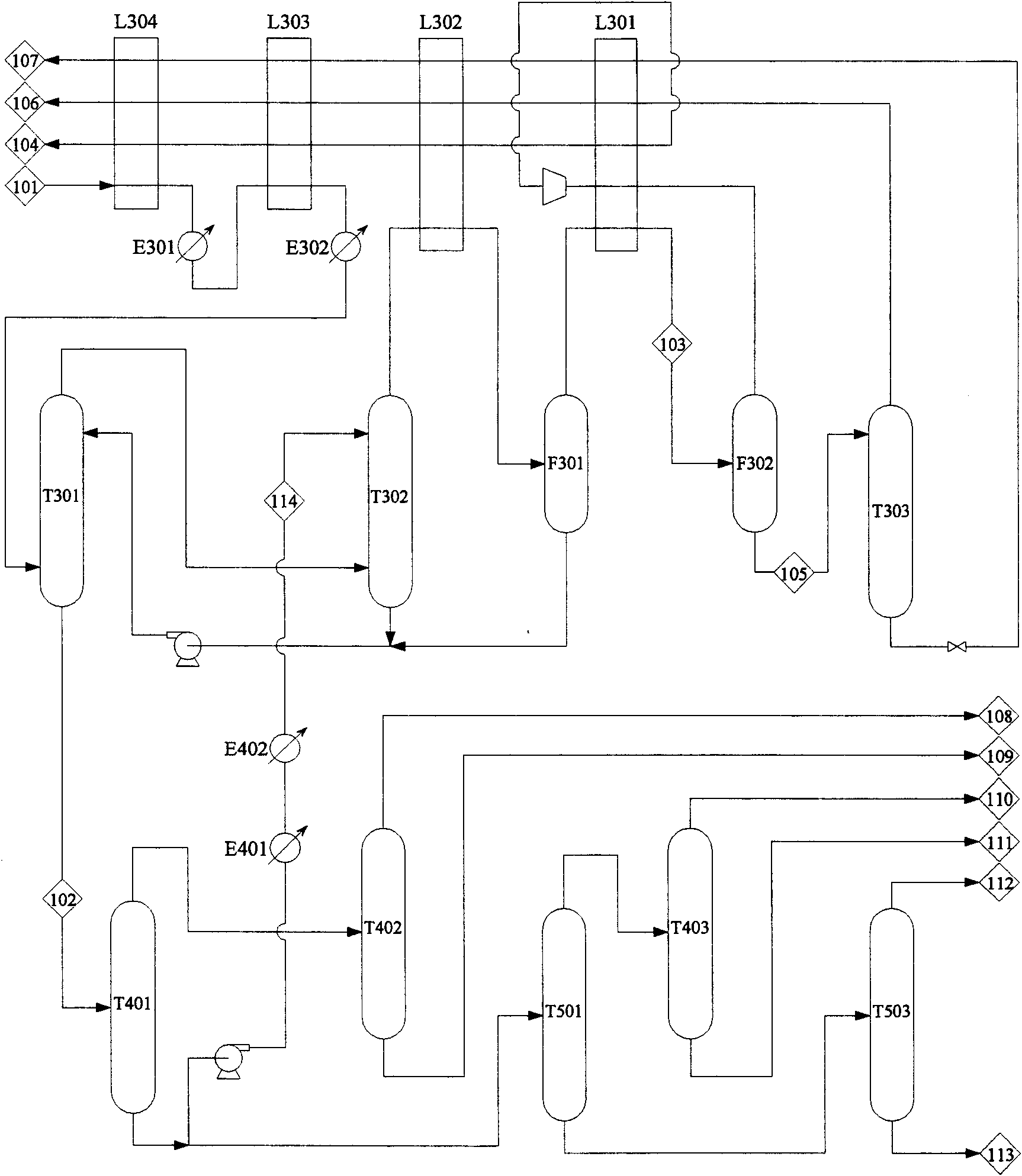

Method and device for recycling saturated dry gas of refinery plant by adopting shallow cold oil absorption technology

InactiveCN109553504AHigh recovery rateReduce energy consumptionHydrocarbonsAbsorption purification/separationDesorptionGas phase

The invention relates to the field of dry gas treatment, the invention discloses a method and a device for recycling a saturated dry gas of a refinery plant by adopting a shallow cold oil absorption technology, the method comprises the following steps: sequentially compressing the saturated dry gas, cooling the saturated dry gas, and feeding the saturated dry gas into a C4 absorption tower for treatment, and respectively sending an obtained gas phase and an obtained liquid phase into a gasoline absorption tower and a C4 desorption tower; recovering a gas phase obtained by treating in the C4 desorption tower to serve as a C2 concentrated gas product, allowing most of an obtained liquid phase to be returned to the C4 absorption tower for recycling, and sending a small part of the obtained liquid phase to a gasoline stabilization tower; and sending the liquid phase treated by the gasoline absorption tower to the gasoline stabilization tower for treatment, allowing most of the obtained liquid phase to be returned to the gasoline absorption tower for recycling and the small part of the obtained liquid phase to serve as an extraction gasoline product, performing condensation and gas-liquid separation treatment in turn on the gas phase obtained by processing in the gasoline stabilization tower, respectively returning the obtained gas phase and the obtained liquid phase to the inlet ofa compressor, and respectively sending the obtained gas phase and the obtained liquid phase to the gasoline stabilization tower and the C4 absorption tower for treatment. The method disclosed by theinvention has the advantages that the material consumption is low, the process is simple, the investment is small, and the recovery rate of the C2 and C3 is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Separation method of Fischer-Tropsch synthesis gas by combining rectification and solvent absorption

ActiveCN101559320AIncrease concentrationEasy to separateSolidificationLiquefactionHydrogenHydrocarbon mixtures

The invention relates to a separation method of Fischer-Tropsch synthesis gas by combining rectification and solvent absorption. The separation method comprises the following steps: Fischer-Tropsch synthesis gas pretreated is conveyed to a demethanizer after being cooled; the top of the demethanizer separates hydrogen and other light gas, methane, part of C2 fraction and little amount of C3; the mixed gas enters an absorption tower and uses C3, C4 or C5 or hydrocarbon mixture as an absorbing agent to absorb C2 and heavier components; the products of the top of the absorption tower comprise hydrogen and other light gas, methane, the little balanced amount of C2 and the absorbing agent; the products of the bottom of the tower are components above C2 and little amount of hydrogen and methane; the materials are conveyed to the demethanizer for further absorbing C2 and heavier fraction and removing the methane and lighter components therein. The light hydrocarbon mixture of the bottom of the demethanizer can adopt conventional light hydrocarbon separation method to separate out various light hydrocarbon products with needed purity and recycling rate. Compared with the prior art, the invention has the advantages of simple process, low energy consumption and high recycling rate of various components and the like.

Owner:WISON ENG

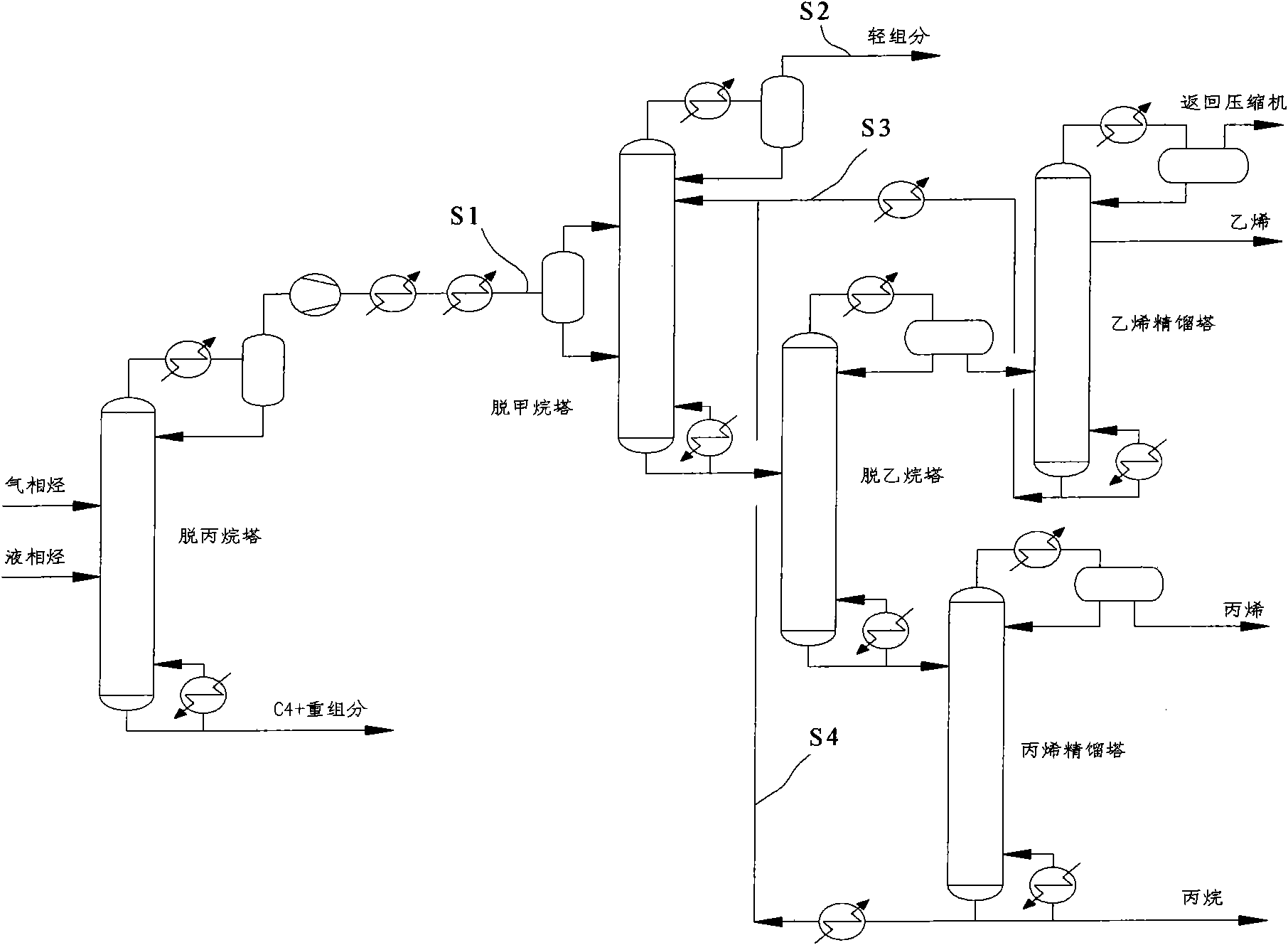

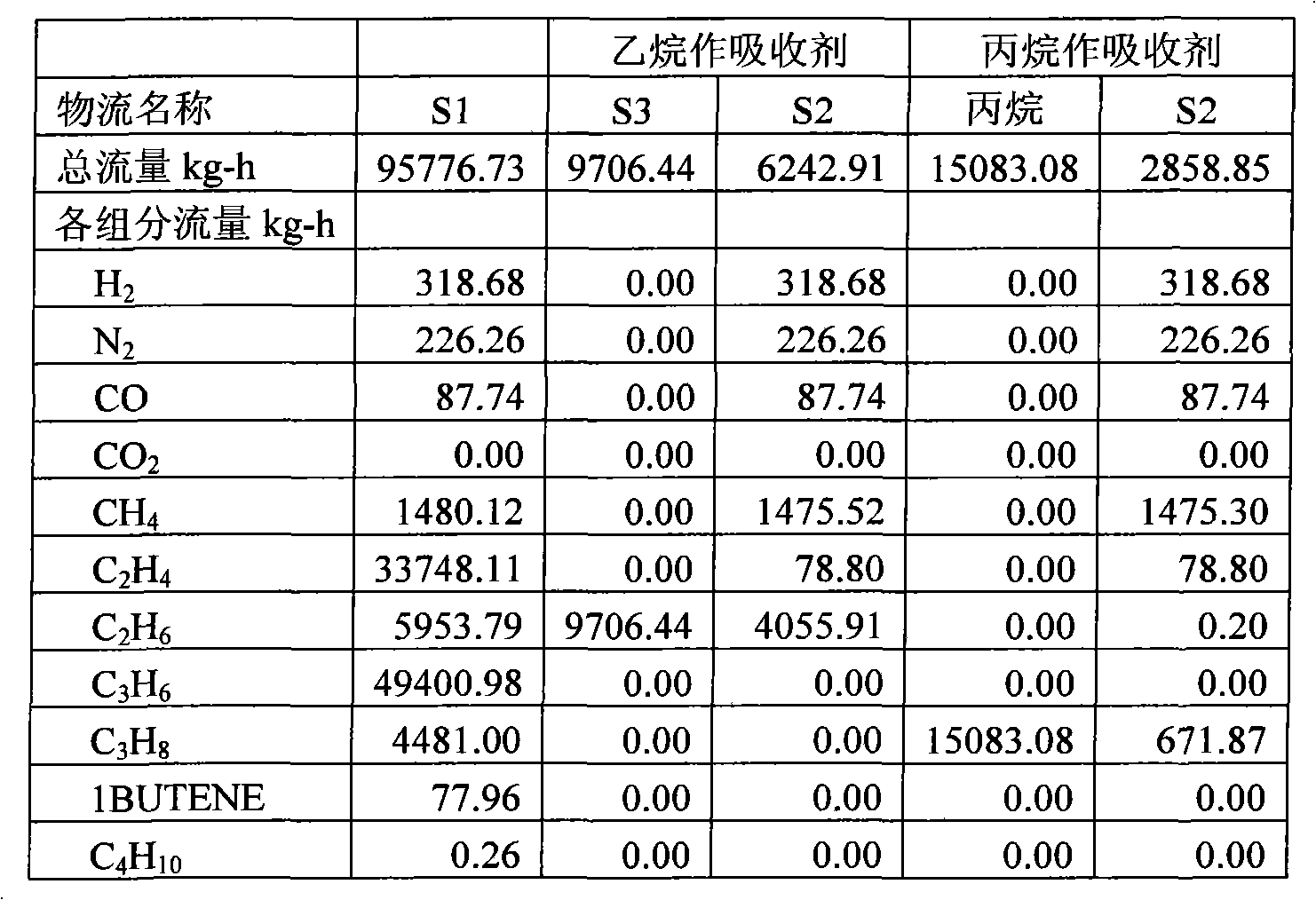

Method for separating low-carbon olefins

ActiveCN102115355AReduce investmentReduce energy consumptionHydrocarbon from carbon oxidesEthylene productionSolventEnergy consumption

The invention discloses a separation method of low-carbon olefins, which adopts the mature normal separation process flow of the traditional ethylene industry and improves ethylene yield by using a solvent absorption process in a demethanizer. In the invention, the normal separation process is adopted, ethane, propane or mixture of ethane and propane is used as an absorbent, a deep-cooling cold box and an ethylene compressor are not used, equipment investment and energy consumption are lowered, and the method is very applicable to a process for producing low-carbon olefins by using oxygenatedchemicals or catalytic reaction of olefins.

Owner:EAST CHINA ENG SCI & TECH

Refinery dry gas separation method and refinery dry gas separation apparatus

ActiveCN109912379AReduce the reflux ratioReduce loadDistillation purification/separationEnergy inputChemical industryDesorption

The invention belongs to the field of chemical industry gas separation, and particularly provides a refinery dry gas separation method and a refinery dry gas separation apparatus. The method comprises: (1) compression: pressurizing refinery dry gas; (2) cooling: cooling the compressed gas, and conveying to an absorption tower; (3) absorption: making the stream on the top of the absorption tower enter a re-absorption unit or be cooled, and conveying the stream on the tower kettle to a desorption tower; (4) desorption: obtaining C2 concentrated gas from the top of the desorption tower, obtaininga lean solvent from the tower kettle, cooling the lean solvent, and returning to the top portion of the absorption tower; (5) purification: purifying the C2 concentrated gas obtained from the top ofthe desorption tower; (6) methane removing: making the purified C2 concentrated gas enter a methane removing tower, wherein the material from the top of the methane removing tower returns to a compressor or is conveyed outside the boundary area, and the material from the tower kettle is conveyed to an ethylene rectification tower; and (7) ethylene rectification: extracting a polymerization-grade ethylene product from the top of the ethylene rectification tower, wherein the material from the tower kettle is an ethane-rich product. According to the present invention, the method and the apparatushave advantages of simple process, high recovery rate, low energy consumption and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Selective absorption method for reducing propylene in catalytic cracking dry gas

InactiveCN1689688ANo decontamination requiredNo refinementChemical industryDispersed particle separationDesorptionDiethyl benzene

The propylene absorbing process is to eliminate propylene from catalytically cracked dry gas from oil refinery without any purifying and refining in a propylene selectively absorber. The dry gas and the absorbent are contacted through convection. The absorbent may be benzene, ethyl benzene, diethyl benzene, triethyl benzene, polyethyl benzene, diesel oil, gasoline, etc. or their mixture. The absorption conditions include operation temperature of -10 deg.c to +40 deg.c, pressure of 0.1-3.5 MPa, and the absorbent / dry gas volume ratio of 3-25 ml / L. The desorption conditions for the absorbed absorbent include temperature of 20-300 deg.c, pressure of 0.1-3.5 MPa, the sweeping gas / absorbent volume ratio of 1-15, and the sweeping time of 1-10 hr. The sweeping gas may be N2, H2, methane, ethane, etc. or their mixture. The desorbed absorbent may be reused.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Adsorbent beds for removal of hydrides from hydrocarbons

InactiveUS6960700B1Good removal effectImprove regenerative abilityHydrocarbonsAdsorption purification/separationSorbentSulfur

A process for removal of trace impurities of hydrides of arsenic, phosphorus, antimony, silicon, and boron and sulfur and oxygenates and compounds containing these impurities from a hydrocarbon stream comprising contacting the hydrocarbon stream with an adsorbent material selected from the group consisting of zeolites and promoted alumina to adsorb compounds containing sulfur and / or oxygenates, contacting the hydrocarbon stream with an adsorbent material comprising one or more active metal oxides to remove the hydrides and contacting the hydrocarbon stream with an adsorbent material that removes water.

Owner:UOP LLC

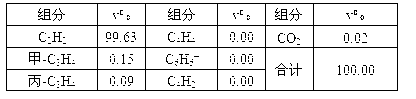

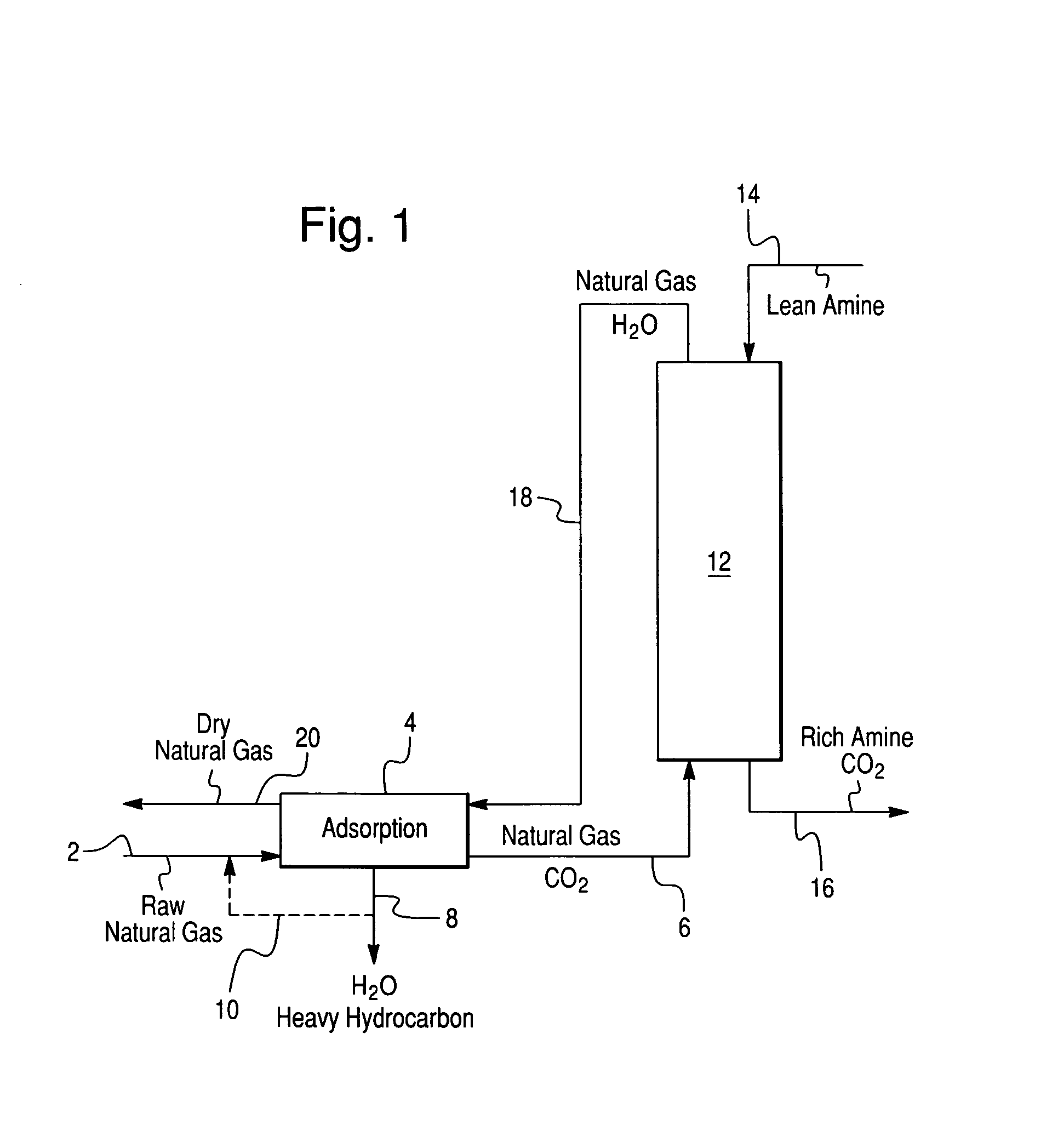

Composite solvent for purifying acetylene and purification method thereof

InactiveCN102701896AHigh selectivityImprove stabilityHydrocarbonsAbsorption purification/separationHigh concentrationAlkyne

The invention relates to a composite solvent used for purifying acetylene in acetylene mixed gas prepared from hydrocarbon and a purification method of the composite solvent. High-purity acetylene and higher alkyne, which are obtained from the acetylene feed gas, can be used as chemical materials. The invention adopts the technical scheme that the components of the composite solvent are as follows in mass percentage: 70-85 percent of physical solvent, 10-20 percent of CO2-removing chemical assistant, 1-5 percent of polymerization inhibitor in an addictive, and 0.5-5 percent of corrosion inhibitor. A device used in the purification method consists of an absorption tower, three desorbers and accessory equipment; the feed gas is firstly in countercurrent contact with the composite solvent in the absorption tower, wherein the acetylene, the higher alkyne and CO2 are absorbed by the composite solvent, then the high-concentration acetylene is absorbed out in the first desorber, the residual acetylene is absorbed out in the second desorber, and the higher alkyne and the CO2 are absorbed out in the third desorber. The composite solvent is high in selectivity, excellent in stability and easy to regenerate; and the purification method is simple in flow and mild in operation conditions, and the acetylene product whose purity is higher than 99.5 percent can be obtained.

Owner:SOUTHWEST PETROLEUM UNIV

Integrated heavy hydrocarbon removal, amine treating and dehydration

The present invention is directed to an improved integrated process for the removal of heavy hydrocarbons, carbon dioxide, hydrogen sulfide, and water from a raw natural gas feed stream. More specifically, the integrated process of the present invention comprises a three step process involving the adsorption of heavy hydrocarbons and water on an adsorbent bed selective for the same, a subsequent aqueous lean amine treatment for the absorptive removal of acid gases, such as carbon dioxide and hydrogen sulfide, and an adsorptive removal of water. The process of the present invention results in a highly purified natural gas product stream.

Owner:BASF CATALYSTS LLC

Method for Gas Separation, Purification and Clarification by FTrPSA

InactiveUS20180318750A1Scope of applicationReduced service lifeSolidificationLiquefactionDesorptionAdsorption separation

A method for gas separation, purification and clarification by FTrPSA uses the temperature and pressure of different raw gases as well as the differences in adsorption separation coefficients and physicochemical properties among all components in the raw gases at a temperature range of −80-200° C. and a pressure range of 0.03-4.0 Mpa, regulates the adsorption or desorption regeneration operation in the PSA cycle process by coupling various separation methods, and expands the adsorption theory that the PSA or TSA separation process is limited to the cyclic operation of adsorption and desorption regeneration through pressure or temperature changes, thus realizing the gradient utilization of energy in the process of gas separation, purification and clarification as well as the easy-to-match and easy-to-balance cyclic operation of adsorption and desorption regeneration in the process of intercooling & shallow-cooling and medium & high-temperature PSA separation to separate, purify and clarify various raw gases.

Owner:SICHUAN TECHAIRS

Combined technology of catalytic cracking absorbing stabilizing system and C3 intercooling oil absorption

ActiveCN102382680AReduce loadReduce energy consumptionCatalytic crackingHydrogen separationDesorptionAbsorption column

The invention discloses a combined technology of a catalytic cracking absorbing stabilizing system and C3 intercooling oil absorption, belonging to the technical field of integration of oil refining and ethylene, and providing a method for recovering dry gas by the combination of the absorbing stabilizing system and the C3 intercooling oil absorption. The method eliminates a desorption column of the absorbing stabilizing system, and avoids the constant circulation of a great amount of ethylene, ethane and liquefied gas in desorption gas between absorption and desorption, thus reducing the load of an absorption column and saving the energy consumption of the desorption column; as coarse C3 in a dethanizing column kettle of an ethylene unit is used as an absorbent, raw material is easy to obtain, and the cost is low; the desorption column of an original C3 oil absorption column for absorbing intercooling oil is eliminated, the constant circulation of a great amount of C2 and C3 in the desorption gas between absorption and desorption is avoided, and an expansion engine and an ice chest are adopted for recovering refrigeration capacity, thus saving consumption of the refrigeration capacity and heat capacity; and the regeneration of a C3 absorbing agent, the demethanation and the separation of the ethylene are all conducted in the ethylene unit, thus fully showing the reciprocity of the oil refining and ethylene, and being reasonable in flow.

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Bulk chemical production Hydrogen/synthetic gas production Gas purification with selectively adsorptive solids Gas purification by non-gaseous materials condensation Gas purification by liquid washing Gas contaminants removal Gas dust removal Specific gas purification/separation Oxygen/ozone/oxide/hydroxide Petrochemical industry

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com