Patents

Literature

33 results about "Amine gas treating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Amine gas treating, also known as amine scrubbing, gas sweetening and acid gas removal, refers to a group of processes that use aqueous solutions of various alkylamines (commonly referred to simply as amines) to remove hydrogen sulfide (H₂S) and carbon dioxide (CO₂) from gases. It is a common unit process used in refineries, and is also used in petrochemical plants, natural gas processing plants and other industries.

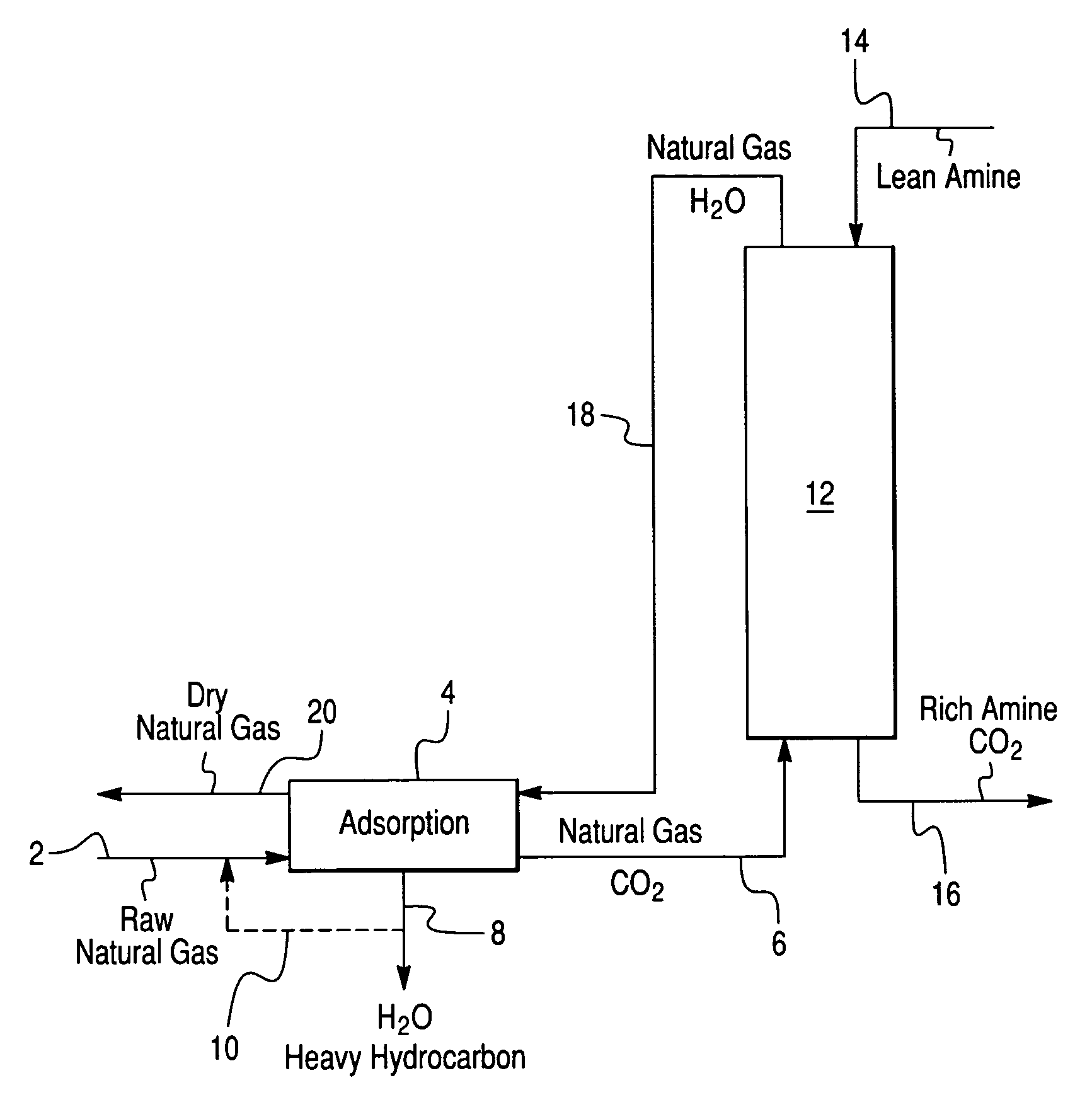

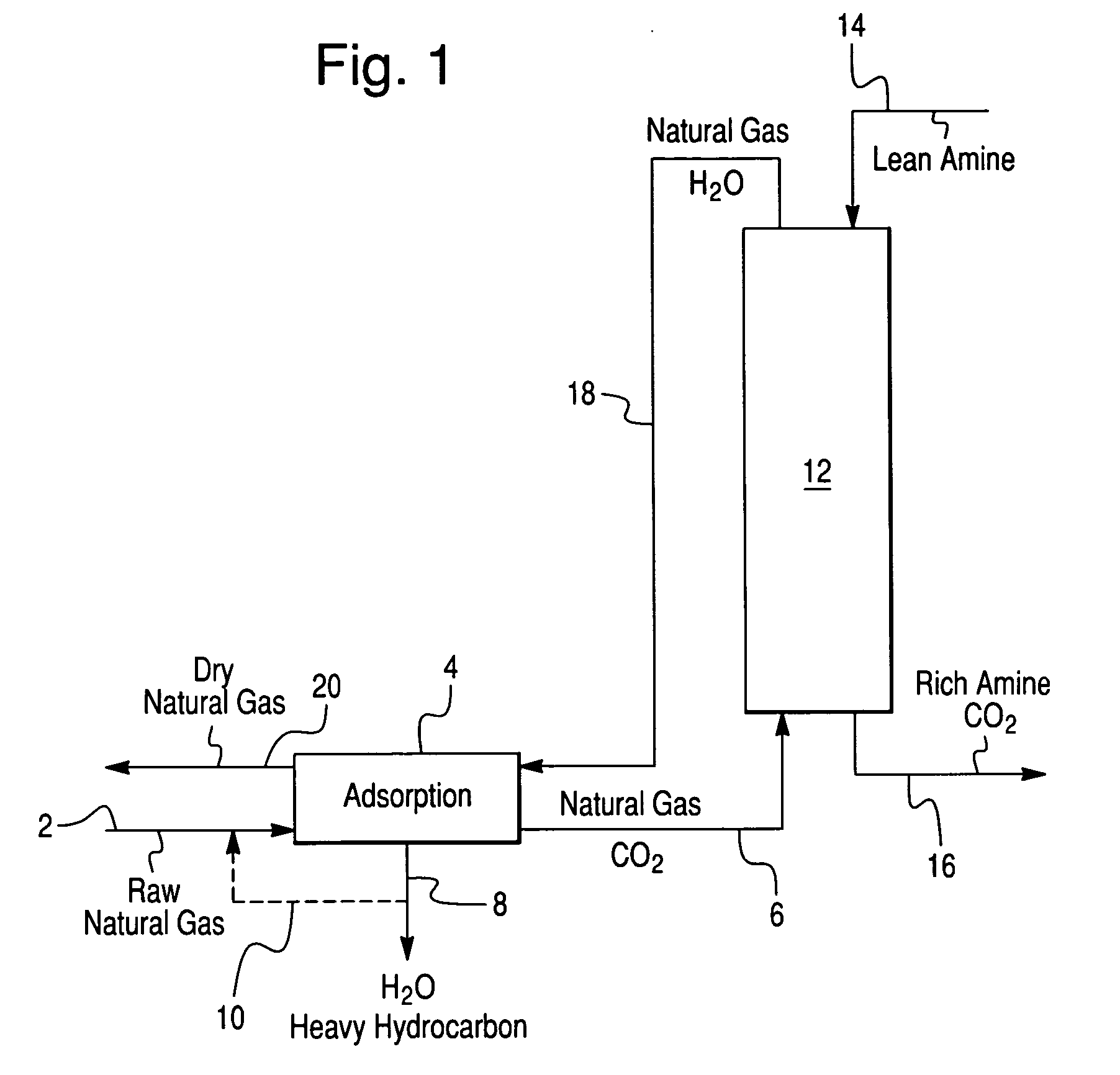

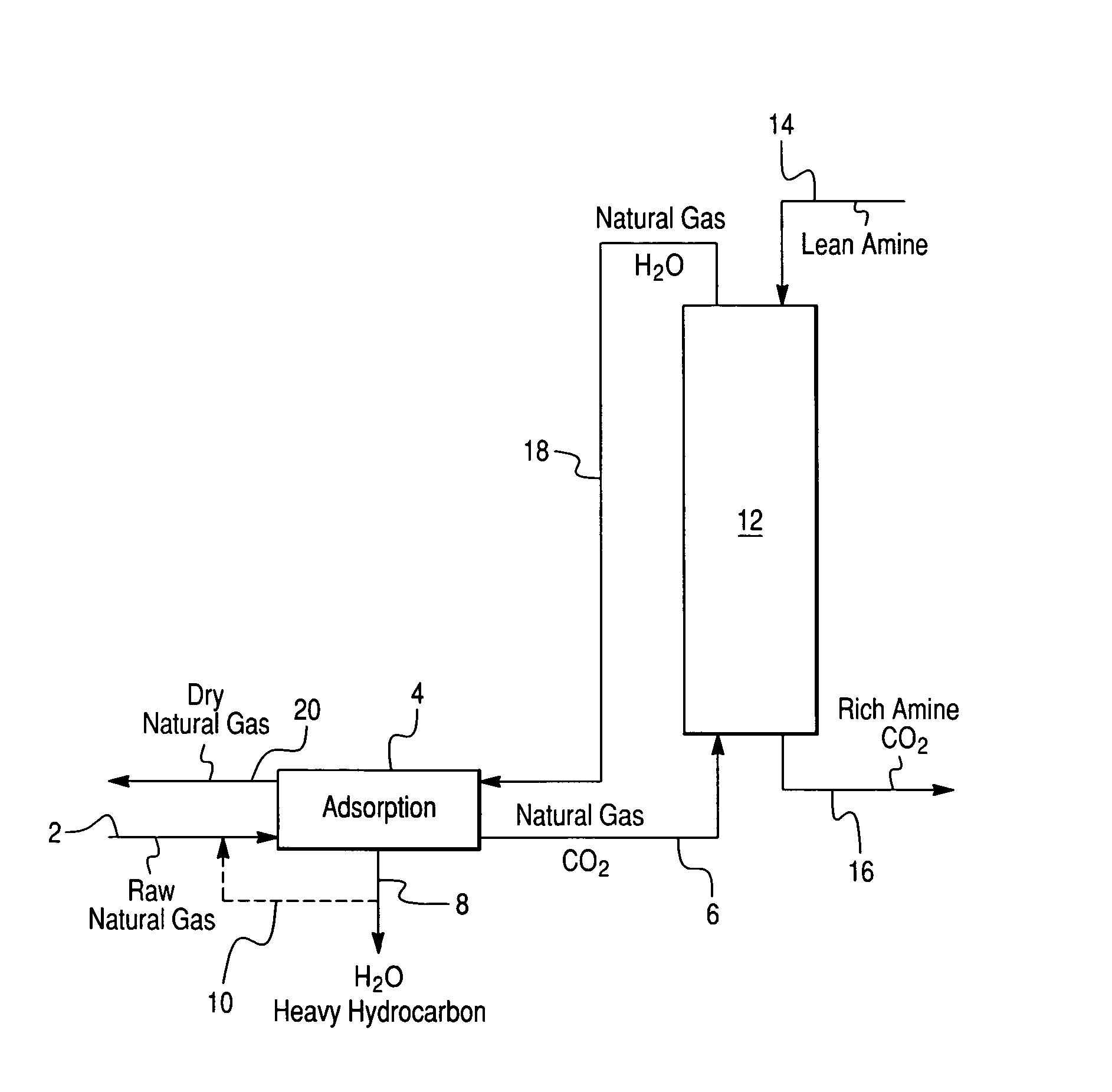

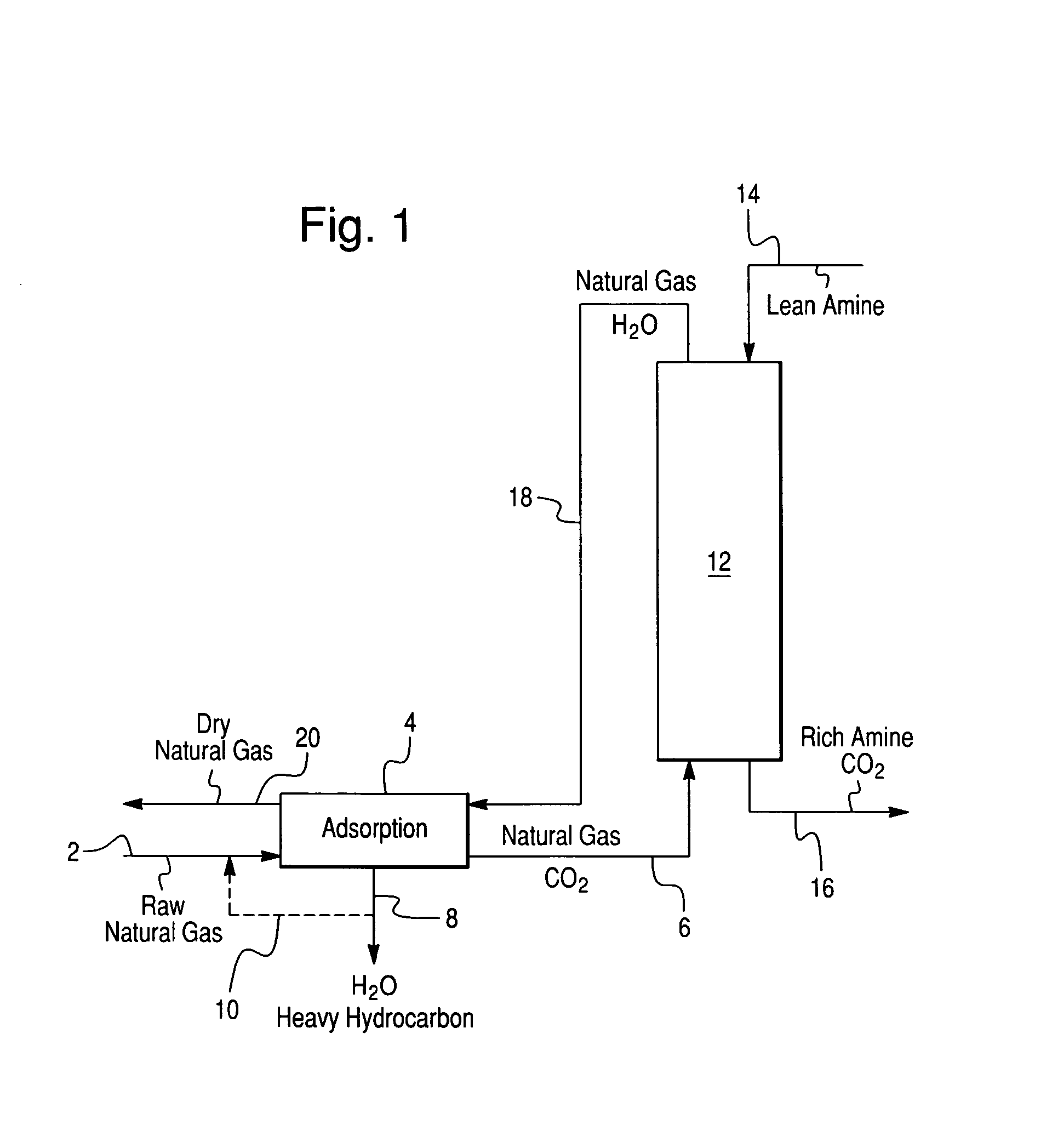

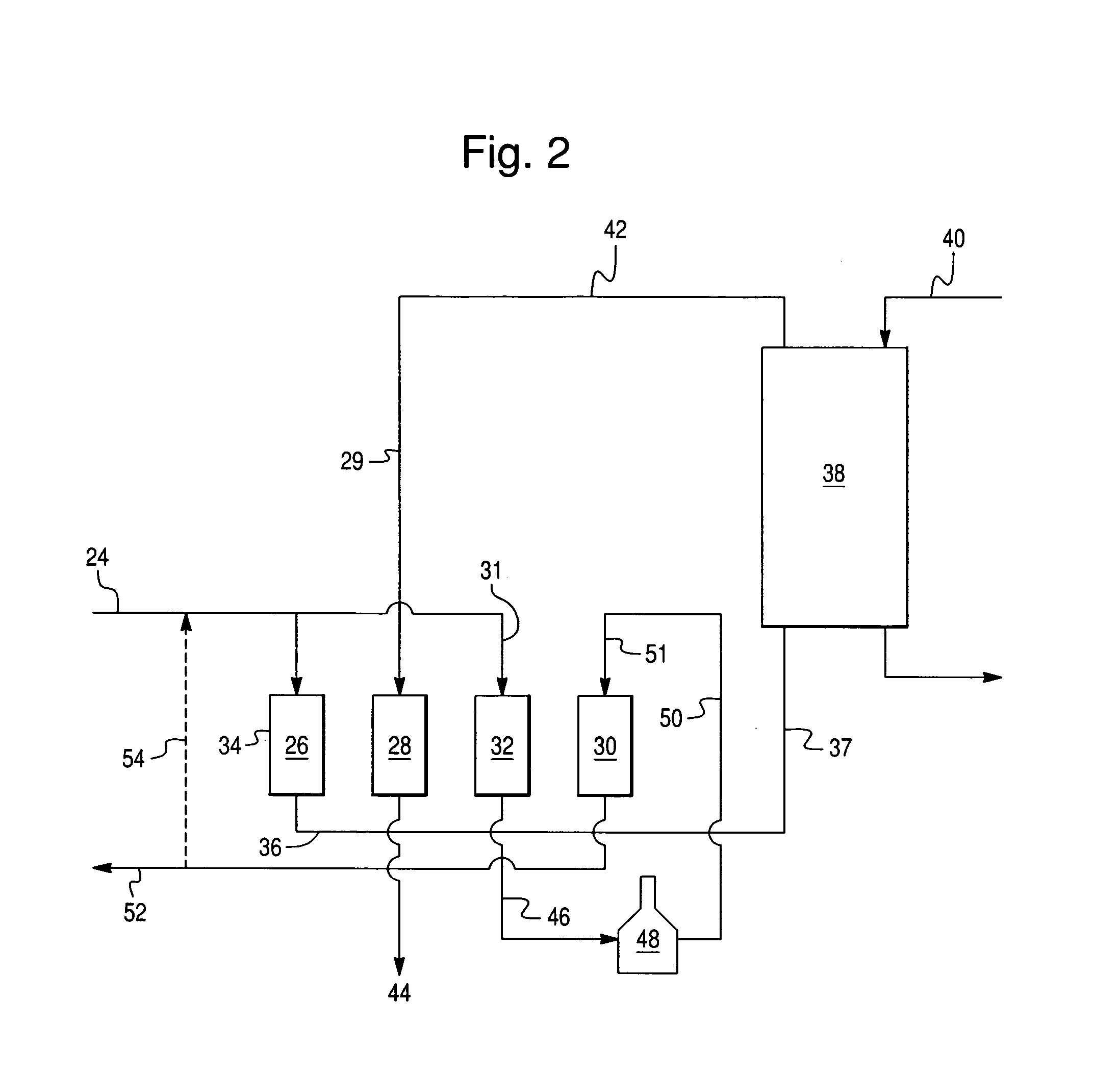

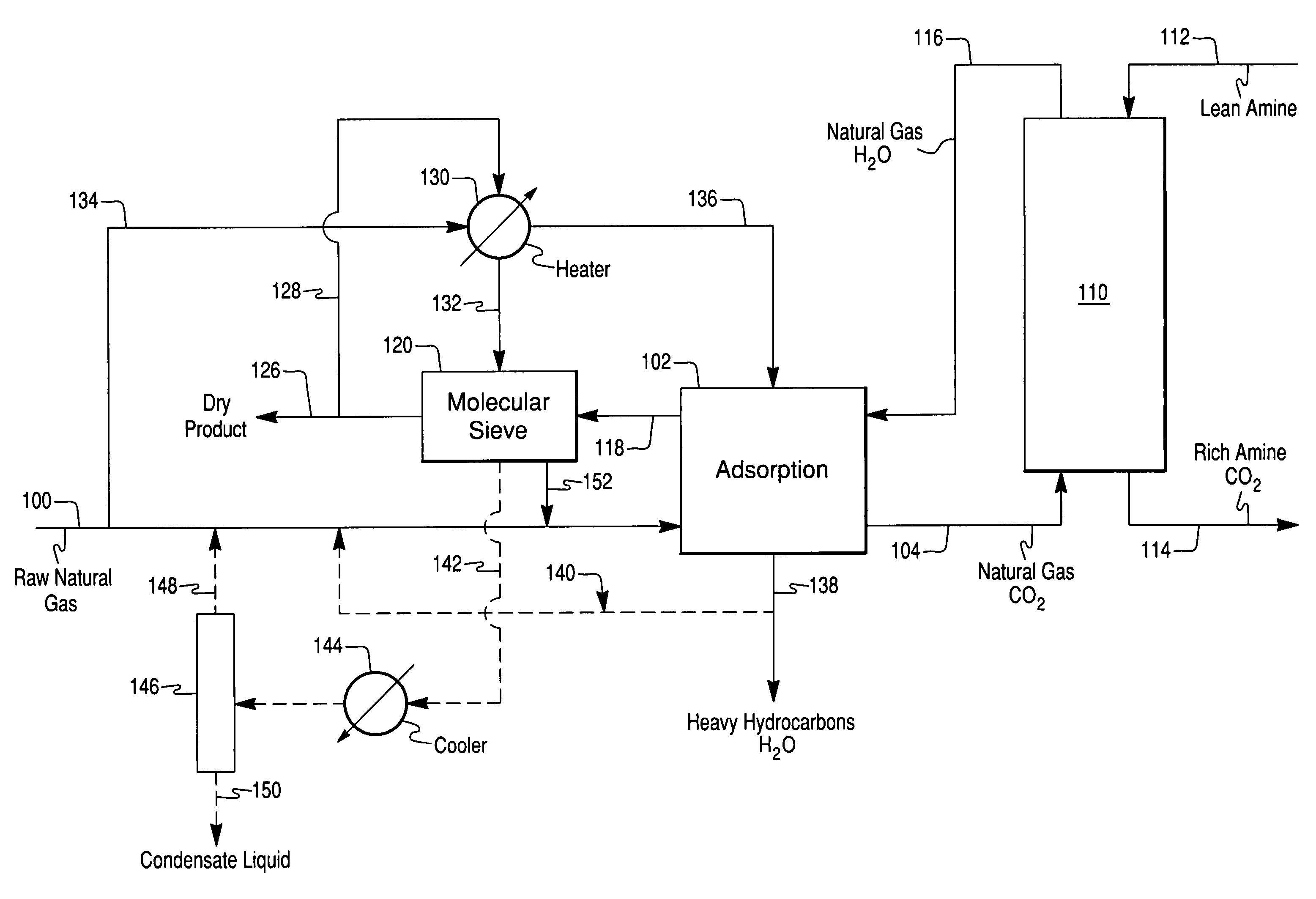

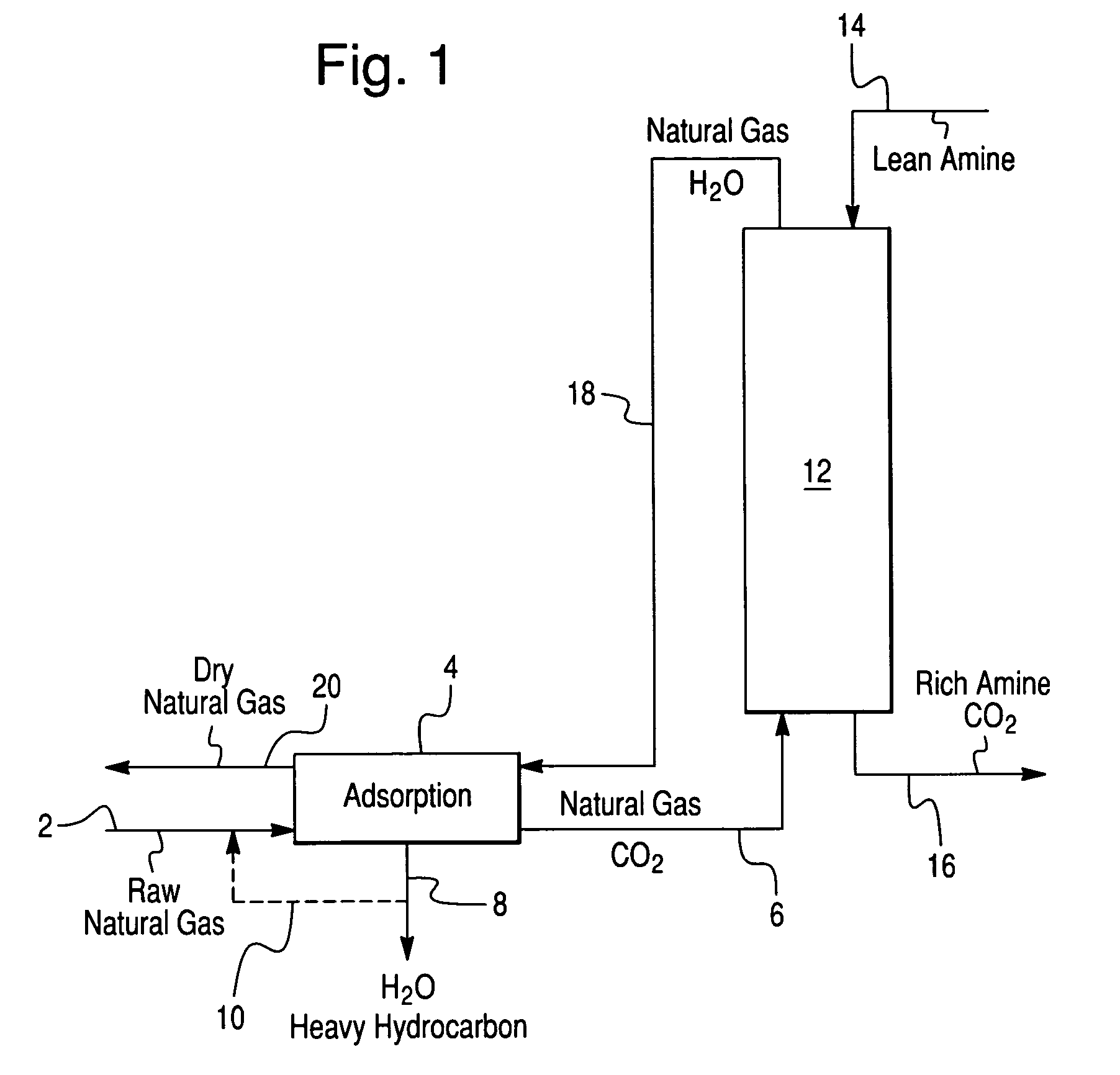

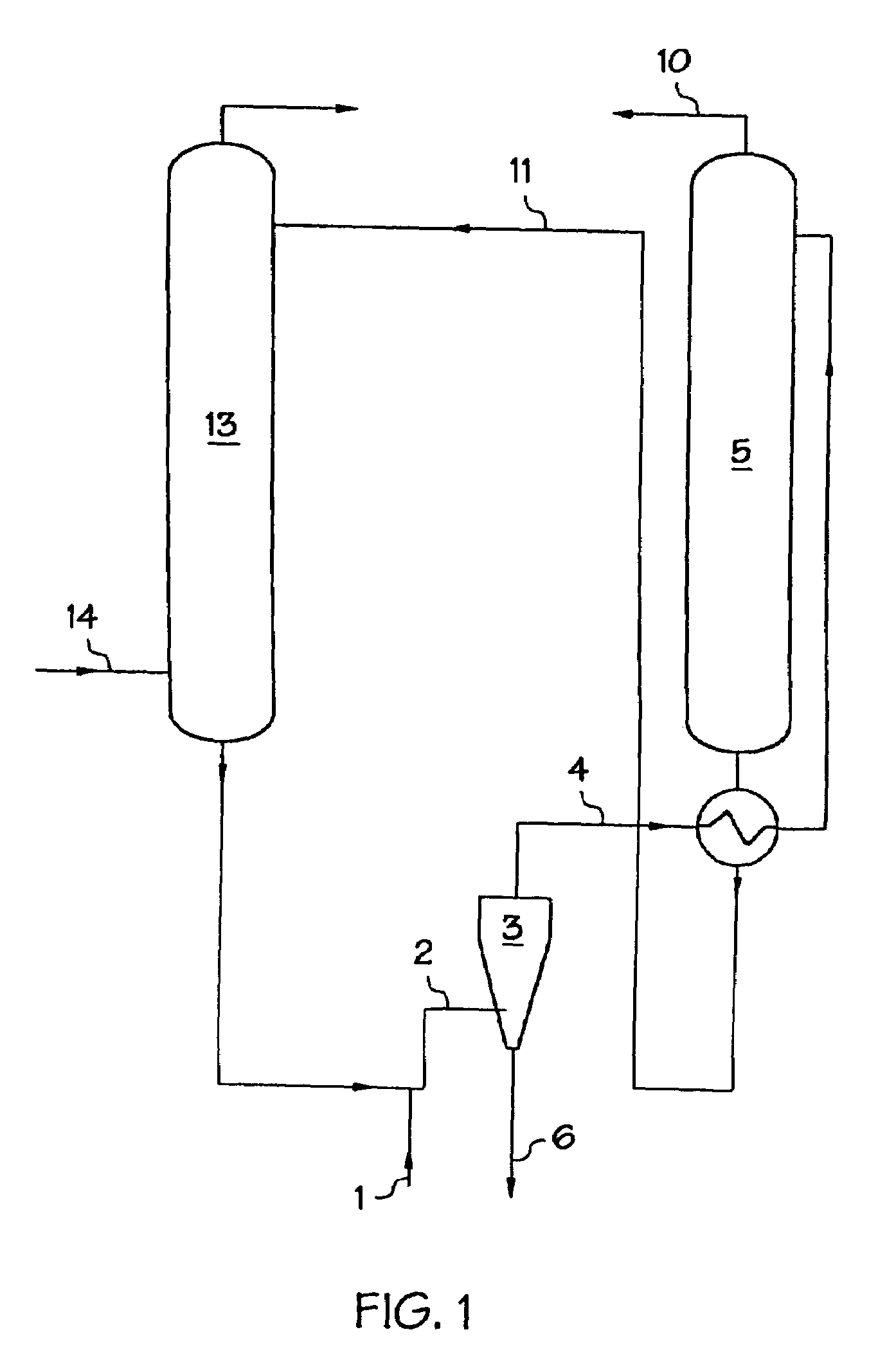

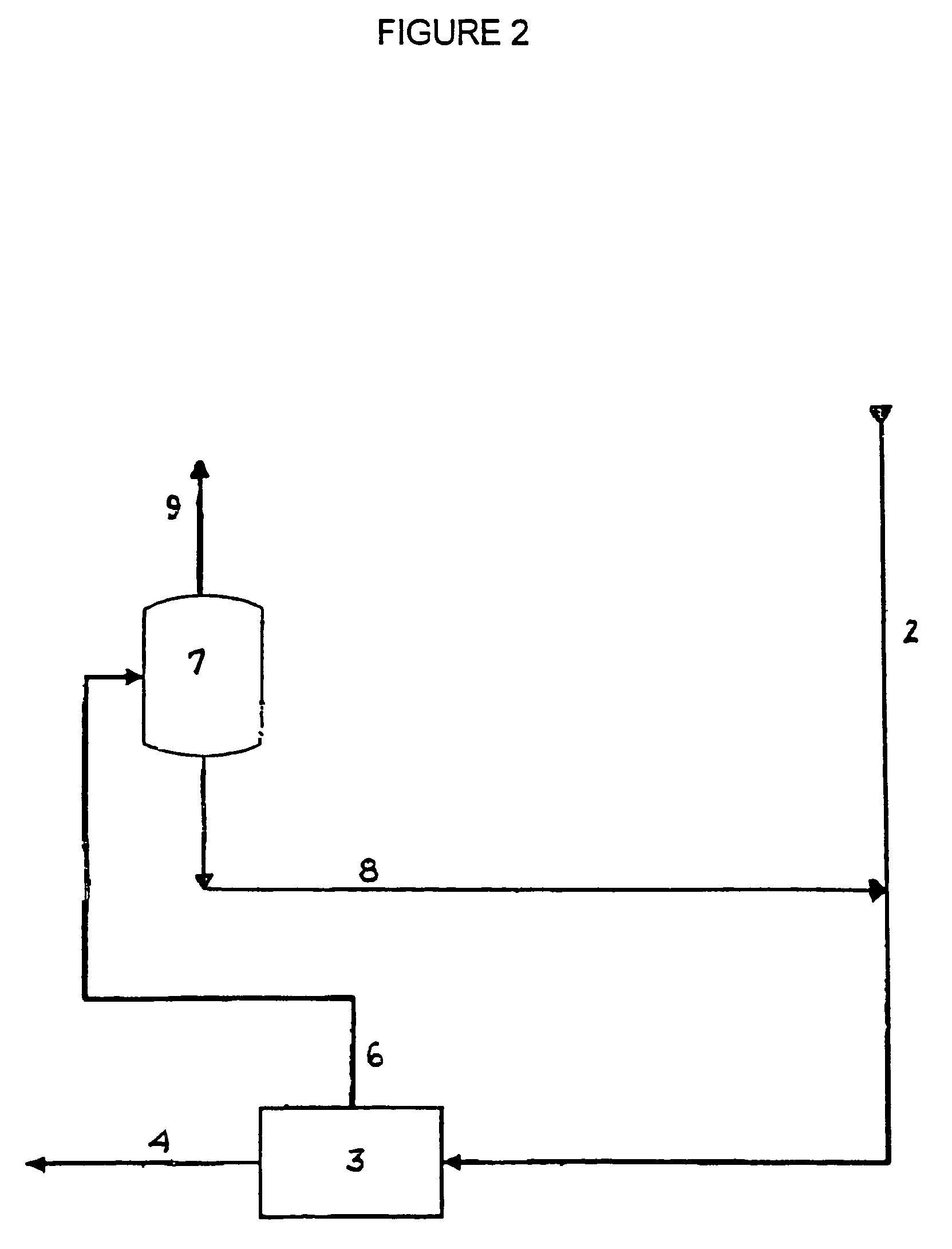

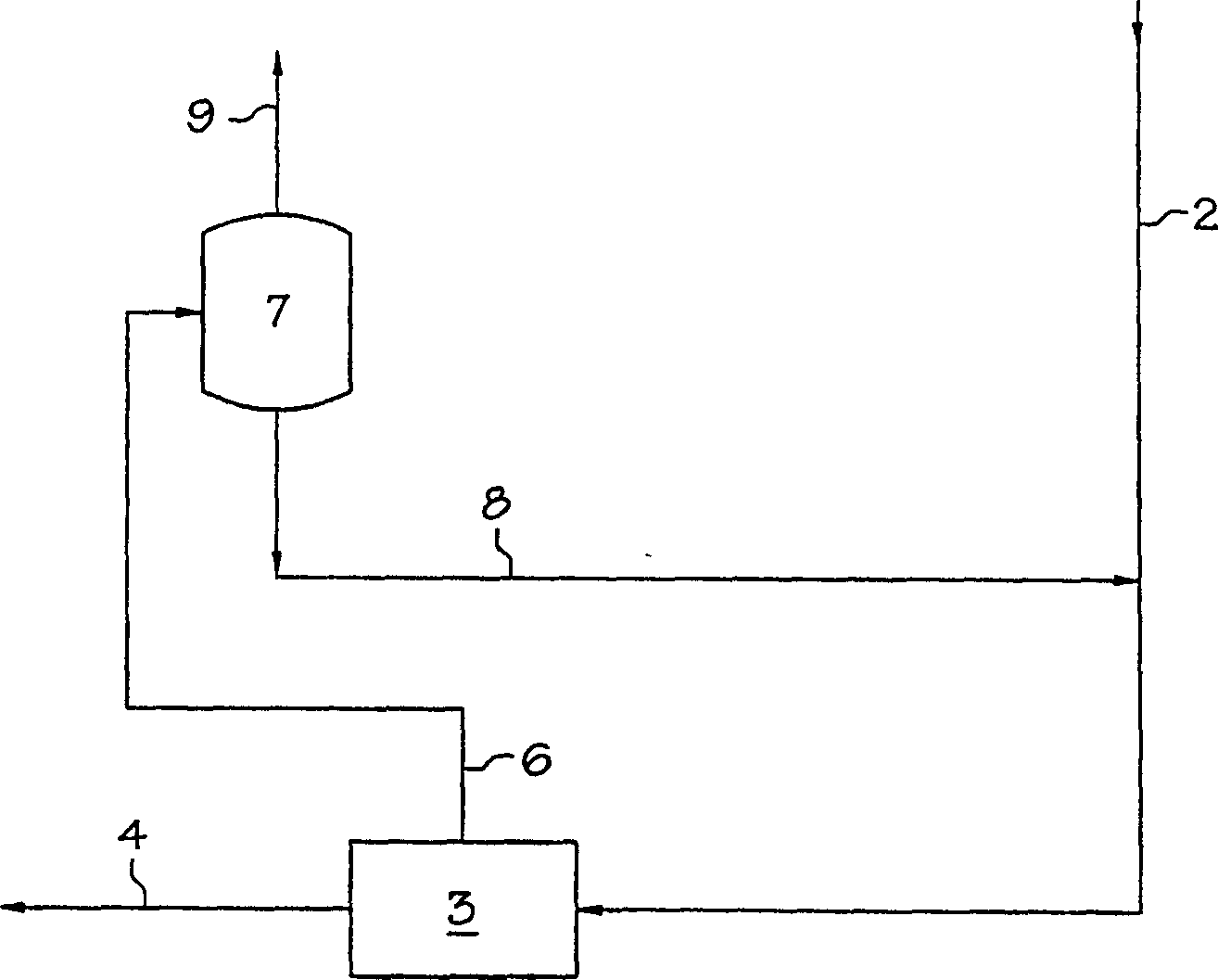

Integrated heavy hydrocarbon removal, amine treating and dehydration

The present invention is directed to an improved integrated process for the removal of heavy hydrocarbons, carbon dioxide, hydrogen sulfide, and water from a raw natural gas feed stream. More specifically, the integrated process of the present invention comprises a three step process involving the adsorption of heavy hydrocarbons and water on an adsorbent bed selective for the same, a subsequent aqueous lean amine treatment for the absorptive removal of acid gases, such as carbon dioxide and hydrogen sulfide, and an adsorptive removal of water. The process of the present invention results in a highly purified dry natural gas product stream.

Owner:BASF CATALYSTS LLC

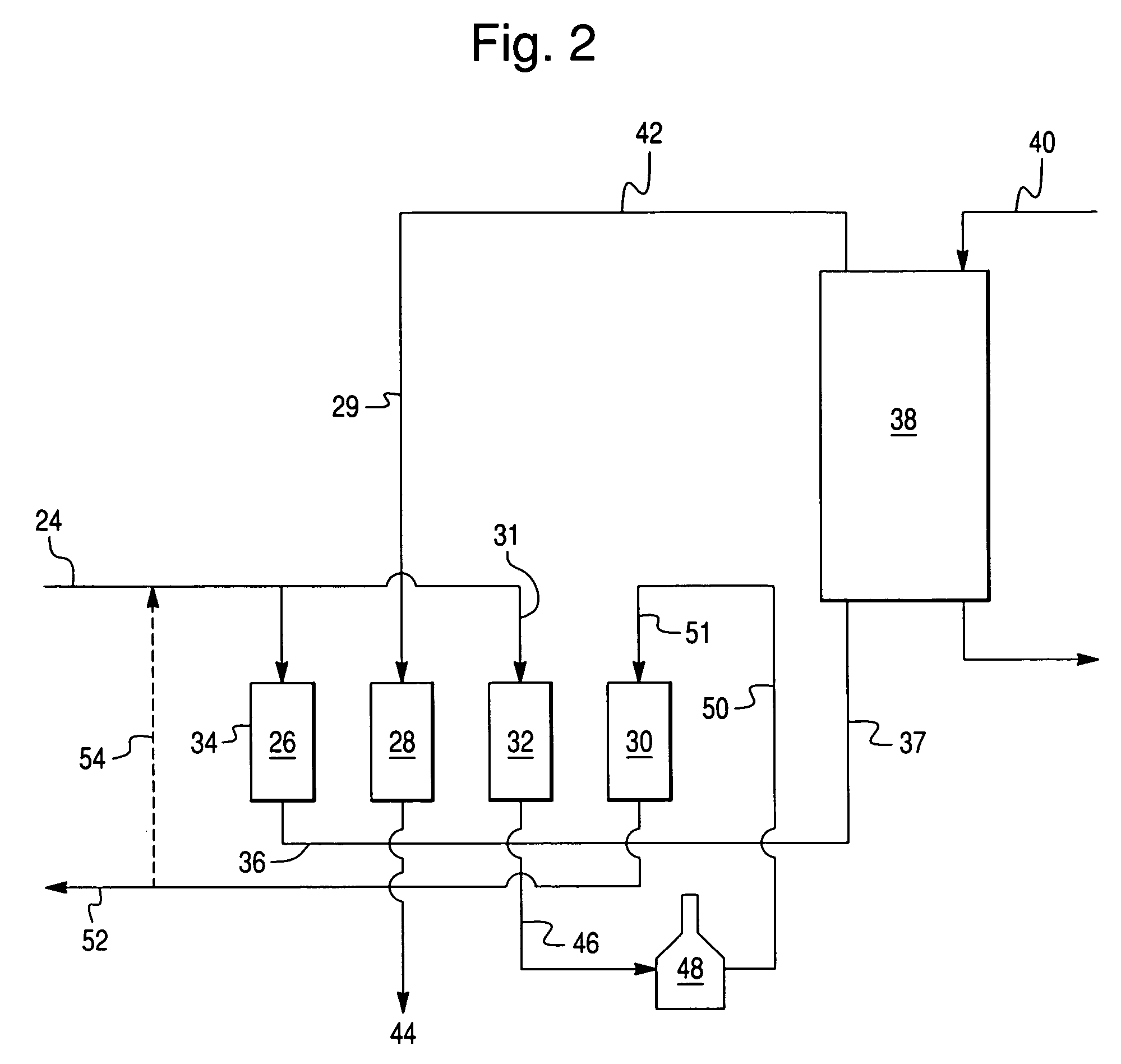

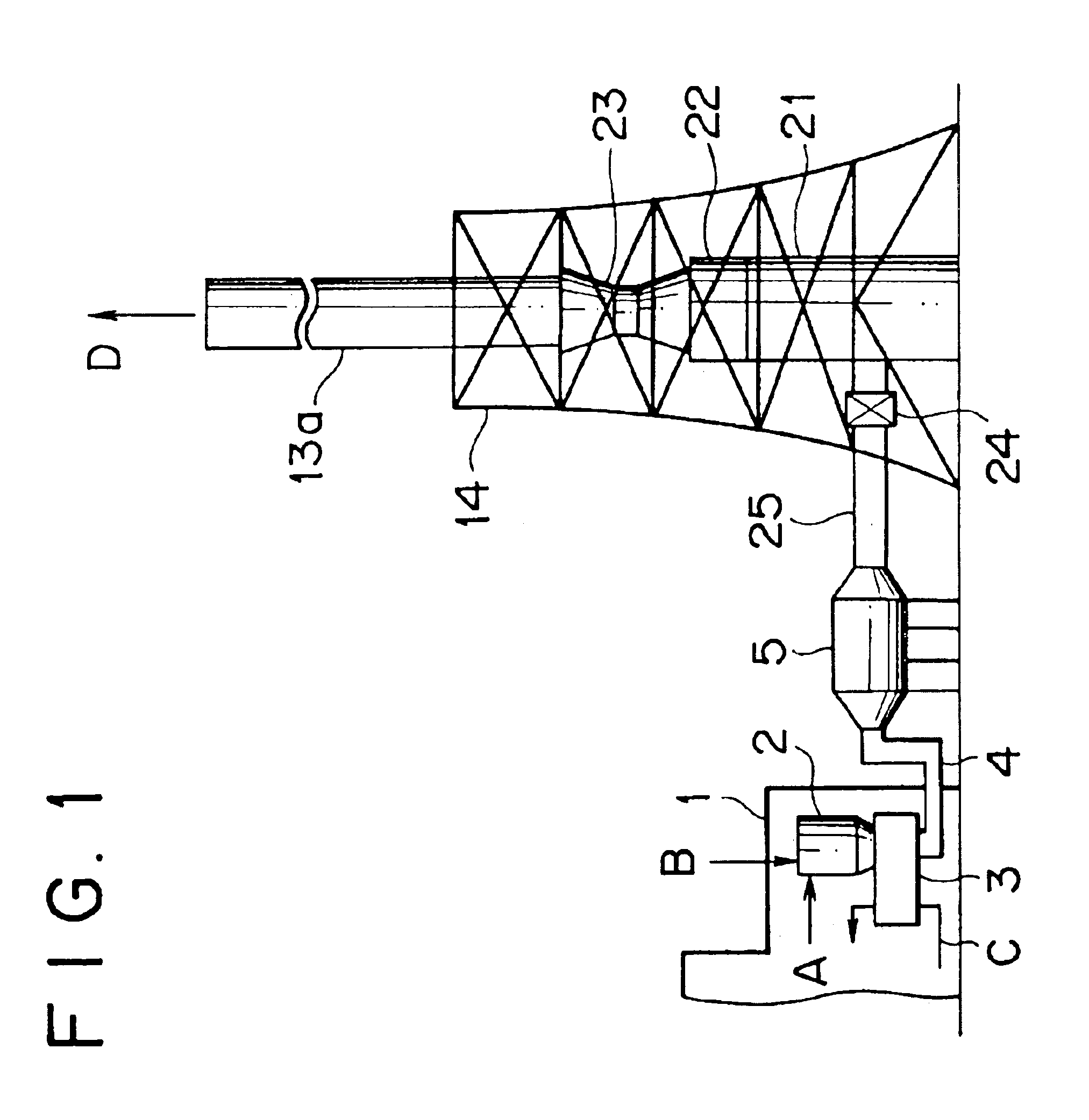

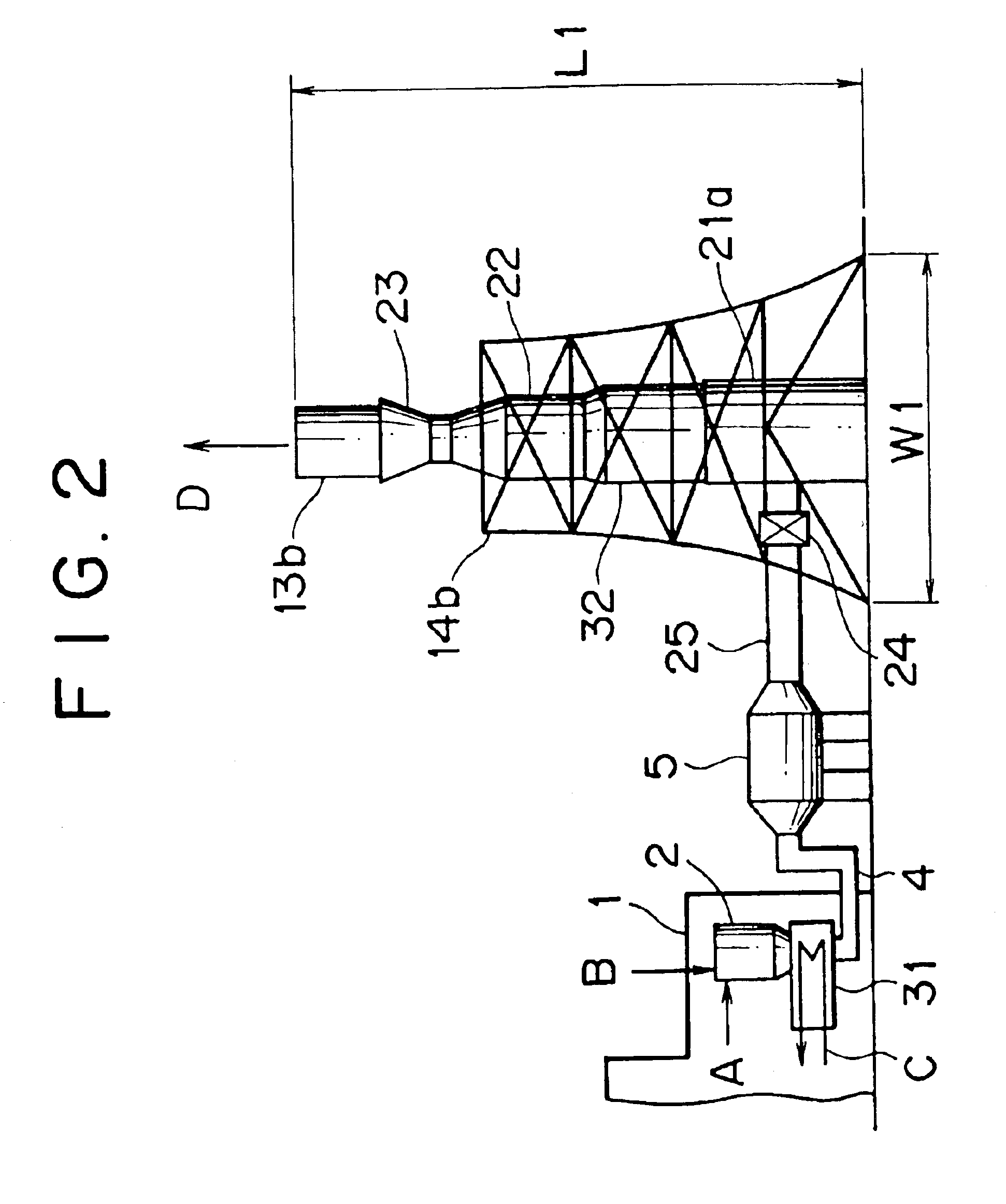

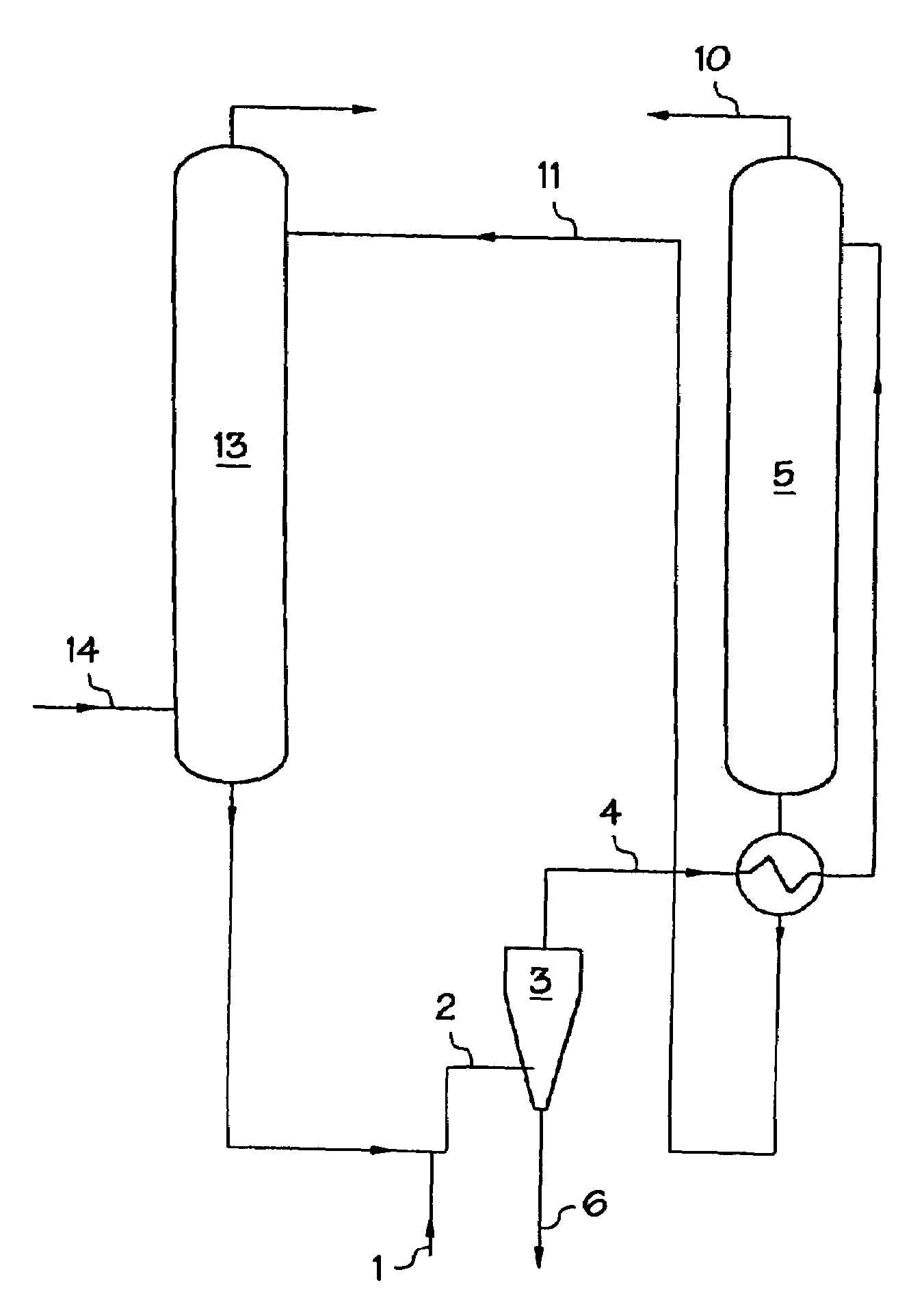

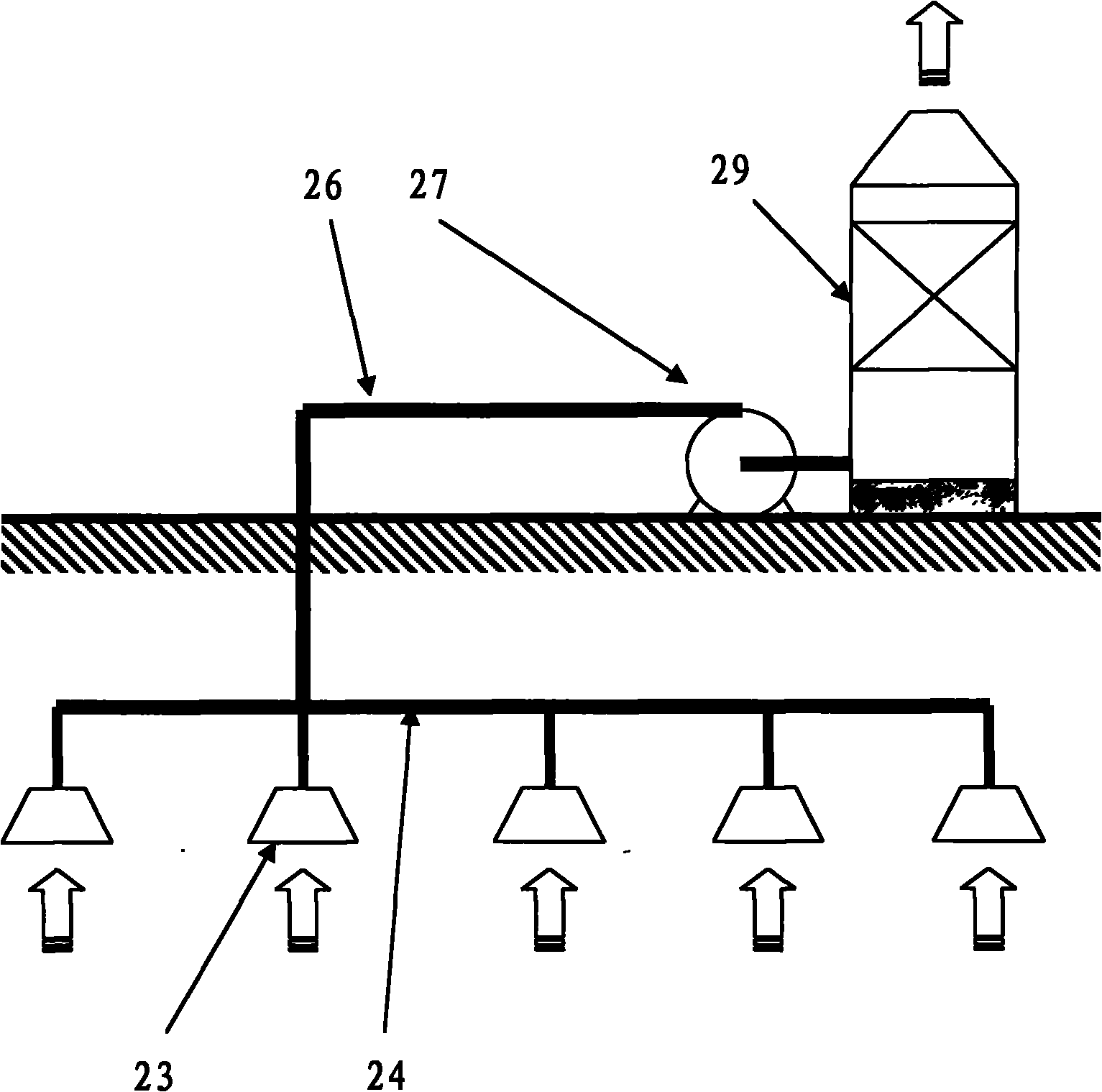

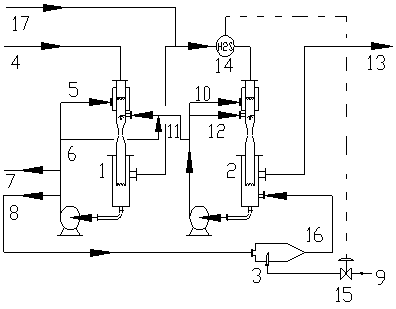

Flue gas treating system and process

In a flue gas treating system, an absorption tower (21), a reheating section (22) and a fan (23) are arranged in line on a vertical axis so as to function as at least a part of a stack for emitting the treated flue gas into the atmosphere. Moreover, in a flue gas treating process, the amount of ammonia injected in the denitration step (a denitrator (2)) and / or the amount of ammonia at a point downstream of the denitration step are determined so as to be on such an excessive level that ammonia or ammonium salt will remain in the flue gas introduced into the desulfurization step (absorption tower (21)). Thus, the size and cost of the equipment can be reduced.

Owner:MITSUBISHI HEAVY IND LTD

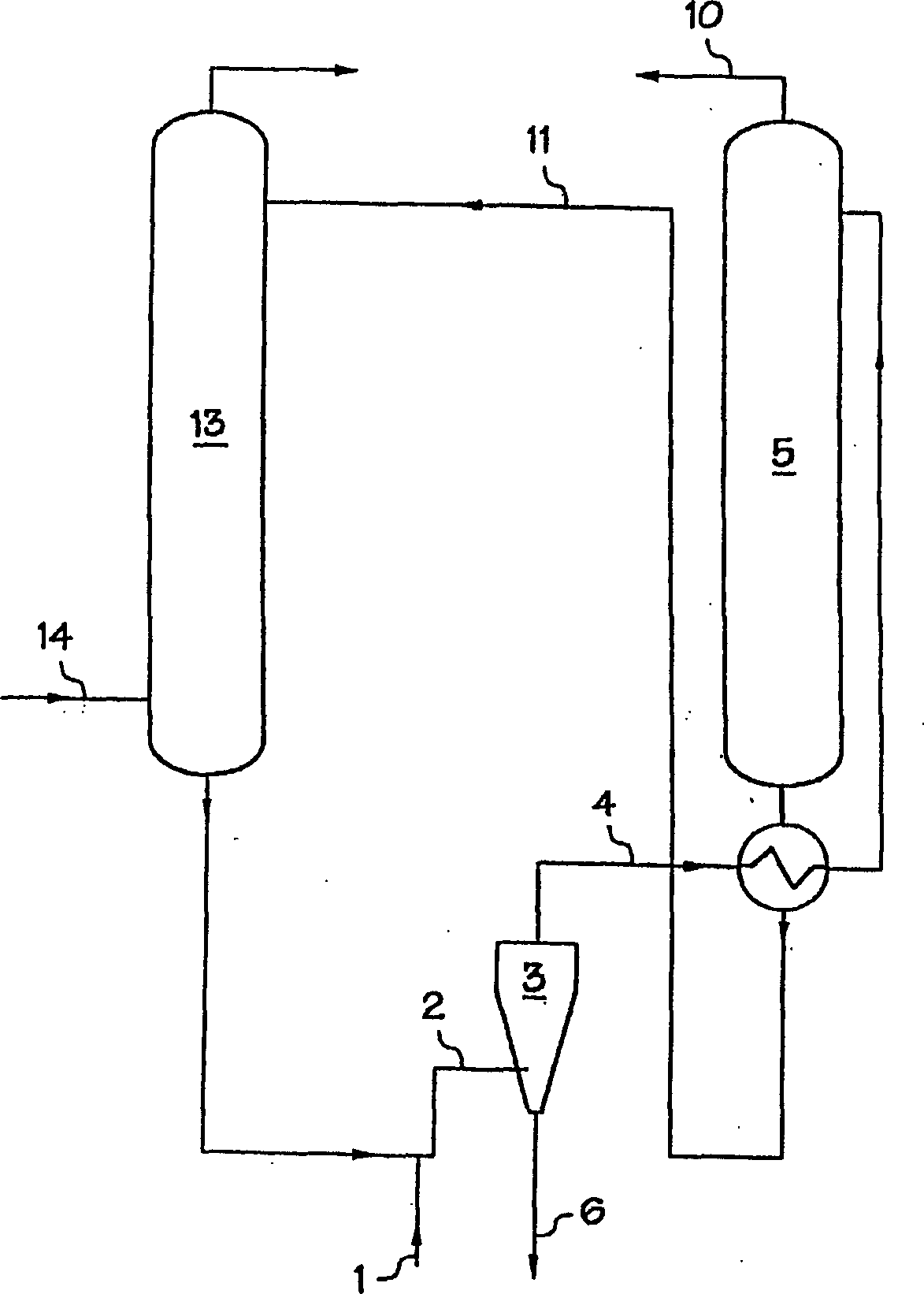

Integrated heavy hydrocarbon removal, amine treating and dehydration

The present invention is directed to an improved integrated process for the removal of heavy hydrocarbons, carbon dioxide, hydrogen sulfide, and water from a raw natural gas feed stream. More specifically, the integrated process of the present invention comprises a three step process involving the adsorption of heavy hydrocarbons and water on an adsorbent bed selective for the same, a subsequent aqueous lean amine treatment for the absorptive removal of acid gases, such as carbon dioxide and hydrogen sulfide, and an adsorptive removal of water. The process of the present invention results in a highly purified natural gas product stream.

Owner:BASF CATALYSTS LLC

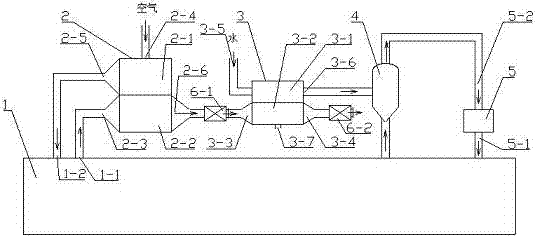

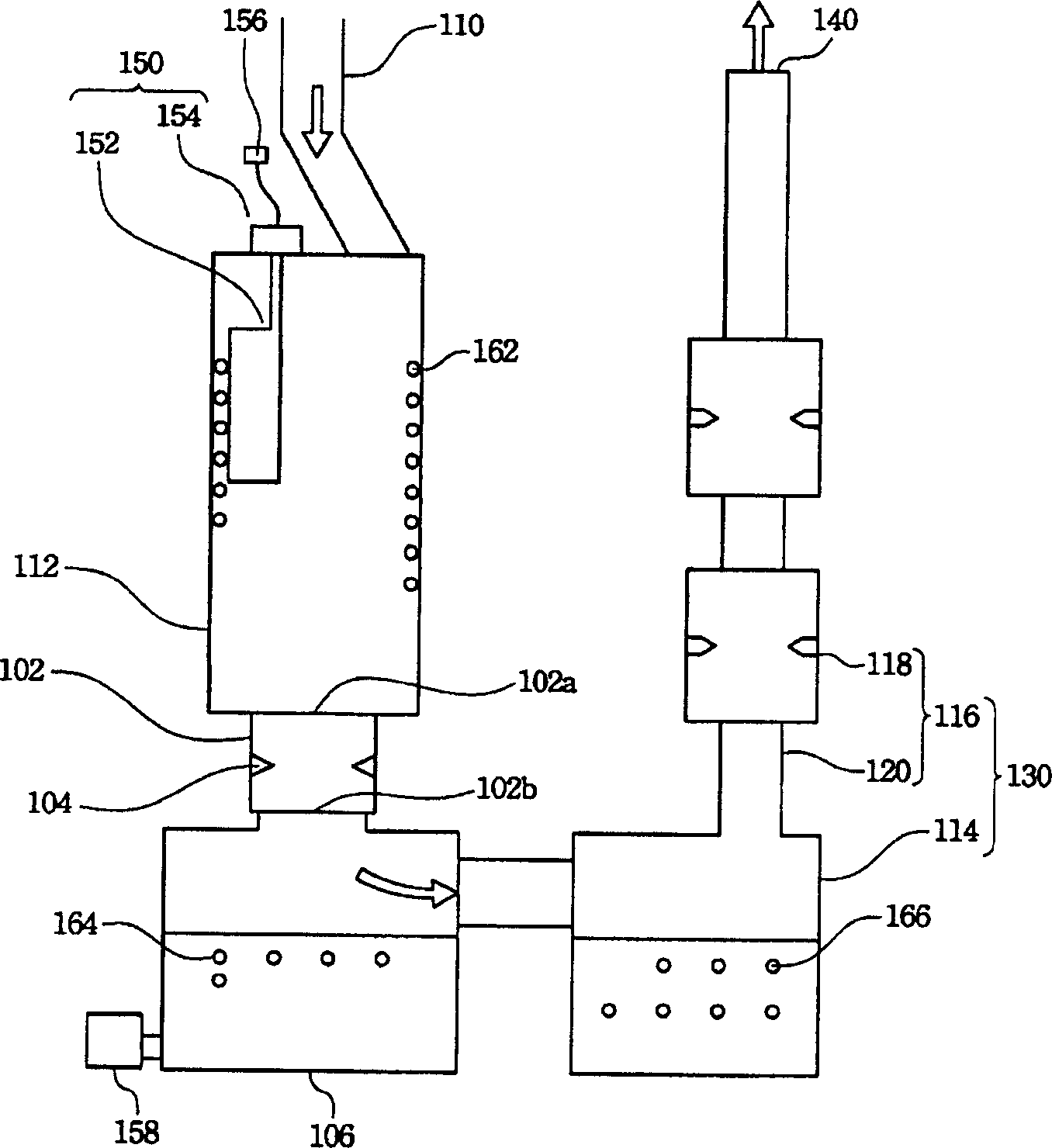

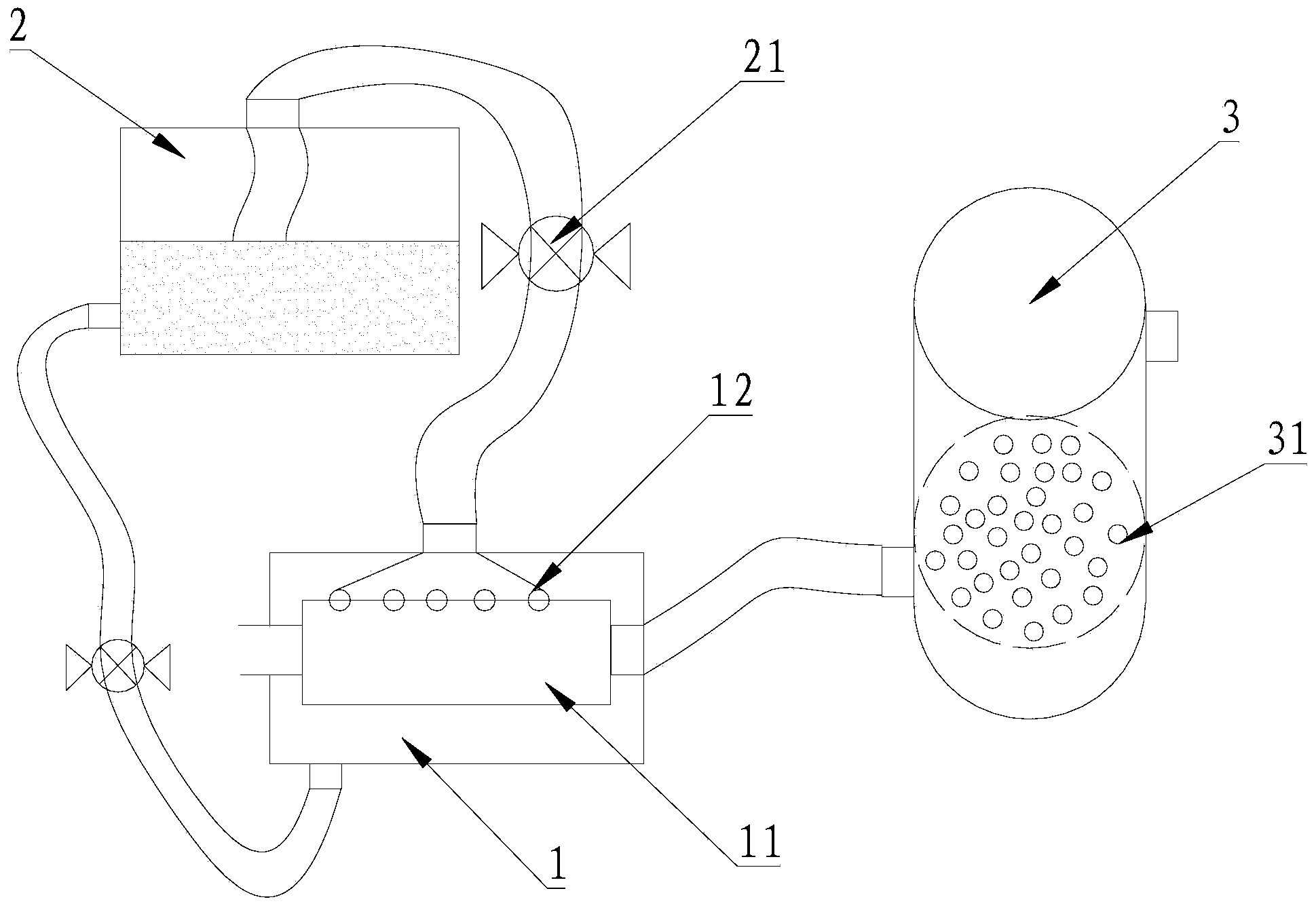

Waste gas treatment and waste heat recovery device and method thereof

InactiveCN102268796AHigh recovery rateAchieve recyclingHeating/cooling textile fabricsStationary tubular conduit assembliesWaste heat recovery unitThermal energy

The invention provides a waste gas treating and waste heat recycling device. The device comprises a setting machine, a thermal conductive medium heater, a steam generator and a gas-gas exchanger, and further comprises a gas-liquid exchanger, wherein the gas-liquid exchanger includes a liquid chamber and a gas chamber which are independent mutually; the gas chamber is provided with a gas inlet anda gas outlet; the gas inlet is connected with the waste gas outlet of the gas-gas exchanger by a draught fan, and the gas outlet is connected with the draught fan; the liquid chamber is provided witha water inlet and a water outlet; the water outlet is connected with the steam generator; the thermal conductive medium heater and the setting machine form a return circuit therebetween by an outlet medium pipe and a return medium pipe; and the steam generator is arranged on the return circuit. In addition, the invention further provides a waste gas treating and waste heat recycling method. The waste gas treating and waste heat recycling device disclosed by the invention is simple in structure and simple in operation, makes full use of heat energy of waste gases, reduces production cost, and is energy-saving and environmentally-friendly.

Owner:桐乡市好阳光能源科技有限公司

Integrated heavy hydrocarbon removal, amine treating and dehydration

Owner:BASF CATALYSTS LLC

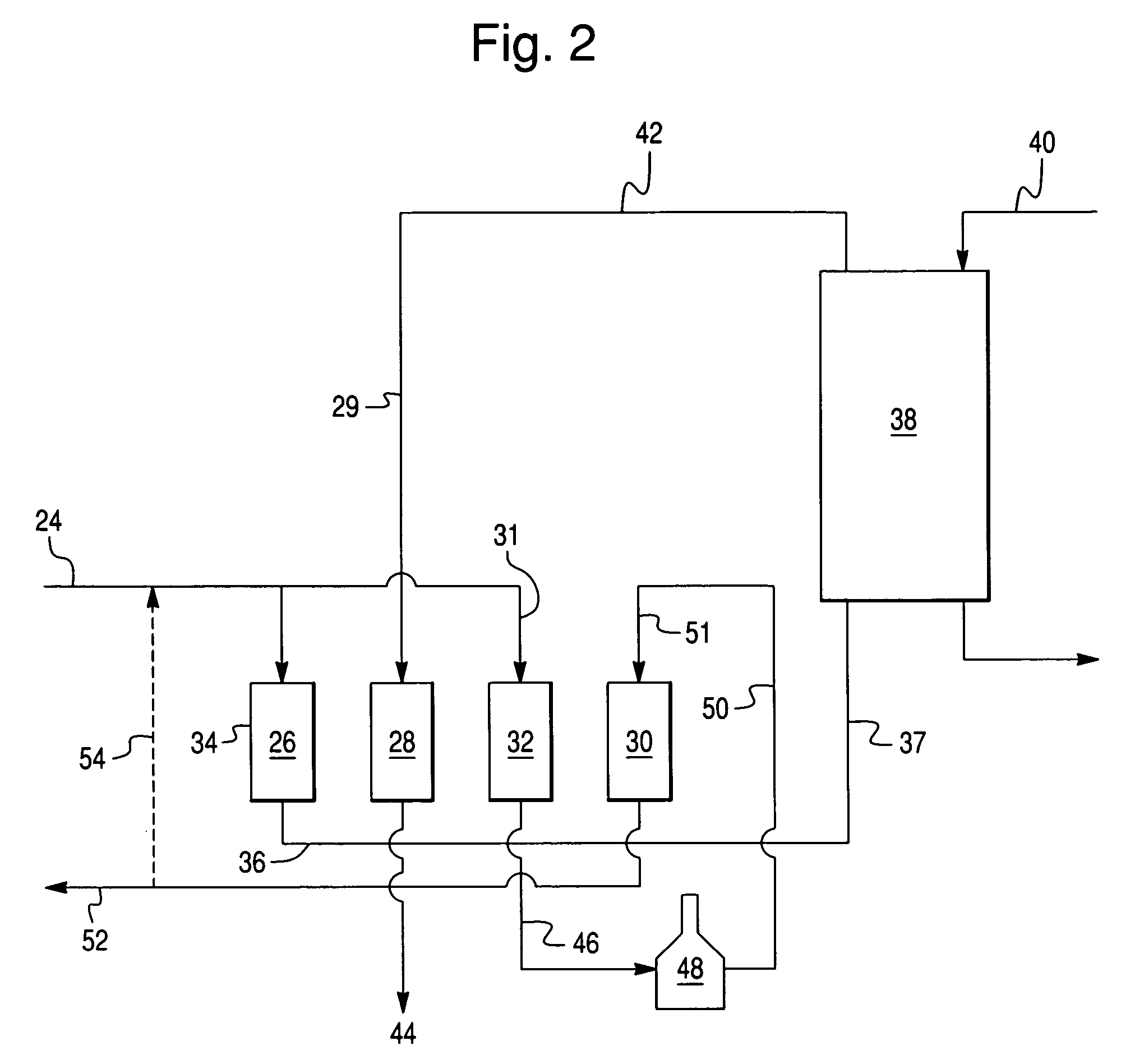

Method for removing polymer from an acid gas treating system

InactiveUS6989046B1Minimize contaminationMinimize overheadLiquid degasificationUsing liquid separation agentAmine gas treatingHydrocarbon solvents

A method for removing polymer from an acid gas treating system comprising contacting an acid gas containing stream with an aqueous alkanolamine solution and hydrocarbon solvent to form a mixture of an alkanolamine rich solution having the acid gases or byproducts thereof contained therein and the hydrocarbon solvent, where the hydrocarbon solvent has about 60 to 100 volume % aromatics content; and about 50 to 85 volume % two ring aromatic content, based on the total volume of the solvent.

Owner:EXXONMOBIL CHEM PAT INC

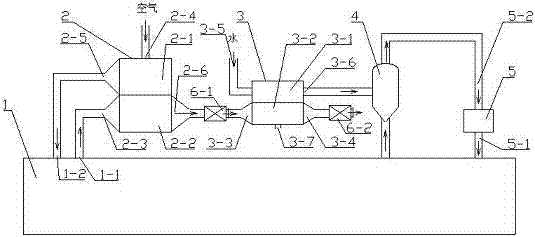

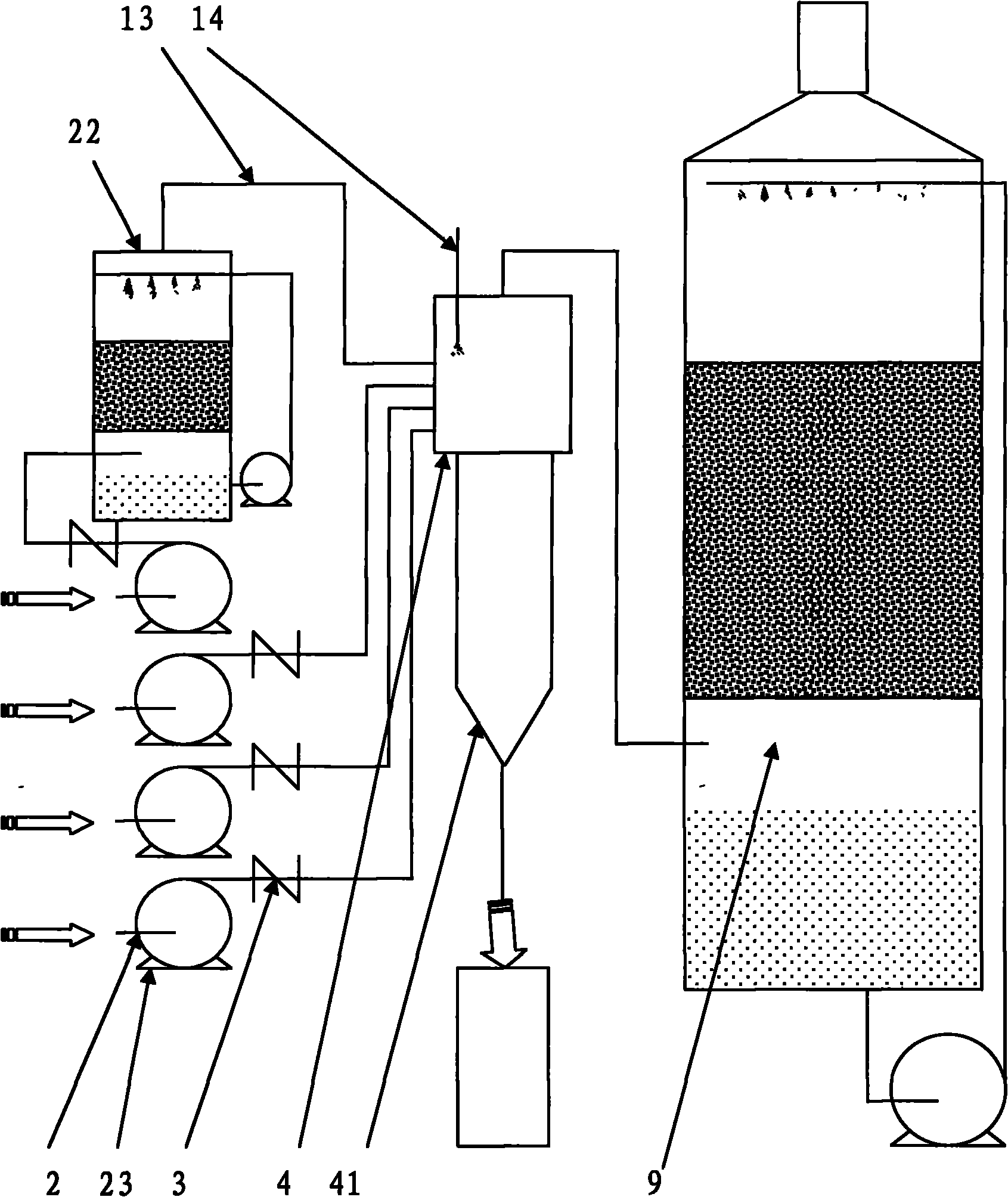

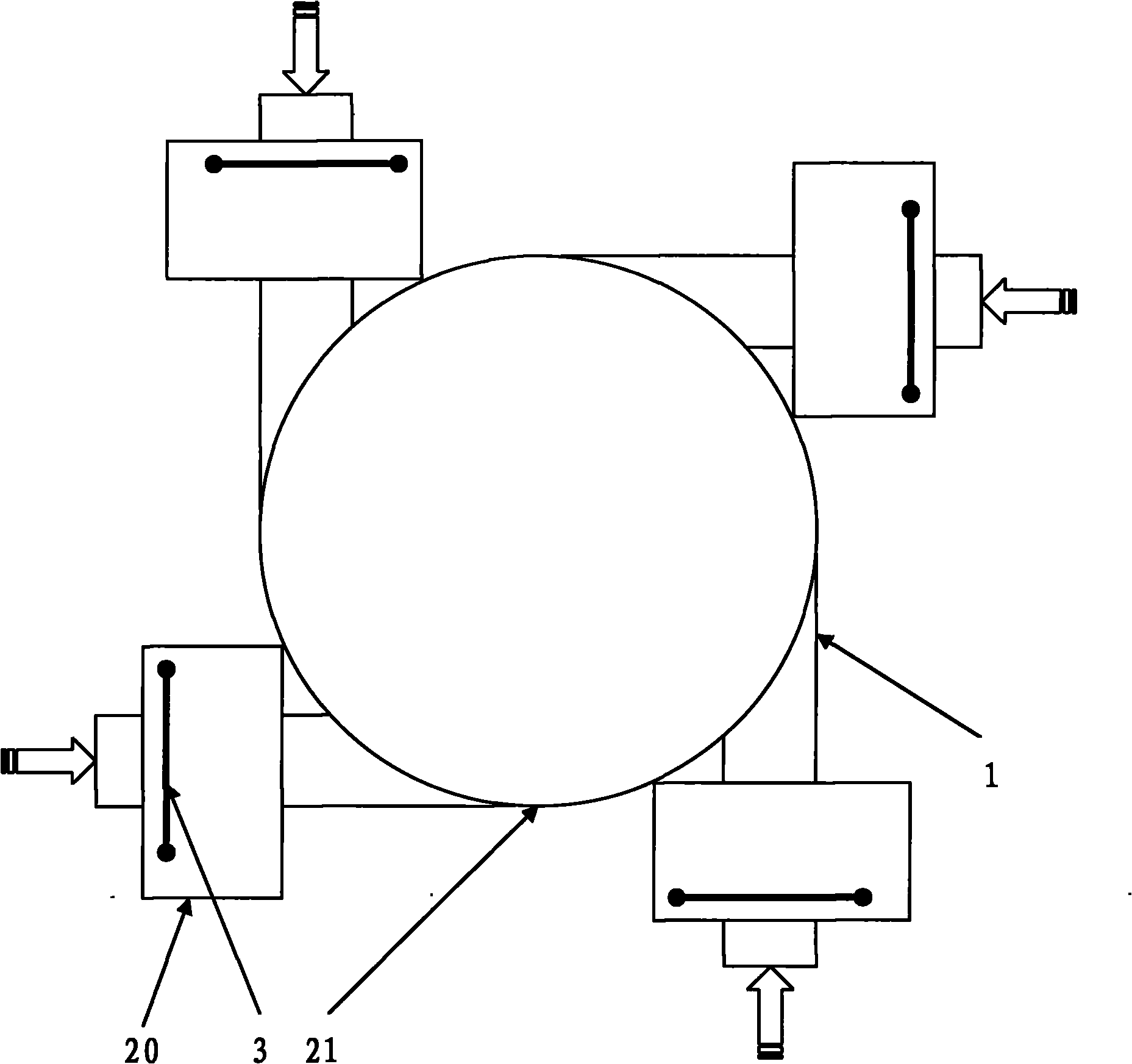

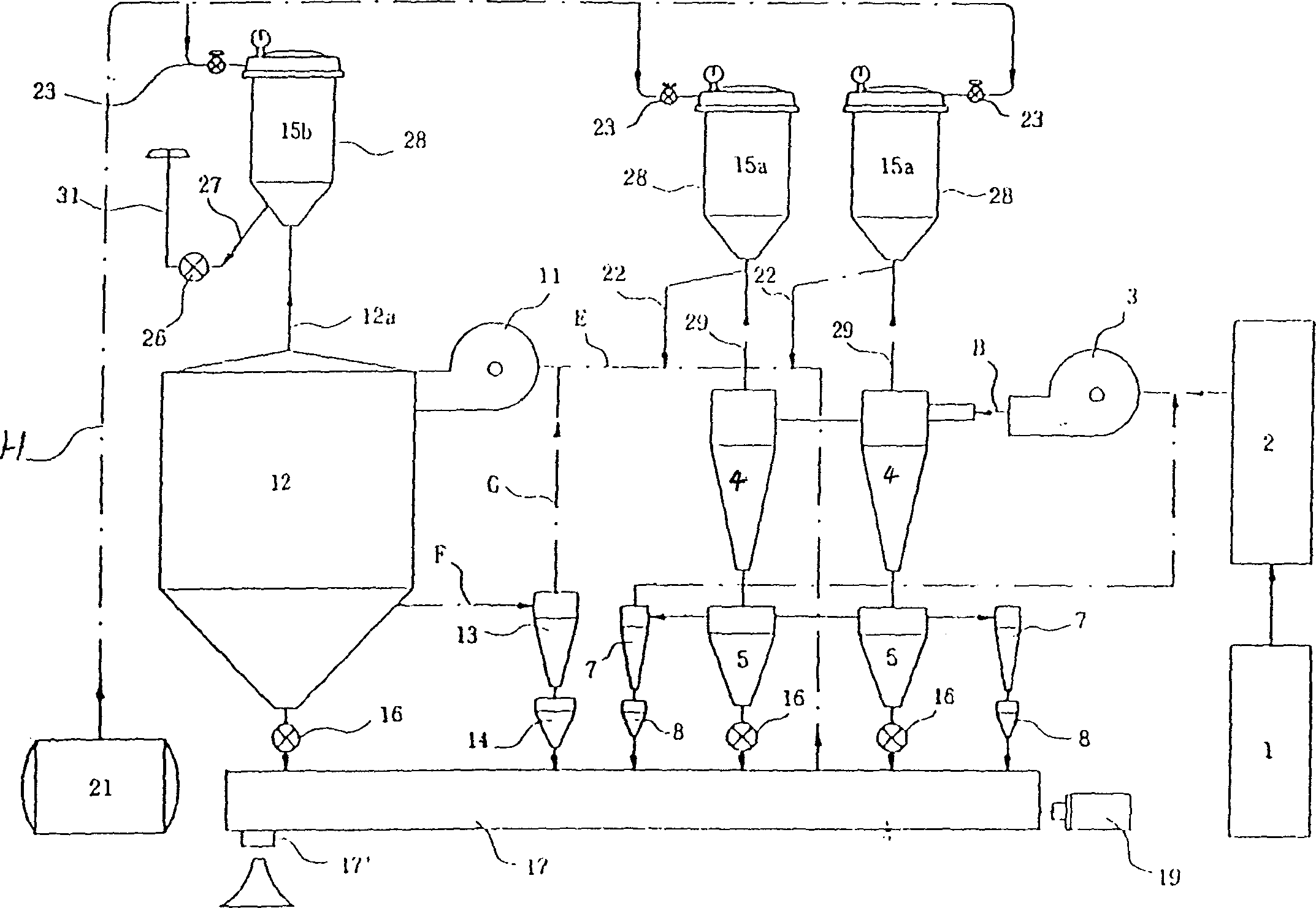

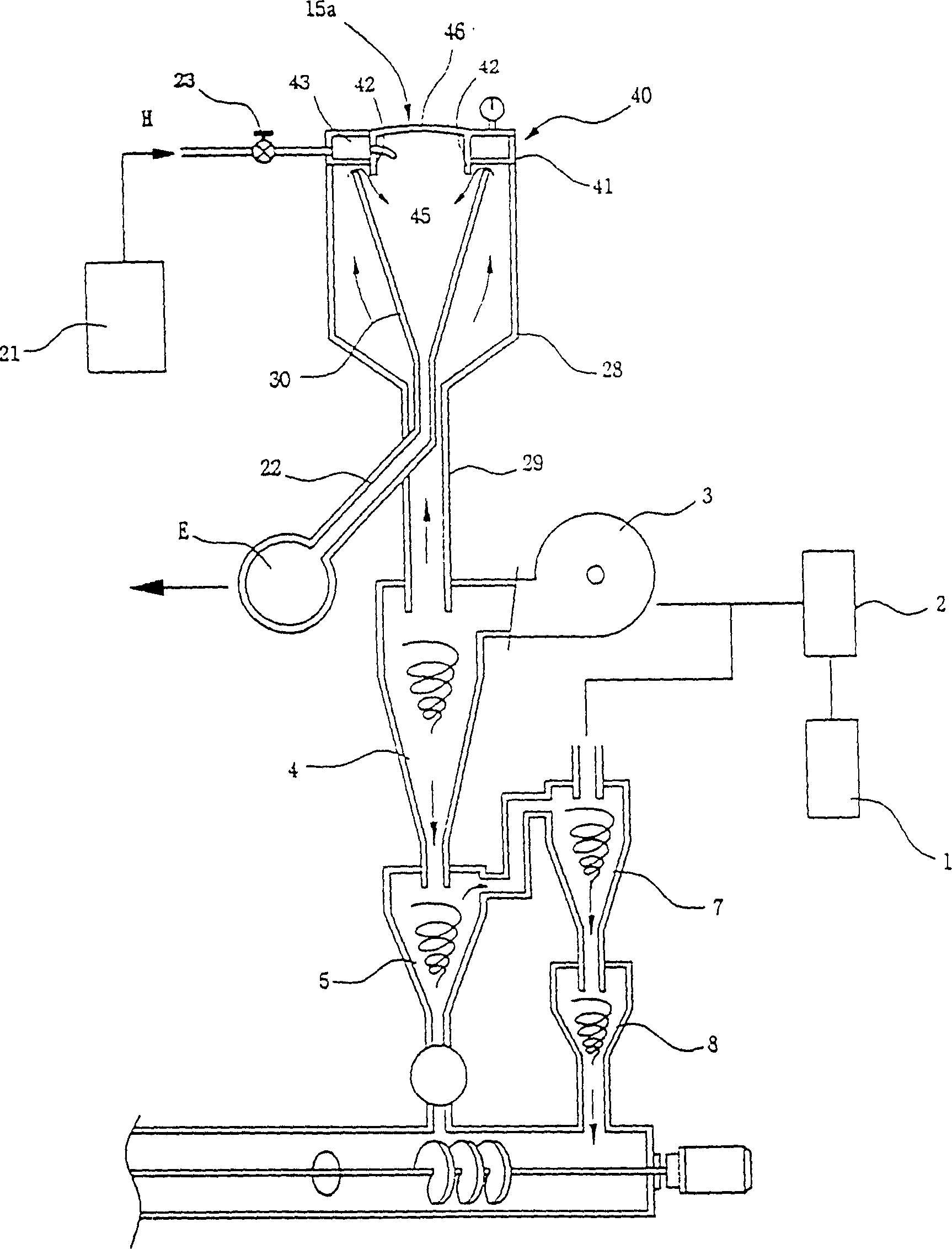

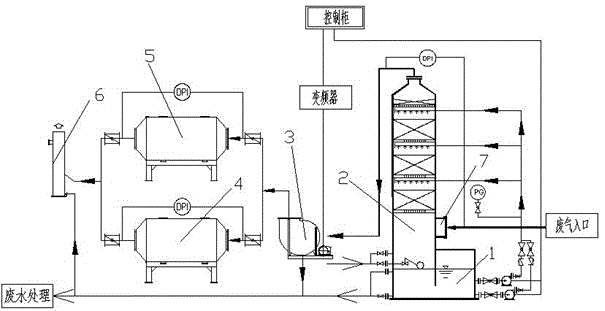

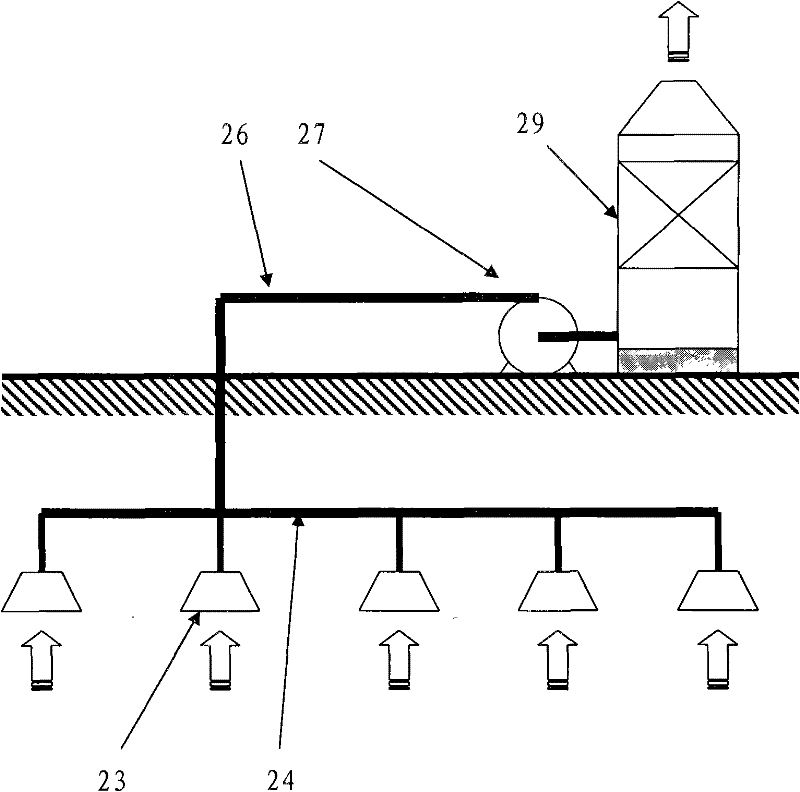

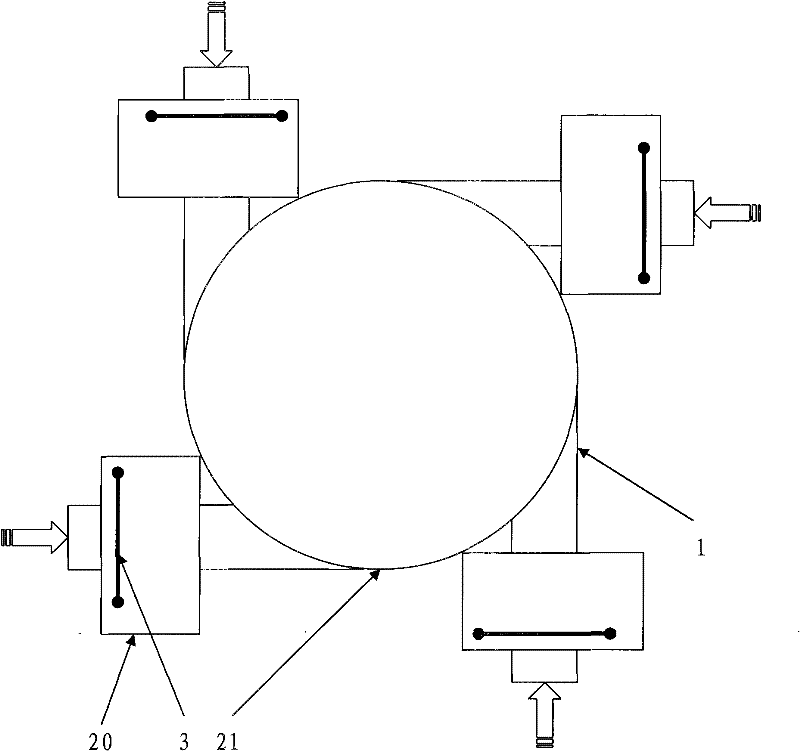

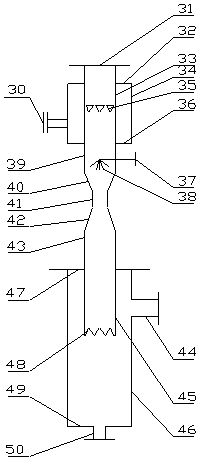

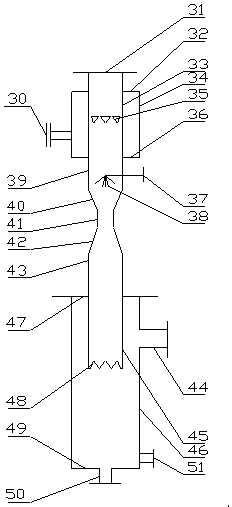

Waste gas central treating system

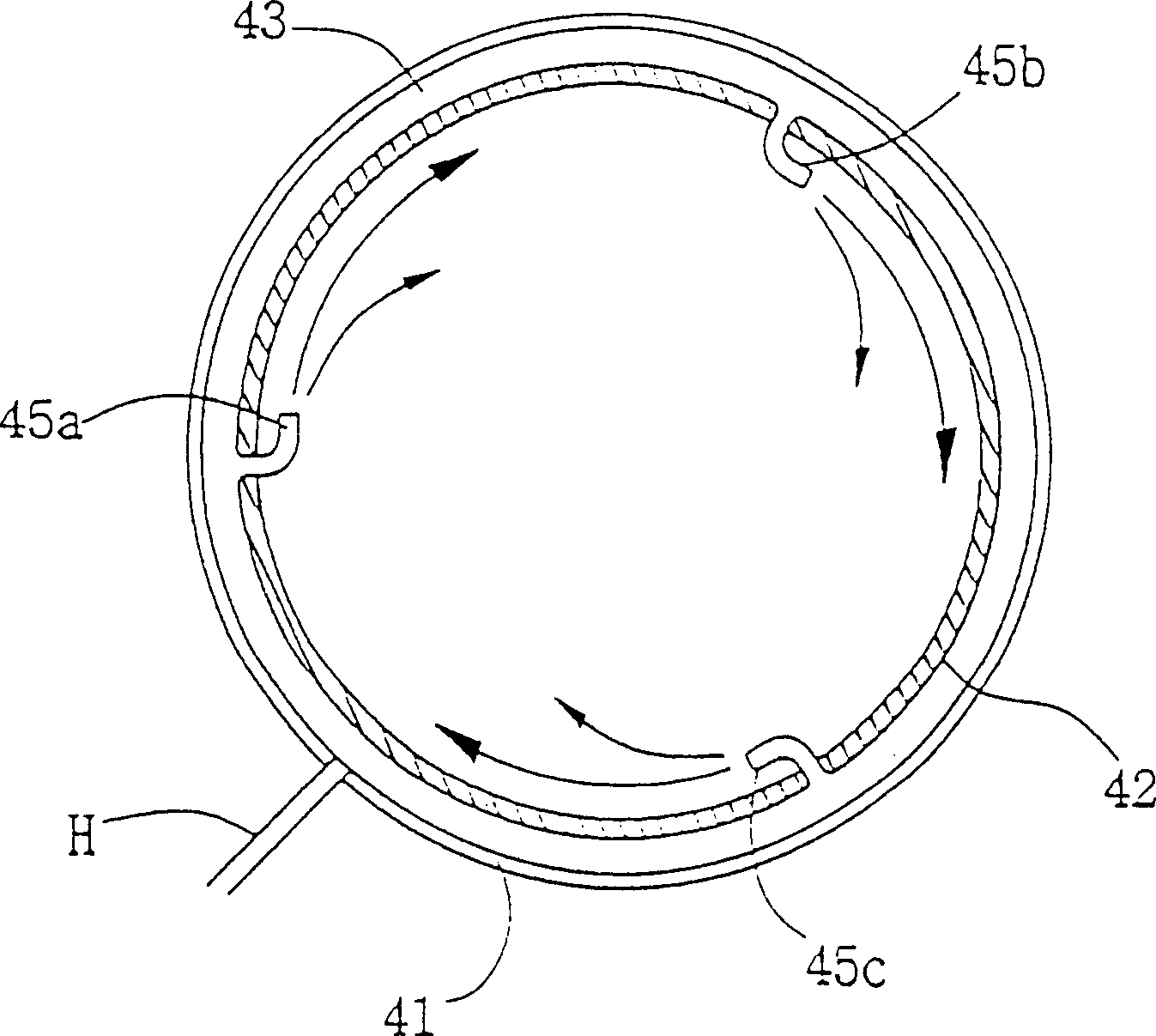

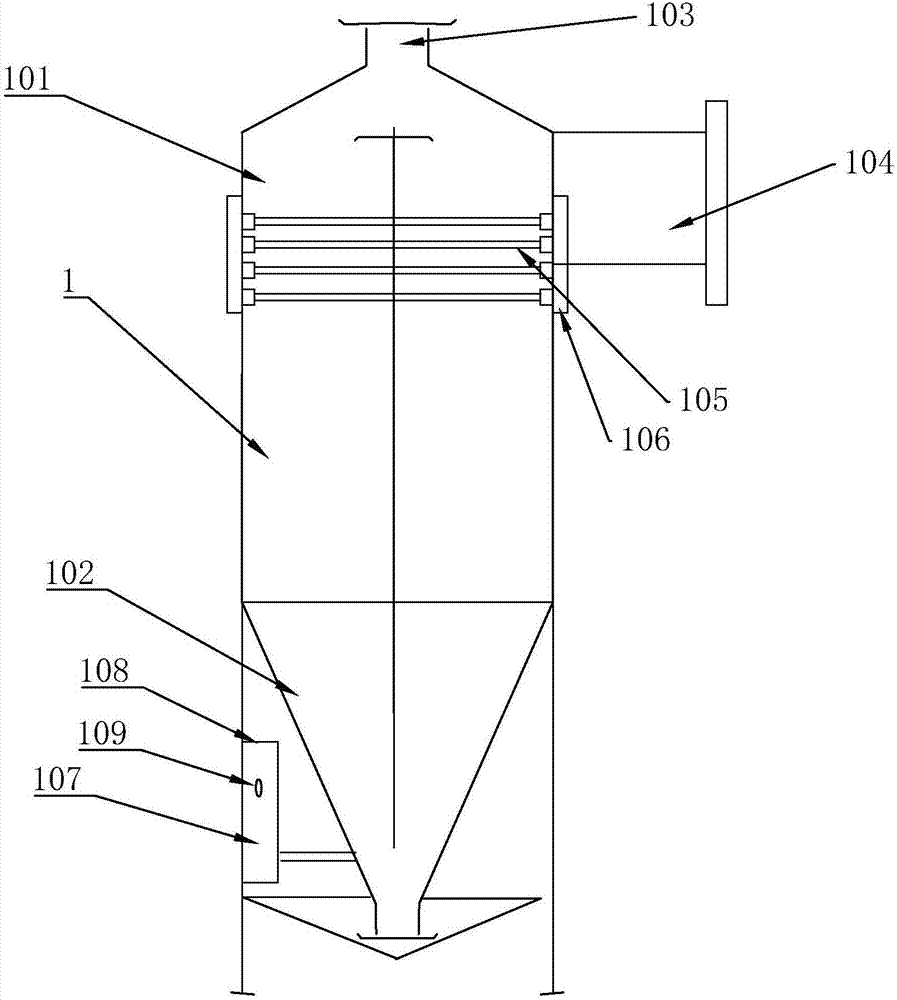

InactiveCN101791516AReduce intake air temperatureImprove acid removal effectCellsDispersed particle separationAmine gas treatingCyclone

The invention relates to the waste gas treating field of electroplating industry, in particular to a waste gas treating system. The waste gas treating system comprises a gas scrubbing tower. The front end of the gas scrubbing tower is provided with a cyclone separating tower, an air inlet part of which is provided with a plurality of gas inlet pipelines, and each gas inlet pipeline is respectively provided with a suction fan and an air suction cover. By taking the air inlet part of the cyclone separating tower as a connecting part, the gas inlet pipelines are counterclockwise arranged in the circumferential tangential direction of the air inlet pipeline. The gas inlet pipeline is respectively provided with a check baffle plate. At least one gas inlet pipeline at the front end of the cyclone separating tower is provided with equipment for pretreating special waste gas. The cyclone separating tower is provided with a cooling device. The system is provided with switches for flexibly adjusting the suction fans according to the treating requirement, therefore, the operation cost can be controlled, and the waste gas of different sources and properties can be flexibly treated; the gas inlet temperature of the gas scrubbing tower is decreased, the Reynolds number is increased, the acid removing effect of the gas scrubbing tower is enhanced, the usable waste acid can be recycled, and the resources are sufficiently saved.

Owner:惠州益伸电子有限公司

Exhaust gas treatment system

ActiveCN1807979AImprove the problem of dust accumulationShort cycleUsing liquid separation agentIncinerator apparatusAmine gas treatingExhaust fumes

The invention relates to a waste gas treating system, which comprises a guide channel, a fluid nozzle and a dust-collection box. Wherein, the guide channel is used to guide the burnt waste gas; the fluid nozzle is inside the guide channel to spray the fluid to cool the waste gas and adhere the dust on the fluid; and the dust-collection box is vertically connected to the lower outlet of guide channel to collect the dust and fluid.

Owner:AU OPTRONICS CORP

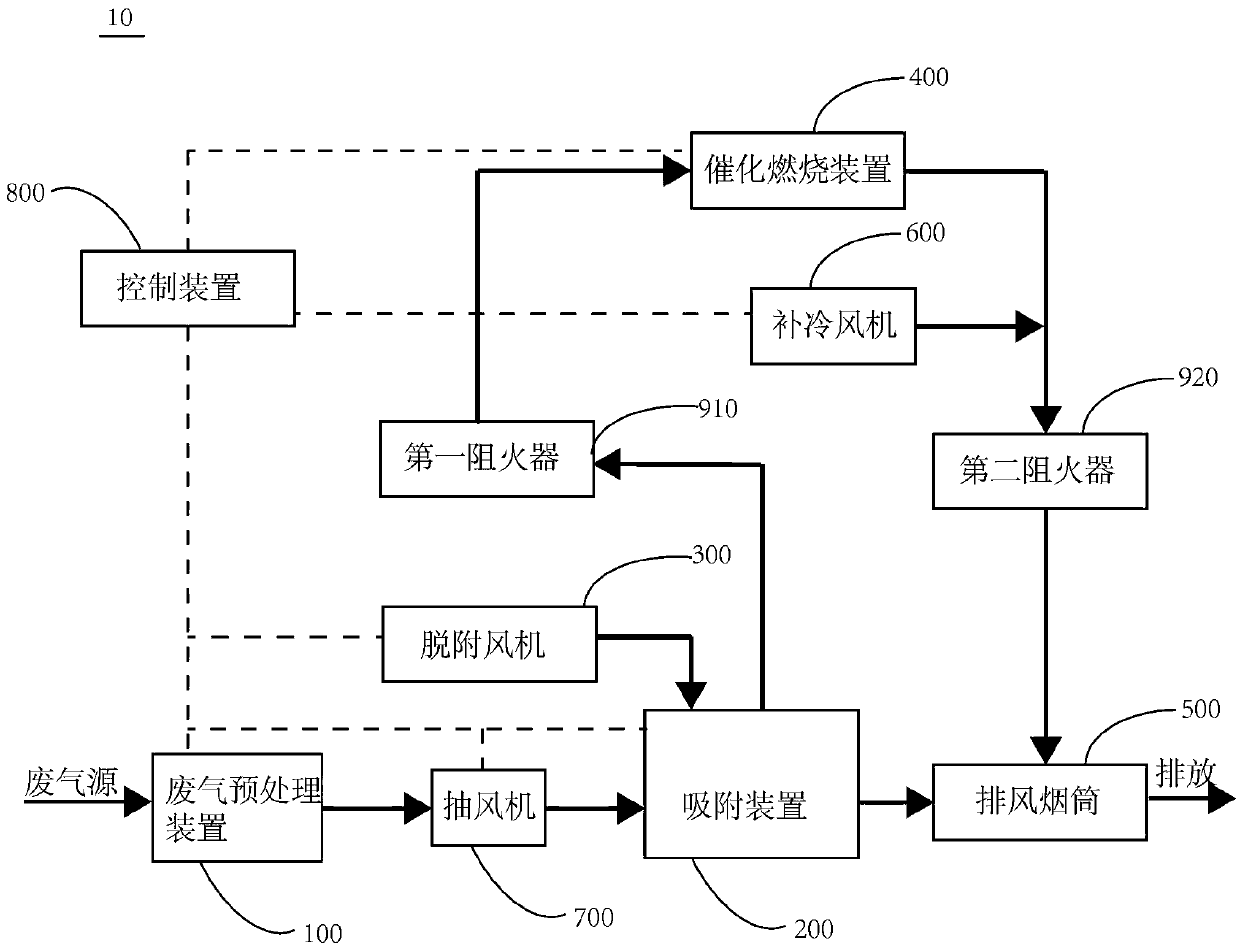

Waste gas treatment system

InactiveCN105498442AGuaranteed uptimeLow running costGas treatmentDispersed particle separationAmine gas treatingDesorption

The invention discloses a waste gas treatment system. The waste gas treatment system comprises a waste gas pretreatment device, an adsorption system, a desorption device and a catalytic combustion device. The waste gas pretreatment device is used for pre-treating waste gas from a waste gas source; the adsorption system is provided with an adsorption unit and used for performing adsorption treatment on waste gas treated by the waste gas pretreatment device; the desorption device comprises a desorption draught fan and a desorption valve; the desorption draught fan is connected with the adsorption unit; the desorption valve is arranged between the adsorption unit and the desorption draught fan and used for turning on / off the adsorption unit; the desorption draught fan is used for introducing hot air into the adsorption unit to obtain organic waste gas through desorption of the adsorption unit; a catalytic combustion bed is arranged on the catalytic combustion device, is communicated with the adsorption unit, and is used for sucking the organic waste gas desorbed from the adsorption unit, and decomposing the organic waste gas into CO2 and H2O through combustion. The waste gas treating system is simple to operate, high in purification efficiency, capable of saving energy and reducing consumption, and high in degree of automation.

Owner:SWELL MARUI GUANGZHOU AUTOMOBILE PARTS

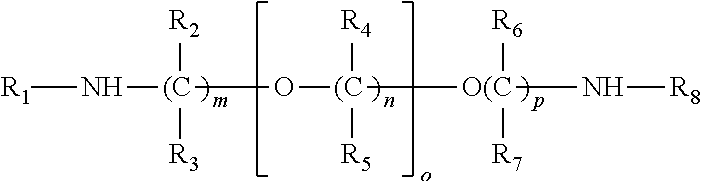

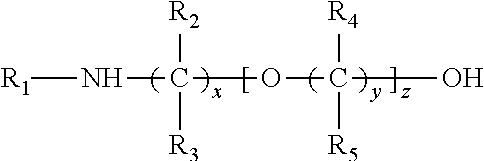

Amine gas treatment solutions

InactiveUS20130310623A1Readily availableGas treatmentOther chemical processesAmine gas treatingAntioxidant

A process for the selective absorption of acidic components from normally gaseous hydrocarbon mixtures using an aqueous amine absorbent solution comprising an antioxidant and a non-detergent co-solvent for the amine and the antioxidant.

Owner:EXXON RES & ENG CO

Waste gas treatment equipment and waste gas treatment system

InactiveCN1415425ALarge amount of processingReduce processing costsReversed direction vortexDispersed particle separationCycloneToxic gas

A waste gas treating system is composed of incinerator, cooler, blower, primary and secondary cyclone units, waste gas treater, multi-tube cyclone separator, motor, valves, pipeline, chimney and steam generator communicated to waste gas treater. Its advantages are large area for capturing impurities and toxic gas, high treating capacity and energy to adsorb dust particles.

Owner:威海元泰克环保设备有限公司

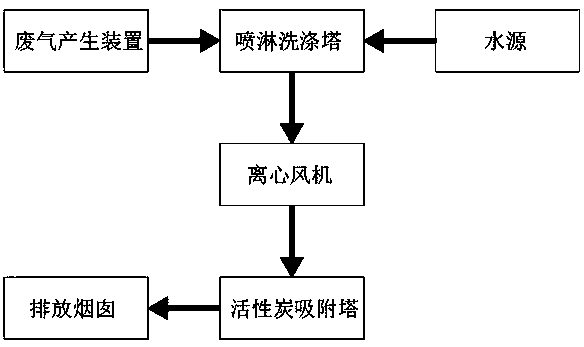

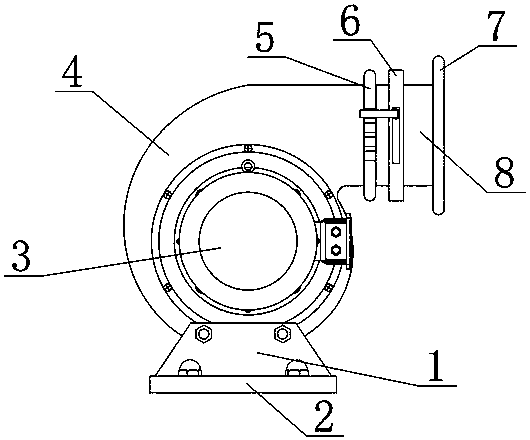

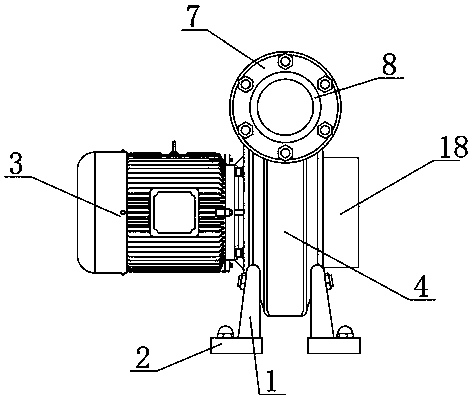

Waste gas treating system

InactiveCN108479303AReduce vibrationAvoid damageDispersed particle separationAmine gas treatingActivated carbon

The invention discloses a waste gas treating system. The waste gas treating system comprises a spraying tower, a centrifugal fan, an activated carbon adsorption tower, a blowdown stack and a fan casing, wherein a motor is fixedly connected to one side of the fan casing; an exhaust pipe is fixedly connected to the upper side of the fan casing; an air quantity regulating ring is arranged on one sideof the exhaust pipe; a fixed plate is arranged on one side of the air quantity regulating ring and is fixedly connected with the exhaust pipe by screws; a connecting flange is fixedly connected to one end of the exhaust pipe; an inner pore diameter plate is fixedly connected to the inner side of the air quantity regulating ring; an air outlet is formed in the surface of the inner pore diameter plate; an inner revolving ring is arranged on one side of the inner pore diameter plate. The air quantity regulating ring is arranged on the exhaust pipe; when the centrifugal fan is used, baffles rotate to adjust the size of the air outlet by rotating an adjusting rod, so that the problem that air quantity of the centrifugal fan cannot be adjusted is solved.

Owner:杭州绿一环保技术有限公司

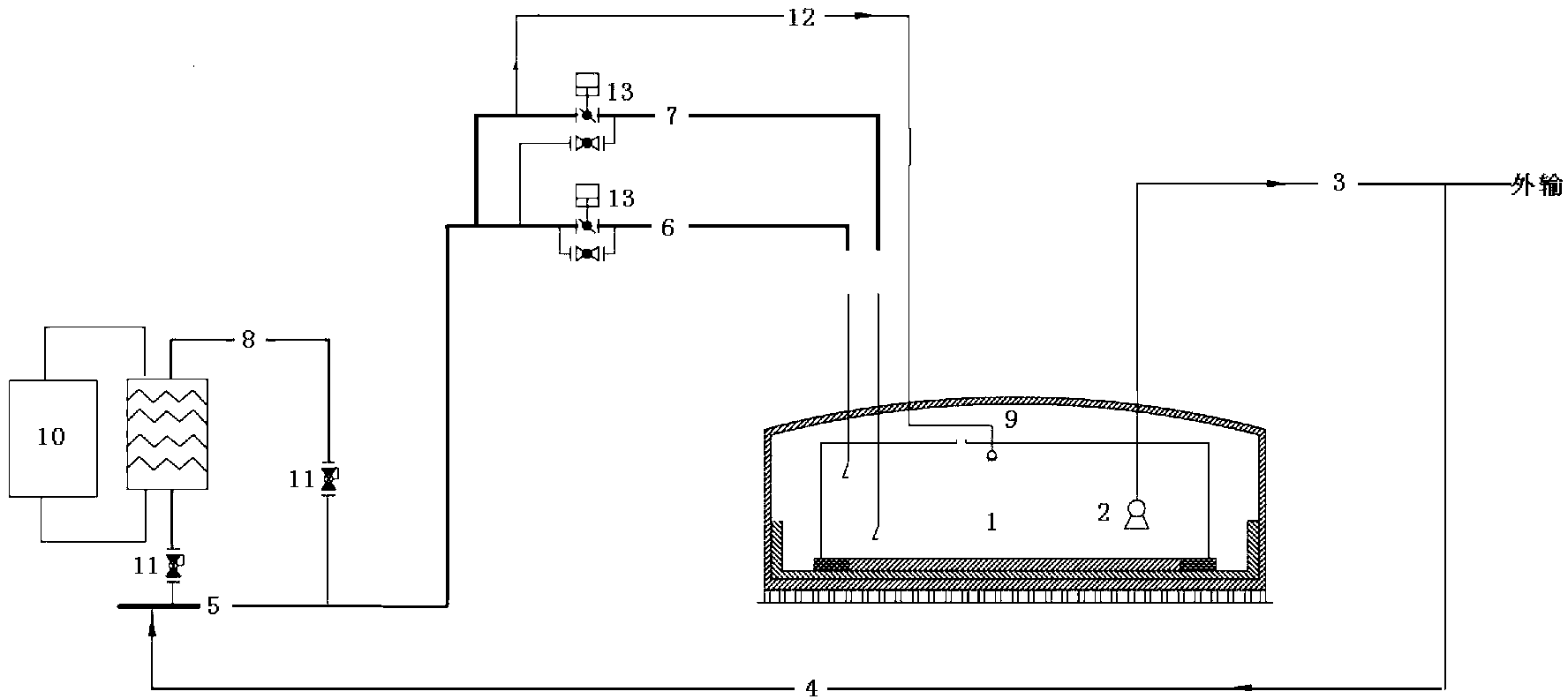

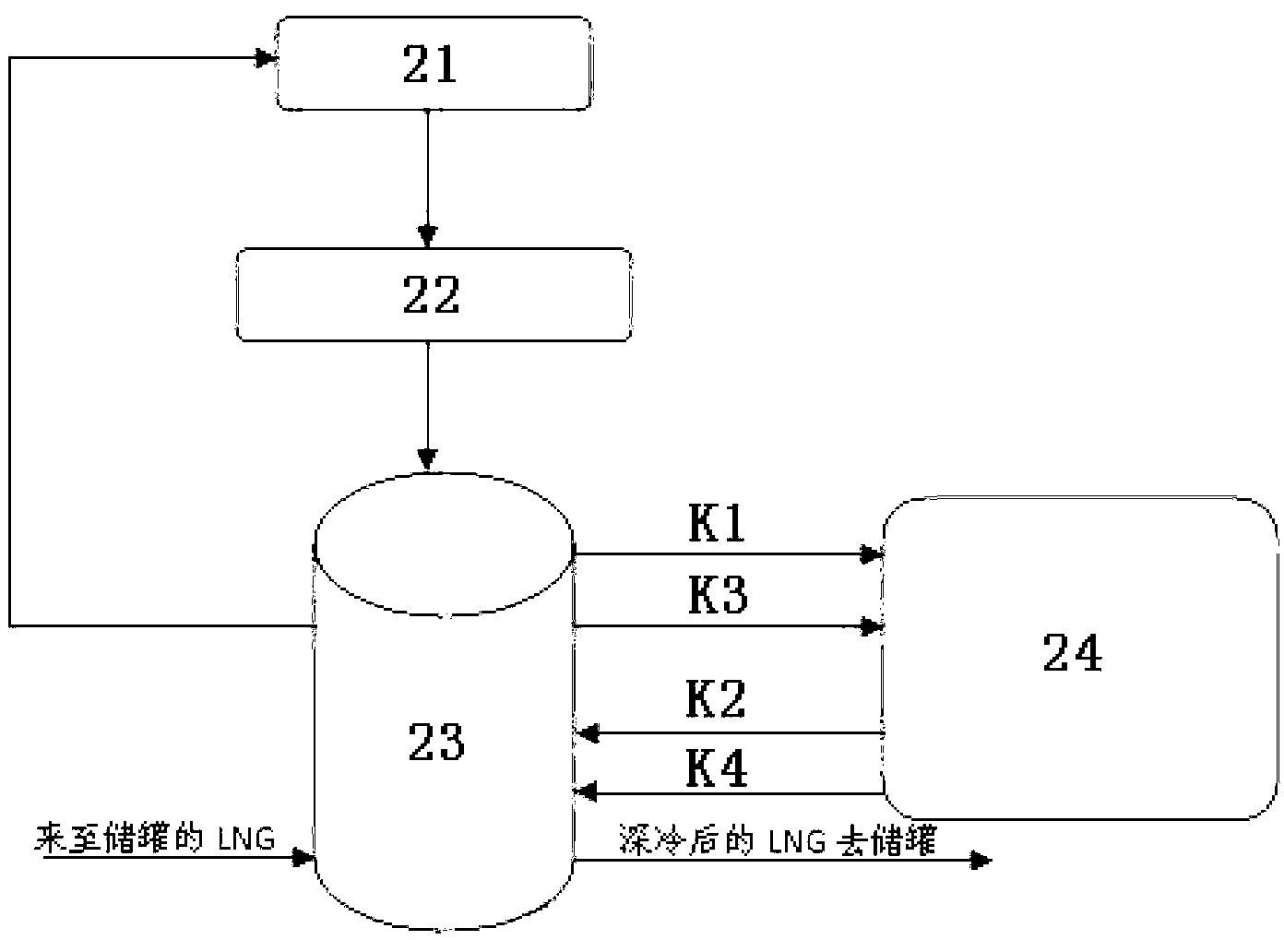

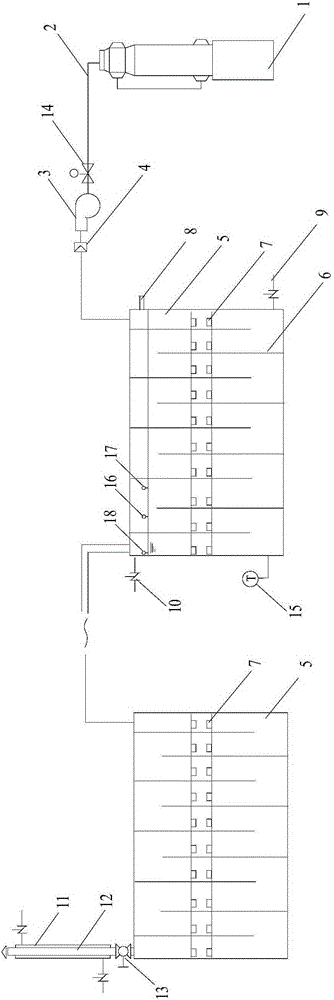

Low-energy-consumption zero-emission evaporated gas treating system of liquefied natural gas (LNG) receiving station

ActiveCN103234117APressure change controlRelieve pressurePipeline systemsAmine gas treatingEconomic benefits

The invention relates to a low-energy-consumption zero-emission evaporated gas treating system of a liquefied natural gas (LNG) receiving station. The characteristics that wharf unloading pipelines need to be opened in normal operation working conditions and intermittent zero outward conveying working conditions of the LNG receiving station for cold insulation circulation are utilized, an LNG refrigerating branch is arranged on a cold insulation circulation pipeline of the existing wharf discharging pipeline of the LNG receiving station, LNG is led out from the cold insulation circulation pipeline and further cooled by aid of a refrigerating device, and the cooled LNG is fed back to a previous pre-cooling spraying system at the top of an LNG storage tank and sprayed into the LNG storage tank through the previous pre-cooling spraying system, so that boiled off gas (BOG) in the tank can be absorbed, and zero-emission treatment of the BOG can be achieved. The low-energy-consumption zero-emission evaporated gas treating system is particularly suitable for peak adjusting type LNG receiving stations, can ensure safe operation of the system under the working conditions of intermittent zero outward conveying, can avoid huge waste caused by the traditional BOG discharging depressurizing mode and has outstanding economic benefit.

Owner:CHINA NAT OFFSHORE OIL CORP +1

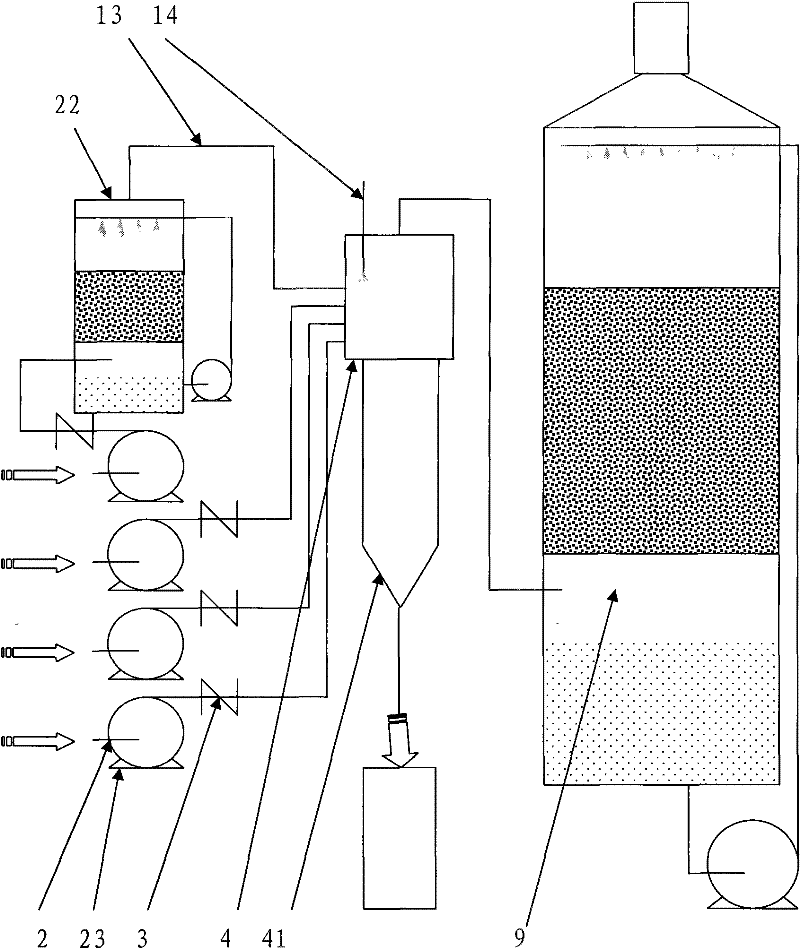

Organic waste gas treatment system

InactiveCN104689682AThorough treatmentReduce consumptionUsing liquid separation agentActivated carbonAmine gas treating

The invention discloses an organic waste gas treatment system, which comprises a suspended hood, an exhaust duct system, an electronic control system and a waste gas treating system, and is characterized in that the waste gas treating system comprises a wet-type scrubbing tower, an exhaust fan and a dry-type activated carbon absorption tower, the suspended hood is connected with the wet-type scrubbing tower, the outlet of the wet-type scrubbing tower is provided with the exhaust fan, the exhaust fan is connected with the dry-type activated carbon absorption tower, and a flue is connected with the dry-type activated carbon absorption tower. The organic waste gas treatment system has the beneficial effects that the comprehensive wet-type water scrubbing and dry-type absorption are adopted, waste gas first enters the wet-type scrubbing tower, then is subjected to absorption treatment of the double-stage activated carbon absorption tower, the process structure is simple, the ventilation quantity and wind pressure are uniform, dry-type activated carbon is small in consumption, the efficiency is high, the equipment is stable in operation, the waste gas is thoroughly treated, and the national requirements on discharge standard are met.

Owner:苏州仕净科技股份有限公司

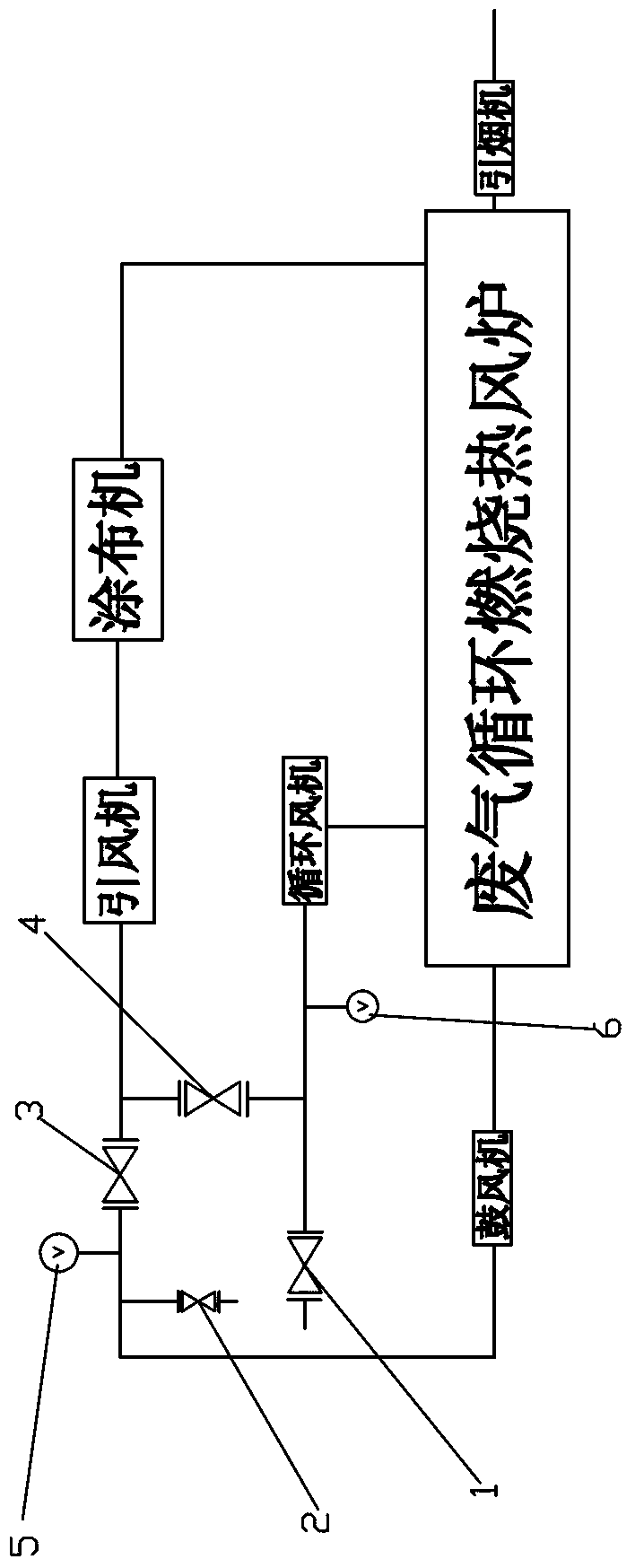

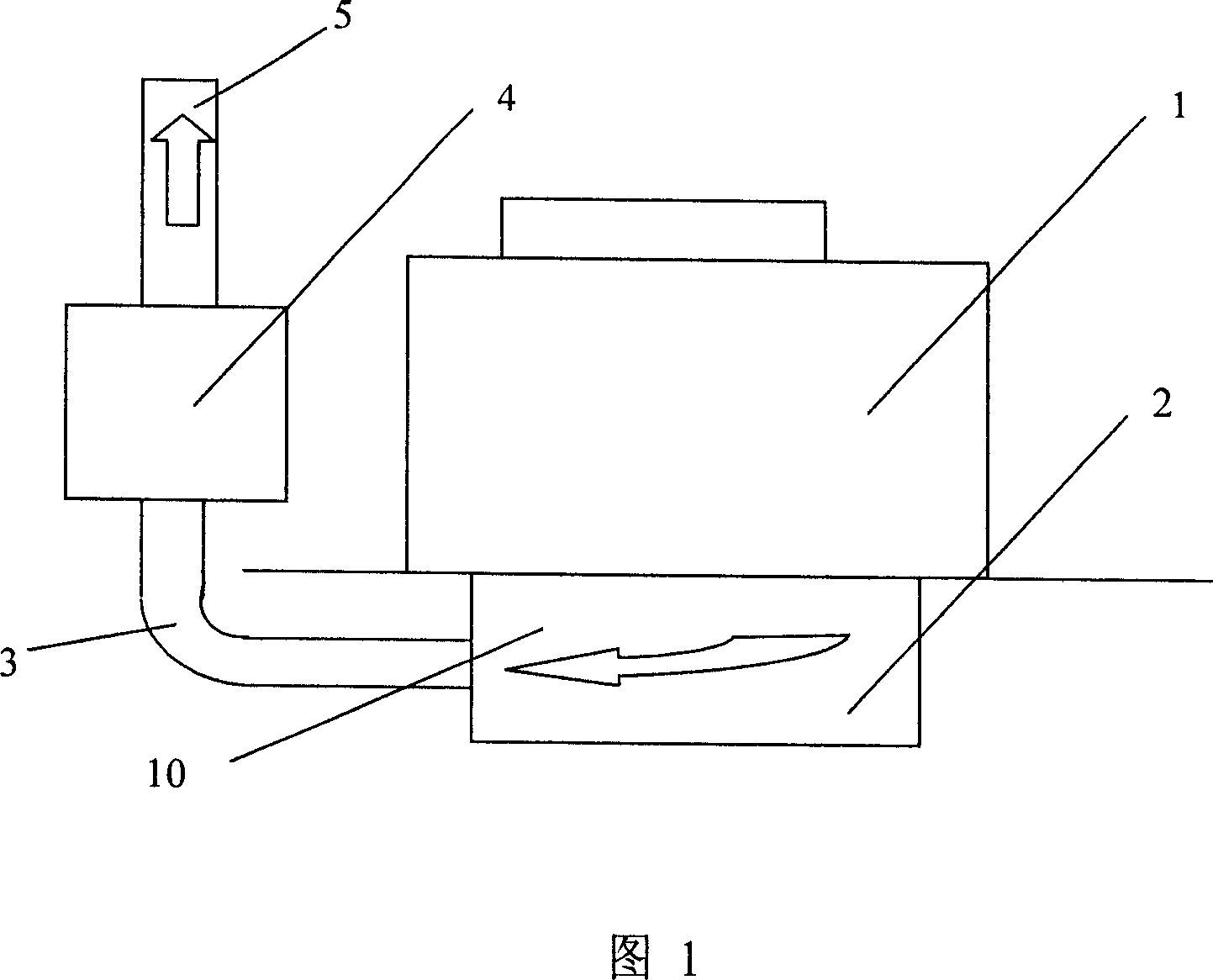

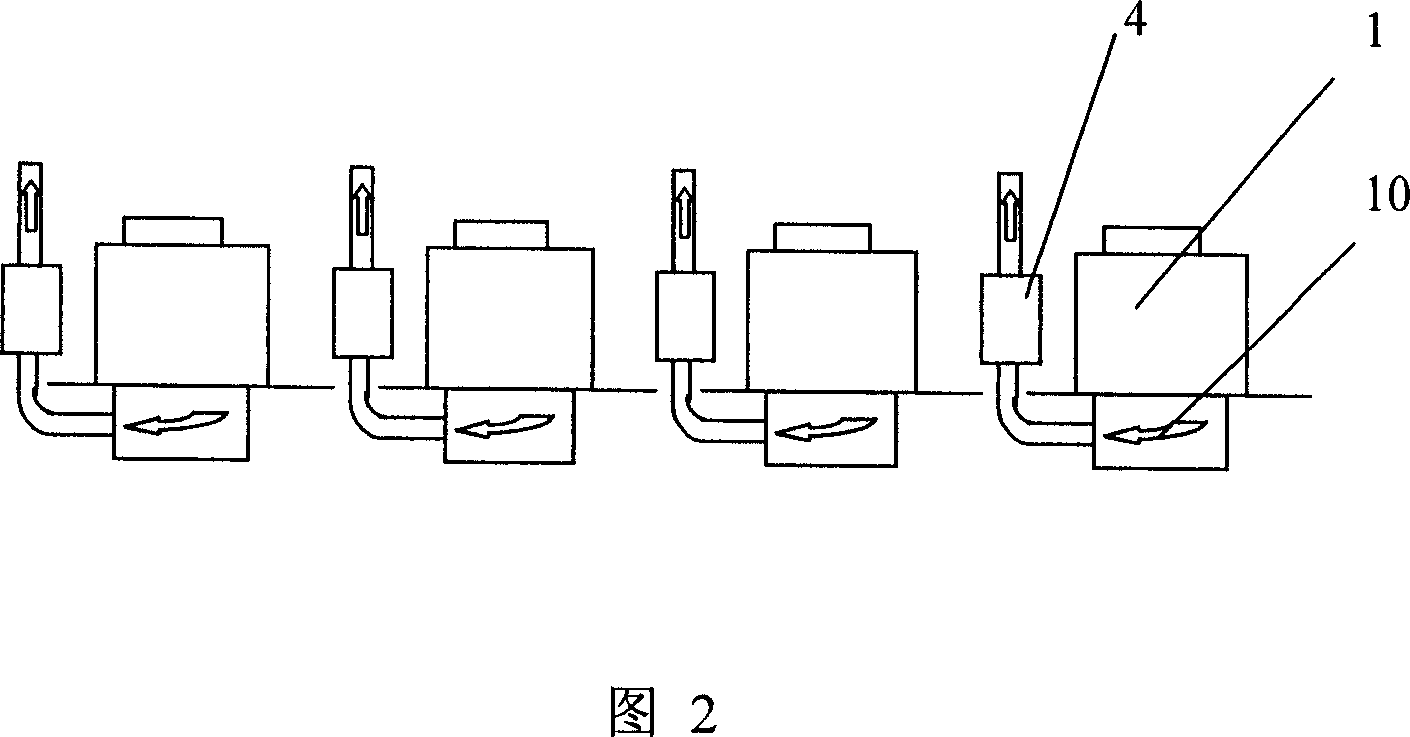

Circulation thickening waste gas treating system

InactiveCN103267411AAvoid pollutionWill not affect the coating effectDrying gas arrangementsHeating arrangementAmine gas treatingCombustion

The invention relates to a circulation thickening waste gas treating system. The circulation thickening waste gas treating system comprises a coating machine which is connected with a waste gas circulation combustion hot blast stove and an induced draft fan. The waste gas circulation combustion hot blast stove is connected with an air blower and a circulating fan. The circulating fan is connected with an air valve. The air blower is connected with a first valve. The induced draft fan is connected with a second valve. The first valve is connected with the induced draft fan. One end of the second valve is connected between the air valve and the circulating fan, and the other end of the second valve is connected between the first valve and the induced draft fan. An oxygenating valve is connected between the first valve and the air blower. Organic waste gas in the coating machine is extracted from the induced draft fan and then recycled, on the premise of safety control, stable combustion is conducted, combustion of biomass fuel can be replaced by released heat, the organic waste gas released from the coating machine can be effectively utilized, air pollution is avoided, and the purposes of energy conservation and emission reduction are actually achieved.

Owner:浙江光炎节能环保科技股份有限公司

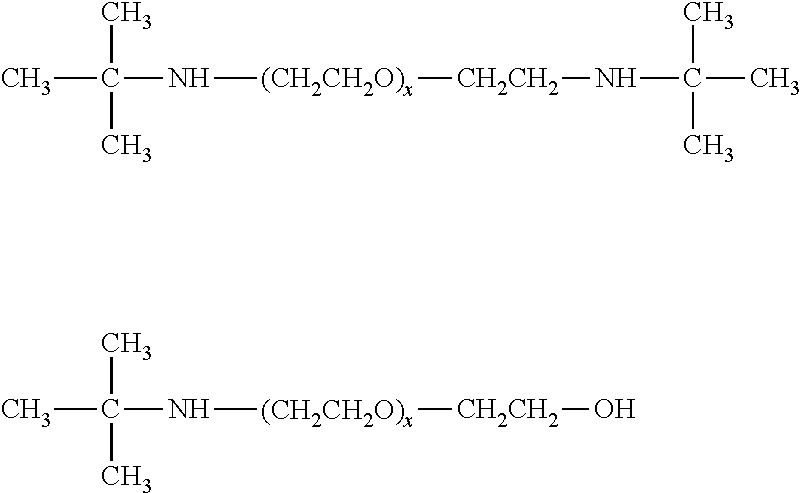

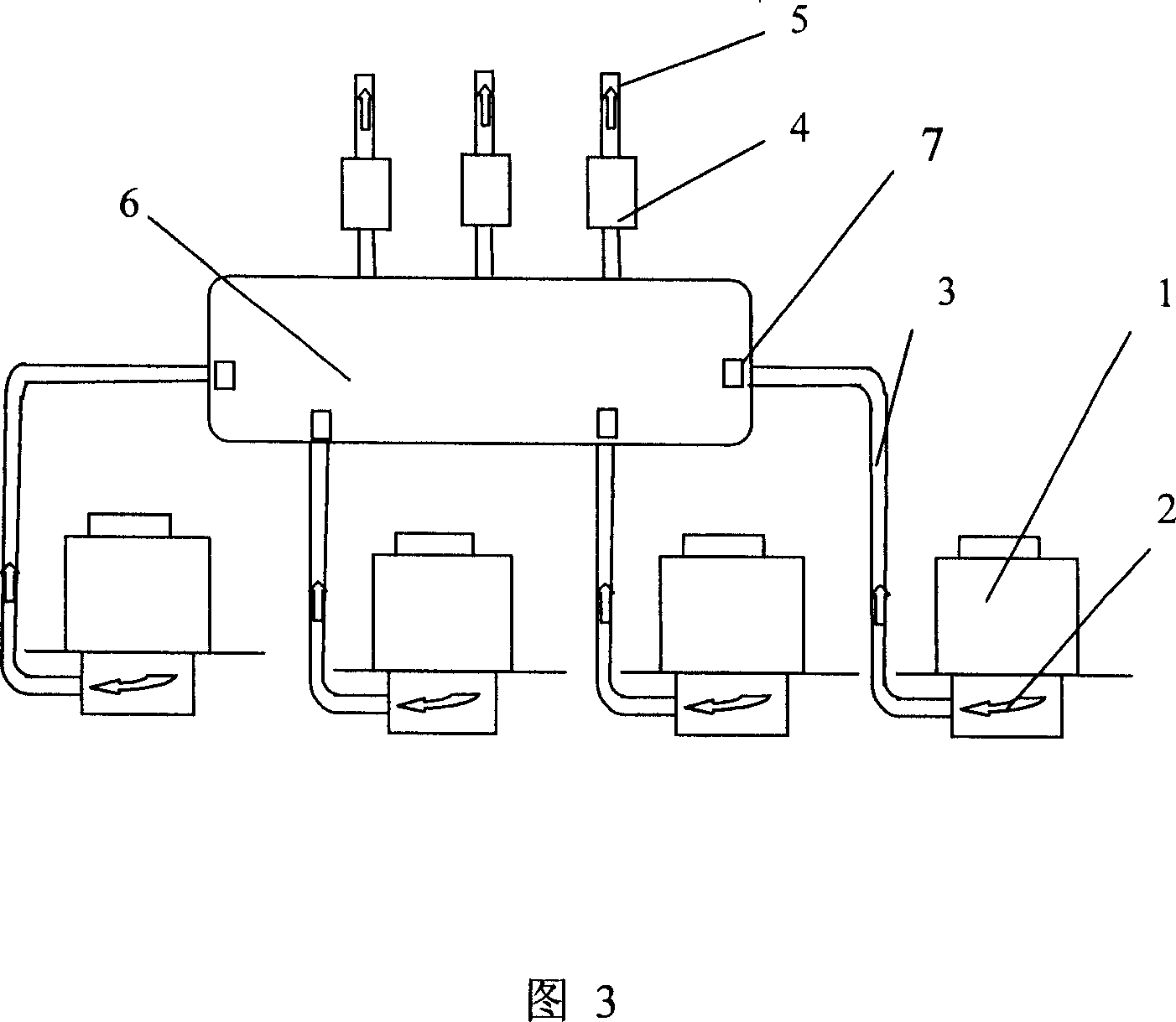

Paint refused-gas treating system and treatment for paint house

ActiveCN1939599AEven workloadImprove efficiencyLiquid surface applicatorsCoatingsAmine gas treatingAir cleaning

A paint-contained air treating system for the painting rooms is composed of more than two sets of stage-one air treating unit, one set for one painting room, a stage-two air cleaning unit with an exit communicated to atmosphere, and a buffer container connected between said air treating units and air cleaning unit for the flow matching.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

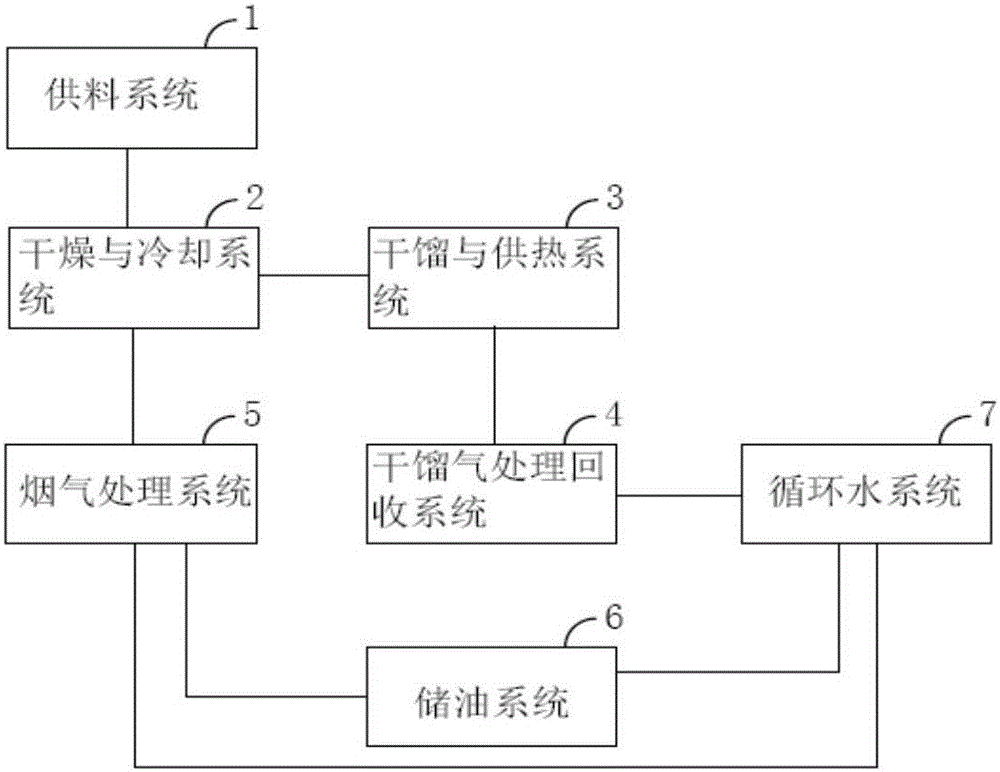

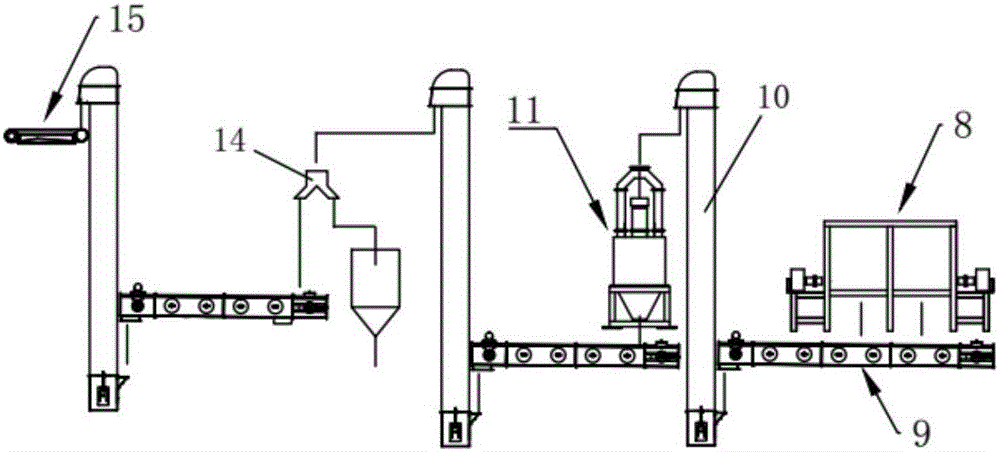

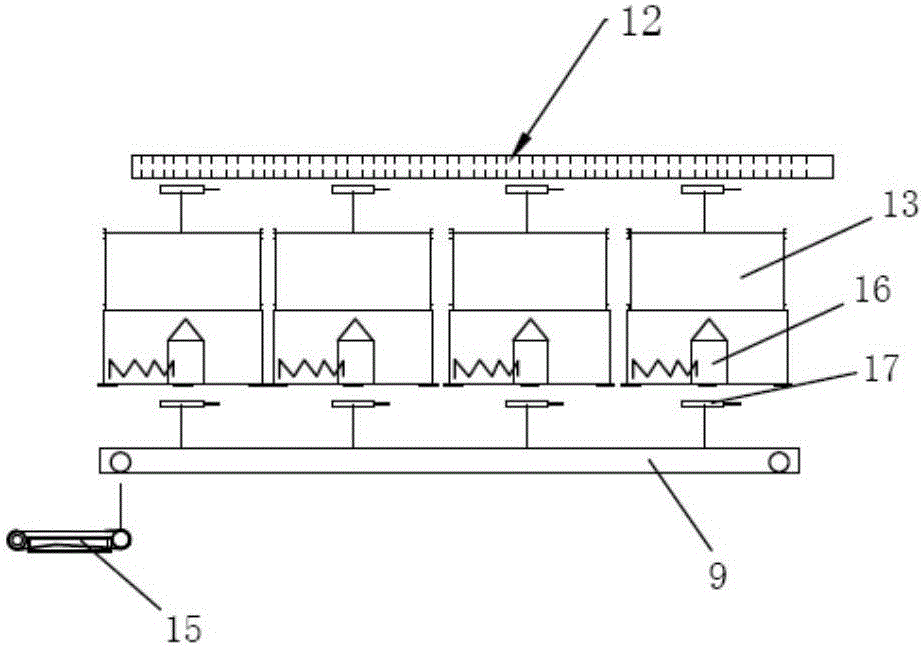

Oil sand dry distilling system

InactiveCN106833692ARealize continuous dry distillationFast distillationLiquid hydrocarbon mixture productionSpecial form destructive distillationAmine gas treatingProcess equipment

The invention relates to the technical field of dry distilling equipment and provides an oil sand dry distilling system. The oil sand dry distilling system comprises a feeding system, a drying and cooling system, a dry distilling and heat supply system, a dry distilling gas treating and recycling system, a flue gas treating system, an oil storage system and a circulating water system, wherein the feeding system comprises a raw material feeding device and a raw material storing device; the drying and cooling system comprises a scraper dryer; the dry distilling and heat supply system comprises a dry distilling device and a heat supply mechanism; the dry distilling gas treating and recycling system comprises a heating area dry distilling gas treating recycling device and a dry distilling area dry distilling gas treating recycling device; the flue gas treating system comprises a wet dust collector; the oil storage system comprises an oil storage tank used for storing end product of oil; the circulating water system comprises a centrifugal water pump and a water reservoir; and the continuous dry distilling for the oil sand is realized, the dry distilling speed is high, the energy consumption is low and the service life of the system is prolonged.

Owner:克拉玛依市恒通能源有限公司 +1

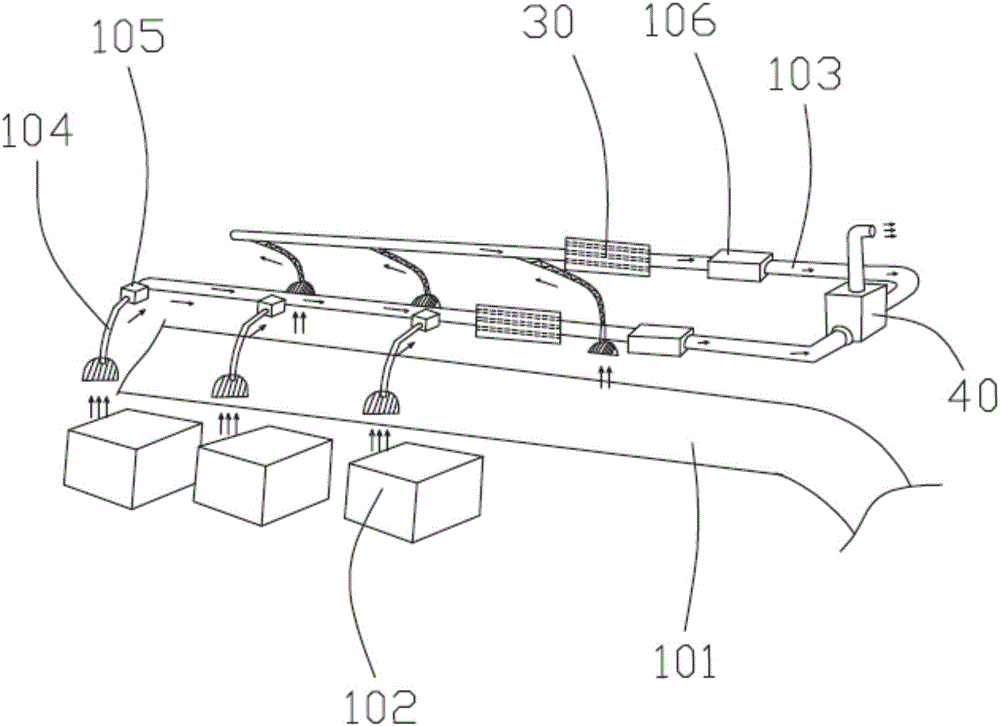

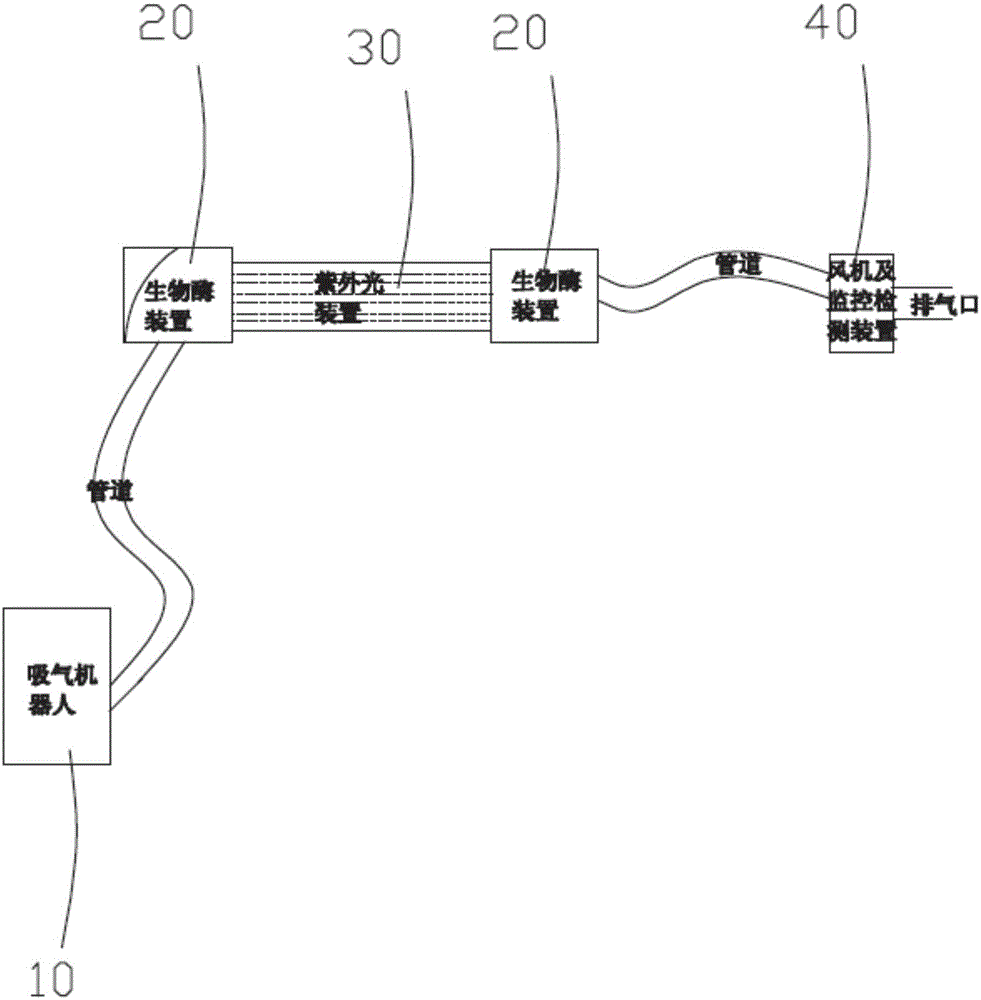

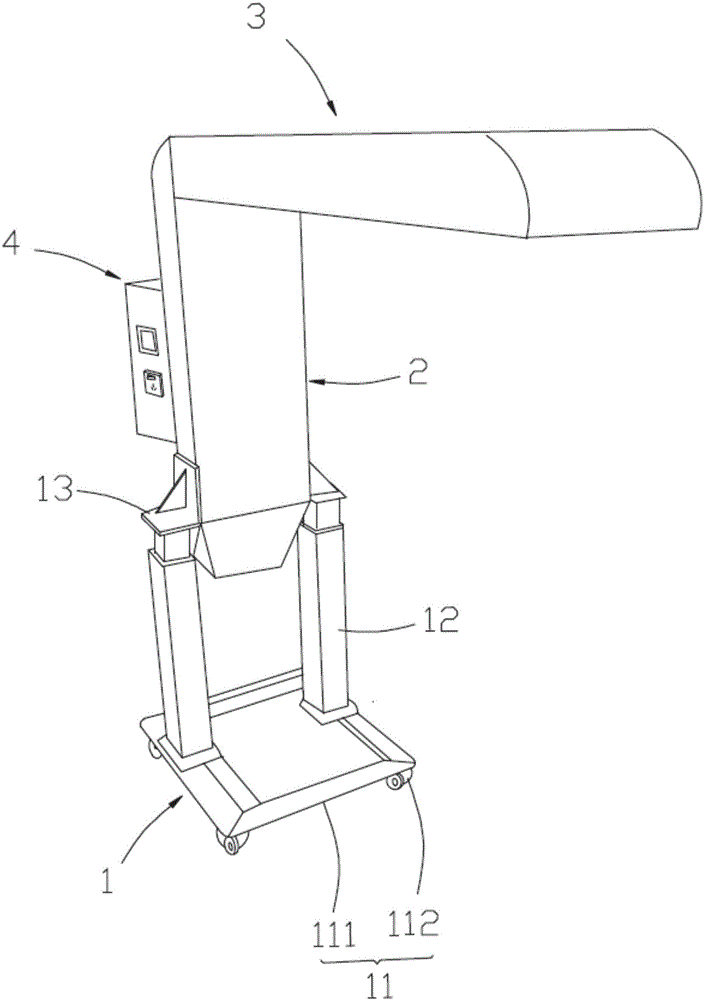

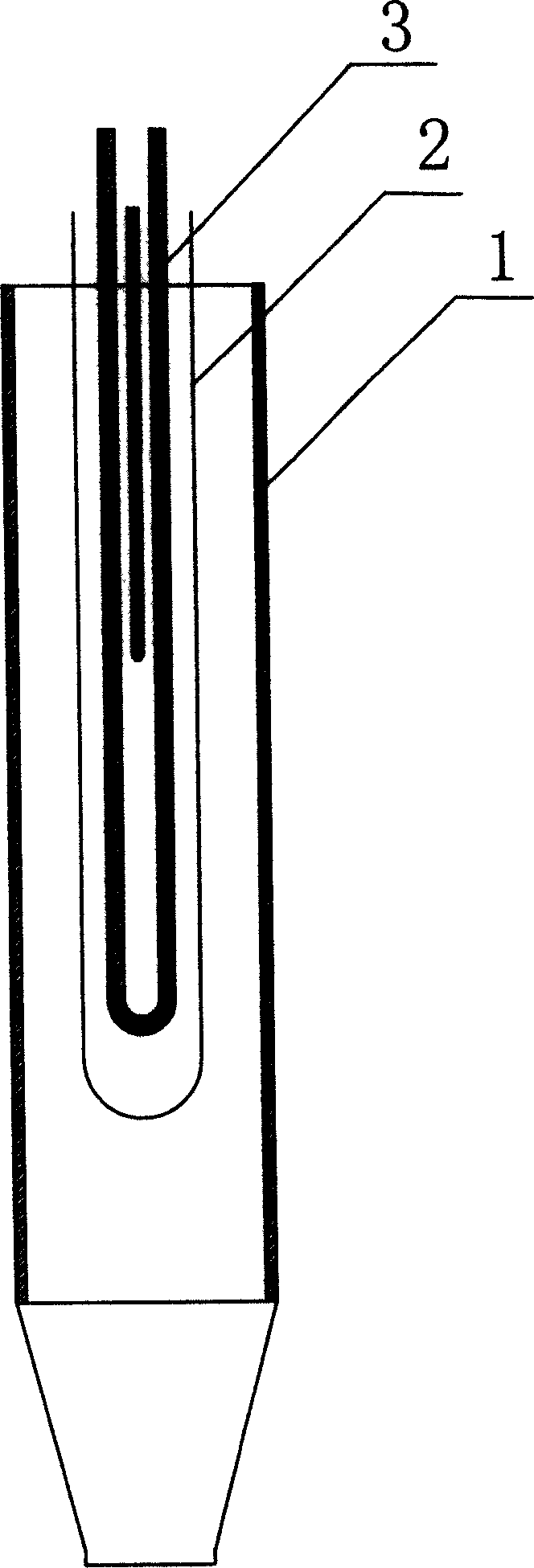

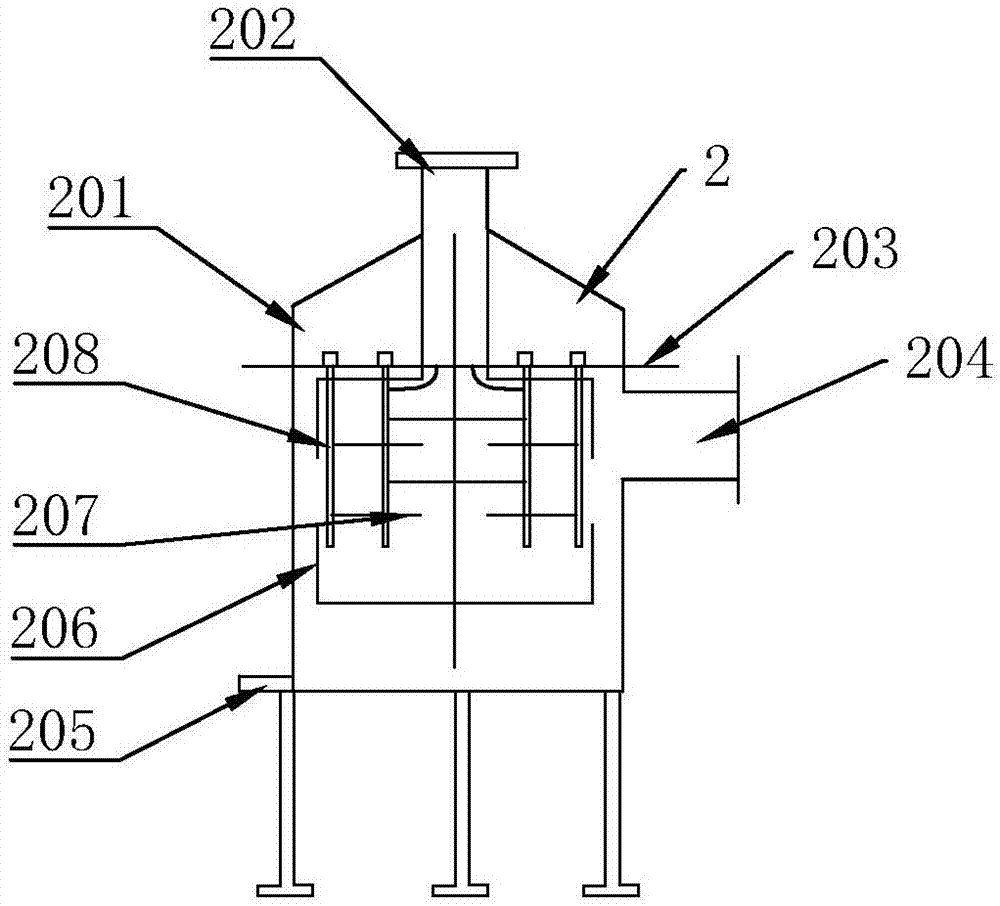

Bio-enzyme device and VOC (Volatile Organic Compounds) gas treating system with same

ActiveCN106000083ASimple structureGood enzymatic effectGas treatmentDispersed particle separationAmine gas treatingEnzyme digestion

The invention provides a bio-enzyme device. The bio-enzyme device comprises a box body and a plurality of solution sucking rods, wherein the box body comprises a top frame, a middle frame and a bottom frame, a microbial culture solution and / or a nutrient solution are separately accommodated in the top frame and the bottom frame, one pair of opposite sides of the middle frame are run-through and can enable gas flow to pass through, the solution sucking rods are arranged in the middle frame, and the two ends of each solution sucking rod separately extend into the top frame or bottom frame so as to suck the solution in the top frame or bottom frame. The bio-enzyme device provided by the invention is simple in structure and has a good enzyme digestion effect on VOC, and the VOC gas treating system with the bio-enzyme device can be used for adequately removing organic components from VOC gases.

Owner:佛山瀚兽环境科技服务有限公司

Combustion chamber structure of waste gas treating system

This invention is a structure of firebox in a waste gas treating system. The structure includes firebox, heating rod and protection jacket of heating rod. Its characteristics are: there is a coating on the internal wall of firebox, this coating is one of zirconium oxide complex, alumina and alumina complex coating. The material of protection jacket of heating rod is alumina ceramics. This invention is tolerant not only to the corrosion of poisoning gas, but also to the high temperature, can safely treat waste gases and poisoning gas with high efficiency, makes the discharging gas meet the regulations of environment protection.

Owner:真一(上海)集成电路设备有限公司

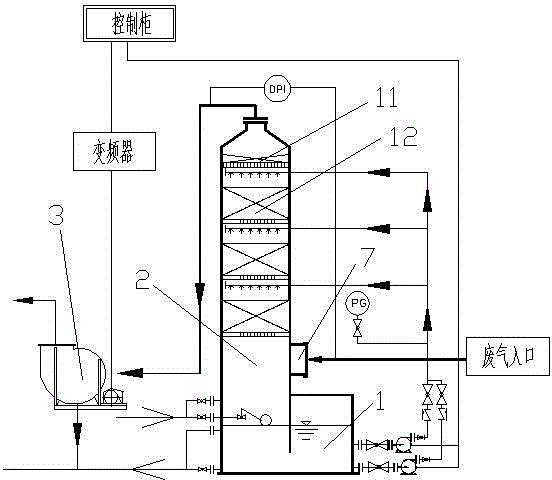

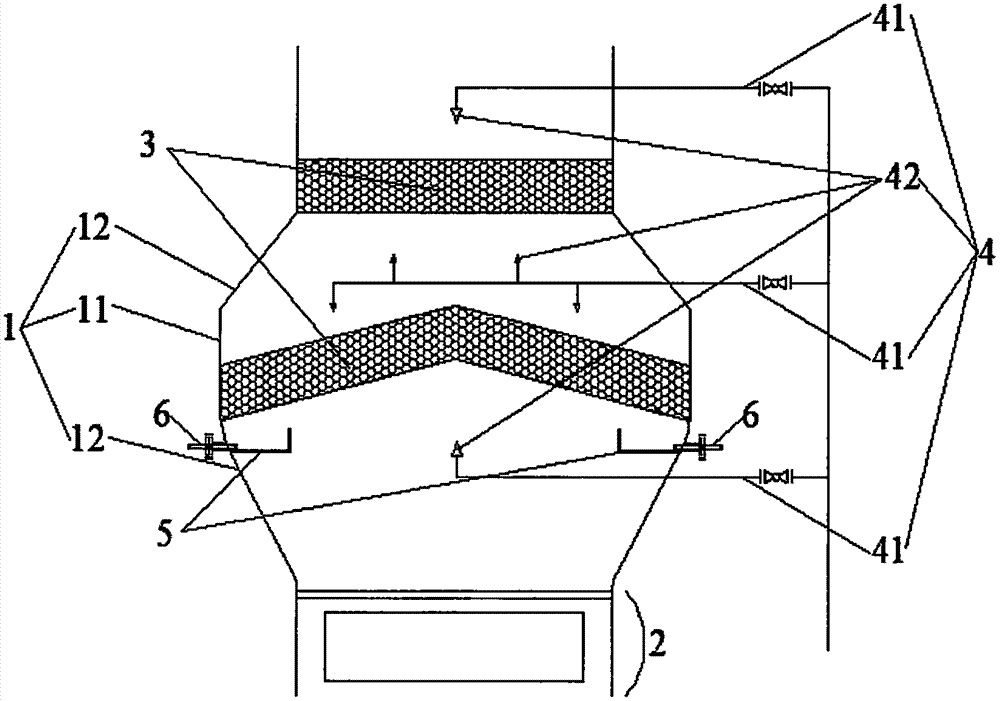

High-efficiency gas purification tower and gas treating system

ActiveCN106984116AImprove purification efficiencyEffective racemizationCombination devicesGas treatmentAmine gas treatingFlue gas

The invention provides a gas treating tower and a gas treating system. The gas treating tower is used for gas purification or separation and comprises a tower body, a packing layer and a pipeline spray-washing system, wherein at least one packing layer is arranged in and across the tower body, and the sidewalls of the packing layer are connected with the peripheral inner wall of the tower body; the pipeline spray-washing system is arranged in the tower body and used for flushing the packing layer; and the packing layer comprises a silk screen layer and a plurality of spherical filling materials arranged in the silk screen layer. According to the gas treating tower, since the packing layer is arranged in the tower body, when flue gas passes through the packing layer, the packing layer can realize better gas-liquid distribution and sufficient contact and effectively eliminates rotation of rotationally-flowing gas and disperses the rotationally-flowing gas; entrainment and flue dust entrained in gas are effectively and rapidly adsorbed and intercepted by the spherical filling materials and a liquid film formed by the filling materials; so the purpose of cleaning flue gas is achieved, and flue gas purifying efficiency is improved. Meanwhile, the pipeline spray-washing system is employed for flushing flue gas, so flue gas is further purified.

Owner:BEIJING CHINA SCI PURIFICATION ECO TECH

Waste-gas treating system

PendingCN107344064AFully atomizedFully decomposedGas treatmentDispersed particle separationElectricityAmine gas treating

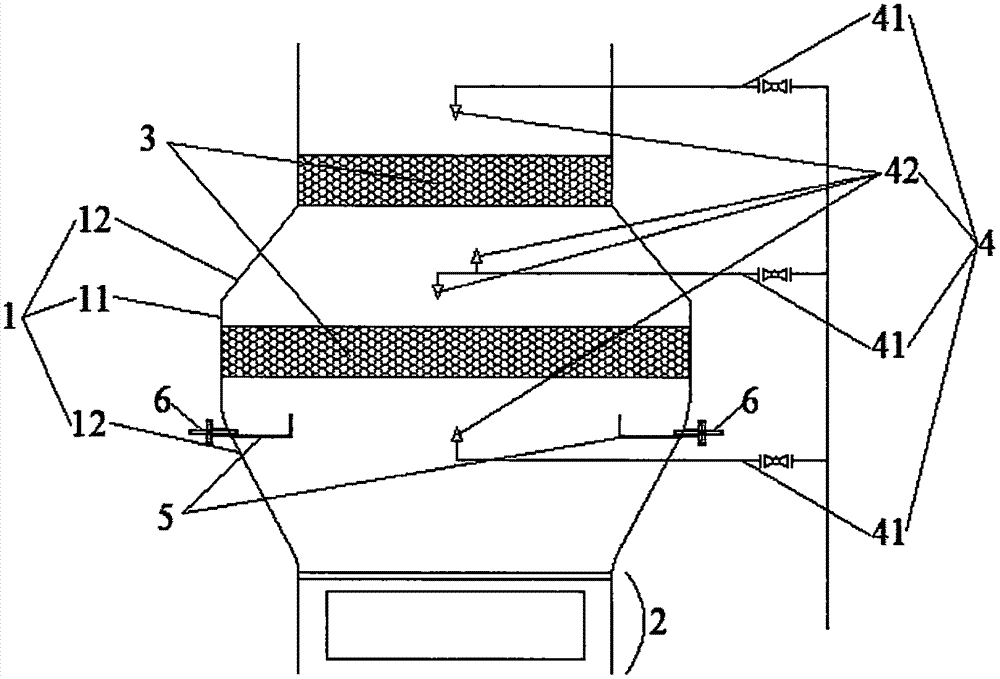

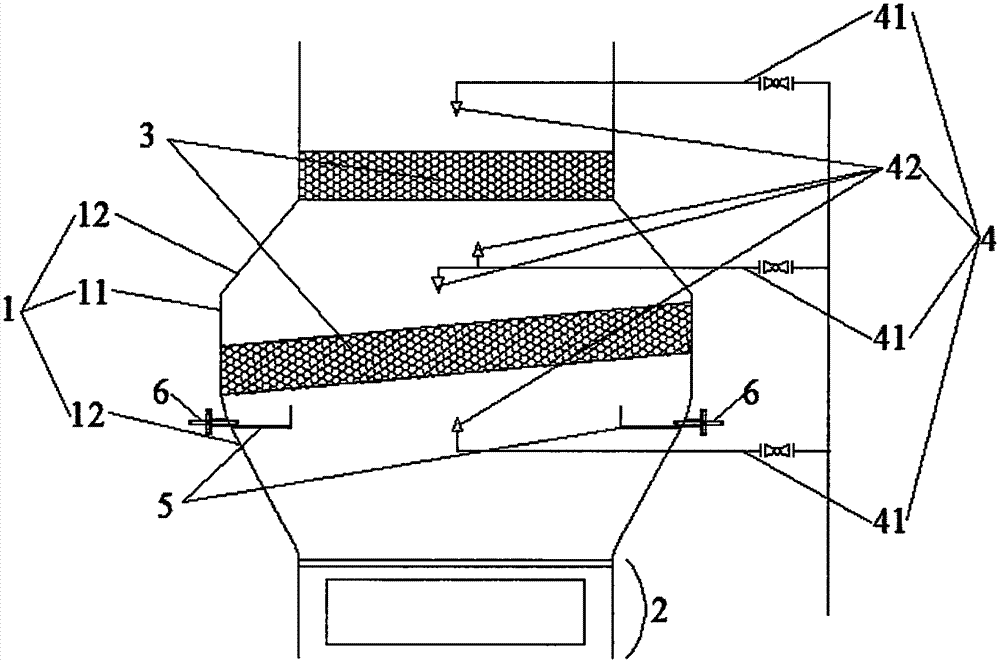

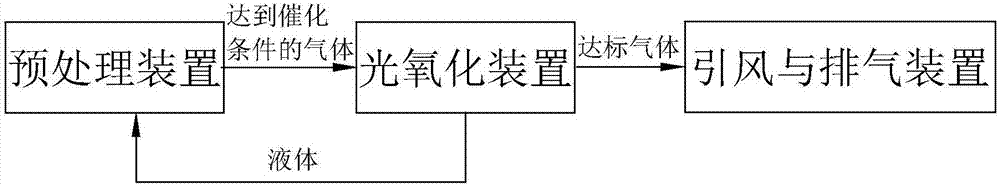

The invention relates to a waste-gas treating system. The waste-gas treating system comprises a pretreating device, a photooxidation device and an air inducing and exhausting device which are connected in sequence, wherein the pretreating device comprises a pretreating tank and a catalyzing tank; a first air inlet is arranged at the top end of the pretreating tank, a first air outlet is arranged at the upper side of the pretreating tank, an electric-shock magnetic resonance device is arranged in the pretreating tank, and the catalyzing tank is positioned at the lower part of the pretreating tank and is in a shape of an inverted cone; the photooxidation device comprises a photooxidation shell; the top end of the photooxidation shell is provided with a second air inlet communicated with the first air outlet; the upper side of the photooxidation shell is provided with a second air outlet communicated with the air inducing and exhausting device; the photooxidation shell is internally provided with a photooxidation module and a convolution device; the convolution device comprises a convolution disc body which is communicated with the second air inlet; and the photooxidation module is positioned in the convolution disc body. The waste-gas treating system has the advantages that by adoption of a structure form combining an electric-shock magnetic resonance technology and a photooxidation technology, the effects of energy saving, high efficiency and environment friendliness are achieved.

Owner:南京凯创金源科技开发有限公司

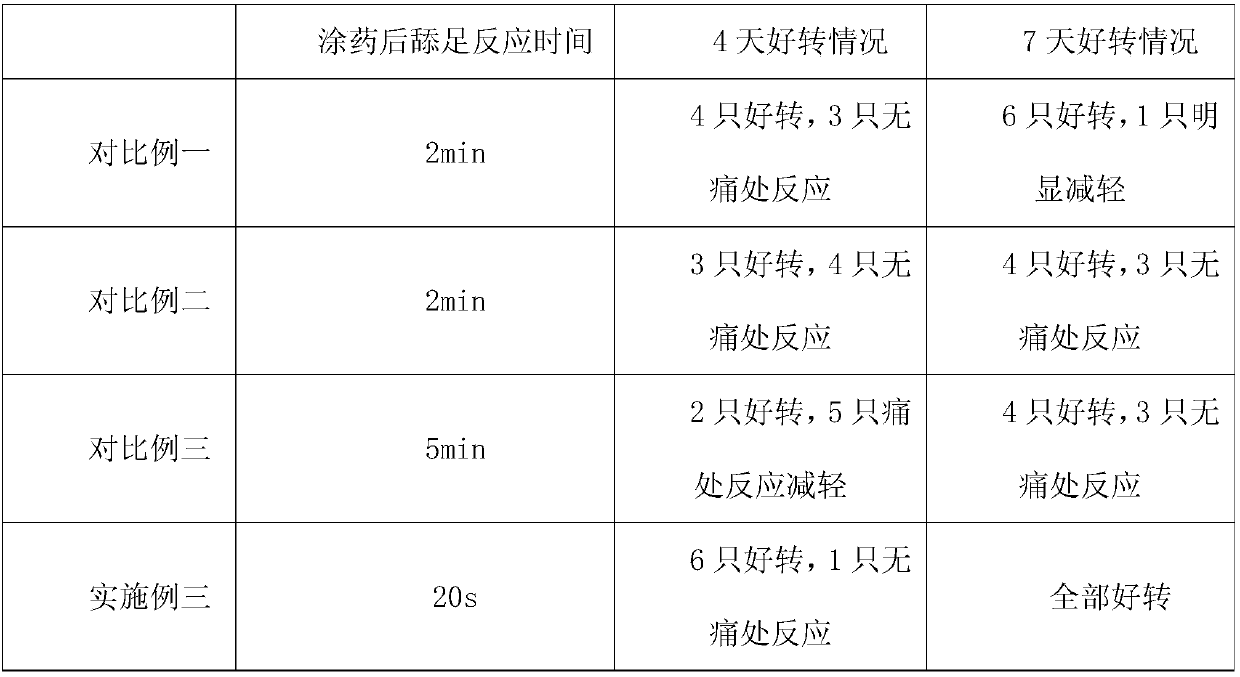

Medicine for painless treating of gingivitis and preparation method thereof

InactiveCN109248308APromote recoveryAvoid breedingAntibacterial agentsDipeptide ingredientsDrug treatmentAntibacterial agent

The invention discloses a medicine for painless treating of gingivitis and a preparation method thereof, and belongs to the technical filed of dental medicine preparation. The medicine for treating ofgingivitis is prepared from the following raw materials in parts by weight: 2-10 parts of zinc gluconate, 1-5 parts of borneol, 1-4 parts of thymol crystals, 30-50 parts of ethyl alcohol, 3-9 parts of antibacterial agents, 20-40 parts of traditional Chinese medicine composition extracting solutions, 3-7 parts of polylysine, 4-10 parts of chitosan powder, 5-9 parts of anti-inflammatory agents, 1-5parts of alanyl glutamine, 3-9 parts of alleviators, 2-6 parts of dexamethasone sodium phosphate, 3-9 parts of surfactants, and 1-4 parts of cetyl pyridine chloride. According to the medicine for painless treating gingivitis, the good effect on treating gingivitis is achieved, the pain when the medicine acts is relieved, recovery of gingivitis is facilitated, and broad clinical application prospects are achieved.

Owner:何凤姣

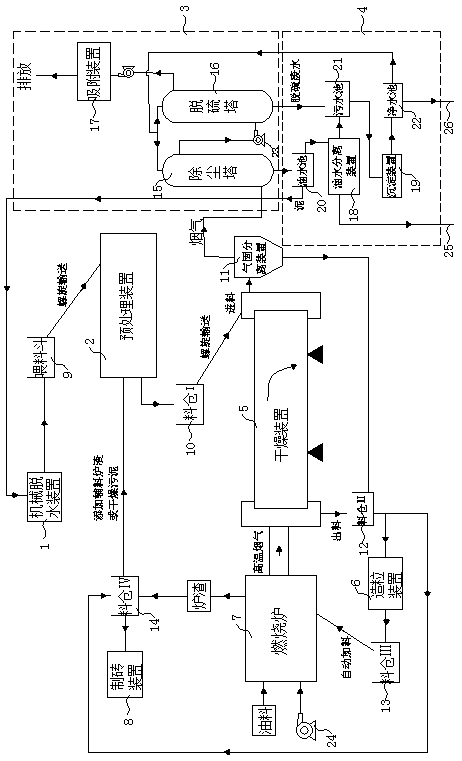

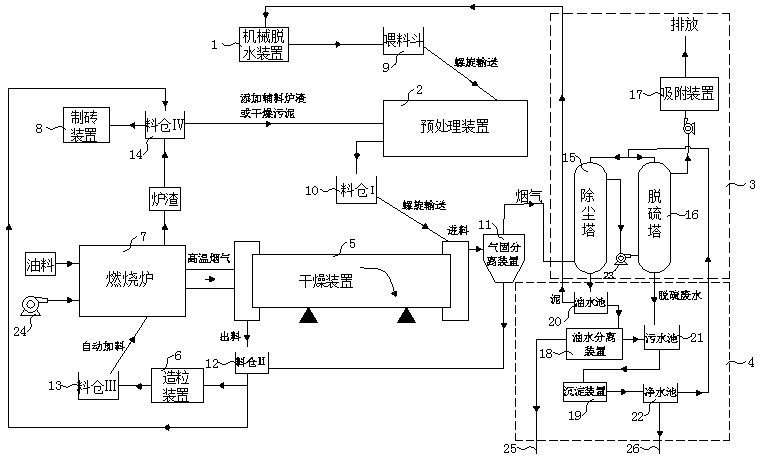

A system and method for harmless treatment of oily sludge

ActiveCN105819644BRealize harmless treatmentReduce processing costsCombination devicesSludge treatment by de-watering/drying/thickeningAmine gas treatingBrick

The invention discloses a harmless treatment system and method for oily sludge, and relates to the technical field of sludge treatment .The harmless treatment system for the oily sludge is composed of a mechanical dewatering device, a pretreating device, a gas treating unit, a water treating unit, a drying device, a granulating device, a combustion furnace and a brick making device .The harmless treatment method for the oily sludge is wide in application range, low energy consumption and cost and free of secondary pollution, and wastewater, waste residues and waste gas which are generated in the oily sludge treating process are thoroughly removed through the processes of pretreating, drying, combusting, waste residue treating, waste gas treating and wastewater treating; meanwhile, heat, the waste residues and purified water which are generated in the technological process are recycled, and therefore the oily sludge treating cost is greatly reduced; in addition, emission of the treated wastewater, waste residue and waste gas meets the national environmental protection requirements, and then harmless treatment for the oily sludge is achieved.

Owner:BEIJING HANGNA TECH CO LTD

Waste gas treatment system and treatment method for waste disposal

InactiveCN104001411BQuick breakdownAchieve emissionsDispersed particle separationAmine gas treatingElectrolysis

The invention belongs to the field of garbage treatment, and provides a waste gas treating system. The system comprises 1-30 pressure-bearing electrolytic brine tanks which are connected in series, wherein the tops of the tanks are connected with a pipeline for discharging waste gas in a garbage treating process; the tanks are internally provided with N partition plates, the pressure-bearing electrolytic brine tanks are divided into isometric N-1 cavities, the partition plates with serial numbers being odd numbers are connected with the tops of the pressure-bearing electrolytic brine tanks and are not contacted with the bottoms of the pressure-bearing electrolytic brine tanks, the partition plates with serial numbers being even numbers are connected with the bottoms of the pressure-bearing electrolytic brine tanks and are not contacted with the tops of the pressure-bearing electrolytic brine tanks, and the pressure-bearing electrolytic brine tanks are internally horizontally provided with positive plates and negative plates. The system provided by the invention has the advantages that an electrolyzing method is adopted to treat waste gas generated by burning, electrolysis, anaerobic and biochemistry methods in the garbage treating process, the waste gas generated by the garbage treating process can be effectively treated, the discharged waste gas achieves the national standard, and the effect is stable.

Owner:杨新玉

Waste gas treating system

InactiveCN103846006AReduce contentSpray water quality has not deteriorated significantlyUsing liquid separation agentRefluxAmine gas treating

The invention discloses a waste gas treating system for treating waste gas produced in tobacco leave threshing and redrying processes. The waste gas treating system comprises a spray chamber, a settling water-storage tank and a dewatering tower, wherein a smog passage is formed in the spray chamber; a smog inlet and a smog outlet are respectively formed in the front end and the rear end of the smog passage; more than one row of spray nozzles are arranged along the smog passage; a water outlet is formed in the bottom of the smog passage; the smog inlet is communicated with the damp outlets of a tobacco leave redryer and a tobacco stem redryer through pipelines; the smog outlet is communicated with a gas inlet of the dewatering tower through a pipeline; the settling water-storage tank is provided with a water pump; a water inlet of the water pump is communicated with a spray liquid in the settling water-storage tank; a water outlet of the water pump is communicated with the spray nozzles through pipelines; a reflux hole is formed in the bottom of the settling water-storage tank; the reflux hole is communicated with the water outlet of the smog passage through a pipeline; multiple adsorption layers are arranged between the gas inlet and a gas outlet in the dewatering tower; the gas outlet of the dewatering tower is communicated with an external boiler chimney through a fan.

Owner:FUJIAN WUYI TOBACCO

Waste gas central treating system

InactiveCN101791516BReduce intake air temperatureImprove acid removal effectCellsDispersed particle separationAmine gas treatingCyclone

Owner:惠州益伸电子有限公司

Biodiesel esterification method

InactiveCN106433996AQuick responseReduce processing costsFatty acid esterificationBiofuelsAmine gas treatingBiodiesel

The invention relates to the field of biodiesel, in particular to a biodiesel esterification method. The method comprises the steps of gas treating and cyclic mixing. Gas which is originally acidic in an esterification reaction is treated with alkaline liquor, proceeding of the esterification reaction is effectively promoted through multiple mixing effects, therefore, the esterification reaction time can be effectively shortened, and then the biodiesel preparation cycle can be shortened; in addition, pollution can be reduced, the cost can be reduced, and the methanol recycling rate can be increased.

Owner:SICHUAN LANBANG NEW ENERGY TECH CO LTD

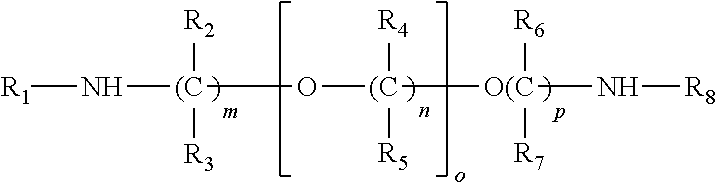

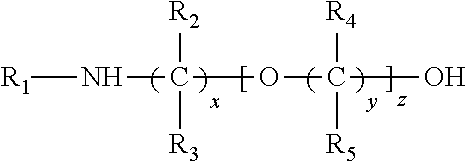

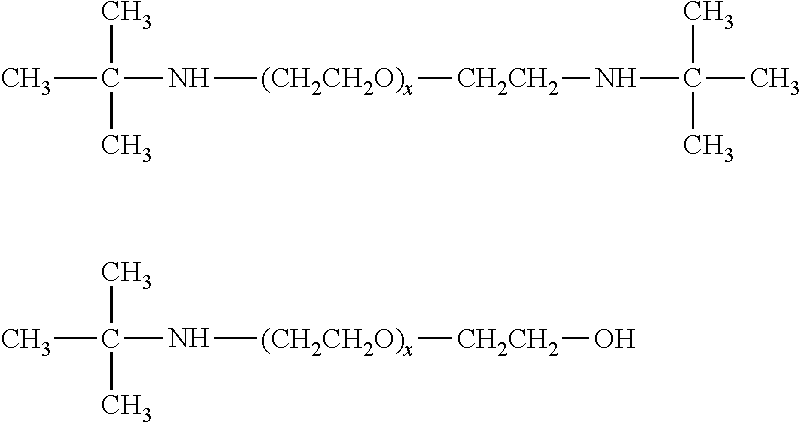

Low temperature transport and storage of amine gas treatment solutions

ActiveUS9458367B2Reduce usageUse of water is particularly attractiveOther chemical processesCarbon compoundsAmine gas treatingChemistry

A liquid aminoether acid gas absorbent which is subject to freezing in a cold climatic zone though which the aminoether is to be shipped is rendered freeze-resistant by mixing the aminoether with water prior to transport through the cold climatic zone; the aminoether / water mixture typically contains 10 to 40 weight percent water, based on the weight of the aminoether. The aminoether / water mixture can also be stored in the cold climatic zone without being externally maintained at a temperature above the inherent freezing point of the aminoether.

Owner:EXXON RES & ENG CO

A sour gas treatment process and system

ActiveCN105727715BAvoid thermal decompositionPrevent crystallizationDispersed particle separationAmine gas treatingChemical products

The invention provides an acid gas treatment process and system. The process uses sodium hydroxide as an absorbent, and through a two-stage gas-liquid reaction and a first-stage liquid-liquid reaction process, the tail gas can be discharged up to the standard, and the product that meets the national product quality standard can be produced. Chemical Products. The acid gas treatment system of the present invention comprises a first processor, a second processor, an alkali liquor mixing tank, a process pipeline and a mechanical pump. The invention can realize the dual goals of purifying acid gas and recycling pollutants.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method of removing polymer from and acid gas treating system

InactiveCN1221502CThermal non-catalytic crackingDigital data information retrievalAmine gas treatingHydrocarbon solvents

A method for removing polymer from an acid gas treating system comprising contacting an acid containing stream with an aqueous alkanolamine solution and hydrocarbon solvent to form a mixture of an alkanolamine rich solution having the acid gases or byproducts thereof contained therein and the hydrocarbon solvent, there the hydrocarbon solvent has about 60 to 100 volume % aromatics content; and about 50 to 85 volume % two ring aromatic content, based on the total volume of the solvent.

Owner:EXXONMOBIL CHEM PAT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com