Patents

Literature

53results about How to "Fast distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

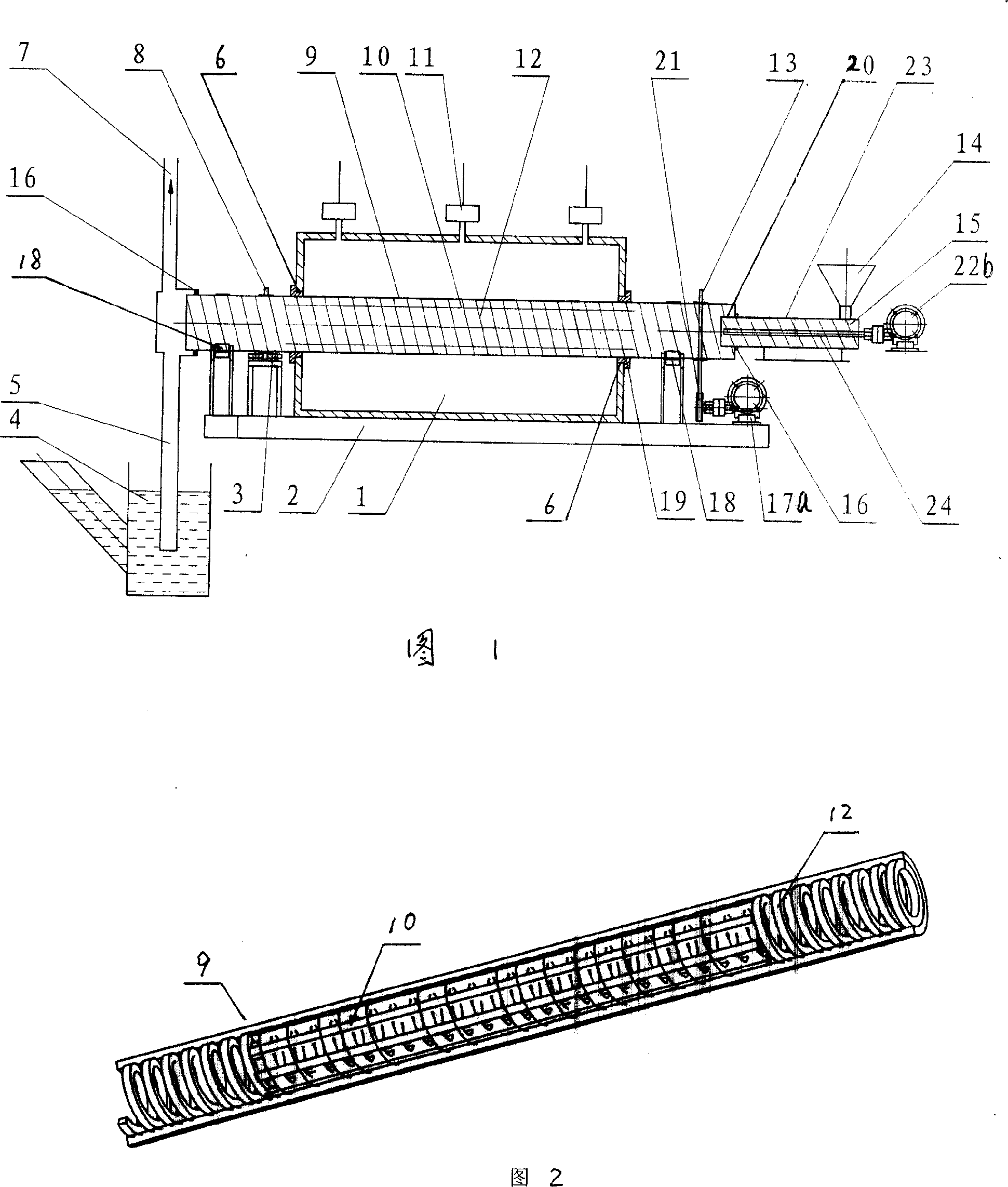

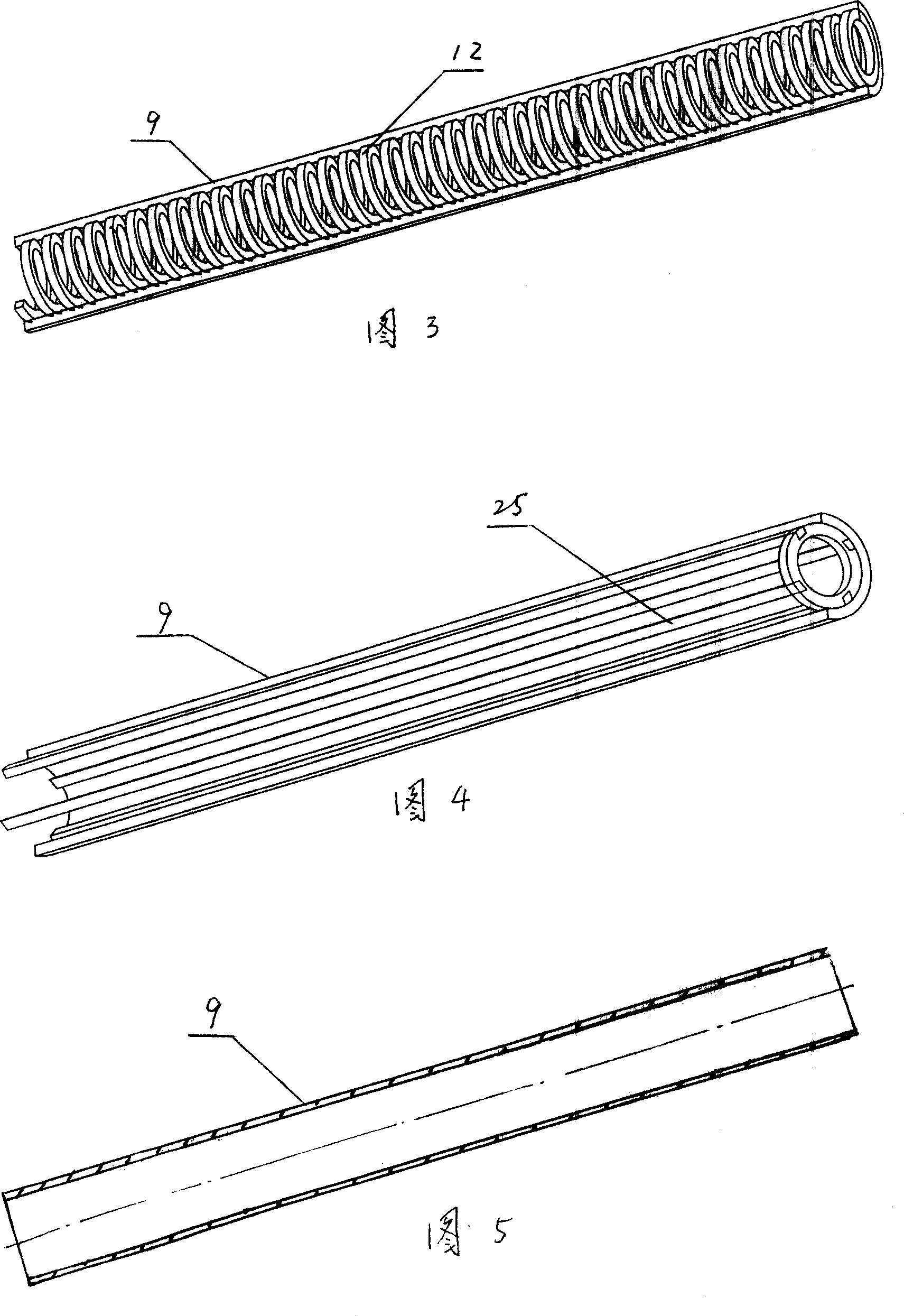

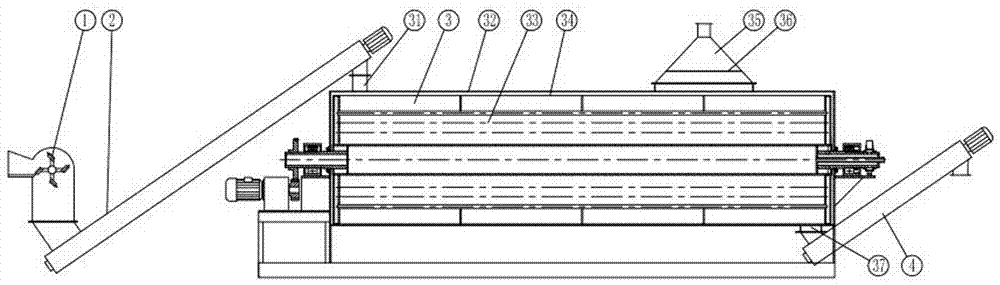

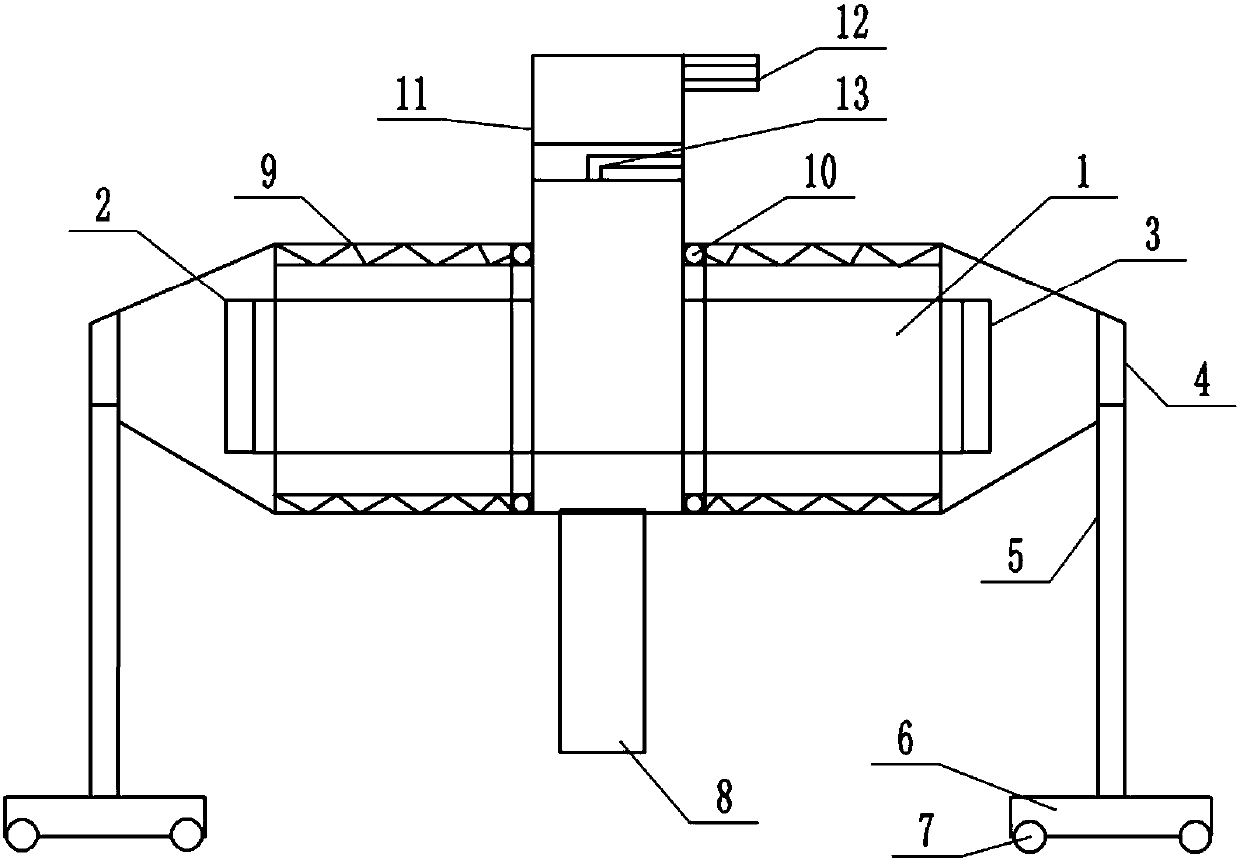

Microwave drum dry distiller and its application in dry distilling and pyrolyzing oil shale

InactiveCN101020828AFast heatingRapid responseSpecial form destructive distillationMicrowave ovenSlag

The present invention relates to carbon material pyrolyzing and dry distilling technology, and is especially one kind of microwave drum dry distiller and its application in dry distilling and pyrolyzing oil shale. The microwave drum dry distiller includes one microwave oven, and one inner screw drum on supporting rolls. The inner screw drum set on the microwave oven has material inlet, slag discharging barrel, gas exhausting pipe, and discharging port connected to the spiral conveyer. Granular oil shale entering to the microwave oven spirally through the inner screw drum absorbs microwave for dry distilling and pyrolysis so as to produce shale oil, fuel gas and semi-coke. The present invention has simple structure, convenient operation, fast dry distilling, high energy utilizing rate, environment friendship and other advantages.

Owner:NORTHEAST DIANLI UNIVERSITY +1

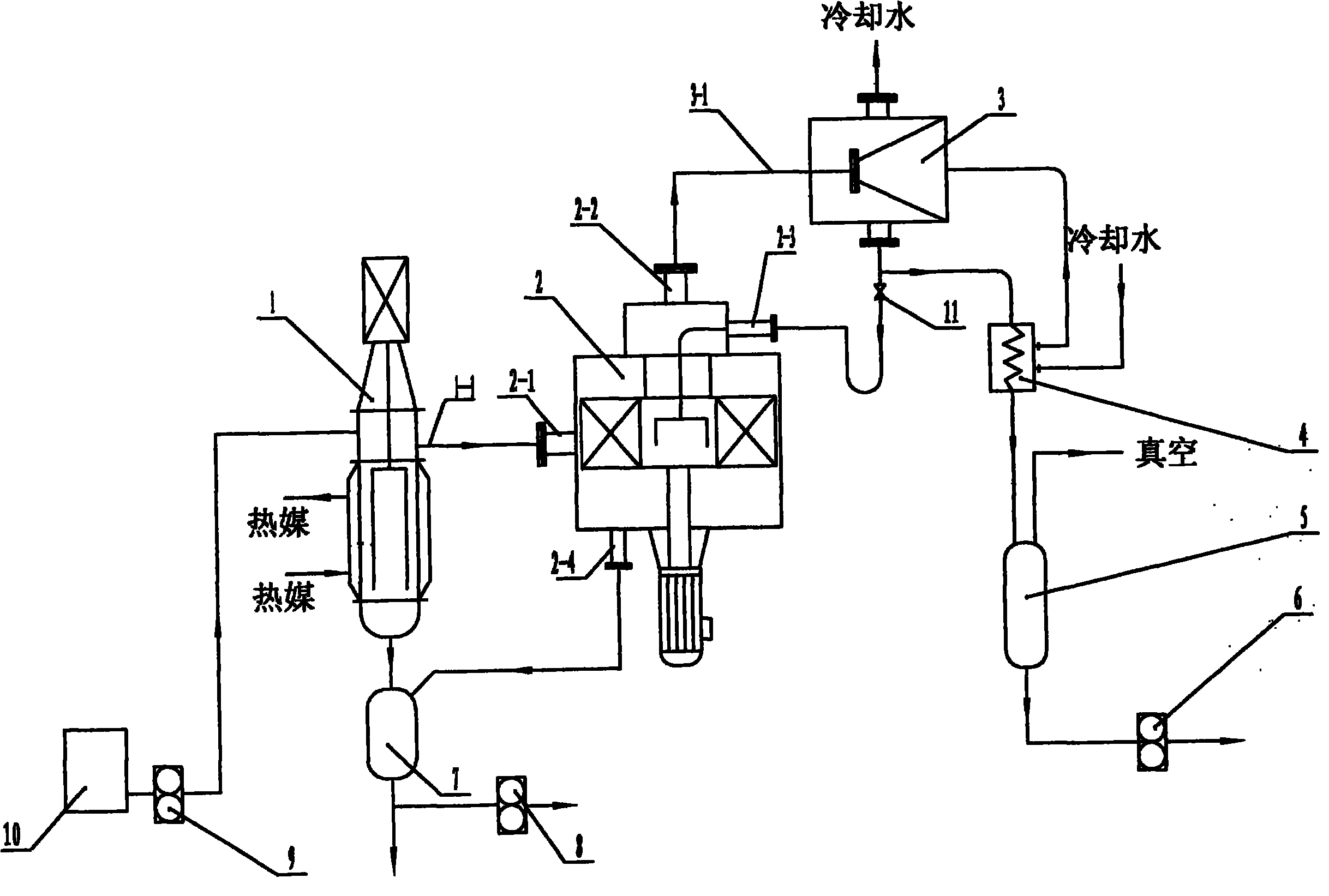

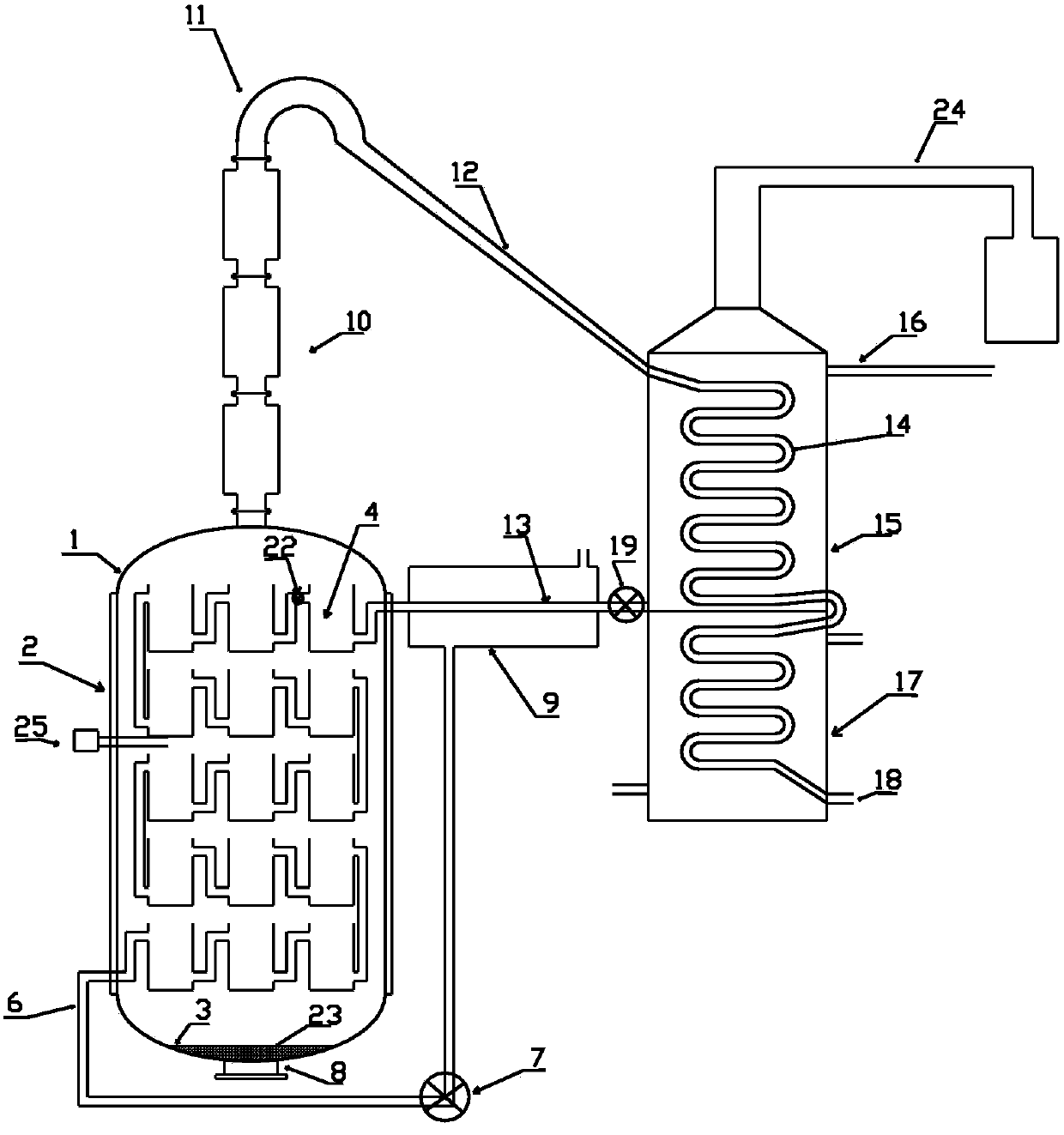

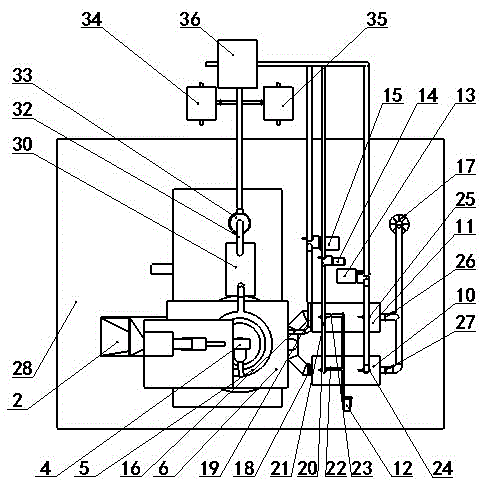

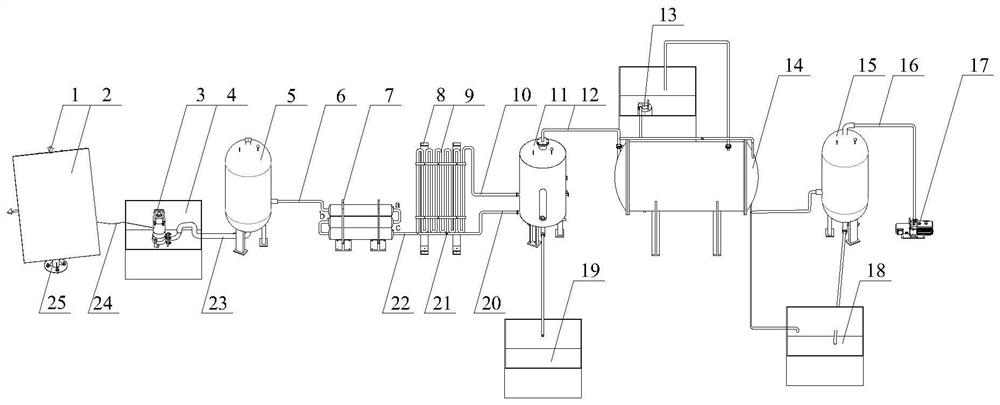

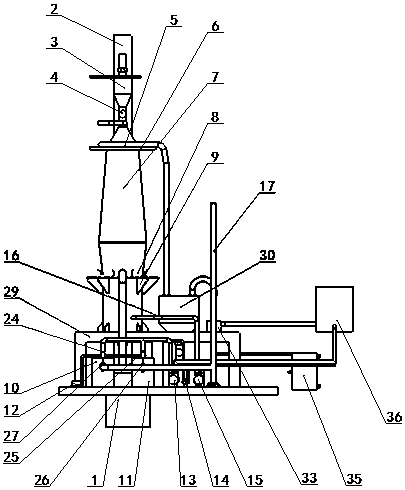

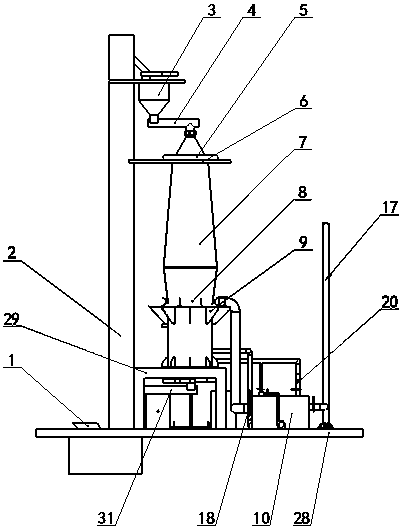

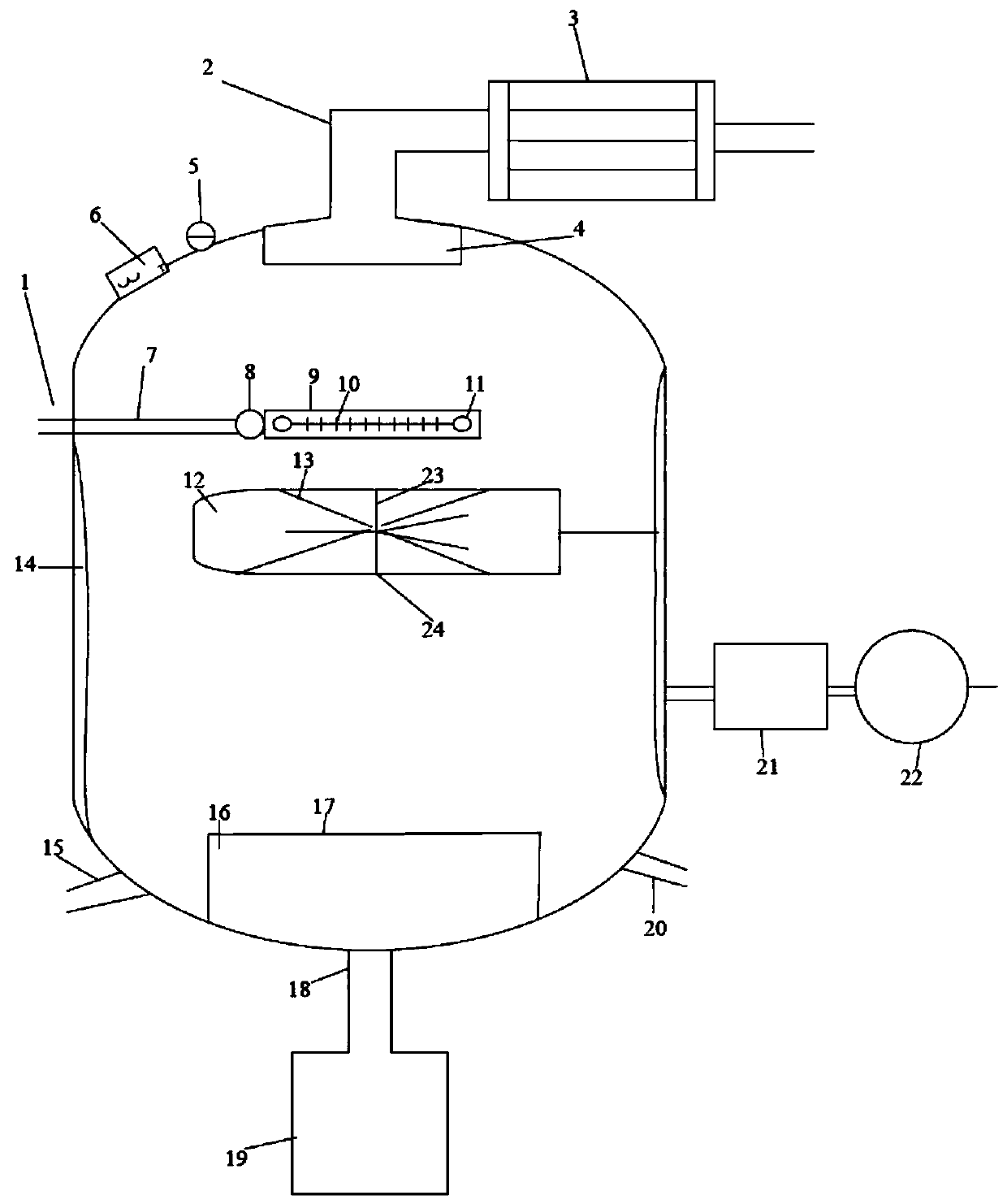

Method for separating and recovering product oil from waste lubricating oil and device thereof

ActiveCN101831348AImprove heating efficiencyShort heating timeLubricant compositionEvaporationEngineering

The invention relates to a method for separating and recovering product oil from waste lubricating oil and a device thereof, which relates to chemical production methods and devices. The method adopts the process that after preliminary treatment of dewatering, degassing and mechanical purity removal, multi-time intermittent rectification or multistage continuous rectification is carried out on the waste lubricating oil by thin-film evaporation and hypergravity revolving field. The device is a 1-4 time intermittent rectifying device or a 1-4 stage multistage continuous rectifying device comprising a raw material tank, a material pump and one to four thin-film evaporators, hypergravity revolving beds, condensers, coolers, finished product tanks, discharging pumps, heavy constituent receiving tanks, material pumps and reflux regulating valves. The method has high rectification speed, good product quality and high recovery rate, and meets the requirements of environmental protection; compared with short path distillation technology, the invention has smaller device volume and higher rectification efficiency and can further refine materials; the device for treating the materials with the same scale has lower requirements for field, less investment and relatively lower vacuum degree requirement.

Owner:HANDWAY TECH FOSHAN

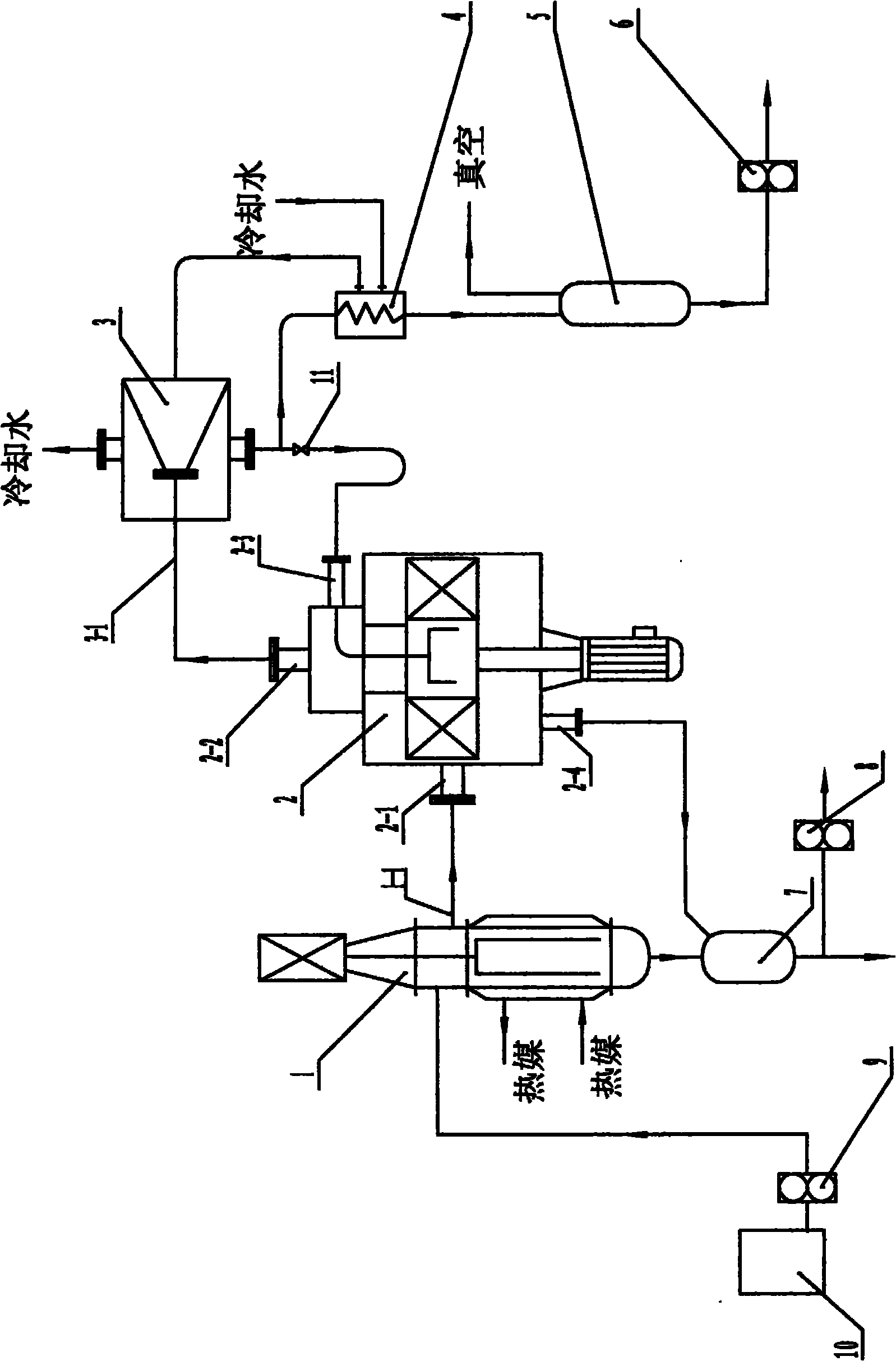

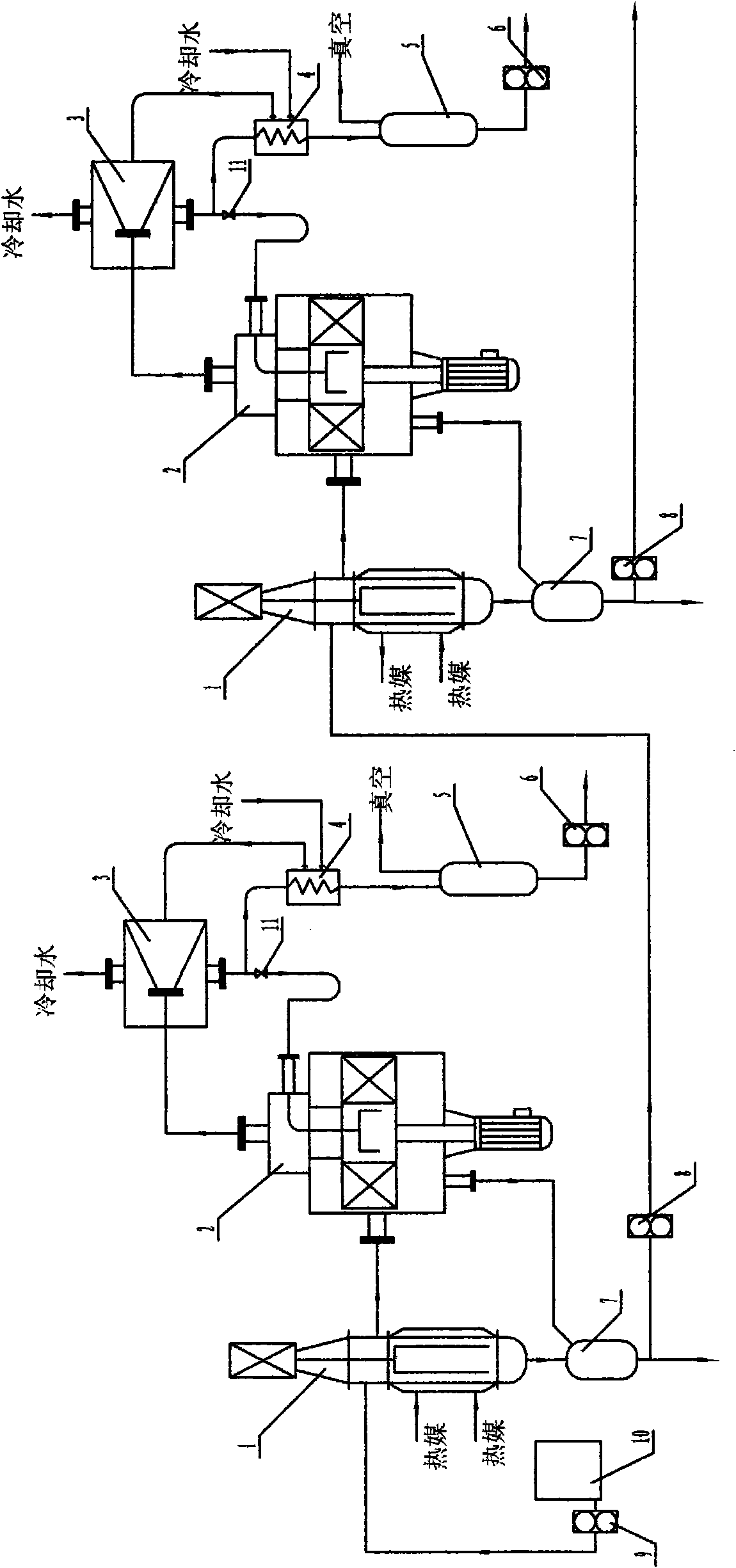

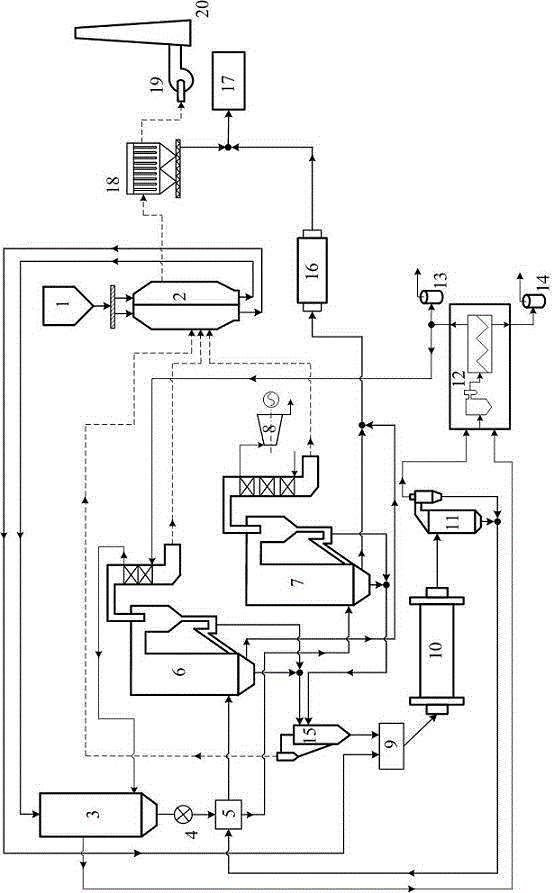

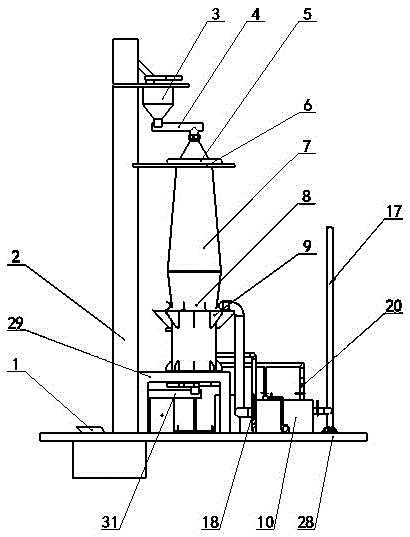

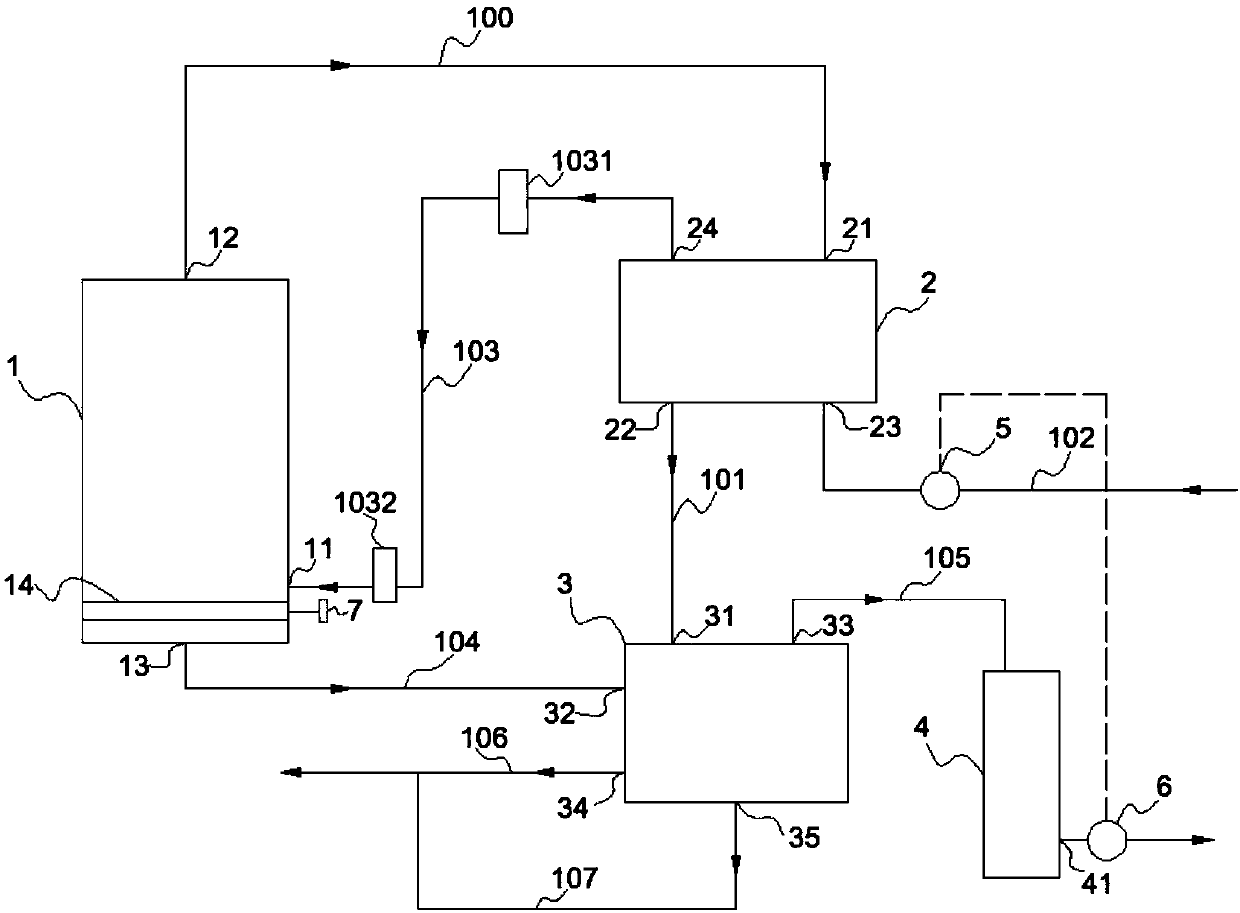

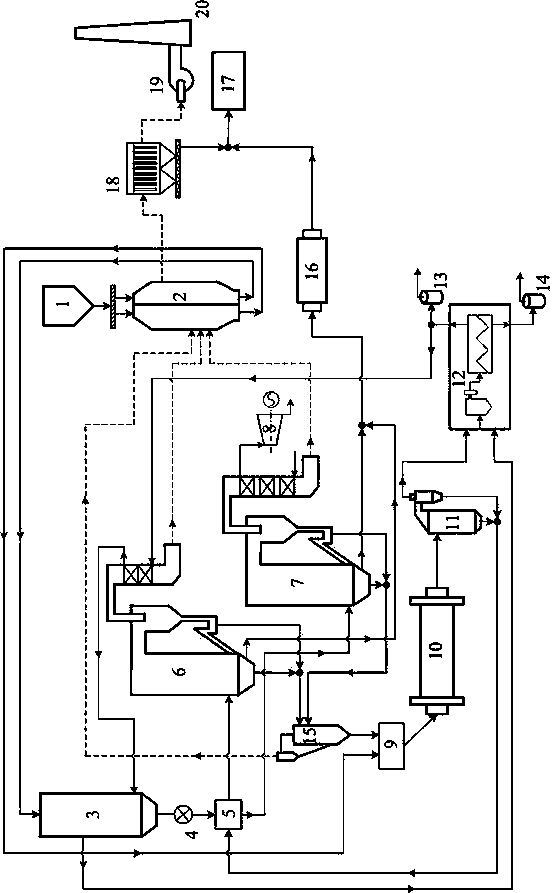

Integral process for oil shale drying, heating, refining and semicoke burning

ActiveCN102952558AImprove broad applicabilityTake advantage ofDirect heating destructive distillationEnergy inputHeat carrierSlag

The invention relates to an integral process for oil shale drying, heating, oil refining and semicoke burning. The integral process is characterized in that the oil shale crushed into the diameter smaller than or equal to 15mm is subjected to the direct or indirect heat exchange by moderate-temperature gas and the heating and drying by a drying heater, and is delivered with hot ash slag burned generated by burning of a circulating fluid bed burning furnace into a solid heat carrier dry distillation reactor to carry outbe subjected to mixed heat exchange and complete dry distillation oil refining; high-temperature smoke burned byfrom the circulating fluid bed burning furnace is delivered into the high-temperature gas indirect dry distillation reactor to exchange heat with the oil shale to realize the dry distillation oil refining of the solid fuels; oil shale semicoke from the solid heat carrier dry distillation reactor, through a semicoke bin hopper, and solid semicoke discharged from the circulating fluid bed burning furnace, are delivered to the circulating fluid bed burning furnace to be burned continue toously burn, and the excessive hot ash slag discharged from the circulating fluid bed burning furnace is cooled by a slag cooler, and is discharged and delivered to building material factories. The integral technology can be used for completing the oil shale fuel drying, heating, oil refining and semicoke burning, and also can also be used for coals, oil sands, waste and scrape tires, petroleum cokes, organic waste materials and biomasses.

Owner:NORTHEAST DIANLI UNIVERSITY

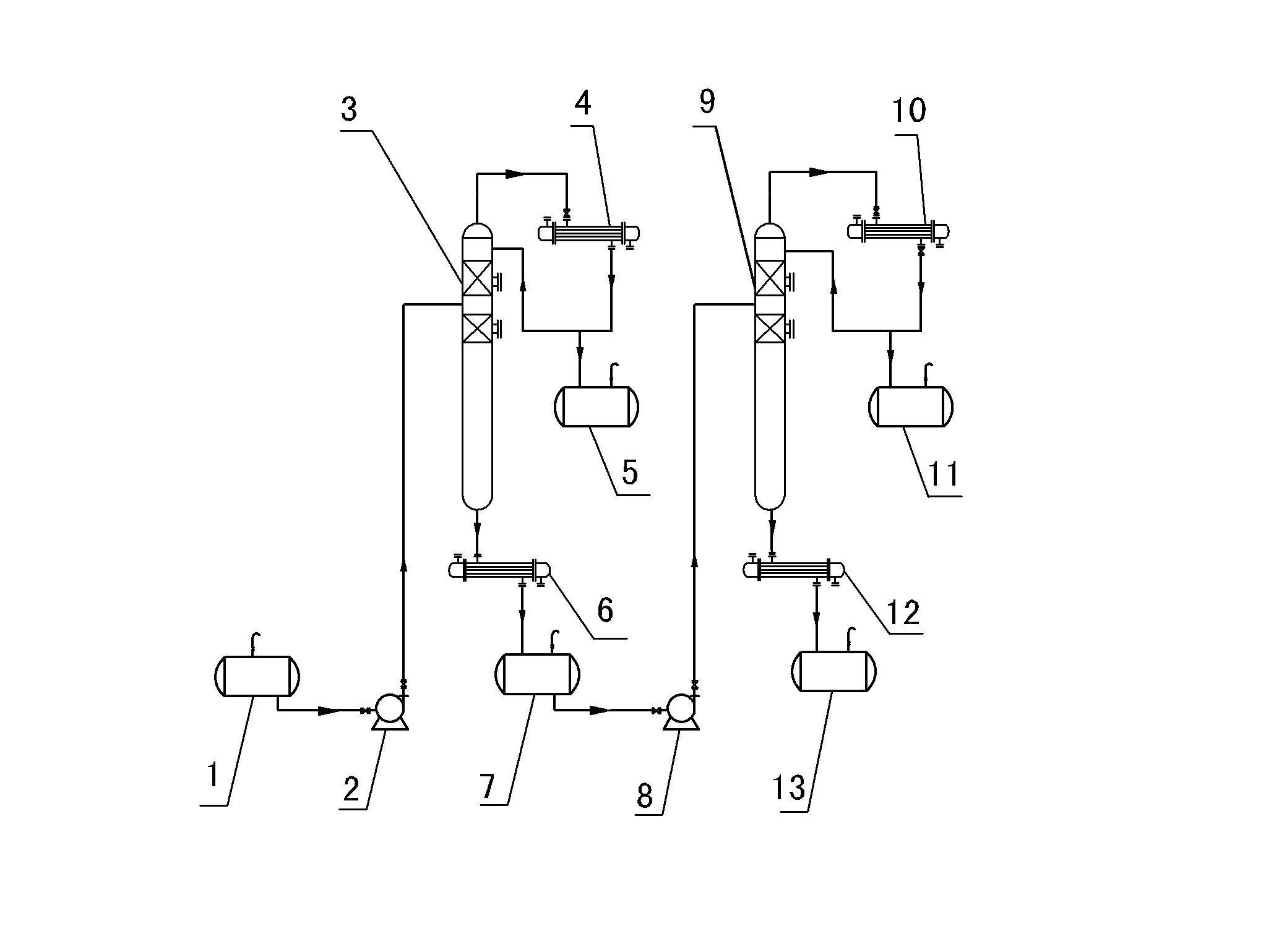

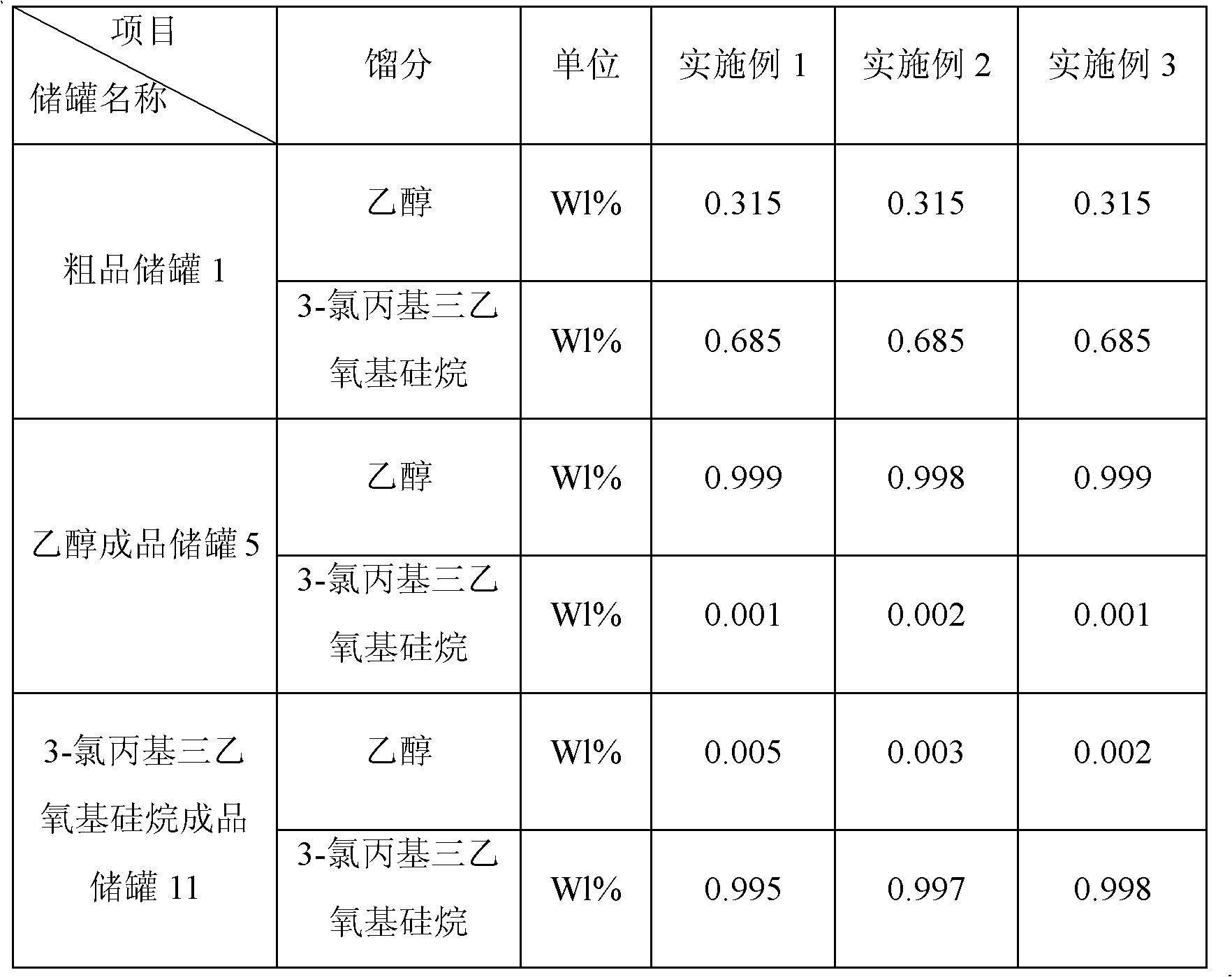

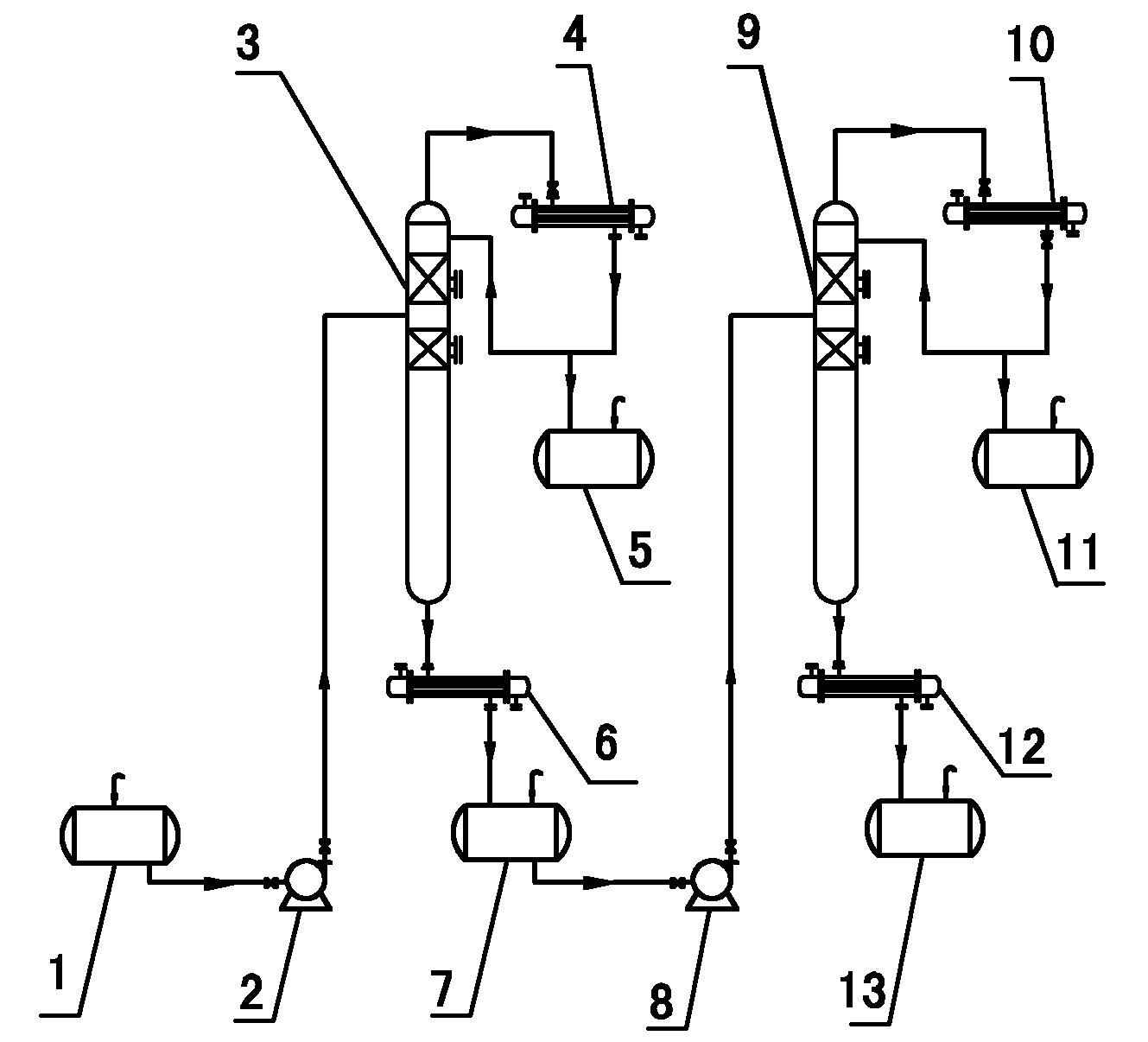

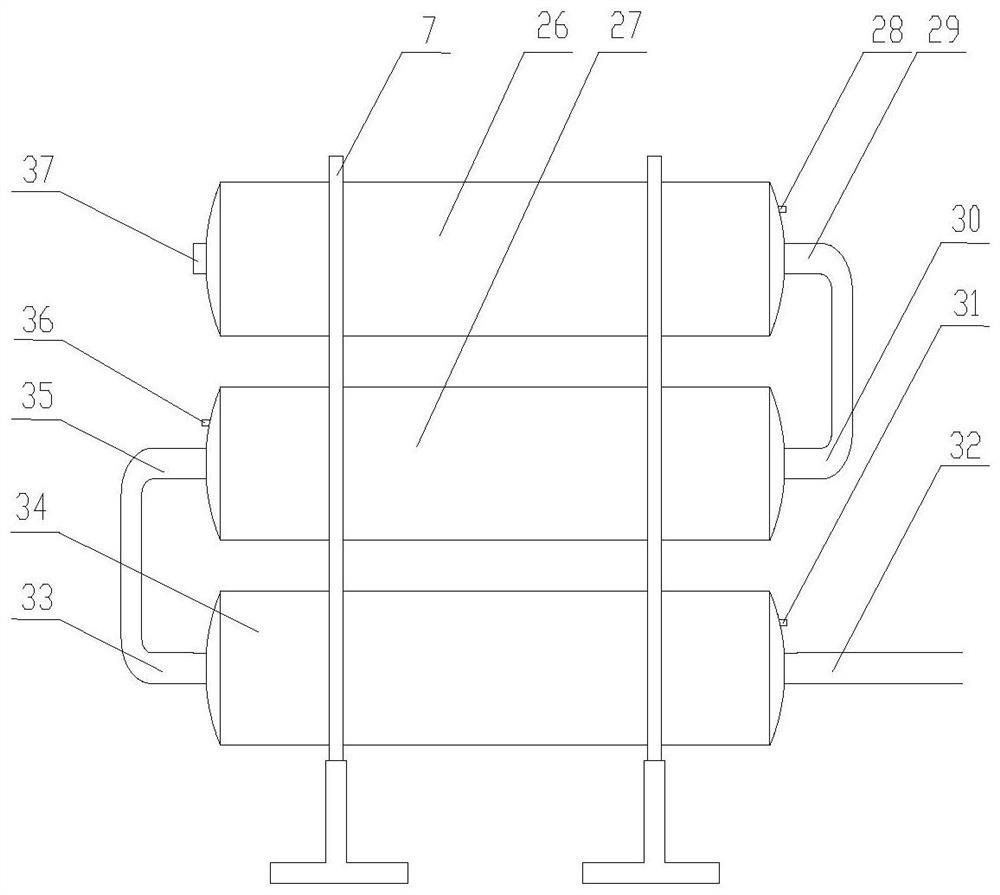

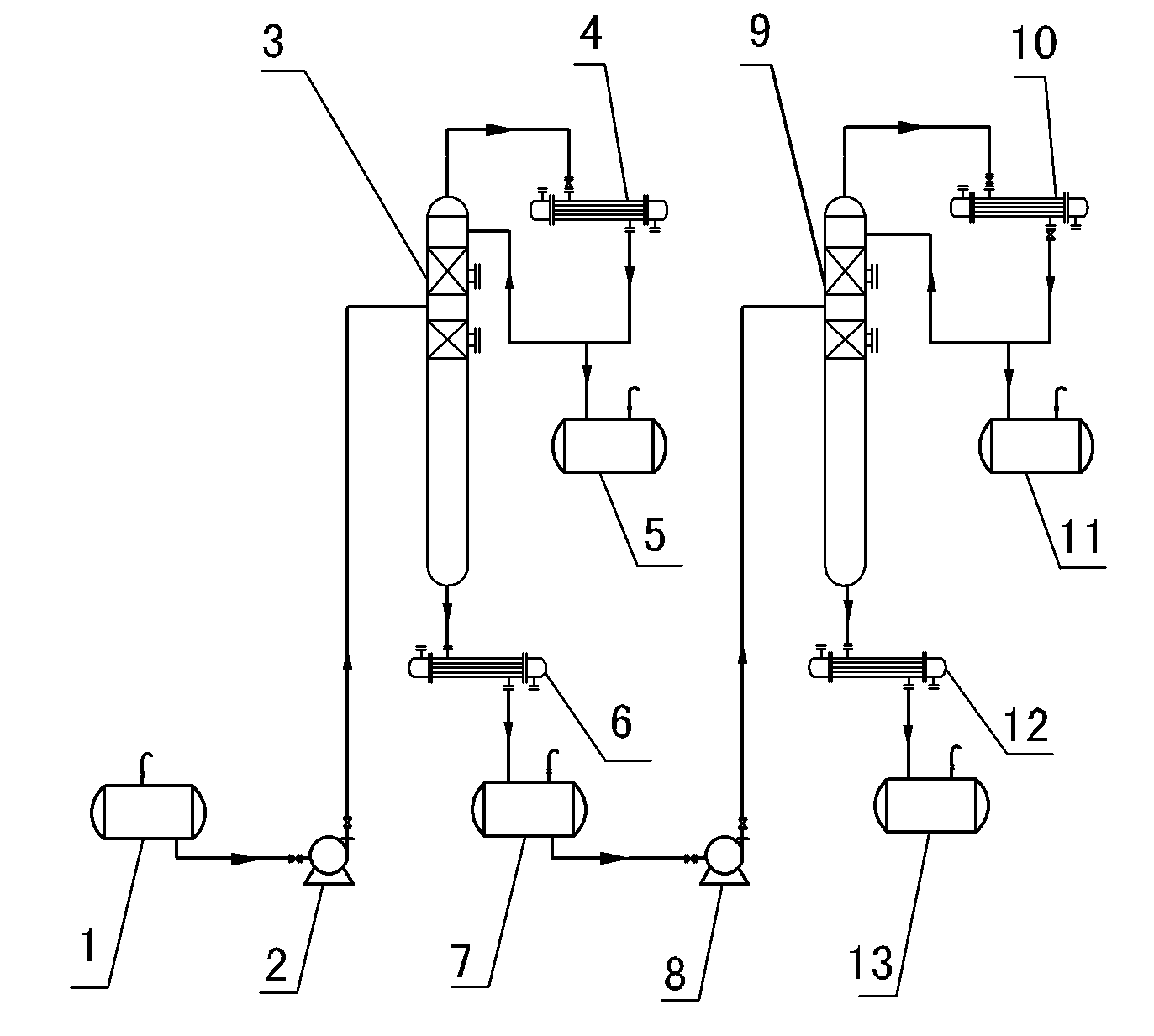

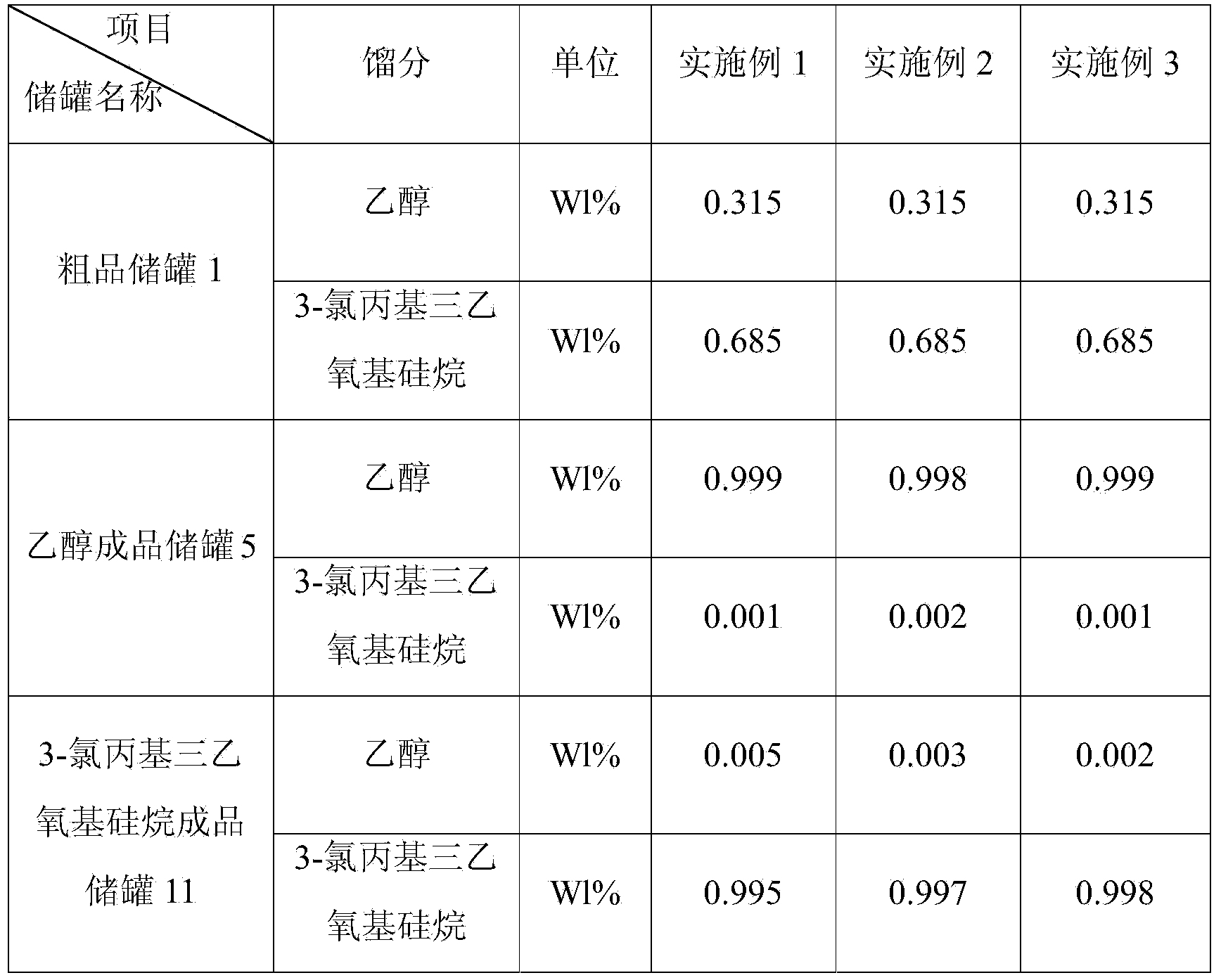

Device and method for continuously rectifying 3-chloropropyl triethoxysilane

InactiveCN102580338AShorten the timeFast distillationGroup 4/14 element organic compoundsFractional distillationRefluxTriethoxysilane

The invention provides a method for continuously rectifying 3-chloropropyl triethoxysilane, belonging to the field of chemical engineering separation. The device is characterized by comprising an ethanol rectifying separating device and a 3-chloropropyl triethoxysilane rectifying separating device which are structured the same and connected in series by a conveying pipeline and a material transforming pump, wherein each of the two rectifying separating devices which are structured the same comprises a rectifying tower, a condenser and a finished product storage tank which are connected with the top of the rectifying tower by a reflux pipeline, a condenser and a crude product storage tank which are connected with the bottom of the rectifying tower by the conveying pipeline. The crude product storage tank is connected with a next group of a rectifying separating device by the material transforming pump. In the first tower, ethanol is removed at normal pressure to reach a purity of more than 99.8%; in the second tower, 3-chloropropyl triethoxysilane is removed by rectifying at a negative pressure of -0.0098Mpa to reach a purity of more than 99.5%.

Owner:淄博市临淄齐泉工贸有限公司

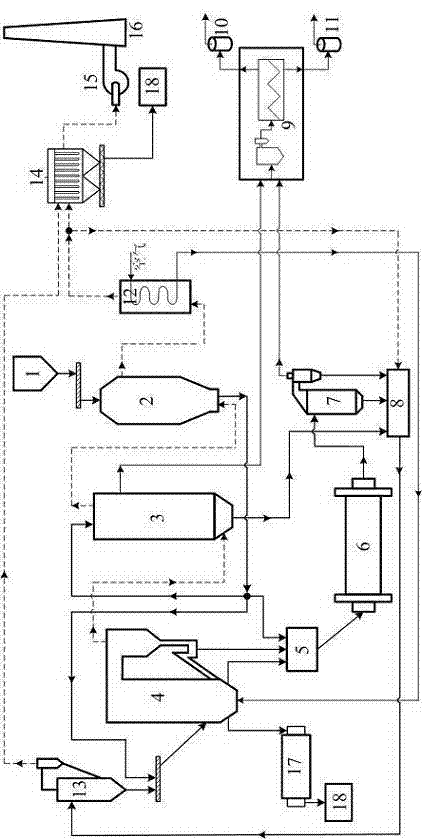

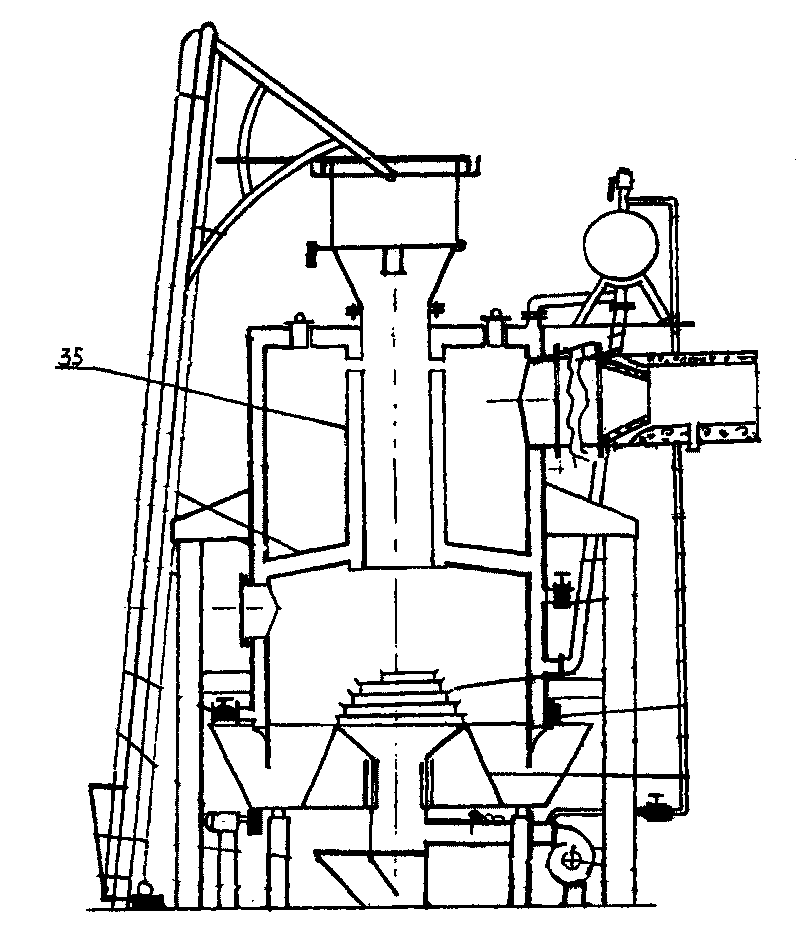

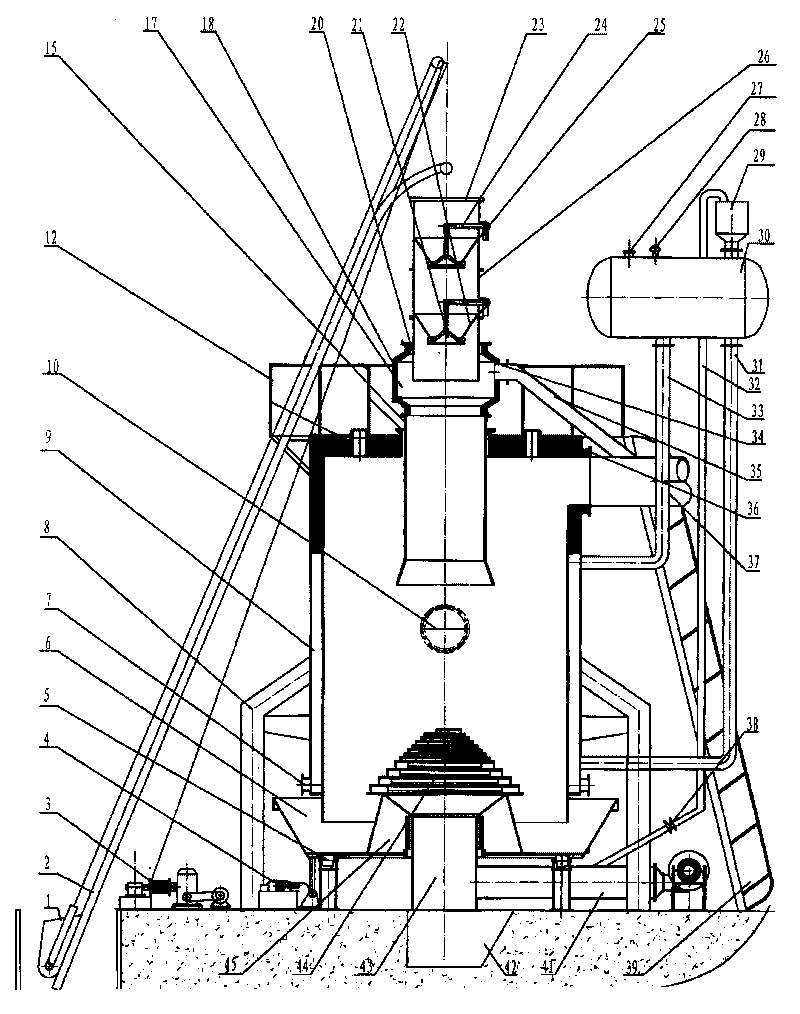

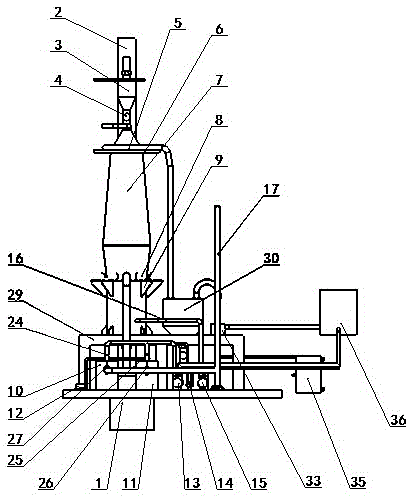

Oil shale gas-solid heat carrier dry distillation and semicoke combustion electricity generation integral process

The invention relates to an oil shale gas-solid heat carrier dry distillation and semicoke combustion electricity generation integral process, which is characterized in that oil shale crushed into at least 75mm is stored in a raw material cabin and is sieved, small-particle oil shale with the particle diameter smaller than 15mm and 15-75 mm large-particle oil shale are respectively conveyed into a left chamber and a right chamber of a medium-temperature gas indirect or direct heat exchange drying heater, and 15-75 mm large-particle oil shale subjected to heating and drying is subjected to gas heat carrier dry distillation; the small-particle oil shale with the particle diameter smaller than 15mm and semicoke are mixed and are subjected to solid heat carrier dry distillation; oil-gas mixtures generated by the solid heat carrier dry distillation are subjected to purification, condensation and separation treatment after sedimentation and gas-solid separation, shale oil is conveyed into an oil storage tank, one part of separated gas is used as heat carriers of the dry distillation of the 15-75 mm large-particle oil shale, and the rest gas is conveyed into a gas storage tank; superheated steam produced by semicoke consumption is conveyed into a steam turbine generator set for electricity generation; one part of semicoke consumption high-temperature hot ash is used as the heat energy of the dry distillation of the small-particle oil shale with the particle diameter smaller than 15mm; and the other part of discharged hot ash is cooled and is then conveyed to a building material factory.

Owner:NORTHEAST DIANLI UNIVERSITY +1

Method for preparing lactide

The invention provides a method for preparing lactide. The method is characterized by including the steps of firstly, performing free water-removing reaction on lactic acid; secondly, adding catalyst into the lactic acid after the free water-removing reaction to perform condensation polymerization so as to obtain lactic acid oligomer; thirdly, adding ionic liquid into the lactic acid oligomer to serve as solvent, heating to perform depolymerization, and performing reduced-pressure distillation to collect crude product; fourthly, purifying the crude product to obtain the finished-product lactide. The method has the advantages that the method is improved on the basis of an existing synthesizing process, the recyclable high-boiling-point ionic liquid is added during the depolymerization to greatly lower the viscosity of a reaction system, the lactide can be fast distilled favorably, carbonization is reduced, the yield and chemical purity of the lactide are increased evidently, purification times are reduced, the production cycle is shortened, and the method is an efficient method for preparing the high-purity lactide.

Owner:DONGHUA UNIV

Purification production process of glycerol

ActiveCN103965019AReduce purification timeShort purification timeOrganic compound preparationHydroxy compound separation/purificationActivated carbonDistillation

The invention discloses a purification production process of glycerol. The process comprises the steps as follows: crude glycerol is sucked into a distillation still, direct steam is fed when the crude glycerol is heated to the temperature of 160+ / -5 DEG C, and theintake amount of the direct steam is controlled to the extent that system vacuum is not lower than 0.08-0.095 MPa; glycerol steam obtained during distillation sequentially passes through a first condenser, a second condenser, a third condenser and a fourth condenser for cooling condensation to obtain distilled glycerol; the weight of the distilled glycerol is M, the distilled glycerol is input into a decoloration tank and heated to the temperature of 90+ / -5 DEG C, then activated carbon is added, the weight of the activated carbon is M*(0.1%-0.5%), the distilled glycerol is fully stirred for 25-35 min, the temperature is kept for 0.5-1.5 h, the glycerol is obtained through filtration, and the filtration pressure is lower than 0.4 MPa. The purification production process of the glycerol is simple in process and thorough in purification process, and the obtained glycerol contains few impurities and is high in yield.

Owner:TIANCHANG KANGNING PLASTIC TECH

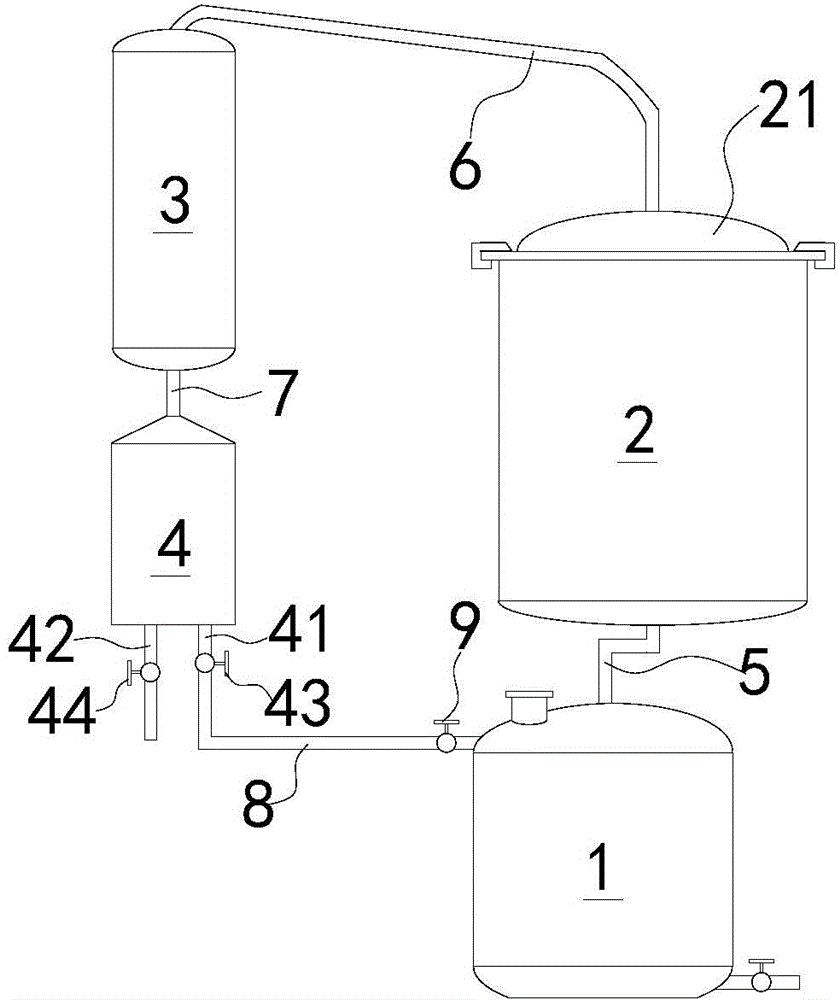

Vegetable oil extracting device

InactiveCN104419524AHeating fastImprove oil yieldEssential-oils/perfumesFatty-oils/fats productionVegetable oilBoiling point

The invention discloses a vegetable oil extracting device and aims at providing a vegetable oil extracting device which is simple in structure and convenient to operate. The vegetable oil extracting device comprises a steam generator, a distilling still, a condenser and an oil-water separator, wherein a water draining tube and an oil removing tube are arranged at the lower end of the oil-water separator, a first valve is arranged on the water draining tube, and a second valve is arranged on the water removing tube; a first branch tube communicated with the bottom of the distilling still is arranged at the upper end of the steam generator; a hose communicated with an inlet of the condenser is arranged on the end cover of the distilling still; a second branch tube communicated with an inlet of the oil-water separator is arranged in the outlet of the condenser; and a third branch tube communicated with the upper part of the steam generator is arranged in an outlet of the water draining tube of the oil-water separator. The vegetable oil extracting device is used for heating and distilling materials in the distilling still by virtue of the steam generated in the steam generator. The vegetable oil extracting device disclosed by the invention is high in distilling speed, capable of shortening the distilling time and lowering the energy consumption. Moreover, components with a high boiling point can be steamed out of the high temperature steam, and the oil extraction rate is high.

Owner:KUNMING OCEAN DEW BIOLOGICAL TECH

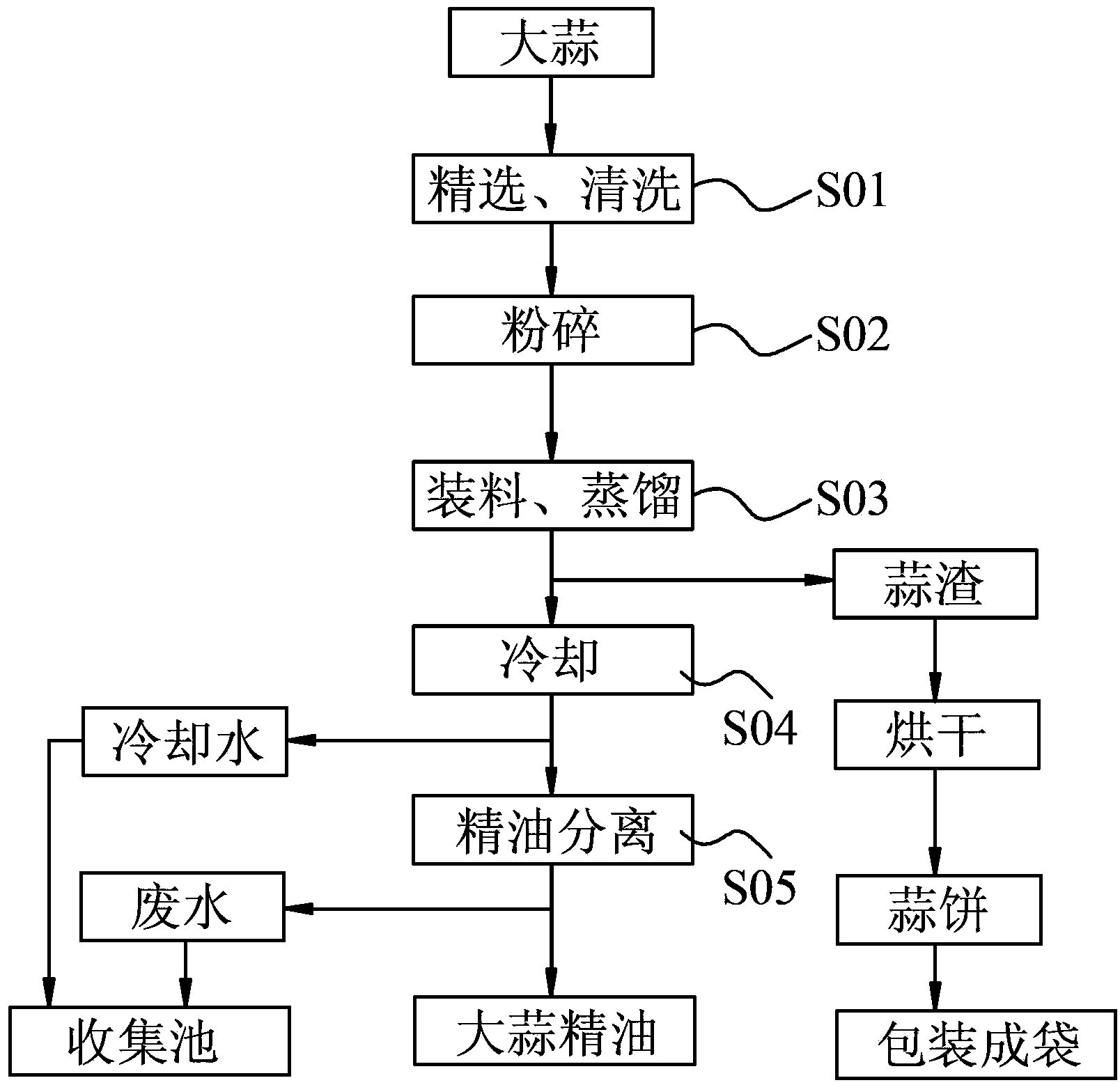

Garlic essential oil extraction method

InactiveCN104046514AImprove distillation efficiencyHigh purityEssential-oils/perfumesCooling towerProcess engineering

The invention discloses a garlic essential oil extraction method which comprises the following steps: carefully choosing and cleaning garlic; crushing the cleaned garlic to powder with diameter of 0.2-0.5mm; sending the crushed garlic powder into a distillation column, adjusting pressure in the distillation column to 0.10-0.20MPa, and keeping distillation for at least 4 hours when temperature in the distillation column rises to 120-150 DEG C; sending a distillate into a cooling tower for cooling; and sending a condensate in the cooling tower into an oil-water separating column to separate garlic essential oil, where a disk-shaped separating disc with several through holes arranged in the surface is also disposed inside the distillation column. Purity of garlic essential oil extracted by the above garlic essential oil extraction method is high; garlic distillation efficiency is raised; and extraction rate of garlic essential oil can reach 0.2-0.5%. In addition, byproducts of garlic essential oil are fully utilized, and economic value is raised. The method provided by the invention is convenient to operate, is cost-saving, and also can be applied in extraction of essential oil of ginger, rapeseed, soybean and the like.

Owner:SHIFANG HENGYUAN GREASE

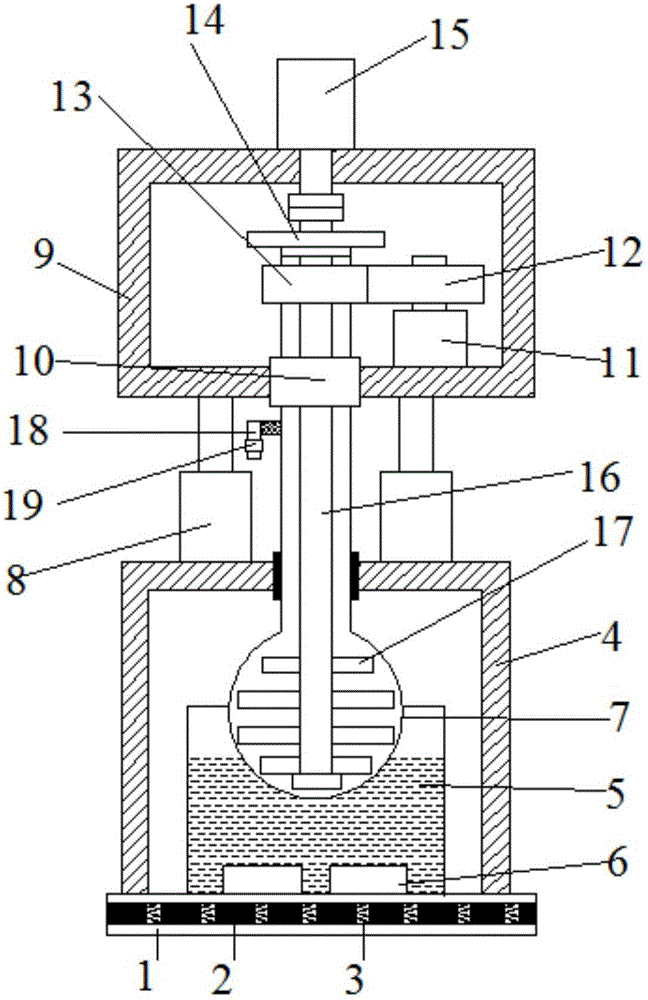

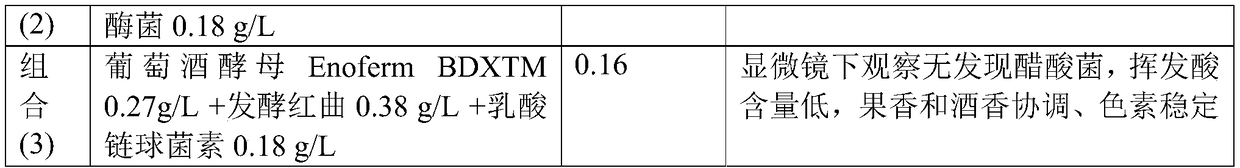

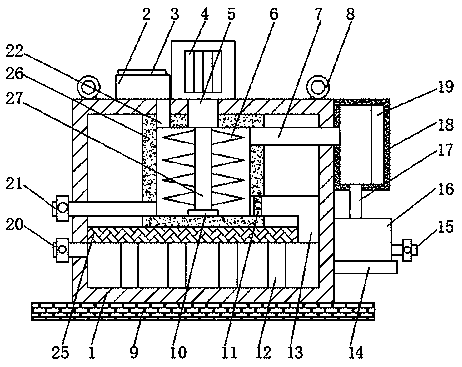

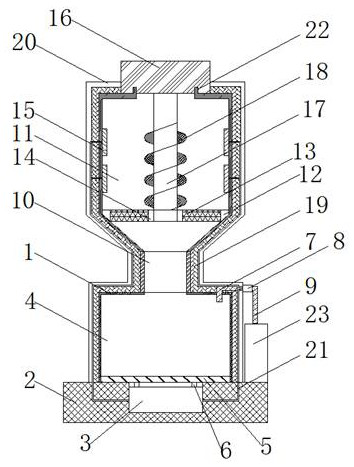

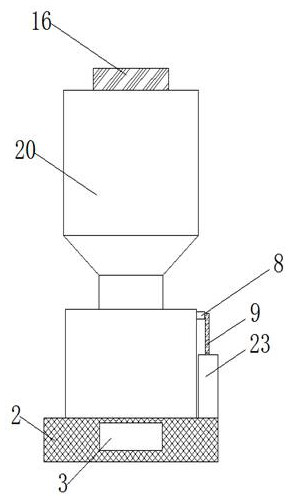

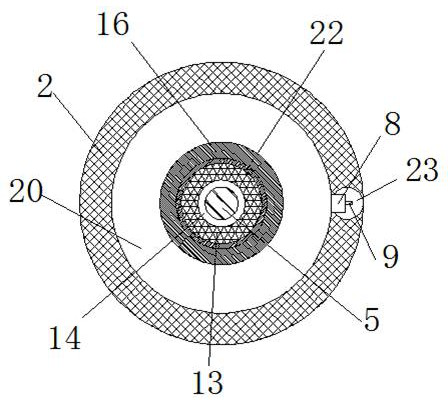

Novel rotary evaporator

ActiveCN106377917AEfficient distillationFinish quicklyDistillation in rotating vesselsWater bathsHydraulic cylinder

The invention discloses a novel rotary evaporator. The novel rotary evaporator comprises a base, wherein the base is internally provided with a vibration absorption cushion; the vibration absorption cushion is internally provided with vibration absorption springs; a distillation chamber is arranged at the upper side of the base; a water-bath pot is arranged in the distillation chamber; heater is arranged at the bottom of the water-bath pot; a distillation flask is arranged at the upper end of the water-bath pot; hydraulic cylinders are arranged at left and right ends of the upper side of the distillation chamber; a motor chamber is arranged at the upper sides of the hydraulic cylinders; a fixed sleeve is arranged at a connecting part of the motor chamber and the distillation flask; a first motor is arranged at the right end in the motor chamber and a driving gear is arranged at the upper end of the first motor; a driven gear is arranged at the upper end of the distillation flask; a second motor is arranged at the upper side of the motor chamber; a stirring shaft is arranged at the lower side of the second motor; stirring blades are arranged at the lower end of the stirring shaft; an exhausting pipe is arranged at the lower side of the fixed sleeve; an air pump is arranged on the exhausting pipe. By arranging a hoisting device, a rotating device, a stirring device and a vibration absorption device, objects needing to be distilled can be effectively distilled, so that the distillation efficiency is improved and the surrounding environment is protected.

Owner:河南健源迷迭香制品有限公司

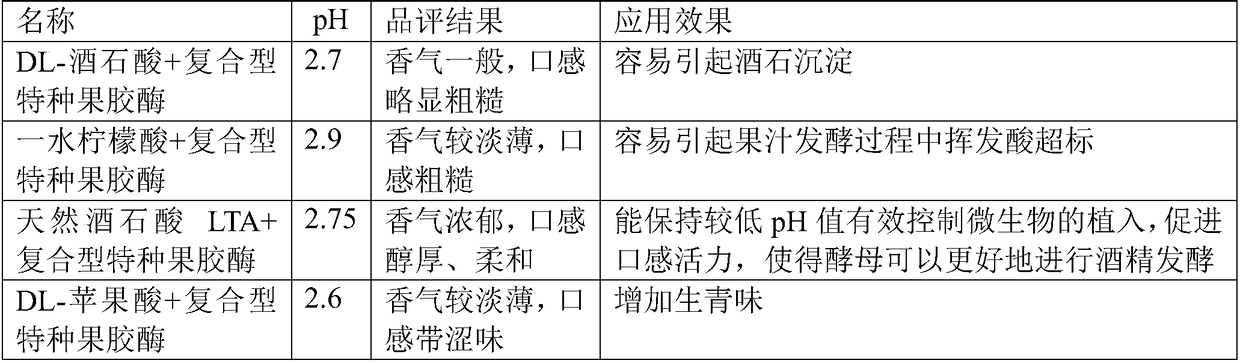

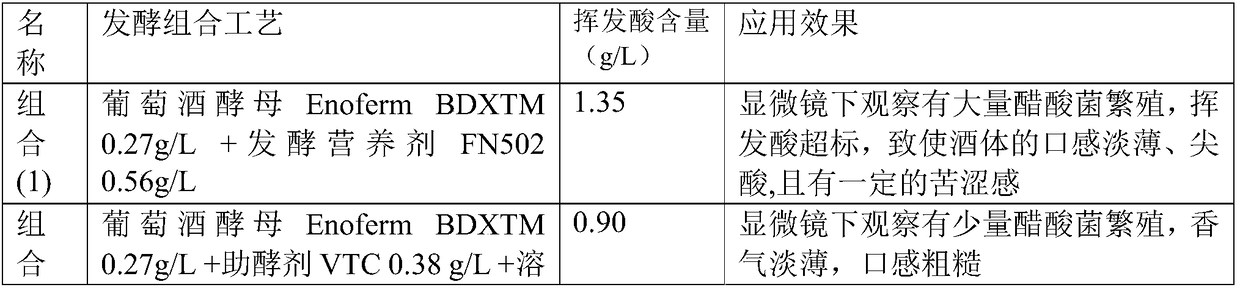

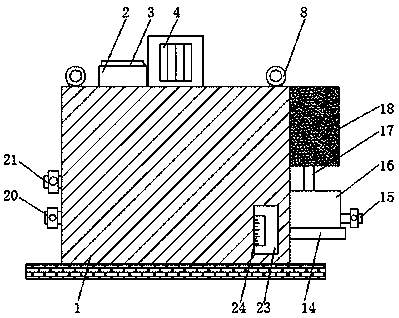

Fermented fructus mori wine and method for preparing same

ActiveCN108795638AControl implantImprove filtering effectMicroorganism based processesAlcoholic beverage preparationPectinaseFruit wine

The invention discloses fermented fructus mori wine and a method for preparing the same. The method includes crushing fructus mori and carrying out low-temperature enzymatic hydrolysis by the aid of pectinase with a low pH (potential of hydrogen) value; adding wine yeast, fermentation monascus and nisin from streptococcus lactis and carrying out mixed temperature-control fermentation; carrying outageing to obtain raw wine liquid. Steps for clarification, after-treatment and the like can be carried out on the raw wine liquid to obtain fructus mori fruit wine when the fructus mori fruit wine isabout to be prepared; distillation and clarification adsorption can be carried out on the raw wine liquid to obtain fructus mori baijiu when the fructus mori baijiu is about to be prepared. The fermented fructus mori wine and the method have the advantages that the fructus mori fruit wine is ruby red and clear, is free of obvious suspended matters or precipitates, has full-bodied and harmonious fruit aroma of original fruits, full-bodied and harmonious wine aroma and mellow and full taste, is good in fructus mori red pigment stability and is in unique style; the fermented fructus mori baijiuhas full-bodied fruit aroma of the fructus mori and full-bodied wine aroma, is mellow, sweet, clear and harmonious, has full wine bodies and pure, delicate and lasting aftertaste and is in typical style of the original fruits.

Owner:广东巴伦比酒业有限公司

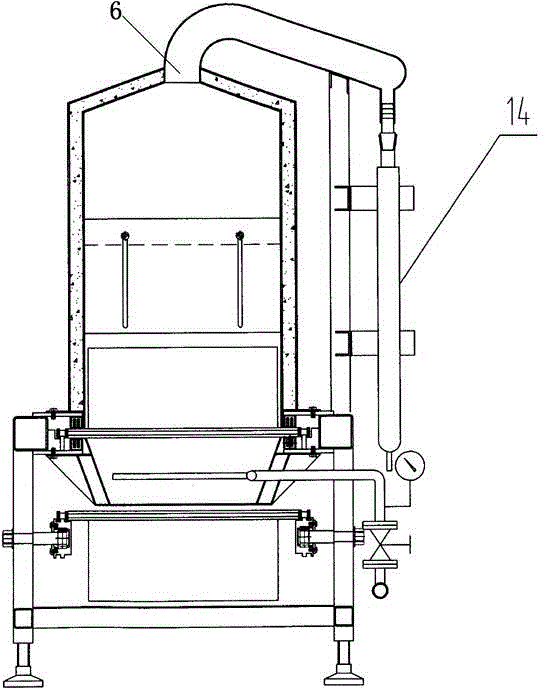

Rose essential oil hydrolat extraction device

PendingCN108485814AAffect extraction speedImprove stabilityEssential-oils/perfumesGrain treatmentsDistillationEngineering

The invention discloses a rose essential oil hydrolat extraction device. The rose essential oil hydrolat extraction device comprises a distillation bin, wherein a partition plate adapted to the distillation bin is fixedly connected to the inside of the distillation bin; heating pipes arranged at equal distances are arranged on the inner bottom wall of the distillation bin; water filling pipes areregularly communicated to the left side surface of the distillation bin; a crushing bin is fixedly connected to the upper surface of the partition plate; the upper surface of the crushing in is fixedly connected with the inner top wall of the distillation bin; a gas transmission pipe is fixedly communicated to the right side of the upper surface of the partition plate; one end of the gas transmission pipe far away from the partition plate penetrates through the crushing bin and extends to the inner side wall of the crushing bin; and a filter screen adapted to the gas transmission pipe is fixedly connected to the inside of the gas transmission pipe. According to the rose essential oil hydrolat extraction device, the extraction speed of the rose essential oil hydrolat as a whole is fast, andthe operation is simple, so that workers can move the extraction device through a lifting device, the labor cost of the workers to carry the extraction device can be reduced, the requirements of production enterprises can be met, and extensive promotion can be facilitated.

Owner:无锡市鹅湖玫瑰园艺文化有限公司

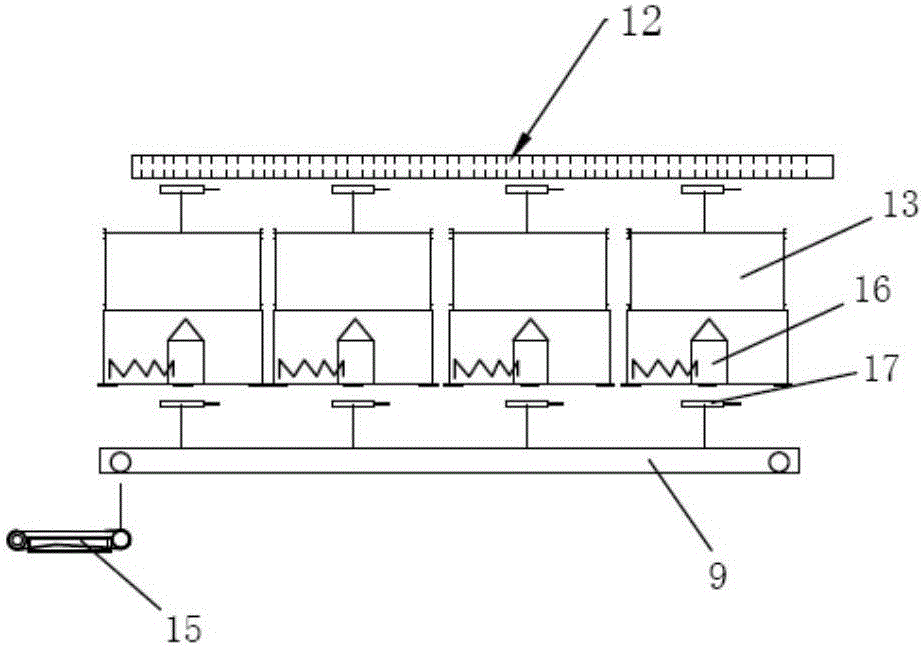

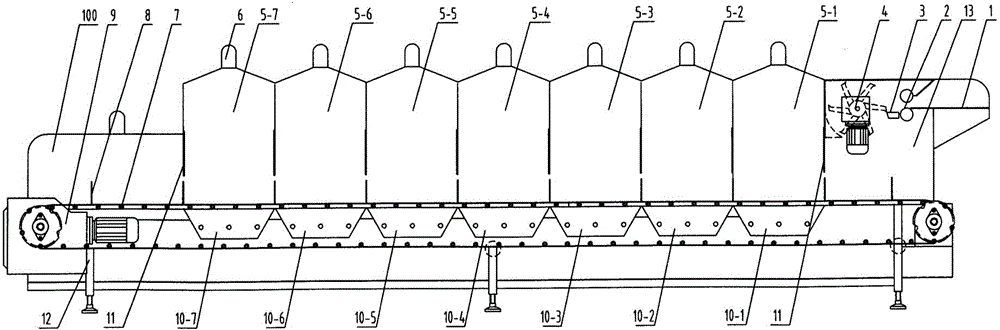

Full-automatic buffer pool tower type continuous distiller

InactiveCN107858255AIncrease the heating areaReduce usageAlcoholic beverage preparationContinuous distillationWaste material

The invention discloses a full-automatic buffer pool tower type continuous distiller which comprises a distilling bucket, a heater, a multi-stage continuous buffer pool, a first heat exchanger, a second heat exchanger and a condenser. The multi-stage continuous buffer pool is installed in the distilling bucket, and comprises multiple layers of buffer pool sets, wherein each layer comprises a plurality of buffer pool units. The multiple layers of buffer pool sets are sequentially connected from top to bottom so that all the buffer pool units can be connected in series. The first heat exchangeris provided with a first passageway and a second passageway. To-be-distilled wine liquid cold materials can enter from an inlet of the second passageway and enter the distilling bucket after being heated by steam of the first passageway. The second heat exchanger is used for further heating the wine liquid cold material heated by the first heat exchanger. The condenser is used for further coolingsteam cooled by the first heat exchanger into liquid. The continuous feeding, distilling and waste discharging operation can be realized, rapid distilling is realized, the use of cooling water is greatly reduced, and heat utilization efficiency is maximized.

Owner:梁进忠

Method capable of increasing content and yield of gamma-chloropropyltriethoxysilane simultaneously

InactiveCN101648966AImprove conversion rateHigh yieldSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsLithium chlorideTriethoxysilane

The invention discloses a method capable of increasing the content and yield of gamma-chloropropyltriethoxysilane simultaneously, and the method comprises the following steps: adopting gamma-chloropropyltrichlorosilane prepared by the reaction of trichlorosilane and chloropropene to react with ethanol and finally obtaining gamma-chloropropyltriethoxysilane though esterification, neutralization anddistillation. The invention adds lithium chloride, 4-methylaminopyridine and fatty alkyl dimethyl tertiary amine as esterifying catalyst in esterification reaction for the synergetic catalysis to thereaction between gamma-chloropropyltrichlorosilane and ethanol so as to increase the product content, greatly increase the conversion rate of gamma-chloropropyltrichlorosilane, increase the product yield, inhibit the side effect, shorten the reaction time, reduce the impurity content of the product and reduce the Cl<-> content in the product of which target value is not more than 50ppm.

Owner:青岛荣达新材料研究所

Method for dry distillation extraction of plant aromatic oil

ActiveCN107011995AImprove daily processing capacityReduce labor intensity and labor costEssential-oils/perfumesHeat transfer tubeProcess engineering

The present invention relates to a method for dry distillation extraction of plant aromatic oil. The method comprises the following steps: cutting a raw material to form a broken material, allowing the broken material to fall into a closed hopper, and conveying the broken material into a dry and hot distillation device by a closed conveying device arranged at the bottom of the hopper, wherein the dry and hot distillation device is composed of a stationary shell and a rotating heat transfer tube bundle; and introducing a heat source medium with a predetermined temperature into the heat exchange tube bundle in order to indirectly heat the material in the dry and hot distillation device in order to make aromatic oil in the material and water form a mixed gas, discharging the mixed gas from a top outlet, condensing the mixed gas by a condenser to form a liquid, and outputting the liquid from a material outlet through the closed conveying device. The method has the advantages of improvement of the daily processing capacity, reduction of the labor intensity and the labor cost, prevention of the loss of the plant aromatic oil, facilitation of the rapid distillation of the material, increase of the thermal efficiency of distillation, facilitation of the evaporation of aromatic oil components with high boiling points, and obtaining of substance components not obtained through traditional processes.

Owner:YIBIN UNIV +1

Processes for producing esters of unsaturated carboxylic acids and polyhydric alcohols with limited polymerization, and apparatus therefor

InactiveUS6903231B1Fast distillationShort reaction timeOrganic compound preparationPreparation by carbon monoxide or formate reactionAlcoholPolyol

Processes and apparatus for producing esters are described. The processes include: (a) providing a liquid reaction mixture comprising (i) an unsaturated carboxylic acid having a boiling point greater than water, (ii) a polyhydric alcohol, and (iii) a first polymerization inhibitor, in a reaction zone having an inner surface; (b) reacting the acid and the polyhydric alcohol to form an ester, such that a gas / vapor phase is formed comprising water of reaction; (c) removing at least a portion of the gas / vapor phase from the reaction zone to a dephlegmation zone having an inner surface; (d) partially condensing the portion of the gas / vapor phase in the dephlegmation zone such that a condensate is formed; and (e) returning the condensate to the reaction zone; wherein a second polymerization inhibitor is introduced into the dephlegmation zone such that the portion of the gas / vapor phase and / or the condensate are contacted with the second polymerization inhibitor. Apparatus for carrying out the processes are also described.

Owner:COGNIS IP MANAGEMENT GMBH

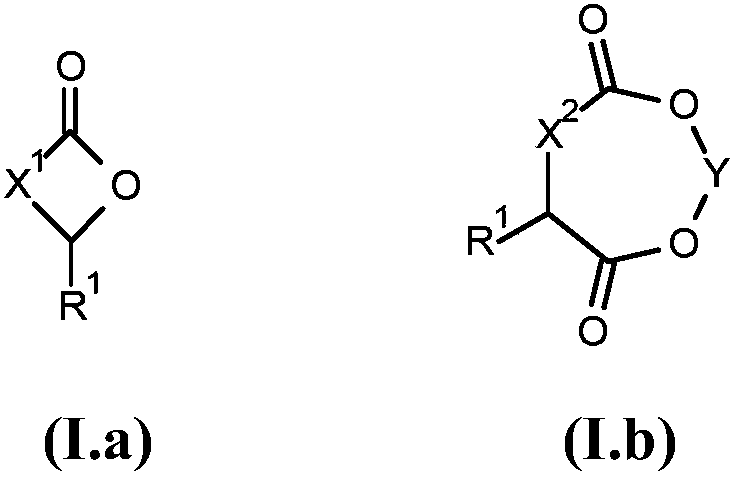

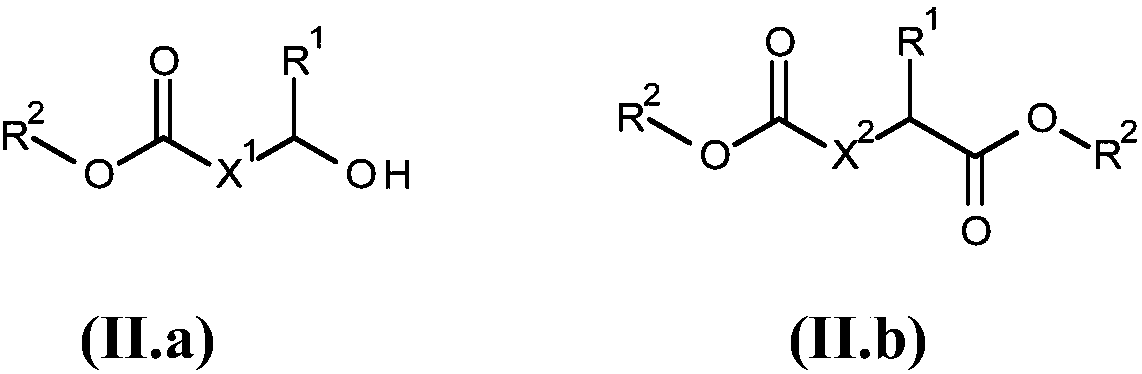

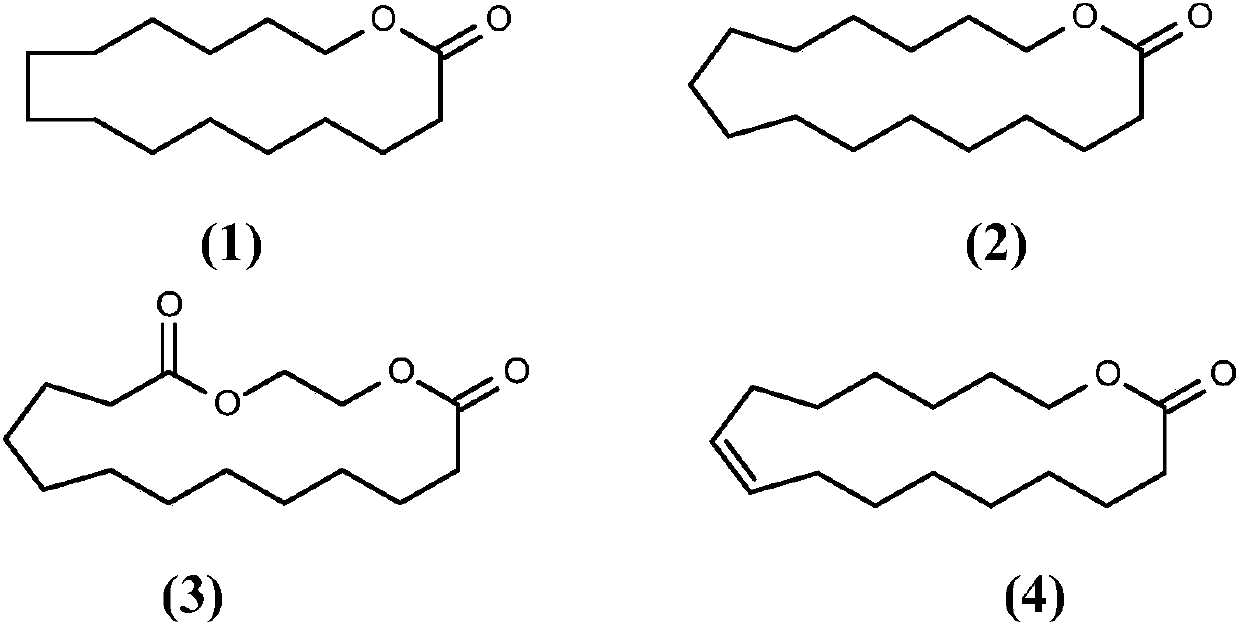

Method for producing cyclic esters

InactiveCN107690430AFast distillationShort reaction timeOrganic chemistryChemical compoundBoiling point

The invention relates to a method for producing cyclic esters of general formula (I.a) or (I.b) in the presence of at least one high-boiling metal alkoxide catalyst. The invention further relates to the stereoisomers of 18-methyl-1-oxacyclooctadec-10-en-2-one and to the use thereof as an odorous substance and / or flavoring substance, to compositions that contain at least one of the stereoisomers of18-methyl-1-oxacyclooctadec-10-en-2-one and additionally a carrier material, to fragrance compositions and / or to fragrant-substance materials that contain at least one of these compounds, and to a method for giving an odor or flavor to or changing an odor or flavor of compositions by adding at least one of the mentioned compounds to said compositions.

Owner:BASF AG

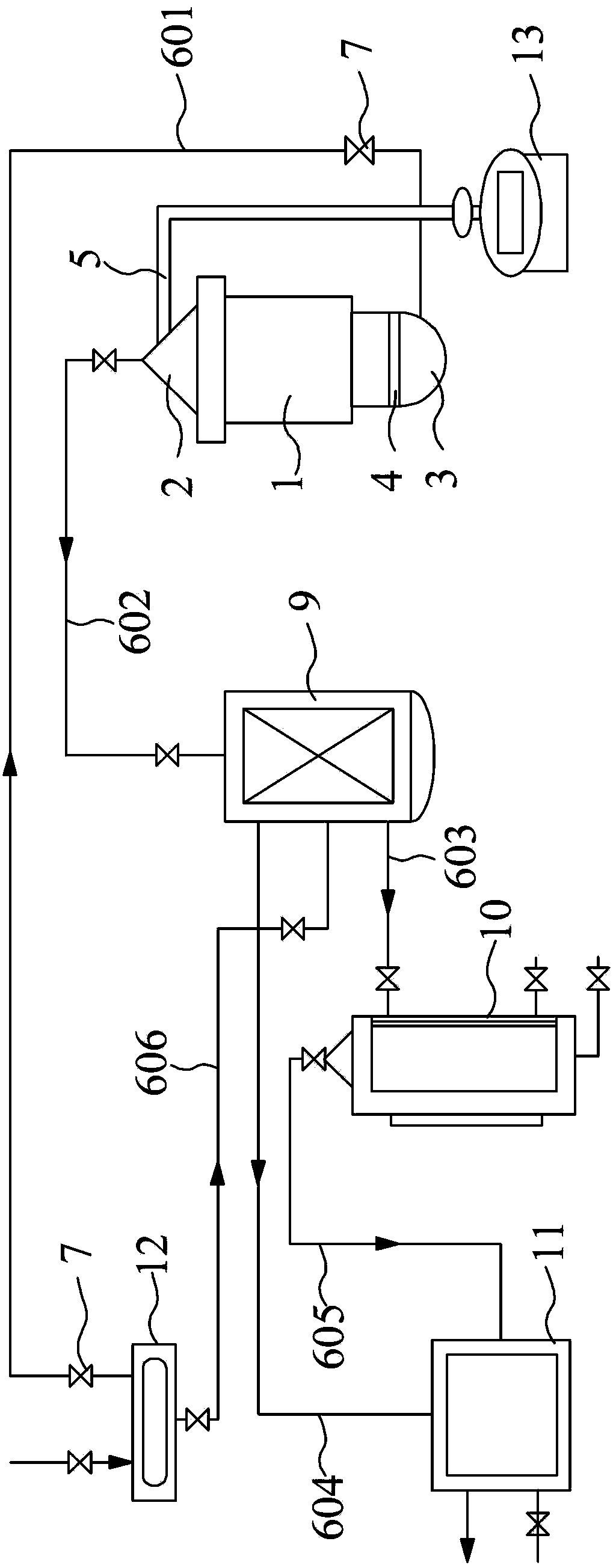

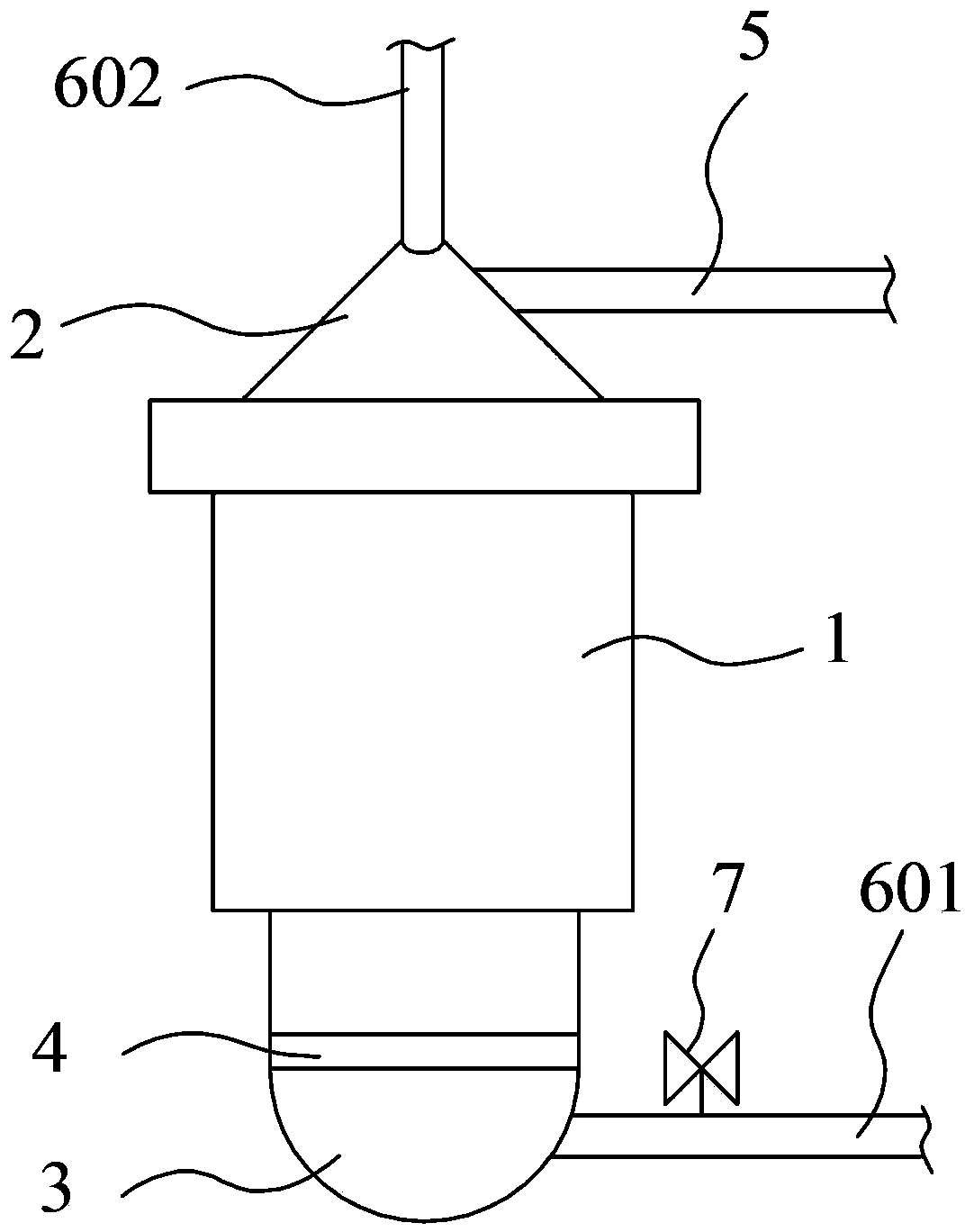

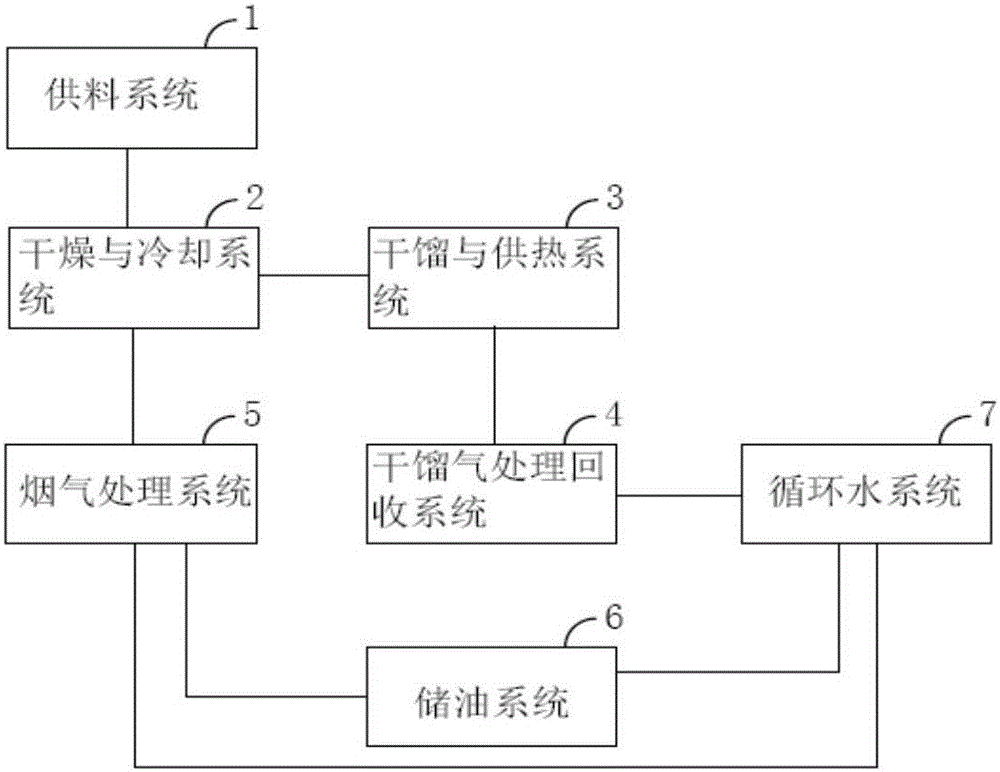

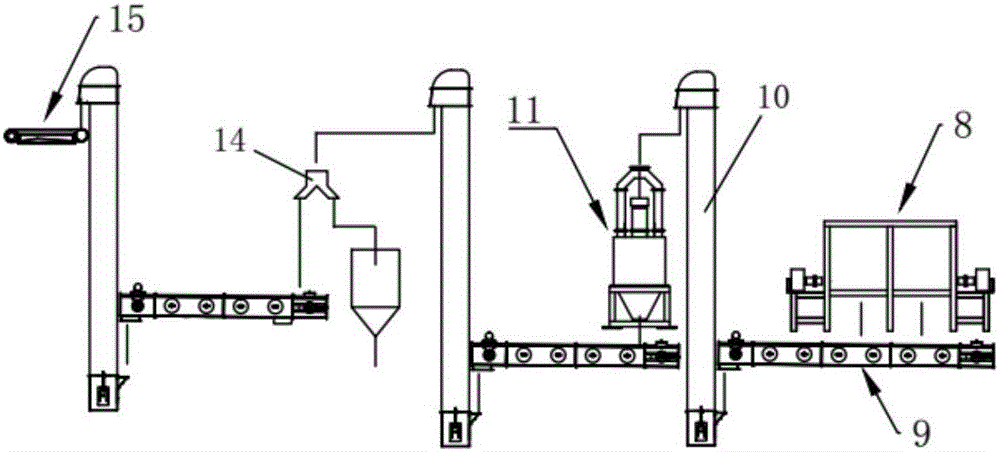

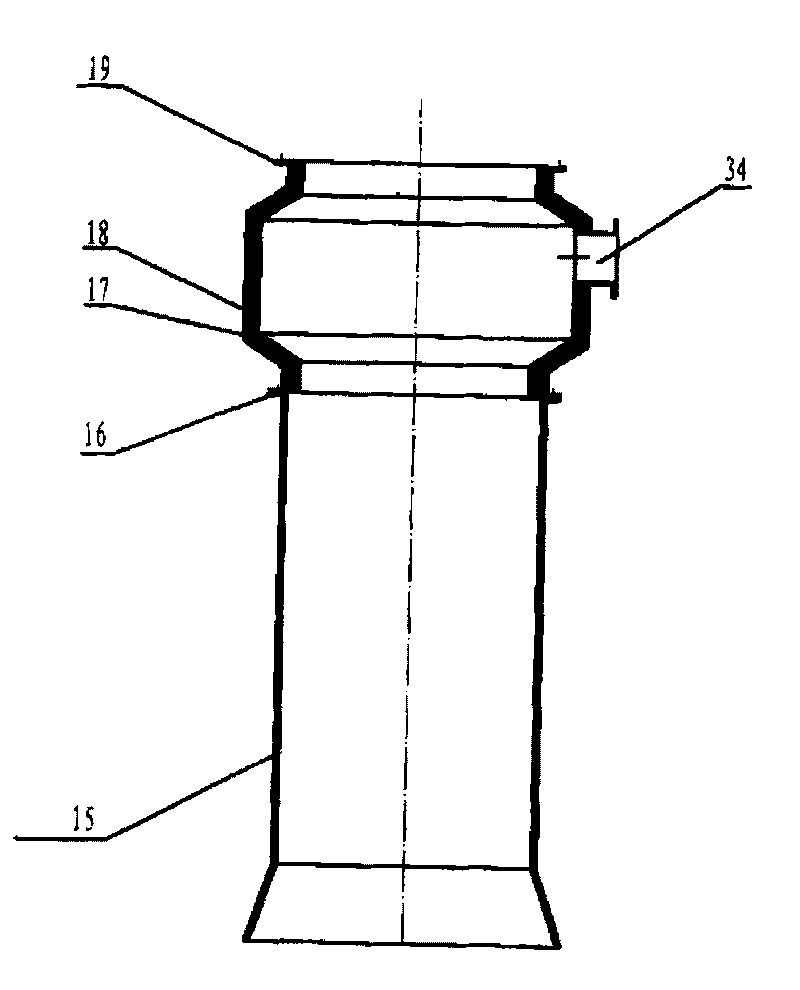

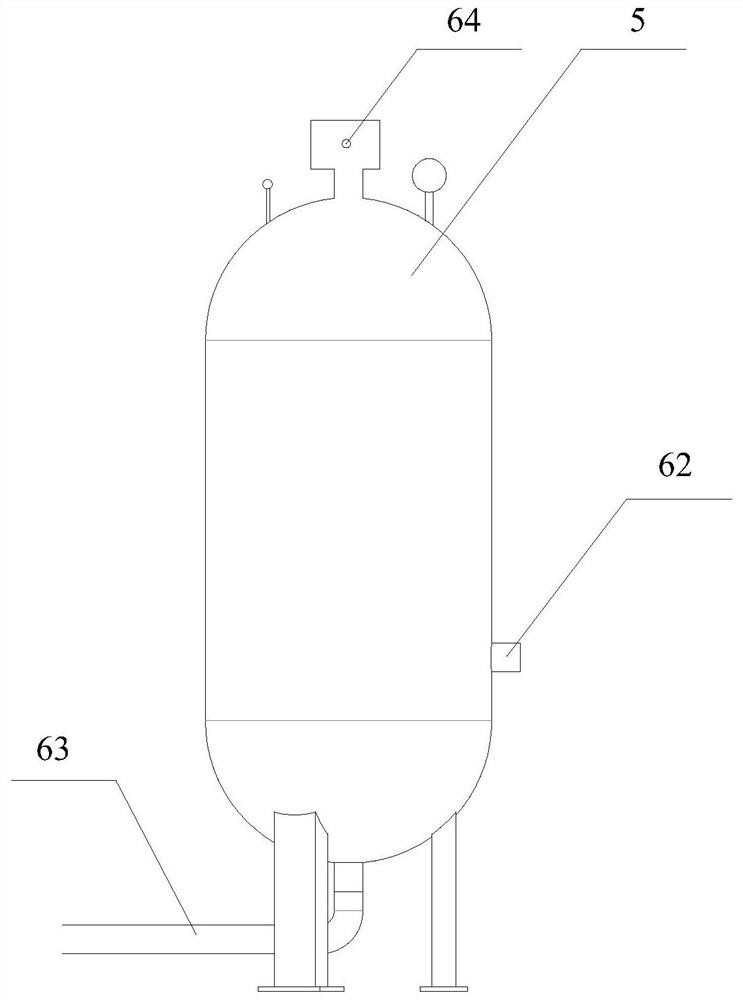

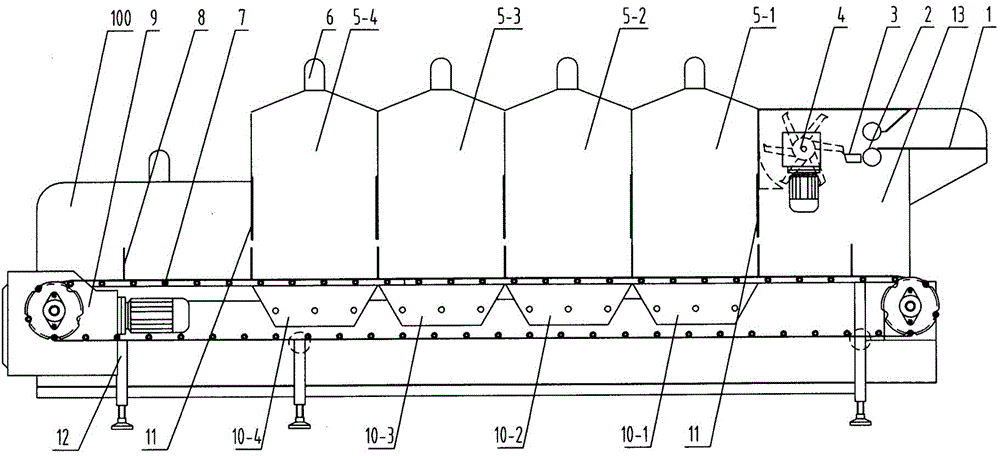

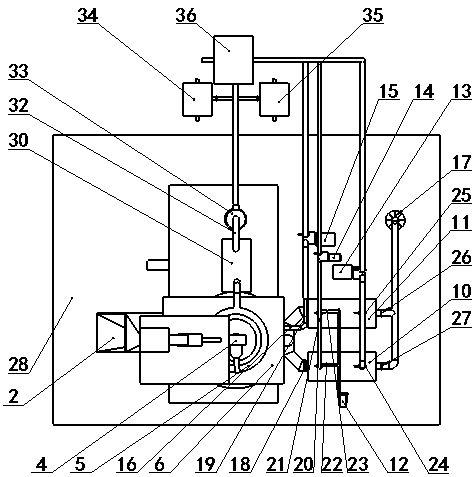

Oil sand dry distilling system

InactiveCN106833692ARealize continuous dry distillationFast distillationLiquid hydrocarbon mixture productionSpecial form destructive distillationAmine gas treatingProcess equipment

The invention relates to the technical field of dry distilling equipment and provides an oil sand dry distilling system. The oil sand dry distilling system comprises a feeding system, a drying and cooling system, a dry distilling and heat supply system, a dry distilling gas treating and recycling system, a flue gas treating system, an oil storage system and a circulating water system, wherein the feeding system comprises a raw material feeding device and a raw material storing device; the drying and cooling system comprises a scraper dryer; the dry distilling and heat supply system comprises a dry distilling device and a heat supply mechanism; the dry distilling gas treating and recycling system comprises a heating area dry distilling gas treating recycling device and a dry distilling area dry distilling gas treating recycling device; the flue gas treating system comprises a wet dust collector; the oil storage system comprises an oil storage tank used for storing end product of oil; the circulating water system comprises a centrifugal water pump and a water reservoir; and the continuous dry distilling for the oil sand is realized, the dry distilling speed is high, the energy consumption is low and the service life of the system is prolonged.

Owner:克拉玛依市恒通能源有限公司 +1

One-segment type energy saving coal gas producer with performance of two-segment producer

InactiveCN101709230AEvenly distributedStable gas productionChemical industryCombustible gas productionProcess engineeringEngineering

The invention discloses a one-segment type energy saving coal gas producer with the performance of a two-segment producer, which aims to solve the problems of serious pollution and the like existing in the prior art. The coal gas producer comprises a producer body and a dry distillation tower, wherein the dry distillation tower comprises a dry distillation tower body arranged on the upper part of the producer body and a coal separator arranged in the producer body; because the outside of the dry distillation tower body is provided with a heat insulated device, the heat is accumulated in the tower, and the internal temperature is relatively high, which facilitates the generation of coal gas in the dry distillation tower; the dry distillation tower body is provided with a gas outlet on the same side of the producer body provided with a coal gas outlet, the gas outlet is outward provided with a dry distillation coal gas outlet tube which is downward inclined and communicated with a coal gas conveying tube, the pressure and the flow rate on the outlet of the coal gas producer are over those of the dry distillation coal gas, so that the dry distillation coal gas is led to enter a main pipeline, the dry distillation speed is improved, and the temperature in the dry distillation tower is increased; and the coal separator consists of a tube body segment and a dispersion opening segment, a coal separating tube of the coal separator is inserted in a producer cylinder, the dispersion opening segment of the coal separating tube is trumpet-shaped, so that the coal can be evenly and continuously charged and the dust can be prevented from generation.

Owner:LIAONING JIUZHOU WEIYE DEV

Bamboo substance continuous carbonization furnace

InactiveCN105482837AEvenly heatedIncrease spawn rateBiofuelsSpecial form destructive distillationProcess engineeringUtilization rate

The invention discloses a bamboo substance continuous carbonization furnace which comprises a heat supply system, a carbonizing system, and a gas and water recovery system. The heat supply system is connected with a furnace body of the carbonizing system through a hot air annular pipe. A water ring type pressurizing machine is connected with a coal gas storage cabinet of the gas and water recovery system. The furnace body of the carbonizing system is connected with the gas and water recovery system through a coal gas collecting annular pipe on a furnace top platform. A cooling cavity of the carbonizing system is connected with the coal gas storage cabinet of the gas and water recovery system through a pipeline. The gas and water recovery system is located at the right end of a bottom plate. The bamboo substance continuous carbonization furnace is high in dry distillation speed, high in char formation rate, high in heat utilization rate, high in resource comprehensive utilization rate, free of waste in the process and free of pollution to the environment.

Owner:TANGSHAN XIRUI AUTOMATION EQUIP CO LTD

Energy saving wine brewing device

PendingCN110016425AImprove distillation efficiencyAchieve recyclingAlcoholic beverage preparationChillerEvaporator

The invention relates to an energy saving wine brewing device. The energy saving wine brewing device comprises a distillation pot, a condenser, a revaporizer and a cooler, wherein a mature distillers'grain inlet and a first wine steam outlet are formed in the distillation pot, the first wine steam outlet communicates with a heat medium inlet of the condenser through a first pipeline, and a heat medium outlet of the condenser communicates with a feed opening of the revaporizer through a second pipeline; a coolant inlet of the condenser is connected with a cold mature distillers' grain conveying pipe, and a coolant outlet of the condenser communicates with the mature distillers' grain inlet through a hot mature distillers' grain conveying pipe; a first waste liquid discharge opening communicating with a heat medium inlet of the revaporizer is also formed in the bottom of the distillation pot, a second wine steam outlet communicating with the cooler is formed in the top of the revaporizer, and liquid wine after being cooled through the cooler is discharged from a liquid wine outlet; and a flow regulator is arranged on the cold mature distillers' grain conveying pipe, and an alcohol concentration detector in connection and communications with the flow regulator is arranged at the liquid wine outlet. The energy saving wine brewing device disclosed by the invention is high in energyutilization rate, and brewed wine is high in purity.

Owner:JIANGSU ZUIKAIXIN LIQUOR CO LTD

Solvent distillation recovery device

InactiveCN107754367AWon't be lostReduce churnEvaporationFractional distillationVertical tubeDistillation

The invention belongs to the field of solvent recovery and in particular discloses a solvent distillation recovery device. A vertical tube penetrates through a distillation tube; an upright post for supporting is arranged at the bottom of the vertical tube; an inlet door is installed at the left side of the distillation tube; an outlet door is installed at the right side of the distillation tube;two concentric sliding chutes positioned outside the distillation tube are symmetrically arranged on the side walls of the vertical tube; balls are sequentially connected into the sliding chutes in asliding manner; spiral heating wires are connected onto the balls; v-shaped covers are arranged outside the inlet door and the outlet door; edges at larger ends of the v-shaped covers are connected with the heating wires; a rotating motor is arranged at smaller ends of the v-shaped covers; supporting rods are arranged at the bottom of the motor; a pressure block is connected into the vertical tubein a sliding manner; a curved tube through which a solvent circulates is arranged inside the pressure block; and an outlet tube matched with the curved tube is arranged on the side wall of the vertical tube. With the adoption of an annular heating manner, the problem of non-uniform heating of distillation equipment is solved; and with the adoption of a unique structural design, rapid distillationis realized, and heat loss is reduced.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

System and method for discharging alkali and washing salt in saline-alkali soil by utilizing solar heat collection drying pipe

ActiveCN112645519AHigh salinityImprove the growing environmentWater/sewage treatmentMultistage water/sewage treatmentSoil scienceAlkali soil

The invention discloses a system and method for discharging alkali and washing salt in saline-alkali soil by utilizing a solar heat collection drying pipe. Condensed water resources are obtained from saline-alkali water by utilizing a solar photo-thermal method, evaporation of the saline-alkali water can be accelerated, separation of salt and alkali from fresh water is promoted, finally a large amount of condensed fresh water is obtained, and water resource shortage can be relieved, and the alkali removal and salt leaching efficiency of saline-alkali soil can be improved.

Owner:TARIM UNIV

Preparation method of high-quality natural borneol (d-borneol) without camphor

InactiveCN109111346AReduce oxidationReduce exposureOrganic compound preparationOrganic chemistry methodsOxygenBULK ACTIVE INGREDIENT

The invention relates to a preparation method of high-quality natural borneol (d-borneol) without camphor, and relates to the technical field of a medicine, in particular to the preparation method ofhigh-quality natural borneol (d-borneol) without camphor. In view of the fact that the products in the prior art contain camphor, organic solvents or other chemical residues, and the cost is high, Themethod adopts extraction by vacuum distillation, reduces the extraction temperature, reduces the contact with oxygen, reduces the loss of active ingredients, and improves the efficiency and reduces the cost; the volatile oil (essential oil) obtained by distillation extraction is employed for dissolving crystals, and the obtained product has zero organic solvent and other chemical component residue, the content of the d-borneol is more than 98.5%, the high-quality natural borneol does not contain camphor through detection by a gas chromatographic method, and the yield of the product is increased by more than 15%. The product quality and price competitiveness are strong.

Owner:欧晓英

Method for continuously rectifying 3-chloropropyl triethoxysilane

InactiveCN102580338BShorten the timeFast distillationGroup 4/14 element organic compoundsFractional distillationTriethoxysilaneProcess engineering

The invention provides a method for continuously rectifying 3-chloropropyl triethoxysilane, belonging to the field of chemical engineering separation. The device is characterized by comprising an ethanol rectifying separating device and a 3-chloropropyl triethoxysilane rectifying separating device which are structured the same and connected in series by a conveying pipeline and a material transforming pump, wherein each of the two rectifying separating devices which are structured the same comprises a rectifying tower, a condenser and a finished product storage tank which are connected with the top of the rectifying tower by a reflux pipeline, a condenser and a crude product storage tank which are connected with the bottom of the rectifying tower by the conveying pipeline. The crude product storage tank is connected with a next group of a rectifying separating device by the material transforming pump. In the first tower, ethanol is removed at normal pressure to reach a purity of more than 99.8%; in the second tower, 3-chloropropyl triethoxysilane is removed by rectifying at a negative pressure of -0.0098Mpa to reach a purity of more than 99.5%.

Owner:淄博市临淄齐泉工贸有限公司

Method for continuously distilling aromatic oil by subsectional temperature control

InactiveCN103215137BImprove daily processing capacityReduce labor intensityEssential-oils/perfumesFatty-oils/fats productionTemperature controlDistillation

Owner:YIBIN UNIV

A continuous carbonization furnace for bamboo

InactiveCN105482837BFast distillationEvenly heatedBiofuelsSpecial form destructive distillationProcess engineeringPollution

The invention discloses a bamboo substance continuous carbonization furnace which comprises a heat supply system, a carbonizing system, and a gas and water recovery system. The heat supply system is connected with a furnace body of the carbonizing system through a hot air annular pipe. A water ring type pressurizing machine is connected with a coal gas storage cabinet of the gas and water recovery system. The furnace body of the carbonizing system is connected with the gas and water recovery system through a coal gas collecting annular pipe on a furnace top platform. A cooling cavity of the carbonizing system is connected with the coal gas storage cabinet of the gas and water recovery system through a pipeline. The gas and water recovery system is located at the right end of a bottom plate. The bamboo substance continuous carbonization furnace is high in dry distillation speed, high in char formation rate, high in heat utilization rate, high in resource comprehensive utilization rate, free of waste in the process and free of pollution to the environment.

Owner:TANGSHAN XIRUI AUTOMATION EQUIP CO LTD

Integrated rose essential oil extraction device

InactiveCN112824514AQuick extractionEasy to operateEssential-oils/perfumesThermodynamicsInsulation layer

The invention relates to the technical field of extraction, and discloses an integrated rose essential oil extraction device which comprises an inner shell, the bottom of the inner shell is fixedly connected with a base, the interior of the base is fixedly connected with a controller, the top of the base and the lower half part of the inner shell are a distillation chamber, and the top of the distillation chamber is fixedly connected with a channel pipe; the top of the channel pipe and the upper half part of the inner shell are an extraction chamber, the bottom of the extraction chamber is in threaded connection with an annular fixing seat, the top of the extraction chamber is movably connected with a motor, the bottom of the motor is fixedly connected with a rotating shaft, stirring paddles are arranged around the rotating shaft, the outer side of the inner shell is fixedly connected with a heat insulation layer, and the outer side of the heat insulation layer is fixedly connected with an outer shell. According to the integrated rose essential oil extraction device, materials are put into the extraction chamber through the feeding port in the top of the inner shell to be stirred and distilled, the stirred liquid is distilled to obtain rose essential oil, and the integrated rose essential oil extraction device has the advantages of being convenient and rapid to use, easy to operate and small in overall occupied area.

Owner:HUNAN UNIV OF TECH

Oil shale gas-solid heat carrier dry distillation and semicoke combustion electricity generation integral process

The invention relates to an oil shale gas-solid heat carrier dry distillation and semicoke combustion electricity generation integral process, which is characterized in that oil shale crushed into at least 75mm is stored in a raw material cabin and is sieved, small-particle oil shale with the particle diameter smaller than 15mm and 15-75 mm large-particle oil shale are respectively conveyed into a left chamber and a right chamber of a medium-temperature gas indirect or direct heat exchange drying heater, and 15-75 mm large-particle oil shale subjected to heating and drying is subjected to gas heat carrier dry distillation; the small-particle oil shale with the particle diameter smaller than 15mm and semicoke are mixed and are subjected to solid heat carrier dry distillation; oil-gas mixtures generated by the solid heat carrier dry distillation are subjected to purification, condensation and separation treatment after sedimentation and gas-solid separation, shale oil is conveyed into an oil storage tank, one part of separated gas is used as heat carriers of the dry distillation of the 15-75 mm large-particle oil shale, and the rest gas is conveyed into a gas storage tank; superheated steam produced by semicoke consumption is conveyed into a steam turbine generator set for electricity generation; one part of semicoke consumption high-temperature hot ash is used as the heat energy of the dry distillation of the small-particle oil shale with the particle diameter smaller than 15mm; and the other part of discharged hot ash is cooled and is then conveyed to a building material factory.

Owner:NORTHEAST DIANLI UNIVERSITY +1

A kind of pine resin vacuum distillation device

ActiveCN106975236BFully dispersedFully dispersed joinVacuum distillation separationNatural resin purificationVacuum extractionTurpentine

Owner:广西产学研信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com