Microwave drum dry distiller and its application in dry distilling and pyrolyzing oil shale

A drum and dry distillation technology, which is applied in the field of pyrolysis and dry distillation of carbonaceous materials, can solve the problems of short continuous operation time, low utilization rate of oil shale, complex and huge equipment, etc., and achieves small equipment footprint, fast heating speed, The effect of high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

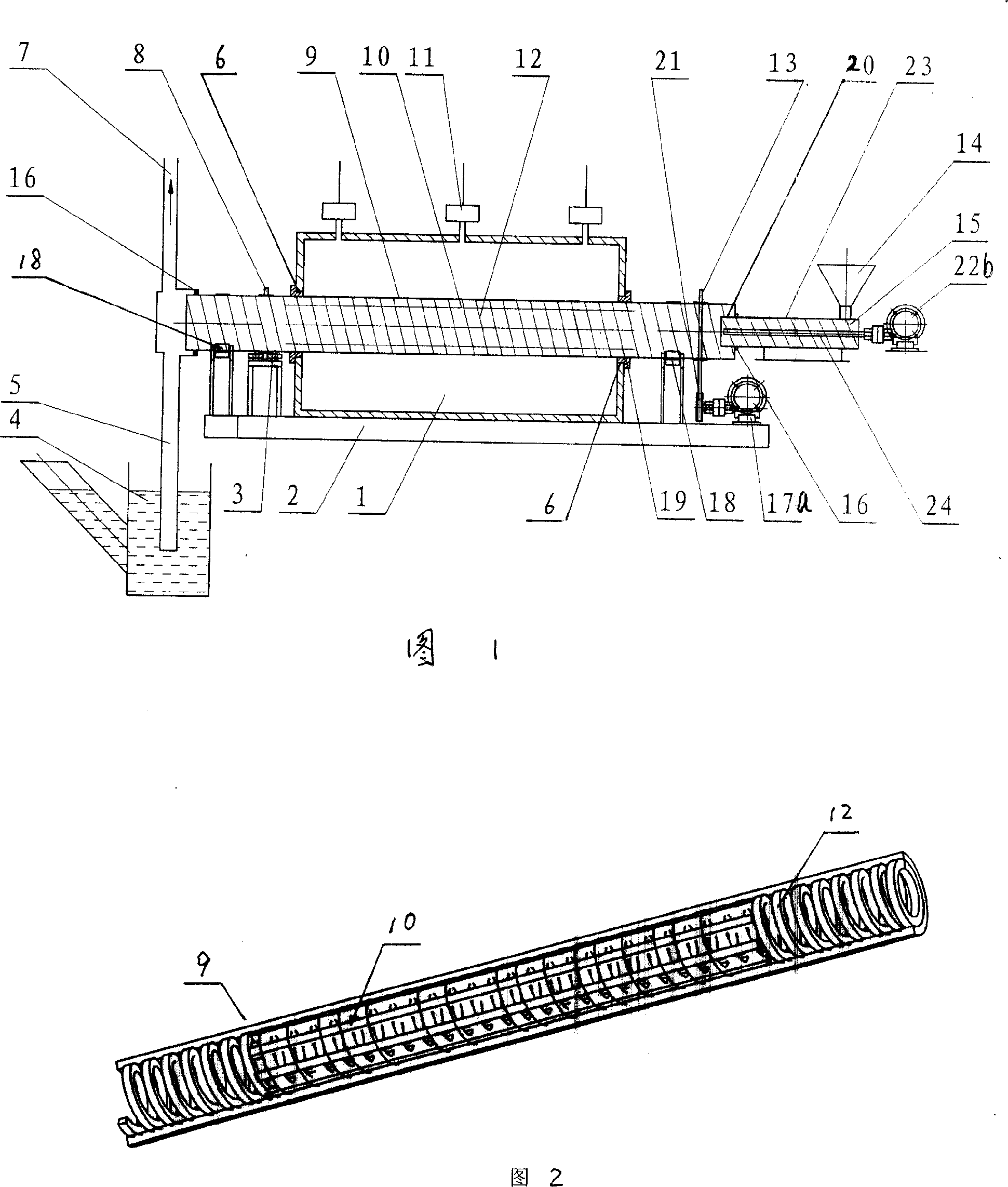

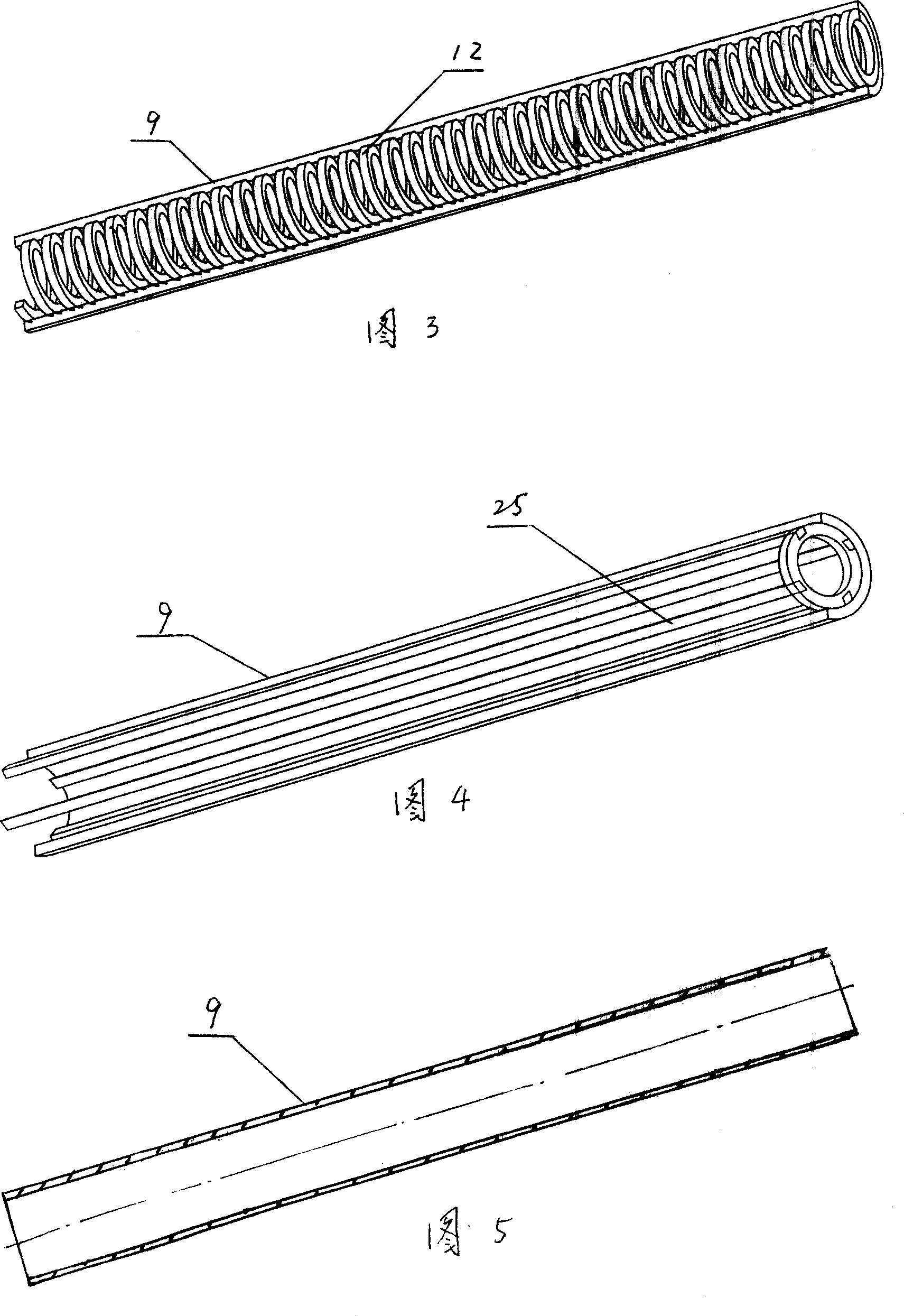

[0030] Referring to FIG. 1 , the microwave drum dry distillation device has a machine base 2 on which a microwave oven body 1 and supporting rollers 18 are placed. An inner spiral drum 9 is provided on the support roller 18, and the inner spiral drum 9 has a feed inlet 20, a slag discharge cylinder 5 and an air outlet pipe 7 communicating with the slag discharge cylinder 5, and the inner spiral drum 9 is provided with a power wheel 13. The feeding port 20 of the inner screw drum 9 is connected with the screw conveyor 15 through a mechanical seal 16 . The inner spiral drum 9 is connected with the slag tapping cylinder 5 and the air outlet pipe 7 communicating with the slag tapping cylinder 5 through a mechanical seal 16 . The inner spiral drum 9 is made of high-temperature-resistant and high-strength materials that pass through microwaves. The material can be heat-resistant ceramics and heat-resistant glass steel. Heat-resistant ceramics and heat-resistant glass steel also have...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com