Patents

Literature

357 results about "Contact process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The contact process is the current method of producing sulfuric acid in the high concentrations needed for industrial processes. Platinum used to be the catalyst for this reaction; however, as it is susceptible to reacting with arsenic impurities in the sulfur feedstock, vanadium(V) oxide (V₂O₅) is now preferred.

Electroless plating processes

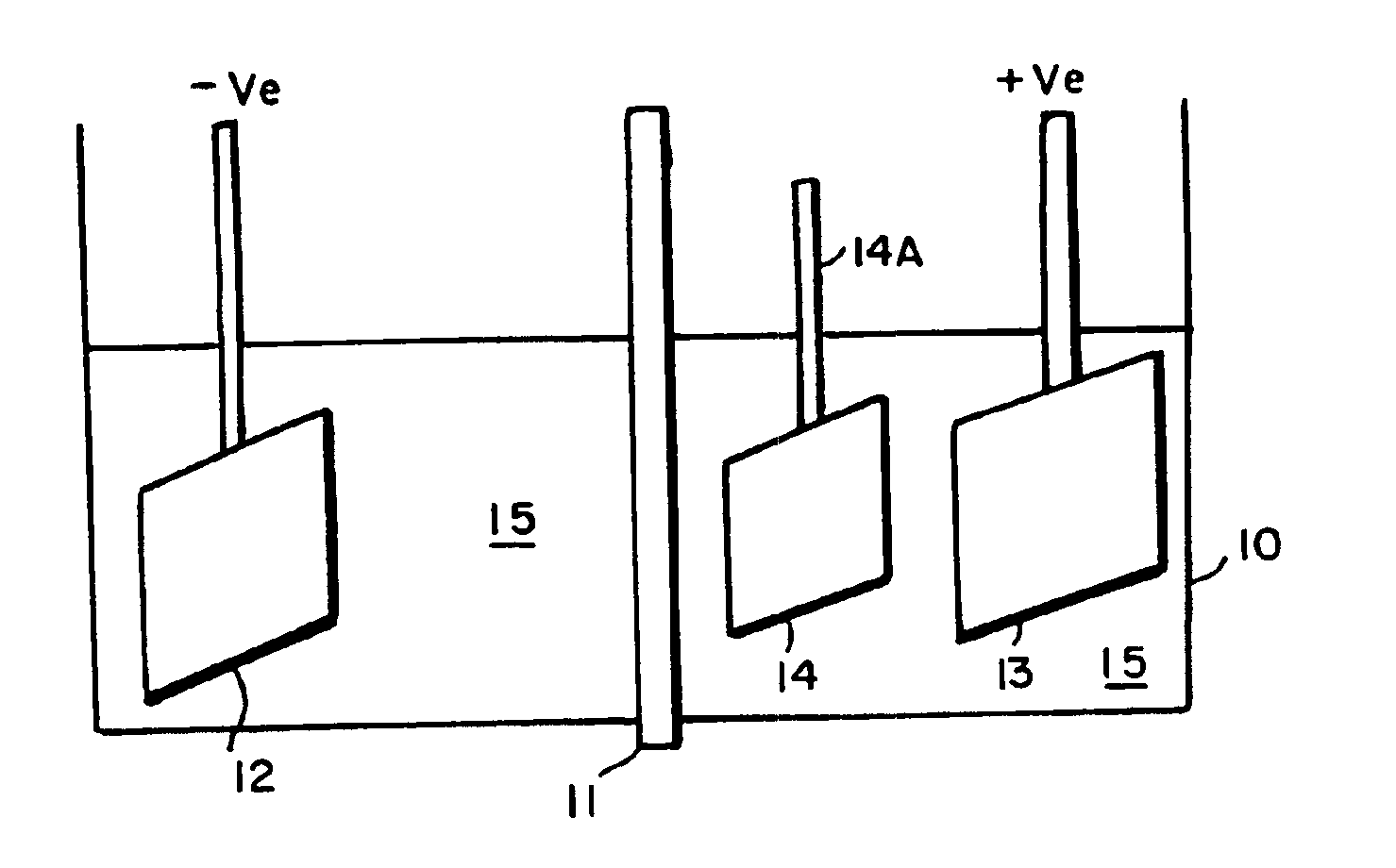

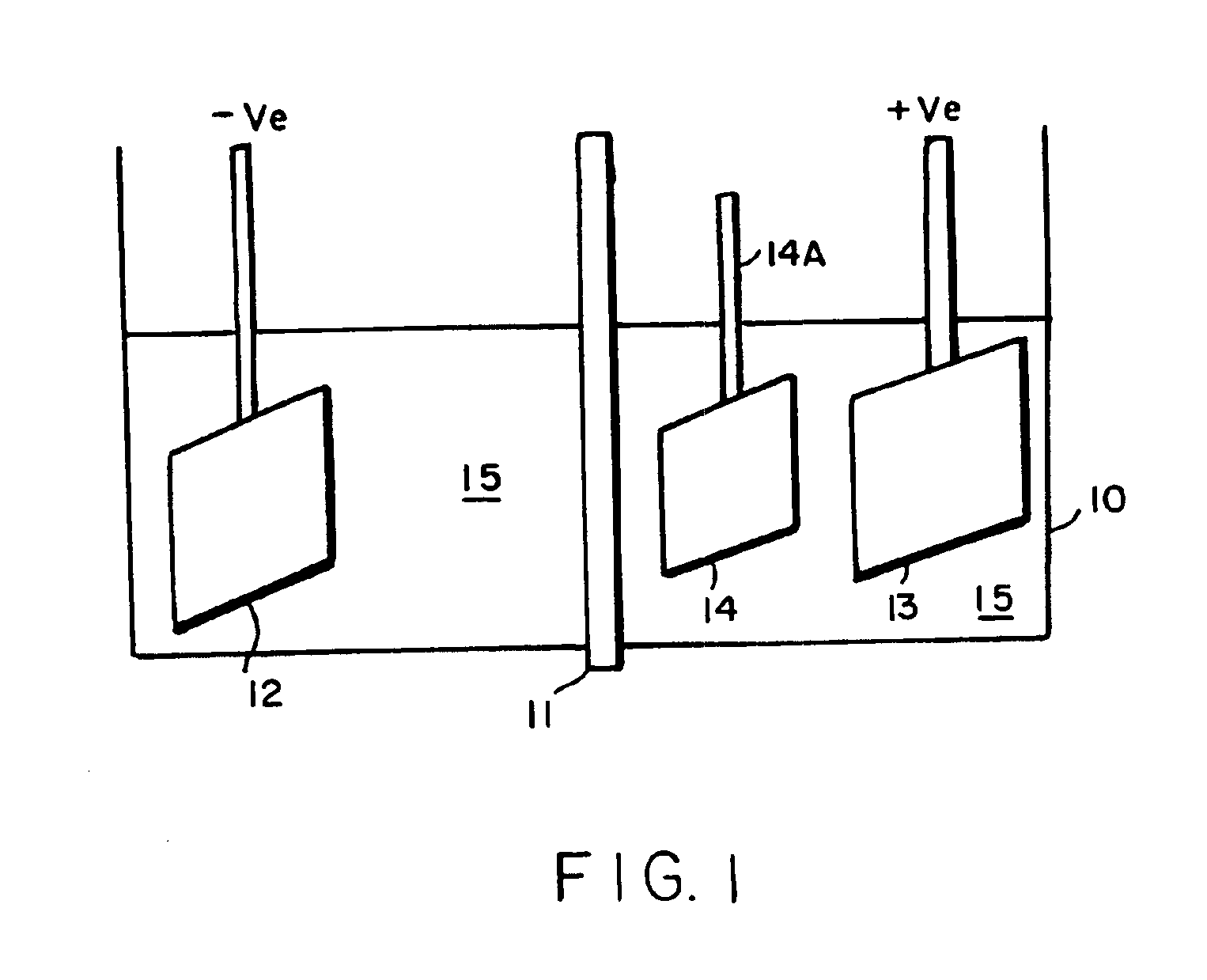

InactiveUS6861097B1Reducing problem encounteredSimple methodPaper/cardboard articlesDecorative surface effectsPolymeric surfaceOxidation state

The invention includes processes for combined polymer surface treatment and metal deposition. Processes of the invention include forming an aqueous solution containing a metal activator, such as an oxidized species of silver, cobalt, ruthenium, cerium, iron, manganese, nickel, rhodium, or vanadium. The activator can be suitably oxidized to a higher oxidation state electrochemically. Exposing a part to be plated (such as an organic resin, e.g. a printed circuit board substrate) to the solution enables reactive hydroxyl species (e.g. hydroxyl radicals) to be generated and to texture the polymer surface. Such texturing facilitates good plated metal adhesion. As part of this contacting process sufficient time is allowed for both surface texturing to take place and for the oxidized metal activator to adsorb onto said part. The part is then contacted with a reducing agent capable of reducing the metal activator to a lower ionic form, or a lower oxidation state. That reduction can result in the formation of metallic catalytic material over the surface of the part. The reduced metal activator can then function to catalyze the electroless deposition of metal such as copper from solution by contacting the part with the plating solution.

Owner:SHIPLEY CO LLC

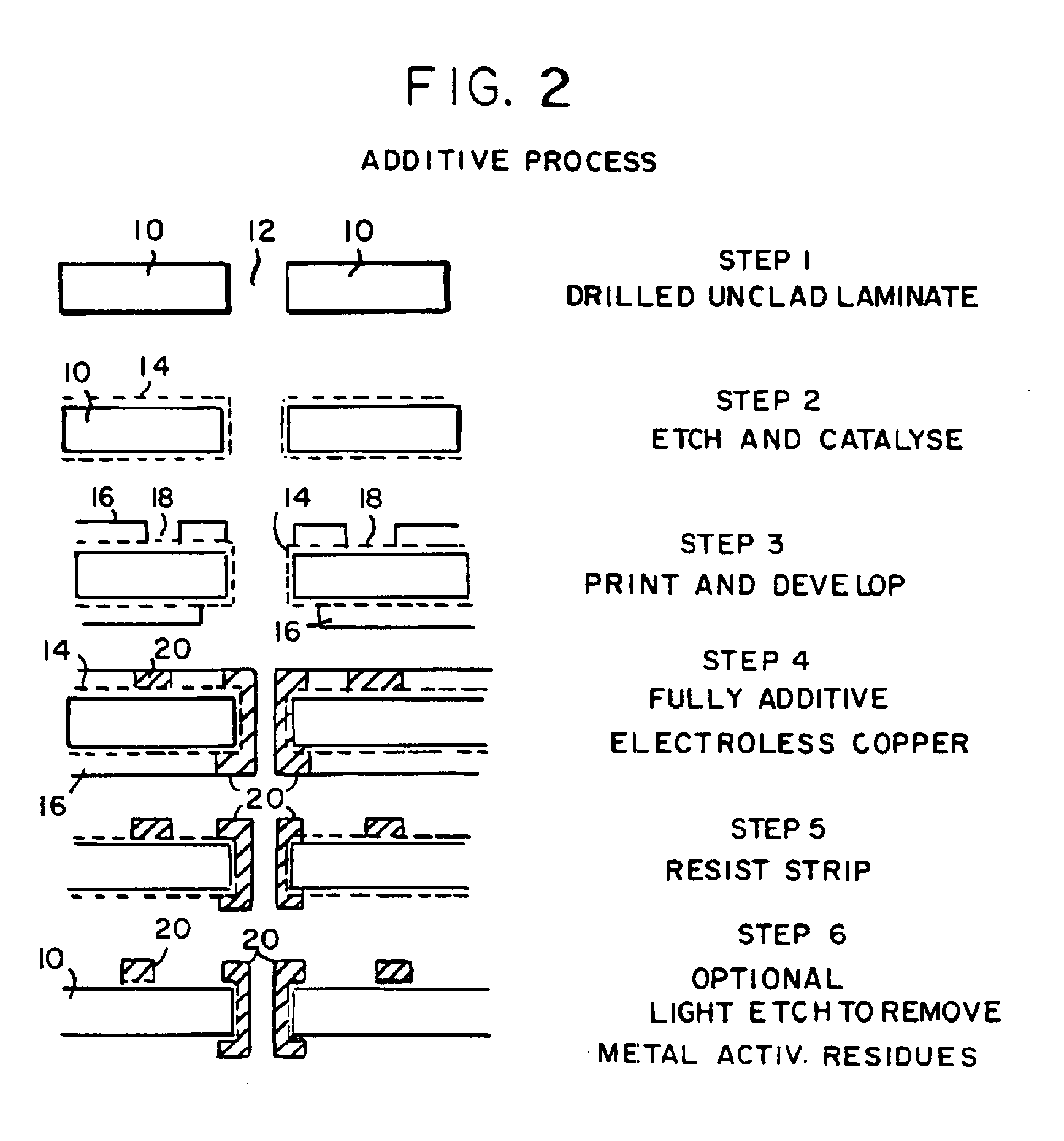

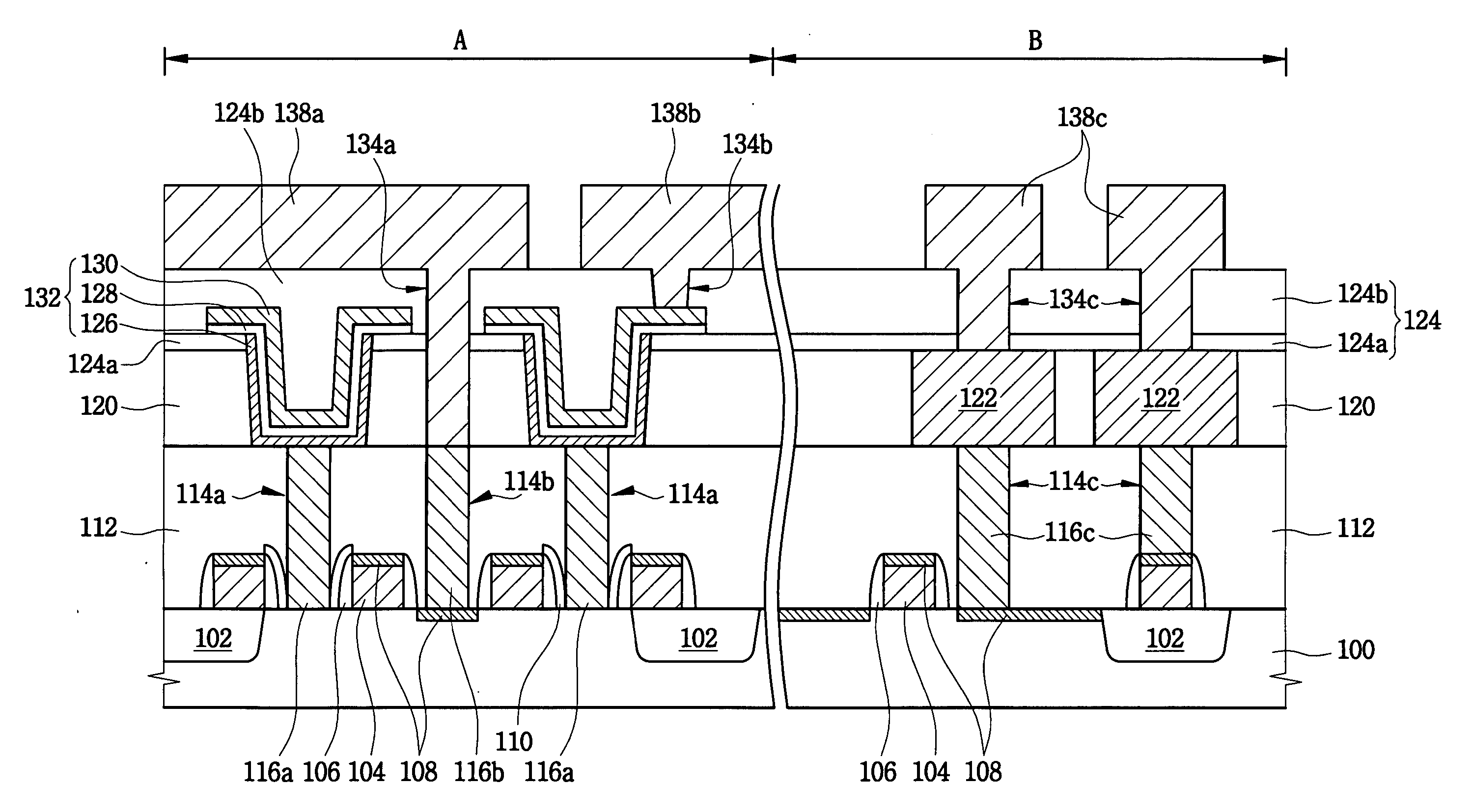

Method for manufacturing a semiconductor integrated circuit device circuit device

ActiveUS20100129974A1Increased integration scaleLower gate resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesMetal silicideField-effect transistor

When a natural oxide film is left at the interface between a metal silicide layer and a silicon nitride film, in various heating steps (steps involving heating of a semiconductor substrate, such as various insulation film and conductive film deposition steps) after deposition of the silicon nitride film, the metal silicide layer partially abnormally grows due to oxygen of the natural oxide film occurring on the metal silicide layer surface. A substantially non-bias (including low bias) plasma treatment is performed in a gas atmosphere containing an inert gas as a main component on the top surface of a metal silicide film of nickel silicide or the like over source / drain of a field-effect transistor forming an integrated circuit. Then, a silicon nitride film serving as an etching stop film of a contact process is deposited. As a result, without causing undesirable cutting of the metal silicide film, the natural oxide film over the top surface of the metal silicide film can be removed.

Owner:RENESAS ELECTRONICS CORP

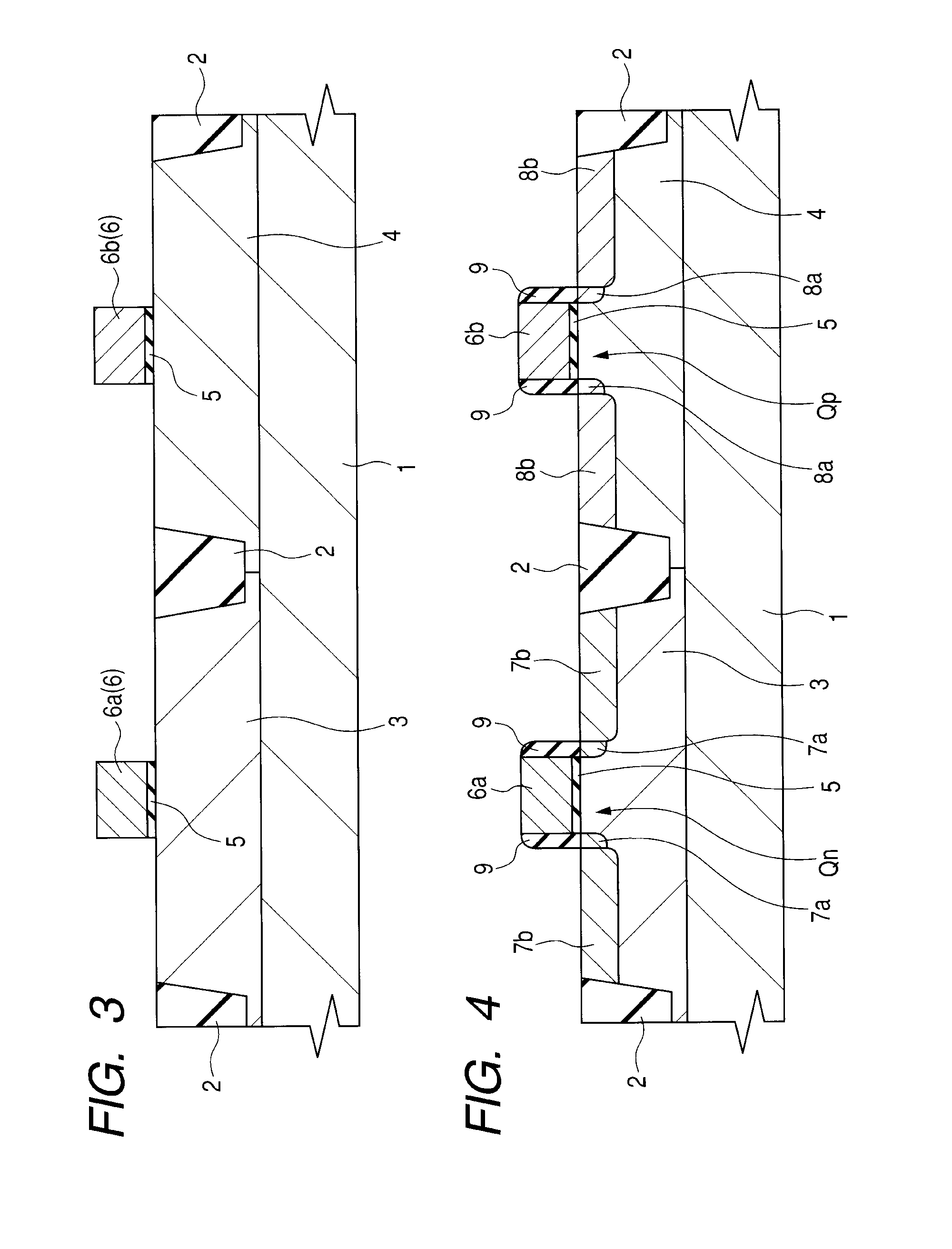

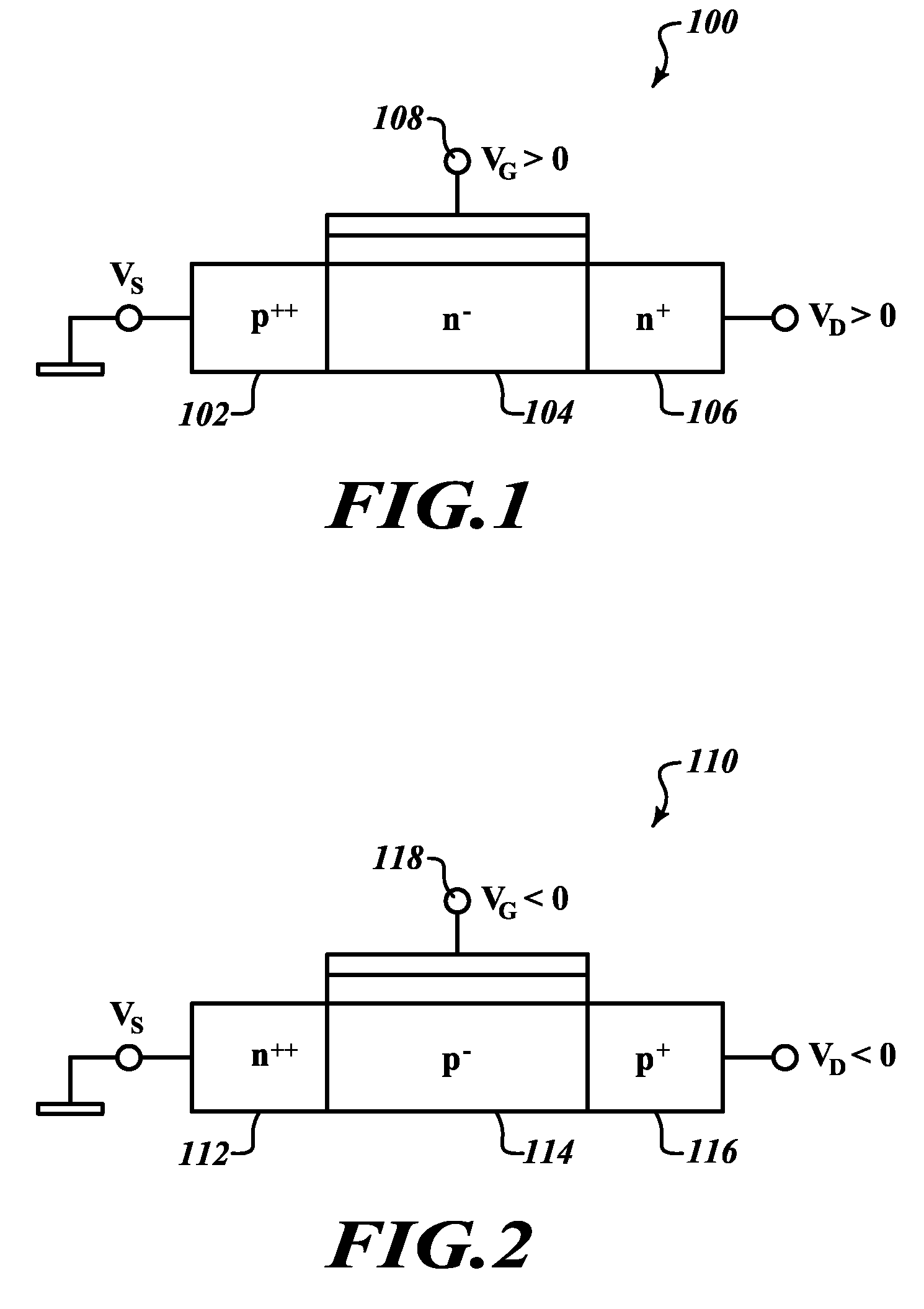

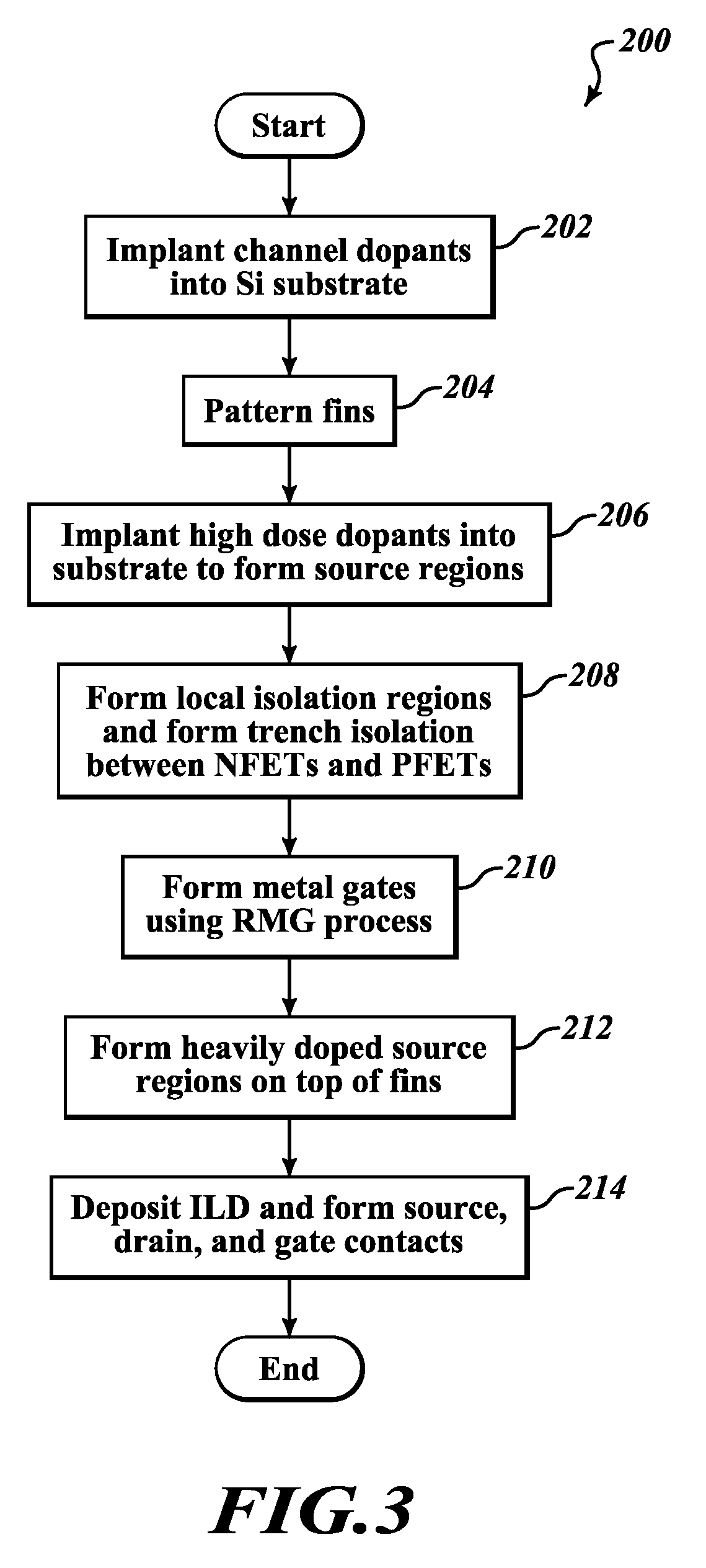

Vertical tunneling finfet

ActiveUS20160293756A1Increase current densityTransistorSemiconductor/solid-state device manufacturingHigh current densityCMOS

A tunneling transistor is implemented in silicon, using a FinFET device architecture. The tunneling FinFET has a non-planar, vertical, structure that extends out from the surface of a doped drain formed in a silicon substrate. The vertical structure includes a lightly doped fin defined by a subtractive etch process, and a heavily-doped source formed on top of the fin by epitaxial growth. The drain and channel have similar polarity, which is opposite that of the source. A gate abuts the channel region, capacitively controlling current flow through the channel from opposite sides. Source, drain, and gate terminals are all electrically accessible via front side contacts formed after completion of the device. Fabrication of the tunneling FinFET is compatible with conventional CMOS manufacturing processes, including replacement metal gate and self-aligned contact processes. Low-power operation allows the tunneling FinFET to provide a high current density compared with conventional planar devices.

Owner:STMICROELECTRONICS SRL

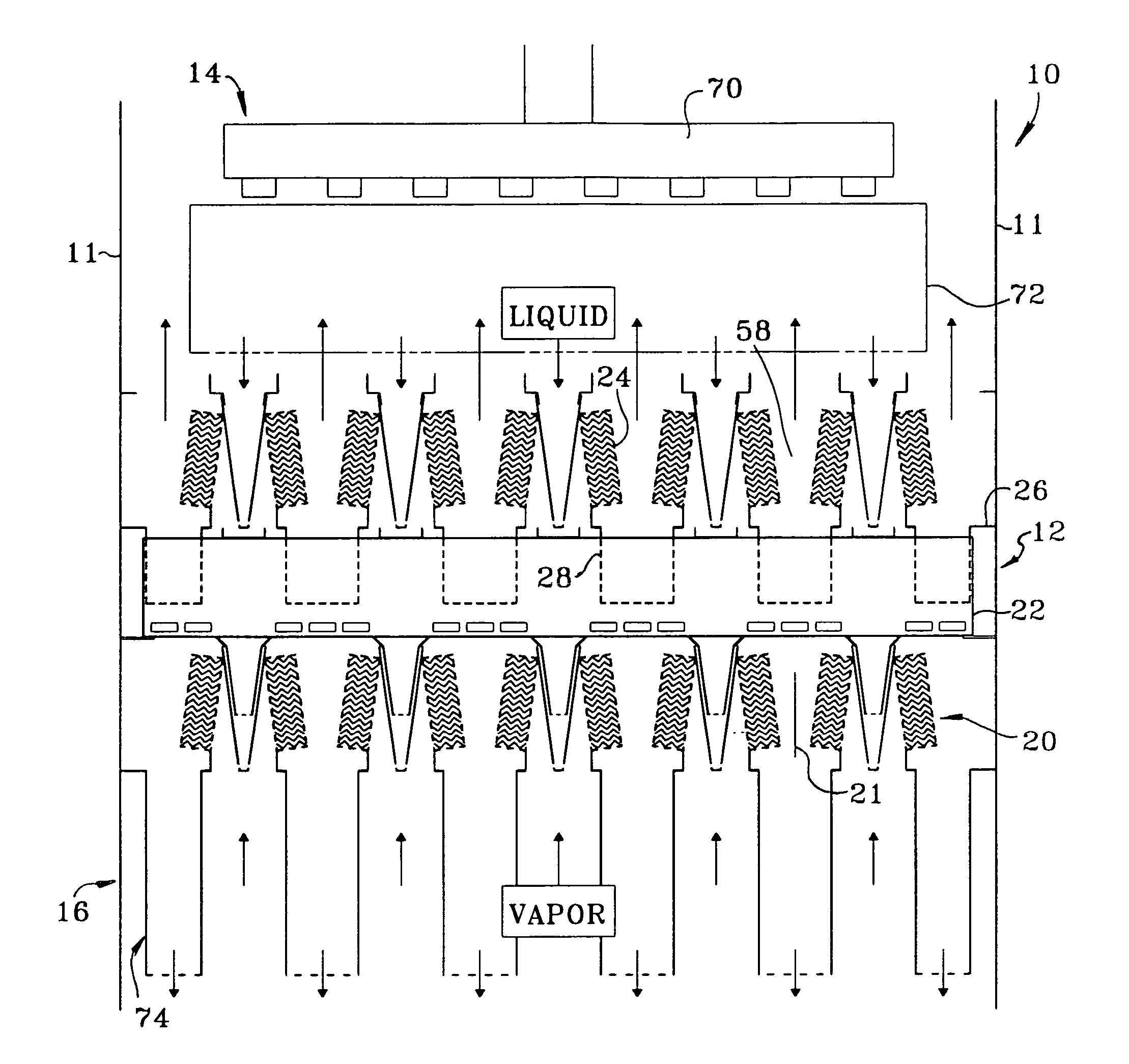

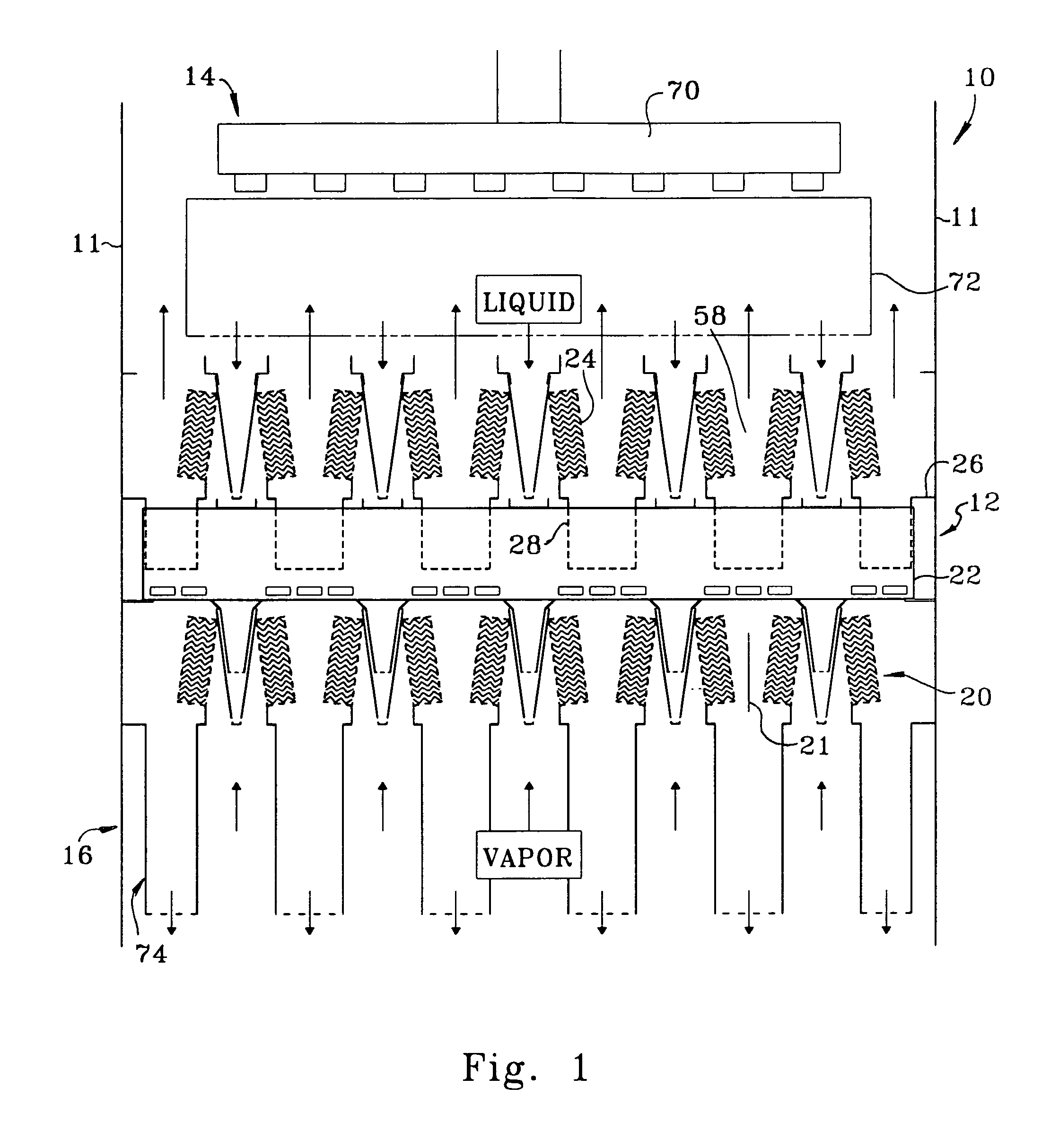

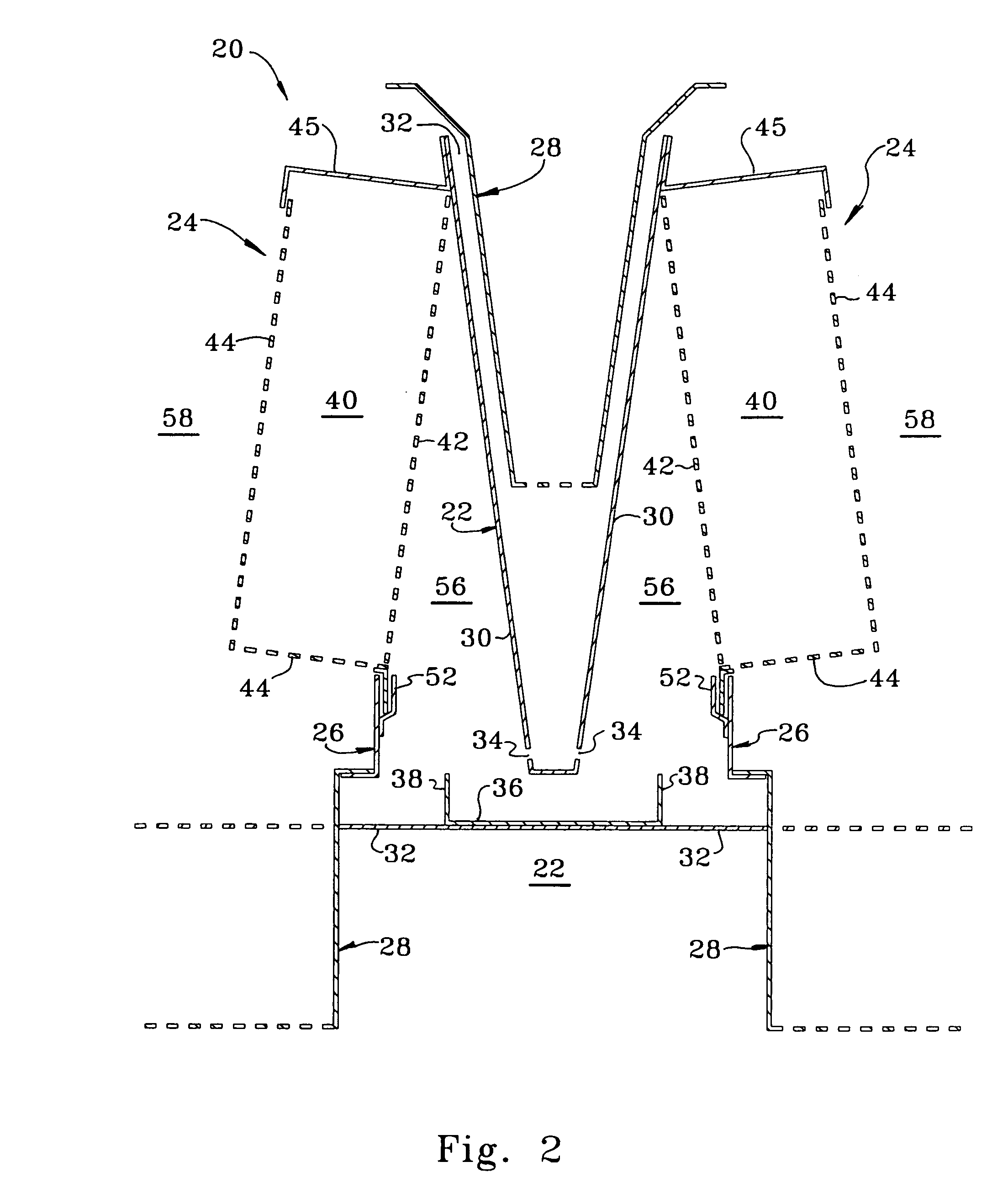

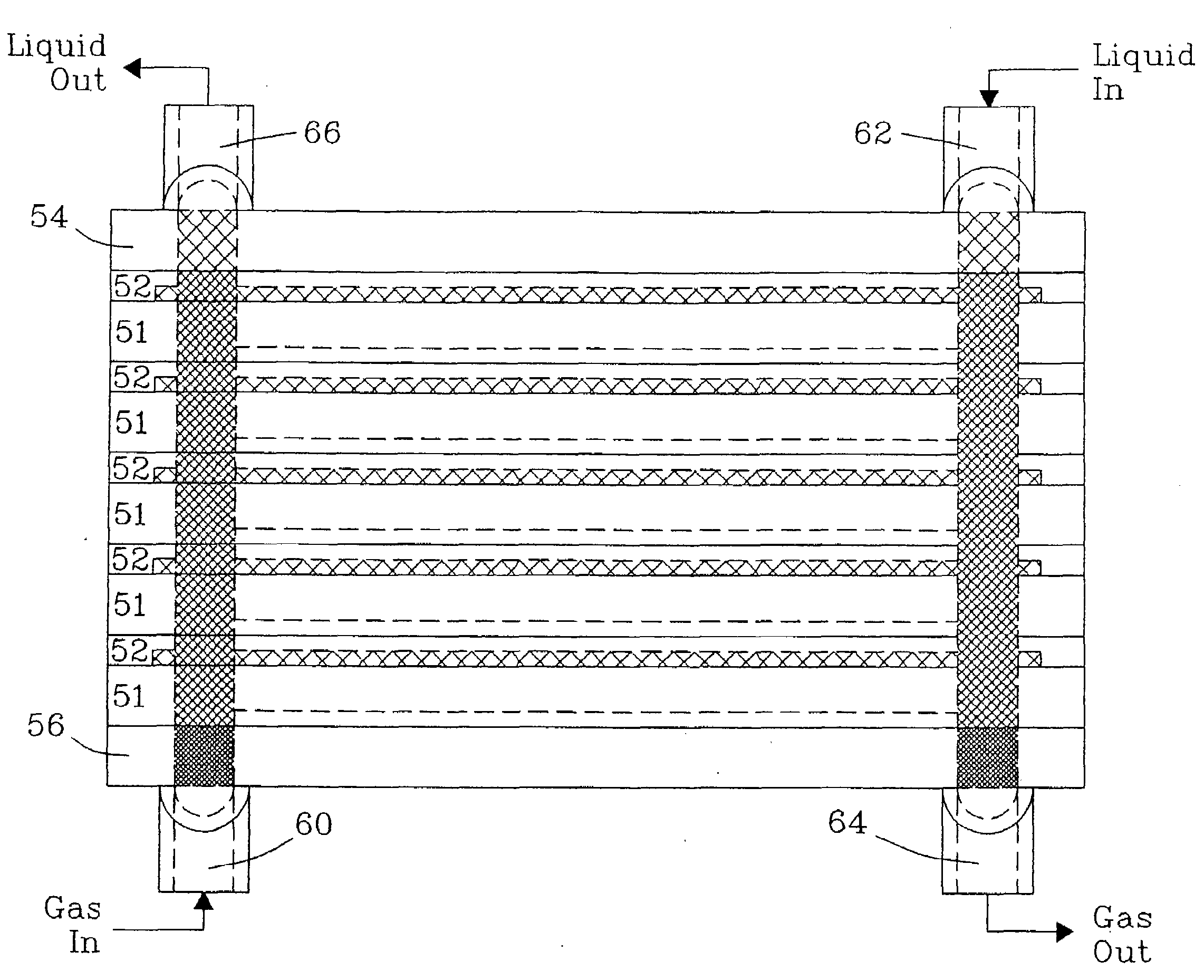

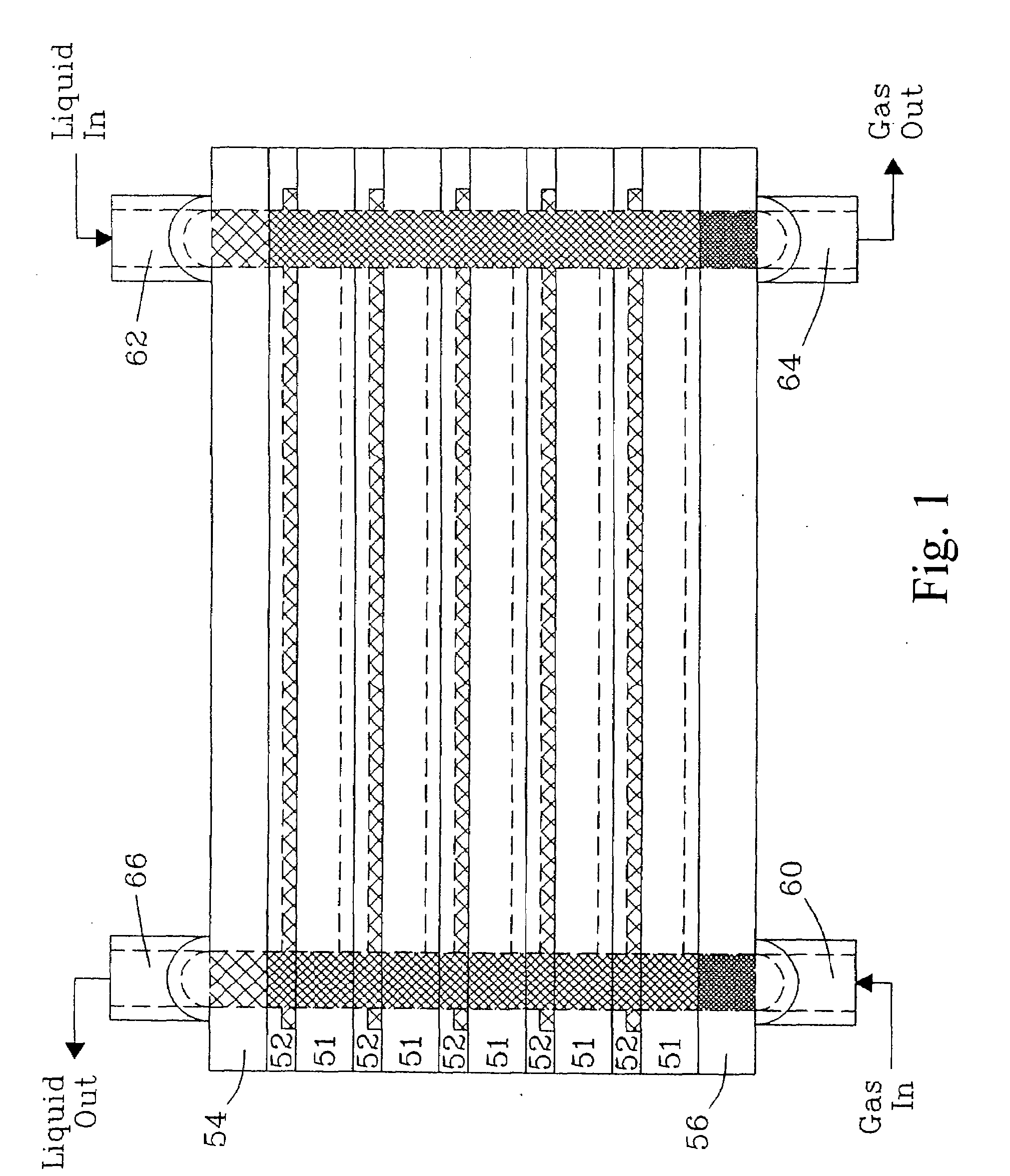

Co-current vapor-liquid contacting apparatus

ActiveUS7424999B2Easily redistributedIncrease capacityCombination devicesLiquid degasificationVapor liquidFractionating column

Owner:UOP LLC

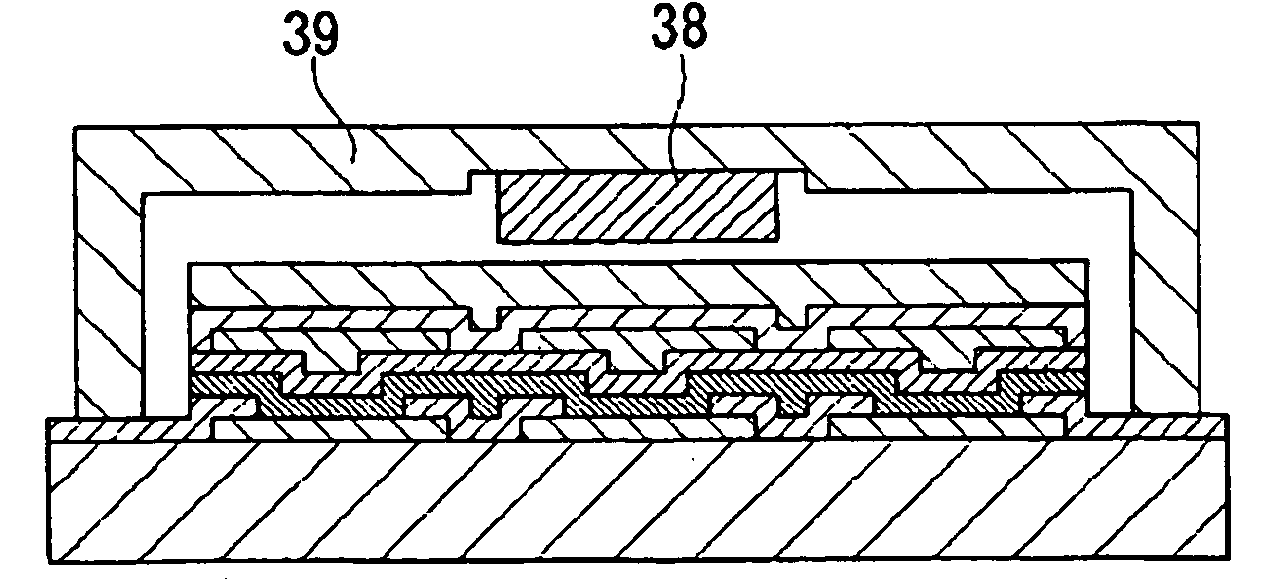

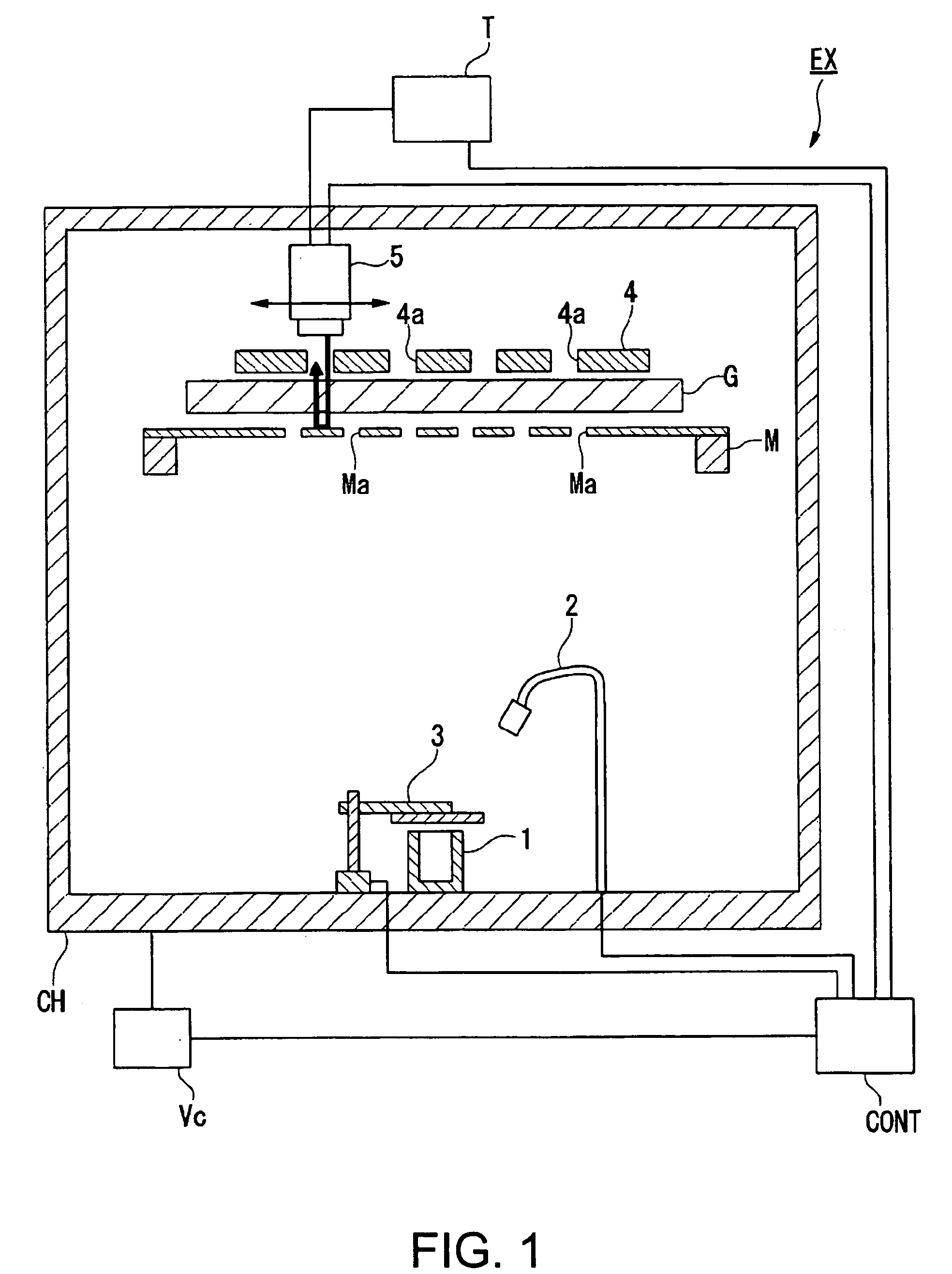

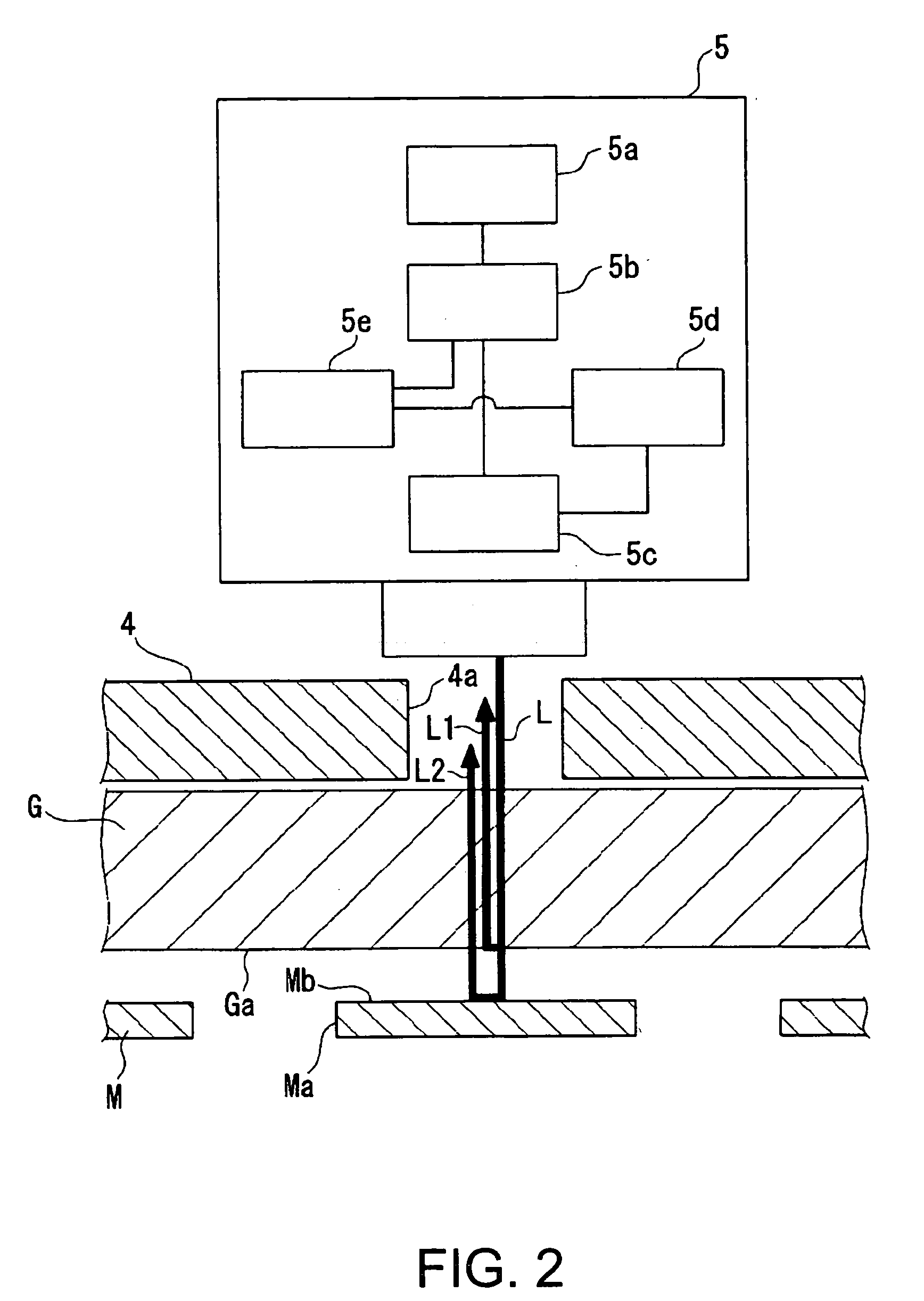

Thin film formation method, thin film formation equipment, method of manufacturing organic electroluminescence device, organic electroluminescence device, and electronic apparatus

InactiveUS20050153472A1Increase productionImprove accuracyMolten spray coatingSemiconductor/solid-state device testing/measurementOptoelectronicsOrganic electroluminescence

A thin film formation method is provided which can carry out various kinds of patterning deposition correctly and with high precision, and a thin film formation equipment. The thin film formation method arranges a mask between a substrate and a material source and forms the material of the material source as a thin film on the substrate. The method further includes: a substrate contacting process to contact the mask and the substrate; a gap measurement process to measure a gap between the mask and the substrate; and a thin film formation process to form the thin film according to the measurement result in the gap measurement process.

Owner:SEIKO EPSON CORP

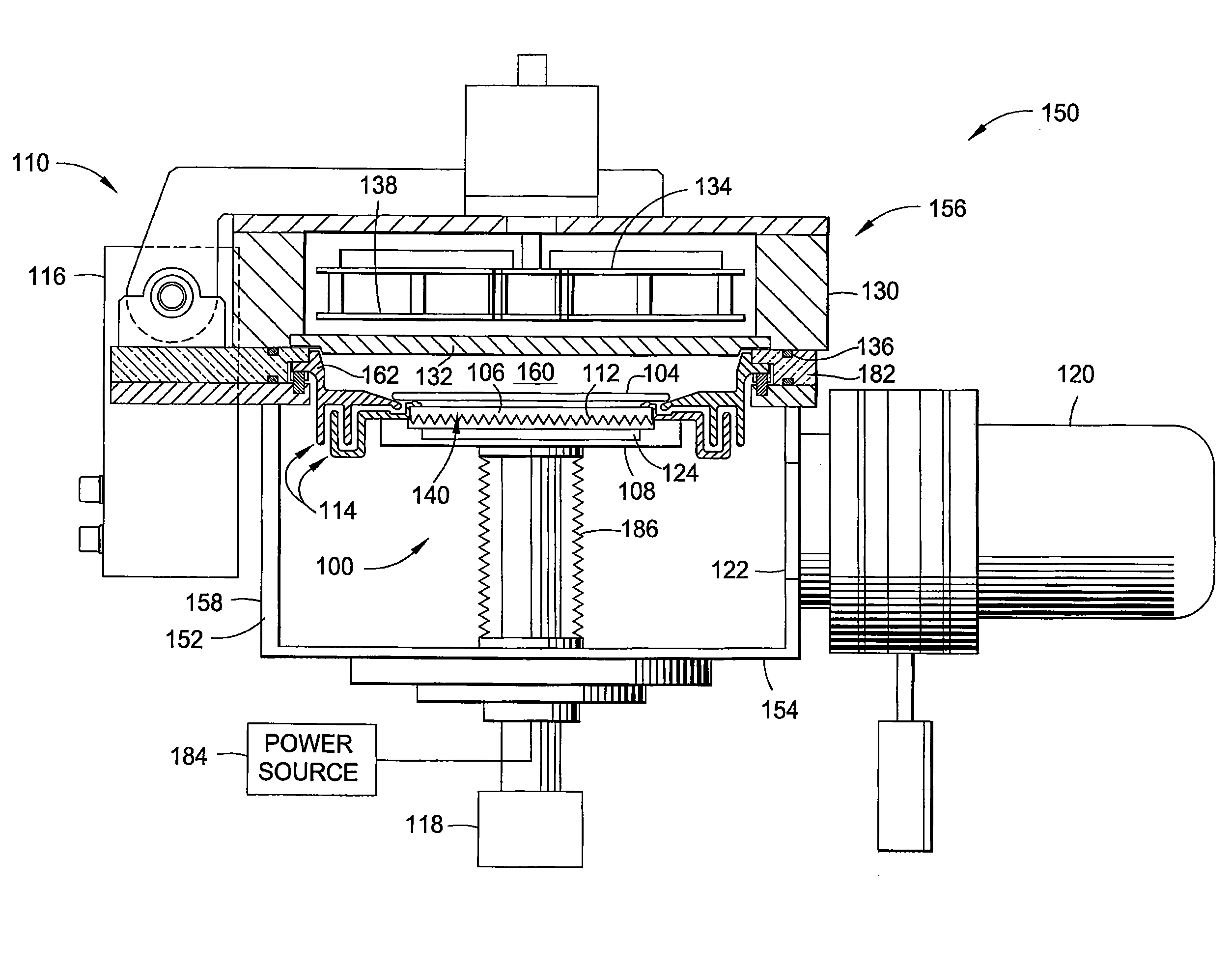

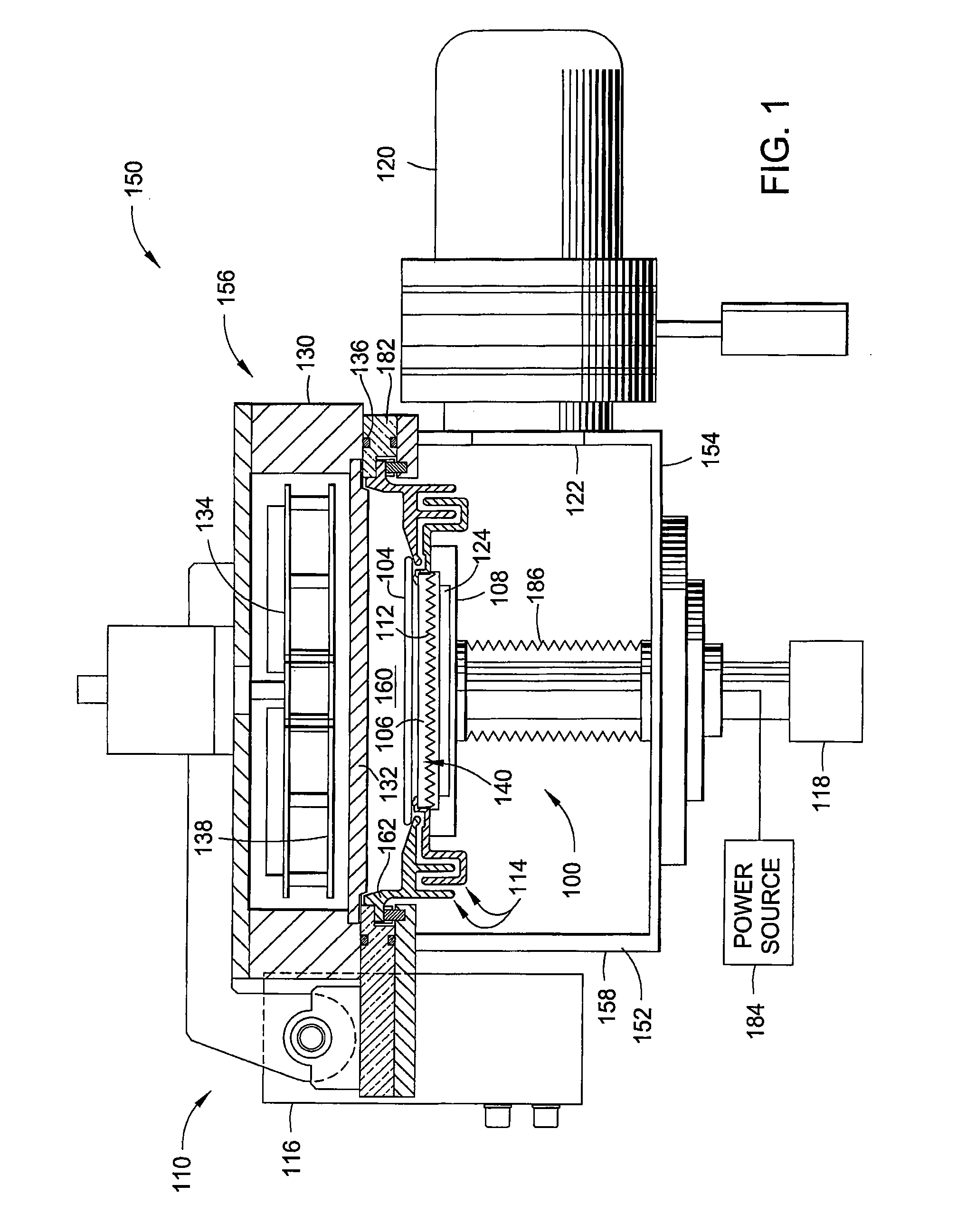

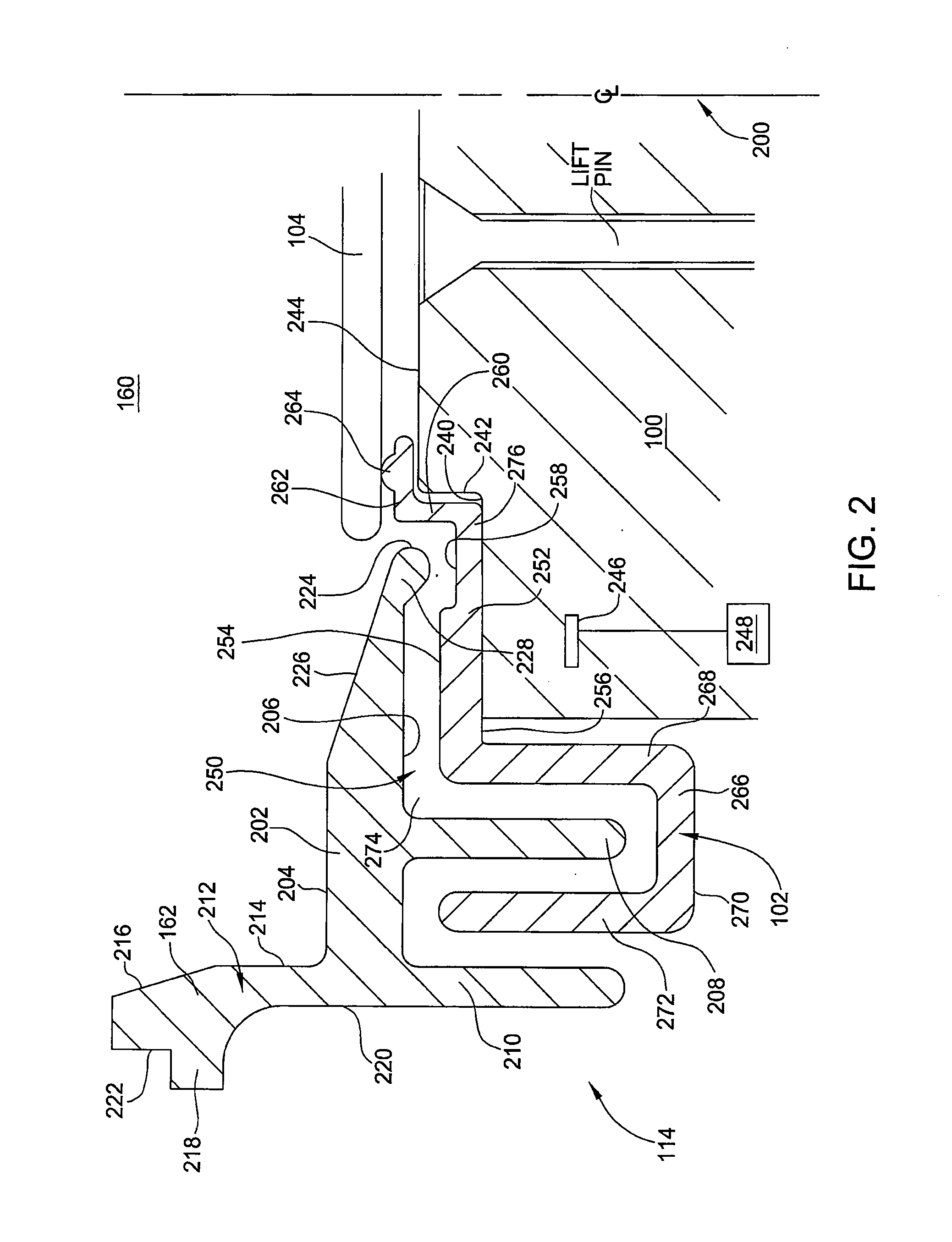

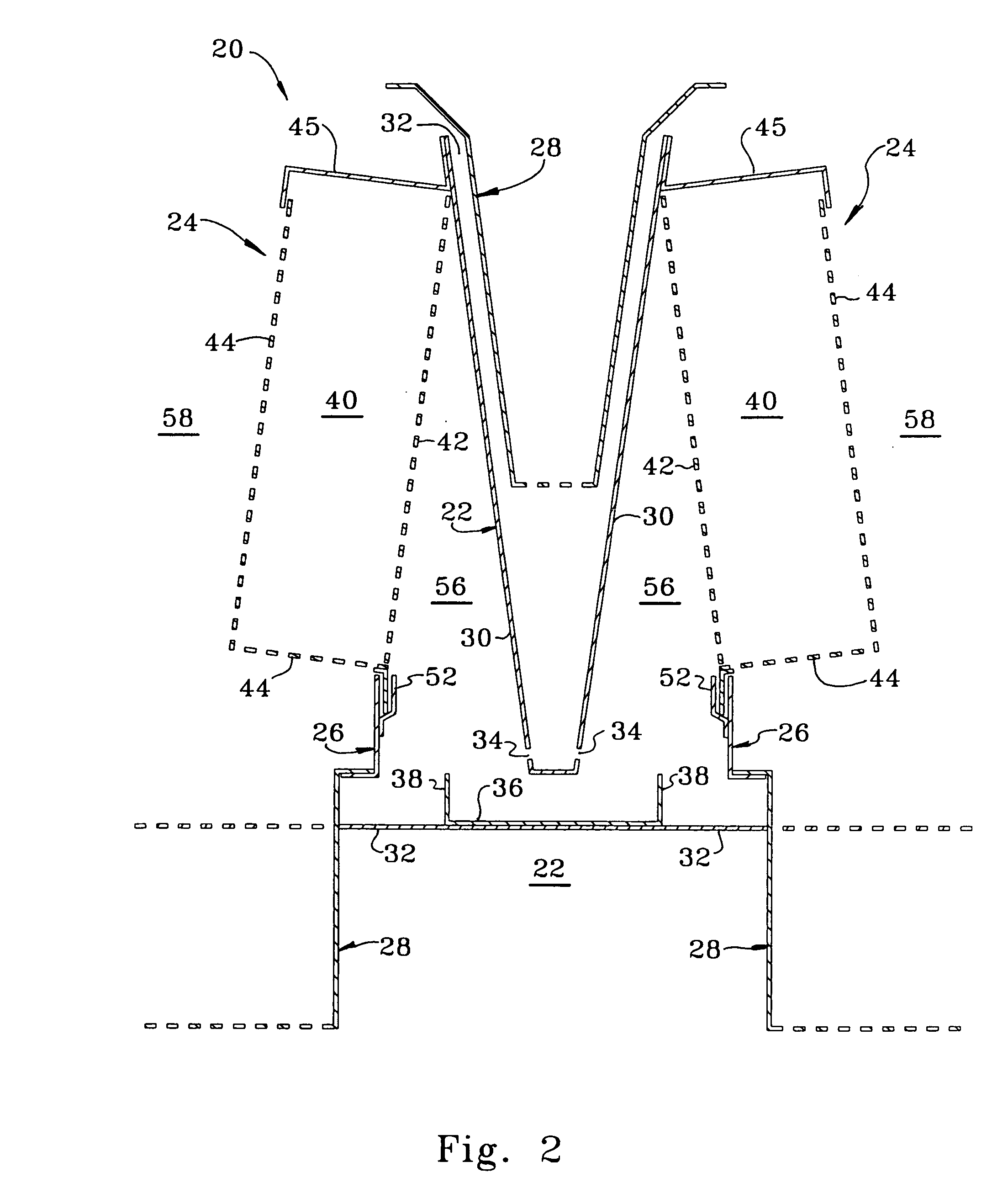

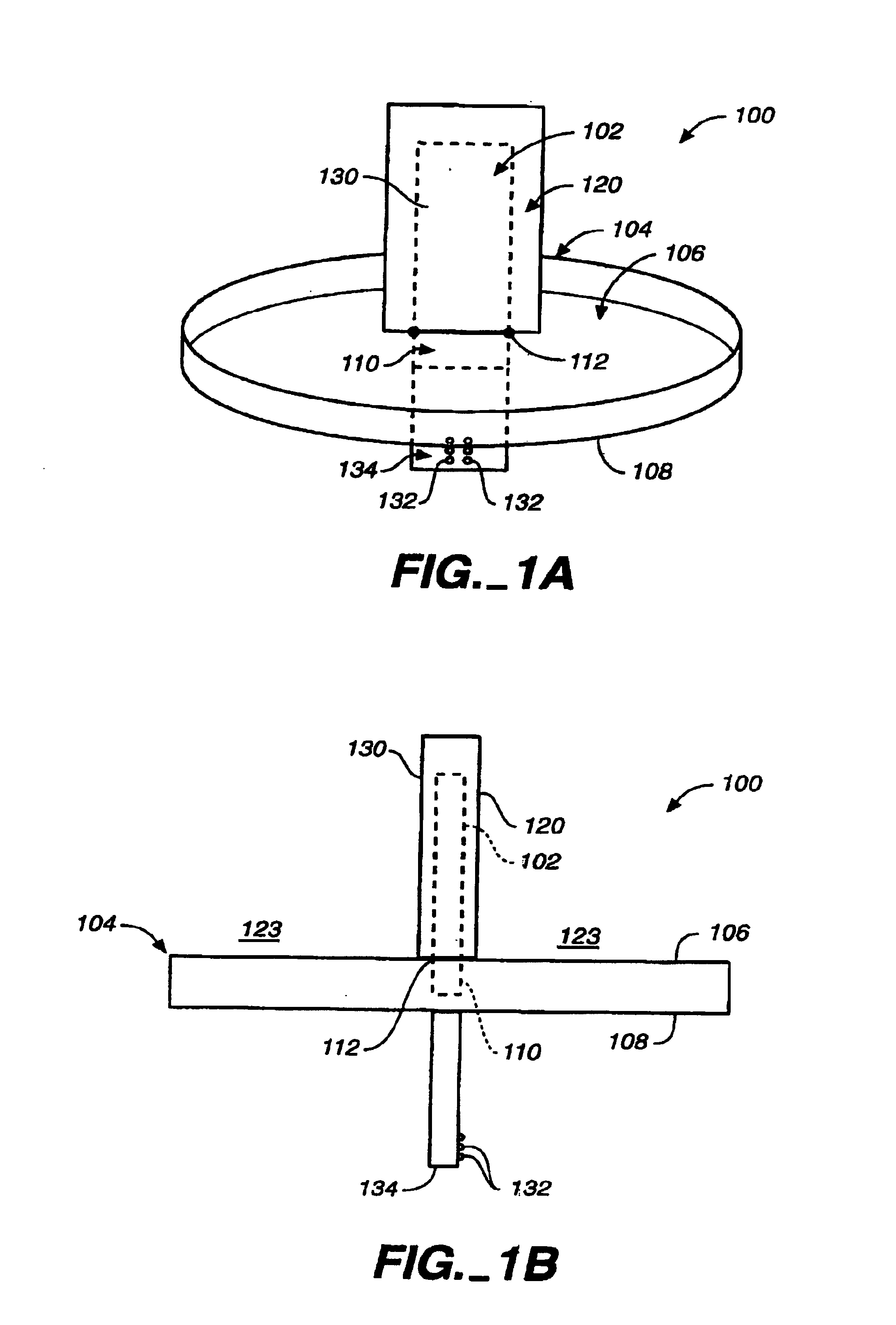

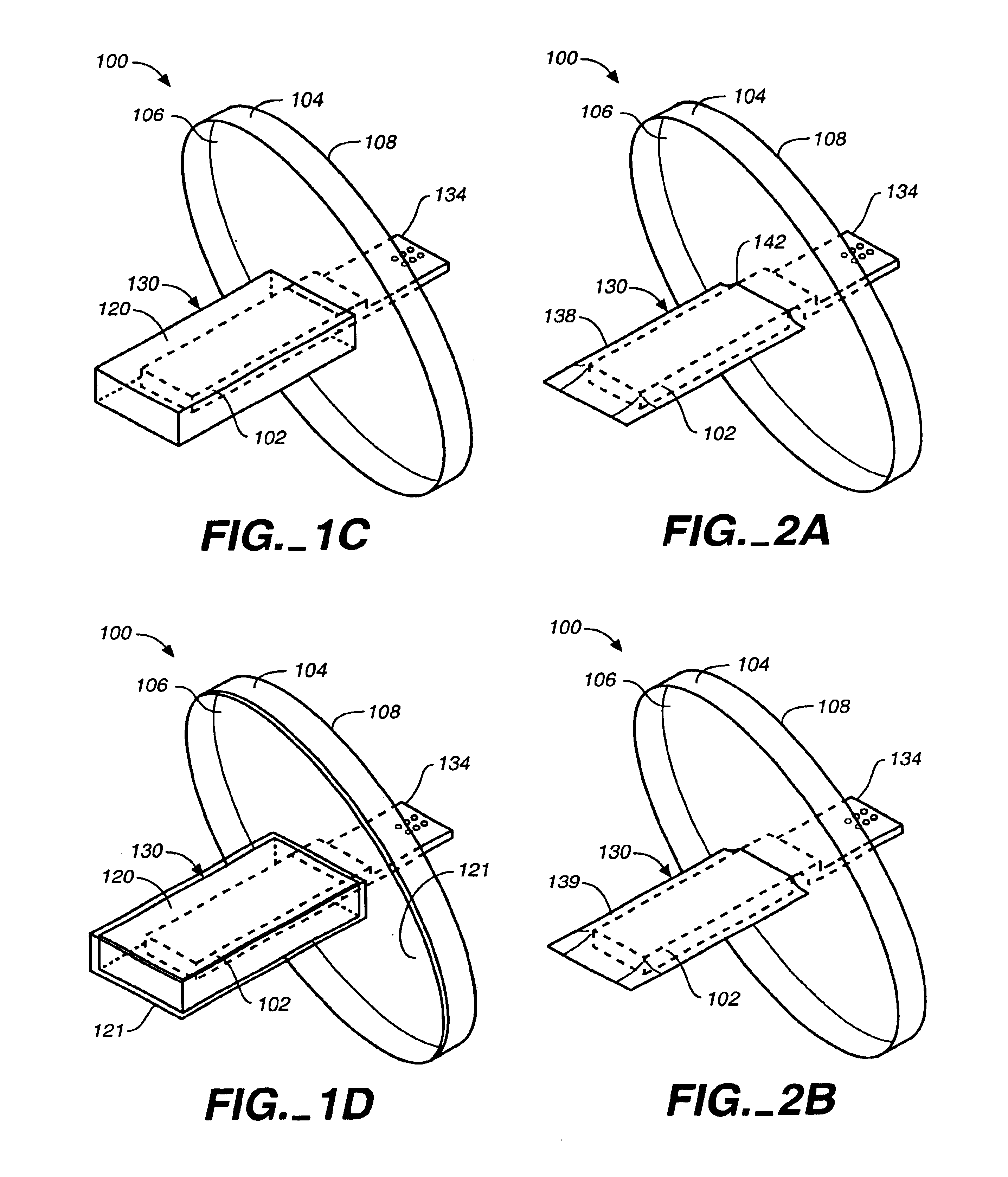

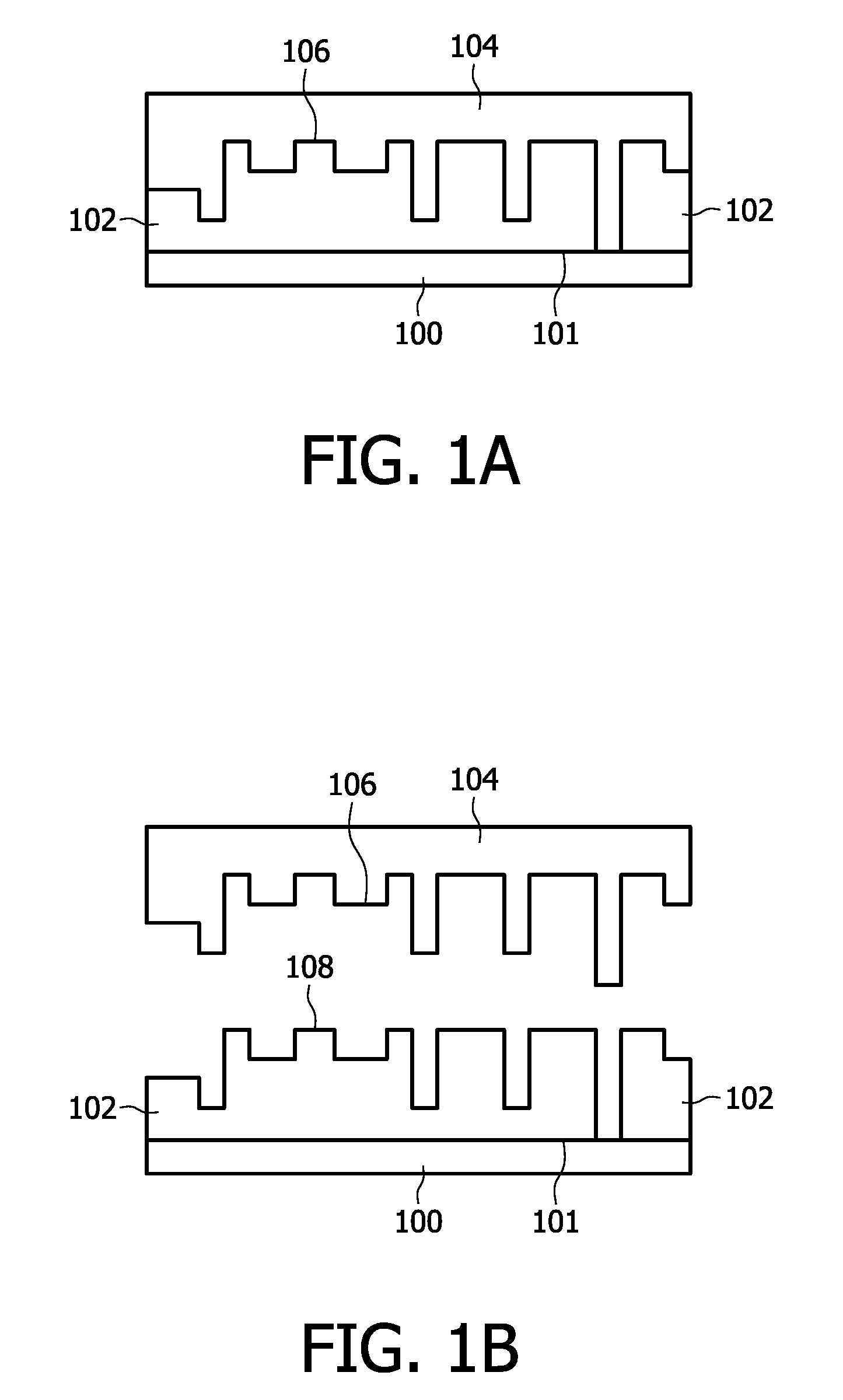

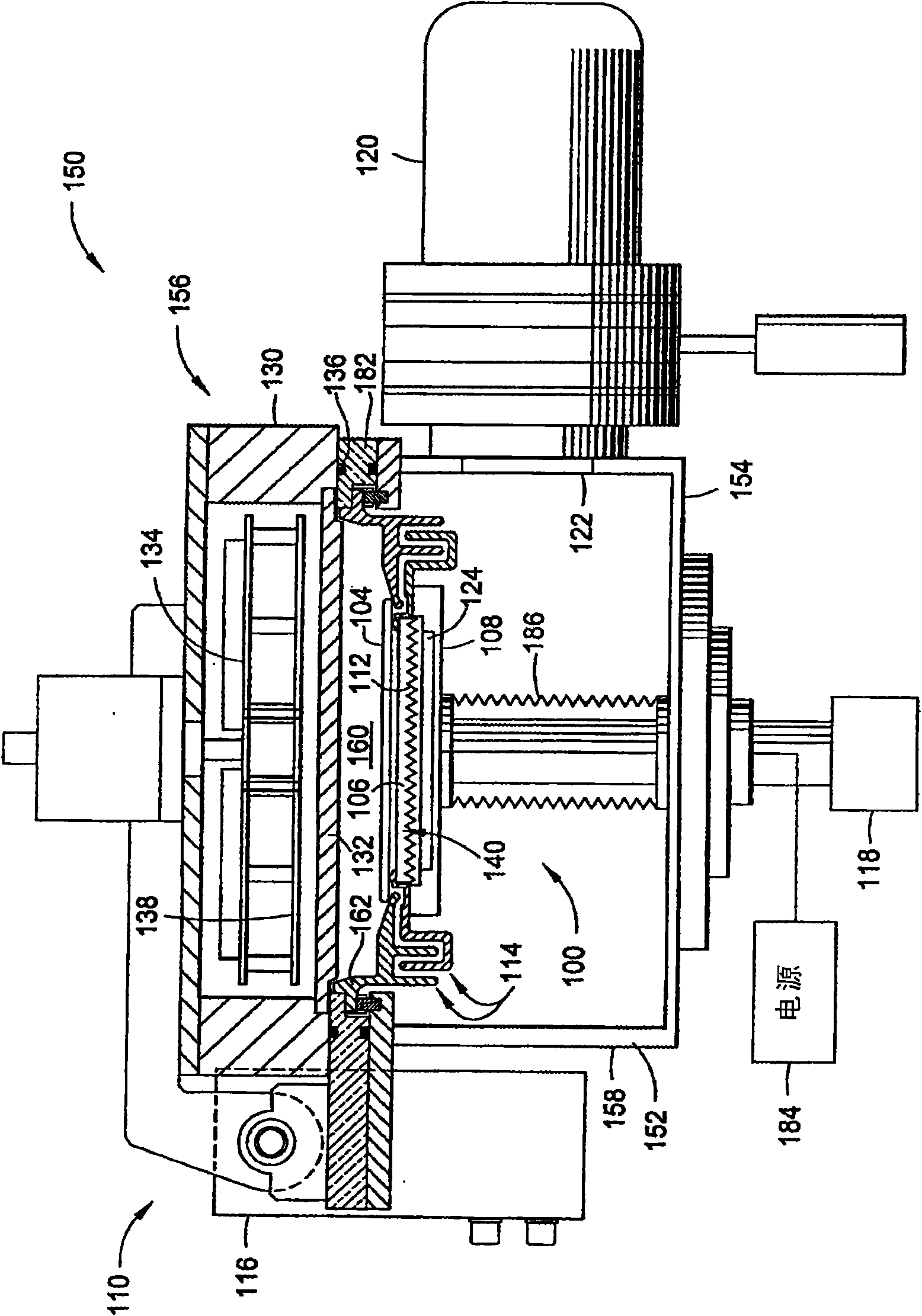

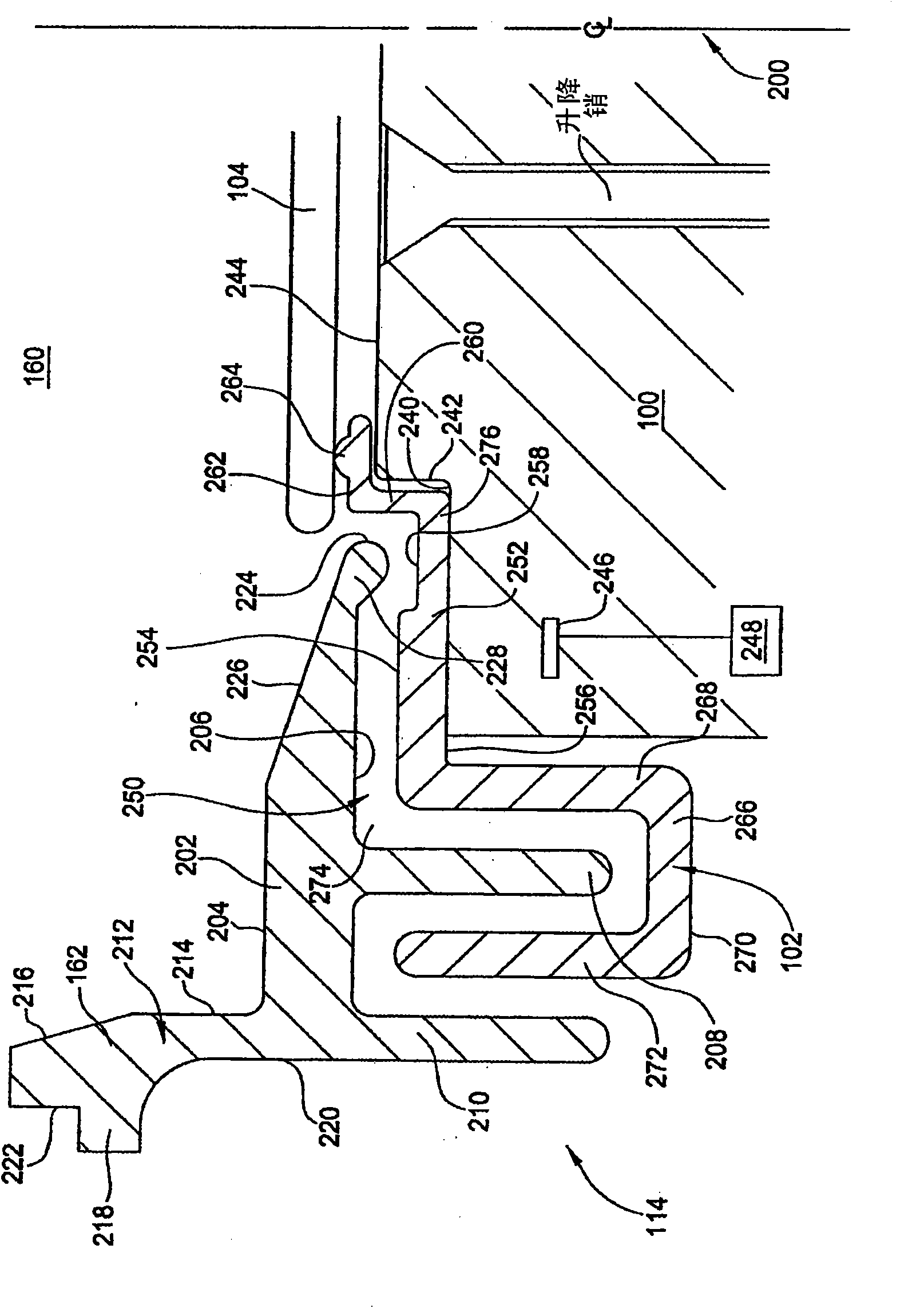

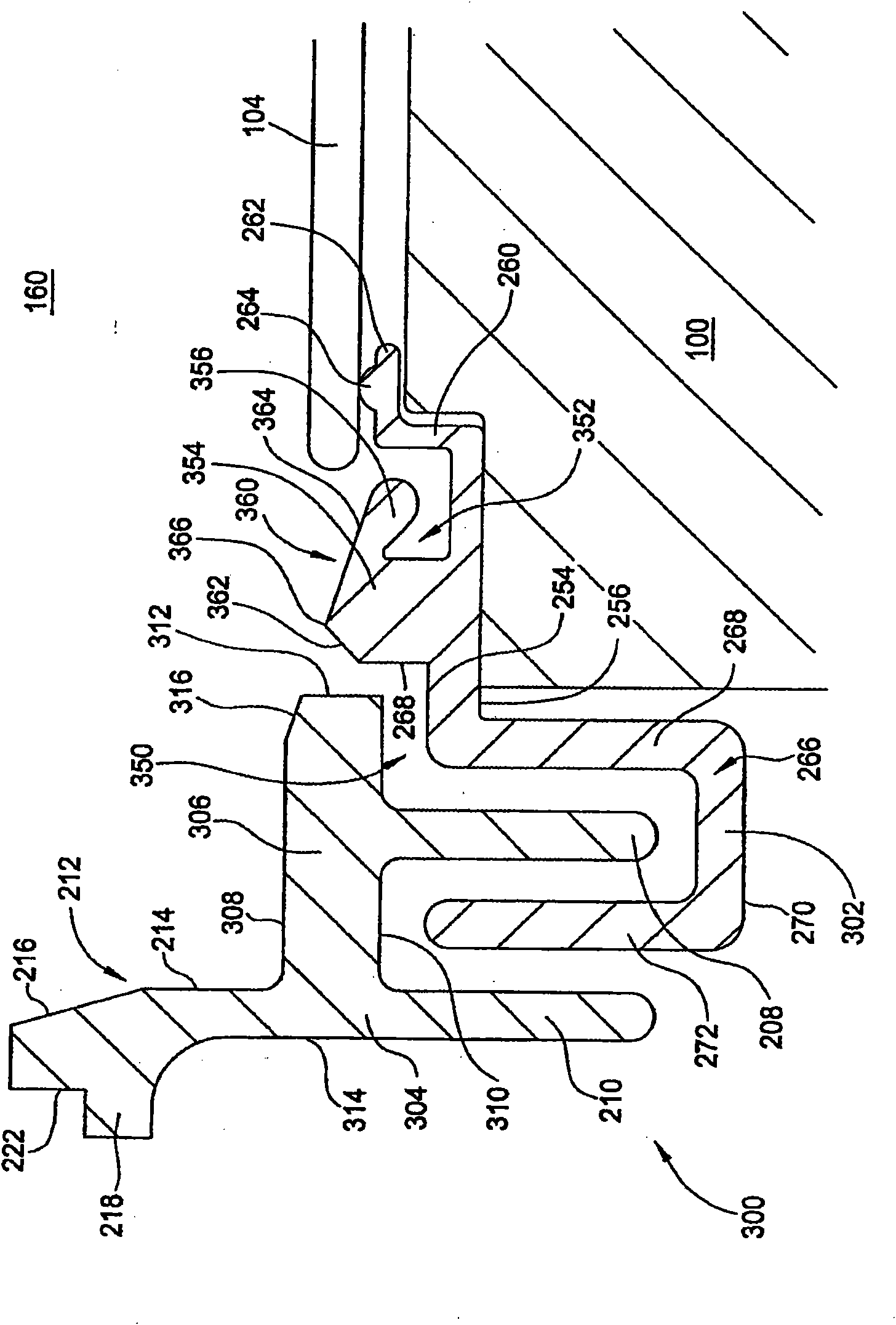

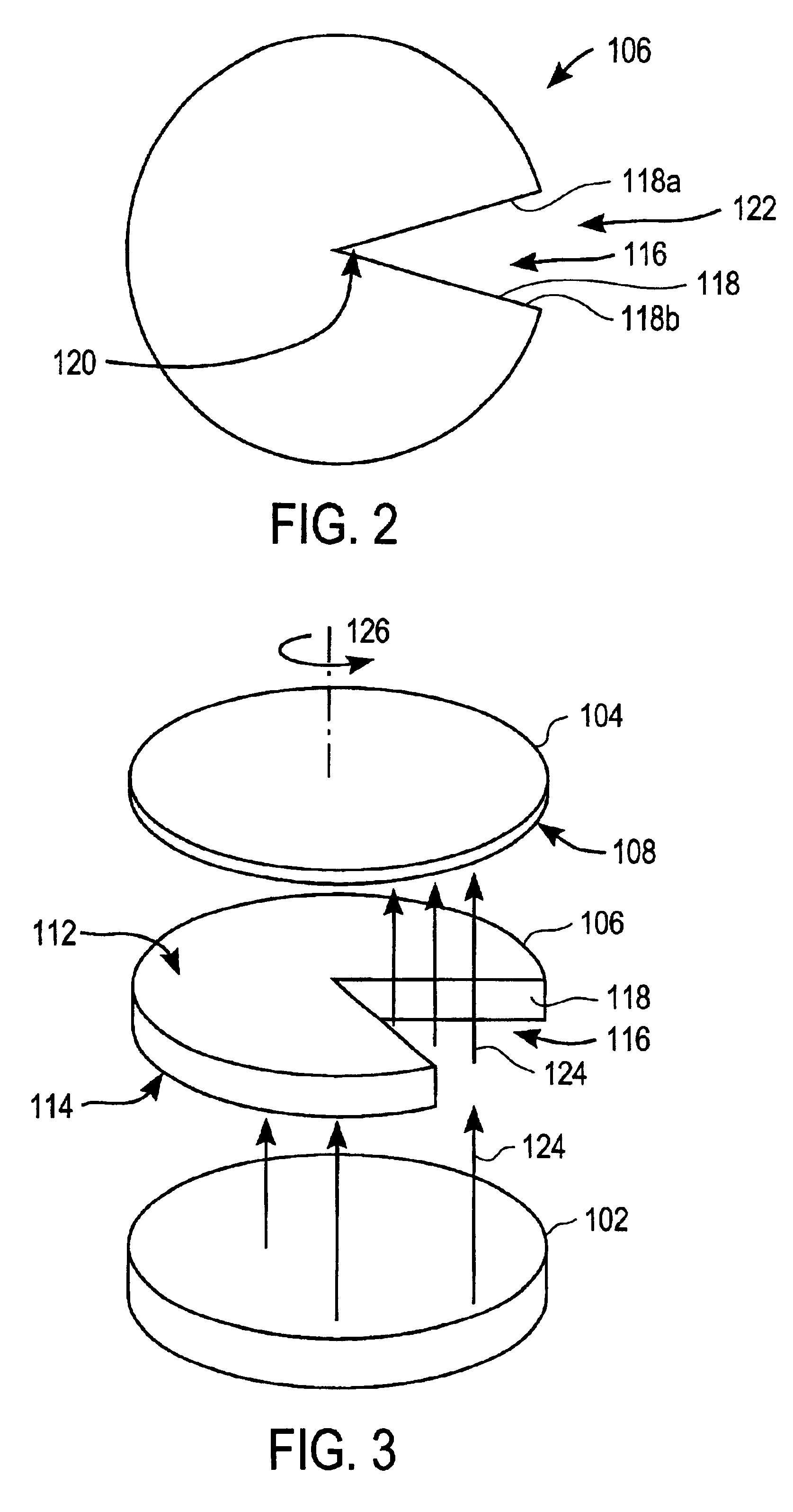

Non-contact process kit

ActiveUS20080141942A1Excellent and predictable temperature controlProcess can be minimizedCellsVacuum evaporation coatingEngineeringPhysical vapor deposition

A process kit for use in a physical vapor deposition (PVD) chamber, along with a PVD chamber having a non-contact process kit are provided. In one embodiment, a process kit includes a generally cylindrical shield that has a substantially flat cylindrical body, at least one elongated cylindrical ring extending downward from the body, and a mounting portion extending upwards from an upper surface of the body. In another embodiment, a process kit includes a generally cylindrical deposition ring. The deposition ring includes a substantially flat cylindrical body, at least one downwardly extending u-channel coupled to an outer portion of the body, an inner wall extending upward from an upper surface of an inner region of the body, and a substrate support ledge extending radially inward from the inner wall.

Owner:APPLIED MATERIALS INC

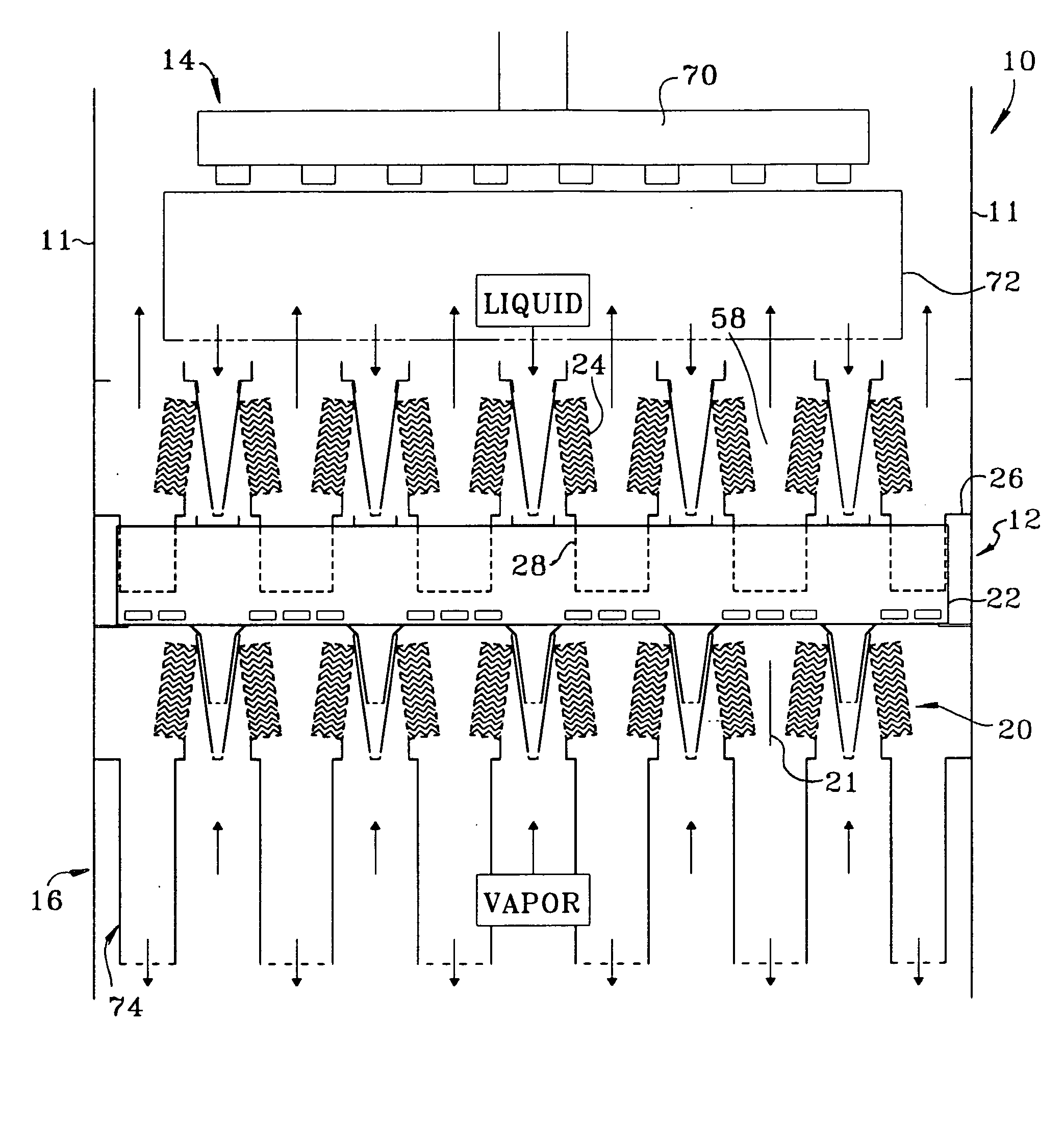

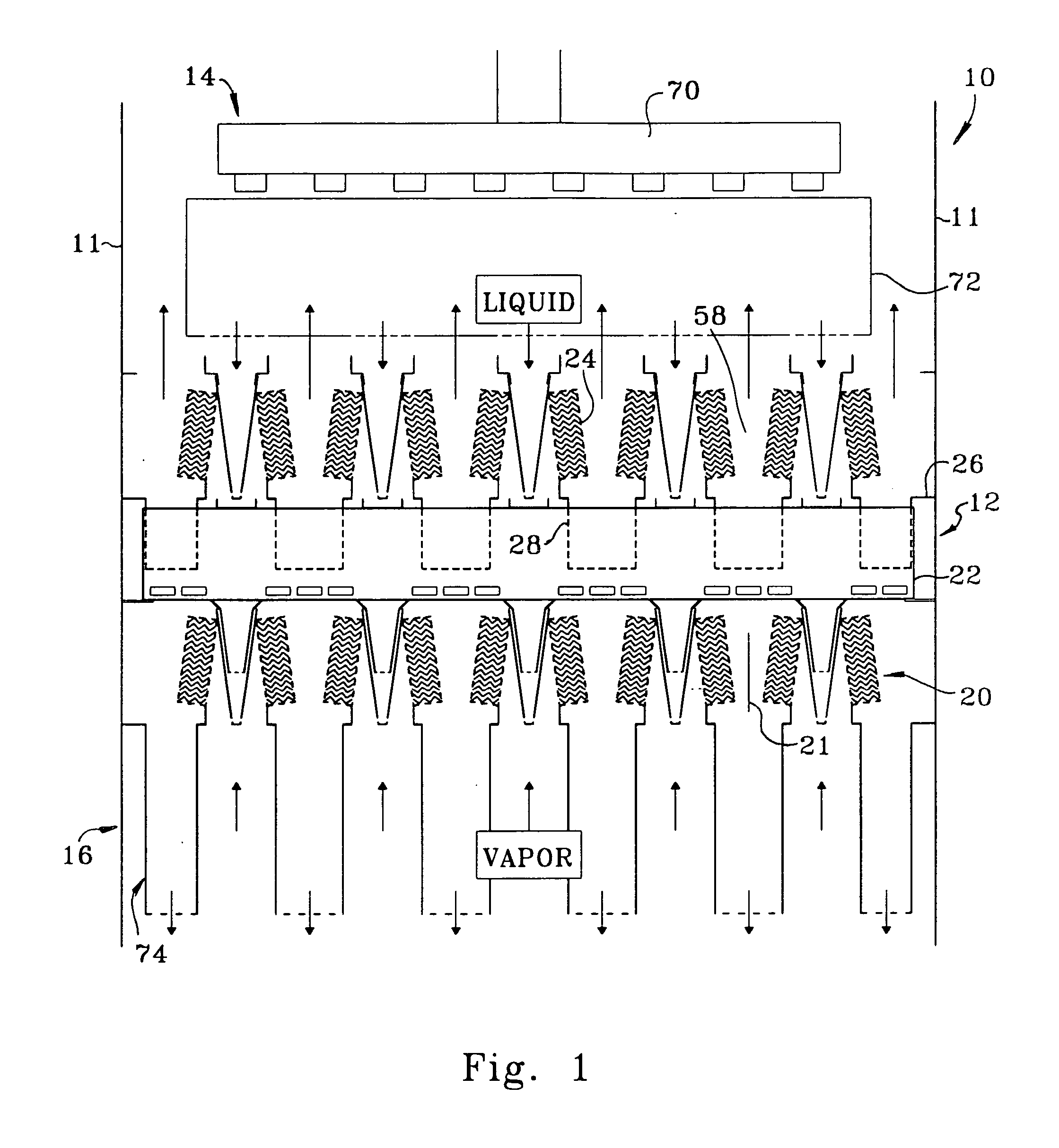

Co-current vapor-liquid contacting apparatus

ActiveUS20070137482A1Easily redistributedIncrease capacityCombination devicesTransportation and packagingVapor liquidFractionating column

The invention is a high capacity and high efficiency co-current vapor-liquid contacting apparatus for use in distillation columns and other vapor-liquid contacting processes. The apparatus is characterized by an arrangement of modules in horizontal stages rather than tray-like construction. The modules define a co-current contacting volume and in an exemplary configuration the modules include a liquid distributor, a demister, a receiving pan and a duct. The modules of one stage are rotated to be non-parallel with respect to the modules of an inferior stage, a superior stage, or both. Variations relate to the design of the individual elements such as the demister, liquid distributor, ducts, and contacting volumes, and the overall arrangement of the apparatus.

Owner:UOP LLC

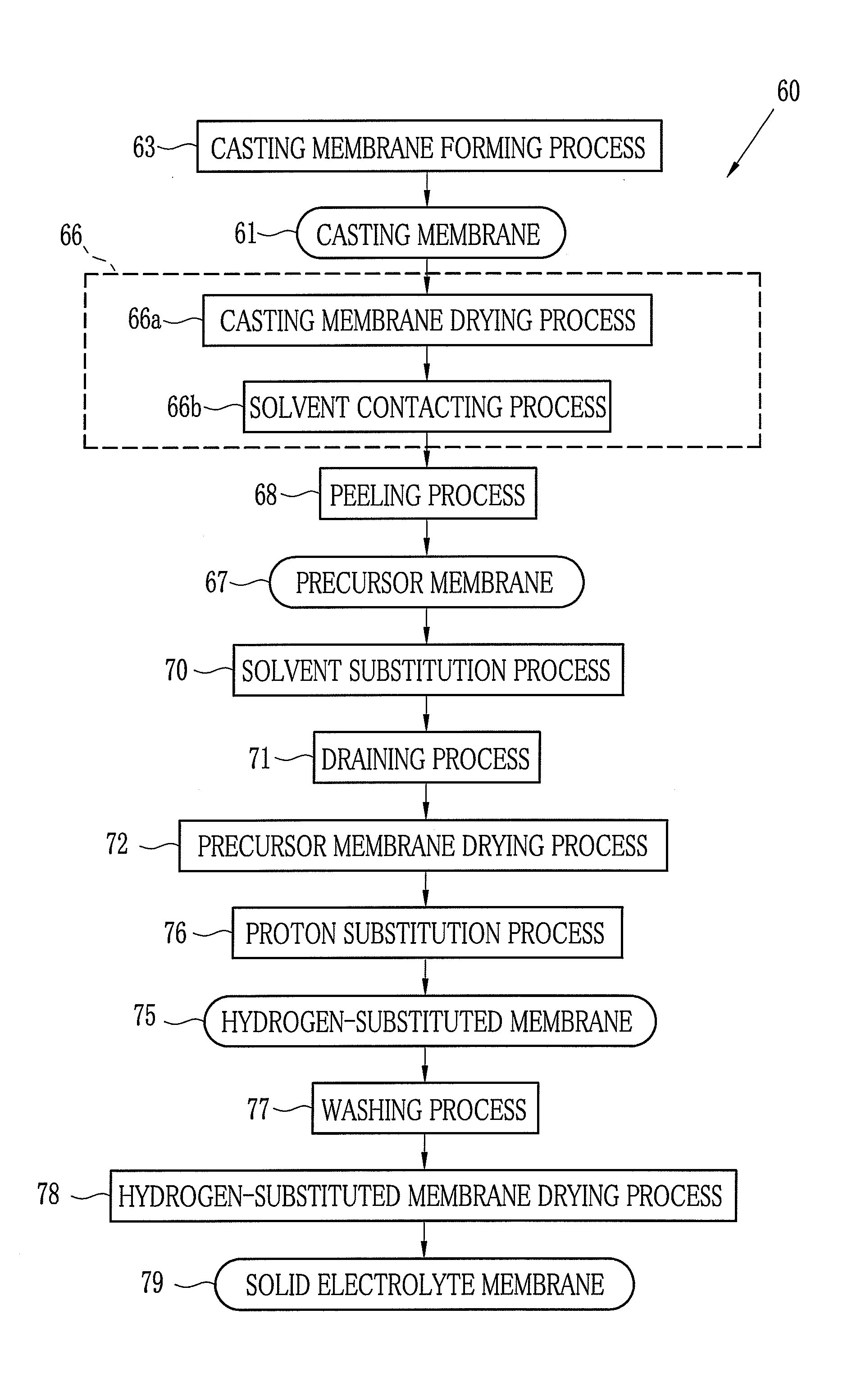

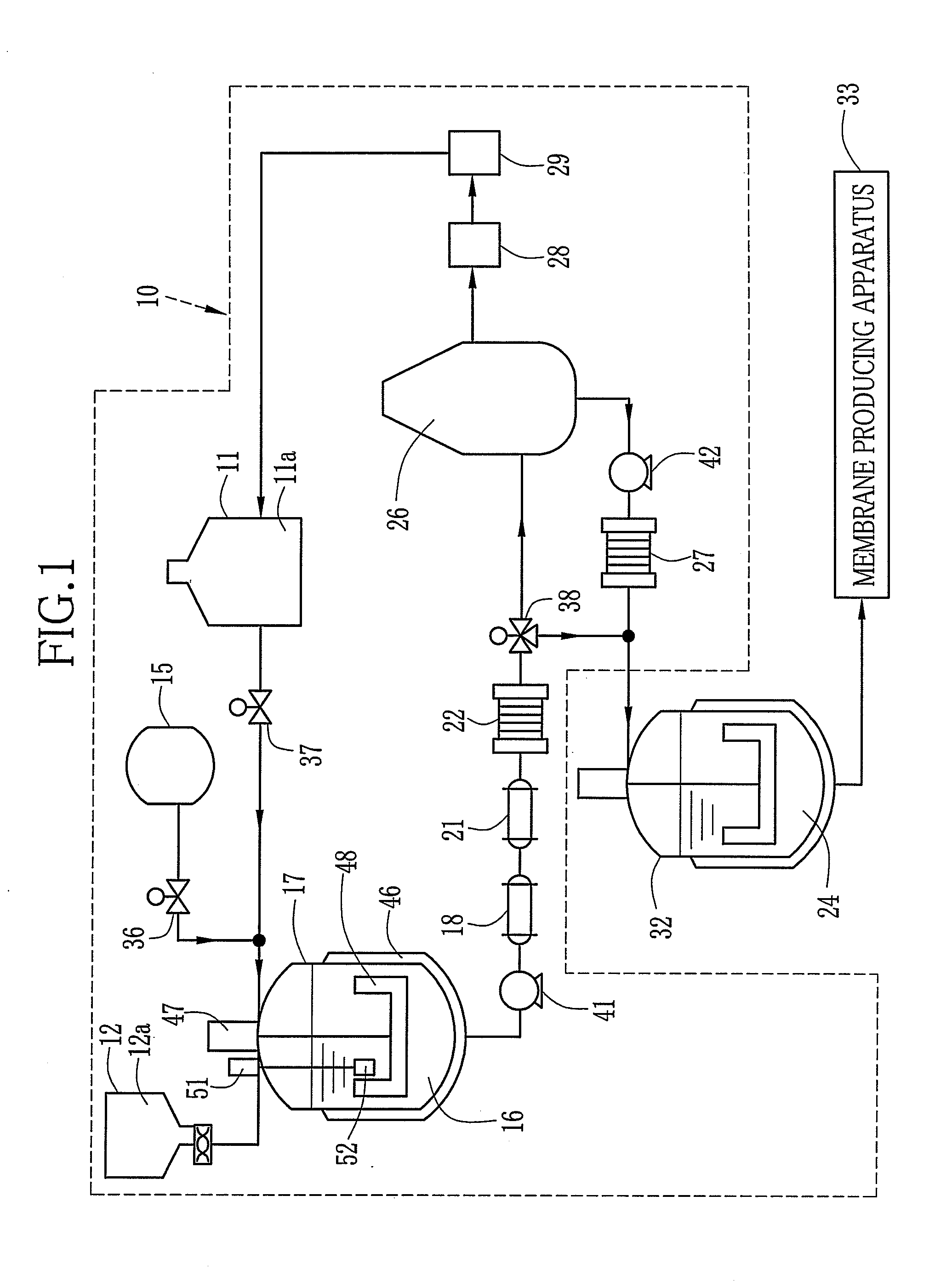

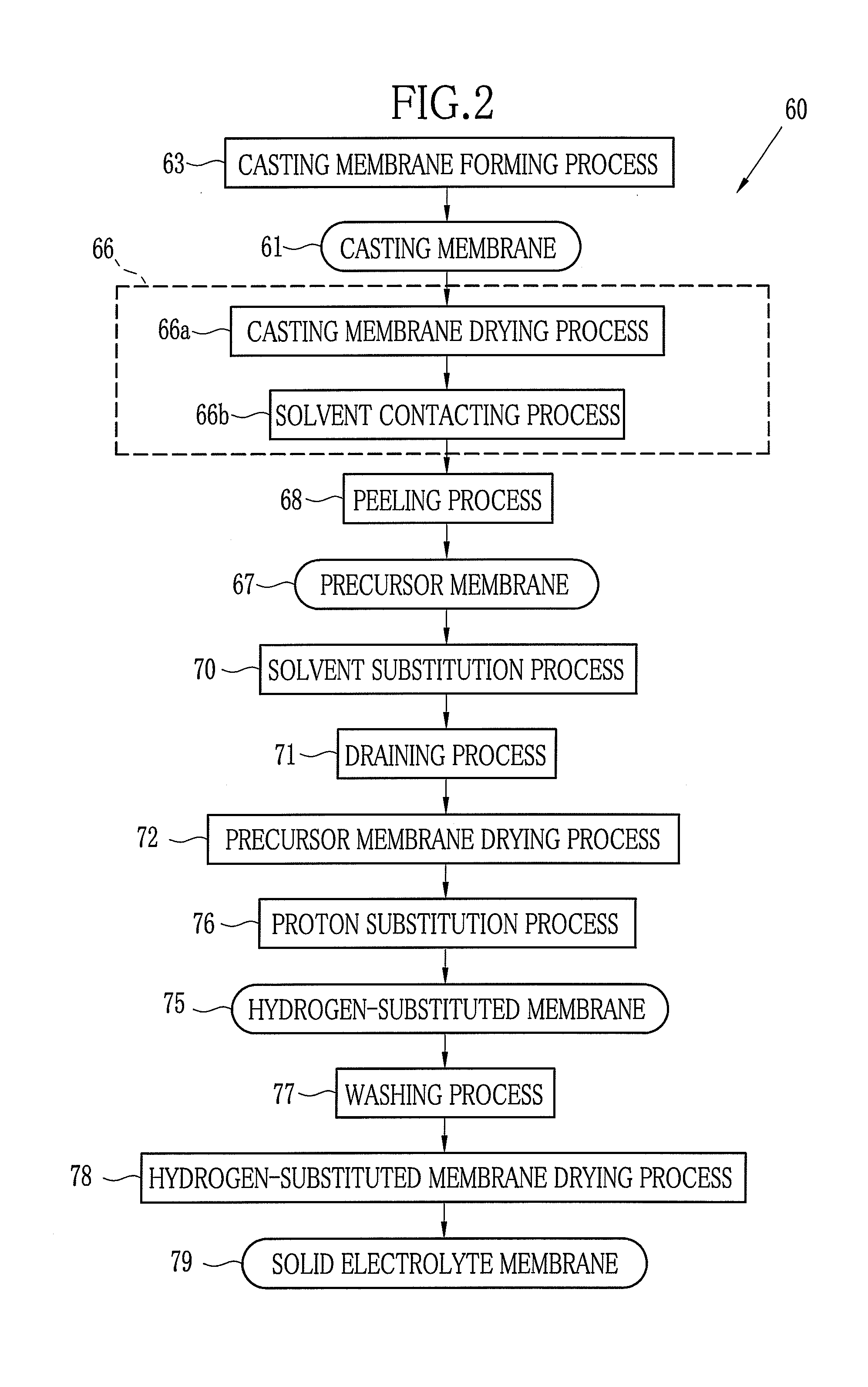

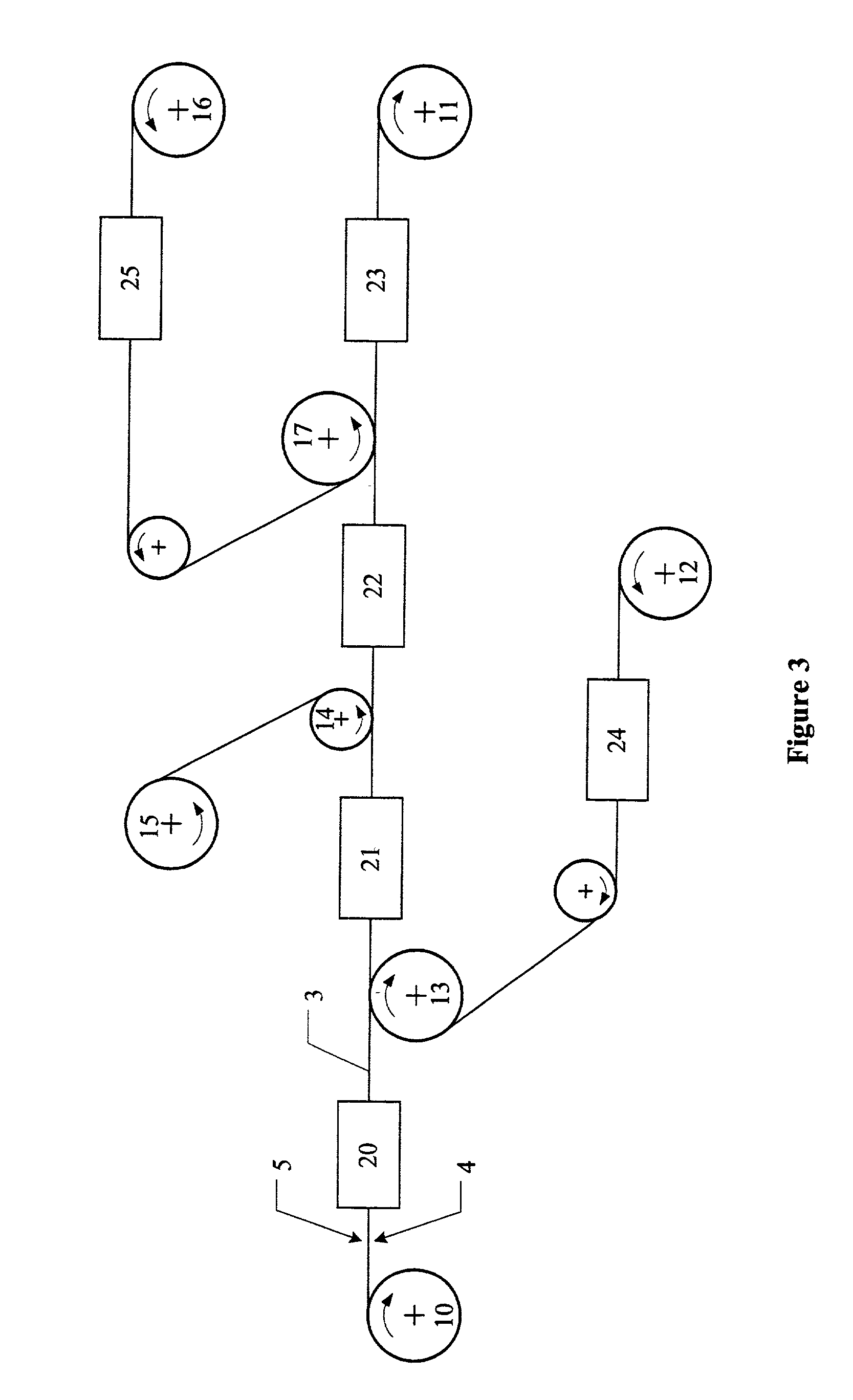

Solid electrolyte membrane, method and apparatus for producing the same, membrane electrode assembly and fuel cell

InactiveUS20090110998A1Excellent electromotive forceReduce processMouldsConfectioneryFuel cellsHydrogen

In a casting membrane forming process (63), a dope containing a solid electrolyte is cast on a casting belt (93) from a casting die. On the casting belt, a casting membrane (61) is formed. In a casting membrane drying process (66a), the casting membrane (61) is dried. In a solvent contacting process (66b), the casting membrane (61) contacts a poor solvent of the solid electrolyte. By a self-supporting property developing process (66), a self-supporting property is given to the casting membrane (61) for a short time. The casting membrane (61) is peeled from the casting belt (93) as a precursor membrane (67). The precursor membrane (67) is immersed into water. After the precursor membrane (67) is dried, a proton substitution is performed to obtain a hydrogen-substituted membrane (75). By washing and drying of the hydrogen-substituted membrane (75), a solid electrolyte membrane (79) is obtained.

Owner:FUJIFILM CORP

Standpipe distributor for short time contact of hydrocarbon compounds with particles

InactiveUS6143253ACompact and convenientSmall and convenientCatalytic crackingFluidised-bed furnacesParticle flowJet flow

An arrangement for the controlled production of an essentially linear array of hydrocarbon feed injection jets reduces required clearances and elevation while facilitating modification of the contacting locating a feed distributor containing a linear array of jets at a standpipe junction point to provide choke point for particle flow control. The flow properties of the extended particle layer are controlled by adjusting the density of the particles above the choke point created by the upper part of the standpipe inside diameter and the top of the distributor. Steam or another fluidization medium may be added to the particles directly above the distributor for this purpose. This invention can also modify the particle or feed injection characteristics by changing the projection of the distributor into the standpipe to adjust the flow area over the choke point and by the use of bottom slides or baffles to change the flow area size and configuration. Location of the distributor at a standpipe junction will also typically allow the placement of the distributor at a lower location in the process which eliminates the need to add vessel height for supplying pressure drop for the particle discharge point. The distributor arrangement also fits compactly into most common standpipe junctions. Thus, the arrangement of this invention solves the problem of inserting an extended array of feed injection points into a fluidized particle contacting process without providing a large amount of clearance or additional vessel height.

Owner:UOP LLC

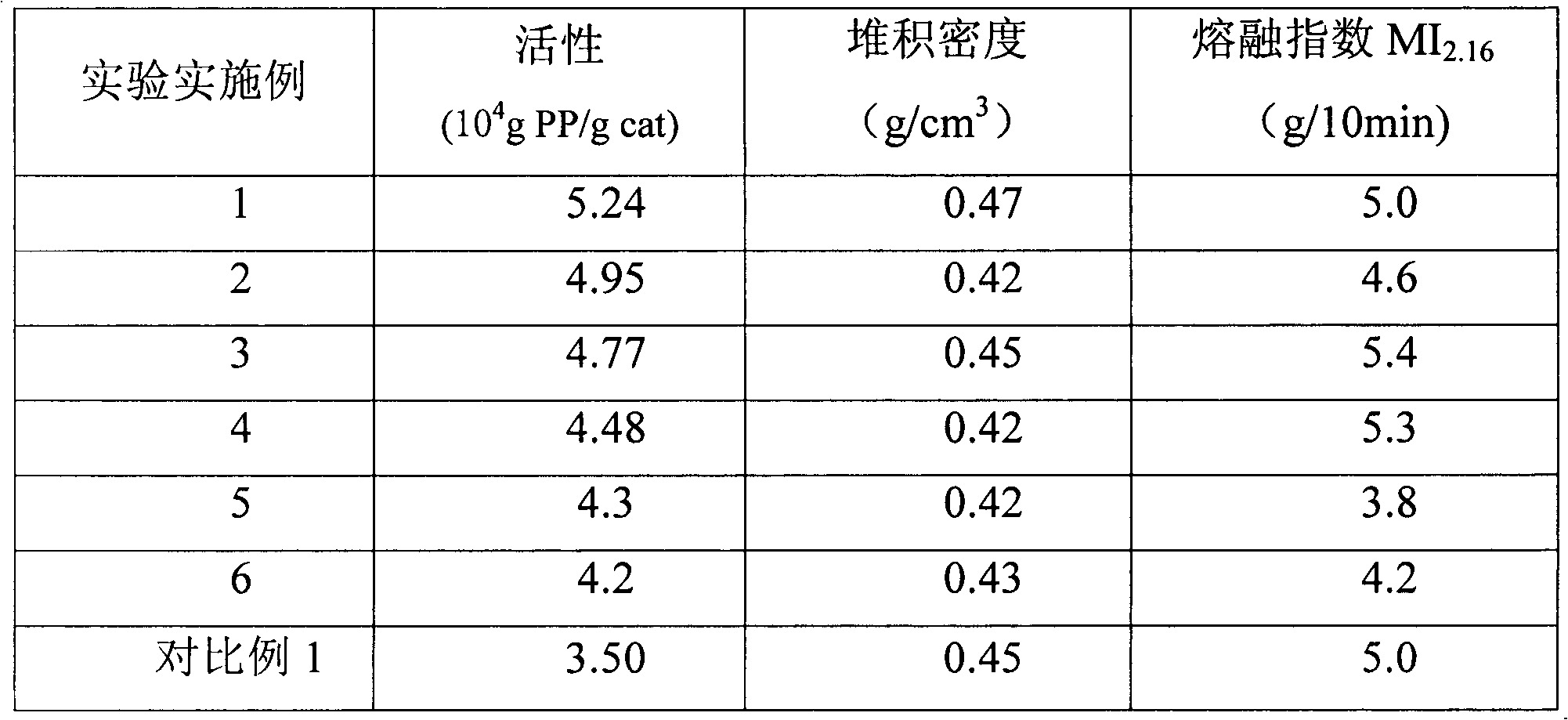

Olefin polymerization catalyst and preparation method thereof and olefin polymerization method

The invention provides an olefin polymerization catalyst, which contains titanium, silicon, magnesium, phosphorus, an internal donor compound and halogen. The invention further provides a method for preparing the olefin polymerization catalyst disclosed by the invention. The invention further provides an olefin polymerization method. Silicon is introduced into the olefin polymerization catalyst, so that the catalytic activity of the olefin polymerization catalyst for olefin polymerization is 1.1-1.5 times higher than that of a catalyst into which silicon is not introduced in the prior art. According to the method for preparing the olefin polymerization catalyst disclosed by the invention, a silane compound is introduced in the contacting process of a magnesium compound, an organic epoxy compound and an organic phosphorus compound in a solvent, so that the activity of the prepared catalyst is much higher than that of a catalyst obtained with a method in which a silane compound is not introduced in the prior art. The method disclosed by the invention has the advantages of readily-available raw materials and low production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

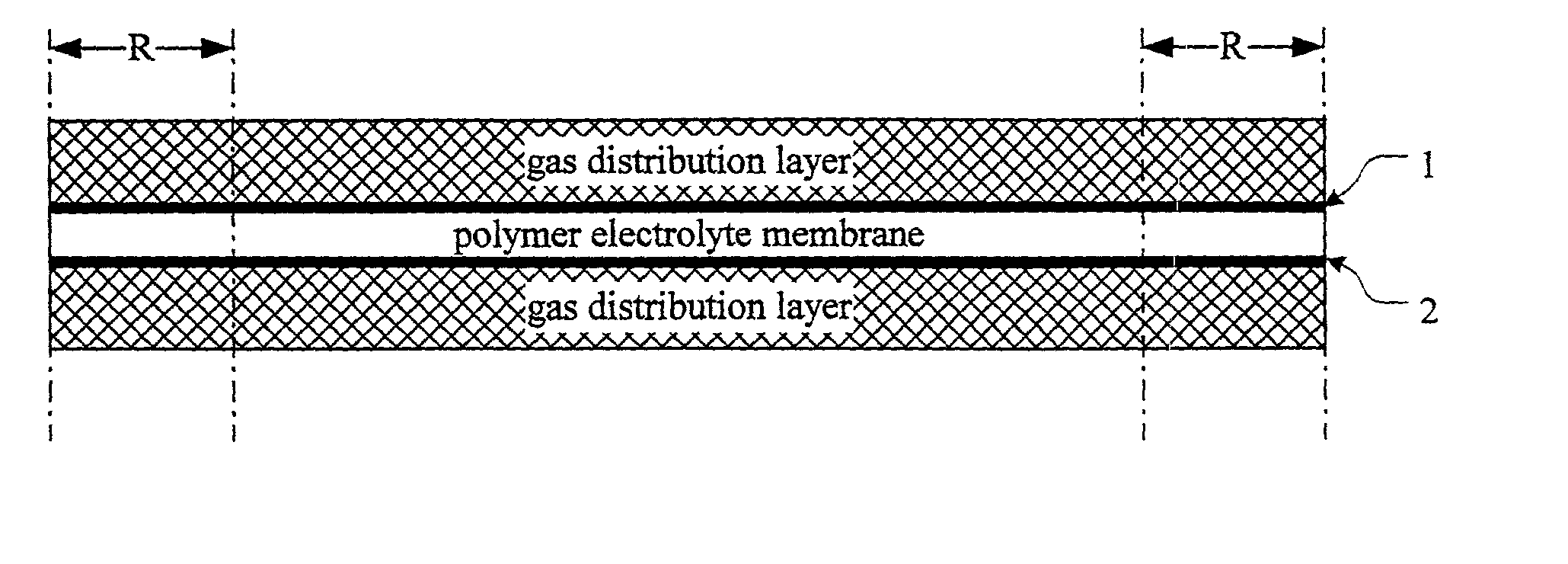

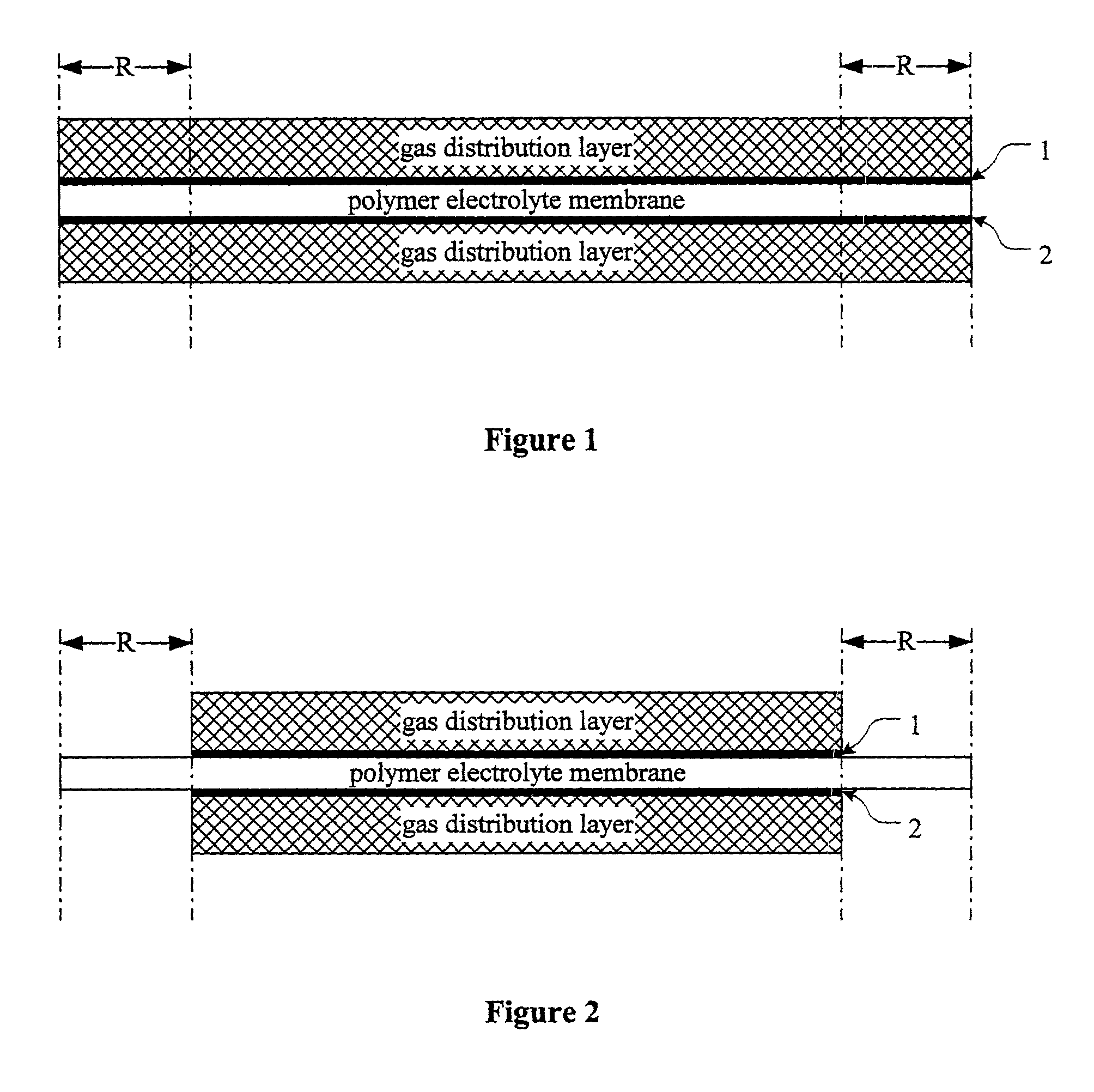

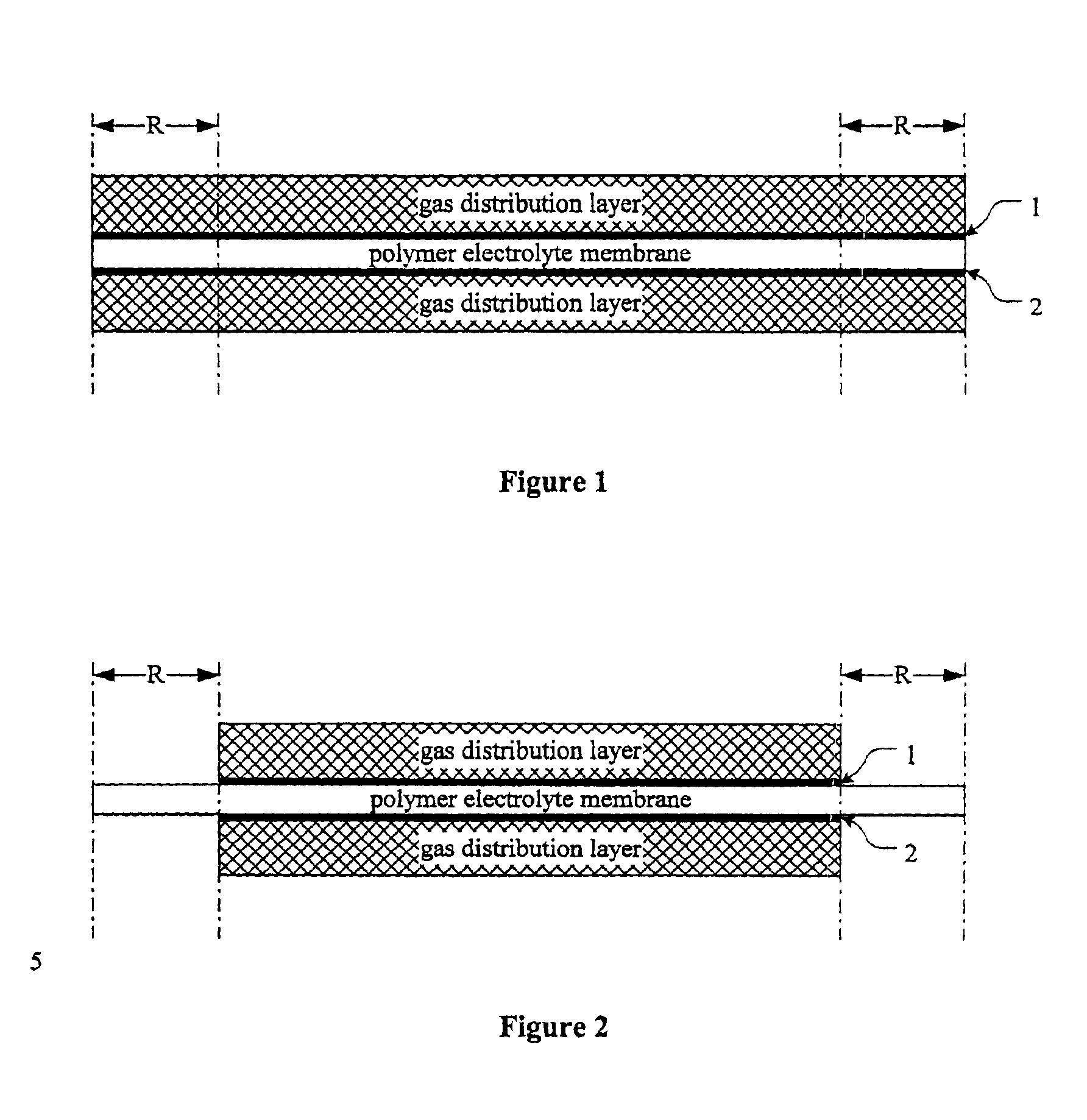

Process for producing a membrane electrode assembly for fuel cells

InactiveUS20020064593A1Improve electrical performanceSmooth connectionSolid electrolytesFinal product manufactureIonomerPolymer electrolytes

A process for producing a membrane electrode assembly for fuel cells containing a polymer electrolyte membrane having a first and a second surface parallel to each other. The first surface forms a firm composite with a first catalyst layer and a first water repellent gas distribution layer and said second surface form a firm composite with a second catalyst layer and a second water repellent gas distribution layer. The catalyst layers are prepared by using inks containing electrocatalysts, one or more solvents, proton-conducting ionomer and optionally water repelling agents and pore-forming agents. In the process the two catalyst layers are applied to or contacted with the respective surfaces of the polymer electrolyte membrane successively, wherein during the application or contacting process to one surface always the opposite surface of the membrane is supported.

Owner:UMICORE AG & CO KG

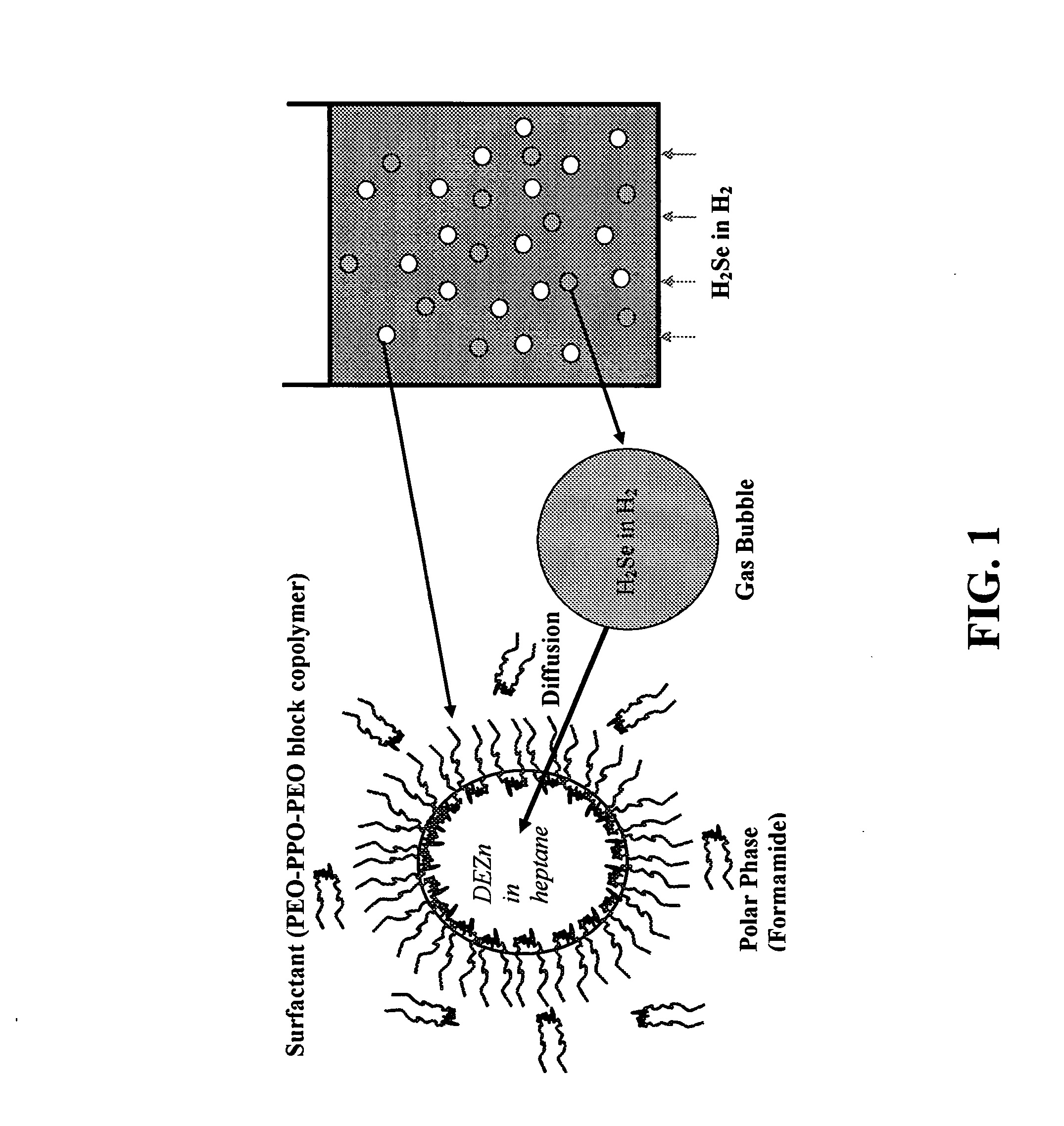

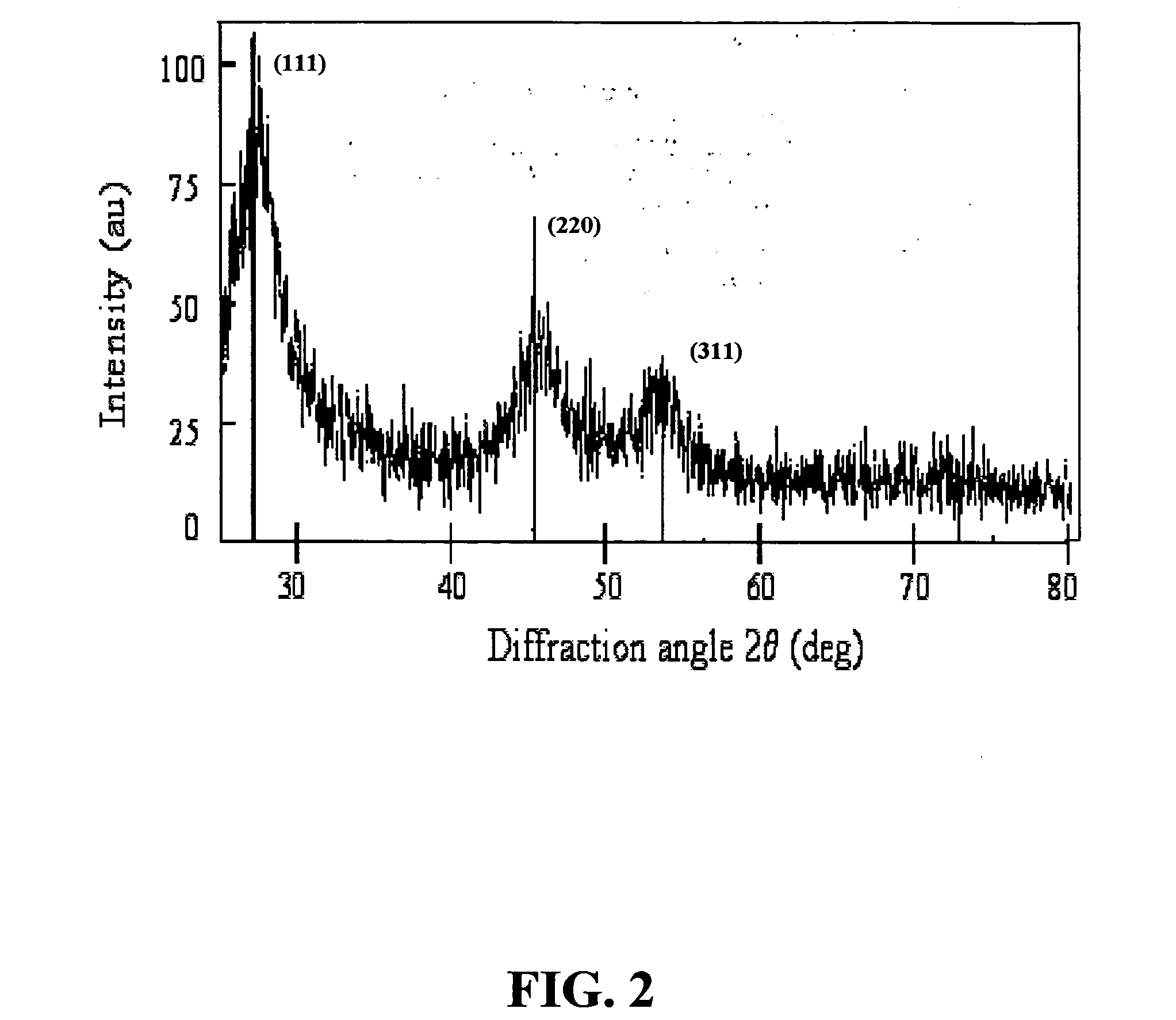

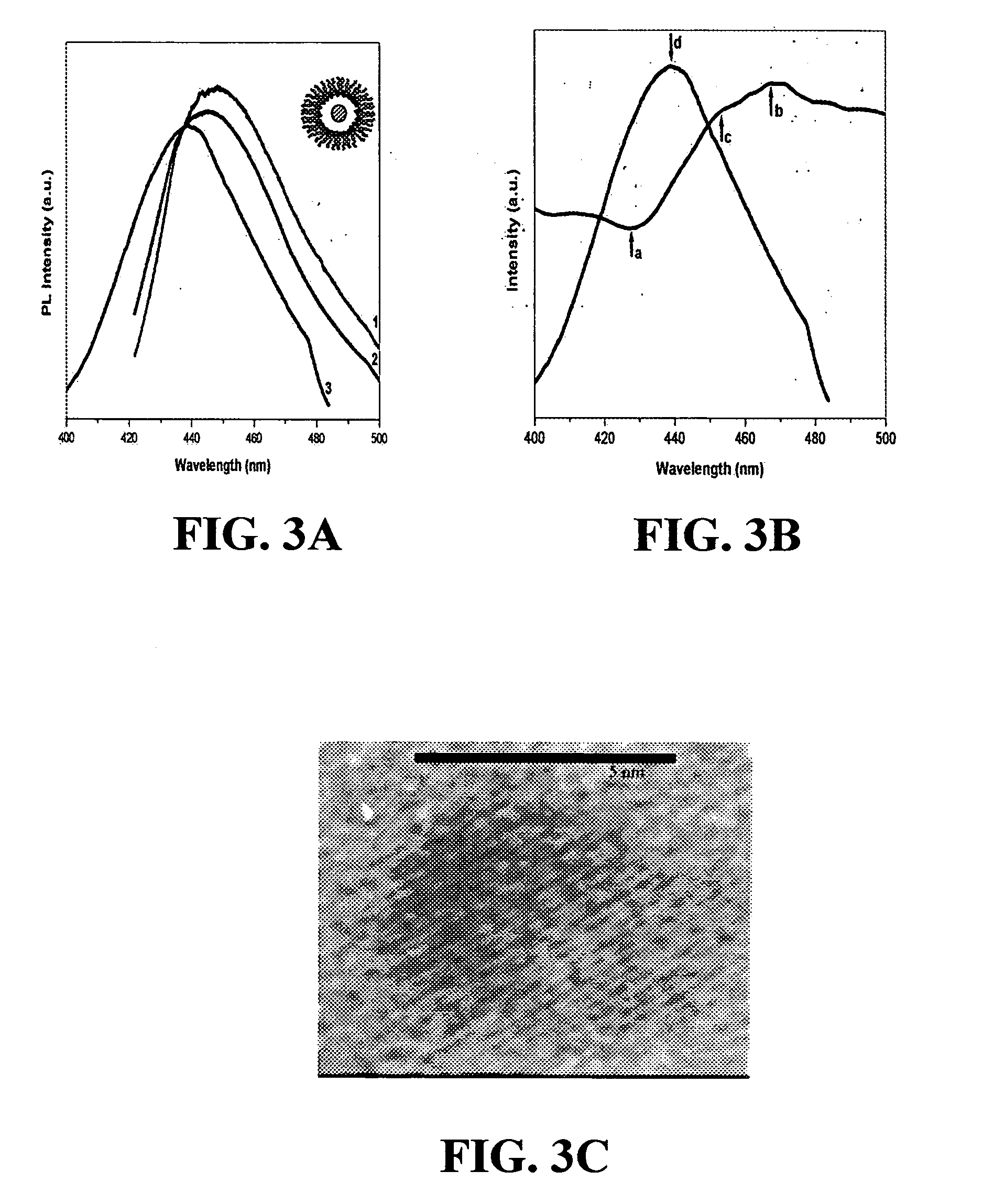

Synthesis of nanoparticles by an emulsion-gas contacting process

ActiveUS20050006800A1Easy to controlEasily scaled-upPowder deliveryMaterial nanotechnologyEmulsionGas phase

The present invention is directed to a process for synthesizing nanoparticles. This process involves providing a stable emulsion containing a plurality of droplets suspended in a continuous phase. The droplets, which are encapsulated by an interfacially-active material, contain a first reactant dissolved in a dispersed phase. The process also involves contacting a gas phase containing a second reactant diluted in a carrier gas with the stable emulsion under conditions effective to permit the first reactant and second reactant to react and form nanoparticles. The present invention further relates to nanoparticle-loaded emulsions and their uses in formulations for various purposes.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

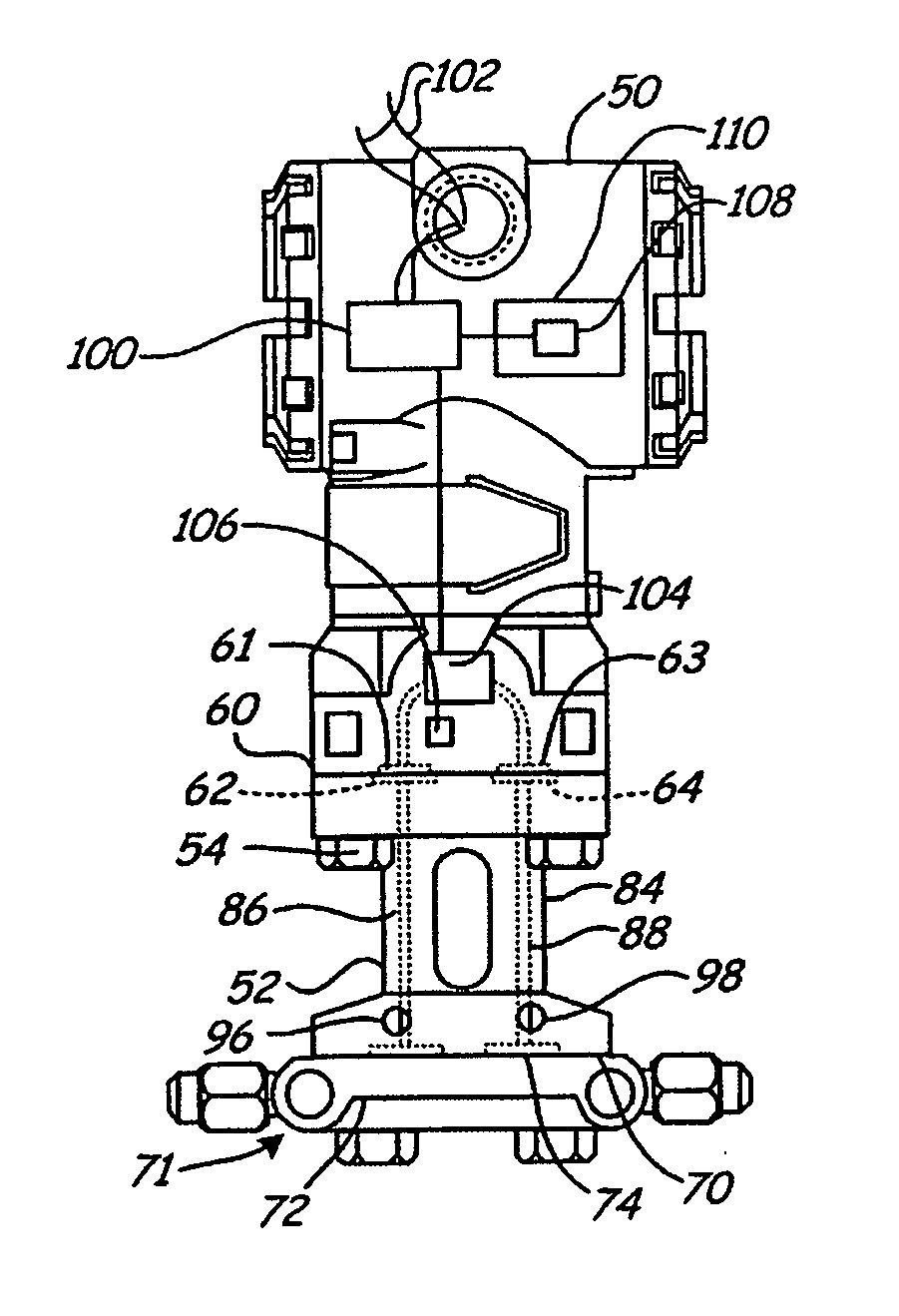

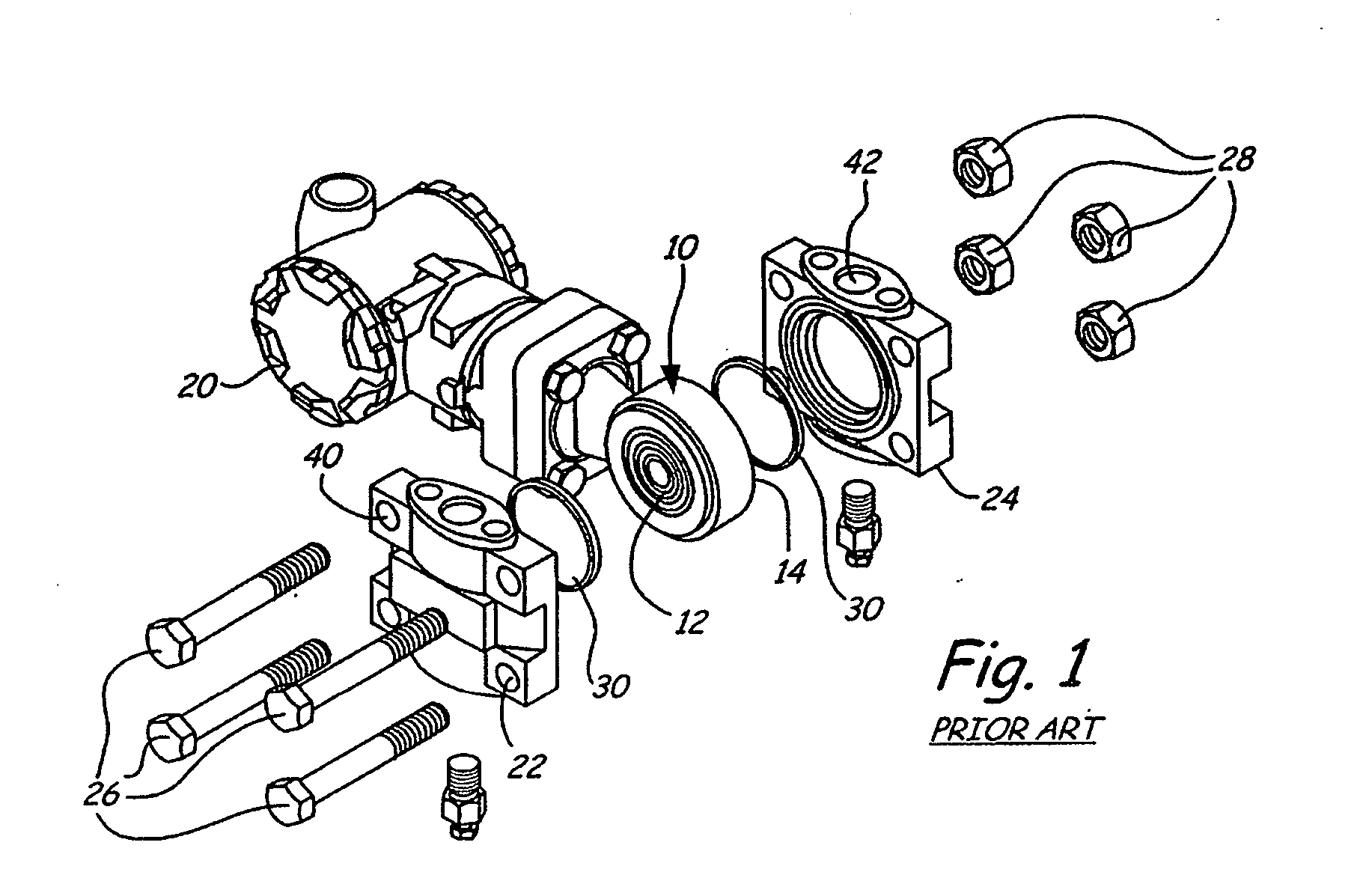

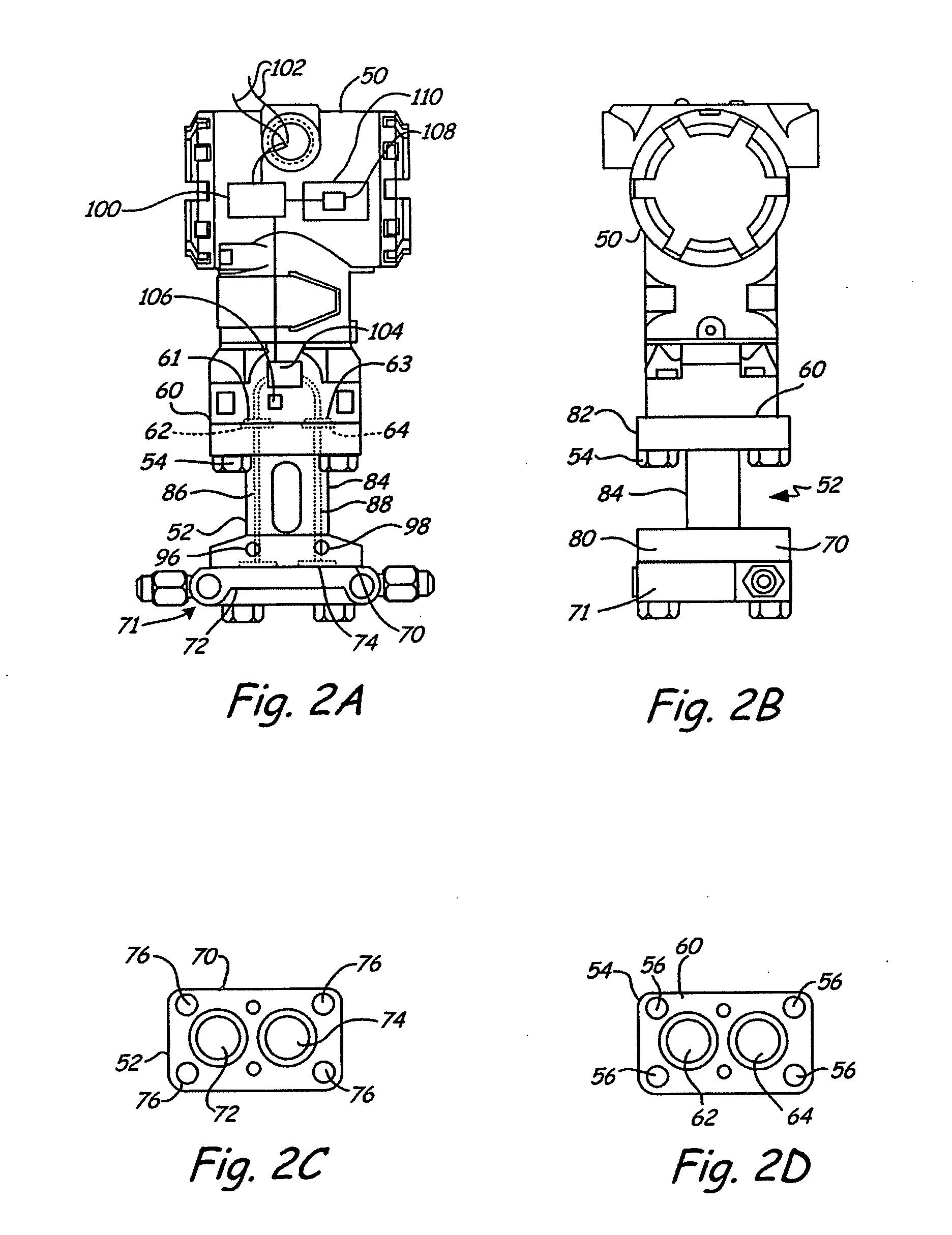

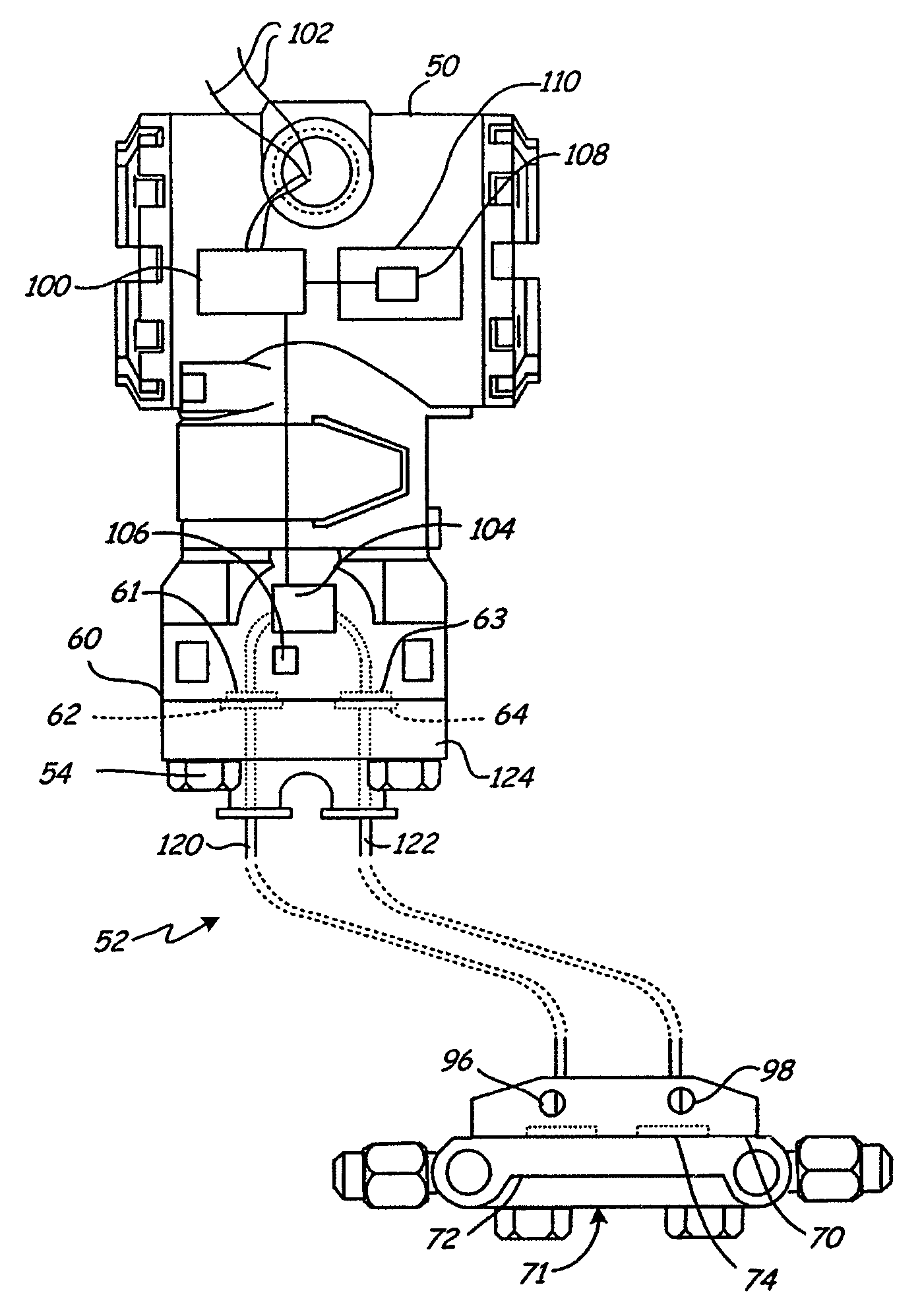

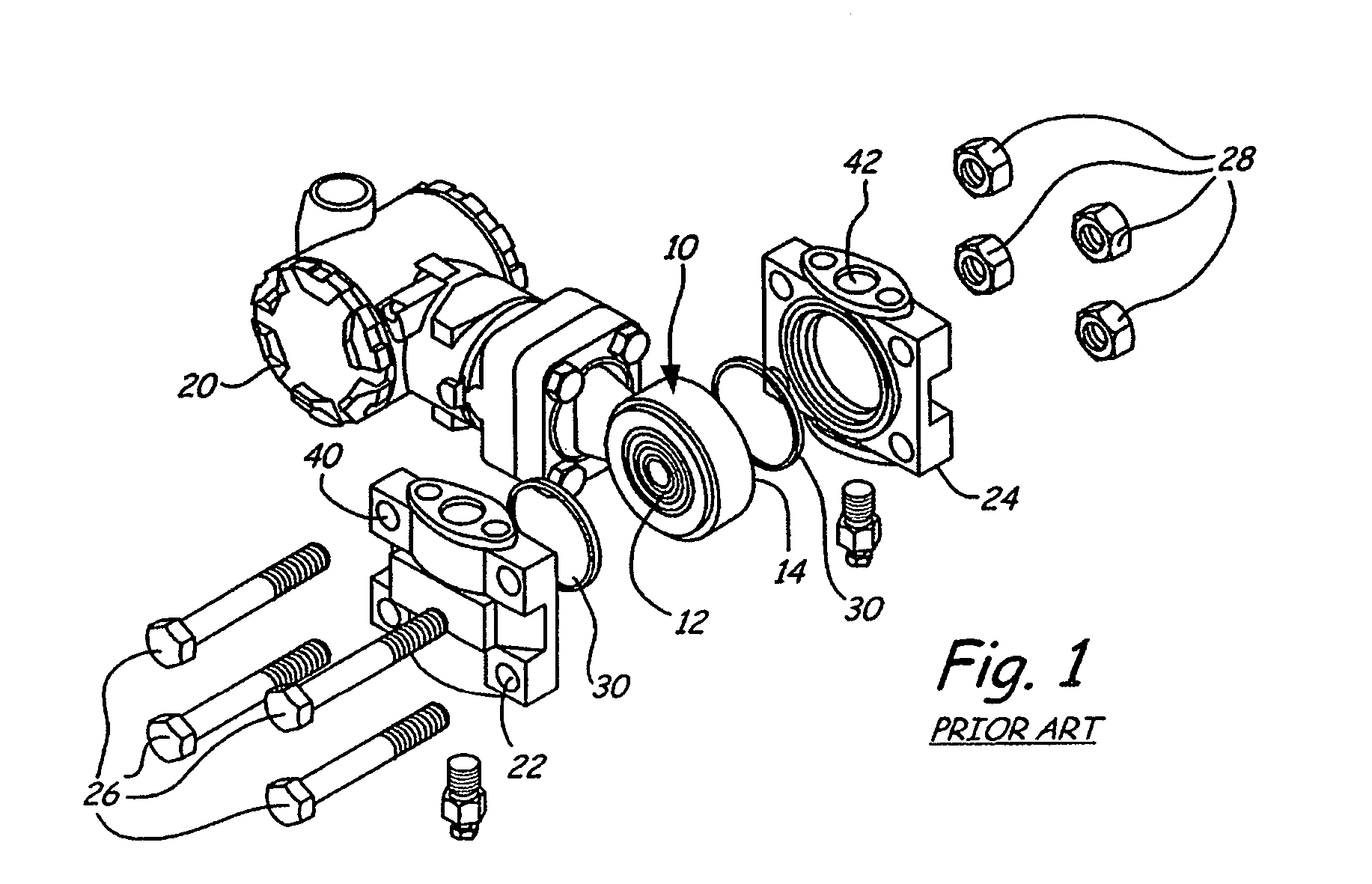

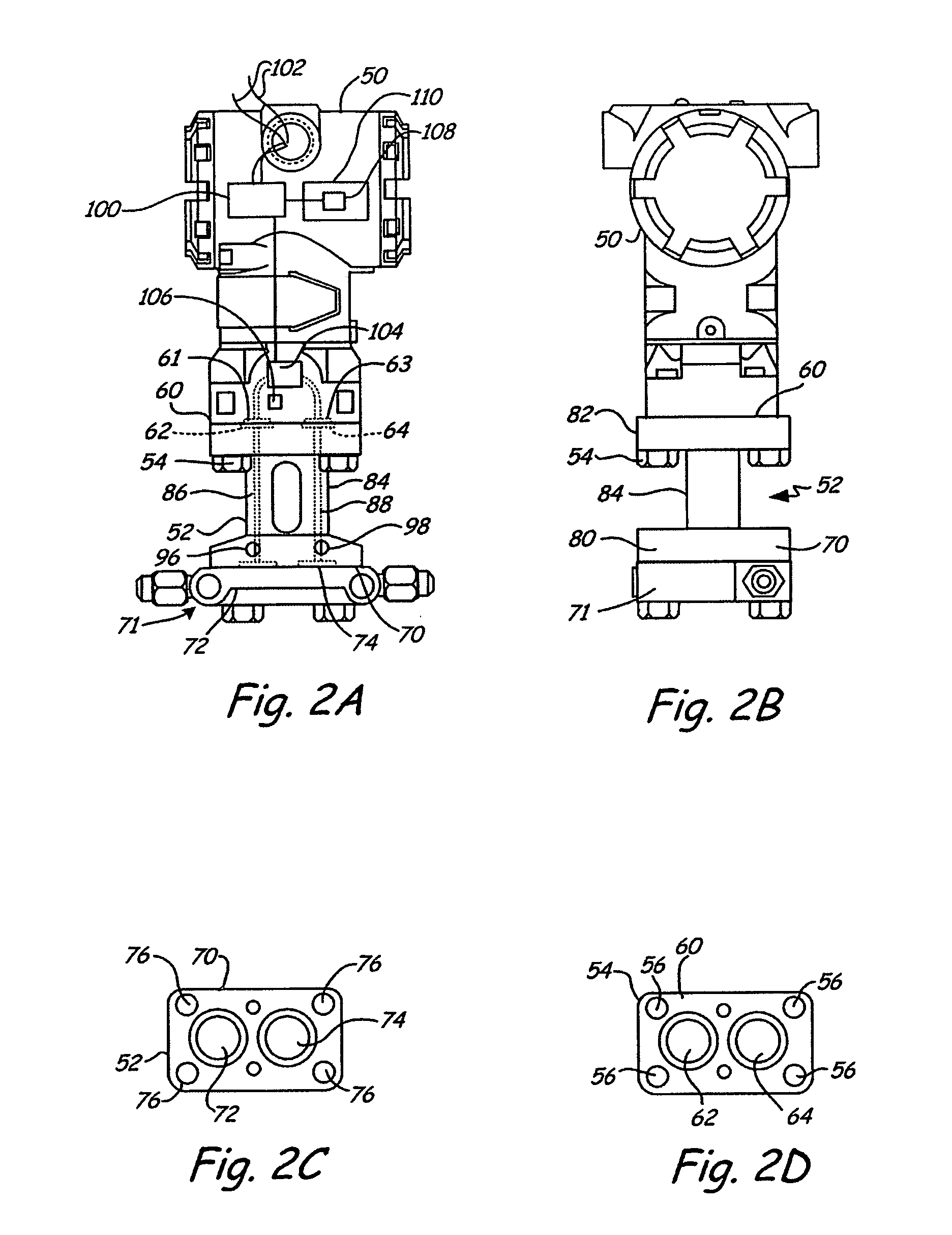

Process transmitter isolation assembly

ActiveUS20060162458A1Mitigating high-temperature effectFluid pressure measurement by electric/magnetic elementsFluid pressure measurement by mechanical elementsCouplingEngineering

An isolation assembly for connection to a process transmitter and for mitigating high temperature effects of a process fluid includes a process coupling face having an isolation diaphragm configured to contact process fluid. A transmitter coupling has a pressure coupling configured to couple to a pressure port of the process transmitter. A temperature isolation fluid conduit extends between the process coupling face and the transmitter coupling and carries an isolation fluid which couples a pressure applied to the isolation diaphragm to the pressure coupling to minimize high temperature effects of the process fluid on the process transmitter.

Owner:ROSEMOUNT INC

Process transmitter isolation assembly

ActiveUS7258021B2Mitigating high-temperature effectFluid pressure measurement by electric/magnetic elementsFluid pressure measurement by mechanical elementsCouplingEngineering

An isolation assembly for connection to a process transmitter and for mitigating high temperature effects of a process fluid includes a process coupling face having an isolation diaphragm configured to contact process fluid. A transmitter coupling has a pressure coupling configured to couple to a pressure port of the process transmitter. A temperature isolation fluid conduit extends between the process coupling face and the transmitter coupling and carries an isolation fluid which couples a pressure applied to the isolation diaphragm to the pressure coupling to minimize high temperature effects of the process fluid on the process transmitter.

Owner:ROSEMOUNT INC

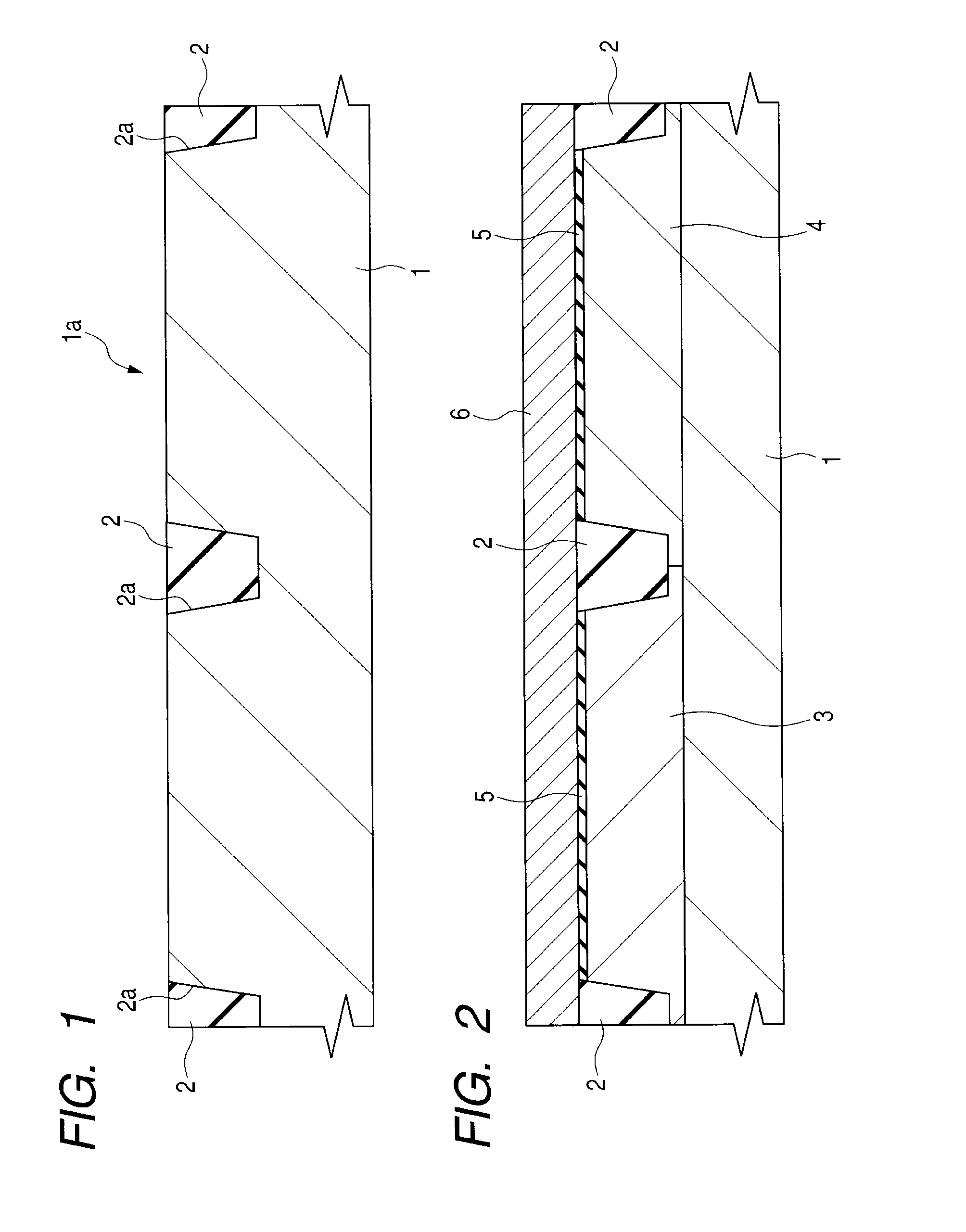

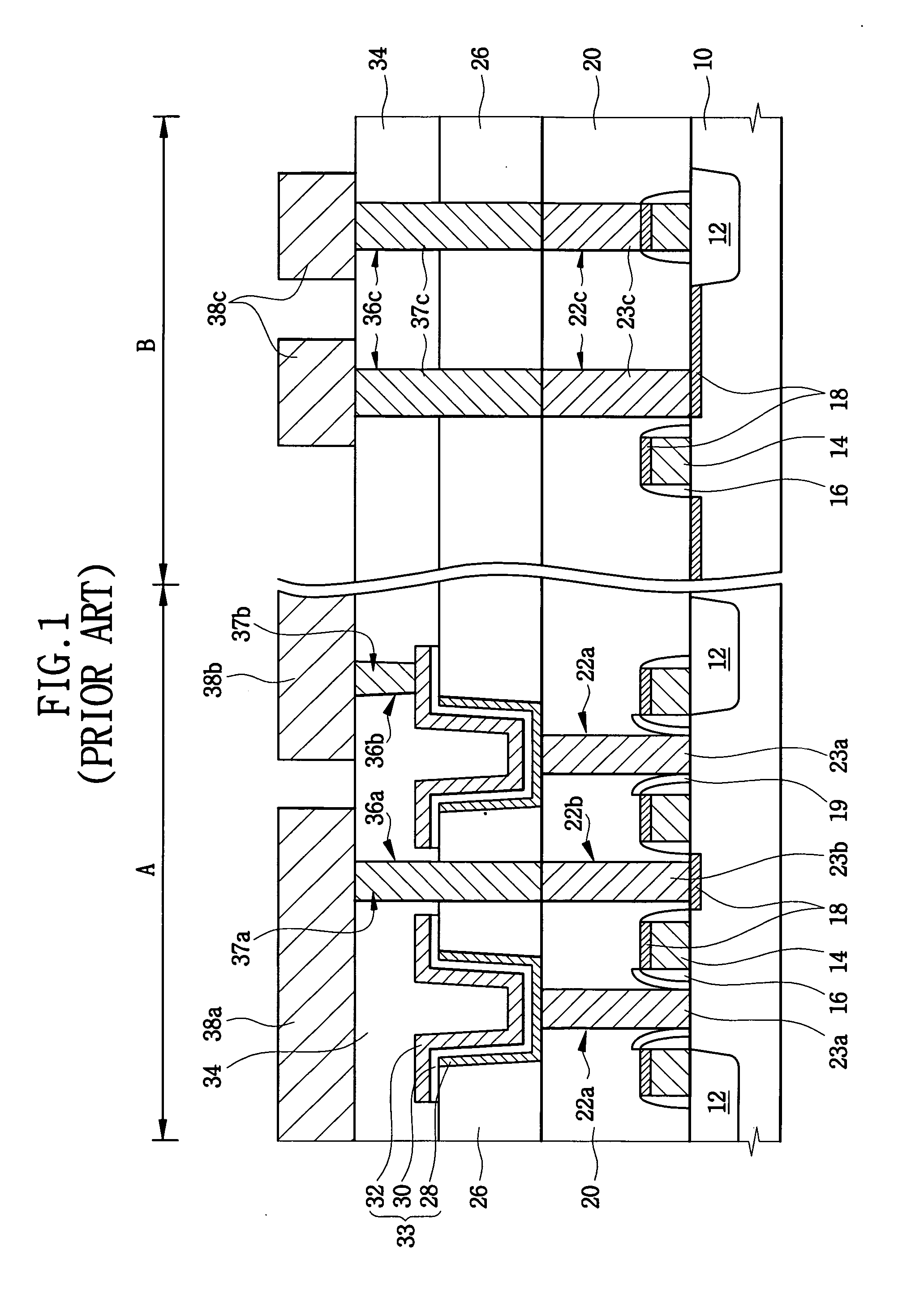

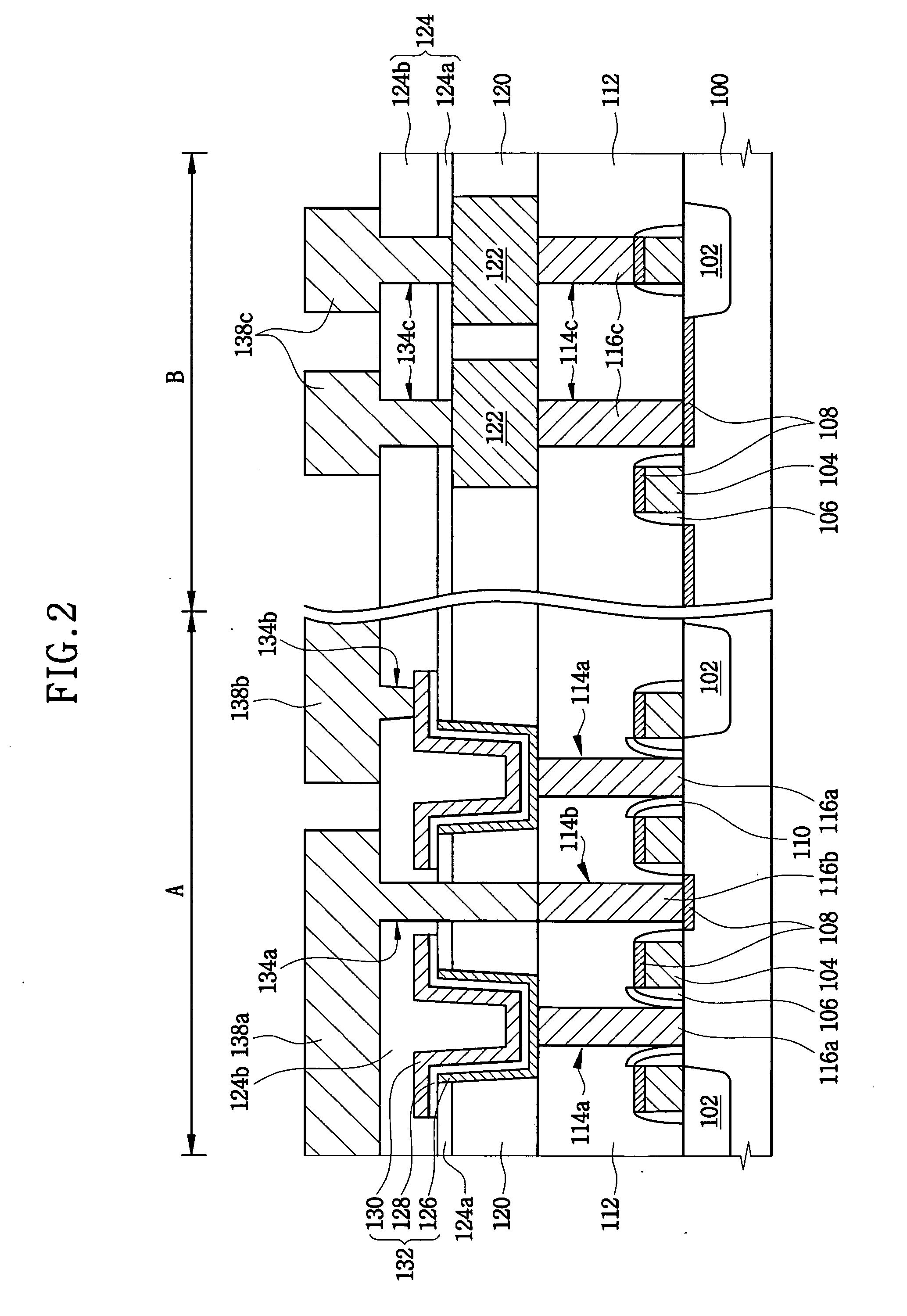

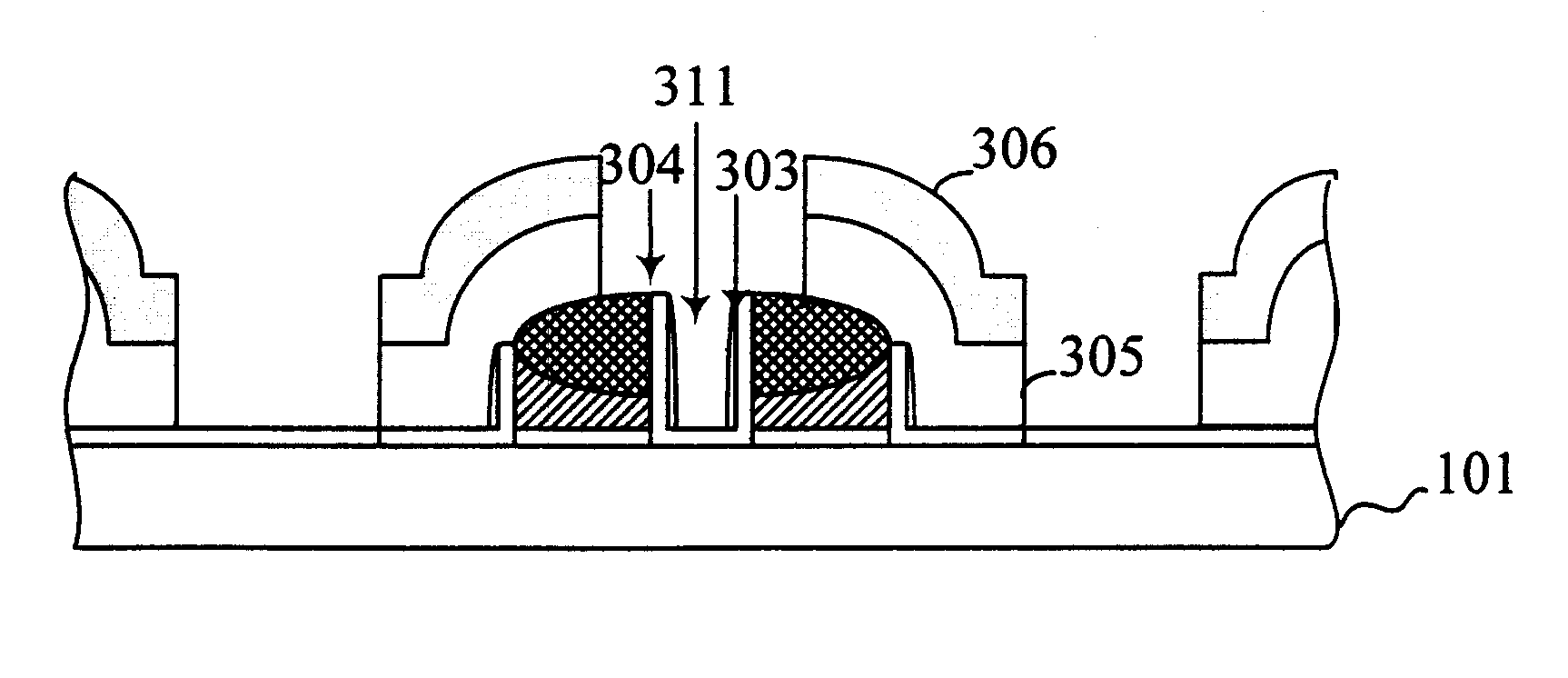

Semiconductor device and method of manufacturing the same

ActiveUS20040173836A1TransistorSemiconductor/solid-state device testing/measurementManufacturing cost reductionEngineering

Provided are semiconductor devices having a system-on-chip (SOC) configuration that combines both a capacitor-based cell-array memory region and one or more MOS core / peripheral circuit / logic regions on a single chip and a method for manufacturing such devices. The manufacturing process reduces the number of additional photolithographic processes required and modifies the relationship between the sizing of various layers and / or structures to reduce the fabrication cost and improve the reliability of the resulting devices. In particular, the capacitors for the memory region are formed in the same insulating layer as the first metal pattern for the core / peripheral circuit / logic regions of the devices, thereby producing capacitors and metal patterns of substantially the same height and thickness respectively. A landing structure may also be formed in the cell array region in combination with the first metal pattern for improving the contact process in the cell array region.

Owner:SAMSUNG ELECTRONICS CO LTD

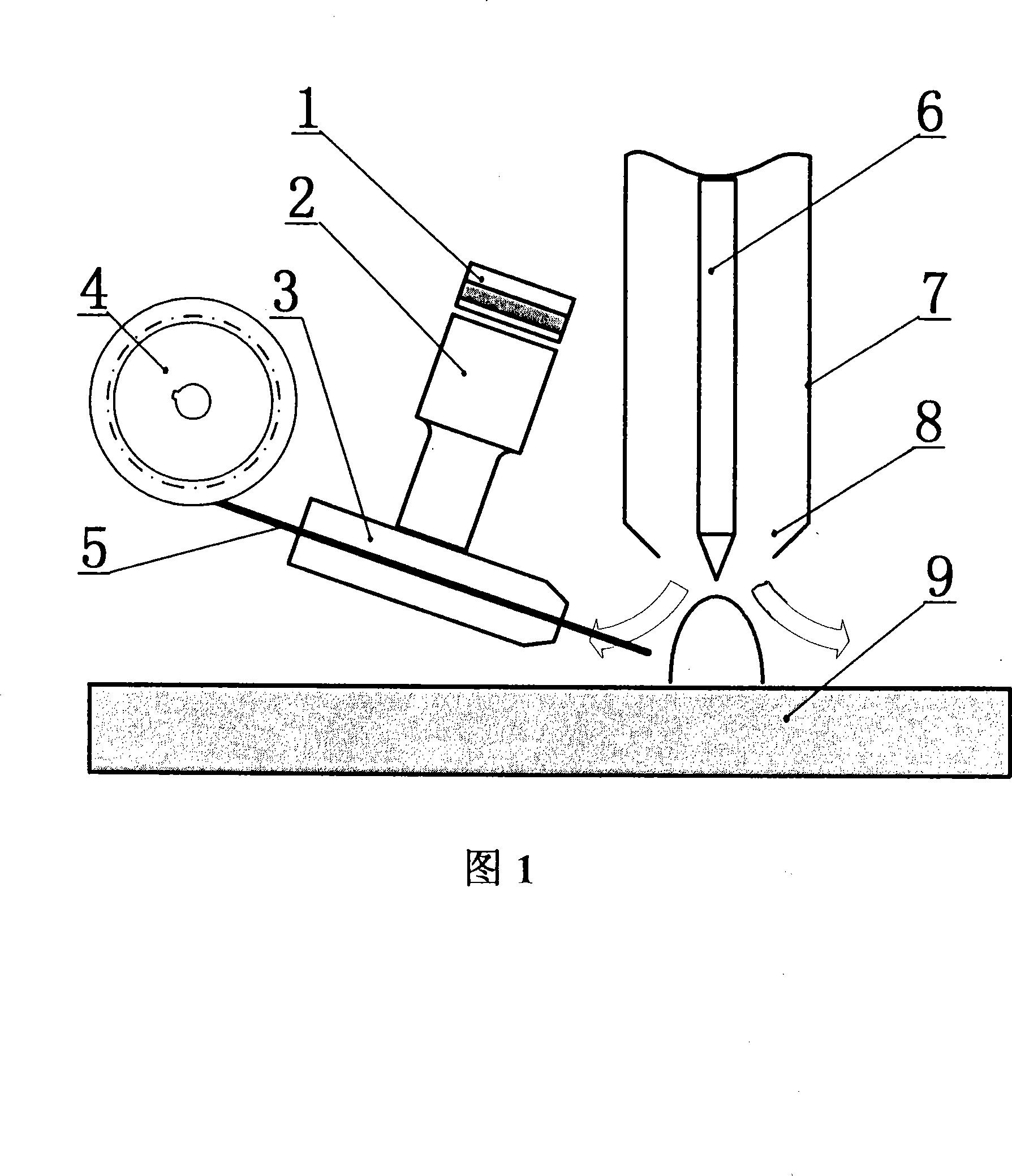

Ultrasonic vibration and welding stick feeding system compound welding method and device thereof

InactiveCN101239415AControl transitionAchieve welding productionArc welding apparatusMelting tankCavitation

The invention discloses an ultrasonic vibration and welding wire feed system composite welding method and a device thereof which are provided with a stable welding process, high quality of welding seams, controllable welding pool grain growth phenomenon after welding, and high welding quality in normal welding surroundings. The objective is achieved by following steps: transmitting cavitation effect and vibration effect to the welding pool during the welding wire and welding pool contacting process by broadcasting the ultrasonic in the welding wire feed system. The melt drop size at the terminal of the welding wire is controlled effectively by ultrasonic action during welding process, transition from melt drop to welding pool is more stable, and welding seam quality is further improved. Since ultrasonic is applied in the welding feed system during welding process, welding wire melt drop transition condition is affected, energy distribution status during welding process is improved, thereby refinement and homogenization degree of the joint, and mechanical property such as intensity are further enhanced.

Owner:HARBIN INST OF TECH

Manufacturing method of a gate-split flash memory

InactiveUS6589842B2Solid-state devicesSemiconductor/solid-state device manufacturingSalicidePeak value

The present invention relates to discloses a manufacturing method of a gate-split flash memory, which is suitable for a self-align contact process and fully-salicide-compatible process. The present invention masks the invalid peaks with a thick passivation layer to obtain the purpose of removing the invalid peaks in the manufacturing process of a gate-split flash memory. The present invention deposits a nitride spacer to define a pattern of a floating gate of the flash memory, so that a channel length of the floating gate can be finely defined. The present invention also utilizes a mask pattern to define the floating gate region of the flash memory, and the manufacturing process will be smooth and cheap.

Owner:WINBOND ELECTRONICS CORP

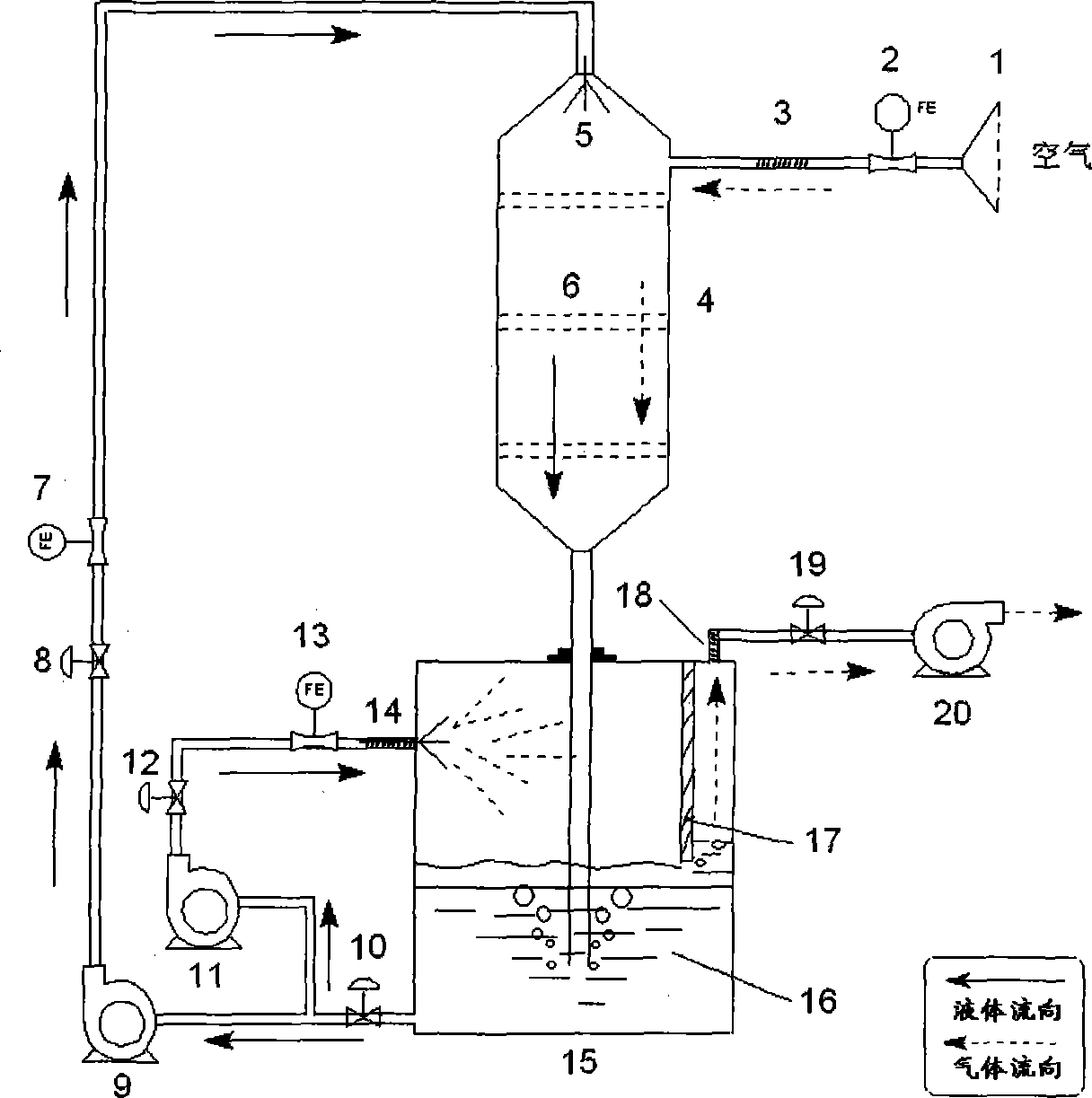

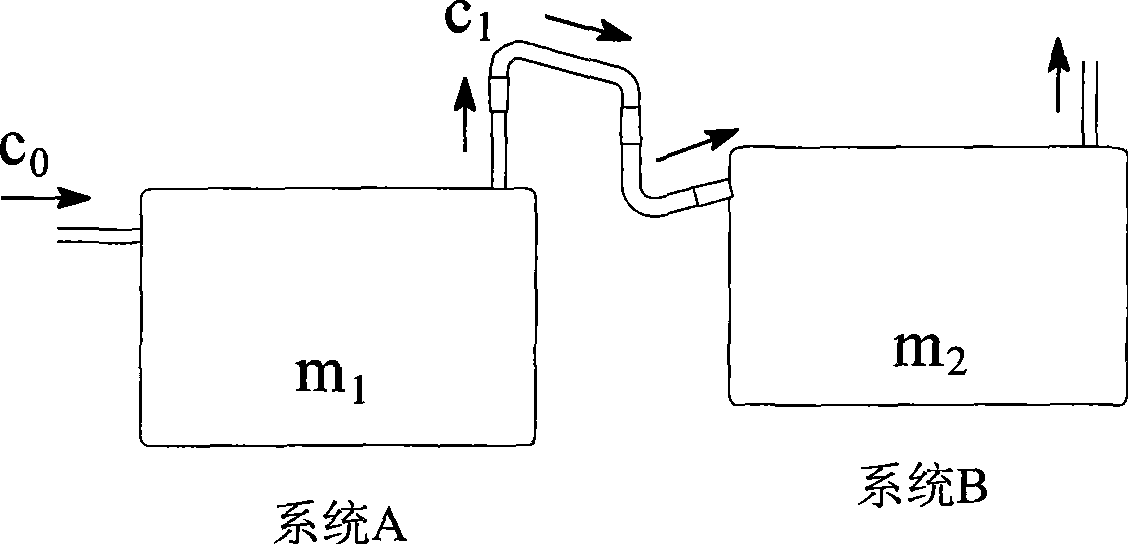

High-efficient trapping system for micro-nano powder dust in air

InactiveCN101502735AEfficient captureImprove wettabilityCombination devicesUsing liquid separation agentMicro nanoFiber

The invention discloses an efficient trapping system of micro-nanometer dust in the air. The invention comprises an air trapping opening, a filter core, a sprayer, a big and small flow micro pump, an atomizing nozzle, a liquid storage chamber, trapping liquid, a baffle and a vacuum pump, which construct an air flow route and a liquid circulation route, the system designs the air containing dust and the trapping liquid to experience four different absorption and trapping processes continuously, so as to realize efficient trapping of the micrometer and nanometer dust composed of various grains. By changing the variety of the trapping liquid or adjusting the hydrophile-lipophile balance (HLB) value of the trapping liquid, and improving the wettability of the trapping liquid and the nano dust in the air, micro nanometer fiber, thin sheet dust and other solid dust particles of various forms, containing micro-nano particles, can be efficiently trapped. The invention designs a plurality of air-liquid continuous contact processes, the air containing dust and the trapping liquid are only mixed and absorbed in the system, thus efficiently trapping nano dust in various dust density environment air including occupation workplaces.

Owner:NANJING UNIV OF SCI & TECH

Pressure sensor assembly

InactiveUS6848316B2Avoid bondingFluid pressure measurement by electric/magnetic elementsForce measurementEngineeringPressure sensor

A pressure sensor assembly includes an elongate pressure sensor mounted to a sensor mounting block. A protective element covers the elongate pressure sensor to prevent the pressure sensor from contacting process fluid.

Owner:ROSEMOUNT INC

Process for producing a membrane electrode assembly for fuel cells

InactiveUS6998149B2Smooth connectionImprove relationshipSolid electrolytesFinal product manufactureSolventPolymer chemistry

Owner:UMICORE AG & CO KG

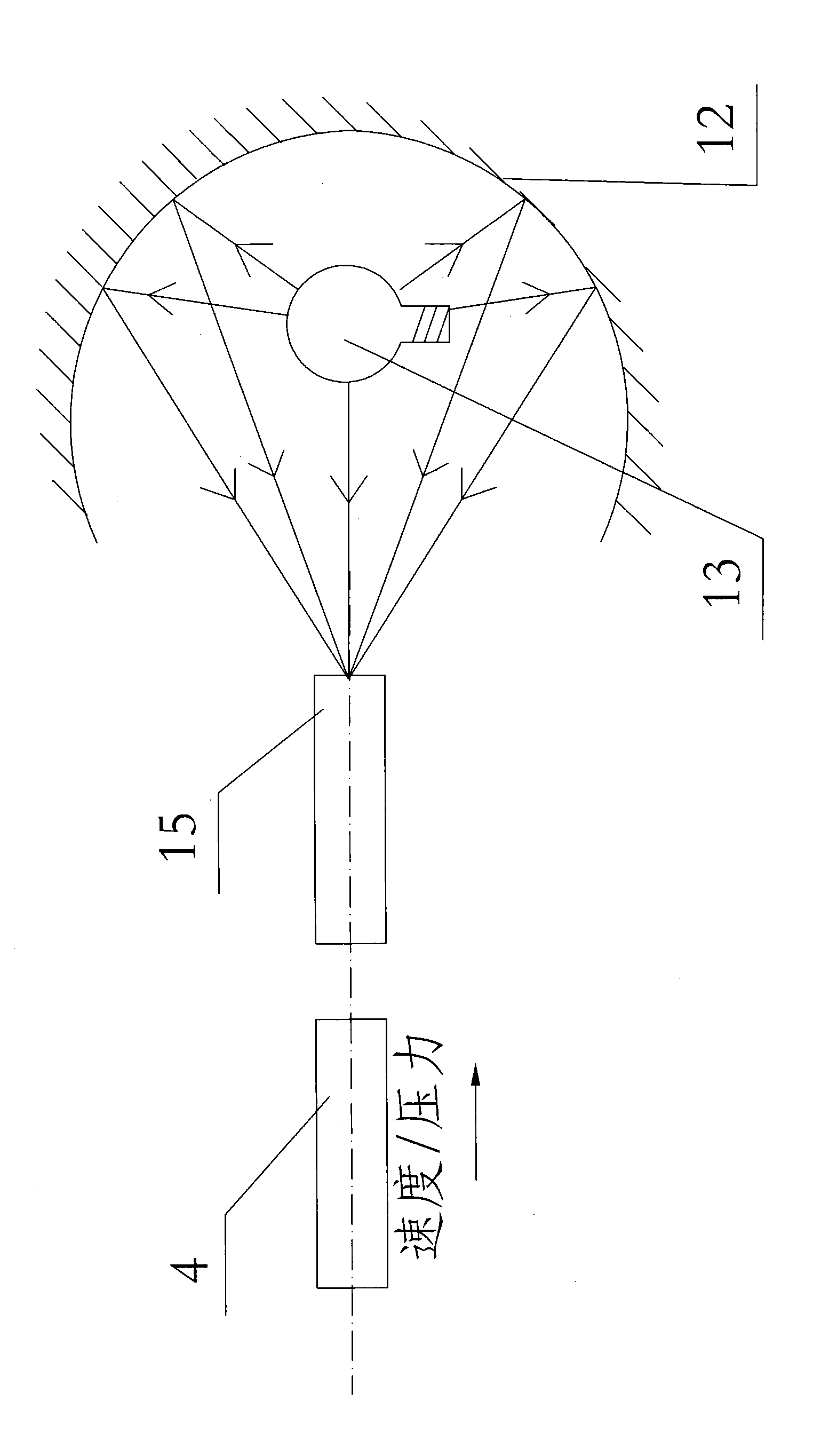

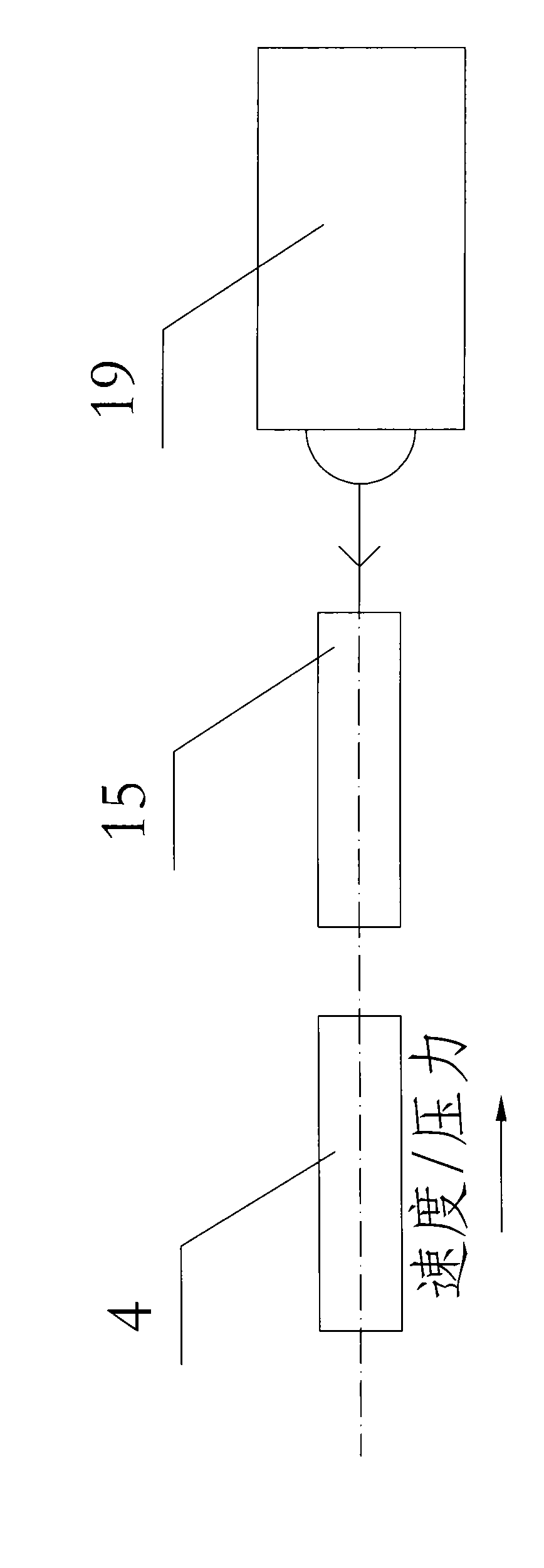

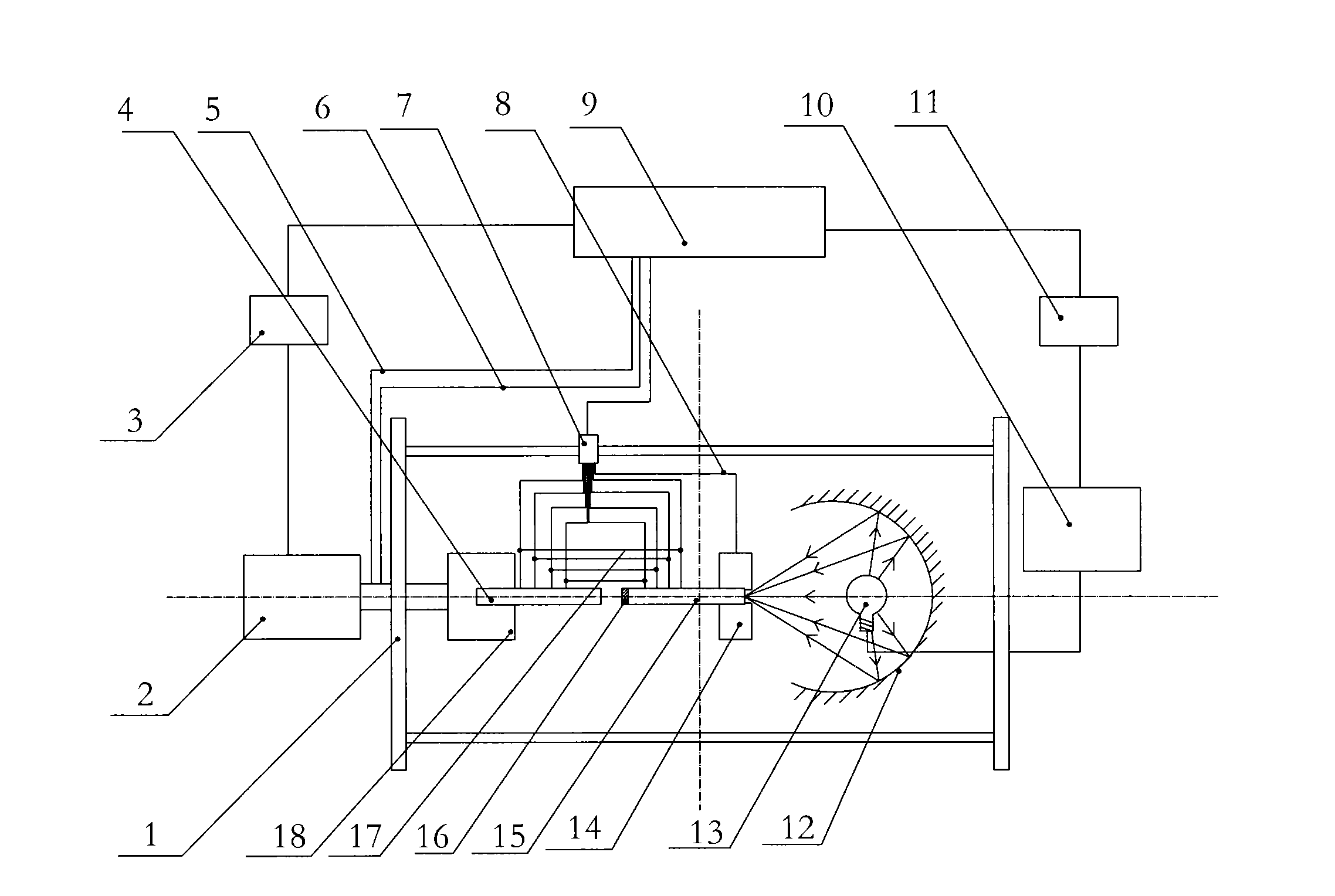

Method and device for measuring dynamic contact heat exchange coefficient of high-temperature solid interface

InactiveCN101661009ARealize measurementEfficient heatingMaterial thermal conductivityMaterial heat developmentContact pressureMeasurement device

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

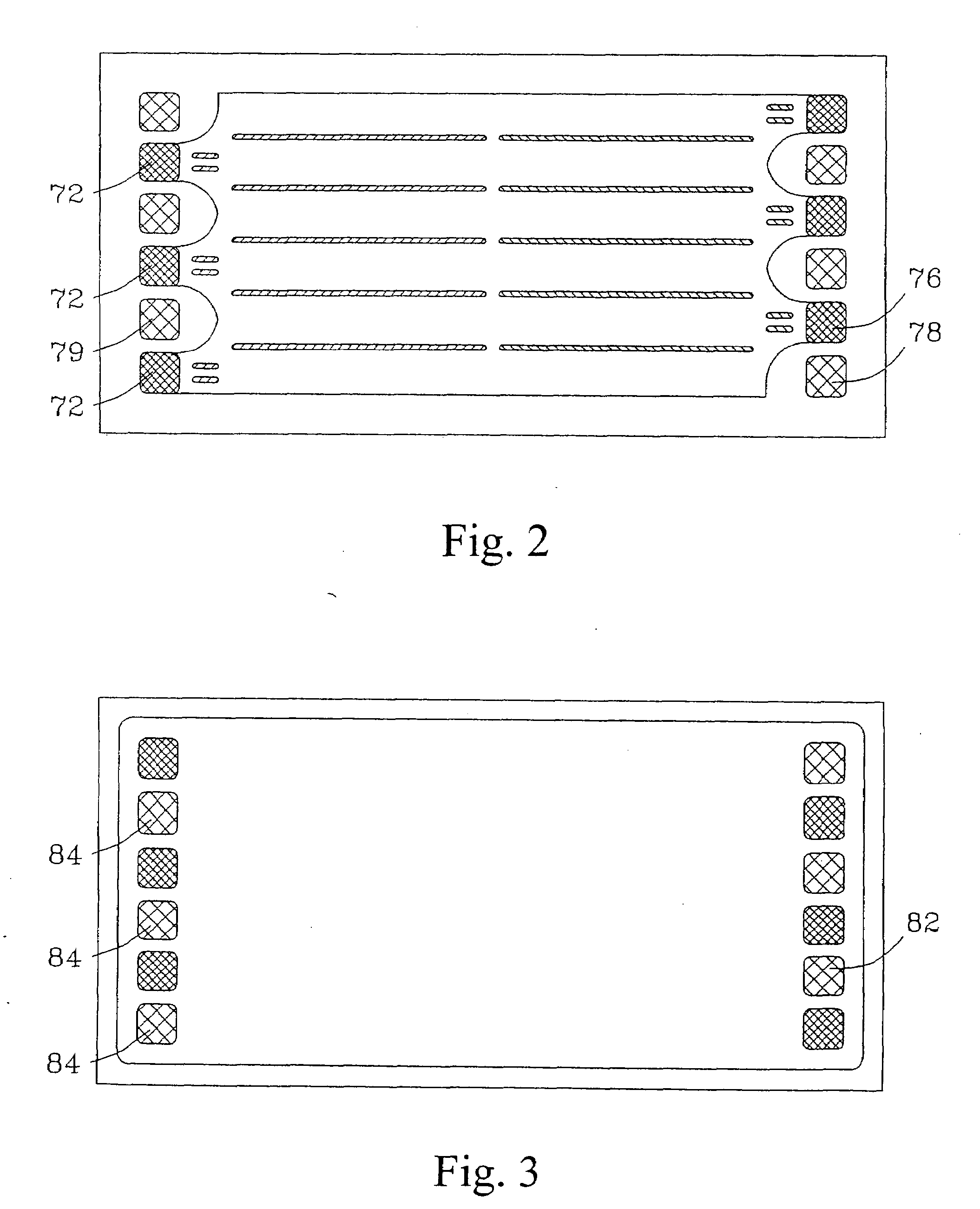

Mixing in Wicking Structures and the Use of Enhanced Mixing Within Wicks in Microchannel Devices

ActiveUS20090211735A1Increase heatImprove transportFlow mixersTransportation and packagingCapillary pressureEngineering

Advanced wicking structures and methods utilizing these structures are described. The use of advanced wicking structures can promote rapid mass transfer while maintaining high capillary pressure through the use of small pores. Particularly improved results in fluid contacting processes can be achieved by enhanced mixing within a wicking layer within a microchannel.

Owner:BATTELLE MEMORIAL INST

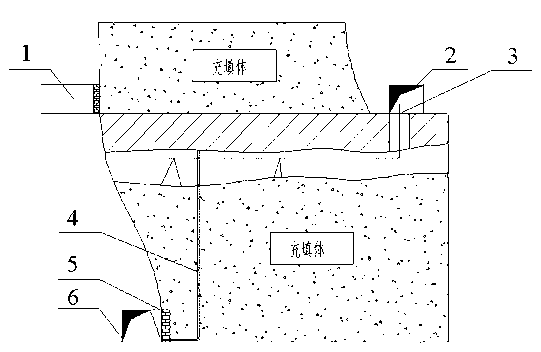

Roof contacting process in goaf filling treating procedure

InactiveCN103233771ALow costGuarantee normal productionMaterial fill-upEngineeringUltimate tensile strength

The invention relates to a roof contacting process in a goaf filling treating procedure and belongs to the technical field of mining engineering. The technical scheme of the roof contacting process in the goaf filling treating procedure includes: detecting a goaf to obtain the coordinate of the top point position of a top plate; drilling a filling drill hole at the top point position of the top plate, and performing cementing filling; installing a three-way plug valve on a filling pipe of the filling drill hole, and guiding a washing pipeline out on the filling pipe through the three-way plug valve; when the position with 1m away from the top point of the top plate is filled, extending the filling pipe to the position farthest from the filling drill hole, and simultaneously, arranging a 1-1.5m temporary retaining wall on the filling drill hole portion; when cement body is full, continuing to fill; and finally opening the three-way plug valve, guiding water away through the washing pipeline and finishing the filling roof contacting work. The roof contacting process is particularly suitable for filling the goaf generated during the filling exploitation process afterwards, is good in filling roof contacting effect and low in working intensity, saves filling roof contacting cost, achieves the roof contacting maximumly, is high in roof contacting efficiency, and ensures normal production of mines.

Owner:HEBEI IRON & STEEL GRP MINING +2

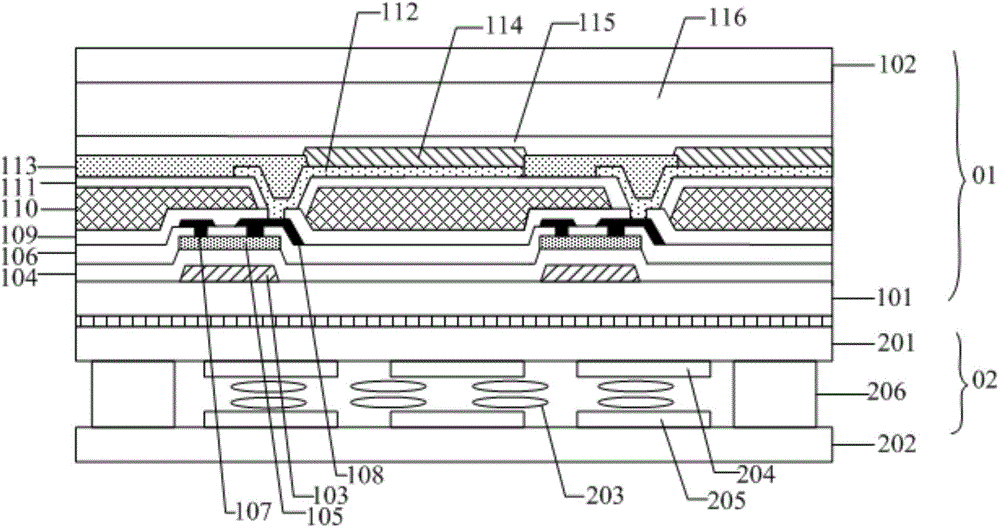

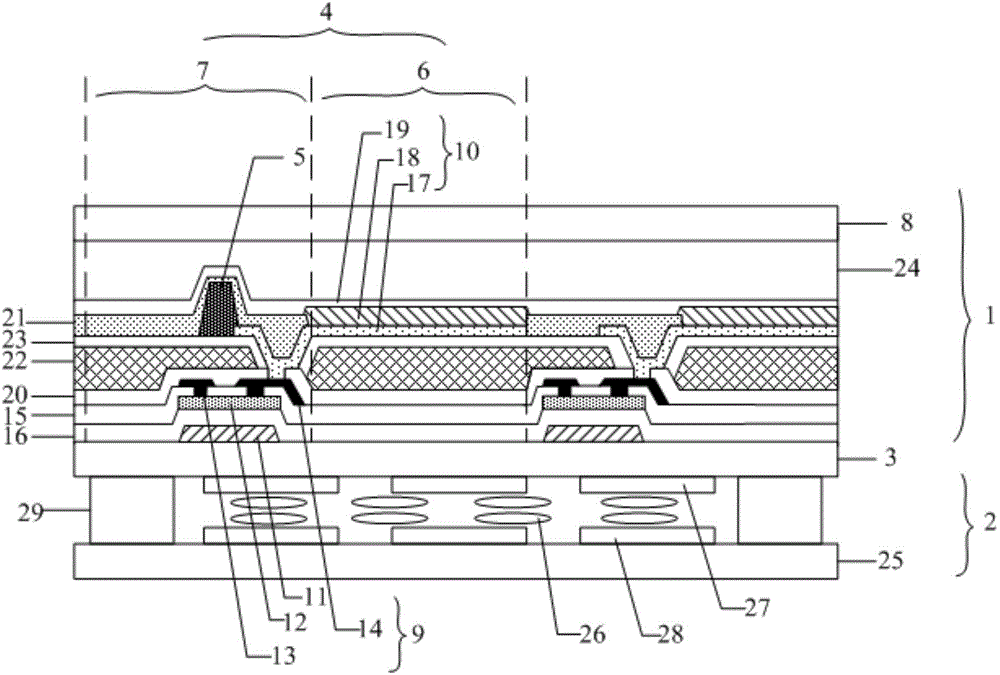

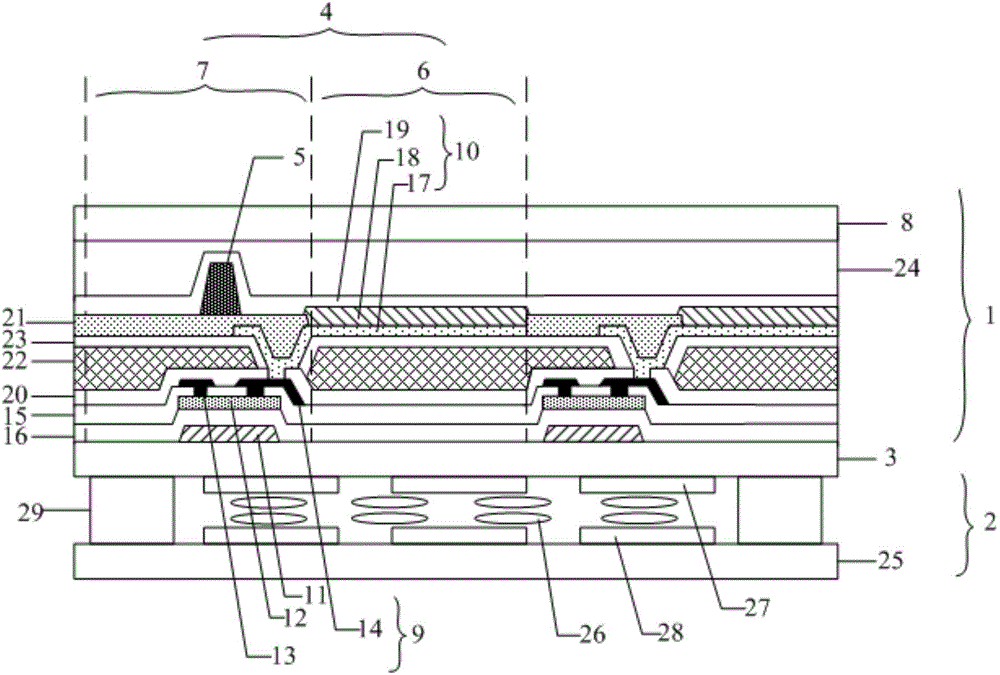

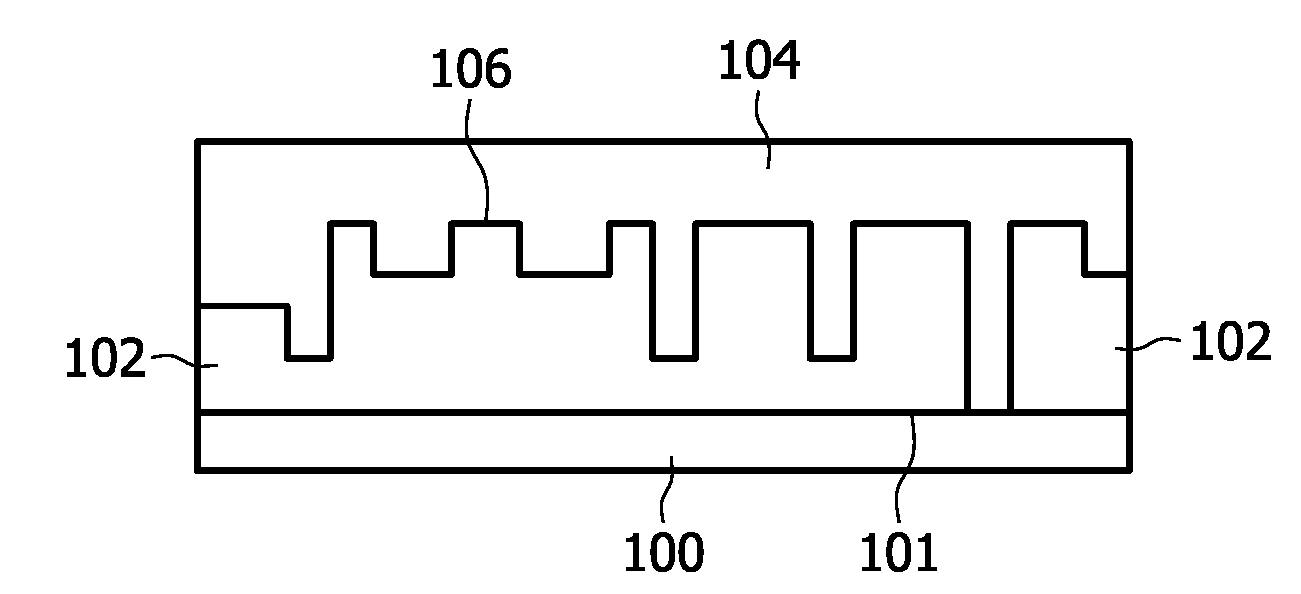

Three-dimensional display panel and manufacturing method thereof, and three-dimensional display device

InactiveCN103824876AReduce thicknessReduce manufacturing costSolid-state devicesSteroscopic systemsGratingOrganic electroluminescence

The invention discloses a three-dimensional display panel and a manufacturing method thereof, and a three-dimensional display device. The three-dimensional display panel comprises an organic electroluminescent display device and a liquid crystal raster arranged at the light-emitting side of the organic electroluminescent display device. Because the organic electroluminescent display device and the liquid crystal raster share one substrate, so that one substrate is saved and thus the production cost is lowered; and the thickness of the three-dimensional display panel is reduced. Moreover, the process of contact of the organic electroluminescent display device with the liquid crystal raster is saved; the manufacturing process is simplified; and a problem of poor display caused by damages of all film layers in the organic electroluminescent display device can be avoided during the contact process.

Owner:BOE TECH GRP CO LTD

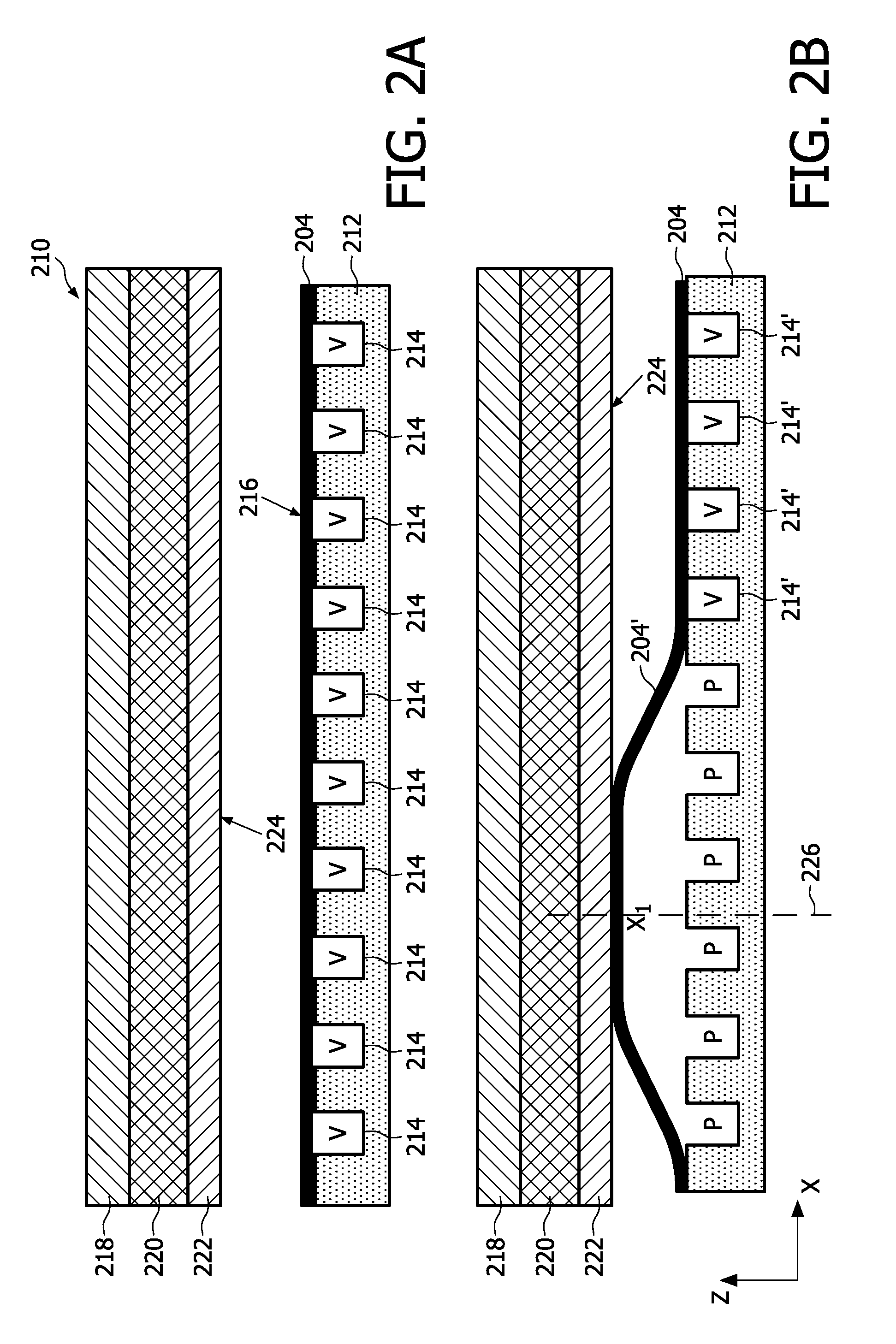

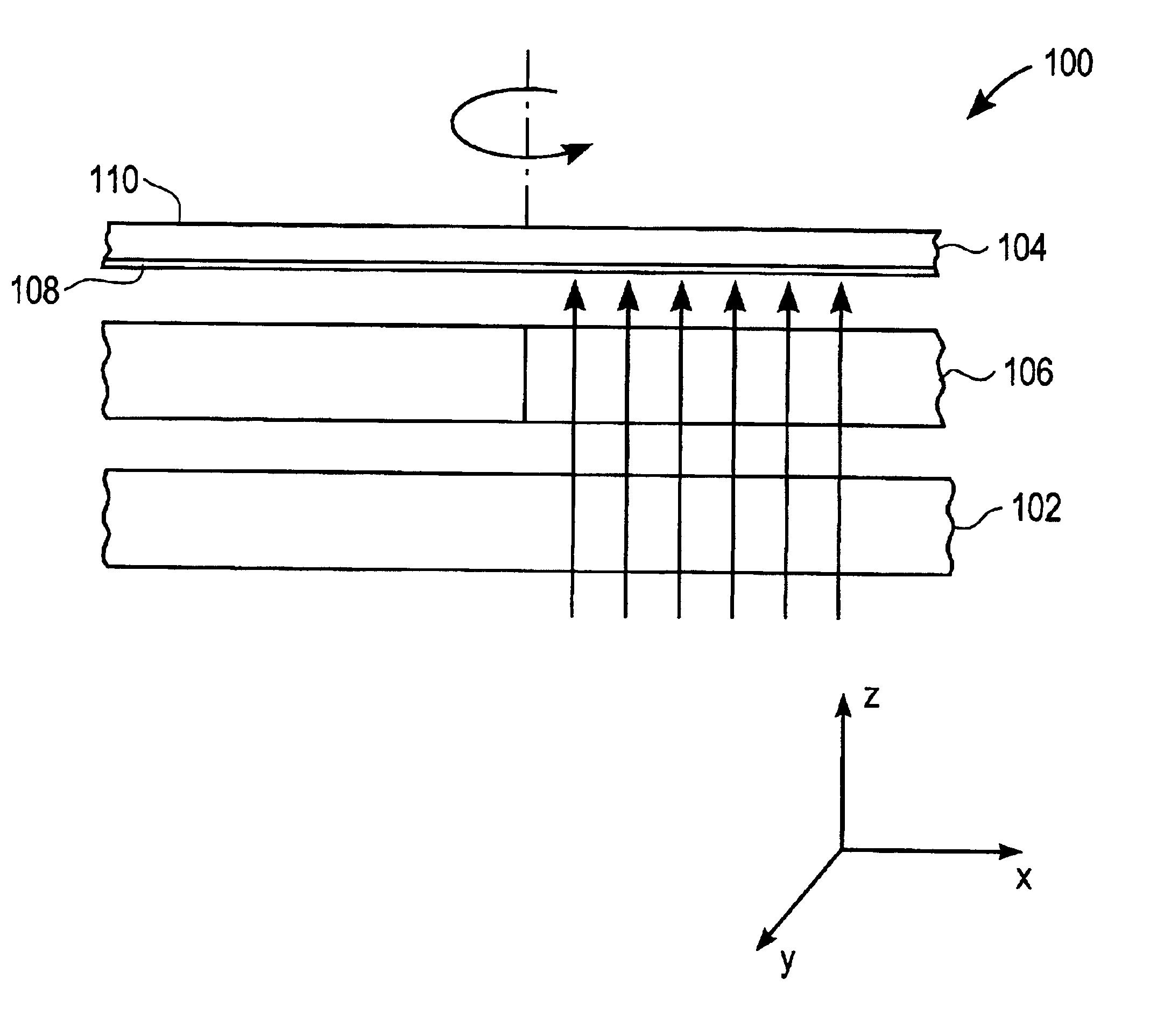

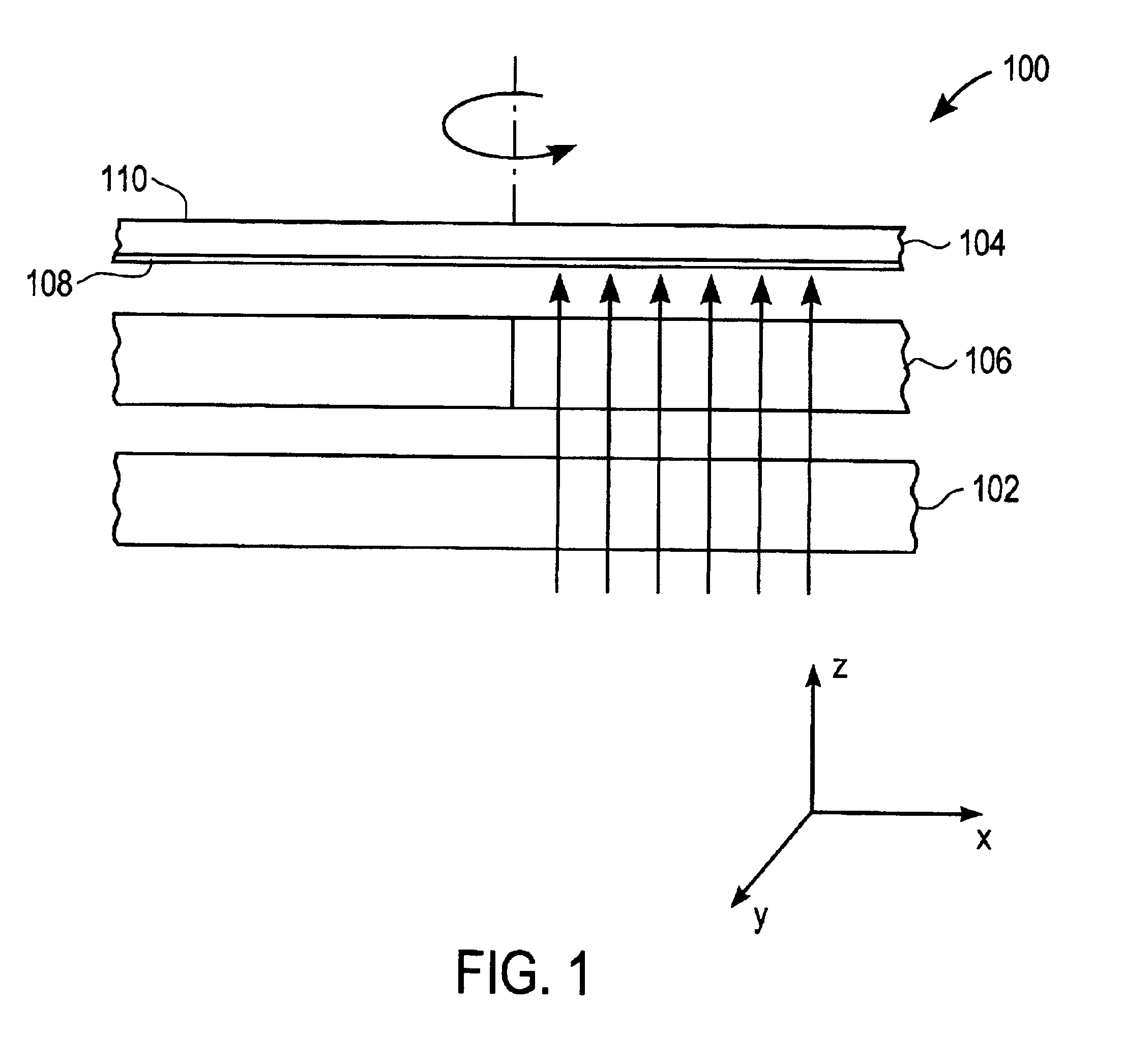

Method and system for contacting of a flexible sheet and a substrate

ActiveUS20090314414A1Less thicknessIncrease stiffnessPlaten pressesNanoinformaticsSecondary stageEngineering

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

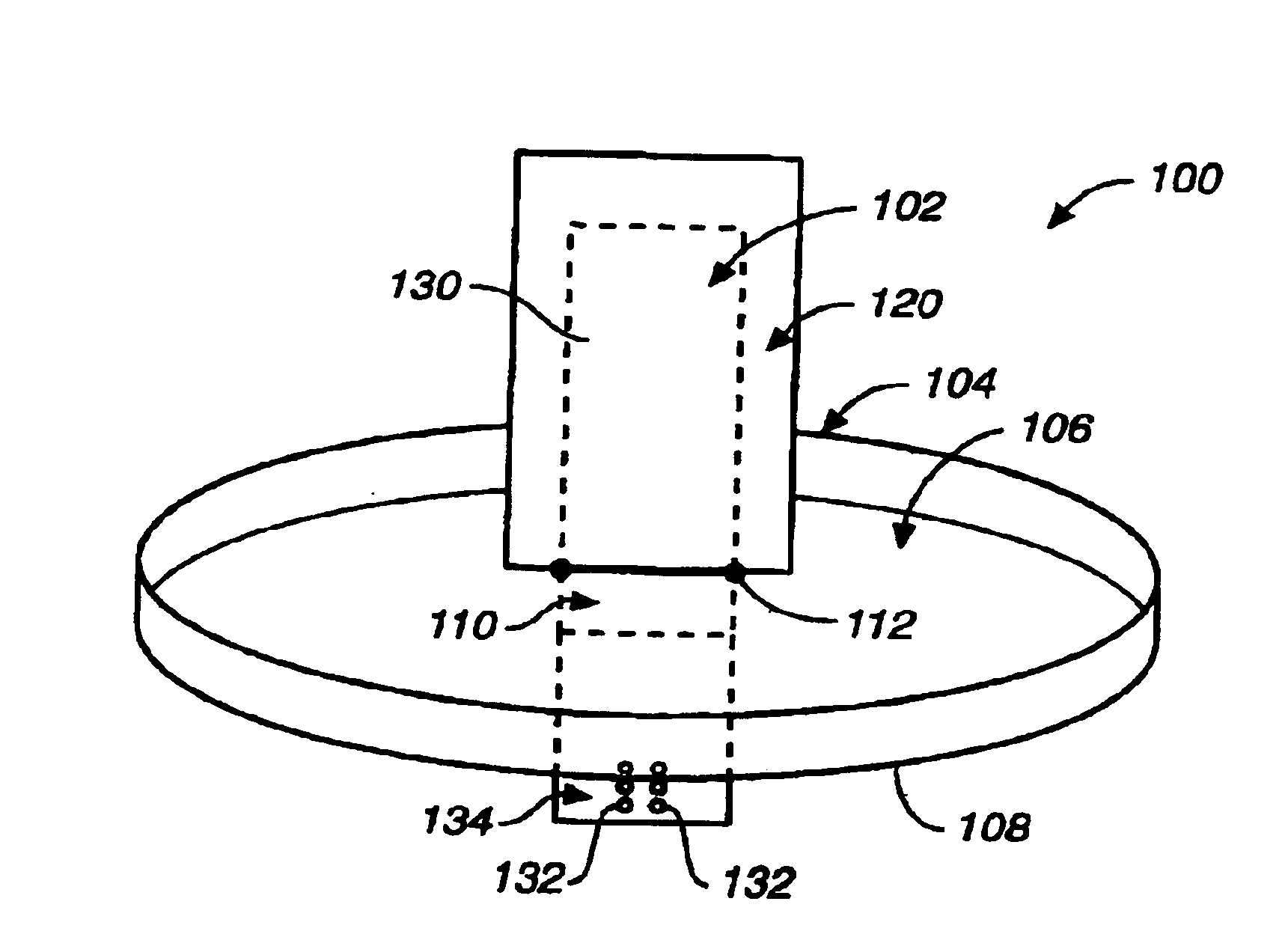

Non-contact process kit

A process kit for use in a physical vapor deposition (PVD) chamber, along with a PVD chamber having a non-contact process kit are provided. In one embodiment, a process kit includes a generally cylindrical shield that has a substantially flat cylindrical body, at least one elongated cylindrical ring extending downward from the body, and a mounting portion extending upwards from an upper surface of the body. In another embodiment, a process kit includes a generally cylindrical deposition ring. The deposition ring includes a substantially flat cylindrical body, at least one downwardly extending u-channel coupled to an outer portion of the body, an inner wall extending upward from an upper surface of an inner region of the body, and a substrate support ledge extending radially inward from the inner wall.

Owner:APPLIED MATERIALS INC

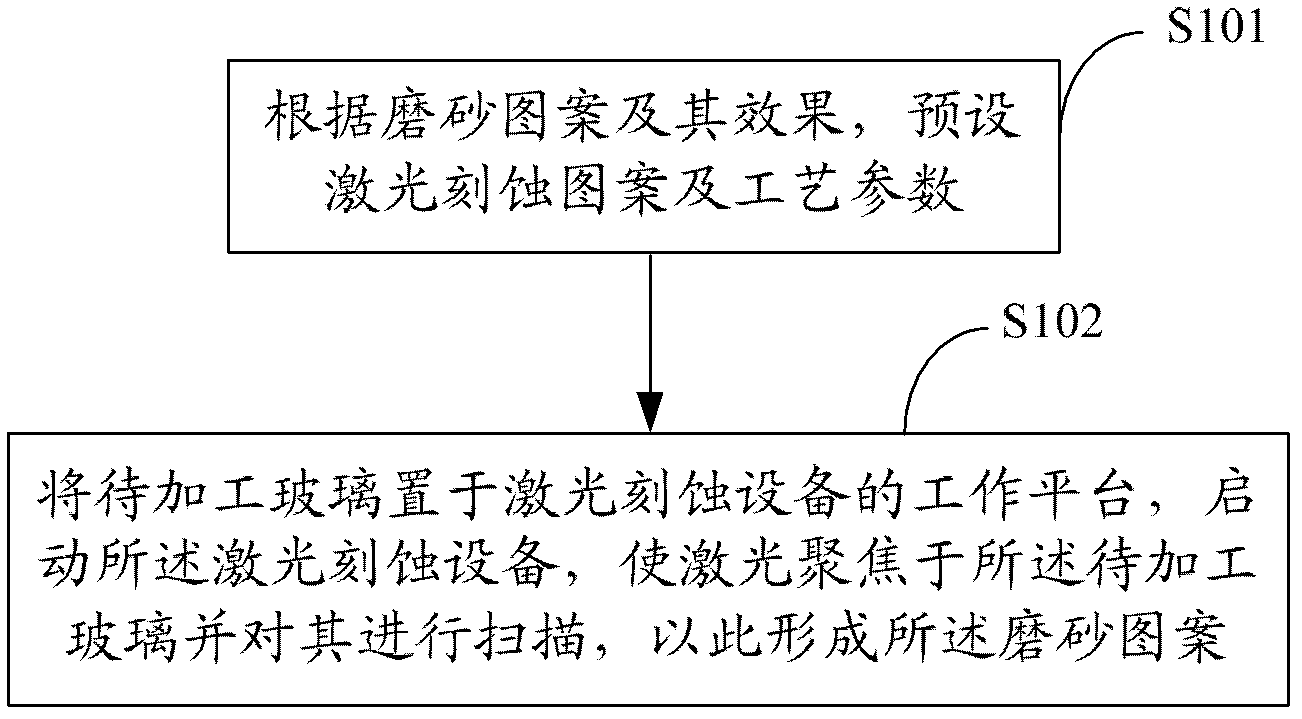

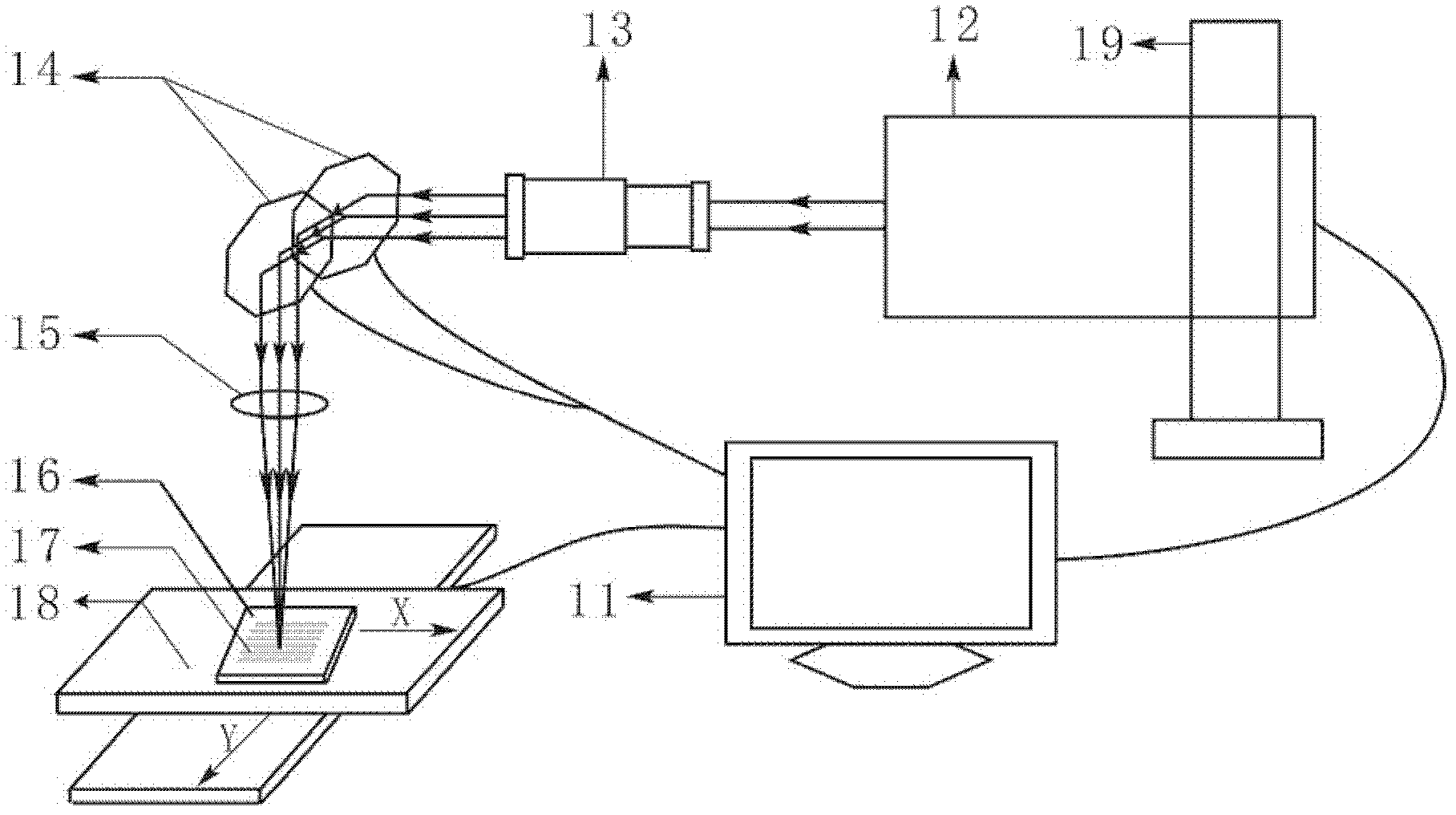

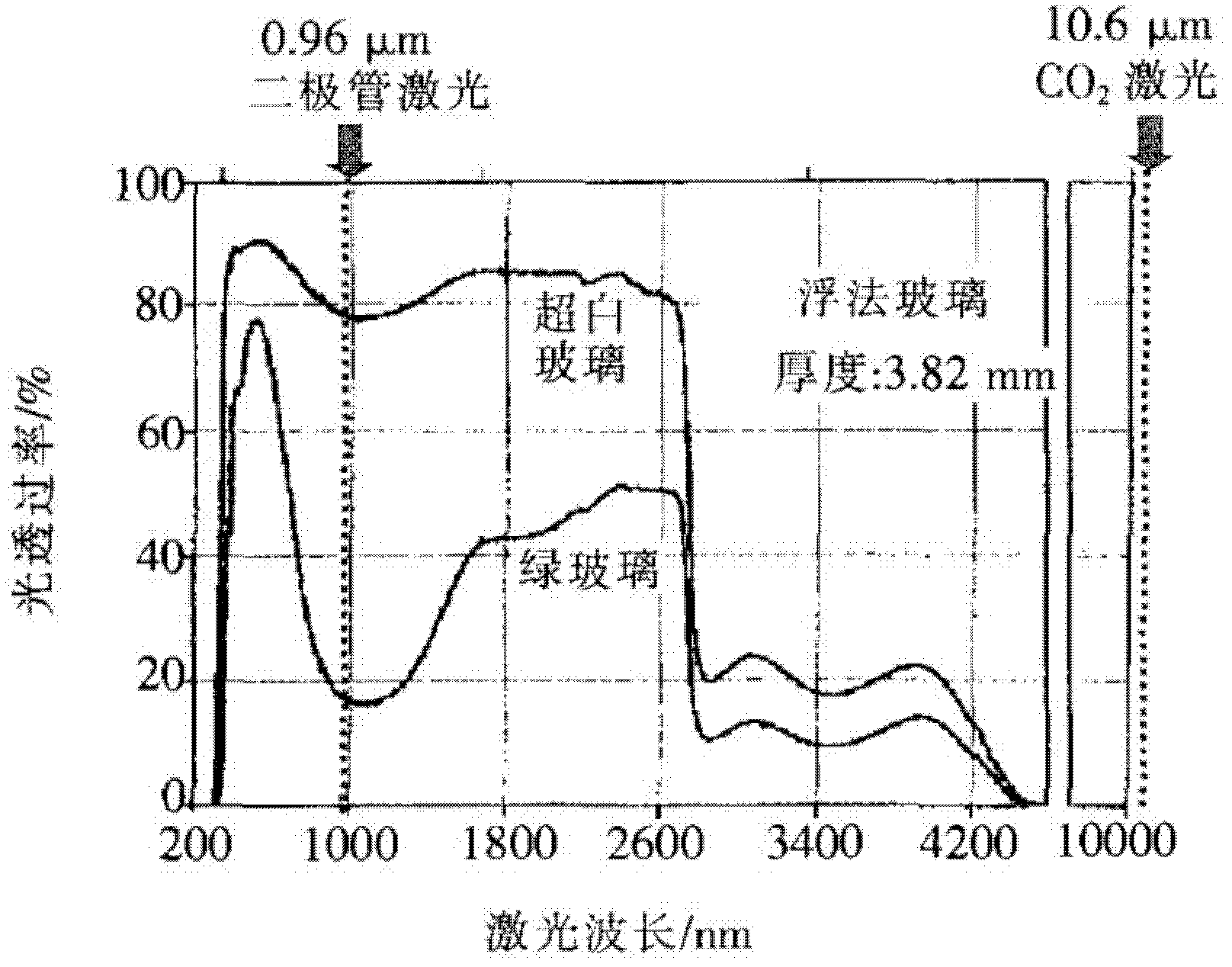

Manufacturing method of ground glass

ActiveCN103042310AImprove qualityImprove yieldLaser beam welding apparatusLaser etchingLaser processing

The invention is suitable for the technical field of laser machining and provides a manufacturing method of ground glass. The manufacturing method includes the following steps: presetting a laser etching pattern and technological parameters according to a ground pattern and a ground pattern effect; and placing glass to be processed on a working platform of a laser etching device, starting the laser etching device, and enabling a laser to be focused on the glass to be processed and scan the glass so as to form the ground pattern. The laser is used for performing non-contact process on common glass so as to enable the common glass to become the ground glass, a base body of the glass cannot be damaged, and the manufacturing method facilitates improvement of quality and finished product rate of the ground glass.

Owner:HANS LASER TECH IND GRP CO LTD

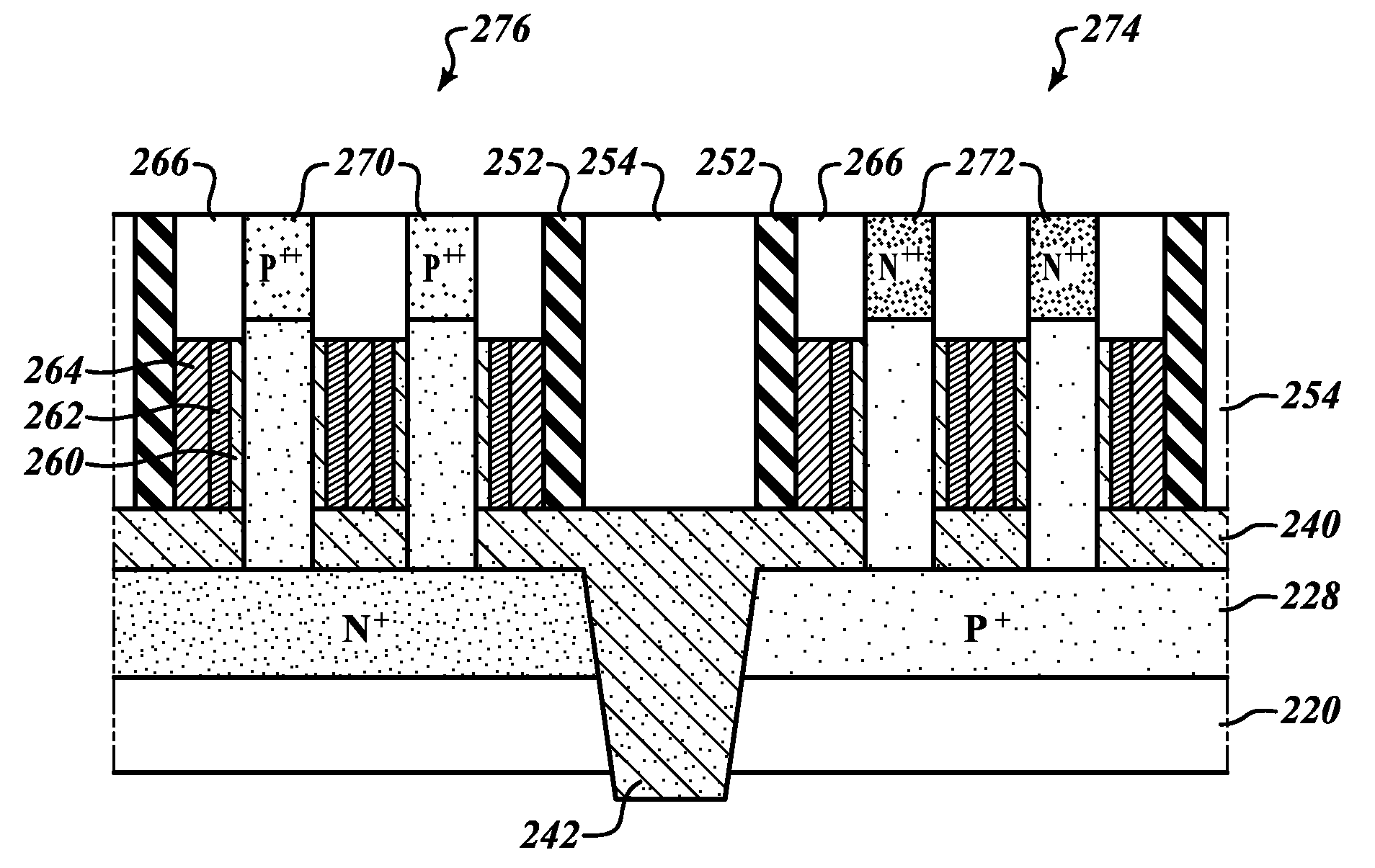

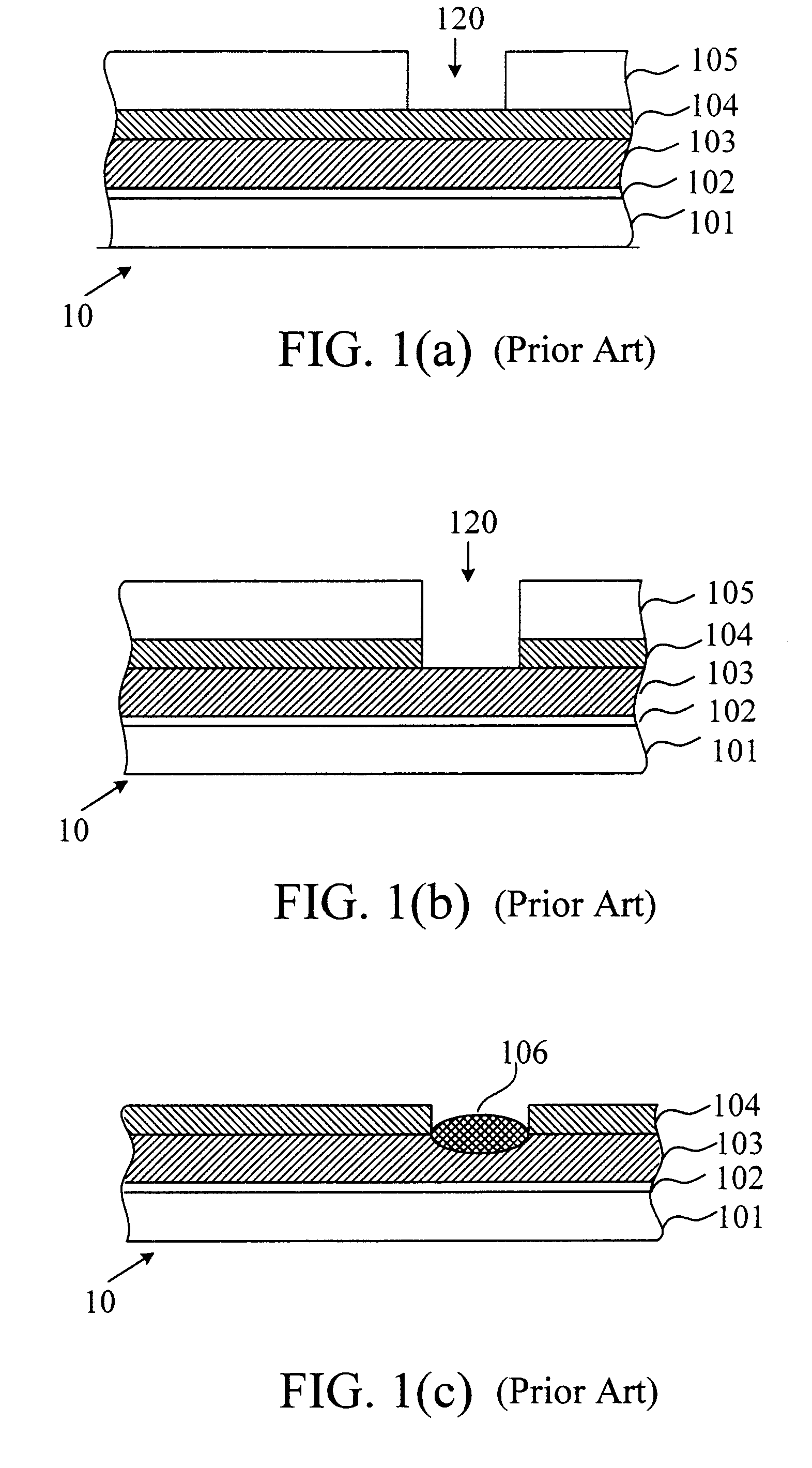

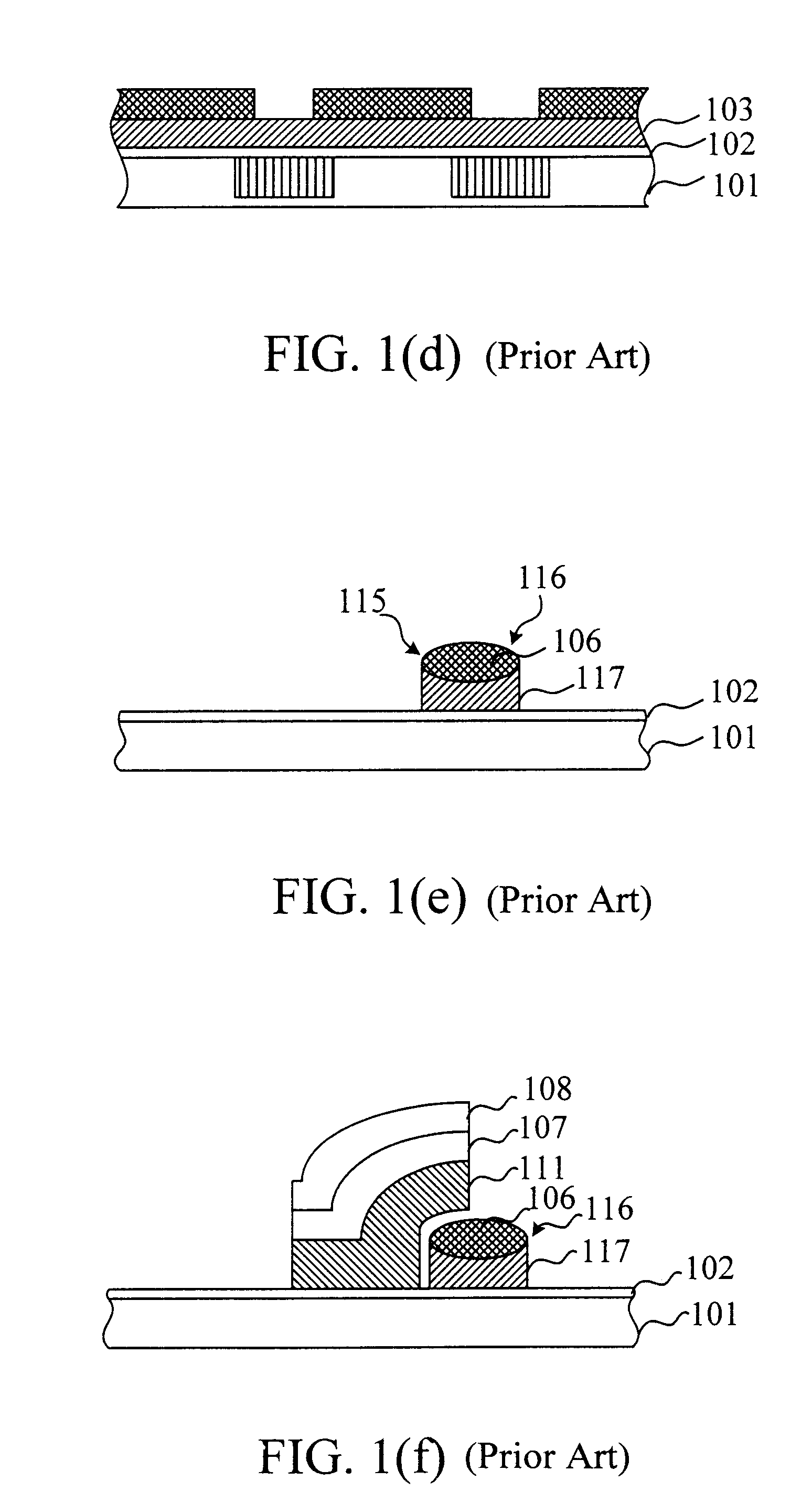

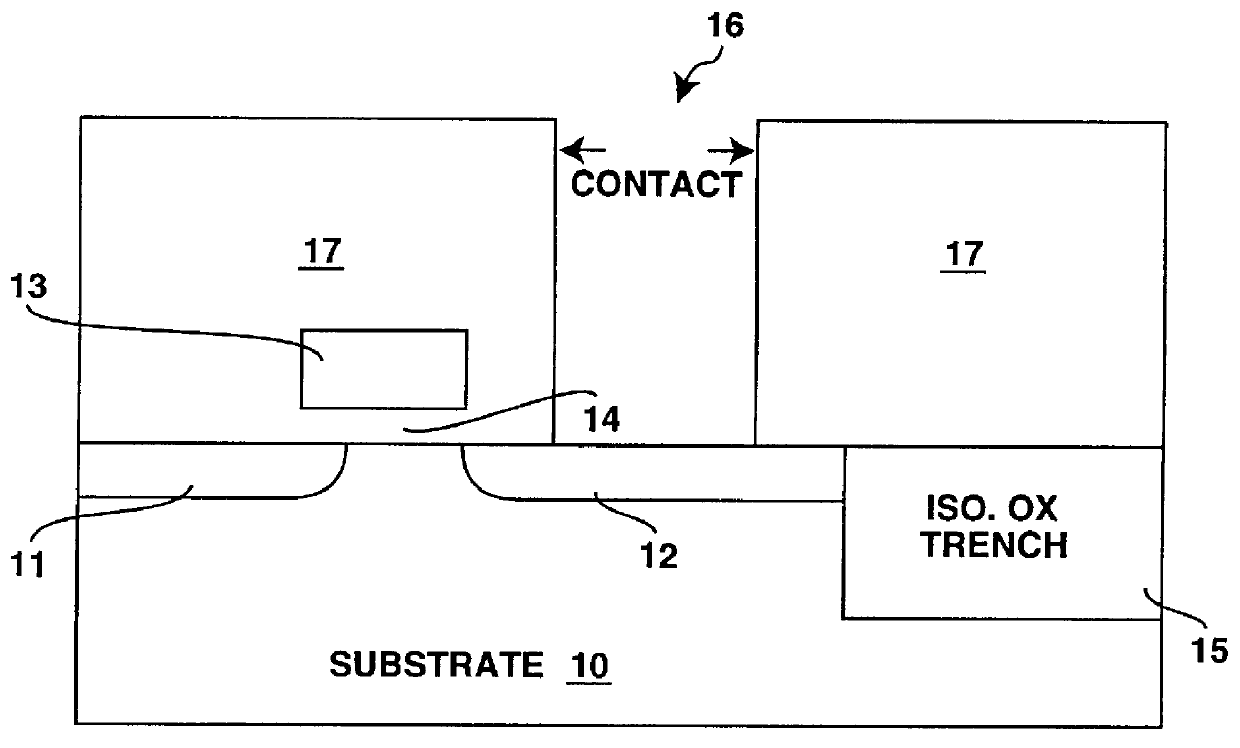

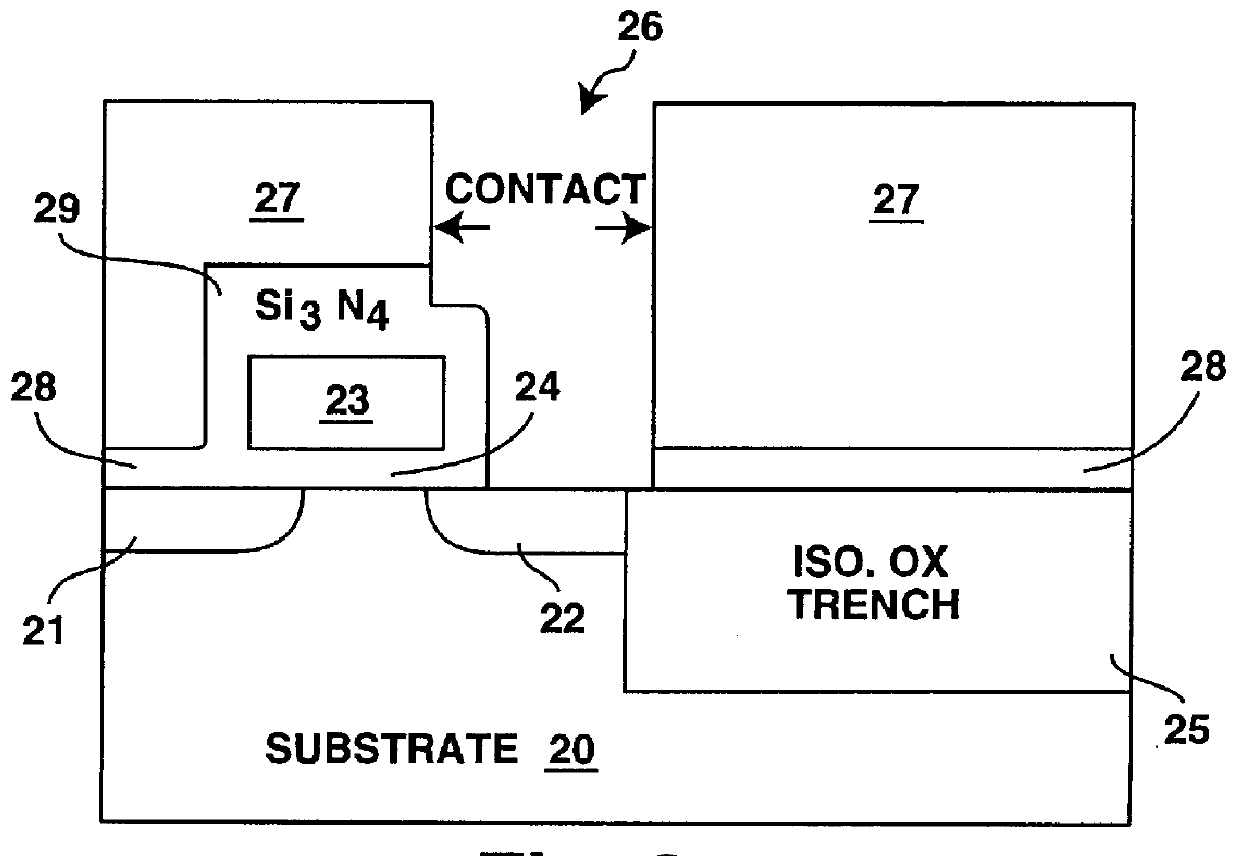

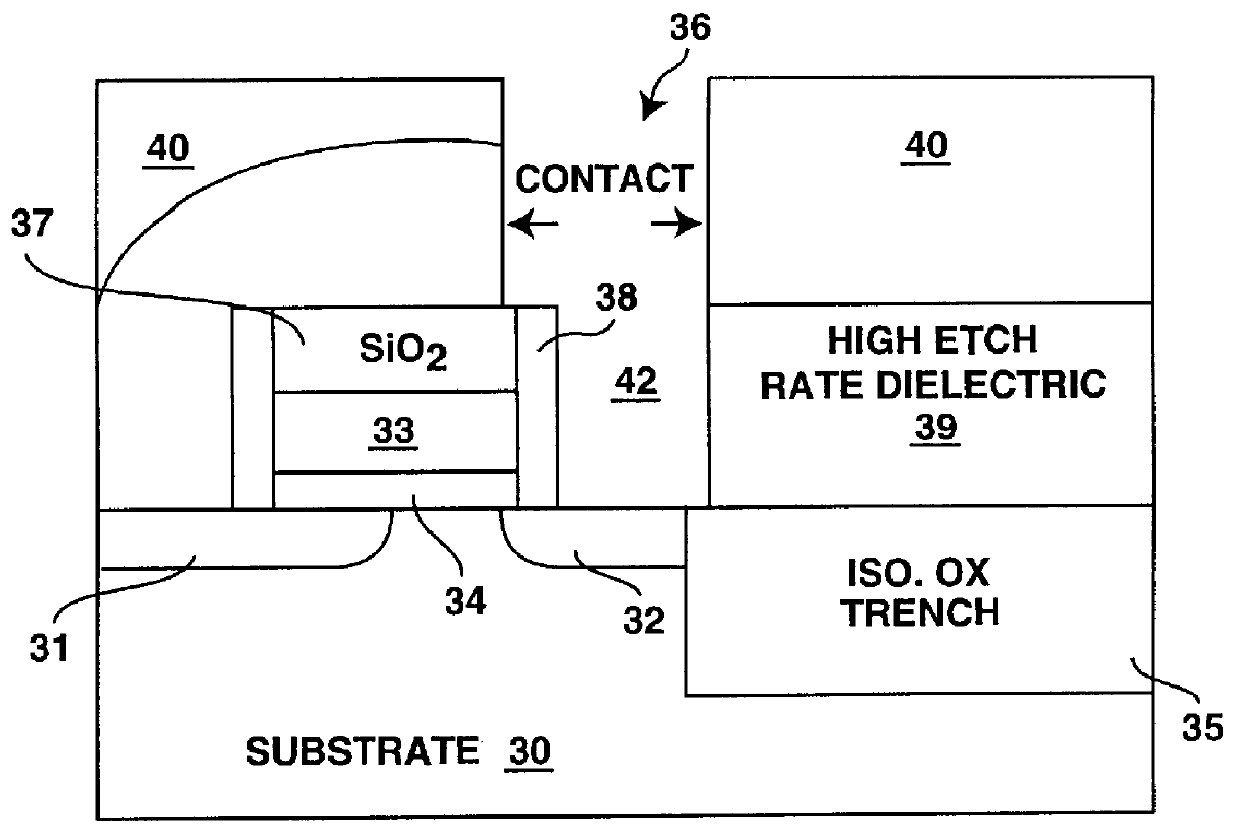

Self-aligned contact process using low density/low k dielectric

Method and apparatus for fabricating contacts to substrate regions through a low k, low density dielectric. A cap is formed over gates and side spacers are formed along the edges of the gates so as to surround the gates in a relatively dense (e.g., silicon dioxide) insulative material. A low k or low density layer of a polymer or silica aerogel or xerogel material is formed in contact with the substrate covering the gate structures including the spacers. An unlanded contact opening is etched through the low k, low density dielectric with an etchant that provides high selectivity between the insulation surrounding the gate and the low k, low density layer.

Owner:INTEL CORP +1

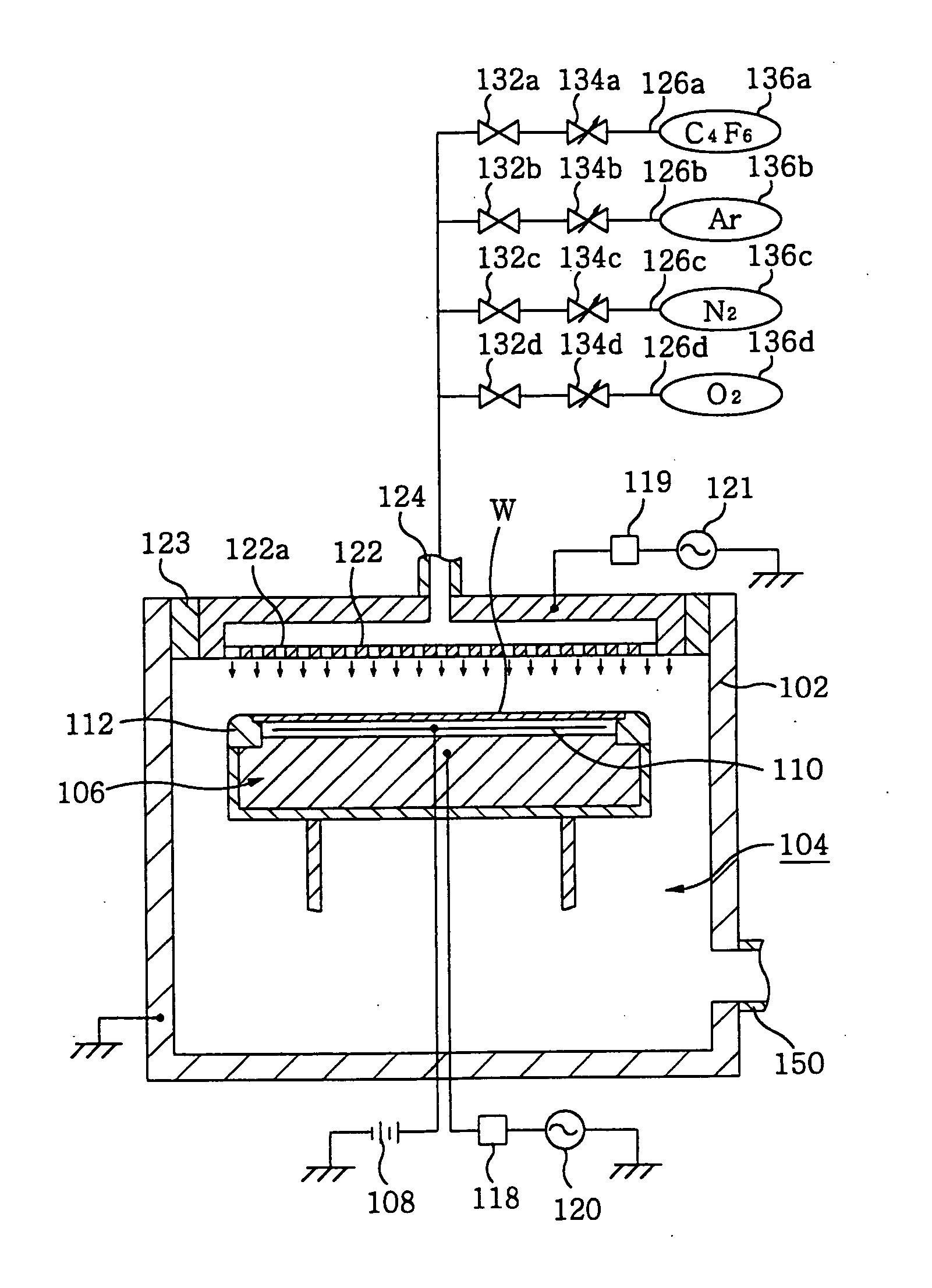

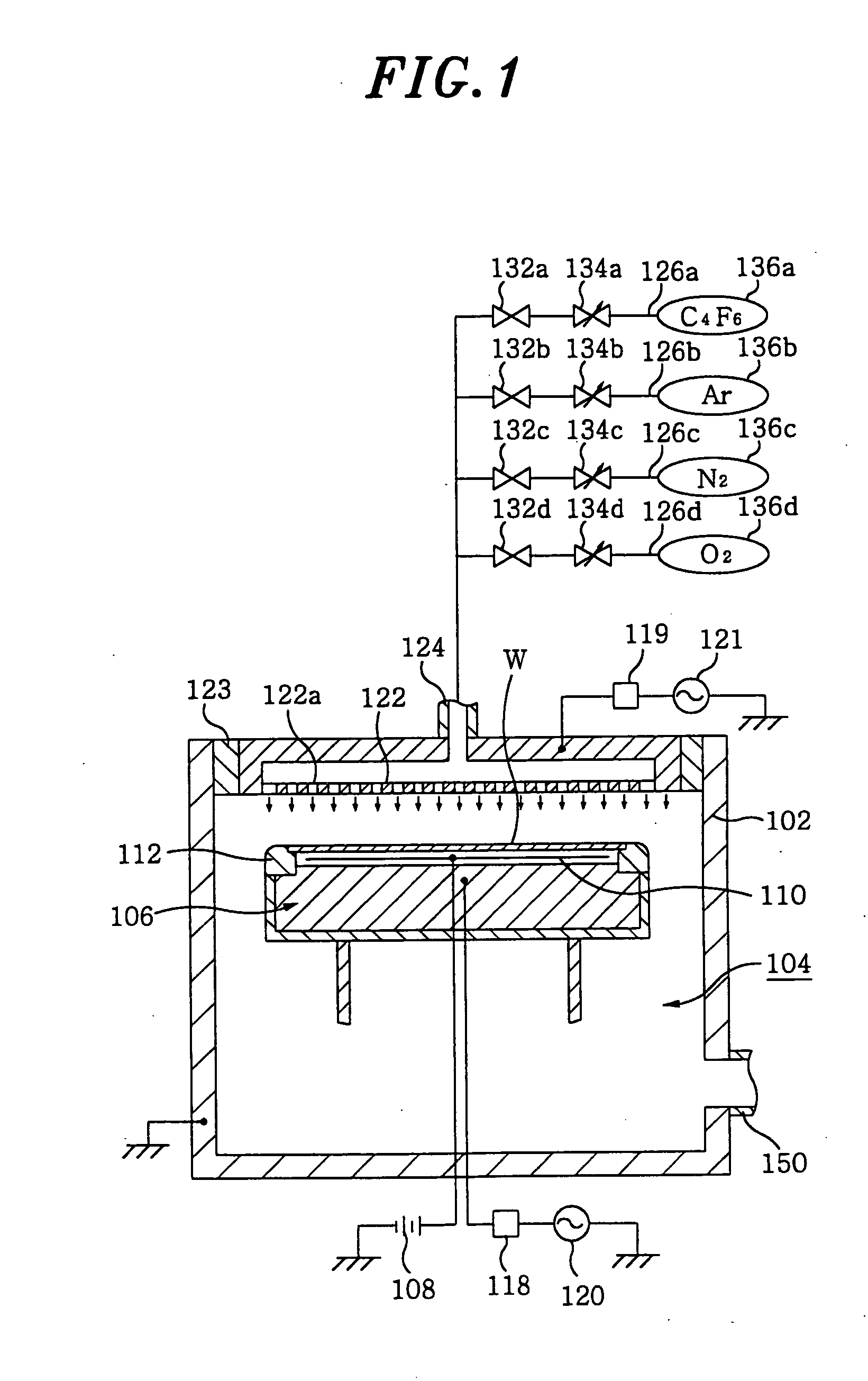

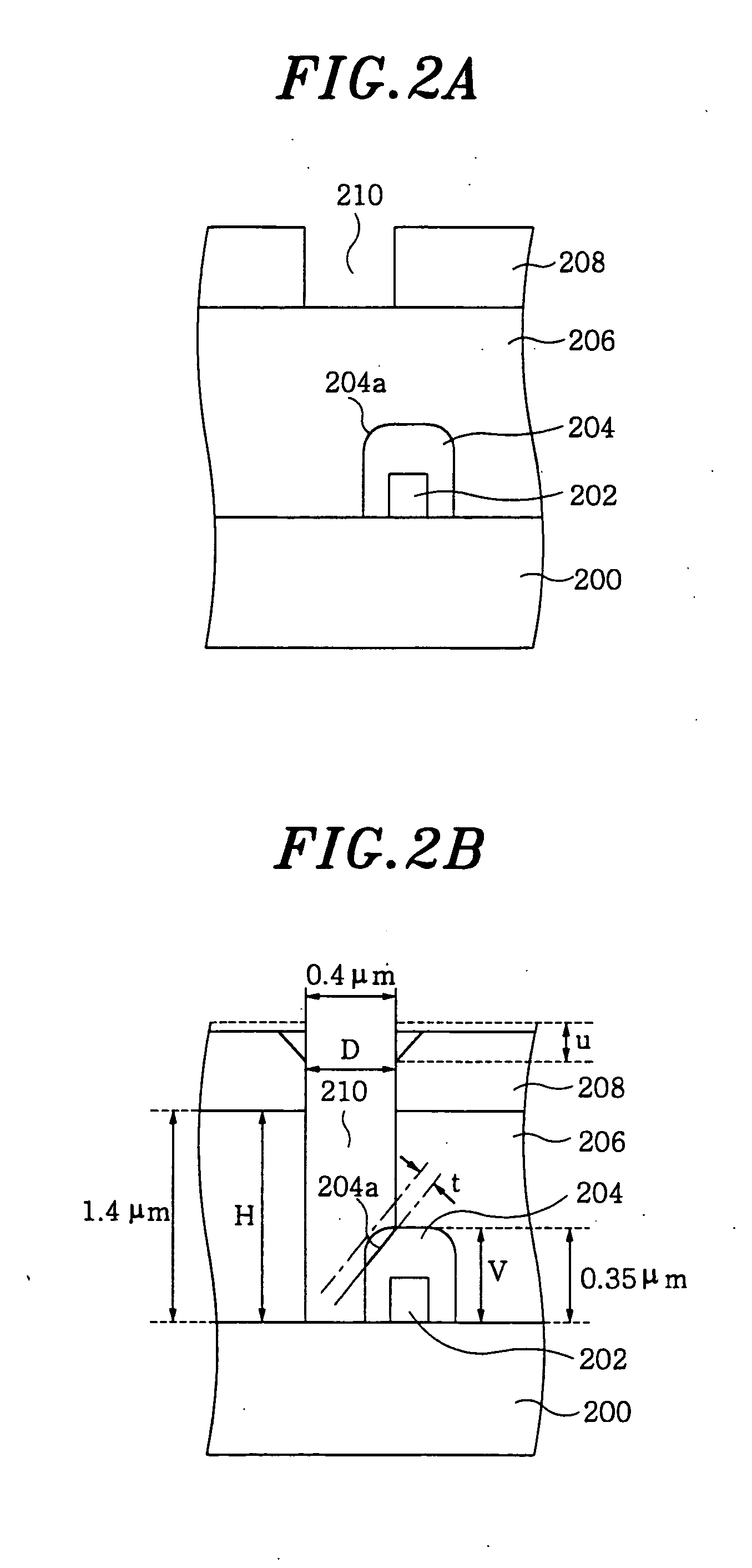

Method of etching and etching apparatus

InactiveUS20050042876A1Improve controllabilityHigh aspect ratioSemiconductor/solid-state device manufacturingSilicon oxideSelf alignment

Silicon oxide film having, as a sublayer, a silicon nitride film layer serving as a protective film layer for gate formed on silicon substrate is etched by introducing a processing gas including a gaseous mixture containing at least C4F6, Ar, O2 and N2 into an airtight processing chamber and carrying out a plasma treatment in a self-alignment contact process, thereby forming contact hole. For the processing gas, e.g., the ratio of N2 gas flow rate to C4F6 gas flow rate ranges from 25 / 8 to 85 / 8, the ratio of O2 and N2 gas flow rate to C4F6 gas flow rate ranges from 15 / 4 to 45 / 4 and the ratio of N2 gas flow rate to O2 gas flow rate ranges from 5 to 17. Accordingly, stable contact holes of high aspect ratio exhibiting desirable control characteristics is formed while minimizing etching the silicon nitride film, a protective film layer for gate.

Owner:TOKYO ELECTRON LTD

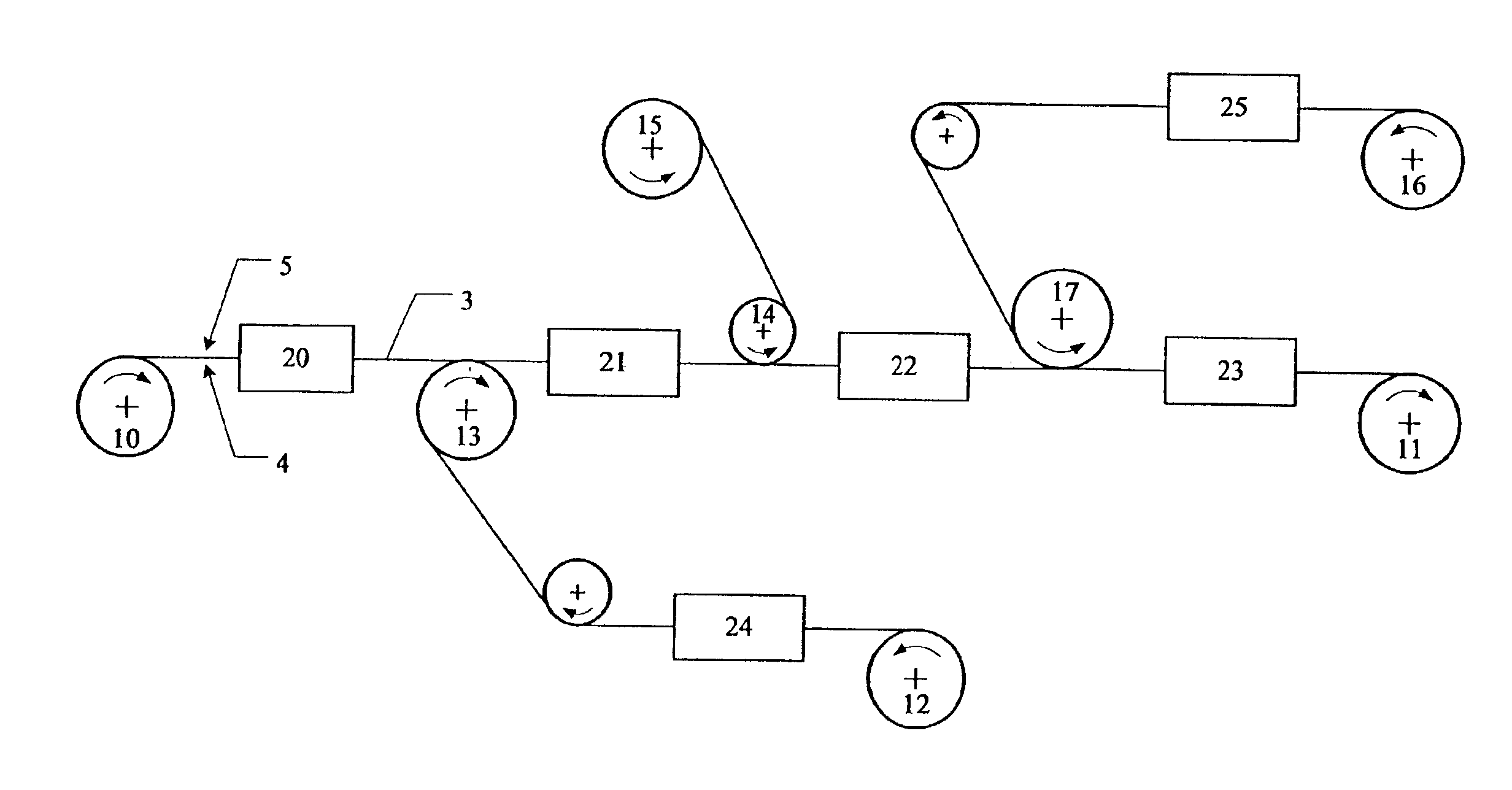

Multi step electrodeposition process for reducing defects and minimizing film thickness

ActiveUS6946066B2Semiconductor/solid-state device manufacturingPrinted circuit manufactureElectrochemistryMaterials science

The present invention relates to a method for forming a planar conductive surface on a wafer. In one aspect, the present invention uses a no-contact process with electrochemical deposition, followed by a contact process with electrochemical mechanical deposition.

Owner:NOVELLUS SYSTEMS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com