Patents

Literature

1110 results about "Plug valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plug valves are valves with cylindrical or conically tapered "plugs" which can be rotated inside the valve body to control flow through the valve. The plugs in plug valves have one or more hollow passageways going sideways through the plug, so that fluid can flow through the plug when the valve is open. Plug valves are simple and often economical.

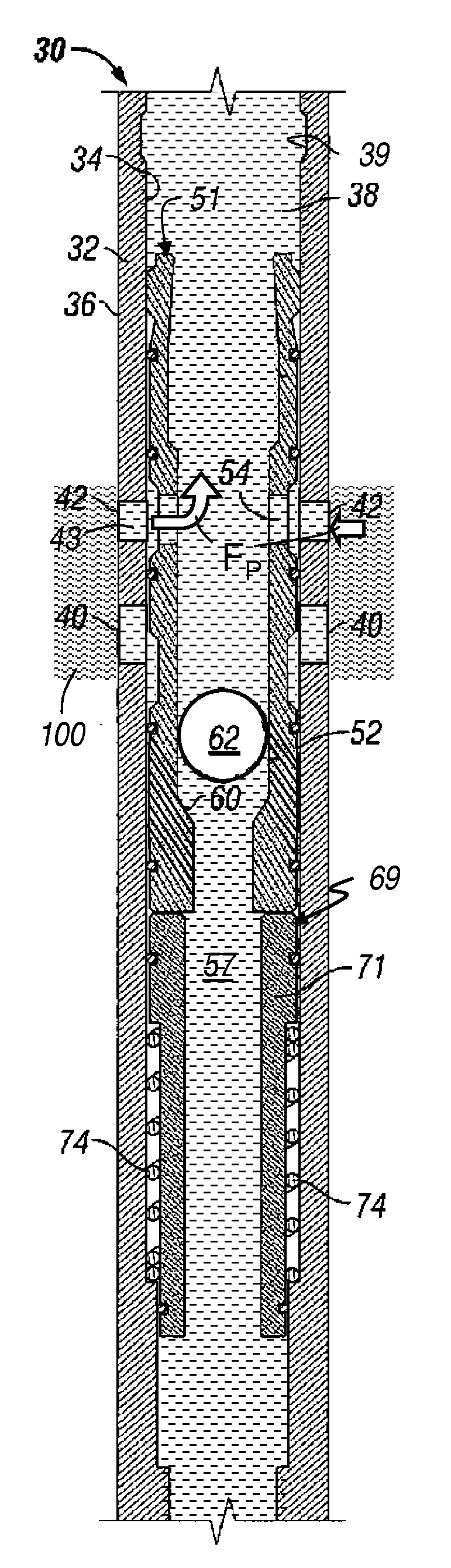

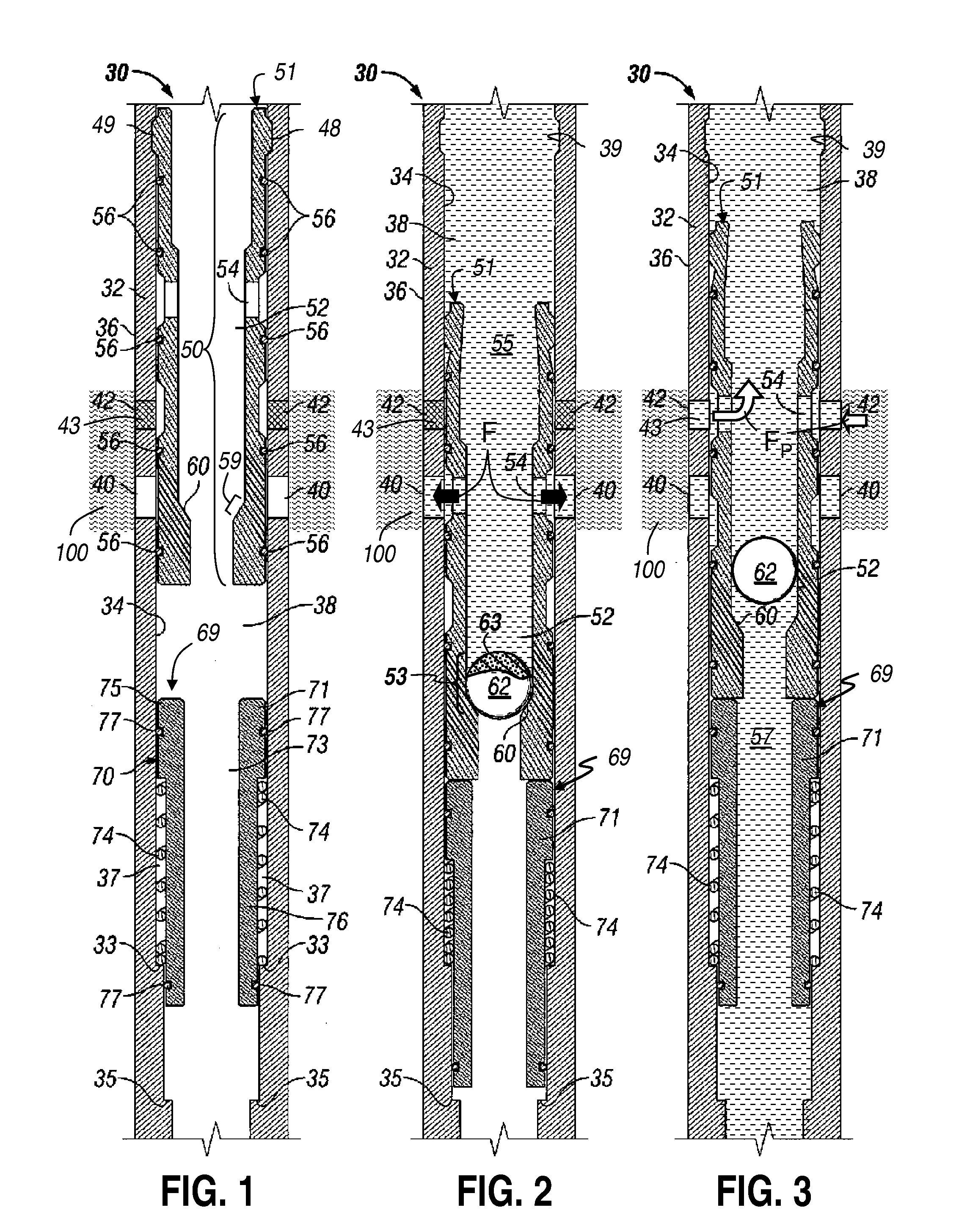

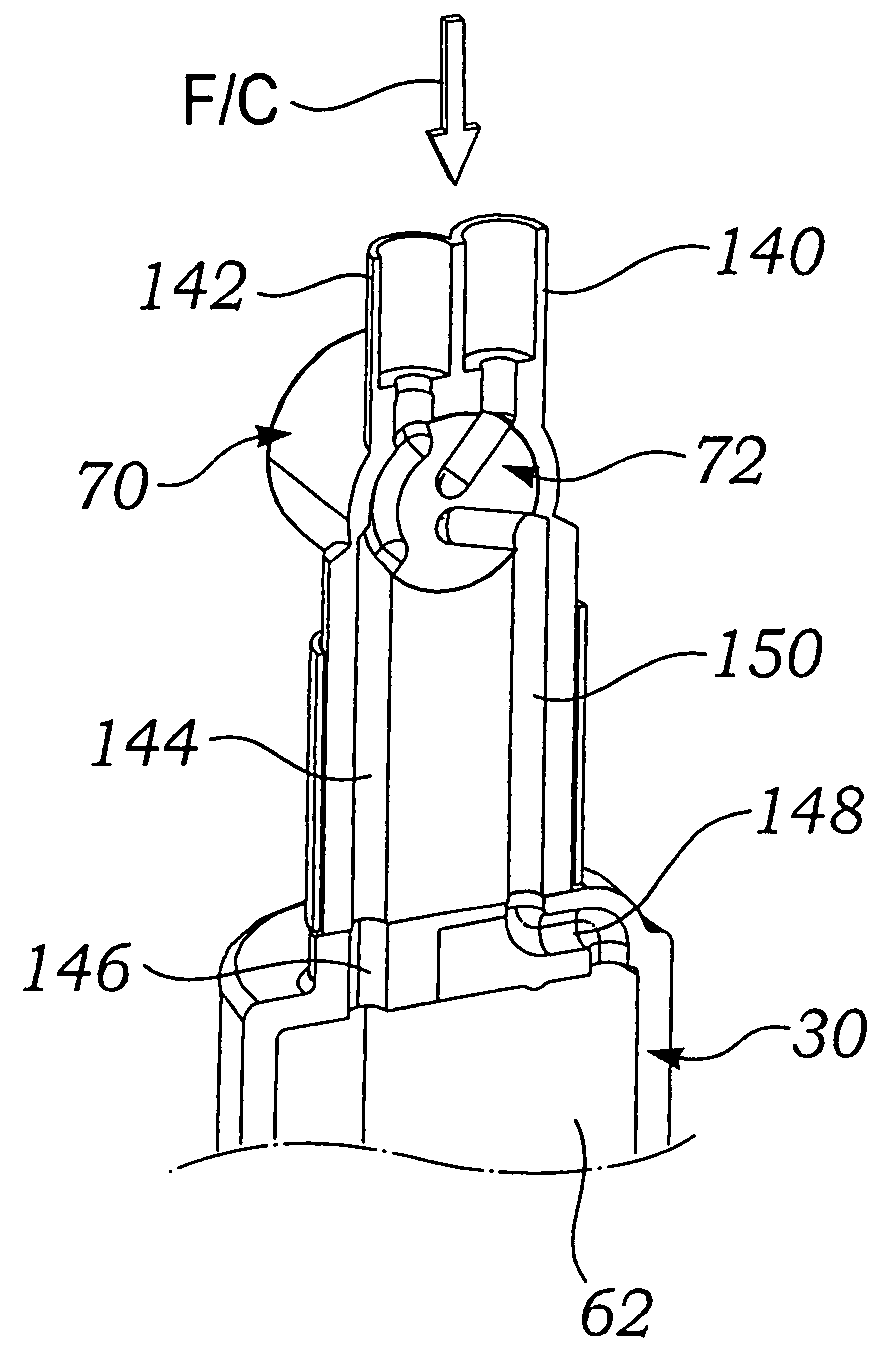

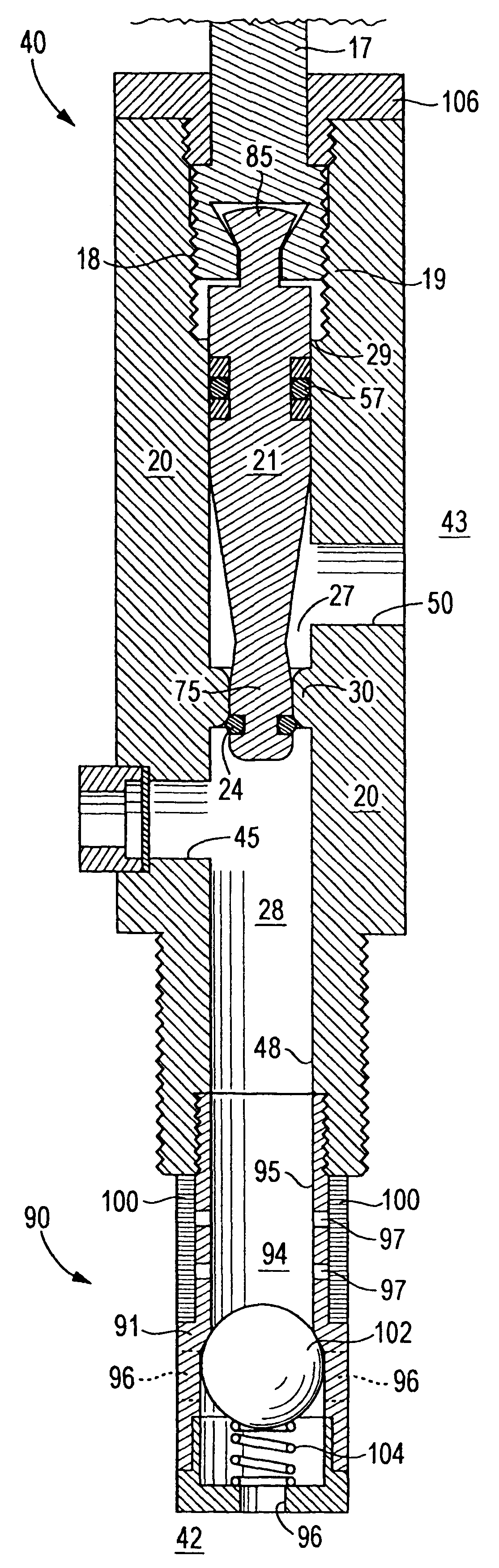

Disposable Downhole Tool

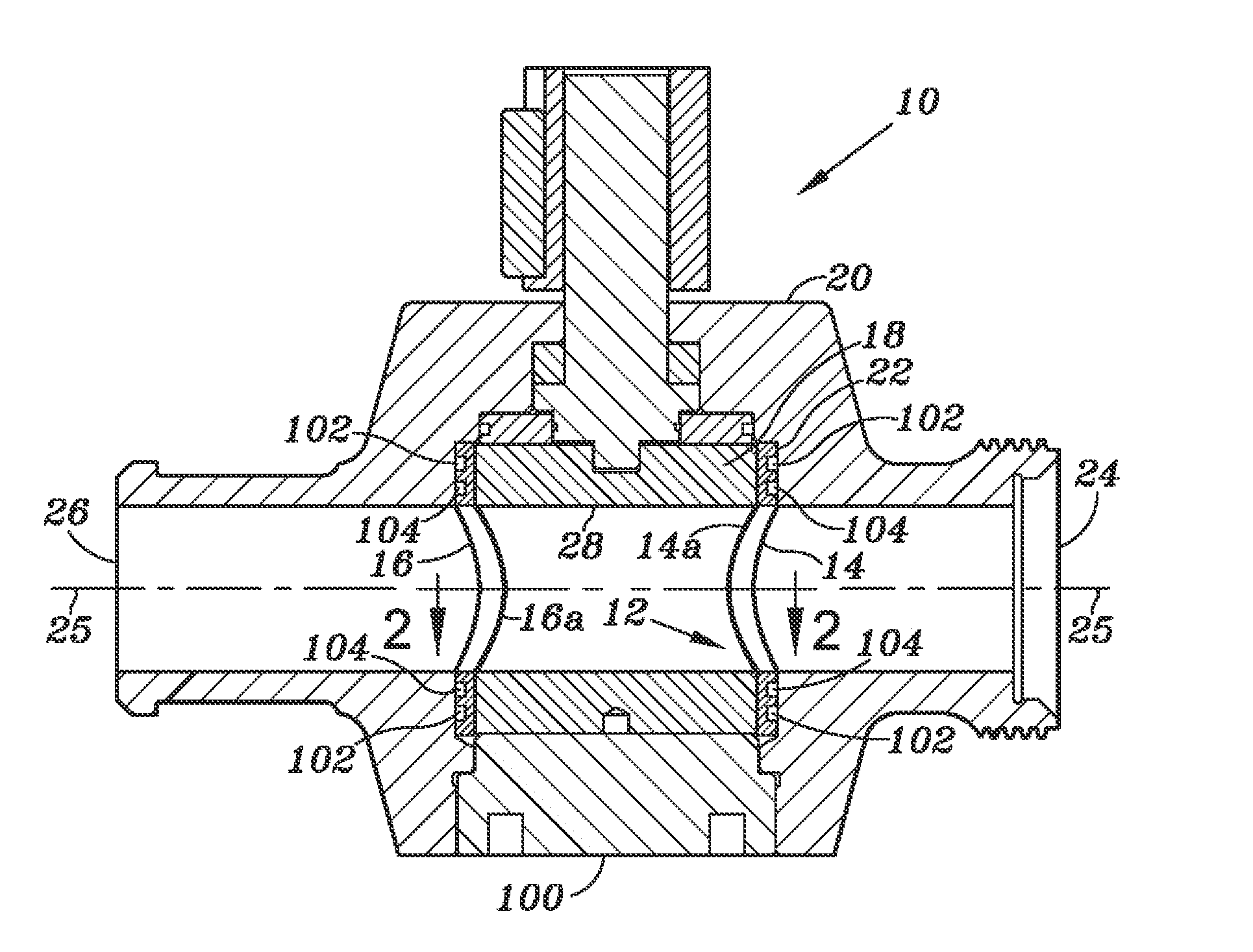

A disposable downhole tool is disclosed. The tool is suitable for use as a frac tool. The tool includes a housing having an inner wall surface defining a bore. The tool also includes a valve structure disposed within the bore, the valve structure comprising a disposable plug seat, the disposable plug seat comprising a first natural material. The disposable tool may also include a disposable plug in fluid sealing engagement with the seat, the plug comprising a second natural material, the plug and the plug seat comprising a plug valve. The first and second natural materials may include sedimentary rock, such as various forms of limestone, including Carrara marble or Indiana limestone.

Owner:BAKER HUGHES INC

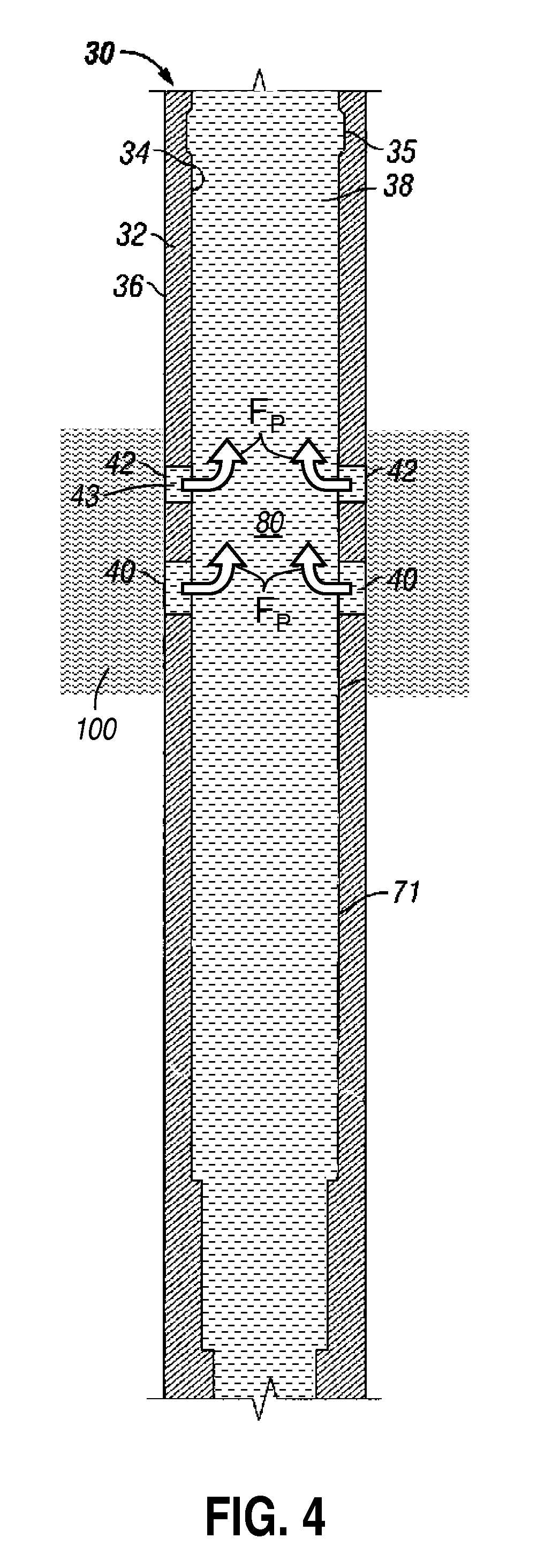

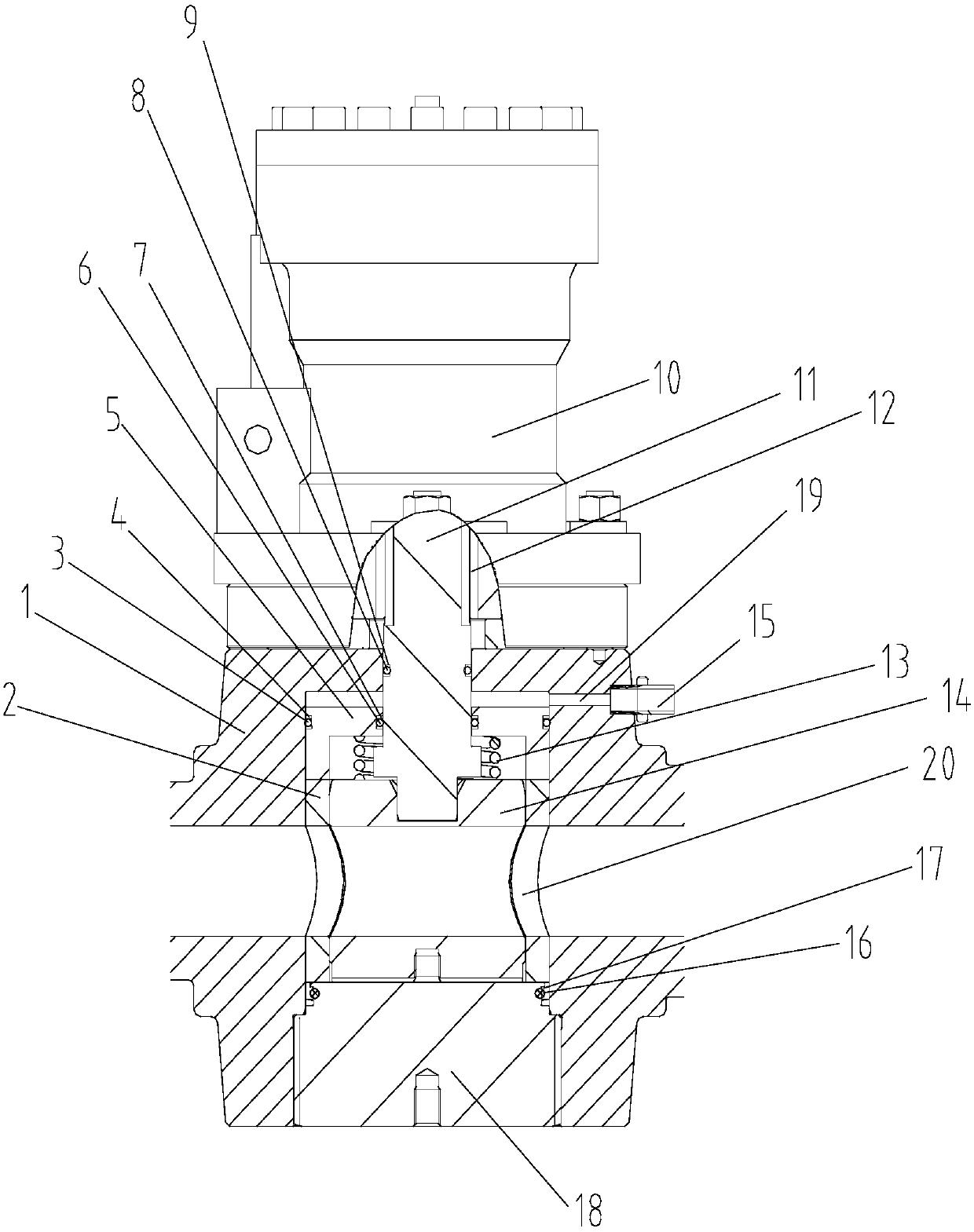

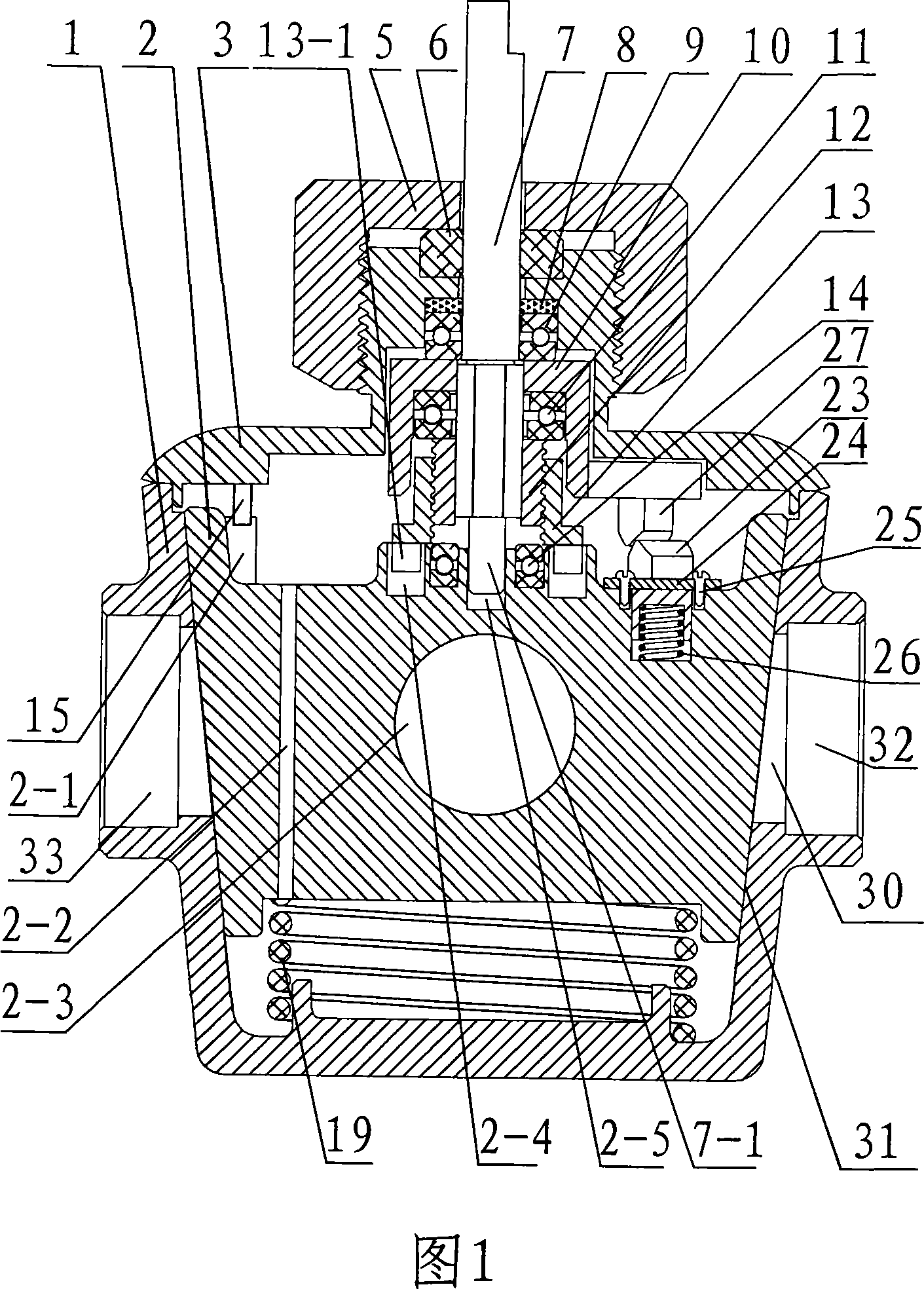

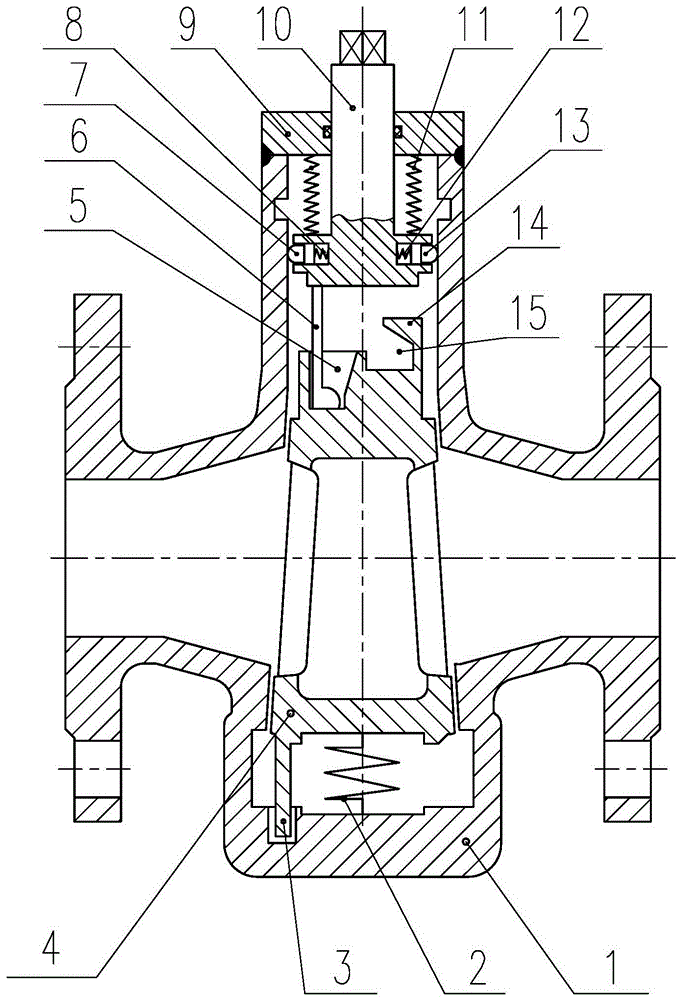

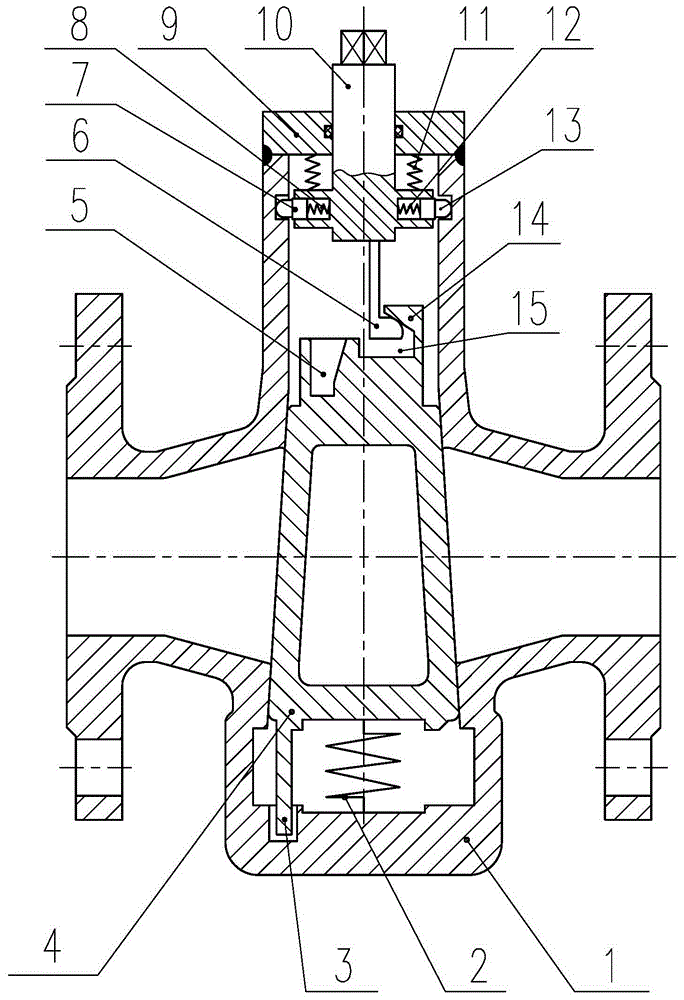

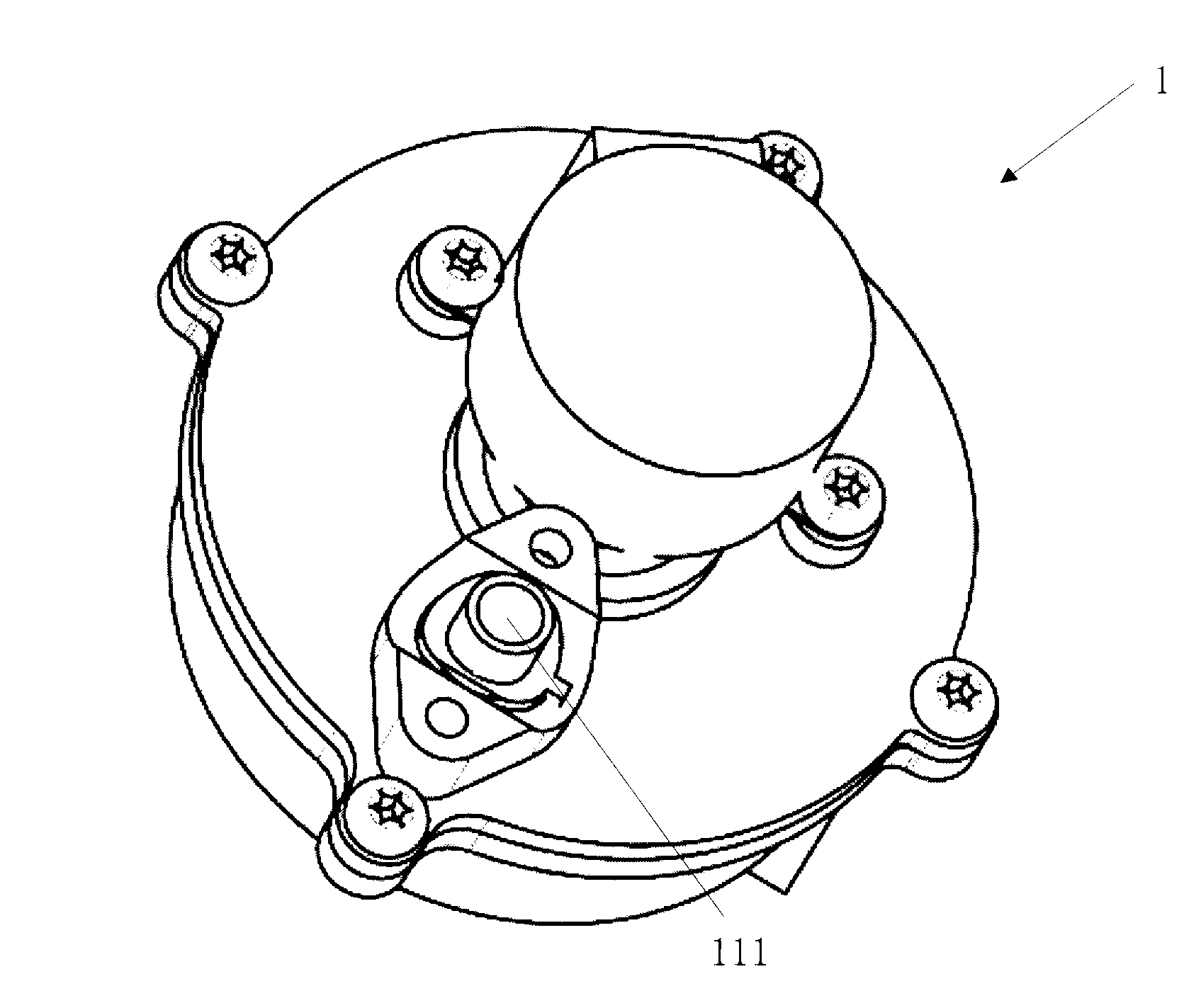

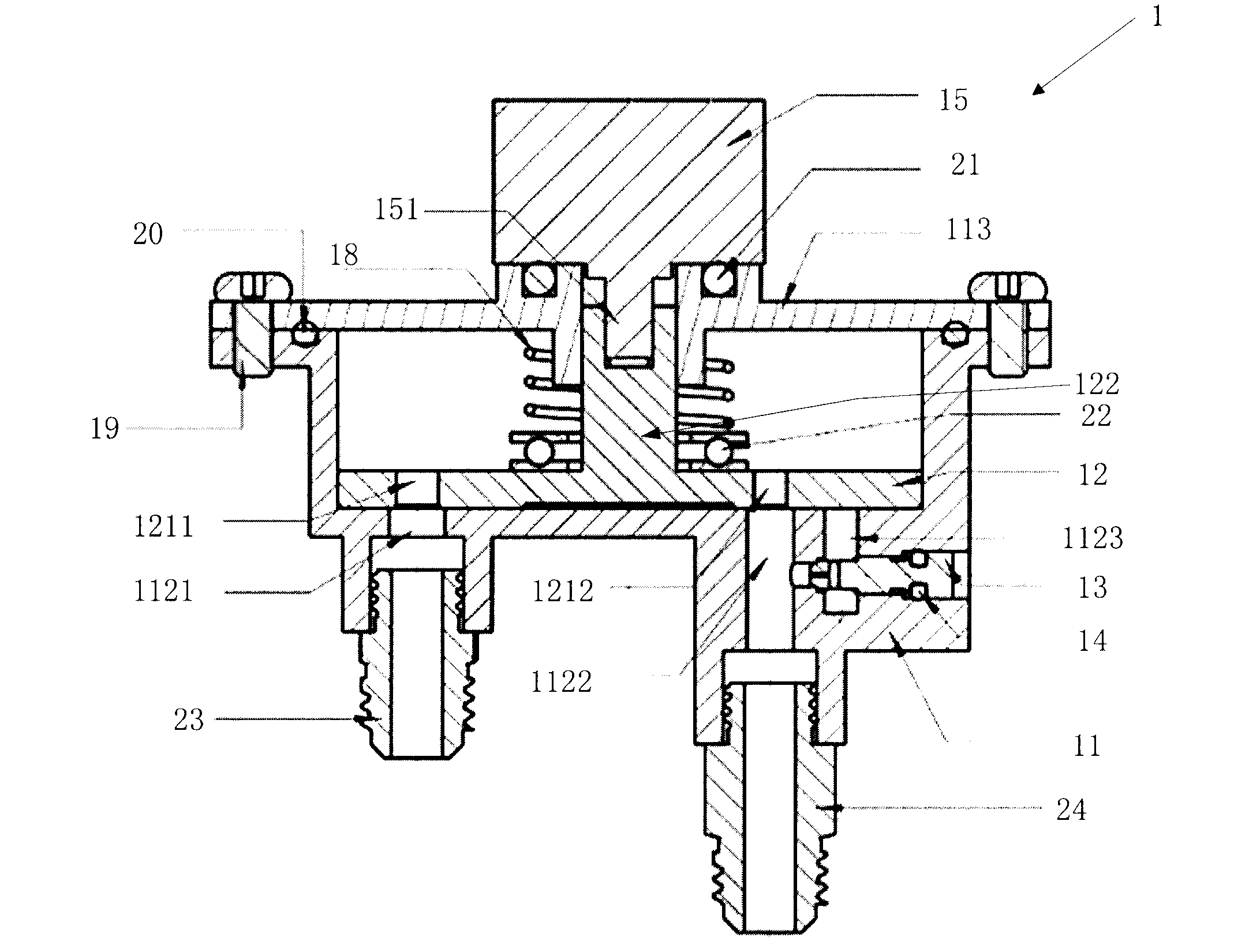

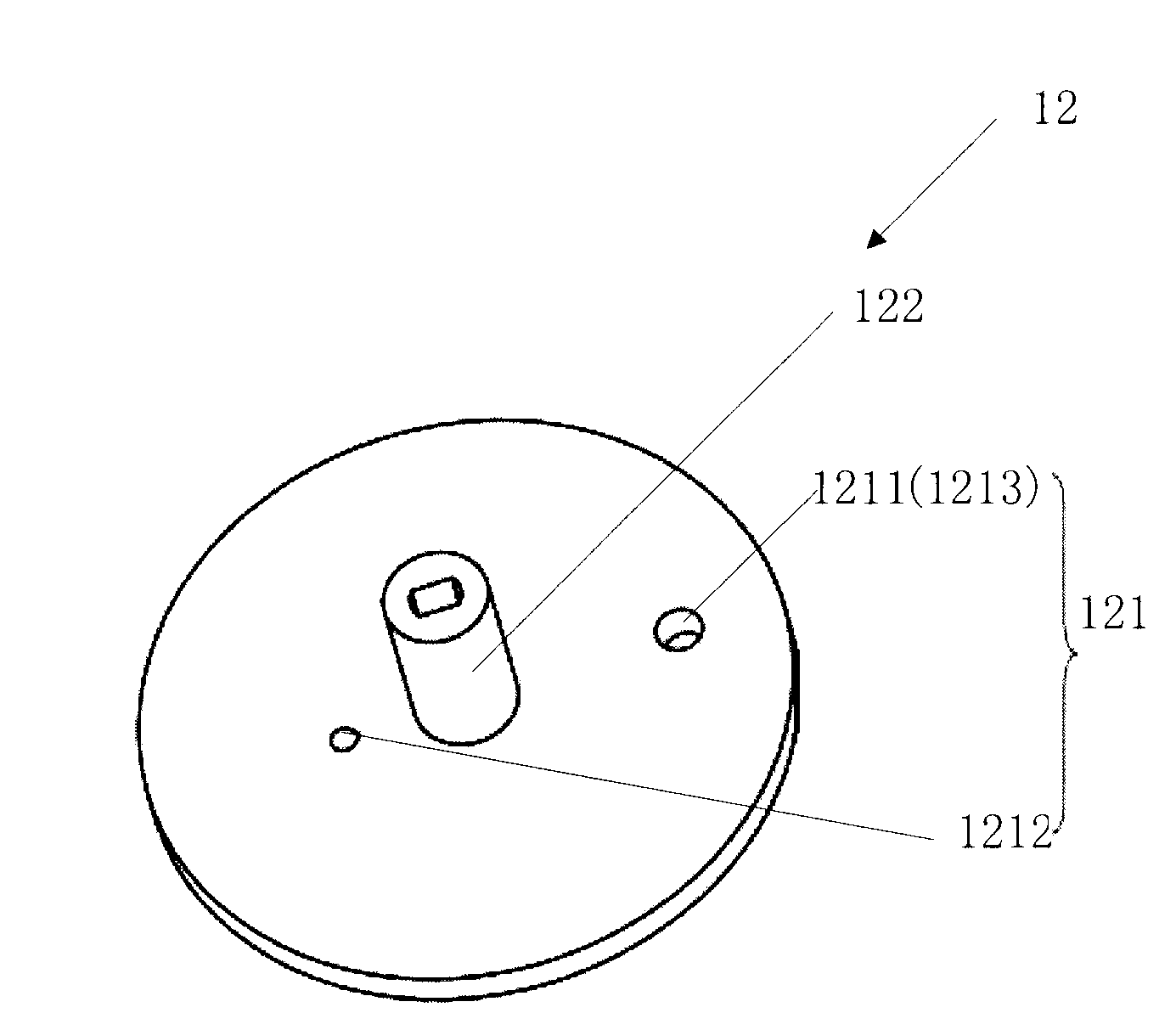

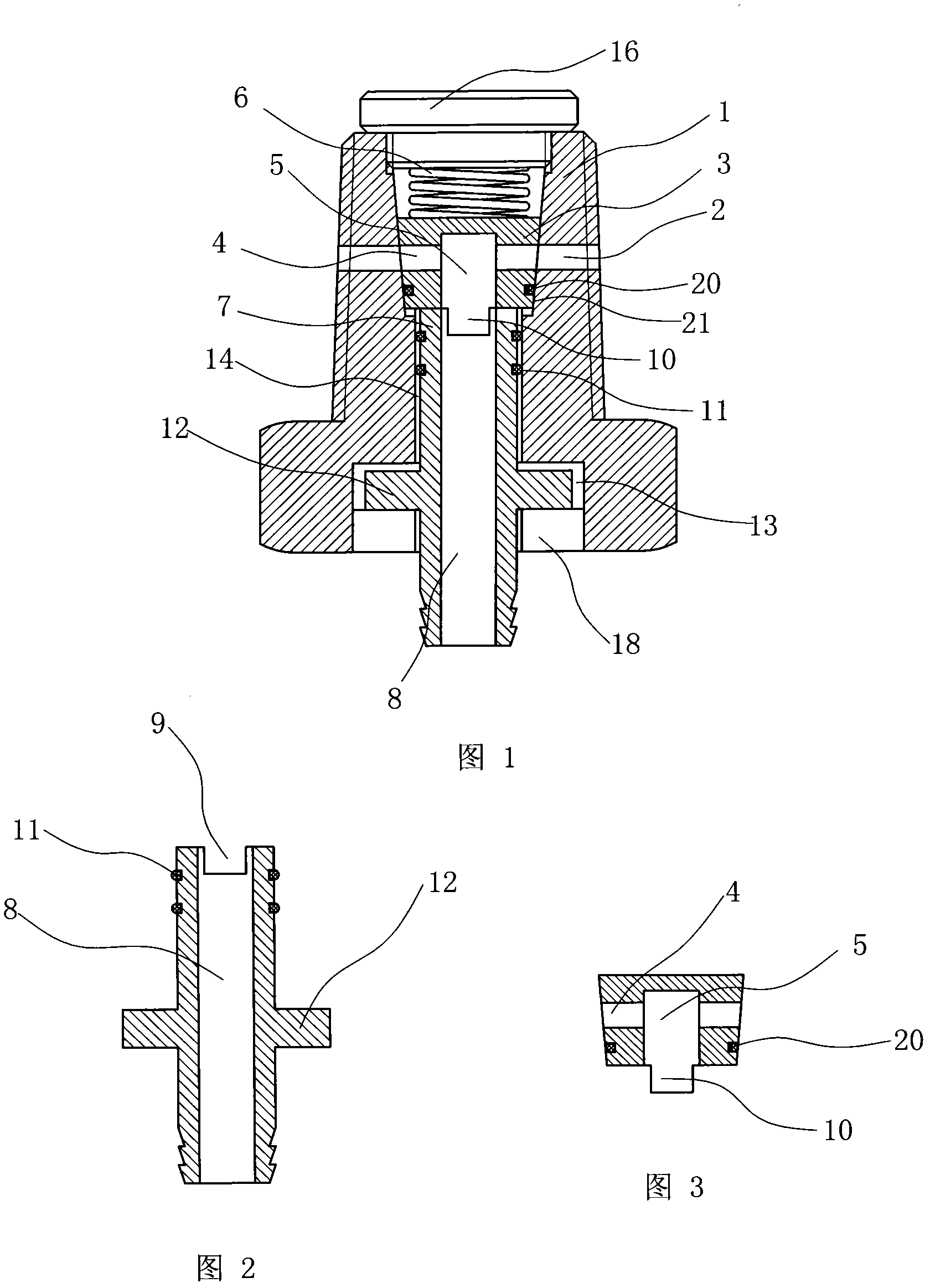

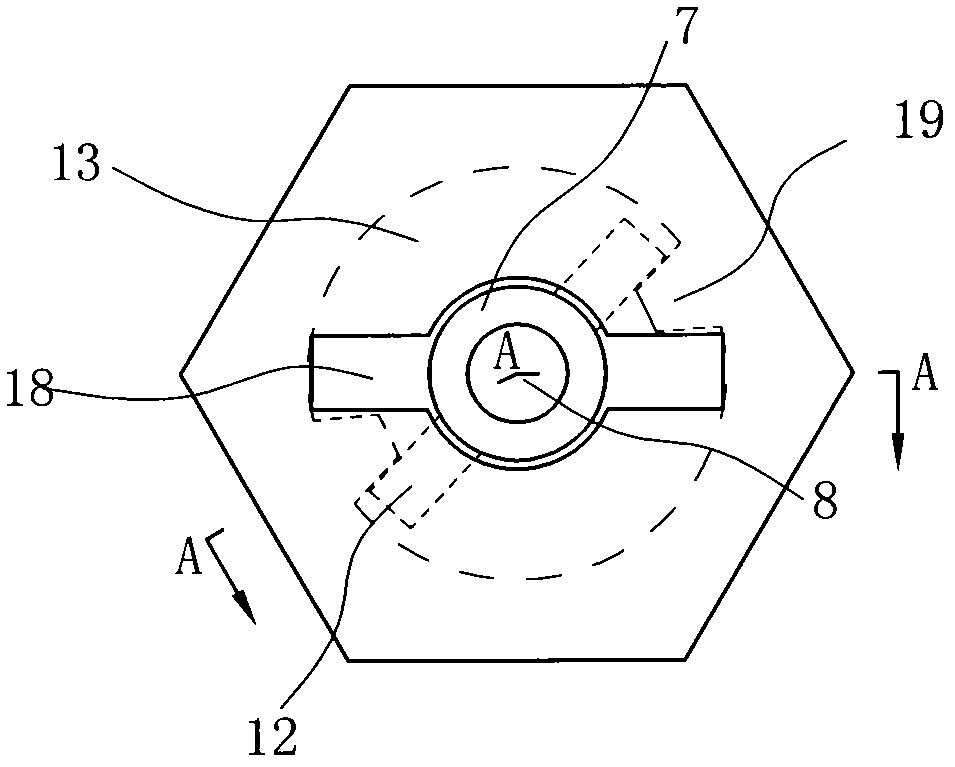

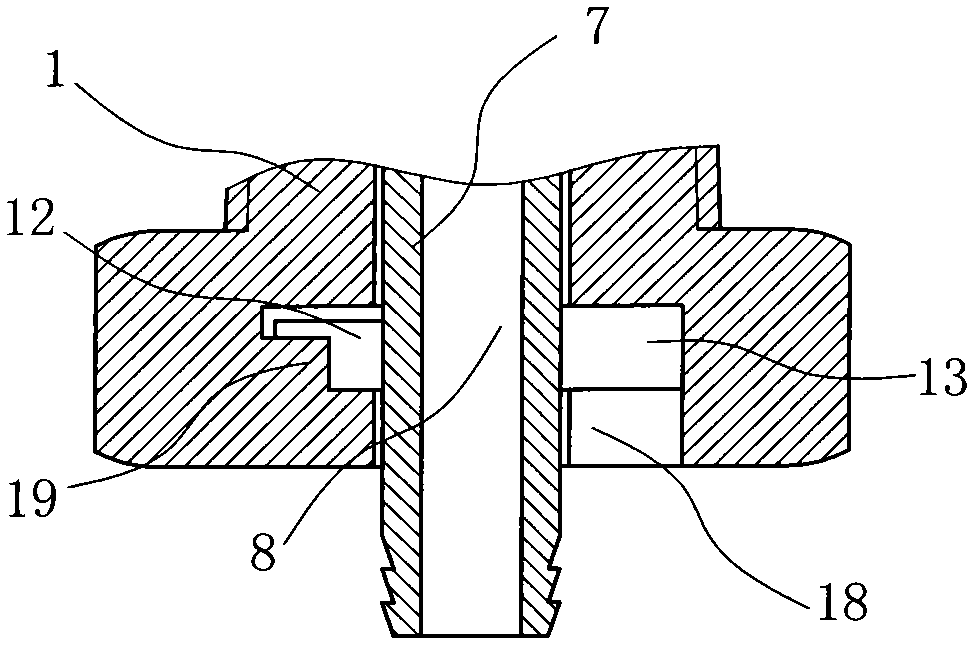

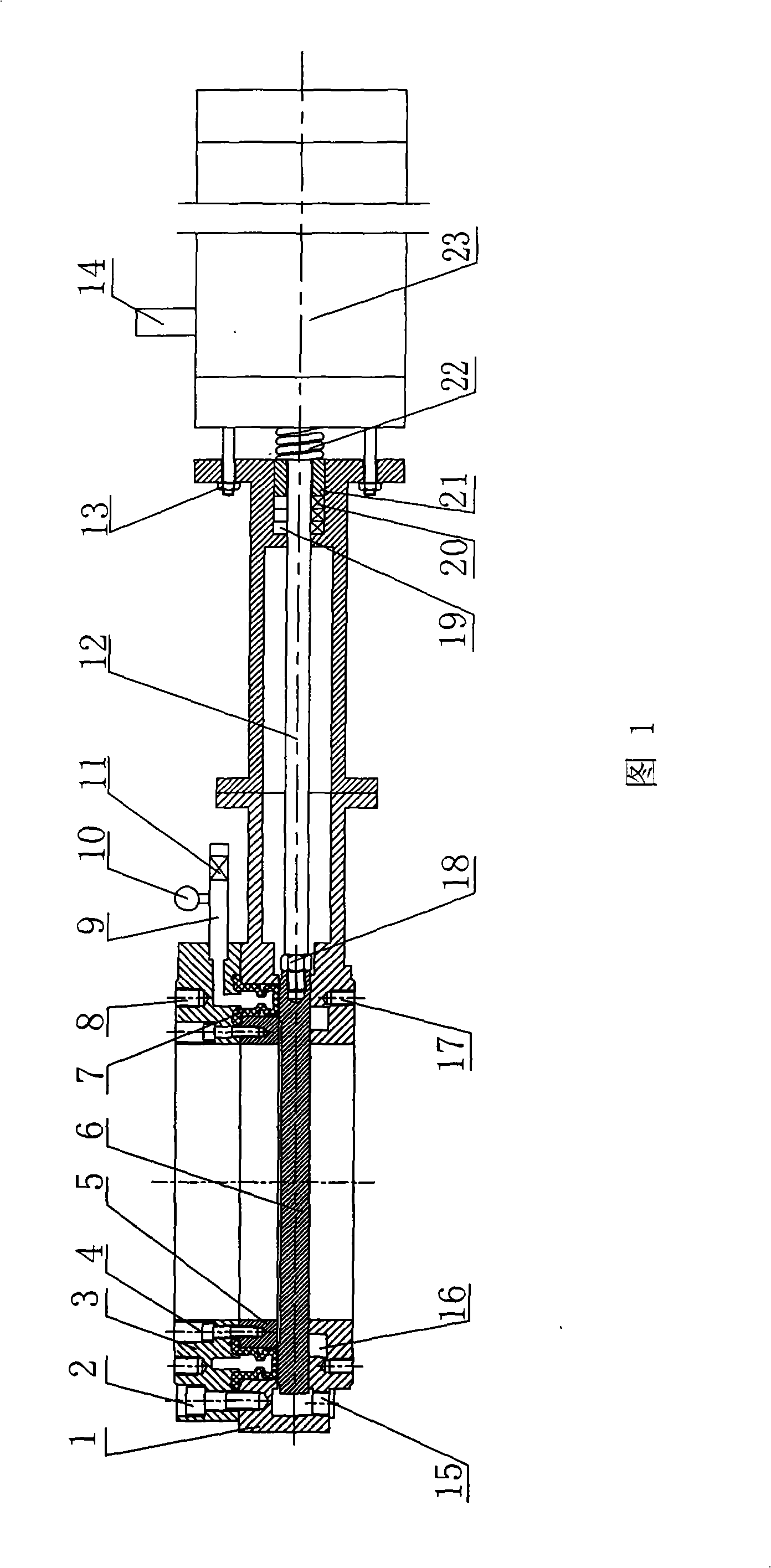

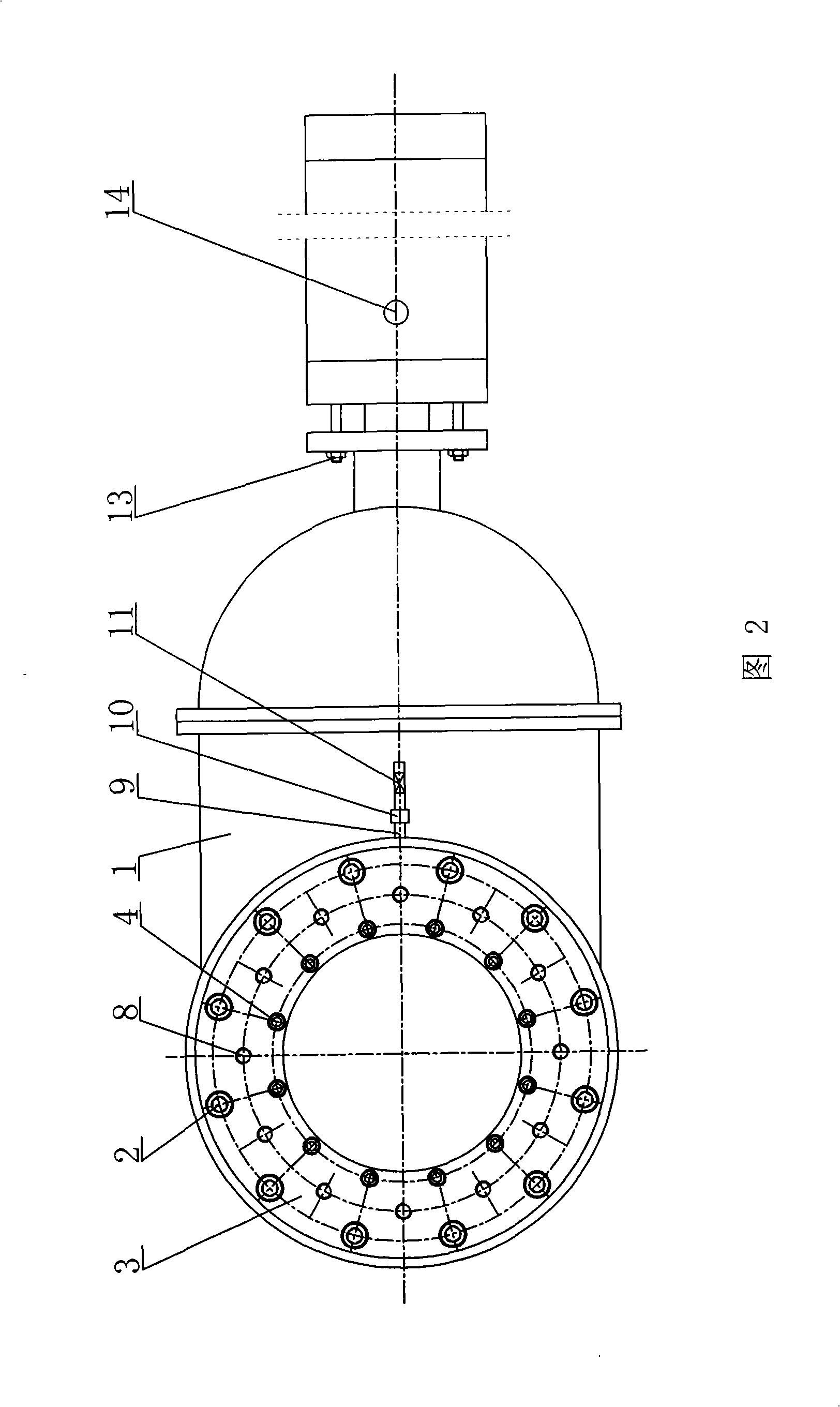

Anti-sand-accumulation plug valve

ActiveCN108036071AClearance adjustableGap noSpindle sealingsPlug valvesEngineeringMechanical engineering

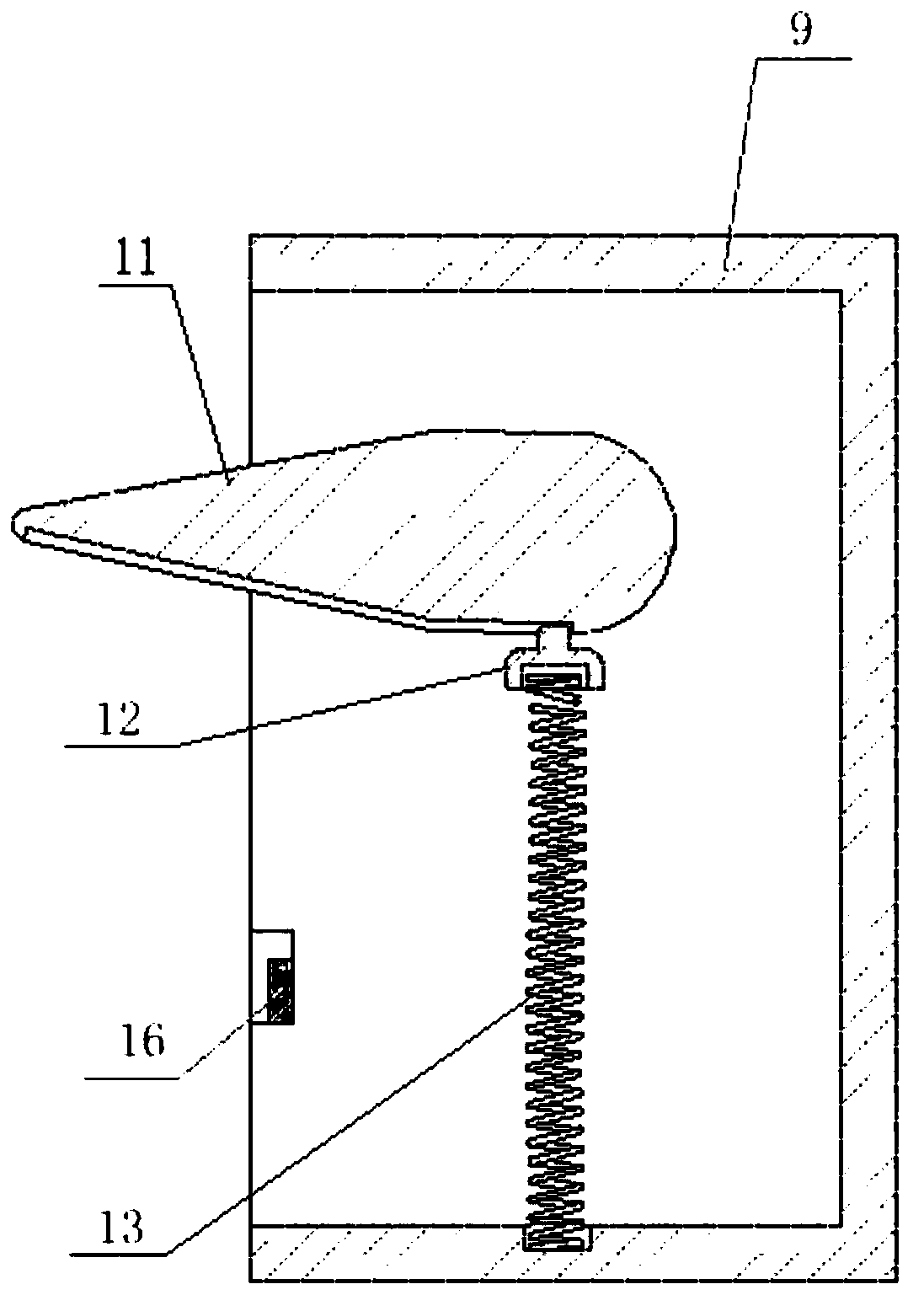

The invention relates to the technical field of oil-gas field construction operation equipment, in particular to an anti-sand-accumulation plug valve which comprises a valve body, a valve cover and aplug rod arranged in the valve body. The valve body is connected with the valve cover; the lower end part of the plug rod is connected with a plug; a driver is arranged on the upper end part of the valve body and is connected with the valve body; the driver transmits a torque to the plug rod through a flat key; a sealing rubber core is arranged on the outer part of the plug; a piston is arranged on the upper part of the sealing rubber core; an annular seal cavity is formed among the plug, the plug rod and the piston; a spring is arranged in the seal cavity; the piston, the plug rod, the sealing rubber core and the plug are located in an inner core of the valve body; the inner core of the valve body communicates with an oil passage; and the oil passage is filled with hydraulic oil for driving the piston to move up and down. According to the anti-sand-accumulation plug valve provided by the invention, a gap between the sealing rubber core and the plug can be adjusted, and no gap exists among the plug, the sealing rubber core and the valve body during a pressure-bearing and fluid conveying process, so that sand is prevented from being accumulated.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

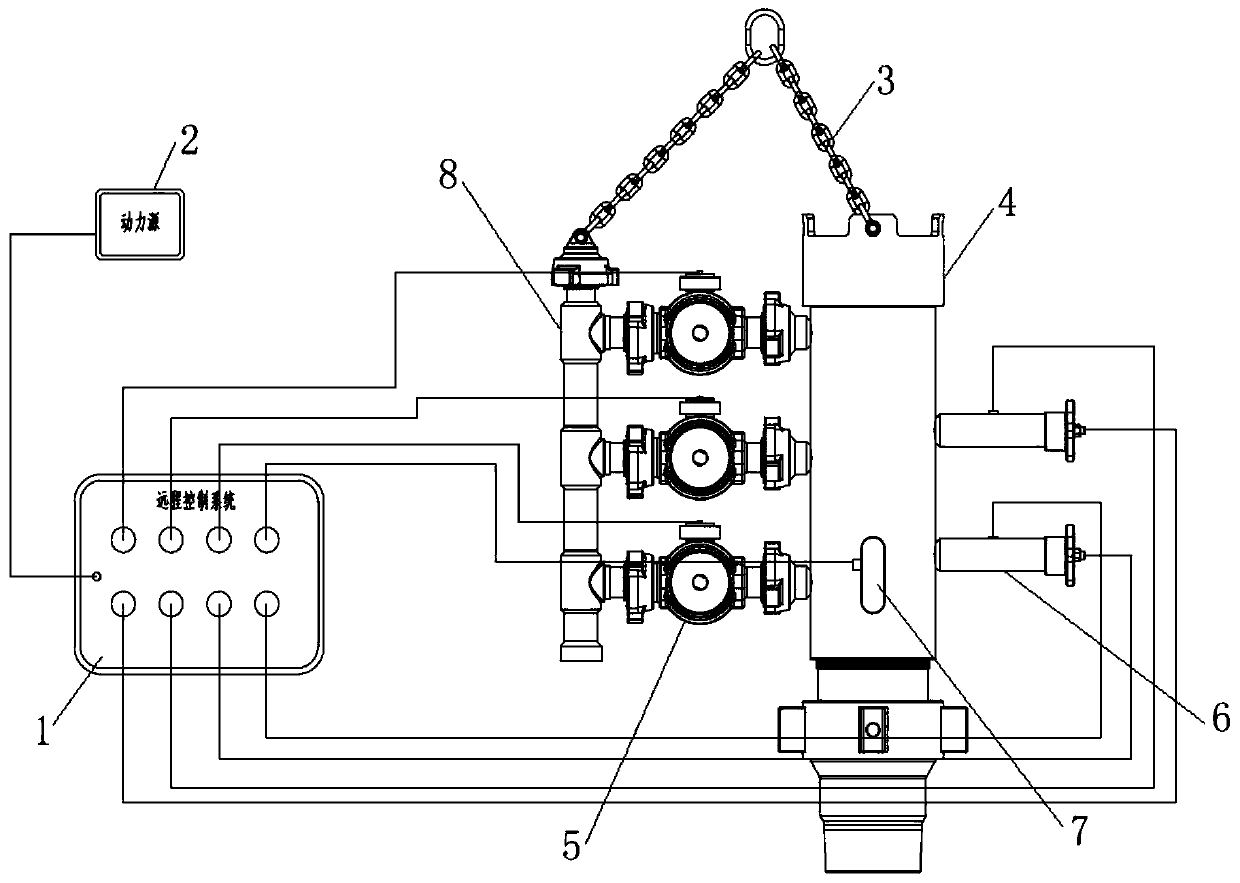

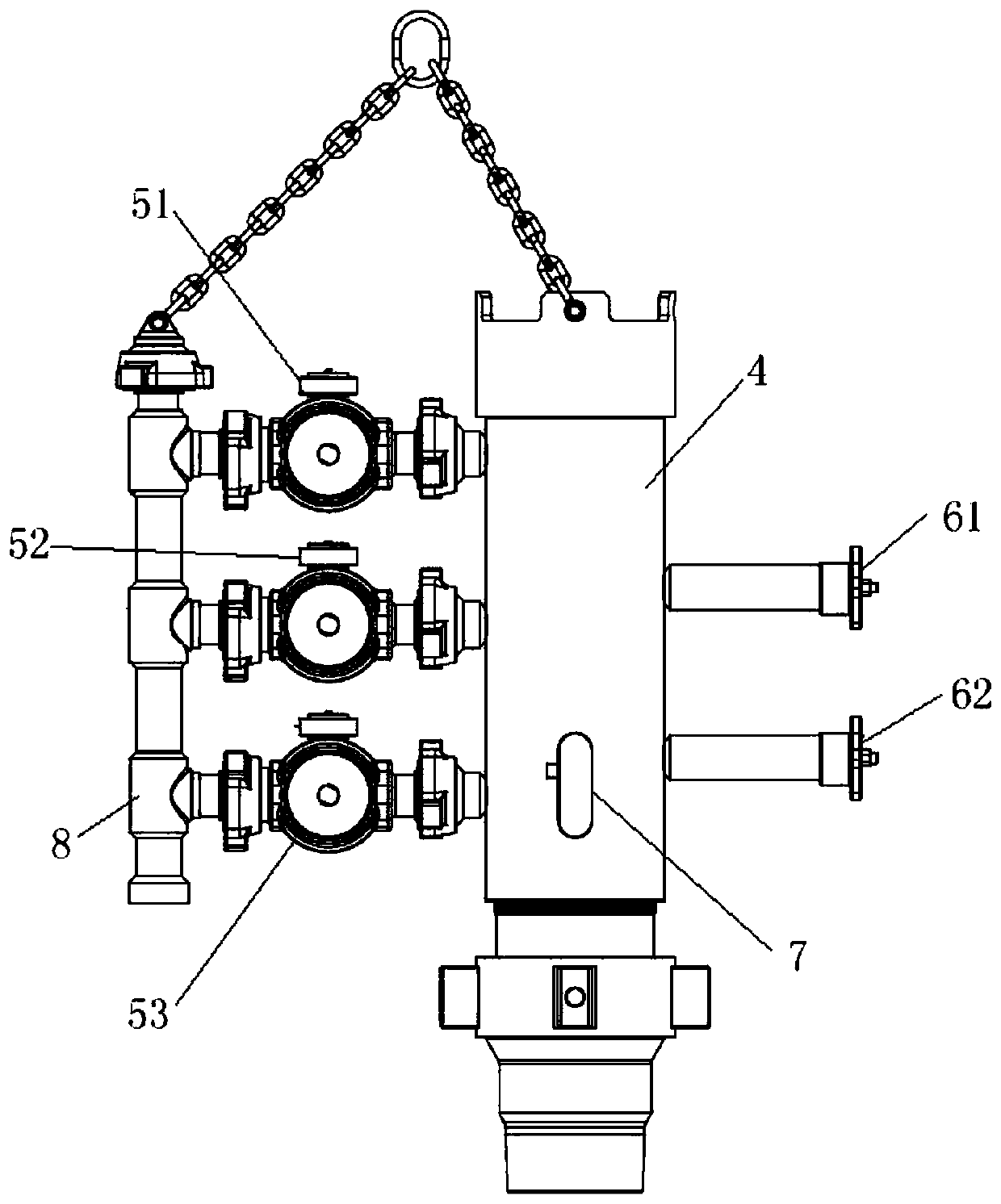

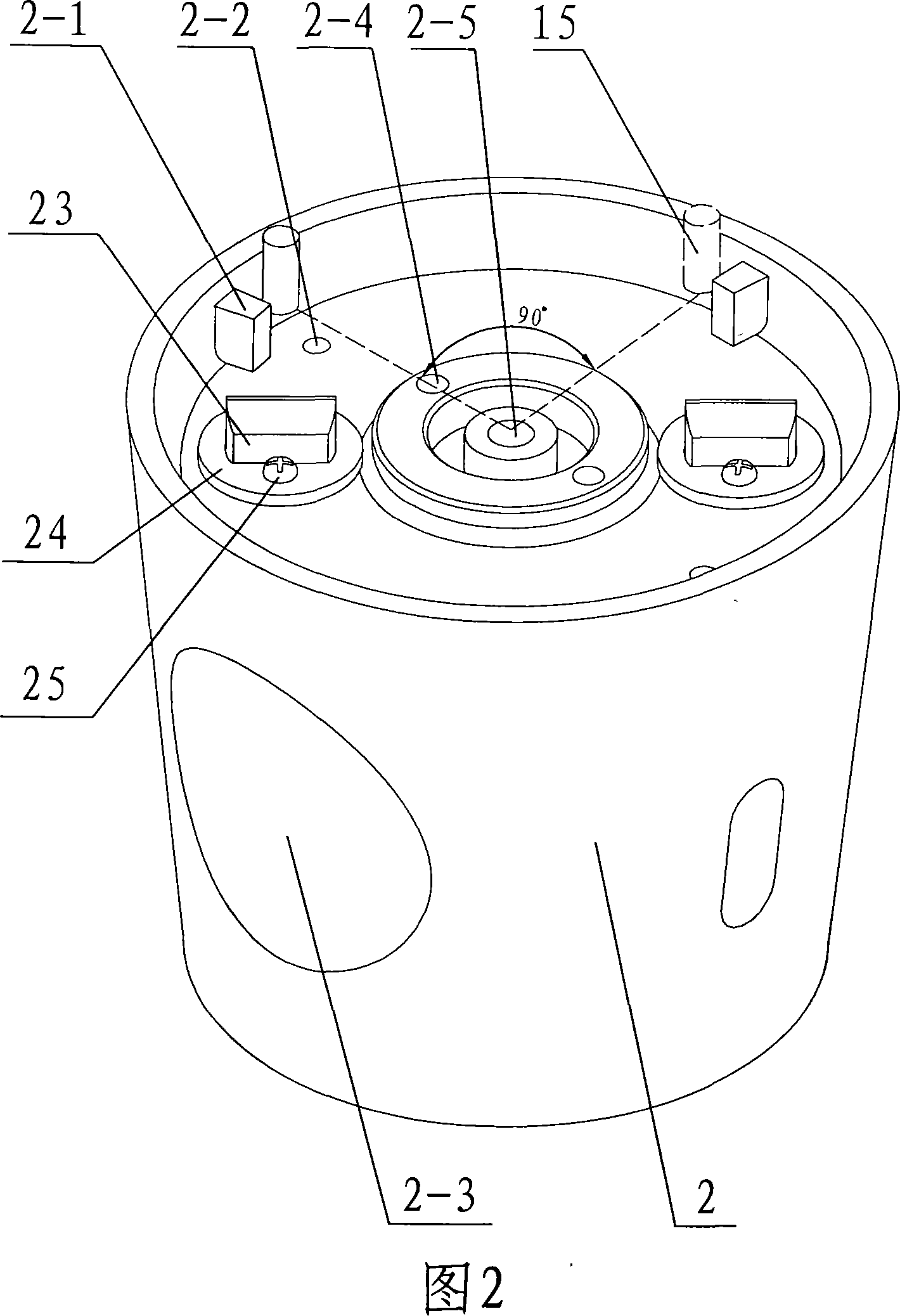

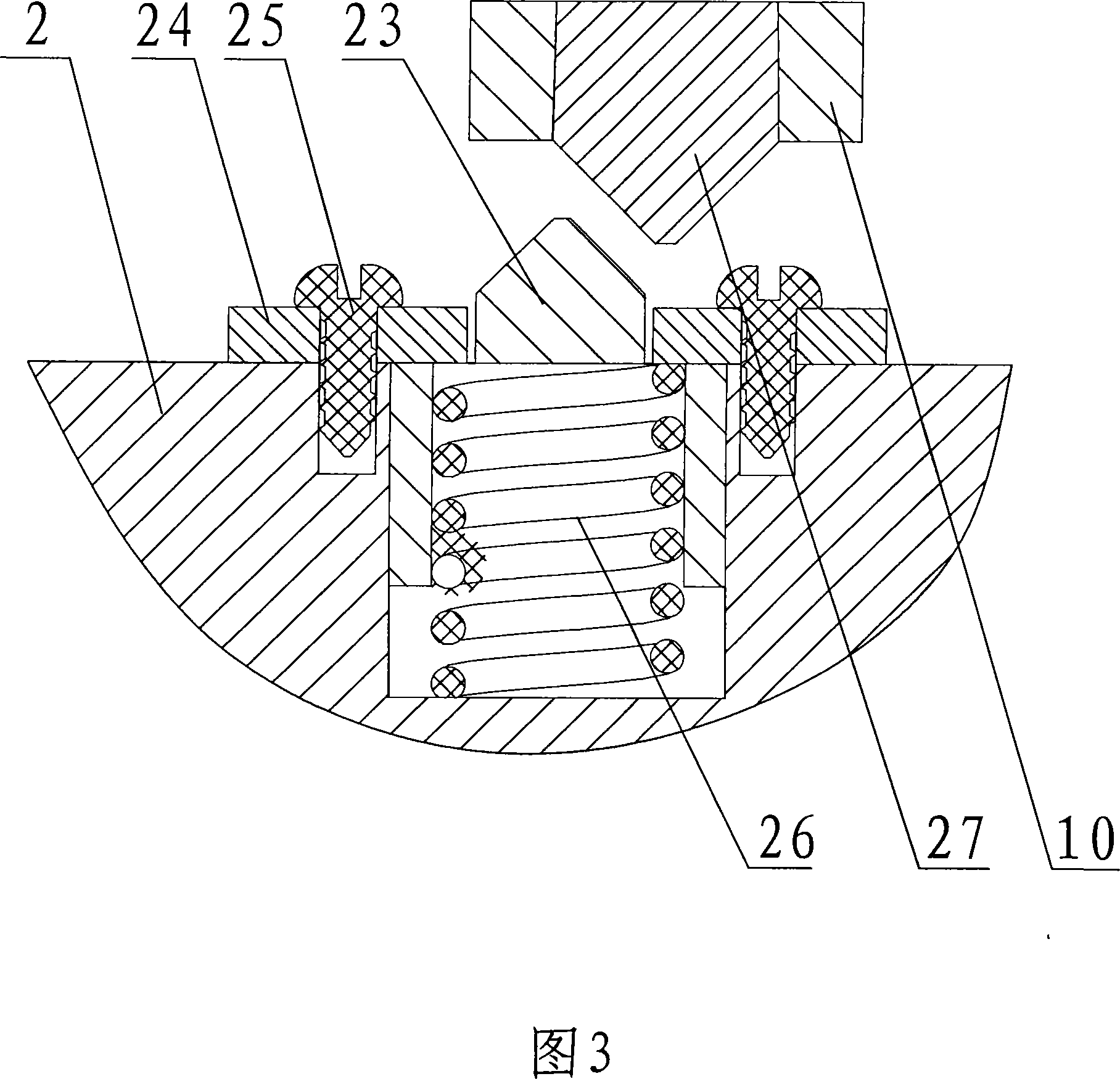

Remote control cement head

The invention discloses a remote control cement head, comprising a hydraulic control cement head, a remote control system and a power source, the power source is connected with the remote control system; the remote control system is connected with the hydraulic control cement head; the hydraulic control cement head is composed of a cement head main body, a hydraulic plug valve, a hydraulic stop pin, an indicator mechanism, and a circulating manifold, wherein the cement head main body and the circulating manifold are vertically arranged in parallel; one end of the hydraulic plug valve is connected with the circulating manifold; the other end of the hydraulic plug valve is connected with the cement head main body, the hydraulic stop pin is connected with the cement head main body and arranged on the opposite face of the hydraulic plug valve, the indicator mechanism is arranged on the cement head main body, and the indicator mechanism, the hydraulic stop pin and the hydraulic plug valve are not repeatedly arranged on the side face of the cement head body. The remote control cement head has the advantages that through remote operation of well cementation cement operation, safety of personnel is guaranteed, and operation risks are reduced.

Owner:JEREH ENERGY SERVICES

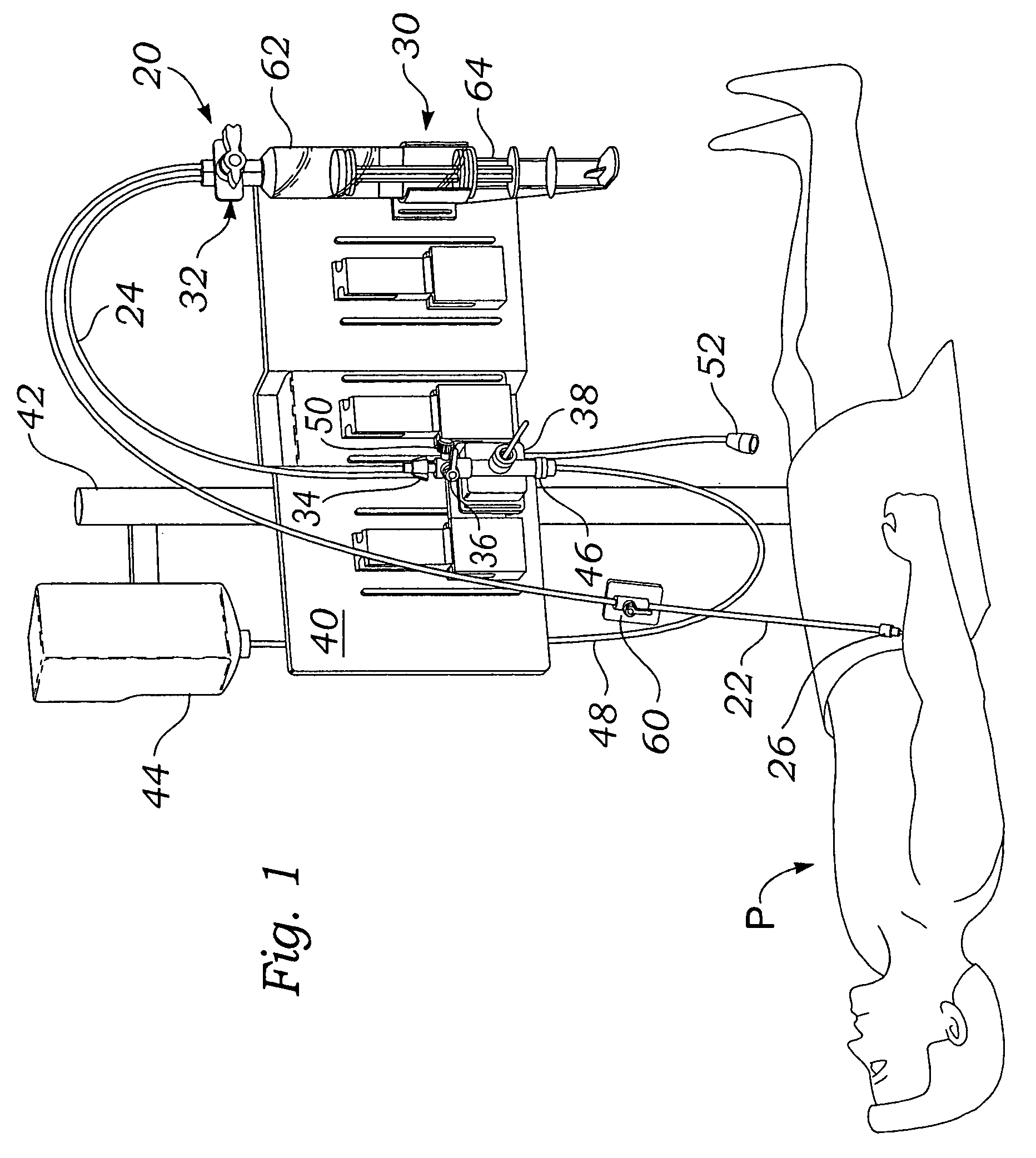

Closed blood sampling system with isolated pressure monitoring

ActiveUS7744573B2Easy to optimizeImprove pressure qualityCatheterIntravenous devicesMedical intensive care unitIntensive care

Owner:EDWARDS LIFESCIENCES CORP

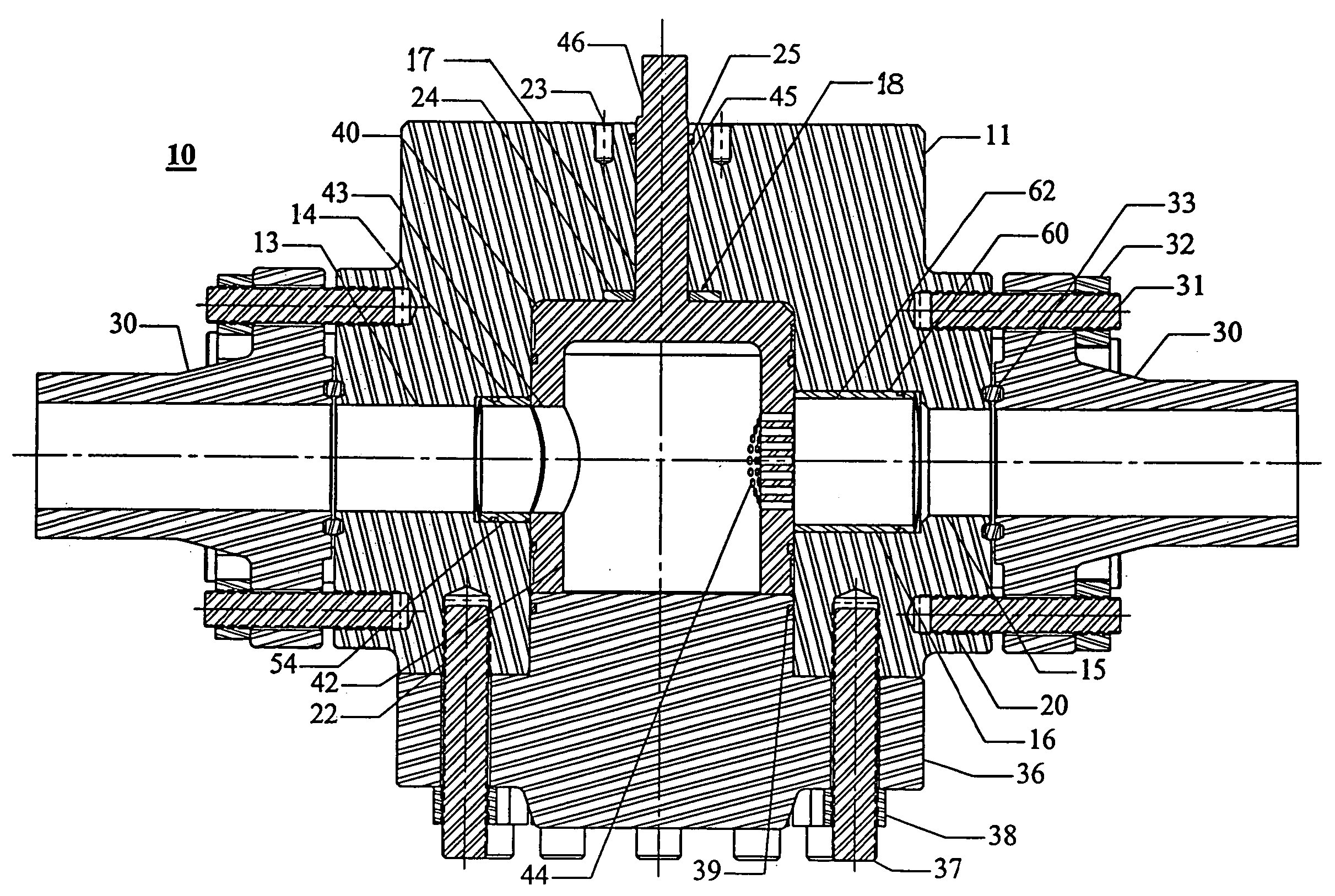

Solids strainer system for a hydraulic choke

InactiveUS20050006150A1Improve liquidityDrilling rodsValve members for absorbing fluid energyTransverse planeEngineering

The invention contemplates a strainer based upon a four-way, two-position rotary cylindrical plug valve having a hollow plug. The normal entry port for the sealing plug of the plug valve is a circular radial hole passing from the exterior of the plug into the interior cavity of the plug. The normal exit port for the sealing plug is a regular array of small holes across from and coaxial with the normal entry hole. The ports for the valve body are in two pairs positioned at 90° from each other, with the axes of the ports lying in the same transverse plane as the ports of the valve plug.

Owner:EXPRO AMERICAS

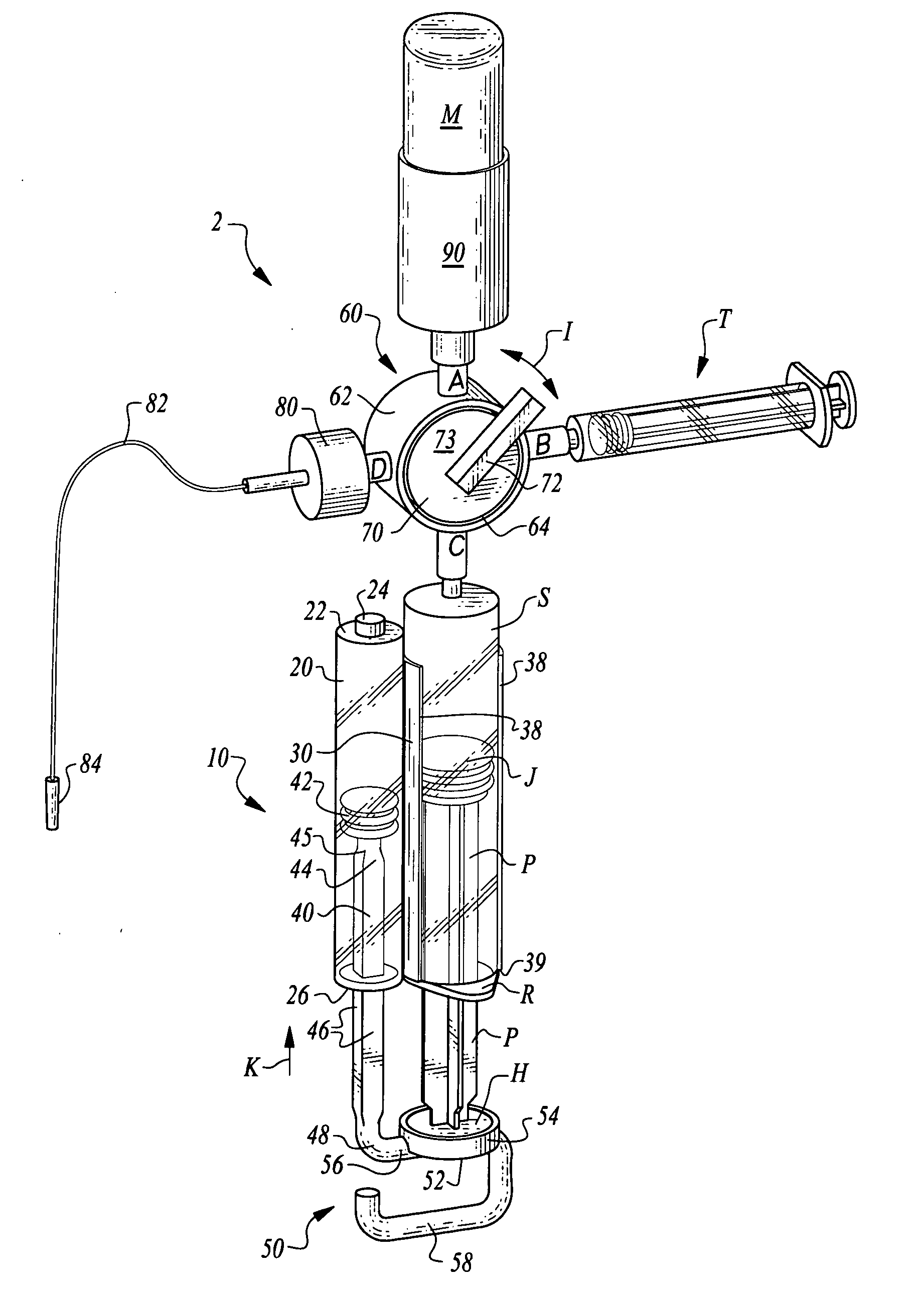

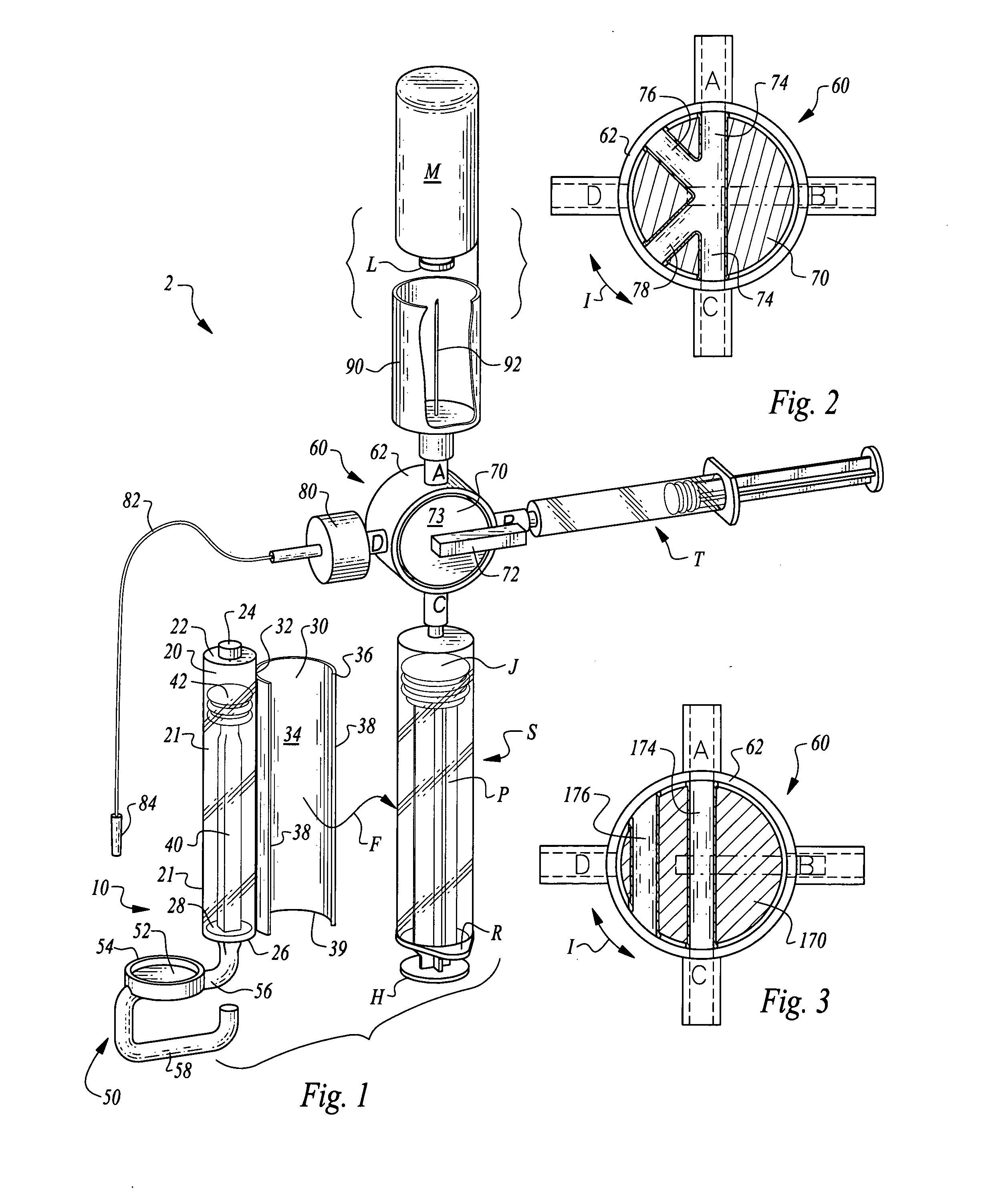

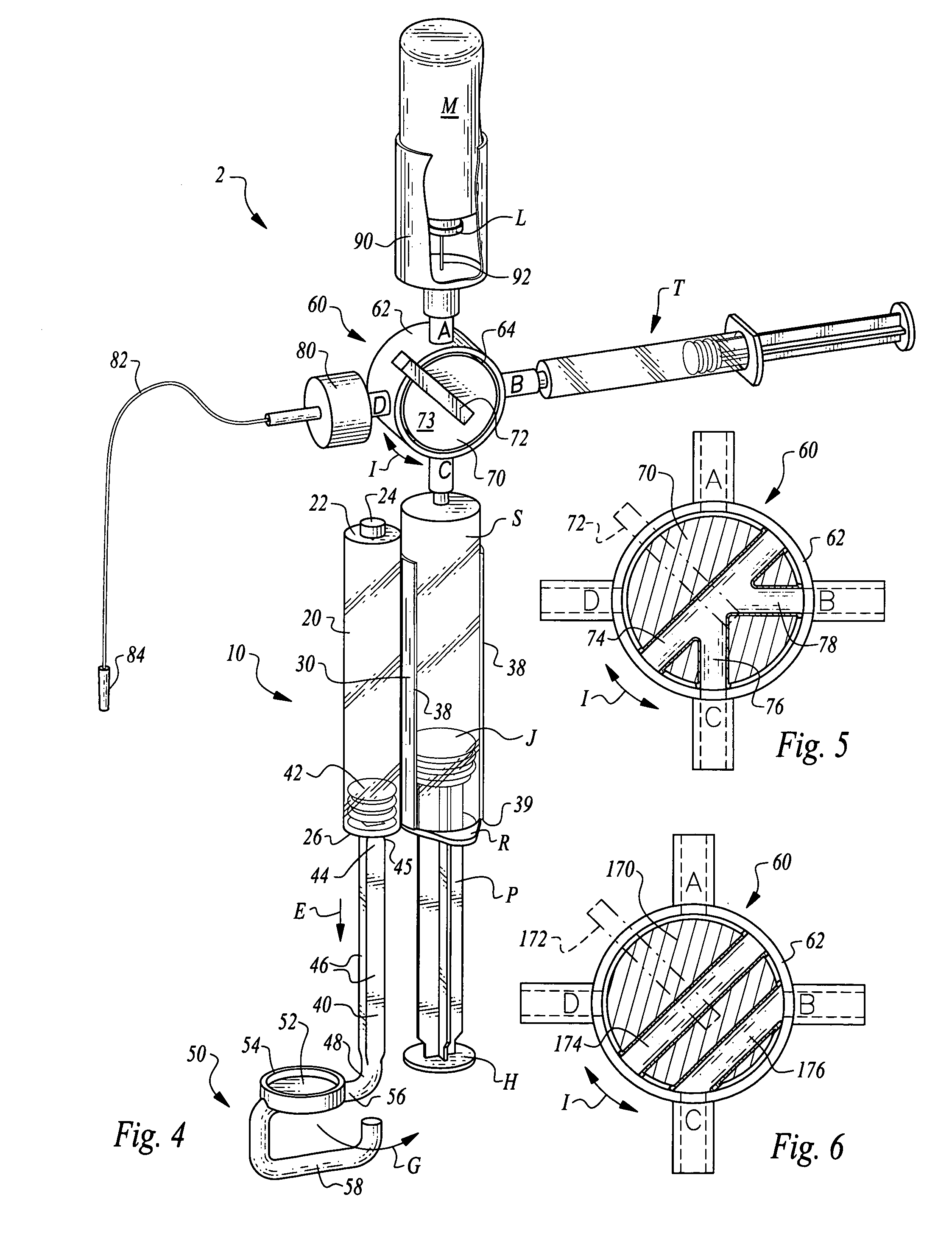

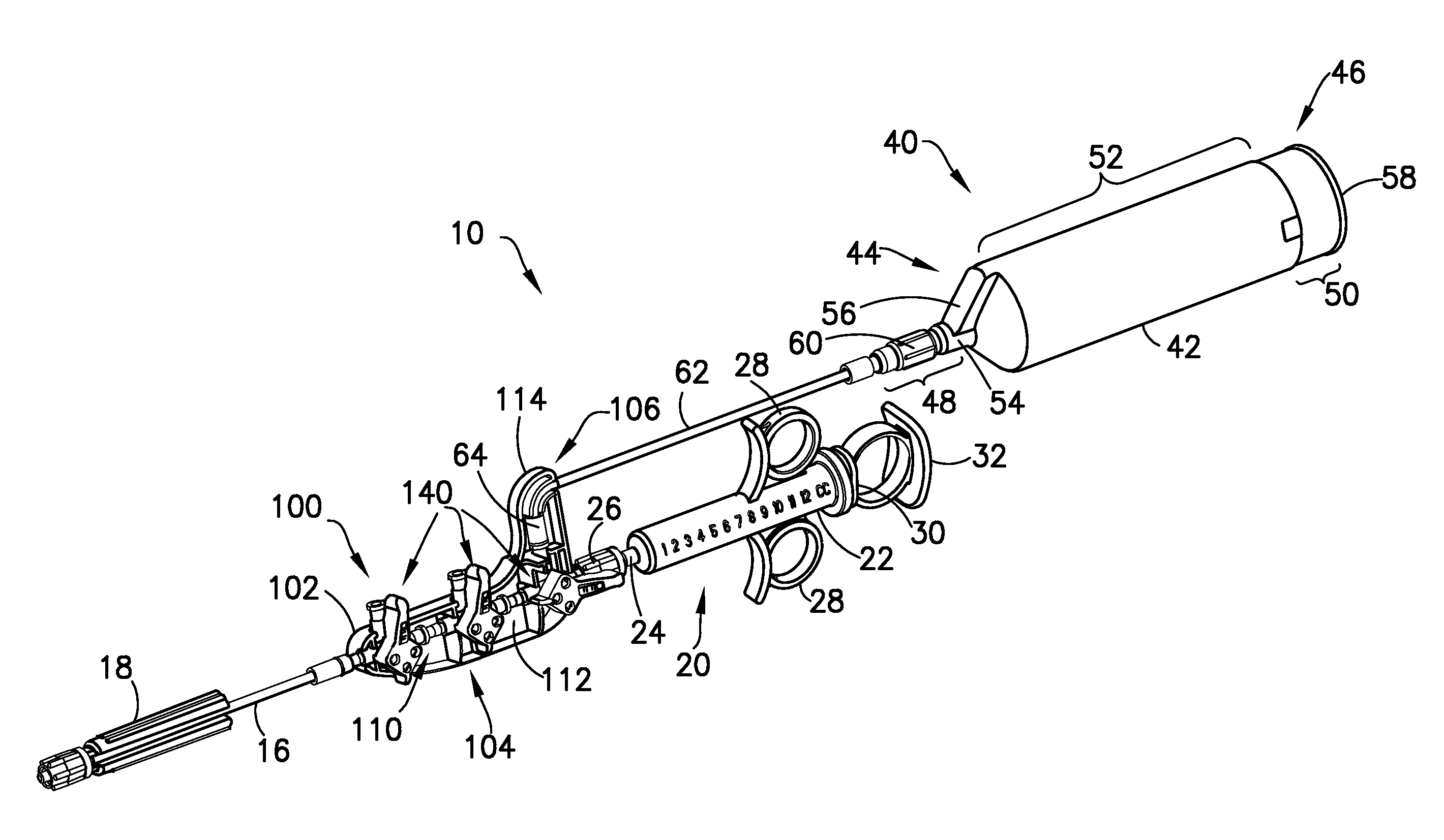

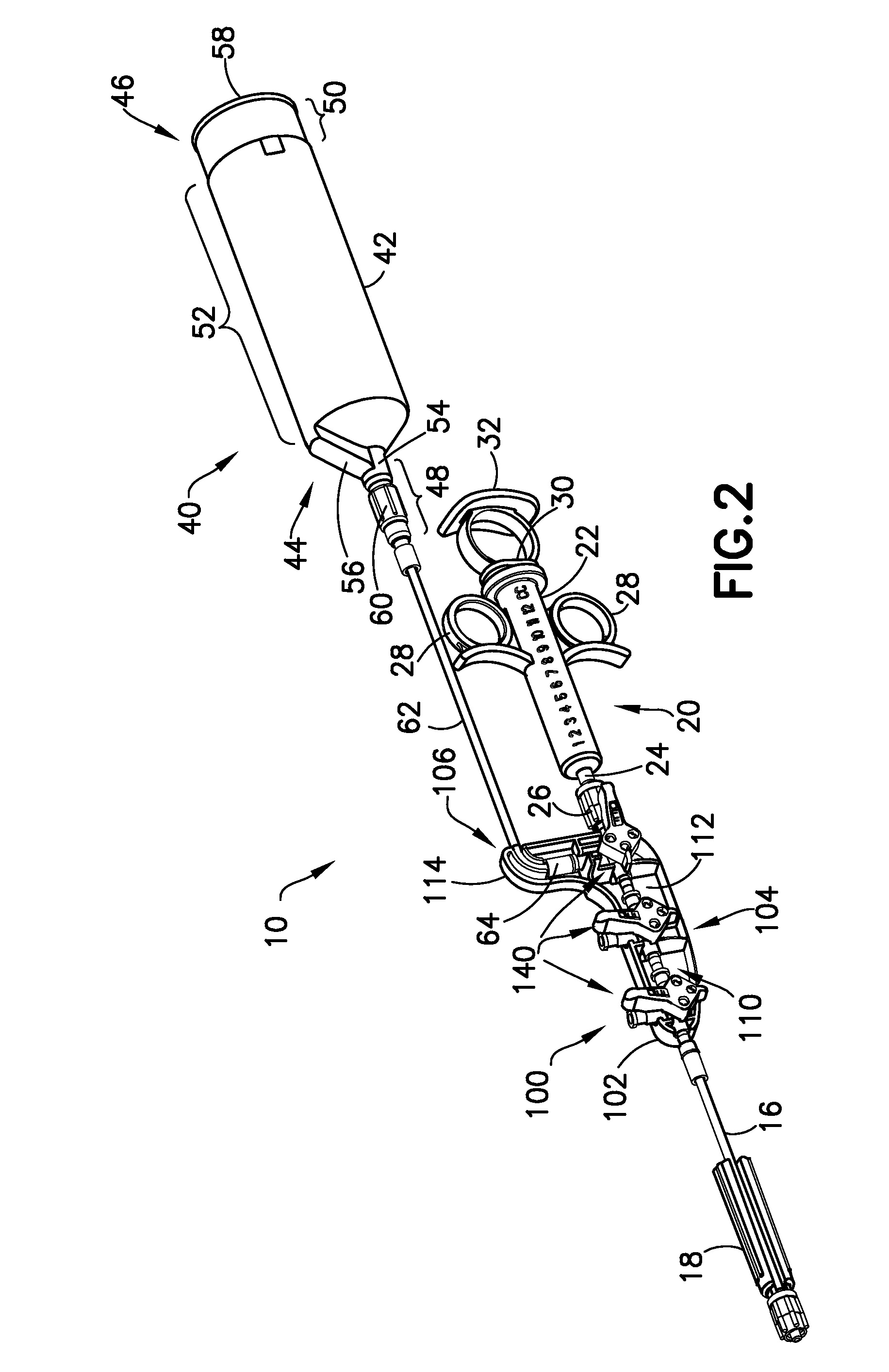

Compact non-electric medicament infuser

ActiveUS20100305507A1Easily attached to patientStable force transmissionIntravenous devicesSuction devicesMedication injectionDriver/operator

An assembly is provided which includes an infusion device coupled to a standard medication syringe. The medication syringe may be coupled to a stopcock valve having multiple ports and to which syringes, vial adapters, infusion tubing, and multiple other items may be coupled. The infusion device includes a source of power based on a resistance force such as vacuum, spring or gas power. The infusion device converts the resistance based force to usable work in the form of a force applicator. The force applicator includes a driver section on one section of a reciprocating arm and an attachment to the power source on another section of the arm. The driver is pulled outward (excursion) to increase the size of the chamber, creating a force that tends to return the driver back inward, causing incursion. The driver can be attached removably to the syringe plunger to induce the infusion process.

Owner:MONUMEDICAL

Floating taper cock valve

Owner:虞仕君

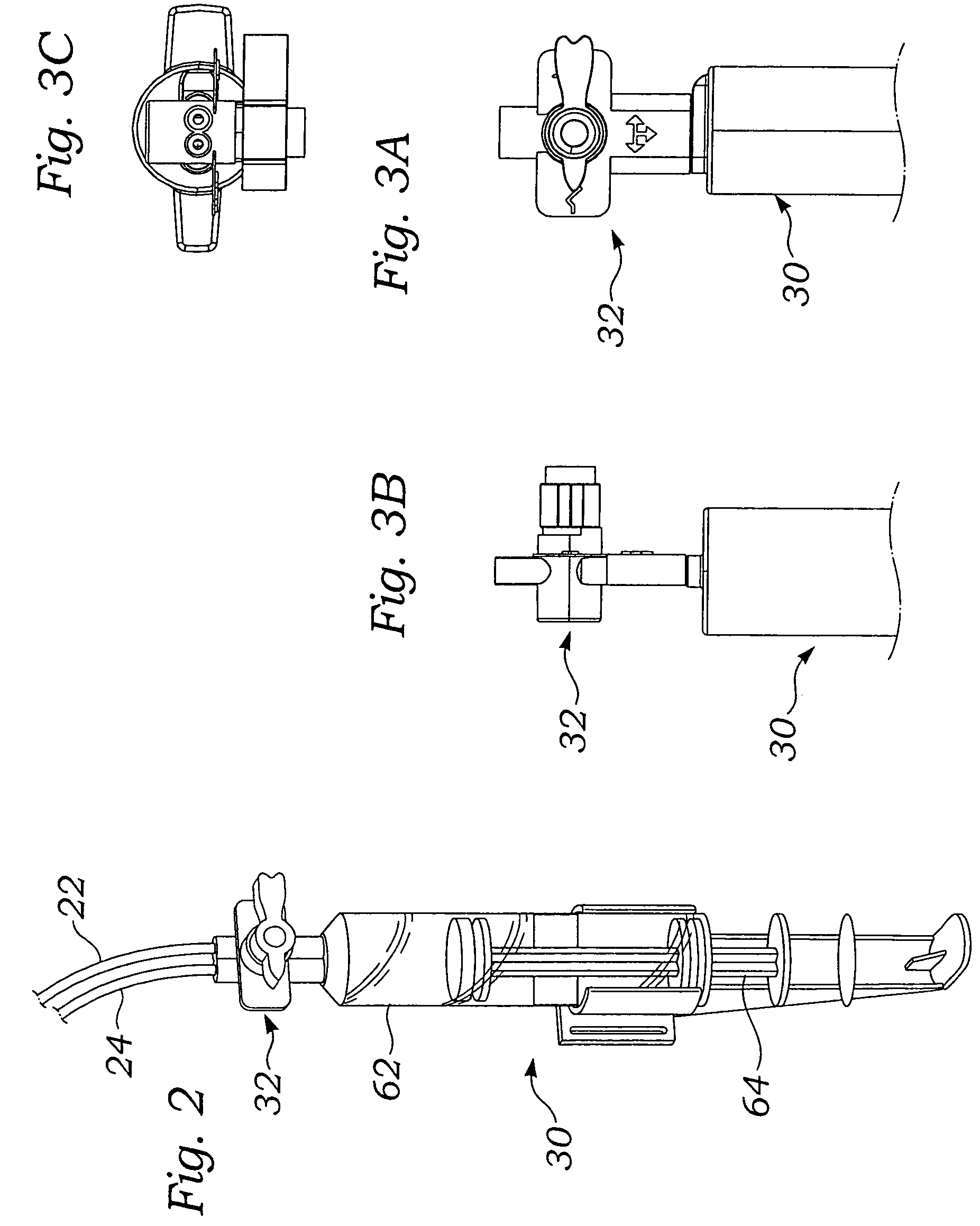

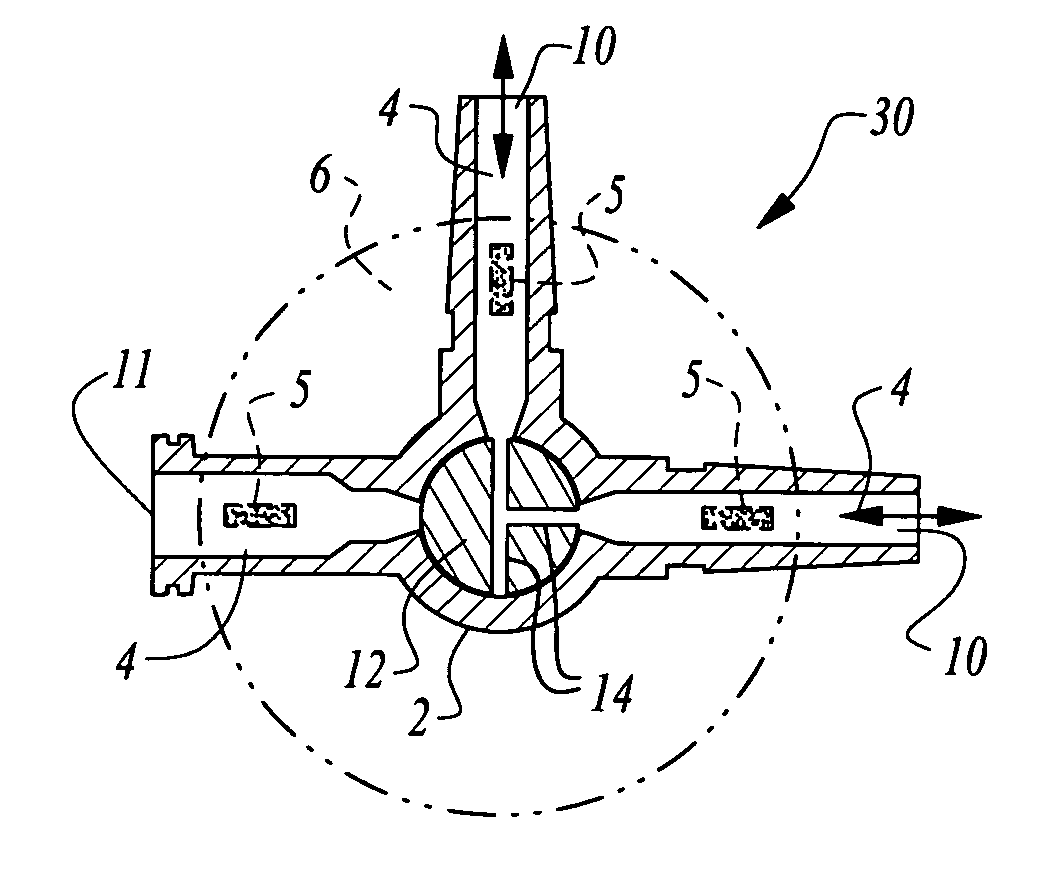

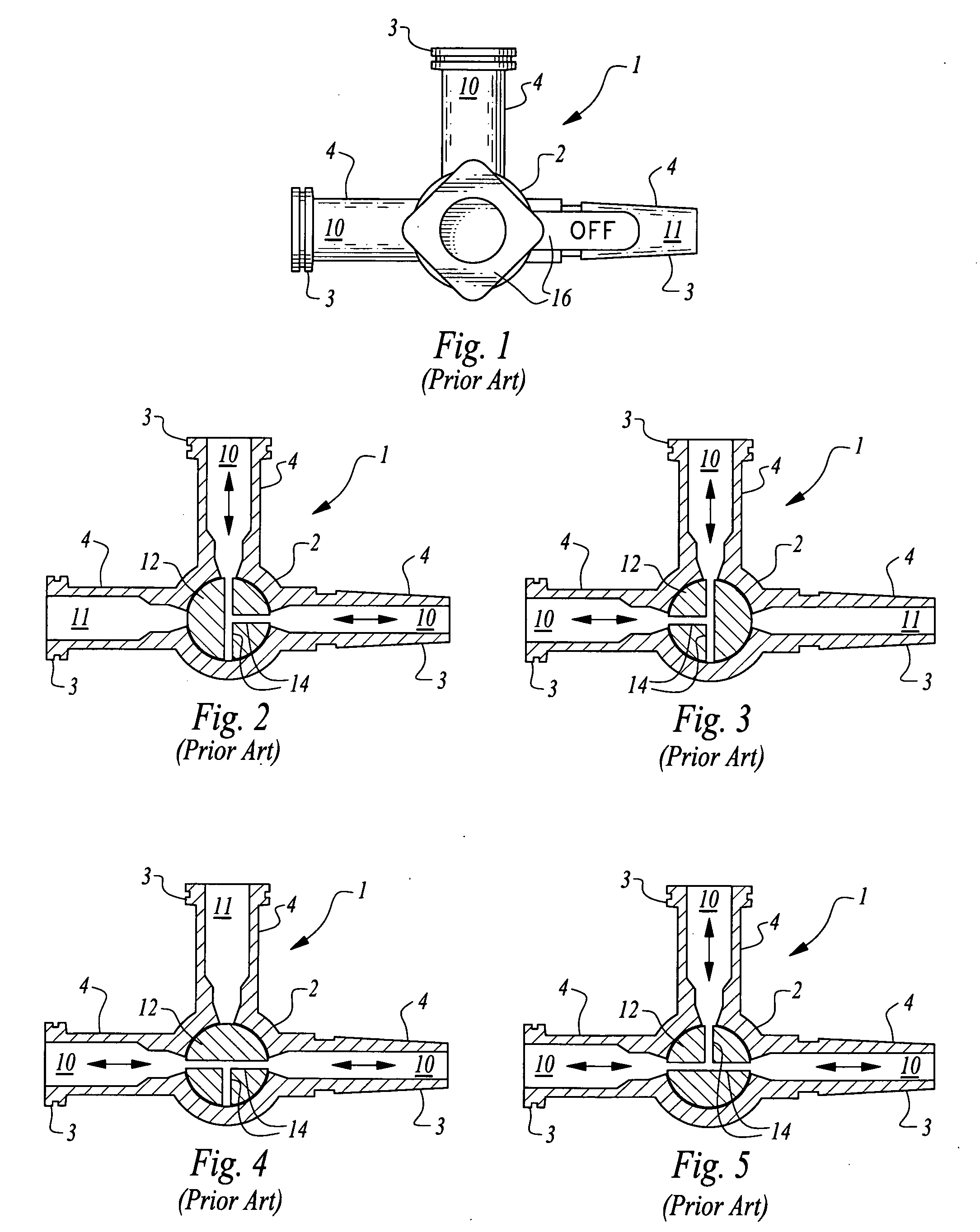

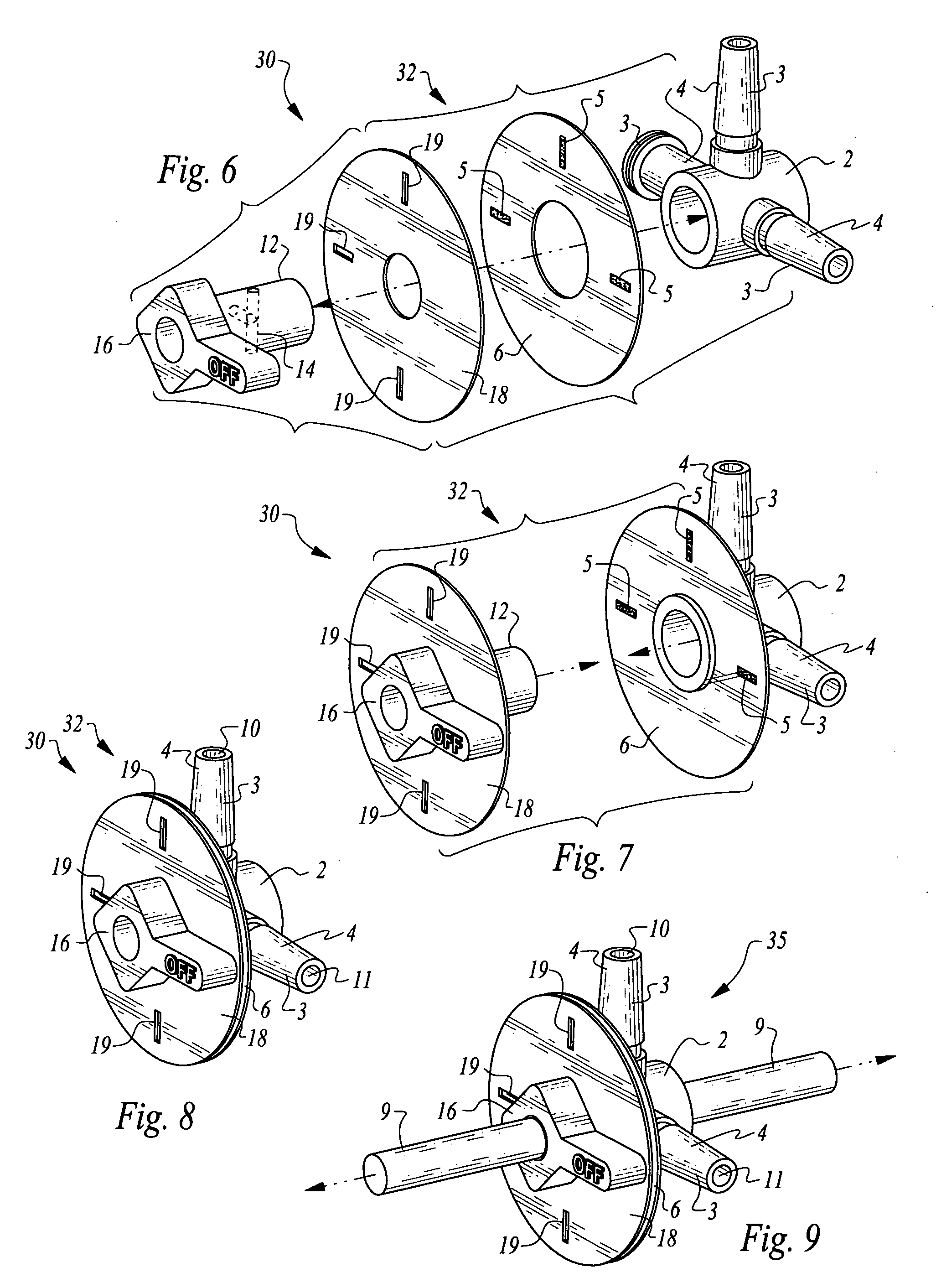

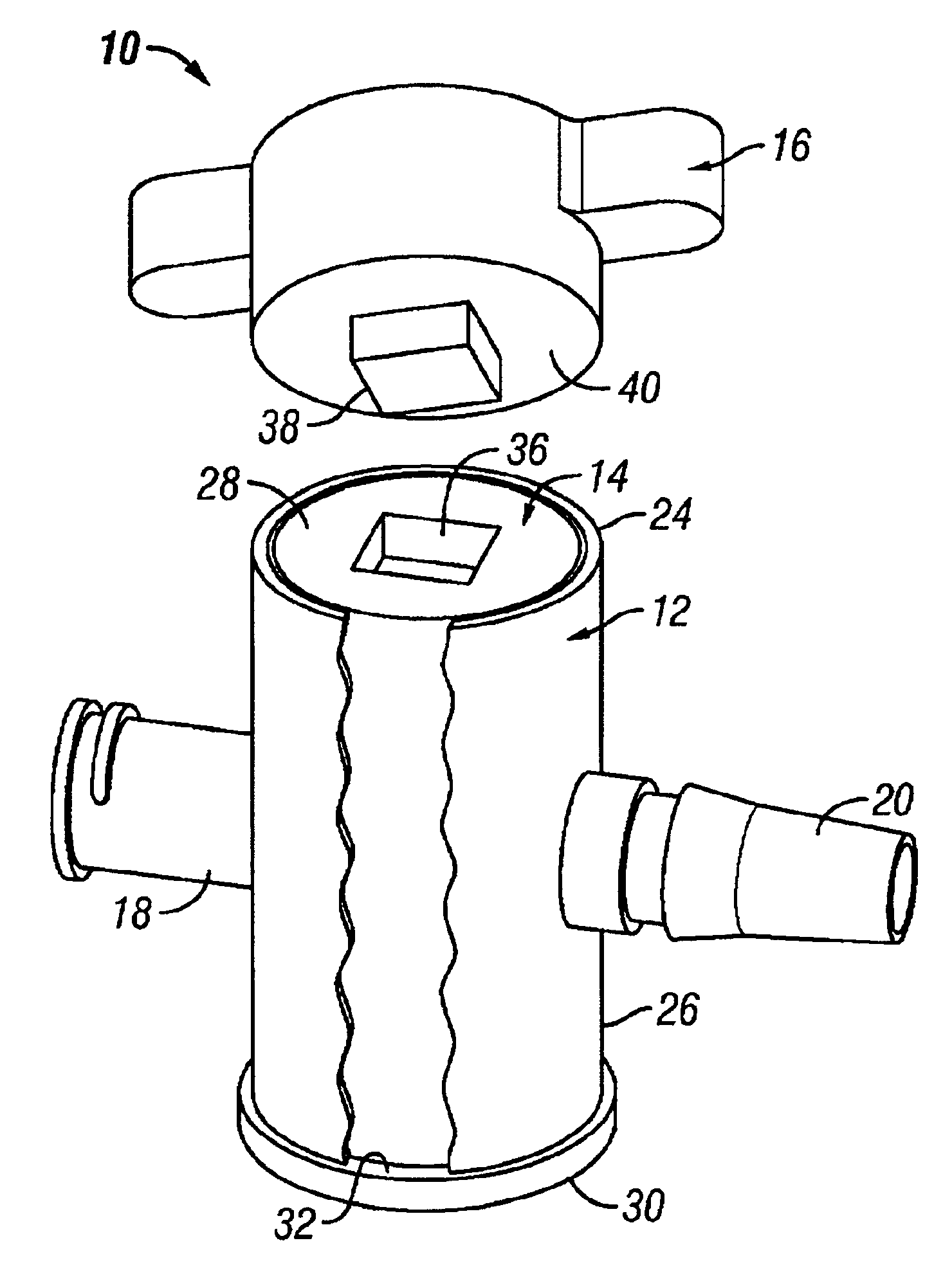

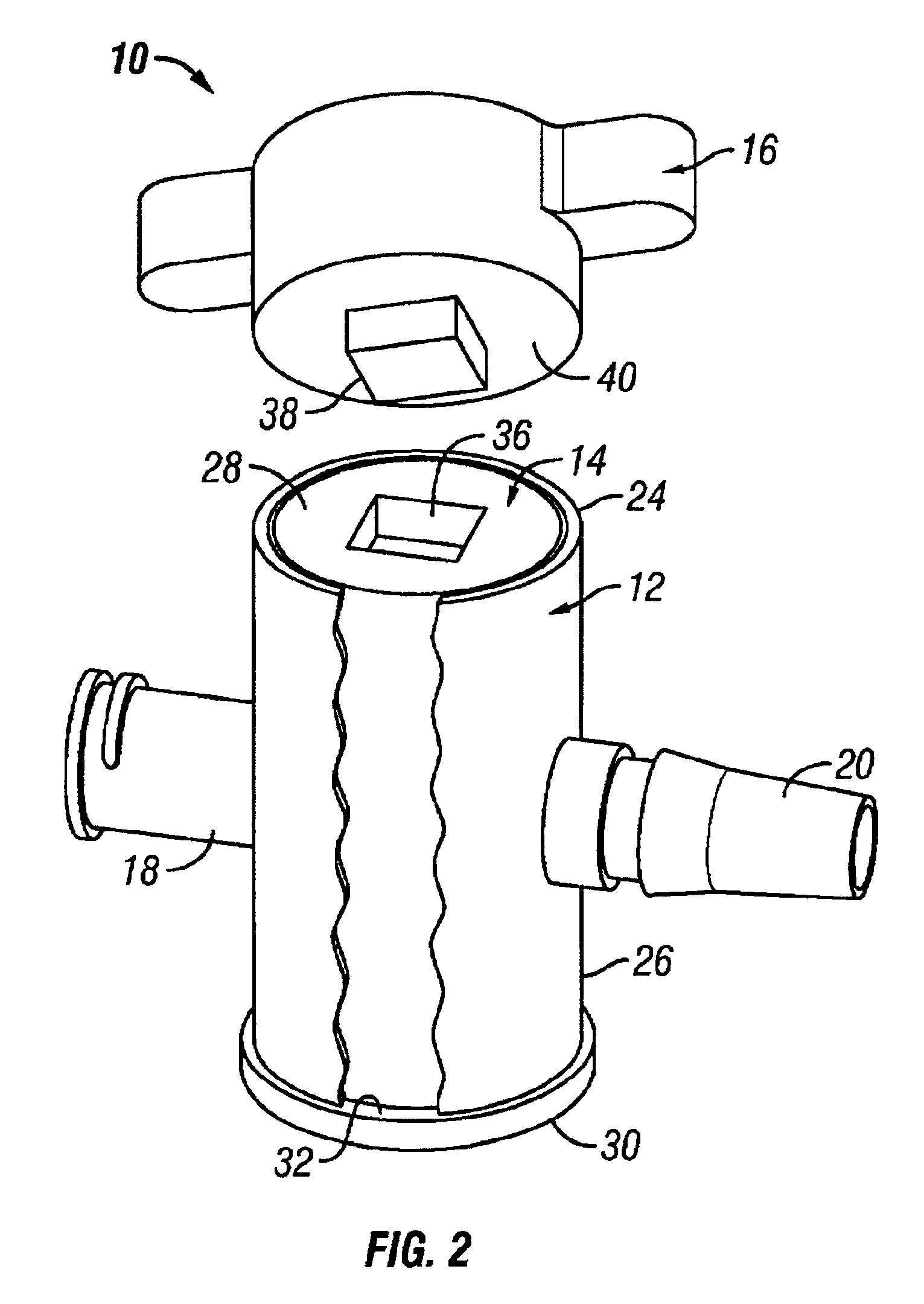

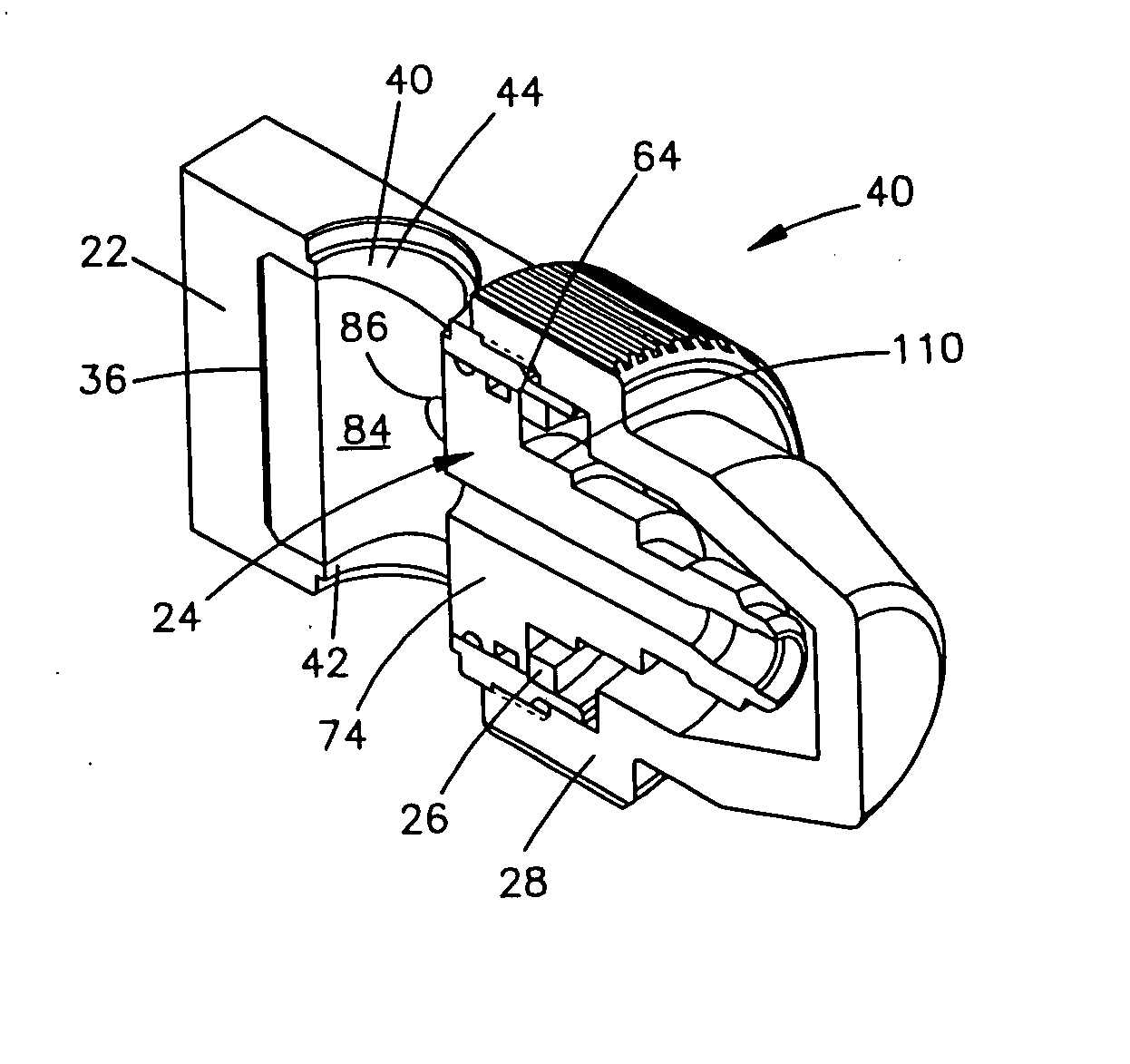

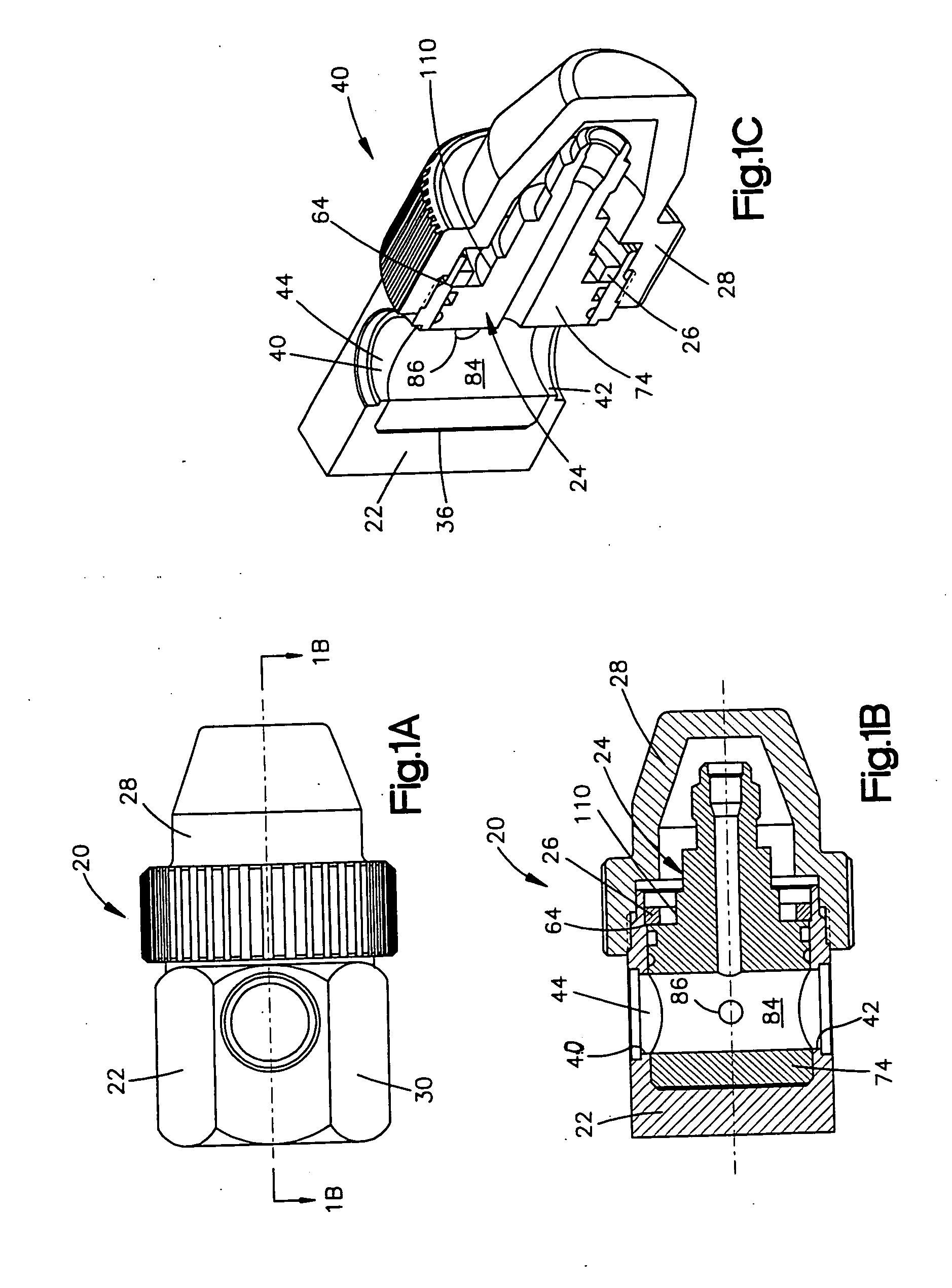

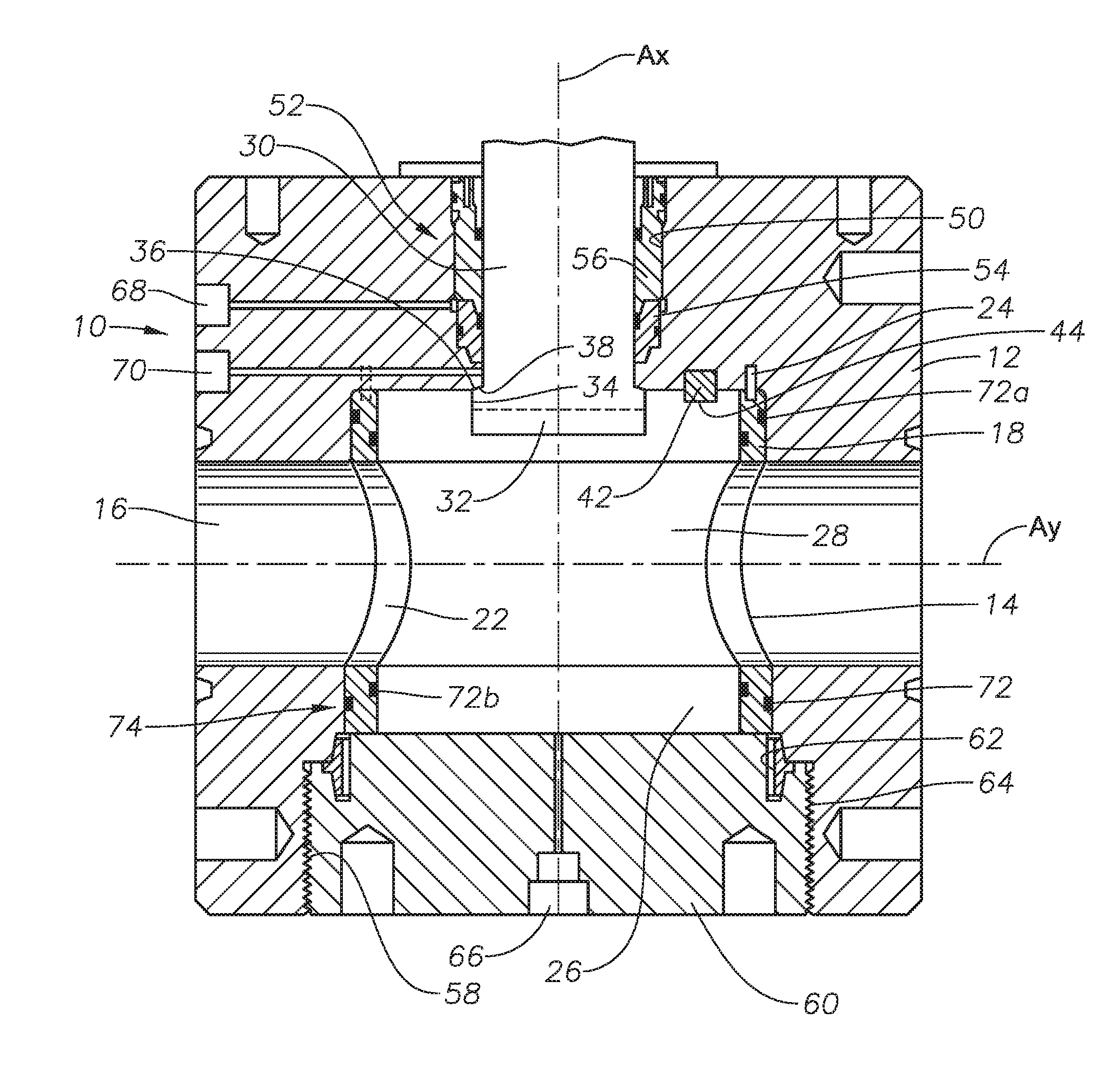

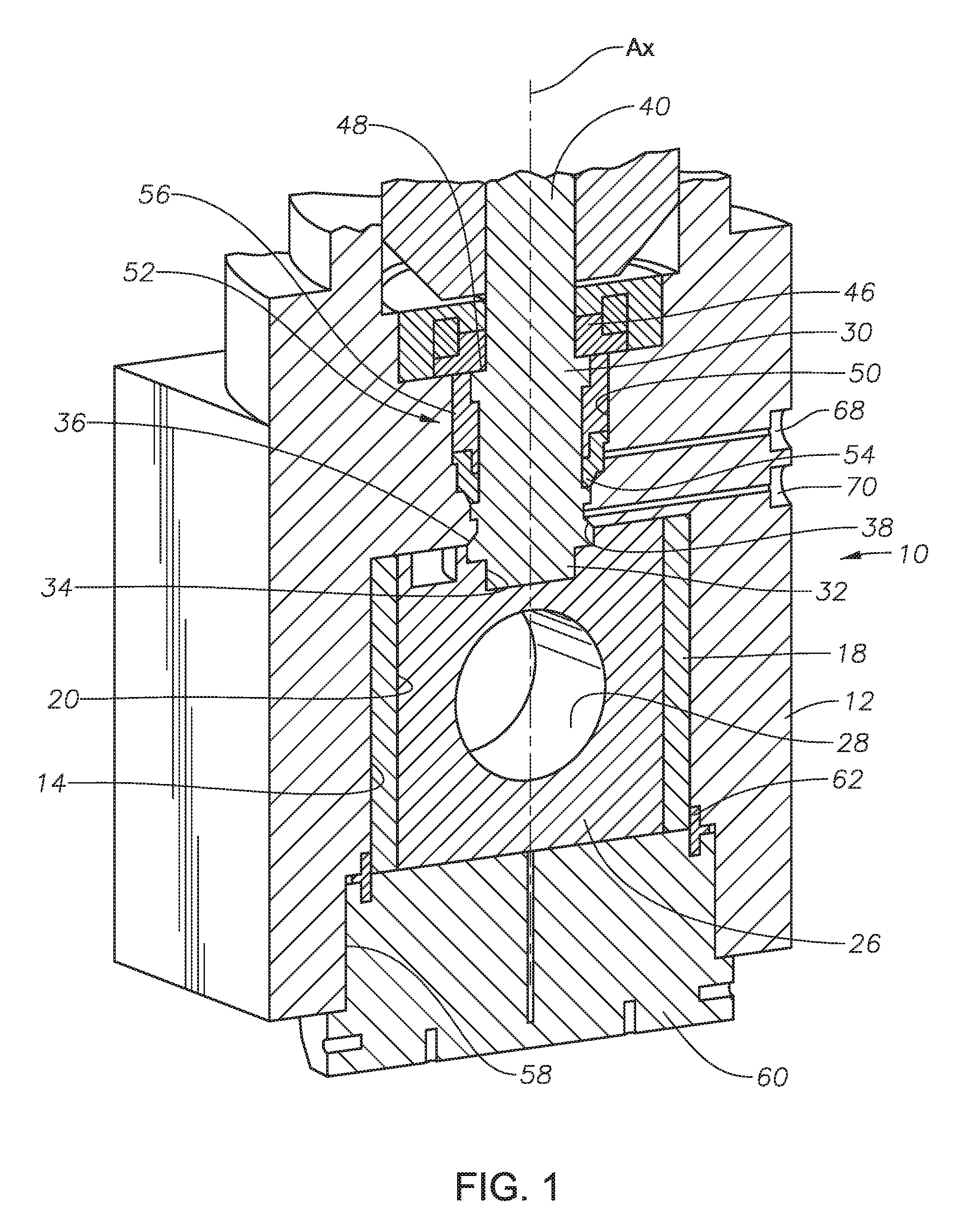

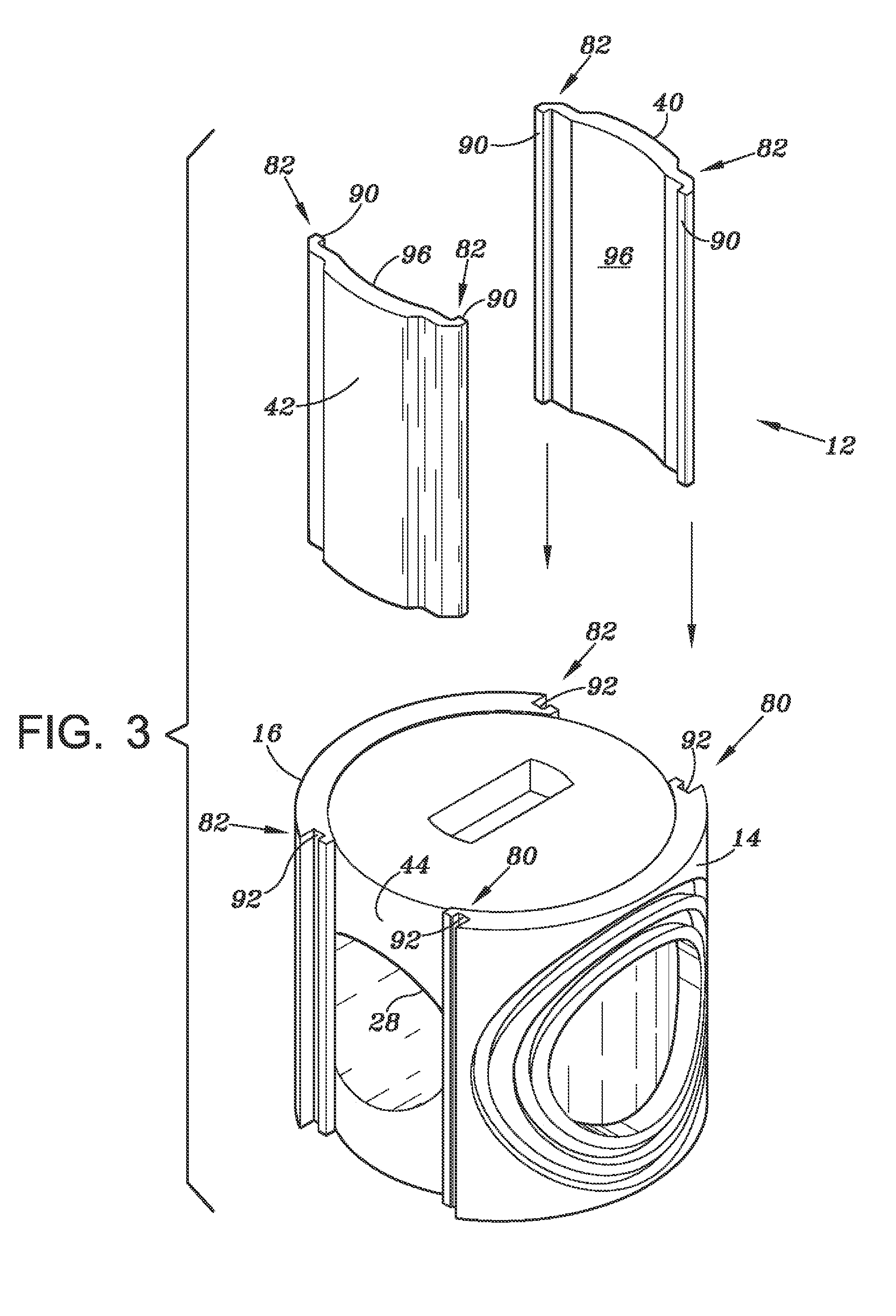

Multi-port stopcock valve and flow designating system

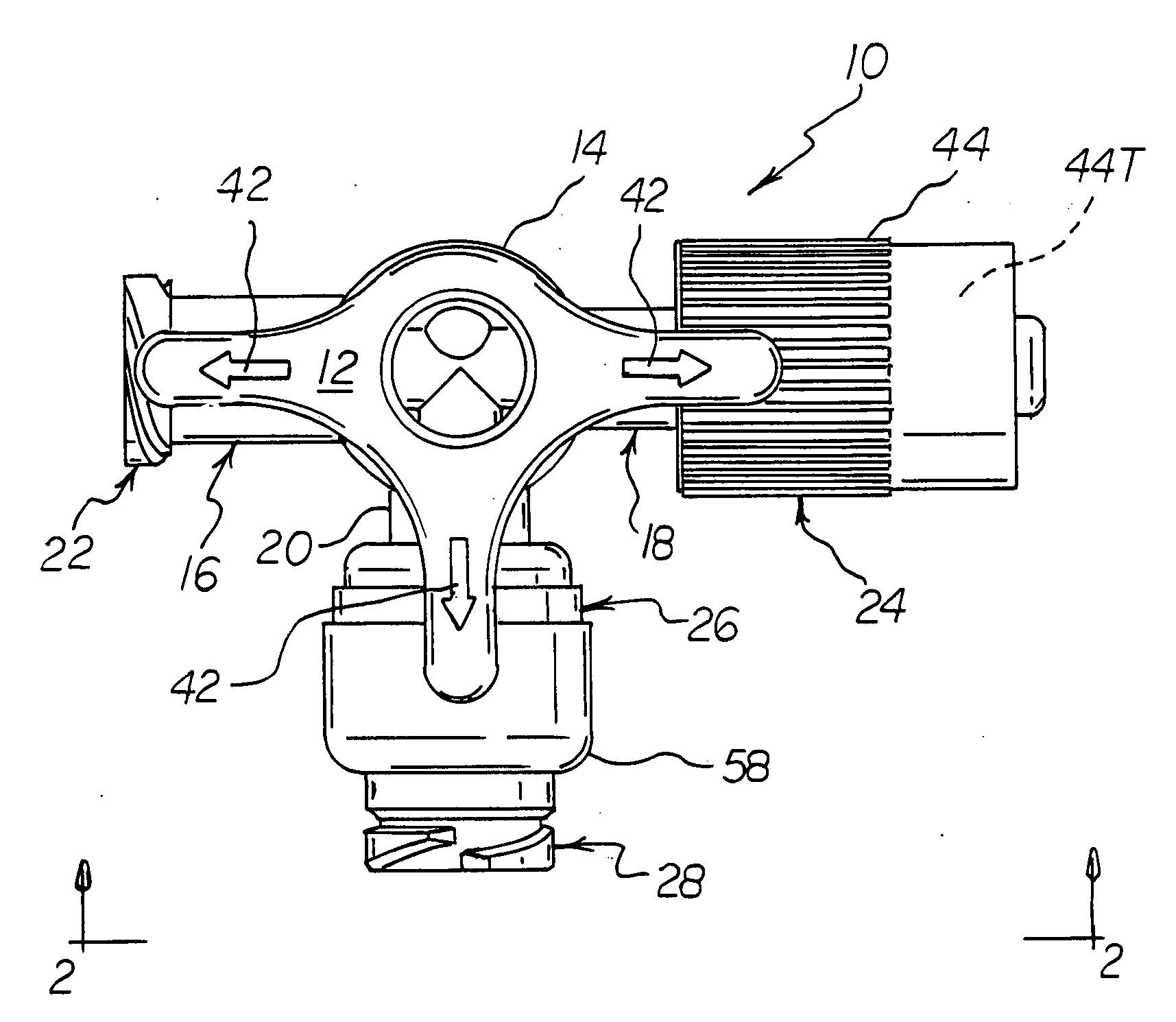

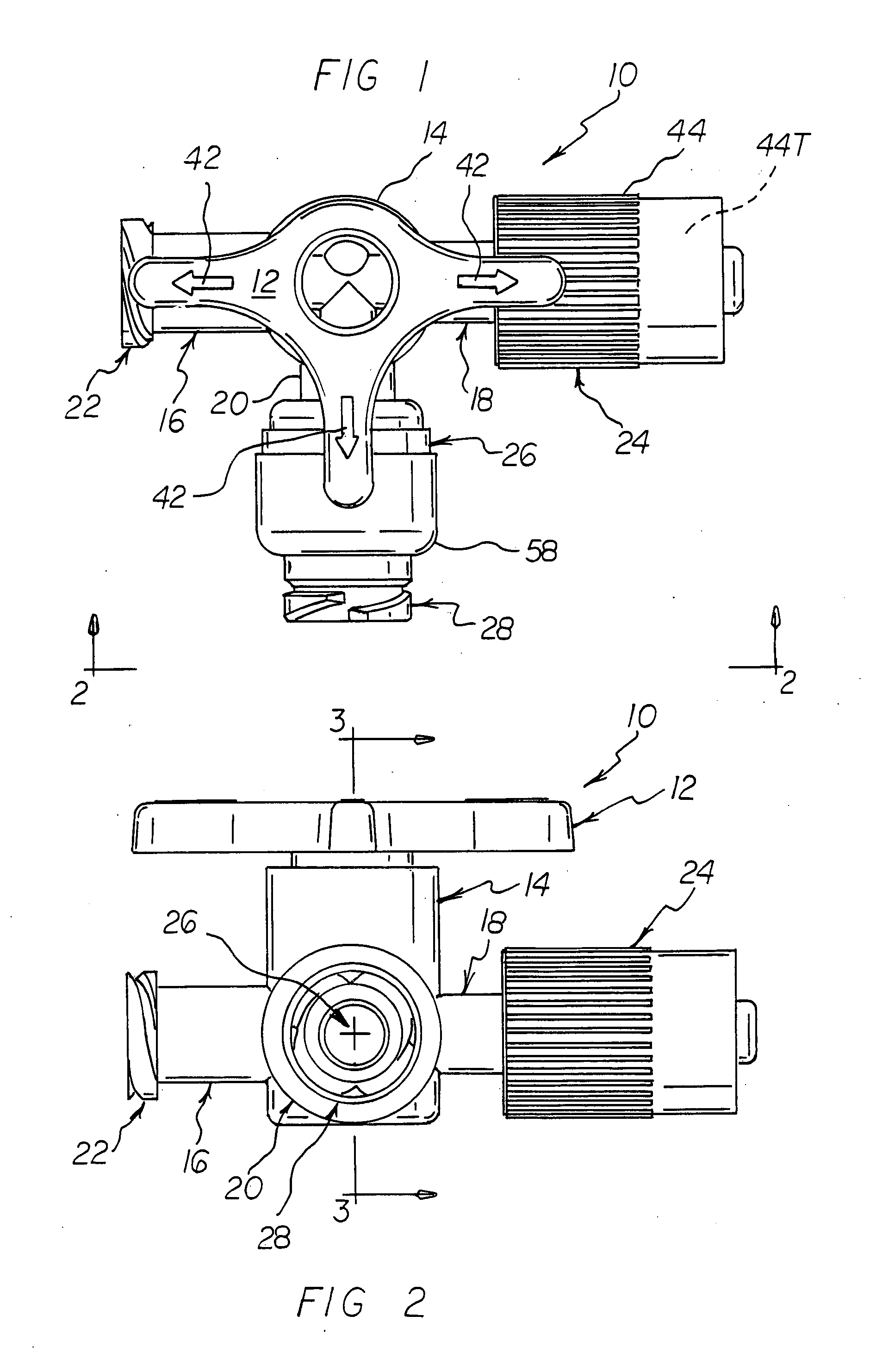

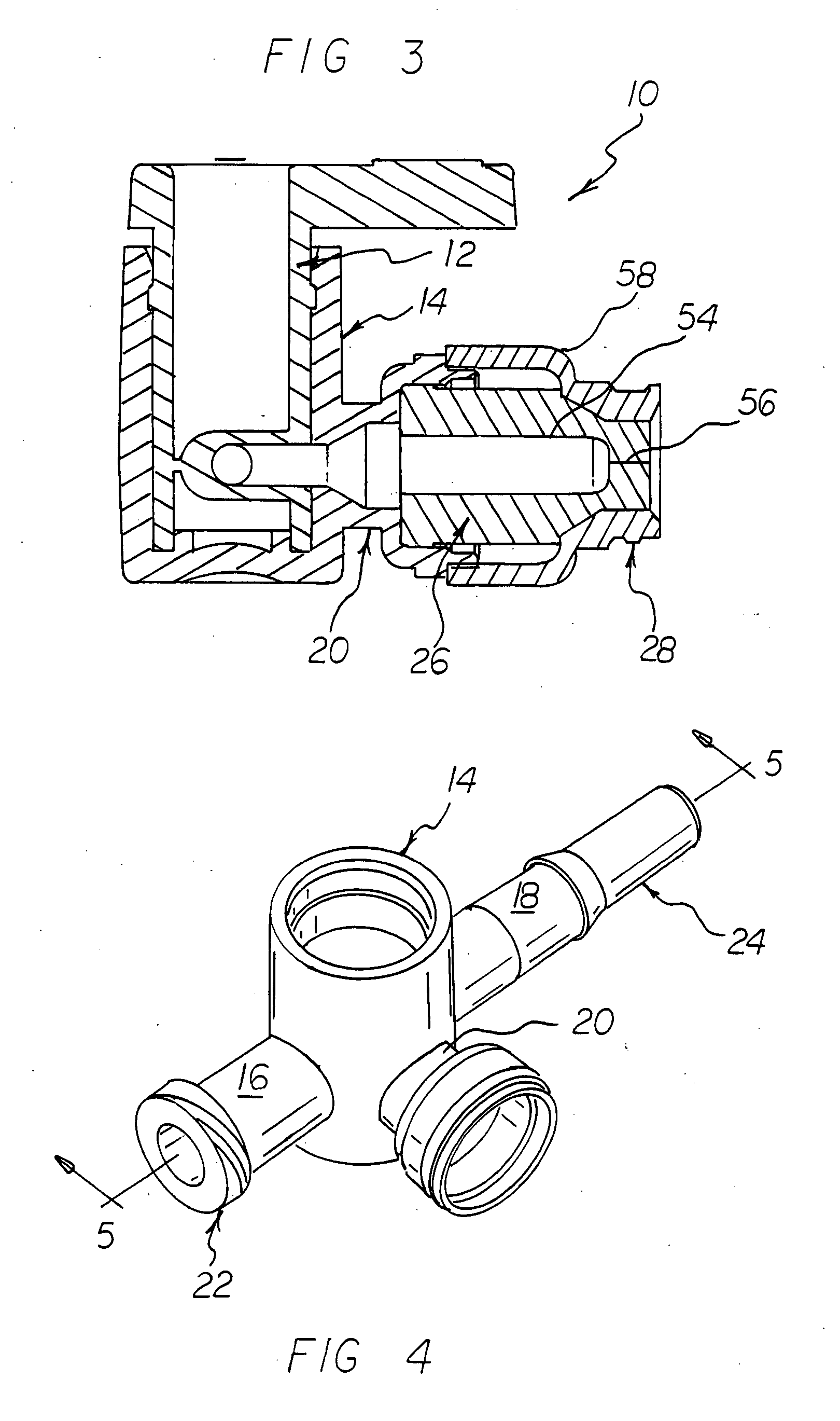

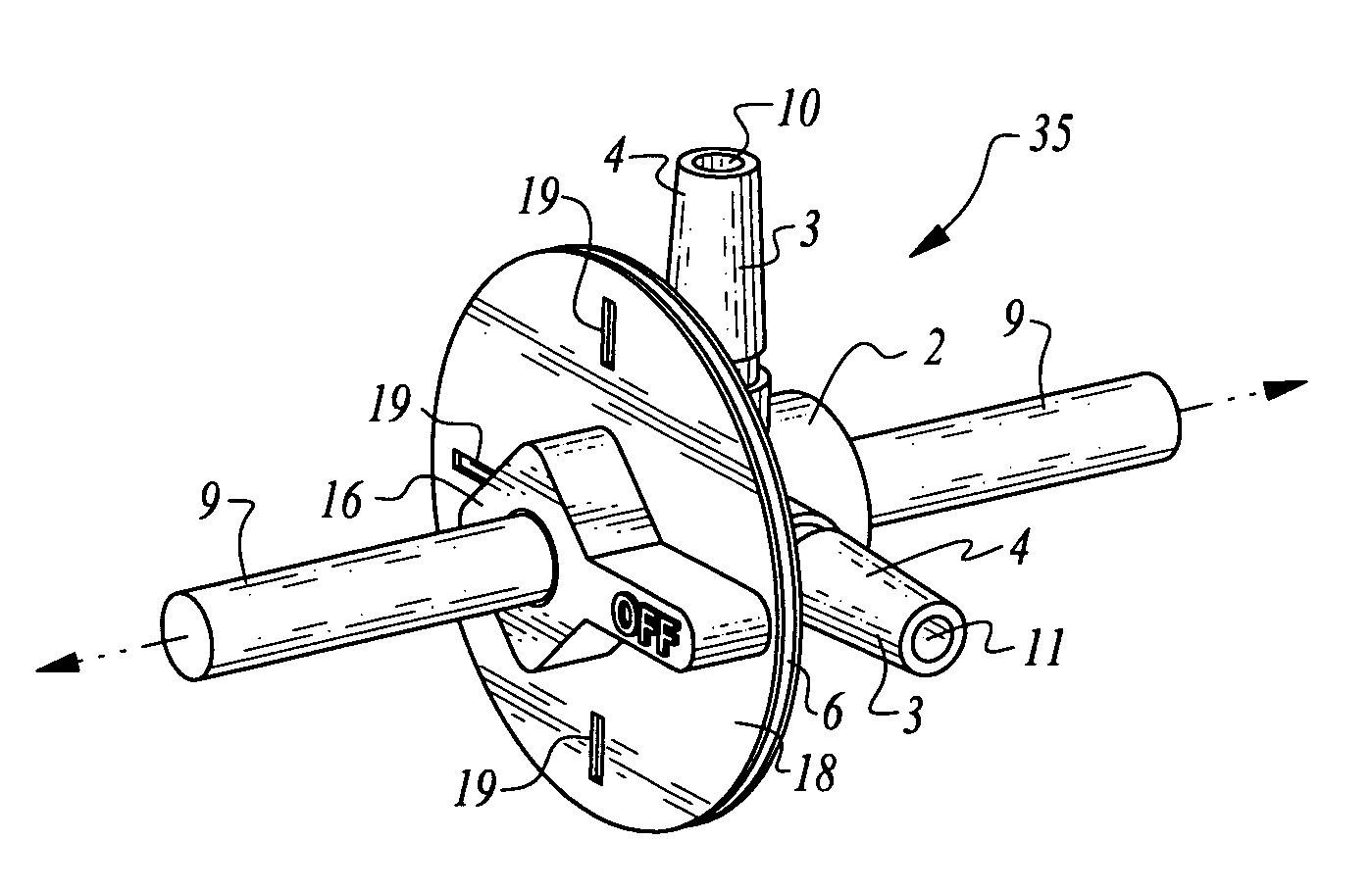

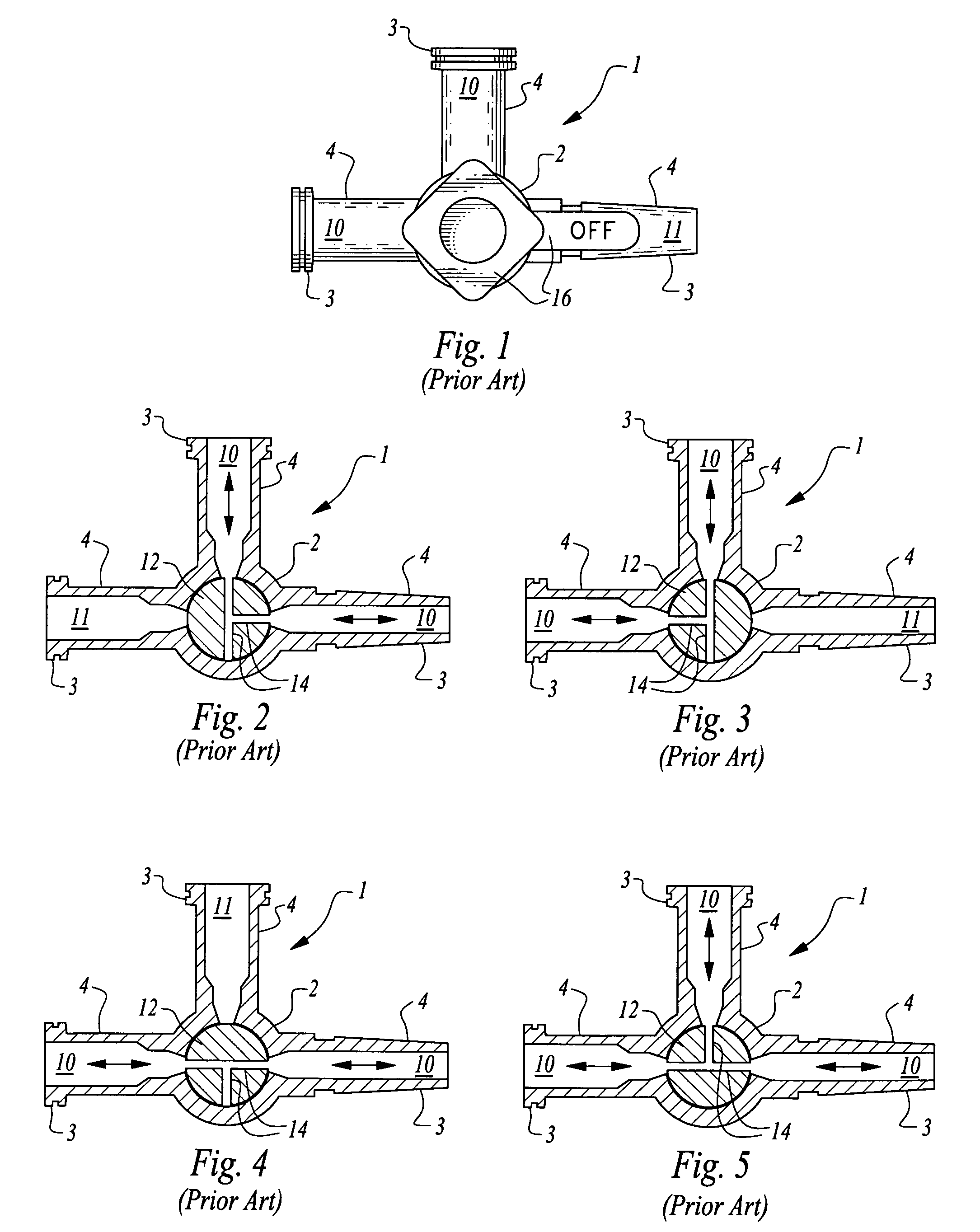

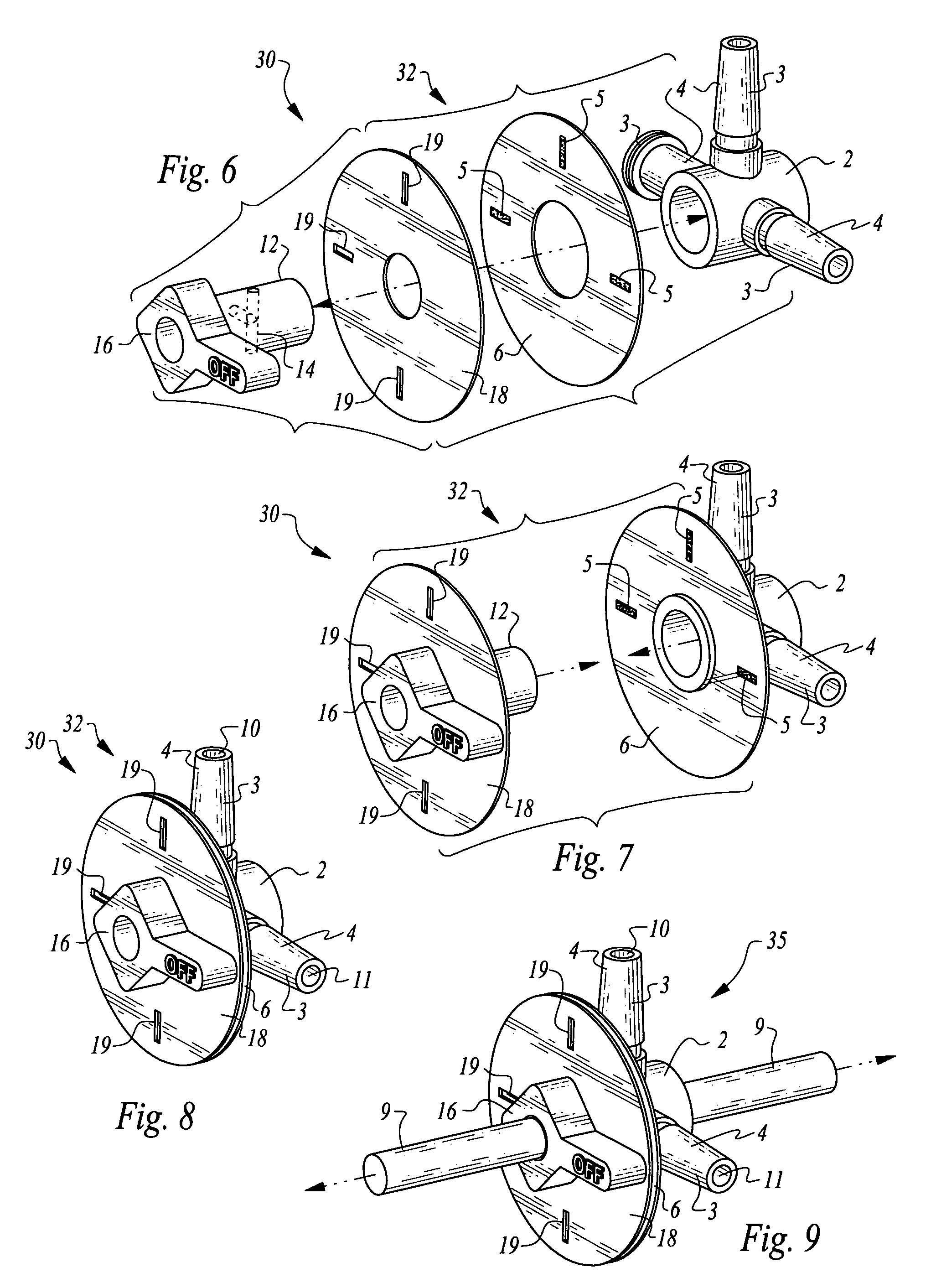

A stopcock is provided with multiple ports joining multiple fluid conduits leading between fluid sources and fluid destinations. A central hub manifold resides within a valve body supporting the ports, and can rotate relative to the valve body. Fluid flow paths within the central hub are selectively aligned or not aligned with the ports. The stopcock indicates which ports are open by providing marks corresponding with positions of the ports. When the marks are visible, the corresponding ports are open. With different positioning of ports and different configurations of fluid flow paths within the central hub, stopcocks having different numbers of operable positions are provided including two, three, four, six and eight way stopcocks. By providing an axial flow path through a central axis of the central hub intersecting the embedded fluid flow paths within the central hub, still further numbers of operational states are provided.

Owner:MONUMEDICAL

High-pressure plug valve

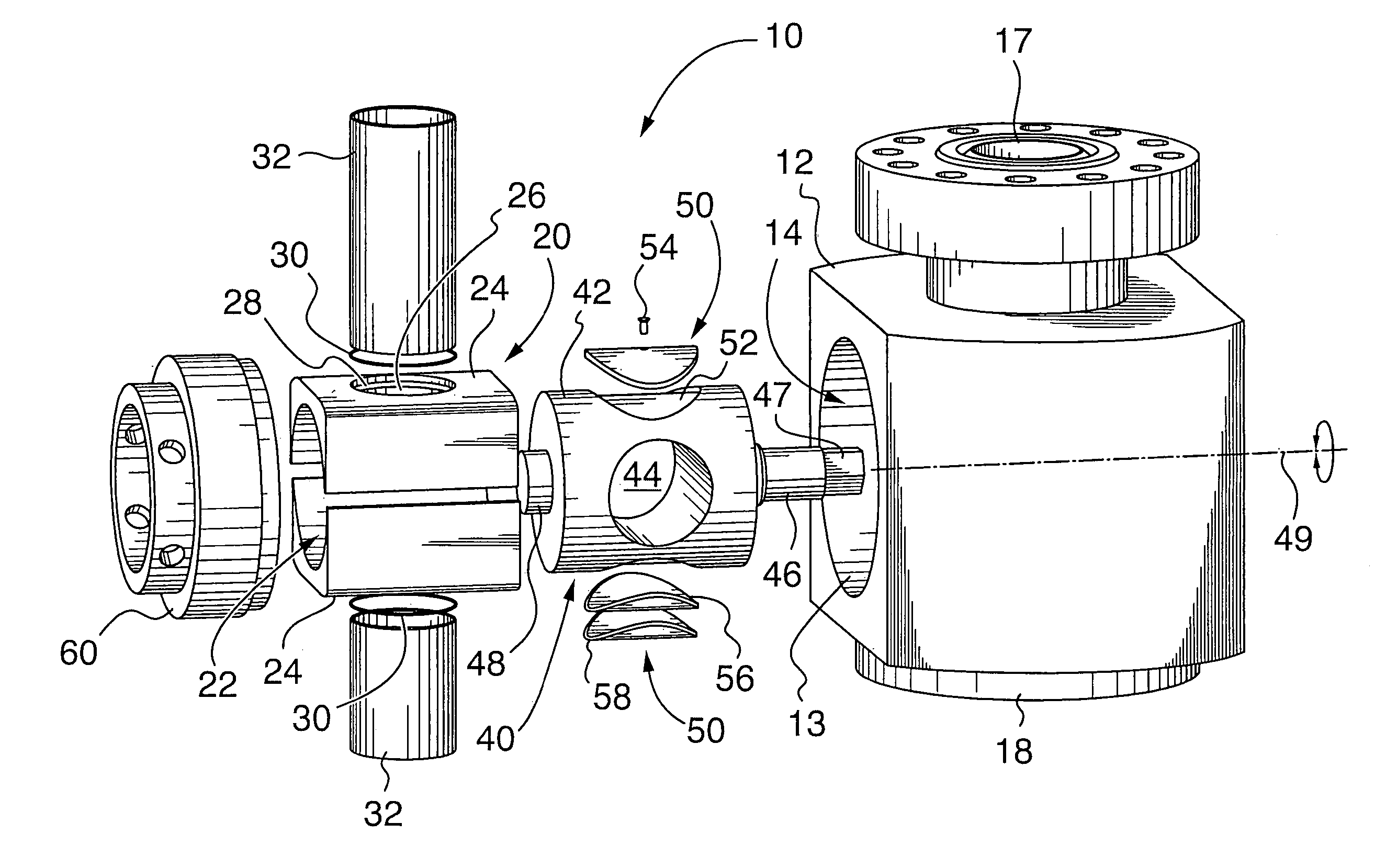

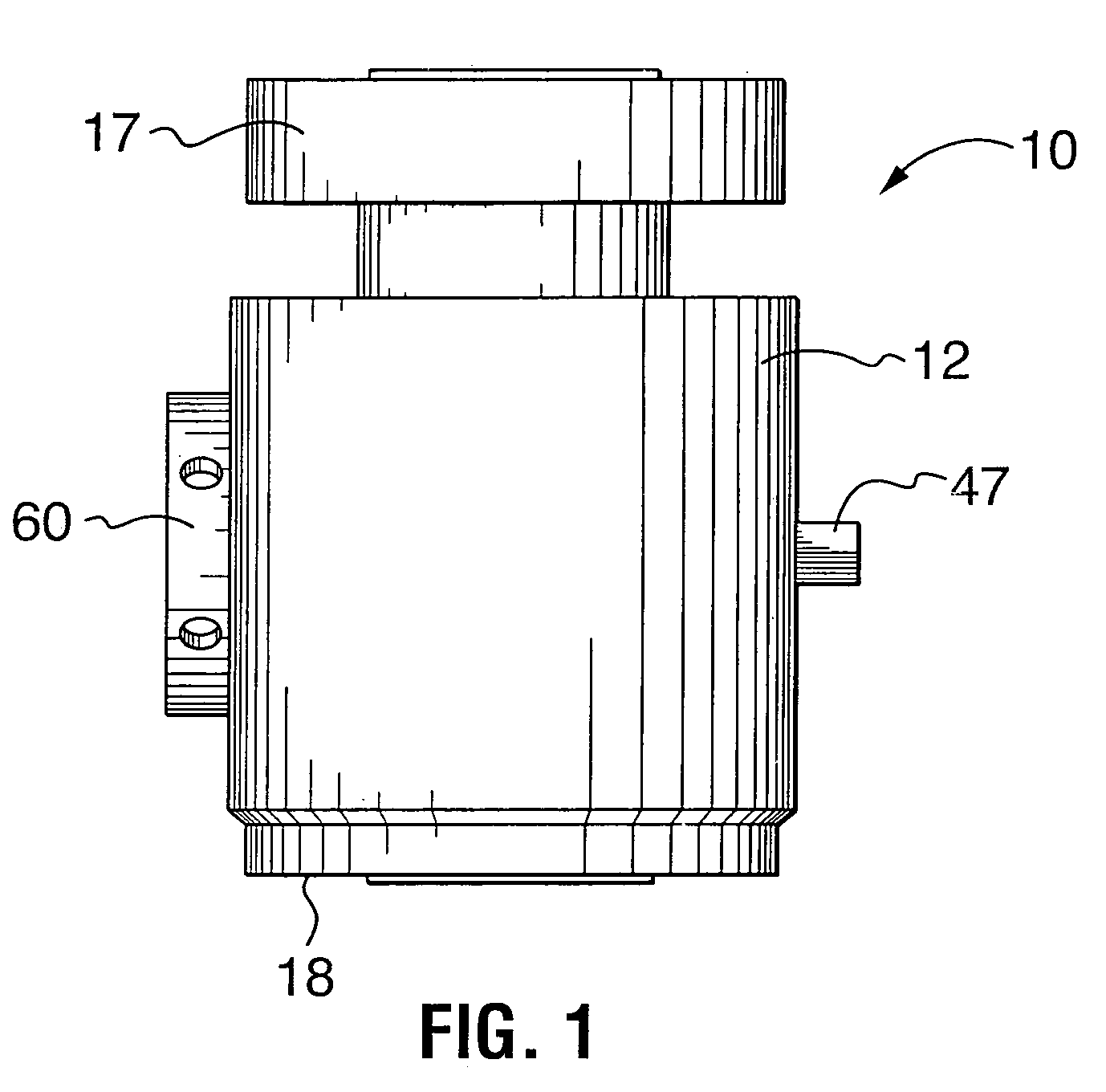

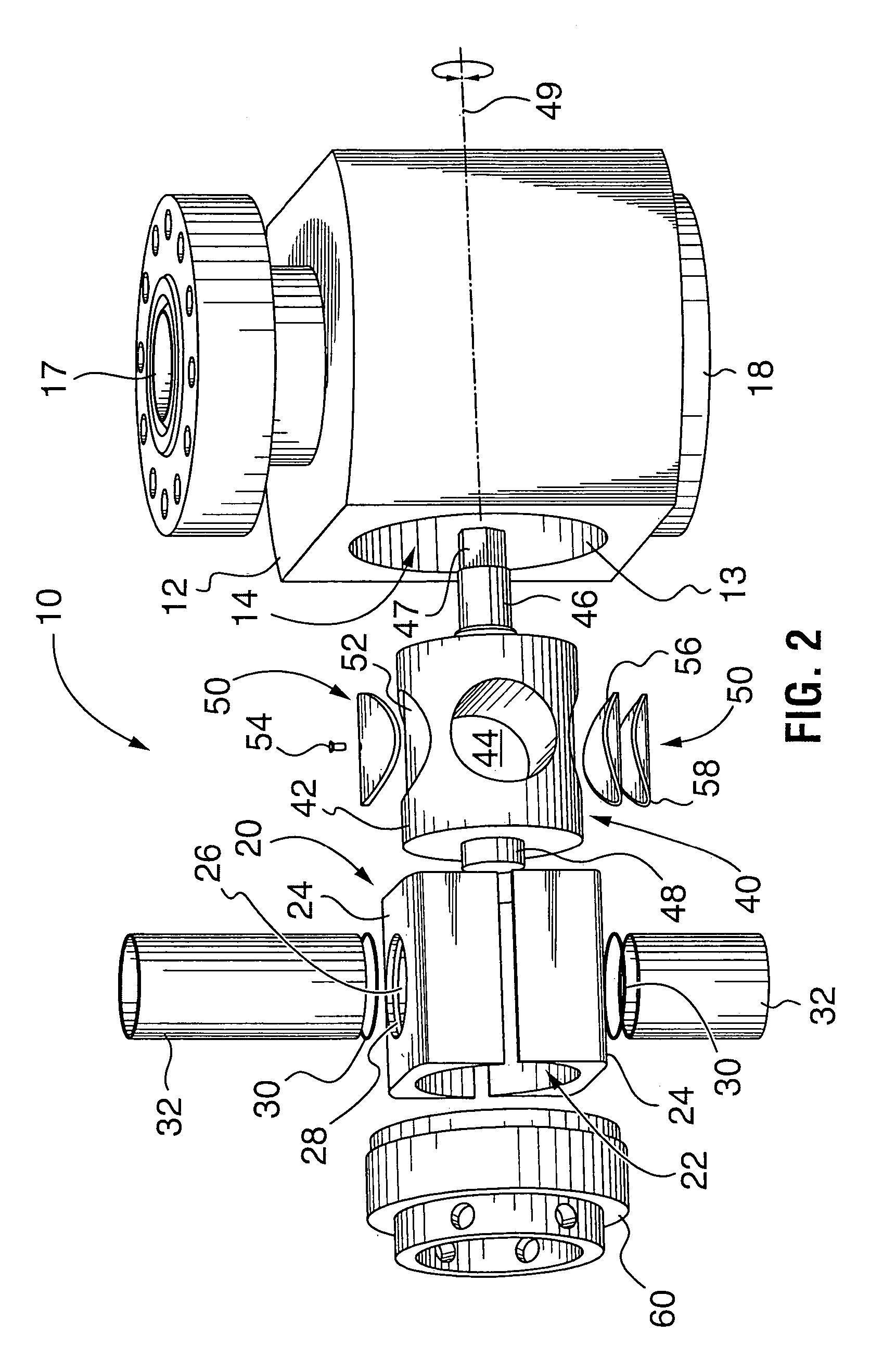

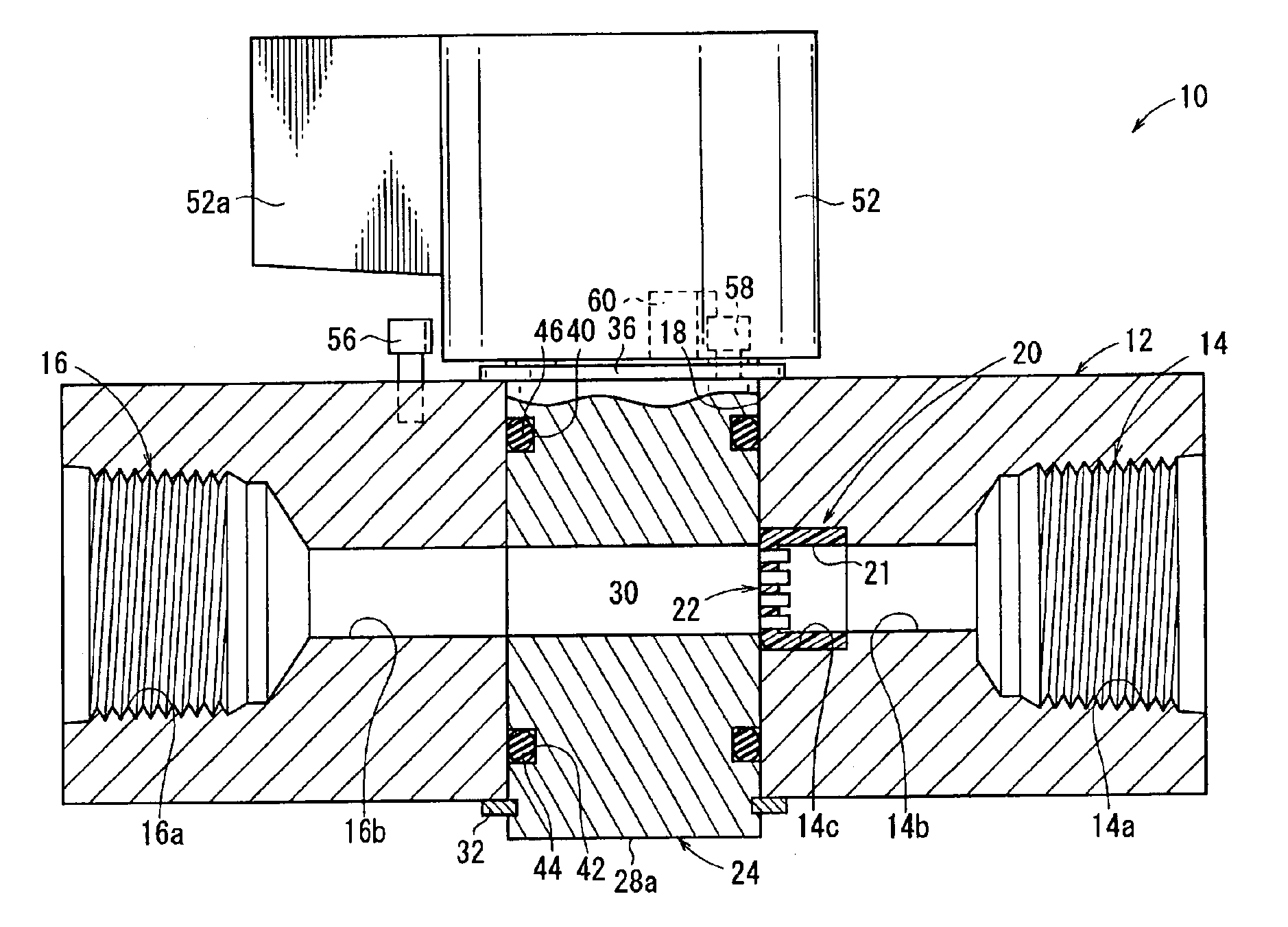

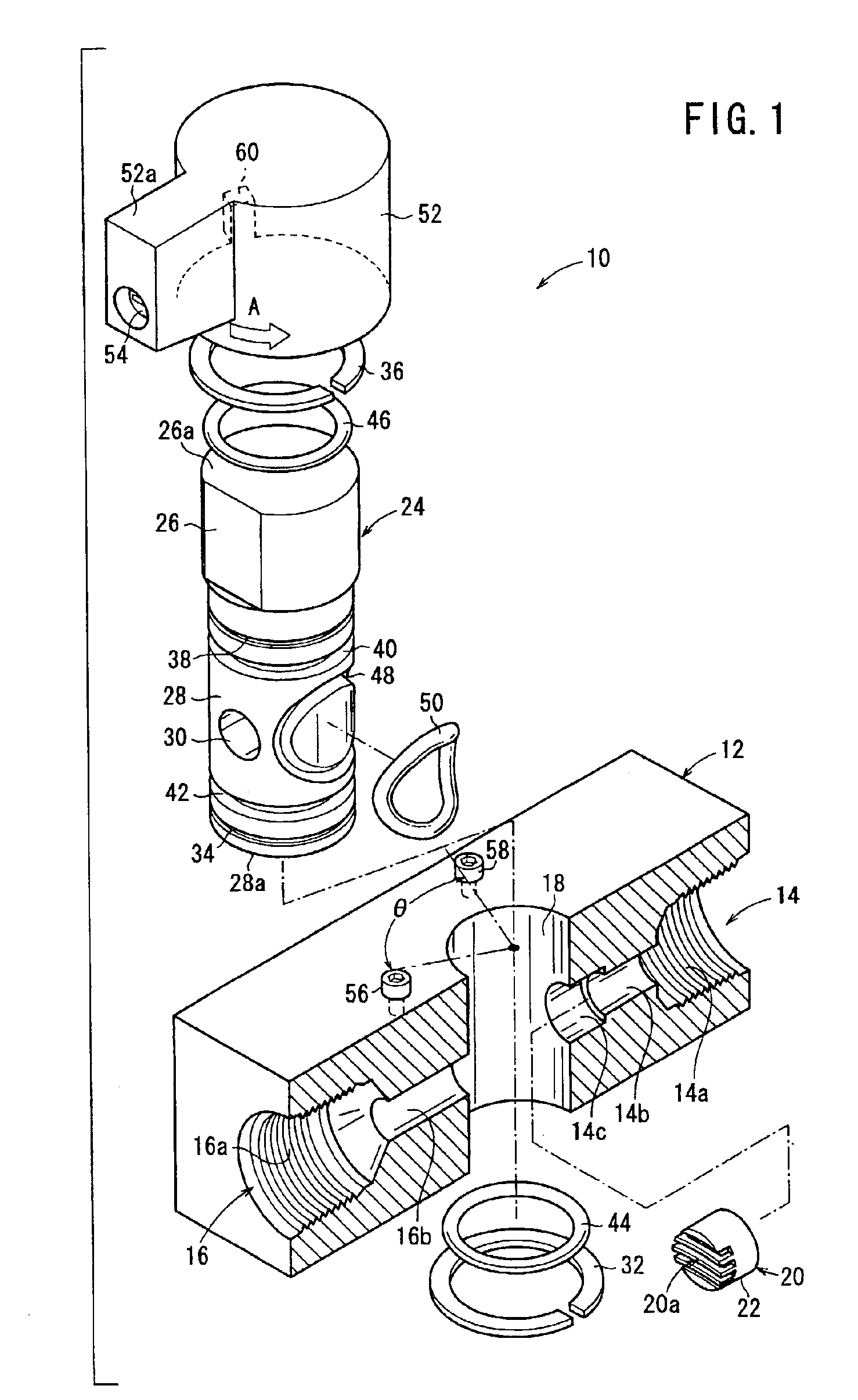

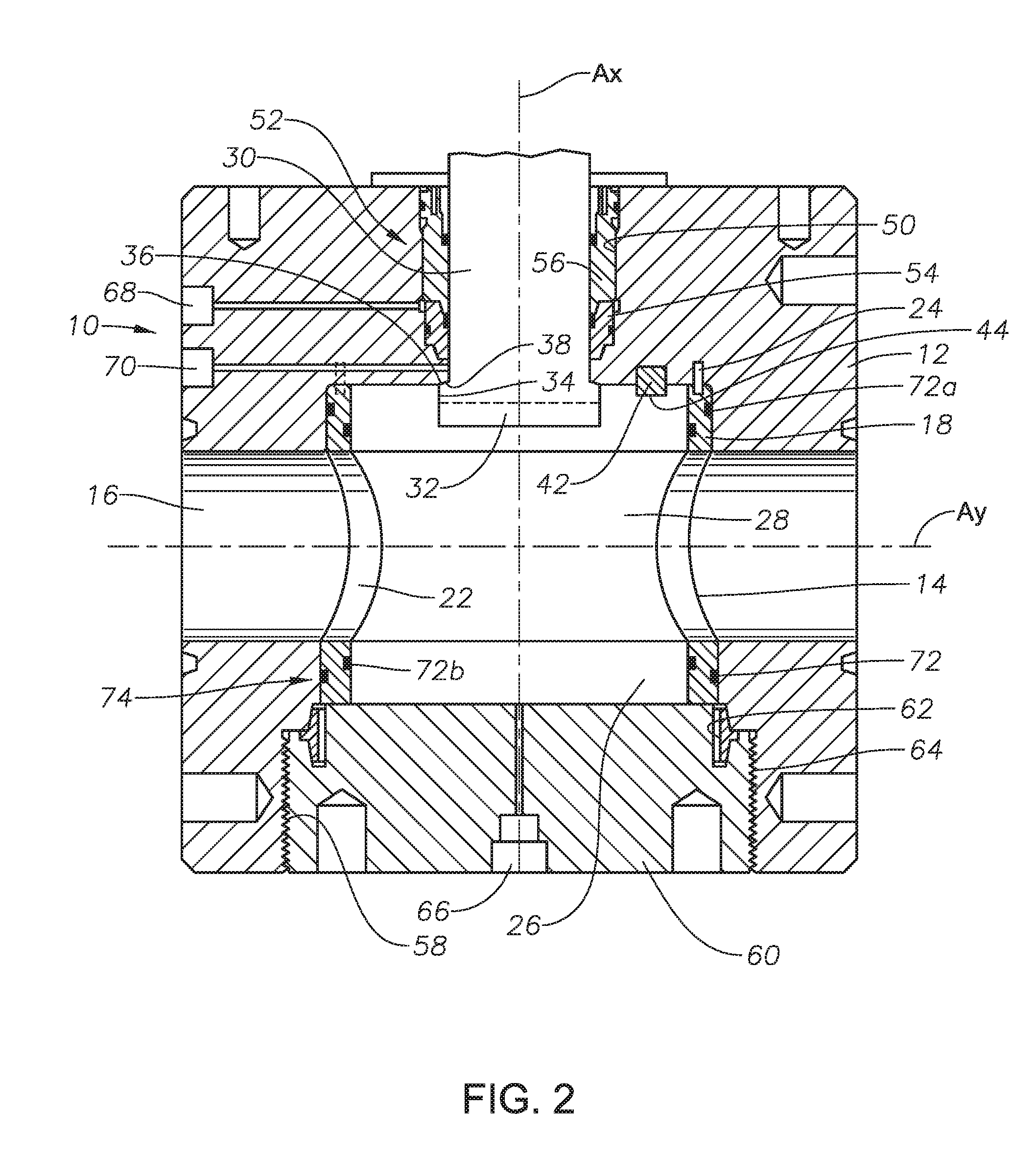

ActiveUS7204474B2Improve wear resistanceQuickly and easily refurbishedPlug valvesThin material handlingHigh pressureVALVE PORT

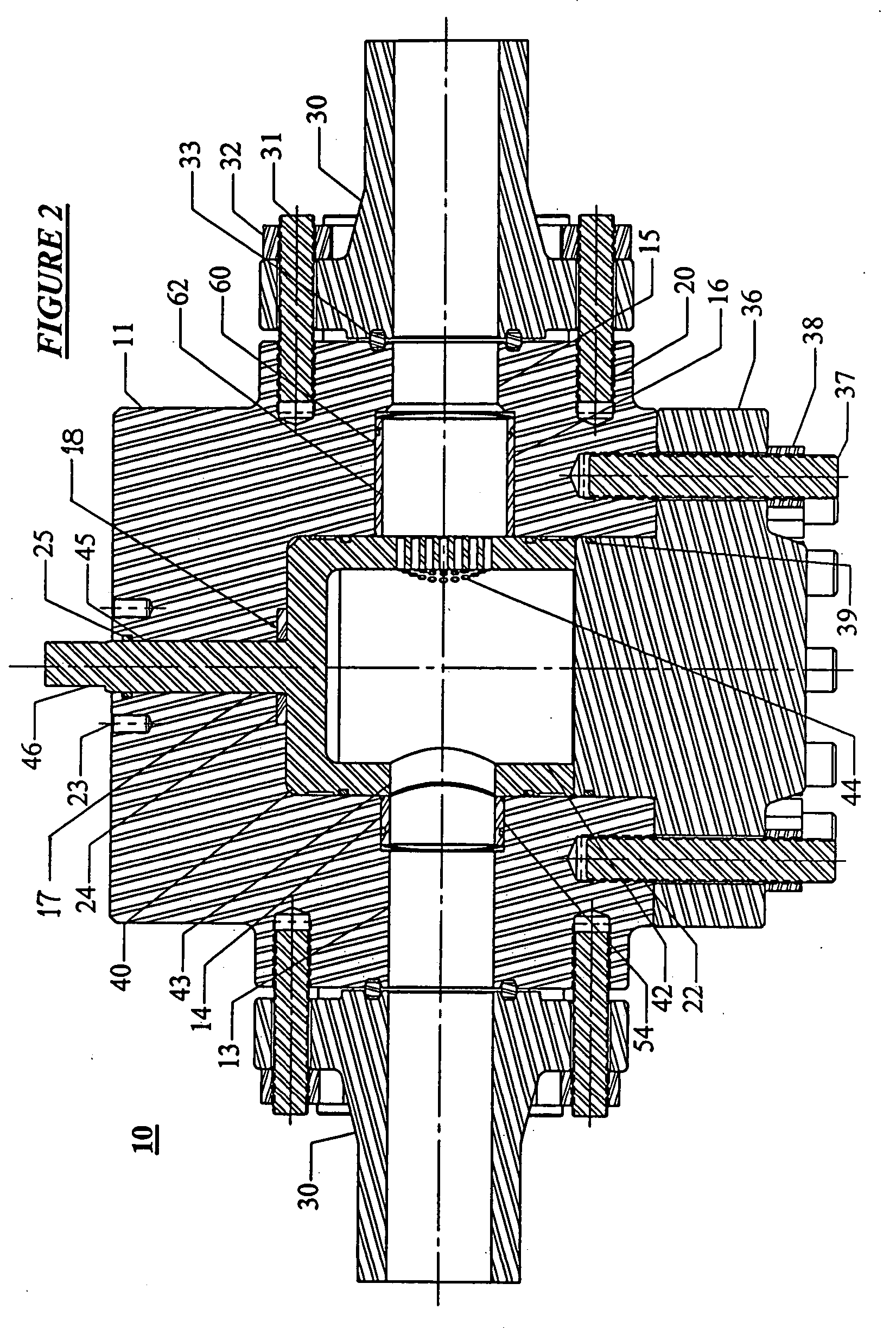

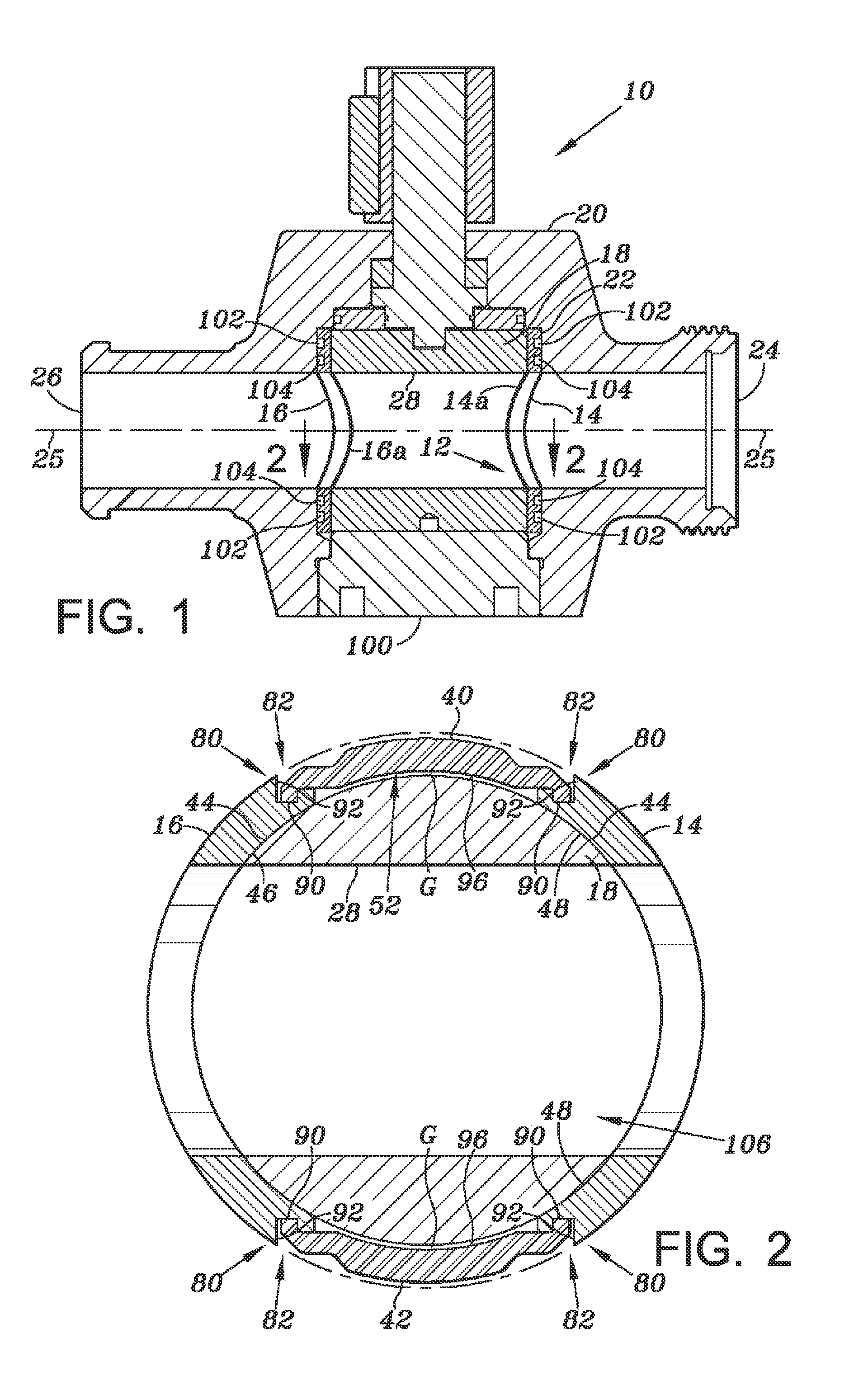

A plug valve has a valve body, a cage fitted within the valve body and a rotatable plug housed within a cylindrical cavity in the cage, for controlling fluid flow through the valve. The cage has first and second opposed flat side surfaces, each side surface has a port for receiving a replaceable flow-path insert in a fluid-tight seal. In one embodiment, the plug also includes at least one inset seal for sealing the at least one of the ports when the plug is in a closed position to inhibit leakage through the valve at low fluid pressures.

Owner:WELLS FARGO BANK NAT ASSOC +1

Gamma-stable high pressure stopcock

InactiveUS6880808B2Improve fitDifferent melting pointPlug valvesThin material handlingGamma irradiationStopcock

A medical stopcock is provided that is constructed and arranged to withstand high pressures and gamma irradiation. The stopcock generally includes a housing and a valve member. The valve member is trapped within the housing so that, when subjected to relatively high pressures, the valve member is unlikely to become separated from the housing. A handle member is attached to the valve member and allows the valve member to be rotated from open to closed positions. In some preferred embodiments, the handle member locks the valve member within the housing, when attached. All of the components are constructed of gamma-stable materials so that the stopcock may be sterilized, in its package, using gamma irradiation.

Owner:ACIST MEDICAL SYST

Cylinder valve and bayonet check-filter with excess-flow protection feature

InactiveUS6607007B1Reduce the risk of fireLower potentialFunctional valve typesContainer filling methodsOxygen systemHigh pressure oxygen

A valve apparatus especially well-suited for use in gaseous oxygen delivery systems. A valve apparatus is provided that substantially reduces the risk of fire in high-pressure oxygen systems. The apparatus is particularly well-suited for use as a plug valve on ordinary cylinder containers, but may be beneficially used in any pressurized gas system, particularly oxygen systems such as those encountered in many industrial facilities. The wetted portion of the valve is isolated from threaded portions to prevent particulate contamination of the gas stream. The valve seat is located to protect it from direct impact of high-velocity gas streams. The inventive valve, and its associated inventive check-filter and excess-flow prevention features, reduces the potential for hazardous combustion at valve points within oxygen delivery systems.

Owner:LUXFER INC

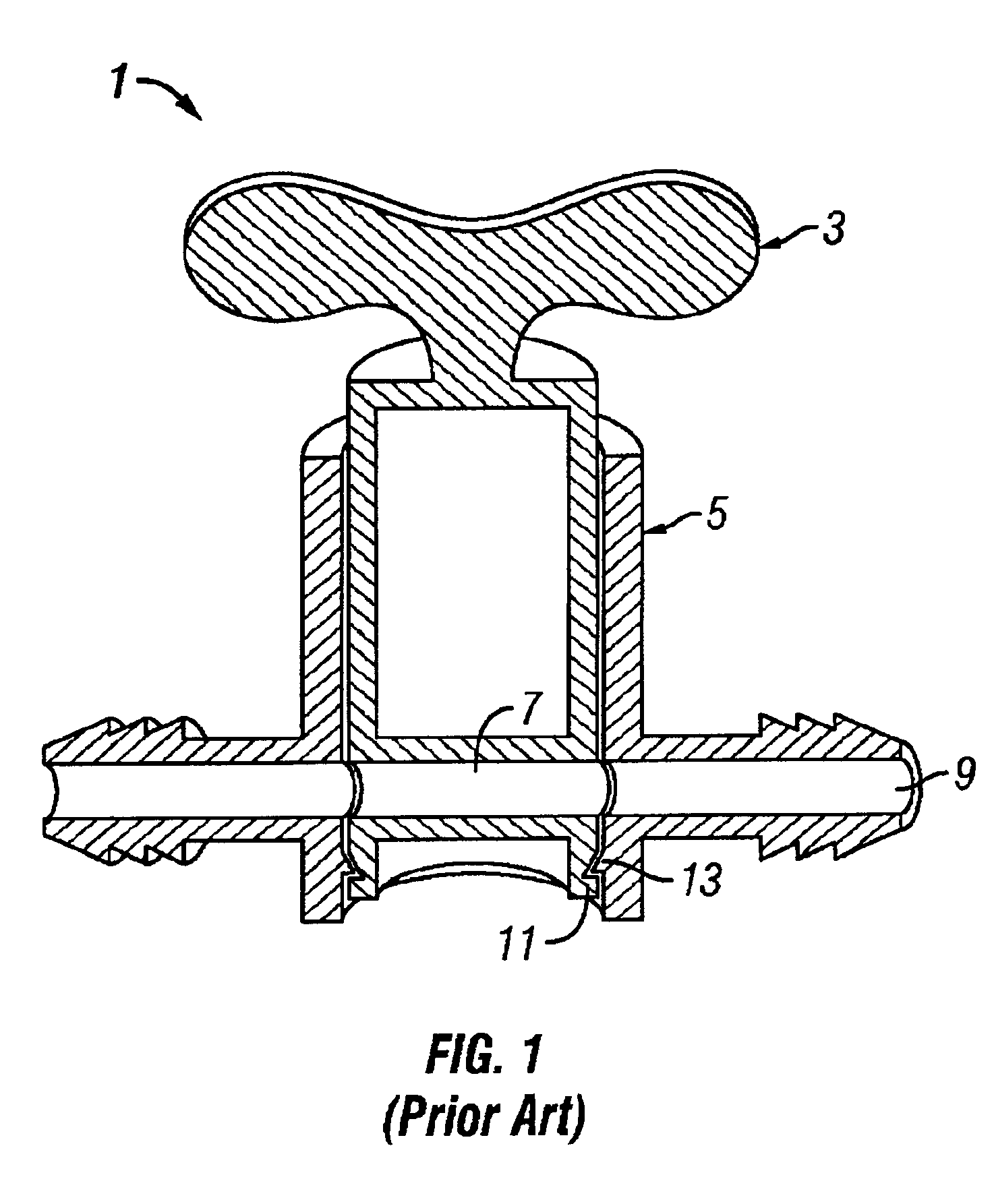

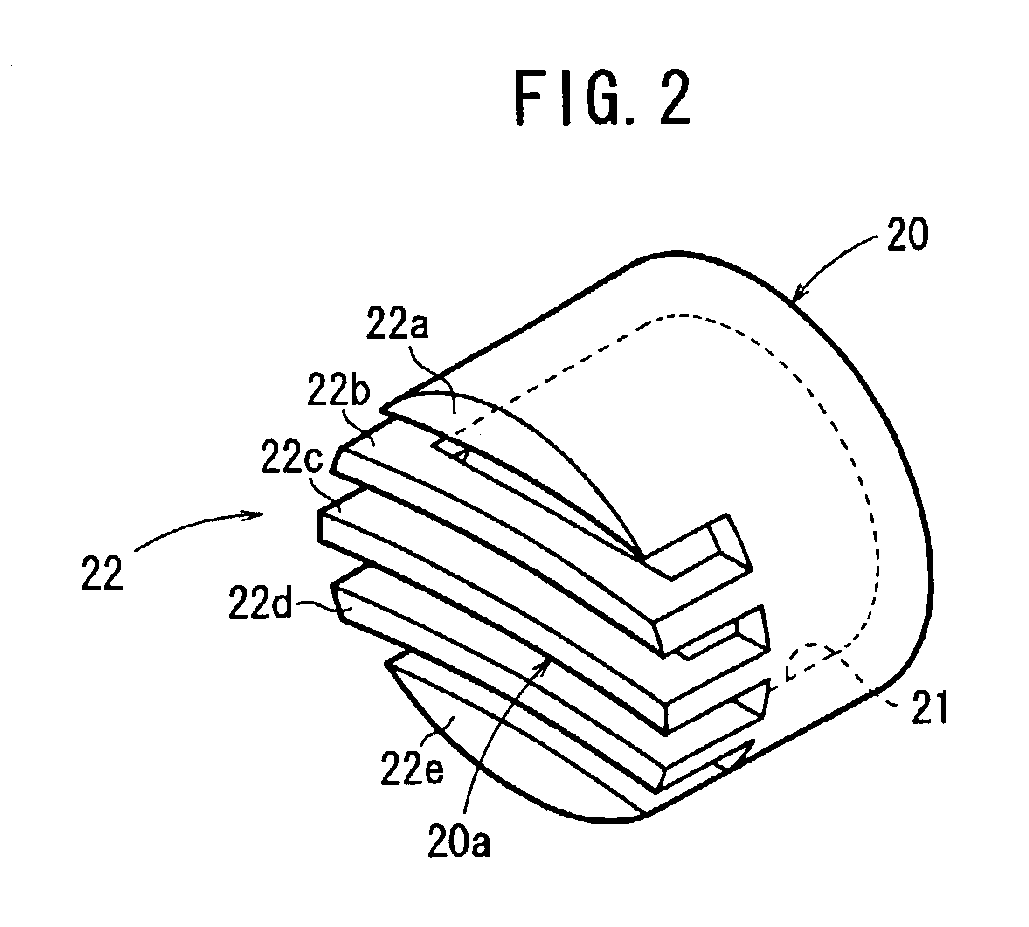

Plug valve

InactiveUS6874759B2Prevent projectionPrevent liquid leakagePlug valvesMechanical engineeringPlug valve

A main valve body has a first passage, a second passage, and an opening which intersects the first passage and the second passage. A main plug body is rotatably inserted into the opening, and has an upper section into which a handle is inserted, and a lower section having a through-hole. An O-ring is seated on an annular groove which is provided in the vicinity of the through-hole. A seal-retaining member for preventing the O-ring from projecting is fitted to an expanded diameter section of the first passage. One end of the seal-retaining member tightly contacts an end surface of the expanded diameter section. A curved surface corresponding to an inner circumferential surface of the opening is formed at the other end of the seal-retaining member.

Owner:SMC CORP

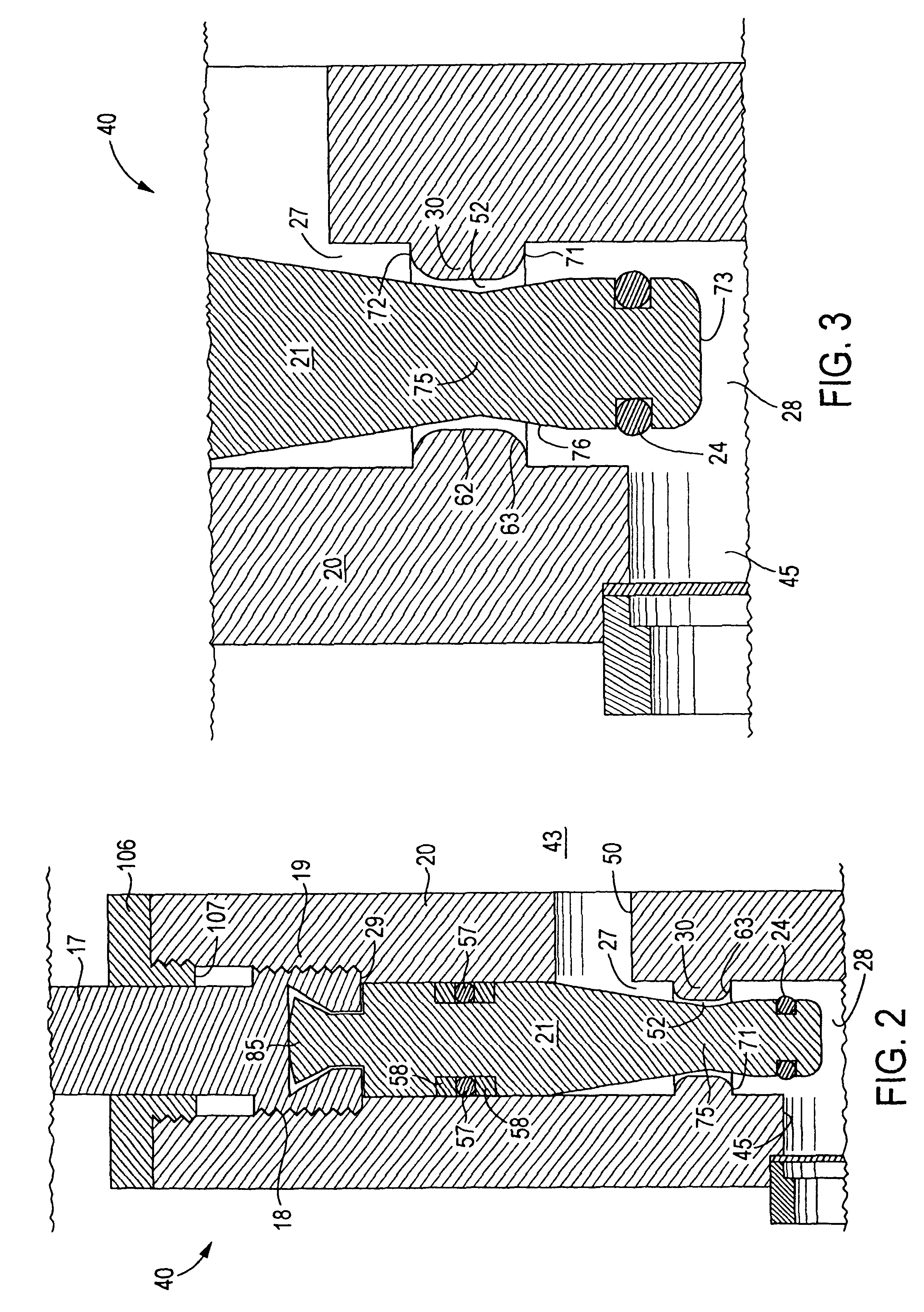

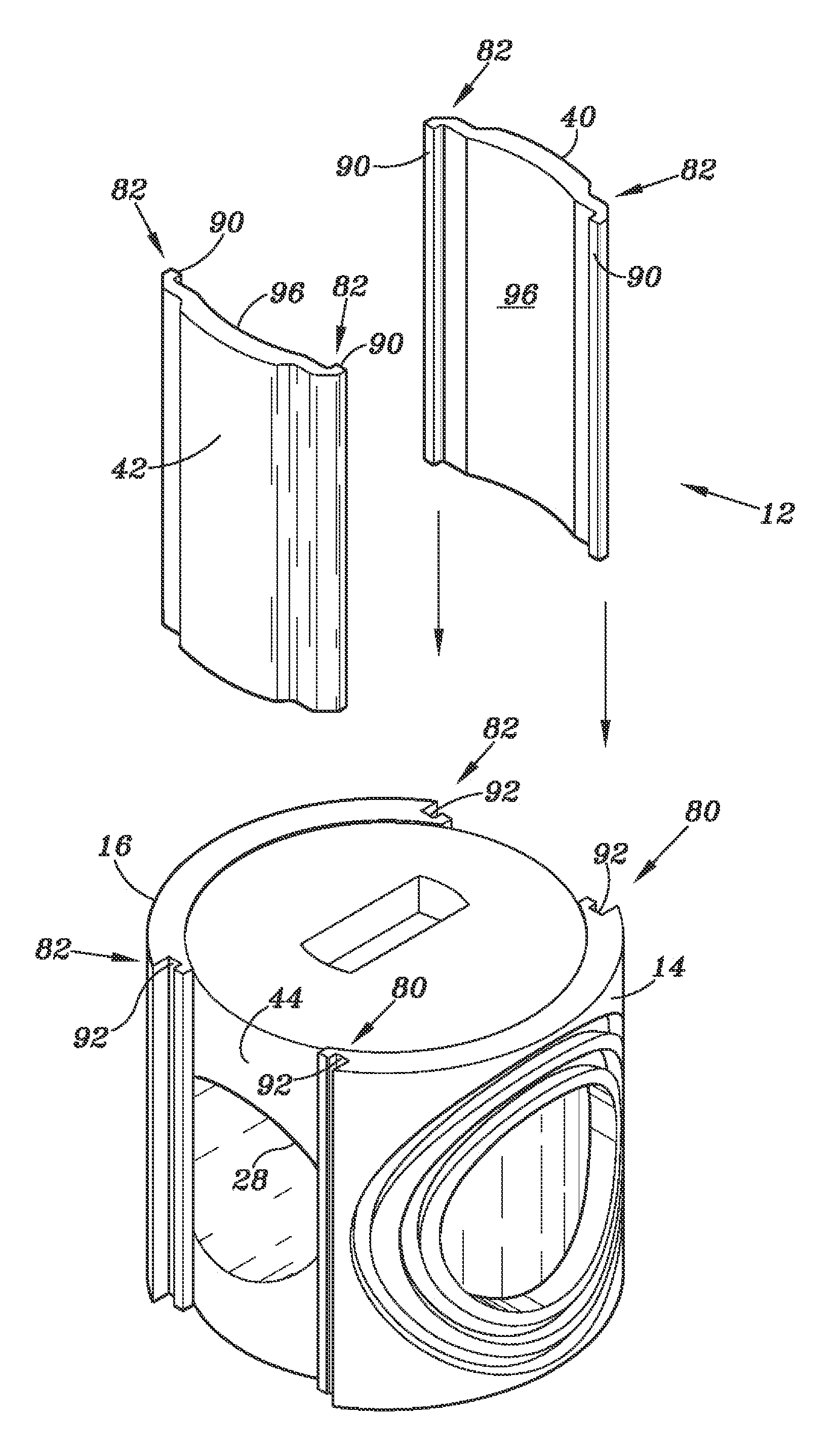

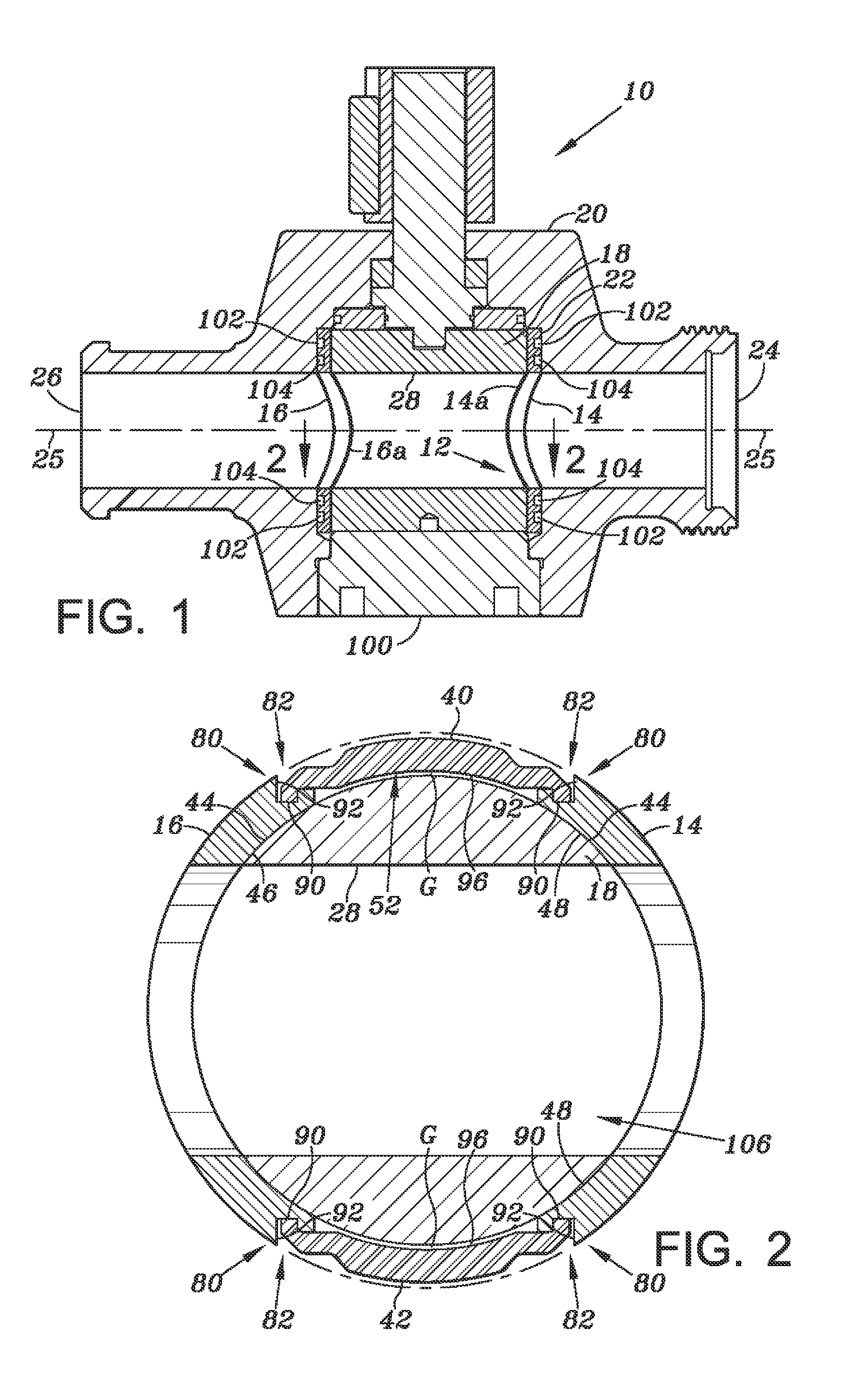

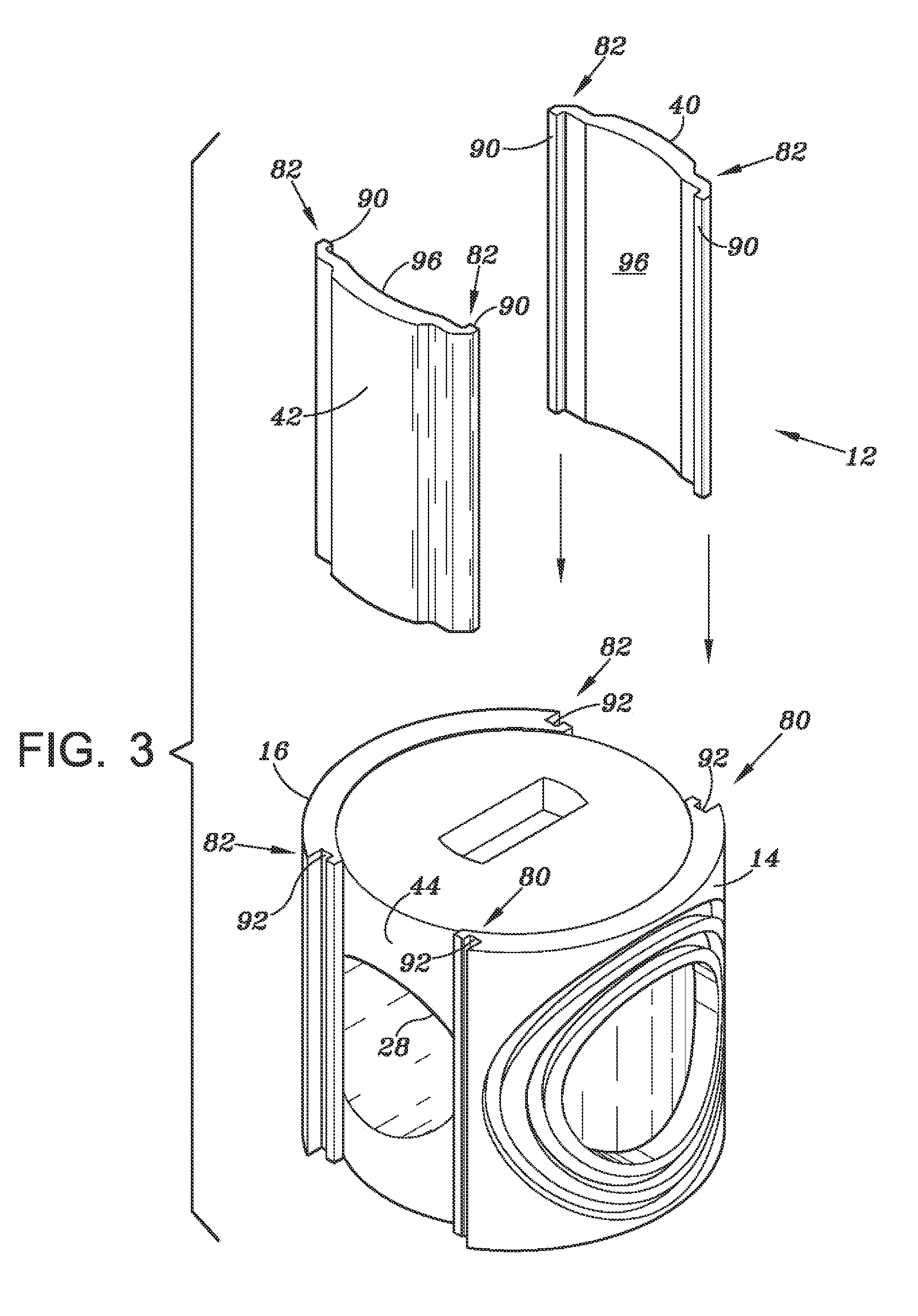

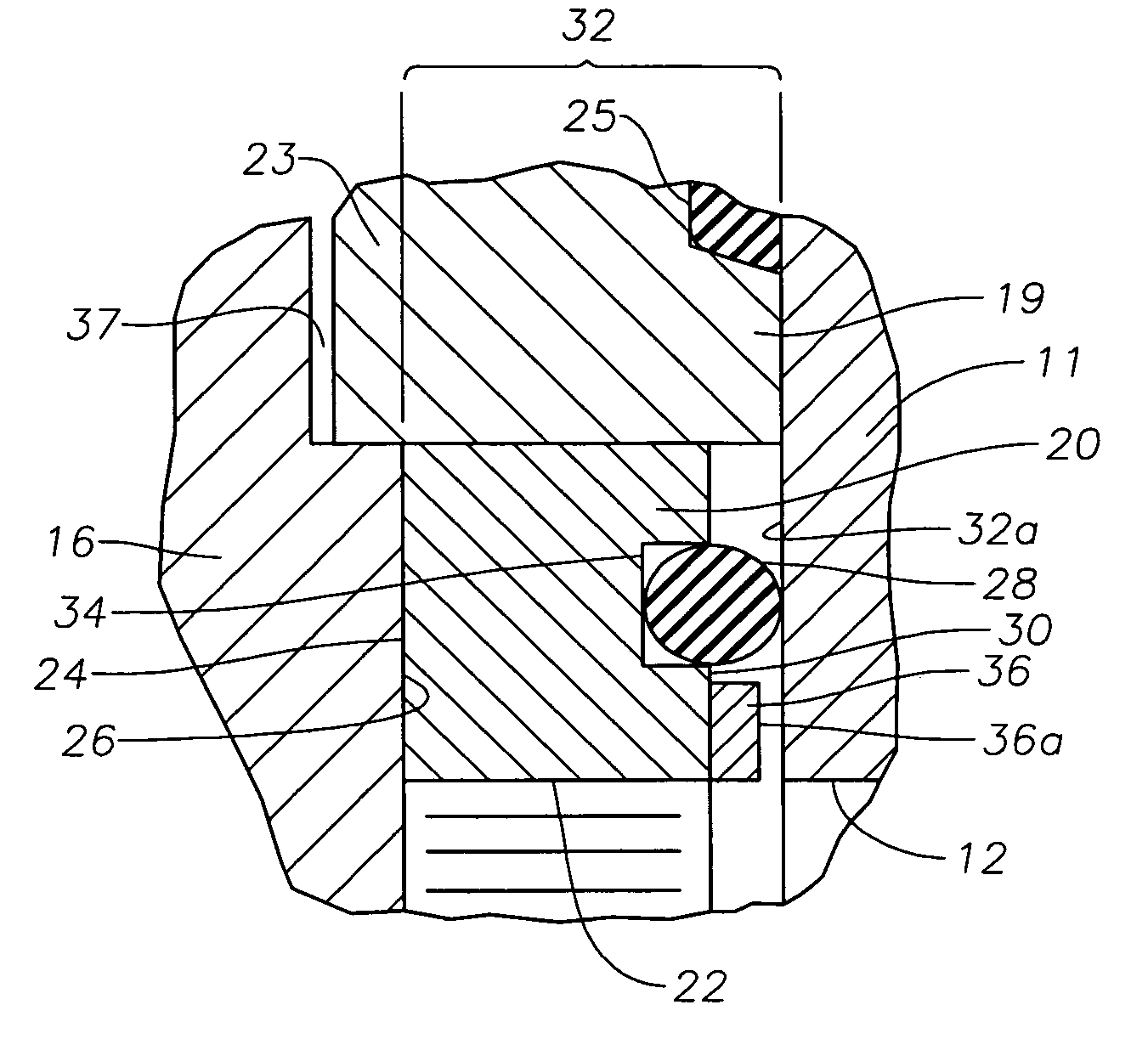

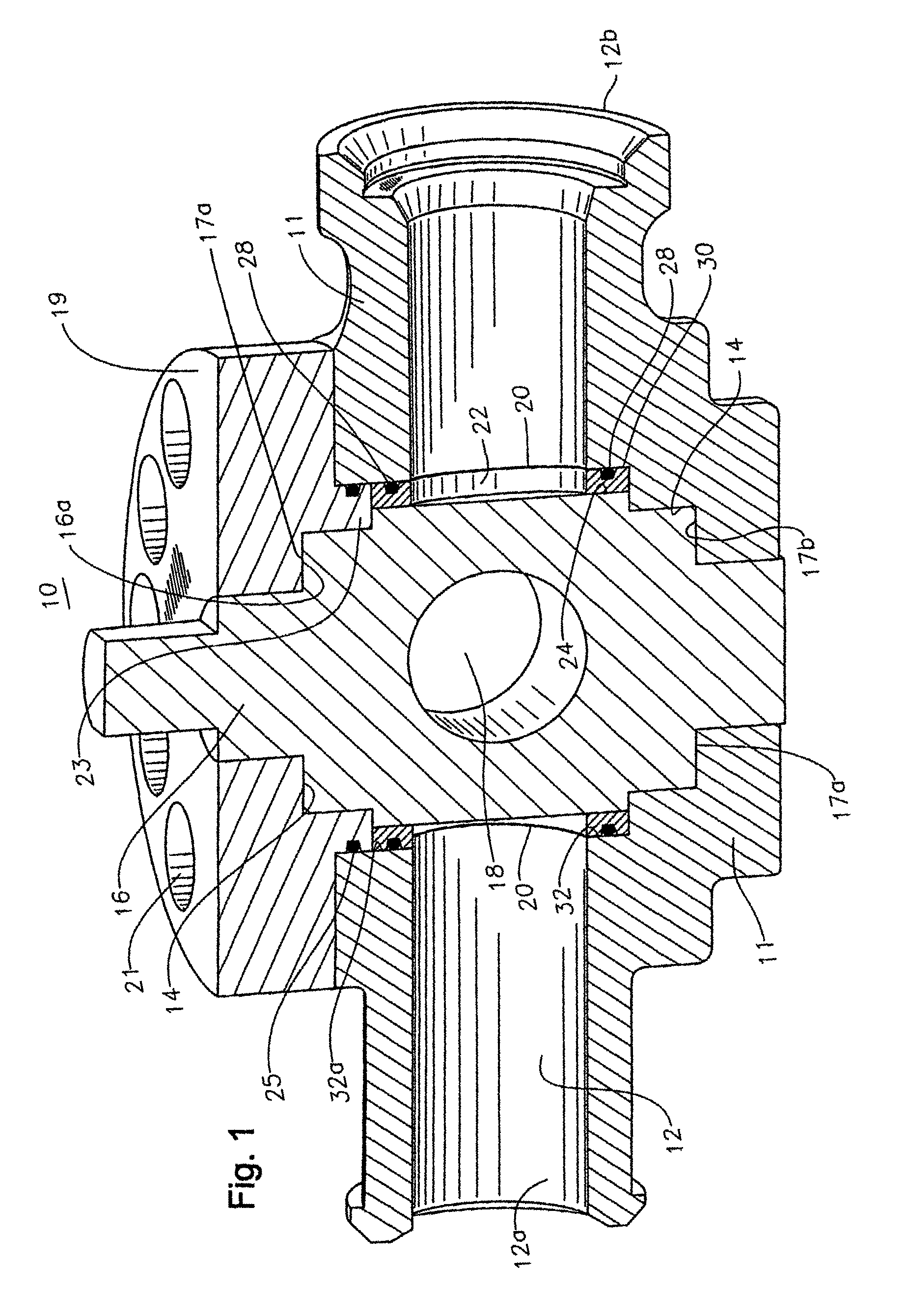

Plug valve having preloaded seal segments

A plug valve including a valve body having an inlet port, an outlet port and a central chamber extending between the inlet port and the outlet port. The valve also includes an inlet seal segment within the central chamber and includes a bore extending therethrough and aligned with the inlet port. An outlet seal segment is disposed within the central chamber having a bore extending therethrough and aligned with the outlet port. A plug member is disposed in the central chamber and is moveable between an open position, to facilitate fluid flow through the plug valve, and a closed position, to block fluid flow through the plug valve. First and second side segments are disposed between and interlocked to the inlet and outlet seal segments to encircle the plug member. The side segments are tensioned to preload the seal segments against the plug member to prevent the flow of fluid between the seal segments and the plug member.

Owner:SPM OIL & GAS INC

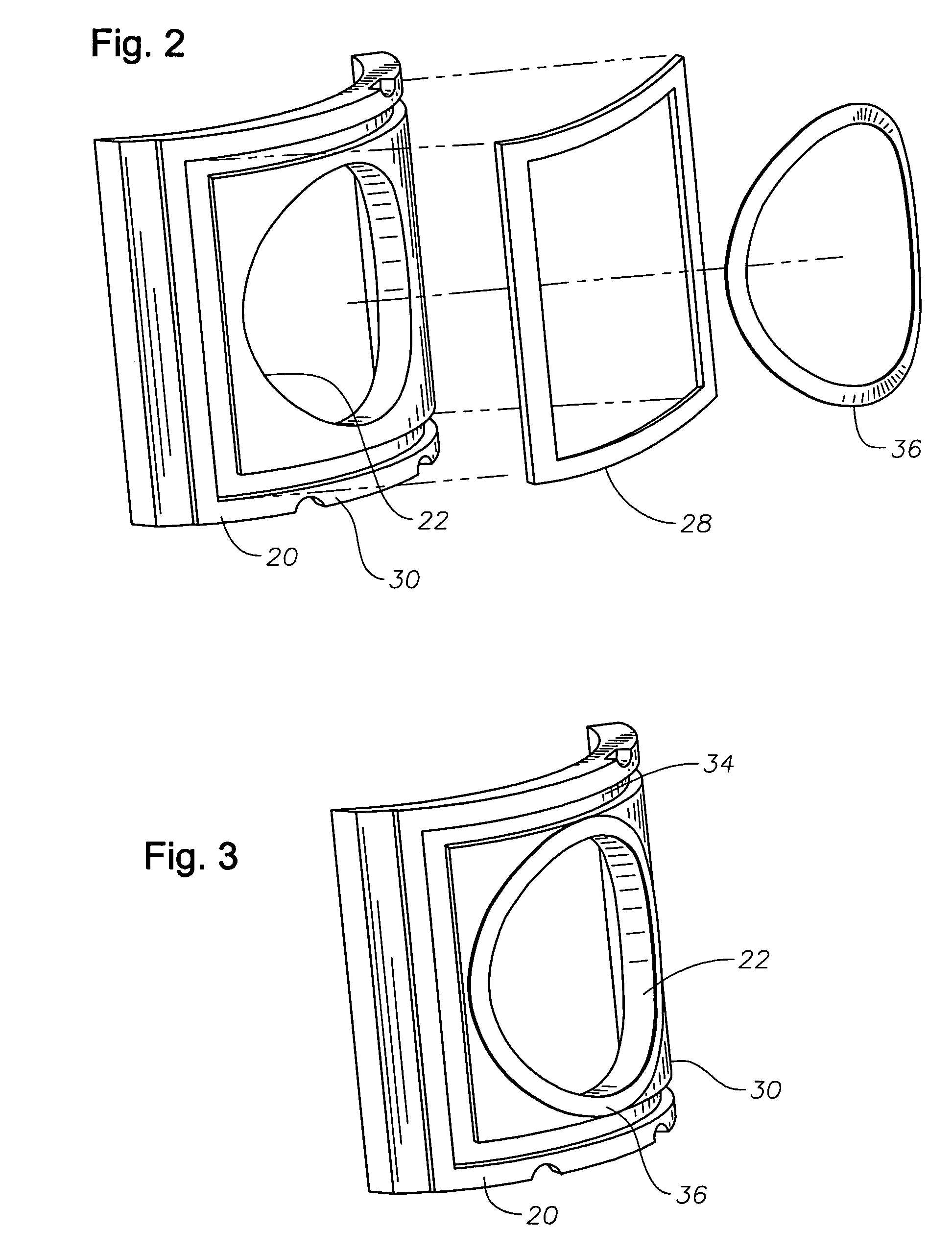

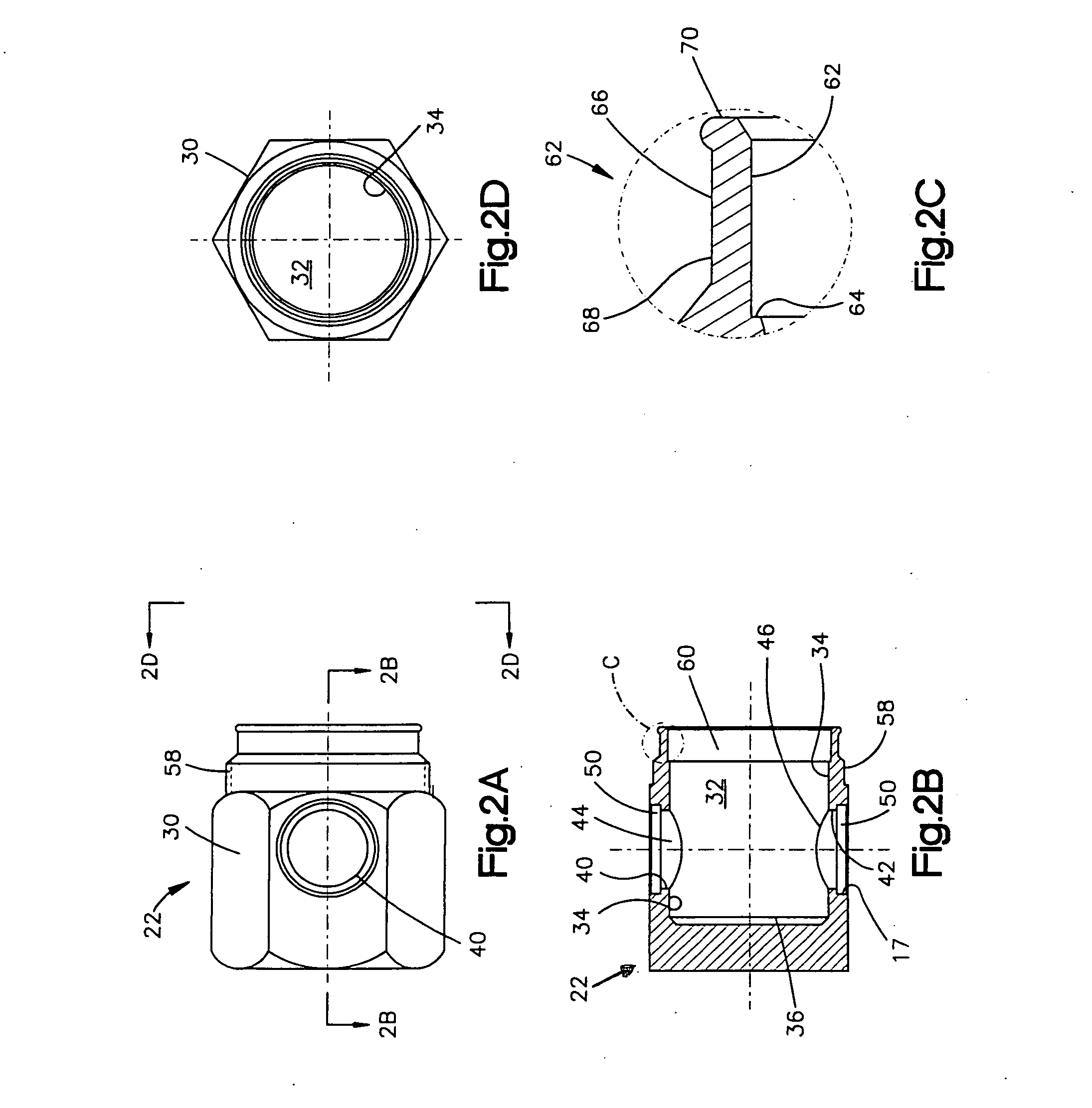

Plug valve having a seal boss

ActiveUS7451959B2Increase heightControl deformationPlug valvesThin material handlingFluid controlEngineering

A fluid control valve utilizes a rotatable plug valve member mounted in a fluid passage to control the flow of fluids. Two segments are placed on each side of the plug valve member within a recess located between the plug valve member and the body of the fluid passage. The outer surface of the segments includes an elastomeric seal and metal annular boss, which acts as a stop to limit deformation of the seal when the valve is closed and under pressure.

Owner:SPM OIL & GAS INC

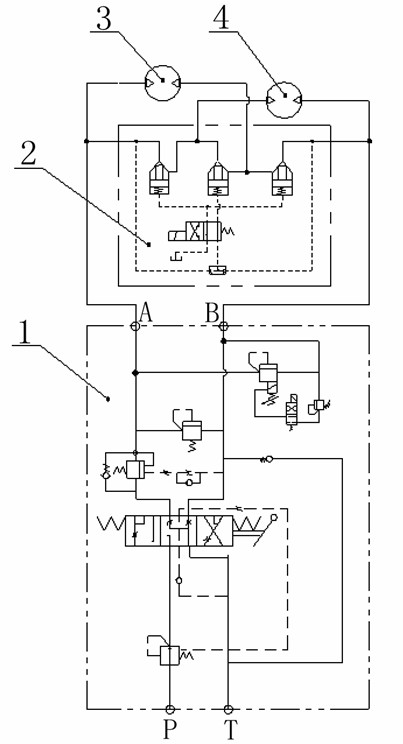

Novel double-motor serial-parallel automatic switching device

InactiveCN102425578ALow costImprove efficiencyServomotor componentsServomotorsEconomic benefitsControl valves

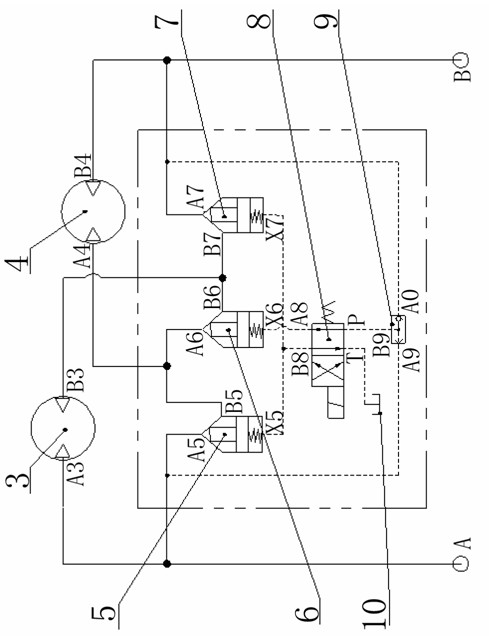

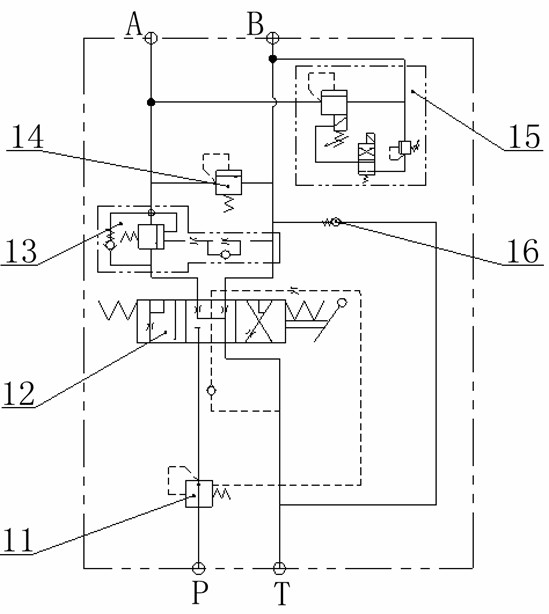

The invention relates to a novel double-motor serial-parallel automatic switching device, which comprises a motor main control valve bank, a motor serial-parallel switching valve bank, a motor I and a motor II, wherein the motor serial-parallel switching valve bank consists of a two-way plugging valve I, a two-way plugging valve II, a two-way plugging valve III, an electromagnetic reversing valve and a shuttle valve, and the motor main control valve bank comprises a reducing valve, a main reversing valve, a balance valve, a safety valve, a passive cable laying valve and an oil compensation retaining valve. The novel double-motor serial-parallel automatic switching device has a simple structure, is convenient to operate and control, is reliable to work, can save the cost, and has remarkable economic benefit.

Owner:WUHAN MARINE MACHINERY PLANT

Multi-port stopcock valve and flow designating system

A stopcock is provided with multiple ports joining multiple fluid conduits leading between fluid sources and fluid destinations. A central hub manifold resides within a valve body supporting the ports, and can rotate relative to the valve body. Fluid flow paths within the central hub are selectively aligned or not aligned with the ports. The stopcock indicates which ports are open by providing marks corresponding with positions of the ports. When the marks are visible, the corresponding ports are open. With different positioning of ports and different configurations of fluid flow paths within the central hub, stopcocks having different numbers of operable positions are provided including two, three, four, six and eight way stopcocks. By providing an axial flow path through a central axis of the central hub intersecting the embedded fluid flow paths within the central hub, still further numbers of operational states are provided.

Owner:MONUMEDICAL

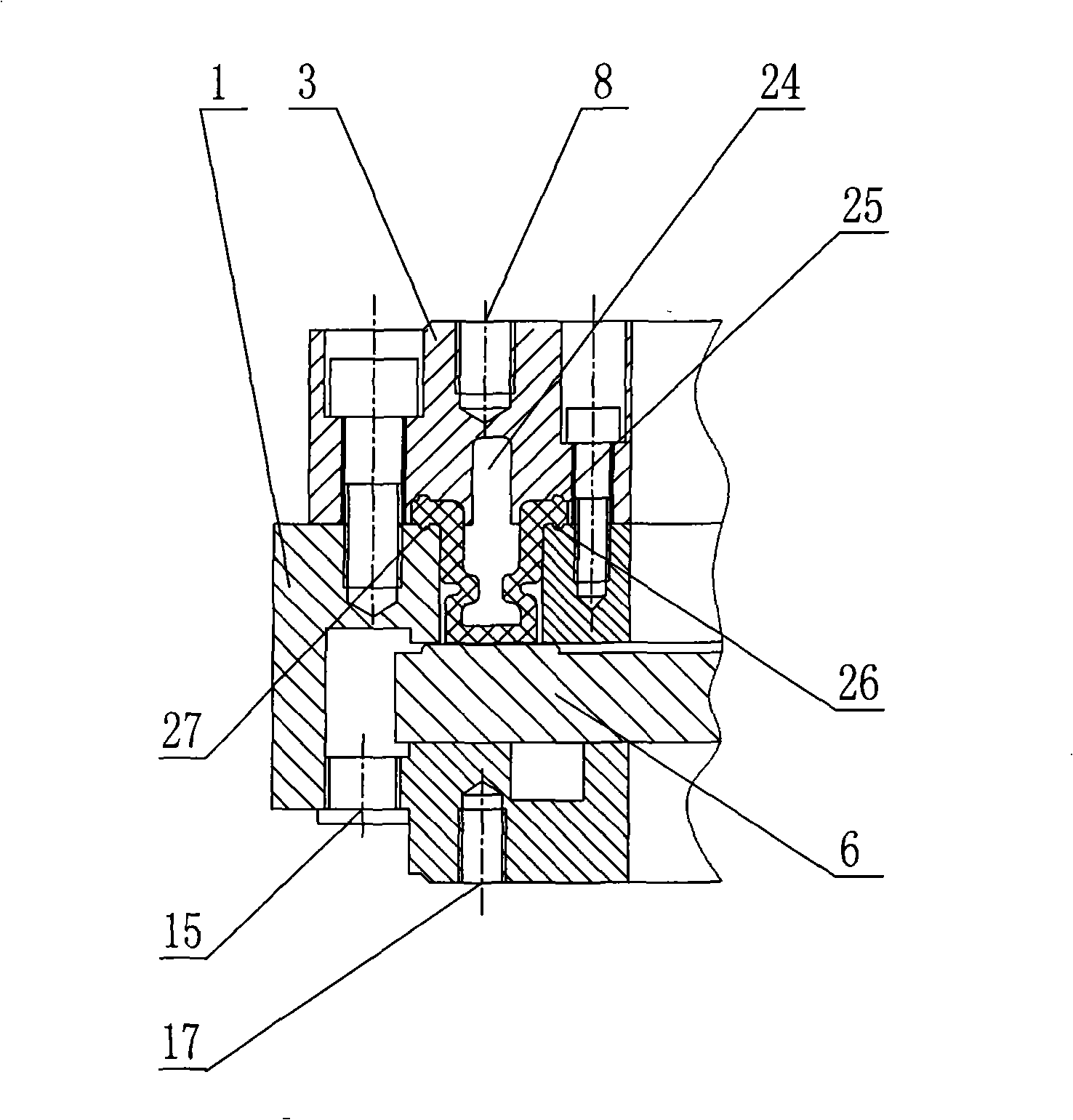

Non-wear sealing plug valve

The invention relates to a non-wear sealing plug valve. The non-wear sealing plug valve comprises a valve body, a valve plug, a valve deck and valve rods. The non-wear sealing plug valve is characterized in that a limiting groove is formed in the bottom of an inner cavity of the valve body; a limiting rod and an extension spring are arranged at the lower end of the valve plug, a regulation groove is formed in the outer circle of the upper end of the valve plug, a lifting block is further arranged at the upper end of the valve plug, and a groove is formed below the lifting block; the valve rods include the upper valve rod and the lower valve rod, the upper end of the upper valve rod is connected with an external driving device, and the lower end of the upper valve rod is fixedly mounted at the upper end of the lower valve rod; reset springs are arranged between the upper end face of the lower valve rod and the lower end face of the valve deck, a regulation rod which can stretch into the regulation groove is arranged at the lower end of the lower valve rod, and the lower valve rod is further provided with compression springs and balls; and the outer end faces of the balls make contact with the wall of an inner cavity of the valve body, and two clamping grooves are formed in the wall, above the balls, of the inner cavity of the valve body and symmetrically distributed with the center line of the lower valve rod as the center. The non-wear sealing plug valve is provided with a valve plug sealing surface and a valve body sealing surface, and friction is avoided; and the non-wear sealing plug valve has the advantages that wear of the sealing surfaces is avoided, airtightness is good, and the service life is long.

Owner:MUDANJIANG CITY LINHAI PETROLEUM REFLOATATION INSTR

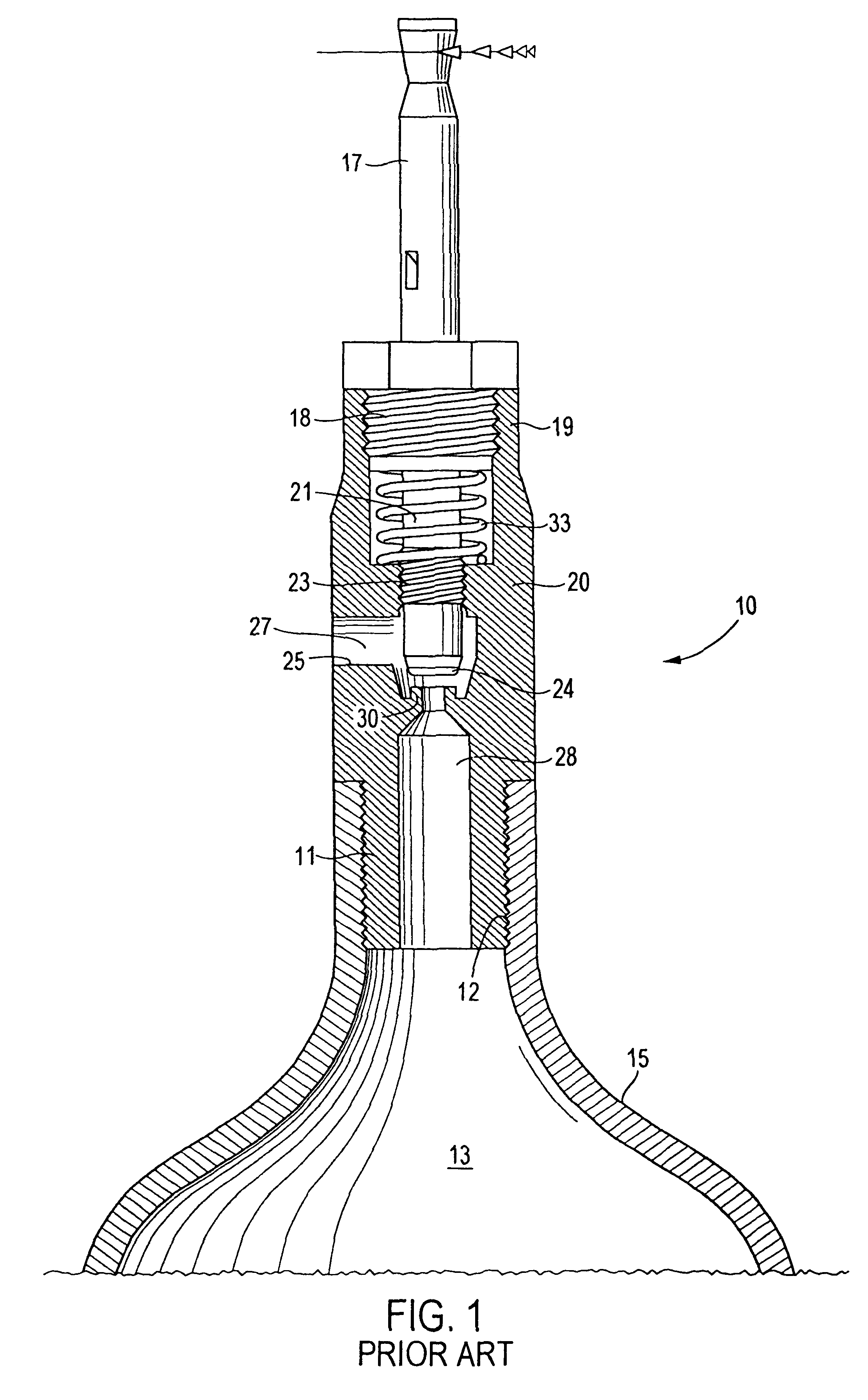

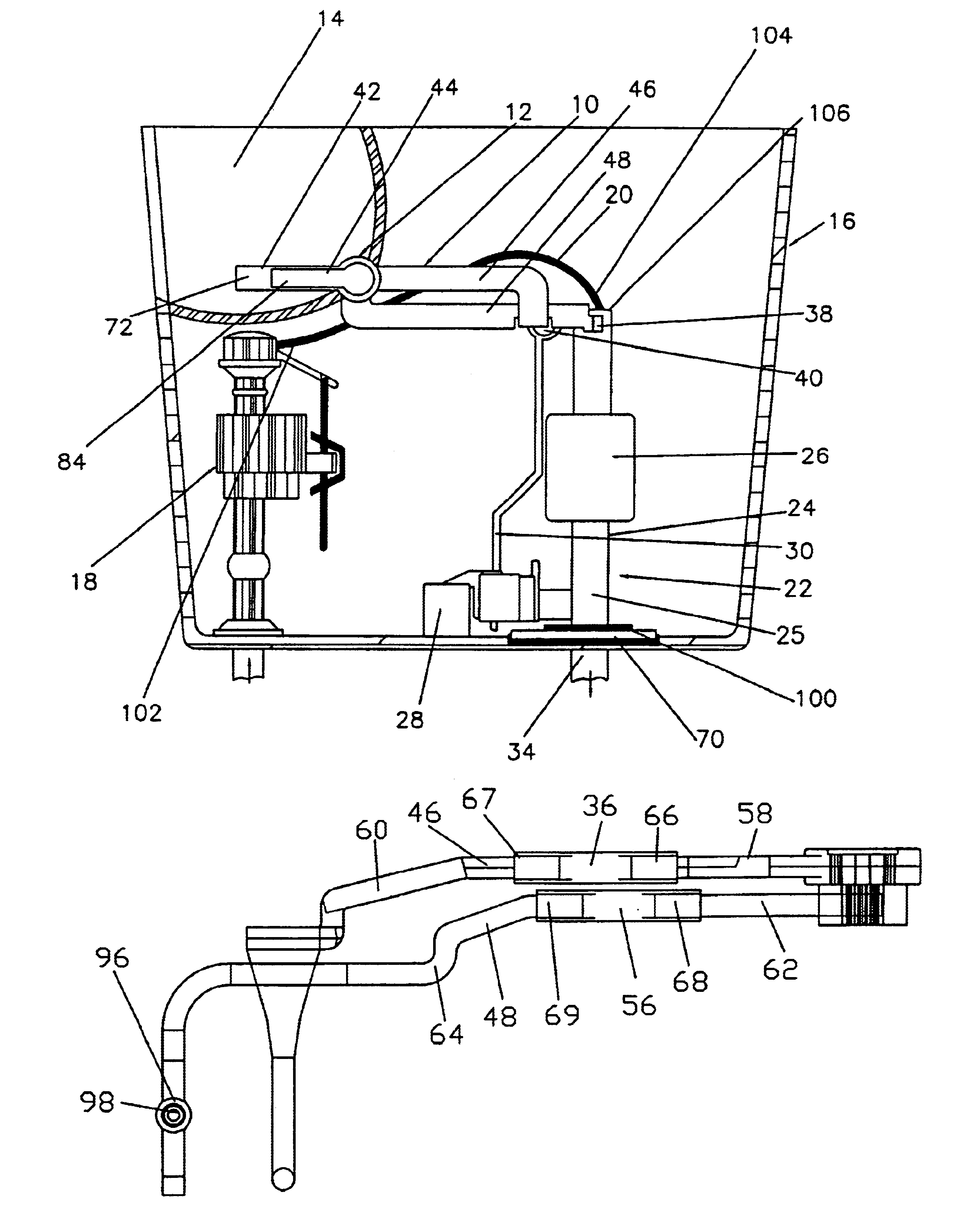

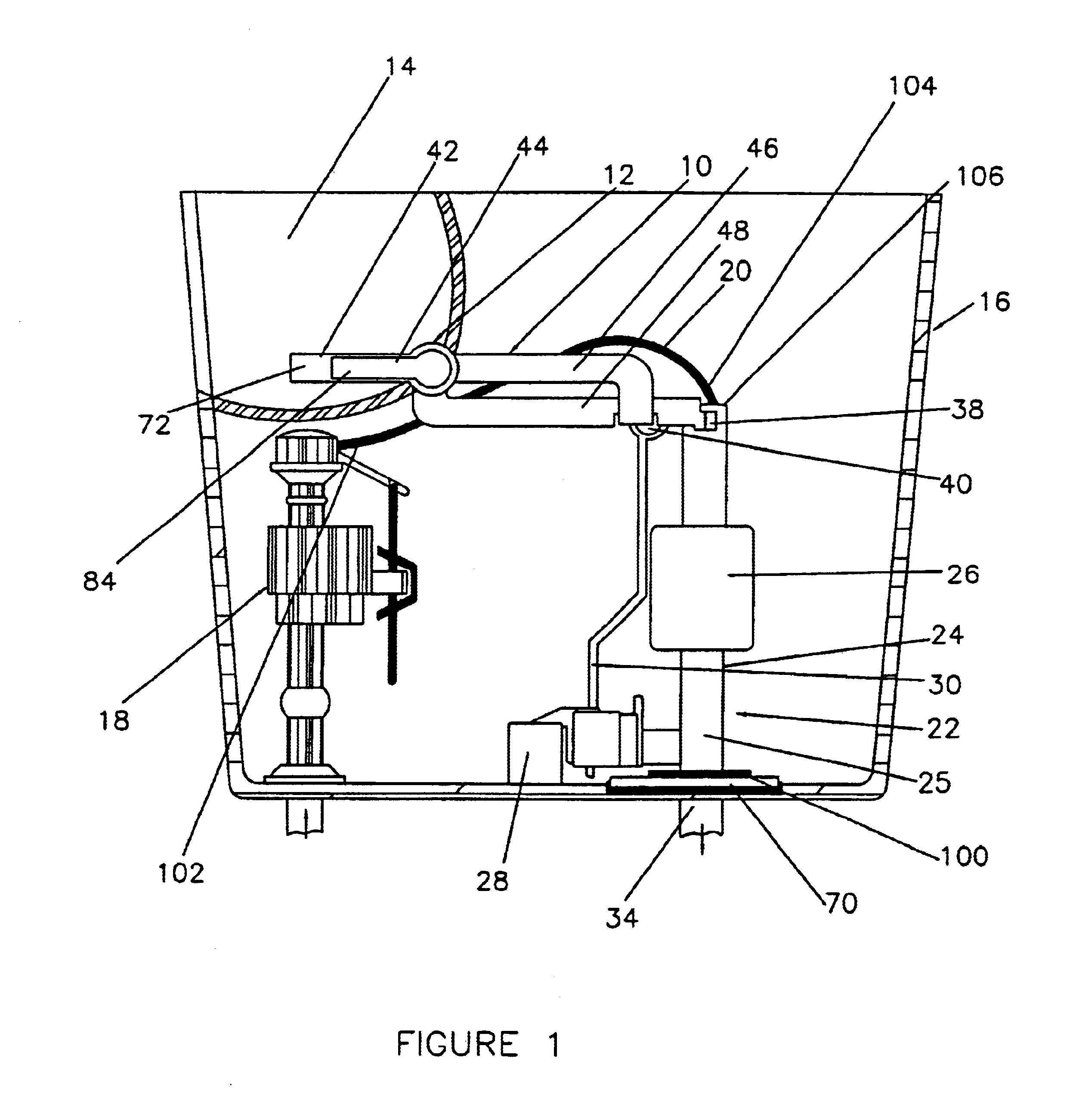

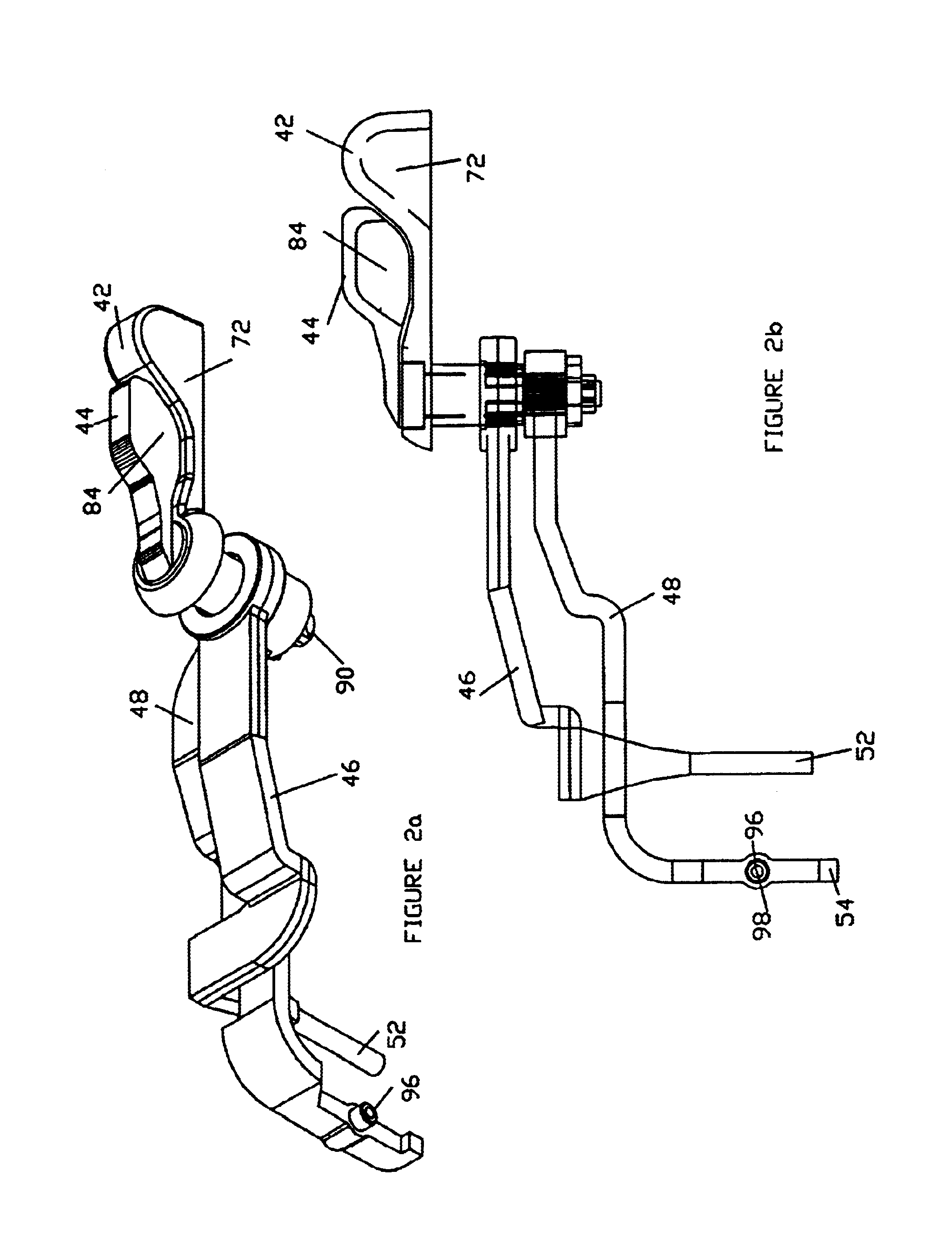

Dual flushing mechanism

A double trip handle type flush control assembly is disclosed, which operates to allow either a full volume of water to be drawn out of the toilet tank or a partial volume of water to be drawn out of the tank. In particular, the double trip handle type flush control assembly of the present invention is adaptable for use in any size toilet tank. Further, the flush control assembly of the present invention has been adapted to accommodate a refill tube, which directs water from a ball cock valve into an overflow tube to refill the toilet trapway after flushing.

Owner:AQUANOTION

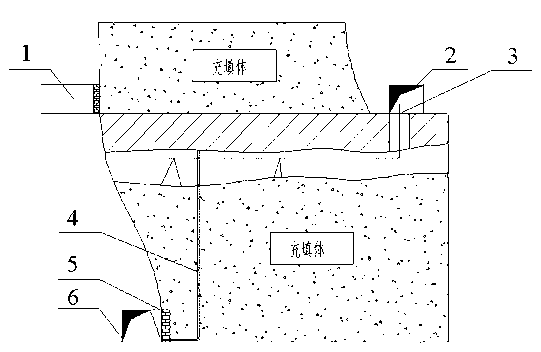

Roof contacting process in goaf filling treating procedure

InactiveCN103233771ALow costGuarantee normal productionMaterial fill-upEngineeringUltimate tensile strength

The invention relates to a roof contacting process in a goaf filling treating procedure and belongs to the technical field of mining engineering. The technical scheme of the roof contacting process in the goaf filling treating procedure includes: detecting a goaf to obtain the coordinate of the top point position of a top plate; drilling a filling drill hole at the top point position of the top plate, and performing cementing filling; installing a three-way plug valve on a filling pipe of the filling drill hole, and guiding a washing pipeline out on the filling pipe through the three-way plug valve; when the position with 1m away from the top point of the top plate is filled, extending the filling pipe to the position farthest from the filling drill hole, and simultaneously, arranging a 1-1.5m temporary retaining wall on the filling drill hole portion; when cement body is full, continuing to fill; and finally opening the three-way plug valve, guiding water away through the washing pipeline and finishing the filling roof contacting work. The roof contacting process is particularly suitable for filling the goaf generated during the filling exploitation process afterwards, is good in filling roof contacting effect and low in working intensity, saves filling roof contacting cost, achieves the roof contacting maximumly, is high in roof contacting efficiency, and ensures normal production of mines.

Owner:HEBEI IRON & STEEL GRP MINING +2

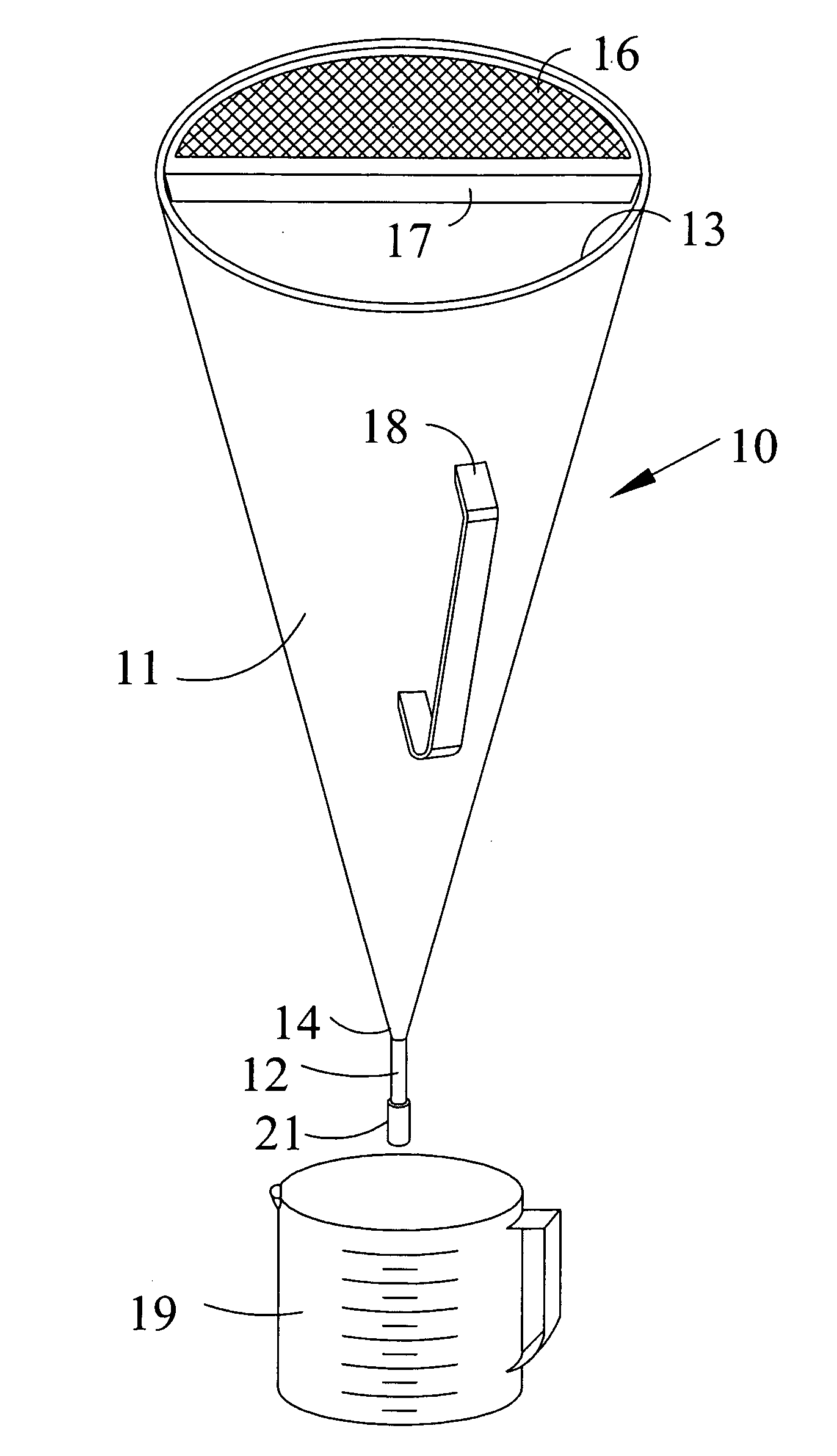

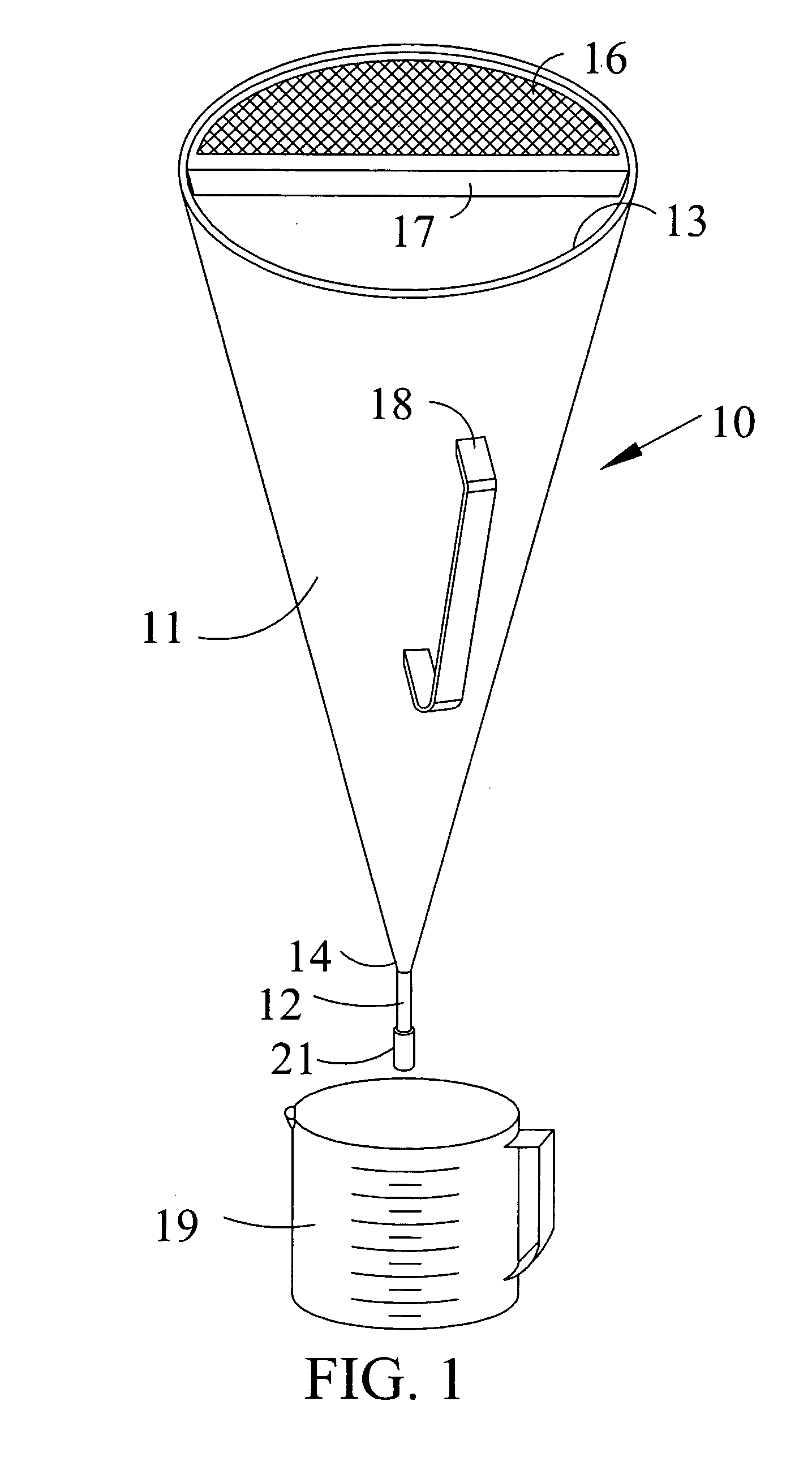

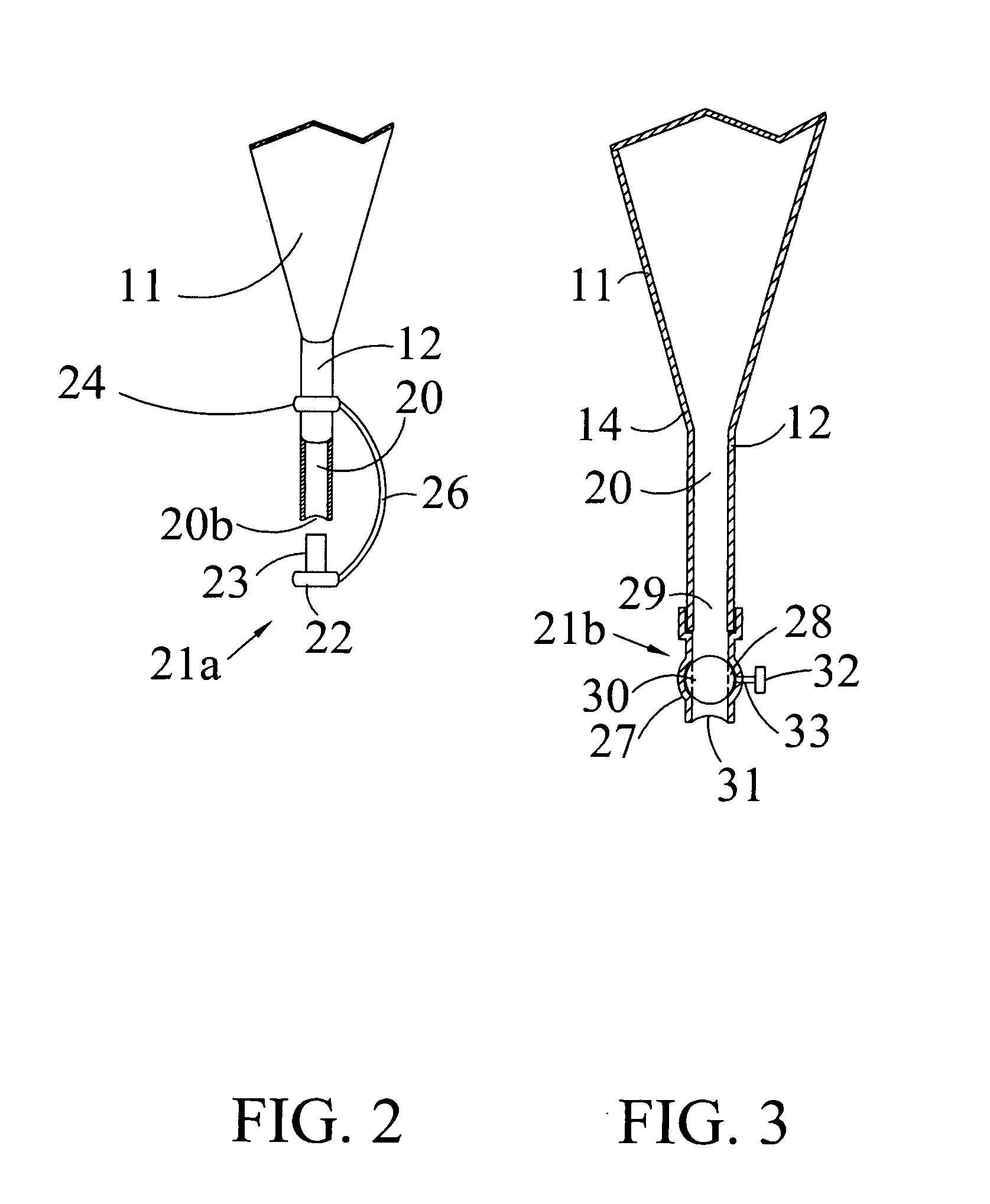

Funnel viscosimeter

InactiveUS20070227234A1Easy to collectImprove testLarge containersMaterial testing goodsSpool valveButterfly valve

Owner:PICHOTTA LARRY G

Plug-style air-conditioning service valve

InactiveUS20070205387A1Lower overall pressure dropLow costPlug valvesEngineering safety devicesEngineeringAir conditioning

An air-conditioning service plug-type valve includes a valve body having a chamber. First and second openings extend through the valve body. The air conditioning plug-type valve also includes a stem having a plug portion configured for being received in the chamber of the valve body. The stem, when the plug portion is received in the chamber, is rotatable relative to the valve body between a closed position blocking fluid communication between the first and second openings of the valve body and an open position enabling fluid communication between the first and second openings of the valve body. The plug portion includes a fluid blocking portion located immediately adjacent the first opening when the stem is in the closed position. A groove extends into a peripheral surface of the plug portion defining the fluid blocking portion. A seal is disposed in the groove and extends between the plug portion and the valve body. The seal, when located in the groove, is stretched by at least a predetermined amount. The predetermined amount is an amount sufficient to offset refrigeration medium absorption effects thereon.

Owner:PARKER INTANGIBLES LLC

Gas adjusting valve and electric control gas adjusting valve used for gas stove and gas stove

ActiveCN103133718ARealize segment controlEasy to controlFuel supply regulationGaseous fuel feeder/distributionEngineeringElectric control

A gas adjusting valve used for a gas stove comprises a valve body and a rotary disc which contacts the plane of the inner cavity surface of the valve body and rotates relative to the inner cavity surface of the valve body, wherein a gas inlet and a gas outlet are formed in the valve body. The valve body matches with the contact face of the rotary disc in a sealed mode. The rotary disc is provided with a connecting passage, and the connecting passage can selectively enable the gas outlet which is formed in the valve body to be connected or disconnected with the inner cavity of the valve body or change a connecting degree. The invention further provides an electric control gas adjusting valve used for the gas stove and the gas stove with the gas adjusting valve or the electric control gas adjusting valve. Due to the technical scheme, the problems that the existing gas stove adopts a plug valve which is inconvenient to manufacture and is high in cost can be avoided.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

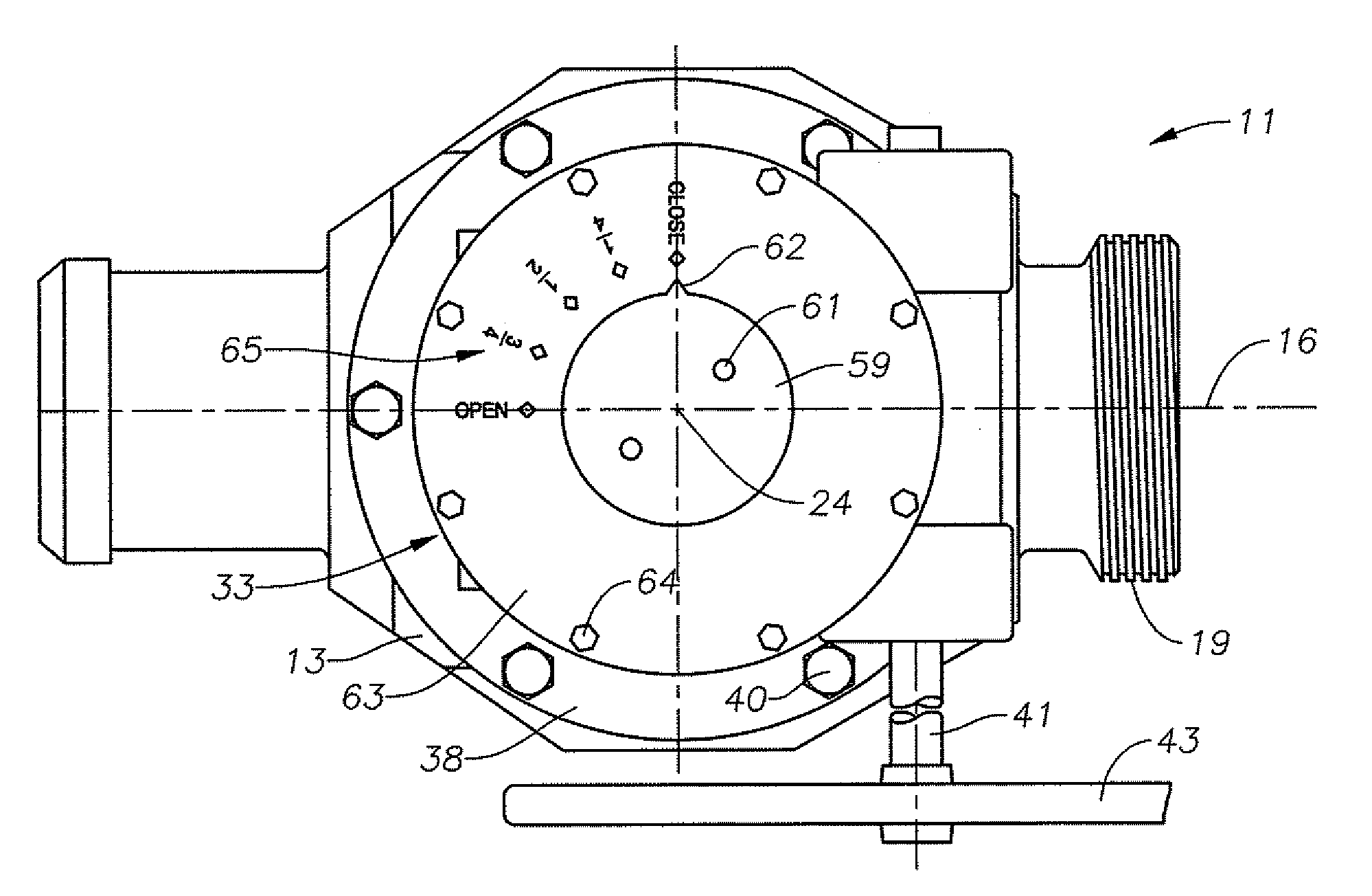

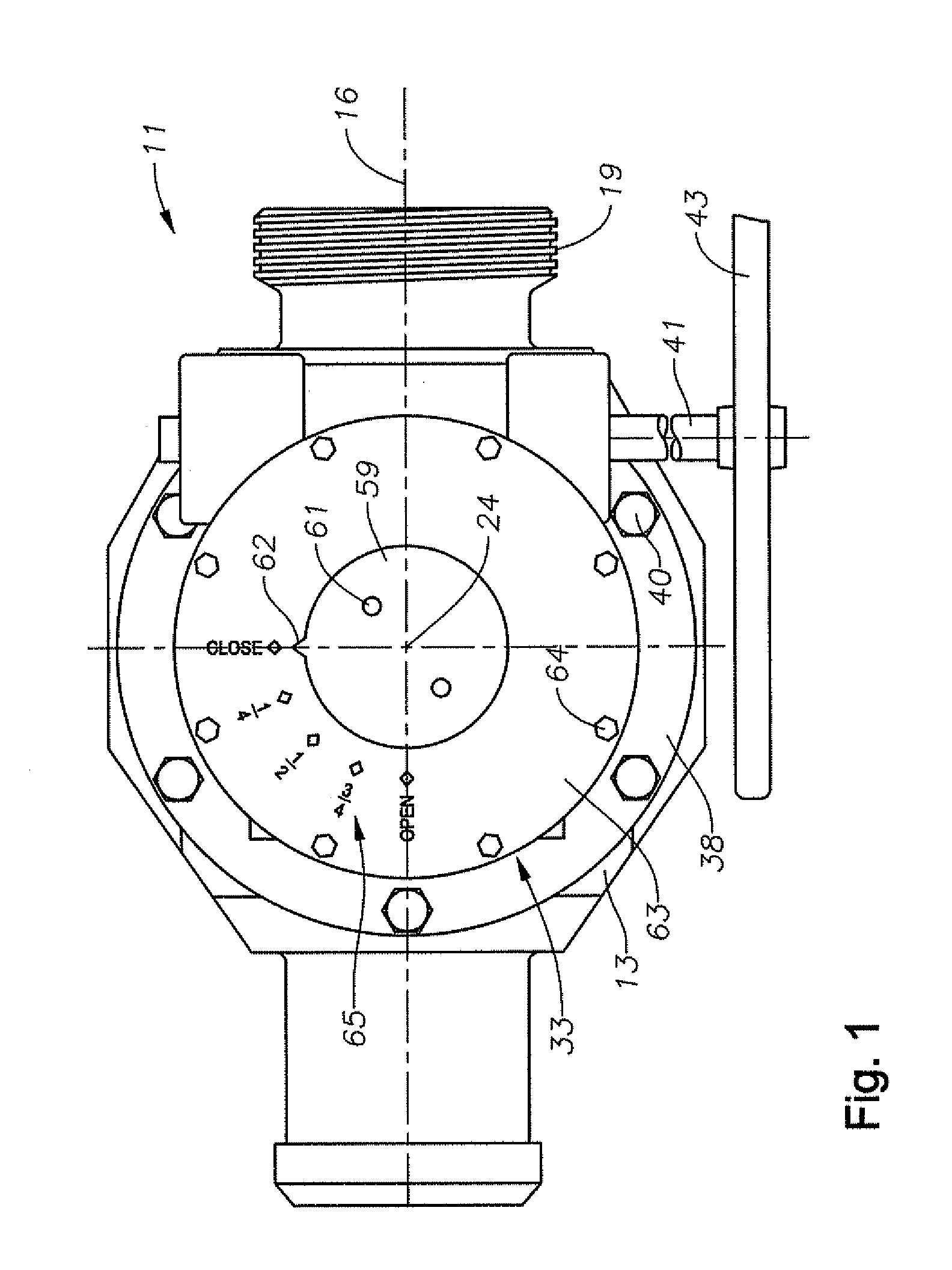

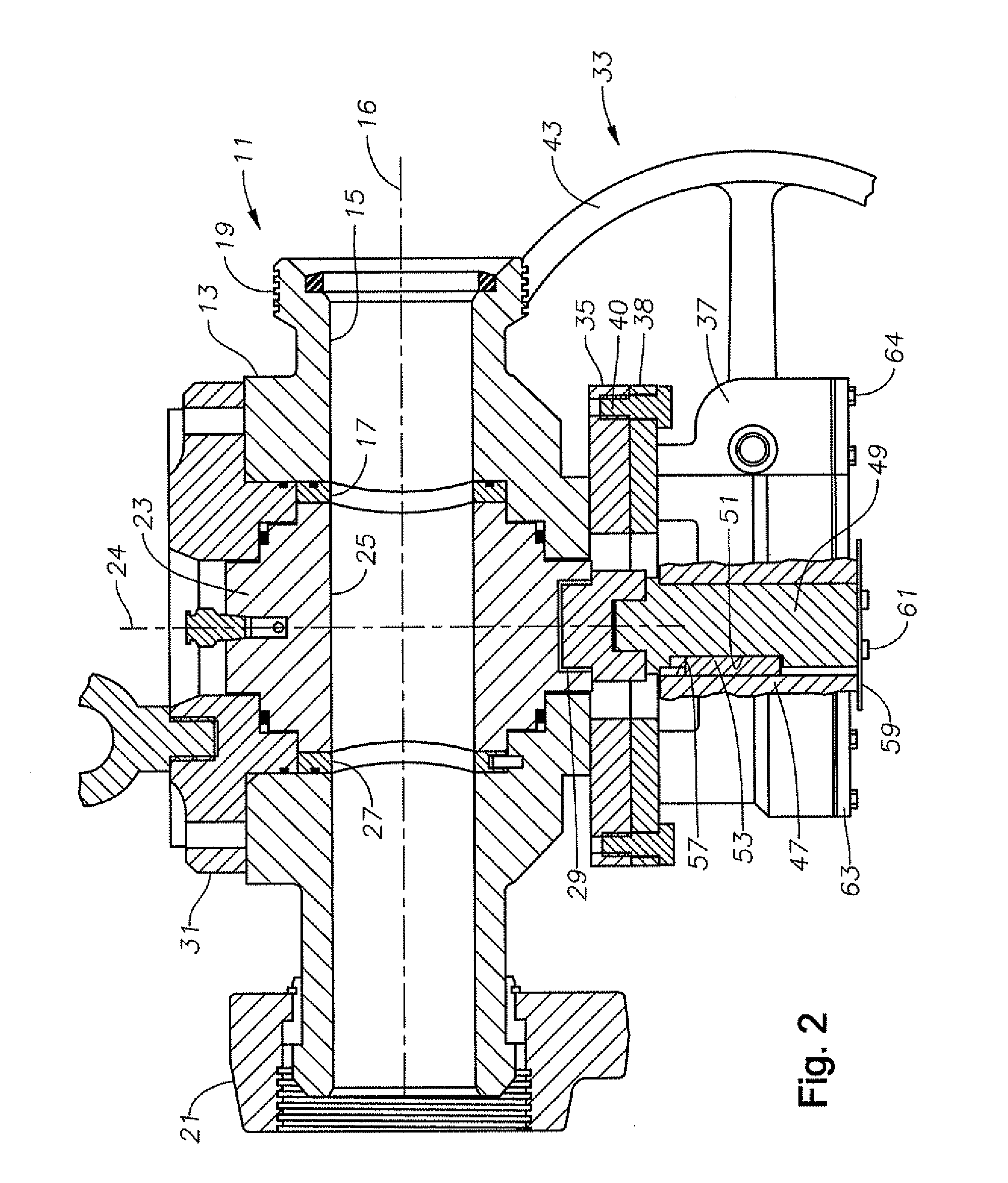

Plug valve indicator

Owner:WEIR SPM

Detachment-free oil drainage bolt

The invention discloses a detachment-free oil drainage bolt, which comprises a valve body, a plug valve core and an oil drainage device. The valve body also serves as an oil drainage bolt and is provided with an external thread, a valve body oil inlet and a valve body oil outlet; the plug valve core is mounted in an inner cavity of the valve body and provided with a valve core oil inlet channel; a valve core oil outlet channel communicated with the valve core oil inlet channel is also arranged in the plug valve core; the valve core oil outlet channel is communicated with the valve body oil outlet; a valve core sealing device is arranged between the plug valve core and the valve body; the oil drainage device comprises an oil drainage pipe inserted into the valve body oil outlet; the oil drainage pipe is provided with an oil drainage channel communicated with the valve core oil outlet channel; a valve core opening device is arranged between the oil drainage pipe and the plug valve core;and an oil drainage pipe inserting / fixing device is also arranged between the oil drainage pipe and the valve body. The oil drainage pipe drives the plug valve core to rotate through the valve core opening device, the valve body oil inlet is opened, and the waste oil enters the valve core oil outlet channel through the valve core oil inlet channel from the valve body oil inlet and then flows out through the oil drainage pipe. Through the invention, the waste oil is prevented from spattering around, and the pollution is reduced.

Owner:铜陵市世纪朝阳数码科技有限责任公司

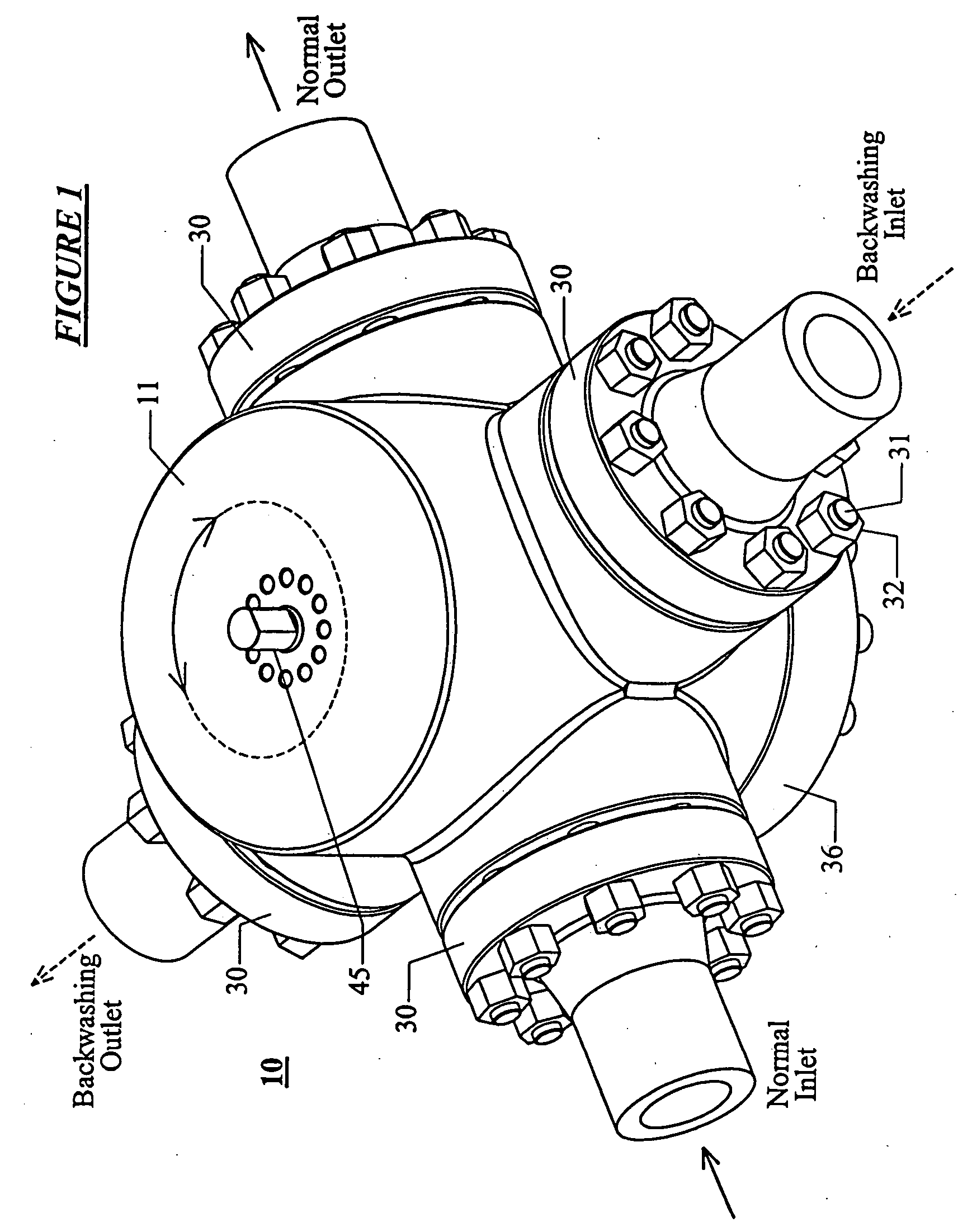

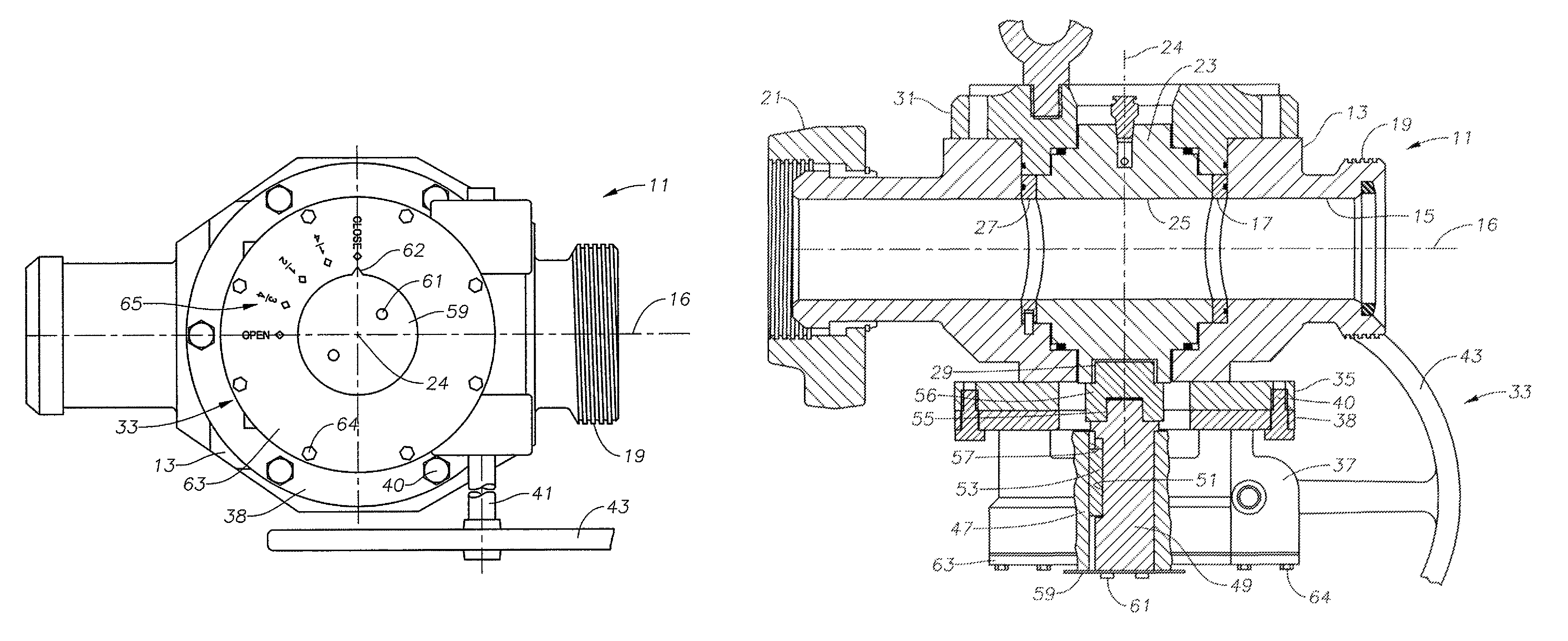

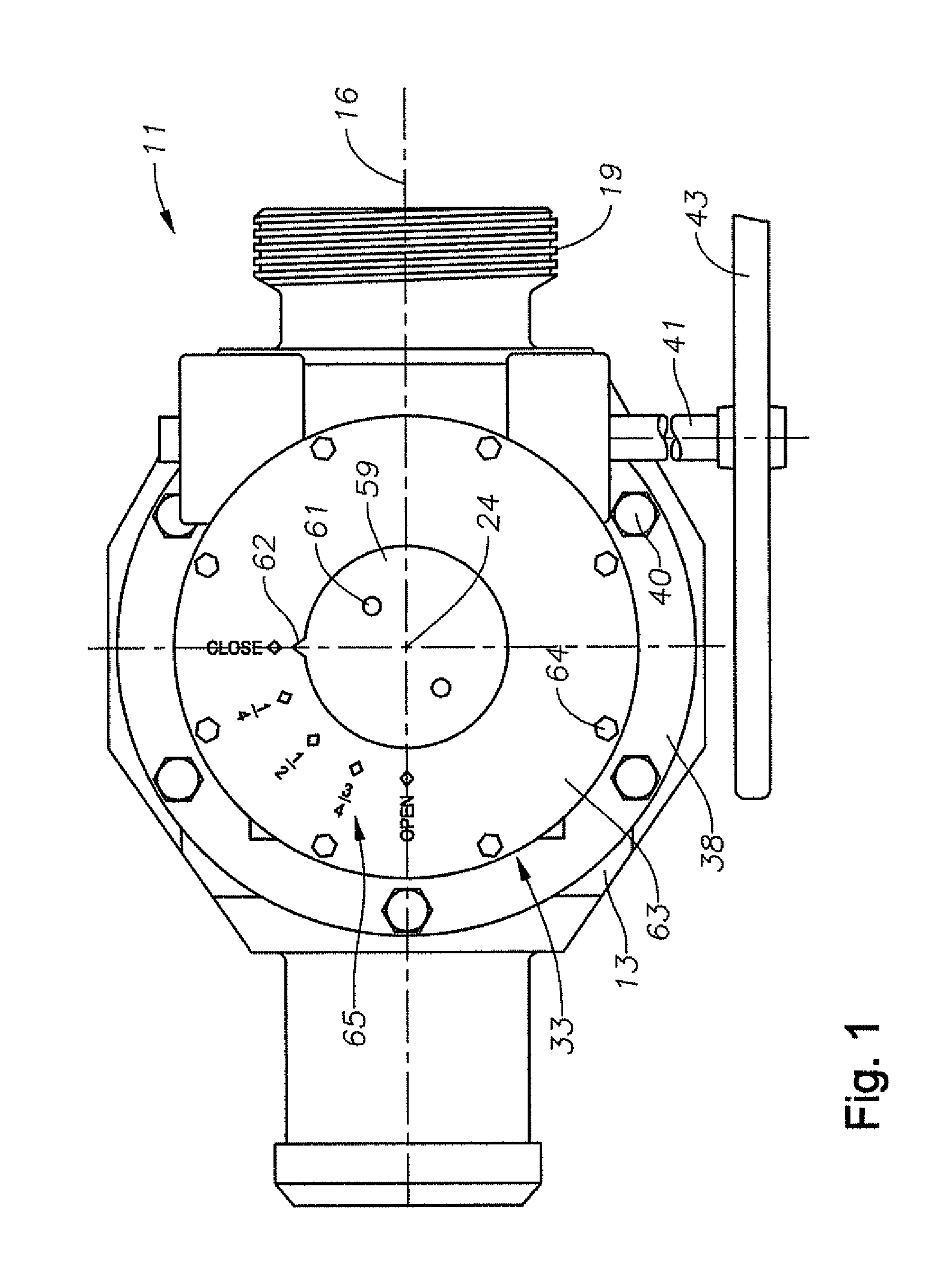

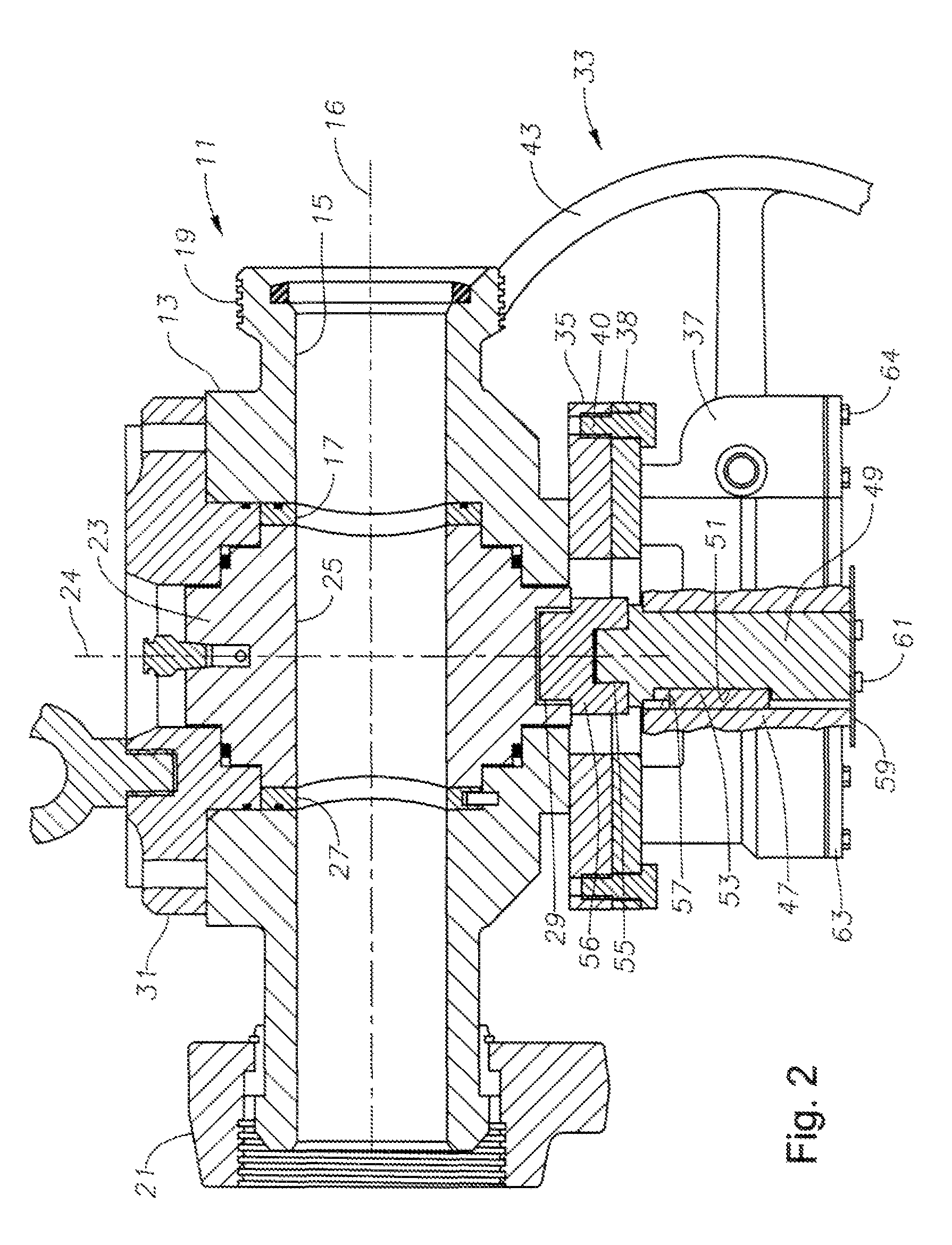

Extreme service plug valve

InactiveUS20160201811A1Reduce torquePlug valvesReciprocating drilling machinesEngineeringMechanical engineering

A valve assembly for managing a flow of fluids in hydrocarbon development and production operations includes a valve body having an internal body cavity and a body bore intersecting the body cavity. A valve plug is located within the body cavity and is rotatable between an open position and a closed position. A sleeve is located between the valve plug and the valve body and is rotationally fixed to the valve body and remains rotationally static relative to the valve body as the valve plug rotates. A seal groove is located on a sidewall surface of the sleeve and circumscribes one of the sleeve openings. A seal assembly has a seal ring that is U shaped in cross section with an inner leg that engages the seal groove and an outer leg that extends out of the seal groove and engages one of the valve body and the valve plug.

Owner:VAULT PRESSURE CONTROL LLC

Gasproof damper valve

InactiveCN101493151ASimple sealing structureImprove sealingSlide valveValve housingsEngineeringLubricant

The invention relates to the technical field of mechanical sealing board plug valve, in particular to an air-tight board plug valve which comprises a valve seat, an upper valve cover, an upper valve cover hold-down bolt, a board plug, a board plug lock nut, a board plug push rod and a board plug push rod driving device; wherein, a special section rubber sealing ring provided with a cavity is arranged between the upper valve cover and the board plug, the outer side of the special section rubber sealing ring is contacted with the valve seat, and the inner side is contacted with a chuck ring of the sealing ring; the cavity of the special section rubber sealing ring is communicated with a venting cavity of the upper valve cover to form an air-tight cavity, and a compressed-air pipeline is connected with the venting cavity of the upper valve cover to charge the air-tight cavity. Sealing grooves are respectively arranged at the lower side of the upper valve cover, the upper end surface of the chuck ring of the sealing ring and the upper end surface of the valve seat and matched with preiection of the special section rubber sealing ring, thus ensuring the board plug valve to have good sealing structure. A solid lubricant column is arranged between the valve seat and the board plug. The air-tight board plug valve has the advantages of good sealing performance, flexible and convenient operation and long service life.

Owner:王为

Plug Valve Indicator

Owner:WEIR SPM

Plug valve having preloaded seal segments

ActiveUS20140048734A1Improve fluid flowBlock fluid flowPlug valvesMetal-working apparatusVALVE PORTPlug valve

A plug valve including a valve body having an inlet port, an outlet port and a central chamber extending between the inlet port and the outlet port. The valve also includes an inlet seal segment within the central chamber and includes a bore extending therethrough and aligned with the inlet port. An outlet seal segment is disposed within the central chamber having a bore extending therethrough and aligned with the outlet port. A plug member is disposed in the central chamber and is moveable between an open position, to facilitate fluid flow through the plug valve, and a closed position, to block fluid flow through the plug valve. First and second side segments are disposed between and interlocked to the inlet and outlet seal segments to encircle the plug member. The side segments are tensioned to preload the seal segments against the plug member to prevent the flow of fluid between the seal segments and the plug member.

Owner:SPM OIL & GAS INC

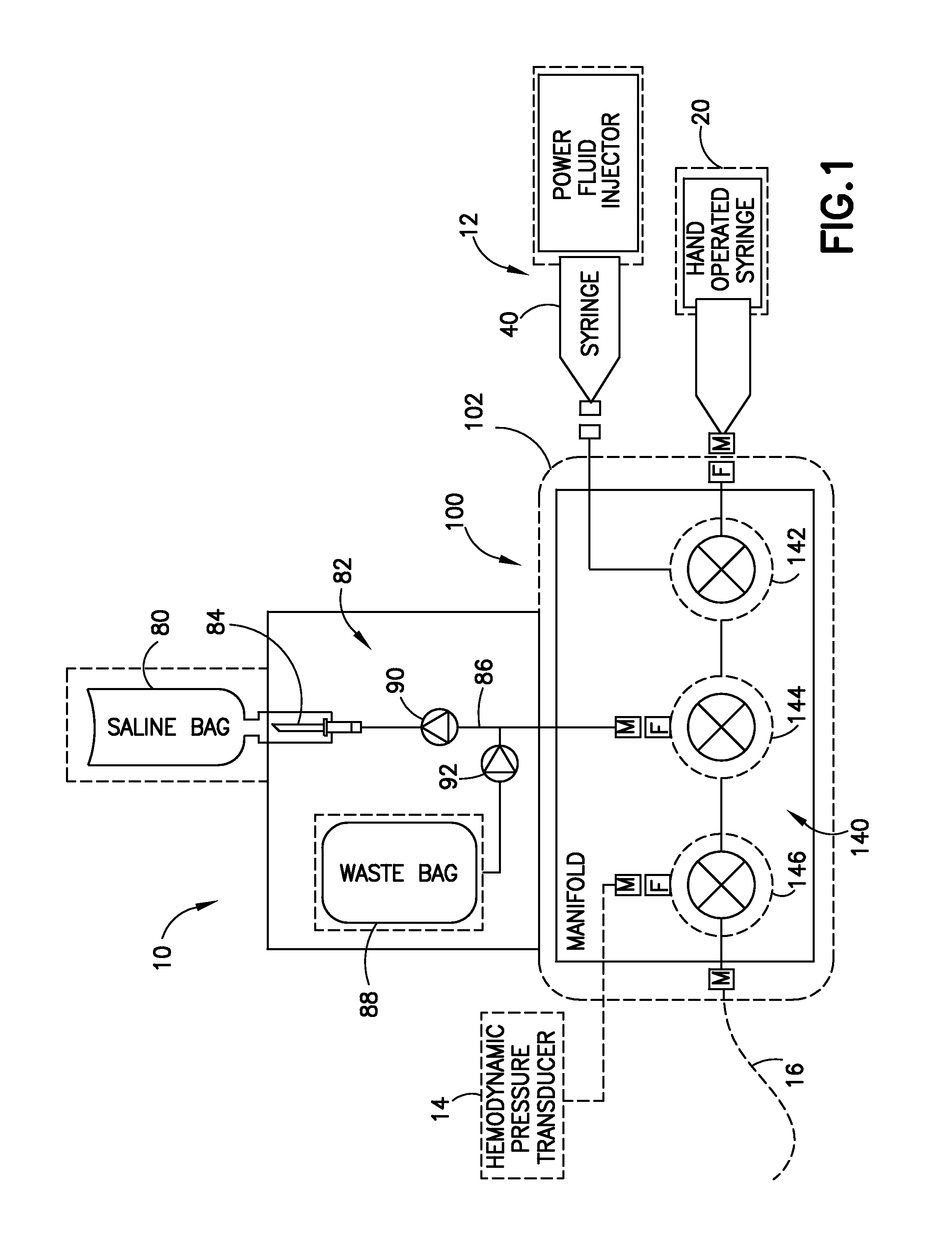

Fluid delivery system with high and low pressure hand manifold

A fluid delivery system is provided and includes a power injector supporting a high pressure syringe. The fluid delivery system further includes a manifold and a low pressure hand-operated syringe. The manifold generally includes a plurality of fluid control valves in series fluid communication. A first fluid control valve of the plurality of fluid control valves has a first port, a second inlet port, and a third port. The third port of the first fluid control valve is in fluid connection with a first port of a second fluid control valve. The low pressure hand-operated syringe is in fluid connection with the first port of the first fluid control valve, and the high pressure syringe is in fluid connection with the second port of the first fluid control valve. The fluid control valves may be multi-position stopcock valves.

Owner:BAYER HEALTHCARE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com