Gas adjusting valve and electric control gas adjusting valve used for gas stove and gas stove

A technology for gas regulation and gas stoves, which is applied in the field of gas stoves and can solve the problems of inconvenient processing and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

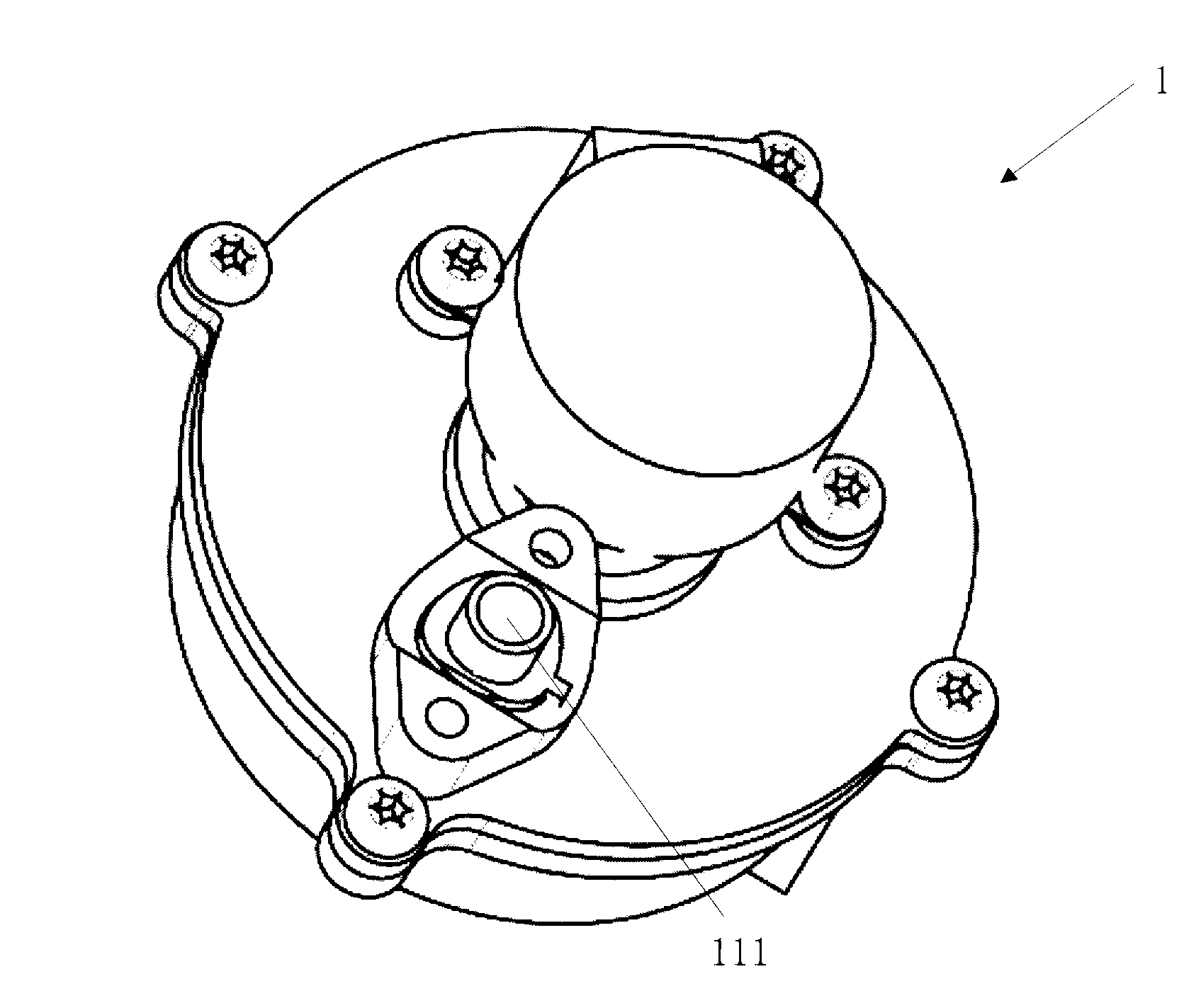

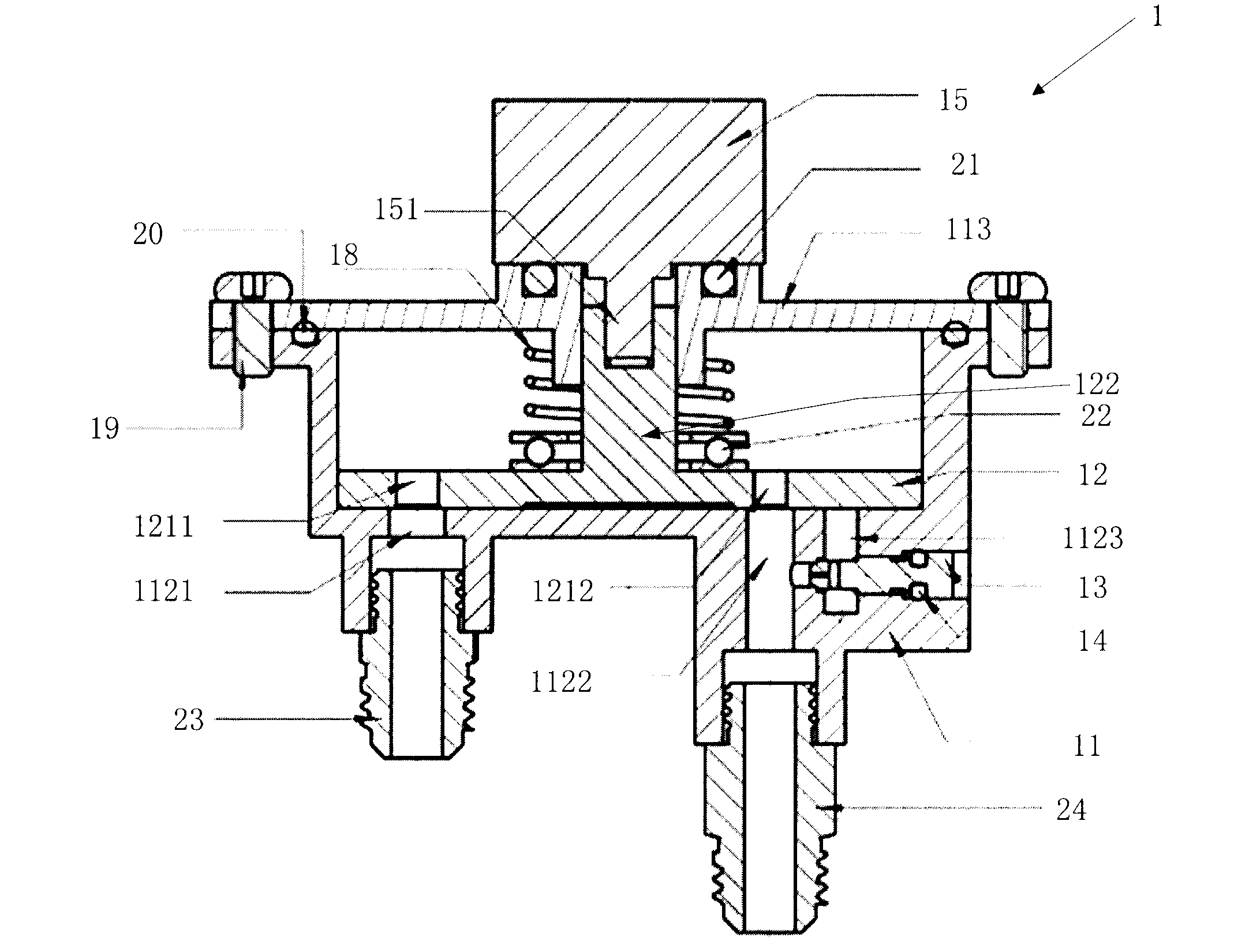

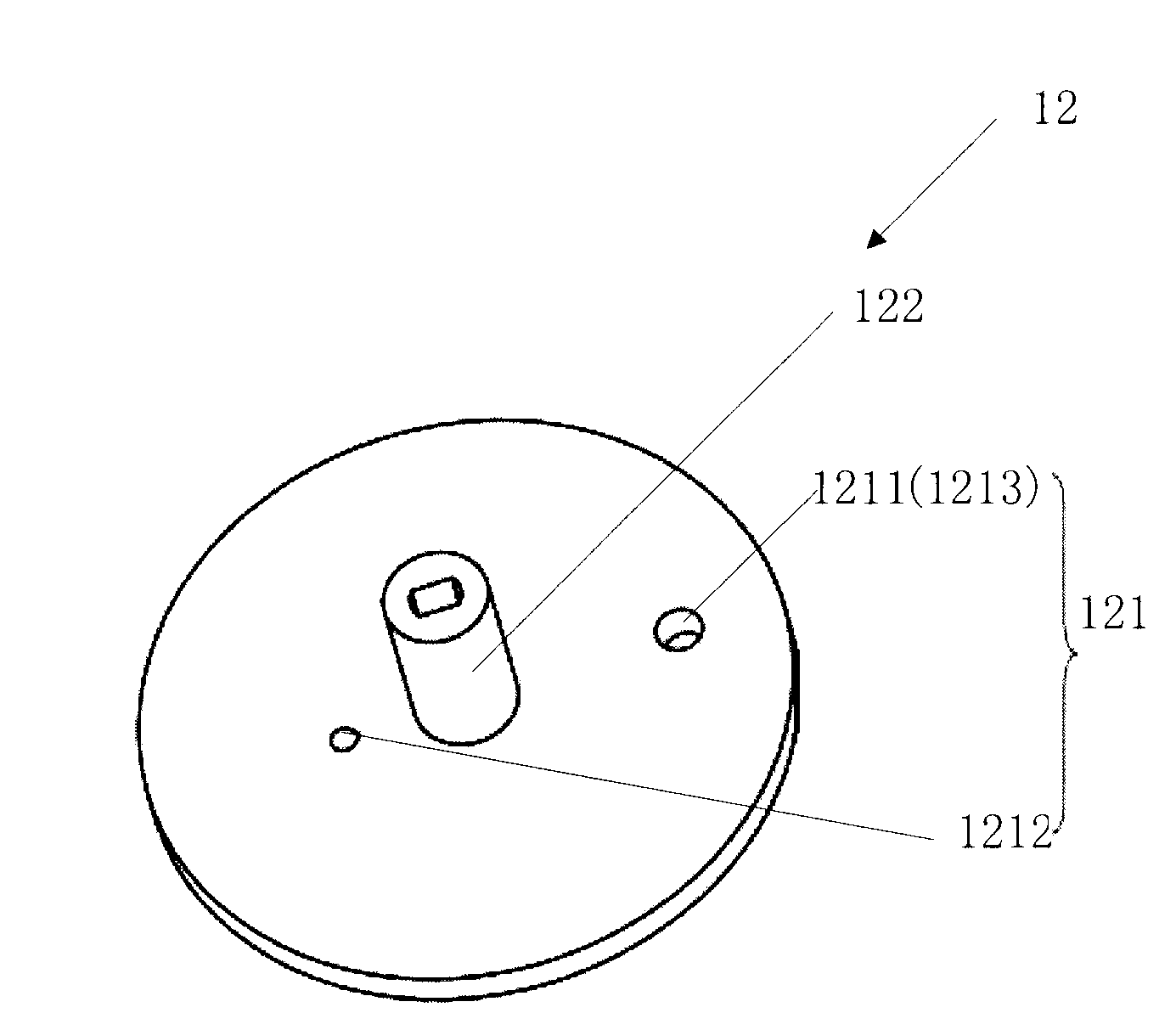

[0067] figure 1 It is a three-dimensional structural schematic diagram of an electrically controlled gas regulating valve 1 for a gas cooker provided by Embodiment 1 of the present invention, figure 2 yes figure 1 cutaway view of the structure, image 3 is a schematic diagram of the turntable structure.

[0068] combine figure 1 and figure 2 , the regulating valve 1 includes:

[0069] A valve body 11, the valve body 11 has an inner cavity and is provided with a gas inlet 111 and a gas outlet;

[0070] The turntable 12 that is in plane contact with the surface of the inner cavity of the valve body 11 and can rotate relative to the surface of the inner cavity of the valve body 11, the contact surface of the valve body 11 and the turntable 12 is tightly fitted; in addition, the turntable 12 has the function of selectively making the valve turn when it rotates. The gas outlet on the body 11 is connected with the inner chamber of the valve body 11 or disconnected or the con...

Embodiment 2

[0097] The difference between the second embodiment and the first embodiment is that in the gas regulating valve provided, the distances between the rotation center of the turntable 12 and the first gas outlet 1121 and the minimum fire inlet 1123 are set to be unequal. The structure of the turntable 12 that embodiment two provides is as Image 6 shown, combined with figure 2 , the distance between the rotation center of the turntable 12 and the first connecting channel 1211 and the third connecting channel 1213 is not equal. During the rotation of the turntable 12, the size of the overlapping area between the first gas outlet 1121, the second gas outlet 1122, and the minimum fire inlet 1123 and the first connecting channel 1211, the second connecting channel 1212, and the third connecting channel 1213 respectively can be changed. The degree of communication between the two gas outlets 1121 and 1122 and the inner cavity of the valve body 11 further achieves the purpose of con...

Embodiment 3

[0099] The difference between the third embodiment and the first and second embodiments is that there is no clear distinction between the inner and outer ring fires on some gas stoves, and the two fires are mixed, that is, only one fire is provided. For this kind of gas stove, this implementation The structure of the rotating disk 12 that example three provides is as Figure 7 As shown, only one connection channel 121 is provided. Similarly, the size of the overlapping area between the gas outlet and the connecting channel 121 can change the degree of communication between the gas outlet and the inner cavity of the valve body 11 , and can also achieve the purpose of controlling the gas in sections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com